Patents

Literature

2586 results about "Hydraulic drive system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

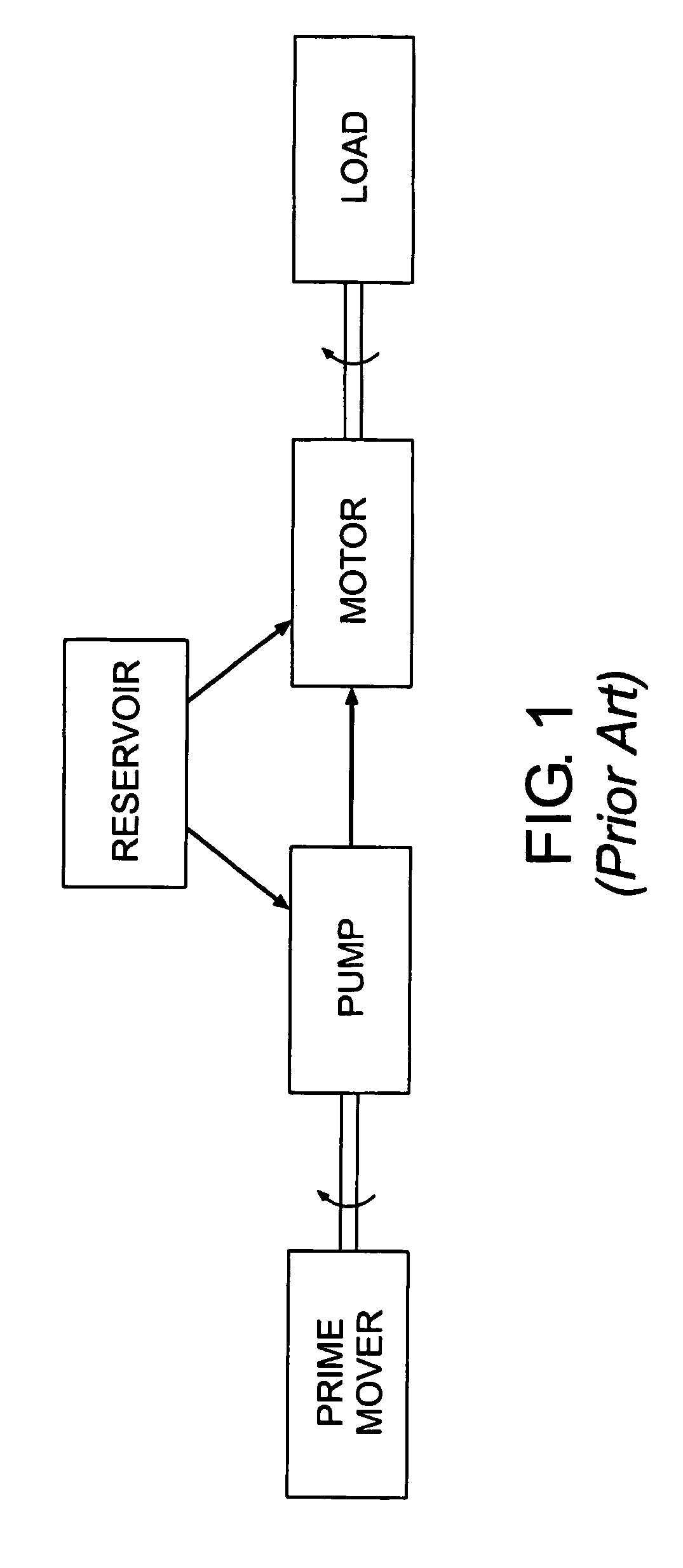

A hydraulic drive system is a quasi-hydrostatic drive or transmission system that uses pressurized hydraulic fluid to power hydraulic machinery. The term hydrostatic refers to the transfer of energy from pressure differences, not from the kinetic energy of the flow.

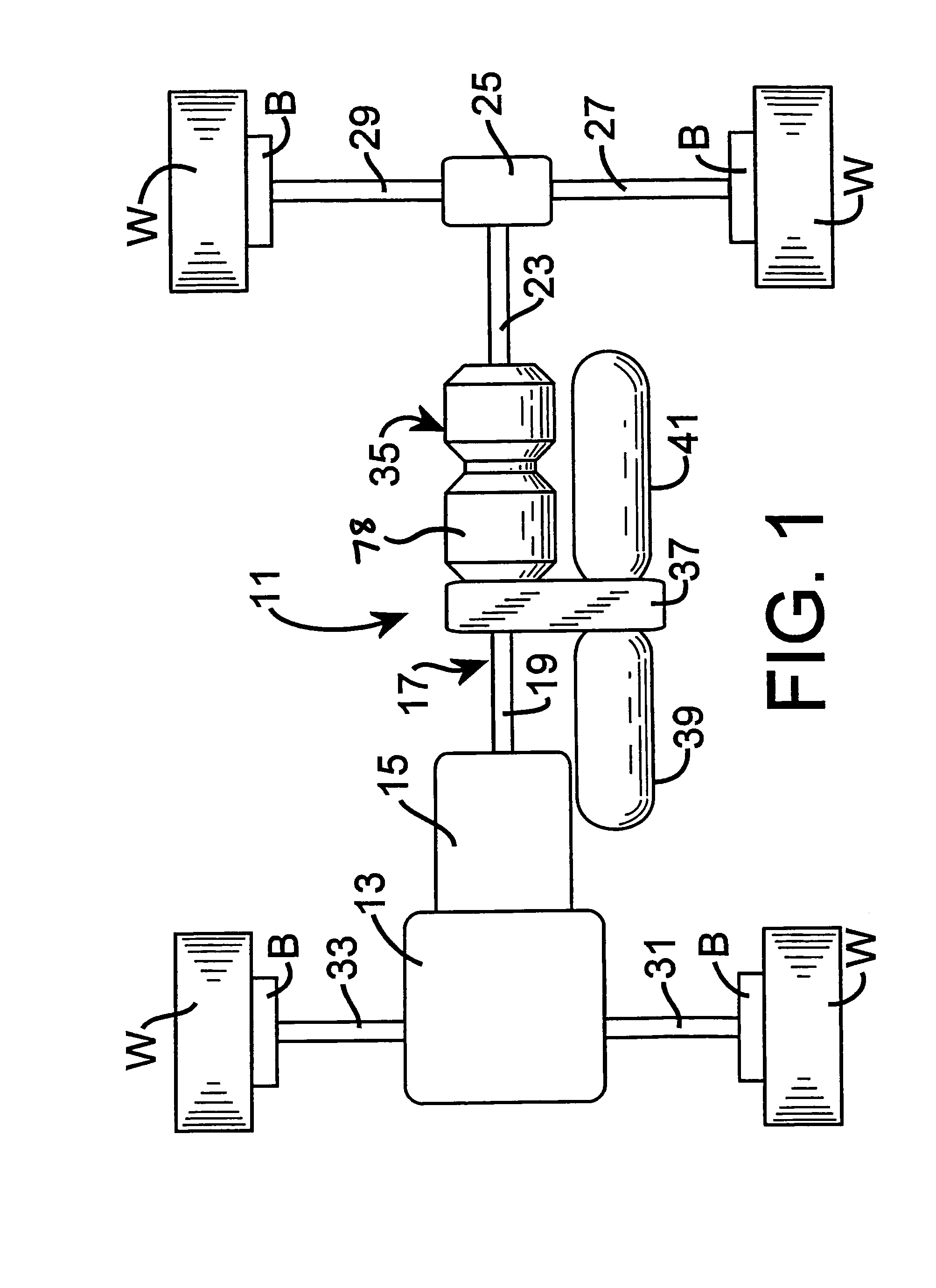

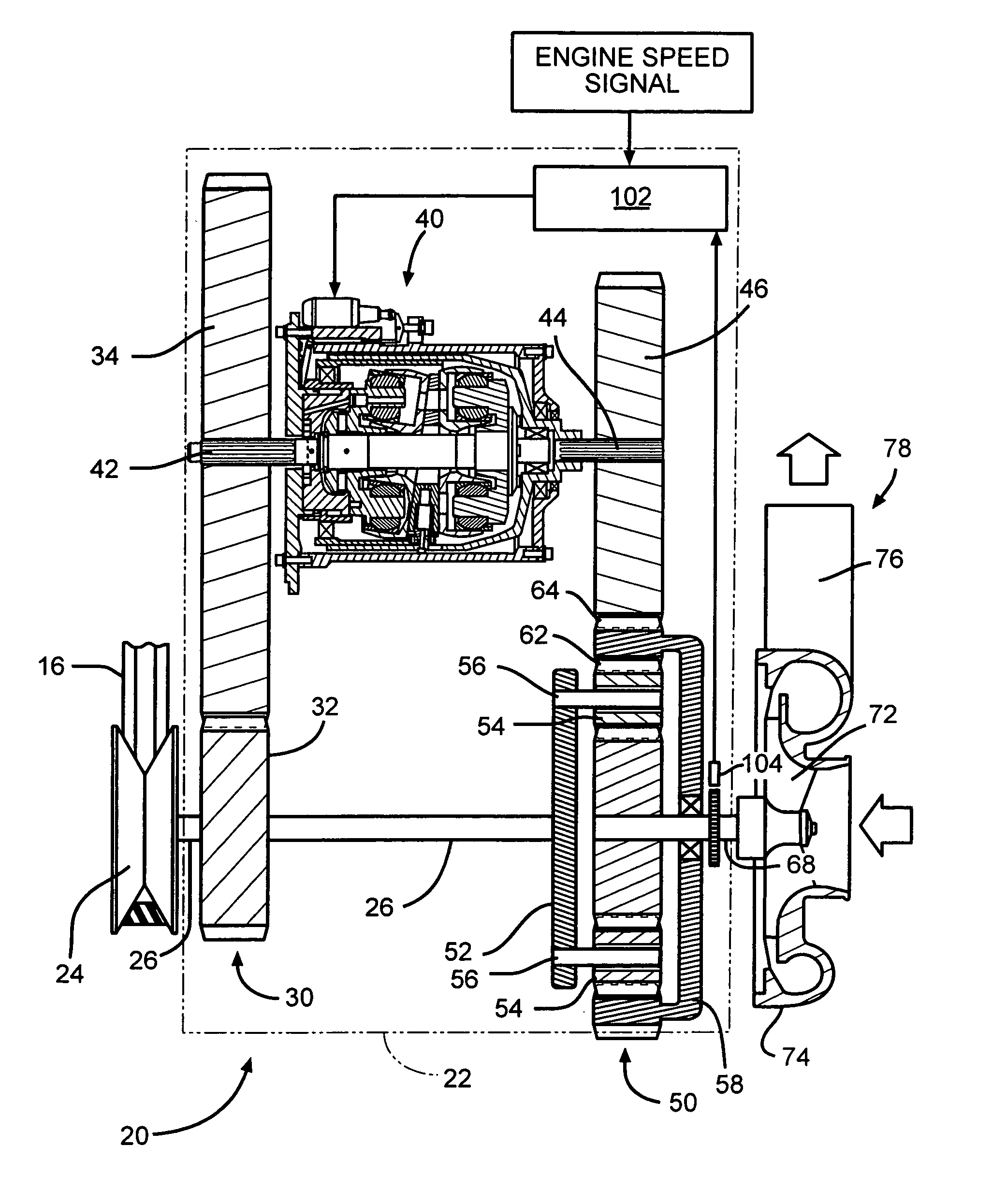

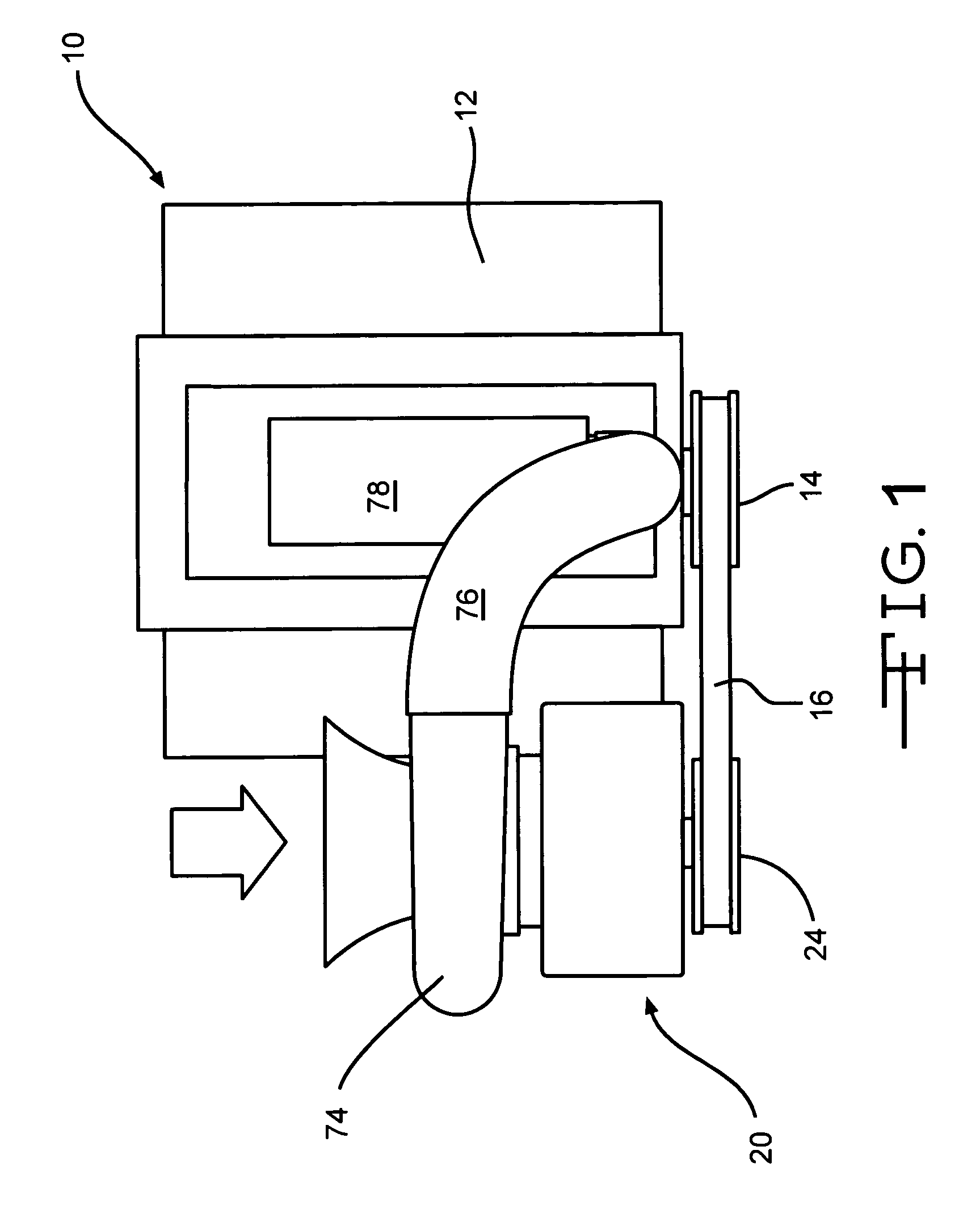

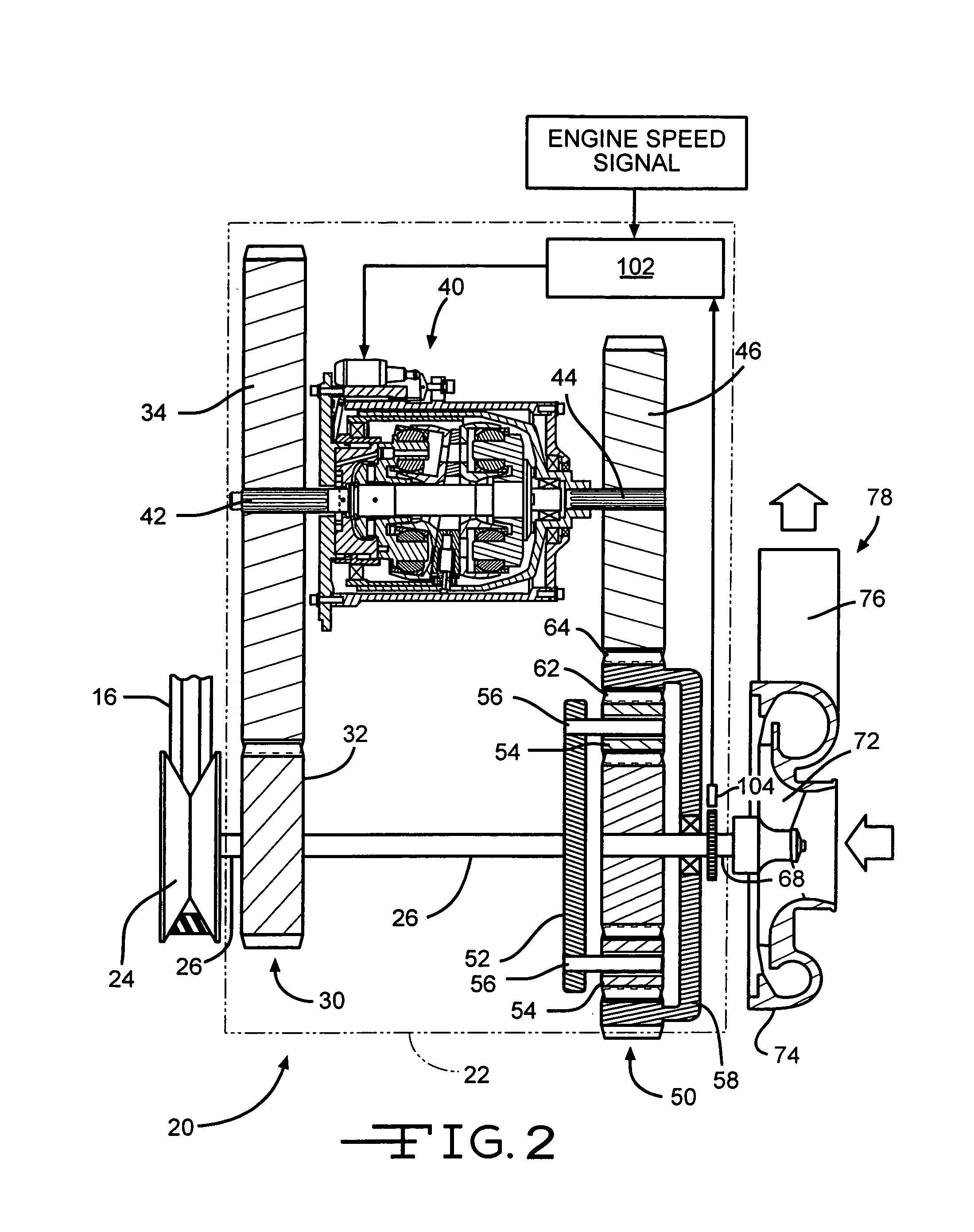

Hybrid hydraulic drive system with engine integrated hydraulic machine

InactiveUS7273122B2Equivalent performance levelsLow costAuxillary drivesGas pressure propulsion mountingDrive wheelEngineering

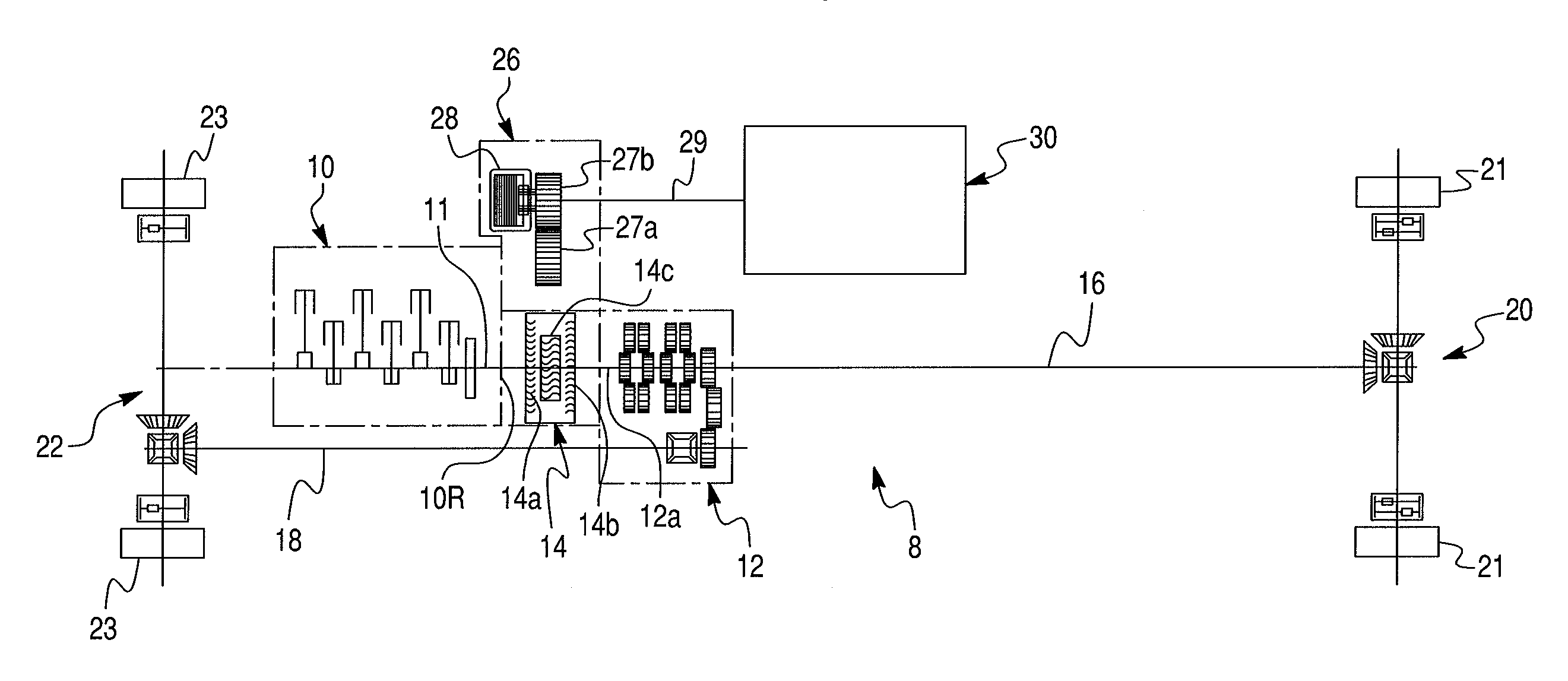

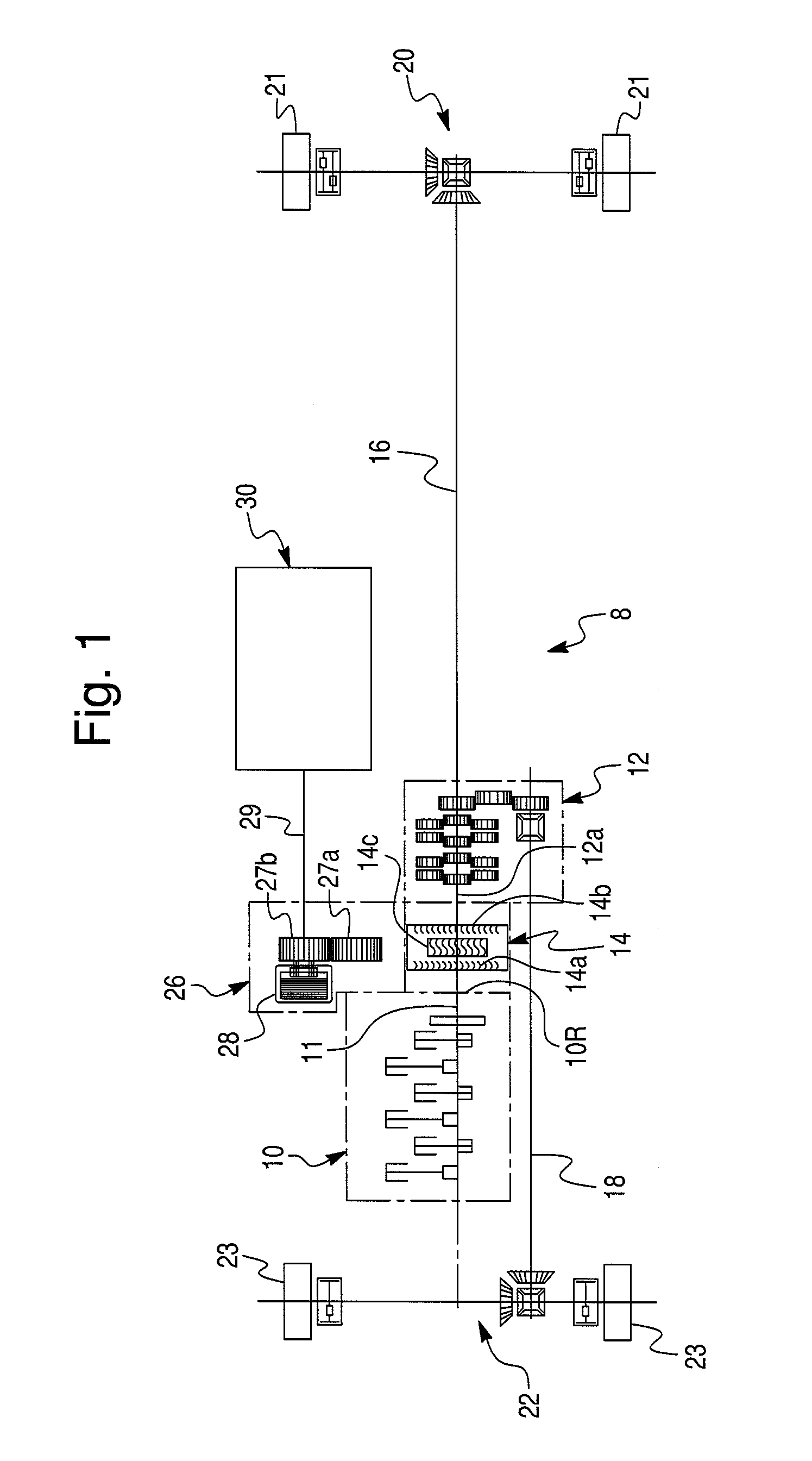

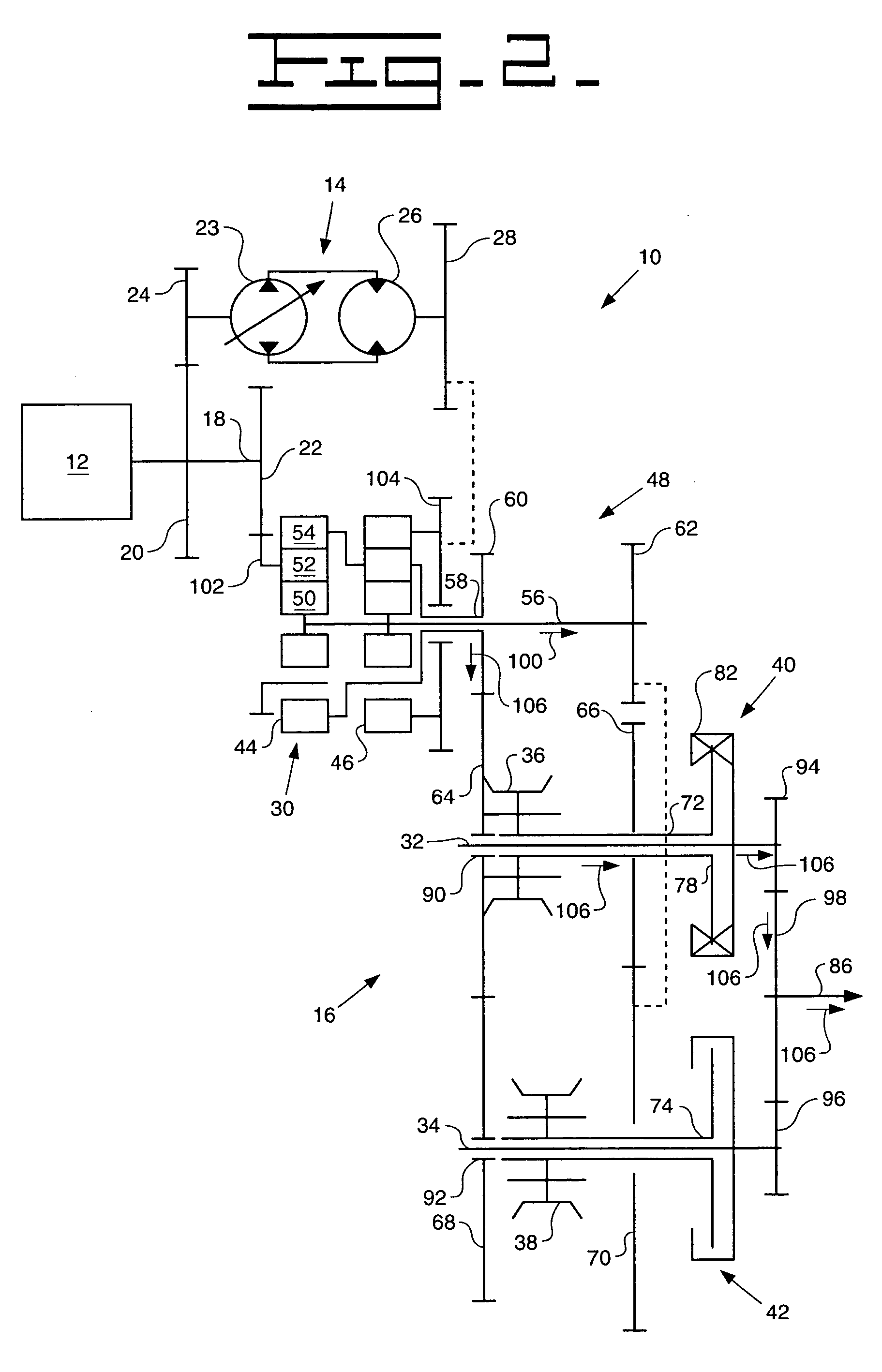

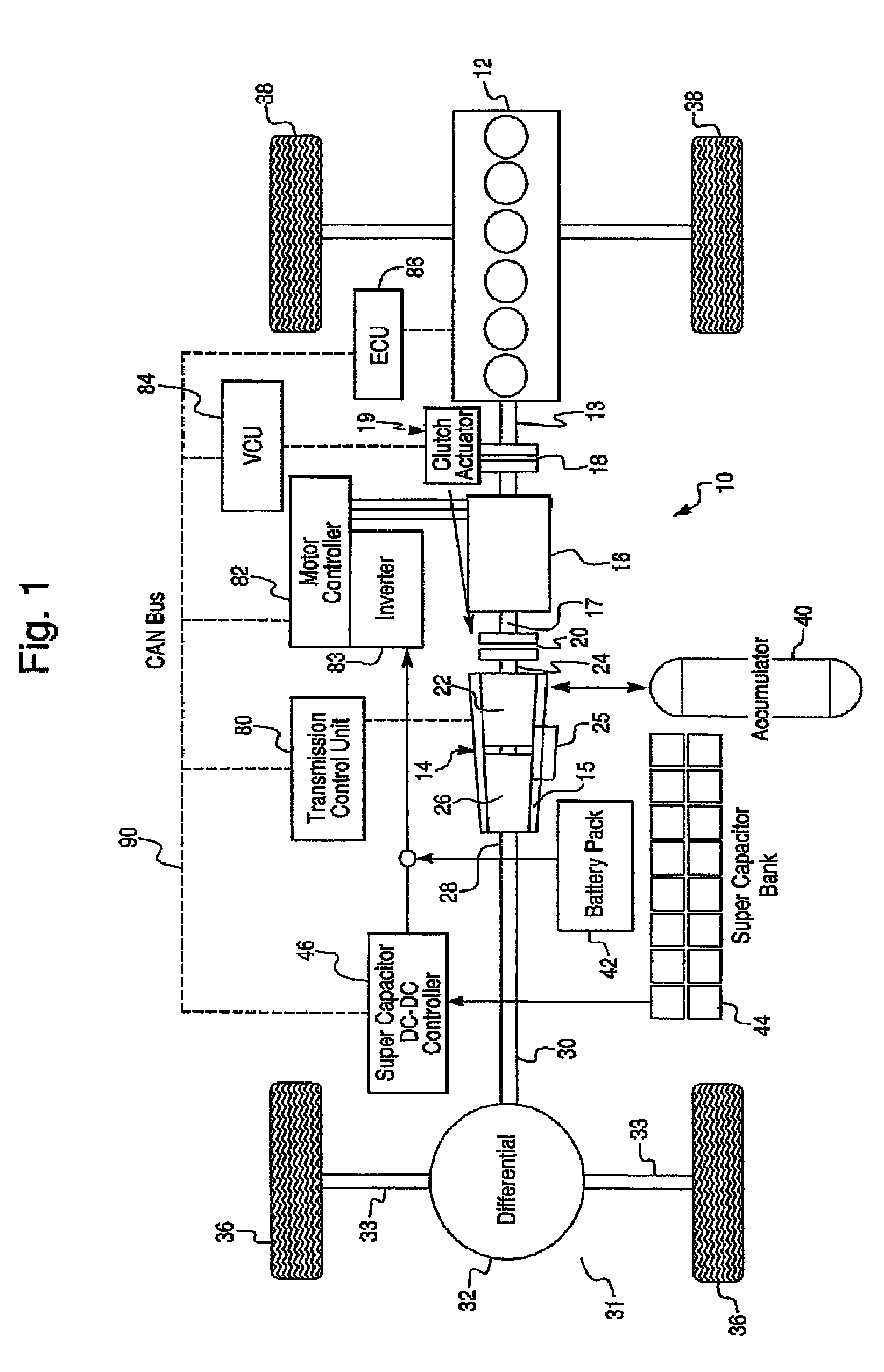

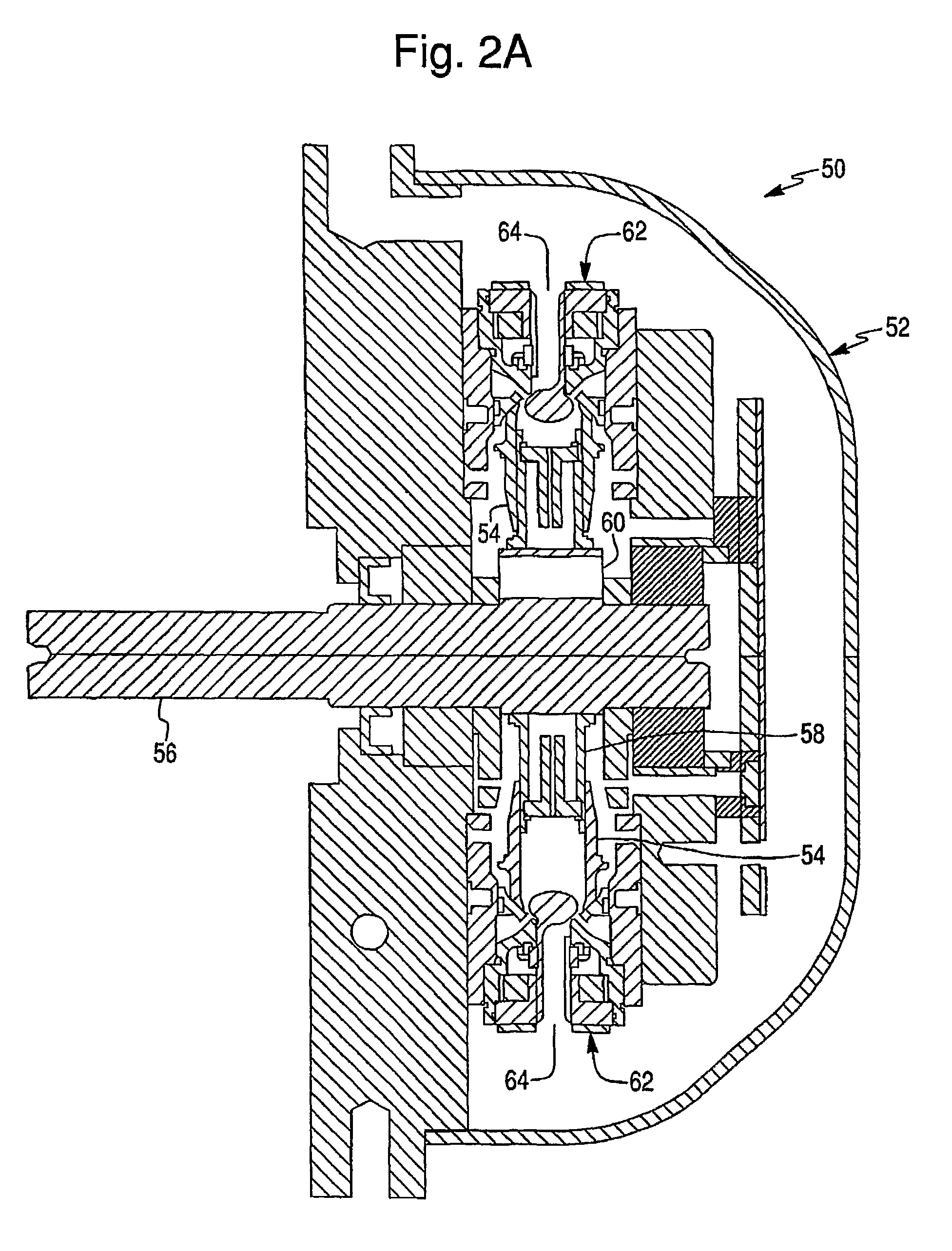

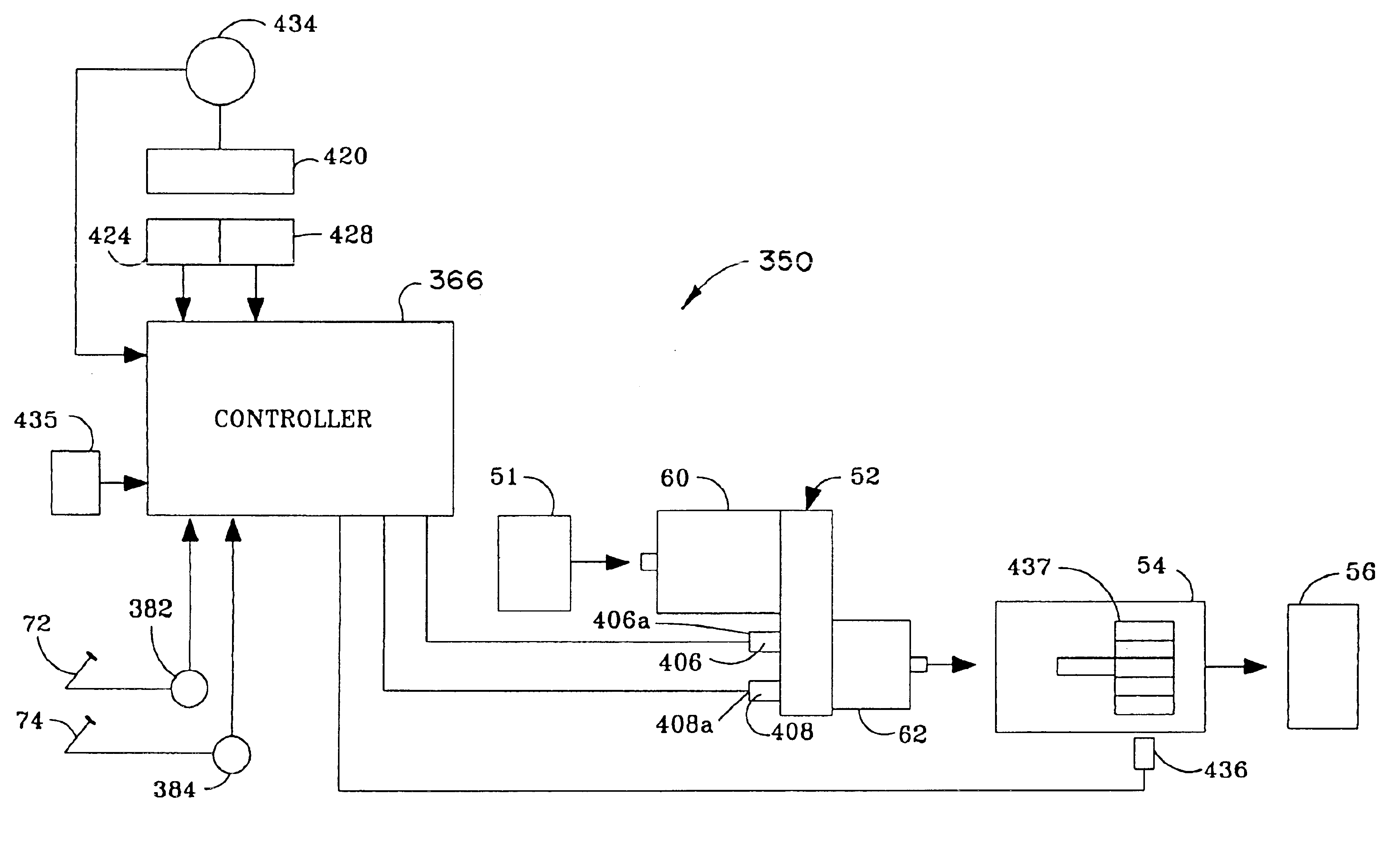

A hybrid hydraulic drive system for a vehicle comprises a prime mover, a transmission connecting the prime mover to drive wheels, a fluid energy storage accumulator, and a reversible hydraulic machine in fluid communication with the energy storage accumulator and drivingly coupled to the prime mover upstream of the transmission. The hybrid hydraulic drive system is arranged such that in a retarding mode the reversible hydraulic machine retards the drive wheels of the vehicle by pumping fluid into the accumulator. In a driving mode the reversible hydraulic machine supplies a supplementary power to the drive wheels of the vehicle using the pressurized fluid from the accumulator to assist propulsion of the vehicle. In a neutral mode the reversible hydraulic machine is disconnected from the prime mover to render the reversible hydraulic machine substantially inoperative to exert any significant driving or retarding influence on the drive wheels.

Owner:BOSCH REXROTH AG

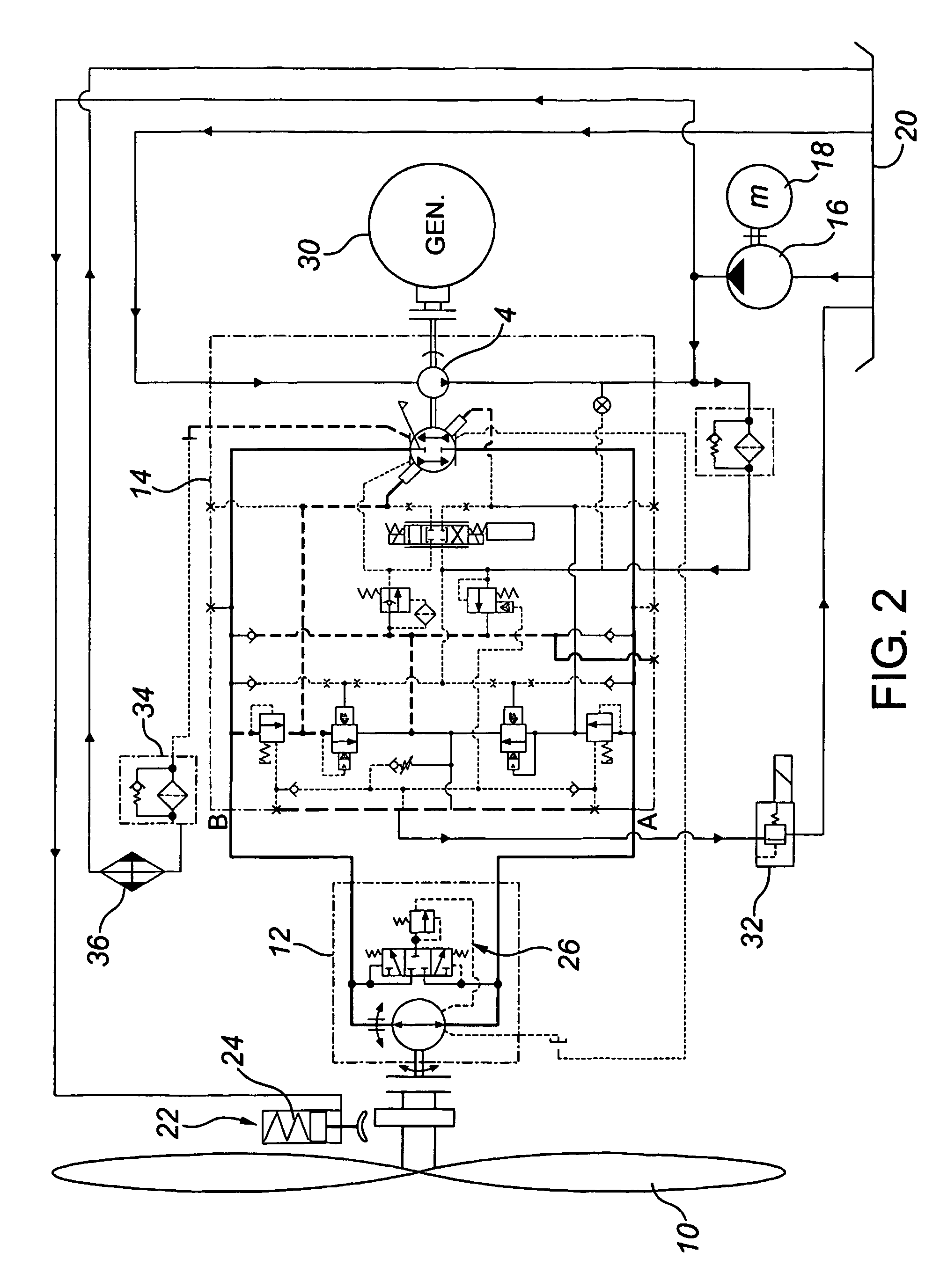

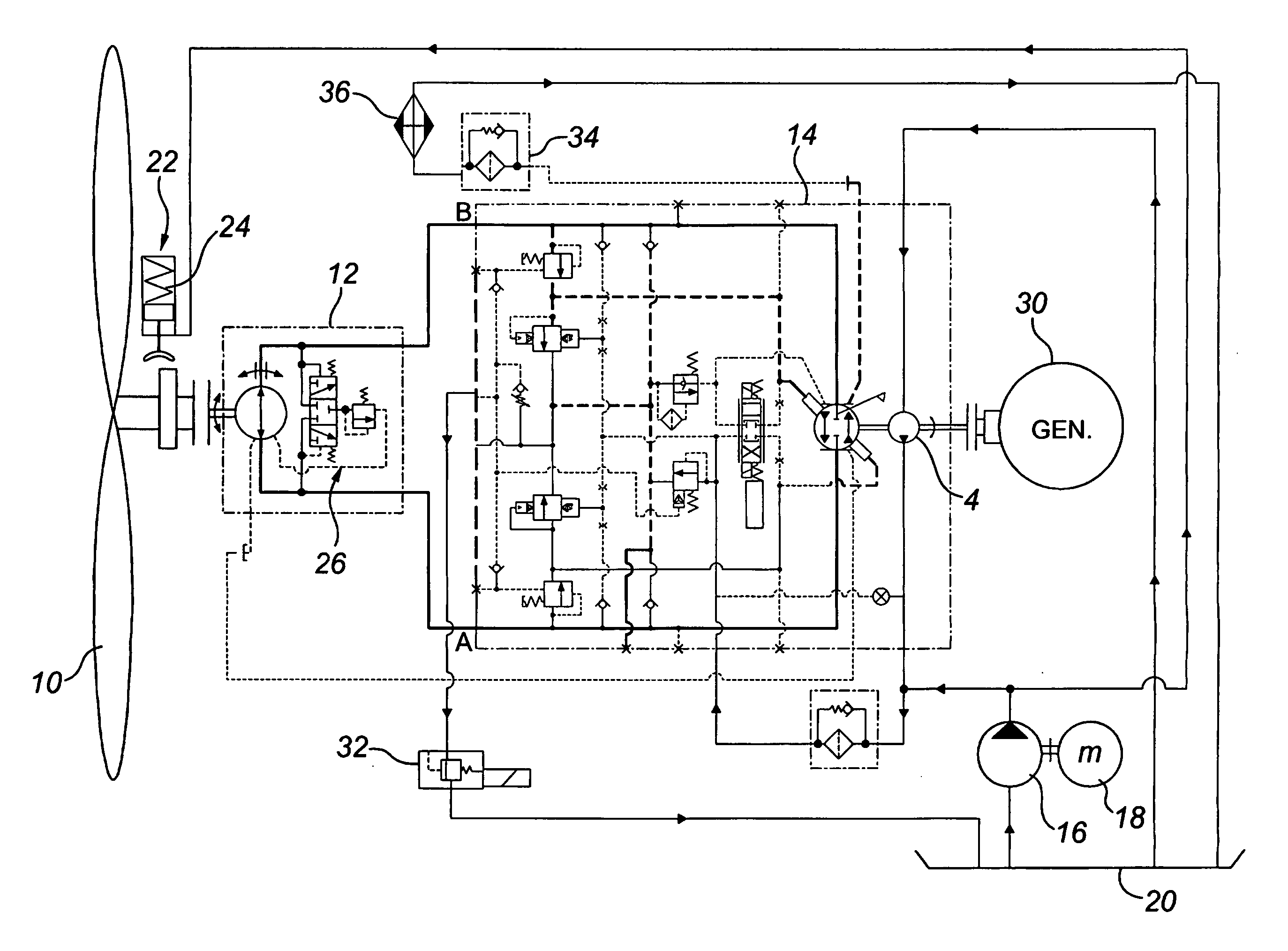

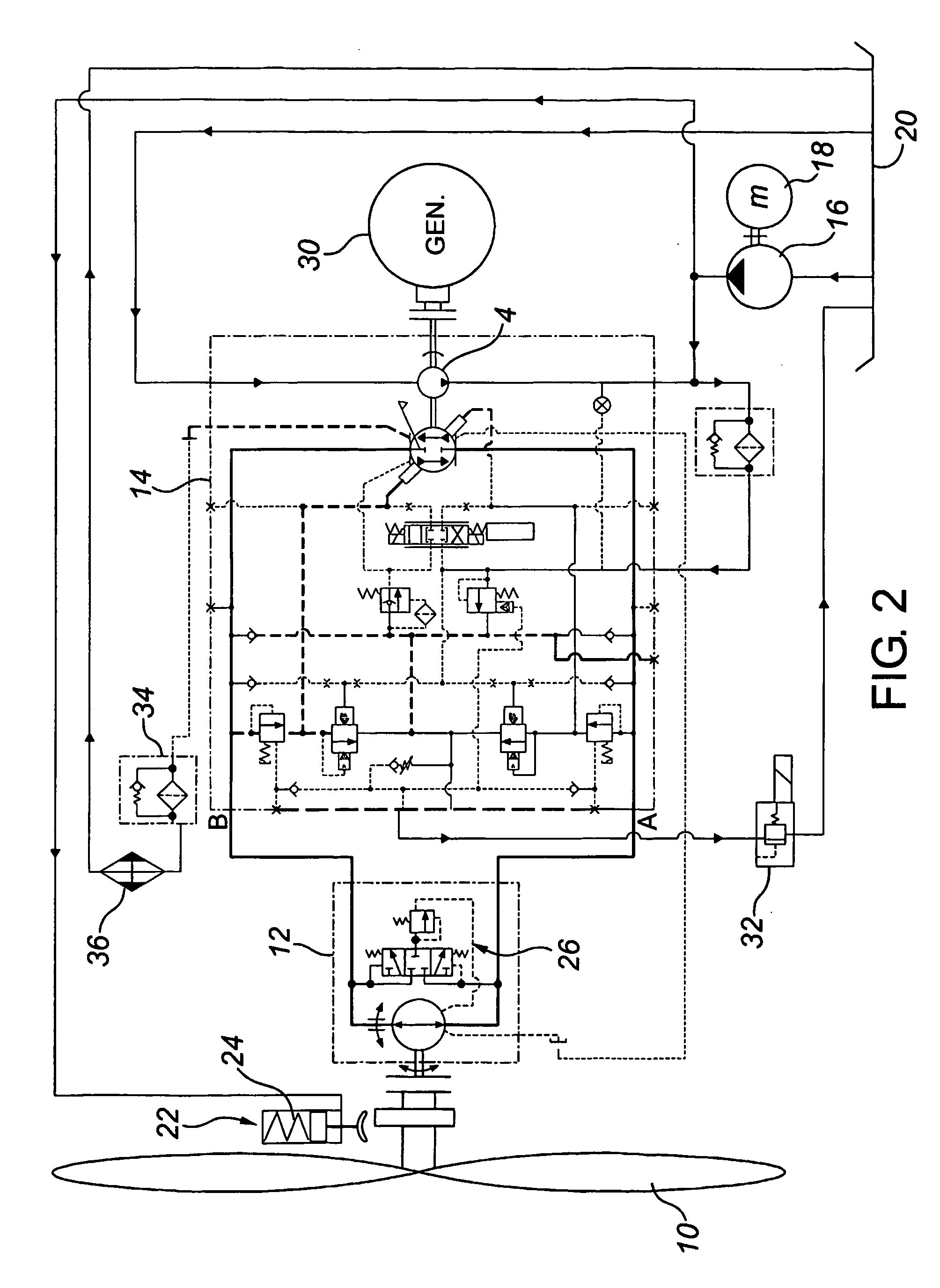

Wind turbine with hydraulic transmission

InactiveUS7418820B2Guaranteed normal transmissionAbsorb more horsepowerWind motor controlEngine fuctionsNacelleLow speed

Owner:MACKAY GARY

Hydromechanical transmission

A hydromechanical transmission having an input member, a hydrostatic transmission, and a mechanical transmission. The mechanical transmission includes first and second synchronizing assemblies for synchronizing at least one of a first or second output member with a combined output speed from the input member and the hydrostatic transmission. First and second clutch assemblies alternately engage to transfer power from the synchronized output member to a final drive.

Owner:CATERPILLAR INC

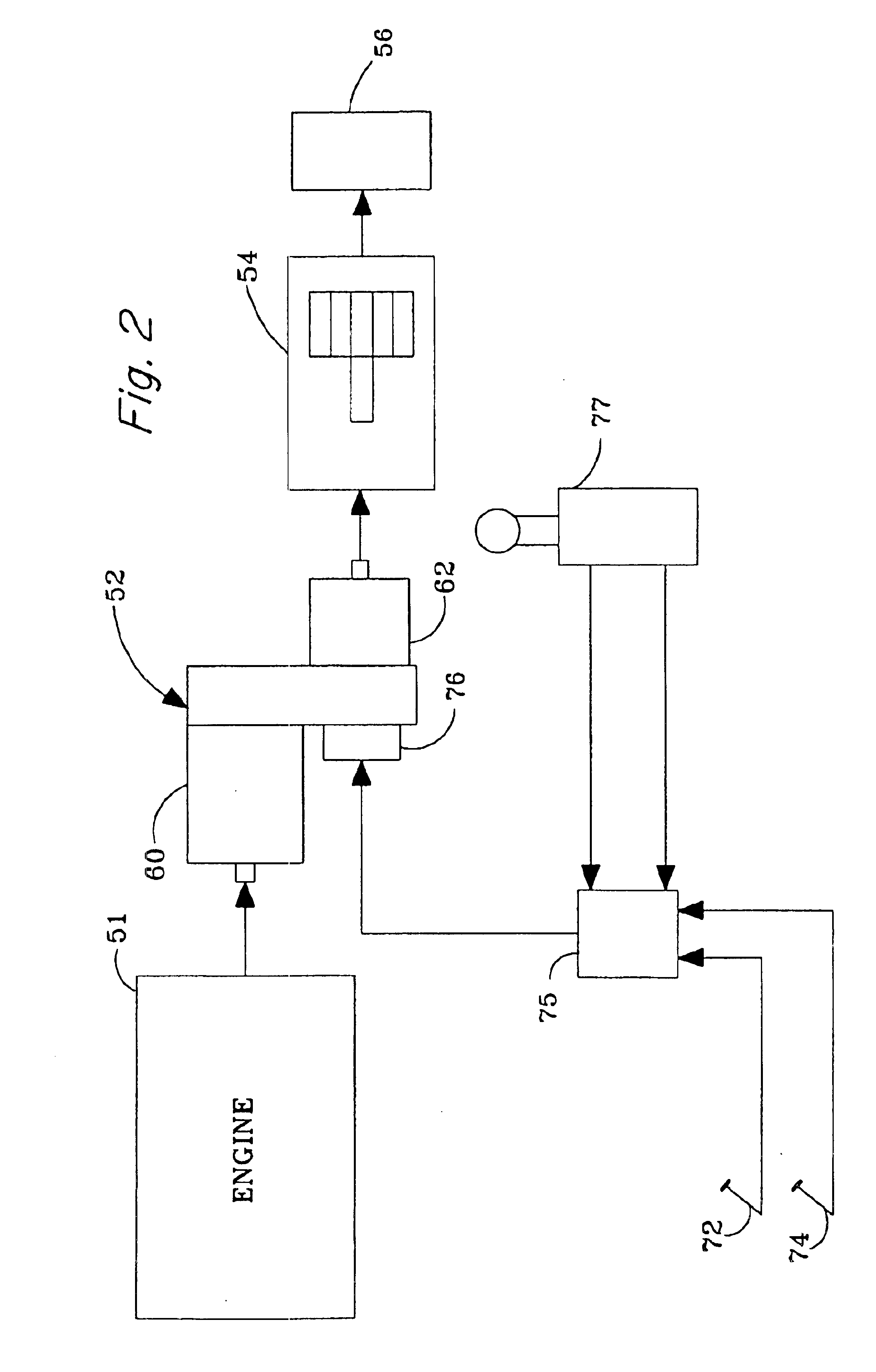

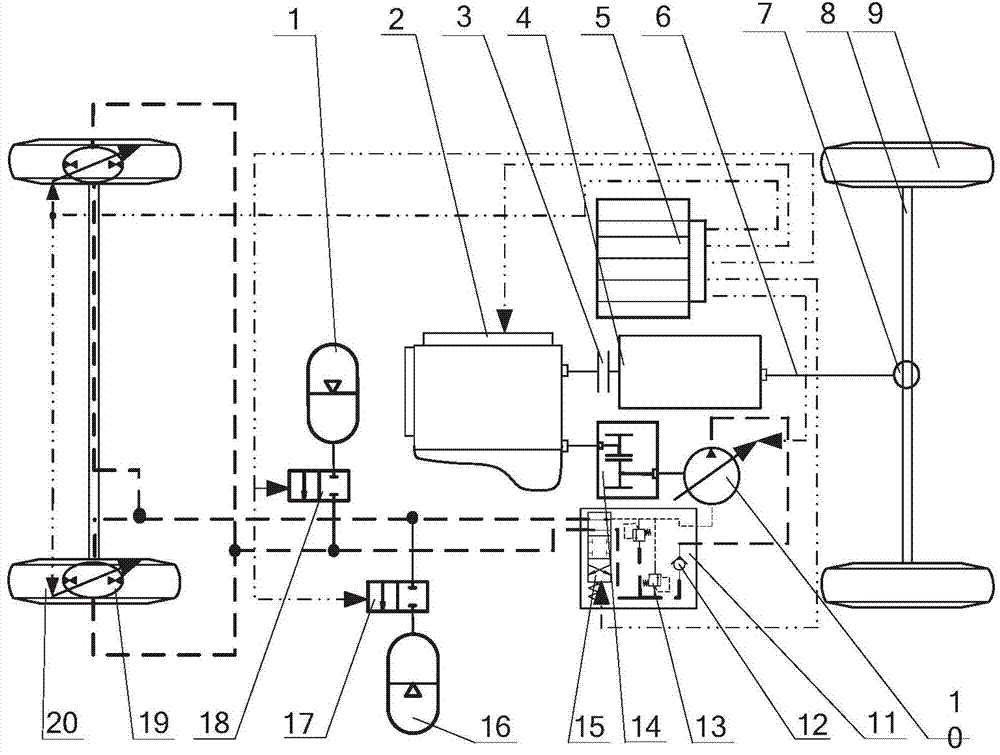

Hybrid hydraulic drive system with engine integrated hydraulic machine

InactiveUS20060068970A1Equivalent performance levelsLow costAuxillary drivesGas pressure propulsion mountingDrive wheelEnergy storage

A hybrid hydraulic drive system for a vehicle comprises a prime mover, a transmission connecting the prime mover to drive wheels, a fluid energy storage accumulator, and a reversible hydraulic machine in fluid communication with the energy storage accumulator and drivingly coupled to the prime mover upstream of the transmission. The hybrid hydraulic drive system is arranged such that in a retarding mode the reversible hydraulic machine retards the drive wheels of the vehicle by pumping fluid into the accumulator. In a driving mode the reversible hydraulic machine supplies a supplementary power to the drive wheels of the vehicle using the pressurized fluid from the accumulator to assist propulsion of the vehicle. In a neutral mode the reversible hydraulic machine is disconnected from the prime mover to render the reversible hydraulic machine substantially inoperative to exert any significant driving or retarding influence on the drive wheels.

Owner:BOSCH REXROTH AG

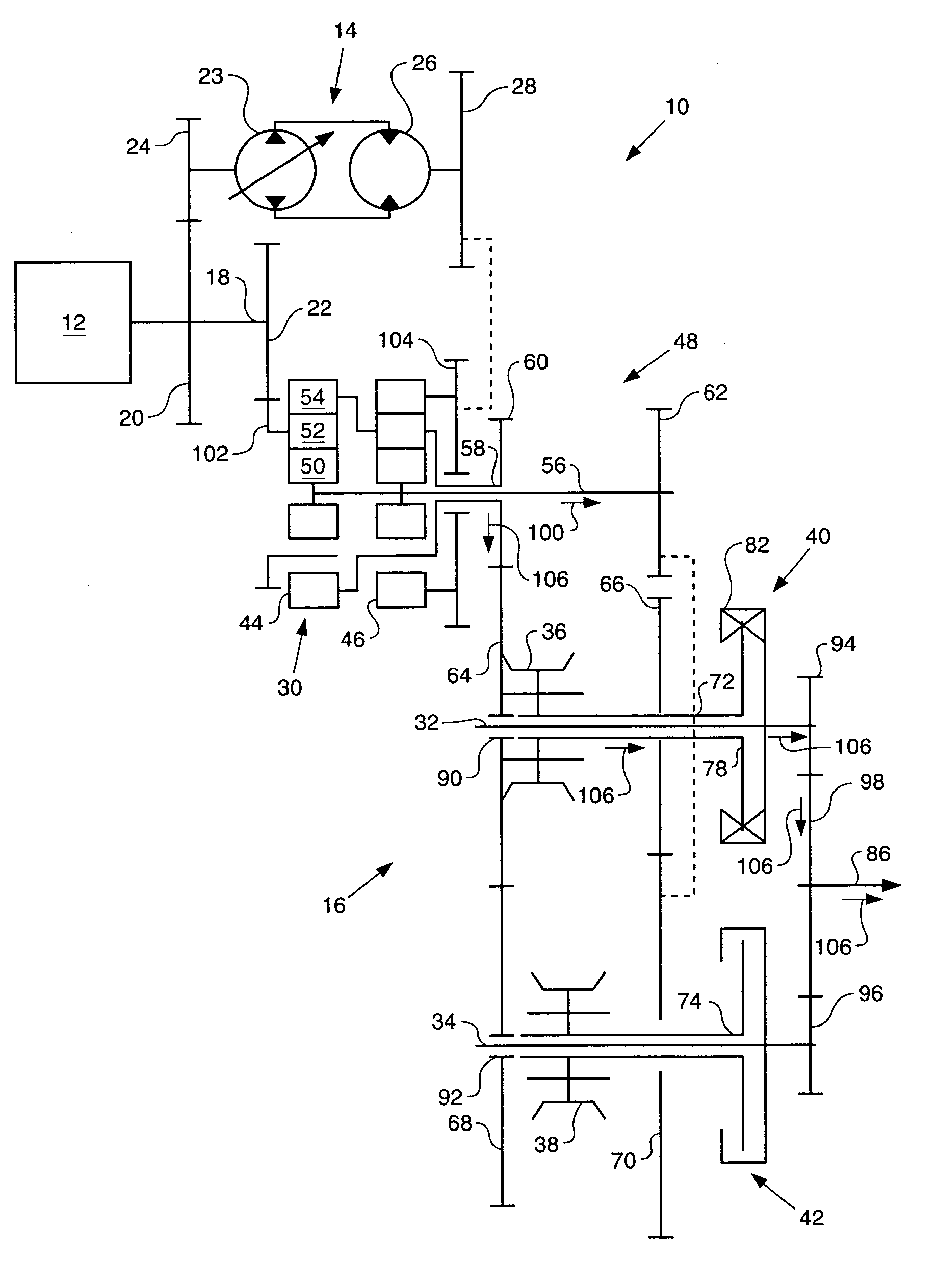

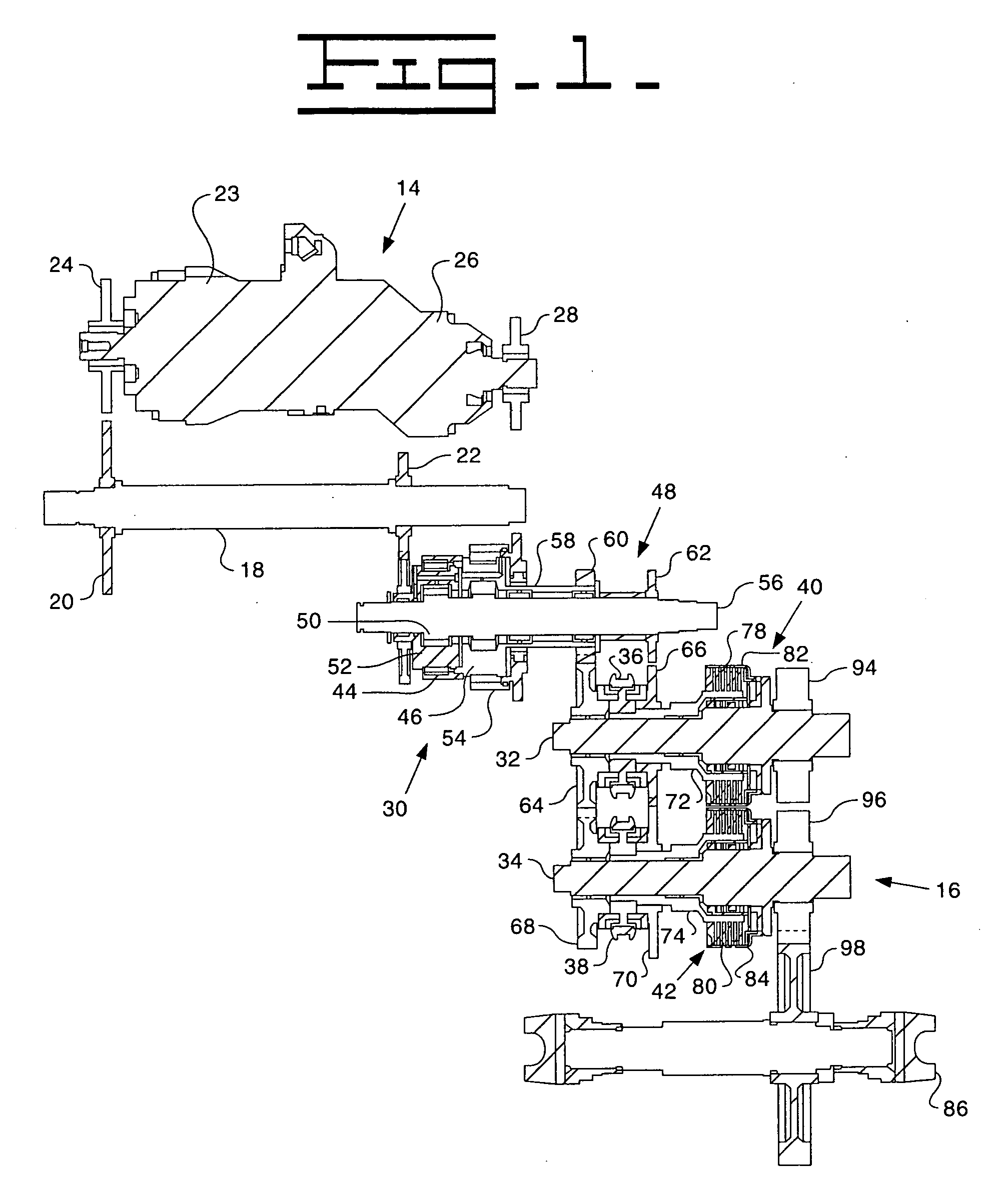

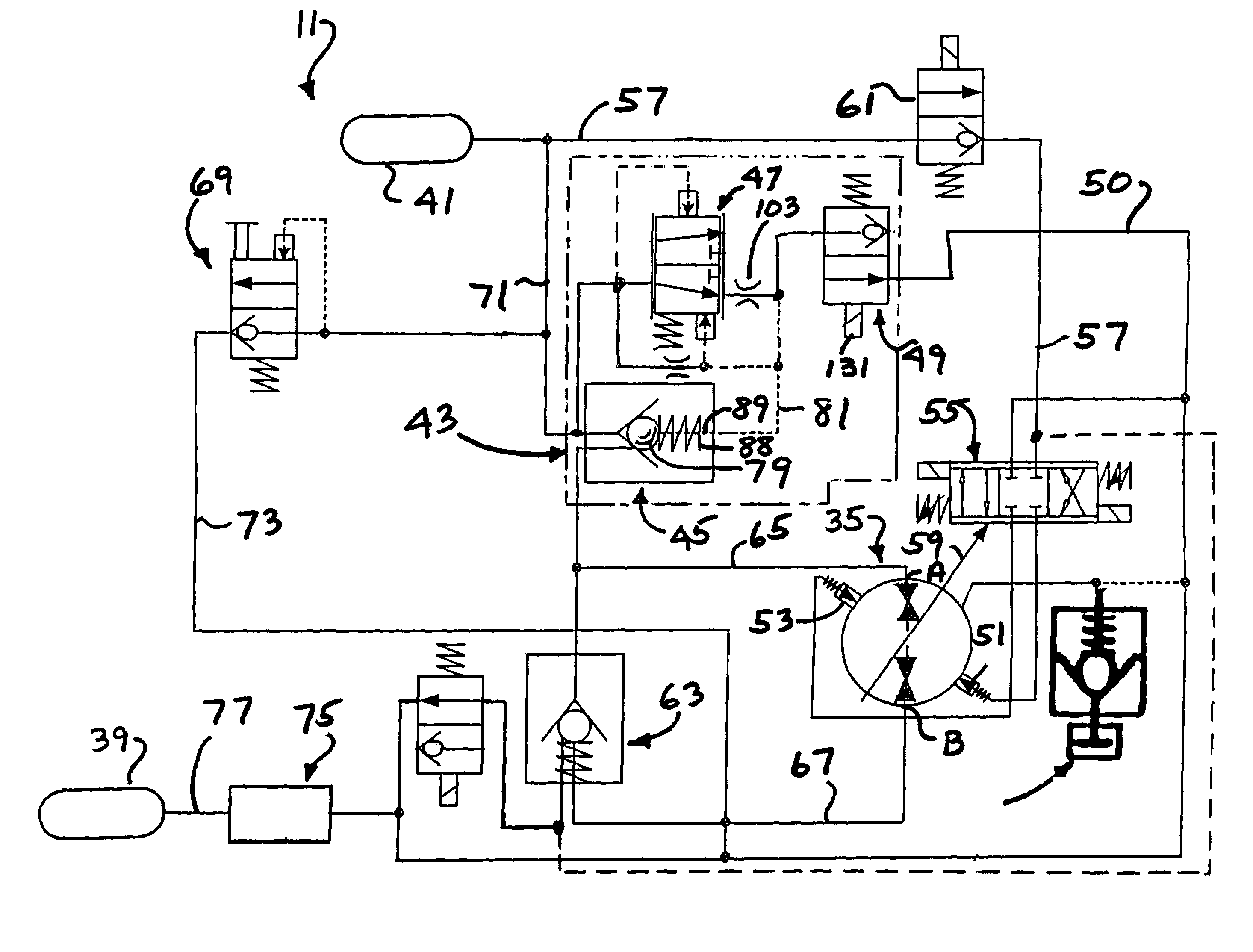

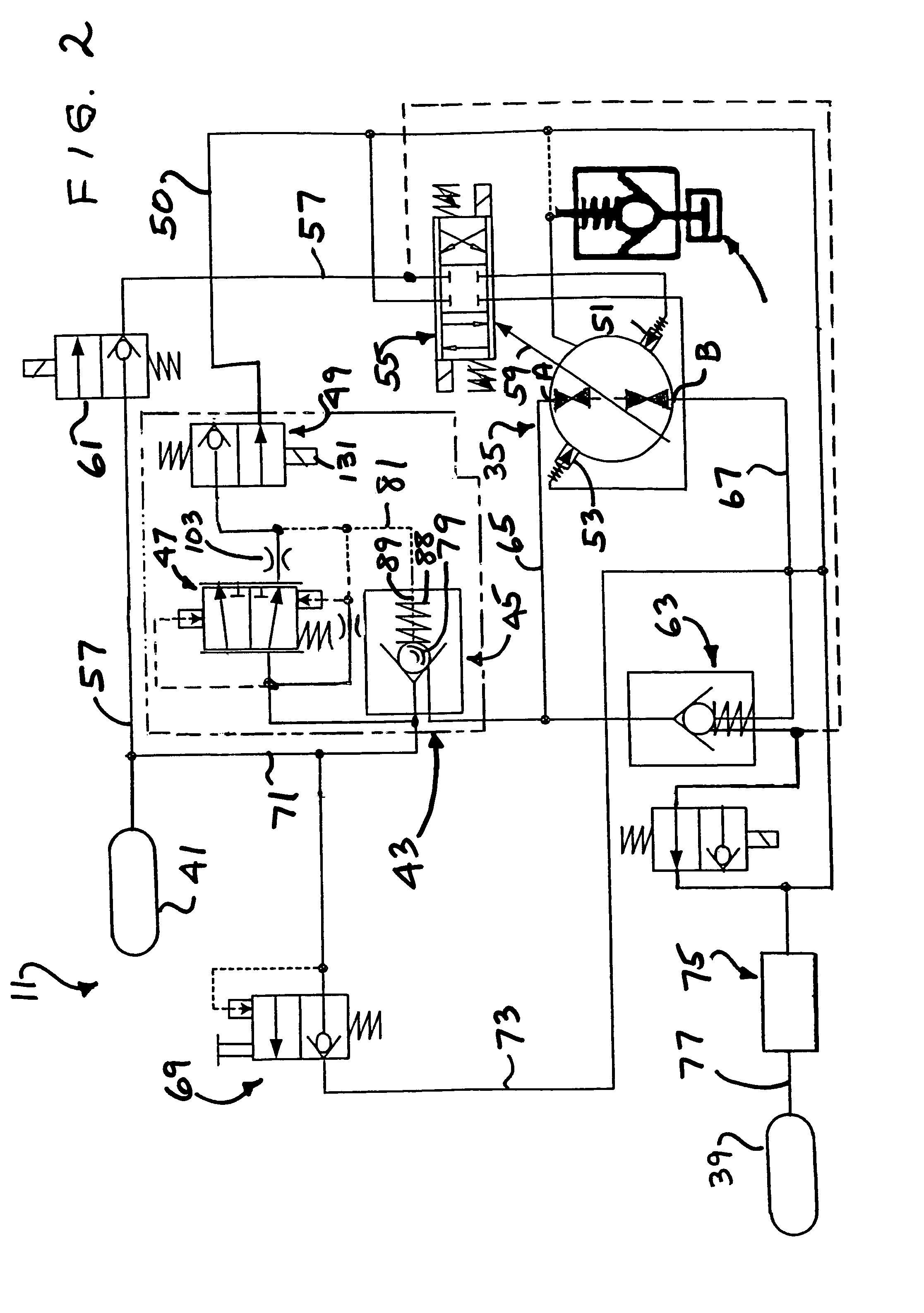

Hydraulic drive system and improved control valve assembly therefor

InactiveUS6971232B2Fast response timeSmall pressure dropBraking element arrangementsServomotor componentsEngineeringHigh pressure

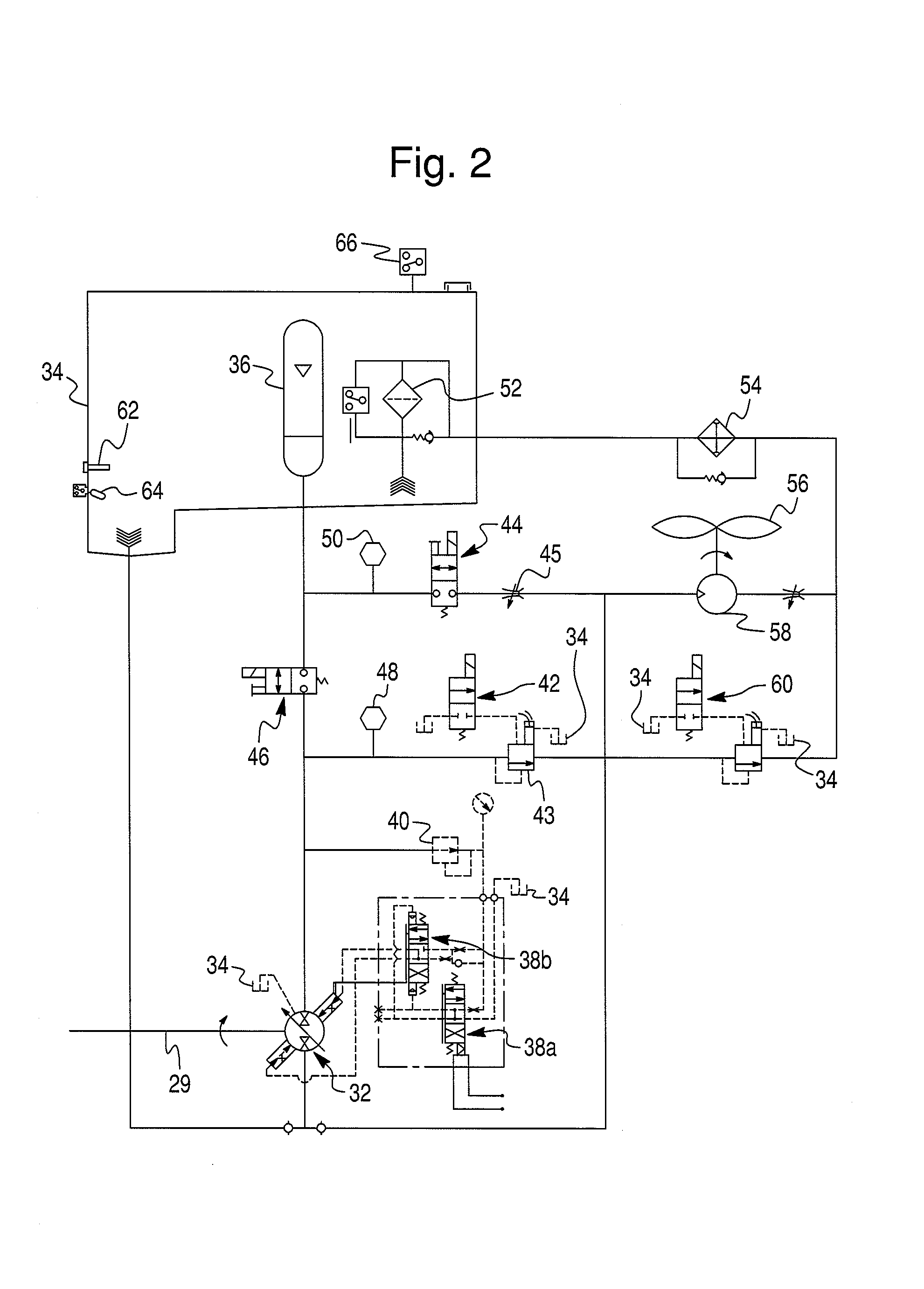

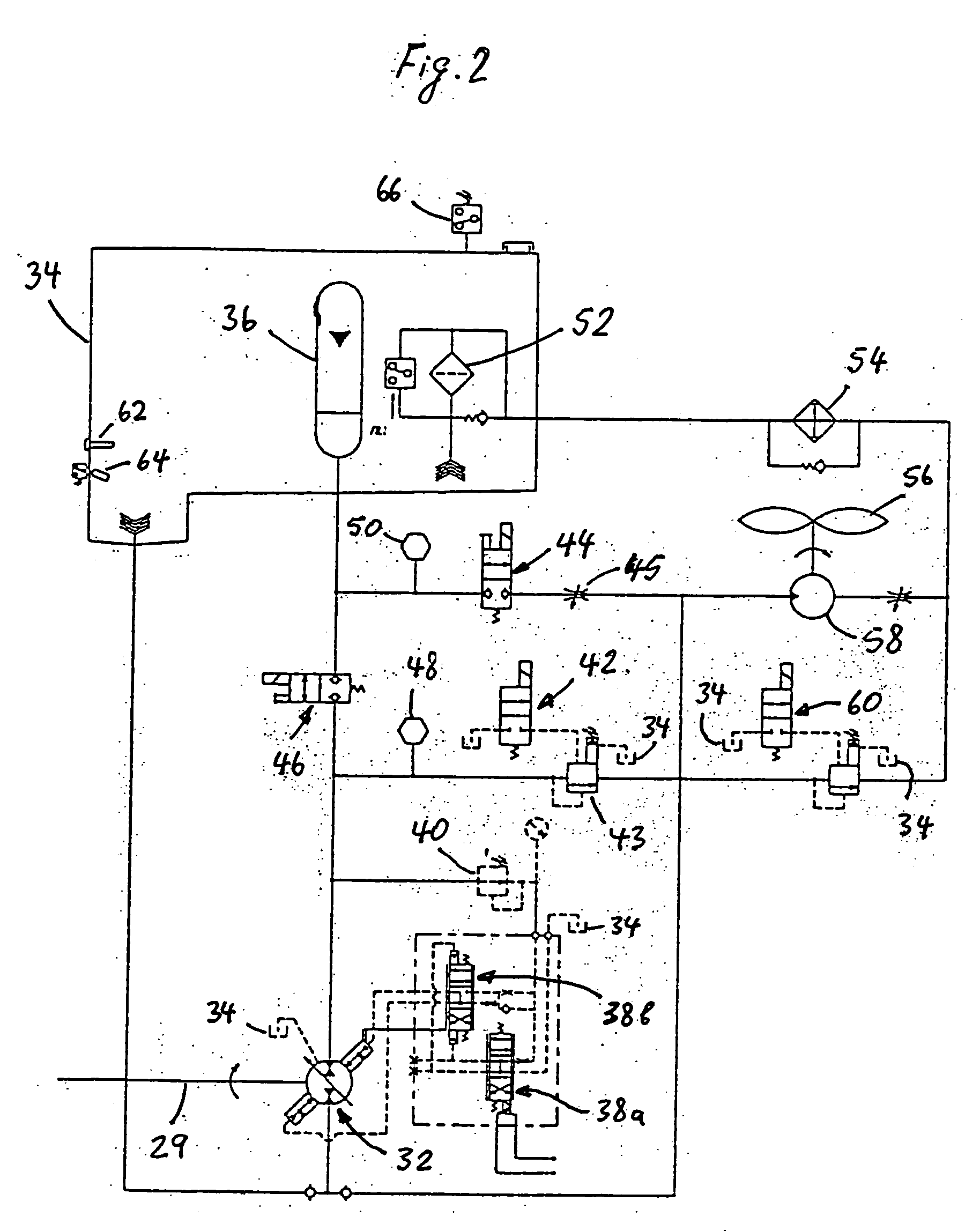

A control valve assembly (43) for use in a system in which a pump-motor unit (35) can either receive drive torque from a drive-line (17) or transmit torque thereto. The system includes a high pressure accumulator (41) and the control valve assembly is disposed between the pump-motor unit and the accumulator, and includes a mode valve (45) normally biased closed by pressure in a control cavity (89), the fluid pressure in which is controlled by a pilot valve assembly (49) in response to an electrical signal (133). A step-orifice valve (47) associated with the mode valve poppet member (79) provides a relatively larger orifice (115) into the control cavity (89) when pressure therein is high, and a relatively smaller orifice (119) into the control cavity when pressure therein is low, i.e., when the pilot valve assembly (49) is open. Thus, a large volume of flow can occur from the accumulator to the unit (35) in a motoring mode, with a relatively low pressure drop, while the poppet member is able to have softer, relatively longer opening time, but a relatively faster closing time.

Owner:EATON CORP

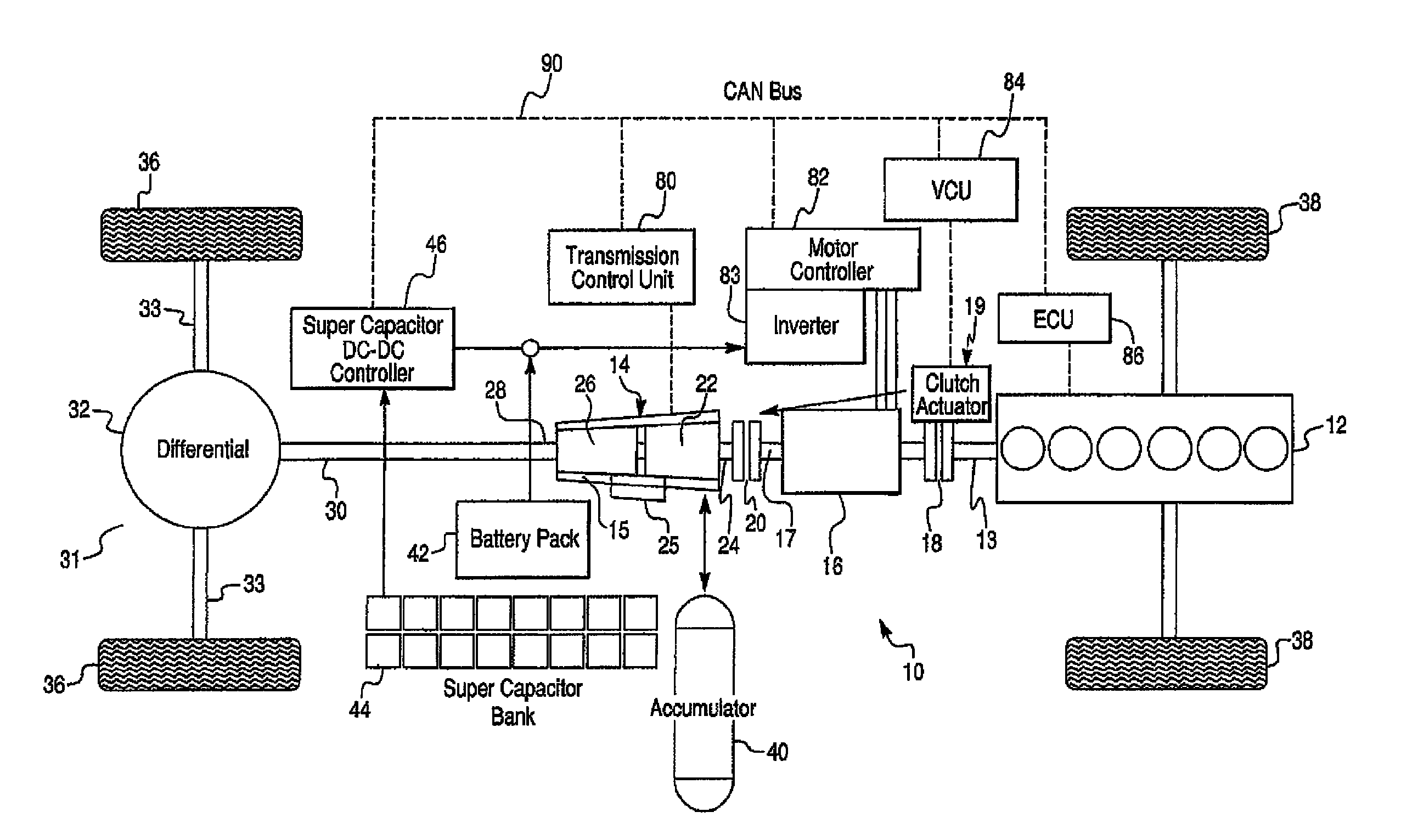

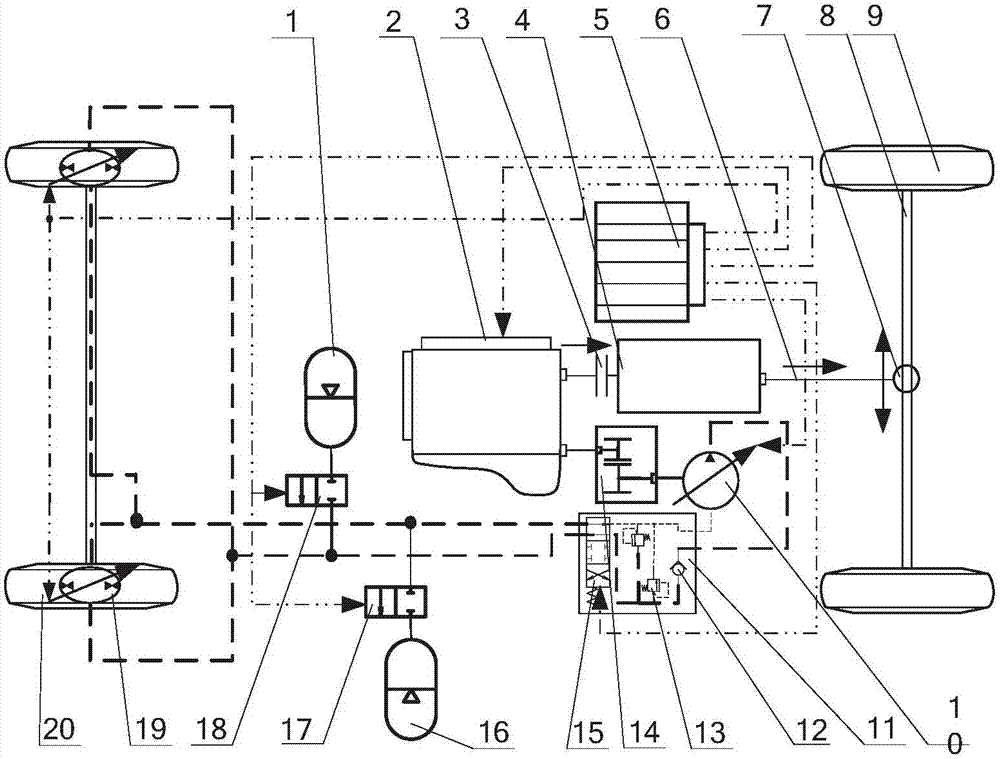

Hydro-electric hybrid drive system for motor vehicle

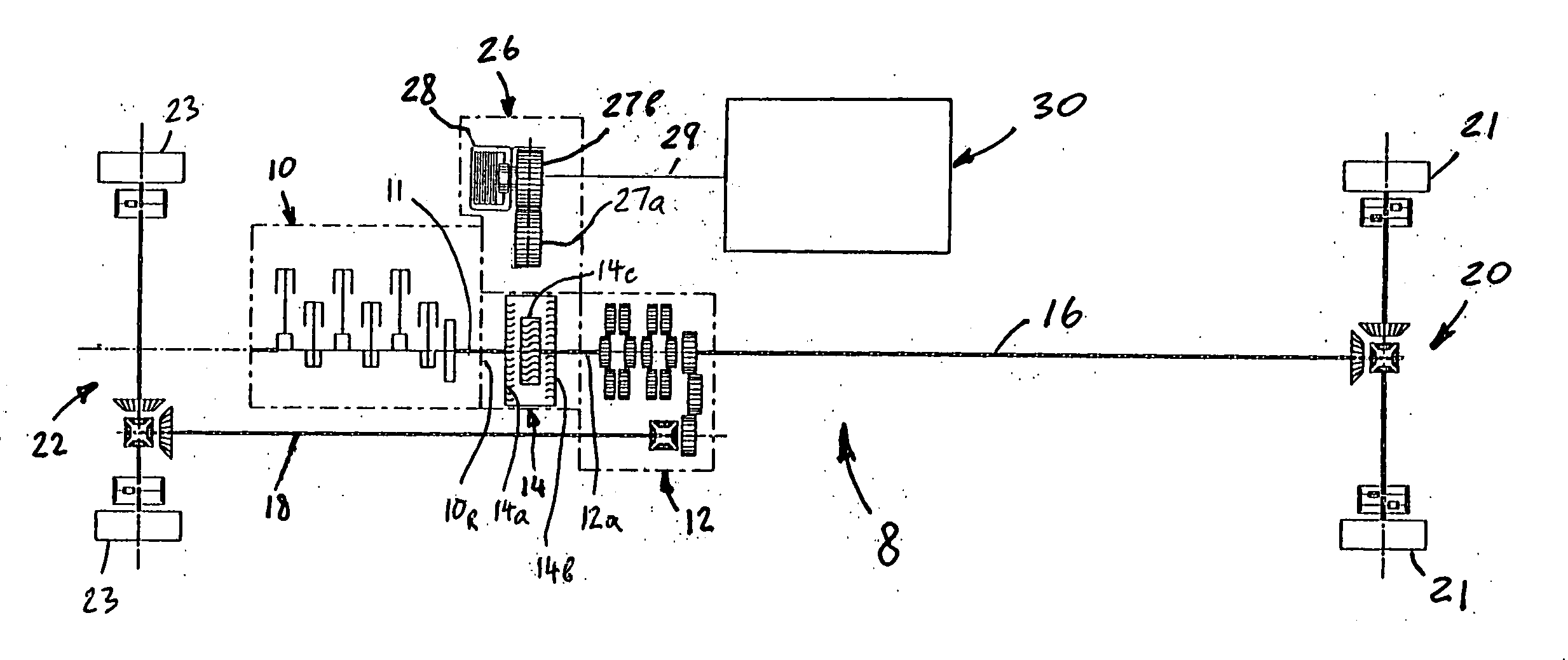

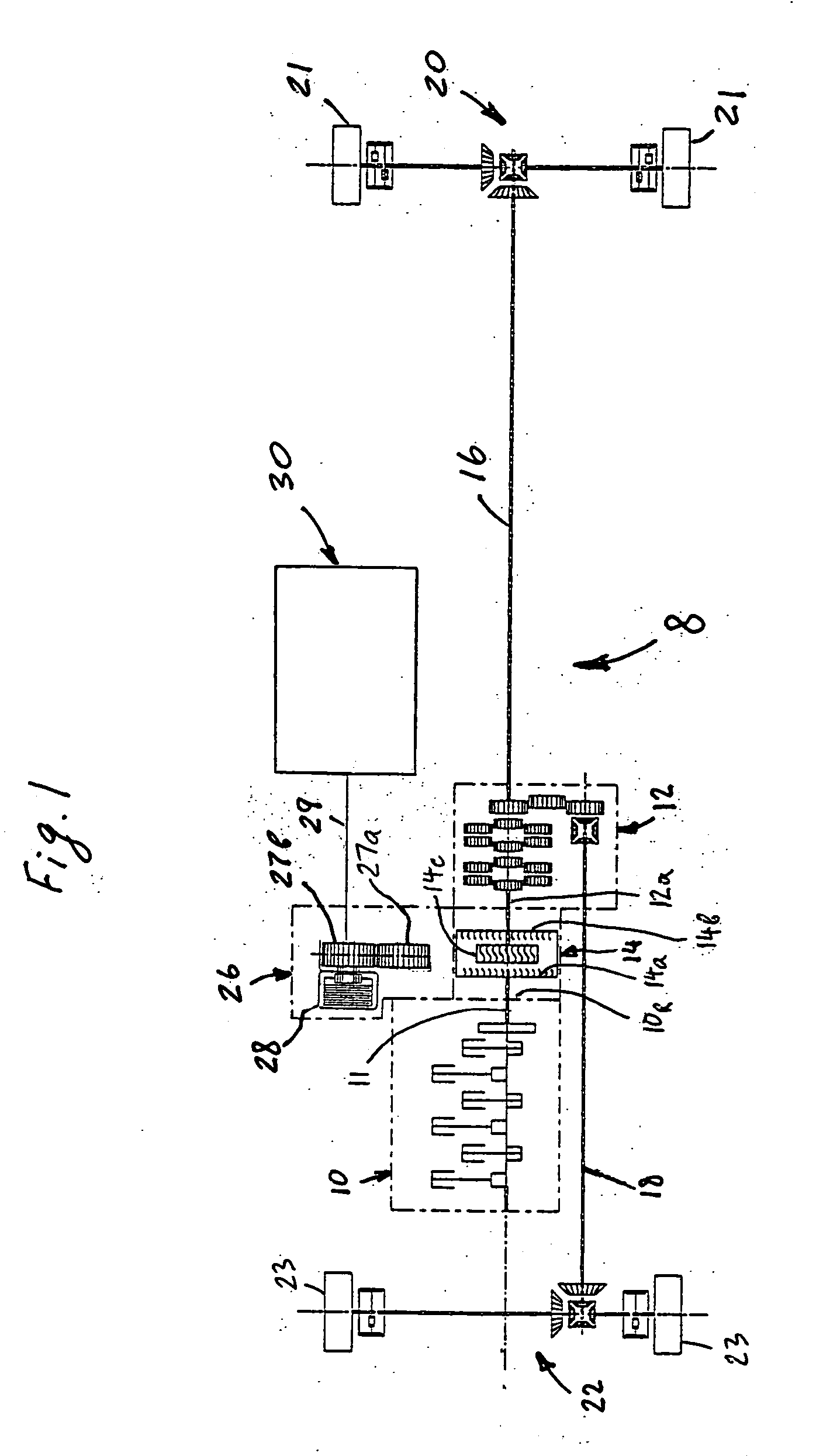

InactiveUS7841432B2Equivalent performance levelsStarters with fluid-driven auxillary enginesPlural diverse prime-mover propulsion mountingDrive wheelHydraulic pump

A hybrid electro-hydraulic drive system is provided for a vehicle and comprises a hydraulic transmission including a first hydraulic machine and at least one second hydraulic machine drivingly connected to drive wheels of the motor vehicle for driving thereof, an electric motor / generator operatively connected to the first hydraulic machine, and at least one energy storage device operable to store and release a hydraulic fluid energy or an electrical energy. The second hydraulic machine is a reversible hydraulic pump / motor unit capable to function both as a hydraulic pump and a hydraulic motor. The energy storage device is operatively connected to either the hydraulic transmission or the electric motor / generator. In a retarding mode the hydraulic transmission and / or the electric motor / generator retard the vehicle, while in a driving mode they supply a supplementary power to the drive wheels to assist propulsion of the vehicle.

Owner:BOSCH REXROTH AG

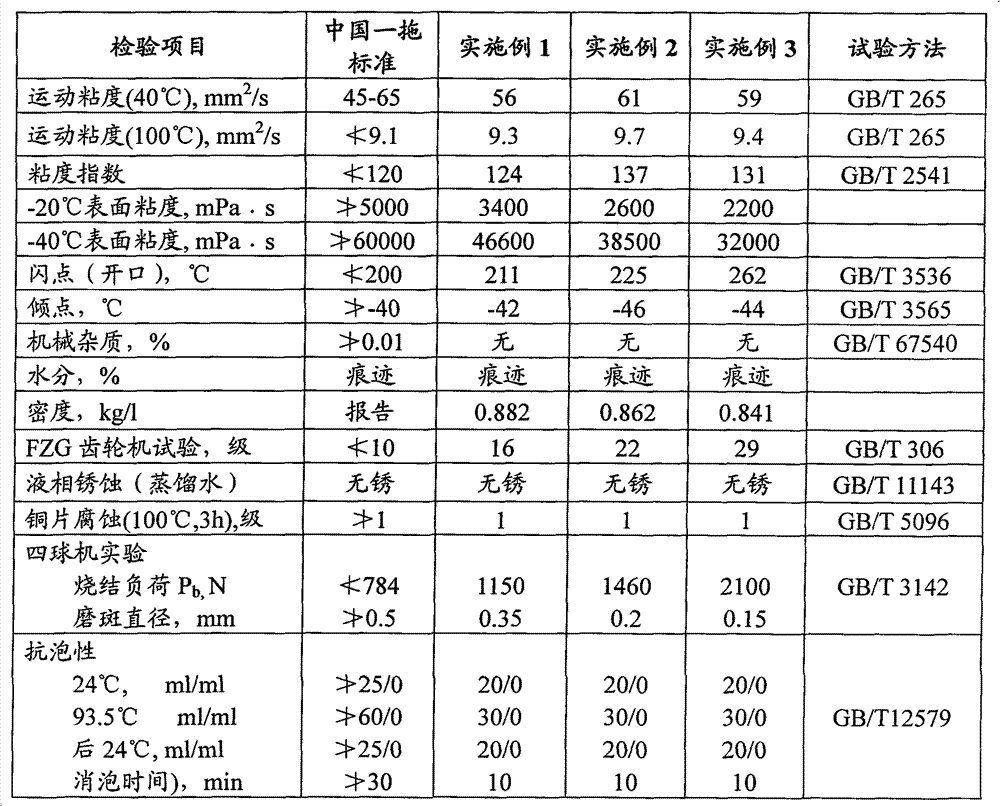

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

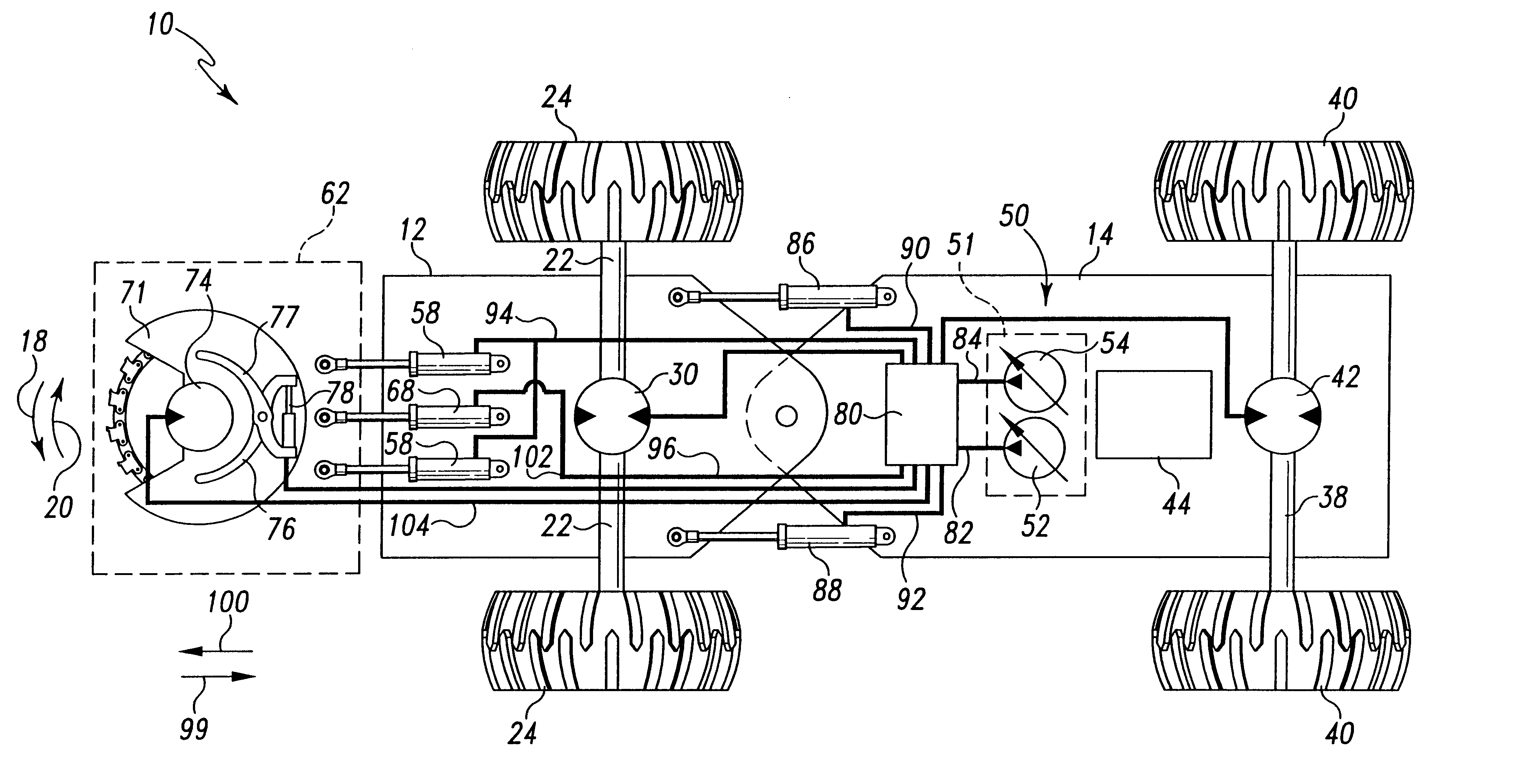

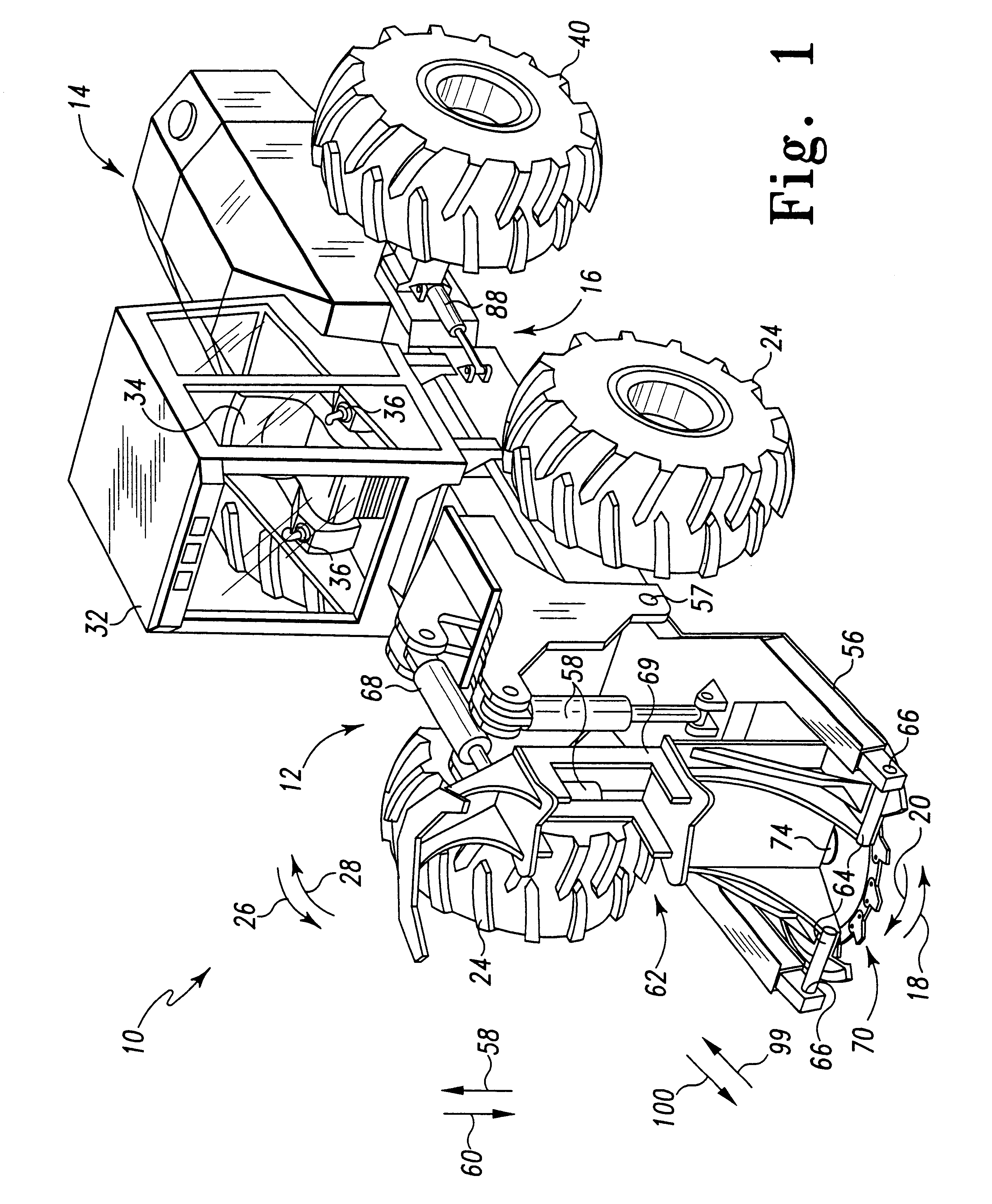

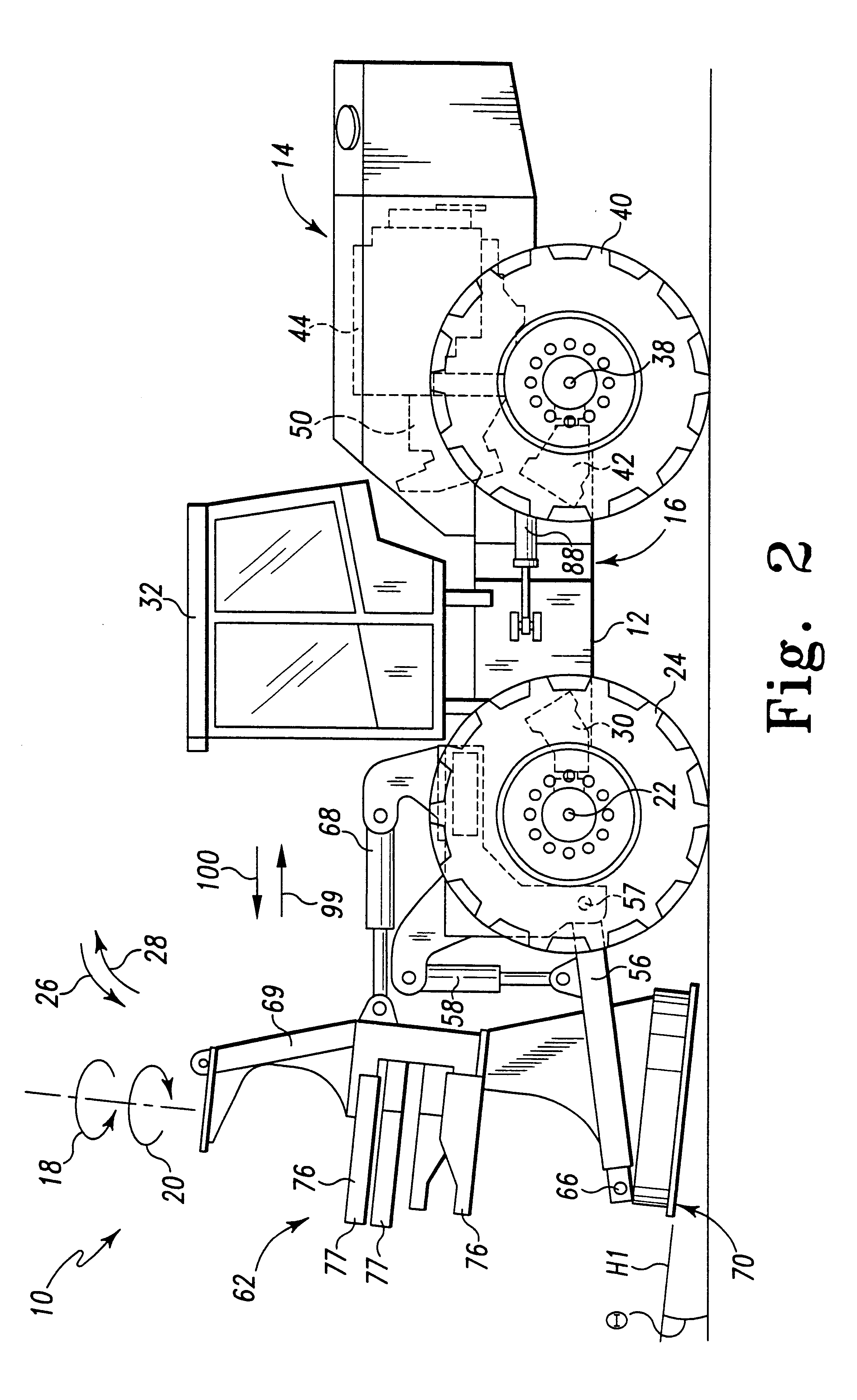

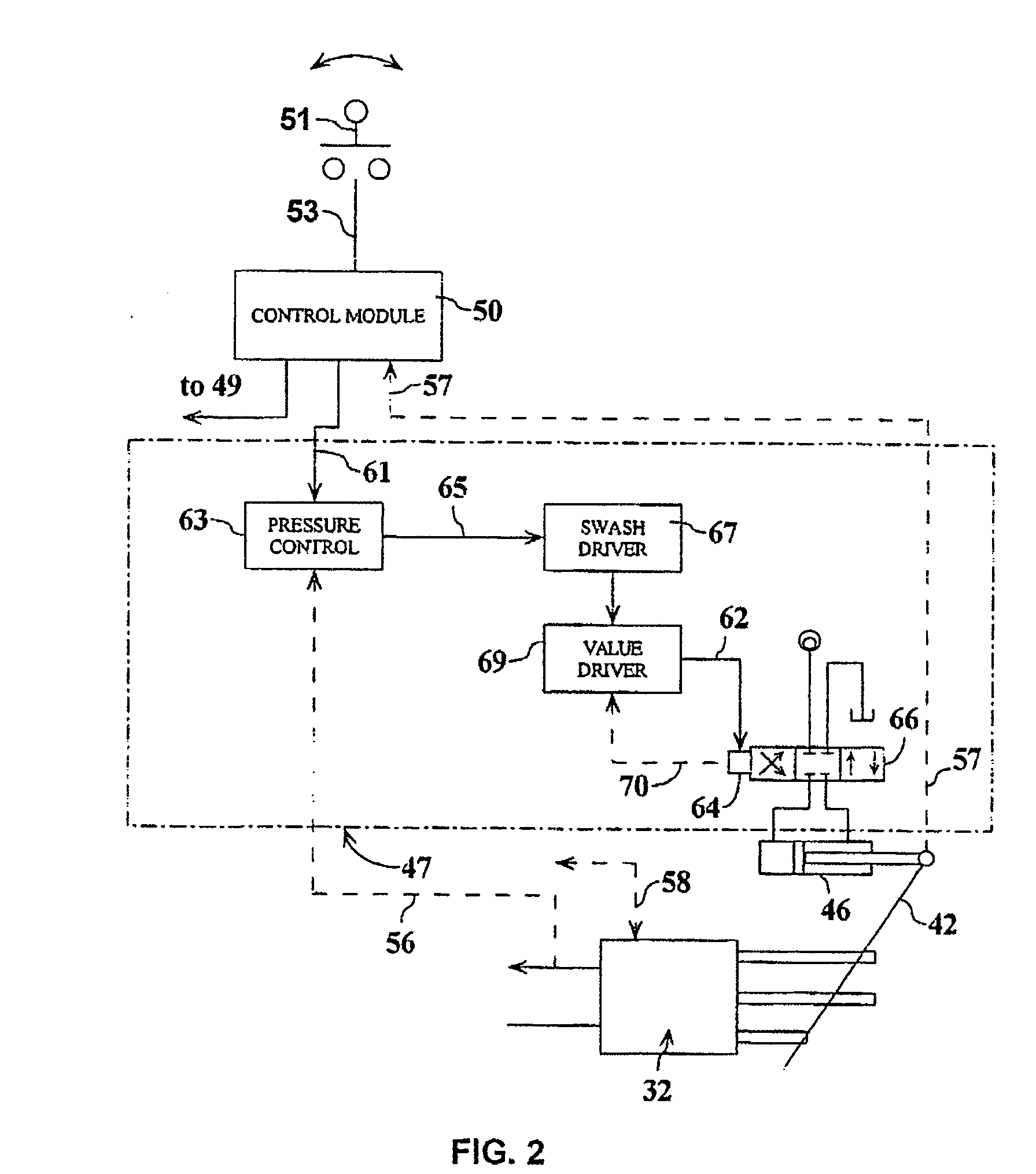

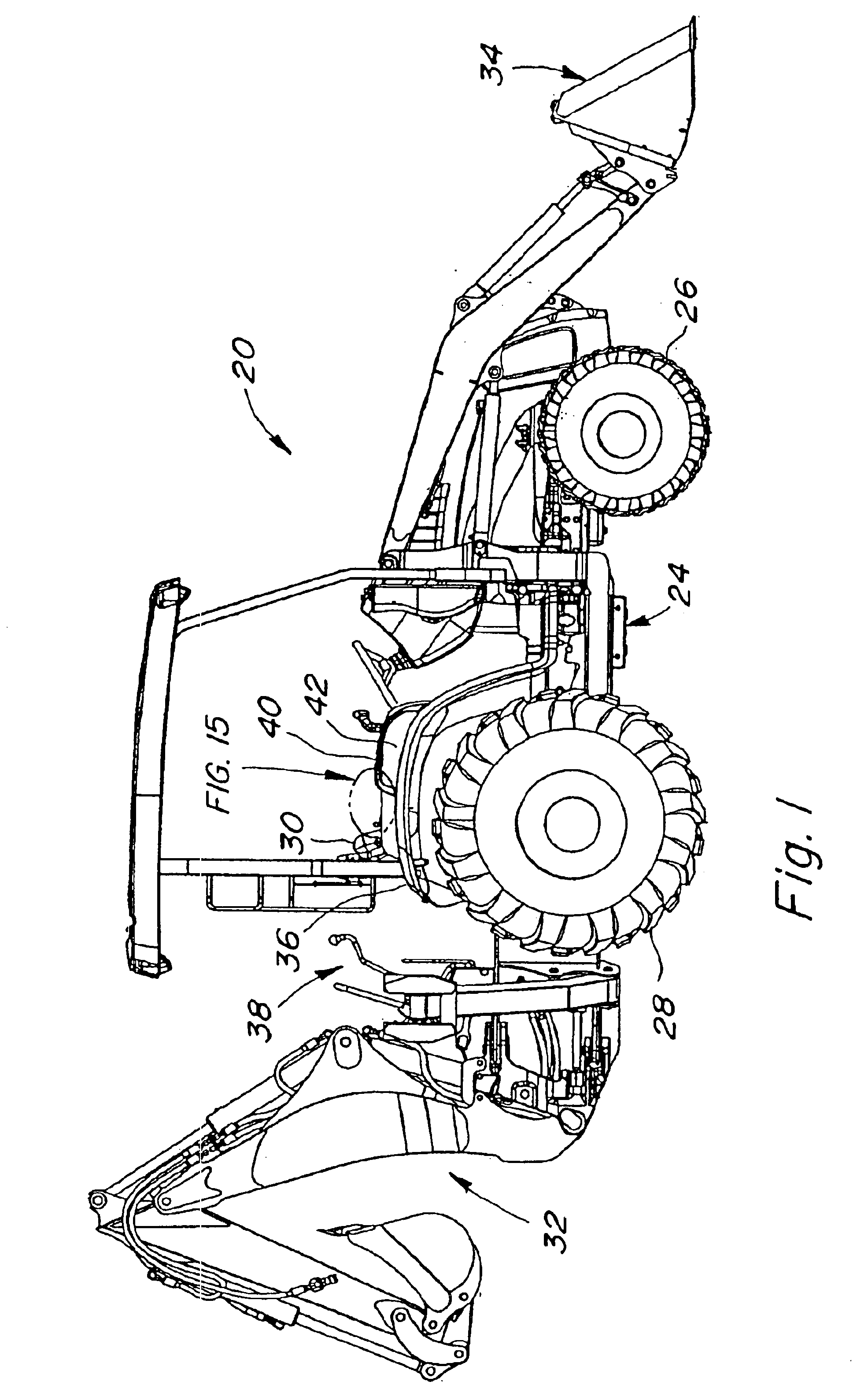

Method and apparatus for operating a hydraulic drive system of a feller-buncher

A feller-buncher includes a first axle having a number of first wheels attached thereto and a second axle having a number of second wheels attached thereto. The feller-buncher also includes a first hydraulic motor operable to rotate the first axle and a second hydraulic motor operable to rotate the second axle. The feller-buncher also includes a first hydraulic pump operable to supply pressurized hydraulic fluid. Yet further, the feller-buncher includes a first flow sharing valve fluidly coupled to each of the first hydraulic pump, the first hydraulic motor, and the second hydraulic motor. The first flow sharing valve is configured to distribute the pressurized hydraulic fluid from the first hydraulic pump evenly between the first hydraulic motor and the second hydraulic motor, whereby the first axle and the second axle are driven at a substantially equal speed relative to one another. A method of operating a feller-buncher is also disclosed.

Owner:CATERPILLAR INC

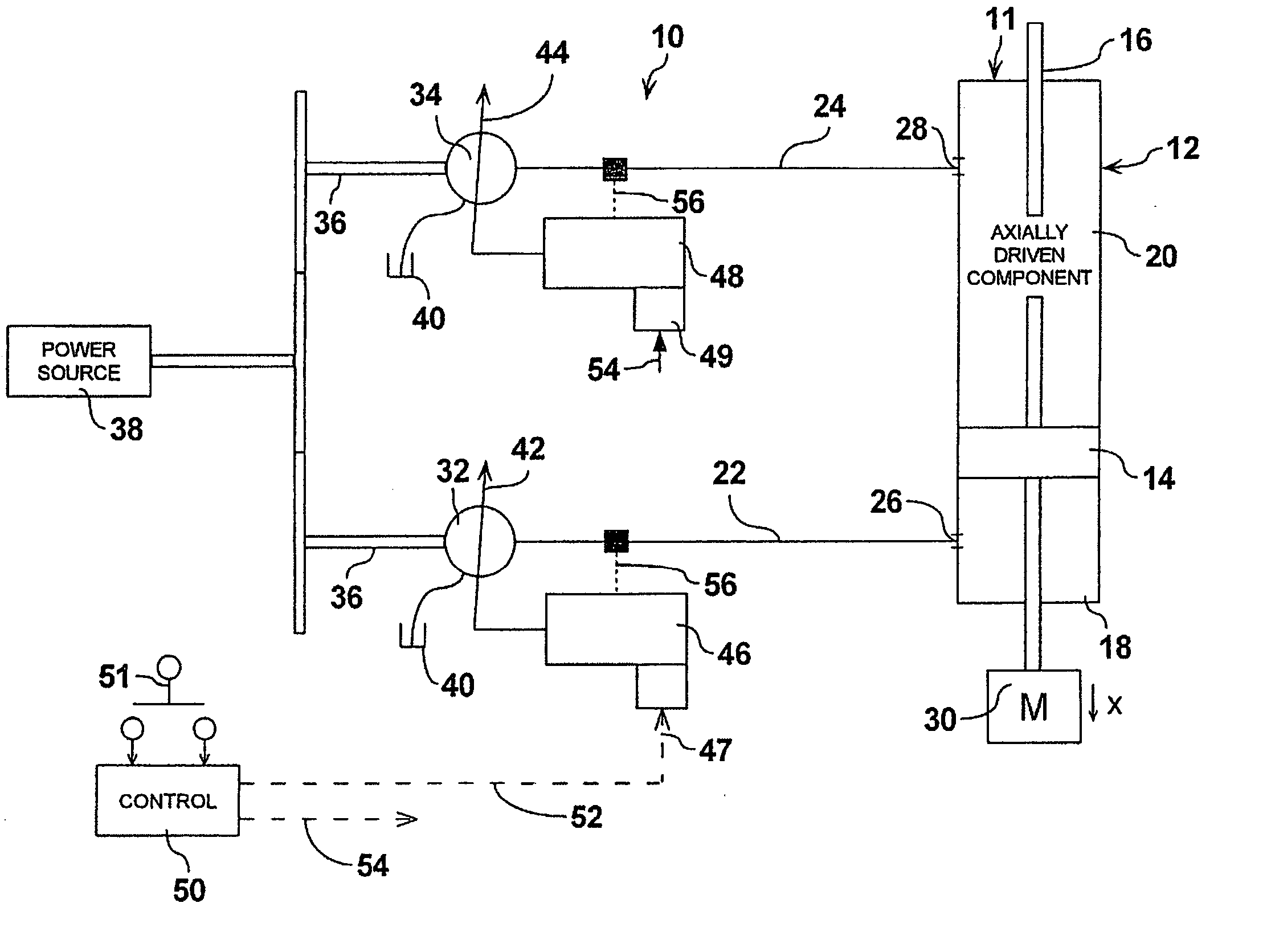

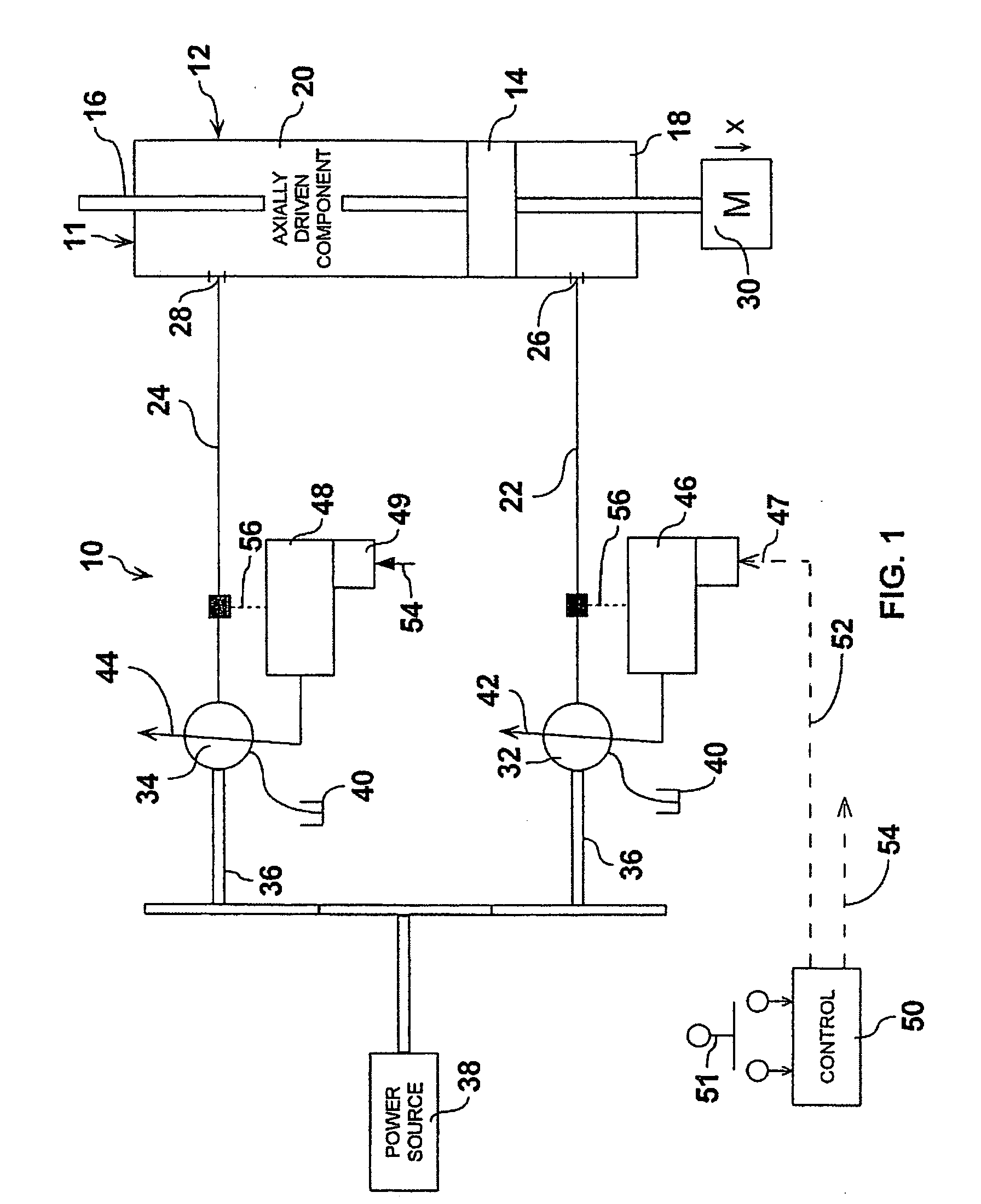

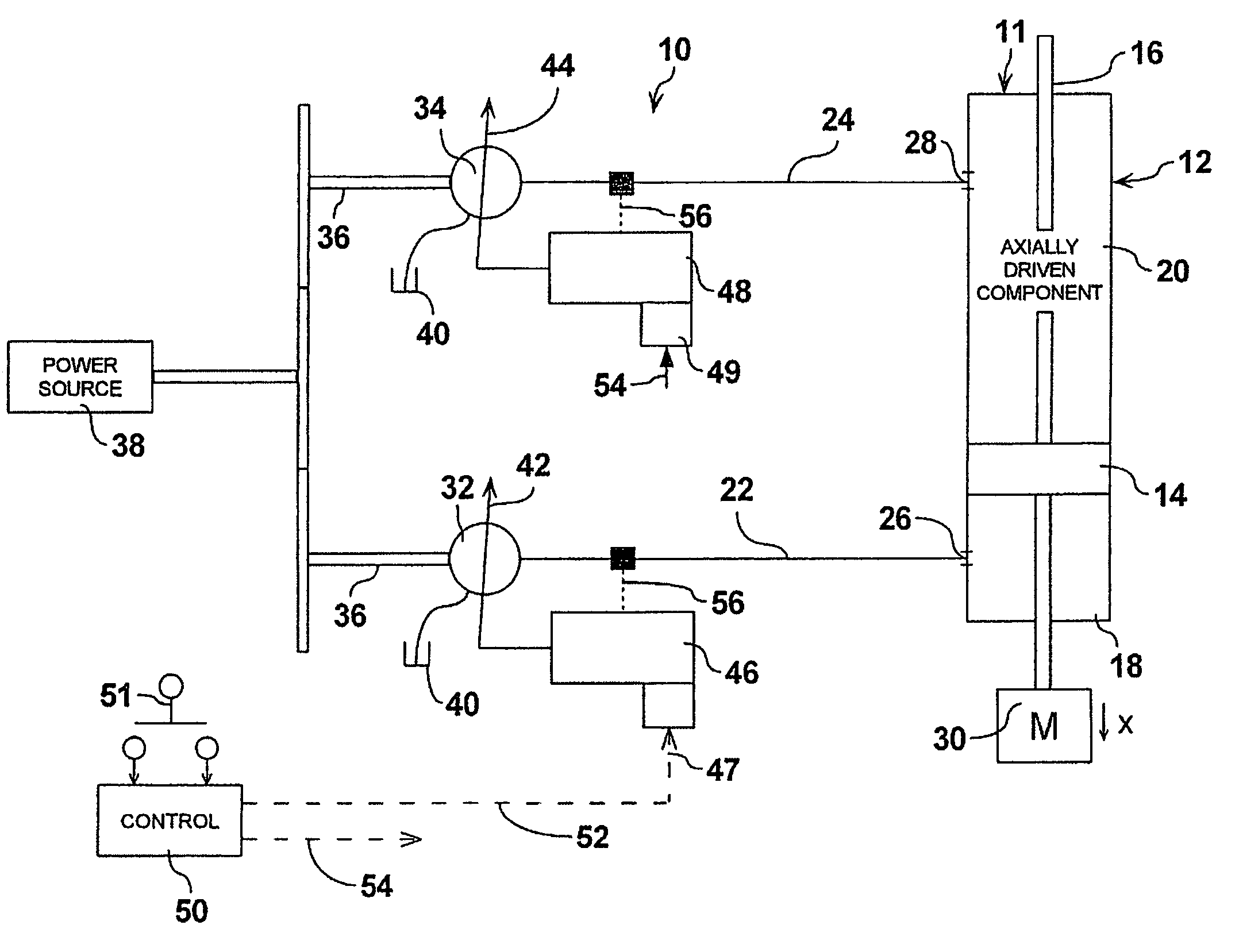

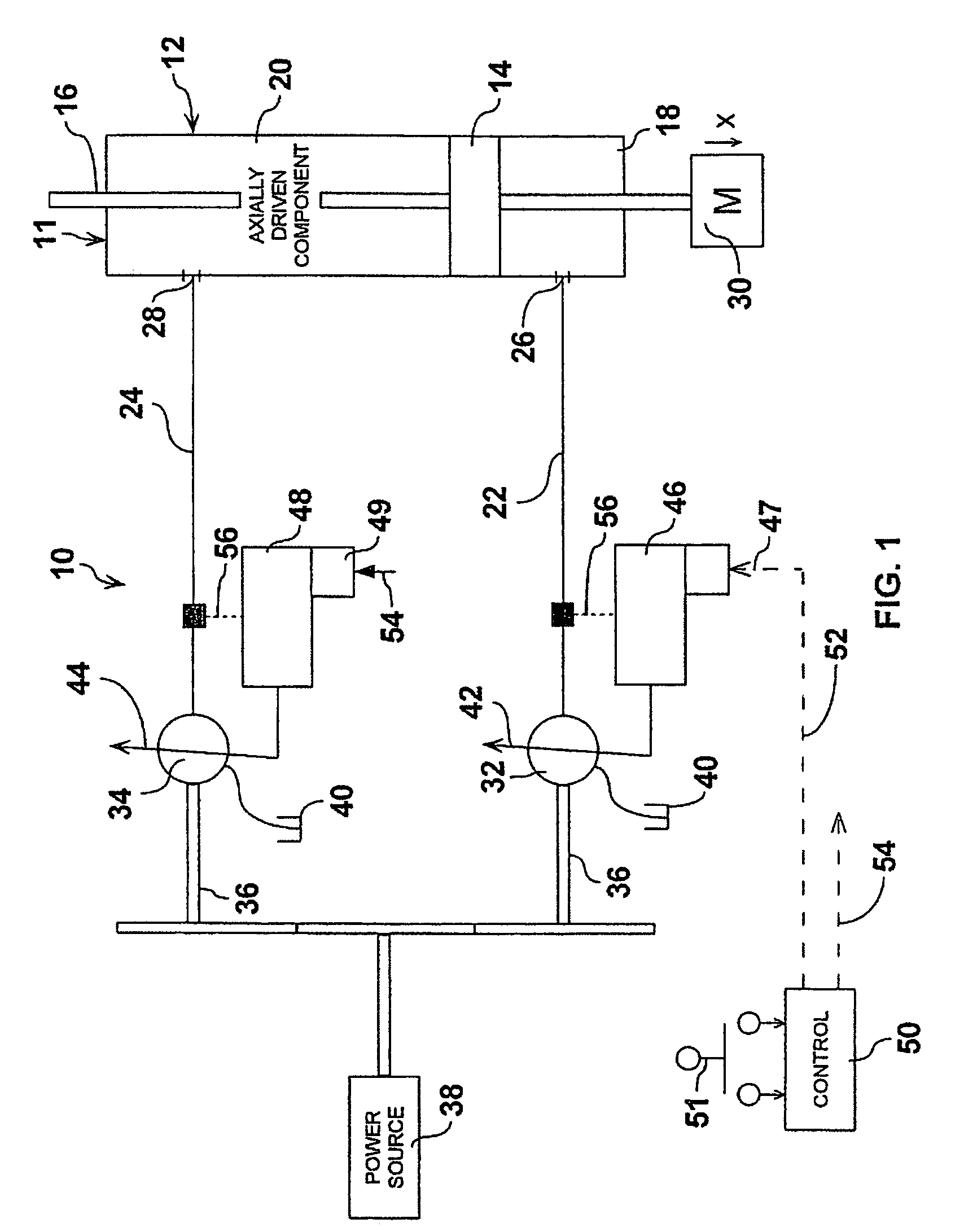

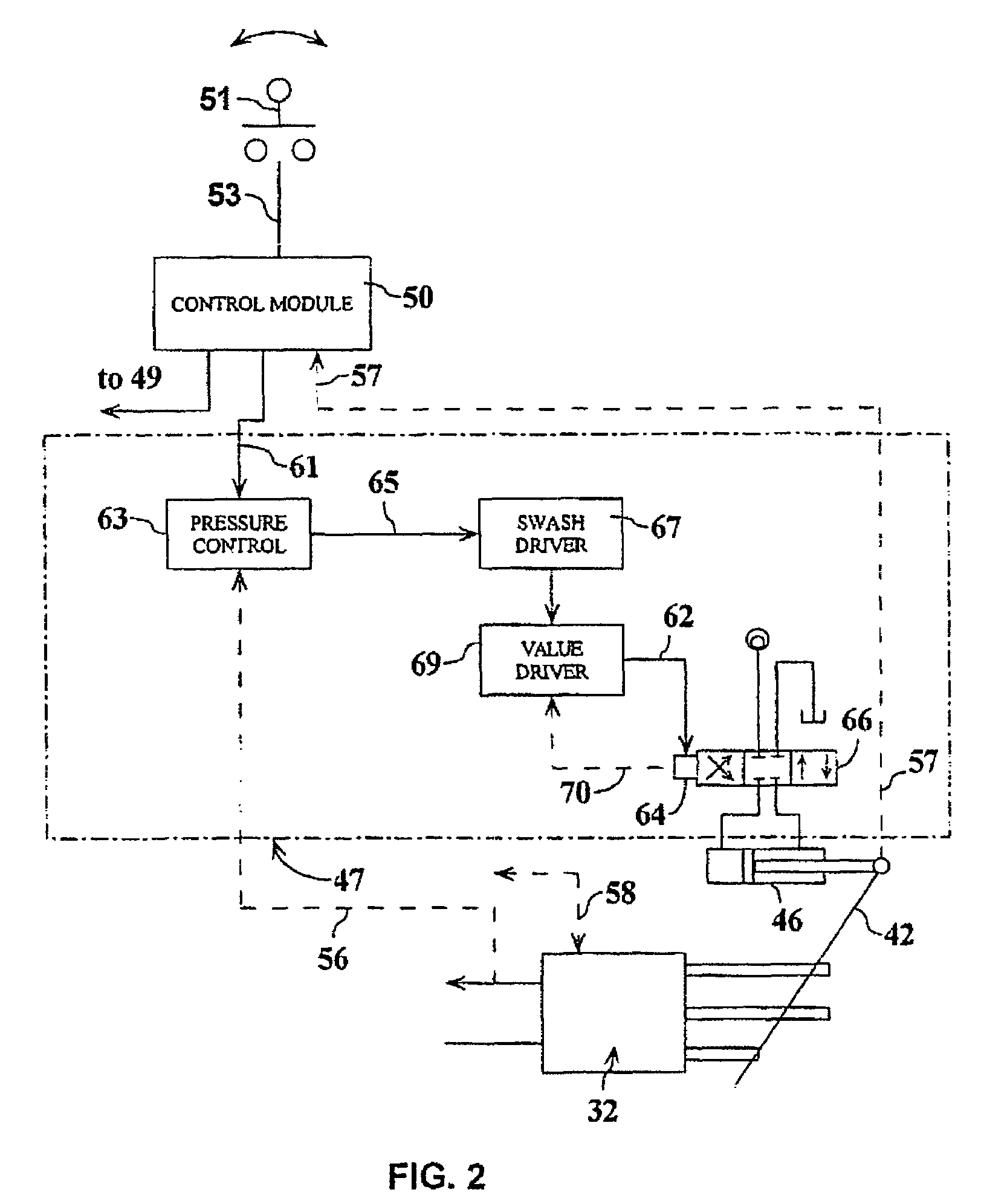

Hydraulic drive system

InactiveUS20060156713A1Keep the pressureReduce forceFluid couplingsAccumulator installationsBattery chargeEngineering

A hydraulic drive system for an actuator uses a pair of pressure compensated hydraulic machines to control flow to and from the drive chambers of the actuator by varying the controlled pressure of one of the machines. The machines are mechanically coupled to permit energy recovery and charge an accumulator to store supplies energy. The drive system may be combined with other services including a transmission for incorporation in a vehicle. The transmission uses a pressure compensated supply and torque control of the wheels.

Owner:CONCENTRIC ROCKFORD

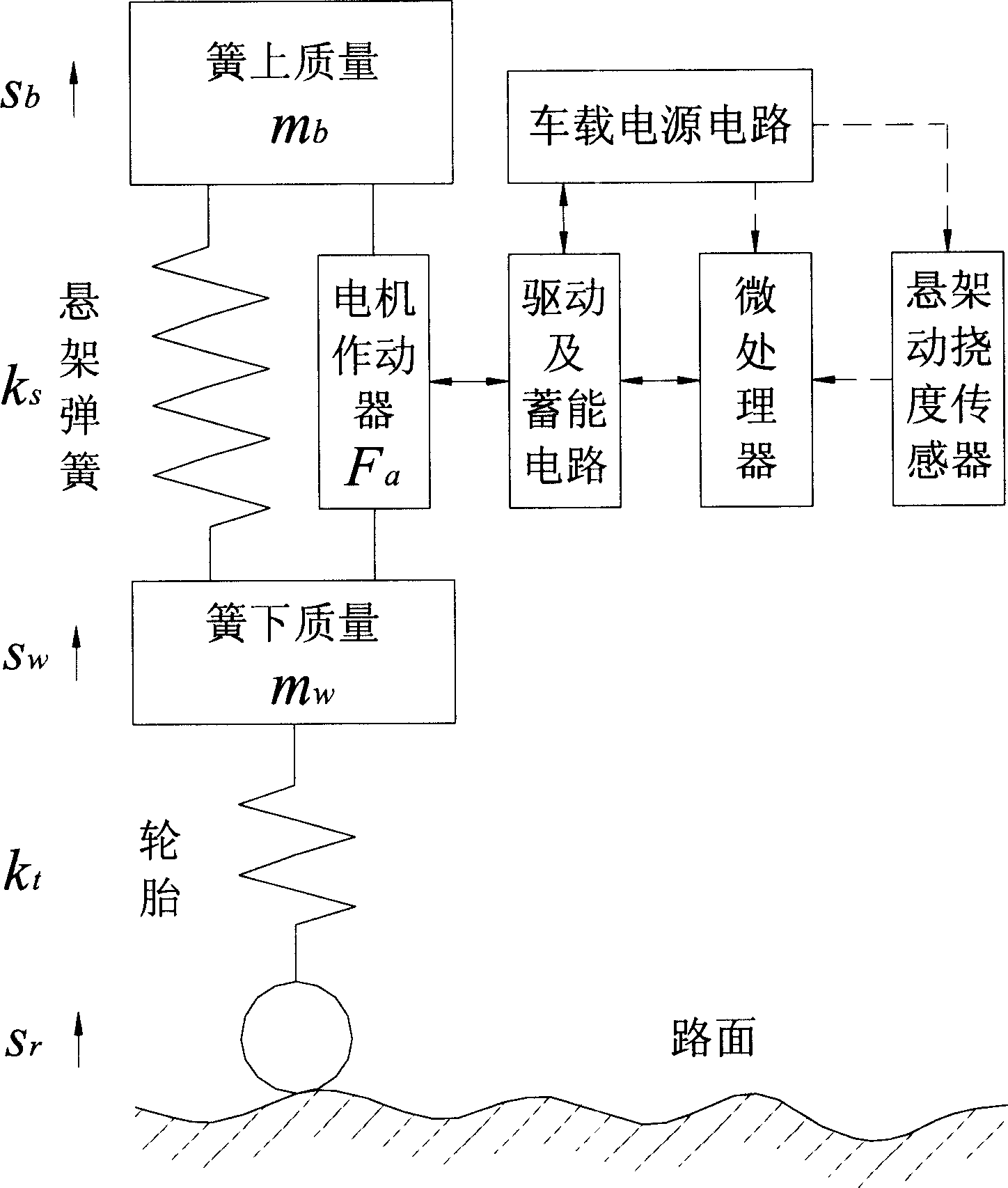

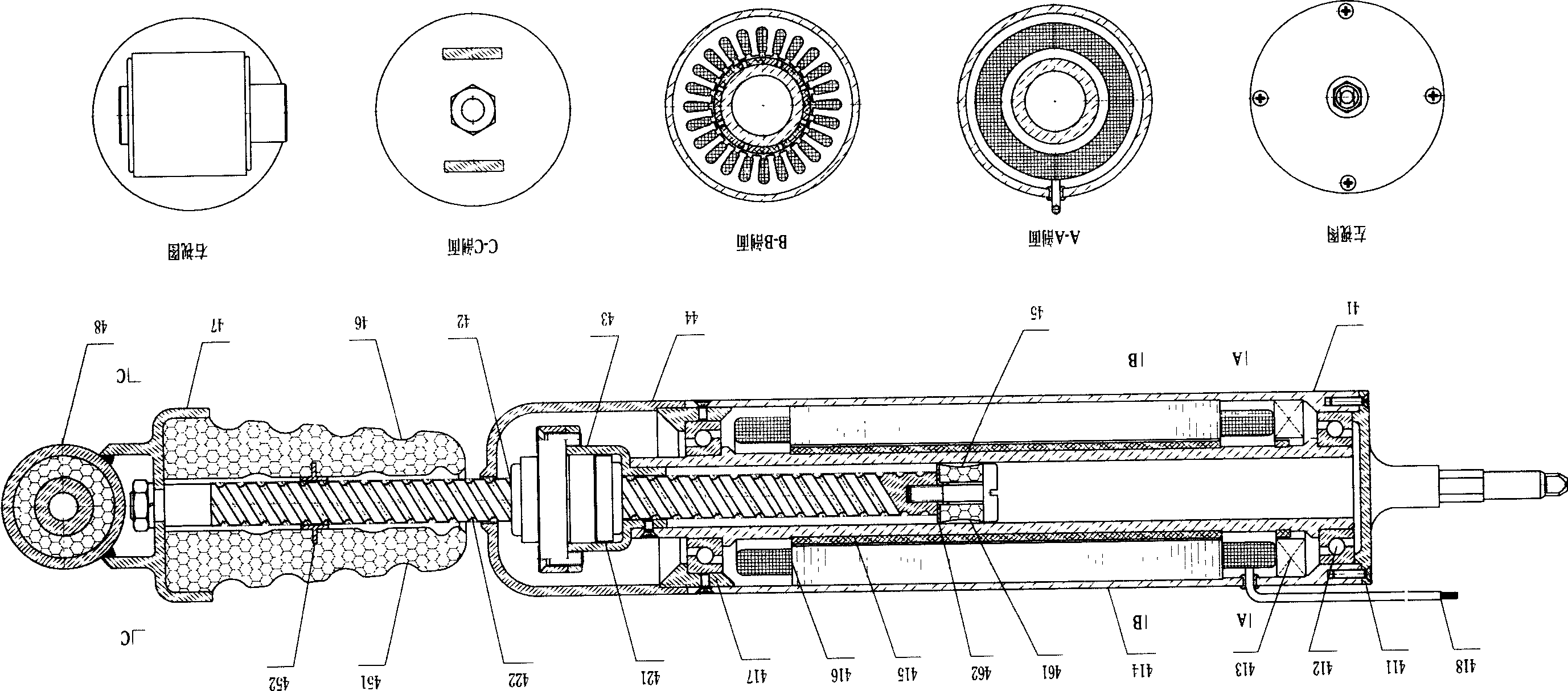

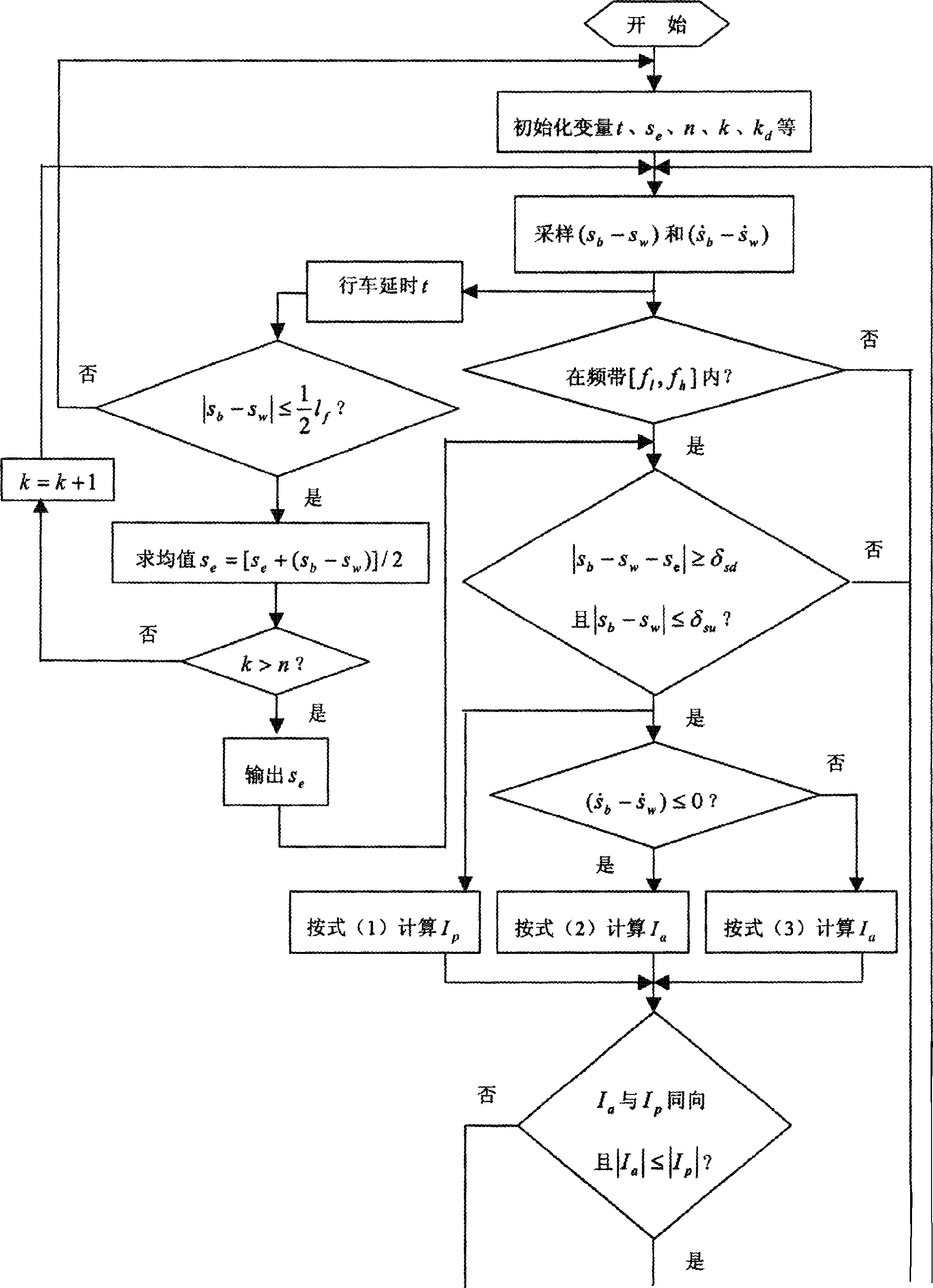

Energy storage driving pendant in motor

An active suspension with electric motor actuator and electromagnetic energy accumulating action features use of motor drive system instead of hydraulic driven system. The coded signals obtained by dynamic flexure sensor for suspension and the pulse signals obtained by rotor position sensor for motor are output to microprocessor. After they are processed, the electric motor actuator is real-time controlled for electric, reverse, or regenerative braking, so damping the shock and vibration caused by uneven road surface and recovering the braking energy.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG +2

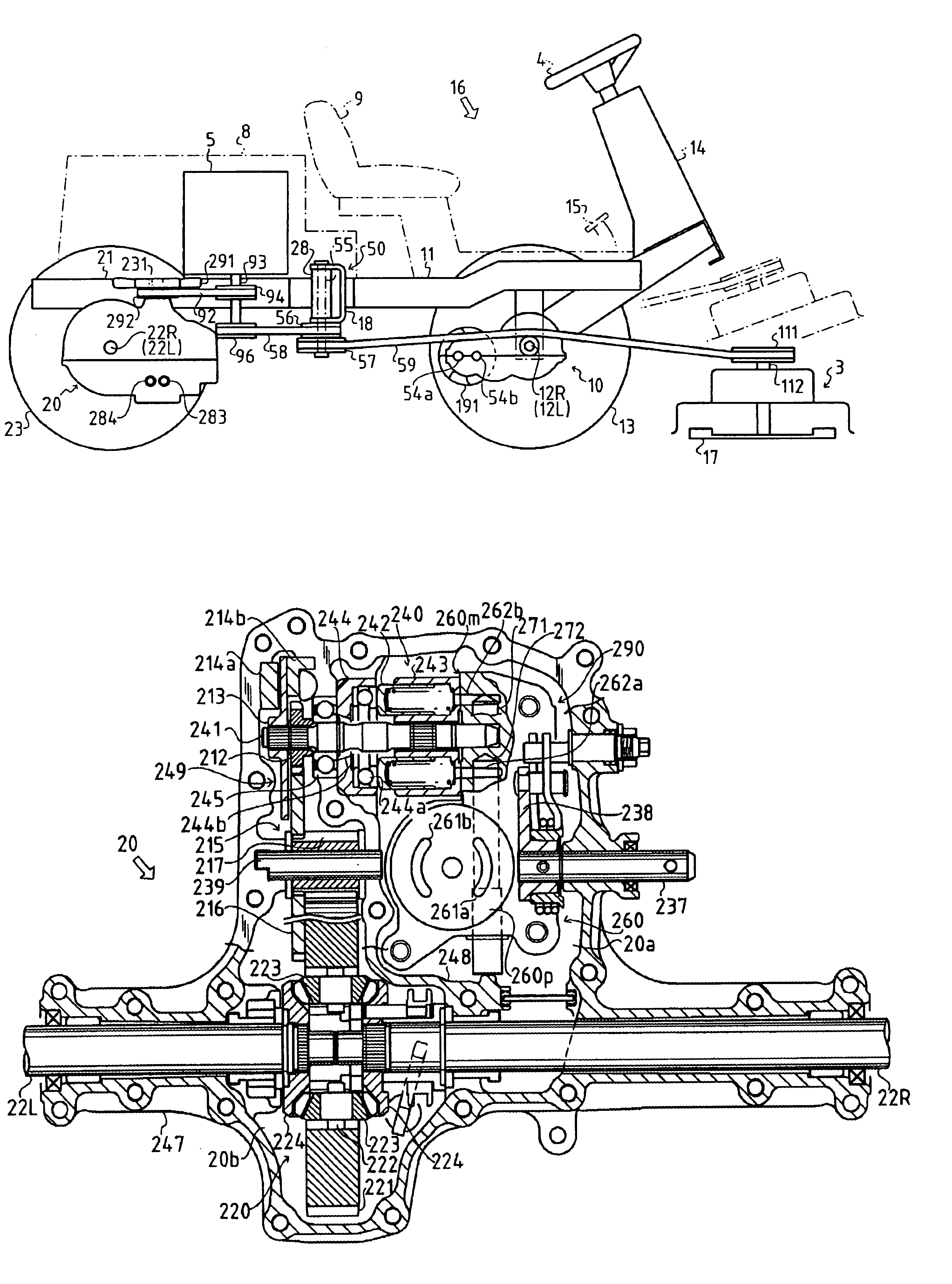

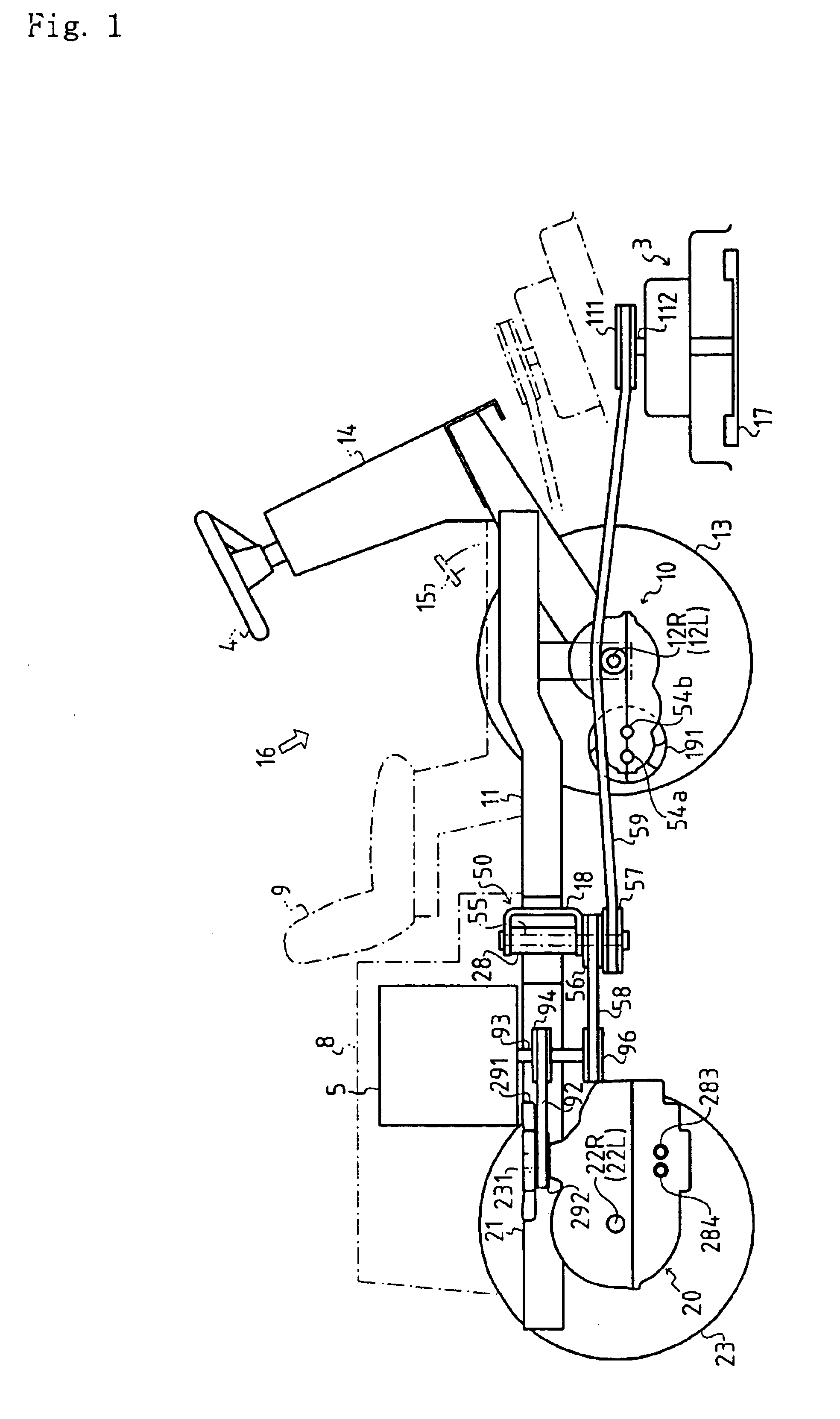

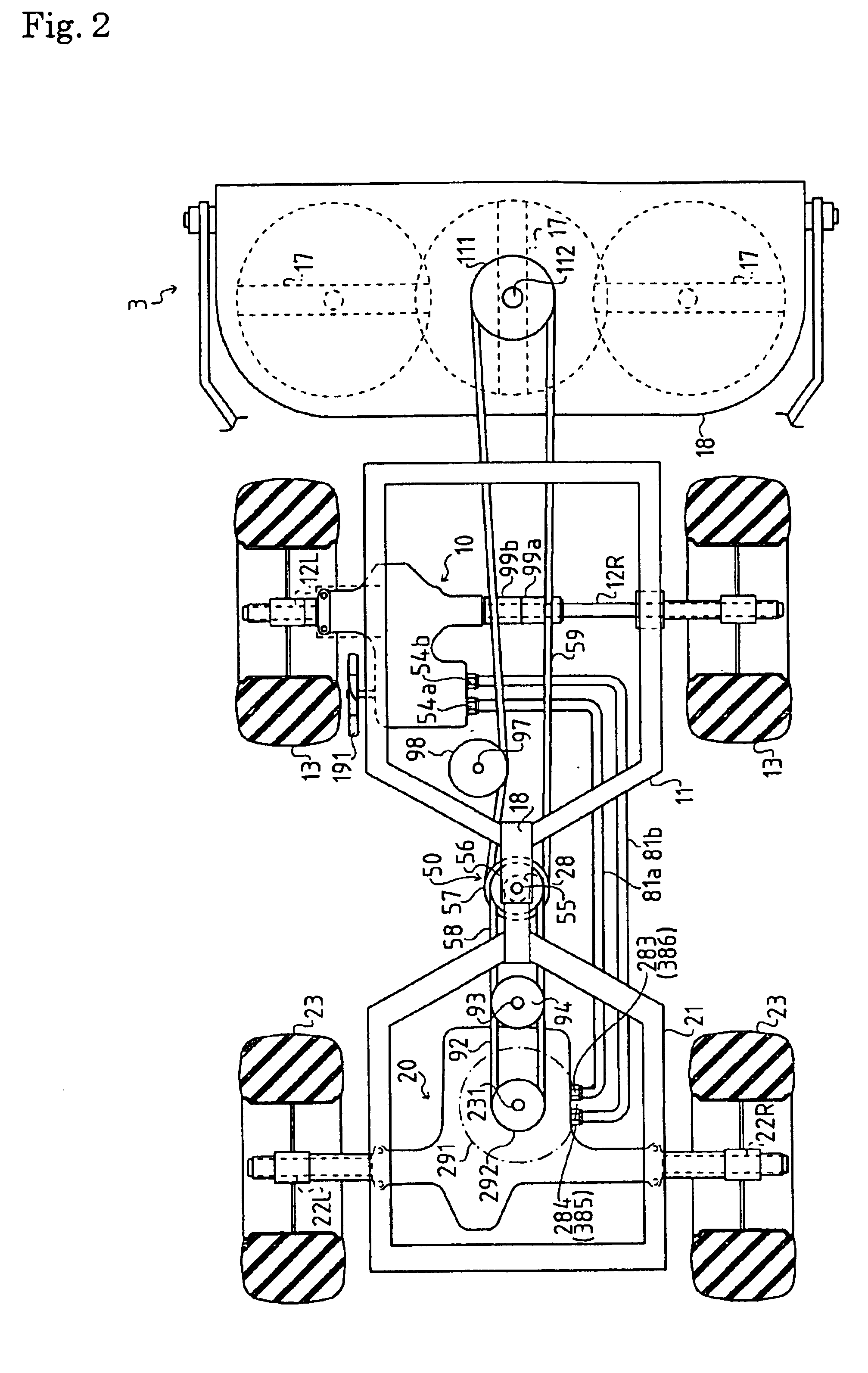

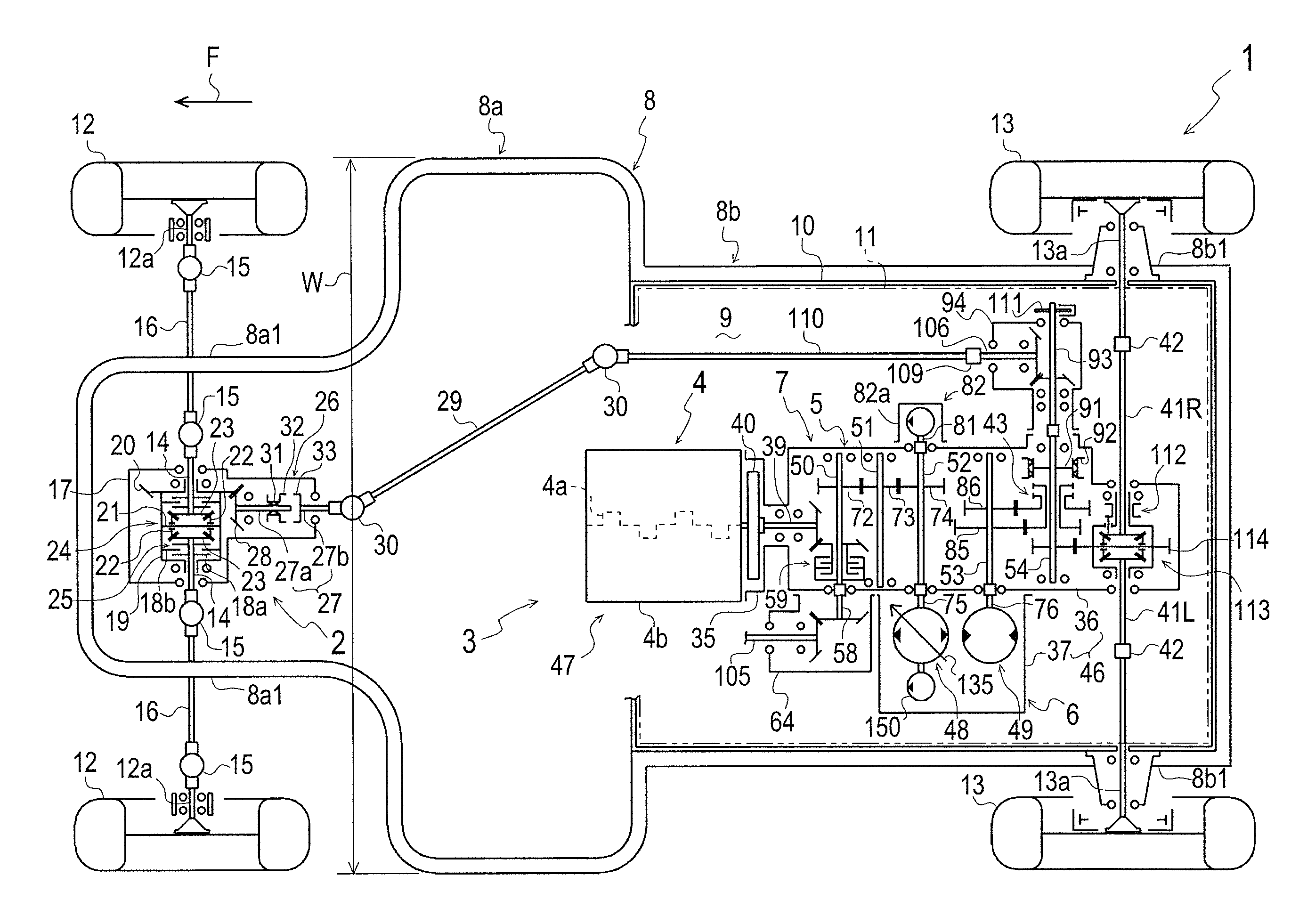

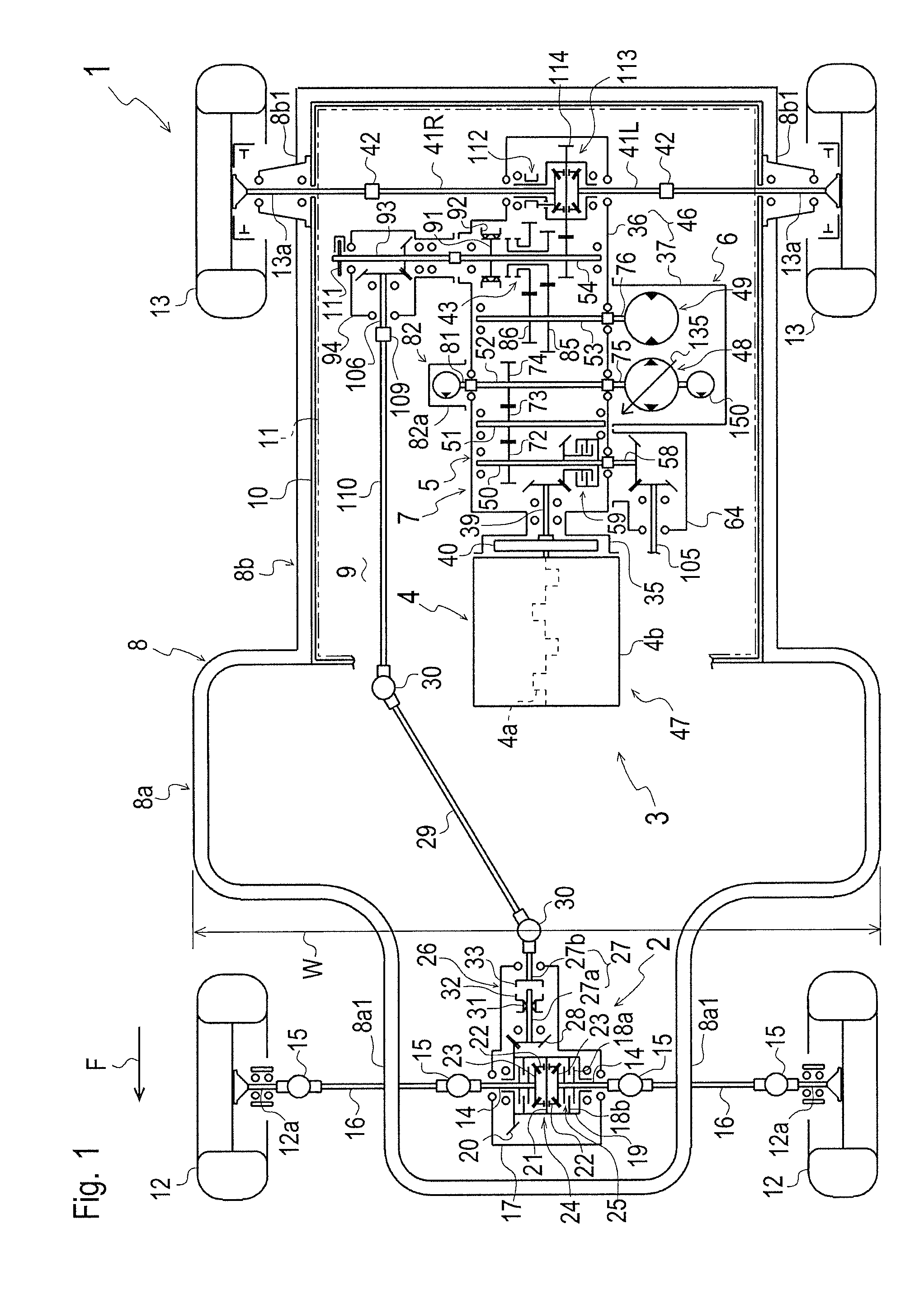

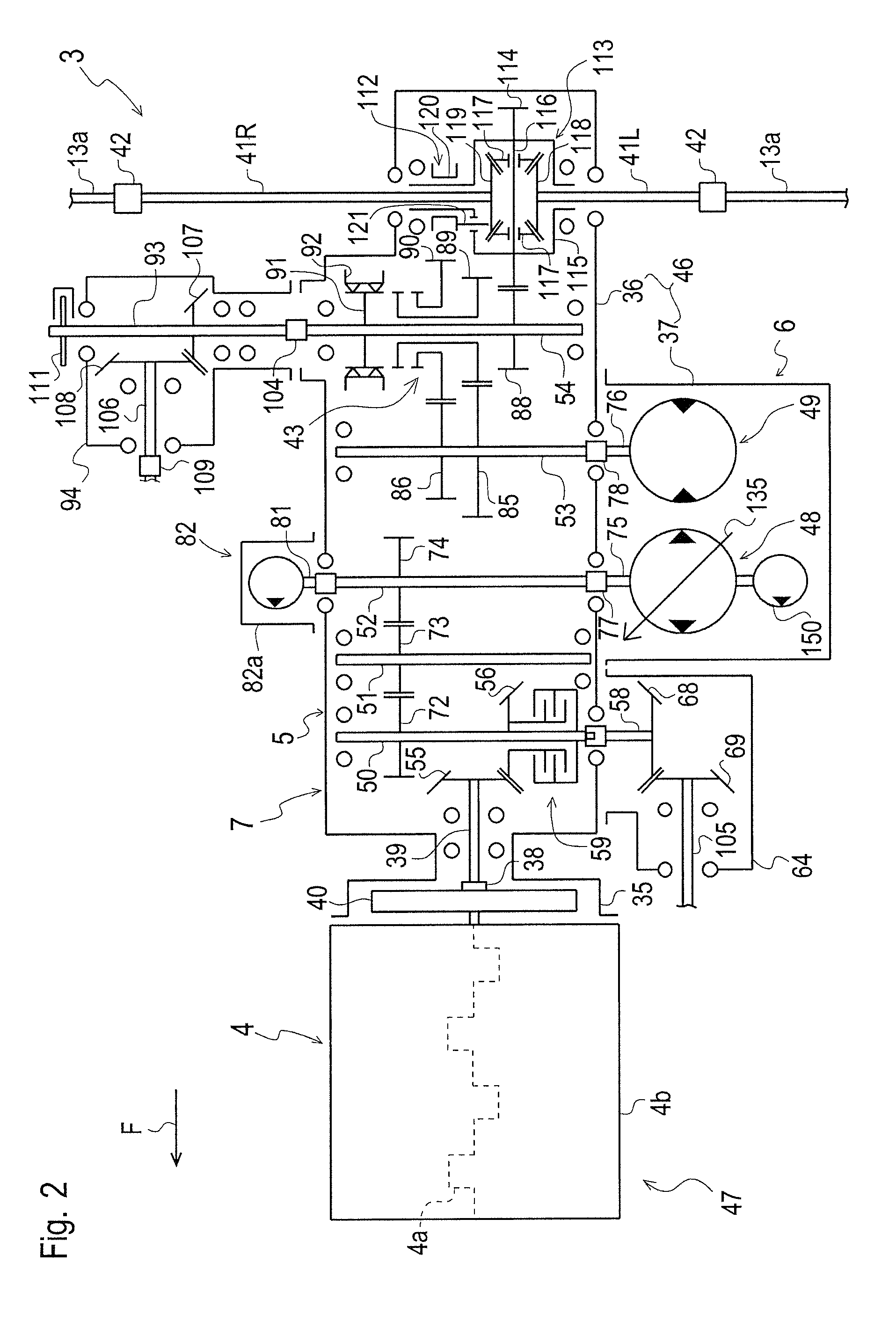

Hydraulic transaxle apparatus for a four-wheel driving vehicle and four-wheel driving vehicle using the apparatus

InactiveUS6845837B2Prevent liquid leakageEasy to manufactureFluid couplingsElectric devicesHydraulic pumpArticulated vehicle

An articulated vehicle with a working device has a first frame having a prime mover mounted thereon and supporting a first transaxle apparatus. The first transaxle apparatus includes an input shalt receiving power from the prime mover, a pair of first axles, and a hydrostatic transmission. The hydrostatic transmission comprises a variable hydraulic pump, a first hydraulic motor fluidly connected to the hydraulic pump via a fluid passage, and a housing with a port fluidly connected to the fluid passage. The second transaxle apparatus includes a pair of second axles having different lengths and a second hydraulic motor. The second hydraulic motor is fluidly connected to the port. Proximal ends of the first and second frames with respect to the vehicle are coupled to each other so that the first and second flames are rotatable around a vertical axis relative to each other when steered.

Owner:KANZAKI KOKYUKOKI MFG

Speed control for utility vehicle operable from rearward-facing seat

InactiveUS6851495B2Reduce stepsEffective positioningAuxillary drivesGearing controlSpeed control systemControl system

A speed control system for a utility vehicle, the vehicle having a forward-facing driving position and a rearward-facing seat, includes a creep control system for moving the utility vehicle, controlled from the rearward-facing seat. The vehicle includes a speed-controllable transmission operable to output power to drive a wheel. The vehicle includes a creep speed control actuator located adjacent to the rearward-facing seat and a creep speed control system operatively connected to the actuator and to the transmission. The system converts movement of the actuator to speed change of the transmission. The transmission can be a mechanically or electronically controlled hydrostatic transmission, or an electronically controlled reverser transmission.

Owner:DEERE & CO

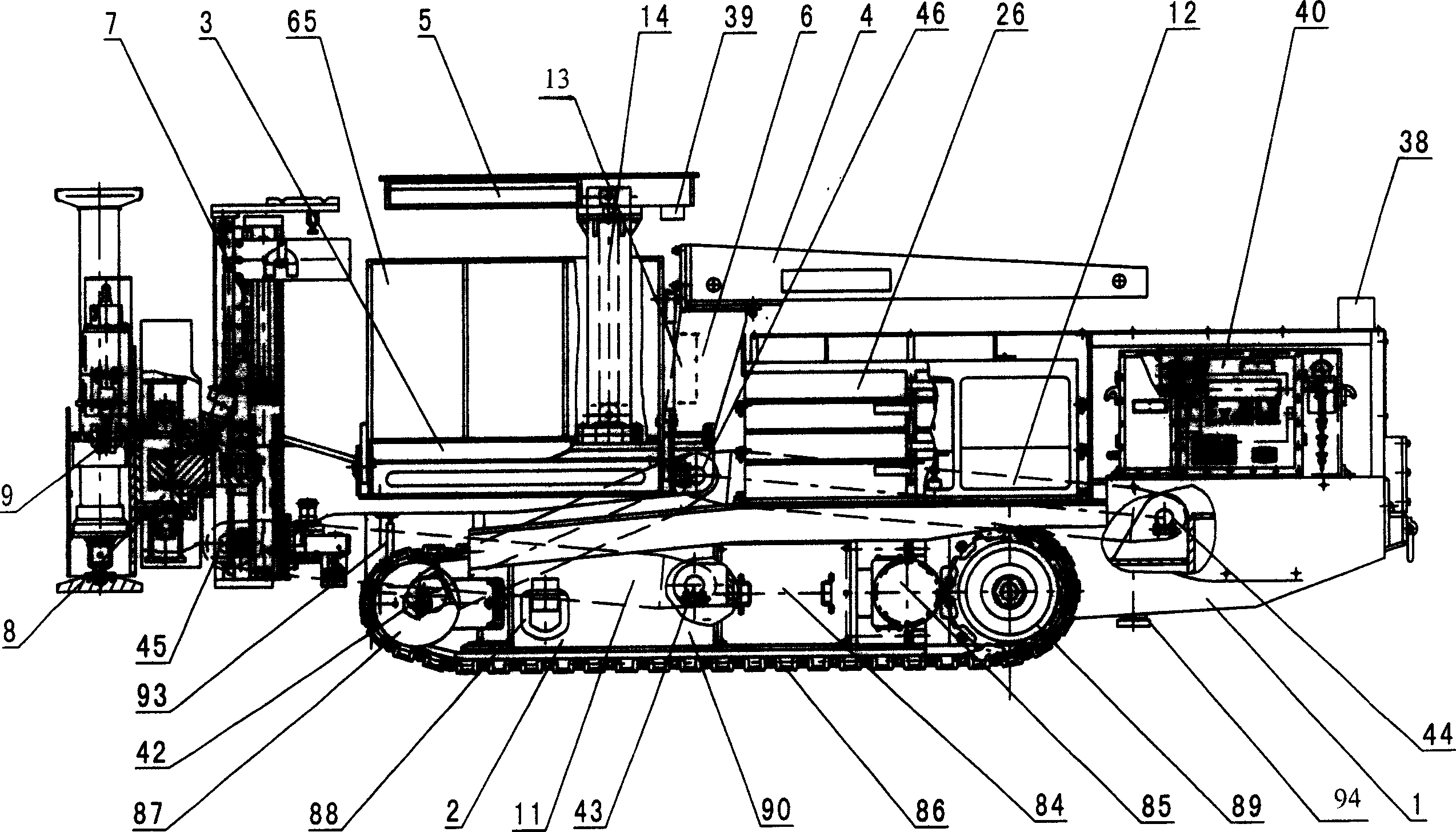

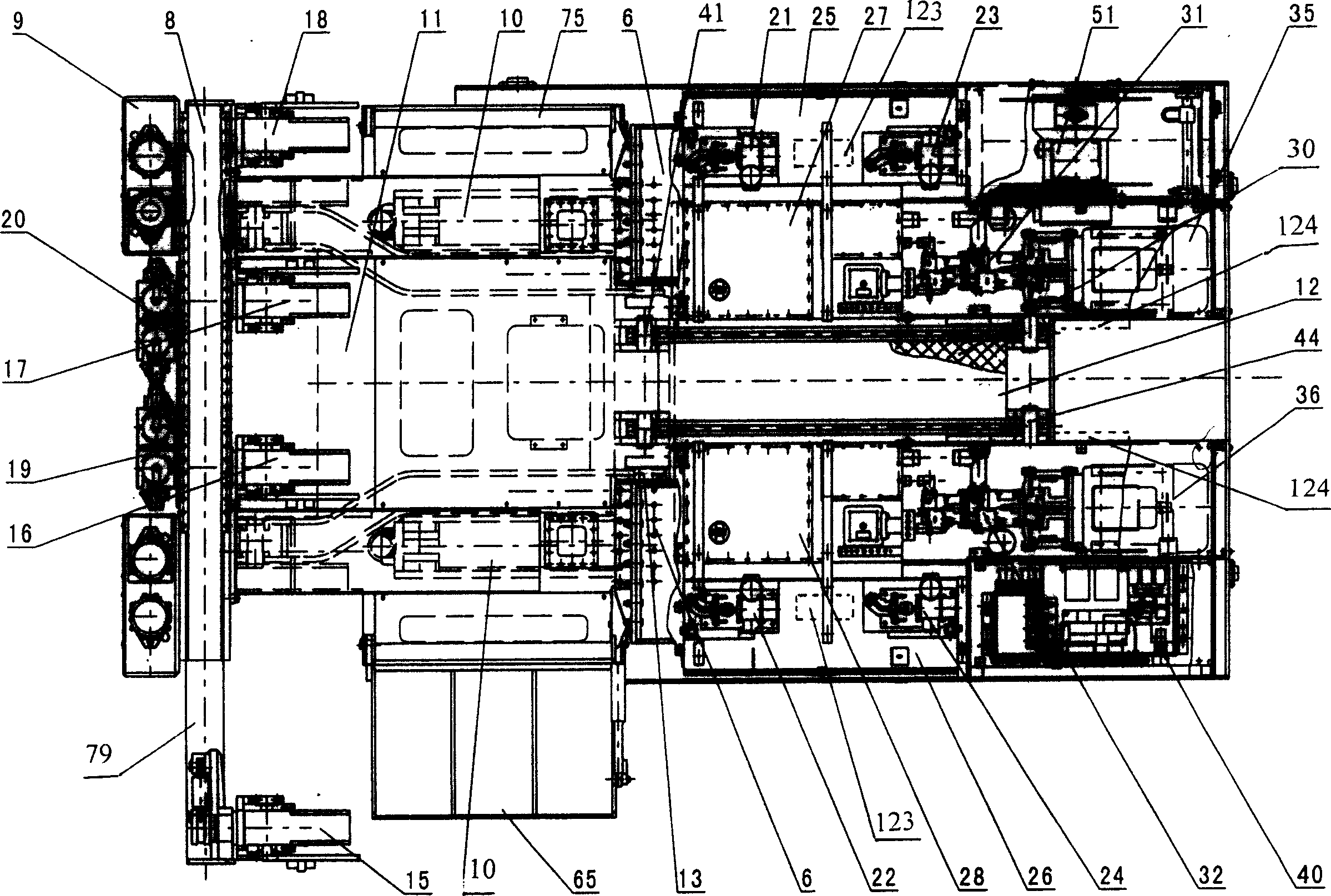

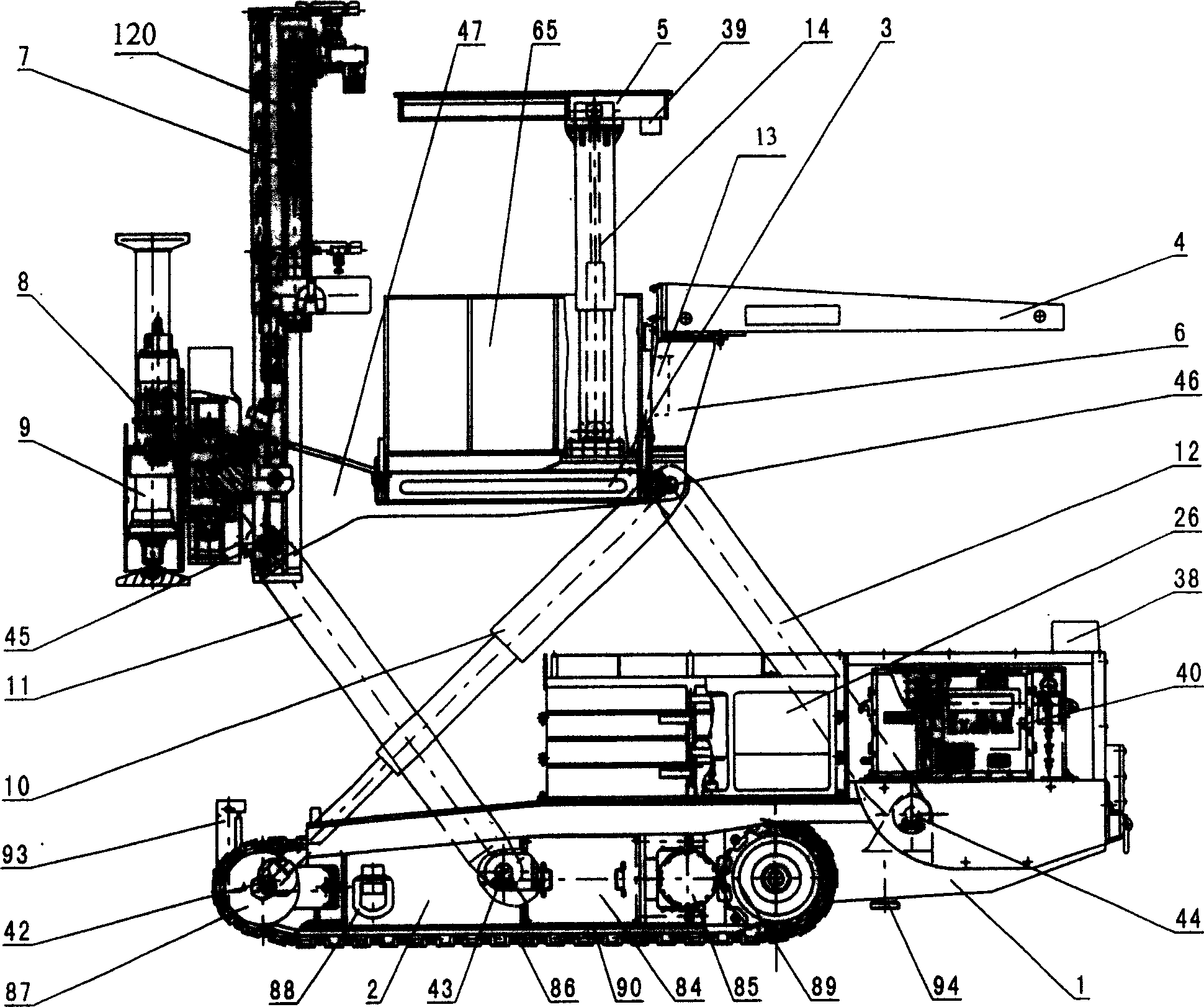

Crawler-type walking rockbolt drilling carriages

ActiveCN1584292AThe mechanical relationship is reasonableMechanizationAnchoring boltsDrilling machines and methodsElectric controlRock bolt

The present invention relates to a crawler running roof-bolting jumbo for coal extraction in the pit. It mainly includes machine seat, working table, running mechanism, lifting mechanism, hydraulic mechanism, dust-removing mechanism, cable-rolling mechanism, drilling cramp component, slideway component, support component and electric control box, said whole machine adopts hydraulic transmission, automatic dust-removing, automatic cable-rolling and crawler running modes, and utilizes the hydraulic oil cylinder to control parallelogram lifting movement and can make moving, lifting and multi-arm roof-bolt drilling works in the excavating tunnel. Said invention is reasonable in structure, large in load-bearing capacity, reliable and high in working efficiency.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

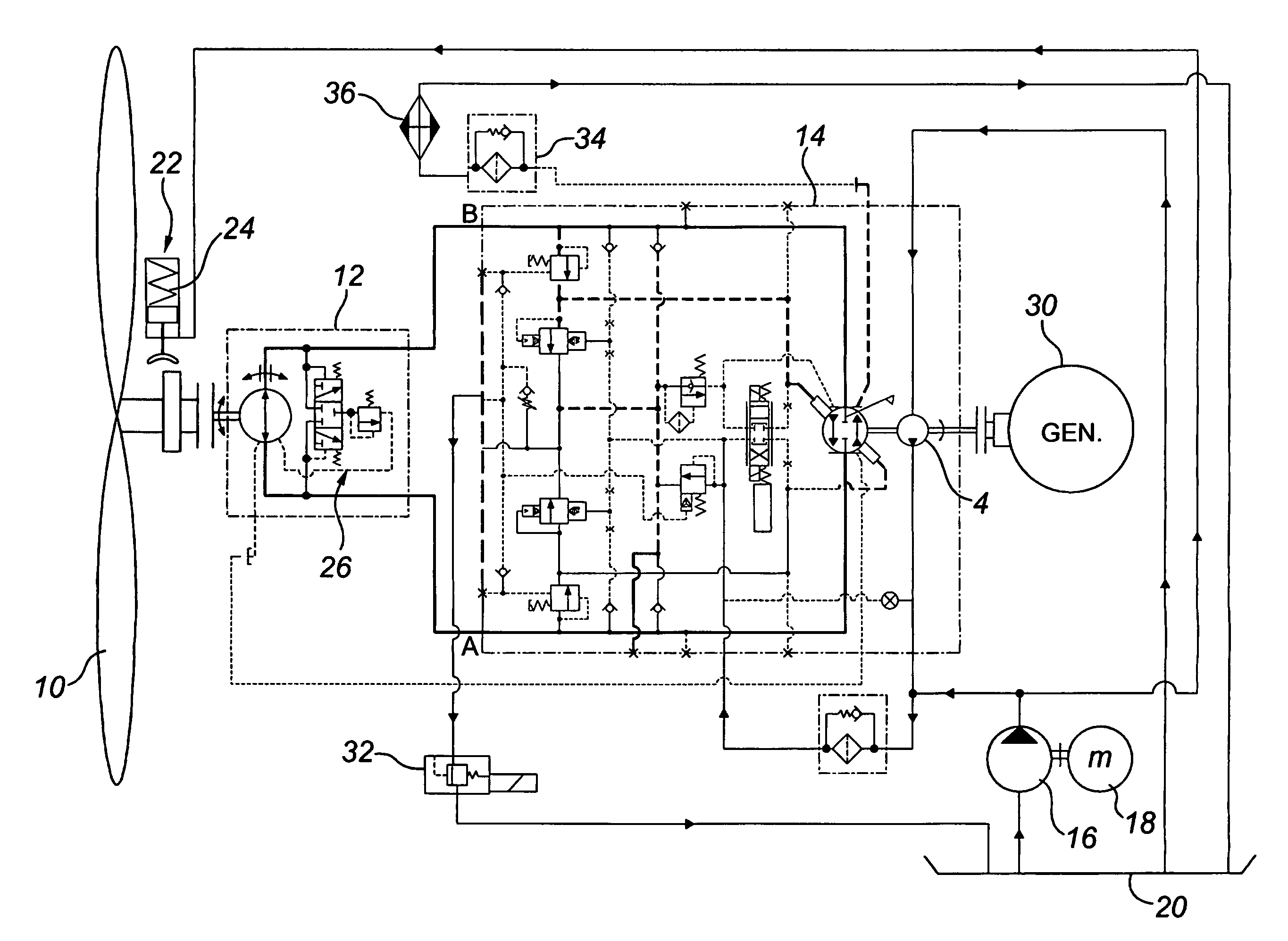

Wind turbine with hydraulic transmission

A wind turbine includes a closed loop hydrostatic transmission. The rotor is directly coupled to a low-speed high torque hydraulic motor, which is pressure-reversible to act as a pump. A variable displacement, pressure compensated hydrostatic transmission receives the hydraulic fluid output and drives a generator. The hydrostatic transmission and the generator may be compactly located in the nacelle of wind turbine tower.

Owner:MACKAY GARY

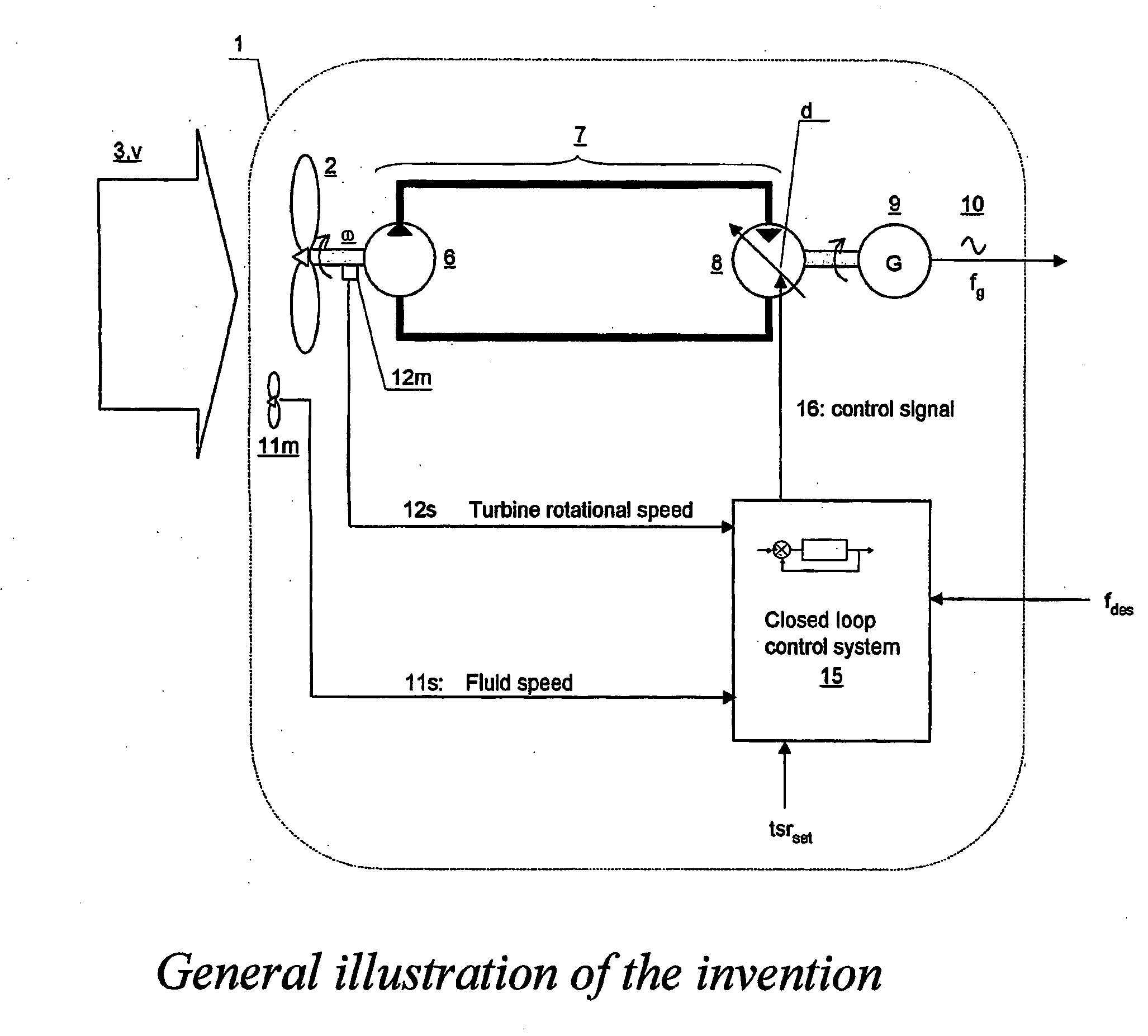

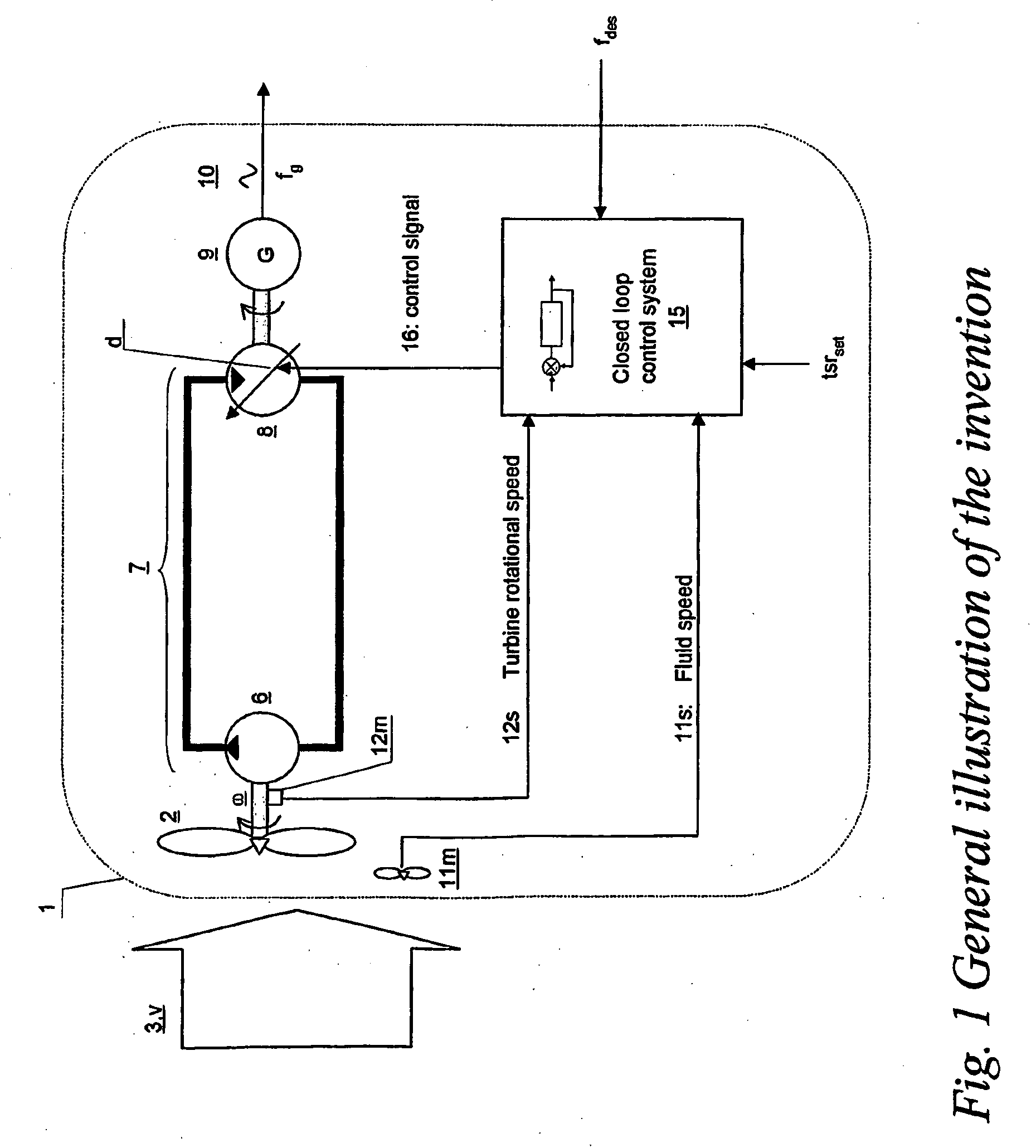

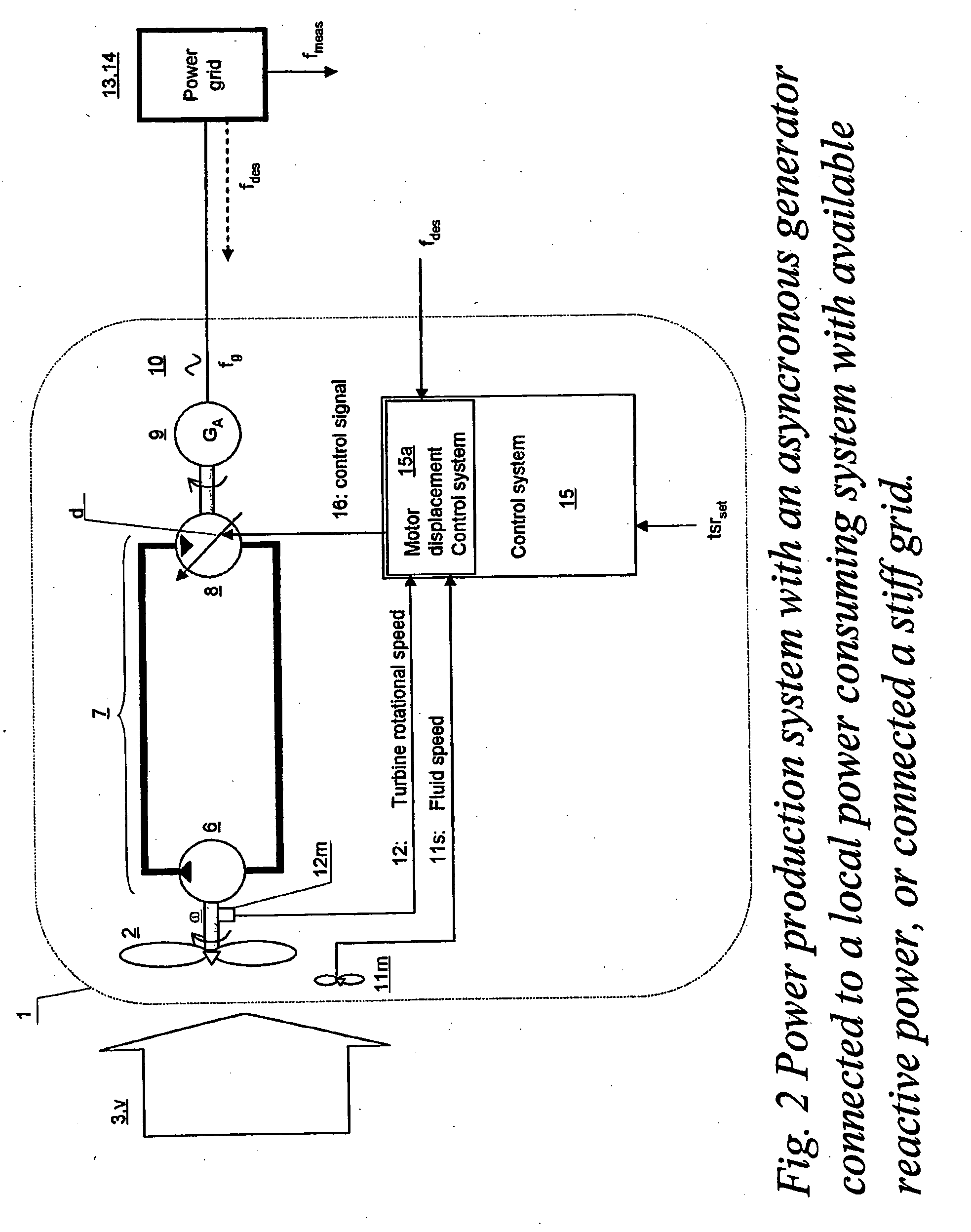

Turbine driven electric power production system and a method for control thereof

InactiveUS20090140522A1Improve power efficiencyImprove accuracyDomestic stoves or rangesWind motor controlControl signalClosed loop

A turbine (2) driven electric power production system (1), —said turbine (2) arranged for being driven by a fluid (3) having a fluid speed (v) varying in time, —said turbine (2) connected to a hydrostatic displacement pump (6) further connected to a hydrostatic displacement motor (8) as part of a closed loop hydrostatic transmission system (7), —said motor (8) arranged for driving an electrical generator (9) supplying AC power (10) at a frequency (fg) near a given desired frequency (fdes), characterized by a closed loop system arranged for controlling a volumetric displacement (13) of the hydrostatic motor (8), comprising —a fluid speed meter (11m) arranged for producing a speed signal (11s) representing a speed (v) of said fluid (3), and —a rotational speed meter (12m) arranged for providing a rotational speed signal (12s) representing a rotational speed measurement (ω) of said turbine (2), —a motor displacement control system (15) for continuously receiving said speed signal (11s) and said rotational speed signal (12s) and arranged for calculating a control signal (16), —a volumetric displacement control actuator (17) on said hydrostatic motor, arranged for receiving said control signal (16) for continuously adjusting a volumetric displacement (d) of said hydrostatic motor (8) for maintaining a set turbine tip speed ratio (tsrset) and thereby providing an improved power efficiency of the power production system (1) during fluctuations in said fluid speed (v).

Owner:CHAPDRIVE AS

Continuously variable drive for superchargers

ActiveUS7055507B2Constant speedImprove performanceCombustion enginesFluid gearingsGear driveEngineering

A drive assembly for a supercharger for an internal combustion engine provides a continuously variable drive ratio between the engine and supercharger to provide a substantially, constant drive speed to the supercharger, thereby optimizing performance. The continuously variable drive may function in increments as well as allow the supercharger to free-wheel. The drive assembly includes a planetary gear drive assembly and a continuously variable hydrostatic transmission having a rotating, variably coupled master and slave pump and motor which, by adjusting its drive ratio, adjusts the ratio of the planetary gear assembly and thus the drive ratio between the engine and the supercharger.

Owner:BORGWARNER INC

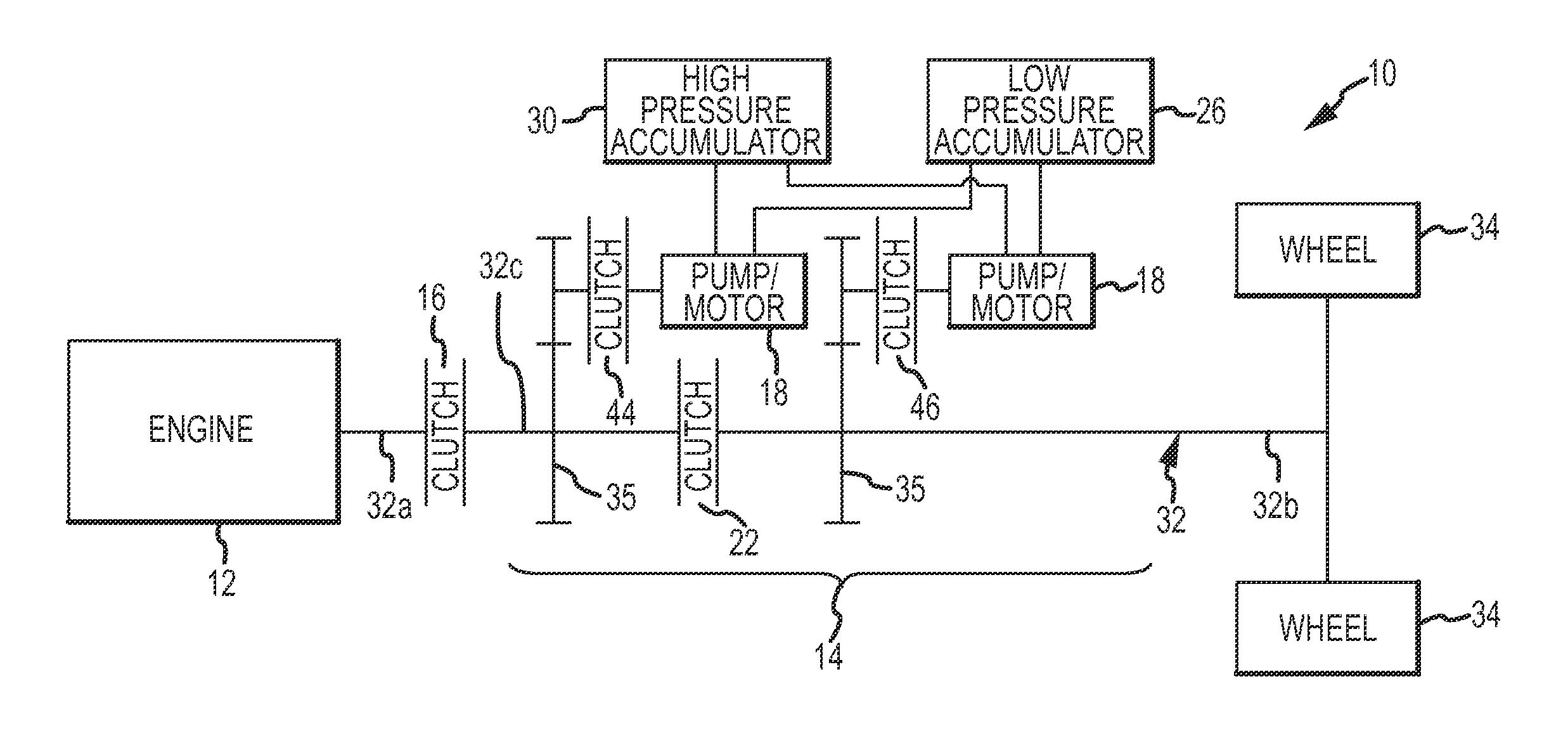

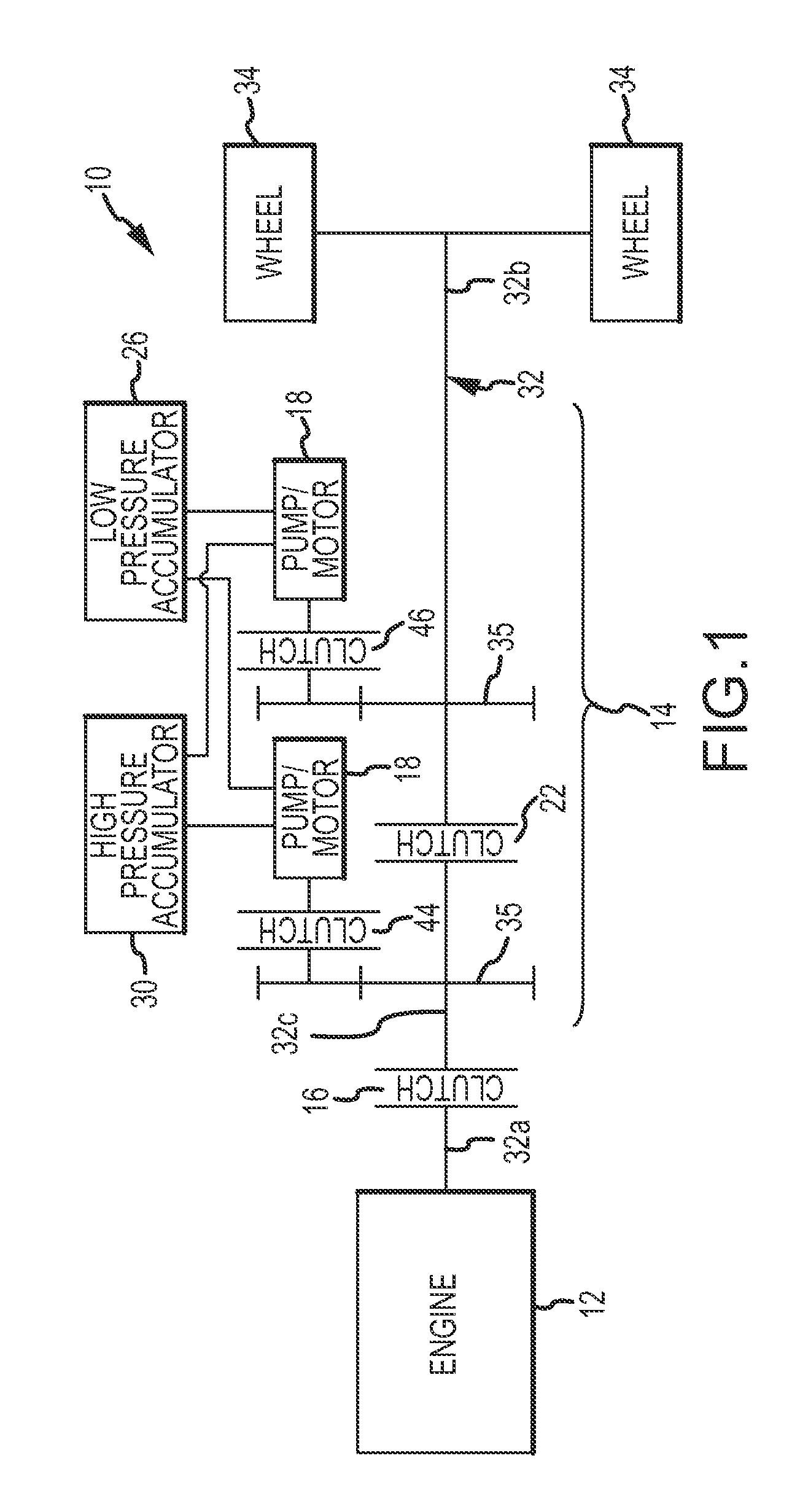

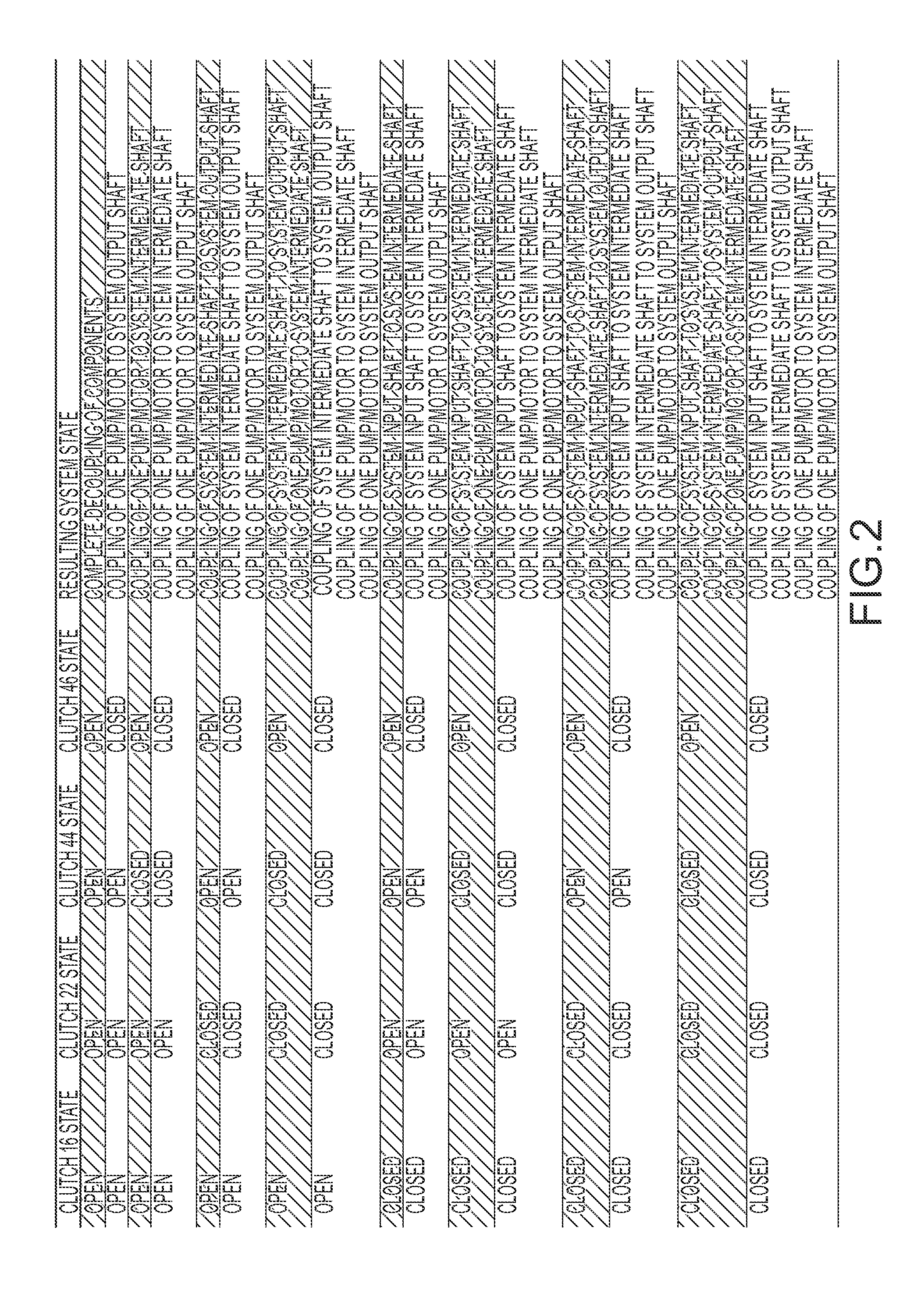

Hybrid hydraulic drive system architecture

A vehicle drivetrain has a first driver, a first clutch to selectively couple the first driver with an engine, an energy storage device coupled to the first driver, a second driver coupled to the energy storage device and connected to a driveshaft, and a second clutch that selectively couples the first and second drivers. In one embodiment, the first clutch is opened and the second clutch is closed during a vehicle operating condition requiring high torque, the first clutch is closed and the second clutch is opened during a transient vehicle operating condition, and the first clutch and the second clutch are closed during a steady-state vehicle operating condition. Additional clutches may be included to reduce energy losses or provide multiple mechanical ratios. The drivers themselves may be pumps, motors, generators, combined pump / motors, or combined motor / generators, making the invention suitable for both hydraulic implementation and electric implementation.

Owner:EATON CORP

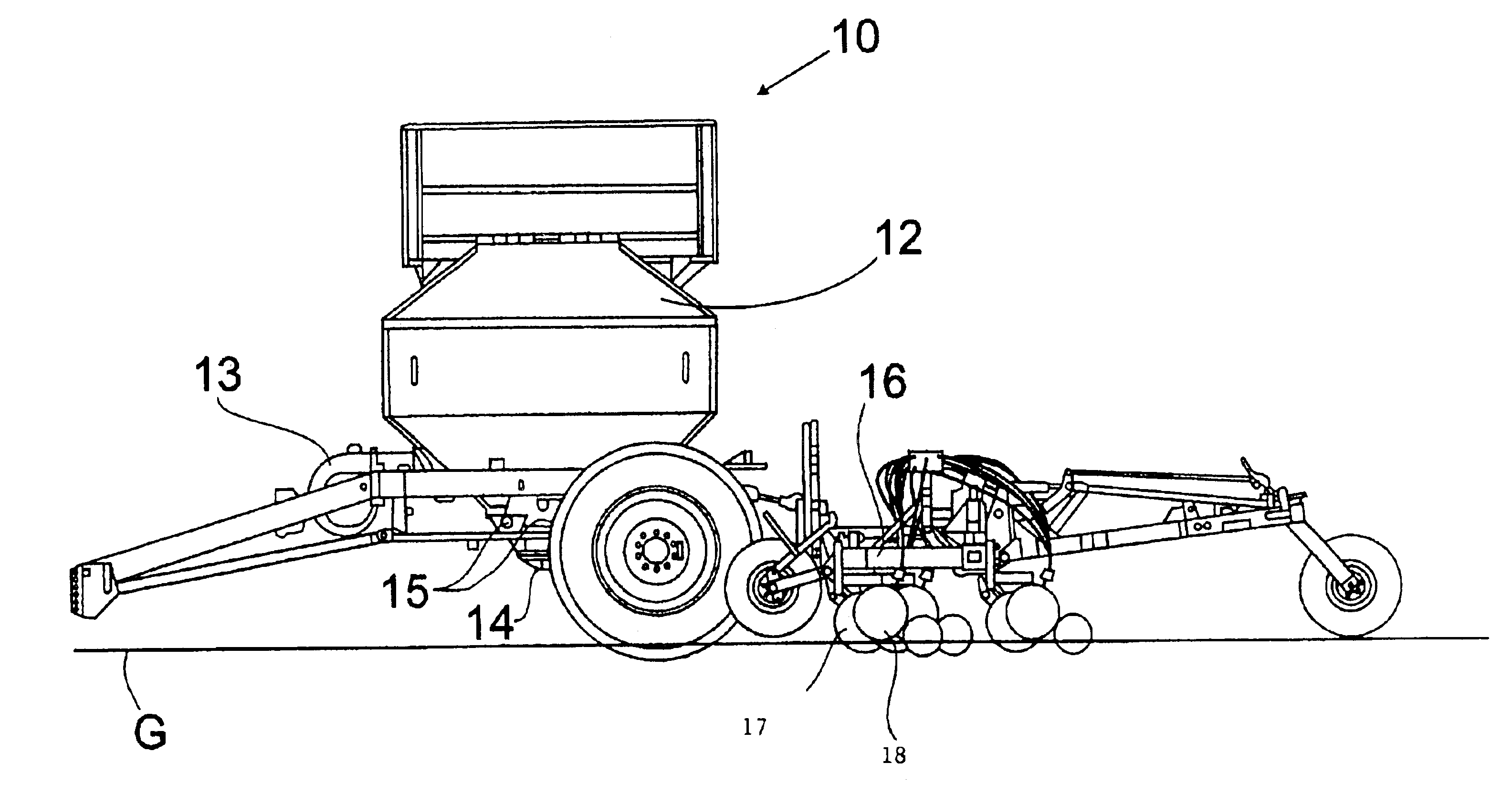

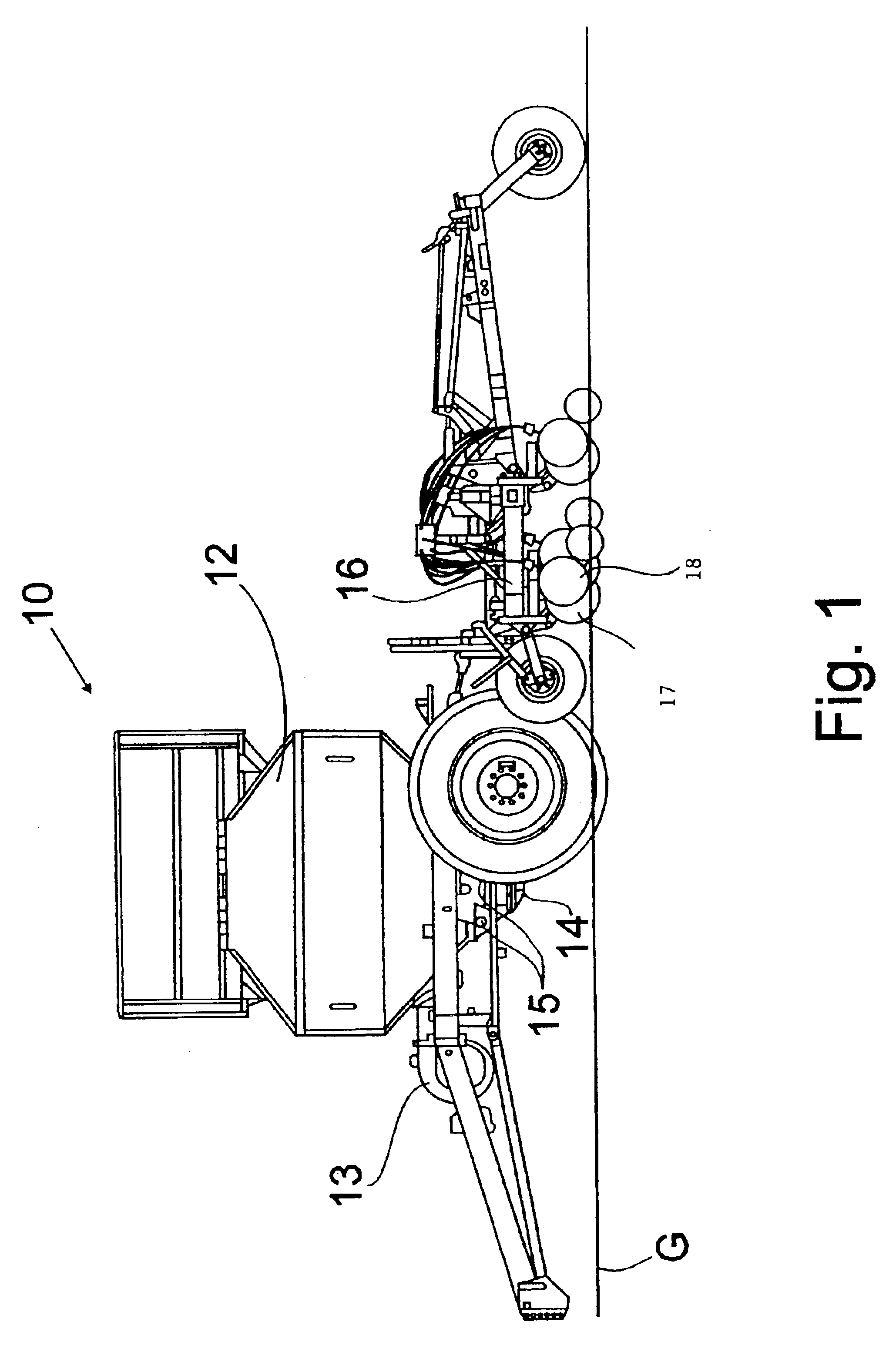

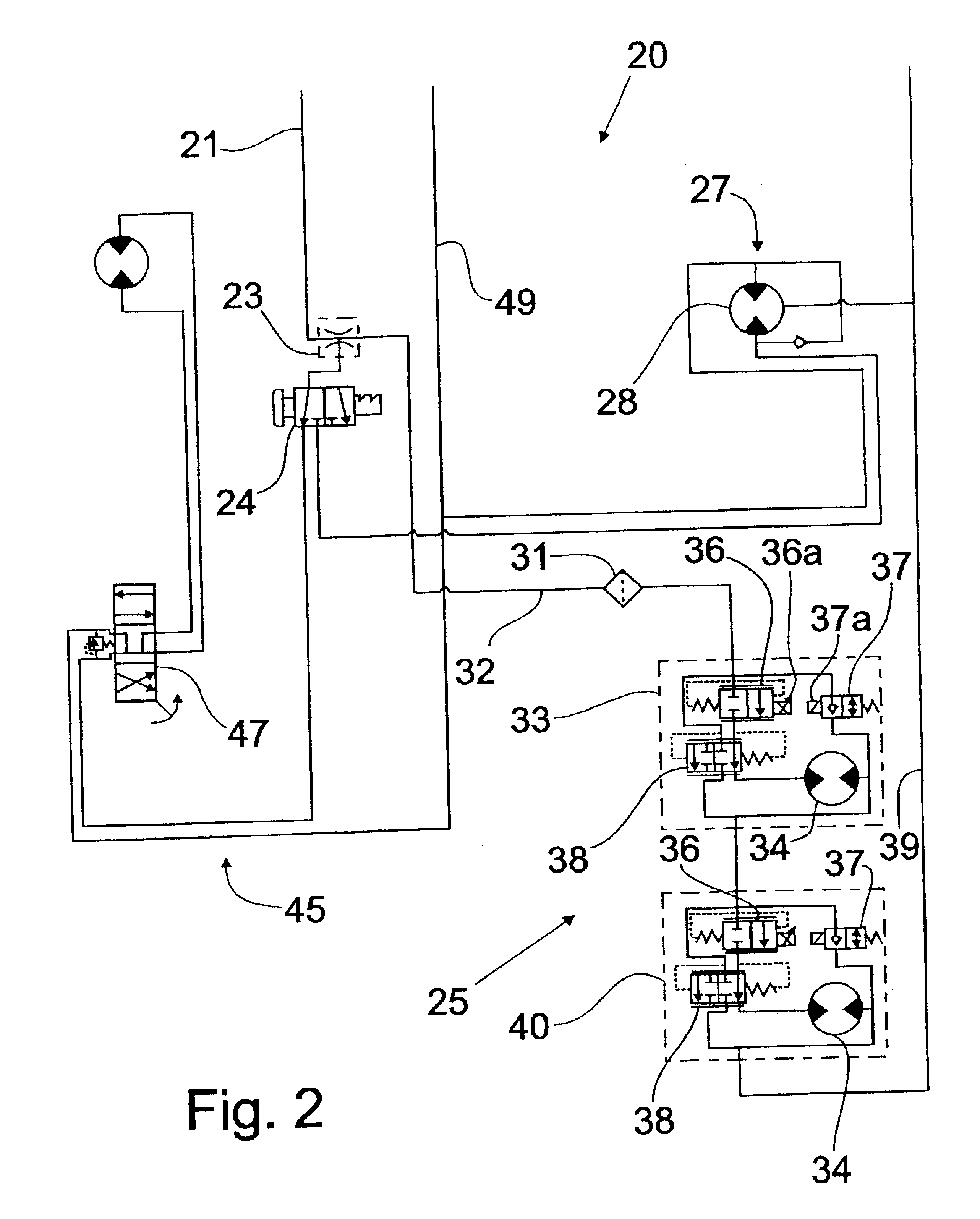

Variable rate meter drive system

InactiveUS6851377B2Efficiently usReduce manufacturing costServomotorsServometer circuitsHydraulic fluidControl theory

A hydraulic drive system provides a priority flow of hydraulic fluid to a variable rate drive system for powering the operation of the metering mechanisms before hydraulic fluid is supplied to a secondary drive mechanism for powering the operation of secondary devices, such as the fan mechanism or the loading auger. The hydraulic drive system includes a priority flow divider valve that diverts a predetermined flow rate to the variable rate drive system. The variable rate drive system includes a drive mechanism arranged in series for a plurality of metering mechanisms. The secondary drive system includes a selector valve that permits a selection between the alternative secondary devices. An alternative embodiment of the hydraulic drive system includes a counter balance valve that operates to provide a priority flow to the variable rate drive system.

Owner:CNH IND CANADA

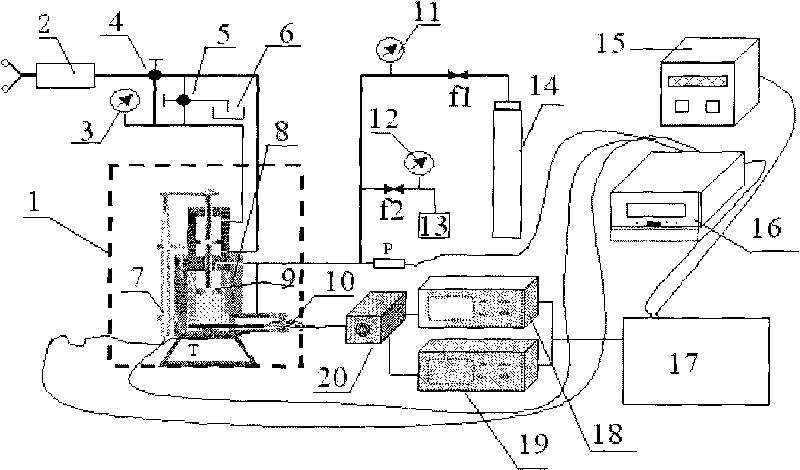

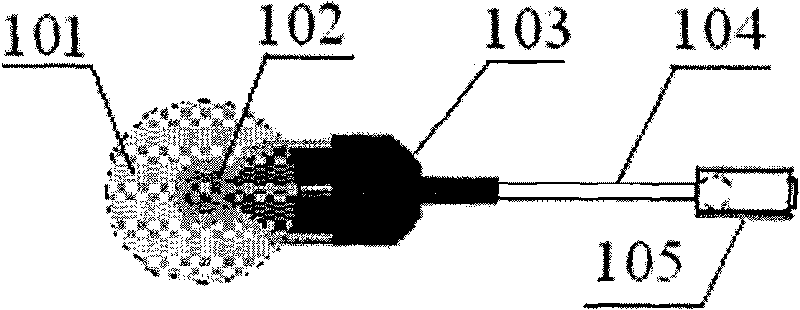

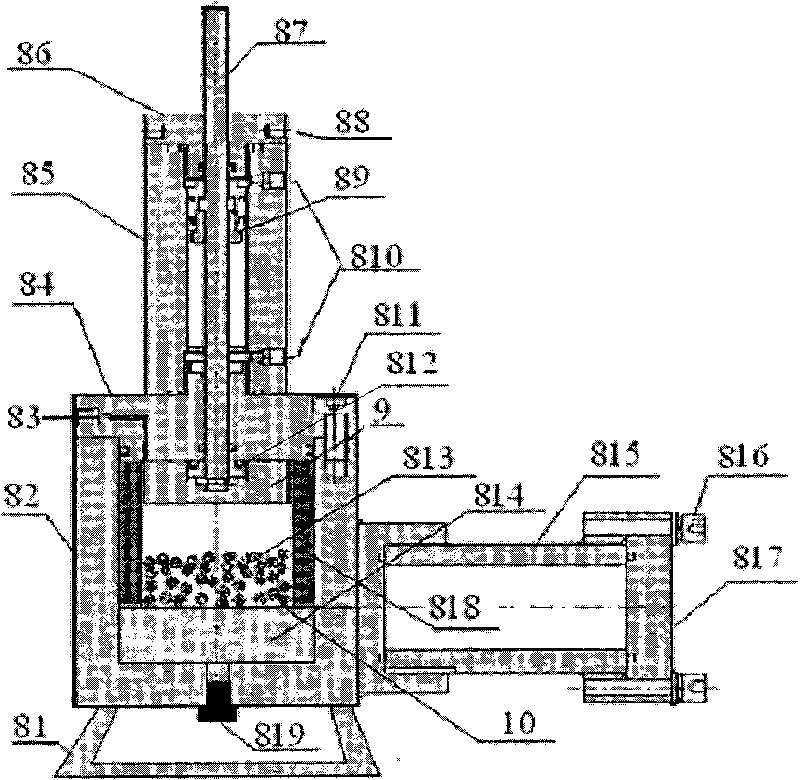

Device for measuring sample thermo-physical property in situ

InactiveCN101718725AFast testMeasurable thermophysical parametersMeasurement of fluid loss/gain rateMaterial thermal conductivityChemical reactionReaction temperature

The invention discloses a device for measuring the sample thermo-physical property in situ, comprising a reaction kettle internally provided with a tested sample, a gas supply system for providing a gas source for the reaction kettle, a temperature control system for maintaining the reaction temperature in the reaction kettle, a hydraulic driving system connected with the reaction kettle and a measurement and control acquisition system connected with the reaction kettle and used for testing the thermo-physical property of the sample, wherein a background material of which the thermal conductivity is less than that of the tested sample is arranged at the bottom inside a barrel of the reaction kettle, and the measurement and control acquisition system comprises a thermo-physical test probe which is inserted between the tested sample and the background material. By adopting a single-side test structure of the thermo-physical test probe, the thermo-physical property test to different samples can be carried out, and the test speed is fast; the thermo-physical property parameters of the sample under different temperatures and pressures can be measured as the temperature and the pressure are respectively regulated; the reaction extent test is carried out according to the change of the thermo-physical property parameters during the chemical reaction; and the system has definite functions of all parts, favorable upgradability and expandability as well as wide adaptability.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

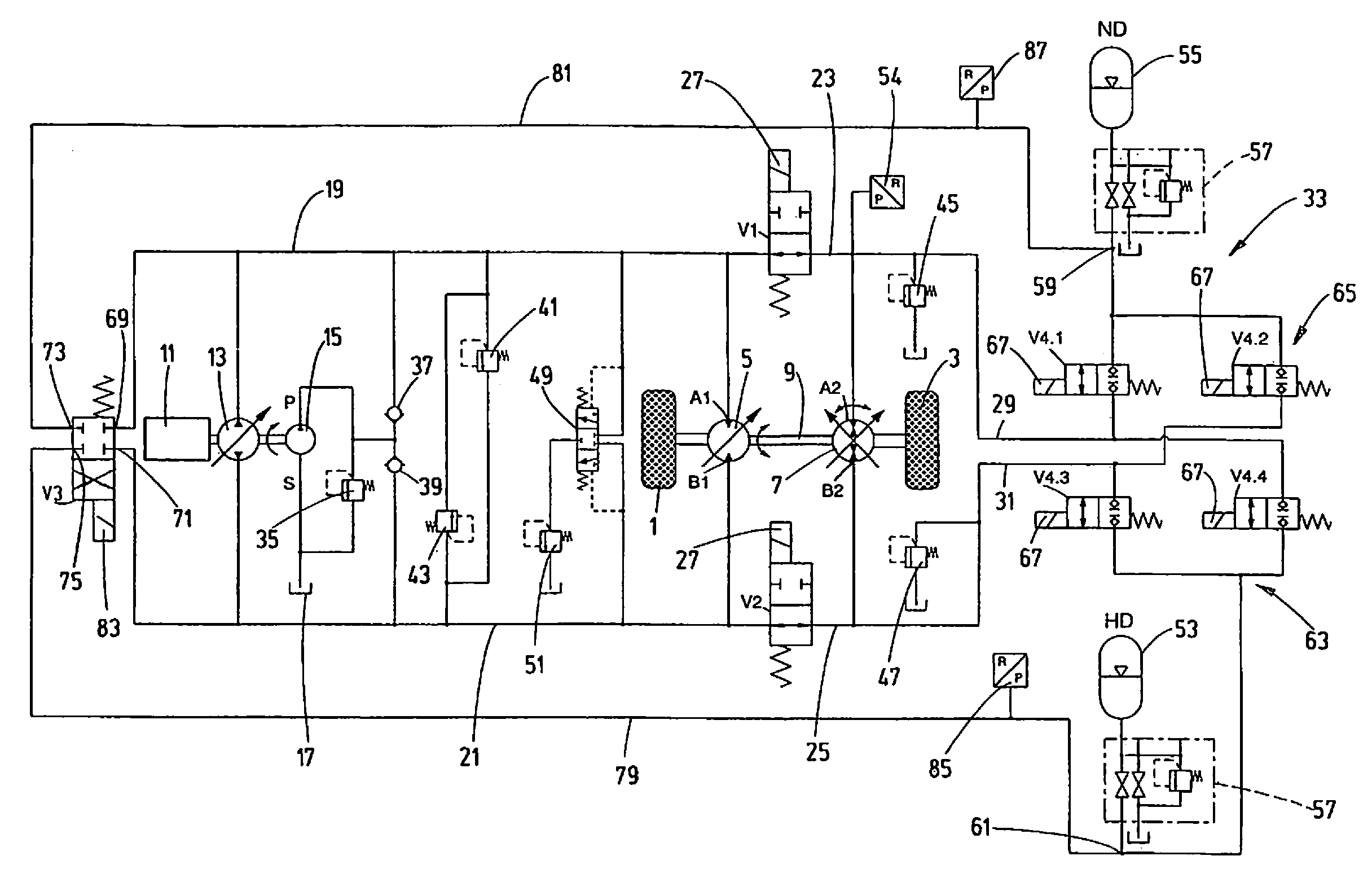

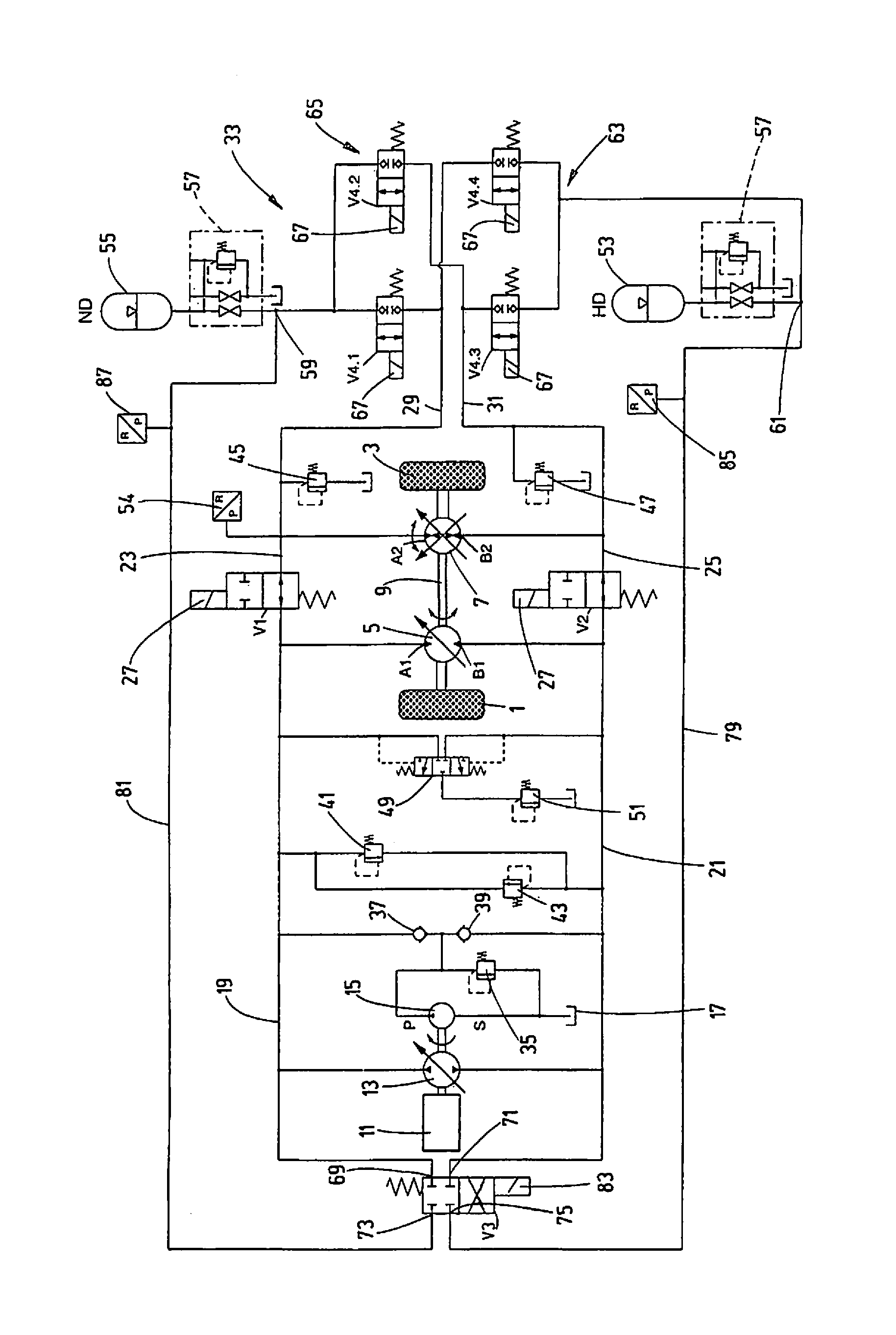

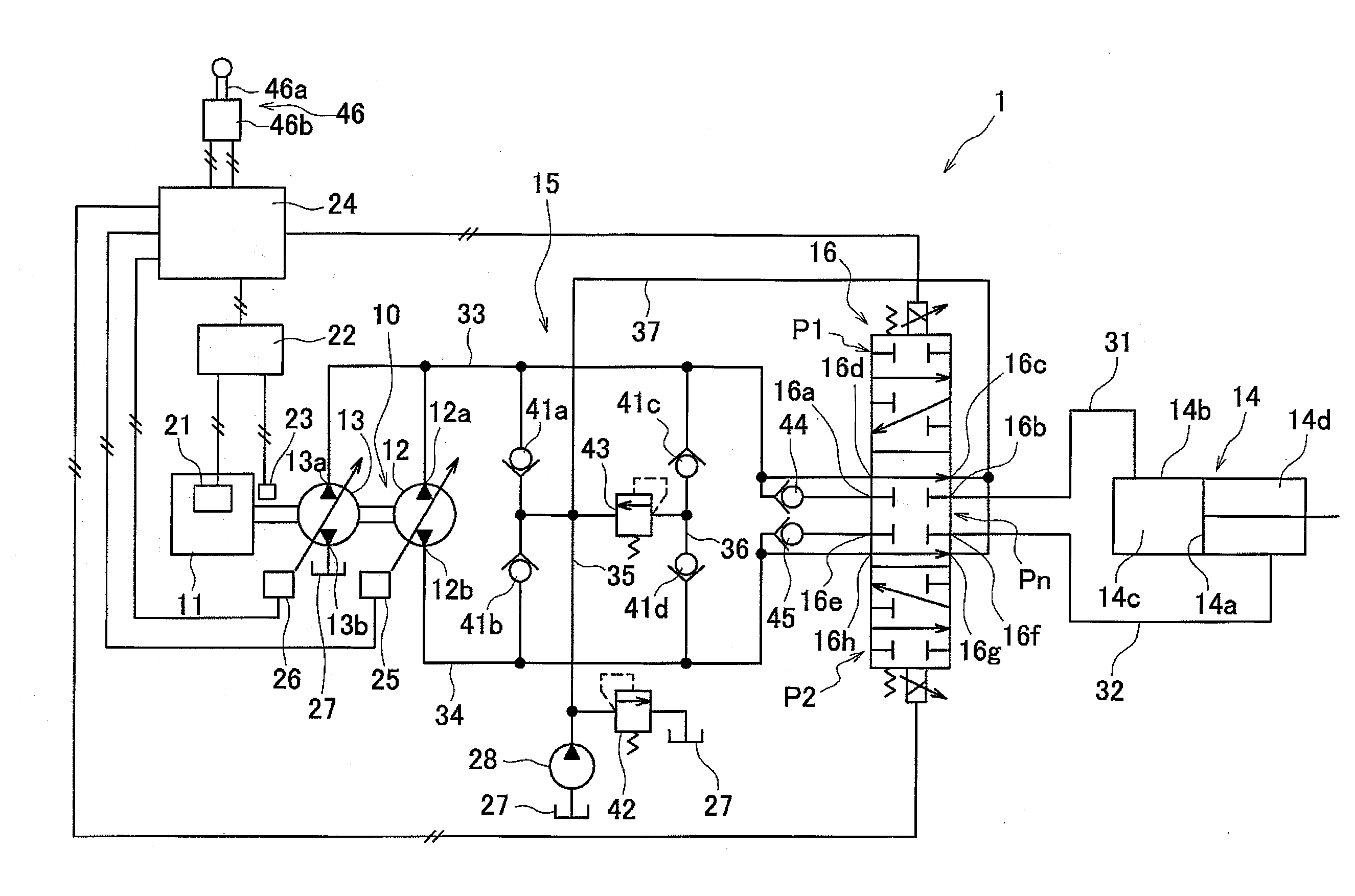

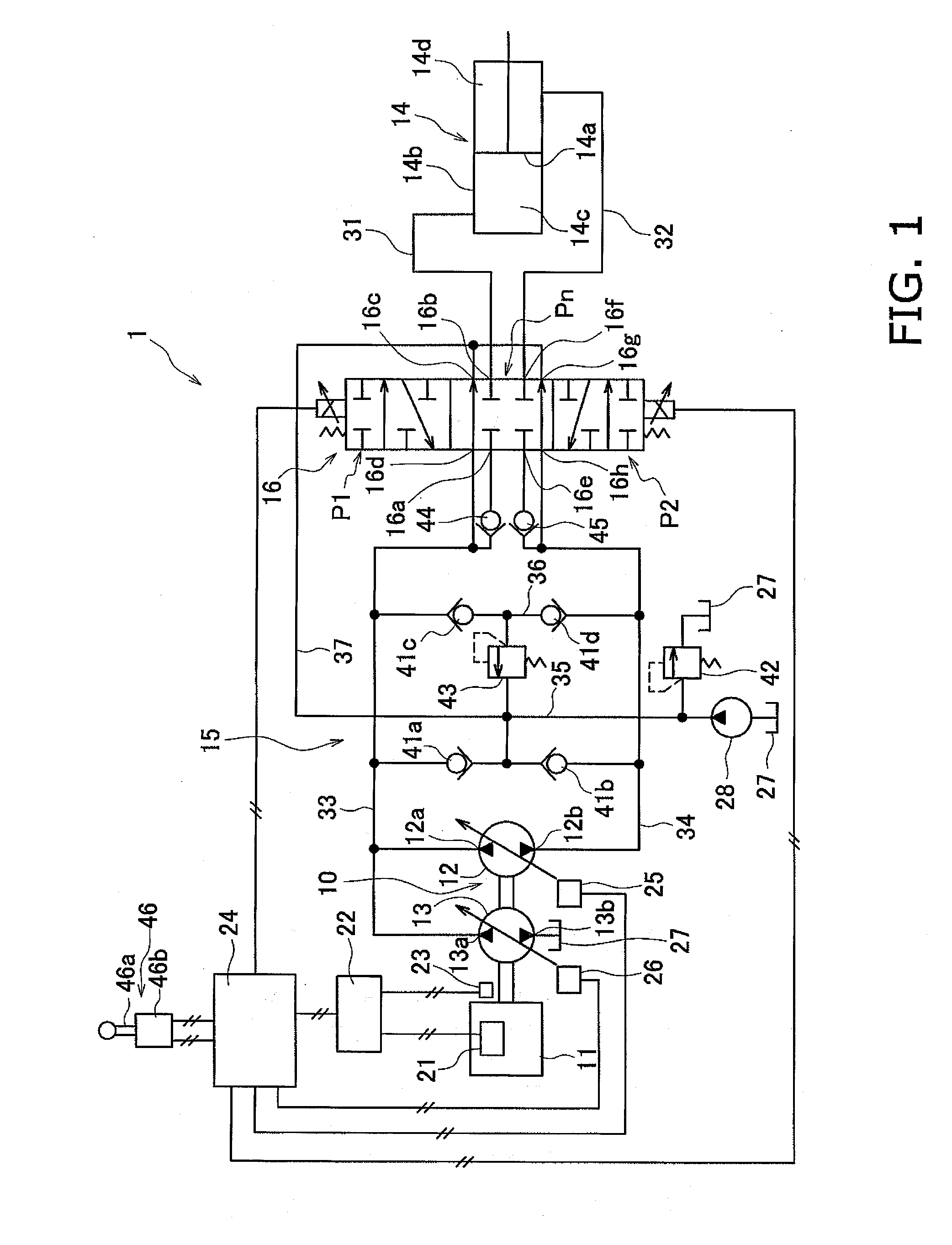

Hydrostatic drive system

ActiveUS8959905B2Simple structureImprove responseFluid couplingsGas pressure propulsion mountingLine tubingMotor drive

A hydrostatic drive system has a motor-driven hydraulic pump (1) connected to at least one hydraulic drive unit (7) by a first working line (19) and a second working line (21) forming a hydraulic circuit. The drive unit is connected to a gear set (1, 3). A first hydraulic accumulator (53) for accumulating pressure energy can be connected to one of the working lines (19, 21). A second hydraulic accumulator (55) can be connected to the other working line (19, 21). A valve device (V1, V2) permits the segment (23, 25) of each working line (19 or 21) extending to the drive unit (7) to be separated to separate an accumulator part (33) from the part of the circuit with the hydraulic pump (13). The accumulator part includes the hydraulic accumulators (53, 55) and at least one drive unit.

Owner:HYDAC TECH GMBH

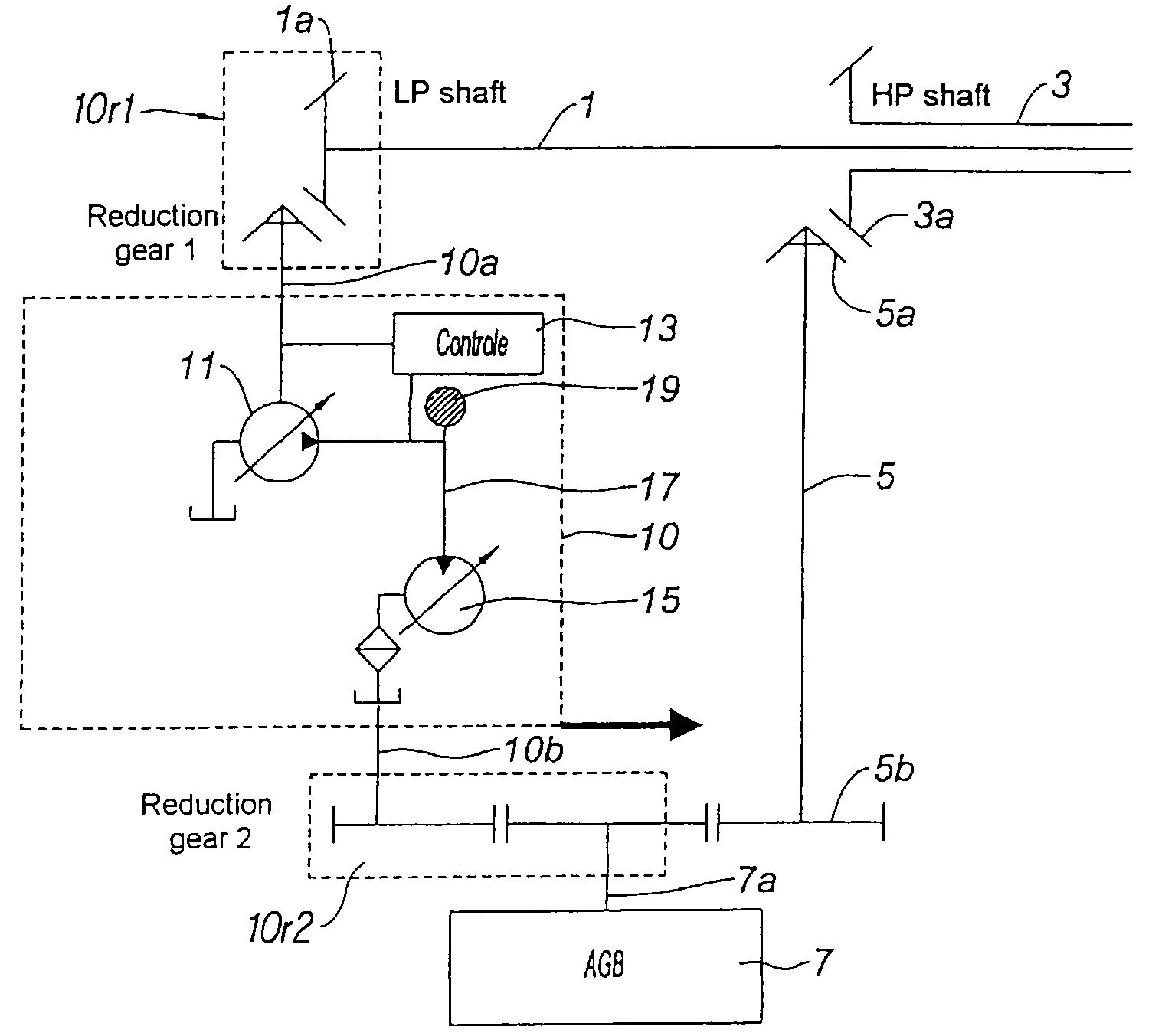

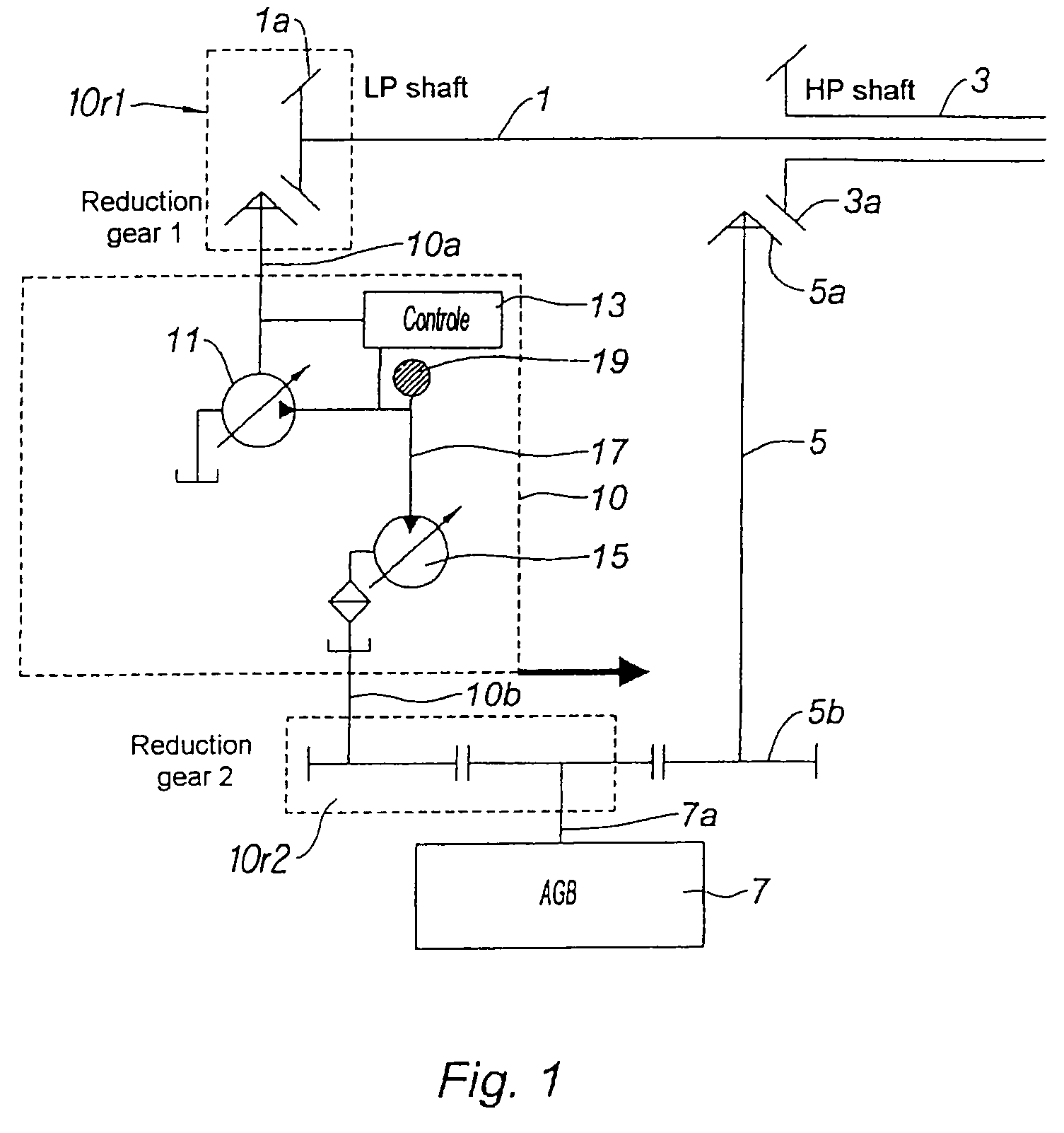

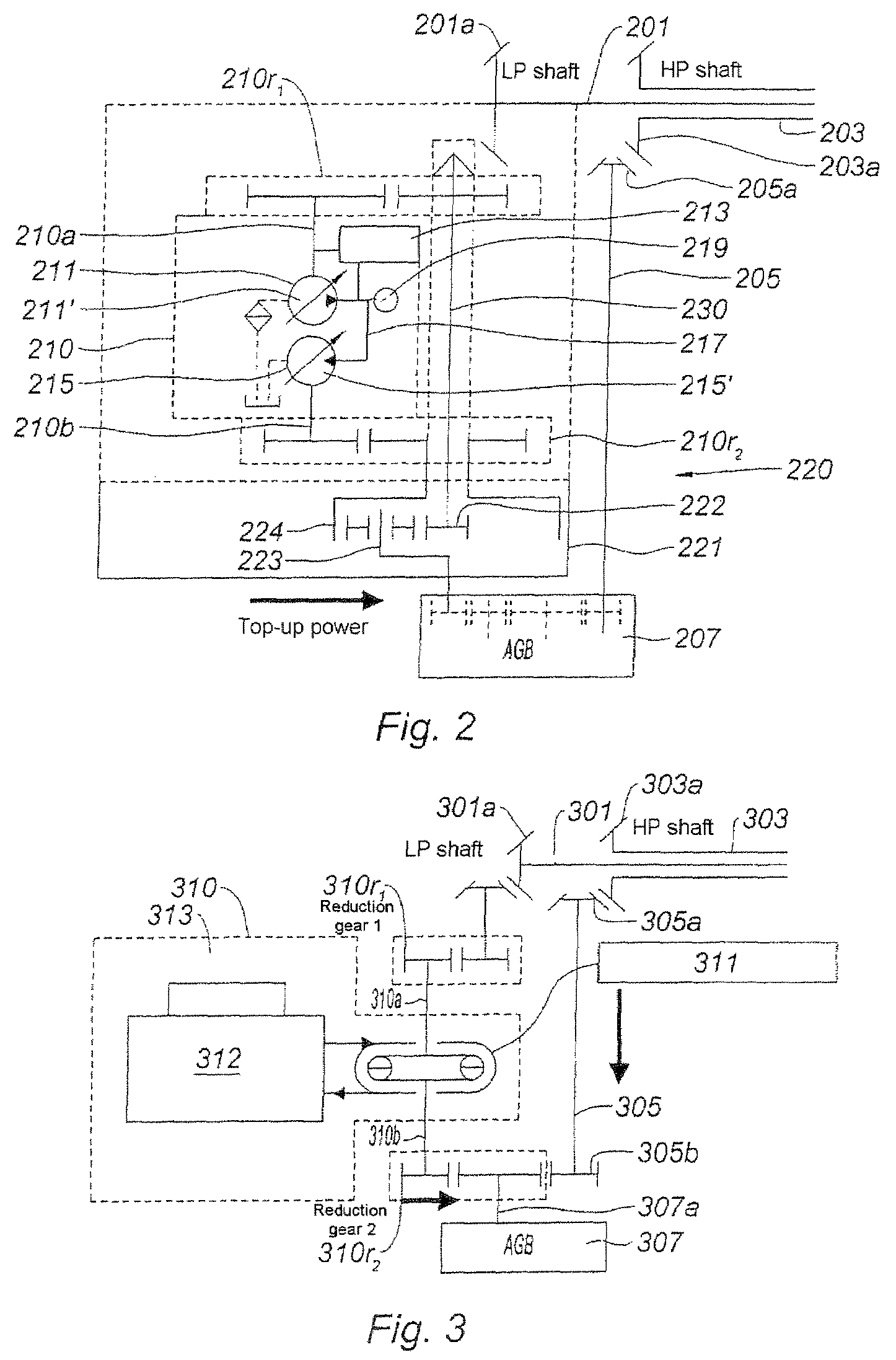

Device for driving accessory machines of a gas turbine engine

ActiveUS7707909B2Limit lossGreat simplicity of applicationGas turbine plantsEfficient propulsion technologiesHigh pressureTurbine

A device drives auxiliary machines by using power extracted from a multi-shaft gas turbine engine. The gas turbine engine may include a LP shaft and a HP shaft. The machines may be installed in a gearbox. The device may include a first mechanical transmission between the HP shaft and the gearbox. The device also may include a hydraulic transmission between the LP shaft and the gearbox. Further, the LP shaft connects a low pressure turbine to a low pressure compressor, the HP shaft connects a high pressure turbine to a high pressure compressor, and the low pressure compressor is upstream of the high pressure compressor.

Owner:SAFRAN TRANSMISSION SYST

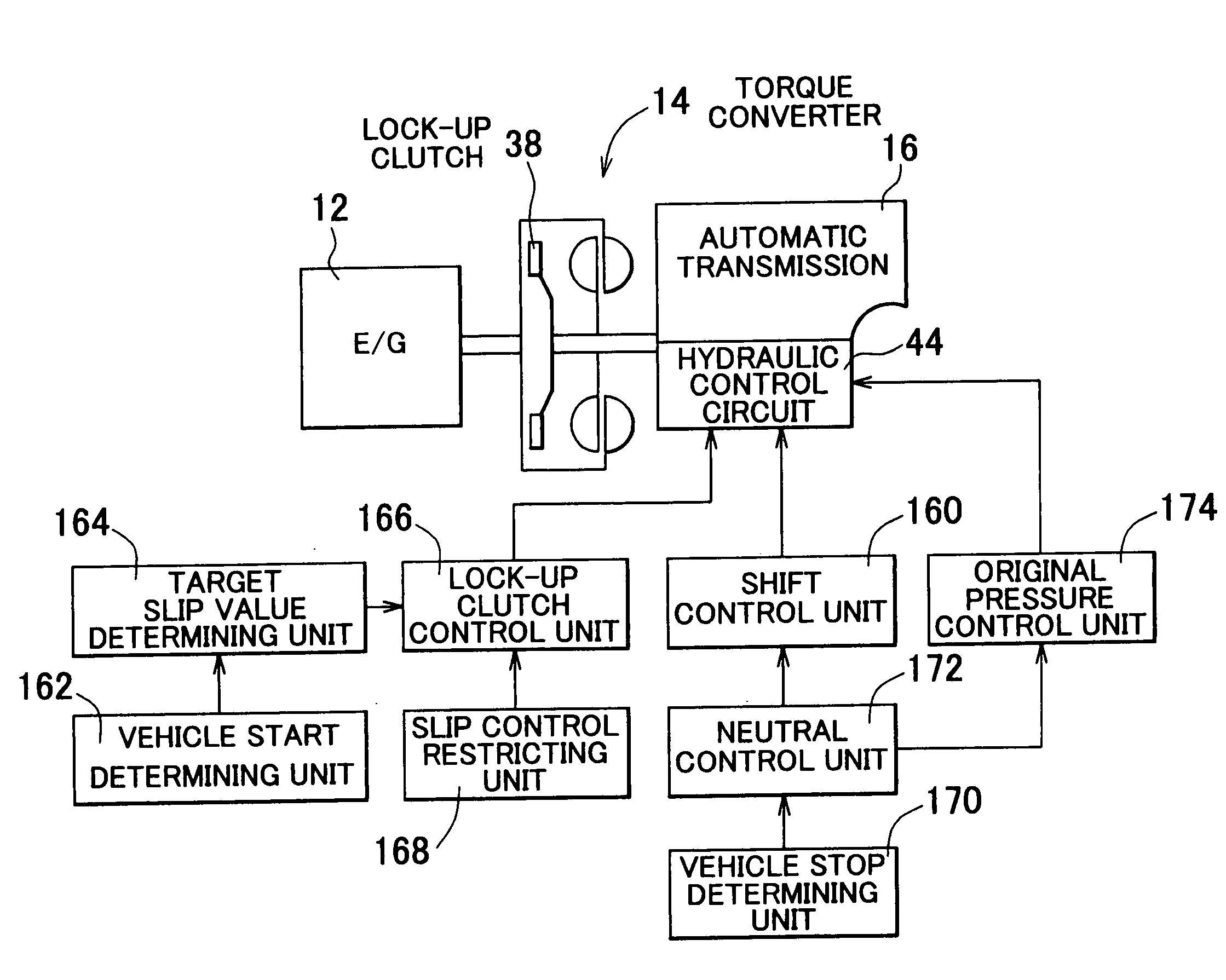

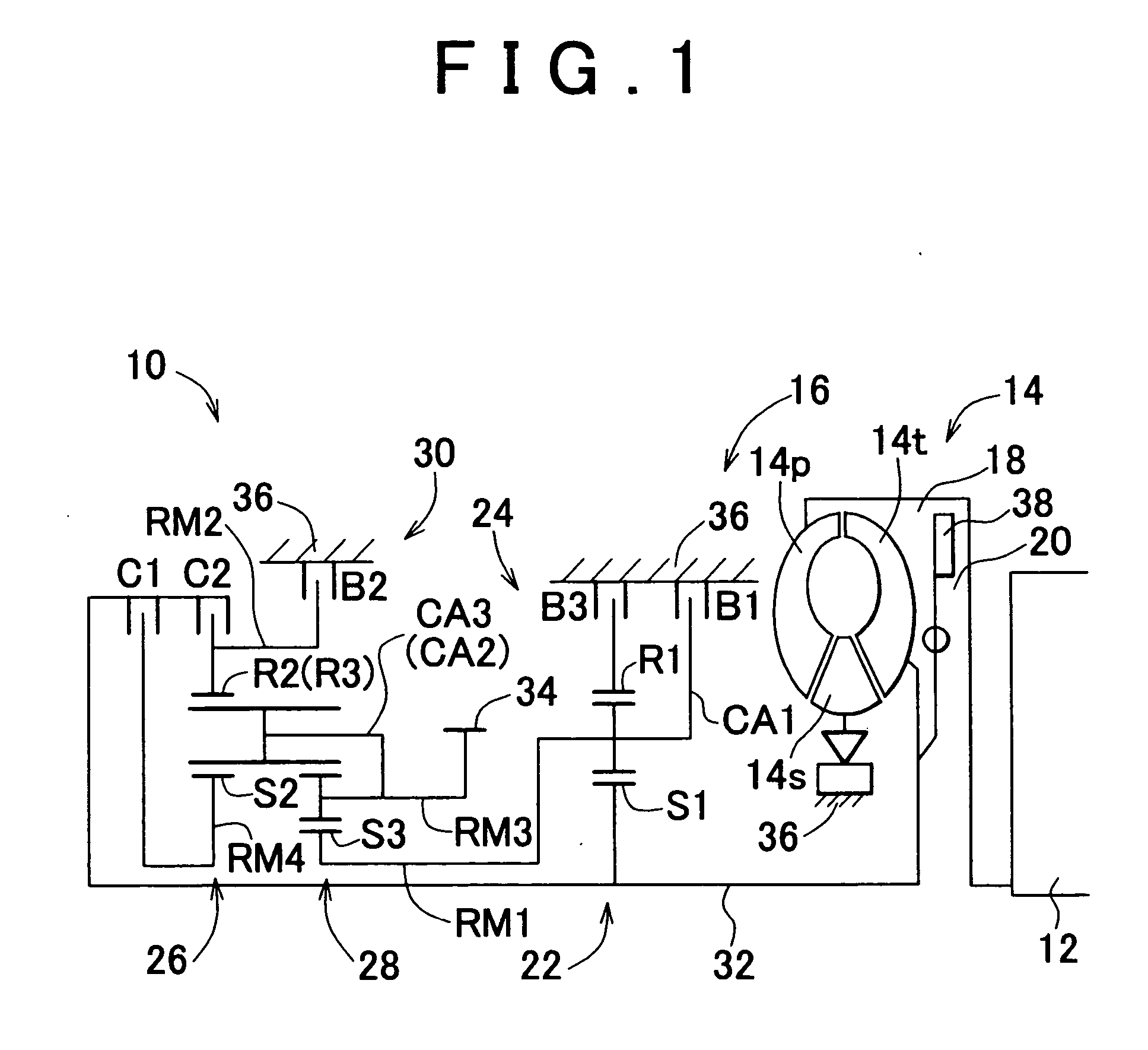

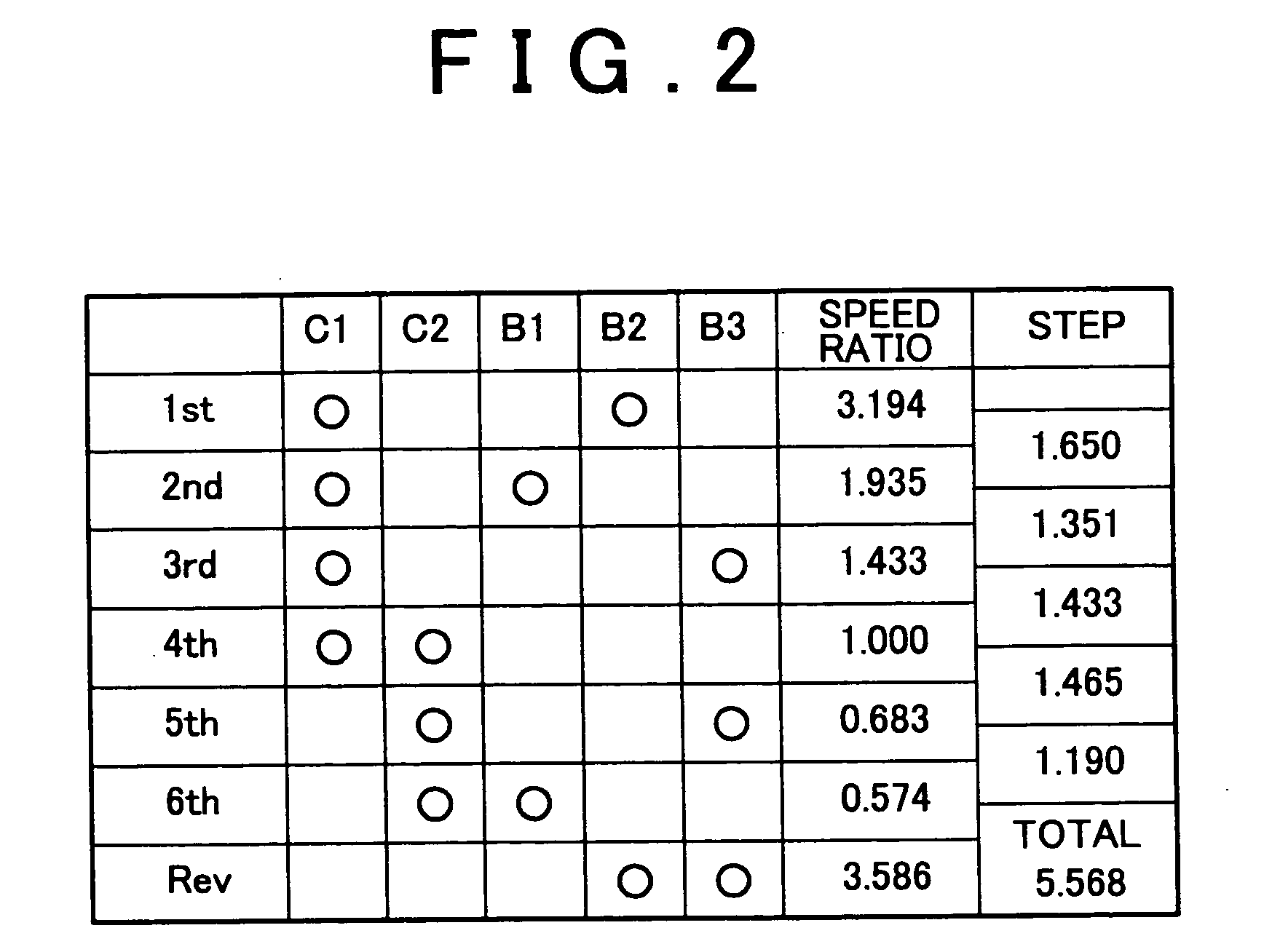

Control apparatus and method for lock-up clutch of vehicle

InactiveUS20040229728A1Improve starting and acceleratingIncrease engine speedGearing controlEngine controllersClutch controlControl theory

In a vehicle having a hydraulic power transmitting device equipped with a lock-up clutch on an output side of the engine, a control apparatus for controlling the lock-up clutch is provided which includes a lock-up clutch control unit that places the lock-up clutch in a slipping state when the vehicle is started so that torque received from the engine is transmitted to a later-stage transmission via the lock-up clutch as well as the hydraulic power transmitting device.

Owner:TOYOTA JIDOSHA KK

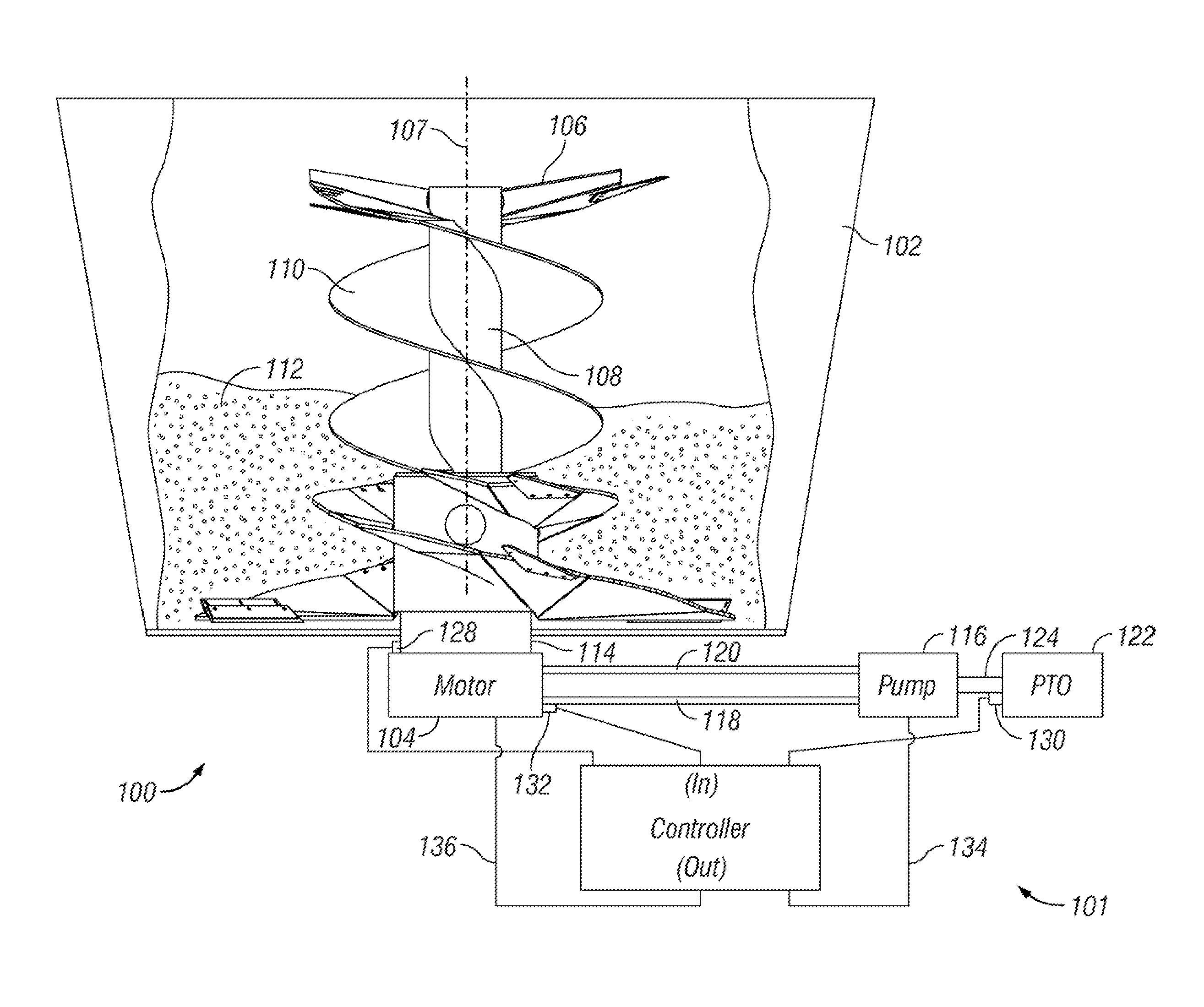

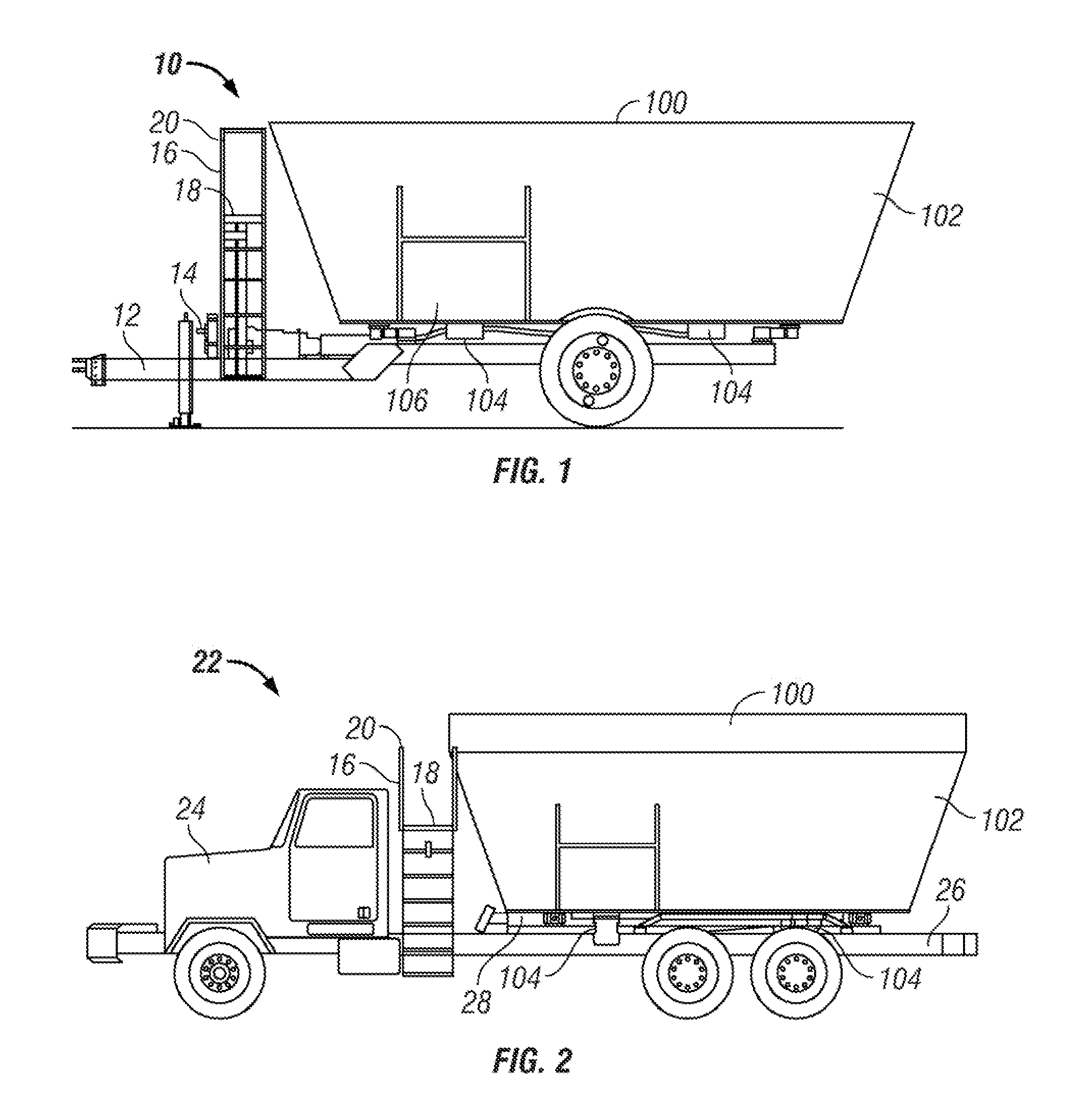

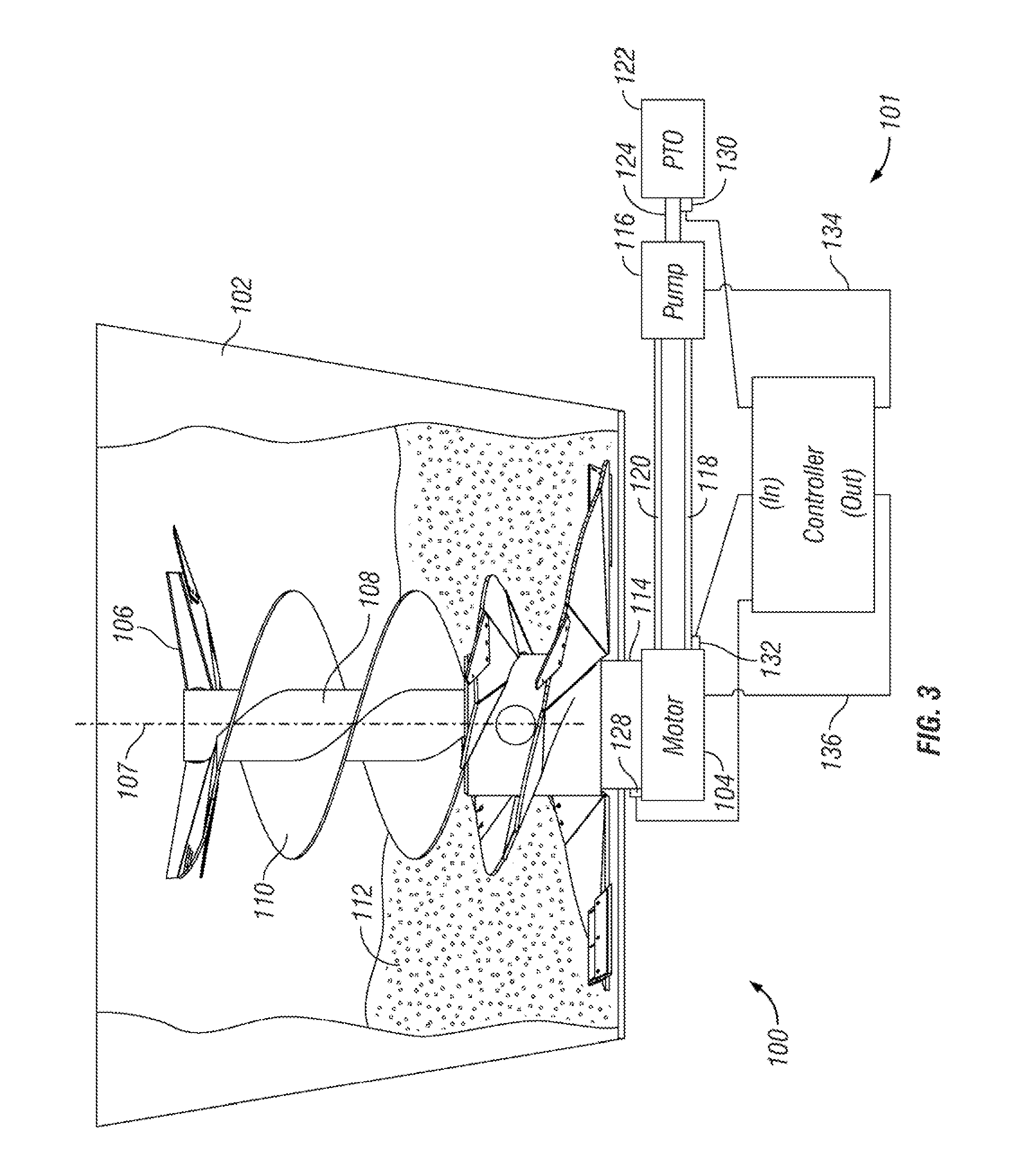

Agricultural mixer with drive system and method of using same

InactiveUS20120008457A1Easy to operateFlow mixersRotary stirring mixersRotation velocityControl theory

An agricultural mixer includes a hydraulic drive system. The mixer includes an automatic jam-resolving feature, whereby if an auger becomes jammed, the drive system will cause the auger to rotate in a reverse direction for a period of time to resolve the jam. The hydraulic drive system will maintain a speed of rotation of the auger at a relatively constant rate during mixing while choosing an efficient displacement setting for the hydraulic motor. The auger is maintained at a constant speed during a discharge mode by maintaining the motor in a maximum displacement setting. A clean-out mode is provided wherein the auger is rotated at a maximum speed to aid in cleaning out the last remaining feed mixture in the mixer.

Owner:ROTO MIX

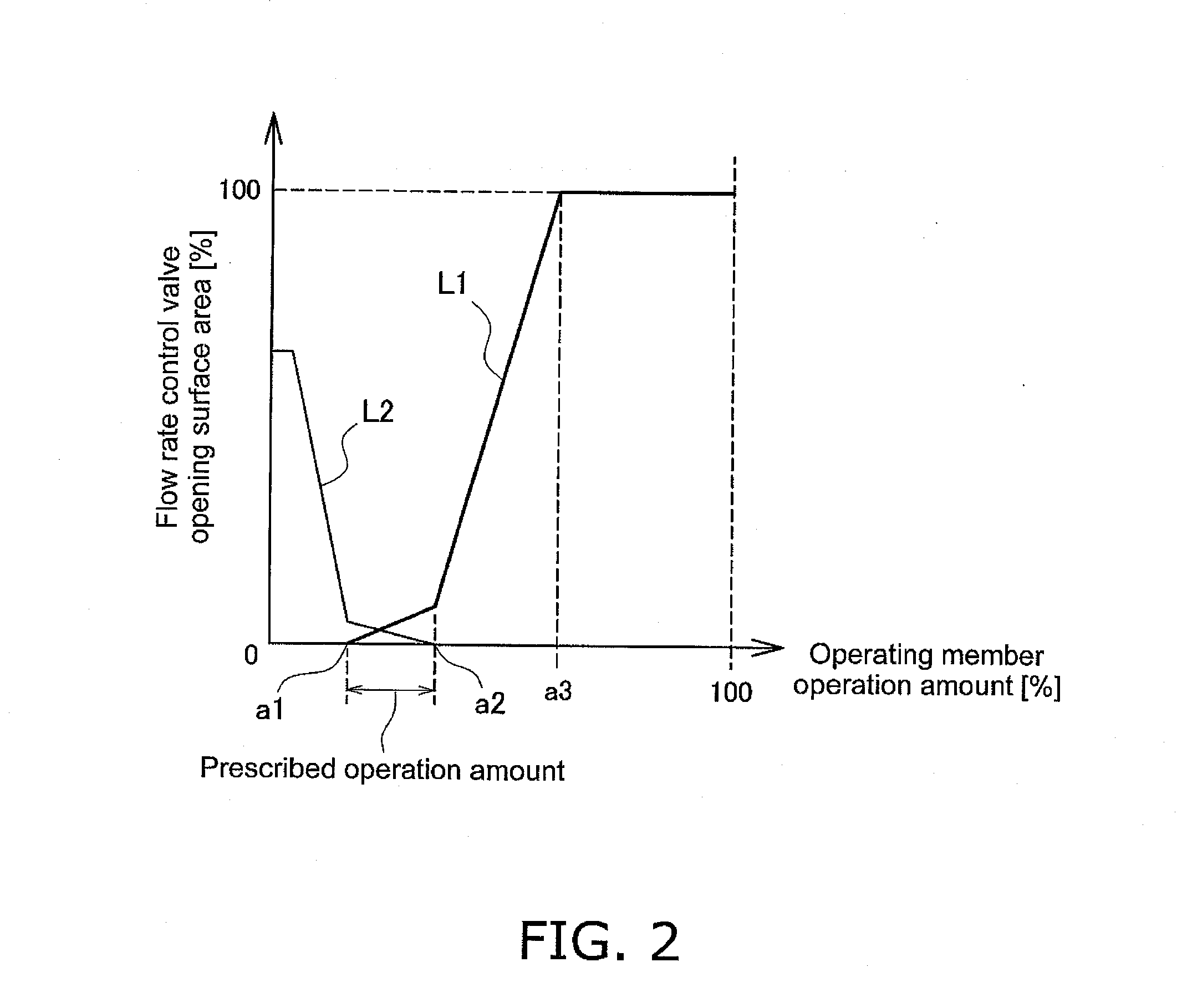

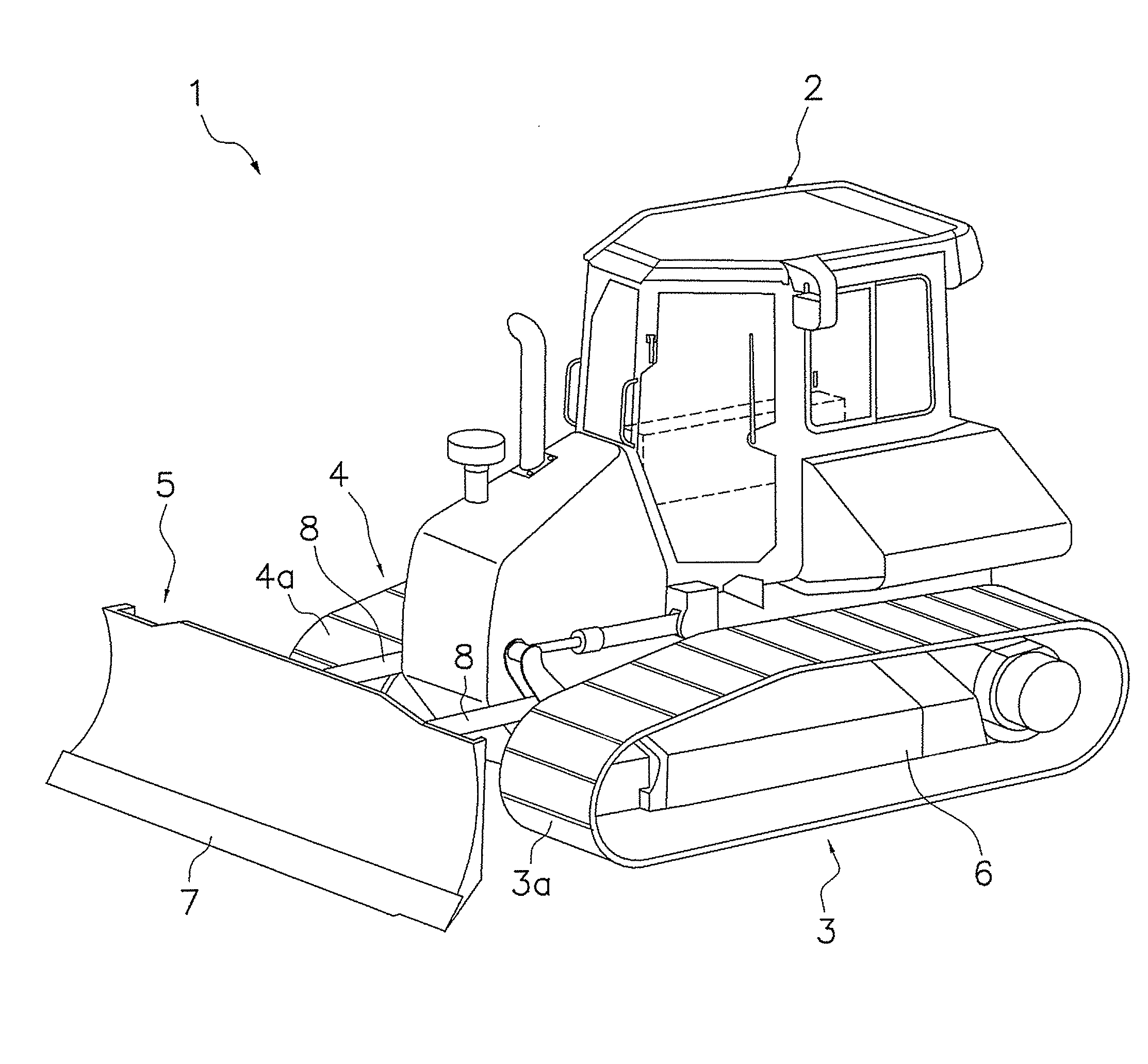

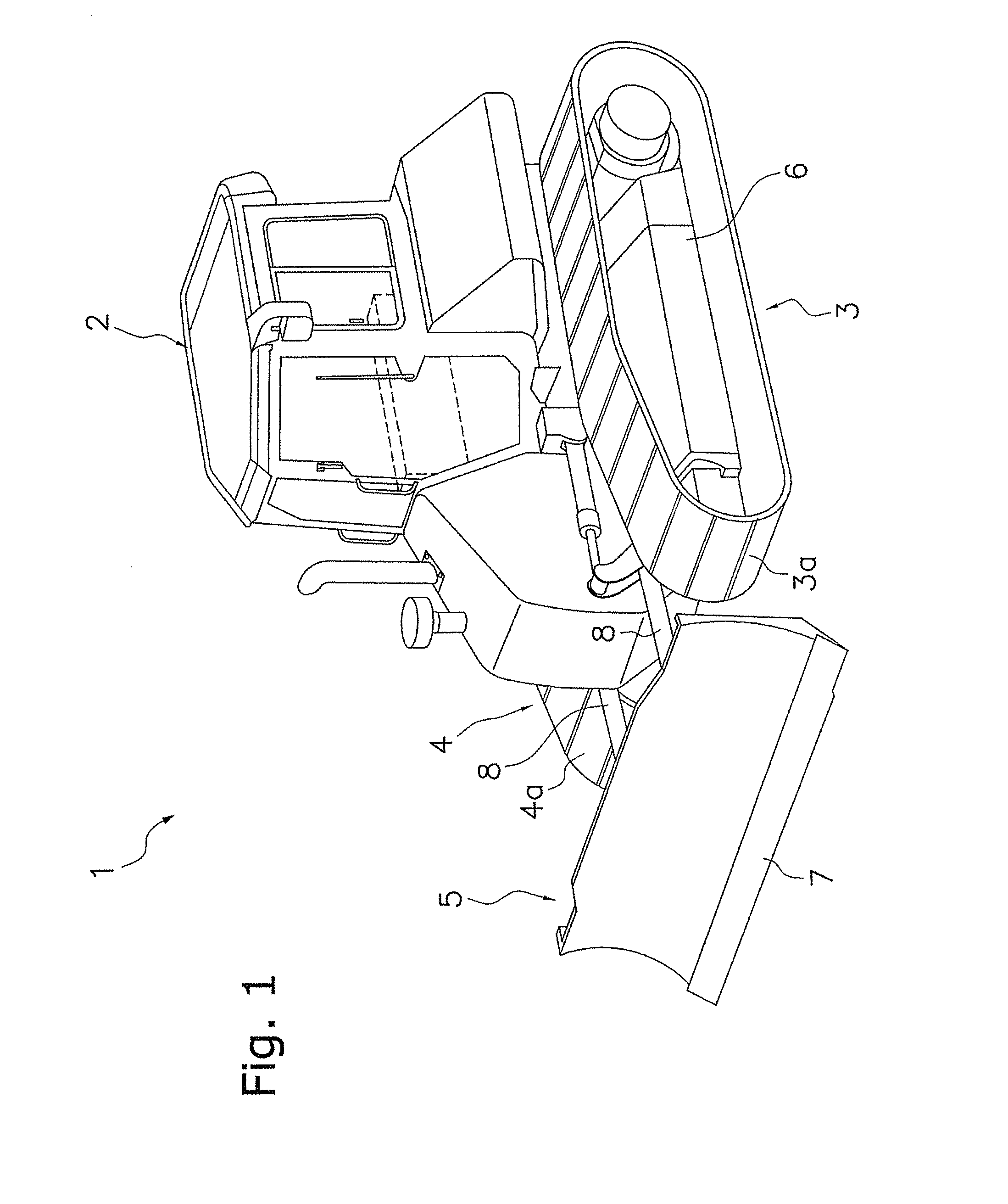

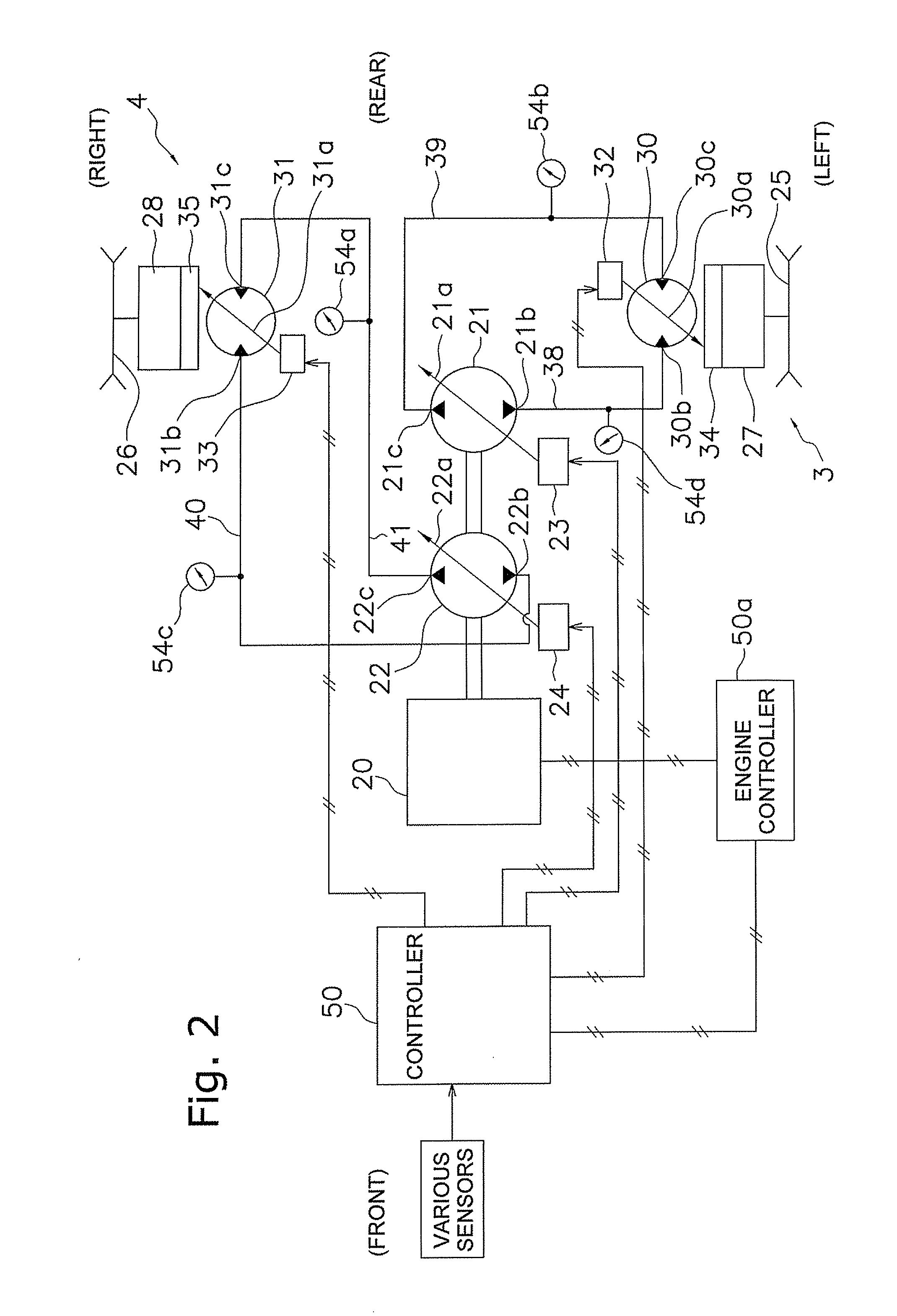

Hydraulic drive system

InactiveUS20140130487A1Control is possibleConvenient and accurateFluid couplingsServomotor componentsHydraulic cylinderHydraulic pump

A hydraulic driving system includes a hydraulic pump, a driving source, a hydraulic cylinder, a closed circuit hydraulic path between the pump and cylinder, a pump-flow-rate control unit controlling a discharge flow rate of the pump, a flow rate control valve between the pump and the cylinder in the fluid path, a directional control unit, a target flow rate setting unit and a control device. The directional control unit allows a flow of fluid from the pump to the cylinder and prohibits a flow of fluid from the cylinder to the pump when fluid is supplied from the pump to the cylinder via the flow rate control valve. The control device controls fluid flow to the cylinder with the flow rate control valve when the target flow rate is within a prescribed range, and with the pump-flow-rate control unit when the target flow rate is greater than the prescribed range.

Owner:KOMATSU LTD

Control device for hydraulic transmission vehicle

ActiveUS20110196585A1Reduce stepsReduce fuel consumptionDigital data processing detailsGearing controlHydraulic circuitSpeed limit

A control device controls a hydrostatic transmission vehicle having a hydrostatic transmission including a variable displacement pump and a variable displacement hydraulic motor. The control device is configured to set a set vehicle speed based on a forward / rearward travel command and a gear stage command instructed by an operator, to set a torque limit usable for the hydrostatic transmission based on an engine speed, to set a vehicle speed limit based on a pressure in the hydraulic circuit and the torque limit, to select a lower one of the set vehicle speed and the vehicle speed limit, and to control respective displacements of the variable displacement pump and the variable displacement hydraulic motor based on the selected vehicle speed.

Owner:KOMATSU LTD

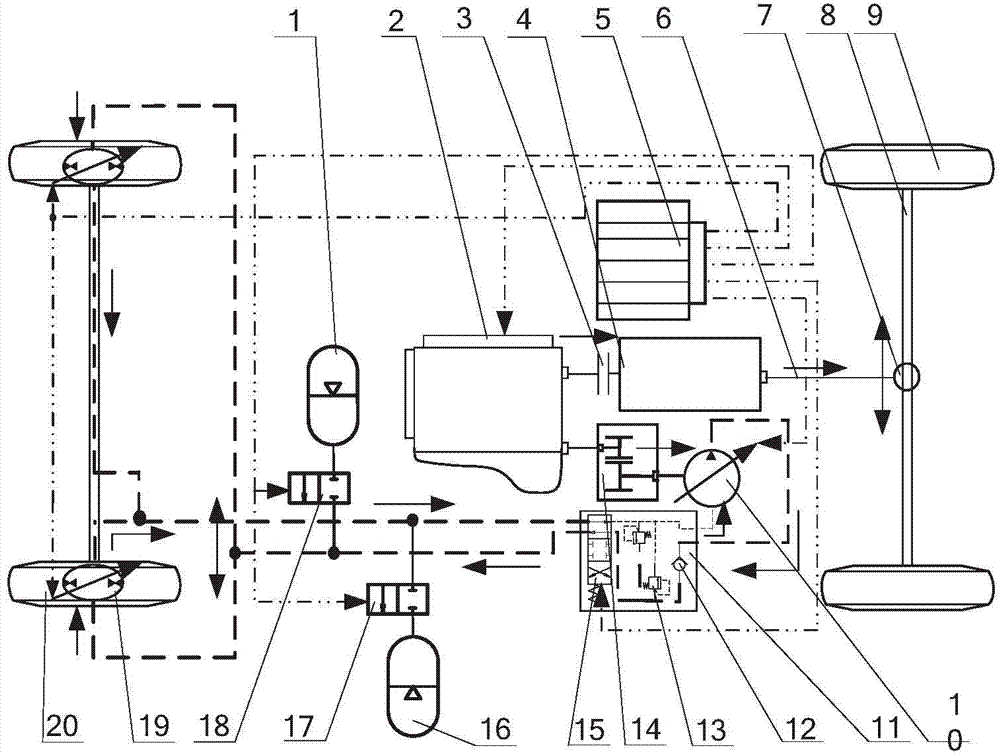

Energy recyclable auxiliary hub motor hydraulic driving system and control method thereof

ActiveCN103568810AHigh specific powerReduce volumeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingLow speedSolenoid valve

The invention discloses an energy recyclable auxiliary hub motor hydraulic driving system which comprises a controller, a power take-off device, a hydraulic pump, a hydraulic control valve set and two hydraulic motors arranged in two front wheel hubs. The energy recyclable auxiliary hub motor hydraulic driving system is characterized in that the system further comprises two energy accumulators and two solenoid valves. A closed loop is formed by the hydraulic pump and the two hydraulic motors through the hydraulic control valve set, and two energy accumulators are mounted on the oil inlet loop and the oil outlet loop of the two hydraulic motors respectively through the solenoid valves. The system can improve the driving force of a whole vehicle on bad condition roads, can further achieve energy recovery when the vehicle brakes, and improve the economical efficiency of the whole vehicle by closing the engine when the vehicle travels at low speed.

Owner:CHINA FIRST AUTOMOBILE

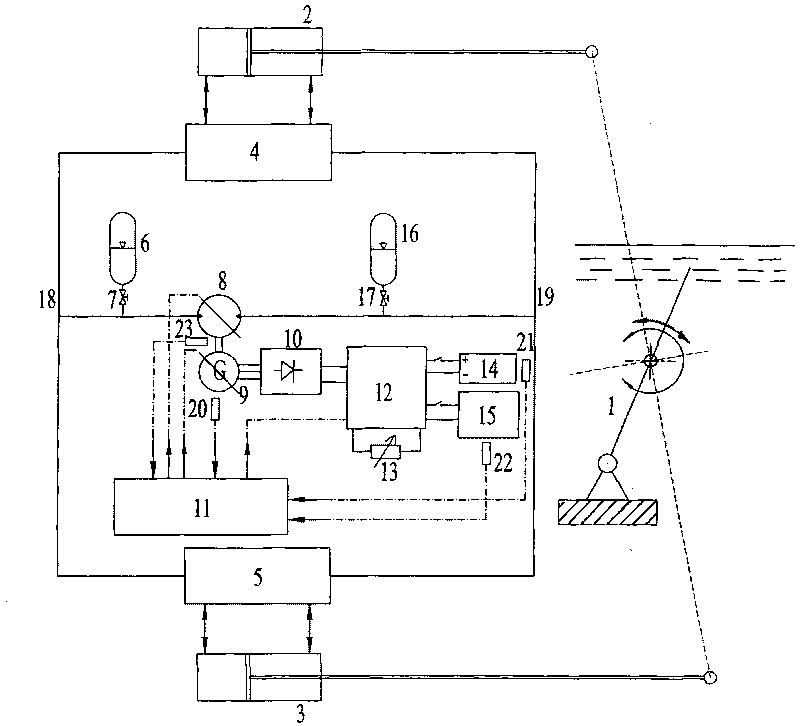

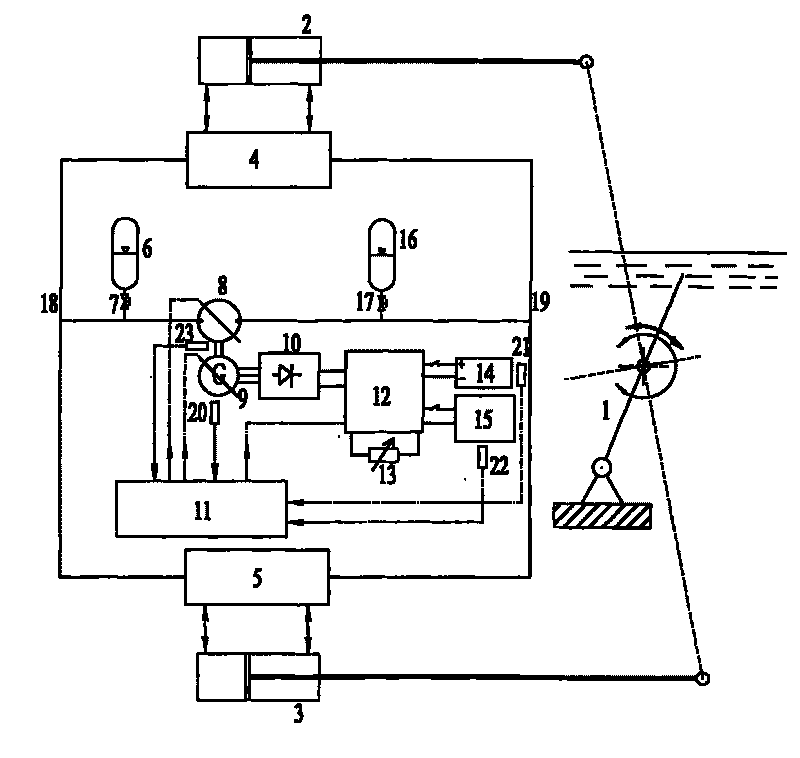

Hydraulic transmission-based method and device for storing energy and realizing stabilized voltage and constant frequency in wave power generation

InactiveCN101737241AThe overall structure is simple and reliableOutput delivery is smoothMachines/enginesEngine componentsPressure stabilizationConstant frequency

The invention discloses a hydraulic transmission-based method and a hydraulic transmission-based device for storing energy and realizing stabilized voltage and constant frequency in wave power generation. In the device, a floating pendulum is connected with a hydraulic cylinder, high pressure oil outputted by a non-rod cavity of the hydraulic cylinder enters a high pressure energy storing device and an oil inlet of a variable motor through a control integrated valve and through a high pressure oil tube, low pressure oil outputted by an oil outlet of the variable motor enters a low pressure big-capacity energy storing device and returns to the rod cavity of the hydraulic cylinder through the control integrated valve, the main shaft of the variable motor is connected with a permanent magnet synchronous generator, and the permanent magnet synchronous generator is connected to a rectifying module and a direct-current electric energy charging-discharging control module and then connected to a stepless unload adjustable load and a storage battery. The high pressure energy storing device and the low pressure big-capacity energy storing device realize the energy storage by absorbing the fluctuation, caused by the change of transient waves, of pressure and flow rate. A controller realizes the pressure stabilization constant frequency by the stepless unload adjustable load and the displacement of the hydraulic motor respectively. The device has the advantage of making the wave power generating device output more smoothly, more free from influence of the wave impact and have higher efficiency.

Owner:ZHEJIANG UNIV

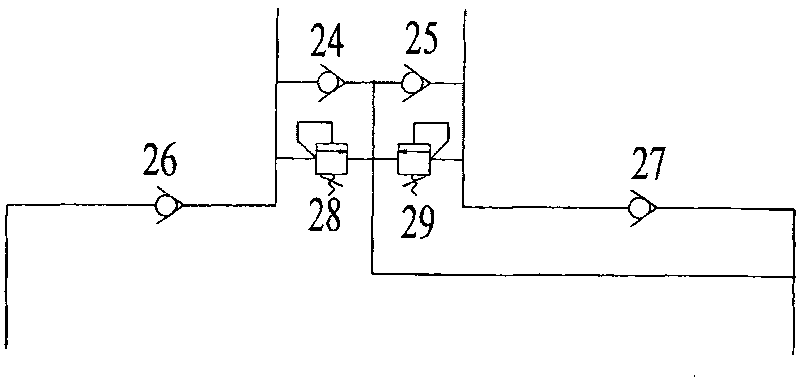

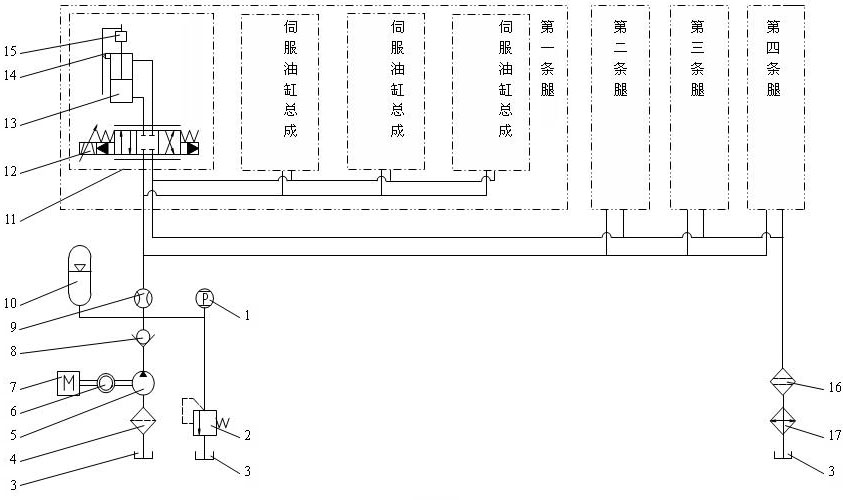

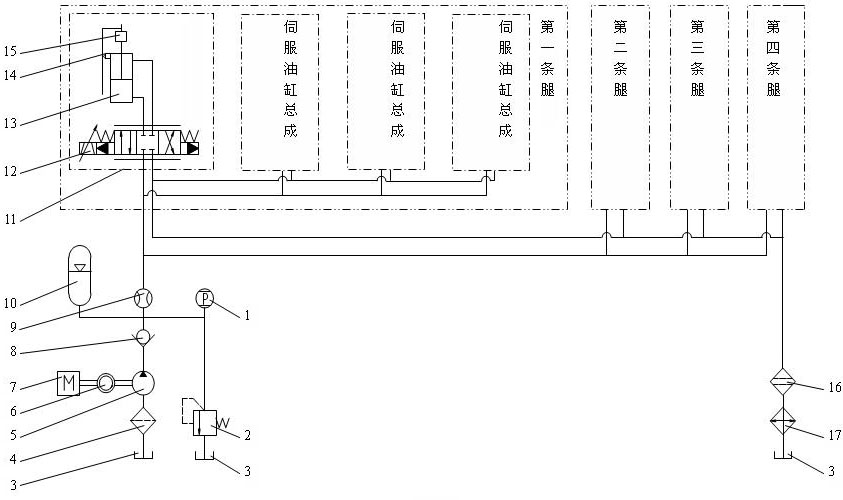

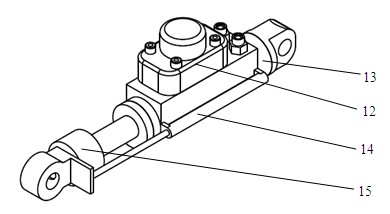

Hydraulic drive system of four-foot walking robot

InactiveCN101811304AIncrease loading capacityImprove battery lifeManipulatorHydraulic cylinderMass ratio

The invention relates to a hydraulic drive system of a four-foot walking robot. The hydraulic drive system comprises a servo cylinder assembly, wherein the servo cylinder assembly is respectively connected with a hydraulic power device and an oil return line by pipelines. The invention has the following advantages: 1. the power-mass ratio is large, thereby enhancing the weight loading capability of the robot; 2. the fuel can be conveniently filled, and the cruising power is high; 3. the robot has faster dynamic response capability, thereby being beneficial to the stability of the robot; 4. the robot has better speed rigidity, thereby reducing the effect of the load change on dynamic characteristics; 5. the allocation of the joint driving power is more convenient, thereby being capable of intensively supplying the system driving power to specified joints in a very short time to meet the driving requirements for special movement; and 6. the hydraulic cylinders can be easily arranged, thereby enabling the leg structure of the robot to be more simple and compact.

Owner:SHANDONG UNIV

Transaxle and working vehicle equipped with the transaxle

InactiveUS20150306954A1Minimizing vehicleLow costFluid gearingsJet propulsion mountingDrive wheelLongitudinal engine

A transaxle is adaptable to a vehicle equipped with a longitudinal engine including an engine output shaft to be oriented in a longitudinal direction of a vehicle. The transaxle comprises a transmission output shaft to be oriented in a lateral direction of the vehicle so as to be drivingly connected to a drive wheel of the vehicle, a hydrostatic transmission and a mechanical transmission for transmitting power from the engine output shaft to the transmission output shaft, and first and second power take-off shafts for taking off power from the mechanical transmission. The engine is joined to the transaxle so that the engine, the hydrostatic transmission and the mechanical transmission are assembled together. The first and second power take-off shafts are distributed rightward and leftward from the engine.

Owner:KANZAKI KOKYUKOKI MFG

Hydraulic drive system

InactiveUS7516613B2Reduce forceEasy to controlHybrid vehiclesFluid couplingsBattery chargeEnergy recovery

A hydraulic drive system for an actuator uses a pair of pressure compensated hydraulic machines to control flow to and from the drive chambers of the actuator by varying the controlled pressure of one of the machines. The machines are mechanically coupled to permit energy recovery and charge an accumulator to store supplies energy. The drive system may be combined with other services including a transmission for incorporation in a vehicle. The transmission uses a pressure compensated supply and torque control of the wheels.

Owner:CONCENTRIC ROCKFORD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com