Patents

Literature

4864 results about "Succinic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Succinic acid (/səkˈsɪnɪk/) is a dicarboxylic acid with the chemical formula (CH₂)₂(CO₂H)₂. The name derives from Latin succinum, meaning amber. In living organisms, succinic acid takes the form of an anion, succinate, which has multiple biological roles as a metabolic intermediate being converted into fumarate by the enzyme succinate dehydrogenase in complex 2 of the electron transport chain which is involved in making ATP, and as a signaling molecule reflecting the cellular metabolic state. It is marketed as food additive E363. Succinate is generated in mitochondria via the tricarboxylic acid cycle (TCA). Succinate can exit the mitochondrial matrix and function in the cytoplasm as well as the extracellular space, changing gene expression patterns, modulating epigenetic landscape or demonstrating hormone-like signaling. As such, succinate links cellular metabolism, especially ATP formation, to the regulation of cellular function. Dysregulation of succinate synthesis, and therefore ATP synthesis, happens in some genetic mitochondrial diseases, such as Leigh syndrome, and Melas syndrome, and degradation can lead to pathological conditions, such as malignant transformation, inflammation and tissue injury.

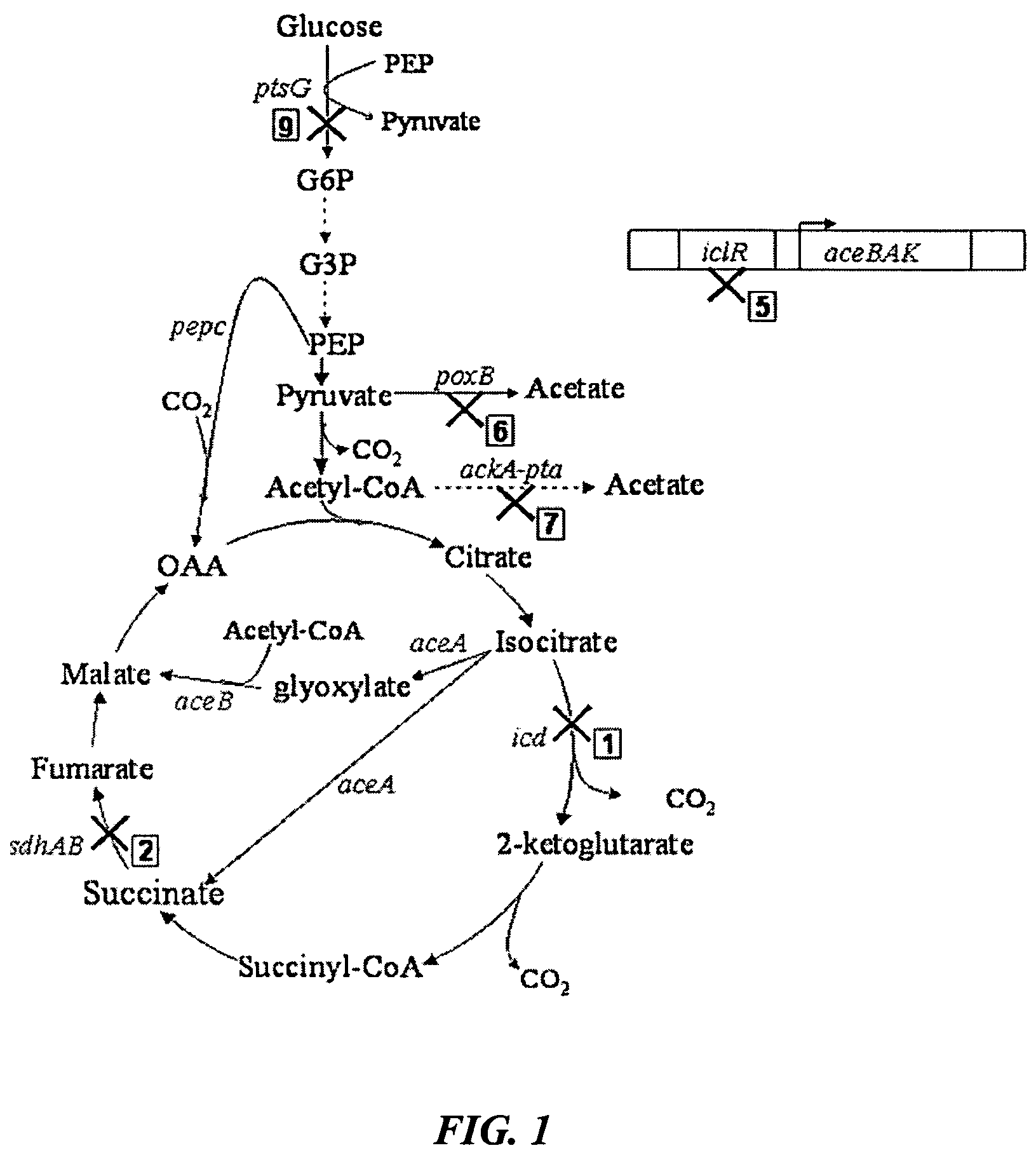

Mutant E. coli strain with increased succinic acid production

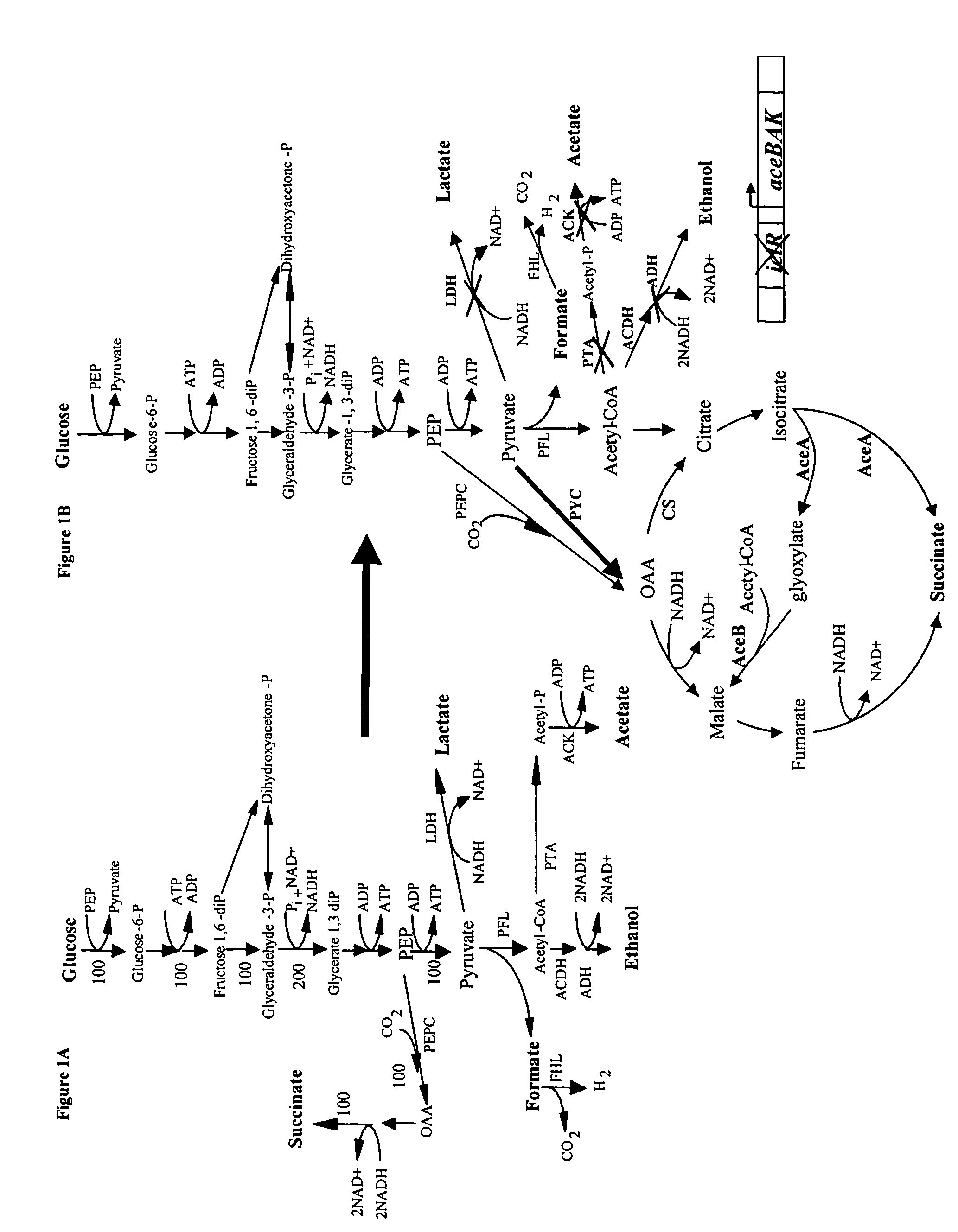

The invention relates to a mutant strain of bacteria, which either lacks or contains mutant genes for several key metabolic enzymes, and which produces high amounts of succinic acid under anaerobic conditions.

Owner:RICE UNIV

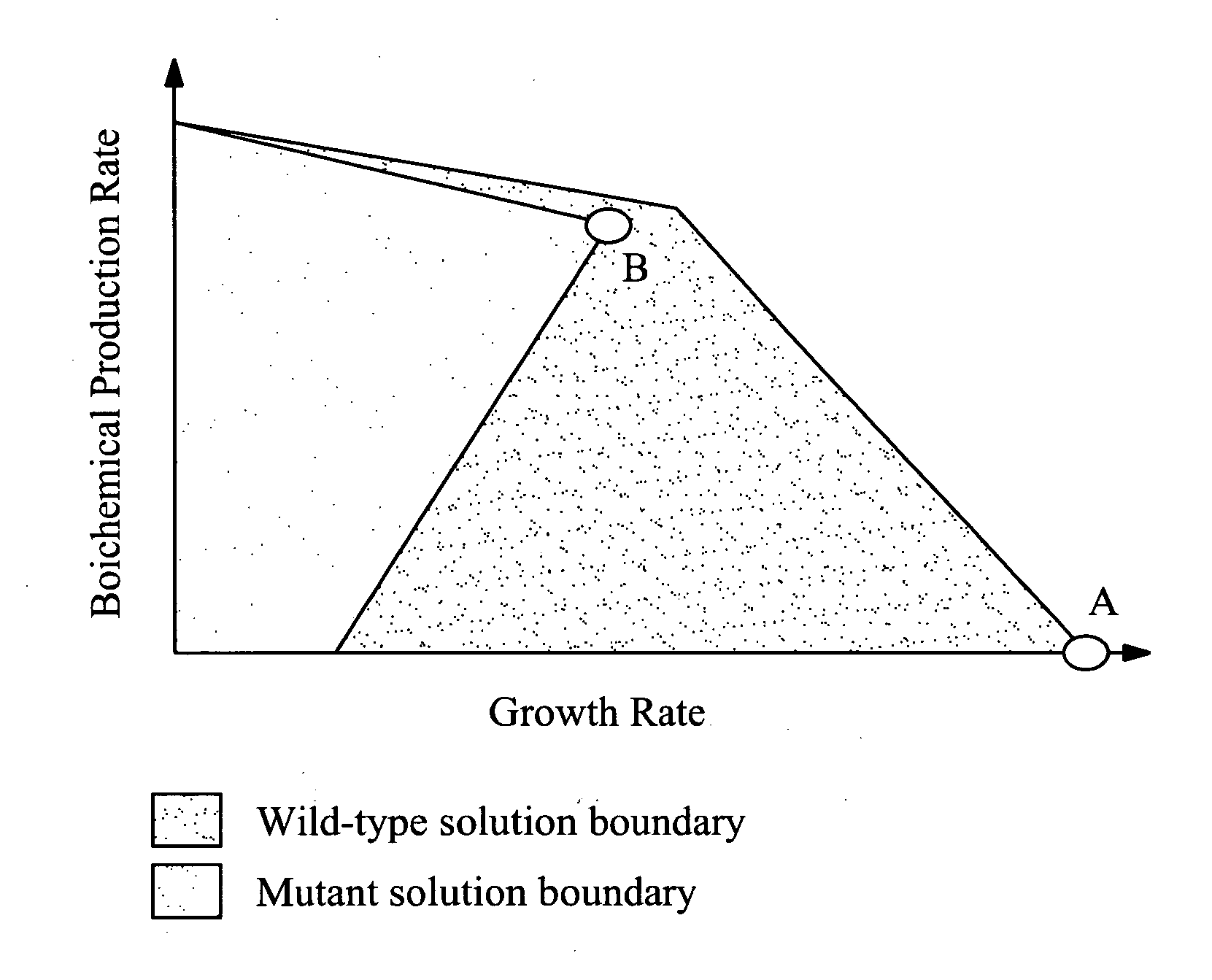

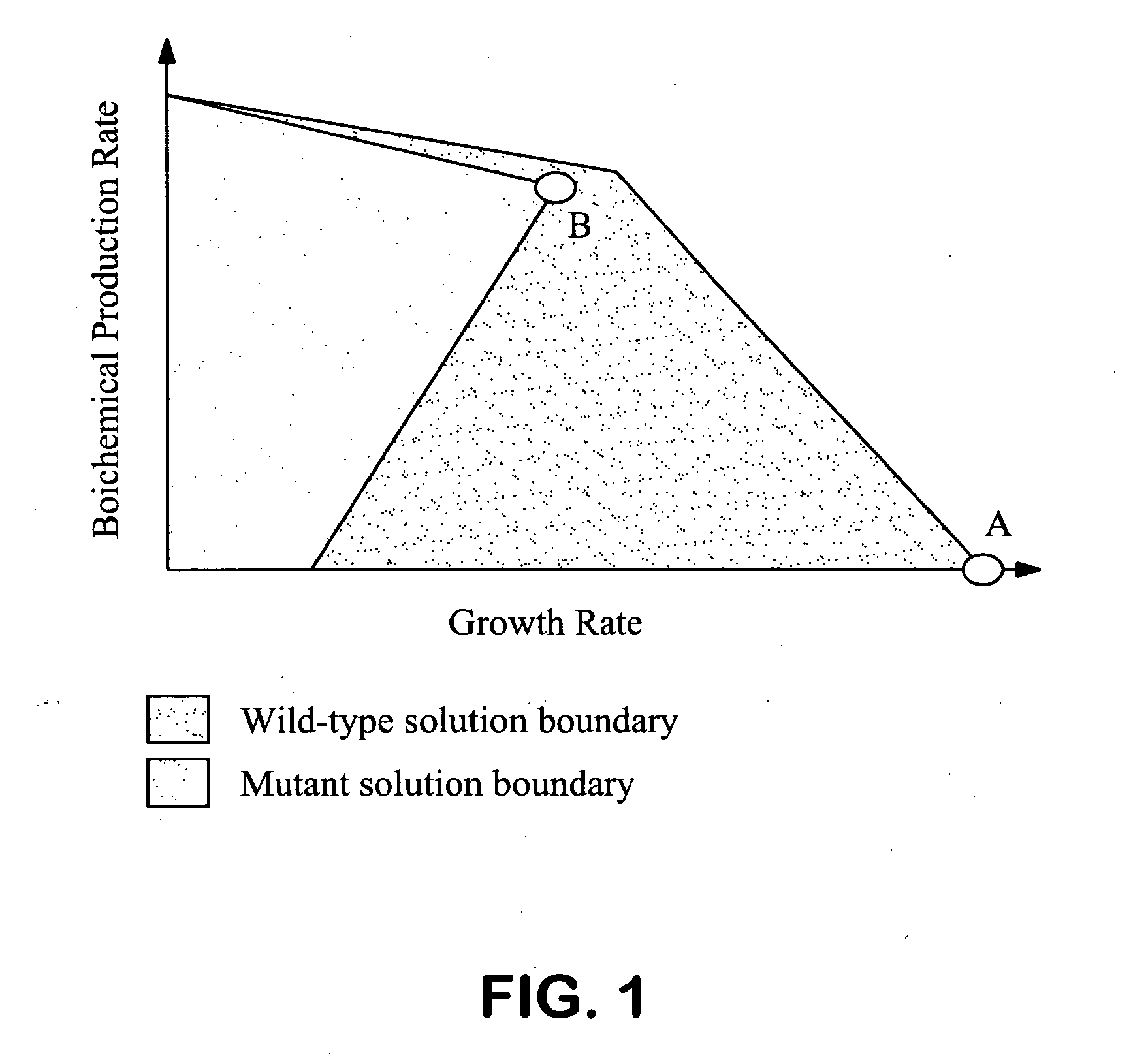

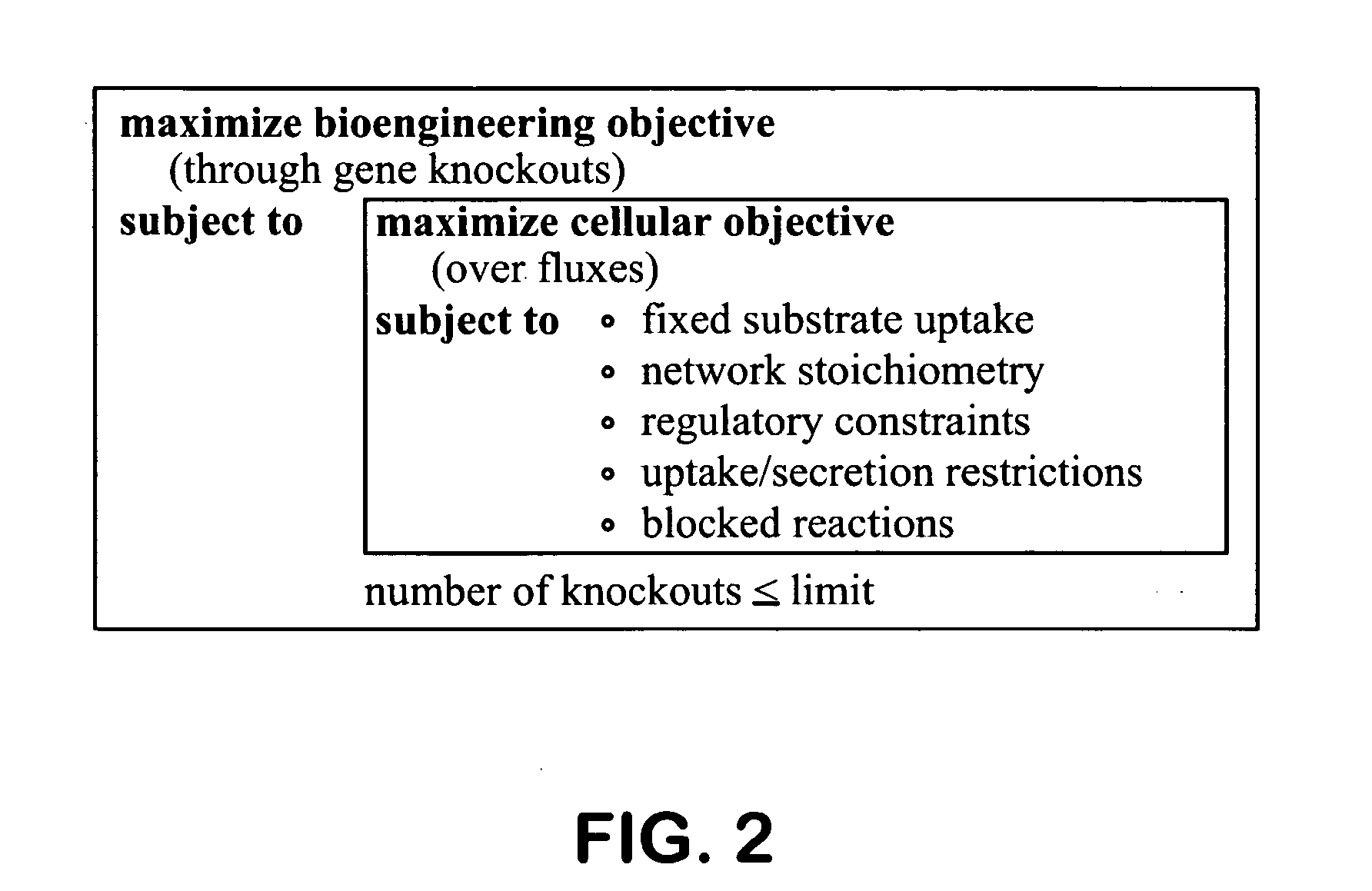

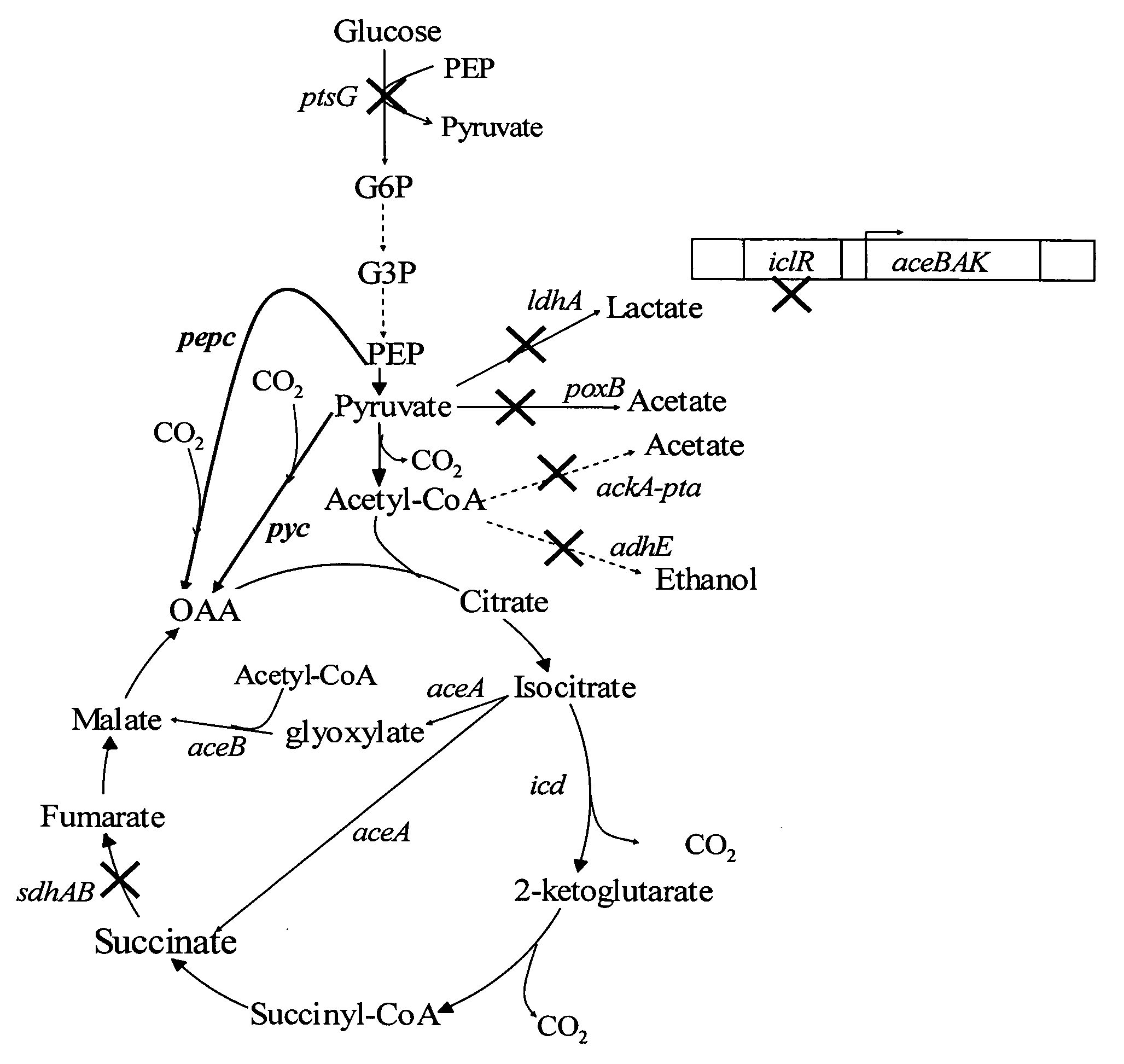

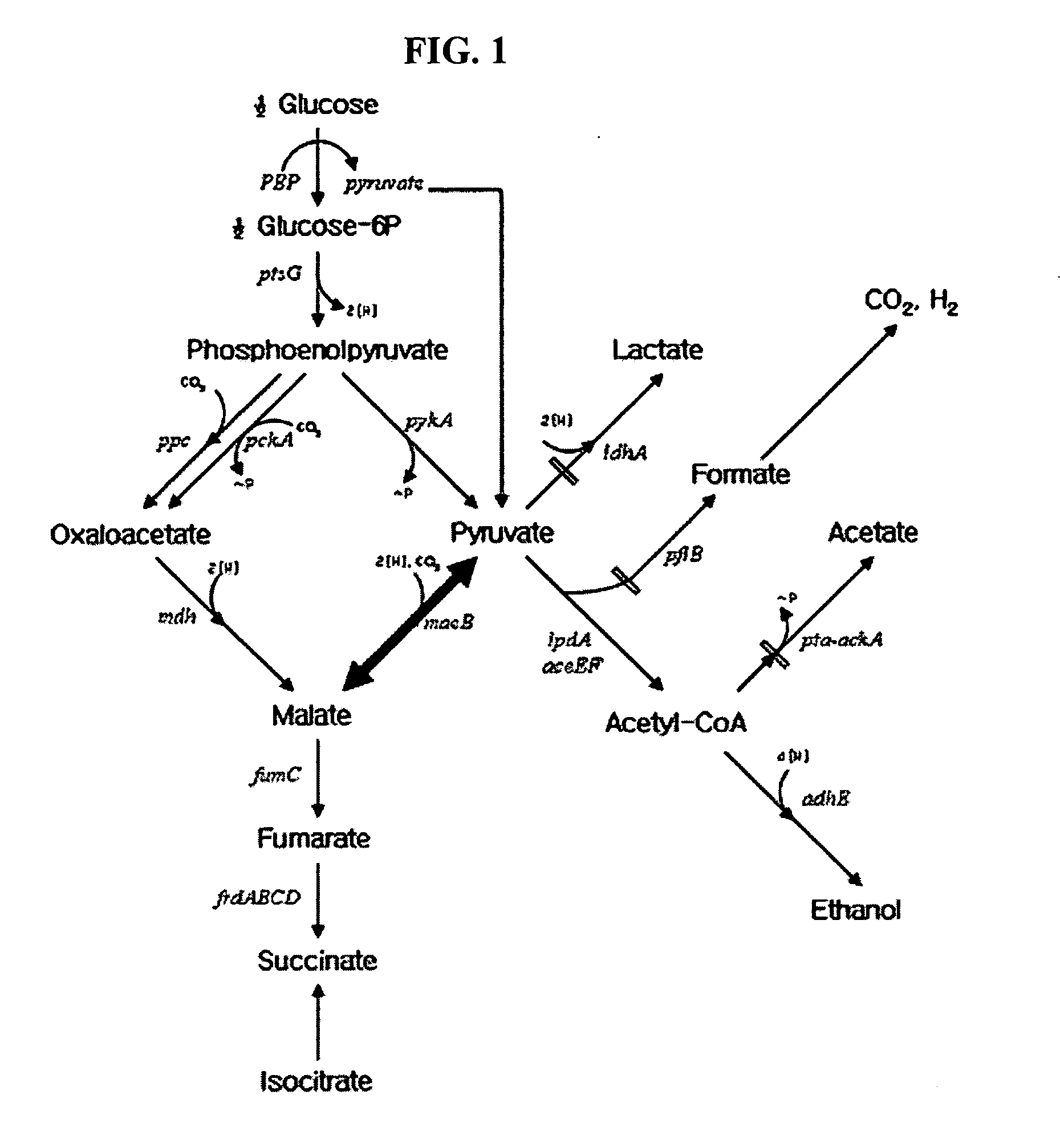

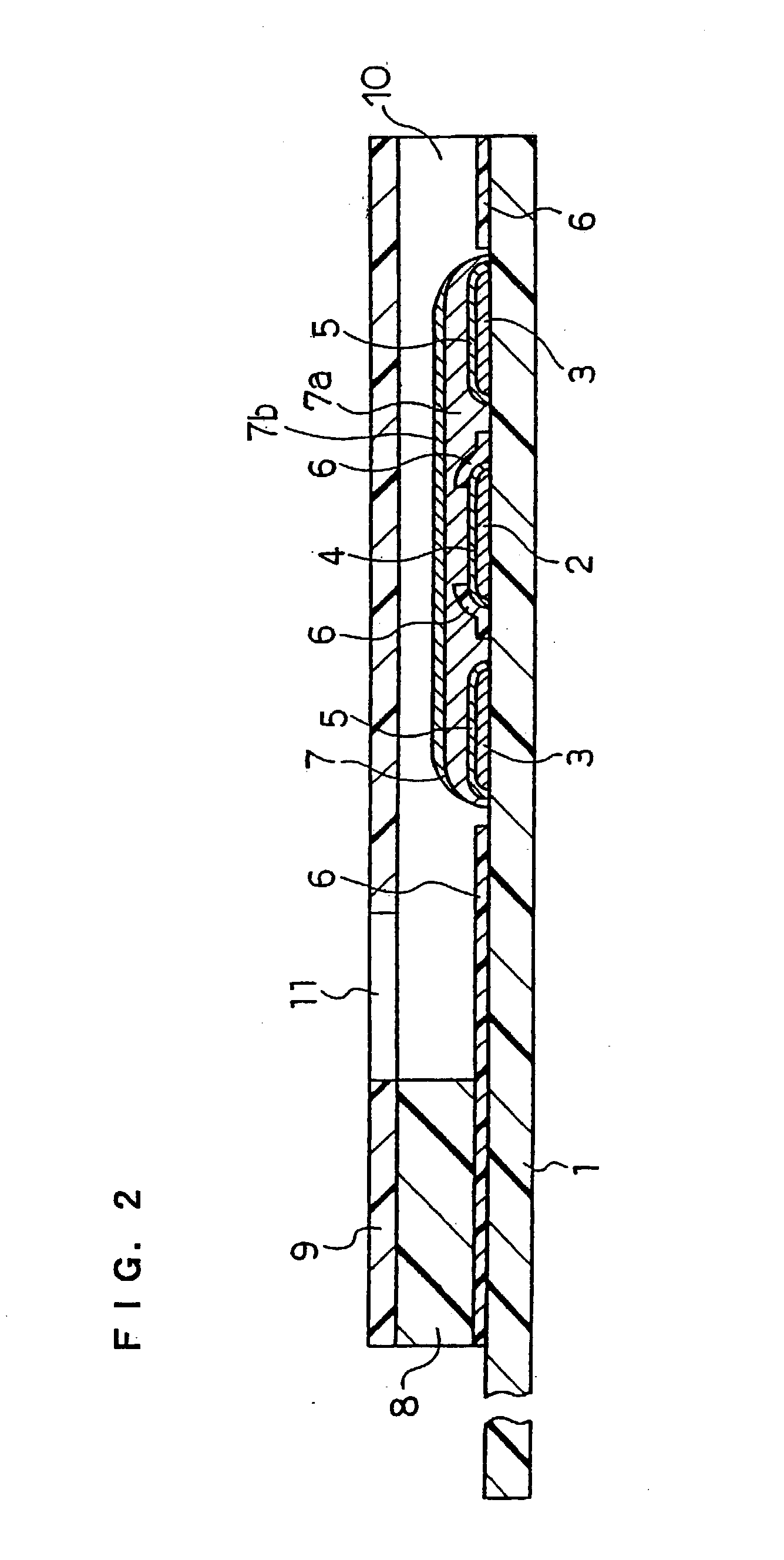

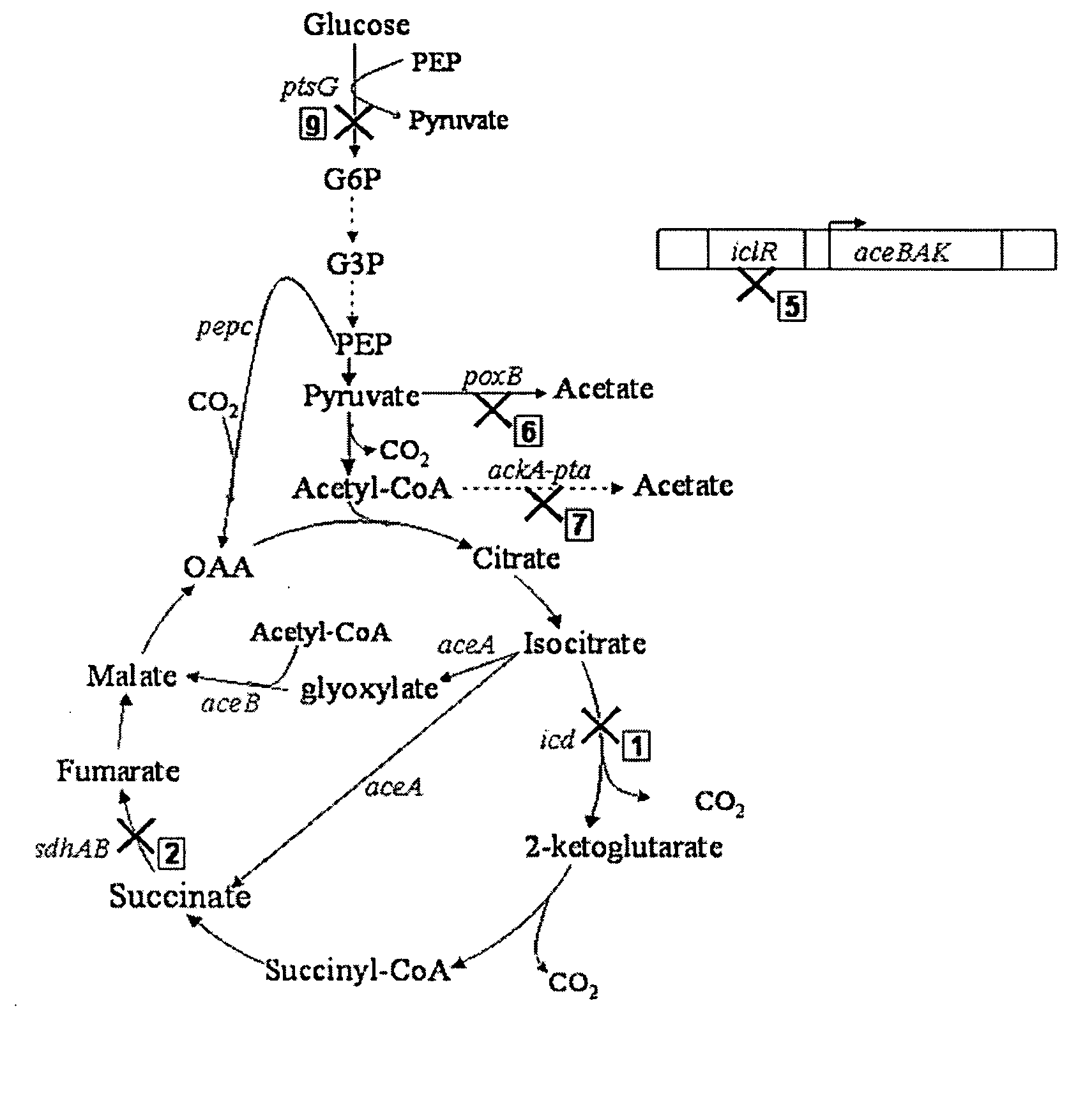

Methods and organisms for the growth-coupled production of succinate

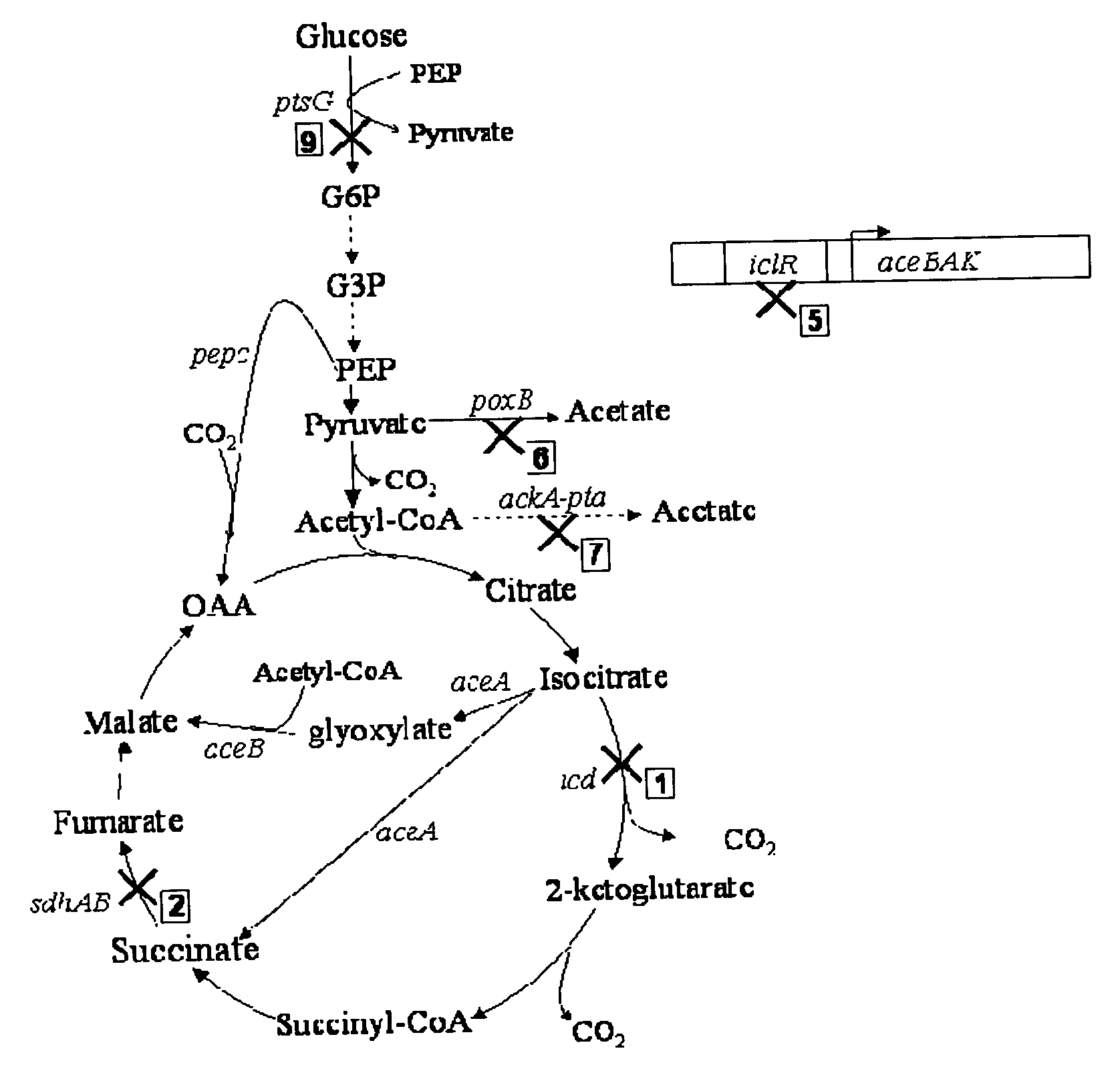

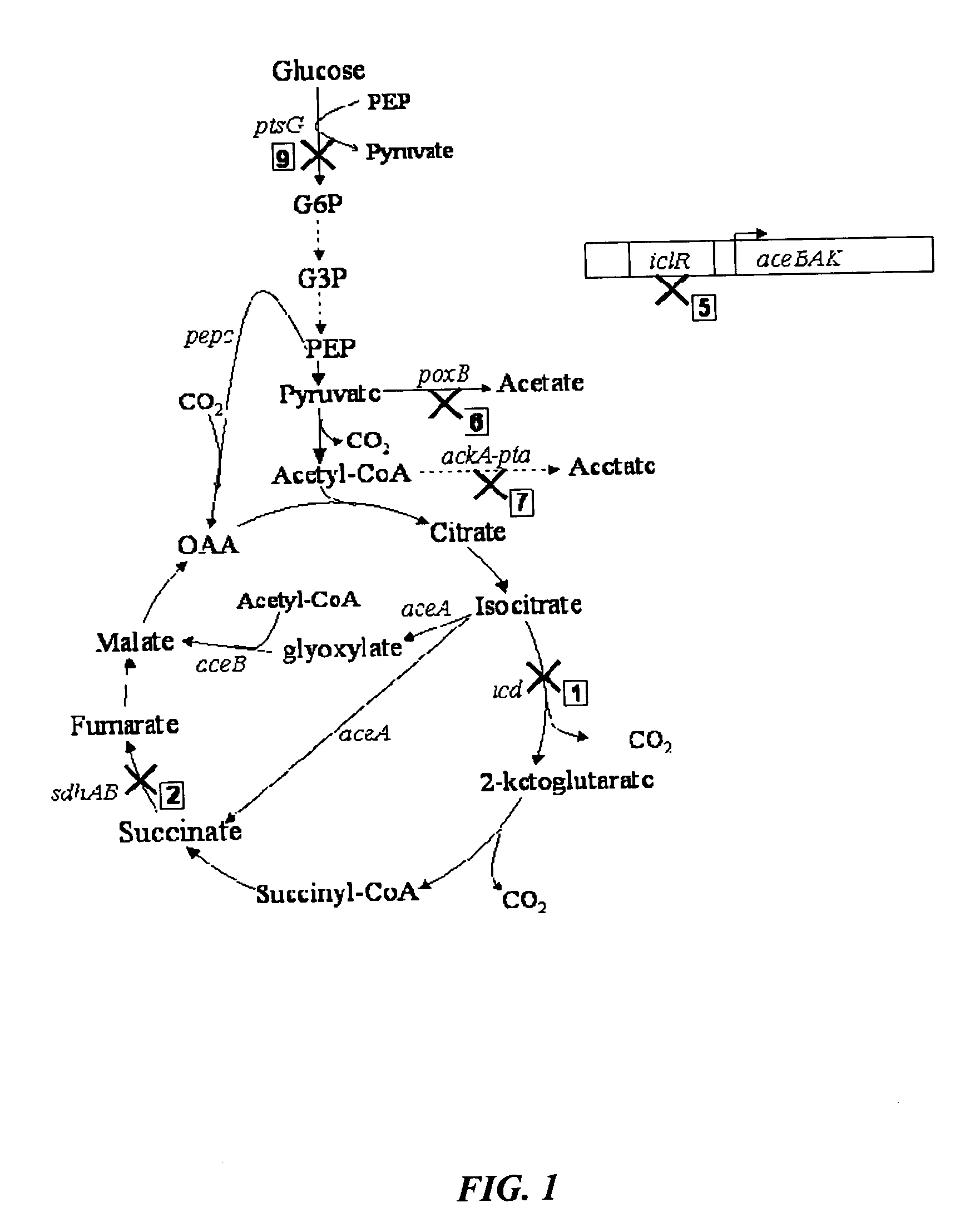

The invention provides a non-naturally occurring microorganism comprising one or more gene disruptions encoding an enzyme associated with growth-coupled production of succinate when an activity of the enzyme is reduced, whereby the one or more gene disruptions confers stable growth-coupled production of succinate onto the non- naturally occurring microorganism. Also provided is a non-naturally occurring microorganism comprising a set of metabolic modifications obligatory coupling succinate production to growth of the microorganism, the set of metabolic modifications comprising disruption of one or more genes selected from the set of genes comprising: (a) adhE, ldhA; (b) adhE, ldhA, acka-pta; (c) pfl, ldhA; (d) pfl, ldhA, adhE; (e) acka-pta, pykF, atpF, sdhA; (f) acka-pta, pykF, ptsG, or (g) acka-pta, pykF, ptsG, adhE, ldhA, or an ortholog thereof, wherein the microorganism exhibits stable growth-coupled production of succinate. Additionally provided is a non-naturally occurring microorganism having the genes encoding the metabolic modification (e) acka-pta, pykF, atpF, sdhA that further includes disruption of at least one gene selected from pyka, atpH, sdhB or dhaKLM; a non-naturally occurring microorganism having the genes encoding the metabolic modification (f) ackA-pta, pykF, ptsG that further includes disruption of at least one gene selected from pykA or dhaKLM, or a non-naturally occurring microorganism having the genes encoding the metabolic modification (g) ackA-pta, pykF, ptsG, adhE, ldhA that further includes disruption of at least one gene selected from pykA or dhaKLM. The disruptions can be complete gene disruptions and the non-naturally occurring organisms can include a variety of prokaryotic or eukaryotic microorganisms. A method of producing a non-naturally occurring microorganism having stable growth-coupled production of succinate also is provided. The method includes: (a) identifying in silico a set of metabolic modifications requiring succinate production during exponential growth, and (b) genetically modifying a microorganism to contain the set of metabolic modifications requiring succinate production.

Owner:GENOMATICA INC

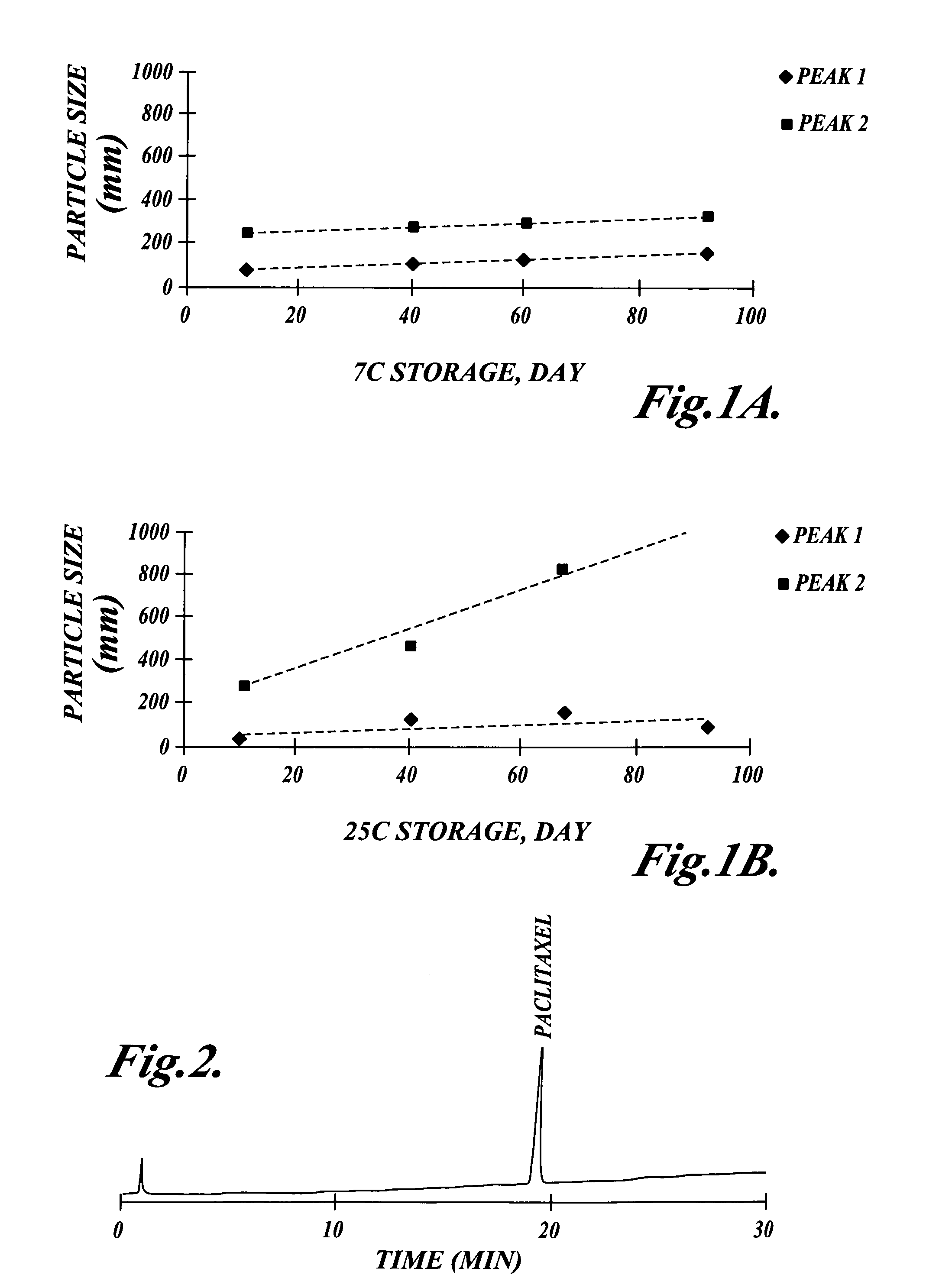

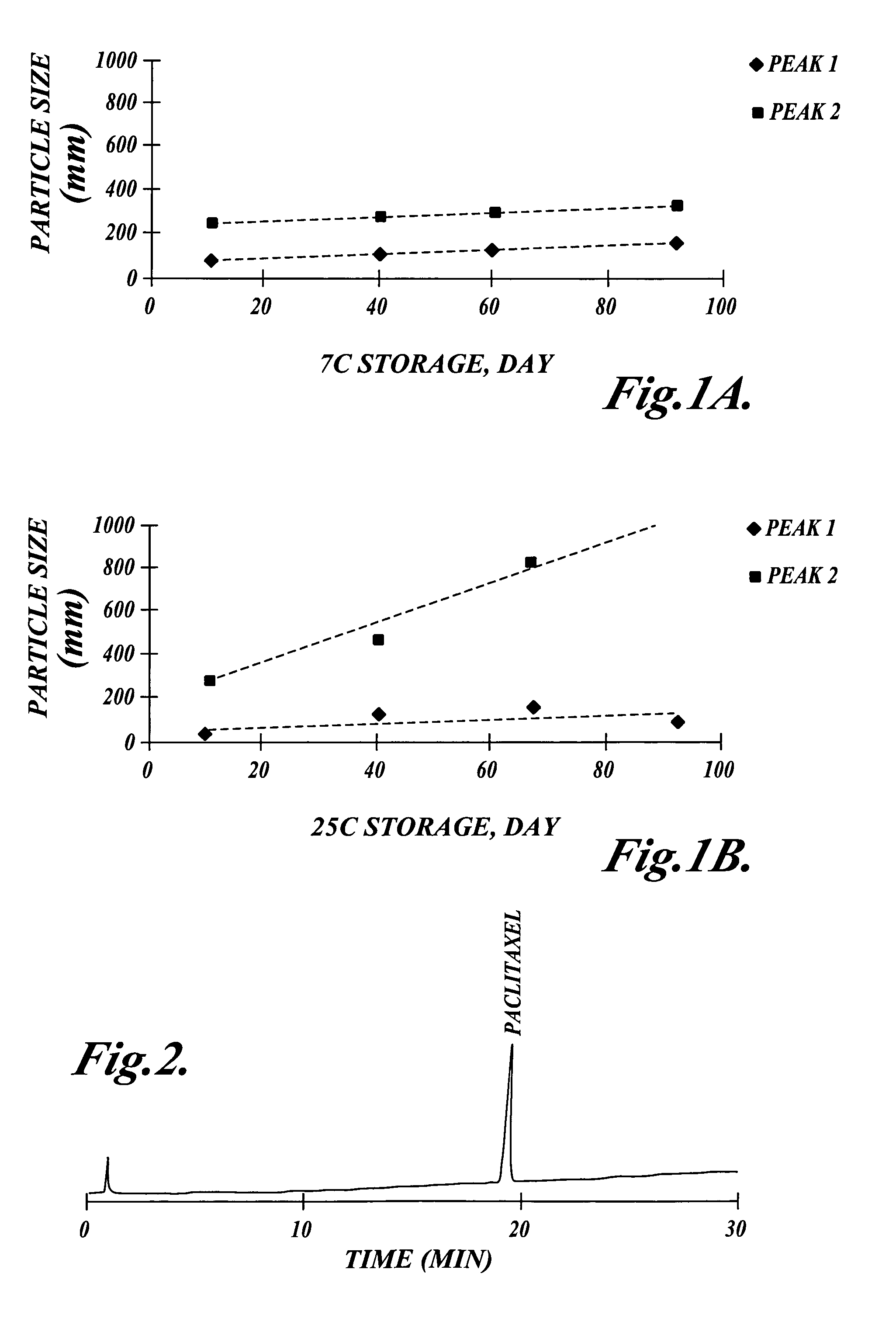

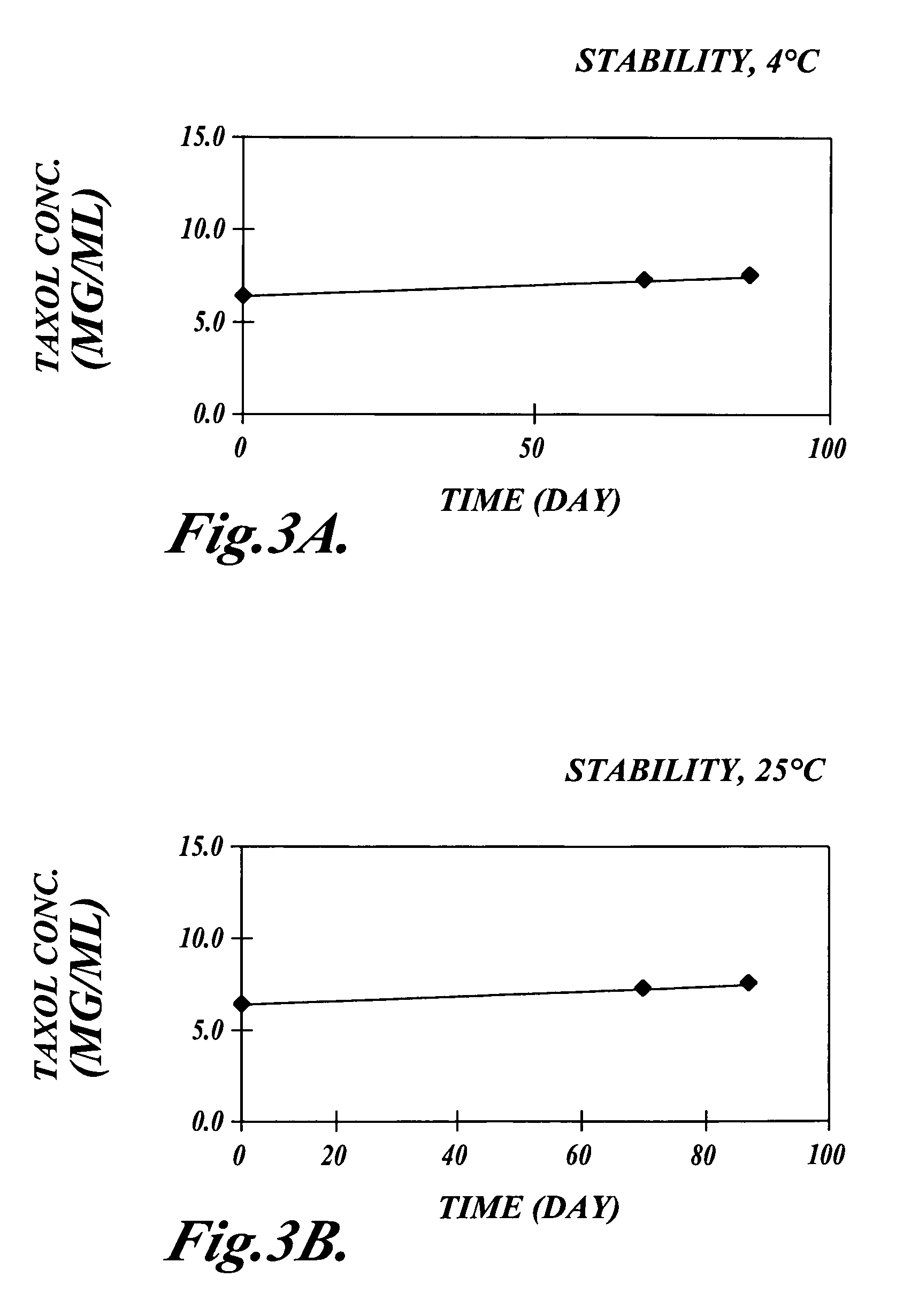

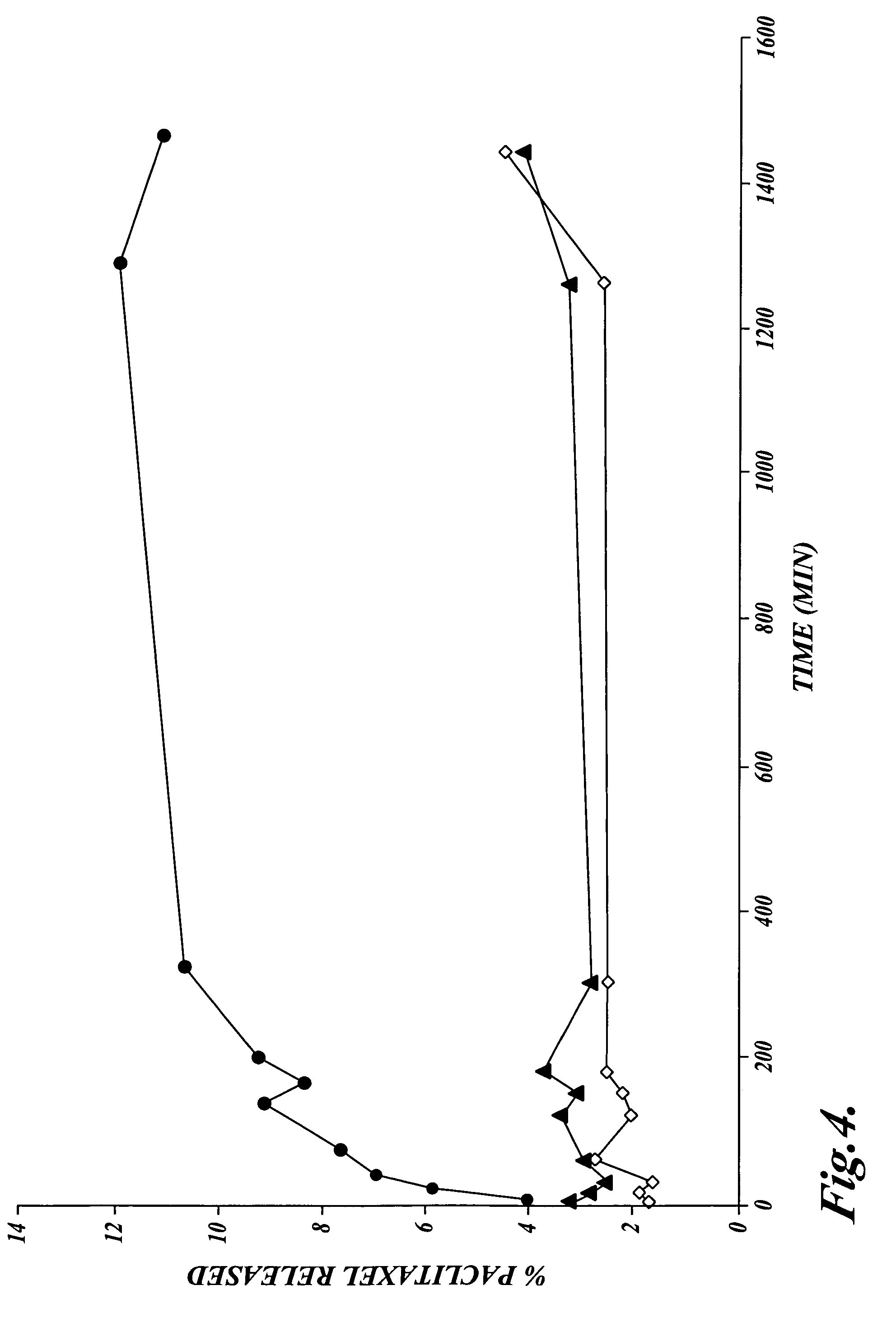

Proteinic drug delivery system using membrane mimetics

A mixed liposome pharmaceutical formulation with multilamellar vesicles, comprises a proteinic pharmaceutical agent, water, an alkali metal lauryl sulphate in a concentration of from 1 to 10 wt. / wt. %, at least one membrane-mimetic amphiphile and at least one phospholipid. The membrane-mimetic amphiphile is hyaluronic acid, pharmaceutically acceptable salts of hyaluronic acid, lauramidopropyl betain, lauramide monoisopropanolamide, sodium cocoamphopropionate, bishydroxypropyl dihydroxypropyl stearammonium chloride, polyoxyethylene dihydroxypropyl stearammonium chloride, dioctadecyldimethylammonium chloride, sulphosuccinates, stearamide DEA, gamma-linoleic acid, borage oil, evening of primrose oil, monoolein, sodium tauro dihydro fusidate, fusidic acid, alkali metal isostearyl lactylates, alkaline earth metal isostearyl lactylates, panthenyl triacetate, cocamidopropyl phosphatidyl PG-diammonium chloride, stearamidopropyl phosphatidyl PG-diammonium chloride, borage amidopropyl phosphatidyl PG-diammonium chloride, borage amidopropyl phosphatidylcholine, polysiloxy pyrrolidone linoleyl phospholipid, trihydroxy-oxo-cholanylglycine and alkali metal salts thereof, and octylphenoxypolythoxyethanol, polydecanol X-lauryl ether, polydecanol X-oleyl ether, wherein X is from 9 to 20, or combinations thereof. The phospholipid is phospolipid GLA, phosphatidyl serine, phosphatidylethanolamine, inositolphosphatides, dioleoylphosphatidylethanolamine, sphingomyelin, ceramides, cephalin, triolein, lecithin, saturated lecithin and lysolecithin, or a combination thereof. The amount of each membrane mimetic amphiphile and phospholipid is present 1 to 10 wt. / wt. % of the total formulation, and the total concentration of membrane mimetic amphiphiles and phospholipids is less than 50 wt. / wt. % of the formulation.

Owner:GENEREX PHARMA

High succinate producing bacteria

InactiveUS20060073577A1Increase productionQuick implementationBacteriaFermentationMicrobiologySuccinic acid

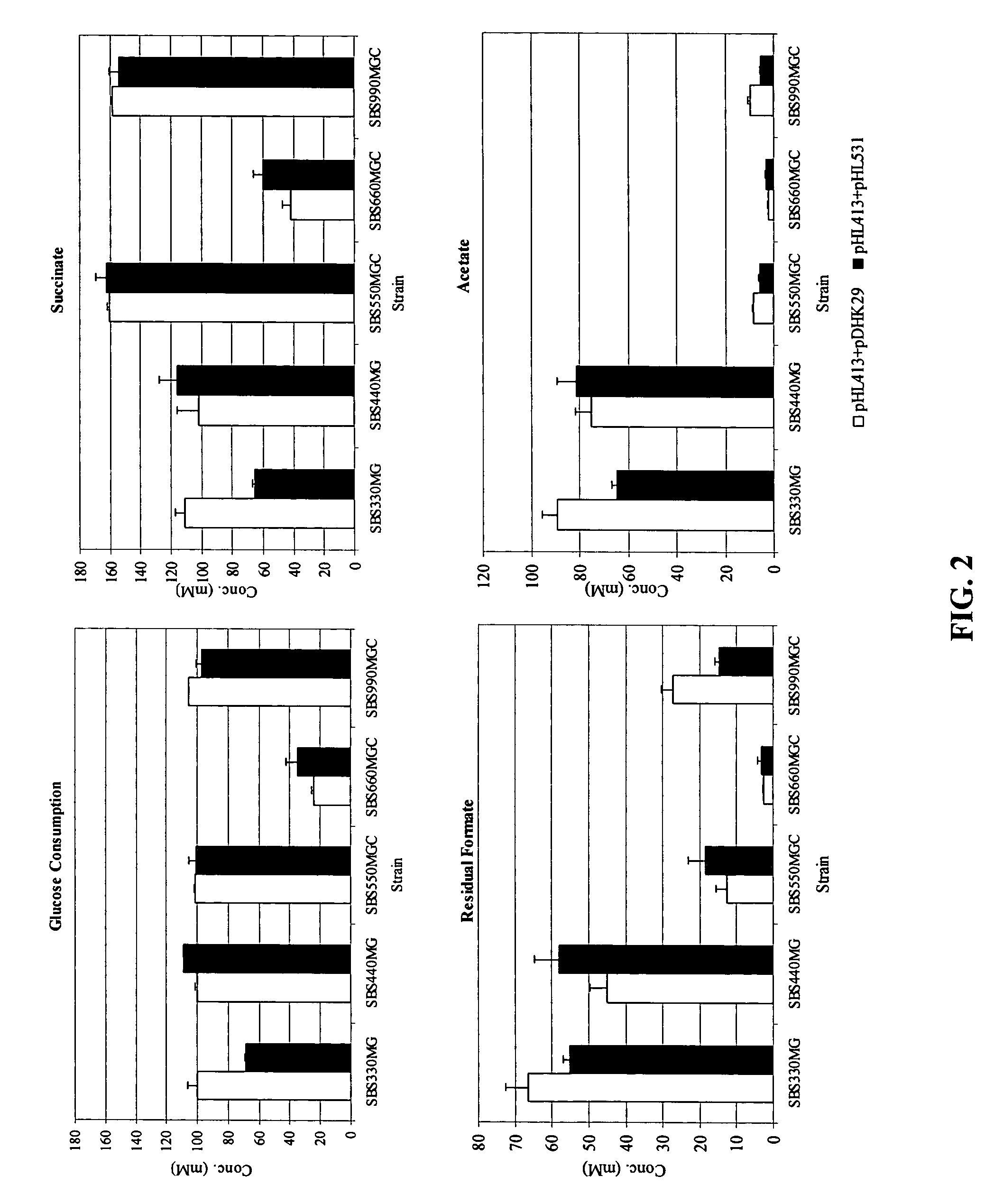

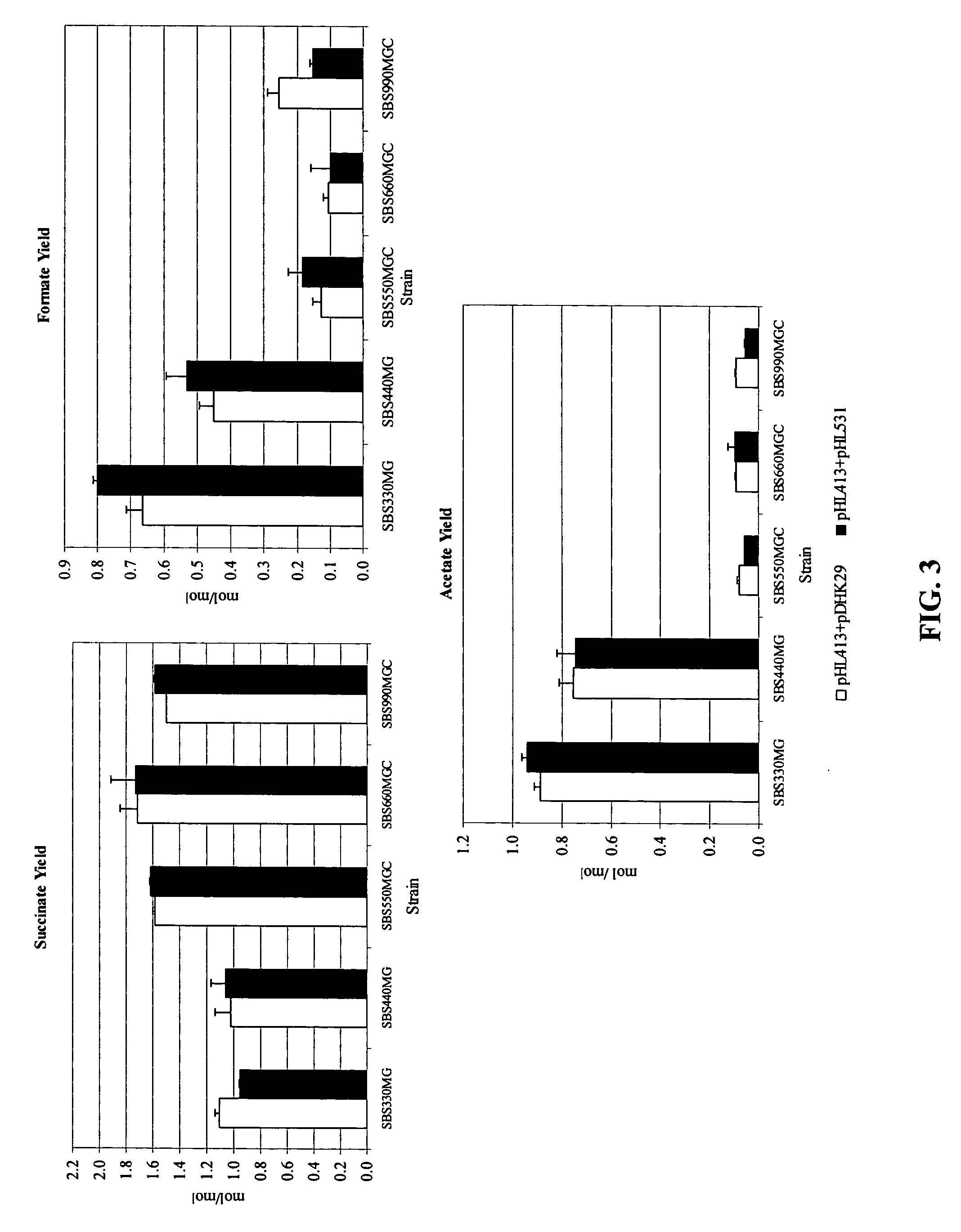

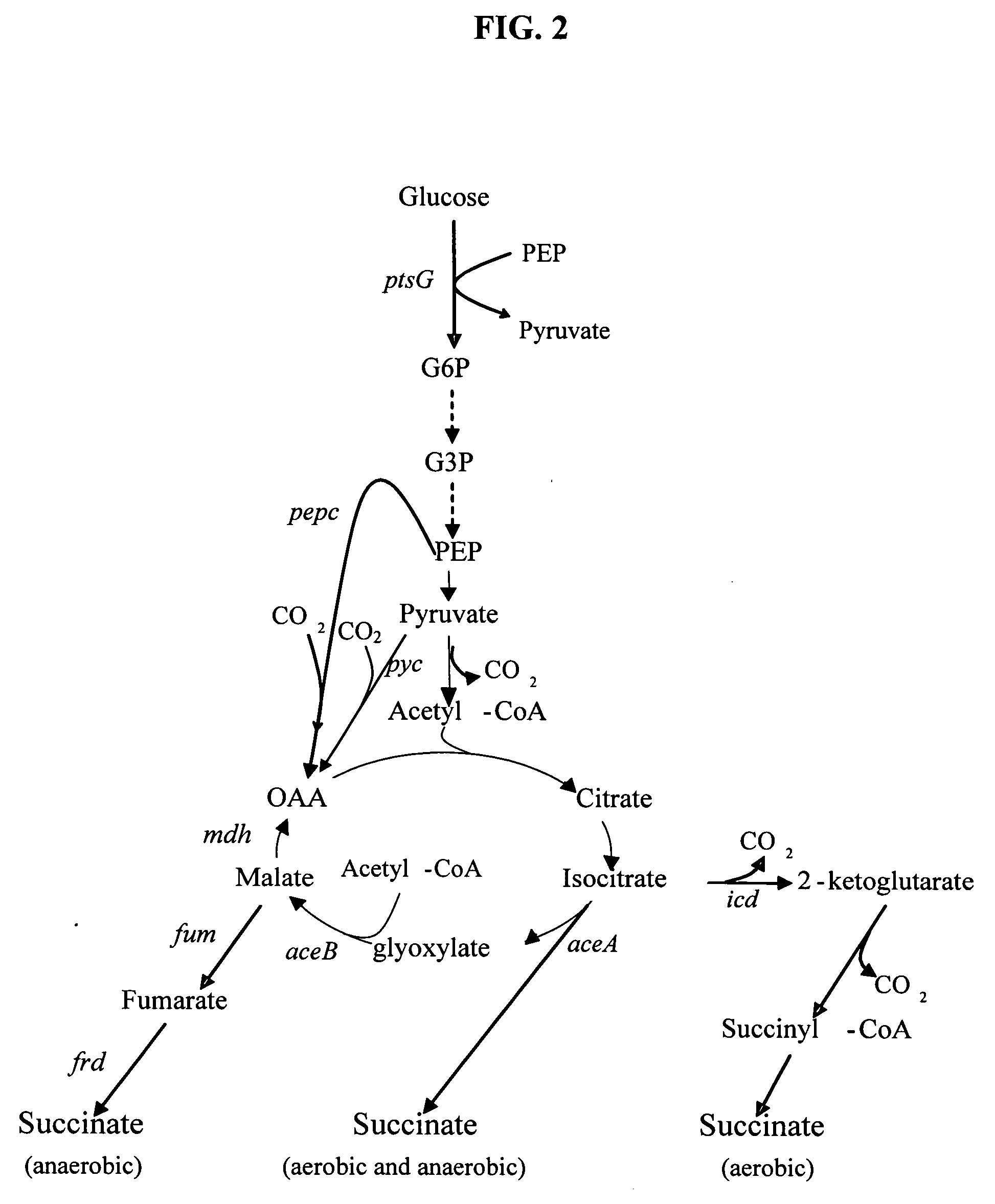

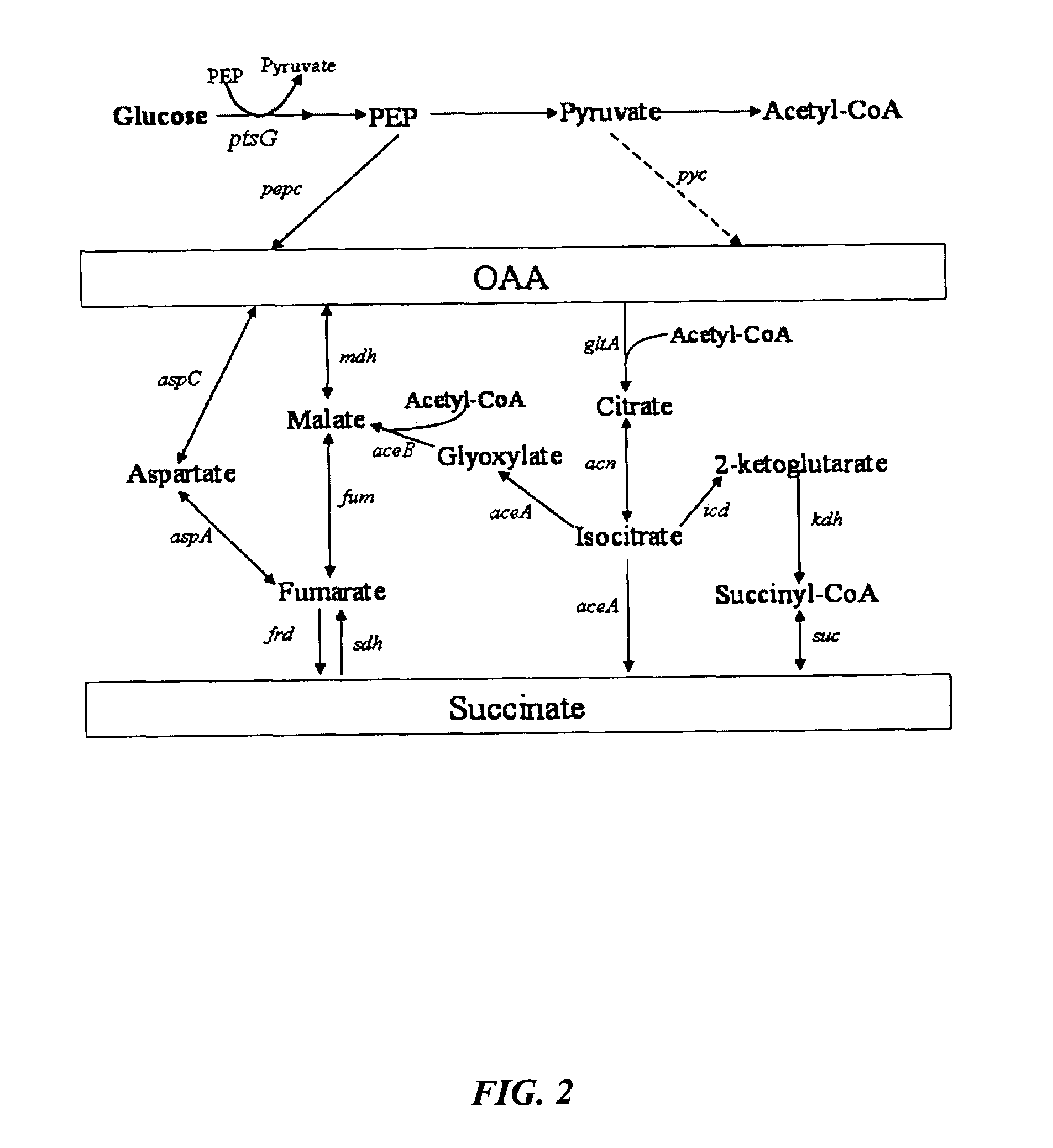

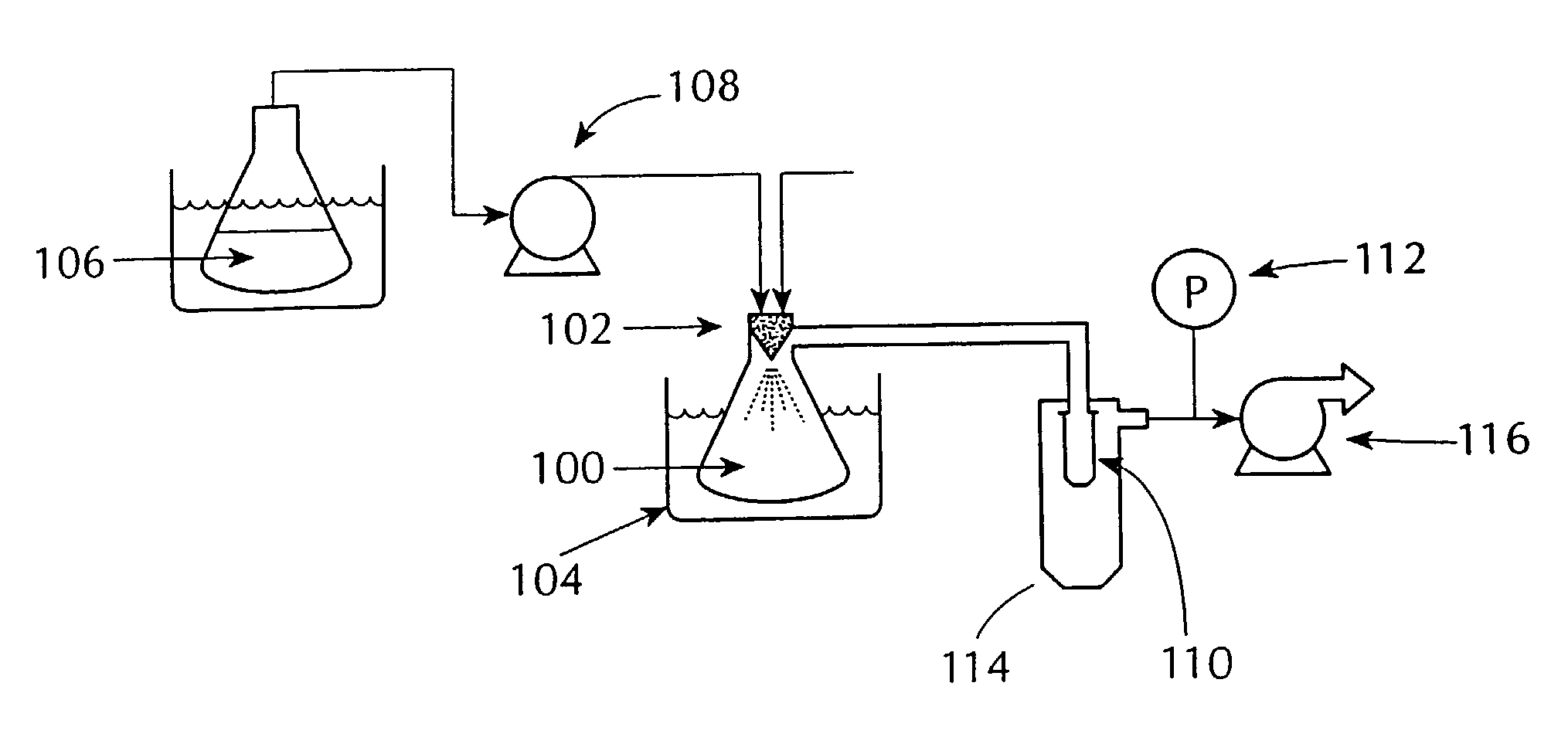

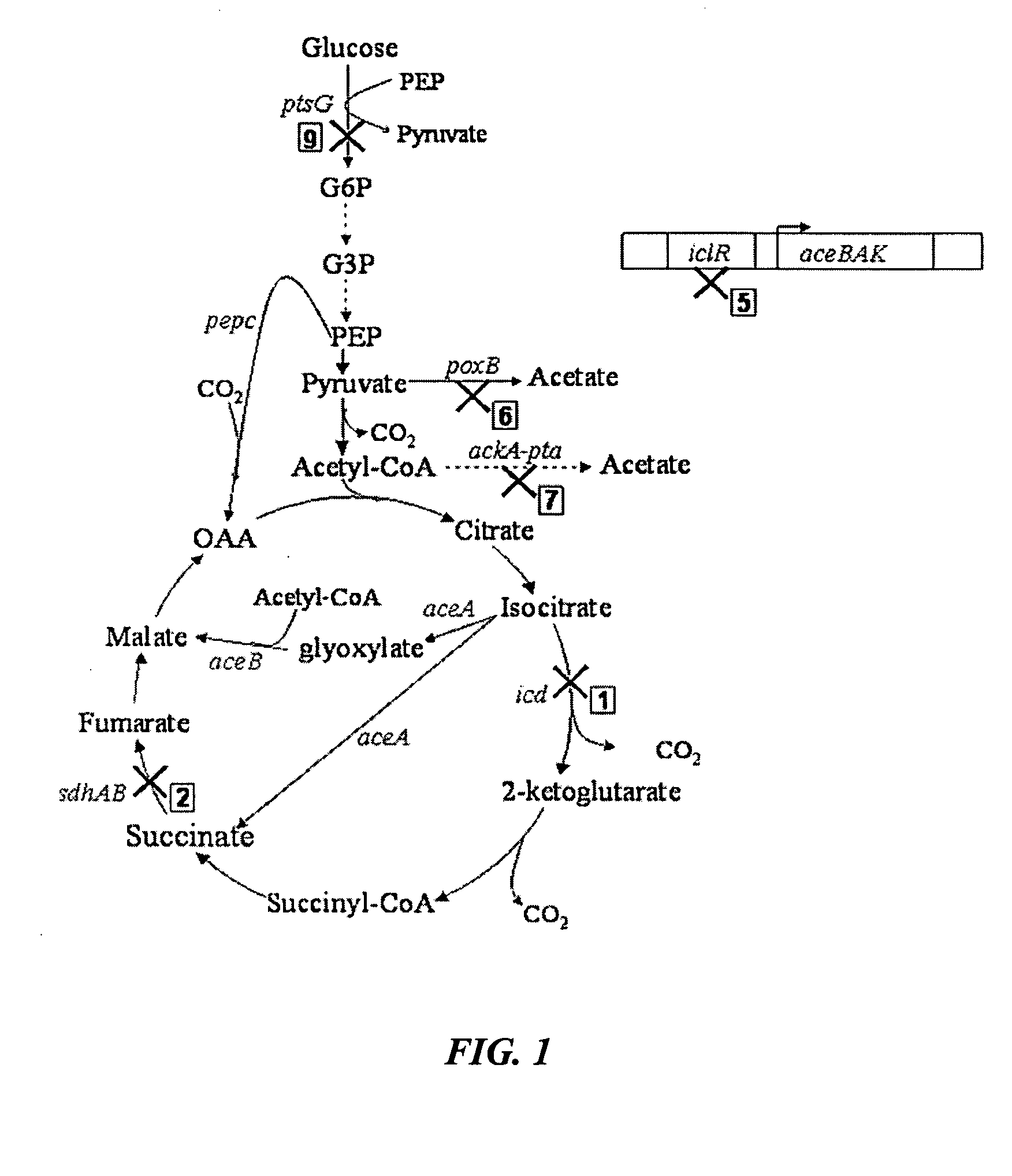

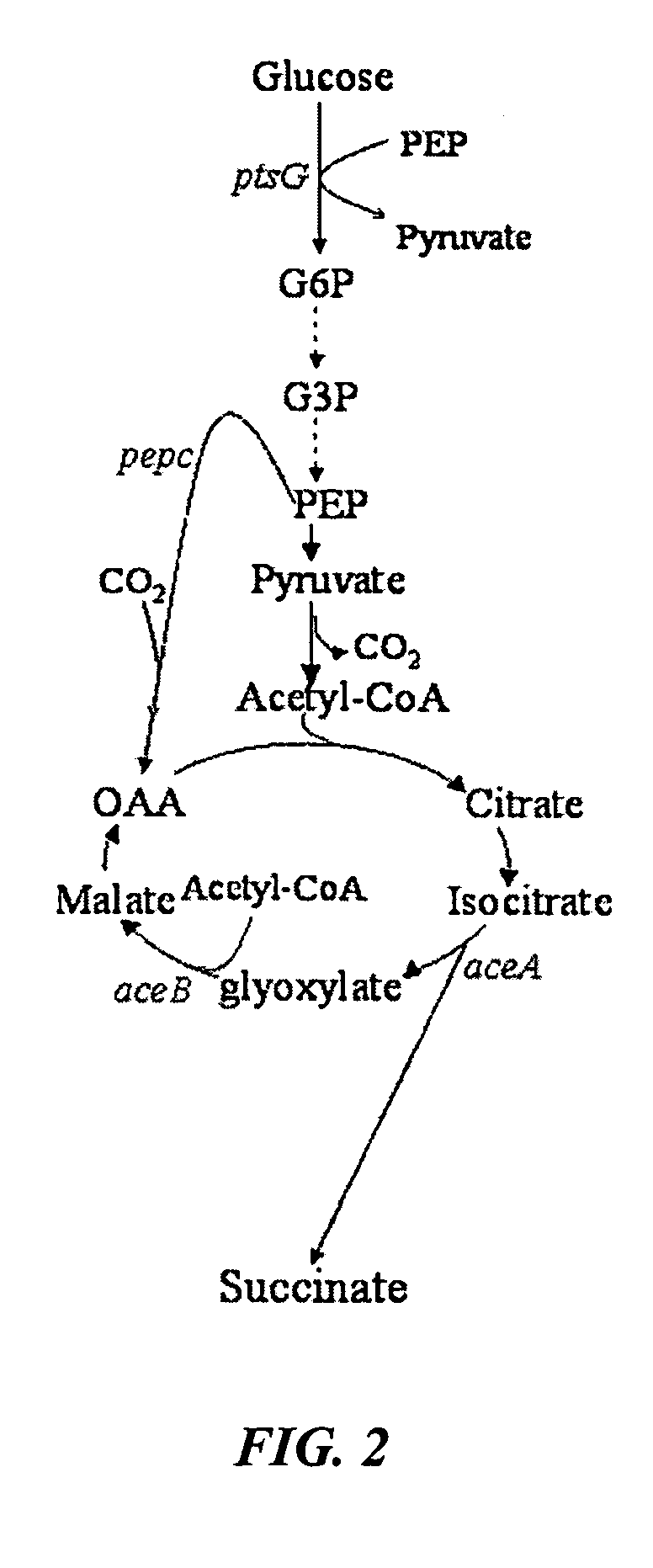

The invention relates to a hybrid succinate production system that has a high capacity to produce succinate under aerobic and anaerobic conditions. The metabolic engineering of a hybrid bacterial succinate production system that can function under both aerobic and anaerobic conditions makes the production process more efficient, and the process control and optimization less difficult.

Owner:RICE UNIV

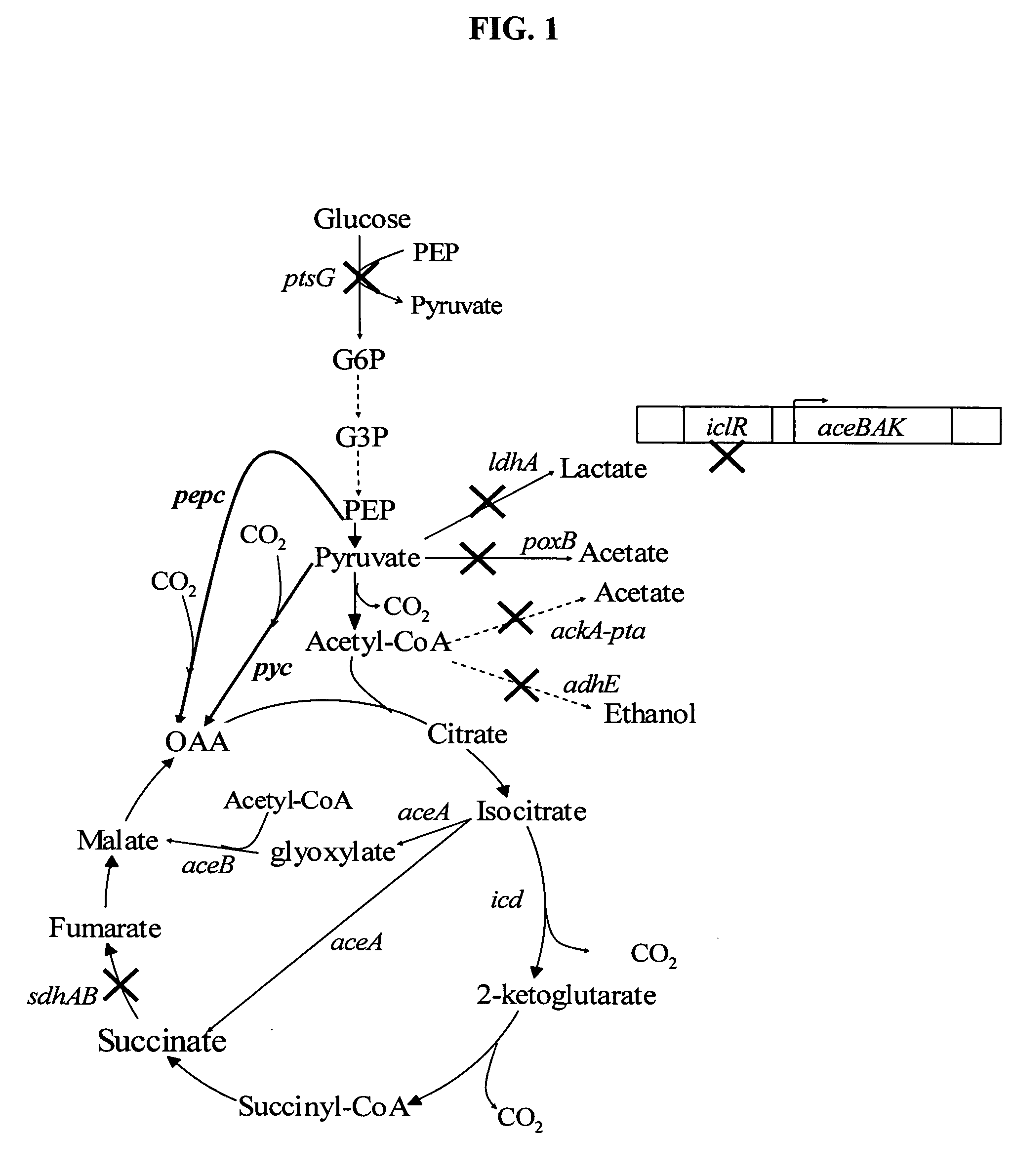

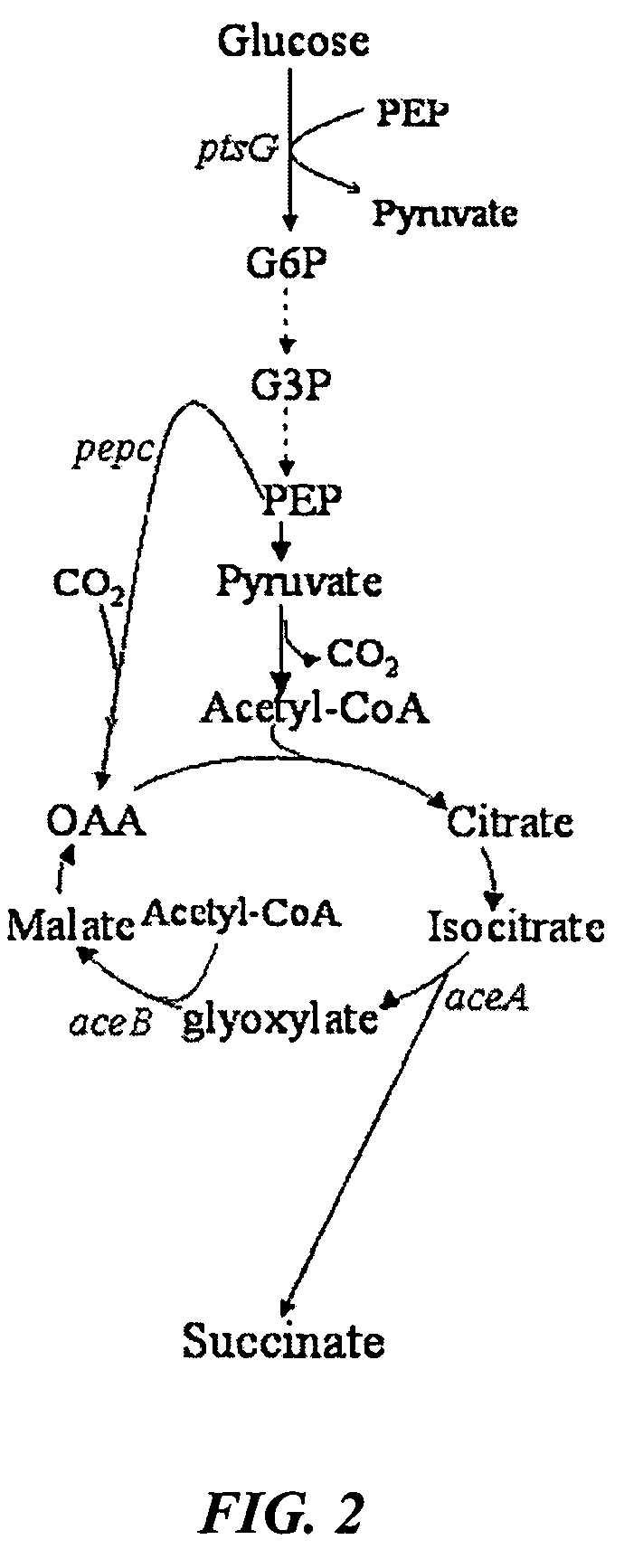

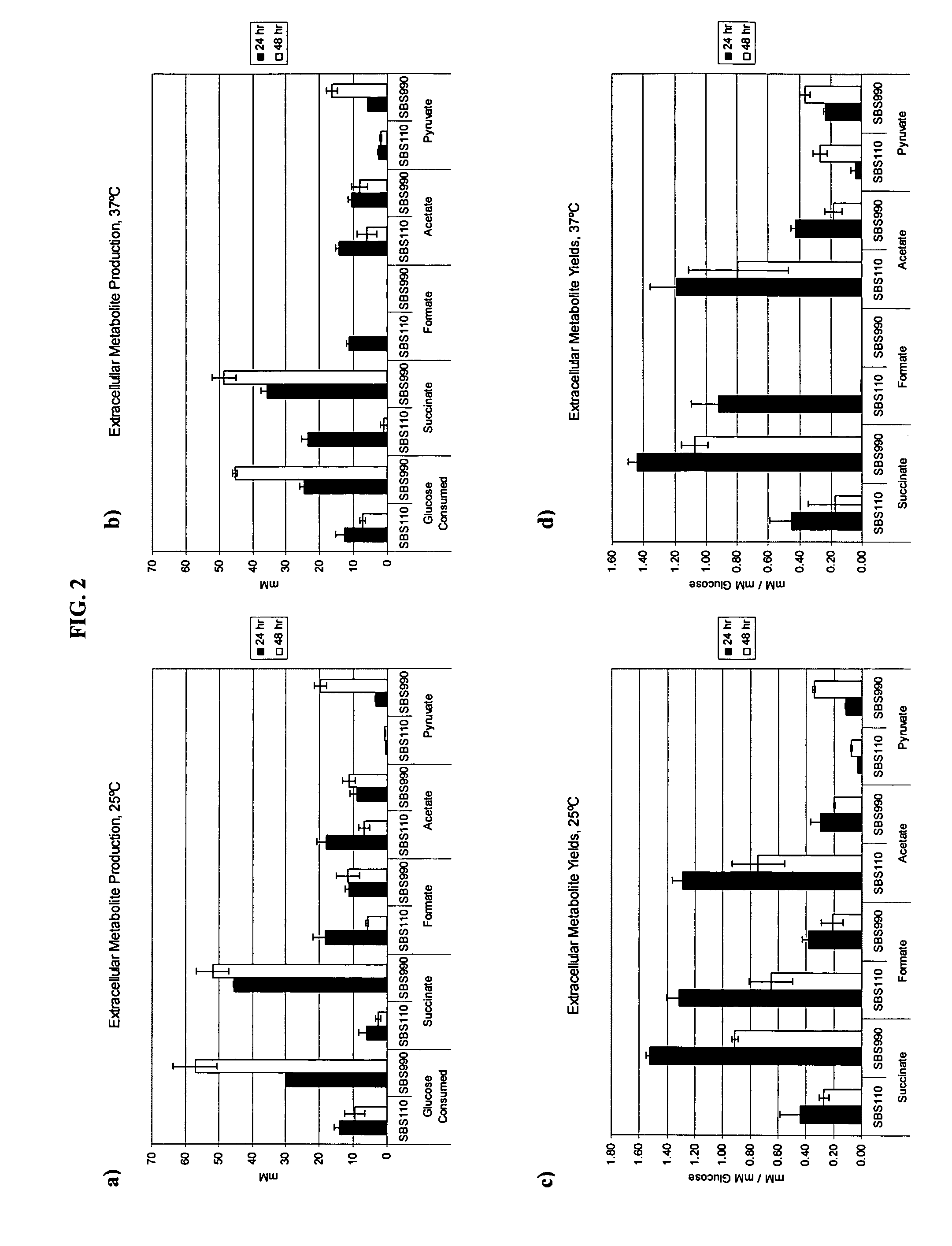

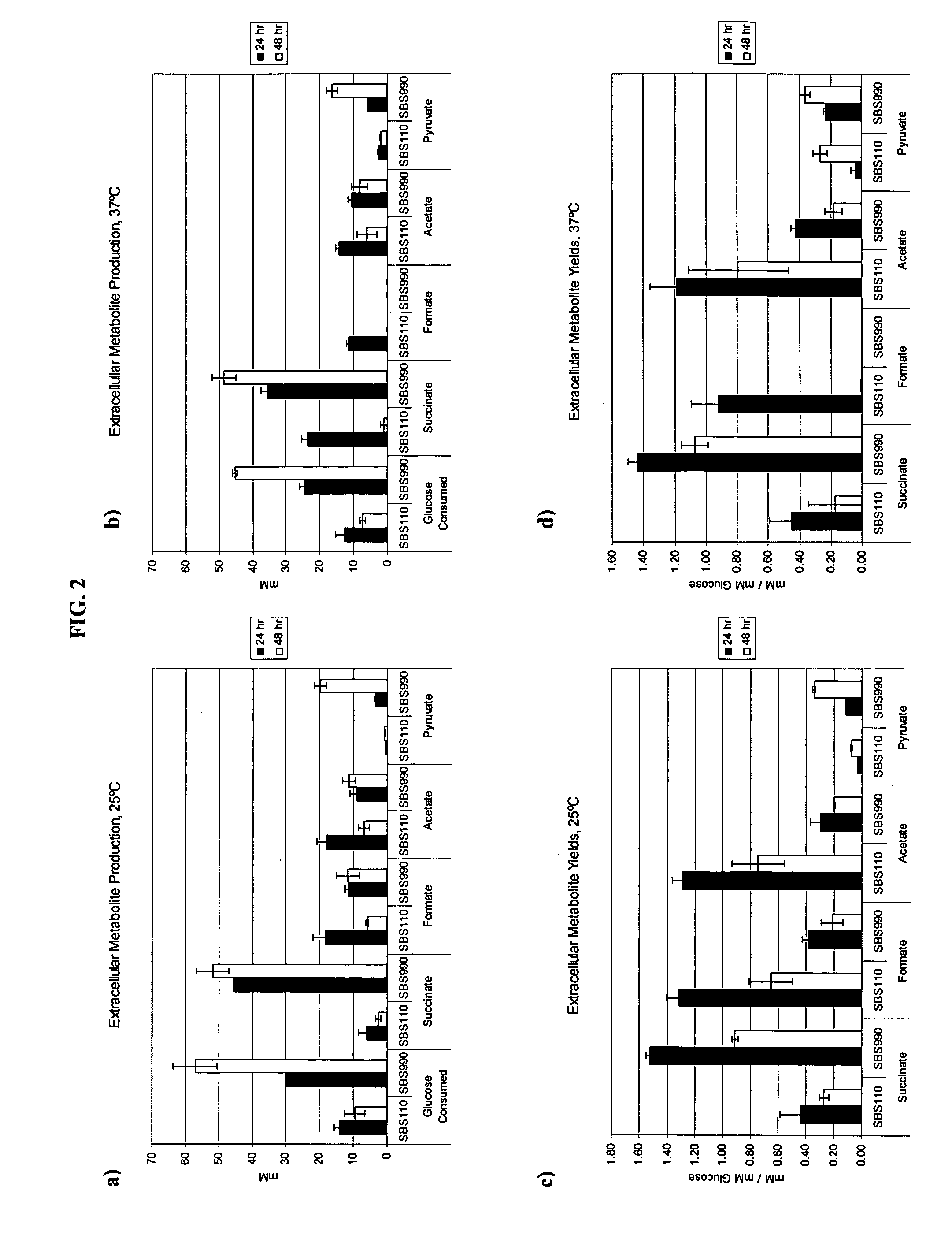

Aerobic succinate production in bacteria

Methods of increasing yields of succinate using aerobic culture methods and a multi-mutant E. coli strain are provided. Also provided is a mutant strain of E. coli that produces high amounts of succinic acid.

Owner:RICE UNIV

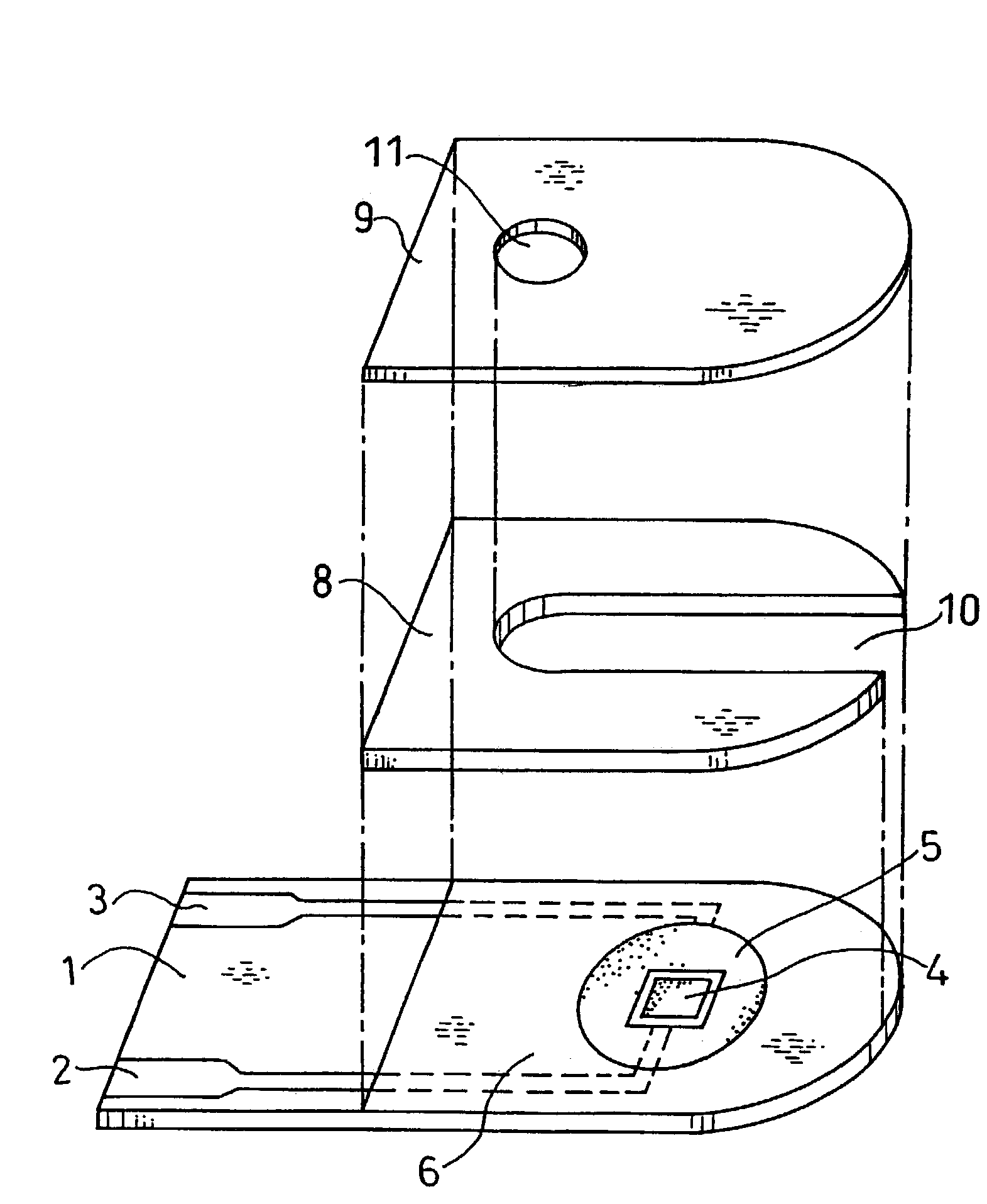

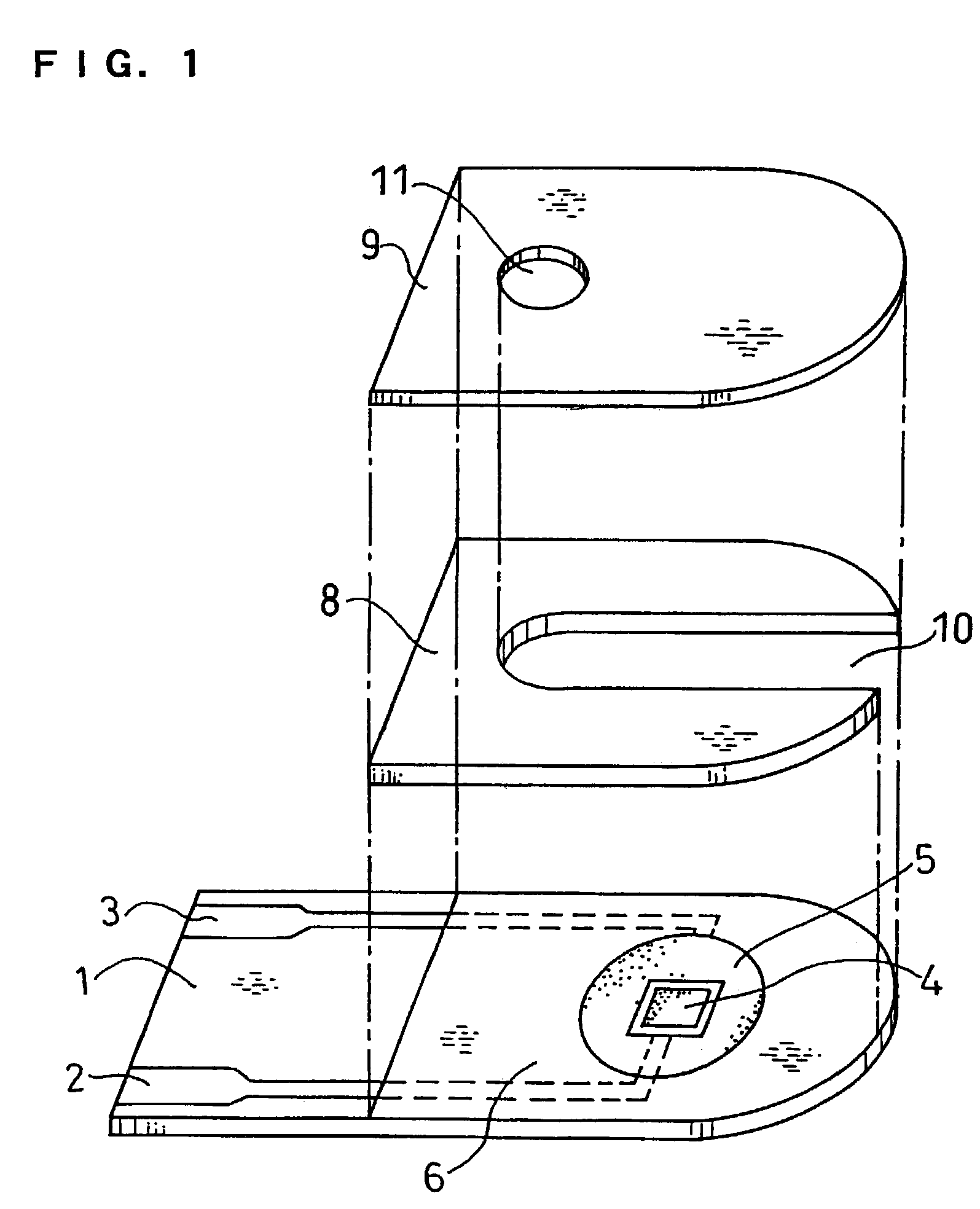

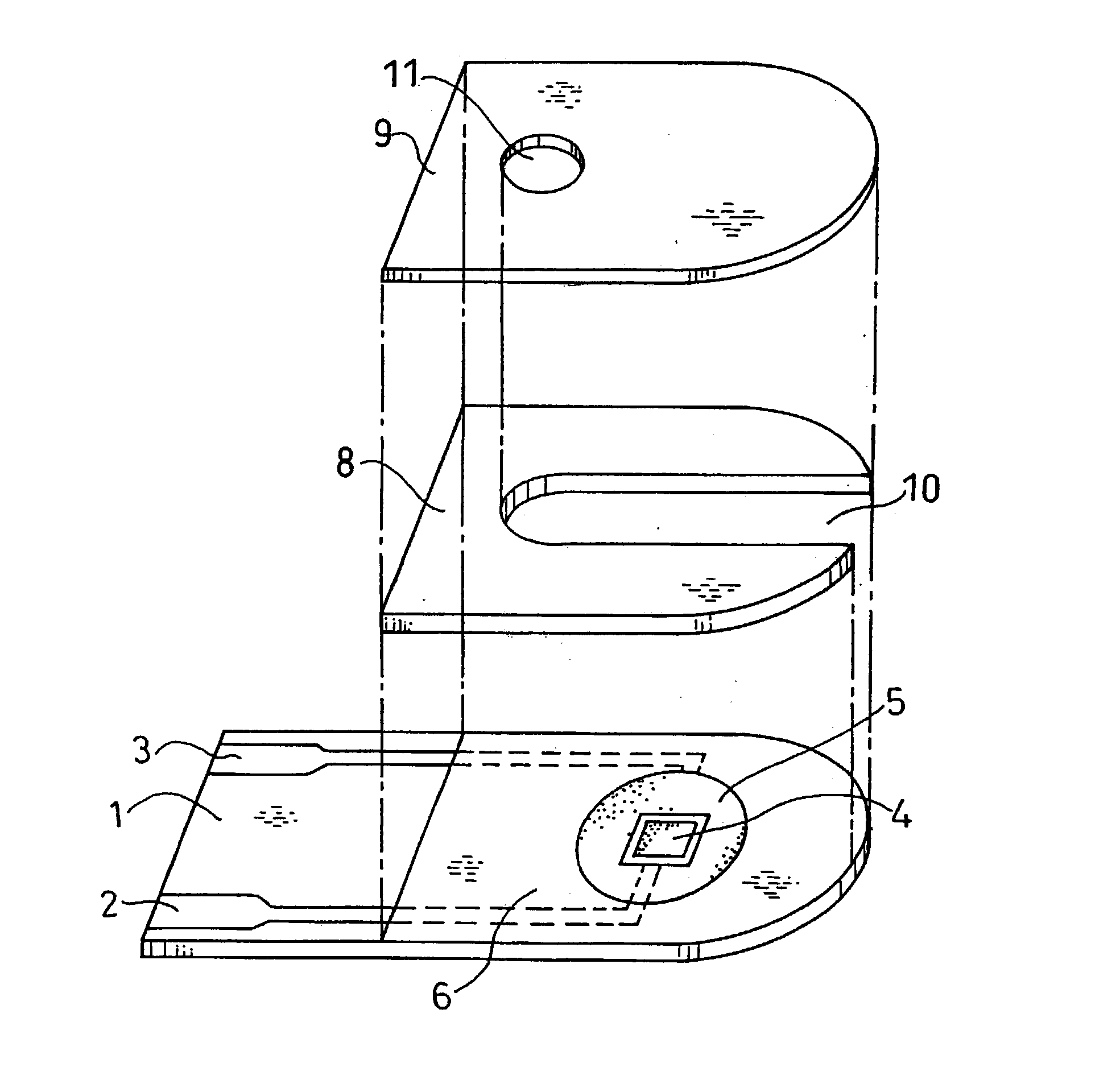

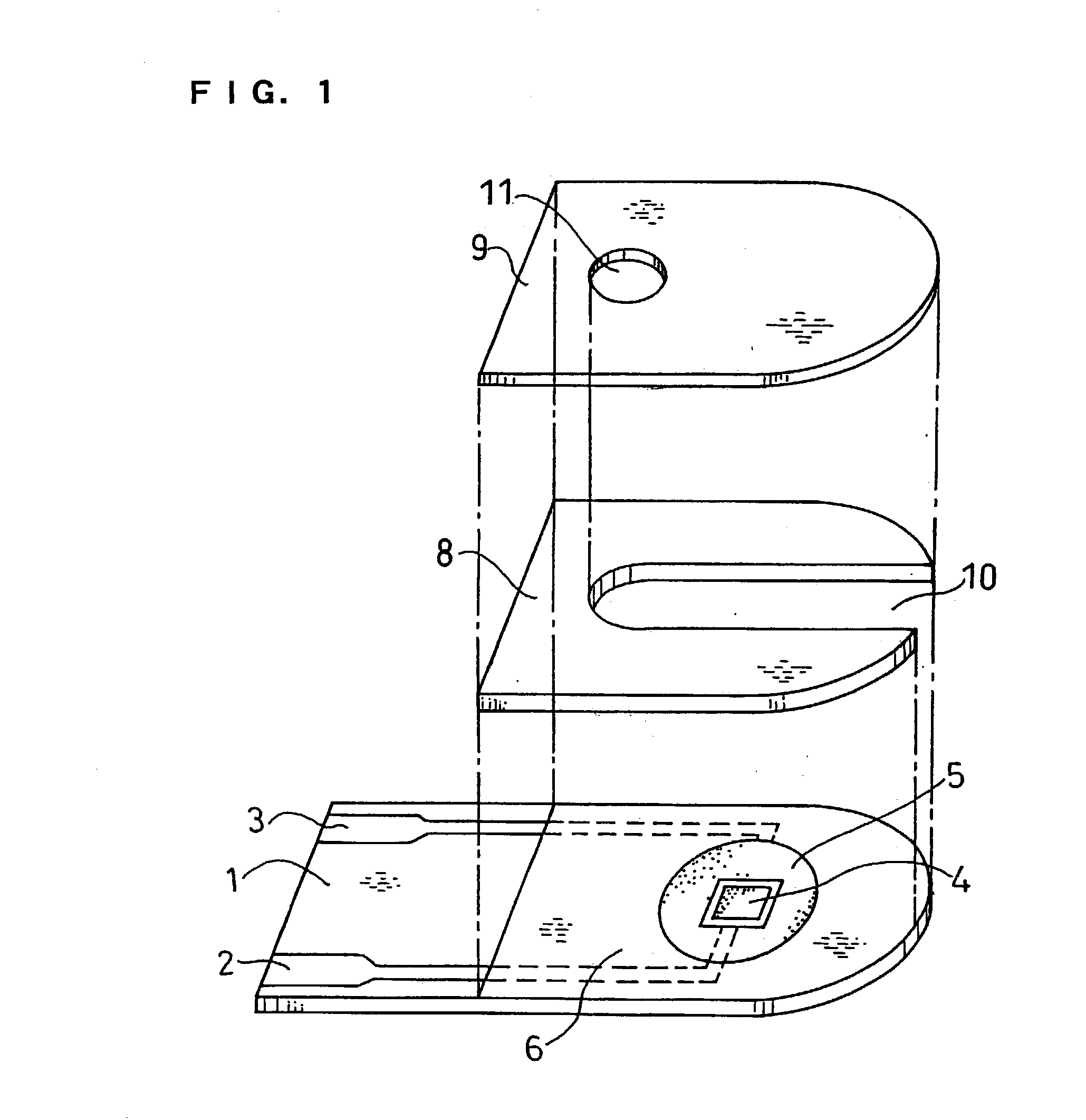

Biosensor

InactiveUS7235170B2Immobilised enzymesBioreactor/fermenter combinationsGluconolactonaseOxidoreductase

A biosensor that is highly responsive and capable of rapid and highly sensitive quantification of a specific component contained in a sample is provided. The biosensor of this invention comprises: an electrically insulating base plate; an electrode system comprising a working electrode and a counter electrode disposed on the base plate; and a reagent system comprising an oxidoreductase which catalyzes the oxidation reaction of glucose, gluconolactonase and a buffer. The buffer is selected from the group consisting of phthalic acid and its salts, maleic acid and its salts, succinic acid and its salts, phospholic acid and its salts, acetic acid and its salts, boric acid and its salts, citric acid and its salts, glycine, tris(hydroxymethyl)aminomethane, piperazine-N,N′-bis(2-ethane sulfonic acid) and the like.

Owner:PHC HLDG CORP

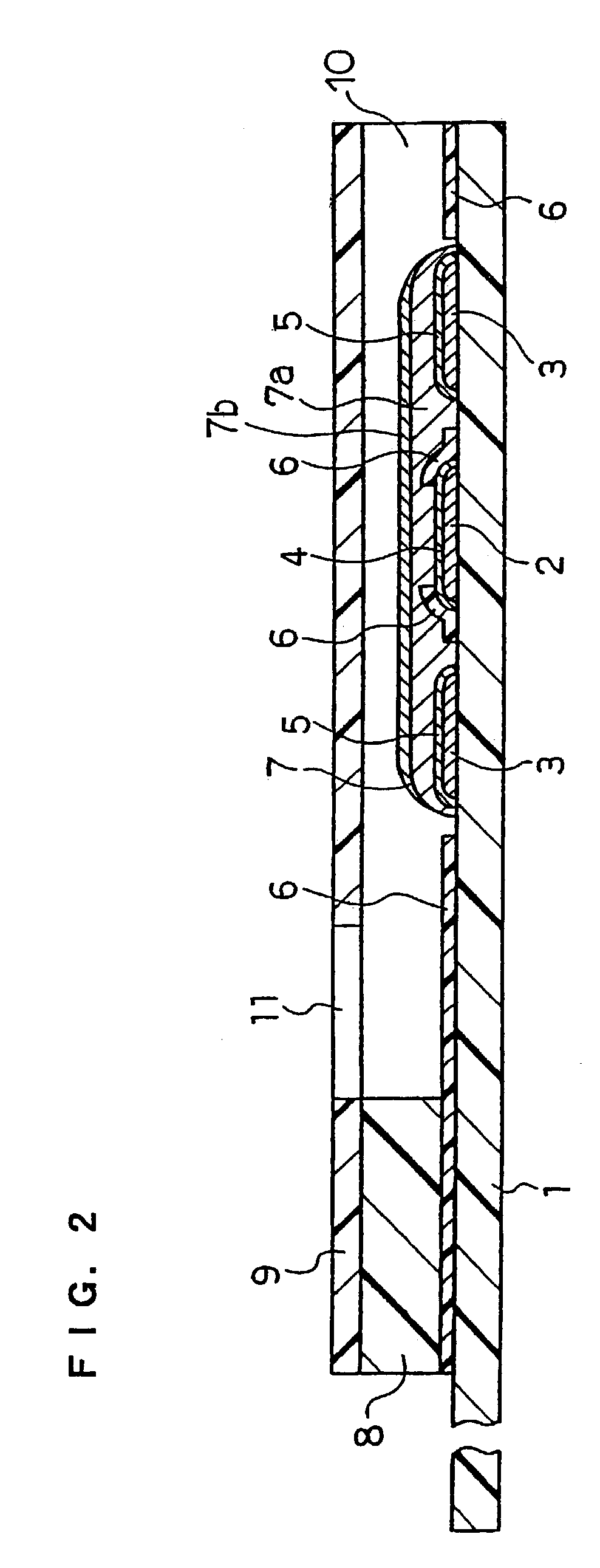

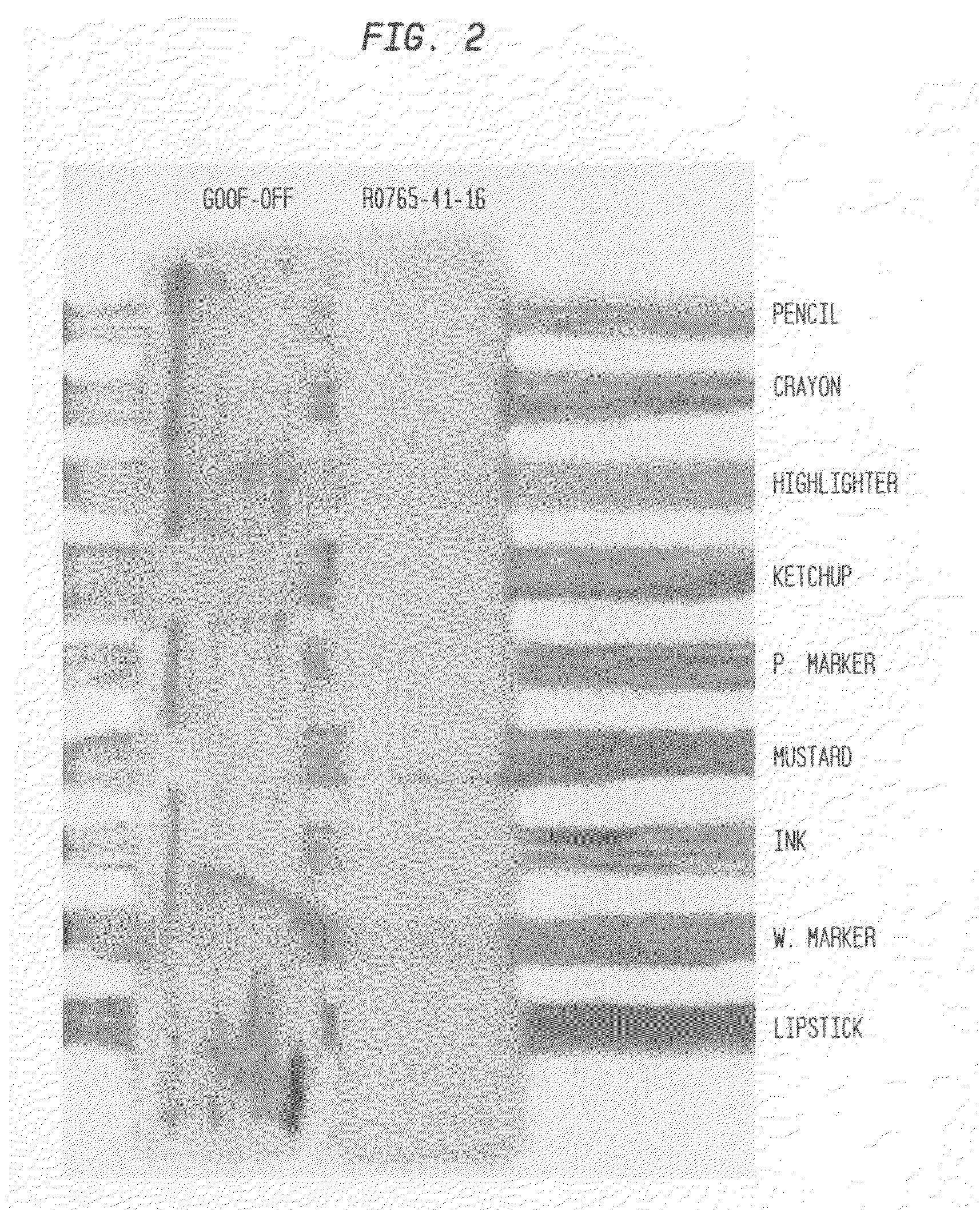

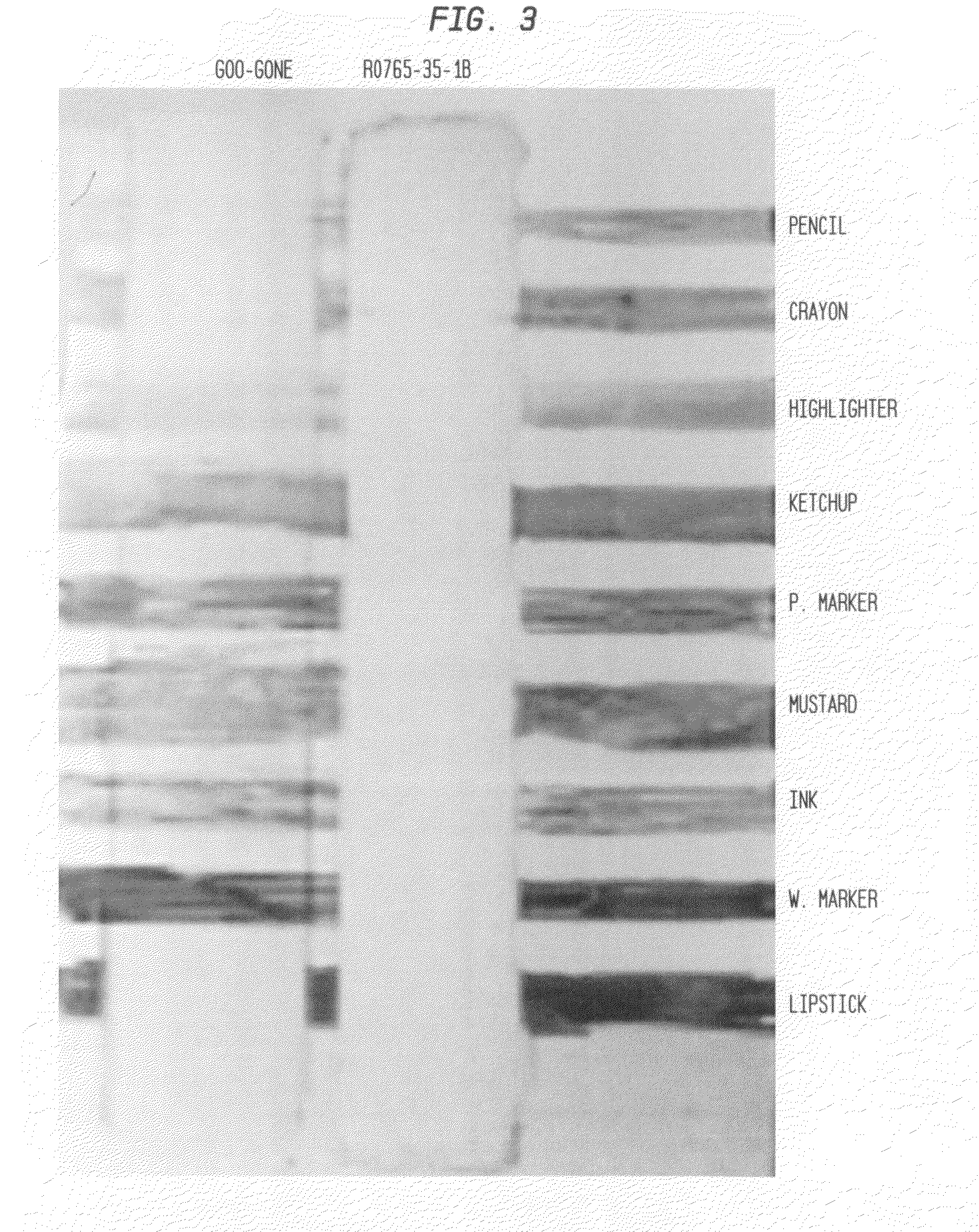

Cleaning compositions incorporating green solvents and methods for use

ActiveUS20090281012A1High flash pointLow vapor pressureOrganic detergent compounding agentsDetergent mixture composition preparationGlutaric acidActive agent

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

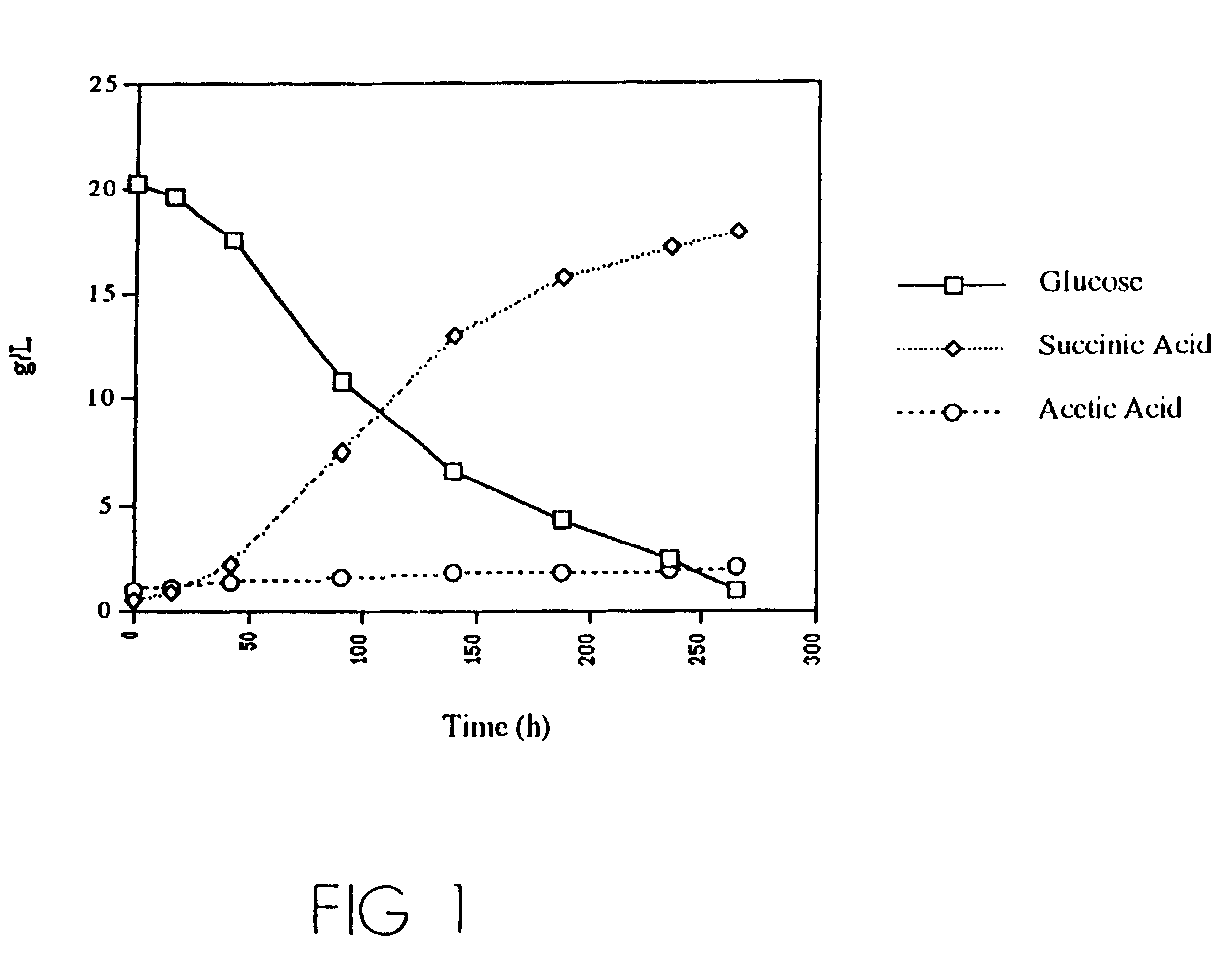

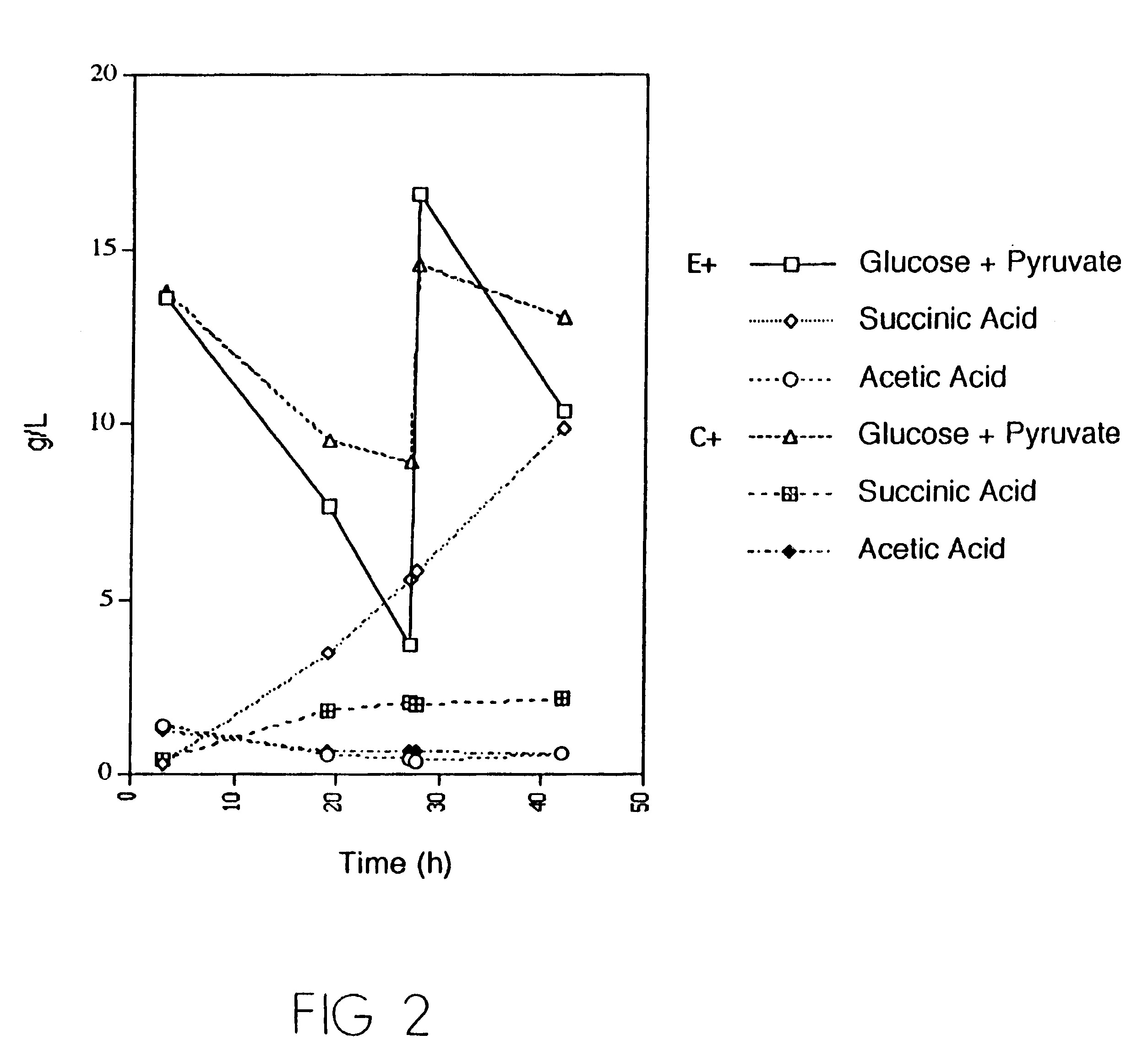

Mutant E. coli strain with increased succinic acid production

InactiveUSRE37393E1Cheap productionIncrease biomassBacteriaUnicellular algaeLactate dehydrogenaseBiological body

A method for isolating succinic acid producing bacteria is provided comprising increasing the biomass of an organism which lacks the ability to catabolize pyruvate, and then subjecting the biomass to glucose-rich medium in an anaerobic environment to enable pyruvate-catabolizing mutants to grow.The invention also provides for a mutant that produces high amounts of succinic acid, which has been derived from a parent which lacked the genes for pyruvate formate lyase and lactate dehydrogenase, and which belongs to the E.coli Group of Bacteria.

Owner:UNIVERSITY OF CHICAGO

Use of phosphoketolase for producing useful metabolites

Owner:AJINOMOTO CO INC

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

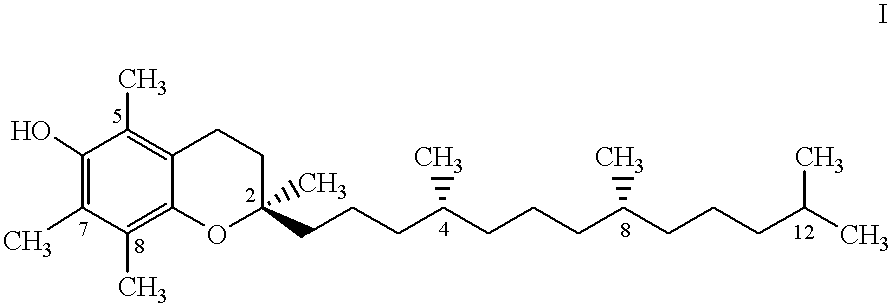

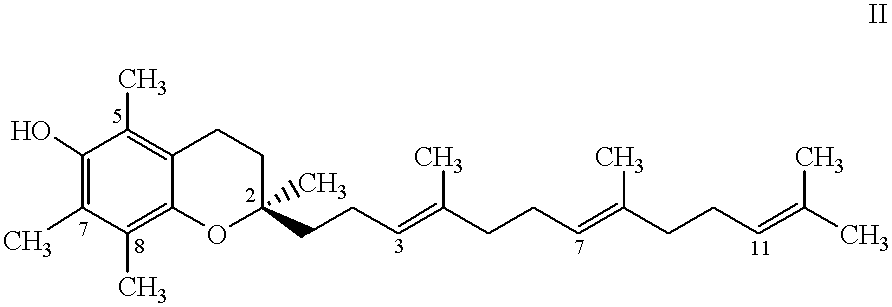

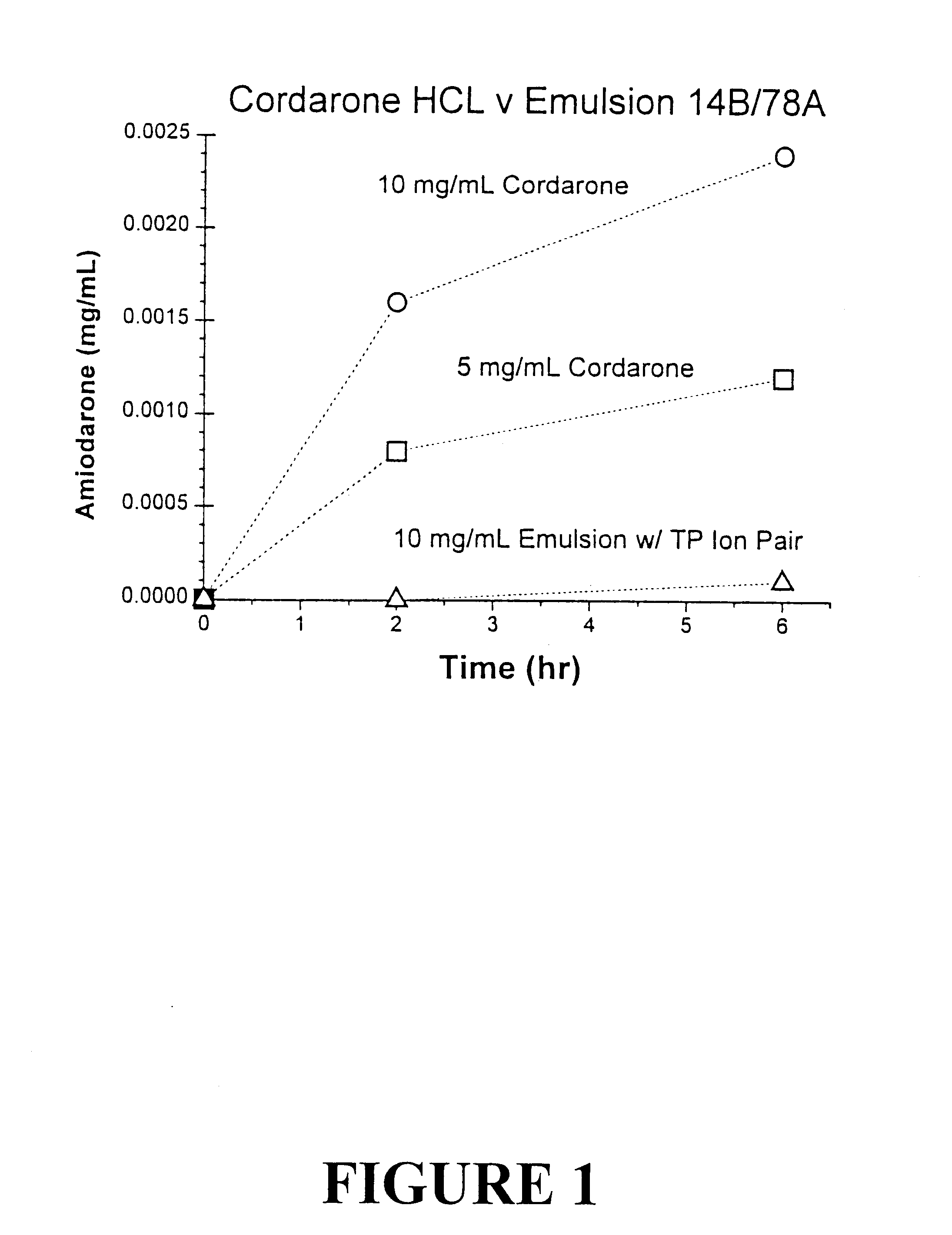

Compositions of tocol-soluble therapeutics

Tocol-based compositions of charged amphiphilic and water soluble pharmaceutically active compounds or their charged precursors are prepared by forming a tocol-soluble ion pair with an oppositely charged ion-pair forming compound capable of forming a tocol-soluble ion-pair with the active compound.Also disclosed are novel compounds tocopherolsuccinate-aspartate and tocopherolsuccinate-glutamate, which are useful as ion-pair forming compounds.

Owner:SONUS PHARM INC

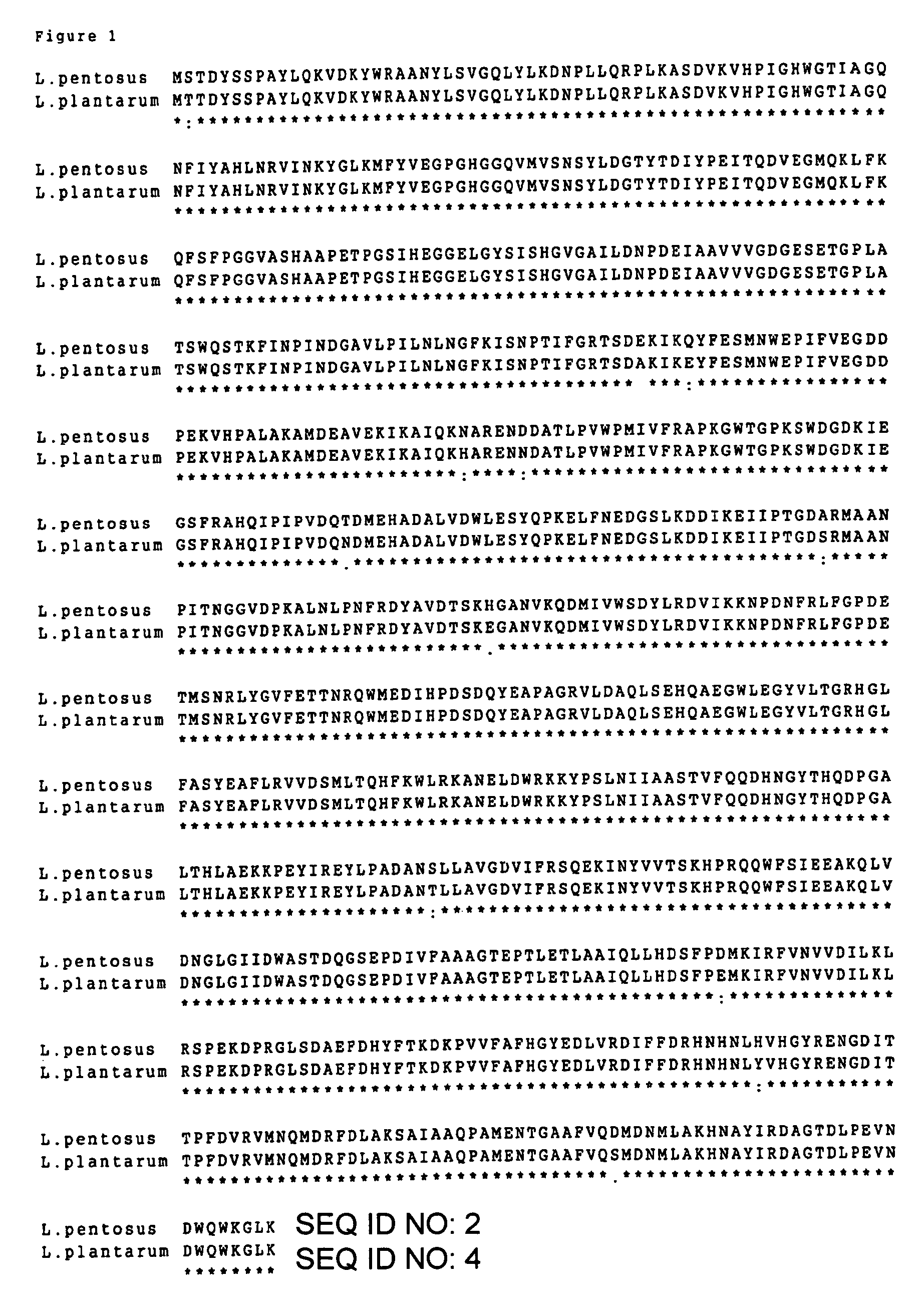

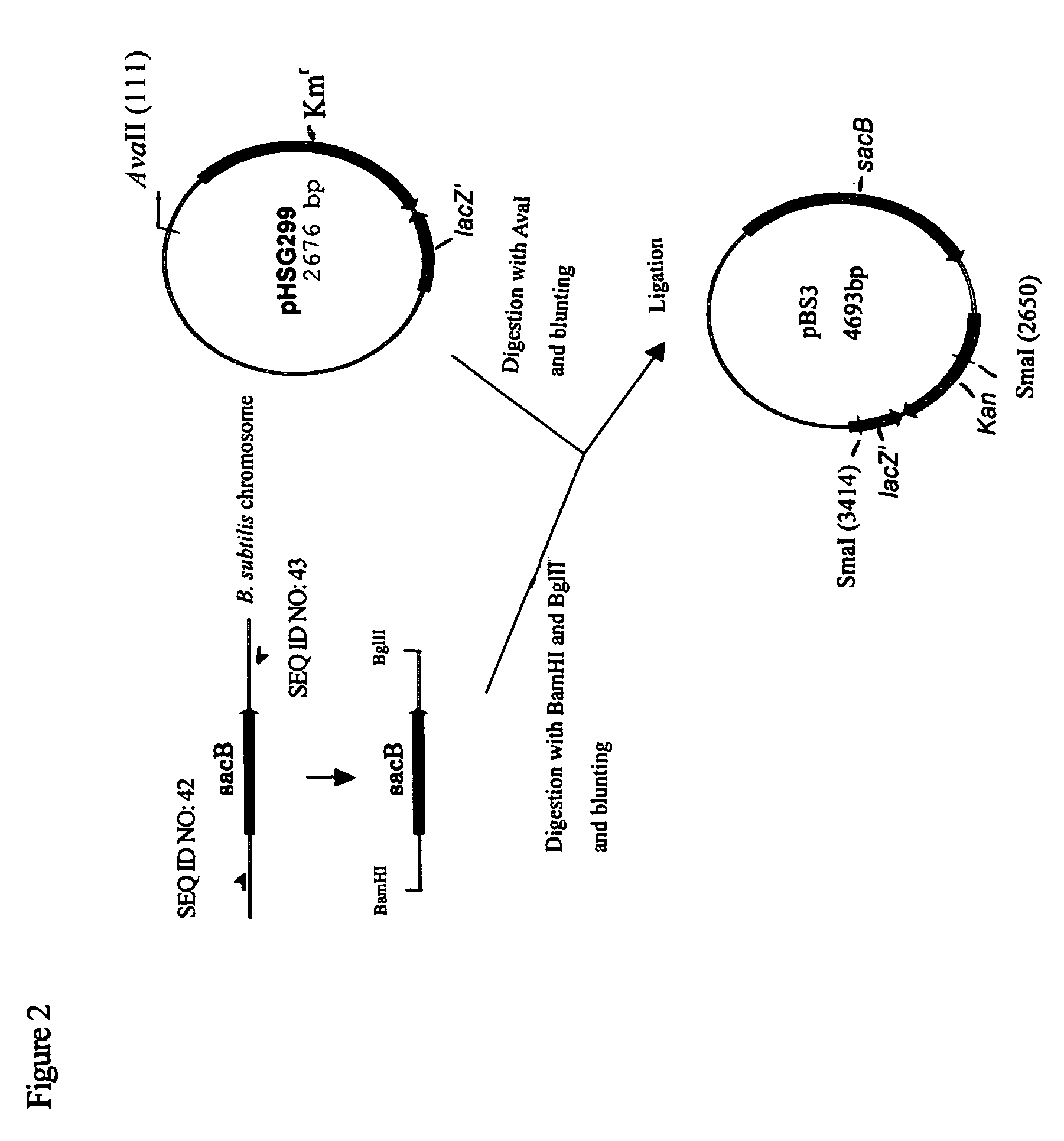

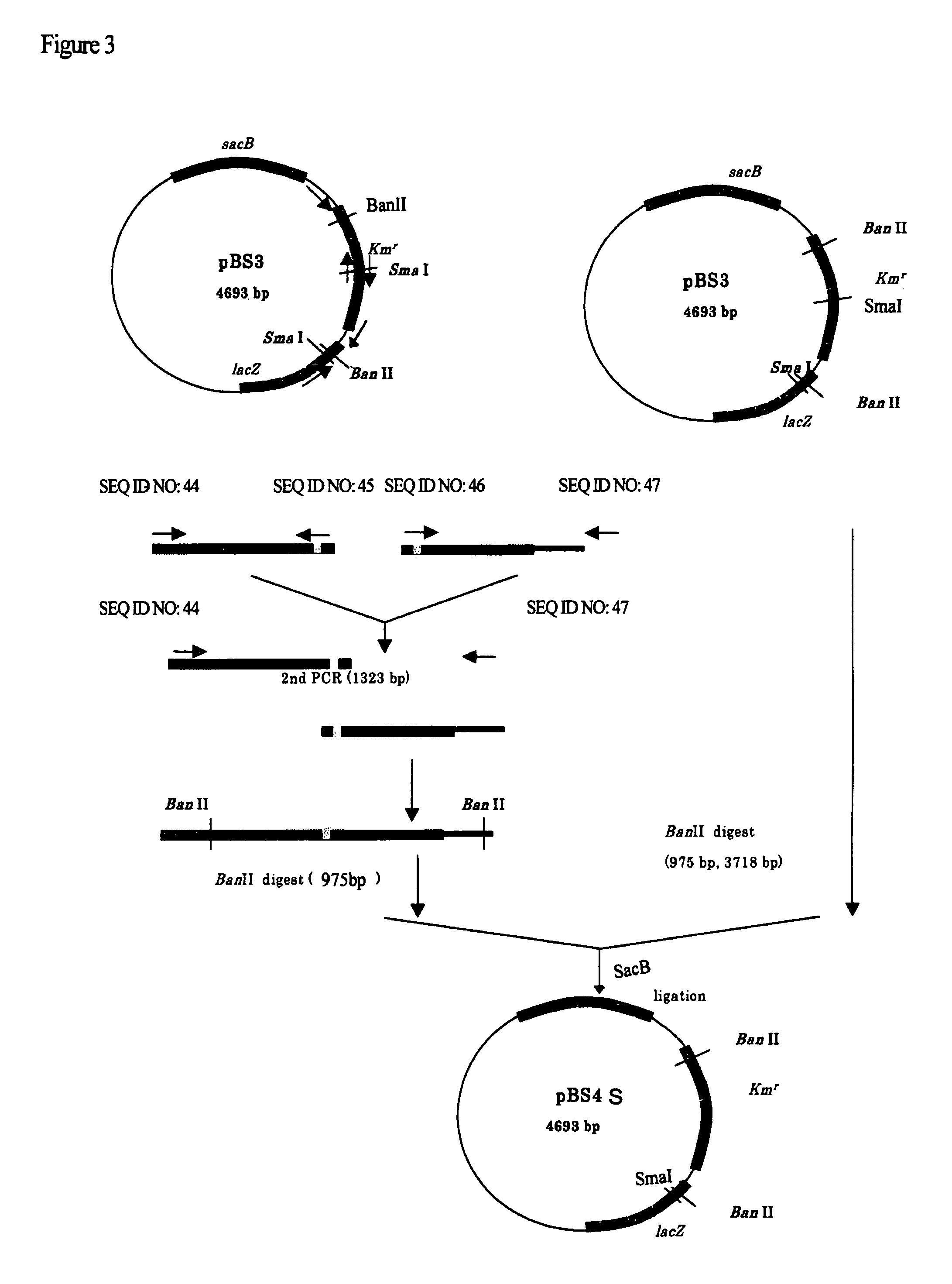

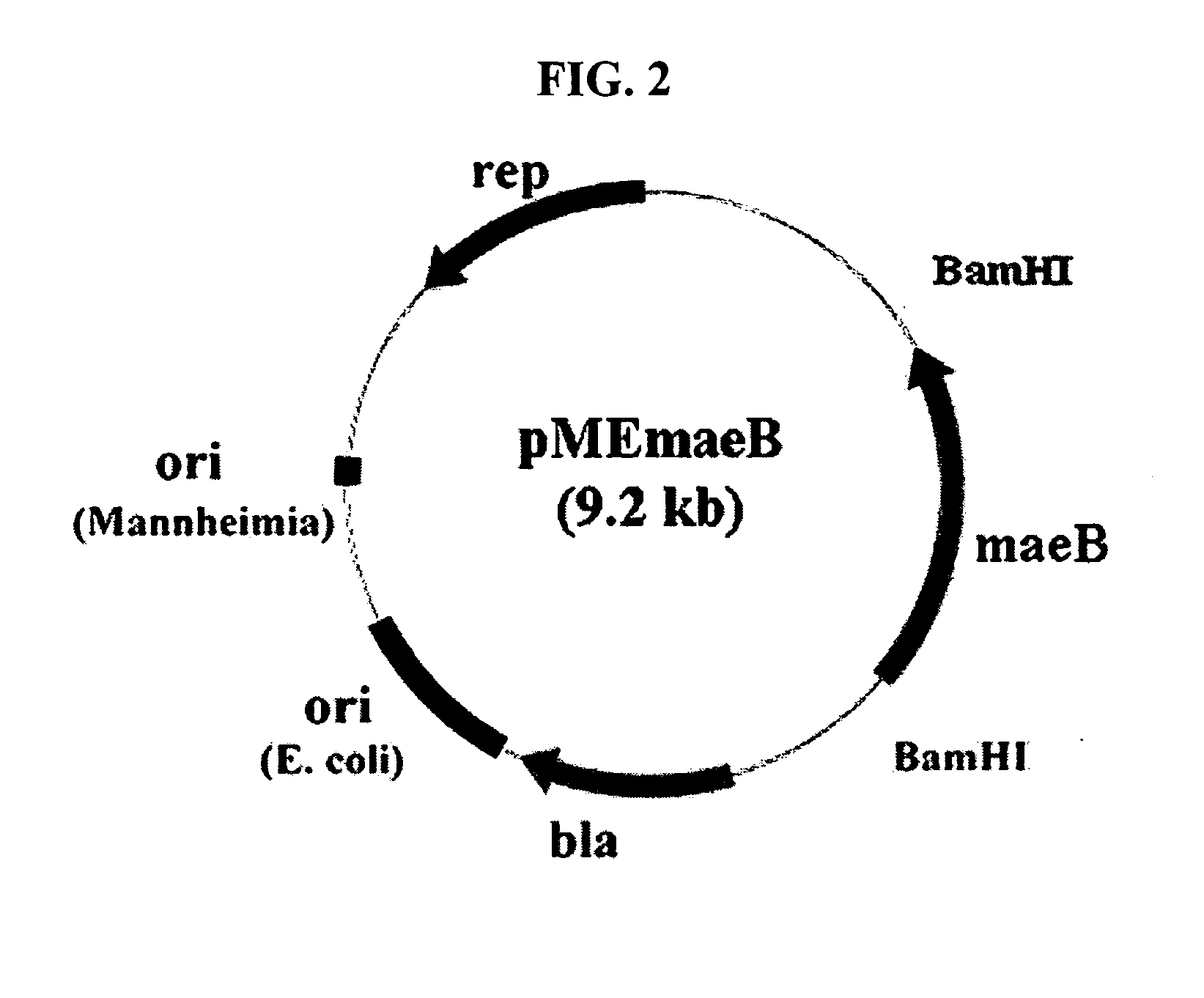

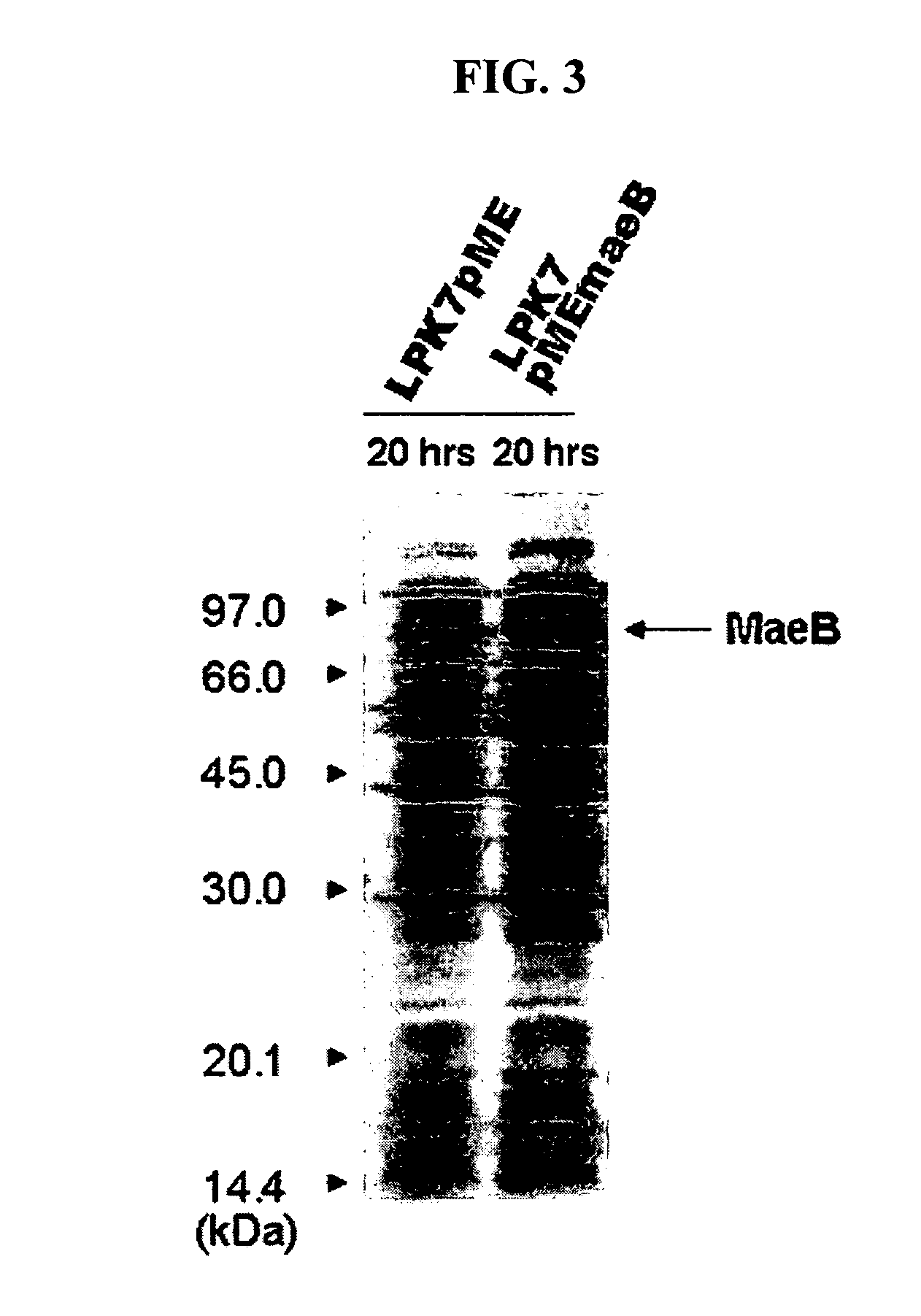

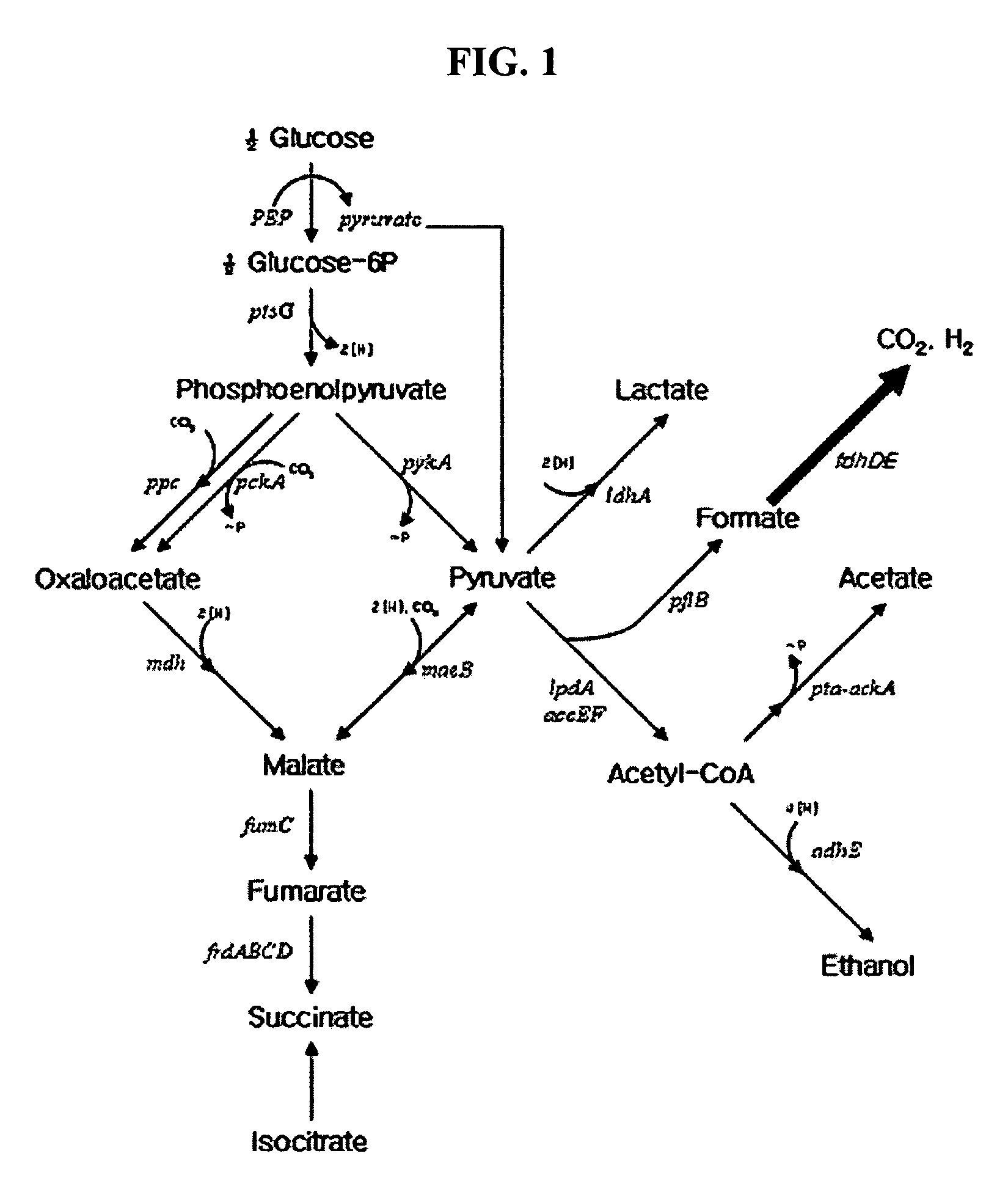

Novel gene encoding malic enzyme and method for preparing succinic acid using the same

ActiveUS20070042476A1Increase productionLightweight productionBacteriaSugar derivativesMicroorganismNucleotide

A nucleotide sequence encoding a malic enzyme and a method for preparing succinic acid using the same, more particularly, a maeB nucleotide sequence encoding a malic enzyme B having the activity of converting pyruvic acid or pyruvate to malic acid or malate, or vice versa, a recombinant vector containing the gene, a microorganism transformed with the recombinant vector, and a method for preparing succinic acid using the transformed microorganism.

Owner:KOREA ADVANCED INST OF SCI & TECH

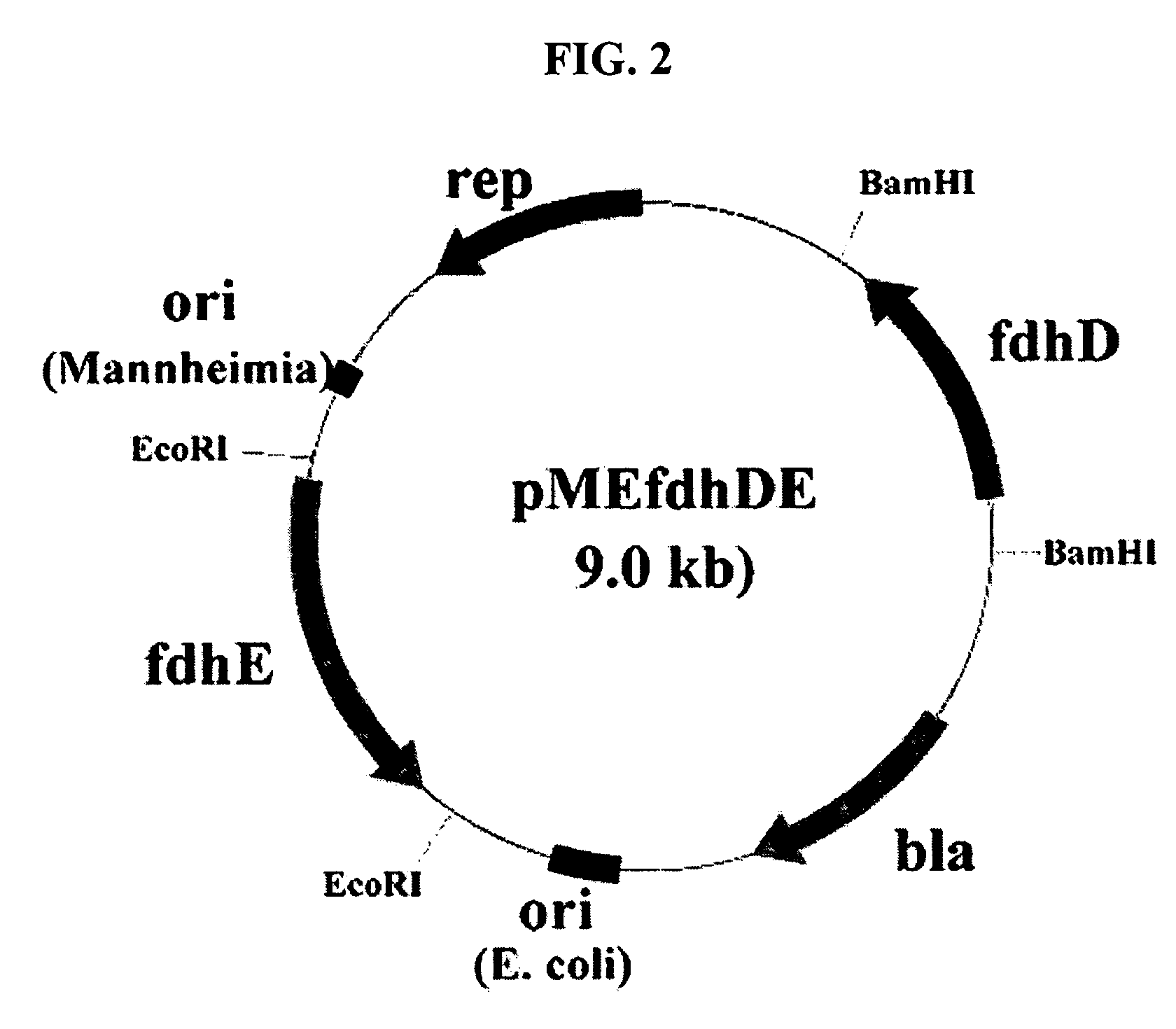

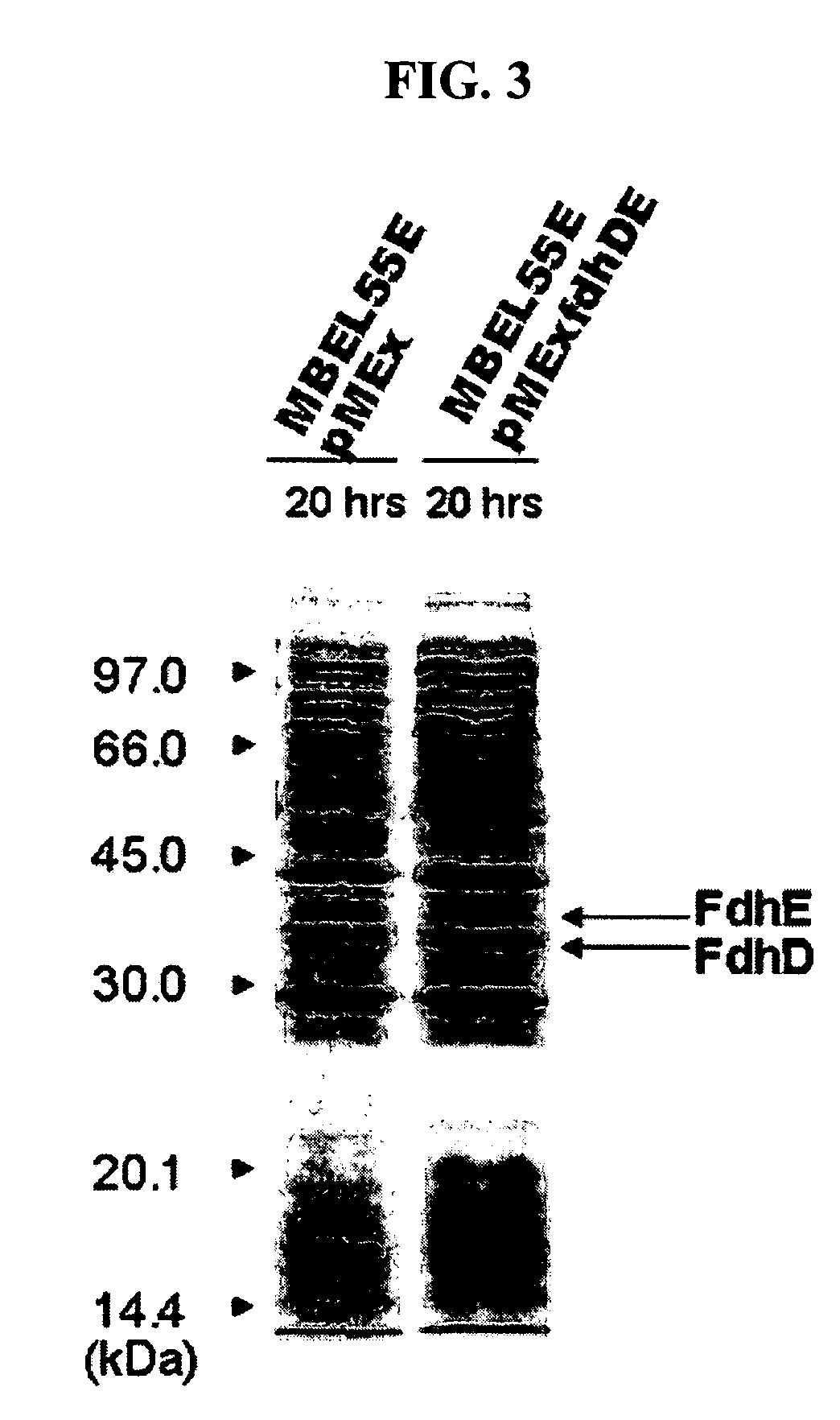

Gene encoding formate dehydrogenases D & E and method for preparing succinic acid using the same

Owner:KOREA ADVANCED INST OF SCI & TECH

Method for purifying succinic acid from fermentation broth

InactiveUS20060276674A1High purityHigh yieldFermentationCarboxylic compound separation/purificationIon exchangeSuccinic acid

Succinic acid is produced by bringing a succinic acid-containing liquid containing succinic acid and cation which is obtained by fermentation or an enzymatic method into contact with an H-type strongly acidic cation-exchange resin in an amount equivalent to or more than the amount of cation other than hydrogen ion contained in the succinic acid-containing liquid, and precipitating a crystal of succinic acid from the obtained ion-exchange-treated liquid to obtain purified succinic acid.

Owner:AJINOMOTO CO INC +1

Biosensor

InactiveUS20030175841A1Avoid influenceReduce solubilityImmobilised enzymesBioreactor/fermenter combinationsGluconolactonaseSuccinic acid

A biosensor that is highly responsive and capable of rapid and highly sensitive quantification of a specific component contained in a sample is provided. The biosensor of this invention comprises: an electrically insulating base plate; an electrode system comprising a working electrode and a counter electrode disposed on the base plate; and a reagent system comprising an oxidoreductase which catalyzes the oxidation reaction of glucose, gluconolactonase and a buffer. The buffer is selected from the group consisting of phthalic acid and its salts, maleic acid and its salts, succinic acid and its salts, phospholic acid and its salts, acetic acid and its salts, boric acid and its salts, citric acid and its salts, glycine, tris(hydroxymethyl)aminomethane, piperazine-N,N'-bis(2-ethane sulfonic acid) and the like.

Owner:PHC HLDG CORP

Aerobic succinate production in bacteria

Methods of increasing yields of succinate using aerobic culture methods and a multi-mutant E. coli strain are provided. Also provided is a mutant strain of E. coli that produces high amounts of succinic acid.

Owner:RICE UNIV

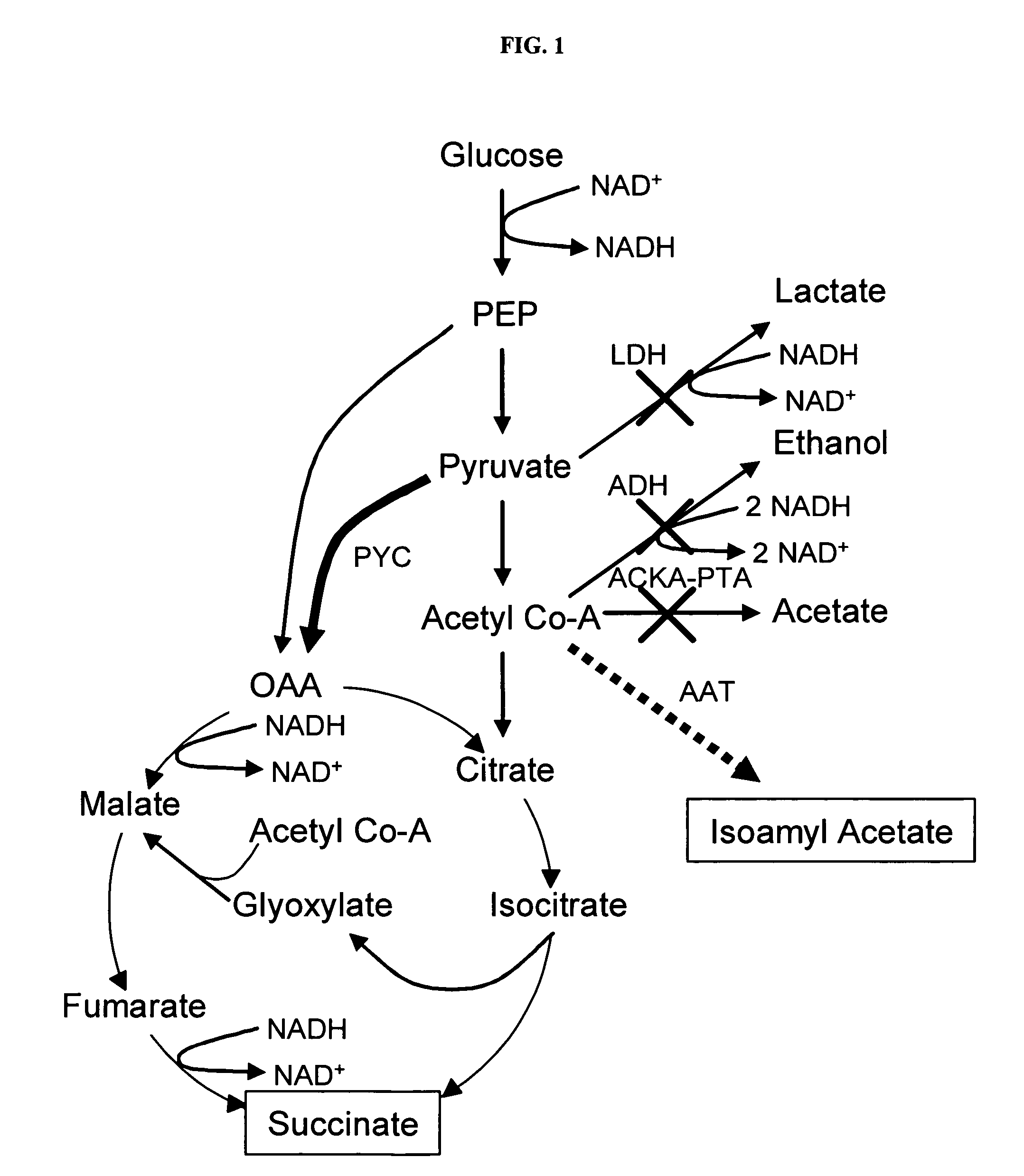

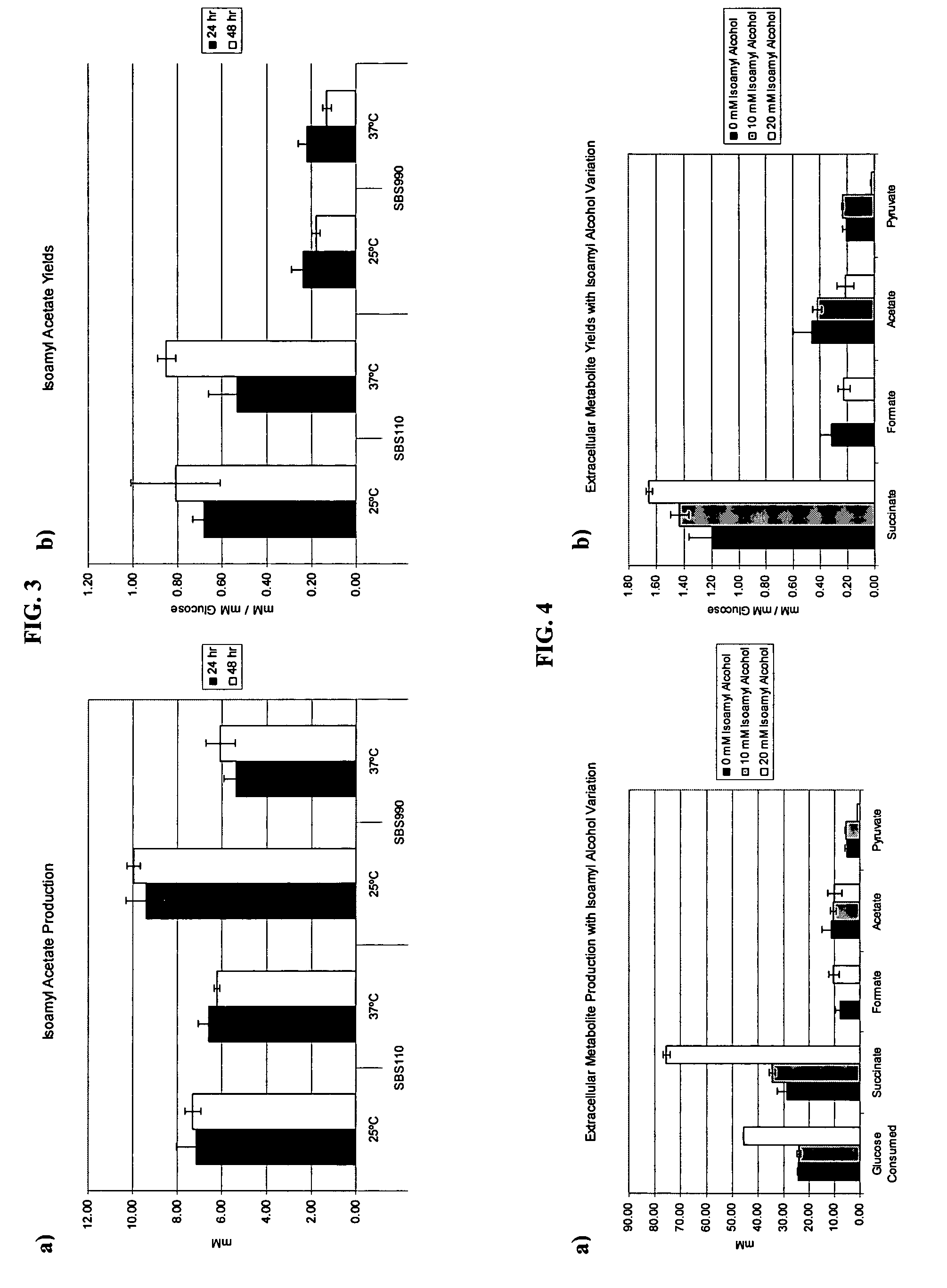

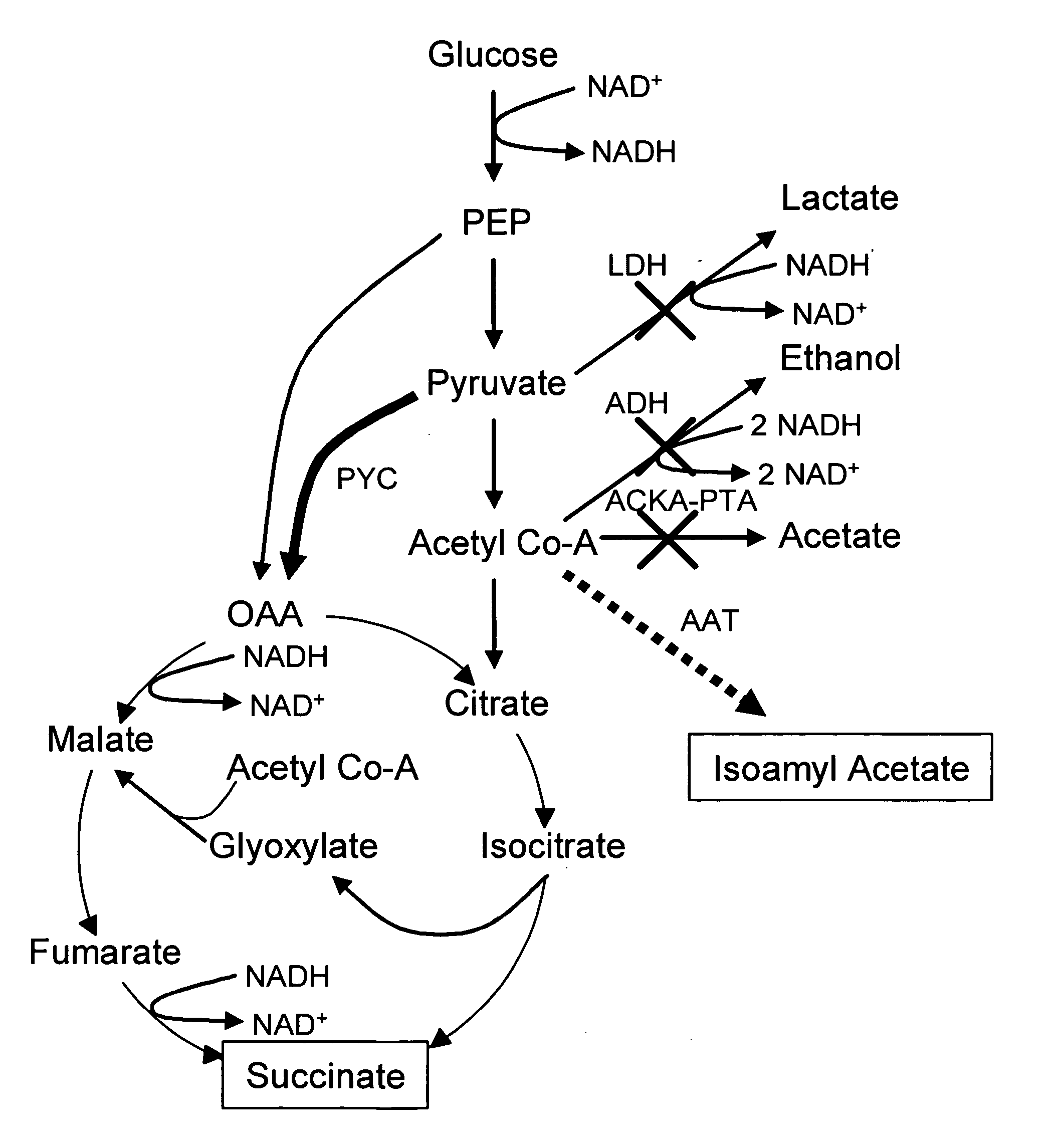

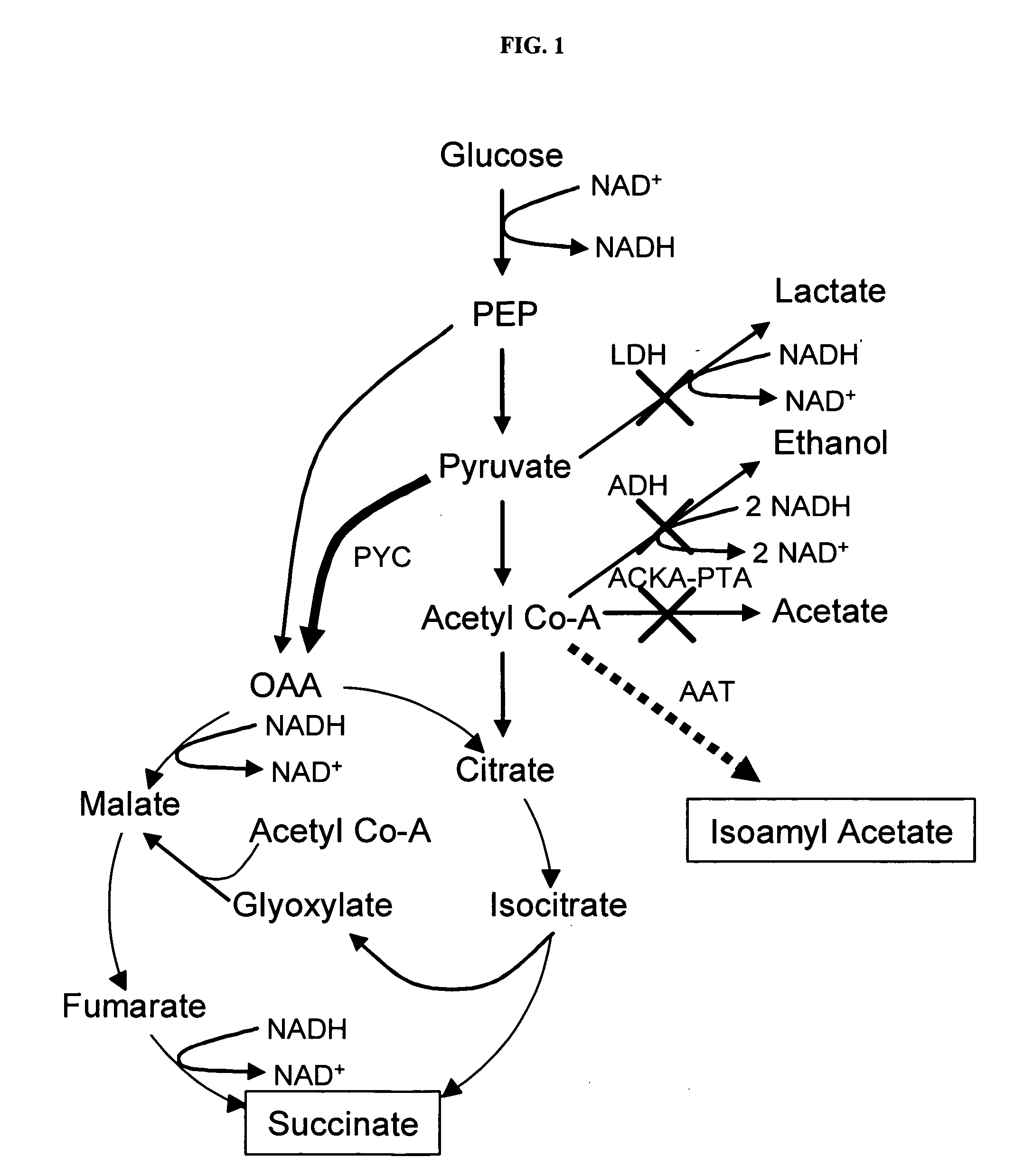

Simultaneous anaerobic production of isoamyl acetate and succinic acid

In vivo method of producing esters from acetyle coA, such as isoamyl acetate and succinate, has been developed by producing null mutants in pathways that use acetyl coA and by overexpressing products that use NADH and in order to maintain the proper redox balance between NADH and NAD+. The method is exemplified with null mutations in ldhA, adhE, ackA-pta and overexpression of pyruvate carboxylase and alcohol acetyltransferase. This strain produces higher levels of both isoamyl acetate and succinate.

Owner:RICE UNIV

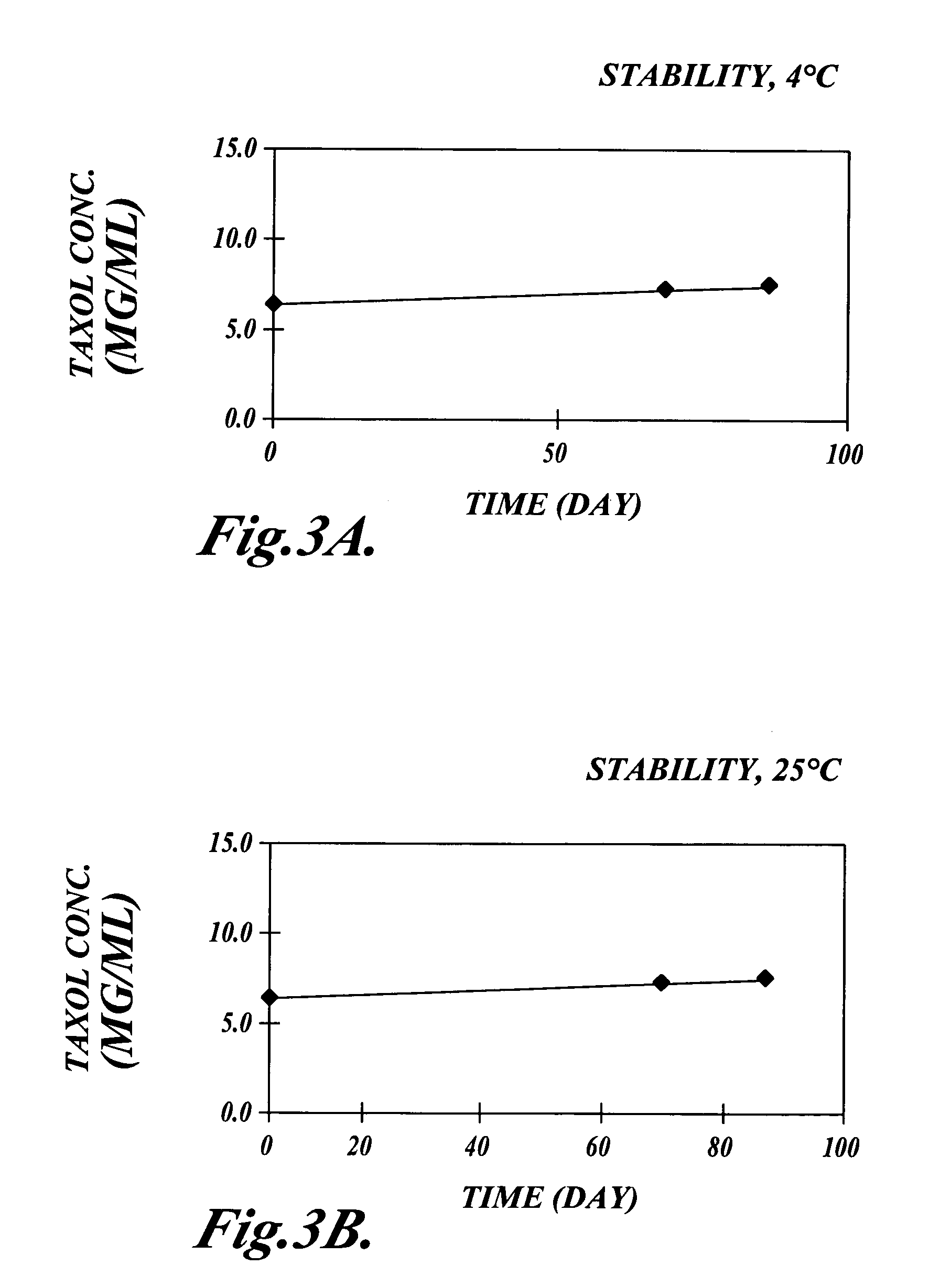

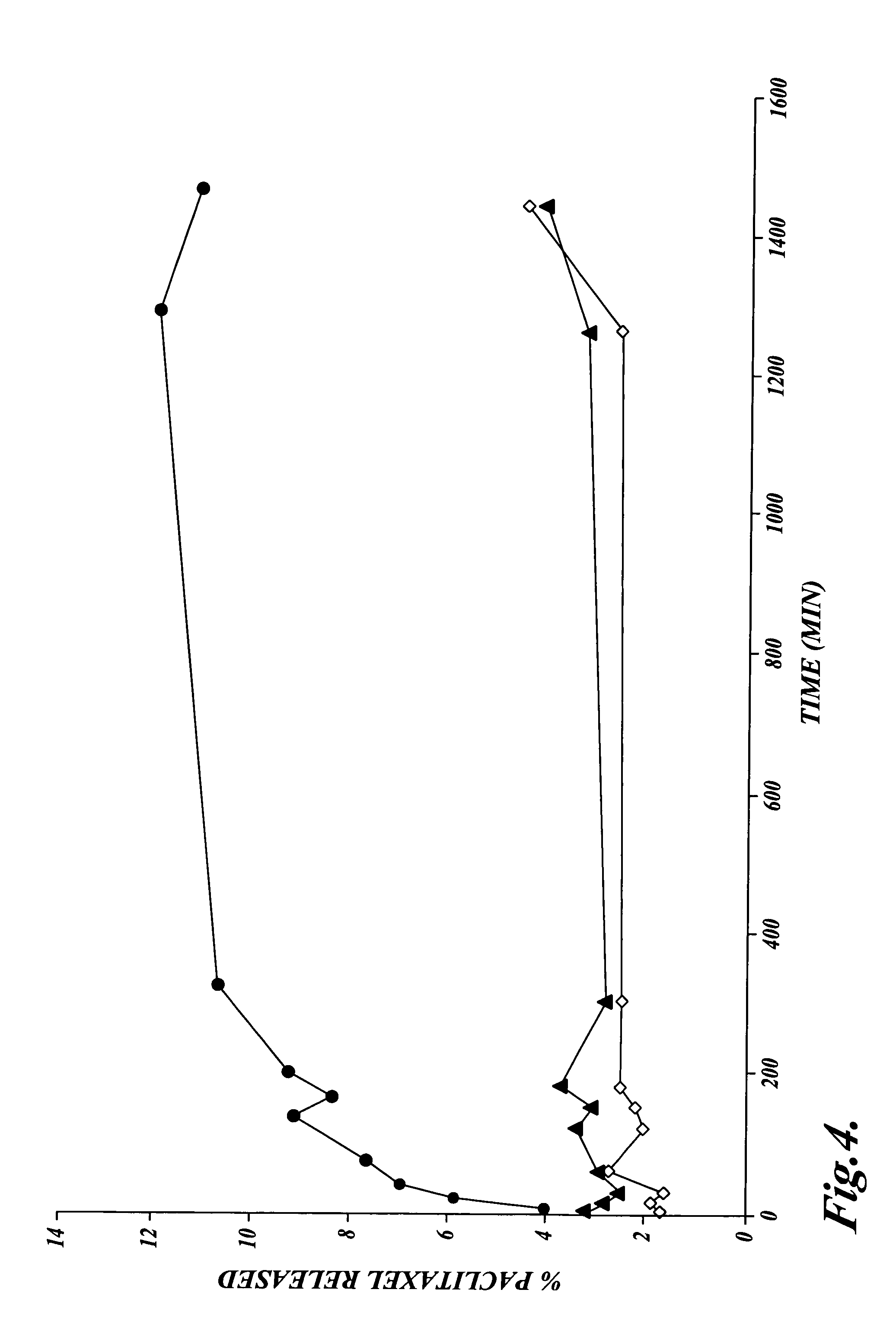

Emulsion vehicle for poorly soluble drugs

An emulsion of α-tocopherol, stabilized by biocompatible surfactants, as a vehicle or carrier for therapeutic drugs, which is substantially ethanol free and which can be administered to animals or humans via various routes is disclosed. Also included in the emulsion is PEGylated vitamin E. PEGylated α-tocopherol includes polyethylene glycol subunits attached by a succinic acid diester at the ring hydroxyl of vitamin E and serves as a primary surfactant, stabilizer and a secondary solvent in emulsions of α-tocopherol.

Owner:IGDRASOL

Simultaneous anaerobic production of isoamyl acetate and succinic acid

InactiveUS20060141594A1Maximizing isoamyl acetate productionEasy to separateBacteriaTransferasesSuccinic acidPyruvate synthesis

In vivo method of producing esters from acetyle coA, such as isoamyl acetate and succinate, has been developed by producing null mutants in pathways that use acetyl coA and by overexpressing products that use NADH and in order to maintain the proper redox balance between NADH and NAD+. The method is exemplified with null mutations in ldhA, adhE, ackA-pta and overexpression of pyruvate carboxylase and alcohol acetyltransferase. This strain produces higher levels of both isoamyl acetate and succinate.

Owner:RICE UNIV

Solid pharmaceutical dispersions with enhanced bioavailability

InactiveUS8257741B2Improve solubilityEffective dispersionPowder deliveryBiocideAcetic acidHydroxypropylmethylcellulose acetate succinate

Spray dried solid dispersions comprising a sparingly soluble drug and hydroxypropylmethylcellulose acetate succinate (HPMCAS) provide increased aqueous solubility and / or biavailability in a use environment.

Owner:BEND RES

Environmentally Friendly Solvent Systems/Surfactant Systems For Drilling Fluids

InactiveUS20140005079A1Good for healthImprove securityFlushingDrilling compositionGlutaric acidActive agent

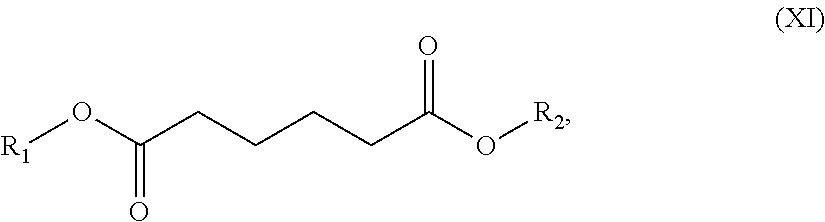

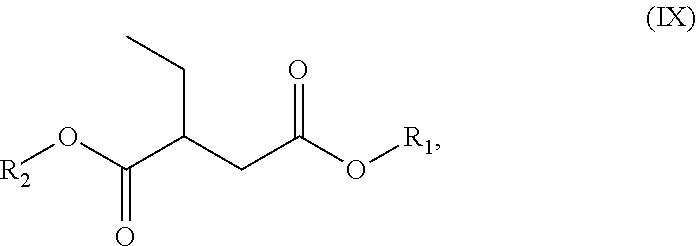

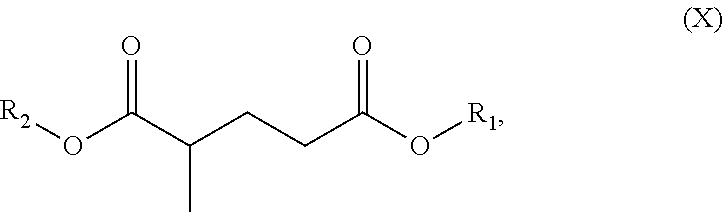

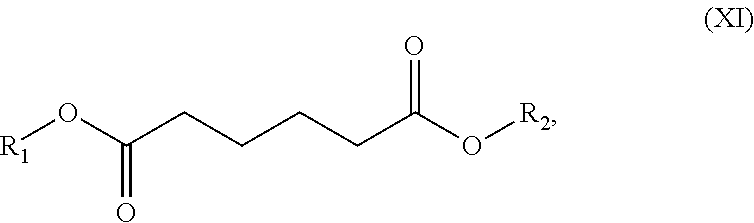

A oil field production fluid, namely a drilling mud composition, comprising a mixture of: (a) at least one base oil component; and (b) an additive component comprising a blend of dibasic esters. The functional fluid can optionally comprise additional additive components. The blend of dibasic esters comprises two or more of dialkyl methylglutarate, dialkyl adipate, dialkyl ethylsuccinate, dialkyl succinate, dialkyl glutarate.

Owner:RHODIA OPERATIONS SAS

Use of eco-friendly microemulsions in oil cleaning applications

InactiveUS20130146545A1Easily biodegradablePoint becomes highSurface-active detergent compositionsTransportation and packagingDibasic esterPhenol

An environmentally-friendly cleaning composition for oil cleaning comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition.

Owner:RHODIA OPERATIONS SAS

Emulsion vehicle for poorly soluble drugs

InactiveUS7030155B2Process stabilityEmulsion stabilizationOrganic active ingredientsBiocideEmulsionSuccinic acid

A method of making an emulsion of tocopherol incorporating a co-solvent and, stabilized by biocompatible surfactants, as a vehicle or carrier for therapeutic drugs, which is substantially ethanol free and which can be administered to animals or humans by various routes, is disclosed. Also included in the emulsion is PEGylated vitamin E. PEGylated α-tocopherol includes polyethylene glycol subunits attached by a succinic acid diester at the ring hydroxyl of vitamin E and serves as a primary surfactant, stabilizer and a secondary solvent in emulsions of α-tocopherol.

Owner:IGDRASOL

Environment-friendly type composite corrosion and scale inhibitor

InactiveCN1919752ACreate pollutionStrong scale resistanceScale removal and water softeningMolybdateSuccinic acid

The invention discloses an environmental-protective composite inhibiting antisludging agent, which comprises the following parts: inhibiting component, antisludging component and deionized water, wherein the inhibiting component is composed of one or more materials in the molybdate, tungstate, borate, organic substituted carboxylic acid or organic heterocyclic compound; the inhibiting component contains one or more materials in the natural macromolecular compound, epoxy succinic acid or acroleic acid ternary copolymer.

Owner:BEIJING HANBOYING ELECTRIC POWER TECH

Aerobic succinate production in bacteria

Methods of increasing yields of succinate using aerobic culture methods and a multi-mutant E. coli strain are provided. Also provided is a mutant strain of E. coli that produces high amounts of succinic acid.

Owner:RICE UNIV

Polylactic acid foaming material and preparation method thereof

The invention provides a polylactic acid foaming material and a preparation method thereof. The polylactic acid foaming material is prepared from the following ingredients according to parts by weight: 45-93 parts of polylactic acid, 5-28 parts of toughener, 1-5 parts of nucleating agent and 1-10 parts of foaming agent. The polylactic acid is one of poly-L-lactic acid, poly-D-lactic acid and poly-DL-lactic acid or a mixture or a polymer thereof, and has the weight average molar mass of 0.8-3.5 million, molecular weight distribution of 1.2-2.5, and degree of crystallinity of 15-60 percent. The toughener is one of poly succinic acid butyl ester and poly adipate / butylene terephthalate or a mixture of two with random ratio. Other accessory ingredients can also be added. The preparation method comprises the following steps: evenly mixing the polylactic acid, the toughener, the nucleating agent, the foaming agent, the accessory ingredients and the like in a high mixing machine according to a certain proportion, then milling for 5-25 minutes at the temperature of 100-170 DEG C, and carrying out die pressing foaming on obtained materials at the temperature of 120-210 DEG C on a vulcanizing machine for 2-10 minutes to prepare the polylactic acid foaming material. The polylactic acid foaming material prepared by using the preparation method has the advantages of high resistance to shock, high elongation at break, high tensile strength and complete biodegradation after used.

Owner:南京冠创生物科技有限公司

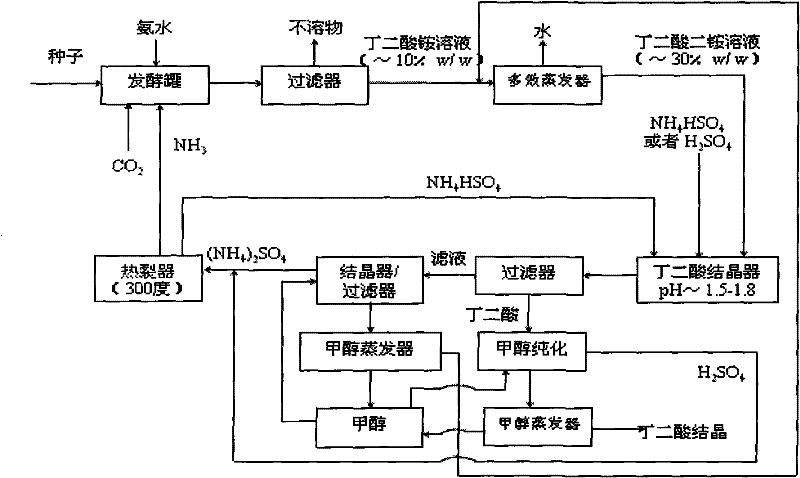

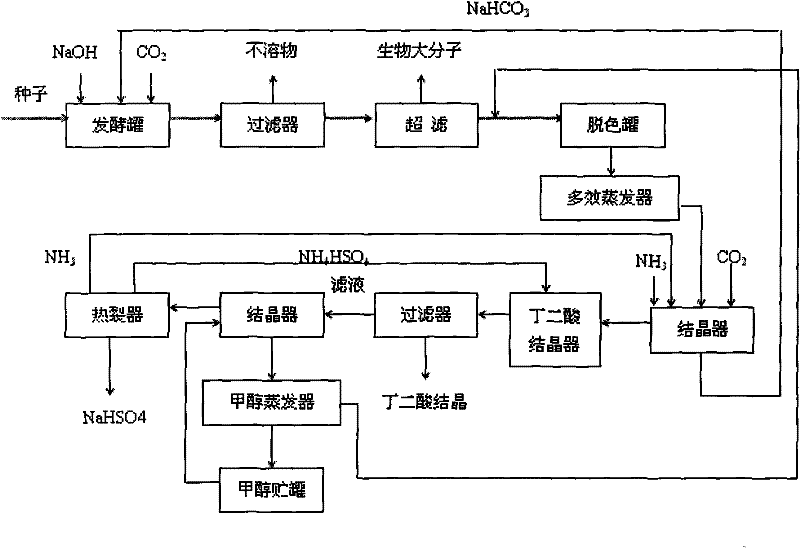

Succinic acid purification process through anaerobic fermentation

InactiveCN101748161APrevent pigmentationQuality assuranceMicroorganism based processesFermentationButanedioic acidEcological environment

The invention belongs to the technical field of biological engineering and discloses a novel succinic acid purification process through anaerobic fermentation. By adopting the separation process based on solid-liquid separation, ultrafiltration, decoloration, acidification and crystallization and by introducing ammonium sulfate thermal cracking technology, the invention realizes cyclic utilization of the acid and the alkali, forms a closed clean production flow and effectively ensures the quality of the succinic acid used for food and medicine. The invention not only reduces the fermentation cost and improves the economic benefits but also reduces environment pollution, improves the ecological environment and promotes the sustainable development of the national economy. Therefore, the invention has wide social benefits.

Owner:NANJING UNIV OF TECH

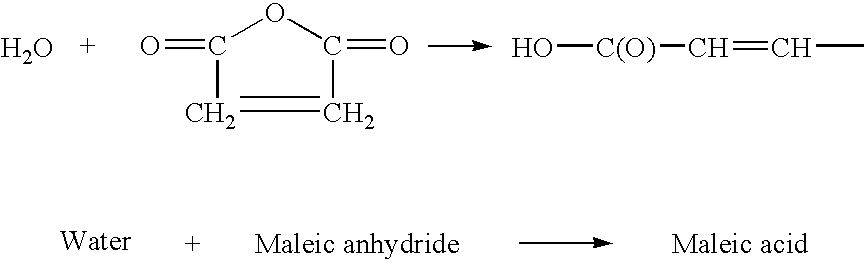

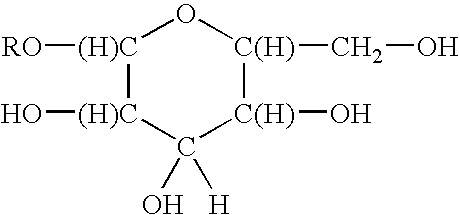

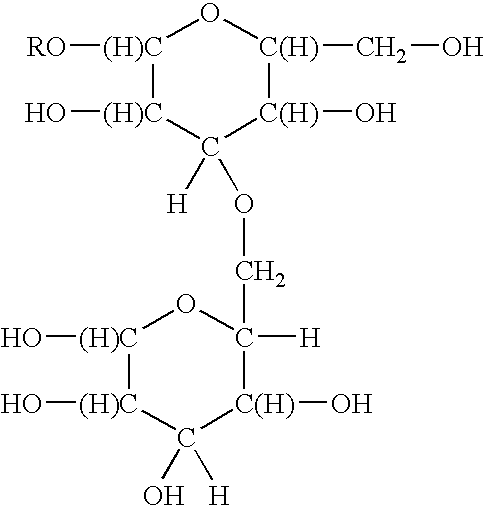

Alkyl polyglycoside derived sulfosuccinates

ActiveUS7087571B1Cosmetic preparationsOrganic detergent compounding agentsGlycoside formationAlkyl polyglycoside

The invention relates to a series of polyglycoside derivatives that contain water-soluble sulfosuccinate groups introduced into the molecule by reaction with the hydroxyl groups present in the starting polyglycoside molecule, with the chloro material. The preferred products have more than one water-soluble group per molecule and are made with mild reagents to avoid discoloration and mal odor. The most preferred products have between 2 and 3 functional groups per molecule.

Owner:SURFATECH

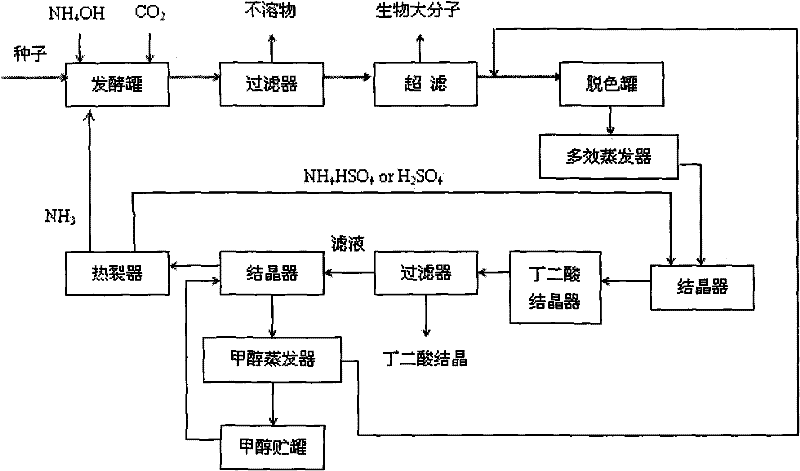

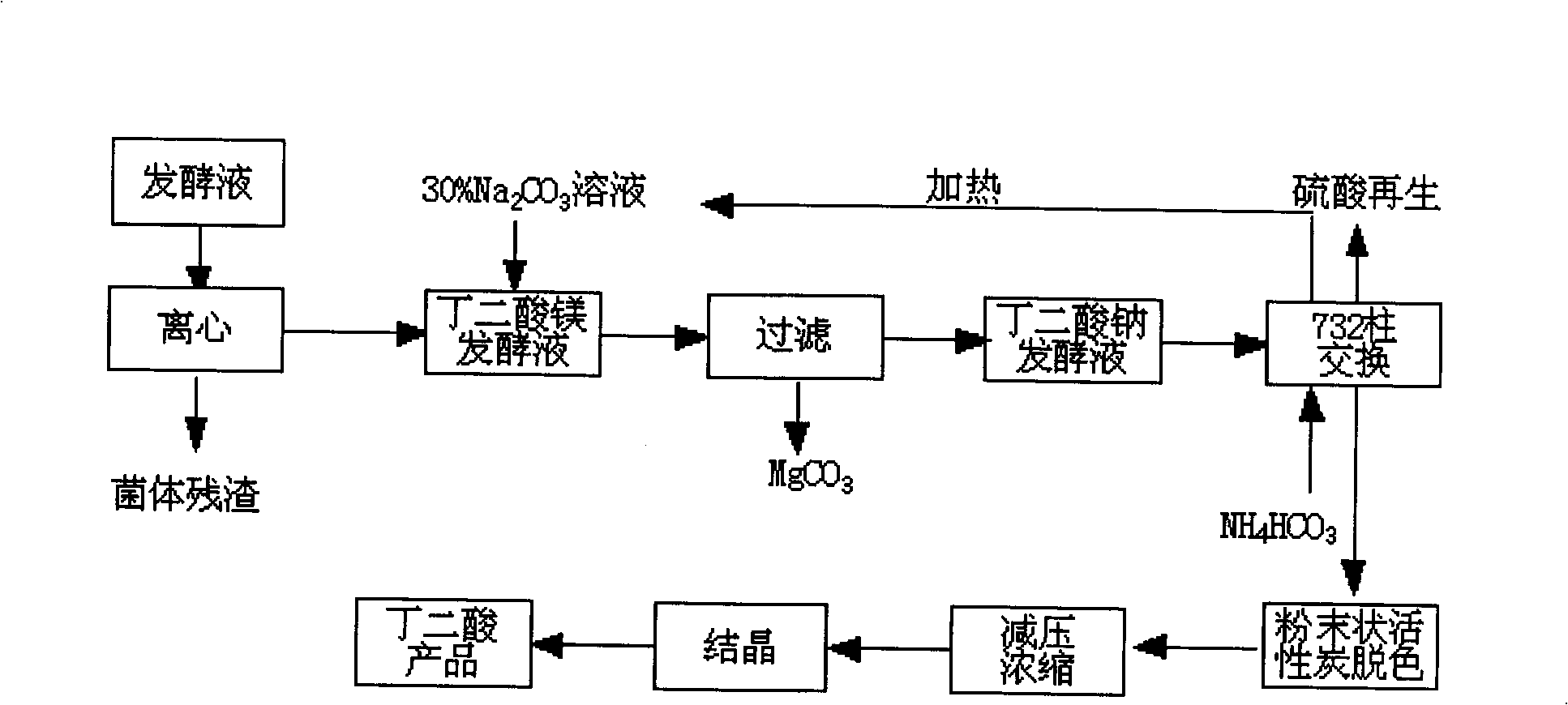

Process of separating and extracting succinic acid from anaerobic fermented liquid

InactiveCN1887843AReduce manufacturing costHigh yieldCarboxylic compound separation/purificationSuccinic acidSewage

The present invention discloses process of separating and extracting succinic acid from anaerobic fermented liquid. The process includes filtering the fermented liquid of succinic acid with microfiltering membrane, filtering with ultrafiltering membrane, decolorizing and depurating with active carbon to obtain clarified succinic acid solution, concentrating, and crystallizing to obtain succinic acid product. The process has the features of mild condition, simple operation, short separating path, low cost, high selectivity and high product quality.

Owner:NANJING UNIV OF TECH

Method for extracting amber acid in fermentation liquor by cationic resin exchange

InactiveCN101348429AAchieving a circular economyShort process routeAmmonium sulfatesFermentationSodium bicarbonateSuccinic acid

A method for extracting succinic acid from fermentation broth through cation resin exchange belongs to the biochemical technical field. The method comprises the following steps that fermentation broth undergoes heated centrifugal filtration or membrane filtration so as to eliminate thalli; sodium carbonate is added in the clear solution to generate magnesium carbonate precipitation; a filter cake is reclaimed after filtration; then, the filtrate flows through a cation resin column, and the effluent is succinic acid solution; a succinic acid product is obtained after decoloring, concentration and crystallization; the cation resin column is eluted by ammonium carbonate after exchange so as to obtain sodium bicarbonate effluent; sodium salt is reclaimed and reused in fermentation broth treatment after ammonia is eliminated by heating; furthermore, resin regeneration can be realized by sulphuric acid through a conventional method, and the generated (NH4)2 SO4 can be used as a fertilizer. The method does not need to carry out acidification for the filtrate, and has the advantages of short technological line and high yield, thereby realizing element cycle economy. The invention provides a method for extracting succinic acid from microorganism fermentation broth with simple operation and economical efficiency.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com