Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

A technology of yield strength and production method, applied in the direction of coating, metal material coating process, hot-dip galvanizing process, etc., can solve the problem of reducing the adhesion of galvanized layer, improving the production cost of color-coated plates for structural use, and the yield strength cannot be reached Waiting for the question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The production method of the structural color-coated plate with yield strength ≥ 550MPa, the thickness of the steel plate is 0.6mm, the steps:

[0021] 1) Smelting: hot metal desulfurization, converter smelting, continuous casting to form components and weight percentages: C: 0.05%, Si: 0.013%, Mn: 0.25%, P: 0.015%, S: 0.012%, Als: 0.05% , N: 0.0021%, Ti: 0.002%, Nb: 0.001%, the rest is continuous casting of Fe and unavoidable impurities and hot rolling;

[0022] 2) pickling;

[0023] 3) Carry out cold rolling, and control the cumulative reduction rate at 65%;

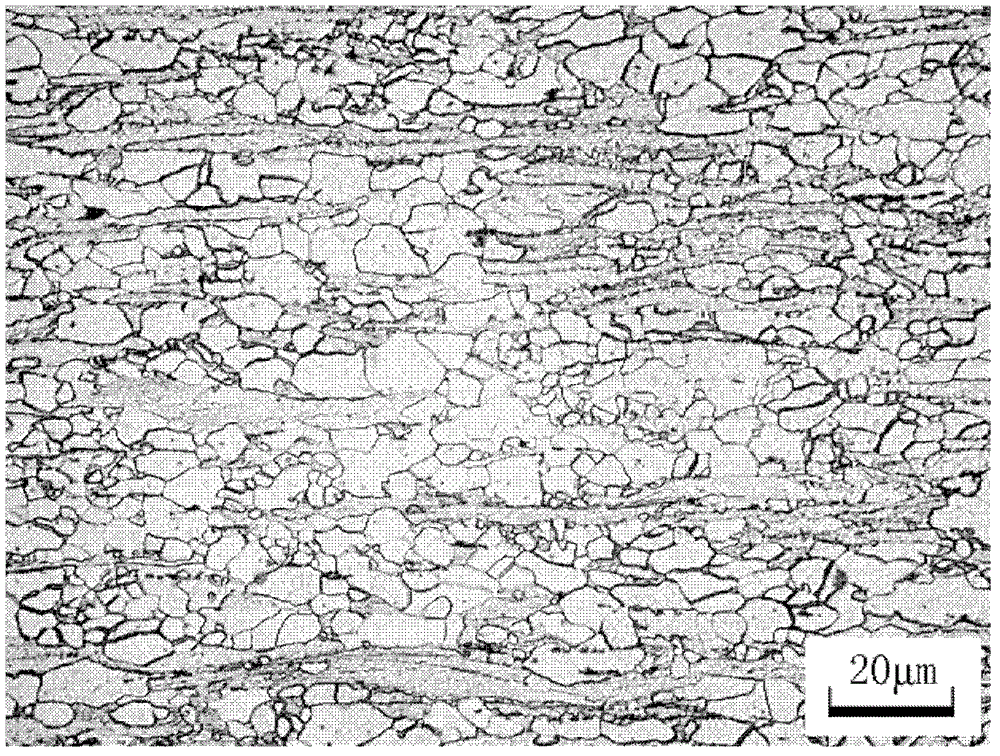

[0024] 4) Carry out continuous annealing, the annealing temperature is controlled at 600 ° C ~ 605 ° C, and the annealing time is 60 seconds; after annealing, the metallographic structure is ferrite + deformed band crystal;

[0025] 5) Perform hot-dip galvanizing, and control the weight of the double-sided hot-dip galvanized metal layer to 150g / m 2 , the composition and weight percentage of the coating are: A...

Embodiment 2

[0029] The production method of the structural color-coated plate with yield strength ≥ 550MPa, the thickness of the steel plate is 0.8 mm, the steps:

[0030] 1) Smelting: Desulfurization of molten iron, converter smelting, and continuous casting to form components and weight percentages: C: 0.04%, Si: 0.011%, Mn: 0.20%, P: 0.02%, S: 0.011%, Als: 0.06% , N: 0.0015%, Ti: 0.003%, Nb: 0.002%, the rest is continuous casting slab of Fe and unavoidable impurities and hot rolling;

[0031] 2) pickling;

[0032] 3) Carry out cold rolling, and control the cumulative reduction rate at 61%;

[0033] 4) Carry out continuous annealing, the annealing temperature is controlled at 615 ° C ~ 620 ° C, and the annealing time is 50 seconds; after annealing, the metallographic structure is ferrite + deformed band crystal;

[0034] 5) Perform hot-dip galvanizing, and control the weight of the double-sided hot-dip galvanized metal layer to 120g / m 2 , the composition and weight percentage of the ...

Embodiment 3

[0038] The production method of the structural color-coated plate with yield strength ≥ 550MPa, the thickness of the steel plate is 1.0 mm, the steps:

[0039]1) Smelting: hot metal desulfurization, converter smelting, continuous casting to form components and weight percentages: C: 0.03%, Si: 0.020%, Mn: 0.18%, P: 0.01%, S: 0.009%, Als: 0.02% , N: 0.0025%, Ti: 0.001%, Nb: <0.001%, and the rest are continuous casting slabs of Fe and unavoidable impurities and hot rolling;

[0040] 2) pickling;

[0041] 3) Carry out cold rolling, and control the cumulative reduction rate at 58%;

[0042] 4) Carry out continuous annealing, the annealing temperature is controlled at 645 ° C ~ 650 ° C, and the annealing time is 20 seconds; after annealing, the metallographic structure is ferrite + deformed band crystal;

[0043] 5) Perform hot-dip galvanizing, and control the weight of the double-sided hot-dip galvanized metal layer to 60g / m 2 , the composition and weight percentage of the coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com