Patents

Literature

84results about How to "Good material compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiple enzyme cleaner for surgical instruments and endoscopes

ActiveUS7491362B1Easy to cleanGood material compatibilityOrganic detergent compounding agentsSurface-active detergent compositionsSurgical instrumentationEndoscope

The liquid composition is based on surfactants and enzymes, and is particularly useful for manual cleaning of instruments. In manual and ultrasonic application the composition in use concentration shows low foaming and gives a cleaning solution which is not cloudy at least at a temperature in the range from 16° C. to 40° C. In addition, the composition has good cleaning efficiacy over a broad temperature range (20 to 55° C.) and shows good material compatibility.

Owner:ECOLAB USA INC

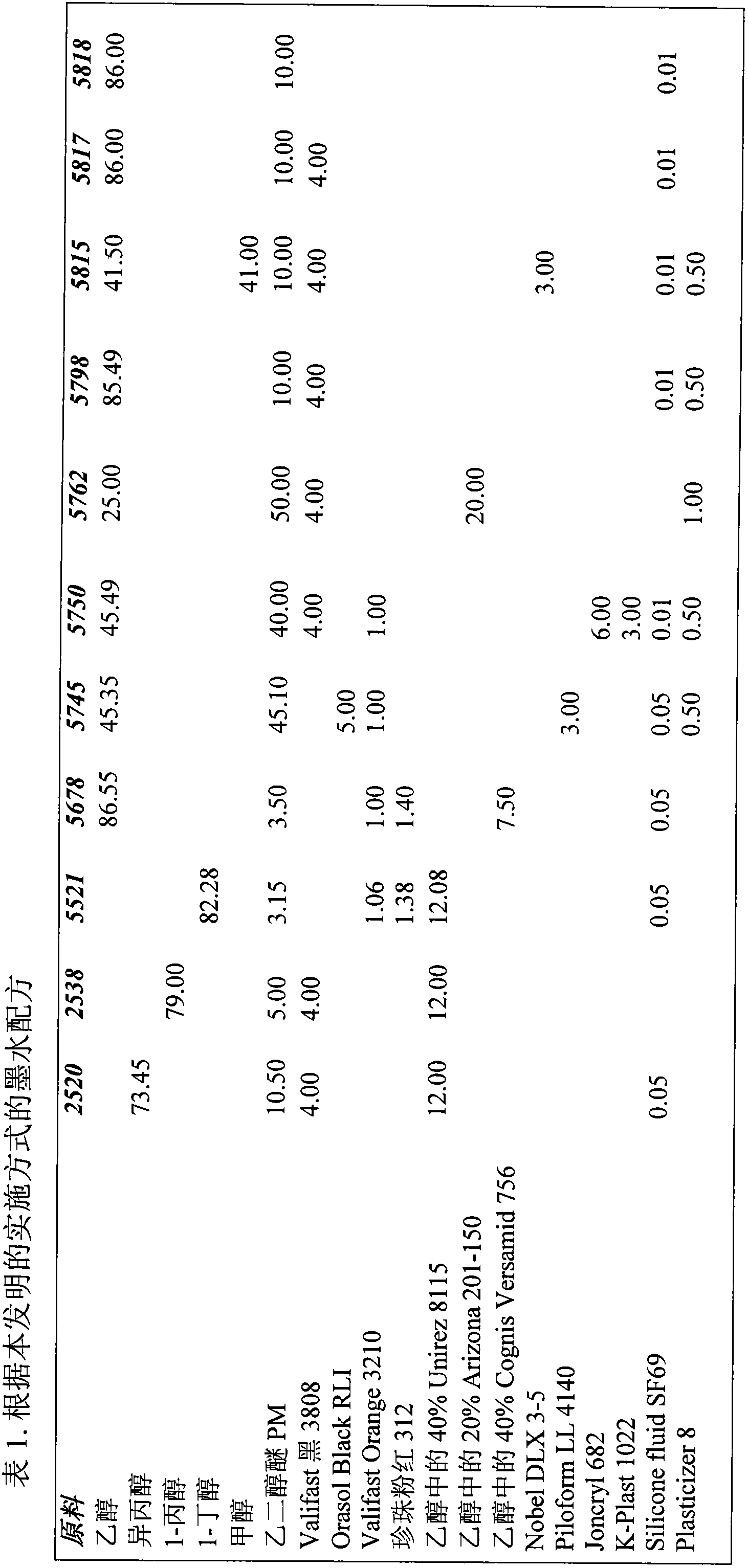

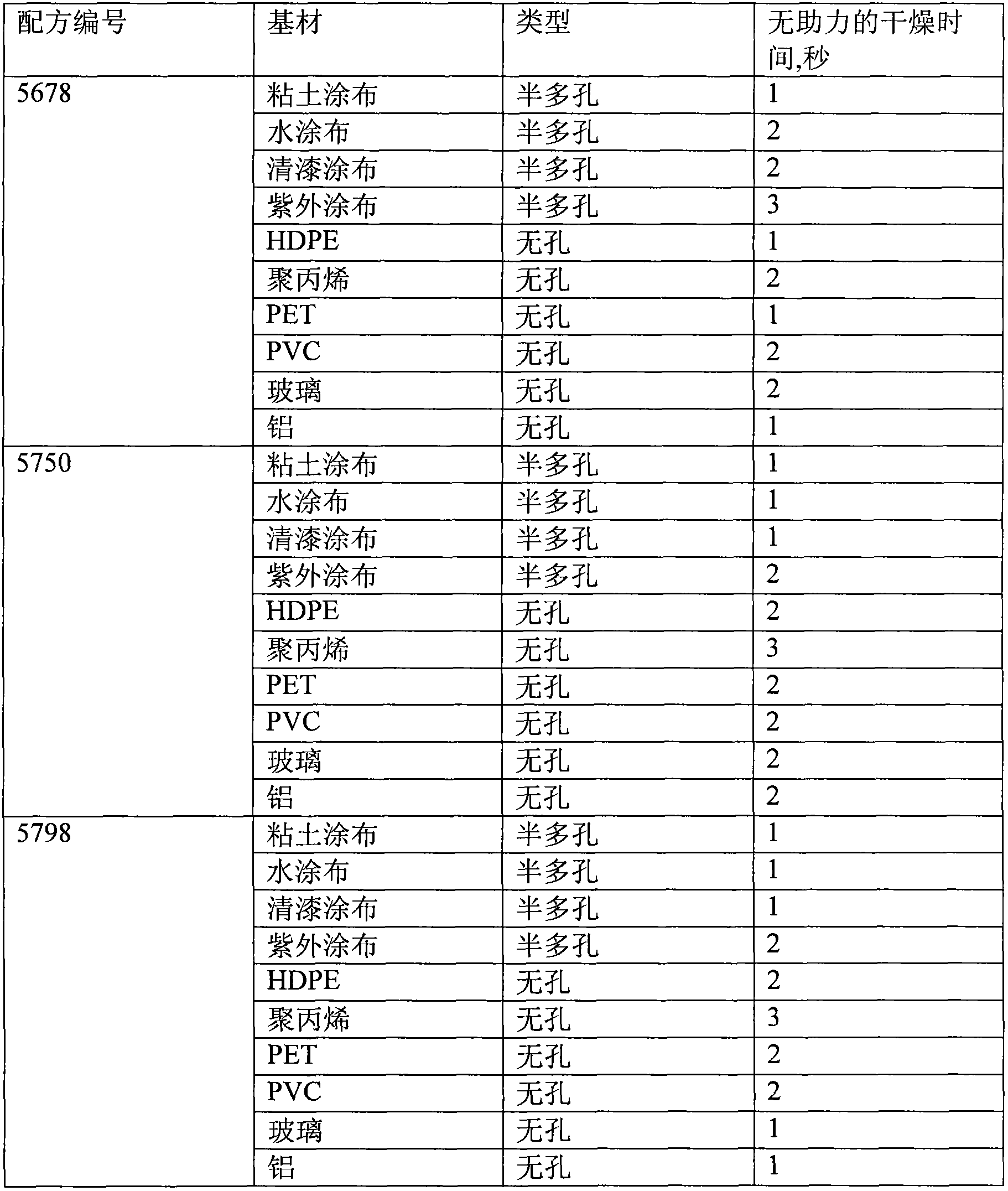

Thermal ink jet ink composition

A thermal ink jet ink composition include a volatile organic solvent, a binder resin, a dye, a humectant in an amount less than 40% by weight of the thermal ink jet ink composition, and an additive for extending the decap time. The additive is present in an amount greater than 0.1% by weight of the thermal ink jet ink composition. The additive is selected from plasticizers, surfactants, aliphatic hydrocarbons, drying oils and mixtures thereof. The additive does not phase separate from the ink jet composition during application of the ink to a substrate in thermal ink jet printing.

Owner:VIDEOJET TECH INC

Thermal ink jet ink composition

ActiveUS8142558B2Shorten drying timeKeep for a long timeFireproof paintsNon-fibrous pulp additionOrganic solventPlasticizer

Disclosed are ink jet ink compositions suitable for use in thermal ink jet printers. The ink jet ink compositions contain one or more volatile organic solvents, one or more humectants, one or more binder resins, and one or more colorants. The ink jet ink compositions may also contain additives such as a plasticizer and / or a surfactant. Embodiments of the ink jet ink compositions have short dry times, good adhesion to a variety of substrates, and / or long decap times.

Owner:VIDEOJET TECH INC

Thermal ink jet ink composition

Disclosed are ink jet ink compositions suitable for use in thermal ink jet printers. The ink jet ink compositions contain one or more volatile organic solvents, one or more humectants, one or more binder resins, and one or more colorants. The ink jet ink compositions may also contain additives such as a plasticizer and / or a surfactant. Embodiments of the ink jet ink compositions have short dry times, good adhesion to a variety of substrates, and / or long decap times.

Owner:VIDEOJET TECH INC

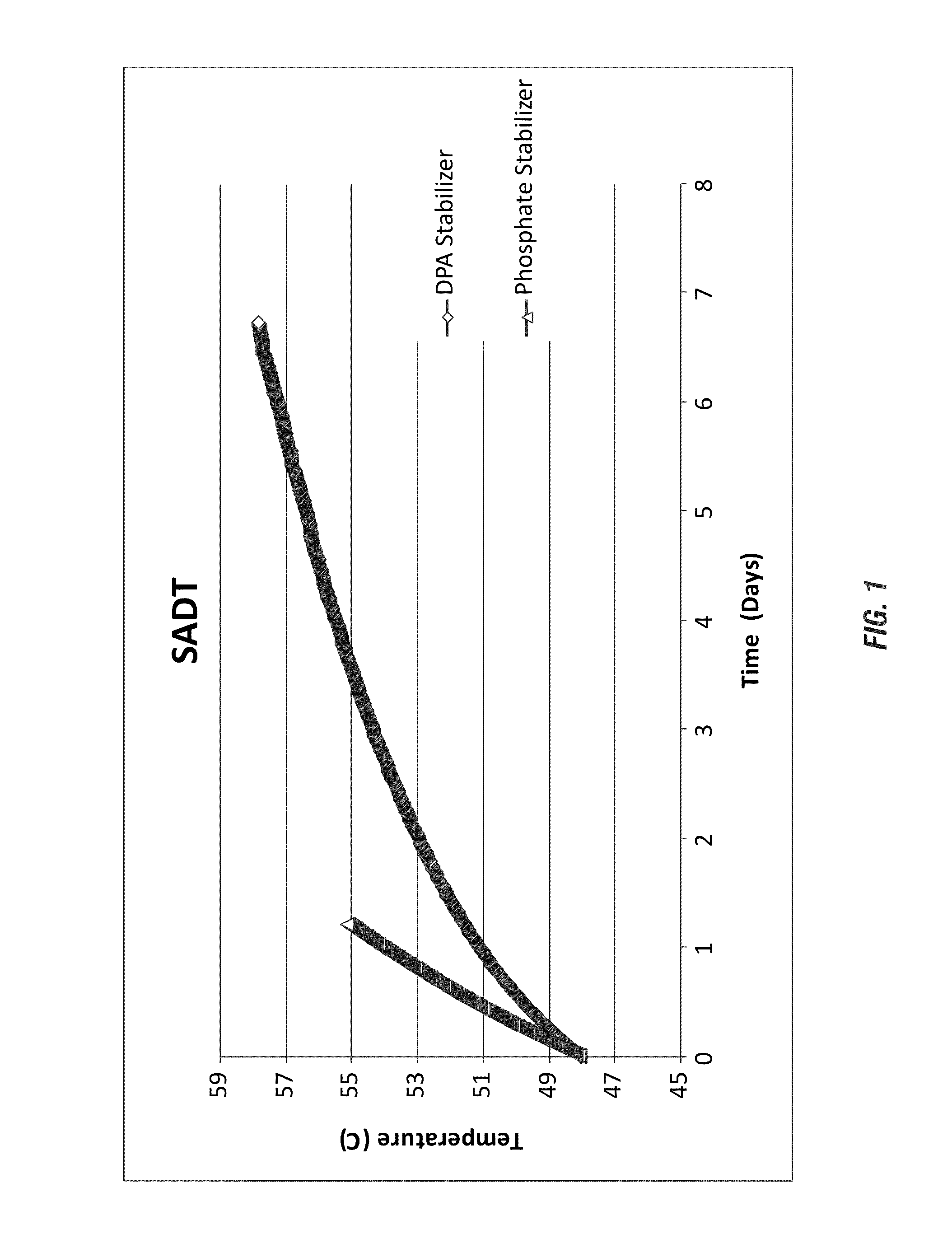

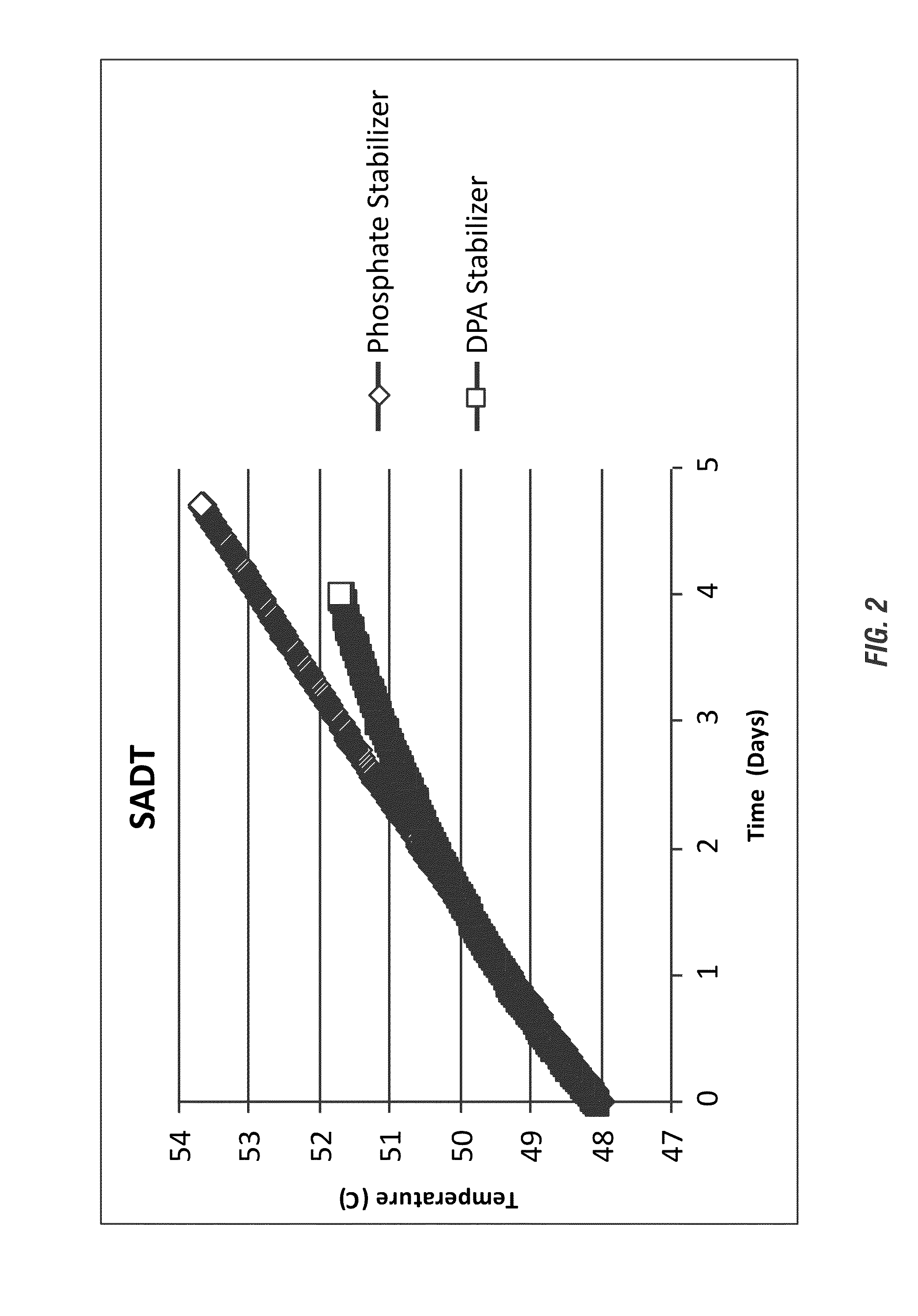

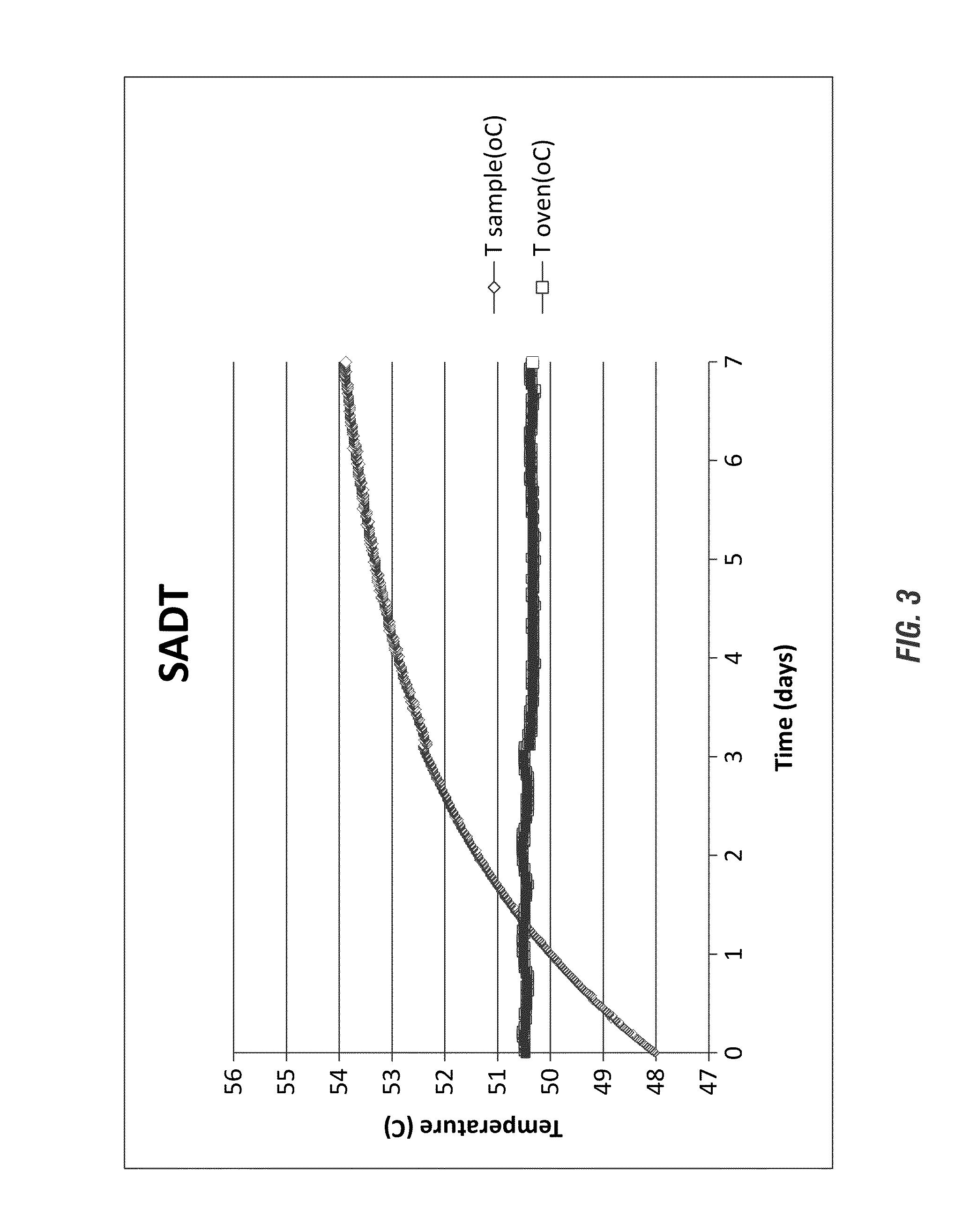

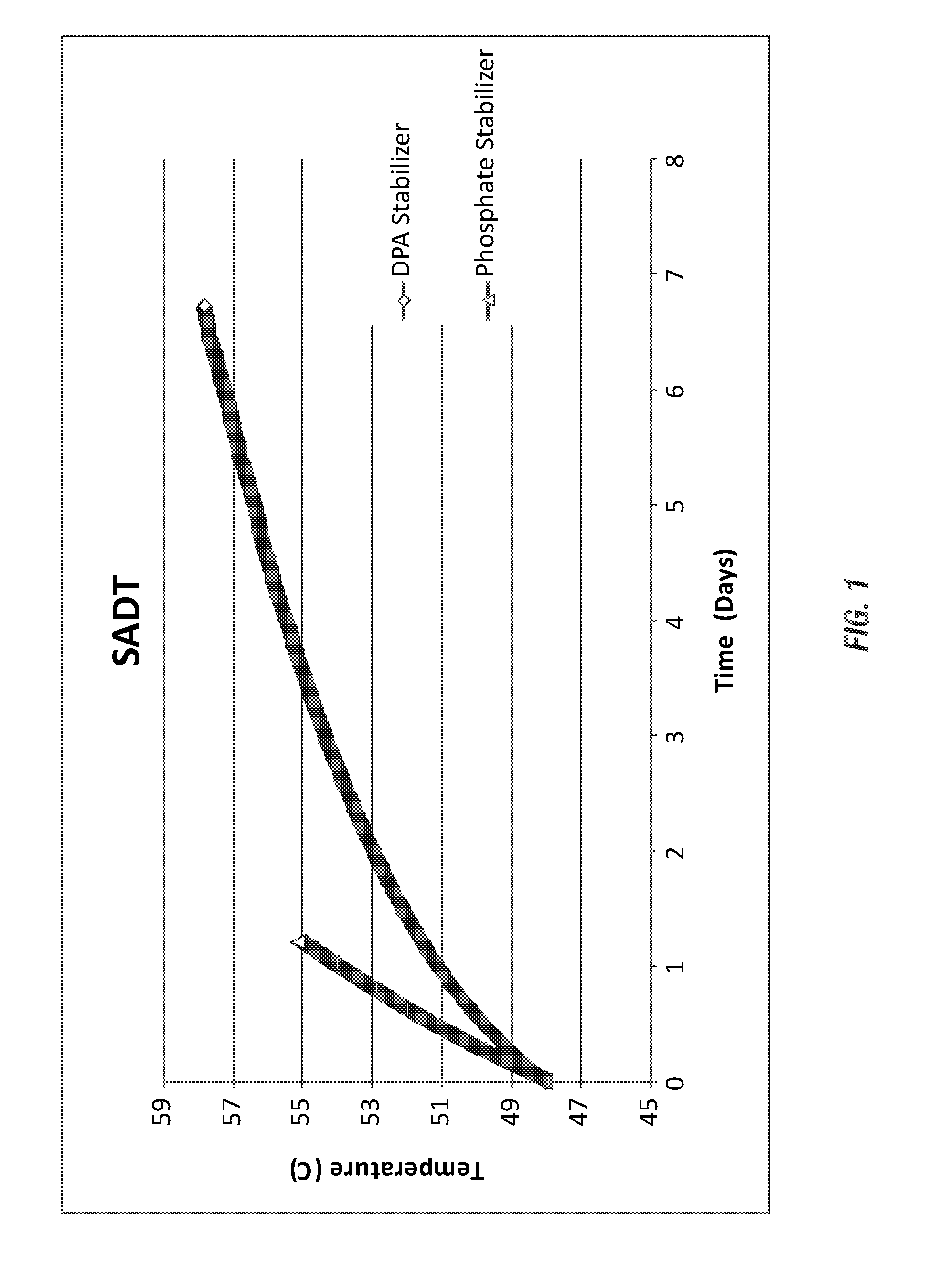

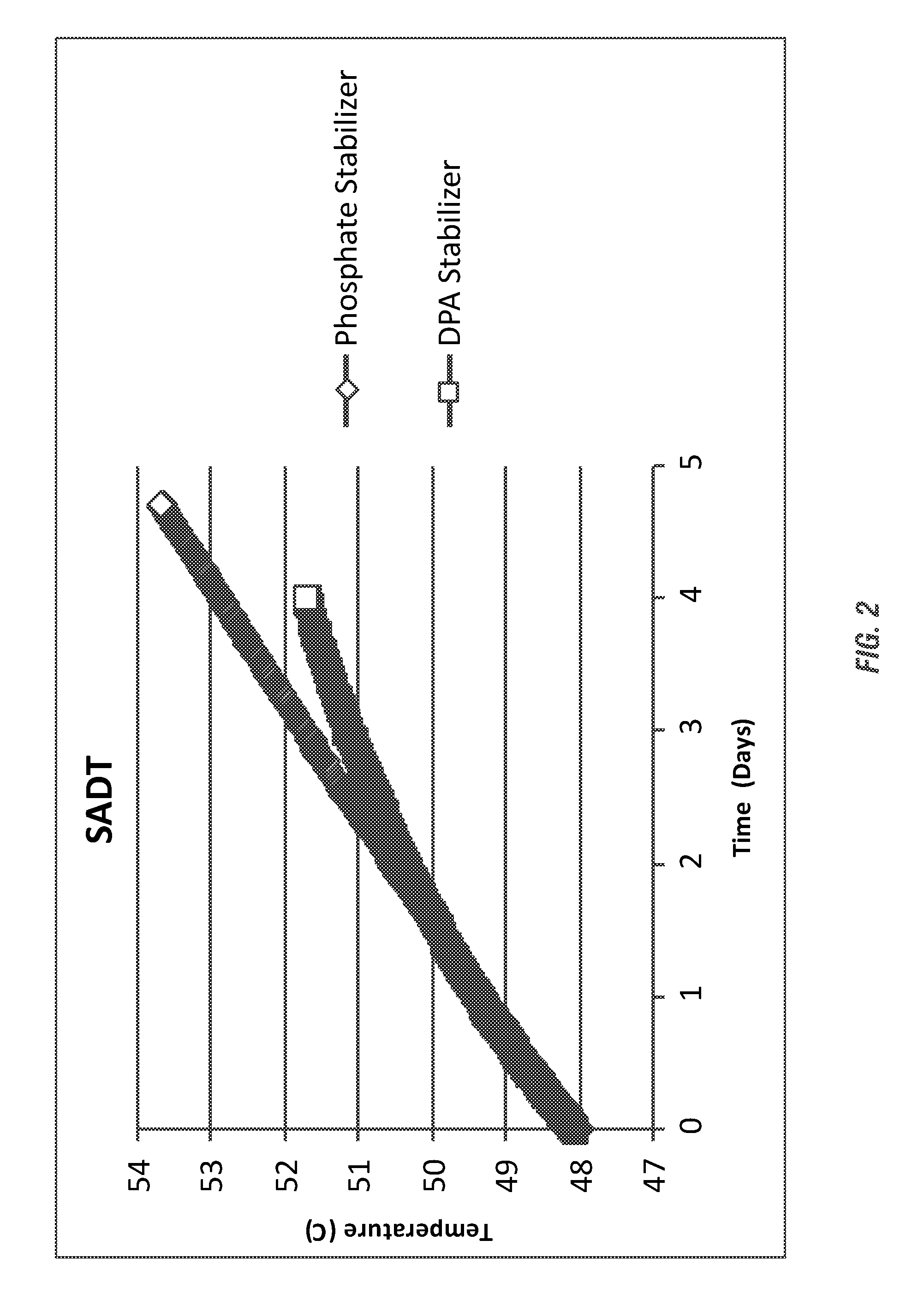

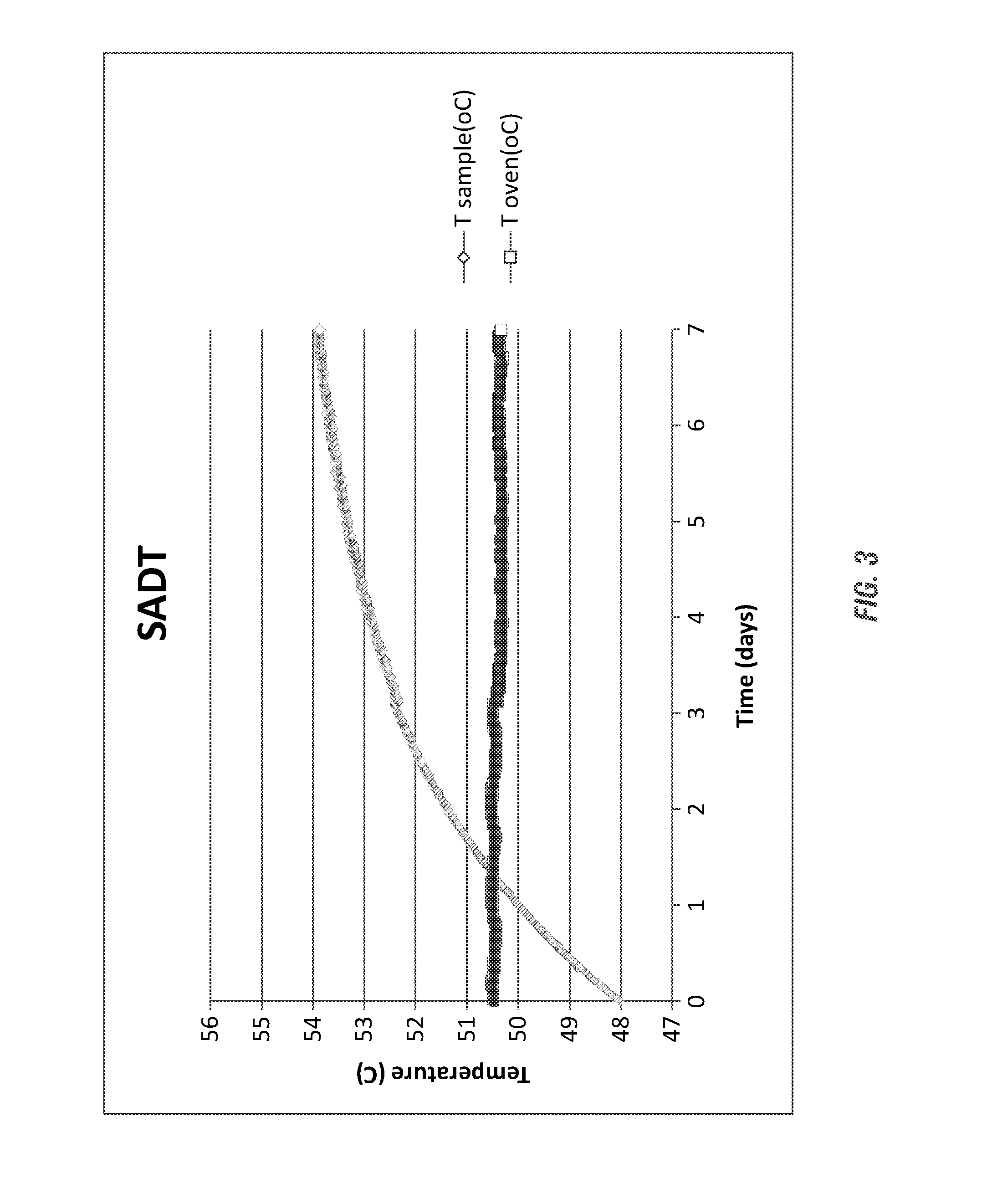

Efficient stabilizer in controlling self accelerated decomposition temperature of peroxycarboxylic acid compositions with mineral acids

ActiveUS9288992B2Low profileGood material compatibilityBiocideAnimal repellantsShip stabilityDecomposition

Highly acidic, stabilized peroxycarboxylic acid compositions are disclosed as having both improved antimicrobial efficacy in comparison to conventional peroxyoctanoic acid and peroxyacetic acid compositions for sanitizing applications, and improved transport and shipping stability. In particular, low odor and low / no VOC compositions having dual functionality as both acid wash and sanitizing compositions are disclosed.

Owner:ECOLAB USA INC

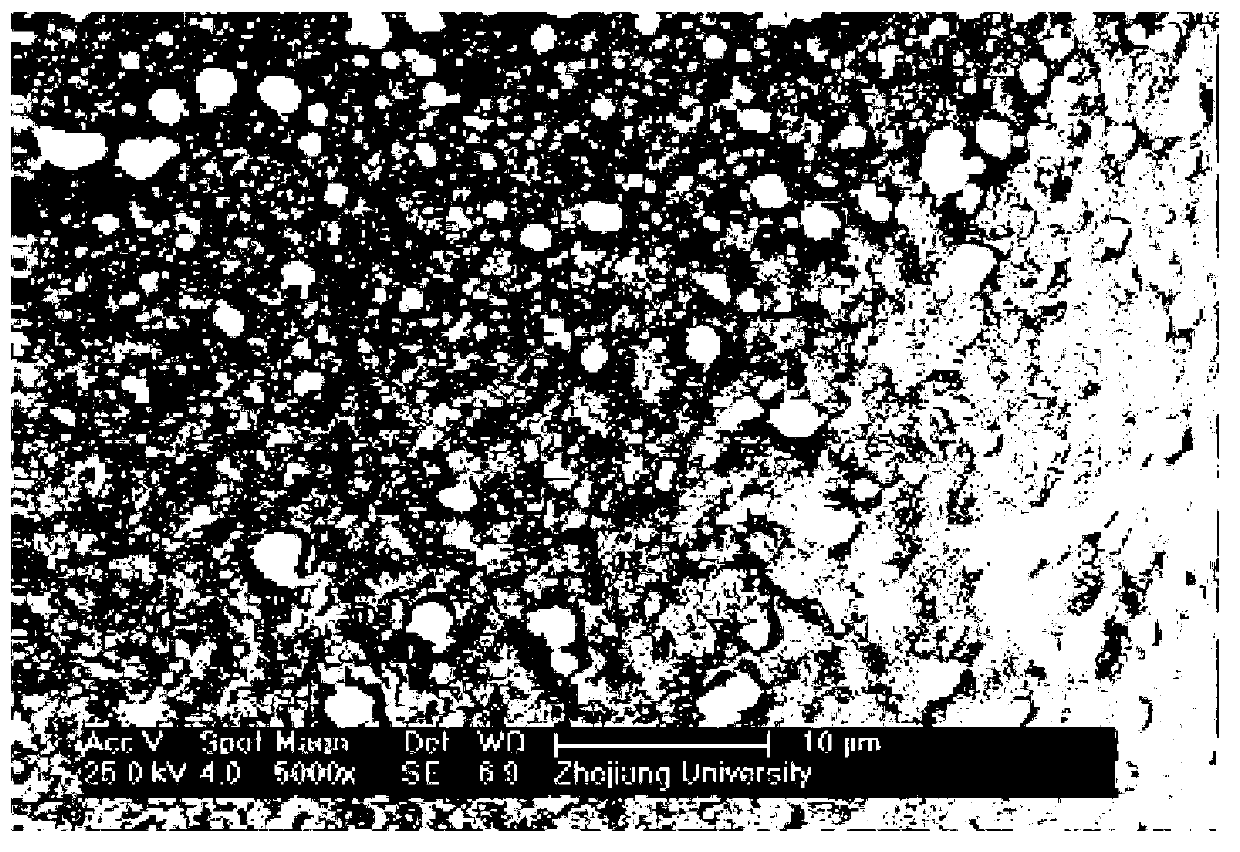

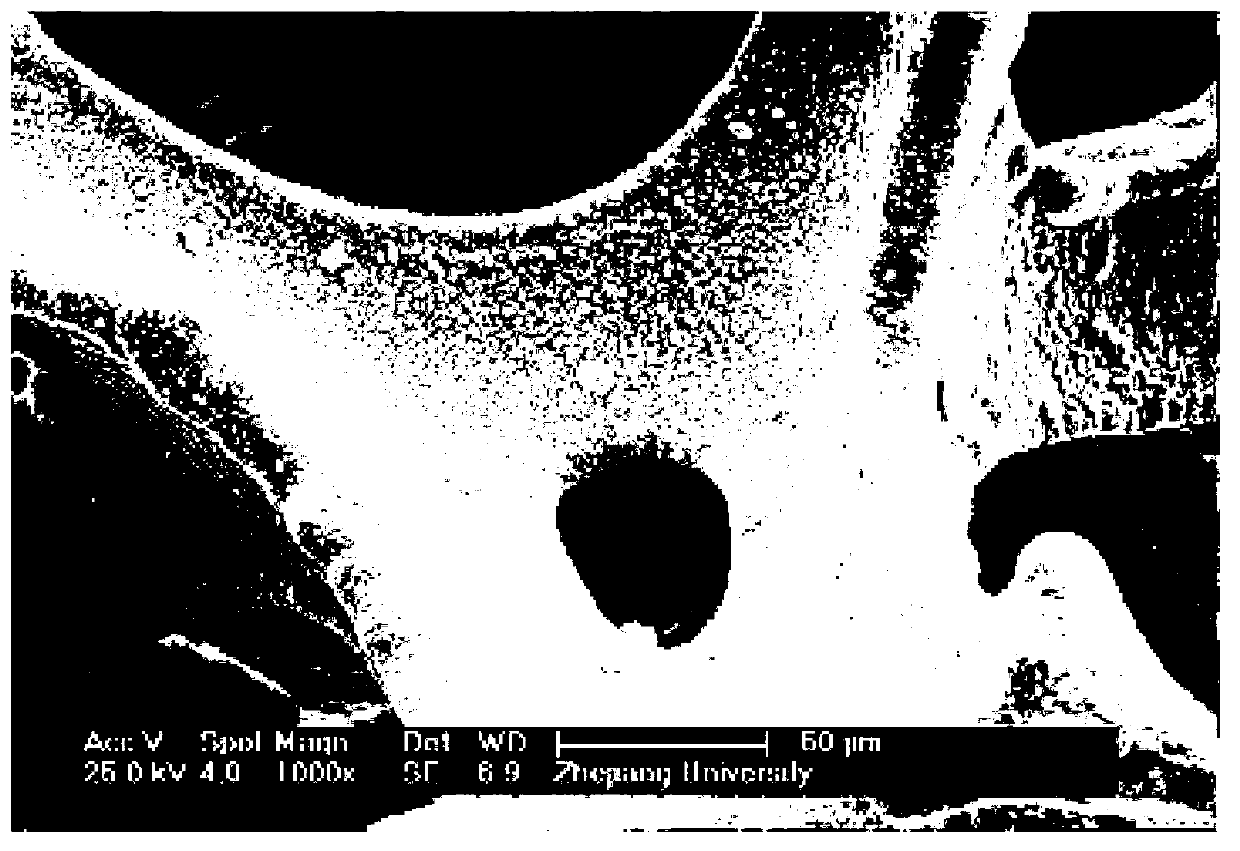

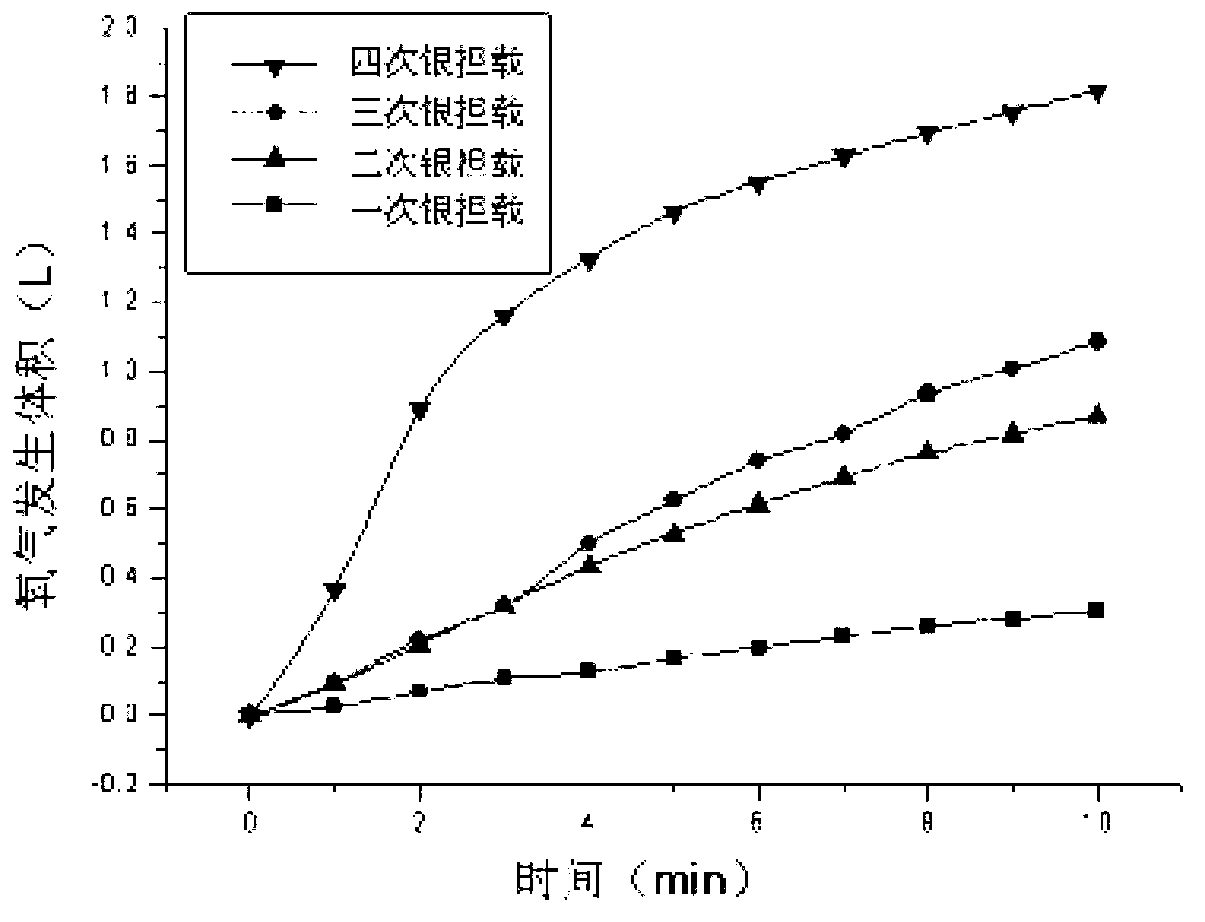

Preparation method of catalysts for oxygen production implemented through decomposition of hydrogen peroxide

InactiveCN103272615AHigh mechanical strengthGood material compatibilityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsShock waveDecomposition

The invention relates to catalyst preparation, and aims to provide a preparation method of catalysts for oxygen production implemented through the decomposition of hydrogen peroxide. The method comprises the following steps of: immersing a nickel-foam solid sample into a silver nitrate solution, heating the obtained object, carrying out a replacement reaction, and cooling the obtained product to room temperature; taking an alkaline sodium borohydride solution, reducing nickel ions in the previous solution to metal nickel and depositing the metal nickel to the solid sample; and taking out the solid sample, calcinating the solid sample for 2-5 hours under nitrogen so as to obtain a silver catalyst taking nickel foam as a carrier. According to the invention, micropores of nickel foam are used as oxygen transport channels, so that the service life of the catalyst is greatly prolonged. Meanwhile, because the structure compatibility of nickel and silver is excellent, and silver atoms are dissolved in the crystal structure of nickel so as to form a solid solution, so that the mechanical strength of nickel foam can be enhanced, and the capability of a carrier to resist shock waves produced by the generation of oxygen is increased, thereby greatly improving the stability and reliability of catalysts.

Owner:ZHEJIANG UNIV

Thermal ink jet ink composition

ActiveUS20100328401A1Shorten speedShorten drying timeSpecial tyresInksSolvent basedPolymer chemistry

A solvent-based inkjet ink composition for inkjet printing includes at least 50 weight percent solvent, a colorant, a humectant, from 0.3 weight % to 8 weight % of a binder resin, and not more than 5 weight percent water. The ink composition is compatible with components of a thermal ink jet printer.

Owner:VIDEOJET TECH INC

Multiple enzyme cleaner for surgical instruments and endoscopes

ActiveUS20090192064A1Easy to cleanGood material compatibilityOrganic detergent compounding agentsSurface-active detergent compositionsActive agentSurface-active agents

The liquid composition is based on surfactants and enzymes, and is particularly useful for manual cleaning of instruments. In manual and ultrasonic application the composition in use concentration shows low foaming and gives a cleaning solution which is not cloudy at least at a temperature in the range from 16° C. to 40° C. In addition, the composition has good cleaning efficacy over a broad temperature range (20 to 55° C.) and shows good material compatibility.

Owner:ECOLAB USA INC

Cleaner composition

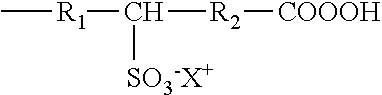

ActiveUS20110319312A1Good material compatibilityFree from corrosionOrganic detergent compounding agentsNon-ionic surface-active compoundsAlkalinityAlcohol

A single phase alkaline composition comprising by weight about 10 to about 25 percent of nonionic surfactant blend comprising a ratio of between about 1:1 to about 1:2 of alcohol ethoxylate:fatty alcohol alkoxylate, about 3-10% of at least one water soluble solvent, about 1-10% of a chelant, 2-12% of an alkalinity source, 0.5-2% of an anionic surfactant blend comprised of at least about 40-70% of a sulfosuccinate, the balance being water. Compositions of the invention are useful for re-moving hydrophobic soils or oils whether they are located on a hard surface or on a linen. A method of cleaning a hard surface is also disclosed comprising the steps of diluting the composition of the invention with water to about 1 to about 3 weight percent, applying the diluted composition to the surface, and wiping the surface, wherein the surface is substantially free of oil or residue and the surface is substantially free of corrosion.

Owner:ECOLAB USA INC

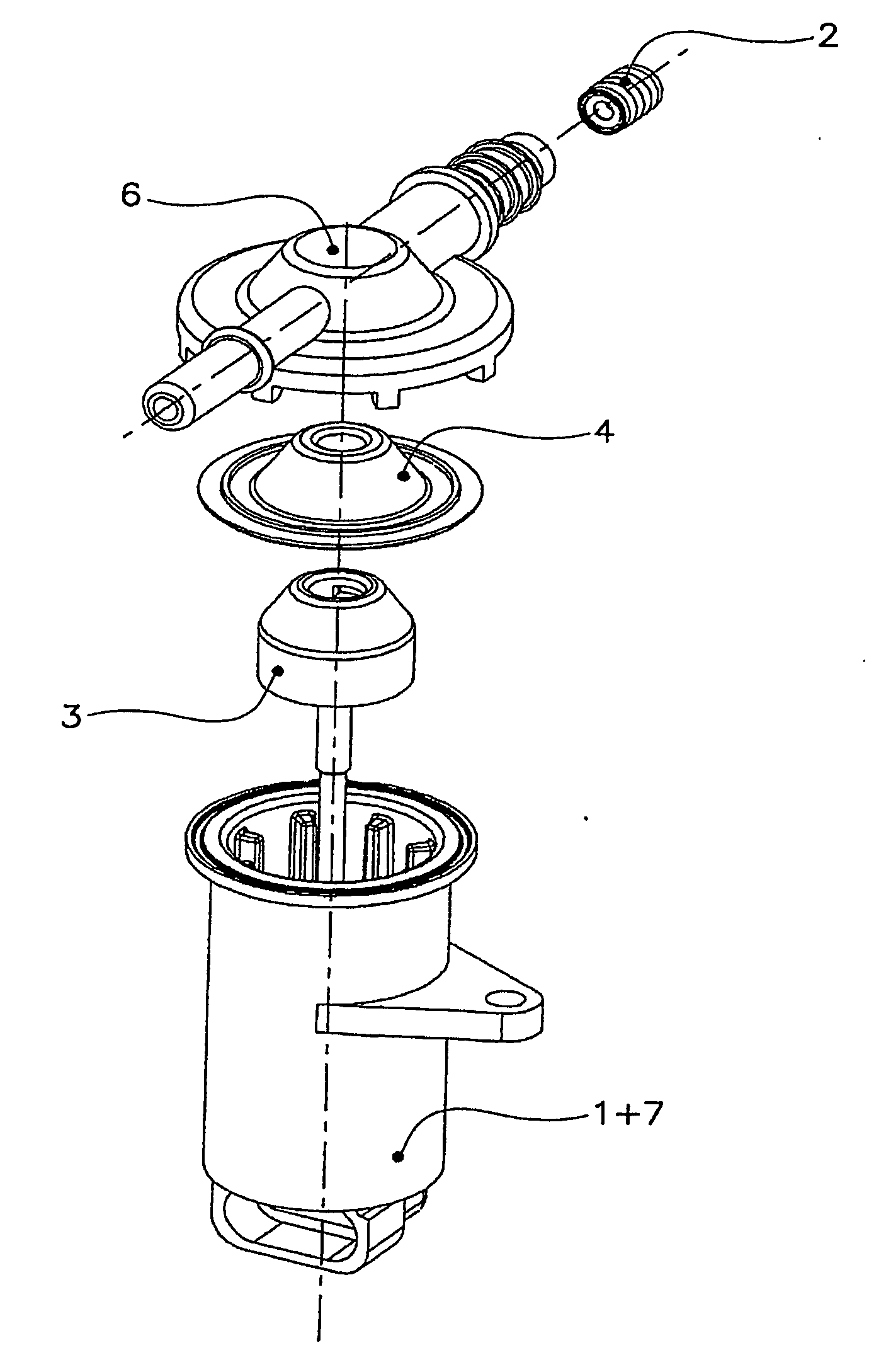

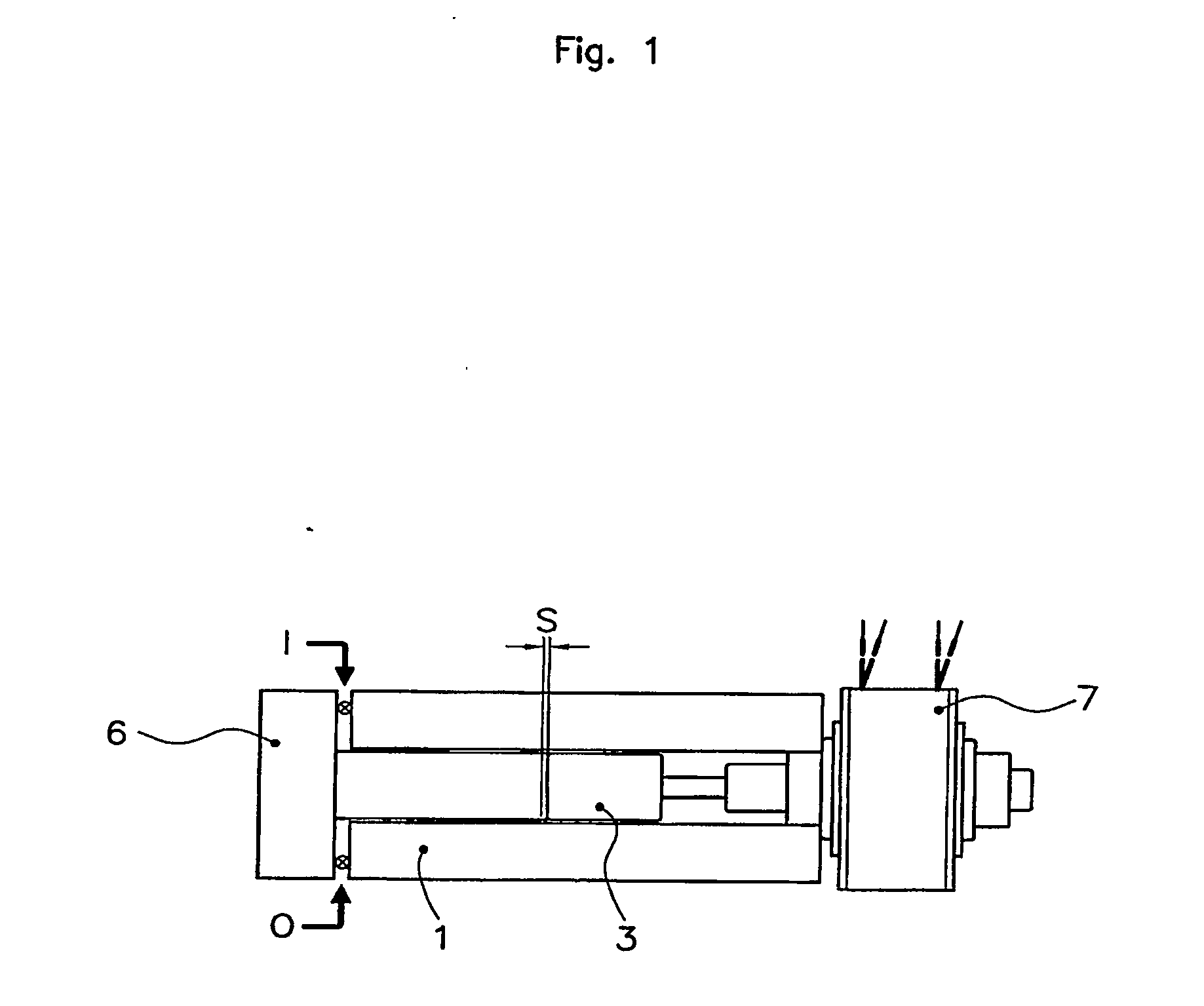

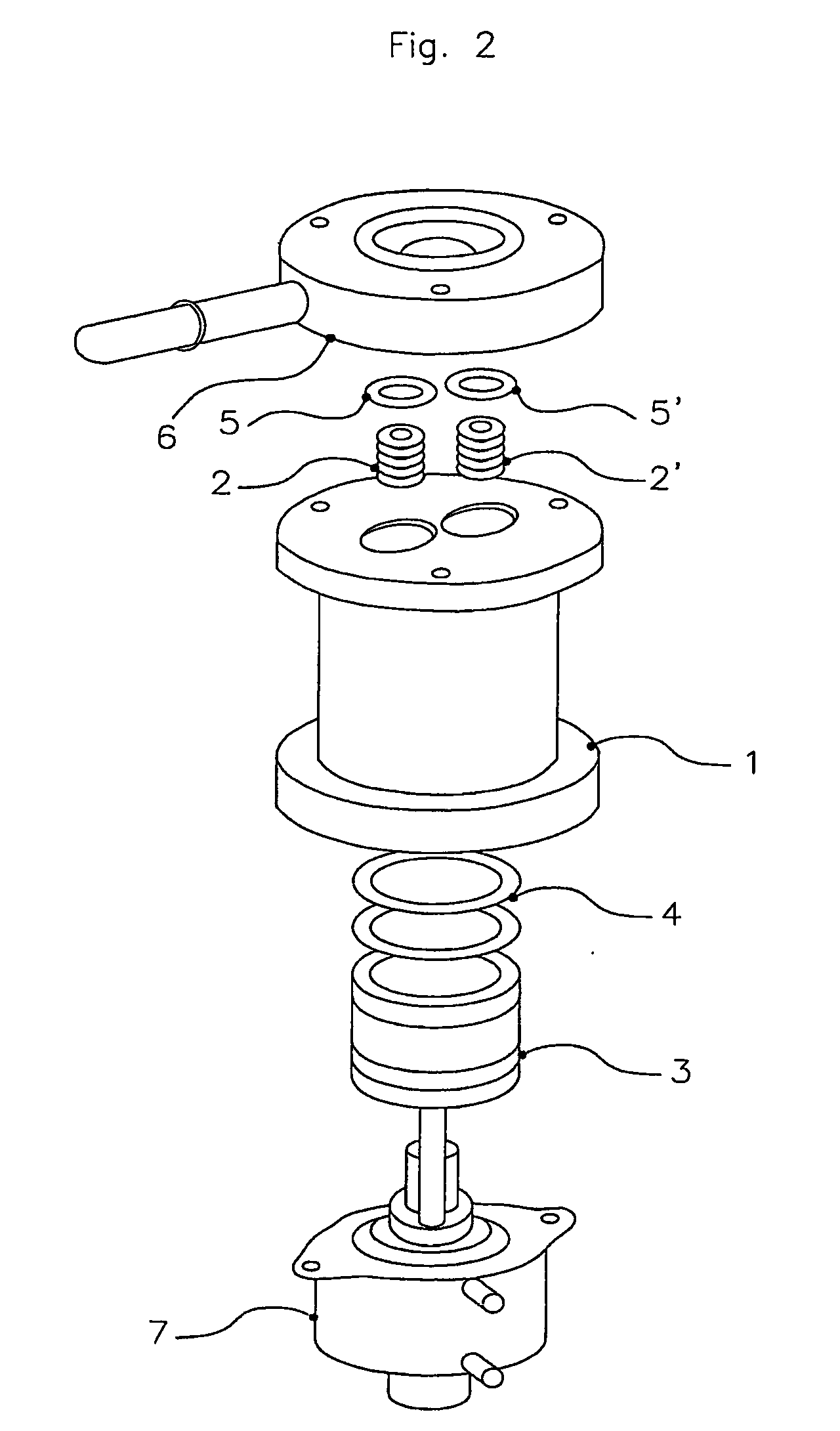

Dosing pump for a liquid fuel additive

InactiveUS20070128054A1Minimizes potential riskGood repeatabilityNon-fuel substance addition to fuelPiston pumpsEngineeringLiquid fuel

A dosing pump for a liquid additive in the fuel of a heavy fuel engine. The pump includes a piston, a cylinder and an actuator for moving the piston axially in the cylinder. The actuator is a high resolution linear actuator.

Owner:PLASTIC OMNIUM ADVANCED INNOVATION & RES SA

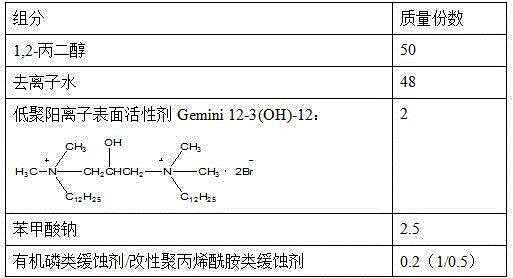

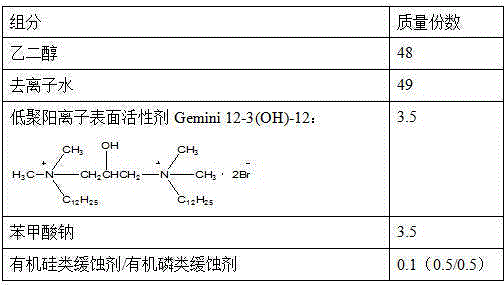

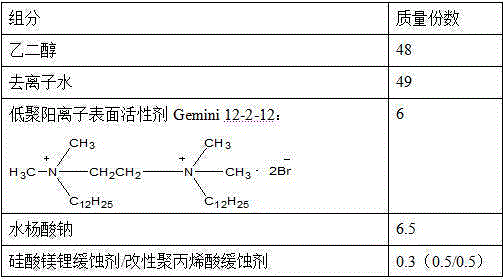

Anti-icing fluid capable of realizing thickening through at least one oligomeric cationic surfactant and preparation method of anti-icing fluid

The invention relates to the field of deicing and icing prevention, particularly to an anti-icing fluid capable of realizing thickening through at least one oligomeric cationic surfactant and formed by a polyol-water mixed solution as well as a preparation method of the anti-icing fluid. The anti-icing fluid comprises components in parts by mass as follows: 0.5-15 parts of at least one oligomeric cationic surfactant, 0.5-15 parts of at least one anionic inorganic salt or organic salt, 30-90 parts of at least one polyol and 0.01-2 parts of at least one corrosion inhibition aid. According to the technology, the at least one micro-molecular oligomeric cationic surfactant is self-assembled to form long flexible worm-like micelles under induction of countra-ions provided by the organic or inorganic salt, the polyol-water mixed solution has the excellent viscosity which can exceed 5,000 cps, the anti-icing time for deicing and icing prevention is guaranteed, and meanwhile, a series of problems about viscosity stability and hydrated gel performance due to the fact that thickening type deicing and anti-icing fluids take polymers as thickeners are solved.

Owner:成都民航六维航化有限责任公司

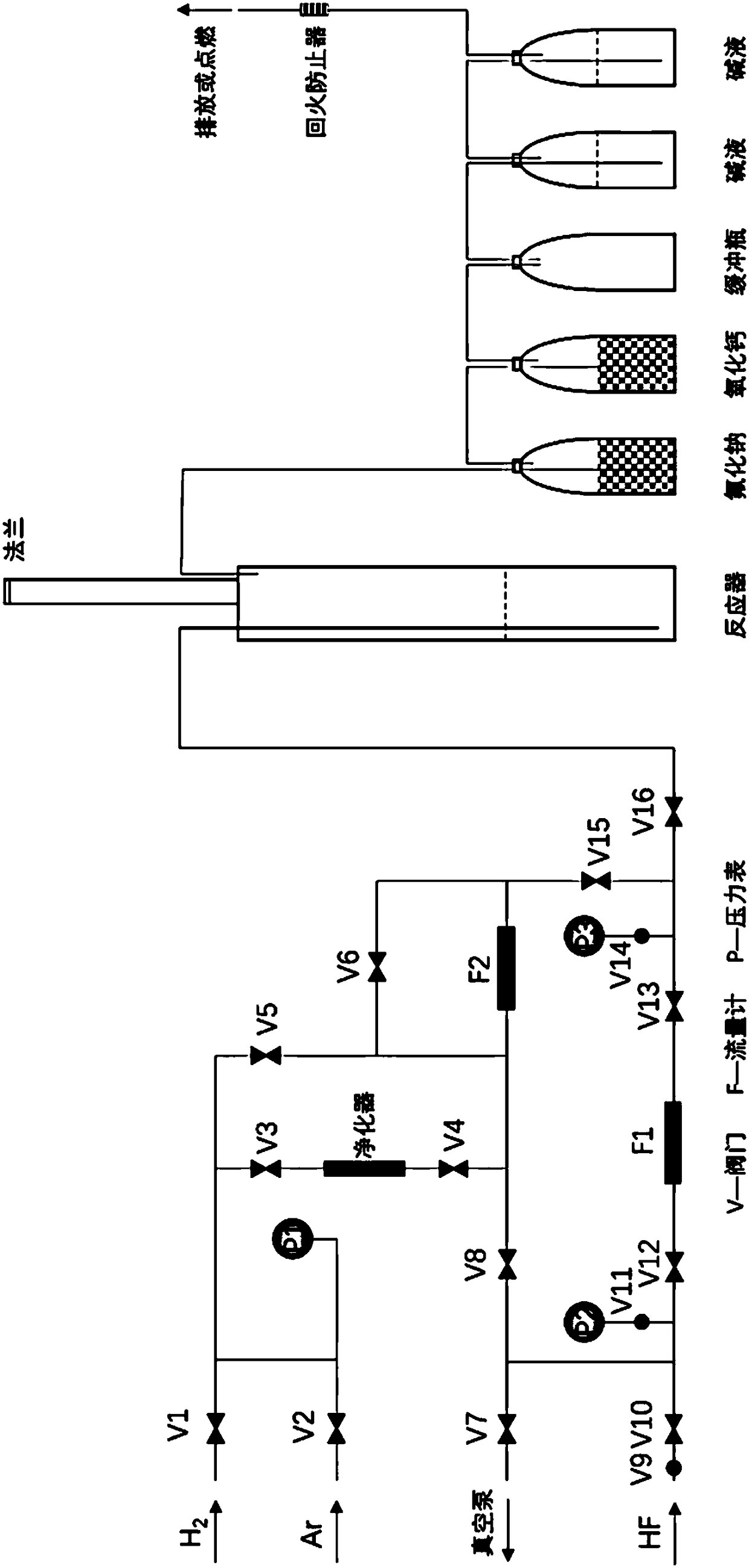

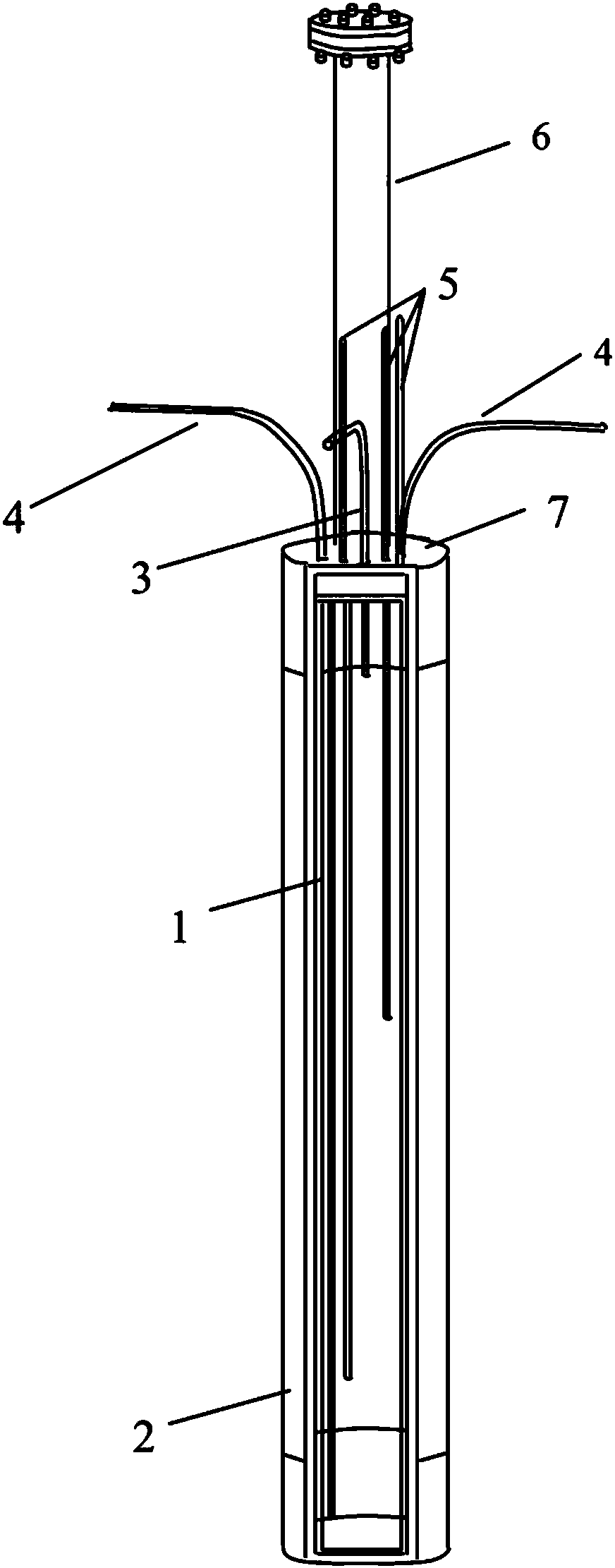

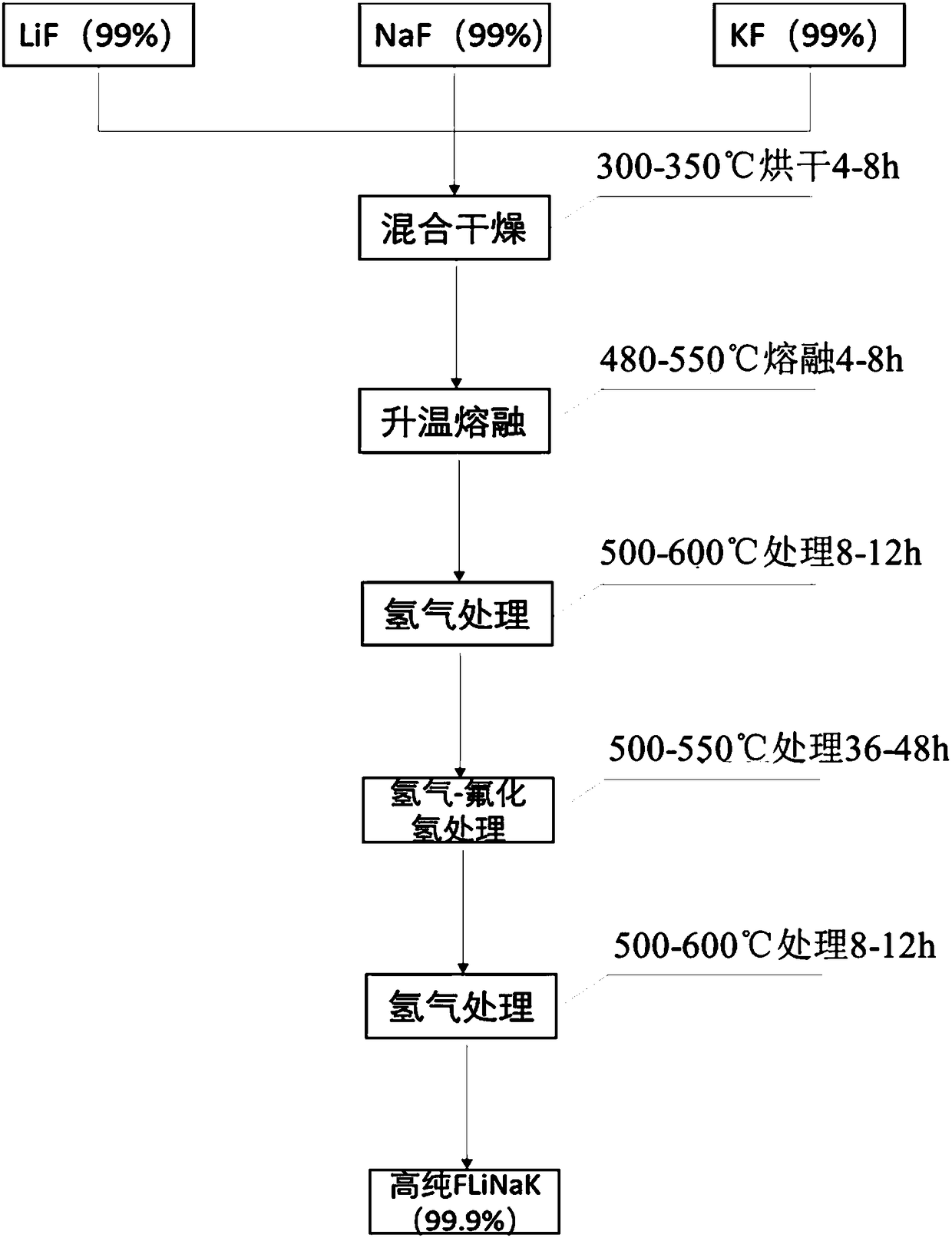

FLiNaK fused salt and preparation method, reactor and preparation device thereof

ActiveCN108376570ALess corrosiveLow molten salt corrosivenessNuclear energy generationCooling arrangementTungstenFLiNaK

The invention discloses a FLiNaK fused salt and a preparation method, a reactor and a preparation device thereof. The contents of oxygen, sulfur, chlorine, silicon, nickel, iron, calcium, aluminum, barium, chromium, cobalt, cadmium, manganese, magnesium, copper, phosphorus, lead, zinc, vanadium, titanium, molybdenum, tungsten, zirconium, strontium, and stannum in the FLiNaK fused salt is lower than 0.01%, and the total content of impurity elements is not more than 0.1%; and the mass ratio of LiF, NaF and KF is 29.3:11.7:59.0. The preparation method includes mixing and drying; (2) heating and melting; (3) performing bubbling treatment with hydrogen for more than 8 hours at the temperature of 500-600 DEG C; (4) performing the bubbling treatment on the mixture gas of hydrogen fluoride and hydrogen with the ratio of 1:(4-9) for more than 36 hours at the temperature of 500-550 DEG C; and (5) performing retreatment with hydrogen. The FLiNaK fused salt has excellent material compatibility with Hastelloy N, GH3535 and SUS316Ti alloy.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

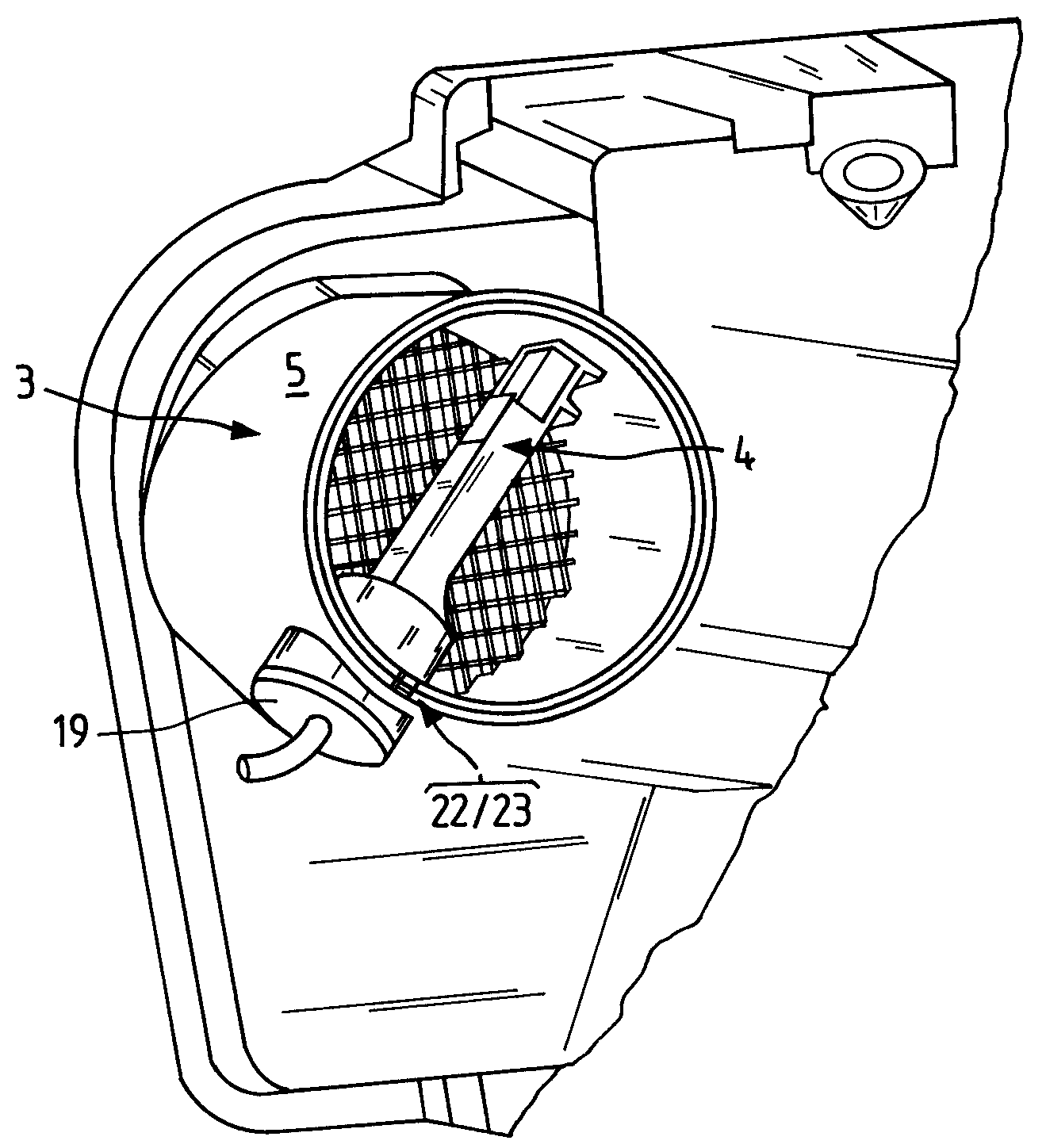

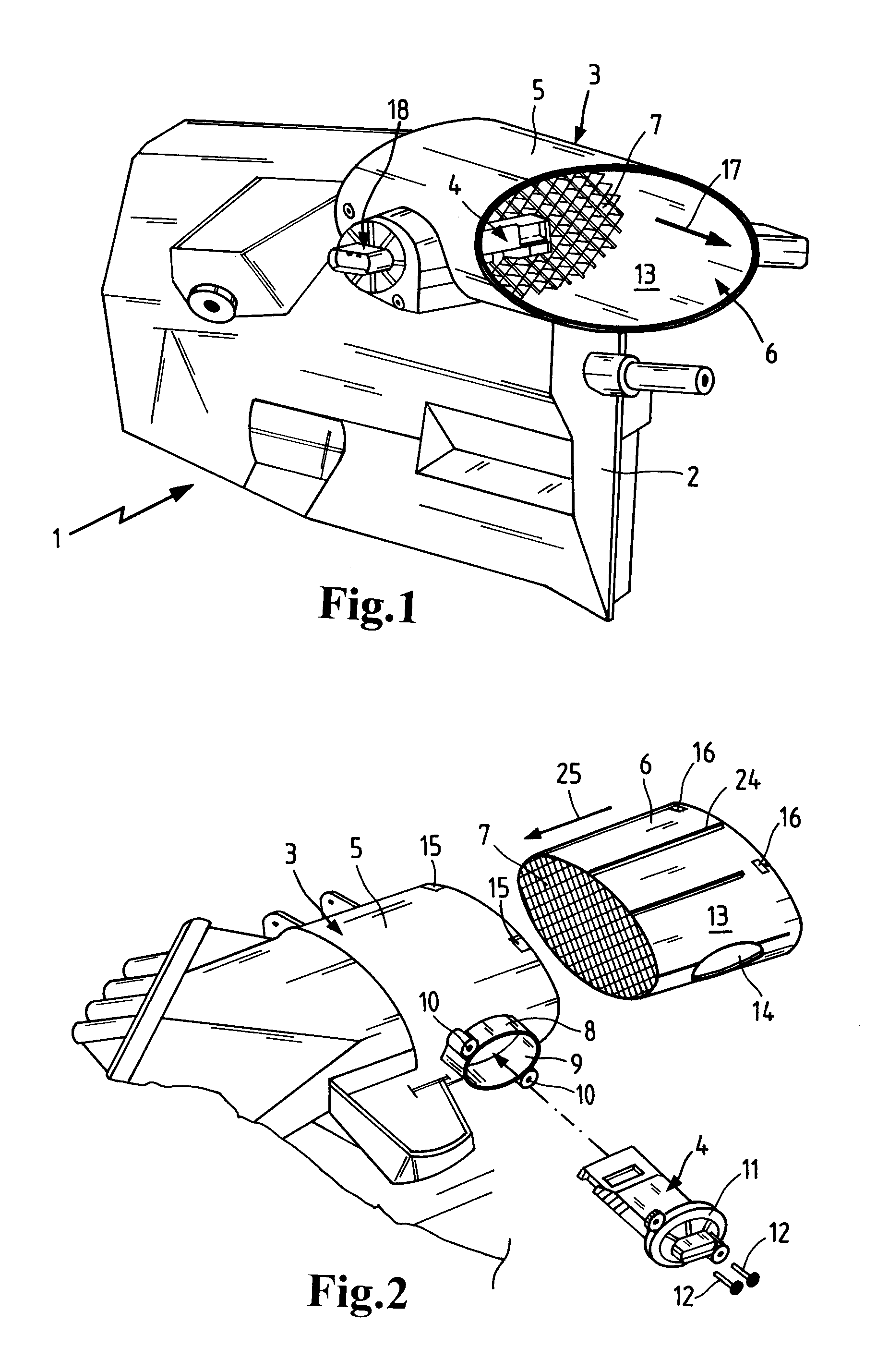

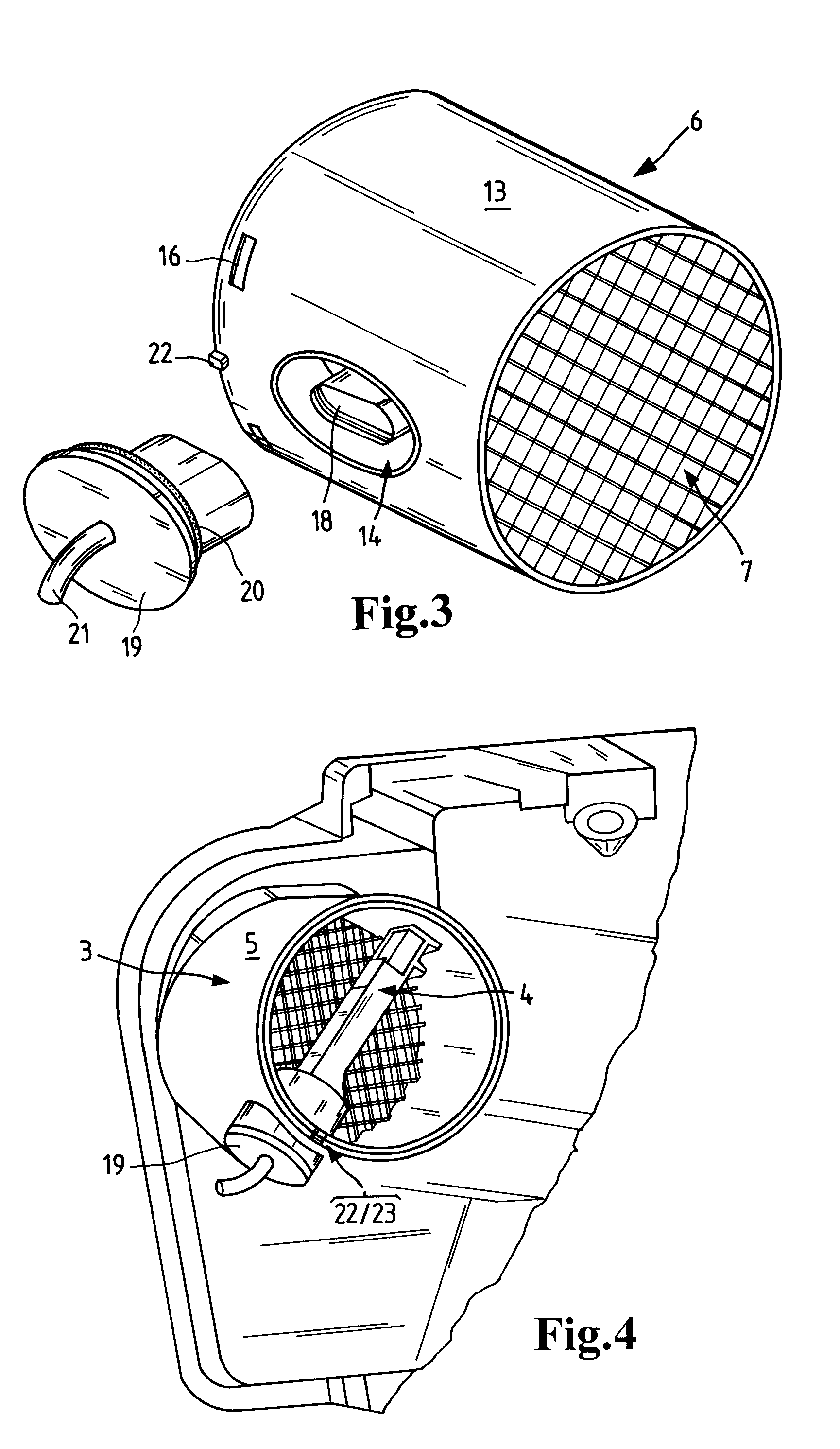

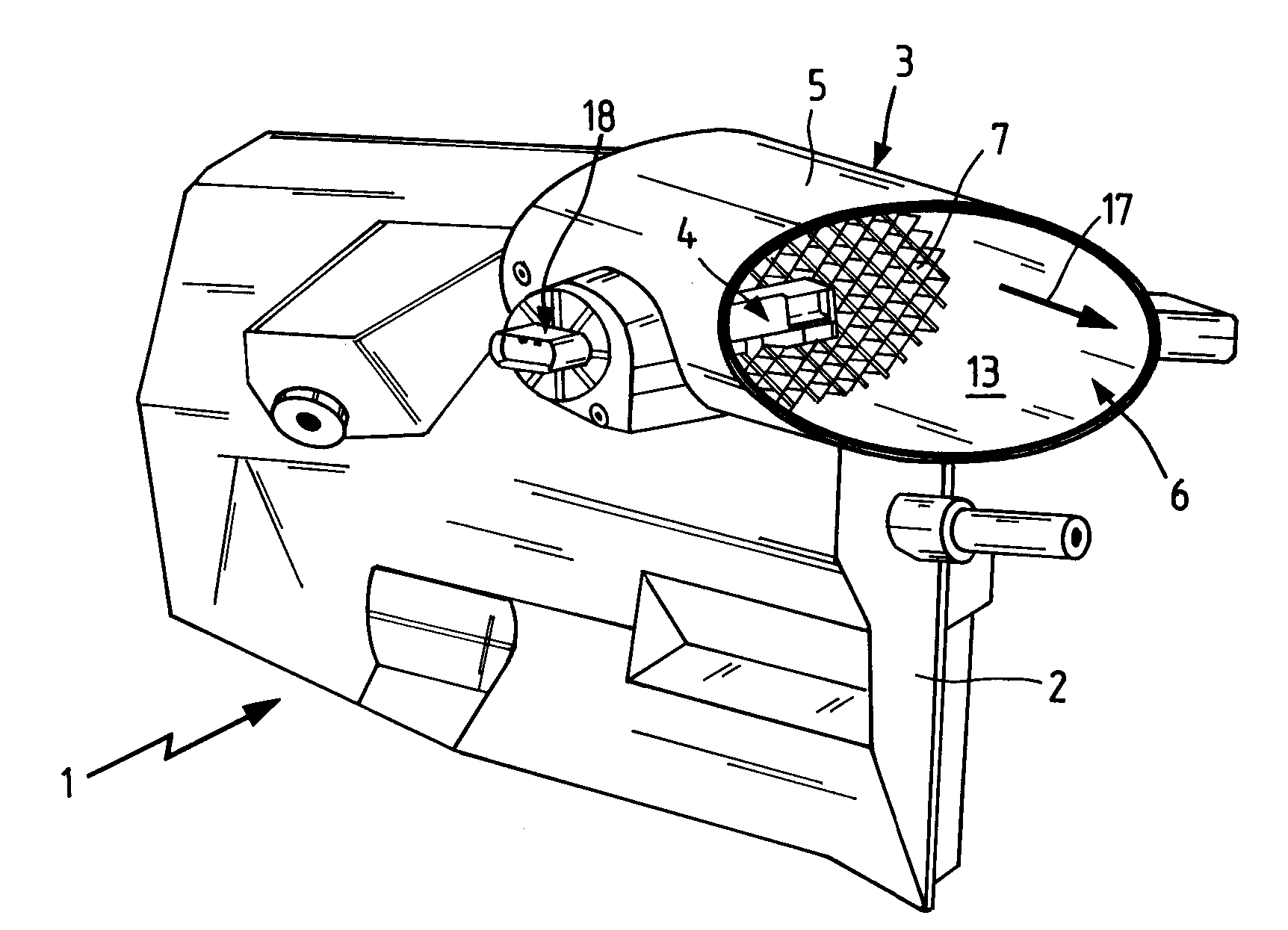

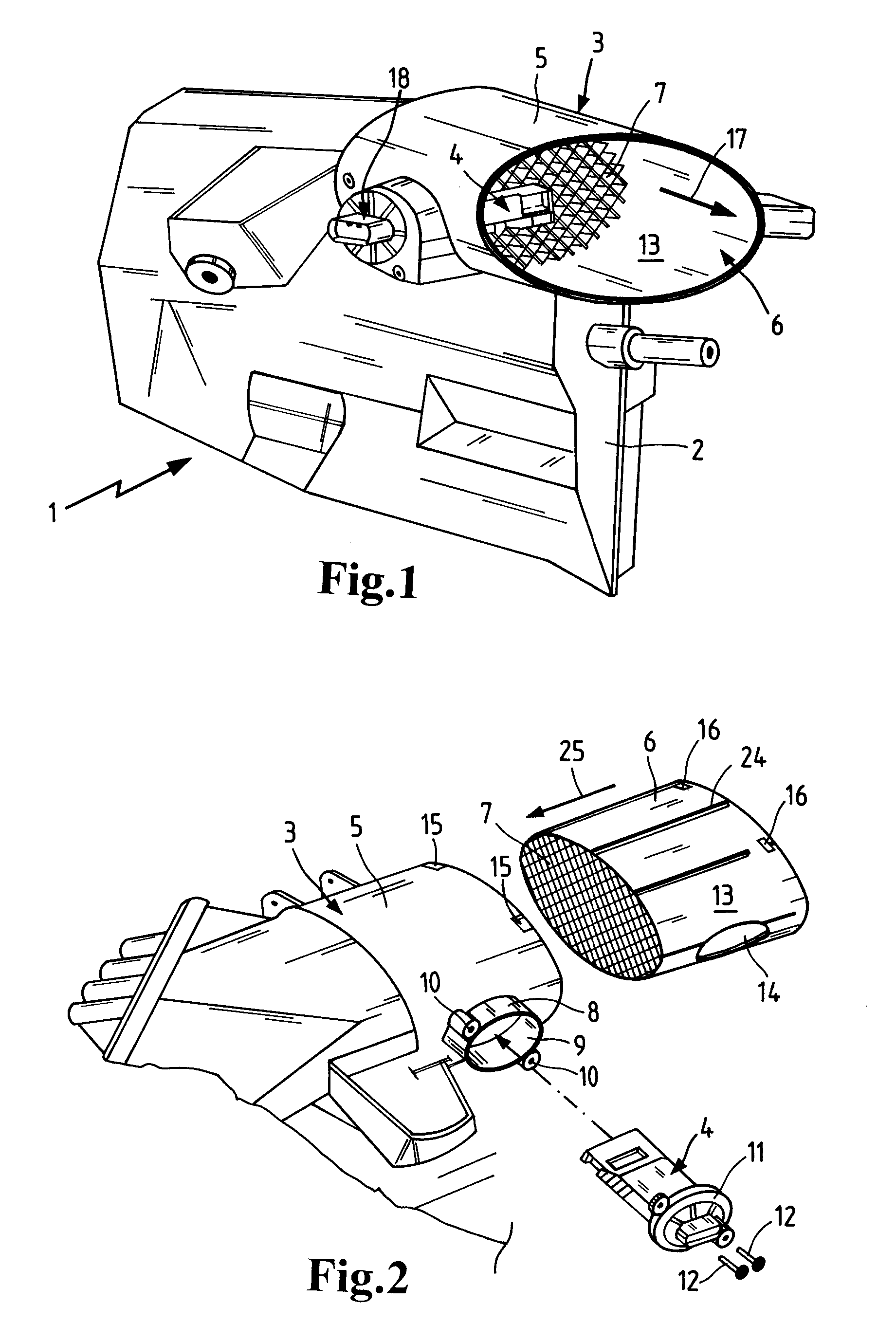

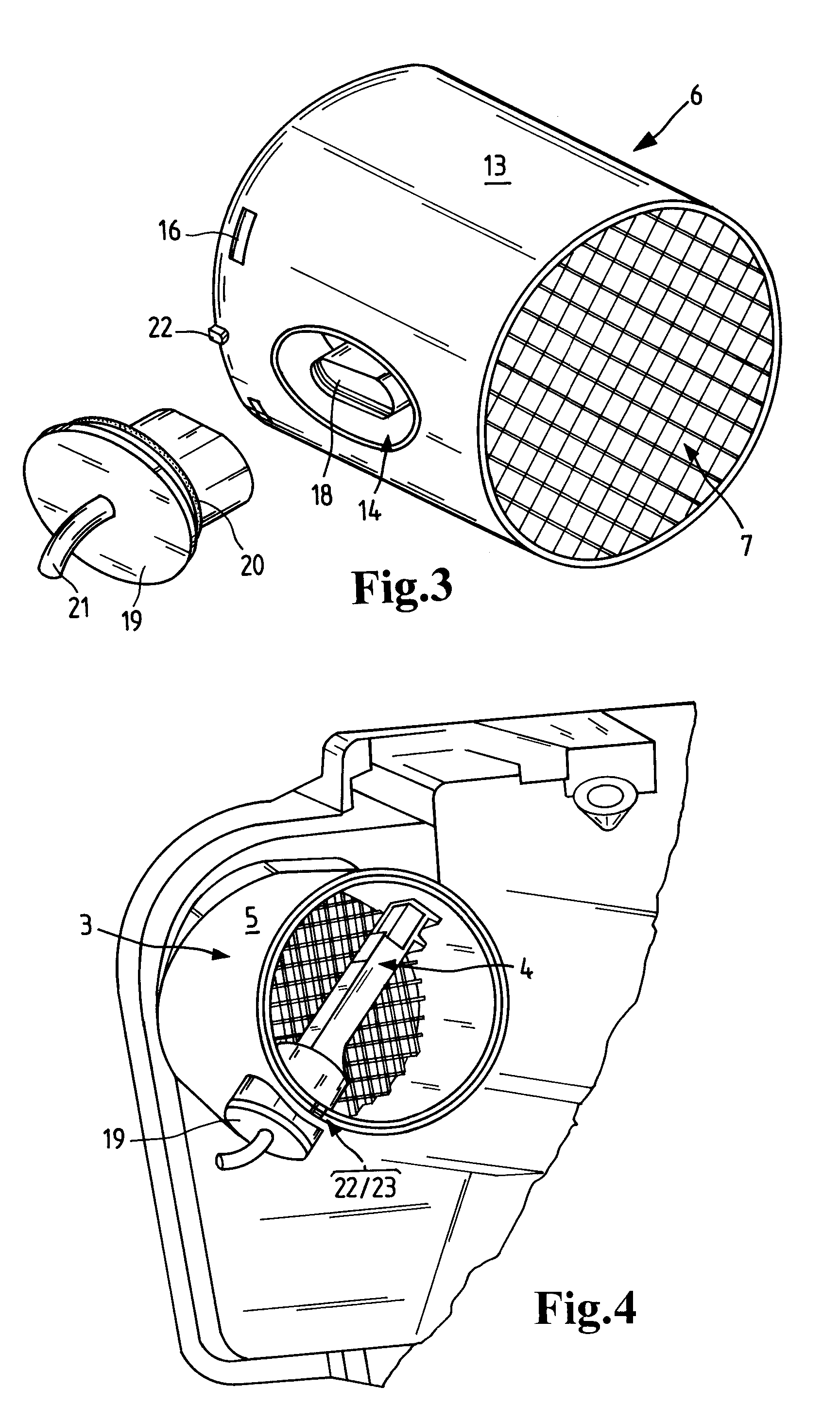

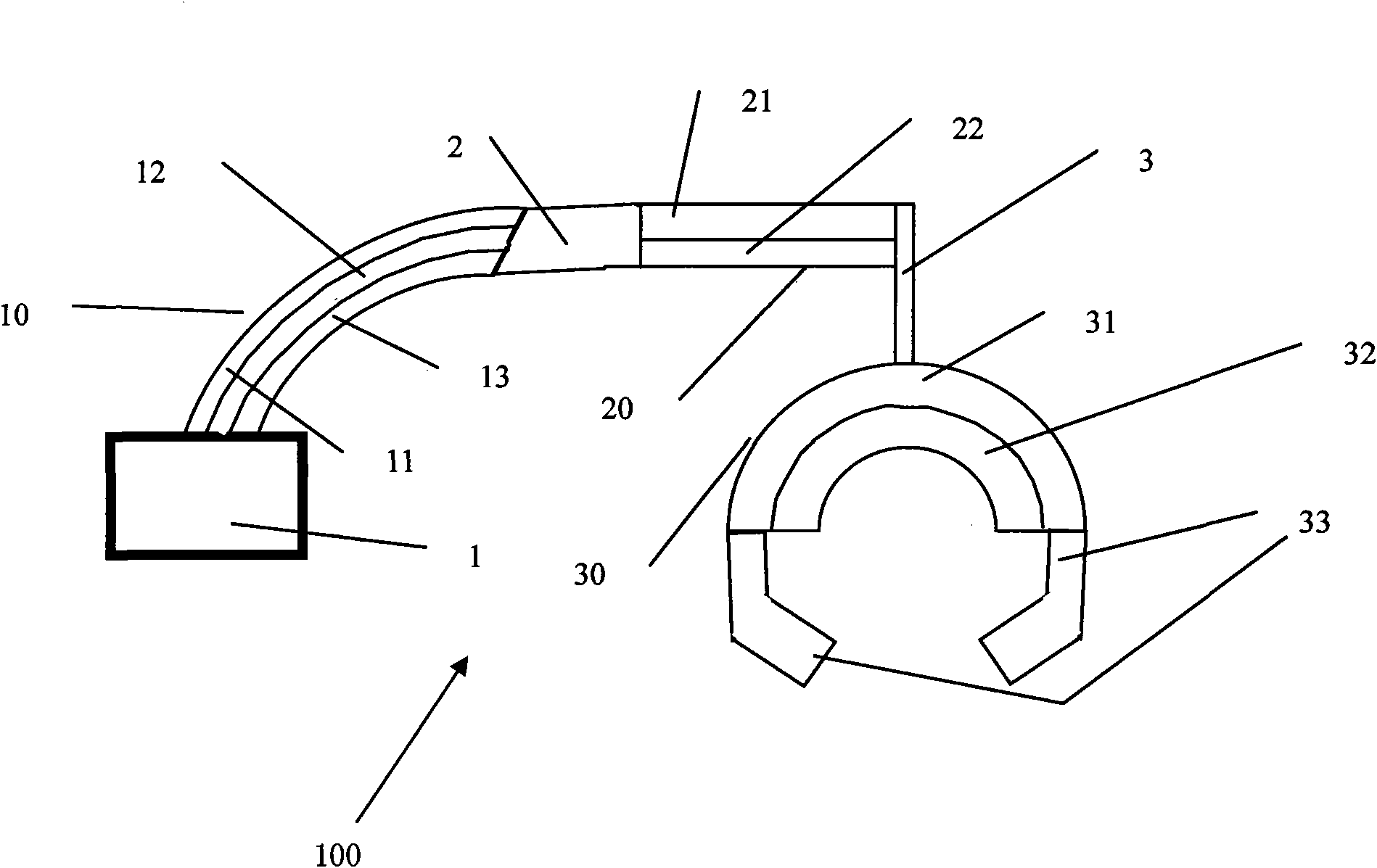

Air Filter System of a Motor Vehicle

ActiveUS20100018400A1High measurement accuracyEasy to measureCombination devicesAuxillary pretreatmentAir filtrationAir filter

An air filter system of a motor vehicle has an air filter housing with a housing part of a moisture-sensitive plastic material and an air passage section with a circumferentially extending passage wall, wherein the passage wall of the air passage section is integrally formed of identical material on the housing part of the air filter housing. A mass air flow sensor is arranged in the air passage section. A plastic insert of a moisture-insensitive plastic material is disposed on an inner side of the passage wall of the air passage section and lines the passage wall.

Owner:MANN HUMMEL GMBH

Air filter system of a motor vehicle

ActiveUS8241413B2Easy to measureEasy to controlCombination devicesAuxillary pretreatmentAir filtrationPlastic materials

An air filter system of a motor vehicle has an air filter housing with a housing part of a moisture-sensitive plastic material and an air passage section with a circumferentially extending passage wall, wherein the passage wall of the air passage section is integrally formed of identical material on the housing part of the air filter housing. A mass air flow sensor is arranged in the air passage section. A plastic insert of a moisture-insensitive plastic material is disposed on an inner side of the passage wall of the air passage section and lines the passage wall.

Owner:MANN HUMMEL GMBH

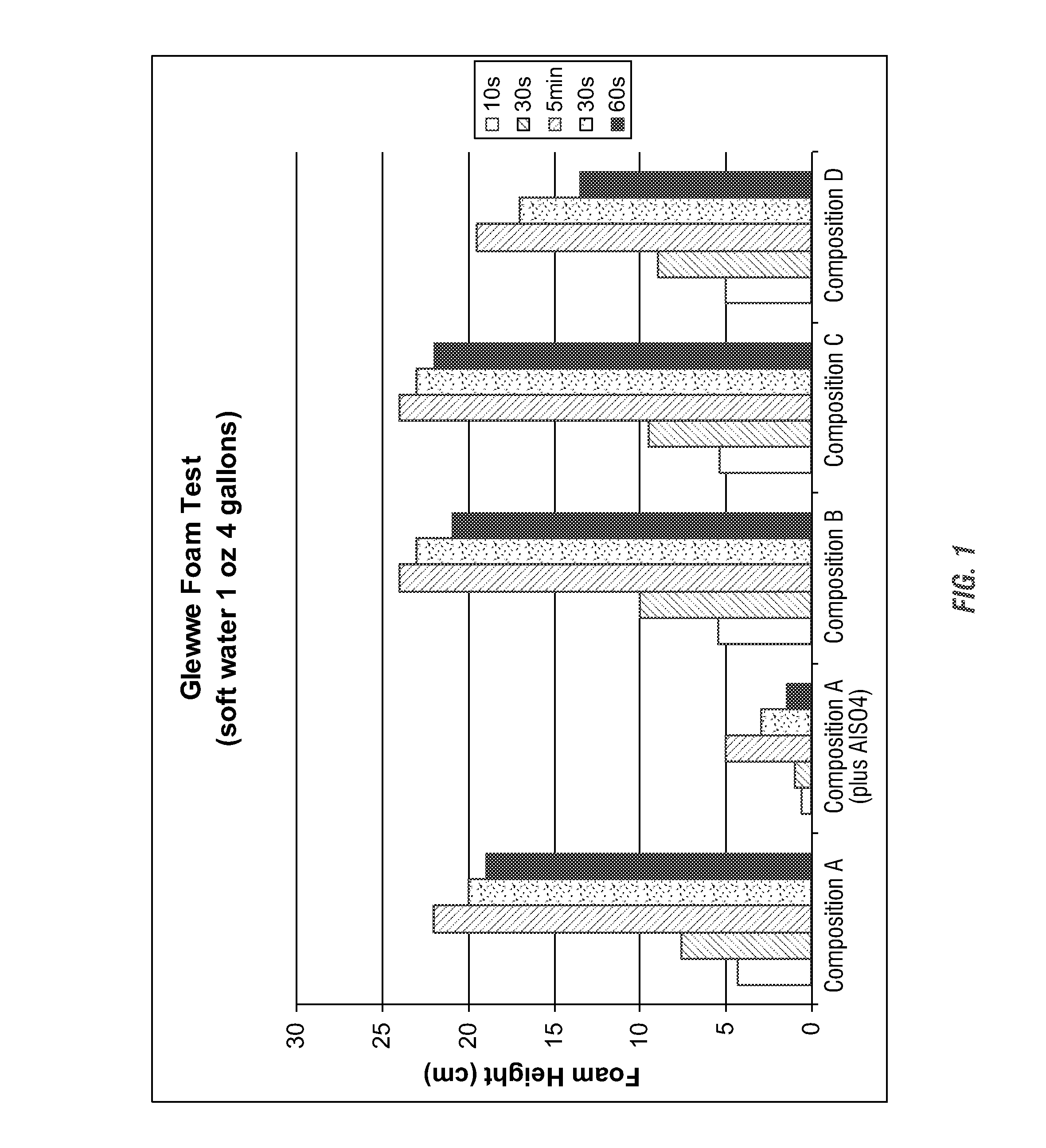

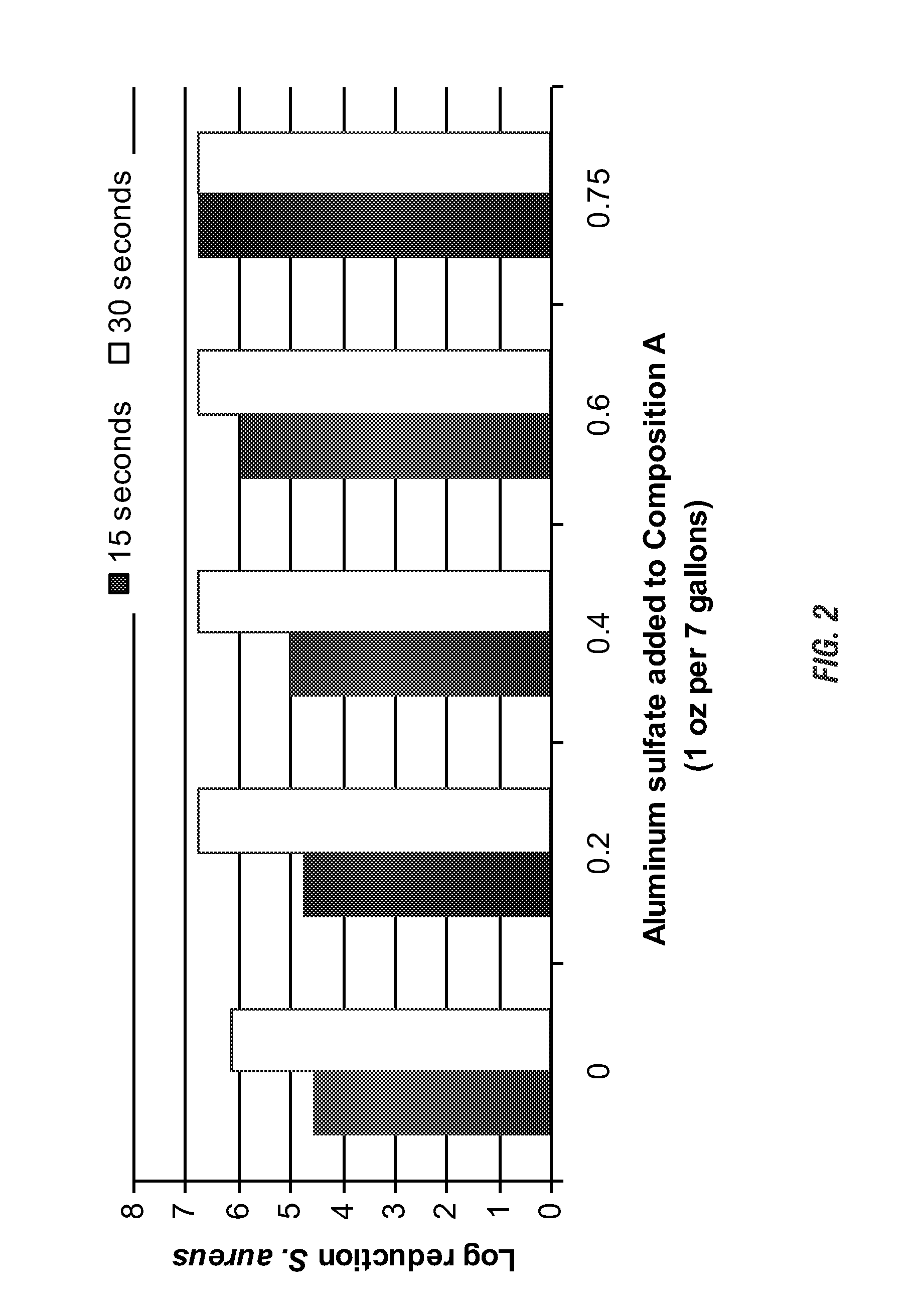

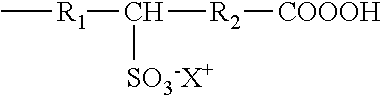

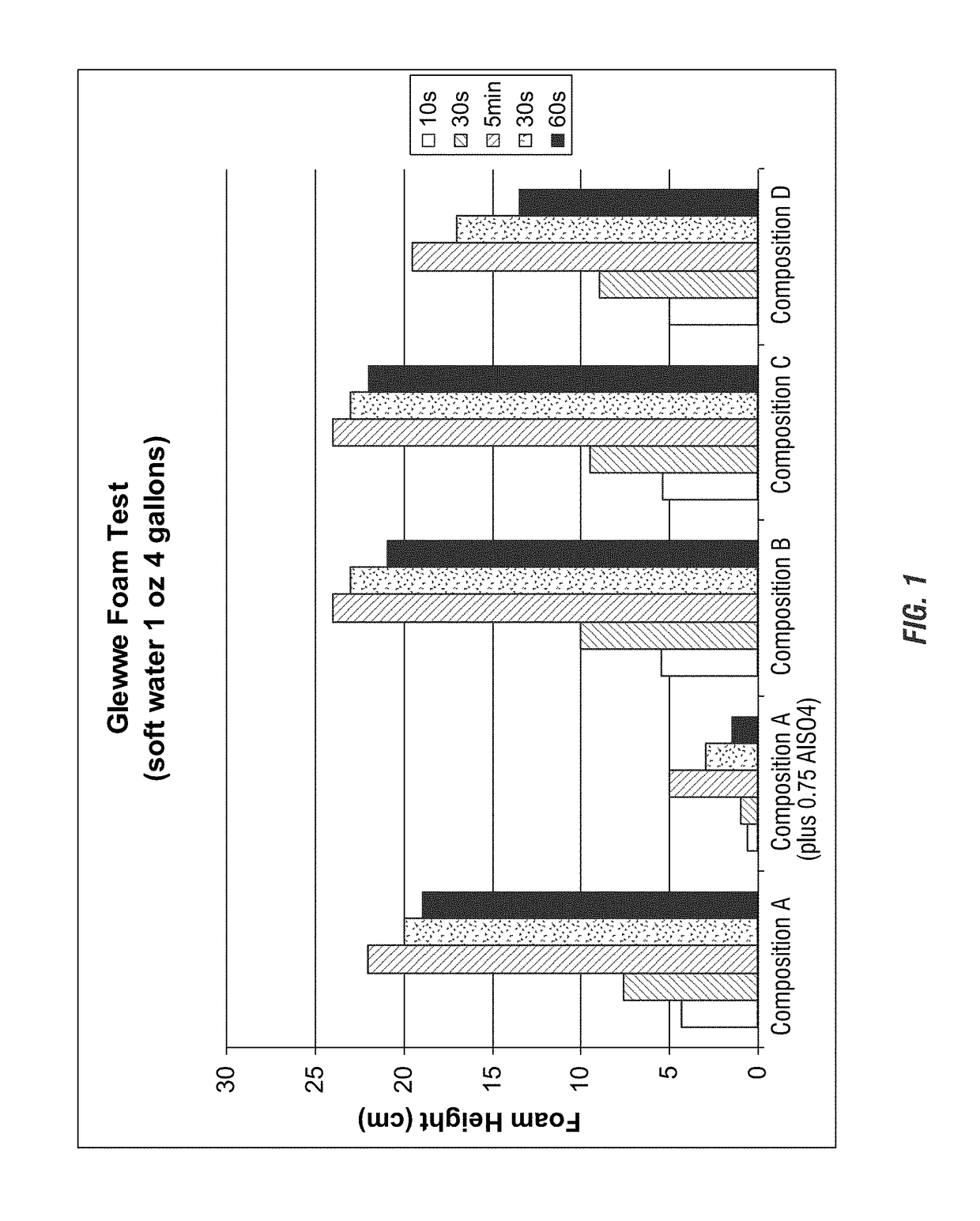

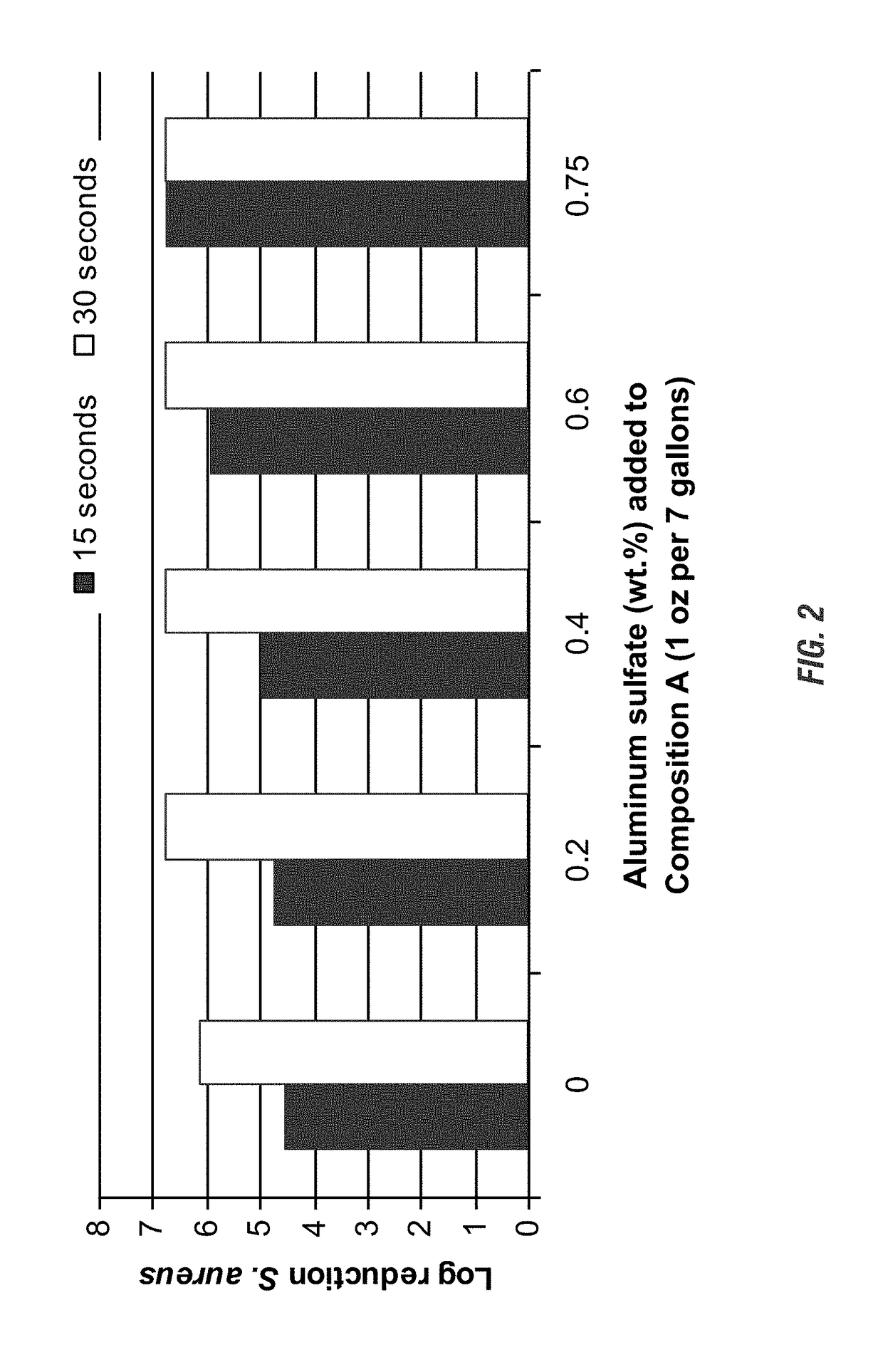

Defoamer useful in a peracid composition with anionic surfactants

ActiveUS20140255514A1Reduce microbial countWithout impacting antimicrobial and/or sanitizing efficacy of the compositionsBiocideAnimal repellantsCarboxylic acidDual function

Low foaming, highly acidic peroxycarboxylic acid sanitizing compositions are disclosed as having both improved antimicrobial efficacy in comparison to conventional peroxyoctanoic acid and peroxyacetic acid compositions for sanitizing applications. The compositions include a combination of a low-foaming surfactant and an aluminum sulfate (or other metal salt) defoaming agent that is compatible with the highly acidic peroxycarboxylic acid sanitizing compositions. In particular, the sanitizing peroxycarboxylic acid compositions are also low odor and low / no VOC dual functioning acid wash and sanitizing compositions.

Owner:ECOLAB USA INC

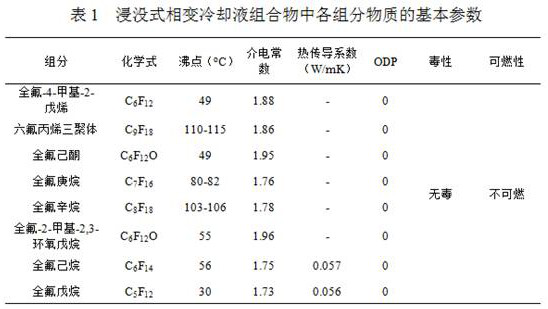

Immersed liquid phase change cooling medium and application thereof in cooling system of electronic equipment

InactiveCN111726971AImprove data transfer performanceHigh electrical insulationCooling/ventilation/heating modificationsEpoxyMeth-

The invention discloses an immersed liquid phase change cooling medium and application thereof in a cooling system of electronic equipment, wherein the cooling medium is a mixture formed by mixing one, two or three of perfluoro-4-methyl-2-pentene, a hexafluoropropylene tripolymer, perfluorohexanone, perfluoroheptane, perfluorooctane, perfluoro-2-methyl-2, 3-epoxy pentane, perfluorohexane and perfluoropentane. The immersed phase change cooling medium provided by the invention has the characteristics of high electrical insulation property, low viscosity, relatively low boiling point, high gasification latent heat, good compatibility and stability, incombustibility, combustion inhibition, low global warming potential (GWP), zero ozone depletion potential (ODP) and the like.

Owner:ZHEJIANG UNIV OF TECH

Thermal ink jet ink composition

ActiveUS8632630B2Keep for a long timeReduce rateCosmetic preparationsToilet preparationsDrop weightOrganic solvent

A thermal ink jet ink composition includes one or more volatile organic solvents, wherein the one or more volatile organic solvents are selected from C1-C4 alcohols, C3-C6 ketones, C3-C6 esters, C4-C8 ethers, and mixtures thereof; one or more humectants, wherein the humectants are present in an amount not more than 30% by weight of the ink composition; one or more binder resins; and one or more dyes. The ink composition is suitable for use in a thermal ink jet printer and the ink composition has a slow rate of kogation such that it is capable of being printed at least 10 million drops per nozzle from the thermal ink jet printer before drop weight of the ink composition is reduced by more than 10%.

Owner:VIDEOJET TECH INC

Thermal ink jet ink composition

ActiveUS20150109390A1Extension of timeShorten drying timeMeasurement apparatus componentsFilm/foil adhesivesOrganic solventSURFACTANT BLEND

A thermal ink jet ink composition include a volatile organic solvent, a binder resin, a dye, a humectant in an amount from 1% to 40% by weight of the ink composition, and an additive for extending the decap time. The additive is present in an amount greater than 0.01% by weight of the thermal ink jet ink composition. The additive is selected from fluorinated surfactants, ionic surfactants, and nonionic surfactants.

Owner:VIDEOJET TECH INC

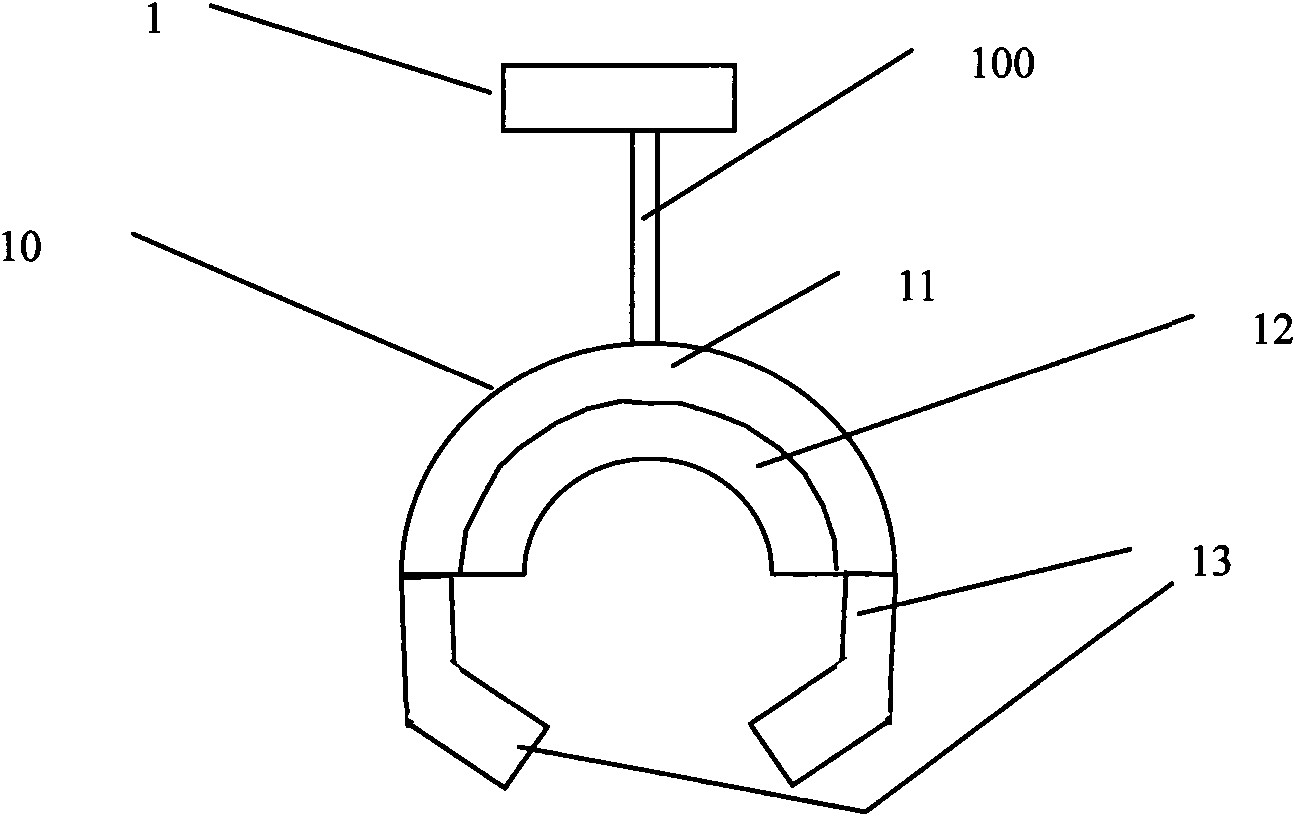

Photic driving robot and method for driving the robot

The invention provides a photic driving robot, at least comprising a base, wherein the base is provided with arms which are provided with at least one unit capable of generating deformation, and components for playing a deformation role in the unit are made from photoinduced deformation materials. The invention also provides a method for driving the robot, i.e. lights is utilized to irradiate the photoinduced deformation materials on the unit of the robot so as to lead the unit to generate deformations, thus controlling the motions of the robot. The robot has an executing mechanism and an operating mechanism which are relatively simple, and the size thereof can be made to be smaller; the photic driving method has the advantages of fastness, accuration, environmental-protection and low energy consumption; and the robot has the characteristics of being capable of remote operation, and the like, which are not provided in other driving modes.

Owner:FUDAN UNIV

Efficient stabilizer in controlling self accelerated decomposition temperature of peroxycarboxylic acid compositions with mineral acids

InactiveUS20140256811A1Low profileGood material compatibilityBiocideDisinfectionDecompositionShip stability

Highly acidic, stabilized peroxycarboxylic acid compositions are disclosed as having both improved antimicrobial efficacy in comparison to conventional peroxyoctanoic acid and peroxyacetic acid compositions for sanitizing applications, and improved transport and shipping stability. In particular, low odor and low / no VOC compositions having dual functionality as both acid wash and sanitizing compositions are disclosed.

Owner:ECOLAB USA INC

Photo gripping device and gripping method

The invention provides a photo gripping device, comprising a pedestal at least, wherein the pedestal is provided with an arm, the arm is provided with a unit capable of producing gripping deformation, and the effective deformation part in the gripping unit is made by photoinduced deformation material. The invention also provides a gripping method, namely light irradiates the photoinduced deformation material on the gripping unit of the gripping device to cause the gripping unit to deform, so as to realize gripping function. The actuating mechanism and operation mechanism of the photo gripping device in the invention are relatively simple, the size can be relatively small; and the gripping device provided by the invention has the advantages of being fast, precise, environmental-friendly and low in energy consumption and has the characteristics of not belonging to other driving modes such as remote manipulation and the like.

Owner:FUDAN UNIV

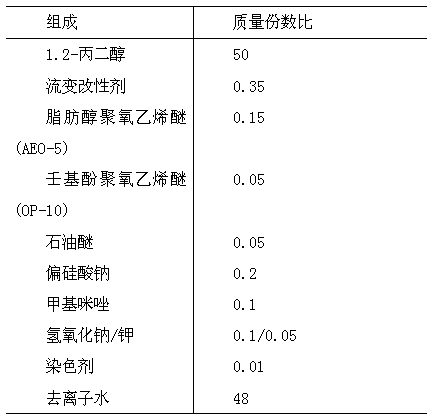

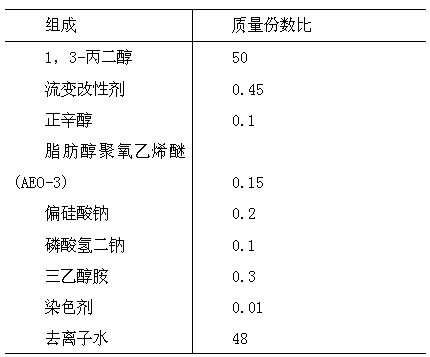

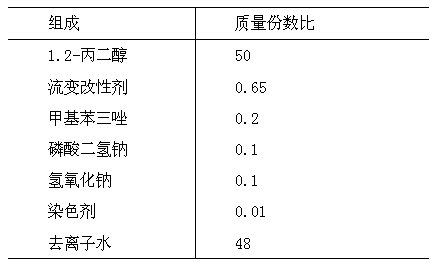

Non-Newtonian fuselage deicing and anti-icing fluid and preparation method thereof

ActiveCN103059813AExcellent shear recovery abilityLong anti-icing timeOther chemical processesPhysical chemistryRheopecty

The invention relates to a deicing and anti-icing fluid, particularly a non-Newtonian fuselage deicing and anti-icing fluid and a preparation method thereof. The non-Newtonian fuselage deicing and anti-icing fluid can reduce adhesion of ice on the object surface to eliminate and prevent icing on the aircraft fuselage surface, and has superlong anti-icing retention time. The non-Newtonian fuselage deicing and anti-icing fluid comprises the following components in parts by mass: 40-60 parts of freezing-point depressant, 0.05-1.2 parts of rheologic modifier, 0.01-0.3 part of anti-icing compounding agent, 0.01-3 parts of pH regulator, 0.01-3 parts of corrosion inhibitor, 0.01-0.5 part of staining agent and 40-60 parts of deionized water. The invention is based on the low-temperature rheologic research, especially aims at the low-temperature operating environment and characteristics of the deicing and anti-icing fluid, and determines the distribution and arrangement of the main chain and branch chain of the rheologic modifier as well as the preparation and acquisition method of the low-temperature conformation. By combining the anti-icing compounding agent, corrosion inhibitor and other assistants in the formula, the prepared deicing and anti-icing fluid has the characteristics of excellent shearing restorability, excellent ice adhesion inhibition capacity at 0 to -20 DEG C, and long anti-icing time.

Owner:成都民航六维航化有限责任公司

Thermal ink jet ink composition with additive

A thermal ink jet ink composition include a volatile organic solvent, a binder resin, a dye, a humectant in an amount from 1% to 40% by weight of the ink composition, and an additive for extending the decap time. The additive is present in an amount greater than 0.1% by weight of the thermal ink jet ink composition. The additive is selected from fluorinated surfactants, ionic surfactants, and nonionic surfactants.

Owner:VIDEOJET TECH INC

Circulation method for preparing expanded cut tobacco

ActiveCN101617854AHigh energy consumptionReduce energy consumptionTobacco preparationFinal product manufactureVacuum pumpingProcess engineering

The invention discloses a circulation method for preparing expanded cut tobacco, comprising the following steps: (1) putting cut tobacco into a preheated impregnating tank, then carrying out vacuum-pumping; (2) spraying liquid expanding agent to the cut tobacco; (3) filling gas expanding agent to the impregnating tank; (4) impregnating; (5) first, recycling the liquid expanding agent, then recycling the gas expanding agent; and (6) expanding the impregnated cut tobacco, and carrying out operations in step (2) or / and step (3) by the liquid expanding agent and the gas expanding agent recycled in step (5). The method of the invention has mild condition and greatly reduced requirement for devices, by fully recycling the expanding agents, the cost is lowered, the complete set of devices has low energy consumption and high automation, continuous mass production can be carried out, all performance indexes of the obtained expanded cut tobacco are high, the expanded efficiency of the cut tobacco is high, and the recycling rate of the expanding agents is high.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Method of constructing graphical magnetic micro-nano structure through laser beam direct writing

ActiveCN105036057AReduce reflectivityModulation of Absorption PropertiesDecorative surface effectsVacuum evaporation coatingThin layerDirect writing

The invention provides a method of constructing graphical magnetic micro-nano structures through laser beam direct writing, wherein the method includes the following processes: (1) at least spreading more than one layers of magnetic material particles on a surface of a substrate, and then applying a controllable magnetic field so that the magnetic material particles are arranged orderly according to magnetic lines on the magnetic field on the surface of the substrate; (2) by means of the laser beam entering from one side of the back side of the substrate to scan the substrate, wherein the position irradiated by the laser beam absorbs laser energy so that the position is subjected to rapid temperature increasing, so that the irradiated position on the back side of the substrate is free of being molten or subjected to thin-layer melted while the parts on the magnetic material particles on the front side of the substrate is partially melted, and finally cooling the substrate to achieve welding between the magnetic material particles to the substrate; and (3) repeatedly doing the step (1) and the step (2) to prepare the micro-nano structure being multilayered, being different in size and being order. The method is used for preparing the graphical magnetic micro-nano structure, wherein the size and the shape of the micro-nano structure are controlled, so that super-hydrophobic property, electromagnetic wave absorption and reflection characters of the surface can be adjusted and controlled.

Owner:WENZHOU UNIVERSITY

Preparation method of heat-conducting, high-temperature-resistant and durable lubricant

InactiveCN110257139AGuaranteed low temperature stabilityImprove high temperature stabilityLubricant compositionWorking fluidHeat conducting

The invention discloses a preparation method of a heat-conducting, high-temperature-resistant and durable lubricant. The preparation method comprises the following steps: carrying out addition melting copolymerization on 1-cyanobenzocyclobutene and a paraphthaloyl chloride monomer to form a prepolymer, preparing a borosiloxane ferrocene prepolymer from dimethylchlorosilane and dicyclopentadiene, and reasonably matching the components to obtain the heat-conducting, high-temperature-resistant and durable lubricant; in addition, a plurality of inorganic components, a clean dispersing agent, an antioxidant and polyadamantane-1,3-diformyl-m-phenylenediamine are compounded for blending modification; therefore, the lubricant has a synergistic lubricating effect and excellent lubricating performance, the lubricating performance reaches or exceeds the same level of a graphite type product, and the lubricant is excellent in miscellaneous oil resistance and long in service life. The lubricant is green and environment-friendly, and is a high-performance environment-friendly hot forging working fluid. The lubricant has the advantages of low raw material consumption, low pollution, long effective lubricating time, low labor intensity, long service life of equipment parts and high temperature resistance.

Owner:蒋辉

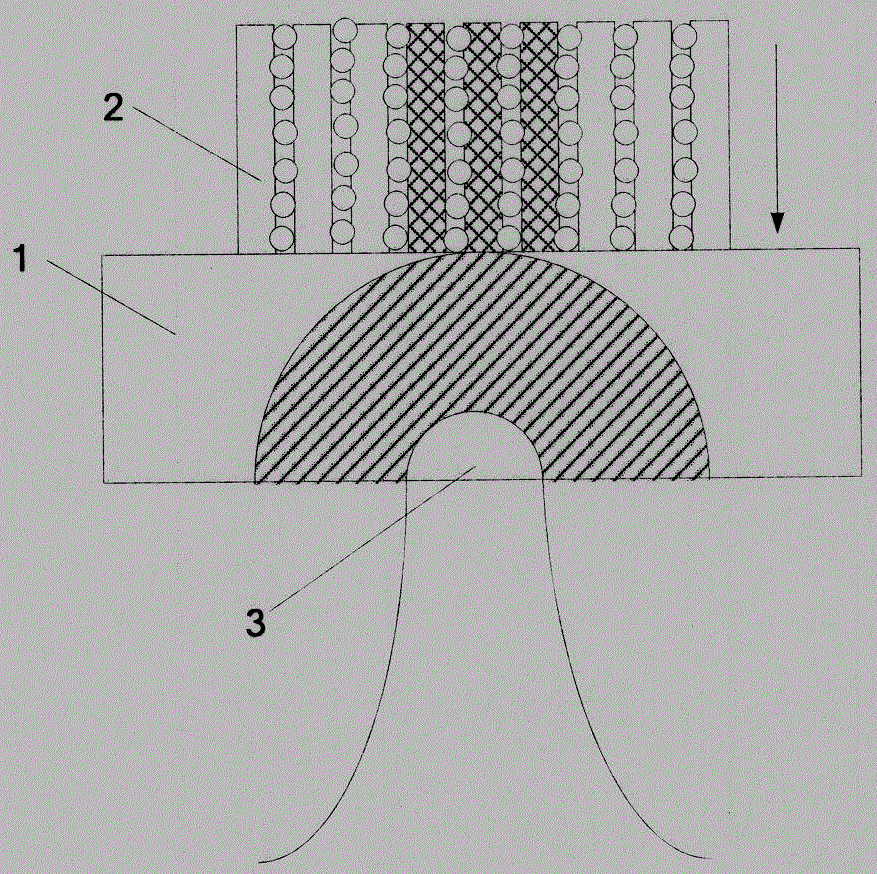

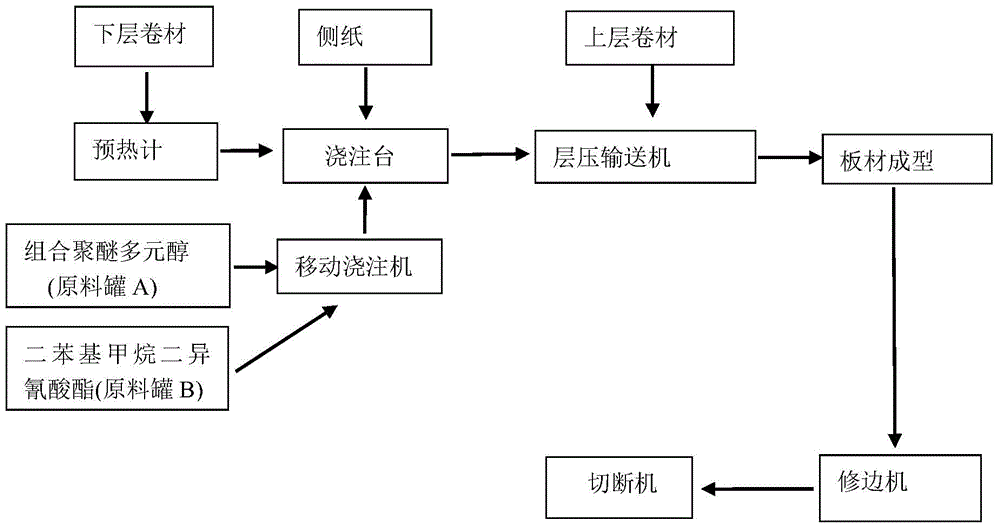

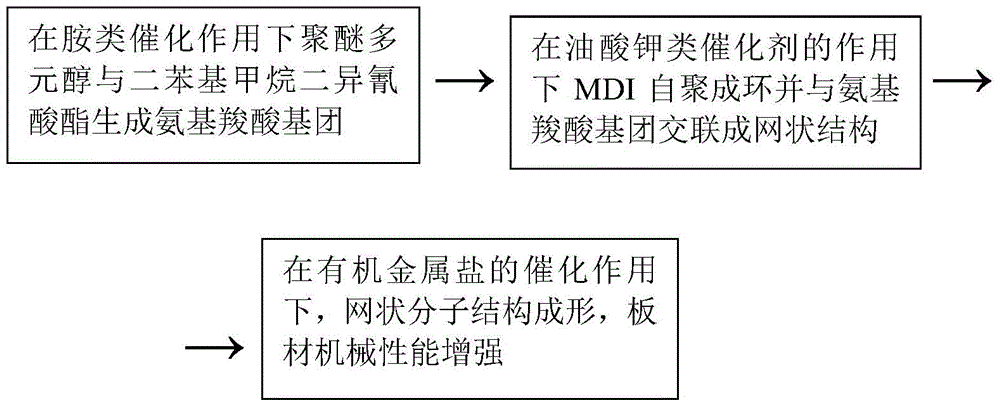

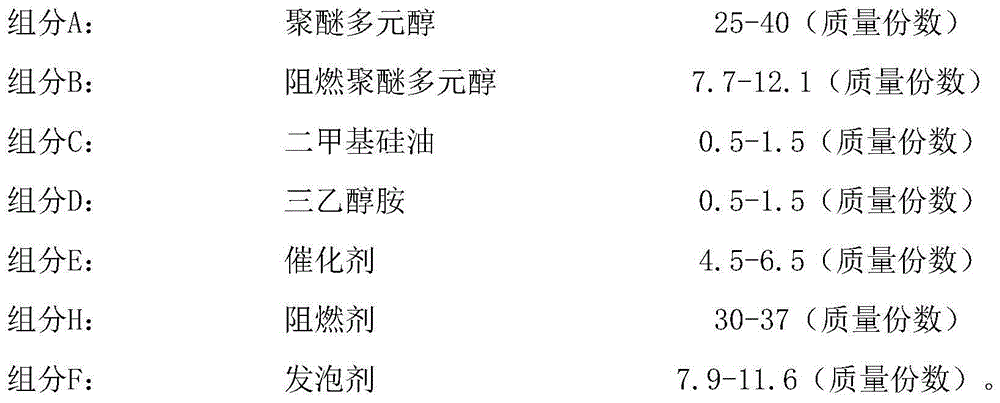

High fire retardation type polyurethane thermal-insulation plate and preparation method thereof

InactiveCN104592481AOvercome the disadvantage of being flammableOvercome mechanical propertiesFoaming agentThermal insulation

The present invention relates to a high fire retardation type polyurethane thermal-insulation plate and a preparation method thereof. The raw materials in the formula of the high fire retardation type polyurethane thermal-insulation plate comprise 1) diphenyl methane diisocyanate and 2) combined polyether polyol, wherein the raw materials in the formula of the combined polyether polyol comprise polyether polyol, fire retardation polyether polyol, dimethyl silicon oil, triethanolamine, a catalyst, a fire retardation agent and a foaming agent. The high fire retardation type polyurethane thermal-insulation plate has the excellent fire retardation performance, wherein the fire retardation grade achieves the B1 grade.

Owner:天津悦纳新型建筑材料有限公司

Immersed phase change cooling medium and application thereof in cooling system of electronic device

InactiveCN111343837AHigh electrical insulationLow viscosityCooling/ventilation/heating modificationsMeth-Engineering

The invention discloses an immersed phase change cooling medium and application thereof in a cooling system of an electronic device. The cooling medium is one or a mixture of two or more of perfluoro-4-methyl-2-pentene, perfluoro-2-methyl-3-pentanone, perfluoro-2-methyl-2, 3-epoxypentane and perfluorohexanone. The immersed phase-change cooling medium provided by the invention has the characteristics of high electrical insulation property, low viscosity, lower boiling point, high gasification latent heat, good compatibility and stability, incombustibility, combustion inhibition, low global warming potential (GWP), zero ozone consumption potential (ODP) and the like.

Owner:浙江诺亚氟化工有限公司

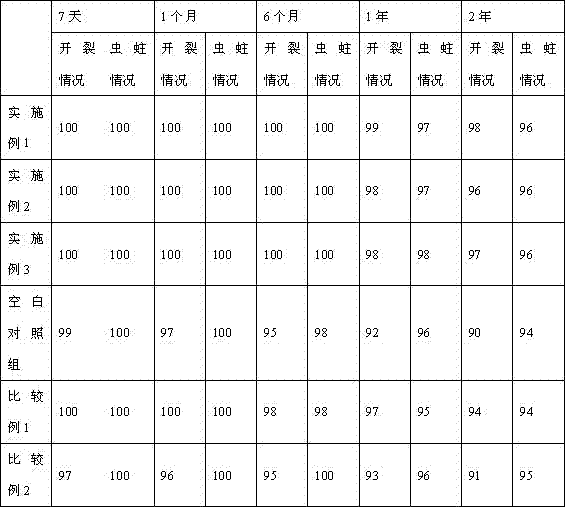

Method for preparing anti-crack log veneer

InactiveCN107057553AHigh bonding strengthPrevent peelingOther plywood/veneer working apparatusAntifouling/underwater paintsEthyl acetateBond strength

The invention provides a method for preparing an anti-crack log veneer. The method comprises the following steps: (1) cutting and peeling off log, placing the cut and peeled log in a cool and ventilate place, performing drying till the water content is 50-60%; (2) brushing two ends of the log with an anti-crack end-capping adhesive, performing curing at the room temperature, and performing rotary-cutting or slicing to obtain the log veneer. The anti-crack end-capping adhesive consists of a component A and a component B, wherein the component A comprises the following ingredients in parts by weight: 20-30 parts of active-hydrogen-containing resin, 3-8 parts of hydroxymethyl cellulose, 1-3 parts of an emulsifier, 1-3 parts of a defoamer, 5-10 parts of montmorillonite and 25-35 parts of ethyl acetate; the component B comprises the following components in parts by weight: 15-25 parts of isocyanate, 5-12 parts of modified rosin and 20-30 parts of ethyl acetate. The method for preparing the anti-crack log veneer is convenient to operate, the veneer has a good breakage prevention effect, the end-capping adhesive is high in bonding strength and low in probability of stripping, and meanwhile, the infested rate can be effectively reduced.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Defoamer useful in a peracid composition with anionic surfactants

ActiveUS10165774B2Without impacting antimicrobial and/or sanitizing efficacy of the compositionsWide range of usesBiocideAnimal repellantsCarboxylic acidDual function

Low foaming, highly acidic peroxycarboxylic acid sanitizing compositions are disclosed as having both improved antimicrobial efficacy in comparison to conventional peroxyoctanoic acid and peroxyacetic acid compositions for sanitizing applications. The compositions include a combination of a low-foaming surfactant and an aluminum sulfate (or other metal salt) defoaming agent that is compatible with the highly acidic peroxycarboxylic acid sanitizing compositions. In particular, the sanitizing peroxycarboxylic acid compositions are also low odor and low / no VOC dual functioning acid wash and sanitizing compositions.

Owner:ECOLAB USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com