Patents

Literature

5482 results about "Manufacturing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing efficiency is the level of performance within your company, and it's something that can always be improved upon. 1. Know your product, and make sure everybody in your company knows the product. Manufacturing efficiency starts with well-trained individuals throughout the entire company.

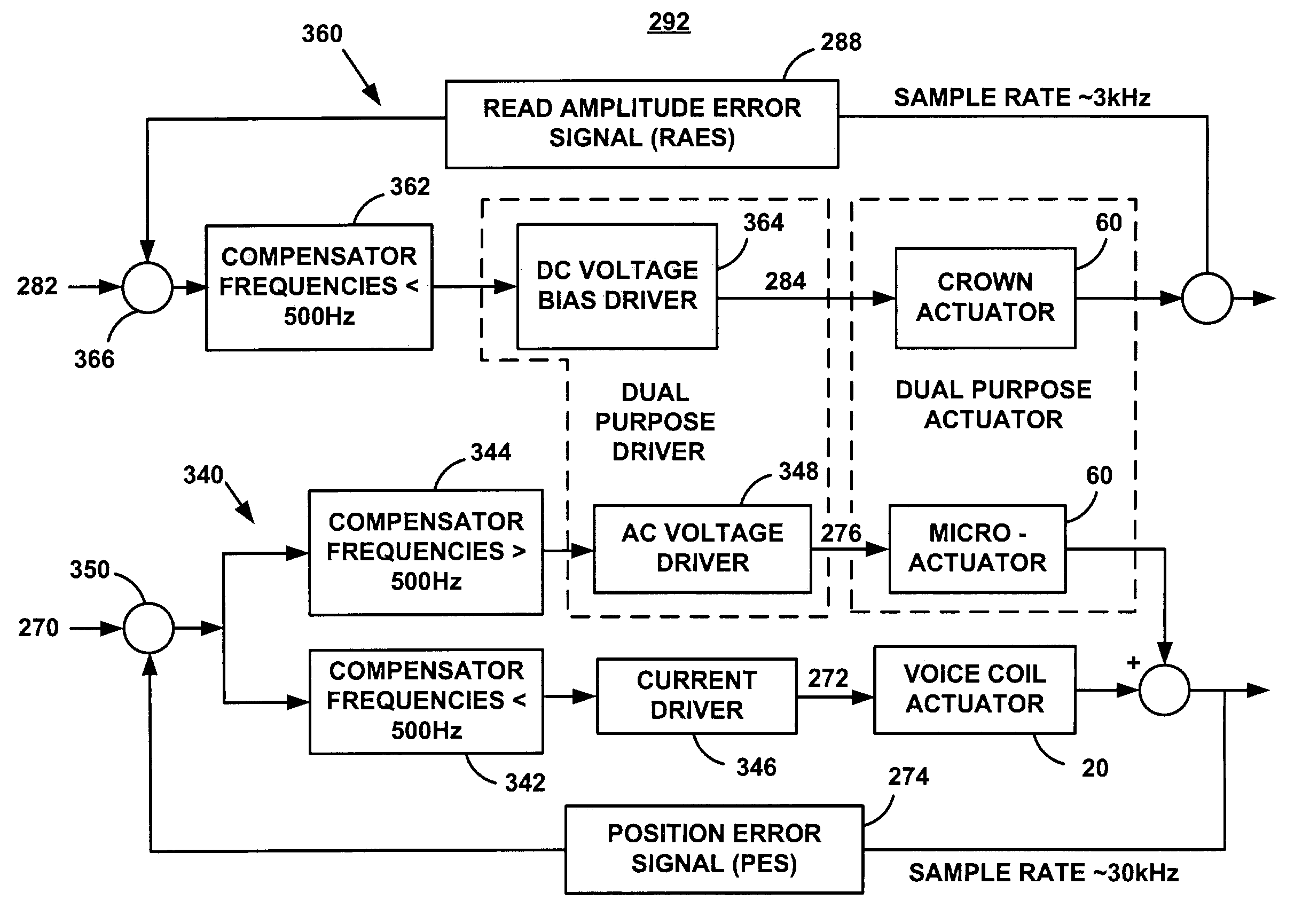

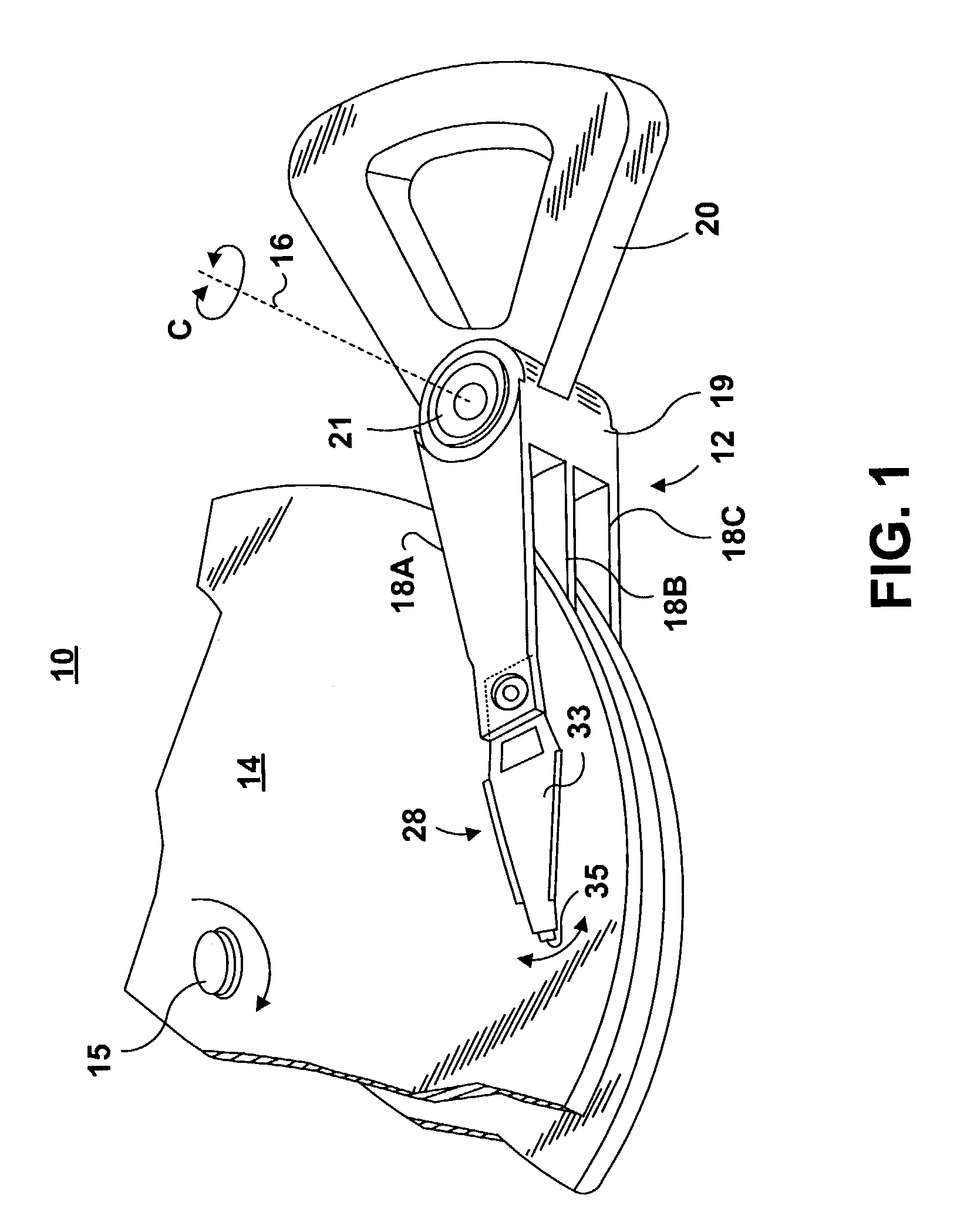

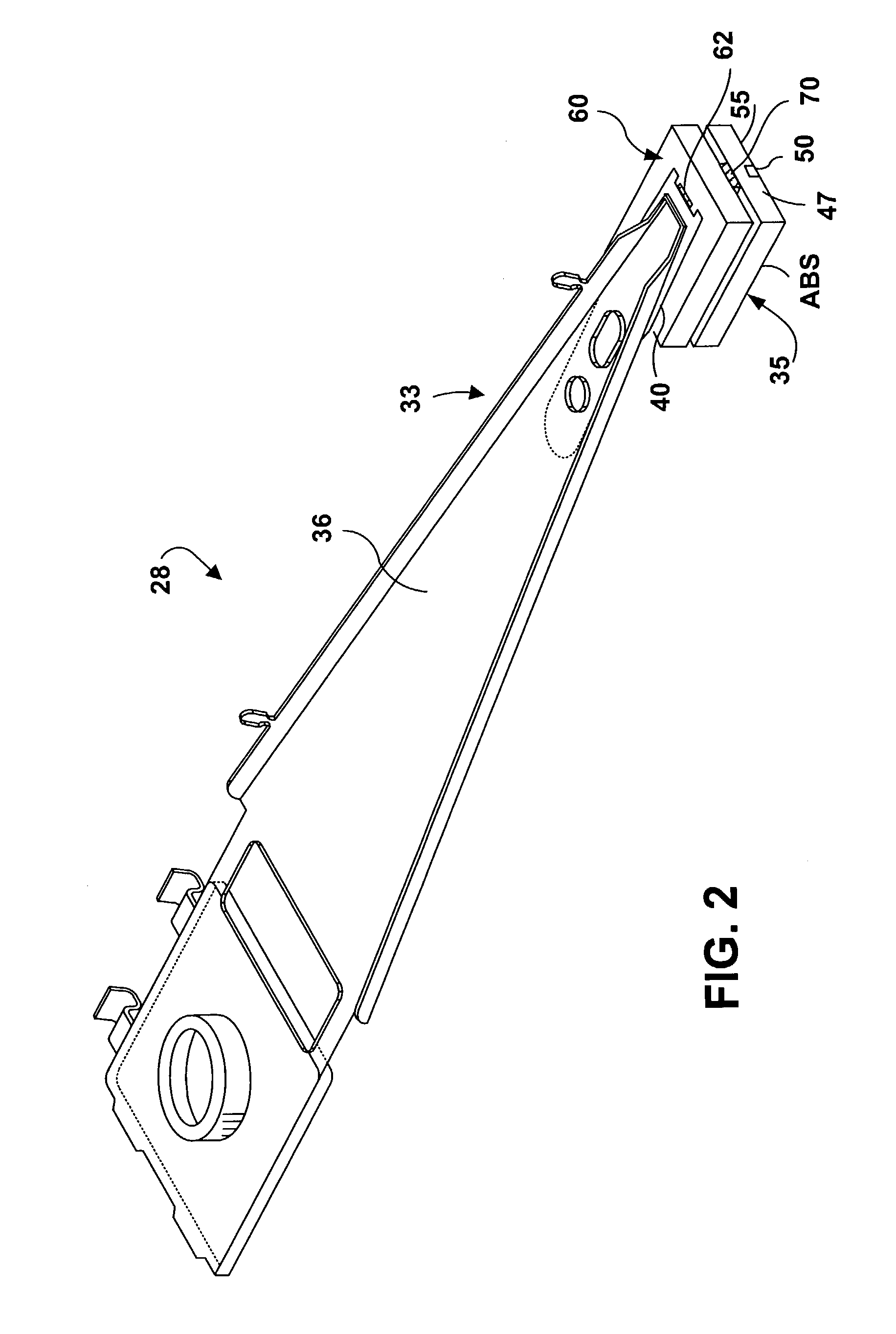

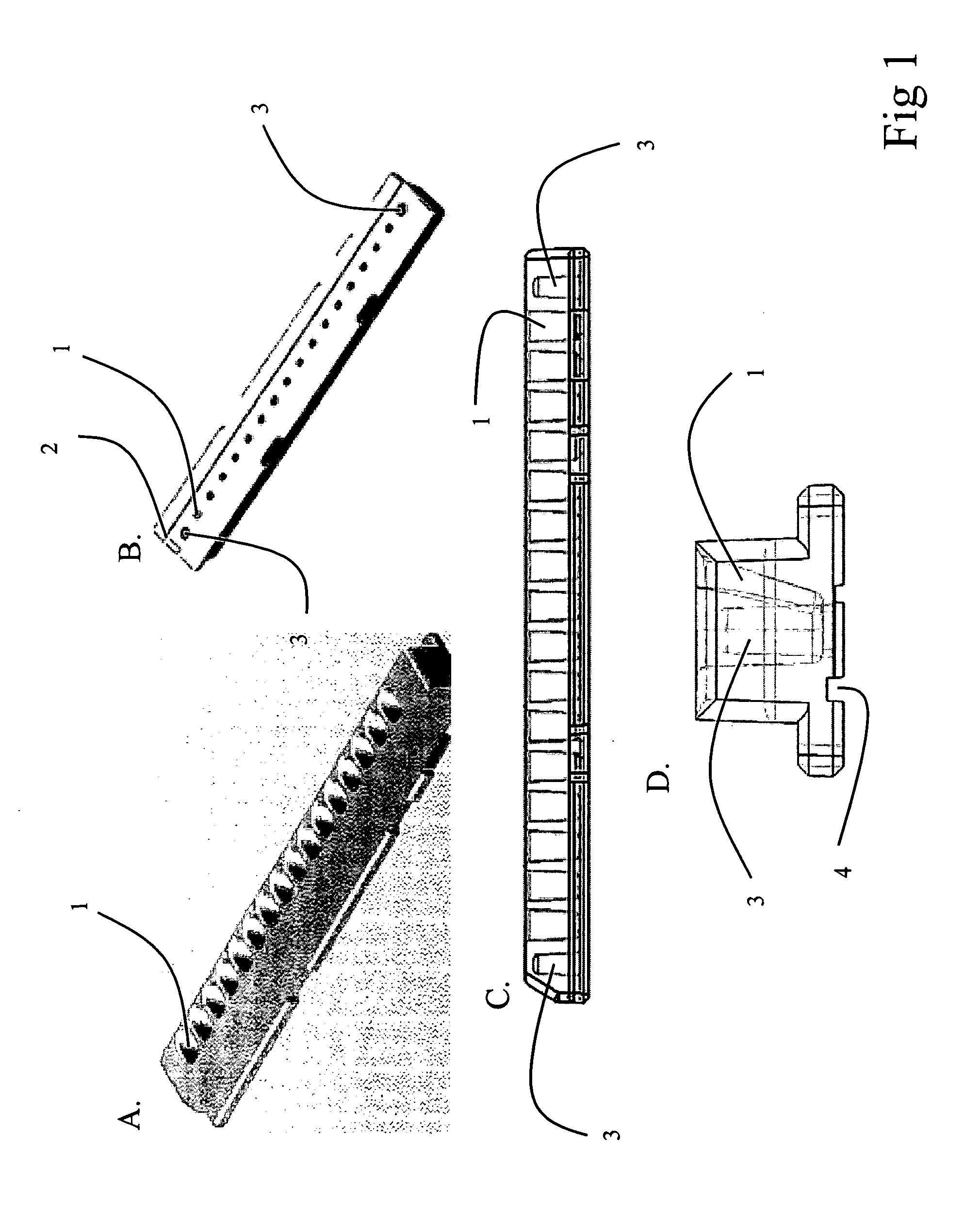

Active fly height control crown actuator

InactiveUS6950266B1Improve production efficiencyReduced altitude sensitivityAnalogue recording/reproducingDriving/moving recording headsData integrityMicro actuator

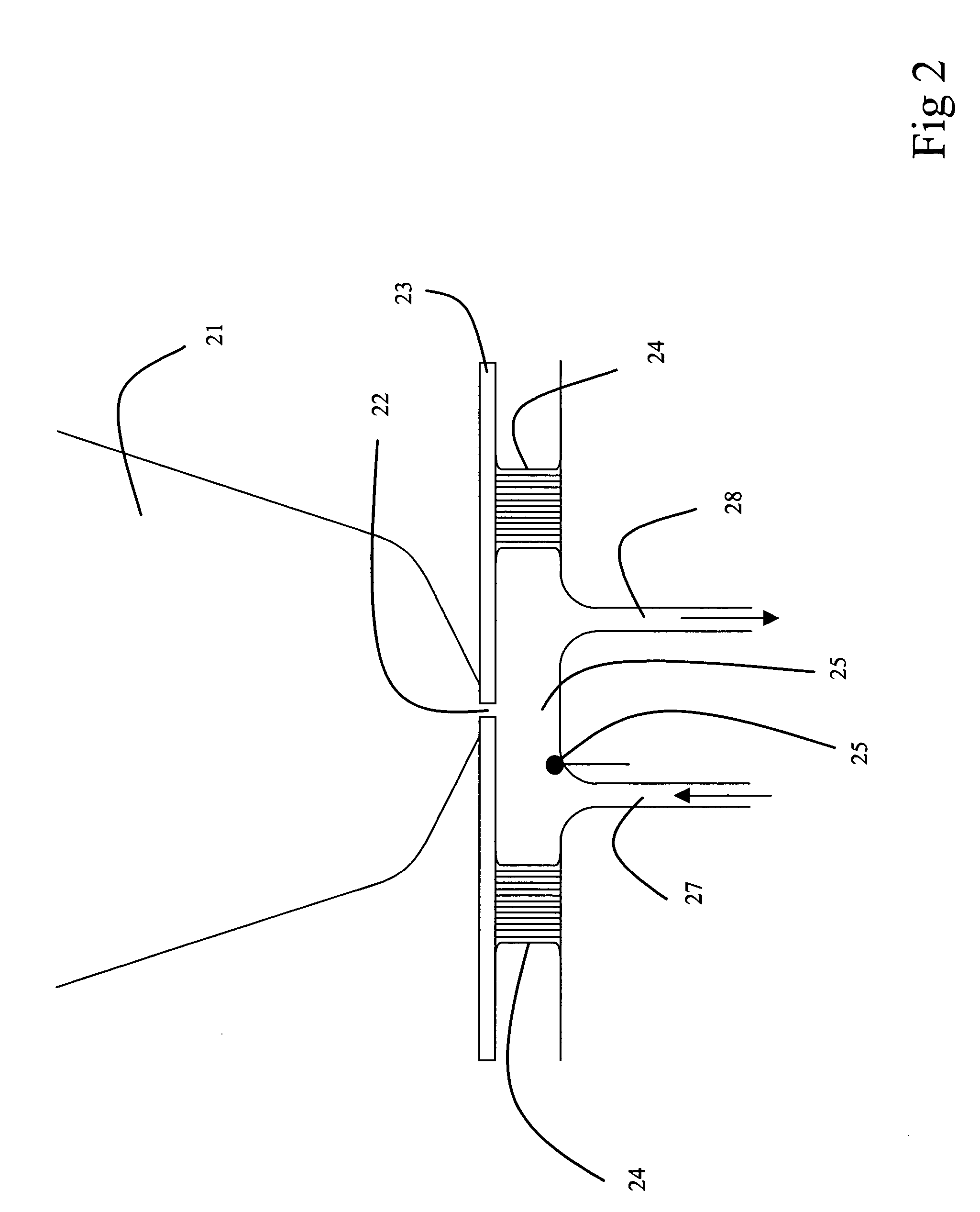

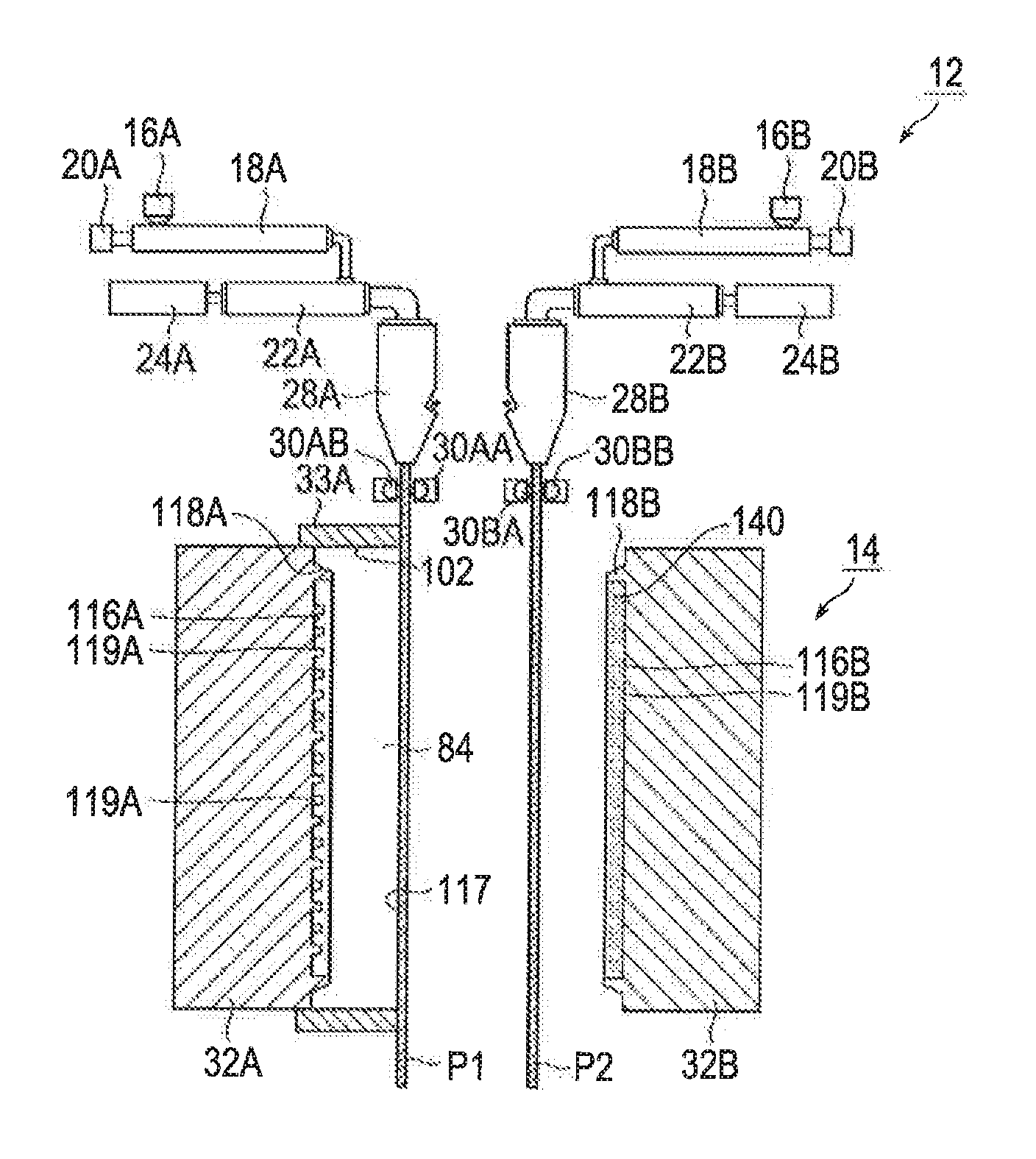

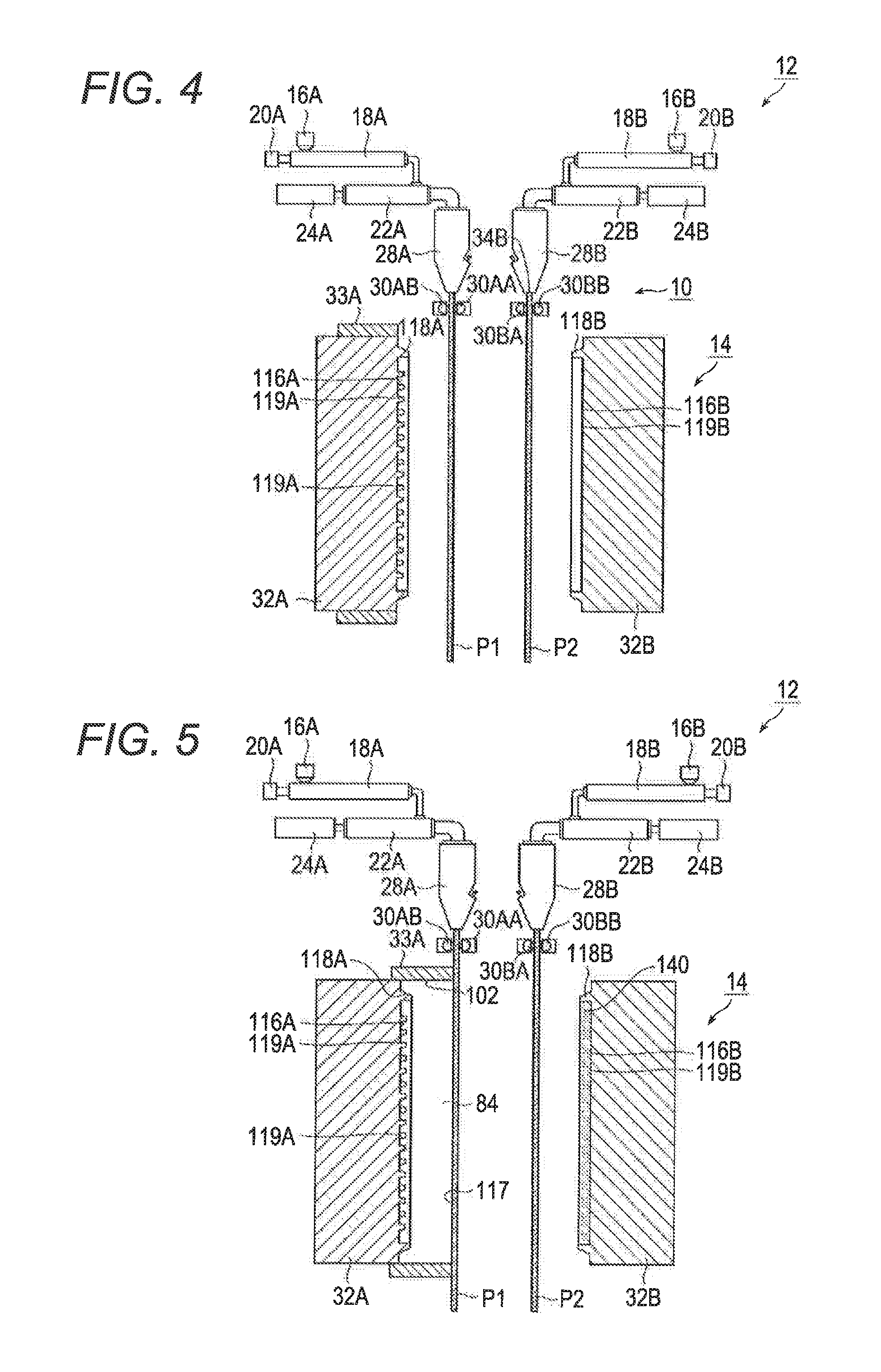

A micro-actuator is comprised of a piezoelectric motor mounted on a flexure tongue with offsetting hinges, to perform a fine positioning of the magnetic read / write head. The substantial gain in the frequency response greatly improves the performance and accuracy of the track-follow control for fine positioning. The simplicity of the enhanced micro-actuator design results in a manufacturing efficiency that enables a high-volume, low-cost production. The micro-actuator is interposed between a flexure tongue and a slider to perform an active control of the fly height of the magnetic read / write head. The induced slider crown and camber are used to compensate for thermal expansion of the magnetic read / write head, which causes the slider to be displaced at an unintended fly height position relative to the surface of the magnetic recording disk. The enhanced micro-actuator design results in reduced altitude sensitivity, ABS tolerances, and reduced stiction. The controlled fly height of the magnetic read / write head prevents a possibility of a head crash, while improving the performance and data integrity.

Owner:WESTERN DIGITAL TECH INC

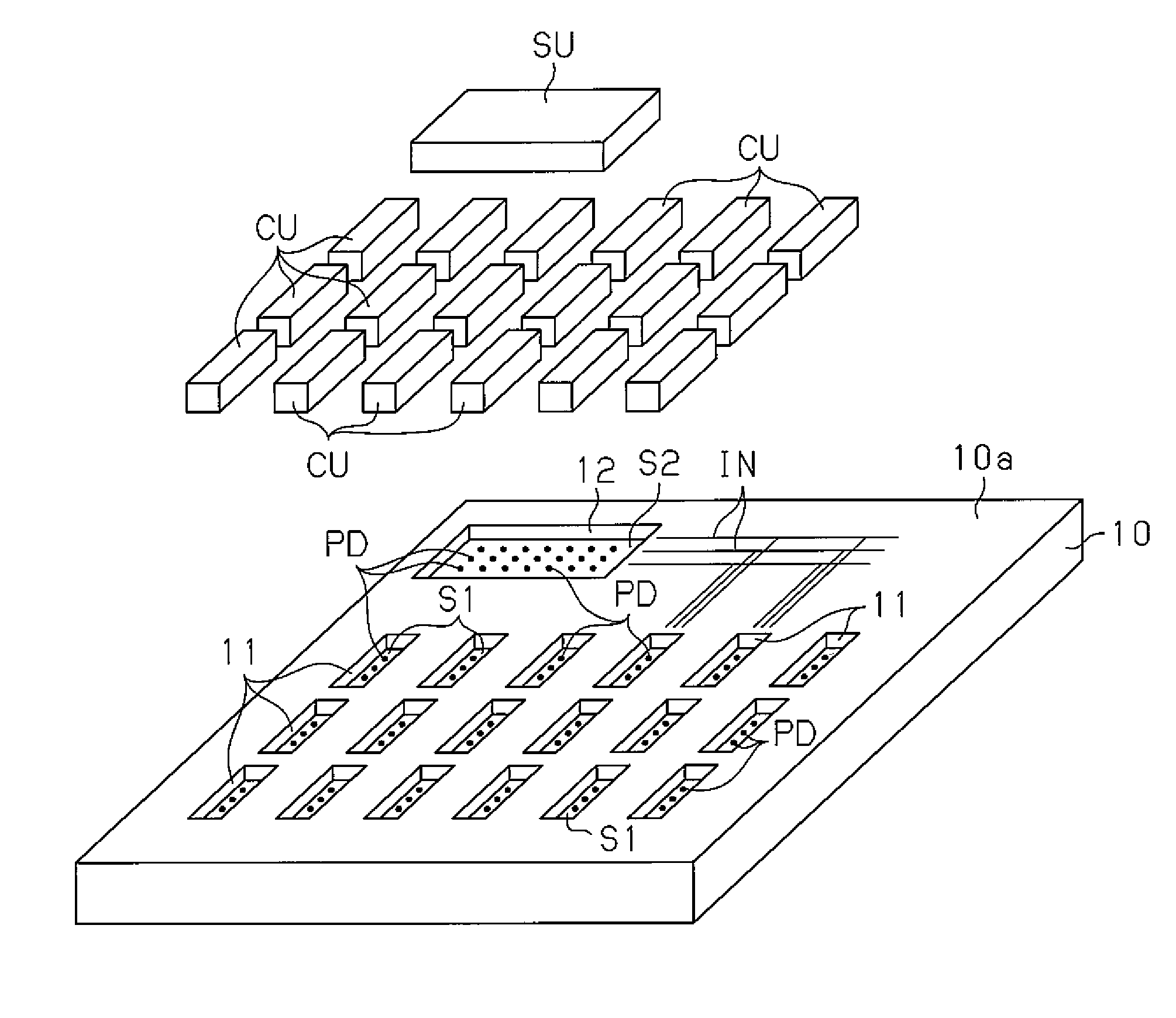

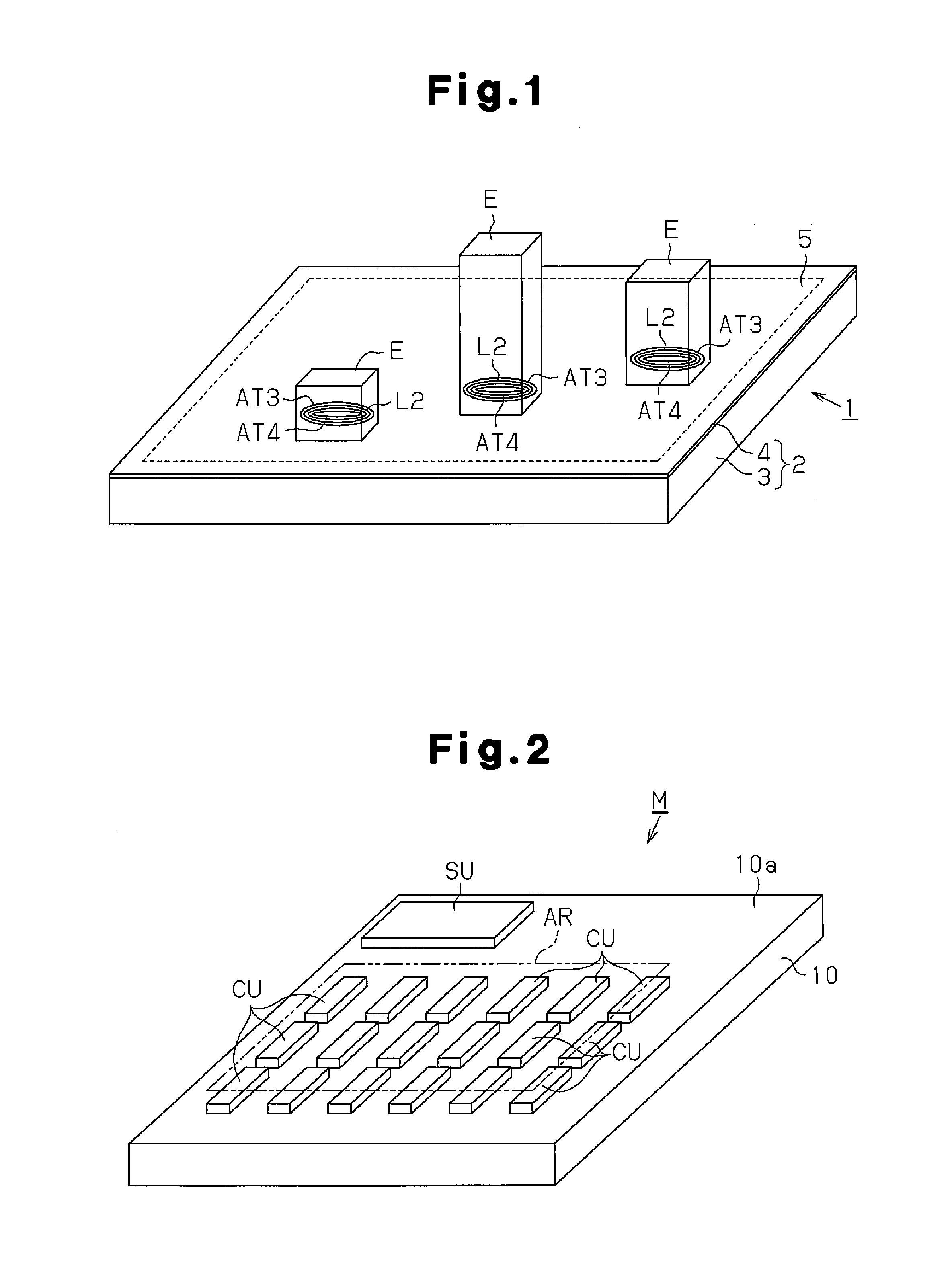

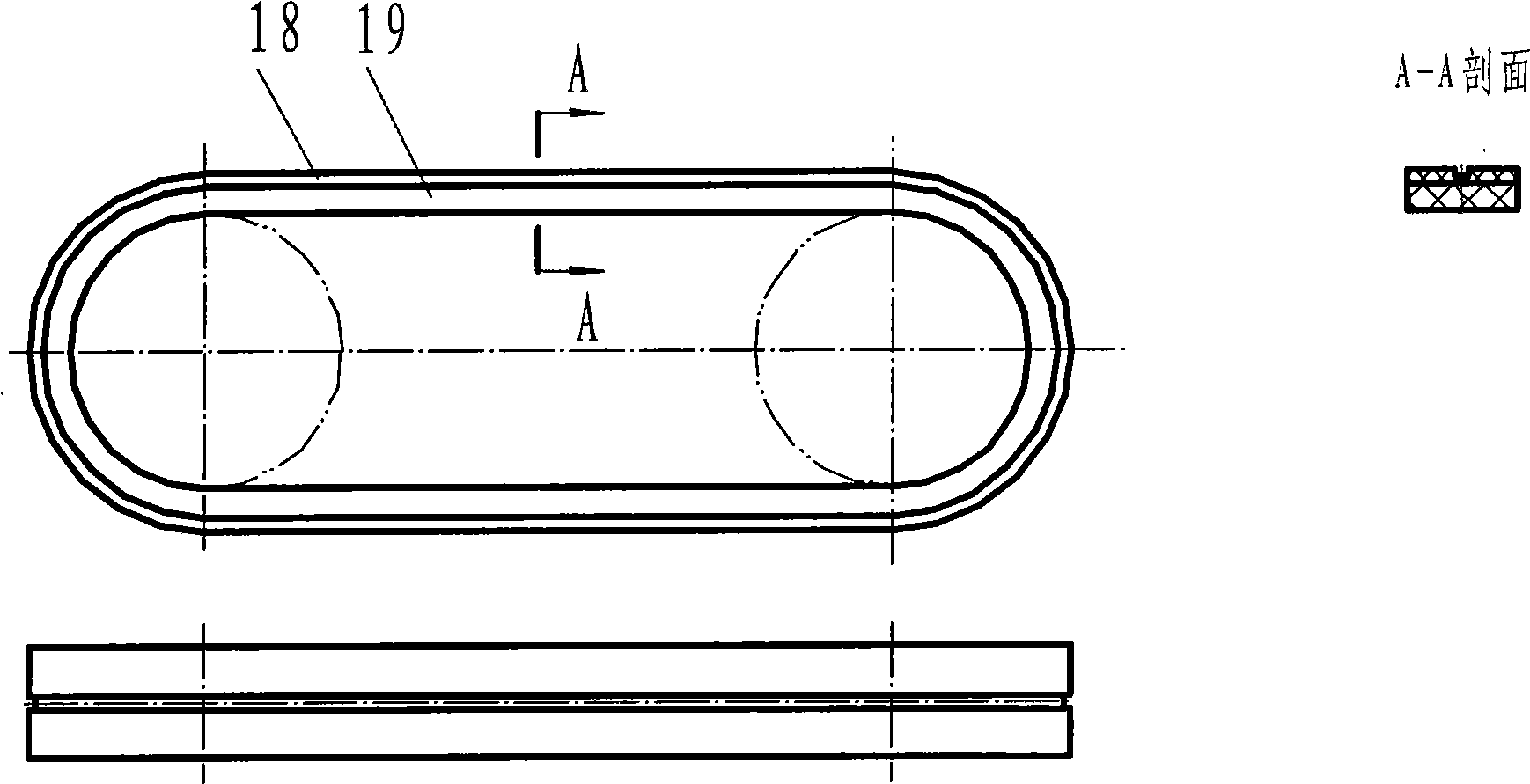

Power supplying module for contactless power supplying device, method for using power supplying module of contactless power supplying device, and method for manufacturing power supplying module of contactless power supplying device

ActiveUS20130175877A1High degree of freedom for designShort timeNear-field transmissionTransformersComputer modulePrinted circuit board

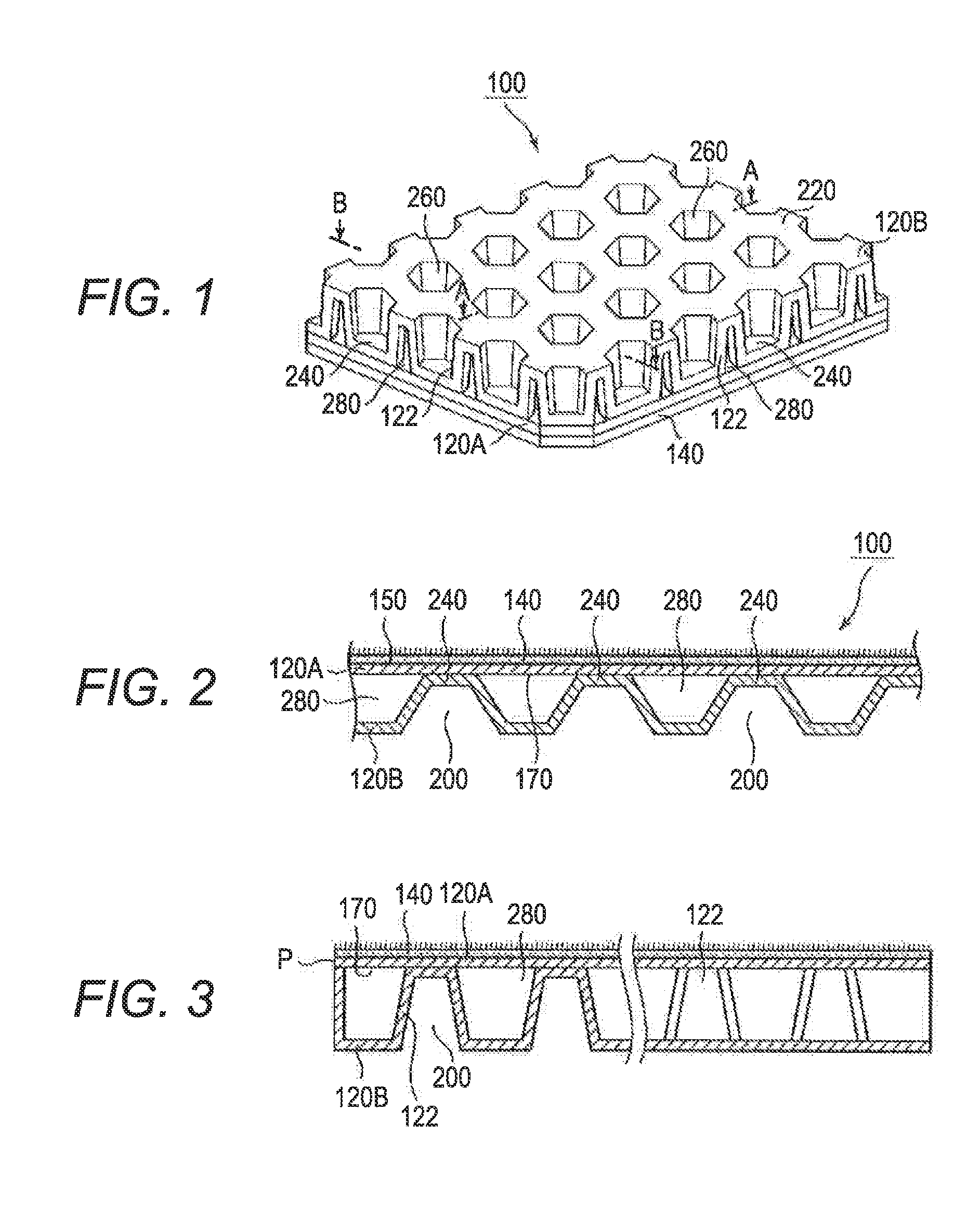

Coil units equipped with primary coils having the same specification are provided in a power feeding module. Coil-unit intermeshing recess sections are formed on a printed circuit board to match each of the coil units. Pads for joining together with electrodes formed on the coil units are formed on the bottom faces of each of the coil-unit intermeshing recess sections. A plurality of coil units can be mounted onto the printed circuit board easily, by fitting each of the coil units into each of the coil-unit intermeshing recess sections and joining them together, which will enable manufacturing efficiency to be improved.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

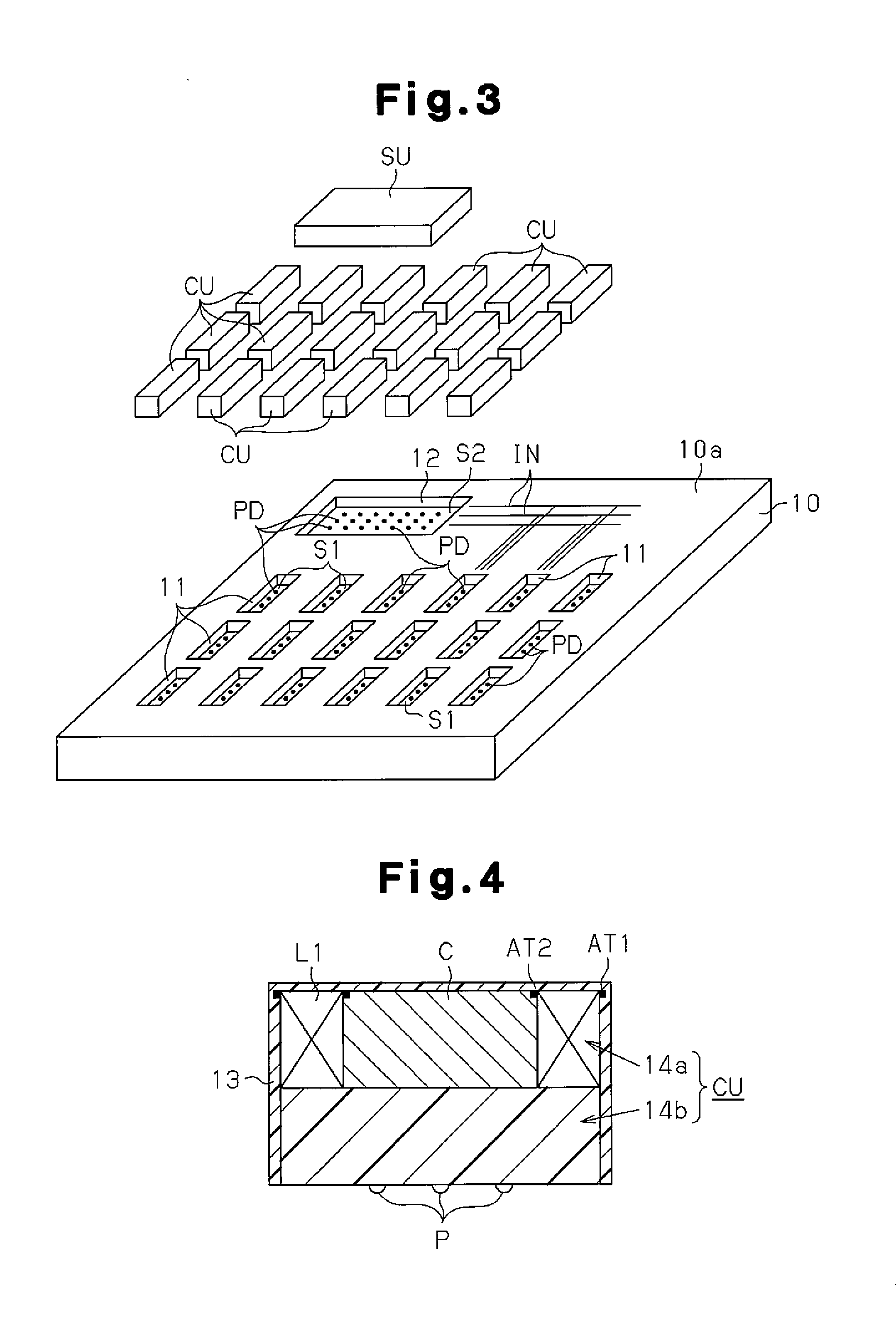

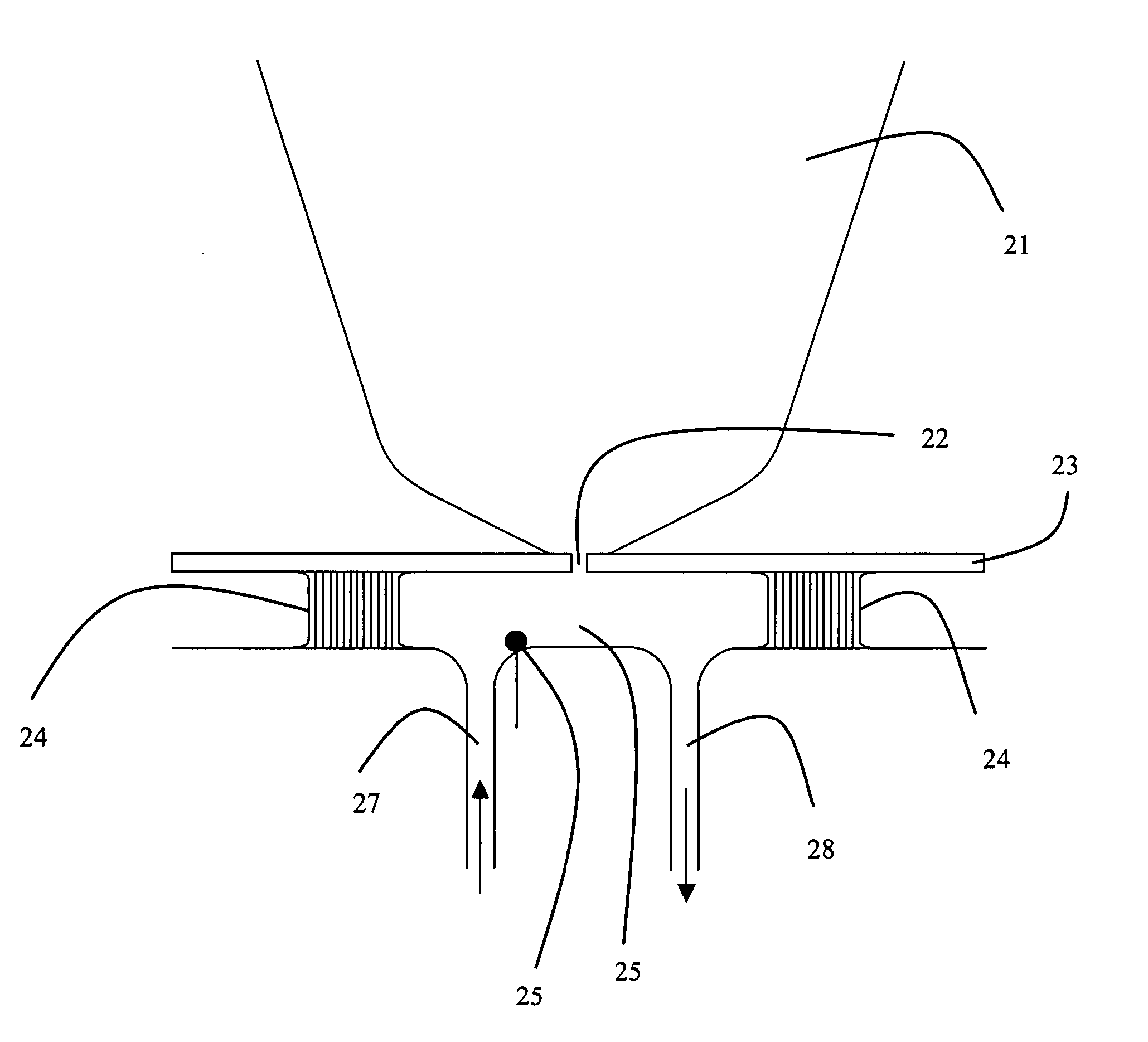

Biochip devices for ion transport measurement, methods of manufacture, and methods of use

InactiveUS20050058990A1Enhanced electrical seal propertyImprove production efficiencyMicrobiological testing/measurementBiological testingPhysical chemistryDirect analysis

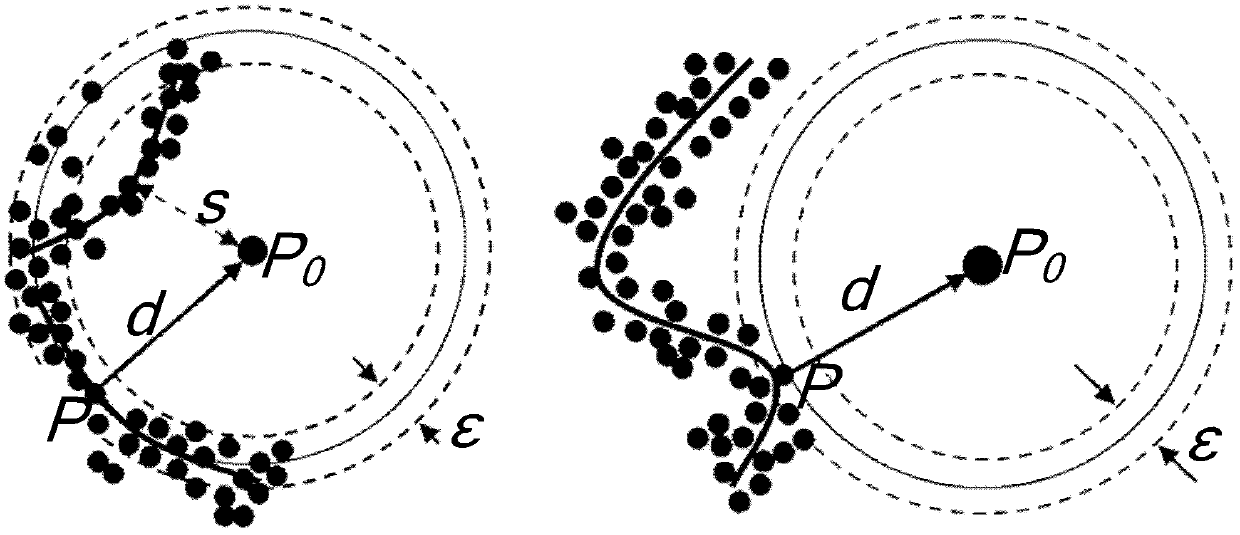

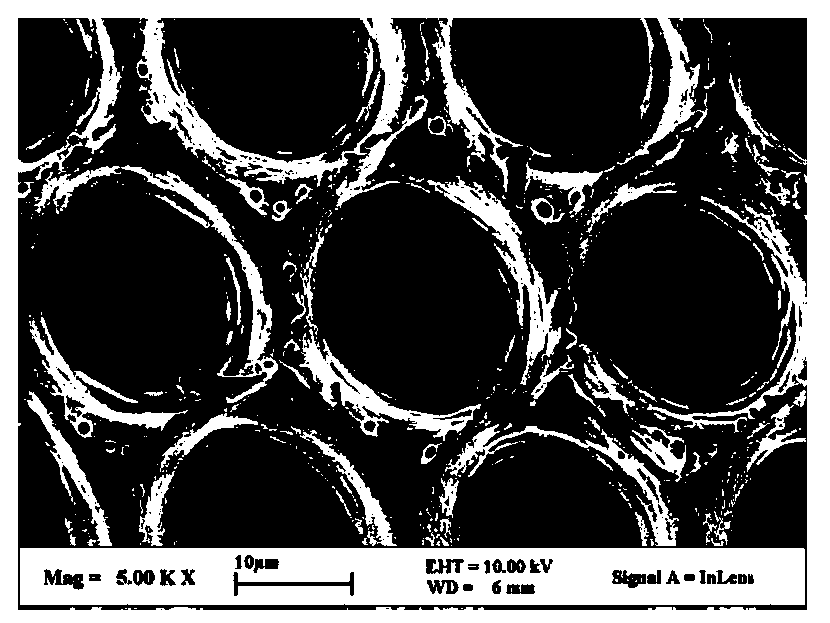

The present invention provides biochips for ion transport measurement, ion transport measuring devices that comprise biochips, and methods of using ion transport measuring devices and biochips that allow for the direct analysis of ion transport functions or properties. The present invention provides biochips, devices, apparatuses, and methods that allow for automated detection of ion transport functions or properties. The present invention also provides methods of making biochips and devices for ion transport measurement that reduce the cost and increase the efficiency of manufacture, as well as improve the performance of the biochips and devices. These biochips and devices are particularly appropriate for automating the detection of ion transport functions or properties, particularly for screening purposes.

Owner:AVIVA BIOSCI

RF transceiver switching system

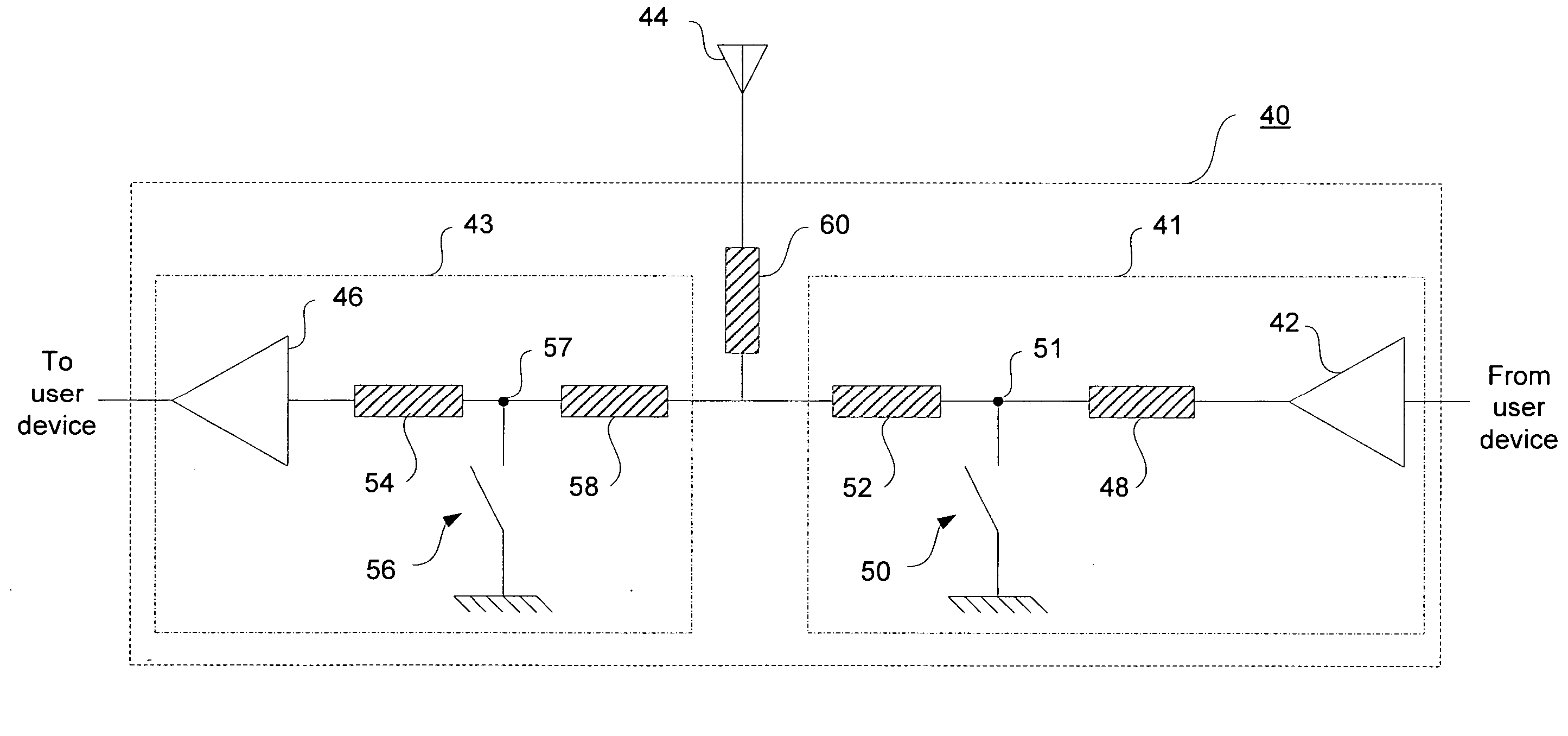

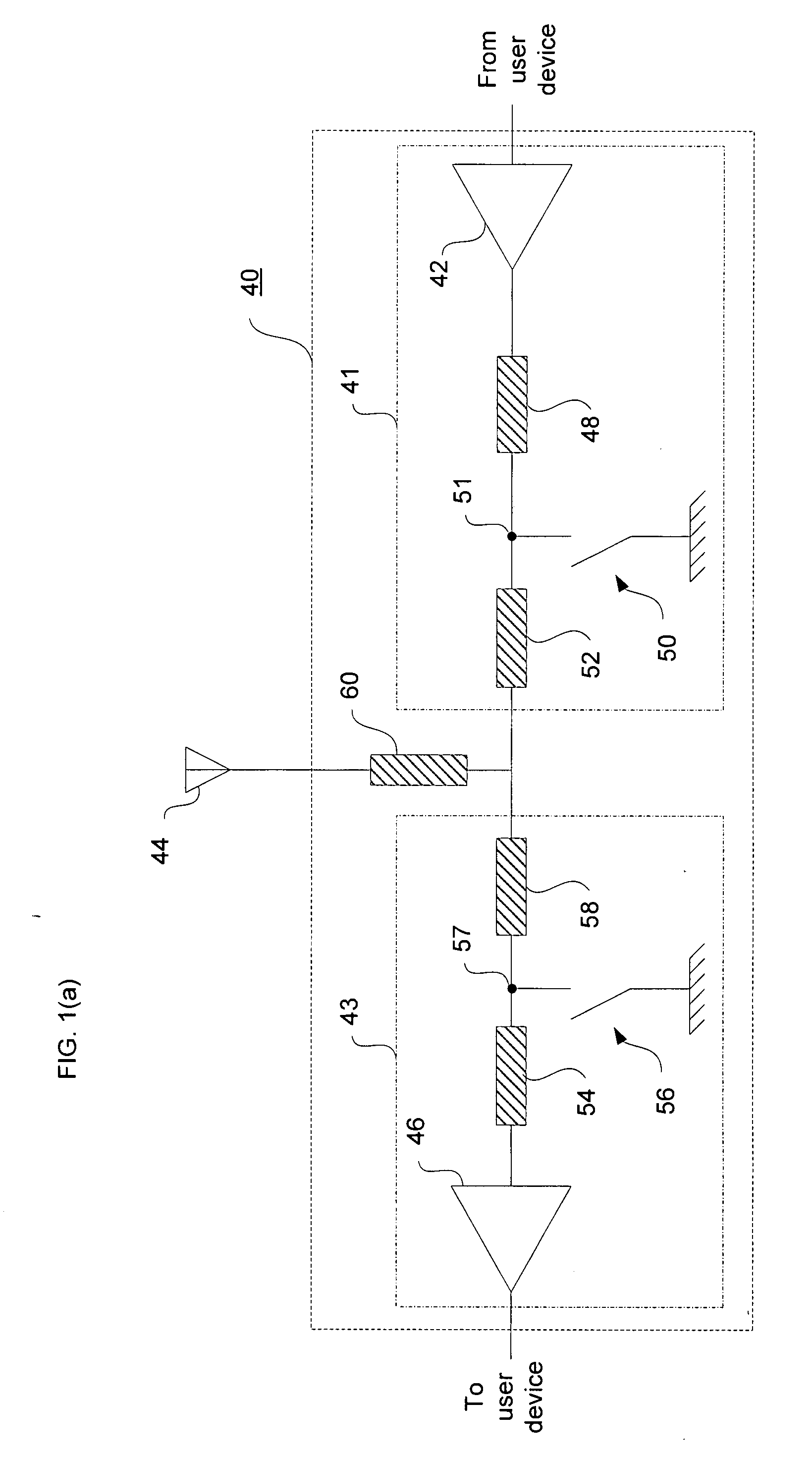

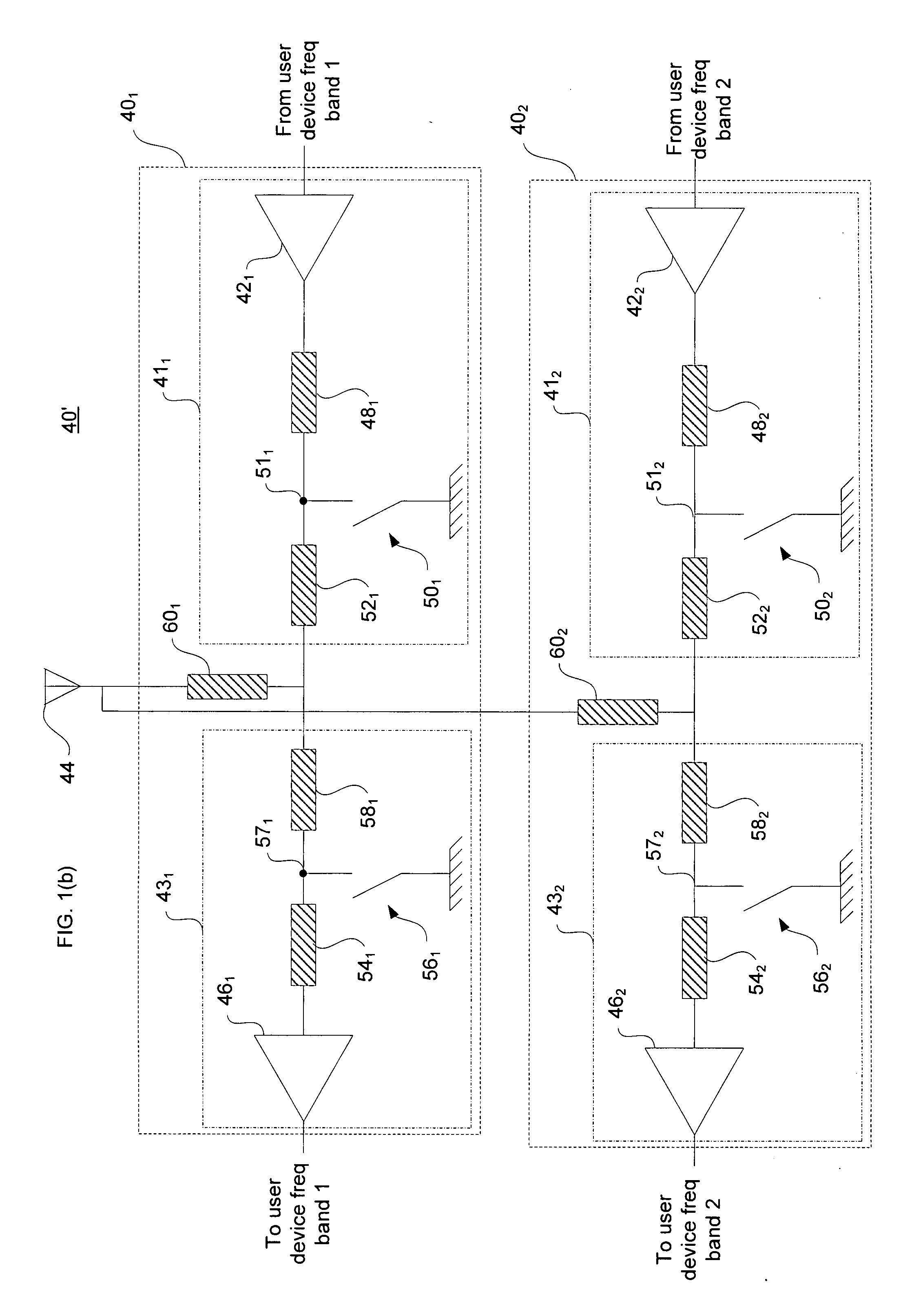

The present invention relates to transceiver systems and methods which employ shunt switches during transmit and receive operating modes. The shunt switches may be configured with various reactive networks to achieve high or low impedance states at power amplifiers or low noise amplifiers in order to reflect or transmit power along a given path. The shunt switches are designed for protection against excessive voltage swings that would otherwise damage components in the transceiver switching circuit. The switching circuits may be implemented in a single chip architecture, which results in manufacturing efficiencies, lower cost and higher reliability circuits. Single or multi band devices may also be employed.

Owner:RESONANCE SEMICON CORP

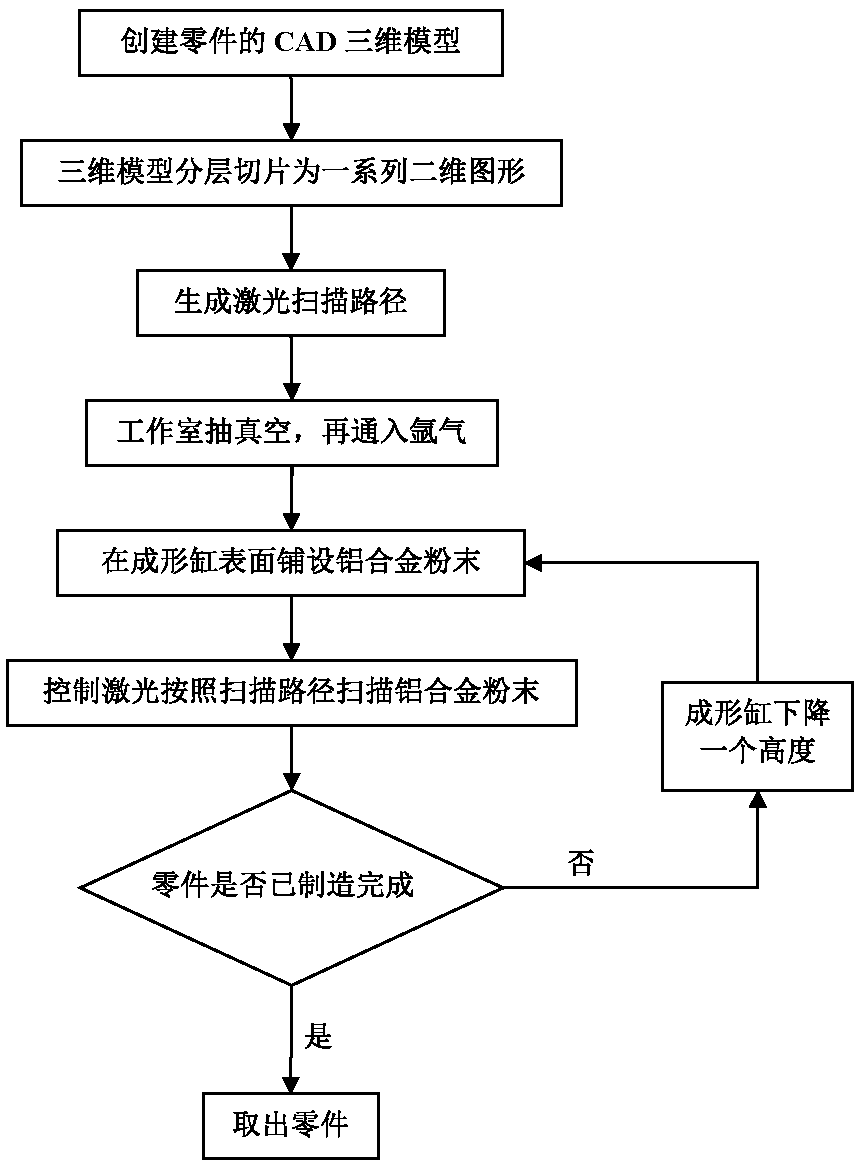

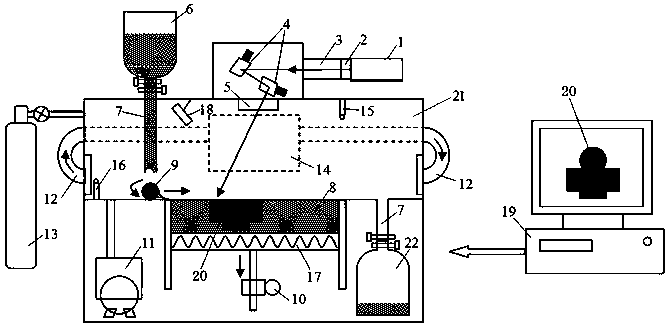

3D printing manufacturing device and method of metal parts

ActiveCN103341625AImprove processing efficiencyHigh material utilizationIncreasing energy efficiencyManufacturing efficiencyHeating system

The invention discloses a 3D printing manufacturing device and method of metal parts. The 3D printing manufacturing device and method aim to efficiently manufacture the metal parts. The 3D printing manufacturing device of the metal parts comprises a laser system, a powder laying system, an atmosphere protecting system, a heating system and a computer control system. The 3D printing manufacturing device further comprises a closed work cavity, a forming cylinder is arranged inside the work cavity, and the laser system is arranged above the forming cylinder; the powder laying system is arranged on the upper side of the work cavity; one side of the work cavity is provided with the atmosphere protecting system, and the bottom of the forming cylinder is provided with the heating system; the lower side of the forming cylinder is provided with a driving device; one side of the work cavity is provided with a vacuum pump; the computer control system comprises a computer which is connected with a control card of the driving device and a control card of the laser system through data wires. According to the 3D printing manufacturing device and method, the metal parts of any structures can be directly manufactured, digital manufacturing from 3D digital models to part entities is achieved, and processing and manufacturing efficiency and the material using ratio of aluminium alloy parts of complex structures can be greatly improved.

Owner:航天科工(长沙)新材料研究院有限公司

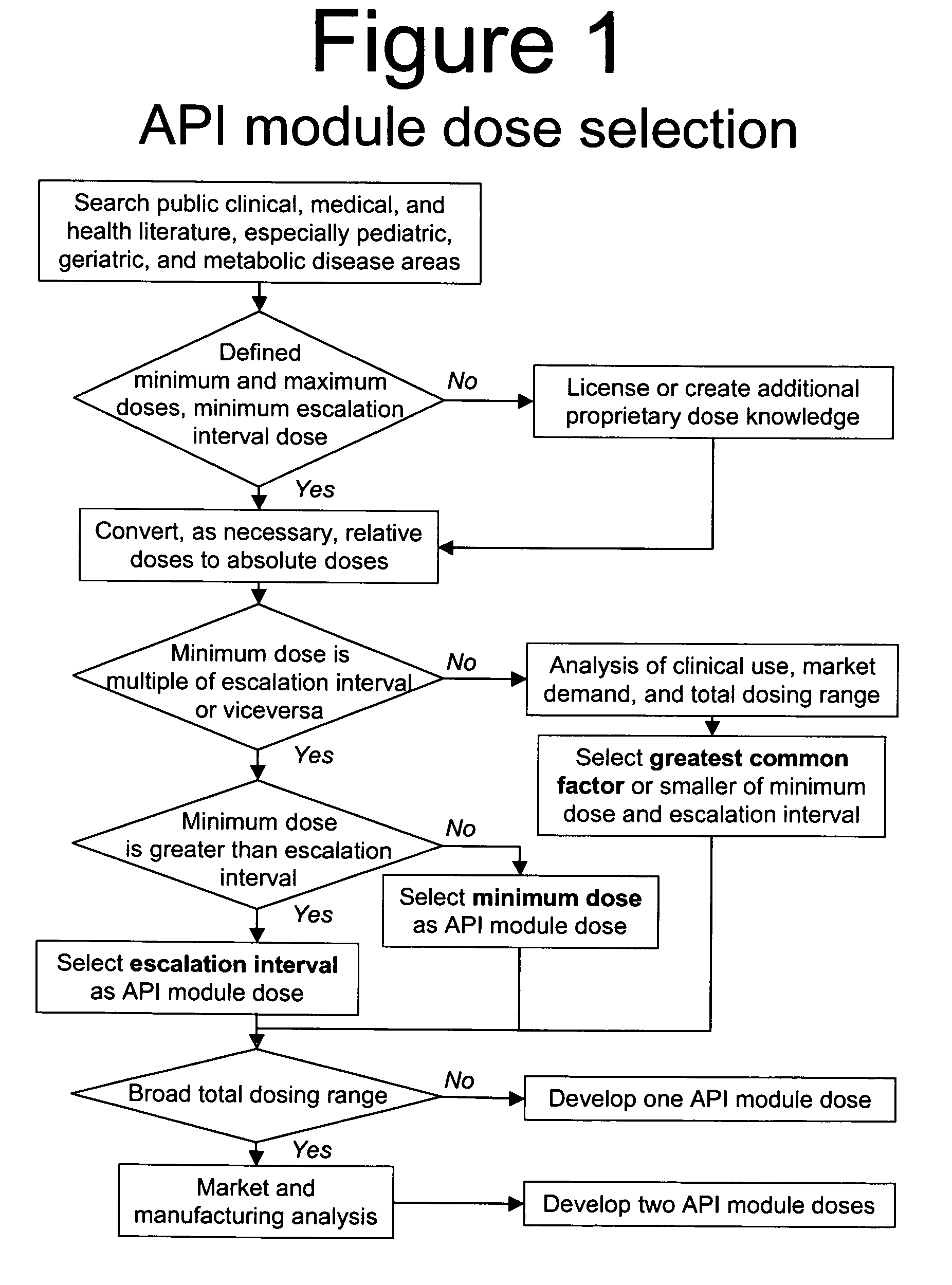

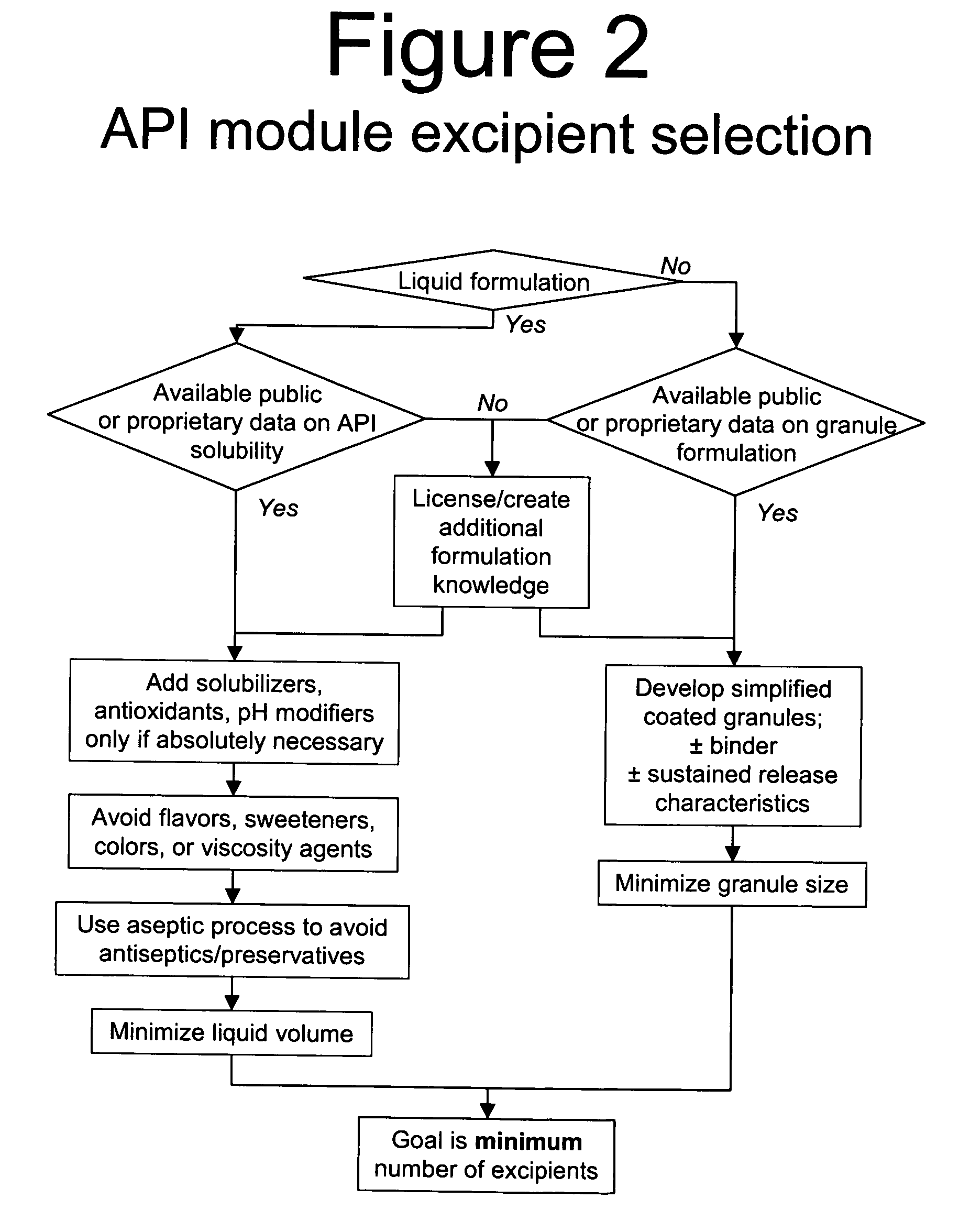

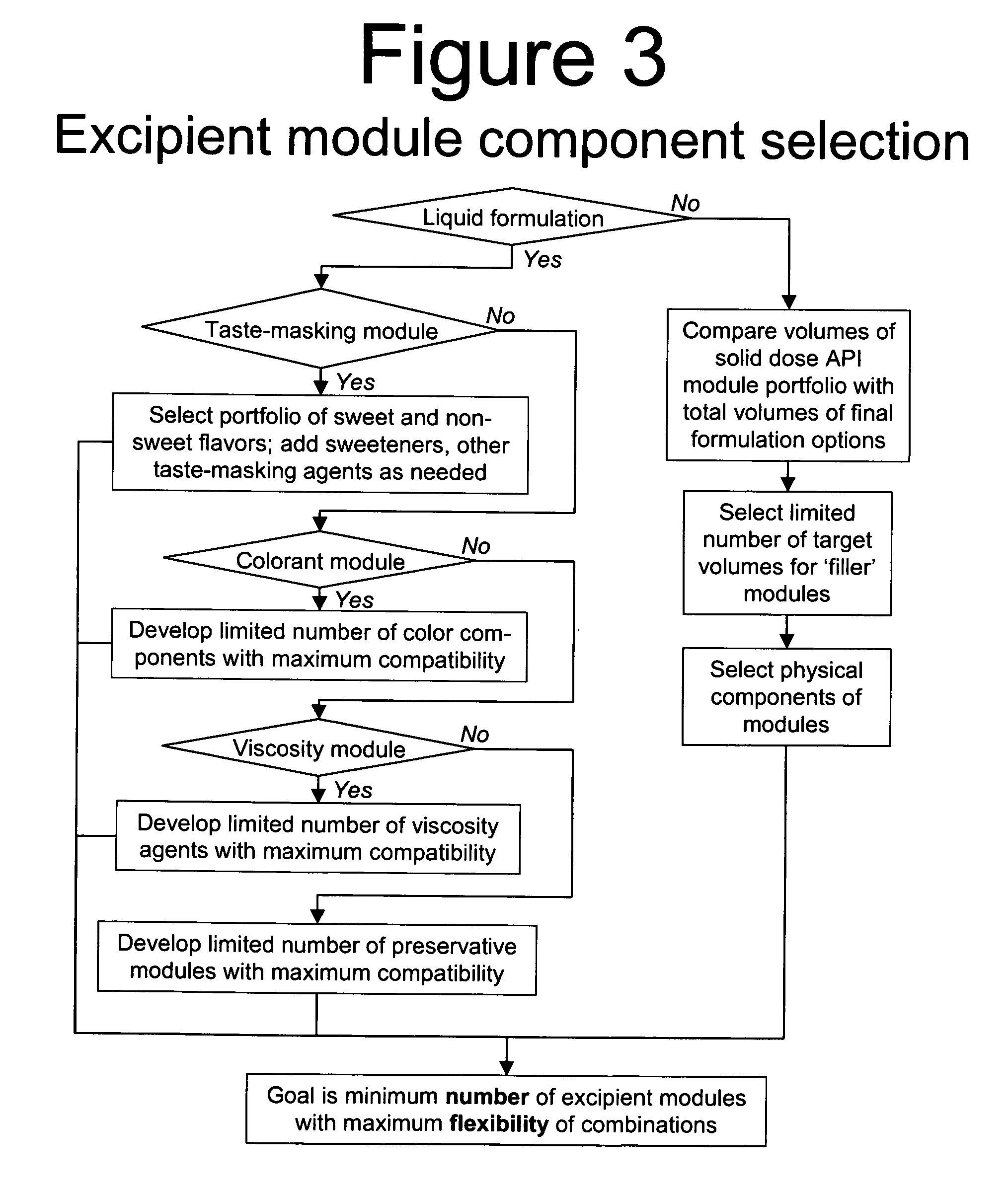

Methods of Making Pharmaceutical Components for Customized Drug Products

InactiveUS20100015184A1Maximize desired pharmaceutical characteristicLow costDrug and medicationsPharmaceutical product form changeFlavorAdditive ingredient

Methods and systems for developing and manufacturing componentized drug product precursor modules that can be simply assembled to create customized drug products are disclosed. Each module contains components of a final drug product (e.g., active pharmaceutical ingredients, nutritional ingredients, and / or excipients) in a fixed mixture selected to maximize desired pharmaceutical characteristics (e.g., stability, manufacturing efficiency) and minimize cost. The modules can be extensively tested for quality and assembled immediately, or at a later time, in multiple combinations to customize the final drug product characteristics (e.g., multiple active ingredients, doses, flavor, viscosity, etc.) to meet individual patient / consumer needs and / or preferences while assuring high quality. Permitted combinations may be maintained in a database to enable networked drug product selection, prescribing, and ordering. Each resulting customized drug product dose can be labeled to facilitate compliance and reduce the number of drug products administered per day.

Owner:TUEL STEPHEN M

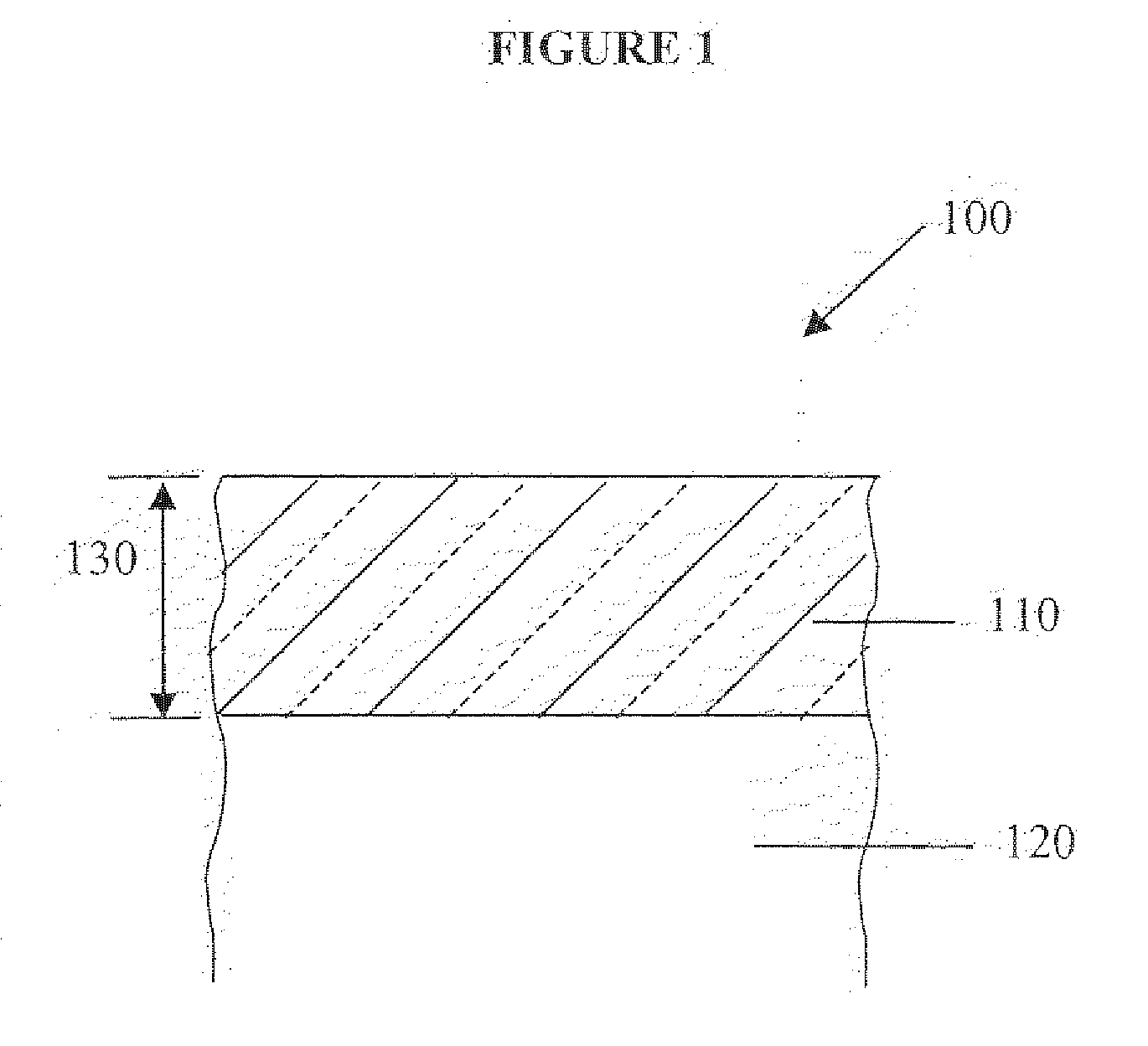

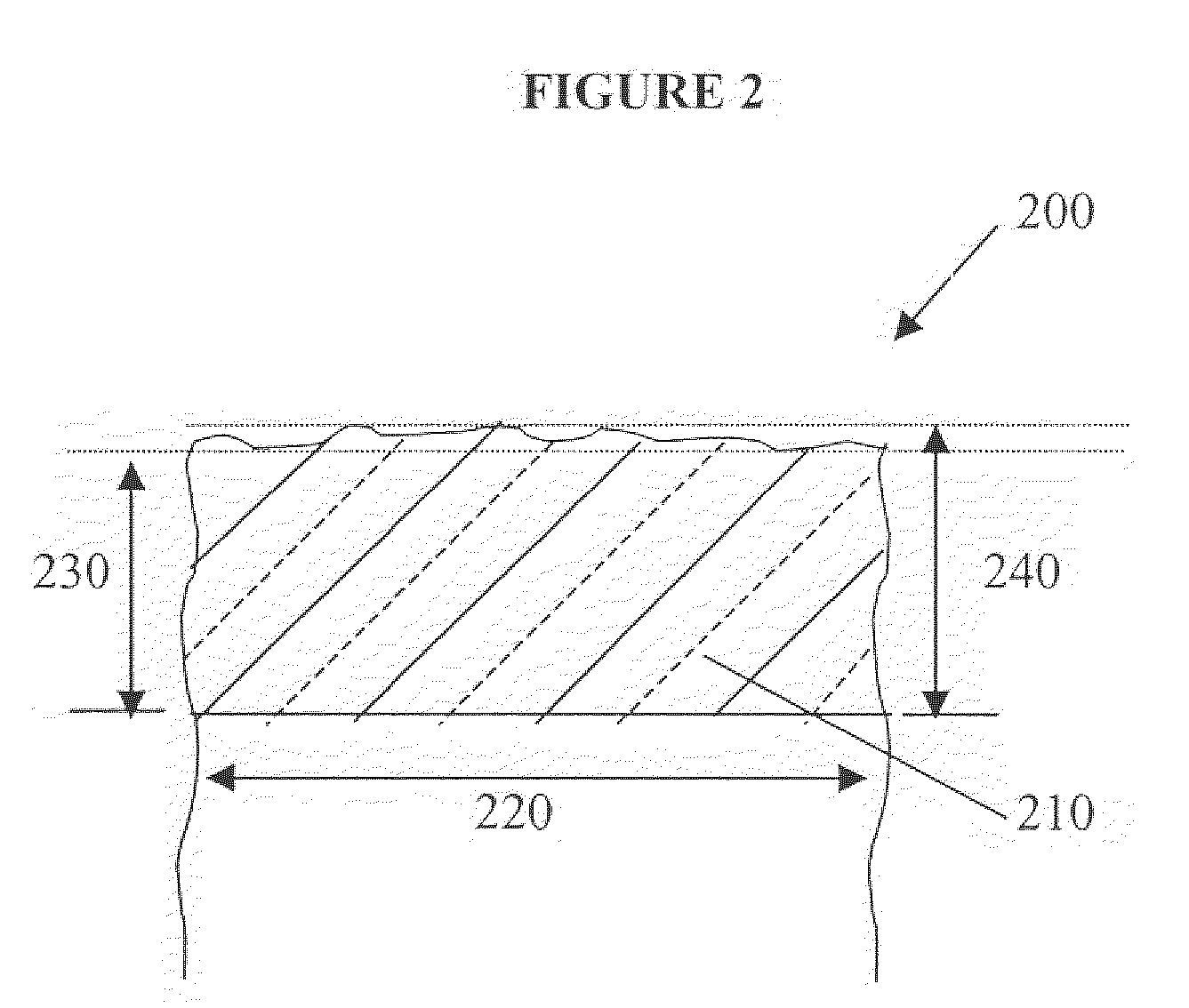

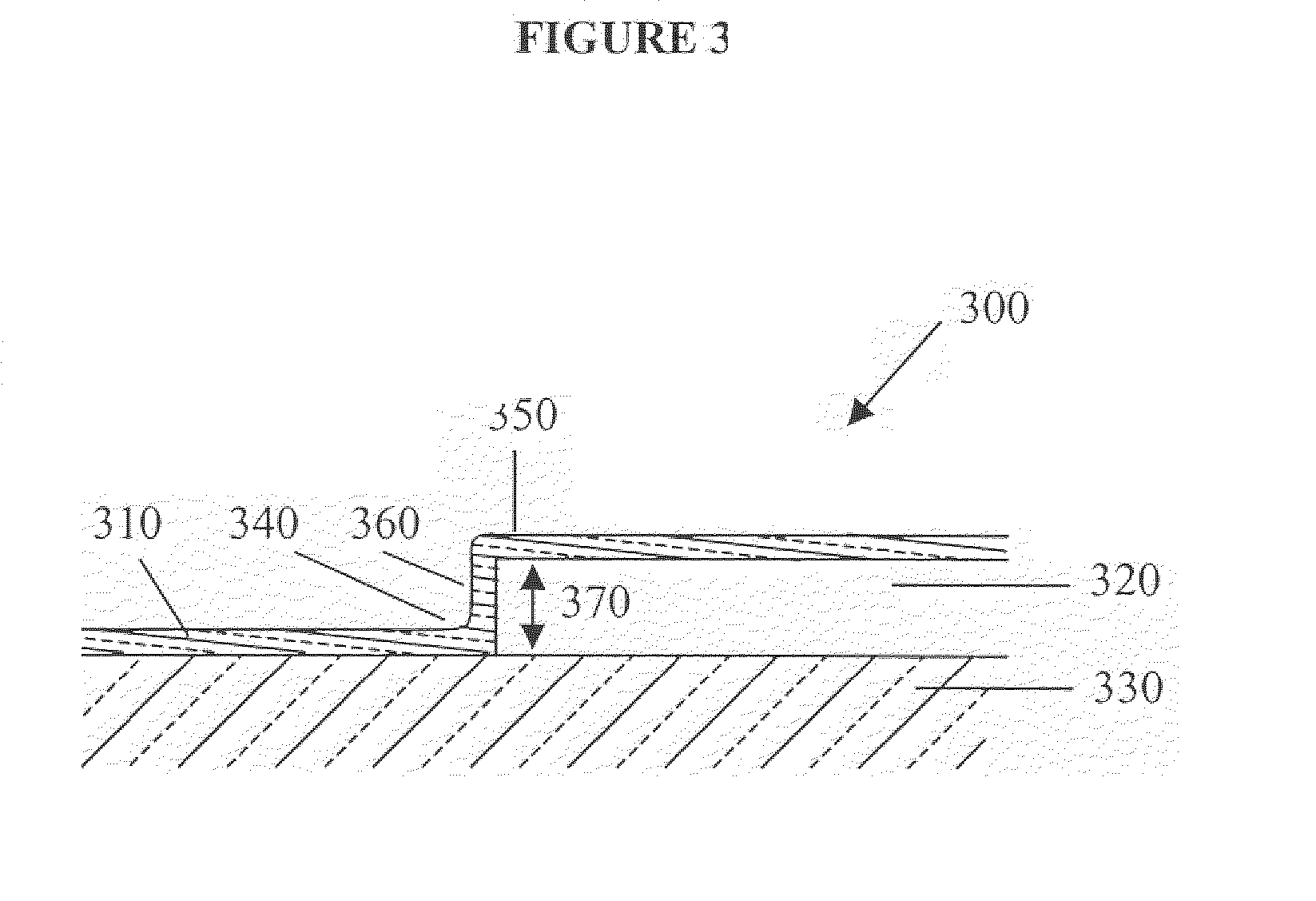

Thin Films and Methods of Making Them

InactiveUS20020197831A1Increase productionImprove device yieldTransistorMaterial nanotechnologyAnti-reflective coatingSilicon membrane

<heading lvl="0">Abstract of Disclosure< / heading> Thin, smooth silicon-containing films are prepared by deposition methods that utilize a silicon-containing precursor. In preferred embodiments, the methods result in Si-containing films that are continuous and have a thickness of about 150 Åor less, a surface roughness of about 5 Å rms or less, and a thickness non-uniformity of about 20% or less. Preferred silicon-containing films display a high degree of compositional uniformity when doped or alloyed with other elements. Preferred deposition methods provide improved manufacturing efficiency and can be used to make various useful structures such as wetting layers, HSG silicon, quantum dots, dielectric layers, anti-reflective coatings (ARC s), gate electrodes and diffusion sources.

Owner:ASM IP HLDG BV

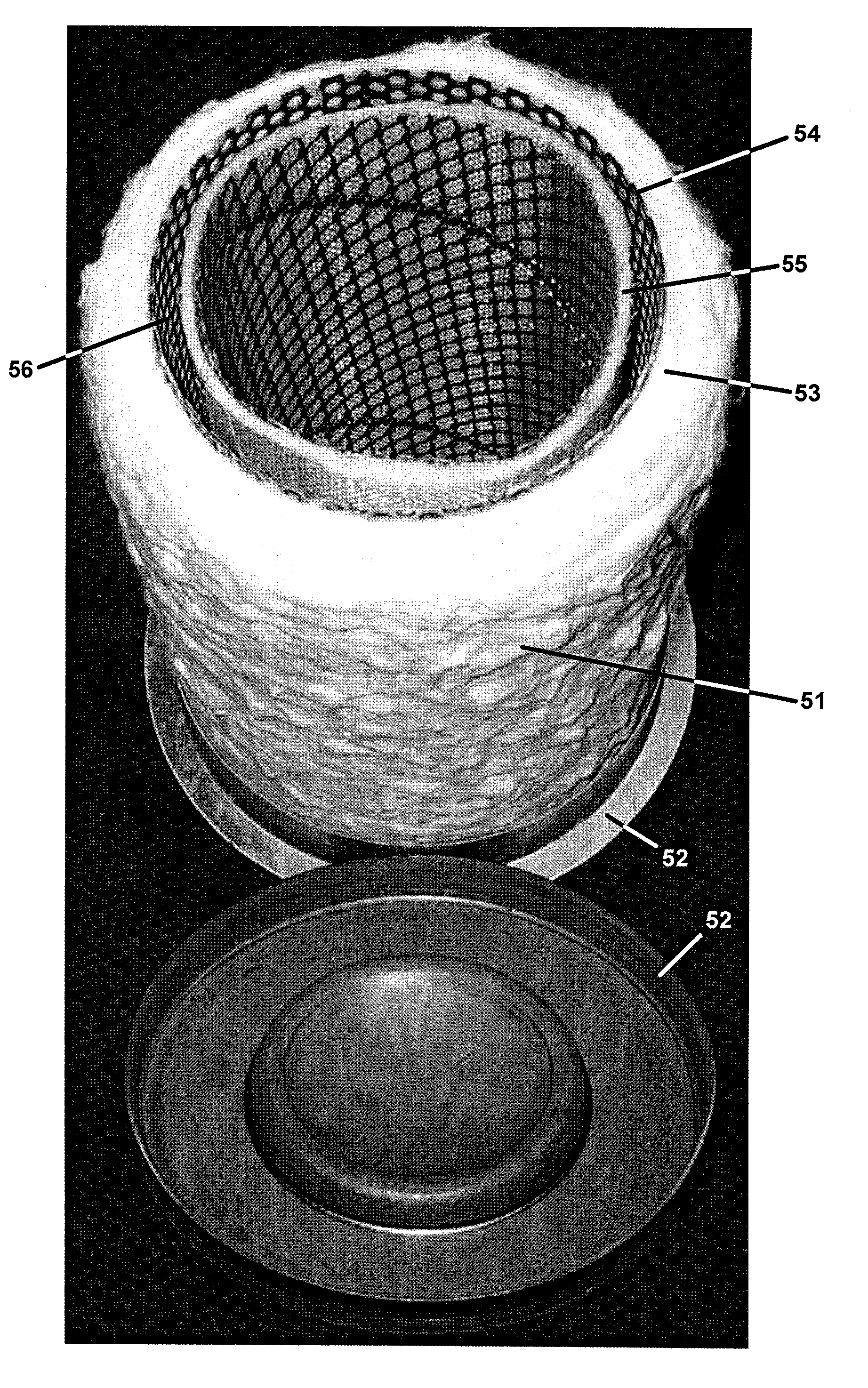

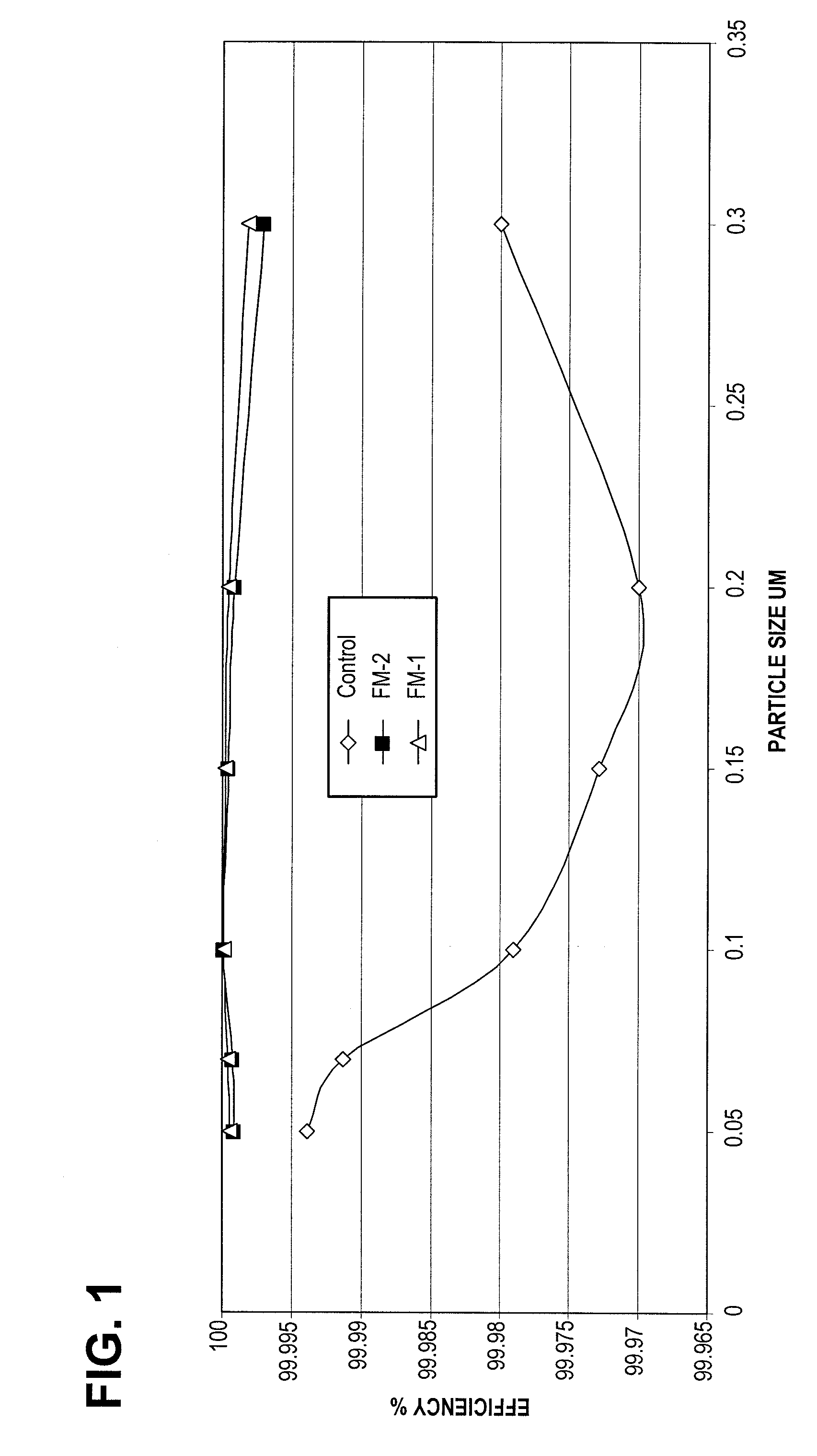

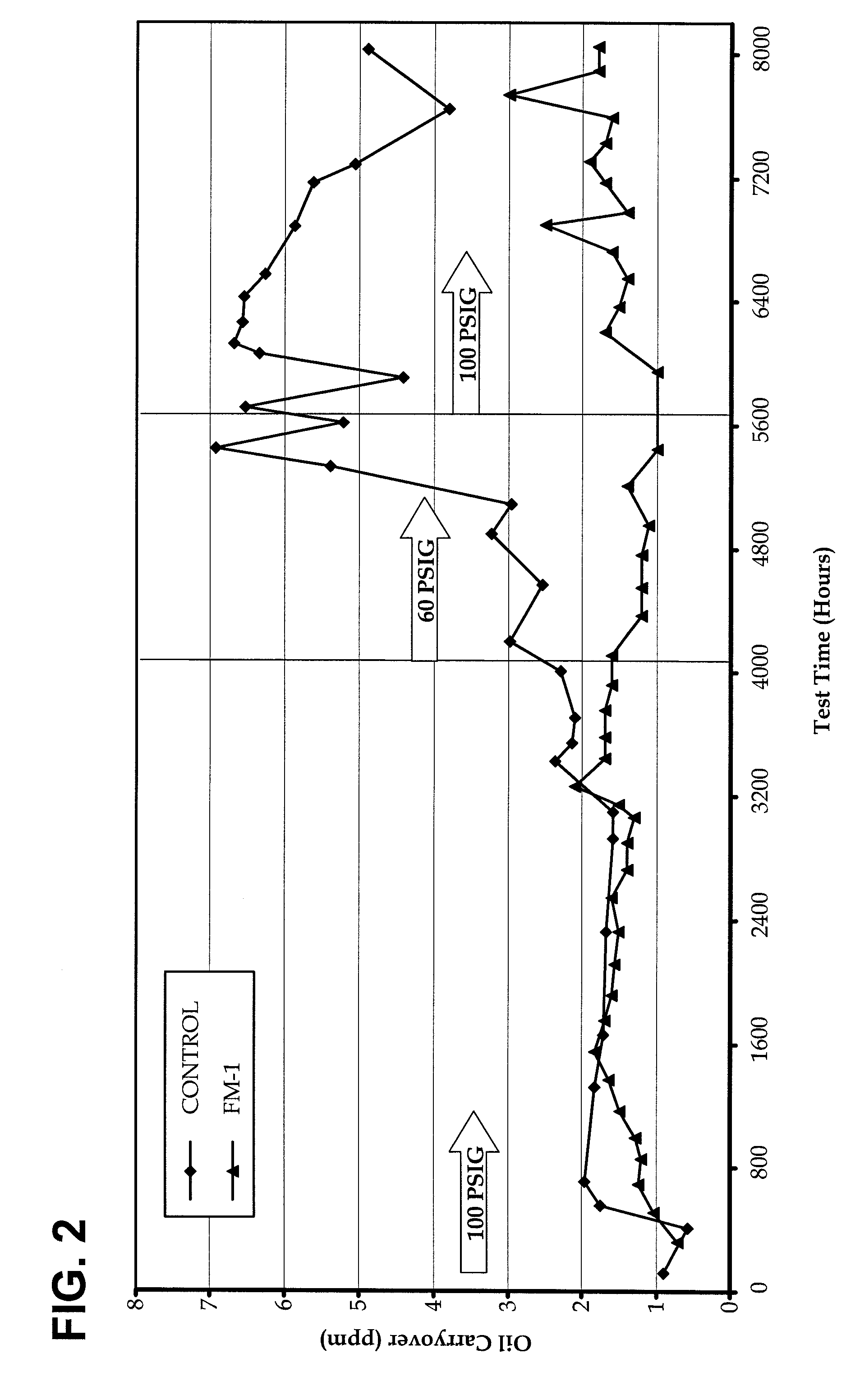

Formed filter element

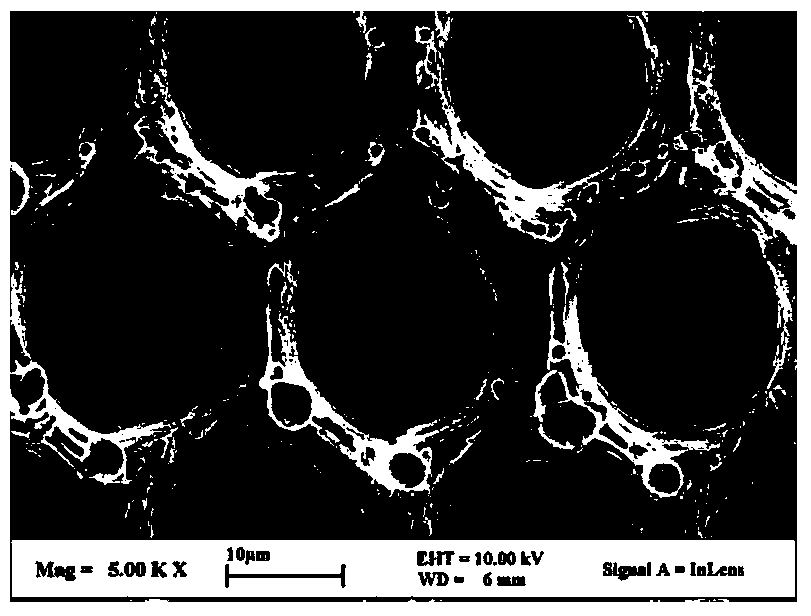

InactiveUS20090050578A1Improve featuresLower overall pressure dropSemi-permeable membranesDispersed particle filtrationBursting strengthFiber

A filter medium for use in filtering a mobile fluid made from at least a bicomponent fiber. Other fibers, particles, or other materials can also be entrained in the filter medium. The filter medium has a substantial thickness compared to filters of the prior art. The fiber length and diameter dimensions are selected to obtain desired filter characteristics including thickness, basis weight, pore size, filtration efficiency, pressure drop, burst strength, and manufacturing efficiency. Further, a multilayer filter medium can be provided with ease. Each layer can have a different composition, pore size, basis weight, and so forth, thus providing the ability to build multiple functionality into the filter media of the invention.

Owner:DONALDSON CO INC

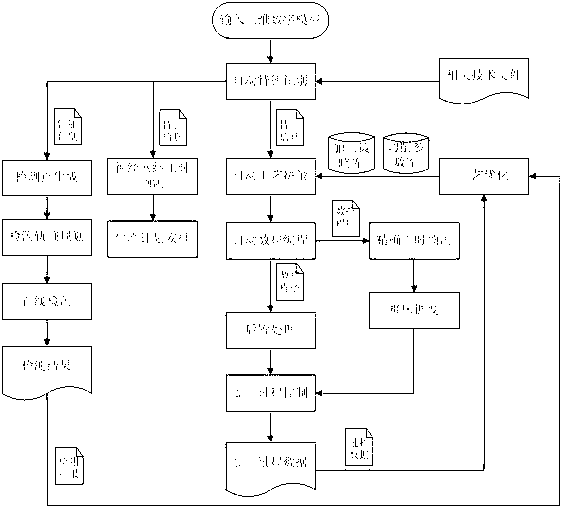

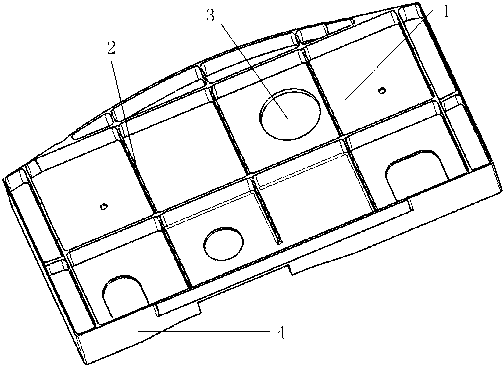

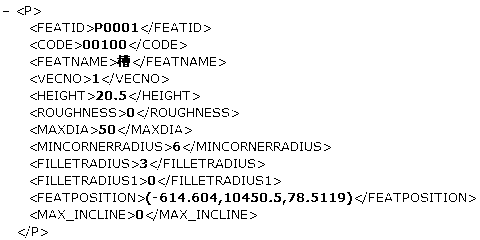

Feature-based numerical-control method for processing and manufacturing complicated parts

ActiveCN103235556AAchieve integrationAchieve deliveryProgramme controlComputer controlNumerical controlClosed loop

Disclosed is a feature-based numerical-control method for processing and manufacturing complicated parts. The feature-based numerical-control method includes expressing features on the basis of a body and an object-oriented process; expressing geometrical and technological information of a part in an integral manufacturing procedure on the basis of the features; utilizing the features as carriers of manufacturing knowledge and experience to implement effective integration and closed-loop control for information of manufacturing stages of designing, processing, detecting and the like; and carrying out automatic technological decision, automatic numerical-control programming, post-processing, control for a processing procedure, online detection, technology optimization and working hour prediction on the basis of automatic feature identification and the features. The feature-based numerical-control method has the advantages that information links are effectively connected with one another in the processing procedure, the manufacturing procedure is automatic and intelligent, dependence on manual experience is reduced in the manufacturing procedure, production management for the manufacturing procedure is facilitated, the manufacturing efficiency is improved, and the production cost is reduced.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

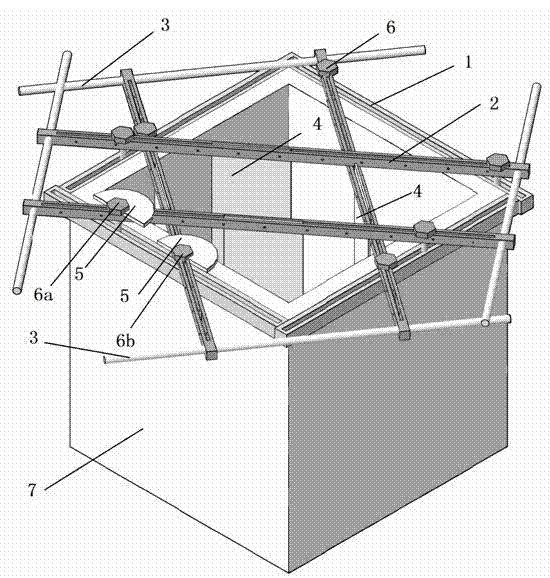

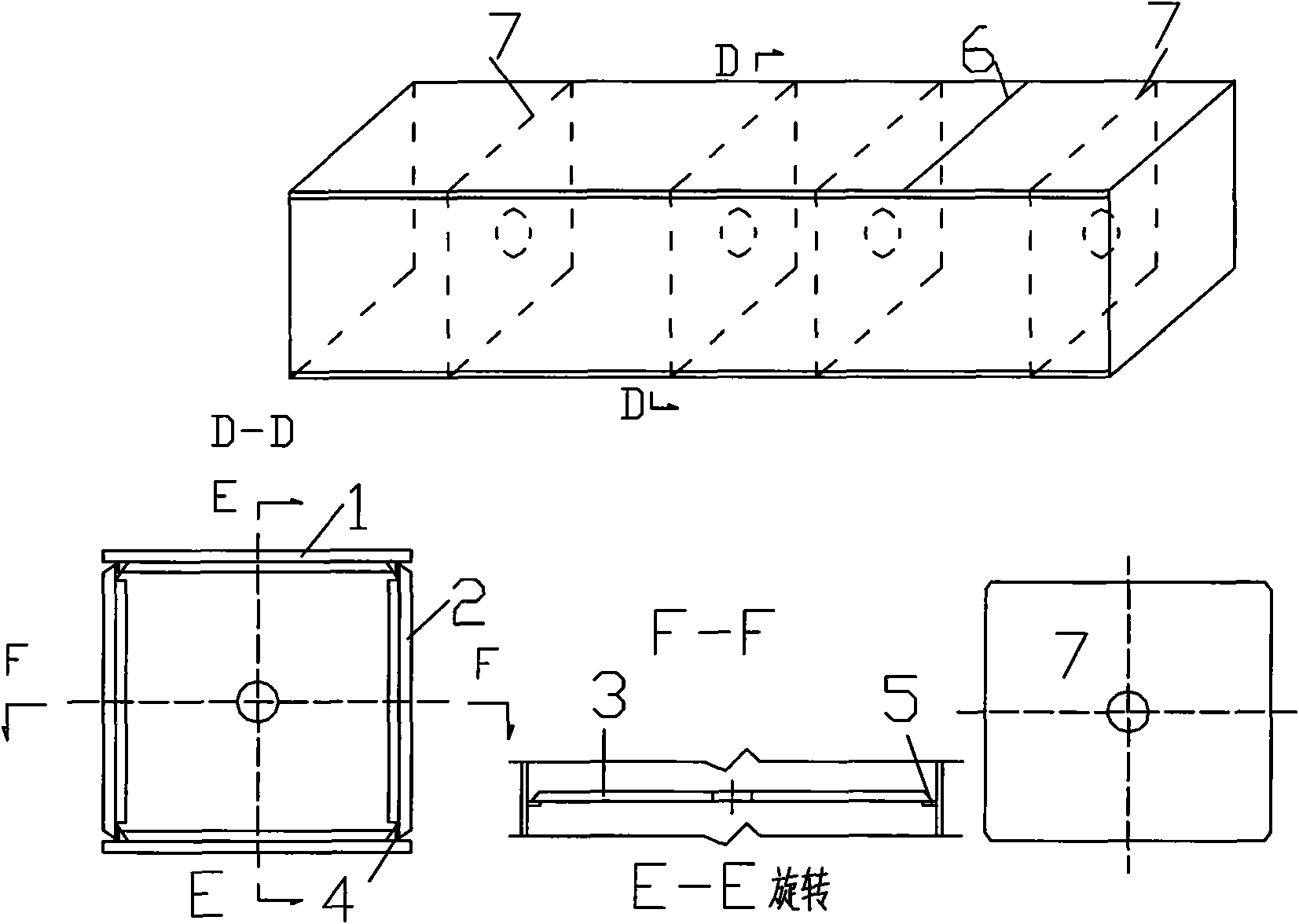

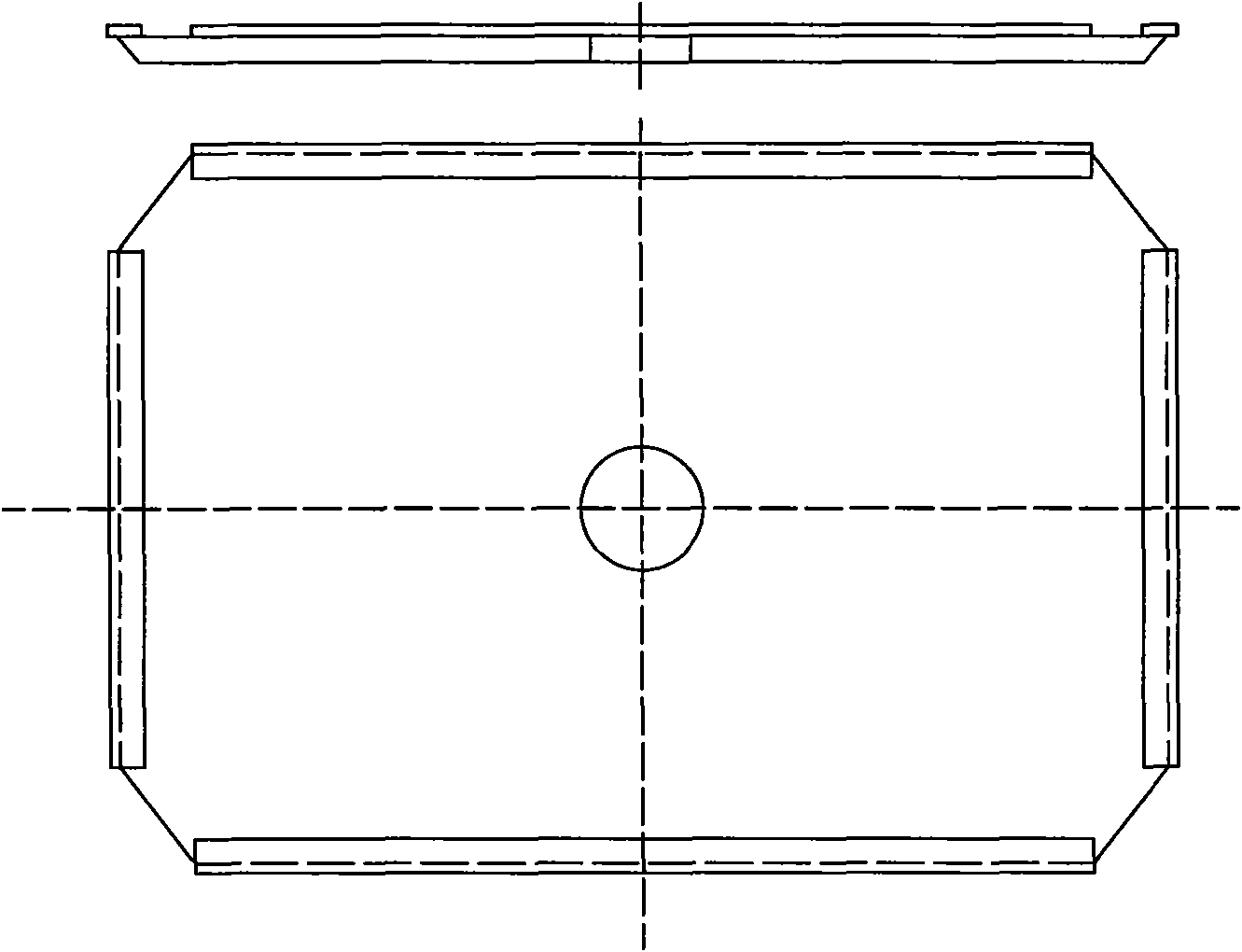

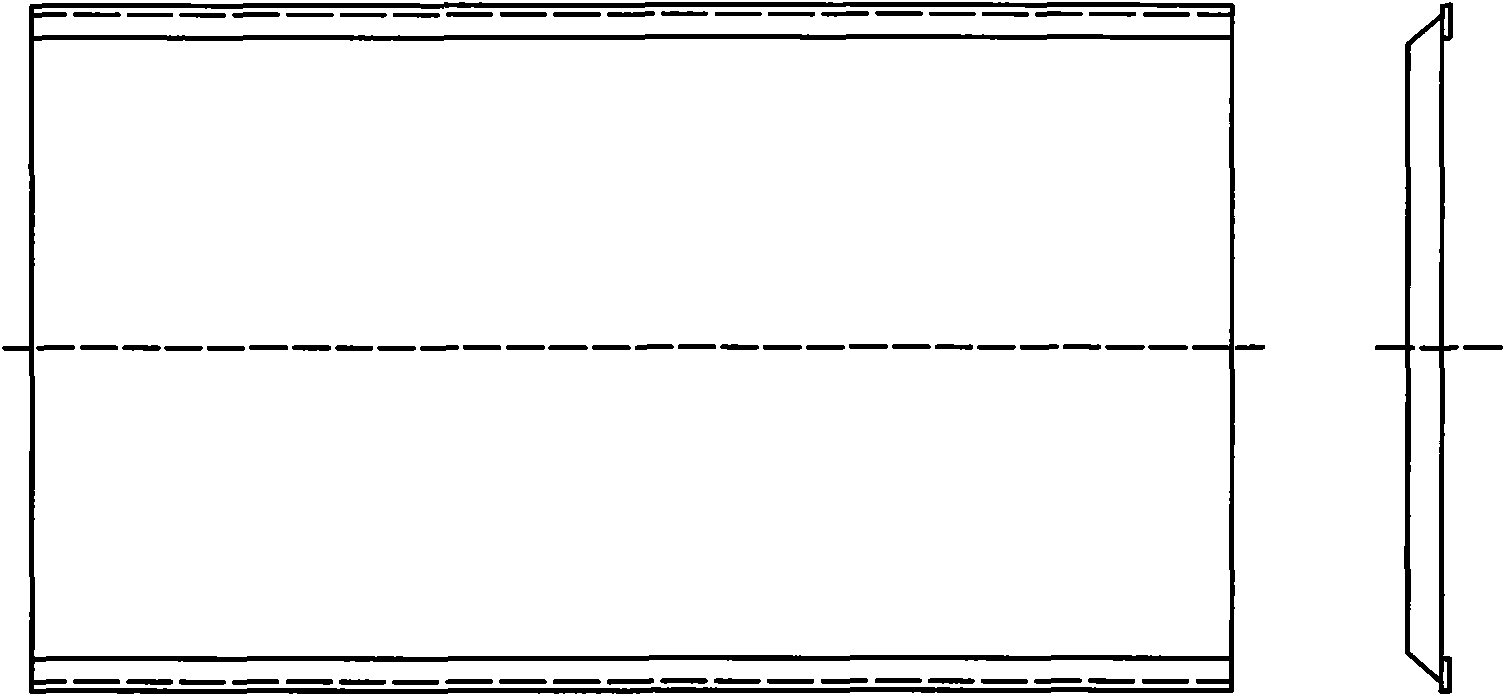

Mould for manufacturing fissure surface of rock like test block

InactiveCN102519767APrevent movementEasy to transformPreparing sample for investigationCeramic shaping apparatusProtractorSheet steel

The invention discloses a mould for manufacturing a fissure surface of a rock like test block. The mould comprises a sliding groove, a sheet steel locating rod, a protractor, a sliding rod and a sheet steel, wherein the sliding groove is a long strip type metal component provided with a straight groove hole; the sheet steel locating rod is a metal rod; the sliding rod is a metal rod marked with ascale; a sheet steel fixing sheet is a hard sheet provided with a notch and stuck on the bottom surface of the test block mould; the sliding groove is fixed on the top of the side wall of the test block mould; the sheet steel locating rod is fixed above the sliding groove; the circle centre of the protractor passes through any bolt and is fixed above the sheet steel locating rod; the sliding rod passes through holes at two ends of the sheet steel locating rod and is vertical to the sheet steel locating rod; one end of the sheet steel is fixed in a through groove of the sheet steel locating rod; and the other end of the sheet steel is clamped in the notch of the sheet steel fixing sheet. The mould disclosed by the invention is capable of conveniently and rapidly adjusting parameters of thefissure surface of the test block, such as an inclination angle, an interval, a communication rate and the like. The mould is easy to process and can be repetitively utilized, thus, the manufacture efficiency and the precision of the test block are increased.

Owner:WUHAN UNIV

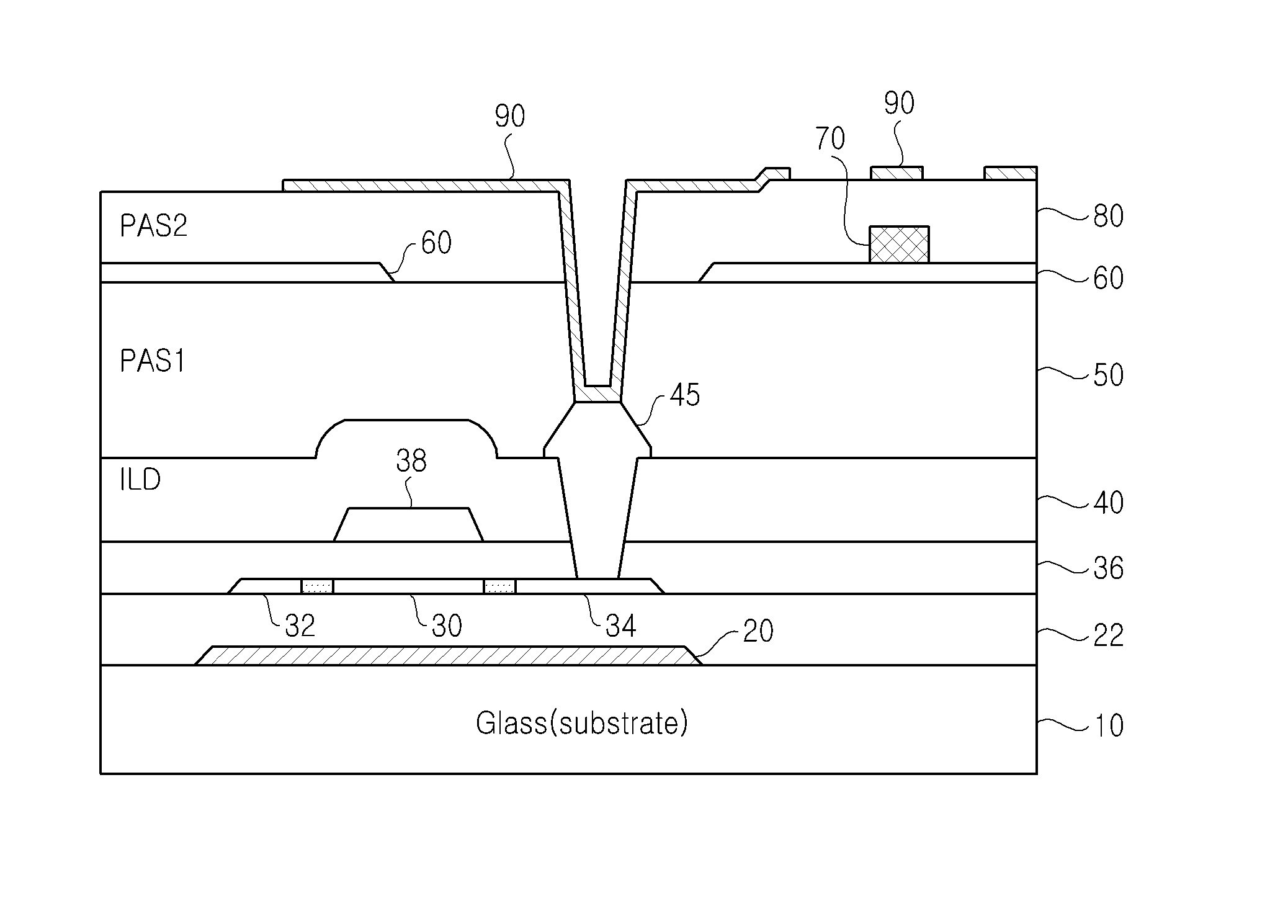

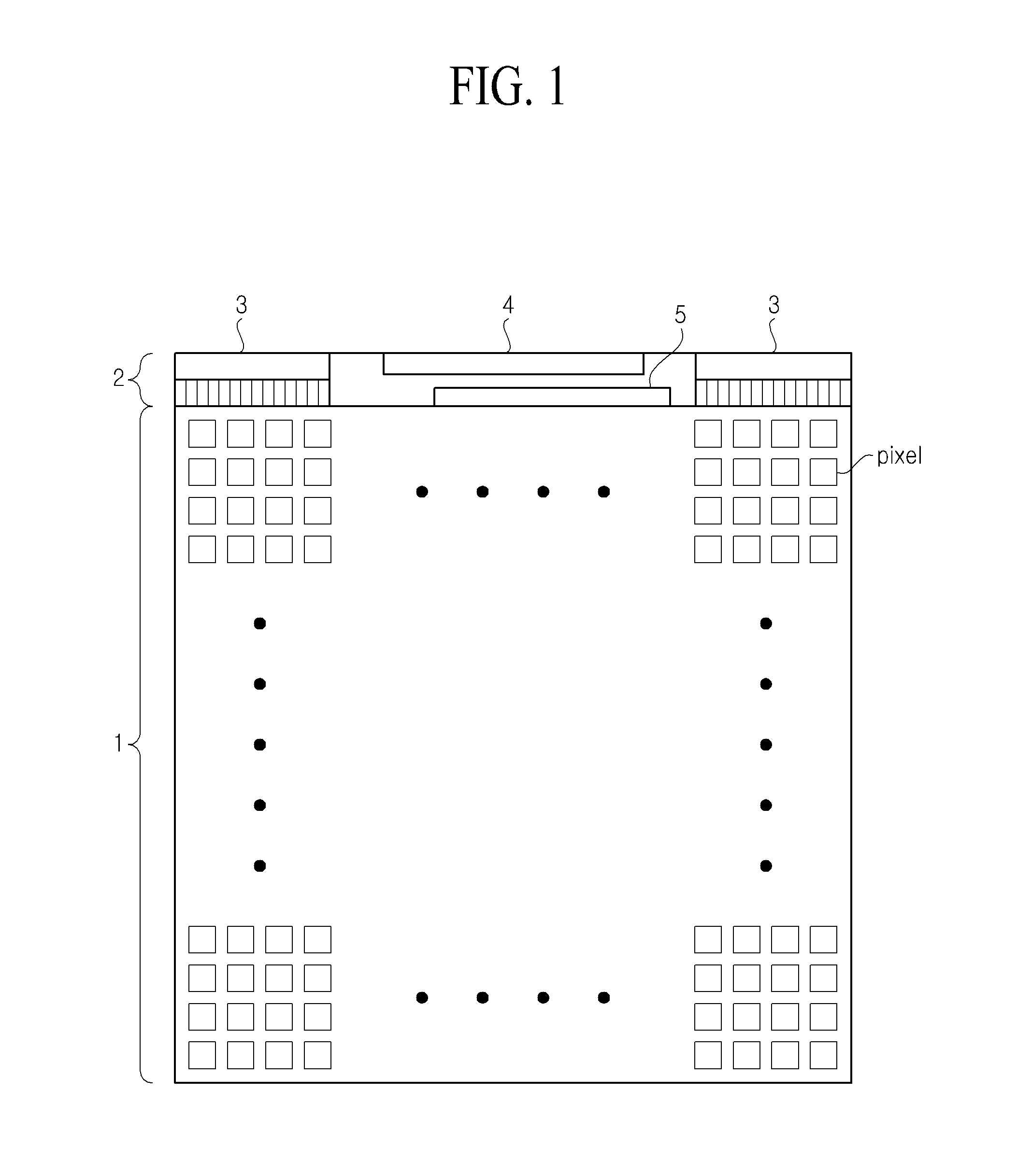

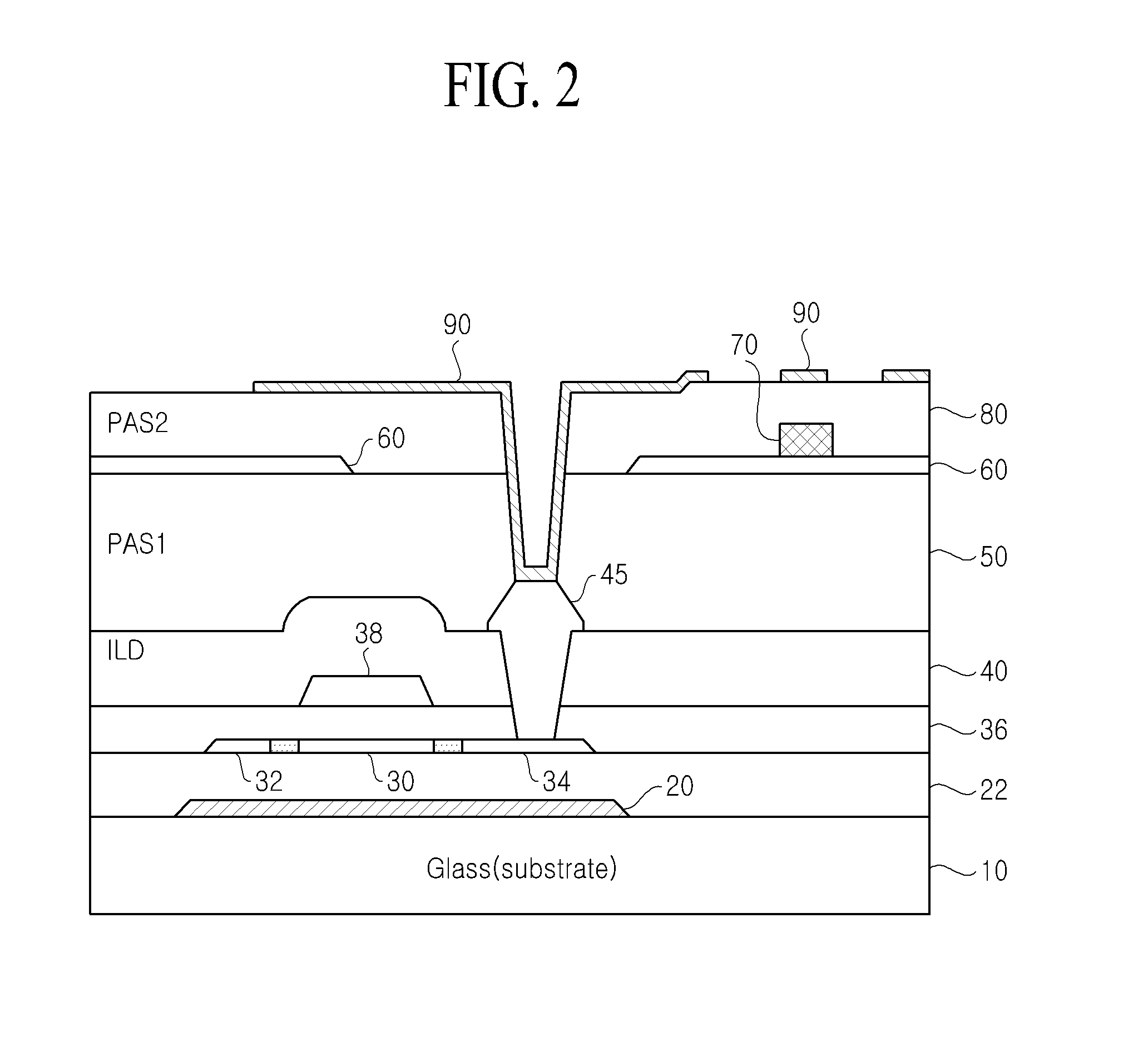

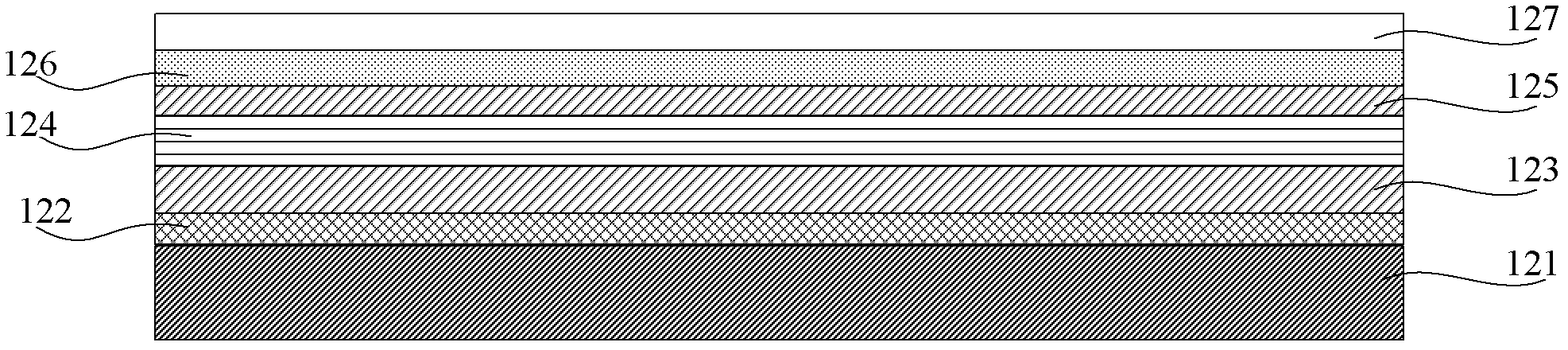

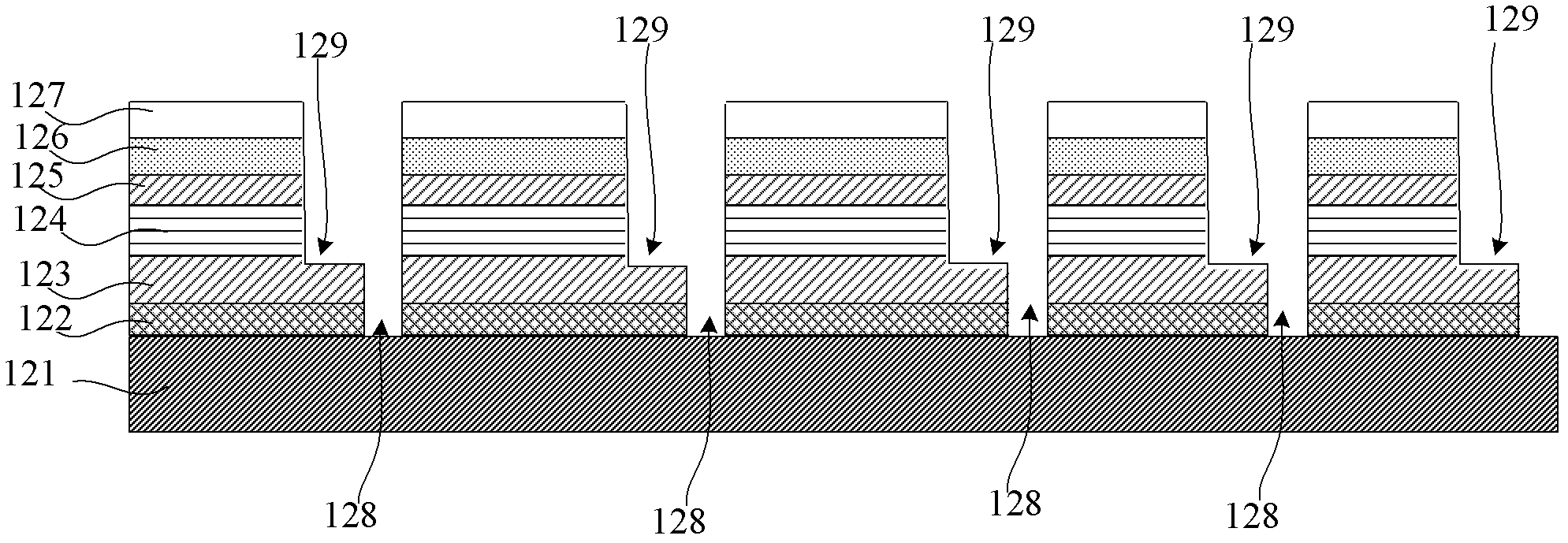

Liquid Crystal Display Device and Method for Manufacturing the Same

ActiveUS20130077034A1Improve production efficiencyAvoid disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayConductive materials

Disclosed are an LCD device and a method of manufacturing the same, in which a passivation layer and a pixel electrode are simultaneously formed by a single mask process using a half tone mask, and thus, manufacturing efficiency increases, and a defective contact due to loss of the pixel electrode can be prevented in a pad area. The LCD device includes a pad part including a pad area and a contact area. The LCD device includes a pixel pad formed in the pad area, a pixel bar formed in the contact area, and a bridge layer contacting the pixel pad with the pixel bar. The bridge layer is formed as a single layer or multi layers, and formed of one or more of a transparent conductive material and an opaque conductive material.

Owner:LG DISPLAY CO LTD

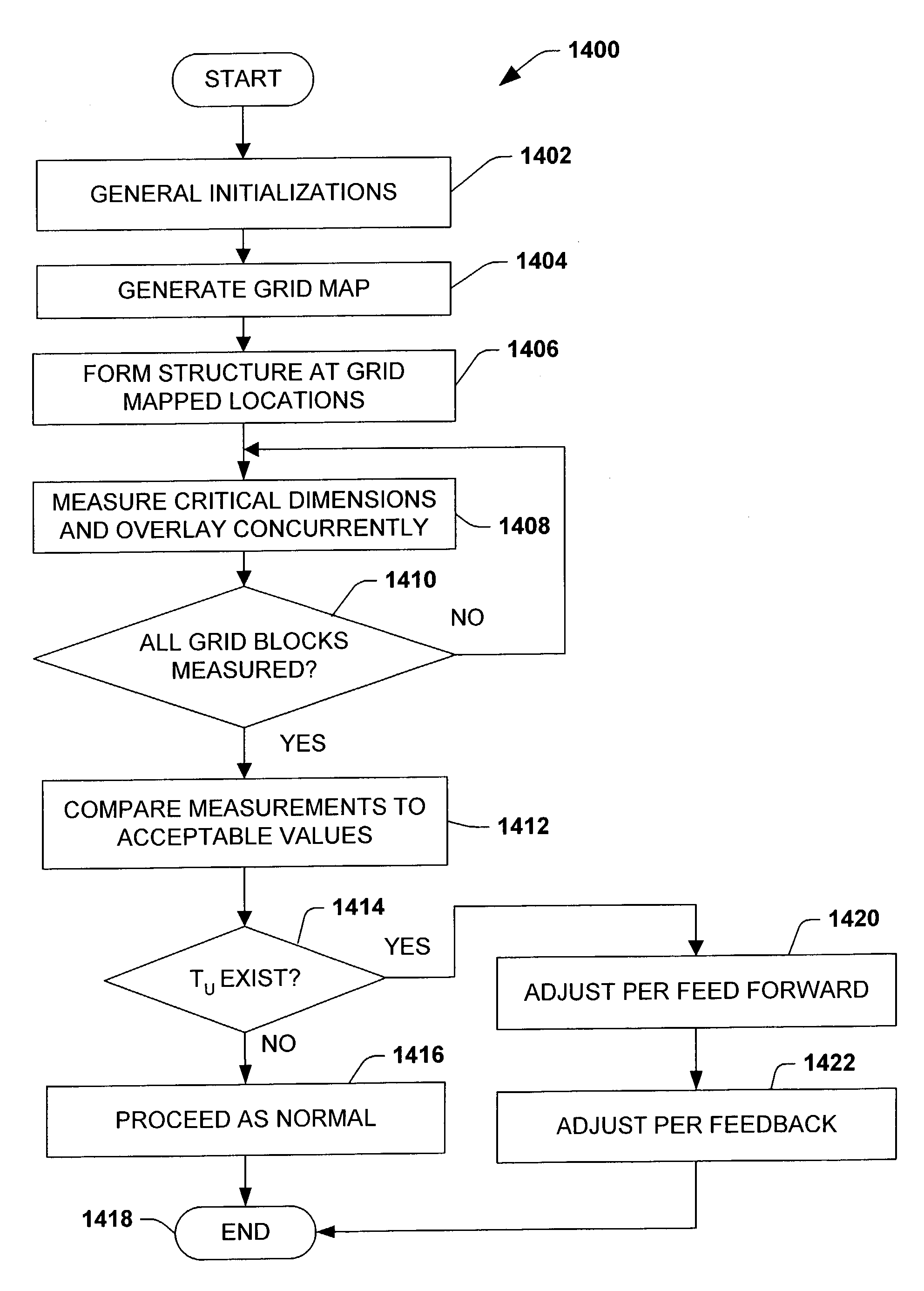

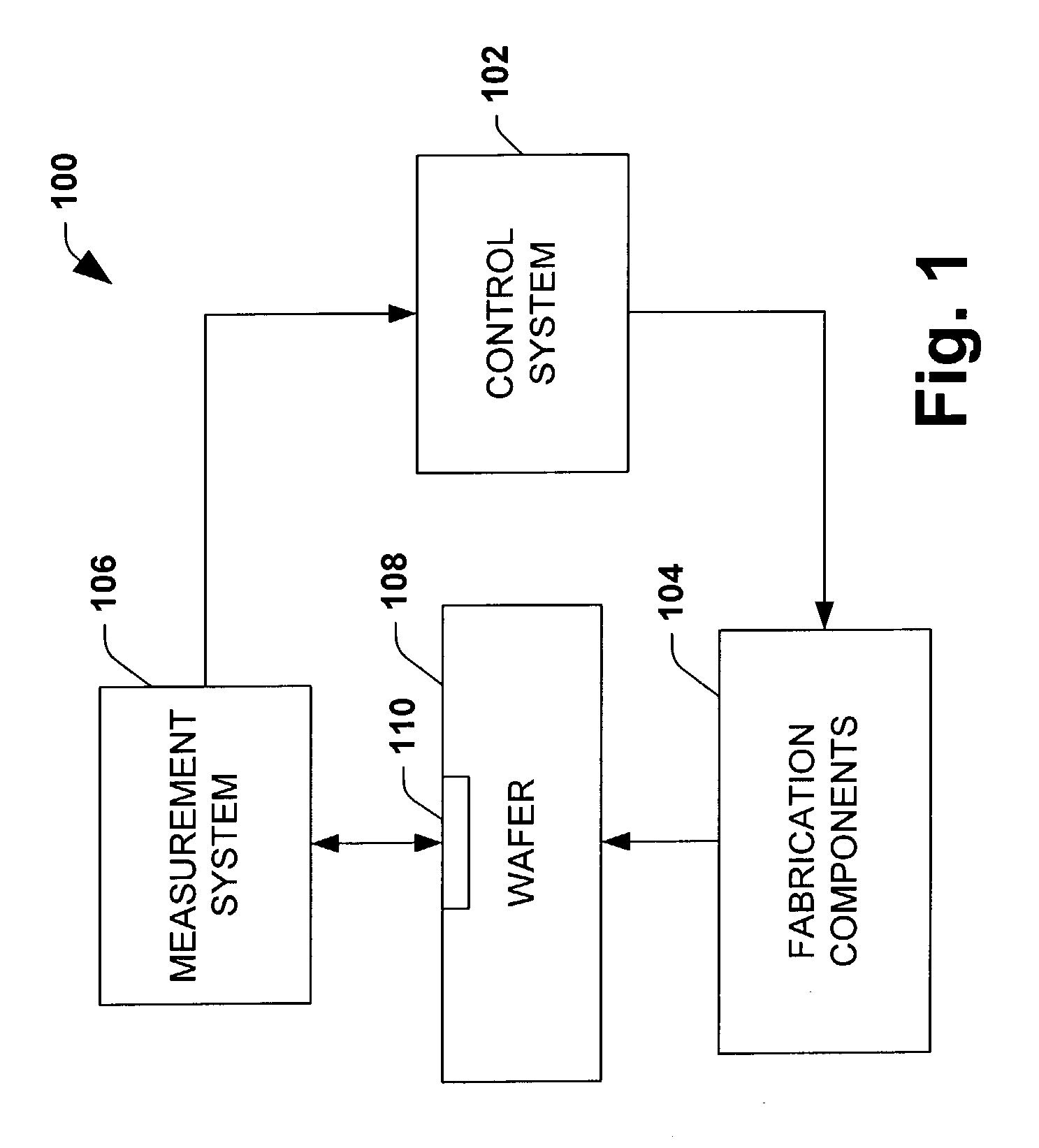

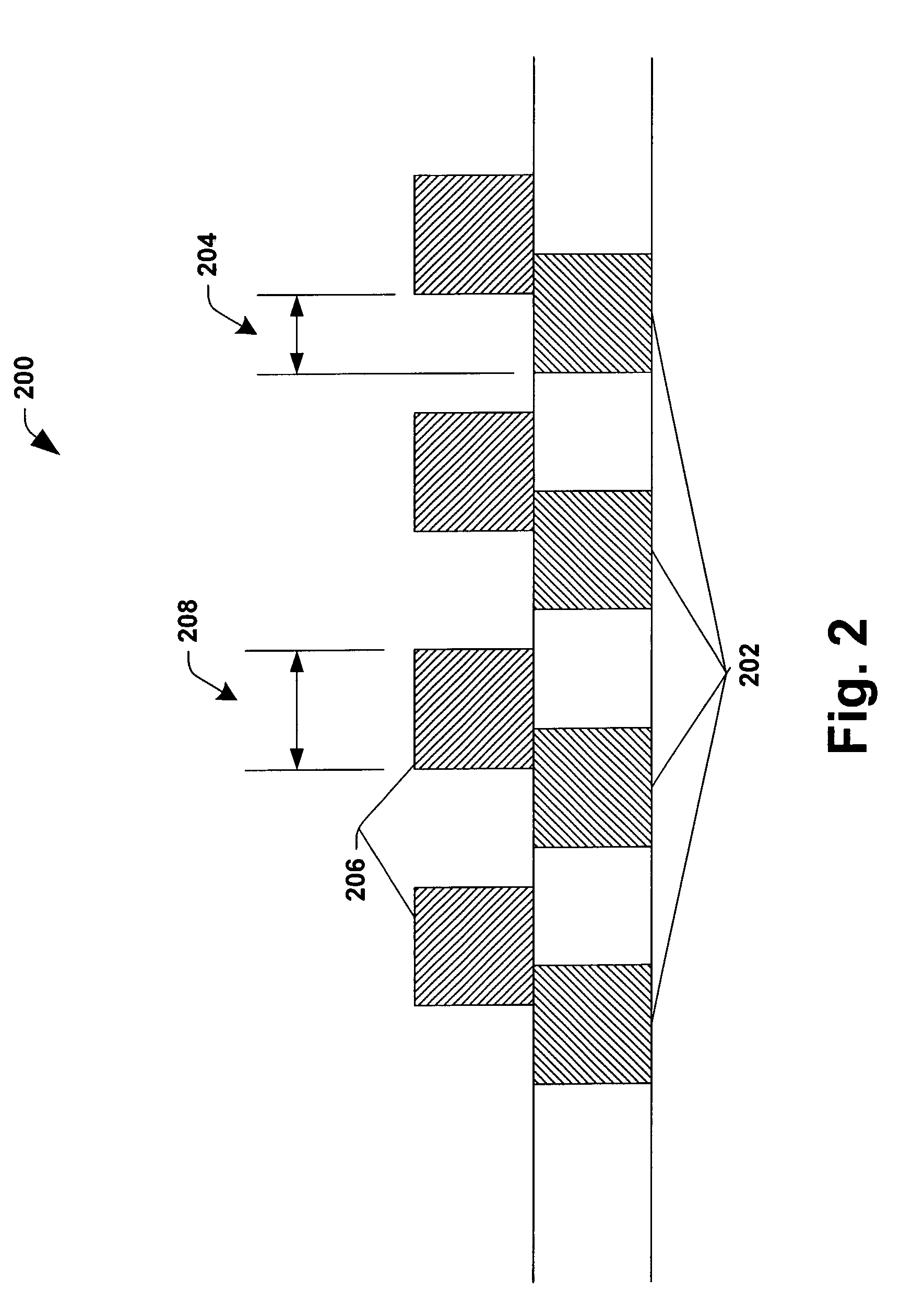

Concurrent measurement of critical dimension and overlay in semiconductor manufacturing

ActiveUS7080330B1Fabrication can be reducedFacilitate a reduction in, among other things, time and real estate requiredDetecting faulty computer hardwarePhotomechanical apparatusScanning electron microscopeEngineering

A system and methodology are disclosed for monitoring and controlling a semiconductor fabrication process. One or more structures formed on a wafer matriculating through the process facilitate concurrent measurement of critical dimensions and overlay via scatterometry or a scanning electron microscope (SEM). The concurrent measurements mitigate fabrication inefficiencies, thereby reducing time and real estate required for the fabrication process. The measurements can be utilized to generate feedback and / or feed-forward data to selectively control one or more fabrication components and / or operating parameters associated therewith to achieve desired critical dimensions and to mitigate overlay error.

Owner:OCEAN SEMICON LLC

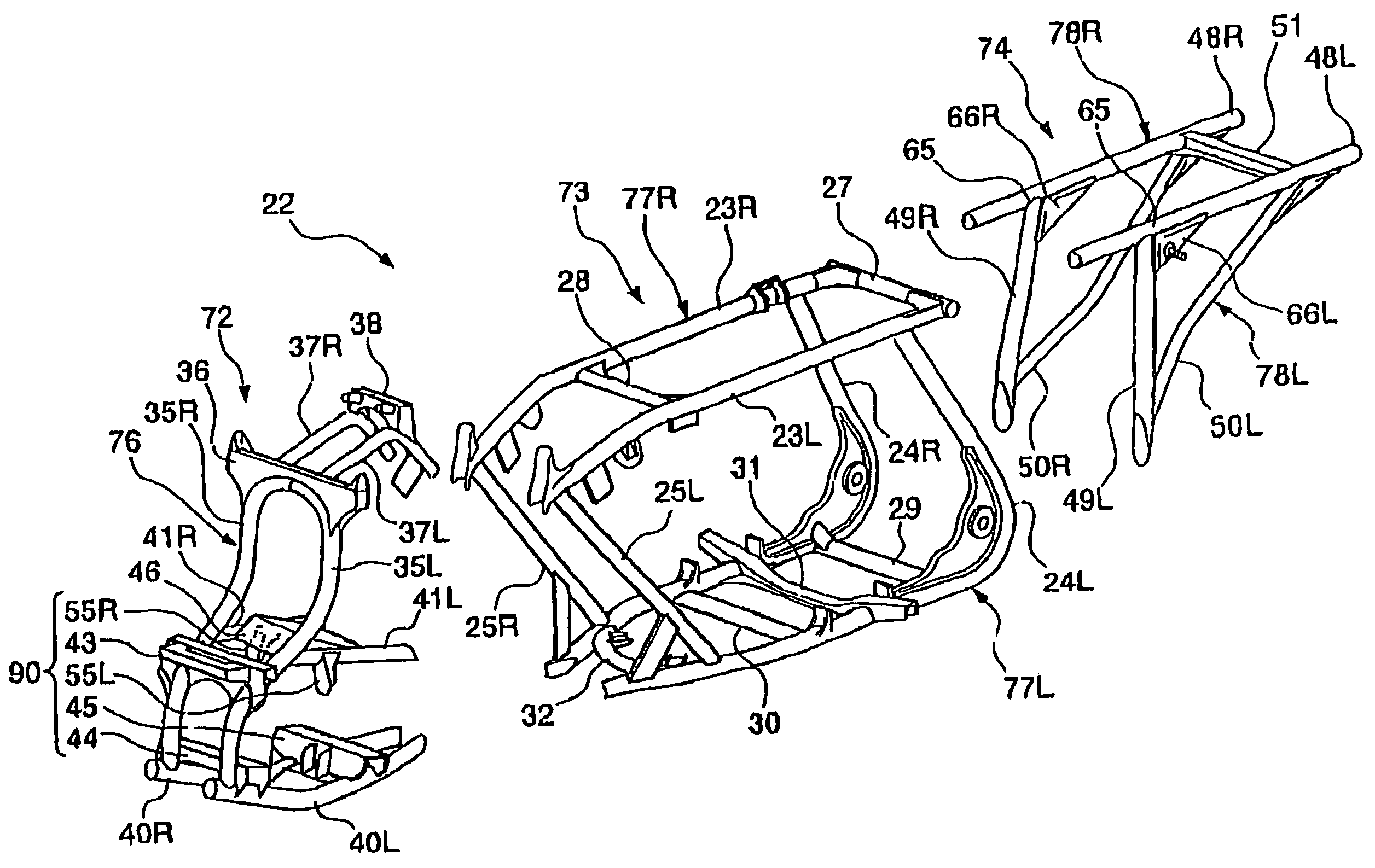

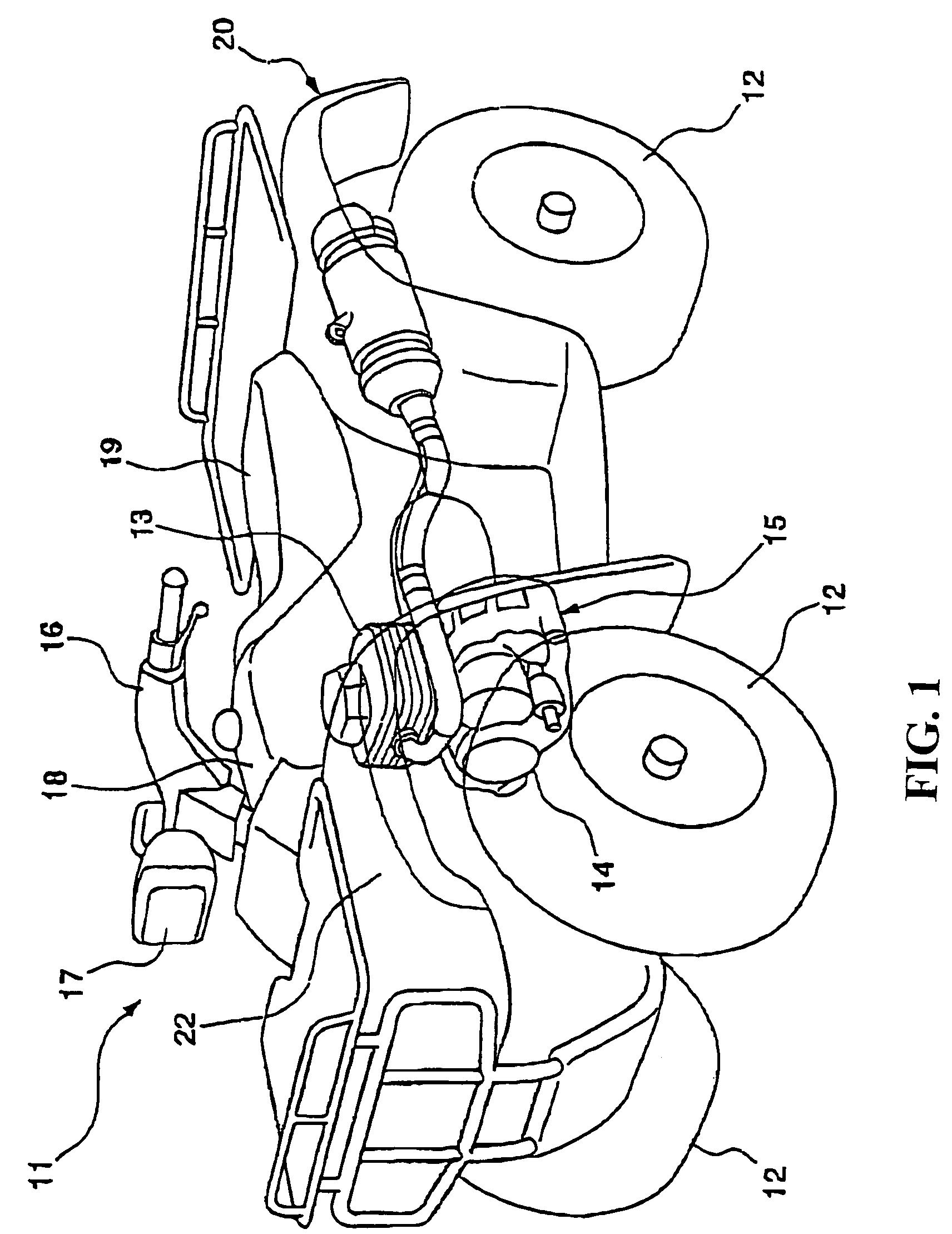

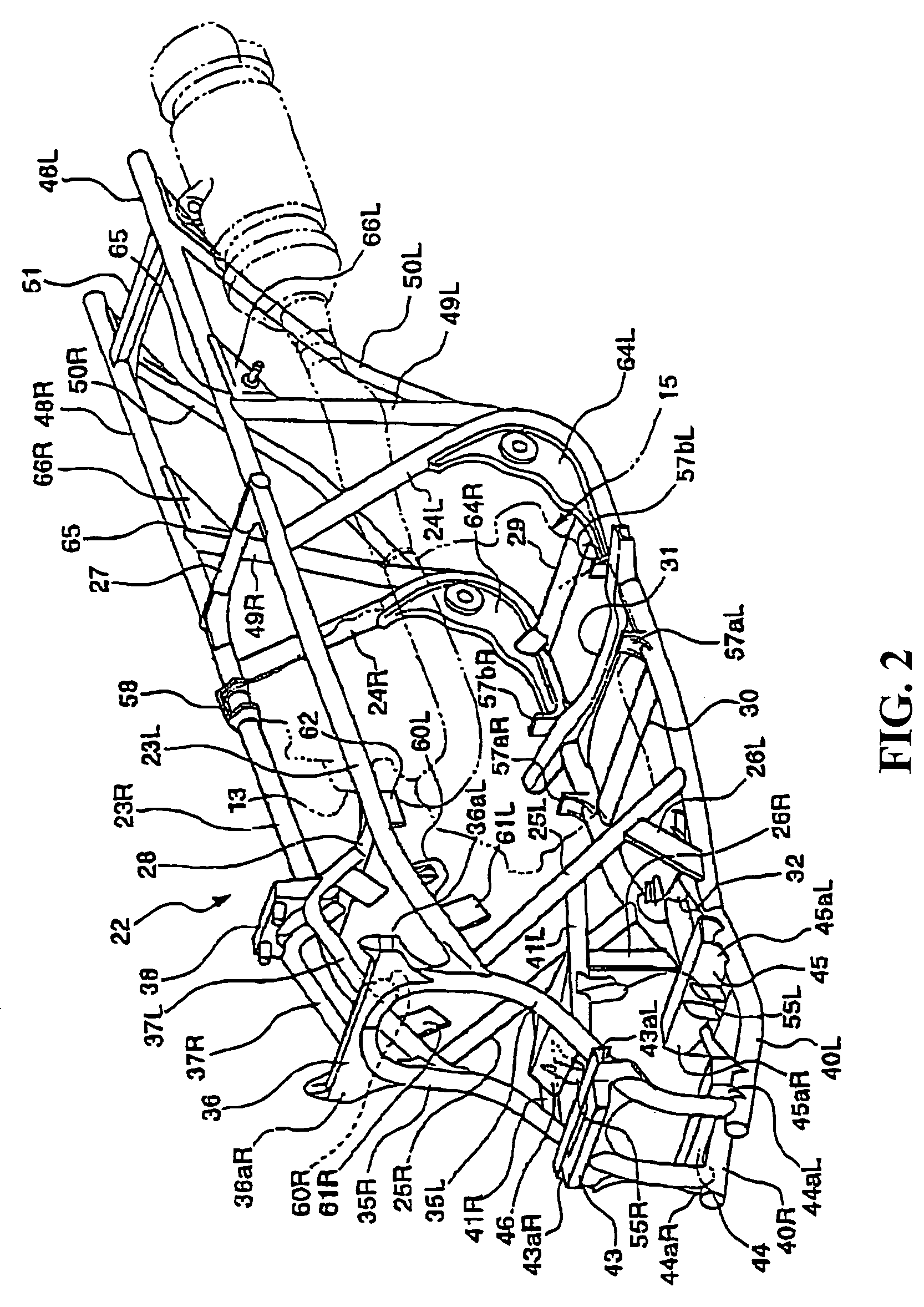

Frame structure in saddle type vehicle and method of manufacturing frame

ActiveUS7306069B2Facilitate carriageEasy to storeCyclesVehicle body-frame connectionsSupporting systemVehicle frame

A frame structure and a method of manufacturing a body frame that is divided into small assemblies to facilitate the carriage and storage of articles and individuals and the manufacturing efficiency. A body frame is divided into three, namely, a front assembly having a closed loop structure, an engine support system assembly having a closed loop structure and a rear suspension support system assembly having a closed loop structure. The front assembly and the rear suspension support system assembly are connected to the engine support system assembly to form the body frame. The small assemblies have a closed loop structure whereby the rigidity is enhanced, and the shape is also stabilized. Therefore, the accuracy management can be performed.

Owner:HONDA MOTOR CO LTD

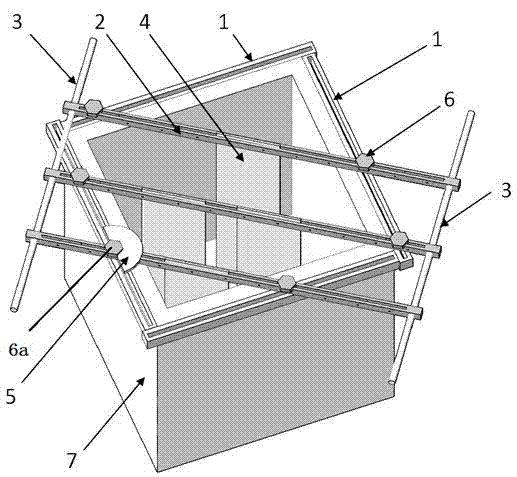

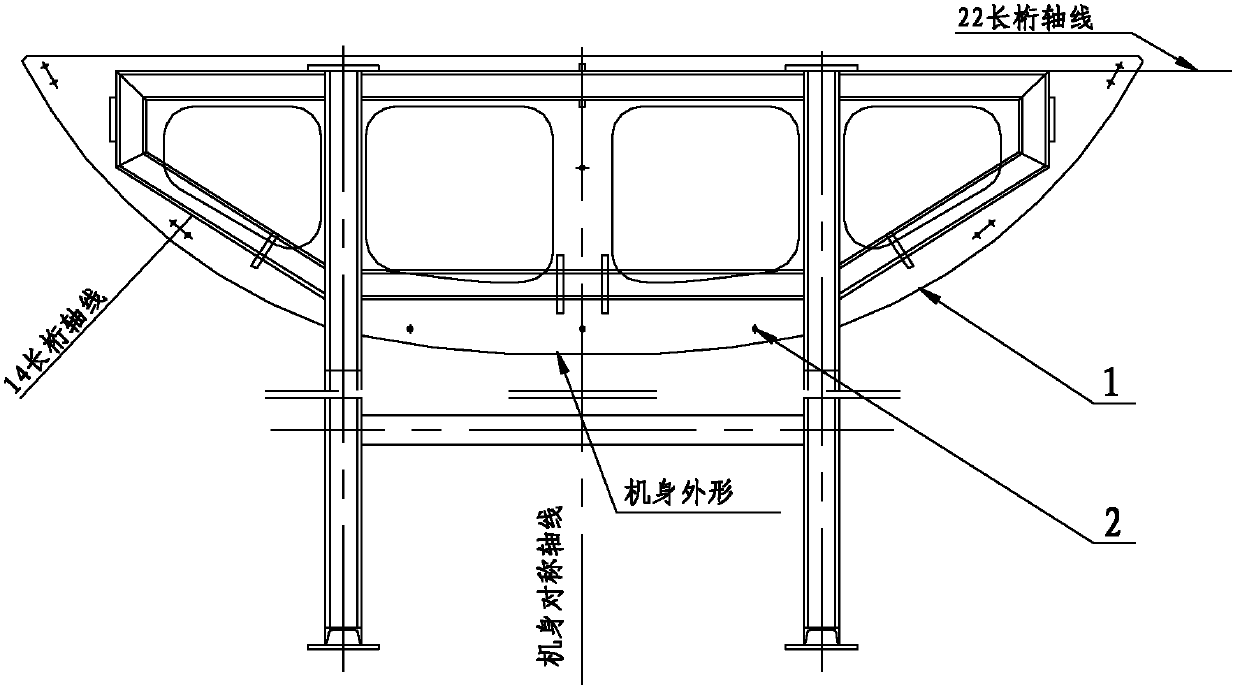

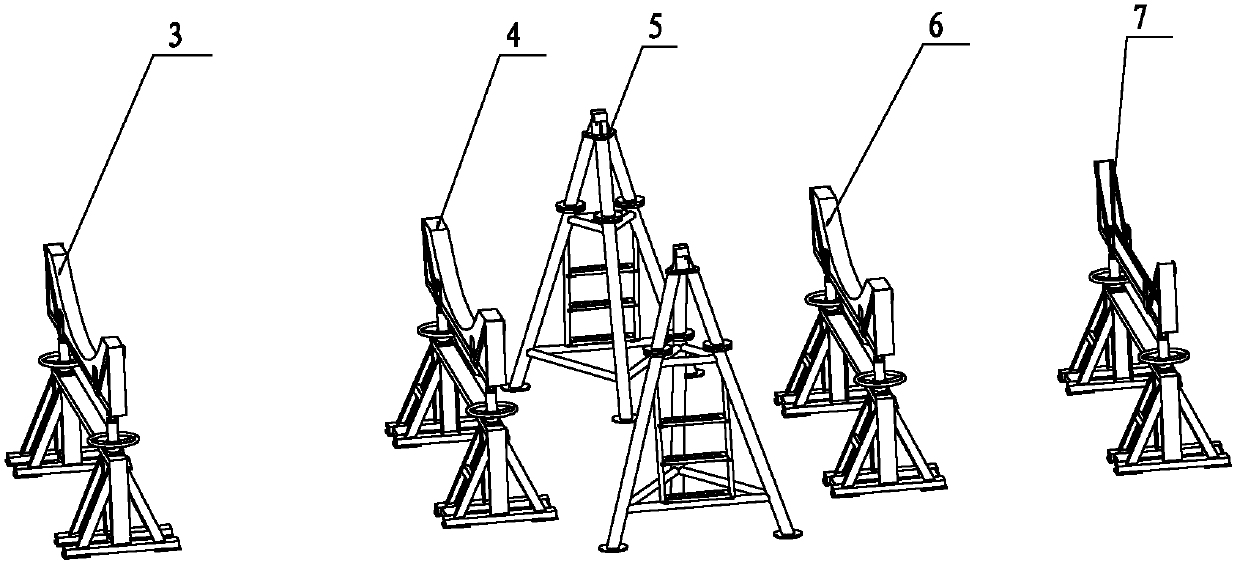

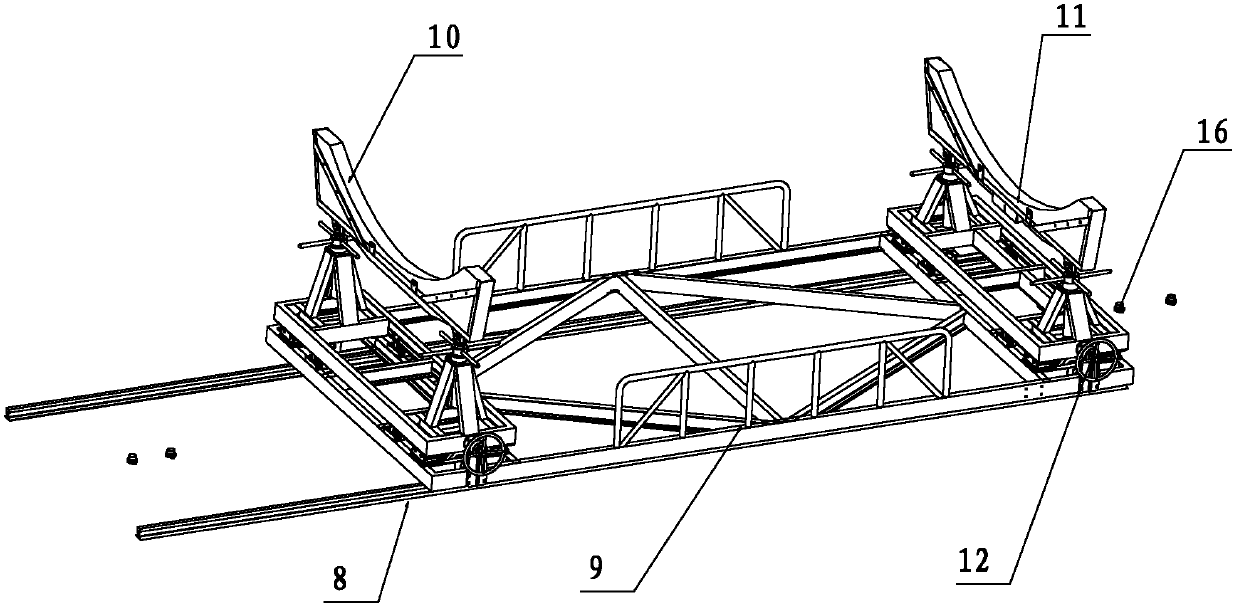

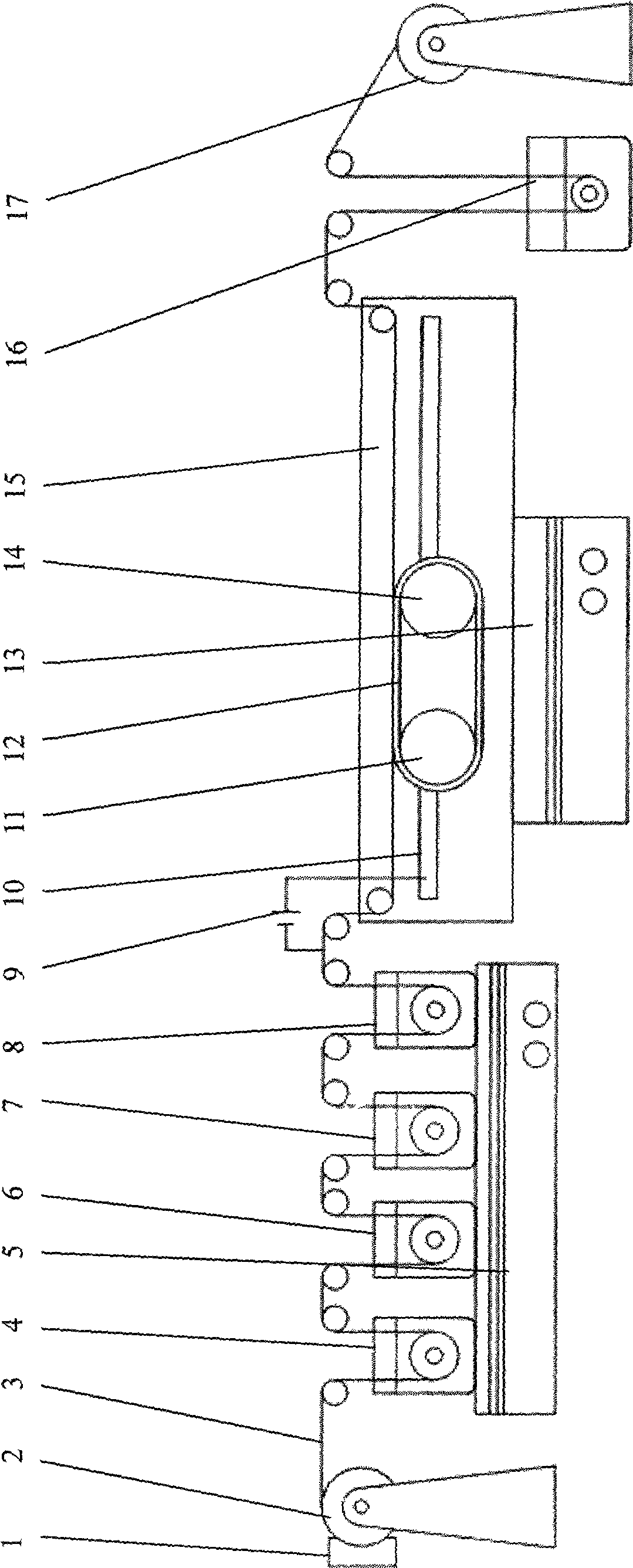

Abutting technological equipment of airplane large components and abutting method thereof

The invention belongs to the technology of airplane abutting, and relates to abutting technological equipment of airplane large components and an abutting method thereof. The abutting technological equipment of the airplane large components disclosed by the invention consists of a fixed part and a movable part, wherein the fixed part comprises a reference flat plate, a main landing gear technological support frame and a plurality of reinforced frame support frames; the movable part comprises a ground rail, a body front section railway car, a locking and positioning device and a centering device, wherein a car body is arranged on the ground rail, the centering device used for preventing the front section from rolling is arranged at the support frame of the car body, and the locking and positioning device is arranged at an abutting surface. When the front section and the middle section of an airplane are abutted via the abutting technological equipment, the position of the middle section is firstly fixed, then the front section is adjusted, and then accurate abutting of the front section and the middle section is realized through railway movement so as to perform subsequent riveting work. According to the abutting technological equipment of the airplane large components and the abutting method thereof, the abutting difficulty and potential safety hazard of the airplane large components are greatly reduced, the manufacturing efficiency and the abutting quality are improved, and the abutting precision of products is effectively ensured.

Owner:SHAANXI AIRCRAFT CORPORATION

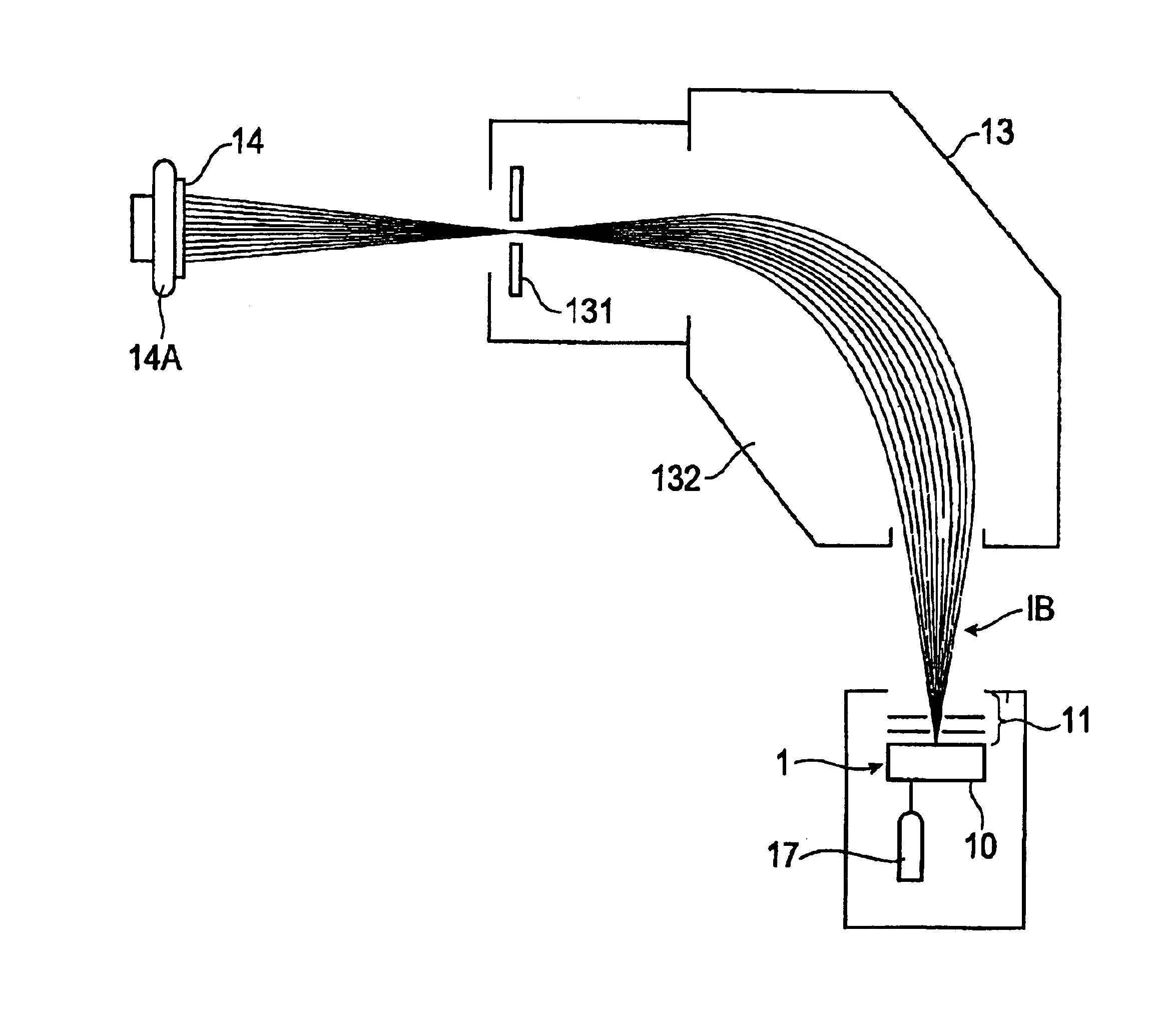

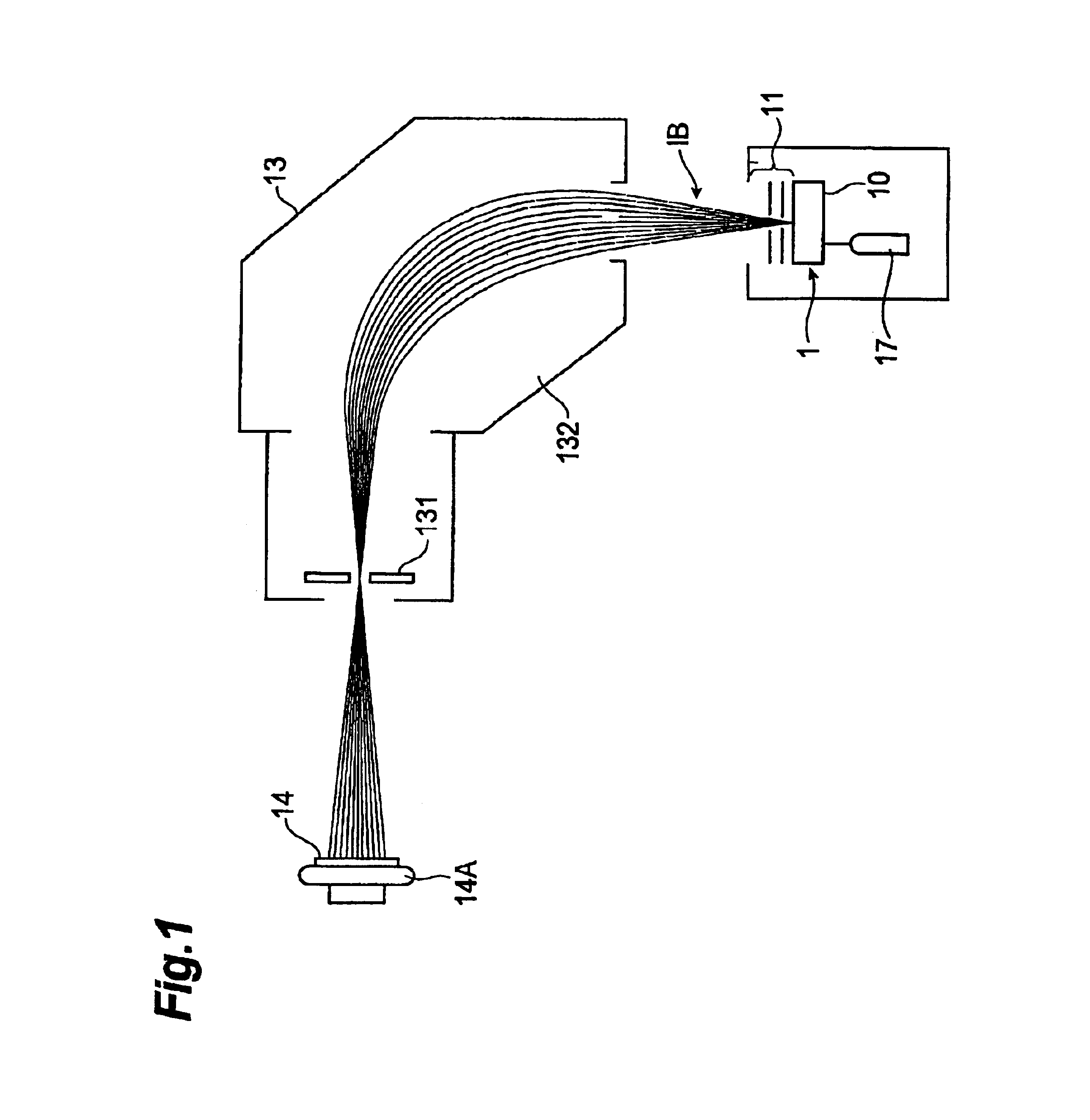

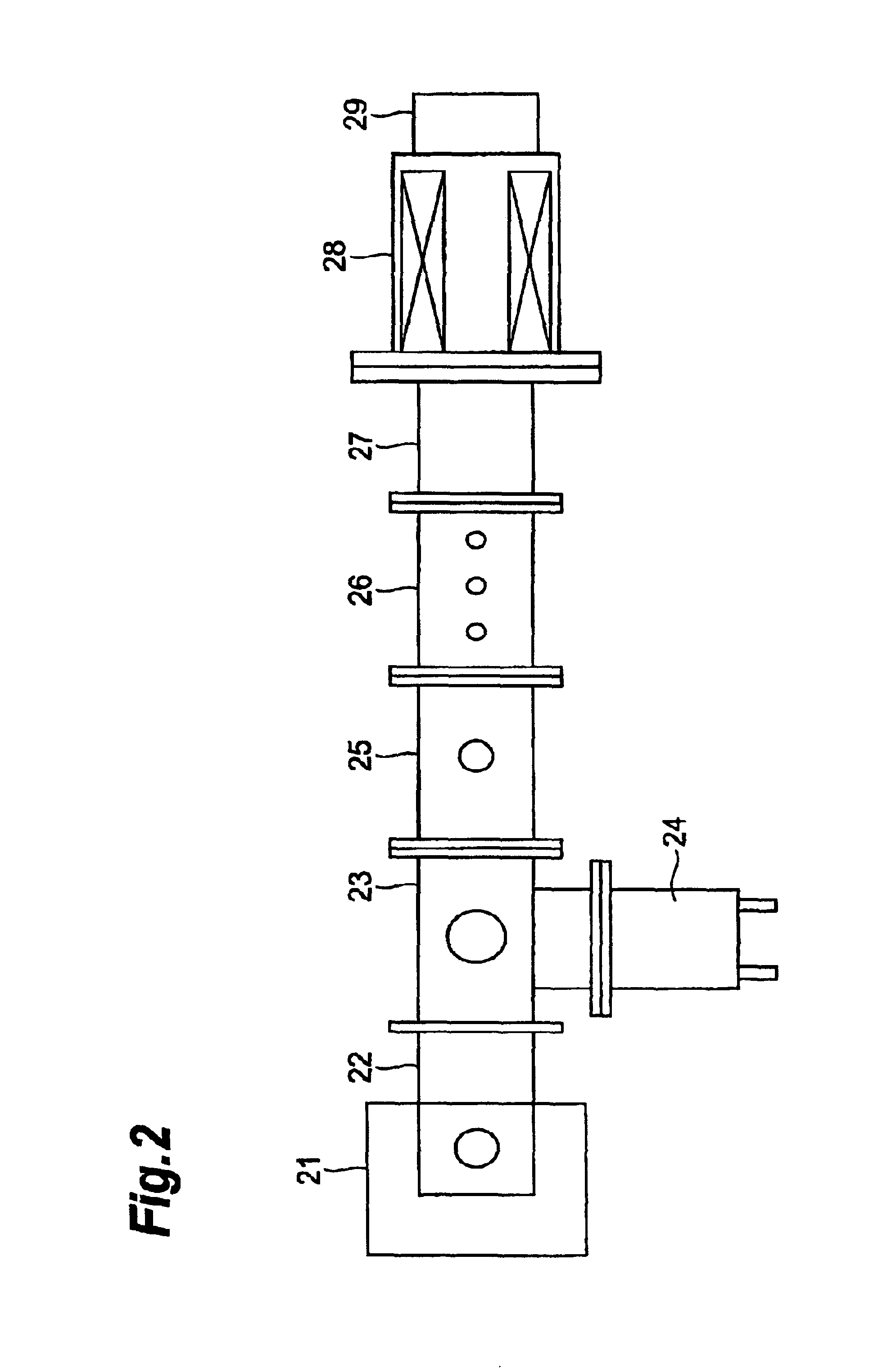

Ion implantation method and method for manufacturing SOI wafer

ActiveUS6927148B2Increase generationIncrease plasma densitySolid-state devicesVacuum evaporation coatingInternal pressureMicrowave

Disclosed are an ion implantation method capable of dramatically increasing an implantation rate of hydrogen ions into a semiconductor substrate and a method for manufacturing an SOI wafer, in which manufacturing efficiency of the SOI wafer is sufficiently high. When the hydrogen ions are implanted to a predetermined depth of the semiconductor substrate, hydrogen gas is introduced into a chamber where an inner pressure is reduced and a predetermined magnetic field is formed, plasma is generated by introducing a microwave into the magnetic field, hydrogen ion beams containing hydrogen molecule ions is extracted from the plasma, and the hydrogen molecule ions are irradiated and implanted onto the semiconductor substrate. Thus, a throughput in the hydrogen ion implantation is improved, thus making it possible to enhance the manufacturing efficiency of the SOI wafer.

Owner:APPLIED MATERIALS INC

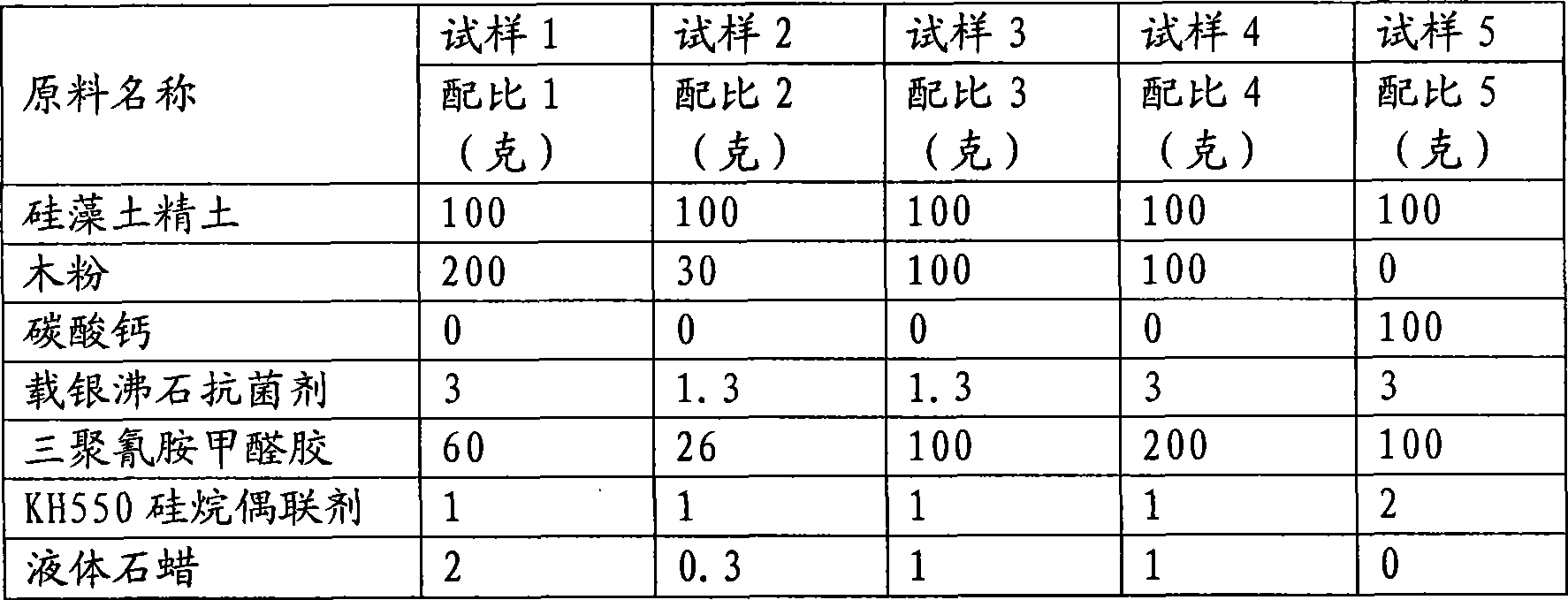

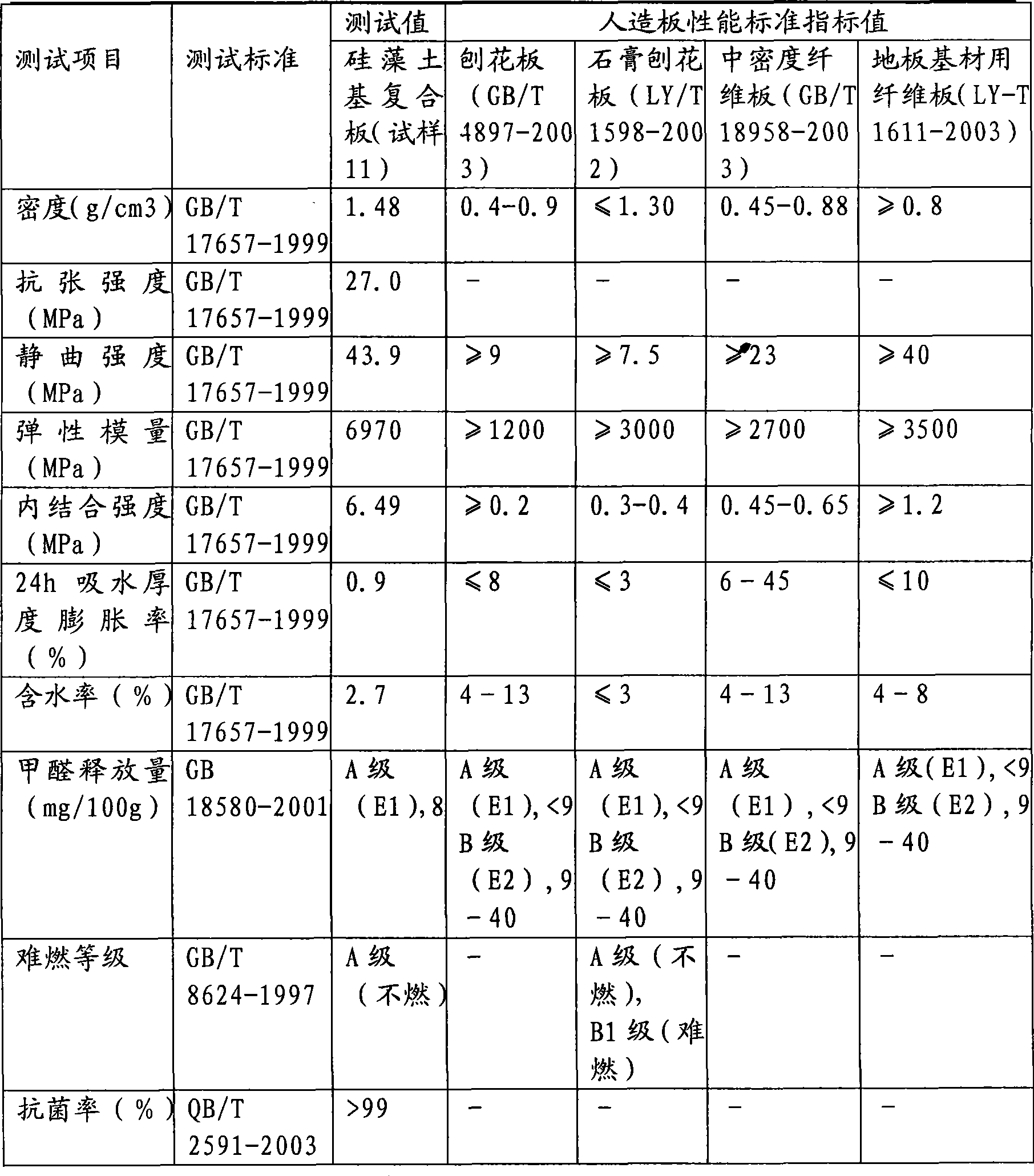

Rapid forming high intensity and high functional diatomite composition and method for making the same

The invention relates to a quickly shaped diatomite composition with high strength and high function and a manufacturing method thereof. The composition comprises 100 portions of diatomite, 0 to 1,000 portions of stuffing, 50 to 300 portions of adhesive, 0 to 30 portions of antibacterial agent, and 0 to 30 portions of shaping and processing aid. Formulation and shaping manufacturing technology ofthe diatomite composition radically solve the problems that a common diatomite product has long producing and shaping period and low manufacturing efficiency; and the obtained product has the advantages of good mechanical property, light weight and low formaldehyde release, and has good functional properties such as flame retarding, water proofing, bacteria resistance and the like. The diatomite composition is applied to be manufactured into plates and profiles, can replace wood and artificial boards, and is used for products such as indoor and outdoor ornaments, office and household furniture, furniture components, acoustics, internal ornaments of vehicles, wall panels, security doors, wall boards, partition wall boards, packing materials, bed boards, floor, solid door frames, shutters, and the like.

Owner:BEIJING CHAMGO NANO TECH

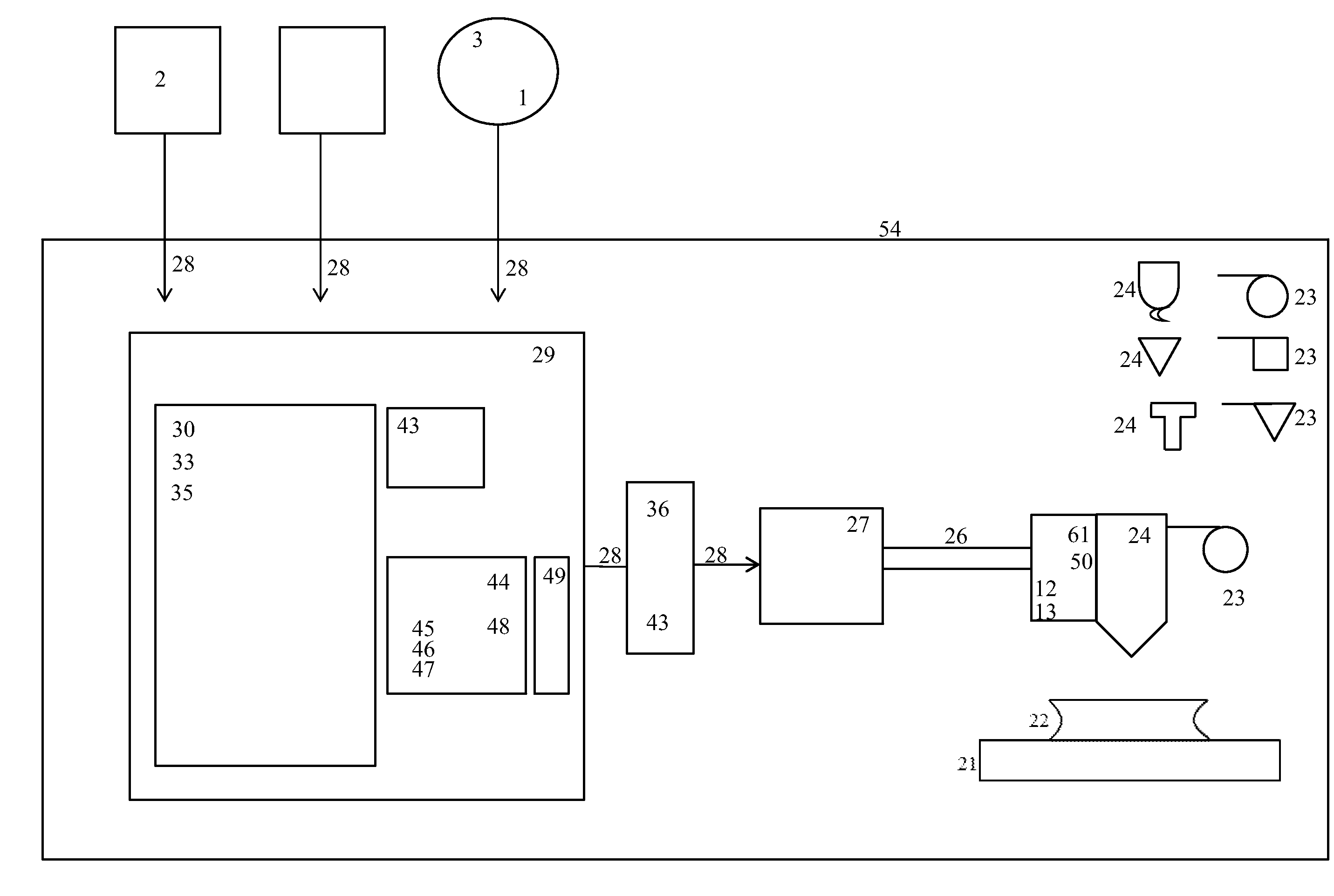

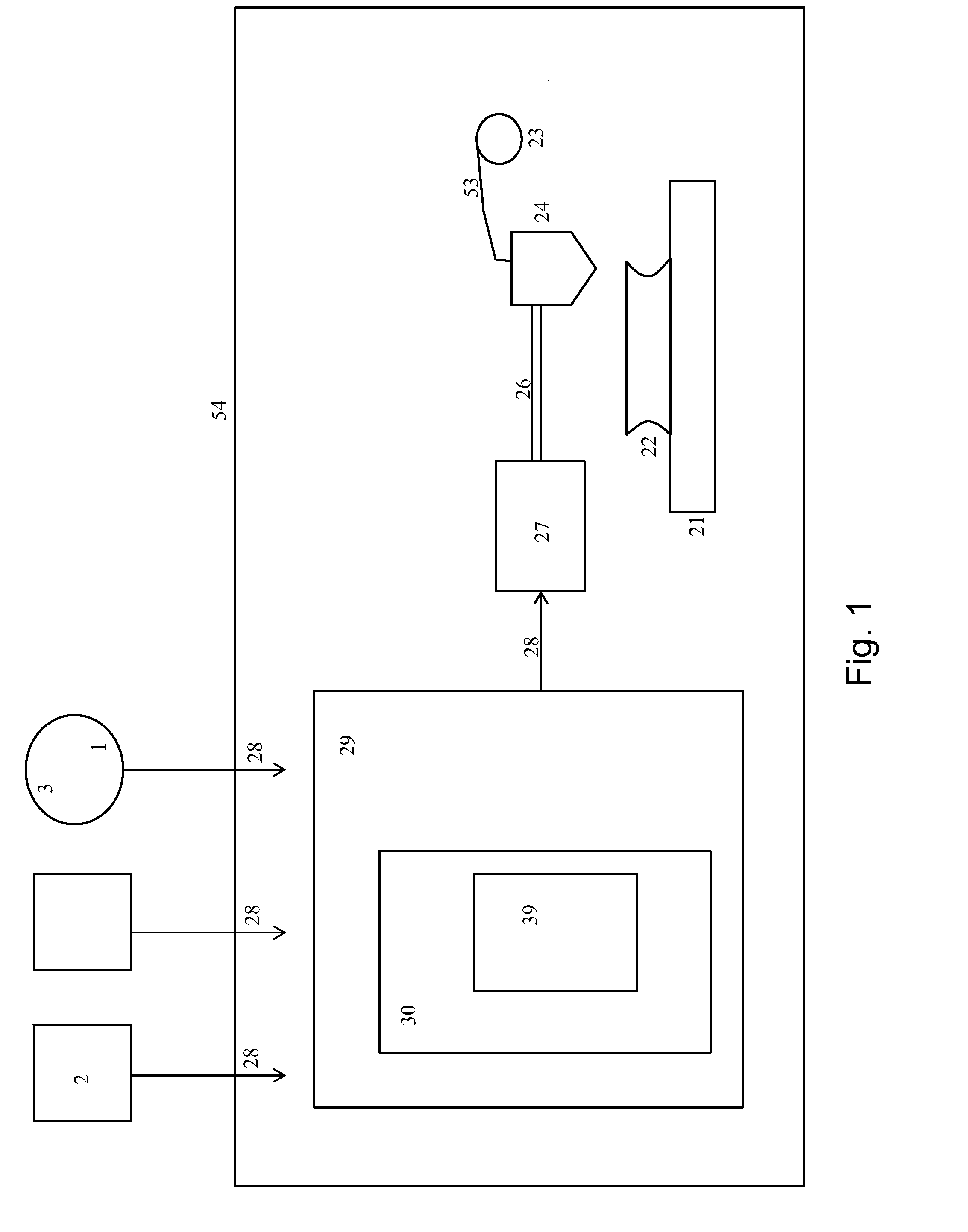

Dynamic Additive Manufacturing System

ActiveUS20160236419A1Speed up preparationEasy to moveAdditive manufacturing apparatusControlling laminationUser input3d printer

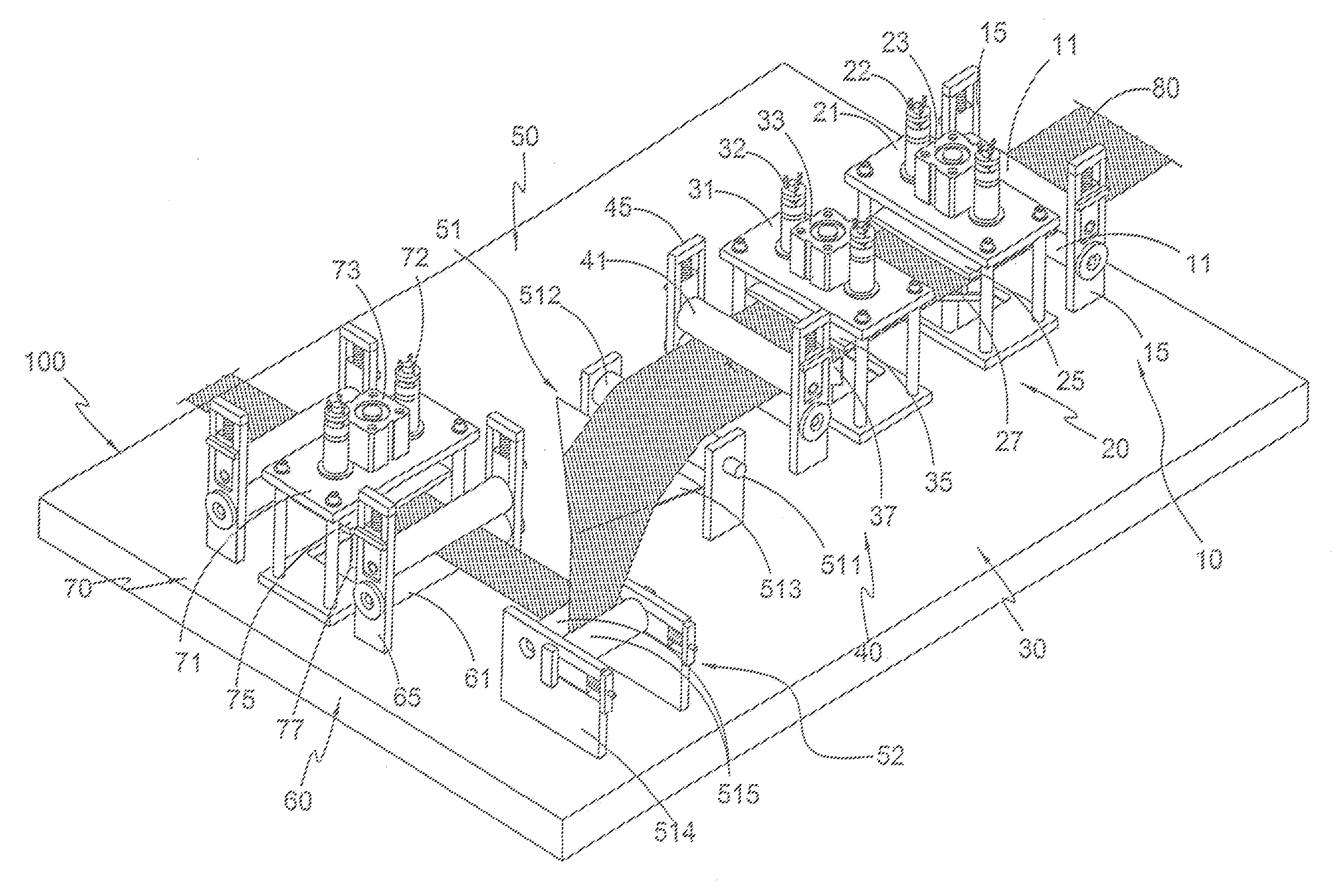

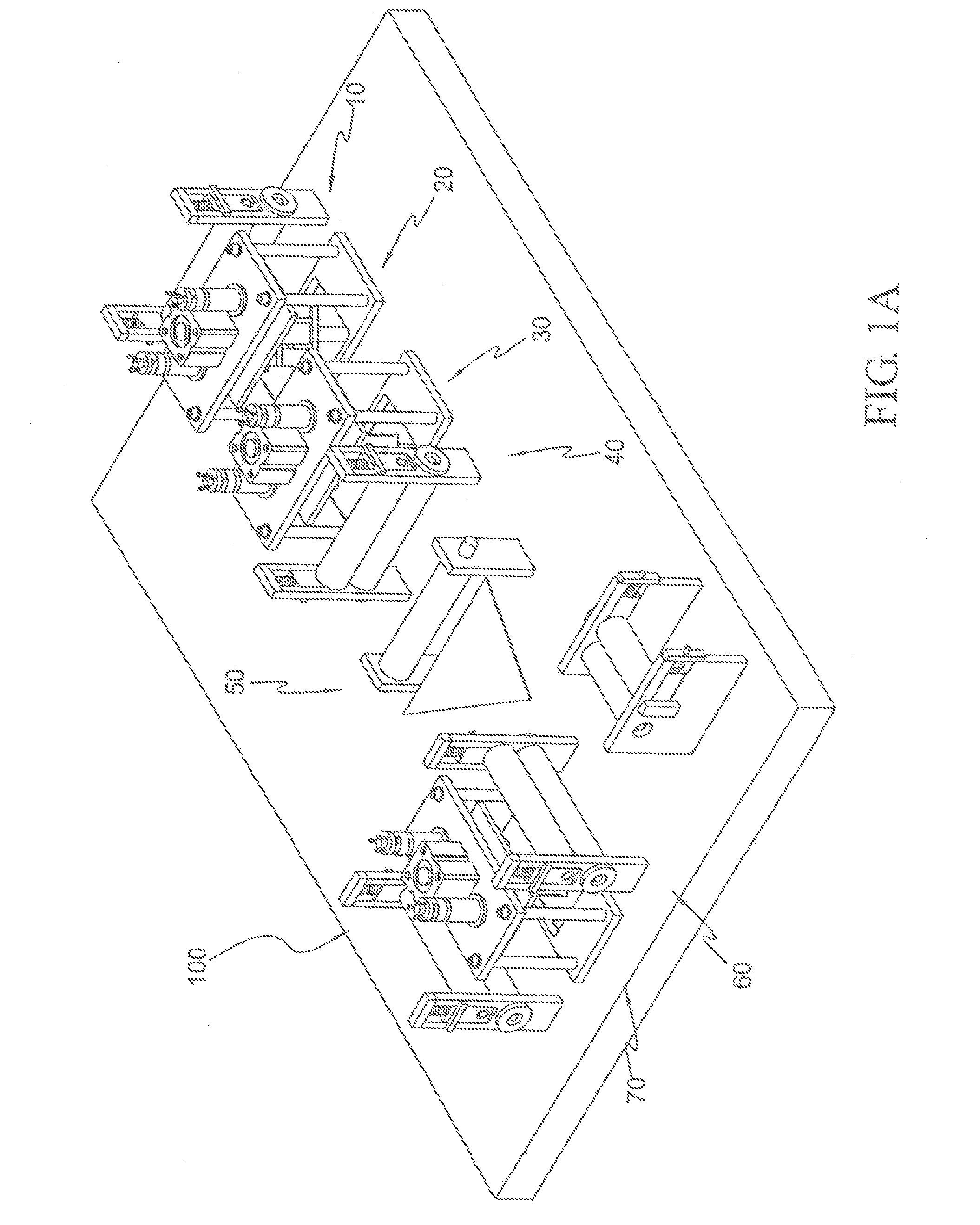

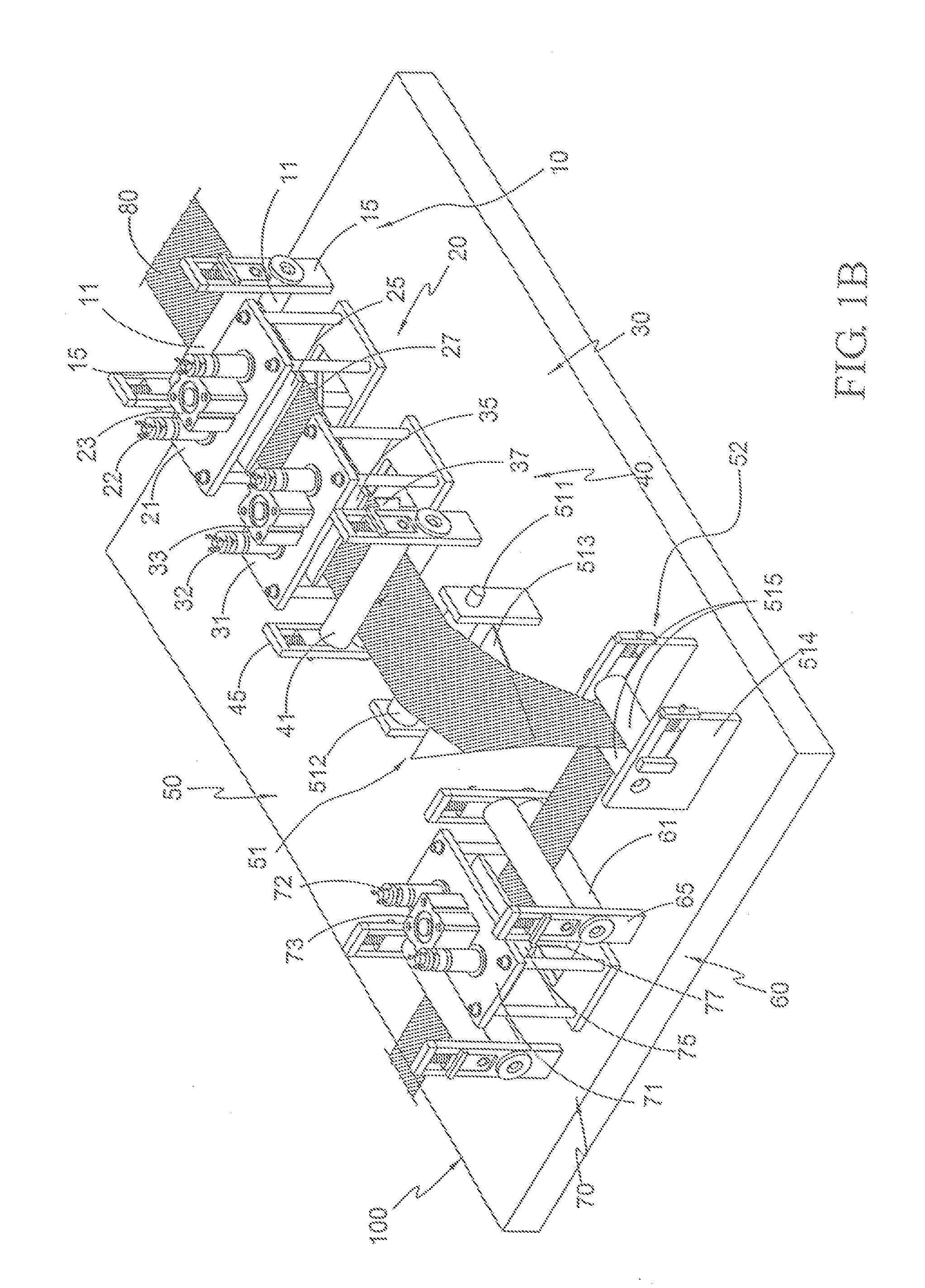

A dynamic manufacturing system such as for the additive manufacture of a fabrication item with multiformative capabilities presents a processor (29) that can refine movement, instructions, or data to achieve greater manufacturing efficiency and substantially uninterruptive change between formative process elements (24) or capabilities with simple user input (28) or indications. Optimization of movements, deposition of material, positioning, variant repositioning for next item layers during fabrication are provided in manners where the functions can be self contained such as in a 3D printer or the like and can be accomplished without significant interruptions to traditional processing times or even in shorter times through the improved transformations.

Owner:KANAWHA AUTOMATION

Face mask manufacturing machine

InactiveUS20080251214A1Inconsistent qualityImprove throughputMechanical working/deformationLamination ancillary operationsAutomatic controlEngineering

A face mask manufacturing machine includes a platform, a first-side edge fusion module, a second-side edge fusion module, a folding device, and a center line fusion module. The first-side and second-side edge fusion modules and the center line fusion module each comprise a pneumatic cylinder, which is operatively coupled to automatic control facility for carrying out automatic operation to thereby reduce the labor needed for operating fusion facility and enhance manufacturing efficiency.

Owner:CHEN HUNG HO

A method for manufacturing electroplating diamond wire saw

InactiveCN101531035AIncrease the concentration of nickel ionsIncrease current densityFine working devicesStone-like material working toolsDiamond wire sawElectroplating

The invention relates to a method for manufacturing electroplating diamond wire saw. The invention has main features as follows: firstly, winding the metal lines on a string releasing wheel, continuous operating the metal lines, completing the fore treatment, pre-plating, sanding and thickening procedures, and finally winding the metal lines on a string receiving wheel to complete the electroplating process, wherein, the pre-plating, sanding and thickening procedures are completed in a same electroplating bath; sanding is completed by annular feather belt subsequent rotated in the electroplating bath; the diamond grinding medium in the plating solution is suspended in the plating solution under the mixing function, and naturally depositing on the annular feather belt; and the linear velocity passing through the annular feather belt and the metal lines of the annular feather belt are identical, so the diamond grinding medium on the metal lines and the annular feather belt has a definite relative still time, to ensure sanding time. The invention uses annular feather belt to perform sanding, improves sanding efficiency, improves the manufacturing efficiency of electroplating diamond wire saw and reduces the manufacturing costs.

Owner:QINGDAO UNIV OF SCI & TECH

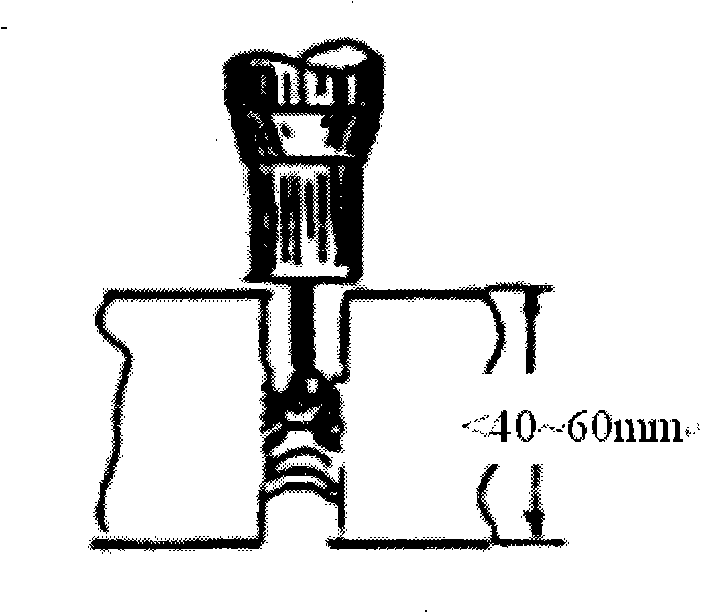

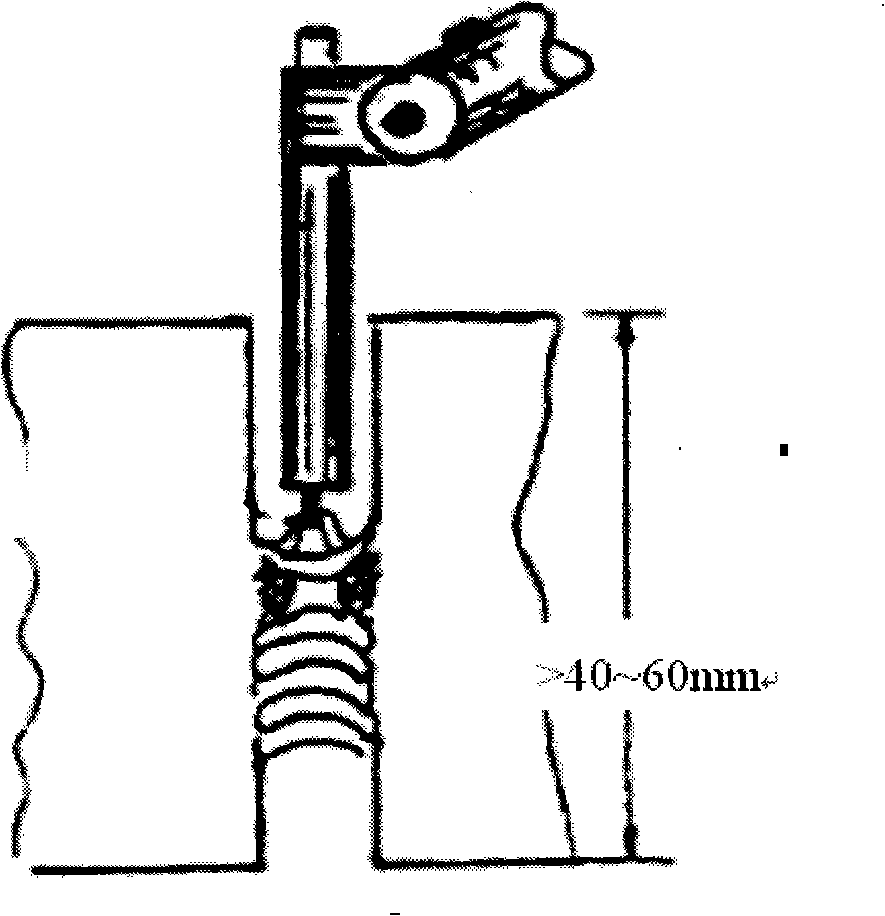

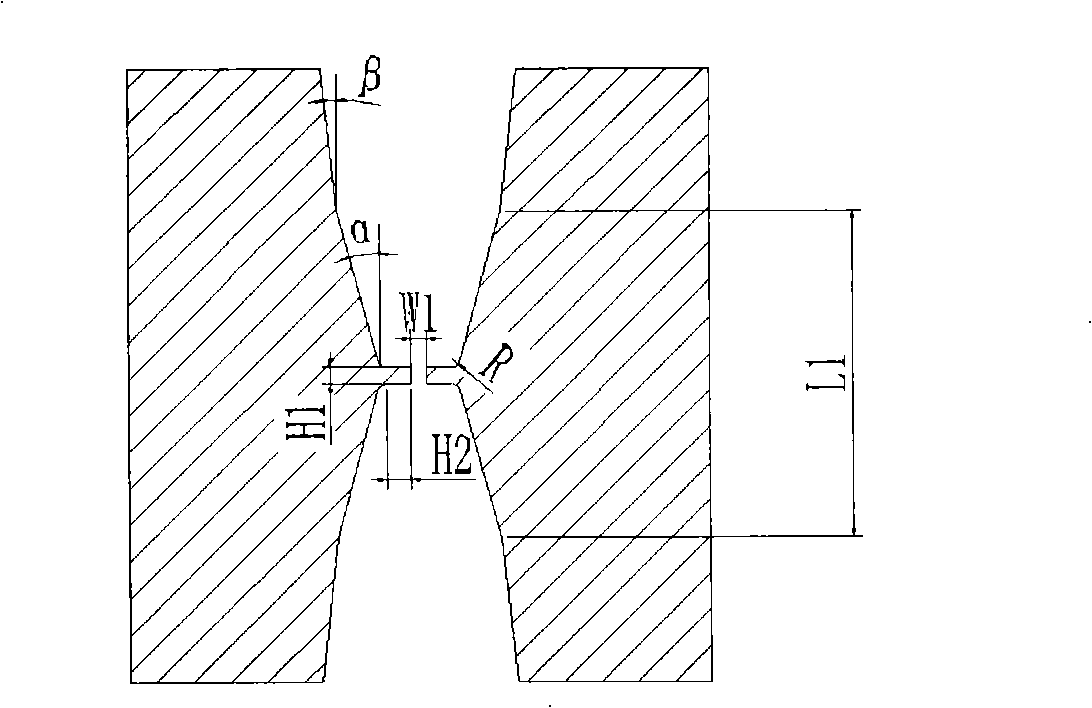

TIG automatic welding technique for titanium alloy thick plate narrow interstice

InactiveCN101293303AEnables narrow gap weldingWeld firmlyElectrode supporting devicesWorkpiece edge portionsEngineeringTitanium alloy

The invention discloses a narrow clearance TIC automatic welding technique for a thick plate of titanium alloy. The welding technique comprises six items of a welding torch form, a welding line spreading form, a bevel for welding form, selecting the parameters of the welding process, selecting the protection atmosphere of the welding process and eliminating a welding stress adopted by welding process. The welding technique of the invention realizes the narrow clearance welding for the large thick plate of the titanium alloy, has stable welding process, can obtain the welding lines which have no defects, qualified properties and 10mm to 16mm of widths of the welding lines on a cover surface layer, thus solving the key technical problems of the narrow clearance TIC automatic welding for the large thick plate of the titanium alloy, realizing the narrow clearance TIC automatic welding for the thick plate of the titanium alloy and having the advantages of high manufacture efficiency, low manufacture cost, small residual stress and residual deformation of joints, relatively thin and small welding line tissues and good mechanical property of the joints.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

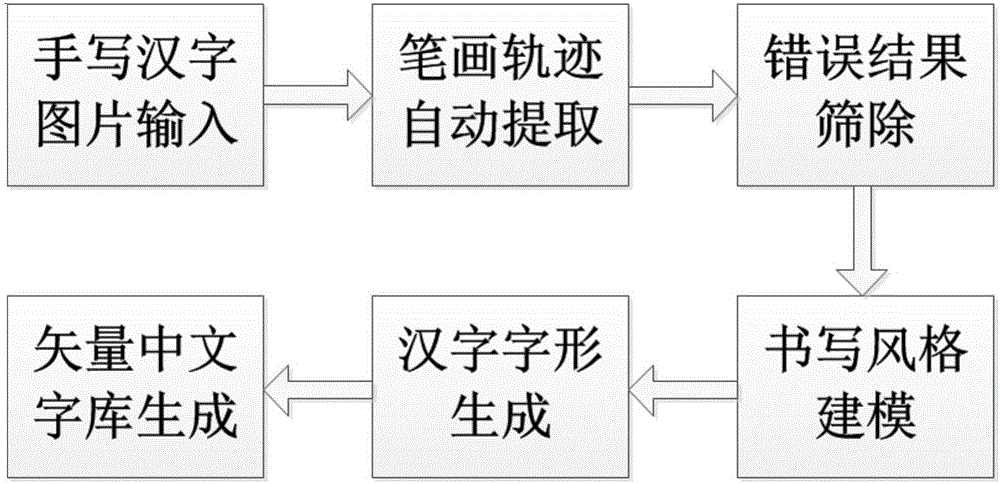

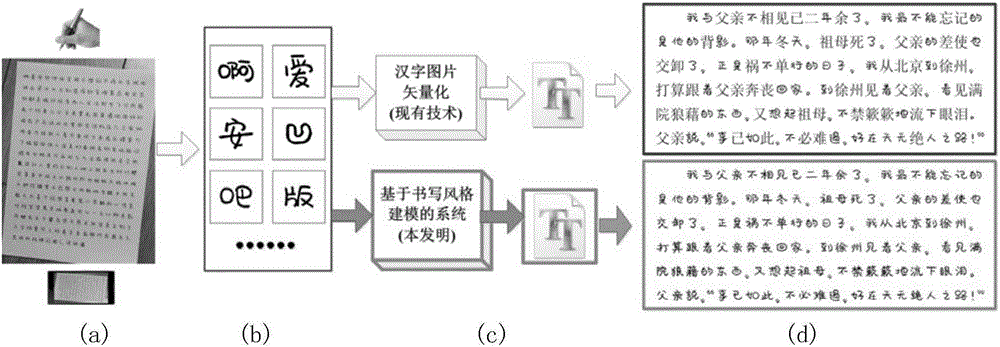

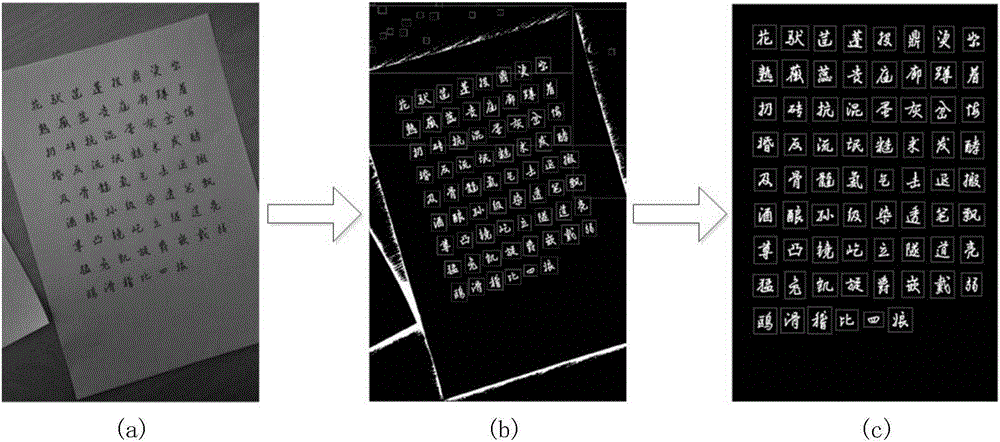

Chinese word stock automatic generation method based on writing style modeling

ActiveCN106384094AHigh glyph qualityMeet practical application needsStill image data indexingNatural language data processingHandwritingChinese characters

The invention discloses a Chinese word stock automatic generation method based on writing style modeling, and the method comprises the steps: carrying out the stroke track automatic extraction and wrong result screening operation of inputted handwritten Chinese character image, and obtaining training data; carrying out the learning and modeling of handwritten Chinese character stroke shape and style and stroke inter-frame structure style through a neural network, and obtaining handwriting stroke connection characteristics and stroke end part contour handwriting features through statistical analysis, and then generating a high-quality Chinese character form consistent with the handwriting style of a user. The method just needs a few of commonly-used Chinese characters as the input, does not need any manual intervention, can automatically generate a vector Chinese word stock comprising a large number of Chinese character patterns, can quickly and automatically generates a handwriting Chinese word stock with other handwriting style for a user, can remarkably improves the manufacturing efficiency of the Chinese word stock, and greatly reduces the production cost.

Owner:PEKING UNIV

Method for producing box beam/column with steel structure

InactiveCN101664847AEasy to produceImprove quality and efficiencyArc welding apparatusWelding/soldering/cutting articlesElectroslag weldingEngineering

The invention relates to a method for producing a box beam / column with a steel structure, comprising the following steps: (1) numerically controlling web plates, blanking based on the size of a partition plate and processing to form a bevel outlet; (2) assembling spot welding lining plates on the backs of the web plates and the partition plate; (3) assembling cover plates and two of the web platesto form a U-shape groove on a box assembling machine; (4) placing the partition plate in the formed U-shaped groove and welding three sides of the partition plate; and (5) assembling the cover platesand welding attachment welds between every two cover plates. The method solves the problem that the box beam / column cannot produce when no special electroslag welding equipment is provided, what is more important, the method solves the problem that welding is difficult by adopting the electroslag welding when the thickness of a wall panel of the beam / column is below 18 mm during multi-layer buildings are built. By adopting the method, the processing process is simplified, the component quality and the manufacture efficiency are greatly improved, favorable economic and societal values are achieved, and polarization and application are easy.

Owner:河南天丰钢结构有限公司

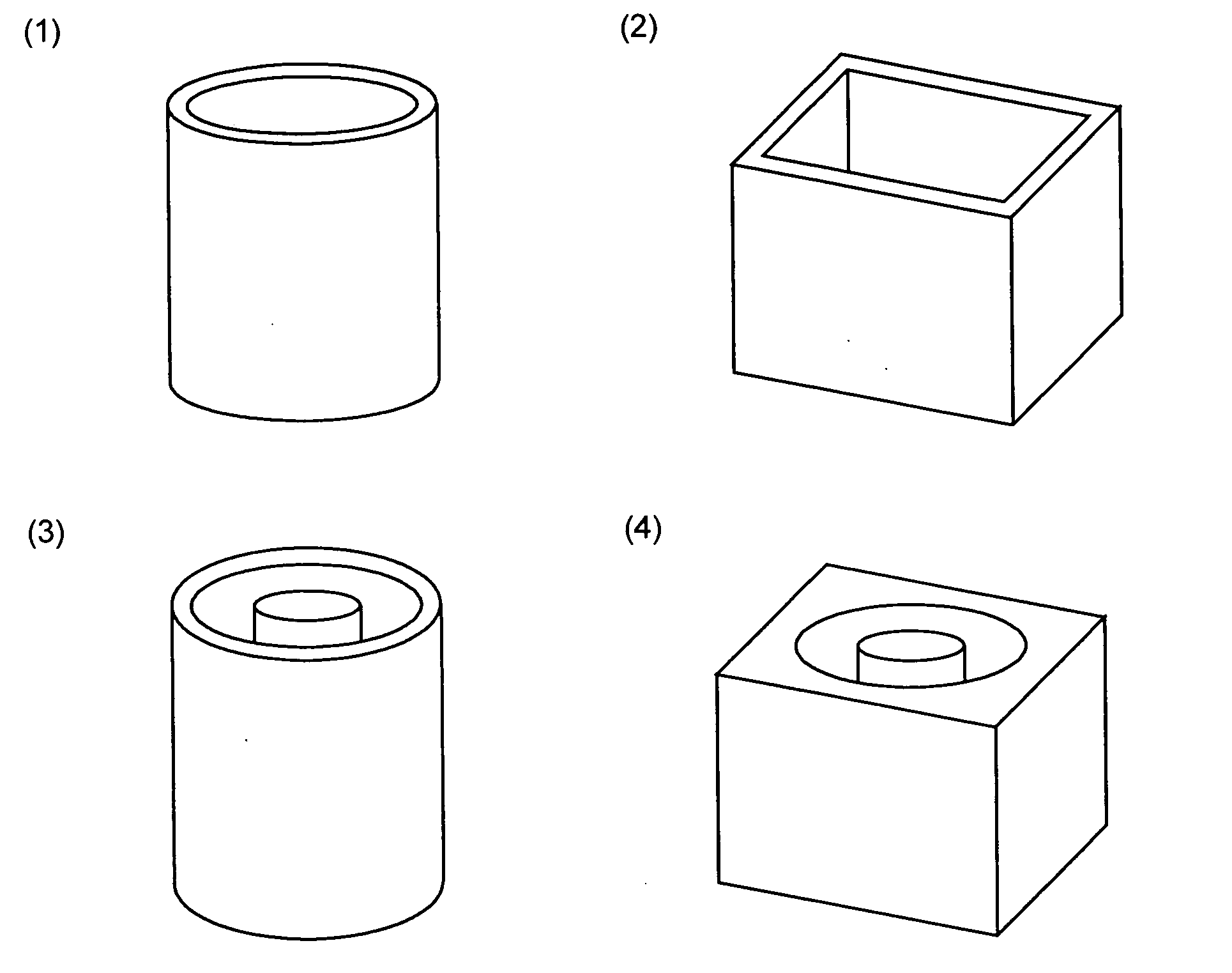

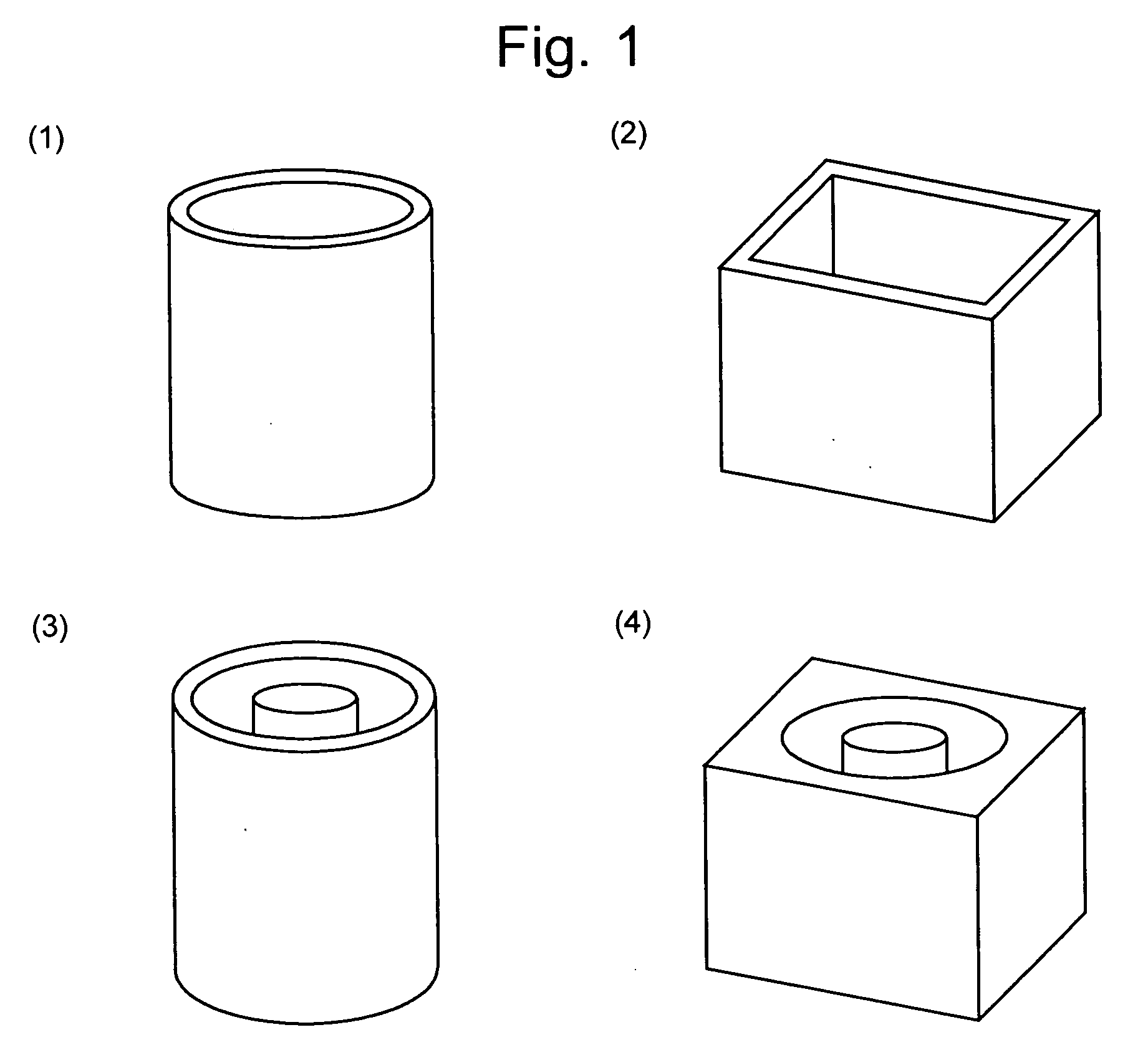

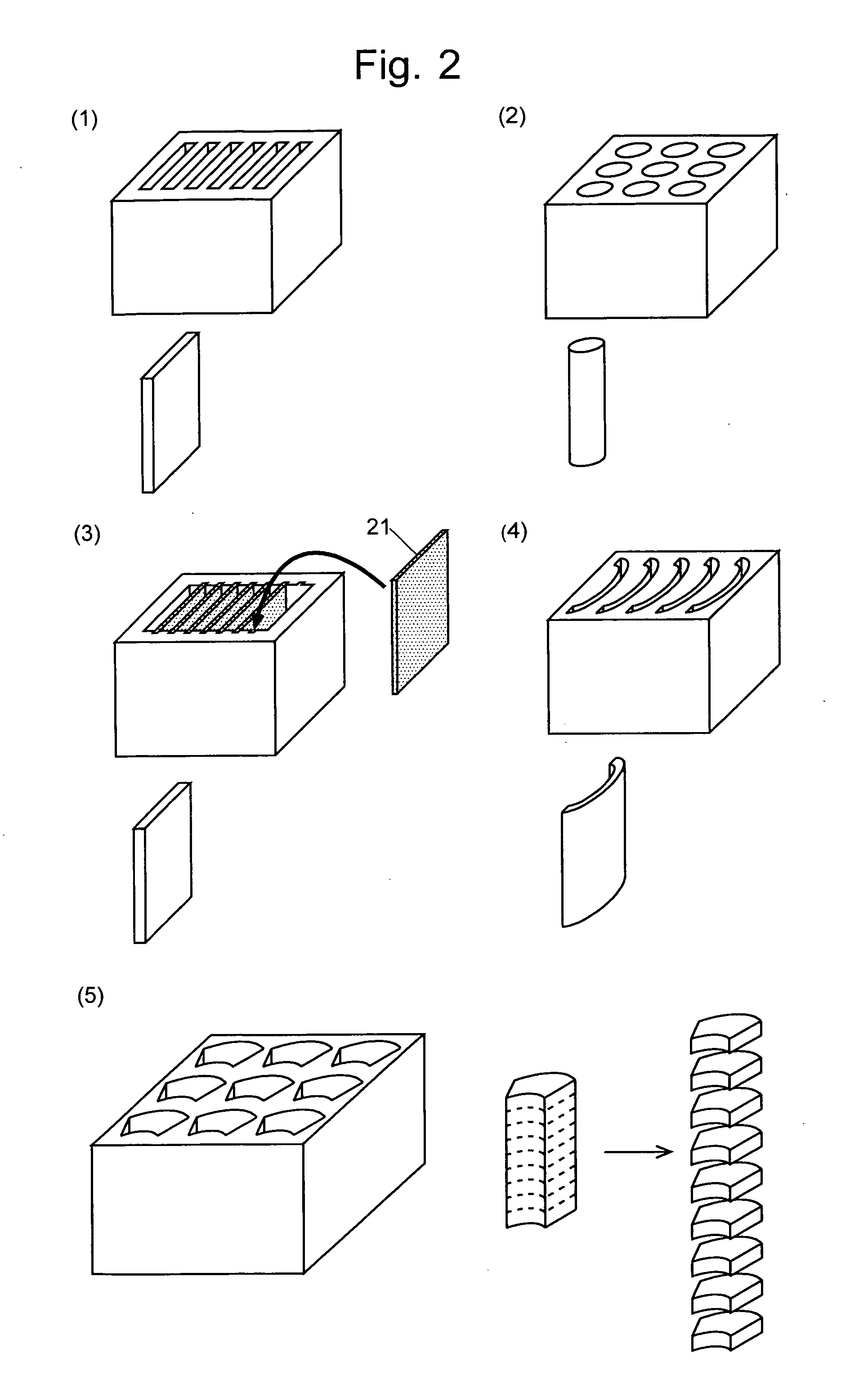

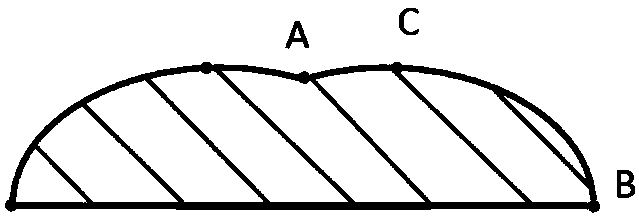

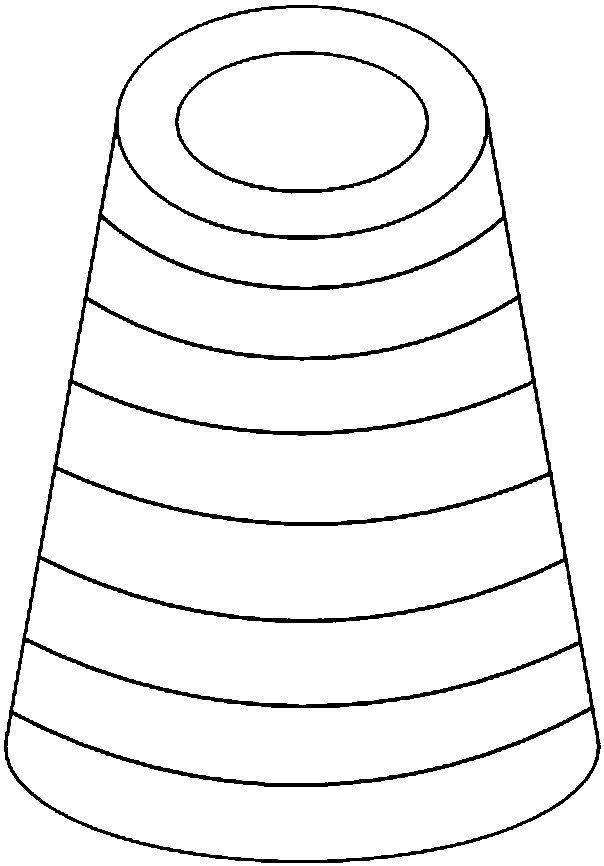

Method and System for Manufacturing Sintered Rare-Earth Magnet Having Magnetic Anisotropy

ActiveUS20070245851A1Improve coercive forceEfficient productionFoundry mouldsInorganic material magnetismManufacturing efficiencyCrystallite

To improve the performance of a rare-earth magnet, it is effective to use a low-oxidized powder having a small grain size. One objective of the present invention is to provide a method for manufacturing a sintered rare-earth magnet having a magnetic anisotropy, in which a very active powder having a small grain size can be safely used in a low-oxidized state. Another objective is to provide a method capable of efficiently manufacturing products having various shapes. In a weighing and loading section 41 and a high-density loading section 42, a fine powder as a material of the sintered rare-earth magnet having a magnetic anisotropy is loaded into a mold until its density reaches a predetermined level. Then, in a magnetic orientation section 43, the fine powder is oriented by a pulsed magnetic field. Subsequently, the fine powder is not compressed but immediately sintered in a sintering furnace 44. The present method enables the mass-producing machine to be simple in its operation and its housing to be accordingly smaller, so that it will be possible to eliminate the danger of oxidization or burning of the powder, which has been a serious problem for a conventional method that uses a large-scale die-pressing machine. Furthermore, the manufacturing efficiency can be improved by using a multi-cavity mold for manufacturing a sintered rare-earth magnet having an industrially important shape, such as a plate magnet or an arched plate magnet.

Owner:DAIDO STEEL CO LTD

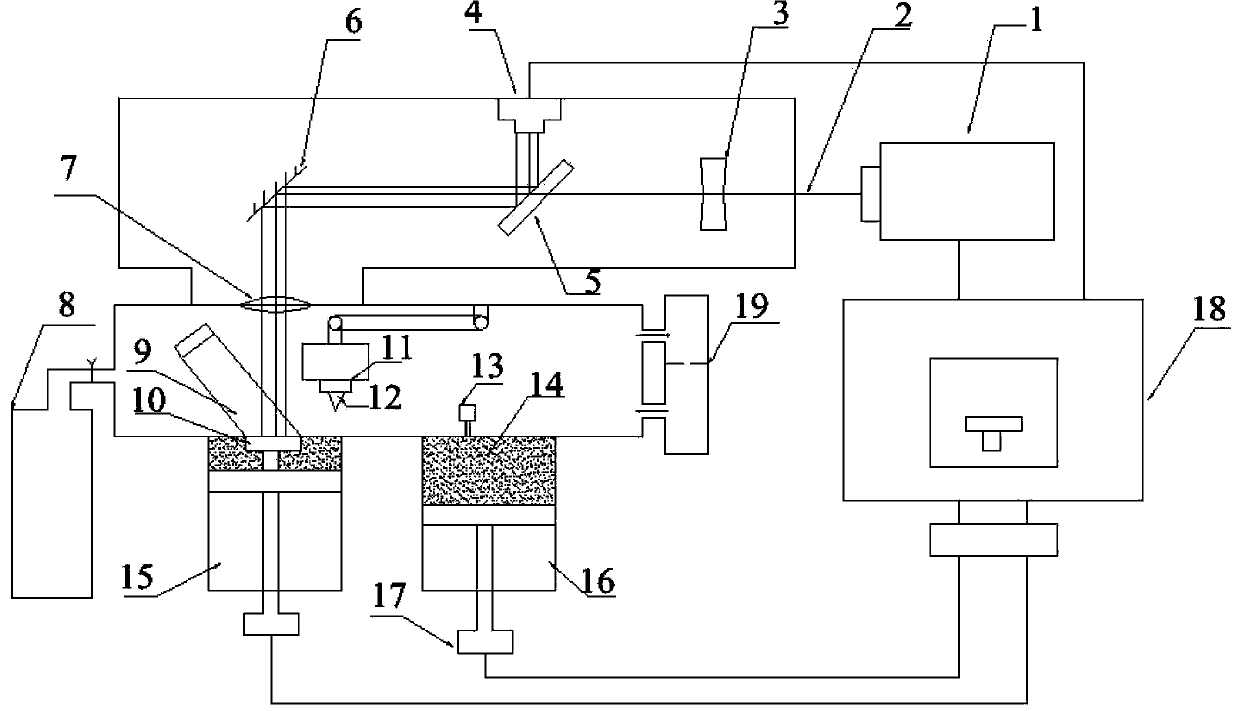

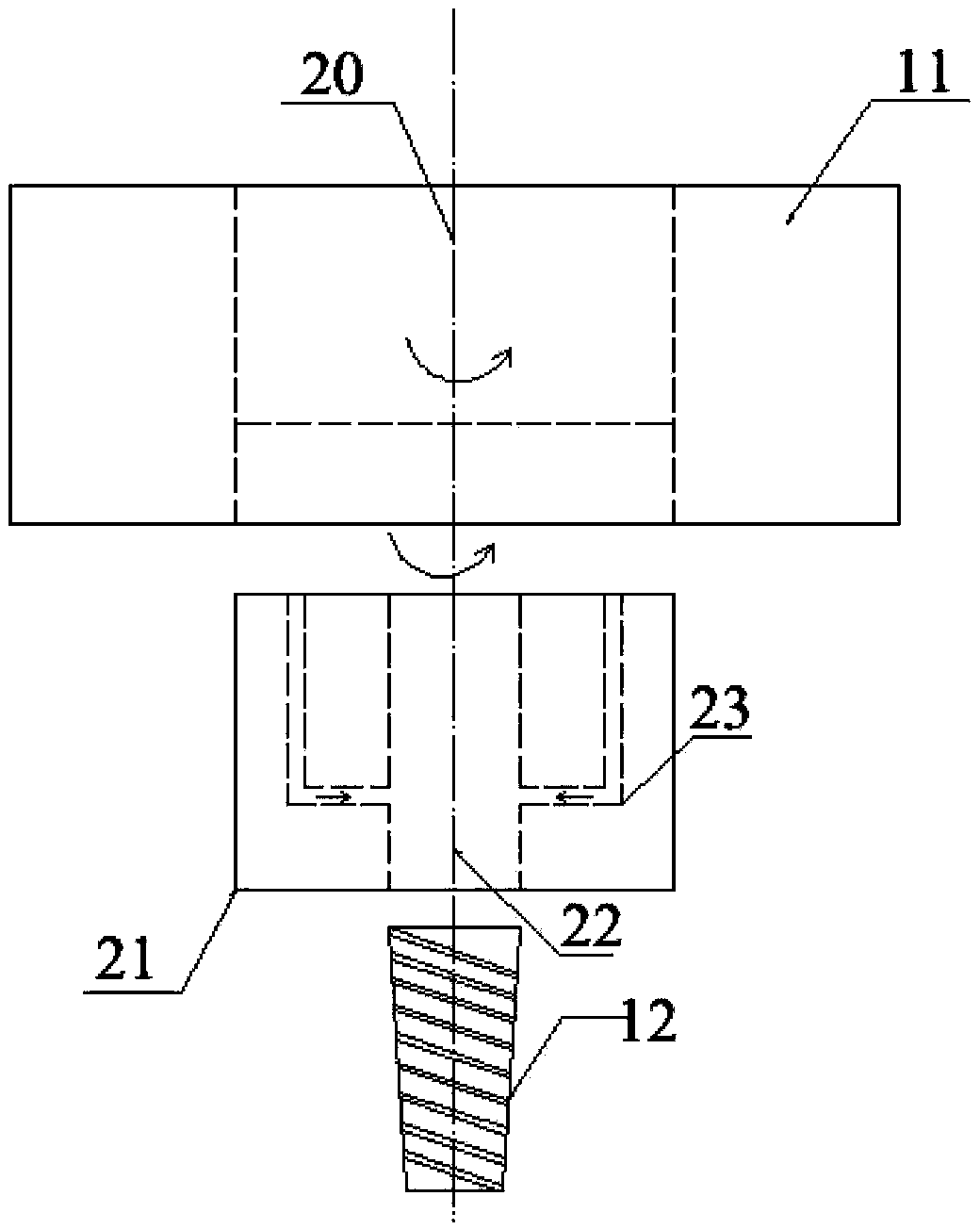

Combination manufacturing method and device for injection mold with conformal cooling water path

ActiveCN103418985AEasy to manufactureAvoid defectsIncreasing energy efficiencyManufacturing technologyLight beam

The invention discloses a combination manufacturing method and device for an injection mold with a conformal cooling water path. The device comprises a light beam focusing system, a close wave length coaxial vision positioning system, a powder pavement system and a gas protection system. The gas protection system comprises a sealed forming chamber, a shielding gas device and a powder purification device, wherein the shielding gas device is connected to one side of the sealed forming chamber, and the powder purification device is connected to the other side of the sealed forming chamber. The method is a combination processing method combined with the laser region selection fusion technology and the precision cutting processing technology, the advantages of the laser region selection fusion flexible processing are retained, and the feature that the precision of the high-speed cutting processing is good is given to play. In the process of region selection laser fusion processing, laser surface refusion processing is carried out on each layer, and the compactness and the surface quality of the mold are improved. The technique of density changing rapid manufacturing is adopted, and manufacturing efficiency is improved. Precision mold components with the interior special-shape cooling water path and the complex inner cavity structure can be integrally processed at a time.

Owner:SOUTH CHINA UNIV OF TECH

Resin laminate manufacturing method

ActiveUS20110303355A1Satisfactory reduction in wall thicknessSatisfactory reduction in weightSynthetic resin layered productsVehicle componentsEngineeringManufacturing efficiency

An object is to provide a method for manufacturing a resin laminate IOU, the method being capable of achieving satisfactory reduction in weight and wall thickness while ensuring manufacture efficiency and product quality. To accomplish the object, a resin laminate manufacturing method includes a step of providing a pair of split mold blocks one of which has a cavity provided with a plurality of protrusions each extending toward the other one, and preparing two molten thermoplastic resin sheets each having a thickness adjusted, a step of feeding the two molten thermoplastic resin sheets between the pair of split mold blocks with a predetermined gap left therebetween such that each thermoplastic resin sheet protrudes around annular pinch-off parts, a step of forming a hermetic space between one of the sheets and the cavity of the one mold block opposed to an outer surface of the one sheet, a step of sucking air in the hermetic space from the one mold block side, pressing the outer surface of the one sheet against the cavity of the one mold block to shape the one sheet, and forming cup-shaped portions, and a step of clamping the pair of mold blocks, welding peripheral edges of the two molten thermoplastic resin sheets to each other, and welding the bottoms of the cup-shaped portions formed on the one sheet to an inner surface of the other sheet. According to this method, in the resin laminate thus manufactured, the two sheets are substantially equal in thickness to each other.

Owner:KYORAKU CO LTD

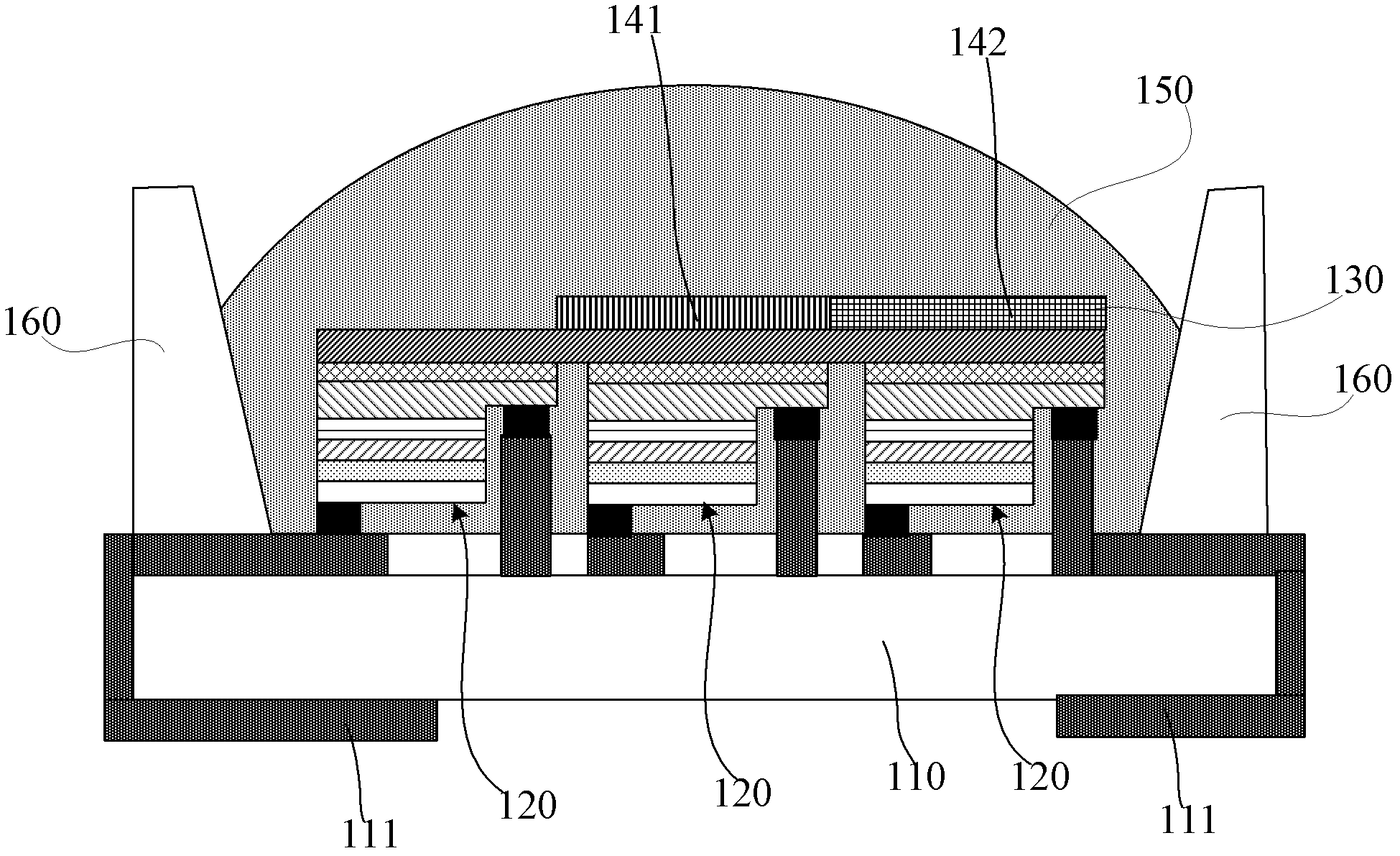

Light emitting diode (LED) pixel unit device structure and preparation method thereof

InactiveCN102214650AAttenuation consistentReduced package areaSolid-state devicesSemiconductor devicesUltrasound attenuationLED display

The invention discloses a light emitting diode (LED) pixel unit device structure. Three blue LED chip units which are connected with one another through the same substrate and electrically isolated from one another are inversely assembled with one another, so a package area is reduced and the resolution of an LED display screen is improved; the structures of the LED chip units are the same; greenfluorescent powder and red fluorescent powder are coated on two of the LED chip units respectively, so the two LED chip units can emit green light and red light respectively; therefore, during use, the attenuation of the LED chip units are consistent, and the color consistency of the display screen is enhanced. The invention also discloses a preparation method of the structure. An LED module is inversely arranged on a heat conducting substrate, so steps of chip bonding and gold line bonding are omitted, the cost is reduced, manufacturing efficiency is improved, the problem that a welding diskand a lead wire in an LED package block light is solved, the light emergent efficiency of an LED is improved greatly, package space is saved, and the LED package can be further miniaturized and integrated.

Owner:ENRAYTEK OPTOELECTRONICS

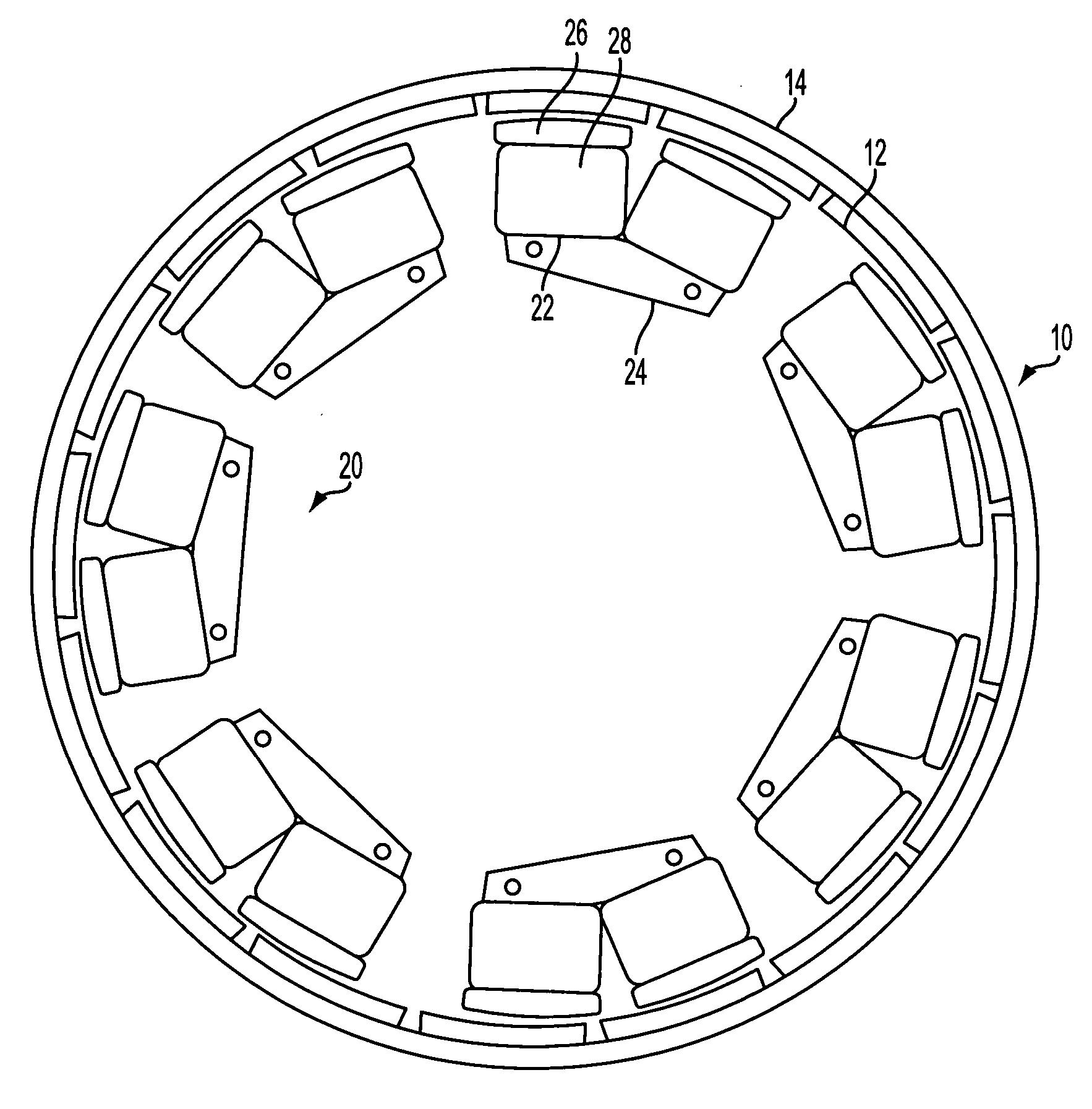

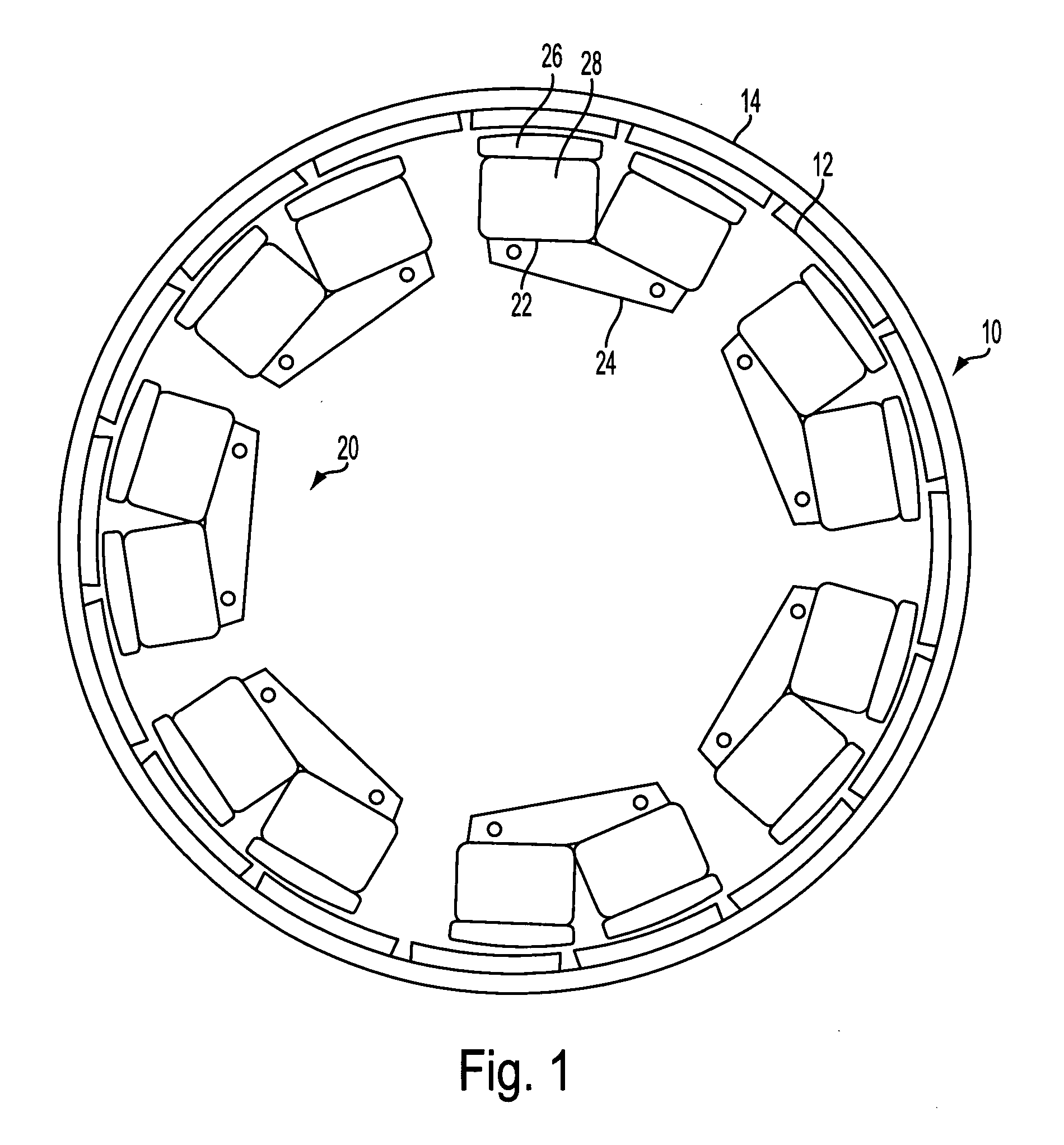

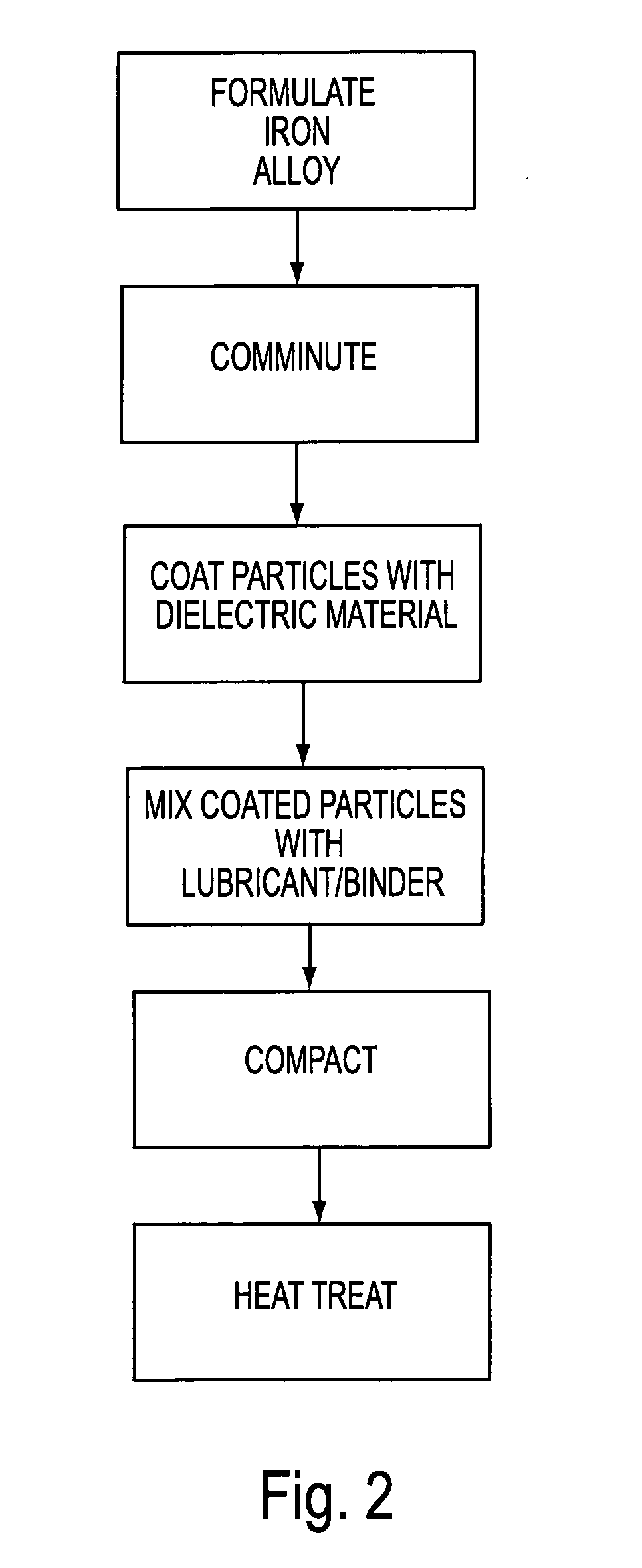

Soft magnetic composites

InactiveUS20050162034A1Readily apparentMagnetic circuit rotating partsMagnetic circuit stationary partsOperation modeIron alloys

Electric motor components, such as a plurality of electromagnetic poles of an annular stator, are formed of soft magnetic composites comprising compacted, electrically isolated iron alloy particles. Embodiments comprise predetermining particular alloy compositions and processing conditions, such as compaction pressures and temperatures, and post compaction heat treating temperatures and atmospheres, for an intended mode of operation, thereby improving manufacturing efficiency and reliability in tailoring soft magnetic composite components for particular design situations.

Owner:MATRA MFG & SERVICES

Online layered detection material increasing and decreasing compound manufacturing method

ActiveCN108031844AProofreading in real timeReal-time layer detectionAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyAdditive layer manufacturing

The invention belongs to the field of intelligent compound material increasing and decreasing manufacturing, and discloses an online layered detection material increasing and decreasing compound manufacturing method. The online layered detection material increasing and decreasing compound manufacturing method comprises the steps that (1) a three-dimensional model of a to-be-formed part is established and transformed into an STL model, the STL model is sliced, theoretical shape data of each layer are obtained, and a material increasing processing path and a material decreasing processing path of each layer are preset; (2) a plurality of cladding channels are formed according to cladding forming of the material increasing processing path of the current layer, the multiple cladding channels form the current cladding layer, section shape information of the cladding channels is collected in real time while cladding forming is conducted and subjected to data processing, and the shape of thecurrent cladding layer is obtained to assist planning the material increasing and decreasing paths; and (3) the step (2) is repeated, cladding forming of each layer is completed, so that manufacturingof the whole part is completed. According to the online layered detection material increasing and decreasing compound manufacturing method, the problem that past manufacturing and measuring separation have no real-time feedback and have deviation in the manufacturing process is solved, the manufacturing efficiency and manufacturing precision are improved, and the online layered detection materialincreasing and decreasing compound manufacturing method adapts to layered formed material increasing manufacturing.

Owner:HUAZHONG UNIV OF SCI & TECH

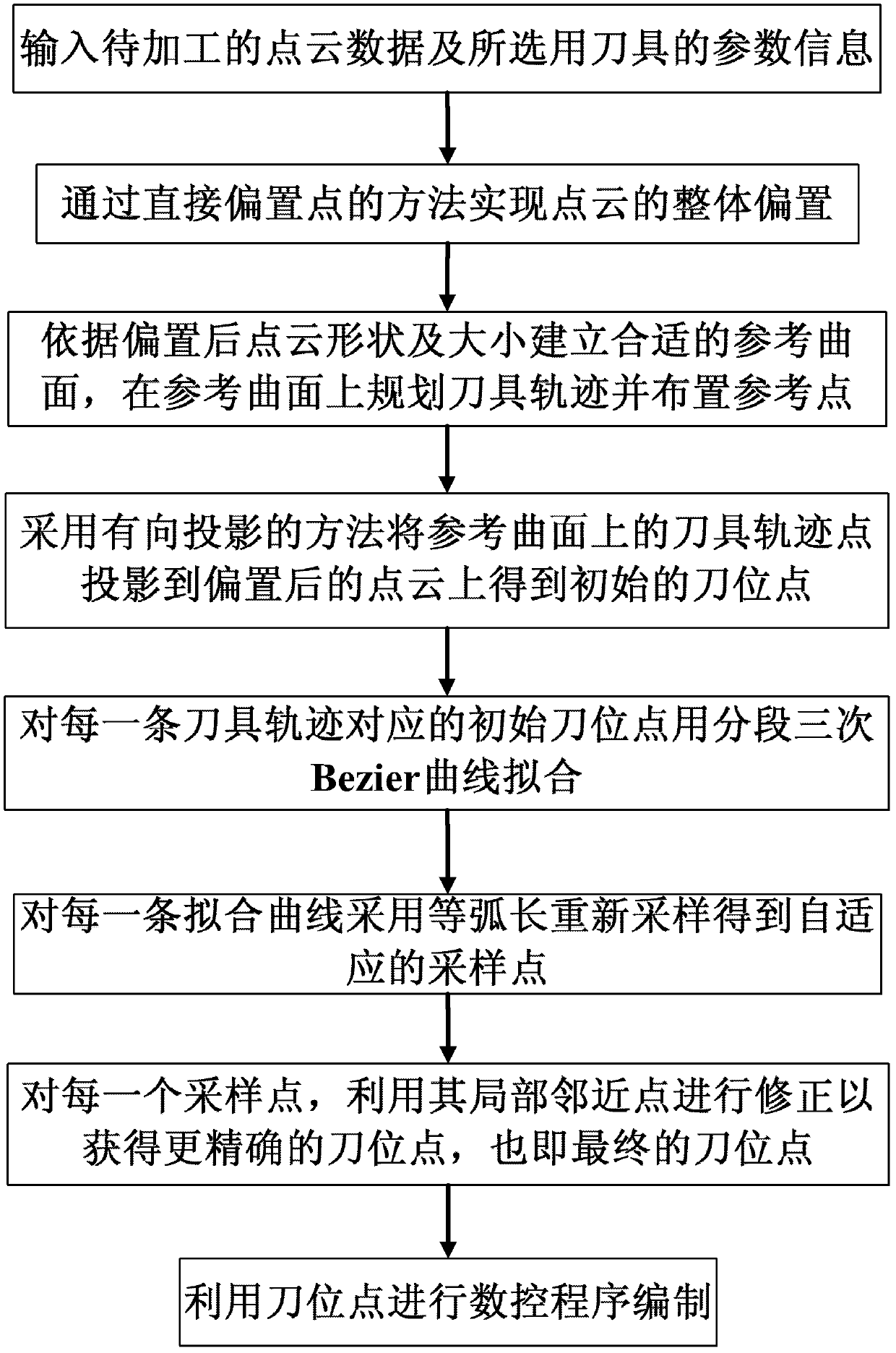

Method for directly generating tool path based on measured data

InactiveCN102608954AAvoid problems with radius compensationAvoid cumbersomeComputer controlSimulator controlNumerical controlPoint cloud

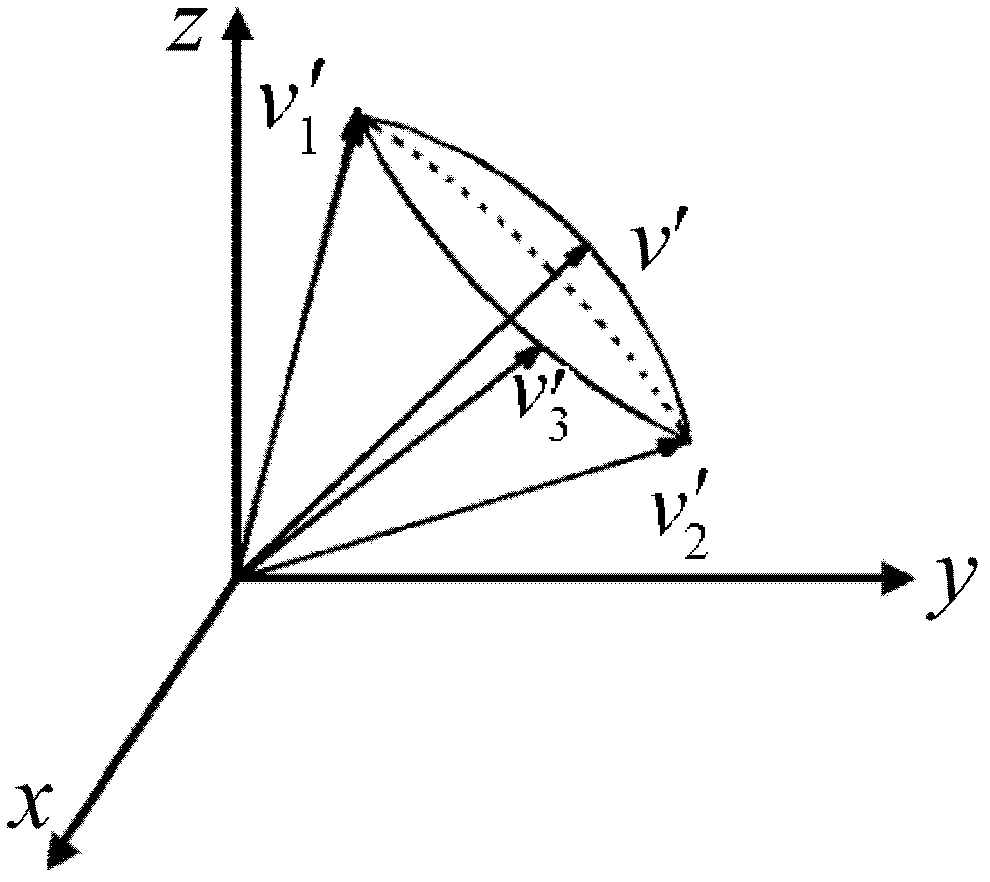

The invention discloses a method for directly generating a tool path based on measured data. The method comprises the following steps of: biasing a point cloud curved surface by means of directly biasing points; establishing a reference curved surface according to the shape and size of biased point cloud and planning the tool path on the reference curved surface; projecting a tool path point on the reference curved surface to the biased point cloud so as to obtain initial tool location information by employing a directed projection method; fitting the projection point by using a segmented triple Bezier curve, re-sampling the projection point by employing an equal arc length method to generate a self-adaptive tool path so as to improve the machining precision; and correcting the sampling point by employing point-based local neighboring orthogonal projection to improve to precision so as to obtain the final tool location point information. The numerical control machining tool path is directly generated by the measured data, a complex process of reconstructing a curved surface model is avoided, reverse engineering and a numerical control technique are effectively integrated, the manufacturing efficiency and precision are improved, and automation is conveniently realized.

Owner:XI AN JIAOTONG UNIV

Metal die for coining super-hydrophobic micro-nanometer surface and laser manufacturing method thereof

ActiveCN103521929AHigh structural fidelityIncrease flexibilityNanotechnologyLaser beam welding apparatusPicosecond laserOptoelectronics

The invention discloses a metal die for coining a super-hydrophobic micro-nanometer surface and a laser manufacturing method thereof. The laser manufacturing method comprises the following steps that an ultra-short pulse laser is used for ablating a metal base material, a symmetrical negative structure of a lotus leaf micro-nanometer structure is obtained on the surface of the metal base material through laser ablating removing, and then the metal die is obtained; the symmetrical negative structure of the lotus leaf micro-nanometer structure is a micrometer-level pit and a nanometer-level substructure on the inner surface of the micrometer-level pit. The invention provides the micro-nanometer coining metal die for coining a non-metal material or a light-metal material so as to form the lotus leaf micro-nanometer structure with the surface being super hydrophobic and the laser manufacturing method of the metal die, and particularly relates to the micro-nanometer coining metal die which is manufactured efficiently in a large area by the utilization of high-power picosecond lasers and the manufacturing method of the metal die. The metal die for coining the super-hydrophobic micro-nanometer surface and the laser manufacturing method of the metal die have the comprehensive advantages that the manufacturing efficiency is high, the micro-nanometer coining die is high in temperature resistance, high in pressure resistance and wide in coning material range, the micro-nanometer structure is precise and adjustable in parameter and the lotus structure is vivid. Moreover, the manufacturing method is far superior than other methods.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com