Patents

Literature

1691results about How to "Good high and low temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

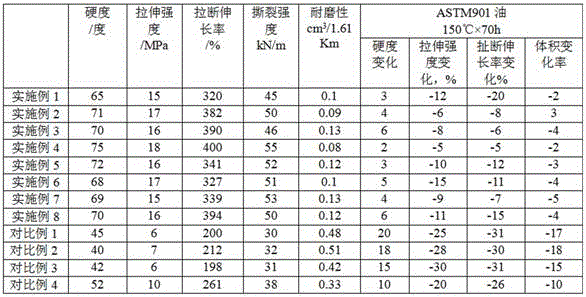

Blend of fluorubber and silastic, and preparation thereof

InactiveCN101412835ASmall compression setThe preparation method is simple and feasibleTemperature resistancePolymer blend

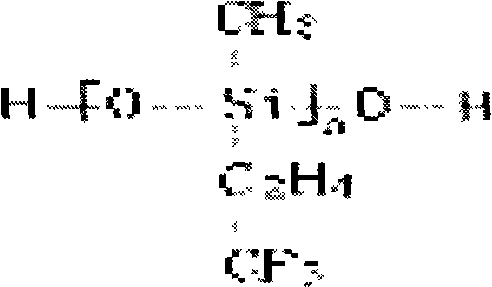

The invention relates to a blend of fluorine rubber and silicone rubber, as well as a preparation method thereof. The composition in weight percentage of the blend of fluorine rubber and silicone rubber is as follows: 12 to 50 percent of fluorine rubber, 12 to 50 percent of silicone rubber, 2.5 to 10 percent of compatibilizer, 2.5 to 10 percent of acid-acceptor, 12 to 35 percent of reinforcing filler, 0.5 to 7 percent of constitution controller, 0.5 to 3 percent of vulcanizing agent and 0.5 to 4 percent of crosslinking additive. The blend of fluorine rubber and silicone rubber is prepared by a mechanical blending method and is vulcanized by use of peroxides. Vulcanized rubber has good mechanical properties, heat resistance, low-temperature resistance, oil resistance and low-compression permanent deformation performance, and can be used for producing and manufacturing high-performance rubber tubes, adhesive tapes, sealing elements, rubber linings and the like needed in automobile, mechanical, chemical, aerospace and other industries.

Owner:SOUTH CHINA UNIV OF TECH

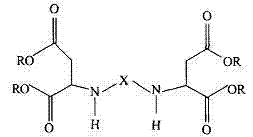

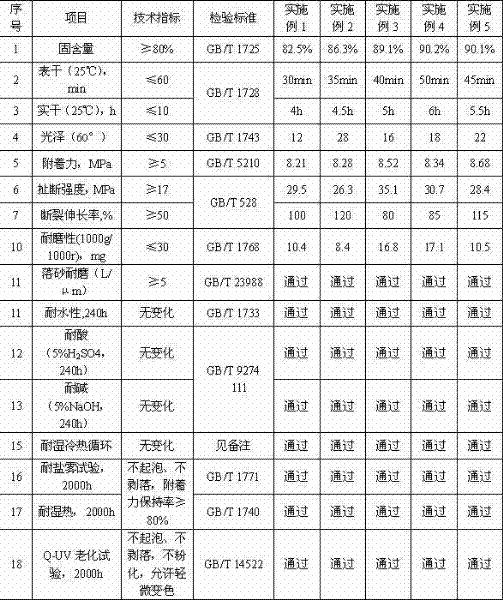

Thick paste quick-drying type weather-resistant and wear-resistant coating for wind turbine blades and preparation method thereof

ActiveCN102391771AFast dryingNot easy to foamAnti-corrosive paintsPolyurea/polyurethane coatingsWear resistantAgricultural engineering

The invention discloses a thick paste quick-drying type weather-resistant and wear-resistant coating for wind turbine blades and a preparation method thereof, the coating takes poly-asparaginic acid ester and elastic resin-modified aliphatic isocyanate as base materials, a nano-material is adopted for being effectively bonded with a resin matrix, and appropriate auxiliaries and additives for enhancing the performances of the coating. The thickness of a film which is formed by the coating for the wind turbine blades once can achieve 300 mu m; furthermore, the drying speed is fast and the coating is less prone to bubbling; the weather resistance is excellent, and the coating has higher tensile strength and elongation at break, and prominent wear resistance and impact resistance; the performances of water resistance, chemical product resistance, wet heat resistance, salt mist resistance and high and low temperature resistance are excellent; and the coating has certain anti-pollution and anti-icing properties. The construction efficiency of the coating is high, the performances of the coating are particularly suitable for wind field environments in China, the service life of a unit can be prolonged and the maintenance cost can be reduced.

Owner:洛阳双瑞防腐工程技术有限公司

High and low-temperature resistant porcelain glaze for enamel

InactiveCN103274764AImprove smoothnessGood high and low temperature resistanceTemperature resistanceLead sulfate

The invention relates to porcelain glaze and in particular relates to high and low-temperature resistant porcelain glaze for enamel. According to the technical scheme, the highnd low-temperature resistant porcelain glaze for enamel is prepared from the following raw materials in parts by weight: 22-38 parts of sodium silicate with the modulus of 2-3.8, 11-19 parts of aluminum oxide, 10-20 parts of manganese dioxide, 6-9 parts of palladium oxide, 6-9 parts of high-boron calcium borate, 23-29 parts of lead sulfate, 2-4 parts of talc, 7-13 parts of calcium carbonate, 8-12 parts of barium sulfate, 12-19 parts of zinc sulfate and 2-9 parts of titanium oxide. The high and low-temperature resistant porcelain glaze has excellent ultralow-temperature resistance and high-temperature resistance.

Owner:XIANGFENG ZHEJIANG METAL PROD

EVA hot melt adhesive composition containing linear hydroxyl-terminated polyurethane resin

InactiveCN101787250AImprove initial strengthIncrease ultimate strengthPolyureas/polyurethane adhesivesWaxAntioxidant

The invention discloses an EVA hot melt adhesive composition containing a linear hydroxyl-terminated polyurethane resin, which comprises the linear hydroxyl-terminated polyurethane resin, an ethylene-vinyl acetate polymer, a tackifier, waxes, an antioxidant, an ultraviolet stabilizer, a filling material, a fire retardant and the like. The EVA hot melt adhesive composition containing the linear hydroxyl-terminated polyurethane resin is used for improving the early strength, the final strength and the high- and low-temperature resistance performances of the EVA hot melt adhesive compositions.

Owner:山东久隆高分子材料有限公司 +1

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

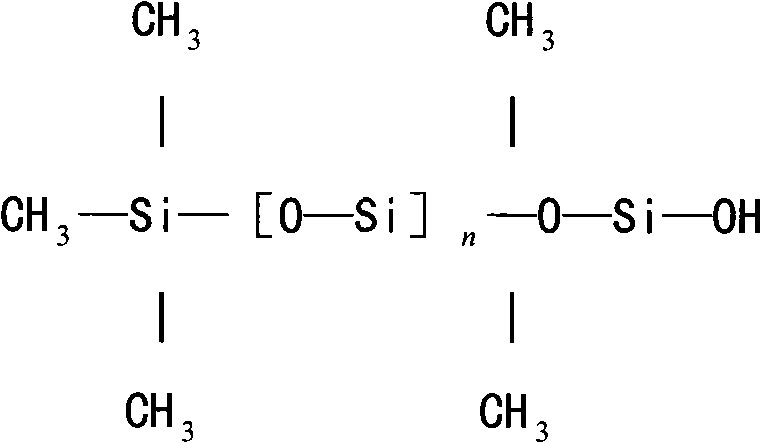

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

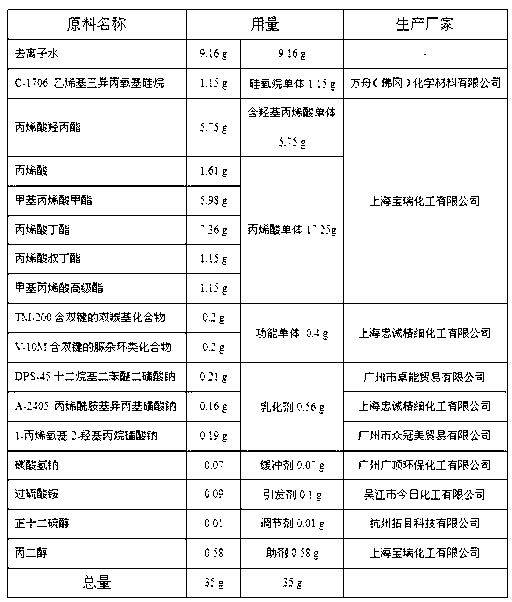

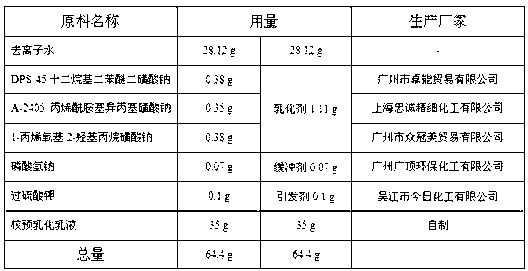

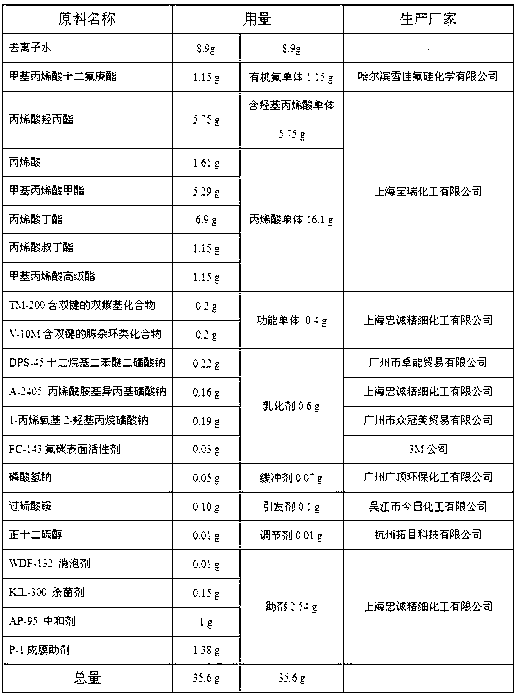

Silicone modified acrylic ester emulsion and preparation method thereof

The invention discloses a silicone modified acrylic ester emulsion and a preparation method thereof. The emulsion is prepared from the following raw materials in parts by weight: 6.5-9 parts of acrylic ester mixed monomers, 1-3.5 parts of an organosilicone monomer, 0.4-0.6 part of an emulsifier, 0.2-0.3 part of an initiating agent, 0.01-0.03 part of a pH conditioning agent, 28-32 parts of deionized water, wherein the acrylic ester mixed monomers are methyl methacrylate and butyl acrylate with the mass ratio of (5.5-6.5):(3.5-4.5); the organosilicone monomer is gamma- 3-[Tris(trimethylsiloxy)silyl]propyl methacrylate. According to the emulsion, the reactive emulsifier is adopted for polymerization reaction, the prepared emulsion is stable, and the latex film of the emulsion has lower surface energy and better water resistance, and can be used as the main film forming matter of a metal anti-corrosion coating.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

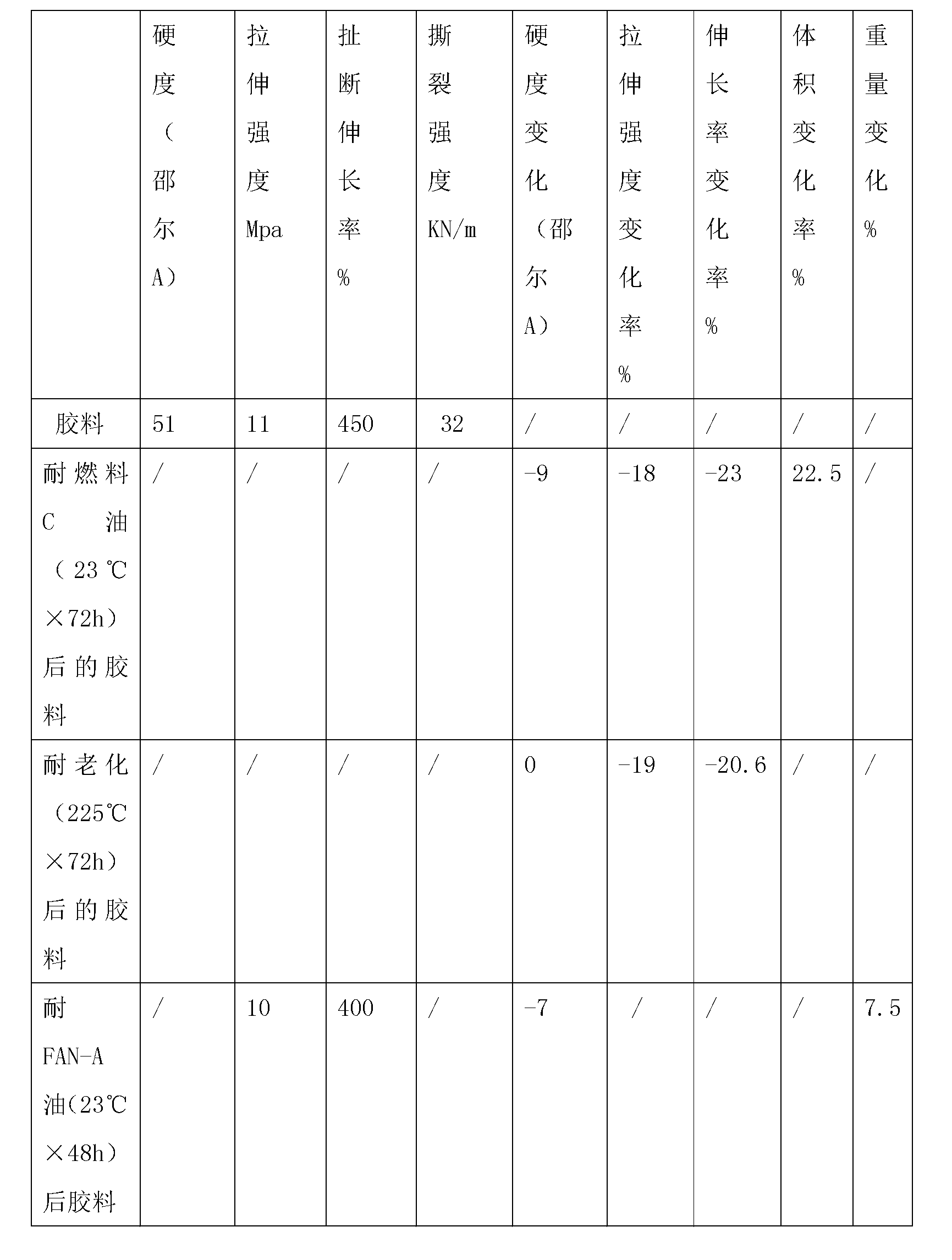

Valve sealing gasket sizing material and preparation method thereof

ActiveCN103012891AImprove performanceGood high and low temperature resistanceDiphenylsilanediolSolvent

The invention discloses a valve sealing gasket sizing material, which is prepared from the following raw materials in parts by weight: 20-30 parts of fluorosilicone rubber, 50-60 parts of hydrogenated nitrile-butadiene rubber, 15-25 parts of chlorosulfonated polyethylene rubber TS-320 (TOSOH, Japan), 2-3 parts of gamma-methacryloxypropyltrimethoxysilane, 1-2 parts of diphenyl silandiol, 14-16 parts of modified tree ash, 2-3 parts of ferrocene, 0.2-0.6 part of dicumyl peroxide (DCP), 20-30 parts of high-abrasion resistant carbon black N330, 20-25 parts of precipitated white carbon black, 5-7 parts of light calcium carbonate, 2-4 parts of zinc oxide, 1-3 parts of calcium stearate, 1-3 parts of aluminium oxide, 5-8 parts of dolomite, 13-15 parts of modified iron tailing powder, 0.1-0.3 part of accelerating agent MBTS, 1-2 parts of sulphur, 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent MB, 1-2 parts of benzimidazole-2-thiol, 1-3 parts of methyltrimethoxy silane, and 2-3 parts of paraffin. The sizing material of the rubber has excellent high and low temperature-resistant, oil-proof, solvent-resistant and chemical-resistant performance, and at the same time is good in mechanical property and low in cost.

Owner:平湖市博宏塑料制品厂

Preparation method of carboxylic styrene butadiene latex

The invention provides a preparation method of carboxylic styrene-butadiene latex. In the method, butadiene and styrene are adopted as main monomers, and unsaturated carboxylic acid or unsaturated carboxylic ester functional monomers are additionally adopted; a compound emulsifying system formed by a reacting type emulsifier, an anion emulsifier and a non-ionic emulsifier is adopted, and a persulfate thermal decomposition initiating agent is also adopted. Low-temperature polymerization is replaced by high-temperature polymerization, and a two-stage stepped temperature control process is adopted so as to ensure that the stability of the polymerization of the latex is greatly improved, prevent the generation of gel, improve the mechanical stability of the latex and reduce the energy consumption. The carboxylic styrene-butadiene latex prepared by the method has excellent oil resistance, solvent resistance, high and low temperature resistance (resistance of high temperature of -45 DEG C and high temperature of 220 DEG C) and good strength and is quite suitable for manufacturing asbestos or the non-asbestes sheet for a sealing gasket of a vehicle.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

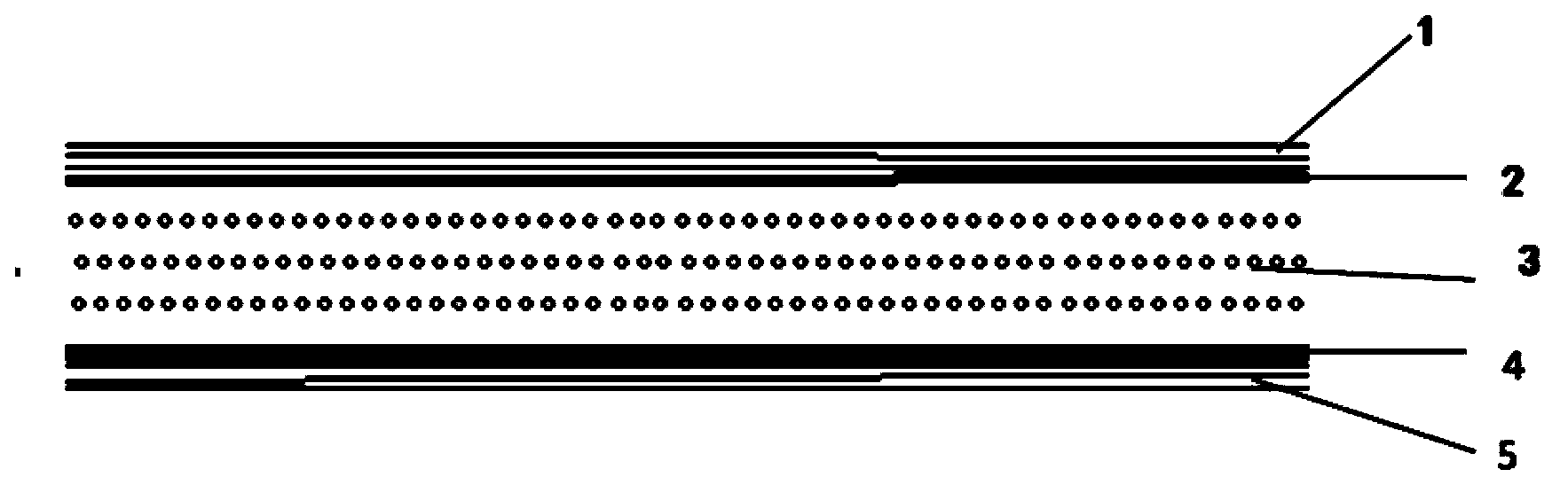

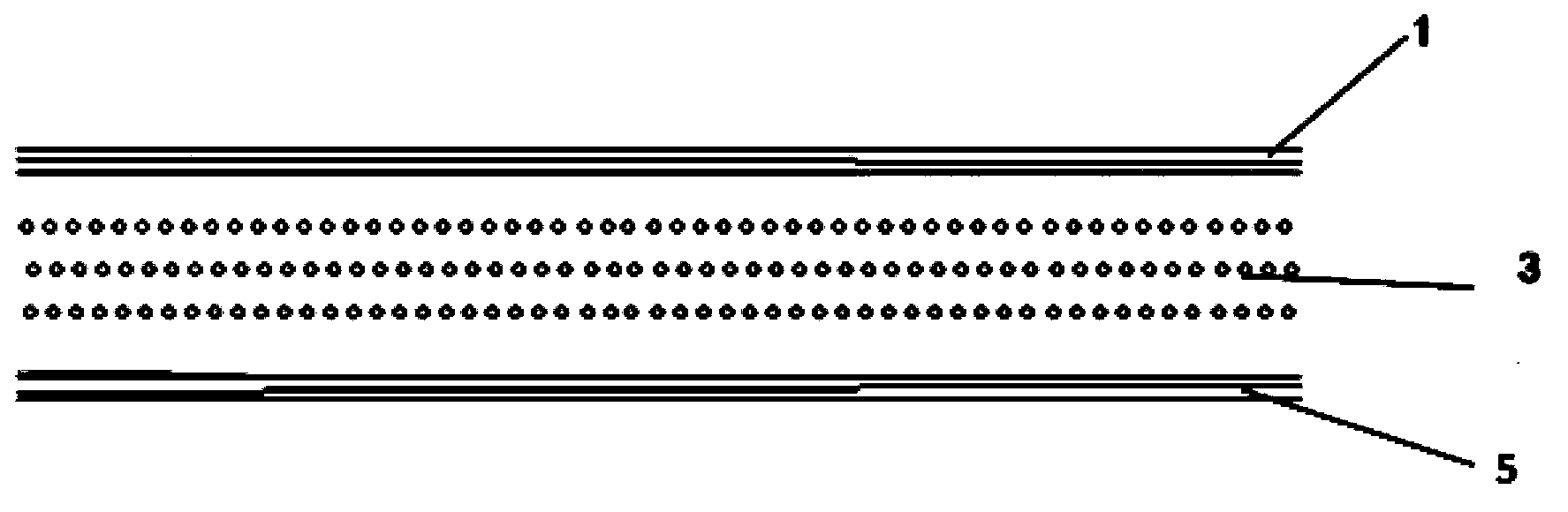

Wave-transmitting core clamping material of antenna cover and manufacturing method and application thereof

ActiveCN103660410AHigh mechanical strengthIncreased protectionSynthetic resin layered productsLaminationUltimate tensile strengthThermoplastic composites

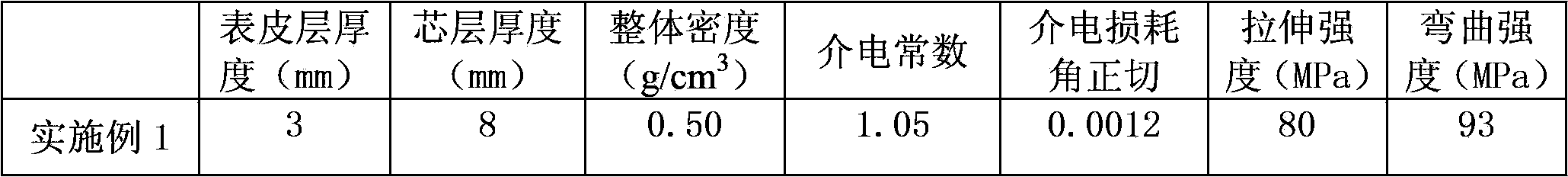

The invention belongs to the technical field of materials, and relates to a wave-transmitting core clamping material and a manufacturing method and application thereof. The wave-transmitting core clamping material comprises an upper skin layer, a core layer and a lower skin layer, wherein the upper skin layer and the lower skin layer are bonded on the two sides of the core layer, respectively; the upper skin layer and the lower skin layer are made of a fiber-reinforced thermoplastic composite material or a laminated material of the fiber-reinforced thermoplastic composite material and a transition material. The prepared wave-transmitting core clamping material provided by the invention has the characteristics that the quality is light, the intensity is high, the wave-transmitting property is good, the adaptive temperature range is wide, and the core clamping material is manufactured to be in different shapes through different manners of hot pressing, vacuum forming and the like so as to meet the requirement on the shape of an antenna cover.

Owner:上海吒吒新材料科技有限公司

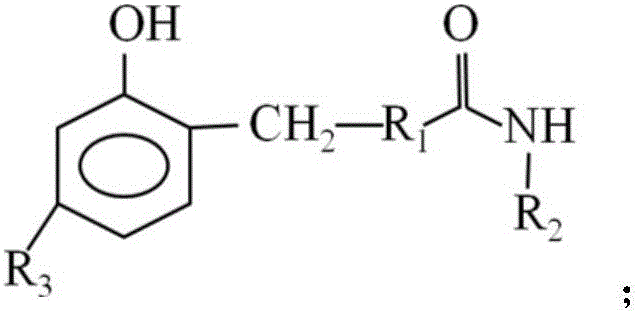

High-adhesive property watersoluble polyurethane adhesion agent and method of producing the same

InactiveCN101429417AHigh solid contentFast dryingPolyureas/polyurethane adhesivesWater basedPolyurethane adhesive

The invention relates to water-based polyurethane adhesive with high adhesive property and a preparation method thereof, and belongs to the field of polyurethane adhesive. The preparation method comprises the following steps: (1) drying a polylol polymer for 1 to 3 hours in vacuum at a temperature of between 100 and 120 DEG C, reducing the temperature to between 80 and 90 DEG C, dripping diisocyanate into the polylol polymer, polymerizing the mixture for 1 to 1.5 hours, adding small molecular polylol and hydrophilic polylol into the mixture to carry out chain extension and polymerization reaction for 1 to 1.5 hours, then adding the diisocyanate into the mixture, and making the mixture subjected to end capping reaction for 0.5 to 1 hour; (2) dripping neutralizing agent into cross linking polyurethane pre-polymer, and adding acetone into the pre-polymer at the same time to reduce viscosity, wherein the neutralization degree is 95 to 100 percent after the mixture is reacted for 0.5 to 1 hour at a temperature of between 35 and 45 DEG C; (3) dripping the obtained hydrophilic cross linking polyurethane pre-polymer into a mixture of a polyamine compound and water, and dispersing the mixture evenly under high-speed shearing function of an emulsifying machine to obtain water-based polyurethane dispersant; and (4) removing organic solvent in the water-based polyurethane dispersant obtained in step (3) by a vacuum decompressing method. The preparation method effectively solves the problem of difficult emulsifying dispersion caused by cross linking, has simple emulsifying process, and reduces equipment requirement remarkably, has high solid content, reduces cost for production, storage and transportation, improves drying time, and is convenient for gluing operating process.

Owner:GUANGZHOU KELIN WAER BORNE MATERIAL

Water-based two-component fluorosilicone acrylic anticorrosive paint and preparation method thereof

InactiveCN103320000AHigh resistivityGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsIonChemistry

The invention relates to a water-based two-component fluorosilicone acrylic anticorrosive paint. A film forming material component consists of 50-70 parts of water-based hydroxyl fluorosilicone acrylic resin, 20-40 parts of a pigment / filler, 1-10 parts of an auxiliary and 3-20 parts of de-ionized water, and a curing agent component comprises 5-10 parts of aqueous polyisocyanate and 1-5 parts of a thinner, wherein the weight ratio of the film forming material to the curing agent is 100: (5-15). The preparation method comprises the steps of dispersing and grinding the de-ionized water, the auxiliary and the pigment / filler, adding the water-based hydroxyl fluorosilicone acrylic resin, and uniformly stirring the prepared film forming material with the curing agent to obtain the paint. The anticorrosive paint has the advantages that a polysiloxane-polyurethane segmented copolymer is synthesized by taking the polysiloxane as a soft segment, thus enhancing water resistance, corrosion resistance and other performances; the shell raw material, which includes a fluorine-containing acrylic monomer, guarantees excellent ultraviolet and nuclear radiation resistance, flexibility, wear resistance and durability of coating. The paint is good in compatibility, self-dried at normal temperature, non-toxic and tasteless, low in volatile organic compound (VOC) and strong in coating adhesion, and can be widely applied to large steel structure, bridge, boat and other fields.

Owner:JIUQING PAINT SHANGHAI

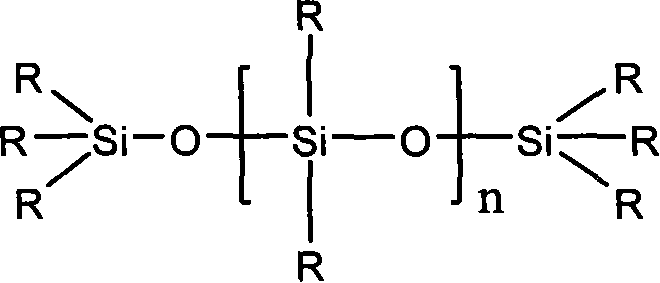

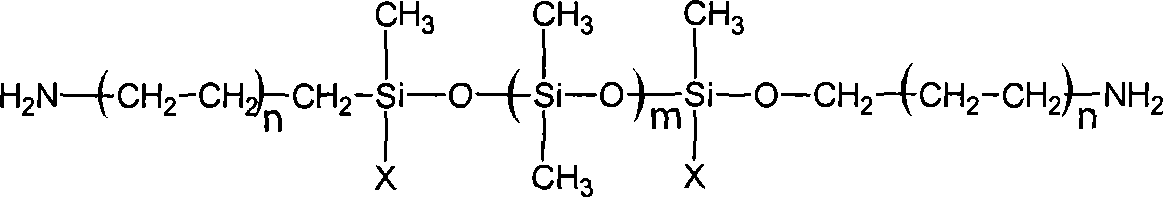

Method for synthesizing water-dispersion organosilicon-polyurethane block copolymer

InactiveCN101225150AEvenly dispersedImprove stabilityNon-fibrous pulp additionLiquid surface applicatorsVegetable oilSynthesis methods

The invention discloses a synthesis method for waterborne organocilicon-polyurethane block copolymer, comprising steps as follows: reaction is carried out between polyisocyanate and polyol (the polyol comprises the one from the castor oil and carboxyl polyol) to generate isocyanate-terminated polyurethane prepolymer; then chain extension is carried out via amino alkyl polysiloxane; eventually alkaline aqueous solution is adopted for neutralization and dispersion, to prepare aqueous dispersion with excellent dispersion and stability. In addition, the aqueous dispersion is applied as coating for the wood and paper, as finishing agent for leathers and textiles, or as adhesives. Since natural vegetable oil from castor beans is selected and amino alkyl polysiloxane is adopted as the chain extender. The synthesis method for waterborne organocilicon-polyurethane block copolymer has the advantages of remarkably improved hydrophobic property, heat resistance and surface smoothness for the polymer films, simple preparation technique, and easy operation.

Owner:ZHEJIANG UNIV

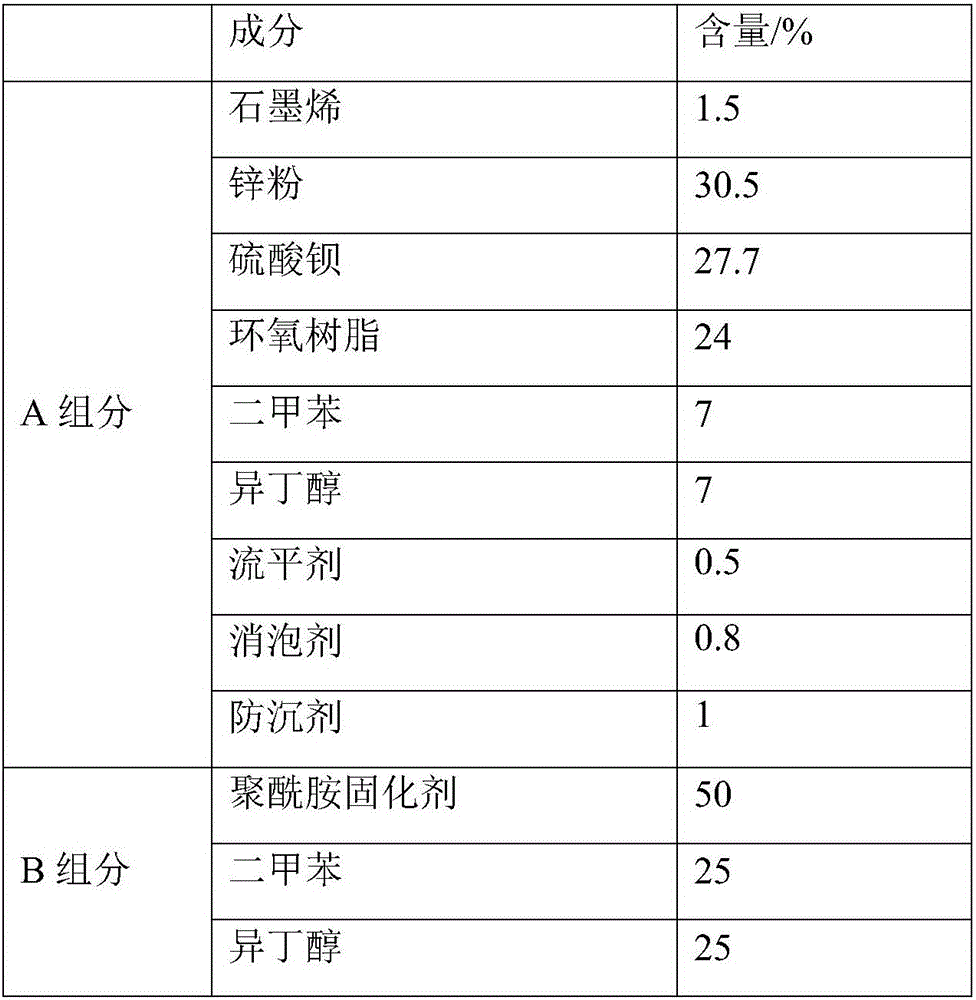

Graphene anticorrosive coating and preparation method thereof

ActiveCN106189719AEasy reunionSolving Dispersion ProblemsAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention provides a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating is prepared from a component A and a component B, wherein in percentage by weight, the component A comprises 20%-30% of epoxy resin, 1%-3% of graphene, 0.5%-2% of a dispersing agent, 15%-25% of talcum powder, 10%-20% of zinc powder and 1%-5% of aluminum paste, and the component B comprises 30%-50% of cashew nut shell oil phenolic amide and 10%-30% of polyamide. The graphene anticorrosive coating provided by the invention is safe and environment-friendly, is moderate in cost, simple and convenient in process, stable in storage, excellent in adhesive force on base materials such as steel, iron and the like, excellent in mechanical performance such as flexibility, wear resistance performance and the like, and prominent in protective effects in chemical media such as an acid, an alkali, a salt and the like, shows excellent protective performance such as high and low temperature resistance, high salinity resistance and the like in a condition of a simulation marine environment experiment, and can be applied as primer for an anticorrosive coating in ocean engineering with various steel and iron materials.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

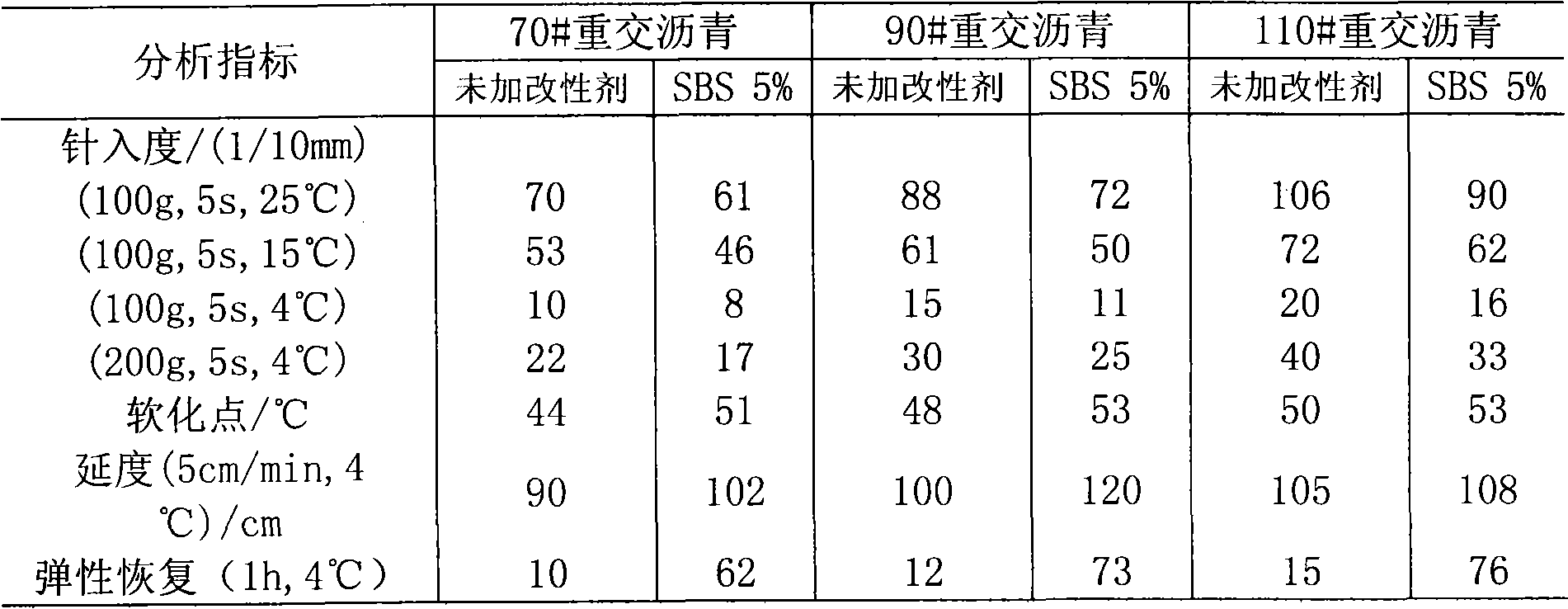

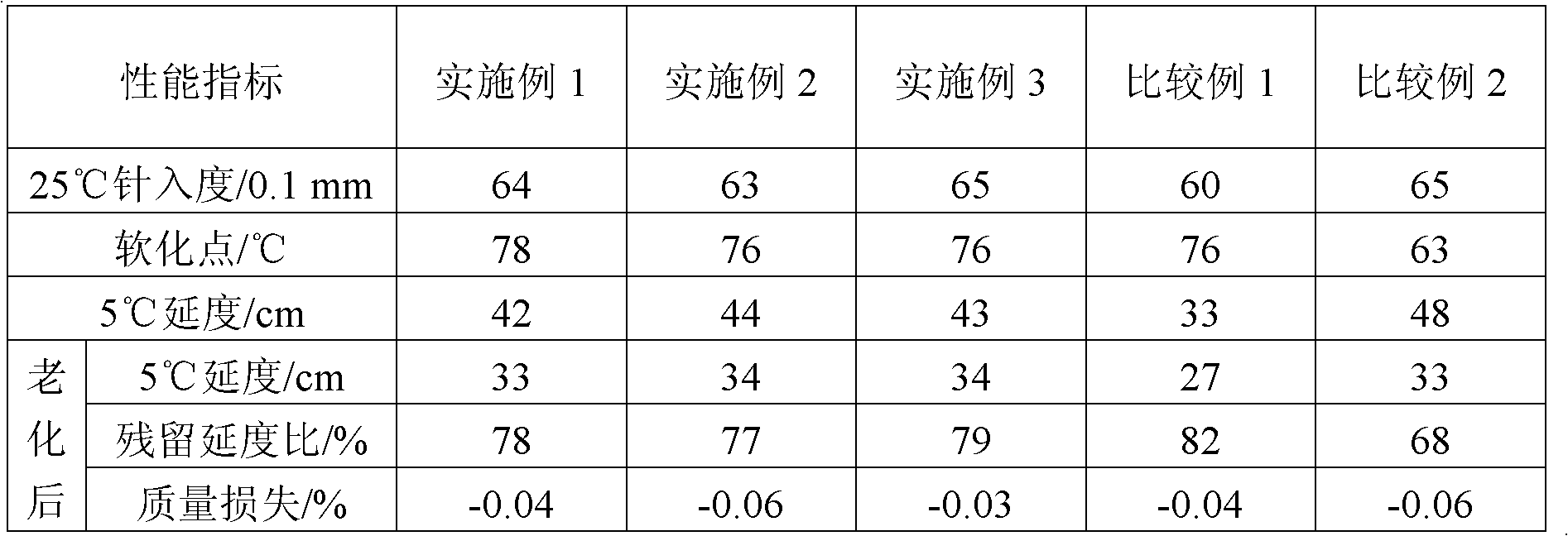

Preparation method of star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt and production method of waterproof coiled material

ActiveCN102220023AGood high and low temperature resistanceImprove stabilityBuilding insulationsBasementAdhesive

The invention provides star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt, which is a composition composed of asphalt, swelling star-shaped SBS, filler and aids and solves the problem that star-shaped SBS used as an asphalt modifier is difficult to process. The production method of the star-shaped SBS-modified asphalt involves the following steps: adding star-shaped SBS swelled by a non-polar solvent to asphalt, modifying at the temperature of 180-210 DEG C for 50-150 minutes by a colloid mill or a powerful high-speed shearing stirrer, adding the filler and aids and uniformly stirring so as to form the uniform and stable modified asphalt. The modified asphalt can be made into a waterproof coiled material with excellent performance as well as a waterproof and leak-proof adhesive used for building roofs, basements, expressways, sealants, tunnels or water conservancy facilities. The modified asphalt has the characteristics of better compatibility with asphalt and better high-temperature and low-temperature resistance, compared with existing SBS modified asphalt.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Single-component high/low-temperature-resistant epoxy resin composition

ActiveCN102827566AImprove performanceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkEther

The invention provides a single-component high / low-temperature-resistant epoxy resin composition which comprises the following ingredients in parts by weight: 100 parts of rubber cross-linked modified epoxy resin, 0-20 parts of cardanol-type glycidol ether, 80-120 parts of alicyclic acid anhydride curing agent, 0.5-10 parts of latent curing accelerator, 10-40 parts of polyacrylate core-shell compound particle toughener, 2-20 parts of thixotropic agent and 50-100 parts of filler. The epoxy resin composition has the advantages of high toughness, high / low-temperature alternation resistance, simple preparation technique, low viscosity and favorable flowability, and can greatly enhance the packaging reliability and durability of electronic devices.

Owner:GUANGDONG TGPM AUTOMOTIVE IND GRP

Novel environment-friendly polyvinyl chloride cable material

The invention provides a novel environment-friendly polyvinyl chloride cable material. The material consists of polyvinyl chloride WS-1300, plasticizer UN399, stabilizer CZ-756E (105), epoxidized soybean oil, bisphenol A antioxygen, antimonous oxide (SB203), polyethylene (PE), activated light calcium carbonate and carbon black. The chemical substance content of the material is reduced by improving the formula of the cable material, so that the product has the advantages of effectively solving the problem of toxic gases releasing in polyvinyl chloride material heating and plastifying process, reducing the harm to the human bodies in the production process, resisting the temperature of between 40 and 105 DEG C, along with cleanness and environmental protection, light specific gravity, high plasticization degree, no deformation, fracture or aging, superior product performance, and wider application range and field.

Owner:ZHENJIANG HUAYIN INSTR & ELECTRICAL EQUIP

High-performance nitrile rubber sealing material and preparation method thereof

The invention discloses a high-performance nitrile rubber sealing material and a preparation method thereof. The high-performance nitrile rubber sealing material is prepared from the following raw materials in parts by weight: 25 to 35 parts of nitrile rubber, 4 to 7 parts of composite sulfurizing reagent, 4 to 5 parts of anti-aging agent, 8 to 15 parts of activating agent, 25 to 30 parts of reinforcing agent and 2 to 5 parts of heat-resistant additive. By adopting the high-performance nitrile rubber sealing material, the problems of poor wear resistance, low tensile strength and low tearing strength in ordinary nitrile rubber are solved, and the prepared product has high mechanical performance and superior high-temperature performance.

Owner:南阳天一密封股份有限公司

Special epoxy impregnating compound for basalt fiber and preparation method of special epoxy impregnating compound

The invention discloses a special epoxy impregnating compound for a basalt fiber and a preparation method of the special epoxy impregnating compound. The special epoxy impregnating compound for the basalt fiber is prepared from the following components in percentage by weight: 5.0%-8.0% of an epoxy latex film-forming agent, 0.1%-1% of a lubricant, 0.5%-1.5% of binder, 0.5%-1.5% of plasticizer, 0.2%-1.0% of an antistatic agent, 0.5%-1.0% of a coupling agent and the balance of soft water. The reinforced textile type impregnating compound is suitable for a basalt-reinforced thermosetting phenolic epoxy resin composite material, is good in textile property, and is capable of promoting the binding force of the basalt fiber and the reinforced thermosetting high-molecular polymer.

Owner:成都中玻复合材料有限公司

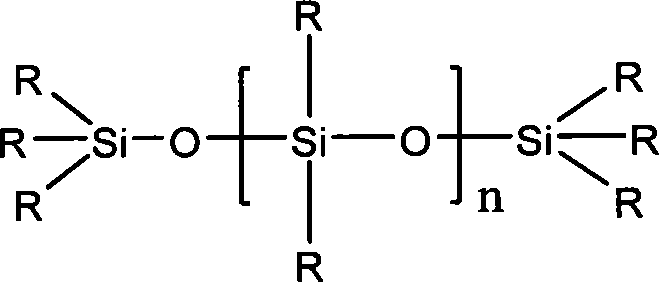

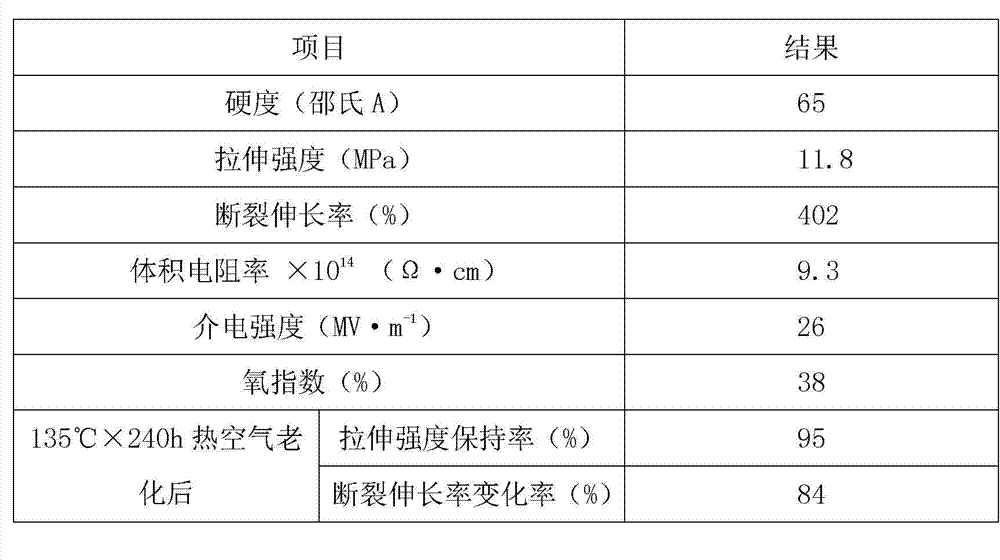

Double-component organic silicon polyurethane elastomer and preparation method thereof

The invention discloses a double-component organic silicon polyurethane elastomer. The double-component organic silicon polyurethane elastomer consists of a component A and a component B, wherein the mass ratio of isothiocyano in the component A to hydroxyl in the component B is 1:(1.05-1.2); the component A is prepared by reacting the following raw materials in part by mass: 10 to 30 parts of polyisocyanate, 30 to 80 parts of polyalcohol, 0.1 to 10 parts of active hydrogen-containing siloxane and 0 to 10 parts of plasticizing agent; and the component B consists of the following raw materialsin part by mass: 10 to 50 parts of polyalcohol, 1 to 10 parts of reinforcing agent, 20 to 60 parts of inorganic filler, 3 to 10 parts of pigment, 0.1 to 10 parts of aid and 5 to 20 parts of plasticizing agent. The double-component organic silicon polyurethane elastomer has high elasticity, hardness, solvent resistance, wear resistance, flexure resistance, high and low temperature resistance, ultraviolet resistance and oxidative degradation resistance, low surface energy and high hydrophobicity, and can meet the long-term using requirement of the sport field.

Owner:GUANGDONG BOSHENG NEW MATERIAL TECH CO LTD

Composite modified asphalt and preparation method thereof

InactiveCN102153874AImprove low temperature performanceImprove anti-aging propertiesBuilding insulationsAging resistanceRoad surface

The invention discloses composite modified asphalt, which is prepared by mixing modifier and matrix asphalt, wherein the modifier consists of the following components in percentage by mass (based on 100 percent of the matrix asphalt): 1 to 10 percent of inorganic substance filler, 1 to 10 percent of polymer, 0.1 to 5 percent of stabilizer, and 0.1 to 5 percent of coupling agent. The prepared modified asphalt has good high and low temperature resistance and ageing resistance, can prolong the service life of roads and reduce the maintenance expense of pavements, and is suitable to be spread in the engineering of high-grade roads, airfield runways, parking lots, bridges and the like.

Owner:SHANDONG JIAOTONG UNIV

Water-based solid lubricant

InactiveCN101768500AReduce coefficient of frictionIncrease frictionAdditivesWater basedOrganic solvent

The invention aims to provide a water-based dispersoid solid lubricant material and the preparation method thereof; wherein, the water-based dispersoid solid lubrication material can be used as solid lubrication material, has good filming and adhesive properties, anticorrosion and wear resistance, and adopts polyamide imide and PTFE as main adhesive material; the water-based solid lubricant is environmental protection, anticorrosive and wear resistant, has low friction coefficient and good high and low temperature resistance, overcomes the problems that the organic solvent of solid lubrication material in prior art has greater toxicity, easy volatilization and is not wear resistant so that the water-based solid lubricant has good application prospect.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

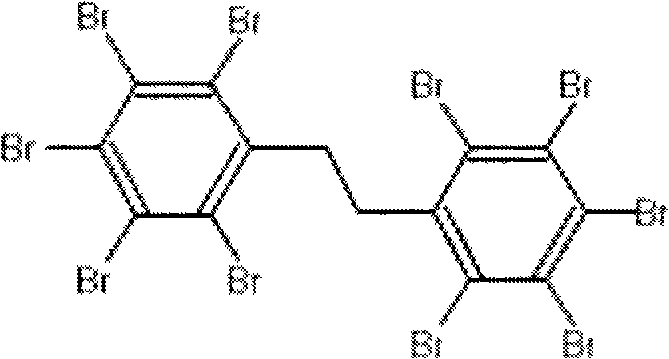

Nanometer enhanced type fluorosilicone rubber long-acting anti-fouling flashing coating

ActiveCN101338159AIncreased hydrophobic migration speedIncreased durability of hydrophobic migrationAntifouling/underwater paintsPaints with biocidesInsulation layerElectric power system

The invention provides a nanometer strengthening fluoride silicone rubber long-acting anti fouling and flashing coating material (nano PRTV coating material) which is used on an external insulation layer of a power system high pressure transmission and transformation device. The coating is composed of the following compositions (weight portion) of 20-40 percent of hydroxyl-fluoride containing polysiloxane, 2-5 percent of small molecular siloxane, 1-6 percent of cross linker, 0.02-1 percent of catalyst, 2-6 percent of nano silicon dioxide, 4-6 percent of decabromodiphenyl ethane, 1-2 percent of pigment and 30-50 percent of solvent. The coating provided by the invention is provided with perfect flame retardancy, solvent resistance, oil resistance, high and low temperature resistance and good self-cleaning performance. The surface of the coating material is smoother than dirt flash preventing coating material. Compared with the dirt flash preventing coating material, the coating material of the invention is greatly improved in aspects of hydrophobic migration speed, proportionality, sustainability, etc. Once filming can be realized. With the service life of more than 20 years, the coating material can be used permanently.

Owner:XIAN TAIPING ELECTRONICS TECH & DEVCO

Aqueous asphalt-based epoxy resin waterproof material composition and preparation process thereof

ActiveCN102464890AImprove stabilityGood high and low temperature resistanceBuilding insulationsEpoxyEmulsion

The invention provides a high-performance aqueous asphalt-based epoxy resin waterproof material composition and a preparation process thereof. The composition comprises 45 to 55% of emulsified asphalt, 25 to 35% of cationic SBR latex, 10 to 20% of epoxy resin emulsion, 2 to 8% of epoxy resin curing agent emulsion and 0.05 to 0.15% of an antifoaming agent. A waterproof material provided in the invention has the following advantages: (1) the waterproof material has excellent resistance to high and low temperature and excellent toughness, and the material does not flow at a high temperature more than 140 DEG C, is not crisp at a low temperature of -20 DEG C and has great adhesion stress; (2) the waterproof material is environment friendly, the preparation process is simple, and a system is stable; (3) construction performance is good, and surface film formation is fast.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano-wollastonite powder modified ethylene propylene diene copolymer cable material

ActiveCN102964697AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsPolyesterPolymer science

The invention discloses a nano-wollastonite powder modified ethylene propylene diene copolymer cable material, which is prepared FROM the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland ethylene propylene diene copolymer 3950, 20-30 parts of butyl rubber BBK232, 10-15 parts of SG-3 PVC (polyvinyl chloride) resin, 10-15 parts of trioctyl trimellitate, 2-5 parts of propanediol sebacate polyester, 2-5 parts of epoxidized soybean oil, 5-10 parts of polyethylene wax, 0.2-0.5 part of bisphenol A, 1-2 parts of zinc stearate, 0.5-1 part of lead sulfate tribasic, 1-2 parts of sulphur, 3-5 parts of zinc oxide, 30-40 parts of wollastonite powder, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

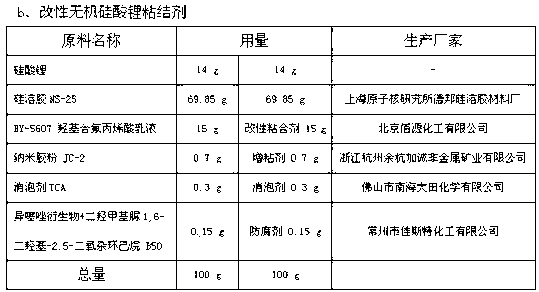

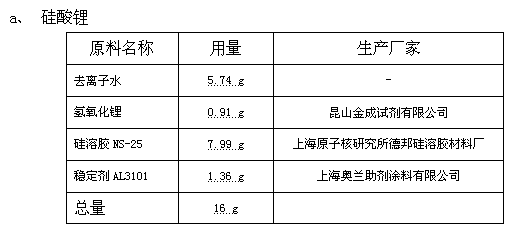

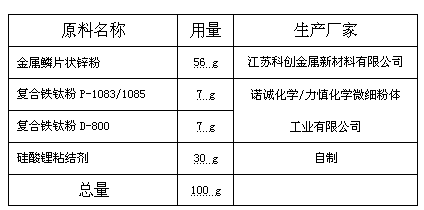

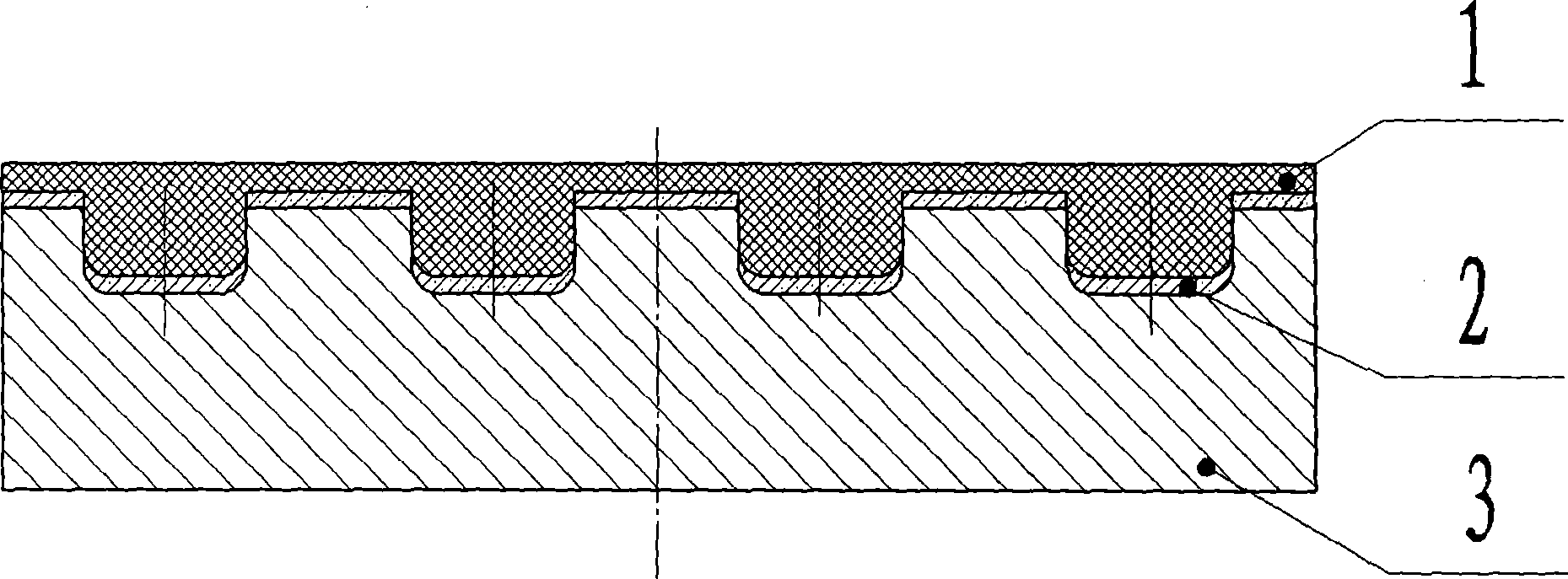

Modified water-based inorganic zinc rich coating and preparation method thereof

ActiveCN103305041ALow viscosityEasy to dryAlkali metal silicate coatingsAlkali metal silicatesWater basedAluminium

The invention relates to a modified water-based inorganic zinc rich coating and preparation thereof. The modified water-based inorganic zinc rich coating is produced by mixing a composite powder with a water-based inorganic binder in a weight ratio of (65-75): (35-25), wherein the composite powder comprises 40-70 parts of metal zinc powder, 3-15 parts of composite iron-titanium powder and 0-15 parts of an antirust agent; the water-based inorganic binder is a lithium silicate binder and comprises 10-25 parts of lithium silicate binder, 60-75 parts of silica sol, 10-15 parts of modified binder and 0.6-3 parts of other auxiliaries; and the modified binder is organic fluorine and / or an organic silicon modified acrylic emulsion. The water-based inorganic lithium silicate binder is used as the base stock of the modified water-based inorganic zinc rich coating, so that the coating is quick in air-drying, nontoxic, tasteless and non-combustible, and has excellent abrasive resistance, flexibility, impact resistance, bending resistance, high / low temperature resistance, electric welding resistance and chemical corrosion resistance, as well as high binding strength, resistance to heat and humidity, salt water resistance and long salt fog resistance time; therefore, the coating is suitable for various building steel structure as a heavy corrosion protective primer, and also can be used as a paint for closure of thermally sprayed zinc, thermally sprayed aluminium anticorrosion layers.

Owner:JIUQING PAINT SHANGHAI

Preparation method of self-adhesion silicon rubber foam material

The invention provides a preparation method of a self-adhesion silicon rubber foam material. The method comprises the following steps: mixing silicon rubber, a foaming agent, a vulcanizing agent, a reinforcing agent and micromolecular silicon oil as raw materials, milling and sheeting, and performing heat treatment foaming to obtain the self-adhesion silicon rubber foam material. Compared with an existing preparation method, the method has the characteristics that the used raw materials have few varieties and are simple and easy to prepare, low in cost and free of environmental pollution; moreover, by adopting the heat treatment foaming technology, the prepared silicon rubber material is a foam material for foaming, which is high in foaming efficiency, light in weight, excellent in heat insulation property, high and low-temperature resistance, chemical stability and physiological inertia and good in self-adhesion performance, and the force of adhesion between the foam material and an aluminum plate is 10-25N / mm.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Soft and flexible heat-shrinkable tube with properties of high fire retardance and oil resistance and production method thereof

ActiveCN103059359AImprove flame retardant performanceMeet environmental protection requirementsElastomerEnvironmental resistance

The invention discloses a soft and flexible heat-shrinkable with properties of high fire retardance and oil resistance. The heat-shrinkable tube comprises the following preparation materials in parts by weight: 10-60 parts of modified thermoplastic polyester elastomers, 0-60 parts of polyethylene, 40-100 parts of oil resistant rubber, 25-100 parts of fire retardant, 0.2-8 parts of lubricant, 0.1-2 parts of sensitized crosslinking agent, 0.5-3 parts of antioxidant, 0-8 parts of carbon black, and 0-10 parts of color master. The soft and flexible heat-shrinkable with properties of high fire retardance and oil resistance disclosed by the invention has a good fire retardance effect which can achieve American UL224VW-1 and comply with ROHS environment-friendly requirements at the same time, and has a good oil resistance effect which can achieve the standard requirements of American military standard SAE-AMS-DTL-23053 / 16.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

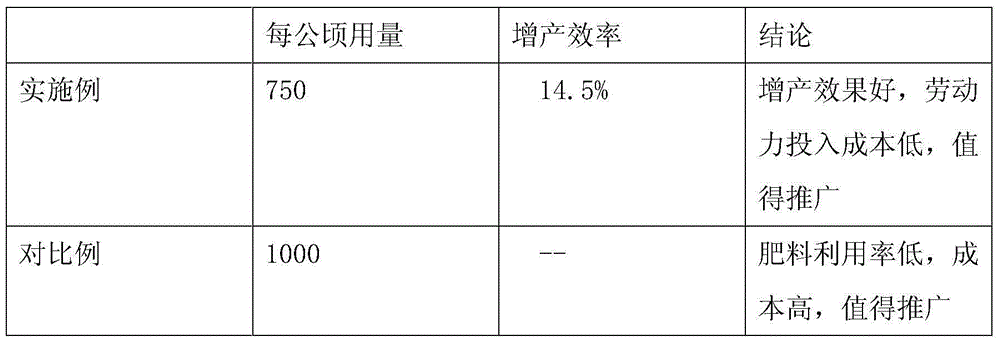

Special slow-release fertilizer for paddy rice and preparation method of special slow-release fertilizer

InactiveCN104311234AReasonable nutritional ratioEasy to useFertilizer mixturesAmmonium sulfateTriethanolamine

The invention provides a special slow-release fertilizer for paddy rice. The special slow-release fertilizer for paddy rice comprises the following raw material components in parts by weight: 20-30 parts of composted cow manure, 4-6 parts of silkworm pupa powder, 10-20 parts of sunflower faceplate, 10-12 parts of egg shell powder, 40-50 parts of potassium dihydrogen phosphate, 20-30 parts of calcium superphosphate, 60-80 parts of plant ash, 30-40 parts of ammonium chloride, 8-10 parts of sodium silicate, 8-10 parts of urea, 0.1-0.2 part of ferrous sulfate, 0.1-0.2 part of zinc gluconate, 0.0001-0.0003 part of S-abscisic acid, 2-3 parts of borax, 0.01-0.02 part of copper sulfate, 6-8 parts of acrylic acid, 3-4 parts of sodium hydroxide, 2-3 parts of acrylamide, 10-15 parts of hydroxypropyl distarch phosphate, 1-2 parts of ammonium persulfate, 8-10 parts of triethanolamine, 4-6 parts of waste plastic powder, an appropriate amount of water and 10-15 parts of fertilizer additives. The special slow-release fertilizer for paddy rice, provided by the invention, has reasonable mixture ratio of nutrients, and can slowly release the nutrients by fertilizing once, keep slow release of fertilizer efficiency, ensure nitrogen-phosphorus-potassium nutrients during the whole growth process of the paddy rice, realize convenience in use, and simultaneously improve the drought resistance, high and low temperature resistance and pest and disease resistance of the paddy rice.

Owner:ANHUI HEQUAN SEED IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com