High heat conduction organosilicon filling and sealing gum

A technology of silicone potting compound with high thermal conductivity, which is applied in the field of potting compound to achieve excellent radiation resistance, lower crystallization temperature and glass transition temperature, and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

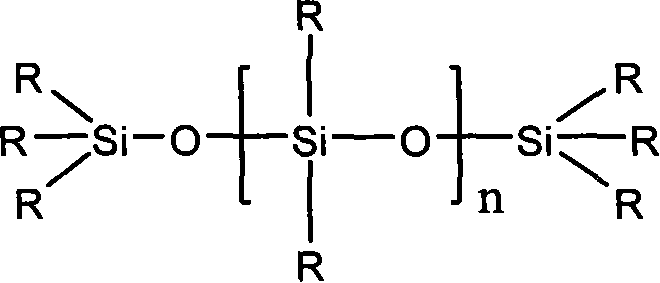

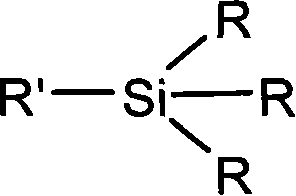

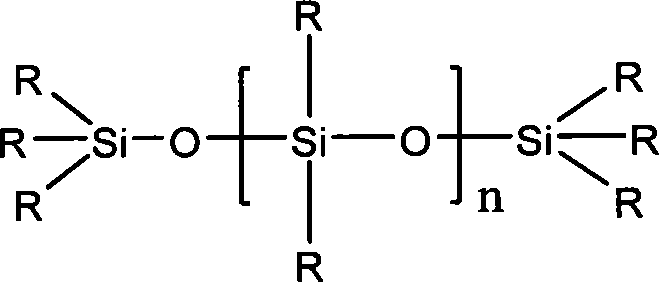

Method used

Image

Examples

Embodiment 1

[0037] Weigh 120 parts of 30 μm silicon carbide, soak for 20 minutes in an alcoholic aqueous solution of 1% vinyltriethoxysilane, filter out the silicon carbide and dry it.

[0038] Get 3000 centipoise, 1.2% vinyl content, 100 parts of methyl phenyl vinyl silicone oil with 10% phenyl content, 55 parts of the above-mentioned processed silicon carbide, 15 parts of linear MQ resin with 2% vinyl content Parts, 11 parts of 270 centipoise terminal vinyl silicone oils, 5 parts of platinum catalysts are mixed uniformly at room temperature to obtain component A; get 3000 centipoise, vinyl content of 1.2%, and phenyl content of 10% methylbenzene 100 parts of base vinyl silicone oil, 65 parts of the above-mentioned treated silicon carbide, 10 parts of hydrogen-containing silicone oil curing agent, and 11 parts of 270 centipoise end vinyl silicone oil were mixed uniformly at room temperature to prepare component B. Mix component A and component B uniformly in a weight ratio of 1:1, cure a...

Embodiment 2

[0040] 120 parts of 30 μm alumina were weighed, soaked in an alcoholic aqueous solution of 1% vinyltriethoxysilane for 20 minutes, the alumina was filtered out and dried.

[0041]Get 3000 centipoise, 1.2% vinyl content, 100 parts of methyl phenyl vinyl silicone oil with 10% phenyl content, 55 parts of the above-mentioned treated alumina, 15 parts of linear MQ resin with 2% vinyl content Parts, 11 parts of 270 centipoise terminal vinyl silicone oils, 5 parts of platinum catalysts were mixed uniformly at room temperature to obtain component A; get 3000 centipoise, vinyl content of 1.2%, and phenyl content of 10% methylbenzene 100 parts of base vinyl silicone oil, 65 parts of the above-mentioned treated alumina, 10 parts of hydrogen-containing silicone oil curing agent, and 11 parts of 270 centipoise end vinyl silicone oil were uniformly mixed at room temperature to prepare component B. Mix component A and component B uniformly in a weight ratio of 1:1, cure at 25°C for 20 hours,...

Embodiment 3

[0043] Weigh 45 parts of 20 μm aluminum nitride and 45 parts of 30 μm aluminum oxide, soak them with 1% vinyltriethoxysilane alcohol aqueous solution for 20 minutes, filter out the aluminum nitride and aluminum oxide and dry them.

[0044] Get 5000 centipoise, 0.8% vinyl content, 100 parts of methyl phenyl vinyl silicone oil with 10% phenyl content, 20 parts each of the above-mentioned treated aluminum nitride and aluminum oxide, 2% vinyl content straight 15 parts of chain-type MQ resin, 11 parts of 270 centipoise terminal vinyl silicone oil, and 5 parts of platinum catalyst were mixed uniformly at room temperature to obtain component A; 100 parts of methyl phenyl vinyl silicone oil, 25 parts of each of the above-mentioned treated aluminum nitride and aluminum oxide, 10 parts of hydrogen-containing silicone oil curing agent, and 11 parts of 270 centipoise end vinyl silicone oil are mixed uniformly at room temperature to prepare Component B is obtained. Mix component A and com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com