Patents

Literature

1374results about "Textile treatment rollers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

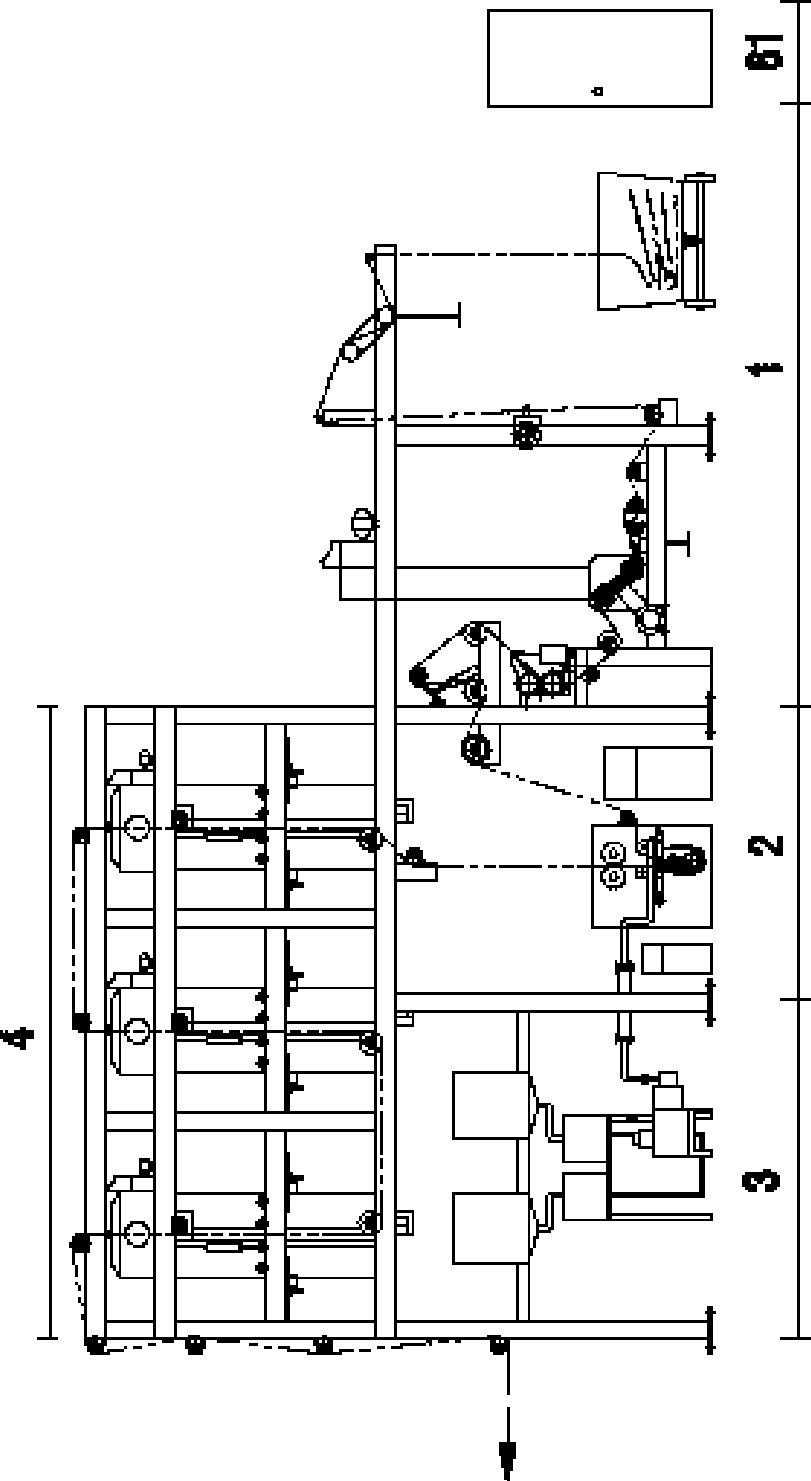

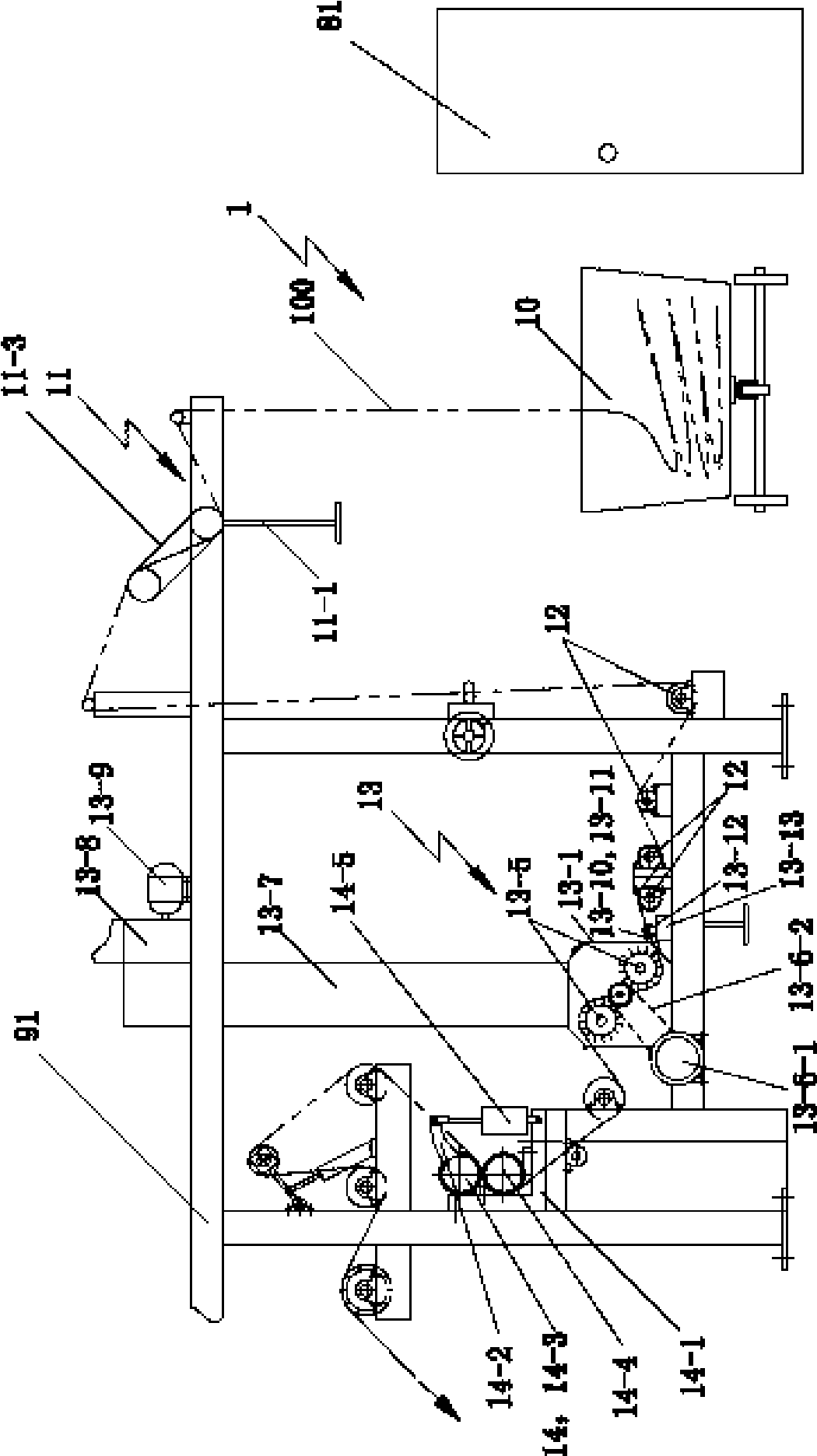

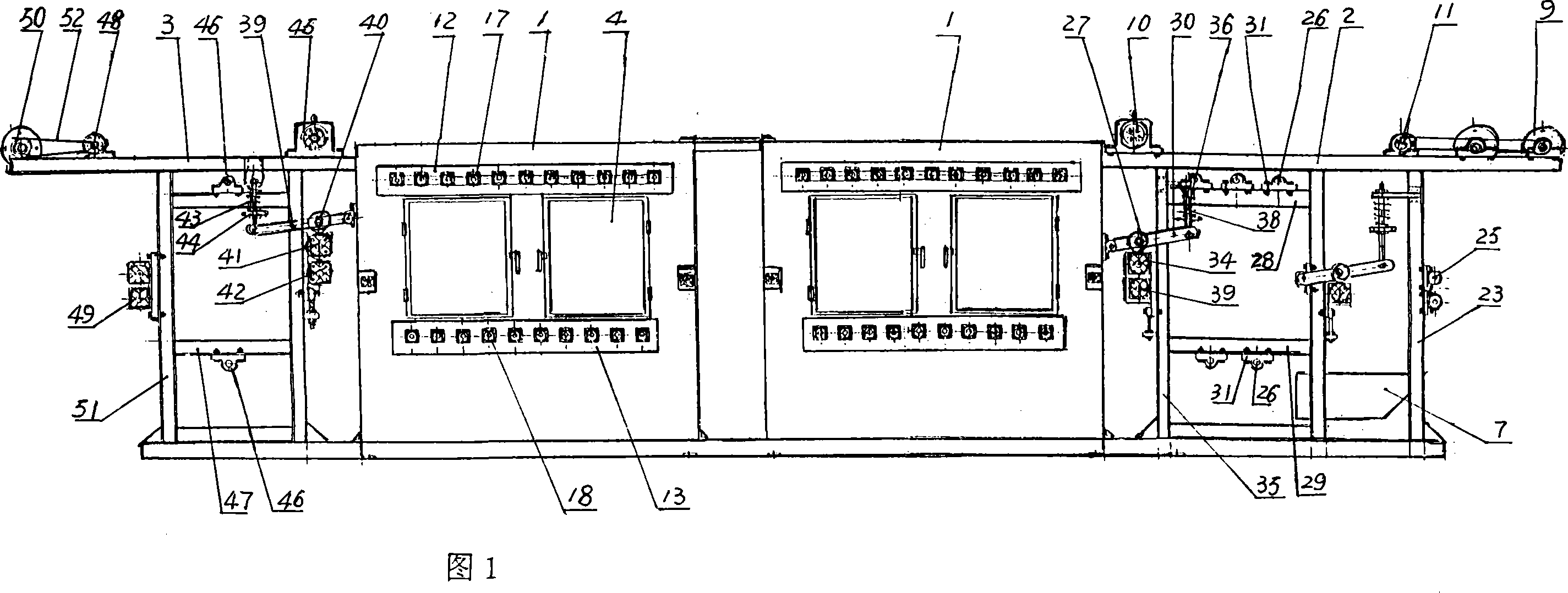

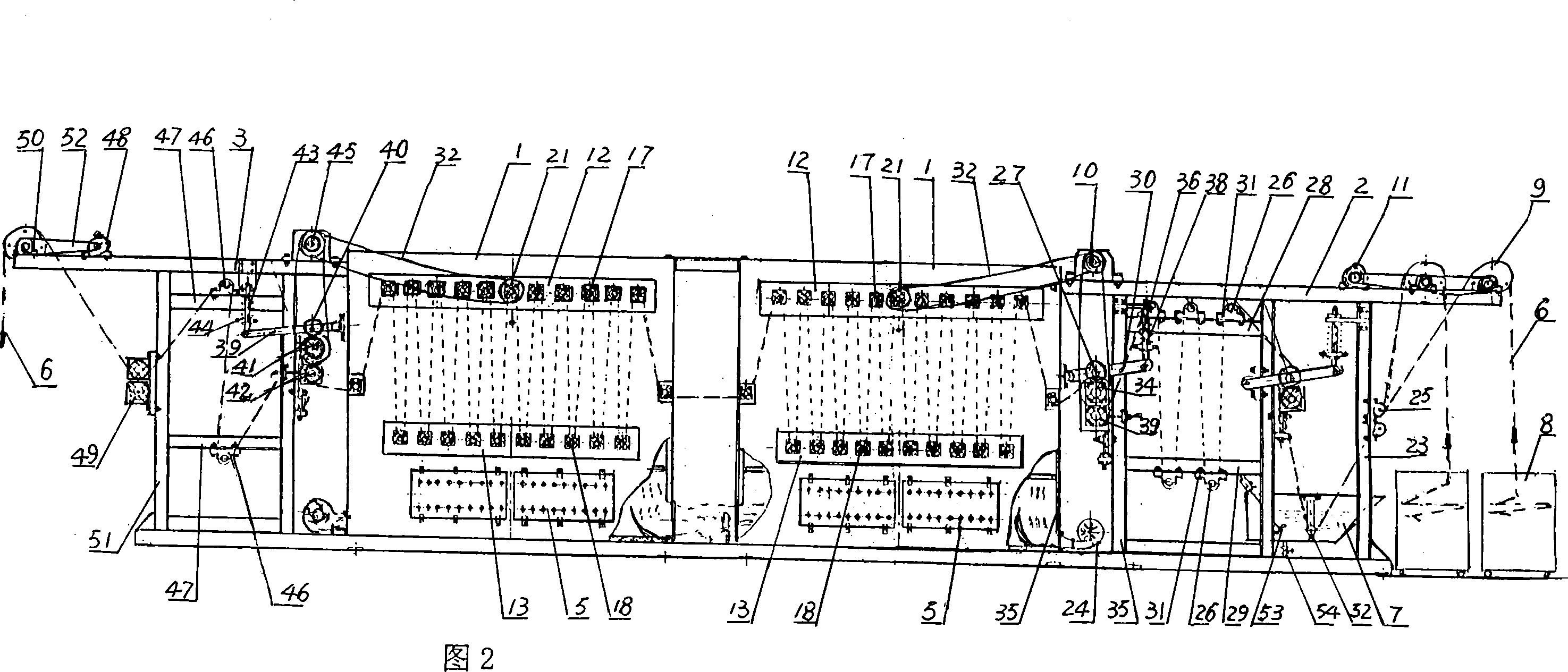

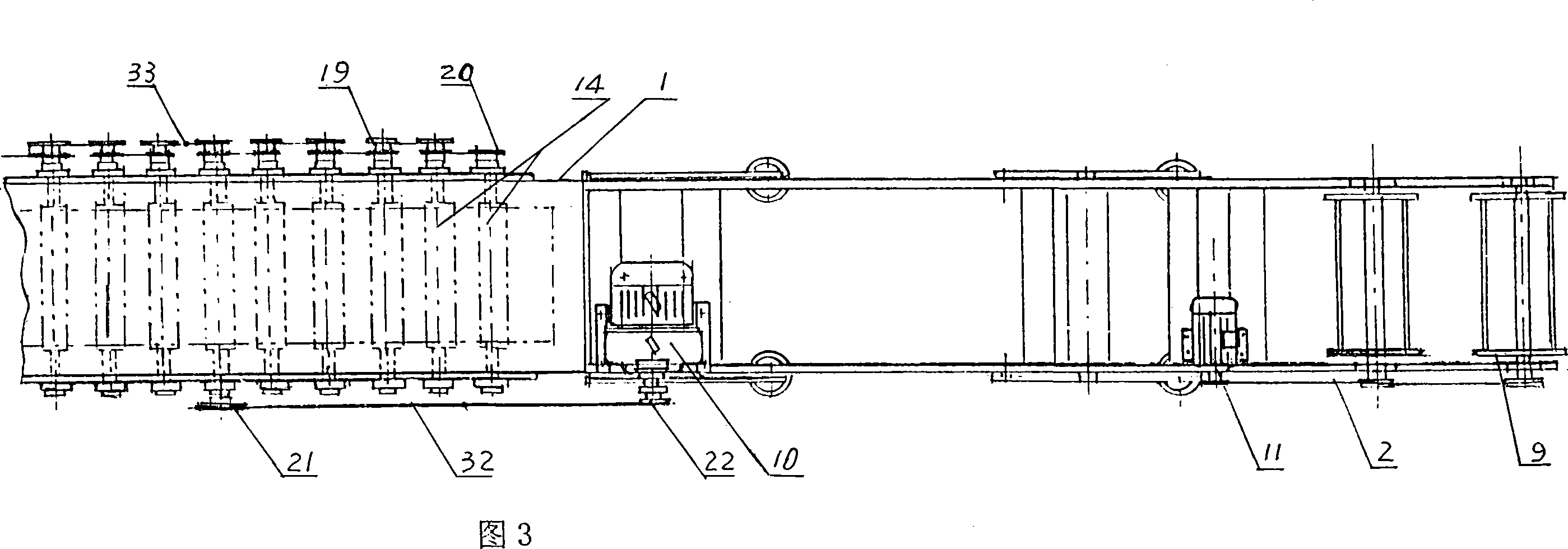

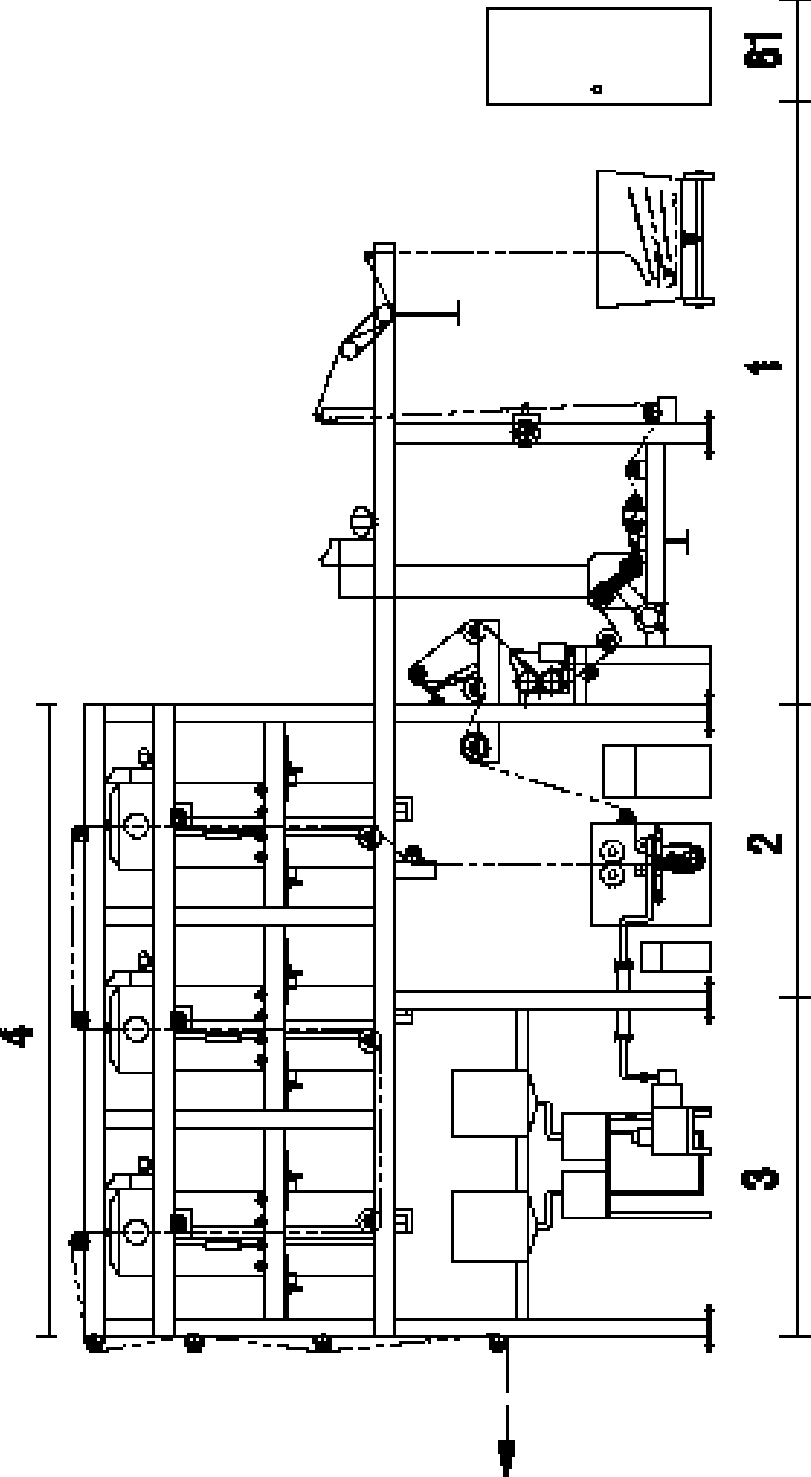

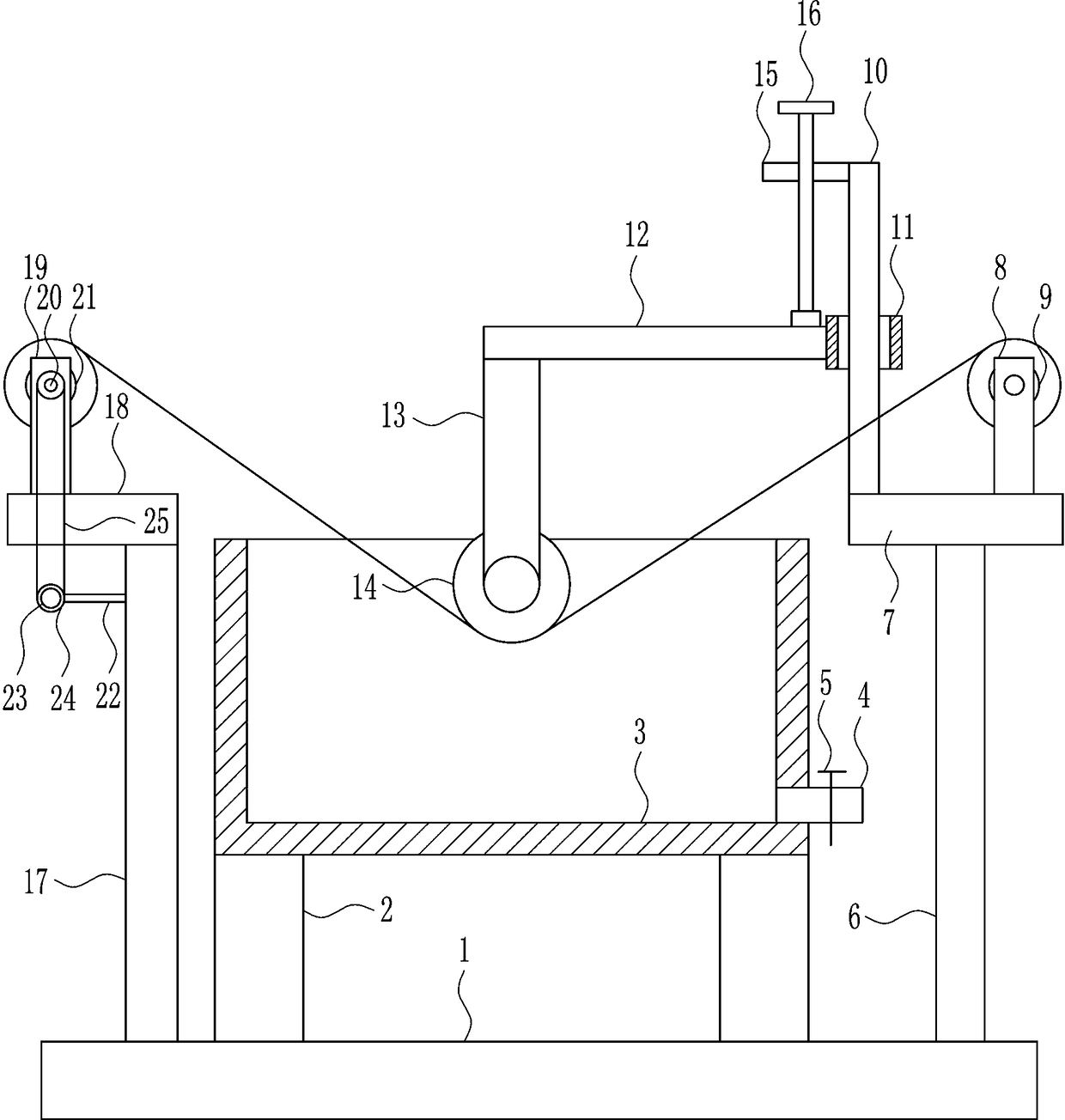

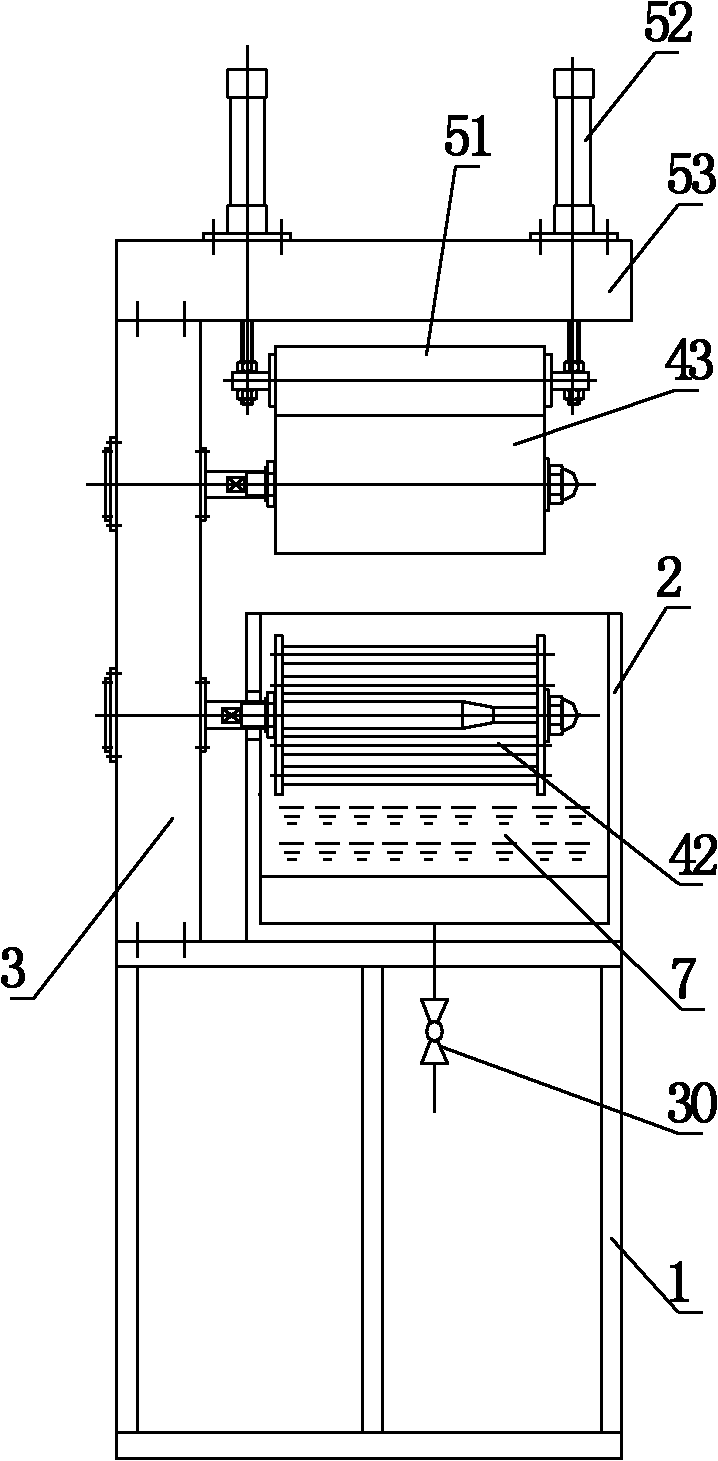

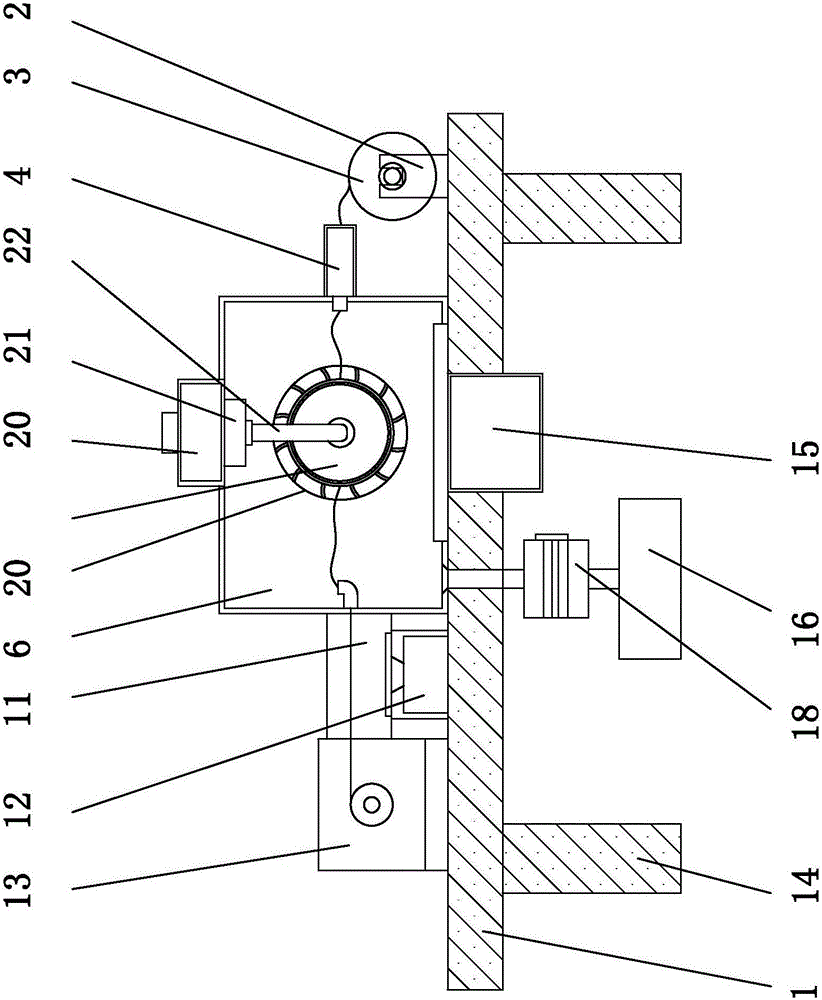

Continuous pigment dyeing pad dyer

InactiveCN101487175AOptimize layoutGuaranteed uptimeSucessive textile treatmentsDrying solid materials with heatEngineeringHot blast

The invention relates to a continuous paint dyeing padding machine. The padding machine comprises a device which brushes hair and collects dusts for the textile, a traction binding vehicle which can obstruct the tensile force of the textile, a padding device, an infrared pre-baking device, a hot-blast pre-baking device, a steam drying device and a fabric outlet disposing device, and all devices are sequentially arranged. All components of the dyeing padding machine are reasonably configured; and when in use, the energy resource is saved, the process is simple and the dyeing effect is good.

Owner:常州市东高染整有限公司

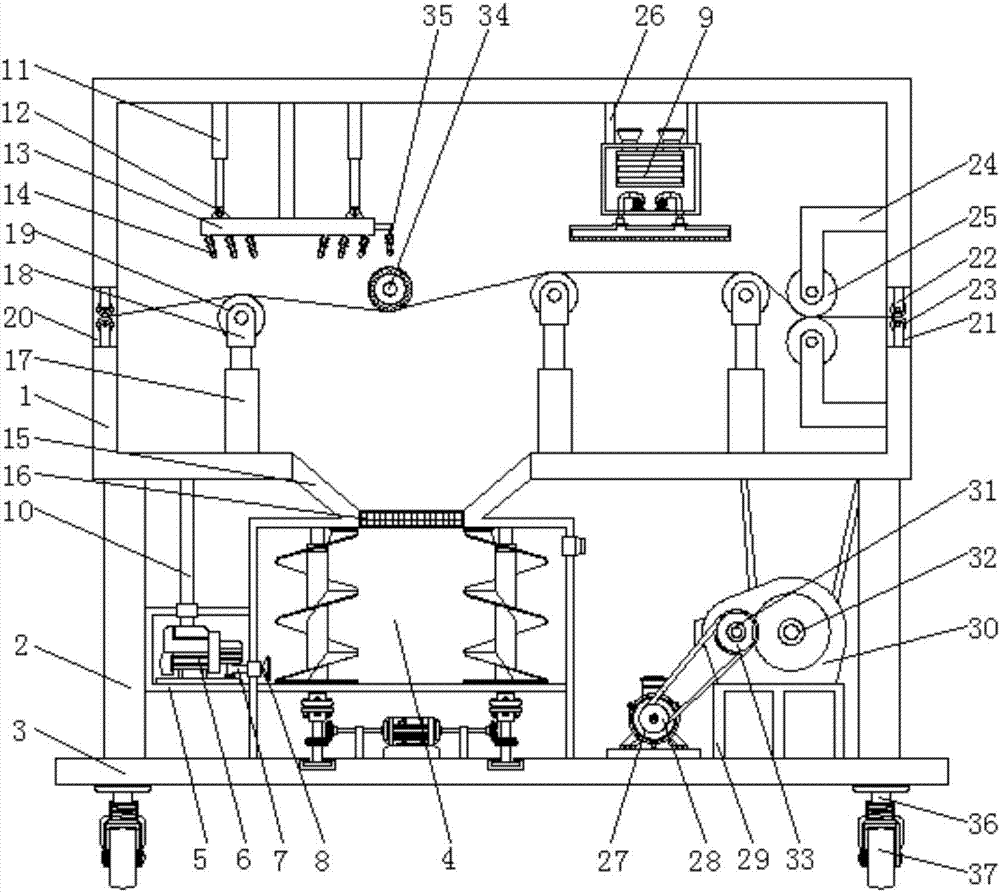

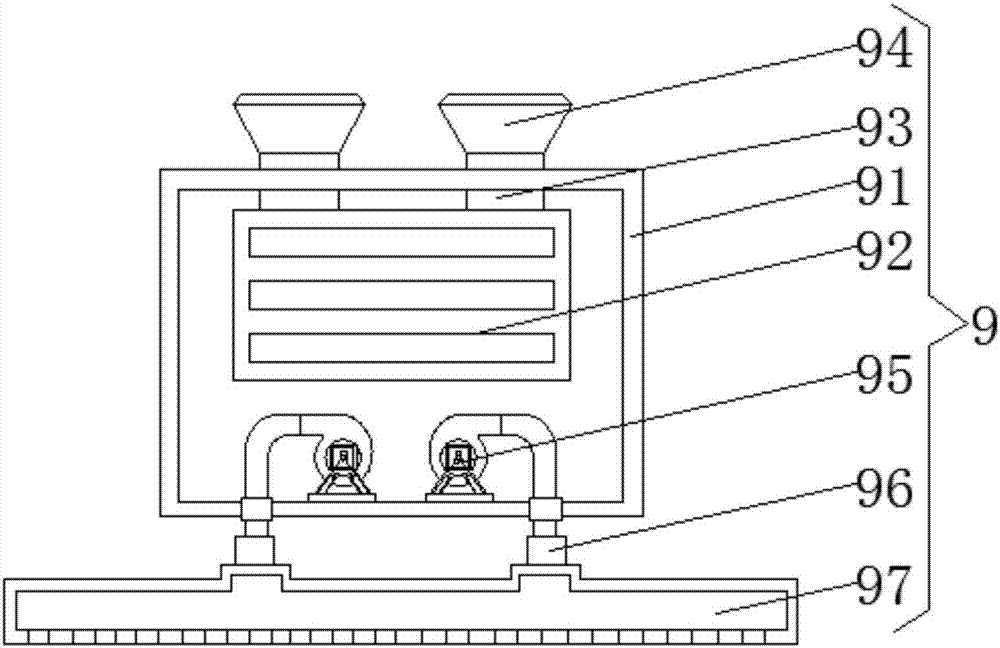

Spraying, dyeing and drying device for textile fabric

InactiveCN107574602AStir fully and evenlyStir wellTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringUltimate tensile strength

The invention discloses a spraying, dyeing and drying device for textile fabric. The device comprises a tank body, supporting vertical plates which are mutually symmetric are fixedly connected to twosides of the bottom of the tank body, and a bottom supporting plate is fixedly connected to the bottoms of the two supporting vertical plates; a dye stirring device is fixedly connected to the left side of the top of the bottom supporting plate, a liquid pumping pump placement tank is fixedly connected between the surface of the left side of the dye stirring device and the surfaces of the right sides of the supporting vertical plates, and a liquid pumping pump is fixedly connected to the bottom of the inner wall of the liquid pumping pump placement tank; a liquid pumping pipe is communicated with the right side of the liquid pumping pump. The invention relates to the technical field of textile machinery equipment. According to the spraying, dyeing and drying device for the textile fabric,the problems of high dyeing cost, environmental pollution, low use ratio and low cloth dyeing effect of an existing drying device for the textile fabric are solved, the use efficiency of dye is effectively improved, the device is safe and environmentally friendly, the pollution to the environment is lowered, manual operation is not needed, the labor intensity is lowered, and the economic efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

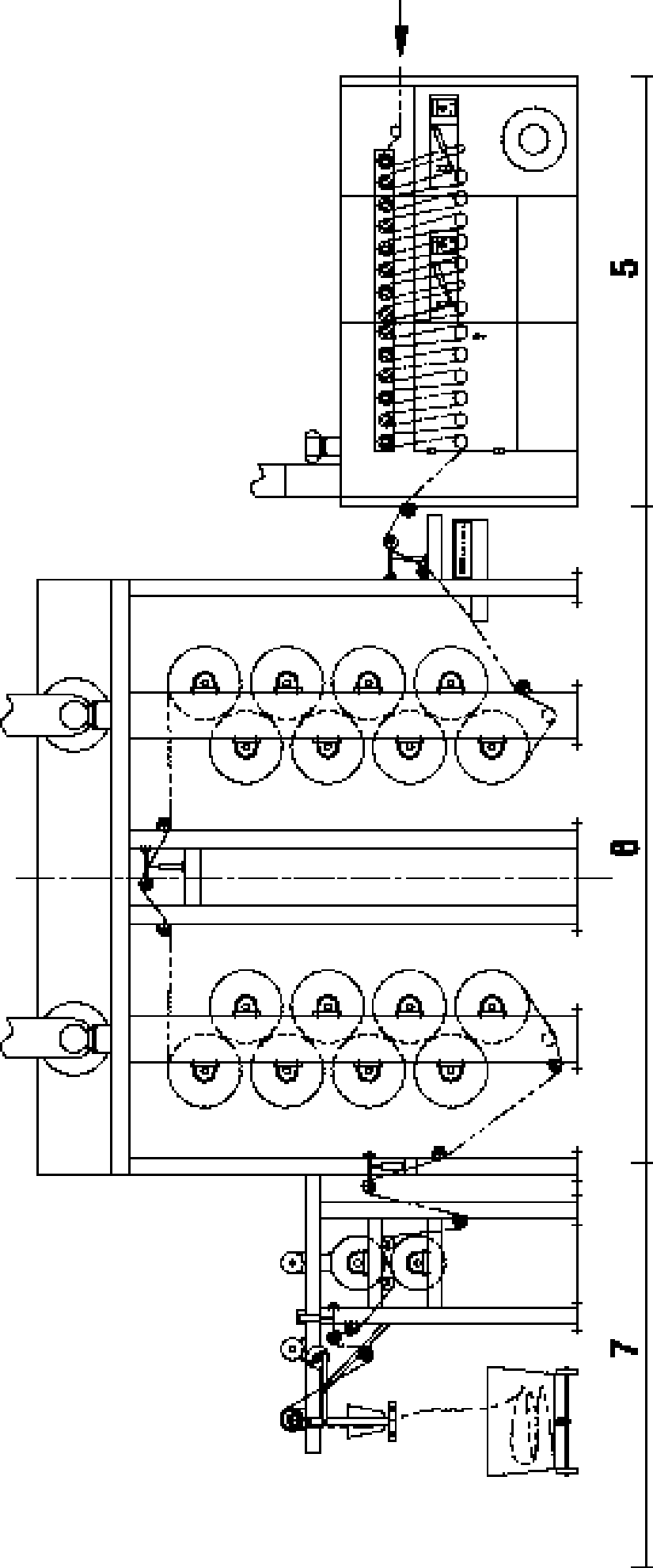

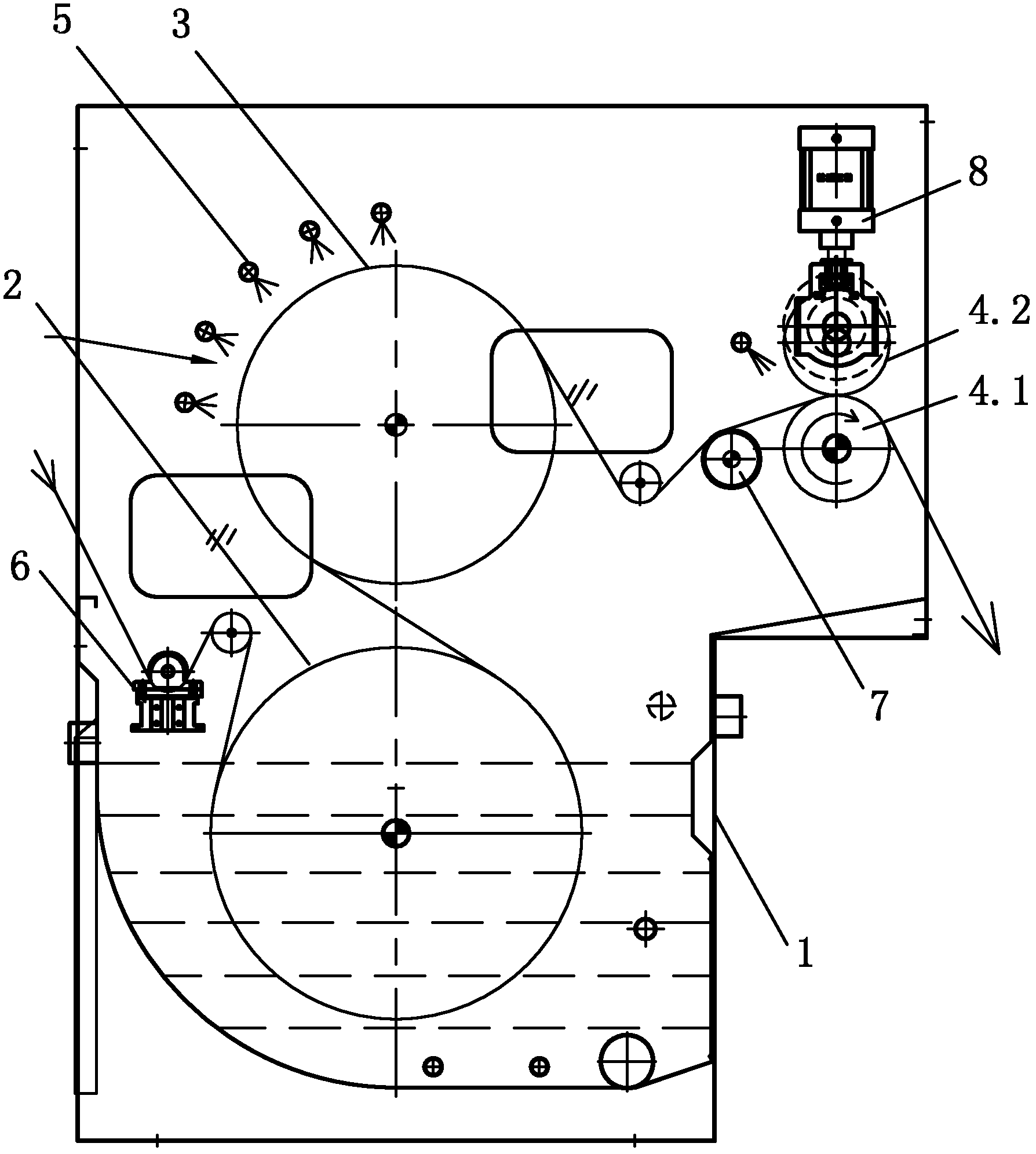

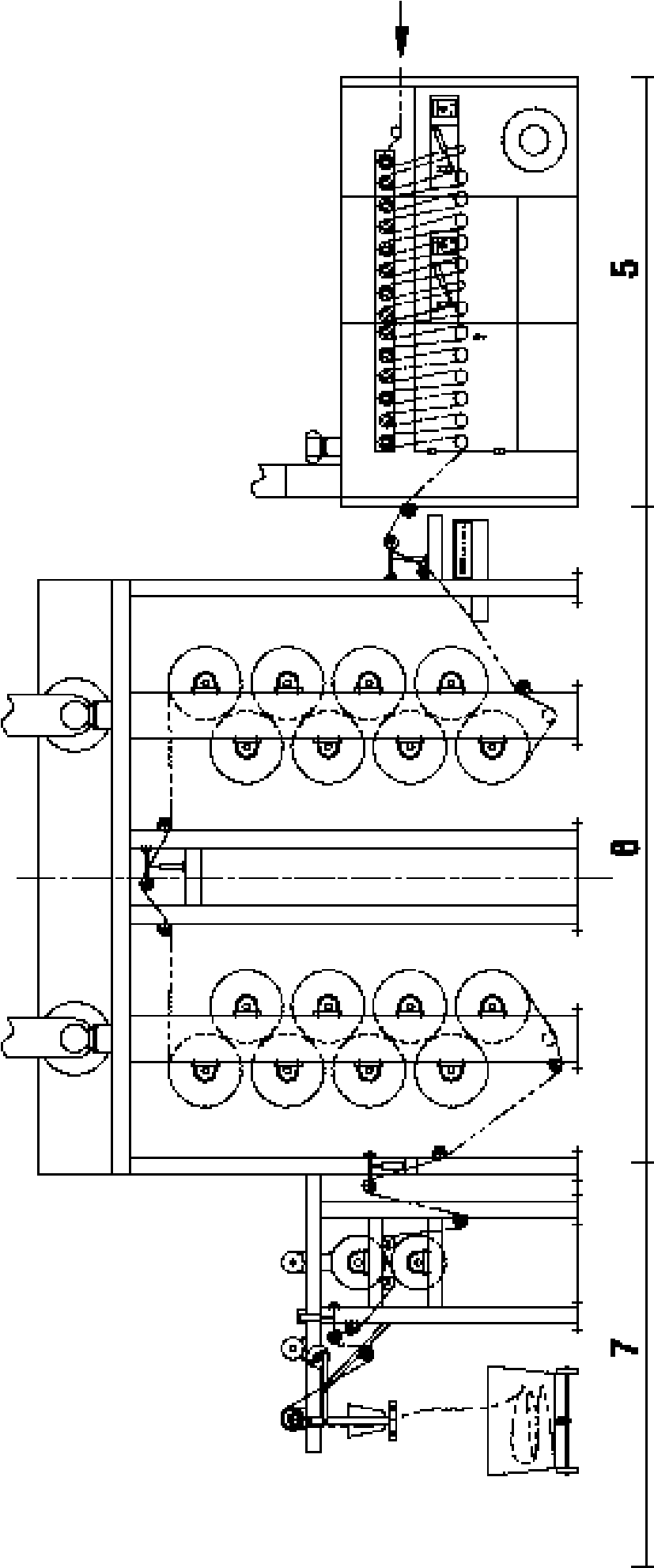

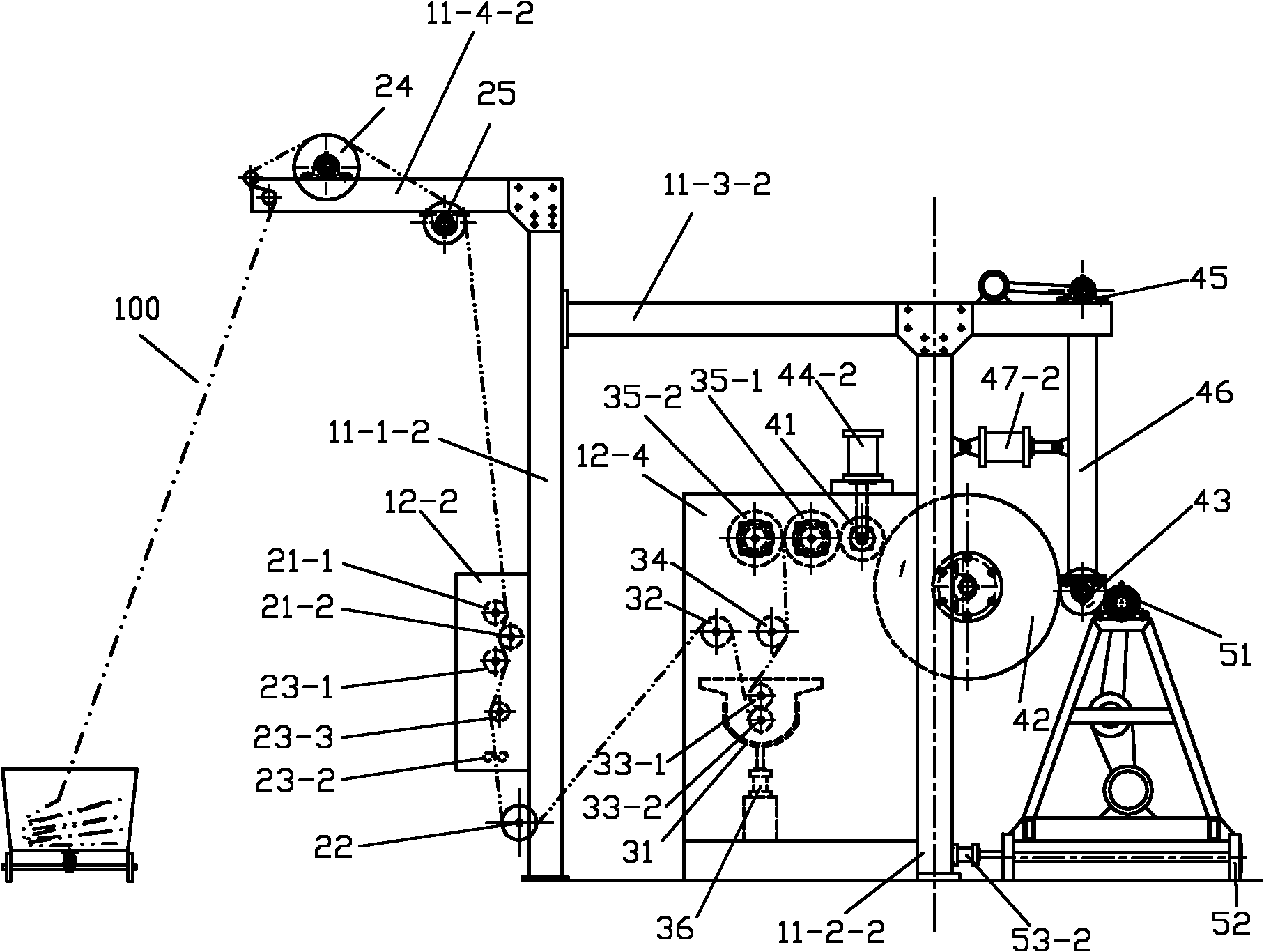

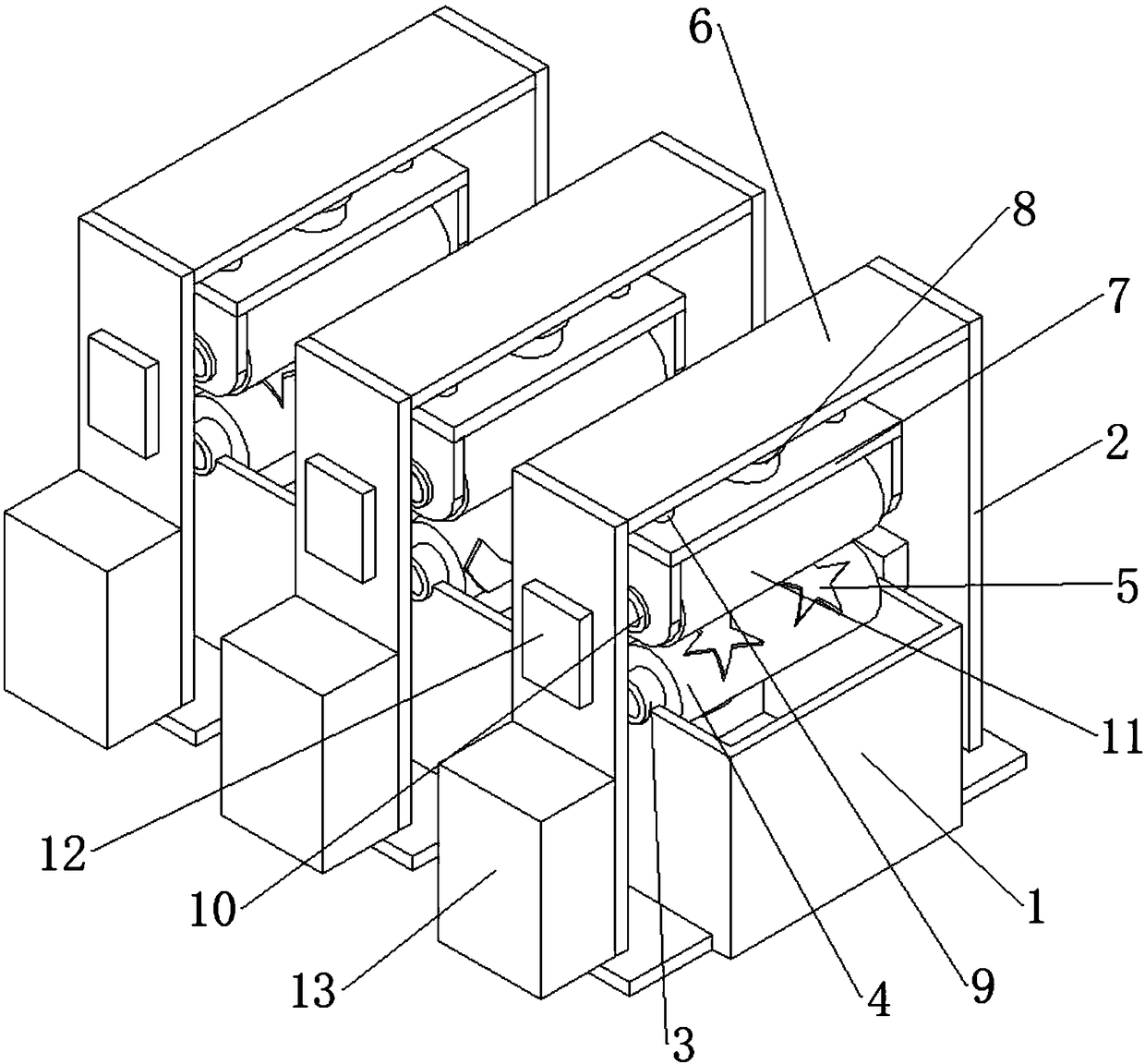

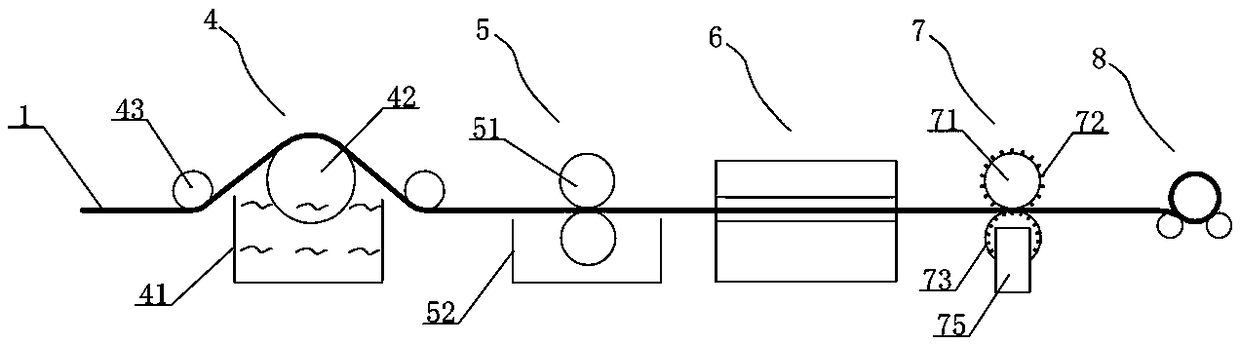

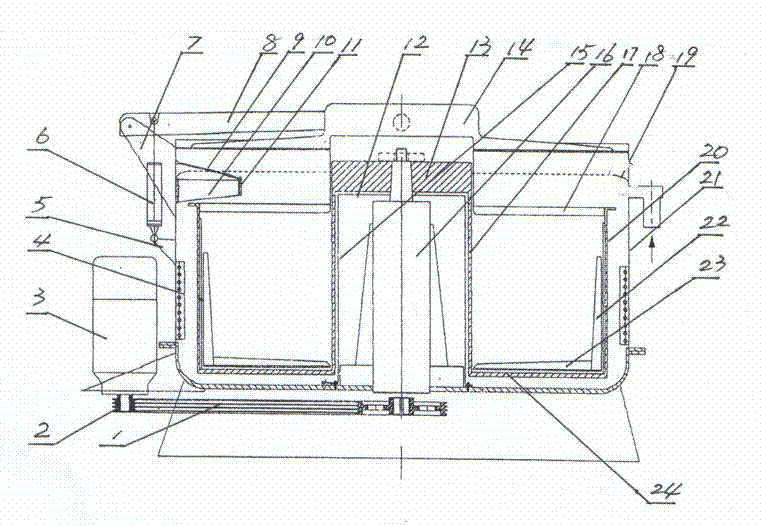

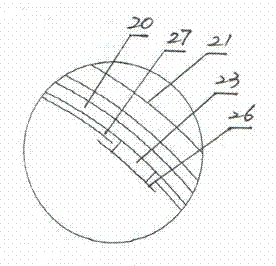

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

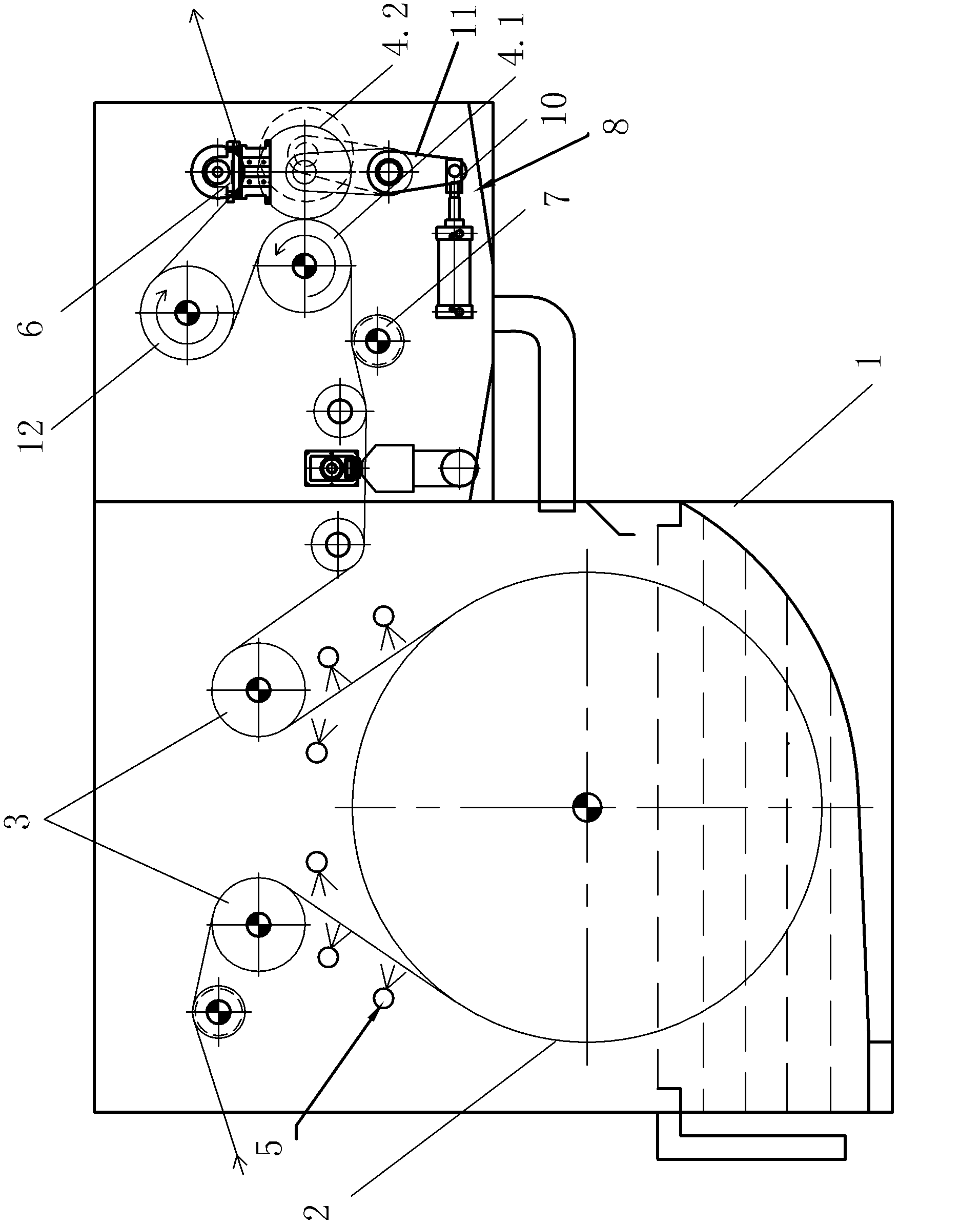

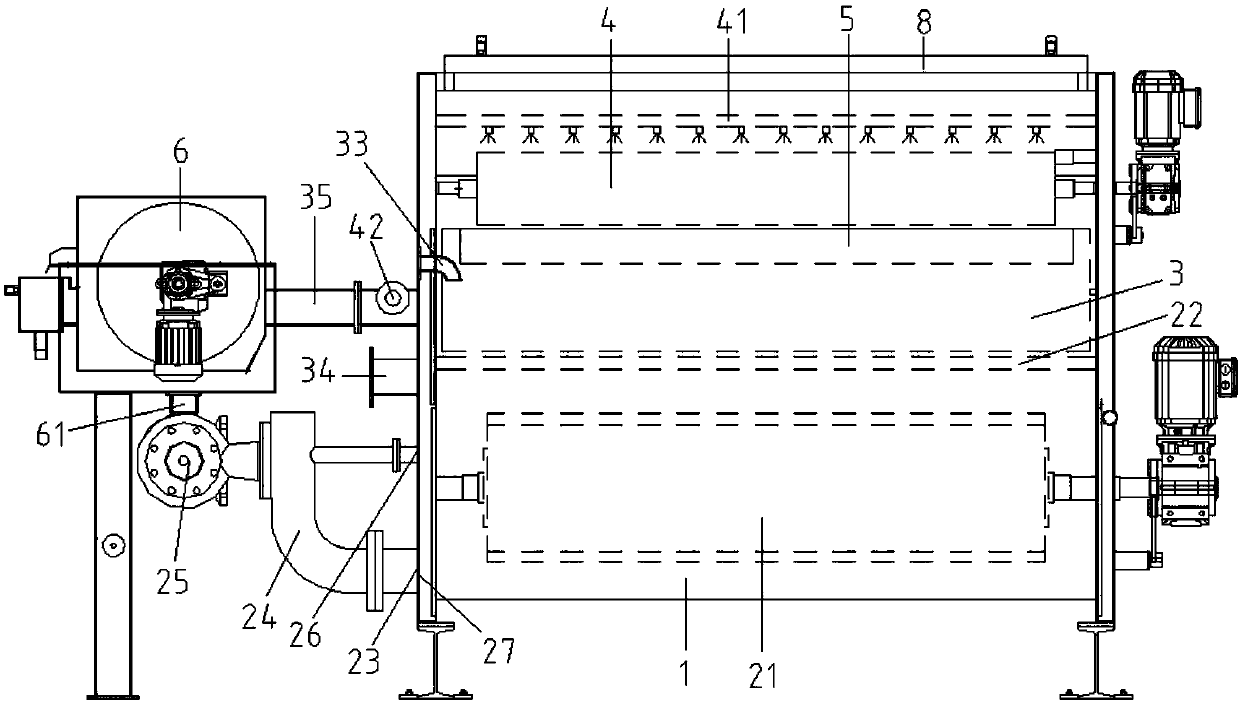

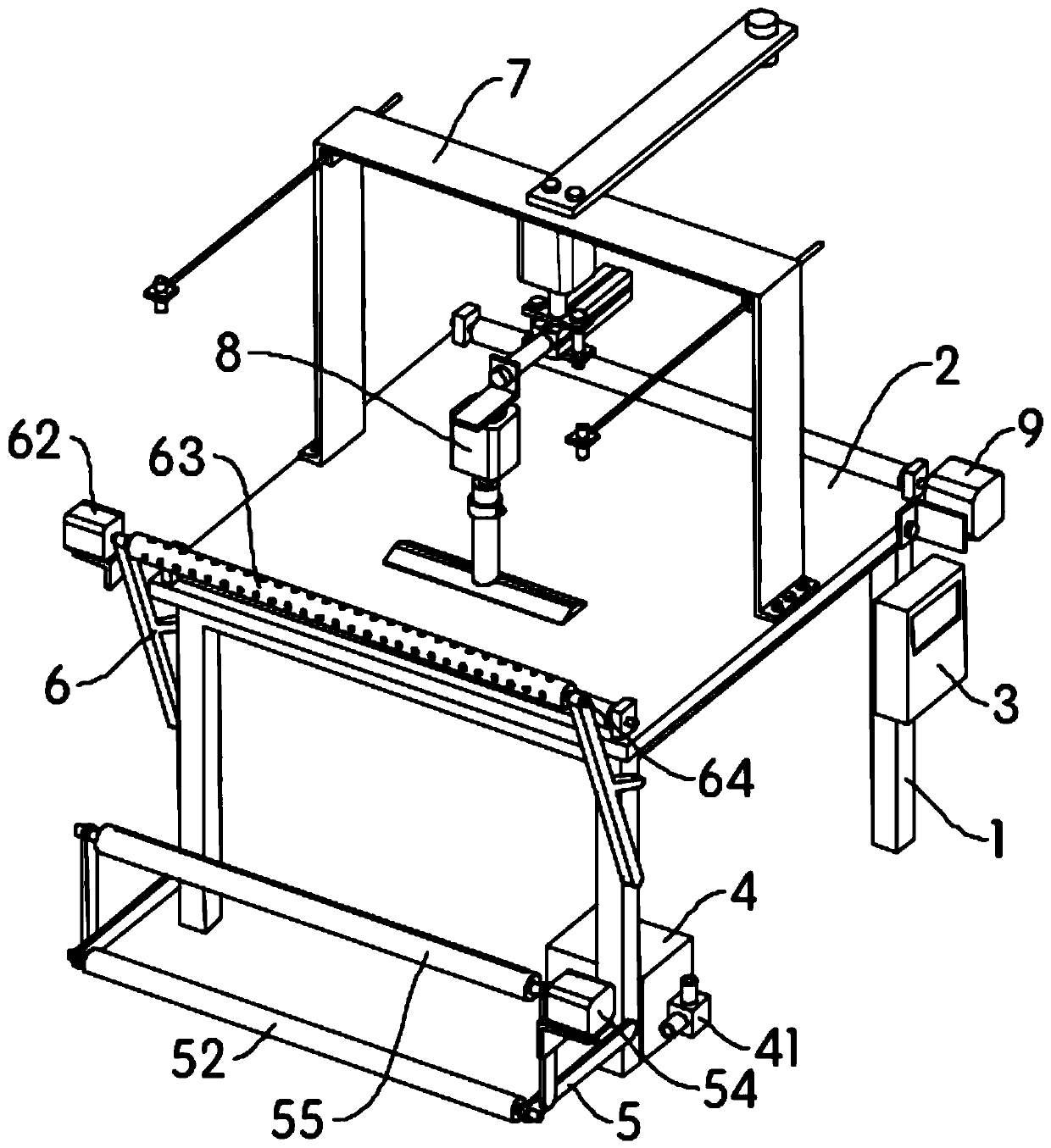

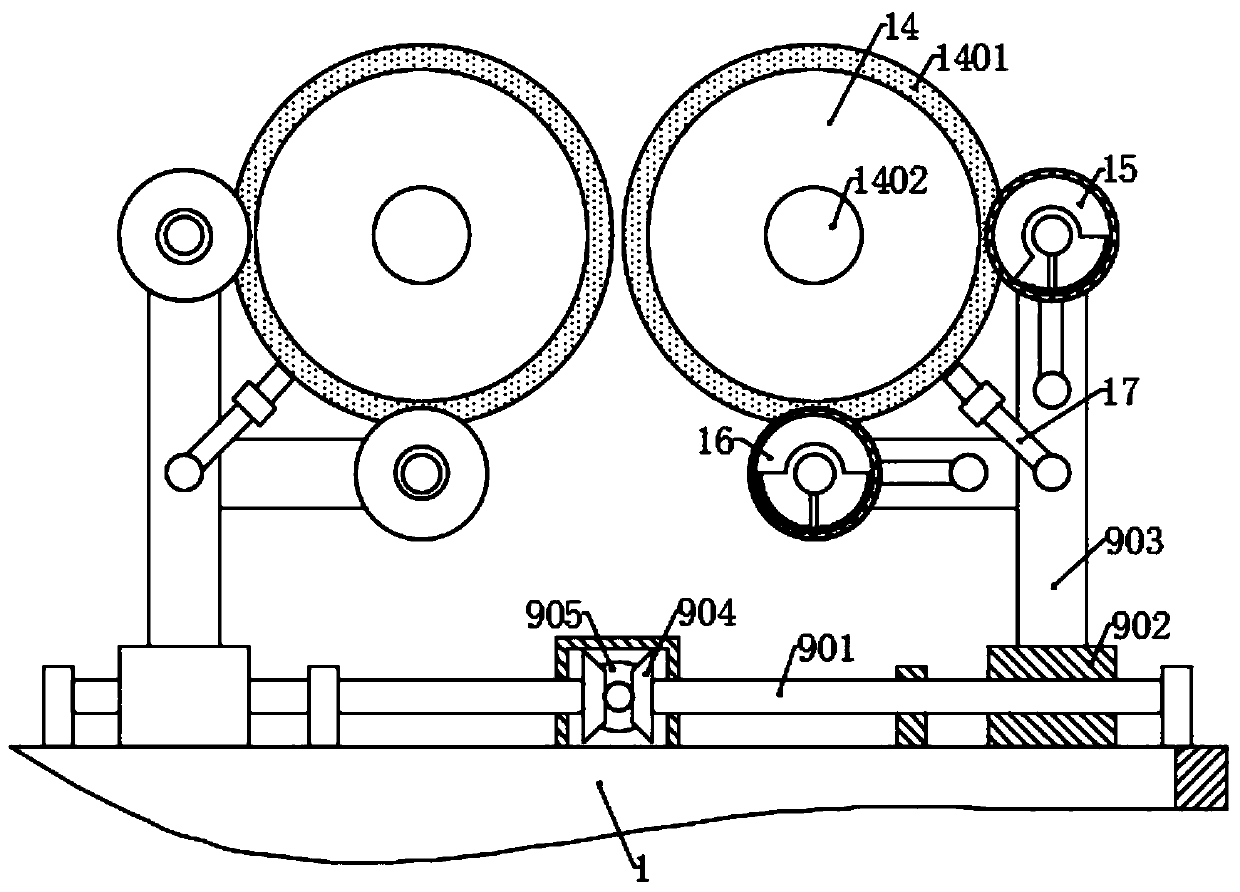

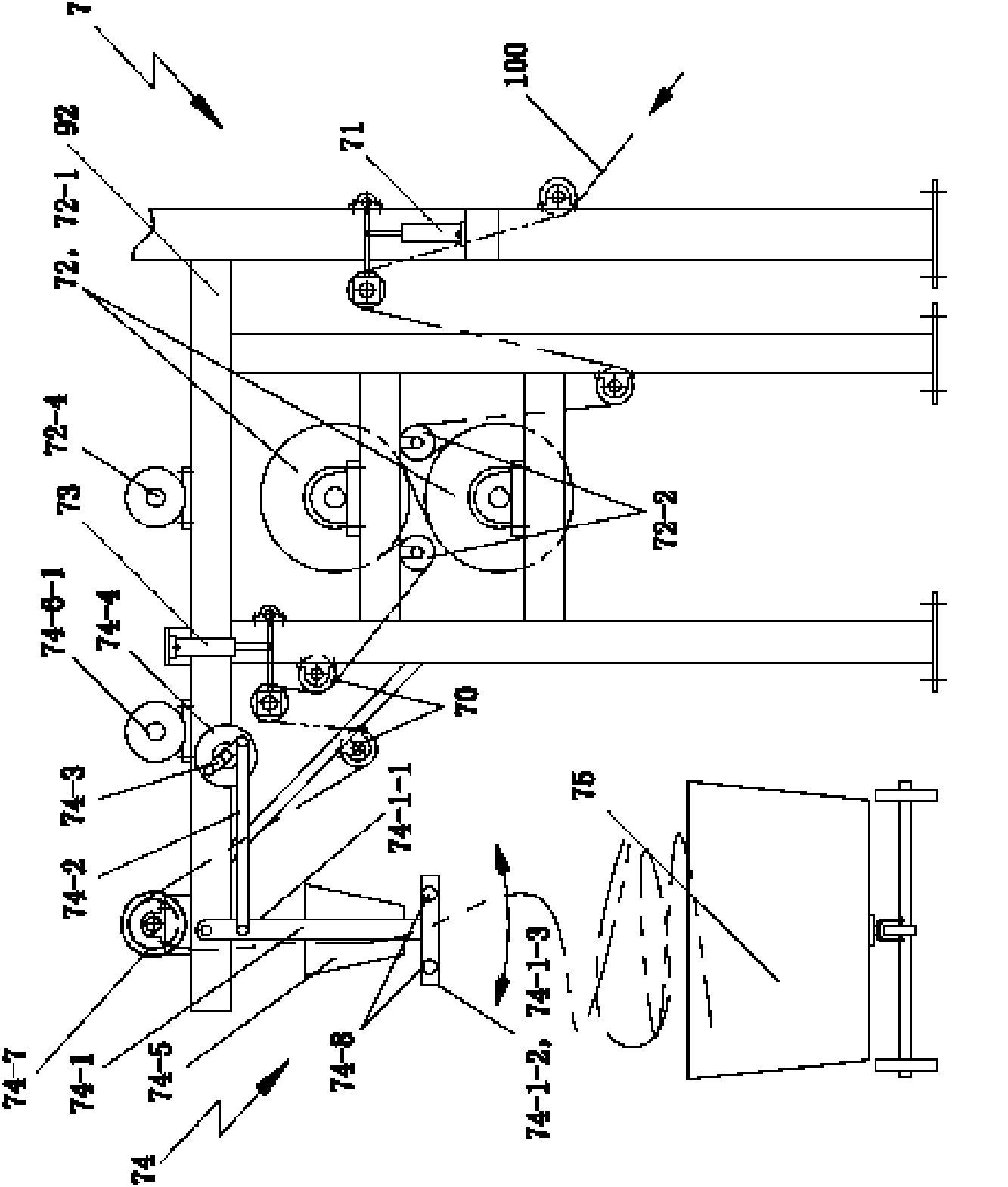

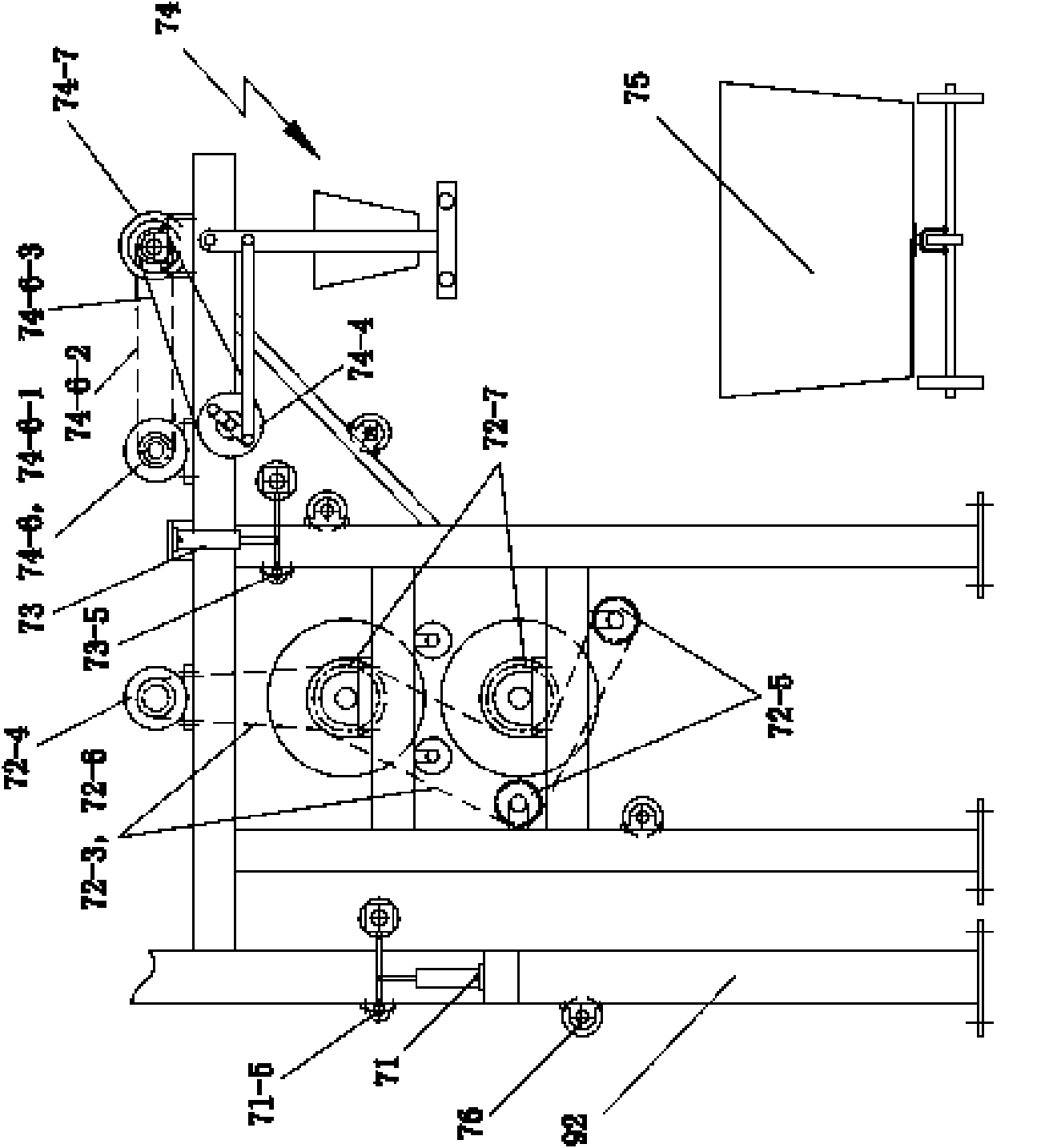

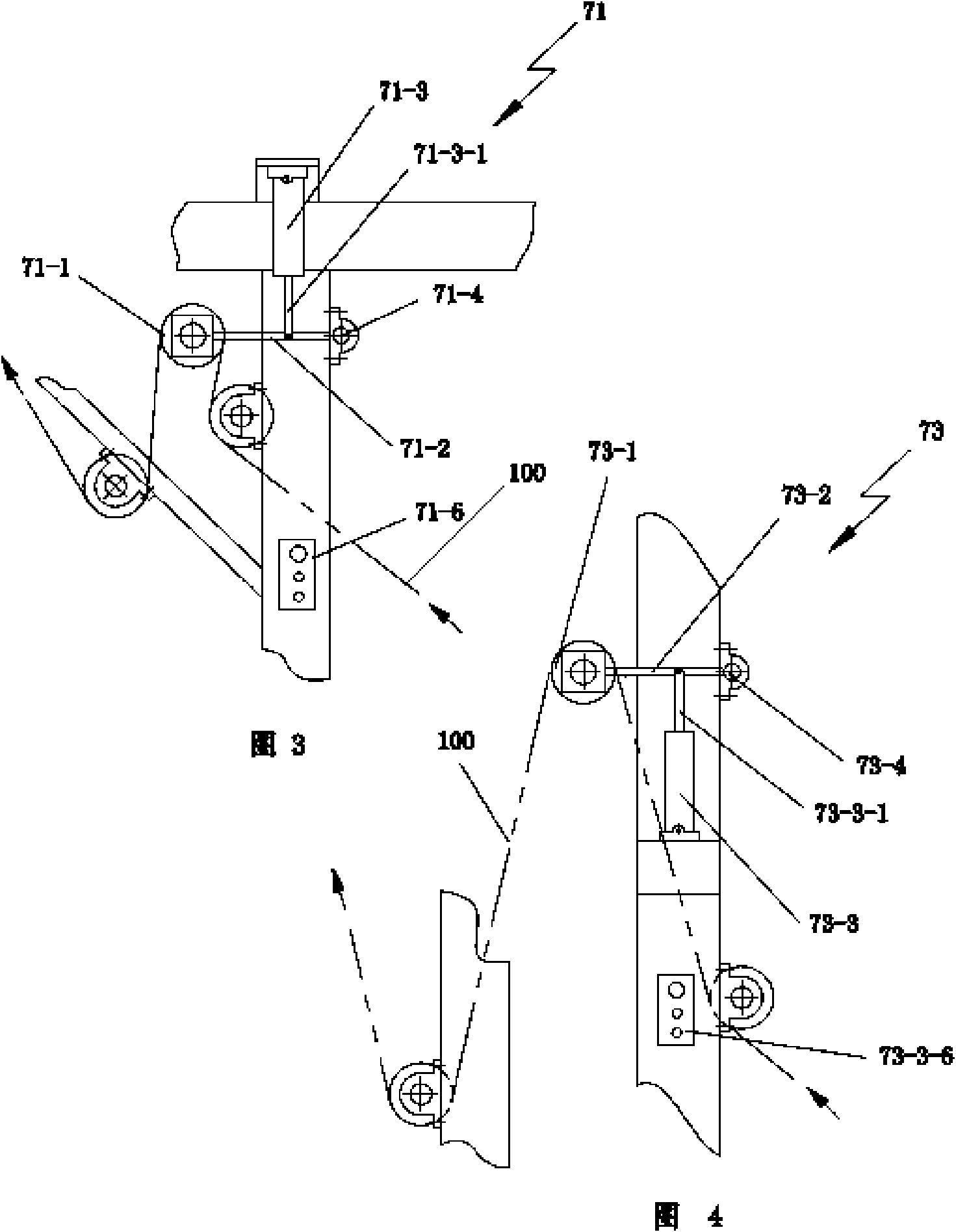

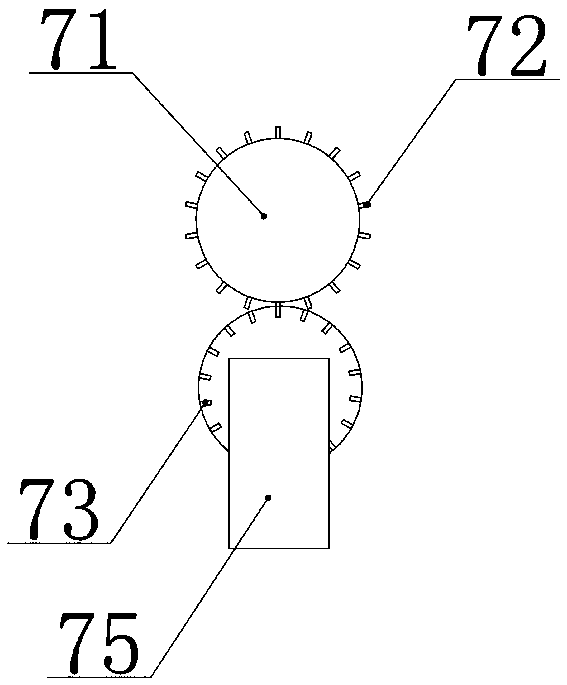

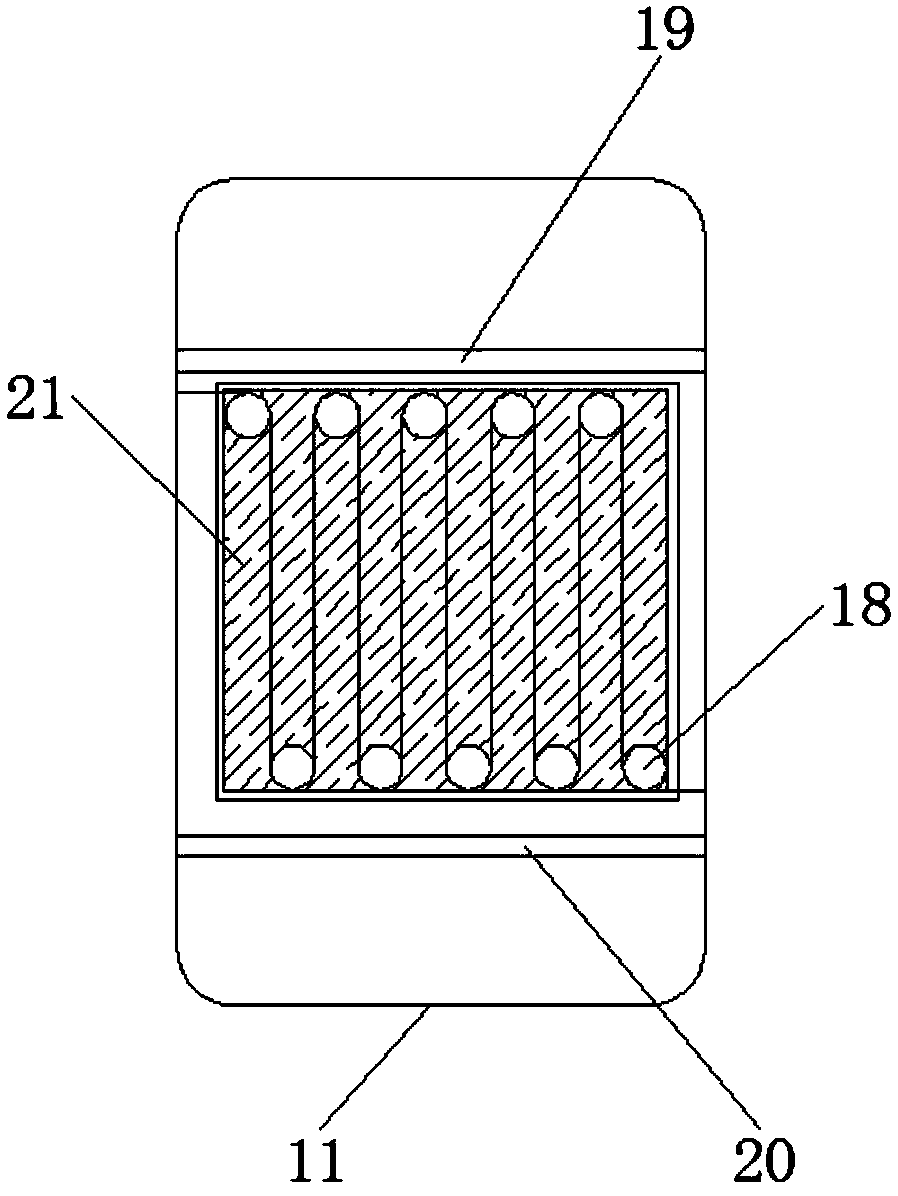

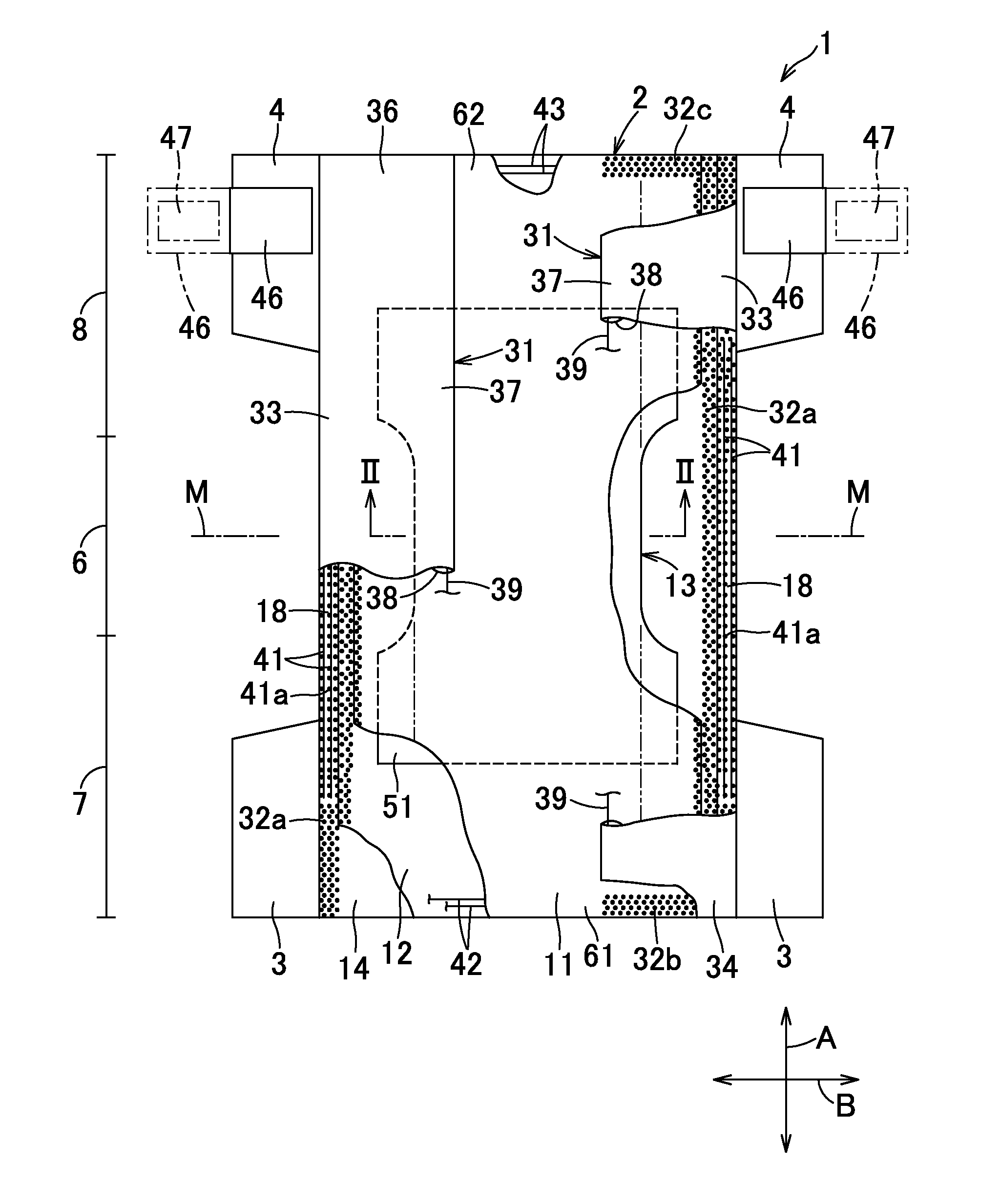

Knitting open-width wet processing unit with spray washing device

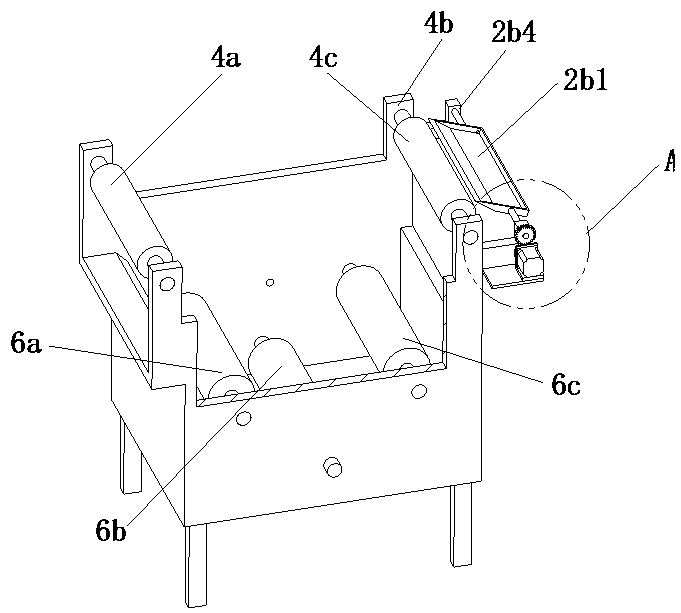

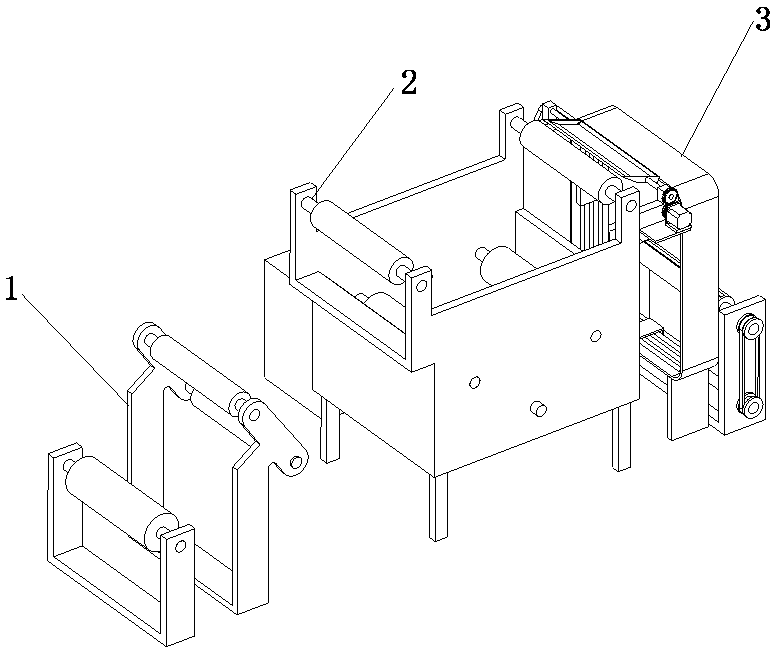

InactiveCN102517828AAvoid Stretch DeformationGuaranteed qualityTextile treatment by spraying/projectingTextile treatment rollersControl systemProcess engineering

The invention relates to a knitting open-width wet processing unit with a spray washing device. The knitting open-width wet processing unit comprises a wet processing unit machine, wherein a drum group and a roller group which is matched with the drum group are arranged in a box body of the wet processing unit machine; the drum group comprises a lower drum and an upper drum which are matched with each other; and the knitting open-width wet processing unit is characterized in that: the lower drum and the upper drum have meshed drum surfaces. The invention has outstanding characteristics that: 1, drums with the meshed drum surfaces are used, so that a penetration rate is improved, and the washing efficiency is improved; 2, soaking, high-penetration-rate spray washing and padder extrusion are integrated, and the washing efficiency is obviously improved; and 3, a drum comprising a cloth guide roller and a traction roller, and a roller are changed into driving rollers, a control system and a pressure sensor are matched to perform real-time monitoring and controlling, the synchronization of the unit is controlled at high precision, fabrics are prevented from being subjected to tensile deformation, and the quality of the fabrics is guaranteed.

Owner:绍兴东升数码科技有限公司

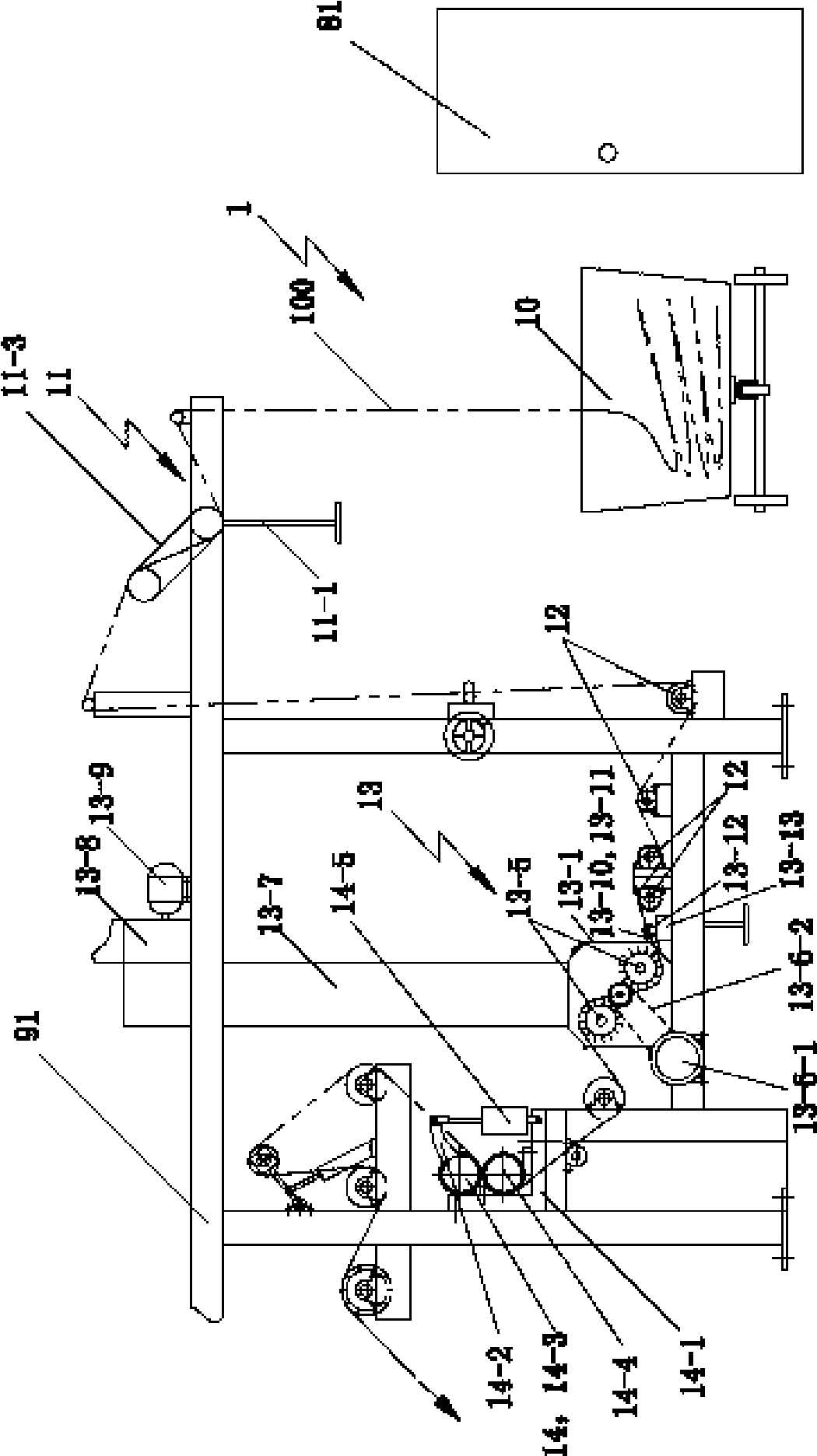

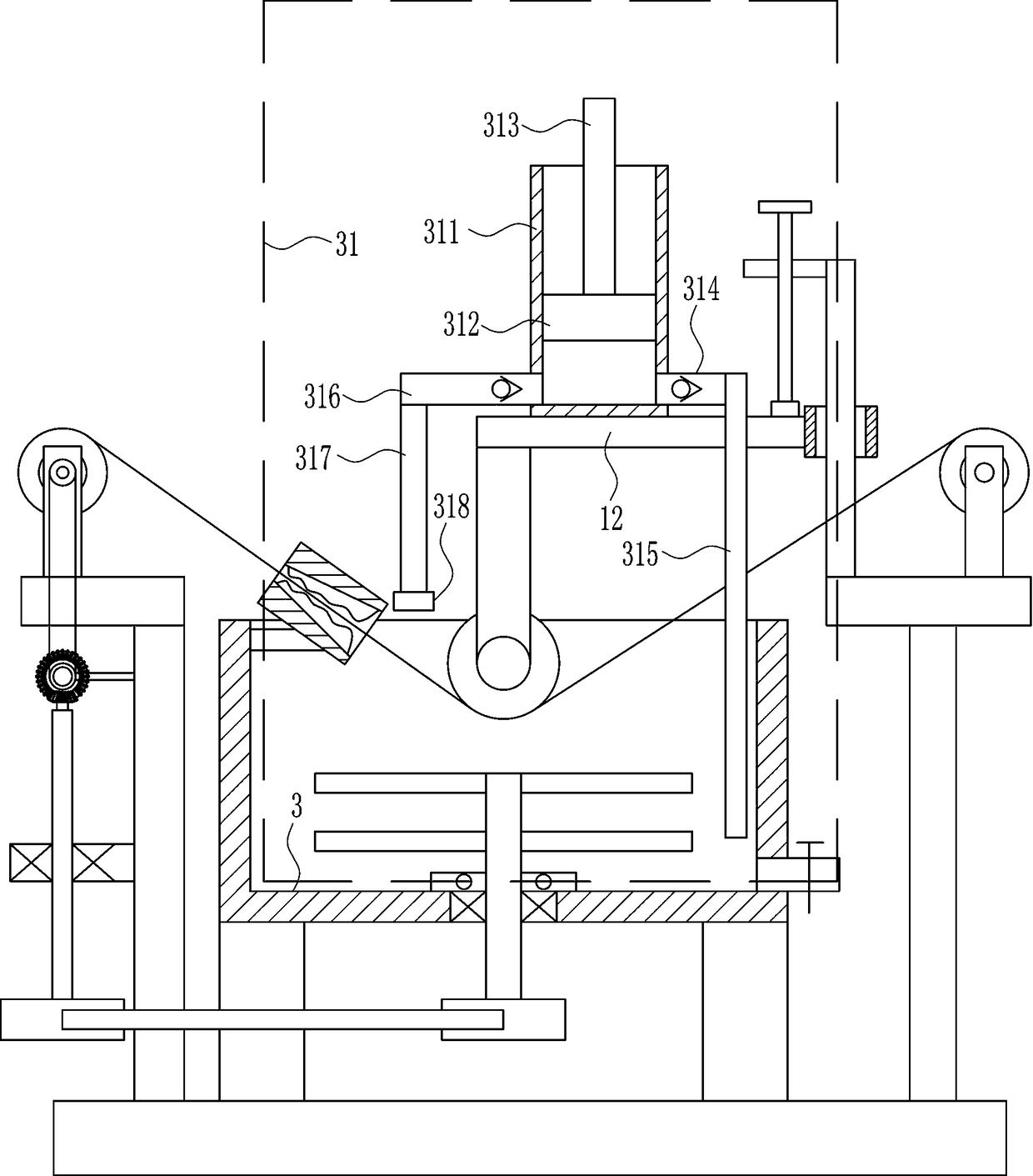

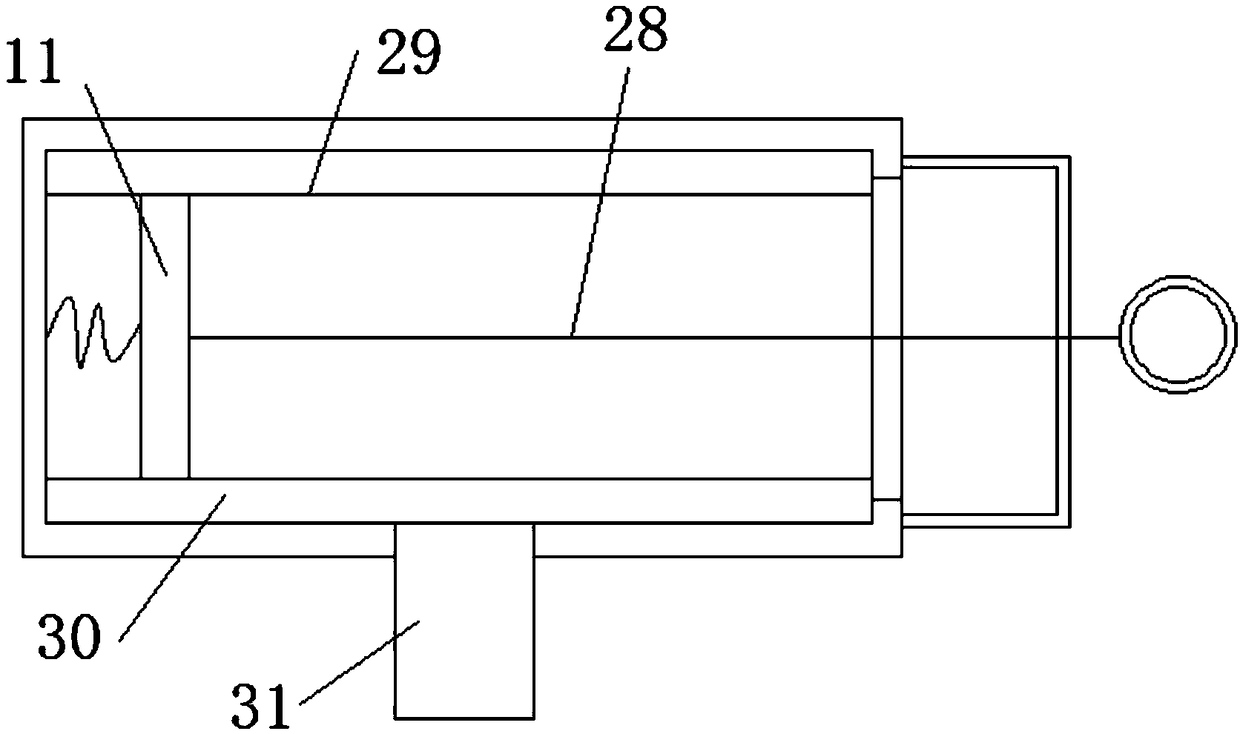

Continuous pigment dyeing pad dyer with infrared pre-baking apparatus

InactiveCN101487177AAvoid damageImprove mobilitySucessive textile treatmentsDrying solid materials with heatEngineeringPre treatment

The invention relates to a continuous paint dyeing padding machine with an infrared pre-drying device. The padding machine comprises a fabric inlet pre-processing device, a padding system, a drying system and a fabric outlet processing device which are sequentially arranged. The drying system comprises an infrared pre-drying device and a steam drying device. The infrared pre-drying device comprises two to five pre-dying mechanisms; each pre-drying mechanism comprises a pair of frame parts; and each pair of frame parts is provided with an infrared emitter. The continuous paint dyeing padding machine is characterized in that the front part of each row of infrared emitters is provided with a shielding device; when the padding machine is in use, the shielding device is arranged at a keep-clear position; and when the padding machine is in a shutdown state, the shielding device is arranged at a shielding position. Furthermore, each pair of frame parts can be arranged in a close state or an open state corresponding to the rolling of a first frame. Therefore, the padding machine has protection effect when in use, better dyeing effect and convenient maintenance.

Owner:常州慧杰电气技术有限公司

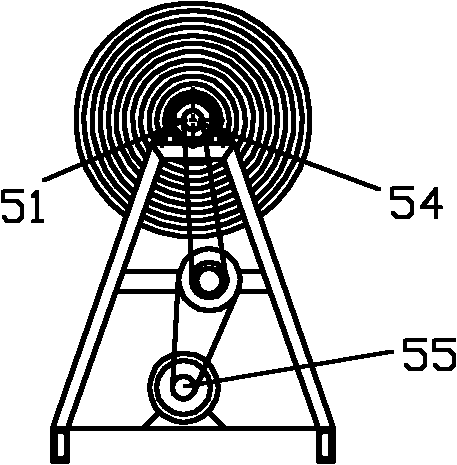

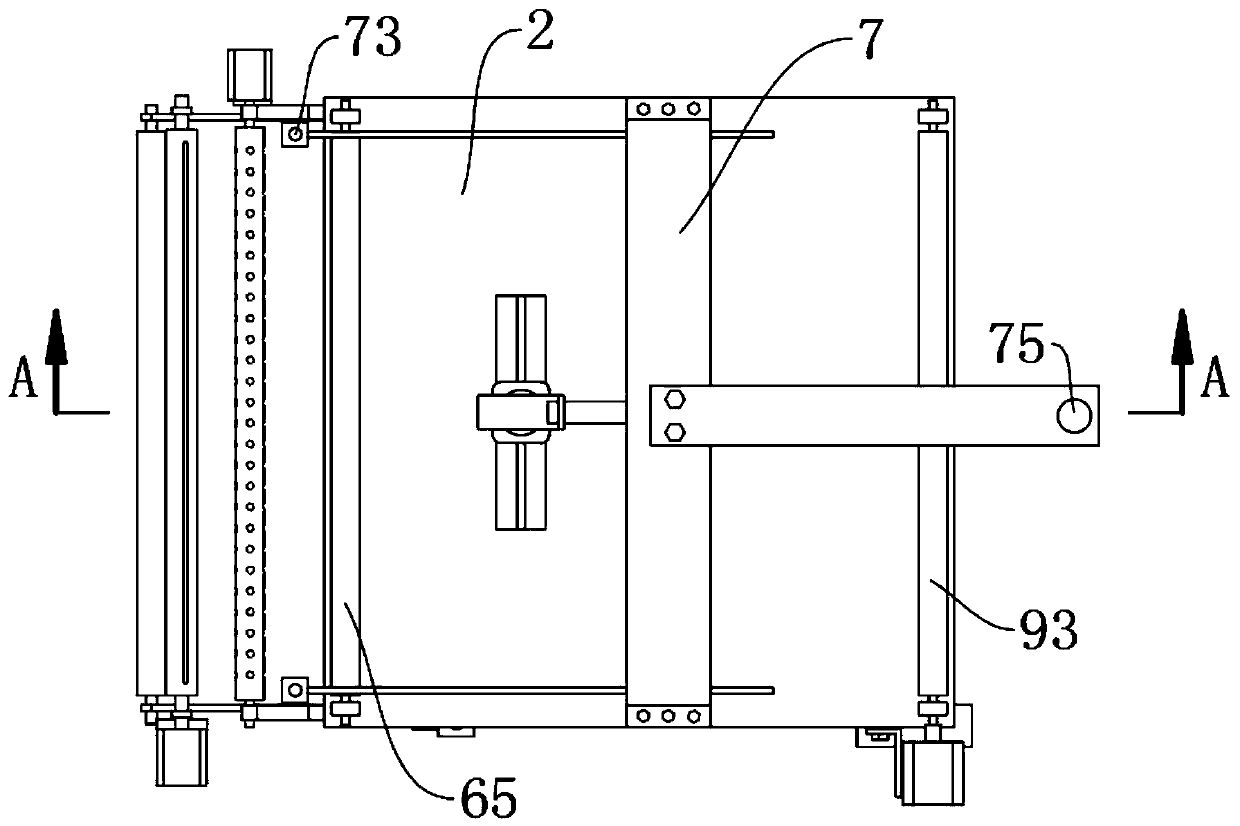

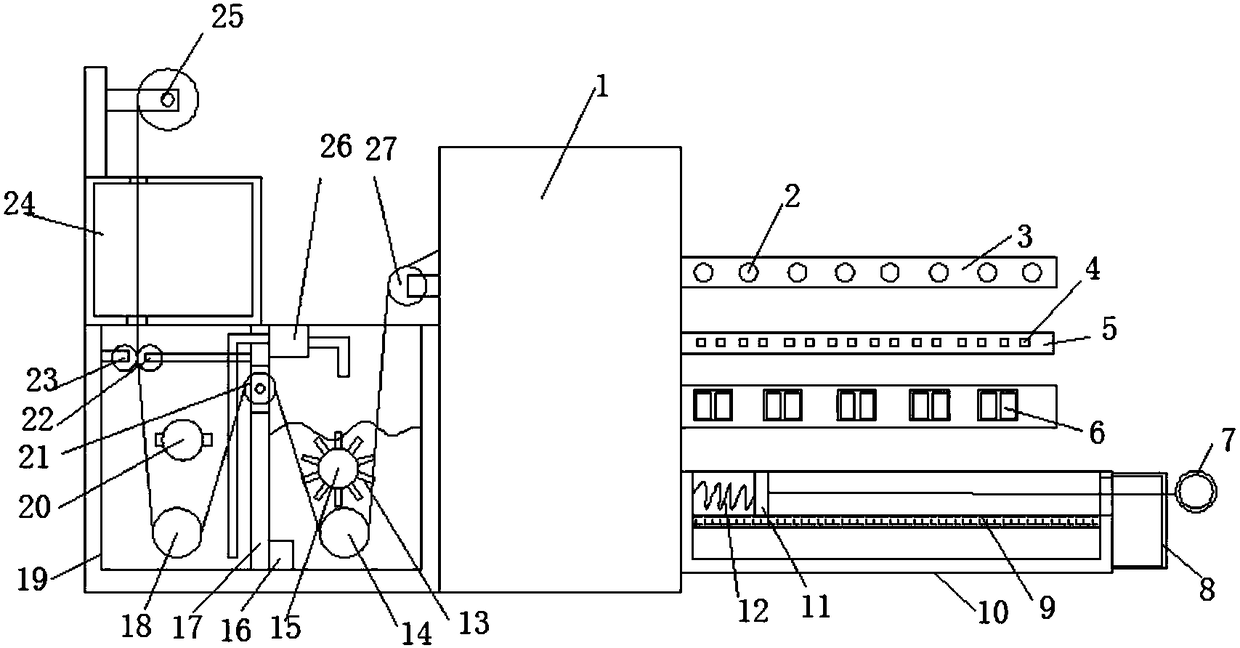

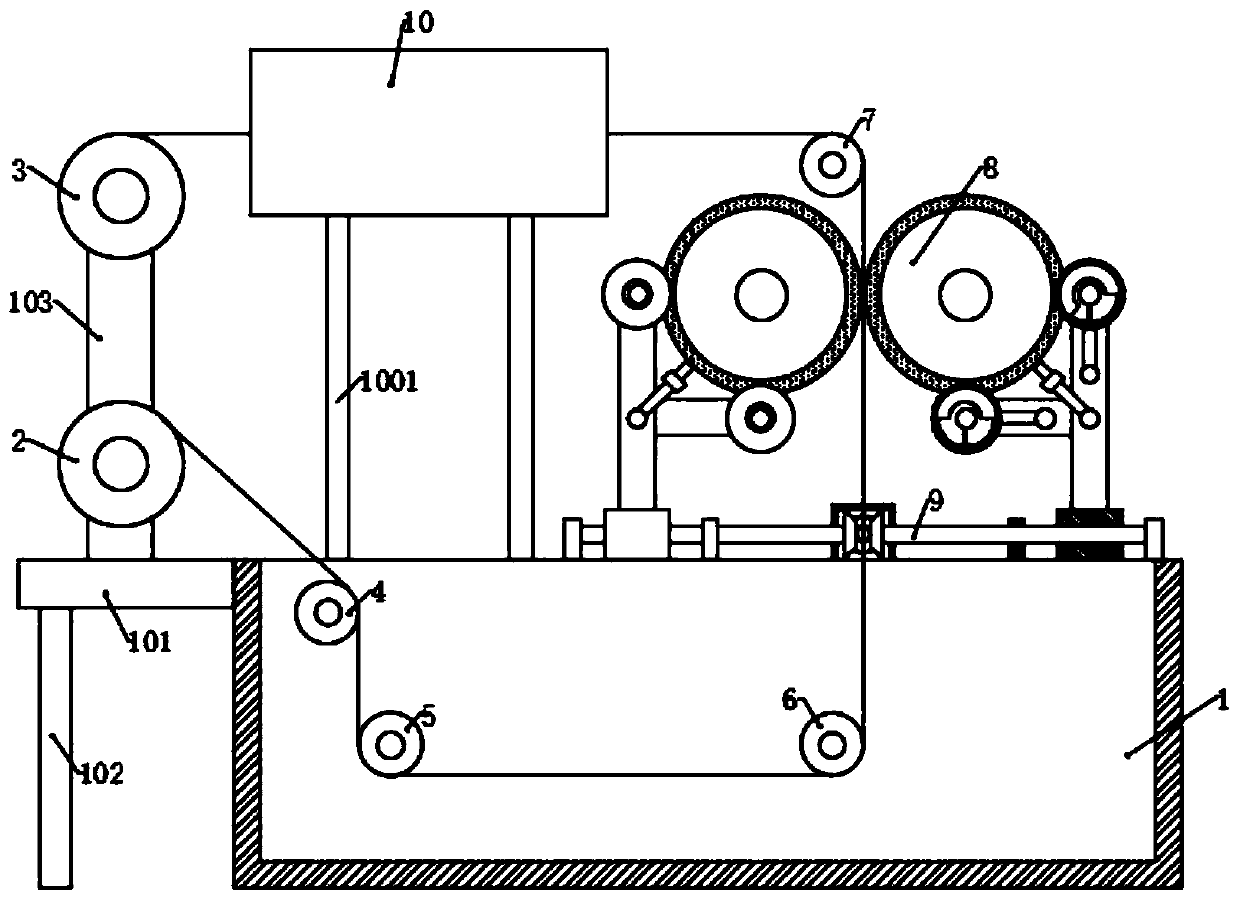

Cold pad-batch dyeing device for open-width knitted fabrics

InactiveCN101818422APrevent deviationAdjustable distanceTextile storage in wounded formLiquid/gas/vapor removal by squeezing rollersEngineeringControl circuit

The invention discloses a cold pad-batch dyeing device for open-width knitted fabrics, which comprises a frame, a cloth feeding device and a dyeing padding liquid device, and further comprises a wet supported cloth conveying device, a rollup device and a control circuit. The cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are arranged on the frame one after another; the cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are all provided with mechanical open-width components, and the open-width knitted fabrics are subject to open-width flattening before entering the units described above; the control circuit controls the rotating speed of electric motors in an active manner so that the cloth feeding device, the dyeing padding liquid device, the wet supported cloth conveying device and the rollup device realize the conveyance of the open-width knitted fabrics under bearable tension in a manner of synchronous operation, the open-width knitted fabrics are free from crumpling and curling in the entire treatment process, and eventually, the open-width knitted fabrics are flatly rolled onto a cloth roller in the form of big batch which can be rotatably piled up like woven fabrics, and the dyeing is completed during the rotatable pile-up, which not only reduces various consumptions and saves cost remarkably, but also improves the quality of the knitted fabrics.

Owner:蔡宗义

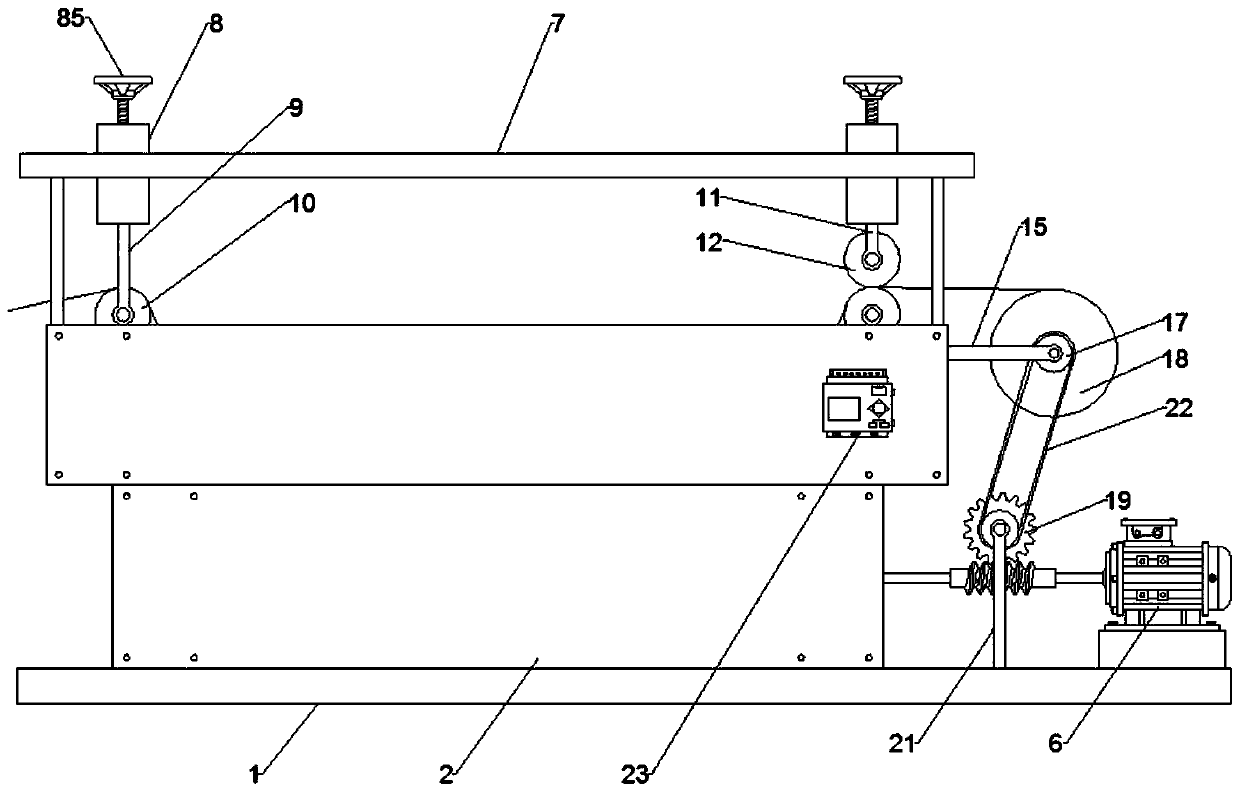

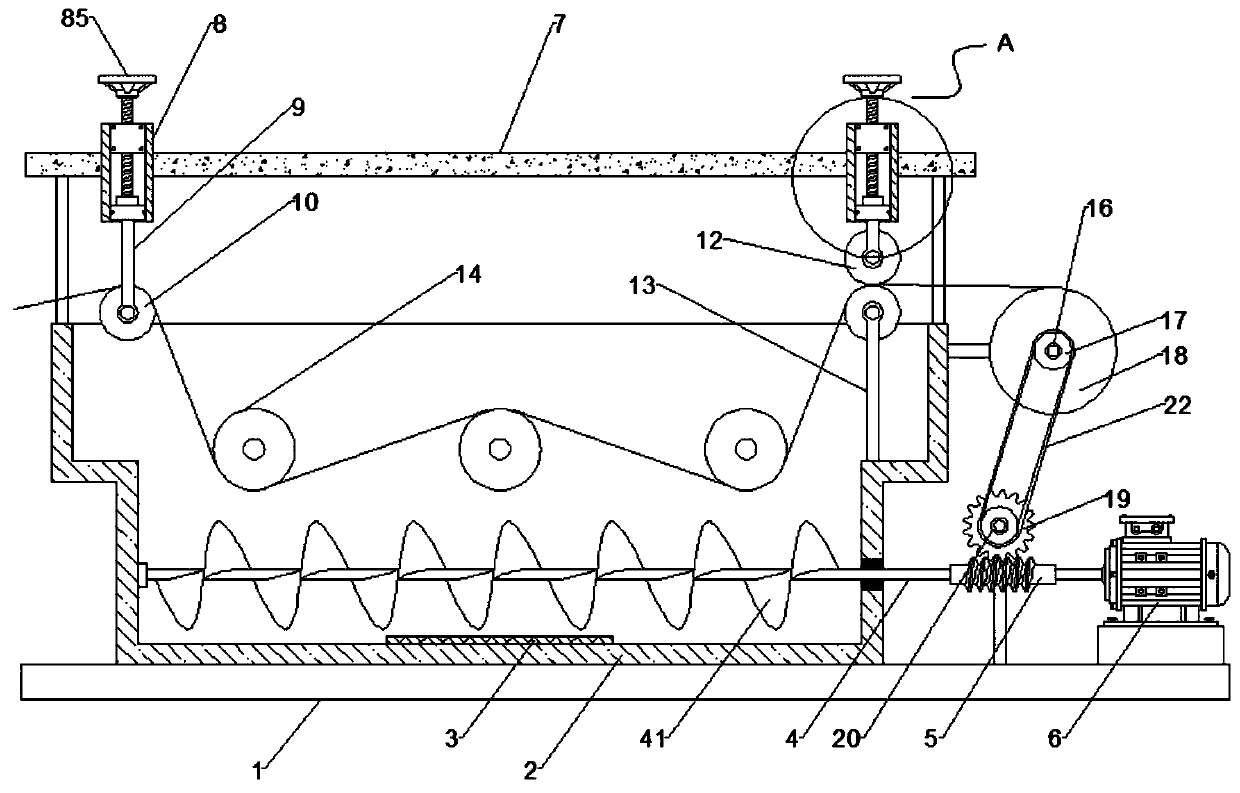

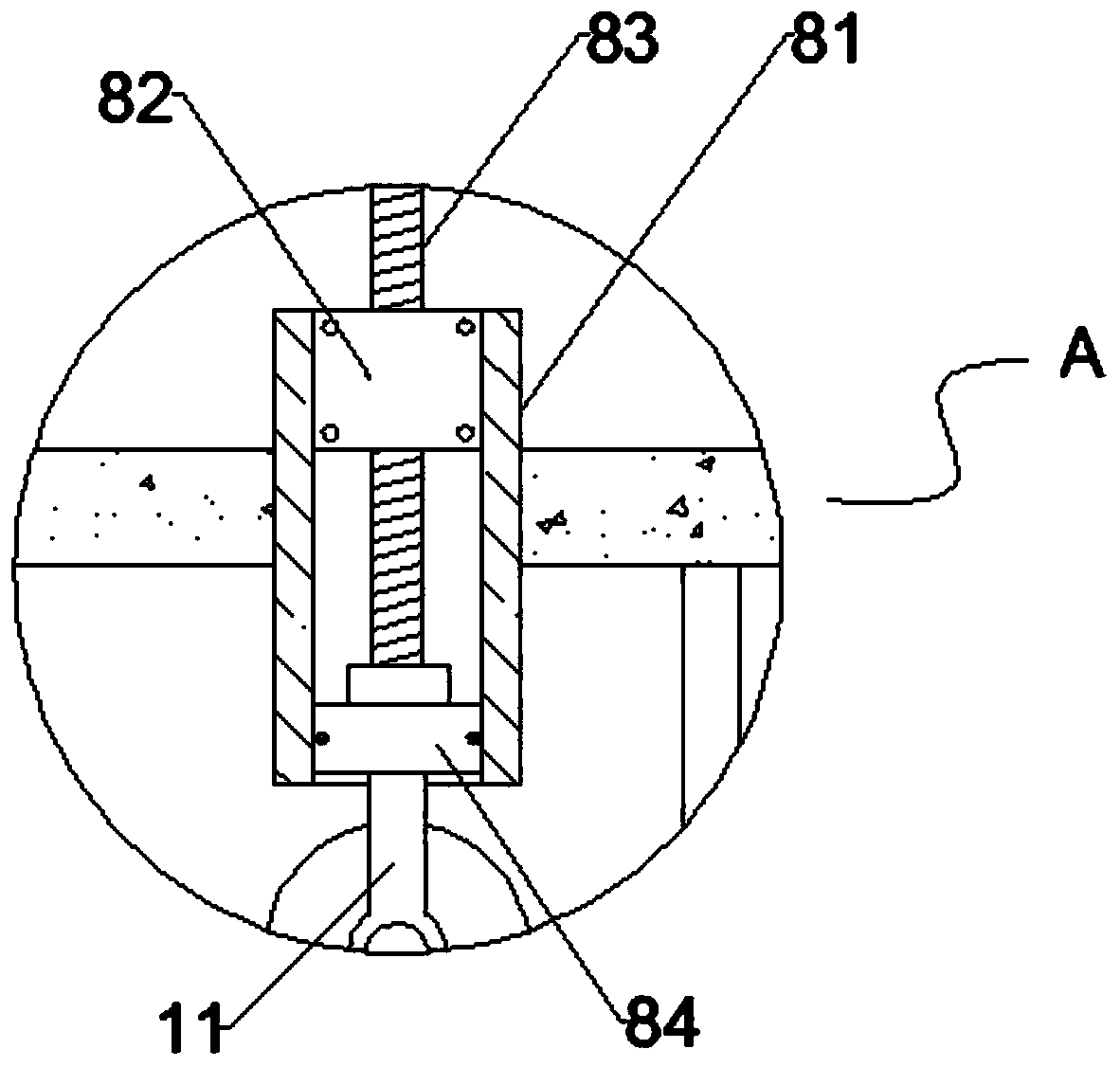

Textile cloth cleaning device for textile cloth production

InactiveCN107287783AAdjustable tensionAvoid pollutionLiquid/gas/vapor removal by squeezing rollersTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention discloses a textile cloth cleaning device for textile cloth production in the technical field of textile cloth production equipment. A tension adjustment roller is installed on the top of the device, and the other end of the rotating shaft runs through the outer wall of the cleaning box to install a brush. The left and right sides of the cleaning box are respectively equipped with a cloth inlet and a cloth outlet, which can clean the two sides of the textile cloth. Washing, and in the process of washing, the motor drives the brush to rotate to wash the textile cloth, which improves the cleaning efficiency. Two sets of electric telescopic rods are used to drive two sets of extrusion rollers, which can squeeze out the washed textile cloth The remaining water stains on the surface can prevent water stains from polluting the workshop. The tension adjustment roller can be driven up and down by the hydraulic lifting device, which can realize the adjustment of the tension of the textile fabric and improve the cleaning efficiency.

Owner:湖州南浔贵丰纺织有限公司

Textile fabric dyeing equipment

ActiveCN108277594AAvoid color inconsistenciesNo precipitationLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringSediment

The invention relates to textile processing equipment, in particular to textile fabric dyeing equipment. The to-be-solved technical problem is to provide the textile fabric dyeing equipment capable ofstirring dye, so that no sediment occurs in the dye, the fabric is dyed uniformly, the upper and lower layers of the fabric both can be dyed with the dye at same depth in a dyeing process. In order to solve the above technical problem, the invention provides the textile fabric dyeing equipment, the textile fabric dyeing equipment comprises a bottom plate, brackets, a dye box, a discharging tube,a valve, a first supporting plate, a first mounting plate, a first connecting rod, and a first sleeve wheel, a guiding rail, a guiding sleeve, a second connecting rod and the like, wherein the left and right sides of the bottom plate both are connected to the brackets, and the dye box is connected between the upper ends of the brackets. According to the textile fabric dyeing equipment, the effectsthat the dye is stirred, so that no sediment occurs in the dye, the fabric is dyed uniformly, and the upper and lower layers of the fabric both can be dyed with the dye at same depth in the dyeing process are achieved.

Owner:嘉兴市永泰五金塑料有限责任公司

Wetting, drying, and ironing device for textile production

InactiveCN108060543AReduce defective rateGuaranteed qualityLiquid/gas/vapor removal by gas jetsTextile treatment by spraying/projectingWater dischargeEngineering

Owner:石小英

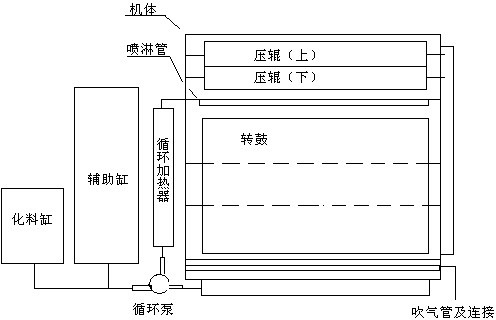

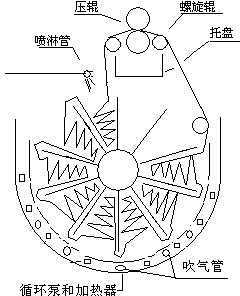

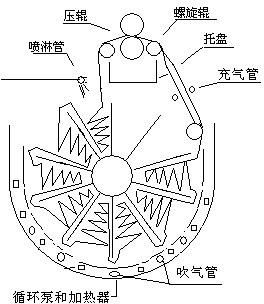

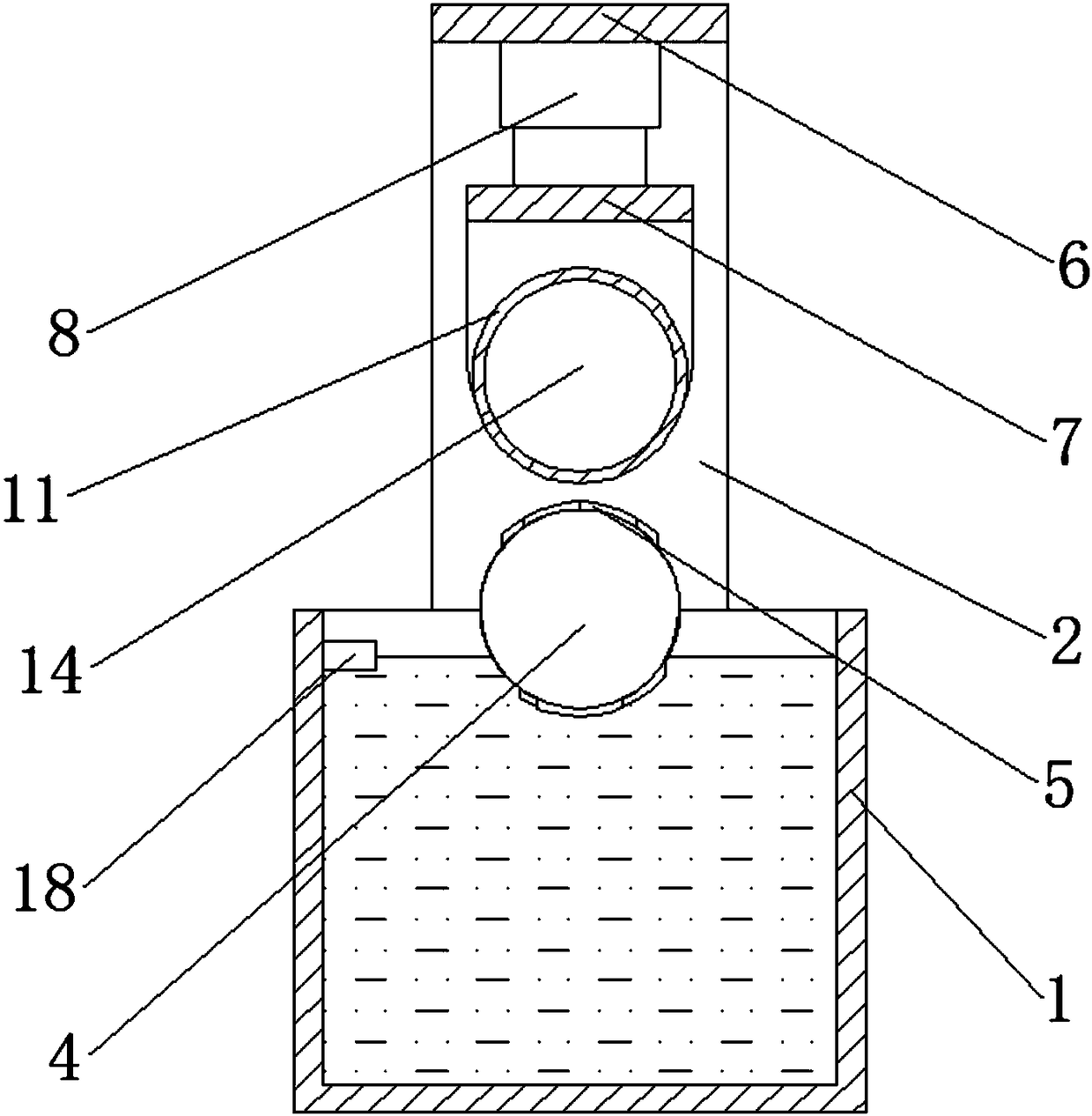

Textile dyeing machine

InactiveCN102587056AReduce dosageImprove washing efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTextile dyeingMechanical engineering

The invention discloses a textile dyeing machine which comprises a cylindrical dye vat, the cylindrical dye vat is internally provided with a rotary drum coaxial with the dye vat, blades are uniformly distributed on the rotary drum, and a group of press rolls arranged above one another is arranged above the cylindrical dye vat. The textile dyeing machine is also provided with a dye solution circulating pipe, one end of the dye solution circulating pipe is communicated with the bottom of the dye vat, the other end of the dye solution circulating pipe is communicated with a sprayer above the dye vat, and a heater and a circulating pump are arranged on the dye solution circulating pipe. The raffinate containing rate after each time of liquid discharge is reduced by the press rolls, so as to improve the washing efficiency, and greatly reduce the use amount of water, electricity and steam. A loose processing manner is adopted for the textile dyeing machine so as to adapt to all textiles and non-woven fabrics; and in operation, no mechanical friction exists between the fabric and the equipment, the fabric is free from rapid impact of the dye solution, and the fabric surface is lint-free.

Owner:SHANDONG COMPANION GROUP

High-efficiency oil-removing washing machine

PendingCN107604568ASolve anti-stickingSolve cleanupSucessive textile treatmentsTextile treatment containersWater resourcesWater flow

The invention discloses a high-efficiency oil-removing washing machine. The high-efficiency oil-removing washing machine includes a washing machine box, washing grooves are formed in the washing machine box, detachable water grooves are mounted on the portions, above cloth rollers, of the interiors of the washing grooves through brackets, and the detachable water grooves are convenient to mount and clean; cloth guide rolls are mounted on the portions, above the detachable water grooves, of the interior of the washing machine box, and spray devices are mounted on the portions, above the cloth guide rollers, of the interior of the washing machine box; after entering the washing machine box, fabric firstly is subjected to spray washing through the spray devices and then passes through gaps between the washing grooves and the detachable water grooves, the fabric is washed by means of water flow and the cloth rollers, the washing process is long, and effects are good; filter screen devicesare mounted at openings in the tops of the detachable water grooves, after being filtered by the filter screen devices, and circulating water is input into an oil-removing filter to carry out secondary oil removing and then is input into the washing grooves to be used for washing. By the adoption of the high-efficiency oil-removing washing machine, the problems of sticking and cleaning in an oil-removing washing technology are solved, energy consumption is reduced, water resources are saved, the automation degree of the washing technology is improved, operation processes are simplified, and labor costs are reduced.

Owner:SHAOXING LIANKE MACHINERY

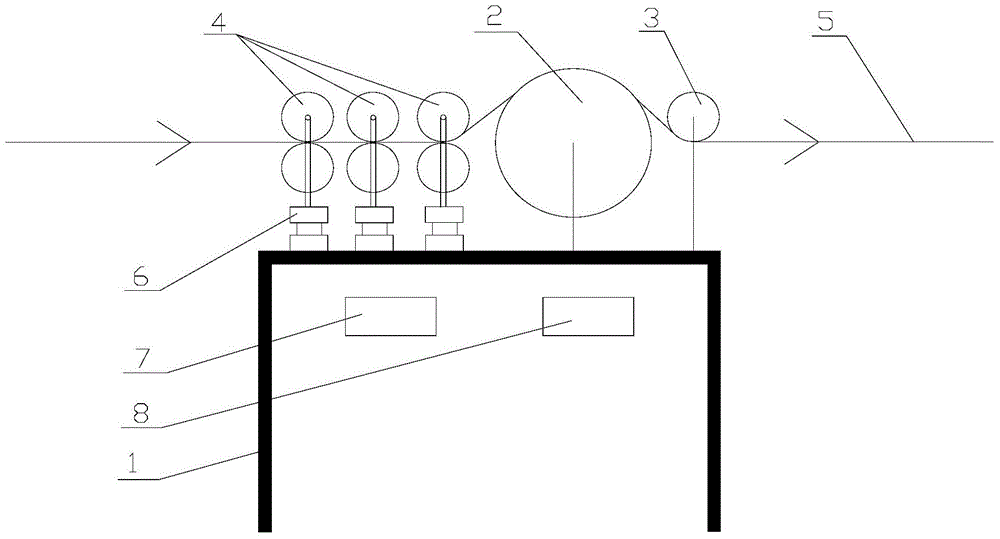

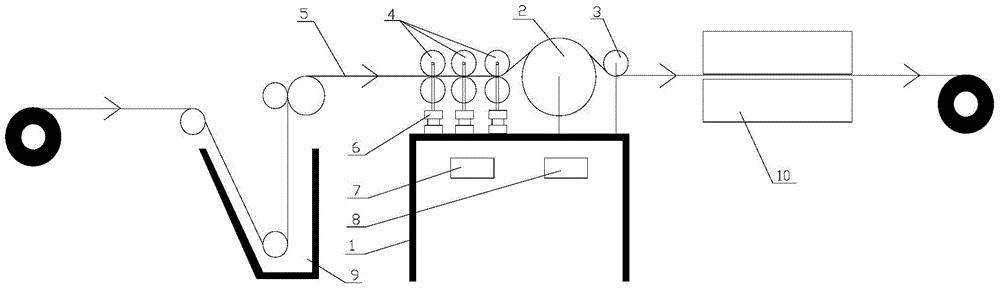

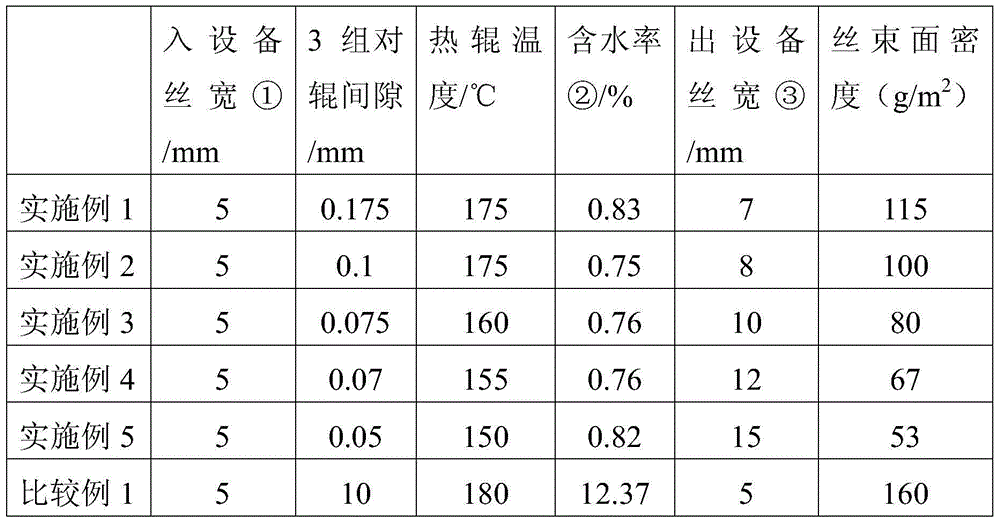

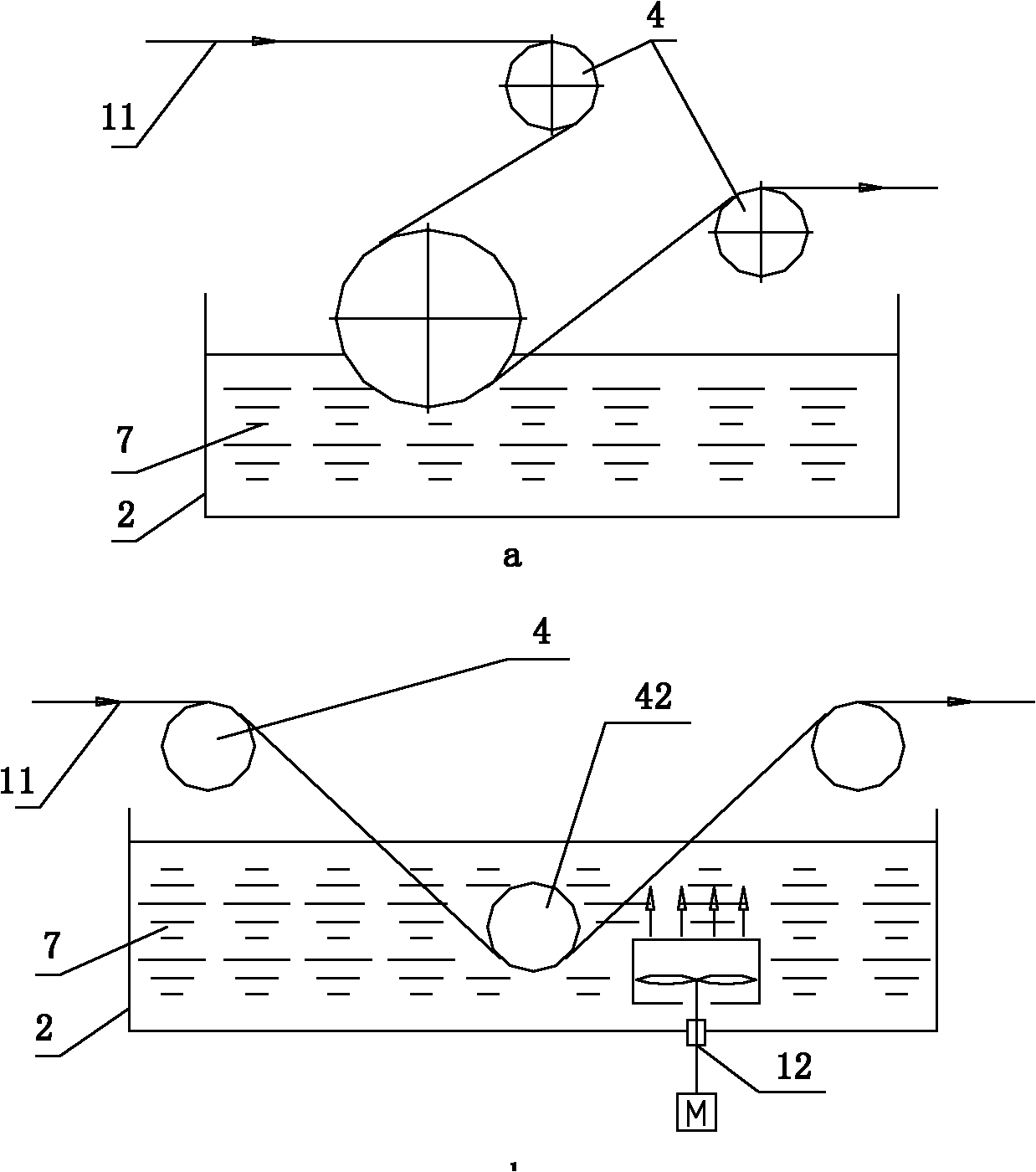

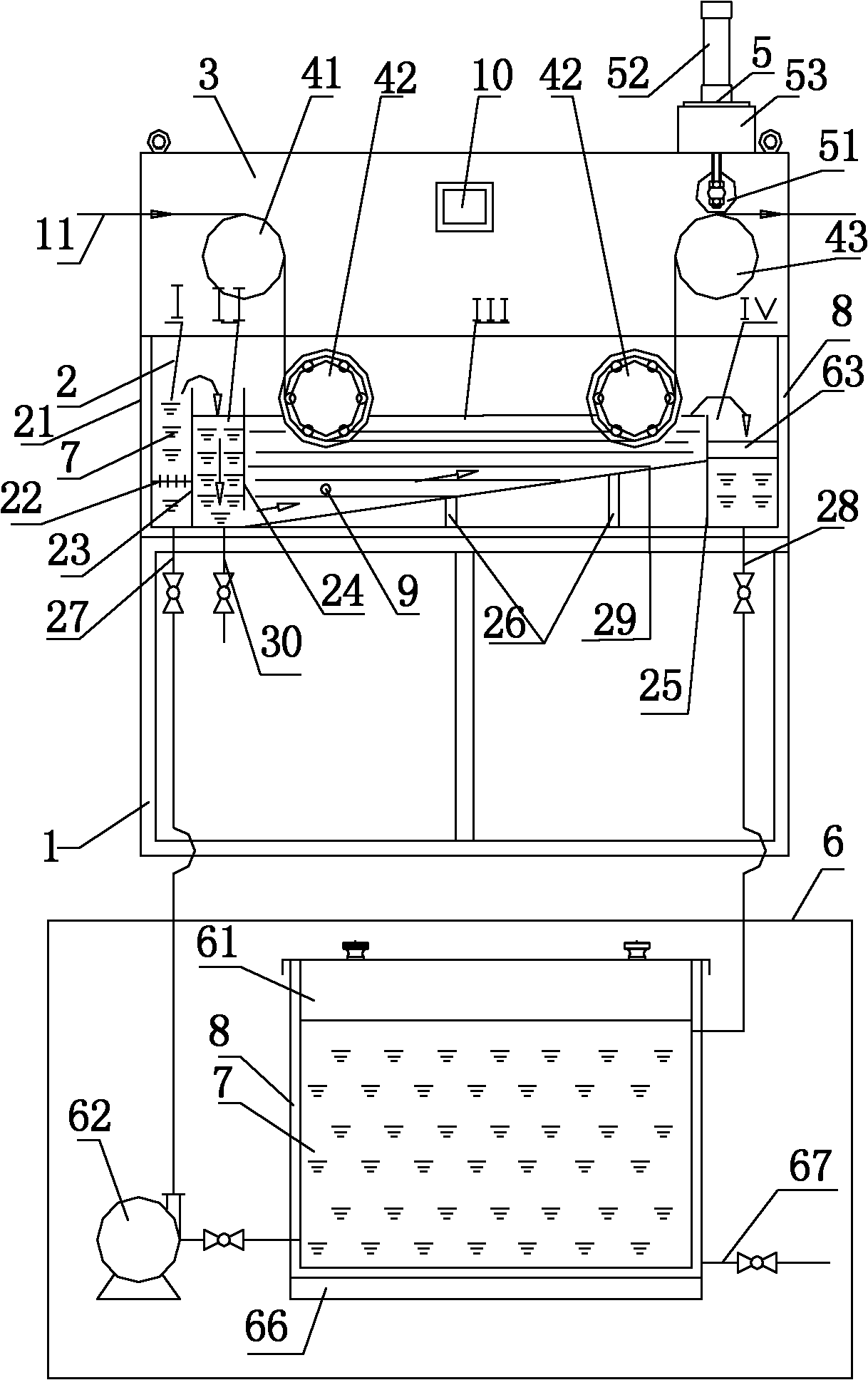

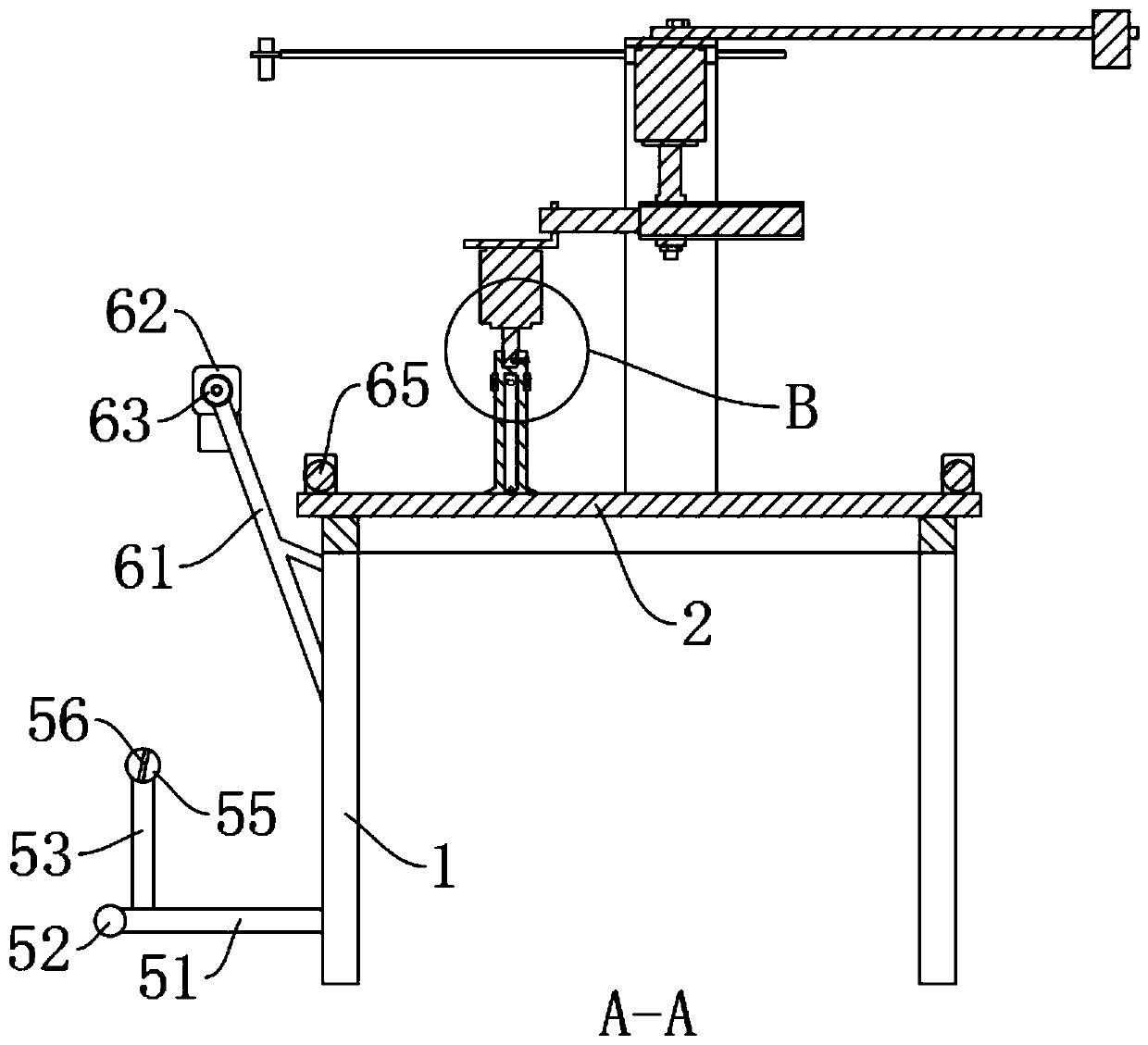

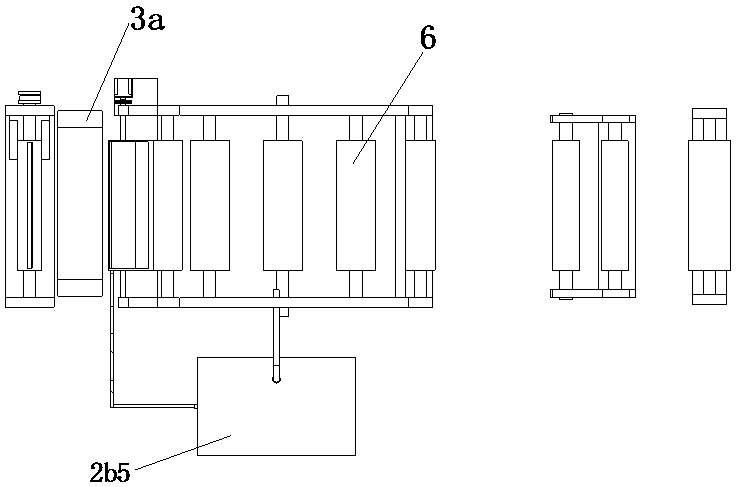

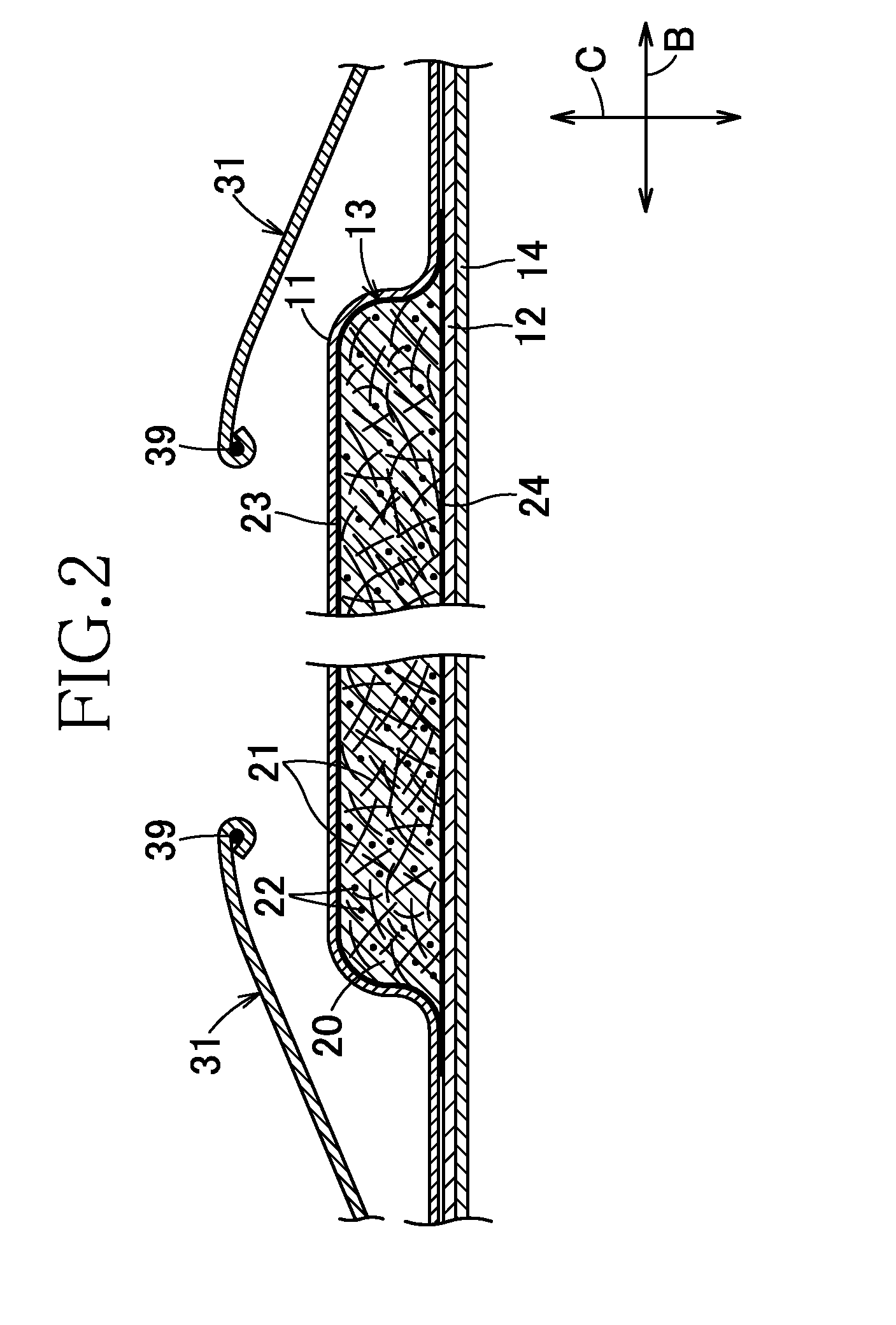

Splitting shaping device and splitting shaping method of ultrathin carbon fiber bundle

ActiveCN104674485AAchieve ultra-thinOnline continuous fastLiquid/gas/vapor removalTextile treatment machine arrangementsCarbon fibersFiber bundle

The invention discloses a splitting shaping device and a splitting shaping method of an ultrathin carbon fiber bundle. The splitting shaping device comprises a plurality of groups of filament spreading double-rollers, a heat roller and a levelness adjusting roller, which are sequentially arranged; each group of filament spreading double-rollers is provided with a hydraulic lifting machine, each hydraulic lifting machine is fixed on a support, two ends of the heat roller are fixedly connected to the support, and two ends of a rotating shaft of the levelness adjusting roller are also fixedly connected to the support; when the carbon fiber bundle is transported, the heat roller is fixed and does not rotate. The splitting and shaping method comprises the steps of enabling the carbon fiber bundle with serous fluid on the surface to sequentially pass through the filament spreading double-rollers, uniformly spreading the carbon fiber bundle under the extruding effect of the filament spreading double-rollers and the lubricating effect of the serous fluid, and pressing and flattening the fluctuated fibers in the carbon fiber bundle; enabling the carbon fiber bundle to pass through the heat roller, enabling the heat roller to be fixed and not to rotate, drying the carbon fiber bundle by virtue of the heat roller, and enabling the carbon fiber bundle to maintain the filament width after he carbon fiber bundle is spread. After the splitting shaping device and the splitting shaping method is applied to the carbon fiber production process, the ultrathin and online continuous and rapid production of the carbon fiber bundle can be realized, and the development of a downstream ultralight ultrathin product can be satisfied.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

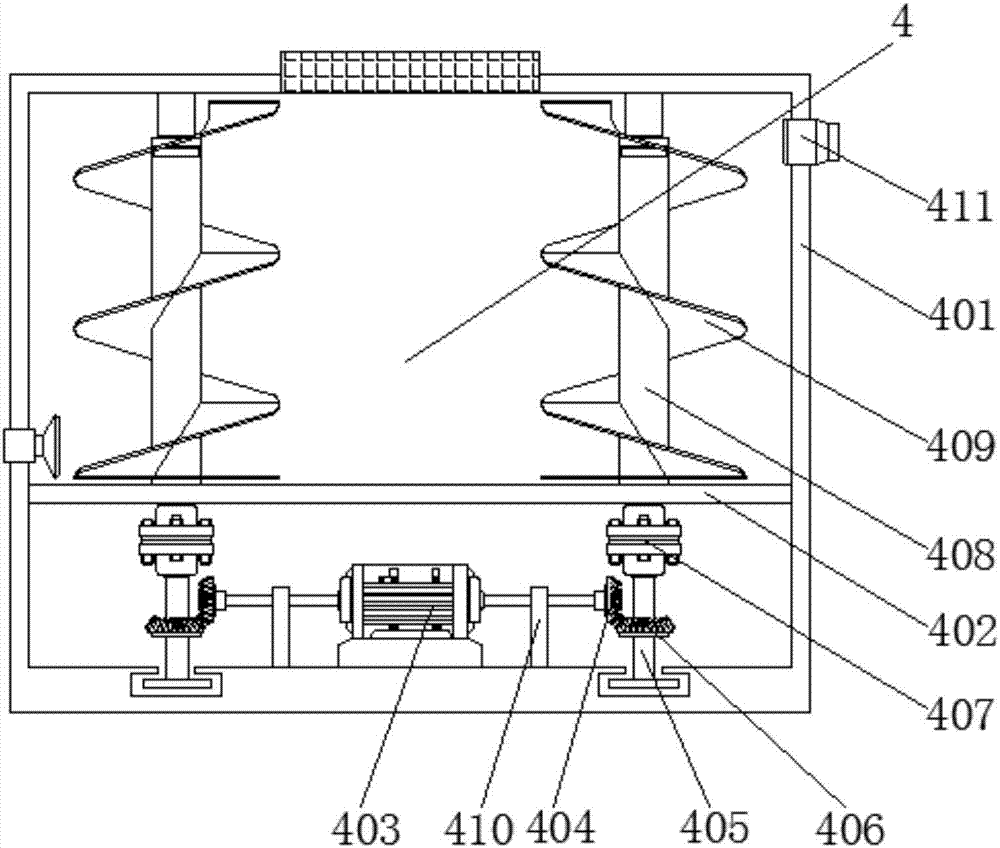

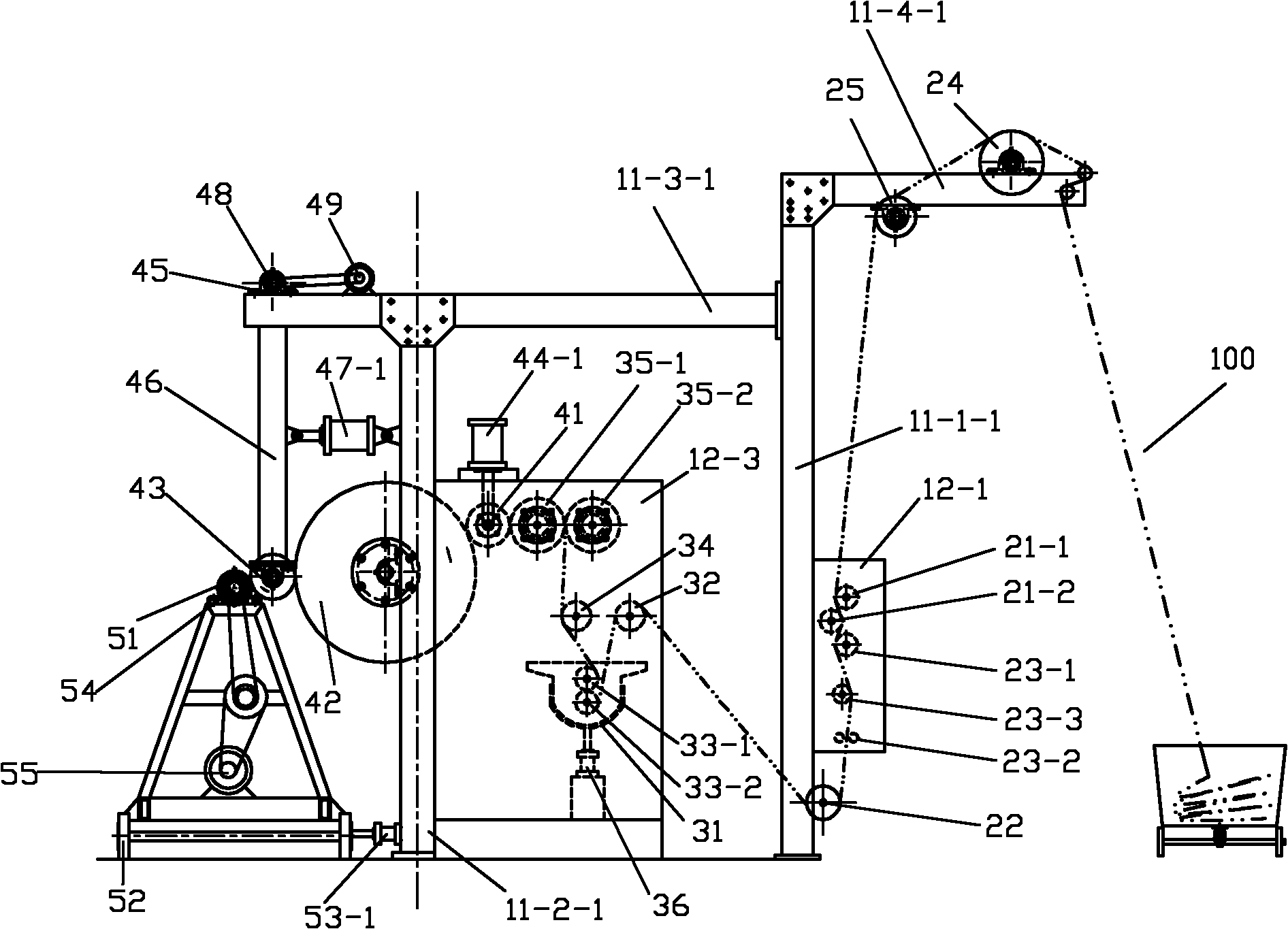

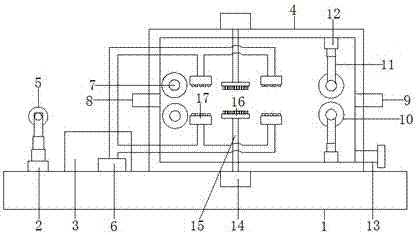

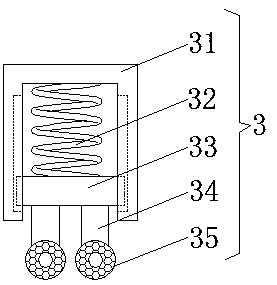

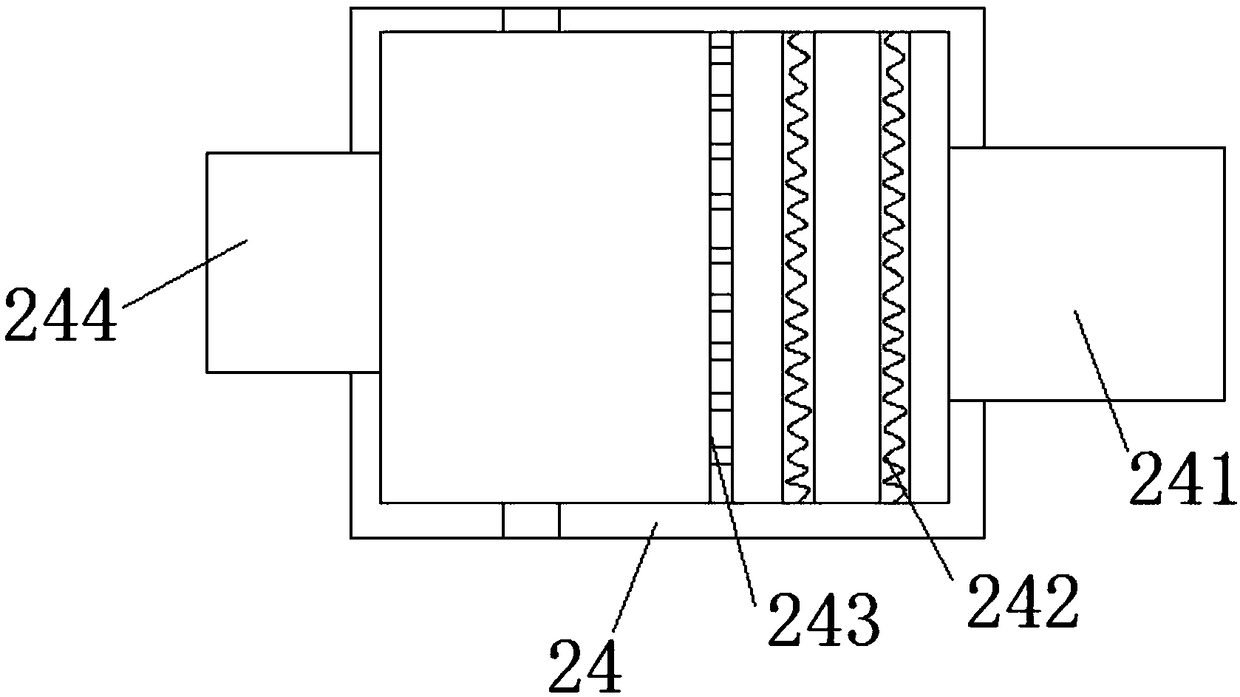

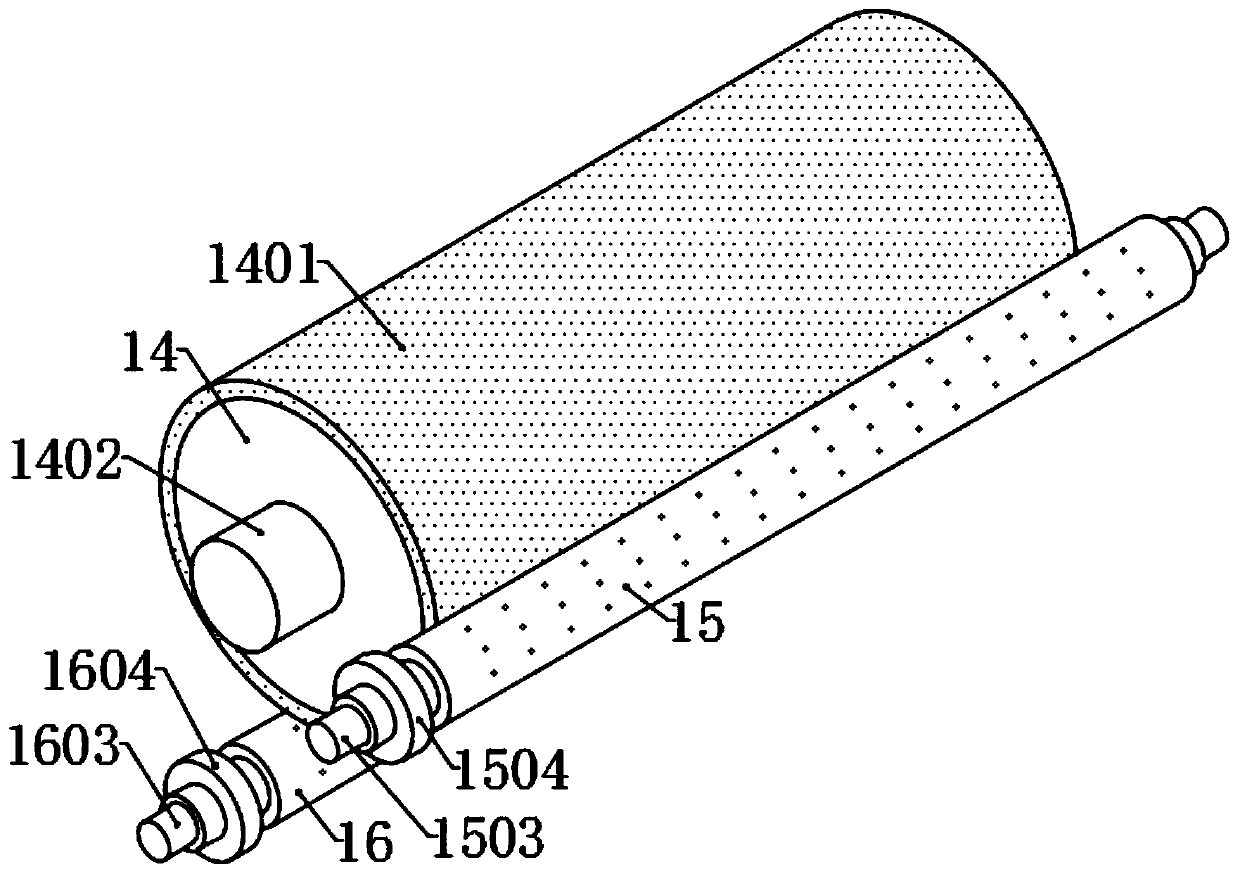

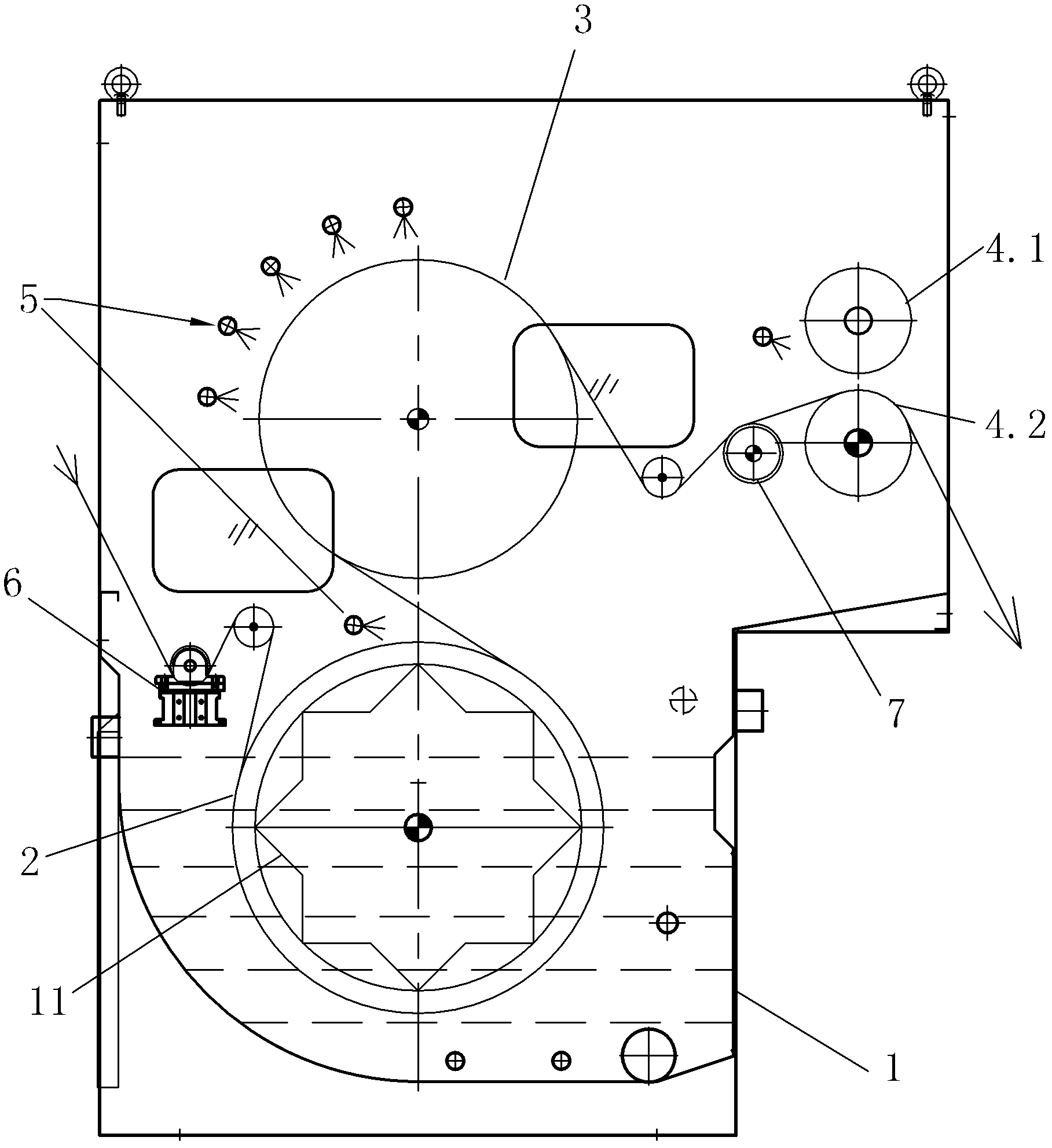

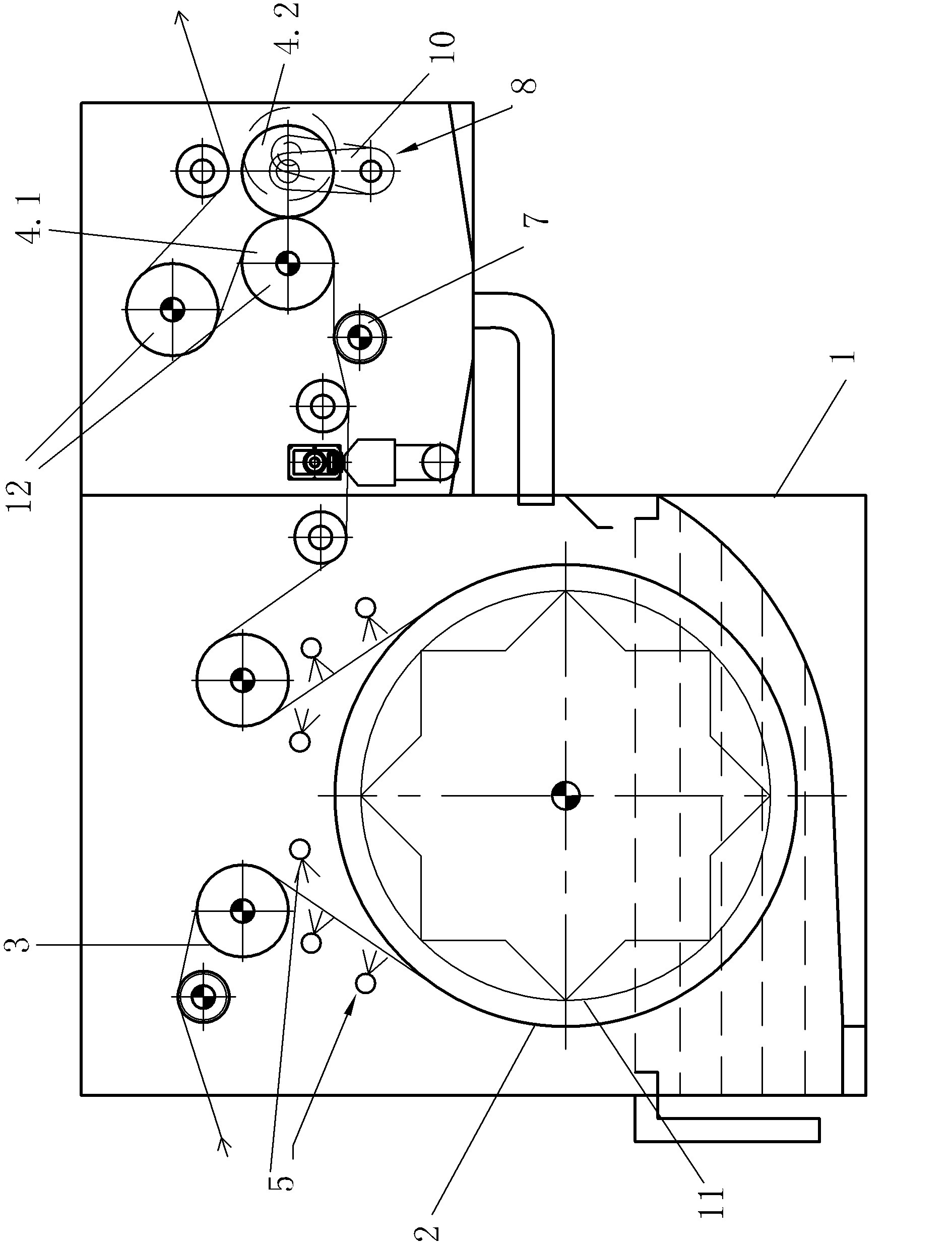

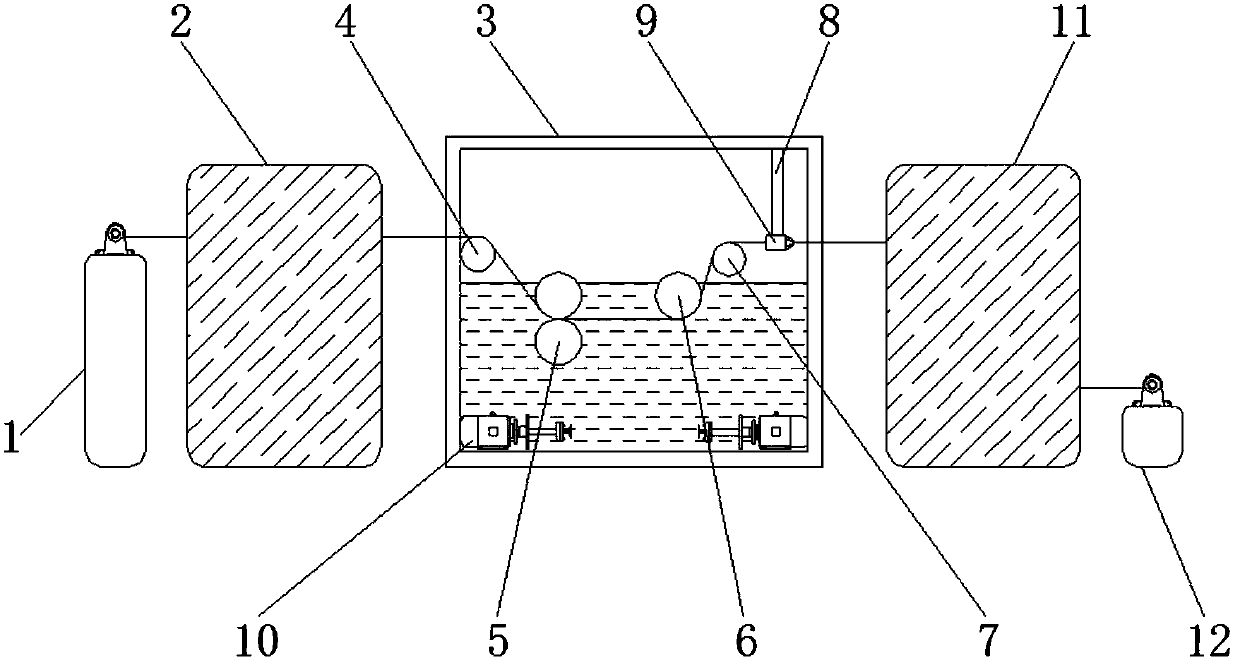

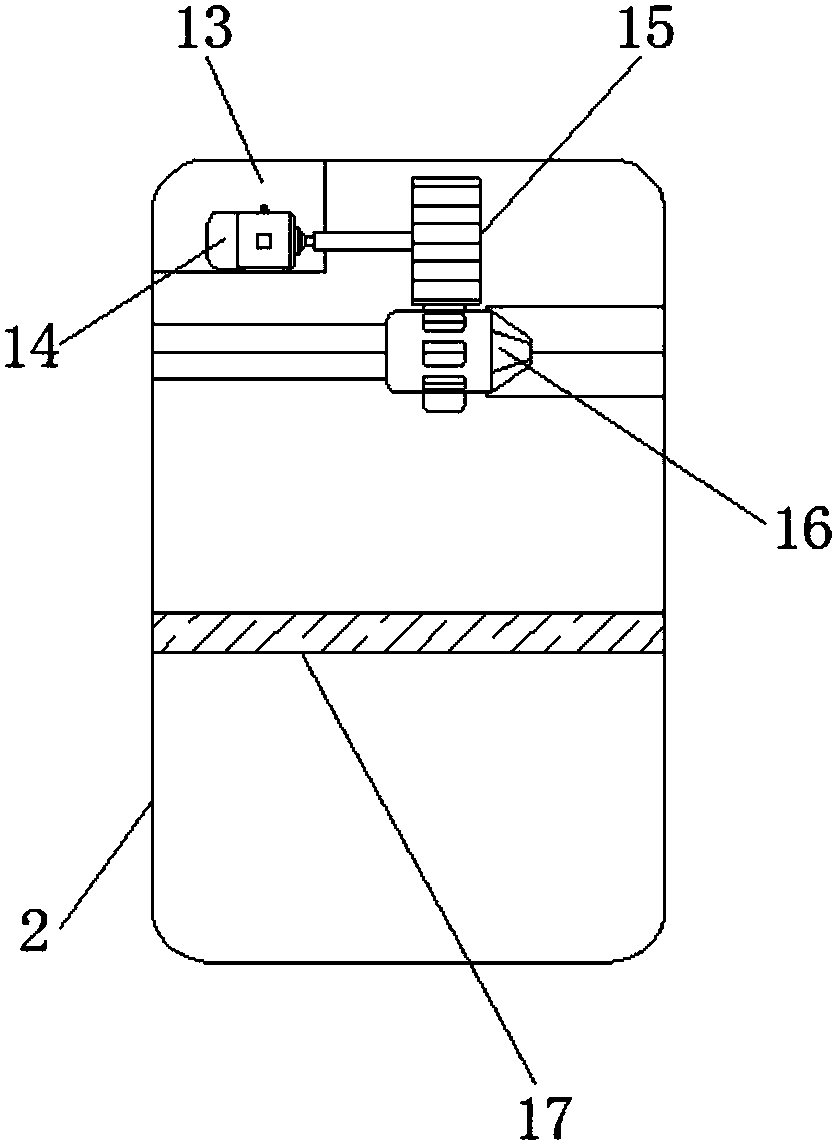

Sizing machine for producing continuous carbon fibers

InactiveCN102031654AAvoid Shaft Sealing ProblemsFlexible rotationTextile treatment rollersLiquid/gas/vapor yarns/filaments treatmentFiberCarbon fibers

The invention belongs to a sizing machine for producing continuous carbon fibers, comprising a box body, a sizing groove arranged in the box body and a driving device fixed on the box body, wherein the sizing groove comprises a groove body and a partition board, a liquid distribution plate and an overflow plate which are arranged in the groove body from left to right and are vertical to the bottom of the groove body; the driving device comprises an inlet driving roller arranged at the upper-left part of the sizing groove, two sizing driving rollers positioned in a sizing area and an outlet driving roller arranged at the upper-right part of the sizing groove; the two sizing driving rollers are horizontally arranged and positioned between the inlet driving roller and the outlet driving roller; and driving shafts of the two sizing driving rollers are higher than the liquid level of a sizing agent of the sizing area. The invention solves the problems of long stay time of the carbon fibers in the sizing agent, poor sizing effect, complex structure, high manufacturing cost and inconvenience for daily cleaning and maintenance caused by the traditional sizing machine. By using the invention, the processing and manufacturing cost of the equipment can be reduced, the time of the carbon fibers in the sizing agent can be prolonged and the favorable sizing effect can be obtained.

Owner:西安航科等离子体科技有限公司

Cloth wrinkle removing device for spinning

PendingCN111501271AAvoid creasesImprove flatnessTextile treatment by spraying/projectingTextile treatment rollersSpinningWorkbench

The invention discloses a cloth wrinkle removing device for spinning, and relates to the technical field of cloth wrinkle removal. The device comprises four table legs, four top ends are fixedly connected with a worktable, the side walls of the table legs are fixedly connected with controllers, the side walls of the bottoms of the table legs are fixedly connected with steam devices, winding devices are fixedly connected to the side walls, reverse to each other, of the bottoms of the two table legs, ironing devices are fixedly connected to the reverse side walls of the tops of the two table legs, a detection support is fixedly connected to the top face of the worktable, a leveling device is fixedly connected to the center of the inner top of the detection support, an infrared sensor is adopted for detecting the cloth, ironing plates are rotated to carry out tilting and leveling on the cloth folding part, it can be ensured that the cloth cannot be wrinkled, meanwhile, folds generated bycloth overlapping can be prevented, a detection camera is arranged, the cloth after wrinkle removing and leveling can be subjected to secondary detection, the disqualified cloth is re-wound for ironing and leveling, and the reliability of the cloth finished product quality can be ensured.

Owner:陈利平

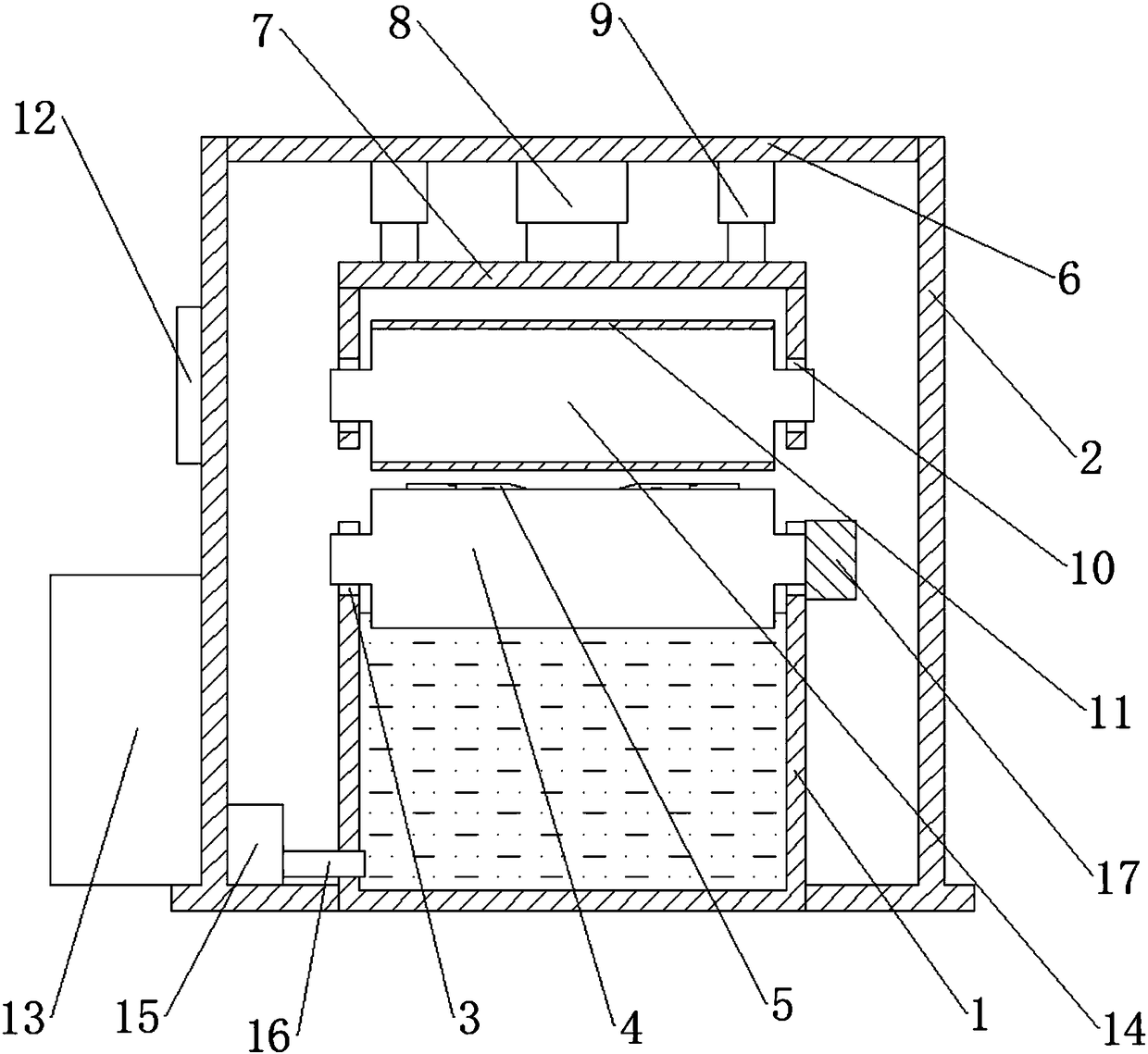

Sizing device of textile fabric

InactiveCN108265428ASimple structureReduce labor intensityTextile treatment containersTextile treatment machine arrangementsSlurry coatingEngineering

The invention provides a sizing device of a textile fabric. The sizing device comprises a feeding mechanism, a slurry coating mechanism and a drying and discharging mechanism, wherein the slurry coating mechanism is located between the feeding mechanism and the drying and discharging mechanism; the slurry coating mechanism comprises a slurry box, a slurry coating assembly, a slurry scraping assembly and a first material guide assembly; the drying and discharging mechanism comprises a drying assembly and a discharging assembly; the slurry scraping assembly comprises a material guide box and twoL-shaped mounting plates; the material guide box is located between the two L-shaped mounting plates; the material guide box and each L-shaped mounting plate are connected through a rotary rod; a slurry scraping plate is arranged at one end, close to the slurry coating assembly, of the material guide box. The sizing device provided by the invention has the beneficial effects that the slurry coating mechanism is simple in structure and can be used for automatically carrying out slurry coating work on the fabric, so that a lot of labor intensity of workers is reduced; the slurry scraping assembly can be used for scraping off slurry dreg on the fabric and preventing the slurry dreg from falling off in a fabric conveying process; the drying assembly can be used for carrying out drying work onthe fabric so that the fabric can be rapidly shaped.

Owner:安聪聪

Cleaning-conveniently spinning device

InactiveCN108118420AAvoid pollutionReduce pollutionLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingYarnEngineering

The invention belongs to the field of a spinning device, and particularly to a cleaning-conveniently spinning device. For a textile machine is polluted by massive spreading of fluff dust and unable toclean the interwoven cloth for the fluff on a yarn is easy to drop when the yarn of the existing textile machine passes through a roll wheel and other guide devices, the following plan is presented;the spinning device comprises a device main body; one side of the device main body is orderly equipped with a horizontal fixing plate, a teasing plate, an ultra-wear-resisting thread crossing device and a collecting box with an opened top end from top to bottom orderly; multiple rotary shafts are rotationally connected to the fixing plate, and multiple comb teeth are connected to the teasing plate; the side wall at one side of the collecting box is equipped with an exhaust fan. The cleaning-conveniently spinning device can collect and clean fluff and dust on the yarn, prevent fluff from polluting the spinning device, reduce the maintenance of the spinning device in later period while clean and dry the interwoven cloth; thus the cloth does not need to clean in later period, the spinning effect is good.

Owner:苏州朦井纺织科技有限公司

Rapid cloth cleaning equipment for textile processing

InactiveCN110924001AEasy to cleanEasy to dryLiquid/gas/vapor removal by suctionTextile treatment cleaning apparatusProcess engineeringMechanical engineering

The invention discloses rapid cloth cleaning equipment for textile processing, and belongs to the technical field of textile processing. The rapid cloth cleaning equipment comprises a cleaning tank, adischarging cylinder, a material collecting cylinder, a drying mechanism, a hot air drying mechanism and adjusting mechanisms. According to the rapid cloth cleaning equipment for textile processing,the cloth is discharged through the discharging cylinder, and then the cloth is movably cleaned in water through the effects of a first guide wheel, a second guide wheel and a third guide wheel; thenwater absorption is carried out through sponge layers on two oppositely rotating drying cylinders after cleaning is performed, and hot air drying is conducted through the hot air drying mechanism after water absorption is performed; when the sponge layer after water absorption is subjected to the extrusion of a first water squeezing cylinder, the sponge layer is kept at relative humidity so as tocontinuously absorb water and dry the subsequent cloth; a second water squeezing cylinder further squeezes the sponge layer, and after the sponge layer works for a period of time, the sponge layer issprayed with clean water through a water outlet pipe; and then a second water collecting pipe is adopted for squeezing and de-watering, and the sponge layer is cleaned, so that the sponge layer is kept relatively clean.

Owner:安徽云至信电子商务有限公司

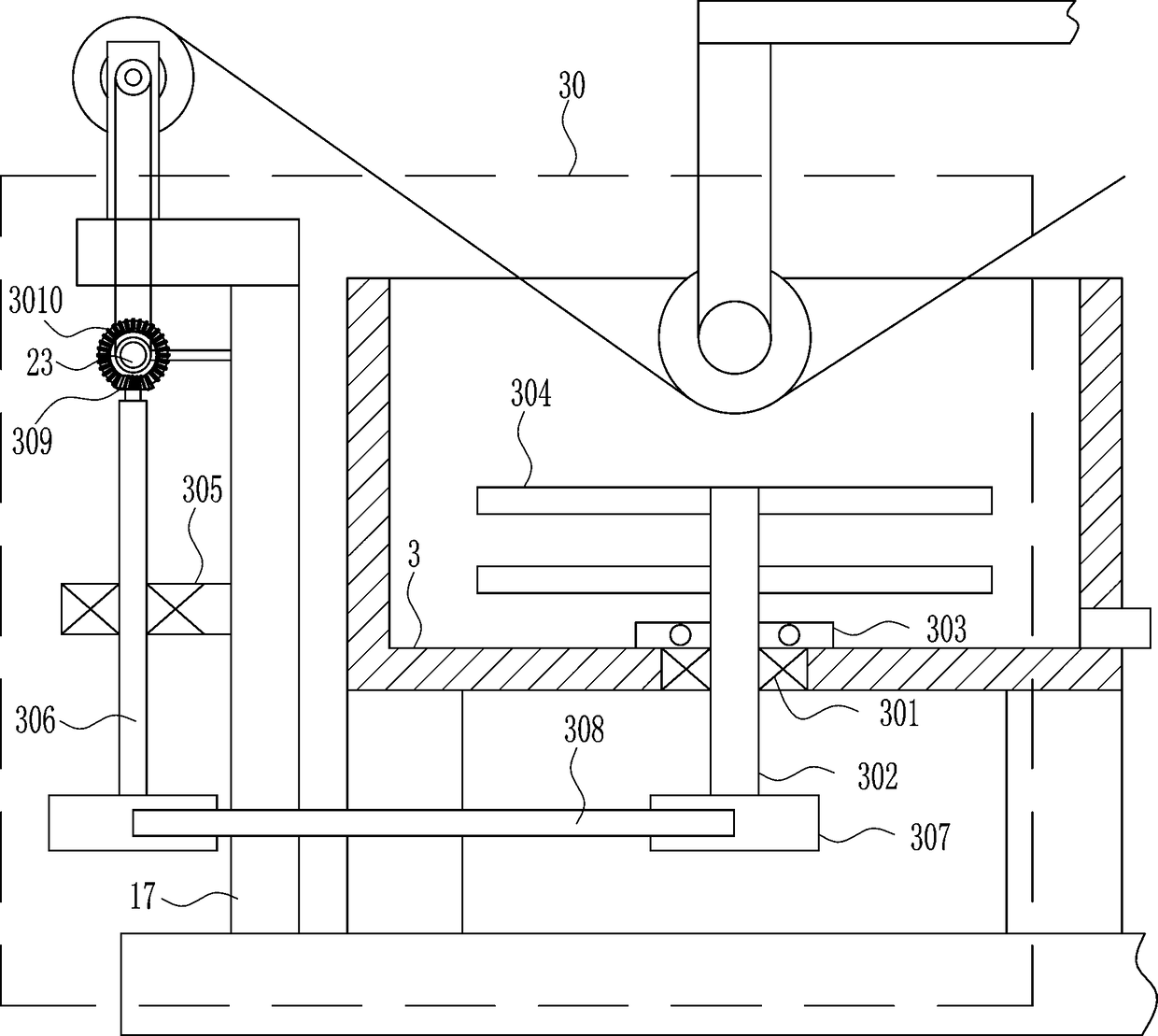

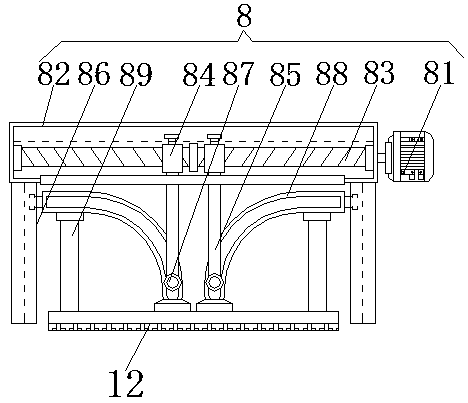

Fabric draw-out processing device of continuous pigment dyeing padding mangle

InactiveCN101597847AGuaranteed uptimeImprove color fixationTextile treatment machine arrangementsTextile treatment carriersEngineeringMechanical engineering

The invention relates to a fabric draw-out processing device of a continuous pigment dyeing padding mangle, which comprises a sixth tension adjusting mechanism, a cooling device, a seventh tension adjusting mechanism and a swinging cropping mechanism which are arranged on a second mangle frame sequentially from front to back. The cooling device of the fabric draw-out processing device cools fabrics passing through a steam drying device of a preceding progress quickly for the color fixing of pigment dyeing. The problem of the unbalance of the front and the back tension of the fabrics caused by quickly reducing temperature can be solved by using tension adjusting mechanisms arranged at the front and the back parts of the cooling device respectively so that the tension of the fabrics in the whole process of fabric draw-out is always in the appropriate size to ensure that the fabrics move stably.

Owner:常州市东高染整有限公司

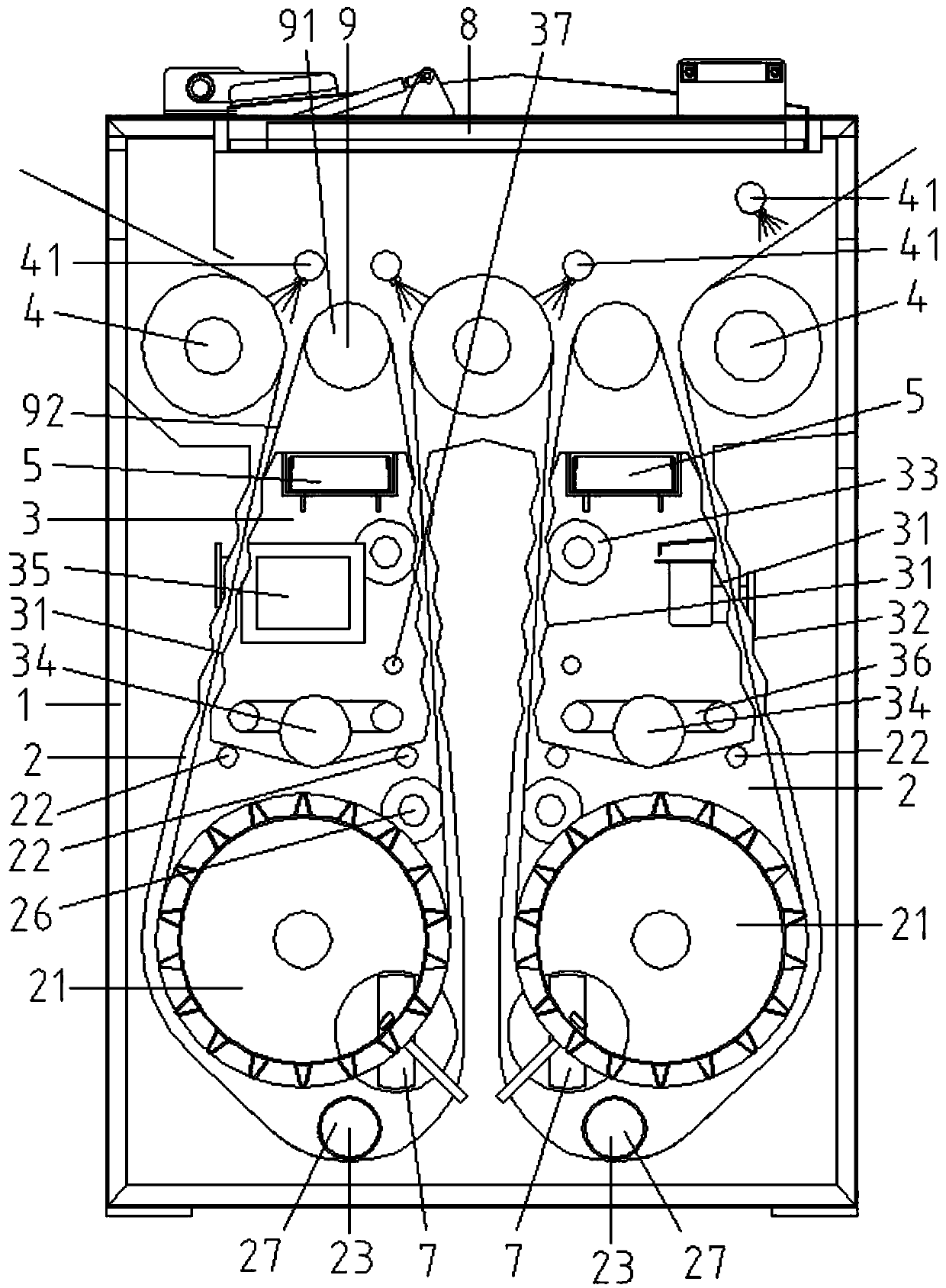

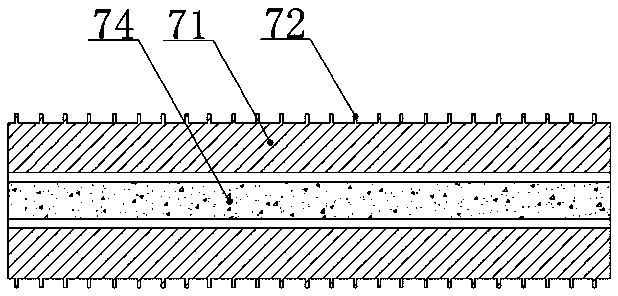

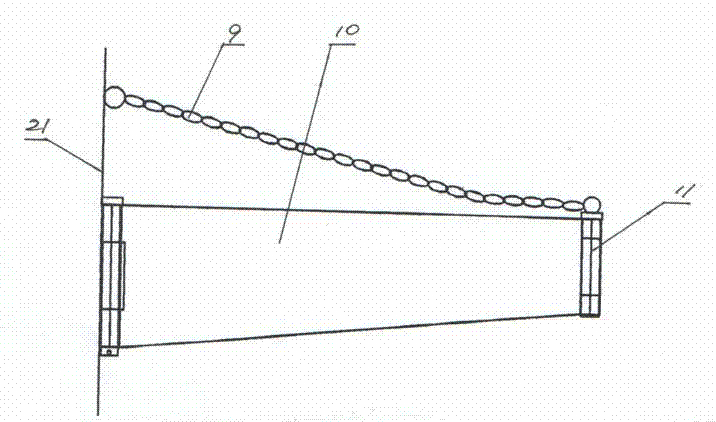

Knitting open-width wet processing unit with oscillating meshed washing cloth guide roller

InactiveCN102517820AAvoid Stretch DeformationGuaranteed qualityTextile treatment carriersLiquid/gas/vapor textile treatmentControl systemEngineering

The invention relates to a knitting open-width wet processing unit with an oscillating meshed washing cloth guide roller. The knitting open-width wet processing unit comprises a wet processing unit machine, wherein a drum group and a roller group which is matched with the drum group are arranged in a box body of the wet processing unit machine; the drum group comprises a lower drum and an upper drum which are matched with each other; the lower drum has a meshed drum surface; and an oscillating roller which is arranged in the same direction as the lower drum and has a polygonal cross section is arranged in an inner cavity of the lower drum. The invention has outstanding characteristics that: soaking washing, spraying washing, oscillating washing and mangling are integrated, a drum with the meshed drum surface is used, a penetration rate is improved, dynamic cleaning is performed in different modes, and the washing efficiency is greatly improved; a drum comprising the cloth guide roller and a traction roller, and a roller are changed into driving rollers, a control system and a pressure sensor are matched to perform real-time monitoring and controlling, the synchronization of the units is controlled at high precision, fabrics are prevented from being subjected to tensile deformation, and the quality of the fabrics is guaranteed.

Owner:绍兴东升数码科技有限公司

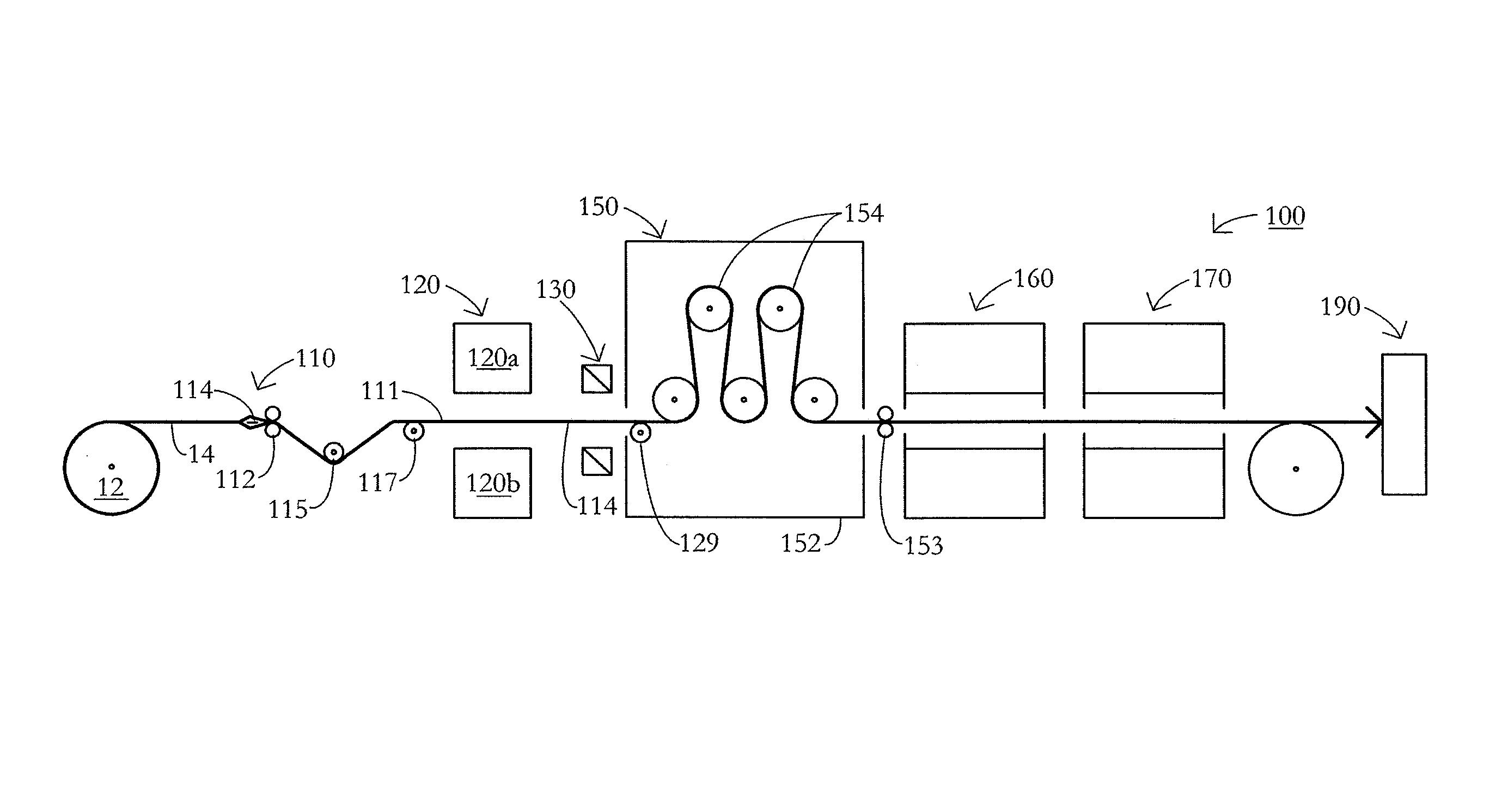

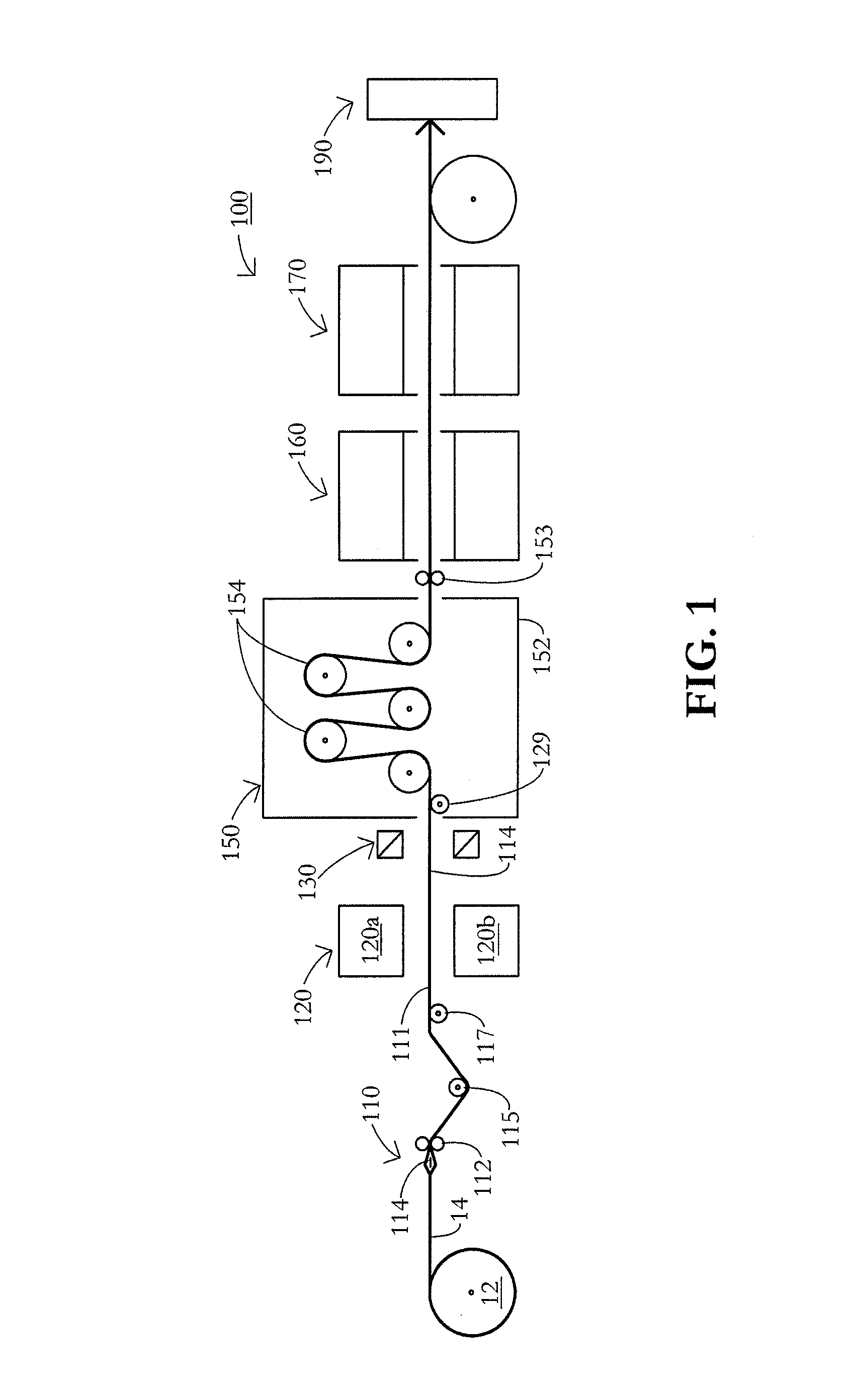

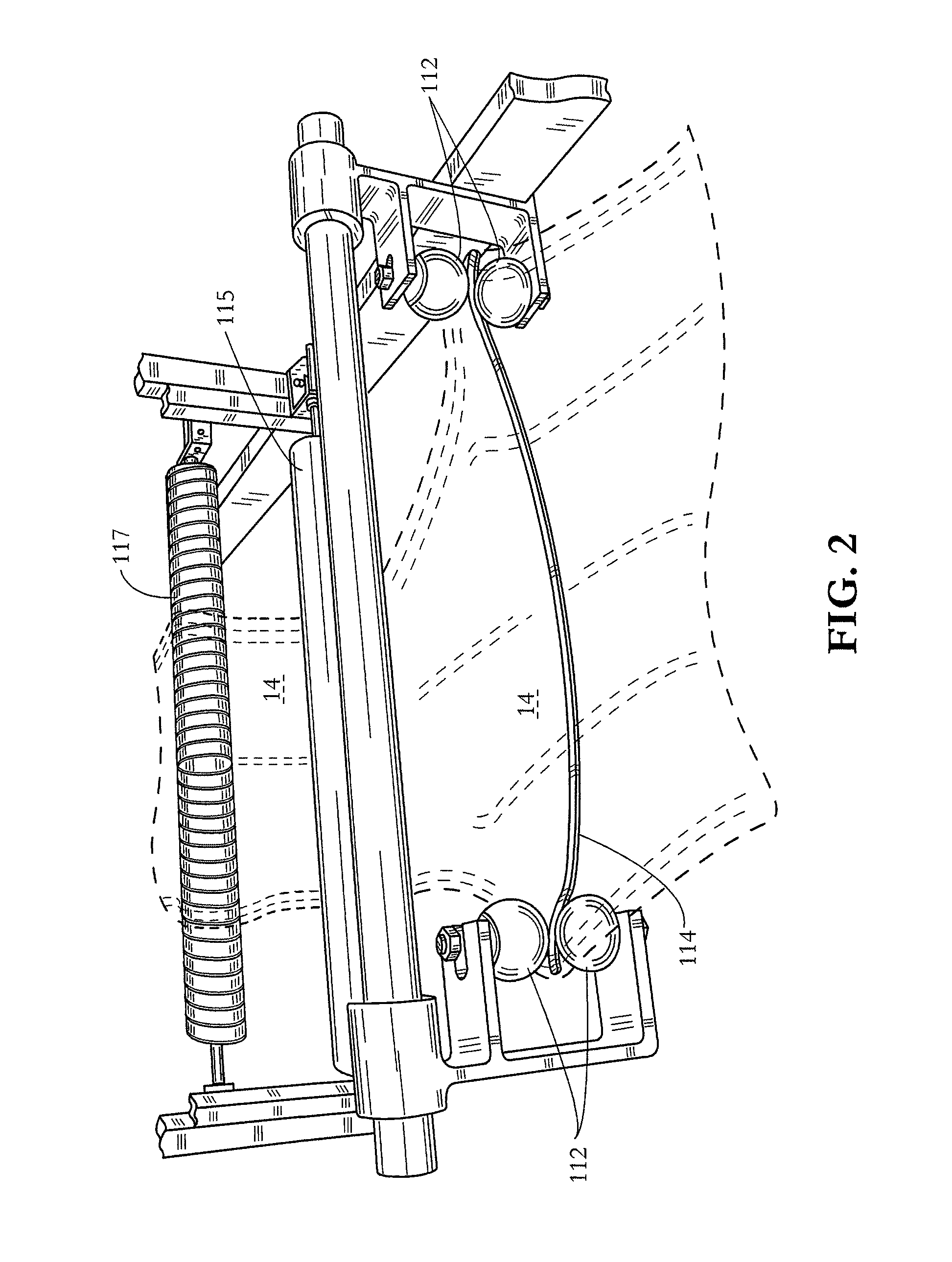

System and method for spray dyeing fabrics

A system and method are provided for dyeing fabric, the system including a dye spray station, a dye fixation station downstream of the dye spray station, and at least one rinse station downstream of the dye fixation station. The process includes opening the fabric with a spreader to maintain the fabric flat and taut, spraying the outer surfaces of the fabric with a dye, and exposing the fabric to atmospheric steam to chemically react and affix the dye to the fabric.

Owner:HBI BRANDED APPAREL ENTERPRISES

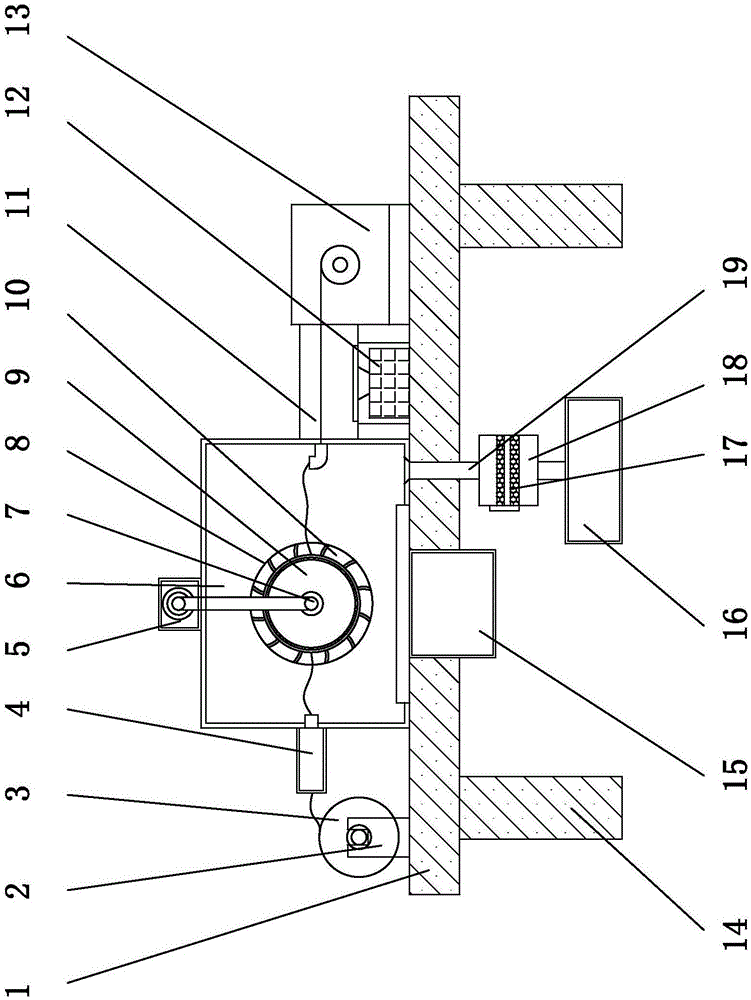

Multi-pattern space dyeing equipment for fabric

InactiveCN108468168AReduce the number of residuesLow costTextile treatment containersTextile treatment machine arrangementsModular compositionEconomic benefits

The invention discloses multi-pattern space dyeing equipment for fabric and belongs to the field of space dyeing equipment. The multi-pattern space dyeing equipment for the fabric comprises a dyeing slurry blending barrel, wherein supports are fixedly connected with two sides of the dyeing slurry blending barrel; a pair of lower bearings are fixedly connected with the upper end of the dyeing slurry blending barrel; a lower press roll is fixedly connected between inner rings of the two lower bearings; an electric motor is fixedly connected onto one side surface of the dyeing slurry blending barrel; the rotating end of the electric motor is fixedly connected with one end of the lower press roll; multiple pattern printing and dyeing modules are fixedly connected onto the lower press roll; dyeing slurry is contained in the dyeing slurry blending barrel; a support plate is fixedly connected between the two supports and located right above the dyeing slurry blending barrel. Multi-pattern ormulti-color synchronous space dyeing for the fabric can be realized, the amount of residual dyeing slurry can be reduced, besides, the dyeing slurry can be recycled, the cost is relatively low, modular combination can be performed as required, and the multi-pattern space dyeing equipment for the fabric has greater competitiveness and economic benefit.

Owner:陶守江

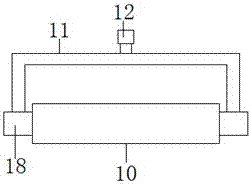

Whole water-repellent natural fiber spunlace non-woven fabric and production equipment thereof

PendingCN108277655ABreathableHydrophilicPersonal careTextile treatment carriersReverse osmosisEngineering

The invention discloses a whole water-repellent natural fiber spunlace non-woven fabric. The whole water-repellent natural fiber spunlace non-woven fabric comprises a natural fiber spunlace non-wovenfabric, wherein the surface of the natural fiber spunlace non-woven fabric is coated with a water-repellent layer; holes are formed in the natural fiber spunlace non-woven fabric and the water-repellent layer in a penetrating way. The invention also discloses the whole water-repellent natural fiber spunlace non-woven fabric and production equipment thereof. The production equipment comprises single-side equipment with a liquid coating layer, a tension control mechanism, a drying machine, a perforating machine, and a coiling machine, wherein the single-side equipment with the liquid coating layer comprises a liquid tank and a liquid coating roll; the liquid tank is used for containing a water-repellent mixed solution of a water repellent, an enhancer and water; one part of liquid coating roll is soaked into the water-repellent mixed solution. The whole water-repellent natural fiber spunlace non-woven fabric has the advantages that the reverse osmosis can be avoided, and the comfortability and hydrophilia are guaranteed.

Owner:韩旭

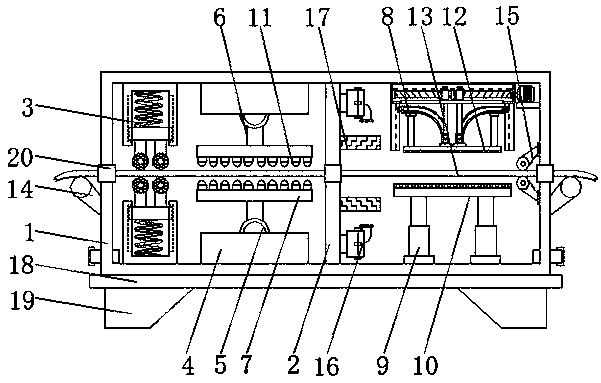

Dyeing device for garment textile fabrics

InactiveCN110130030AFully dyedFull compressionTextile treatment machine arrangementsLiquid/gas/vapor fabric treatmentElectric machineryEngineering

The invention relates to the technical field of textile equipment, and particularly relates to a dyeing device for garment textile fabrics. The device comprises a base, wherein a dyeing vat is fixedlymounted on the top surface of the base, an electrical heating tube is fixedly mounted at the middle end of the bottom side in the dyeing vat, the lower end of the left side in the dyeing vat is rotationally connected with a stirring shaft through a bearing, stirring blades are fixedly mounted on the stirring shaft in equal spacing from left to right, the right end of the stirring shaft penetratesthrough the right side of the dyeing vat, a worm is fixed at the right side end of the stirring shaft in a welding manner, and the right end of the worm is fixed with an output end of a motor in a welding manner. According to the dyeing device for the garment textile fabrics, by driving the worm to drive the stirring shaft and the stirring blades to rotate, dye added to the dyeing vat is stirred,and non-uniform dyeing effects of the fabric bodies due to dye precipitation in the process of fabric dyeing can be avoided, meanwhile, the dye is heated, so that the fabric bodies can be fully dyed.

Owner:安徽职业技术学院

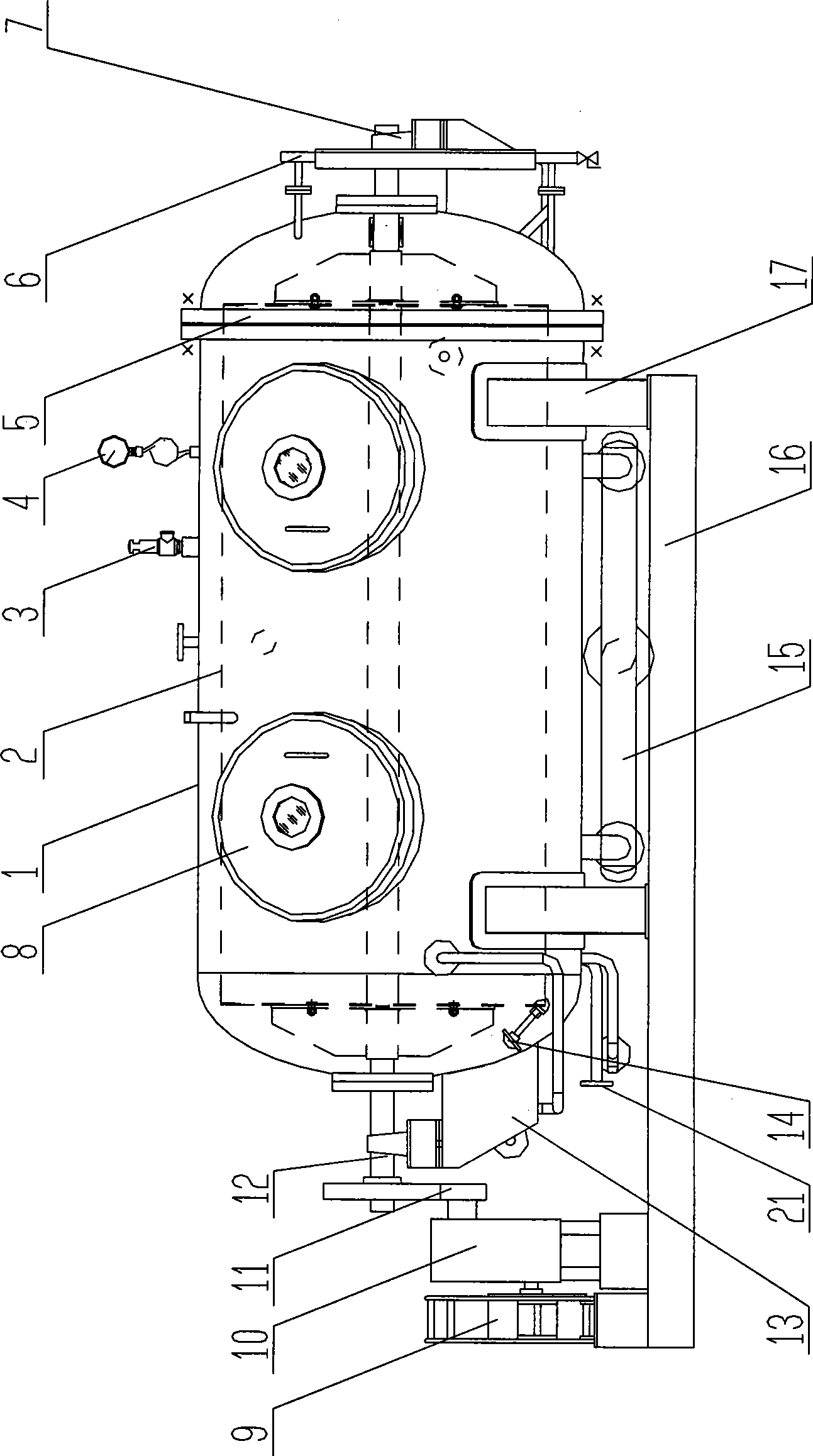

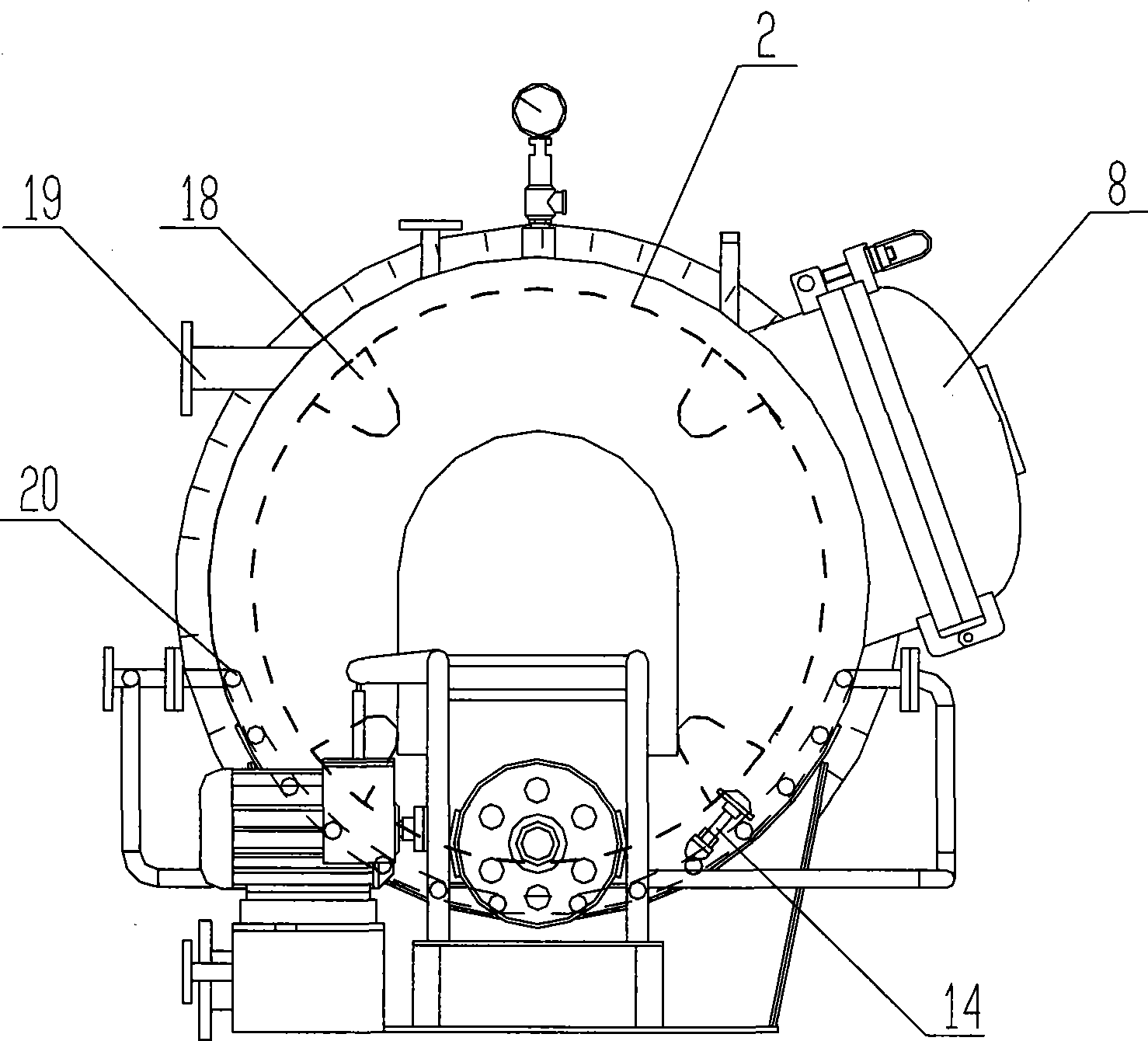

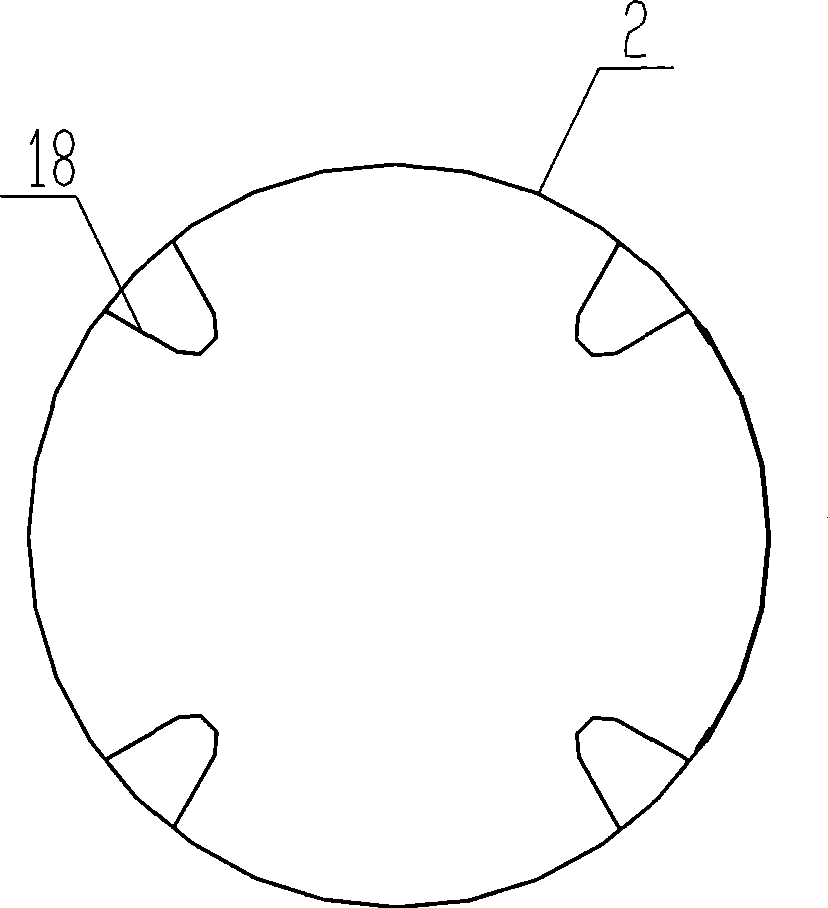

Rotary drum type dyeing machine

InactiveCN101476220AReduce laborReduce processing timeLiquid/gas/vapor open-width material treatmentTextile treatment rollersDrive shaftEngineering

A drum type dyeing machine comprises a pressure-bearing drum body, a safe accessory, a stirring transmission device, a heating device, a controlling means and a base. The stirring transmission device comprises an inner drum, a power reduction box, a transmission shaft and a braking device; both ends of the inner drum are fixed with the transmission shaft; the transmission shaft is installed on the bearing seat outside of the pressure-bearing drum body through mechanical seal, while connected with the power reduction box and the braking device in series. Under a certain pressure and temperature condition, the fabric is dyed while rotating in the drum, consequently, the labor amount in the dyeing process is reduced, the processing time is shortened greatly and the dyeing energy consumption is reduced; the whole dyeing process is performed under high temperature and high pressure, consequently, the mixing operation is performed fully, and better dyed color and dye fixation effect are achieved; all the equipments are mounted on the same base, consequently, the volume is more compact and the mounting is more convenient.

Owner:石建明

Yarn sizing machine capable of uniformly conducting sizing

InactiveCN107675388AExtended drying timeFully dryFibre cleaning/openingTextile treatment machine arrangementsPulp and paper industry

The invention discloses a yarn sizing machine capable of uniformly conducting sizing. The yarn sizing machine comprises a yarn putting device, a cleaning device shell is arranged at the right of the yarn putting device, a driving bin is arranged inside the cleaning device shell, a driving motor is installed inside the driving bin, the front end of the driving motor is connected with a dust tightening device through a gear, a static electricity dust remover is installed inside the cleaning device shell, a size tank is arranged at the right of the cleaning device shell, a first yarn guide rolleris arranged inside the size tank, a yarn extruding roller is arranged at the right of the first yarn guide roller, a sizing roller is installed at the right of the yarn extruding roller, and a secondyarn guide roller is arranged at the upper right portion of the sizing roller. According to the yarn sizing machine capable of uniformly conducting sizing, design of the dust tightening device, the gear, the static electricity dust remover, the yarn extruding roller, an air draft device and an air suction device is adopted, the speed for yarn to absorb sizing agent can be increased, and thereforethe work efficiency of the sizing machine is improved so that the yarn can be more fully dried.

Owner:杭州依翰丝绸文化创意有限公司

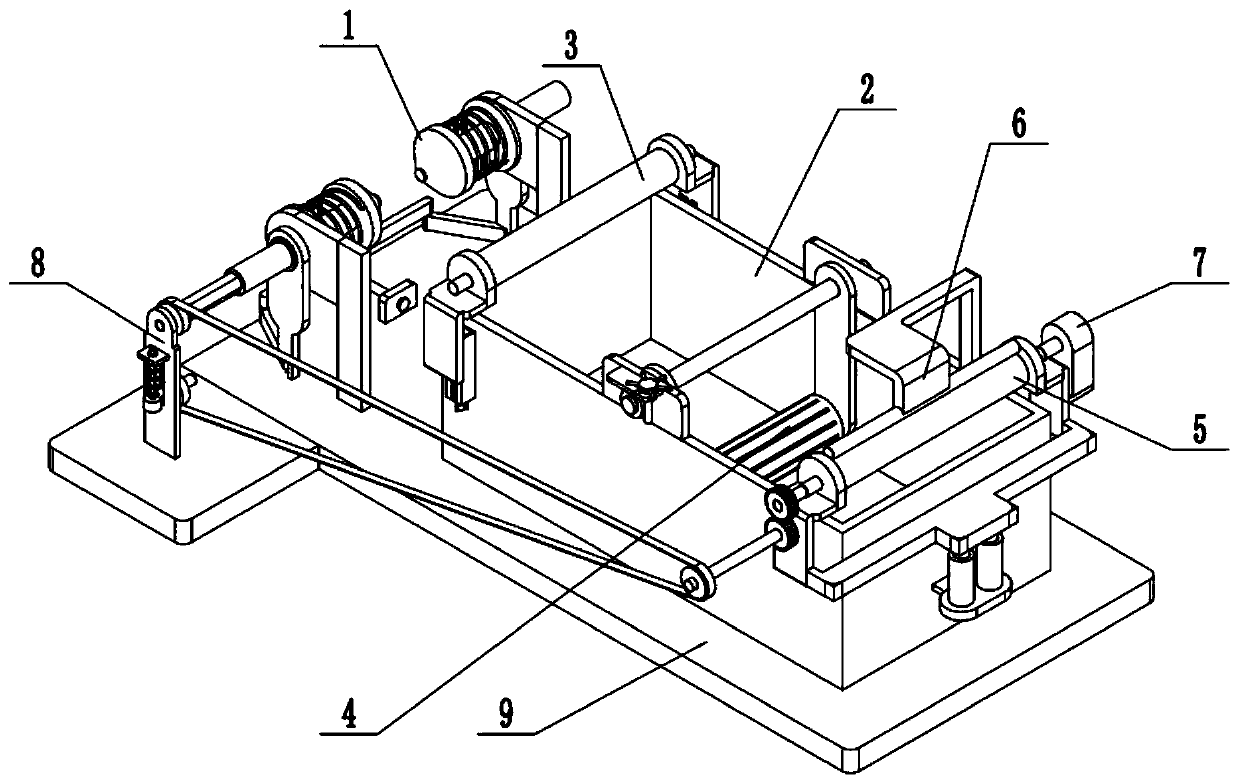

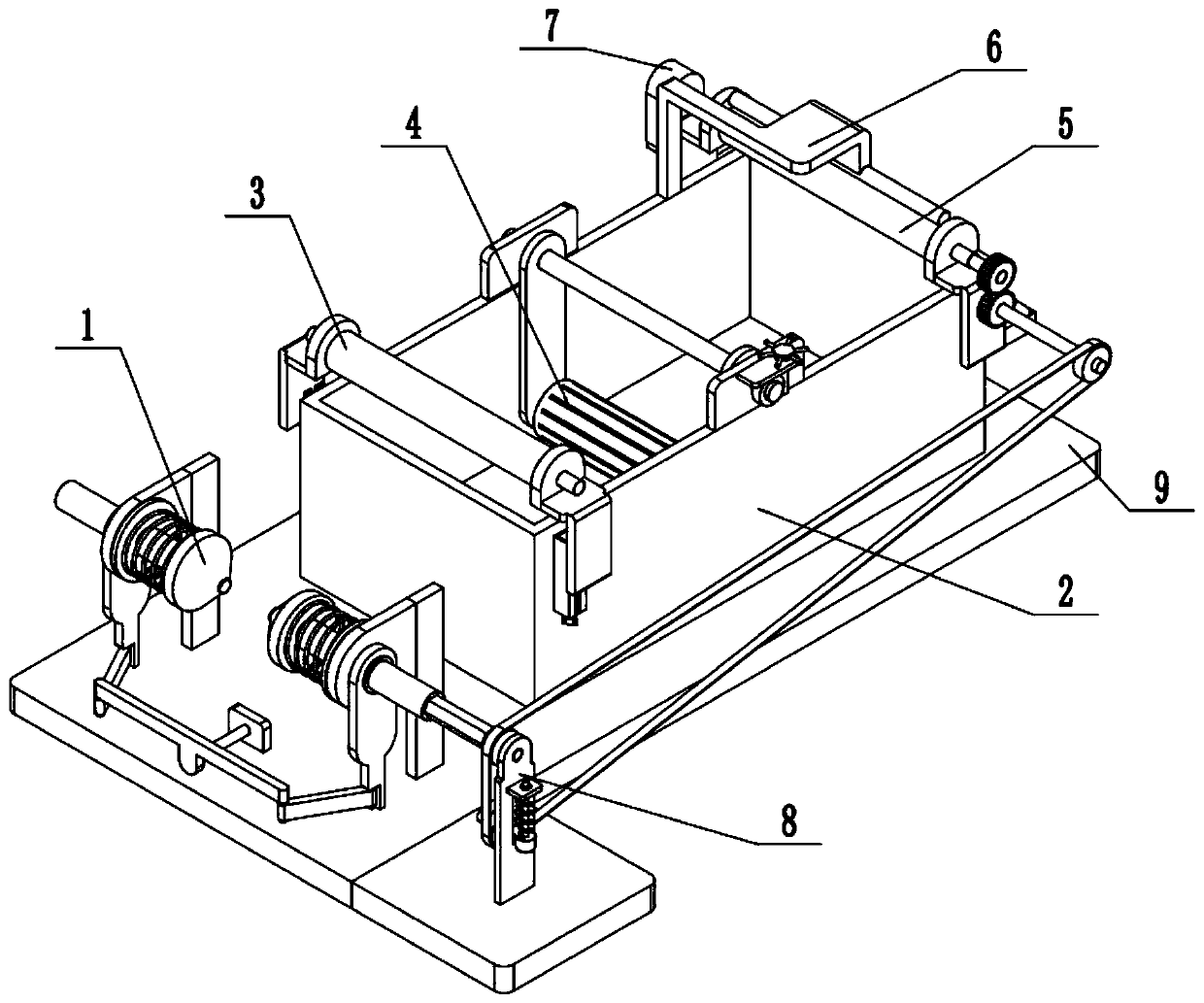

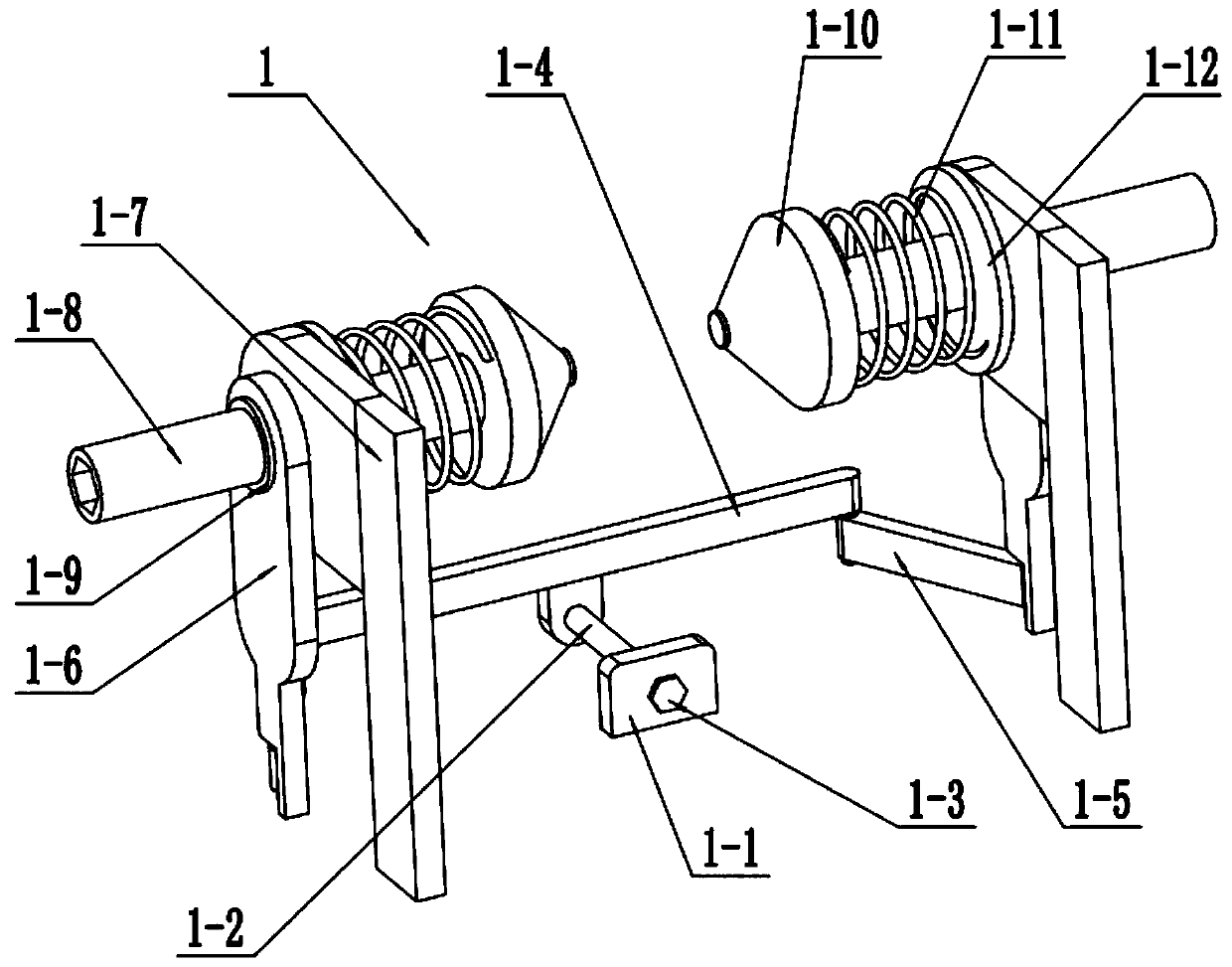

Textile printing and dyeing device

InactiveCN109797503ASolve the problem that the cloth rolls to be printed and dyed in different sizes cannot be fixed and unfoldedImprove flatnessLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalState of artTextile printer

The invention relates to the technical field of the textile processing and in particular to a textile printing and dyeing device. The textile printing and dyeing device comprises a cloth roll clampingmechanism, a top hollowed printing and dyeing box, a cloth feeding guide roller mechanism, a printing and dyeing guide roller mechanism, a cloth discharging guide roller mechanism, an auxiliary clothpressing mechanism, a driving mechanism, a linkage mechanism and a base plate. The cloth roll clamping mechanism is fixedly connected to a left end of a top surface of the base plate. The printing and dyeing box is fixedly connected to a middle end of the top surface of the base plate. The cloth feeding guide roller mechanism is fixedly connected to an upper end of the left side of the printing and dyeing box. The printing and dyeing guide roller mechanism is fixedly connected to an upper end of the middle of the printing and dyeing box. The provided textile printing and dyeing device aims toeffectively solve a problem in an existing technology that the printing and dyeing device cannot fix and unfold different sizes of cloth rolls to be printed and dyed. The interior of the textile printing and dyeing device is provided with the cloth roll clamping mechanism. The cloth roll clamping mechanism is capable of fixing and unfolding the different sizes of the cloth rolls.

Owner:高炆圣

Direct fluorination method for producing surface fluorine-containing fiber

ActiveCN102587058AImprove uniformityImprove efficiencyTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsVacuum assistedEngineering

The invention discloses a direct fluorination method for producing surface fluorine-containing fiber, which is characterized by comprising the steps of: firstly winding raw material fiber on a winding drum with through holes uniformly distributed on the wall, putting in two fluorination reactors and heating and enabling fluorine gas mixture to carry out pulse circulation between the two fluorination reactors by utilizing a vacuum accessory system to ensure that the fluorine gas mixture repeatedly penetrates through fiber layers on the winding drum and is forcedly diffused to uniformly fluoridate the fiber wound on the drum. The method disclosed by the invention has the advantages that the batch surface treatment of whole-drum fiber can be realized; the inner / outer layer surface effect uniformity of the treated fiber is good; the fluorination rate is high; the treatment period is short; the consumed fluorine gas amount is little; the production cost is lower; the safety is high; the process is simple and controllable; and wider application prospect is provided.

Owner:SICHUAN UNIV

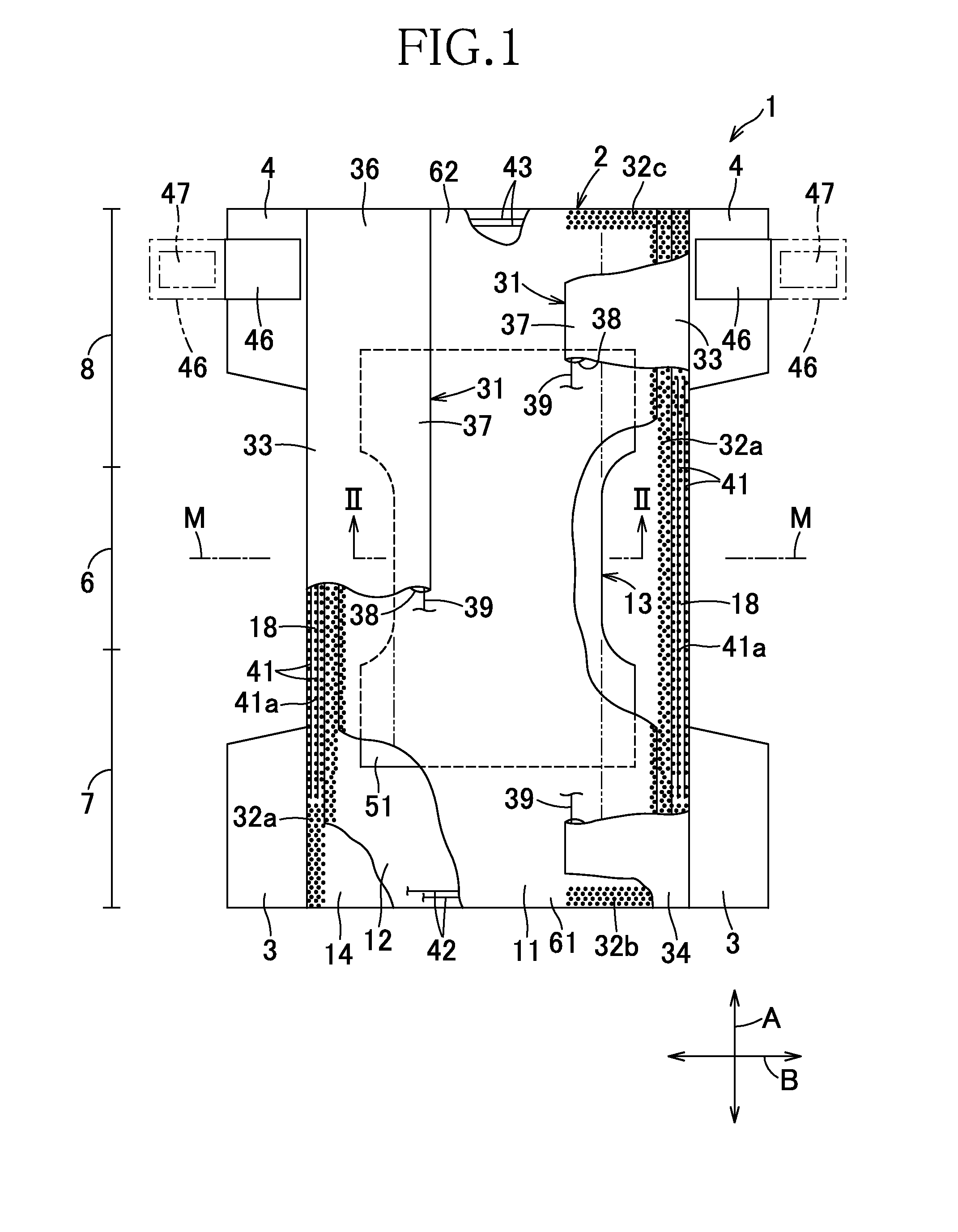

Method for thinning aggregate of water-absorbent material and thin aggregate of water-absorbent material obtained using the method

InactiveUS20120231946A1Easy to thinEasy to transformOther chemical processesFibre treatmentFiberPolymer science

A method for thinning an aggregate of water-absorbent materials. An aggregate of water-absorbent materials includes hydrophilic fibers and superabsorbent polymer particles and has a thickness direction. Steam at a temperature corresponding to water's boiling point or higher is ejected to the aggregate while the aggregate is compressed in the thickness direction.

Owner:UNI CHARM CORP

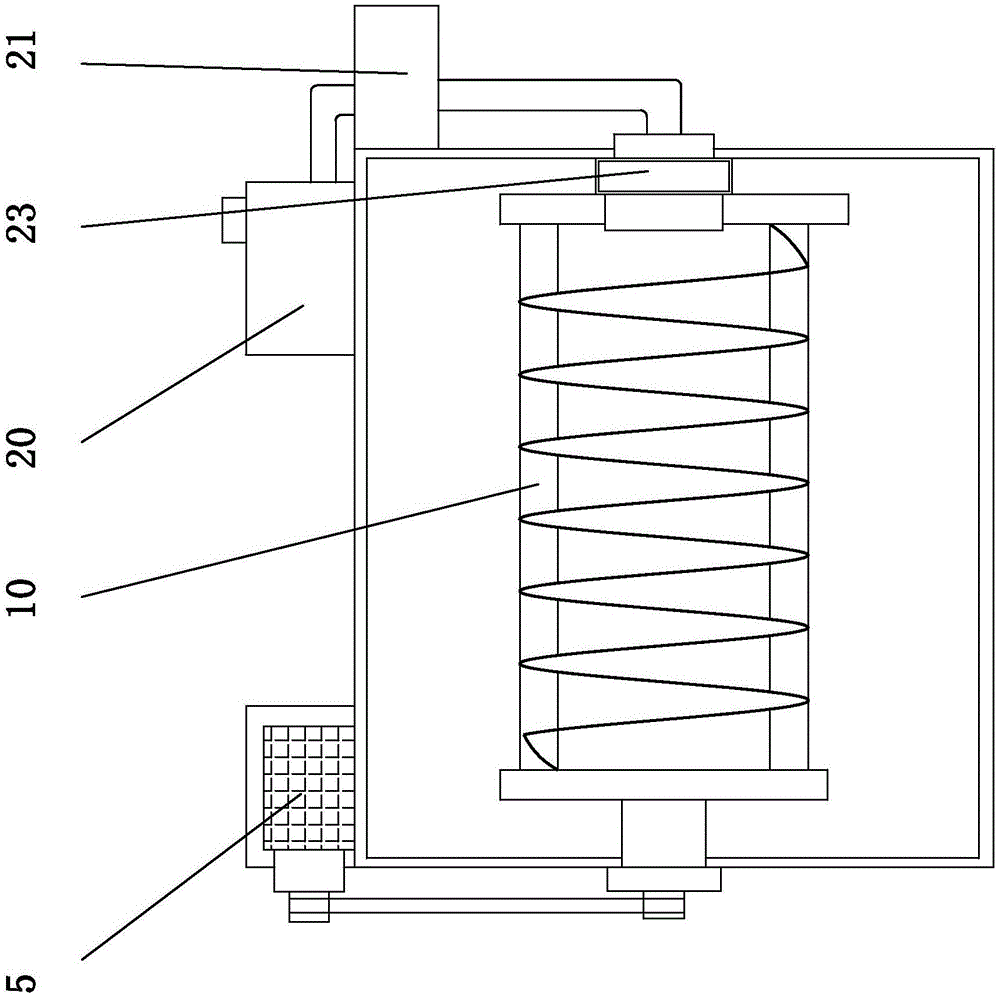

Spiral yarn printing and dyeing equipment

ActiveCN106702633AIncrease productivityExtend dyeing timeLiquid/gas/vapor removalTextile treatment machine arrangementsYarnEngineering

The invention discloses spiral yarn printing and dyeing equipment which comprises a base, a discharge roller, a dyeing and printing chamber, a drying chamber and a pigment tank. The two ends of the bottom of the base are each provided with a support column, a yarn discharge device is installed at a feed inlet formed in the side, close to a discharge base, of the dyeing and printing chamber, the output end of a booster pump is connected with a pigment ejection pipe through a pigment guide pipe, and a bearing structure is installed on the inner side wall of the portion, at the joint of the pigment guide pipe and the pigment ejection pipe, of the dyeing and printing chamber. According to the spiral yarn printing and dyeing equipment, yarn can be spirally wound on a dyeing and printing roller to be dyed through an arranged dyeing and printing roller with a spiral yarn groove, the dyeing time is prolonged, the dyeing uniformity is guaranteed, and the phenomenon that color segments and color points with different lengths and sizes are generated is avoided; meanwhile, pigments can be saved by means of the pigment ejection pipe arranged in the dyeing and printing roller on the premise that the yarn is fully dyed and are greatly saved by cooperating with usage of a pigment recycle tank, the dyeing and printing cost is reduced, and meanwhile the dyeing and printing quality and the yarn dyeing and printing production efficiency are improved.

Owner:海宁鑫港源纺织品有限公司

Multifunctional dehydrator

InactiveCN102517823AQuality improvementEasy to separateTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberEngineering

The invention relates to a multifunctional dehydrator, which comprises a cylinder. A cylinder cover is arranged at an upper opening of the cylinder. The bottom of the cylinder is provided with a center hole, and a spindle is arranged in the center hole. The lower end of the spindle extends out of the bottom of the cylinder, a power mechanism is arranged outside the cylinder, and the lower end of the spindle is connected with an output shaft of the power mechanism through a pulley and a transmission belt. A rotary cage is arranged in the cylinder, and a space is reserved between an inner cylinder of the rotary cage and the spindle while another space is reserved between an outer cylinder and the cylinder. A support board is connected to the upper end of the inner cylinder, and the upper end of the spindle is connected with the support board. An annular cage cover is arranged at the upper end of the rotary cage and is a meshed cage cover. The multifunctional dehydrator is characterized in that a sleeve for water proofing and heat insulation is arranged in the inner cylinder, and the lower end of the sleeve is hermetically connected with the bottom of the cylinder. A heater is arranged between the cylinder wall of the cylinder and the outer cylinder of the rotary cage. The dehydrator is multifunctional and used for treating linen fibers, quality of linen fiber products can be improved, and high loss of short staples is avoided. The multifunctional dehydrator is applicable to boiling, bleaching, washing and dehydrating of the linen fibers.

Owner:WUXI QIANZHOU YAODA MACHINERY FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com