Incremental electro-hydraulic digital flow control valve with double valve cores rotating oppositely

A digital flow, incremental technology, applied in valve details, multi-port valves, valve devices, etc., can solve problems such as incompatibility with the overall development of hydraulic technology, manufacturing and assembly wear errors, and reducing dynamic response speed. Output dead zone and inertial lag, radial hydraulic pressure balance, and the effect of increasing flow changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

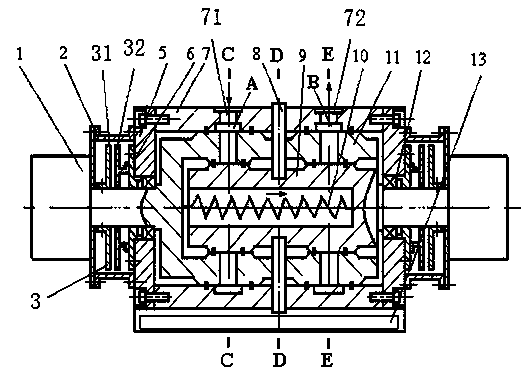

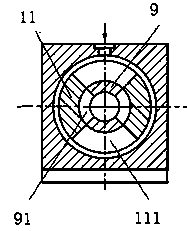

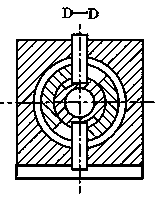

[0032] A double-spool counter-rotating incremental electro-hydraulic digital flow control valve, such as figure 1 shown. The control valve includes a valve body 7 , an outer spool 11 , an inner spool 9 , a stepper motor 1 , a stepper motor controller 13 , a spool angular displacement sensor 3 , a positioning pin 8 and a spool return spring 10 . Valve body 7 outer square inner circles are fixed with screws at the left and right end covers 5 . The outer surface of the valve body is square, and the outer surface of the valve body is provided with an oil inlet, an oil outlet and a stepping motor controller. The oil inlet annular groove A, and the oil outlet annular groove B communicated with the oil outlet. Both the outer spool and the inner spool are foot-cup-shaped, the large open end is a cylindrical sleeve, and the small closed end is a cylindrical shaft; the outer fan-shaped inlet corresponding to the oil inlet annular groove A is arranged on the surface of the outer spool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com