Patents

Literature

2466 results about "Pearlite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pearlite is a two-phased, lamellar (or layered) structure composed of alternating layers of ferrite (87.5 wt%) and cementite (12.5 wt%) that occurs in some steels and cast irons. During slow cooling of an iron-carbon alloy, pearlite forms by a eutectoid reaction as austenite cools below 727 °C (1,341 °F) (the eutectoid temperature). Pearlite is a microstructure occurring in many common grades of steels.

Steel plate having superior toughness in weld heat-affected zone and welded structure made therefrom

Owner:POHANG IRON & STEEL CO LTD

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

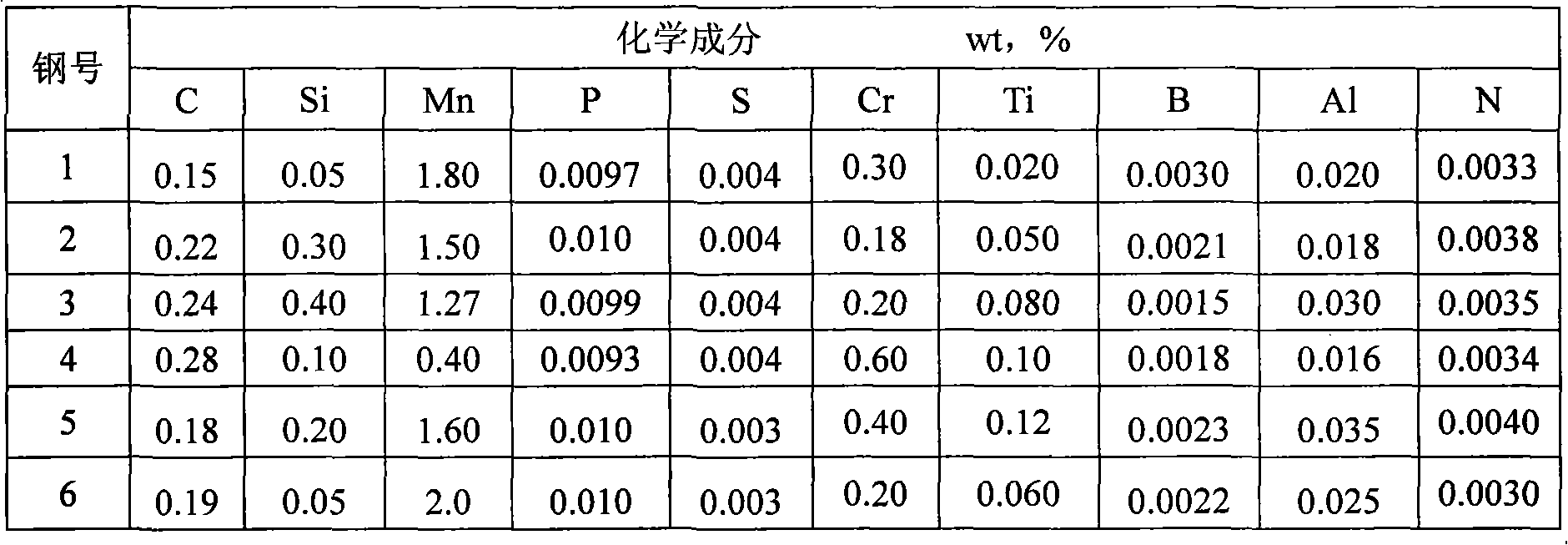

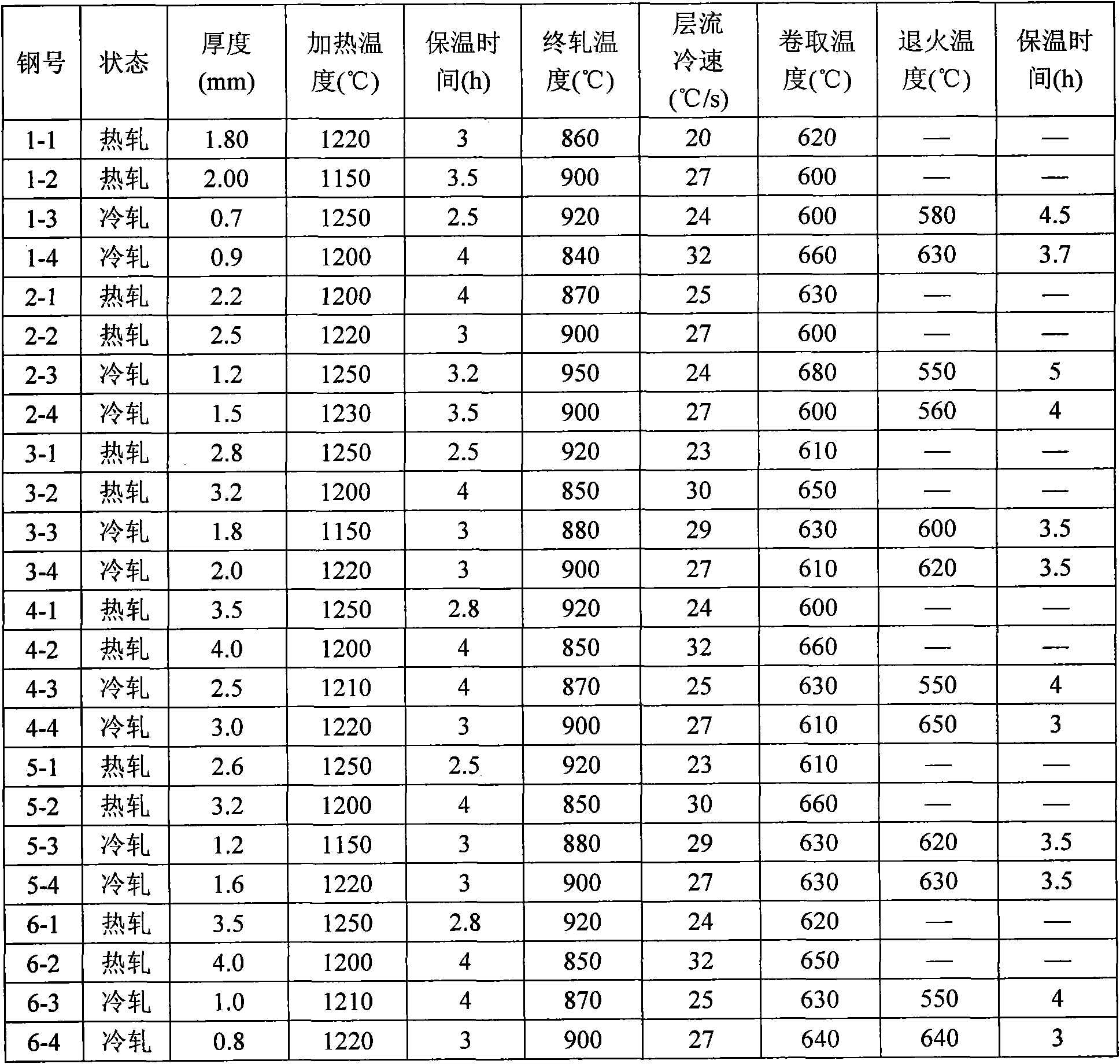

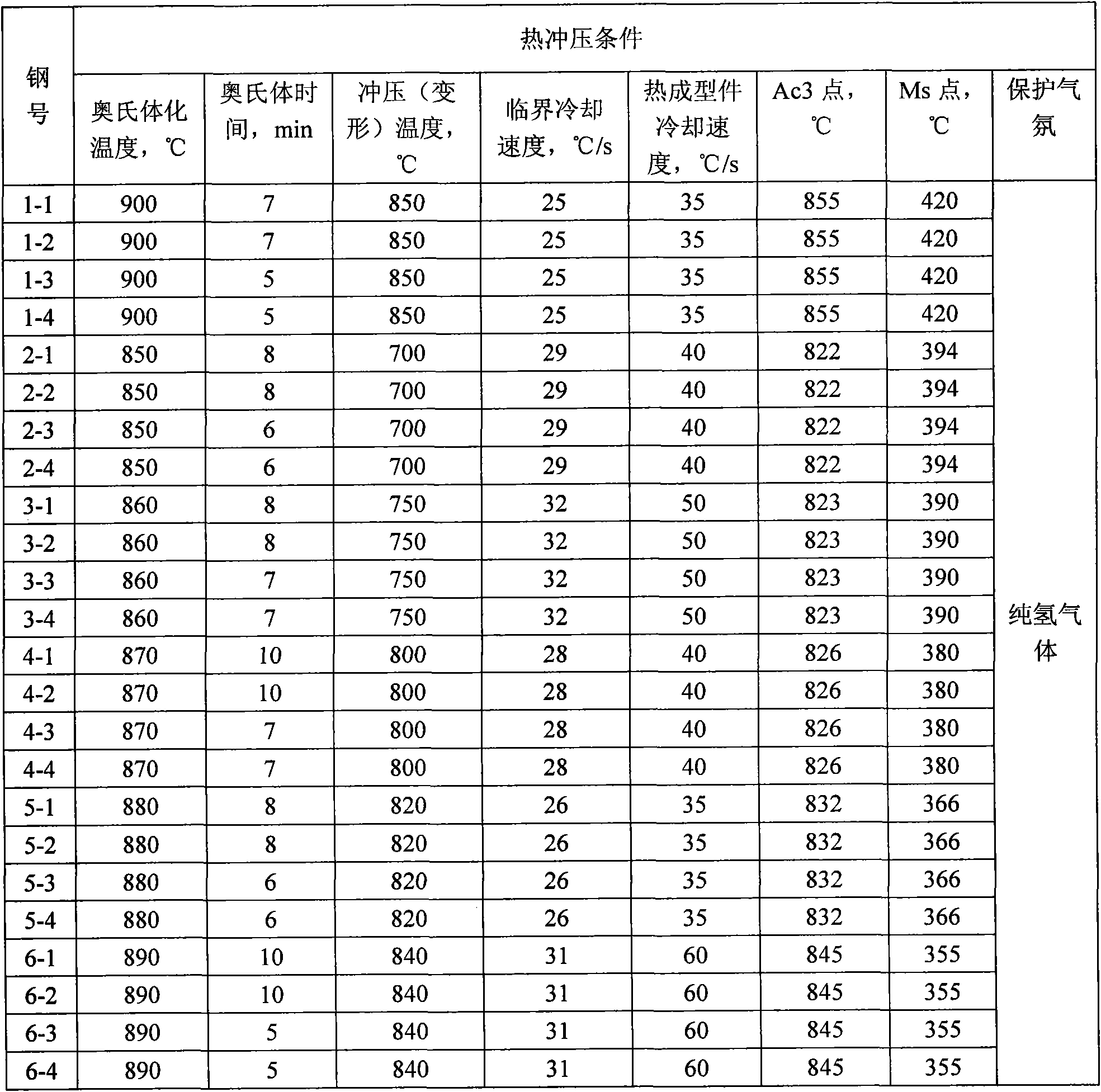

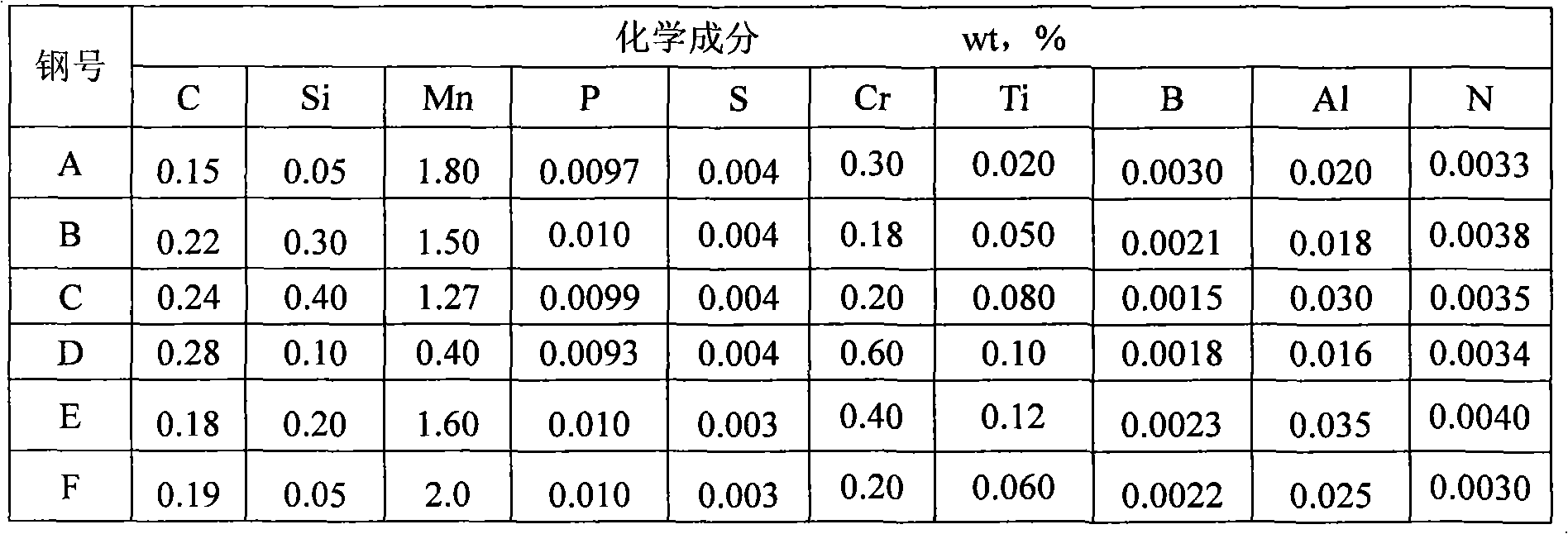

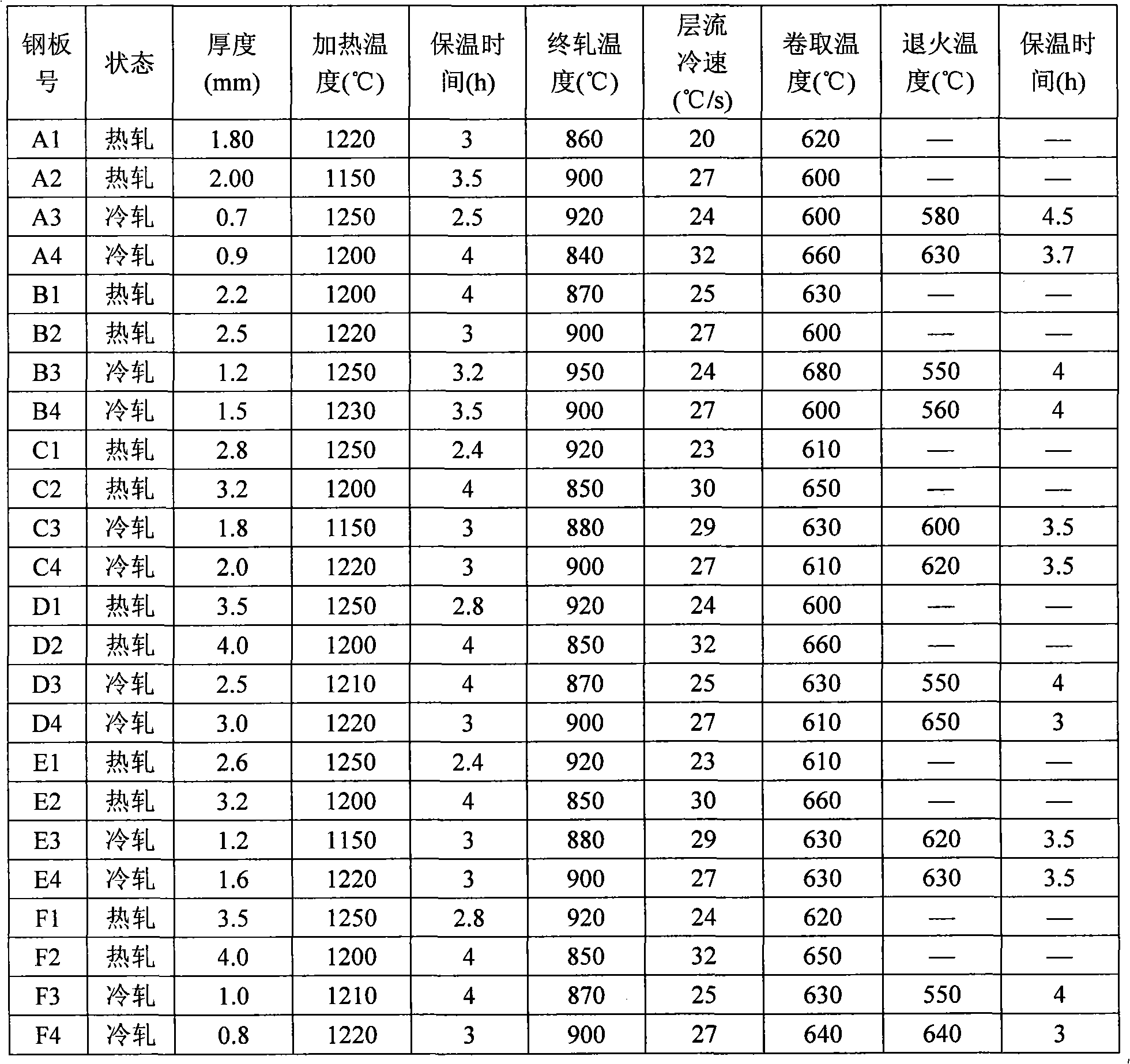

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

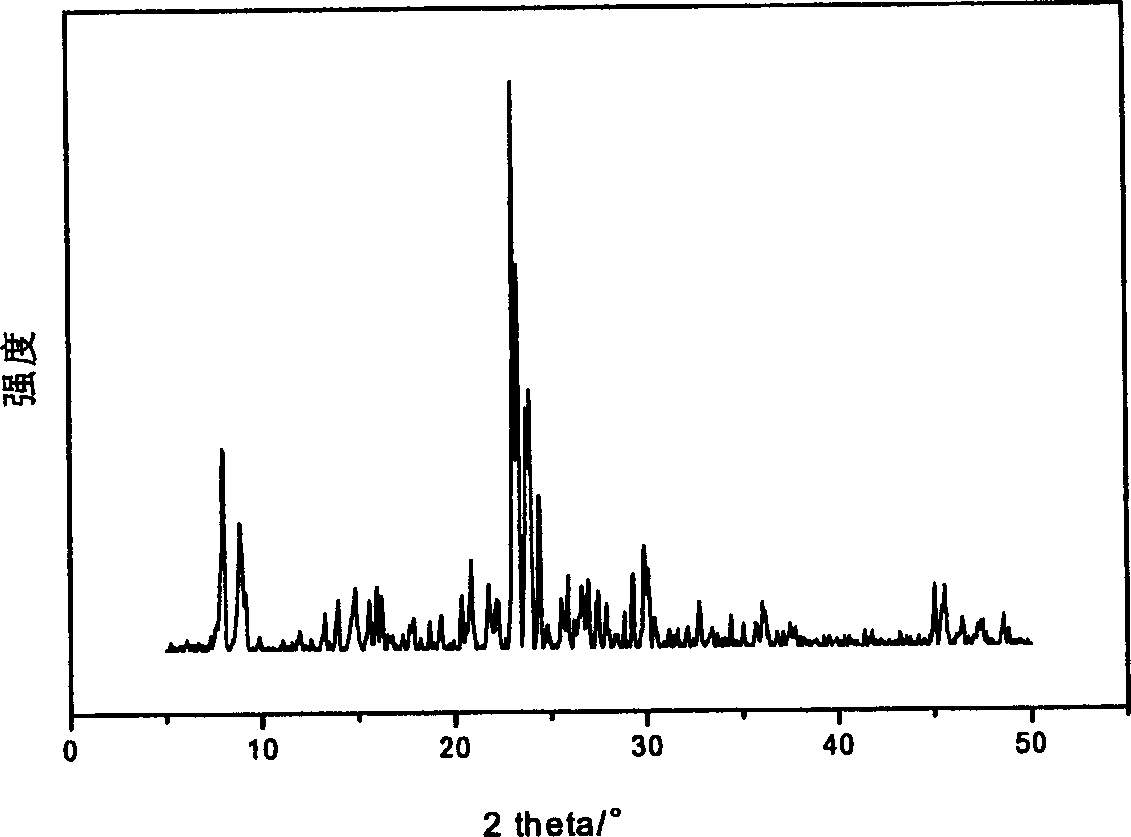

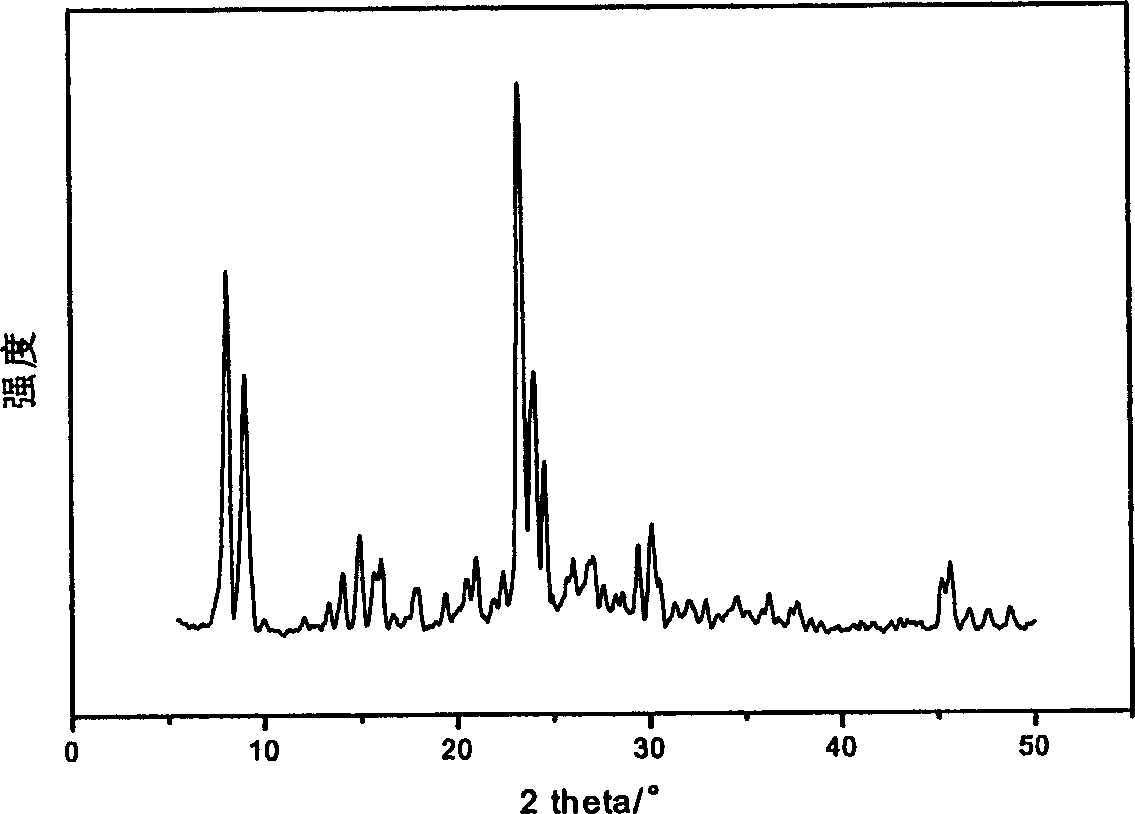

ZSM-5 type molecular sieve and method for preparing the same

ActiveCN1803613AReduce contentPerformance is not affectedMolecular sieve catalystsPentasil aluminosilicate zeolitePearliteZSM-5

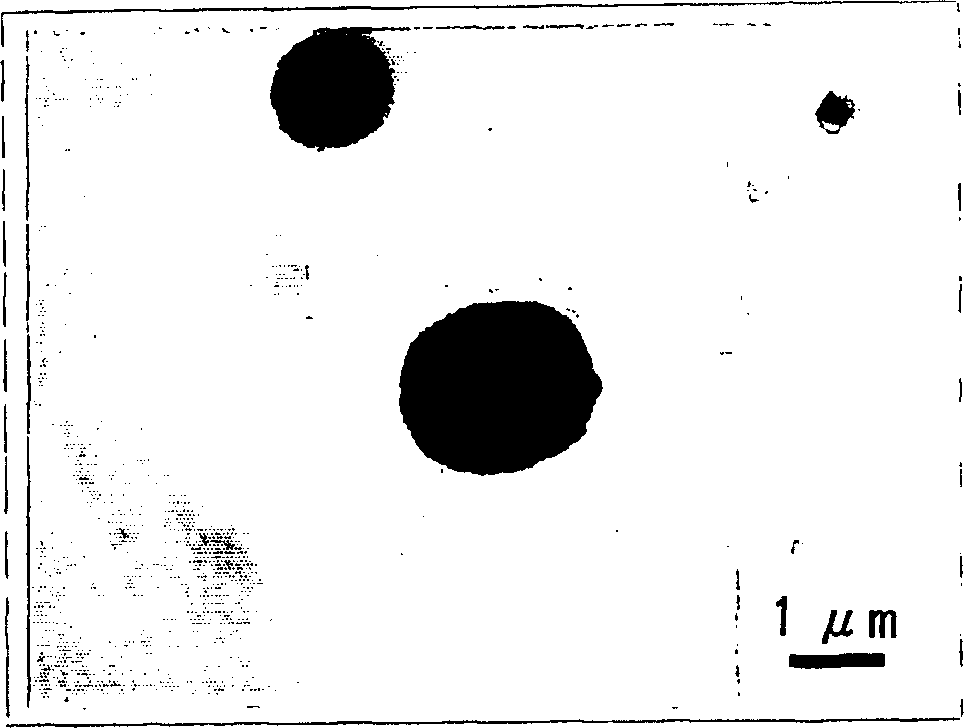

The invention provides a preparation method for small-size ZSM-5 molecular sieve. Wherein, using pearlite and montmorillonite as material for aluminum, adding crystal seed for crystallization reaction on hydrothermal condition, and obtaining a small-size product with 5~95% ZSM-5 that can be used to prepare modified ZSM-5 molecular sieve by different post-treatment method or as the active intergradient or carrier for catalyst. This invention cuts the cost more.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Normalizing type high-strength pressure vessel steel and manufacturing method thereof

The invention provides normalizing type high-strength pressure vessel steel, which comprises the following chemical components in percentage by weight: 0.12 to 0.18 percent of C, 0.15 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.10 to 0.40 percent of Ni, 0.01 to 0.05 percent of Nb and 0.01 to 0.03 percent of Ti, 0.015 to 0.050 percent of Als, one or both of less than or equal to 0.20 percent of V and less than or equal to 0.70 percent of Cu and the balance of Fe and inevitable impurities. In the normalizing type high-strength pressure vessel steel, the specification of the steel is controlled by utilizing a single-rolling process of a steel plate, and the uniform tissue of ferrite and pearlite is obtained by adopting normalizing heat treatment; and in the process of rolling and heat treatment, the sufficient strength and good impact properties are obtained by utilizing the effects of fine-grain strengthening, precipitation strengthening and solid solution strengthening of micro-alloying elements such as the Nb, the V, the Ti and the like. In addition, the normalizing type high-strength pressure vessel steel achieves the excellent welding performance by controlling carbon equivalent and can be welded by adopting methods of manual arc welding, hidden arc welding, gas shielded welding, electroslag welding or tungsten electrode inert gas shielded-arc welding and the like; and the normalizing type high-strength pressure vessel steel has the advantages of little used precious metals, easy control of the component of each element, simple process, low production cost and high efficiency.

Owner:武钢集团有限公司

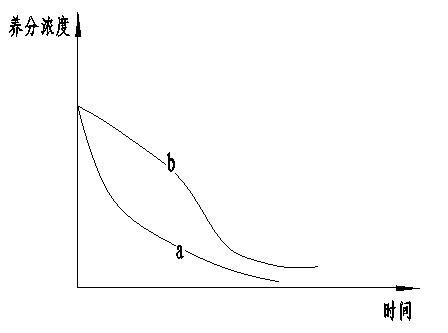

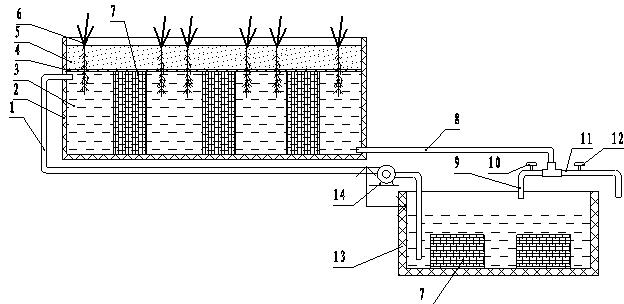

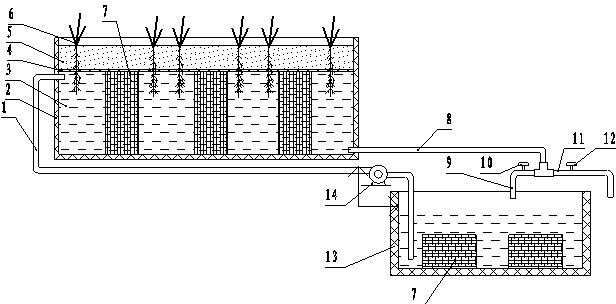

Small soilless culture method and device

ActiveCN102119651AIncrease the concentration of inputFewer deliveriesAgriculture gas emission reductionCultivating equipmentsSlagPeat

The invention relates to a small soilless culture method and device. A nutrient solution is contained in a culture disk or a nutrient solution storage pool; crops are planted into the nutrient solution; a soil copy material is added into the nutrient solution; the soil copy material comprises the following raw materials in parts by weight: 20-90 parts of organic matter and 2-80 parts of nonmetal mineral substance, wherein the organic matter is one or mixture of peat, fermented straw, fermented bagasse and fermented livestock and poultry manure; the nonmetal mineral substance is one or mixtureof coal ash, steel slag, zeolite, bentonite, opal, attapulgite mineral soil, pearlite, vermiculite, rectorite clay, sepiolite clay and kieselguhr; and the proportion of the nutrient solution to the soil copy material is (5-2):1. By adding the soil copy material into the nutrient solution, the nutrient charge concentration can be improved, the nutrient charge frequency is reduced, and the labor cost is reduced; meanwhile, when the concentration is reduced due to the absorption of the nutrients, the concentration reduction range is slower, and a deficiency symptom caused by lacking nutrients ofplants is lightened; in addition, trace elements needed by plants can be also supplemented.

Owner:杜友萍

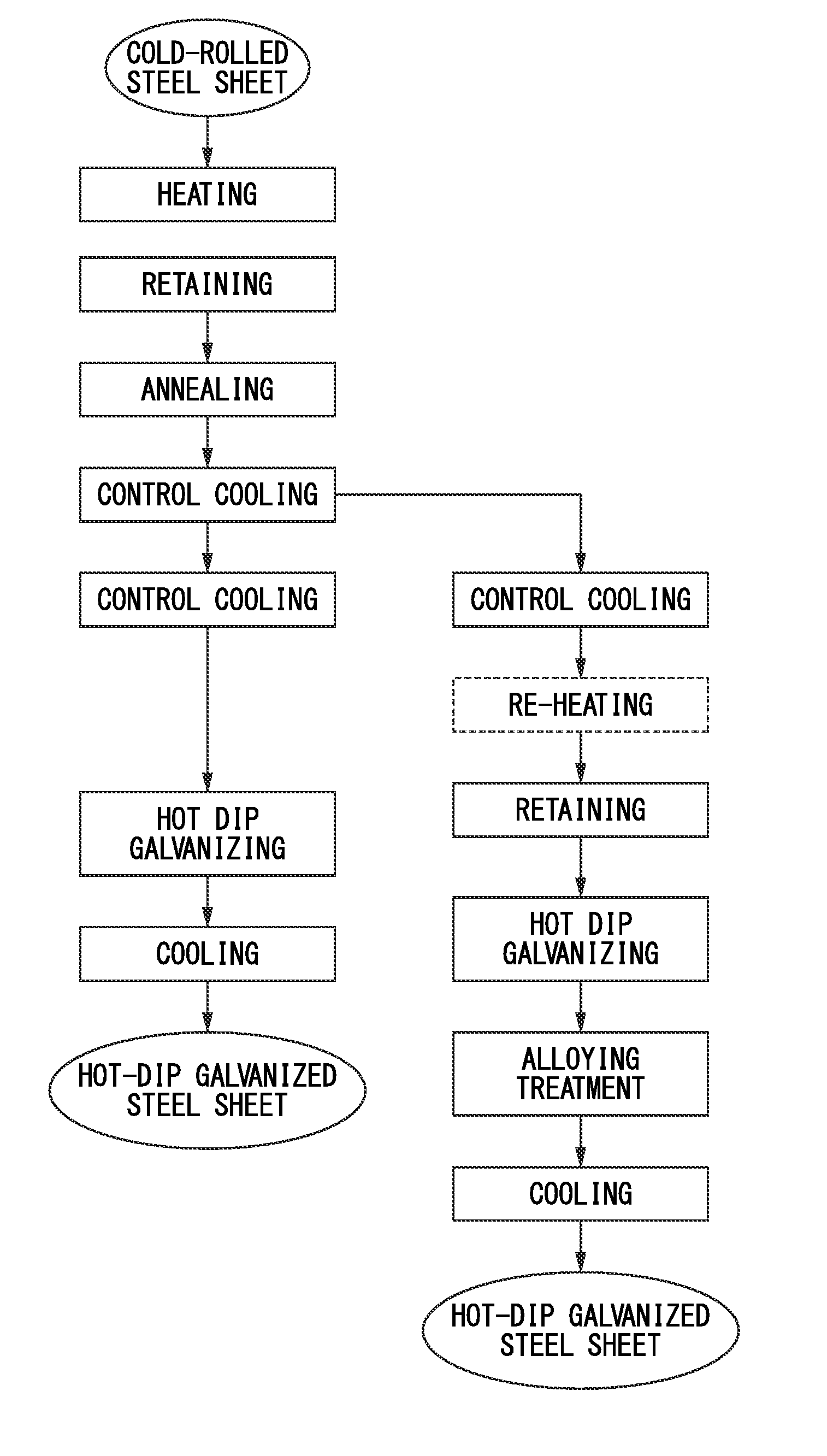

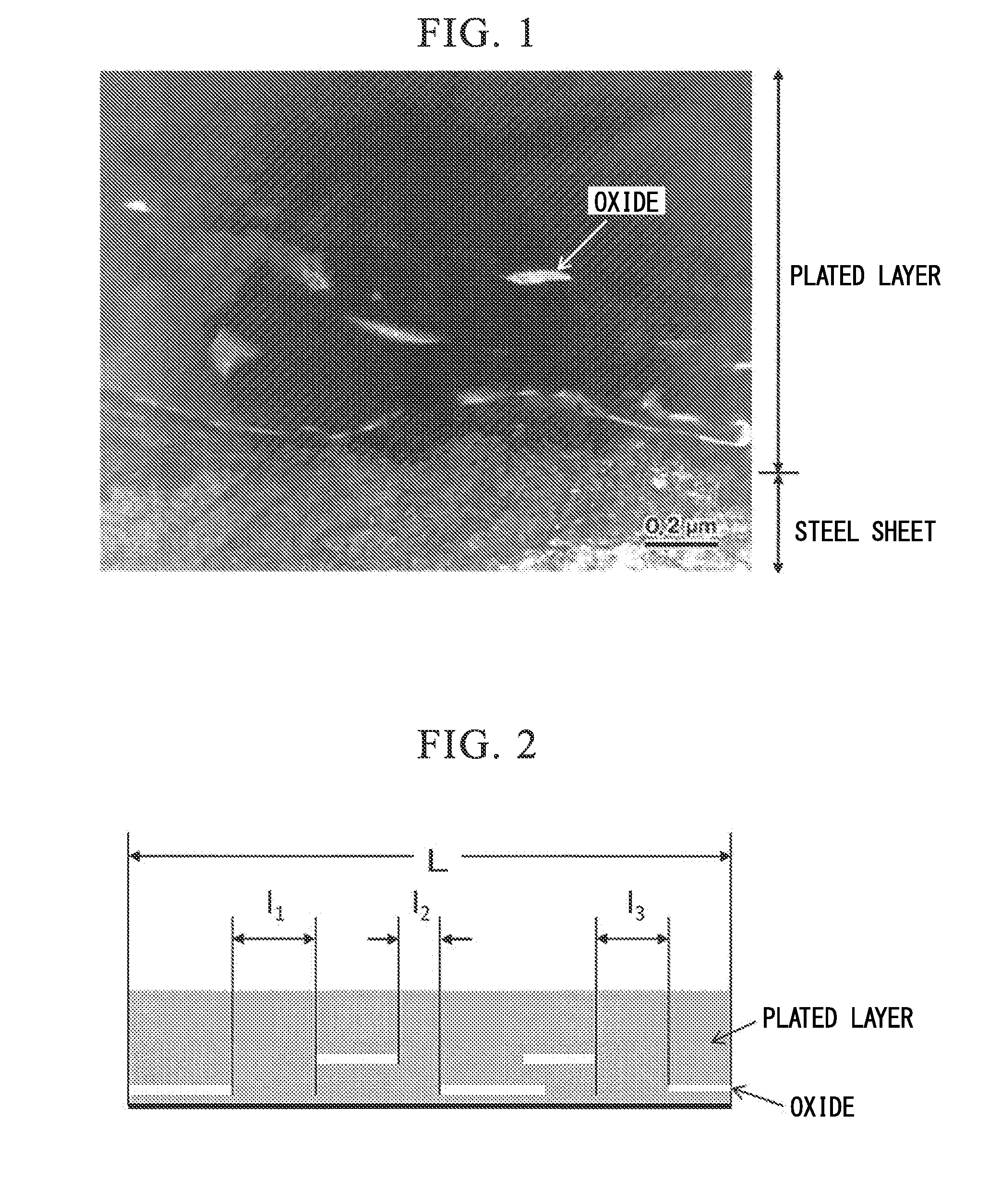

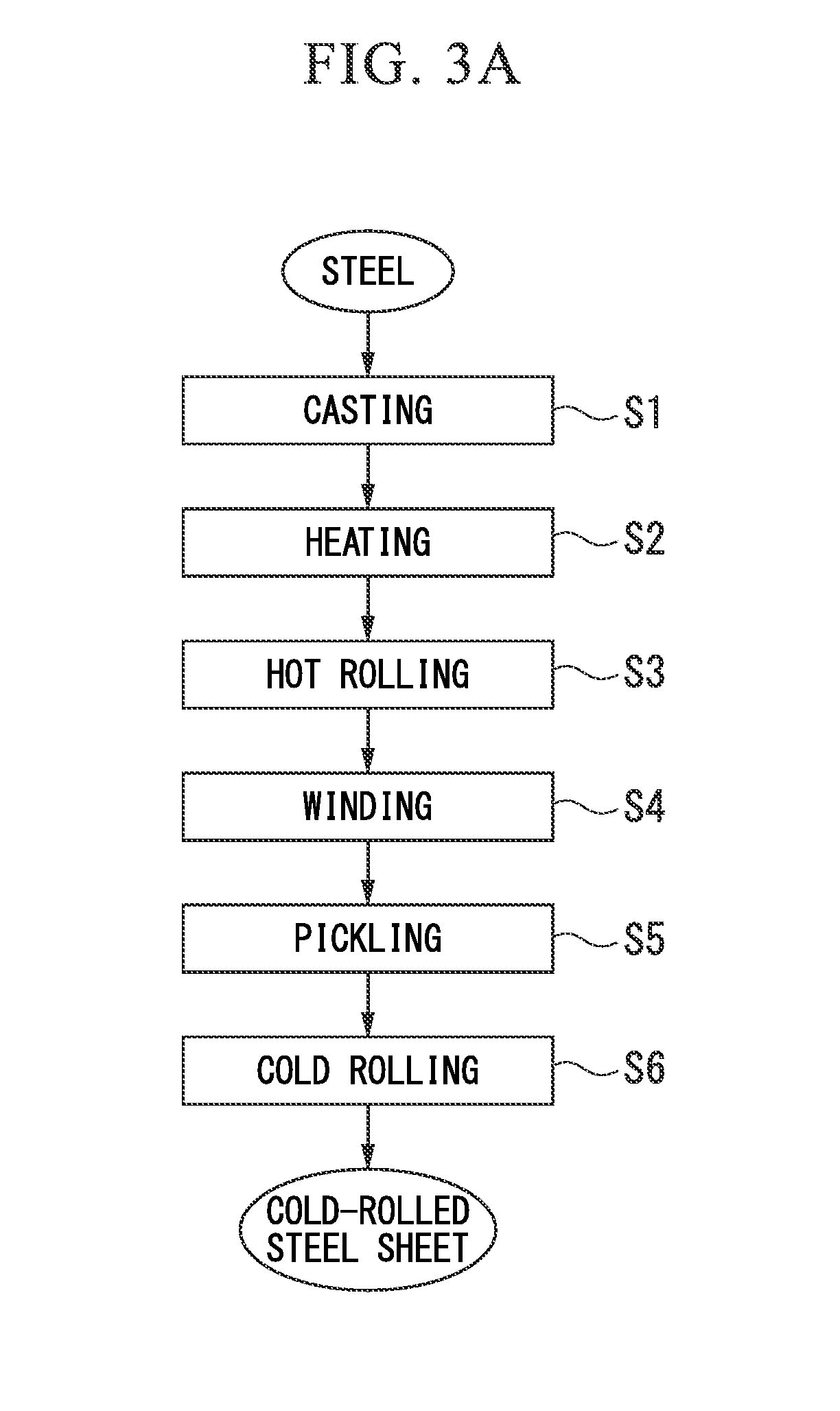

Hot-dip galvanized steel sheet and manufacturing method thereof

ActiveUS20140234657A1Low costImprove adhesionHot-dipping/immersion processesFurnace typesPearliteBainite

A hot-dip galvanized steel sheet includes: a steel sheet; and a plated layer on a surface of the steel sheet, a microstructure contains, by volume fraction, equal to or more than 20% and equal to or less than 99% in total of one or two of martensite and bainite, a residual structure contains one or two of ferrite, residual austenite of less than 8% by volume fraction, and pearlite of equal to or less than 10% by volume fraction, tensile strength is equal to or greater than 980 MPa, the plated layer is a hot-dip galvanized layer which contains oxides including one or two or more of Si, Mn, and Al, contains equal to or less than 15 mass % of Fe, and a remainder including Zn, Al, and unavoidable impurities, and when a cross section including the steel sheet and the hot-dip galvanized layer is seen in a sheet thickness direction, a projected area ratio is equal to or more than 10% and equal to or less than 90%.

Owner:NIPPON STEEL CORP

Nano-composite martensitic steels

Carbon steels of high performance are disclosed that contain dislocated lath structures in which laths of martensite alternate with thin films of austenite, but in which each grain of the dislocated lath structure is limited to a single microstructure variant by orienting all austenite thin films in the same direction. This is achieved by careful control of the grain size to less than ten microns. Further improvement in the performance of the steel is achieved by processing the steel in such a way that the formation of bainite, pearlite, and interphase precipitation is avoided.

Owner:MMFX STEEL CORP OF AMERICA +1

Machinable austempered cast iron article having improved machinability, fatigue performance, and resistance to environmental cracking and a method of making the same

InactiveUS7070666B2Extension of timeInhibition formationFurnace typesQuenching agentsPearliteUltimate tensile strength

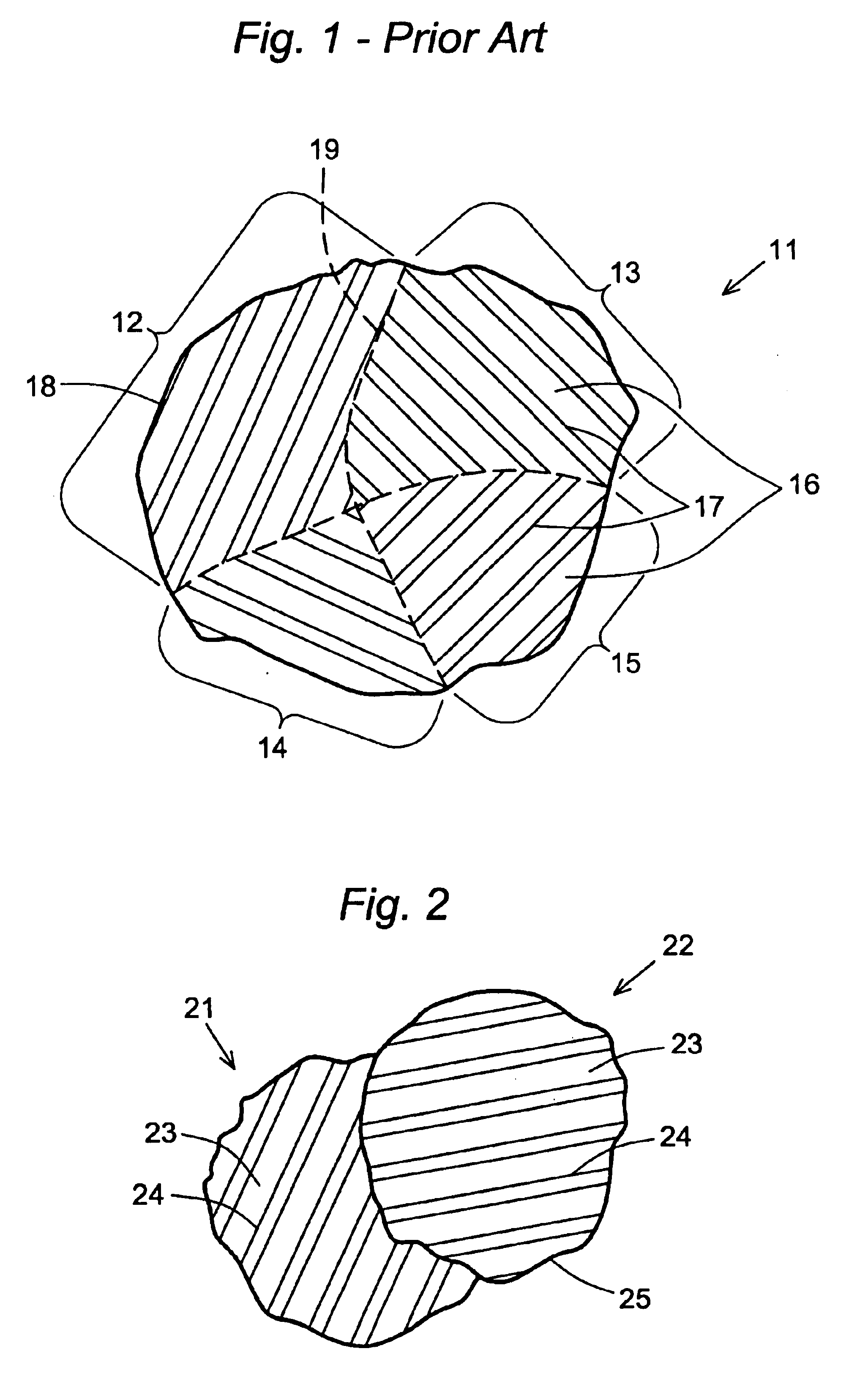

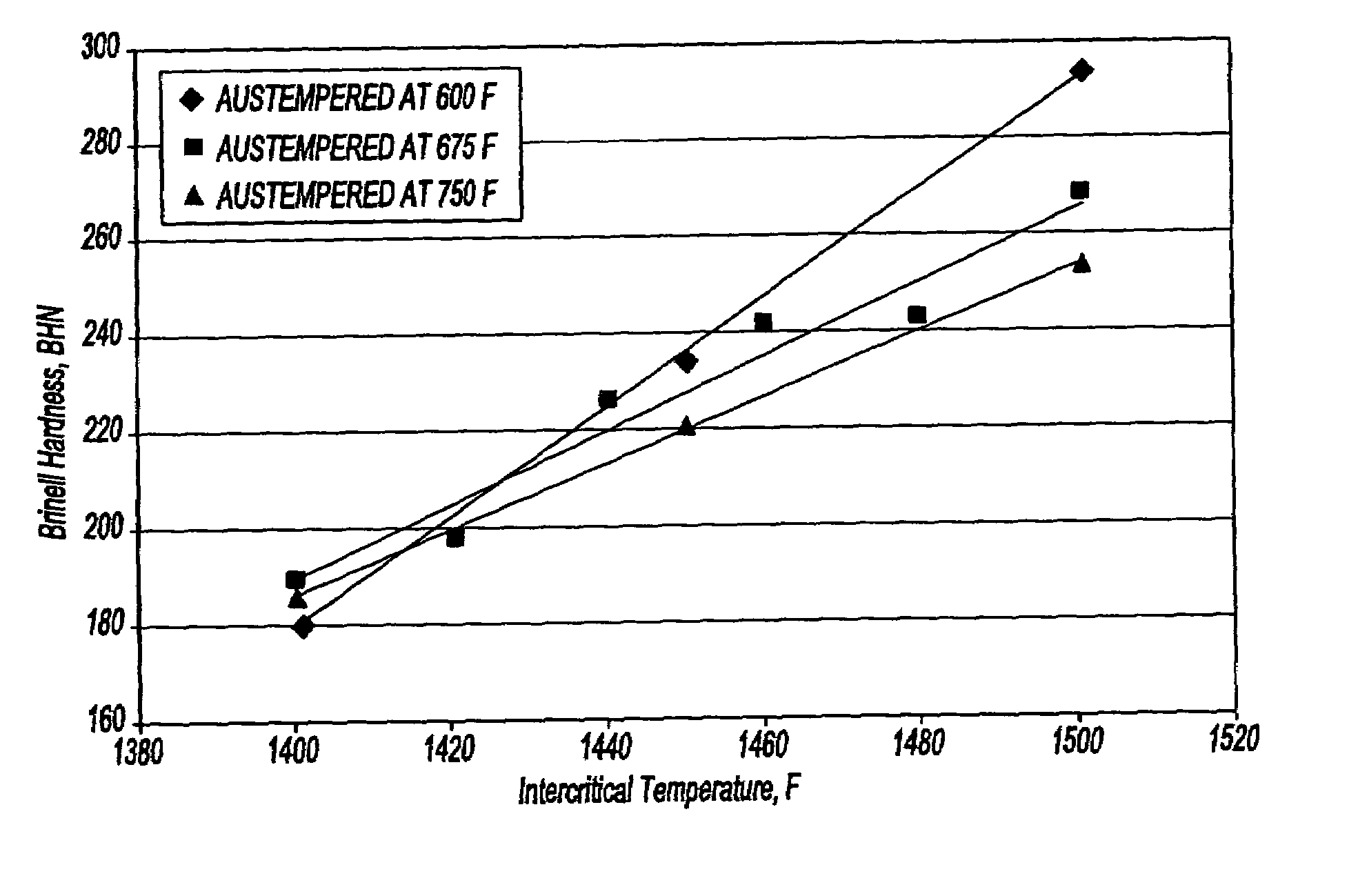

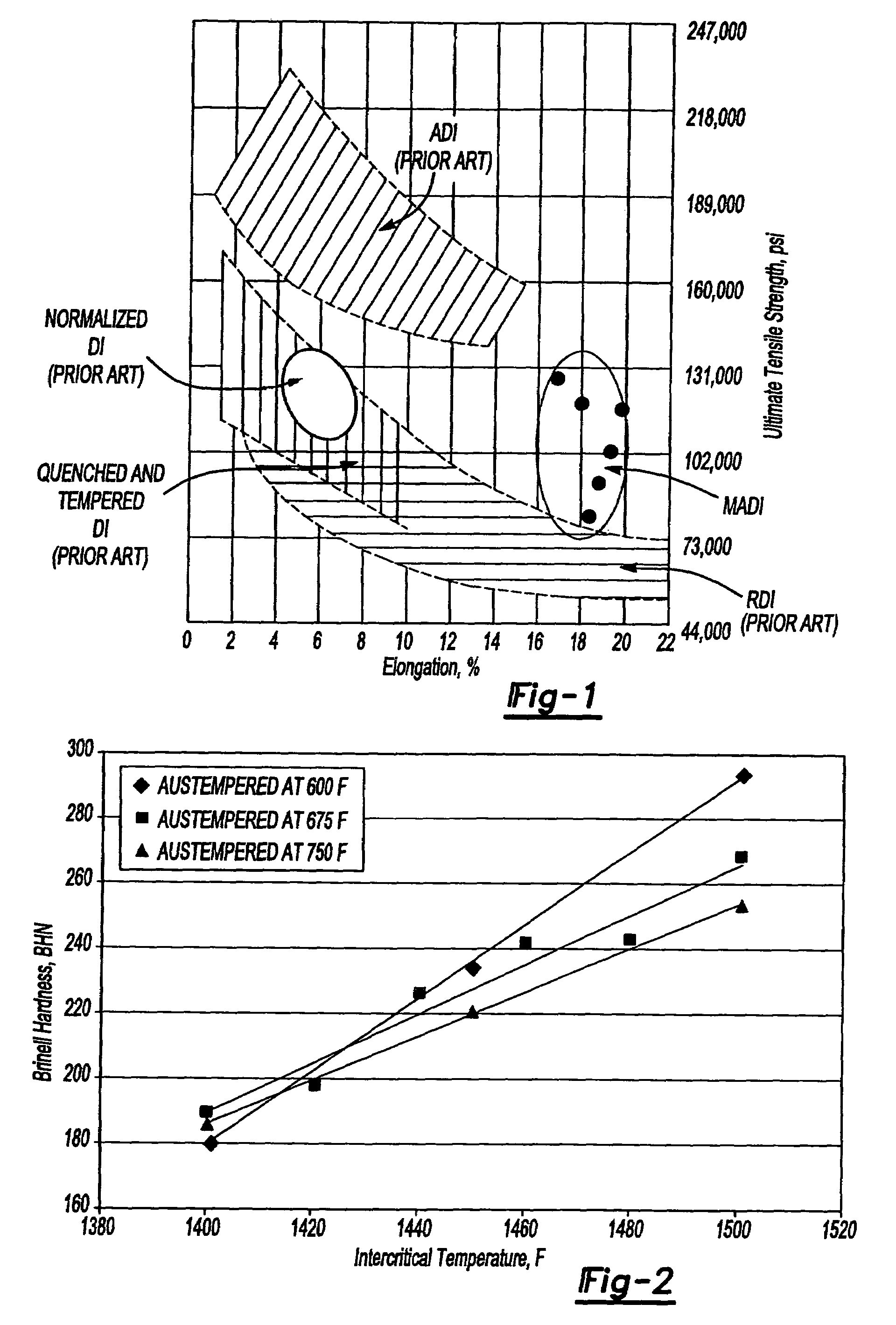

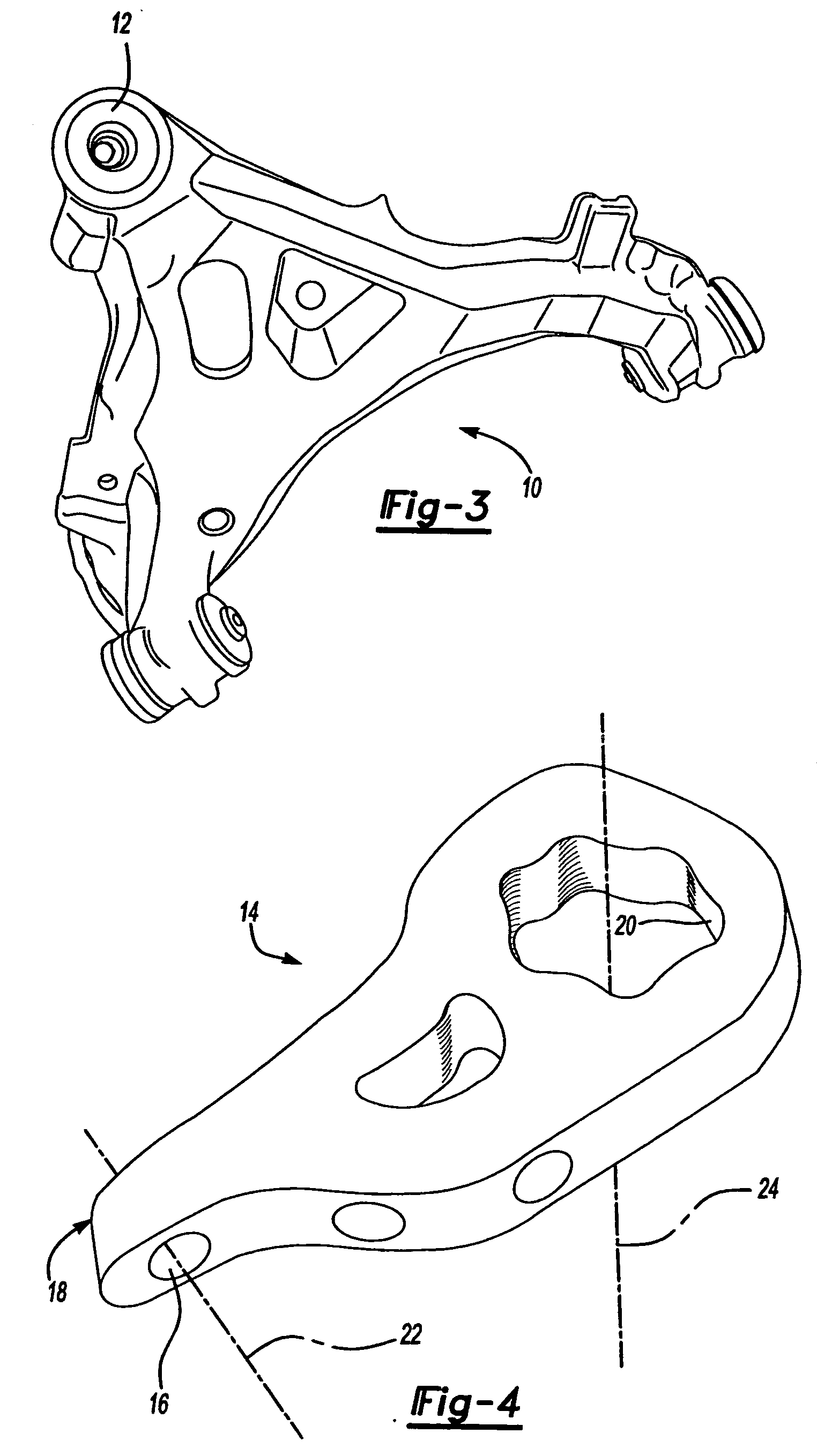

A machinable austempered cast iron article has improved strength, machinability, fatigue performance, and resistance to environmental cracking. A method of making the machinable austempered cast iron article includes austenitizing an iron composition having a substantially pearlitic microstructure in an intercritical temperature range of between 1380° F. and 1500° F. This produces a ferritic plus austenitic microstructure. The ferritic plus austenitic microstructure is quenched into an austempering temperature range of between 575° F. and 750° F. within 3 minutes to prevent formation of pearlite. The ferritic plus austenitic microstructure is then austempered in the austempering temperature range of between 575° F. and 750° F. to produce a microstructure of a continuous matrix of equiaxed ferrite with islands of austenite. Finally, the microstructure of the continuous matrix of equiaxed ferrite with islands of austenite is cooled to ambient temperature to produce the machinable austempered cast iron article.

Owner:INTERMET CORP

Steel plate for stamping and quenching and manufacturing method thereof

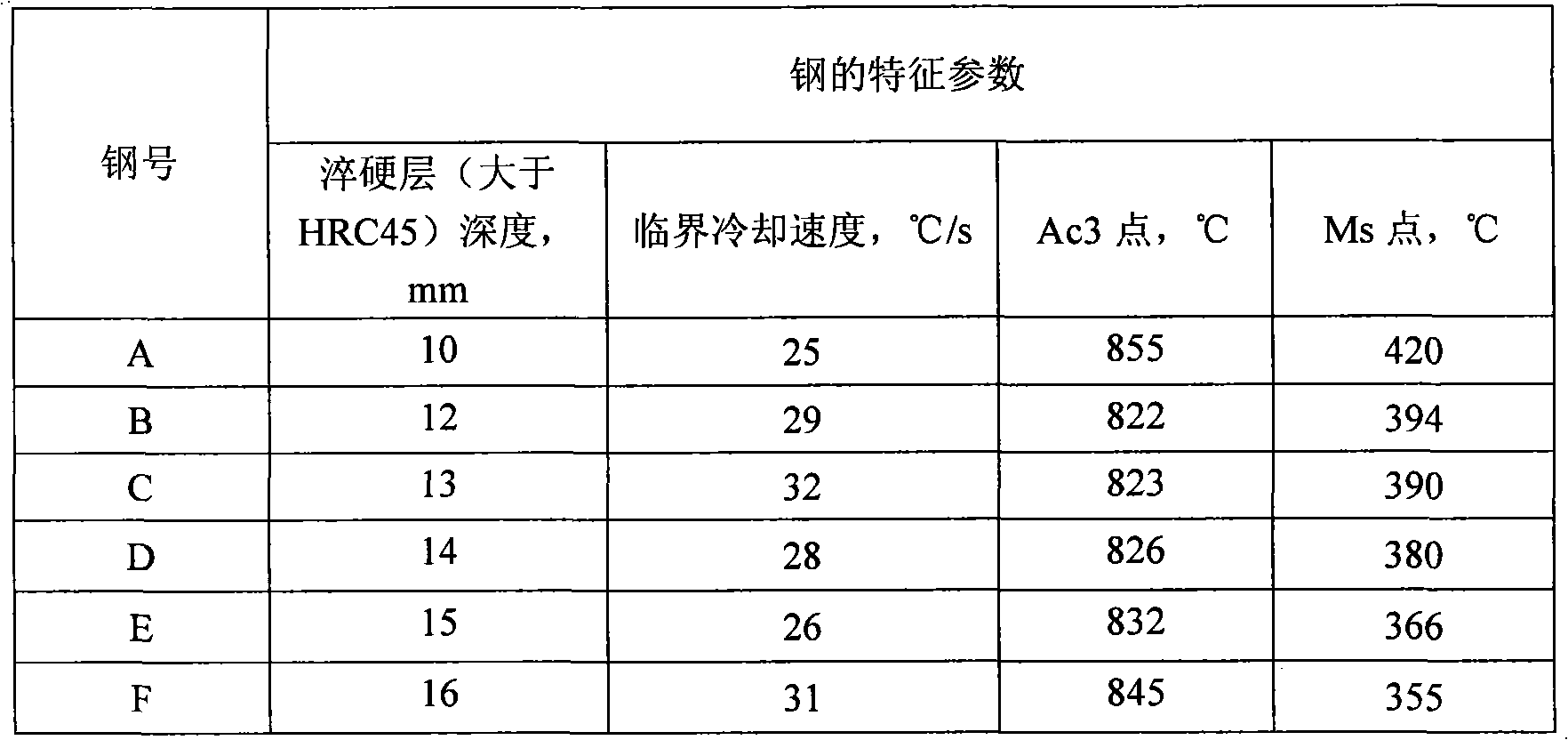

The invention discloses a steel plate for stamping and quenching and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.14 to 0.28 percent of C, less than 0.40 percent of Si, 0.4 to 2.0 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent of S, 0.016 to 0.040 percent of Al, 0.15 to 0.8 percent of Cr, 0.015 to 0.12 percent of Ti, 0.001 to 0.005 percent of B, less than or equal to 0.005 percent of N, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps of: heating a blank to 1,150 to 1,250 DEG C, preserving heat for 2.5 to 4 hours and performing rough rolling, and then performing finish rolling under multichannel pressure and at the final rolling temperature of between 830 and 950 DEG C, performing laminar cooling, and cooling to the rolling temperature at the cooling speed of more than 10 DEG C / s and the rolling temperature of between 600 and 680 DEG C. The cold-rolled steel plate is obtained by the following steps of: performing cold rolling on a hot rolled steel strip, annealing through a pure hydrogen gas cover furnace, and oiling and packaging. The annealing temperature is 550 to 650 DEG C and the heat preserving time is 3 to 5 hours. The steel has a simple component design and high hardenability. The depth of a hardening layer of more than HRC45 is 10 to 16mm. The steel plate consists of ferrite and pearlite. After thermal stamping and quenching, an all-martensite structure can be obtained. The tensile strength is above 1,300N / mm<2>.

Owner:ANGANG STEEL CO LTD

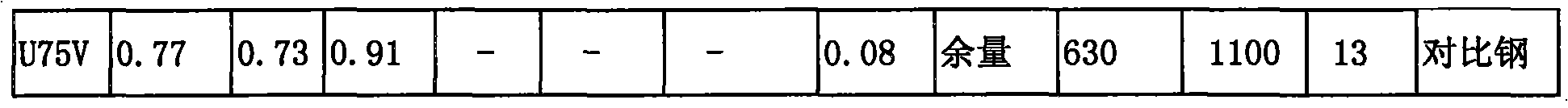

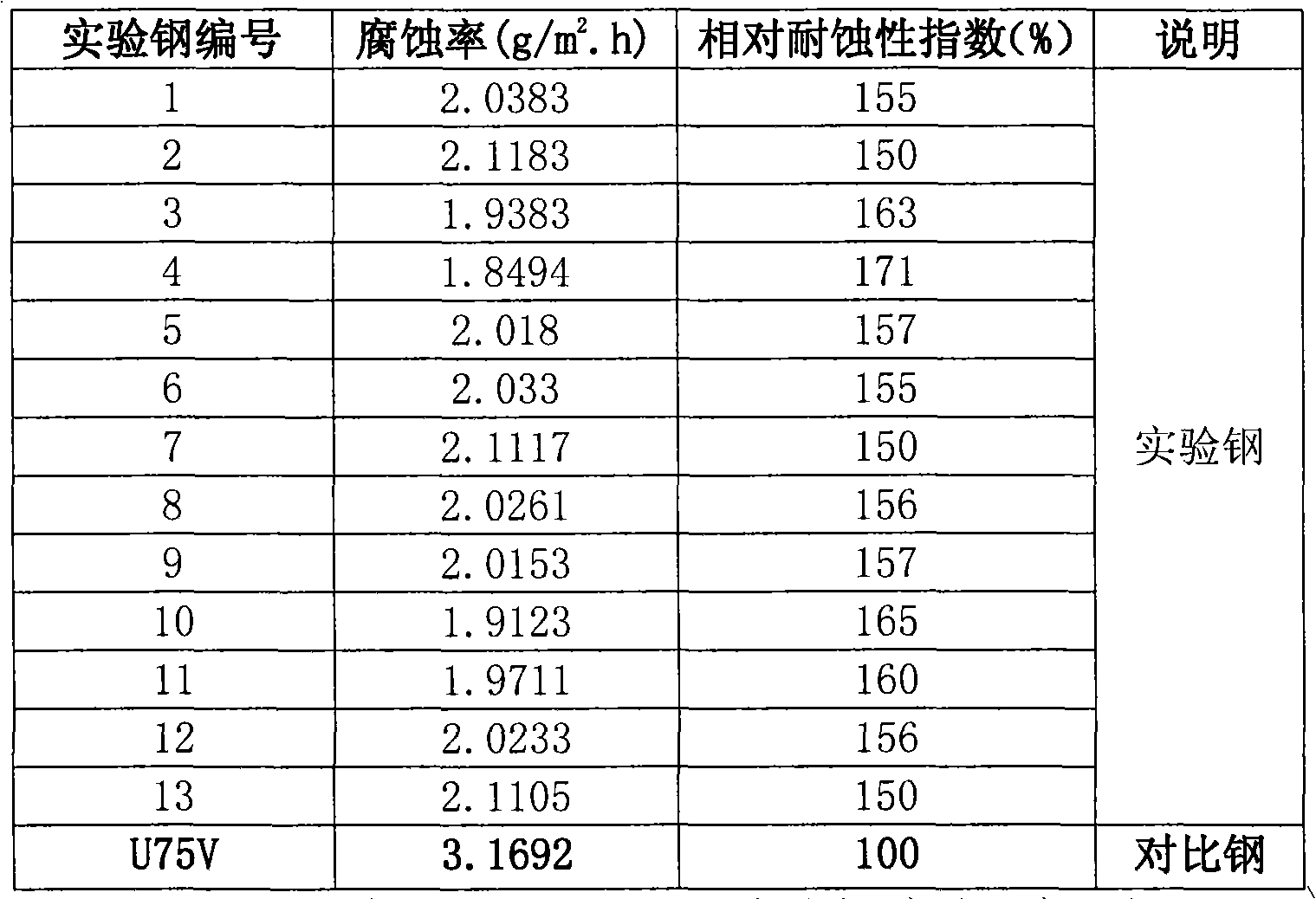

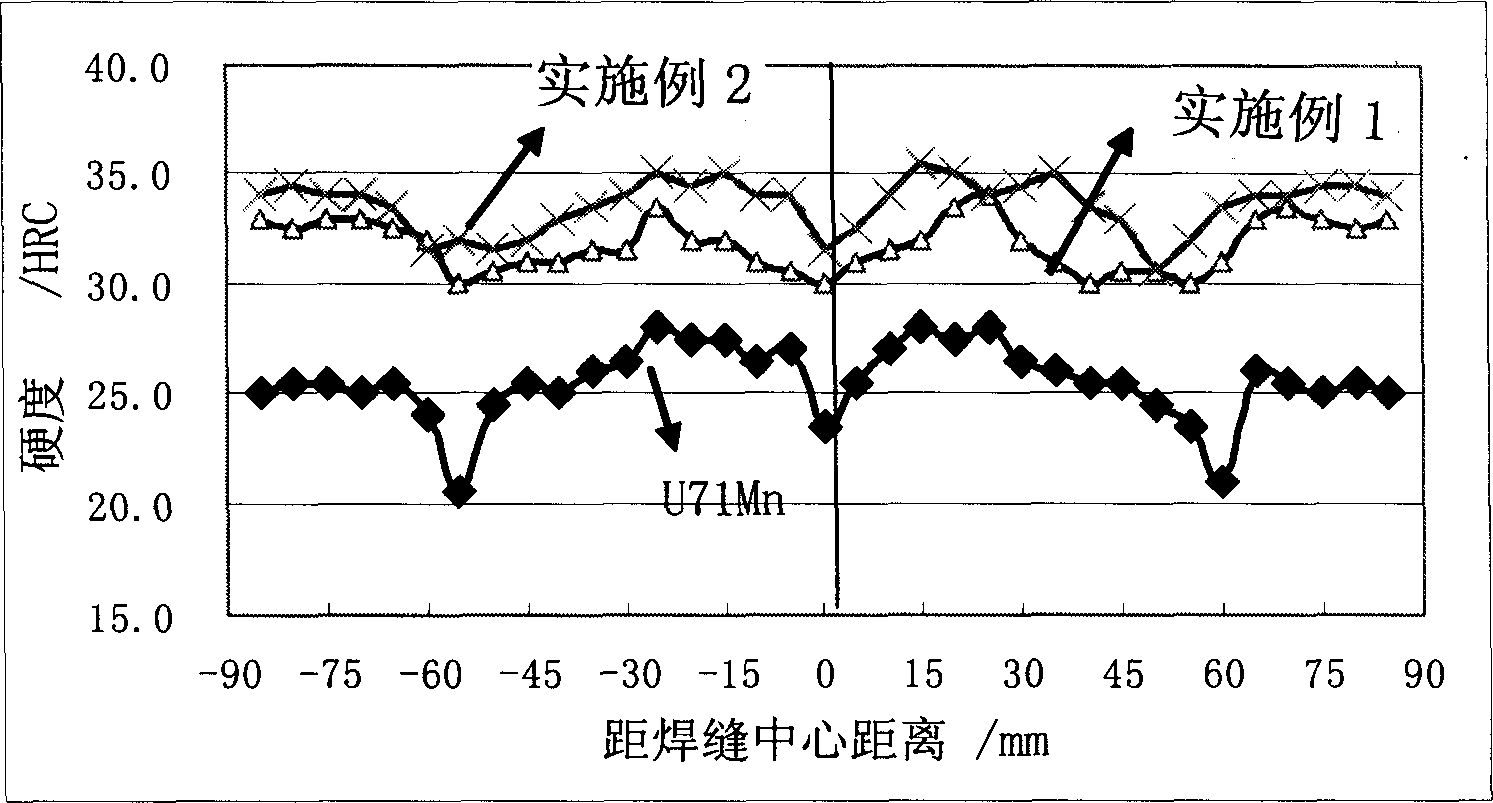

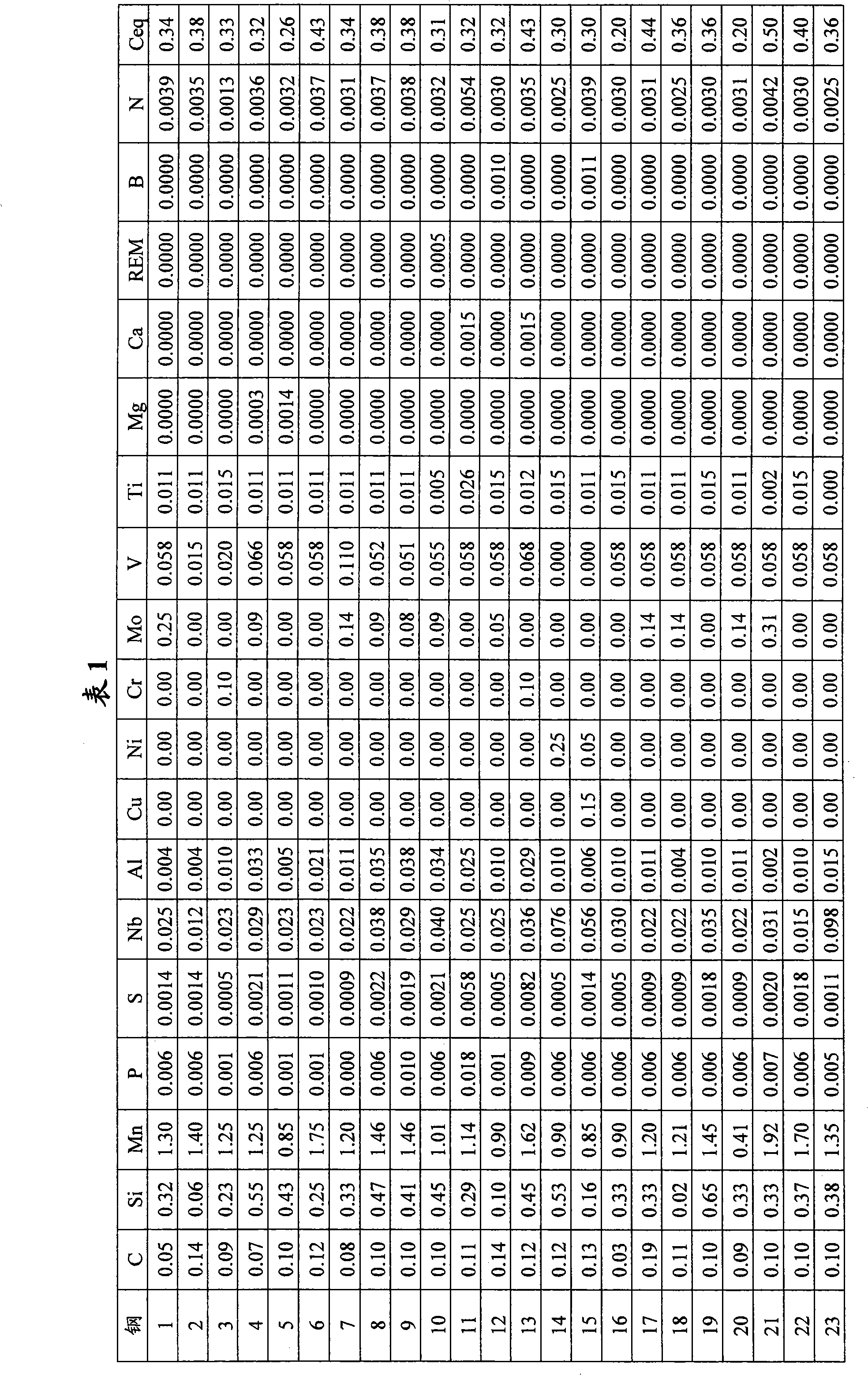

Corrosion resistant heavy rail steel with excellent strength-toughness, fatigue resistance and abrasive resistance

ActiveCN101818312AImprove mechanical propertiesImproved mechanical properties including strengthPearliteToughness

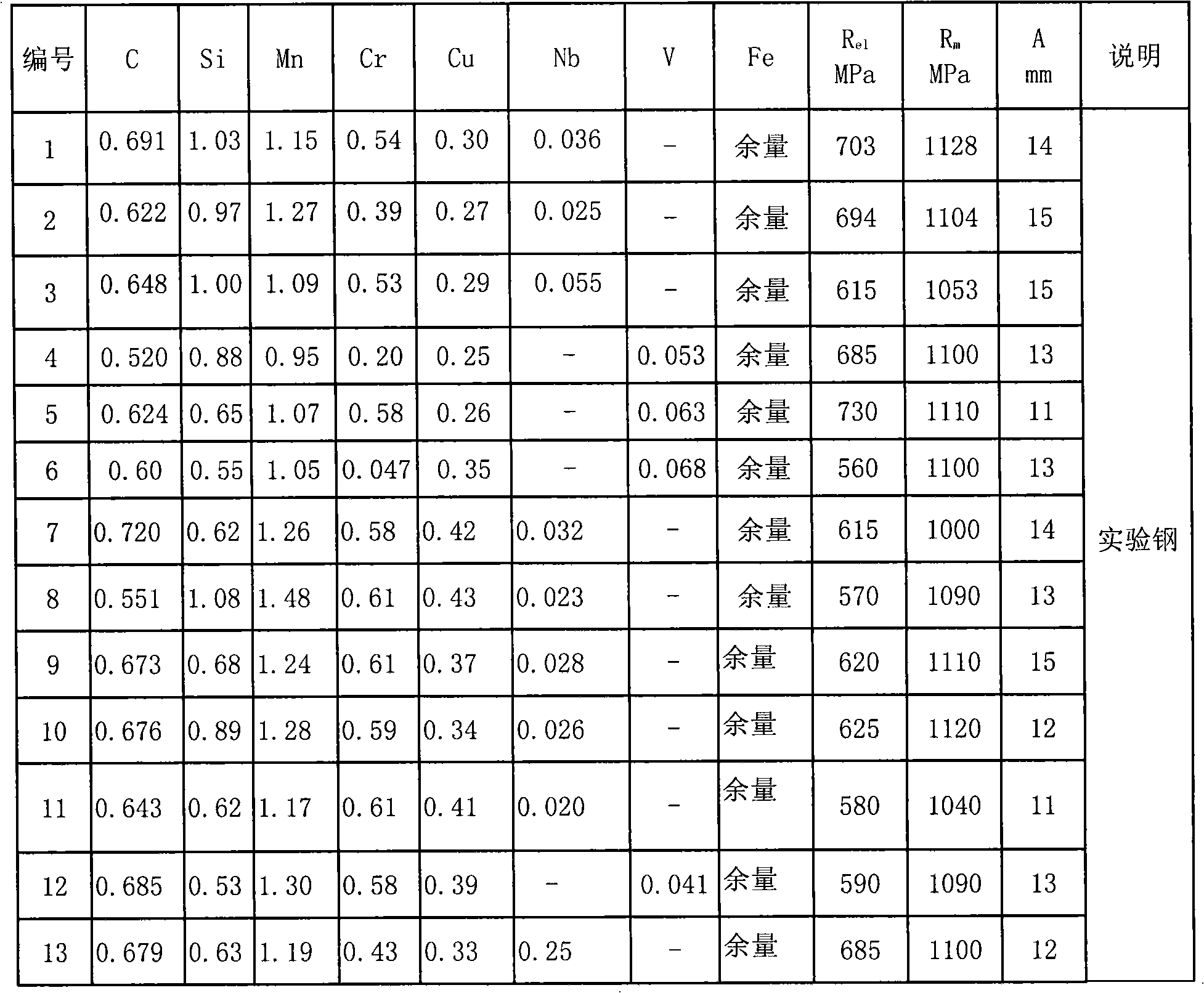

The invention discloses a corrosion resistant heavy rail steel with excellent strength-toughness, fatigue resistance and abrasive resistance, belonging to the technical field of heavy rail steel. A fundamental alloy system comprises the following alloy elements by weight percent: 0.55%-0.72% of C, 0.35%-1.1% of Si, 0.7%-1.40% of Mn, 0.2%-0.65% of Cr, 0.2%-0.65% of Cu and Fe as the balance; on the basis of the above fundamental ingredients, one or more than one microalloy elements are simultaneously added, including: 0.01%-0.055% of Nb, 0.05%-0.10% of V, 0.001%-0.05% of Ti, 0.1%-0.3% of Ni and 0.15%-0.3% of Mo. The heavy rail steel has the advantage that: mechanical properties of steel rail including strength, toughness, fatigue resistance, abrasive resistance, fracture toughness property and welding property are remarkably enhanced, so that superfine pearlite can be obtained without the need of adopting complex production technology such as rail end quenching. And simultaneously, the steel includes corrosive resistance so as to greatly enhance the service property and the service life of steel rail in corrosive environment.

Owner:CENT IRON & STEEL RES INST +1

Vermicular graphite cast iron for producing brake drum of high-speed and heavy-load automobile

The invention discloses alloyed vermicular graphite cast iron produced by alloying the ordinary vermicular graphite cast iron. The cast iron comprises an alloy of two or more of elements such as Cu, Cr, Mo, Ni, Sn, Sb, B, Ti, Al, V and the like. The vermicular graphite cast iron comprises the following chemical ingredients in percentage by weight: 3.00-3.80 percent of C, 2.00-2.80 percent of Si, 0.45-0.95 percent of Mn, less than 0.06 percent of P, less than or equal to 0.02 percent of S, and 0.02-0.60 percent of alloy ingredient. The technical indexes of the vermicular graphite cast iron are that: VG is more than or equal to 80 percent, Rm is more than or equal to 380 MPa, hardness is between 180 HBW and 258 HBW, cast pearlite is more than or equal to 60 percent, and elongation rate is between 1 percent and 2 percent. The vermicular graphite cast iron has the advantages of high intensity, high heat conductivity, high wear resistance, high thermal fatigue resistance, small deformation, simple casting process and easiness in mechanical production. The service life of a produced brake drum for a high-speed and heavy-load automobile is remarkably prolonged, and safety is ensured.

Owner:罗云

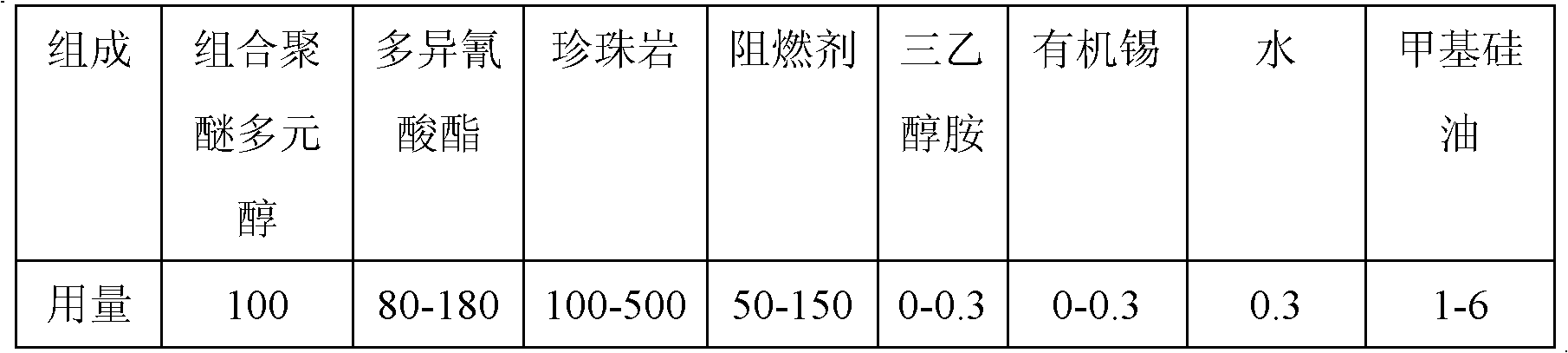

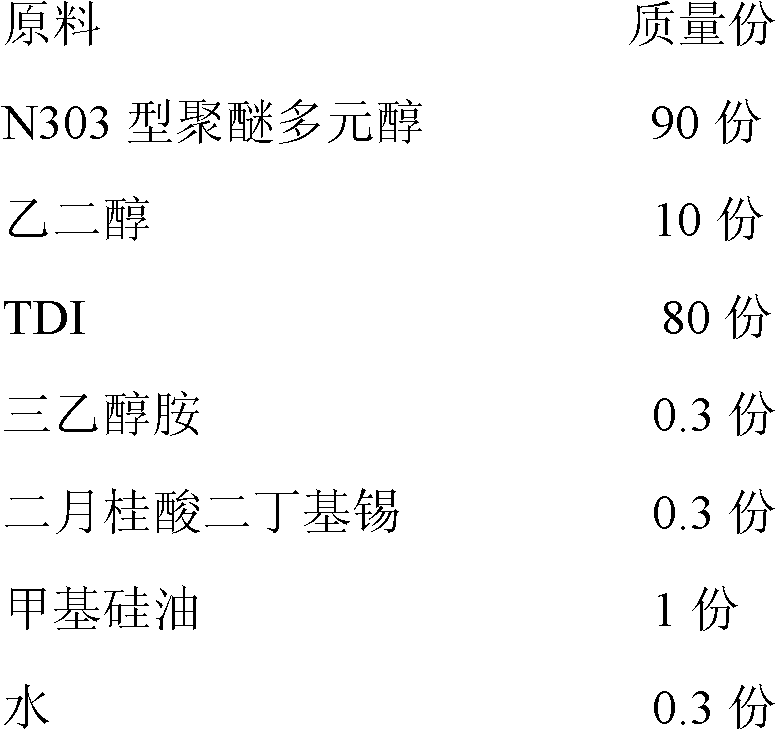

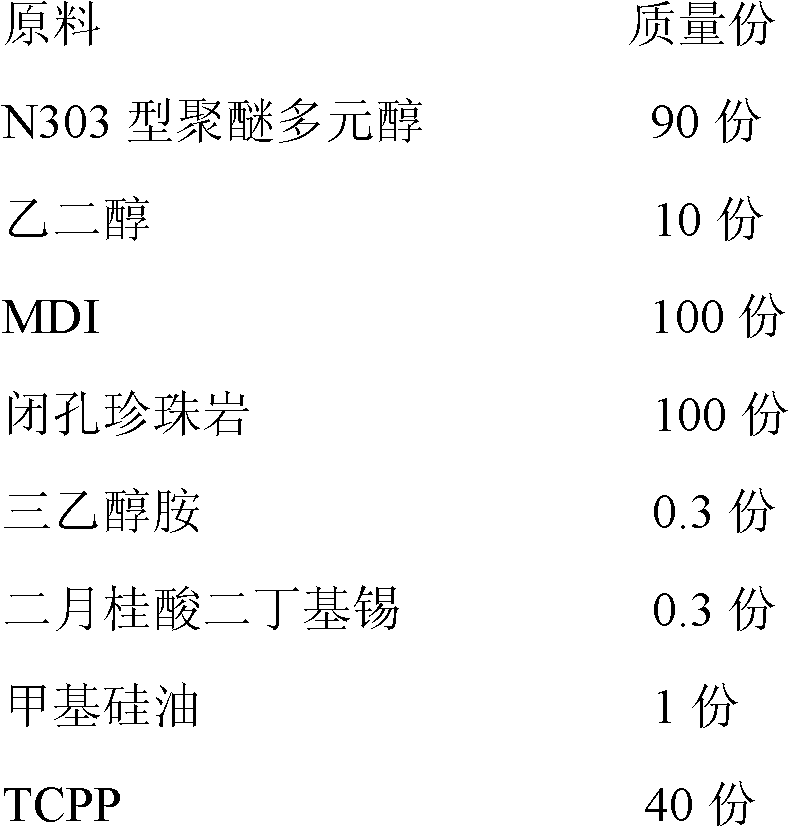

High-flame-retardance temperature preservation plate and preparation method thereof

ActiveCN102633974AMake up for the lack of easy water absorptionLow thermal conductivityHeat proofingPearliteSilicone oil

The invention belongs to the technical field of high polymer materials, and in particular discloses a high-flame-retardance temperature preservation plate and a preparation method thereof. The method is used for producing high-flame-retardance construction temperature preservation plates by utilizing pearlite for filling rigid polyurethane foam materials. The raw materials of the product providedby the invention mainly comprise composite polyether polyalcohol, polyisocyanates, pearlite, flame retardant, hydramine, organic tin, water, silicone oil and the like. The prepared product has bettermechanical property, is much easier for batch production in a plant, and also has a compact crust layer. The compact curst layer of polyurethane can remedy the defect of easiness in water absorption of the pearlite well, and meanwhile, the polyurethane plate material with high flame retardance can even be adaptive to the requirement of flame retardance level of the existing organic temperature preservation material.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

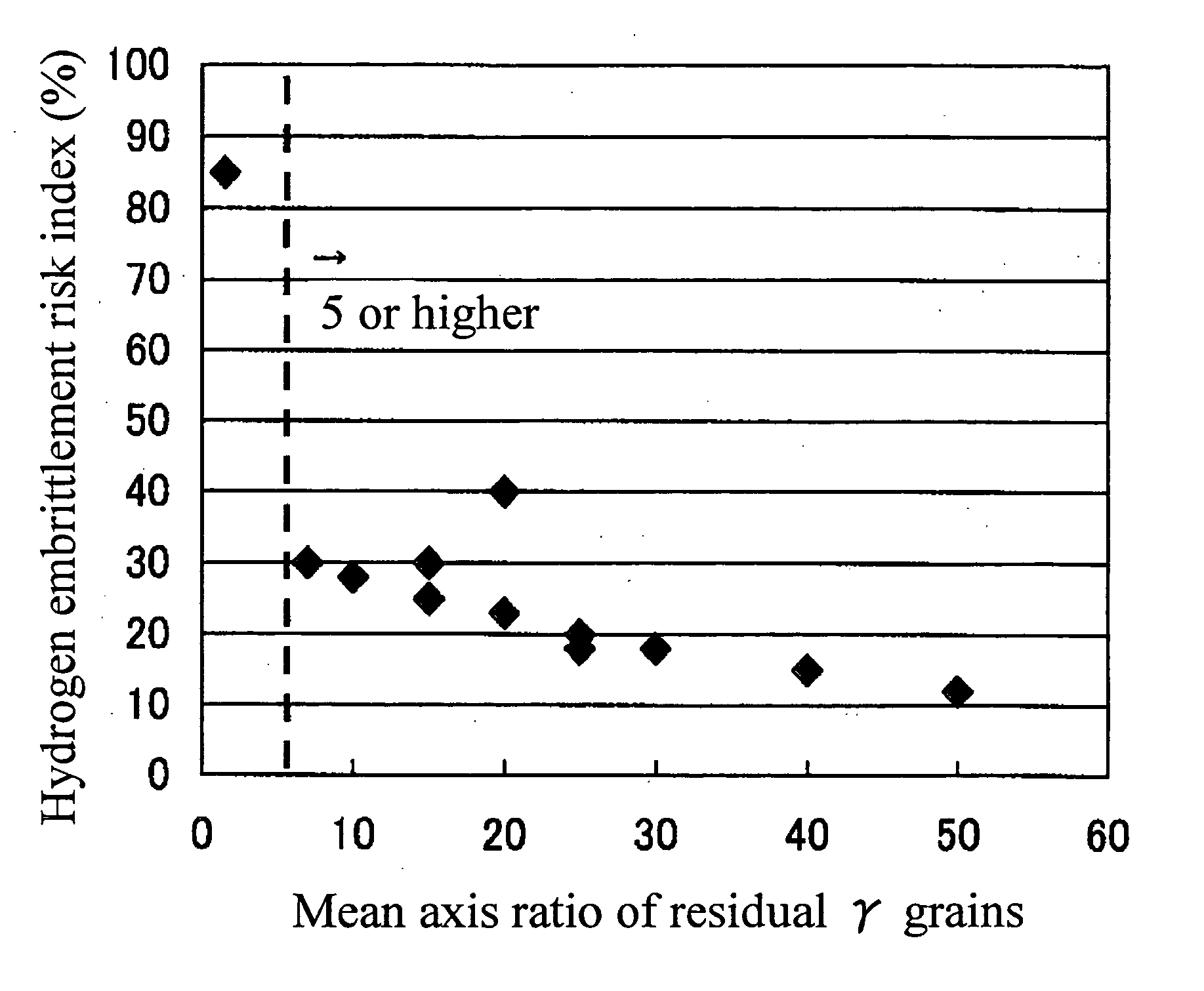

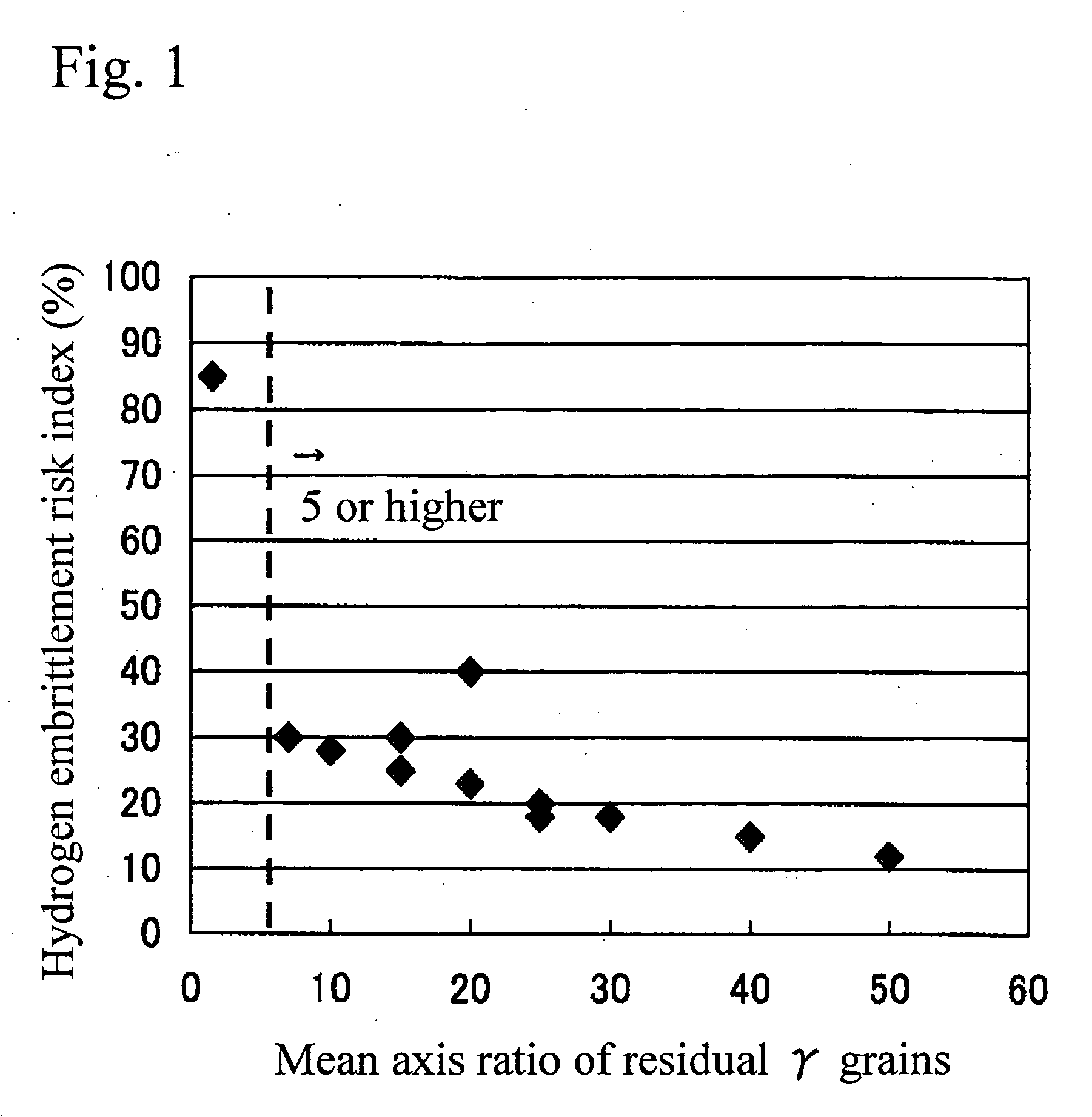

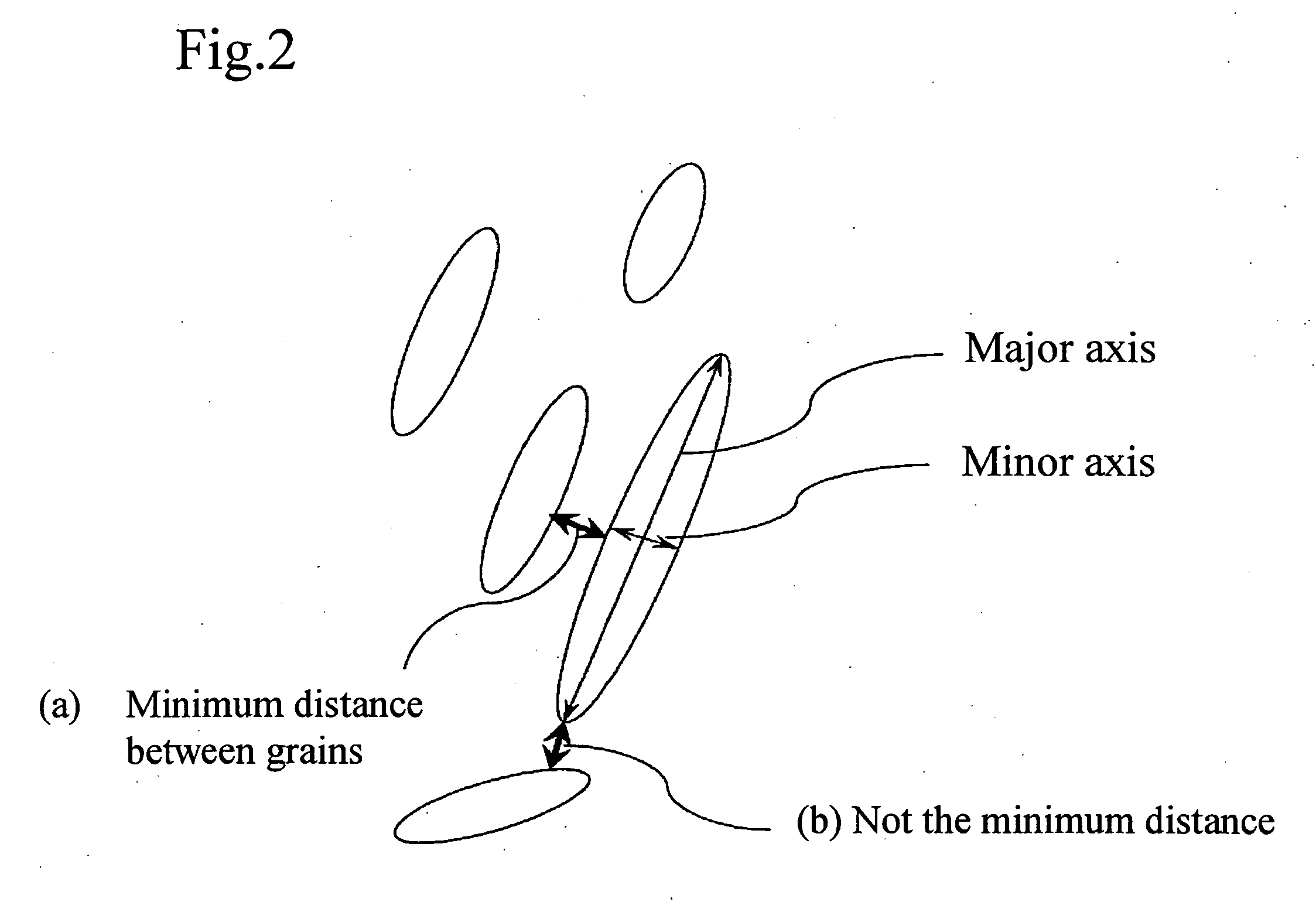

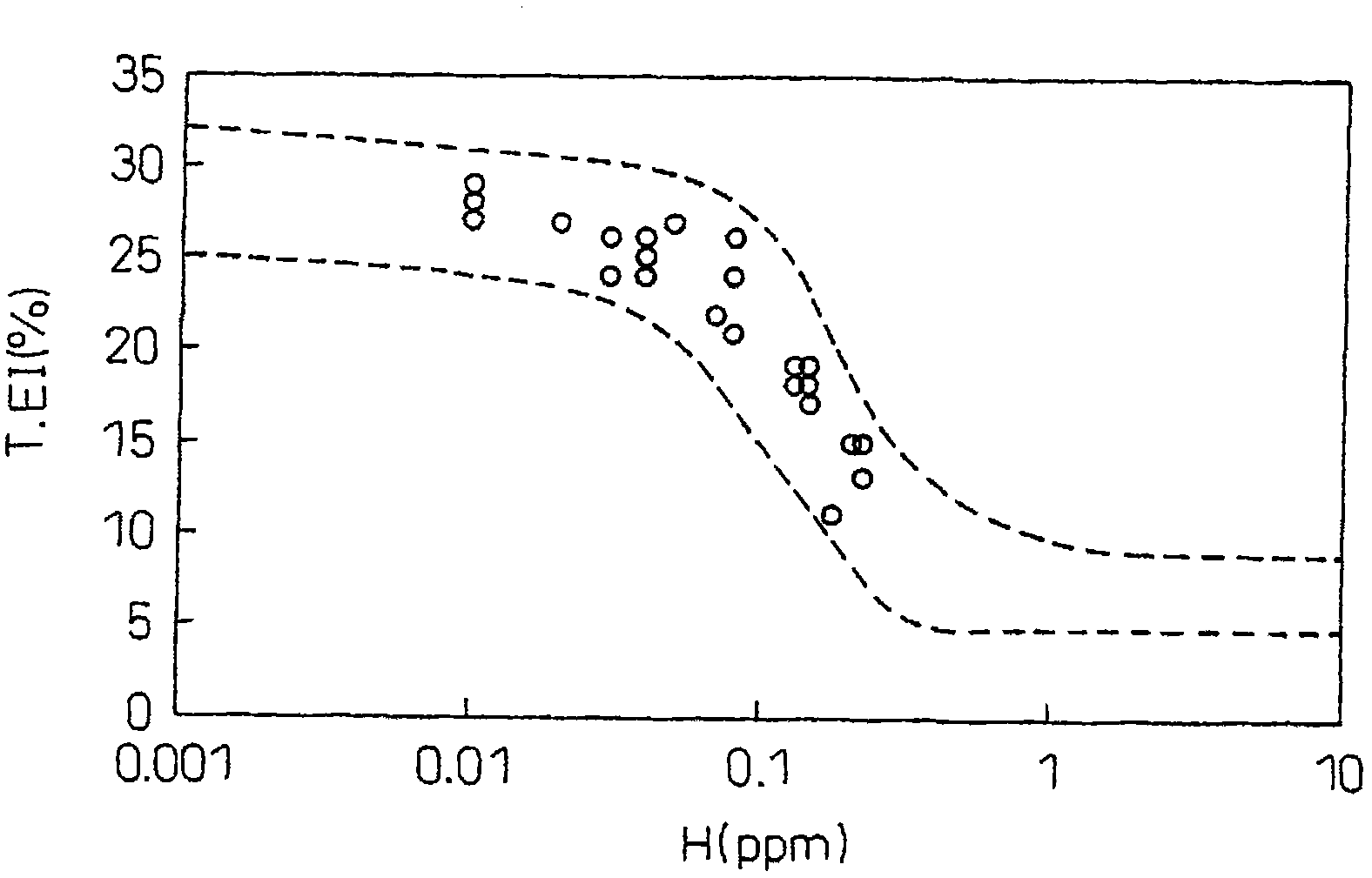

High strength thin steel sheet having high hydrogen embrittlement resisting property

The purpose of the present invention is to provide a high strength thin steel sheet that has high hydrogen embrittlement resisting property. In order to achieve the above purpose, a high strength thin steel sheet having high hydrogen embrittlement resisting property comprises: C: 0.10 to 0.25%; Si: 1.0 to 3.0%; Mn: 1.0 to 3.5%; P: 0.15% or less; S: 0.02% or less; and Al: 1.5% or less (higher than 0%) in terms of percentage by weight, with balance of iron and inevitable impurities; and the metal structure comprises: residual austenite; 1% by area or more in proportion to the entire structure; bainitic ferrite and martensite: 80% or more in total; and ferrite and pearlite: 9% or less (may be 0%) in total, while the mean axis ratio (major axis / minor axis) of said residual austenite grains is 5 or higher, and the steel has tensile strength of 1180 MPa or higher.

Owner:KOBE STEEL LTD

Melon vegetable grow seedling ground substance

The invention discloses a vegetable nursering substrate, which is characterized by the following: allocating raw material with fermented cattle manure, peat, vermiculite, pearlite and composite fertilizer of nitrogen, phosphor and potassium according to certain proportion; avoiding environmental pollution; saving manufacturing cost; reducing cost effectively; improving fertility by over 50%.

Owner:山东商道生物科技股份有限公司

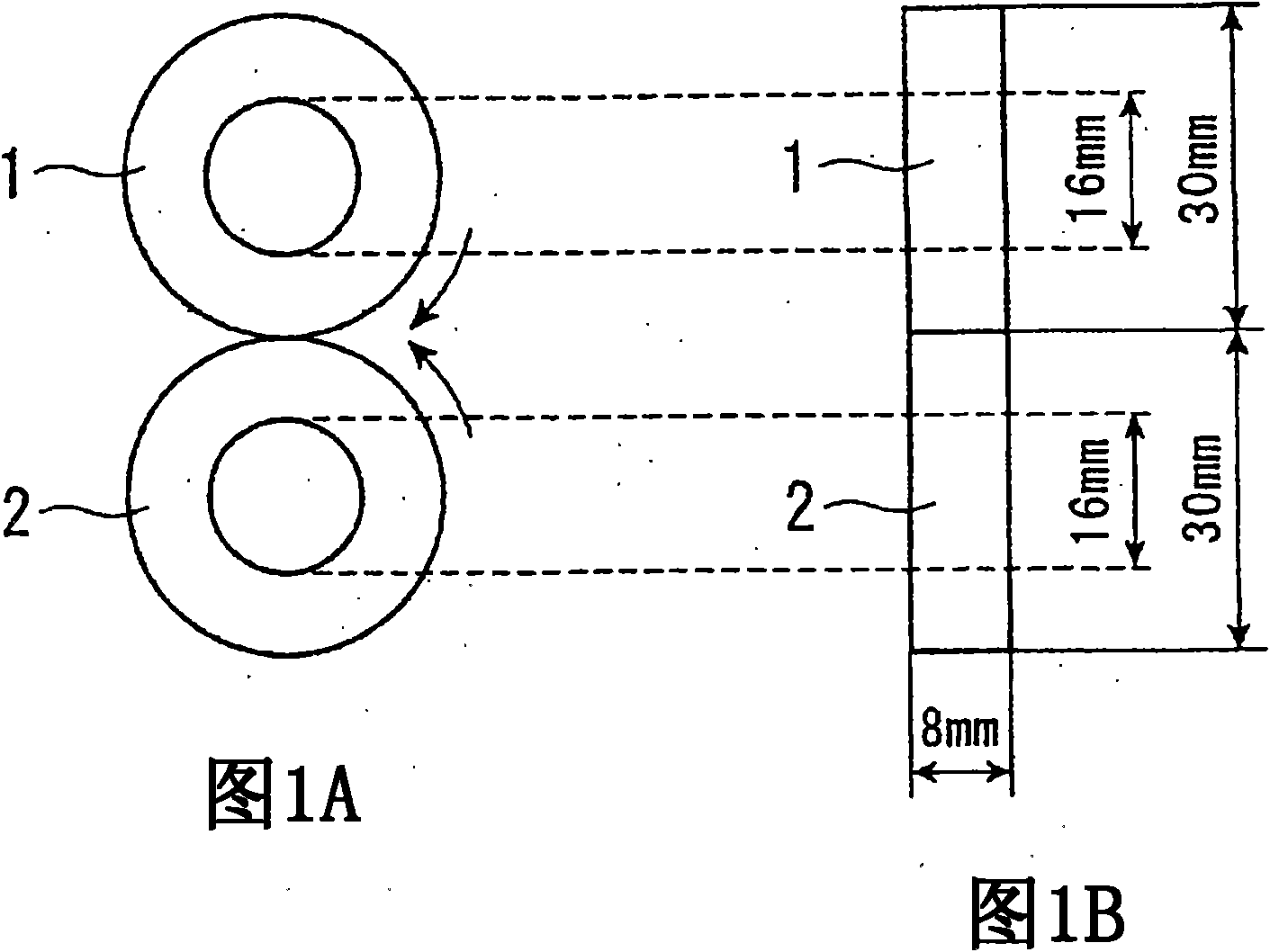

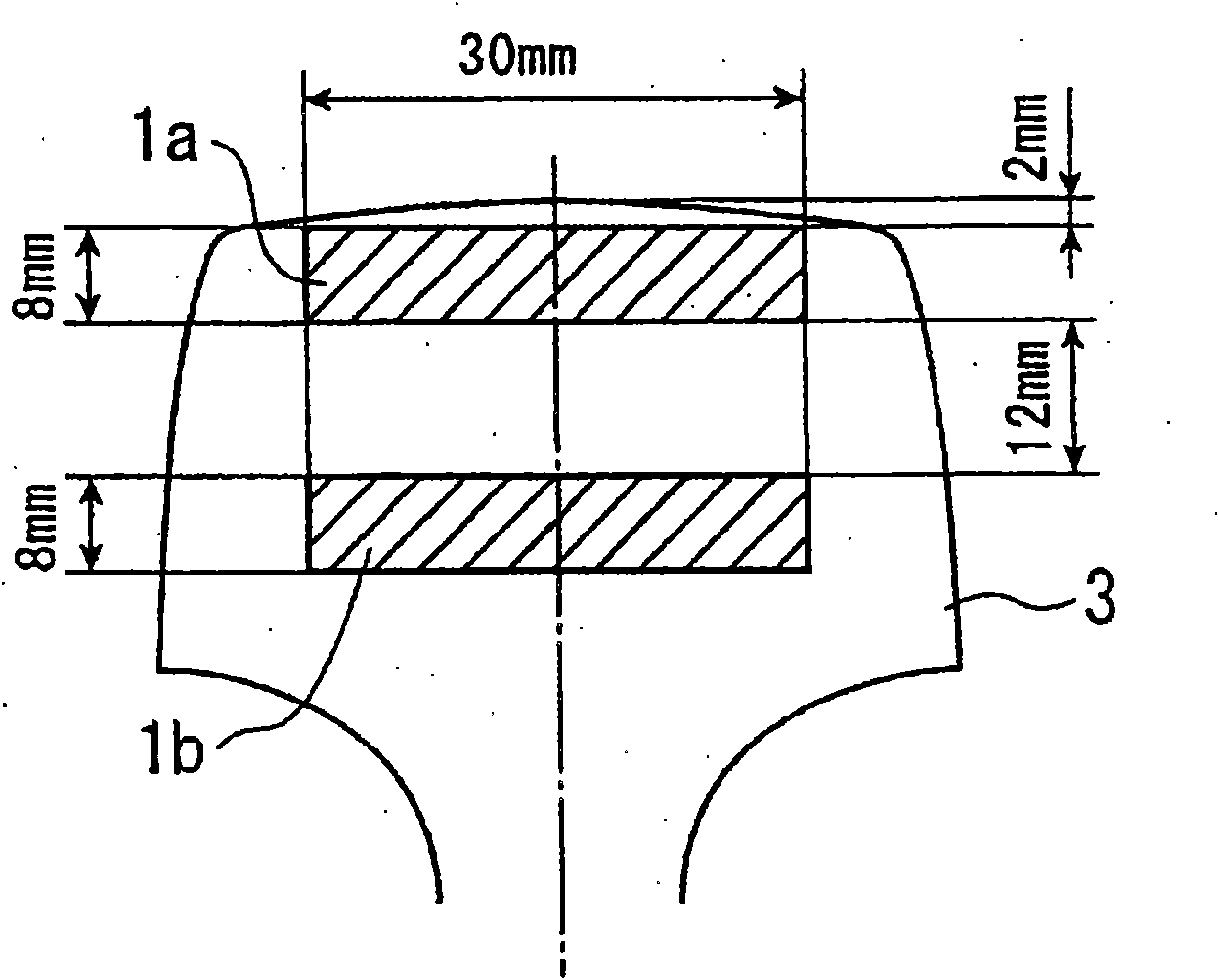

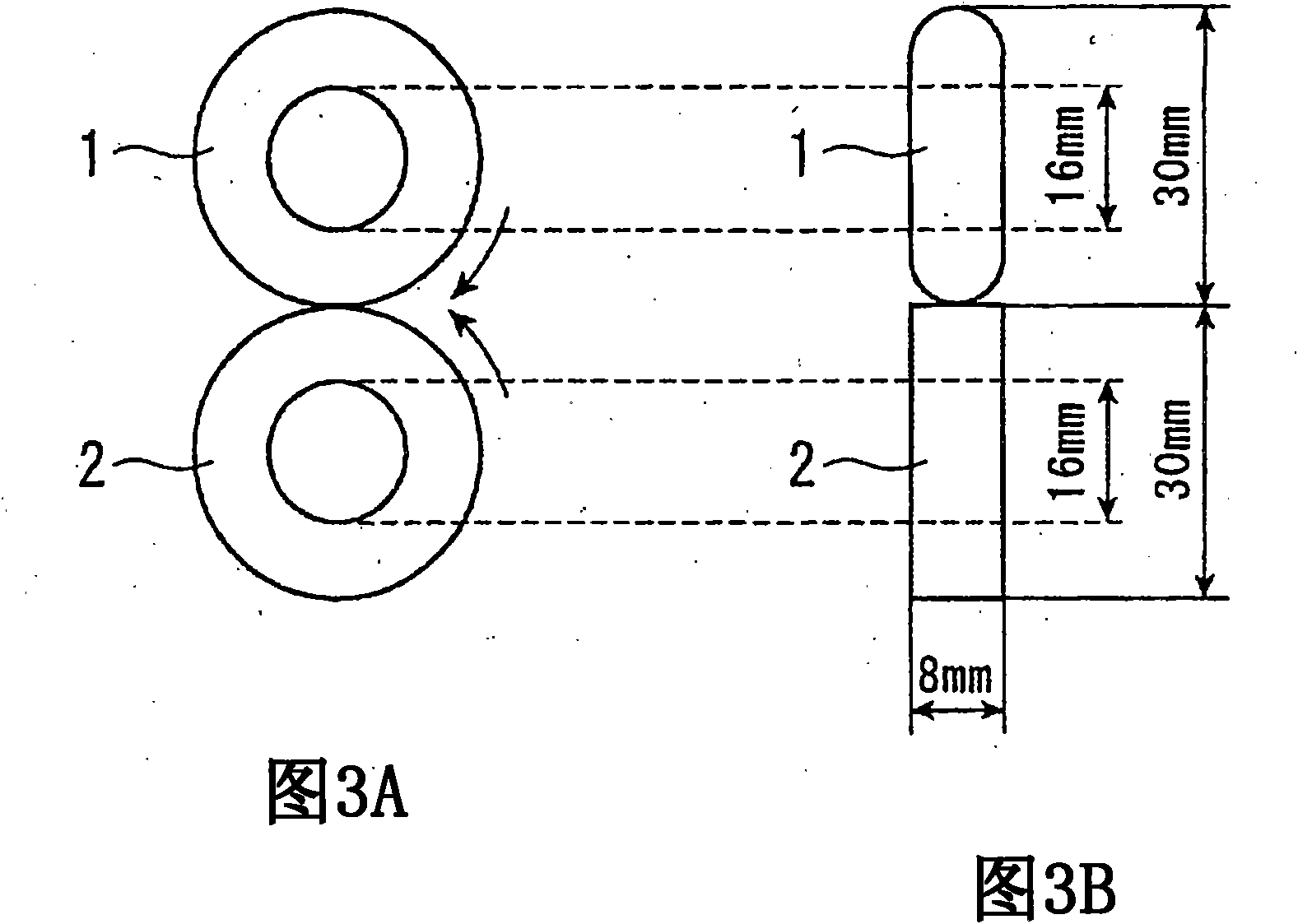

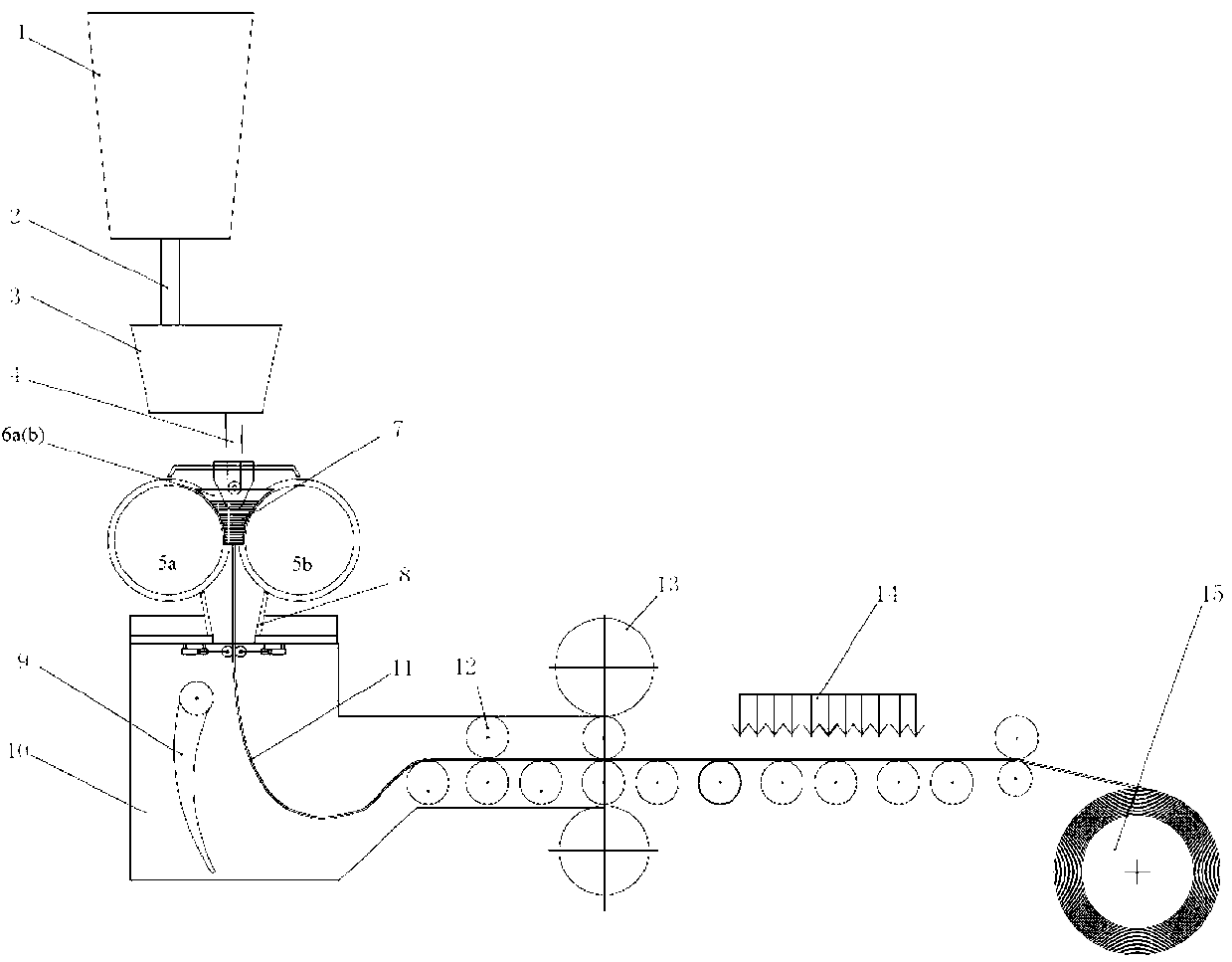

Pearlite steel rail of high internal hardness type excellent in wear resistance and fatigue failure resistance and process for production of the same

ActiveCN101646795AStable manufacturingExcellent wear resistanceFurnace typesMetal rolling arrangementsFatigue damageHardness

The invention provides a pearlite steel rail of high internal hardness type which is excellent in both wear resistance and fatigue failure resistance and a process suitable for the production of the rail. Specifically, a pearlite steel rail which has a composition containing by mass C: 0.73 to 0.85%, Si: 0.5 to 0.75%, Mn: 0.3 to 1.0%, P: 0.035% or below, S: 0.0005 to 0.012% and Cr: 0.2 to 1.3% with the balance consisting of Fe and unavoidable impurities and having a ¢%Mn! / ¢%Cr! ratio of 0.3 or above and below 1.0 (wherein ¢%Mn! is Mn content and ¢%Cr! is Cr content) and whose railhead exhibitsan internal hardness of Hv380 or above and below Hv480 in terms of Vickers hardness (Hv)in a depth range of at least 25mm from the railhead surface.

Owner:JFE STEEL CORP

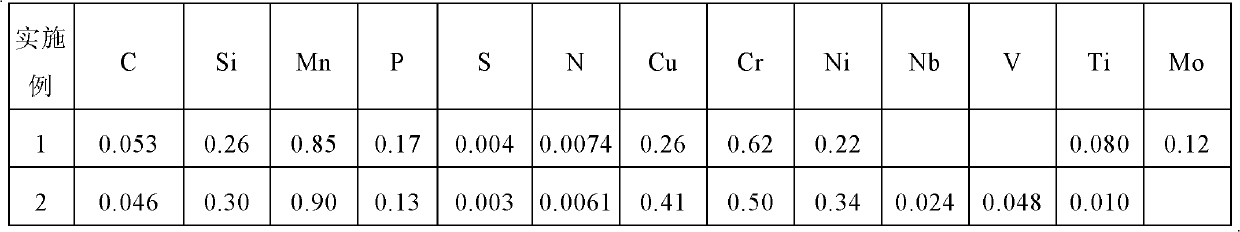

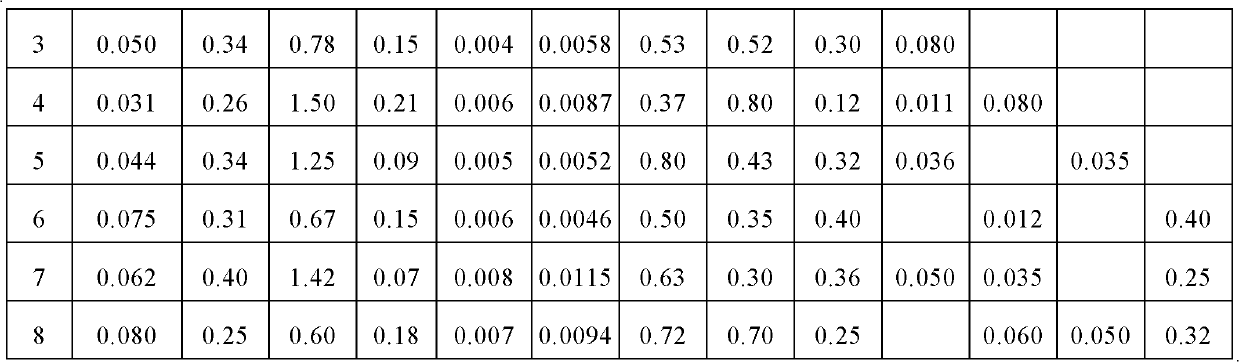

Method for manufacturing 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting

ActiveCN103305770AHigh strengthHigh elongationFurnace typesMetal rolling arrangementsReduction rateChemical composition

The invention provides a method for manufacturing a 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting. The method comprises the following steps of: 1) smelting, wherein molten steel comprises the following chemical components: 0.03-0.08% of C, not more than 0.4% of Si, 0.6-1.5% of Mn, 0.07-0.22% of P, not more than 0.01% of S, not more than 0.012% of N, 0.25-0.8% of Cu, 0.3-0.8% of Cr, 0.12-0.4% of Ni, at least one of microalloy elements including 0.01-0.08% of Nb, 0.01-0.08% of V, 0.01-0.08% of Ti and 0.1-0.4% of Mo, and the balance of Fe and inevitable impurities; 2) strip continuous casting: directly casting a cast strip with thickness of 1-5mm; 3) strip cooling, wherein the cooling rate is more than 20 DEG C / s; 4) online hot rolling of the cast strip, wherein the hot rolling temperature is 1050-1250 DEG C, the reduction rate is 20-50% and the deformation rate is more than 20s<-1>; online austenite recrystallization happens after hot rolling; and the hot-rolled strip is 0.5-3.0mm in thickness; and 5) cooling and coiling, wherein the cooling rate is 10-80 DEG C / s, and the coiling temperature is 570-720 DEG C. The microstructure of the obtained steel strip is mainly formed by fine polygonal ferrite and pearlite.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot-rolled high-strength steel plate for electrostatic enamel and method for manufacturing same

ActiveCN101139684ATemperature control deviceHeat treatment process controlHigh resistanceForeign matter

The invention provides a hot-rolled high-strength steel sheet for static enameling and a manufacturing method for the steel sheet. The main components by weight of the steel sheet are: C: 0.02-0.1%, Si<=0.1%, Mn: 0.2-1.5%, P: <=0.035%, S<=0.035%, Al: 0.01-0.1%, N: 0.001-0.01%, Ti: 0.01-0.1 %, Nb: 0.001-0.1%, and the remainder are iron and unavoidable foreign matters. The structure of the steel sheet comprises ferrite and pearlite, an the average particle diameter of the ferrite is not more than 11 micrometer. The manufacturing method of the steel sheet is, rolling twice the continuously cast or steel blanks after heating to 1100-1250 DEG C with total pressure-down amount <=50%, and final rolling temperature >=800 DEG C, then cooling section by section to coiling temperature 550-700 DEG C, and finally leveling the sheet. The hot-rolled high-strength steel sheet is applicable for pressure vessels such as bladders of water heaters, liquid-storing tanks and water buckets, etc. that are manufactured by static enameling process, is of high strength and good plasticity, high resistance to scaling bursting and air tightness.

Owner:BAOSHAN IRON & STEEL CO LTD

Pearlite like high strength low alloy rail steel and producing method thereof

ActiveCN1793402AImprove wear resistanceHigh strengthTemperature control deviceFurnace typesChemical compositionHigh intensity

The invention relates to a pearly high-strength low-alloy steel rail iron and manufacturing method. Its chemical composition percentage by weight includes: C:0.70-0.95%, Si:0.20-1.10%, Mn:0.50-1.50%, V:0.01-0.20%, Cr:0.15-1.20%, P: not less than 0.035%, S:not less than 0.035%, and Al: not less than 0.005%. The method includes the following steps: smelting; adding carburant and alloy; vacuum processing; billet heating; rolling; and cooling. The cooling speed is not more than 4.0 centigrade degree per second. The formed steel rail has good ware resistance and welding property. The method has simple technology and convenient operation.

Owner:PANZHIHUA IRON AND STEEL

Steel plate for line pipes with excellent strength and ductility and process for production of same

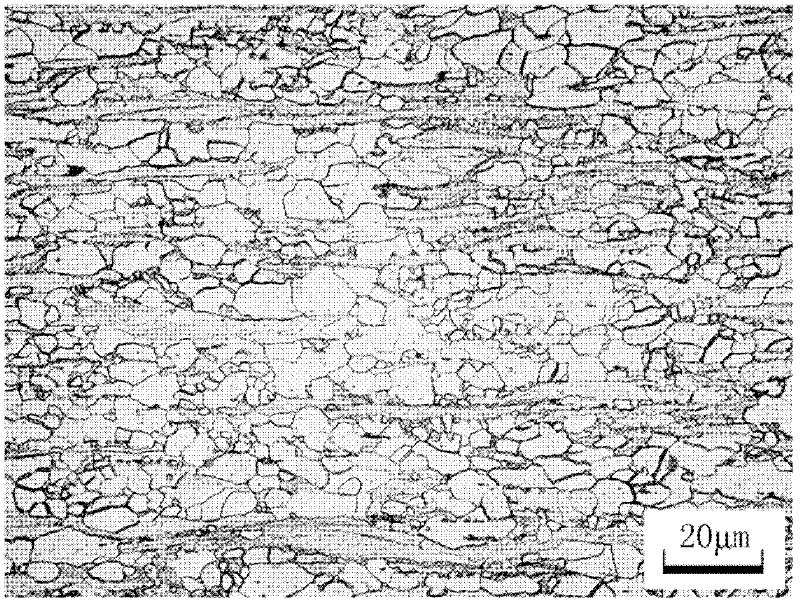

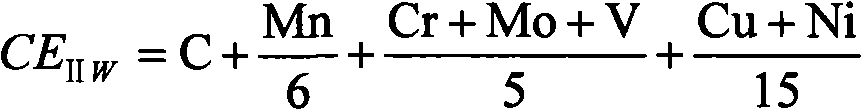

Provided is a steel plate for line pipes which exhibits excellent strength and ductility. Also provided is a process for the production of the steel plate. The steel plate is characterized by: having a steel composition which contains, by mass, 0.04 to 0.15% of C, 0.05 to 0.60% of Si, 0.80 to 1.80% of Mn, at most 0.020% of P, at most 0.010% of S, 0.01 to 0.08% of Nb, and 0.003 to 0.08% of Al with the balance being iron and unavoidable impurities, and which has a Ceq value of 0.48 or lower as defined by formula (1); having a mixed structure which is composed either of ferrite and pearlite or of ferrite and bainite-containing pearlite and which has a ferrite fraction of 60 to 95%; and exhibiting a yield strength of 450MPa or higher and a hydrogen content of 0.1ppm or lower. Ceq = C + Mn / 6 +(Cu + Ni) / 15 + (Cr + Mo + Nb + V + Ti) / 5 + 5B (1).

Owner:NIPPON STEEL CORP

Light ecological concrete brick and preparation method thereof

InactiveCN101823859AImprove immunityImprove water qualitySolid waste managementCeramicwareBrickApposition

The invention discloses a light ecological concrete brick and a preparation method thereof. The light ecological concrete brick is formed by that cement, gravel, pearlite or expanded vermiculite, saw dust (or straw dust, paper scrap and the like), mixed microorganism and water are mixed at certain ratio, are shaped by a mould and are naturally hardened, wherein the mixed microorganism comprises six floras, i.e. bacillus, nitrobacteria, photosynthetic bacteria, saccharomycete, lactic acid bacteria and actinomycete. The light ecological concrete brick of the invention has favourable and long-lasting water purification function because of containing multiple microorganisms and can suspend and even float on the water because of containing light and porous pearlite or expanded vermiculite components with strong adsorption force, which is more favourable for the apposition growth of the microorganism and enlarges contact area with water. The invention can be widely applied on purifying various kinds of water, such as rivers, lakes, ditch water, swimming pools, aquariums and the like.

Owner:ZHONGXU PLANNING & ARCHITECTURE DESIGN

High-strength steel plate with superior crack arrestability

ActiveCN101341269AImprove crack arrest performanceHigh strengthThin material handlingHigh intensityPearlite

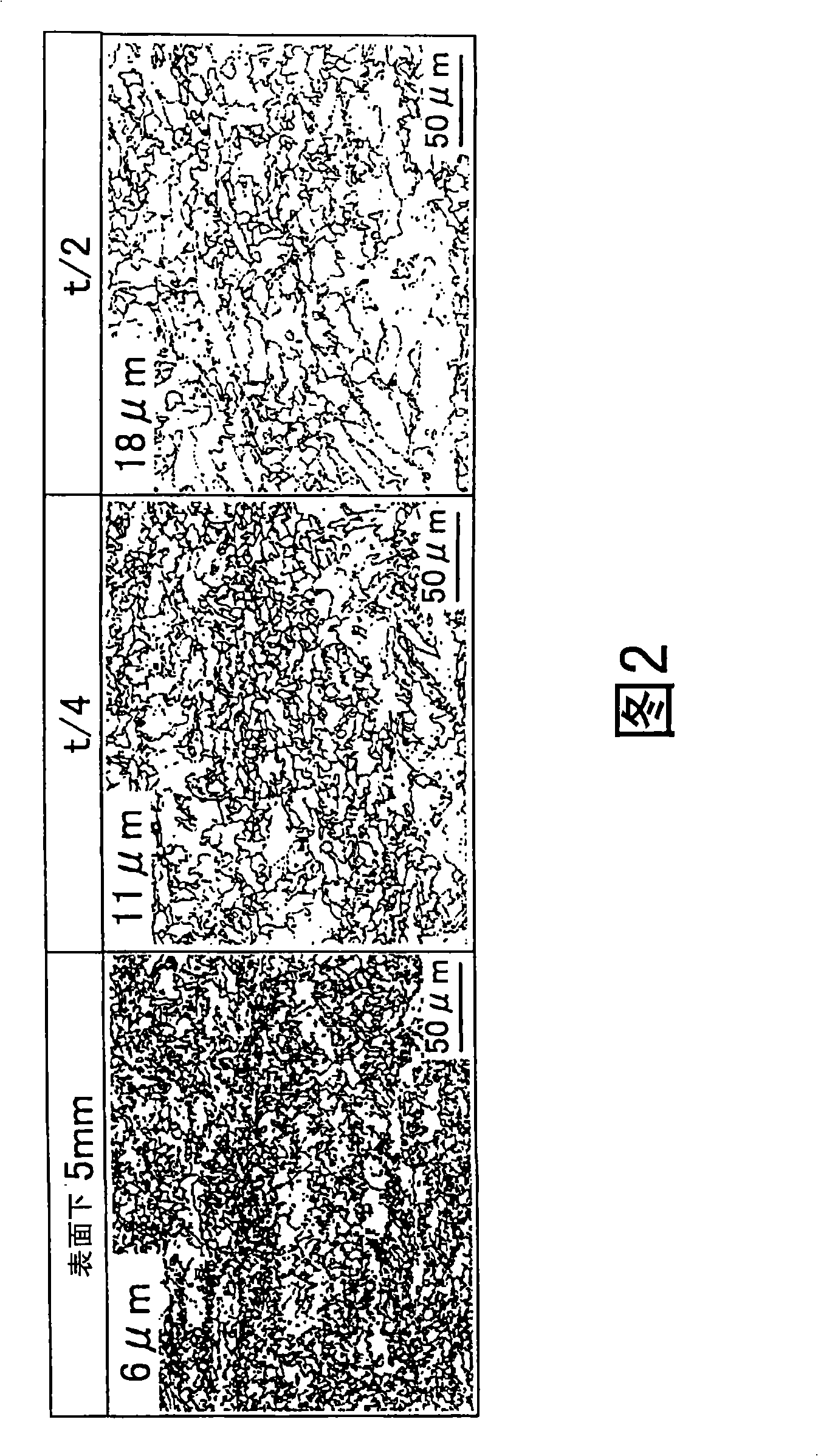

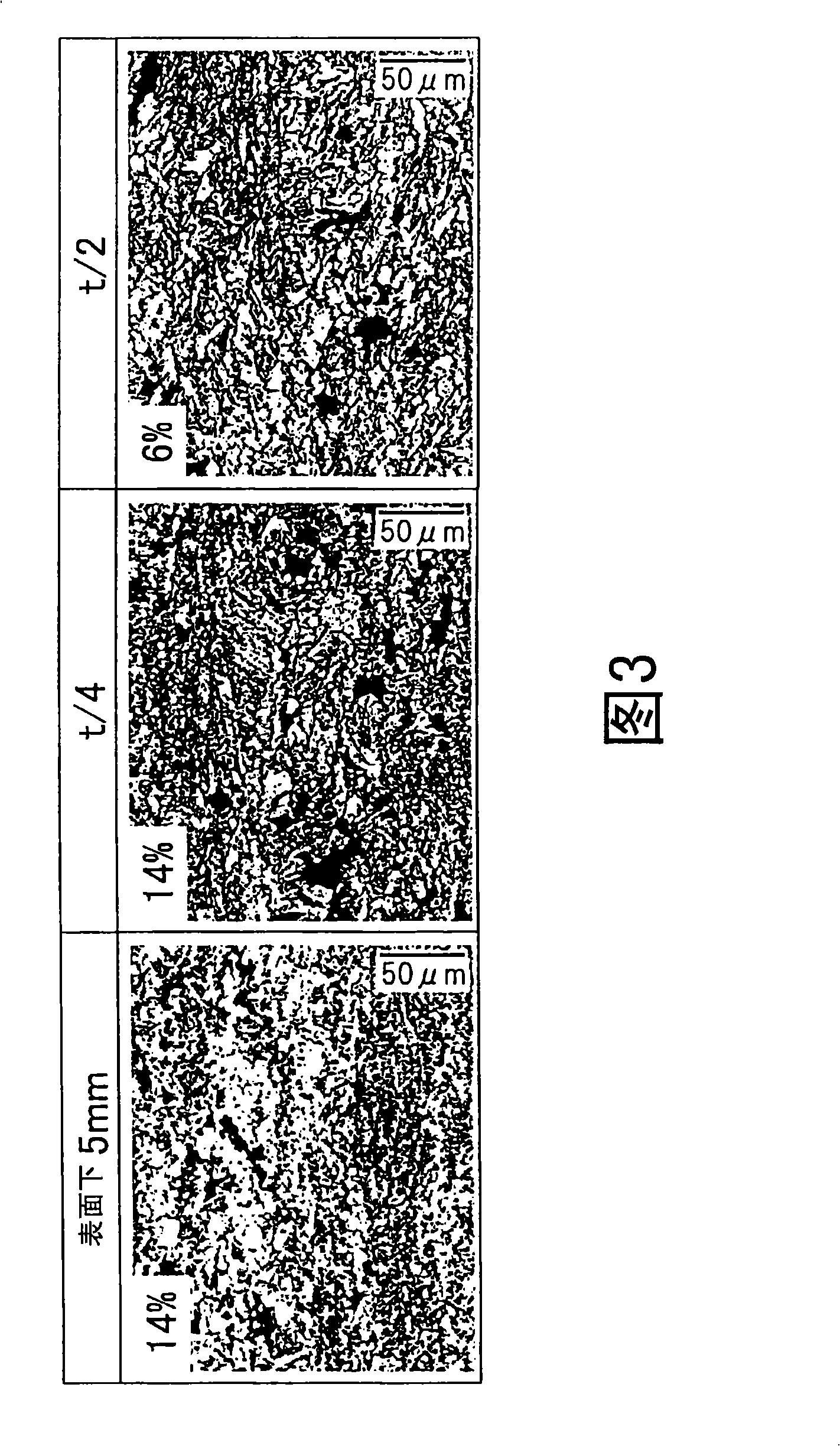

The present invention provides high strength thick steel plate superior in crack arrestability, high in strength, free of deterioration of HAZ toughness, and free of anisotropy, that steel plate containing, by mass%, C: 0.03 to 0.15%, Si: 0.1 to 0.5%, Mn: 0.5 to 2.0%, P: 0.02%, S: 0.01%, Al: 0.001 to 0.1%, Ti: 0.005 to 0.02%, Ni: 0.15 to 2%, and N: 0.001 to 0.008% and having a balance of iron and unavoidable impurities as chemical components, having a microstructure of a ferrite and / or pearlite structure with bainite as a matrix phase, and having an average circle equivalent diameter of crystal grains with a crystal misorientation angle of 15 DEG or more of 15 [mu]m or less in the regions of 10% of plate thickness from the front and rear surfaces and of 40 [mu]m or less in the other region including the center part of plate thickness.

Owner:NIPPON STEEL CORP

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857APrevent rustNo foamingHot-dipping/immersion processesAcid washingCooling chamber

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles,arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

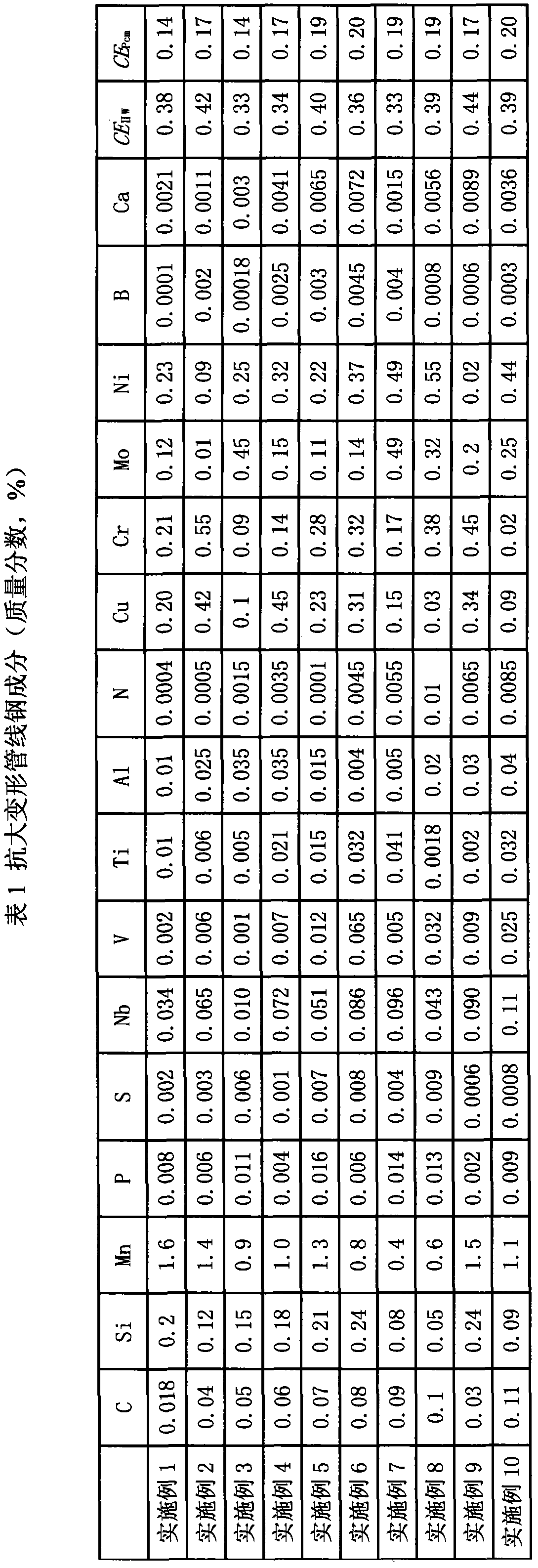

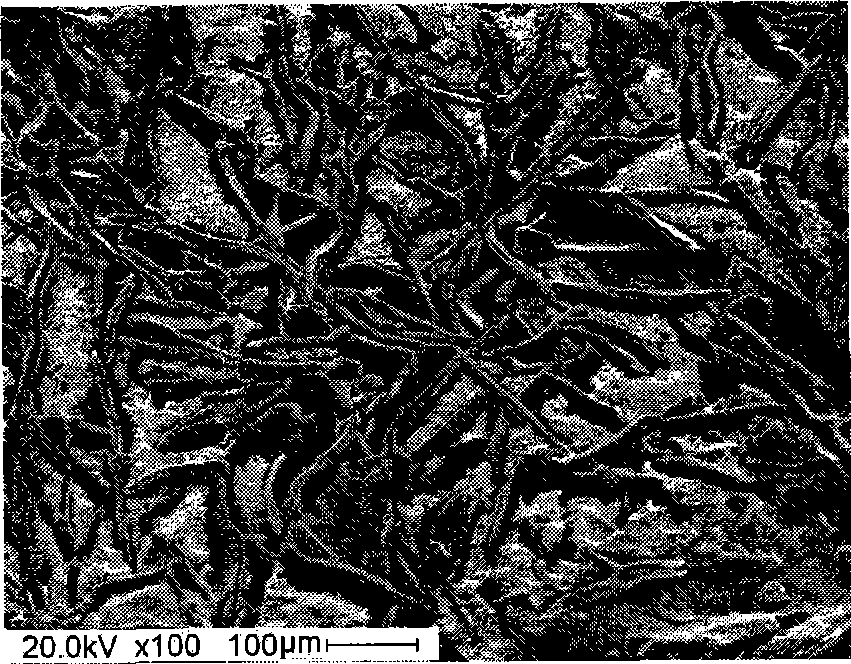

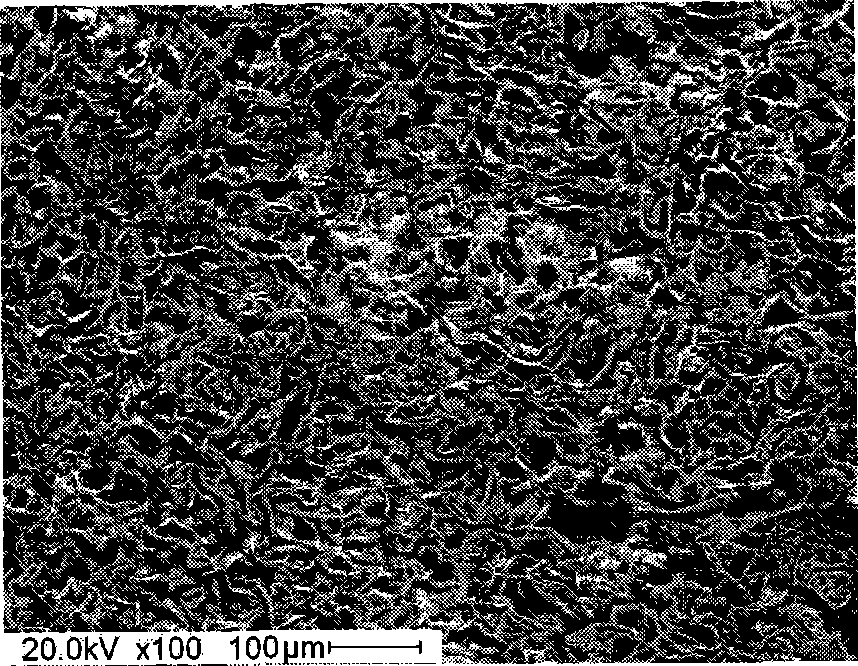

Anti-large-deformation pipe line steel prepared by thermal treatment method and preparation method thereof

The invention discloses anti-large-deformation pipe line steel prepared by a thermal treatment method and a preparation method thereof. The steel comprises the following chemical components of: not less than 0.02% and not greater than 0.12% of C, not less than 0.5% and not greater than 2.0% of Mn, not more than 0.25% of Si, not more than 0.02% of P, not more than 0.01% of S, not more than 0.11% of Nb, not more than 0.08% of V, not more than 0.05% of Ti, not more than 0.06% of Al, not more than 0.012% of N, not more than 0.50% of Cu, not more than 0.60% of Cr, not more than 0.50% of Mo, not more than 0.60% of Ni, not more than 0.005% of B, not more than 0.01% of Ca and the balance of Fe and inevitable impurities, wherein the CEIIW is not less than 0.3% and not greater than 0.45%, and the CEPcm is not more than 0.2%. The preparation method comprises the following steps of: heating steel at 700-950 DEG C in a thermal treatment furnace, maintaining the temperature for 6-15 min, cooling with the rate of 1-400 DEG C / s to room temperature, and simultaneously tempering from room temperature to 500 DEG C to obtain steel with ferrite as a first phase and bainite, martensite, degenerate perlite or any mixture thereof as a second phase. The steel has the advantages of high tensile strength, low yield strength, low yield ratio, high uniform elongation rate and high strain hardening exponent, thereby having good toughness and deformation performance.

Owner:NANJING IRON & STEEL CO LTD

High strength spring steel having excellent hydrogen embrittlement resistance

InactiveUS20060169367A1High strengthLow priceFurnace typesOhmic-resistance heatingAustenite grainHigh intensity

The present invention provides a high strength steel used for spring steel that has excellent hydrogen embrittlement resistance. The high strength steel which spring steel having excellent hydrogen embrittlement resistance comprises 0.20 to 0.60% of C, 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, higher than 0% and not higher than 1.5% of Al, 0.15% or less P, 0.02% or less S, and balance of iron and inevitable impurities and the structure includes: 1% or more residual austenite; 80% or more in total of bainitic ferrite and martensite; and 10% or less (may be 0%) in total content of ferrite and pearlite in the proportion of area to the entire structure, and also the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher and the steel tensile strength is 1860 MPa or higher.

Owner:KOBE STEEL LTD +1

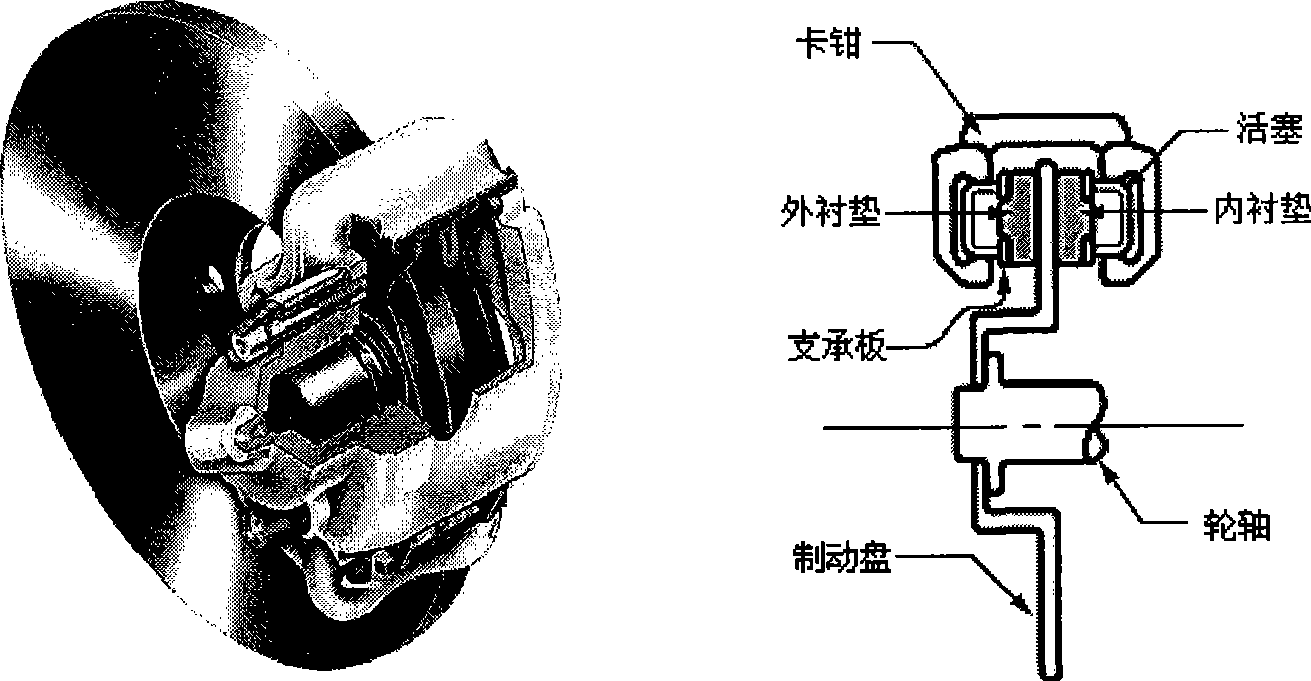

Niobium alloy cast iron brake disk material and technique for producing the same

The invention relates to a material for a niobium alloy cast iron braking disc and a production technology thereof, and belongs to the field of production technology of high-carbon equivalent hypereutectic gray cast iron. The material for the niobium alloy cast iron braking disc comprises the following chemical compositions in weight percentage: 3.7 to 3.9 percent of carbon, 1.8 to 2.2 percent of silicon, 0.5 to 0.8 percent of manganese, less than or equal to 0.08 percent of sulfur, less than or equal to 0.60 percent of copper, less than or equal to 0.20 percent of nickel, less than or equal to 0.05 percent of vanadium, less than or equal to 0.05 percent of stannum, less than or equal to 0.05 percent of titanium, less than or equal to 0.25 percent of chrome molybdenum, 0.08 to 0.3 percent of niobium, and the balance being iron, wherein the iron is melted by an intermediate frequency furnace. The structure of the material is characterized by comprising pearlite, graphite (A3-5), and a small amount of ferrite The performance characteristics of the material are as follows: the hardness HB is more than or equal to 150 and the tensile strength is more than or equal to 170 N / mm<2>. The material is suitable for braking discs for medium-to-high grade sedans made of gray cast iron, and has the advantages of stable performance, low cost, longer service life, and convenient processing.

Owner:SHANGHAI UNIV +1

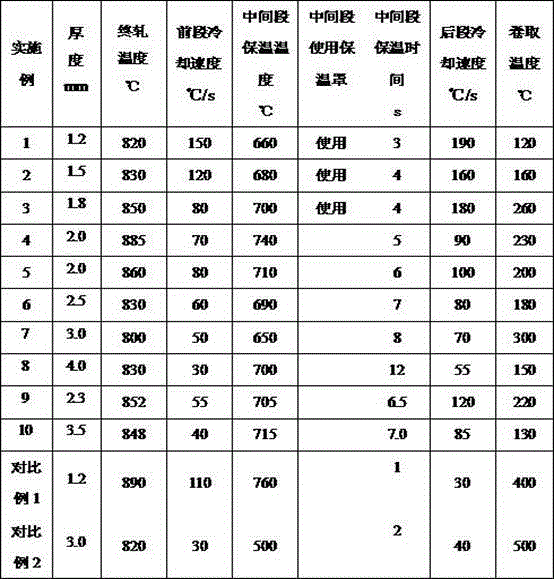

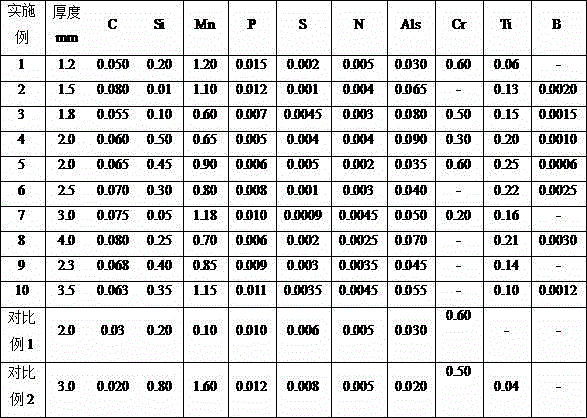

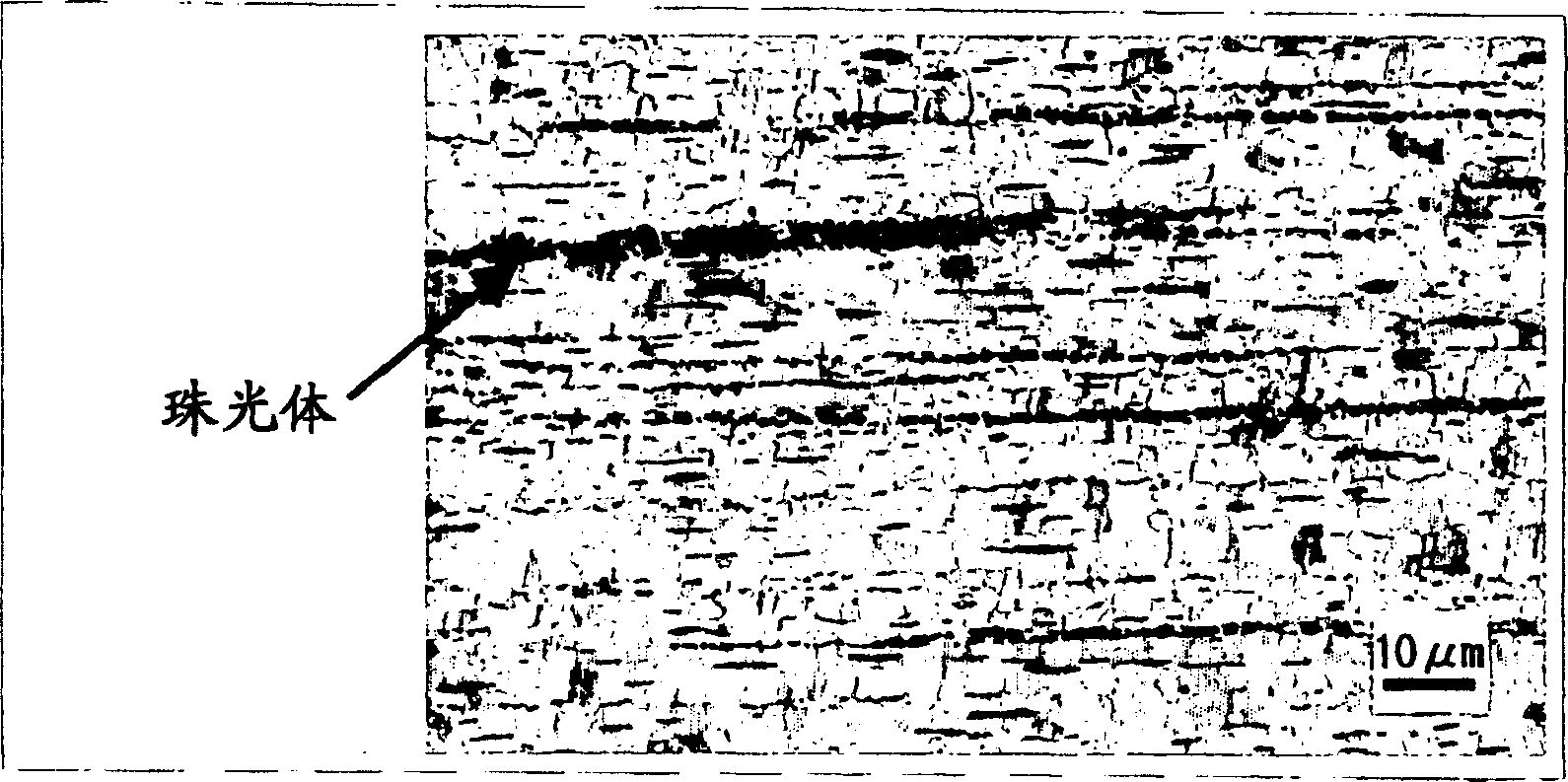

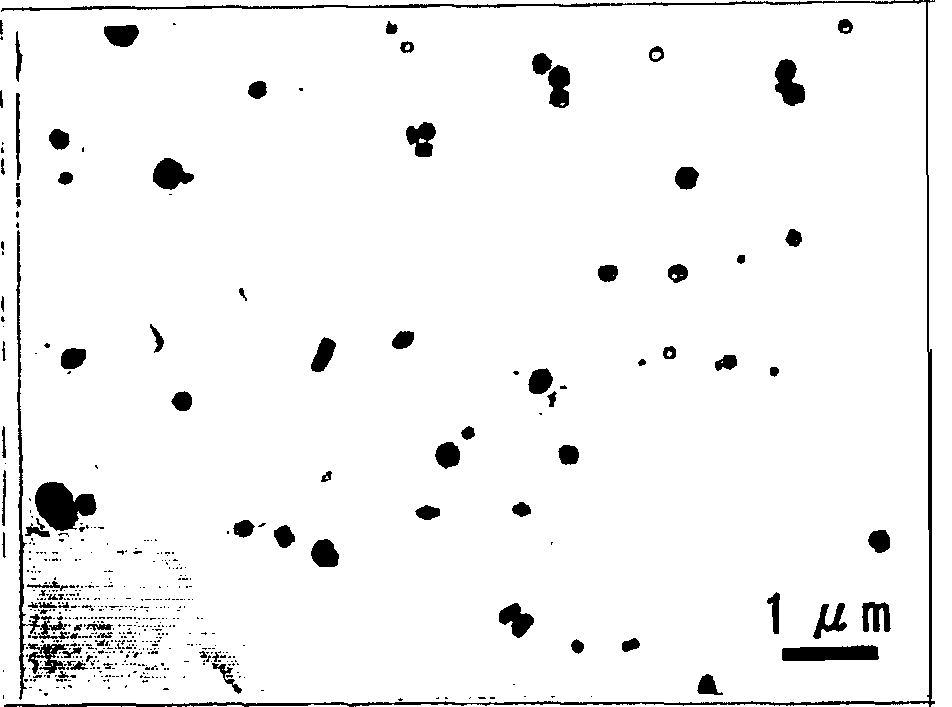

Tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel and production method thereof

The invention provides tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel. The dual-phase steel comprises the following components in percentage by weight: 0.05-0.08 percent of C, not more than 0.5 percent of S, 0.6-1.2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.006 percent of N, 0.01-0.1 percent of Als, 0.05-0.25 percent of Ti, less than or equal to 0.6 percent of Cr or less than or equal to 0.003 percent of B or mixture of Cr and B. The production method by using CSP comprises the following steps: melting and continuously casting to form a slab; heating the continuous cast slab; rolling; carrying out laminar cooling; reeling; and naturally cooling to room temperature. The hot-rolled dual phase steel has the tensile strength of more than or equal to 780MPa, elongation of more than or equal to 15 percent and yield ratio of less than or equal to 0.70. An insulation cover additionally covers the intermediate insulation section, and the band steel cooling speed is reduced, so that generation of pearlite phase change can be effectively prevented. Production of hot-rolled dual phase steel with thickness of 1.2-4.0mm can be realized, the product has the advantages of uniform structure, small molding resilience and no cracking, existing equipment is utilized without adopting ultra fast cooling and other equipment, the production efficiency is high, and the investment is small.

Owner:武汉钢铁有限公司

Steel excellent in machinability and method for production thereof

The present invention consists of C: 0.005-0.2%, Si: 0.001-0.5%, Mn: 0.2-3.0%, P: 0.001-0.2%, S: 0.03-1.0%, B: 0.005-0.05%, total N: 0.002~0.02%, total O: 0.005~0.035%, the balance is Fe and unavoidable impurities, and it is to meet the Mn / s in the steel is limited to 1.2~2.8, or in the steel A steel with excellent machinability characterized by either or both of which the area ratio of pearlite with a particle diameter exceeding 1 μm in the microstructure is 5% or less, and a method for producing the same.

Owner:NIPPON STEEL CORP

Gypsum base plastering mortar and gypsum base gravity flowing levelling mortar

A gypsum-based mortar for plastering is prepared from semi-hydrated gypsum, quartz sand, Ca(OH)2, powdered coal ash, slag, lime stone, hoolamite, volcanic dregs, haydite, polystyrene foam, expanded pearlite, zeolite, and ethene-vinyl acetate copolymer resin. Agypsum-based mortar for automatic leveling is prepared from semi- hydrated gypsum, quartz sand, Ca(OH)2, powdered coal ash, slag, lime stone, ethene-vinyl acetate copolymer resin, methyl hydroxyethyl (or hydroxypropyl) cellulose ether, sulfonated cyanuramide-formaldehyde resin and gluconate.

Owner:BEIJING SOULLEADER TECH DEV

High-toughness weather-resistant steel plate with yield strength of 550MPa and preparation method of high-toughness weather-resistant steel plate

ActiveCN108486466AGood welding performanceExcellent cold forming performanceToughnessAtmospheric corrosion

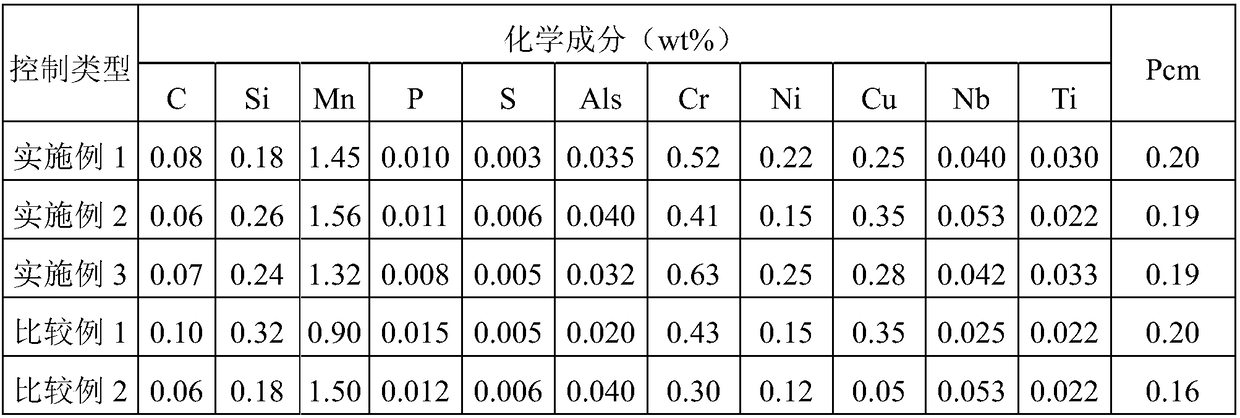

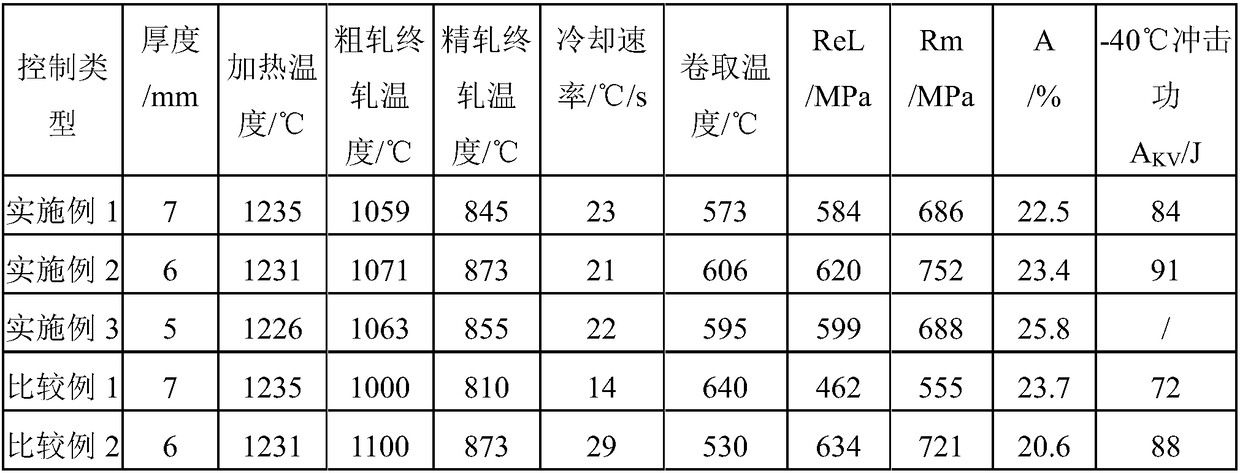

The invention discloses a high-toughness weather-resistant steel plate with the yield strength of 550MPa and a preparation method of the high-toughness weather-resistant steel plate. The high-toughness weather-resistant steel plate is prepared from the following chemical components by weight percent: 0.05 to 0.10 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.008 percent of S, 0.40 to 0.80 percent of Cr, 0.15 to 0.40 percent of Ni, 0.25 to 0.40 percent of Cu, 0.015 to 0.040 percent of Als, 0.030 to 0.070 percent of Nb, and 0.010 to 0.040 percent of Ti, and the balance of Fe and unavoidable impurities, wherein Pcm is equal to C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B and less than or equal to 0.20 percent. The microscopic tissue of the weather-resistant steel plate obtained according to the method disclosed in the invention is composite-phase tissue of ferrite, granular bainite and little pearlite,the ReL is 560 to 650MPa, Rm is 680 to 780MPa, A is 22.0 to 26.0 percent, and the longitudinal Charpy V-type impact power KV2 is greater than 70J at the temperature of -40 DEG C, and the high-toughness weather-resistant steel plate has excellent welding performance, cold bending forming performance and atmospheric corrosion resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

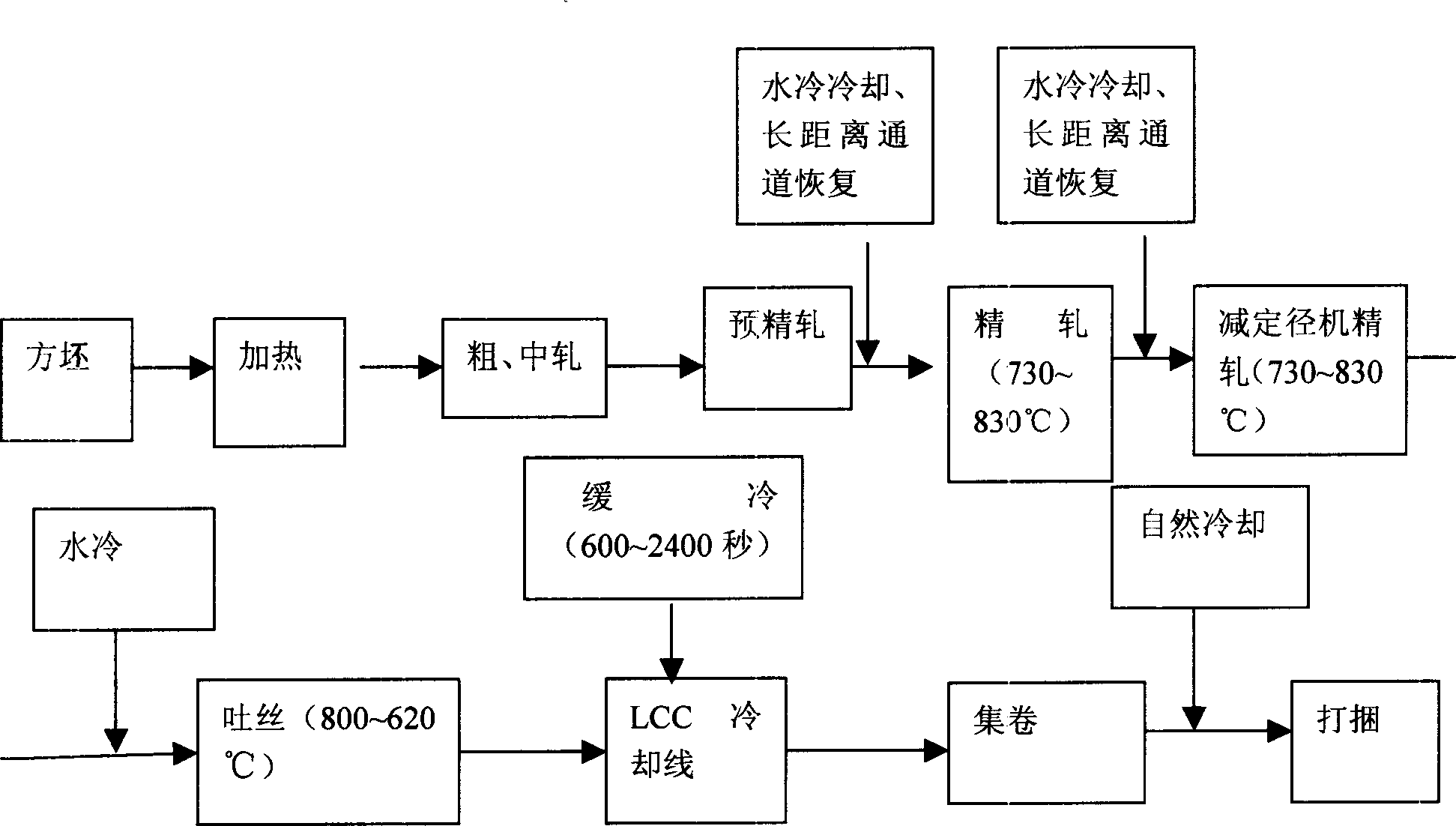

Hot-rolling anneal-free coil rod production method for 8.8 grade high-strength cold forging steel

ActiveCN1799717AReduce pollutionQuality improvementWork treatment devicesMetal rolling arrangementsPearliteDuctility

The invention provides a method which uses hot-finished non-anneal rod to produce 8.8-grade high-strength cold heading steel. The invention still utilizes general ultra-liner rolling device in the process of rolling medium carbon cold heading steel and utilizes general temperature of 950-1050Deg. C in the rough, middle and pre-finished rolling steps. The finished rolling step utilizes heat engine rolling process which is characterized in that the rolled piece is recovered via water cooling and long channel after the pre-finished rolling, and it is fed into finished-rolling machine when the temperature is reduced to the low-temperature area of 730-830Deg. C, and the steel is transformed at dual-phase (ª†+ª‡) region with large transformation valve; the accumulated draft can reach 35-82%; then the rolled piece is quickly water cooled to 800-620Deg. C to be kept temperature for 600-2400 second and natural cooled to room temperature. The invention can reduce the proportion of pearlite via increasing the proportion of ferrite, to spheroidize a part of pearlite and reduce the strength and rigidity and improve the ductility of material, therefore it can realize the purpose of beating bolt without anneal before cold heading.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com