FLiNaK fused salt and preparation method, reactor and preparation device thereof

A preparation device and reactor technology, applied in reactors, cooling devices, nuclear power generation, etc., can solve the problems of high corrosiveness and high impurity content of FLiNaK molten salt, and achieve the effect of low corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

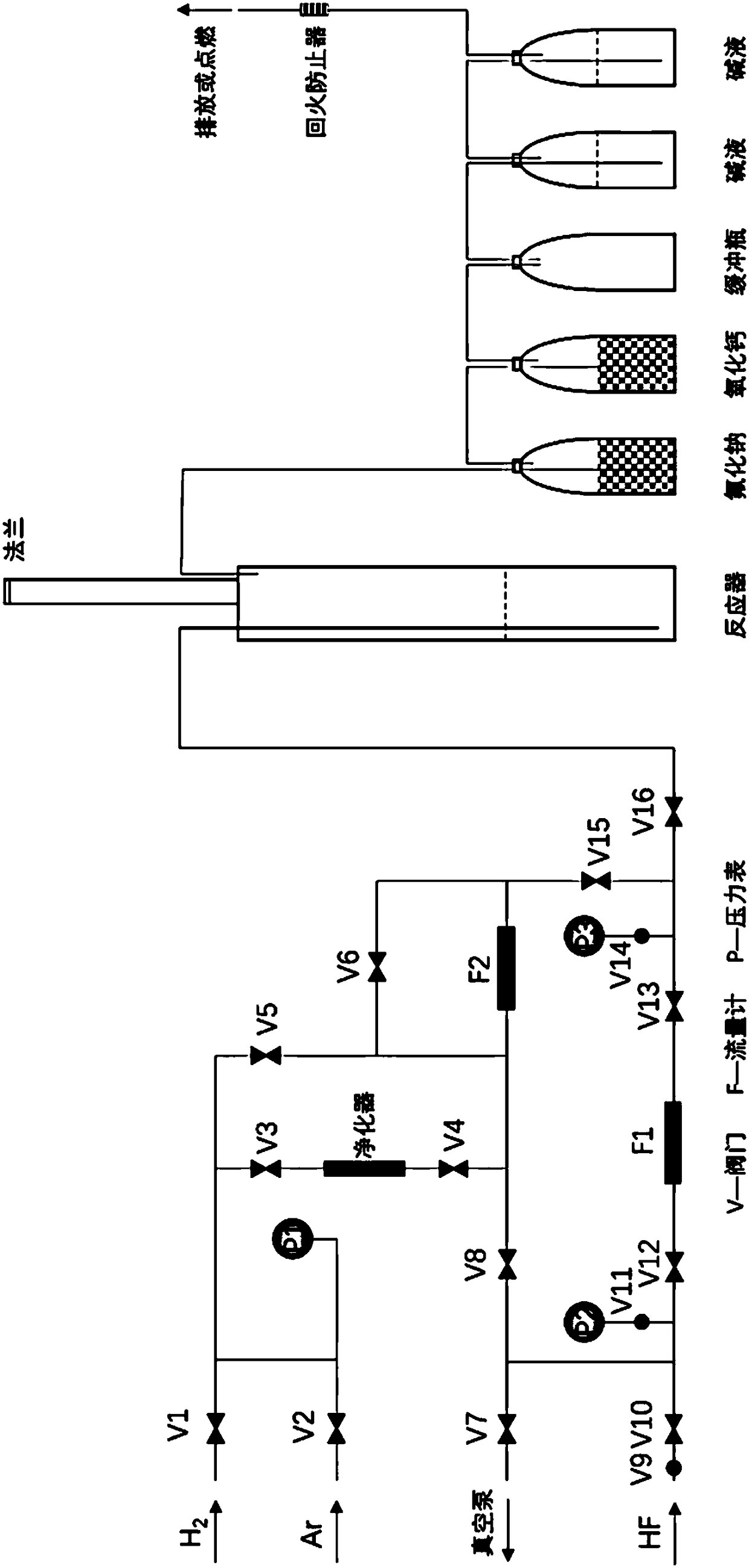

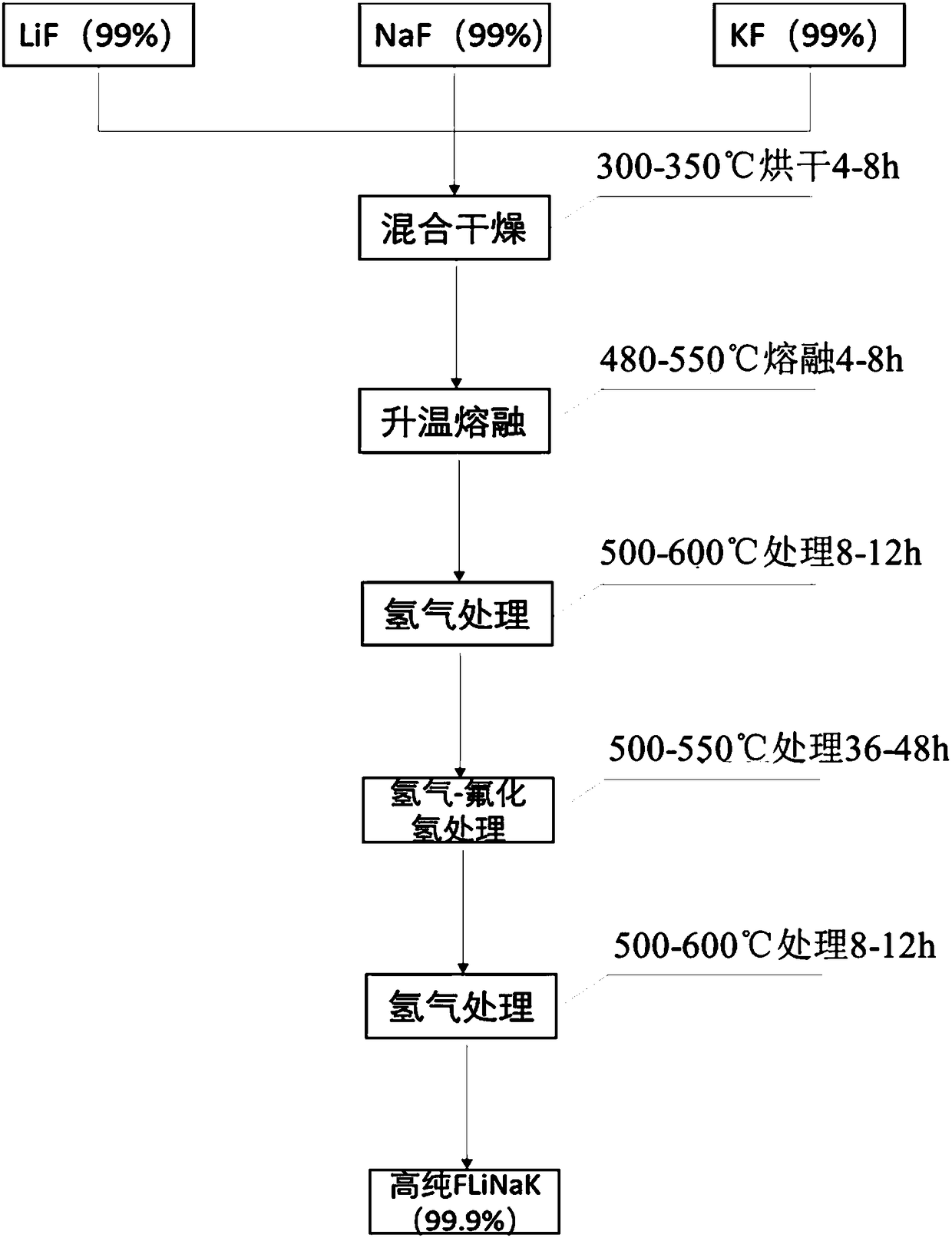

[0066] A preparation device for FLiNaK molten salt, which includes a gas supply module, a reactor and a tail gas treatment module connected in sequence, for details, please refer to the attached figure 1 schematic diagram;

[0067] Among them, the pipes of the gas supply module are all made of 316L stainless steel, and a heating and heat preservation device is installed for the pipes through which the HF gas flows.

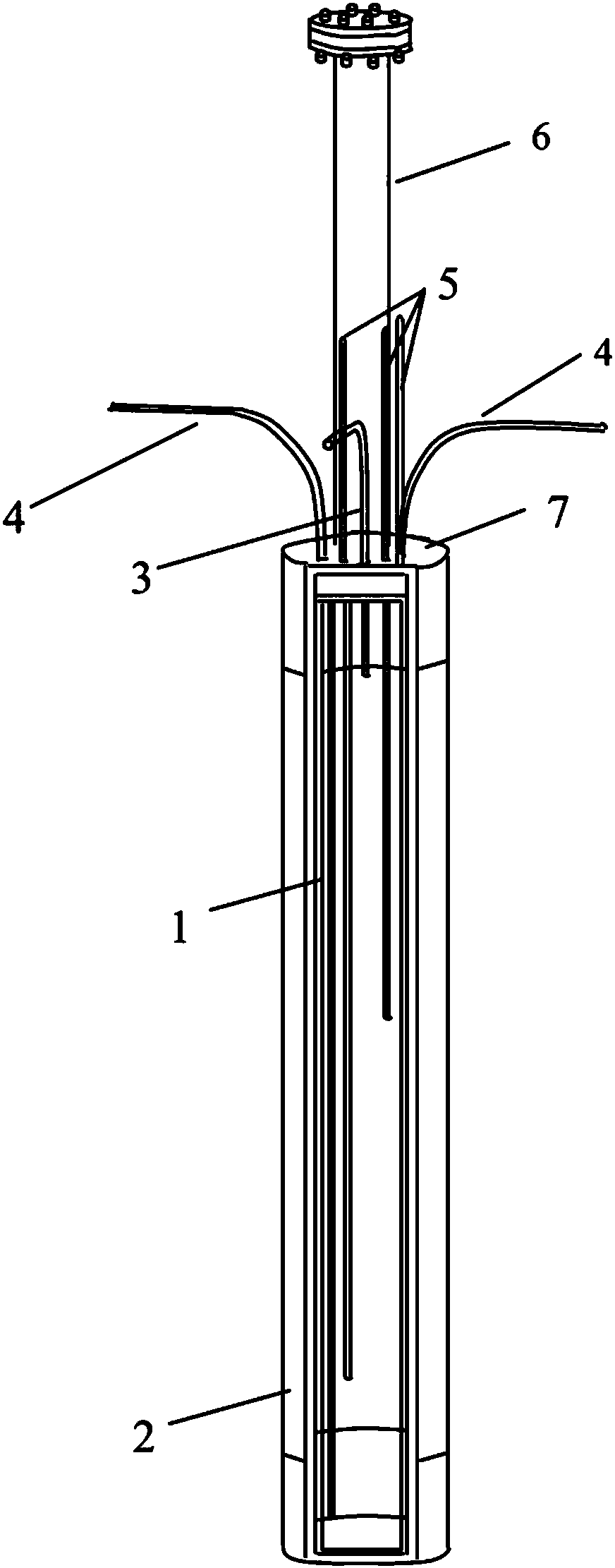

[0068] Wherein, the reactor includes a main body 2 and a lining 1 arranged inside the main body 2, and the upper part of the main body 2 is sealed and connected with a flange 6 and a large cover 7, and the large cover 7 is provided with an air outlet pipe 3, two bubbling pipes 4 and 3 thermocouple casings 5 and 2 bubbling tubes are respectively arranged on both sides of the large cover 7; the main body 2 of the reactor is made of N06625 alloy material; the lining 1 of the reactor is made of N02201 pure nickel material; the height-to-diameter ratio of the reactor...

Embodiment 2

[0071] A FLiNaK molten salt, the content of impurity elements in the FLiNaK molten salt is: oxygen content 97ppm, sulfur content 15.7ppm, chlorine content 23.0ppm, silicon content 90.0ppm, nickel content 14ppm, iron content 19.1ppm, calcium content 21.2ppm, Aluminum content 2.6ppm, barium content 33.4ppm, chromium content 8.1ppm, cobalt content 0.5ppm, cadmium content 0.1ppm, manganese content 1.0ppm, magnesium content 16.8ppm, copper content 1.2ppm, phosphorus content 9.1ppm, lead content <0.8ppm , zinc content 1.2ppm, vanadium content <0.1ppm, titanium content 0.9ppm, molybdenum content <0.1ppm, tungsten content <0.8ppm, zirconium content 0.5ppm, strontium content 1.3ppm, tin content 1.0ppm, the sum of the impurity elements is not more than 0.1%;

[0072] The mass ratio of LiF, NaF, and KF in the FLiNaK molten salt is 29.3:11.7:59.0, and the error of any component does not exceed ±0.3%; the melting point of the FLiNaK molten salt is 457.2°C.

[0073] The FLiNaK molten salt ...

Embodiment 3

[0080] A FLiNaK molten salt, the content of impurity elements in the FLiNaK molten salt is: oxygen content 95ppm, sulfur content 14.1ppm, chlorine content 20.7ppm, silicon content 94.3ppm, nickel content 7ppm, iron content 8.1ppm, calcium content 19.7ppm, Aluminum content 2.5ppm, barium content 32.3ppm, chromium content 10.4ppm, cobalt content 0.6ppm, cadmium content 0.1ppm, manganese content 1.1ppm, magnesium content 18.3ppm, copper content 1.3ppm, phosphorus content 10.4ppm, lead content <0.8ppm , zinc content 1.8ppm, vanadium content <0.1ppm, titanium content 0.8ppm, molybdenum content <0.1ppm, tungsten content <0.8ppm, zirconium content 0.3ppm, strontium content 1.4ppm, tin content 0.9ppm, the sum of the impurity elements is not more than 0.1%;

[0081] The mass ratio of LiF, NaF, and KF in the FLiNaK molten salt is 29.3:11.7:59.0, and the error of any component does not exceed ±0.3%; the melting point of the FLiNaK molten salt is 456.9°C.

[0082] The FLiNaK molten salt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com