Cleaning-conveniently spinning device

A technology of textile equipment and cleaning room, applied in the field of textile equipment that is easy to clean, can solve the problems of easy shedding of yarn fluff, diffusion of fluff and dust, and inability to clean cloth, so as to reduce air pollution, reduce maintenance, and achieve a compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

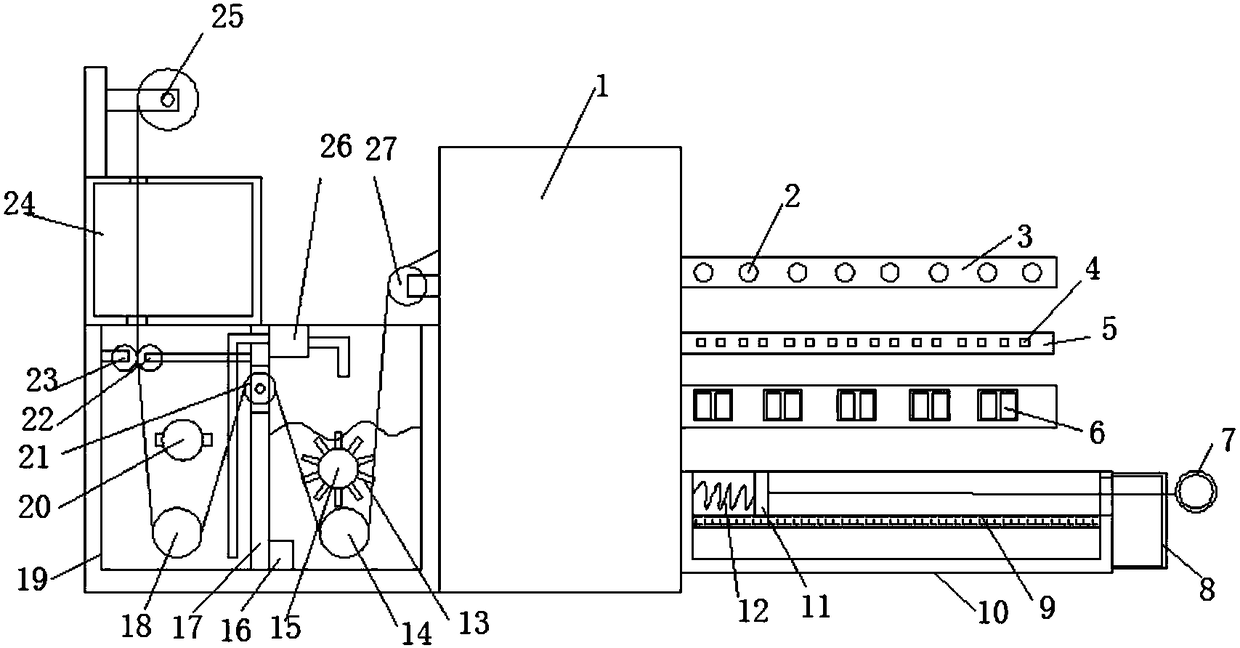

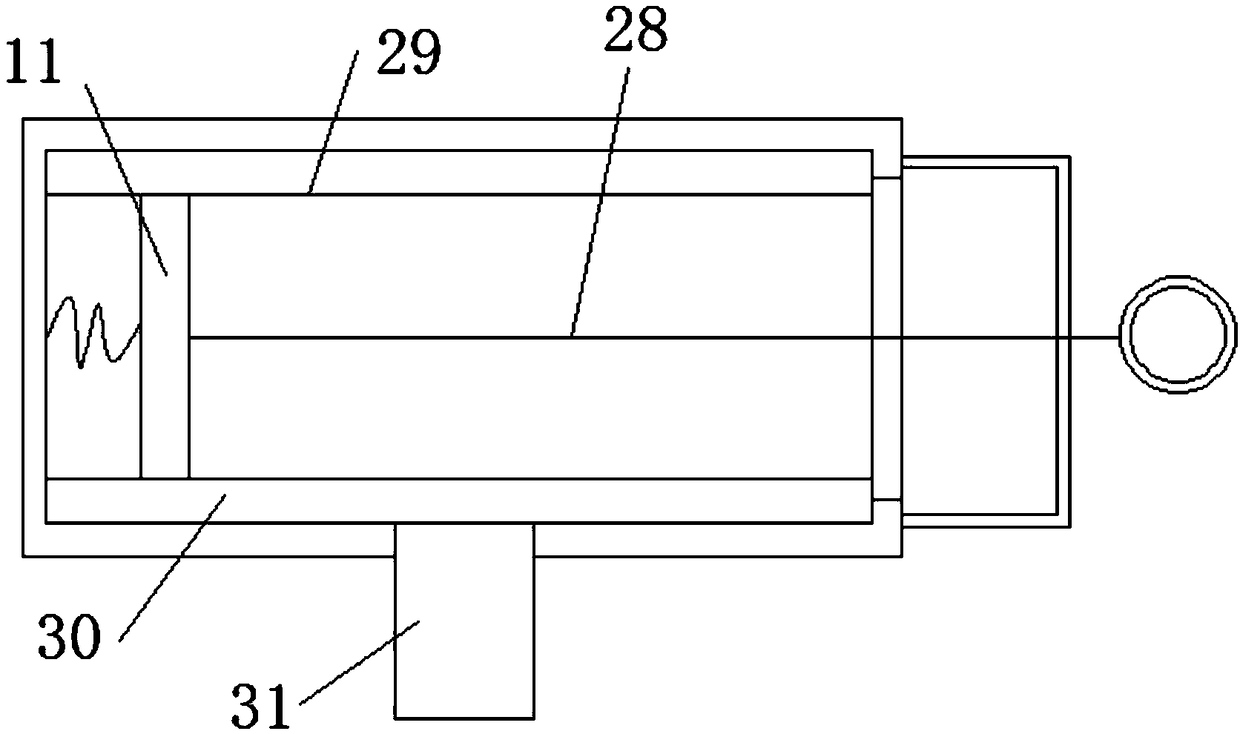

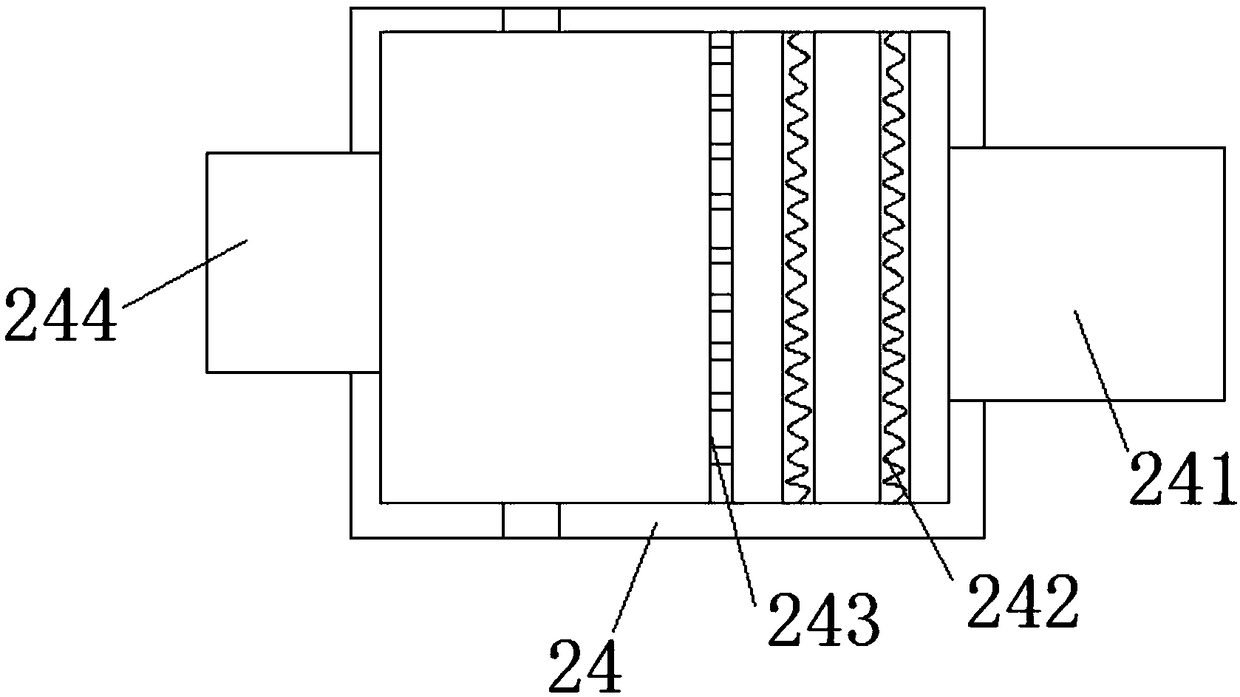

[0024]Embodiment: Pass one end of the yarn through the super wear-resistant threader 6, and through the combing action of the comb teeth 4 on the carding plate 5, the lint and dust on the yarn are removed, and enter through the rotating shaft 2 on the fixed plate 3 In the device body 1, weaving is carried out, and the exhaust fan 31 on the material receiving box 10 is started, and one end of the exhaust fan 31 is connected with a suction disk, and the suction disk is positioned on the bottom inner wall of the material receiving box 10, and the suction disk has a A plurality of evenly distributed air suction holes, under the action of the exhaust fan 31, suck the lint and dust on the yarn into the material receiving box 10, and at the same time, static electricity is generated between the anode plate 29 and the cathode plate 30, and the yarn is adsorbed The lint and dust produced by the textile machine prevent the lint and dust from adhering to the textile machine after a long p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com