Patents

Literature

5287results about How to "Prevent rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

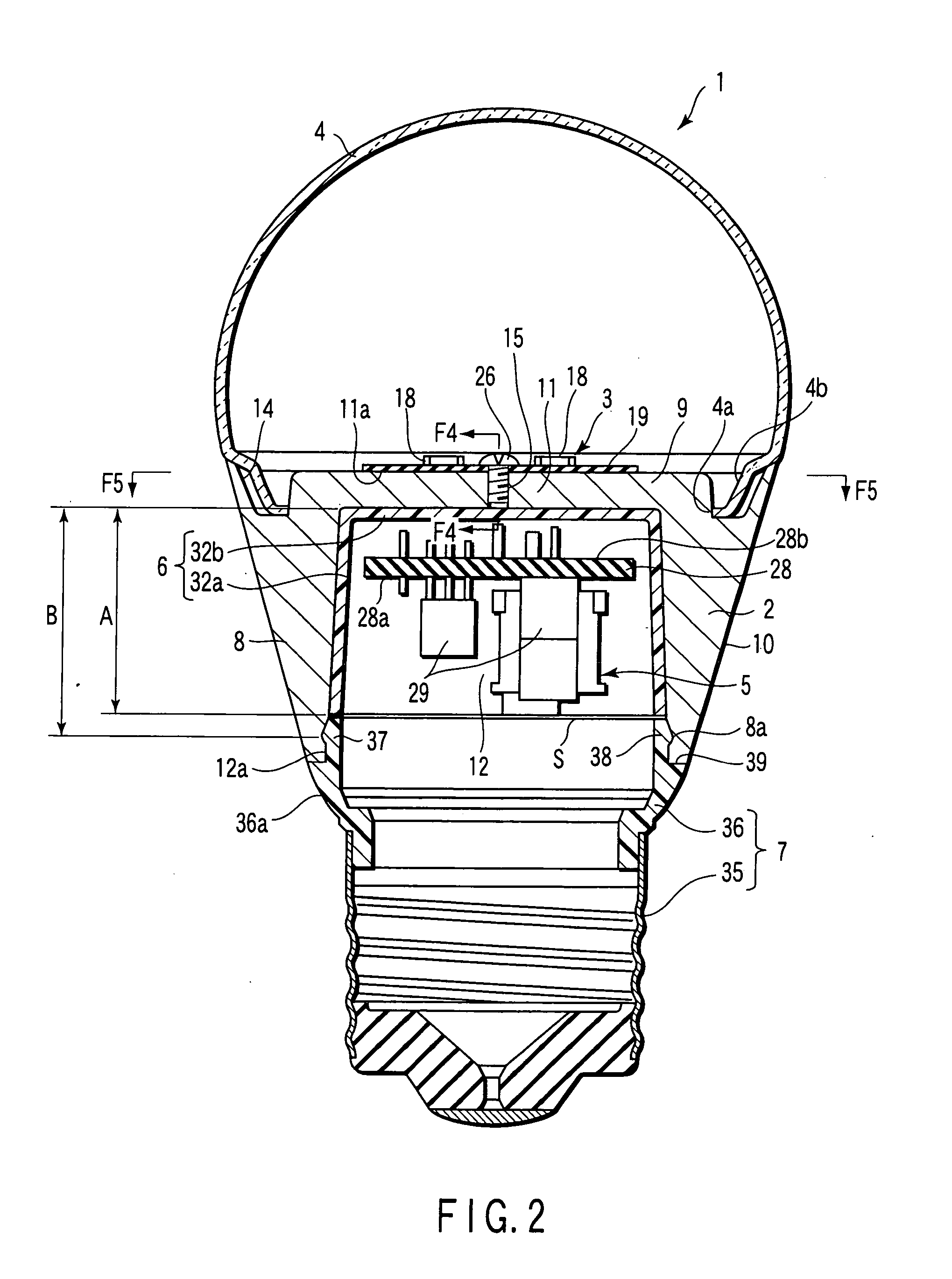

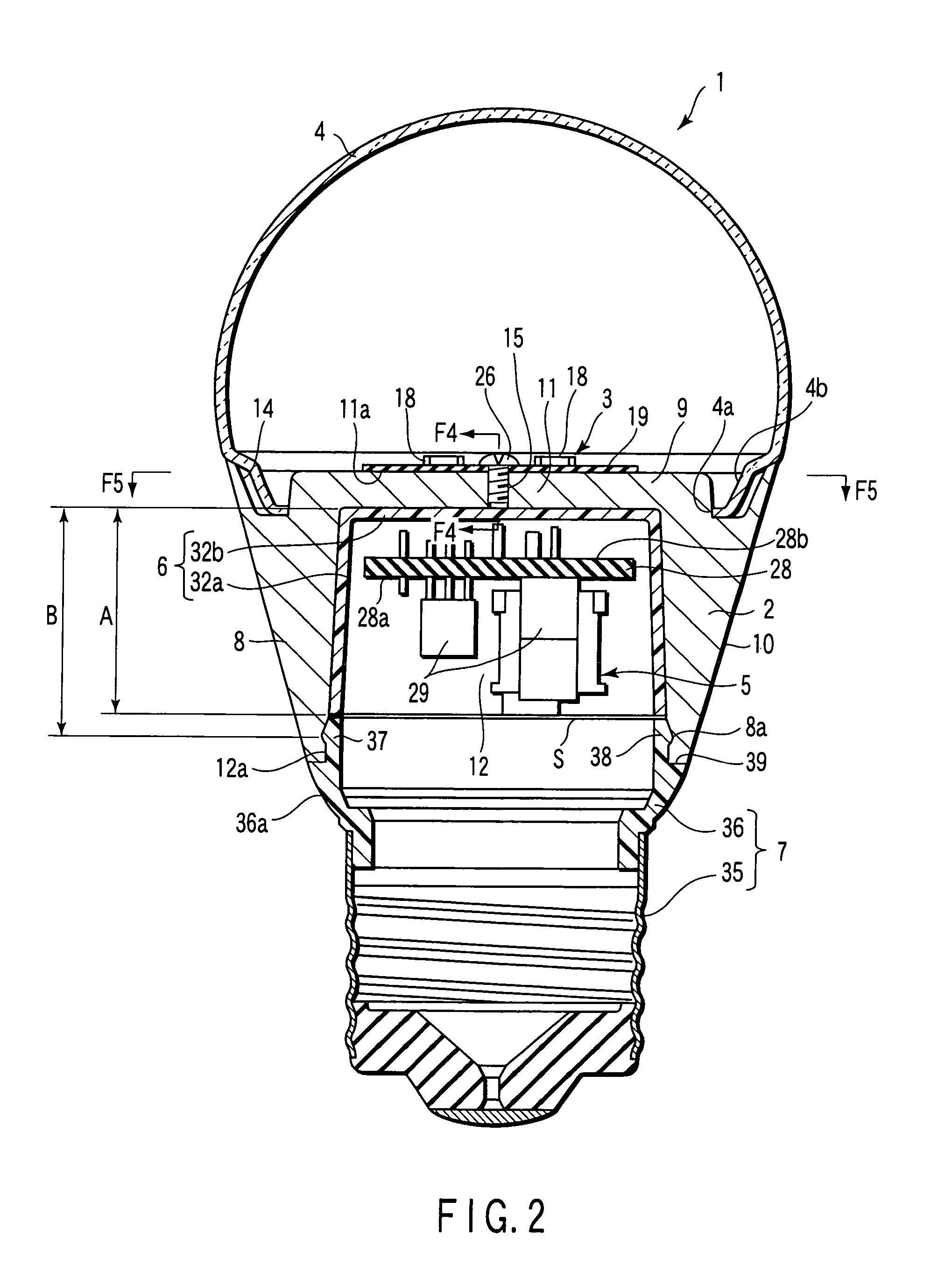

Lamp having outer shell to radiate heat of light source

InactiveUS20060227558A1Efficient transferImprove thermal conductivityCoupling device connectionsPoint-like light sourceEffect lightThermal radiation

Owner:TOSHIBA LIGHTING & TECH CORP

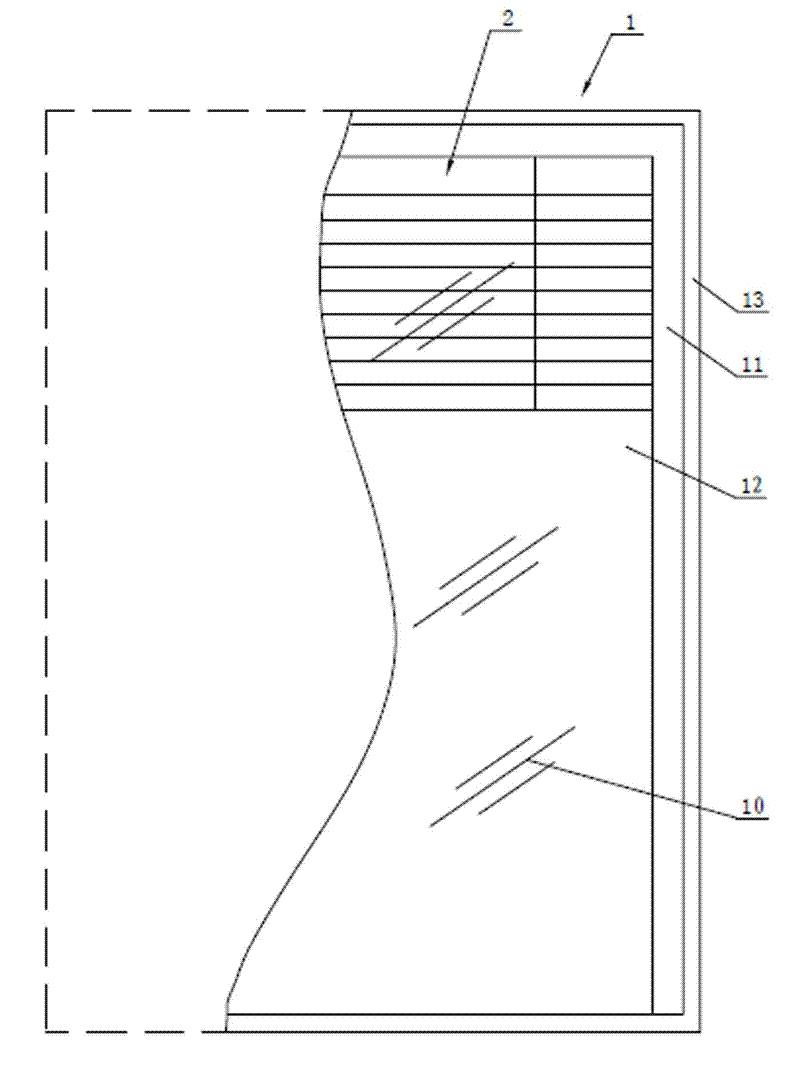

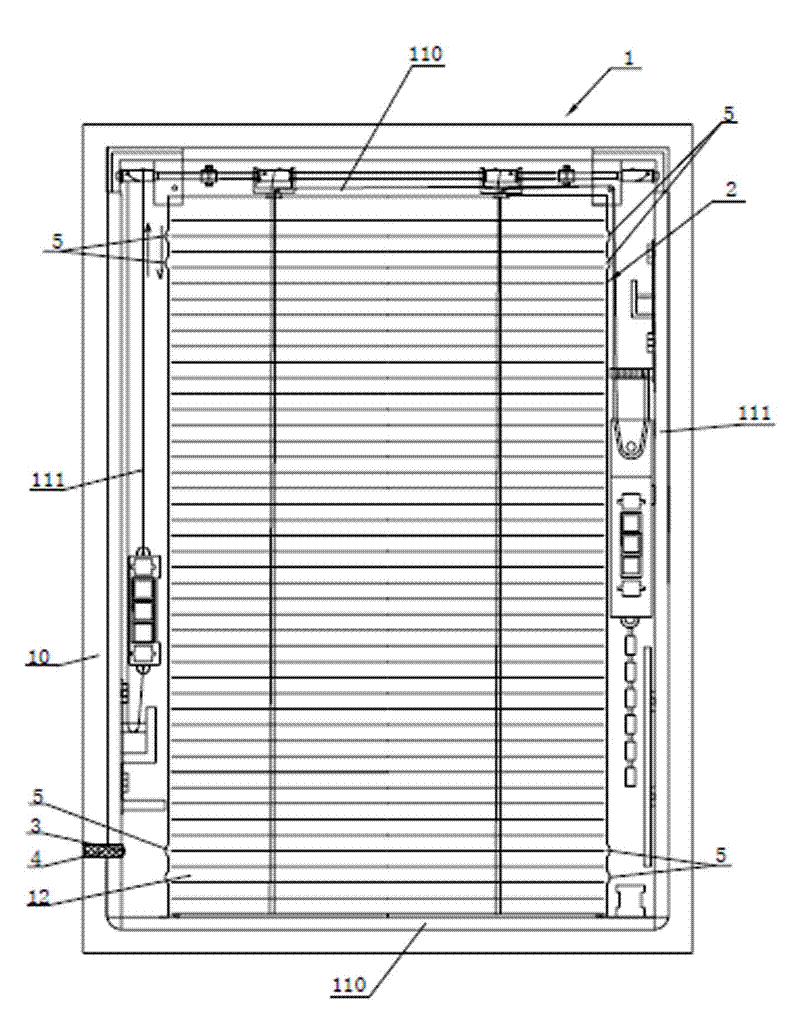

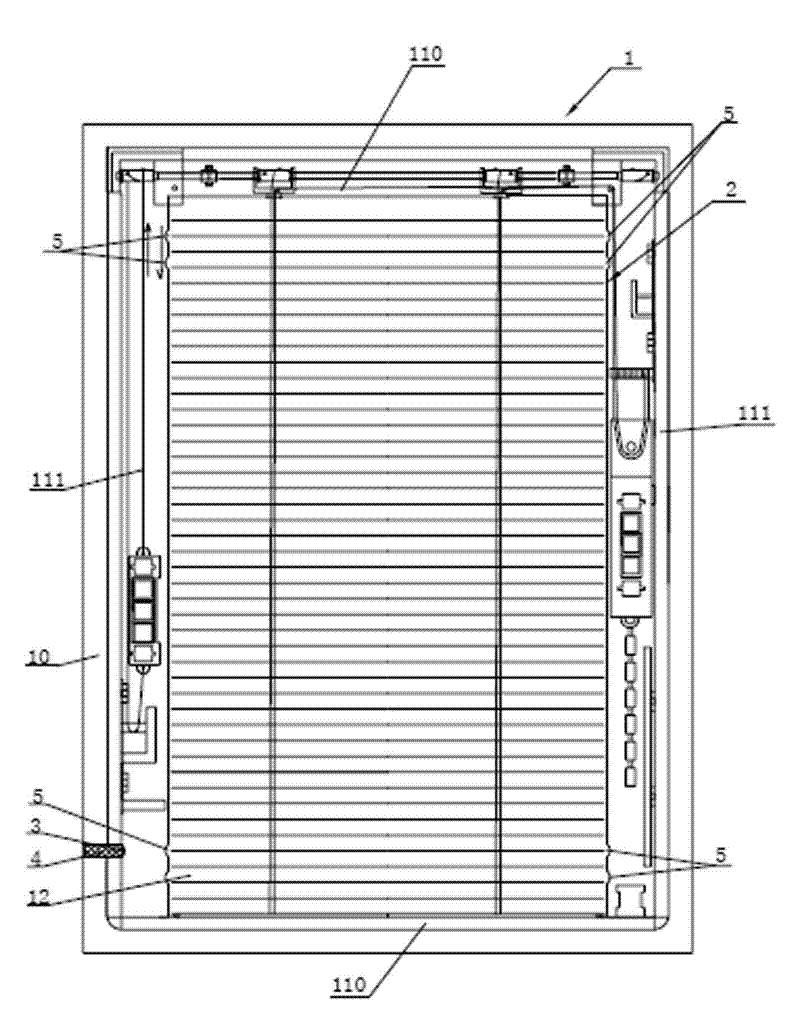

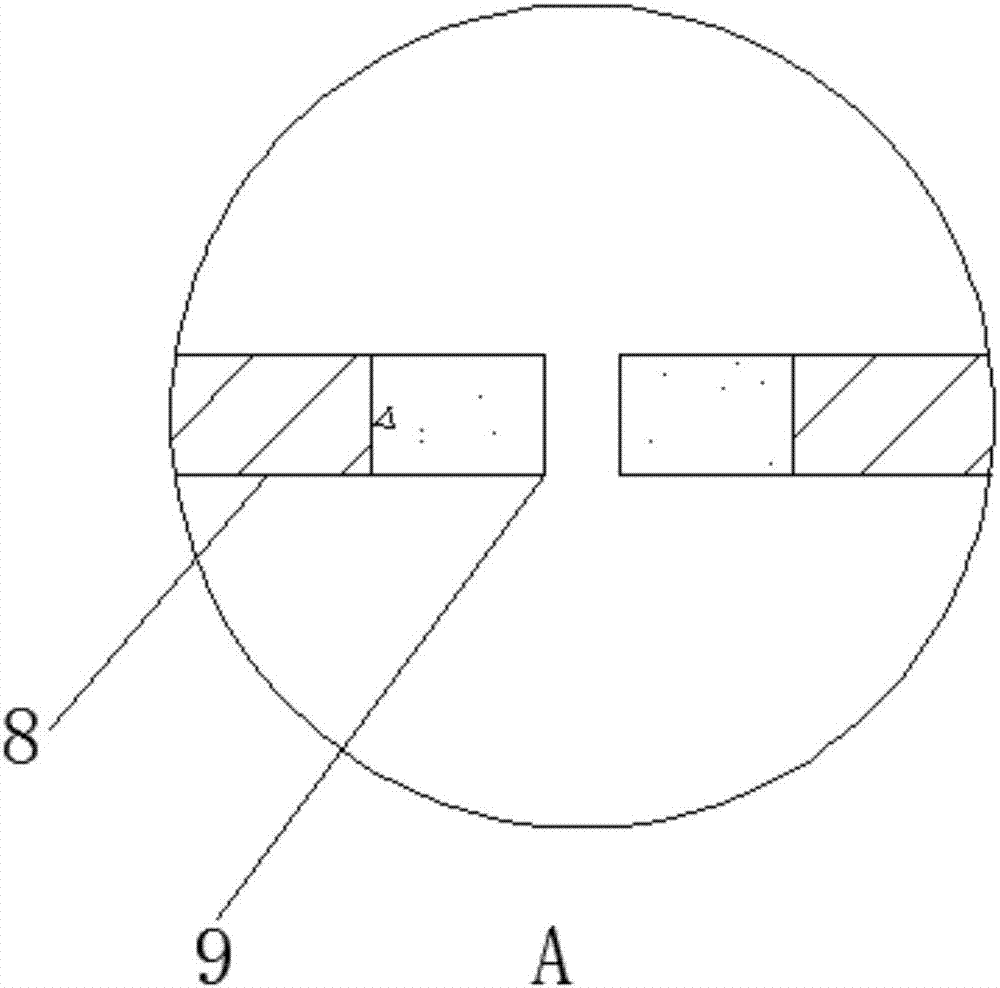

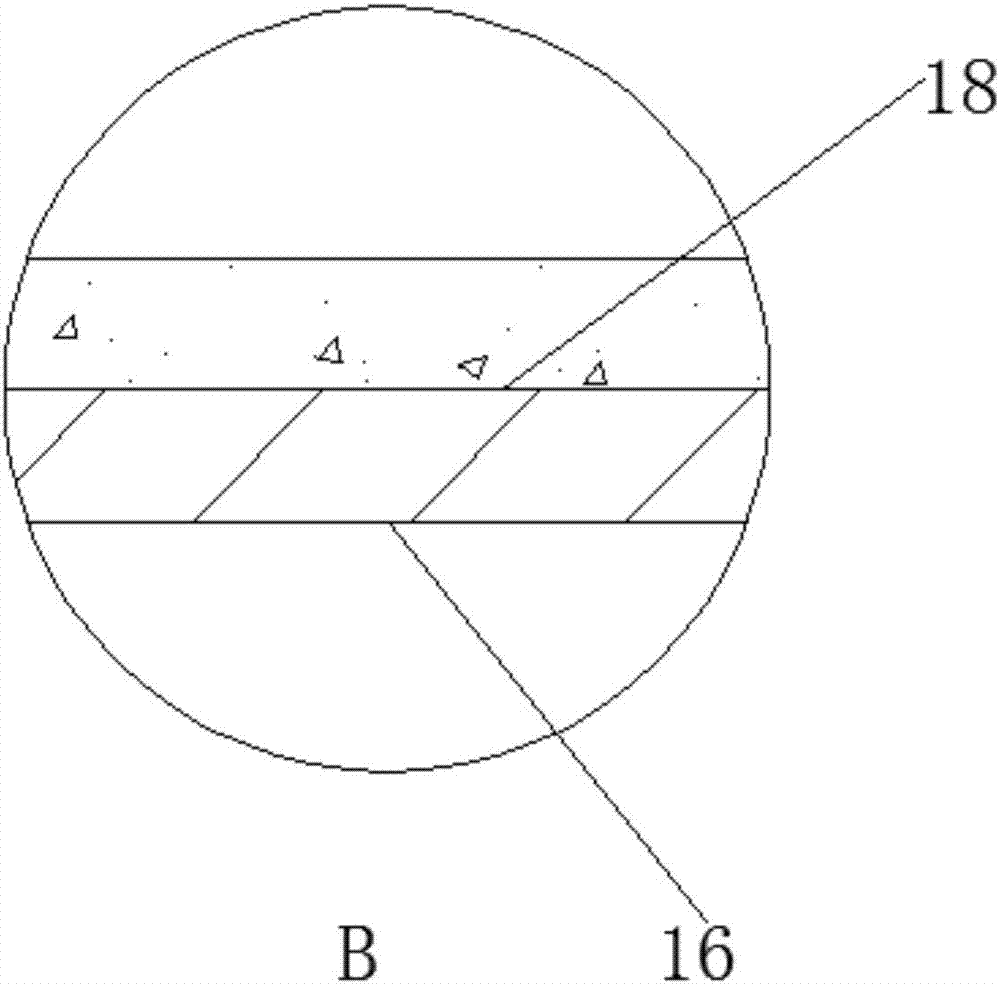

Internally-arranged sun-shading hollow shutter

InactiveCN102444372AExtended service lifePrevent oxidationDoor/window protective devicesClimate change adaptationWindow shutterEngineering

The invention relates to an internally-arranged sun-shading hollow shutter, which comprises hollow glass, a shutter curtain and a control mechanism. The hollow glass comprises a two glass original sheets which are parallel to each other, a metal hollow frame clamped between the two glass original sheets, a hollow portion enclosed by the two glass original sheets and the metal hollow frame, and sealing glue. The shutter curtain is arranged in the hollow portion. The internally-arranged sun-shading hollow shutter further comprises a port arranged on the outer lateral side of the metal hollow frame and a sealing plug for sealing the port. The inner lateral side of the metal hollow frame is provided with an air vent hole for communicating the metal hollow frame and the hollow portion, wherein the hollow portion is filled with inertia gas. The port can be connected with a vacuumizing device to vacuumize the inside of the hollow portion, the inertia gas is delivered into the hollow portion through the port, and inertia gas environment can prevent parts such as a pull rope and a ladder rope in the hollow glass from being oxidized so as to prolong service life of the internally-arranged sun-shading hollow shutter.

Owner:张家港市虹壹玻璃制品有限公司

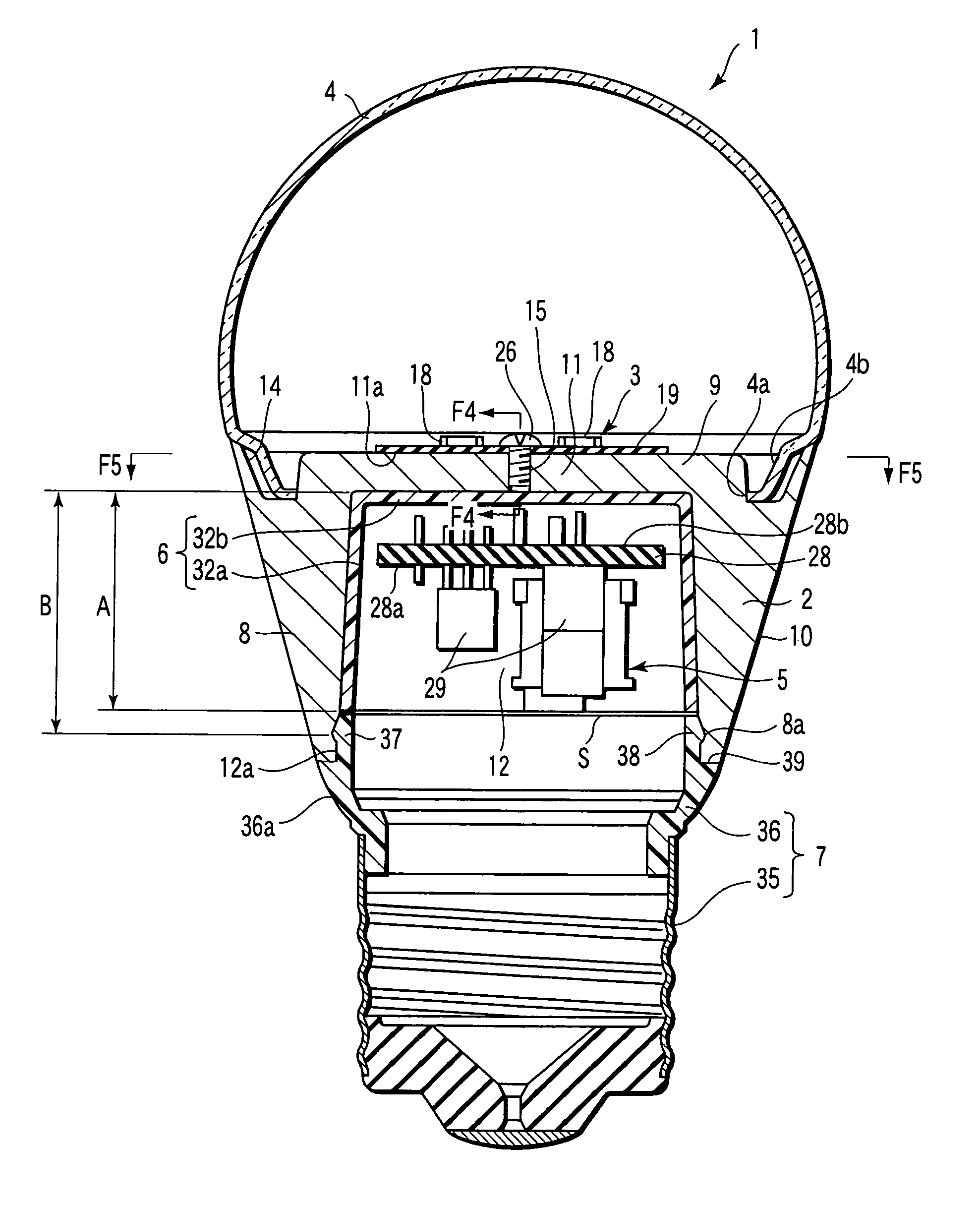

Lamp having outer shell to radiate heat of light source

InactiveUS7758223B2Increase the areaPrevent rustCoupling device connectionsLighting support devicesEngineeringMechanical engineering

A lamp includes an outer shell having heat conductivity, a base provided in the outer shell, and a cover provided in the outer shell. The outer shell has a light source support, and a heat radiating surface exposed to the outside of the outer shell. The light source support is formed integral with the heat radiating surface. A light source is supported on the light source support. The light source is heated during lighting, and thermally connected to the light source support. The light source is covered with the cover.

Owner:TOSHIBA LIGHTING & TECH CORP

Screw thread adhesion abrasion resisting self-lubricating coating and preparation method thereof

InactiveCN101125995APrevent Adhesive WearReduce coefficient of frictionPolyurea/polyurethane coatingsEpoxy resin coatingsWear resistantSolvent

The invention relates to a self-greasing paint which can prevent screw thread from sticking and wearing and a preparation method thereof. The self-greasing paint which can prevent screw thread from sticking and wearing is a two-component self-greasing paint that consists of a component A and a component B. Component A consists of raw materials with weight proportion of 40-90 percent of film-forming material, 5-60 percent of solid greasing material, 0-10 percent of additive, 0-50 percent of solvent, 0-10 percent of color paint and 0-10 percent of filling while component B consists of raw materials with weight proportion of 50-100 percent of curing agent and 0-50 percent of solvent. The weight ratio of component A and component B is 1 to 0.1-5. The friction coefficient of the coat formed by the paint is low and the paint has self greasing function, anti-sticking and wearing resistant performances; the invention reduces and even avoids the use of grease and solves pollution problem caused by grease. The self-greasing paint is applicable to various mechanical parts such as bolt, screw, etc., in particular to screw threads of oil pipe, cashing and drill rod, etc. that are special for oil industry.

Owner:王新虎

Water-soluble total-synthesis metal working fluid and application thereof

The invention discloses a water-soluble total-synthesis metal working fluid and application thereof. The working fluid is prepared from the following raw materials in percentage by weight: 1wt%-30wt% of a lubricant, 1wt%-40wt% of a corrosion inhibitor, 1wt%-40wt% of organic amine, 1wt%-20wt% of a cleaning agent, 1wt%-20wt% of a coupling agent, 0.5wt%-5wt% of an antifoaming agent and the balance of water. The working fluid can form water-based steam with anti-rust property in an induction manner in the use procedure, so that the problem of rusting caused by steam which is easily generated by a closed machine tool is solved, and therefore, the working fluid is suitable for a high-precision machine tool, especially a numerical control machine tool with a closed structure.

Owner:TSINGHUA UNIV

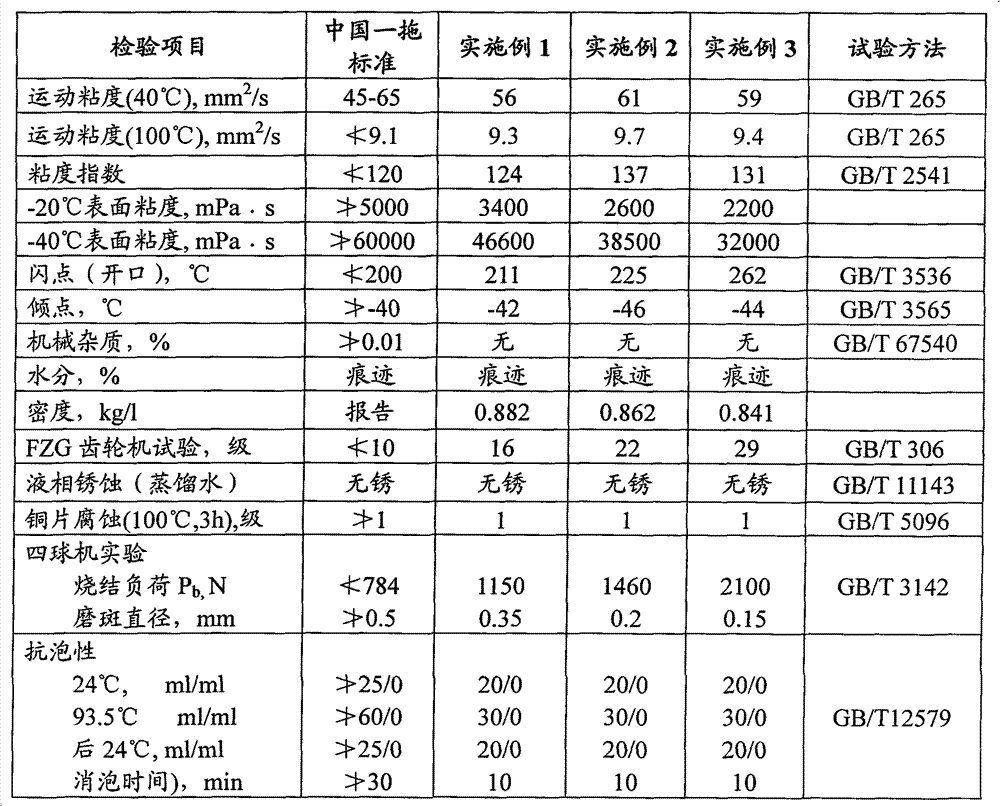

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

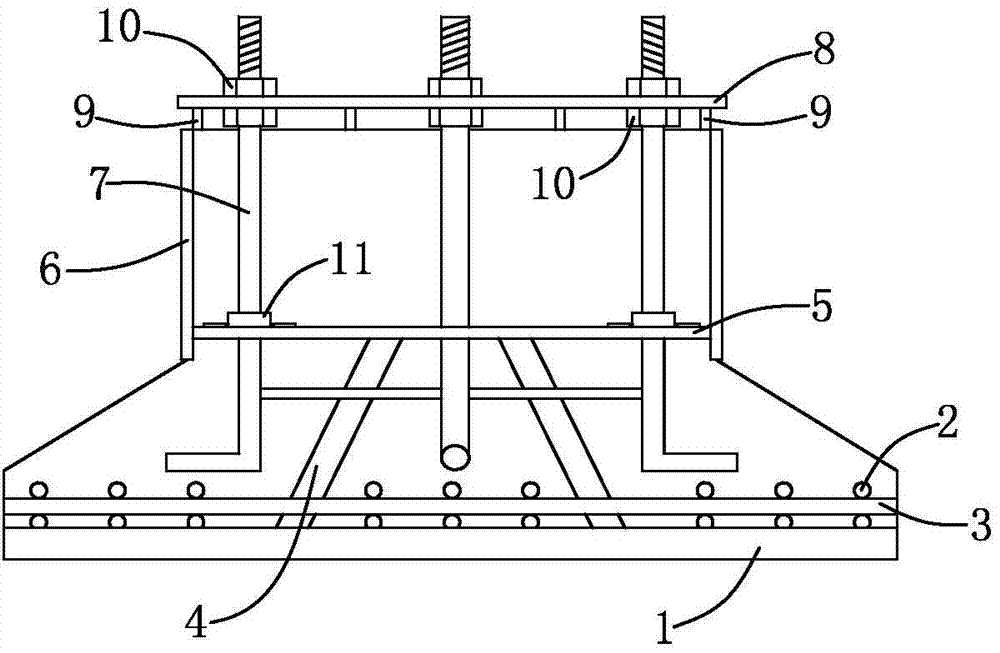

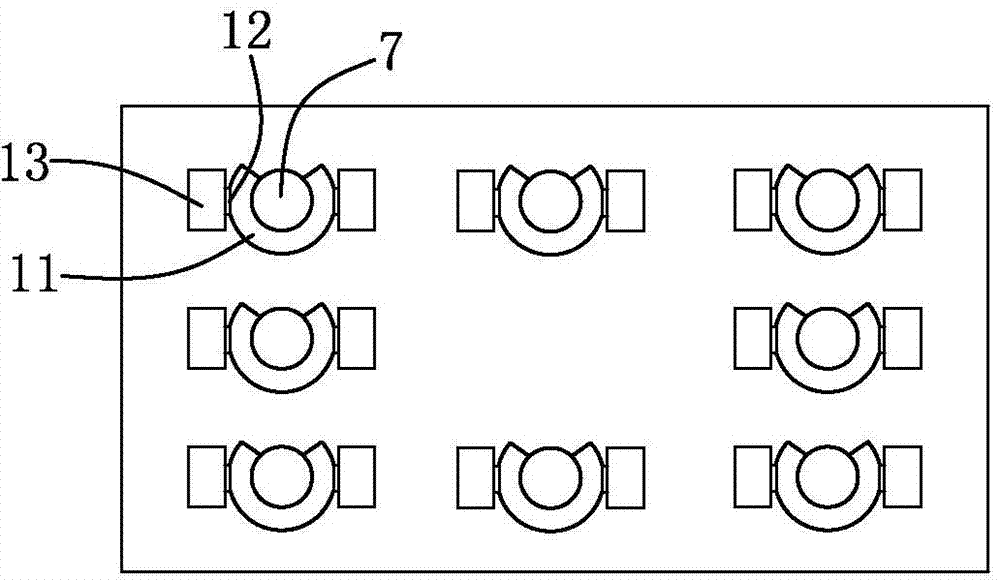

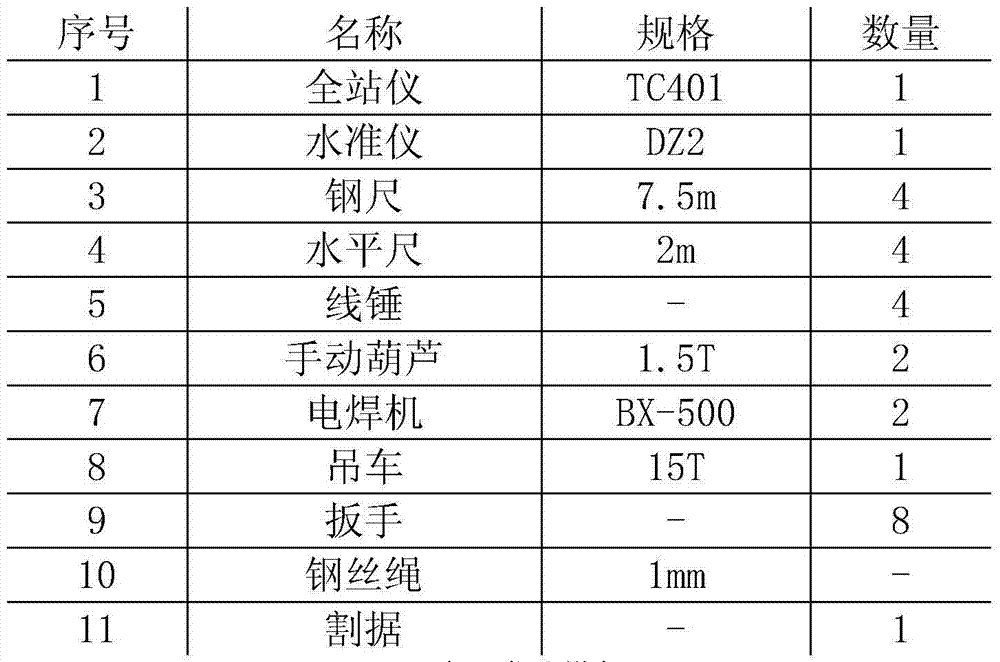

Pre-buried construction method for high-precision foundation bolts

The invention discloses a pre-buried construction method for high-precision foundation bolts. The method includes the following steps that (a), construction preparation is performed; (b), a control net is established; (c), a positioning clamp and a positioning control plate are manufactured; (d), foundation steel bars are buried in advance; (e), the positioning clamp is installed; (f), the foundation bolts are installed; (g), the foundation bolts are reinforced and protected; (h), concrete pouring is performed; (i), the clamp is dismantled; (j) acceptance inspection and handover are performed to finish the pre-buried construction. The manufactured high-precision positioning clamp is adopted for performing clustering control over the pre-buried foundation bolts of each set of equipment foundations, elastic clamping tools are arranged on the outer sides of the foundation bolts, supporting legs of the elastic clamping tools are embedded into clamping holes in the positioning clamp, and the elastic clamping tools are clamped on the positioning clamp of the foundation bolts, so that the foundation bolts are further reinforced and prevented from loosening. The pre-buried construction method has the effects of being reliable in technology, high in construction precision, easy to understand and master and convenient to operate, and meanwhile is short in construction period and low in cost.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Grasping apparatus having bag members filled by a granular substance

ActiveUS20130033050A1Abrasion resistanceResistant to cuttingGripping headsLoad-engaging elementsStructural engineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

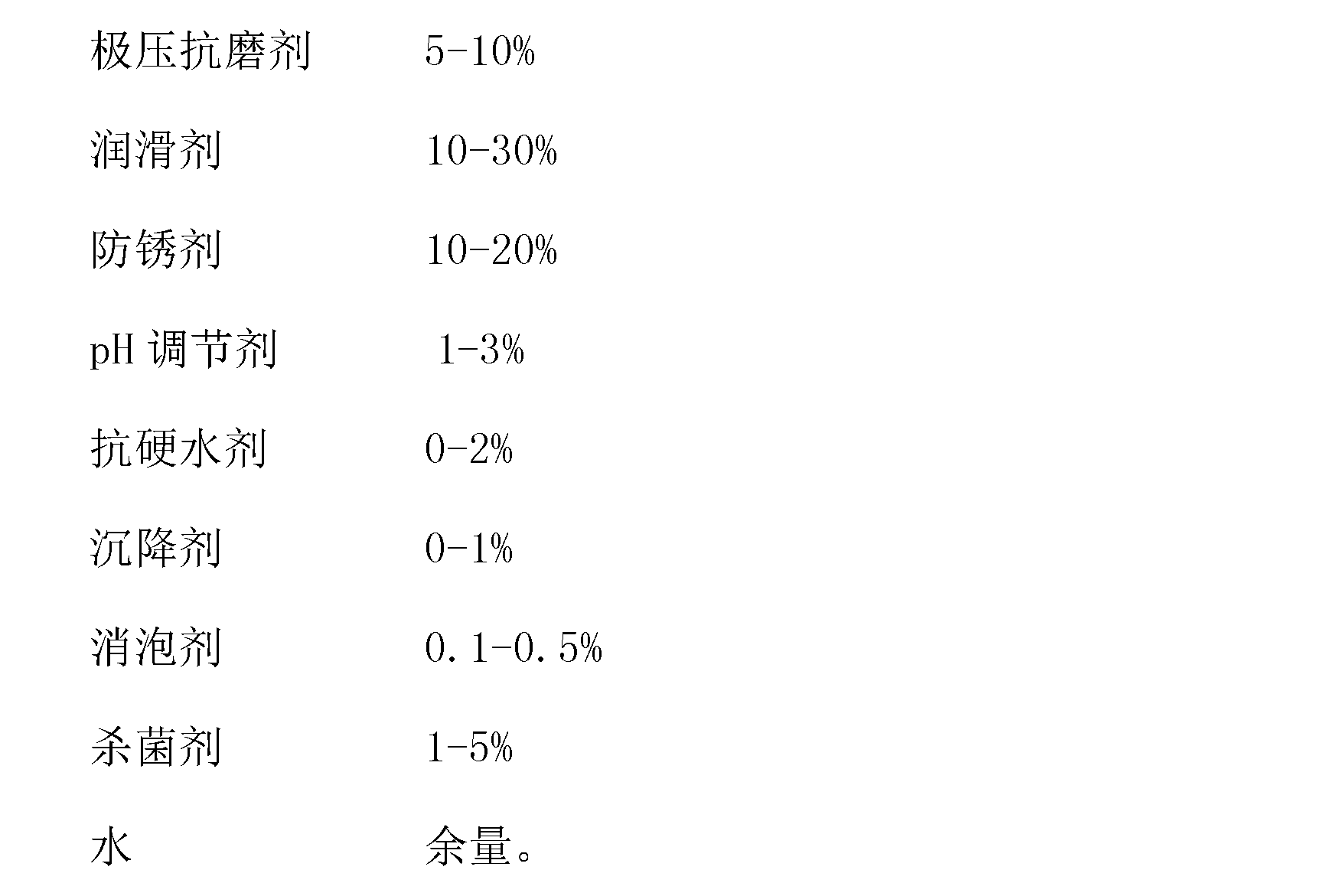

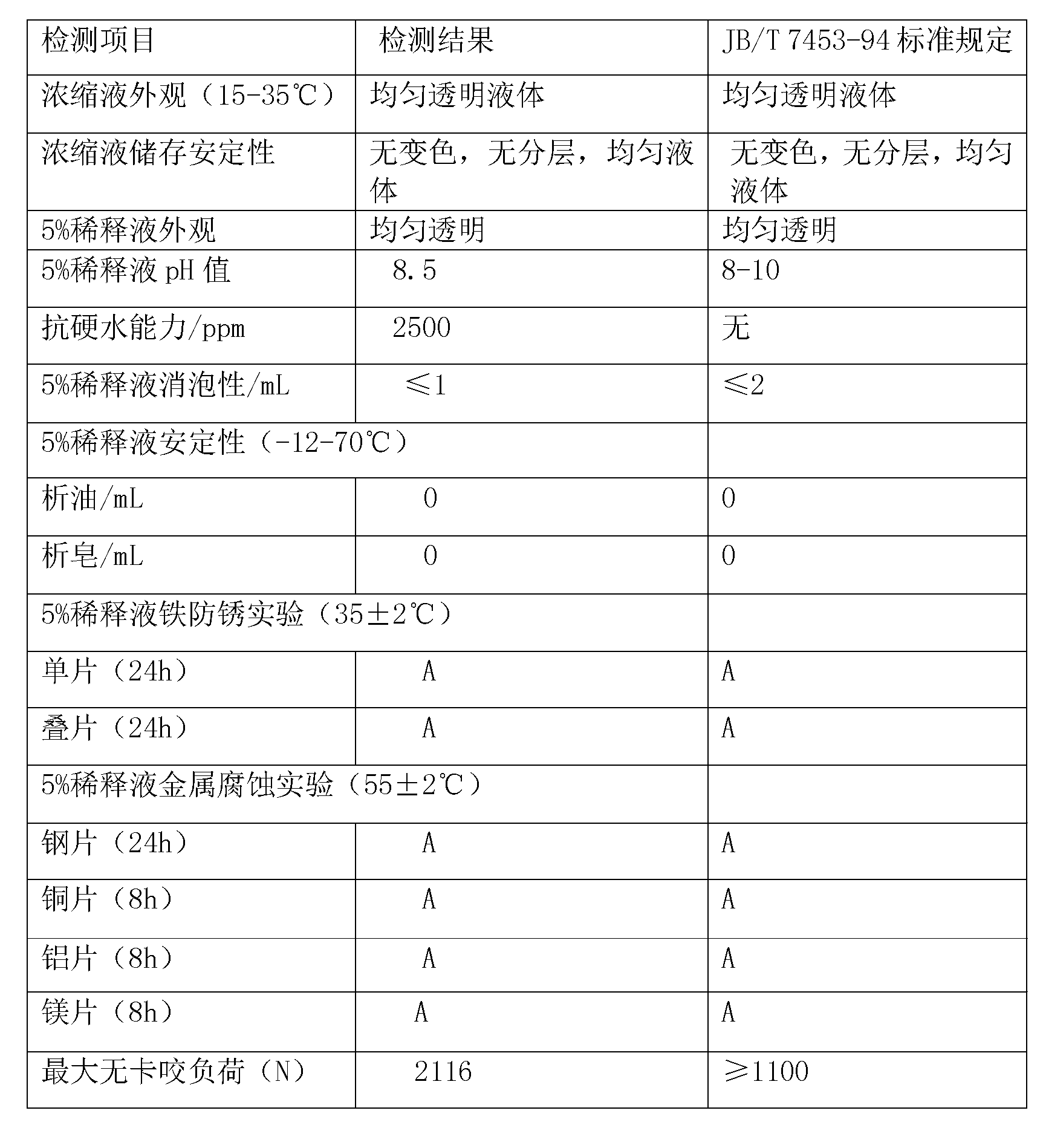

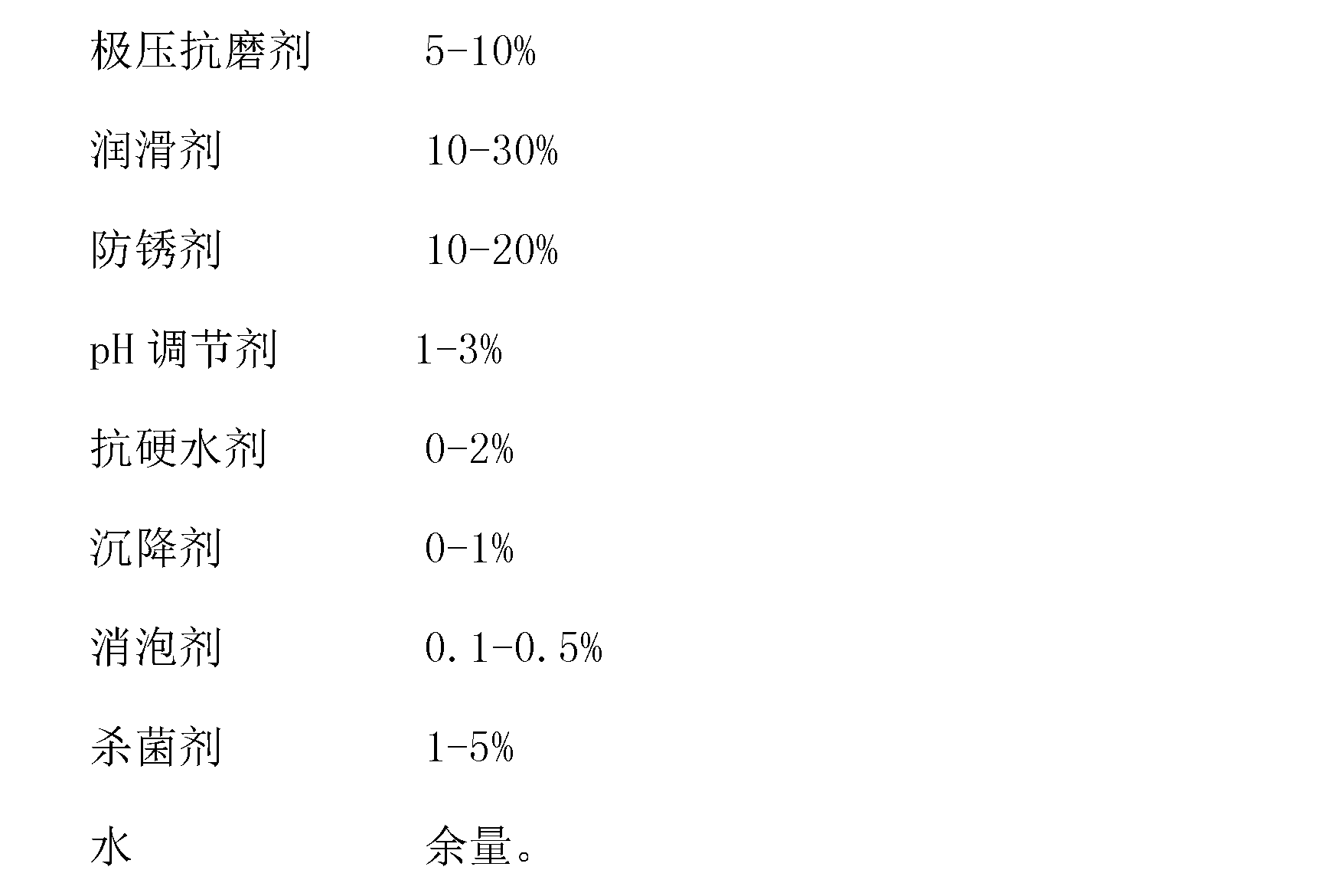

Aluminum-magnesium alloy cutting fluid

ActiveCN102703194AExcellent lubricating and anti-wear propertiesImprove cooling effectLubricant compositionRust converterDefoaming Agents

The invention discloses an aluminum-magnesium alloy cutting fluid which consists of the following components in percentage by weight: 5-10 percent of extreme pressure anti-wear additive, 10-30 percent of lubricating agent, 10-20 percent of anti-rusting agent, 1-3 percent of pH regulator, 0-2 percent of hard water resisting agent, 0-1 percent of settling agent, 0.1-0.5 percent of defoaming agent, 1-5 percent of sterilizing agent and the balance of water. According to the aluminum-magnesium alloy cutting fluid, excellent lubricating and wear resisting performances, cleaning and cooling performance and rust and corrosion resisting performances are obtained, thus cutting bumps can be avoided, a cutter is effectively protected and the processing quality is improved; more heat generated in the processing process is taken away, so that the temperature of the processing surface is reduced and the defects of the curling and the deformation of workpieces caused by high temperature, flammabilityof scrap magnesium at high temperature and the like are effectively overcome; and a processing technique is simplified, and thus the processing period is shortened and the production efficiency is increased.

Owner:上海福岛新材料科技有限公司

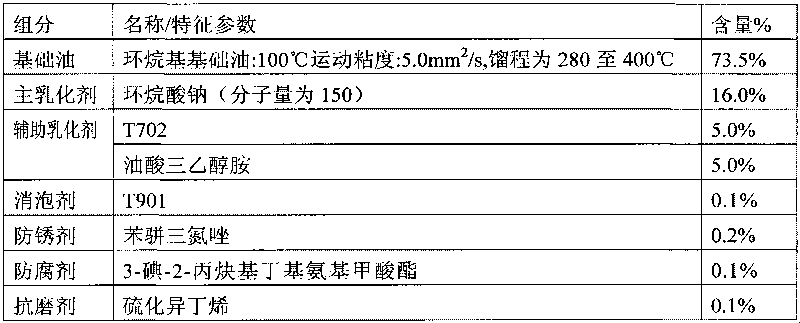

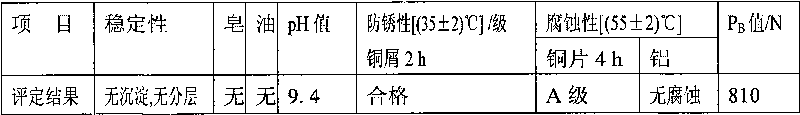

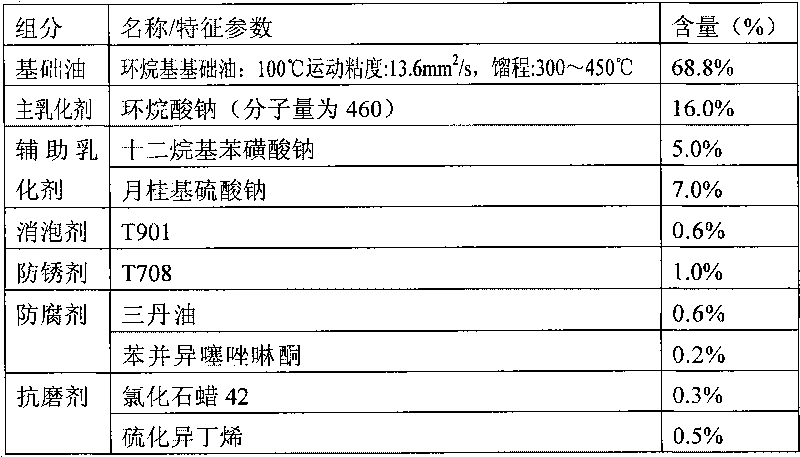

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

Migration-type organic reinforced concrete anti-corrosion admixture

The invention relates to a migration-type organic reinforced concrete anti-corrosion admixture which is prepared by mixing organic carboxylic acid and organic amine in the following percentage by weight: 40-80% of the organic carboxylic acid and 20-60% of the organic amine; adding the mixture into water; heating to 60-70 DEG C; and stirring the mixture for reaction for 1-2 hours to obtain the migration-type organic reinforced concrete anti-corrosion admixture. The anti-corrosion admixture does not contain nitrite and inorganic base and can prevent damage on reinforcing steel bar passive films caused by chloride ions, thus preventing corrosion.

Owner:JIANGSU SUBOTE MATERIAL +1

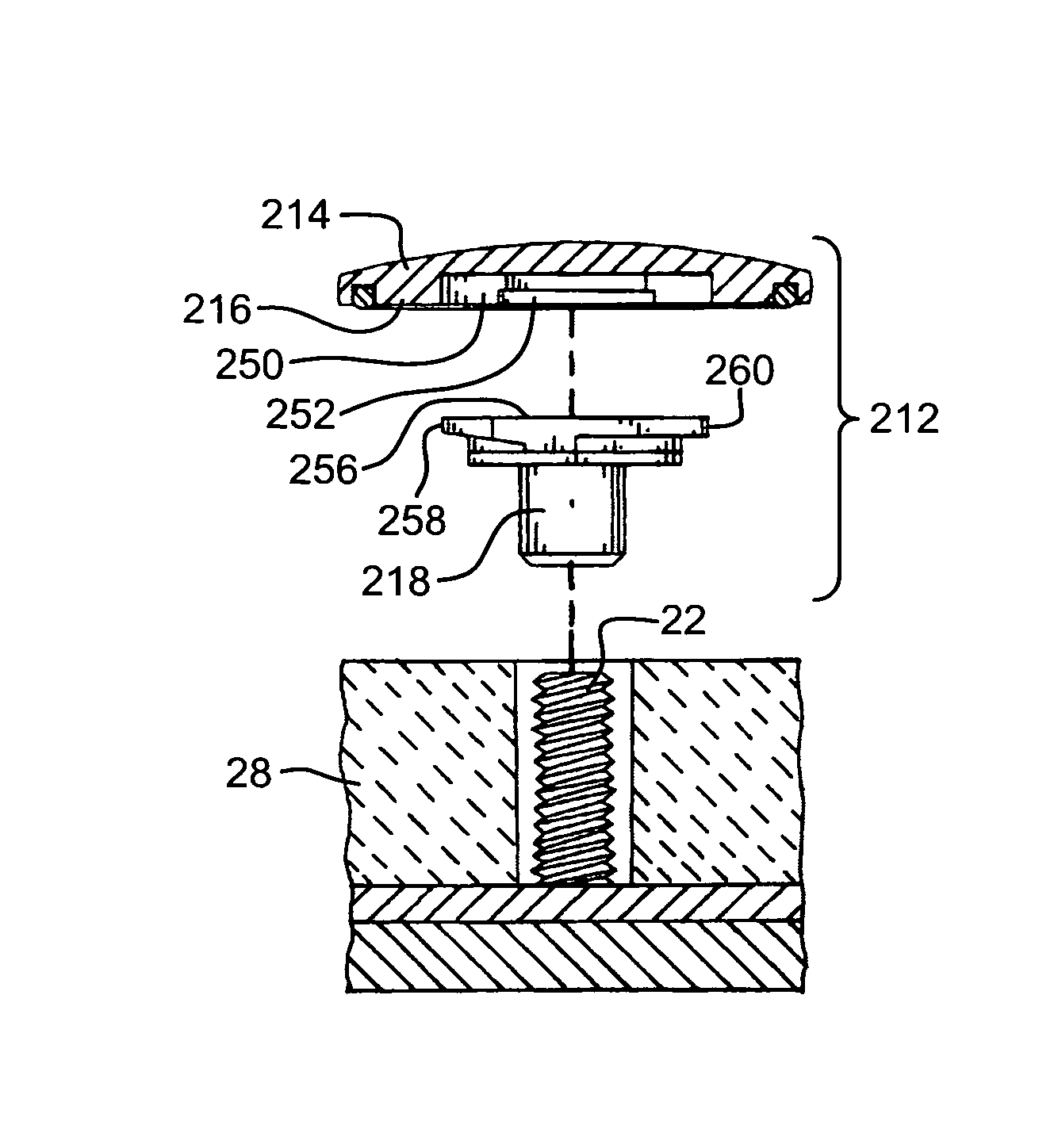

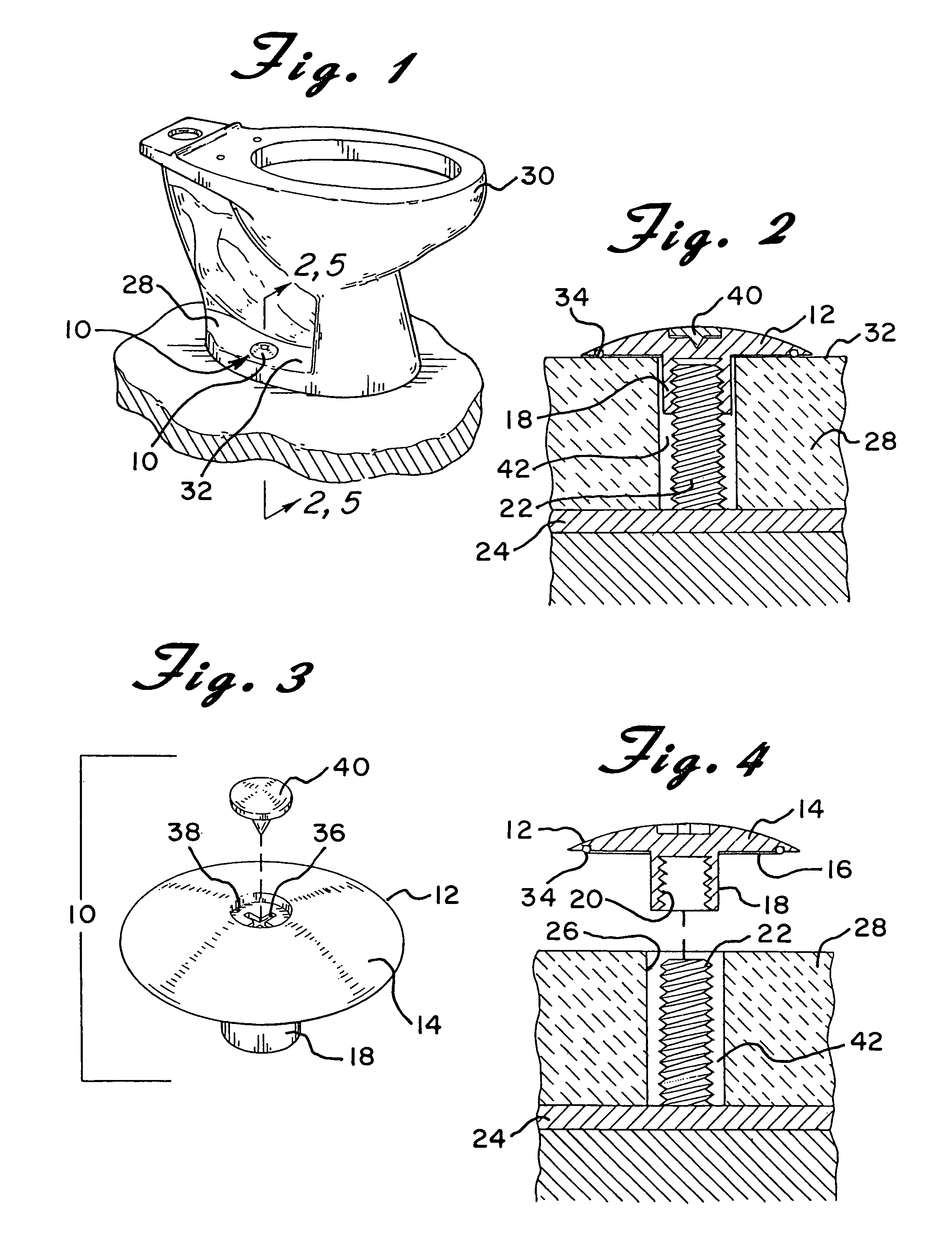

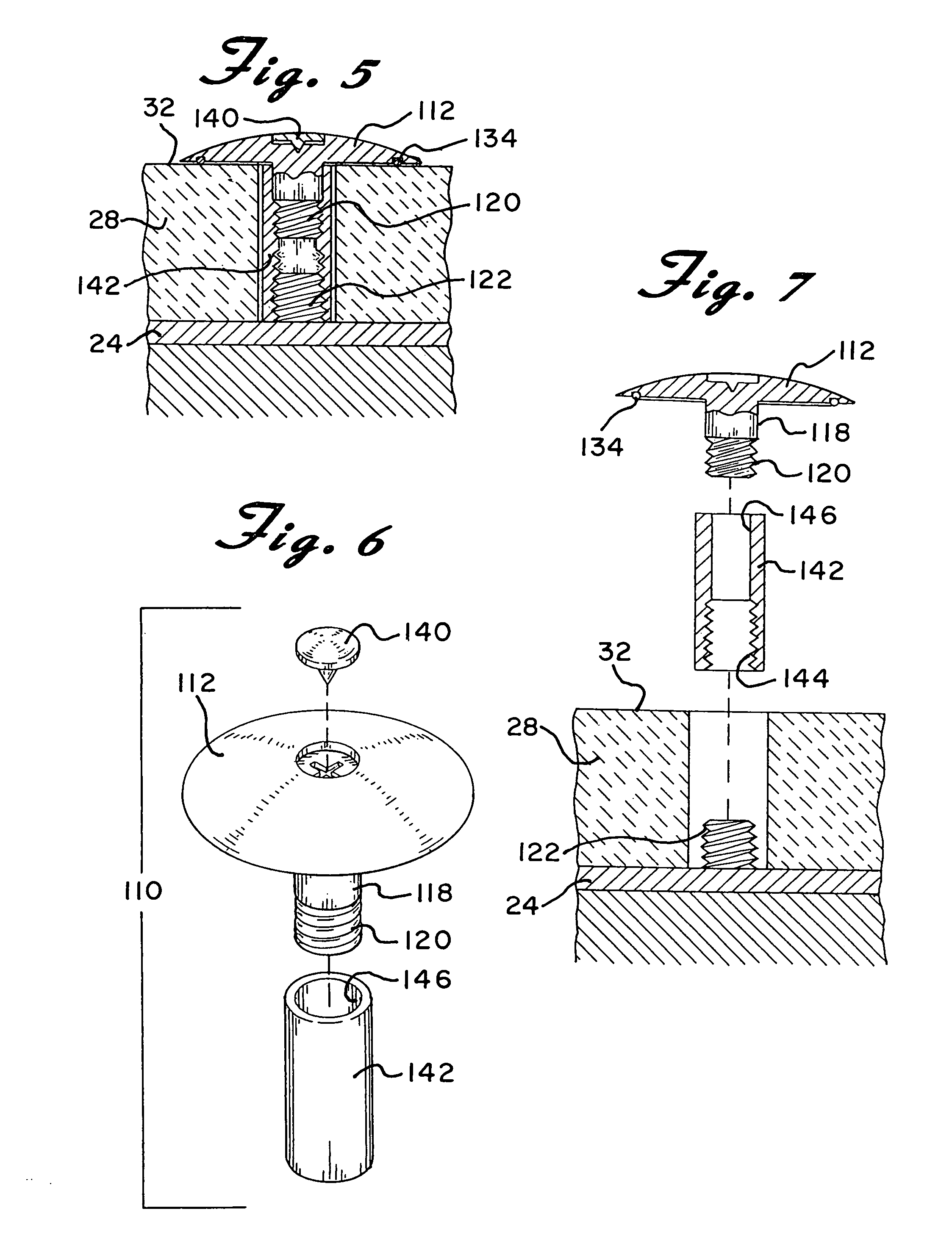

Decorative cap and nut for toilet base

InactiveUS8210785B1Easy to useOvercome deficienciesRemovable ornamentalWater closetsEngineeringMechanical engineering

A decorative cap and nut for securing a toilet base to a floor includes a top substantially disc-shaped member having an upper disc surface and a lower disc surface. The diameter of said disc-shaped member is substantially greater than the thickness thereof so as to lie substantially flush with the toilet base. A coaxial cylindrically shaped stem extends vertically downwardly from the top and is connected to the lower disc surface. The stem includes an internal thread adapted to be threaded onto a floor bolt that extends upwardly through an aperture in the toilet base. A slot in the upper disc surface can be engaged by a tool for rotating the top and an O-ring located on the under disc surface seals the disc-shaped member to the upper surface of the toilet base. A plug fits within the slot to hide the same. The stem and top can be integrally formed in a single piece or can be made of more than one piece joined together.

Owner:GAGER DENNIS J

Corrosion-and scaling-inhibiting water treating agent

InactiveCN1435384AInhibition of localized corrosionPrevent rustFatty acids production/refiningScale removal and water softeningWater useLiquid state

A corrosion-inhibiting and scale-inhibiting agent for treating the water used as circulated cooling water or for boiler is prepared from liquid-state dielectric hydrophobic substance, oil-soluble corrosion inhibitor, water-soluble disperser, and composite sensitive emulsifier. Its advantages are high effect and low dosage.

Owner:BEIJING UNIV OF CHEM TECH

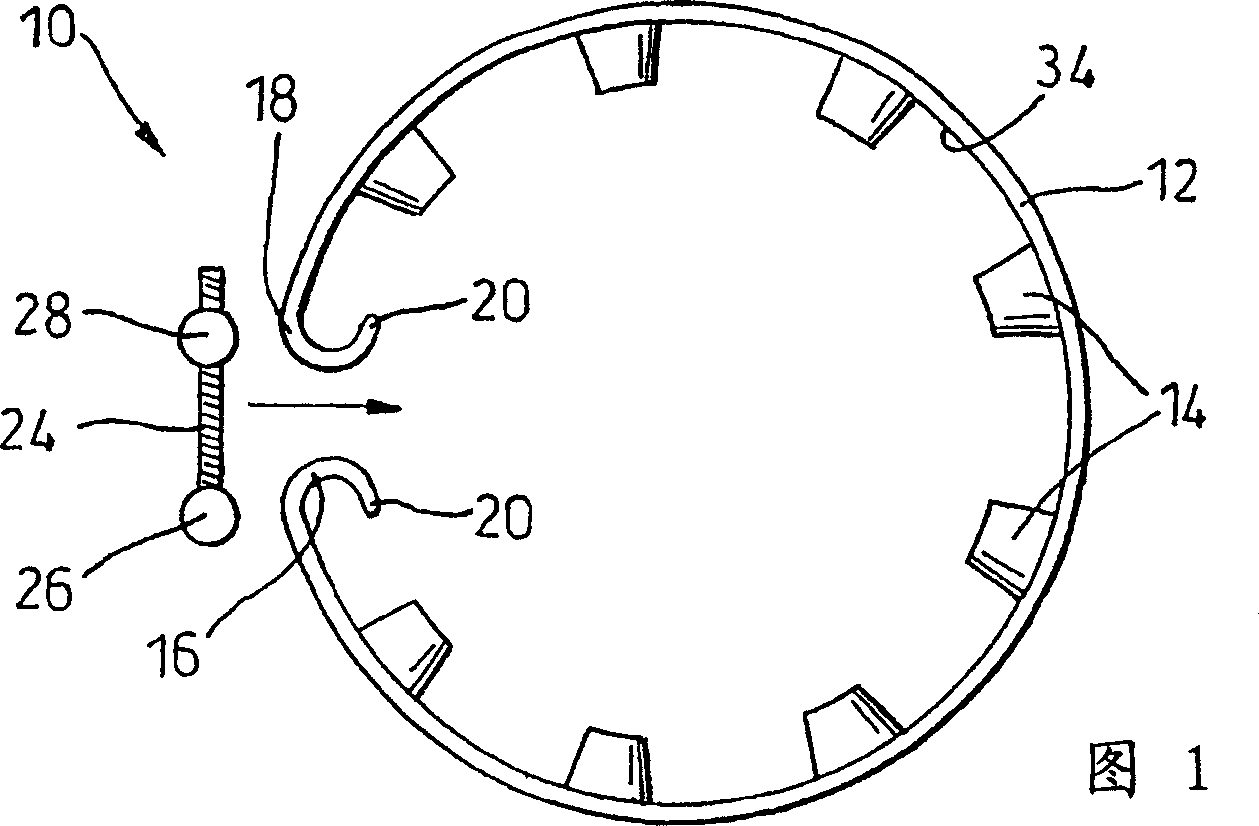

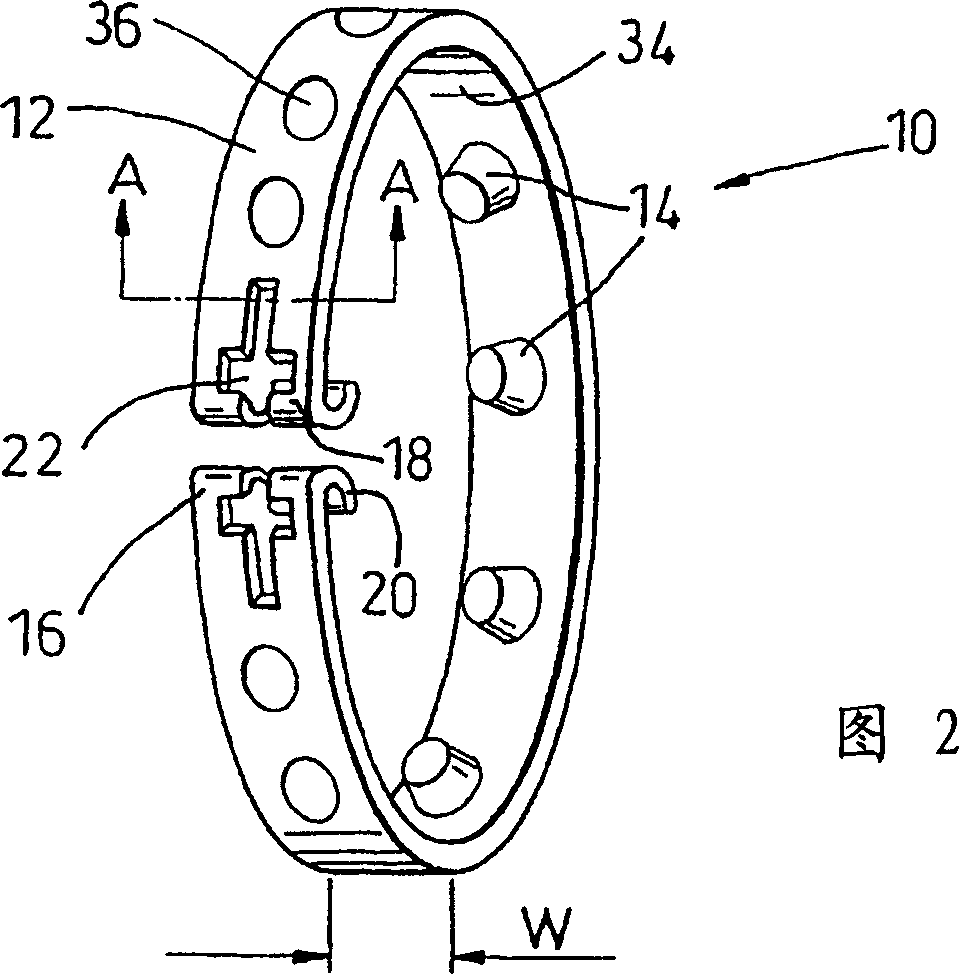

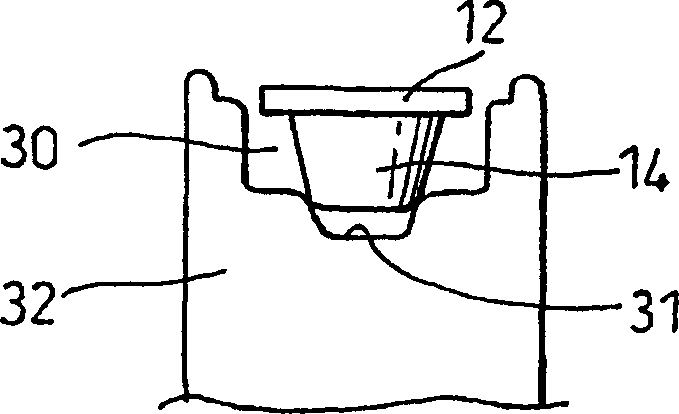

Band device for a wheel rim

An assembly ( 10 ) for location around a wheel rim ( 32 ) includes an annular support band ( 12 ) being formed of a relatively inextensible material. The support band ( 12 ) is split at at least one circumferential location to define a pair of opposed ends ( 16, 18 ). Adjustment bolt ( 24 ) is operably connected to the opposed ends ( 16, 18 ) for enabling adjustment of the diameter of the support band ( 12 ), and feet ( 14 ) depend from the radially inner face ( 34 ) of the support band ( 12 ). The feet ( 14 ) are formed from a relatively non-compressible material and, in use, are seated upon the wheel rim ( 32 ) to maintain the support band ( 12 ) in a spaced apart relationship with the wheel rim ( 32 ). The assembly may be adapted for use as a runflat assembly or as a beadlock assembly.

Owner:蒂龙爆胎保护有限公司

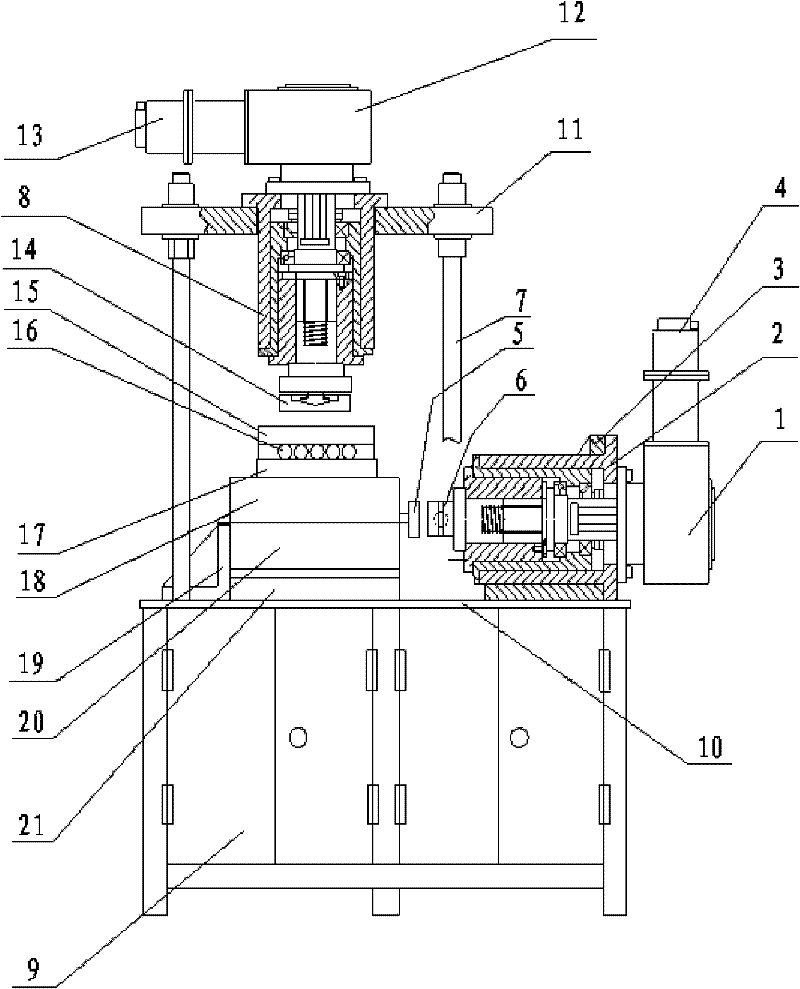

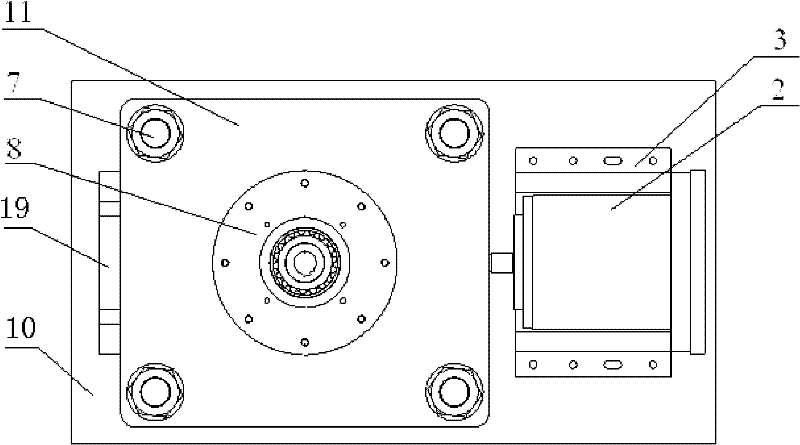

Full-automatic, digital and large frozen soil direct shear apparatus

InactiveCN102313673APrevent rustDigital display automatic control loading speedMaterial strength using steady shearing forcesFreeze thawingTemperature control

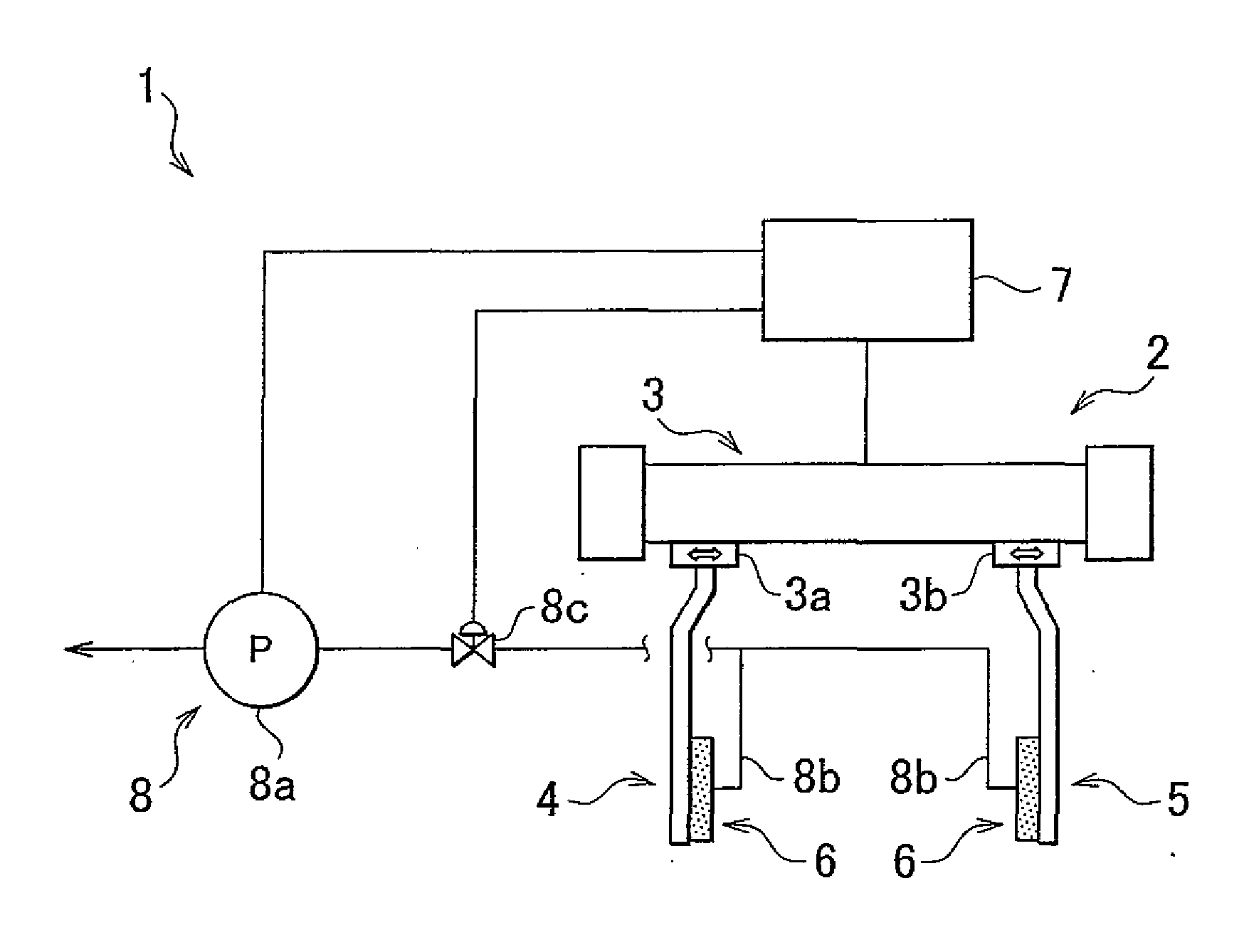

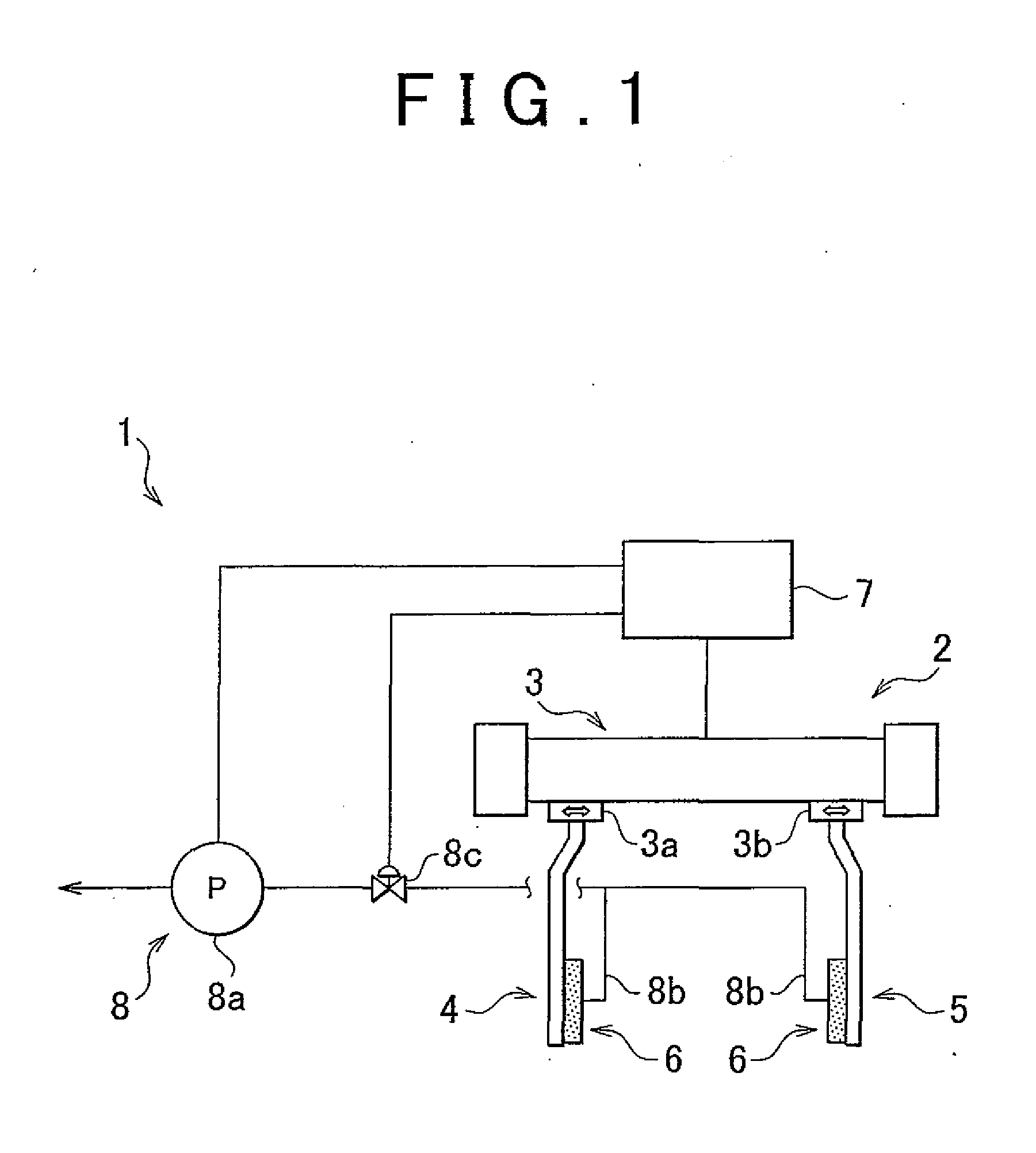

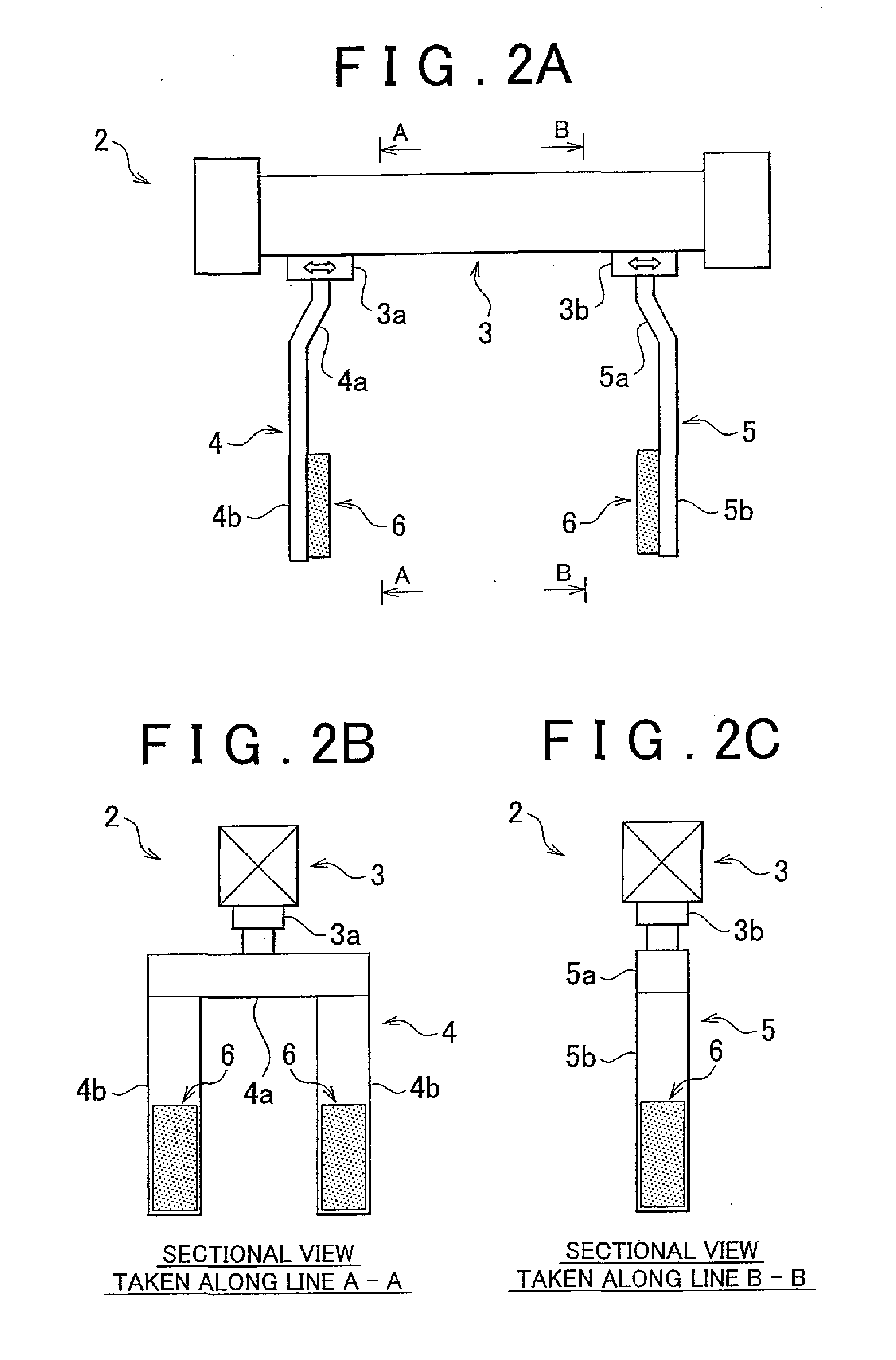

The invention which belongs to the field of civil engineering equipment relates to a full-automatic, digital and large frozen soil direct shear apparatus. The large frozen soil direct shear apparatus which comprises a shear box, a refrigeration system of an upper shear box, a refrigeration system of a lower shear box, a vertical servo loading and monitoring system, a horizontal servo loading and monitoring system, and a measurement and control system is to determine the shear strength of the freeze-thaw interface of the frozen soil or determine the shear strength of full frozen soil and full thawy soil. The size of a frozen soil sample in the embodiment of the invention is 305mm*305mm*200mm, static force and a layered compacting method are adopted to prepare remolded soil samples of different initial water contents and dry densities for shear tests; temperature control systems of the upper shear box and the lower shear box are adjusted to control the temperatures of soils in the shearboxes to guarantee the shear plane to be superposed with the freeze-thaw interface of the frozen soil sample. The direct shear apparatus of the present invention solves problems that the difficulty of testing the shear strength of the freeze-thaw interface is large, the shear tests of coarse grain soil are difficult and the like and provides reasonable design parameters for civil engineering and traffic engineering in cold or highly cold regions.

Owner:BEIJING JIAOTONG UNIV

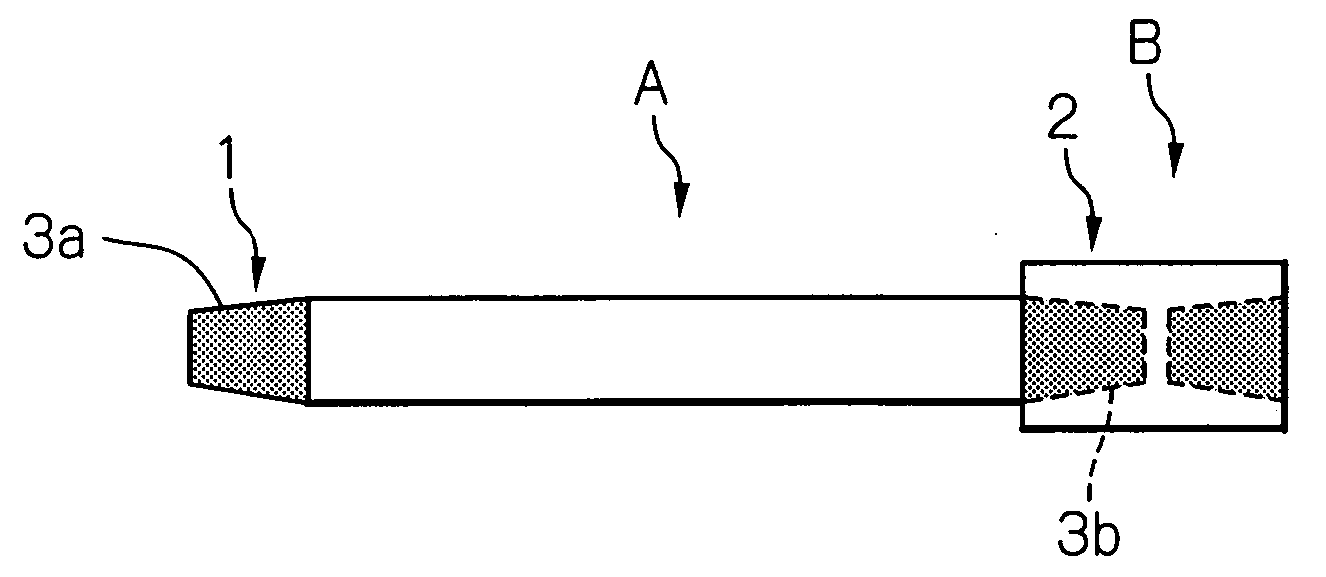

Threaded joint for steel pipes

InactiveUS20060228505A1Improve the lubrication effectLubricating property worsenEarth drilling toolsDrilling rodsViscous liquidAlkaline earth metal

A threaded joint for steel pipes for use in an oil well which has improved galling resistance and which is protected from rusting comprises a pin and a box each having a contact surface including a threaded portion and an unthreaded metal contact portion. The contact surface of at least one of the pin and the box has a lower layer of a viscous liquid or semisolid lubricating coating comprising at least wax and a fatty acid alkaline earth metal salt and not containing a harmful heavy metal such as lead and an upper layer of a dry solid coating formed from an aqueous resin coating composition, an organic solvent type coating composition, or an ultraviolet curing coating composition.

Owner:NIPPON STEEL CORP +1

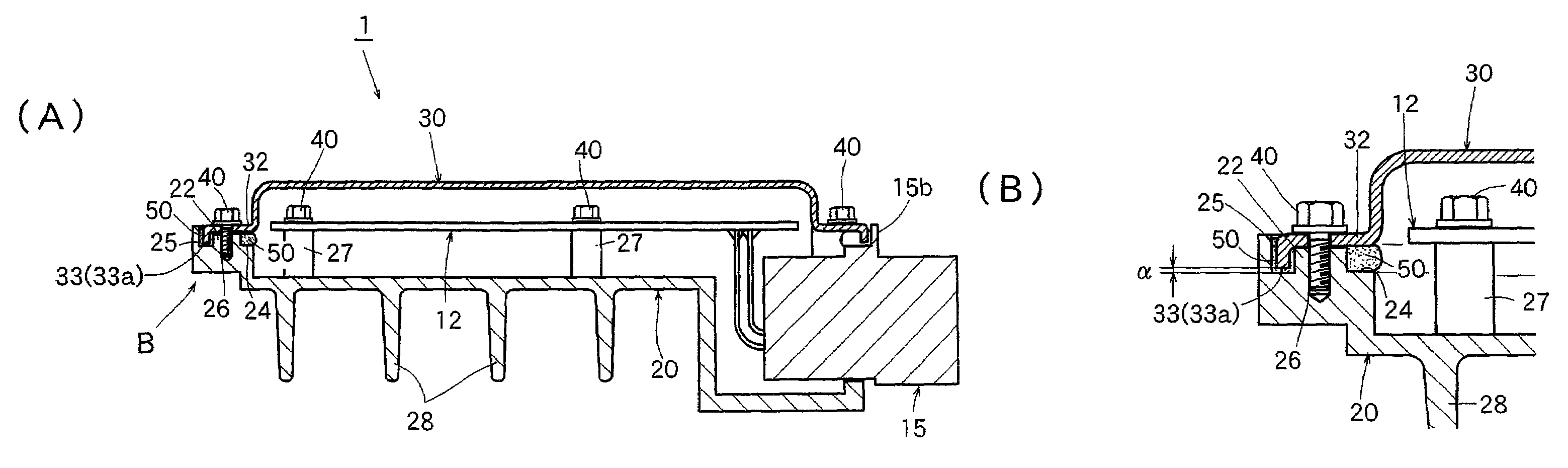

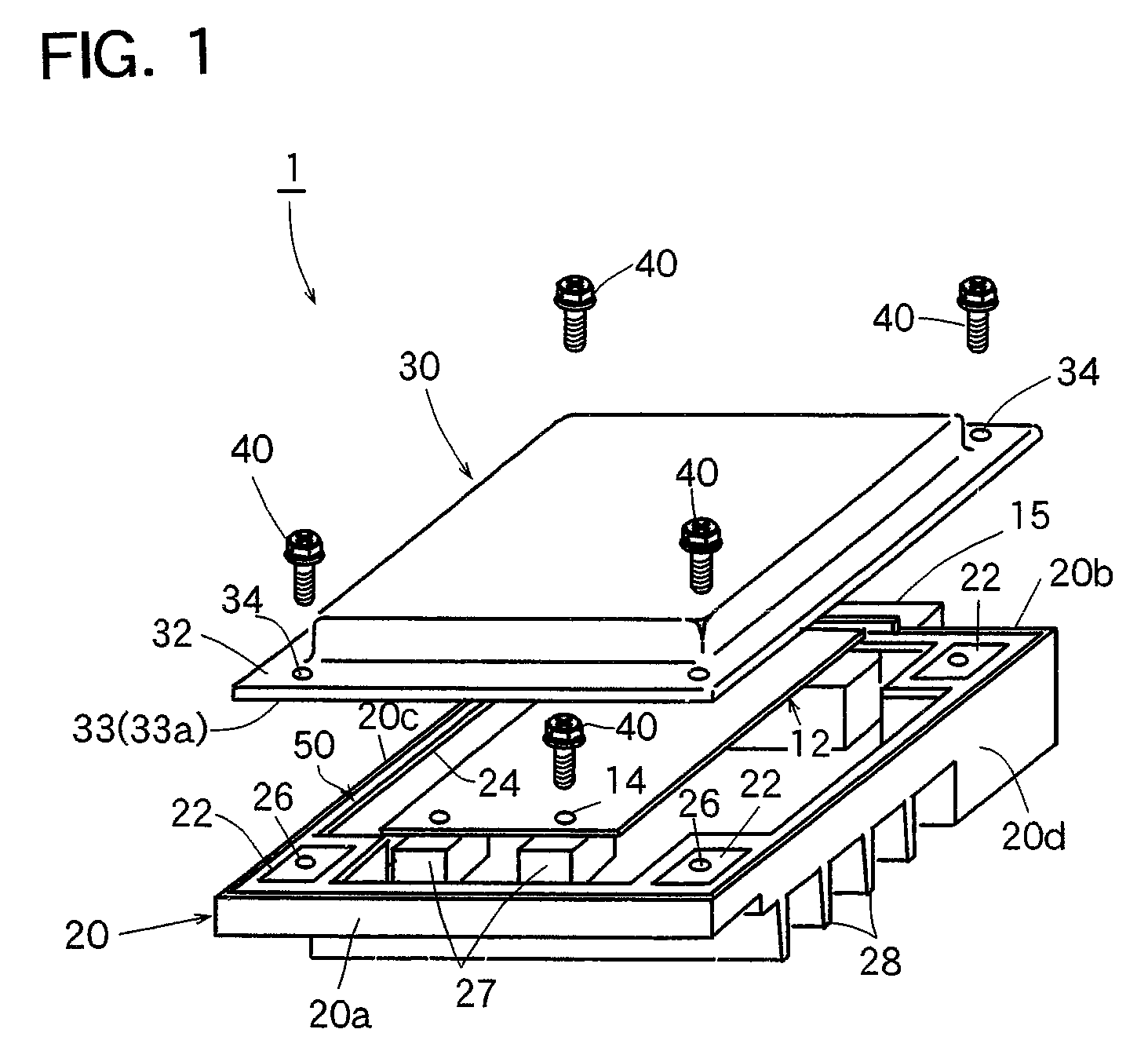

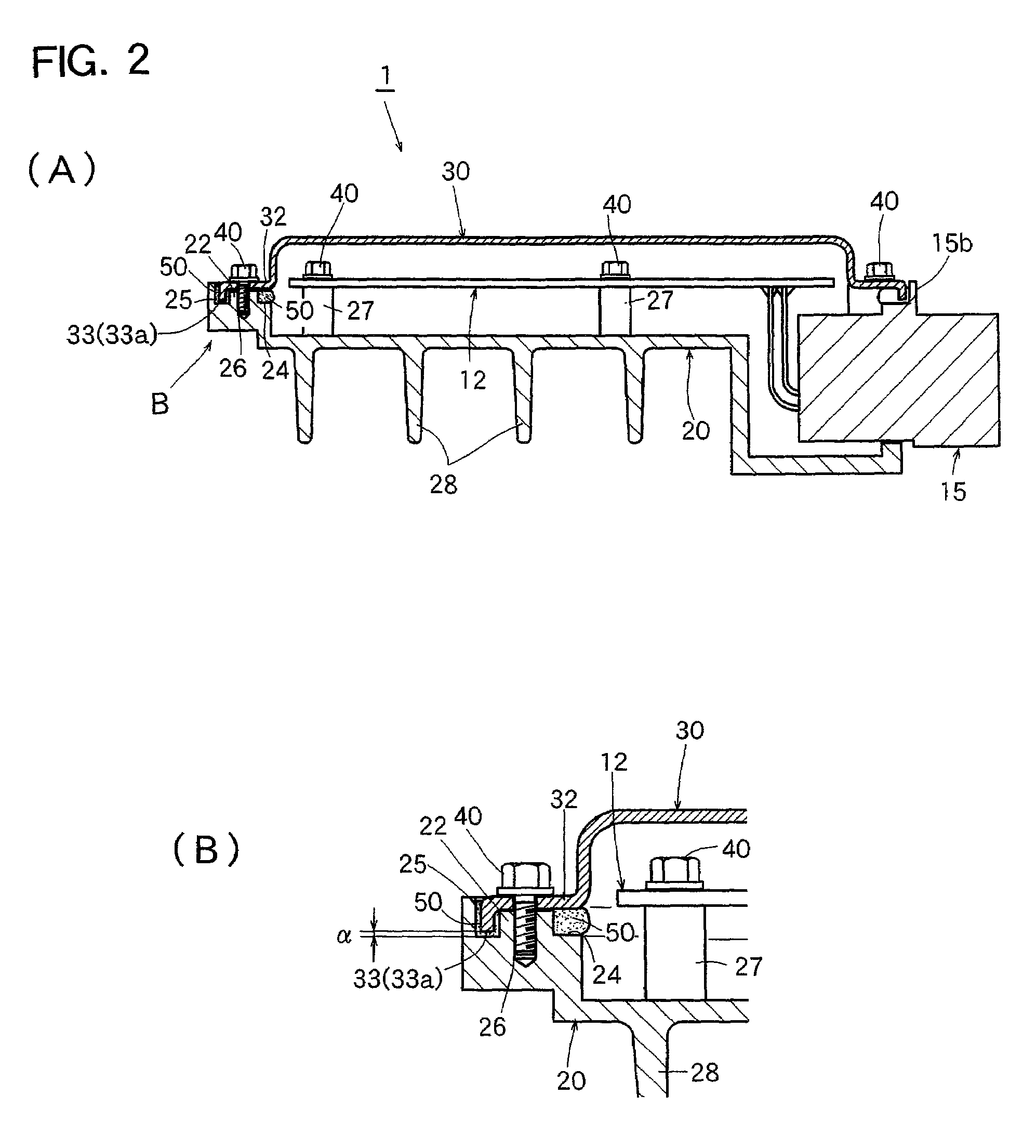

Engine controller

ActiveUS7561435B2Improve reliabilityAvoid contactCasings/cabinets/drawers detailsCouplings bases/casesAdhesiveDie casting

There is proposed an engine controller which is excellent in reliability in that the outer peripheral edge face (cut surface) of covering member can be prevented from being rusted while securing the water-proofness and dust-proofness. This engine controller comprises a circuit board (12) for controlling an engine; an aluminum die-cast main case body (20) having an open top; and a covering member (30) made of an iron-based metal plate which is preliminarily applied with surface treatment, the covering member (30) being fixedly clamped to the main case body (20) by means of a setscrew (40) so as to hermetically close the open top of the main case body (20); wherein the main case body (20) is provided thereon with a pedestal (24) or groove (25) on which a liquid or jellied water-proofing adhesive (50) is coated or filled (piled), thereby enabling entire outer peripheral edge face (33a) of the covering member (30) to be covered by the water-proofing adhesive (50).

Owner:HITACHI ASTEMO LTD

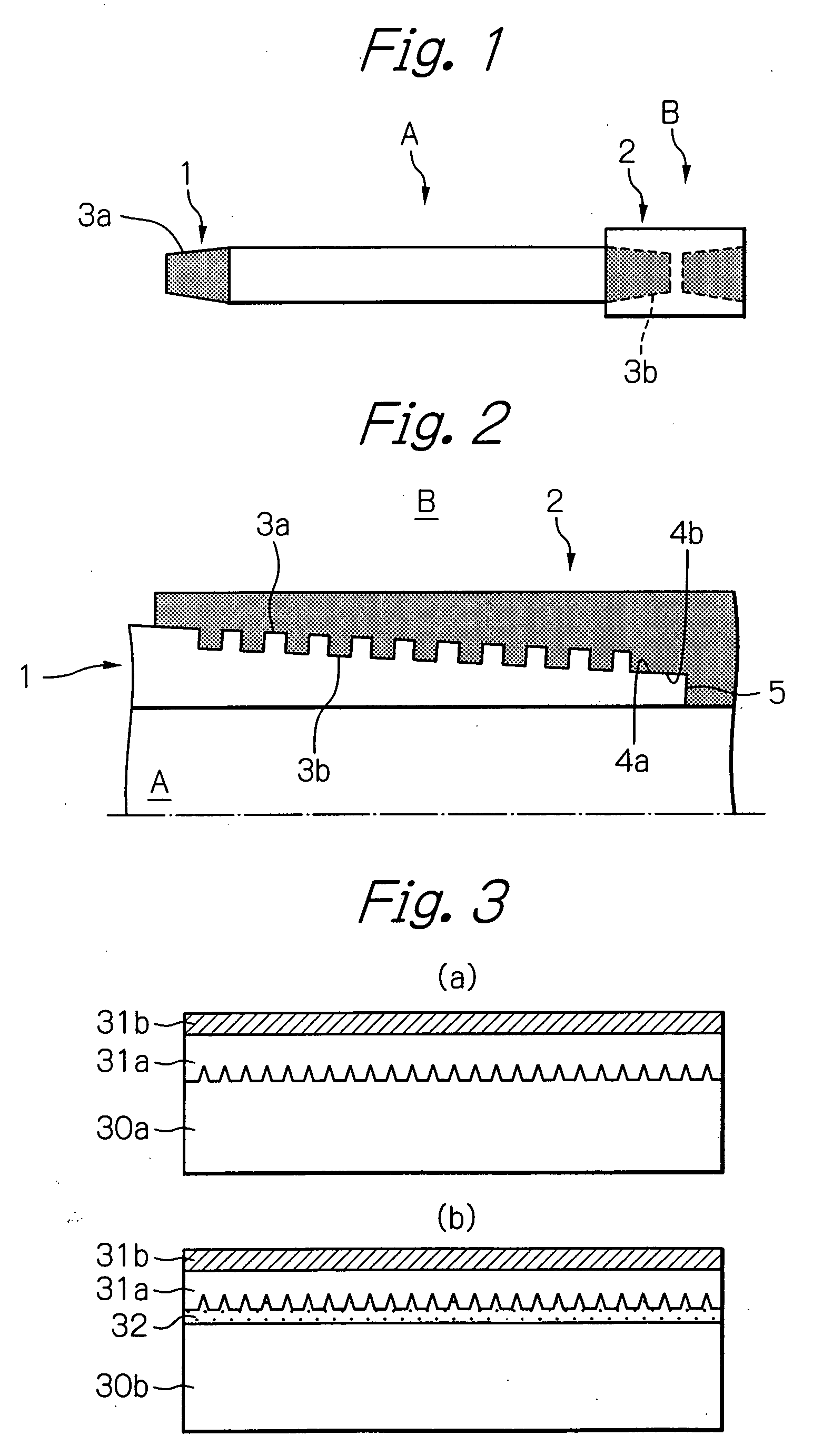

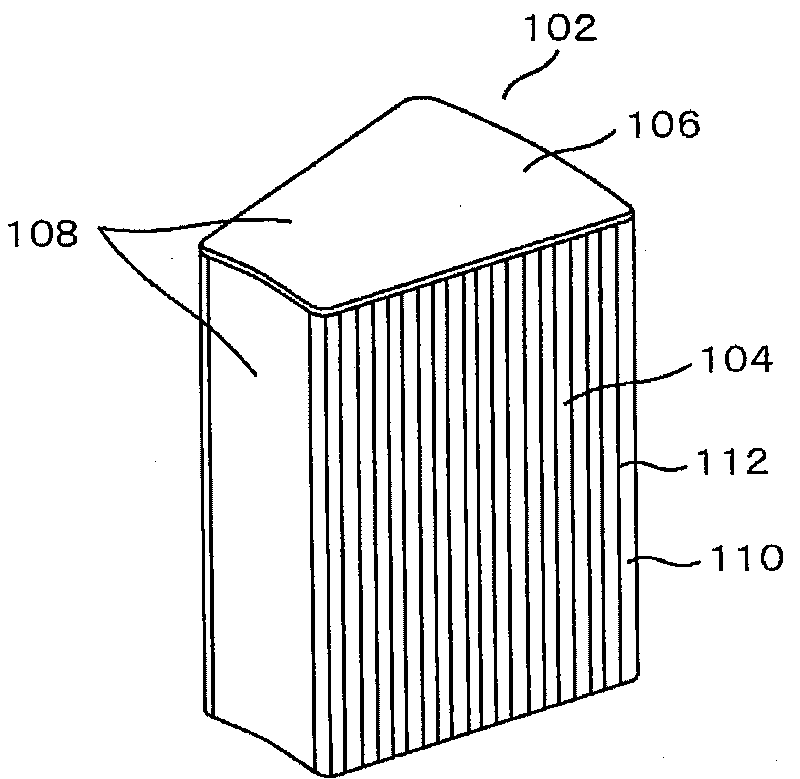

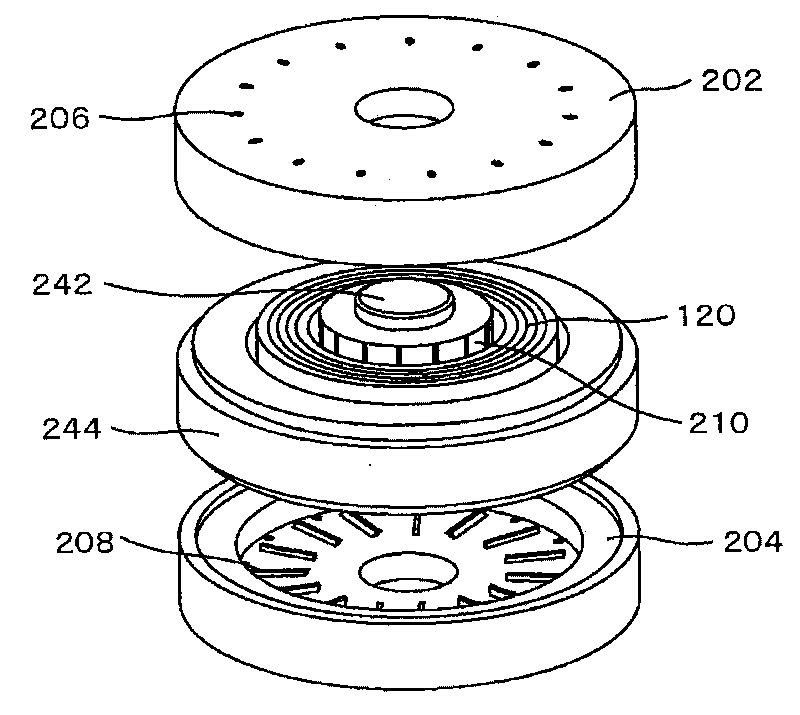

Armature core, motor and axial gap electrical rotating machine using same and method for making same

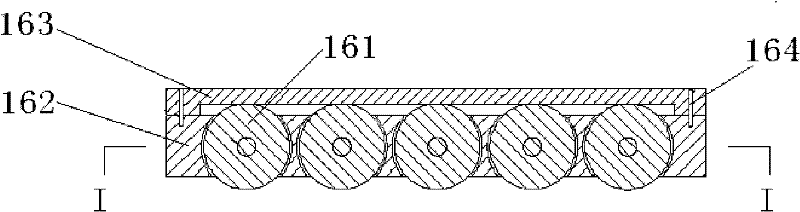

InactiveCN101741153APrevent peelingPrevent rustMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringConductor Coil

A noncrystalline armature core, motor and axial gap electrical rotating machine using same. For the amorphous core, a resin mold is formed, and the peel off is prevented and the gap surface is prevented from rusted. The contact portions between winding wires and amorphous are provided with edge roundness, thus the winding wires can be arranged around the amorphous core. Further, an axial gap motor using cut cores of amorphous lamination as stator cores is provided. Still further, the stator includes: a plurality of stator cores in a bar shape, the stator cores being disposed along circumferential direction, wherein the axial line of the rotor shaft is the central axis of the circumferential direction, and wherein an axial direction of the stator cores is along the axial line direction AXof the rotor shaft; a stator core holding member in a disc form, the stator having a plurality of holes or recessions that are substantially in the same shape as a cross-sectional shape of the statorcores and are arranged along the circumferential direction, wherein the axial line of the rotor shaft is the central axis of the circumferential direction; and coils wound around the stator cores, and wherein the stator cores are inserted in the holes or recessions of the stator core holding member and held by fixing in vicinities of respective central portions thereof, the central portions beingwith respect to the axial direction thereof.

Owner:HITACHI IND EQUIP SYST CO LTD

Process for macromolecularizing phenolic compounds etc. and use thereof

InactiveUS20010007762A1Prevent rustLoss of strengthAntibacterial agentsOrganic active ingredientsPoulticeAdhesive

A process for macromolecularizing phenolic compounds or aromatic amine compounds by the action of a catalyst comprising an enzyme having a polyphenol oxidizing activity in the alkali region; applications of the compounds obtained by the above process to thickeners, stabilizers, coagulants, emulsifiers, dispersants, water retainers, antioxidants, adhesives, concrete admixtures, dyes, coating materials, petroleum recovering agent, soil conditioner, a blow-applied seed bearing surface soil stabilizer, deodorants, smell eliminators, agricultural chemical spreaders, feeding stuff binders, bactericides, antimicrobial agents, viral infection inhibitors, bioadhesion preventives, biotic repellents, insecticides, poultices, ink bases or wood treating agents; and method of waste water disposal, a method of deoxygenation and a method of treating wood, concrete or soil in which use is made of the above reaction.

Owner:SDS BIOTECH CO LTD

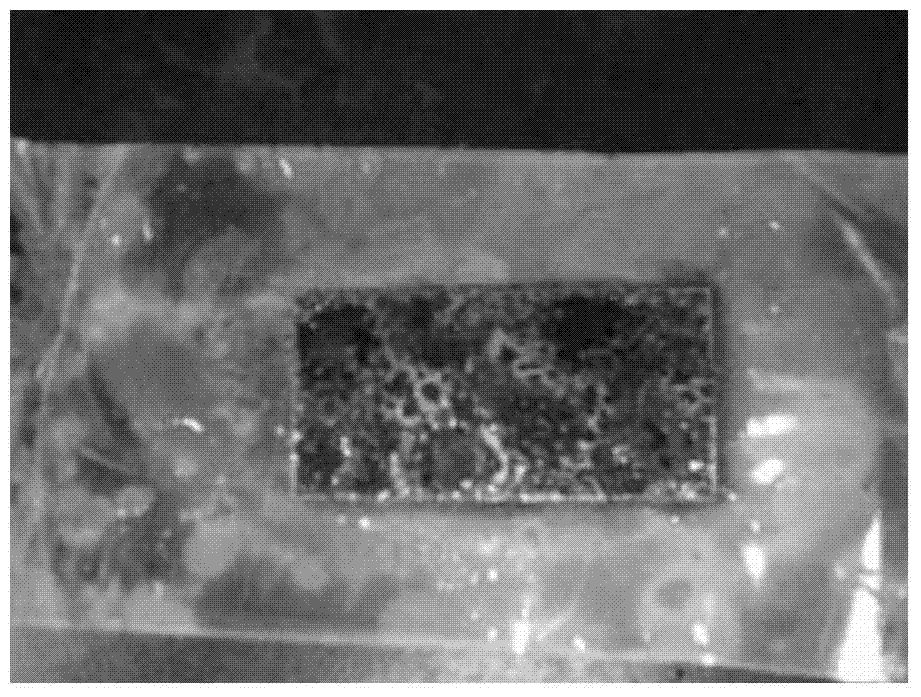

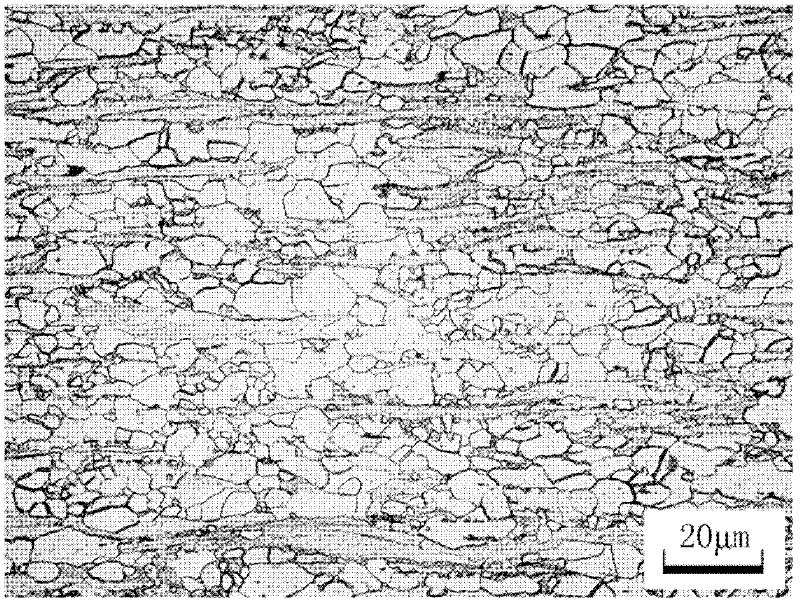

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857APrevent rustNo foamingHot-dipping/immersion processesAcid washingCooling chamber

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles,arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

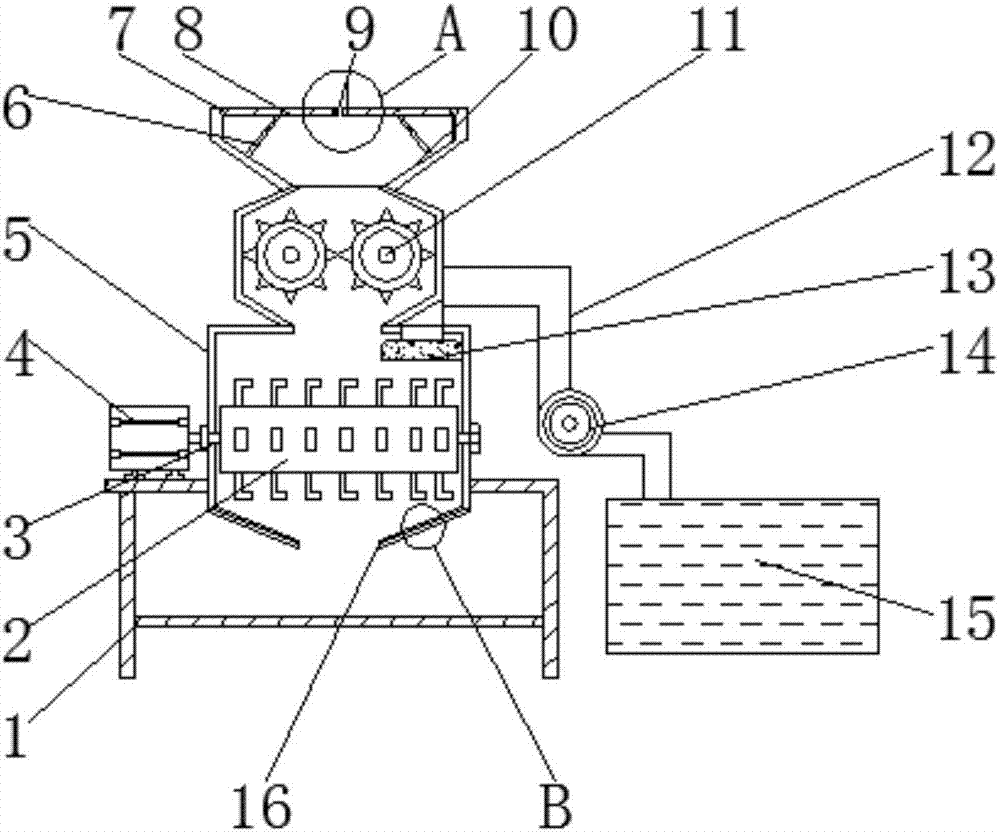

Building rubbish crusher

InactiveCN106925378ACause wasteImprove dust removal efficiencyCombination devicesGas treatmentArchitectural engineeringCrusher

The invention discloses a building rubbish crusher which comprises a rack and baffles. An electromotor is mounted at the upper end of the left side of the rack. A machine body is arranged at the upper end of the rack. A feeding opening is fixed to the upper end of the machine body. The lower end of the feeding opening is connected with the baffles through supporting rods. A sealing ring is arranged on the outer side of each baffle. Crushing rollers are mounted in the machine body. An exhaust opening is formed in the upper end of the right side in a cavity of the machine body and located below the crushing rollers. A filter screen is mounted in the exhaust opening. The upper end of an air suction motor is connected with the exhaust opening through an air outlet pipe. The machine body is mounted on the left side of the exhaust opening. A water tank is fixed below the air suction motor and located on the right side of the rack. A discharging opening is mounted below the machine body. A shock absorption mat is arranged at the upper end in the discharging opening. The building rubbish crusher is provided with the water tank, sucked-out building rubbish dust can be removed through water in the water tank, the dust removal efficiency is high, and water resources cannot be wasted.

Owner:THE FOURTH OF CHINA CONSTR SEVENTH ENG

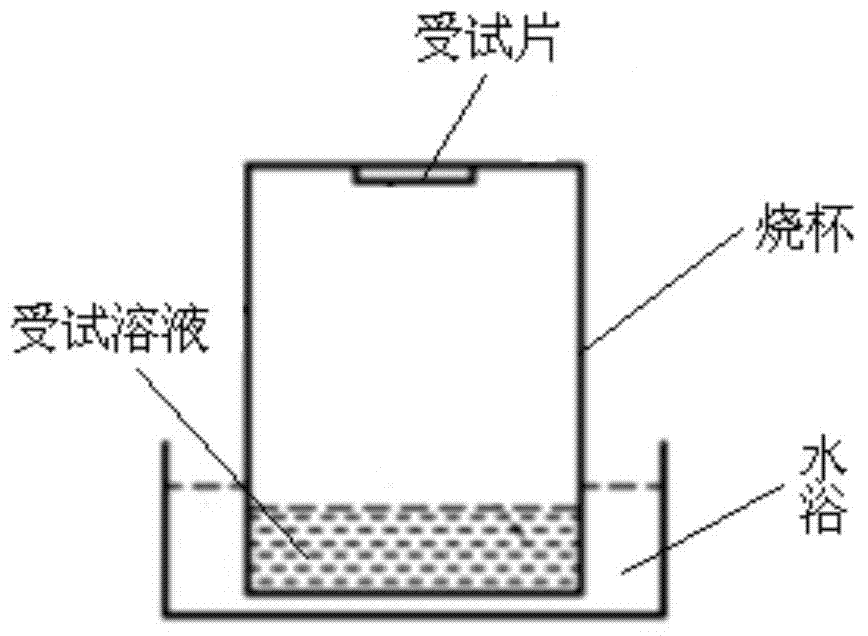

Neodymium iron boron magnet material phosphating treatment and organic coating double layers protection method

InactiveCN102732871AGood anti-corrosion abilityGood bindingLiquid surface applicatorsMetallic material coating processesCorrosion resistantPre treatment

The invention relates to a surface protection technology of a neodymium iron boron magnet material, concretely relates to a neodymium iron boron magnet material surface phosphating treatment and an organic coating double layers protection method. The method comprises the following steps: removing oil on neodymium iron boron, removing rust, and then immersing neodymium iron boron in a phosphating liquid for 5-15 minutes to generate a layer of phosphating coat, washing and drying, and then coating a layer of organic paint to form an organic coating. The method of the invention aims at the problems of complex, rigorous pre-treatment and poor anti-corrosive property in a surface protection method during electroplating and chemical plating. According to the invention, the surface treatment technology of phosphatization treatment and organic coating double layers protection can be used, the technology is simple without complex pre-treatment, under the prerequisite that the combination force of the coating and the matrix and the magnetic property are not be influenced, the neutral salt spray corrosion resistant performance of the coating can be largely enhanced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Rolling oil composition for 12-roller reversing mill

The invention relates to a rolling oil composition used for a twelve-high reversing cluster mill; the rolling oil composition belongs to the field of metallurgical steel rolling oil products, and comprises the components according to weight percent as follows: 60-70 percent of compound neopentyl polyol ester, 14-28 percent of mineral oil, 1-5 percent of phosphorus-containing extreme-pressure and anti-wear agent, 1-5 percent of sulfur-containing extreme-pressure and anti-wear agent, 2-12 percent of compound emulsifier, 1-3 percent of anti-rust agent, 1-3 percent of antioxidant and 0.01-0.5 percent of defoamer; the rolling oil composition takes the compound neopentyl polyol ester synthetic ester with excellent lubricating performance as the lubricating basic component; an oiliness agent main body with high lubricating performance and high extreme-pressure and anti-wear performance is composed by adding the scientific components of the phosphorus-containing and the sulfur-containing extreme-pressure and anti-wear agents; and the anti-rust performance and the emulsion stability are ensured by adopting the mineral oil, the anti-rust oil, the emulsifier and the antioxidant with the appropriate proportion for coordination, thereby creatively solving the contradiction between the lubricating performance and the detergence, ensuring the requirements on the lubricating performance of the quality when rolling steel plates with thin specifications, protecting the lubricating requirements of back-up bearings and ensuring the volatility and the annealing detergence under the cleaning-free condition.

Owner:WUHAN TONGSHENG FINE CHEM TECH DEV

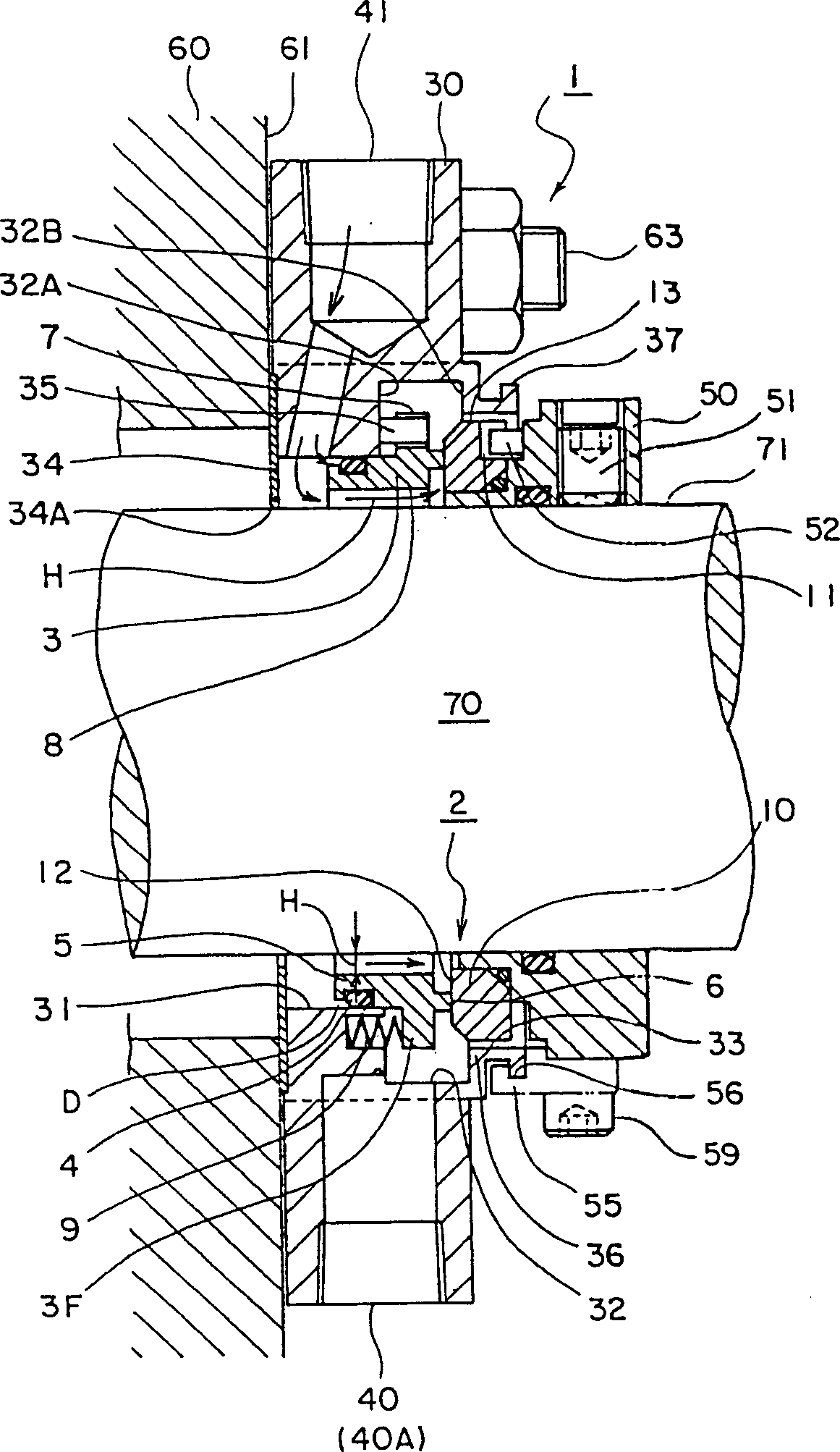

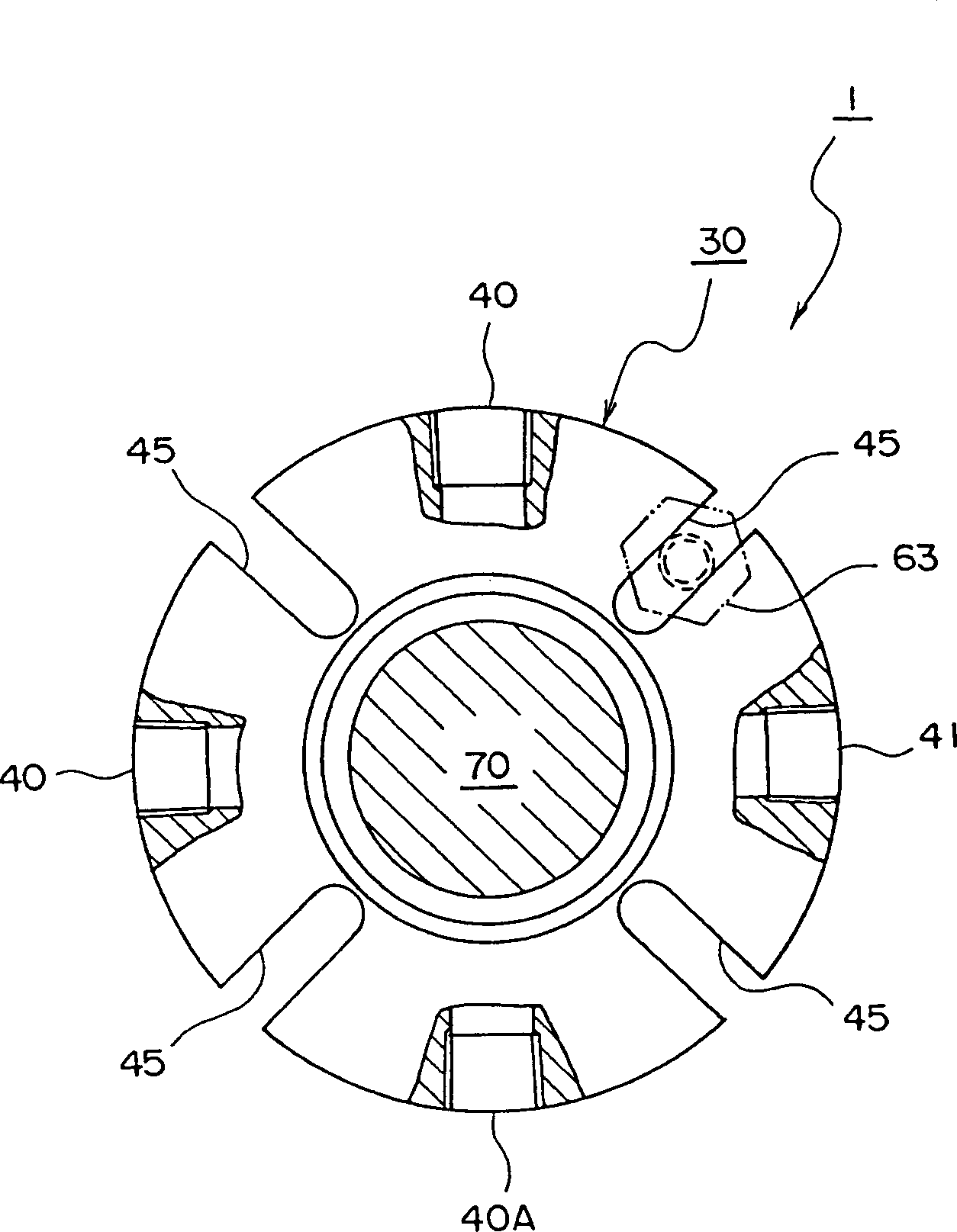

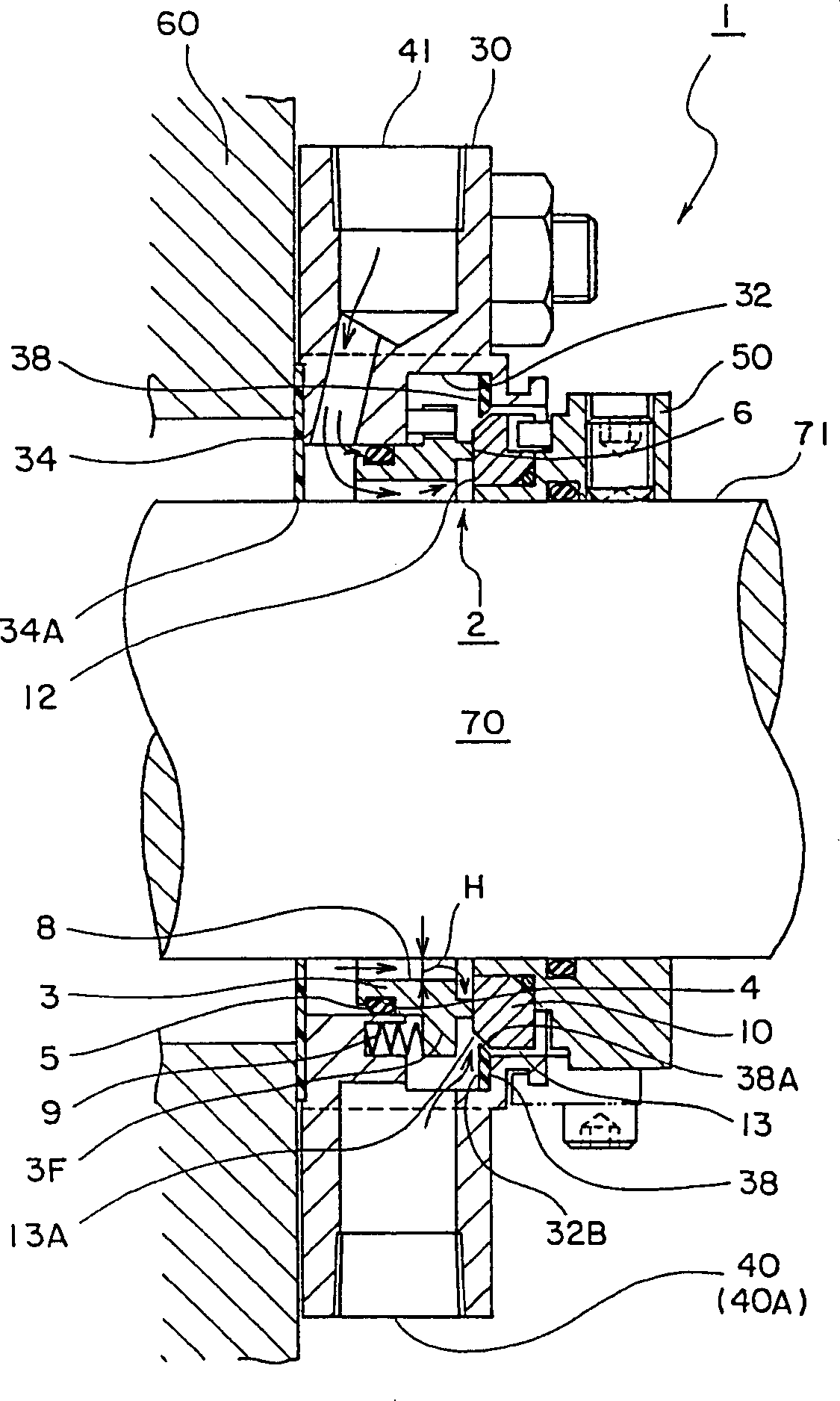

Mechanical seal device

A first seal ring (3) has a clearance H allowing the passage of a sealed fluid, between a shaft (70) and the first seal ring (3) and constituted to communicate a flushing port (41) with the inner peripheral side of the seal face (6) through the clearance (H). A mounting part (30) has a cooling annular groove (32) in the form of covering the seal face (6) of the first seal ring (3) mounted to the inner peripheral surface (8), from the outer diameter side, and the outer throttle face (33) of the cooling annular groove (32) is fitted in proximity to the outer peripheral seal face of a second seal ring (10) while having a cooling fluid passage (40) communicating with the cooling annular groove (32). The invention reduce the sliding heat of a seal face while preventing clogging and sticking of solid matter of a sealed fluid to a mechanical seal externally mounted to a device body.

Owner:EAGLE INDS

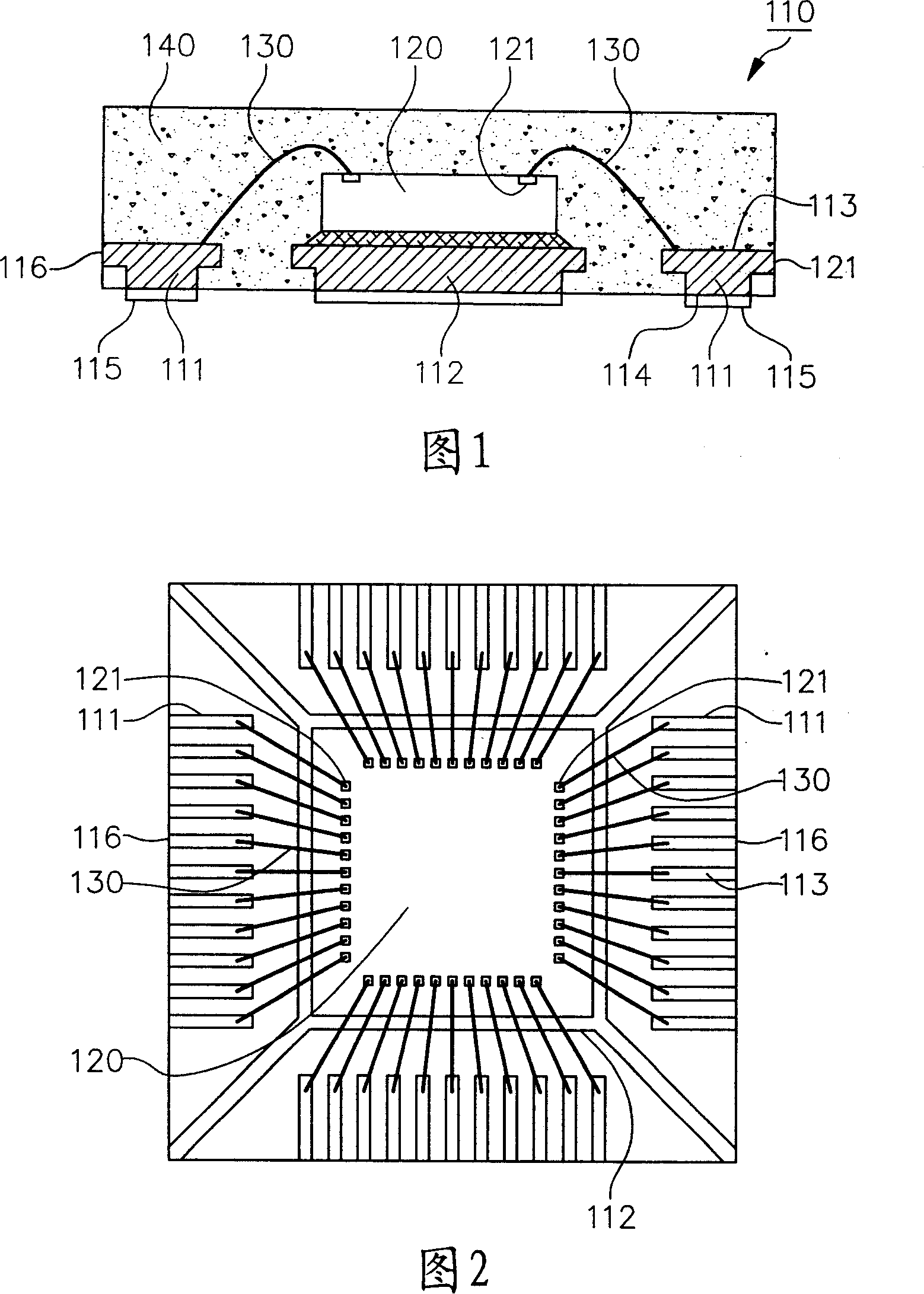

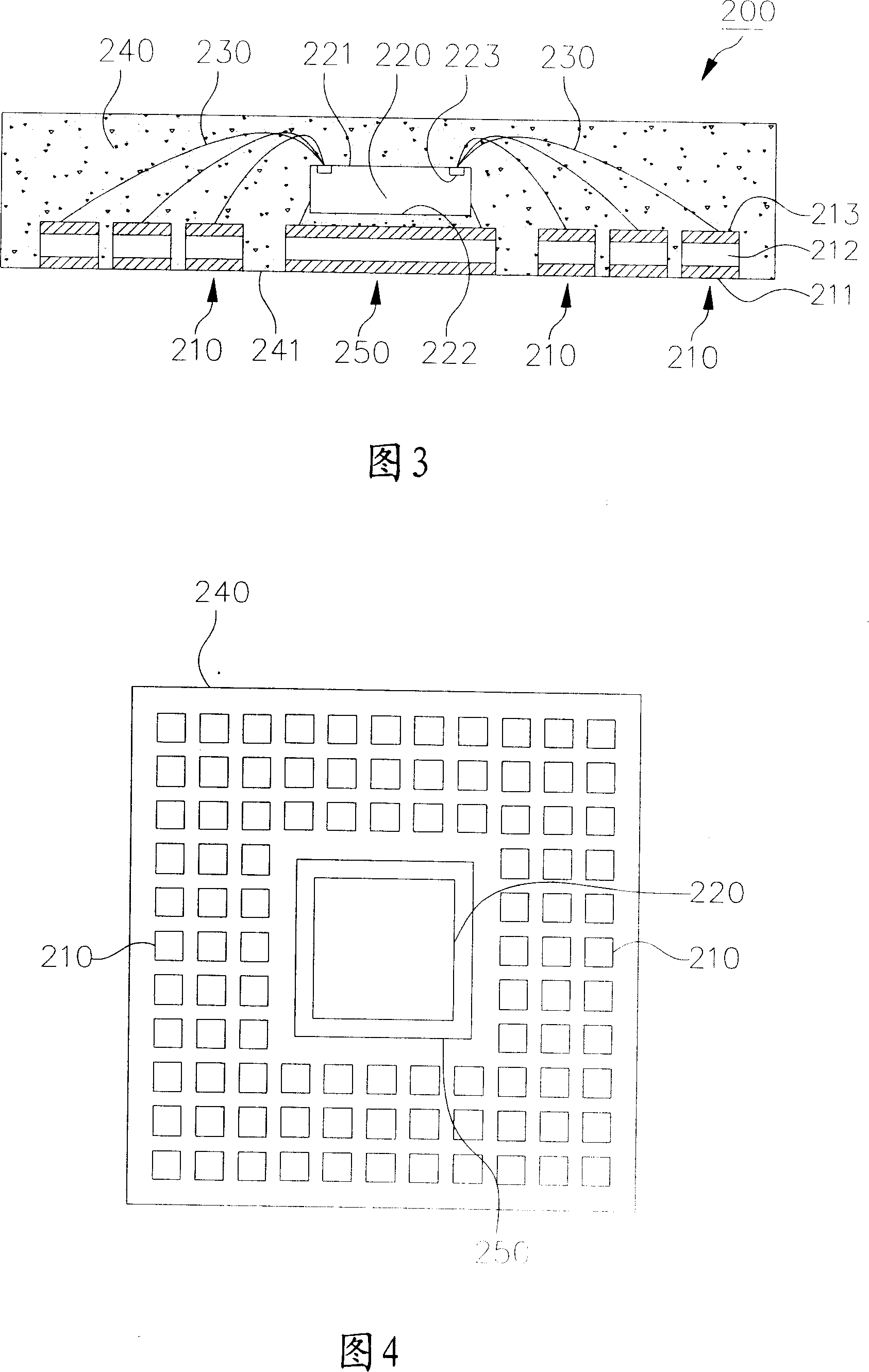

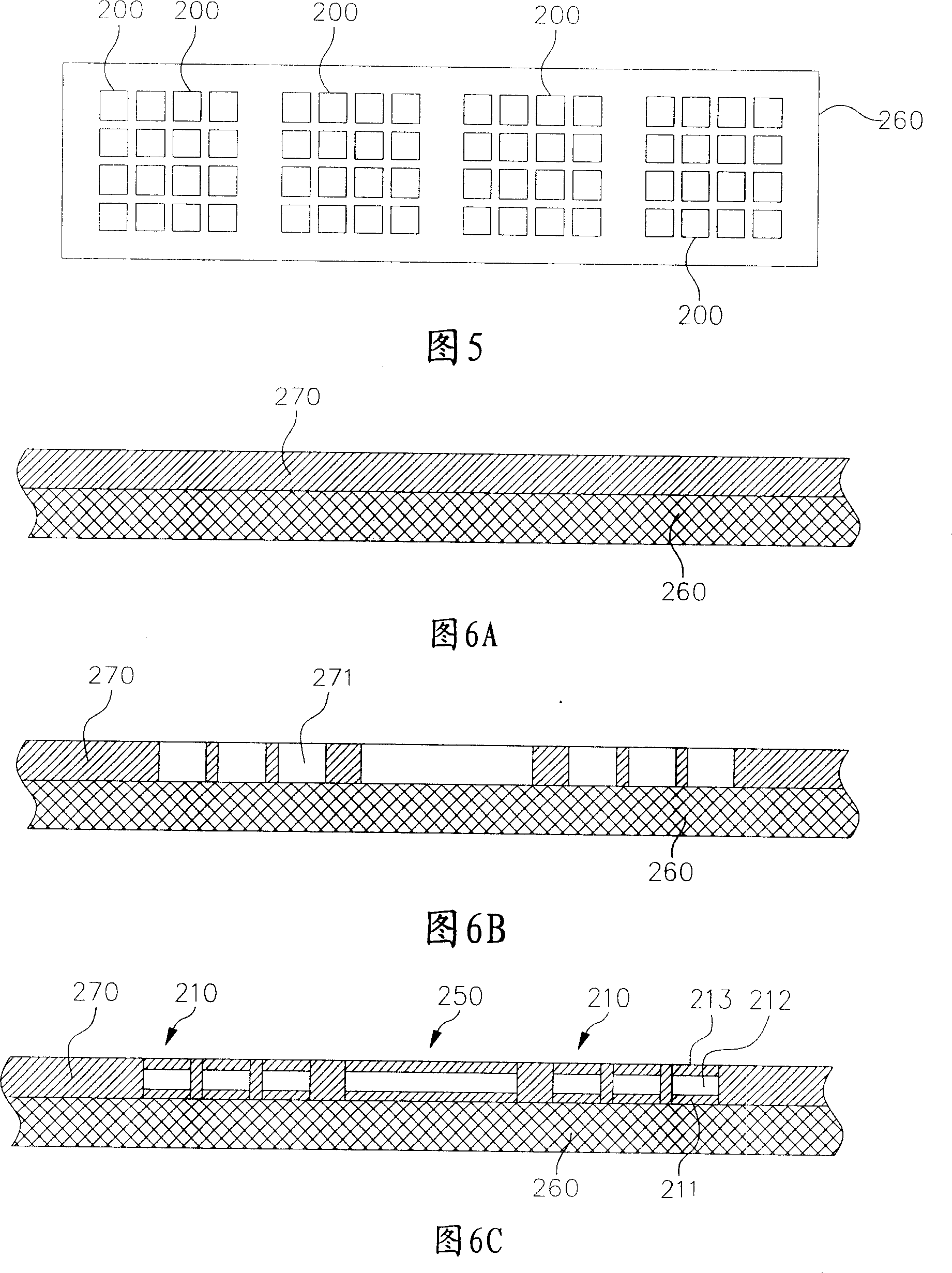

Wafer packaging construction with array connecting pad and method of manufacturing the same

InactiveCN101131980AHigh densityPrevent rustSemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

The present invention relates to a wafer packaging with array pads and its processing method. The wafer packaging mainly includes even numbers of wire-bonded pads, a wafer, even numbers of welding line and a sealing colloid. An upper and a lower combination layers are separately formed on cores of the wire-bonded pads, in which materials of the cores include copper. These welding lines electric connect the wafer with the upper combination layer of the wire-bonded pads. The sealing colloid seals these welding lines, cores and upper combination layers, in which only the lower combination layers are exposed out of the sealing colloid. The present invention can solve the former rusting problem of exposed cutting surface of pins in non-external-pin wafer packaging of conductor frame substrate, and has array pads which can achieve high density of wafer packaging. The processing method of the present invention keeps using a rigid conductive mold in packaging process to carry steps of electroforming, wafer attaching, wire bonding and packaging to achieve coherence of the packaging process.

Owner:CHIPMOS TECH INC

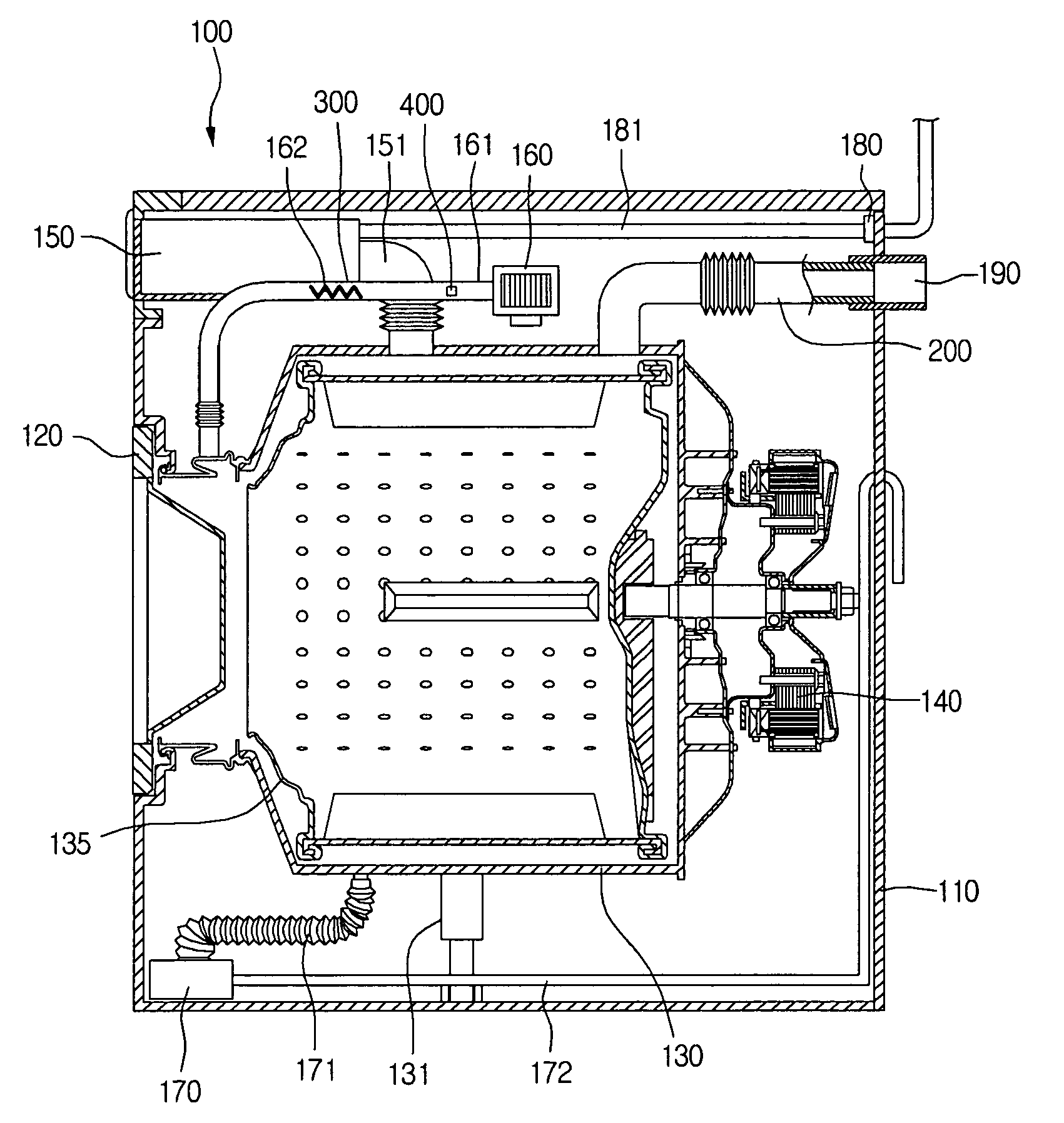

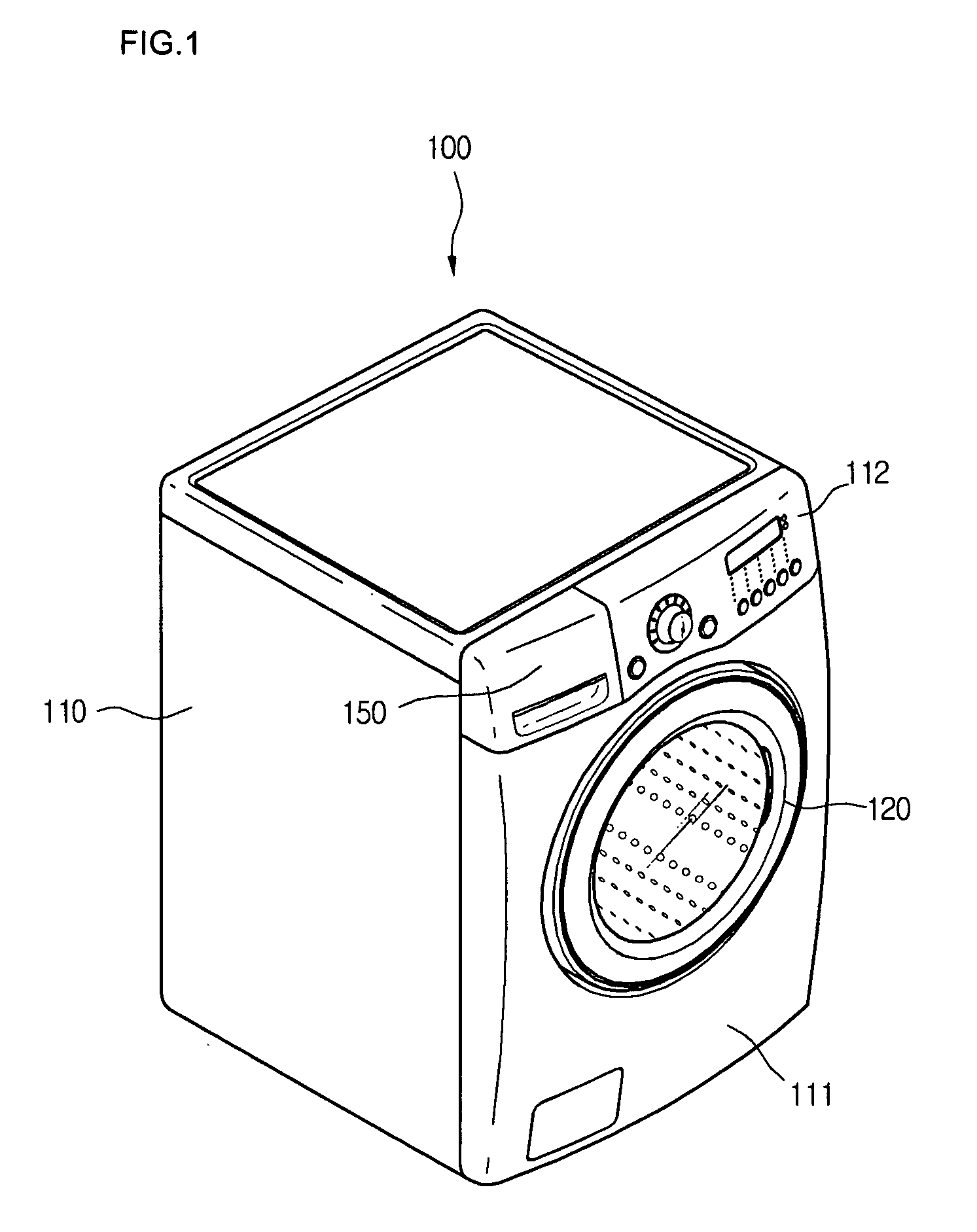

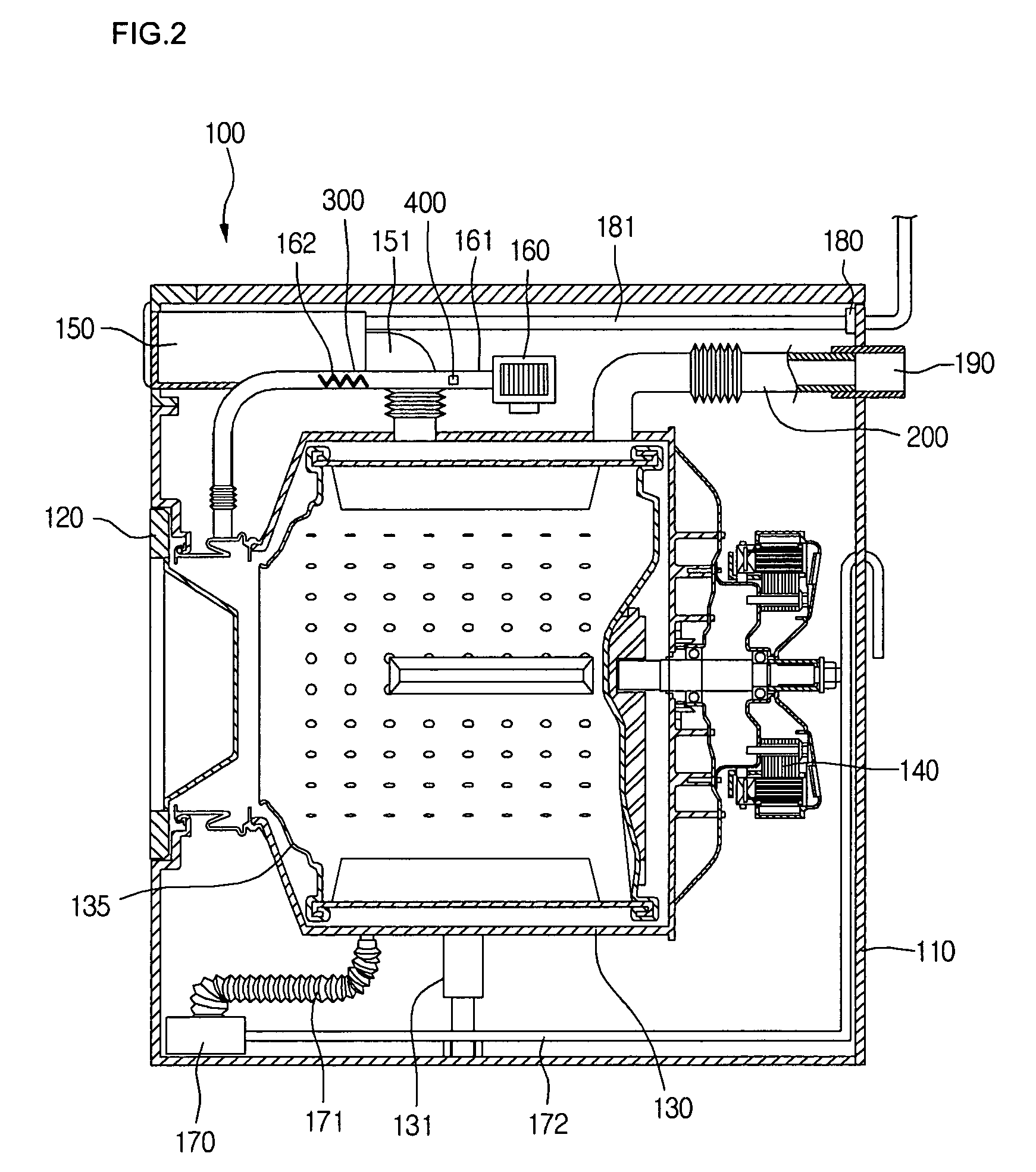

Washing machine combined with dryer and controlling method thereof

InactiveUS7520145B2Prevent backflowAvoid flowOther washing machinesControl devices for washing apparatusPulp and paper industry

A washing machine combined with a dryer is provided. In the washing machine combined with a dryer, a tub is provided, a dryer duct is installed outside of the tub to introduce a surrounding air into the tub, a heater is installed in the dryer duct to apply heat to the surrounding air, a temperature sensor is installed in the dryer duct to measure temperature inside the tub or temperature inside the dryer duct, and a dryer fan is installed in the dryer duct to draw in the surrounding air.

Owner:LG ELECTRONICS INC

Mechanical equipment cleaning liquid

InactiveCN102618396AEasy to cleanImprove safety and environmental protectionNon-ionic surface-active compoundsDetergent compounding agentsHazardous substanceMechanical equipment

The invention discloses a mechanical equipment cleaning liquid, which consists of monohydric alcohol, glycol, complexing agent, anionic surfactant, nonionic surfactant, compound corrosion inhibitor, coloring agent and water. The mechanical equipment cleaning liquid is prepared by using environmental-friendly substances, is a universal cleaning fluid for mechanical equipment maintenance and repair, does not have inflammables and explosive characteristics during use, does not cause higher adverse influences on a working environment, does not contain environmentally hazardous substances such as nitrite, phenol and formaldehyde, is nonflammable, is nontoxic to operators and has a better effect of cleaning inorganic fouling such as asphalt, better safety and environmental friendliness are realized, the processing environment and sanitary conditions can be improved, the working efficiency can be improved and the cost can be reduced.

Owner:苏州安美润滑科技有限公司

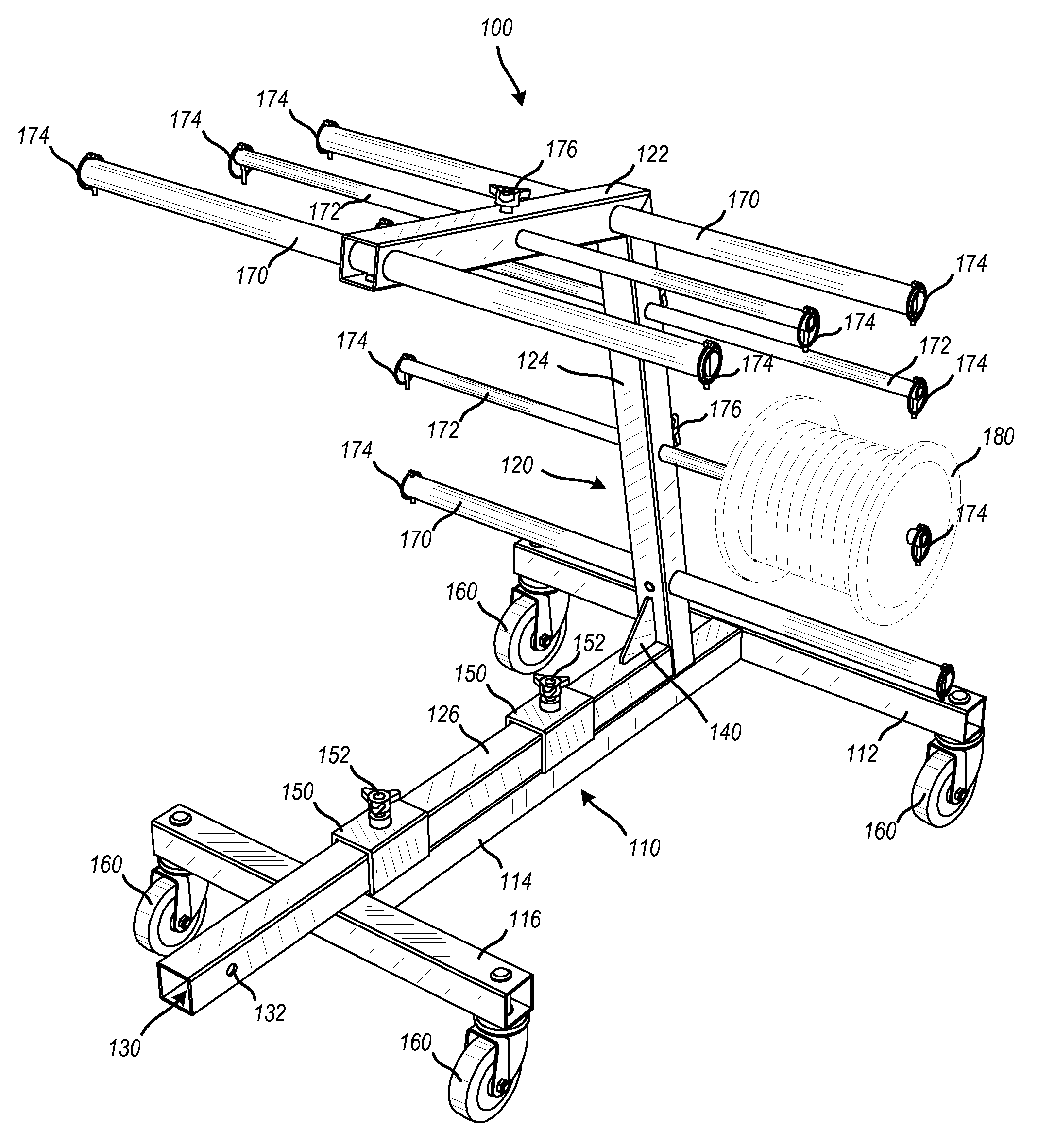

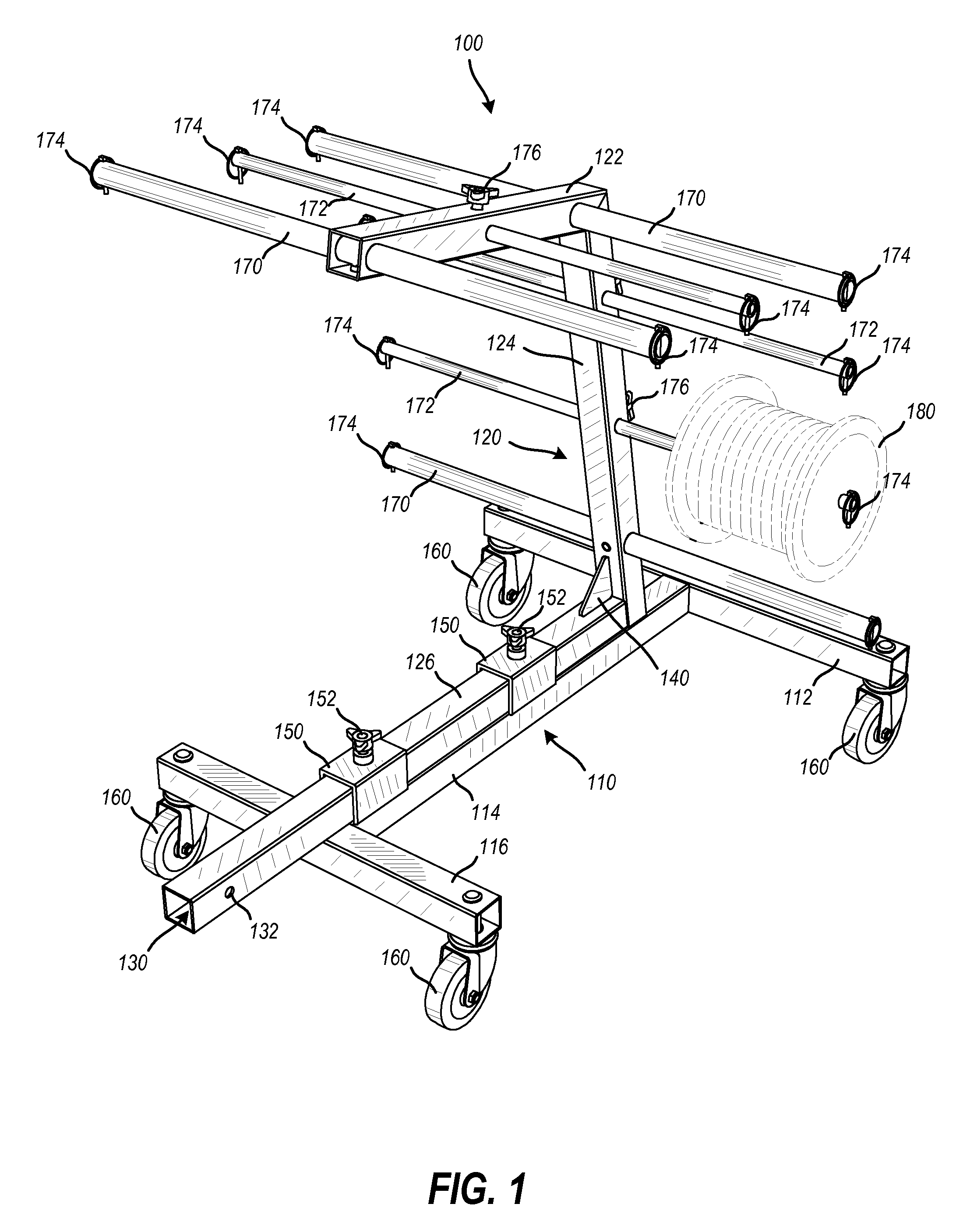

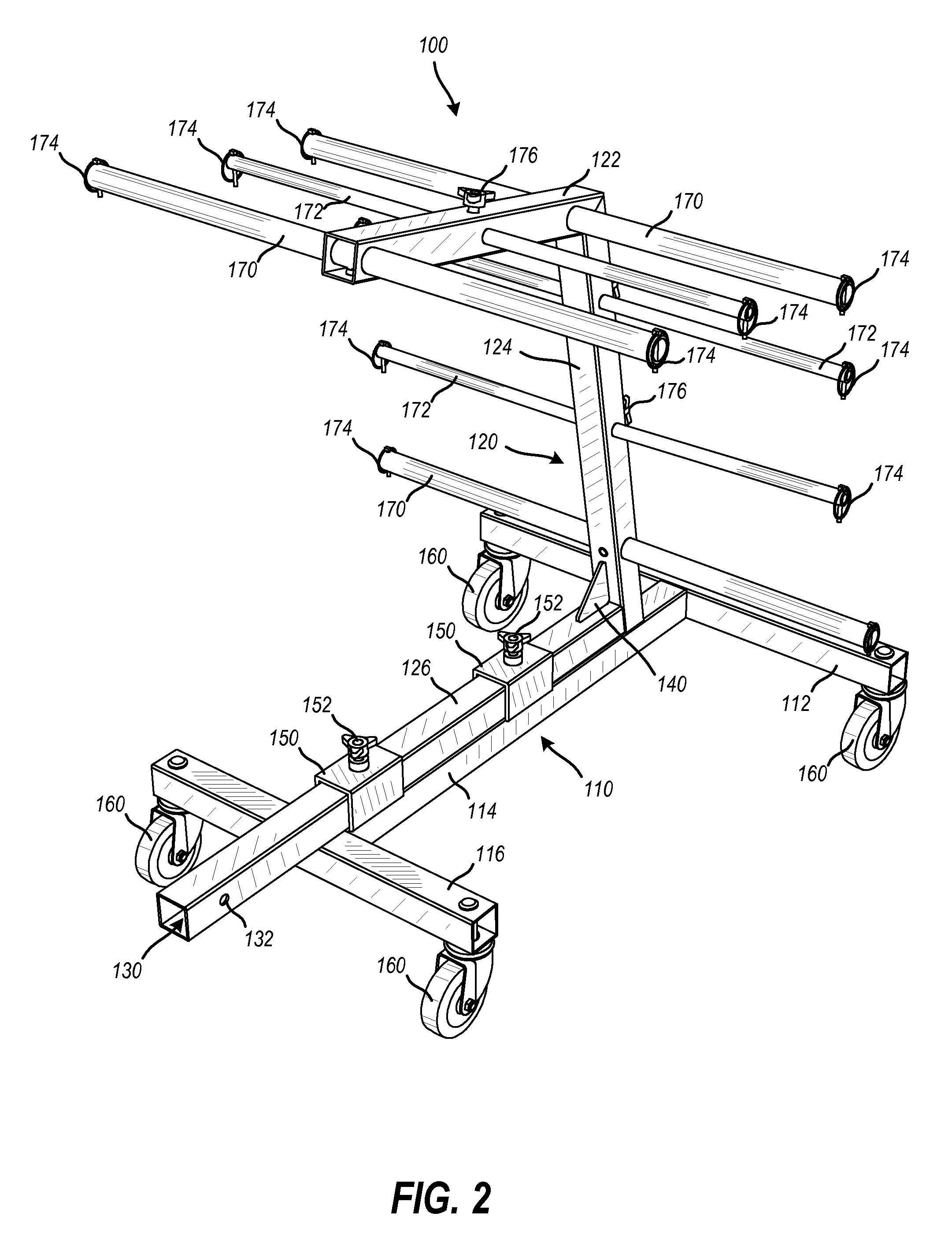

Wire and Cable Assembly Device and Associated Methods

InactiveUS20090224498A1Small diameterEase and rapid removalHand carts with one axisHand carts with multiple axesEngineeringOptical fiber cable

The technology described herein provides a wire and cable assembly device and associated methods for holding multiple spools of wound material, such as electrical, telephone, fiber optic cables, or the like, for selective dispensing. The technology described also provides a portable, foldable, and adaptable wire and cable assembly device to facilitate the installation of wire and cable products in a building, parking lot, or the like. The device is transportable both manually and by a means of towing.

Owner:DIEDERICKS JOHANNES P L

Water high-temperature resistant flaming-proof anticorrosive paint

ActiveCN101165129AHigh temperature resistance hasPrevent rustFireproof paintsAnti-corrosive paintsEmulsionHeat resistance

The present invention relates to paint, and is especially one kind of water soluble high temperature fireproof antirust paint comprising silicone propylene emulsion 30-40 (in wt%, the same below), water 8-16, polysodium acrylate 0.3-0.5, sodium hexametaphosphate 0.1-0.3, moldproof fungicide 0.1-0.2, antirust agent 0.2-0.3, fire retardant 5-8, aluminum tripolyphosphate 3-5, titania powder 8-10, magnet powder 8-10, mica powder 3-5, barium metaborate 8-10, silica sol 3-5, potassium silicate 2-5, defoaming agent 0.1-0.3, and leveling agent 0.1-0.2. The water soluble high temperature fireproof antirust paint is prepared through mixing, stirring and depurating. It has heat resistance, fireproof effect and capacity of preventing metal from rusting.

Owner:青岛居芳环保技术有限公司

Method of preparing blueberry leaf tea beverage

InactiveCN101129152APrevent rustPrevent bacterial growthTea substituesFood preparationNervous systemProanthocyanidin

The invention relates to a blueberry leaves drink with health function based on the blueberry leaves as main material and its making method, wherein the blueberry leaves contents a great amount of flavonoid with more than 40 physiologically activities of reducing blood sugar and blood fat and resisting arrhythmia, the resisting free radical oxidation ability of the blueberry is not compared with the other anti-oxidizing agent, meanwhile there is great amount proanthocyanidins contented in the blueberry with very good health function to the nervous system for children especially for the pregnant woman conspicuously. The making method is characterized by the following: picking the blueberry leaves with more than 90 days growth; using the technique process of washing, immersing, quick freezing, disintegrating, chilling, extracting with vacuum low-temperature, freezing, filtering, allocating, flash sterilizing and germ-free canned. The invention guarantees not to damage the nutrition and effective and active substances in the material almost, which makes the product have certain health function.

Owner:LIAONING TODAY AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com