Patents

Literature

348results about How to "No foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857APrevent rustNo foamingHot-dipping/immersion processesAcid washingCooling chamber

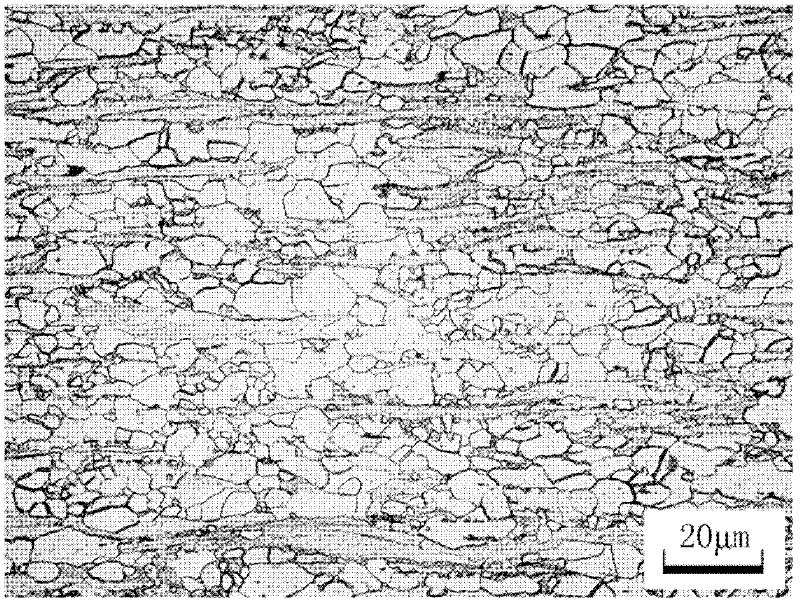

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles,arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

Inorganic powder texture coating, and its applying method

ActiveCN1757688AEasy constructionUnique texturePowdery paintsCement coatingsInorganic pigmentsMaterials science

A inorganic dry powder paint with good mass sensation is prepared proportionally from cement, color sand, re-dispersed emulsoid powder, hydrophobic agent, inorganic pigment and filler. Its advantages are high adhesion to concrete, high weatherability, good air permeability, and no pollution. Its application method is also disclosed.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Gold-plating method of high silicon-aluminum composite material

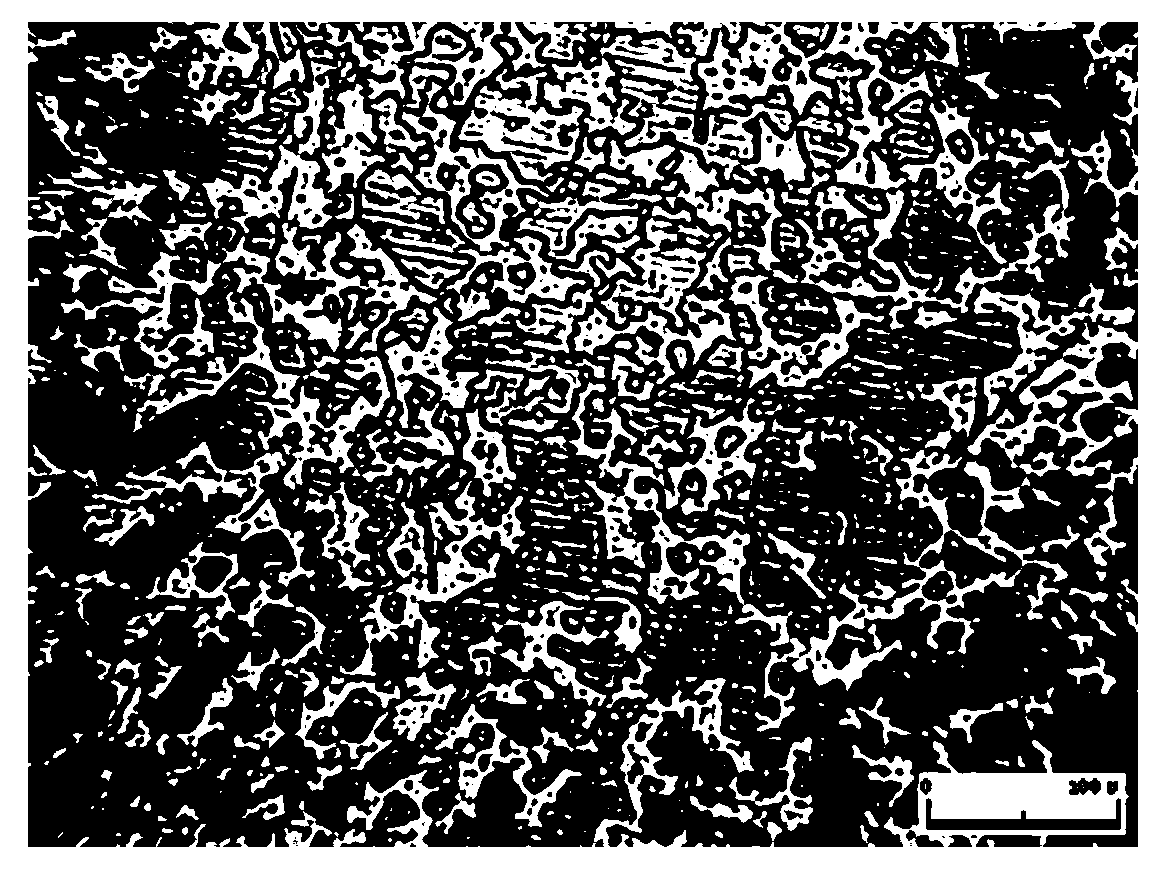

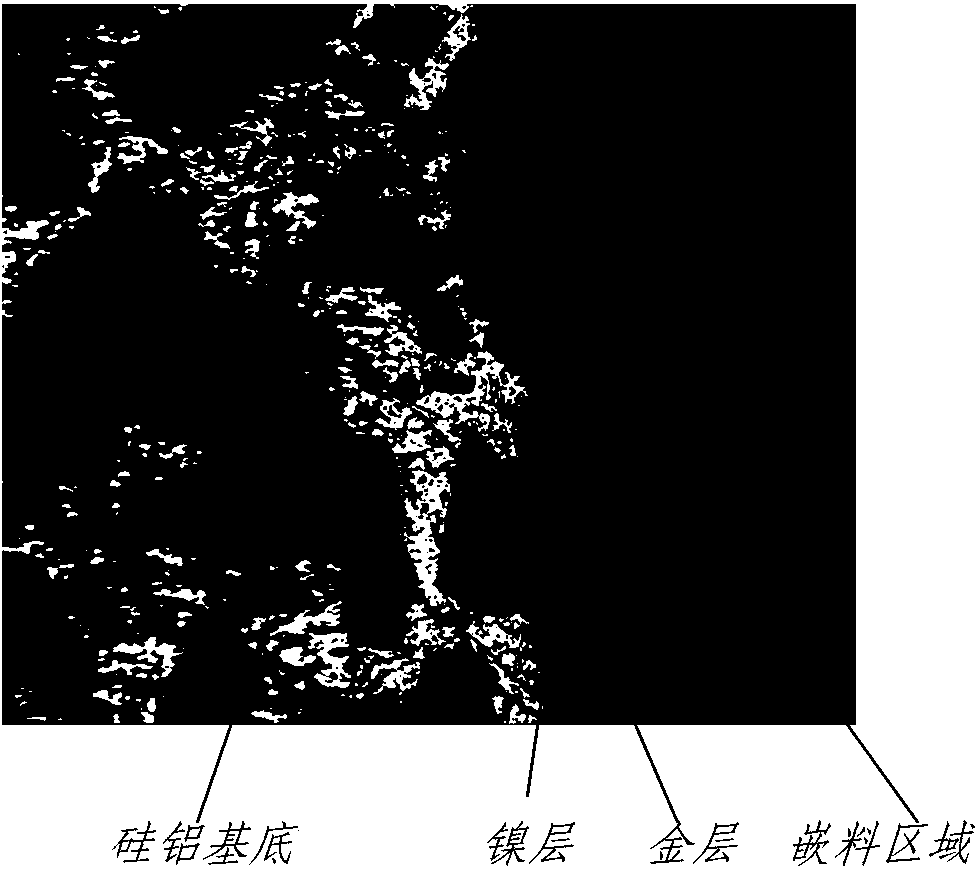

ActiveCN103540935AImprove bindingNo foamingSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBinding forceAlkaline etching

The invention relates to a gold-plating method of a high silicon-aluminum composite material. According to a second zinc immersion treatment method of conventional aluminum alloy electroplating, pre-treatment of the method comprises the following six steps: cleaning and oil removing; alkaline etching; bright dipping; primary zinc immersion; zinc annealing; secondary zinc immersion. The gold-plating method subsequently comprises the following steps: I, preplating chemical nickel in a chemical nickel-plating liquid; II, plating nickel for the first time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; III, performing aging treatment; IV, performing activating treatment; V, plating nickel for the second time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; VI, taking a pure gold plate or a platinum titanium mesh as an anode and the high silicon-aluminum composite material as a cathode according to a conventional pure gold-plating method, wherein the gold layer is 2-3 microns thick; VII, detecting the binding force of the plating layer. The plating layer observed under tenfold amplifying glass is free from peeling and bubbling phenomena and good in binding force. The binding force of the gold-plating plating layer and a high silicon-aluminum base material adopted by the method provided by the invention is firm and reaches the standard of appendix A of GJB1420 General Specification of Semiconductor Integrated Circuit Shell.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Capacitor coating with deep drawing resistant performance and high temperature yellowing resistance and preparation thereof

The invention discloses a non-yellowing capacitor coating at a high temperature having deep drawing resistance performance and a preparation method thereof. The capacitor coating in the invention is prepared from the materials according to the following parts by weight: 20 to 50 parts of hyperbranched polyester resin, 1 to 7 parts of saturated polyester resin, 3 to 12 parts of isocyanate, 0 to 0.5 parts of adhesion promoter, 0 to 0.15 parts of slipping wax, 0 to 0.3 parts of organic tin catalyst, 2.0 to 6.0 parts of resin modifier, 0.07 to 1.0 parts of defoamer, 0.15 to 0.20 parts of flatting agent, and 30 to 62 parts of solvents. The hyperbranched polyester resin, saturated polyester resin and isocyanate are put into a container so as to prepare a mixture after high-speed dispersing; the rest of the materials are then put into the mixture so as to mix homogeneously by medium-speed dispersing, thereby obtaining the non-yellowing capacitor coating at a high temperature having deep drawing resistance performance. The capacitor in the invention has the characteristics of deep drawing resistance, good percentage elongation of coating film and no yellowing at a high temperature.

Owner:清远慧谷新材料技术有限公司

Novel protection technique for plating multilayer coating on surface of sintered Nd-Fe-B permanent magnet

InactiveCN101440490AImprove corrosion resistanceNo foamingLiquid/solution decomposition chemical coatingSuperimposed coating processChemical platingAlloy

The invention relates to a protective technology for plating a plurality of plating layers on the surface of sintered neodymium iron boron. The technology is characterized in that firstly the surface is subjected to pretreatment before plating; secondly, NiZnP alloy is chemically plated on the surface; and finally, a plurality of NiWP alloy (at least three layers) are plated on the surface through controlling potential or current. The technology adopts the following specific steps: A, pretreatment before plating; B, chemical plating of the NiZnP alloy; and C, electroplating of a plurality of NiWP alloy layers. The technology has the following advantages: (1) the plating layer resists neutral salt mist corrosion; (2) a moist heat resistant test of the plating layer: in a moist heat box, the temperature is 85 DEG C; the humidity is between 80 and 90 DEG C; the testing time is 360 hours; after testing, the plating layer has no bubble, rust spot or stain; and (3) the bonding force of the plating layer: a scratch method: scratch of 1*1mm<2> is scratched to a basal body from the plating layer by a knife; and the plating layer does not fall off.

Owner:CHINA JILIANG UNIV

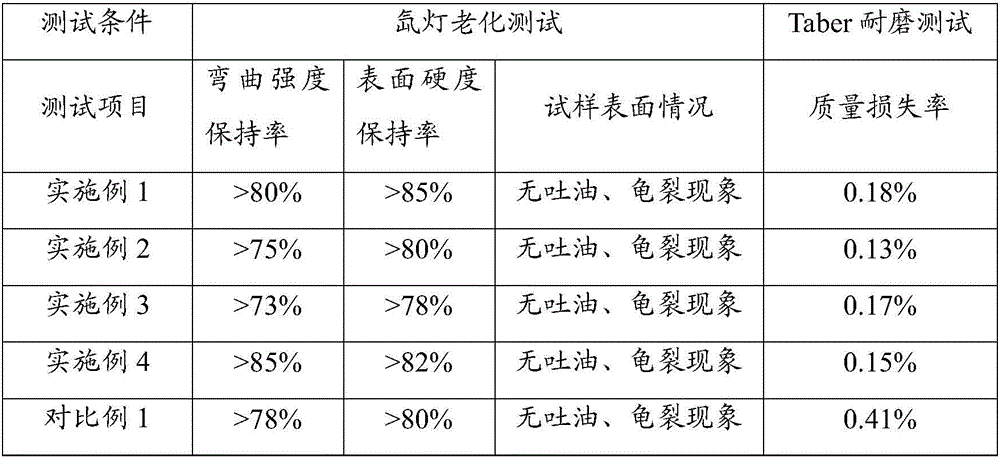

Thermoplastic elastomer composition and resin as well as preparation method and application of thermoplastic elastomer composition and resin in manufacturing of runways and courts

ActiveCN106009714AImprove wear resistanceGood weather resistanceGround pavingsWeather resistanceChemistry

The invention discloses thermoplastic elastomer composition and resin as well as a preparation method and an application of the thermoplastic elastomer composition and resin in manufacturing of runways and courts. The thermoplastic elastomer composition is prepared from, in percentage by mass, 20%-40% of SEBS (styrene-ethylene-butylene-styrene) resin, 20%-50% of white oil, 10%-30% of polypropylene, 10%-30% of filler, 0.2%-1% of a lubricant, 0.3%-0.6% of an anti-oxidant auxiliary, 0.2%-0.4% of an anti-aging auxiliary, 0.05%-0.2% of a crosslinking agent and 0.2%-2% of a wear-resistant auxiliary, wherein the mass percentages of all the components add up to 100%. The thermoplastic elastomer resin is prepared from the thermoplastic elastomer composition. The thermoplastic elastomer composition and resin are used for preparing outdoor runways and courts and can improve the wear resistance and the weather resistance of outdoor sport fields such as the runways, the courts and the like in the use process.

Owner:唯美康(广东)实业发展有限公司

Special adhesive for underwater construction and preparation method thereof

InactiveCN103555243AIncrease elasticityGood resistance to cold and heat shockNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveActive agent

The invention discloses a special adhesive for underwater construction, and the special adhesive comprises an A component and a B component at a weight ratio of 100:(20-100):25, wherein the A component is prepared from the following raw materials in parts by weight: 30-60 parts of modified epoxy resin, 5-30 parts of tackifier, 2-10 parts of accelerant, 5-15 parts of reactive diluent, 0.1-0.3 parts of surfactant, and 10-35 parts of filler powder; the B component is prepared from the following raw materials in parts by weight: 0-60 parts of ketimine, 0-60 parts of phenalkamine, 30-65 parts of modified polyamide, 1-6 parts of curing accelerator, and 2-15 parts of moisture repellent. The special adhesive for underwater construction has the advantages of being good in bonding strength in water, good in toughness, water-resistant, capable of resisting chemical attack, strong in initial viscous force and convenient to construct, and great improvement is brought for the underwater construction field.

Owner:YANTAI DARBOND TECH

Low-cost high-strength prepainted steel sheet and manufacture method thereof

InactiveCN101880832AHigh strengthGood stamping performanceHot-dipping/immersion processesMetal rolling arrangementsCorrosion preventionHigh intensity

The invention discloses a low-cost high-strength prepainted steel sheet and a manufacture method thereof. The low-cost high-strength prepainted steel sheet comprises the following base materials containing chemical components in percent by weight: 0.06-0.10 percent of C, not more than 0.05 percent of Si, 0.30-0.70 percent of Mn, 0.01-0.03 percent of P, not more than 0.02 percent of S, 0.01-0.07 percent of solAl, not more than 0.005 percent of N, not more than 0.08 percent of Cr, not more than 0.11 percent of Cu, not more than 0.06 percent of Ni and the balance of Fe and unavoidable impurities. The preparation method comprises the steps of: steel-making through molten iron, continuously casting, hot-rolling, acid-washing, hot dipping, alloying, finishing and prepainting. The prepainted steel sheet has the advantages of good stamping property, excellent corrosion prevention property, low production cost and better economic and social benefits, and can be widely applied to the outdoor large building industry.

Owner:WUHAN IRON & STEEL (GROUP) CORP

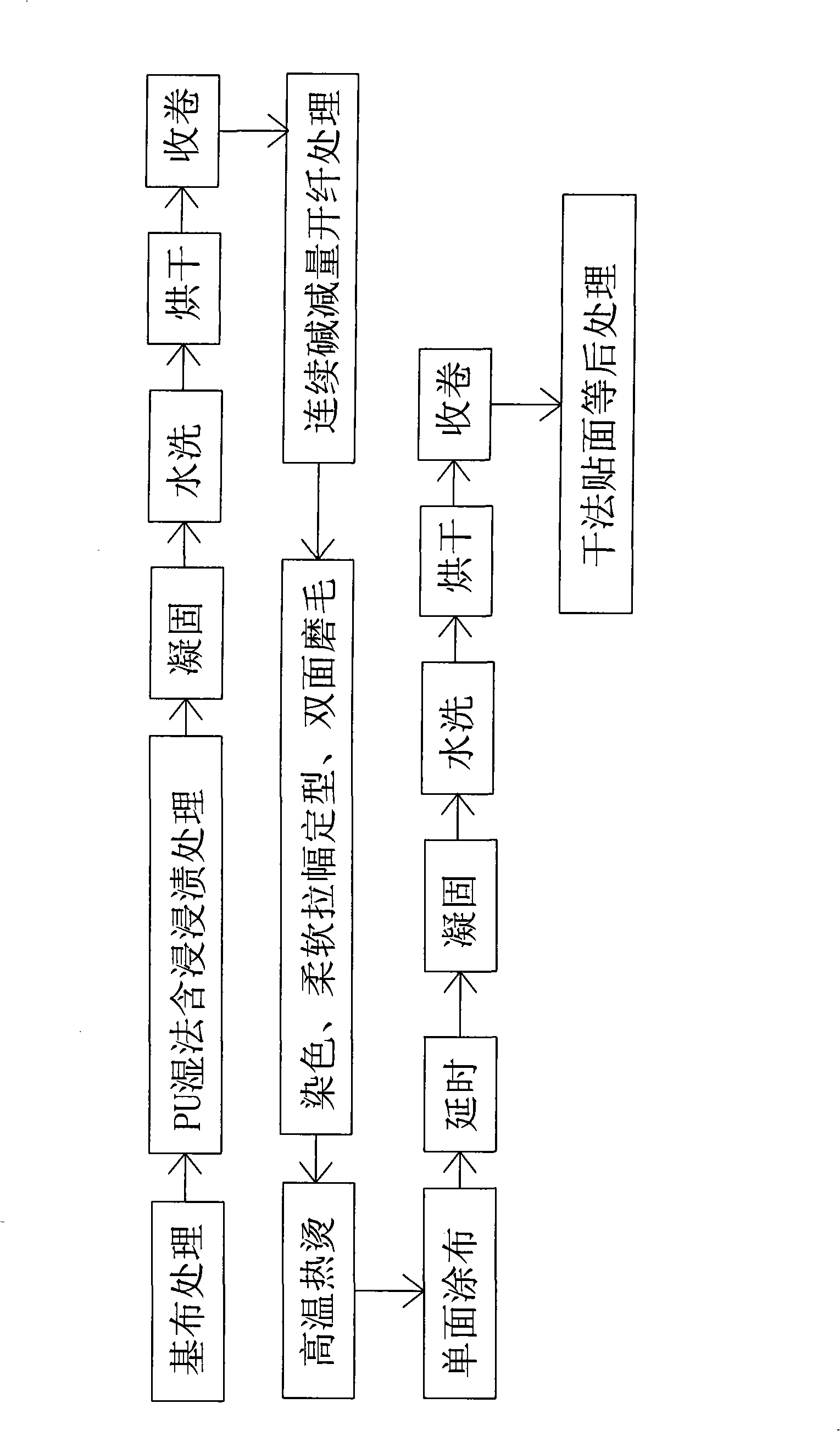

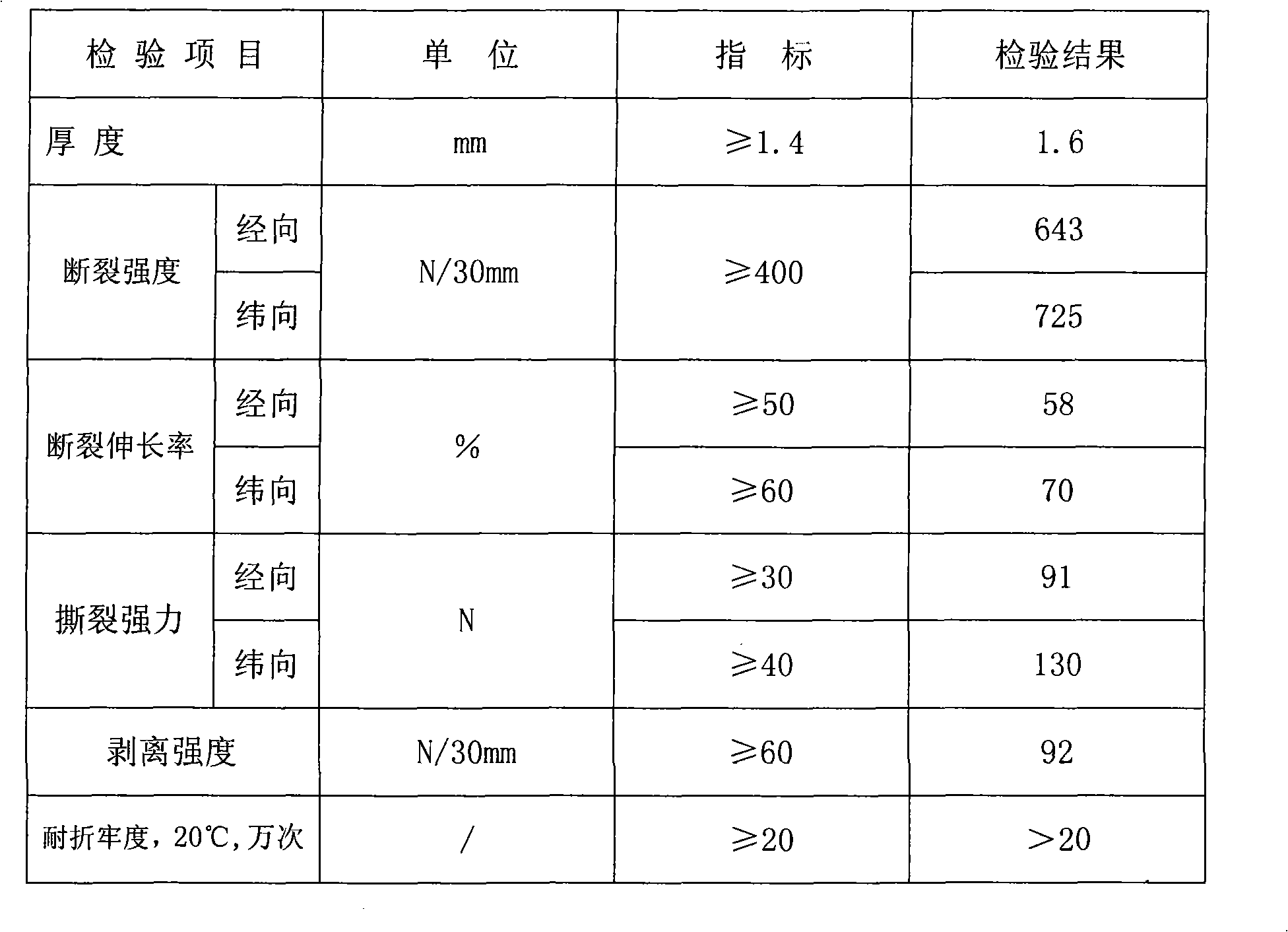

Method for processing island ultra-thin fiber high-density needling non-woven fabrics emulation leather

InactiveCN101260619AUniform thicknessHigh tear strengthFibre treatmentHeating/cooling textile fabricsHigh concentrationTime delays

The invention relates to a method for machining an island superfine fiber high density pinprick non-woven fabrics artificial leather, which is applied to the artificial leather manufacture and comprises the following processes: (1) the foundation process; (2) the PU wet method dipping process; (3) the continuous alkali abatement fiber opening process; (4) the pigmentation, the flexible tentering and shaping, the peached finish on two sides by a roughing-up machine; (5) the post treatments such as the dry method facing. The method is characterized in that the following processes are performed between the (4) process and the (5) process which are as follows: (6) the rolling blanching at a high temperature of 80 to 120 DEG C; (7) the high concentration polyurethane DMF solution with a weight ratio of PU: DMF of 100:50-93 is coated on the single side of the fabrics; (8) the time delay of 30 to 80 seconds; (9) a low temperature of 10 to 15 DEG C high concentration of 15 to 25 percent of DMF solution coagulating basin is coagulated, washed by water, dried and wrapped up. The method has the advantages that the manufactured finished leather has even thickness, excellent anti-tear strength and good ventilation property, the shortcoming that the cross breaks of the fibril synthetic leather is concave is overcome; the single spreading effectively avoids the foaming phenomenon on the coating surface; the section color is constant, etc.

Owner:NANPING JINYUE ARTIFICIAL LEATHER

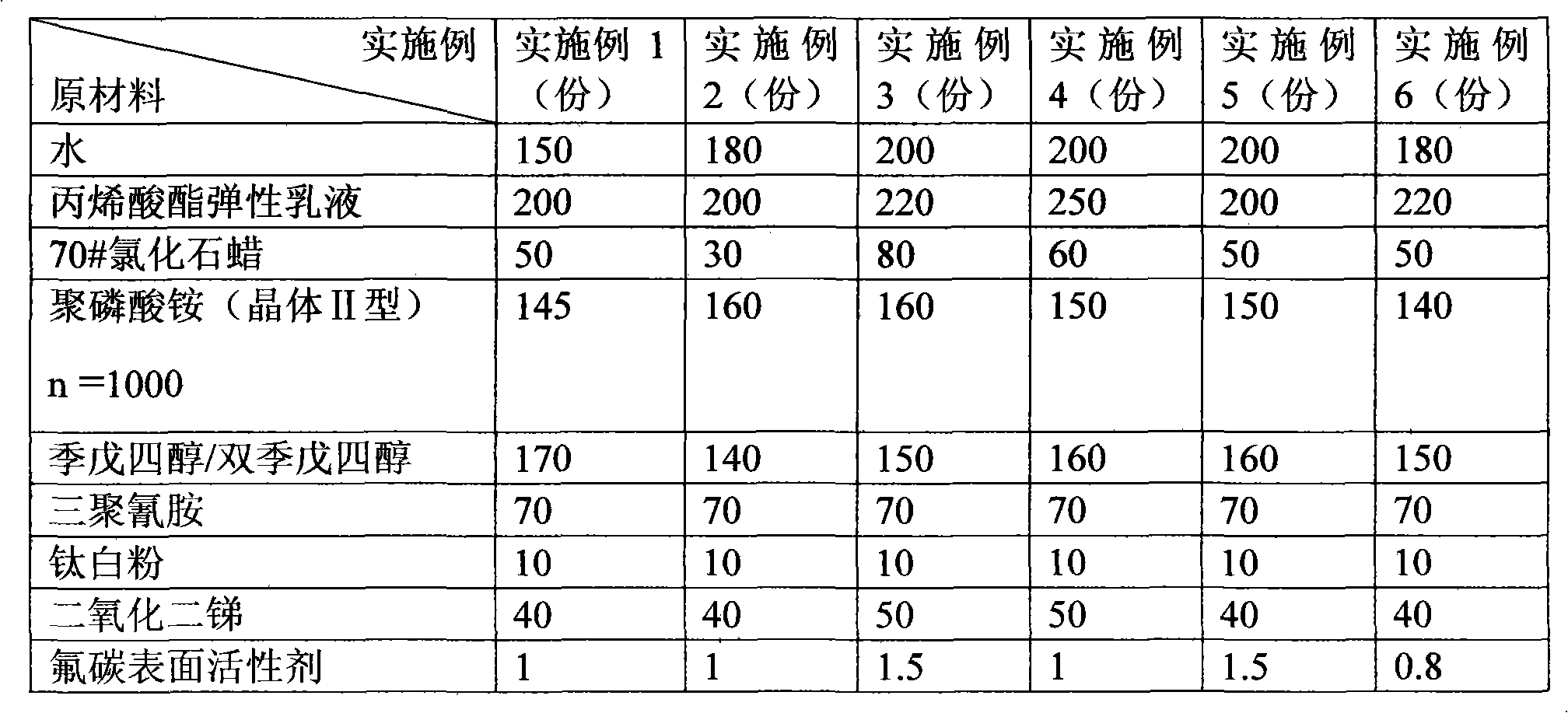

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

InactiveCN101597454AGood film forming effectGood water resistanceFireproof paintsSolventAmmonium polyphosphate

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

Self-layered low-surface energy antifouling paint

InactiveCN101434805AStrong adhesionTight molecular structureAntifouling/underwater paintsPaints with biocidesEpoxyOrganic solvent

The invention provides an antifouling coating which can be self-layered and solidified, has low surface energy and consists of component A and component B, wherein, according to the weight formula, the component A consists of 50-100 parts of epoxy resin, 0-50 parts of epoxy-capped esserbetol, 60-240 parts of polymethyl siloxane resin, 0-20 parts of pigment, and 0-70 parts of organic solvent; component B consists of 25-40 parts of amine curing agent, 2-16 parts of organic silicone cross-linking agent, 0-0.5 part of organic silicon-crosslinked catalyst and 0-5 parts of organic solvent. The coating uses a principle that the epoxy resin and the organic silicon resin are incompatible in each other, and can be automatically layered during the film-forming process; and the epoxy resin deposits at the bottom and the organic silicon resin is exposed on the external surface. The antifouling coating with low surface energy has the characteristics of excellent adhesion of epoxy resin and low surface energy of the organic silicon and has certain antifouling effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Acrylic polyurethane silicofluoride coating as well as preparation method and application method thereof

ActiveCN104017480AImprove adhesionGood flexibilityAntifouling/underwater paintsPretreated surfacesPolymer scienceAcrylic resin

Owner:湖南惠电科技有限公司

PVC (Polyvinyl Chloride) stone-bumping resistant paint and preparation method thereof

The invention relates to PVC (Polyvinyl Chloride) stone-bumping resistant paint and a preparation method thereof. The PVC stone-bumping resistant paint is formed by mediating, reacting and finely rolling dioctyl phthalate, dibutyl phthalate, dioctyl sebacate, light calcium carbonate, heavy calcium carbonate, nano active calcium carbonate, zinc stearate, barium stearate, organic bentonite, polyamide resin, carbon black, titanium pigment and PVC resin. The low-temperature flexibility of the PVC stone-bumping resistant paint can be improved by compounding three plasticizers of the dioctyl phthalate, the dibutyl phthalate and the dioctyl sebacate; the thixotropic performance of the paint can be improved by combining the organic bentonite with the nano active calcium carbonate; the adhesive force and the high-temperature yellowing resistance of the paint can be enhanced by combining the polyamide resin with heat stabilizers of the zinc stearate and the barium stearate and the paint has no foaming, crack and falling after baked at 210DEG C, so that the coating effect of the automobile body can be improved and the service life of the automobile body can be prolonged. The PVC stone-bumping resistant paint has no lead salt heat stabilizers and avoids the damage to the environment and human body; and the produced PVC stone-bumping resistant paint has excellent performance and can carry out the multilayer anticorrosion protection of the body and the bottom of the automobile.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

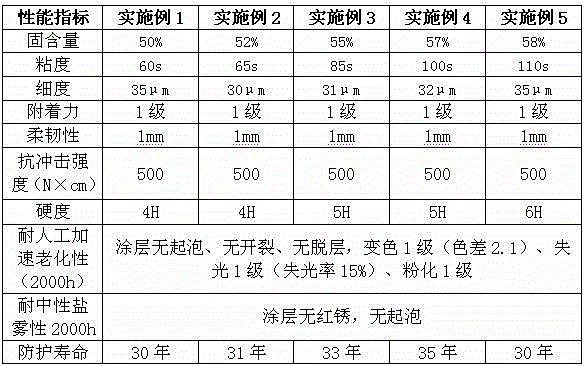

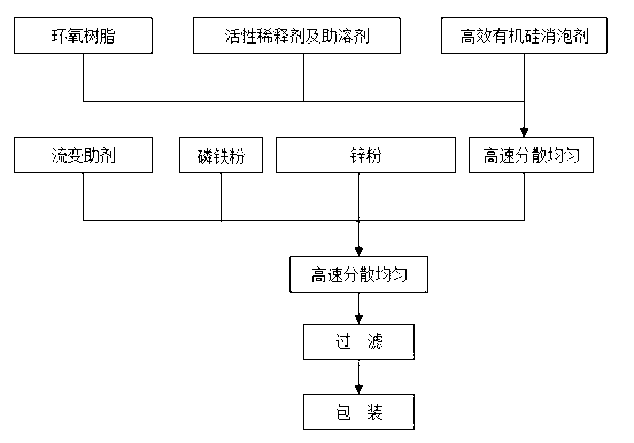

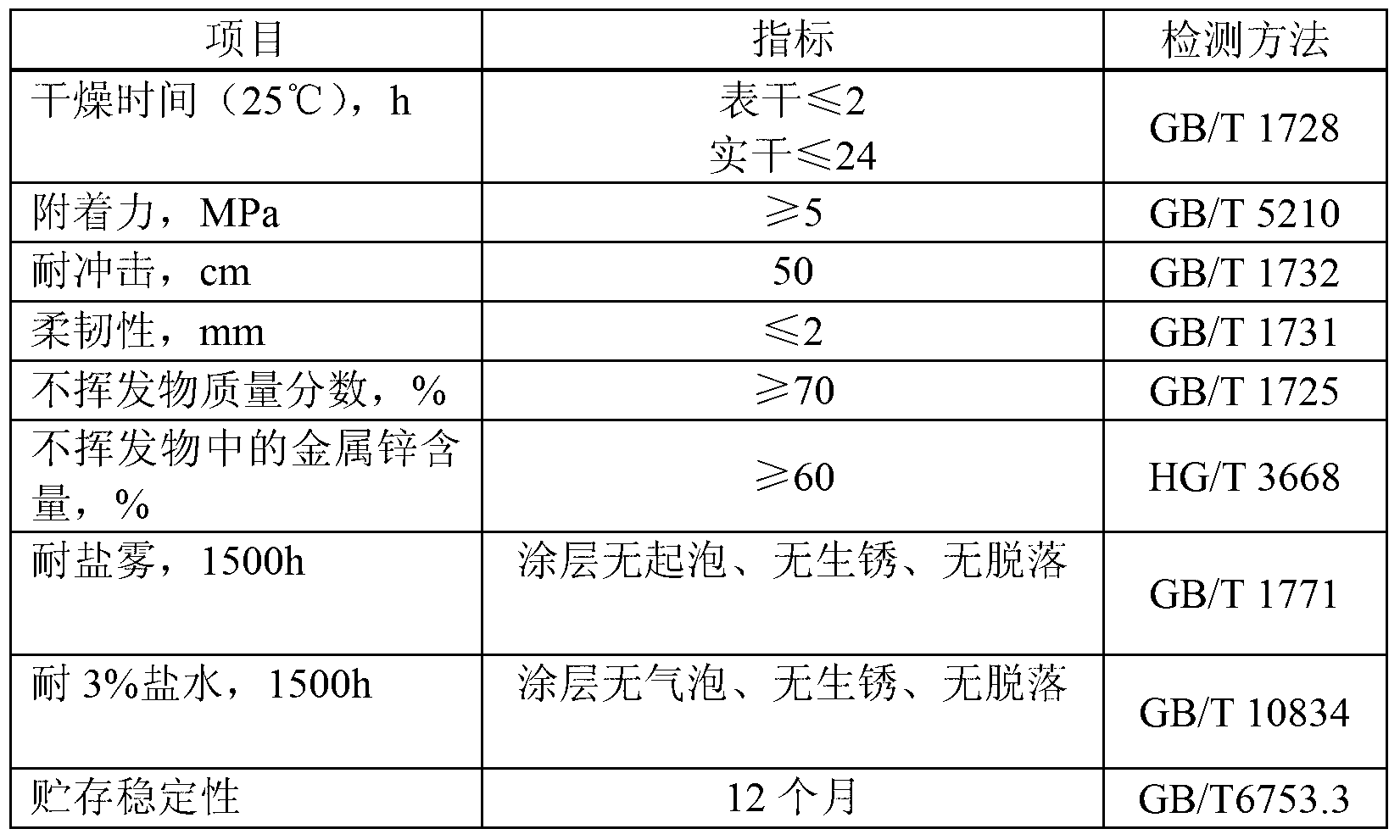

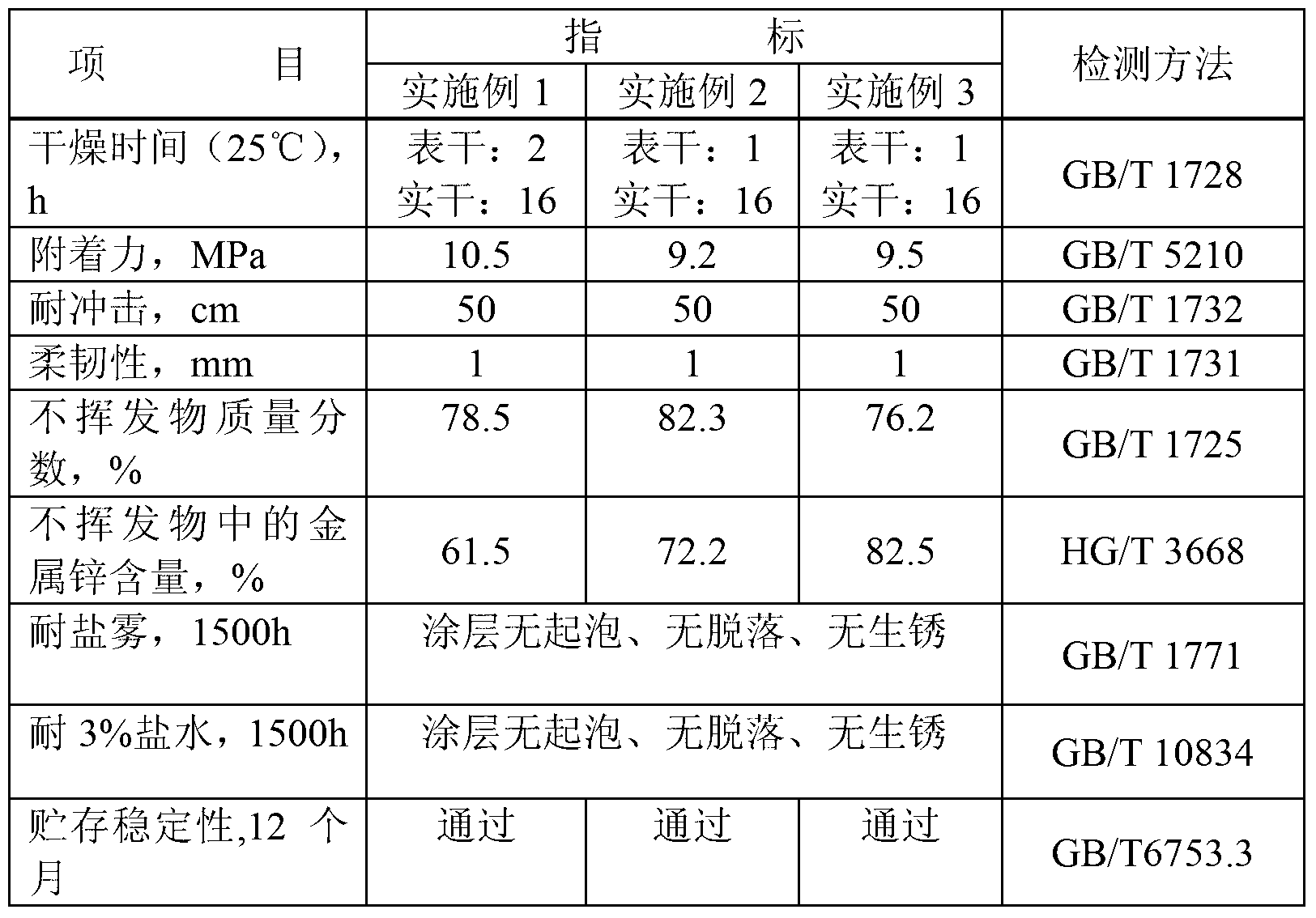

High-performance easy-construction two-component aqueous epoxy zinc-rich coating and preparation method thereof

ActiveCN103319981AModerate viscosityEasy to operateAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention relates to an easy-construction two-component packaging aqueous epoxy zinc-rich coating. The coating selects a low-molecular-weight epoxy resin, an active diluent, a high-efficiency antifoaming agent, a wetting dispersant, ultrafine zinc powder, a self-emulsifying aqueous epoxy hardener, a cosolvent and water as raw materials. The aqueous epoxy zinc-rich coating has the advantages of good corrosion resistance, realization of resisting salt spray for 1500h, no foaming, rust or shredding of the coat of the coating, according with requirements of HG / T3668-2009 Zinc Rich Primer, good application performance, convenient onsite use, realization of the thickness of the once-formed coat of above 80mum, 1h surface drying and 16h hard drying at 25DEG C, and satisfying of the steel structure anticorrosion construction requirement. The aqueous epoxy zinc-rich coating can be applied to the anticorrosion of steel structures comprising ships, bridges, sea engineering apparatuses and the like, and can also be applied to the steel plate pretreatment streamline as a workshop primer.

Owner:XIAMEN SUNRUI SHIP COATING

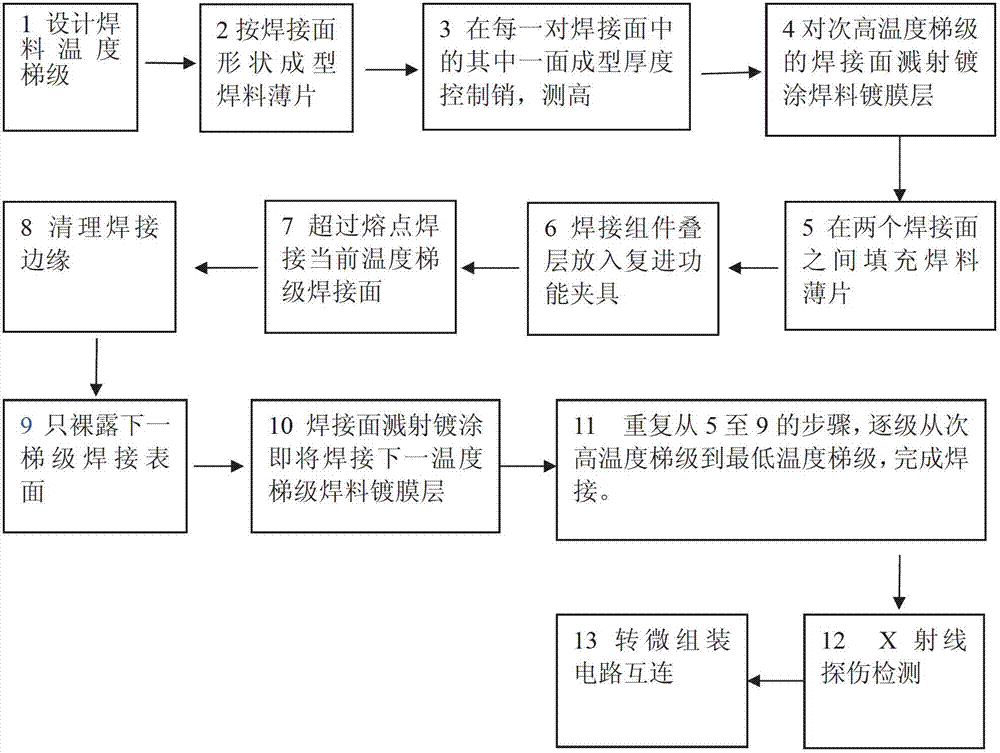

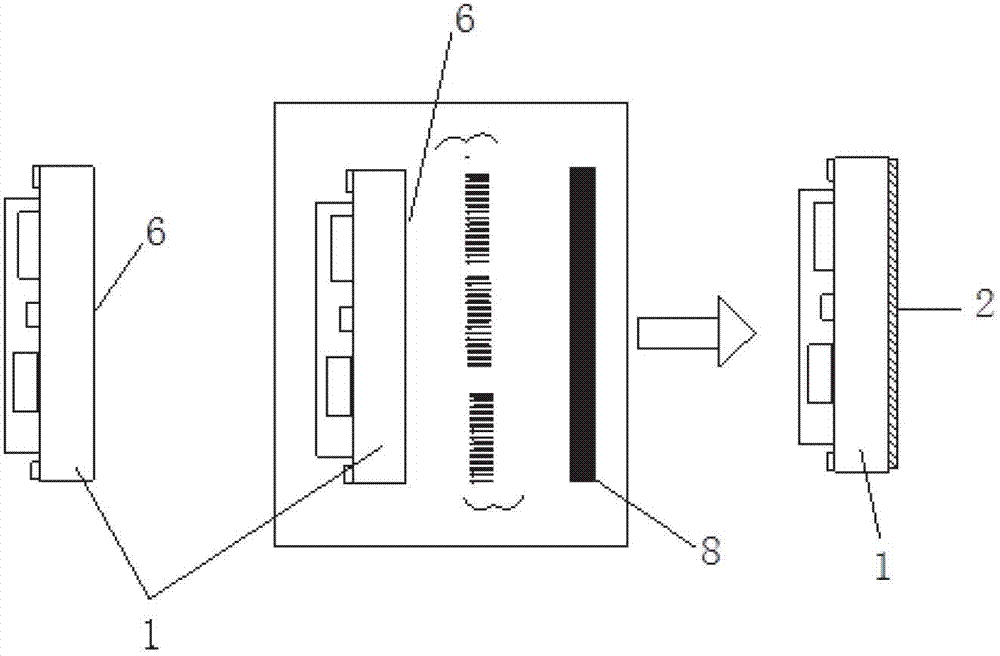

Process for welding electronic microcomponents based on multi-temperature gradient

InactiveCN102950350AEfficient removalNo discharge restrictionsSoldering apparatusElectronic componentRecoil pressure

The invention discloses a process for welding electronic microcomponents based on a multi-temperature gradient. The process is simple, convenient, efficient, stable and reliable in processing quality, good in welding flowability and little in welding hollows. The process is realized by the following technical scheme: designing the temperature gradient of welding fluxes according to melting points of different welding fluxes and respectively manufacturing welding flux slices at different temperature gradients from a secondary high temperature to a minimum temperature; dividing a function substrate and a transition parent plate on each electronic microcomponent into welding surfaces of the welding fluxes at different temperature gradients and coating a welding flux film coating layer on the welding surfaces directly and respectively by sputter coating; arranging welding flux thickness control pins at more points on the welding surfaces of the electronic component; laminating the electronic microcomponents (1), the welding flux slices (3) and the substrate component (5) sequentially, putting into a clamp with a counter-recoil pressure holding mechanism and putting the clamp into a furnace for vacuum welding; firstly completing the welding at a high temperature gradient, and then protecting other surfaces, which are not used for the welding at the next temperature gradient, of the substrate component, and coating one welding flux film coating layer on the welding surfaces respectively by the sputter coating at the next temperature gradient.

Owner:10TH RES INST OF CETC

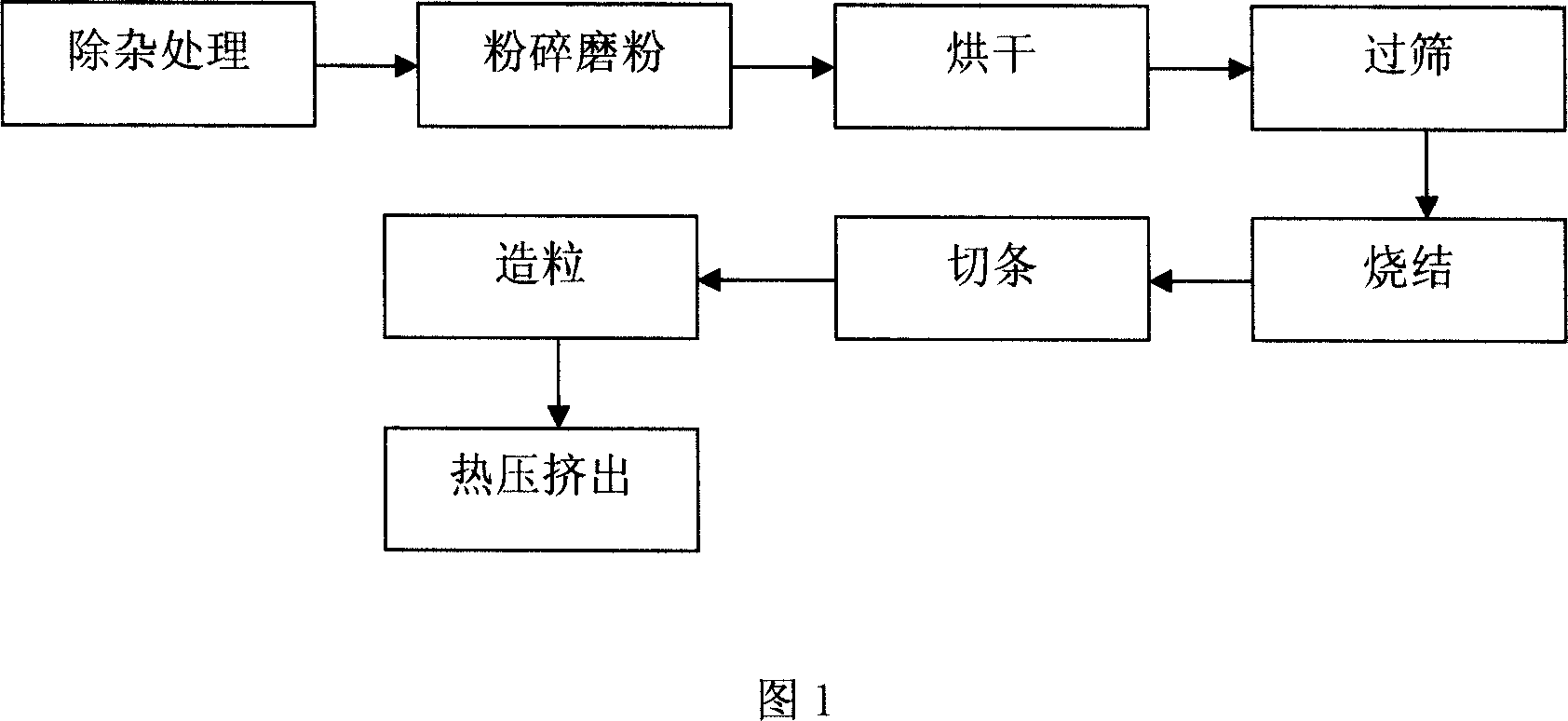

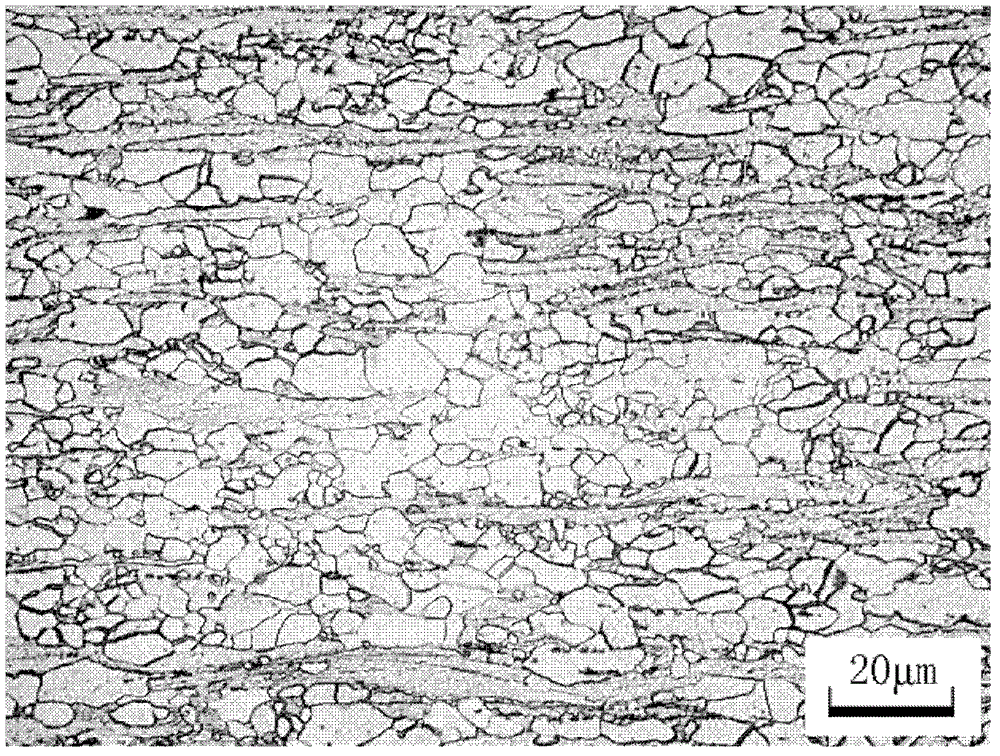

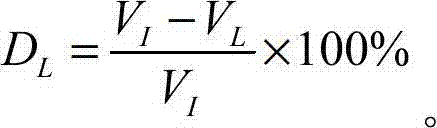

Polytetrafluoroethylene regenerative powder, process for producing same and bar produced thereby

The invention relates to a method for preparing politef waste regenerate powder and relative rod. The inventive method comprises that 1, washing and removing foreign material, 2, breaking, grinding, screening, 3, sintering, 4, cutting bars, 5, preparing particles, 6, packing and storing. With inventive method, the politef regenerate powder can reach the property of original powder, to produce variable politef products. In addition, the powder can be thermally extruded into politef regenerate rod, with uniform mass and non foam condition.

Owner:ZHEJIANG SONGHUA NEW MATERIAL CO LTD

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857BPrevent rustNo foamingHot-dipping/immersion processesCooling chamberAcid washing

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610 MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles, arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

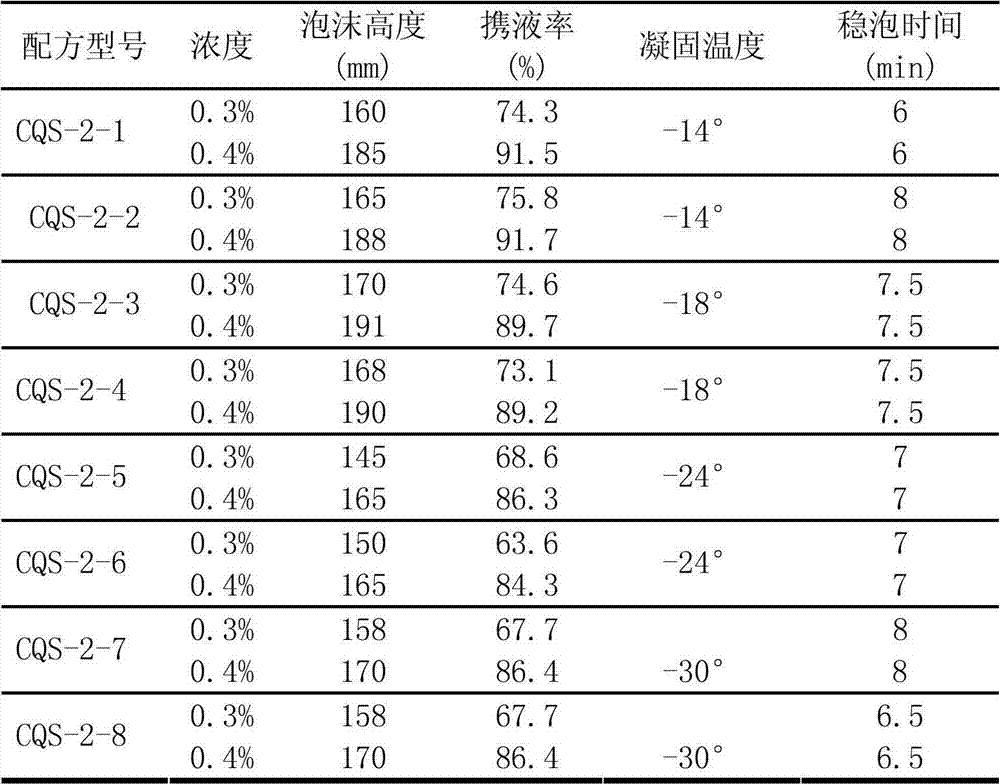

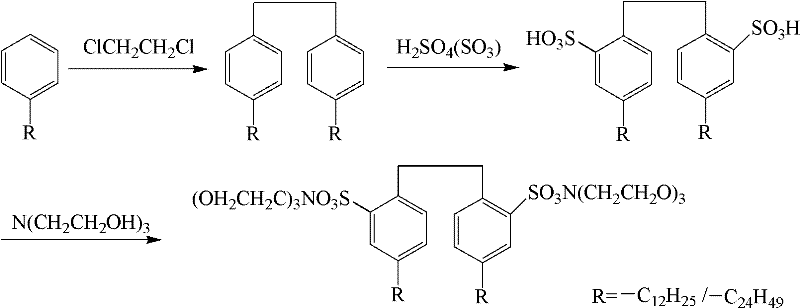

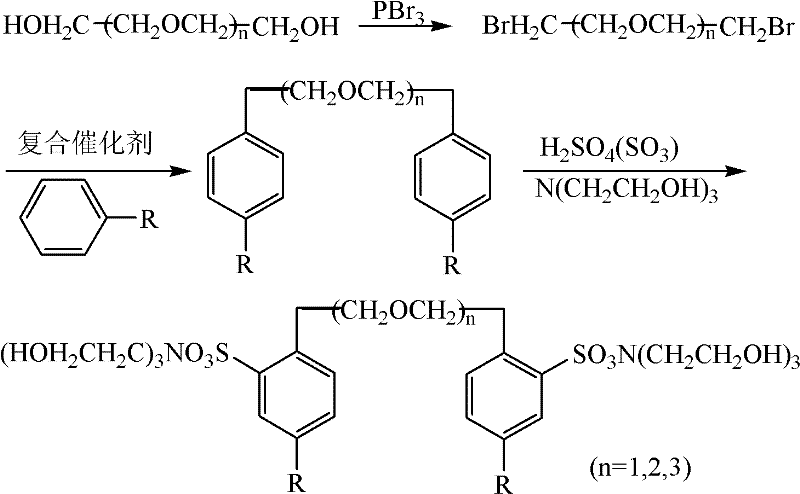

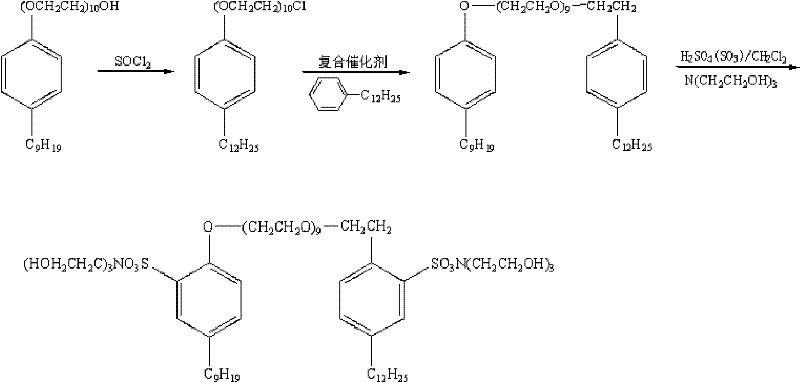

Salt-resistant type low-temperature foam lifting drainage chemical additive, and preparation method and application thereof

ActiveCN102965092AWon't freezeMeet construction requirementsDrilling compositionSalt resistanceEthylene glycol

The invention relates to a salt-resistant type low-temperature foam lifting drainage chemical additive, and a preparation method and an application thereof. The chemical additive is prepared through mixing cocamidopropylamine oxide, dodecyl polyglucoside, lauryl hydroxypropyl sulphobetaine and ethylene glycol according to a certain proportion uniformly. The chemical additive cannot be frozen under the lowest temperature condition in winter in various gas fields in China, satisfies site ground construction requirements and has a wide application prospect. Moreover, the chemical additive does not have stimulus and has excellent salt resistance; and under the condition that the mineralization degree is 200000 milligrams / liter, the chemical additive does not generate precipitation and still has excellent foaming and liquid carrying capabilities.

Owner:PETROCHINA CO LTD

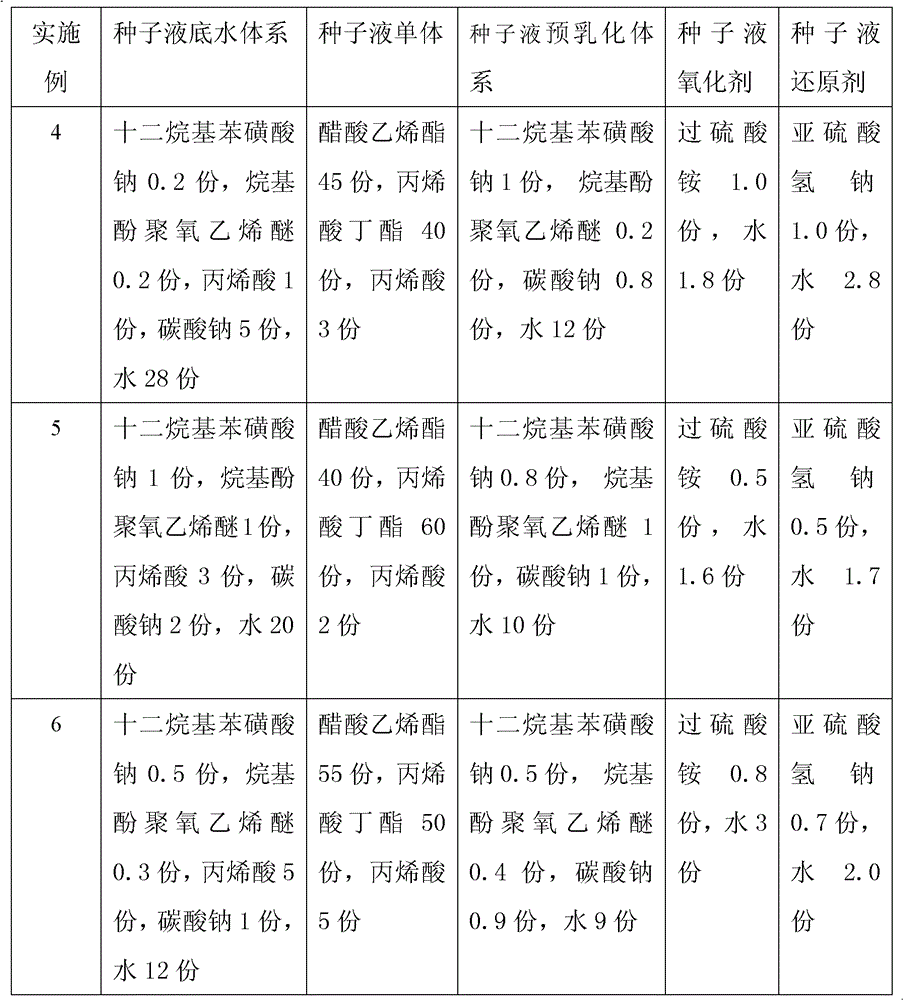

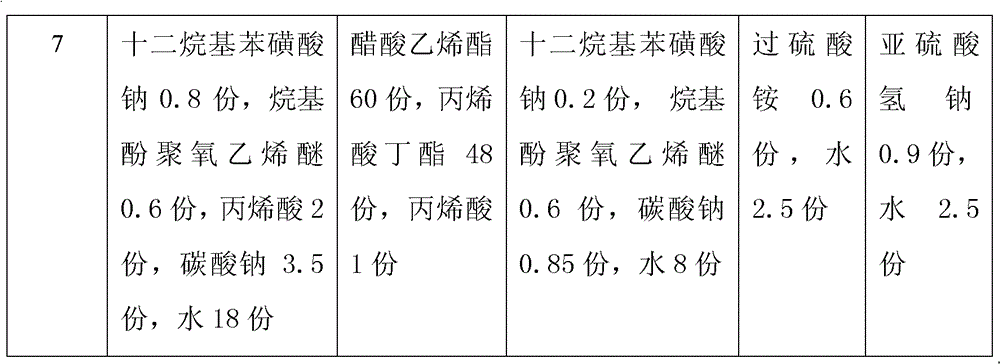

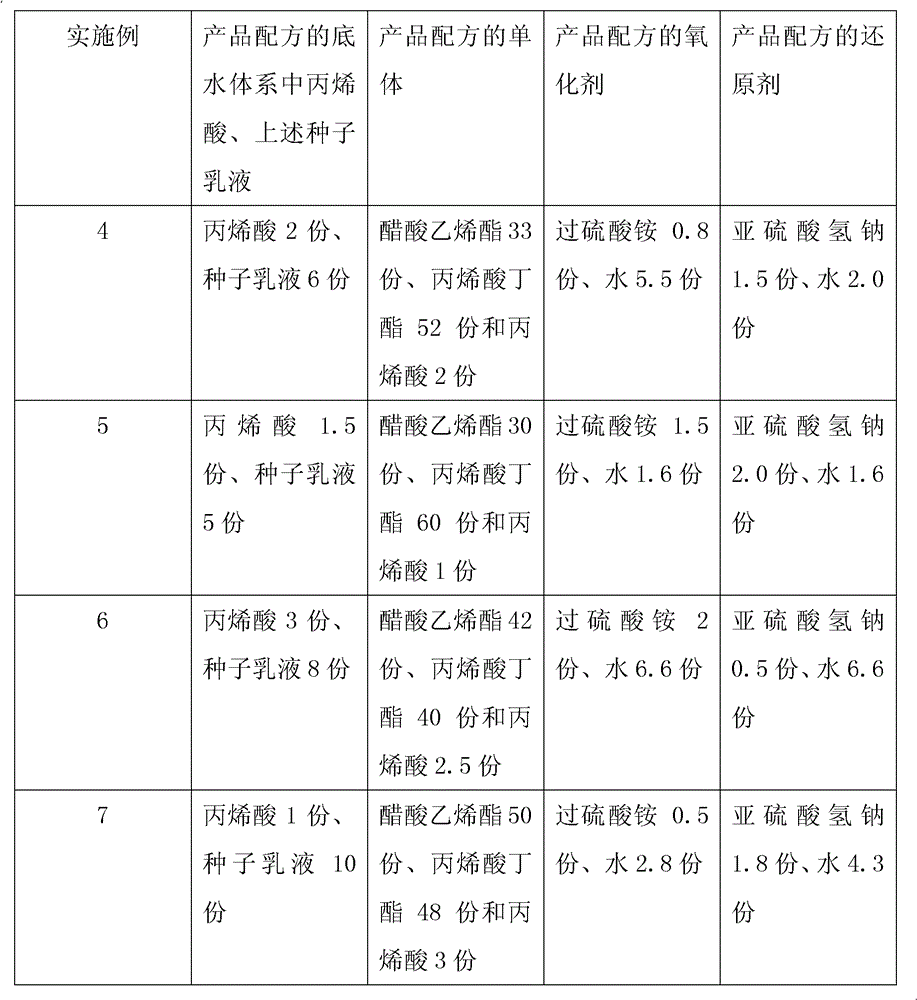

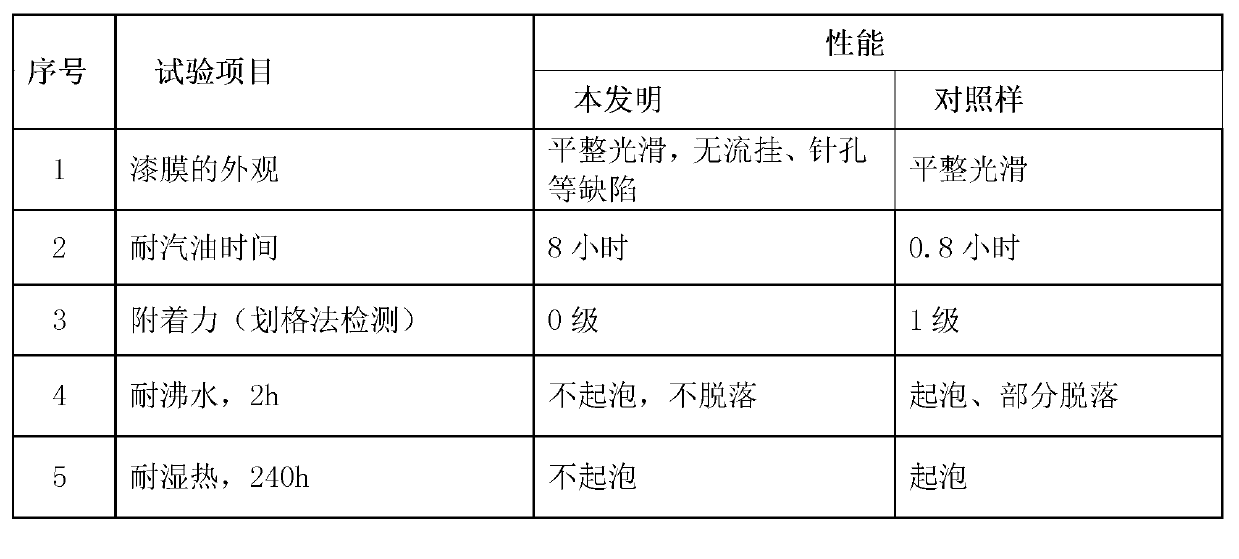

Vinyl acetate-acrylate copolymer emulsion, its synthesis method and application

ActiveCN103059211ALow coating viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesAdhesiveSynthesis methods

The invention relates to a vinyl acetate-acrylate copolymer emulsion, which is prepared by adopting OP-10, SDBS, SVS, water, acrylic acid and a seed emulsion as the bottom water system, taking VAc, BA and AA as the monomer, employing ammonium persulfate as the oxidant, and using sodium bisulfite as the reducing agent. Specifically, the seed emulsion in the bottom water system is prepared by using SDBS, OP-10, AA, sodium carbonate and water as the base solution, adopting VAc, BA and AA as the monomer, employing SDBS, OP-10, sodium carbonate and water as the pre-emulsification system, taking ammonium persulfate as the oxidant, and adopting sodium bisulfite as the reducing agent. The emulsion provided in the invention has a solid content of 40%-45%, viscosity (in terms of a 4-cup application amount) of 20S-26S, bonding peel strength (N / 2.5cm) of 1.4-2.5, a surface tension force of 32-37 dyne, and a film contact angle of 25-29 degrees, thus being particularly suitable for application in dry paper-plastic or plastic-plastic composite adhesives. The preparation method of the vinyl acetate-acrylate copolymer emulsion has the characteristics of mild reaction conditions and safety reaction system, thus being conducive to factory mass production.

Owner:CHINA PETROCHEMICAL CORP +2

Polyurethane adhesive for compounding high-temperature insulation material and preparation thereof

InactiveCN101372609AImprove high temperature resistanceMeet the requirements of insulation composite usePolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The present invention relates to a compound polyurethane adhesive for high-temperature insulation materials and a preparation method thereof. The polyurethane adhesive contains a host agent and a solidified agent. The host agent contains aliphatic diacid, aliphatic diols, aromatic diacid, diisocyanate, organic solvents and mating agent. The solidified agent contains diisocyanate, polyhydric alcohol and organic solvents. The host agent and the solidifying agent are evenly mixed into glue according to the weight proportion of 100:15-20 and solidified for 4 hours at 100 DEG. The present invention has good compounding process performance and adhesion property on polyester film / p-aramid insulation paper and polyimide / p-aramid insulation paper.

Owner:SHANGHAI XINGUANG CHEM

Middle coating paint for polypropylene plastic and preparation method thereof

InactiveCN103342933AImprove storage stabilityAbundant sources of raw materialsCoatingsChemistryPolypropylene

The invention provides a middle coating paint for a polypropylene plastic, which consists of chlorinated polypropylene modified acrylic resin, modified chlorinated polypropylene, a curing agent, pigment, filler, a dispersing agent, an auxiliary and the like. The invention also provides a preparation method of the middle coating paint, which comprises the following steps of: mixing the chlorinated polypropylene modified acrylic resin with the auxiliary, putting the mixture into a sand mill and uniformly dispersing; and adding the modified chlorinated polypropylene and the curing agent, and uniformly mixing to obtain the paint. The middle coating paint provided by the invention has the advantages of low cost, simple preparation technology, wide application and great market potential; when in use, the paint can be coated through special treatment on substrates, the coated paint does not need roasting and can be naturally dried, the construction is convenient, and the energy is saved; and the obtained composite paint film is resistant to ethanol gasoline for 8 hours.

Owner:TIANCHANG JULONG TRAVEL PAINT

Super-weather resistant alkali-activated-fly ash-slag bicomponent outer wall inorganic coating

InactiveCN101880151AGood flexibilityHigh activitySolid waste managementPliabilityPulverized fuel ash

The invention provides a super-weather resistant alkali-activated-fly ash-slag bicomponent outer wall inorganic coating. In the coating, sodium water glass and water are selected as base materials, and pulverized fuel ash, high-aluminum cement, slag, titanium white powder, pigment, talcum powder, redispersable latex powder, hydroxyethylcellulose, a naphthalene-based water reducing agent and a powdery antifoaming agent are used as padding. By testing the washing resistance of the coating of the invention, a specimen is washed 25,000 times without bubbling or cracking or dropping; by testing the water resistance, the specimen is soaked for 4,320 hours without bubbling or cracking or dropping; by testing acid rain resistance, the specimen is soaked in a solution, of which the pH is equal to 3 and is adjusted every day to be maintained to be 3, for 960 hours without bubbling or cracking or dropping; by testing salt resistance and alkali resistance, the specimen is soaked in 0.2mol / L of KOH solution of 5 percent of NaCl for 960 hours without bubbling or cracking or dropping; by testing bonding strength, the specimen has the bonding strength of 1.14MPa; and by testing flexibility, the specimen is qualified by 100 percent by being inspected through a grid scoring method of 1mm.

Owner:王建华 +1

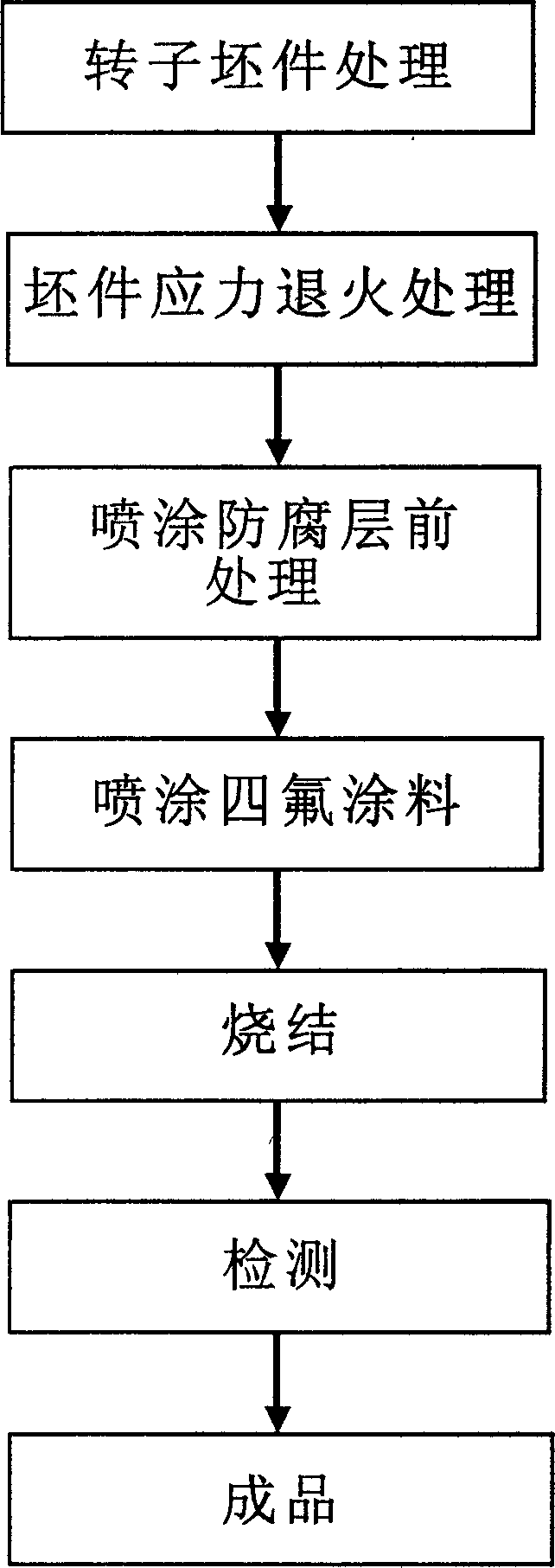

Tech. for spraying corrosion resistant coating on dry screw compressor rotor

InactiveCN1786476AUniform thicknessImprove heat resistanceRotary piston pumpsRotary piston liquid enginesHeat resistanceStress relief

An anticorrosive coating spraying process for a dry-screw compressor rotor belongs to a technical field of mechanical spraying process, which includes the following steps: first, pretreating the rotor parent material and stress relief annealing heat treating the rotor blank; then pretreating the spray anticorrosive coating and spraying polytetrafluoroethylene coating and at last sintering treating and detecting to be the rotor finished products. The inventive coating thickness is uniform and its colour is black. When the dry-screw compressor is in a normal state, the service life of the coating can reach more than 24000 hours.

Owner:WUXI COMPRESSOR CO LTD

Fast-drying solvent type epoxy resin intermediate paint

InactiveCN101386766AGood drying performanceSimple painting operationEpoxy resin coatingsSolventChemistry

The invention relates to fast-dry solvent type intermediate epoxy resin paint, which comprises a main agent and a curing agent, wherein the ratio of the main agent to the curing agent is between 20 to 1 and 5 (weight). Compared with the prior art, the intermediate epoxy resin paint has good drying property as well as simple and convenient coating operation, adapts to flow coating of the prior containers, can be thickly coated to the specified film thickness at one time, has good anticorrosion property, and has good binding force with a last-pass primer and a next-pass primer; and for thicker outer finish, particularly polyurethane finish, the intermediate epoxy resin paint has good usability, can not froth, and has good anticorrosion property.

Owner:中涂化工(上海)有限公司

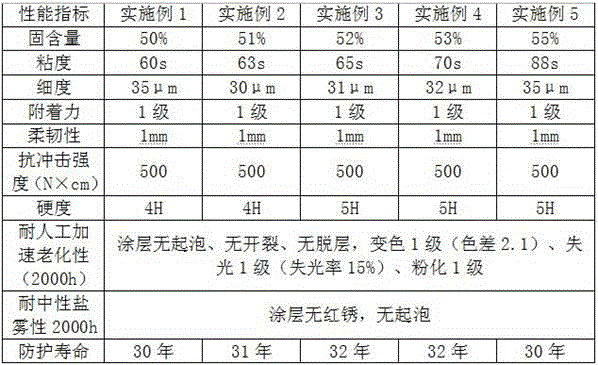

Bicomponent silicofluoride acrylic polyurethane coating as well as preparation and application methods thereof

ActiveCN104017479AImprove adhesionGood flexibilityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention relates to the technical field of protection coatings and in particular relates to a bicomponent silicofluoride acrylic polyurethane coating. The coating comprises a first component and a second component, wherein the mass ratio of the first component to the second component is (3 : 1) to (5 : 1); the first component comprises the following raw materials by weight parts: 50-70 parts of hydroxy acrylic resin, 15-24 parts of a solvent, 0.1-3 parts of fluorine-containing micropowder, 10-25 parts of a pigment, 1-3 parts of high-hardness oxide and 2-5 parts of aids; the second component comprises the following raw materials in parts by weight: 50-80 parts of a closed isocyanate curing agent and 20-50 parts of a solvent. According to the coating, the capability of protecting a steel structure can be improved; the coating has the characteristics of good ageing resistance, scratch resistance, corrosion prevention, color change prevention, pollution prevention and the like, and can achieve a very good long-acting protection effect on the steel structure by combination with other base paint and intermediate paint with excellent performance; and the protection life can be 30 years.

Owner:广东惠电科技发展有限公司

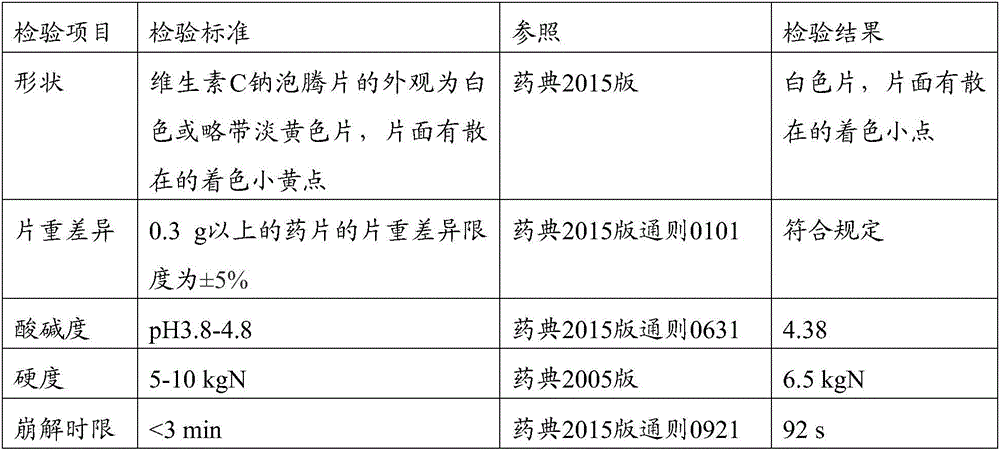

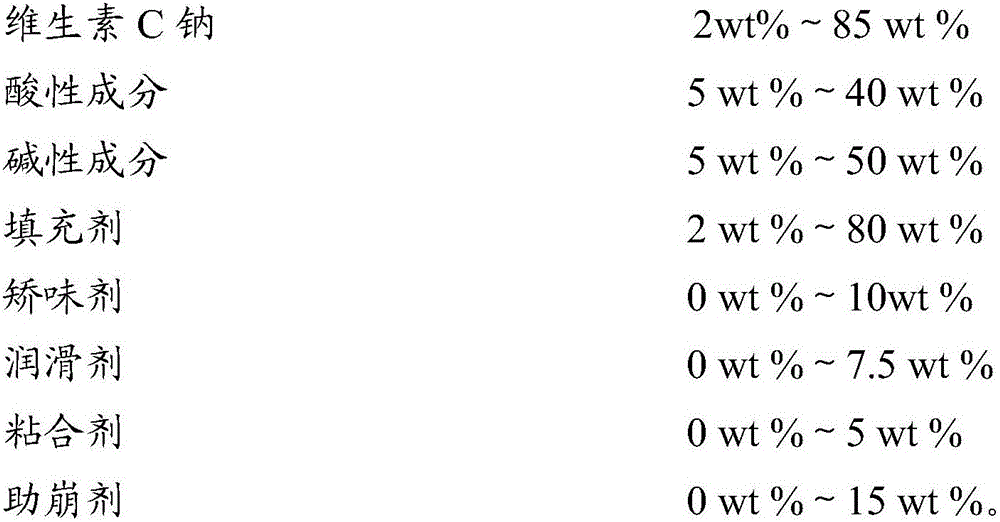

Vitamin C sodium effervescence formulation and preparation method thereof

InactiveCN106387918AImprove stabilityNo gastrointestinal irritationFood shapingFood ingredient functionsVitamin CAdhesive

The invention belongs to the field of health-care products, and particularly relates to a vitamin C sodium effervescence formulation and a preparation method thereof. The vitamin C sodium effervescence formulation provided by the invention comprises acidic components, alkaline components, a filling agent, a correctant, a lubricant, an adhesive and a disintegration auxiliary. The effervescence formulation is an effervescent tablet agent or effervescence solid particles, is good in stability and free from irritant to the stomach and the intestinal tracts, and can be effectively used as a supplementing agent of vitamin C. The invention further discloses the preparation method of the effervescence formulation. The preparation method is simple to operate. The prepared vitamin C sodium effervescence formulation is smooth, clean and level in appearance, free from bubbling phenomena, large in effervescence particle size and low in hygroscopicity.

Owner:GUANGDONG UNIV OF TECH

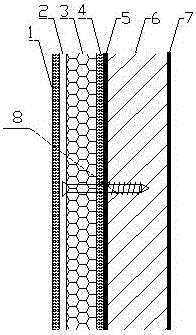

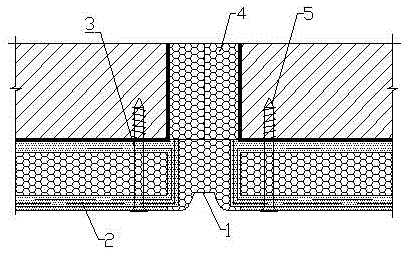

Wind resistance and heat preservation EPS board outer wall structure and construction method thereof

The invention discloses a wind resistance and heat preservation EPS board outer wall structure which comprises a wall body, a galvanized steel wire netting, a bonding layer, an EPS heat preservation plate layer, a gridding cloth, an elastic coating and anchor bolts. The wind resistance and heat preservation EPS board outer wall structure is characterized in that composite mortar is laid on the inner side of a wall body, a plastering layer is arranged on the outer side of the wall body, the galvanized steel wire netting is laid inside the plastering layer, the EPS heat preservation plate layer is stuck to the outer side of the plastering layer, the thickness of an adhesive layer stuck to the surface of the heat preservation plate is controlled to be 4-5 mm, the anchor bolts penetrate through EPS heat preservation plates, the galvanized steel wire netting is fixed to the outer side of the wall body, each EPS heat preservation plate is provided with two anchor bolts and installed on a middle line, the anchor bolts press the bottom layer gridding cloth to form a fire barrier, and the gridding cloth and elastic coating are stuck to the outer sides of the EPS heat preservation plates. The construction method comprises the steps of base layer wall treatment, sticking of the heat preservation plates and the base layer, fixing of the fire barrier, auxiliary fixing of the heat preservation plates, sticking of the gridding cloth and a facing layer, and field testing and inspection.

Owner:克拉玛依市建设工程质量监督站

Chlorinated polythylene fire retardant jacket compositions

ActiveCN101289563ANo foamingNo porosityInsulated cablesInsulated conductorsRare earthChlorinated polyethylene

The invention discloses a chlorinated polyethylene flame-retardant sheath material compound. The flame-retardant sheath material compound comprises compositions with the following weight portions: 100 portions of chlorinated polyethylene, 5 to 8 portions of rare earth complex stabilizer REC-LS, 25 to 30 portions of high-performance complex flame retardant HZR-2, 3 to 5 portions of thiadiazole derivative curing agent, and 1.5 to 2 portions of aldehyde-amine condensate accelerant. A cable obtained by the invention has more comprehensive performance, good mechanical property, ozone-resistant and chemical-resistant performance, flame resistance and oil resistance, high temperature-resistant class, and free color matching.

Owner:四川川东电缆有限责任公司

Method for preparing waterborne anticorrosion coating resin vinylidene chloride-acrylate

InactiveCN102250275AReduce adhesionGood emulsifying effectAnti-corrosive paintsEmulsionPolymer science

The invention discloses a method for preparing waterborne anticorrosion coating resin vinylidene chloride-acrylate. In the method, vinylidene chloride, acrylate and different compounded emulsifiers are pre-emulsified, and azodiisobutyronitrile is used for initiating polymerization reaction. The method comprises the following steps of: adding partial pre-emulsion into a reactor; heating to temperature higher than the initiation temperature of an initiator, adding the initiator, and performing polymerization reaction at constant temperature to obtain seeded emulsion; and dripping the rest pre-emulsion into the reactor and continuously performing the reaction at constant temperature. The emulsion has high stability, uniform particle size, high resin adhesion and high film and anticorrosion properties, is environment-friendly and nontoxic, and can provide good corrosion protection for carbon steel matrixes.

Owner:TIANJIN UNIV +1

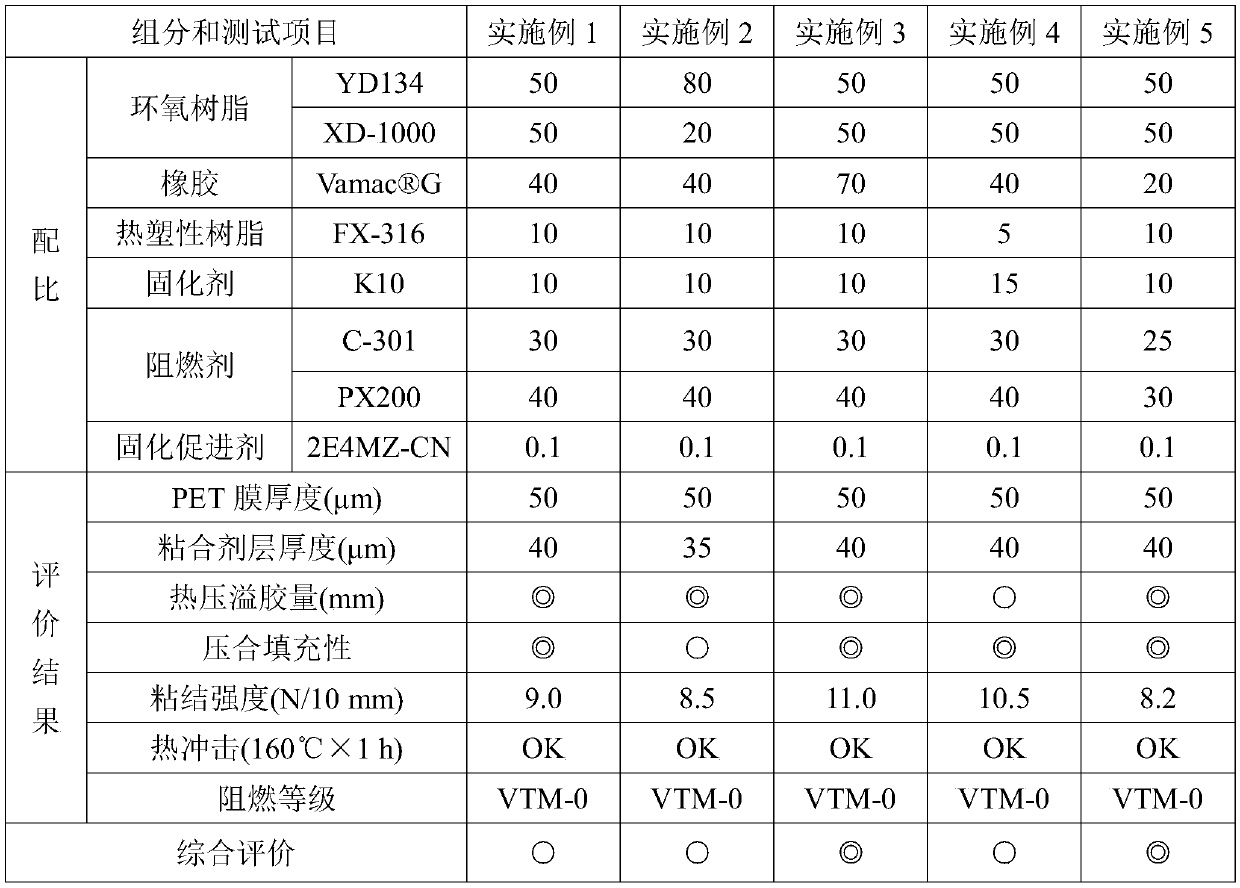

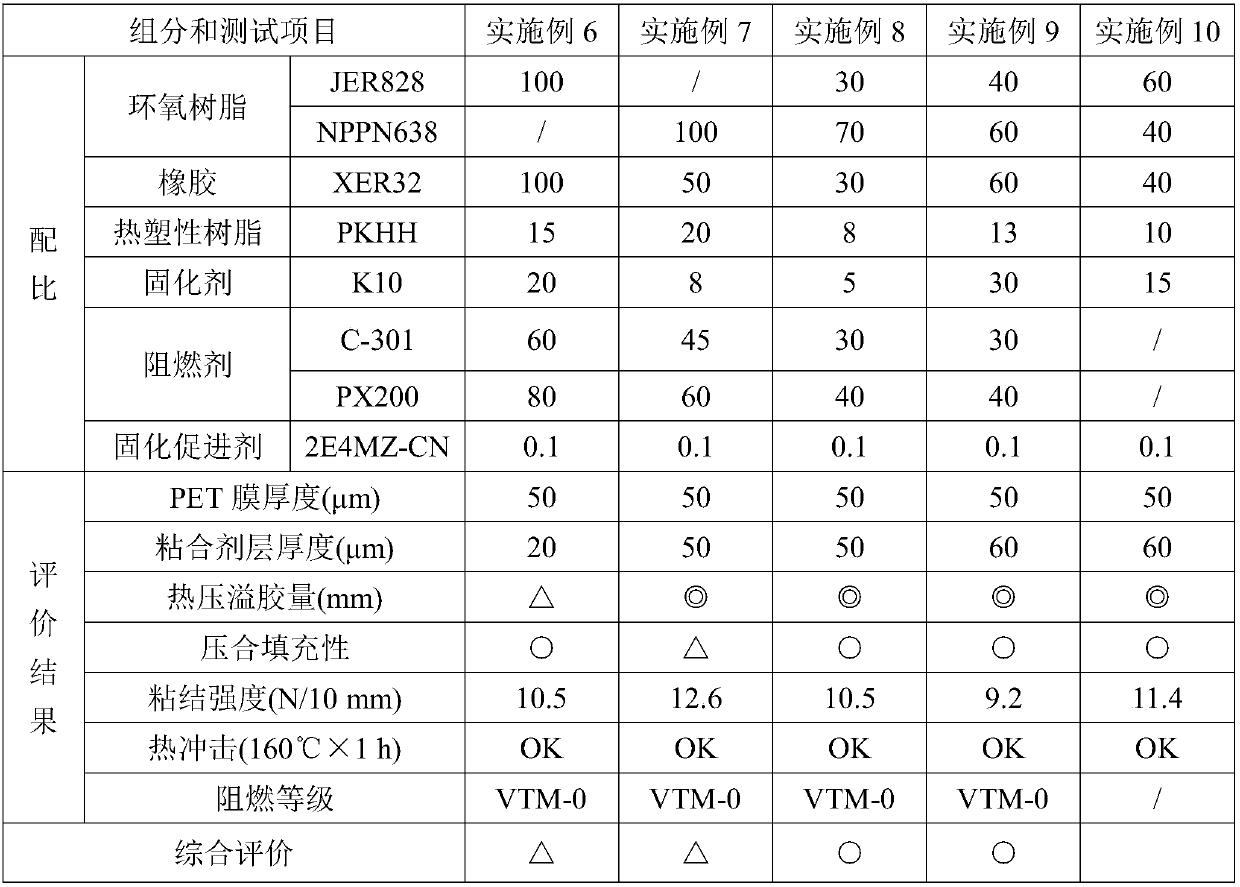

Adhesive and insulating reinforcing tape containing adhesive

InactiveCN109651988AImprove adhesionImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyFlexible circuits

The invention provides an adhesive and an insulating reinforcing tape including the adhesive. The adhesive includes the following components (by weight): 100 parts of epoxy resin, 5-20 parts of thermoplastic resin, 20-100 parts of rubber, and 5-30 parts of a curing agent. The insulating reinforcing tape includes an insulating substrate and an adhesive layer disposed on the insulating substrate, wherein the adhesive layer is formed of the above adhesive. The adhesive provided by the invention has high adhesive force, heat resistance and good fluidity, and the insulating reinforcing tape prepared by the invention has small amount of glue overflow during hot-pressing, good adhesive property, strong deformation plasticity and good pressure fillibility, is easy for hot-press forming, low-cost,can be used for reinforcement and insulation coating of flexible circuit boards.

Owner:CYBRID TECHNOLOGIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com