Patents

Literature

1414results about How to "Lower glass transition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

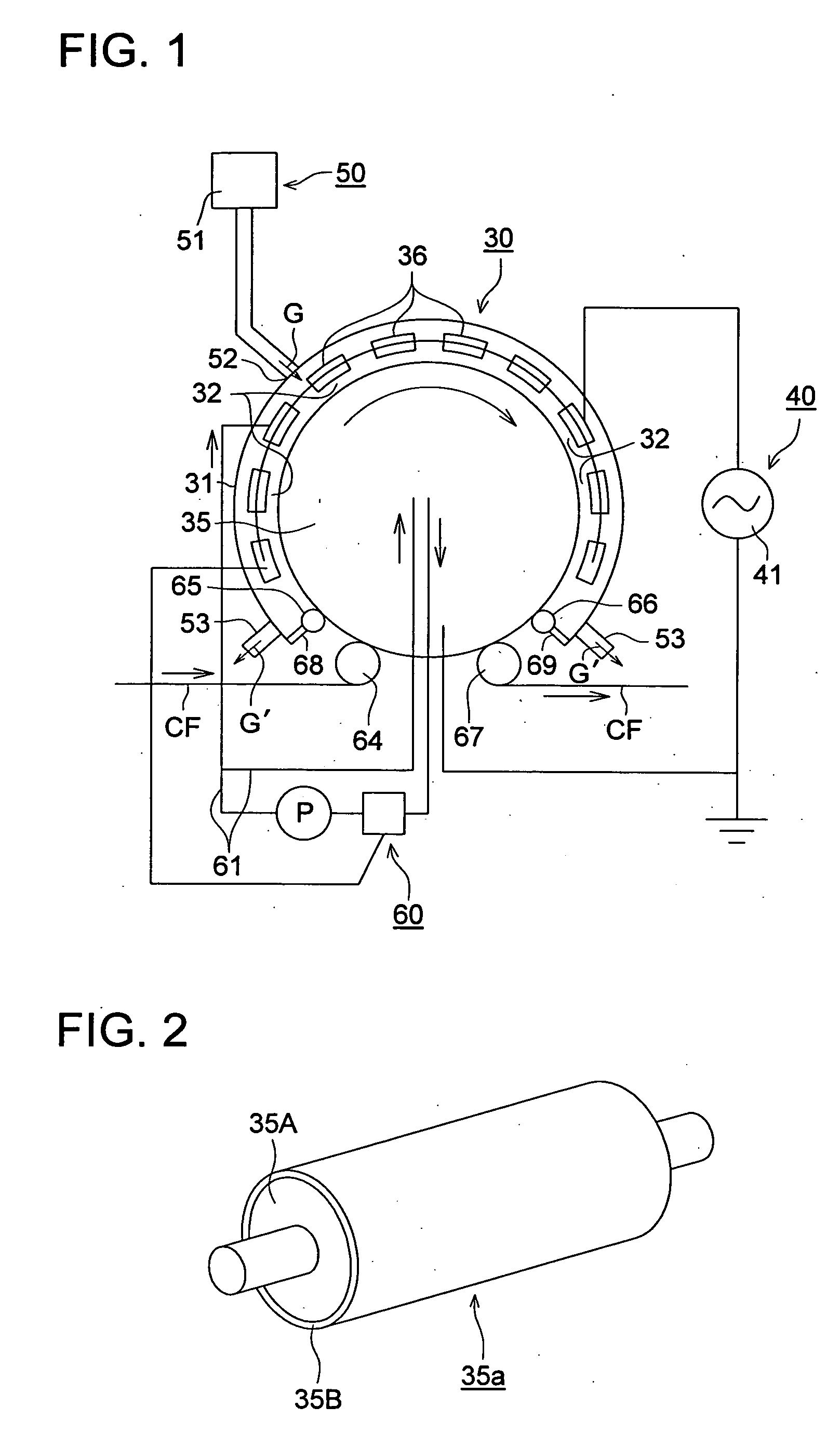

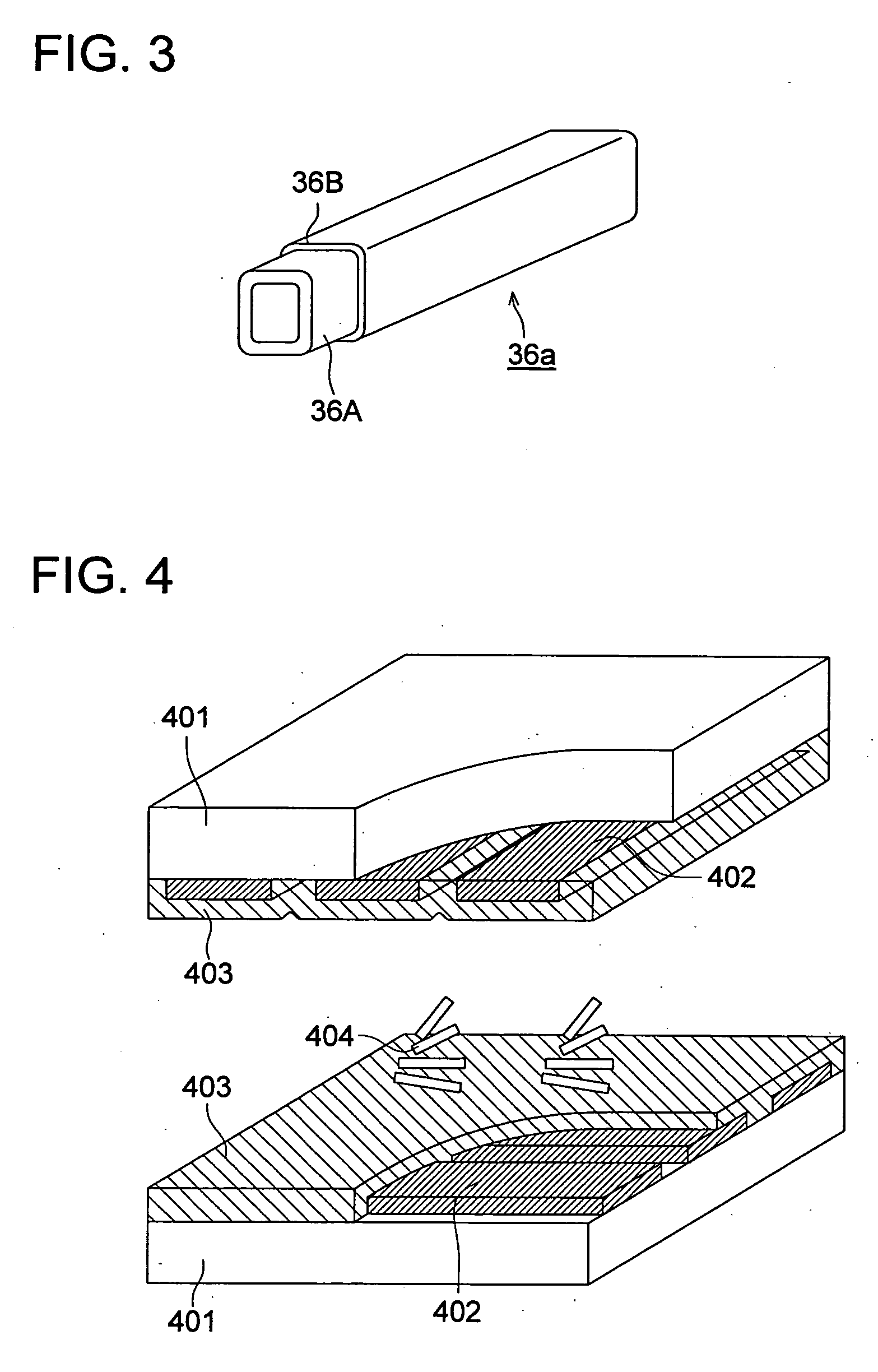

Polymer solution for nanoimprint lithography to reduce imprint temperature and pressure

InactiveUS20040110856A1Reduce pressureReduce the temperatureNanostructure manufactureDecorative surface effectsCross-linkVitrification

A method of forming features on substrates by imprinting is provided. The method comprises: (a) forming a polymer solution comprising at least one polymer dissolved in at least one polymerizable monomer; and (b) depositing the polymer solution on a substrate to form a liquid film thereon; and then either: (c) curing the liquid film by causing the monomer(s) to polymerize and optionally cross-linking the polymer(s) to thereby form a polymer film, the polymer film having a glass transition temperature (Tg); and imprinting the polymer film with a mold having a desired pattern to form a corresponding negative pattern in the polymer film, or (d) imprinting the liquid film with the mold and curing it to form the polymer film. The temperature of imprinting is as little as 10° C. above the Tg, or even less if the film is in the liquid state. The pressure of the imprinting can be within the range of 100 to 500 psi.

Owner:HEWLETT PACKARD DEV CO LP

Effervescent granules and methods for their preparation

InactiveUS6071539AMinimize degradationMelt and soften binderPowder deliveryPill deliveryPlasticizerHot melt

According to the present invent, effervescent granules having a controllable rate of effervescence are provided. Such granules comprise an acidic agent, an alkaline agent, a hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process.

Owner:ETHYPHARM SA

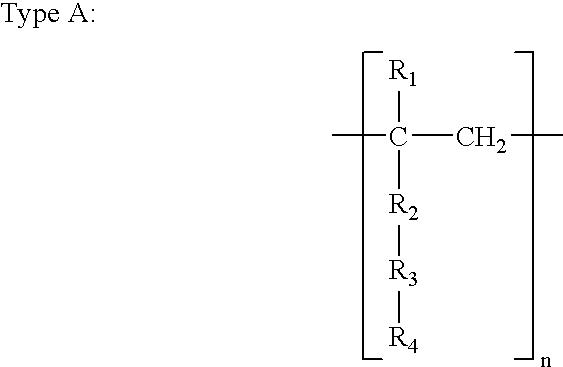

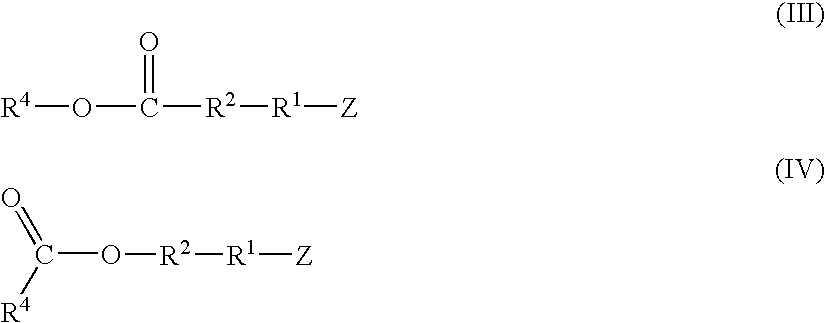

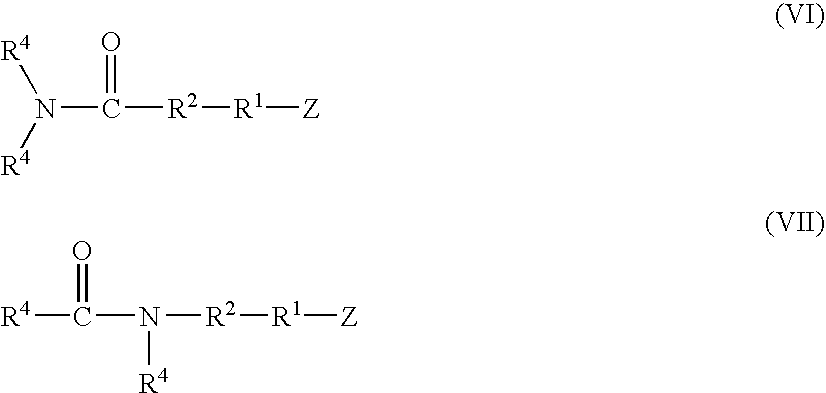

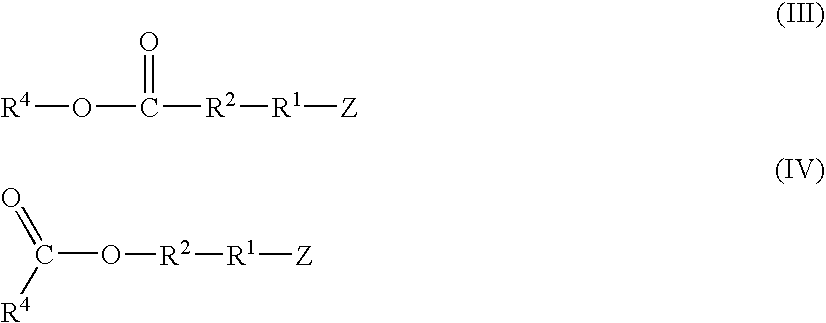

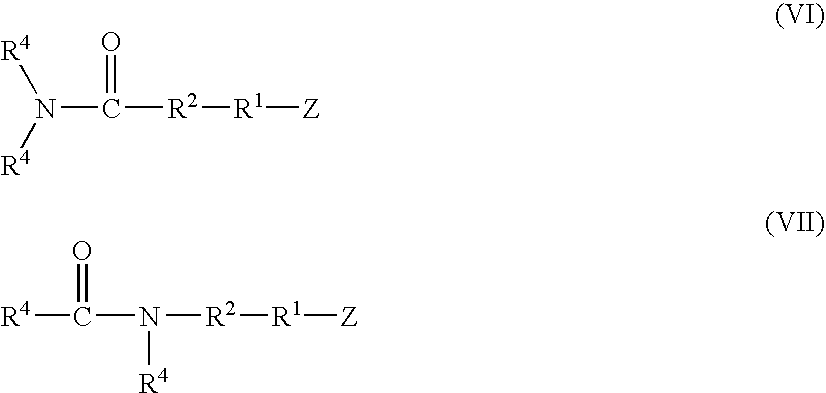

Functionalized high cis-1,4-polybutadiene prepared using novel functionalizing agents

InactiveUS20060004131A1High ci microstructureLower glass transition temperatureInksActive polymerPolymer science

A functionalized polymer prepared by a process comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with a functionalizing agent defined by the formula (I) A-R1-Z (I) where R1 is a divalent bond or divalent organic group comprising from 0 to about 20 carbon atoms, A is a substituent that will undergo an addition reaction with a pseudo-living polymer, and Z is a substituent that will react or interact with silica or carbon black reinforcing fillers, with the proviso that A, R1, and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

Effervescent granules and methods for their preparation

InactiveUS6649186B1Improve stabilityParticular regionPowder deliveryNervous disorderHYDROMORPHONE HYDROCHLORIDEAlpha adrenergic blockade

Disclosed here are effervescent granules having a controllable rate of effervescence. In some embodiments, the such granules comprise an acidic agent, an alkaline agent, a pharmacologically active agent, hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process. The present invention also provides a thermal heat process for preparing a pharmacologically active agent containing effervescent granule. In certain aspects, the granules contain pharmacologically active agents such as narcotics, antidiarrheal agents, antiviral agents, anxiolytic agents, a cholesterol lowering agent, an alpha adrenergic blocking agent, a phenanthrene derivative. By way of example, some of the narcotics that may be included in the granules and in the process of preparing the granules include, by way of example: phenanthrene derivatives (e.g., morphine sulfate), and morphine derivatives (e.g., hydromorphone hydrochloride).

Owner:ETHYPHARM SA

Effervescent granules and methods for their preparation

InactiveUS6488961B1Improve stabilityParticular regionPowder deliveryBiocideAnesthetic AgentHYDROMORPHONE HYDROCHLORIDE

Disclosed here are effervescent granules having a controllable rate of effervescence. In some embodiments, the such granules comprise an acidic agent, an alkaline agent, a pharmacologically active agent, hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process. The present invention also provides a thermal heat process for preparing a pharmacologically active agent containing effervescent granule. In certain aspects, the granules contain pharmacologically active agents such as narcotics, antidiarrheal agents, antiviral agents, anxiolytic agents, a cholesterol lowering agent, an alpha adrenergic blocking agent, a phenanthrene derivative. By way of example, some of the narcotics that may be included in the granules and in the process of preparing the granules include, by way of example: phenanthrene derivatives (e.g., morphine sulfate), and morphine derivatives (e.g., hydromorphone hydrochloride).

Owner:ETHYPHARM SA

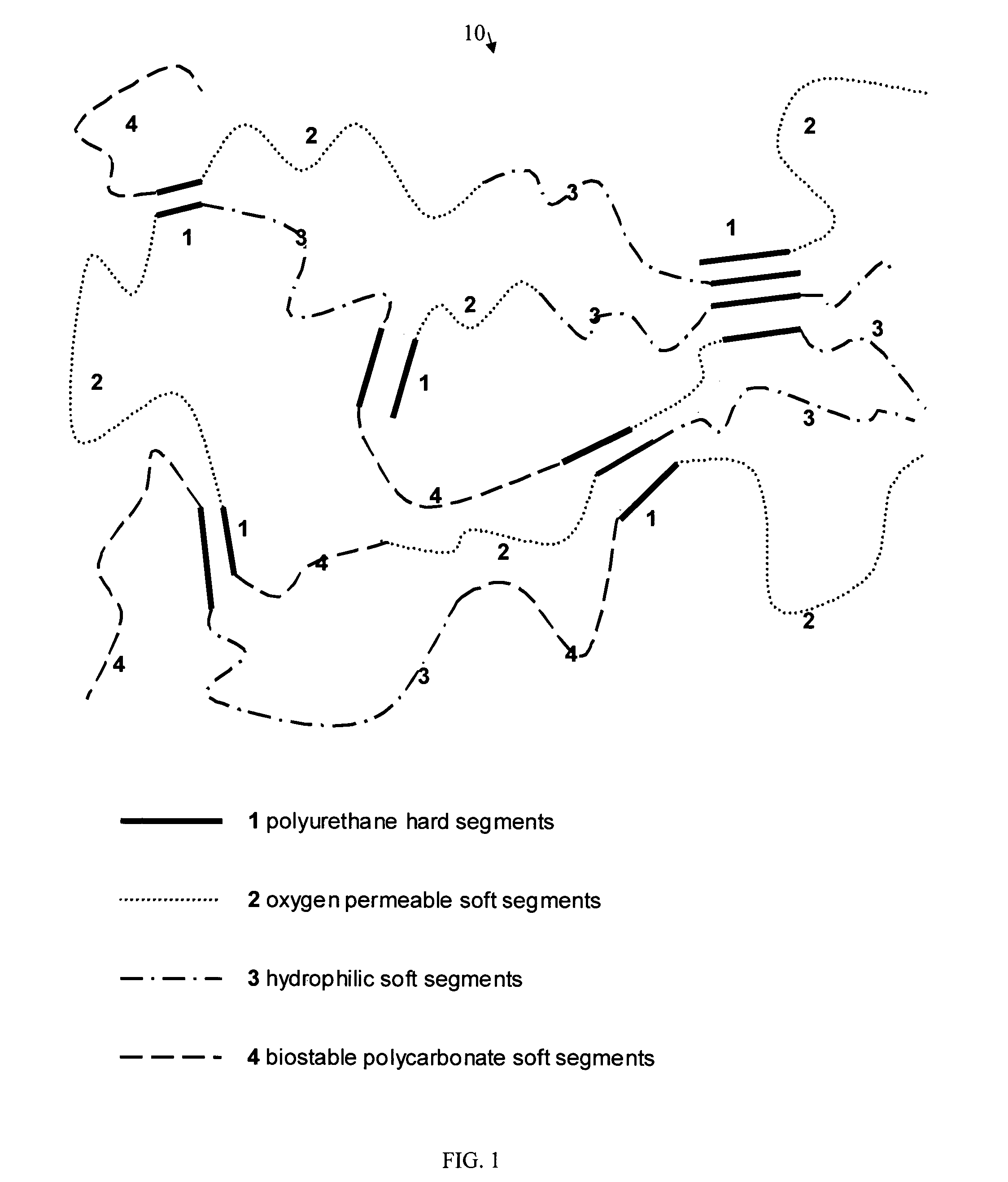

Permselective structurally robust membrane material

ActiveUS7157528B2Easy to understandWeaken energyImmobilised enzymesBioreactor/fermenter combinationsOxygenSoft segment

Owner:THE POLYMER TECH GROUP

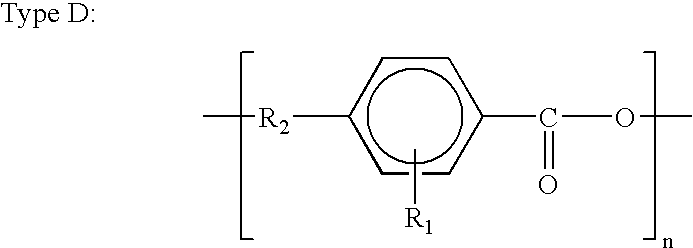

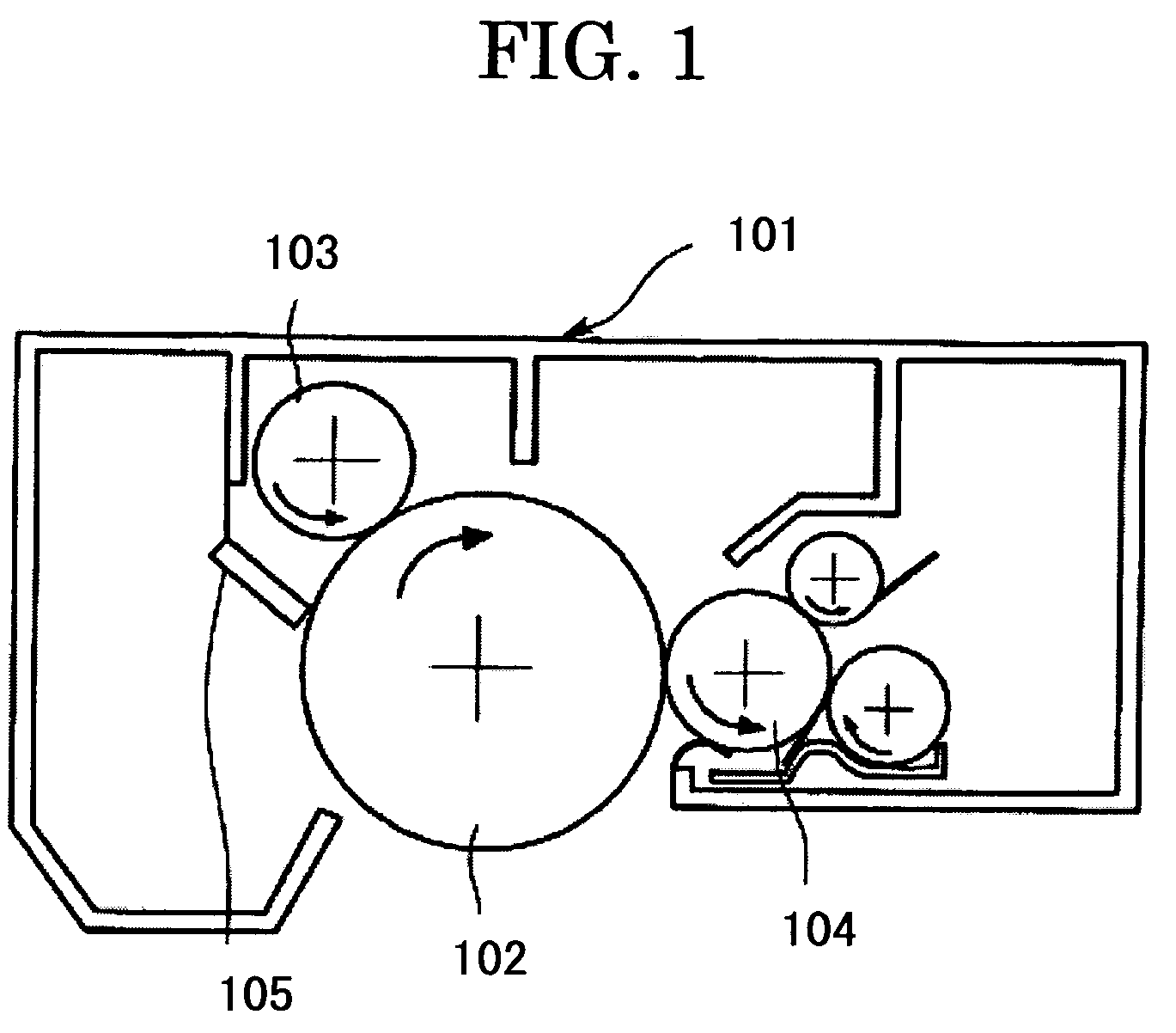

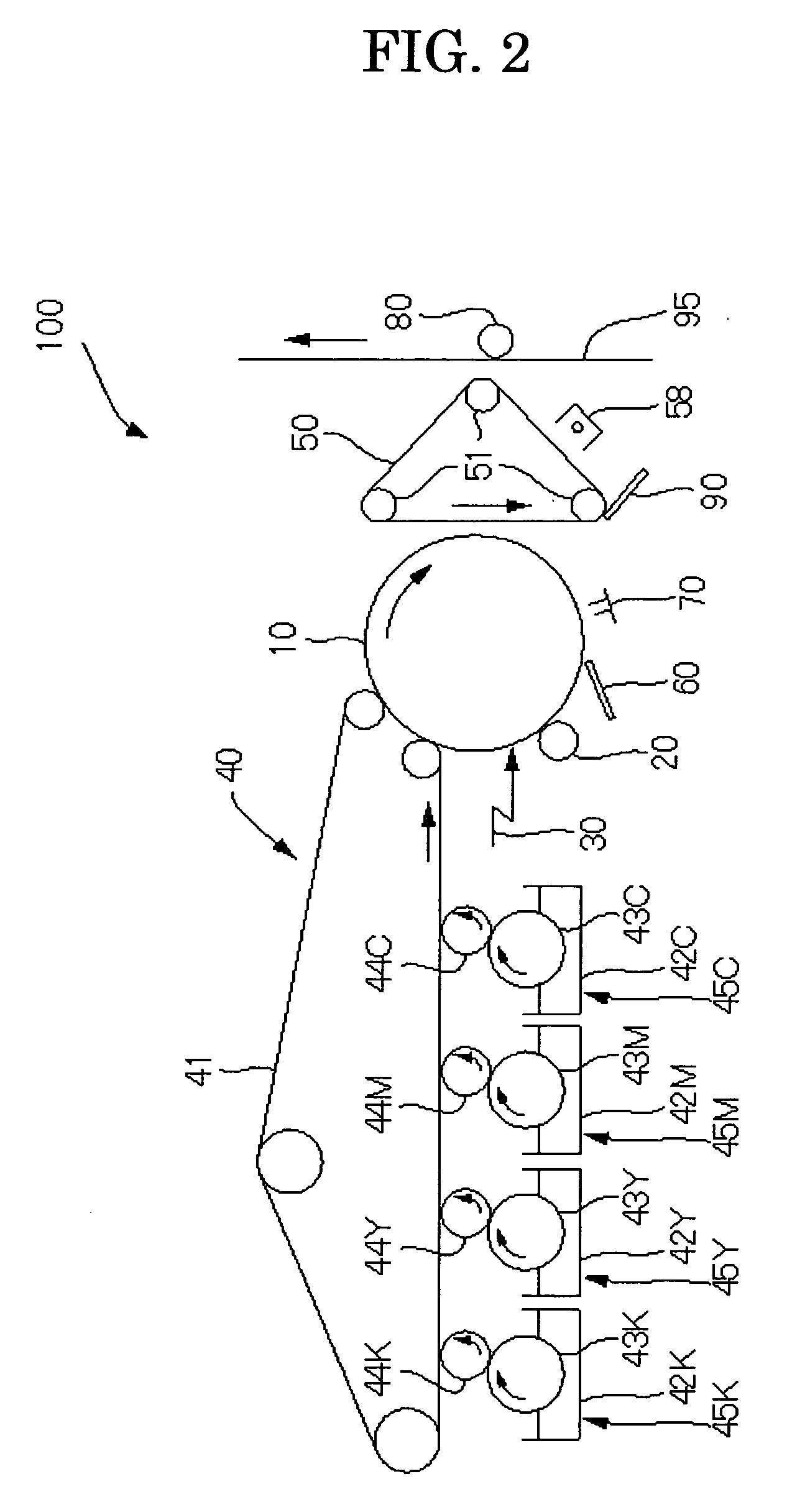

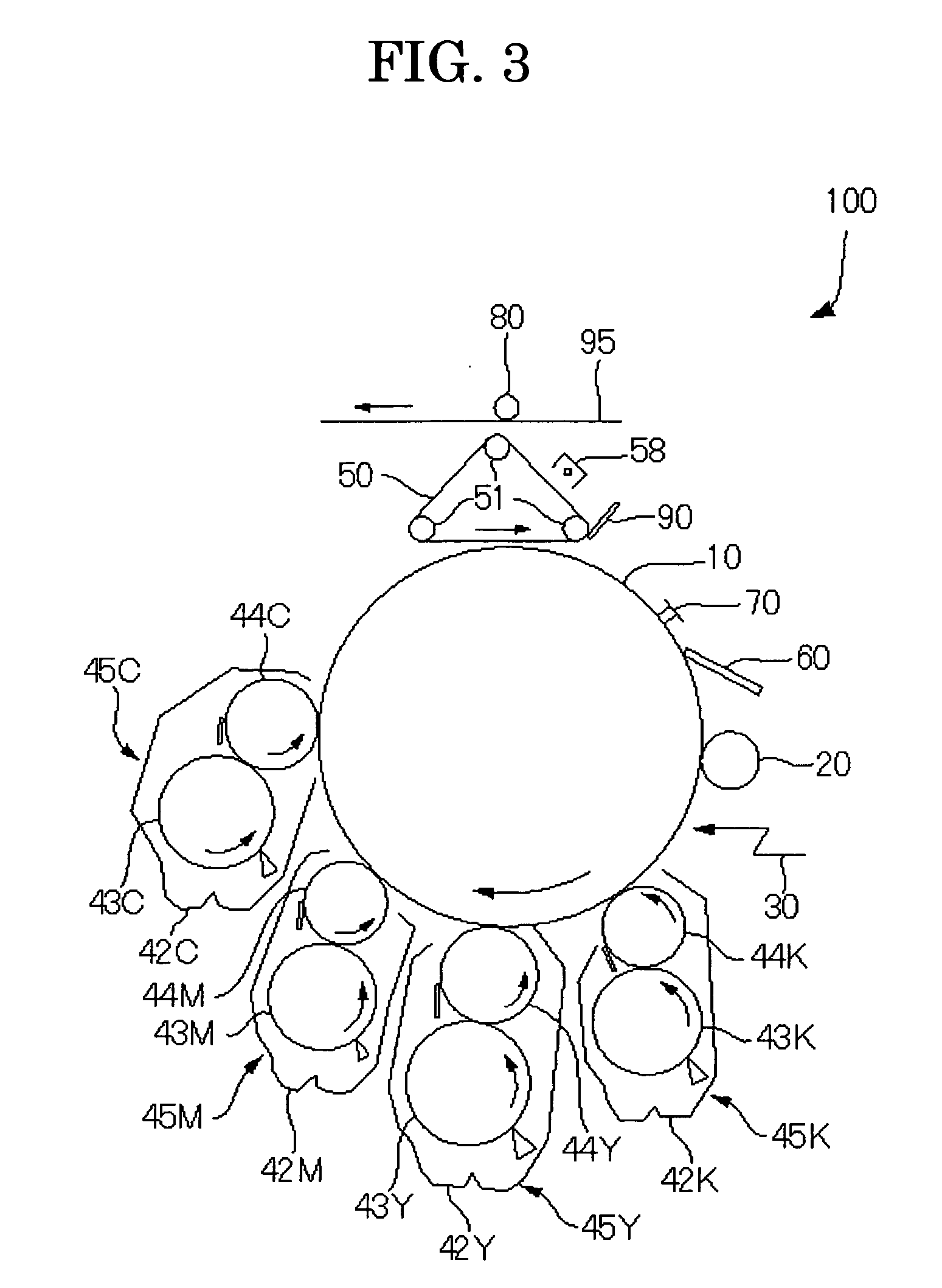

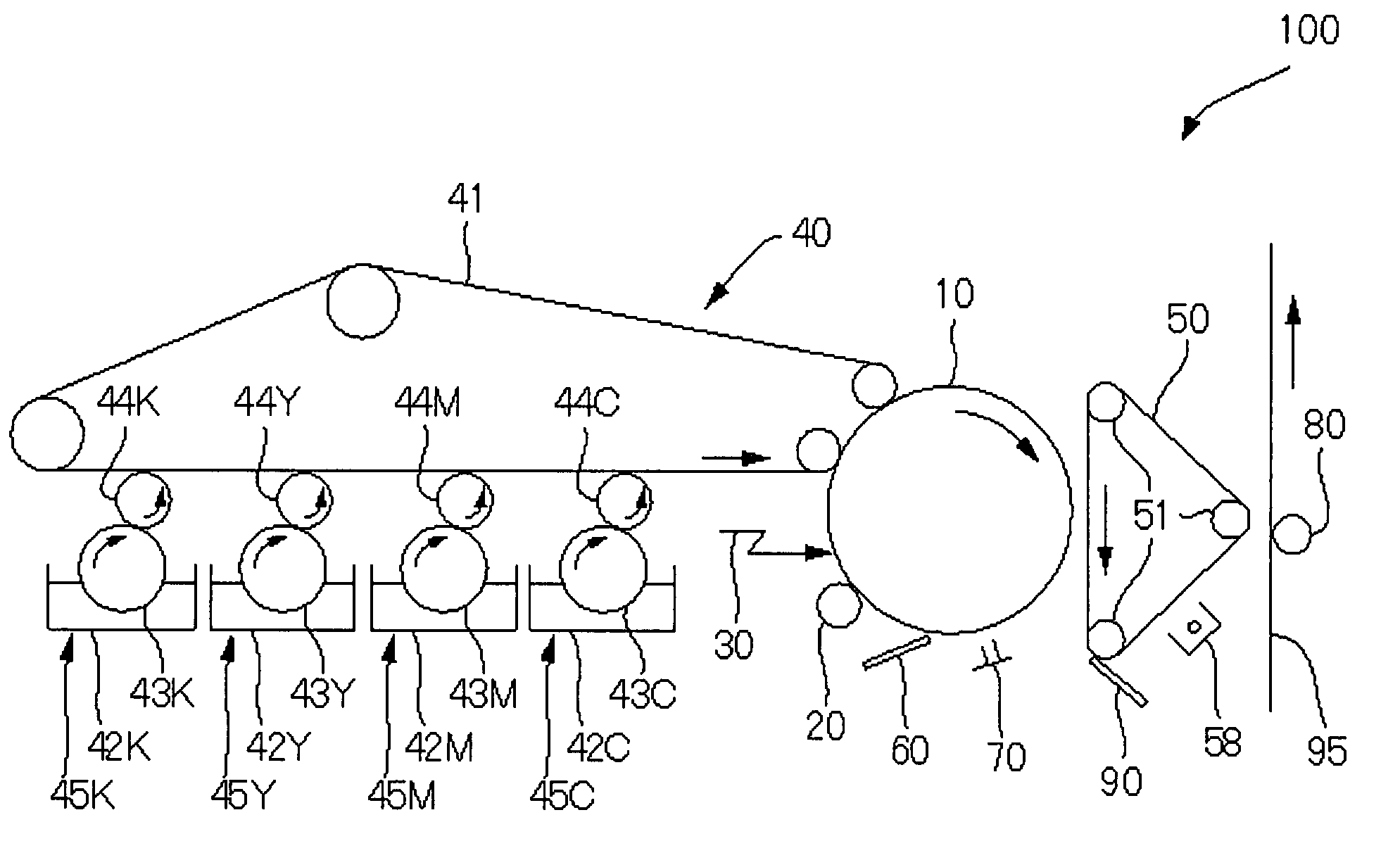

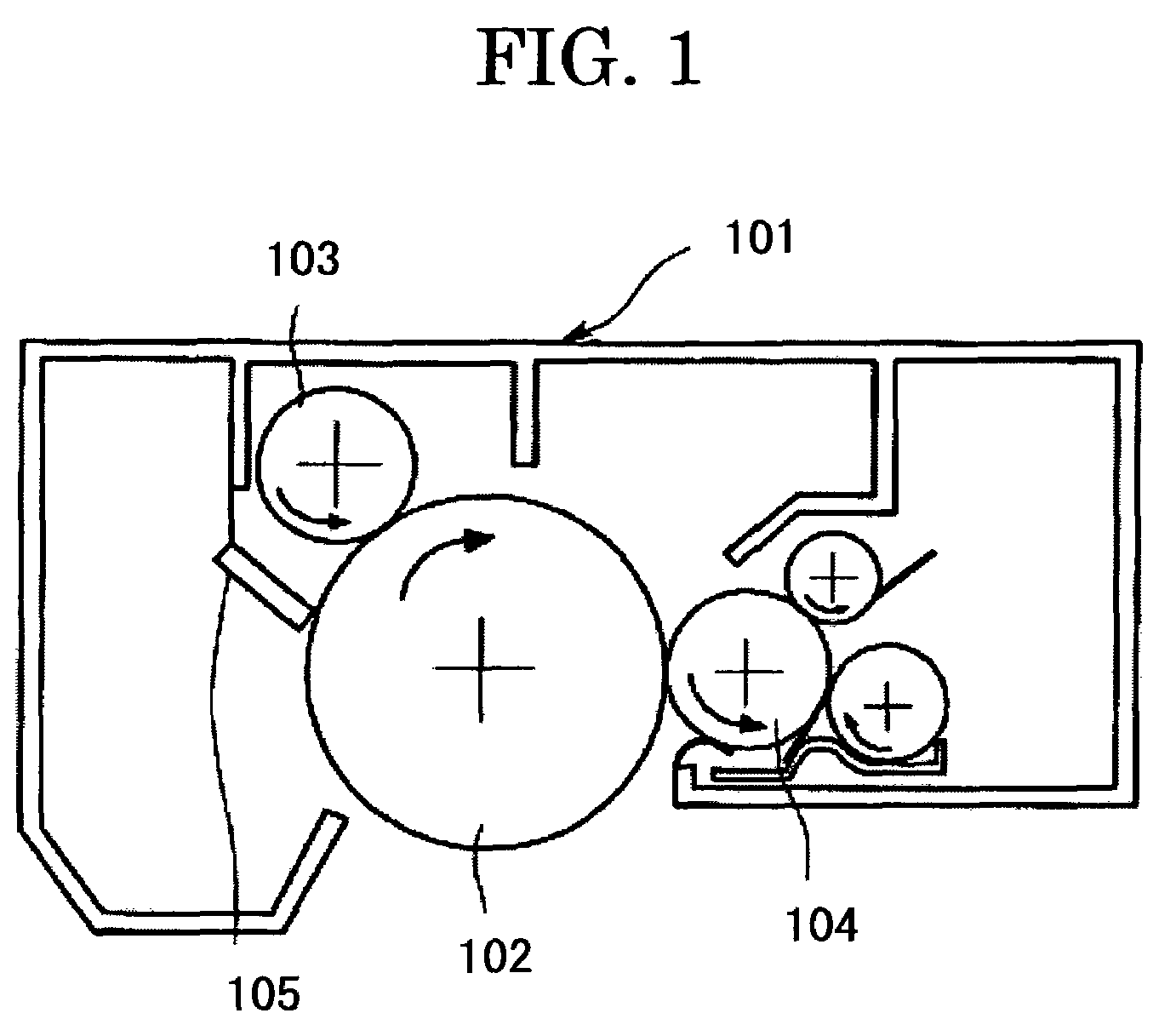

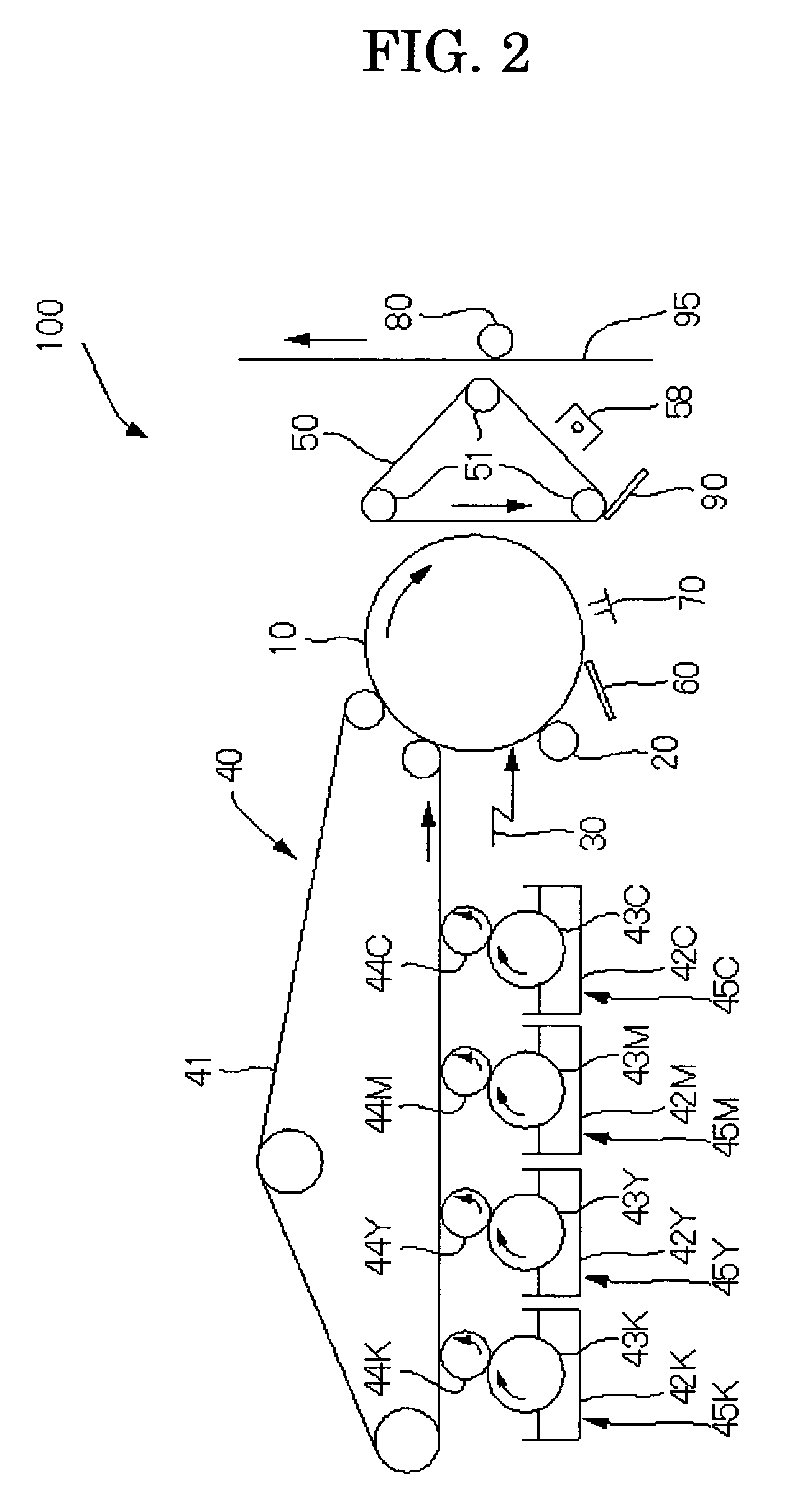

Toner, and, developer, toner container, process cartridge, image forming apparatus and image forming method

ActiveUS20060204883A1Good effectPreservability (especially heat resistanceElectrographic process apparatusDevelopersImage formationEngineering

Owner:RICOH KK

Toner, and, developer, toner container, process cartridge, image forming apparatus and image forming method

ActiveUS7374851B2Good effectPreservability (especially heat resistanceElectrographic process apparatusDevelopersEngineeringElectrical and Electronics engineering

Owner:RICOH KK

Tissue degeneration protection

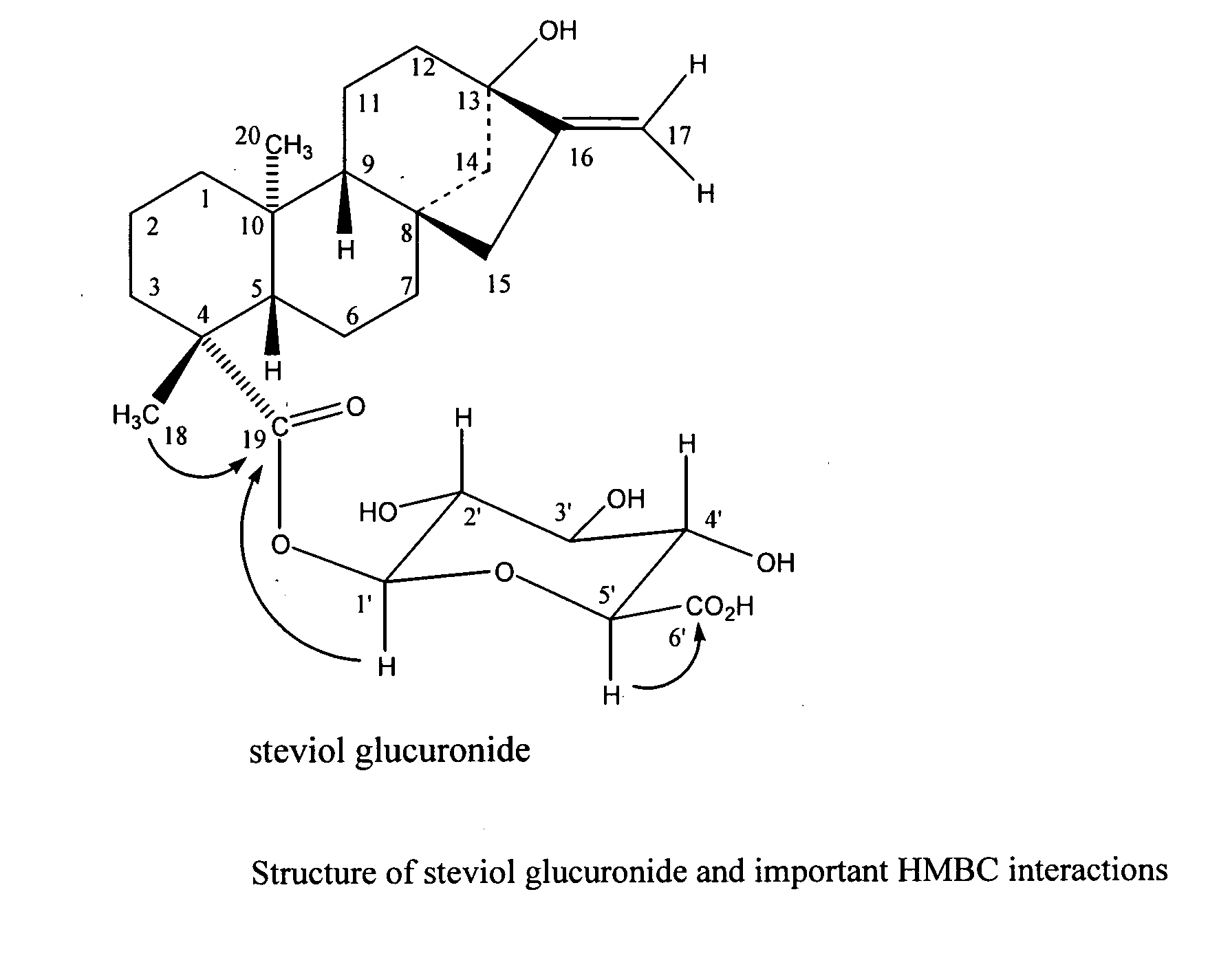

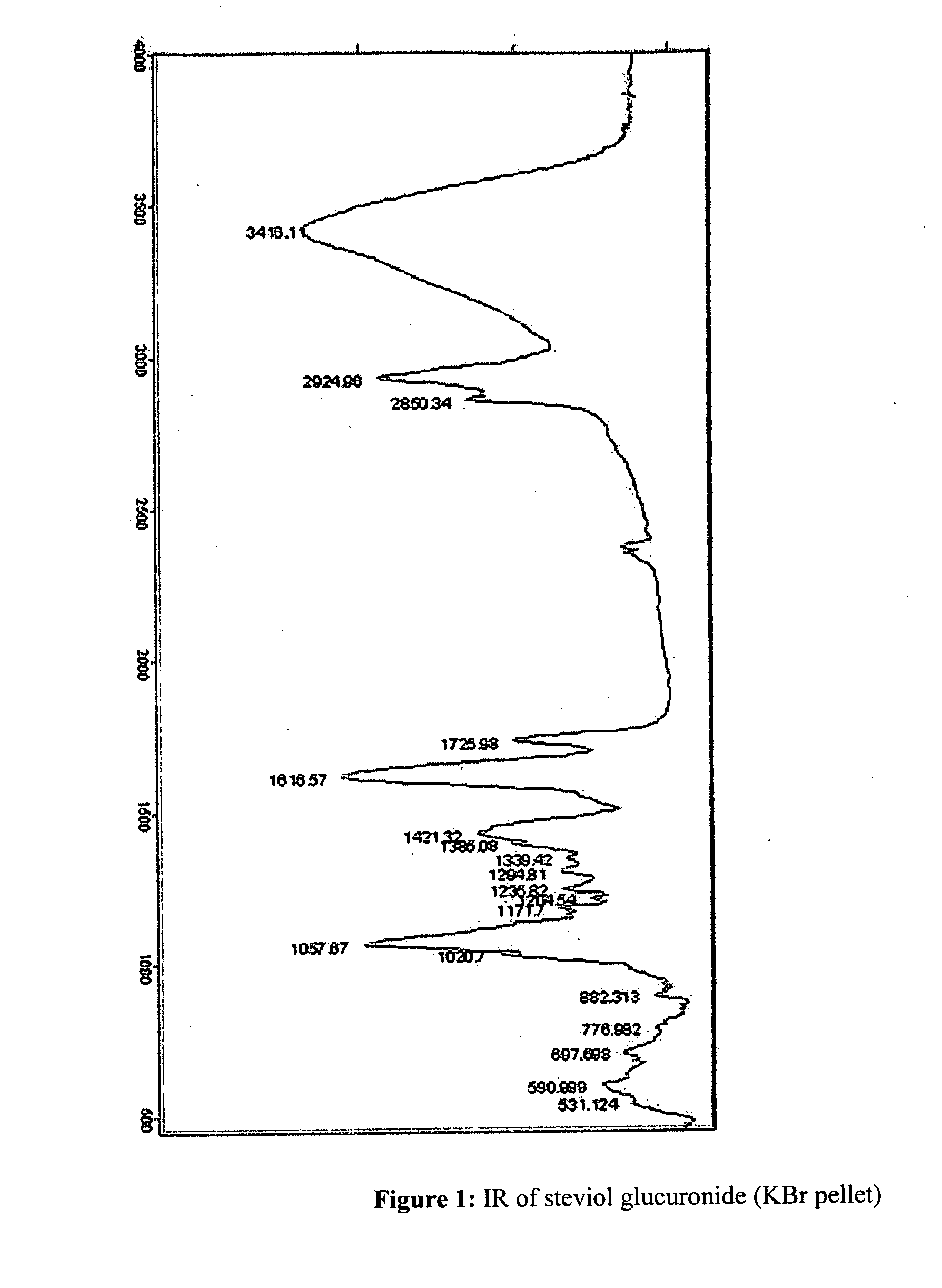

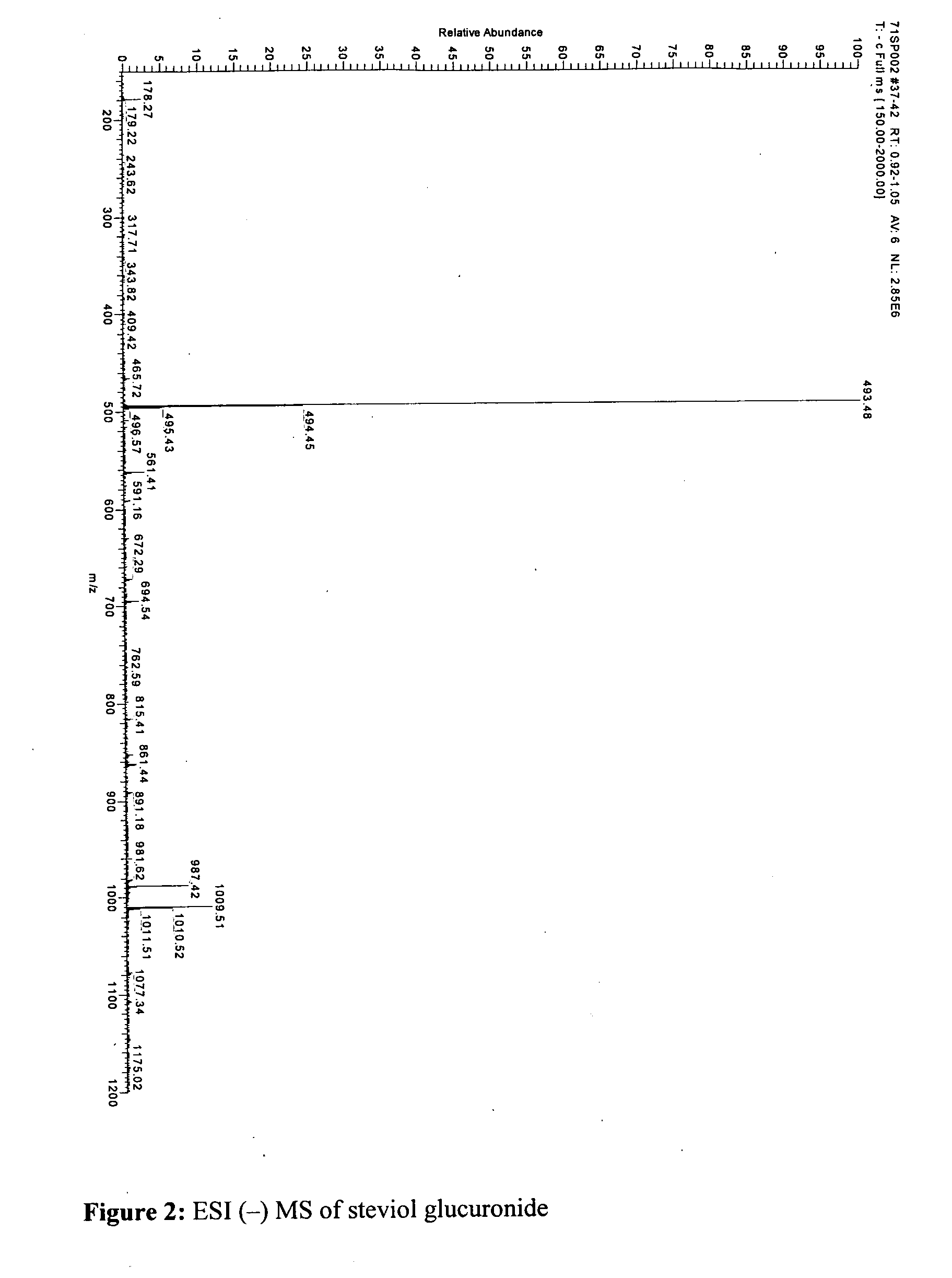

InactiveUS20100099640A1Improve solubilityHigh dissolution rateBiocideSugar derivativesPharmaceutical medicinePharmacology

The present invention provides isolated or essentially pure diterpenoic tetrahydropyran, such as steviol-19-glucuronide, steviol, stevioside and rebaudioside processes for obtaining the same and methods for obtaining stable pharmaceutically acceptable salts of the same for use of such compounds or compositions in a treatment of cardiovascular disorders or vascular disease or for the manufacture of medicaments to treat a condition of a cardiovascular disorder or vascular disease.

Owner:GEUNS JOANNES +1

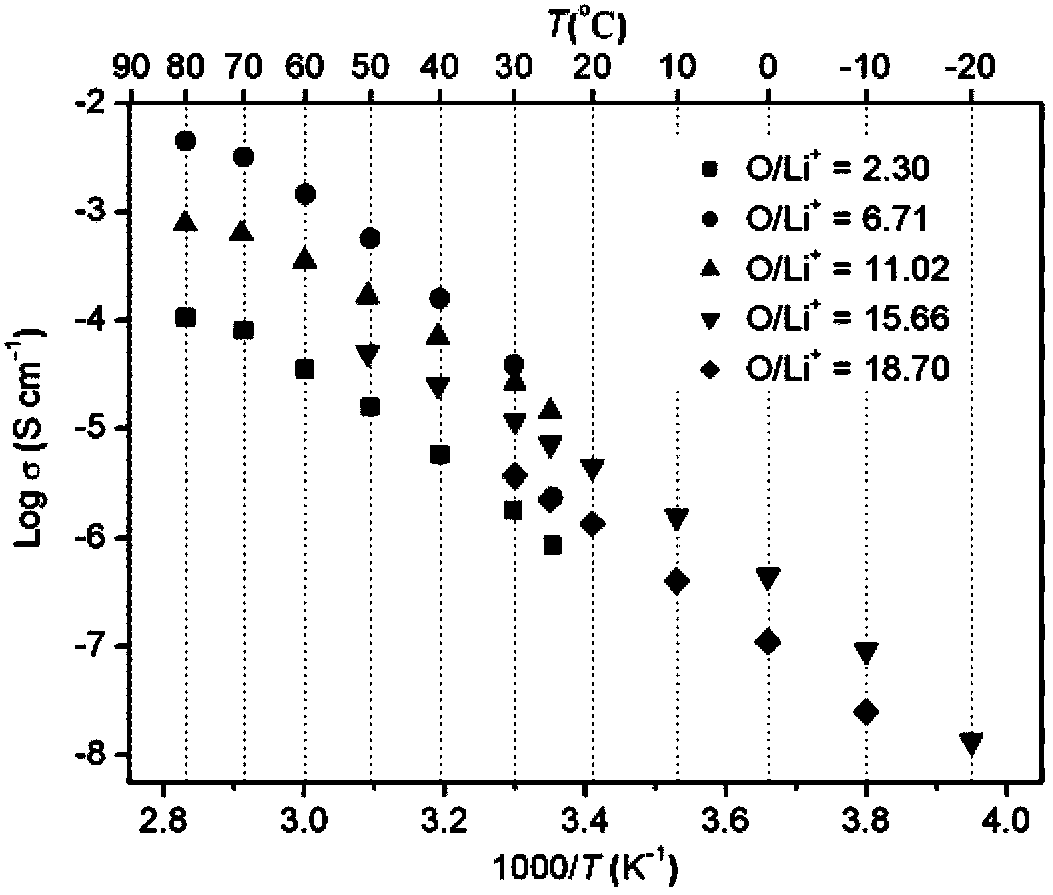

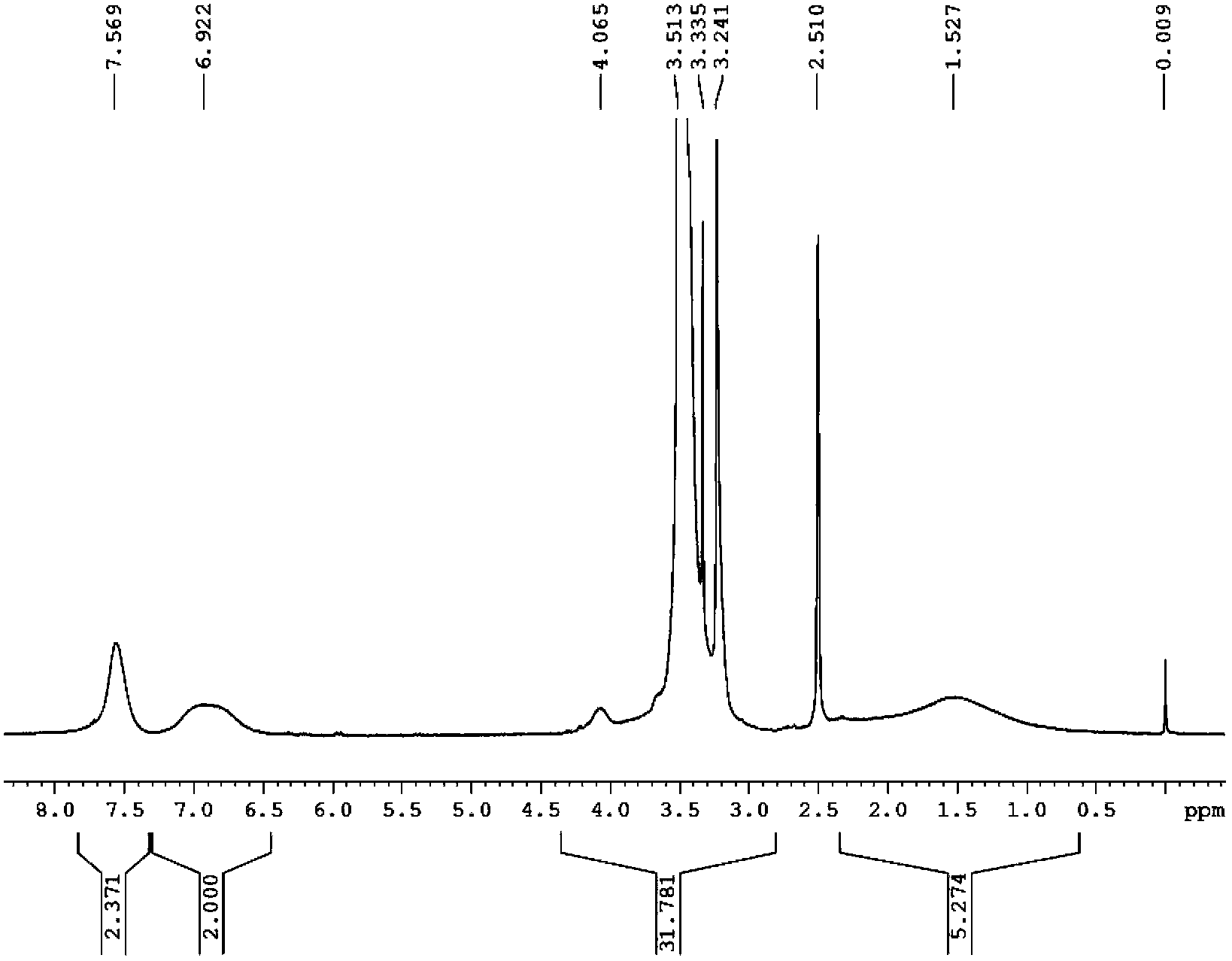

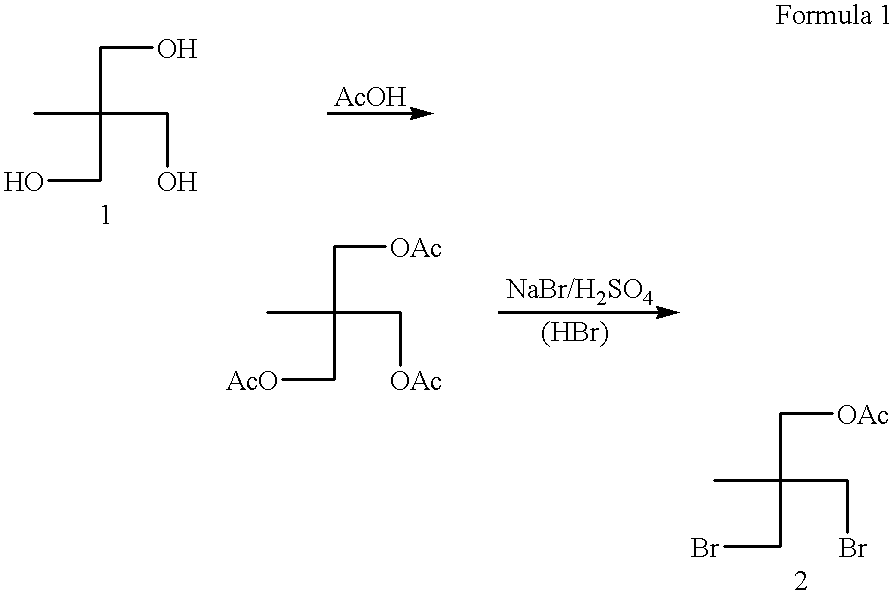

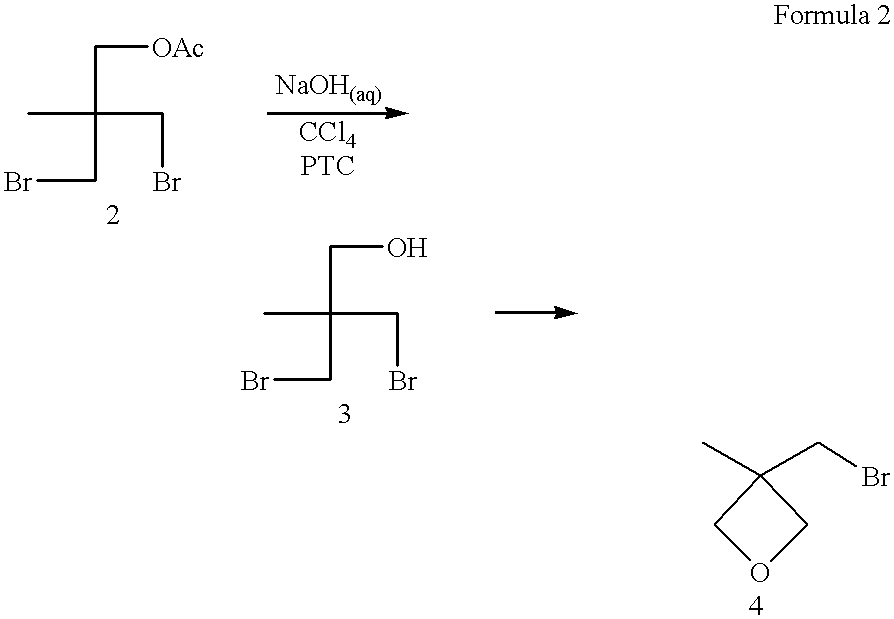

Polymer single-ion electrolyte and preparation method thereof

ActiveCN103509153AHigh conductivity at room temperatureReduce crystallinitySecondary cellsLithium imideCrystallinity

The invention discloses random copolymerization single-ion polymer electrolyte or block copolymerization single-ion polymer electrolyte which is obtained through copolymerization between a (p-vinyl phenylsulfonyl) (perfluoroalkyl sulfonyl) lithium imide monomer and a methoxyl polyethylene glycol acrylate monomer, and a preparation method of the electrolyte. The polymer single-ion electrolyte prepared by the method disclosed by the invention has the advantages of high room-temperature conductivity, high lithium ion transference number, low glass state temperature and degree of crystallinity, good mechanical strength and film-forming properties, wide electrochemical window, good thermal stability and the like, and has potential application values in the aspects of lithium (ion) batteries, carbon-based super-capacitors, solar batteries and the like.

Owner:武汉市瑞华新能源科技有限公司

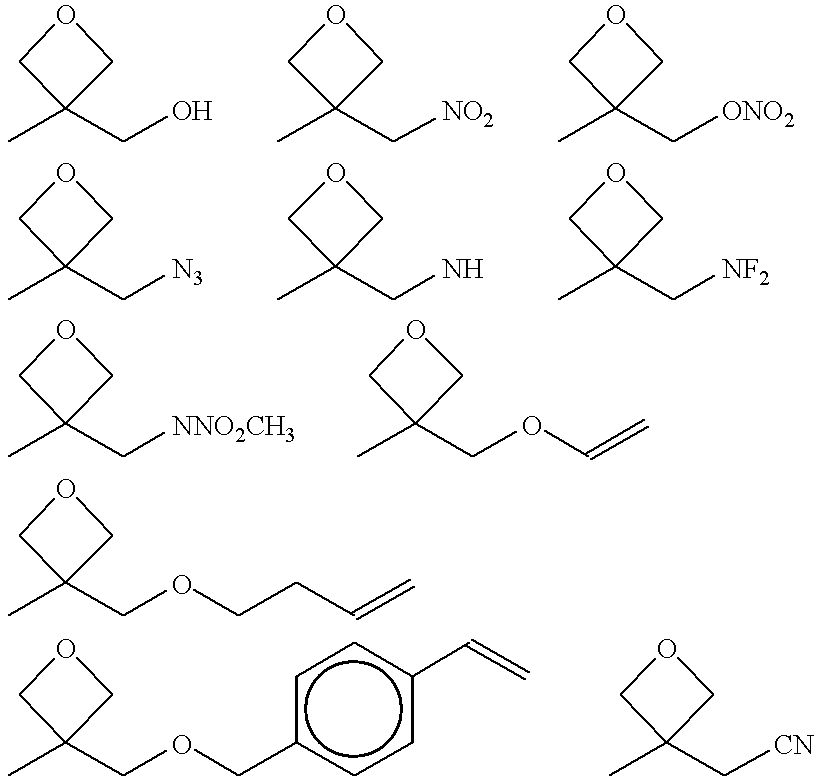

Copolymers and coprepolymers formed from mono-substituted fluorinated oxetane monomers and tetrahydrofuran

InactiveUS6380351B1Improve hydrophobicityLower surface energyOrganic chemistry methodsPolyurea/polyurethane coatingsSide chainButane

Owner:AEROJET GENERAL CORP +1

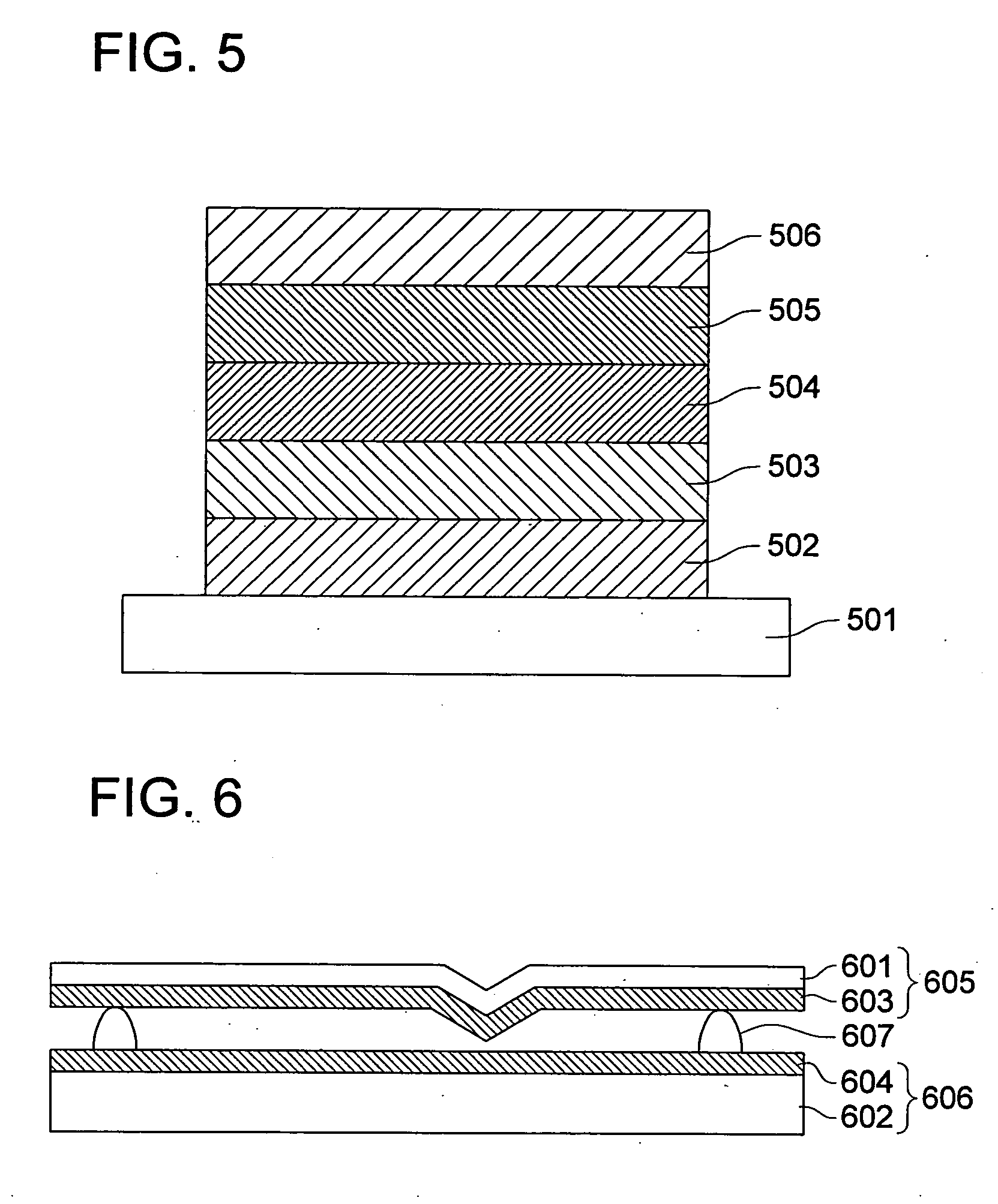

Transparent film for display substrate, display substrate using the film and method of manufacturing the same, liquid crystal display, organic electroluminescence display, and touch panel

ActiveUS20070009674A1High moisture absorbing expansion coefficientLower glass transition temperatureLiquid crystal compositionsThin material handlingCelluloseLiquid-crystal display

A transparent film for display substrate containing a cellulose ester, a plasticizer content in an amount of less than 1 percent, the aformentioned film being drawn 3 through 100 percent both in the direction of conveyance and across the width.

Owner:KONICA MINOLTA INC

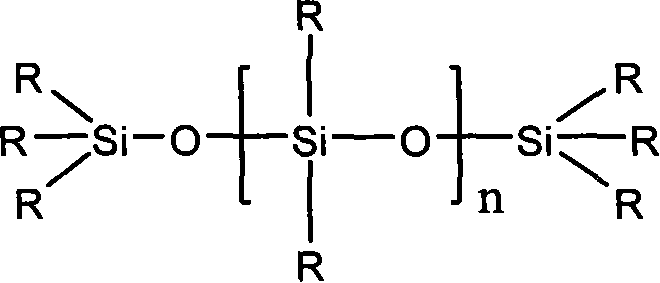

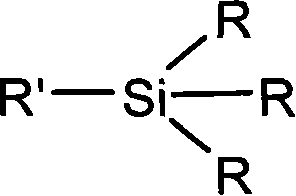

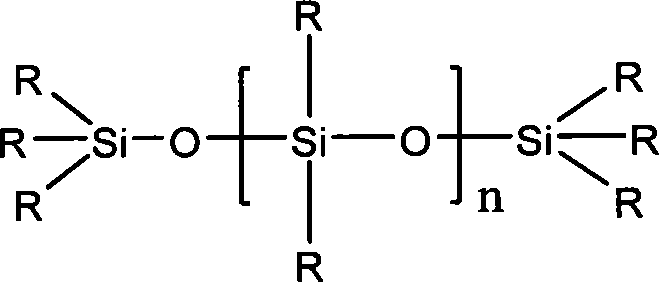

Hydrogenated block copolymer having alkoxysilyl group and use therefor

InactiveUS20130244367A1High glass transition temperatureImprove heat resistanceNon-fibrous pulp additionAluminium compoundsHigh humidityPolymer science

Provided are: an alkoysilyl group-containing hydrogenated block copolymer produced by introducing an alkoxysilyl group into a hydrogenated block copolymer that is obtained by hydrogenating 90% or more of unsaturated bonds of a block copolymer that includes at least two polymer blocks [A] and at least one polymer block [B], the polymer block [A] including a repeating unit derived from an aromatic vinyl compound as a main component, the polymer block [B] including a repeating unit derived from a linear conjugated diene compound as a main component, and a ratio (wA:wB) of a weight fraction wA of the polymer block [A] in the block copolymer to a weight fraction wB of the polymer block [B] in the block copolymer being 20:80 to 60:40; a method for producing the same; a solar cell element encapsulating material; a sheet, a laminated sheet; a multilayer sheet; and a method for encapsulating a solar cell element. The alkoxysilyl group-containing hydrogenated block copolymer exhibits low hygroscopicity, a low water vapor permeability, transparency, weatherability, and flexibility, maintains excellent adhesion to glass even when exposed to a high-temperature / high-humidity environment for a long time, and can encapsulate a solar cell element without applying a special waterproof treatment.

Owner:ZEON CORP

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

Ion conducting polymers and polymer blends for alkali metal ion batteries

ActiveUS20150288028A1Reduced flame retardancyLower glass transition temperatureSolid electrolytesFuel and secondary cellsPolyethylene oxideLithium–air battery

Electrolyte compositions for batteries such as lithium ion and lithium air batteries are described. In some embodiments the compositions are liquid compositions comprising (a) a homogeneous solvent system, said solvent system comprising a perfluropolyether (PFPE) and polyethylene oxide (PEO); and (b) an alkali metal salt dissolved in said solvent system. In other embodiments the compositions are solid electrolyte compositions comprising: (a) a solid polymer, said polymer comprising a crosslinked product of a crosslinkable perfluropolyether (PFPE) and a crosslinkable polyethylene oxide (PEO); and (b) an alkali metal ion salt dissolved in said polymer. Batteries containing such compositions as electrolytes are also described.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Insulating and environment-friendly PVC modified material and preparation method thereof

The invention relates to the technical field of PVC modified materials and particularly relates to an insulating and environment-friendly PVC modified material and a preparation method thereof. The insulating and environment-friendly PVC modified material contains the following raw materials: 80-120 parts of PVC resin, 40-60 parts of bulking agent, 40-60 parts of plasticizer, 10-15 parts of insulation modifier, 3-7 parts of heat stabilizer and 0.5-1.5 parts of lubricant, wherein the plasticizer is a mixture prepared from dioctyl terephthalate and tri-n-butyl citrate which are in the weight ratio of (5-7): 1; the insulation modifier is a mixture prepared from kaolin, titanium white and glass micro-beads which are in the weight ratio of (2-4): (1.5-2.5): 1, and the particle size of the glass micro-beads is smaller than 20 microns. According to the modified material prepared by the preparation method, all properties exceed the national standards, the insulating property is good, the resistivity reaches up to 5.1*10<14> omega, and the modified material is environment-friendly; the preparation method disclosed by the invention is simple in process, convenient in operation and control, stable in quality and high in production efficiency and can be applied to large-scale industrial production.

Owner:广东祺龙科技有限公司

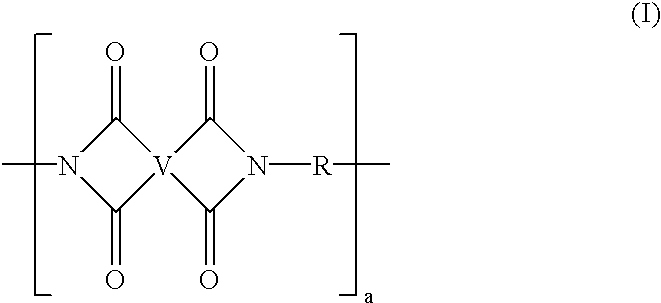

Functionalized high cis-1,4-polybutadiene prepared using novel functionalizing agents

InactiveUS7642322B2Lower glass transition temperatureReduce hysteresis lossInksLanthanideSilicon dioxide

A functionalized polymer prepared by a process comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with a functionalizing agent defined by the formula (I)A-R1-Z (I)where R1 is a divalent bond or divalent organic group comprising from 0 to about 20 carbon atoms, A is a substituent that will undergo an addition reaction with a pseudo-living polymer, and Z is a substituent that will react or interact with silica or carbon black reinforcing fillers, with the proviso that A, R1, and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

Method to prepare processable polyimides with reactive endgroups using 1,3-bis (3-aminophenoxy) benzene

InactiveUS6133401AImprove adhesionImprove composite effectSynthetic resin layered productsThin material handlingSolubilityAdhesive

Polyimide copolymers were obtained containing 1,3-bis(3-aminophenoxy)benzene (APB) and other diamines and dianhydrides and terminating with the appropriate amount of reactive endcapper. The reactive endcappers studied include but should not be limited to 4-phenylethynyl phthalic anhydride (PEPA), 3-aminophenoxy-4'-phenylethynylbenzophenone (3-APEB), maleic anhydride (MA) and nadic anhydride (5-norbornene-2,3-dicarboxylic anhydride, NA). Homopolymers containing only other diamines and dianhydrides which are not processable under conditions described previously can be made processable by incorporating various amounts of APB, depending on the chemical structures of the diamines and dianhydrides used. By simply changing the ratio of APB to the other diamine in the polyimide backbone, a material with a unique combination of solubility, Tg, Tm, melt viscosity, toughness and elevated temperature mechanical properties can be prepared. The copolymers that result from using APB to enhance processability have a unique combination of properties that include low pressure processing (200 psi and below), long term melt stability (several hours at 300 DEG C. for the phenylethynyl terminated polymers), high toughness, improved solvent resistance, improved adhesive properties, and improved composite mechanical properties. These copolyimides are eminently suitable as adhesives, composite matrices, moldings, films and coatings.

Owner:NAT AERONAUTICS & SPACE ADMINSTRATION NASA THE

Preparation method of high-reaction-activity hydroxyl acrylic resin

InactiveCN103130944AImprove molecular structureHigh glass transition temperaturePolyurea/polyurethane coatingsAcrylic resinSolvent

The invention relates to a preparation method of high-reaction-activity hydroxyl acrylic resin. According to the invention, a solvent in a reactor is heated to a preset temperature under the protection of an inert gas; a mixture of a monomer component A with hard monomer as a main component (and comprising a small amount of soft monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; a reaction is carried out for a certain period of time with maintained temperature; a mixture of a monomer component B with soft monomer as a main component (and comprising a small amount of hard monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; and reaction is carried out for a certain period of time with maintained temperature, such that acrylic resin comprising hydroxyl is obtained. The invention has the characteristic that common monomers are adopted, and only the synthesis process is changed wherein monomer dropping sequence is changed, such that resin molecular structure is substantially changed, and the synthesized hydroxyl acrylic resin shows high reaction activity during a curing reaction. The method provided by the invention also has the advantages of low cost, simple process, and suitability for industrialized productions.

Owner:XI AN JIAOTONG UNIV +1

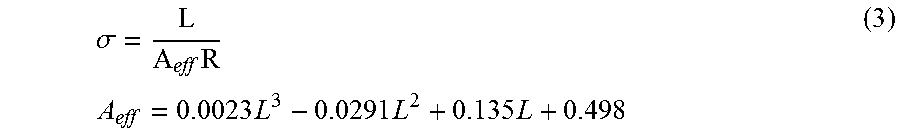

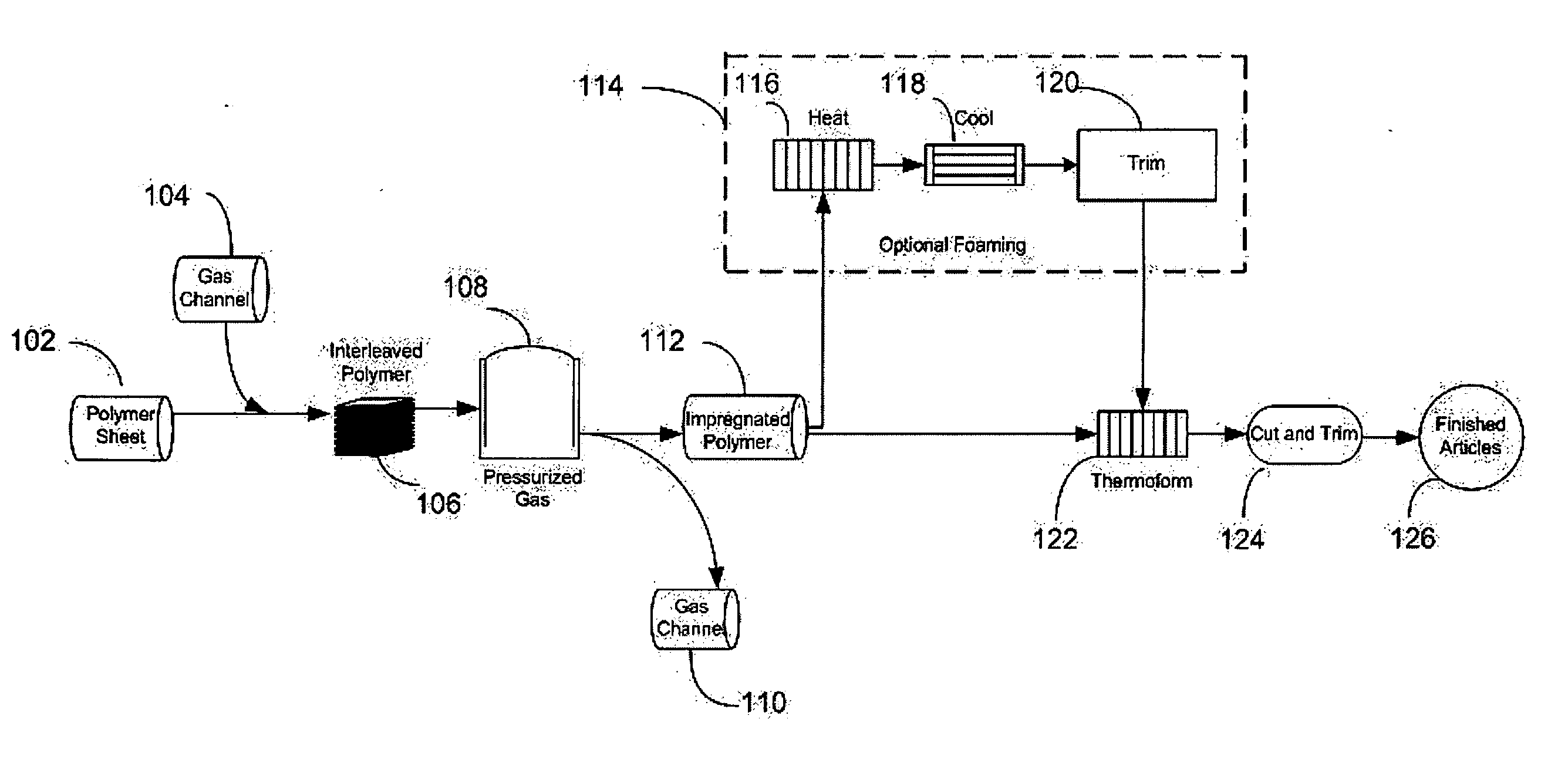

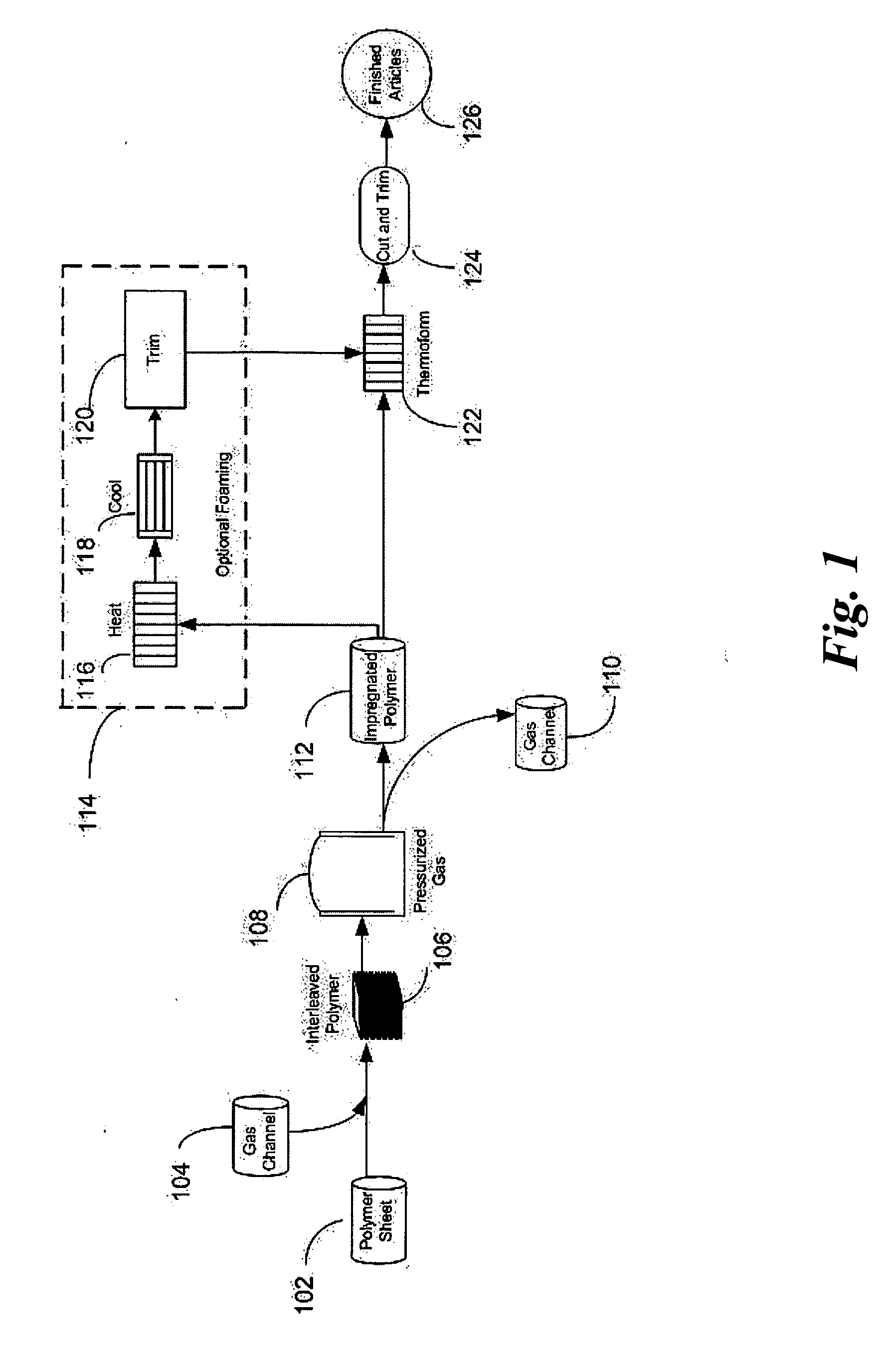

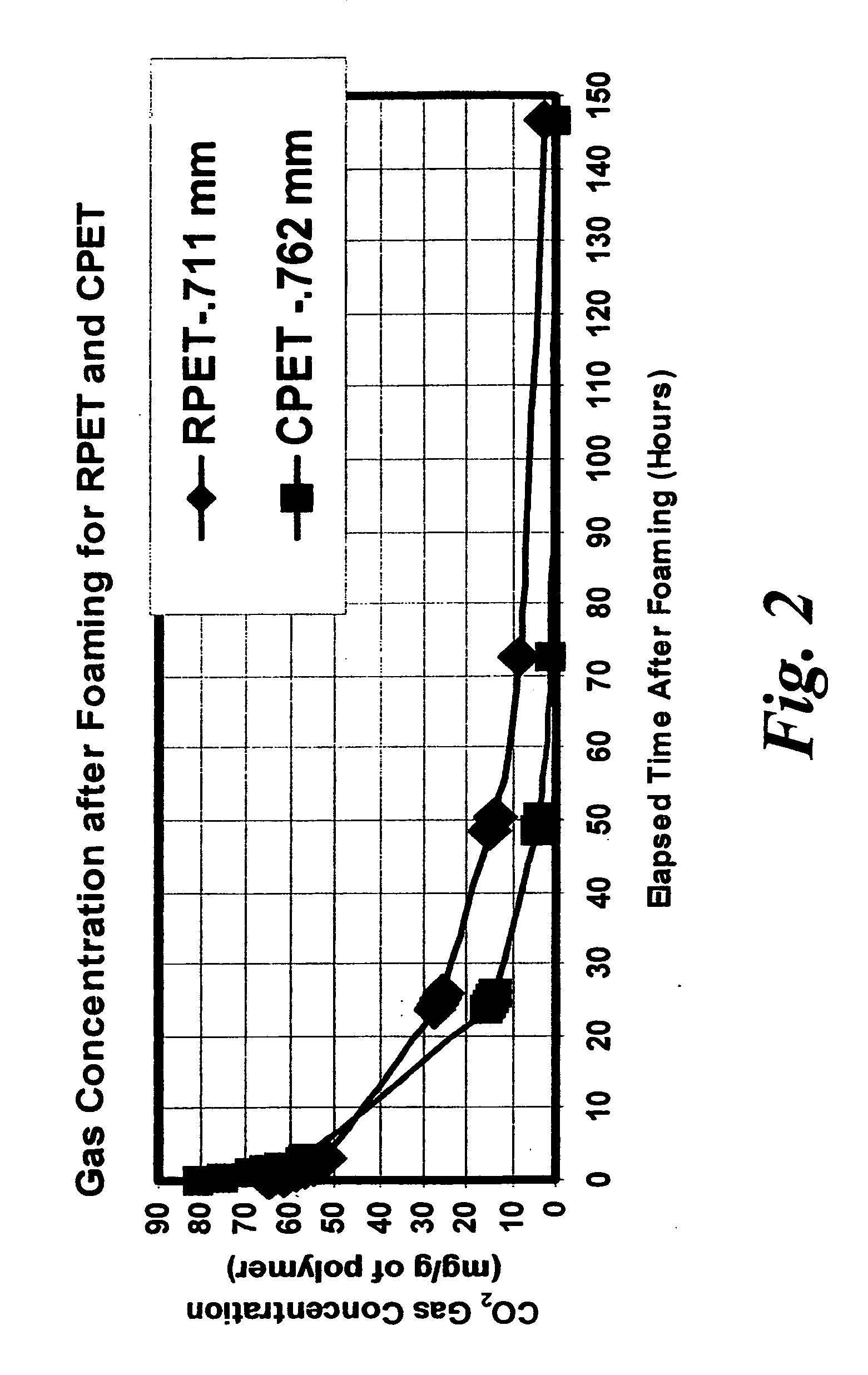

Method of producing thermoformed articles from gas impregnated polymer

InactiveUS20050203198A1Improve performanceLower glass transition temperatureBoxesLidsVitrificationPolymer science

A solid state process utilizes gas impregnation to enhance thermoforming of thermoplastic material. If the gas is plasticizing, the article is thereby plasticized for thermoforming. In some embodiments, the invention provides foaming the polymer prior to or during thermoforming by creating high levels of dissolved gas during gas exposure. Foaming may proceed spontaneously upon decompression from gas pressure, or foaming may be enhanced by heating the polymer sheet near to or above the polymer's glass transition temperature, thereby producing plasticized foamed polymer for thermoforming. When objects of unfoamed polymer are desired, foaming may be suppressed by thermoforming gas saturated articles under gas pressure. This process may be used to enhance the thermoforming performance of articles that have been previously foamed, including articles foamed by prior art processes. In some embodiments, polymer is sufficiently plasticized so that it may be thermoformed without heating. Plasticization of the polymer is reversible.

Owner:DART CONTAINER

Composite solid electrolyte and preparation method thereof

InactiveCN109786816AReduce interface contact resistanceImprove lithium ion conductivityLi-accumulatorsGap fillingPorosity

The present invention discloses a composite solid electrolyte and a preparation method thereof. The composite solid electrolyte comprises an inorganic solid electrolyte and a polymer electrolyte. Theinorganic solid electrolyte is of a porous structure; the porosity of the inorganic solid electrolyte is less than 30%; and the inside of the inorganic solid electrolyte is provided with a continuouslithium ion channel composed of particles communicating with each other. The polymer electrolyte is arranged between the inorganic solid electrolytes for filling gaps, and account for less than 30% ofthe composite solid electrolyte. The porous inorganic solid electrolyte of the invention constitutes a main frame structure, which has a porosity below 30% and is the main bearer of lithium ion transportation. The polymer electrolyte is a gap filling material, which is mainly used for improving the overall flexibility of the composite solid electrolyte and reducing the impedance of the solid-solid contact interface between the positive electrode plate and negative electrode plate.

Owner:杭州阳名新能源设备科技有限公司

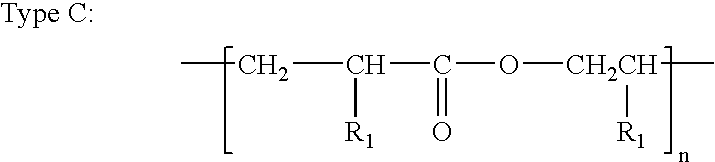

Acrylic film and moldings made using the same

InactiveUS6147162ALower glass transition temperatureReduced impact strengthSynthetic resin layered productsPolymer scienceAcrylic resin

PCT No. PCT / JP97 / 00382 Sec. 371 Date Aug. 12, 1998 Sec. 102(e) Date Aug. 12, 1998 PCT Filed Feb. 13, 1997 PCT Pub. No. WO97 / 30117 PCT Pub. Date Aug. 21, 1997An acrylic film or sheet made from a resin composition comprising 95 to 50 wt. % of an acrylic resin which comprises methyl methacrylate as a main component and has a glass transition temperature in the range of 40 to 105 DEG C., and 5 to 50 wt. % of a multilayer-structured acrylic polymer containing an elastomeric layer, wherein the polymer is dispersed in the acrylic resin, a molded article comprising a thermoplastic resin molded material and the above film or sheet which is adhered and unified with the surface of the molded material, and a method for the production of the above molded article are provided. This film or sheet is an excellent film for use in a simultaneous injection molding and lamination method.

Owner:SUMITOMO CHEM CO LTD

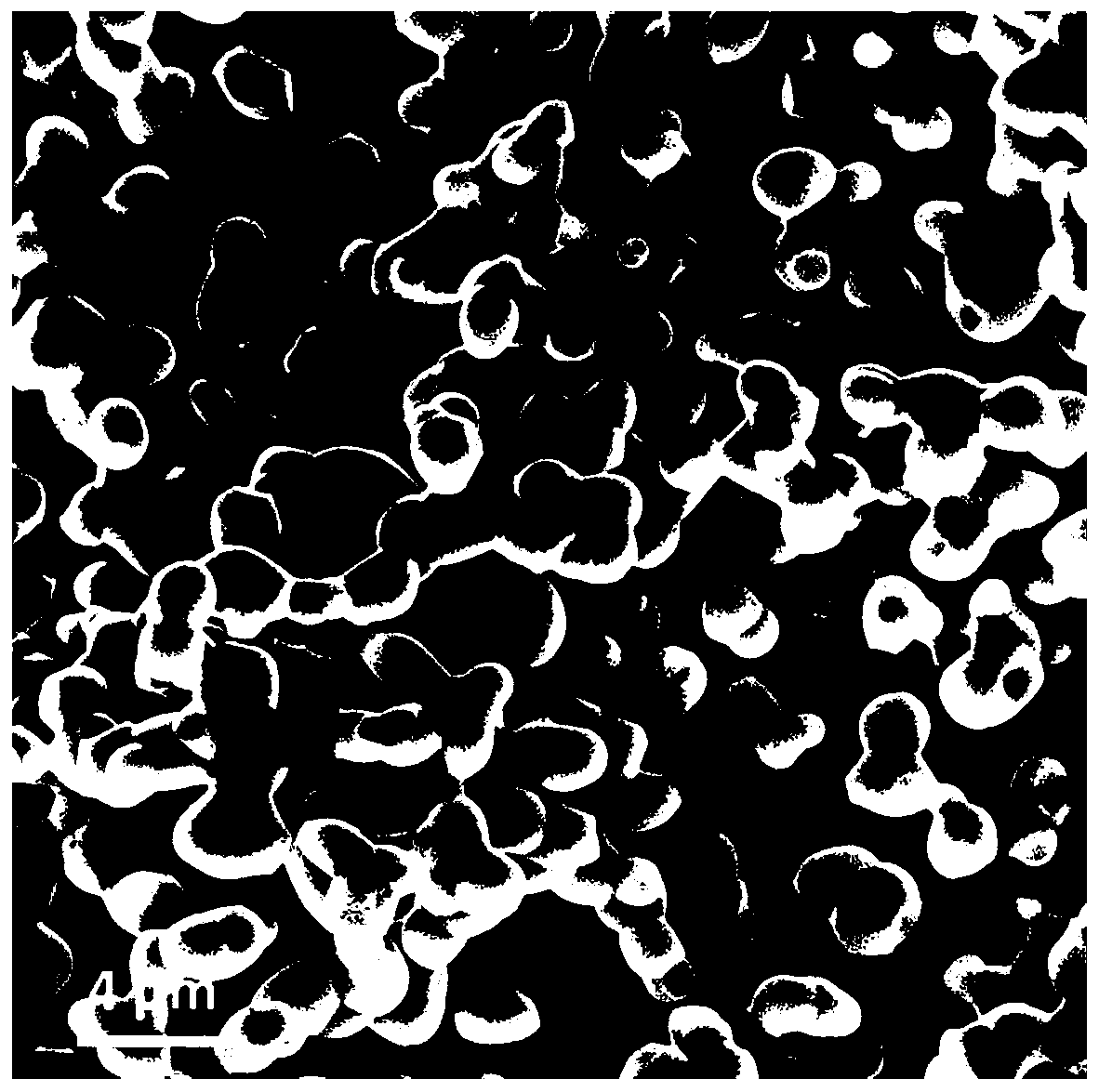

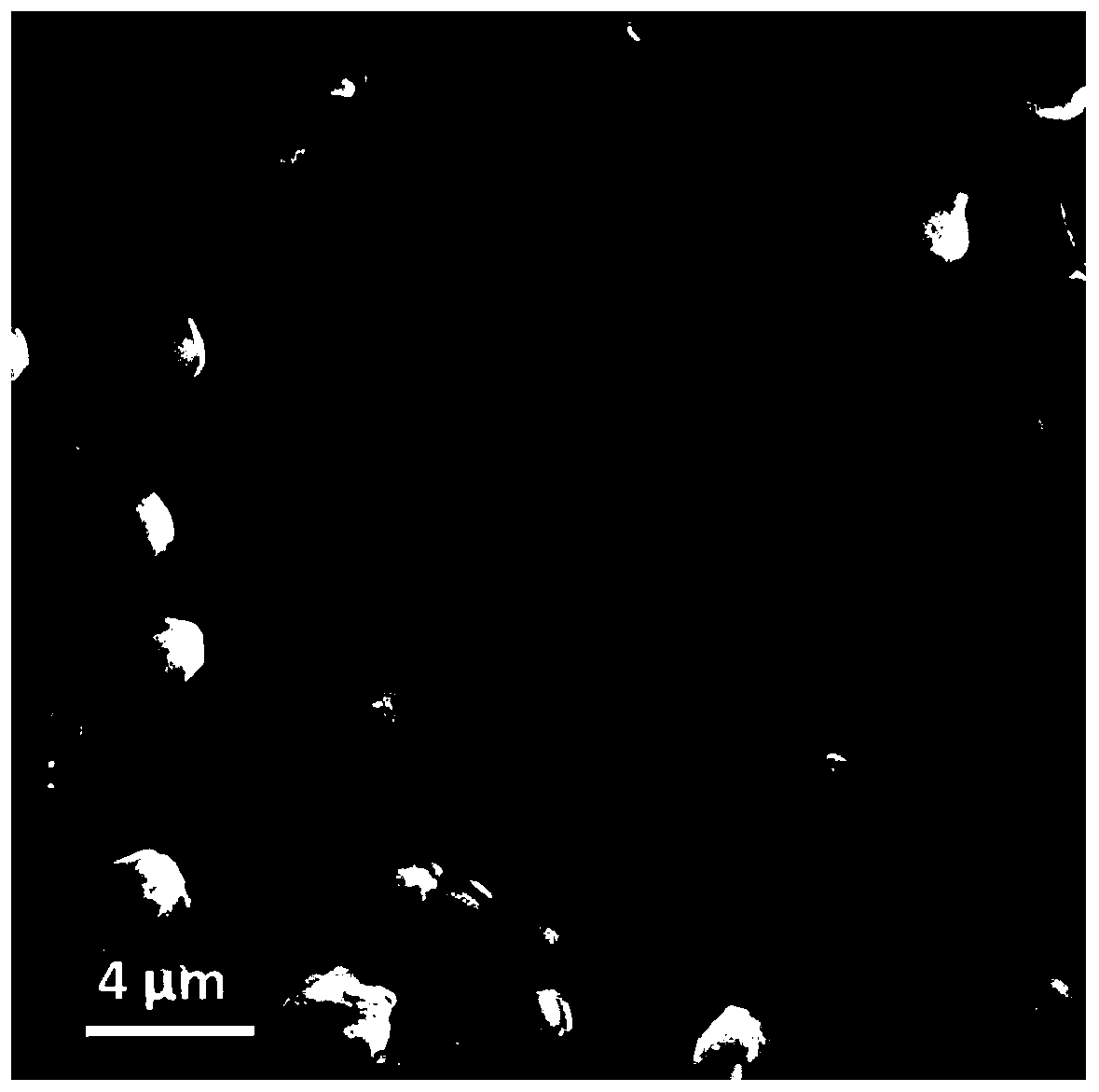

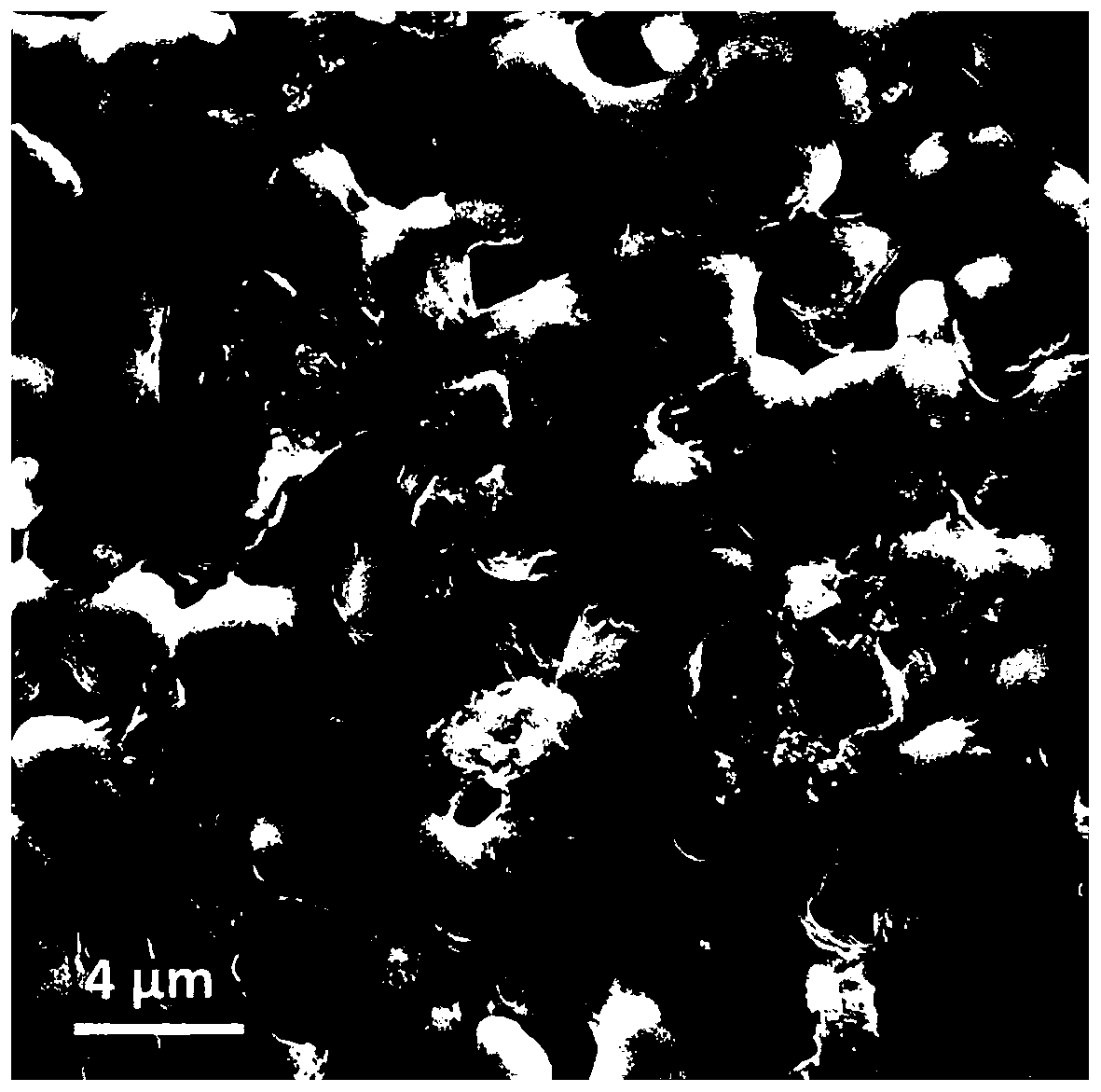

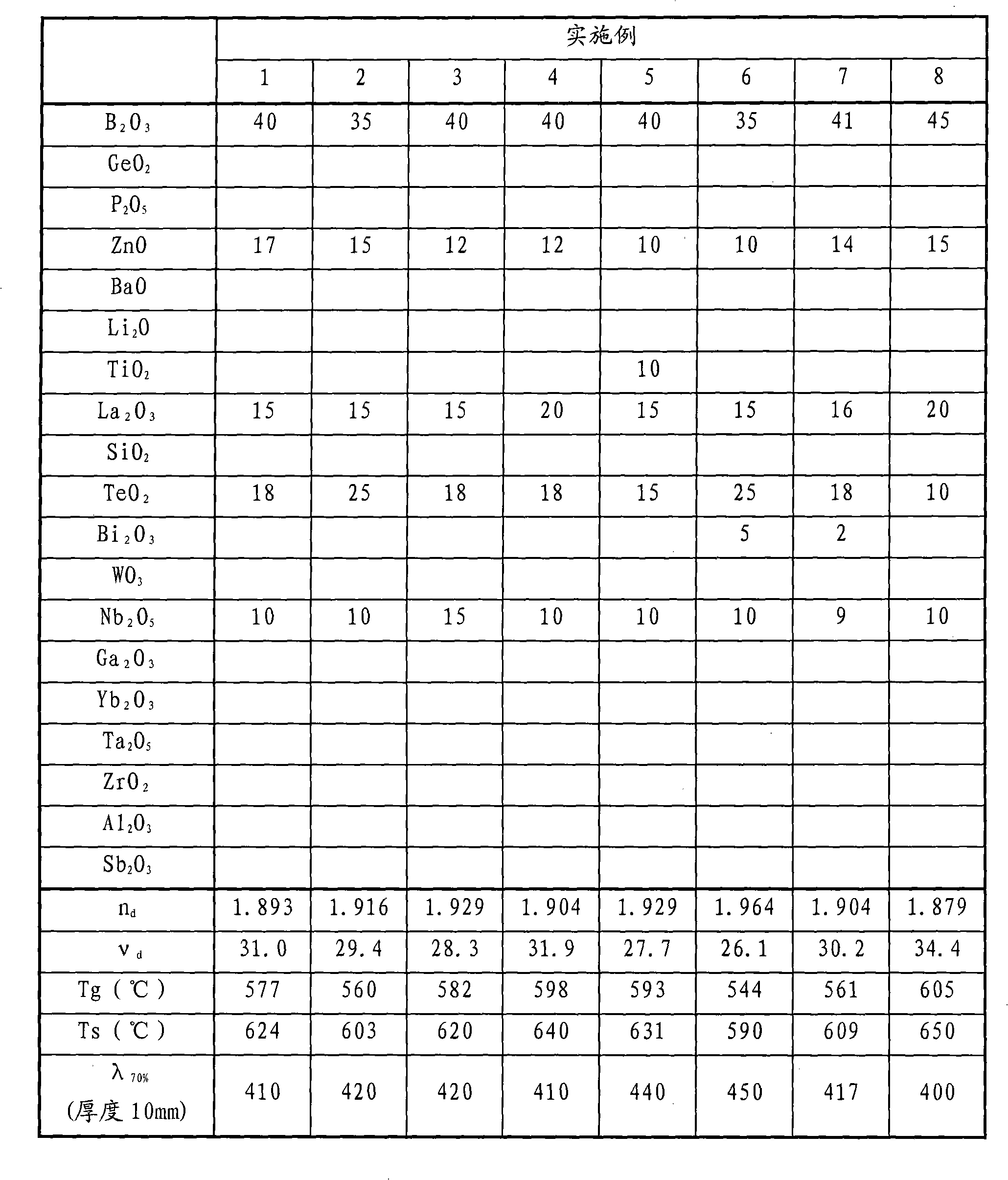

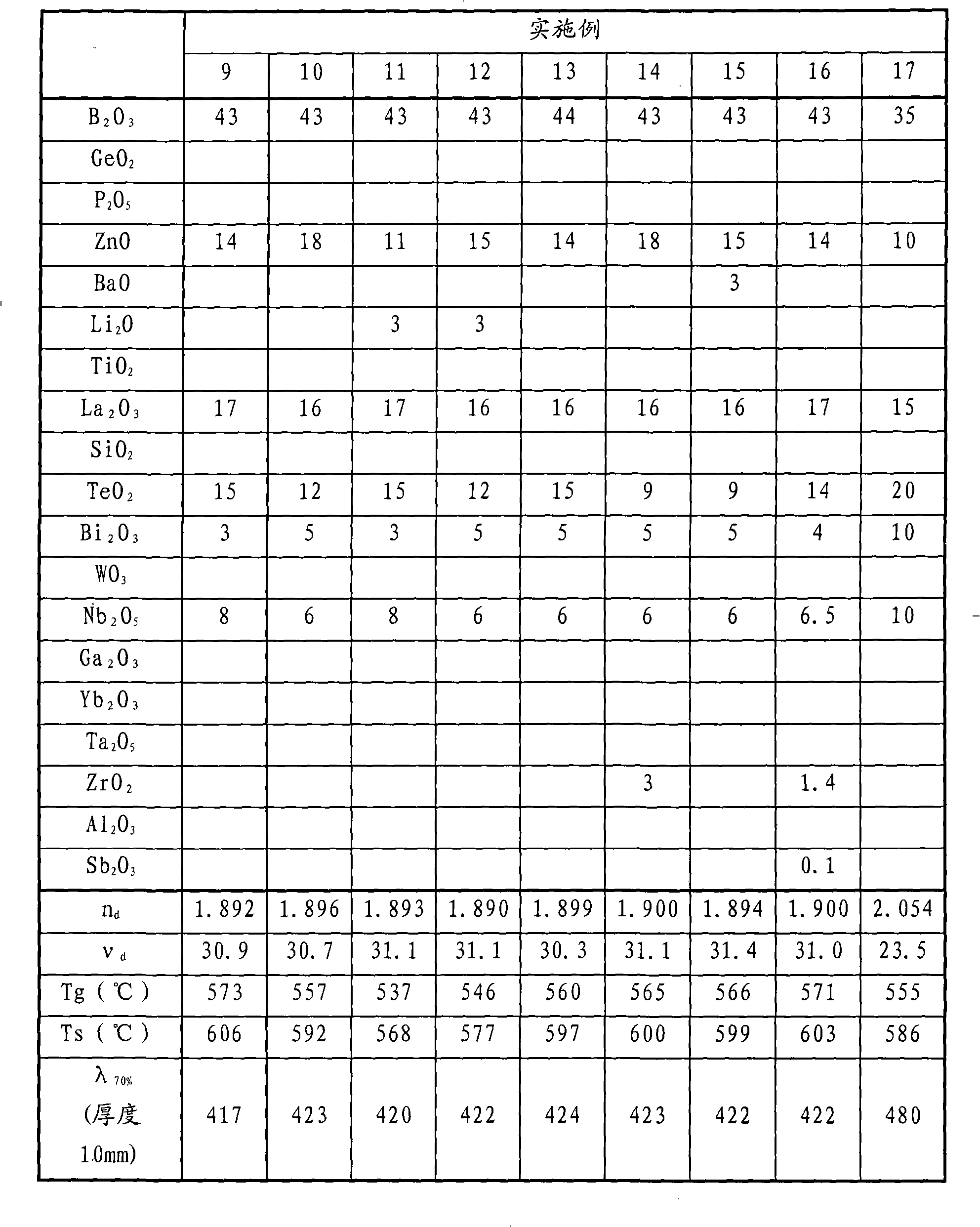

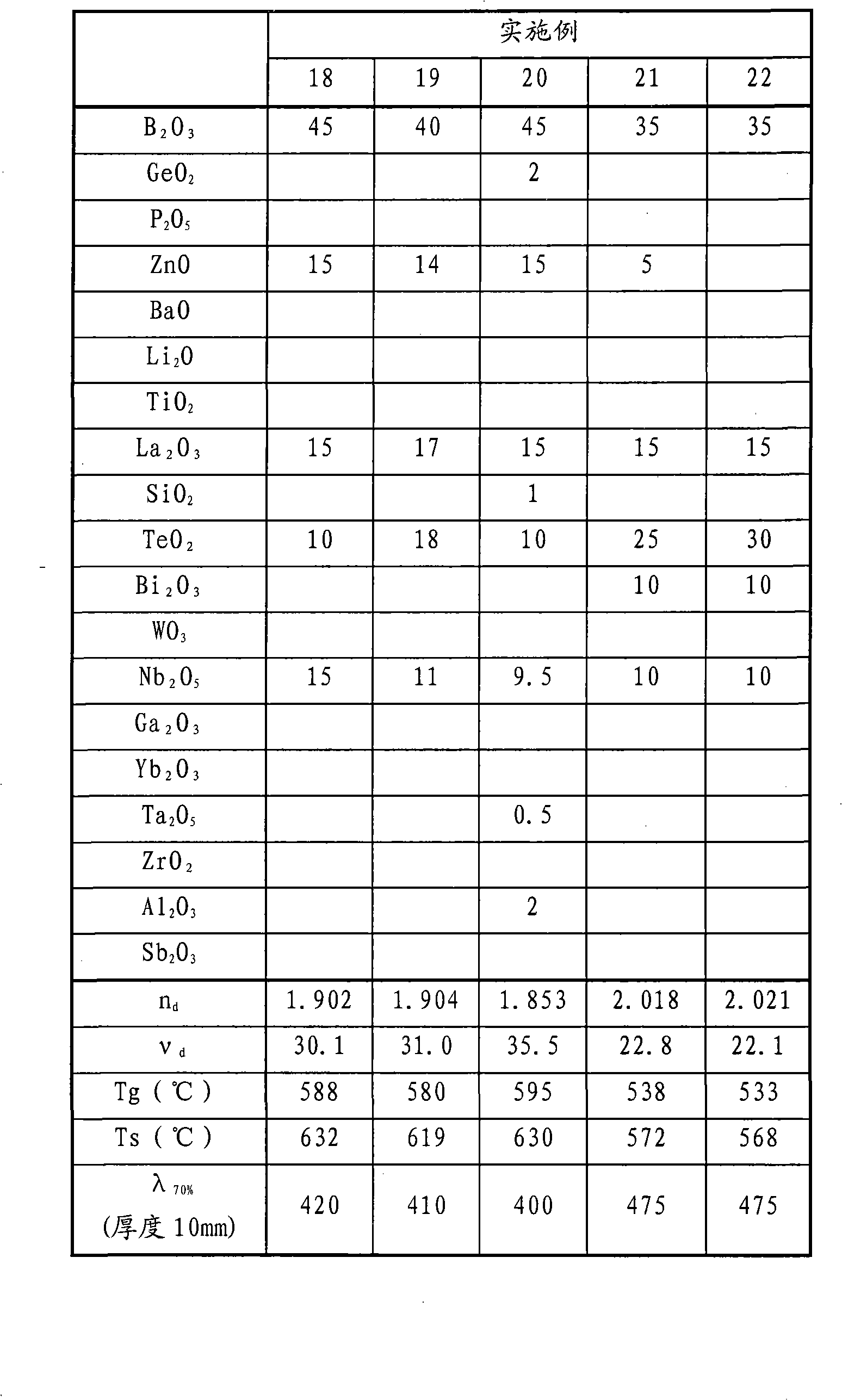

Optical glass

InactiveCN101279816ALower glass transition temperatureExcellent devitrification resistanceGlass pressing apparatusOptical elementsCompression moldingResist

The present invention provides a novel optical glass, which is B2O3-TeO2-La2O3 composed of glass with good resist-losing of transparency at the same time, having optical constant (refractive index, abbe number and so on) required by aspheric lens and so on, having low glass transition temperature, and being suitable for accurate compression molding.The optical glass is characterized in that: mole percentage (Mol%) based on oxide, having 5-60% B2O3, and having 0.2-60% TeO2.In addition, refractive index (nd) being 1.80-2.20, abbe number (Gammad) being 16-40 optical constant, and glass transition temperature (Tg) below 680 EDG C.

Owner:OHARA

Poly lactic acid composition film and its preparing method and use

The polylactic acid film contains polylactic acid 85-98 wt% and medical plasticizer 2-15 wt%, the polylactic acid may be poly L-lactic acid, poly DL-lactic acid, lactic acid-glycolic acid copolymer or the copolymer of poly L-lactic acid and poly DL-lactic acid with molecular weight of 20-1500 KDa, and the medical plasticizer is tributyl citrate, tributyl acetylcitrate, polyethylene glycol or lactic acid oligomer. The polylactic acid composition of the present invention has excellent flexibility, may be used in introducing the growth of hard and soft tissues in repairing cleft palate or as regenerating film, and introducing the regeneration of bone tissue.

Owner:成都迪康中科生物医学材料有限公司

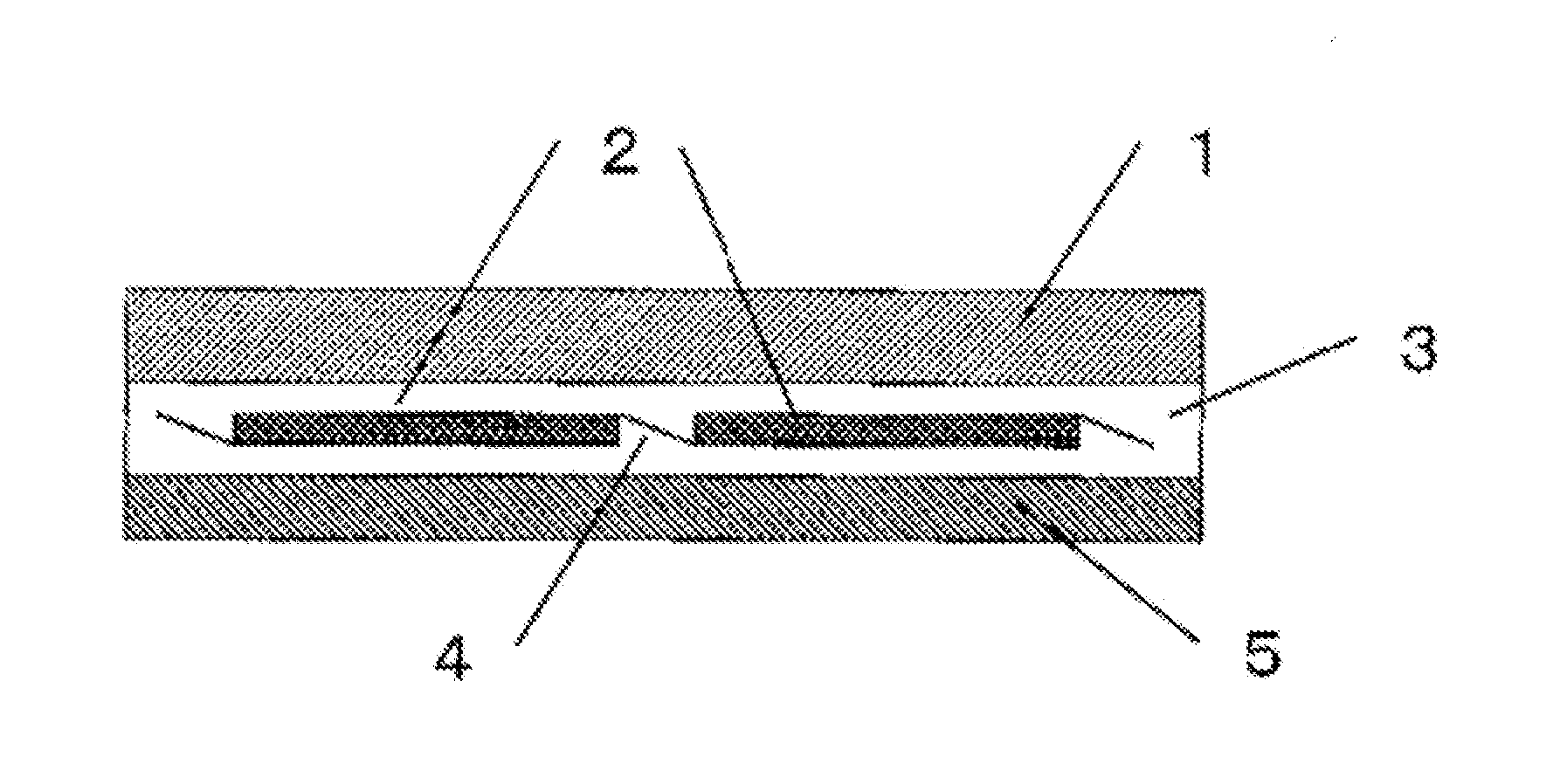

Glass laminate, and method for using block copolymer hydrogenation product as binder for glass laminate

InactiveUS20150104654A1Improve heat resistanceHigh glass transition temperatureAdhesive processesFilm/foil adhesivesPolymer scienceSilylene

A laminated glass may be obtained by integrally bonding glass sheets through an adhesive, the adhesive comprising a hydrogenated block copolymer obtained by introducing an alkoxysilyl group into a hydrogenated block copolymer that is obtained by hydrogenating unsaturated bonds of a block copolymer that comprises at least two polymer blocks and at least one polymer block, the polymer block comprising a repeating unit derived from an aromatic vinyl compound as a main component, the polymer block comprising a repeating unit derived from a linear conjugated diene compound as a main component, and a ratio (wA:wB) of a weight fraction wA of the polymer block in the block copolymer to a weight fraction wB of the polymer block in the block copolymer being 30:70 to 60:40. The laminated glass may employ a block copolymer hydrogenation product comprising an alkoxysilyl group and excellent light-fastness, heat resistance, moisture resistance and transparency.

Owner:ZEON CORP

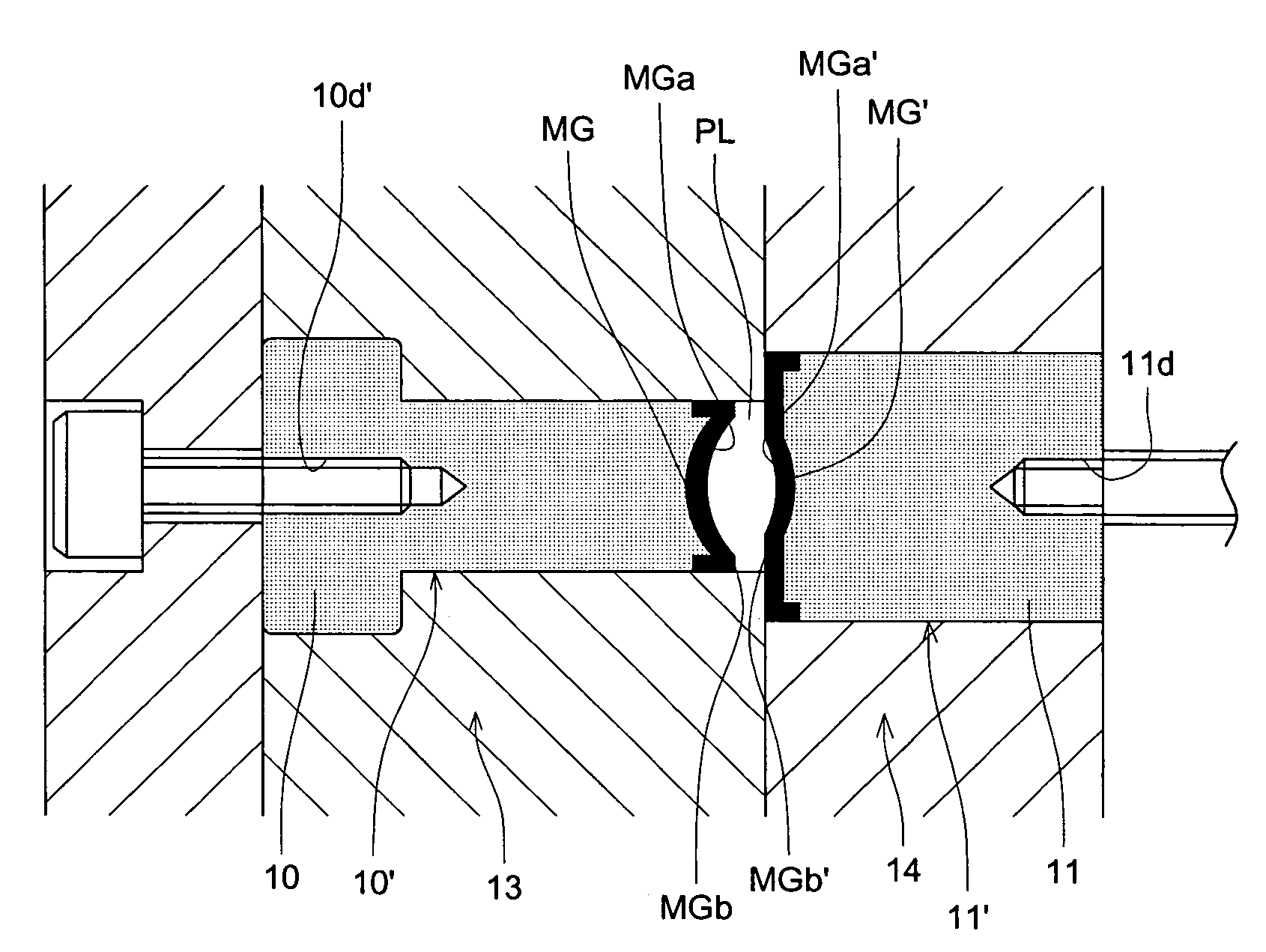

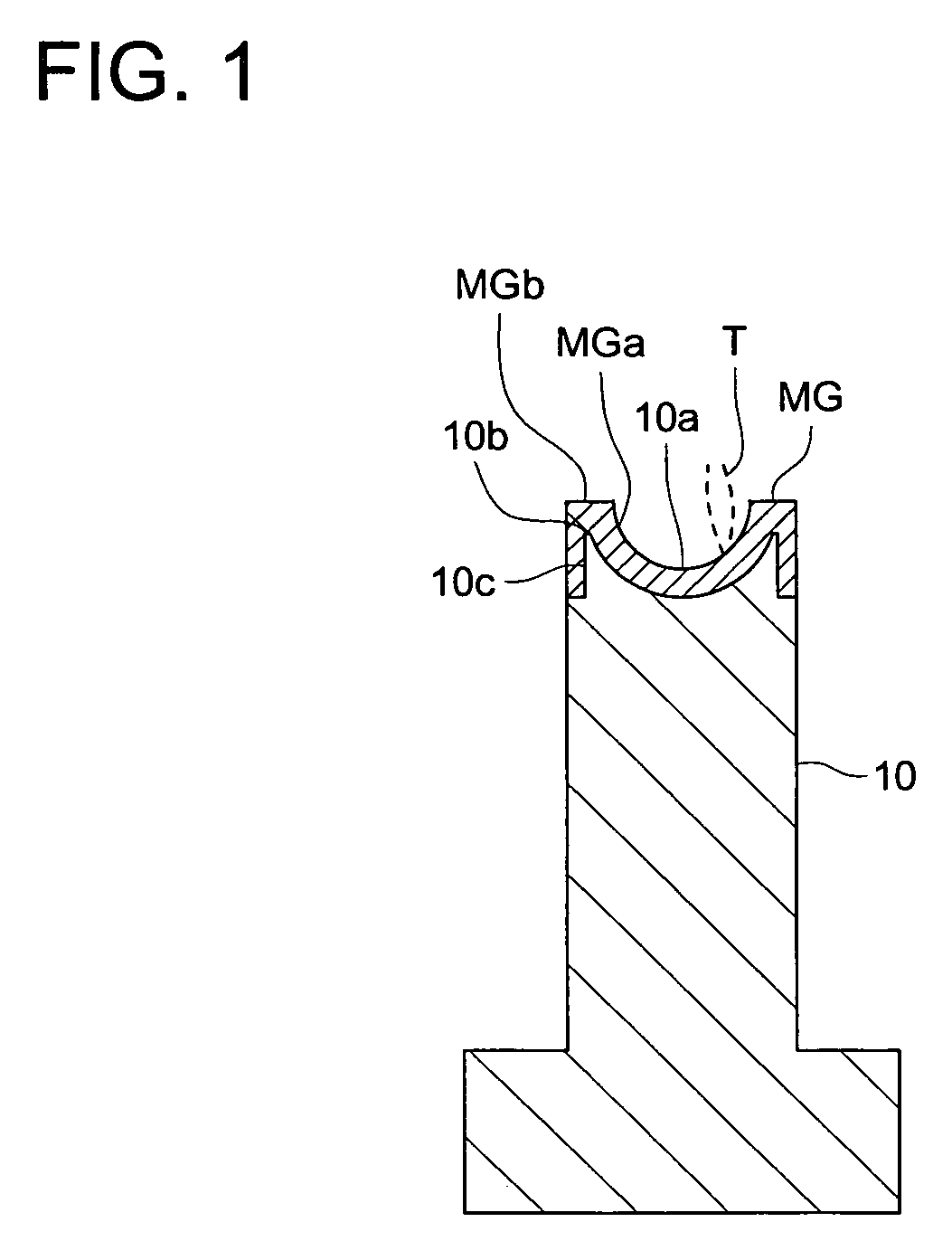

Metallic mold for optical element and optical element

InactiveUS7488170B2Improve cutting performanceHigh dimensional accuracyConfectioneryOptical articlesVitrificationLiquid state

Owner:KONICA MINOLTA OPTO

Functionalized silicones with polyalkylene oxide side chains

ActiveUS20140221549A1Reduce eliminate attachmentReduce prevent adhesionAntifouling/underwater paintsPaints with biocidesPolymer scienceSide chain

Novel silicone polymers are provided which possess grafted pendant hydrophilic polyalkylene oxide side chains and, optionally, reactive functional end groups. These features make them well suited for use in chemical, marine, biomedical and industrial applications, particularly those involving surface modifications.

Owner:NORTH DAKOTA STATE UNIV RES FOUND

Structural polyurethane adhesive having a low glass transition temperature

ActiveUS20150203728A1Improve stabilityImprove mechanical propertiesAdhesive processesNon-macromolecular adhesive additivesVitrificationAdhesive

The invention relates to a two-component polyurethane adhesive having high strength and elasticity at a particularly low glass transition temperature, suitable as a structural adhesive. The adhesive according to the invention contains a triol, a diol, a polyamine, a polyisocyanate and a polyurethane polymer having isocyanate groups in certain ratios, and a Fe(III) or Ti(IV) or Zr(IV) or Hf(IV) chelate-complex-catalyst.

Owner:SIKA TECH AG

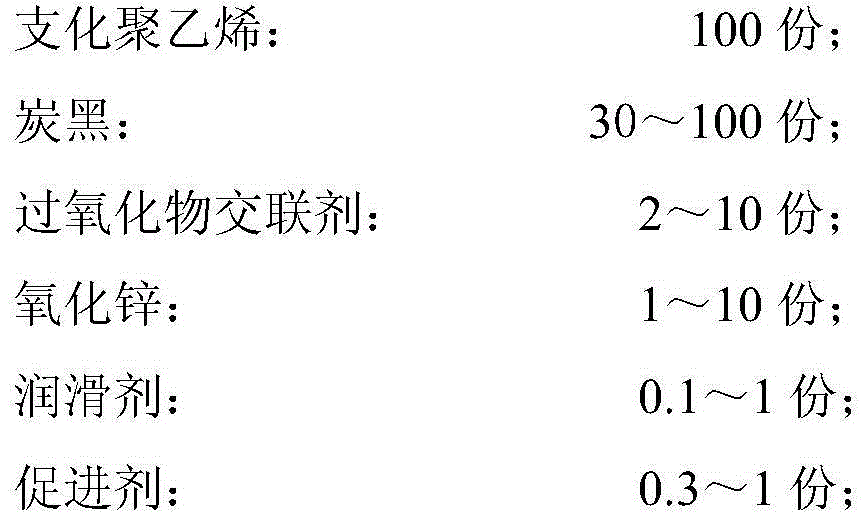

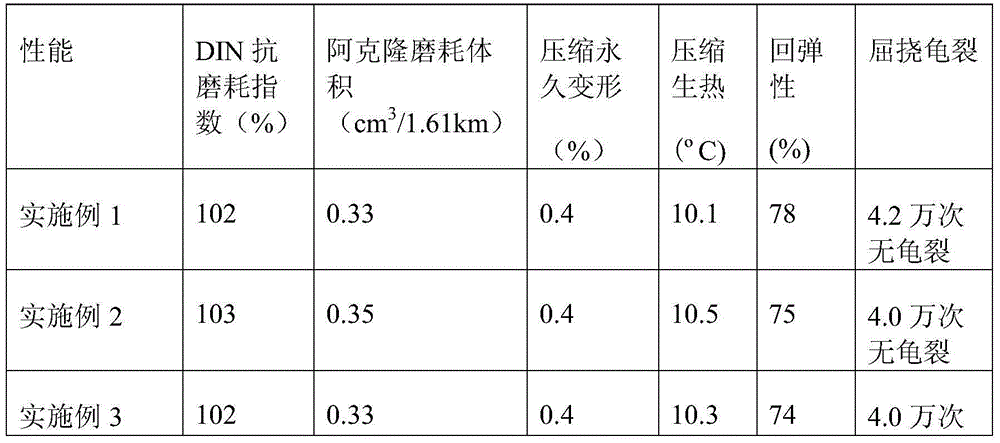

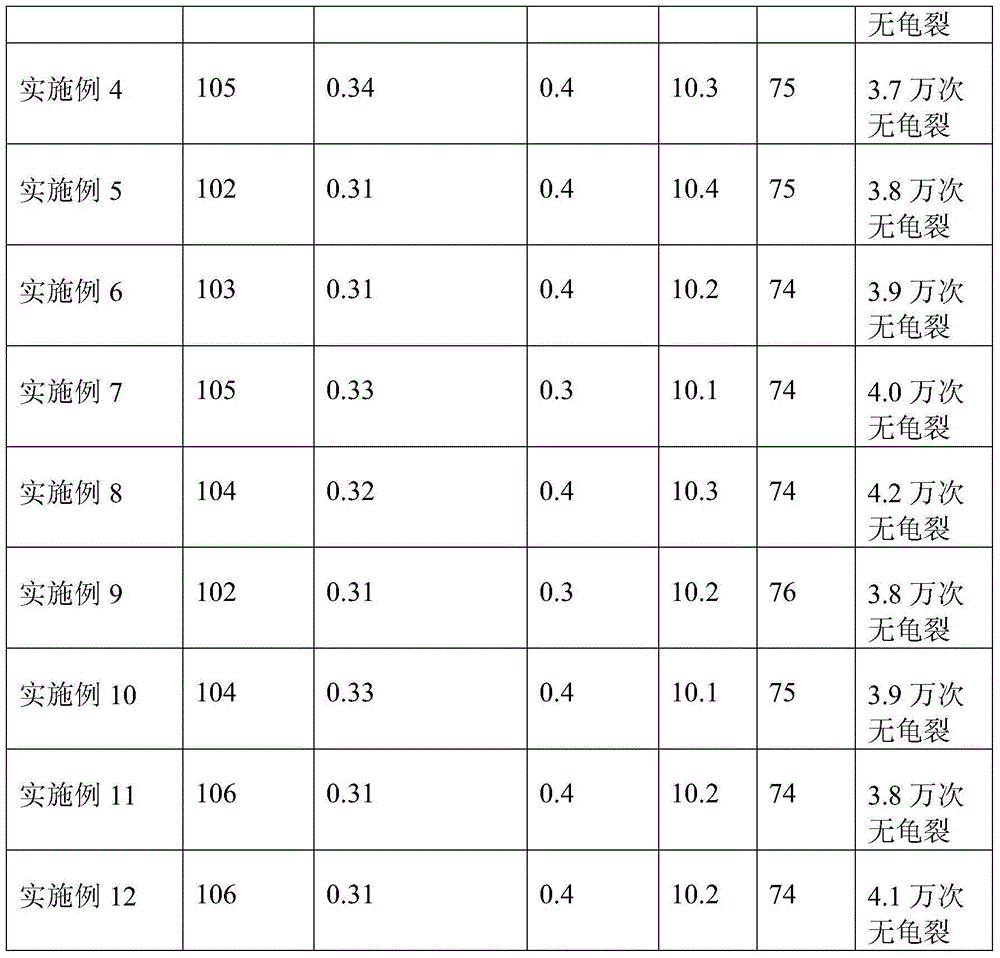

High-wearability sole material and preparation method thereof

InactiveCN104910487ALower glass transition temperatureImprove cold resistanceSolesCompound sCompression set

The invention relates to the field of the preparation of a sole material, and provides a high-wearability sole material and a preparation method thereof. The high-wearability sole material comprises the following raw materials: branched polyethylene, carbon black, a peroxide crosslinking agent, zinc oxide, a lubricating agent and an accelerant. The preparation method comprises the following steps: setting an initial temperature and an initial rotor speed of an internal mixer, sequentially charging the branched polyethylene, zinc oxide, the lubricating agent, carbon black, the peroxide crosslinking agent and the accelerant into the internal mixer according to a formula, mixing to obtain a rubber compound, folding and thin-passing the rubber compound on an open mill, encapsulating the rubber compound, finally vulcanizing by utilizing a panel vulcanizing machine, and standing for a period of time at the room temperature to obtain the high-wearability sole material. The wearability of the high-wearability sole material is better than that of natural rubber and equivalent to that of a natural rubber / butadiene styrene rubber composite, the rebound resilience is good, less heat is produced by compression, the probability of the compression permanent deformation is low, and the shape retention property is good.

Owner:ZHEJIANG UNIV

Methods for embossing and embossed articles formed therby

InactiveUS20030057601A1Facilitated releaseImprove adhesionDifferent record carrier formsPlastic/resin/waxes insulatorsPolymeric surfacePolymer science

A method for manufacturing an embossed surface comprising a polymer with a first glass transition temperature Tg1 comprises embossing the surface a temperature Temb; and raising the first glass transition temperature Tg1 of the embossed polymeric surface to a second glass transition temperature Tg2 such that Tg2>Temb. In another embodiment, a method for improving the release of a polymeric surface from an embossing tool comprises incorporating of one or more of fluorine atoms, silicon atoms, or siloxane segments into the backbone of polymer. The methods are particular suited for direct patterning of photoresists, fabrication of interdigitated electrodes, and fabrication of data storage media.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com