Patents

Literature

5298 results about "Electro hydraulic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus to monitor operation of an auxiliary hydraulic pump in a transmission

The invention comprises a method and apparatus to monitor operation of an electrically-actuated hydraulic pump selectively operative to supply pressurized fluid to a hydraulic circuit for a transmission device operably connected to an internal combustion engine of a vehicle. It includes monitoring vehicle operation and passively and intrusively monitoring hydraulic circuit pressure. The hydraulic pump is functioning properly when the monitored pressure in the hydraulic circuit exceeds a threshold. A fault related to the hydraulic circuit is identified when the monitored pressure in the hydraulic circuit does not exceed the threshold.

Owner:ELECTRONICS DATA SYST CORP +1

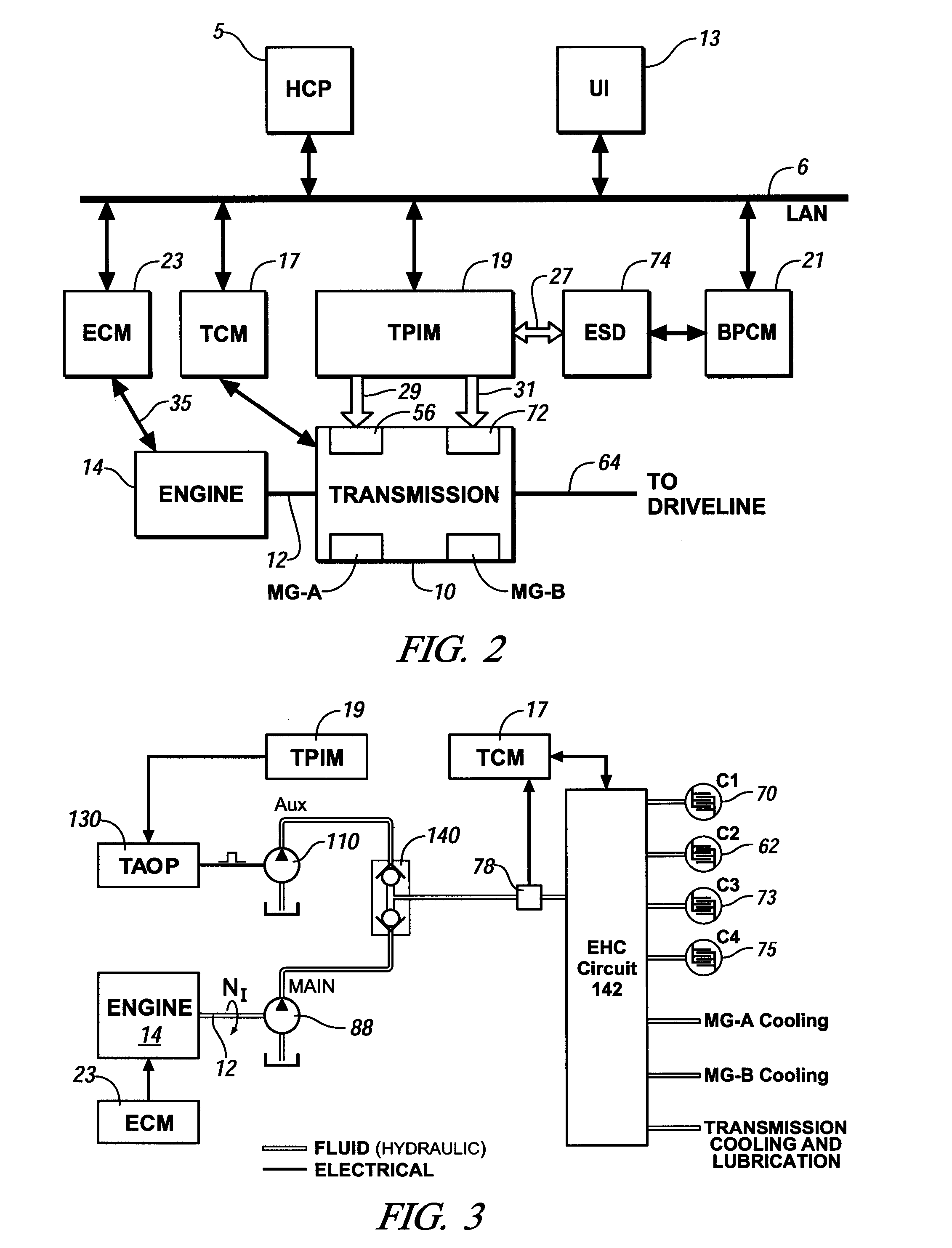

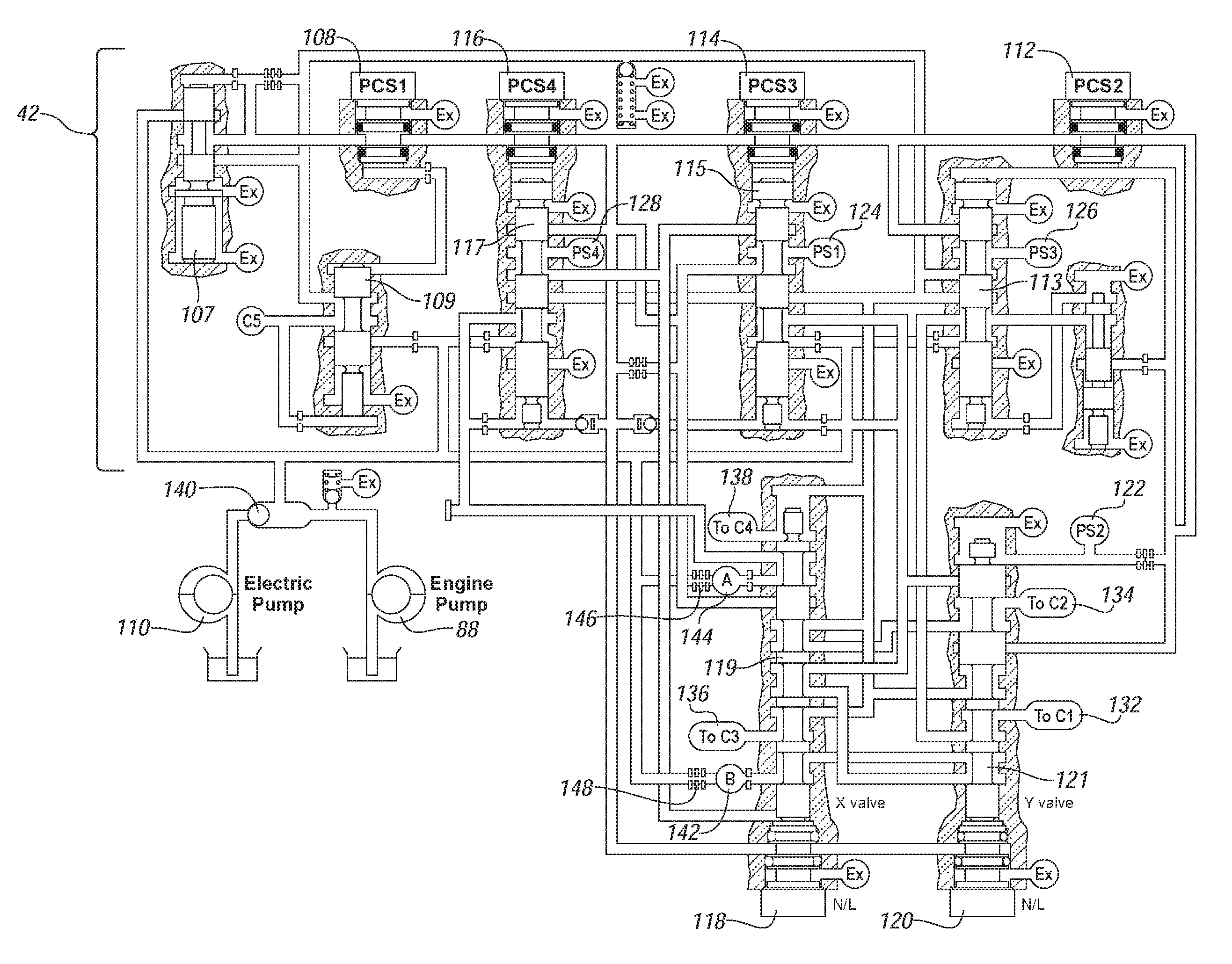

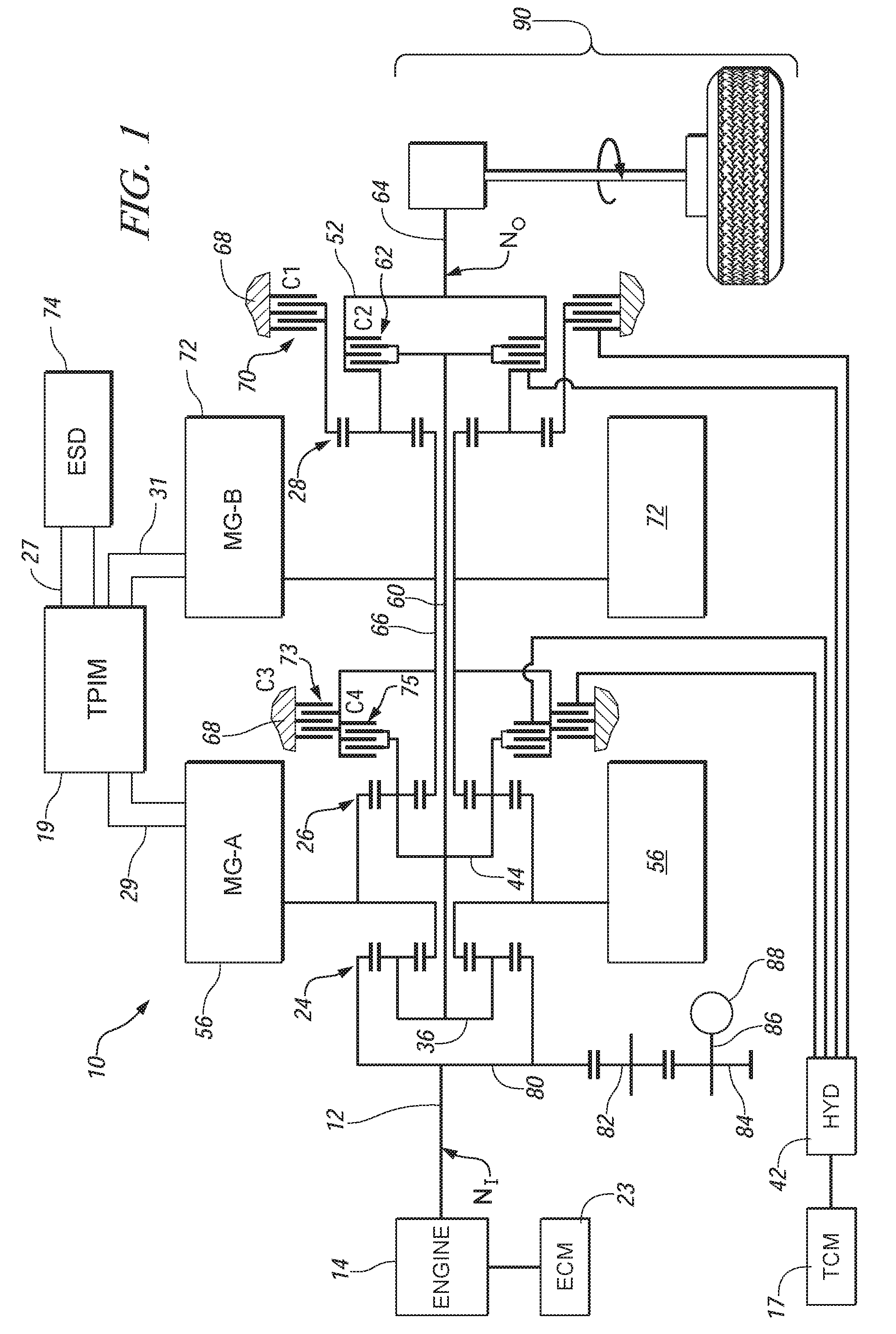

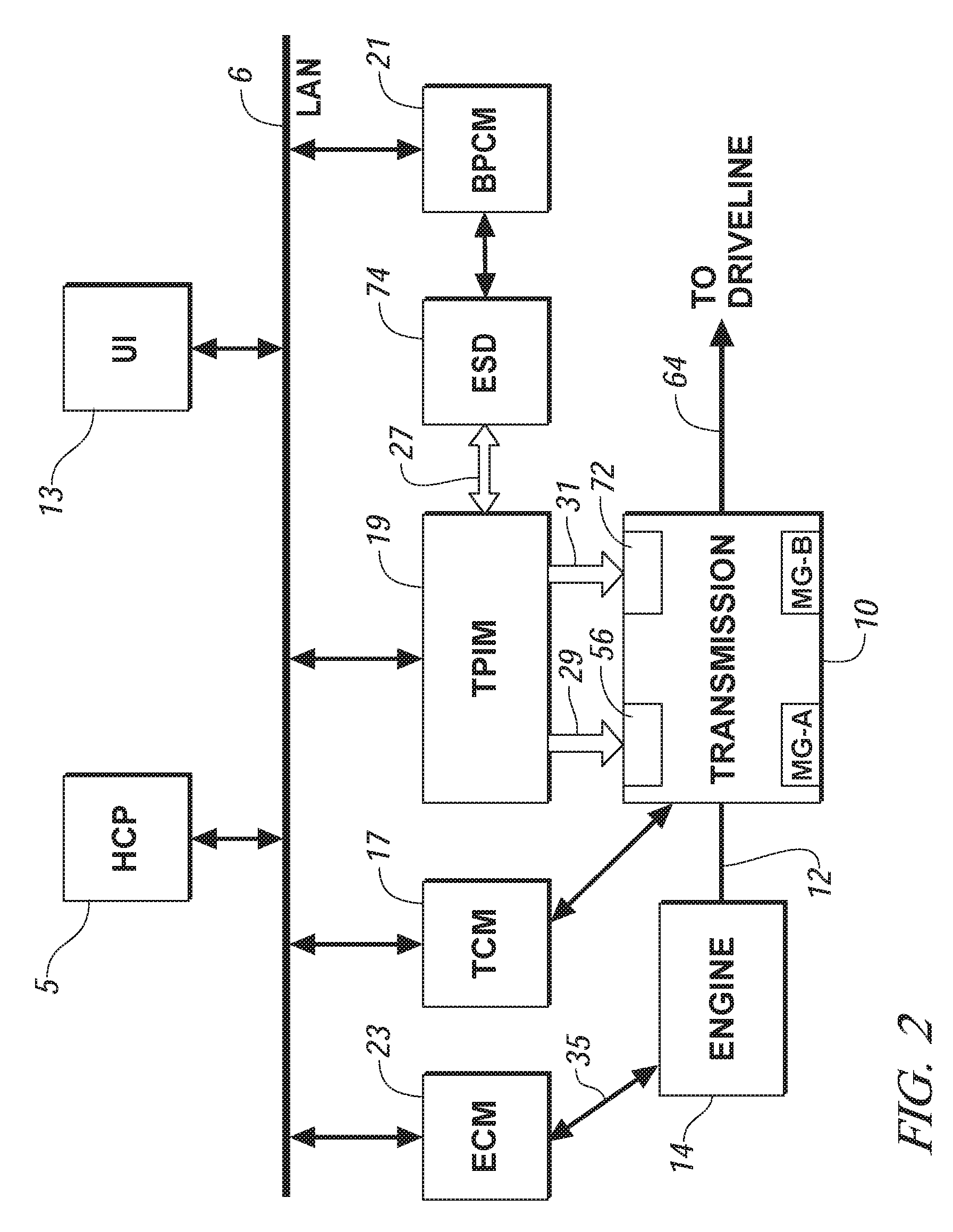

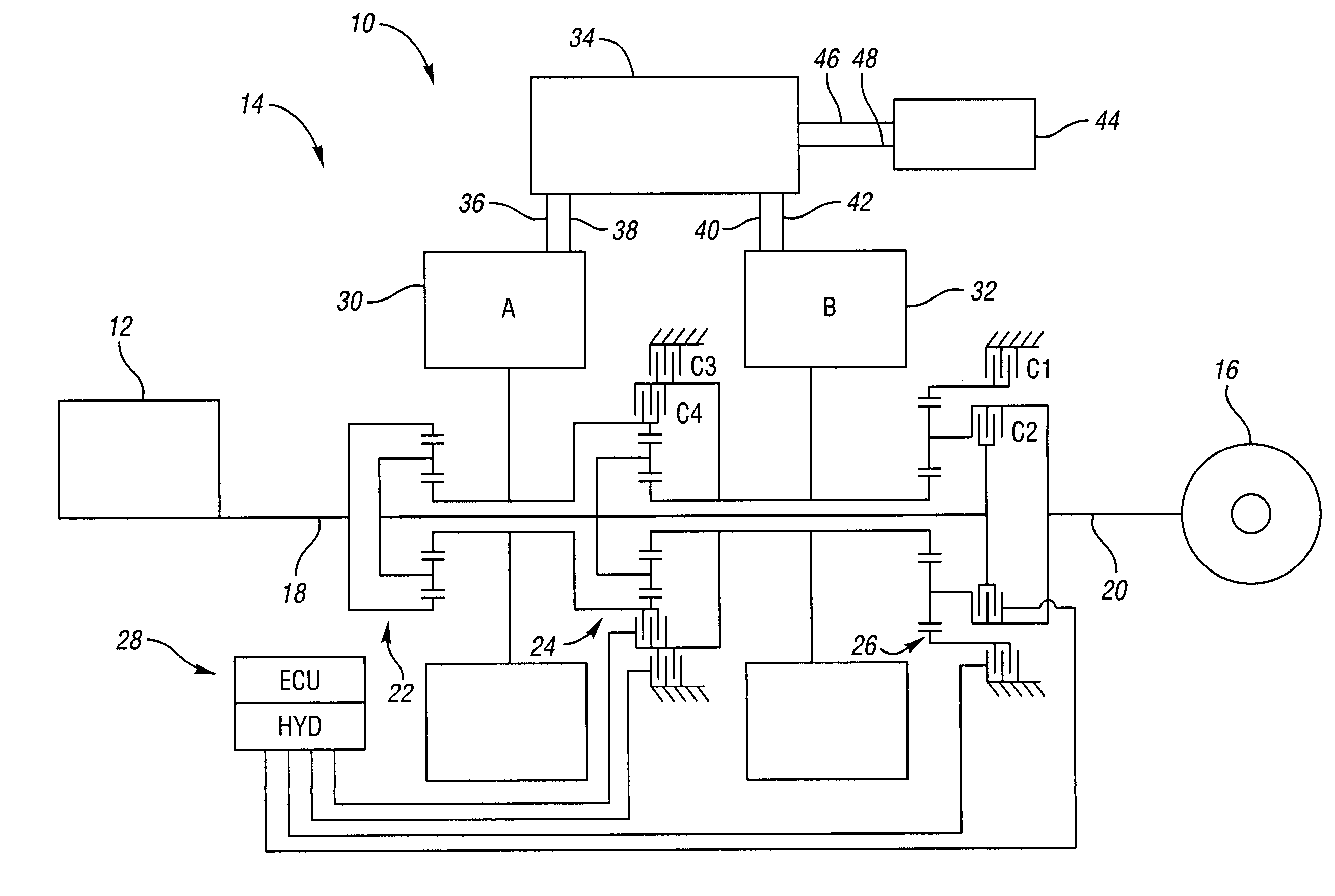

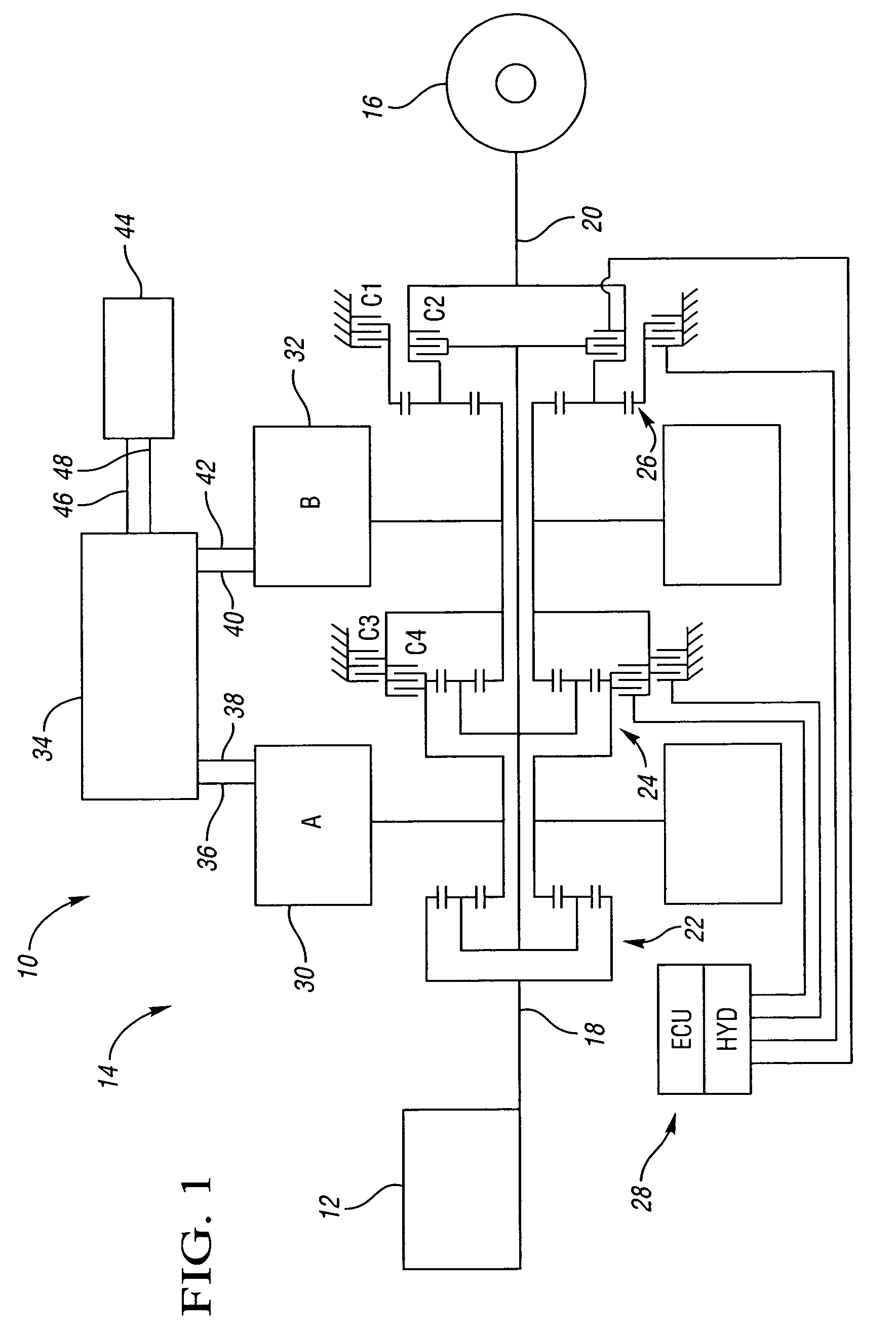

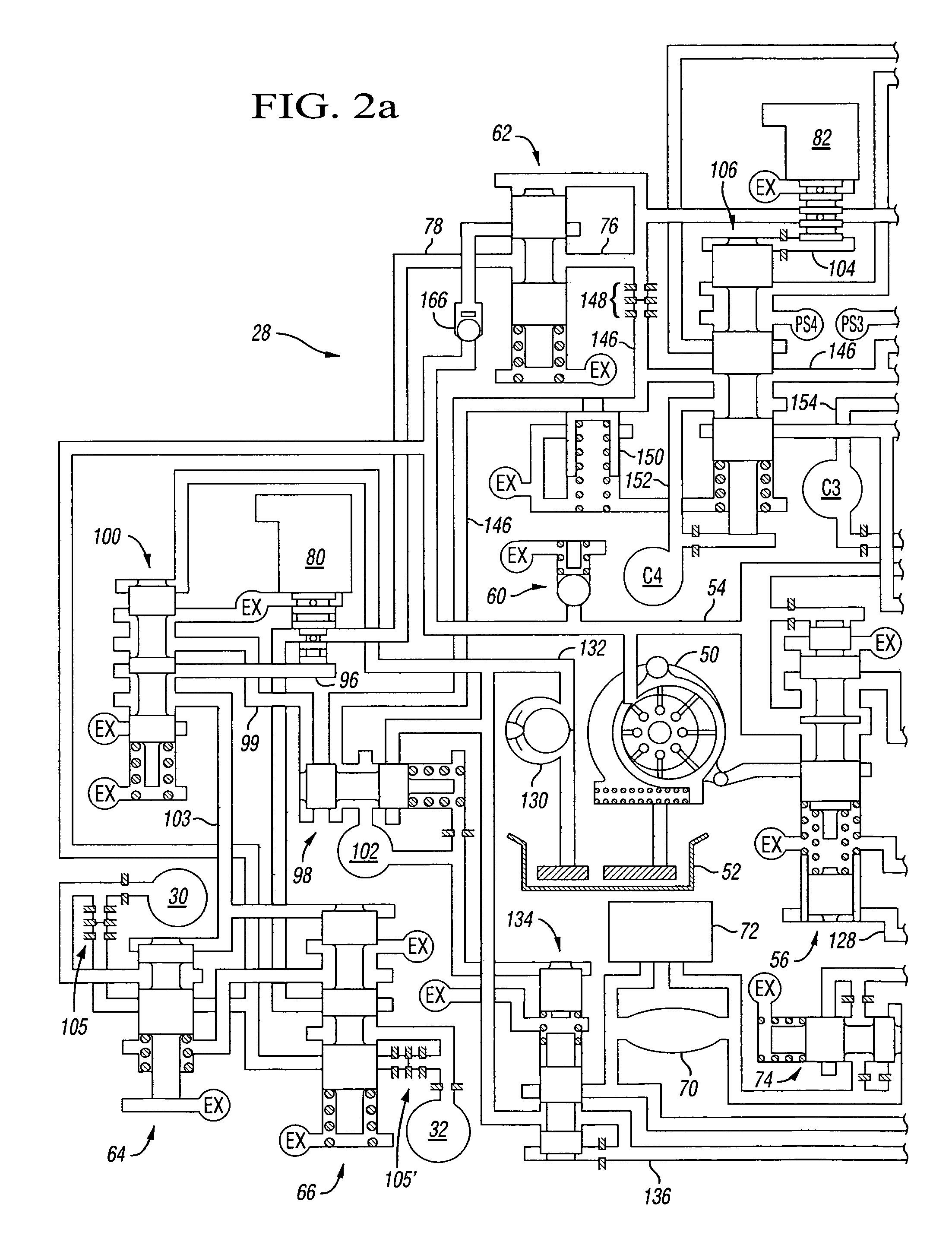

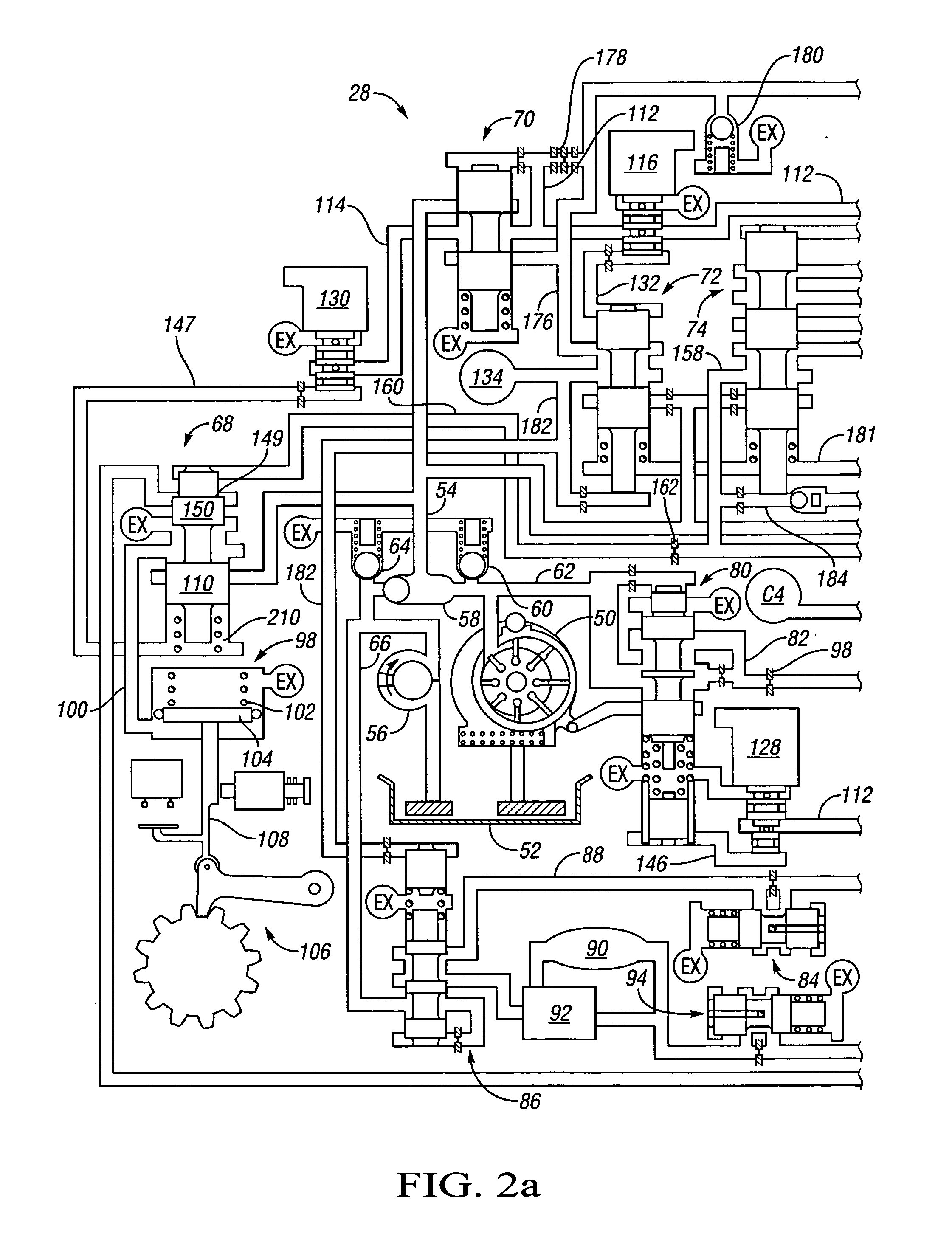

Method and apparatus to monitor devices of a hydraulic circuit of an electro-mechanical transmission

A method and an apparatus are provided to control operation of an electro-mechanical transmission device selectively operative in one of a plurality of fixed gear modes and two continuously variable modes. The method comprises controlling the flow control devices of the electro-hydraulic control circuit, and monitoring a plurality of pressure monitoring devices in the electro-hydraulic control circuit. A fault is identified in the electro-hydraulic control circuit when a signal output of one of the pressure monitoring devices does not correspond to an expected signal output for the pressure monitoring device after an elapsed time period.

Owner:GM GLOBAL TECH OPERATIONS LLC

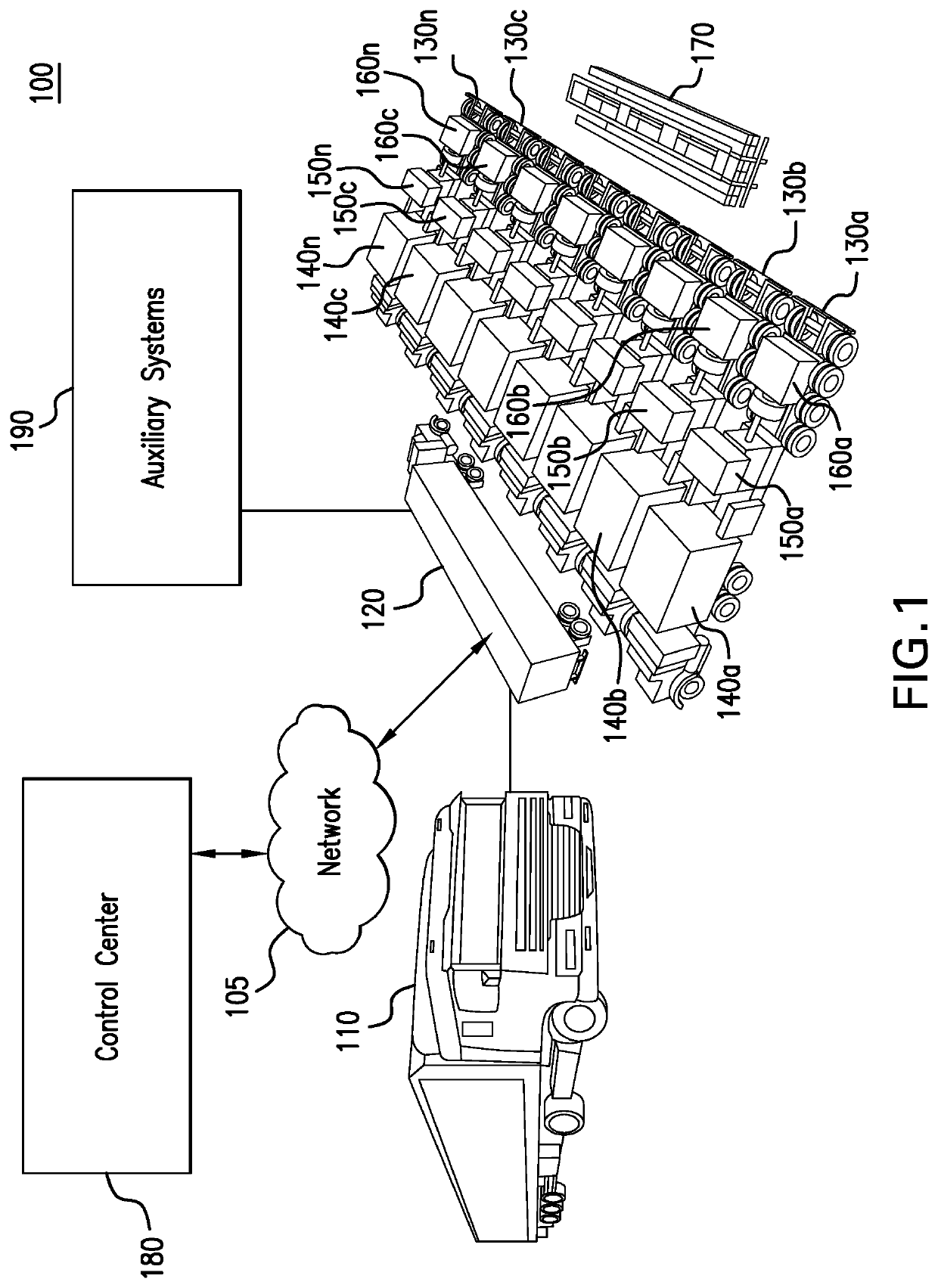

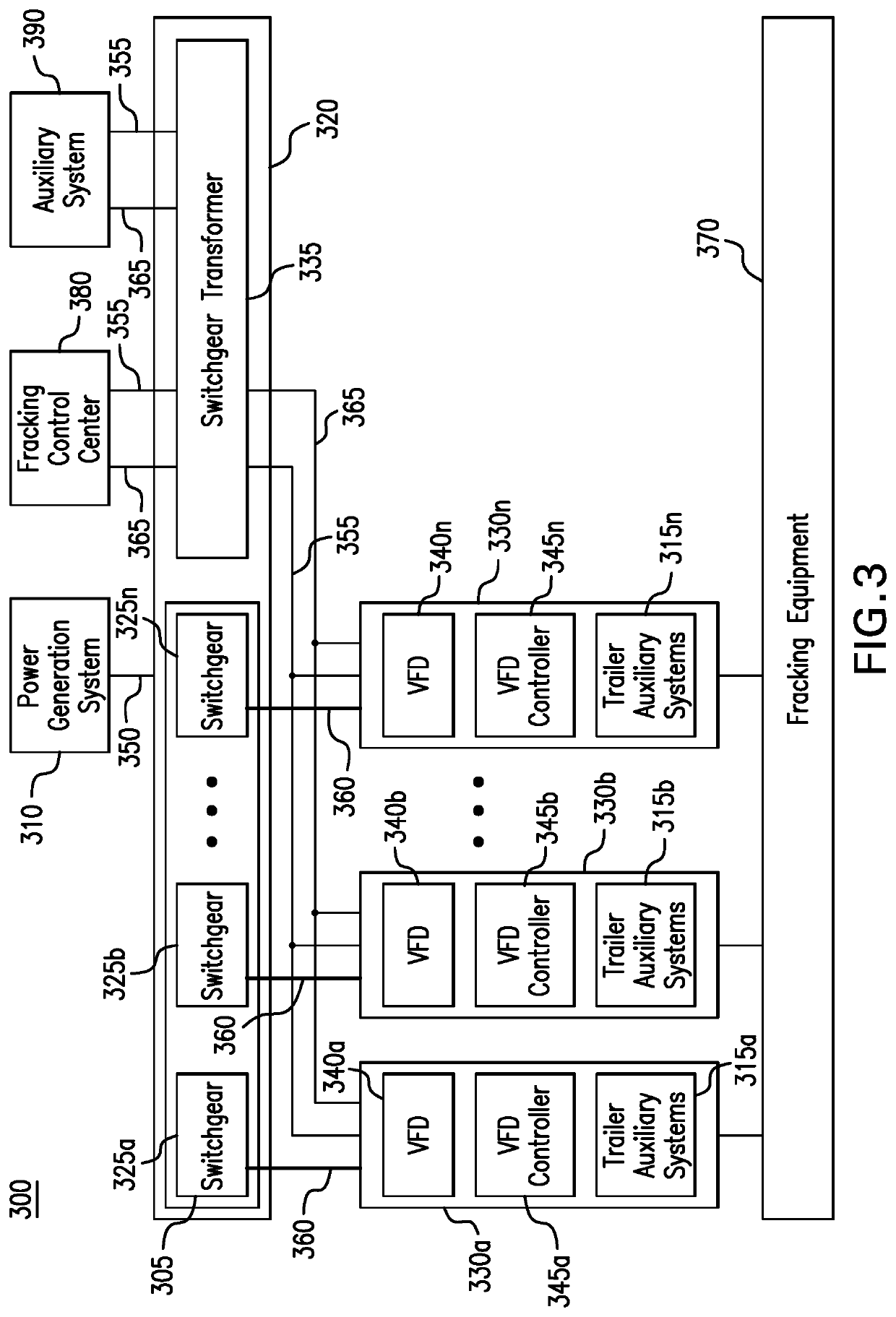

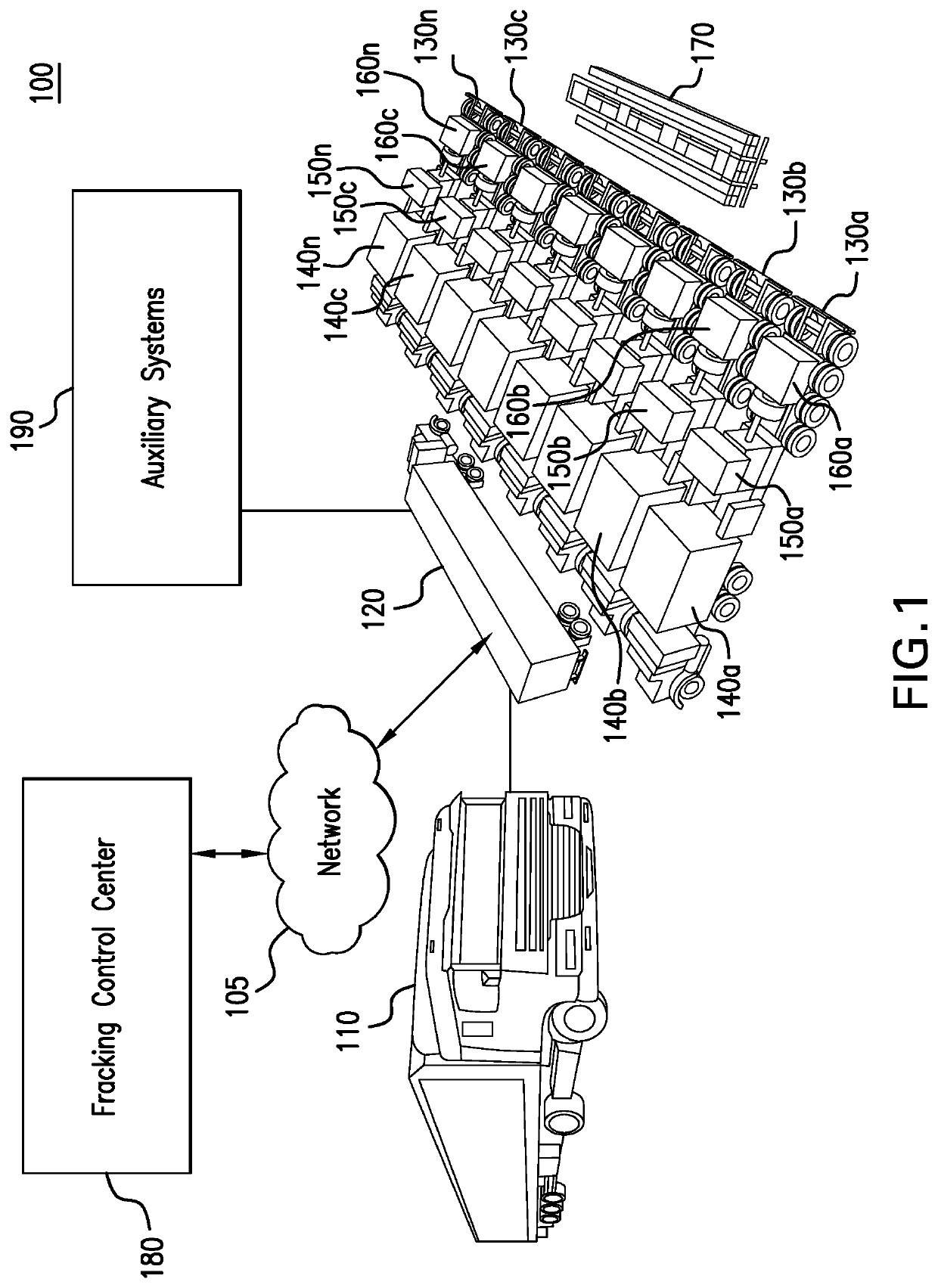

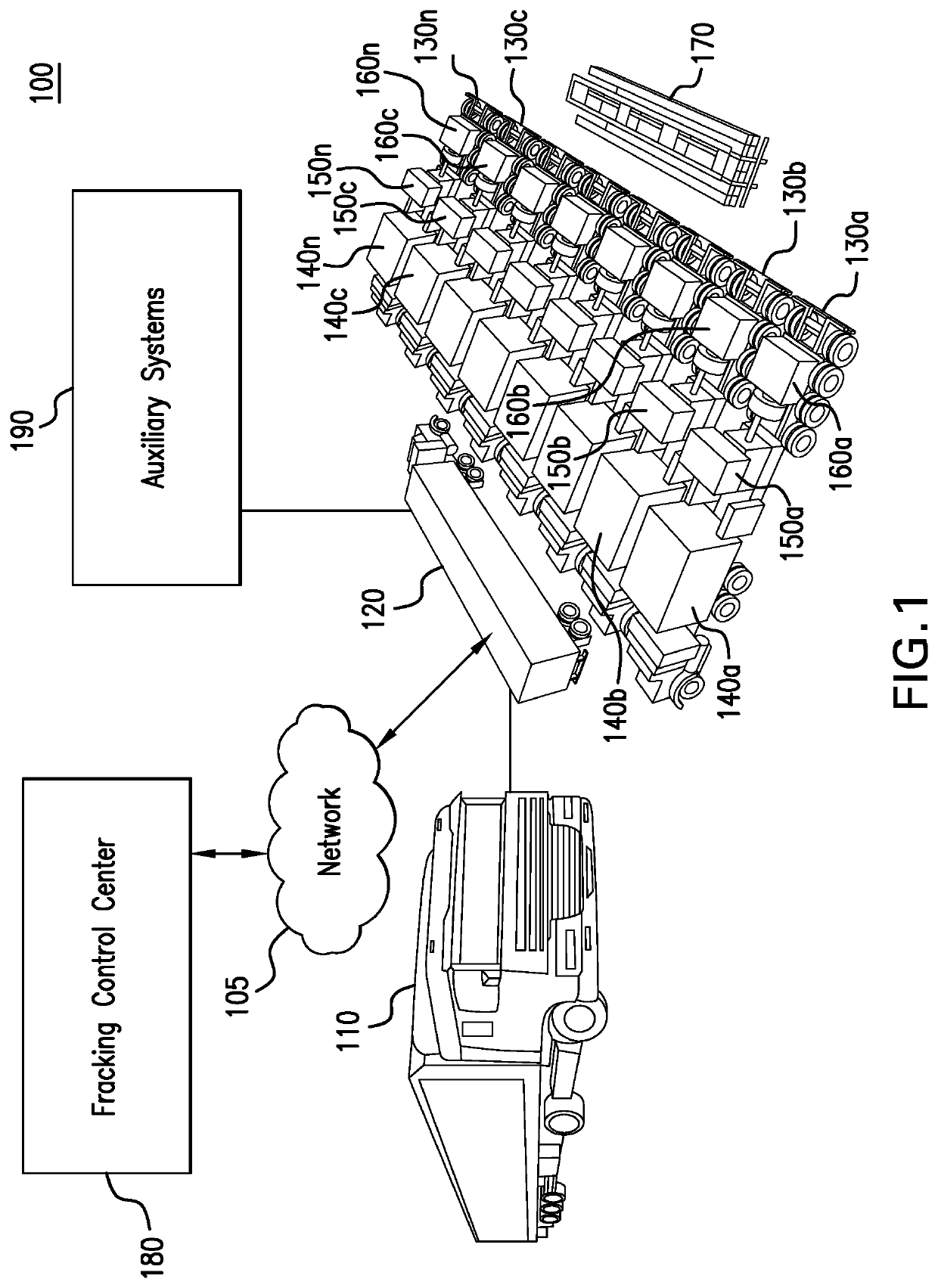

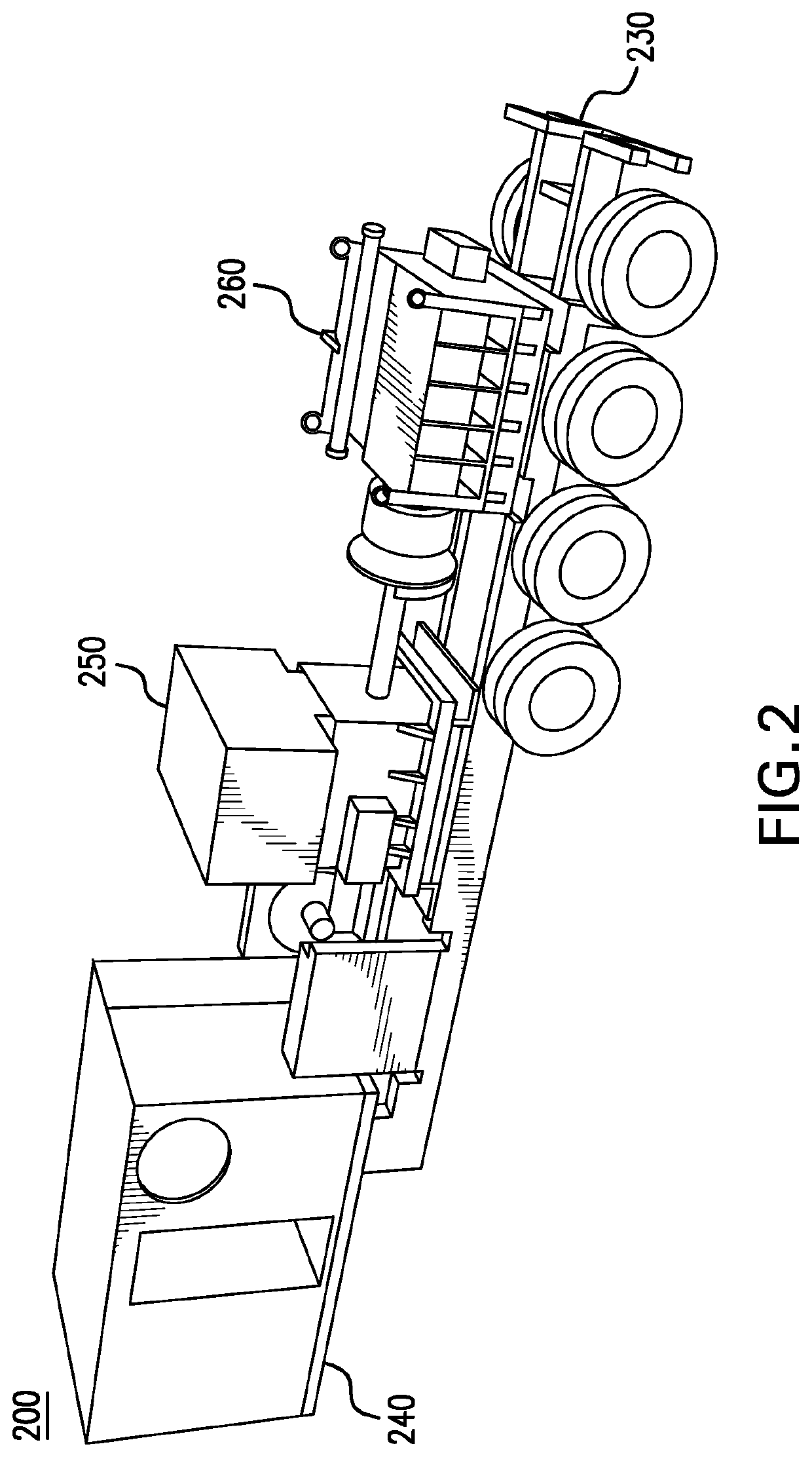

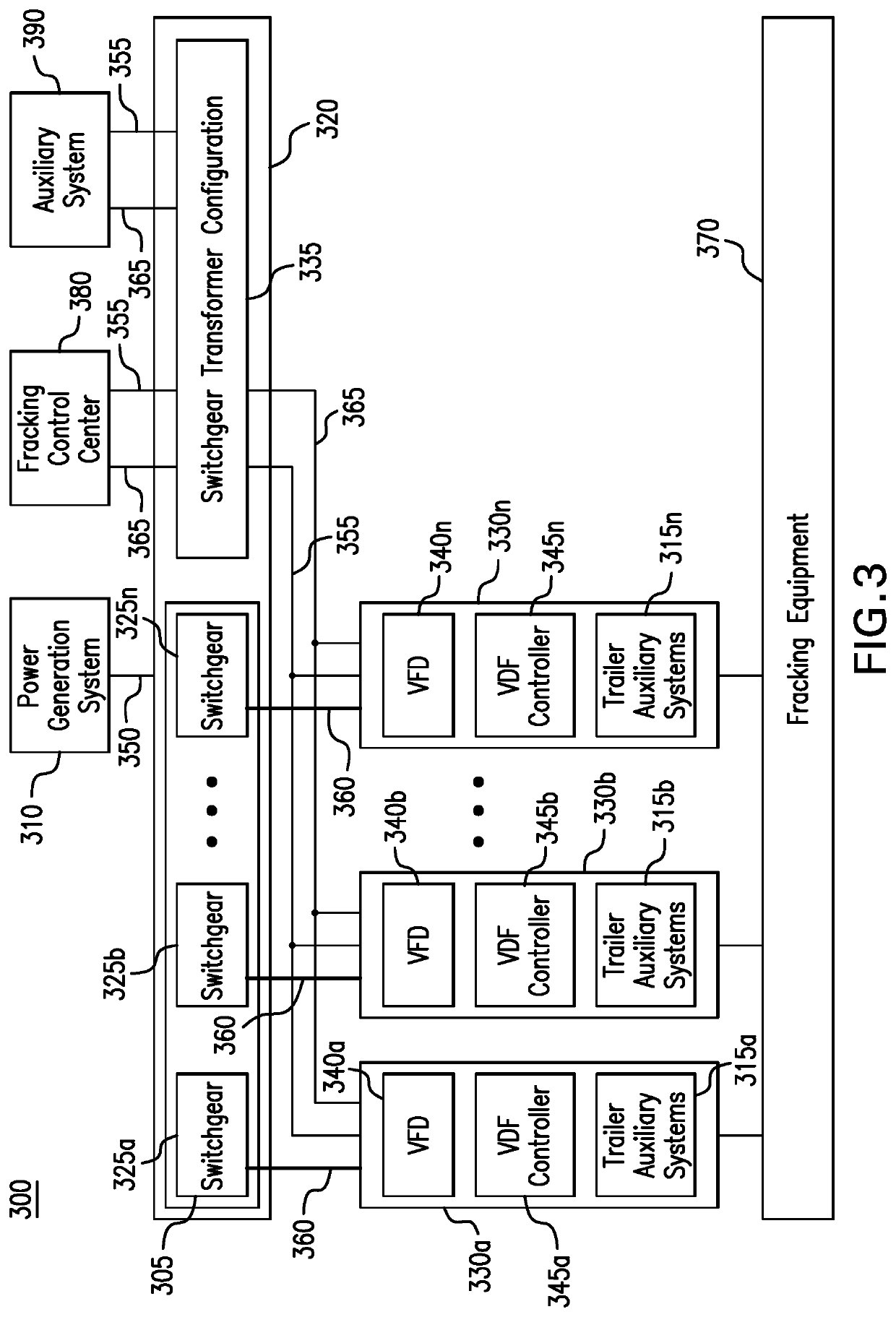

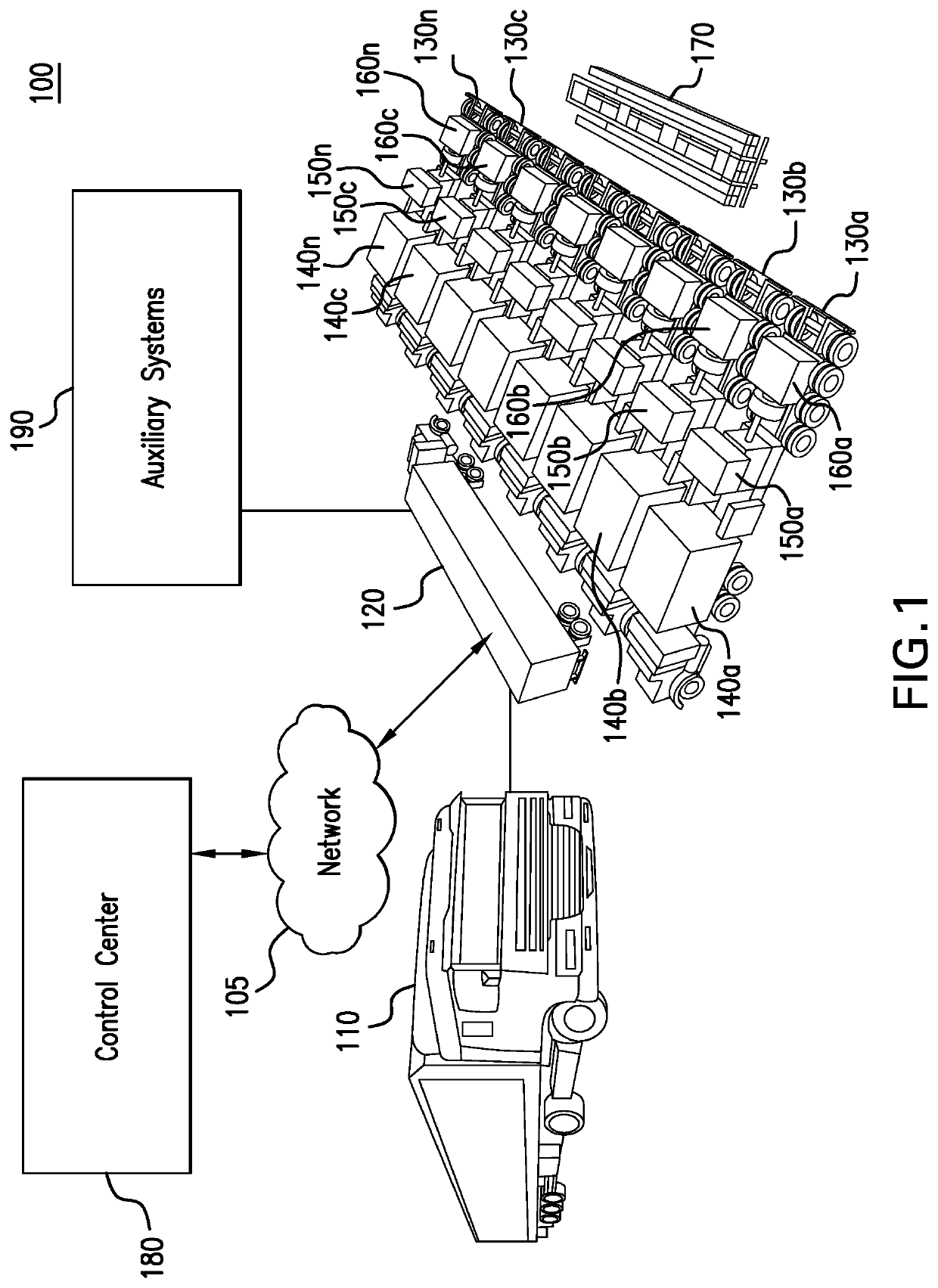

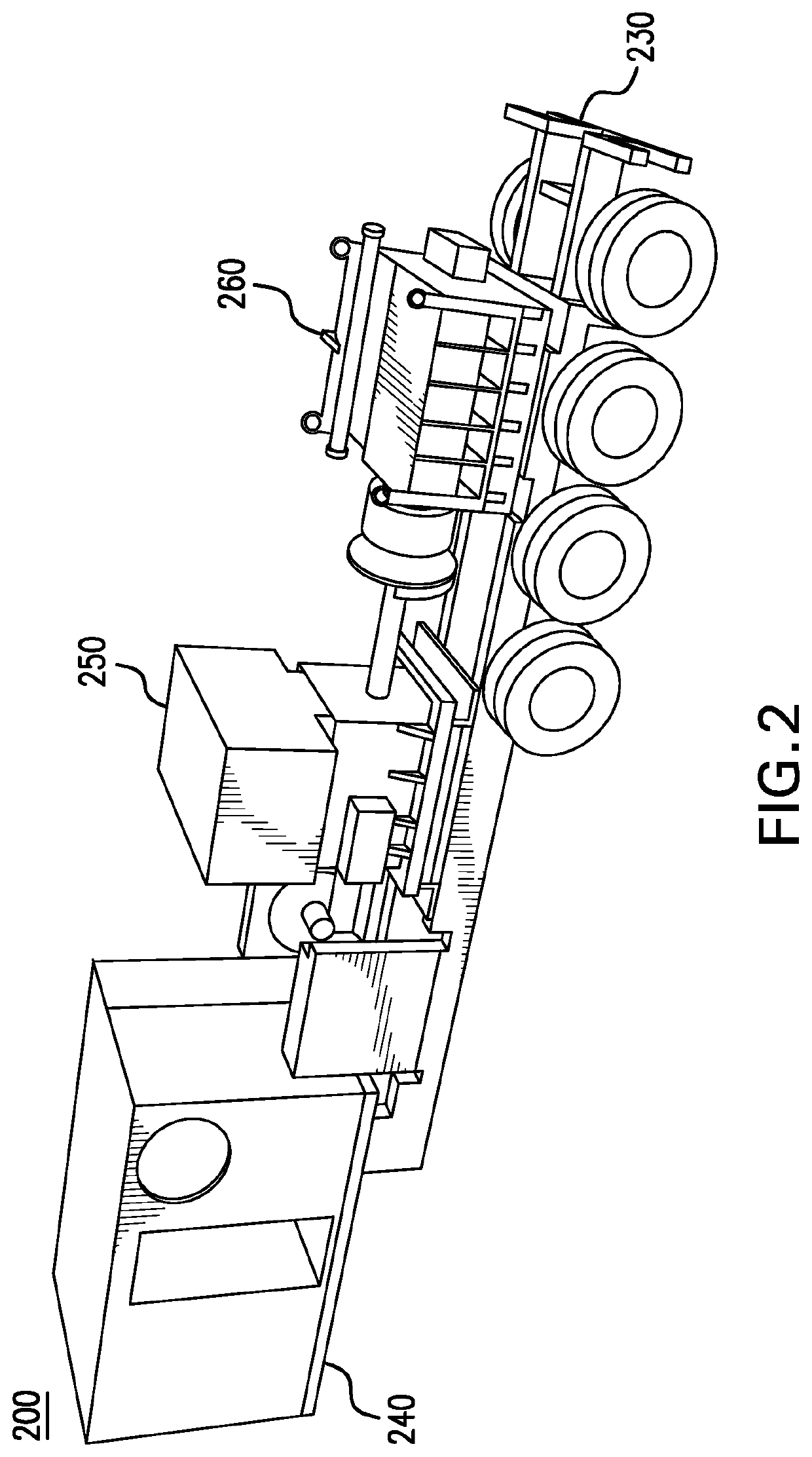

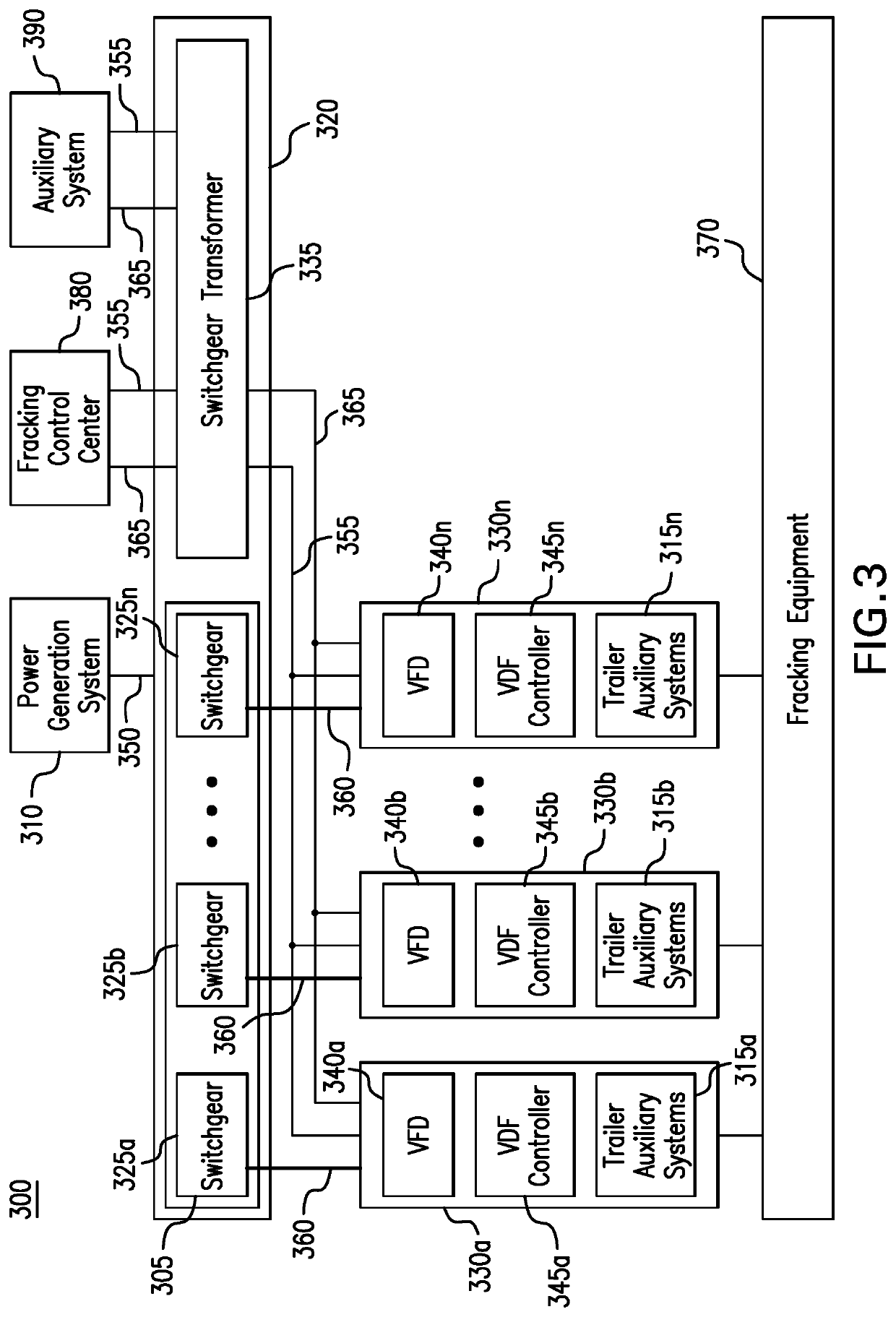

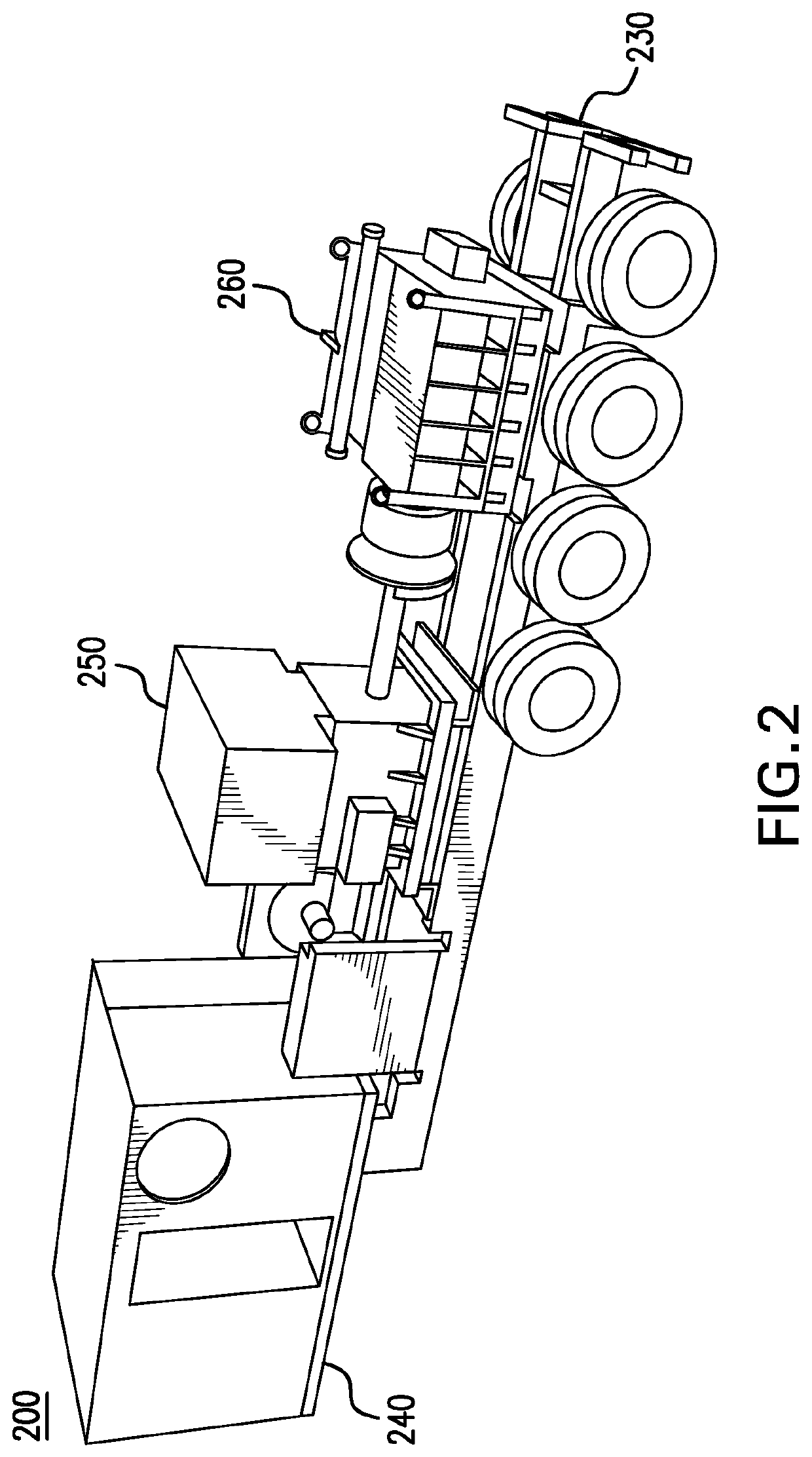

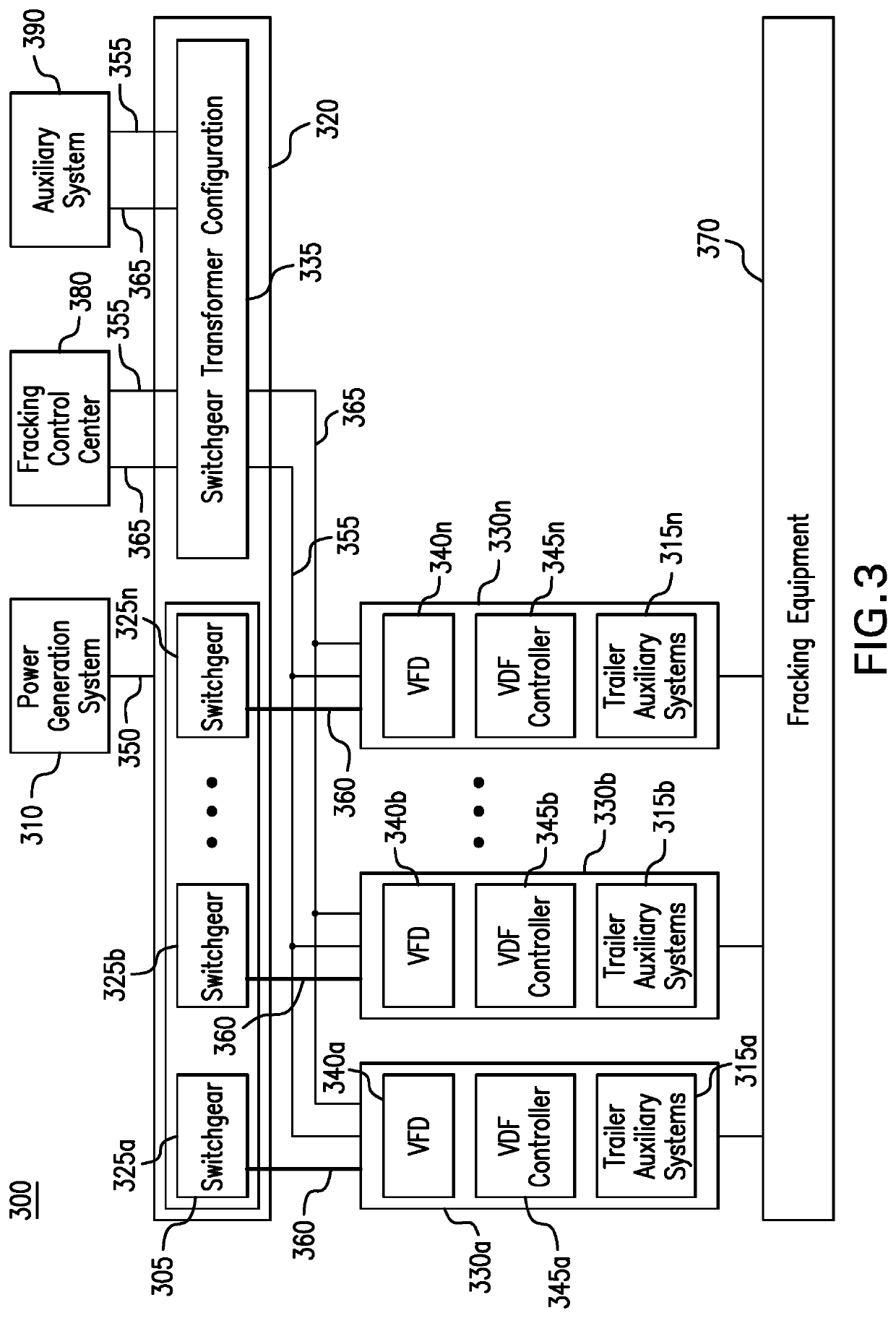

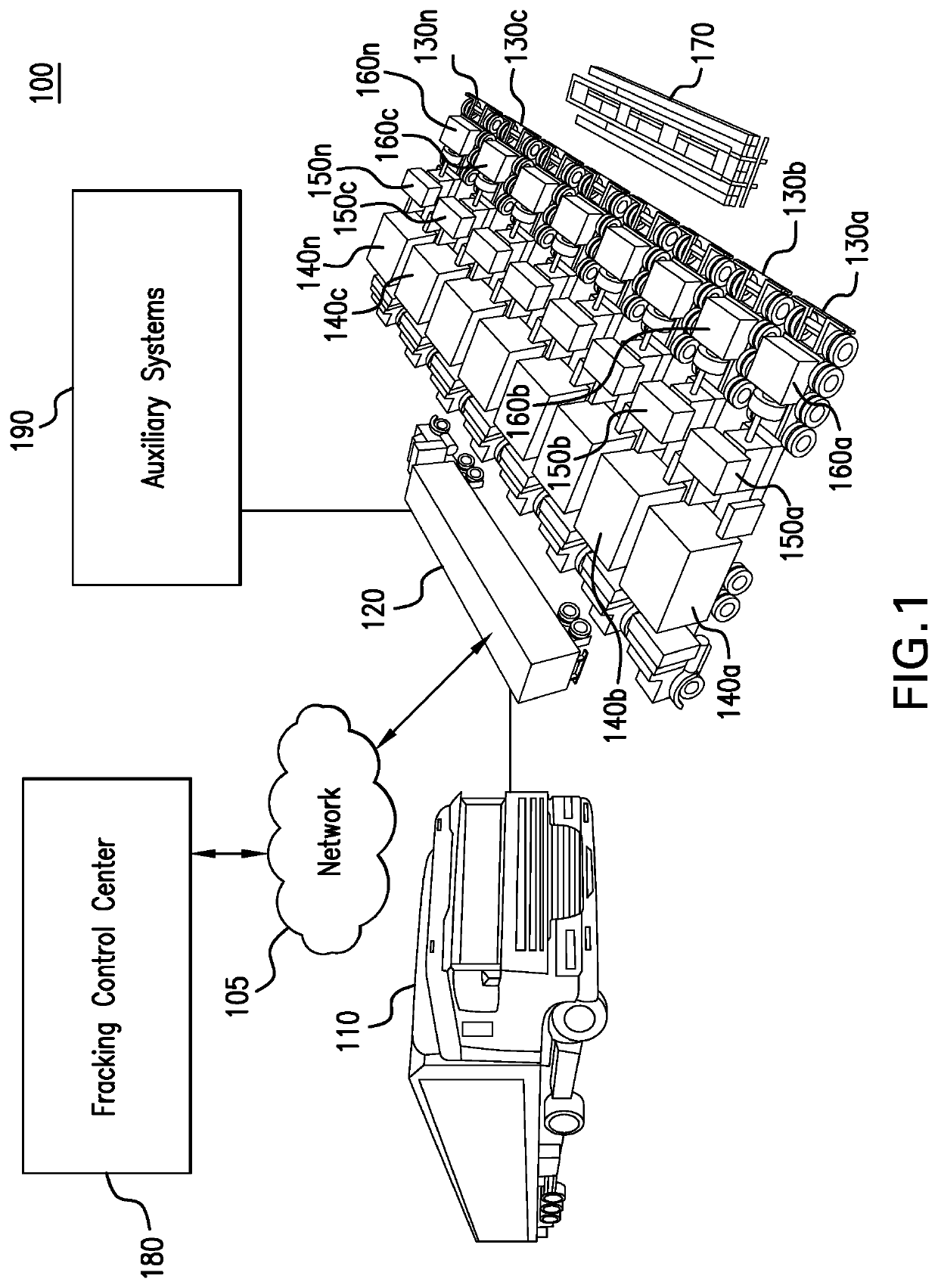

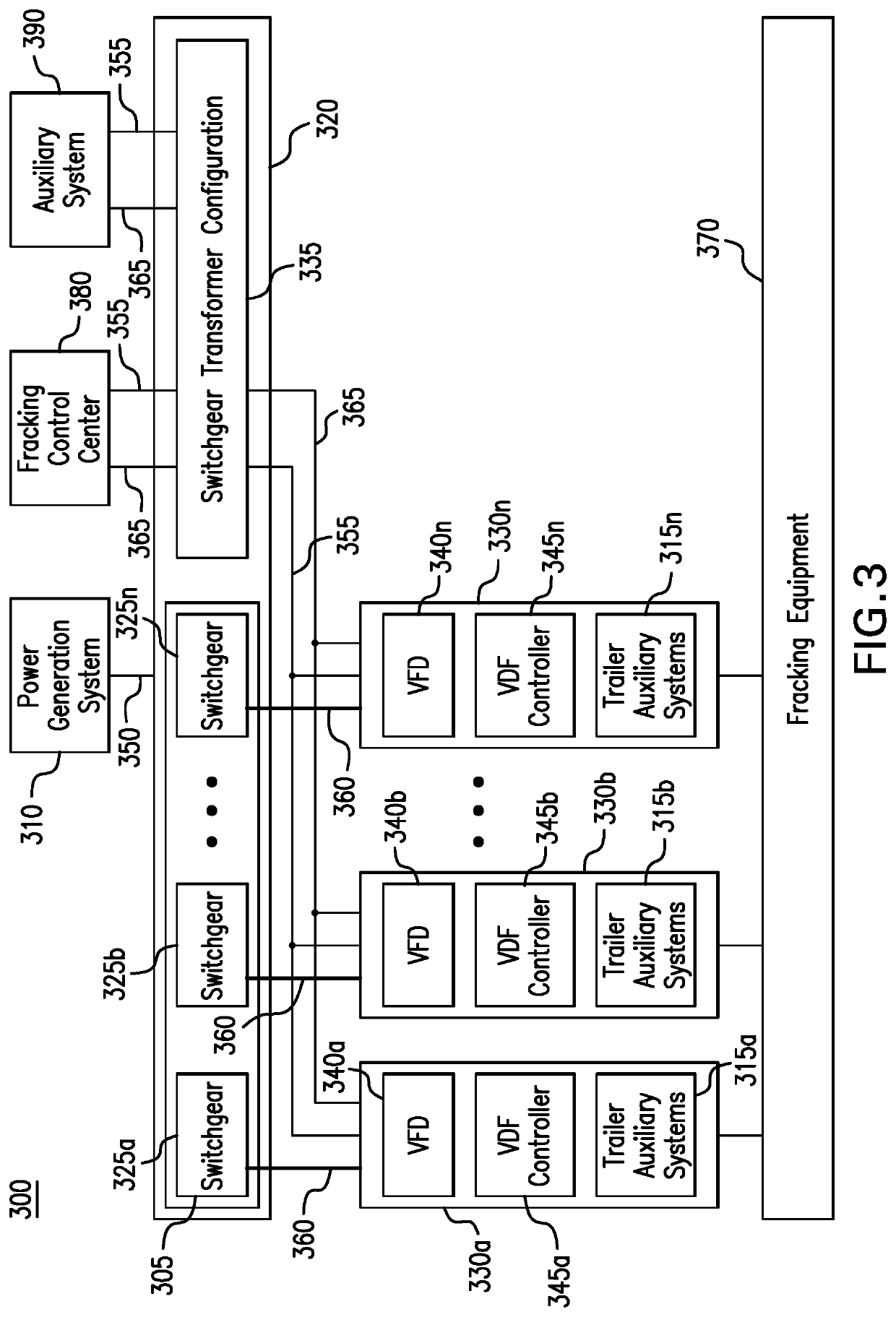

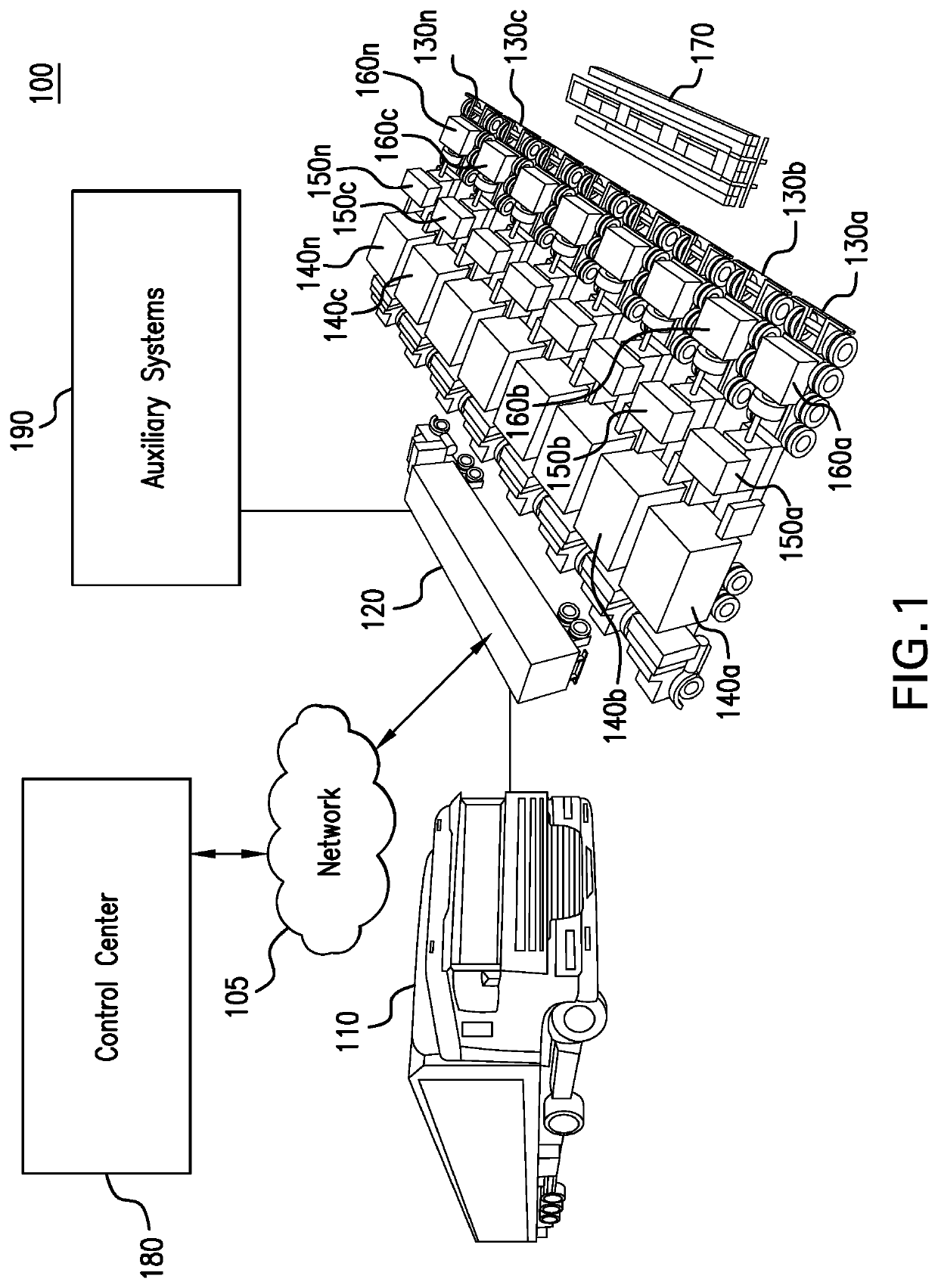

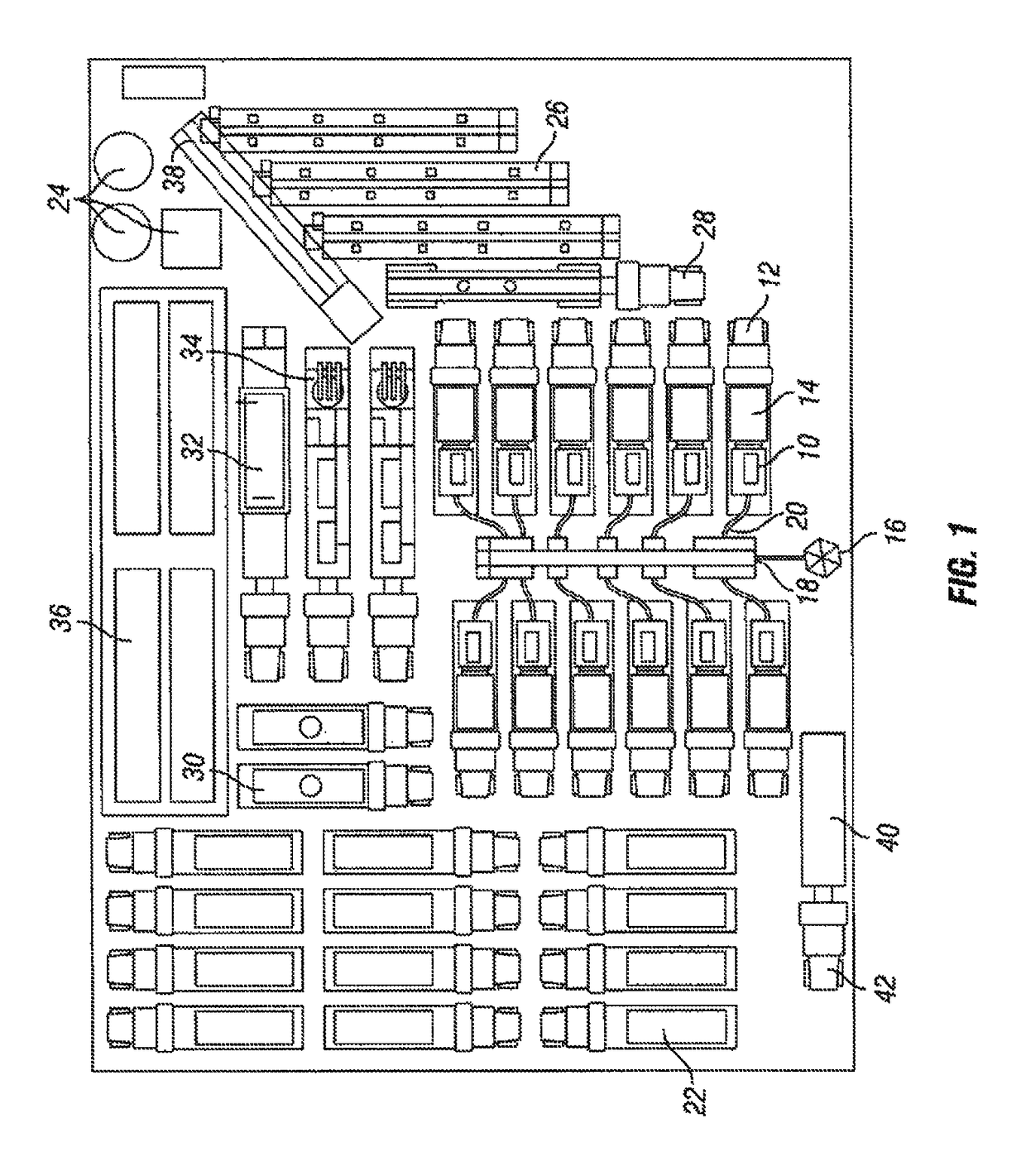

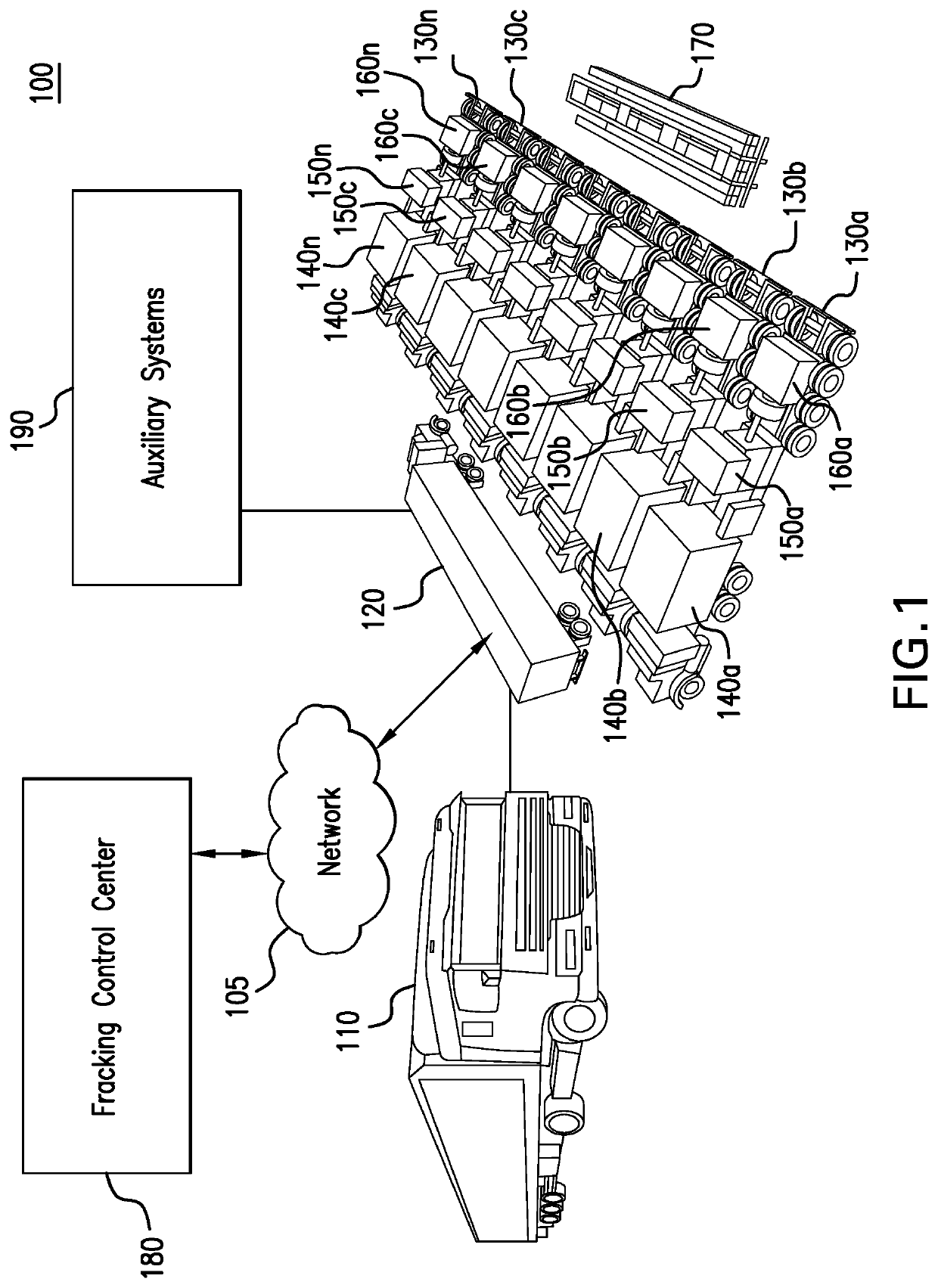

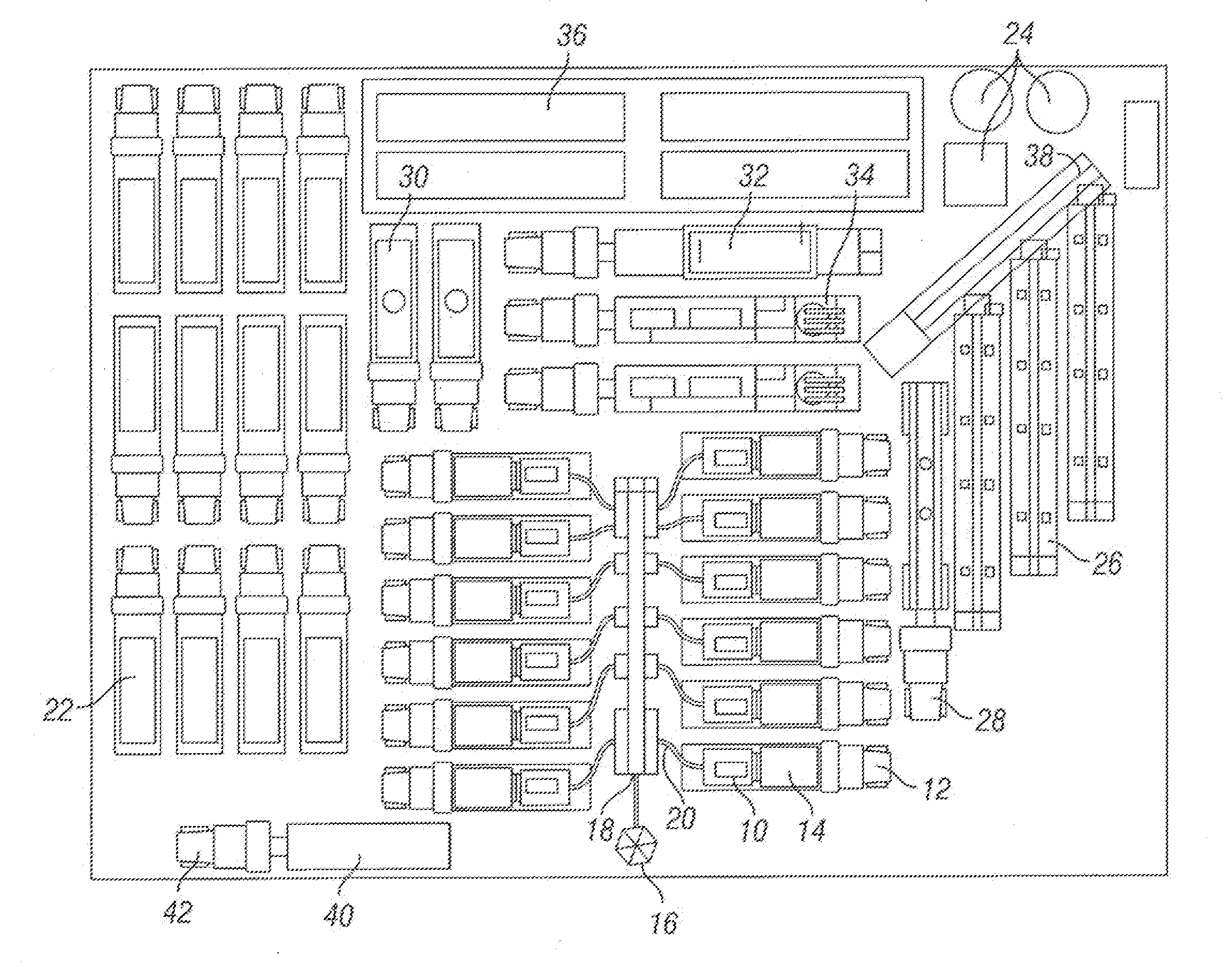

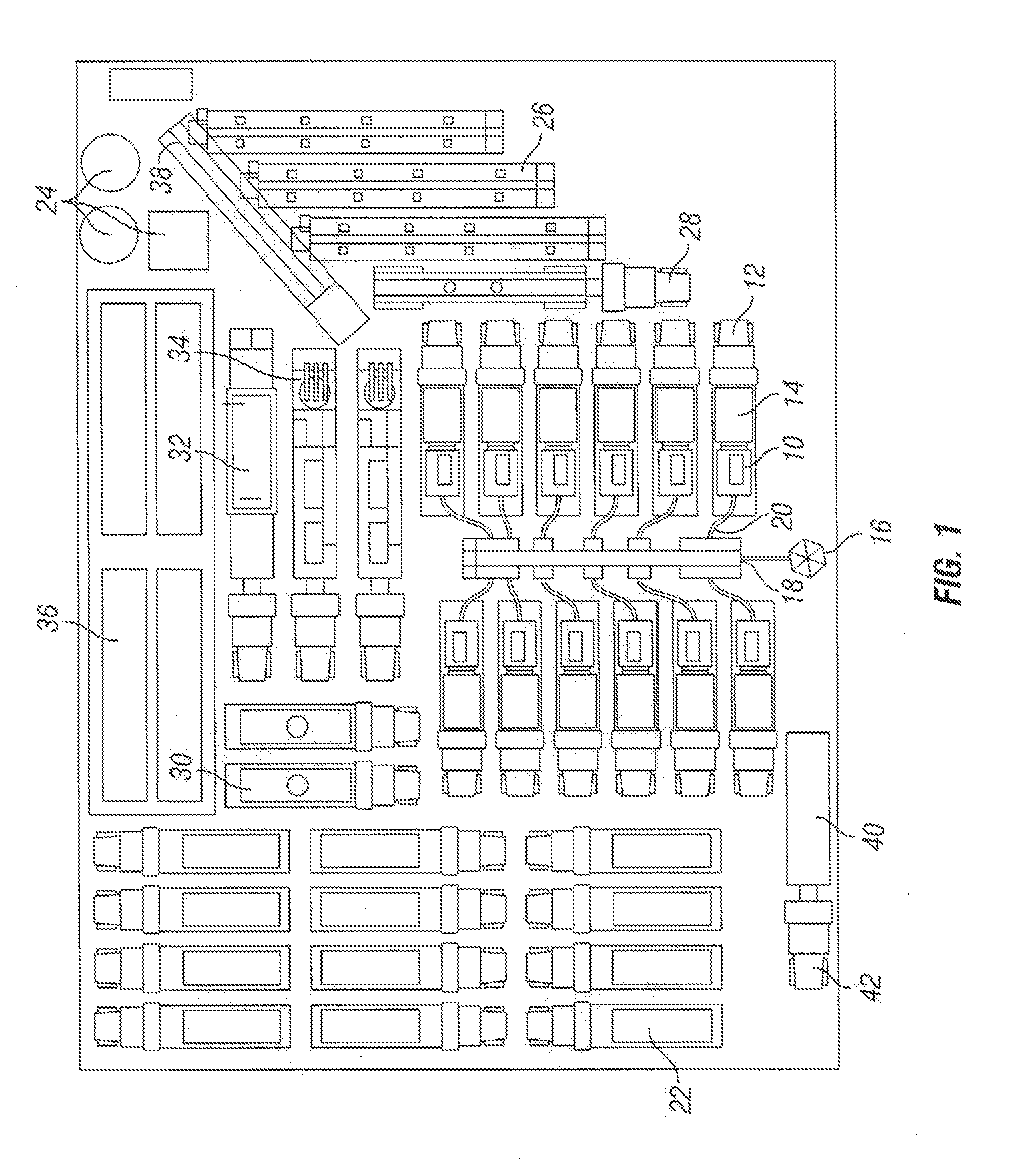

Power distribution trailer for an electric driven hydraulic fracking system

Owner:HALLIBURTON ENERGY SERVICES INC

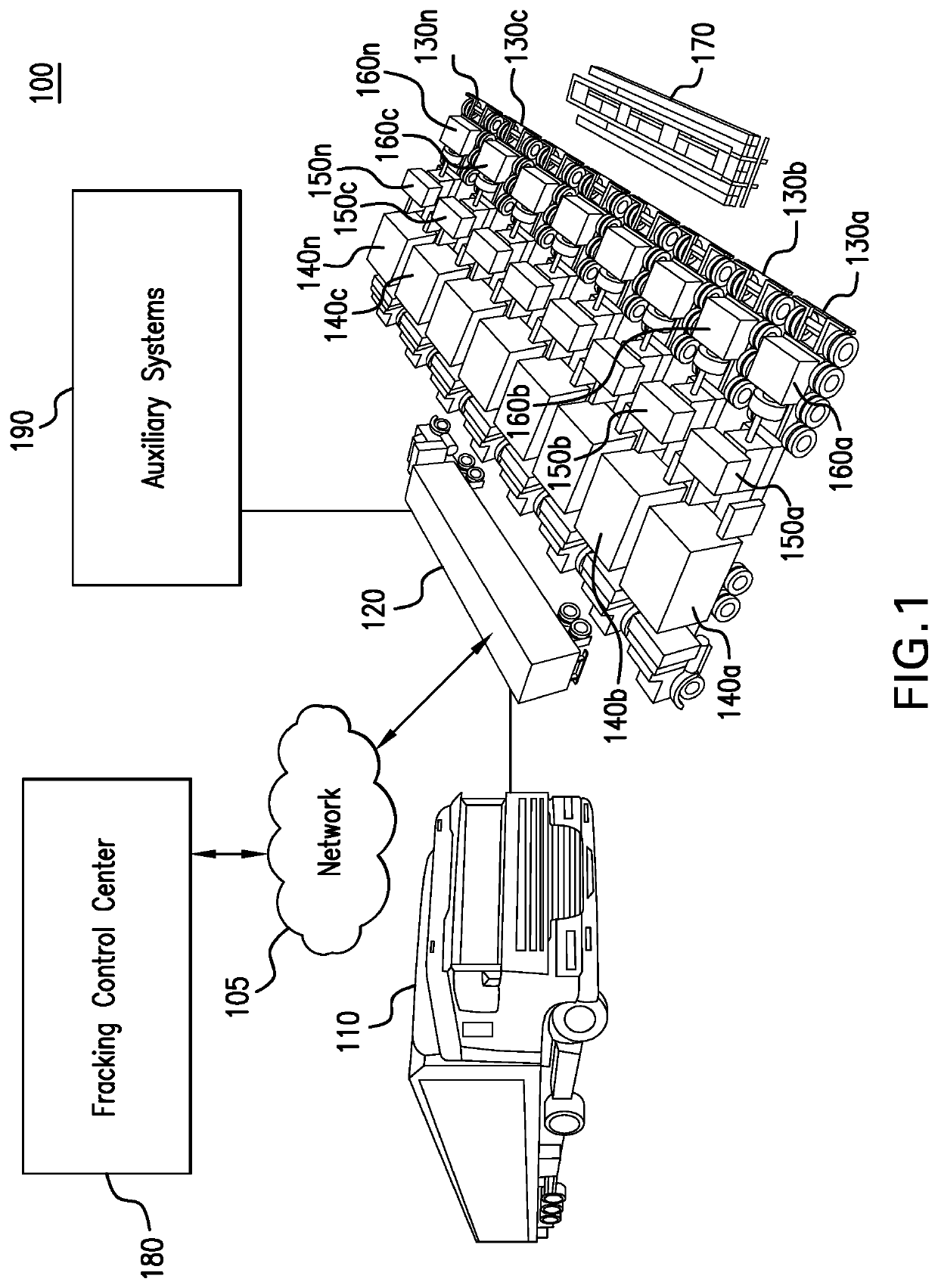

Parameter monitoring and control for an electric driven hydraulic fracking system

An electric driven hydraulic fracking system is disclosed. A pump configuration includes the single VFD, the single shaft electric motor, and the single hydraulic pump mounted on the single pump trailer. A controller associated with the single VFD and is mounted on the single pump trailer. The controller monitors operation parameters associated with an operation of the electric driven hydraulic fracking system as each component of the electric driven hydraulic fracking system operates to determine whether the operation parameters deviate beyond a corresponding operation parameter threshold. Each of the operation parameters provides an indicator as to an operation status of a corresponding component of the electric driven hydraulic fracking system. The controller initiates corrected actions when each operation parameter deviates beyond the corresponding operation threshold. Initiating the corrected actions when each operation parameter deviates beyond the corresponding operation threshold maintains the operation of the electric driven hydraulic fracking system.

Owner:HALLIBURTON ENERGY SERVICES INC

Parameter monitoring and control for an electric driven hydraulic fracking system

An electric driven hydraulic fracking system is disclosed. A pump configuration includes the single VFD, the single shaft electric motor, and the single hydraulic pump mounted on the single pump trailer. A controller associated with the single VFD and is mounted on the single pump trailer. The controller monitors operation parameters associated with an operation of the electric driven hydraulic fracking system as each component of the electric driven hydraulic fracking system operates to determine whether the operation parameters deviate beyond a corresponding operation parameter threshold. Each of the operation parameters provides an indicator as to an operation status of a corresponding component of the electric driven hydraulic fracking system. The controller initiates corrected actions when each operation parameter deviates beyond the corresponding operation threshold. Initiating the corrected actions when each operation parameter deviates beyond the corresponding operation threshold maintains the operation of the electric driven hydraulic fracking system.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

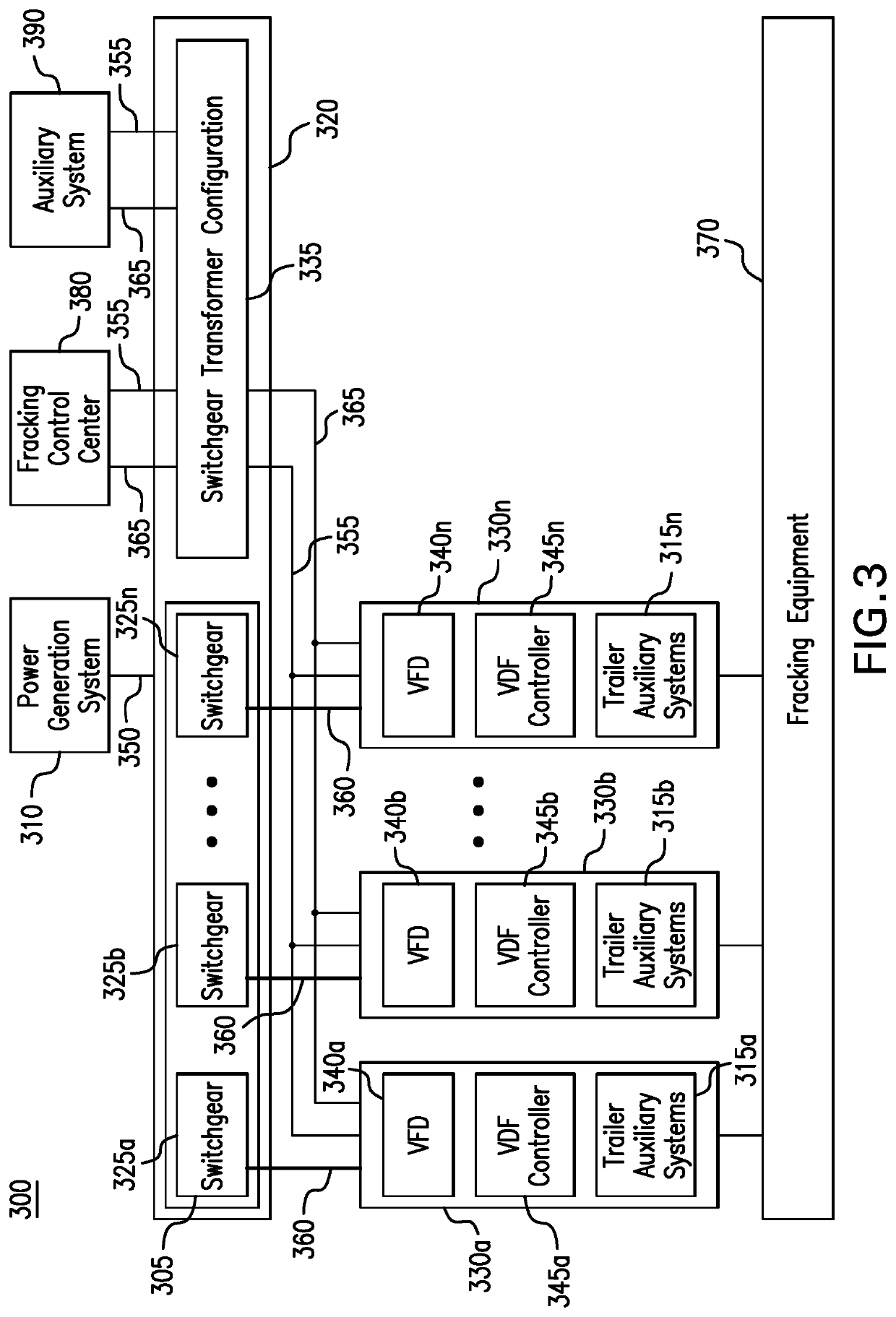

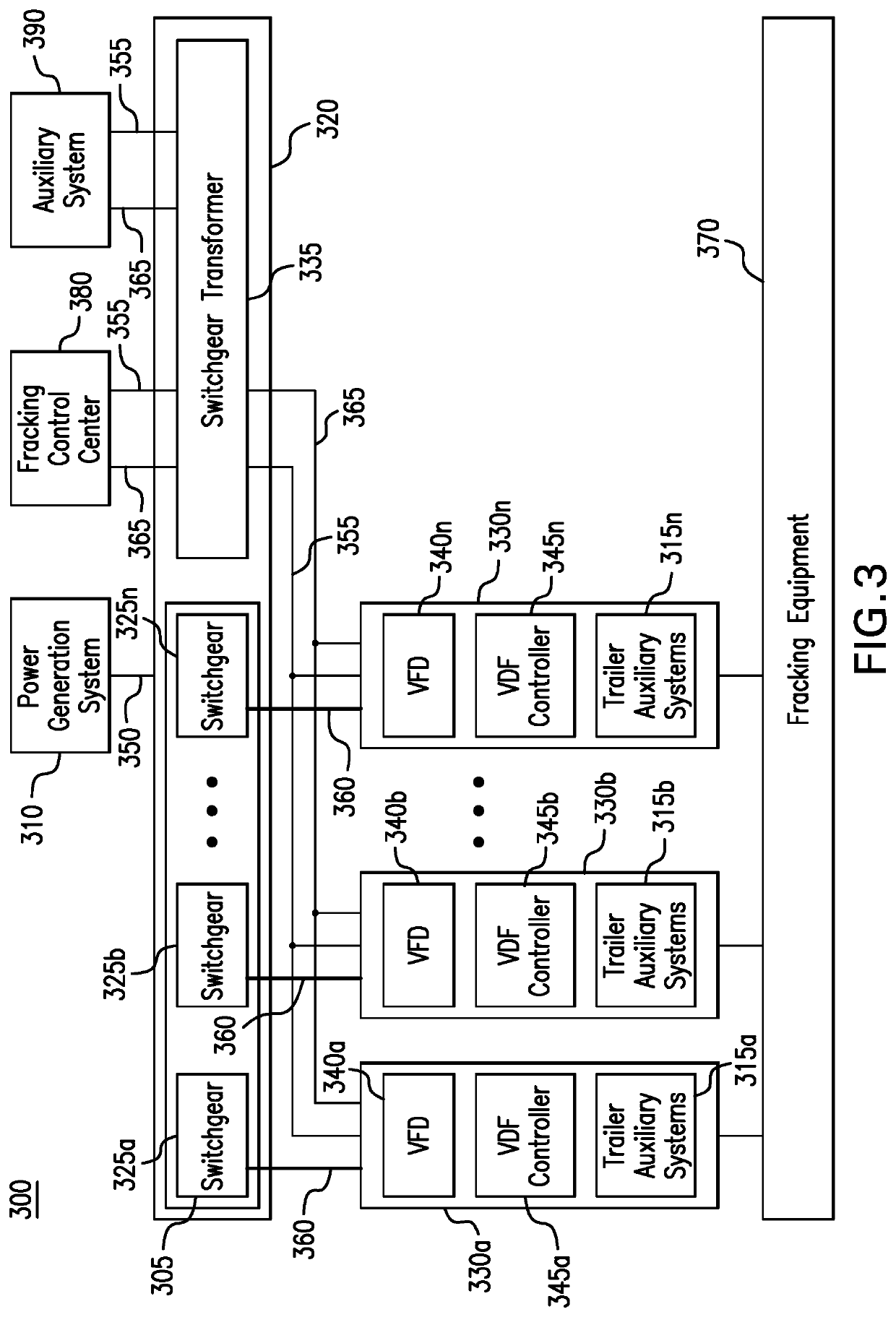

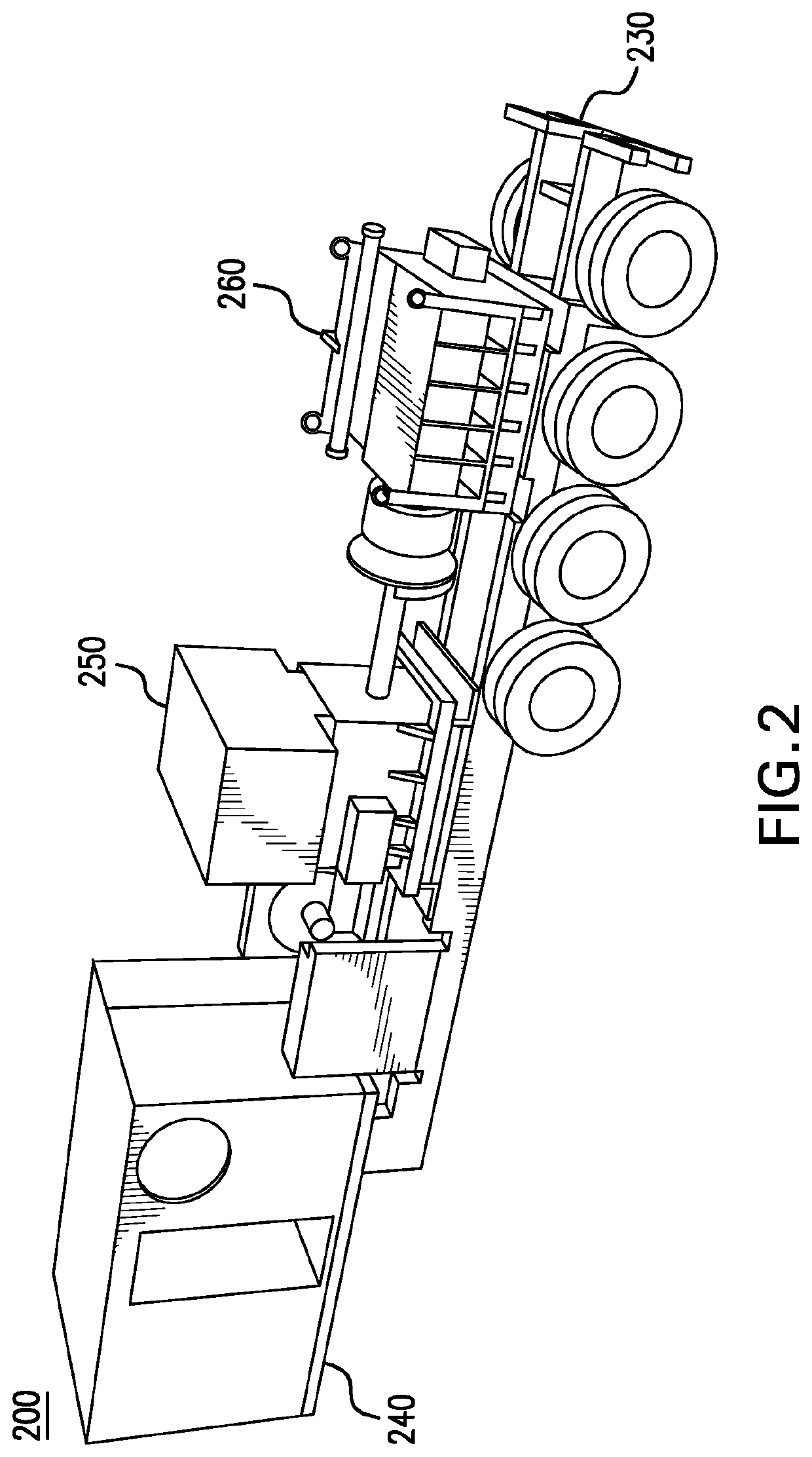

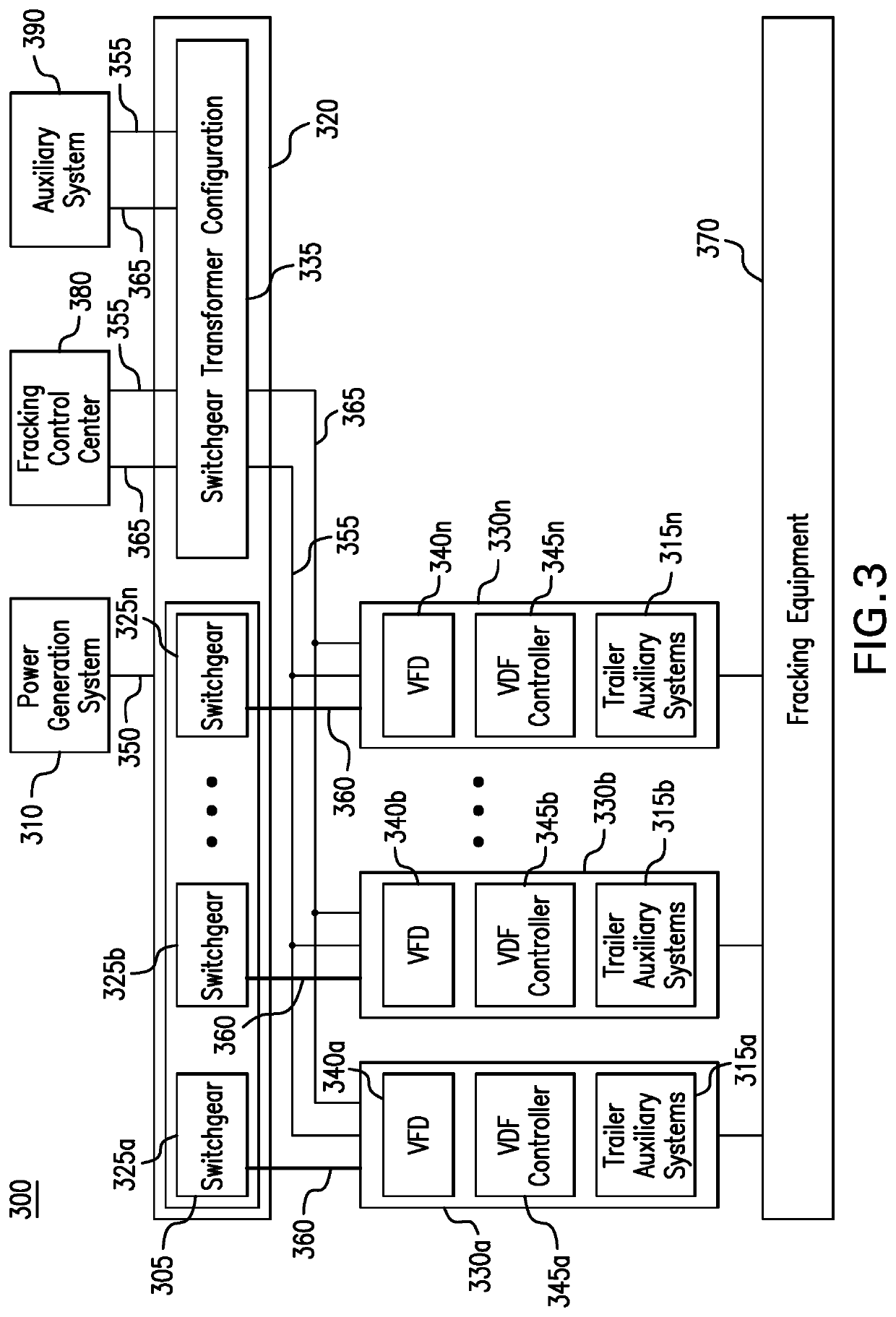

Power distribution trailer for an electric driven hydraulic fracking system

ActiveUS20200263527A1Non-enclosed substationsSubstation/switching arrangement detailsHydraulic pumpElectro hydraulic

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. A power distribution trailer distributes the electric power generated by the power generation system at the power generation voltage level to the single VFD and converts the electric power at a power generation voltage level to a VFD voltage level and controls the operation of the single shaft electric motor and the single hydraulic pump. The power distribution trailer converts the electric power generated by the power generation system at the power generation level to an auxiliary voltage level that is less than the power generation voltage level. The power distribution trailer distributes the electric power at the auxiliary voltage level to the single VFD that controls an operation of the of the auxiliary systems.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

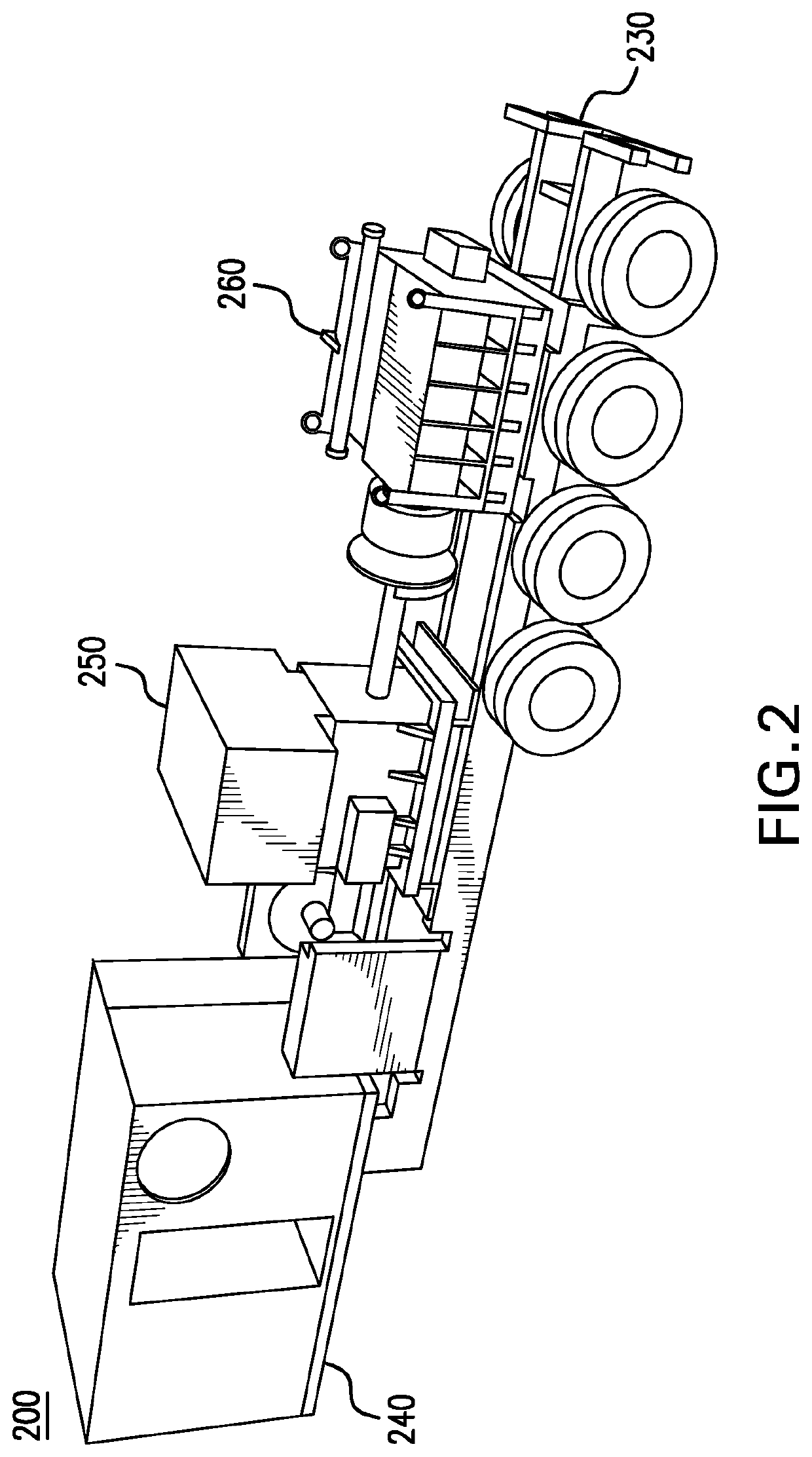

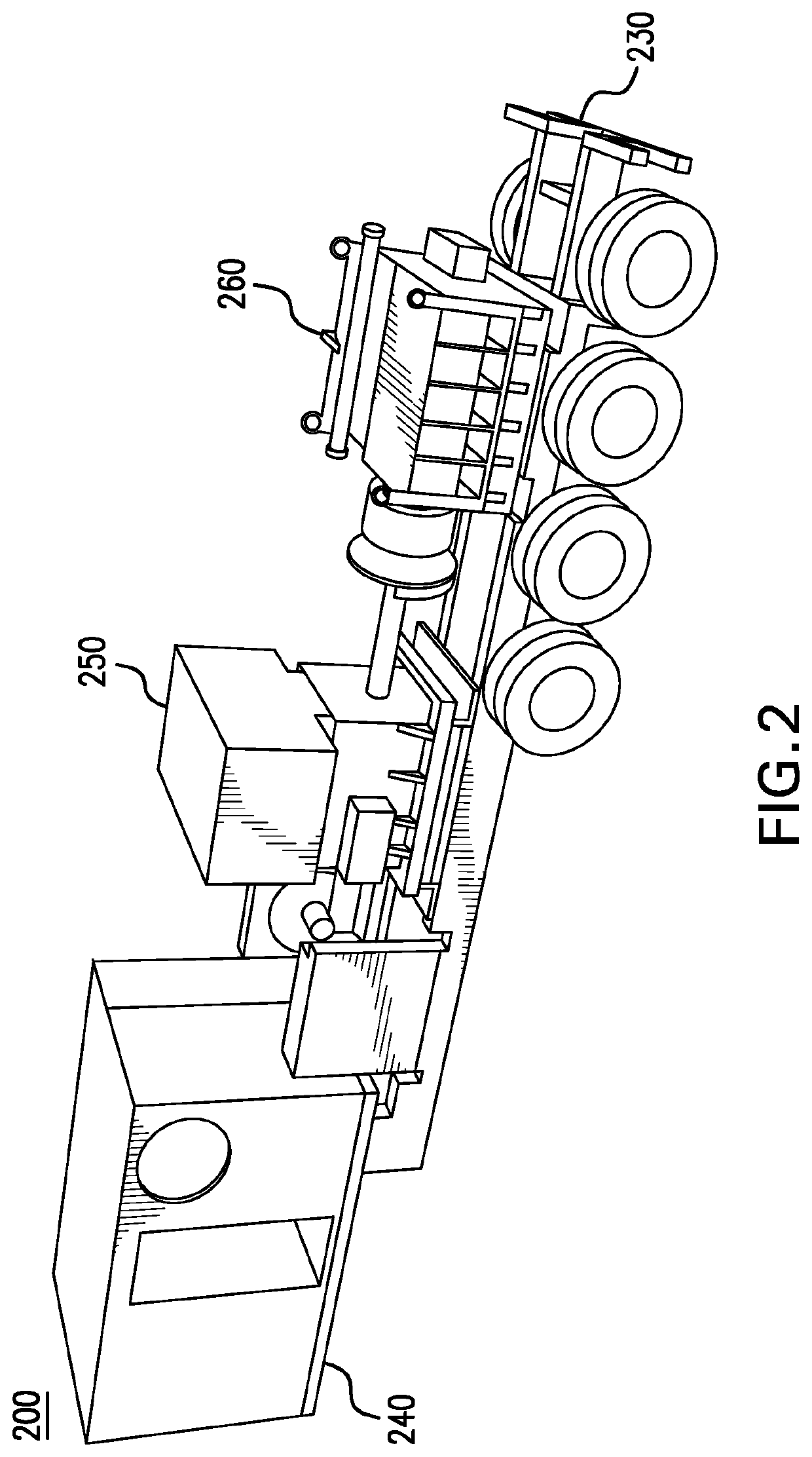

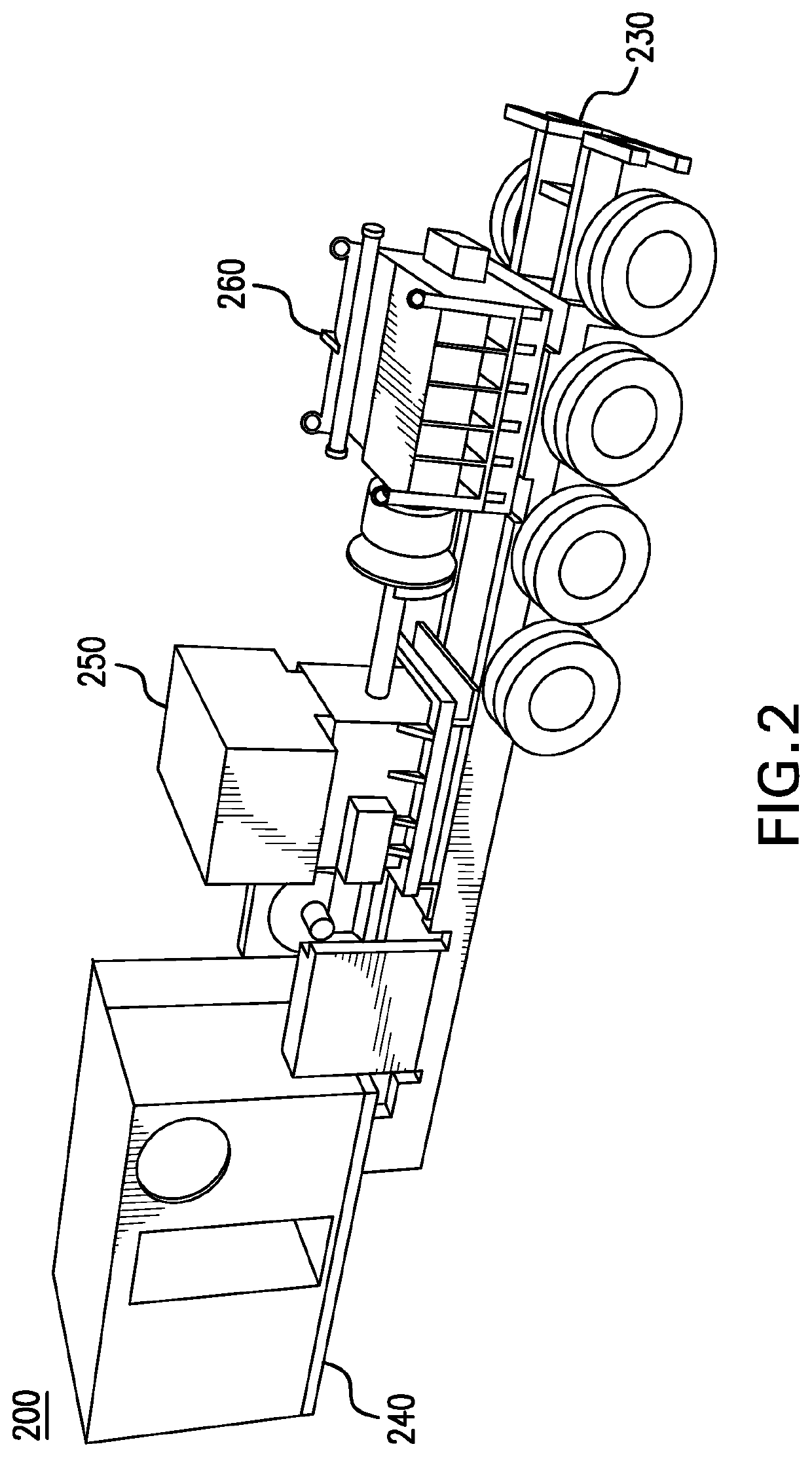

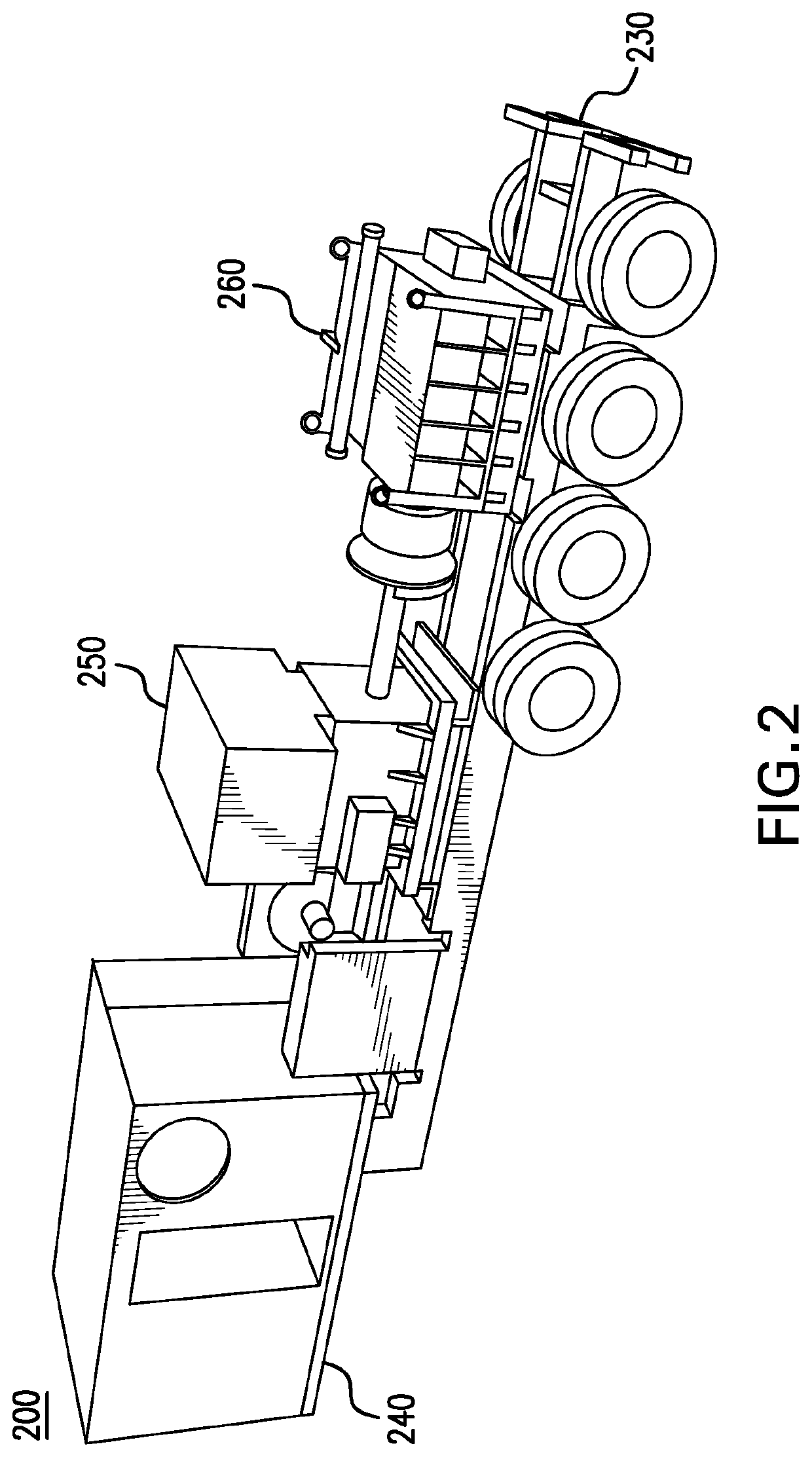

Electric driven hydraulic fracking system

ActiveUS10738580B1Non-enclosed substationsSubstation/switching arrangement detailsHydraulic pumpElectro hydraulic

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. The single VFD converts the electric power of at least 13.8 kV to a VFD rated voltage level of at least 4160V and drives the single shaft electric motor at the VFD voltage level of up to 4160V to control the operation of the single shaft electric motor and the single hydraulic pump. The single shaft electric motor drives the single hydraulic pump with the rotation at the rated RPM level of at least 750 RPM. The single hydraulic pump continuously pumps the fracking media into the well at the HP level of at least 5000 HP. The single hydraulic pump operates on a continuous duty cycle to continuously pump the fracking media at the HP level of at least 5000 HP.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

Electric driven hydraulic fracking system

Owner:HALLIBURTON ENERGY SERVICES INC

Variable frequency drive configuration for electric driven hydraulic fracking system

ActiveUS20200263498A1Non-enclosed substationsCharge equalisation circuitHydraulic pumpElectro hydraulic

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. A pump configuration includes a single VFD configuration, the single shaft electric motor, and the single shaft hydraulic pump mounted on the single pump trailer. The single VFD configuration converts the electric power at the power generation voltage level distributed from the power distribution trailer to a VFD voltage level and drives the single shaft electric motor to control the operation of the single shaft electric motor and the single hydraulic pump. The VFD voltage level is a voltage level that is required to drive the single shaft electric motor. The VFD configuration also controls operation of the auxiliary systems based on the electric power at the auxiliary voltage level.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

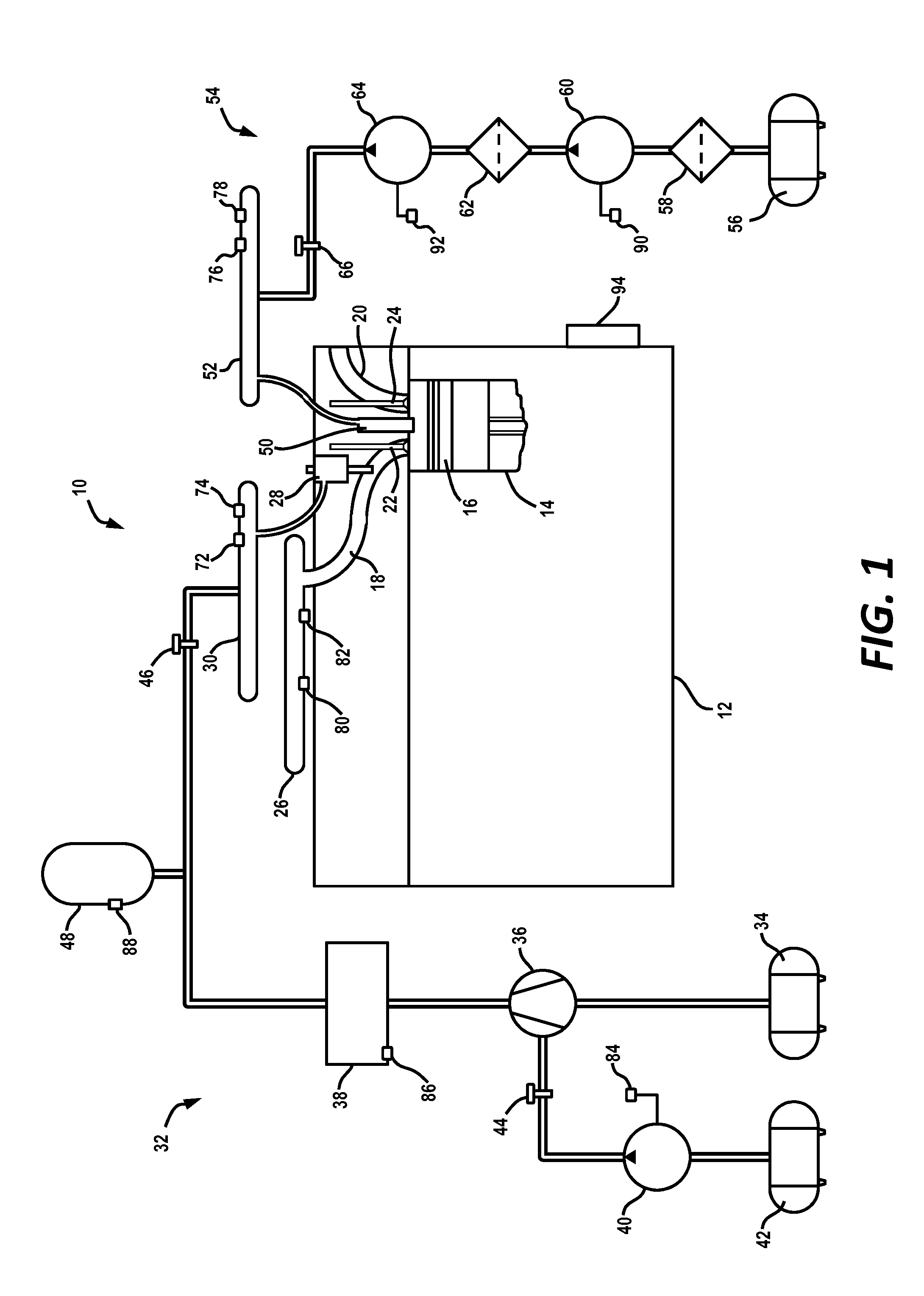

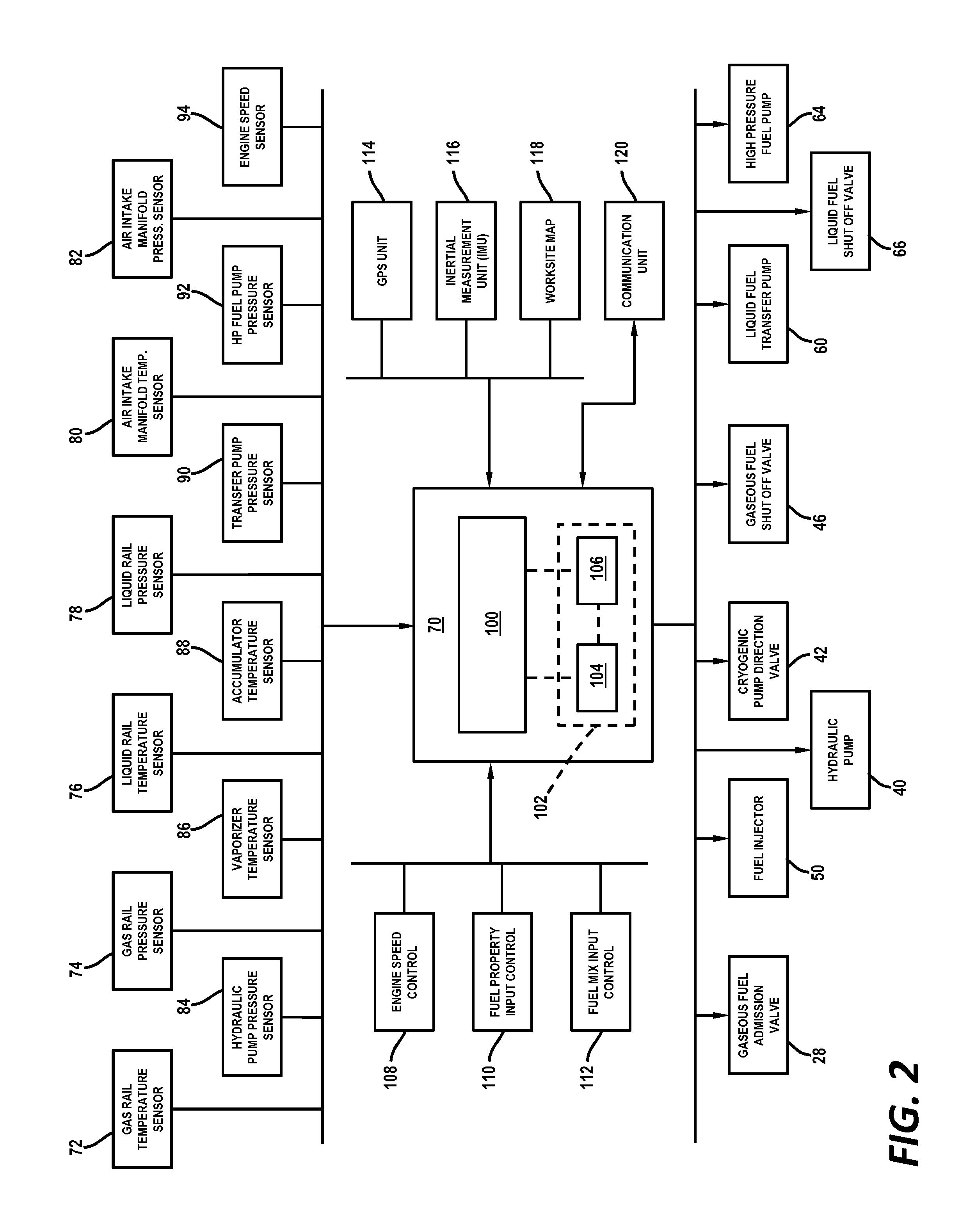

Hybrid Pump Control for Multi Fuel Engine System

ActiveUS20150226140A1High energyElectrical controlInternal combustion piston enginesHydraulic pumpElectro hydraulic

In an engine system of a machine having a multi fuel engine system, an energy accumulator is provide to accumulate and store energy when the engine system is in a low engine power usage or low engine load state, and to discharge energy from the energy accumulator when the engine system is in a high engine usage or high engine load state. The energy accumulator may be implemented, for example, in the form of a gaseous fuel accumulator that delivers gaseous fuel to the engine, a hydraulic fuel accumulator that provides pressurized fluid to power a fuel pump, or a battery pack that powers an electric hydraulic pump.

Owner:CATERPILLAR INC

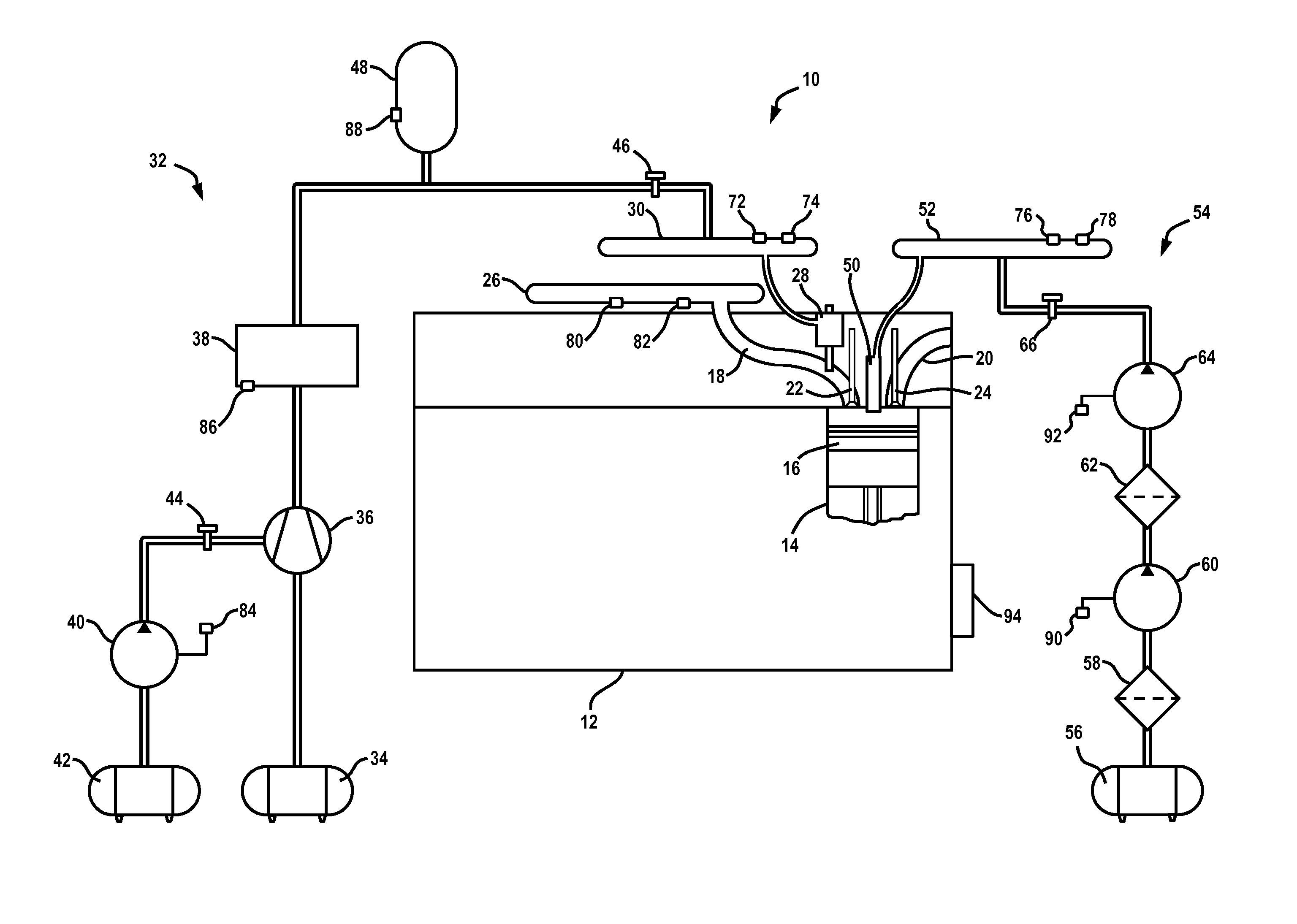

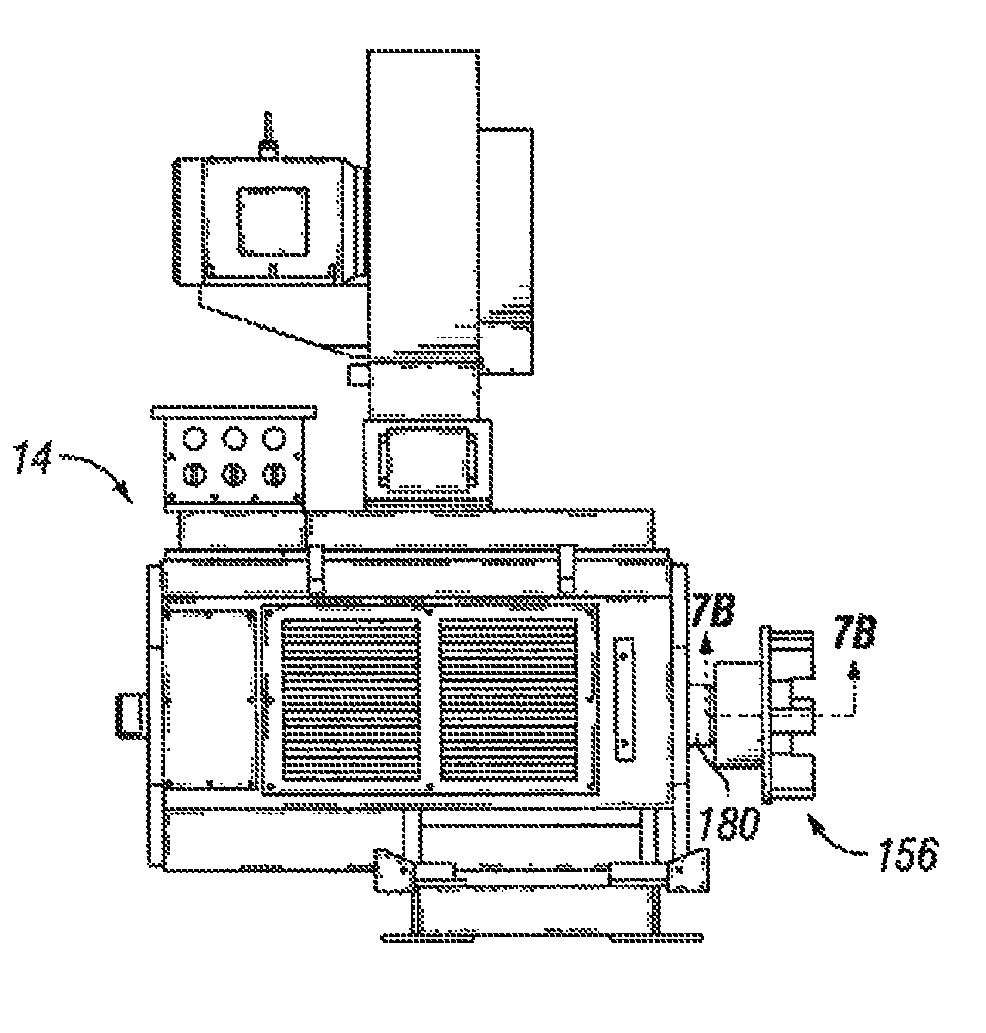

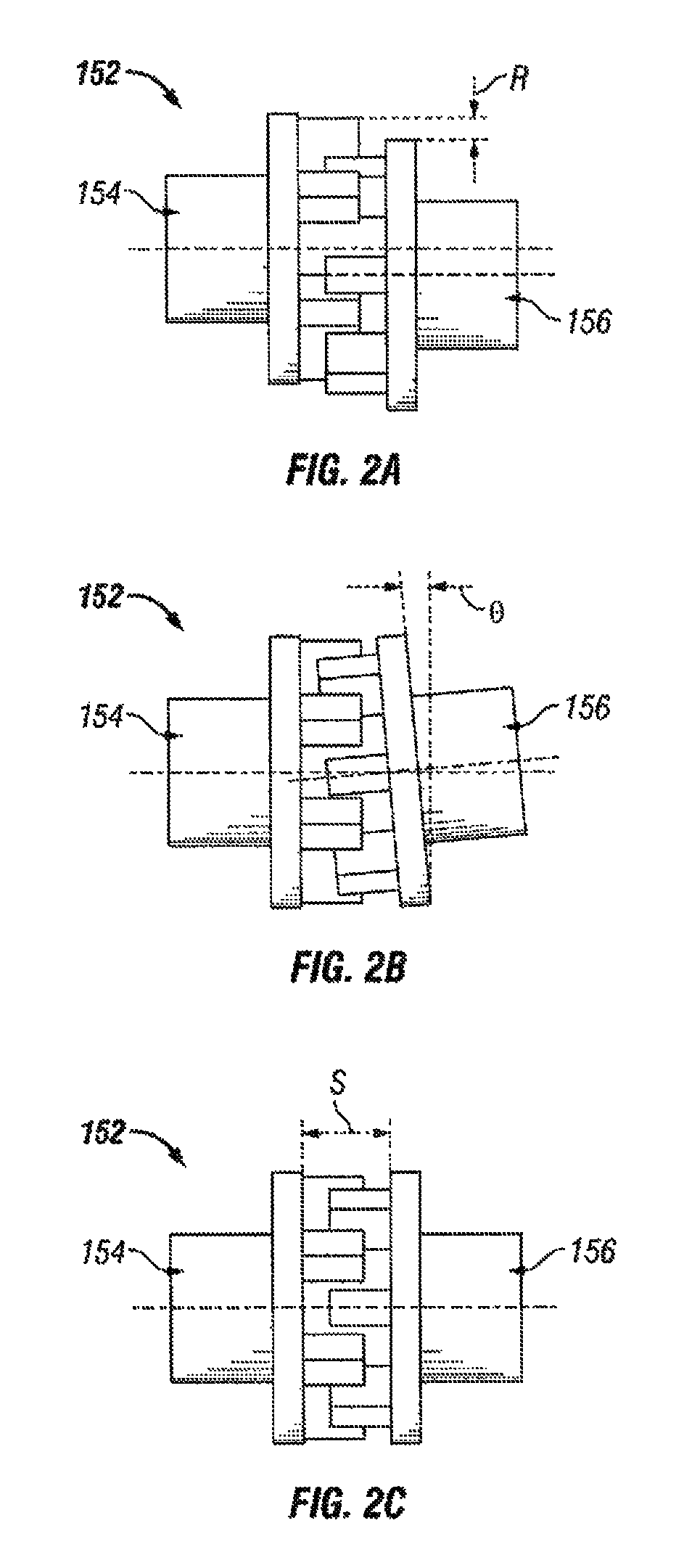

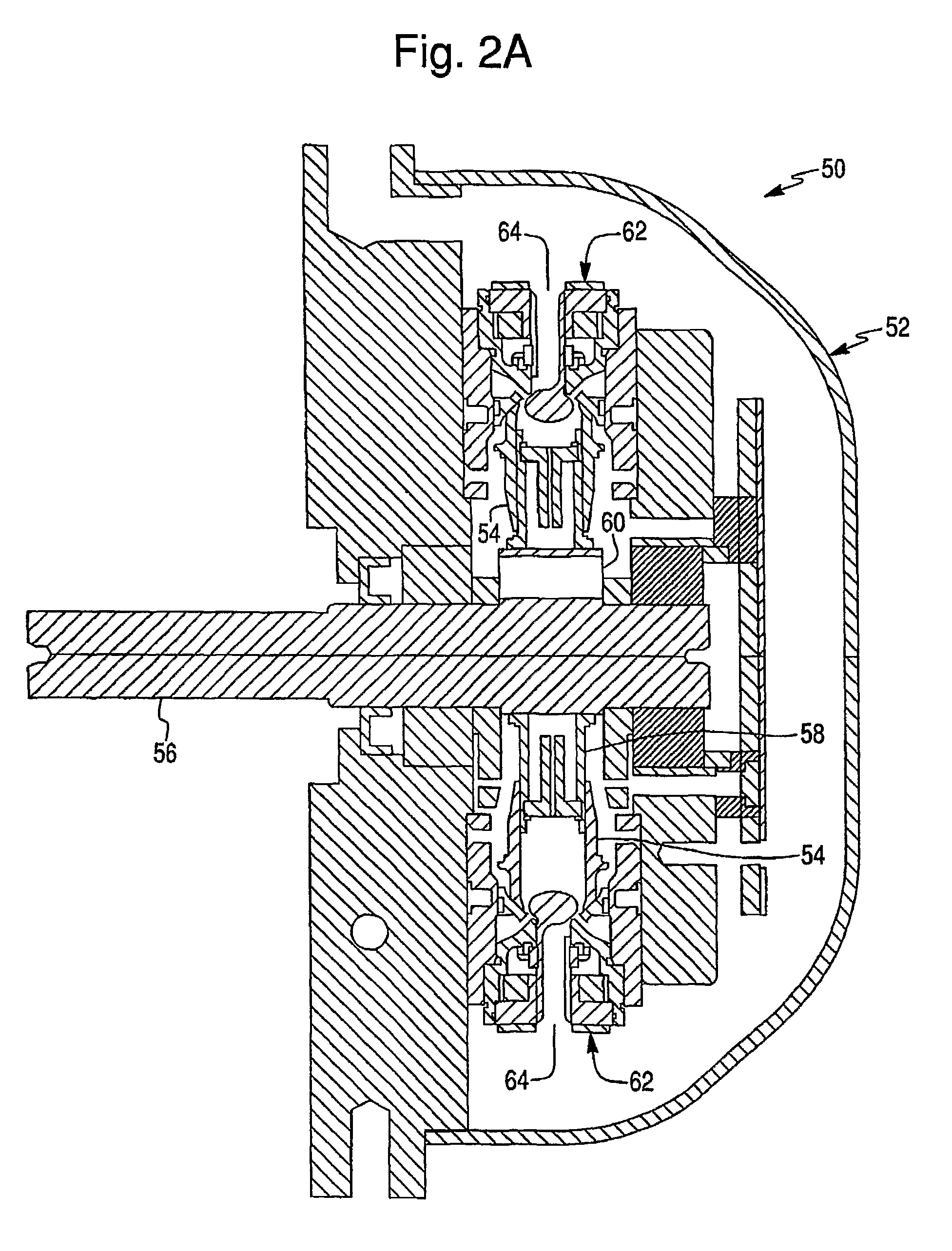

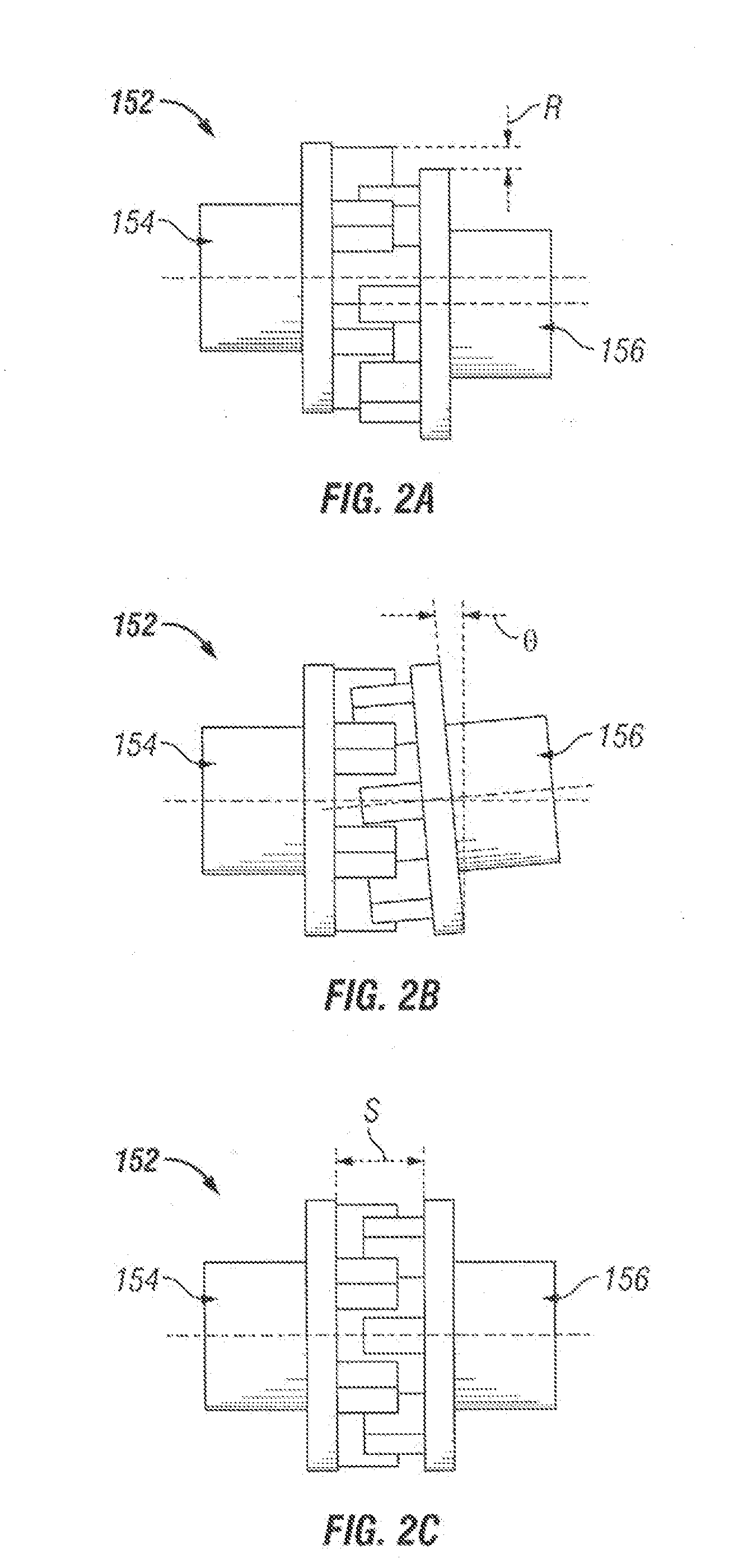

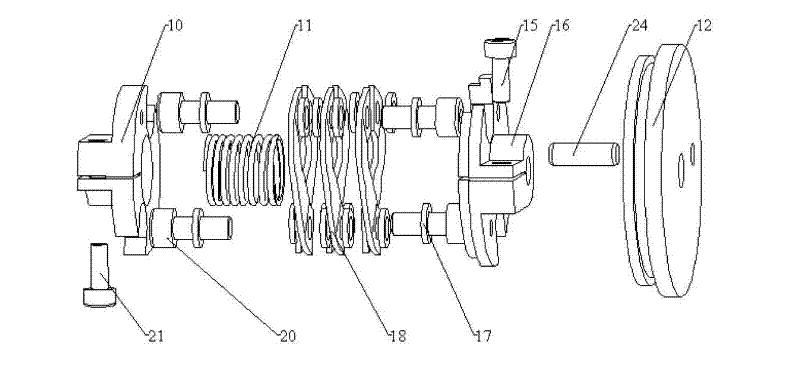

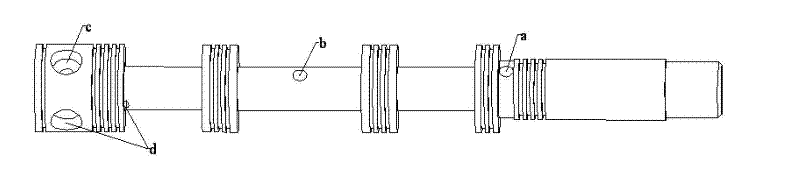

Torsional coupling for electric hydraulic fracturing fluid pumps

A system for hydraulically fracturing an underground formation in an oil or gas well, including a pump for pumping hydraulic fracturing fluid into the wellbore, the pump having a pump shaft, and an electric motor with a motor shaft mechanically attached to the pump to drive the pump. The system further includes a torsional coupling connecting the motor shaft to the pump shaft. The torsional coupling includes a motor component fixedly attached to the motor shaft and having motor coupling claws extending outwardly away from the motor shaft, and a pump component fixedly attached to the pump shaft of the pump and having pump coupling claws extending outwardly away from the pump shaft. The motor coupling claws engage with the pump coupling claws so that when the motor shaft and motor component rotate, such rotation causes the pump component and the pump shaft to rotate, thereby driving the pump.

Owner:US WELL SERVICS LLC

Parameter monitoring and control for an electric driven hydraulic fracking system

An electric driven hydraulic fracking system is disclosed. A pump configuration includes the single VFD, the single shaft electric motor, and the single hydraulic pump mounted on the single pump trailer. A controller associated with the single VFD and is mounted on the single pump trailer. The controller monitors operation parameters associated with an operation of the electric driven hydraulic fracking system as each component of the electric driven hydraulic fracking system operates to determine whether the operation parameters deviate beyond a corresponding operation parameter threshold. Each of the operation parameters provides an indicator as to an operation status of a corresponding component of the electric driven hydraulic fracking system. The controller initiates corrected actions when each operation parameter deviates beyond the corresponding operation threshold. Initiating the corrected actions when each operation parameter deviates beyond the corresponding operation threshold maintains the operation of the electric driven hydraulic fracking system.

Owner:HALLIBURTON ENERGY SERVICES INC

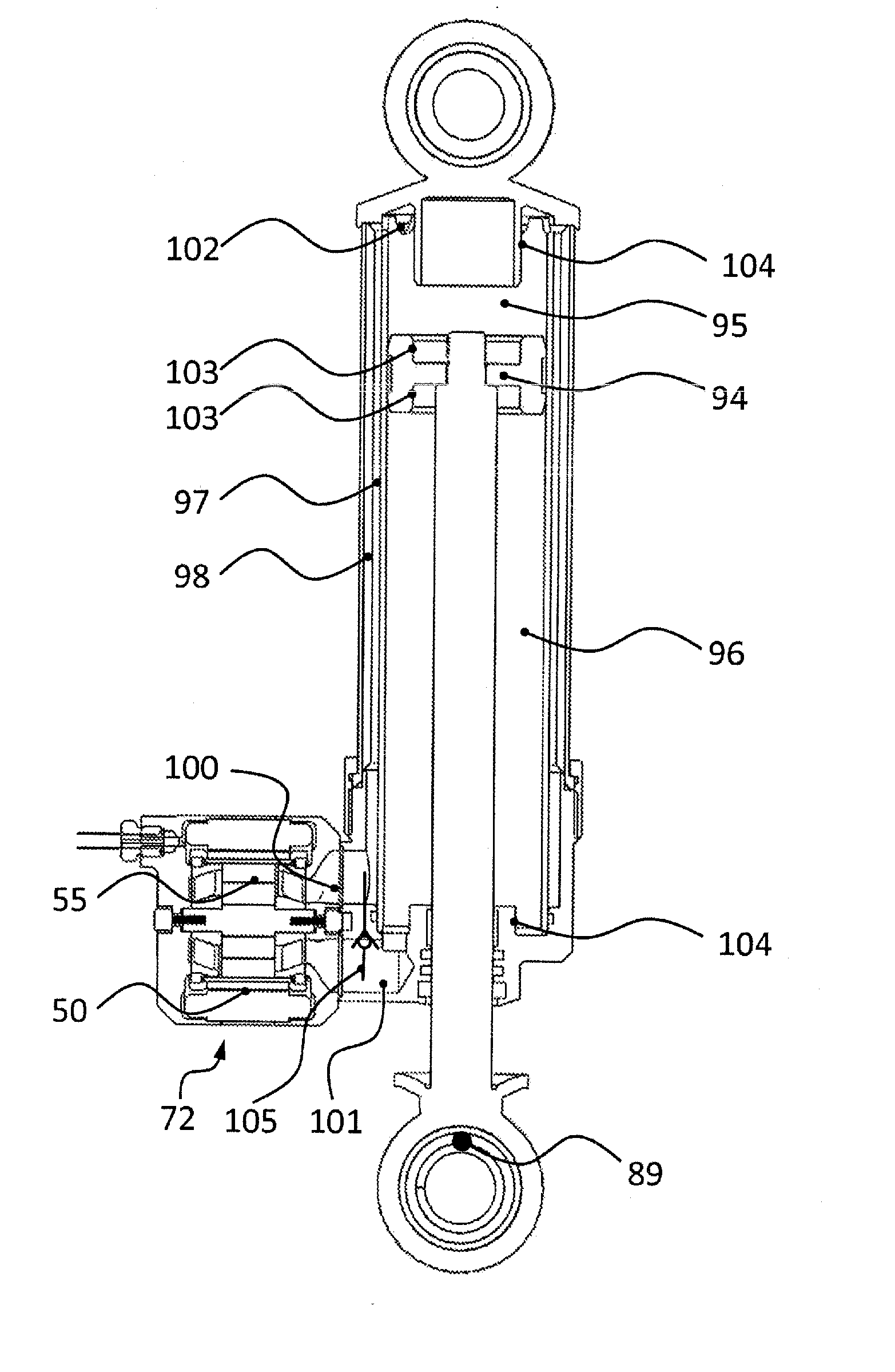

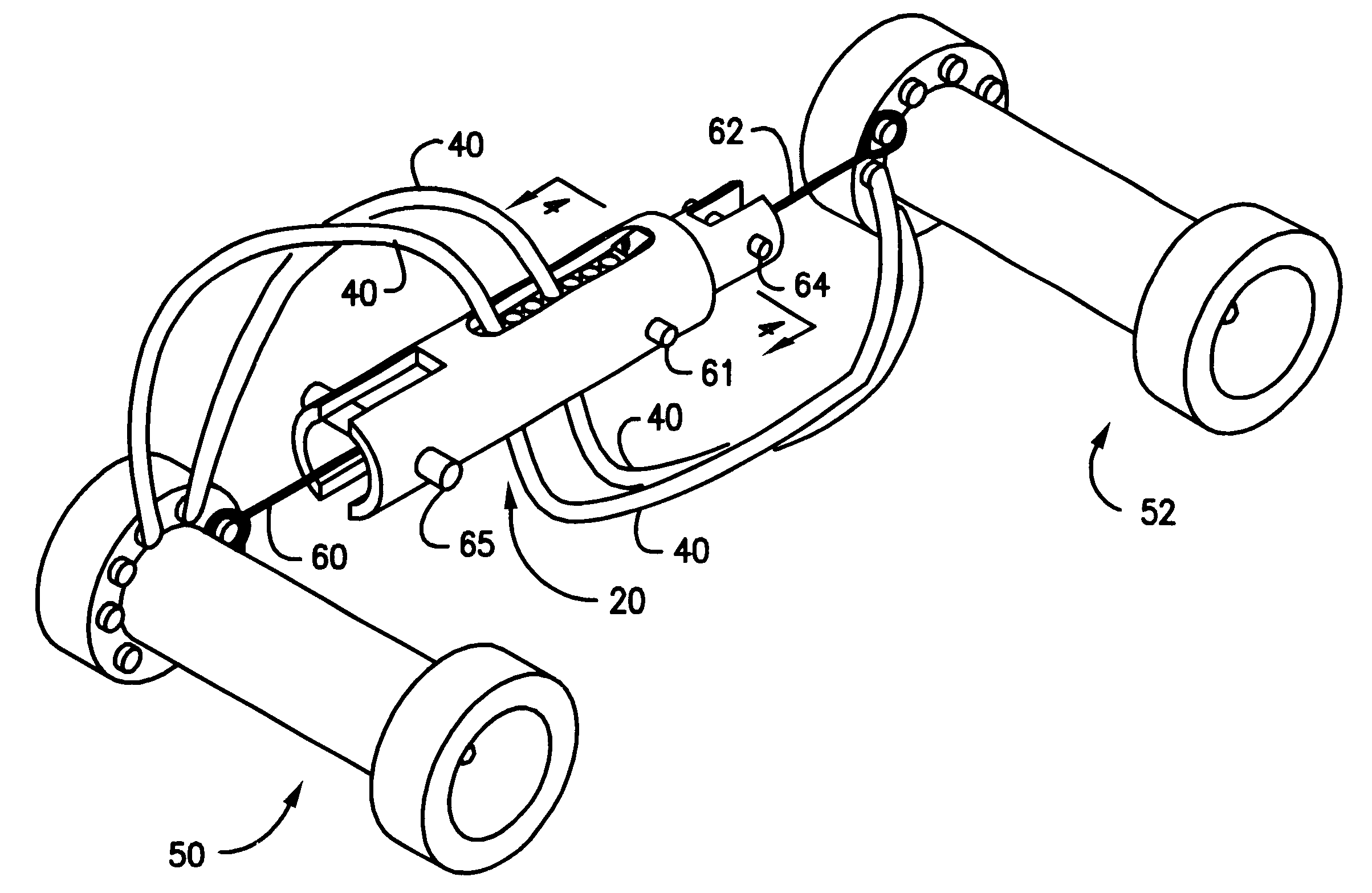

Integrated energy generating damper

A linear energy harvesting device that includes a housing and a piston that moves at least partially through the housing when it is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor drives an electric generator that produces electricity. Both the motor and generator are central to the device housing. Exemplary configurations are disclosed such as monotube, twin-tube, tri-tube and rotary based designs that each incorporates an integrated energy harvesting apparatus. By varying the electrical characteristics on an internal generator, the kinematic characteristics of to the energy harvesting apparatus can be dynamically altered. In another mode, the apparatus can be used as an actuator to create linear movement. Applications include vehicle suspension systems (to act as the primary damper component), railcar bogie dampers, or industrial applications such as machinery dampers and wave energy harvesters, and electro-hydraulic actuators.

Owner:CLEARMOTION INC

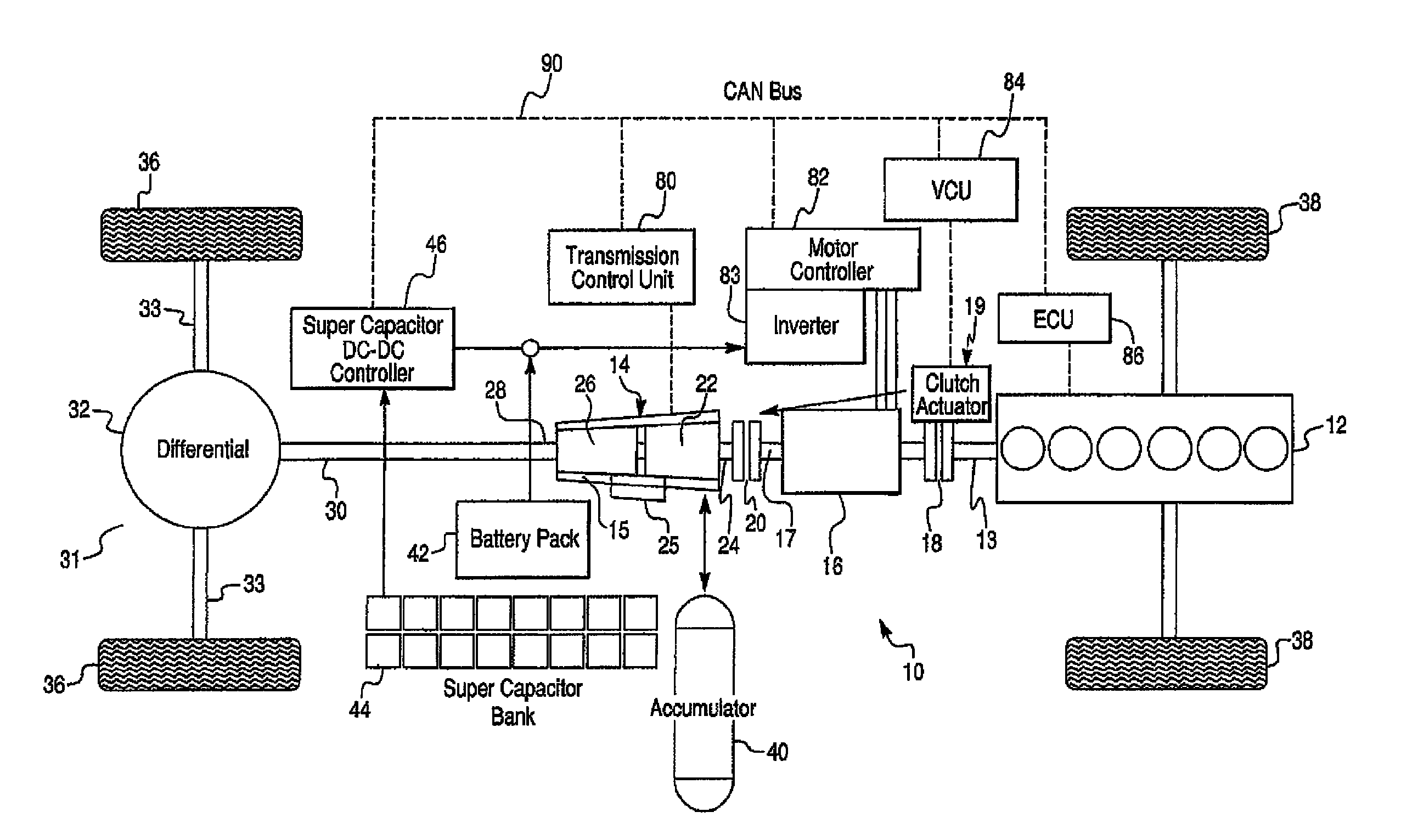

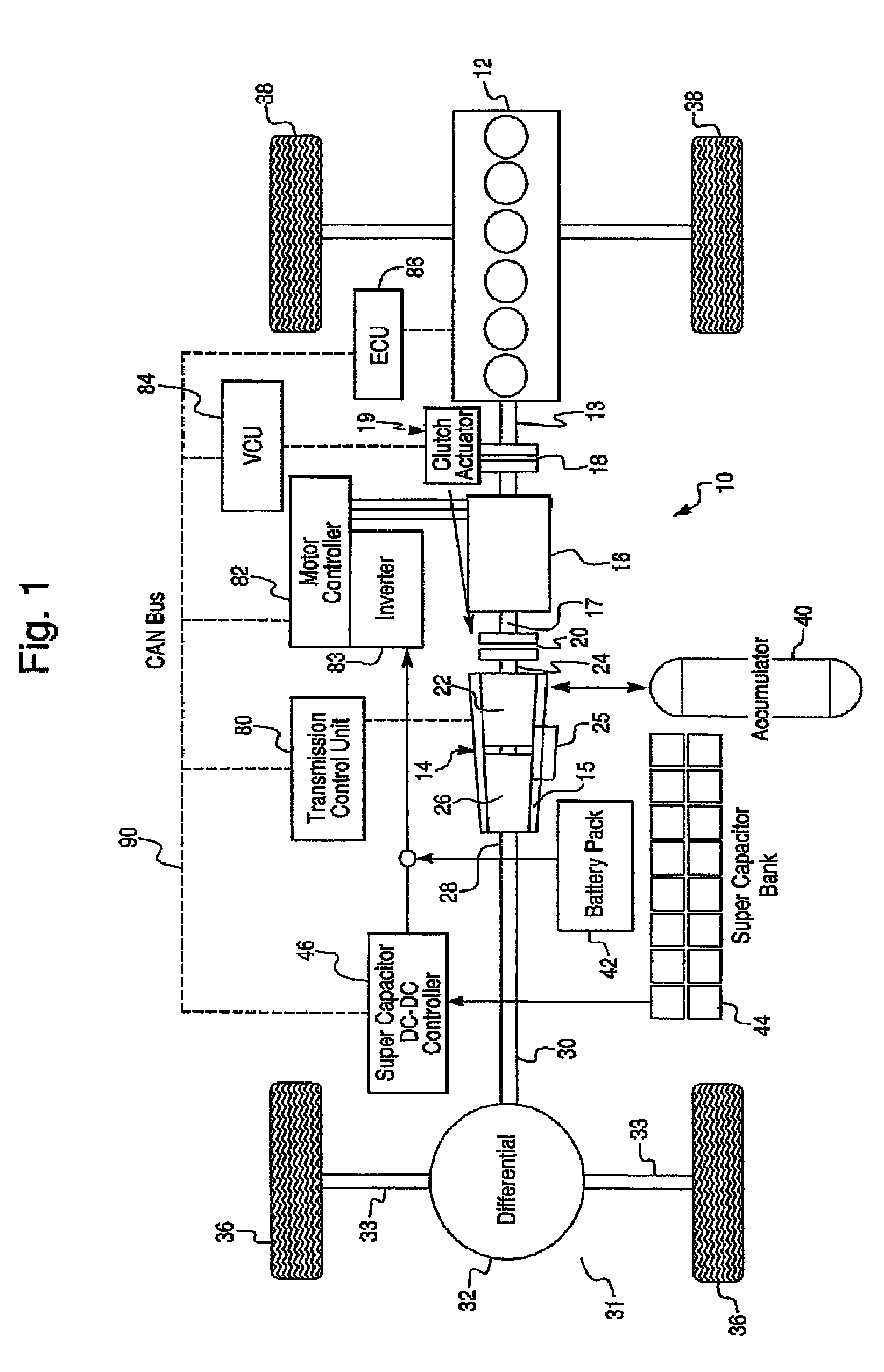

Hydro-electric hybrid drive system for motor vehicle

InactiveUS7841432B2Equivalent performance levelsStarters with fluid-driven auxillary enginesPlural diverse prime-mover propulsion mountingDrive wheelHydraulic pump

A hybrid electro-hydraulic drive system is provided for a vehicle and comprises a hydraulic transmission including a first hydraulic machine and at least one second hydraulic machine drivingly connected to drive wheels of the motor vehicle for driving thereof, an electric motor / generator operatively connected to the first hydraulic machine, and at least one energy storage device operable to store and release a hydraulic fluid energy or an electrical energy. The second hydraulic machine is a reversible hydraulic pump / motor unit capable to function both as a hydraulic pump and a hydraulic motor. The energy storage device is operatively connected to either the hydraulic transmission or the electric motor / generator. In a retarding mode the hydraulic transmission and / or the electric motor / generator retard the vehicle, while in a driving mode they supply a supplementary power to the drive wheels to assist propulsion of the vehicle.

Owner:BOSCH REXROTH AG

Torsional coupling for electric hydraulic fracturing fluid pumps

A system for hydraulically fracturing an underground formation in an oil or gas well, including a pump for pumping hydraulic fracturing fluid into the wellbore, the pump having a pump shaft, and an electric motor with a motor shaft mechanically attached to the pump to drive the pump. The system further includes a torsional coupling connecting the motor shaft to the pump shaft. The torsional coupling includes a motor component fixedly attached to the motor shaft and having motor coupling claws extending outwardly away from the motor shaft, and a pump component fixedly attached to the pump shaft of the pump and having pump coupling claws extending outwardly away from the pump shaft. The motor coupling claws engage with the pump coupling claws so that when the motor shaft and motor component rotate, such rotation causes the pump component and the pump shaft to rotate, thereby driving the pump.

Owner:US WELL SERVICS LLC

Multiplexed pressure switch system for an electrically variable hybrid transmission

Owner:GM GLOBAL TECH OPERATIONS LLC

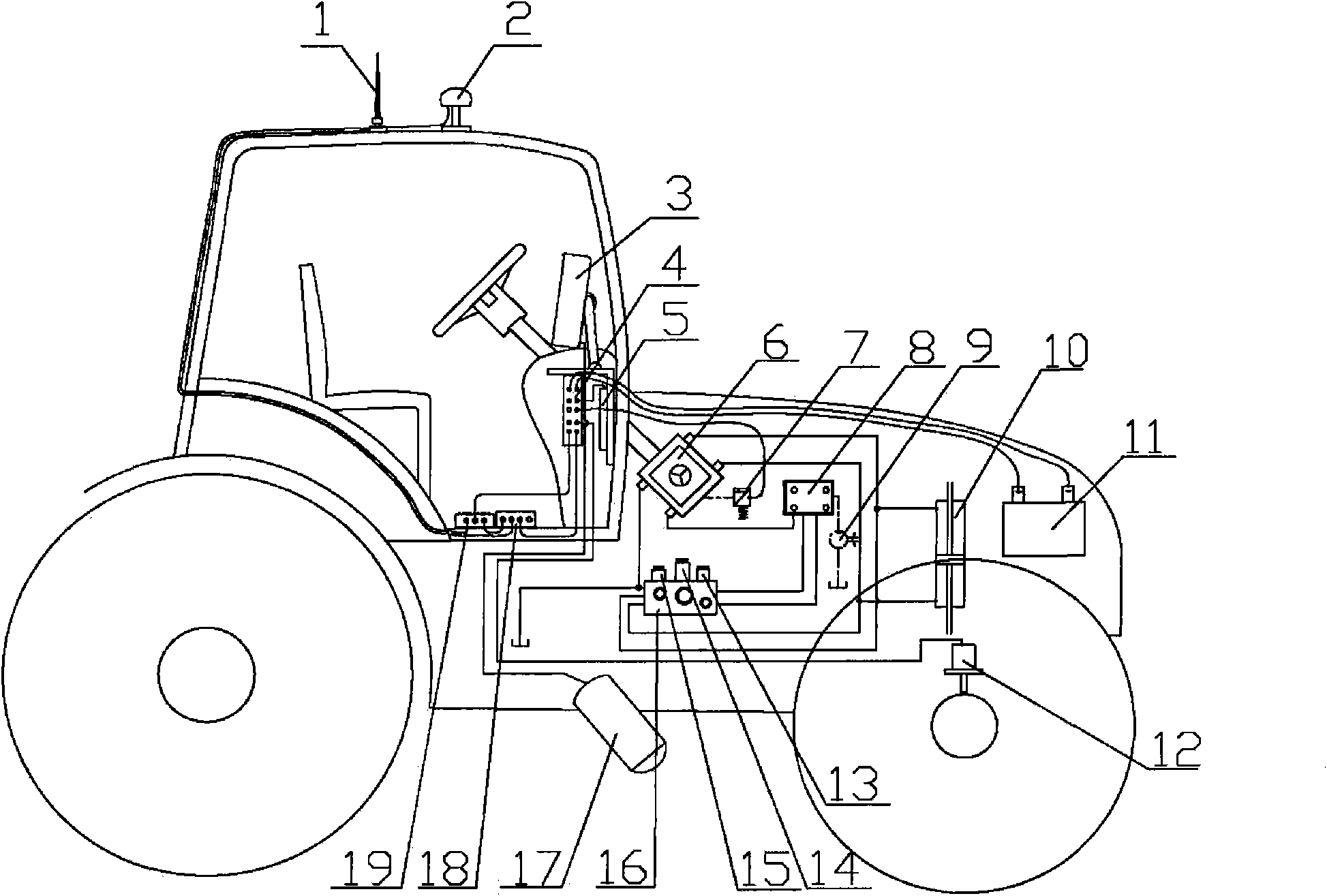

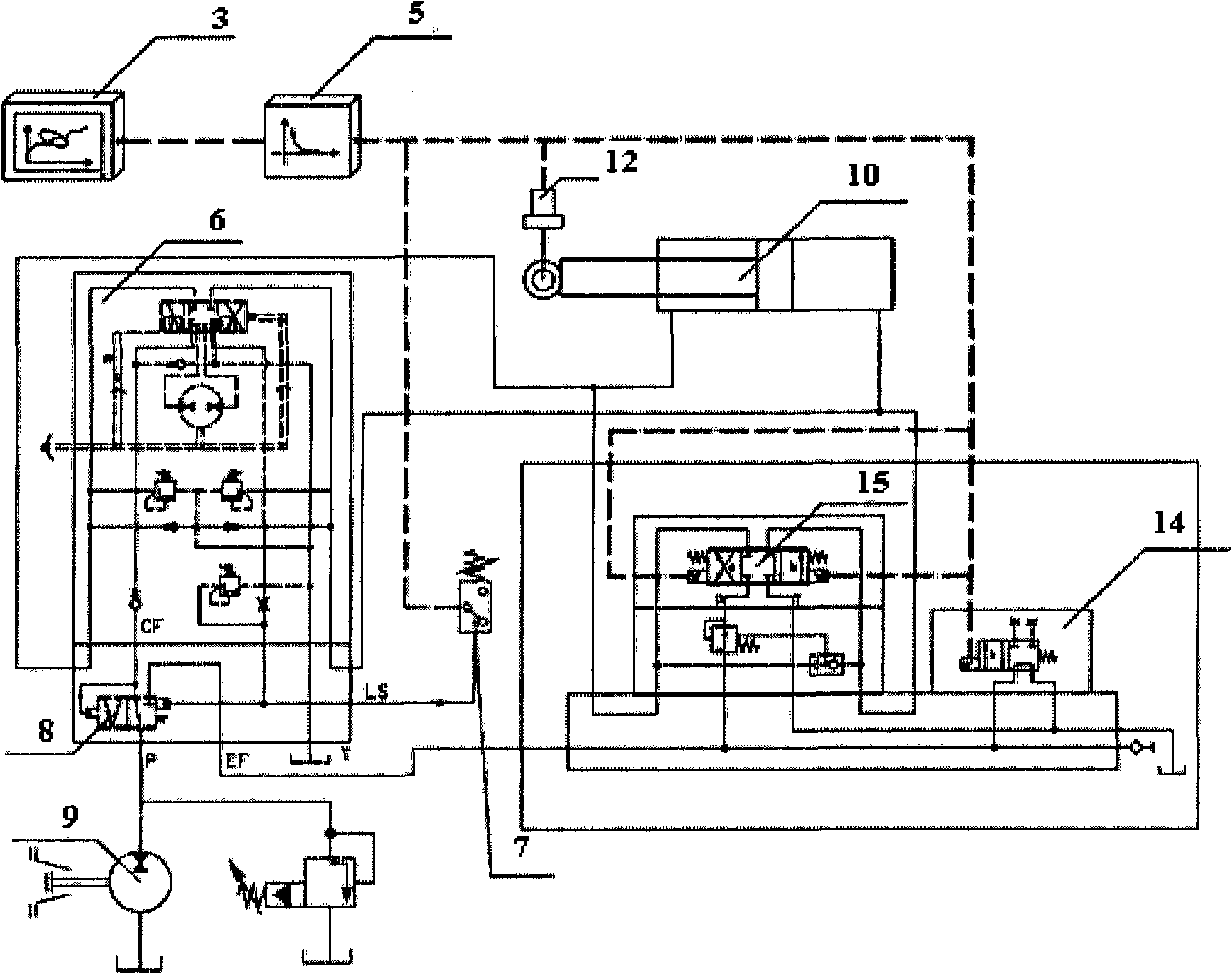

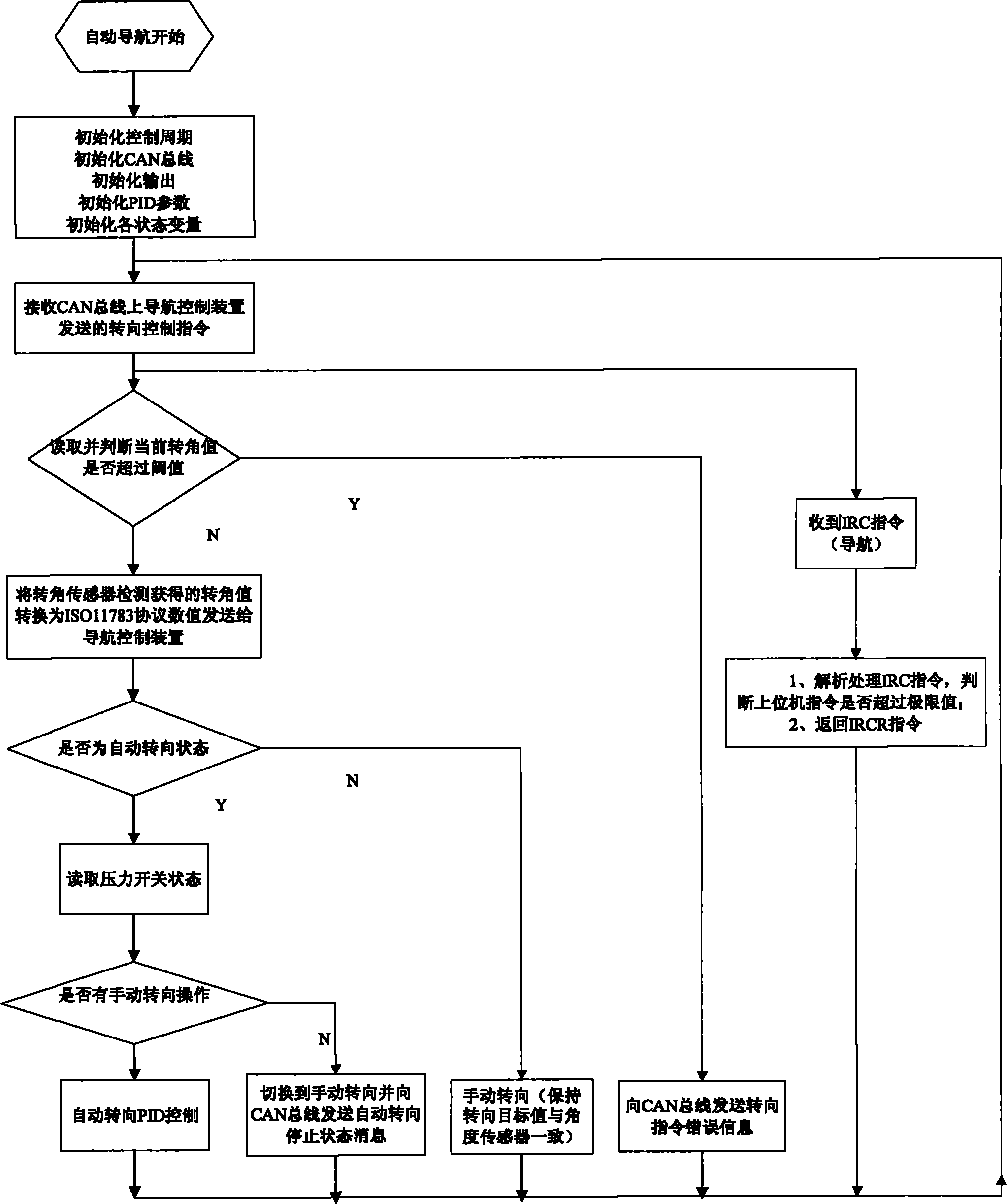

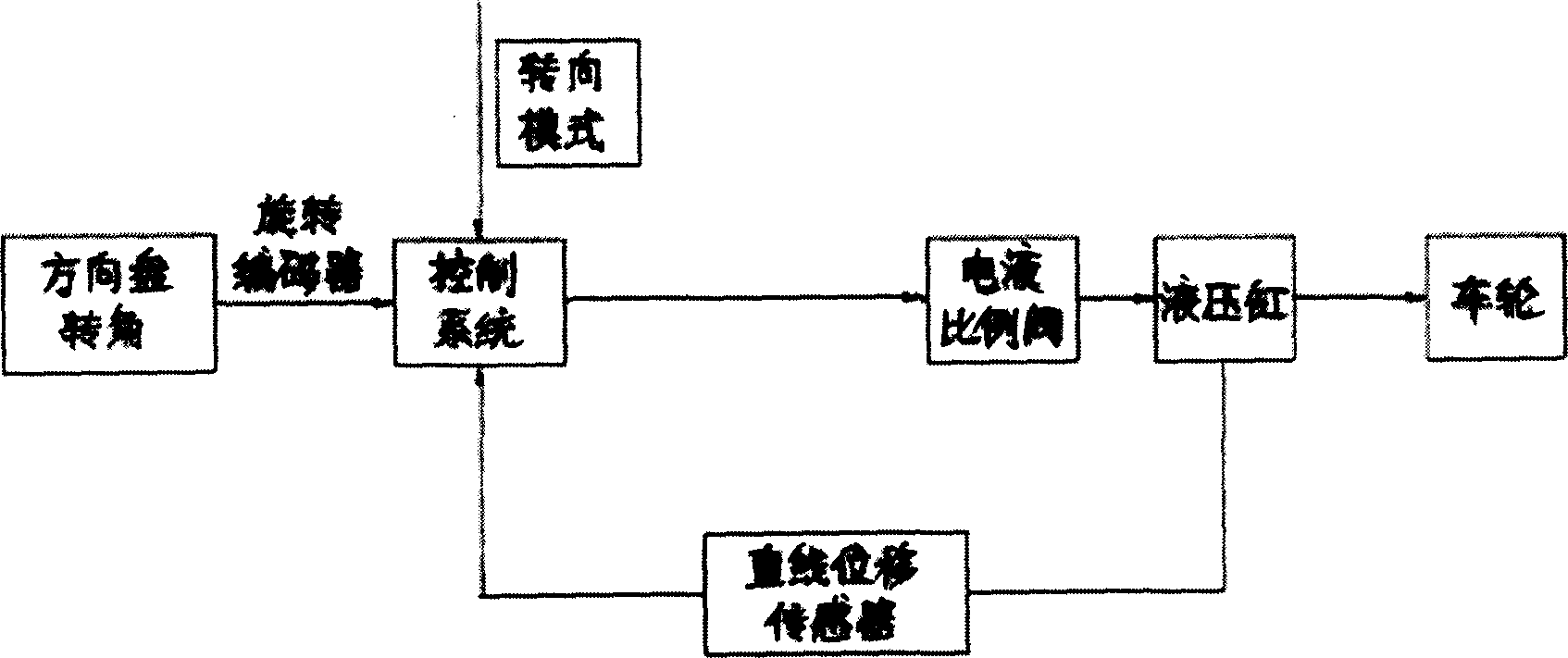

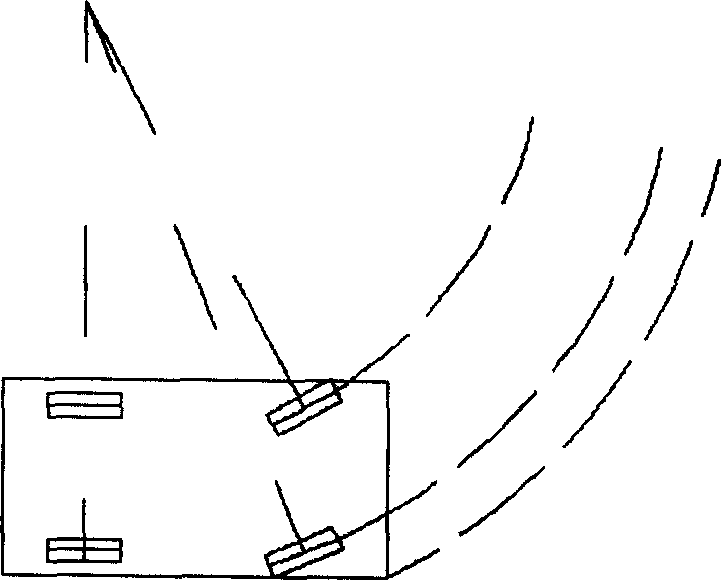

Tractor automatic navigation control system and method thereof

ActiveCN101833334AReal-time communicationDigital control possiblePosition/course control in two dimensionsControl signalSteering control

The invention provides a tractor automatic navigation control system. The system comprises a navigation control device, a steering control unit and an electro-hydraulic proportion steering executing device, wherein the navigation control device receives GPS positioning data in real time, calculates a lateral deviation between a current tractor position and an operation navigation target, calculates a target steering angle of a steering wheel in a current control period according to the lateral deviation and a tractor running speed value measured in real time, converts the target steering angle into a steering control command and then sends the steering control command to the steering control unit; the steering control unit judges whether a steering angle measured value of the steering wheel of the tractor is less than a preset limit value; if the steering angle measured value is less than the preset limit value, the steering control unit compares the target steering angle with the measured value, calculates a PWM duty cycle according to a steering angle difference value and outputs a control signal for driving the electro-hydraulic proportion steering executing device; and the electro-hydraulic proportion steering executing device responds to the PWM control signal and controls the flowing direction and the flowing speed of oil of a tractor steering system by the opening of a valve core of an electro-hydraulic proportion direction valve to make a piston of a steering hydraulic cylinder extend out or retract to deflect the steering wheel to the target steering angle.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

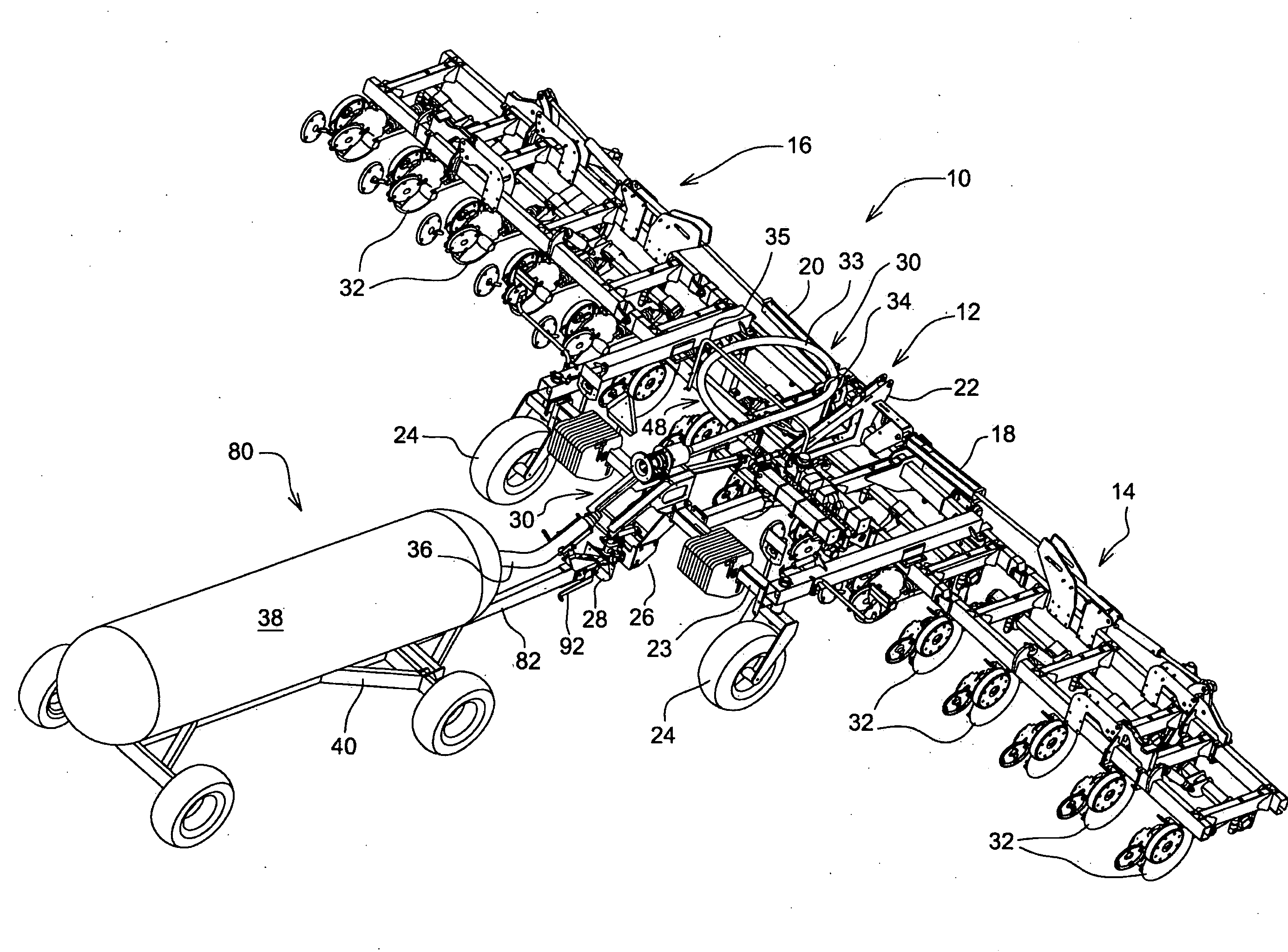

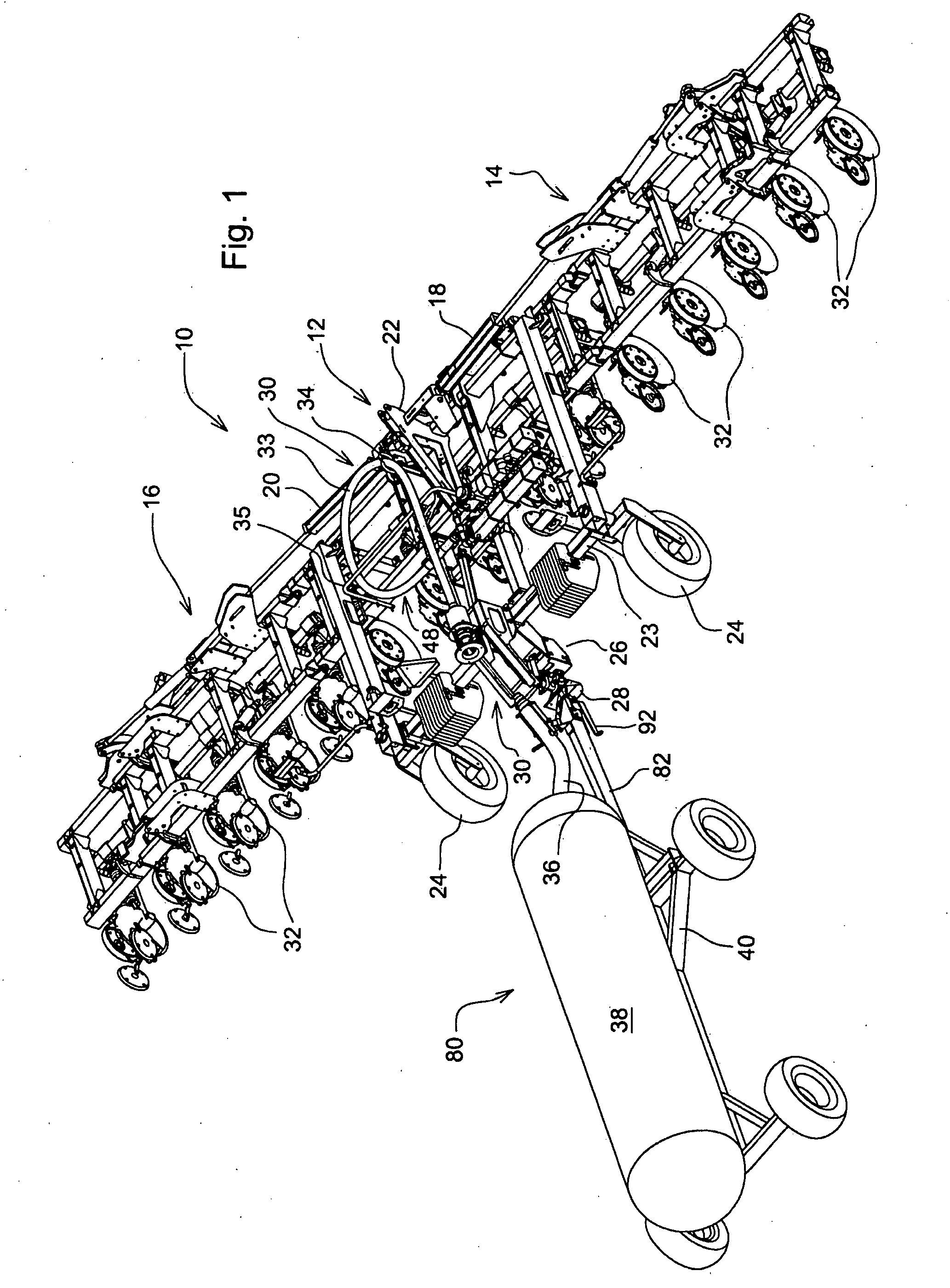

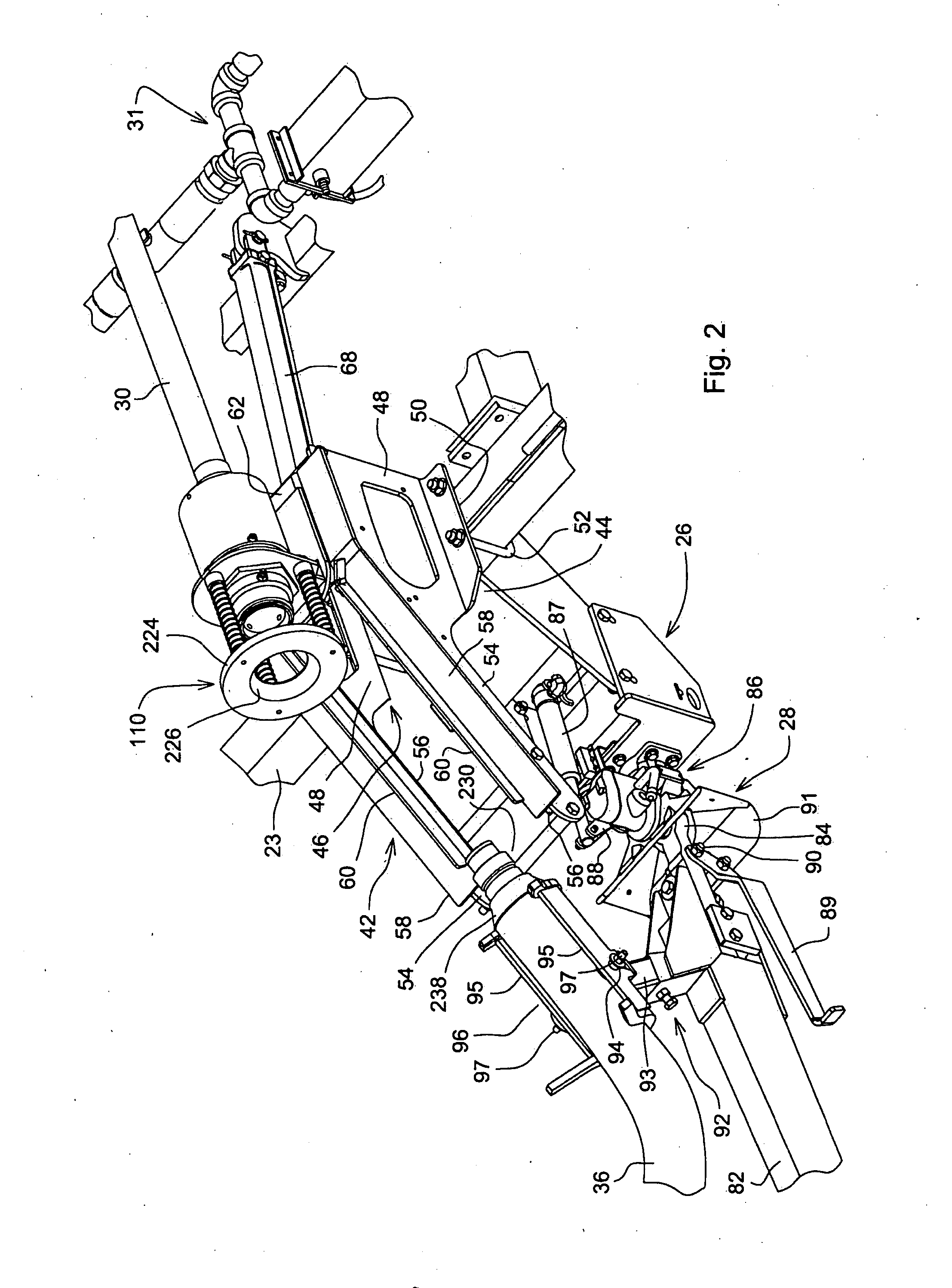

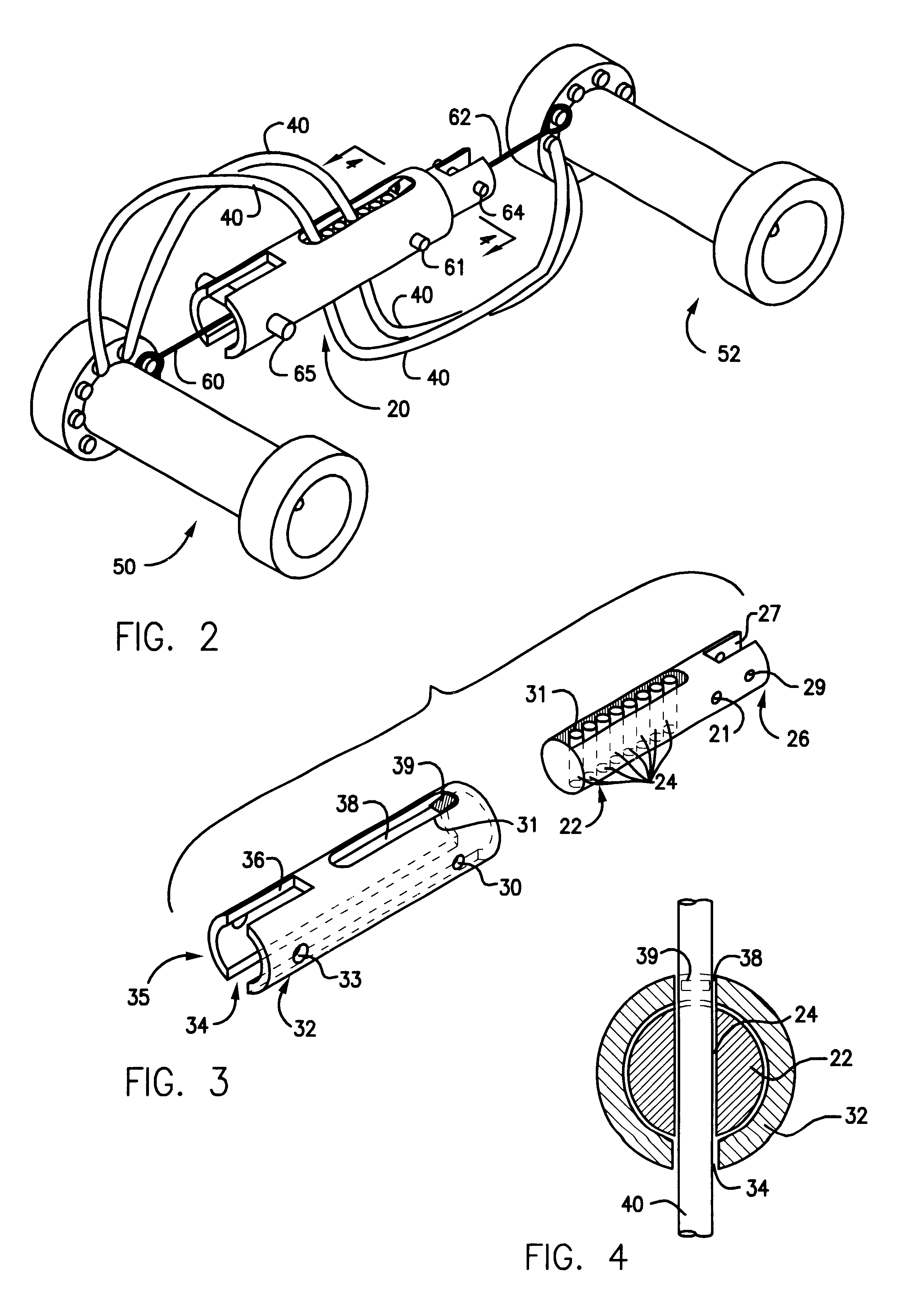

Hitch and coupling arrangement for automatically effecting towing hitch and fluid quick-coupler connections between a nurse tank wagon and an nh3 applicator implement

ActiveUS20100019471A1Shorten the timeMinimizing exposure of operatorAgricultural machinesWatering devicesRelay logicFully coupled

An NH3 applicator implement is equipped with a hitch arrangement for automatically effecting a connection with a tongue of an NH3 nurse tank wagon. A quick-connect coupler assembly is provided for connecting the transfer hose of the nurse tank wagon to the supply hose of the implement. The quick-connect coupler assembly includes a first coupler section mounted to the applicator implement for powered, guided movement into engagement with a second coupler section mounted to the tongue of the nurse tank wagon. An electro-hydraulic control system including relay logic is used to first lock the fully coupled coupler sections together and then to engage the flow of NH3 by remote actuation of a main on / off valve located at the nurse tank.

Owner:DEERE & CO +1

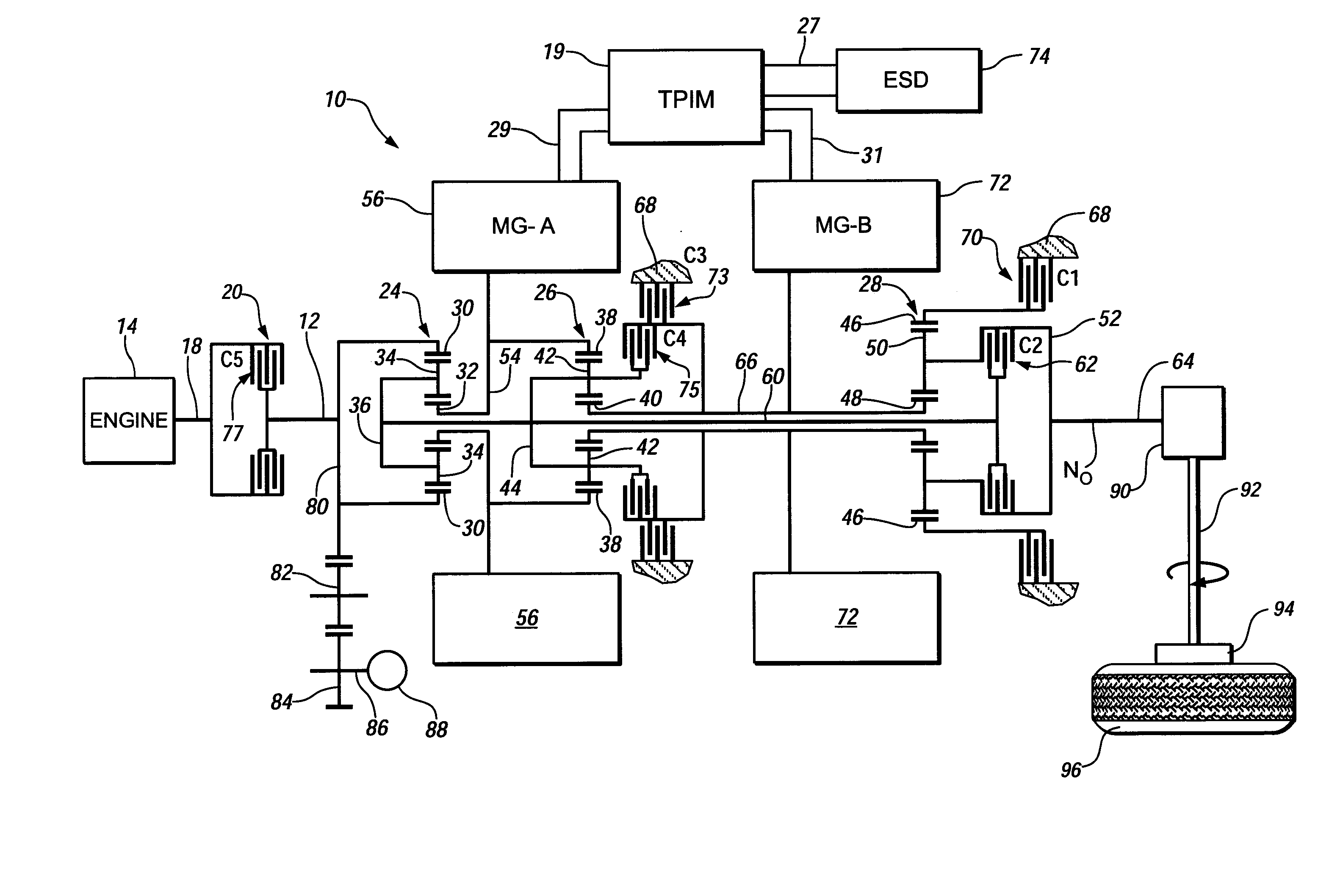

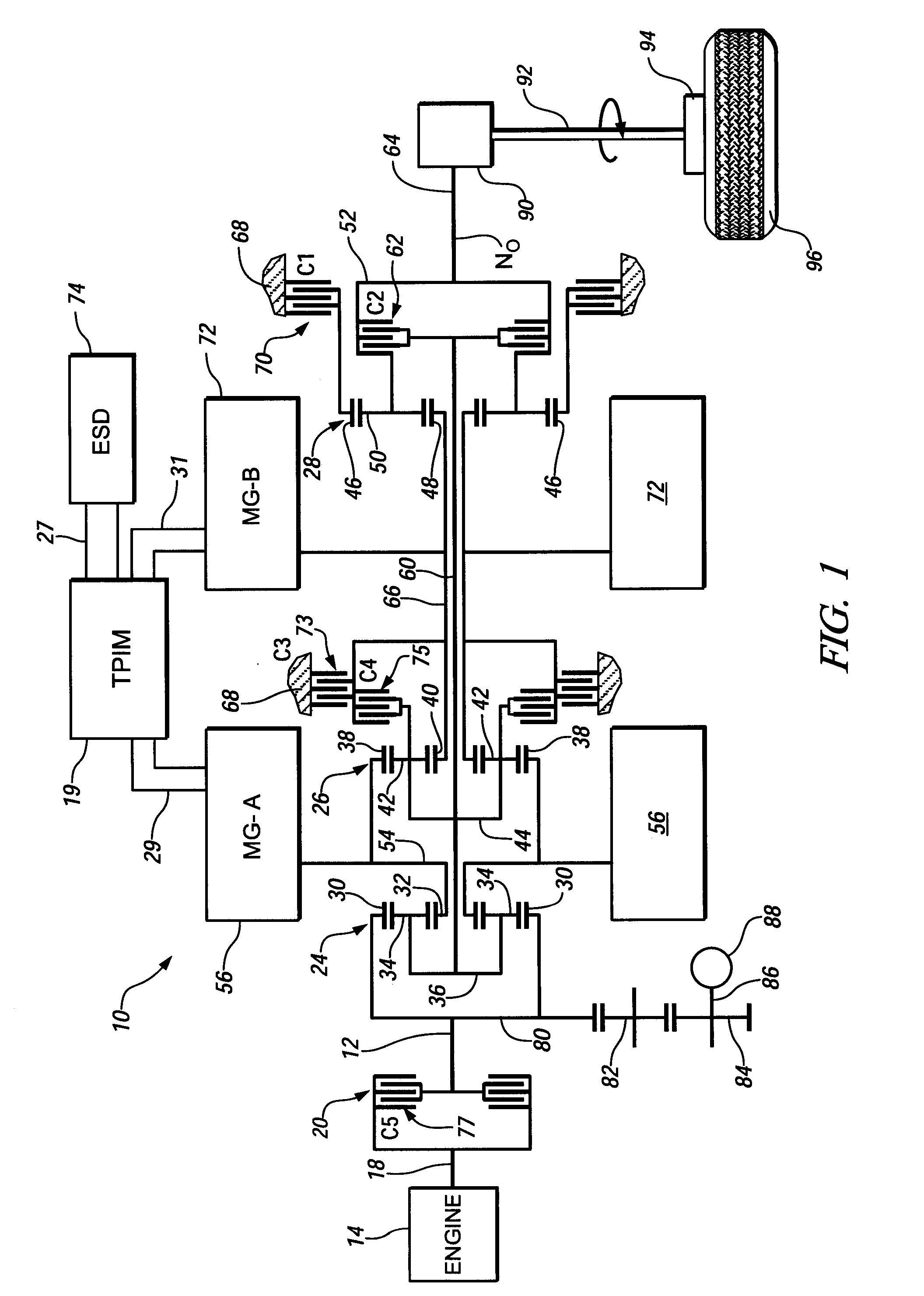

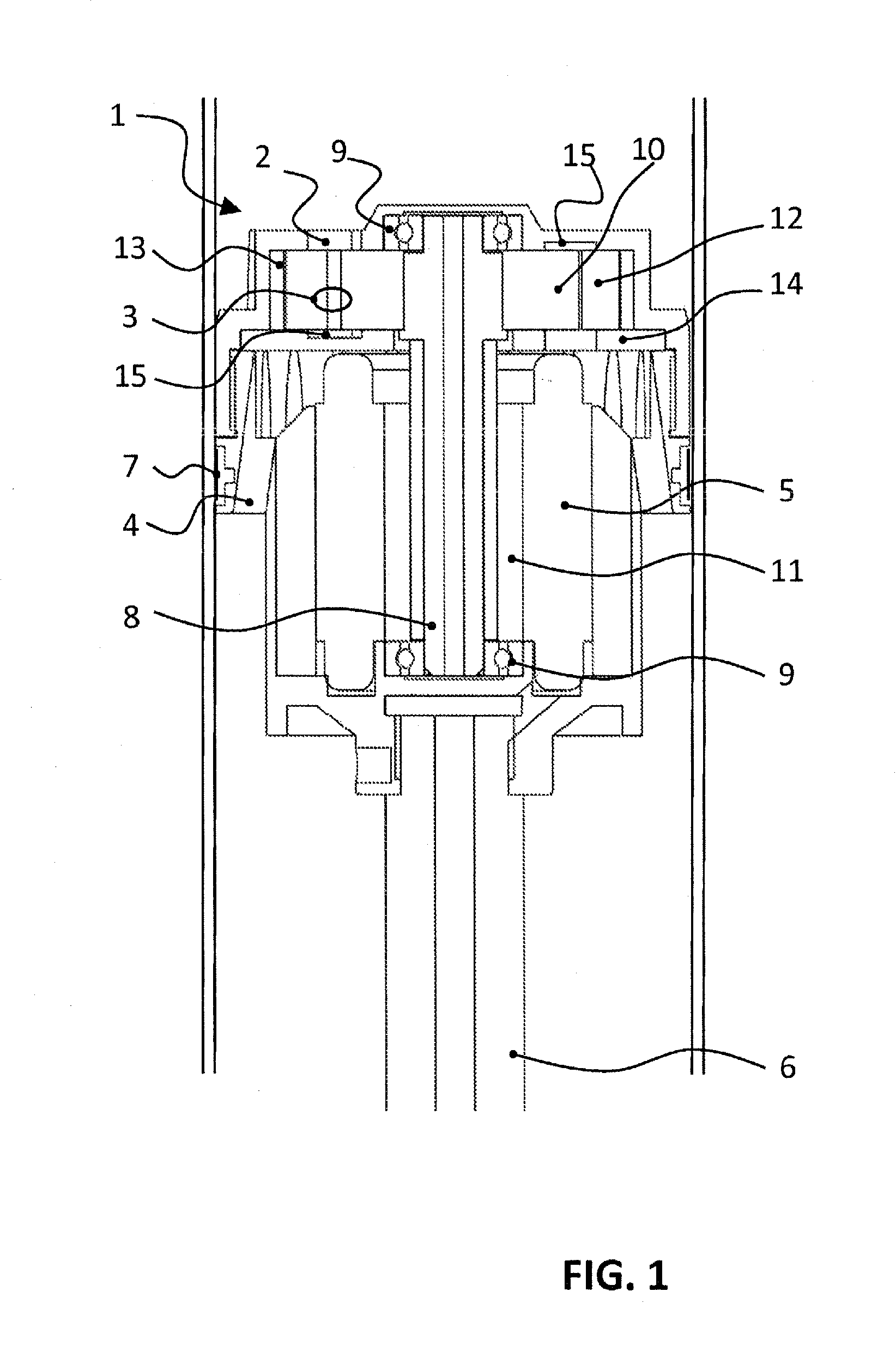

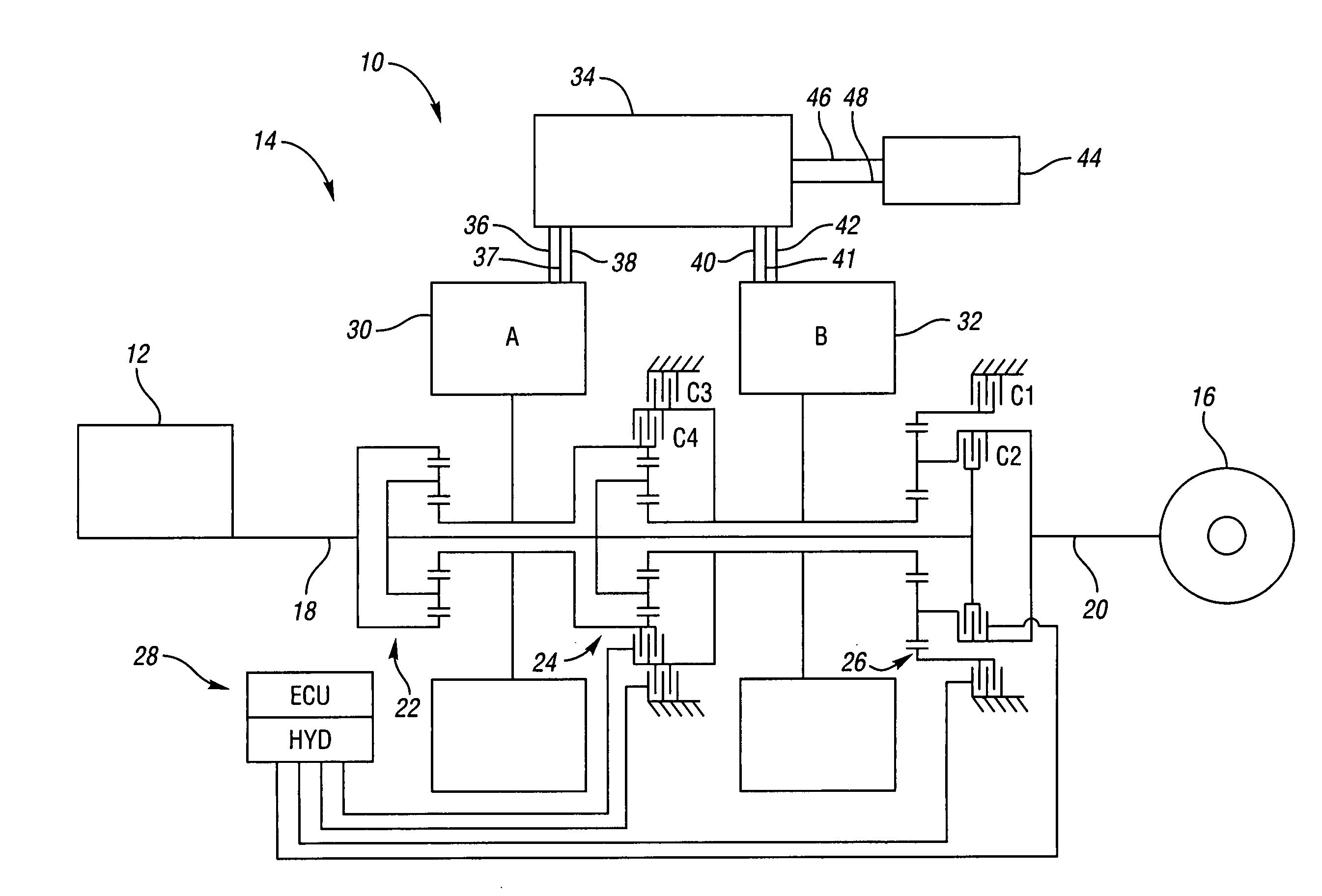

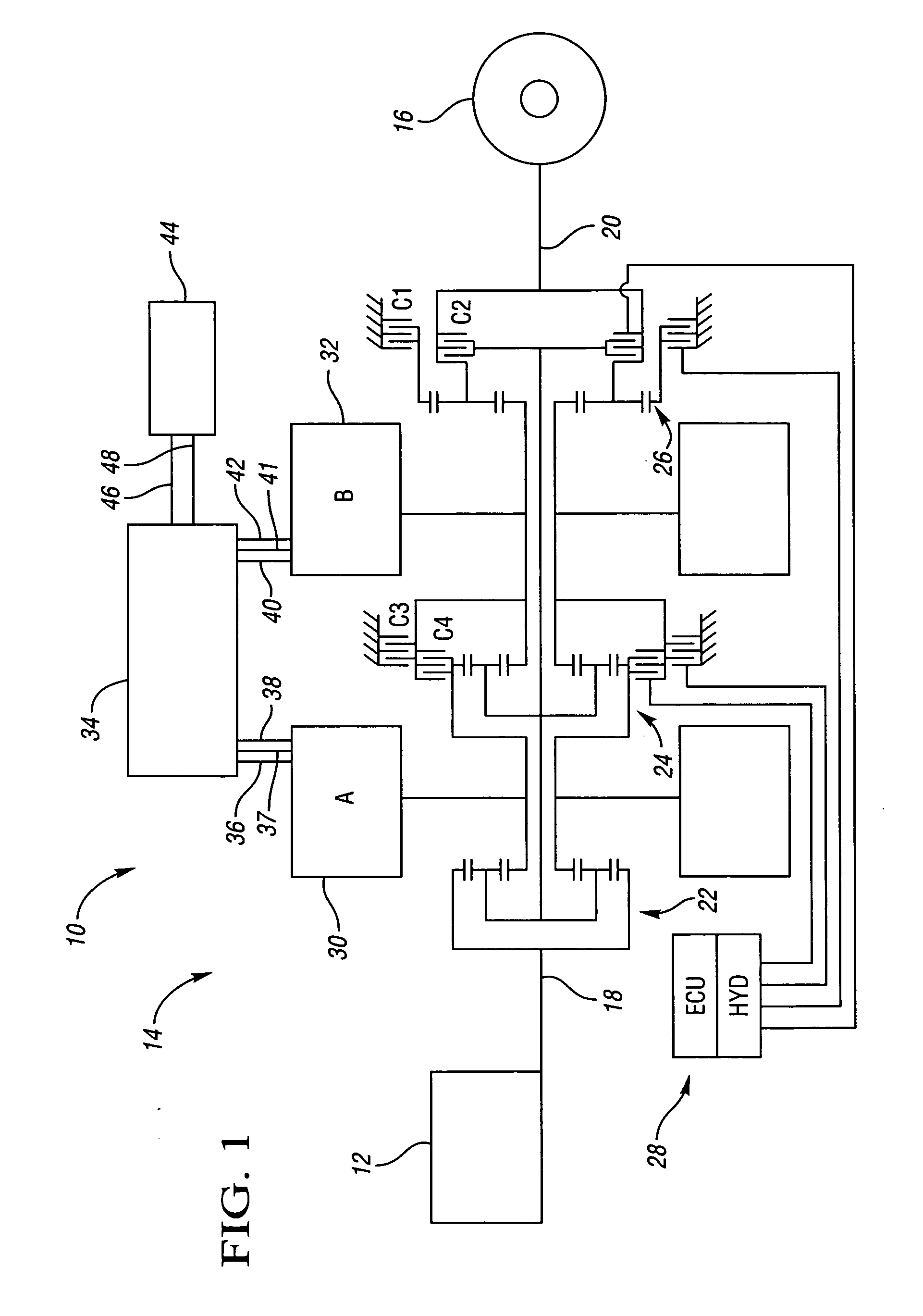

Multiplexed pressure switch system for an electrically variable hybrid transmission

A powertrain has an electrically variable hybrid transmission having an electro-hydraulic control system, plurality of electrical power units, and a plurality of torque transmitting mechanisms selectively engageable by the electro-hydraulic control system to provide four forward speed ranges, a neutral condition, an electric low speed mode, an electrically variable low and high speed mode, and two electrical power off drive home modes. The electro-hydraulic control system includes a multiplexed pressure switch system. The multiplexed pressure switch system of the present invention allows position detection of five torque transmitting mechanism control valves through the use of only four pressure switches.

Owner:GM GLOBAL TECH OPERATIONS LLC

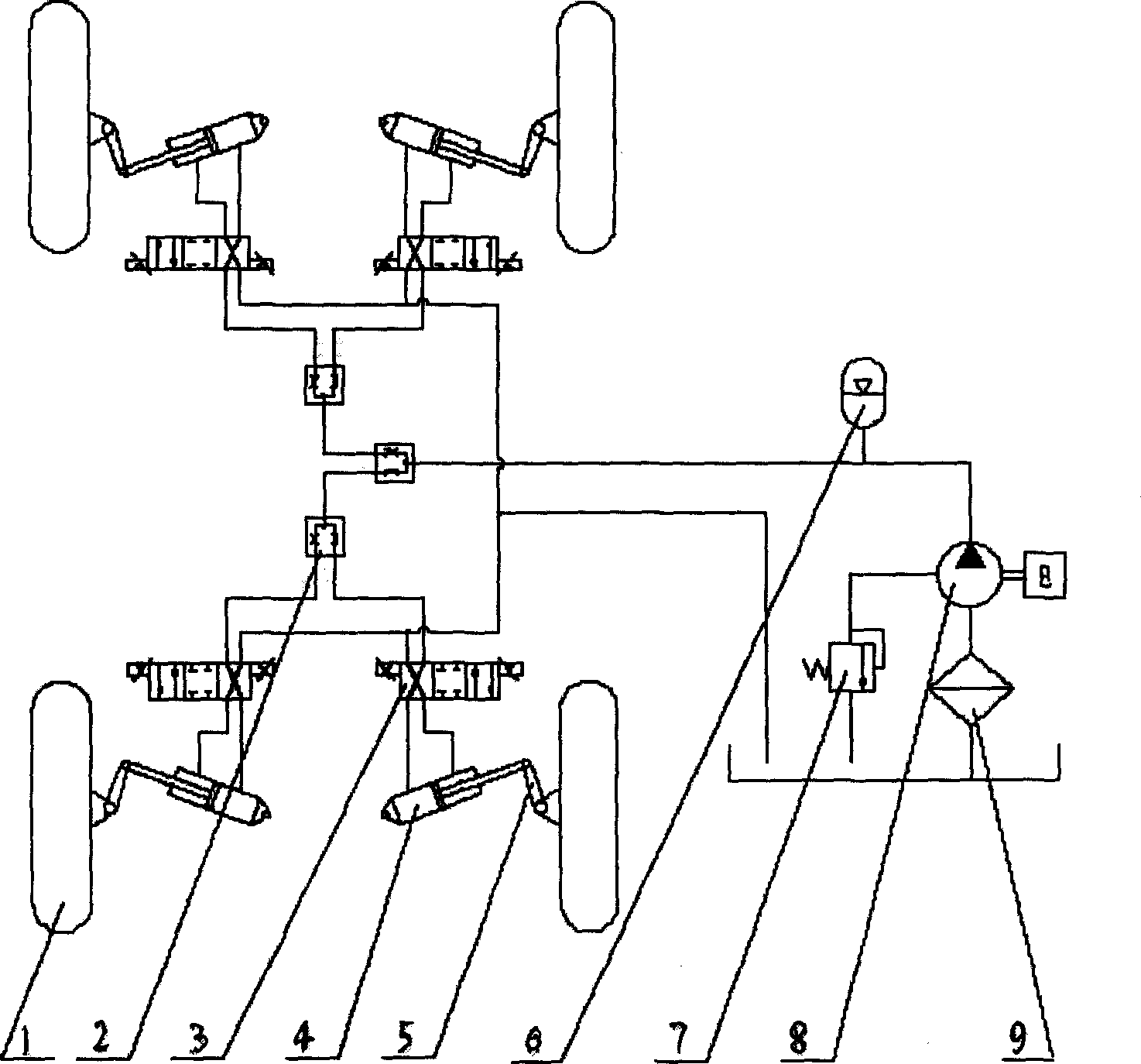

Separated steering device for vehicular four wheels and its control method

The invention relates to domain of special purpose vehicle and especially to a separate four-wheel steering device of vehicle and controlling means, which is mainly used in steering system of special purpose vehicle to guarantee steering behavior. The device comprises steering knuckle arm, steering hydraulic cylinder, electro-hydraulic proportional control valves, and accumulator, easing valve, hydraulic pump, clarifier and electronic control system. The invention is characterized in that every wheel is controlled by independent oil-hydraulic cylinder, electronic control system comprises steering emulator, signal processor and measuring apparatus of displacement line and hydraulic pump driven by engine in steering hydraulic system controls hydraulic cylinder of steering system via electro-hydraulic proportional control valves of steering system. Hydraulic cylinder connects with linear movement pickup to feed variable of displacement line of hydraulic cylinder back to CPU. System adopts closed-loop control. Control circuit equips system failure diagnosis element to realize alarm when system steering error occurs and steering mode switching control unit to complete steering mode switching of vehicle.

Owner:JIANGSU UNIV

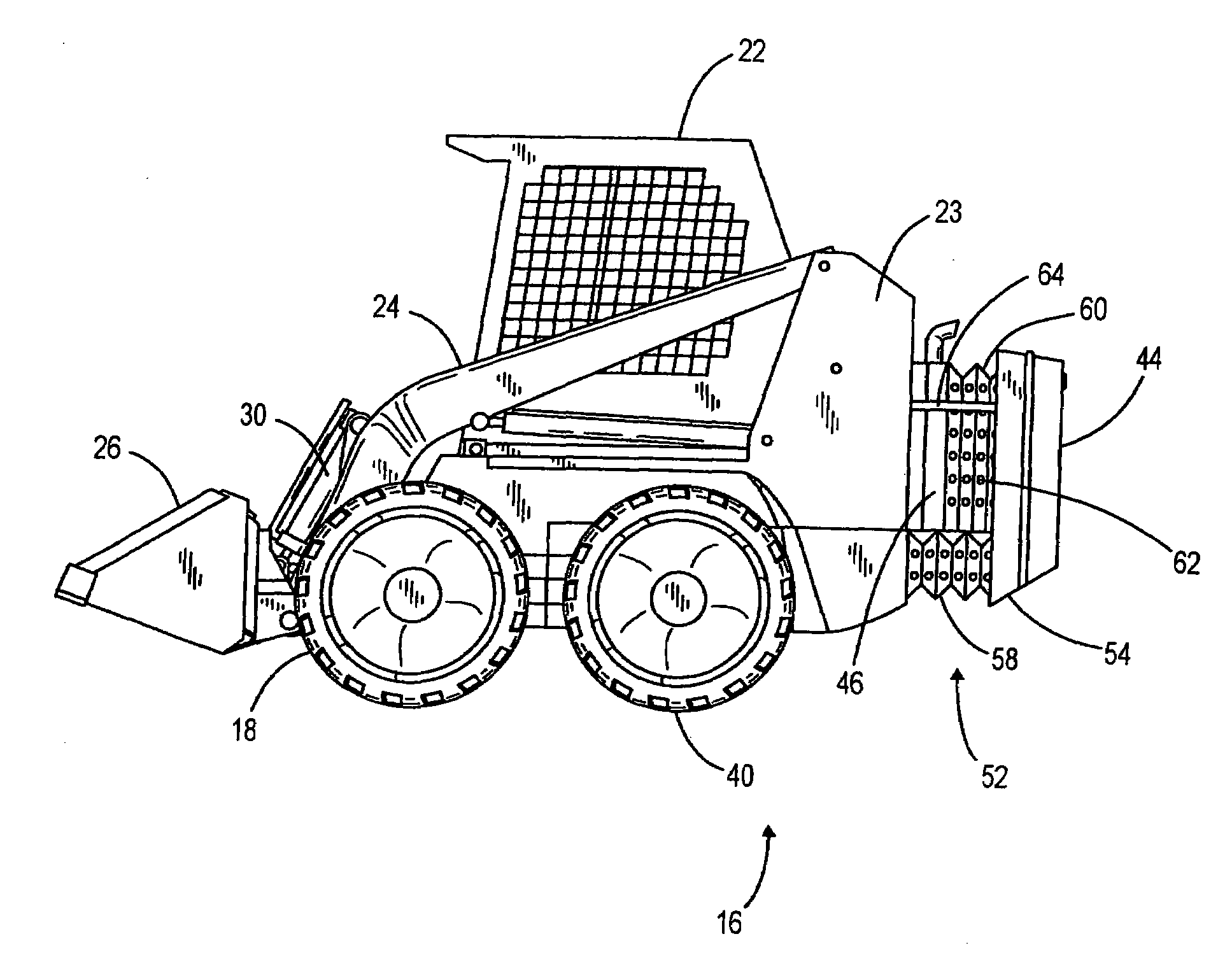

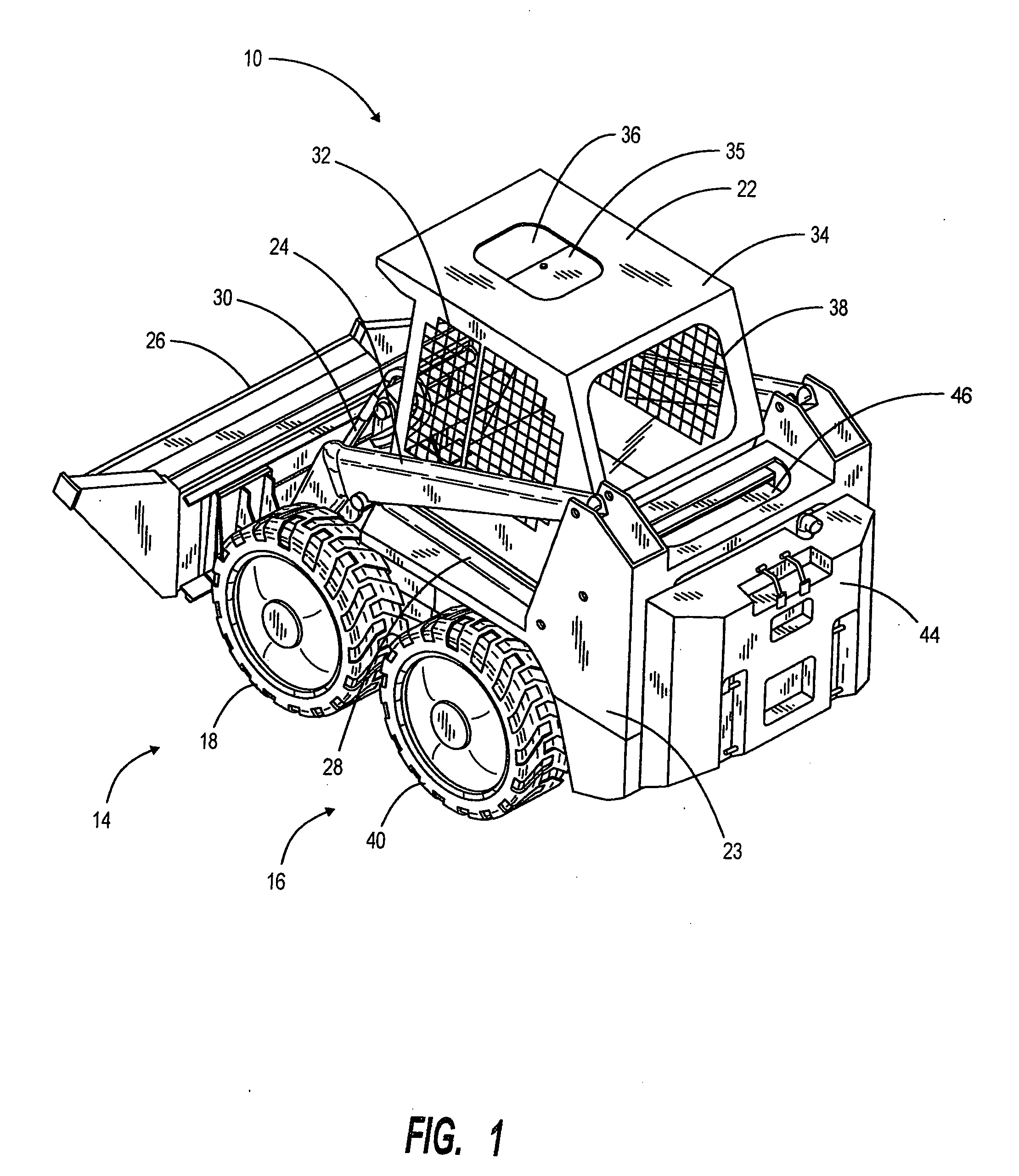

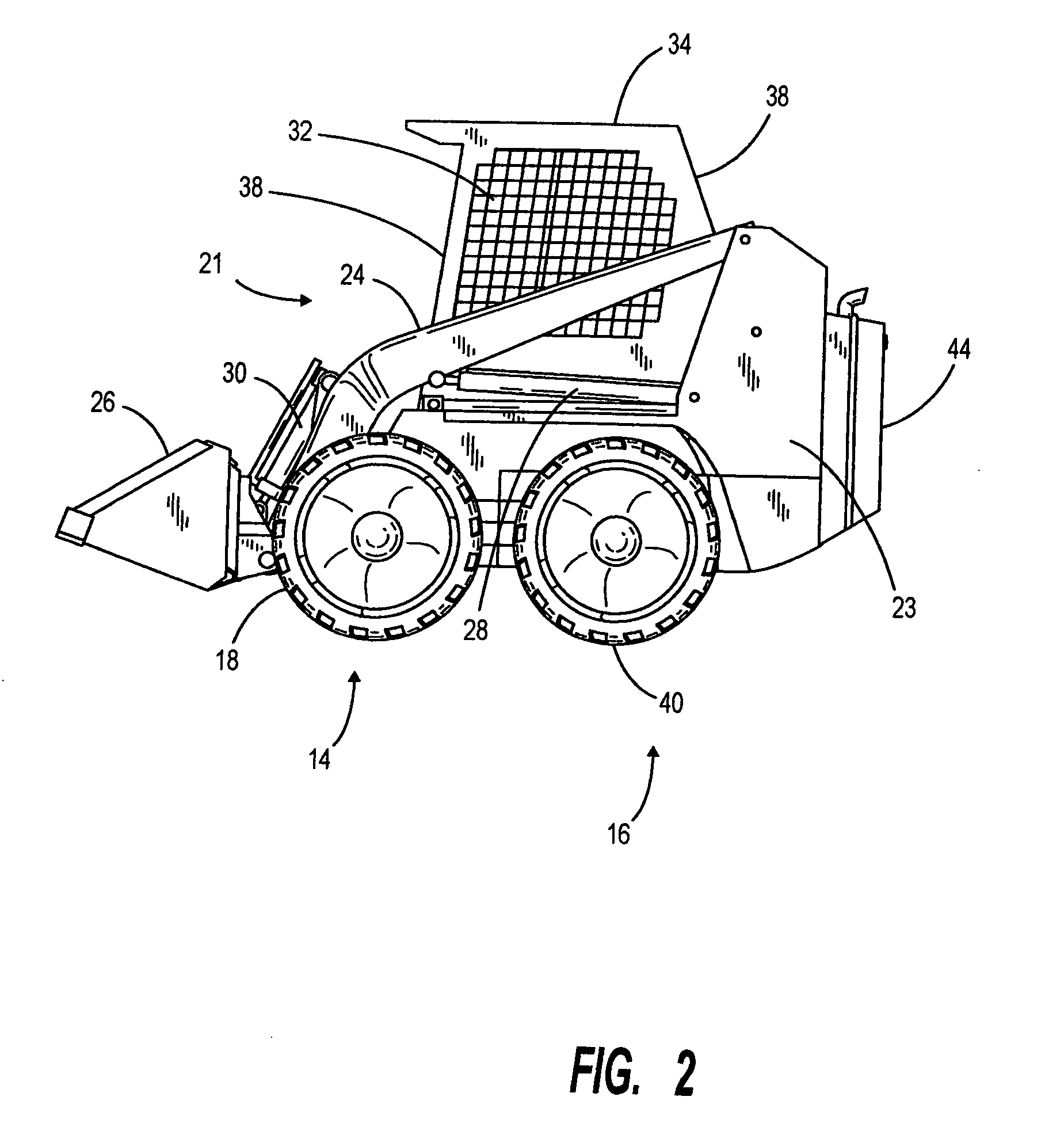

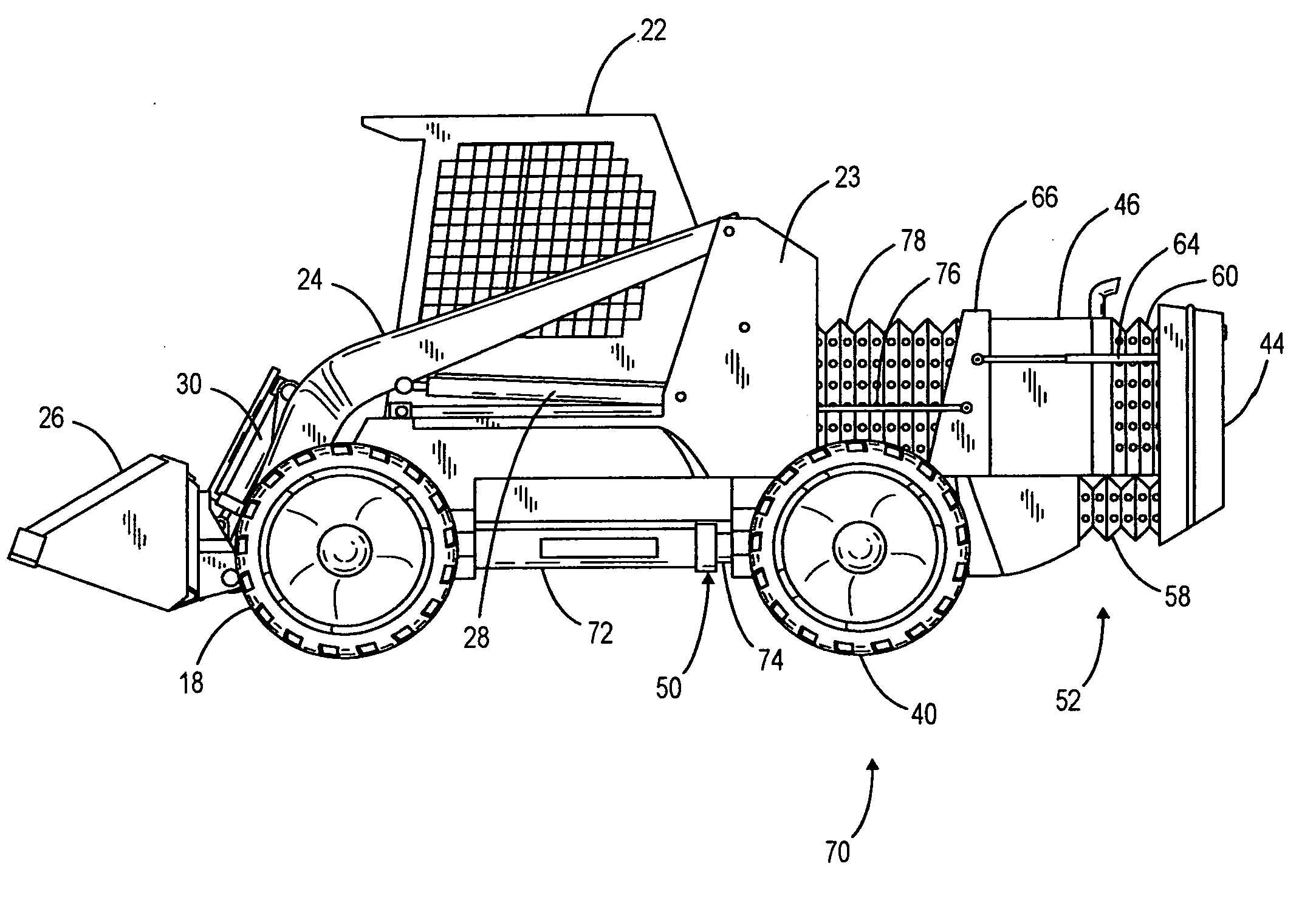

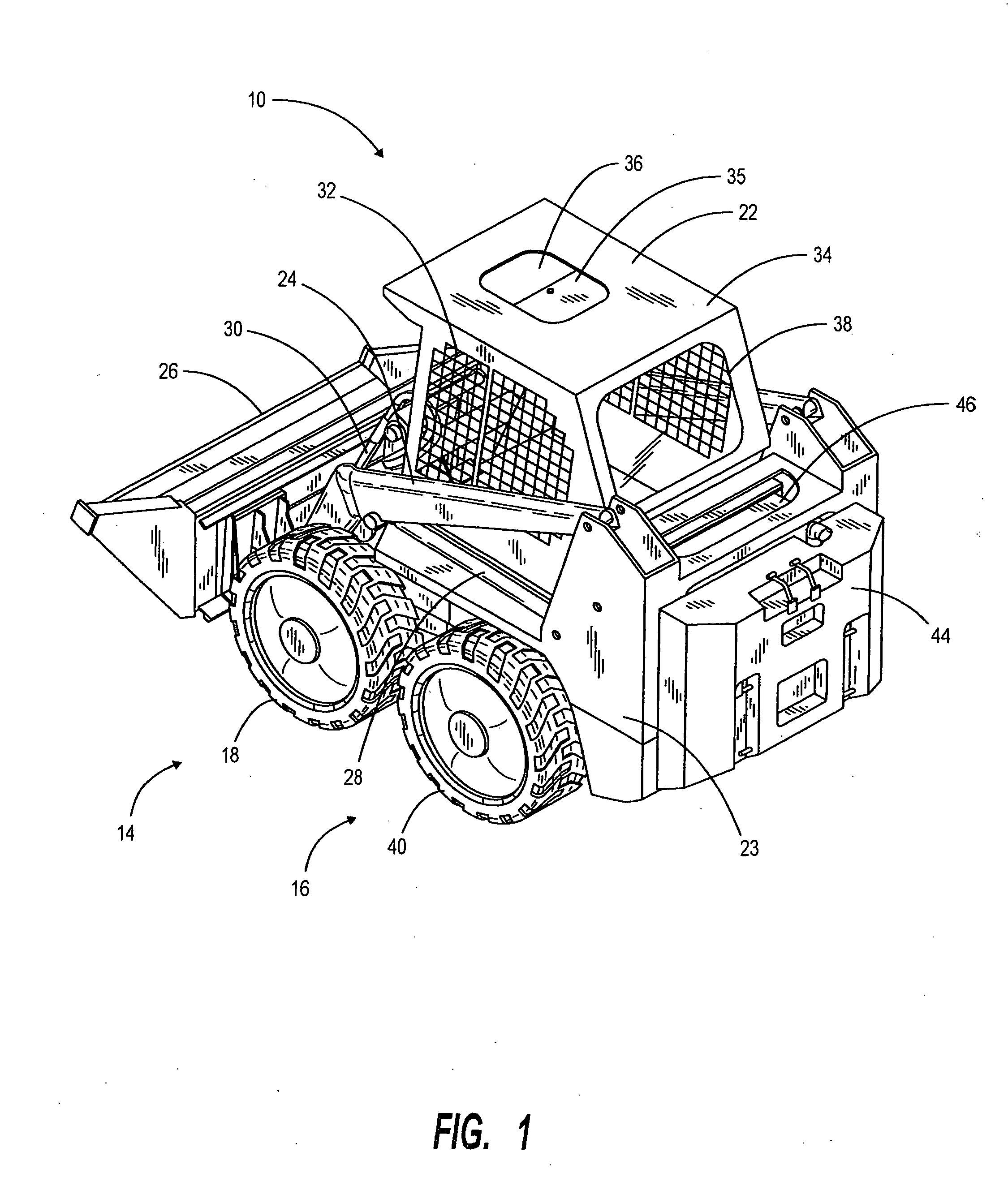

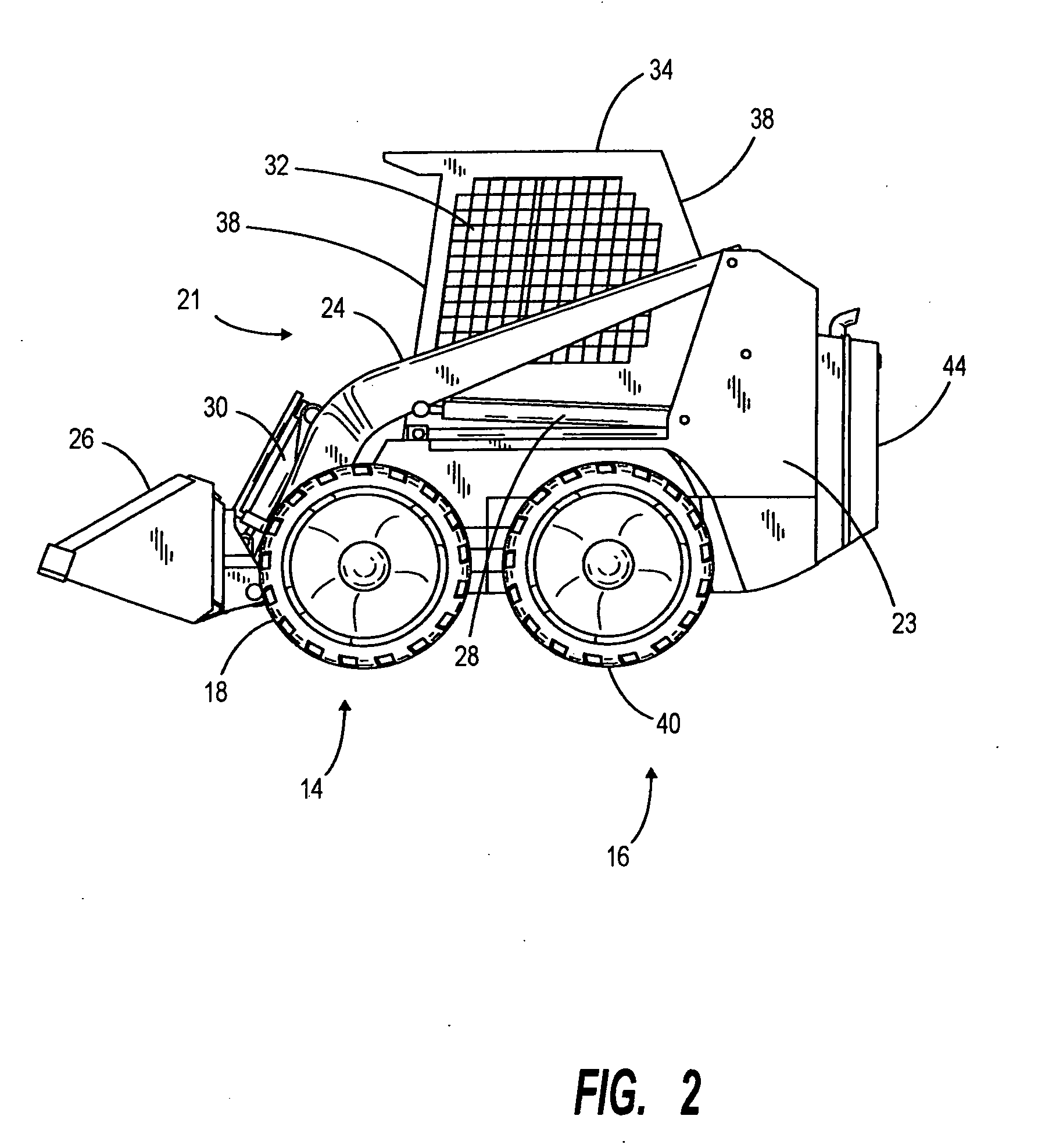

Extendable frame work vehicle

ActiveUS20090038186A1Improve versatilityImprove securitySafety devices for lifting equipmentsAuxillary drivesHydraulic motorVehicle frame

An extendable frame work vehicle offering enhanced versatility, safety and effectiveness. The vehicle includes an adjustable frame with front and rear portions that extend or retract with respect to each other. The front portion is supported by a first pair of wheels and said rear portion is supported by a second pair of wheels. Each wheel is independently driven and steered. The vehicle also includes an engine mounted on the rear portion of the frame. Incorporated into the vehicle is an electro-hydraulic assembly which enables extension and retraction of the adjustable frame. The assembly includes a sensor-responsive microprocessor controller, at least one hydraulic pump, at least one hydraulic drive motor, and at least one valve network.

Owner:EXTENDQUIP LLC

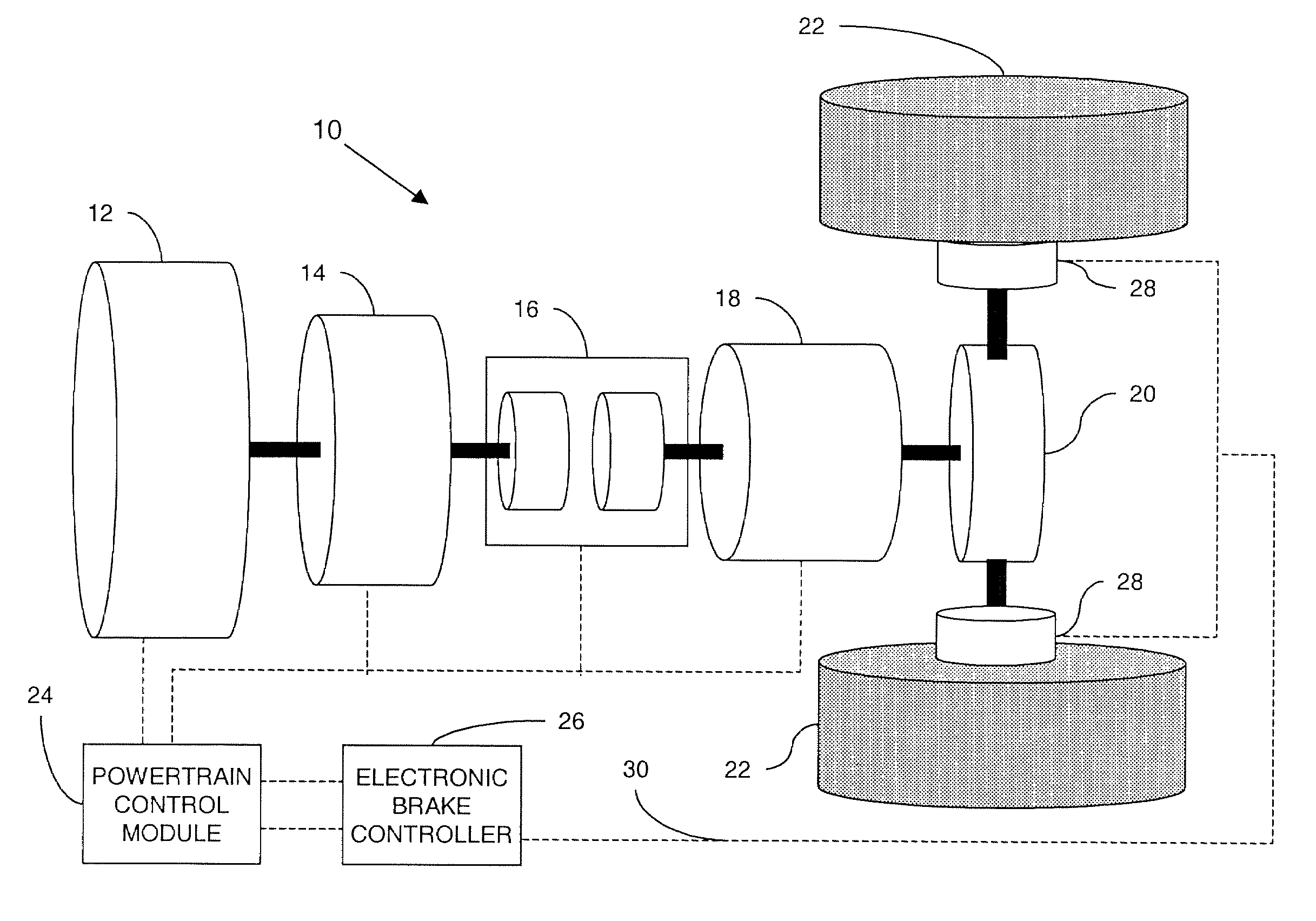

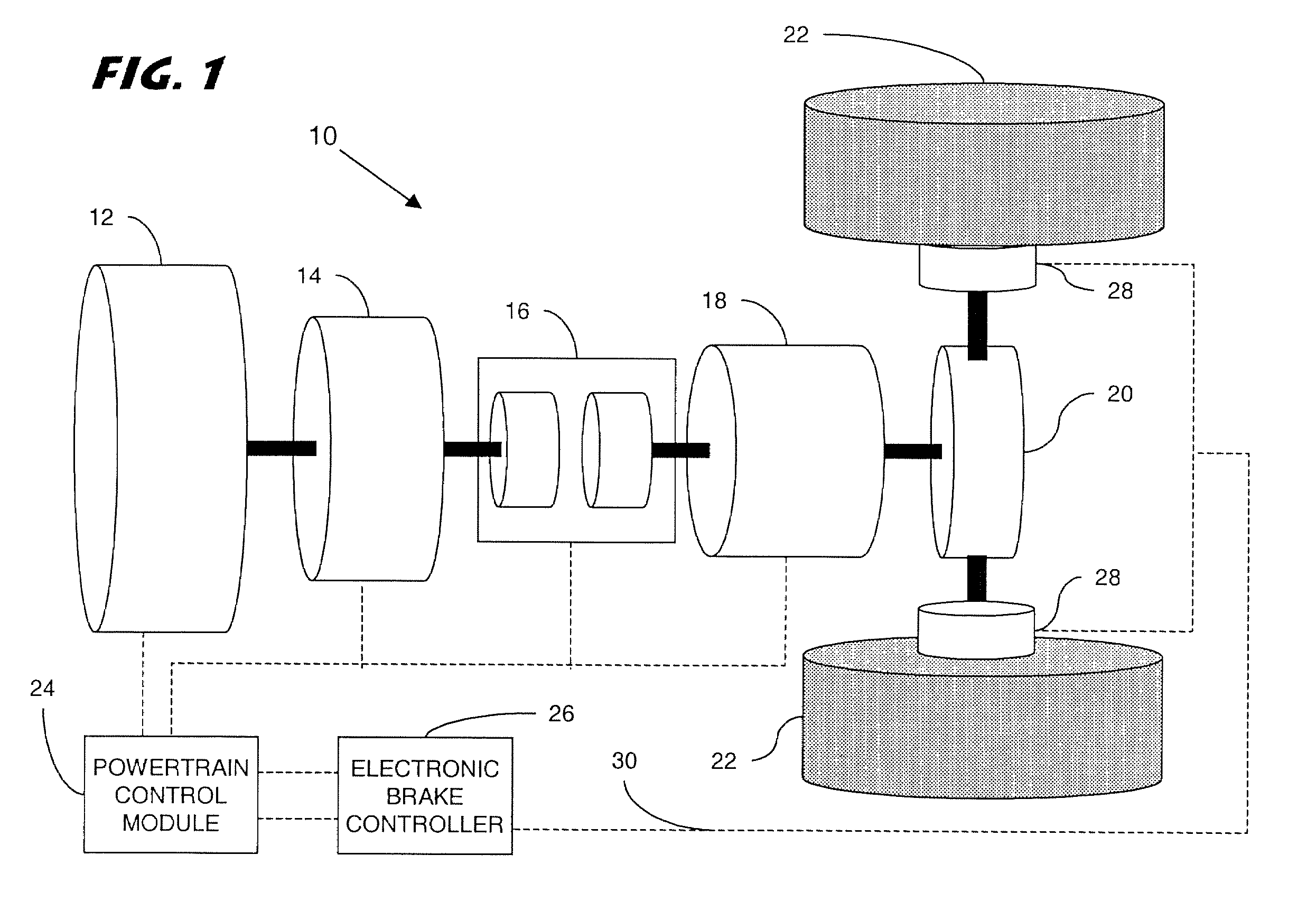

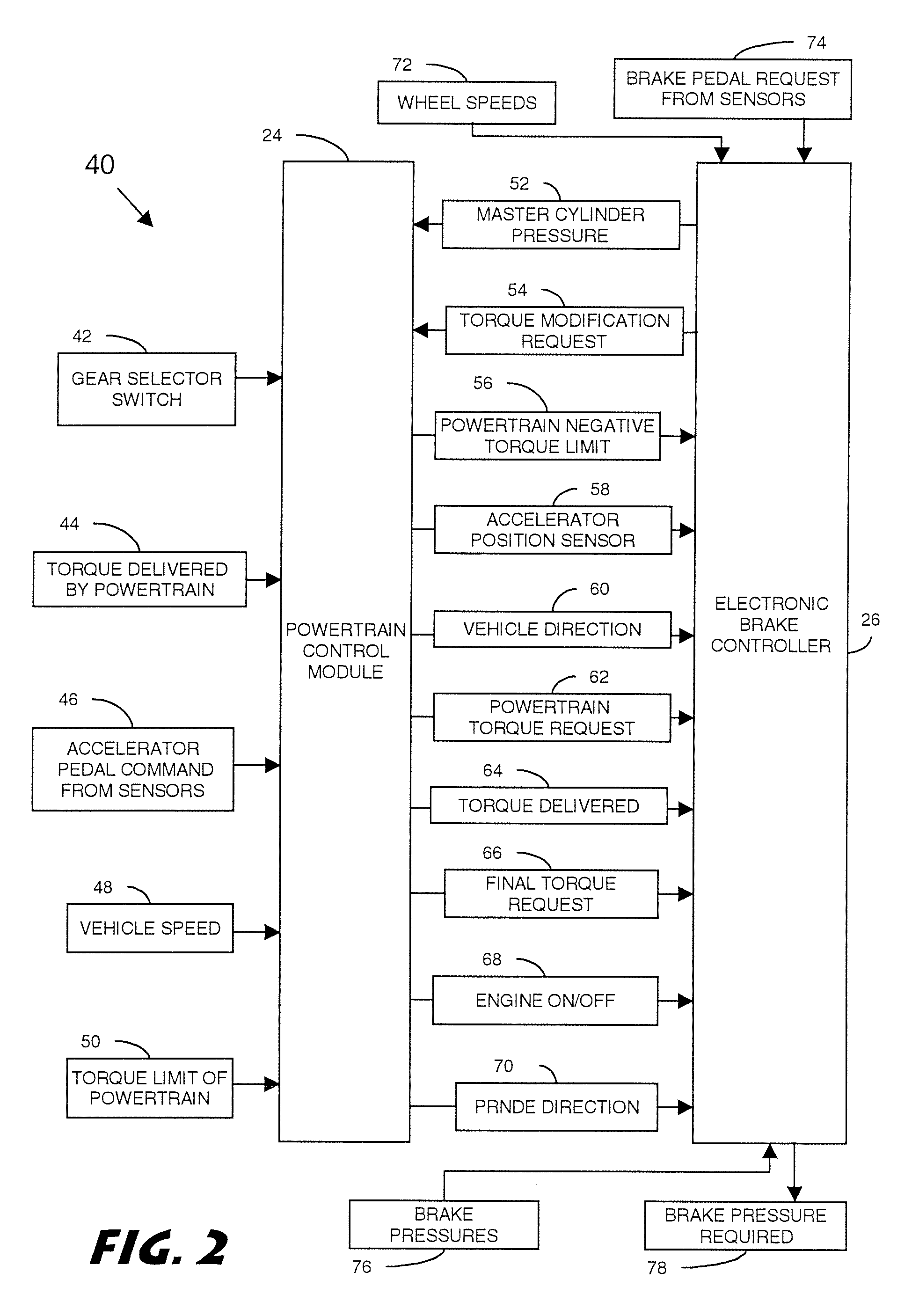

Hill holding brake system for hybrid electric vehicles

InactiveUS20050017580A1Improves operating efficiency and driveabilityReduces electro-hydraulic brake torquePlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsBrake torqueControl system

A hill holding function of a hybrid electric vehicle is initiated when the powertrain control module determines that a hill holding condition exists. In the hill holding condition, the electro-hydraulic brakes will provide brake torque to each wheel and the powertrain control module will turn off the internal combustion engine. The system can also detect a two footer condition where the vehicle operator requests both acceleration torque and brake torque simultaneously. The hill holding function of the hybrid electric vehicle in a two footer situation will apply the electro-hydraulic brakes and turn off the internal combustion engine. When the operator requests acceleration in either the hill holding or the two footer condition, the electric brake controller will transition the release of the electro-hydraulic brakes and the powertrain control module will turn on the internal combustion engine.

Owner:FORD GLOBAL TECH LLC

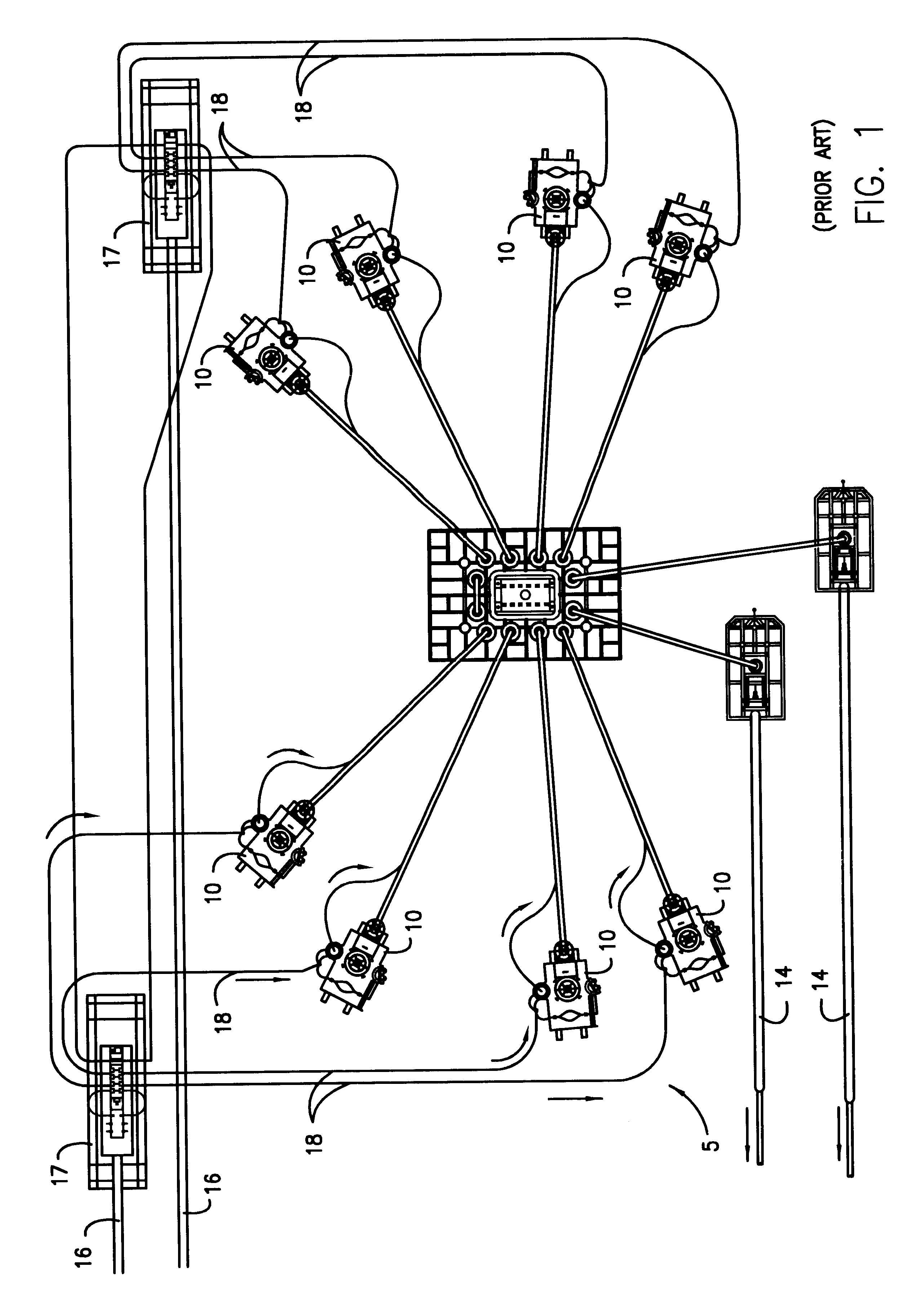

Shearing arrangement for subsea umbilicals

InactiveUS6397948B1Effective and reliable load limiting break awayLittle strengthVessel partsFluid removalOcean bottomElectro hydraulic

A load limiting break away arrangement for a subsea umbilical includes telescoping inner and outer bodies. The inner body includes multiple cross-bored holes; the outer body has slotted openings on its top and bottom sides. A shearing blade is positioned at one end of a top slot of the outer body. Individual umbilical tubes pass through a bottom slot of the outer body, through individual holes in the inner body and out a top slot of the outer body for attachment to multiple quick connect couplers on an umbilical termination head of an Umbilical Termination Assembly (UTA) and of an Electro-Hydraulic Distribution Module (EHDM). Tension resistant actuation members run between the UTA and EHDM so that when a snag of an umbilical occurs, the inner and outer bodies are pulled apart and the tubes are severed one by one by the blade of the outer body.

Owner:FMC TECH INC

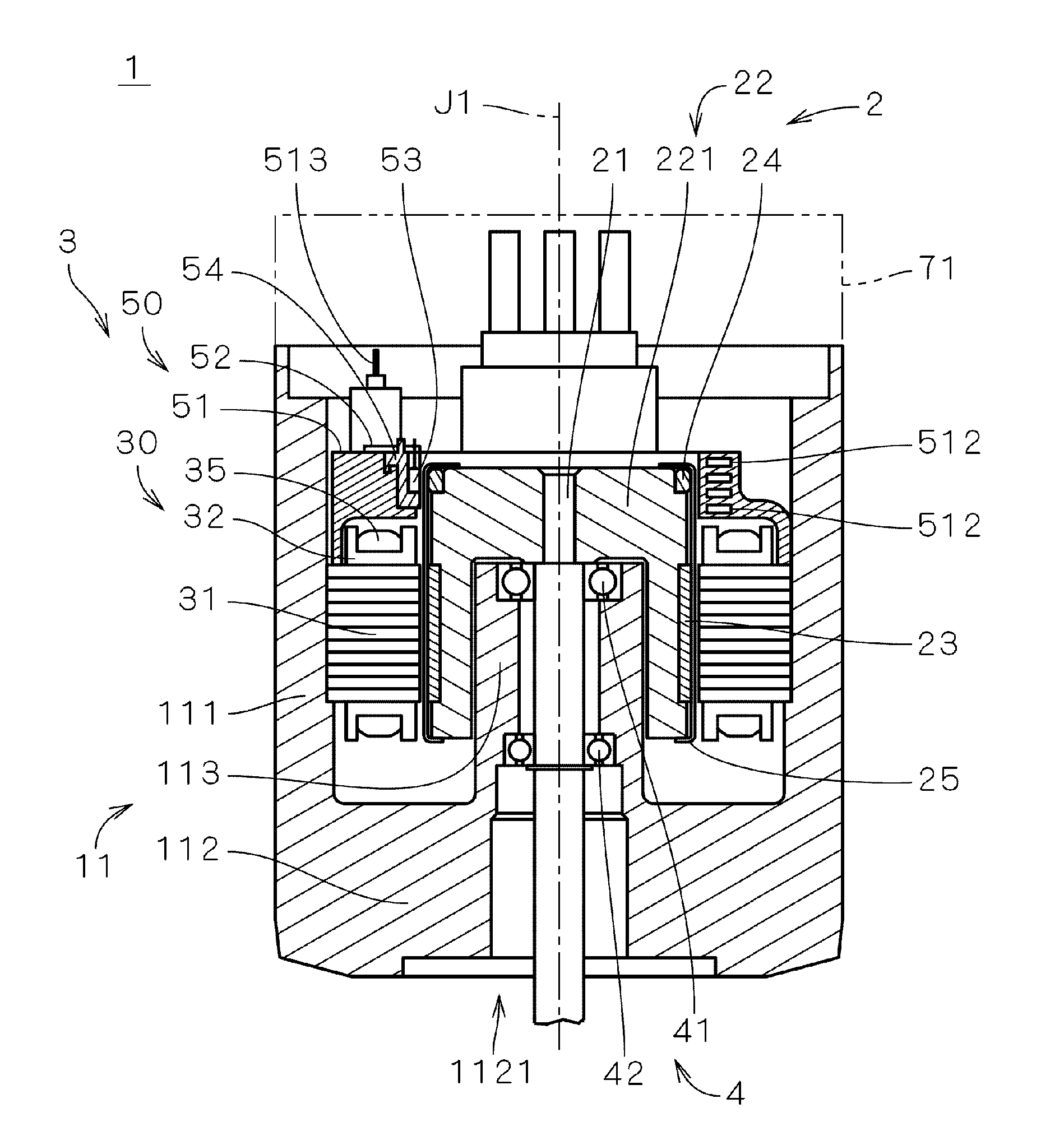

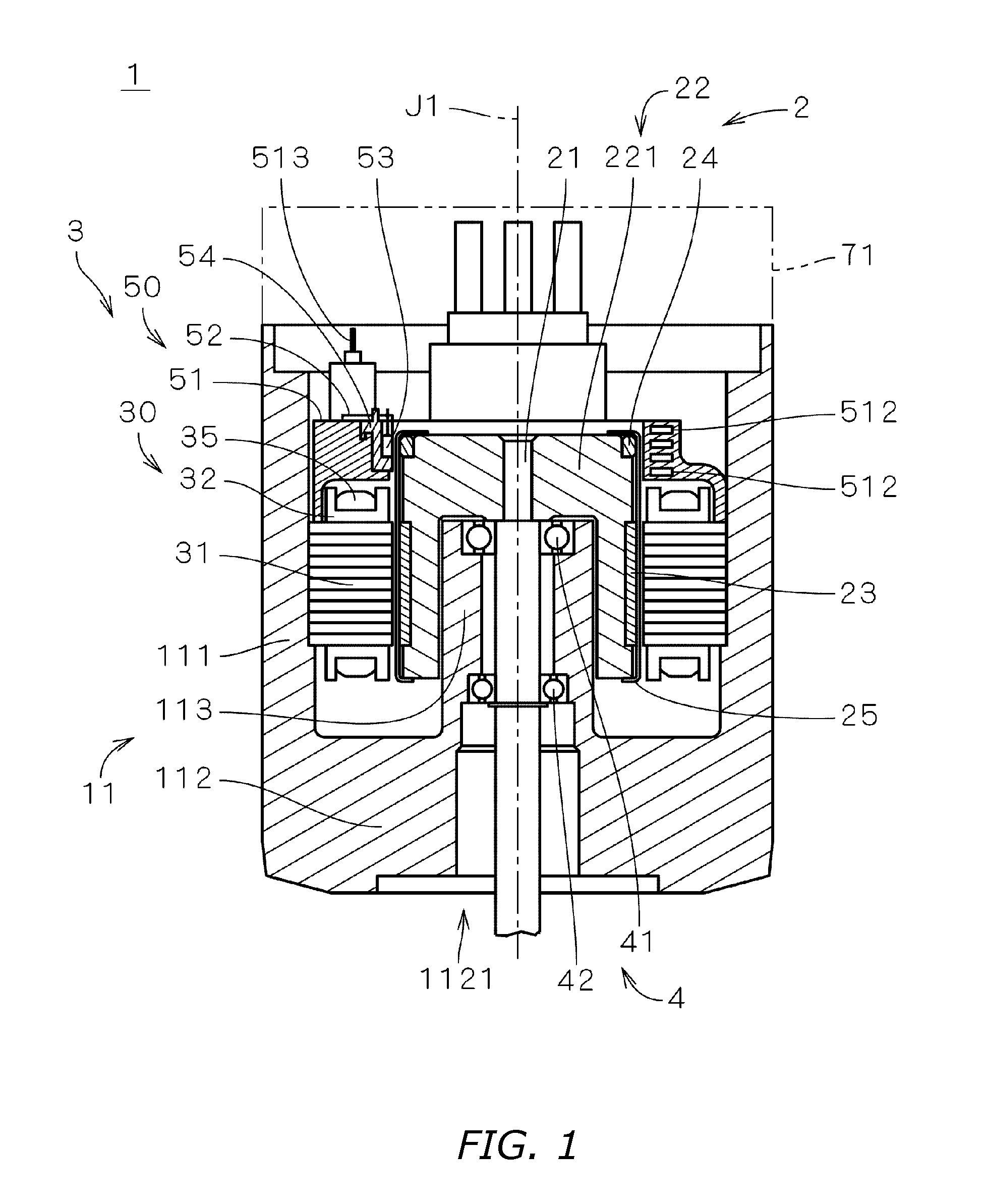

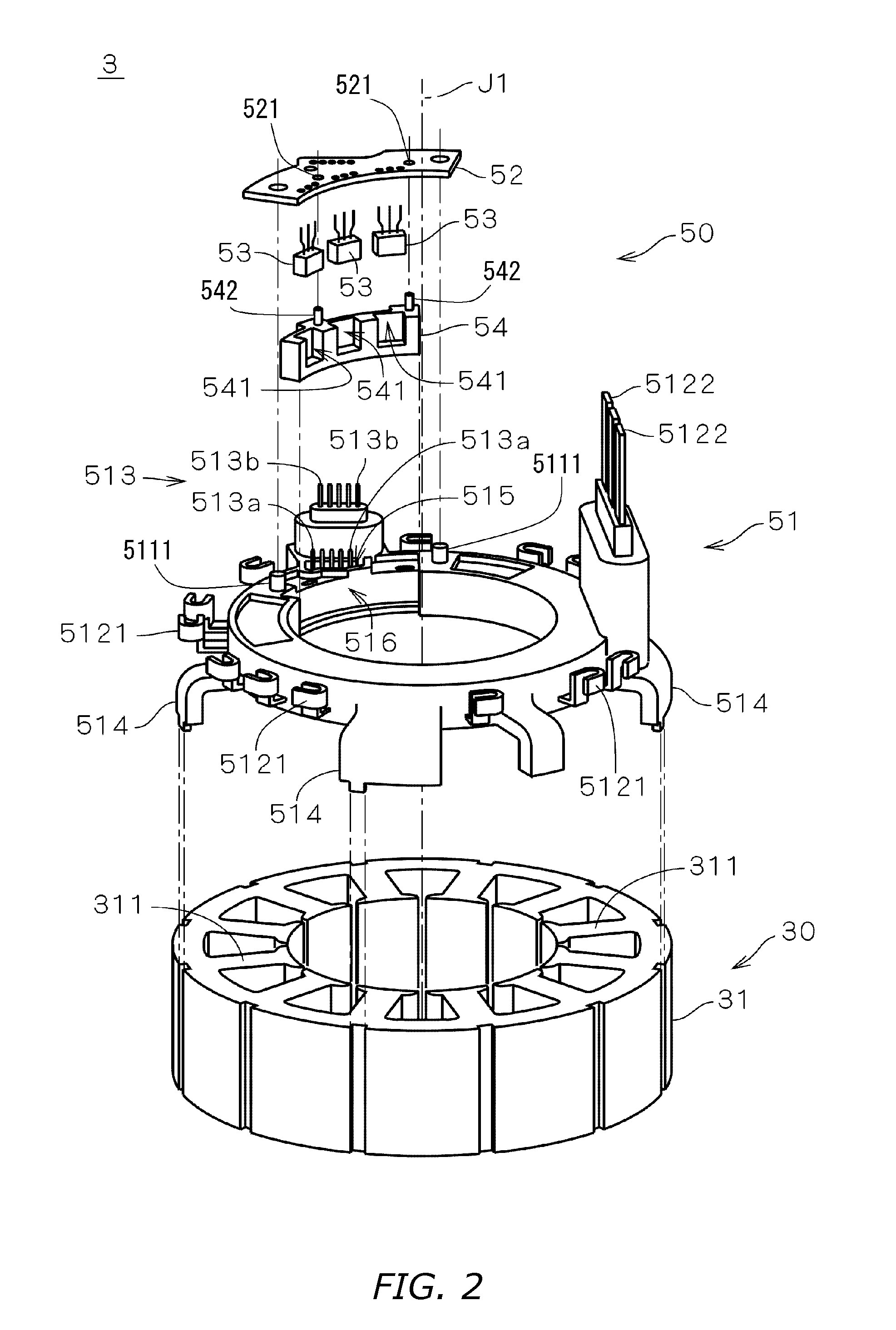

Busbar Unit, Electric Motor and Electrohydraulic Power Steering System Furnished With the Busbar Unit, and Method of Manufacturing the Busbar Unit

ActiveUS20070178723A1Force be absorbShort circuiting can be preventedAssociation with control/drive circuitsWindingsPower steeringBusbar

A busbar unit for attachment to on an electric-motor armature is furnished with: busbars having terminals for supplying drive current to the armature; a plurality of connecting pins each of approximately J-shaped metal; a busbar holder retaining the busbars and the connecting pins; and a circuit board disposed on the upper side of the busbar holder, and in which a sealant injection port and an air-bleeding hole are formed.

Owner:NIDEC CORP

Extendable frame work vehicle having lift member movable in a true vertical fashion

ActiveUS20090206589A1Improve versatilityImprove effectivenessSafety devices for lifting equipmentsVehicle body stabilisationHydraulic motorVehicle frame

An extendable frame work vehicle offering enhanced versatility, safety and effectiveness. The vehicle includes an adjustable frame with front and rear portions that extend or retract with respect to each other. The front portion is supported by a first pair of wheels and said rear portion is supported by a second pair of wheels. Each wheel is independently driven and steered. The vehicle also includes an engine mounted on the rear portion of the frame. Incorporated into the vehicle is an electro-hydraulic assembly which enables extension and retraction of the adjustable frame. The assembly includes a sensor-responsive microprocessor controller, at least one hydraulic pump, at least one hydraulic drive motor and at least one valve network.

Owner:EXTENDQUIP LLC

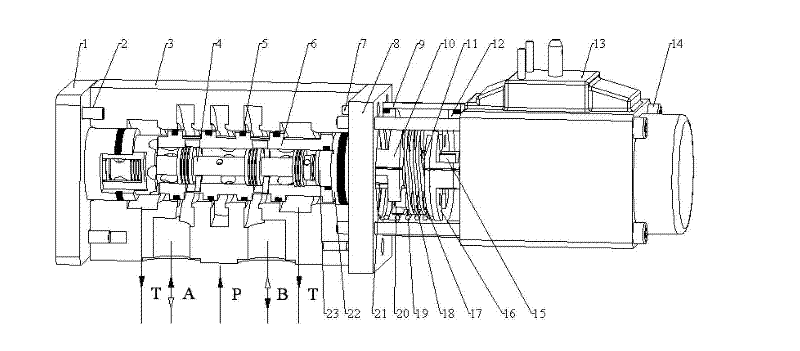

2D hydraulic-power-assisted electro-hydraulic proportional reversing valve

ActiveCN102650305AHigh precisionReduce adverse effectsServomotor componentsElectricityProportional control

The invention provides a 2D (2-dimensional) hydraulic-power-assisted electro-hydraulic proportional reversing valve, which comprises a valve body, a valve core, a valve sleeve, a linear electro-mechanical converter and a compressive-torsional coupling, wherein the valve core, the compressive-torsional coupling and the linear electro-mechanical converter are coaxially connected; an output shaft of the linear electro-mechanical converter is fixedly connected with an input end of the compressive-torsional coupling; an output end of the compressive-torsional coupling is fixedly connected with the right end of the valve core; a sensitive cavity is formed by the left end of the valve core, the valve sleeve and a left cover plate; a pair of axisymmetric high pressure holes and a pair of axisymmetric low pressure holes are respectively formed on the surfaces of shoulders of the valve core in the sensitive cavity; a pair of axisymmetric sensing channels are arranged on the inner surface of the valve sleeve outside the sensitive cavity; and one end of each receptive channel is communicated with the sensitive cavity, and the other ends of the receptive channels cover areas between adjacent high pressure holes and low pressure holes. The 2D hydraulic-power-assisted electro-hydraulic proportional reversing valve not only has the characteristics of high flow rate, high working pressure, and the like of an ordinary pilot-control type electro-hydraulic proportional valve, but also fulfils a proportional control function like a direct-actuated proportional valve under the circumstance of zero pressure (pressure loss).

Owner:ZHEJIANG UNIV OF TECH

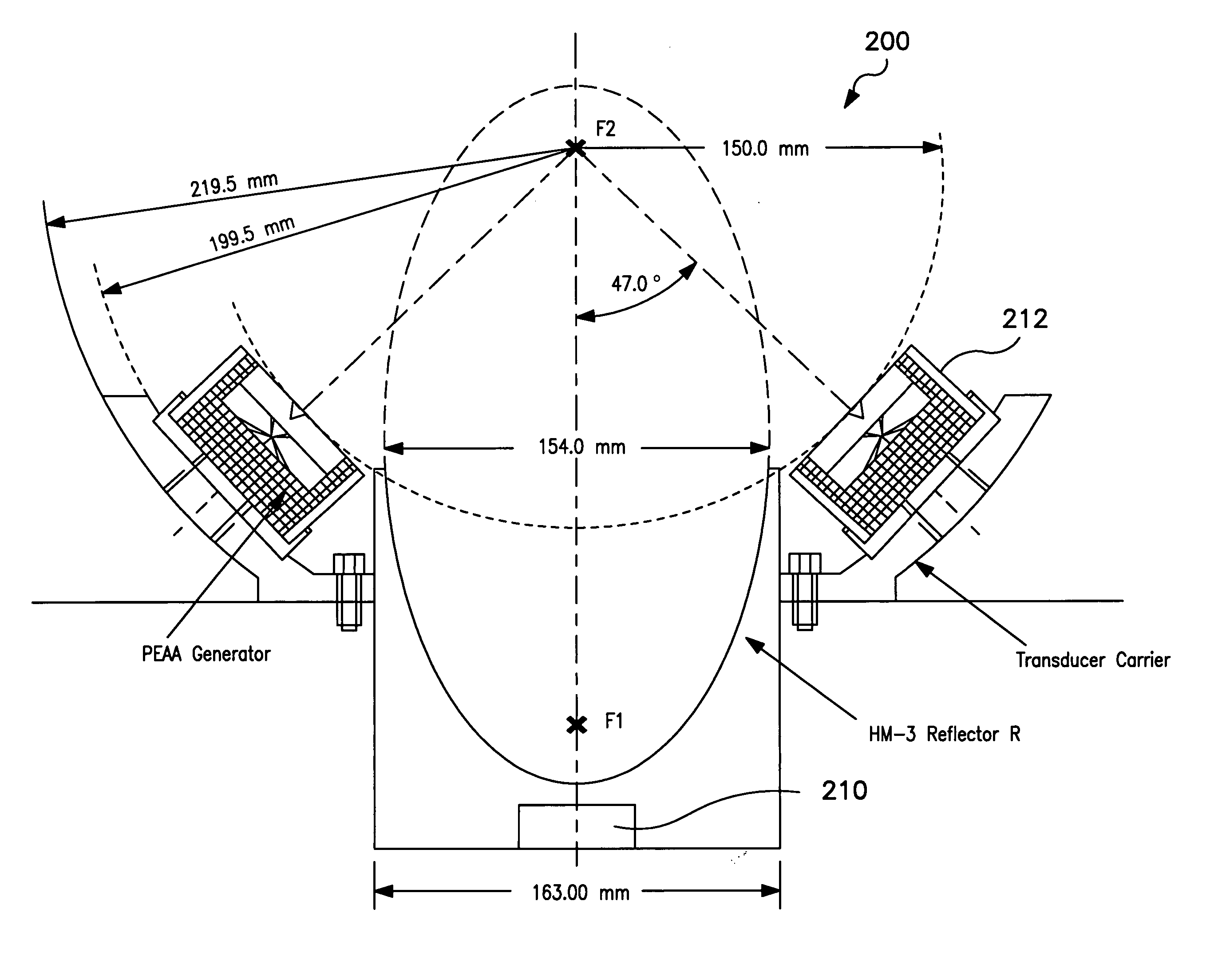

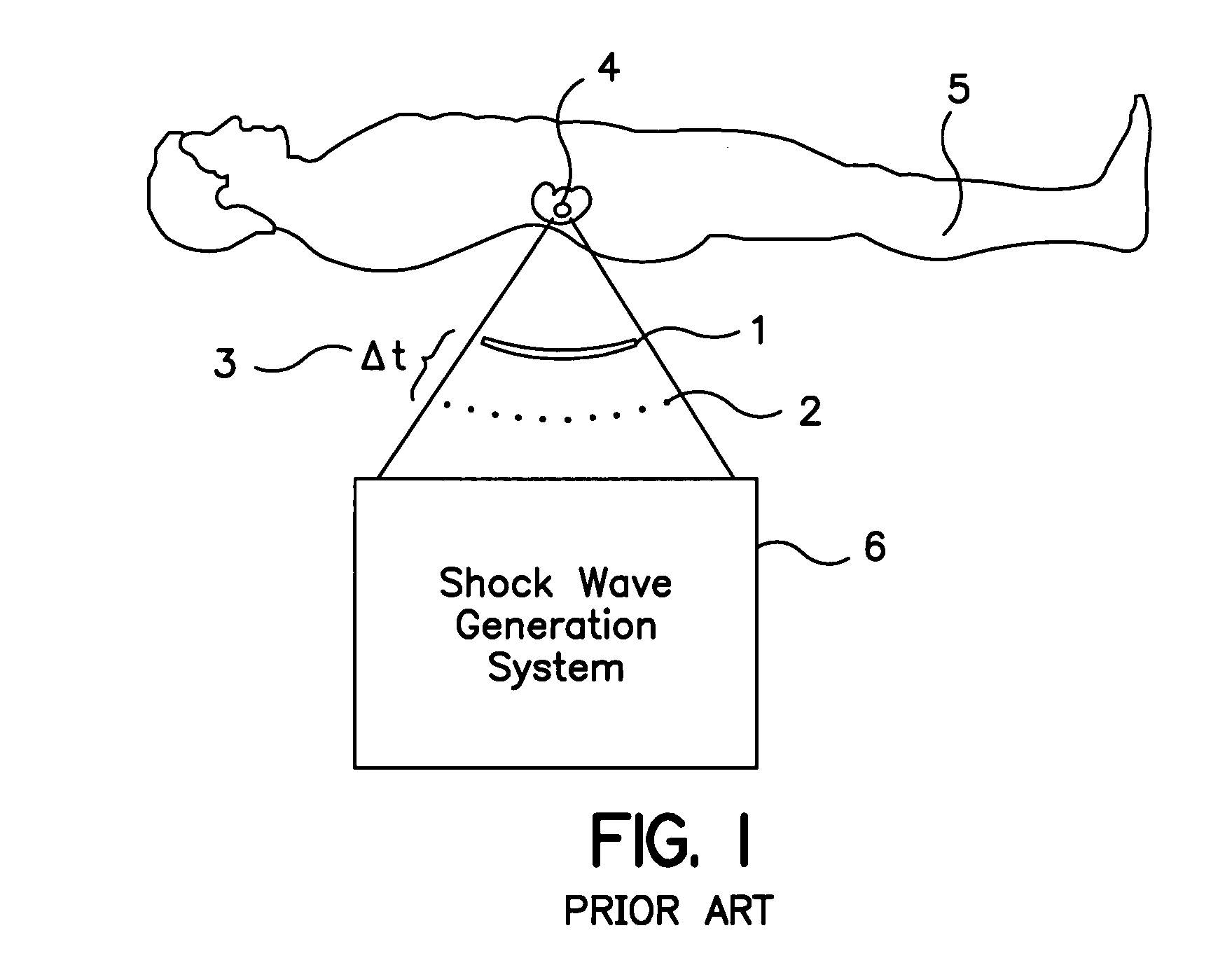

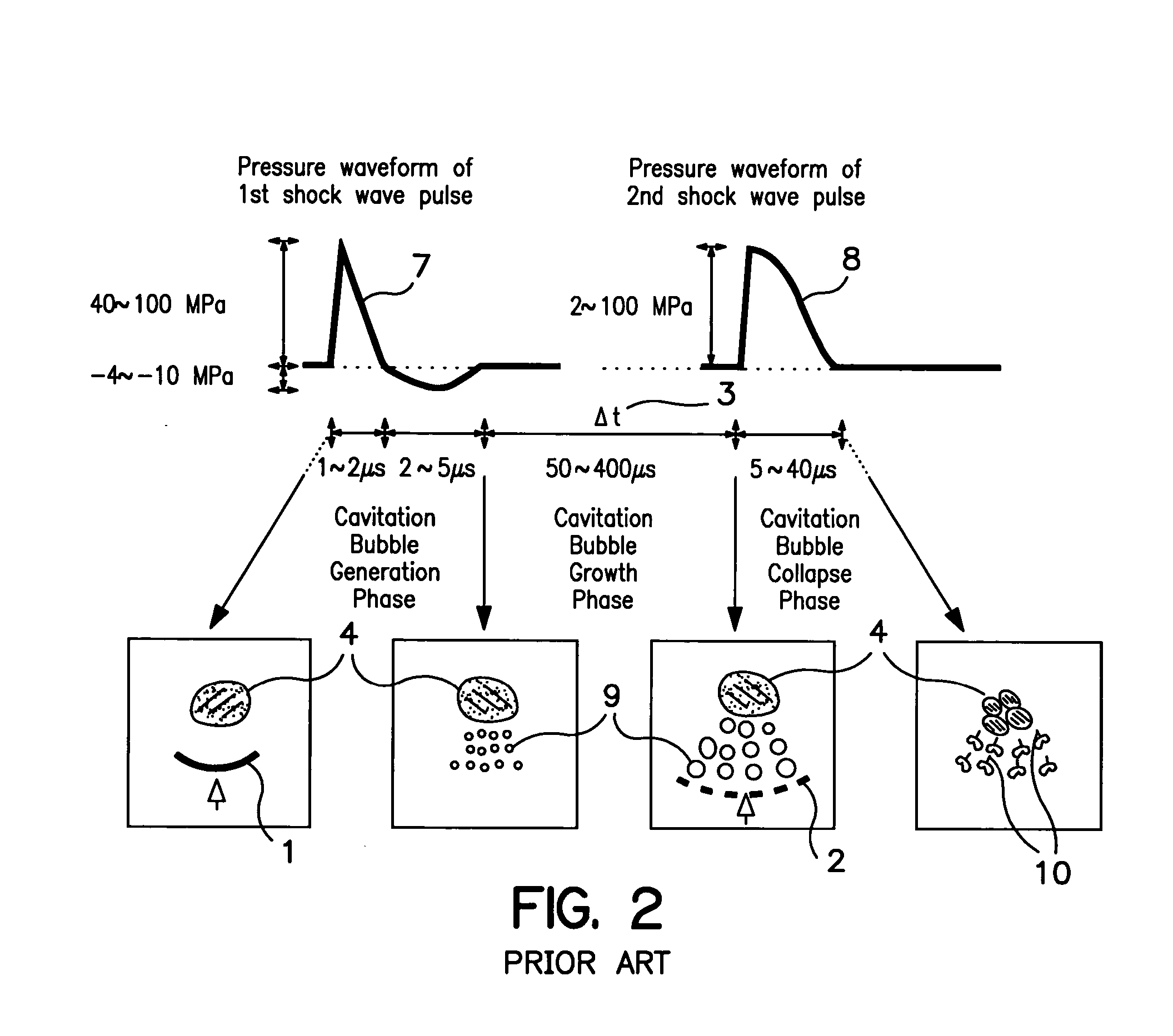

Apparatus for improved shock-wave lithotripsy (SWL) using a piezoelectric annular array (PEAA) shock-wave generator in combination with a primary shock wave source

InactiveUS20050038361A1Improve sharding efficiencyReduce tissue damageSurgeryChiropractic devicesElectricityTime delays

The invention relates to an improved apparatus for the comminution of concretions in vivo by controlled, concentrated cavitation energy using two shock wave pulses with a specified time delay and pressure relationship, with the first shock wave pulse being used to induce a transient cavitation bubble cluster near the target concretion, and the second shock wave pulse to control and force the collapse of the cavitation bubble cluster towards the target concretion with concentrated energy disposition while avoiding injury to surrounding tissue. The invention contemplates the use of an improved combined electrohydraulic or electromagnetic and a piezoelectric annular array shock wave generator to produce improved stone comminution with reduced tissue injury in vivo.

Owner:DUKE UNIV

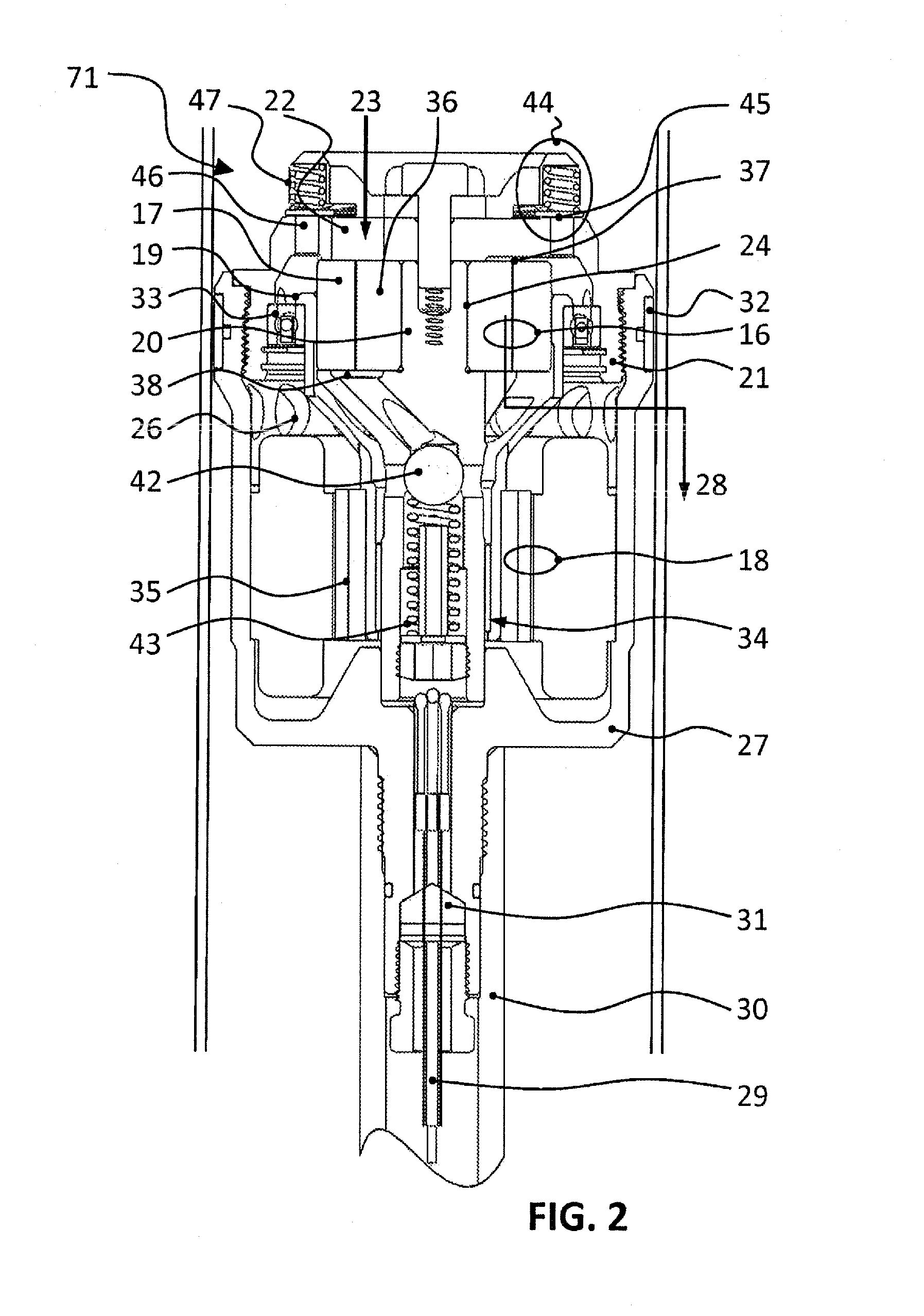

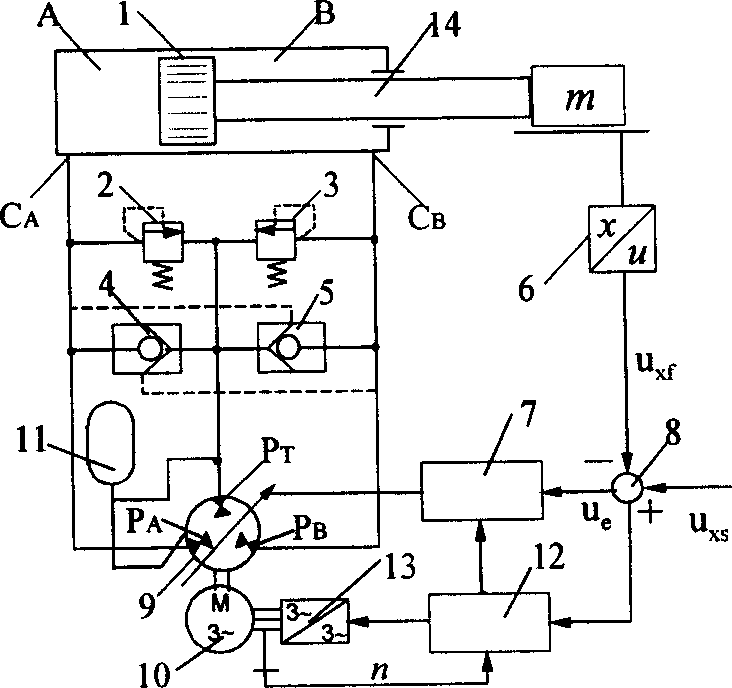

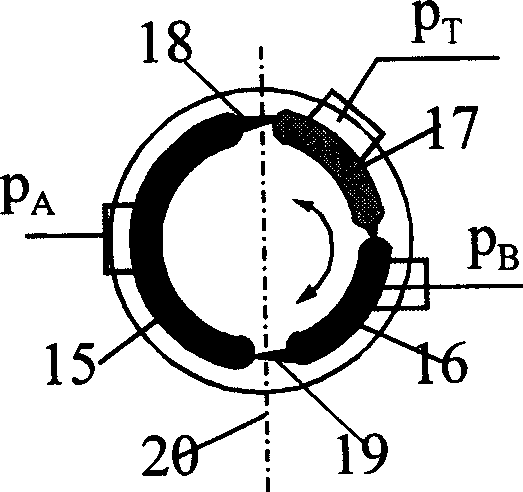

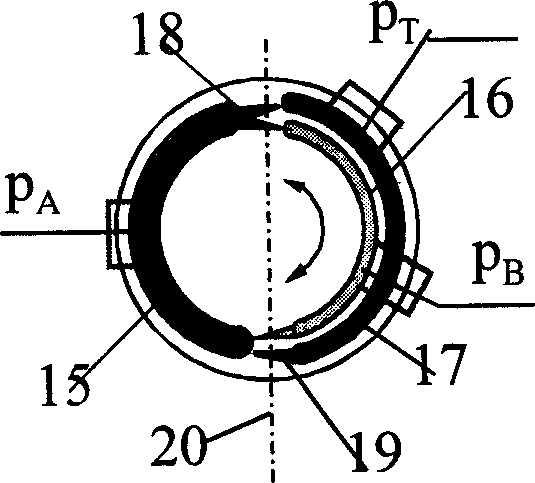

Closed electrohydraulic controlling system

InactiveCN1818382AControl movementPromote sportsFluid-pressure actuatorsPump controlHydraulic cylinderControl system

A closed electro-hydraulic control system comprised a differential hydraulic cylinder, two safety valves, a small path fluid one-way valve, a displacement transducer, a subtractor, two controllers, a hydraulic pump, a prime motor, a low-pressure oil-supply system and a rotational speed governor. The hydraulic pump has three oil ports connected with a rod-free cavity, a rod cavity of the differential hydraulic cylinder and the low-pressure oil-supply system separately.

Owner:TAIYUAN UNIV OF TECH

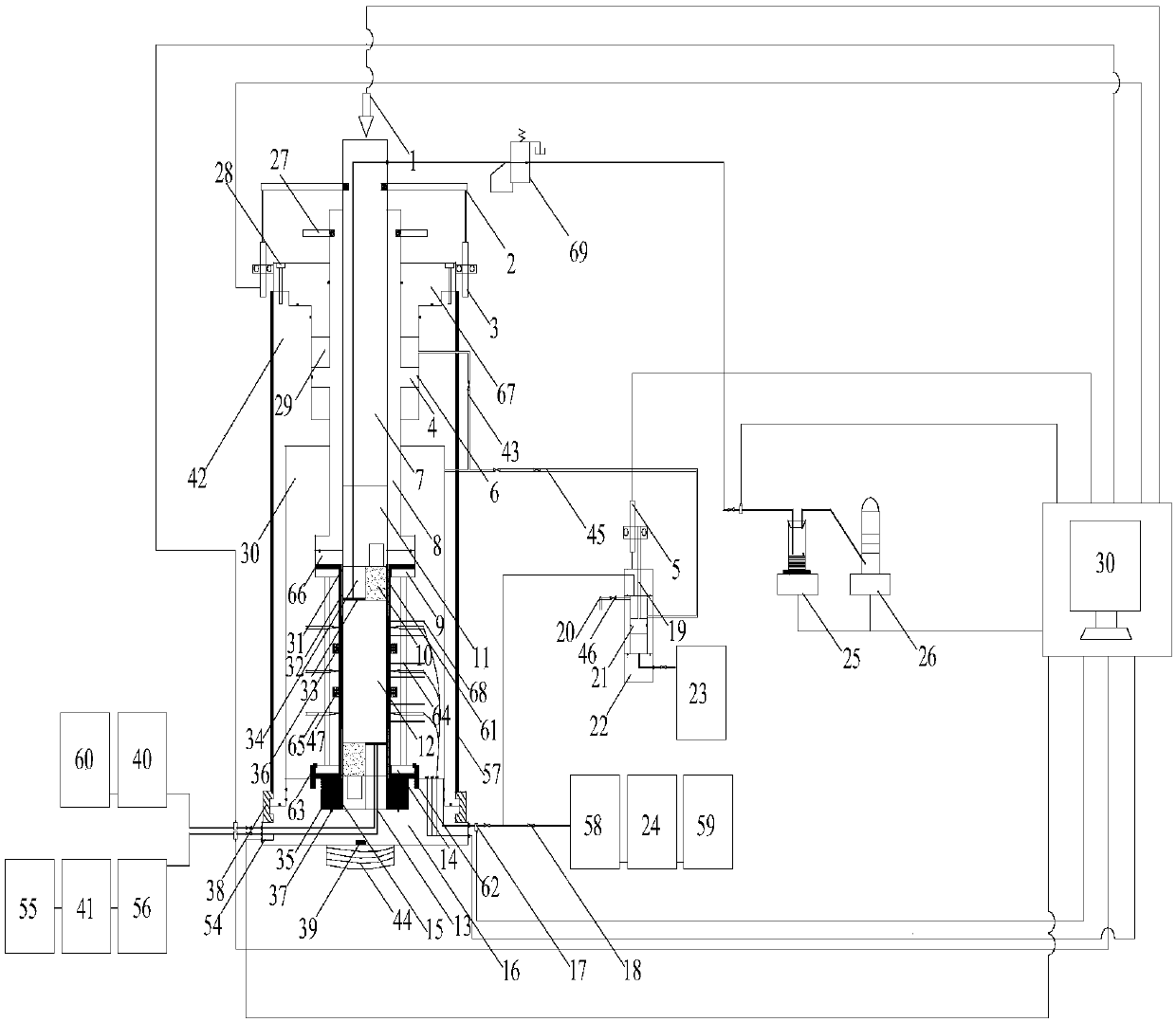

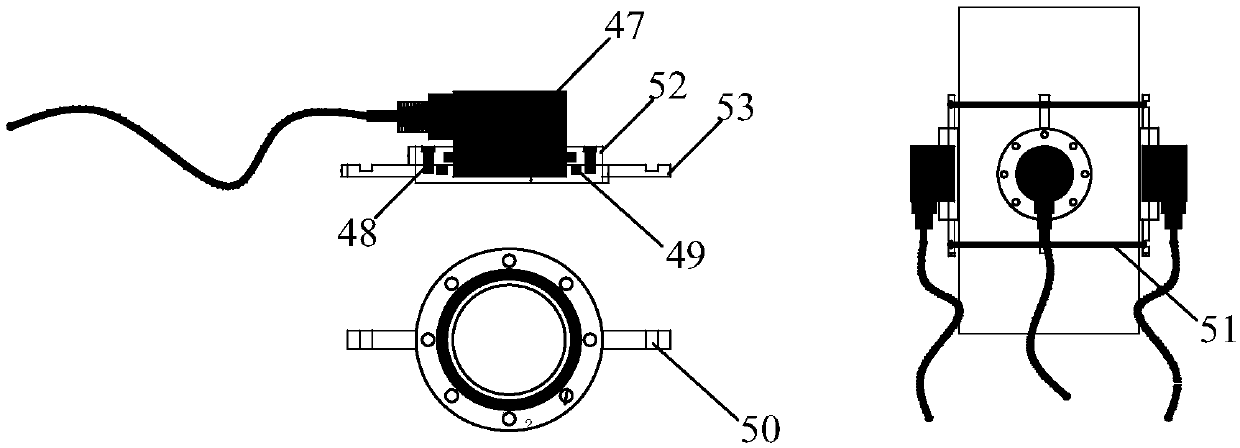

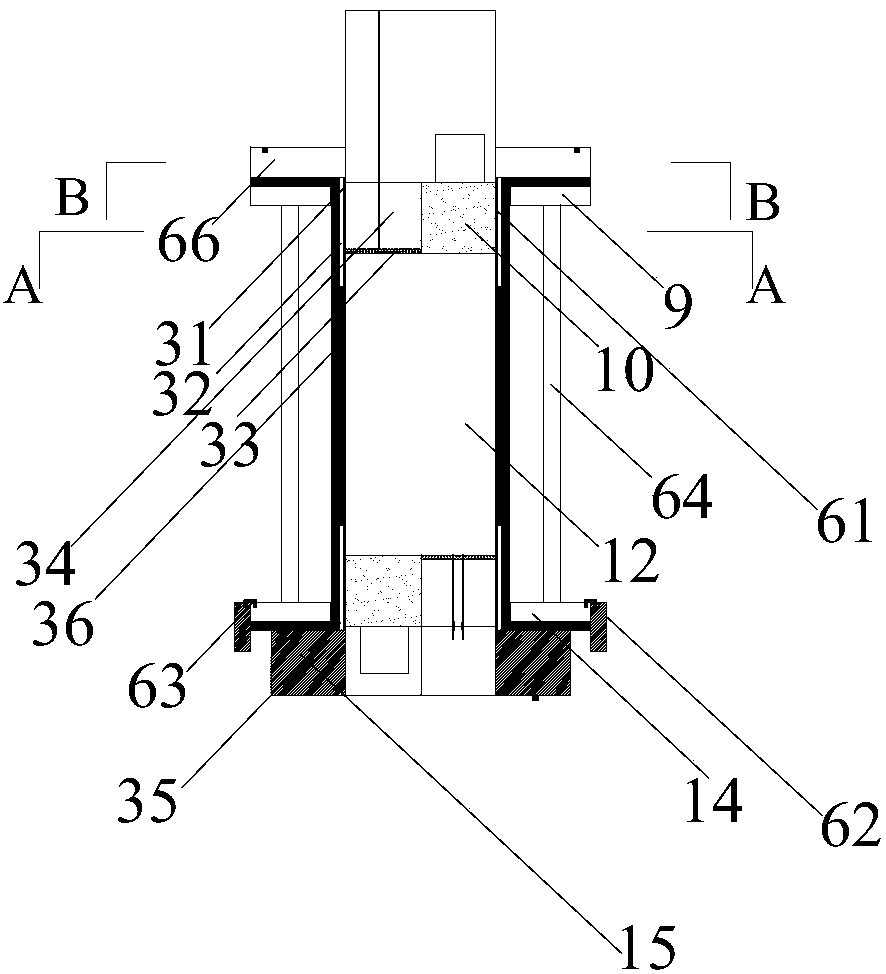

Microcomputer-controlled electro-hydraulic servo rock tri-axial dynamic shear-seepage coupling multifunctional test method

ActiveCN107748110AOvercoming direct shear-seepageEasy to disassembleMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesAxial pressureData acquisition

A microcomputer-controlled electro-hydraulic servo rock tri-axial dynamic shear-seepage coupling multifunctional test method belongs to the technical fields of rock mechanics and engineering technology and is characterized in that a test apparatus is composed of a loading system, a sealing system, a multiphase fluid injection system, an acoustic emission monitoring system, a deformation monitoringsystem and a data collection system. The test method not only solves technical problems that a tri-axial pressure chamber cannot be used for performing large displacement shear-seepage coupling of rocks under high confining pressure and high seepage pressure, and also can achieve various extended functions on the basis of the technology. The apparatus can achieve servo control loading of force, displacement and strain rate in shear direction and injection seepage of a multiphase fluid during dynamic shear. In addition, the apparatus is equipped with a temperature control system for performingconstant temperature control to the tri-axial pressure chamber at 0-200 DEG C; therefore, a series of extended experiments of dynamic shear-seepage coupling features of rocks under effect of temperature can be carried out.

Owner:TAIYUAN UNIV OF TECH

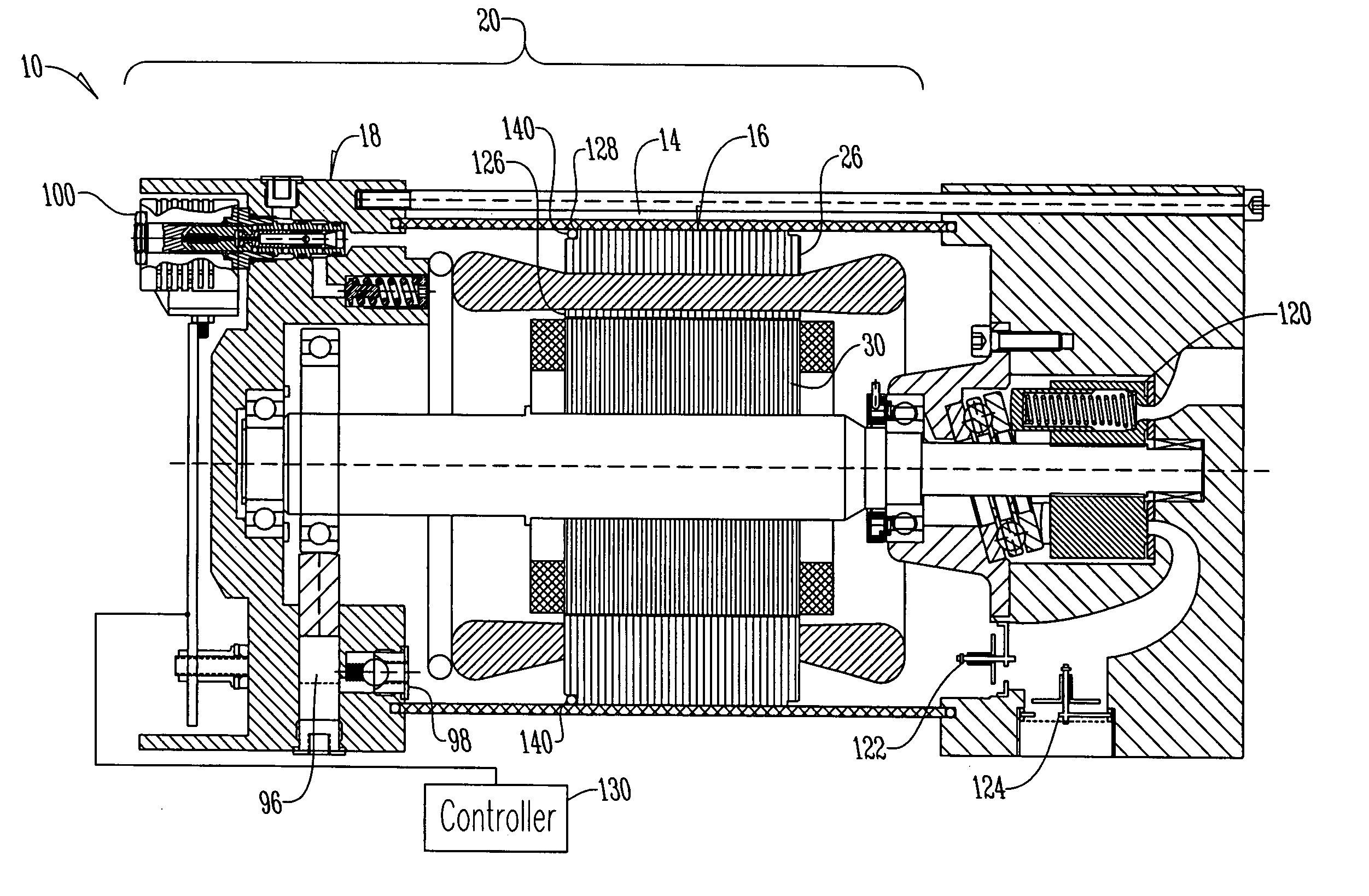

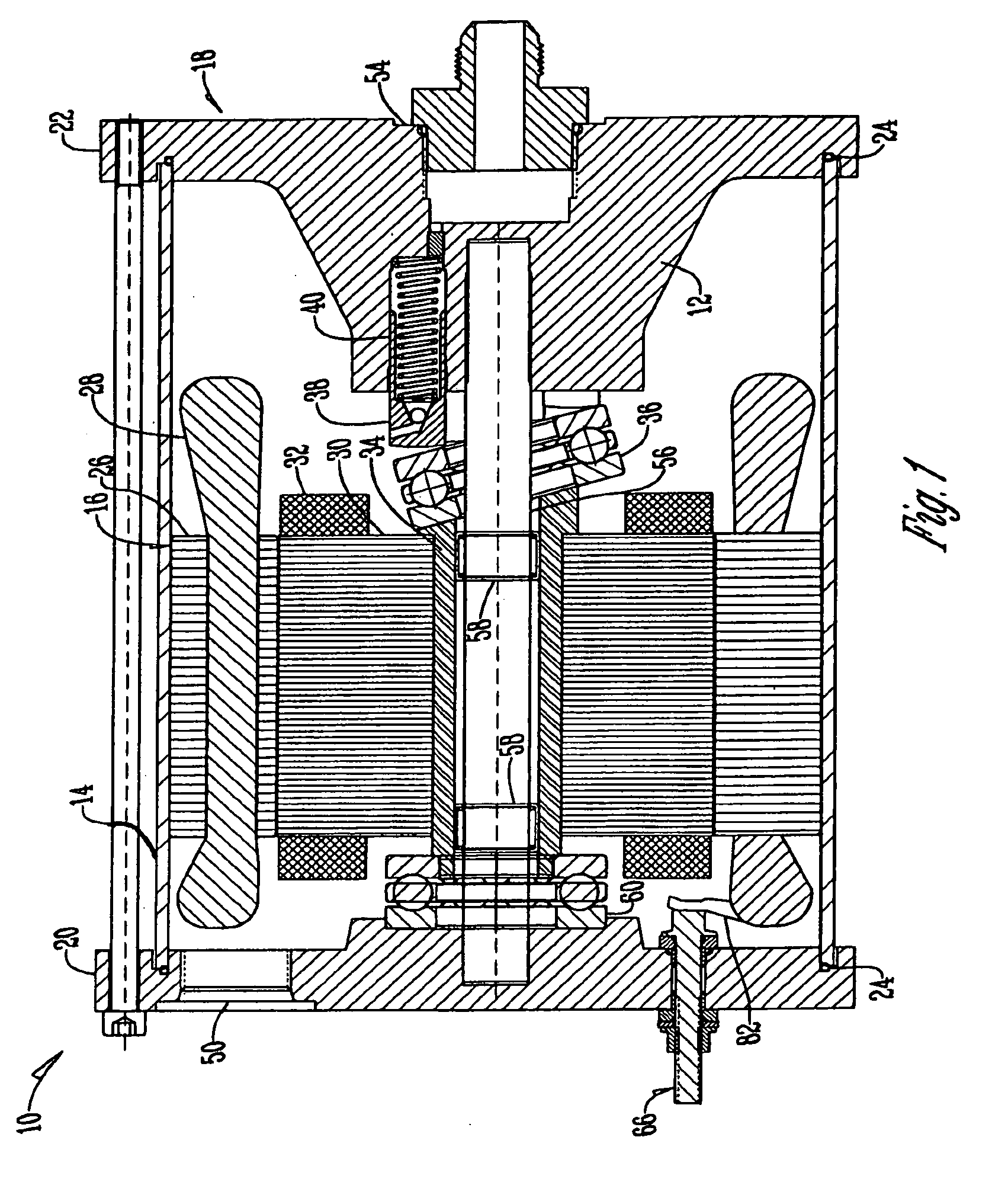

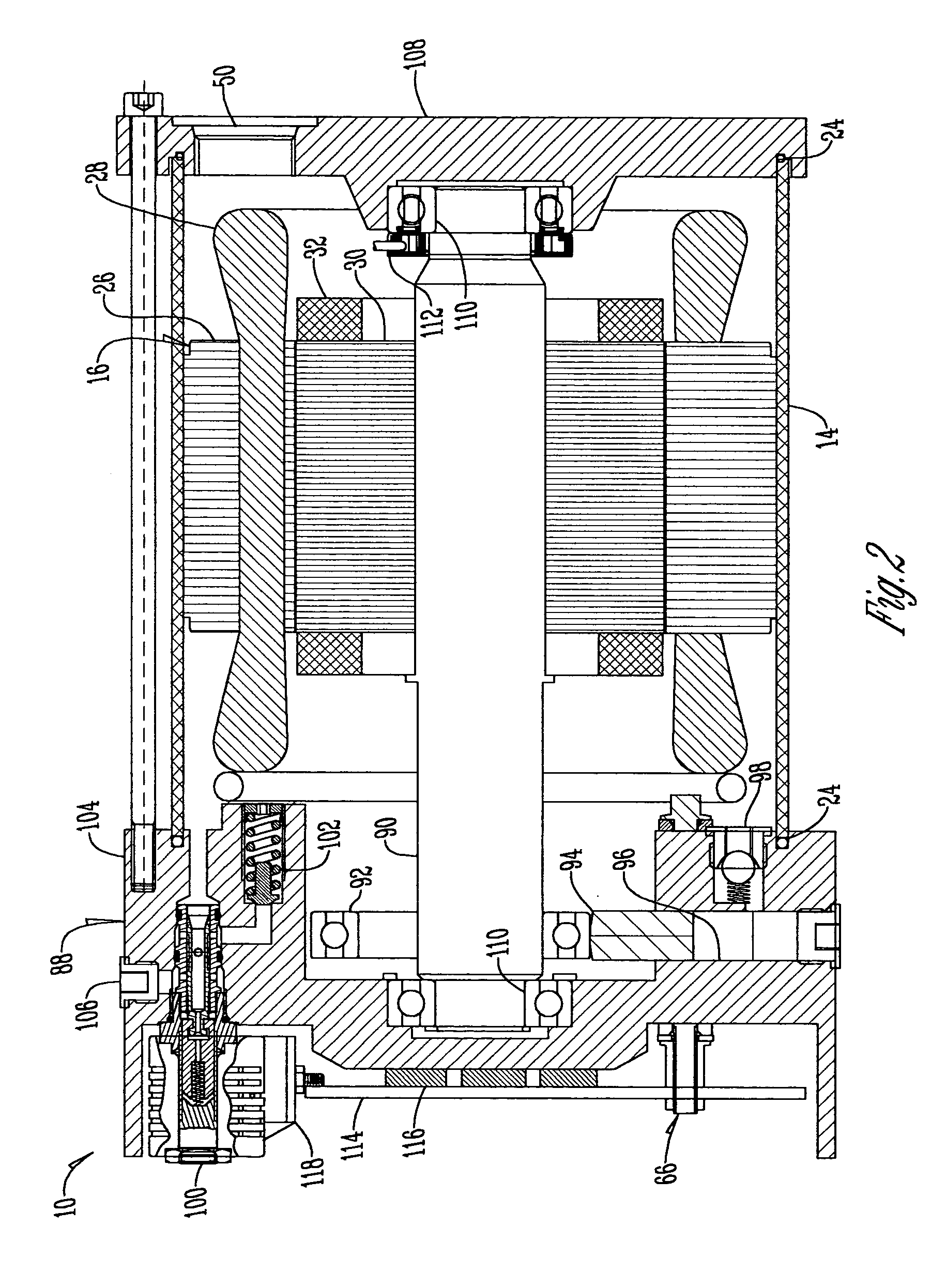

Electro-hydraulic power unit with a rotary cam hydraulic power unit

InactiveUS7182583B2Improve efficiencyImprove performancePositive displacement pump componentsGearing controlElectric machineElectro hydraulic

An electro-hydraulic power unit is disclosed that includes a housing filled with hydraulic fluid. A hydraulic power unit is disposed within the housing, the power unit having a mechanical power shaft. Additionally, an electric machine is disposed within the housing adjacent to the hydraulic power unit, the electric machine having a rotor secured to the mechanical power shaft of the hydraulic power unit. Hydraulic fluid within the housing passes over the electric machine, thus cooling the electric machine and providing for improved efficiency and performance.

Owner:SAUER DANFOSS NORDBERG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com