Steel excellent in machinability and method for production thereof

A manufacturing method and machinability technology, applied to steel with excellent machinability and its manufacturing field, can solve the problems of easy occurrence of built-up edge, insufficient uniform dispersion, inability to improve surface finish, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] The effects of the present invention will be described using examples. Table 1, Table 2 (continued from 1 of Table 1), Table 3 (continued from 2 of Table 1), Table 4 (continued from 3 of Table 1), Table 5 (continued from 4 of Table 1), Table 6 (continued from 5) Among the test materials shown, No.13 was smelted in a 270-ton converter, and the others were smelted in a 2-ton vacuum melting furnace, rolled into steel plates in pieces, and then rolled into 60 mm.

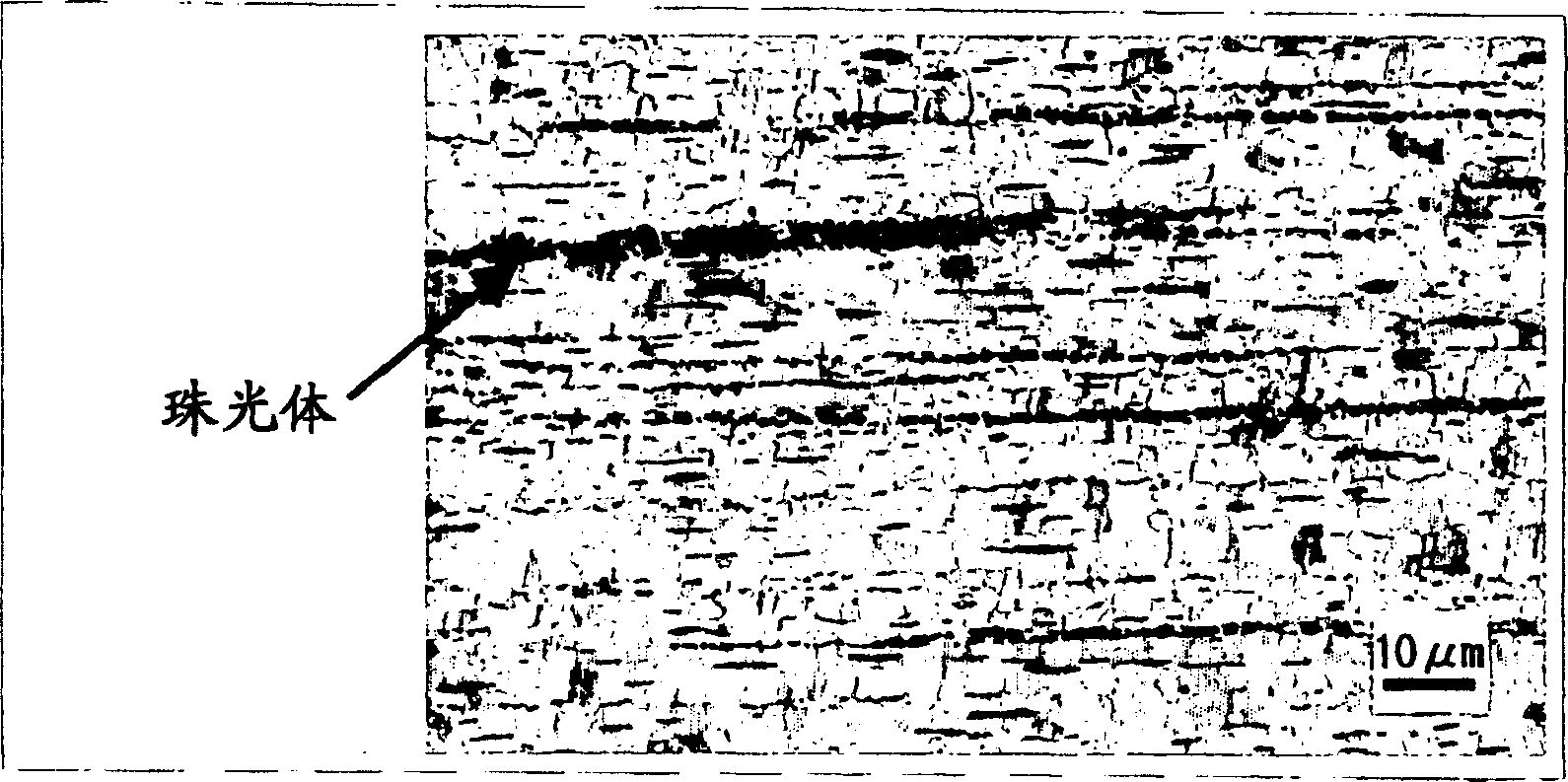

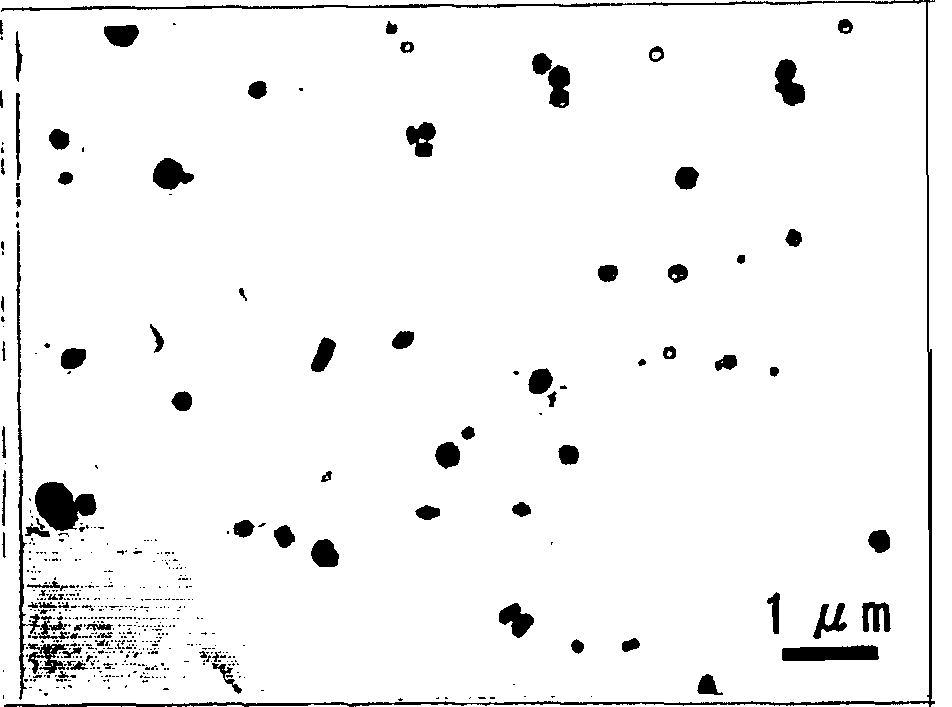

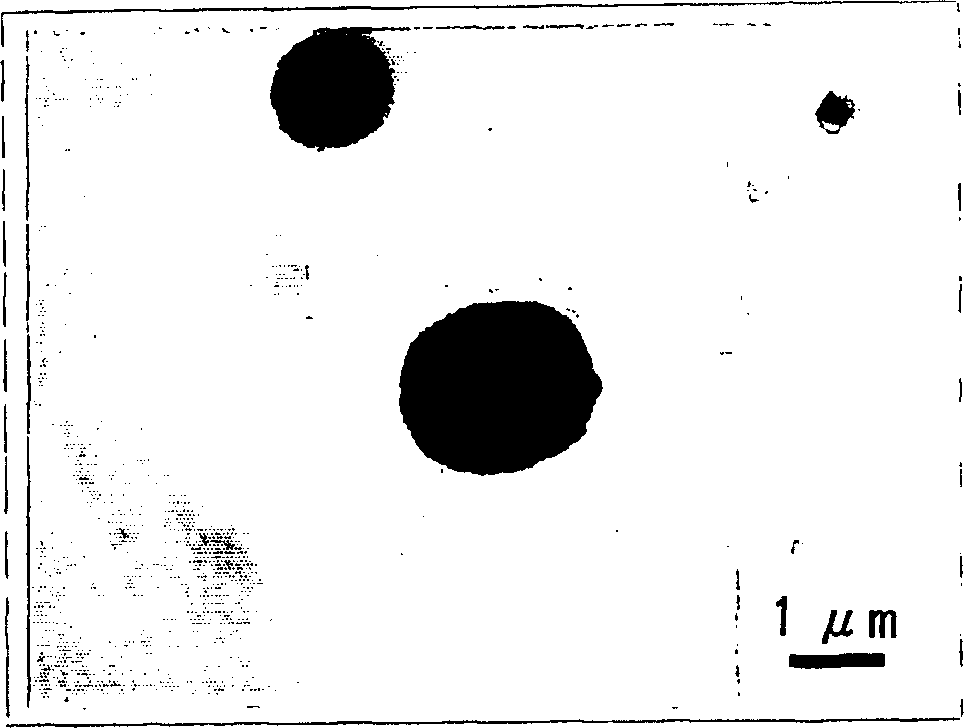

[0138] In the item of heat treatment in the table, the examples described as normalizing were kept at 920° C. for 10 minutes or more, and then air-cooled. In the example of the present invention, which is referred to as QT (Quenching and Tempering), it is quenched from 920° C. in a water tank at the rear end of the rolling line, and then kept at 710° C. for 1 hour or more during annealing. This adjusts the pearlite area ratio. In the example of the present invention, although the amount of C is low, the pearli...

Embodiment 2

[0157] Table 9, Table 10 (Continued from 1 of Table 9), Table 11 (Continued from 2 of Table 9), Table 12 (Continued from 3 of Table 9), Table 13 (Continued from 4 of Table 9), Table 14 (Continued from Table 9 5) A part of the test material shown in 5) was smelted in a 270-ton converter, and cast at a cooling rate of 10 to 100° C. / min. Rolled into steel plates in blocks, and then rolled into 50 mm. Others are smelted in a 2-ton vacuum melting furnace and rolled into 50 mm. At this time, the cooling rate of the ingot is adjusted by changing the cross-sectional size of the mold. The machinability of the material was evaluated by the drill piercing test under the conditions shown in Table 7 and the plunge cutting under the conditions shown in Table 8. The drilling and piercing test is a method of evaluating machinability at the highest cutting speed (so-called VL1000, unit: m / min) capable of cutting to a cumulative hole depth of 1000 mm. Plunge cutting is a method of evaluati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com