Patents

Literature

62results about How to "Good textile properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent temperature-adjusting viscose fibre and its production

InactiveCN101029421AGood textile propertiesArtificial filaments from viscoseCelluloseBreakdown strength

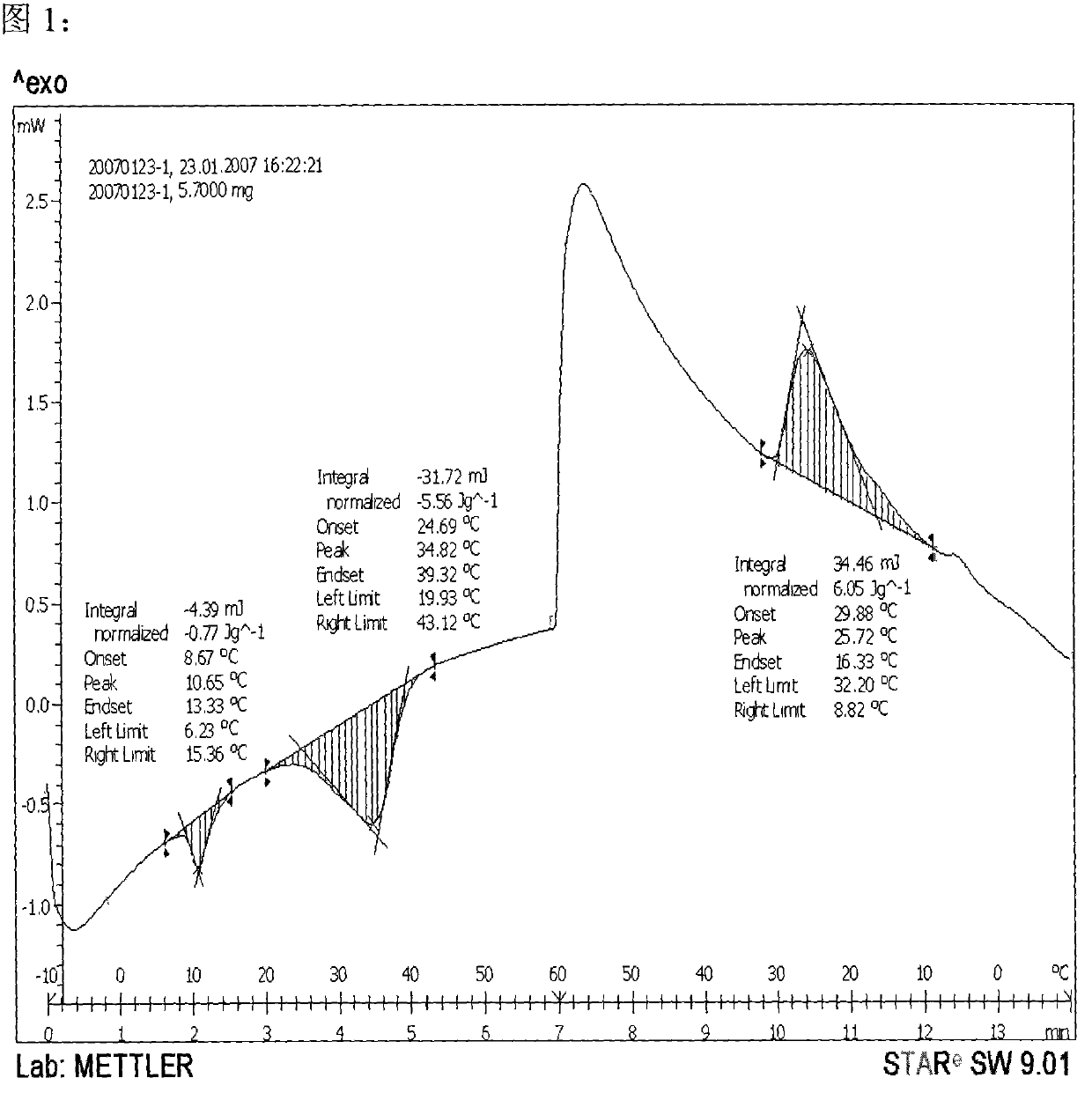

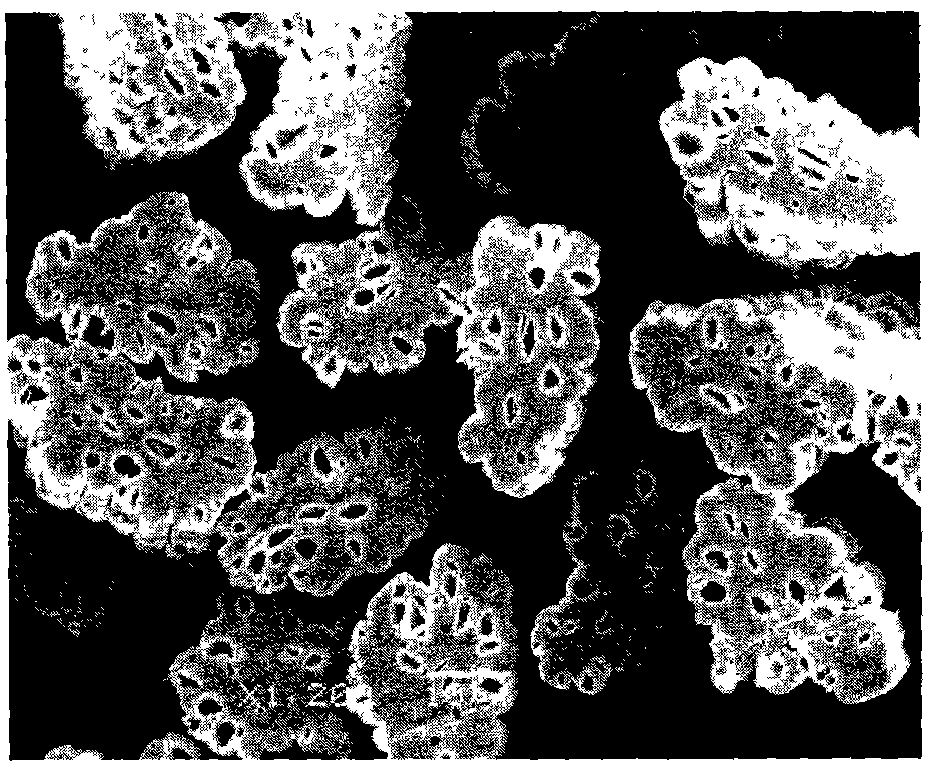

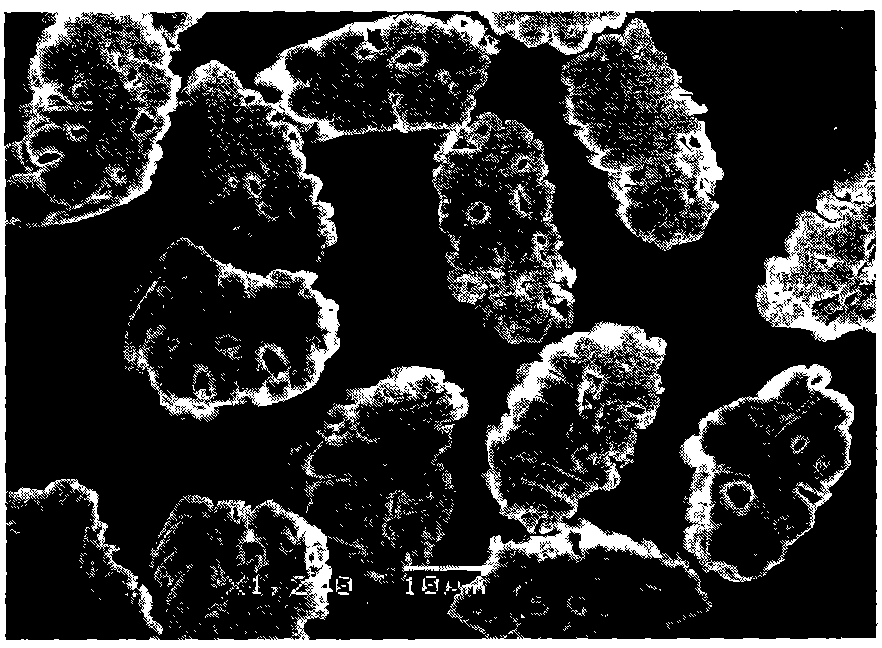

A phase-variable material micro-capsule as temperature-adjusting functional material, an intelligent temperature-adjusting viscose fiber and its production are disclosed. Dry breakdown strength is >=1.42CN / dtex, wet breakdown strength is>=0.64CN / dtex; It consists of cellulose 84.7-92.75wt%, micro-capsule 5-30wt% and water-content 7-15wt% and oil solution 0.15-0.30wt%. The fiber coagulation heat-liberation enthalpy valueDeltaH>=1.0J / g, melt heat-adsorption enthalpy value DeltaH>=1.0J / g. It is non-toxic, has better adaptability and no harm.

Owner:HEBEI JIGAO CHEM FIBER +1

Special epoxy impregnating compound for basalt fiber and preparation method of special epoxy impregnating compound

The invention discloses a special epoxy impregnating compound for a basalt fiber and a preparation method of the special epoxy impregnating compound. The special epoxy impregnating compound for the basalt fiber is prepared from the following components in percentage by weight: 5.0%-8.0% of an epoxy latex film-forming agent, 0.1%-1% of a lubricant, 0.5%-1.5% of binder, 0.5%-1.5% of plasticizer, 0.2%-1.0% of an antistatic agent, 0.5%-1.0% of a coupling agent and the balance of soft water. The reinforced textile type impregnating compound is suitable for a basalt-reinforced thermosetting phenolic epoxy resin composite material, is good in textile property, and is capable of promoting the binding force of the basalt fiber and the reinforced thermosetting high-molecular polymer.

Owner:成都中玻复合材料有限公司

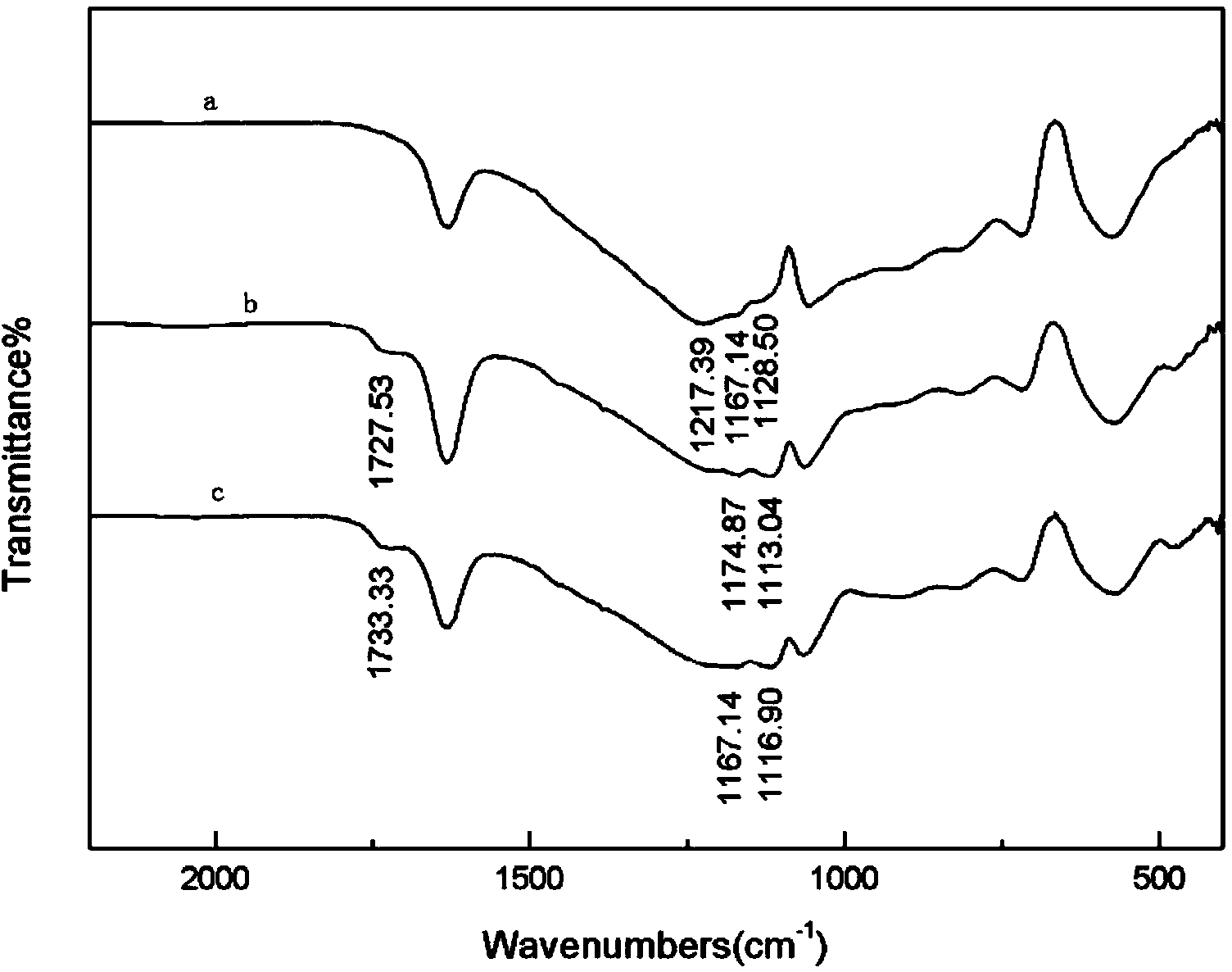

Mullite fiber surface modification method

The invention relates to a mullite fiber surface modification method which comprises the following specific steps: 1, compounding a surface modifier; 2, performing surface modification, namely (1) hydrolyzing, (2) infiltrating and grafting, namely immersing the surface modifier from the fibers for infiltrating, enabling the hydroxyl groups of silanol or the hydroxyl groups and -Si-OH on the fiber surface to be subjected to etherification reaction so as to form a Si-O-Si structure, so that the structure is grafted to the fiber surface; then enabling active groups at the other end of a silane coupling agent to react with organic components in an impregnating compound, thereby obtaining the modified mullite fibers; and (3) drying and forming, namely infiltrating within 90 minutes, drying the taken mullite fibers in a drying box at the temperature of 105 DEG C to constant weight. According to the mullite fibers subjected to surface modification, silanol generated by hydrolyzing the silane coupling agent is enabled to act with the -OH on the fiber surface so as to form the Si-O-Si structure, the surface of the modified fiber sample contains coupling agent and film-forming agent components, the fibers are adhered to one another, the surface of the fiber sample is glossy, the softness is greatly improved, and the fiber surface properties are improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Wetting agent used for pretreated enhancement type filter cloth

The invention relates to a wetting agent used for pretreated enhancement type filter cloth, which is characterized by comprising the following components by weight ratio: 2-2.5% of color fixing agents, 2-2.5% of epoxy resins, 2.5-3% of water-soluble unsaturated polyester resins, 0.5% of A151, 0.5% of alcohol, 0.2% of tween-80 and the balance water. The pH value of the wetting agent is regulated to5 by glacial acetic acid. The filter cloth weaved by the yarns adopting the wetting agent formula can directly undergo surface chemical treatment without dewaxing, thus saving the electric energy andmaintaining the strength of the filter cloths. The wetting agent overcomes the defect that the existing filter cloth weaved by the yarns adopting the paraffin wetting agent formula need dewaxing before surface chemical treatment, which not only consumes the electric energy but also damages the cloth cover strength.

Owner:山东兴国大成特种纤维科技有限公司

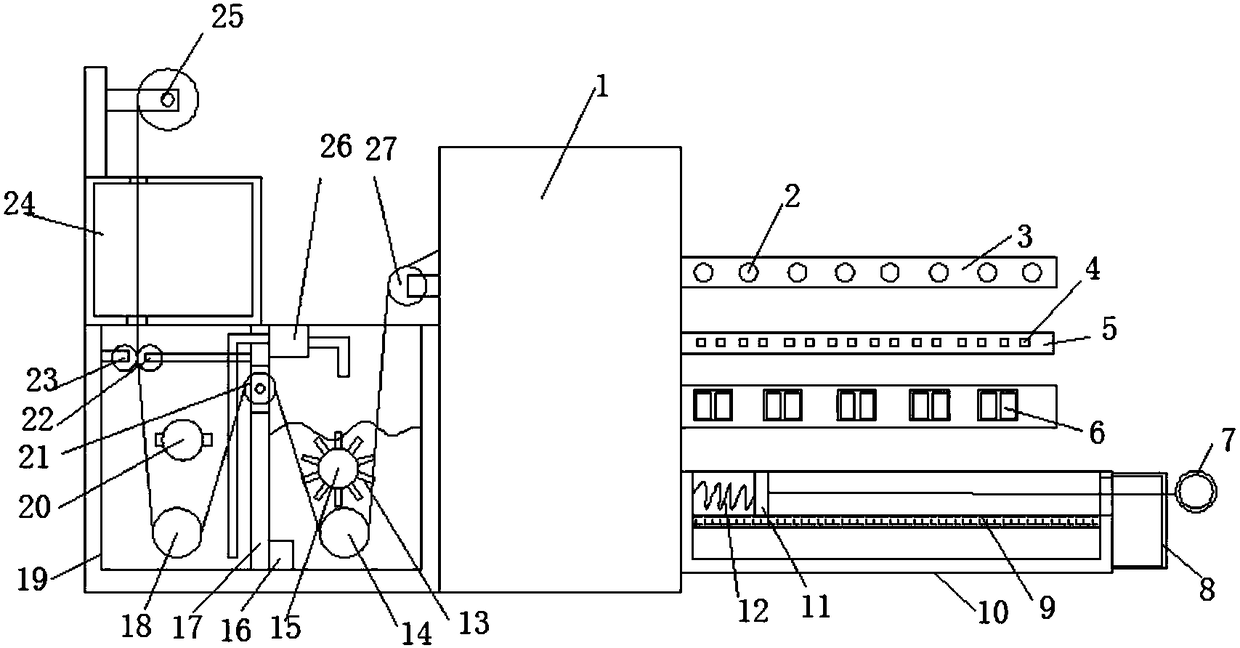

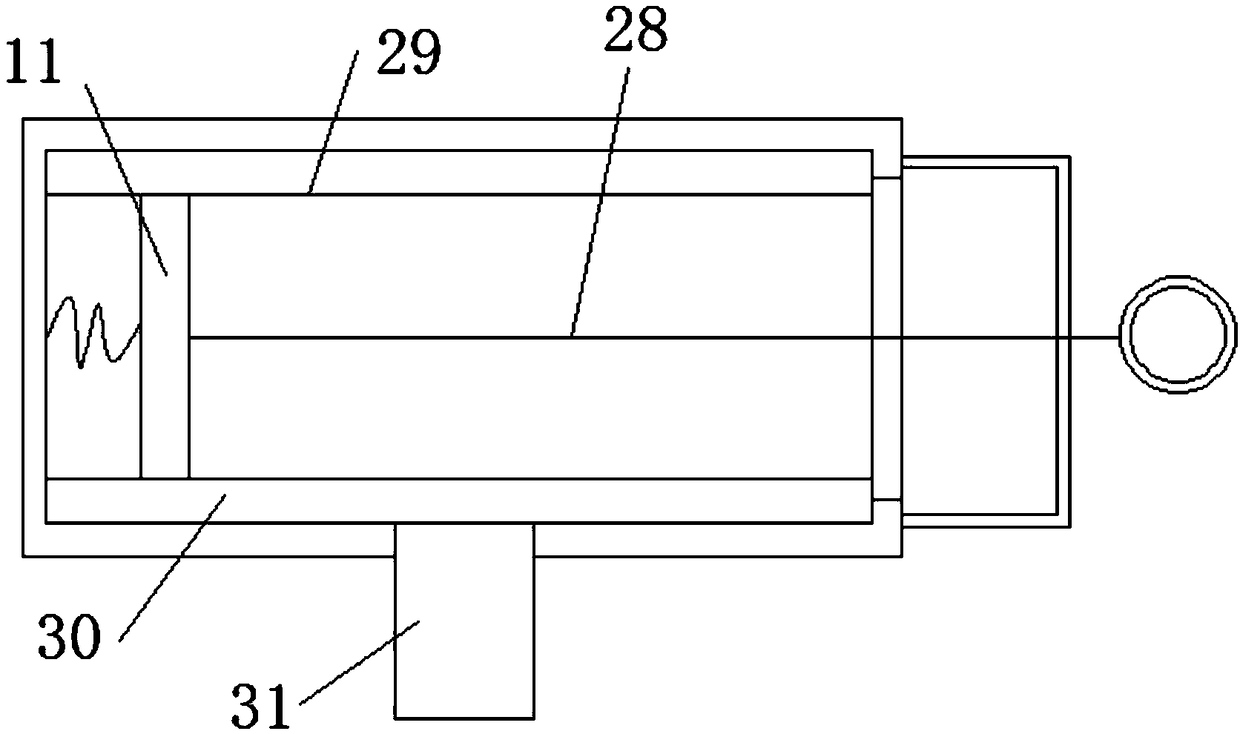

Cleaning-conveniently spinning device

InactiveCN108118420AAvoid pollutionReduce pollutionLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingYarnEngineering

The invention belongs to the field of a spinning device, and particularly to a cleaning-conveniently spinning device. For a textile machine is polluted by massive spreading of fluff dust and unable toclean the interwoven cloth for the fluff on a yarn is easy to drop when the yarn of the existing textile machine passes through a roll wheel and other guide devices, the following plan is presented;the spinning device comprises a device main body; one side of the device main body is orderly equipped with a horizontal fixing plate, a teasing plate, an ultra-wear-resisting thread crossing device and a collecting box with an opened top end from top to bottom orderly; multiple rotary shafts are rotationally connected to the fixing plate, and multiple comb teeth are connected to the teasing plate; the side wall at one side of the collecting box is equipped with an exhaust fan. The cleaning-conveniently spinning device can collect and clean fluff and dust on the yarn, prevent fluff from polluting the spinning device, reduce the maintenance of the spinning device in later period while clean and dry the interwoven cloth; thus the cloth does not need to clean in later period, the spinning effect is good.

Owner:苏州朦井纺织科技有限公司

Tea polyphenol cellulose fiber and preparation method thereof

ActiveCN106521671AGood textile propertiesPrevent agingArtificial filaments from viscoseRoom temperatureViscose

The invention discloses tea polyphenol cellulose fiber which is composed of, by weight, 5-10% of tea polyphenol and 90-95% of cellulose, wherein the tea polyphenol is grafted on the cellulose through a coupling agent. A preparation method of the tea polyphenol cellulose fiber includes following steps: (1), preparing tea polyphenol pretreatment liquid: preparing a tea polyphenol water solution of 10-20% in mass fraction, adjusting pH value of the tea polyphenol water solution to 4-5, heating the tea polyphenol water solution to 70-80 DEG C, dropwise adding a silane coupling agent, increasing temperature of a system to 100-130 DEG C after dropwise adding is finished, maintaining reaction for 8-10h, adjusting pH value of reaction liquid to 7-8 to obtain the tea polyphenol pretreatment liquid, and cooling to room temperature for standby use; (2), performing viscose grafting treatment: adding the tea polyphenol pretreatment liquid into viscose, sufficiently mixing, entering a ripening intermediate bucket constantly maintained in a stirring state, and maintaining reaction for 30-36h to obtain tea polyphenol pre-grafting viscose; (3), directing spinning, washing and drying the tea polyphenol pre-grafting viscose obtained in the step (2) to obtain the tea polyphenol cellulose fiber.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

Glass fiber reinforced impregnating agent

The invention discloses a glass fiber reinforced impregnating agent, which is prepared from the following components in parts by weight: 20 to 30 parts of vinyl aqueous epoxy resin, 20 to 30 parts of epoxy dicyclopentadiene epoxy resin, 10 to 20 parts of acrylate emulsion, 5 to 8 parts of linseed oil, 3 to 5 parts of coupling agent, 0.5 to 2 parts of lubricant, 0.5 to 1 part of collecting agent, 0.5 to 1 part of emulsifier, 0.5 to 2 parts of polyvinylpyrrolidone, 0 to 0.5 part of polyvinyl alcohol, 0 to 0.5 part of antistatic agent, 0.5 to 1 part of antifoaming agent, and 300 to 500 parts of water. Due to the added polyvinylpyrrolidone and polyvinyl alcohol, the adhesive force of the impregnating agent is strengthened; the viscosity is also improved; the breaking of fibers is prevented, the plasticity and stiffness are enhanced, and the generated broken filaments are reduced. Three film forming agents are adopted; the impregnating agent has an excellent high temperature resistant performance and electric properties, a high adhesive force, and a good film forming performance and protective property; thus the impregnating agent can well protect and collect glass fibers during the process of high speed ejection and rolling, the production efficiency is improved, and the mechanical performance of glass fibers is enhanced.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

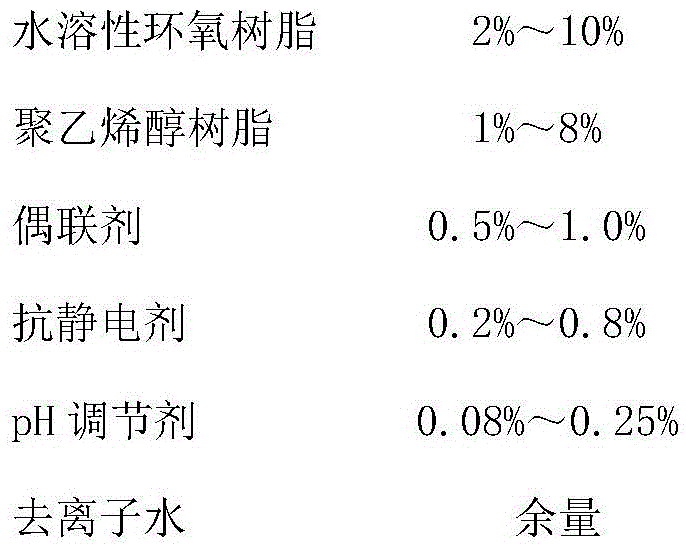

Impregnating compound for basalt fibers

The invention discloses a special impregnating compound for basalt fibers and a preparation method of the impregnating compound. The impregnating compound comprises raw materials in percentage by weight as follows: 2%-10% of water-soluble epoxy resin, 1%-8% of polyvinyl alcohol, 0.5%-1.0% of a coupling agent, 0.2%-0.8% of an antistatic agent, 0.08%-0.25% of a pH regulating agent and the balance of deionized water. The impregnating compound for surface modification of the basalt fibers is prepared in the rated weight proportion and directly coats surfaces of the basalt fibers during basalt production drawing, surface modification is completed after drying, and the impregnating compound is more convenient to use and has the good adhesion and film-forming property.

Owner:晏玲莉

Quartz glass fiber reinforced textile size

The invention relates to a quartz glass fiber reinforced textile size which belongs to the technical field of glass fiber surface treatment. The size is prepared by physically mixing the following raw materials by weight percent: 1-30% of water-soluble epoxy resin, 0.1-10% of modified epoxy resin, 0.1-2.0% of cation surfactant, 0.1-2.0 nonionic surfactant, 0.1-2.0% of silane coupling agent, 0.1-10% of water-based inorganic additive, 0.1-2% of plasticizer, 0.05-0.5% of pH regulator and 20-95% of deionized water and then stirring evenly. The quartz glass fiber has favorable production process performance, favorable textile performance, high breaking strength and low hairiness amount and is capable of fully exploiting the excellent performance, so that the quartz glass fiber can be better applied to the fields of aerospace, war industry, heat insulation and the like so as to satisfy the demands of national economy and defense-related science and technology.

Owner:HUBEI FEILIHUA QUARTZ GLASS

Reinforcing yarn size for glass fibers and preparation method thereof

The invention relates to a reinforcing yarn size for glass fibers and a preparation method thereof, and belongs to the technical field of sizes for glass fibers. The size comprises 4.0-5.5% of a filmogen emulsion, 1.7-4% of a lubricating agent, 0.5-1.5% of a water soluble epoxy resin binder, 0.2-1.0% of an inorganic antistatic agent, 0.5-1.5% of an aminosilane coupling agent and the balance softened water. The filmogen emulsion comprises polyethylene glycol-4000 (PEG-4000), boron trifluoride diethyl etherate, epoxy resin E-44, epoxy resin E-20 and water with a ratio of (1-2): (0.005-0.01): (1-1.5): (0.8-1.2): (8-10). Glass fibers drawn through the size can bear repeatedly bending deformation and have a good textile performance, and woven glass fiber cloth can be applied to production of composite materials without heat treatment and is quick in soakage and high in binding force when compounded with matrix resin.

Owner:SICHUAN FIBERGLASS GRP

Preparation method of anti-electrostatic fabric

InactiveCN107460726ASoft touchHigh strengthDry-cleaning apparatus for textilesWoven fabricsEngineeringAramid

The invention provides a preparation method of anti-electrostatic fabric and relates to the technical field of textile materials. The preparation method of the anti-electrostatic fabric comprises the following steps: preparing raw materials: S1, preparing electroconductive aramid fiber and selecting high-strength polyester fiber and cotton fiber; S2, weaving fabric: weaving the fabric by a plane weave structure of warp yarns and weft yarns, wherein the warp yarns adopt electroconductive fibers and high-strength polyester filament yarns which are arranged according to the ratio of 1:4, and the weft yarns adopt mixed weft yarns comprising electroconductive fibers and the cotton fibers according to the ratio of 1:1; S3, performing decontamination treatment: preparing decontamination liquid, soaking the fabric obtained in the step S2 into the decontamination liquid, dipping at 30 to 35 DEG C for 20 to 25 minutes and then washing with water; S4, performing anti-electrostatic treatment: preparing anti-electrostatic treatment liquid, soaking the fabric washed with water in the step S3 into the anti-electrostatic treatment liquid, dipping for twice and rolling for twice, wherein the rolling allowance is 80 percent; and drying and shaping: drying the fabric subjected to anti-electrostatic treatment in the step S4 into a drying box, and performing tenter setting after drying to obtain the anti-electrostatic fabric. The fabric prepared by the invention has high anti-electrostatic performance.

Owner:丹阳新星服饰有限公司

Novel glass fiber impregnating compound and preparing method thereof

The invention discloses a novel glass fiber impregnating compound. The novel glass fiber impregnating compound is prepared from, by weight, 20-30 parts of vinyl water-borne epoxy resin, 20-30 parts of 3,4-epoxy group-6-methyl cydohexane formic acid-3,4-epoxy group-6-methyl cyclohexane methyl ester epoxy resin, 10-20 parts of hydroxypropylation modified pea starch, 3-5 parts of coupling agent, 0.5-2 parts of lubricating agent, 0.5-1 part of collecting agent, 0.5-1 part of surfactant, 0.5-2 parts of polyvinylpyrrolidone, 0-0.5 part of antistatic agent, 0.5-1 part of defoamer and 300-500 parts of water. By adding polyvinylpyrrolidone to the formula, adhesive force of the impregnating compound can be improved, viscosity of the impregnating compound can be improved, fiber breakage can be prevented, plasticity and stiffness can be improved, and broken filament generation can be reduced. Three film-forming agents are adopted; yarn impregnation speed is high, heat resistance is high, binding power is high, film-forming property is high, and protective property is high; protection and collection of glass fiber during high-speed jetting and rolling can be achieved easily, production efficiency is improved, and mechanical property of glass fiber is improved.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

Treating compound special for high textile performance weft yarn and preparation thereof

The invention discloses a special treating compound for weft yarn with high spinning performance, and a preparation method thereof. The special treating compound comprises a polyester emulsion, an epoxy emulsion, water-based epoxy, a lubricant, a coupling agent, glacial acetic acid and water in balancing amount, which are respectively subjected to the dispersion of the coupling agent, the dilution of the water-based epoxy, the dilution of the polyester emulsion, the dilution of the epoxy emulsion and the dilution of the lubricant, and then added into a preparation tank in sequence; and the residual water is added until the total amount is reached, and the stirring-up is carried out for 15 minutes. The treating compound endows the yarn with good convergence, ensures the smooth glass fiber drawing progress, and has excellent spinning performance; the abrasion of the fiber precursors is less during the spinning process; the wool yarn of the cloth cover is less, the compatibility with the back resin is good; the strength of the cloth cover is good; besides, the preparation process is simple, and the operation is easy.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

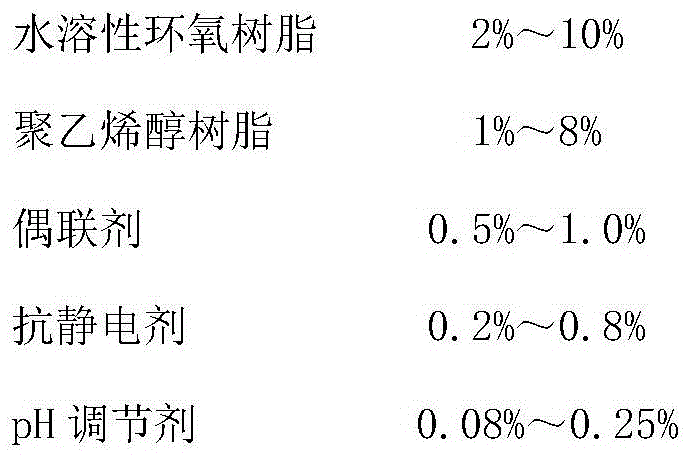

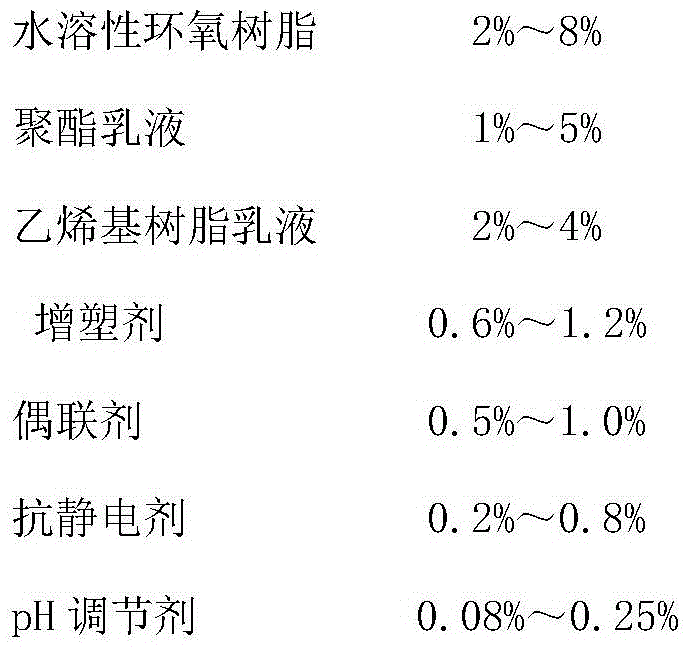

Reinforced soakage agent for basalt fibers

The invention discloses a soakage agent for basalt fibers and a preparation method of the soakage agent. The soakage agent is prepared from 2%-8% of water-soluble epoxy resin, 1%-5% of a polyester emulsion, 2%-4% of a vinyl resin emulsion, 0.5%-1.0% of a coupling agent, 0.2%-0.8% of an antistatic agent, 0.6%-1.2% of a plasticizer, 0.08%-0.25% of a pH regulator and the balance of deionized water. The soakage agent which is prepared in the rated weight ratio and used for surface modification of the basalt fibers can be directly applied to the surfaces of the basalt fibers in the production and drawing process of the basalt fibers, surface modification can be completed after drying, the soakage agent is more convenient to use, and an aqueous solution of the soakage agent has good adhesion and film-forming properties.

Owner:晏玲莉

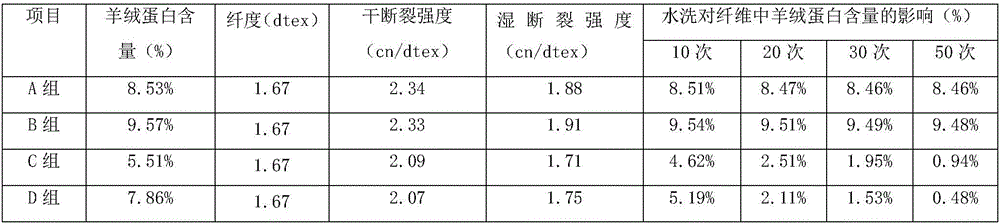

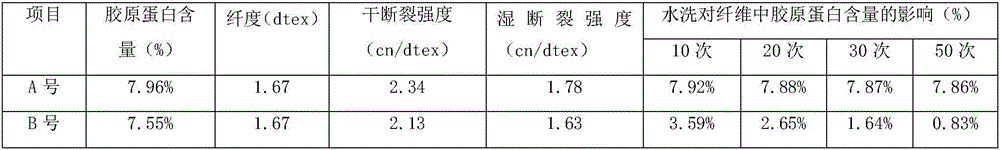

Cashmere protein cellulose fiber and preparation method thereof

ActiveCN106757463AGood textile propertiesDoes not affect mechanical propertiesMonocomponent protein artificial filamentArtificial filaments from cellulose derivativesRoom temperatureCellulose fiber

The invention discloses a cashmere protein cellulose fiber, which contains the following components in parts by weight: 5-15% of cashmere protein and 85-95% of cellulose, wherein the cashmere protein is grafted onto cellulose through a silane coupling agent. A preparation method of the cashmere protein cellulose fiber comprises the following steps: (1) preparing 10-20% by mass of cashmere protein alkaline aqueous solution with pH of 11-12, heating the cashmere protein alkaline aqueous solution to 55-65 DEG C, dropwise adding a silane coupling agent, heating the system temperature to 100-110 DEG C after the dropwise addition is over, maintaining the reaction for 2 to 3 hours to obtain cashmere protein pretreatment solution, and then cooling to room temperature for later use; (2) adding the cashmere protein pretreatment solution into viscose according to the proportion of cashmere protein, the mass of which is 10-20% of alphacellulose in viscose, fully mixing and then flowing into a ripening middle barrel which is always kept at the stirring state, maintaining reaction for 6-10 hours to obtain cashmere protein grafted viscose; and (3) directly spinning, washing and drying the obtained cashmere protein grafted viscose to obtain the cashmere protein cellulose fiber.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

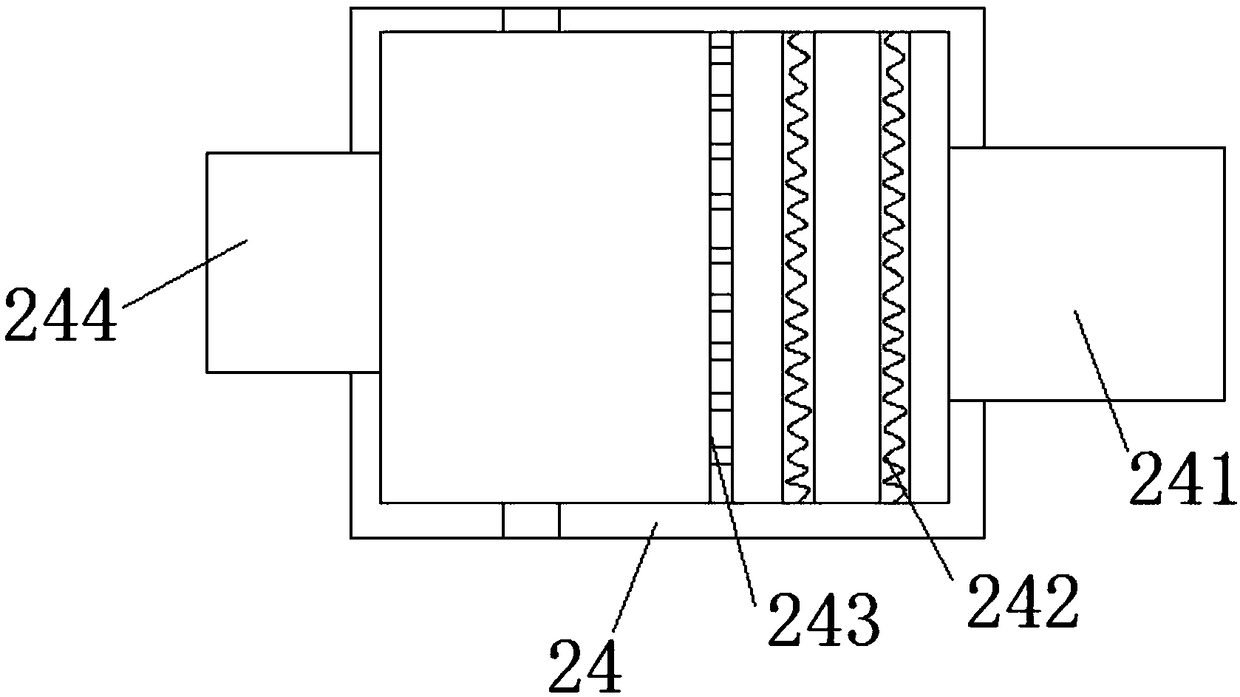

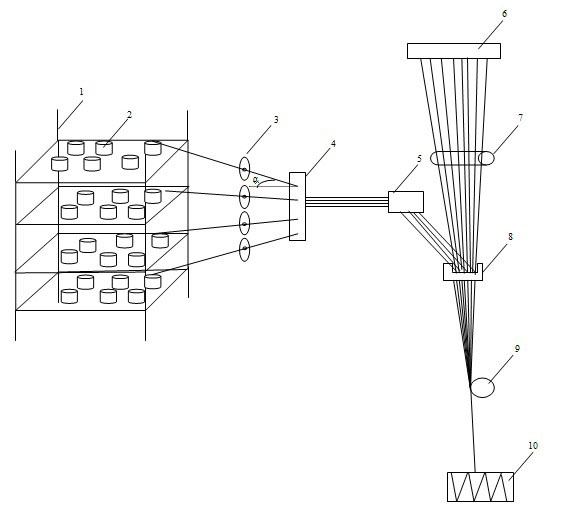

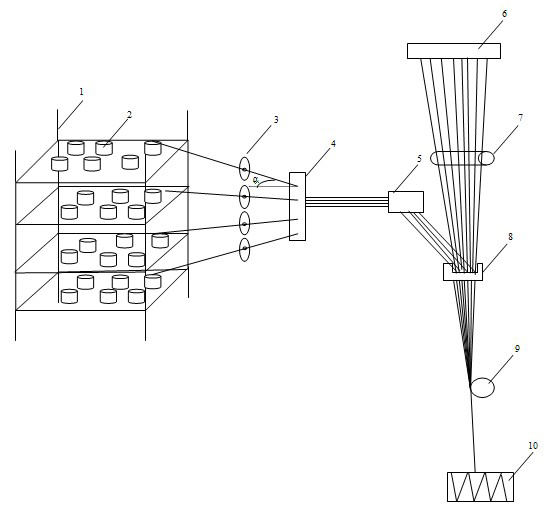

Method and equipment for manufacturing composite fiber containing continuous glass fiber

The invention relates to a method for manufacturing a composite fiber containing a continuous glass fiber. The composite fiber is formed by mutually mixing offline terylene and an online continuous glass fiber; the glass fiber is drawn on line, and the terylene is finished yarn; a plurality of bundles of terylene with different yarn feed angles are drawn to be converged into sheet shapes after being subjected to tension adjustment; and the converged terylene yarn bundles are separated and then compounded with the glass fiber processed with an impregnating compound. The invention has the advantages of simplified process equipment and improved production smoothness; and meanwhile, the introduction of chemical fiber yarn-feed tension adjustment ensures that better practicability and better effect on the baked yarn clew moulding effect are achieved.

Owner:JUSHI GRP CO

Collagen cellulose fiber and preparation method thereof

ActiveCN106757501AReduce wrinklesFast water absorptionConjugated cellulose/protein artificial filamentsMonocomponent synthetic polymer artificial filamentAlpha-CelluloseViscose

The invention discloses a collagen cellulose fiber which is composed of the following components in percentage by weight: 5-15% of collagens and 85-95% of cellulose, wherein the collagens are grafted onto the cellulose through epoxy chloropropane. The preparation process comprises the following steps: (1) preparing collagen alkaline aqueous solution with a mass fraction of 10-20% and a pH value of 9-10, heating the collagen alkaline aqueous solution to the temperature of 55-65 DEG C, dropwise adding epoxy chloropropane, raising the temperature of the system to 100-110 DEG C after dropwise adding, maintaining the reaction for 2-3 hours so as to obtain collagen pretreatment liquid, and reducing to room temperature for later use; (2) adding the collagen pretreatment liquid into viscose according to a ratio of 10-20% of the collagen to alpha cellulose in the viscose, fully mixing, entering a maturing intermediate barrel which is always kept in a stirring state, and maintaining the reaction for 6-10 hours so as to obtain collagen grafted viscose; and (3) directly spinning, washing and drying the obtained collagen grafted viscose, thereby obtaining the collagen cellulose fiber.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

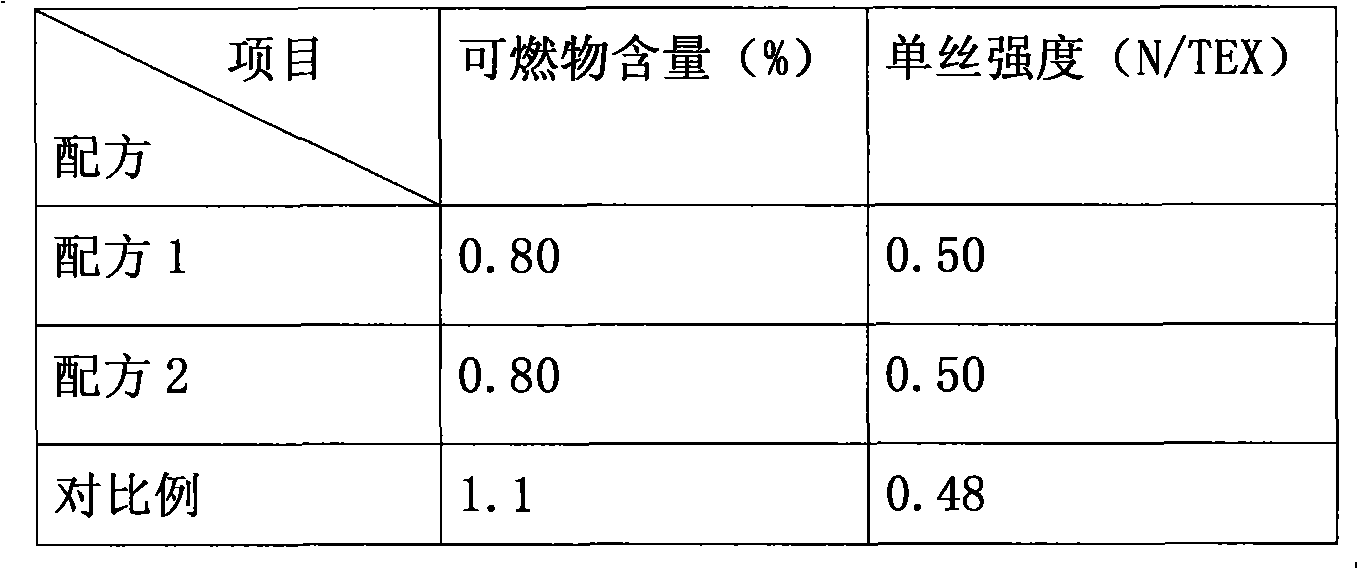

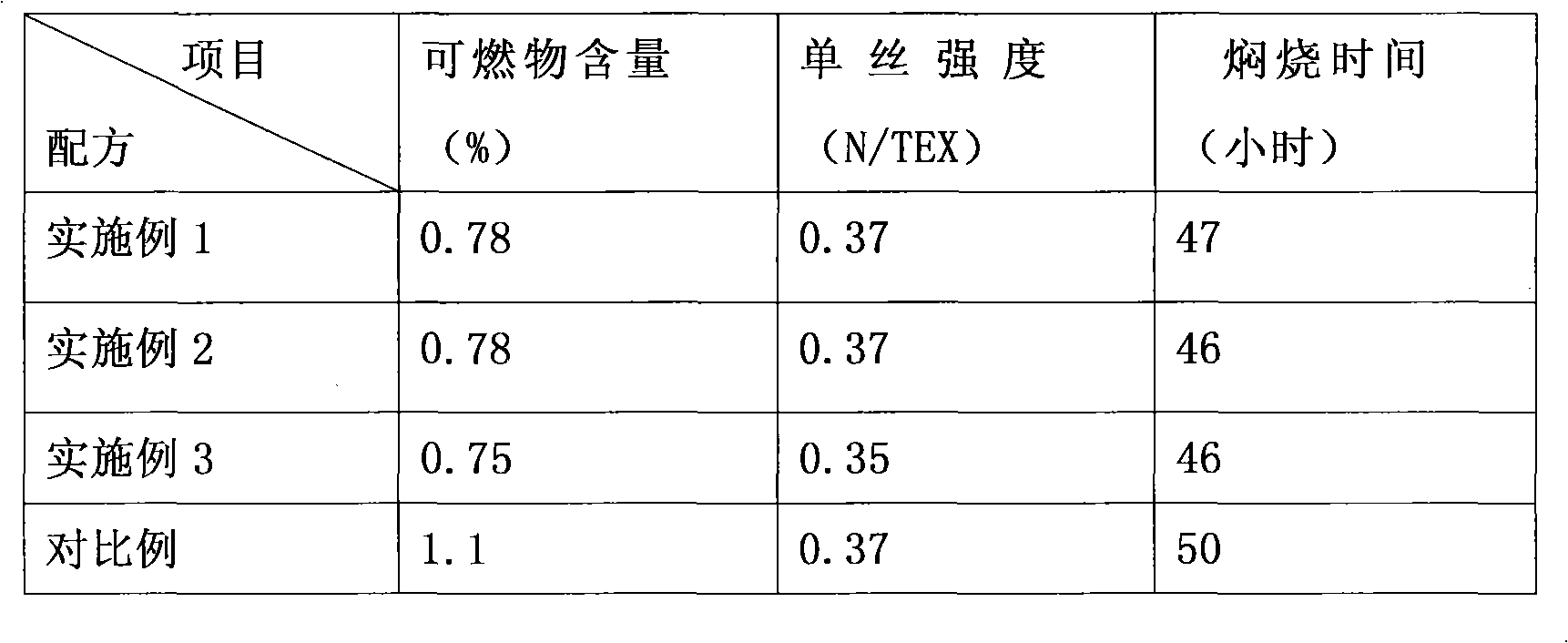

Paraffin sizing material for electronic cloth of low solid content

The invention relates to a paraffin wax impregnating compound with low solid content used by an electronic cloth. The compositions by weight percentage of the paraffin wax impregnating compound are: 1.2 to 1.5 percent of paraffin wax, 0.8 to 1.5 percent of engine oil, 0.8 to 1.5 percent of vaseline, 0.6 to 0.8 percent of emulsifying agent, 0.1 to 0.15 percent of cationic film, 2.5 to 3.8 percent of fixing agent, the balance being water. Moreover, epoxy resin can be also added into the compositions and occupies 0.3 to 0.5 percent of the total weight. The invention reduces the amount of oil substances such as the paraffin wax, the vaseline, the engine oil and so on in the compositions of the impregnating compound and adds the cationic film with a certain proportion. Glass fiber yarns the surface of which is coated by the impregnating compound are soft and have good weaving performance and low combustible content. According to actual detection, the combustible content of the glass fiber yarns produced by the formula is between 0.75 and 0.85 percent and reduces by 15 to 25 percent compared with 1 percent of combustible content of the prior paraffin wax yarns, and the production cost is reduced.

Owner:山东兴国大成特种纤维科技有限公司

Anti-static wool or fibric of wool product and its processing method

The invention relates to antistatic wool or wool mixed spinning produce and its processing method. It contains wool fiber and other fiber. Its feature is that it uses wool fiber and other wool like yarn to blend or interlace with antistatic fiber to form the finished product by knitting or tatting. It has the advantages of good feel, no any stimulation for skin, antifriction, washing resistant, durable antistatic etc.

Owner:INNER MONGOLIA ERDUOSI CASHMERE PRODS

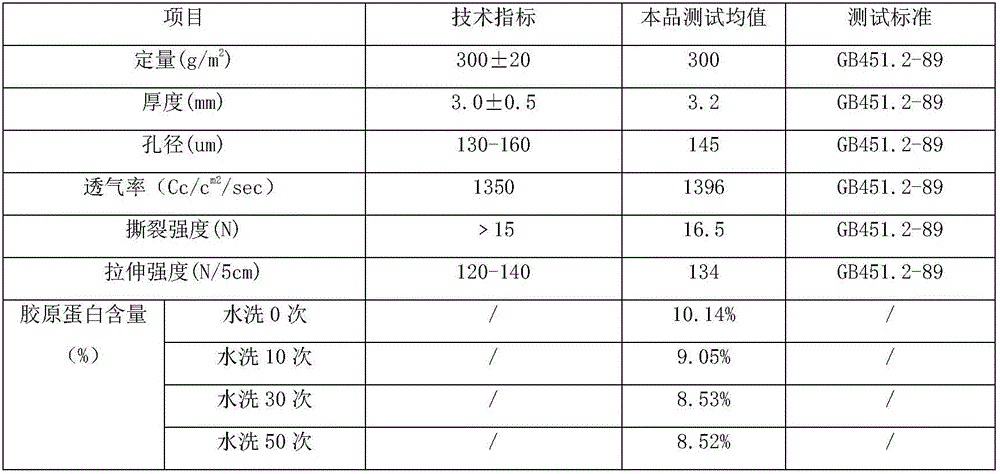

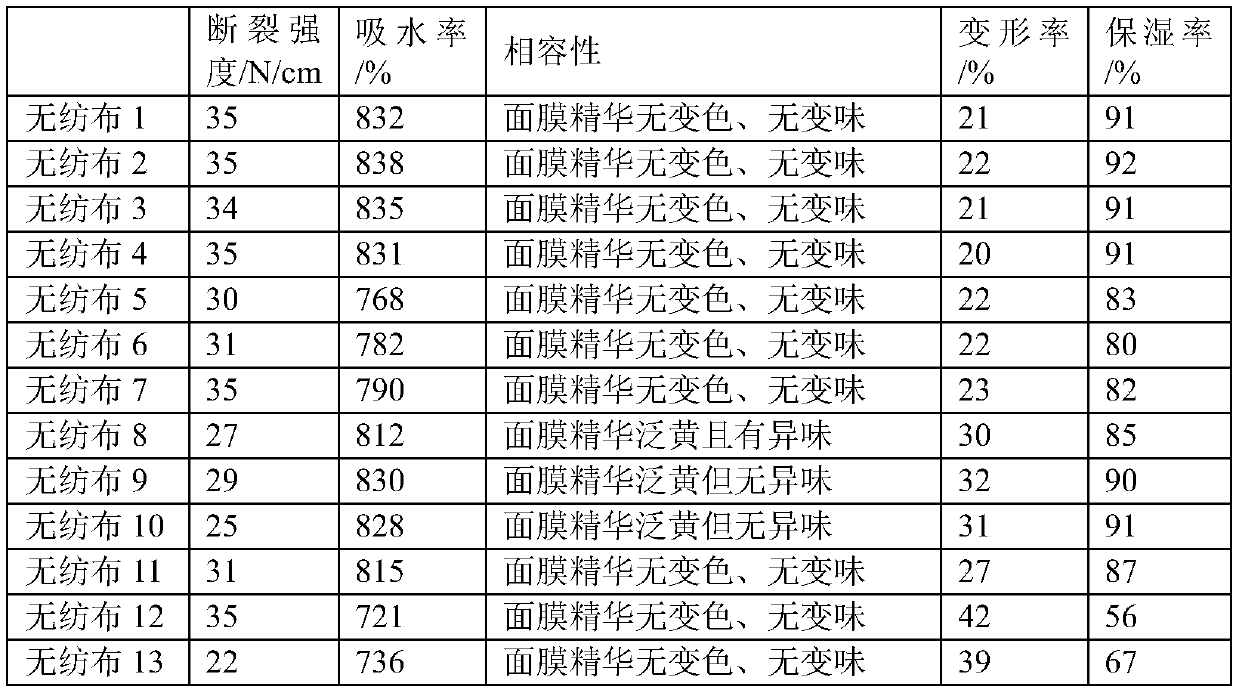

Collagen cellulose fiber spunlaced nonwoven fabric and production method thereof

ActiveCN106757766AIncrease contentImprove antibacterial propertiesNon-woven fabricsVegetal fibresCotton fibreCellulose fiber

The invention discloses collagen cellulose fiber spunlaced nonwoven fabric and a production method thereof and relates to the field of functional spunlaced nonwoven fabric production. The collagen cellulose fiber spunlaced nonwoven fabric comprises, by weight percentage, 10-15% of collagen and 85-90% of cotton fibers or synthetic fibers, wherein 50-75% of the collagen is grafted to cellulose through epichlorohydrin, the rest of 25-50% of the collagen attaches to the cellulose in a free manner, and the size of the fibers is 1.33-1.67dtex. The production method is combined with a production process of collagen cellulose fibers, and collagen preprocessing liquid is used for processing during spunlace to further increase the content of the collagen so as to allow the collagen content of the nonwoven fabric to reach up to 10-20%.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

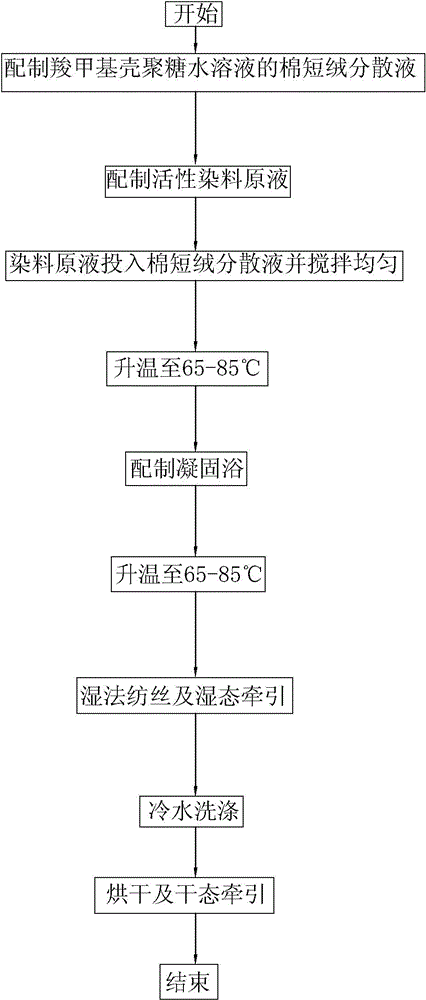

Preparation method of dope-dyed cotton linter composite filament

ActiveCN104831385AExcellent textile performance and wearing performanceHigh color fastnessConjugated cellulose/protein artificial filamentsWet spinning methodsCitrate sodiumReactive dye

The present invention relates to a preparation method of dope-dyed cotton linter composite filament. The method comprises the steps of: 1) preparing a dye stock solution by dissolving a reactive dye in water to prepare a dye stock solution with reactive dye concentration of 20-40wt%; 2) preparing a spinning solution by adding the dye stock solution to a dispersion liquid of cotton linters, wherein the dispersion liquid of cotton linters is an aqueous solution of carboxymethyl chitosan, and the addition amount of the dye stock solution is 1-3.5wt% of the dispersion liquid of cotton linters calculated by the weight of the active dye; stirring uniformly and heating to 65-85 DEG C to obtain the dope-dyed spinning solution; 3) preparing a coagulating bath by dissolving citric acid and lemon sodium in water to prepare the coagulating bath, wherein the concentration of the citric acid in the coagulating bath is 35-45g / l, and the concentration of sodium citrate is 0.8-1.2g / l; and raising the temperature of the coagulating bath to the same temperature of the spinning solution; and 4) using the coagulating bath to conduct spinning on the spinning solution by a conventional method. The composite filament provided in the invention has high color fastness and high utilization rate of reactive dye.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Nano antibacterial bamboo charcoal fibers

InactiveCN104499072ALong-lasting antibacterial propertiesGood textile propertiesArtificial filaments from viscoseLong actingNanometre

The invention discloses nano antibacterial bamboo charcoal fibers which comprise the following components in percentage by mass: 0.0005-0.0020% of nano silver microparticles, 7-18% of bamboo charcoal microparticles and the balance of viscose. The nano antibacterial bamboo charcoal fibers have long-acting antibacterial performance and good weaving performance.

Owner:常熟市欧梦娜家纺有限公司

Special impregnating agent for electronic fabric warps and preparation process of impregnating agent

The invention discloses a special impregnating agent for electronic fabric warps and a preparation process of the impregnating agent, and belongs to the technical field of glass fibers. The impregnating agent is characterized by comprising the following components in percentage by mass: 1.8%-2.0% of No.58 paraffin, 1.5%-2% of engine oil, 0.9%-1% of an emulsifier peregal, 0.1%-0.2% of an alkyl imidazoline lubricant, 4.5%-5% of a color fixing agent, 1%-1.5% of plant oleic acid, 0.4%-0.5% of dibutyl ester and the balance of water. The process comprises the following steps: melting the raw materials and carrying out stirring to obtain mixed raw materials, then adding hot water with a temperature of 83-89 DEG C until the mixed raw materials are pasty, adding hot water with a temperature of 55-75 DEG C, carrying out stirring for 28-35 min, and carrying out diluting by using water with a temperature of 25-30 DEG C until the total amount of the formula is achieved. When glass fiber yarn prepared by using the impregnating agent of the formula are used for weaving, yarn twisting is not required, warping is not needed, smoldering is not needed, and quality of electronic fabrics is improved.

Owner:山东兴国大成特种纤维科技有限公司

Polyester-modified Haifu top and preparation method thereof

PendingCN108624981AHigh color fastnessHigh fastnessMelt spinning methodsPigment addition to spinning solutionMasterbatchPolyester

The invention discloses polyester-modified Haifu top, characterized by comprising 94% of cation-modified polyester and 6% of environment-friendly colored masterbatch; the environment-friendly coloredmasterbatch is made by adding 15% of carbon black to color-fixing polyester as a carrier. A preparation method of the polyester-modified Haifu top is also disclosed. After the environment-friendly colored masterbatch and the modified polyester are mixed, direct melt spinning is performed; polyester modification helps provide good spinnability and improve fiber color fastness and moisture-holding capacity. The prepared fiber has good spinning performance; the polyester-modified Haifu top has good anti-pilling performance; the environment-friendly colored masterbatch used herein has good dispersibility such that the prepared fiber has uniform color, good color fastness, bright color and zero aberration. A spun dyeing technique used herein such that dyeing cost is lowered, and mass wastewater caused during bath dyeing in downstream enterprises is avoided.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

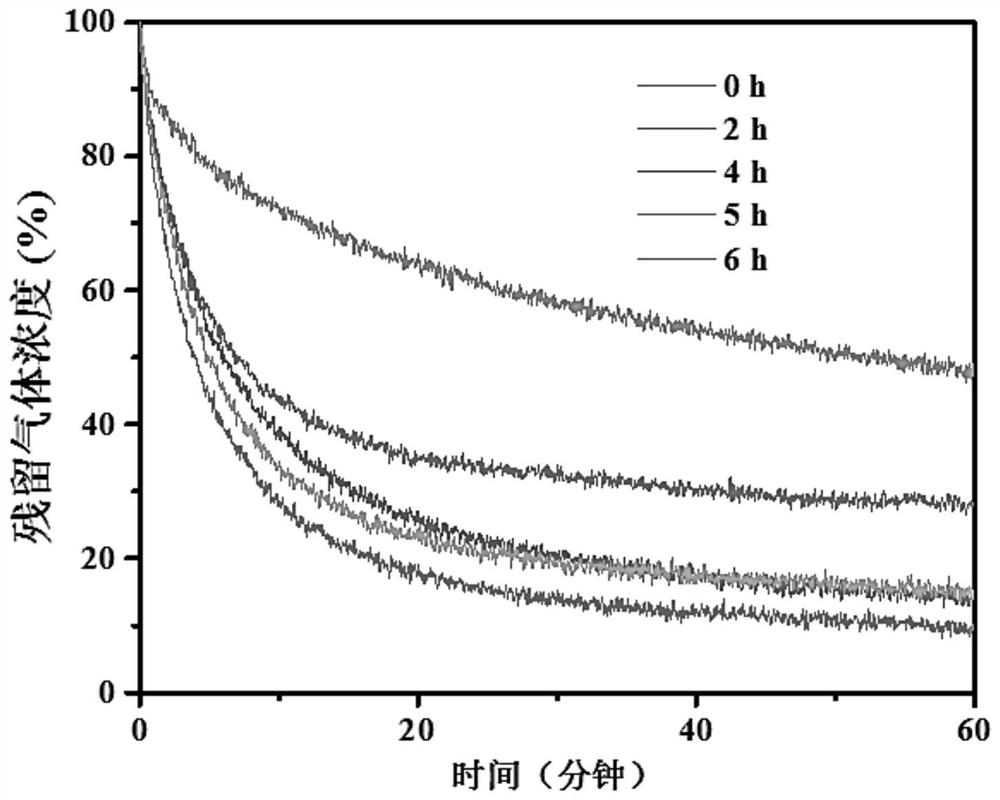

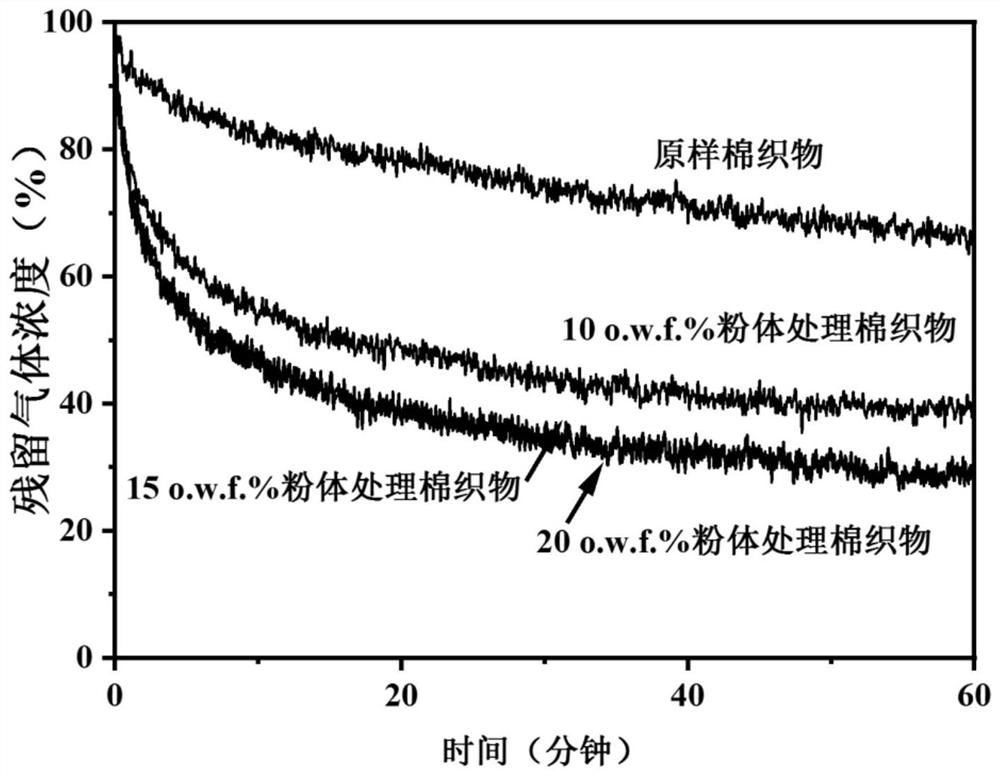

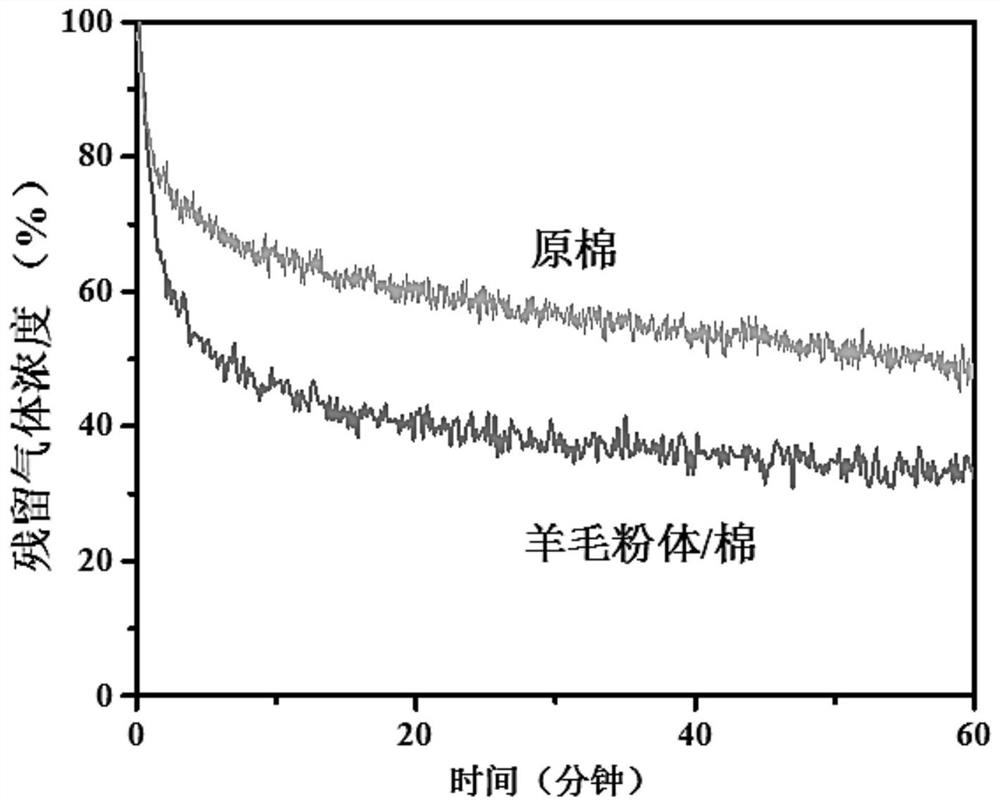

Fabric loaded with wool powder and having peculiar smell adsorption function and preparation method thereof

ActiveCN113694896AFast adsorption rateAdsorptive stabilityGas treatmentOther chemical processesTextile technologyPolymer science

The invention belongs to the technical field of textiles, and particularly relates to a fabric loaded with wool powder and having peculiar smell adsorption function and a preparation method thereof. The method comprises the following steps: 1) preparing wool powder; 2) preparing a wool powder emulsion; and 3) loading the wool powder on the fabric by using the wool powder emulsion as a loading agent, and then drying to obtain the wool powder loaded fabric with the peculiar smell adsorption function. According to the method, the wool powder has an adsorption function, and when the wool powder is loaded on the fabric, the adsorption function can be given to the fabric; the loading method does not use chemical reagents, so that the adsorption performance of the wool powder can be prevented from being influenced.

Owner:WUHAN TEXTILE UNIV

Method for producing regenerated polyester staple fibers from waste plastic bottles

PendingCN112497561AAchieve reuseQuality improvementPlastic recyclingMedical waste disposalPolyesterFiber

The invention discloses a method for producing regenerated polyester staple fibers from waste plastic bottles. The method comprises the following steps: (1) primary selection; (2) disinfection treatment; (3) crushing; (4) cleaning; (5) dehydrating and drying; (6) winnowing; (7) granulating; and (8) preparation of the regenerated polyester staple fibers. Through three times of cleaning, residual liquid, silt, iron and other high-density substances and low-density substances in the plastic bottles are fully removed, labels and rubber are effectively separated from plastic sheets, the quality ofthe regenerated polyester staple fibers is improved, environmental protection is achieved, and reutilization of the waste plastic bottles is achieved. Disinfection is carried out while crushing is carried out, that is, disinfection treatment is carried out twice, so that the prepared regenerated polyester staple fibers are good in textile performance.

Owner:贵州南阳彩纤有限公司

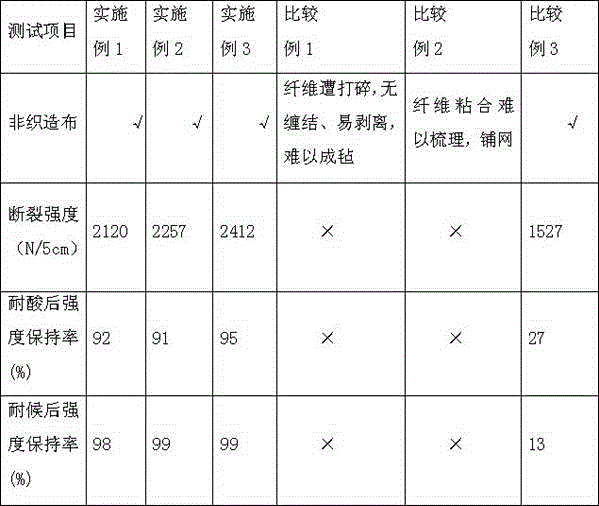

Preparation method of flexible acid-resistant temperature-resistant glass modified fibers

The invention discloses a preparation method of flexible acid-resistant temperature-resistant modified glass fibers for nonwovens. The method comprises the following steps: 1. carrying out dispersion and pretreatment on glass fibers; and 2. carrying out modification treatment on the pretreated glass fibers, and carrying out vacuum drying to obtain the flexible acid-resistant temperature-resistant modified glass fibers. According to the characteristics of poor toughness, high brittleness and high frangibility of glass fibers in the nonweaving process, the invention provides flexible acid-resistant temperature-resistant modified glass fibers for nonwovens. The modified glass fibers have the advantages of high temperature resistance, acid resistance, favorable flexibility, favorable processability and favorable weaving performance.

Owner:XIAMEN ZHONGCHUANG ENVIRONMENTAL TECH CO LTD

Method for preparing alkali-resistant glass fibre jet yarn impregnating compound

The invention relates to a method for preparing an alkali-resistant glass fibre jet yarn impregnating compound. The method comprises the following steps: adding 10-20 times deionized water with temperature of 80-90 DEG C to imidazoline cation lubricant and stirring to obtain uniform and transparent liquid; adding 5-10 times deionized water with temperature of 30-50 DEG C to an antistatic agent SN and stirring to obtain uniform and transparent liquid; adding 10-20 times deionized water with temperature of 50-70 DEG C to one or mixture of lithium nitrate, lithium chloride and ammonium chloride and stirring to obtain uniform and transparent liquid; respectively adding 1-3 times deionized water to a polyacrylate film-forming agent, a water-soluble epoxy film-forming agent, polyvinyl acetate and an acrylate copolymer film-forming agent; and mixing all matters obtained in the previous steps, then adding the rest of deionized water, and stirring for 30-40 minutes at the stirring speed of 50-60rpm.

Owner:陕西汇友友基新材料有限公司

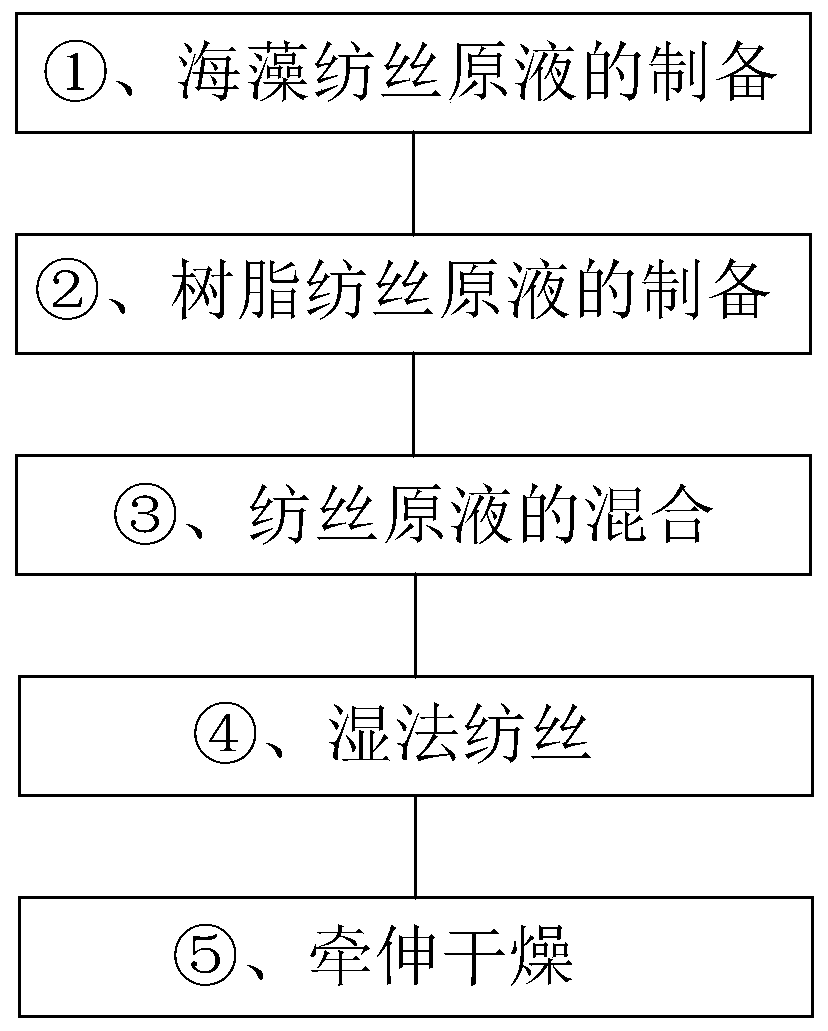

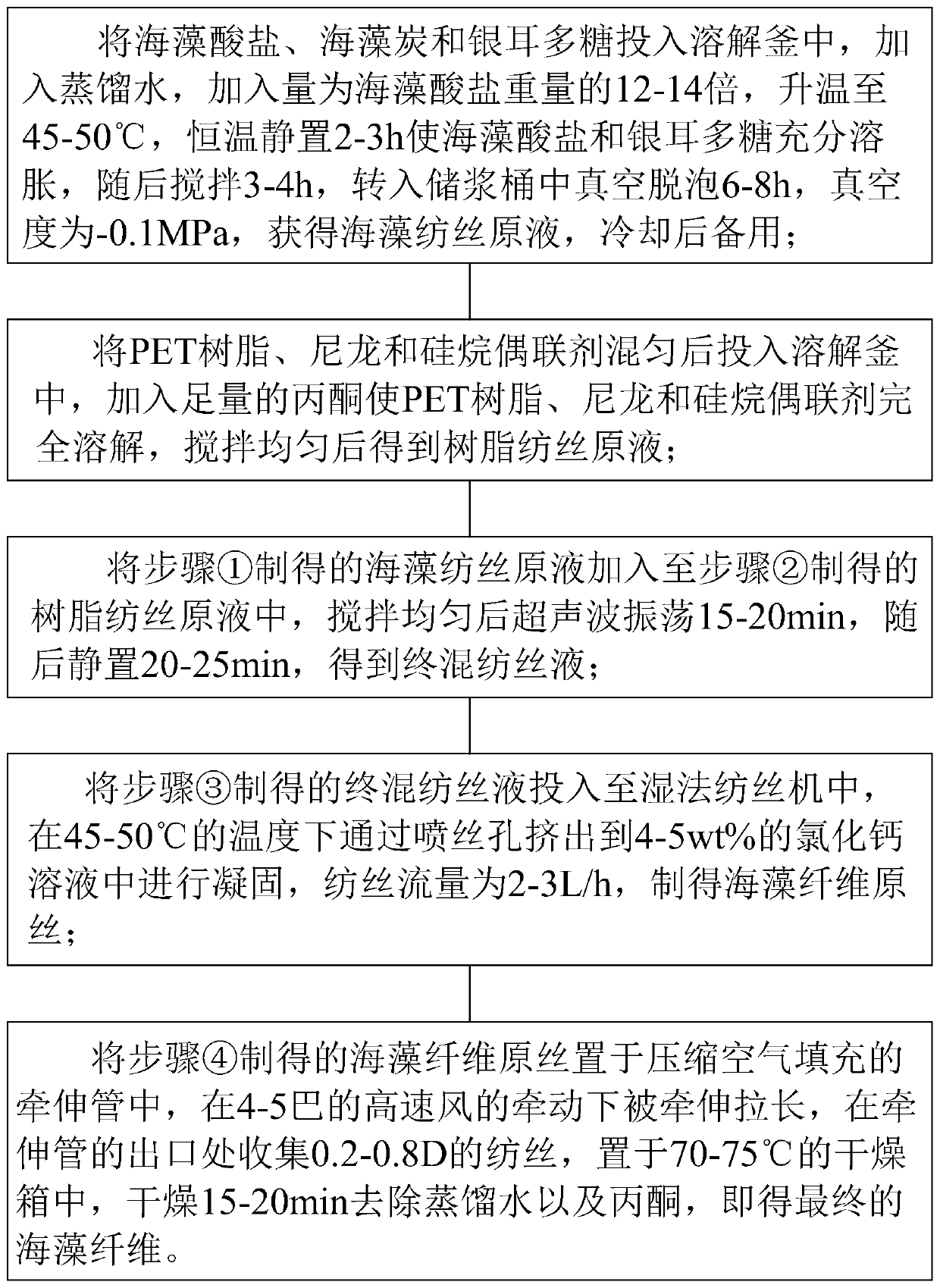

Alginate fiber containing tremella polysaccharide and preparation method thereof

InactiveCN111394830AImprove mechanical strength and flexibilityGood structural stabilityCosmetic preparationsToilet preparationsBatch productionPOLYETHYLENE WAX

The invention relates to the technical field of fiber materials, and particularly relates to an alginate fiber containing tremella polysaccharide and a preparation method thereof. The alginate fiber is mainly prepared from the following raw materials in parts by weight: 25-30 parts of PET resin, 22-26 parts of nylon, 5-8 parts of polyethylene wax, 20-24 parts of alginate, 8-10 parts of seaweed charcoal, 3-5 parts of tremella polysaccharide and 5-8 parts of a silane coupling agent. The preparation method comprises the steps of preparation of a seaweed spinning solution, preparation of a resin spinning solution, mixing of the spinning solutions, wet spinning and solvent evaporation, so that the prepared alginate fiber has excellent moisture absorption effect and moisturizing effect; the whole preparation steps are simple and convenient to operate, so that batch production of the alginate fiber is facilitated; and the alginate fiber has a good application prospect.

Owner:余姚市龙翔水刺热轧无纺有限公司

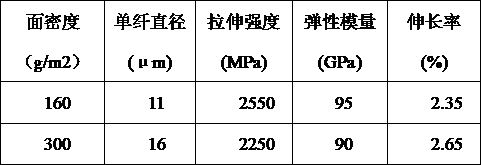

Basalt fiber unidirectional cloth for reinforcing engineering structure and manufacturing method of basalt fiber unidirectional cloth

The invention discloses basalt fiber unidirectional cloth for reinforcing an engineering structure and a manufacturing method of the basalt fiber unidirectional cloth. The unidirectional cloth comprises a unidirectional cloth body made in a plain weave mode; the unidirectional cloth body comprises warp yarns and weft yarns; the warp yarns are premade continuous basalt fibers and have better flexibility, banding performance, self-lubricating performance and spinning performance; gaps are formed between the adjacent warp yarns; and the weft yarns are hot melting filaments. A segmented film forming process is adopted, the production cost is reduced, the mechanical property and the cloth cover structural stability, smoothness and permeability are improved, wrinkling during construction can be effectively avoided, and the advantages of convenient construction, good reinforcing effect, high cost performance and the like are achieved.

Owner:ZHEJIANG GBF BASALT FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com