Patents

Literature

348 results about "Dibasic ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibasic ester or DBE is an ester of a dicarboxylic acid. Depending on the application, the alcohol may be methanol or higher molecular weight monoalcohols. Mixtures of different methyl dibasic esters are commercially produced from short-chain acids such as adipic acid, glutaric acid, and succinic acid. They are non-flammable, readily biodegradable, non-corrosive, and have a mild, fruity odour.

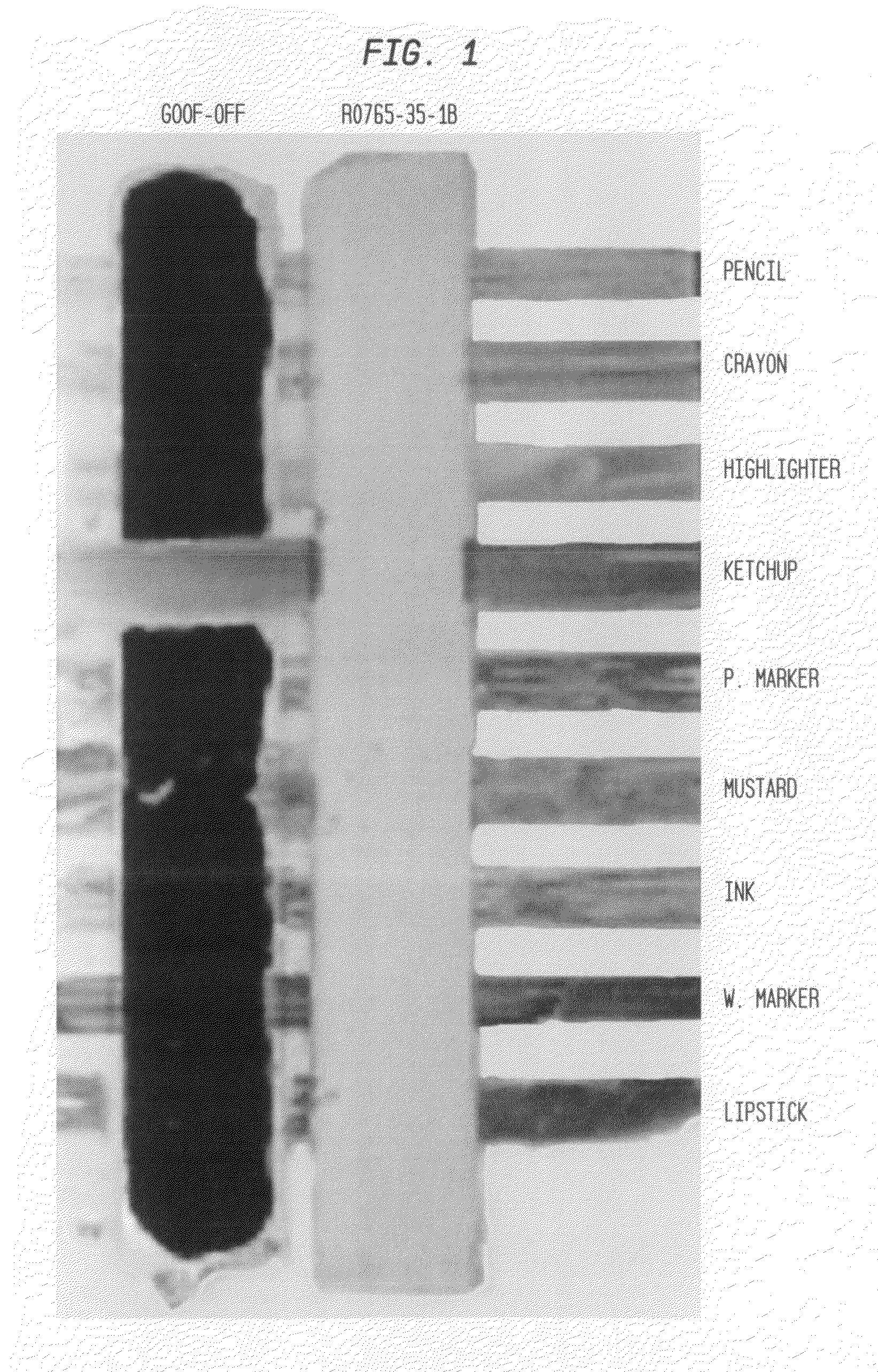

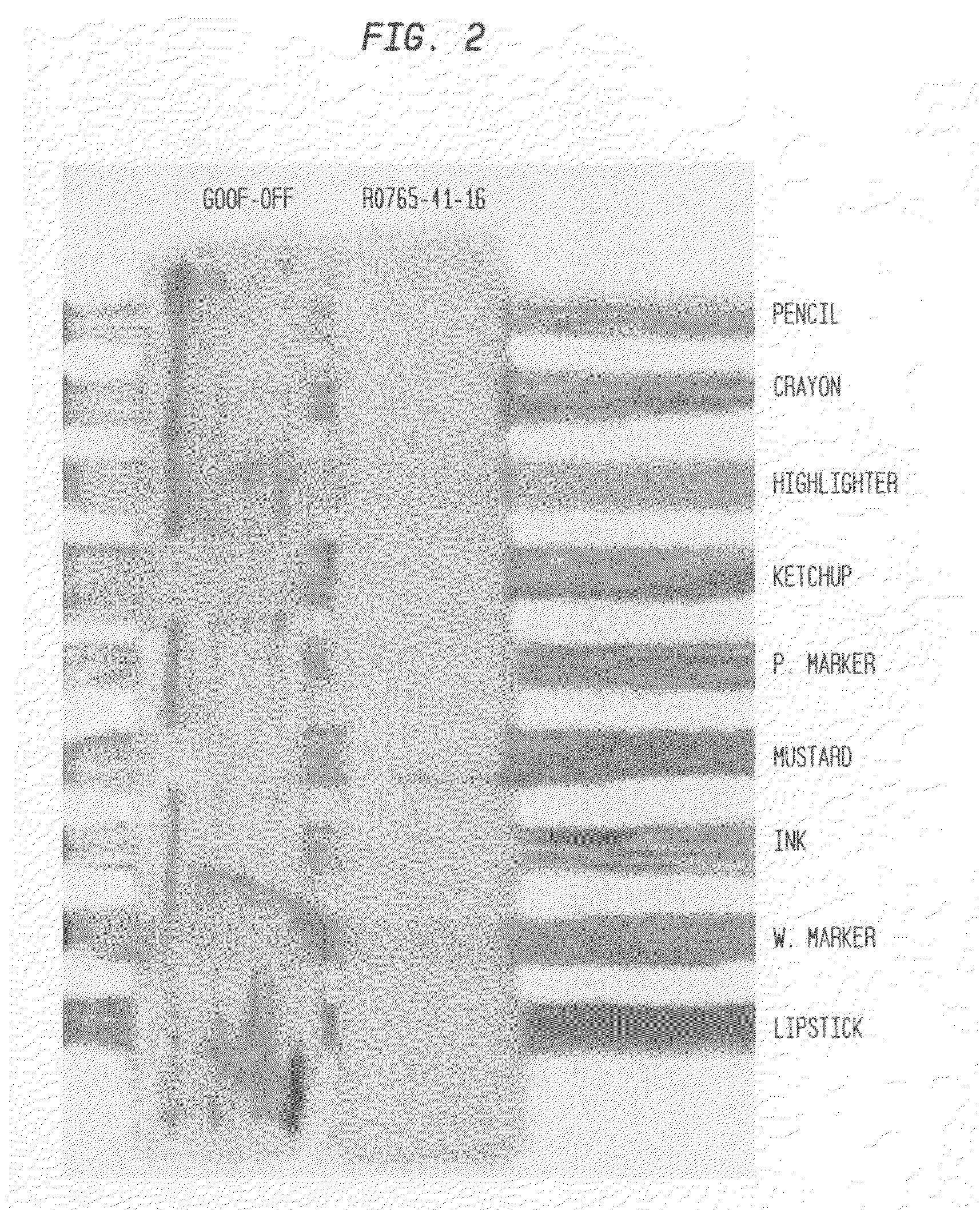

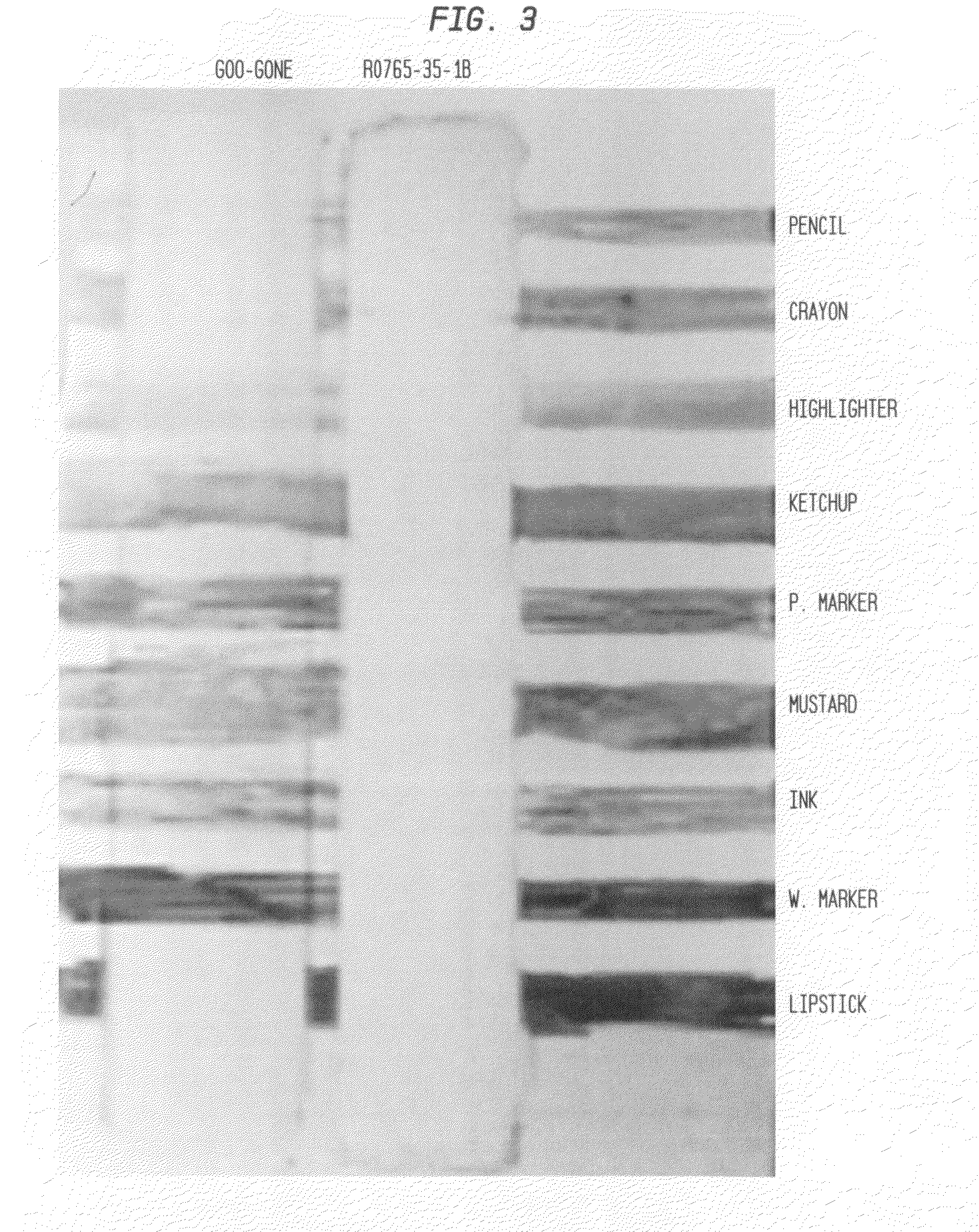

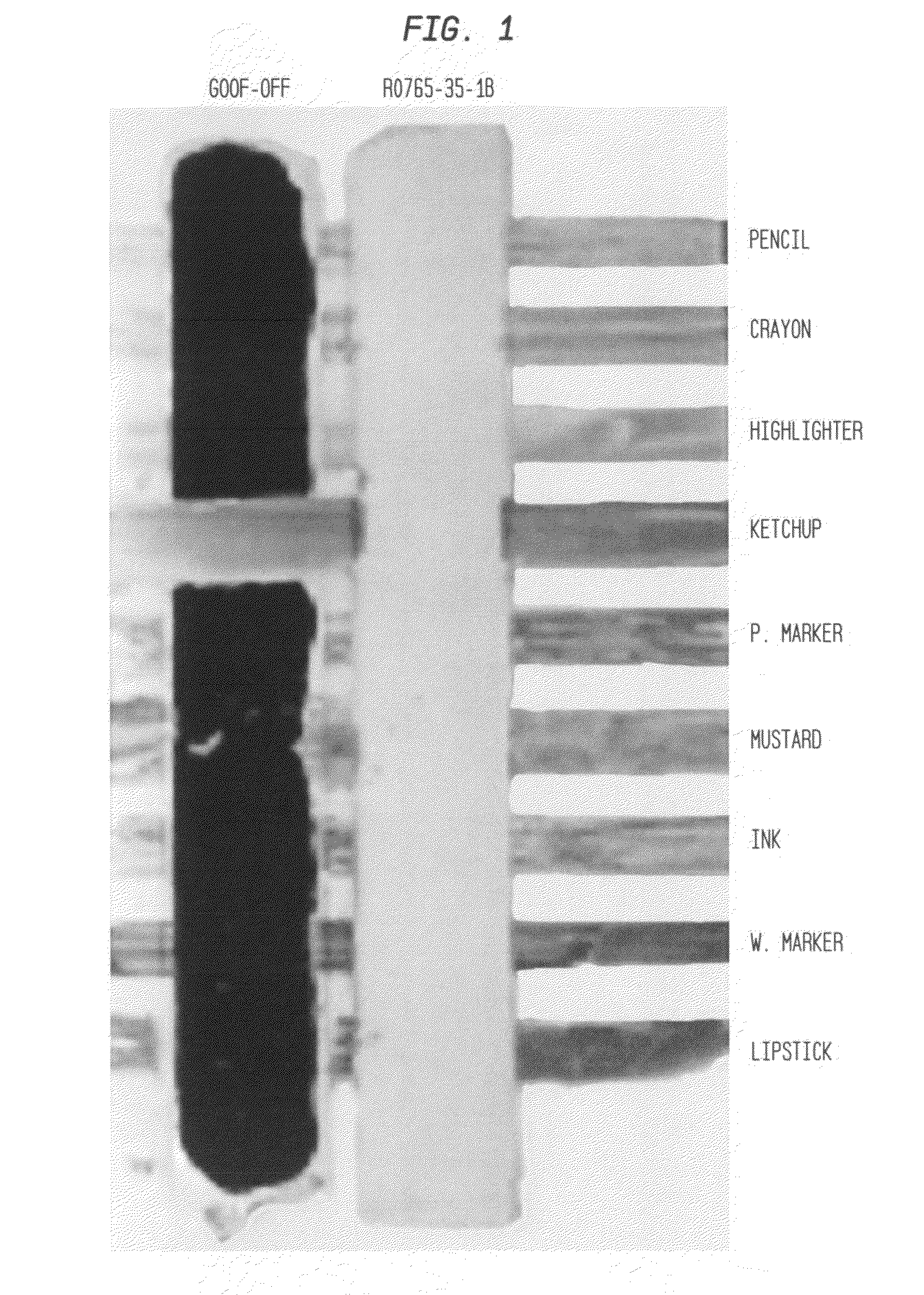

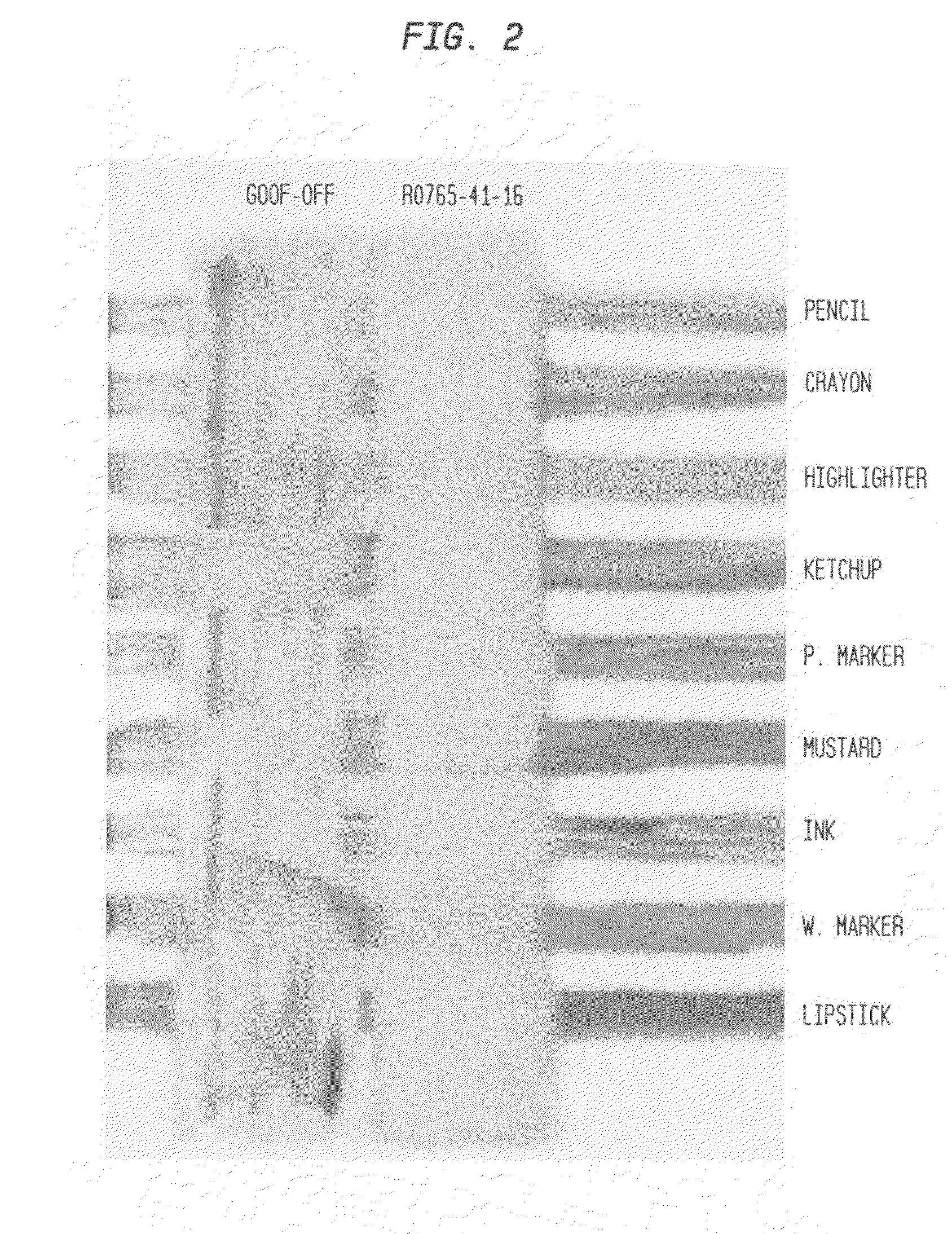

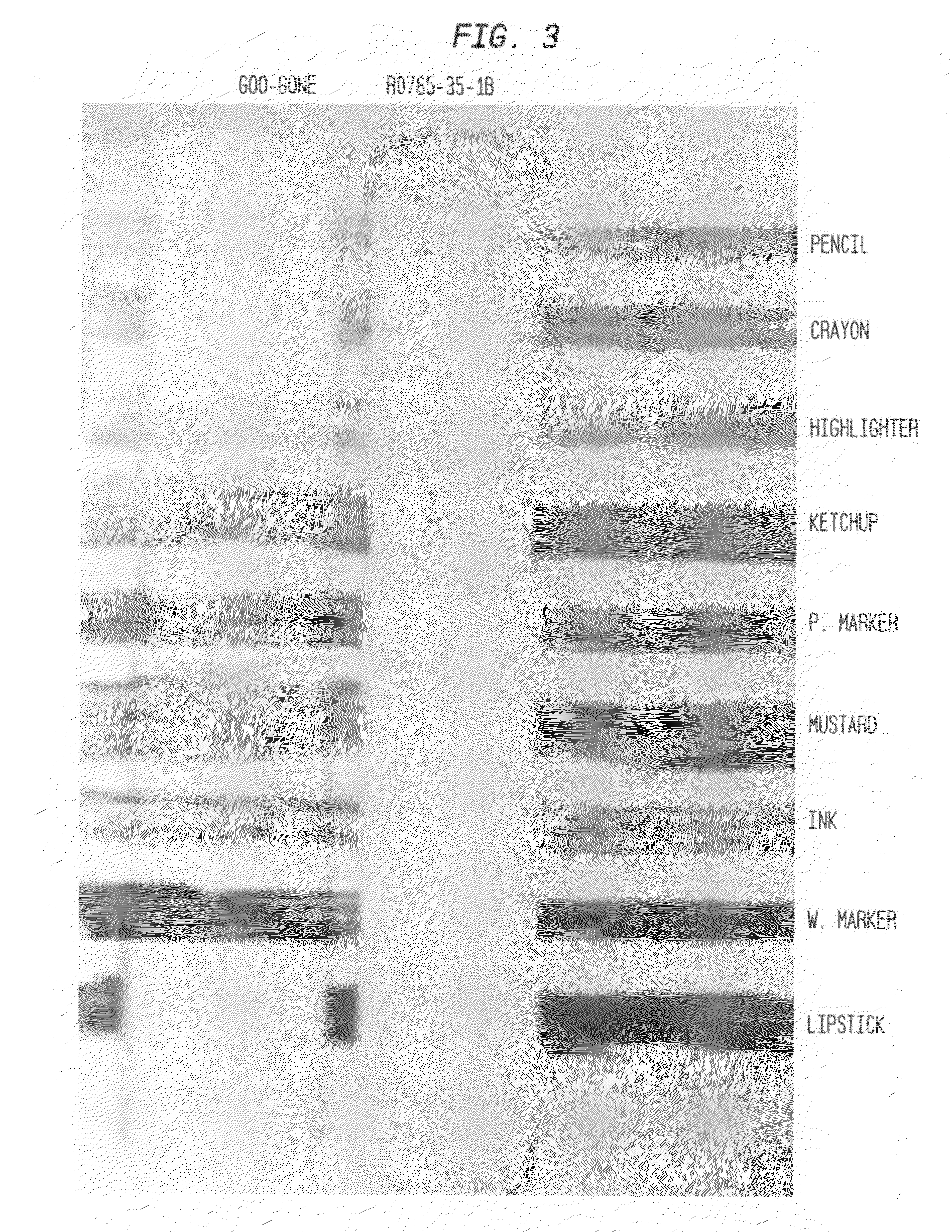

Cleaning compositions incorporating green solvents and methods for use

ActiveUS20090281012A1High flash pointLow vapor pressureOrganic detergent compounding agentsDetergent mixture composition preparationGlutaric acidActive agent

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Additive composition for well treatment fluids

InactiveUS20130137611A1Improve solubilityEfficiently formedFlushingDrilling compositionDibasic esterSURFACTANT BLEND

Described is an additive composition made up of at least one dibasic ester, at least one non-ionic surfactant, at least one terpene or terpene derivative and optionally, at least one polyalkylene glycol and / or water. The composition is useful as an additive for well treatment fluids used for cleaning or stimulation of oil or gas wells.

Owner:CALFRAC WELL SERVICES

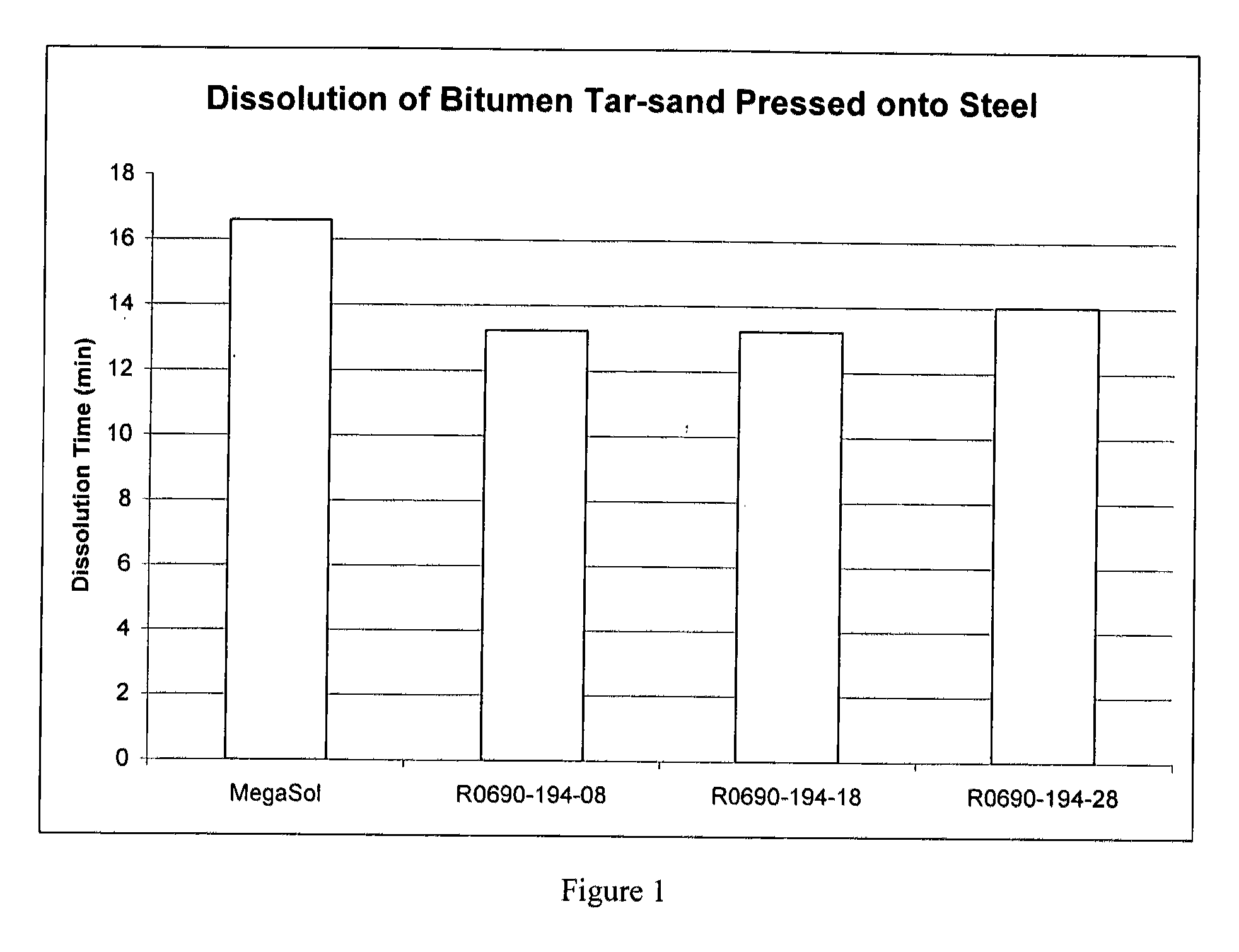

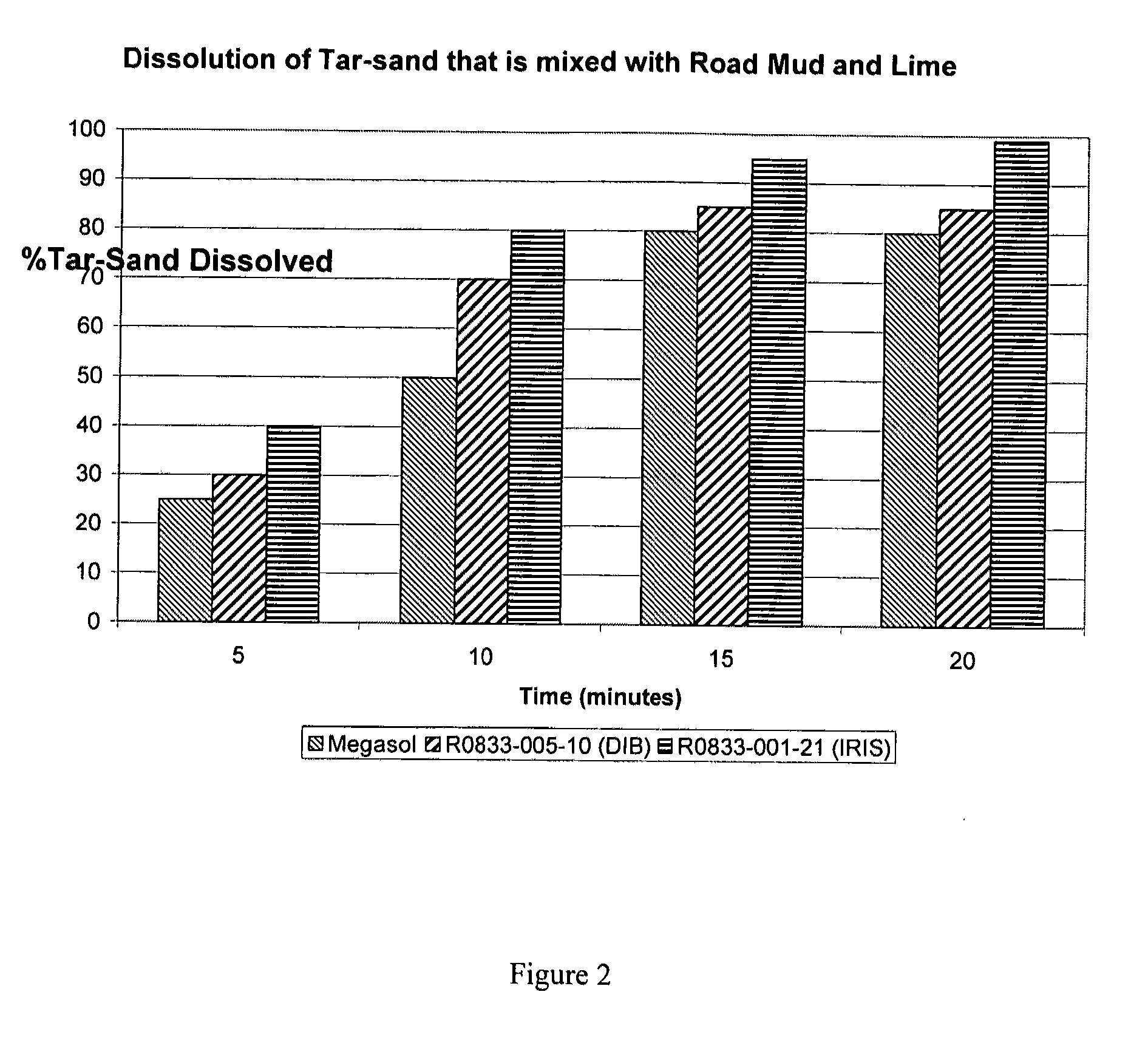

Dibasic esters utilized as terpene co-solvents, substitutes and/or carriers in tar sand/bitumen/asphaltene cleaning applications

ActiveUS20120149626A1Reduce concentrationImprove environmental conditionsOrganic detergent compounding agentsNon-ionic surface-active compoundsCarrier fluidFuel oil

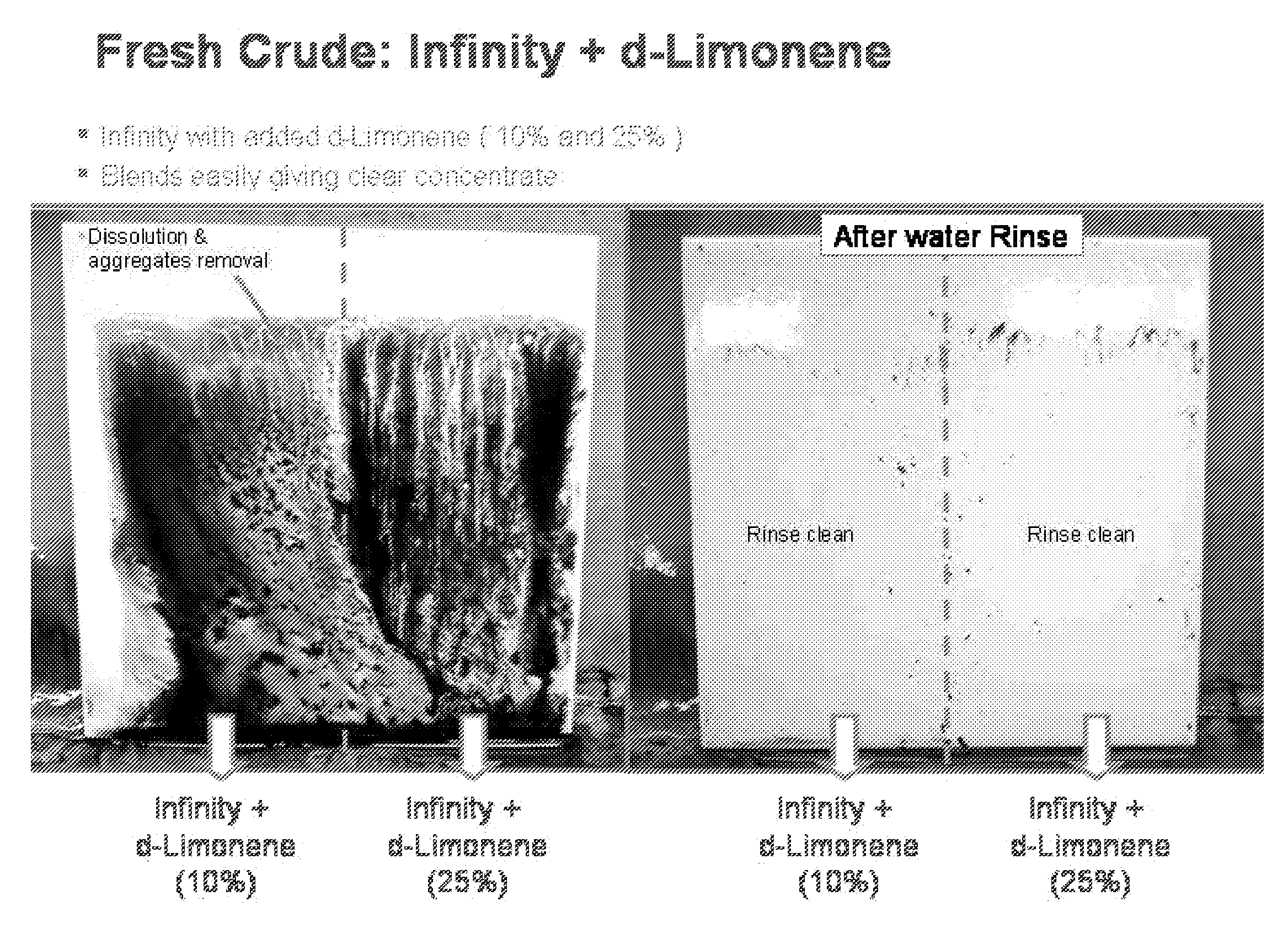

A heavy oil cleaning composition comprising: a) a blend of dibasic esters comprising dialkyl methylglutarate and at least one of a dialkyl adipate or dialkyl ethylsuccinate; b) at least one terpene; and c) at least one surfactant. Also described are methods for delivering a solvent at reduced concentration comprising the steps of: a) obtaining a terpene-based solvent; and b) mixing the terpene-based solvent with a carrier fluid (the carrier fluid comprising a microemulsion of i) a blend of dibasic esters selected from the group consisting of dialkyl methylglutarate, dialkyl adipate, dialkyl ethylsuccinate, dialkyl succinate, dialkyl glutarate and any combination thereof, ii) at least one surfactant selected from the group consisting of a terpene alkoxylate, an alcohol alkoxylate and any combination thereof; and iii) water) in order to obtain a mixture to clean heavy oils.

Owner:RHODIA OPERATIONS SAS

Environmentally Friendly Solvent Systems/Surfactant Systems For Drilling Fluids

InactiveUS20140005079A1Good for healthImprove securityFlushingDrilling compositionGlutaric acidActive agent

A oil field production fluid, namely a drilling mud composition, comprising a mixture of: (a) at least one base oil component; and (b) an additive component comprising a blend of dibasic esters. The functional fluid can optionally comprise additional additive components. The blend of dibasic esters comprises two or more of dialkyl methylglutarate, dialkyl adipate, dialkyl ethylsuccinate, dialkyl succinate, dialkyl glutarate.

Owner:RHODIA OPERATIONS SAS

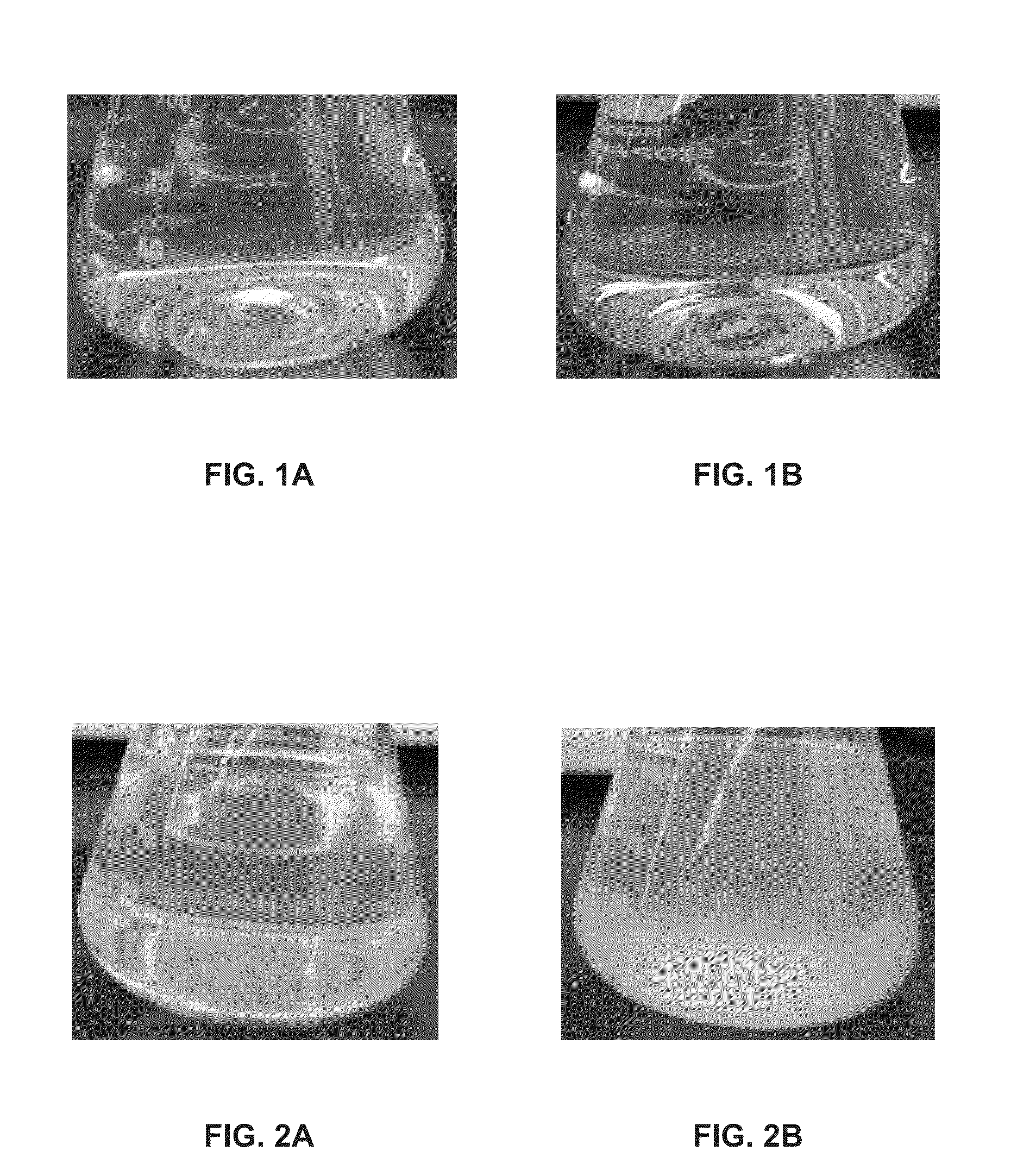

Use of eco-friendly microemulsions in oil cleaning applications

InactiveUS20130146545A1Easily biodegradablePoint becomes highSurface-active detergent compositionsTransportation and packagingDibasic esterPhenol

An environmentally-friendly cleaning composition for oil cleaning comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition.

Owner:RHODIA OPERATIONS SAS

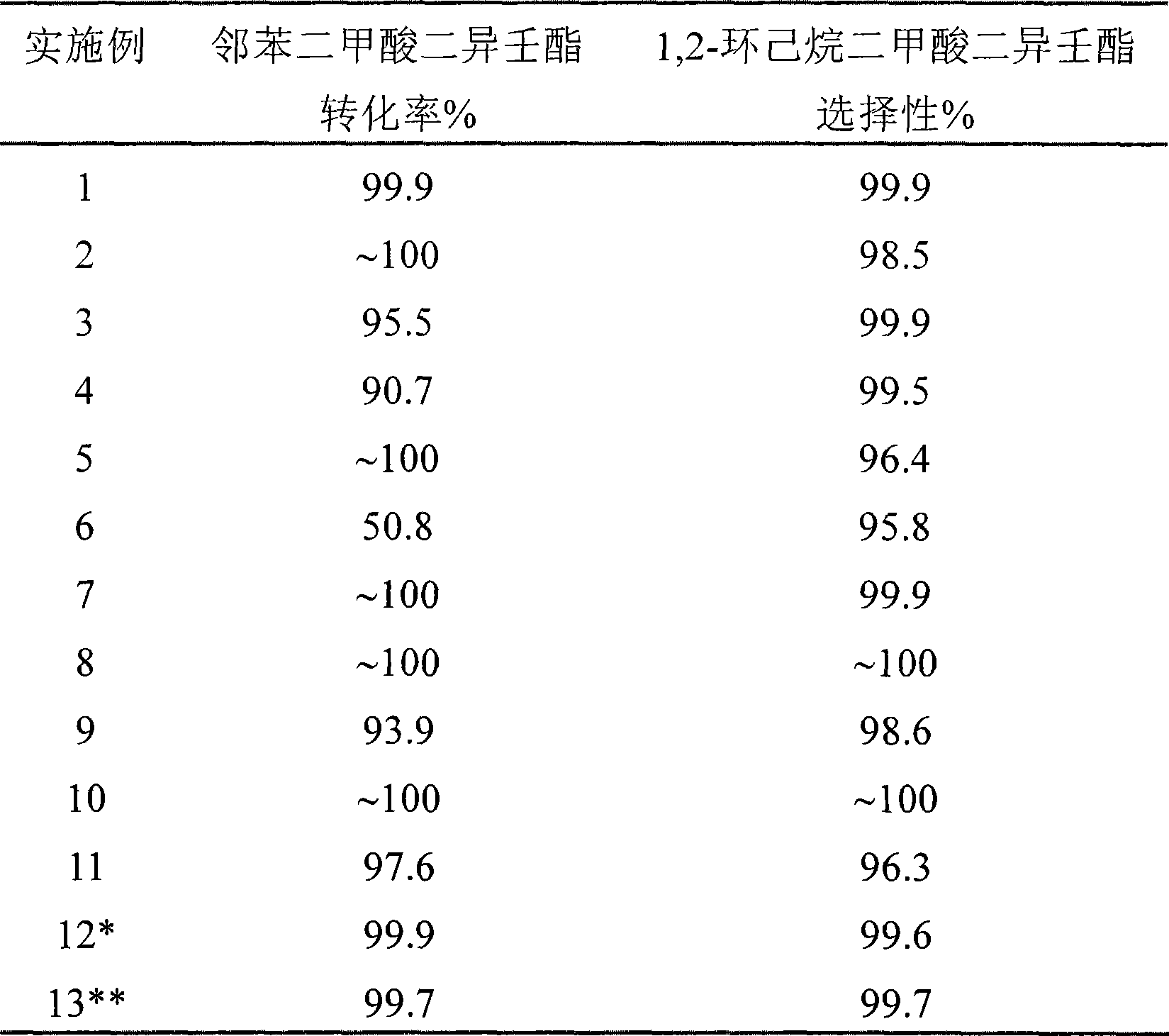

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

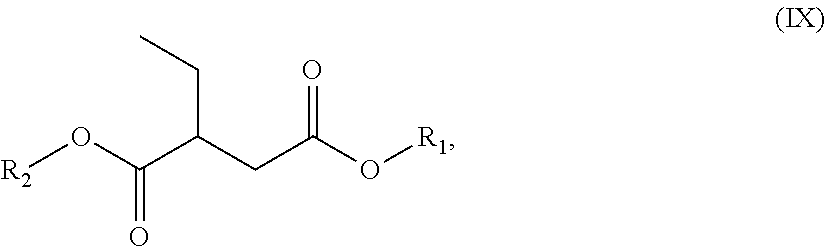

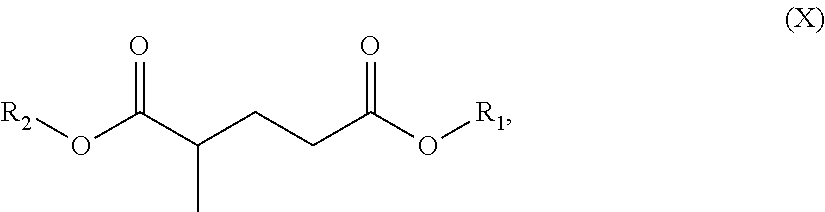

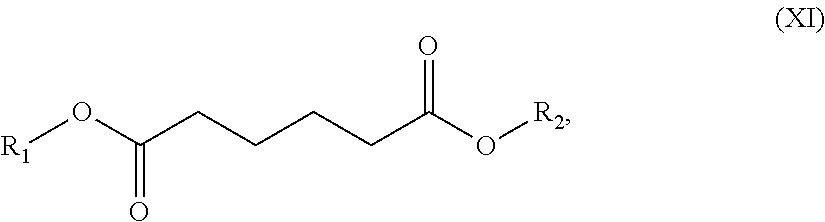

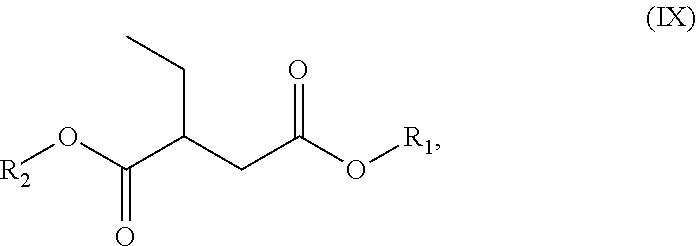

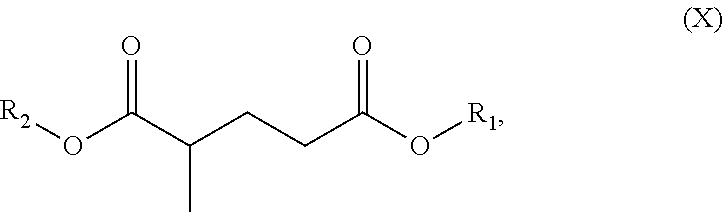

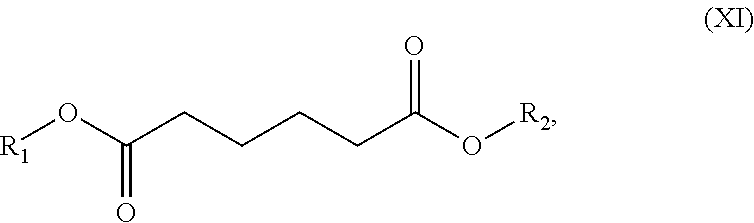

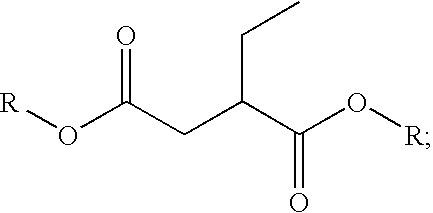

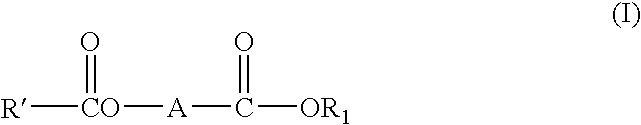

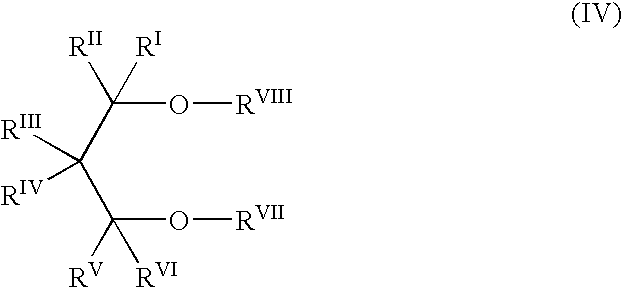

Catalyst component for olefin polymerization and catalyst comprising the same

ActiveUS7351778B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylHydrogen

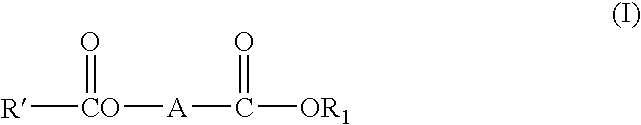

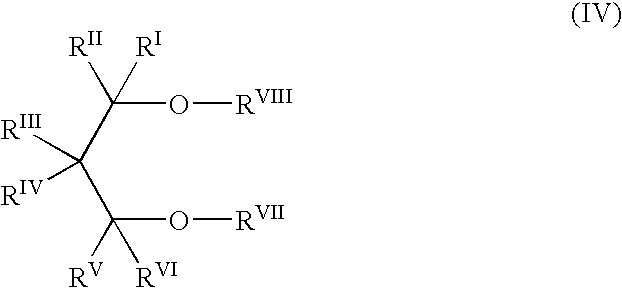

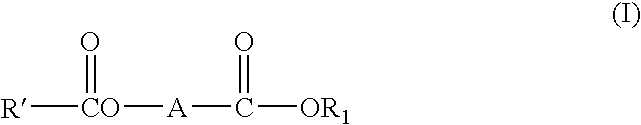

The present invention provides a catalyst component for polymerization of olefin CH2═CHR, in which R is hydrogen or C1-C12 alkyl or aryl, comprising magnesium, titanium, a halogen and an electron donor compound (a) which is at least one selected from the group consisting of dibasic ester compounds of the formula (I), and said catalyst component optionally further comprising an electron donor compound (b) selected from the group consisting of aliphatic dicarboxylic esters and aromatic dicarboxylic esters, and / or an electron donor compound (c) selected from the group consisting of 1,3-diether compounds of formula (IV):wherein, R1, R′ and A are as defined in the description,wherein RI-RVIII are as defined in the description, and a catalyst comprising the catalyst component.

Owner:CHINA PETROCHEMICAL CORP +1

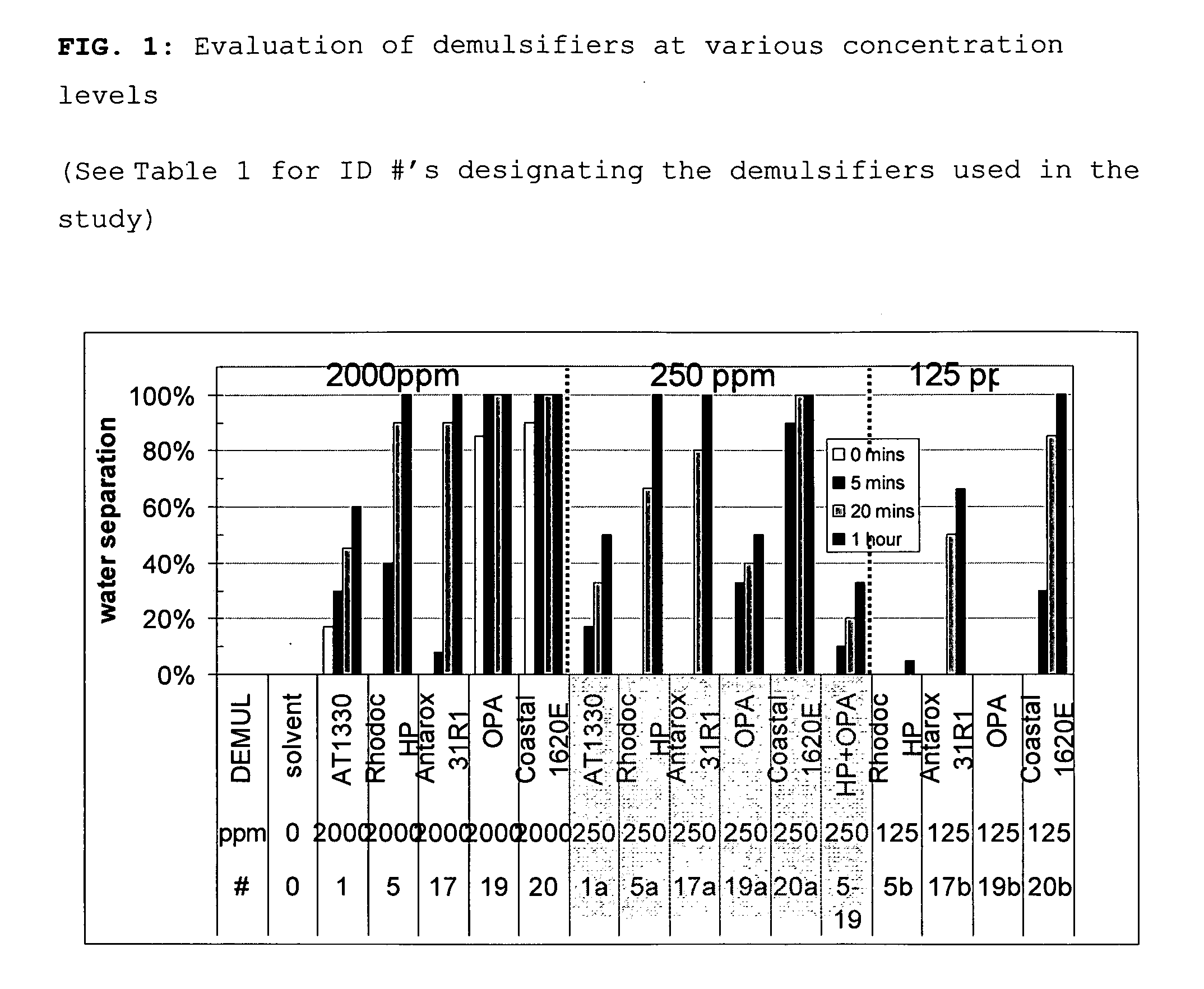

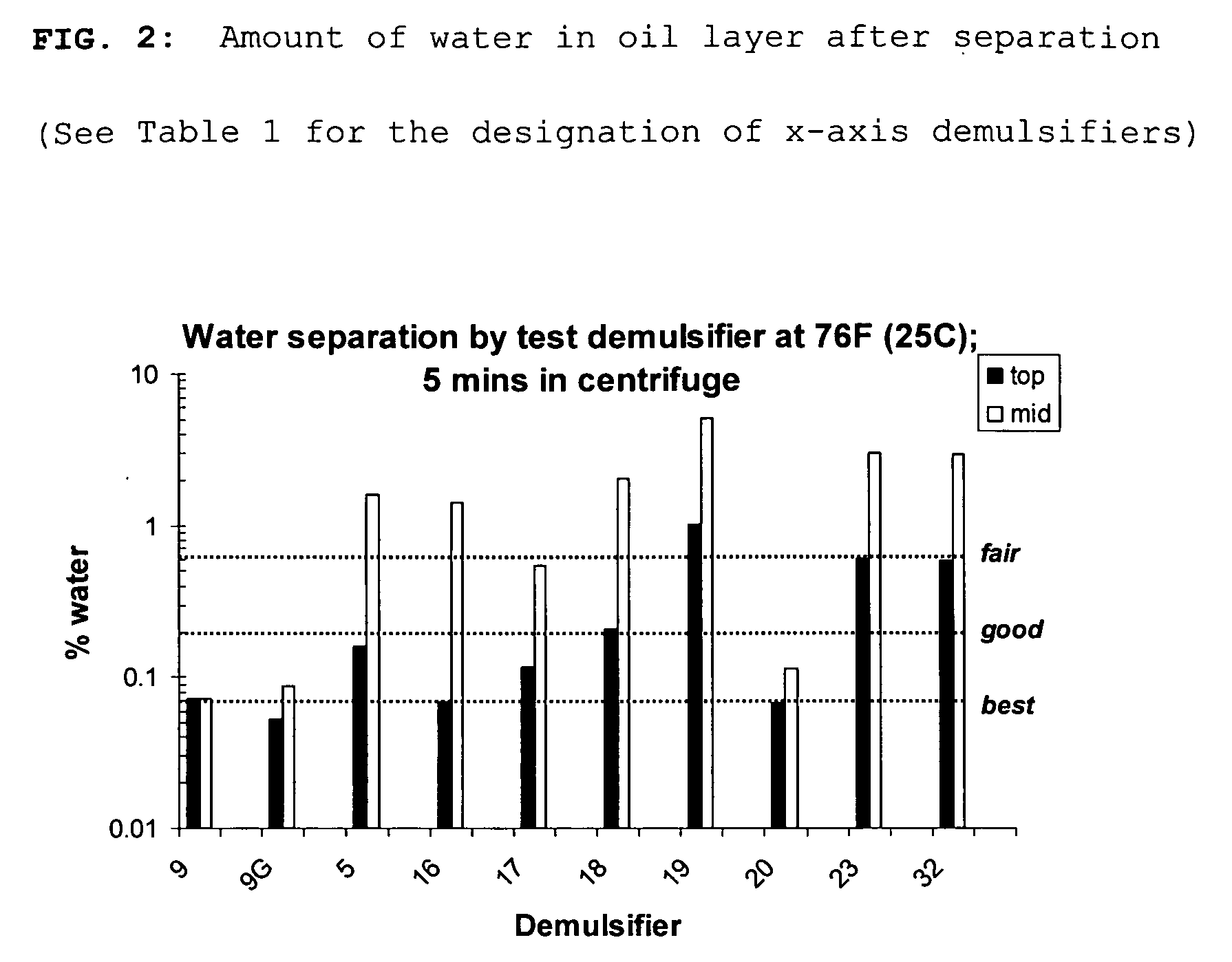

Demulsifiers in solvent base for separating emulsions and methods of use

InactiveUS20090149557A1Improve performanceGuaranteed to workOther chemical processesNon-miscible liquid separationPolymer scienceActive agent

Demulsifiers containing an anionic surfactant selected from alkylsulfosuccinates, alkylphosphonic acids, and their salts; a nonionic surfactant selected from ethylene oxide / propylene oxide copolymers, ethoxylated fatty acids of polyethylene glycol, terpene alkoxylates, and modified alkanolamides; and solvent bases comprising blends of dibasic esters. Methods for breaking emulsions using such demulsifiers and solvent bases are also disclosed.

Owner:RHODIA OPERATIONS SAS

Low odor ester-based microemulsions for cleaning hard surfaces

InactiveUS20070093404A1Easy to cleanLow VOCNon-ionic surface-active compoundsAnionic surface-active compoundsSurface cleaningMicroemulsion

Disclosed is a hard surface cleaning composition employing dibasic esters as a primary solvent in combination with a primary emulsifier, a short-chain cosurfactant, a secondary emulsifier and water. Optional components include a polar solvent and a thickener. The disclosed composition is preferably in the form of an oil continuous microemulsion and is provided as a component of a liquid or spray formulation for use, depending upon the application. The disclosed cleaning agents have a low odor and satisfy the 2005 CARB VOC requirements of less than 8% by weight for oven cleaners.

Owner:COGNIS IP MANAGEMENT GMBH

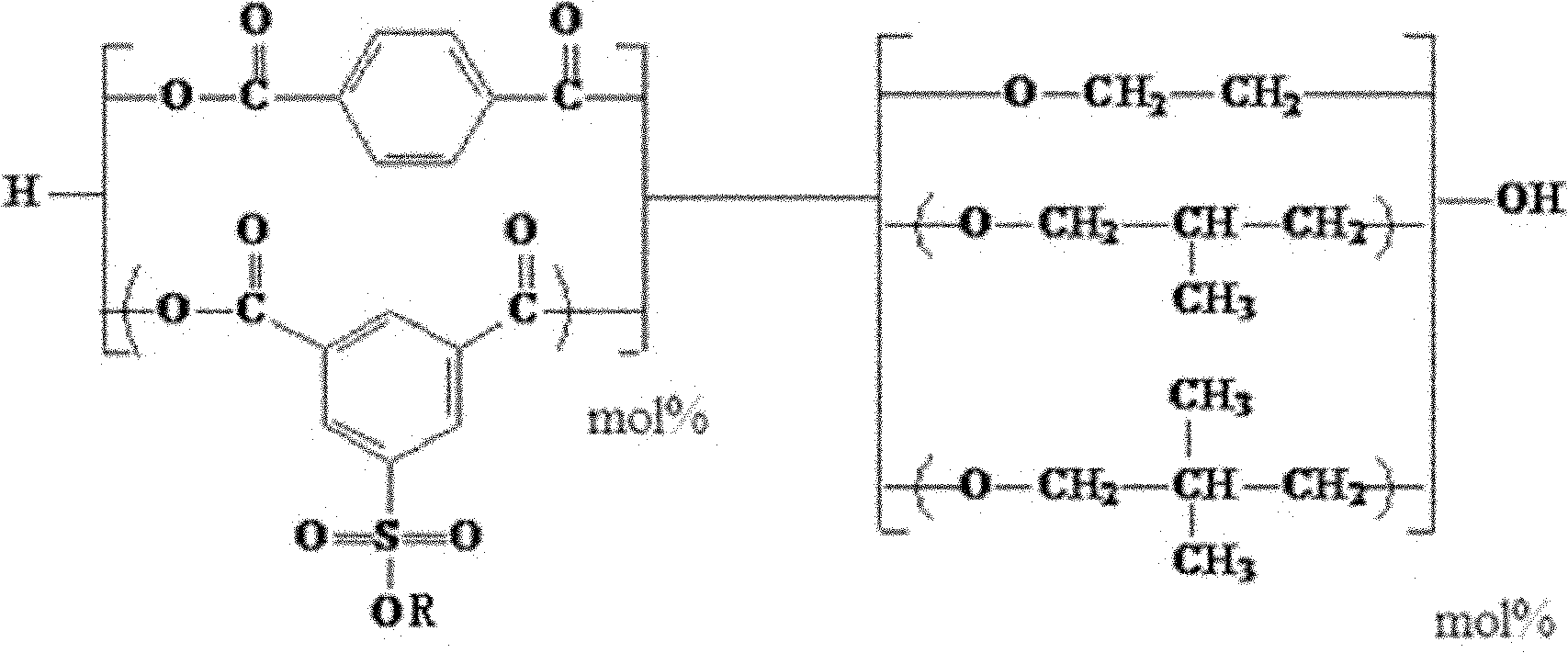

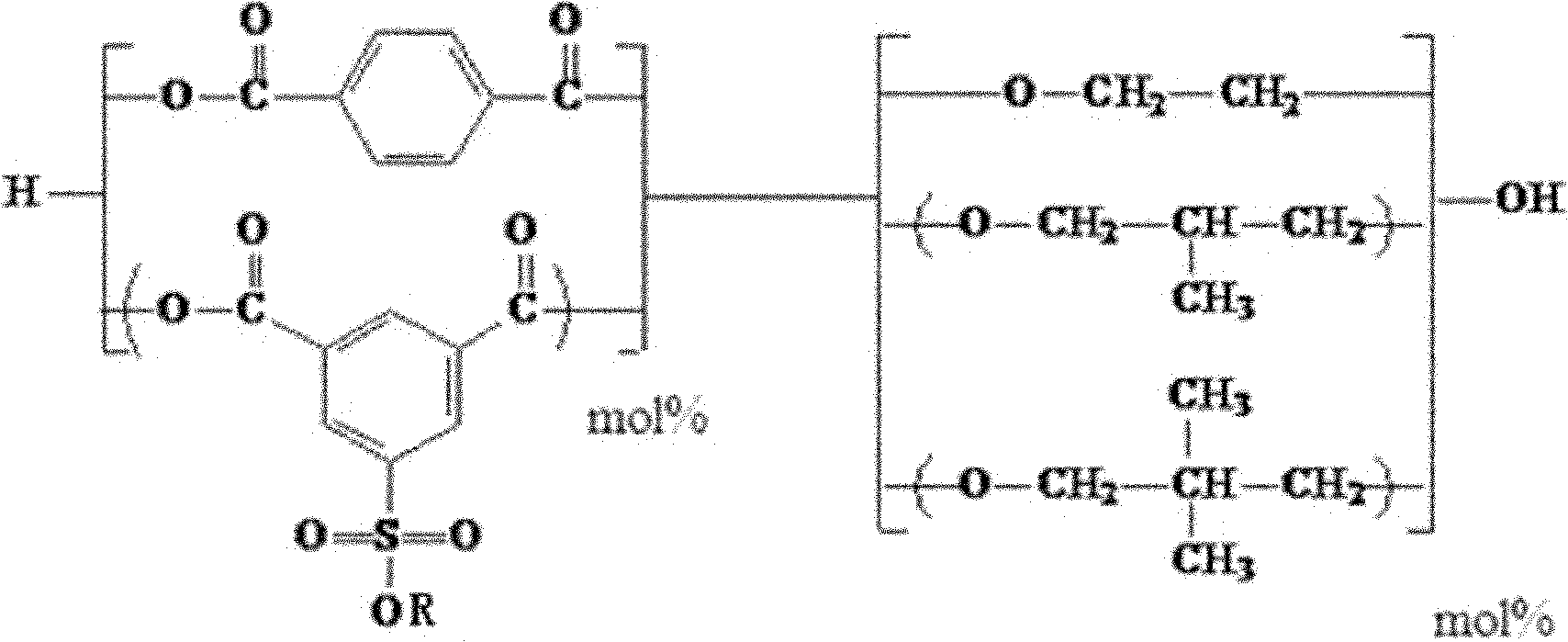

Polyester chip modified by blend with side chain aliphatic diol and preparation method thereof

InactiveCN102120816ALow costEase of industrial productionMonocomponent polyesters artificial filamentDisperse dyeSide chain

The invention relates to a polyester chip modified by the blend with side chain aliphatic diol and a preparation method thereof. The polyester chip is copolymerized by the following monomers: (1) terephthalic acid; (2) ethylene glycol; (3) sodium or potassium 5-sulfoisophthalic acid dibasic ester; and (4) the blend of 2-methyl-1,3-propanediol and 2,2-dimethyl-1,3-propanediol. The preparation method comprises the following steps: adding terephthalic acid and ethylene glycol in a first esterification kettle, adding catalyst and stabilizer simultaneously to perform esterification reaction, transferring the material to a second esterification kettle, injecting the blend of 2-methyl-1,3-propanediol and 2,2-dimethyl-1,3-propanediol to perform esterification with sodium or potassium 5-sulfoisophthalic acid dibasic ester; and (2) transferring the material to a polycondensation kettle, discharging, pelletizing and drying. The modified polyester chip of the invention is used to prepare the cationic or disperse dye atmospheric deep dyeing copolyester fiber; and the method is simple, has low cost and is suitable for industrial production.

Owner:DONGHUA UNIV

Degreasing compositions

InactiveUS6395103B1Improve efficacyLow toxicityElectrostatic cleaningChemical paints/ink removersAlkaneGlycol ethers

A composition useful as a paint remover which may include a carbonate, a dibasic ester and a mono-ester. The paint stripping composition may also contain an organic sulfur-containing compound such as dimethyl sulfoxide (DMSO), a glycol ether, a ketone, or combination thereof. The composition may be used in a process for removing paint by applying it to a painted surface. A degreasing composition is also disclosed which may comprise a carbonate and a alkyl-substituted cyclo-alkane such as naphthene. The compositions have several important attributes, including low toxicity and high efficacy in removing paint and coatings.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

Thickened paint and coating remover

InactiveUS6239090B1Low toxicityImprove efficacyInorganic/elemental detergent compounding agentsChemical paints/ink removersAlcoholTrimethylene carbonate

A thickened composition and process useful for removing paint, comprising: a carbonate such as propylene carbonate or ethylene carbonate, a thickener such as polyvinyl pyrrolidone (PVP), hydrogen peroxide and water. The composition may include additional cosolvents such as glycol ethers and alcohols such as benzyl alcohol, and / or dibasic ester (DBE).

Owner:HUNTSMAN PETROCHEMICAL LLC

Low VOC coalescing agents

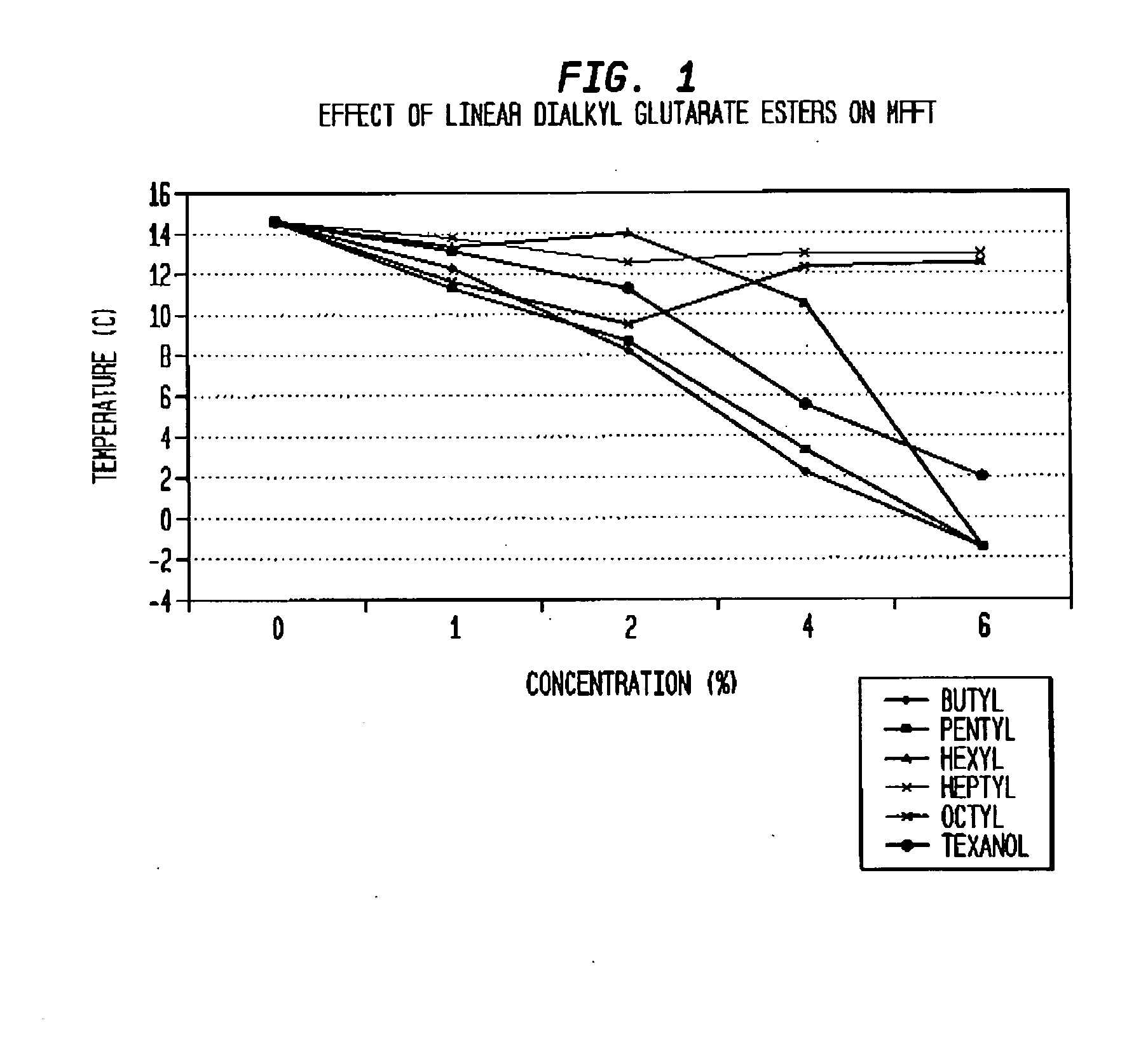

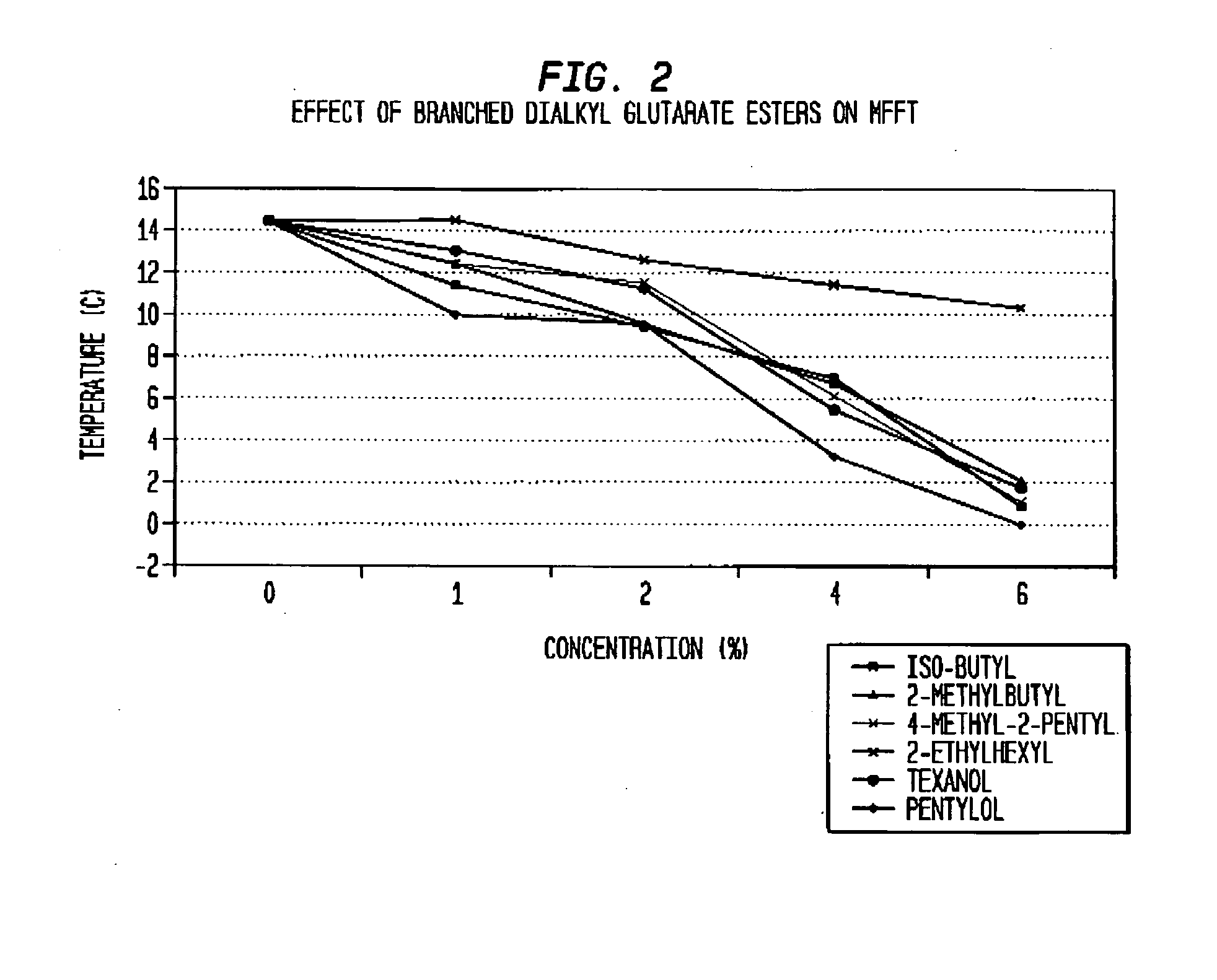

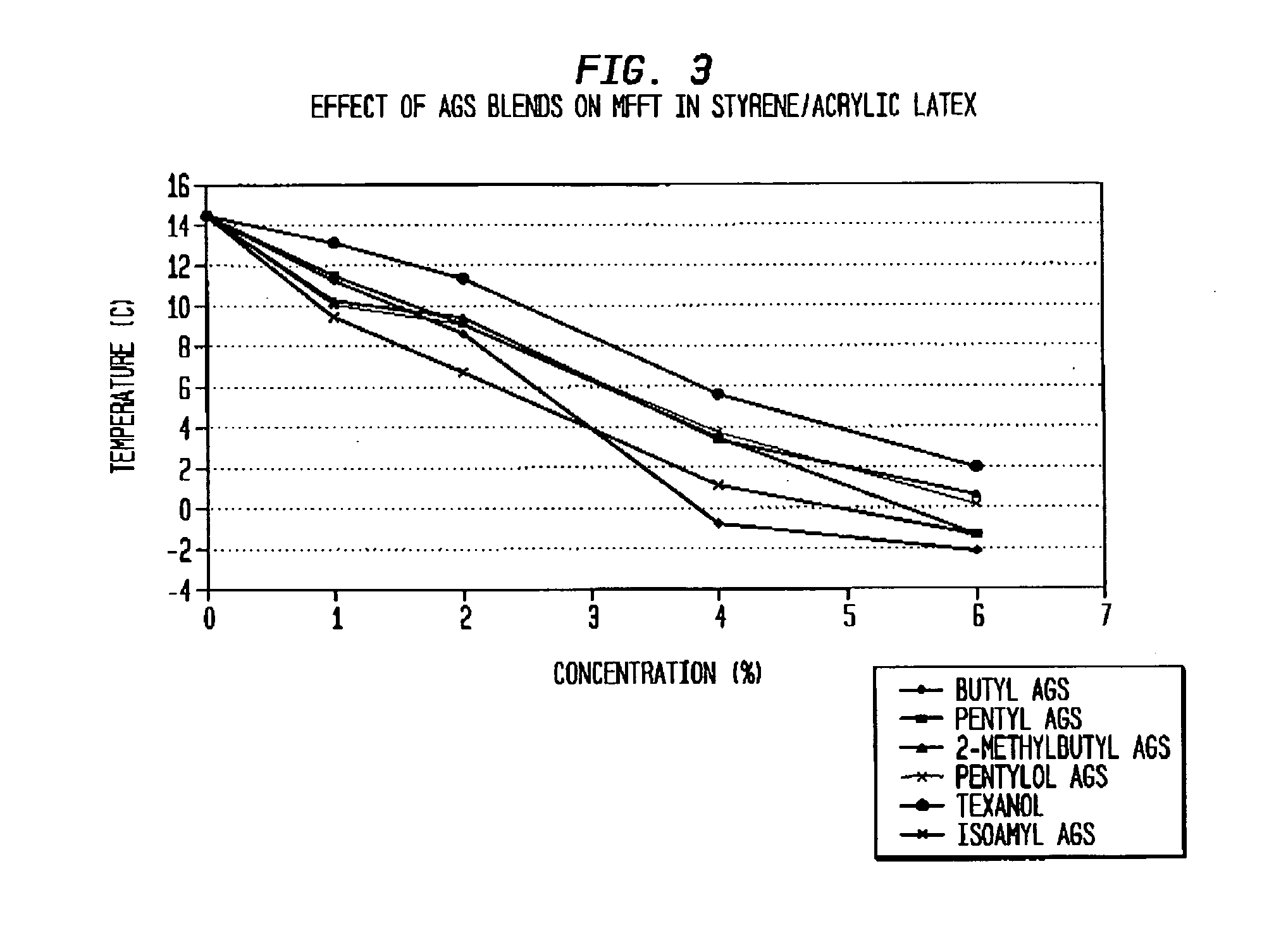

ActiveUS20090198002A1Lower TgImprove efficiencyOrganic chemistryDuplicating/marking methodsAdhesiveAdipic acid

A coalescent composition for coating compositions such as paints, adhesives, and coatings comprising a blend of dibasic esters, specifically (i) esters of adipic, glutaric, and / or succinic diacids and / or (ii) esters of isomers of adipic acid have advantages, including efficiency and low VOC.

Owner:RHODIA OPERATIONS SAS

Paint and coating remover

InactiveUS6169061B1Improve efficiencyLow toxicityChemical paints/ink removersDetergent solventsAlcoholGlycol ethers

This invention concerns a composition useful as a paint remover, comprising: alkylene carbonate such as propylene carbonate or ethylene carbonate, hydrogen peroxide, and water, and optionally an alcohol such as benzyl alcohol. In another broad respect, his invention concerns a process for removing paint, comprising: applying a composition containing alkylene carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. In another broad respect, this invention is a composition useful as a paint remover, comprising: dialkyl carbonate, hydrogen peroxide, and water, optionally containing an alcohol, optionally containing a glycol ether. In another broad respect, this invention is a process for removing paint, comprising: applying a composition containing dialkyl carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. Advantageously, the composition of this invention may include a dibasic ester (DBE).

Owner:HUNTSMAN PETROCHEMICAL LLC +1

Paint and coating remover

InactiveUS6159915ALow toxicityImprove efficacySurface-active detergent compositionsChemical paints/ink removersGlycol ethersKetone

A composition useful as a paint remover. The composition may include a carbonate, a dibasic ester and a mono-ester. The composition may also contain an organic sulfur-containing compound such as dimethyl sulfoxide (DMSO), a glycol ether, a ketone, or combination thereof. The composition may be used in a process for removing paint by applying it to a painted surface. The compositions have several important attributes, including low toxicity and high efficacy in removing paint and coatings.

Owner:INDORAMA VENTURES OXIDES LLC +1

Ink cleaning composition and methods for use

ActiveUS20100273695A1High flash pointLow vapor pressureDetergent mixture composition preparationChemical paints/ink removersDibasic esterGlutarates

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Paint and coating remover

InactiveUS6369009B1Improve efficacyLow toxicityChemical paints/ink removersDetergent solventsPolymer scienceDibasic ester

This invention concerns a composition useful as a paint remover, comprising: alkylene carbonate such as propylene carbonate or ethylene carbonate, hydrogen peroxide, and water, and optionally an alcohol such as benzyl alcohol. In another broad respect, this invention concerns a process for removing paint, comprising: applying a composition containing alkylene carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. In another broad respect, this invention is a composition useful as a paint remover, comprising: dialkyl carbonate, hydrogen peroxide, and water, optionally containing an alcohol, optionally containing a glycol ether. In another broad respect, this invention is a process for removing paint, comprising: applying a composition containing dialkyl carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. Advantageously, the composition of this invention may include a dibasic ester (DBE).

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT

Self-fixing zinc-rich primer in petroleum storage tank for resisting corrosion and preparation method thereof

InactiveCN101191028AImprove corrosion resistanceGood solvent resistanceAnti-corrosive paintsPolyvinyl butyralDibasic ester

The invention relates to a self-fixed zinc-rich primer using for anticorrosion inside an oil tank and a preparation method thereof. The self-fixed zinc-rich primer comprises A solution which consists of tetraethyl orthosilicate, butanol, ethanol, butyl acetate, dibasic ester, 36-38 percent of hydrochloride and distilled water, and B solution which consists of polyvinyl butyral (PVB), butanol, ethanol, zinc powder, ultrafine ferrophosphorus powder, mica powder, fly ash, alkoxy ammonium salt with acidic group and block copolymers, and polysiloxane-polyether copolymer, when in use, the A solution and the B solution are mixed and solidified to form a paint film which is characterized by self-repairing, corrosion resistance, solvent resistance, static conducting, rapid drying and good construction adaptability, etc. The self-fixed zinc-rich primer can be used for surface anticorrosion treatment of steel structures used in inner walls and outer walls of various storage tanks and offshore drilling platforms, etc.

Owner:CNPC RES INST OF ENG TECH +1

Catalyst component for olefin polymerization and catalyst comprising the same

ActiveUS20060287446A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylHalogen

The present invention provides a catalyst component for polymerization of olefin CH2=CHR, in which R is hydrogen or C1-C12 alkyl or aryl, comprising magnesium, titanium, a halogen and an electron donor compound (a) which is at least one selected from the group consisting of dibasic ester compounds of the formula (I), and said catalyst component optionally further comprising an electron donor compound (b) selected from the group consisting of aliphatic dicarboxylic esters and aromatic dicarboxylic esters, and / or an electron donor compound (c) selected from the group consisting of 1,3-diether compounds of formula (IV): wherein, R1, R′ and A are as defined in the description, wherein RI-RVIII are as defined in the description, and a catalyst comprising the catalyst component.

Owner:CHINA PETROCHEMICAL CORP +1

Paint and coating remover

InactiveUS6482270B1Improve efficacyLow toxicitySurface-active detergent compositionsChemical paints/ink removersGlycol ethersKetone

A composition useful as a paint remover. The composition may include a carbonate, a dibasic ester and a mono-ester. The composition may also contain an organic sulfur-containing compound such as dimethyl sulfoxide (DMSO), a glycol ether, a ketone, or combination thereof. The composition may be used in a process for removing paint by applying it to a painted surface. The compositions have several important attributes, including low toxicity and high efficacy in removing paint and coatings.

Owner:HUNTSMAN PETROCHEMICAL LLC

Degreasing compositions

InactiveUS20020111284A1Improve efficacyLow toxicitySurface-active detergent compositionsChemical paints/ink removersAlkaneGlycol ethers

A composition useful as a paint remover which may include a carbonate, a dibasic ester and a mono-ester. The paint stripping composition may also contain an organic sulfur-containing compound such as dimethyl sulfoxide (DMSO), a glycol ether, a ketone, or combination thereof. The composition may be used in a process for removing paint by applying it to a painted surface. A degreasing composition is also disclosed which may comprise a carbonate and a alkyl-substituted cyclo-alkane such as naphthene. The compositions have several important attributes, including low toxicity and high efficacy in removing paint and coatings.

Owner:HUNTSMAN PETROCHEMICAL LLC

Removable adhesive for adhering an image to a surface and a method for removing the image

InactiveUS20070110966A1Easy to removeDecorative surface effectsDuplicating/marking methodsDiacetone alcoholTetrahydrofuranol

A removable adhesive of a combination of acrylic and urethane polymers is provided for securing, among other things, a transfer image to a hard surface. A removable top coat is provided. A top coat comprising a cellulose acetate butyrate alcohol and a diacetone alcohol is provided. A remover for removing the transferred image is provided which is a combination of tetrahydrofuryl alcohol and a dibasic ester and a surfactant.

Owner:WARREN DONALD

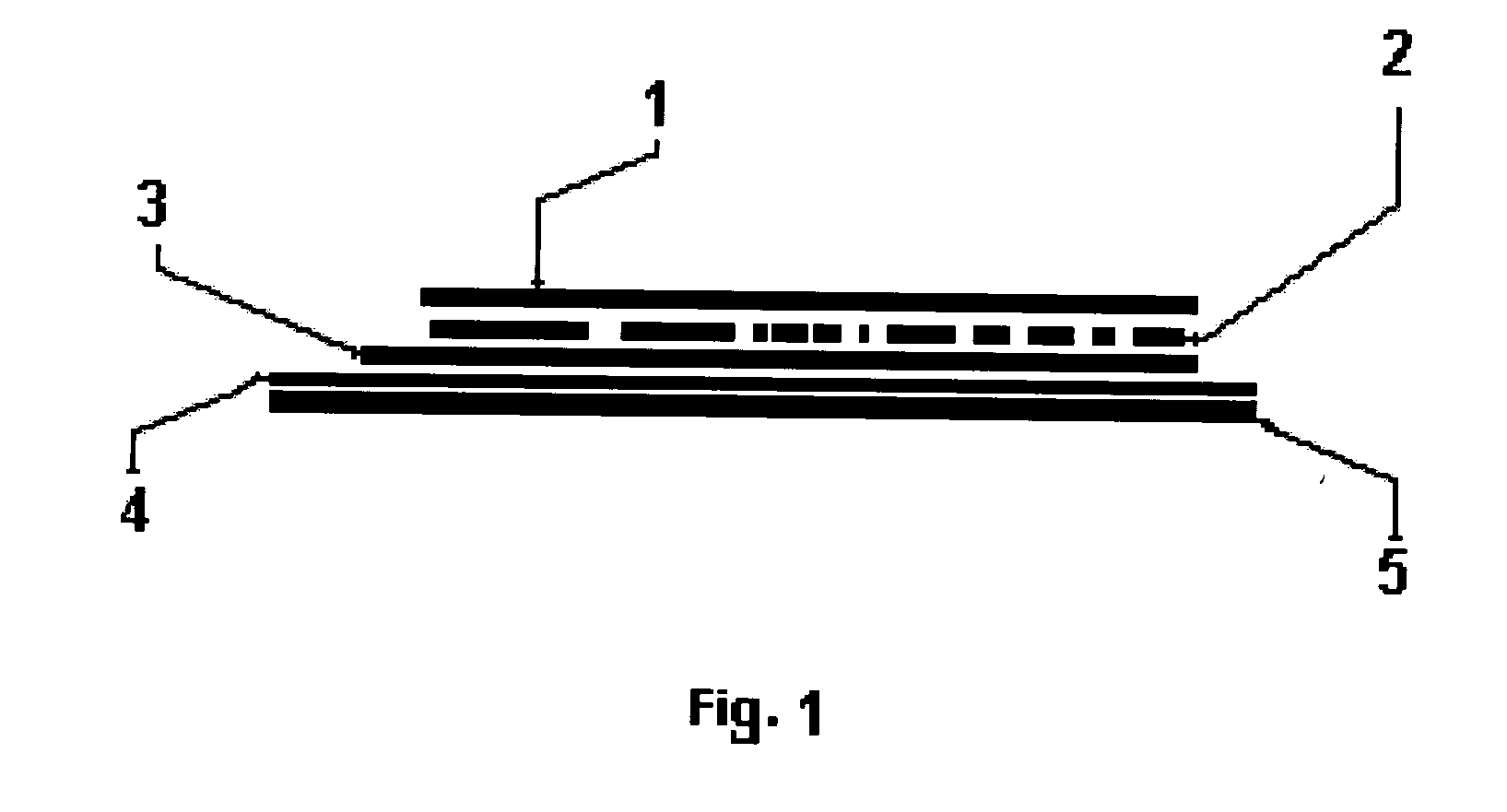

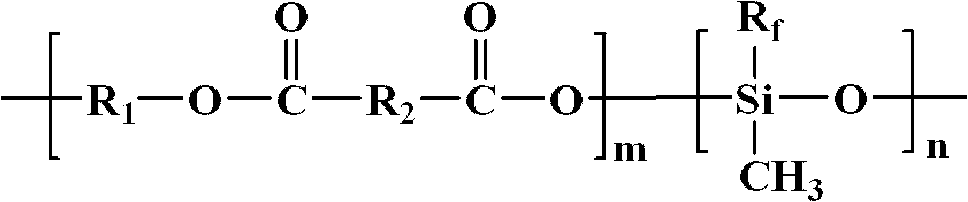

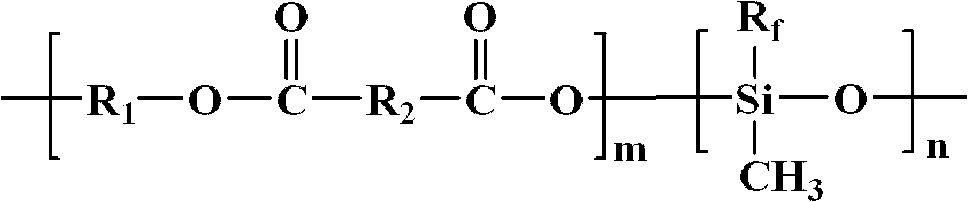

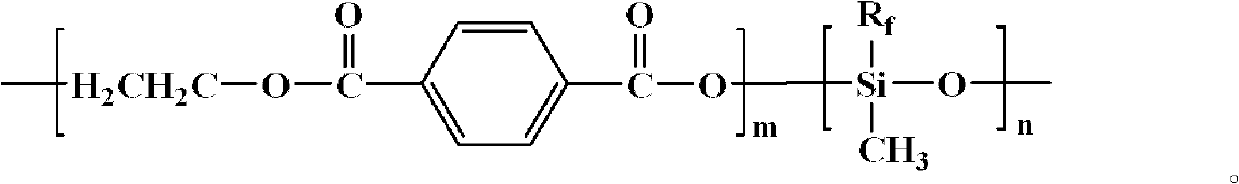

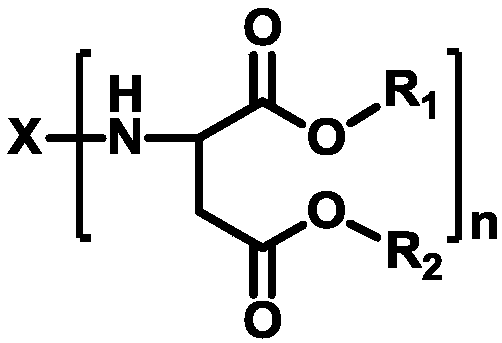

Hydrophobic modified polyester and preparation method thereof

The invention provides hydrophobic modified polyester, with a structural formula, wherein R1 and R2 are respectively C2-C8 alkyl, aryl or cycloalkyl, Rf is C1-C20 fluoroalkyl, n ranges from 6 to 141, m is 42-104. The preparation method of the polyester is as follows: mixing of dibasic acid, dibasic alcohol and a catalyst or mixing of dibasic ester, dibasic alcohol and a catalyst or mixing of oligomer of dibasic acid and dibasic alcohol, dibasic alcohol and a catalyst, and polyreaction under the temperature of 140-300 DEG C and the vacuum degree of 5-150Pa until the expected degree of polymerization is realized, thereby obtaining the hydrophobic modified polyester. The modified polyester has low surface energy and excellent hydrophobic properties, and is suitable for both spinning and textile processing.

Owner:CHINESE TEXTILE ACAD

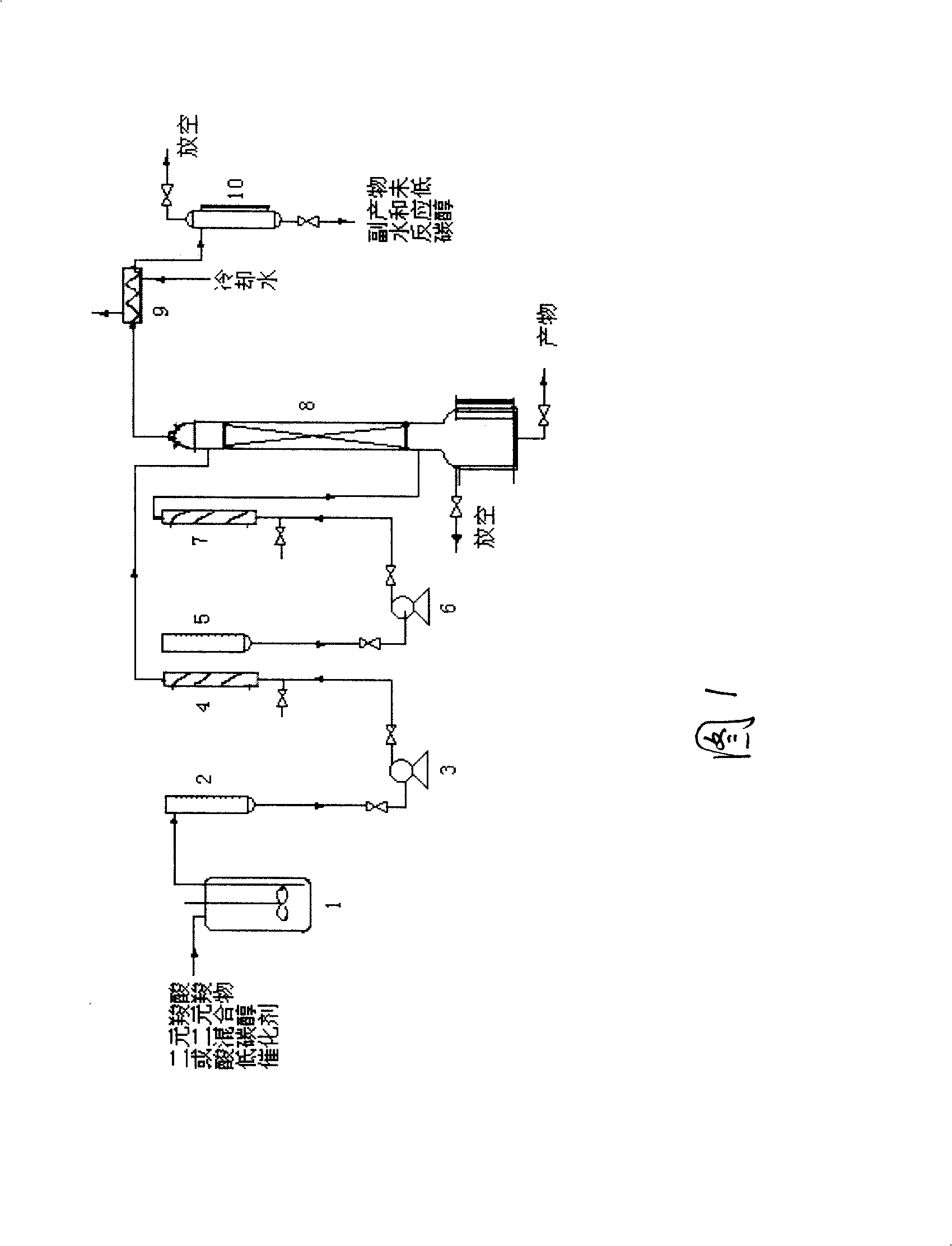

Process for preparing dibasic acid ester

ActiveCN101265184AImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationAlcoholSolid acid

The invention relates to a method of preparing dibasic acid esters. Solid acid catalyst, dualistic carboxylic acid or dualistic carboxylic acid mixture, and low-carbon alcohol are added in a pre-esterification kettle; the addition amount of the solid acid catalyst is 1 to 10 percent of the quality of the dualistic carboxylic acid or the dualistic carboxylic acid mixture; the molar ratio of the alcohol and the dualistic carboxylic acid or the dualistic carboxylic acid mixture is 1 to 10:1; the reaction is performed under the normal atmosphere, wherein, the temperature ranges from 50 to 100 DEG C; the supernatant fluid of reaction products is delivered into the upper part of an esterification reactor; after the low-carbon alcohol is turned into vapour by passing through a carburetor, the low-carbon alcohol vapour enters into the lower part of the esterification reactor; the supernatant fluid and the low-carbon alcohol vapour effect the reflux reaction at a catalyst section of a continuous esterification reactor; reaction products are expelled from the bottom of the esterification reactor, and unreacted low-carbon alcohol and generated water are steamed from the top of the reactor; esterification reaction occurs under the normal atmosphere, the temperature ranges from 70 to 150 DEG C, the liquid airspeed is 0.1 to 0.7Kg / Kg*h, the airspeed of the low-carbon alcohol is 0.1 to 1.0Kg / Kg*h, and the percent conversion can reach more than 99 percent.

Owner:PETROCHINA CO LTD

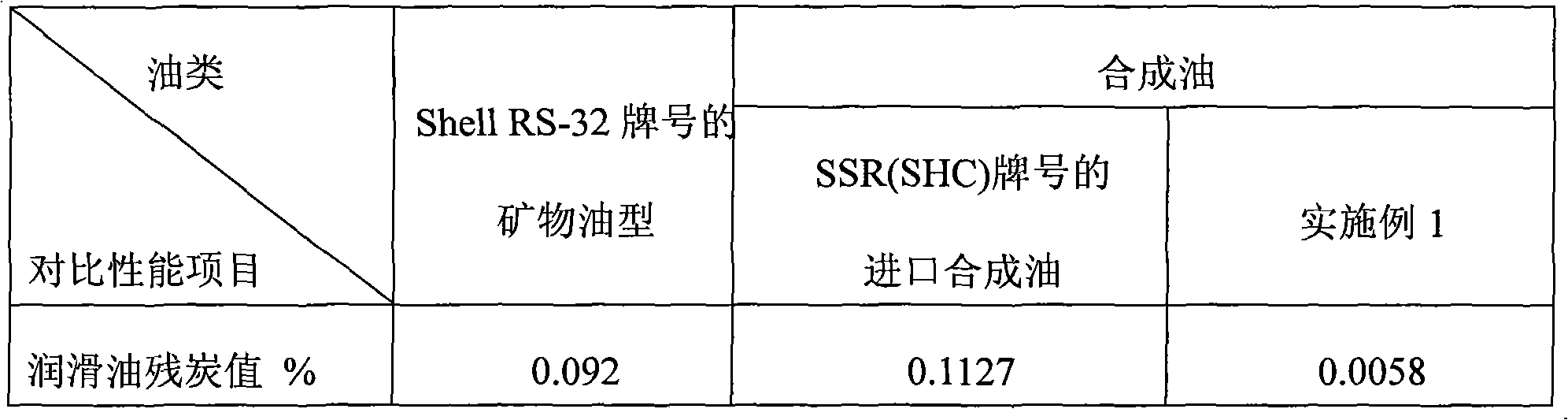

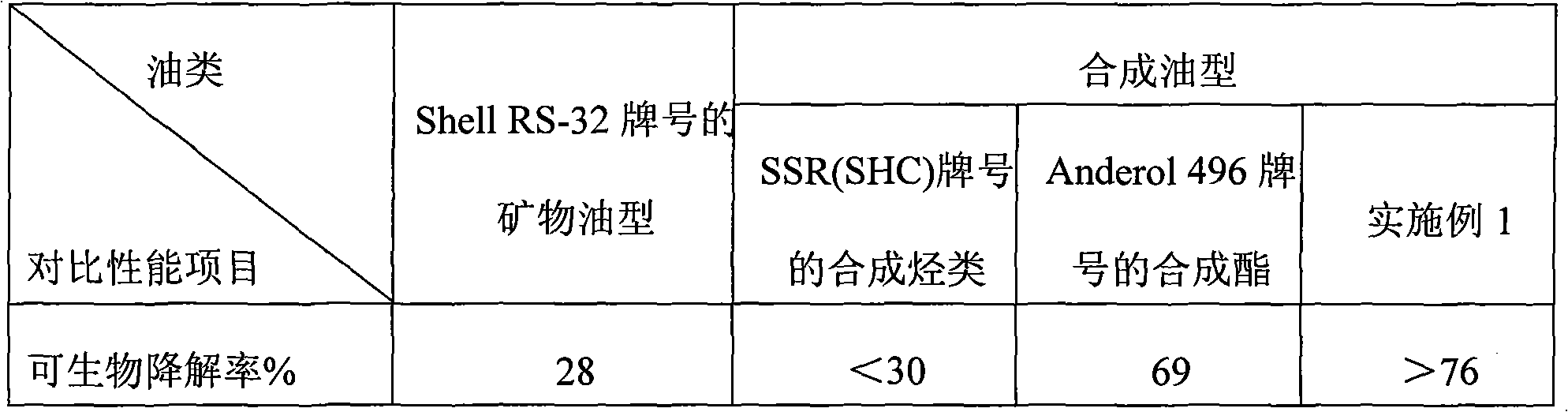

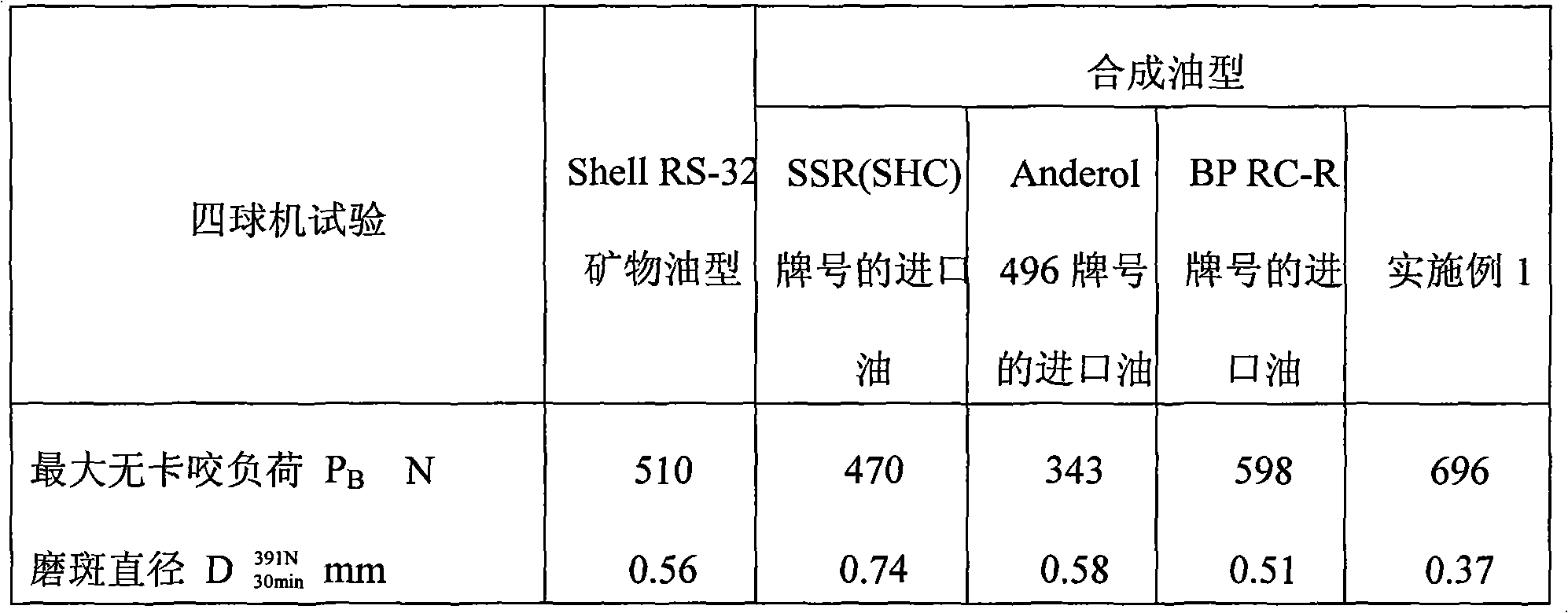

Composite synthetic air compressor oil

The invention discloses composite synthetic air compressor oil comprising the following components: a promoter, diisoalkyl (C8 to C13) linear dibasic ester, poly-alpha-olefin synthetic oil and diisoalkyl (C8 to C13) phthalate esters, wherein, the composite synthetic air compressor oil contains 15% to 20% of diisoalkyl (C8 to C13) linear dibasic ester by weight, 5% to 10% of poly-alpha-olefin synthetic oil by weight and 72% to 74% of diisoalkyl (C8 to C13) phthalate esters by weight. The composite synthetic air compressor oil of the invention can meet the requirements that the carbon residue value thereof is low and the biodegradation rate is higher than 70%; the composite synthetic air compressor oil has high high-temperature anti-oxidation stability, lubricating properties, rust-preventing properties, foam resistance and emulsion resistance; and the invention has the advantages that the energy is saved, the environmental pollution is reduced and the service life is prolonged, therefore, the invention can fully satisfy the operating requirements for rotary-type screw compressors.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Method for preparing cationic dye deeply dyed copolyester fibers at normal pressure

InactiveCN102199808AReduce crystallinityLower glass transition temperatureMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsDisperse dyePolymer science

The invention relates to a method for preparing cationic dye deeply dyed copolyester fibers at normal pressure. The copolyester fibers are prepared by carrying out high speed pure melt spinning, composite spinning and blended spinning on copolyester chips jointly modified by a blend of aliphatic diols with side chains and m-benzene dibasic acid dibasic ester-5-sodium or potassium sulfonate. The method has the following beneficial effects: the fibers can be deeply dyed with cationic dyes or disperse dyes under the condition of boiling dyeing at normal pressure; the fibers and fabrics made from the fibers have soft handfeel, good resilience and excellent pilling resistance; the fabrics dispense with alkali treatment; the fibers are energy-saving, low-carbon and environmentally-friendly and can be widely used for pure spinning or blended spinning with such natural fibers as silk, tough silk, cotton, wool, twine and the like; the preparation process has no special requirements for equipment; and the fibers have low cost and are easy to realize industrialized production.

Owner:DONGHUA UNIV

Cleaning compositions containing dichloroethylene and six carbon alkoxy substituted perfluoro compounds

InactiveUS7288511B2Without usingImprove propertiesDry-cleaning apparatus for textilesOrganic non-surface-active detergent compositionsAlkaneCyclic ether

Chemical solvating, degreasing, stripping and cleaning agents. The agents are cleaning and solvating mixtures of dichloroethylene and alkoxy-substituted perfluoro compounds that contain six carbon atoms, with optionally highly fluorinated materials to retard flammability and / or other enhancement agents that improve and enhance the properties of the composition to accomplish its desired cleaning or solvating task. These other agents are one or more of the following materials: alcohols, esters, ethers, cyclic ethers, ketones, alkanes, aromatics, amines, siloxanes terpenes, dibasic esters, glycol ethers, pyrollidones, or low- or non-ozone depleting halogenated hydrocarbons. These mixtures are useful in a variety of solvating, vapor degreasing, photoresist stripping, adhesive removal, aerosol, cold cleaning, and solvent cleaning applications including defluxing, dry-cleaning, degreasing, particle removal, metal and textile cleaning.

Owner:KYZEN CORP

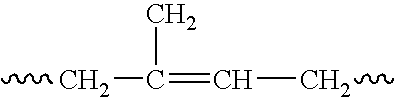

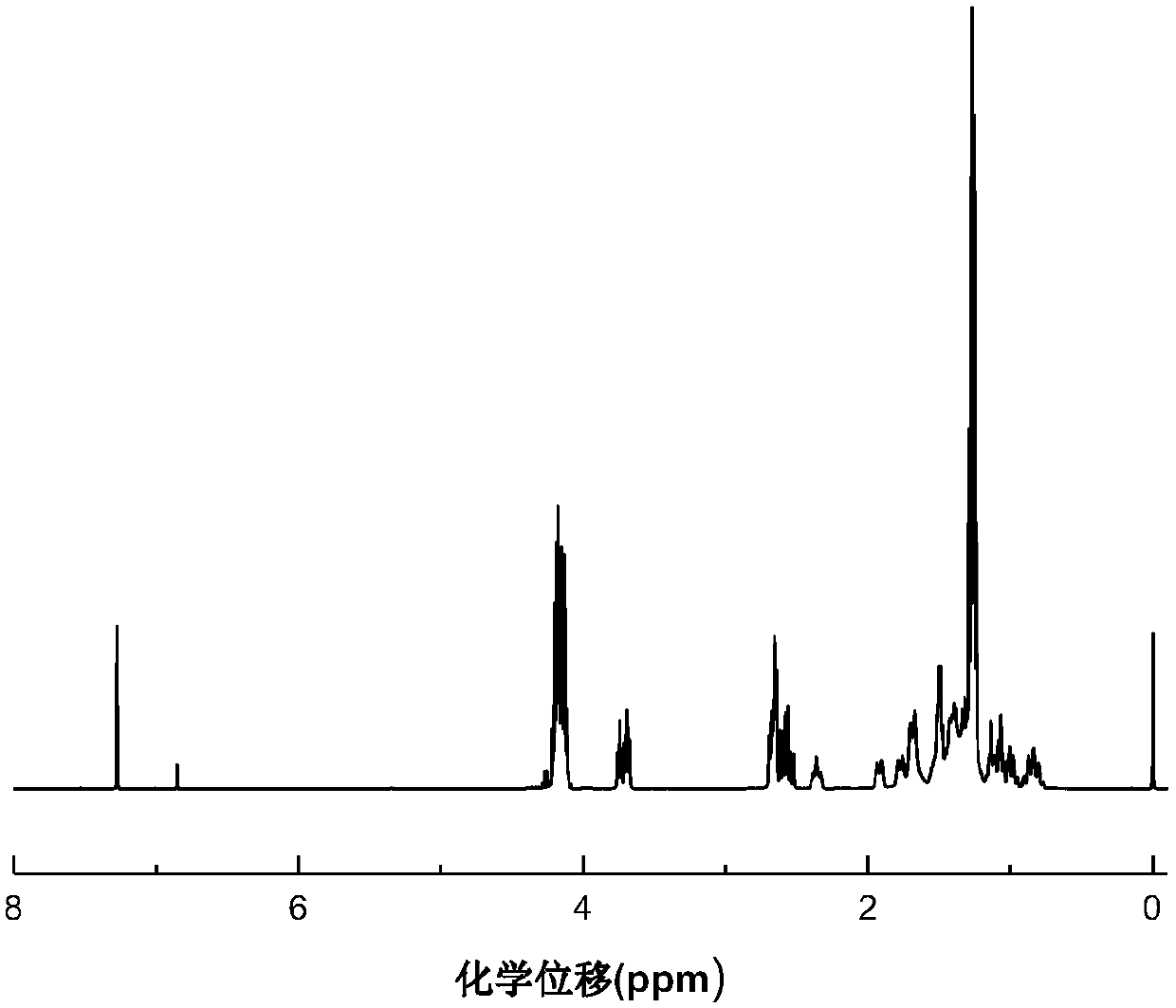

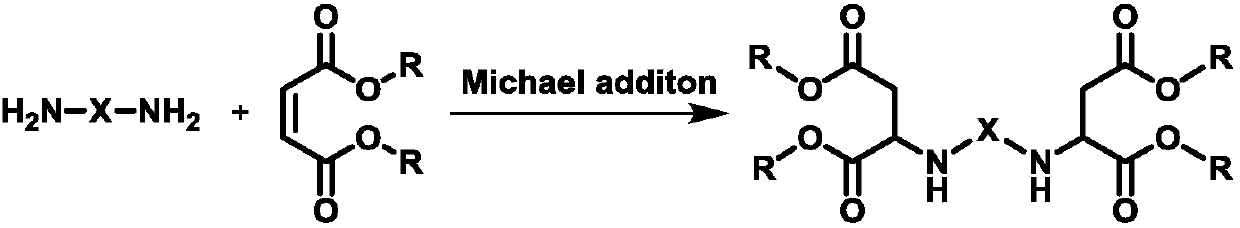

Preparation method of polyaspartic acid ester

ActiveCN107805207AHigh catalytic activityNo pollution in the processOrganic compound preparationAmino-carboxyl compound preparationButenePolyaspartic acid

The invention provides a preparation method of polyaspartic acid ester. Tetraalkylammonium hydroxide is adopted as the catalyst, and organic primary amine reacts with unsaturated dibasic acid ester toobtain the product. As organic strong base, tetraalkylammonium hydroxide can obviously improve the Michael addition reaction activity of the primary amine and butene diacid ester, and at the end of the reaction, the catalyst can be removed completely through simple heating, and no adverse effect can be generated on downstream application of the product. The method provided by the invention has the advantages of high catalytic activity, high primary amine conversion rate, low product colority, no catalyst residue and the like.

Owner:WANHUA CHEM GRP CO LTD

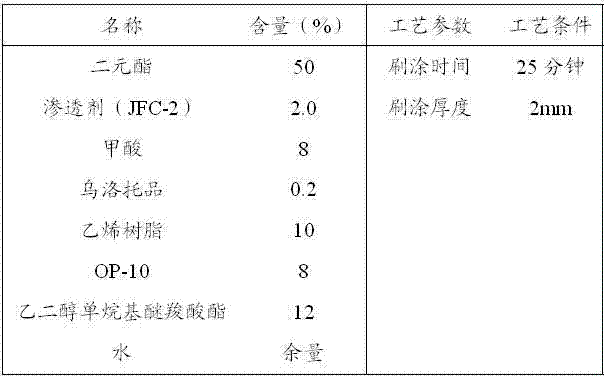

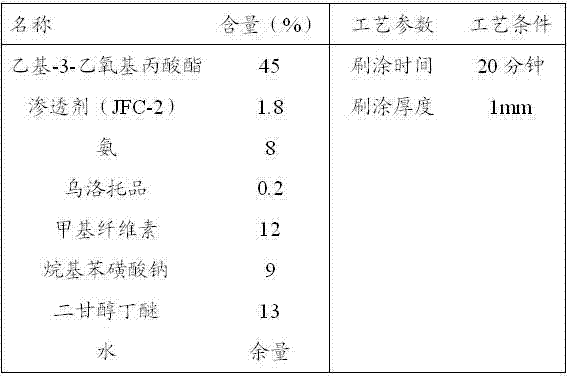

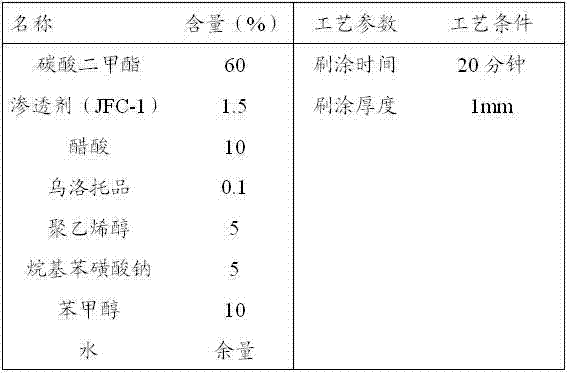

Degumming agent and preparation method and application thereof

The invention discloses a degumming agent and a preparation method and application of the degumming agent. The degumming agent mainly contains the following ingredients in percentage by weight: 40%-60% of main solvent, 1.5%-3% of penetrant, 6%-10% of activating agent, 0.1%-0.3% of corrosion inhibitor, 5%-15% of thickening agent, 5%-10% of emulsifier, 10%-15% of volatilization inhibitor and the balance of water, wherein the main solvent is one or a mixture of several of methyl carbonate, ethyl-3-ethoxy propionate, dibasic ester, alkoxy alcohol, alcohol amine or benzoic alcohol. The degumming agent is simple in using method, is free from being heated and can be used at normal temperature by either brushing or spraying, and the time for washing is short, so that the production efficiency can be greatly increased.

Owner:吉林中路新材料有限责任公司

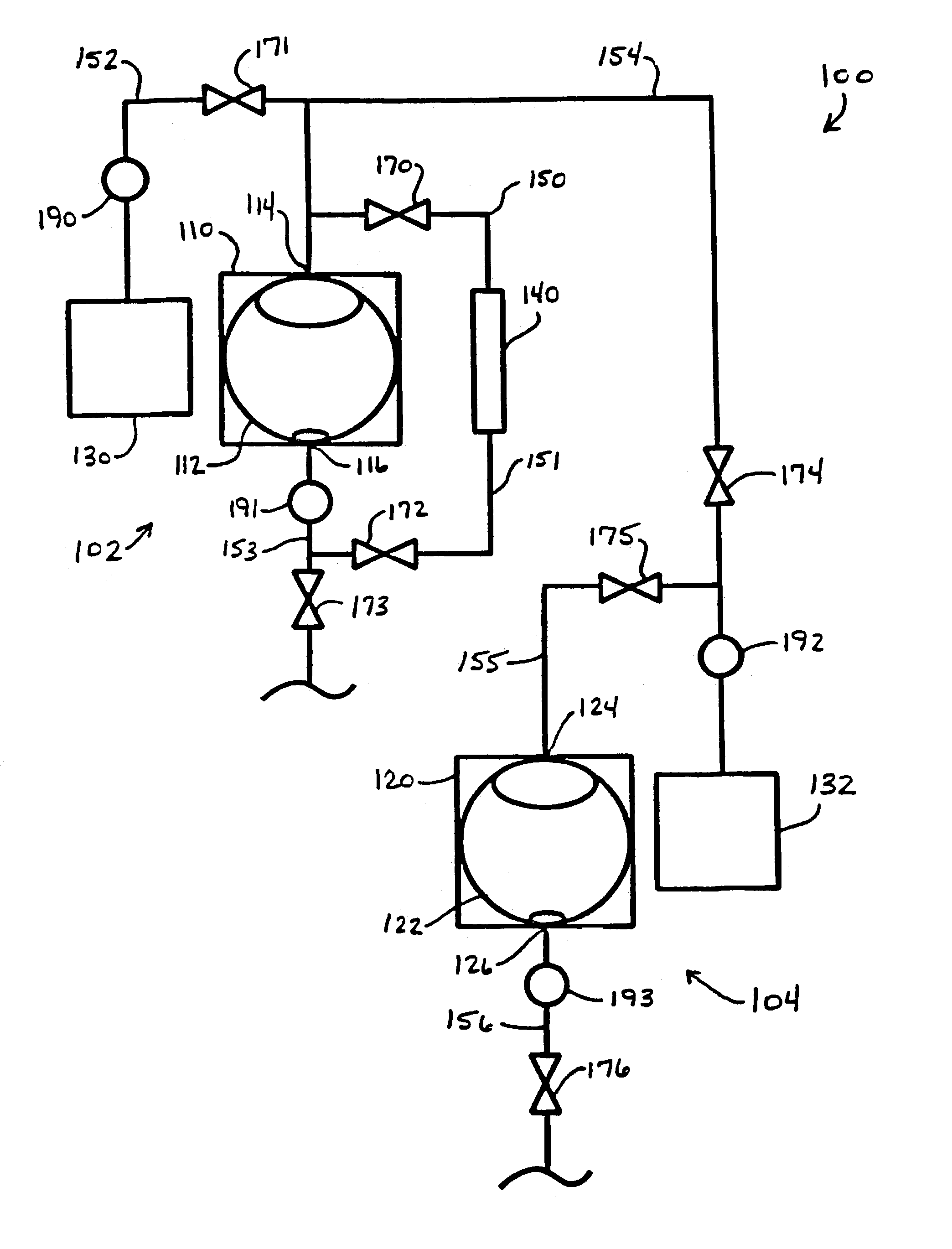

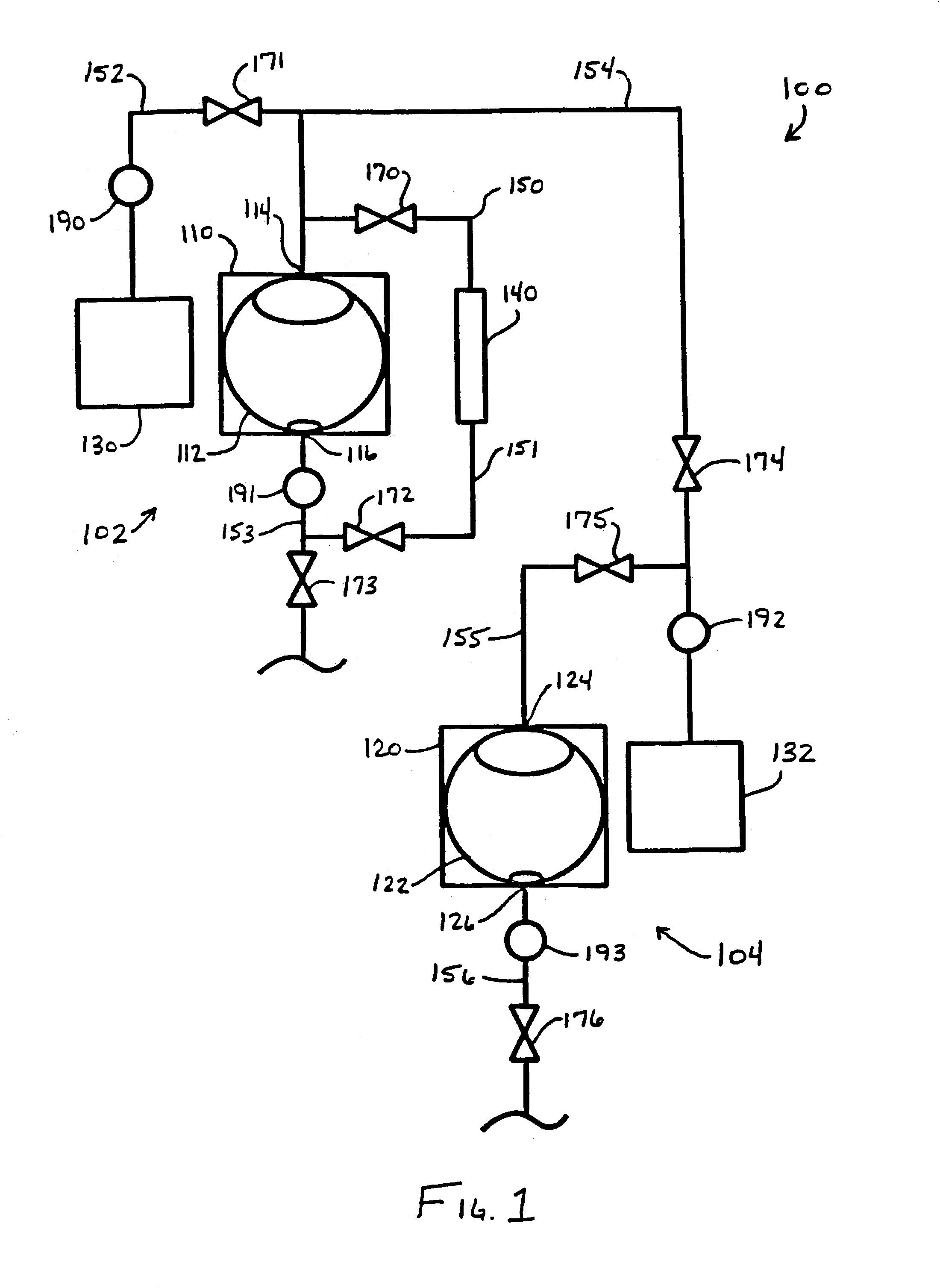

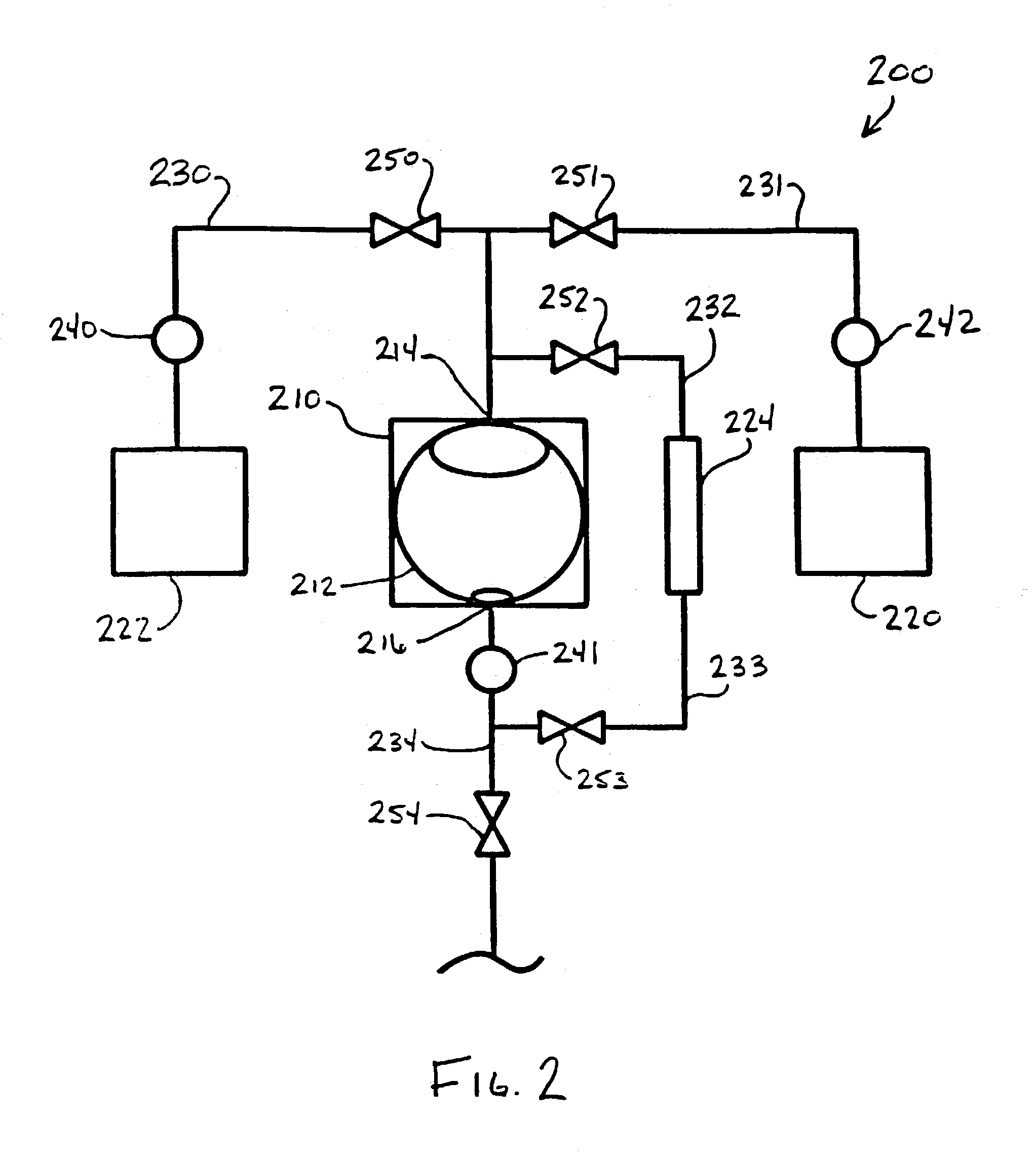

Cleaning system utilizing an organic cleaning solvent and a pressurized fluid solvent

InactiveUS7147670B2Increase vapor pressureLow boiling pointDry-cleaning apparatusDetergent mixture composition preparationSolubilityHalohydrocarbon

A cleaning system that utilizes an organic cleaning solvent and pressurized fluid solvent is disclosed. The system has no conventional evaporative hot air drying cycle. Instead, the system utilizes the solubility of the organic solvent in pressurized fluid solvent as well as the physical properties of pressurized fluid solvent. After an organic solvent cleaning cycle, the solvent is extracted from the textiles at high speed in a rotating drum in the same way conventional solvents are extracted from textiles in conventional evaporative hot air dry cleaning machines. Instead of proceeding to a conventional drying cycle, the extracted textiles are then immersed in pressurized fluid solvent to extract the residual organic solvent from the textiles. This is possible because the organic solvent is soluble in pressurized fluid solvent. After the textiles are immersed in pressurized fluid solvent, pressurized fluid solvent is pumped from the drum. Finally, the drum is de-pressurized to atmospheric pressure to evaporate any remaining pressurized fluid solvent, yielding clean, solvent free textiles. The organic solvent is preferably selected from terpenes, halohydrocarbons, certain glycol ethers, polyols, ethers, esters of glycol ethers, esters of fatty acids and other long chain carboxylic acids, fatty alcohols and other long-chain alcohols, short-chain alcohols, polar aprotic solvents, siloxanes, hydrofluoroethers, dibasic esters, and aliphatic hydrocarbons solvents or similar solvents or mixtures of such solvents and the pressurized fluid solvent is preferably densified carbon dioxide.

Owner:EMINENT TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com