Sizing machine for producing continuous carbon fibers

A technology of carbon fiber and size tank, which is applied in textile processing machine accessories, textile material processing, textiles and papermaking, etc. It can solve the problems of inconvenient cleaning and maintenance, short residence time of carbon fiber, and poor sizing effect, etc., and reduce equipment. Processing and manufacturing costs, good sizing effect, and guaranteed stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

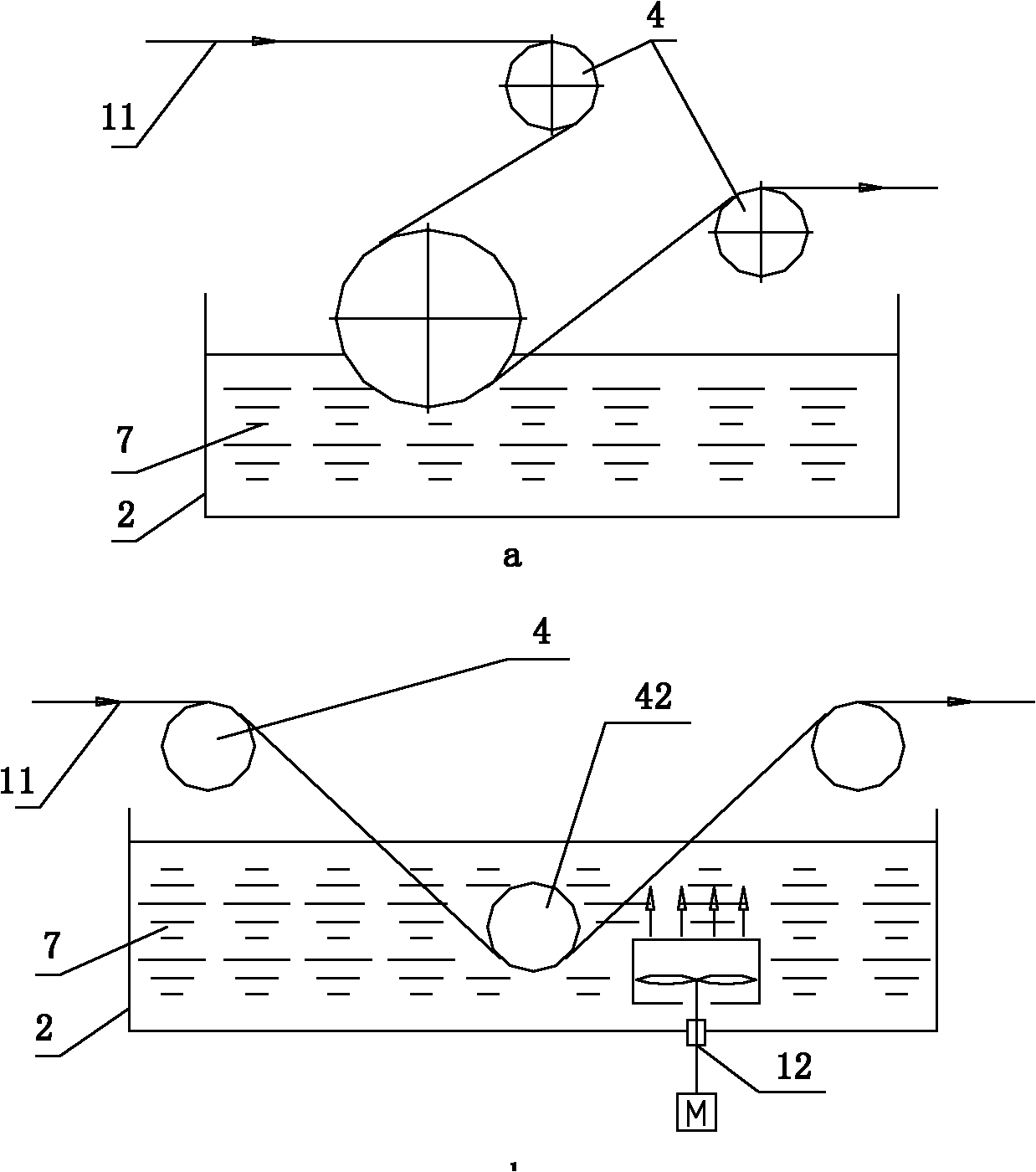

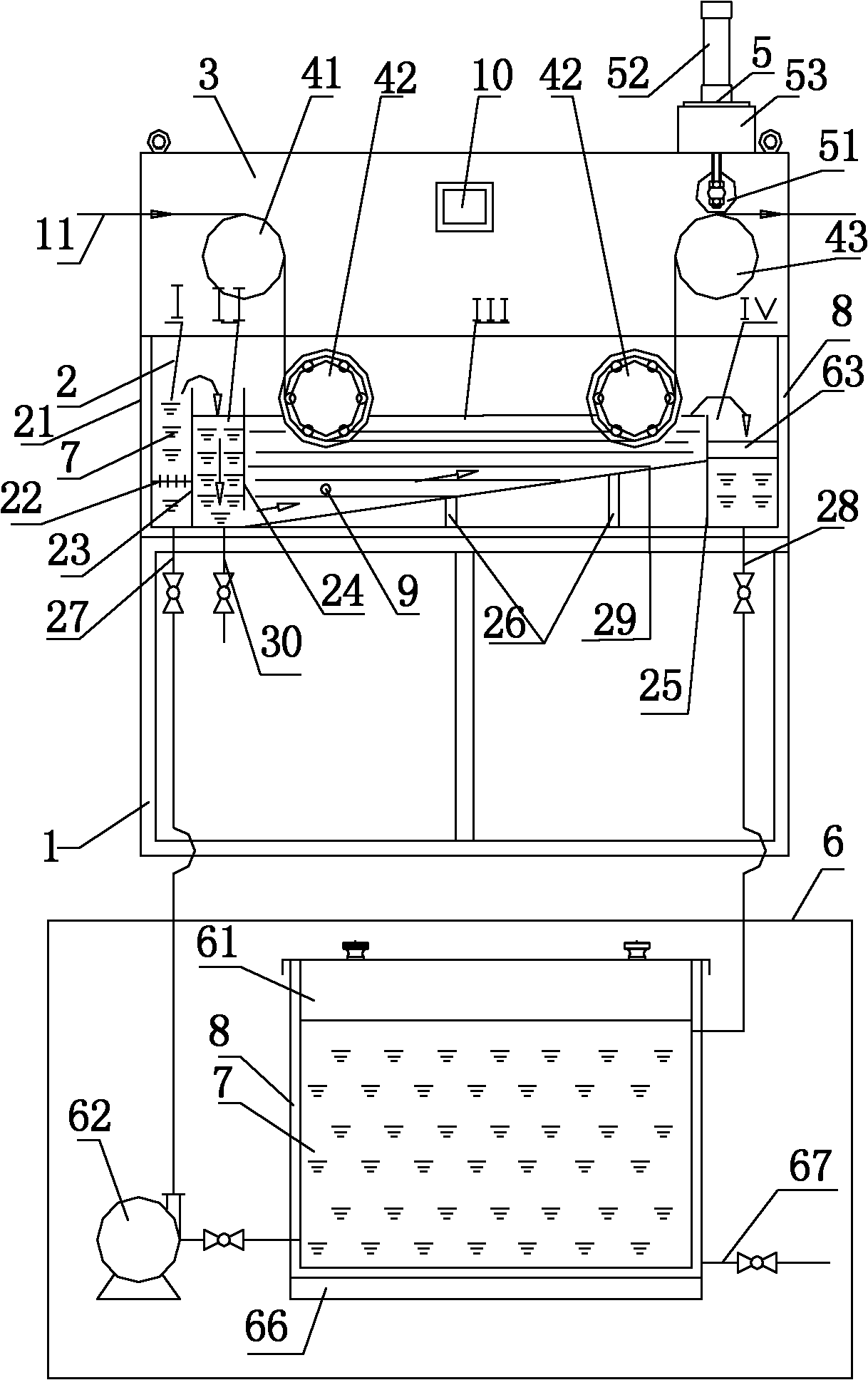

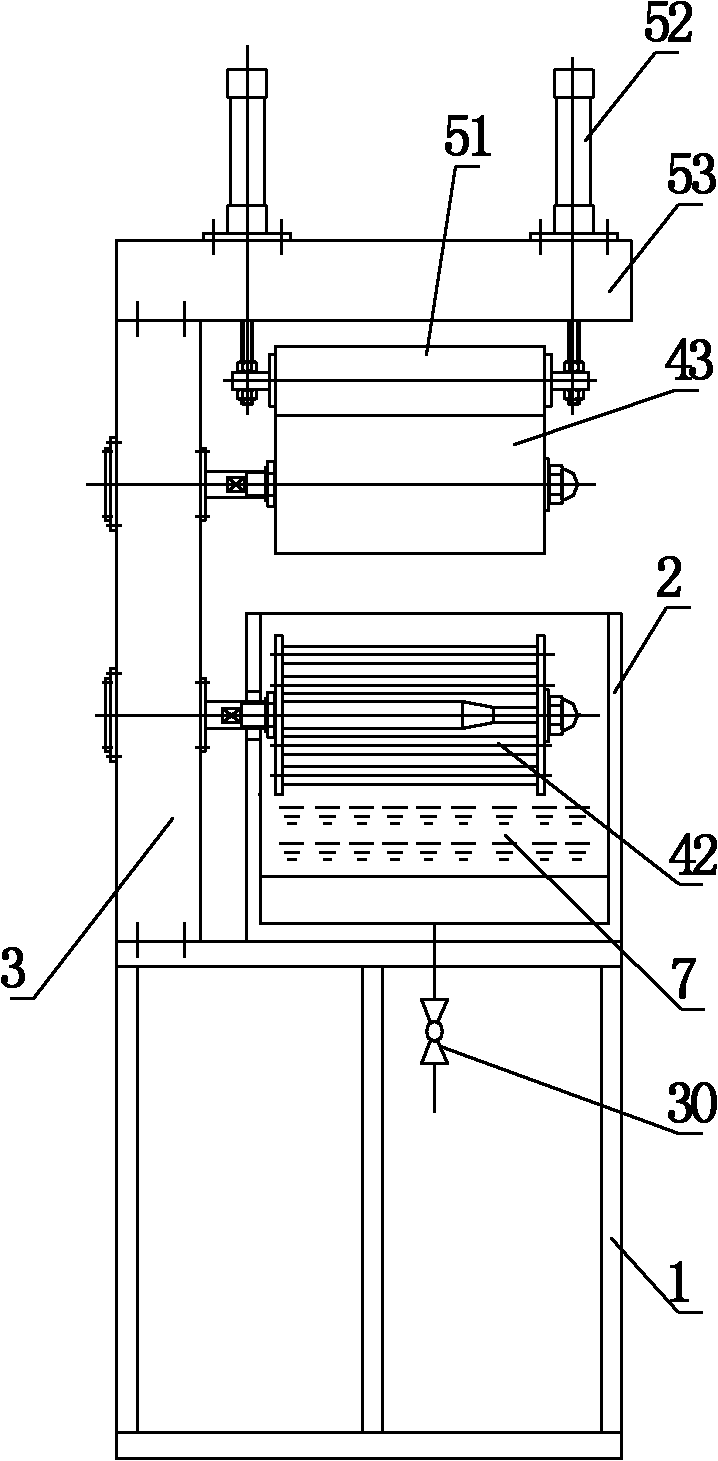

[0030] The present invention is used for the sizing machine of continuous production carbon fiber such as figure 2As shown, it mainly includes a machine base 1, a sizing tank 2, a box body 3, a transmission device 4, a squeeze device 5, and a circulation device 6. The sizing tank 2 and the box body 3 are arranged on the machine base 1, wherein the box body 3 is firmly fixed on the machine base 1 through fasteners and positioning devices; the transmission device 4 includes an entrance drive roller 41, a sizing drive roller 42, an outlet Driving roller 43, entrance driving roller 41 and outlet driving roller 43 are arranged on the top of sizing tank 2, and its rotating shaft is installed on the casing 3 by double fulcrum support, and sizing driving roller 42 is arranged in sizing tank 2, and its rotating shaft passes through The side wall of the sizing tank 2 is supported and installed on the box body 3 by double fulcrums; the squeezing device 5 includes a squeezing rubber roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com