Thermal ink jet ink composition

A technology of inkjet ink and composition, which is applied in the direction of ink, household utensils, applications, etc., and can solve the problems of long ink drying time, poor adhesion to substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

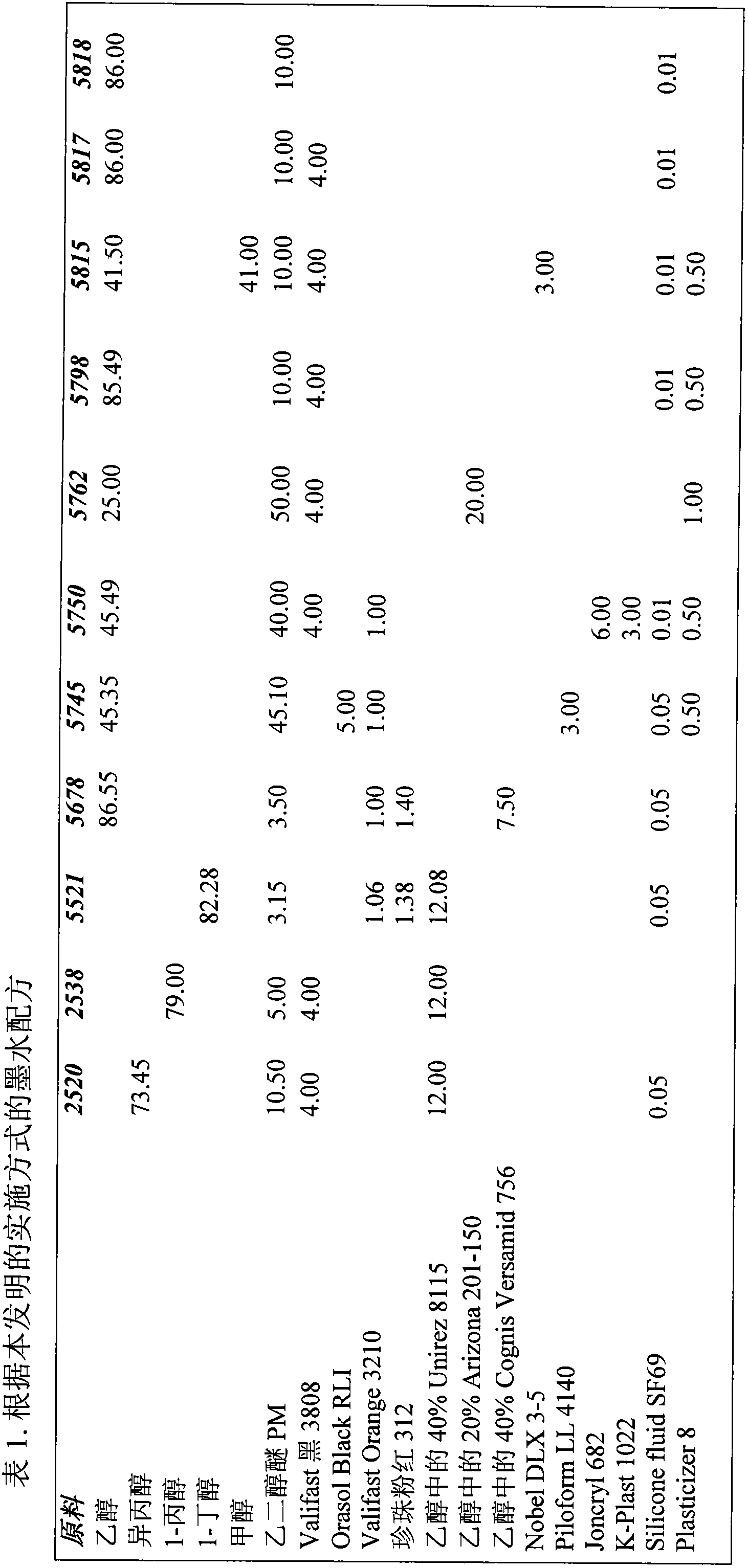

[0041] This example illustrates an embodiment of a thermal inkjet ink composition according to the invention. The raw materials, amounts and formulation numbers used to prepare the inkjet ink compositions are listed in Table 1 below.

[0042]

Embodiment 2

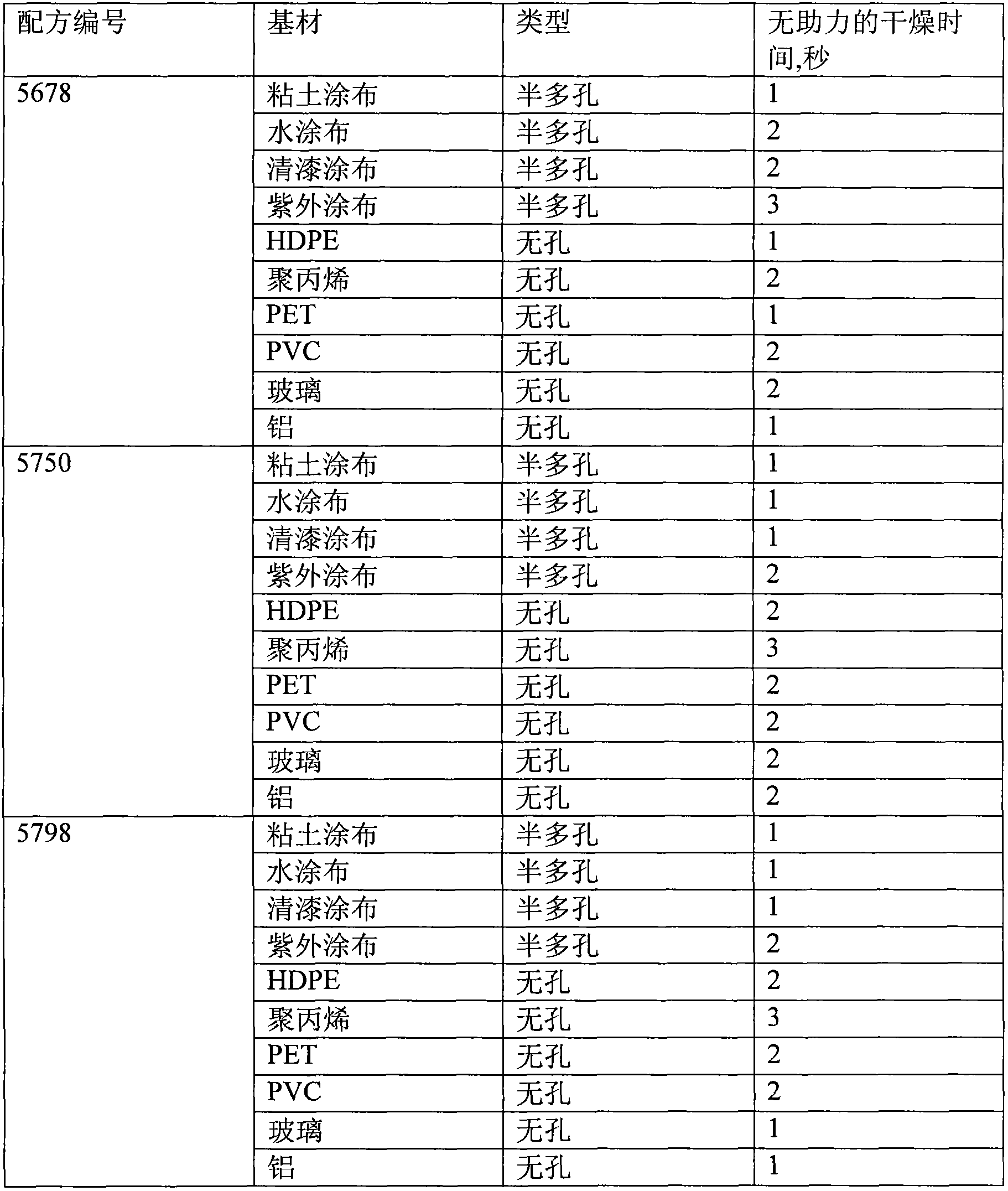

[0044] This example demonstrates the drying time of embodiments of the inkjet ink compositions of the present invention.

[0045] Table 2. Ink Drying Times of Embodiments of Inkjet Ink Compositions on Various Substrates

[0046]

Embodiment 3

[0048] This example demonstrates some of the properties of embodiments of the inkjet ink compositions of the present invention.

[0049] Table 3. Properties of Embodiments of Thermal Inkjet Ink Compositions of the Invention

[0050] recipe number

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| relative evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com