Rotatable machine gripper

A gripper and machine technology, applied in the field of rotatable robot grippers, can solve the problems of difficult grasping, positioning, and 360-degree rotation of grasped objects, so as to achieve flexible control of rotation and opening and closing, and grasp workpieces Convenience and wide range of expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

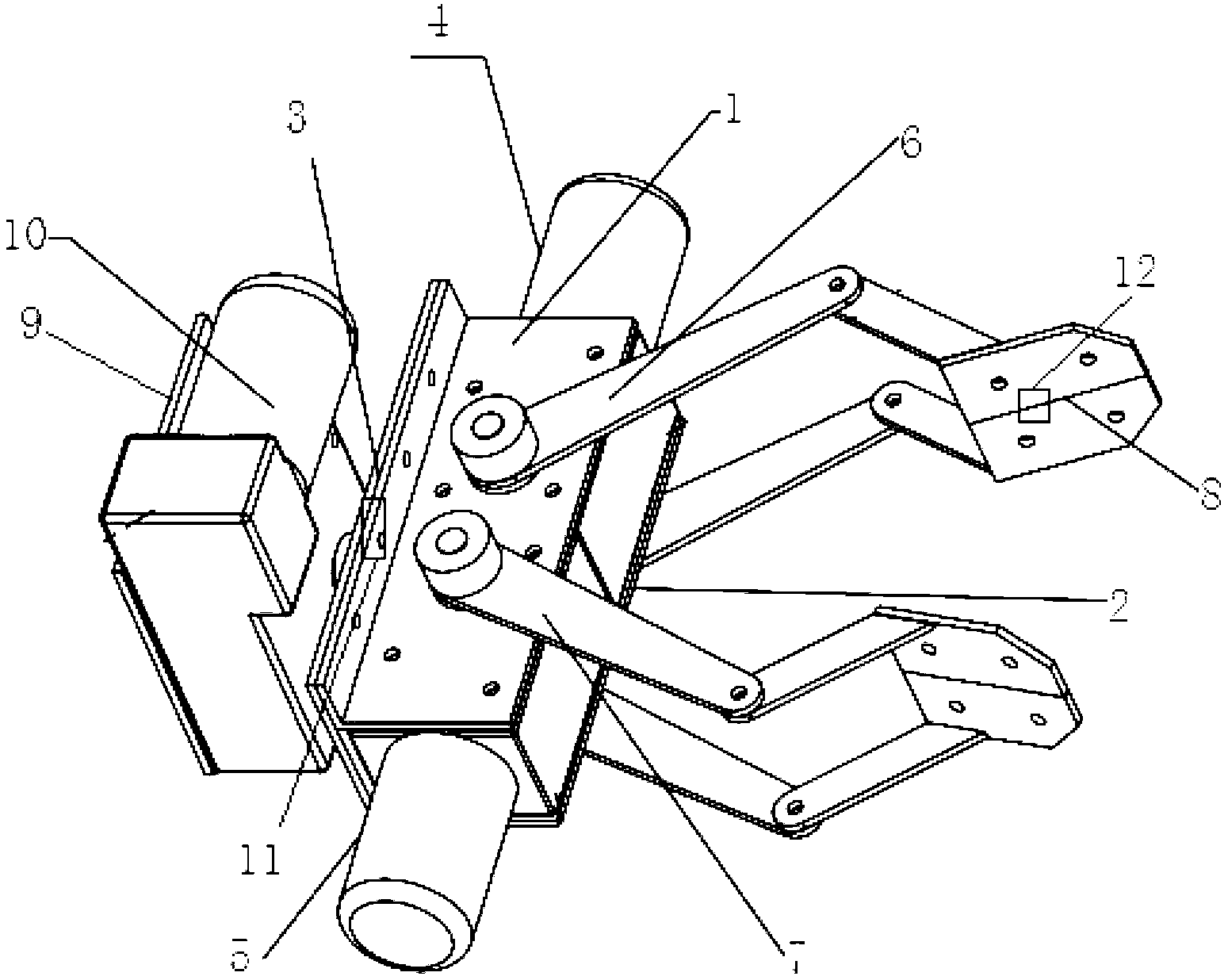

[0013] Such as figure 1 As shown, a rotatable robot gripper includes a rotating part, a positioning part and a finger part, and the positioning part includes an upper base plate 1, a lower base plate 2 and a back plate 3, and the upper base plate 1 and The side of the lower base plate 2 is fixed on the front of the back plate 3, and the front and rear sides between the upper and lower base plates 1 and 2 are respectively fixedly installed with a worm gear reducer motor 1 and a worm gear reducer motor 2 5; the finger part includes The left finger 6 and the right finger 7, the left and right fingers 6, 7 are composed of two rotatable L-shaped push rods placed in parallel, and polygonal iron sheets are fixedly installed on one end of the two L-shaped push rods 8. The two L-shaped push rods of the left finger 6 are connected to the worm gear motor-4 respectively, and the two L-shaped push rods of the right finger 7 are respectively connected to the worm gear motor two 5 connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com