Patents

Literature

2005results about How to "Improve coercive force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

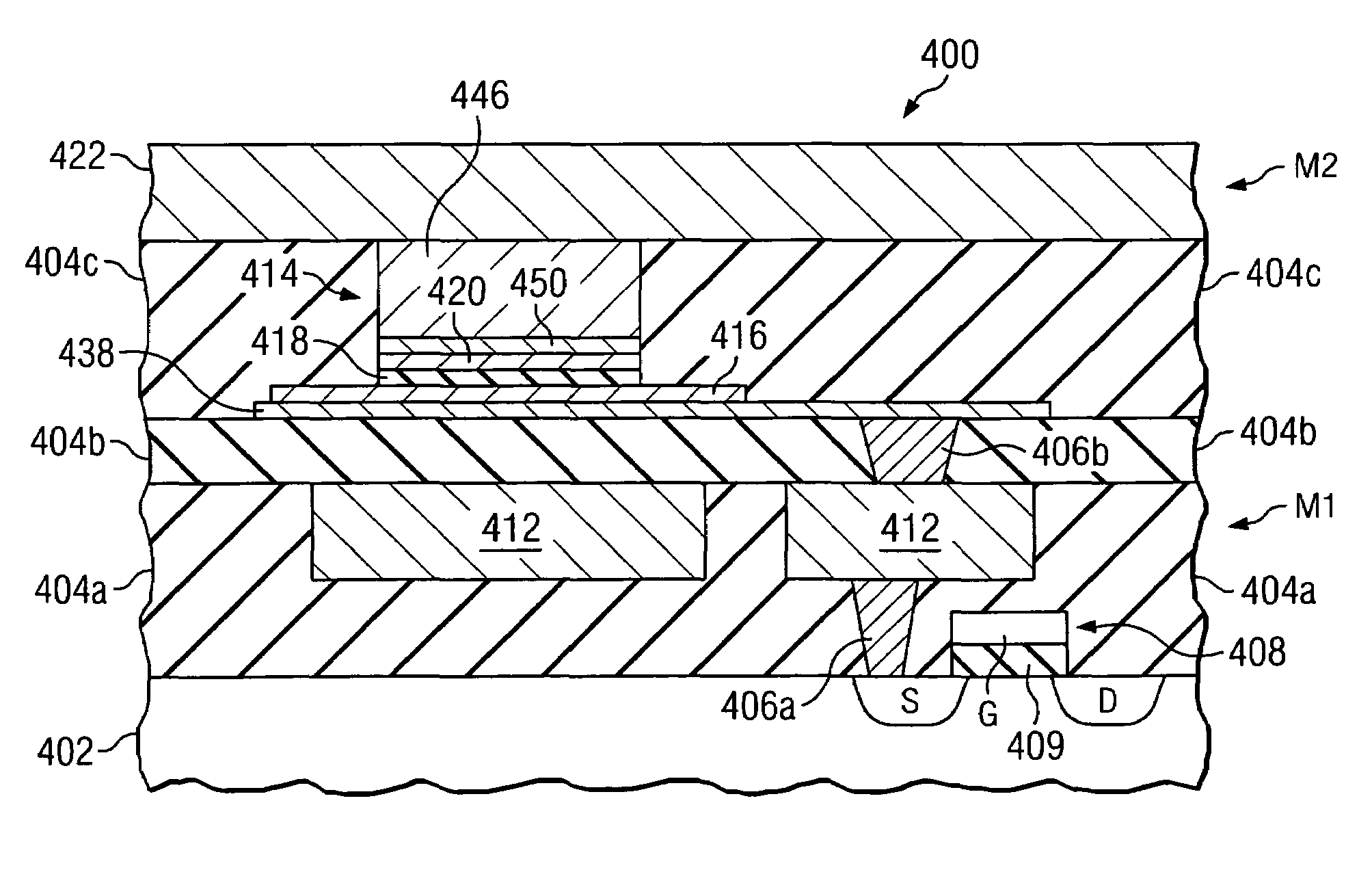

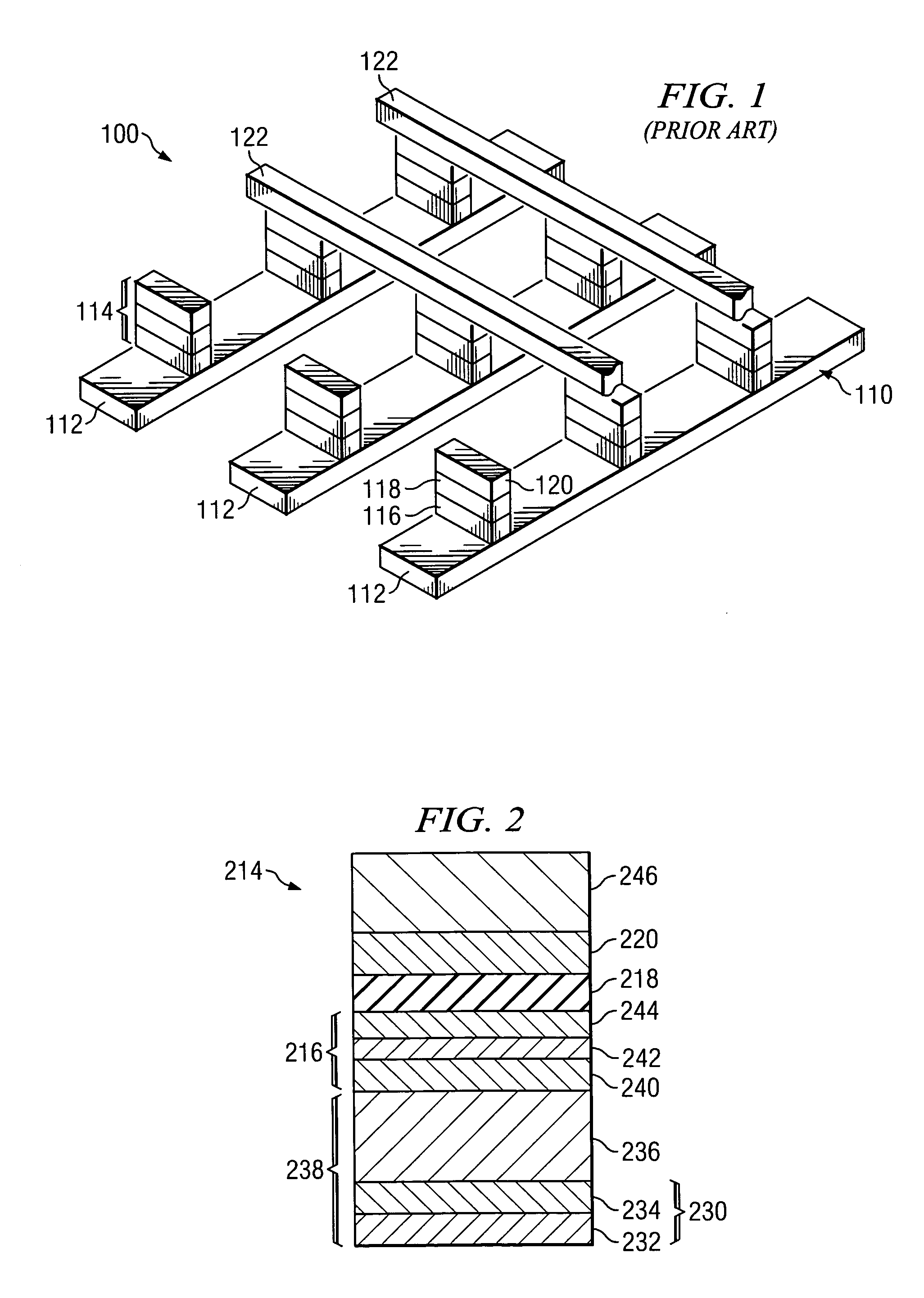

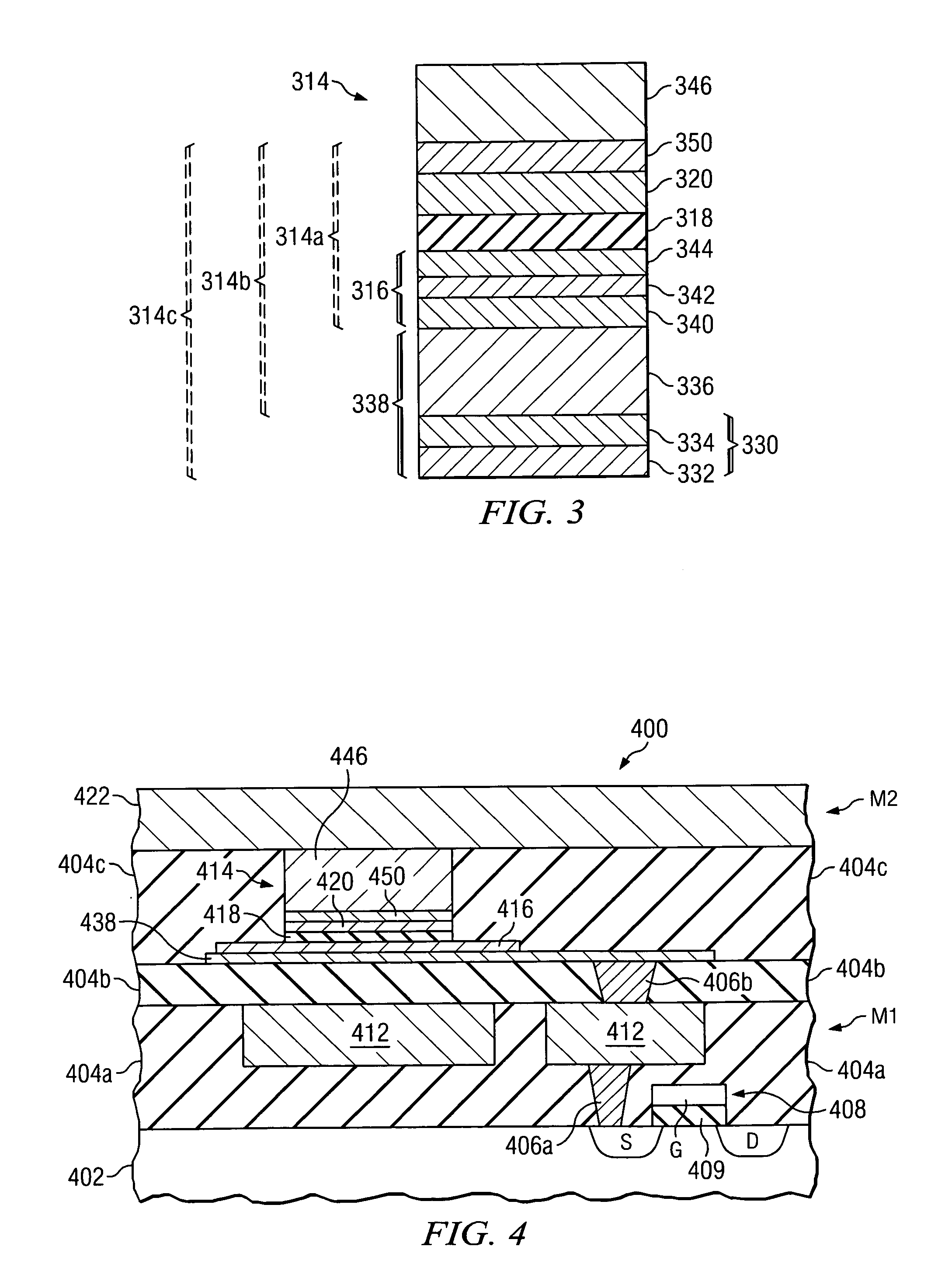

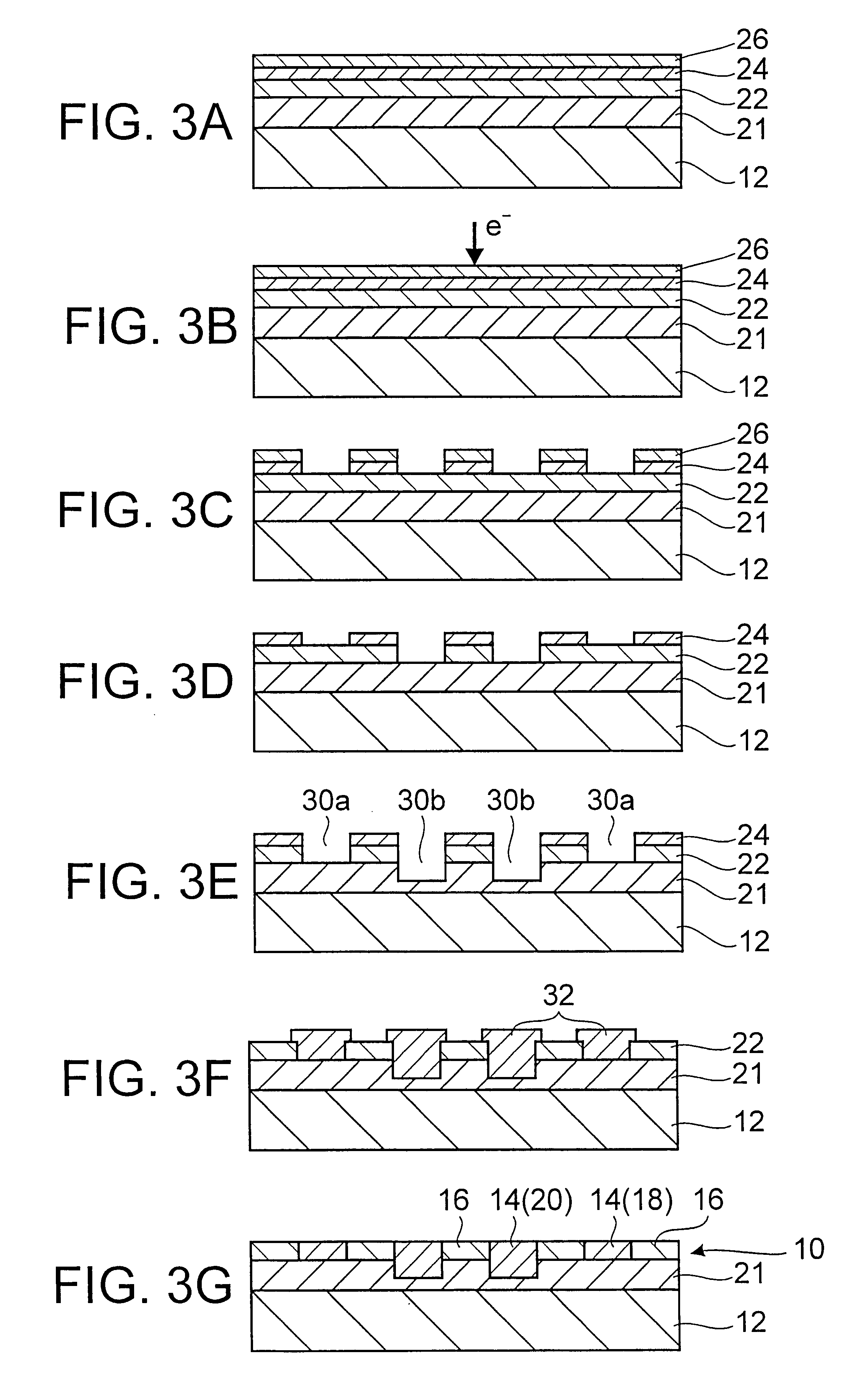

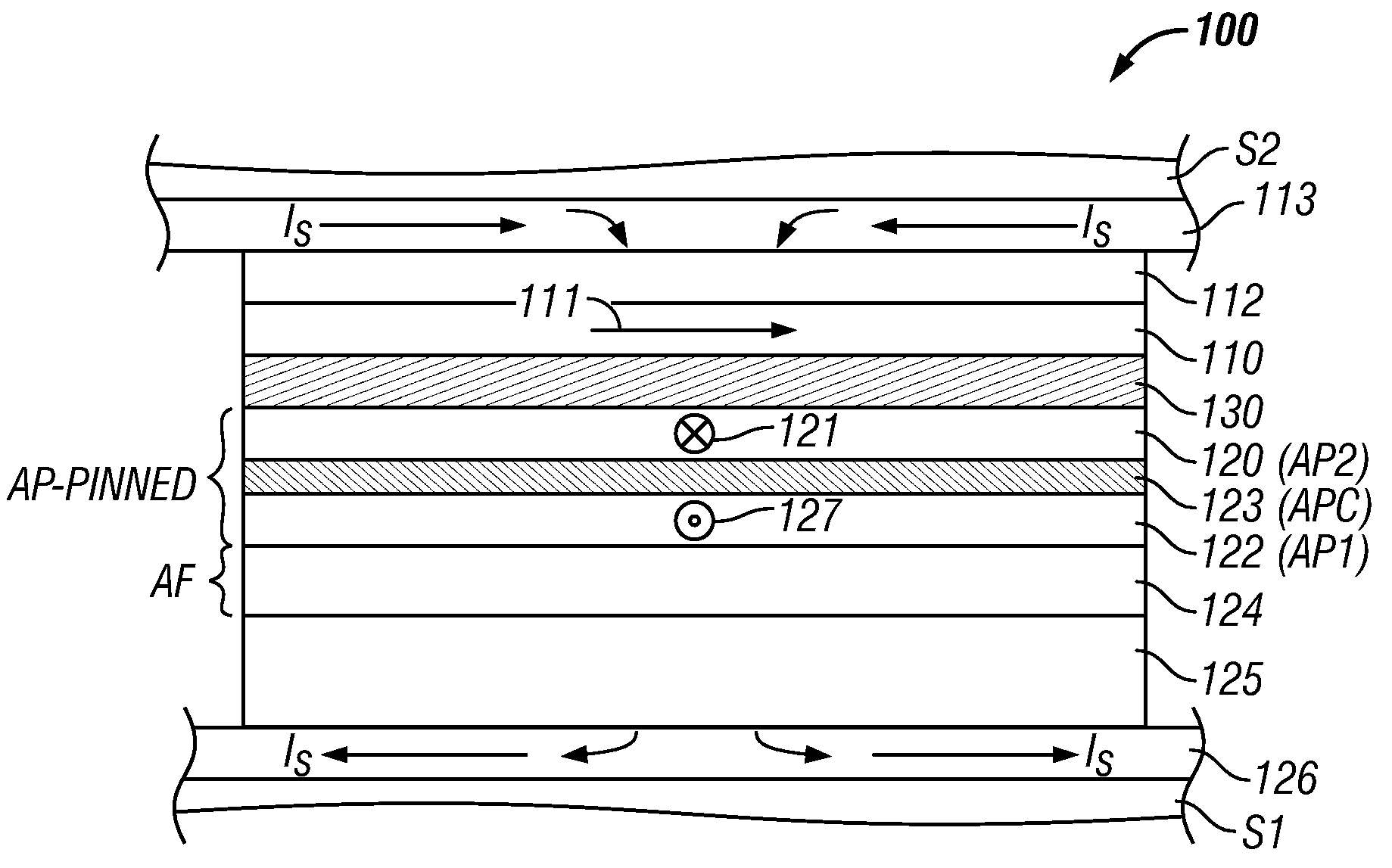

MTJ stack with crystallization inhibiting layer

InactiveUS6977181B1Improve thermal stabilityImprove compatibilityNanoinformaticsSolid-state devicesHeat stabilityCrystallization temperature

A method of forming a magnetic stack and a structure for a magnetic stack of a resistive memory device. A crystallization inhibiting layer is formed over the free layer of a magnetic stack, improving thermal stability. The crystallization inhibiting layer comprises an amorphous material having a higher crystallization temperature than the crystallization temperature of the free layer material. The crystallization inhibiting layer inhibits the crystallization of the underlying free layer, providing improved thermal stability for the resistive memory device.

Owner:POLARIS INNOVATIONS

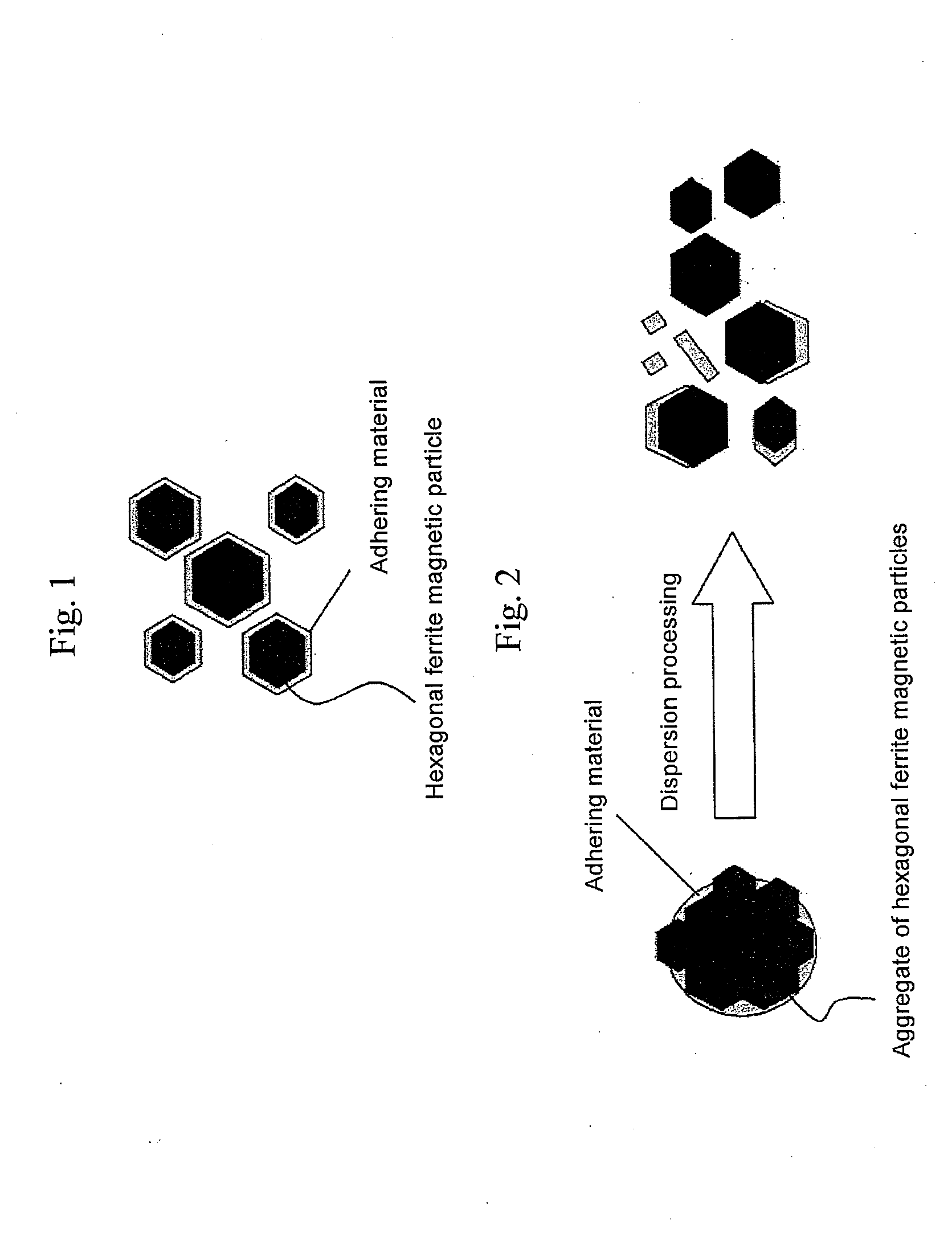

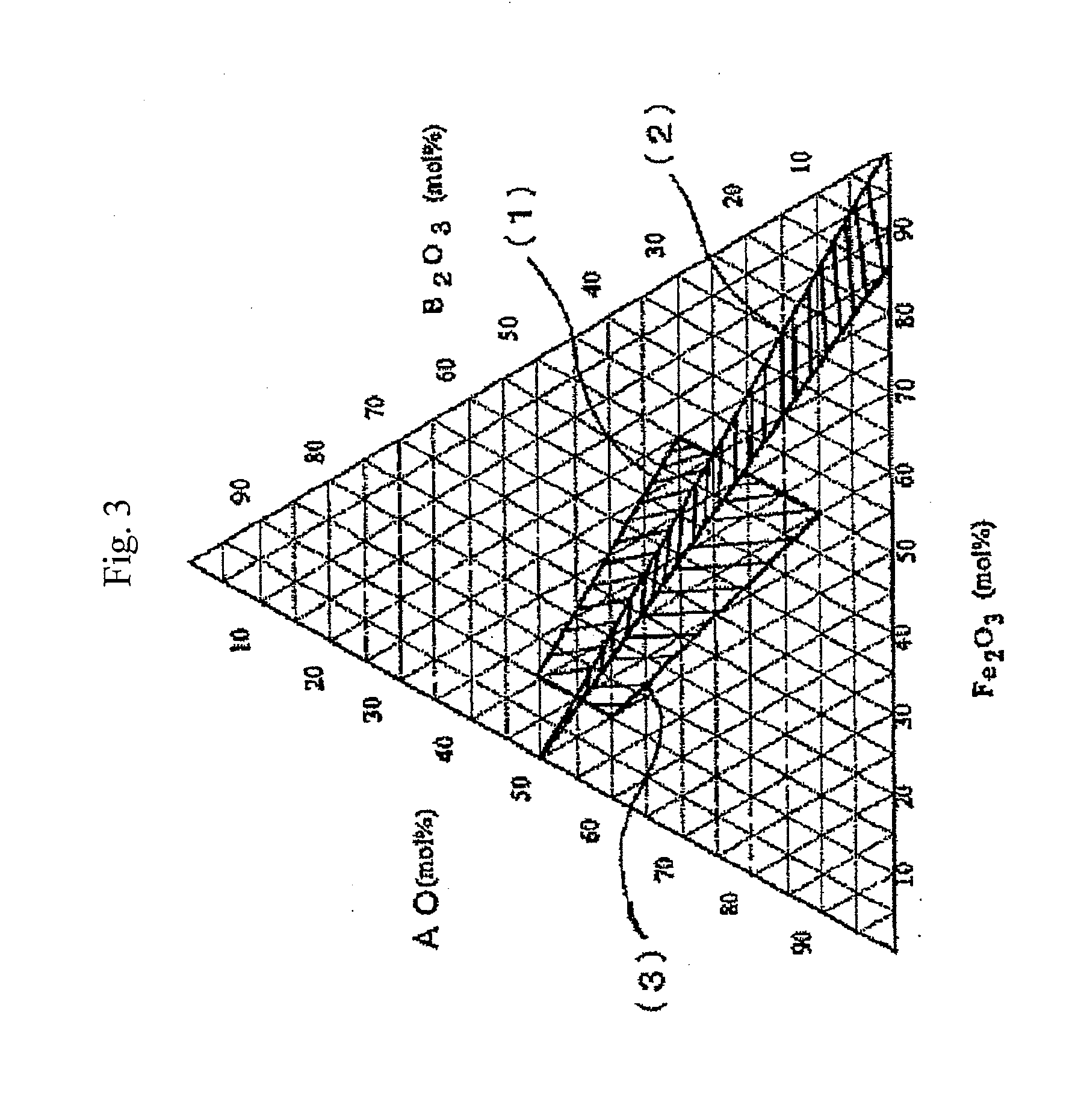

Hexagonal ferrite magnetic particle and method of manufacturing the same, and magnetic recording medium

ActiveUS20110244272A1Improve coercive forceReduce particlesMaterial nanotechnologyMagnetic materials for record carriersHeat treatedMaterials science

An aspect of the present invention relates to a method of manufacturing a hexagonal ferrite magnetic particle comprising melting an Al-containing starting material mixture to prepare a melt and quenching the melt to obtain an amorphous material; subjecting the amorphous material to heat treatment to cause a hexagonal ferrite magnetic particle to precipitate in a product obtained by the heat treatment; collecting a hexagonal ferrite magnetic particle by subjecting the product to treatment with an acid and washing, wherein the hexagonal ferrite magnetic particle collected has a particle size ranging from 15 to 30 nm, comprises 0.6 to 8.0 weight percent of Al, based on Al2O3 conversion, relative to a total weight of the particle, and Al adheres to a surface of the hexagonal ferrite magnetic particle.

Owner:FUJIFILM CORP

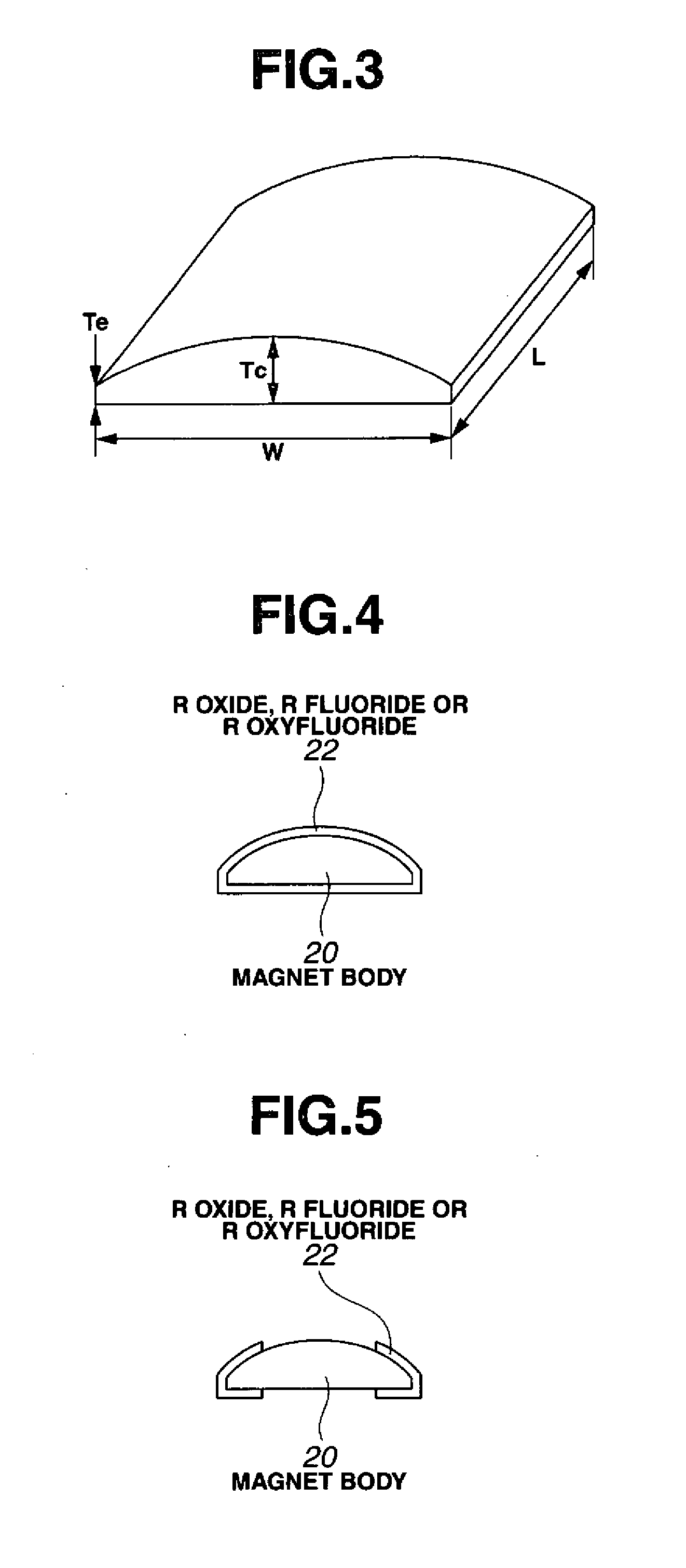

Preparation of Rare Earth Permanent Magnet Material

ActiveUS20080245442A1Improve remanenceImprove coercive forceElectric discharge tubesPermanent magnetsRare-earth elementRemanence

A method for preparing a rare earth permanent magnet material comprising the steps of:disposing a powder comprising one or more members selected from an oxide of R2, a fluoride of R3, and an oxyfluoride of R4 wherein R2, R3 and R4 each are one or more elements selected from among rare earth elements inclusive of Y and Sc on a sintered magnet form of a R1—Fe—B composition wherein R1 is one or more elements selected from among rare earth elements inclusive of Y and Sc, andheat treating the magnet form and the powder at a temperature equal to or below the sintering temperature of the magnet in vacuum or in an inert gas.The invention offers a high performance, compact or thin permanent magnet having a high remanence and coercivity at a high productivity.

Owner:SHIN ETSU CHEM IND CO LTD

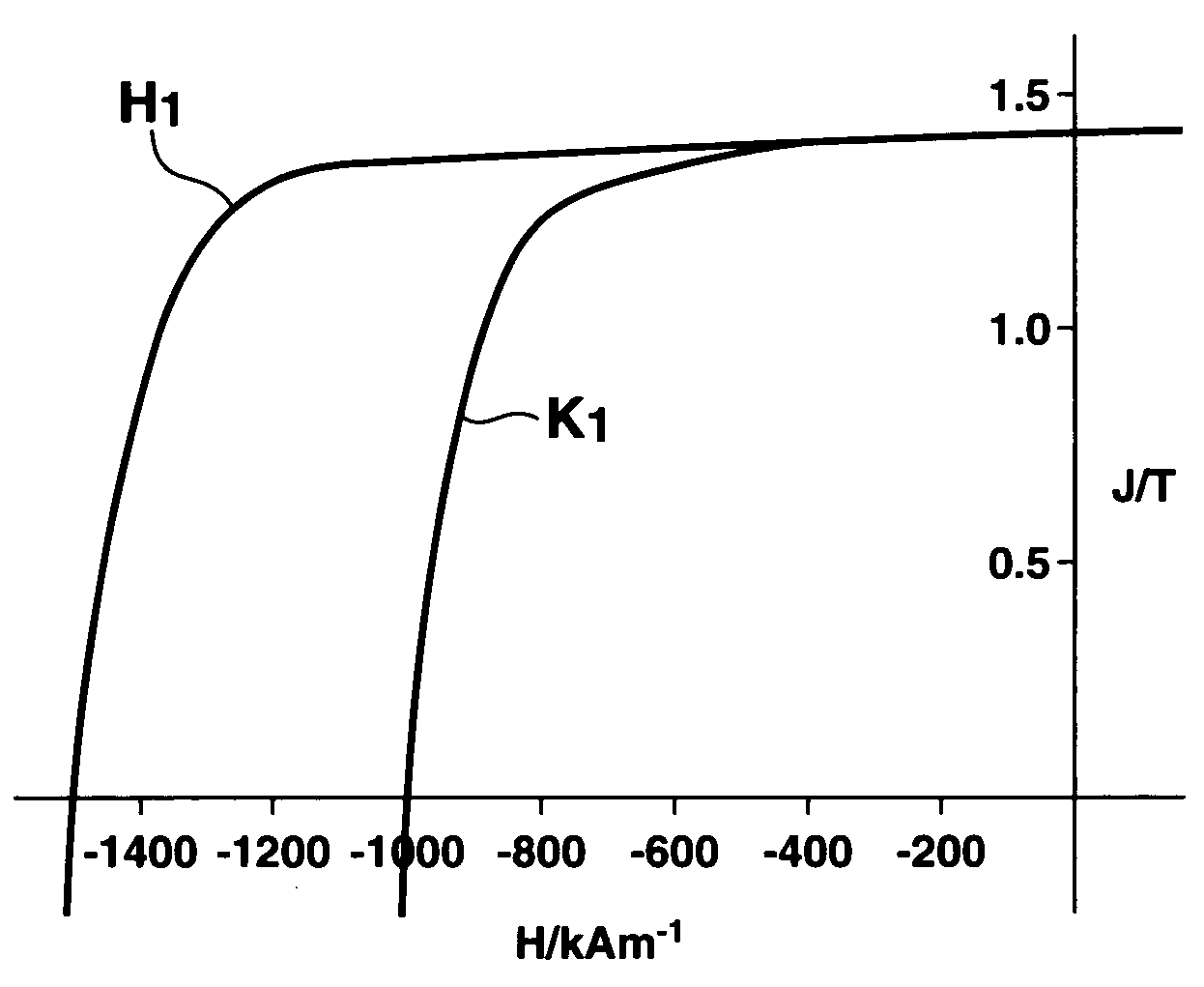

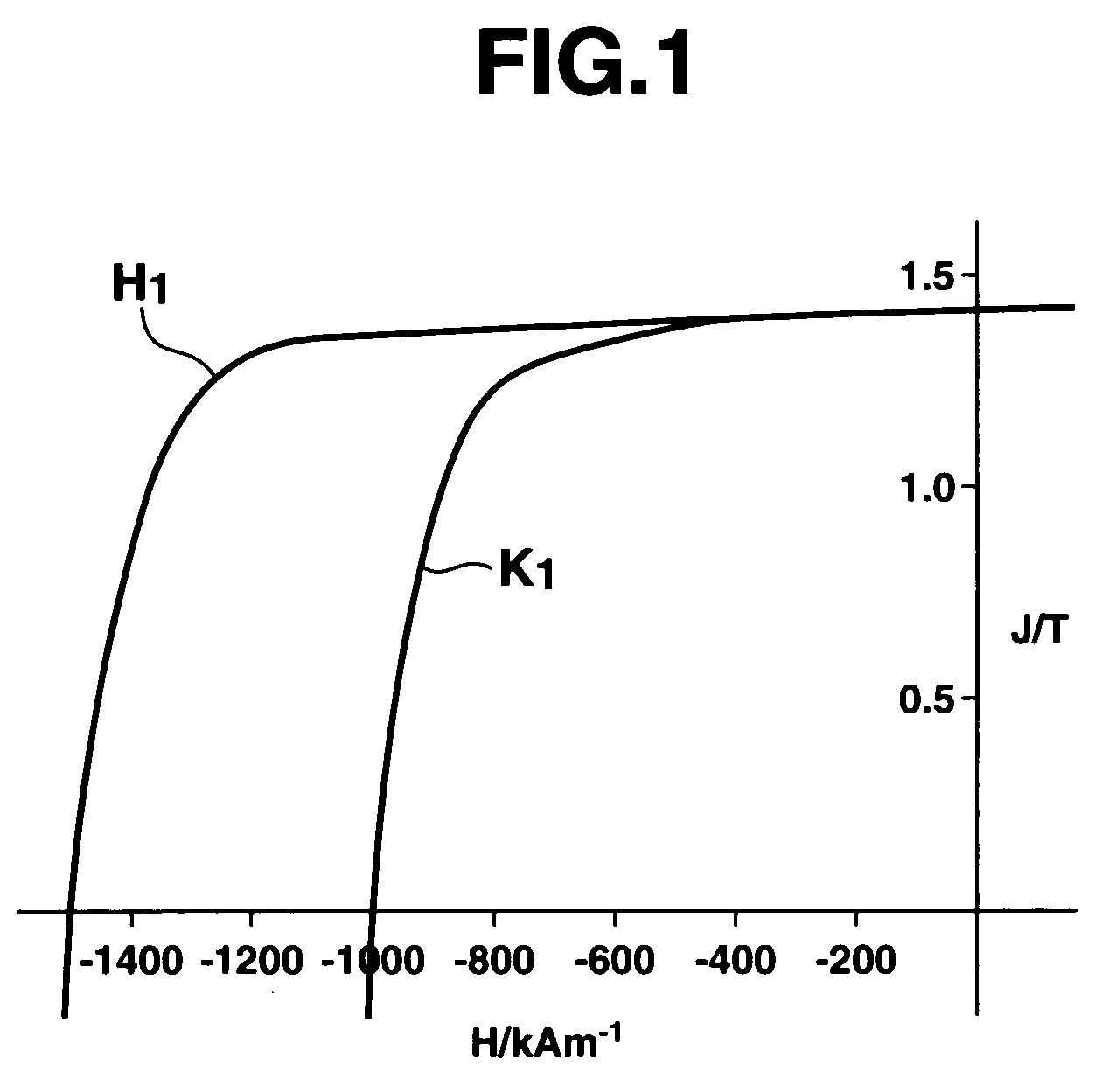

Rare earth - iron - bron based magnet and method for production thereof

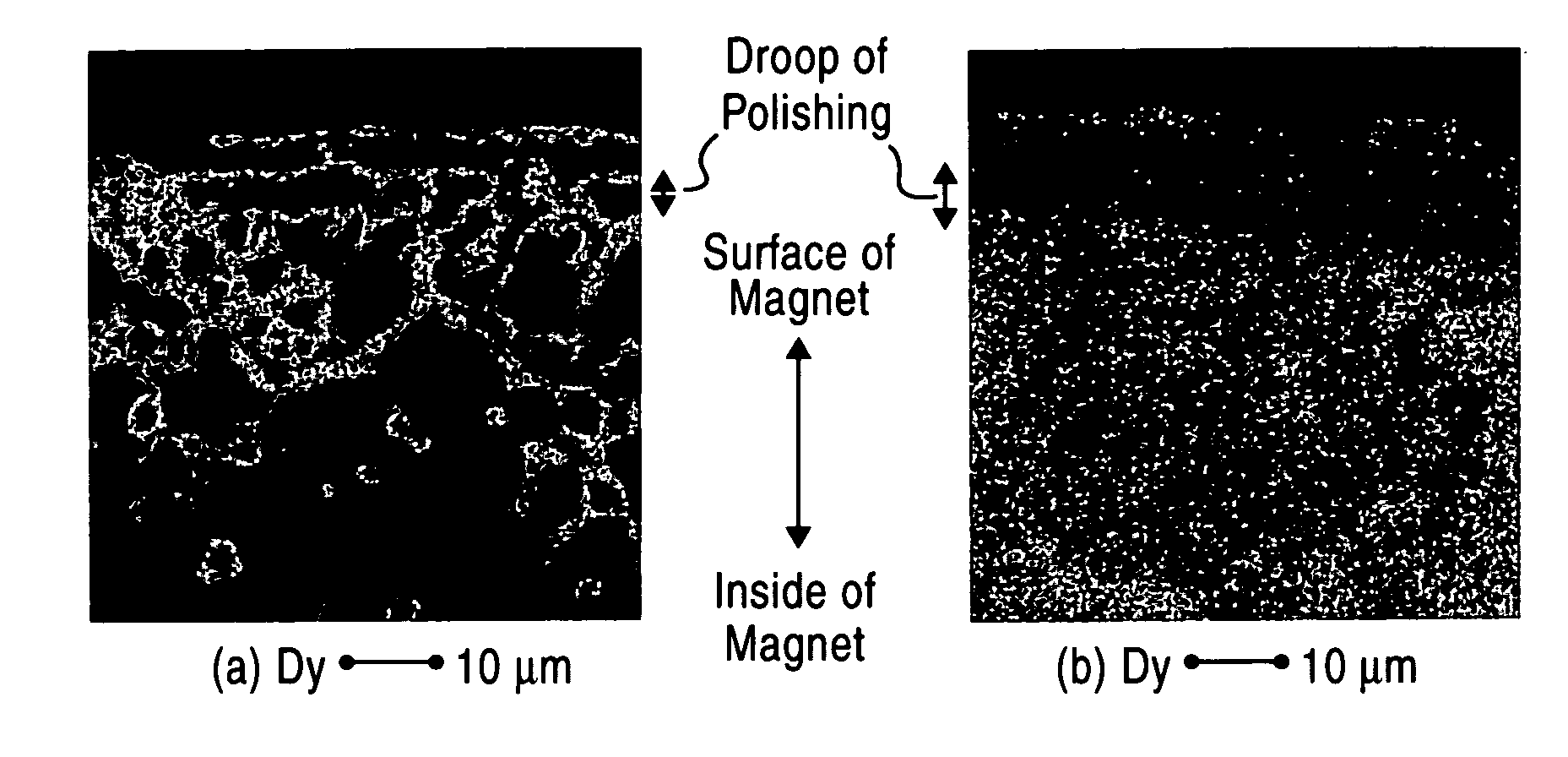

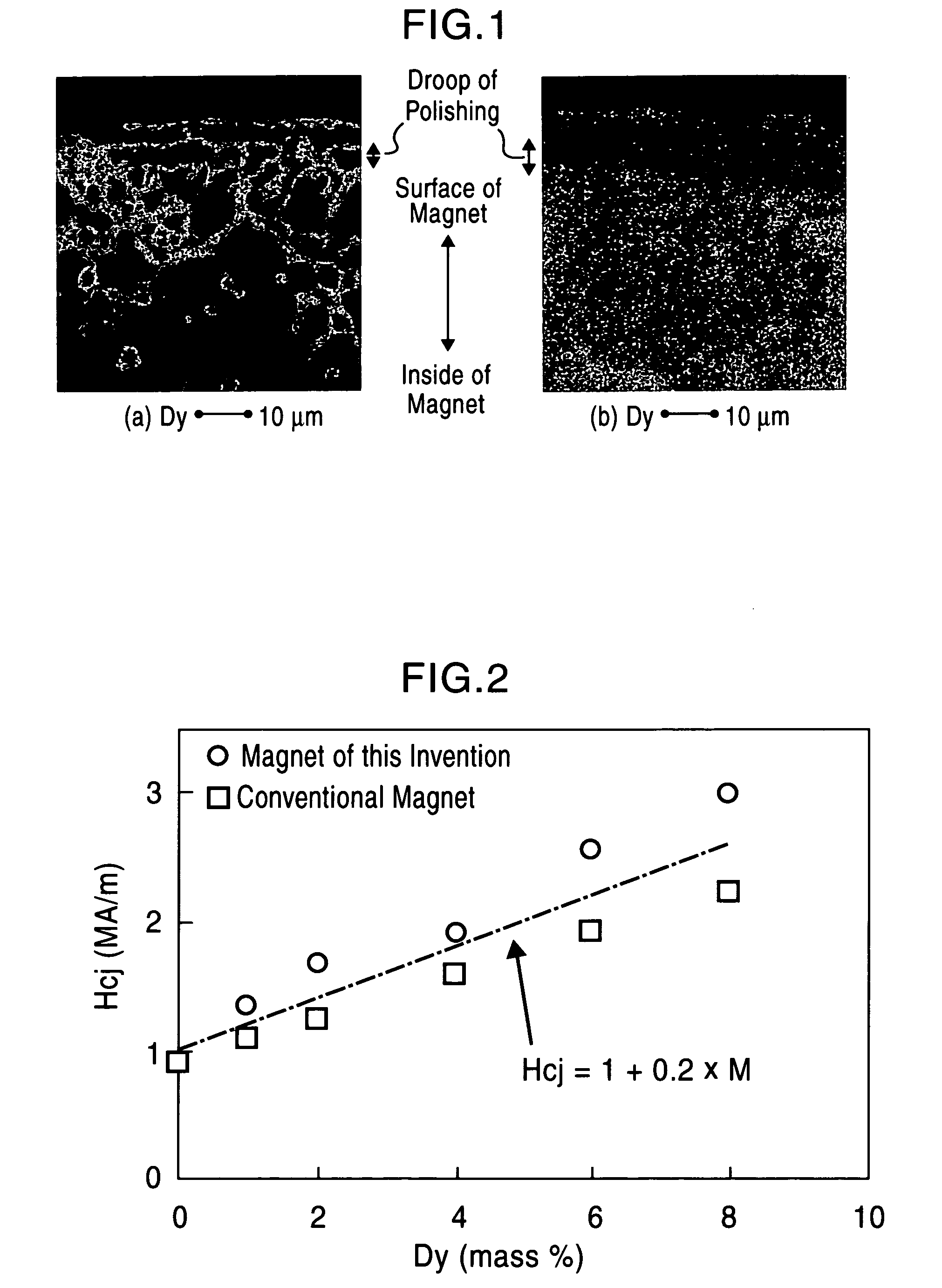

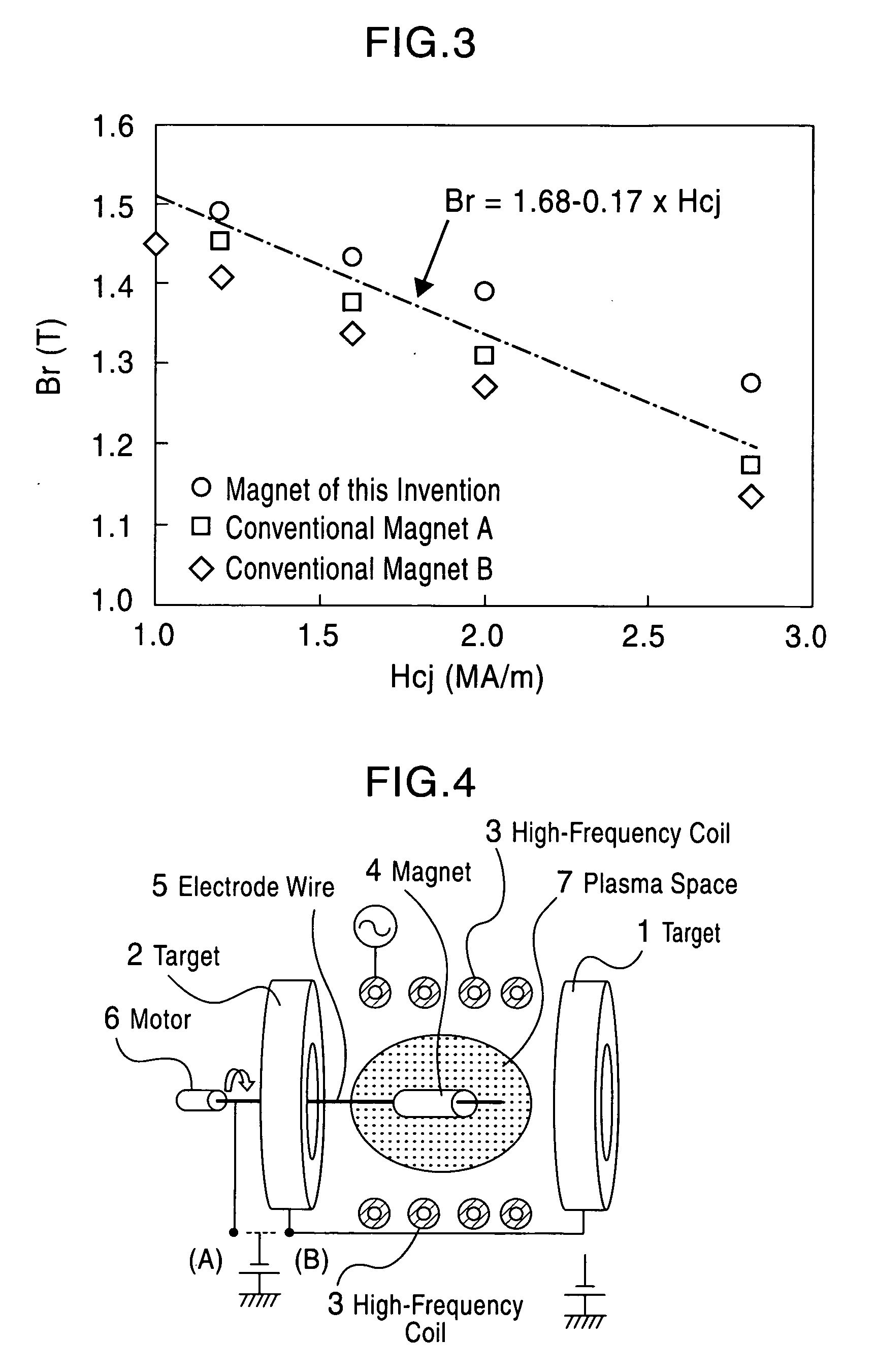

InactiveUS20070034299A1High energyImprove resolutionInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementTrace element

[Object] To provide a high-performance rare earth-based magnet exhibiting a high coercive force or a high residual magnetic flux density even when the content of a rare earth element such as Dy or the like which is scarce is reduced. [Construction] A rare earth-iron-boron based magnet includes a crystal grain boundary layer enriched in element M (M is at least one rare earth element selected from Pr, Dy, Tb, and Ho) by diffusion of the element M from the surface of the magnet, wherein the relation between the coercive force Hcj and the content of the element M in the whole of the magnet is represented by the following expression: Hcj≧1+0.2×M (wherein 0.05≦M≦10) wherein Hcj is the coercive force (unit: MA / m), and M is the content of the element M in the whole of the magnet (% by mass). Furthermore, the magnet satisfies the following expression: Br≧1.68−0.17×Hcj wherein Br is the residual magnetic flux density (unit: T).

Owner:JAPAN SCI & TECH CORP +1

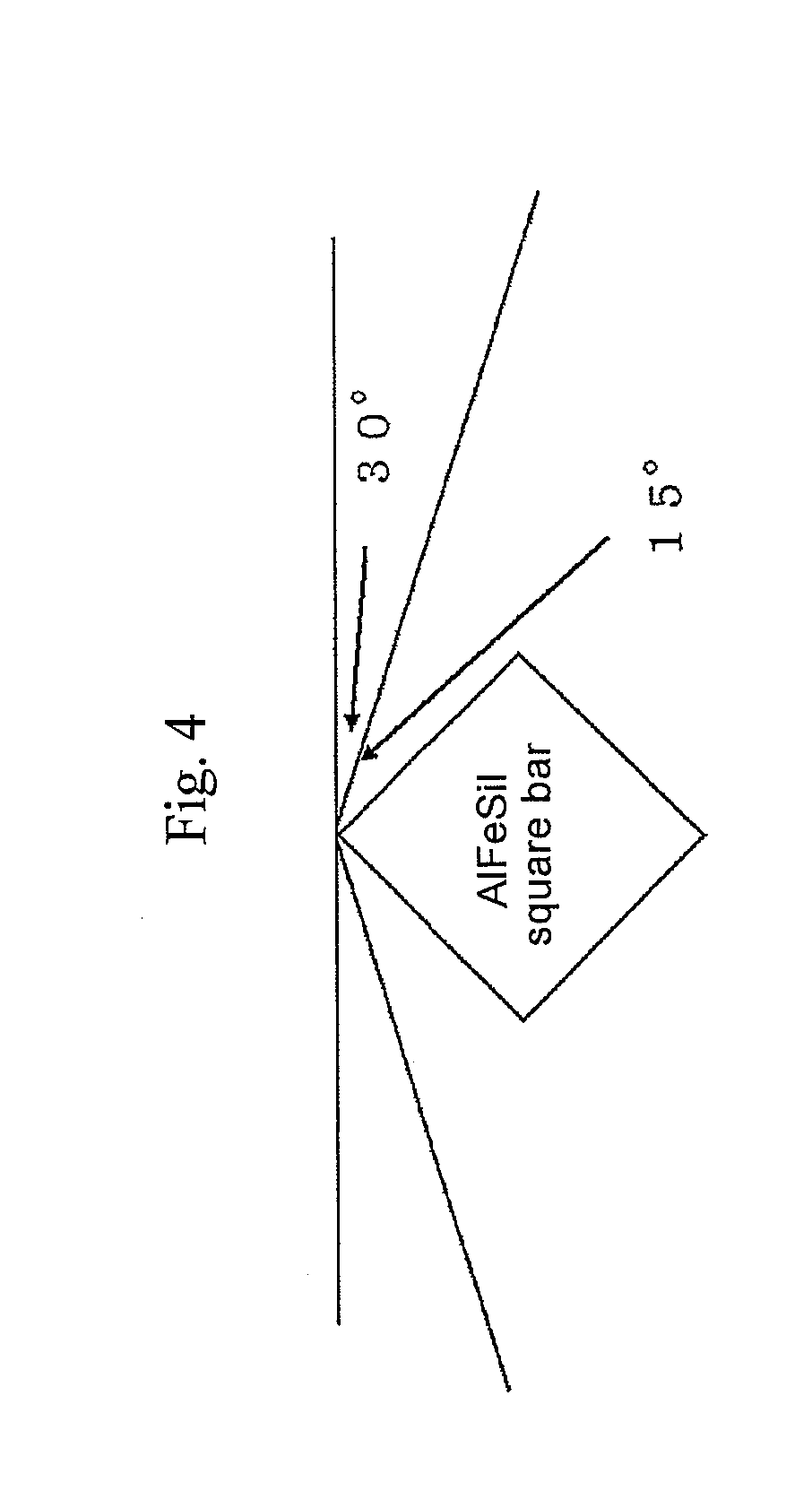

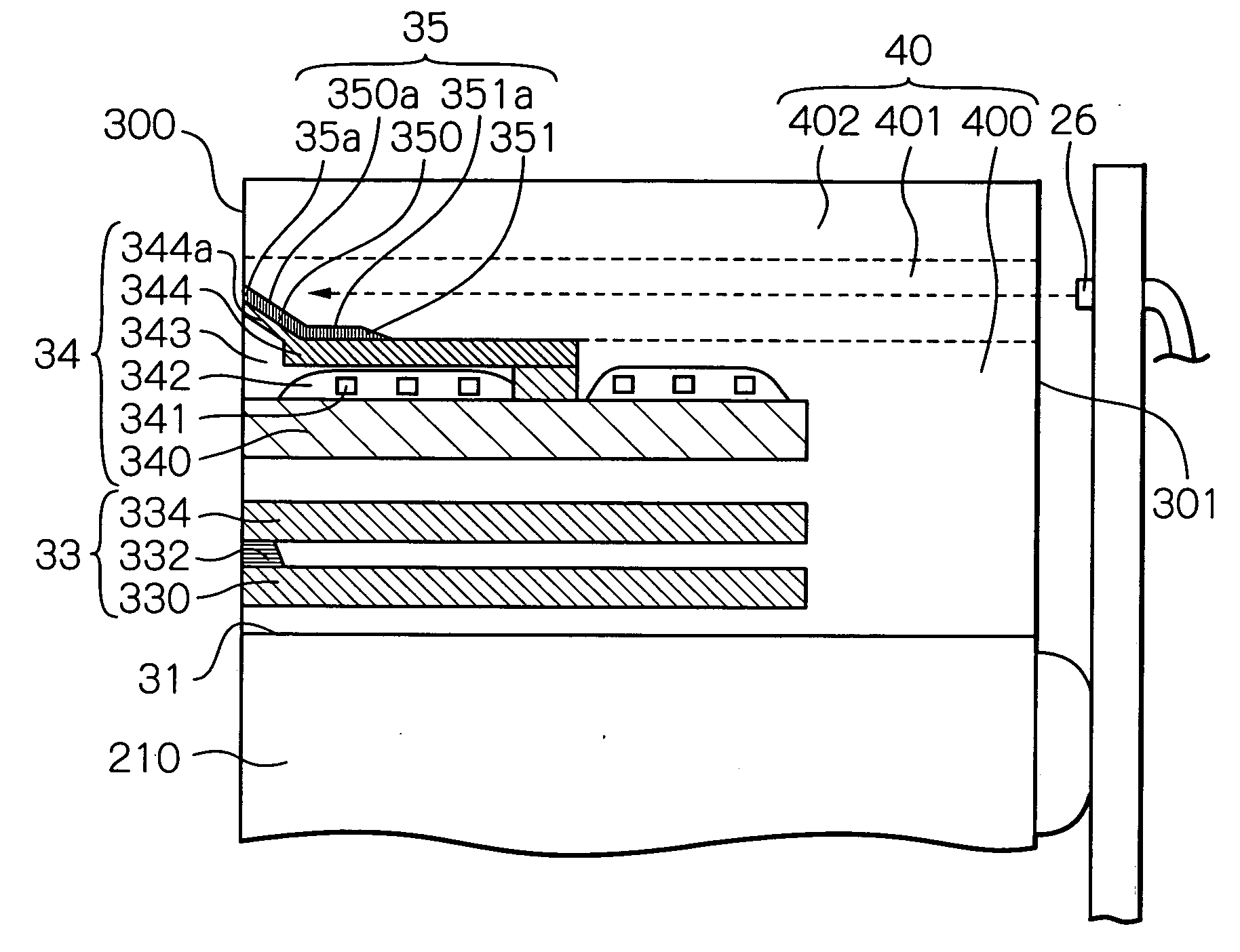

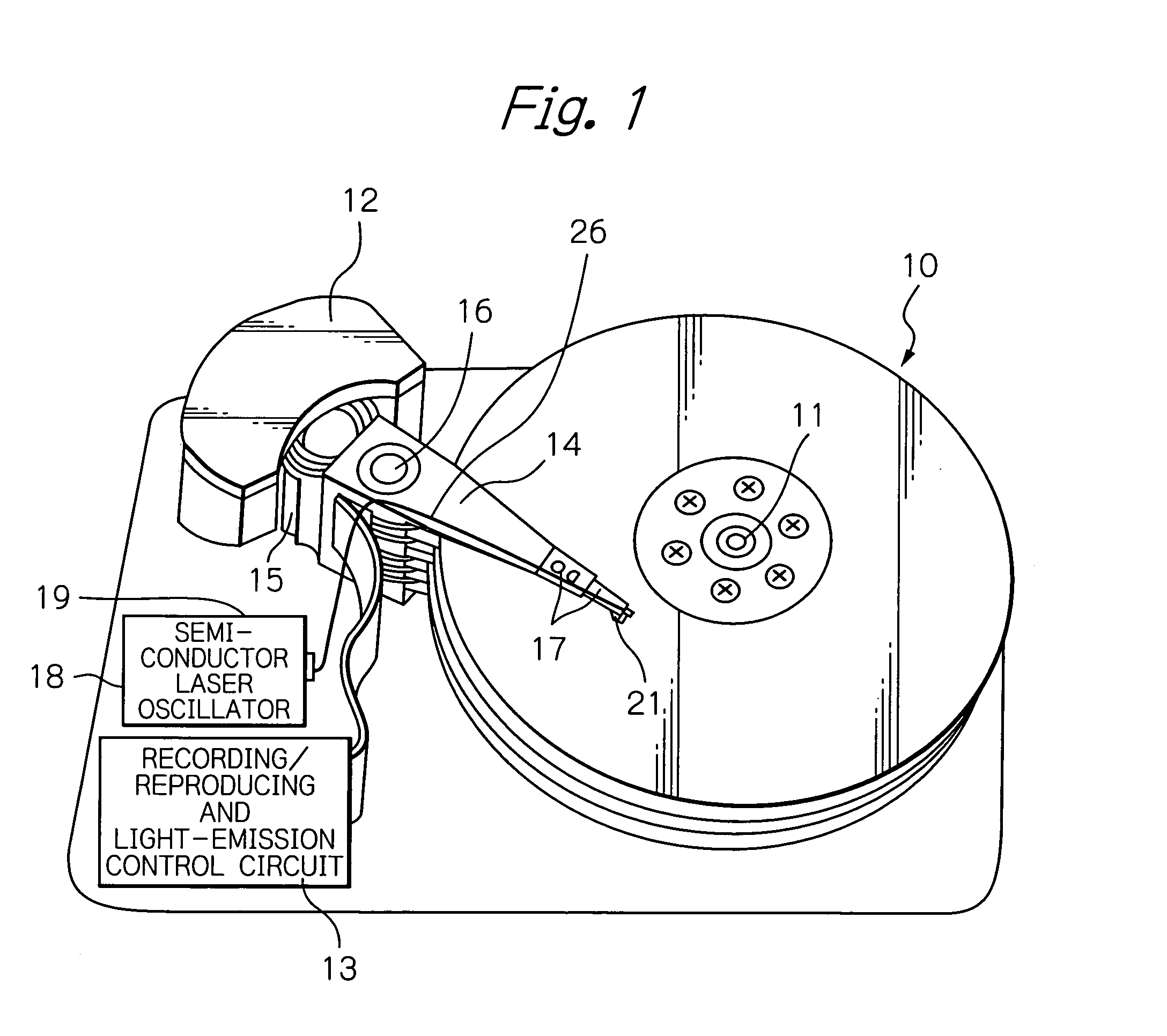

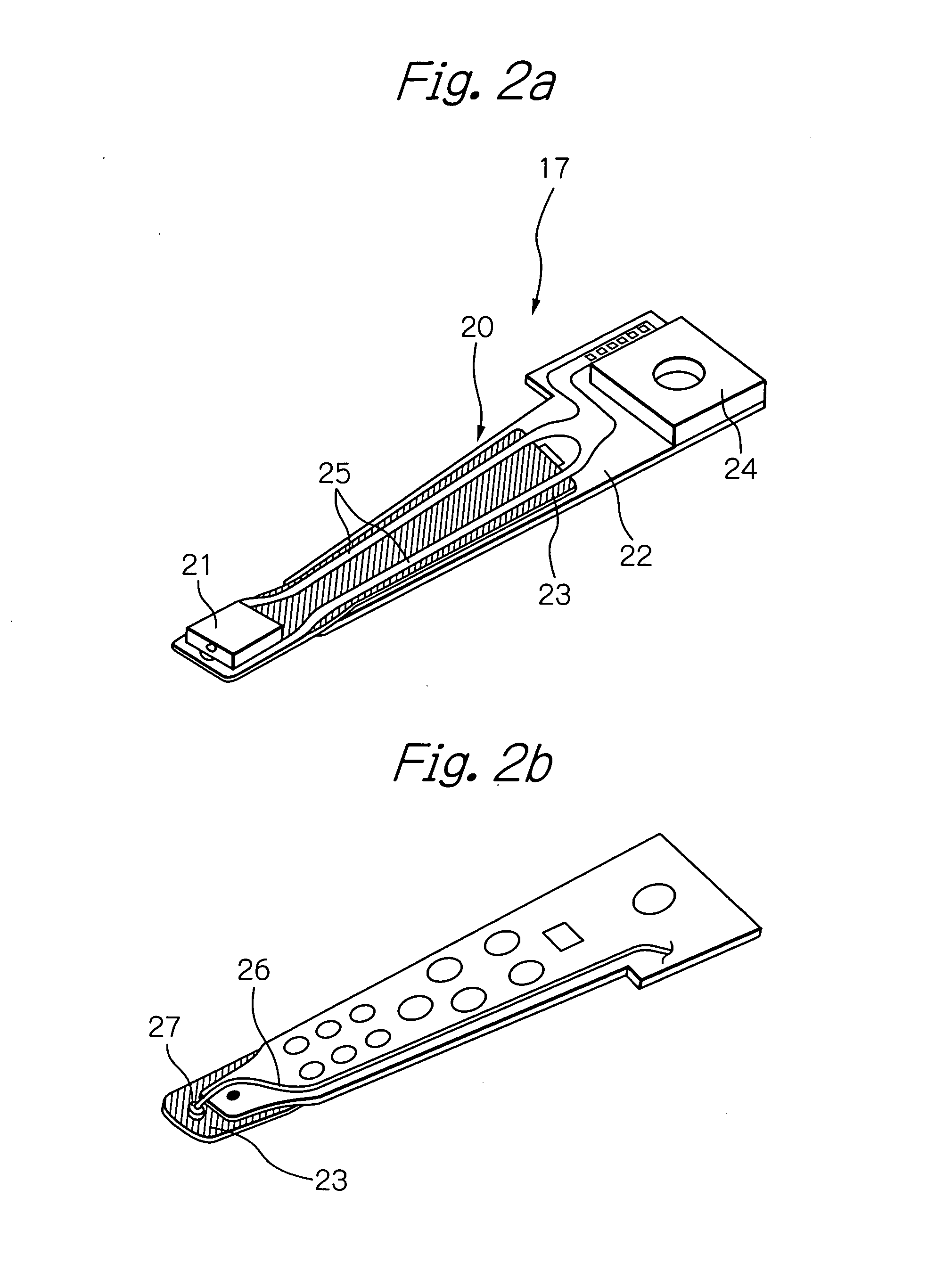

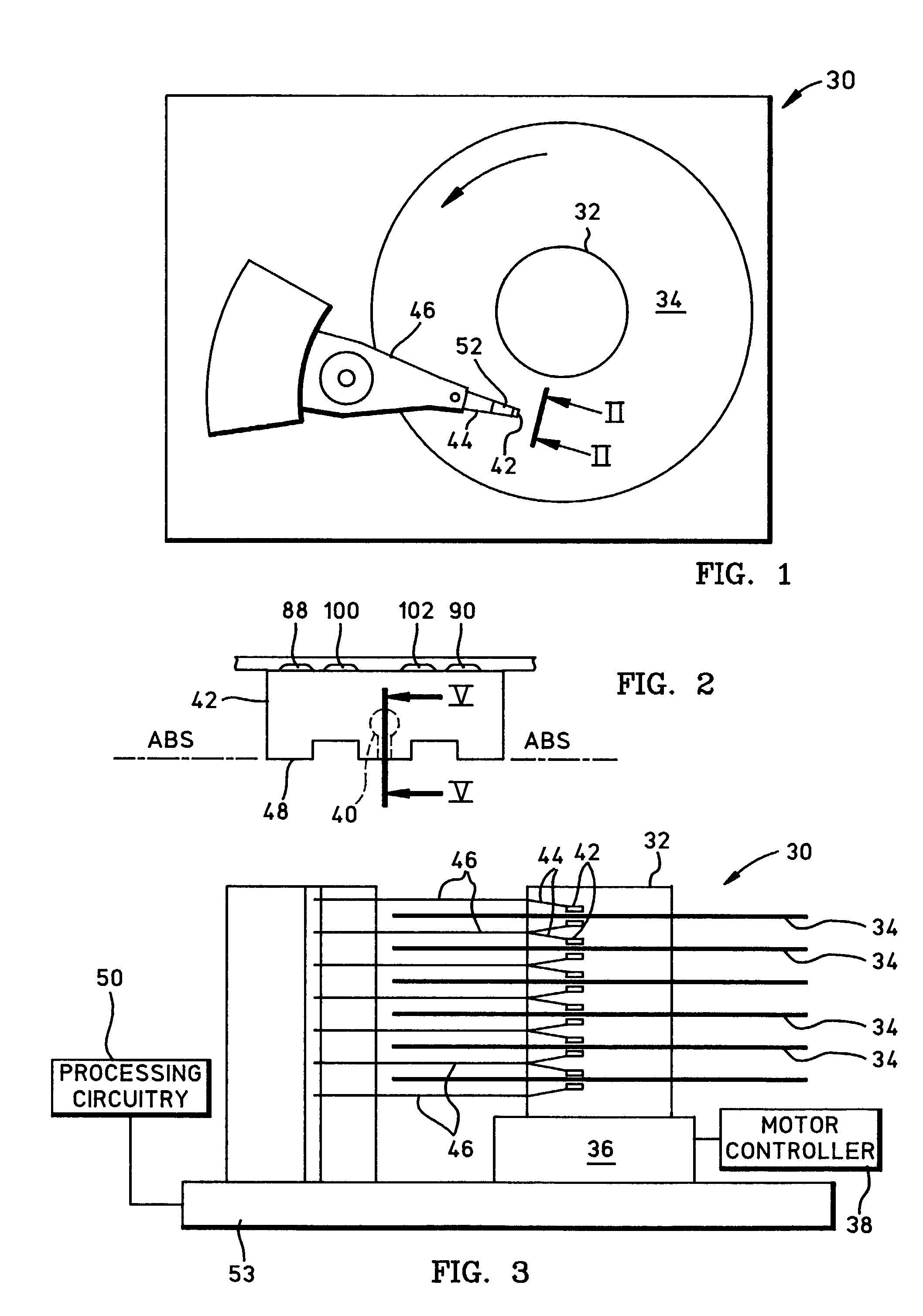

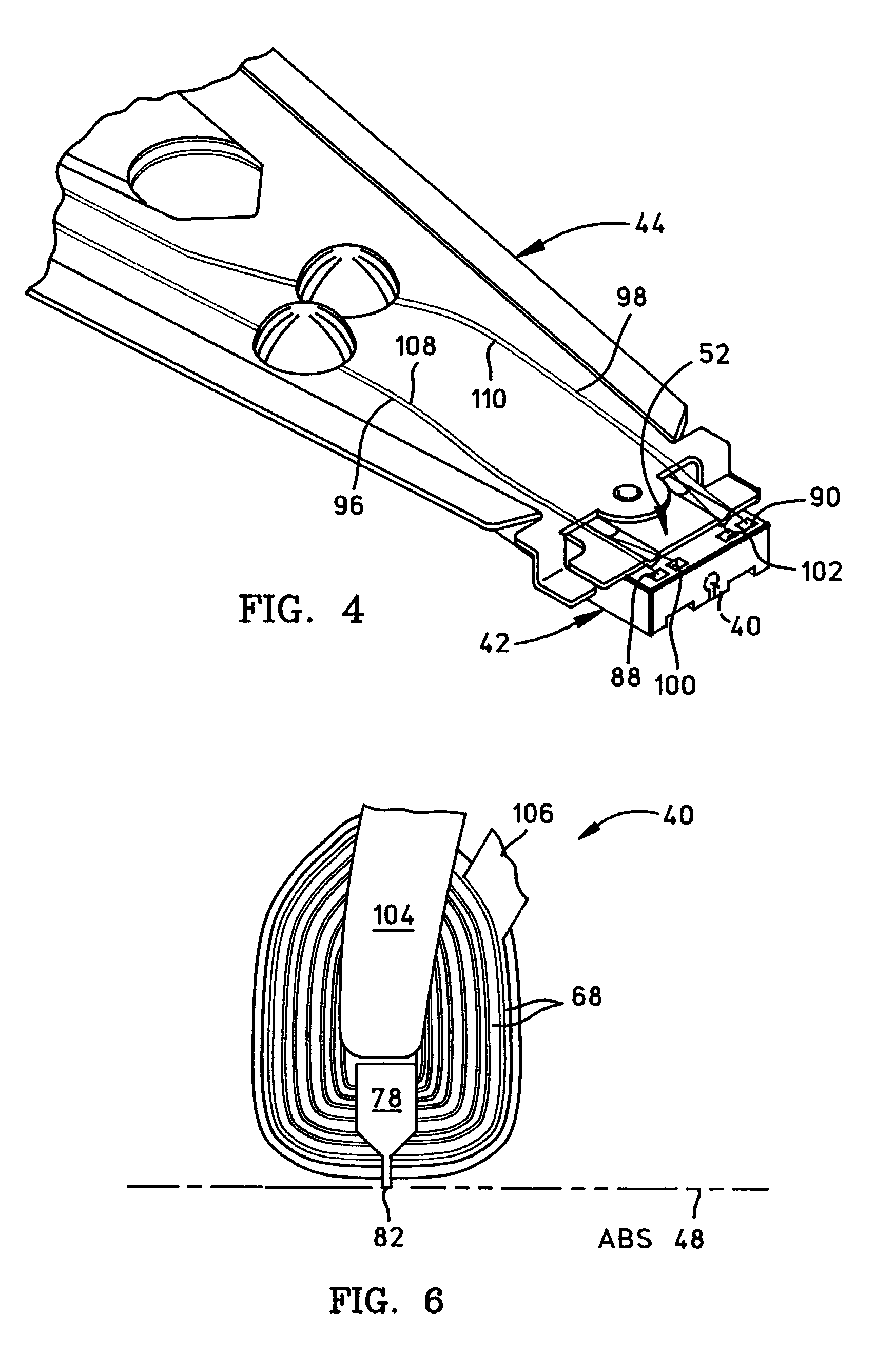

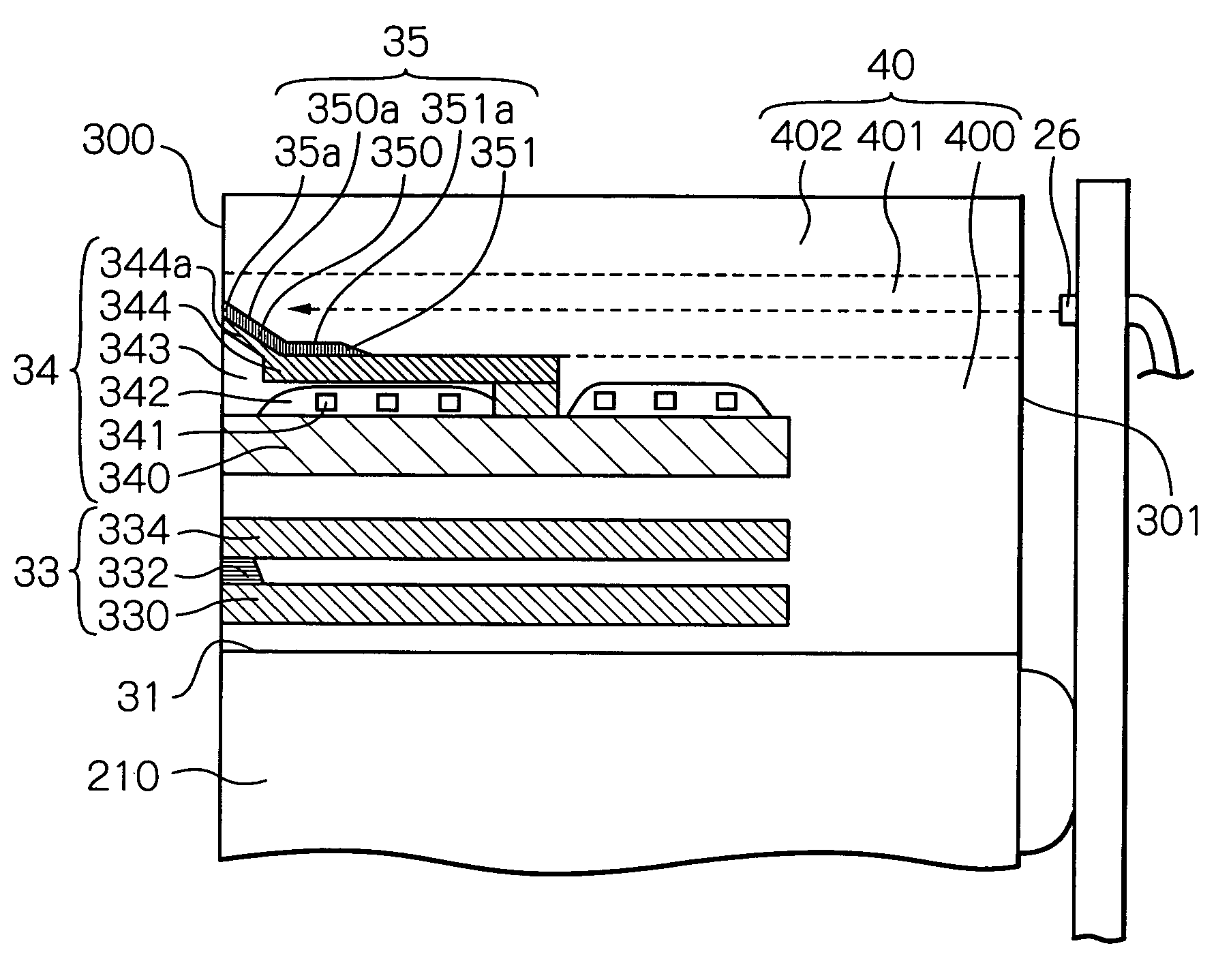

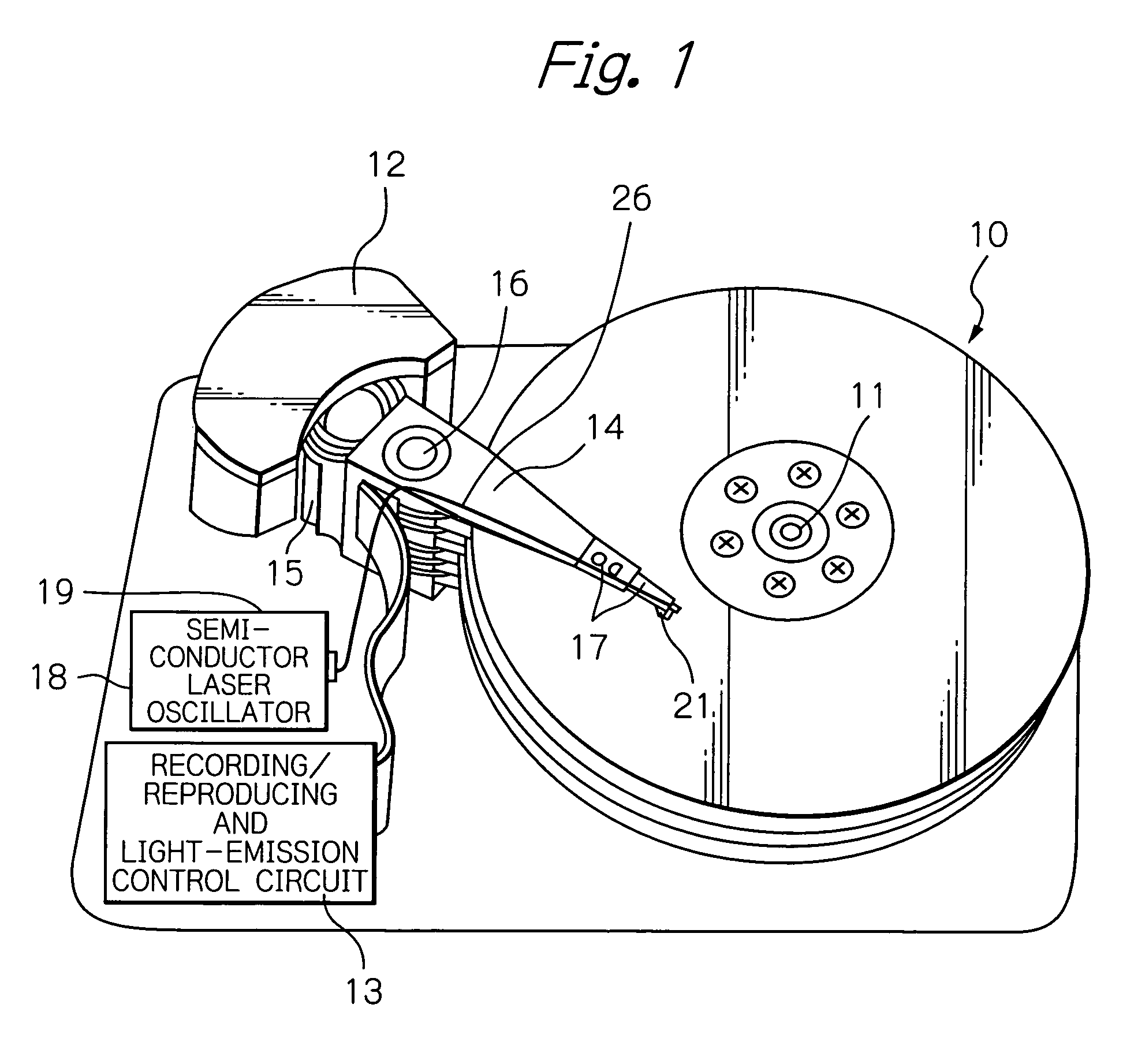

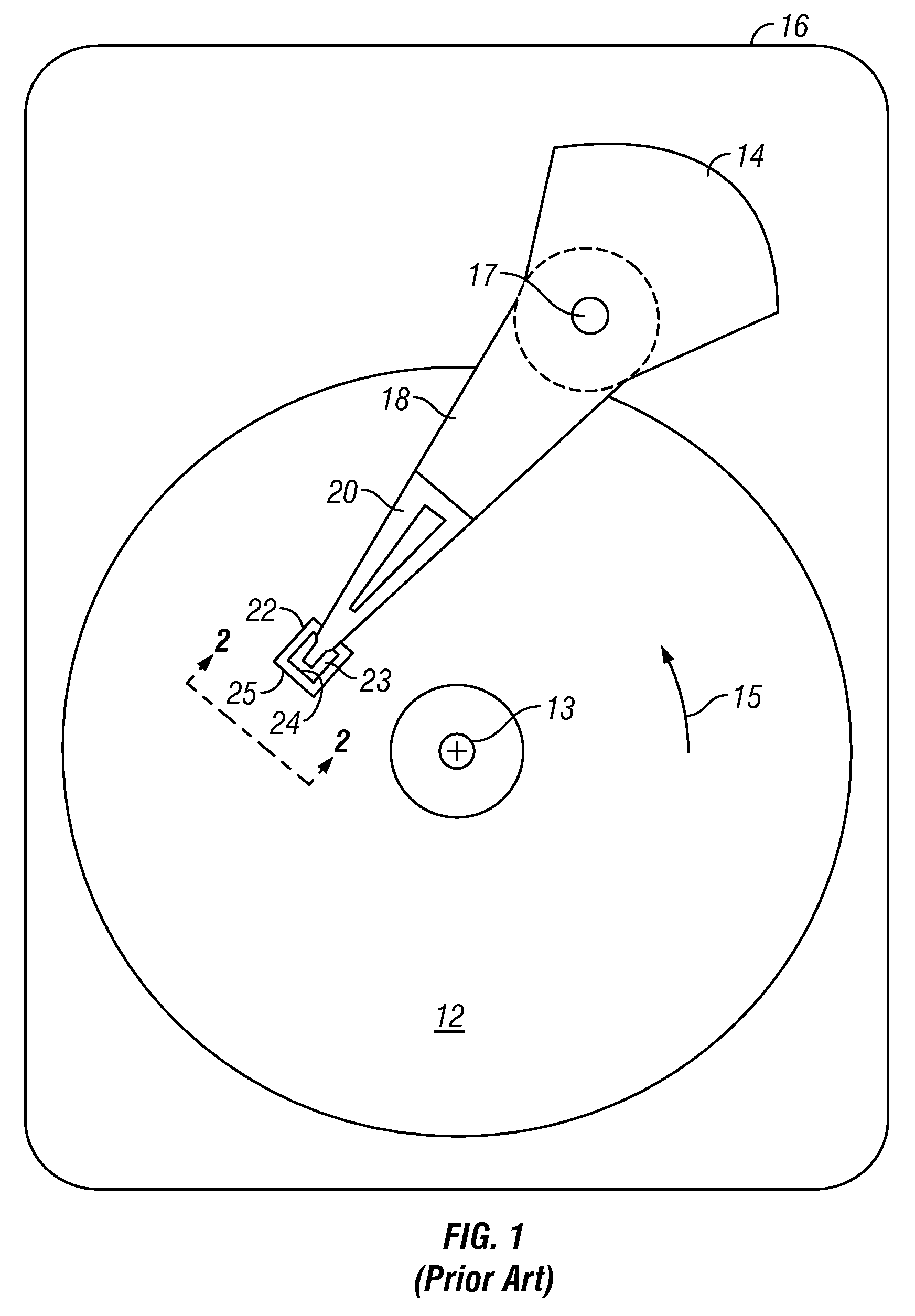

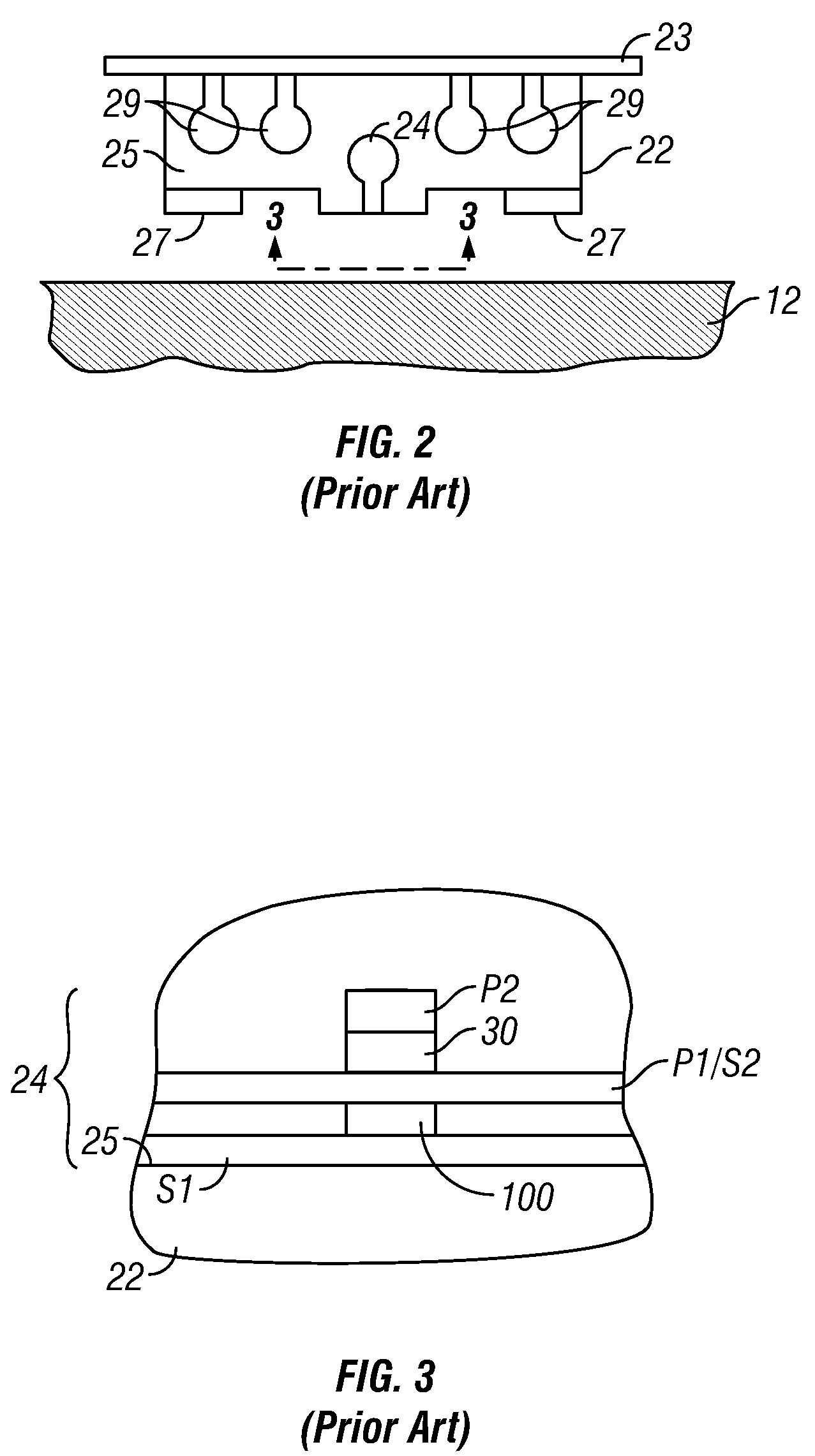

Thin-film magnetic head with near-field-light-generating layer

ActiveUS20070139818A1Improve reliabilityLow coercivityCombination recordingArm with optical waveguideMagnetic mediaBiomedical engineering

A thin-film magnetic head that has a configuration in which the element-formed surface and the opposed-to-medium surface are perpendicular to each other, and a light source is sufficiently distanced from the medium surface is provided. The head comprises at least one near-field-light-generating layer for heating a part of a magnetic medium during write operation by generating a near-field light, having a shape tapered toward a head end surface on the opposed-to-medium surface side, and comprising a near-field-light-generating portion having a light-received surface and a tip reaching the head end surface on the opposed-to-medium surface side, and the light-received surface being sloped in respect to the element-formed surface and being provided in a position where an incident light propagating from a head end surface opposite to the opposed-to-medium surface can reach at least a part of the light-received surface.

Owner:TDK CORPARATION

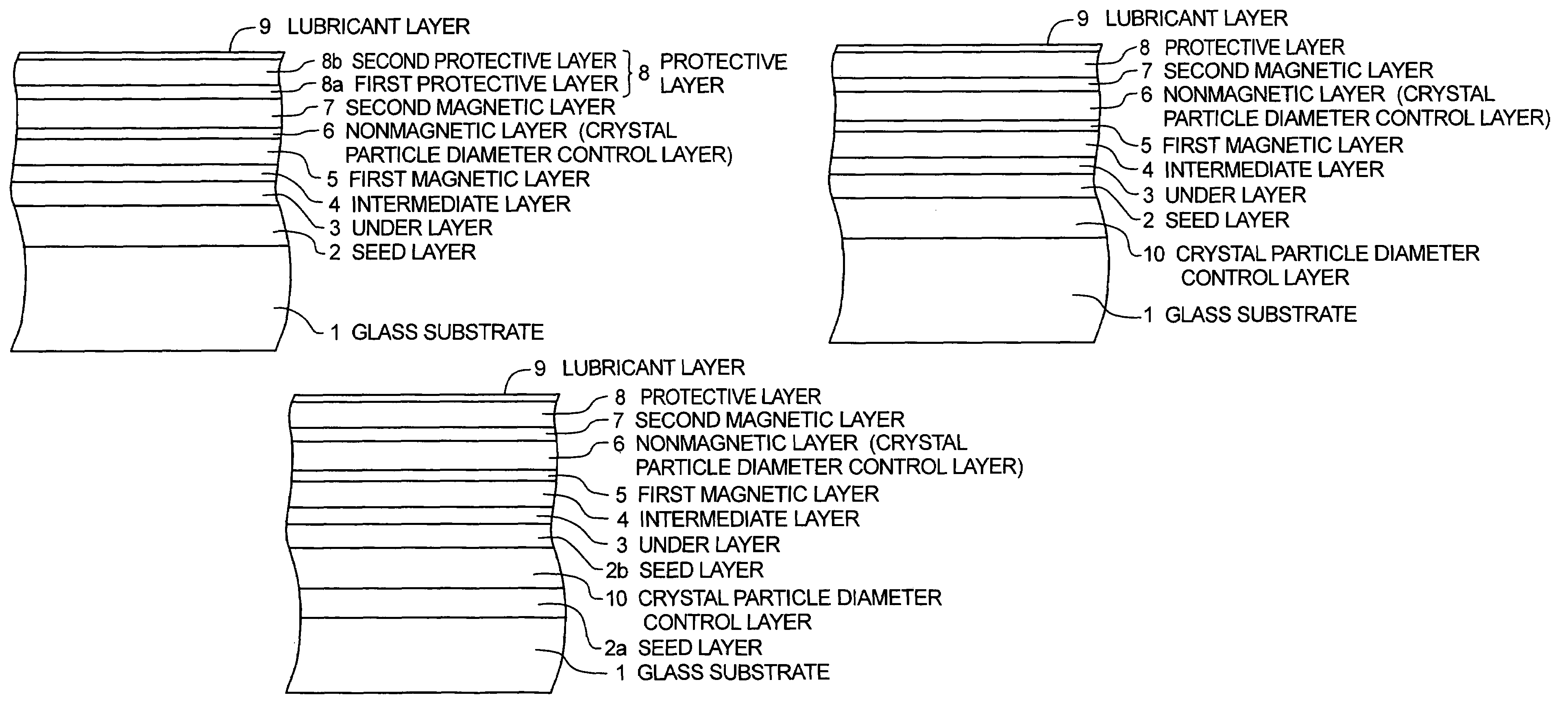

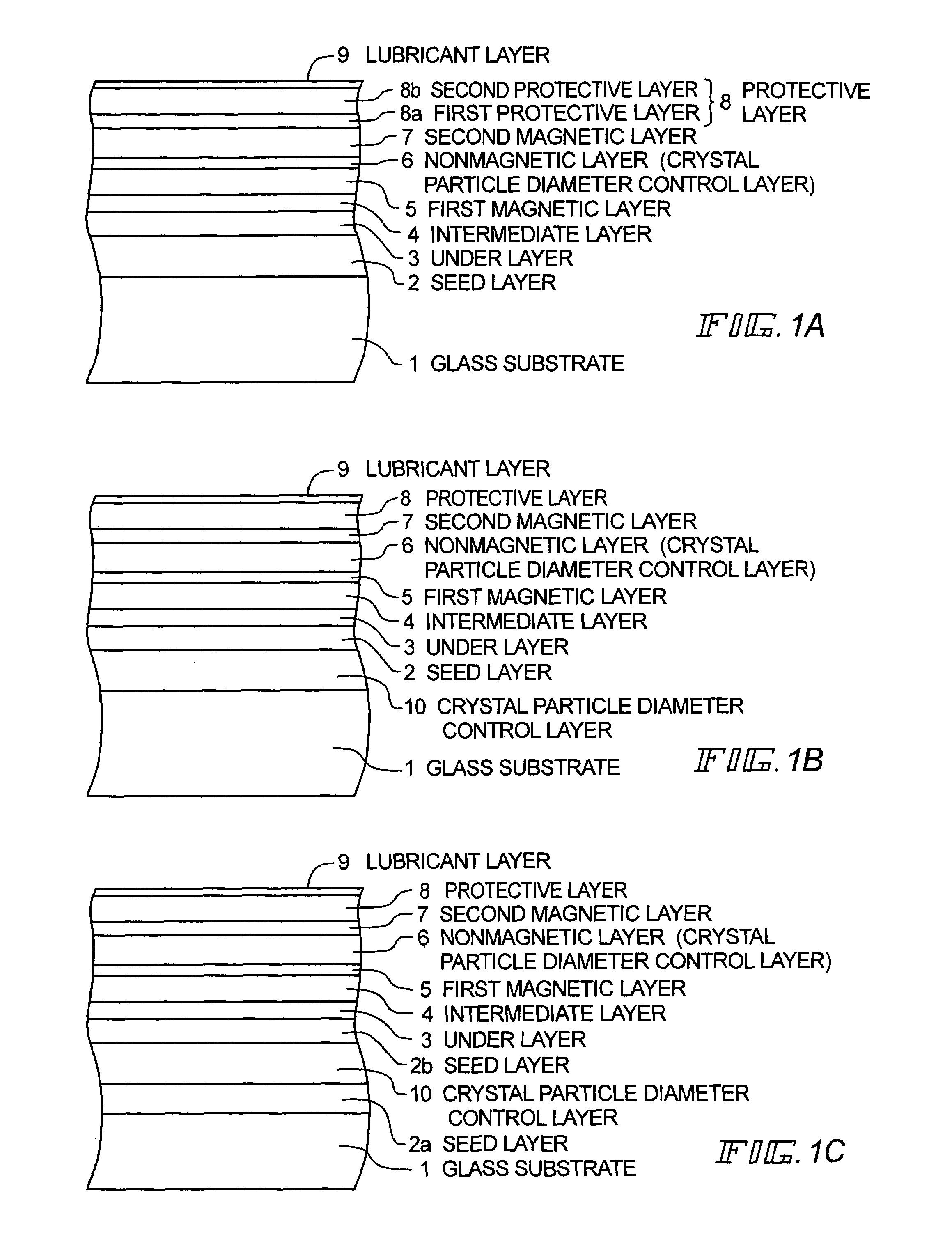

Magnetic recording medium, and thermal stability measuring method and apparatus of magnetic recording medium

InactiveUS7220500B1Accurate measurementAccurate evaluationBase layers for recording layersRecord information storageInter layerAlloy

There is disclosed a magnetic recording medium in which a seed layer, under layer, intermediate layer, first magnetic layer, nonmagnetic layer, second magnetic layer, protective layer, and lubricant layer are successively laminated on a glass substrate, the nonmagnetic layer is constituted of an alloy containing Cr and C, and the magnetic layer is constituted of an alloy containing Co and Pt. The under layer includes at least the seed layer for finely dividing the crystal particles of the magnetic layer, the seed layer includes at least two or more layers of nonmagnetic films, and the intermediate layer formed of the material different from that of the nonmagnetic film is interposed between the nonmagnetic films. In measurement of the thermal stability of the magnetic recording medium, a head is used, the head includes a read / write element, and a write track width is twice or more as large as a read track width in the head.

Owner:WD MEDIA SINGAPORE PTE

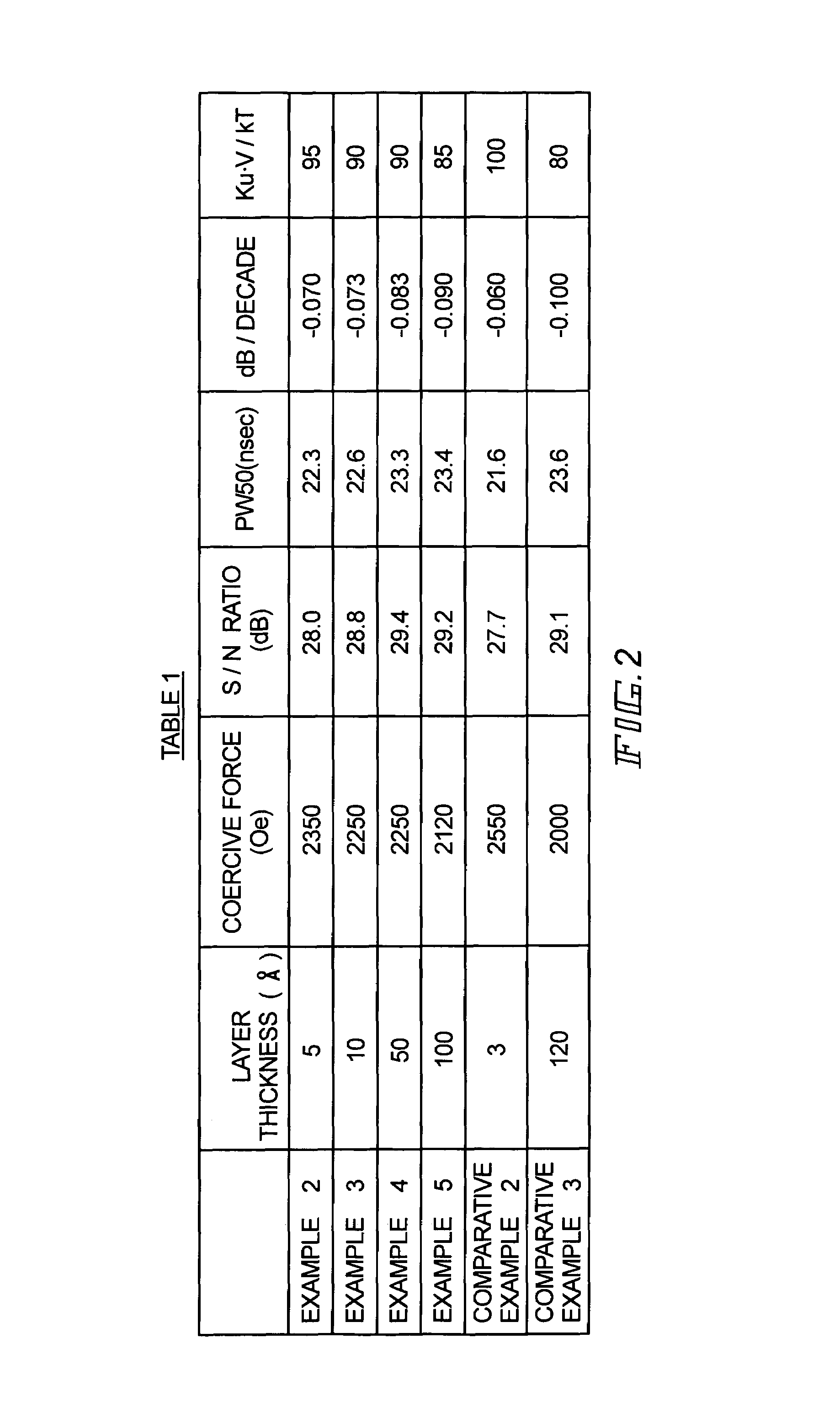

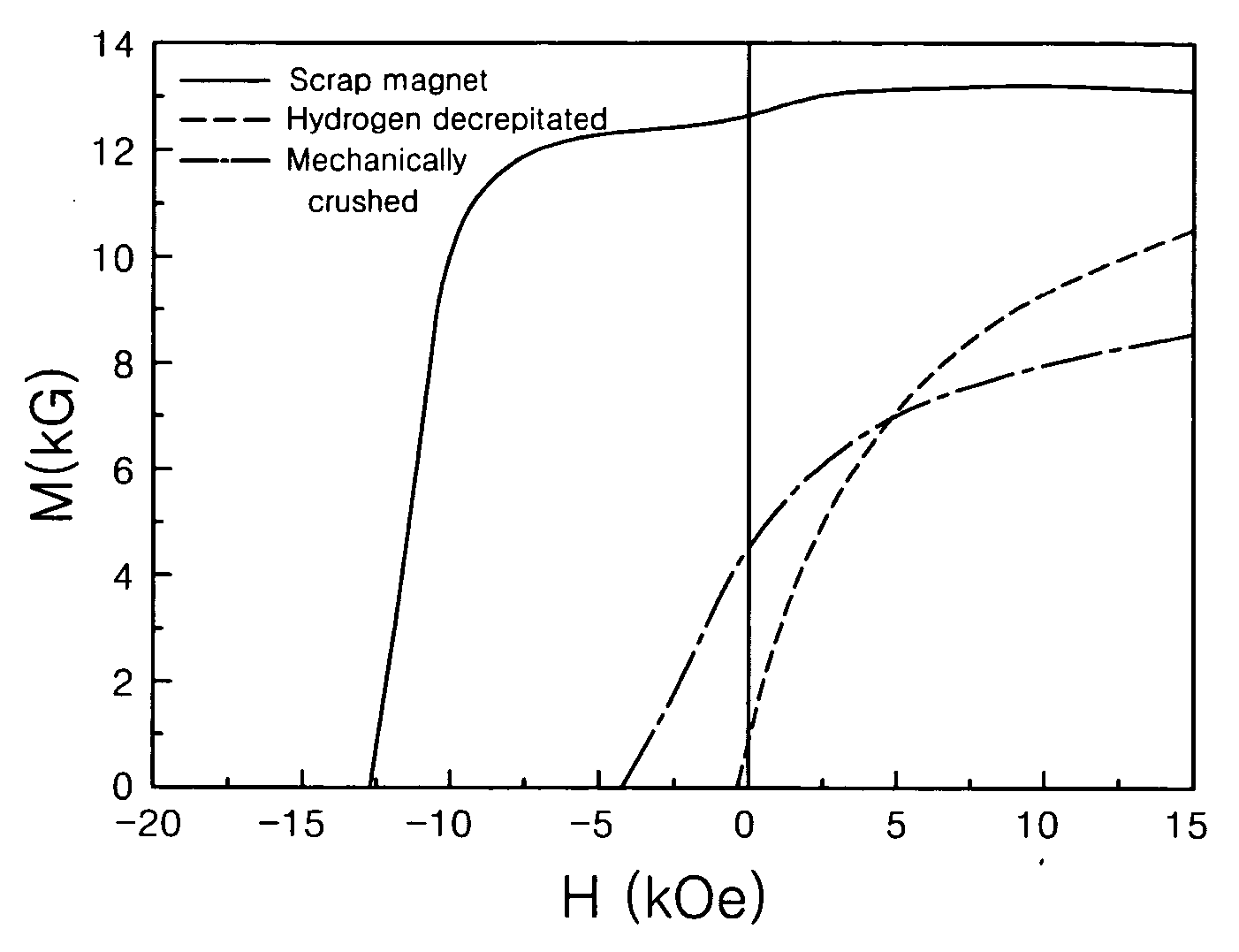

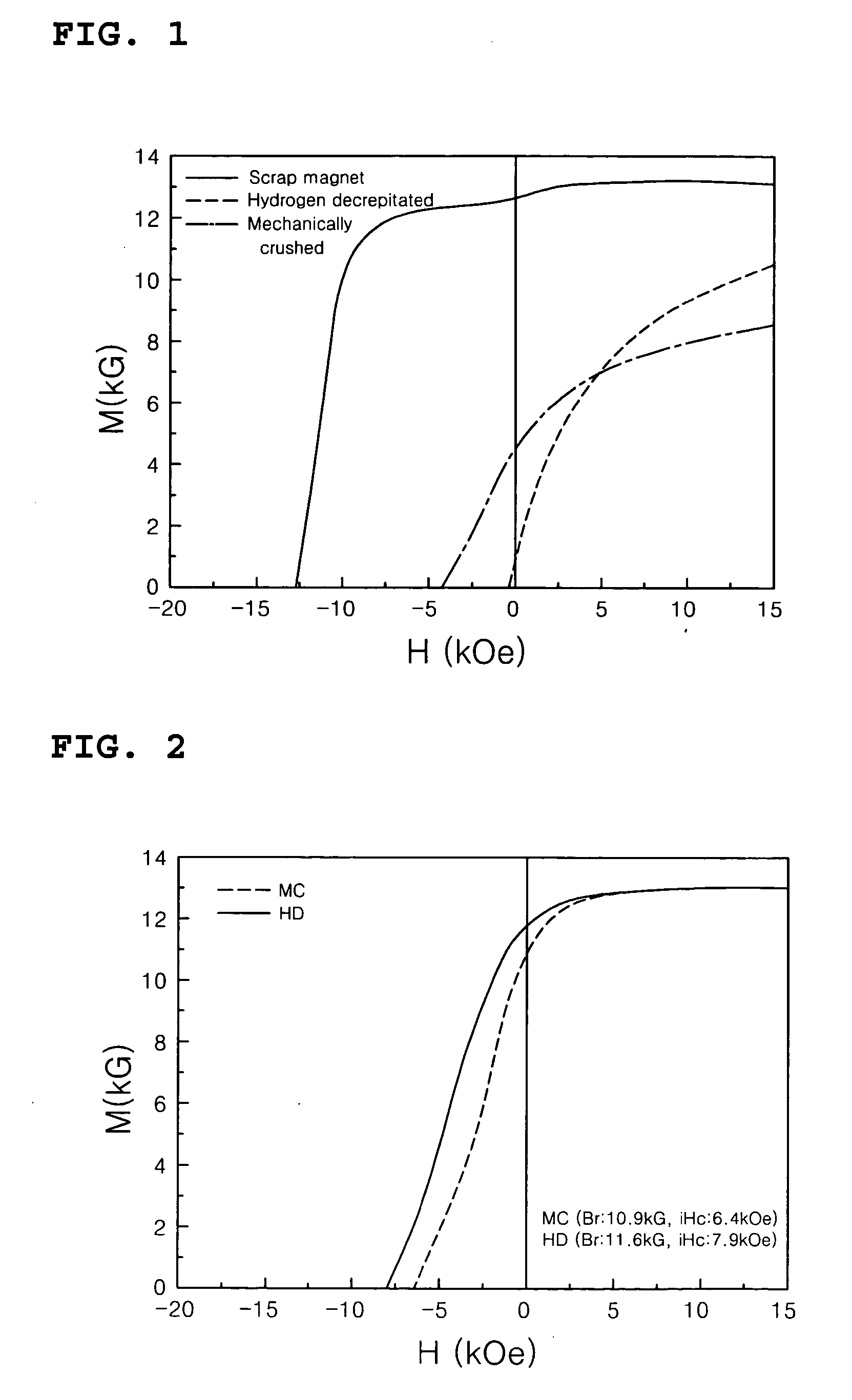

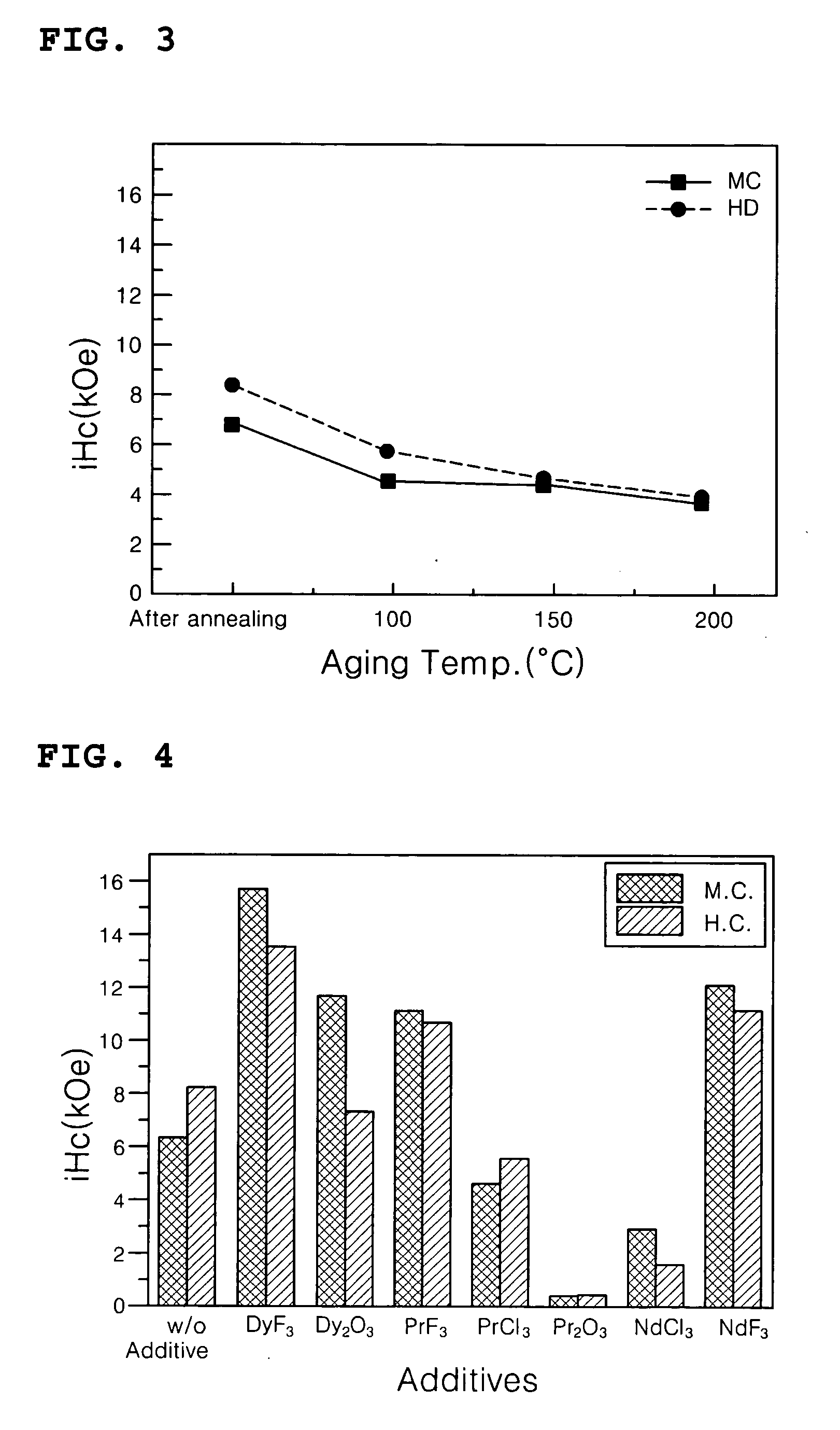

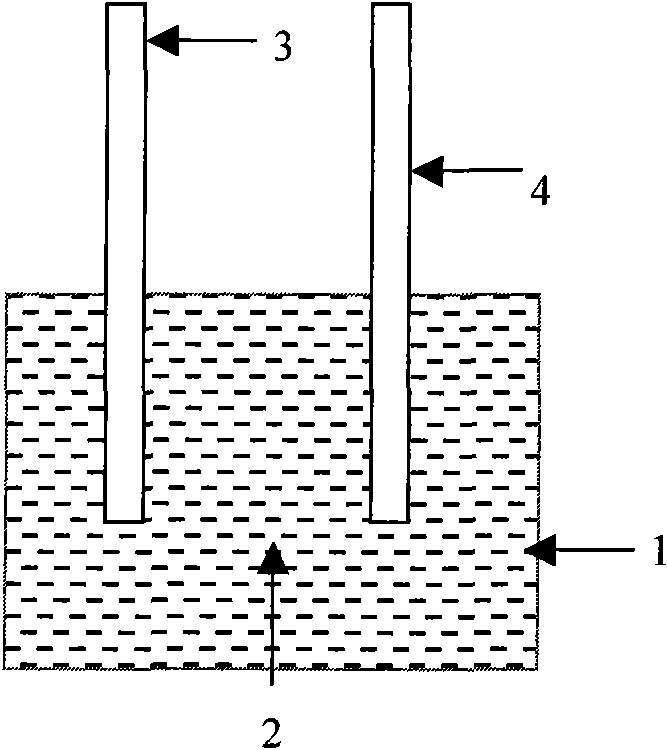

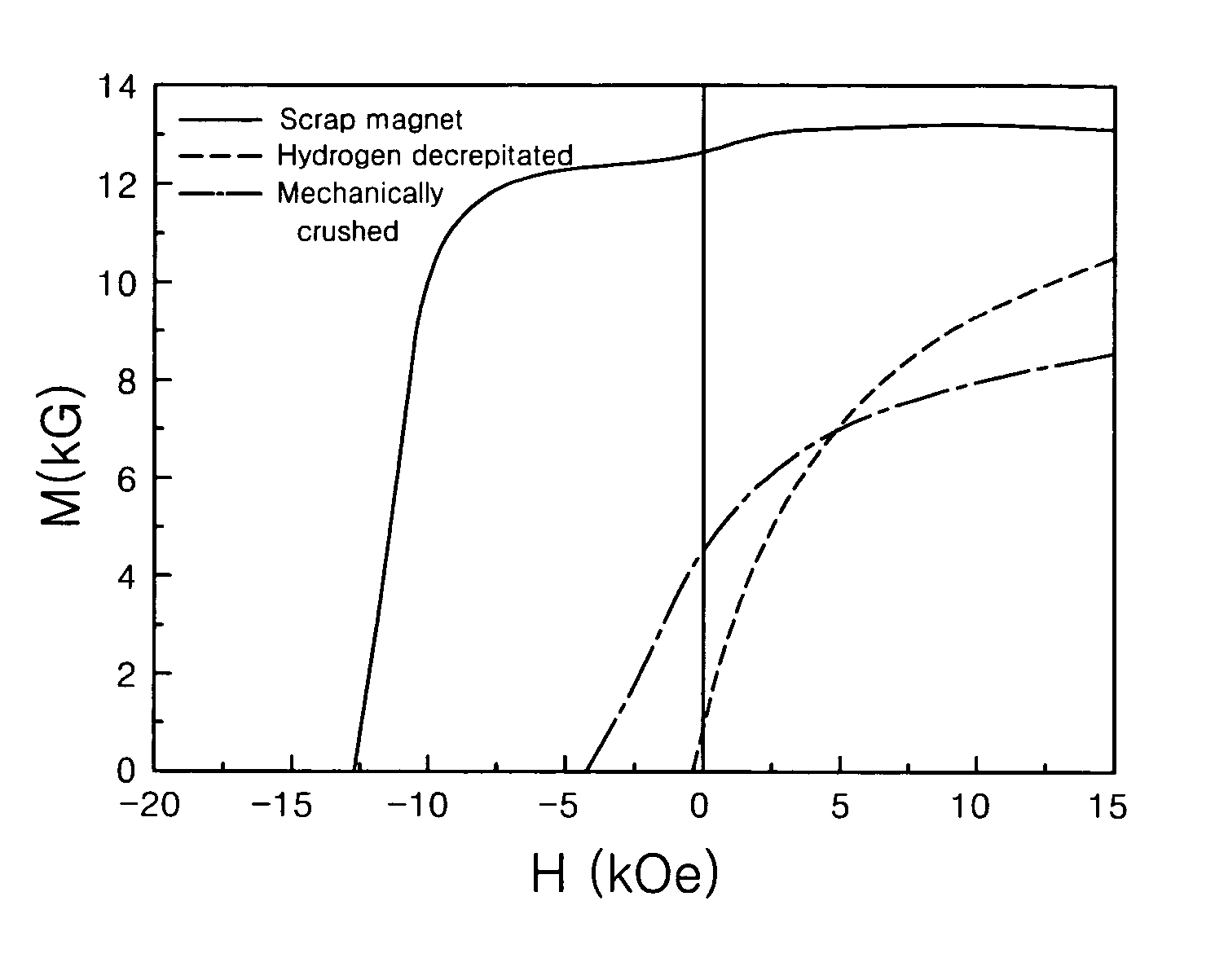

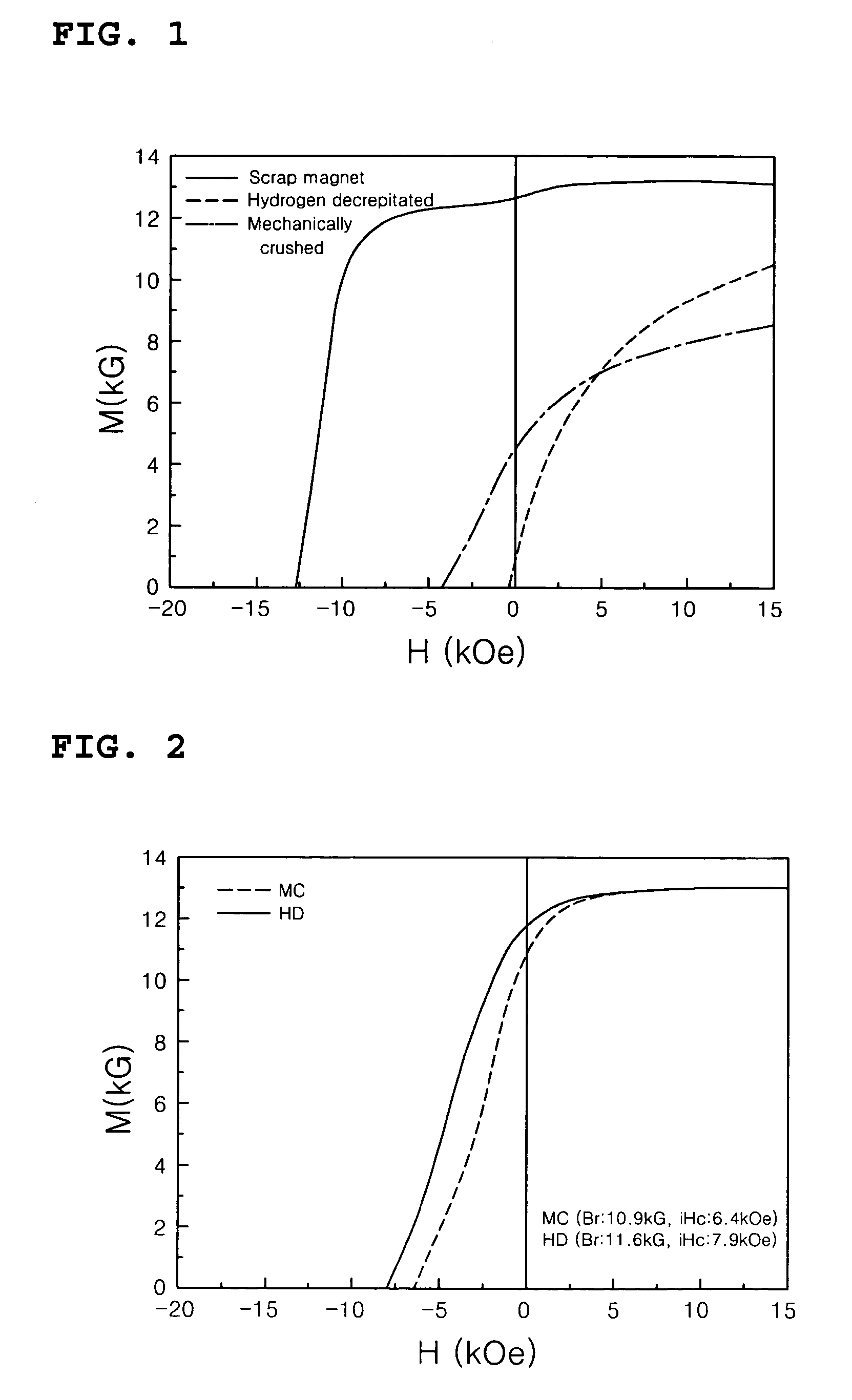

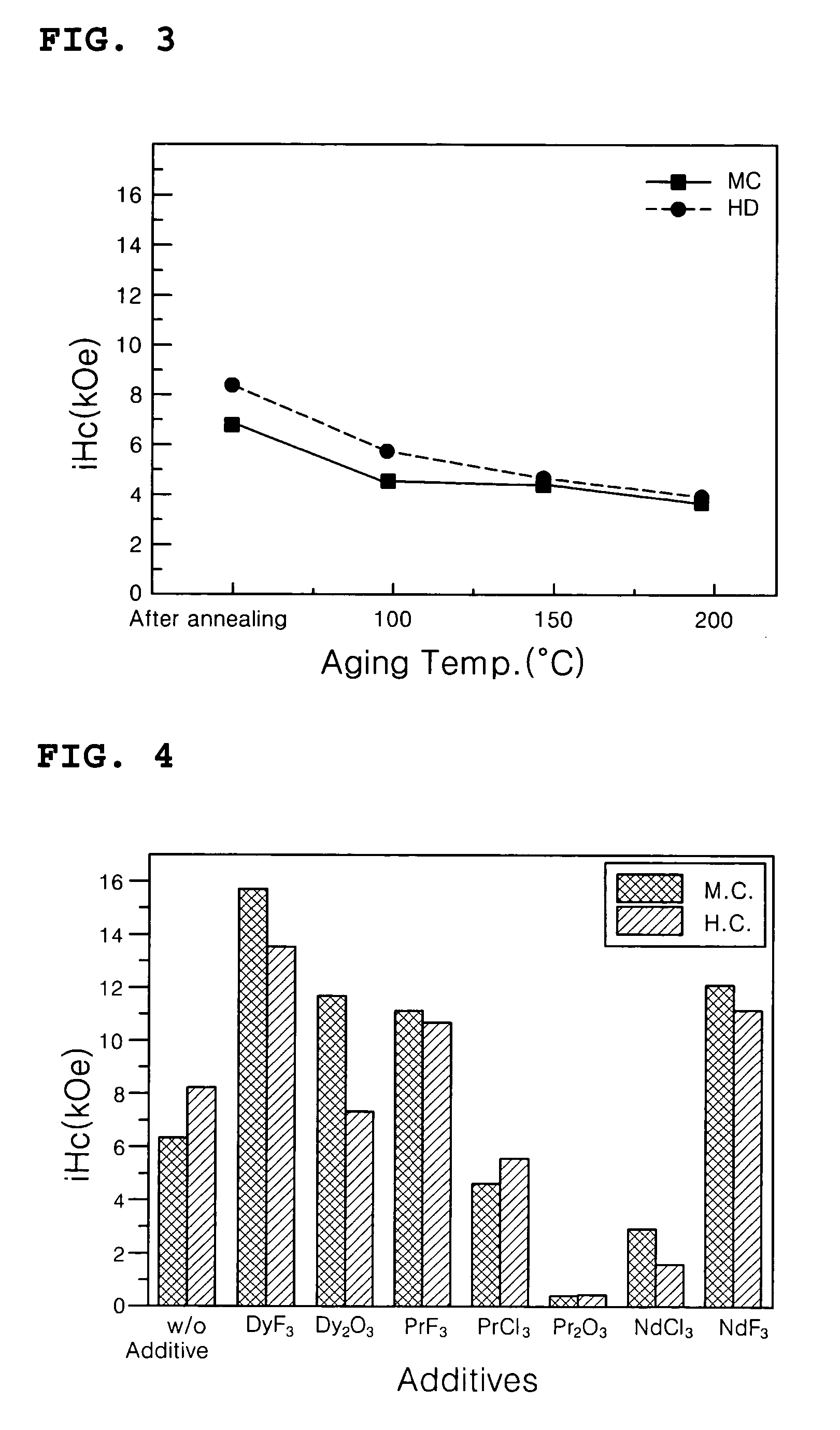

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

InactiveUS20050081959A1Reduce manufacturing costSimplified mass productionInorganic material magnetismRare earthGrain boundary

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50-500 μm sized magnet powders, which are then mixed with 1-10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500-1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1-20 μm, and the powders have an average size of 50-500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

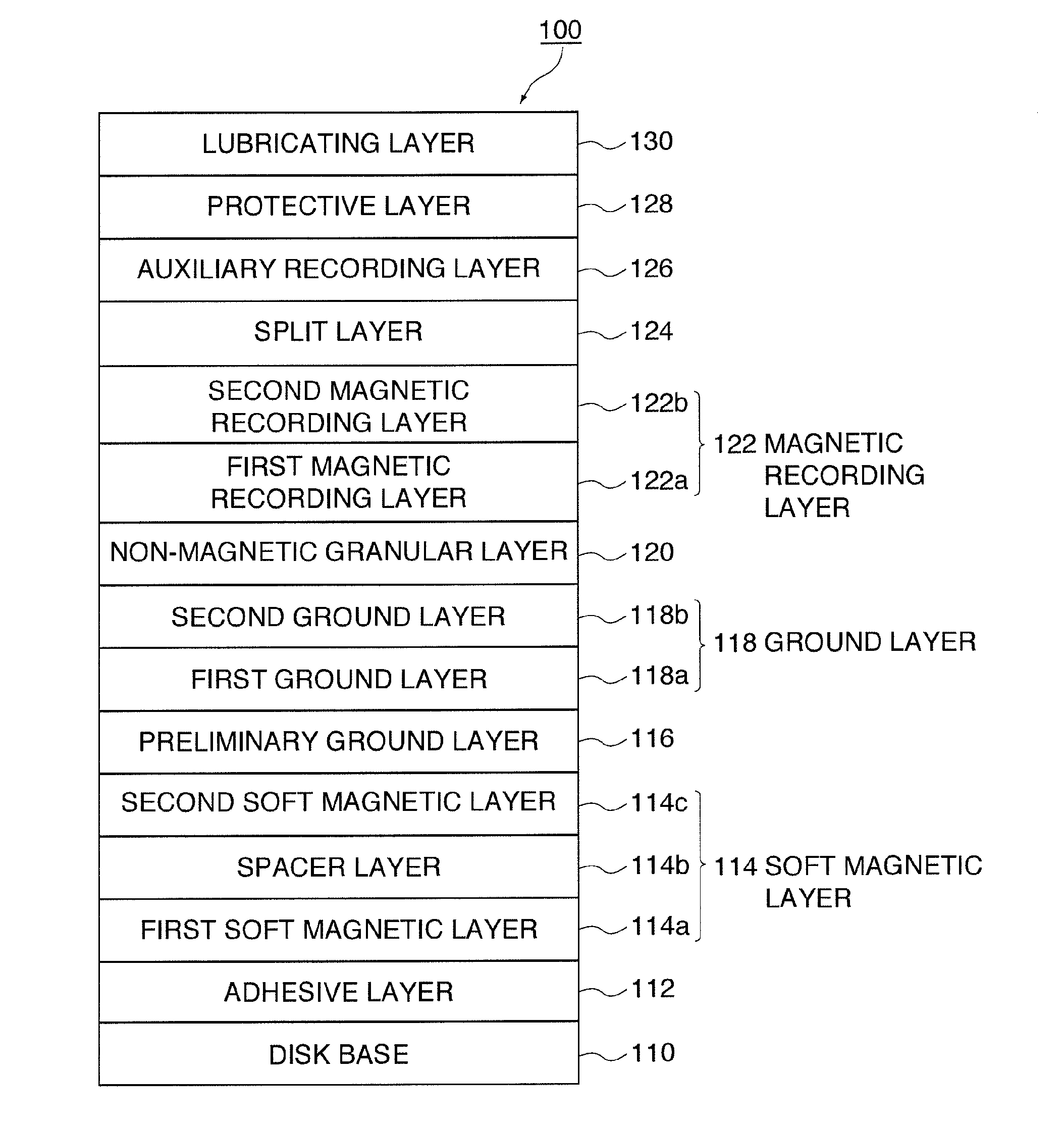

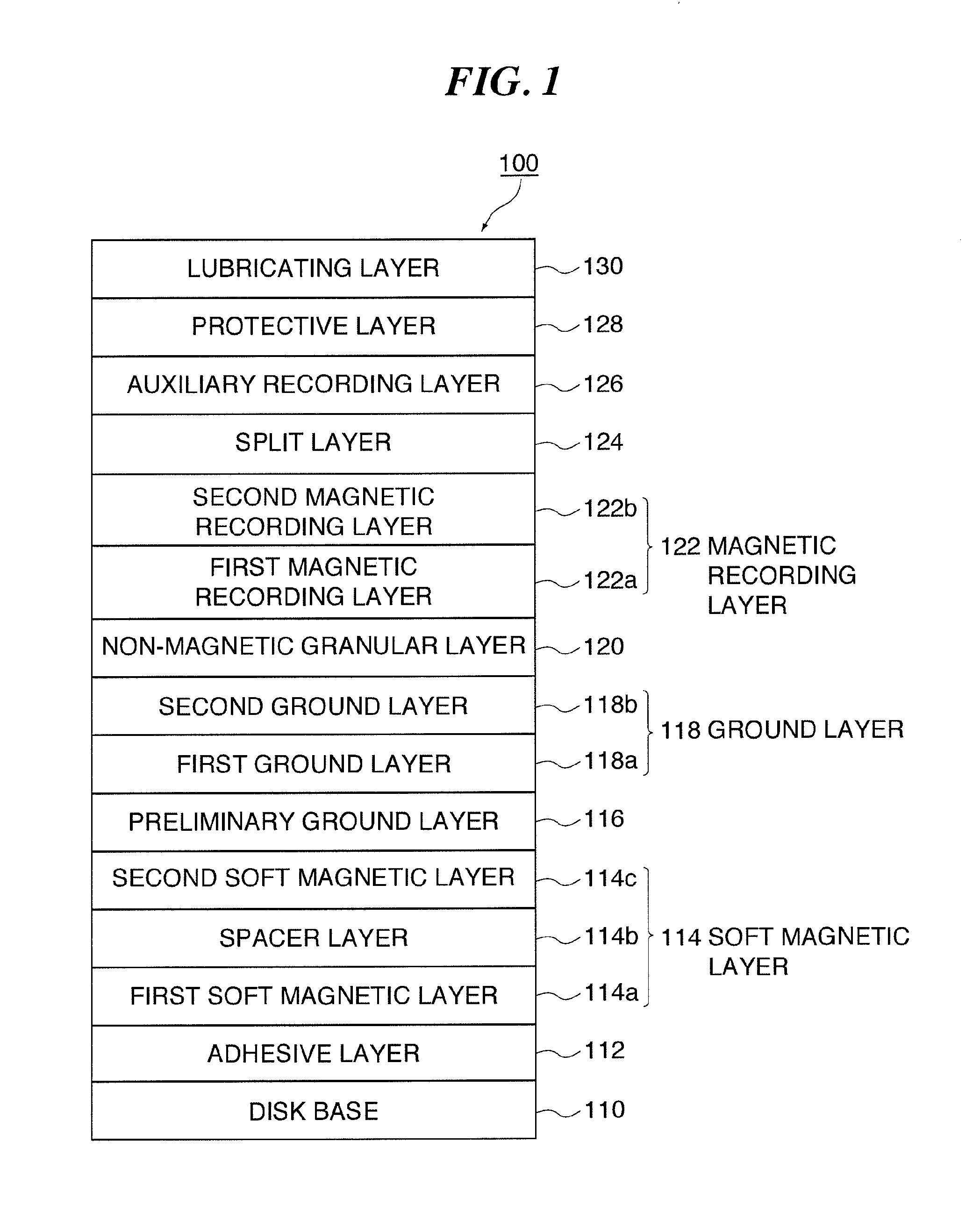

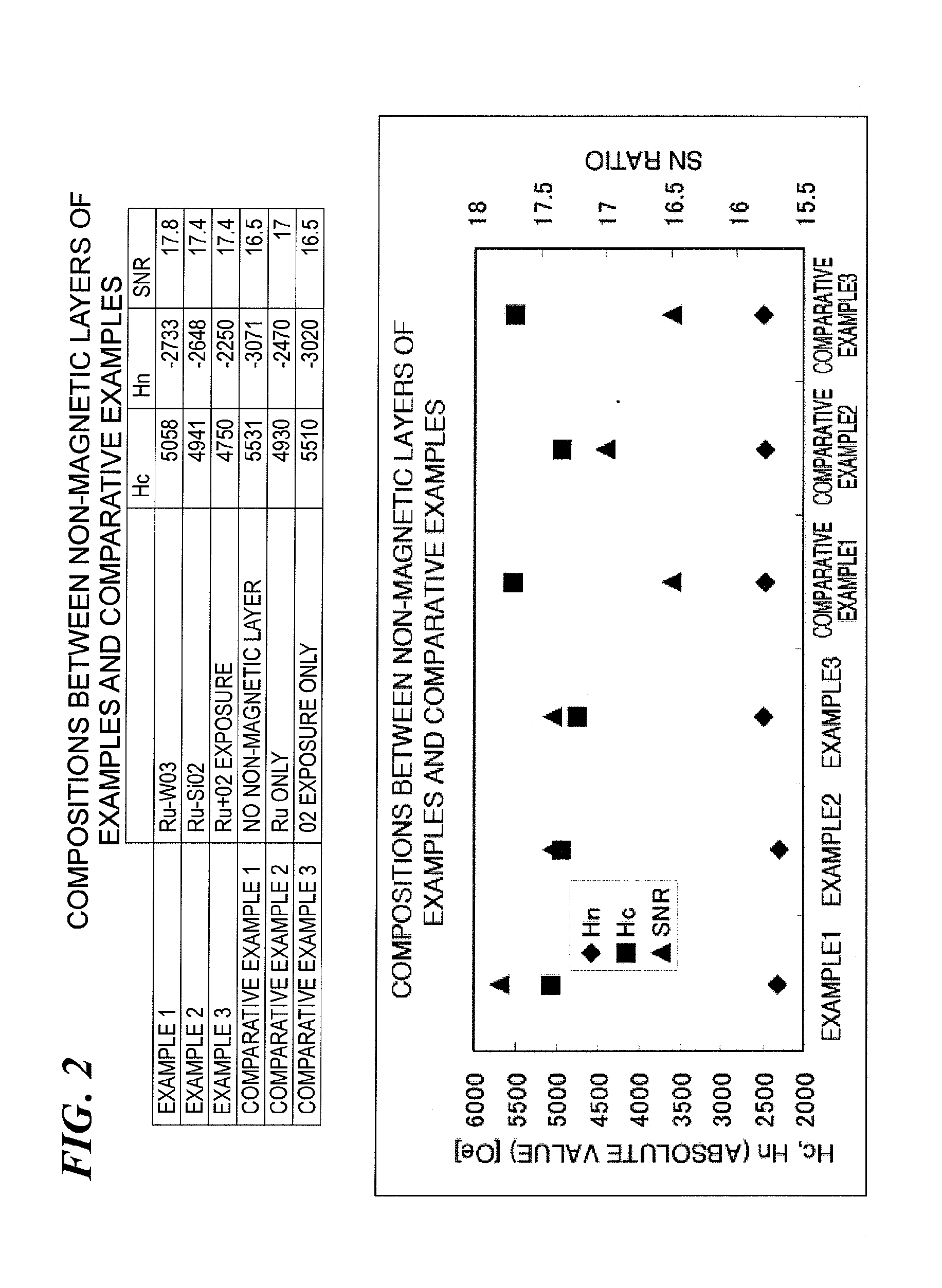

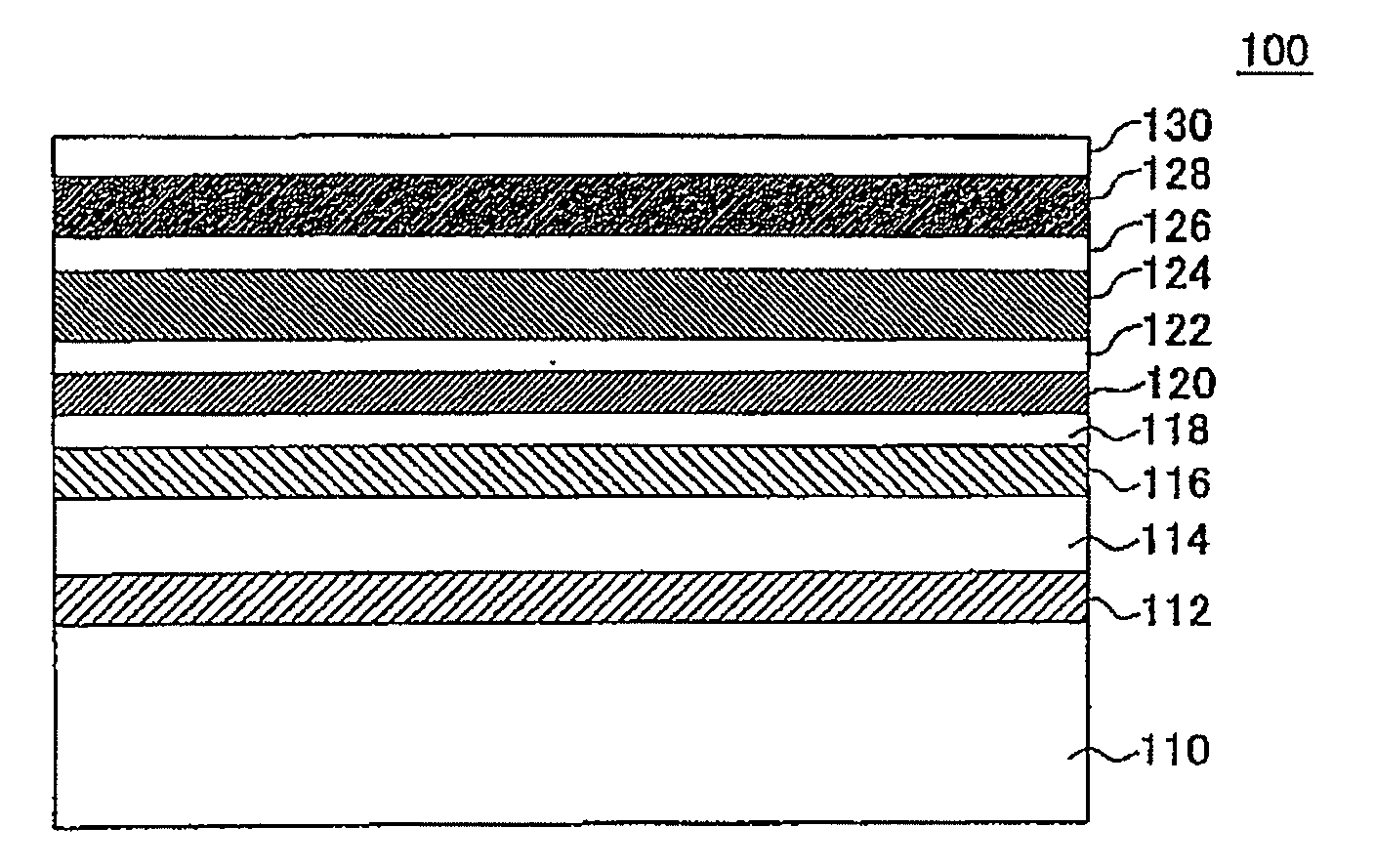

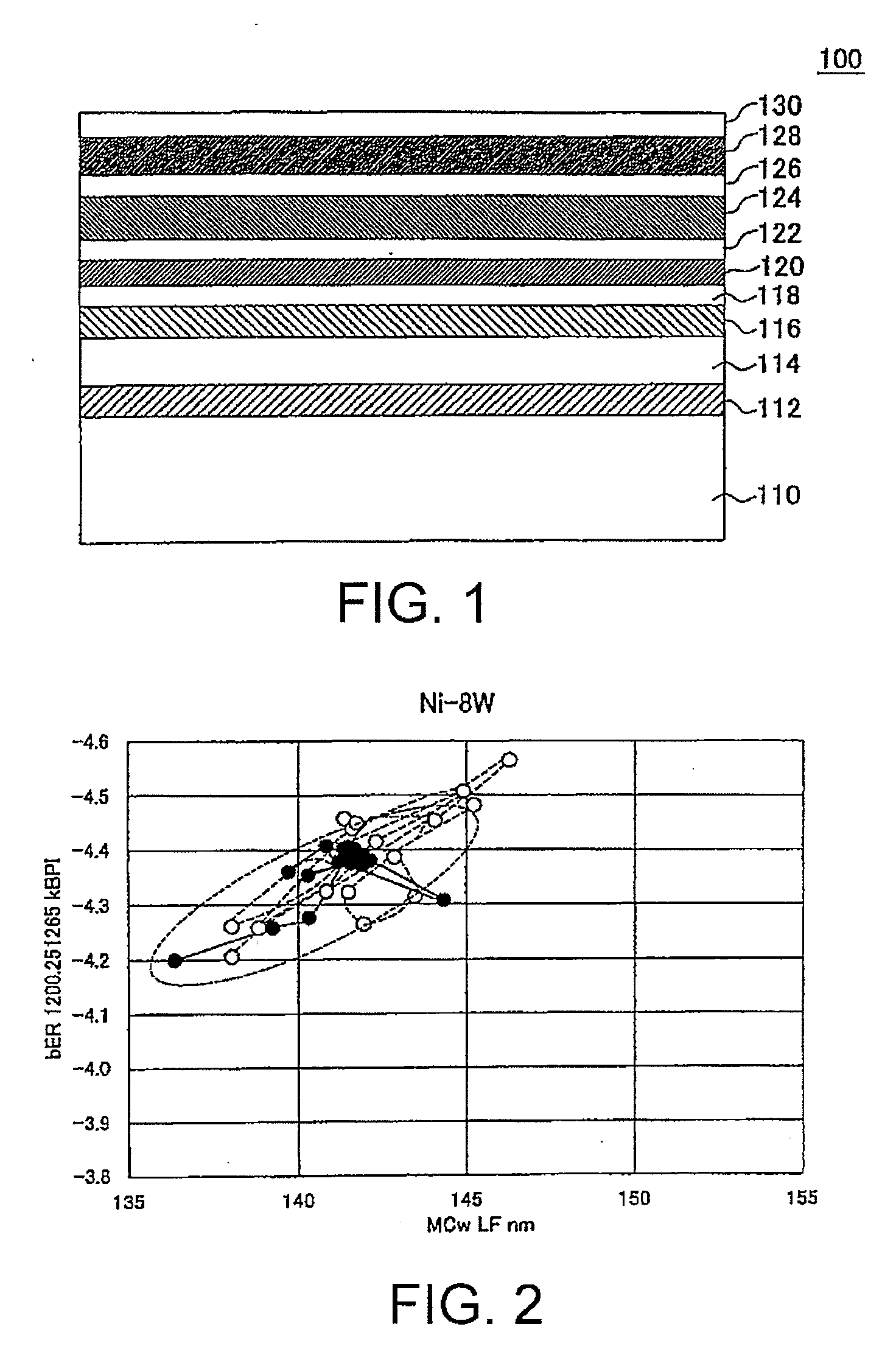

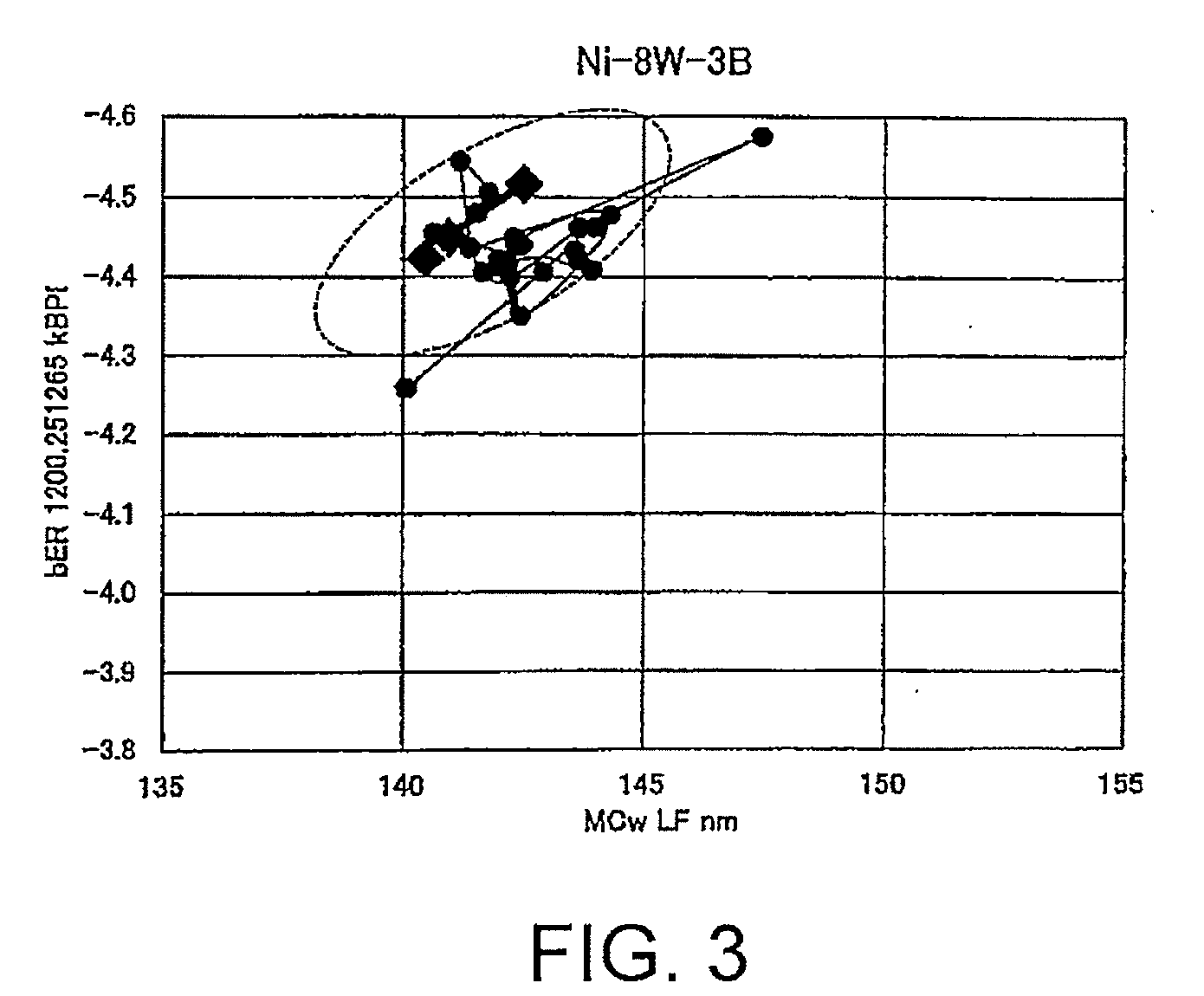

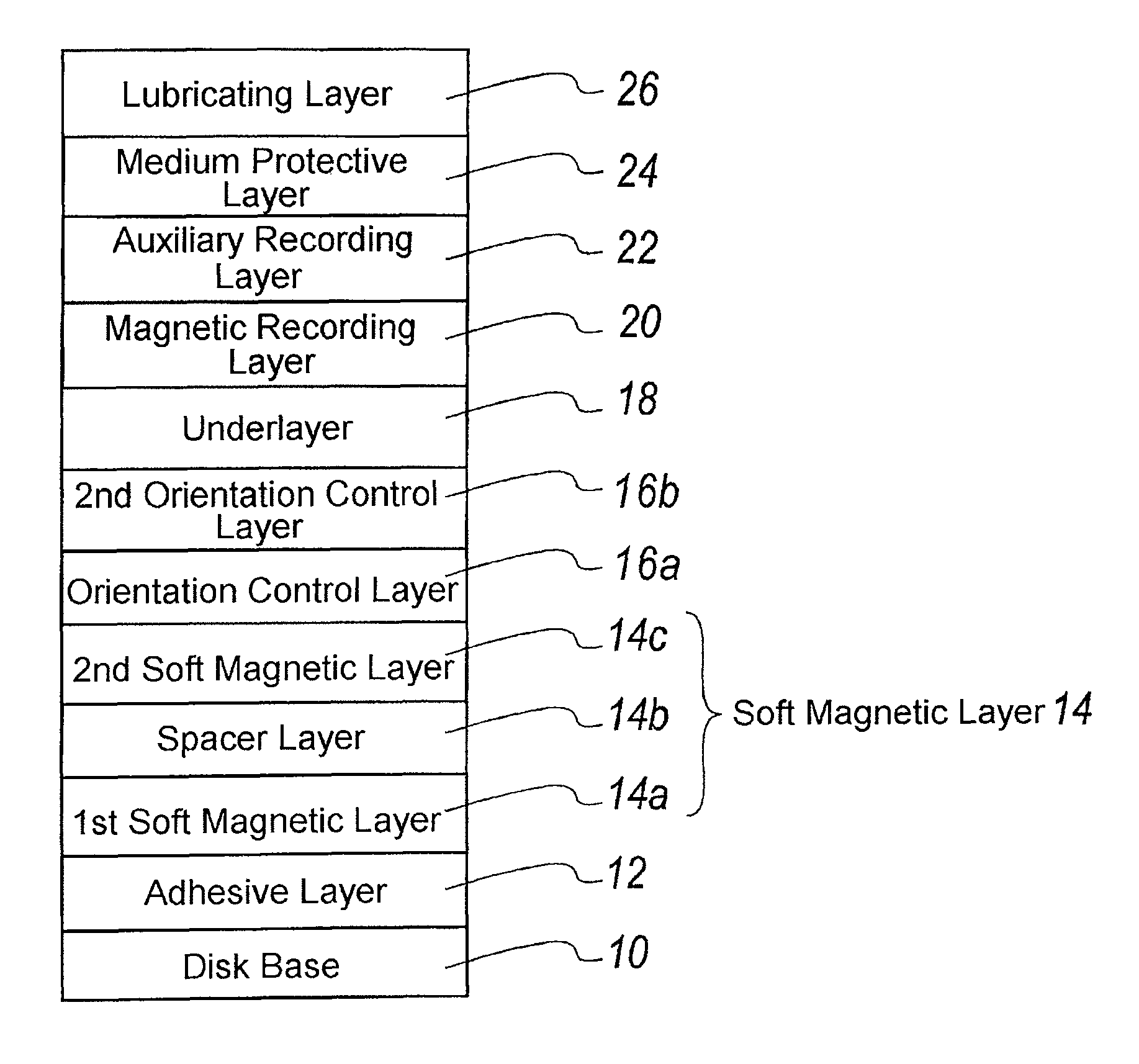

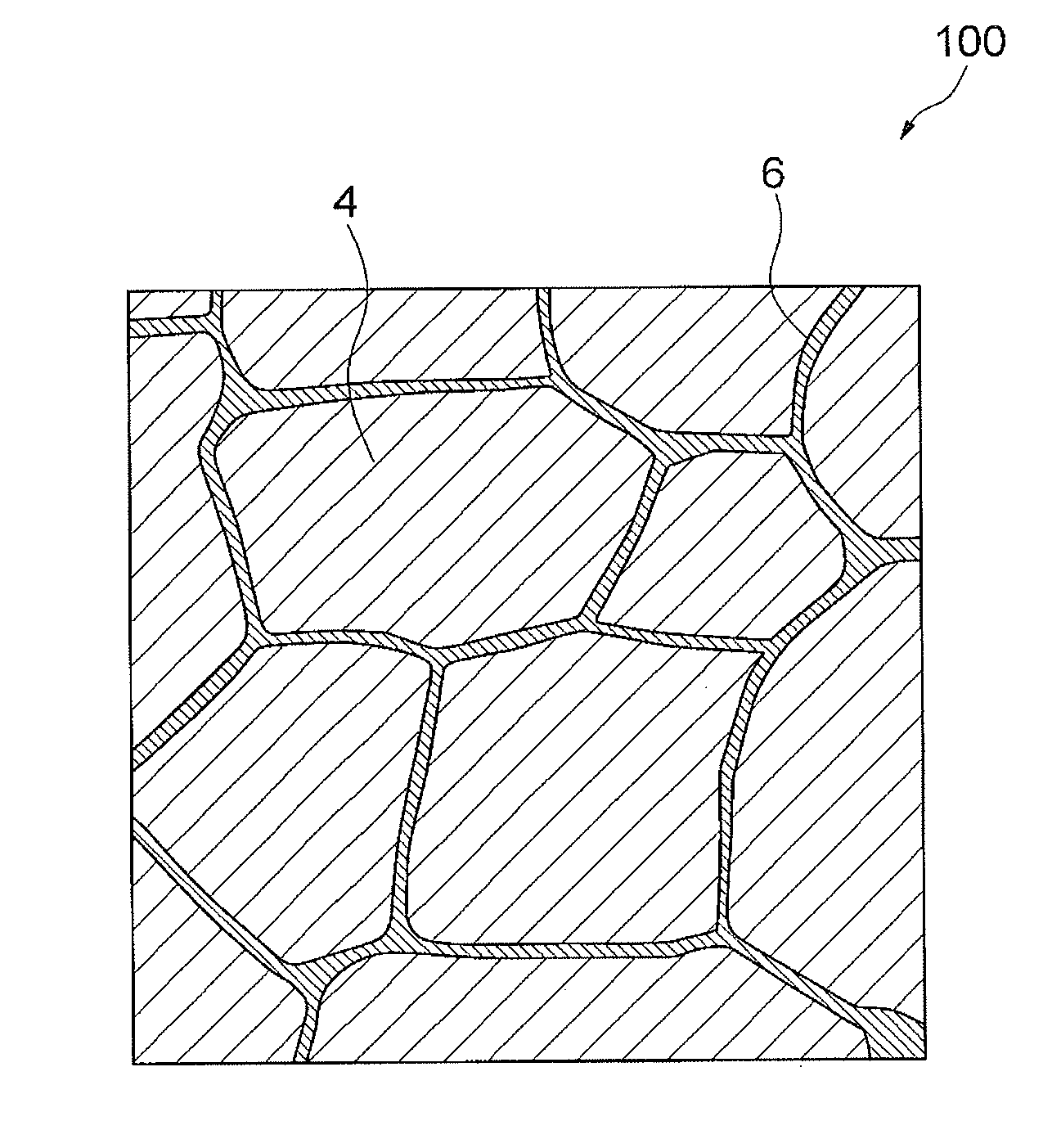

Perpendicular magnetic recording medium and process for manufacture thereof

ActiveUS20110212346A1Improve coercive forceIncrease forceProtective coatings for layersPretreated surfacesIn planeRecording density

An object of the present invention is to provide a perpendicular magnetic recording medium the SNR of which is improved by reducing noise thought to be due to an auxiliary recording layer so that a higher recording density can be achieved, and a method of manufacturing the same.In order to achieve the above object, a representative configuration of a perpendicular magnetic recording medium 100 according to the present invention includes, on a base, at least a magnetic recording layer 122 having a granular structure in which a non-magnetic grain boundary portion is formed between crystal particles grown in a columnar shape; a non-magnetic split layer 124 disposed on the magnetic recording layer 122 and containing Ru and oxygen; and an auxiliary recording layer 126 that is disposed on the split layer 124 and that is magnetically approximately continuous in an in-plane direction of a main surface of the base 110.

Owner:WESTERN DIGITAL TECH INC

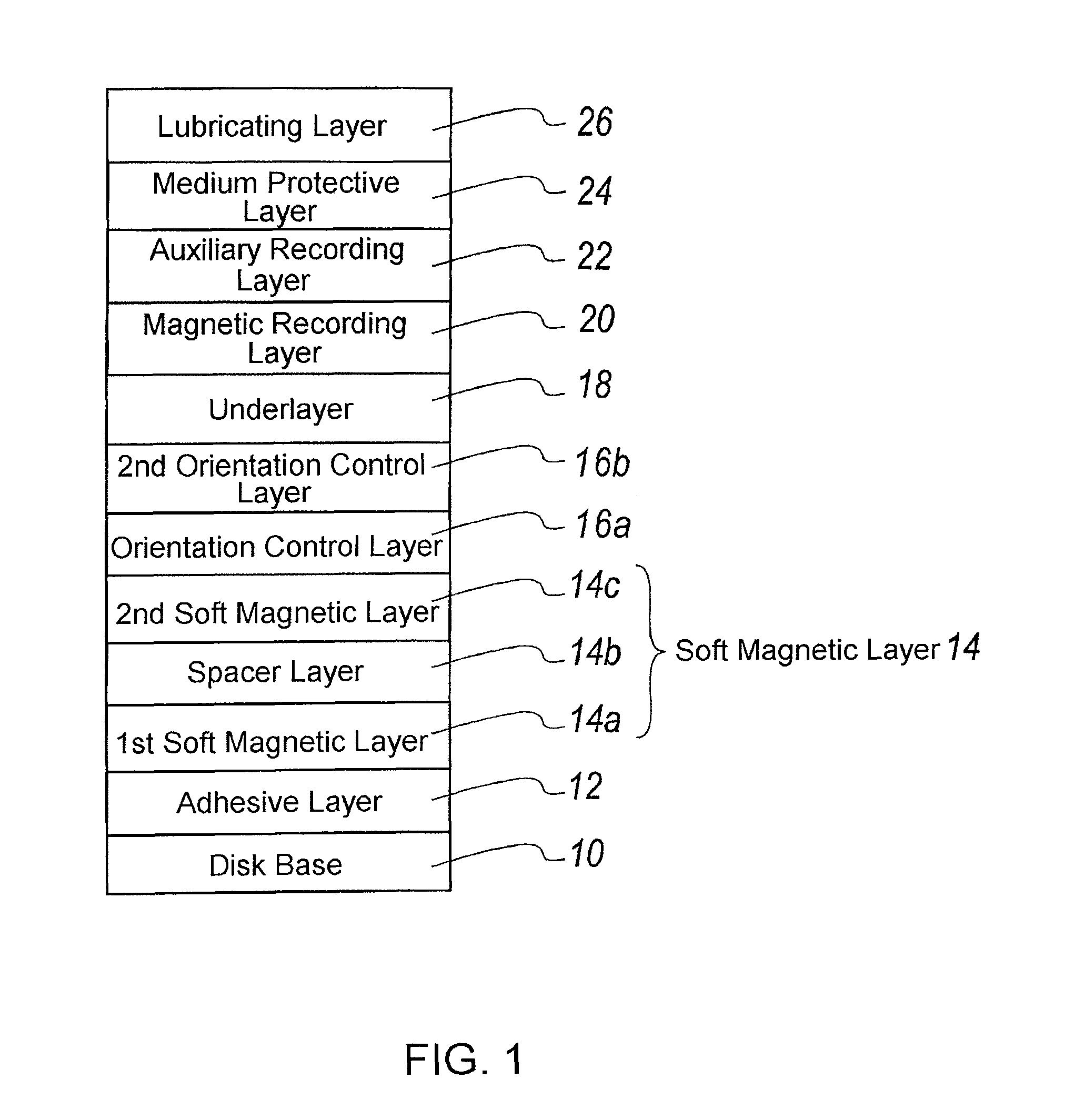

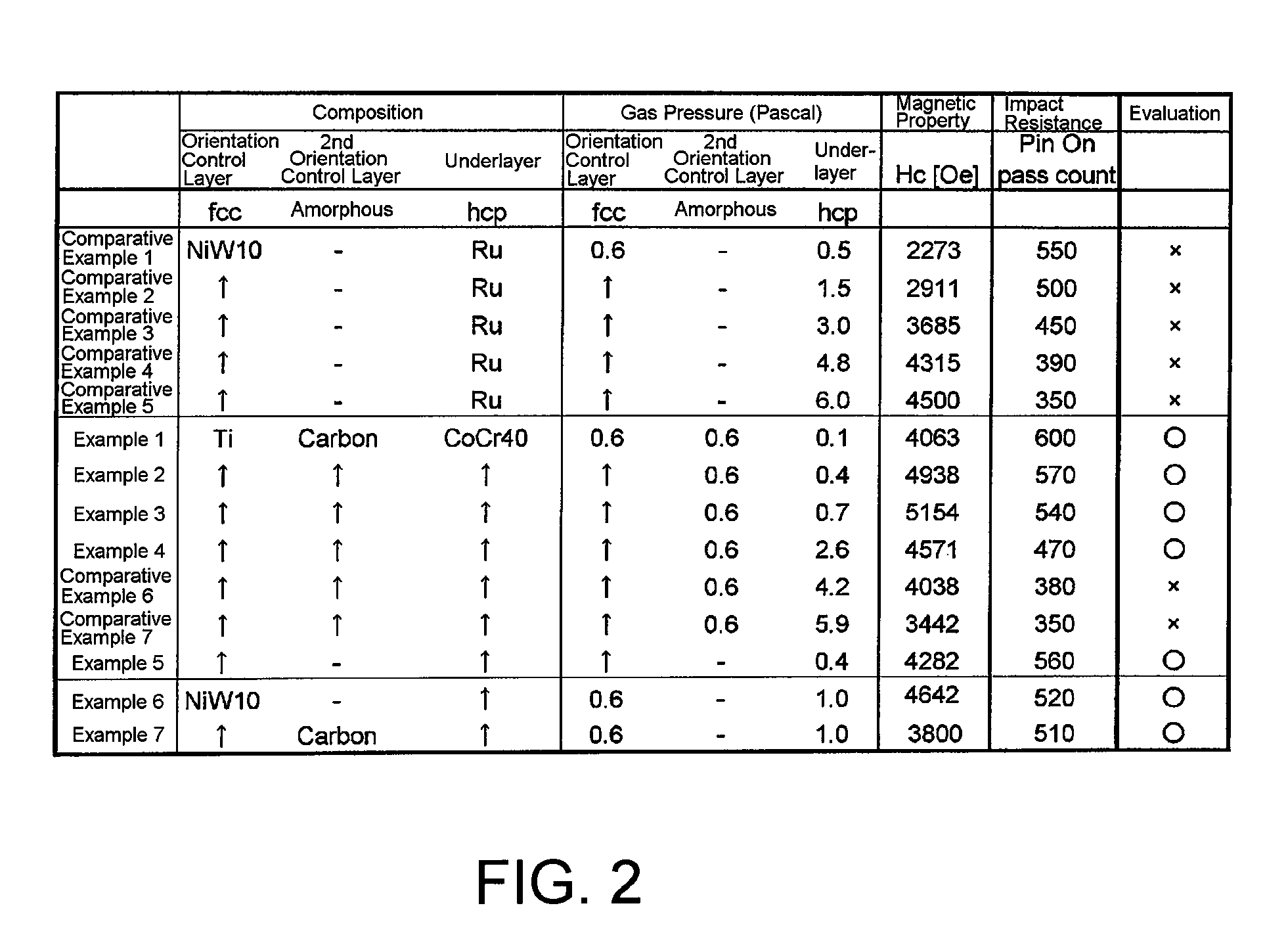

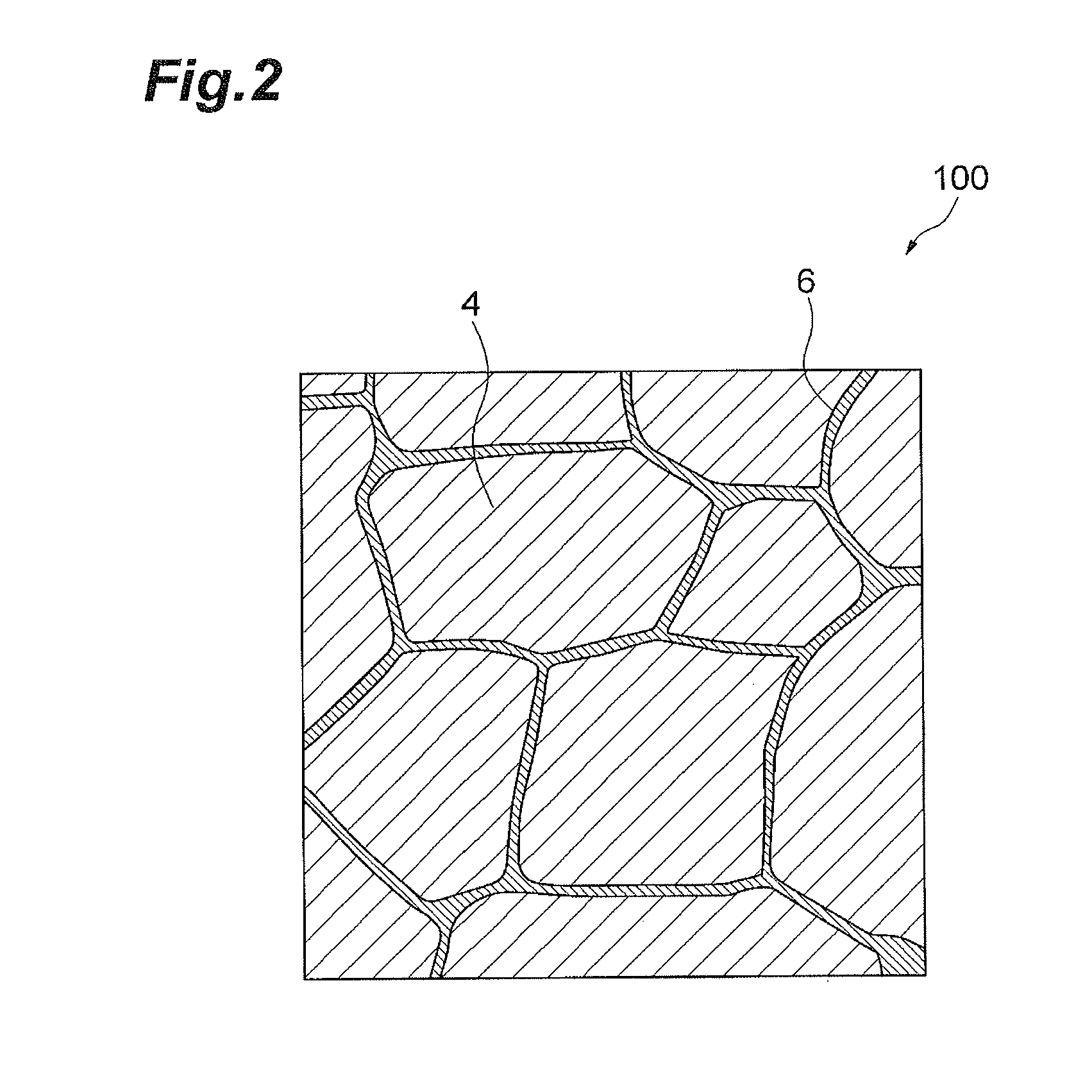

Perpendicular magnetic recording medium and method of manufacturing the same

ActiveUS20100279151A1Improve recording densityImprove coercive forceRecord information storageCoatingsOptoelectronicsRecording layer

A perpendicular magnetic recording medium includes a substrate, a soft magnetic layer, a pre-underlayer, an underlayer, and a main recording layer serving as a magnetic recording layer. The pre-underlayer contains seed crystal grains that serve as a base for crystal grains of the underlayer, and an addition substance that is added between the seed crystal grains and composed of an element having an atomic radius smaller than that of an element forming the seed crystal grains.

Owner:WESTERN DIGITAL TECH INC

Method of manufacturing a perpendicular magnetic recording medium

ActiveUS8298689B2Improve coercive forceImprove recording densityRecord information storageCoating by sputteringForming gasRecording layer

Owner:WESTERN DIGITAL TECH INC

Method for improving performance of sintered Nd-Fe-B permanent magnetic material

ActiveCN101615459AEvenly distributed and orderlySolve bad problems such as α-Fe segregationInorganic material magnetismHigh energyPositive pressure

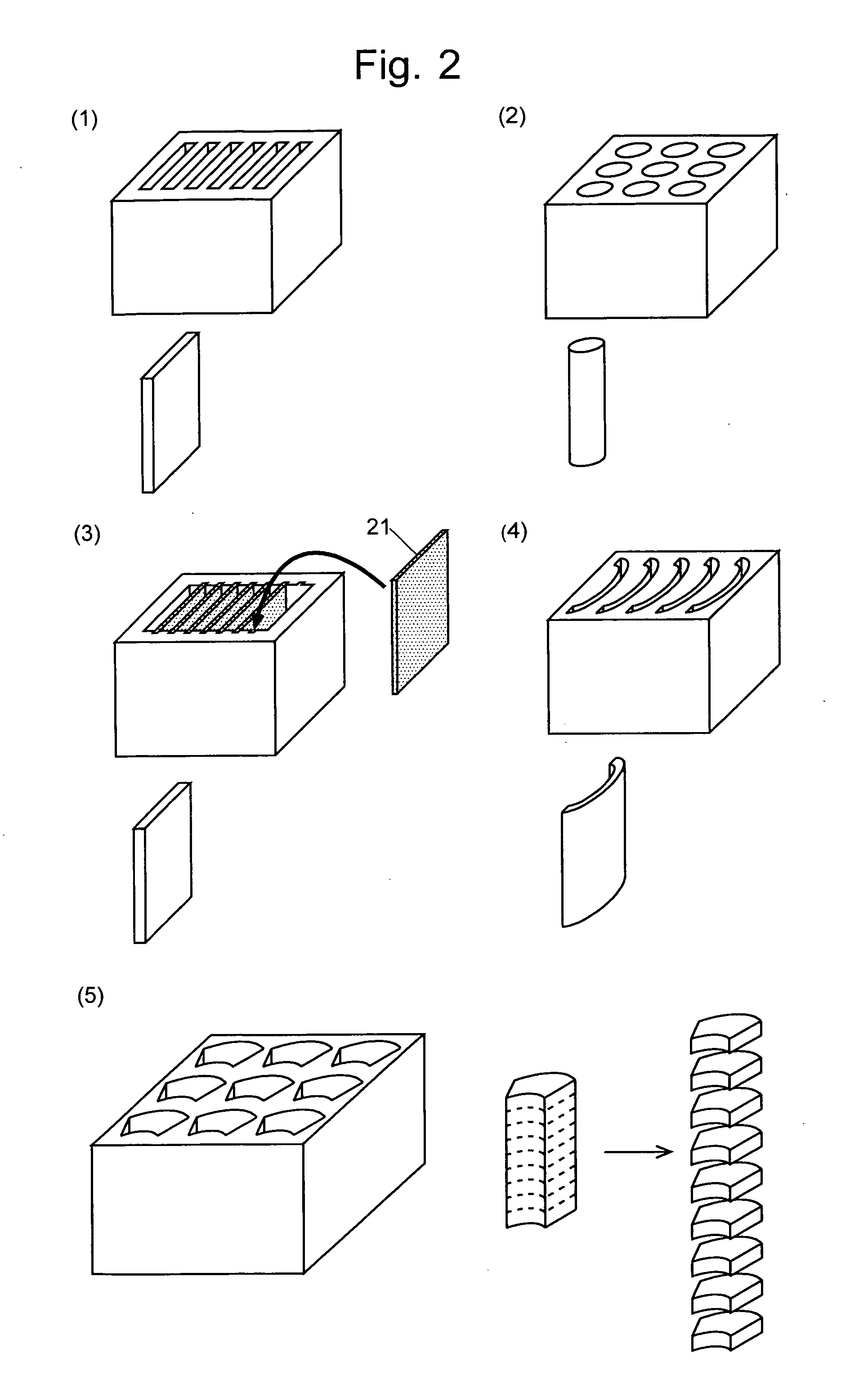

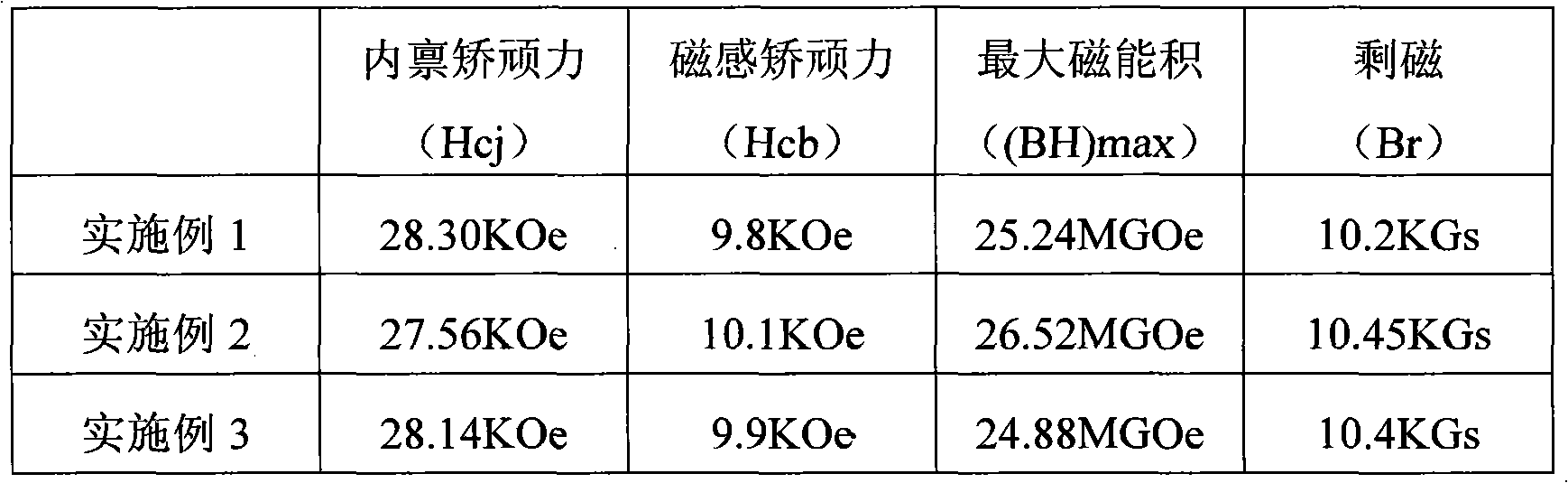

The invention relates to a method for improving performance of sintered Nd-Fe-B permanent magnetic property by a rapid-hardening flake grain boundary diffusion heavy rare earth compound in rare earth material technical field, which comprises the following steps: 1) rapid-hardening technology is adopted to prepare an Nd-Fe-B alloy rapid-hardening flake; 2) a high-energy ball mill is used to prepare the heavy rare earth compound into powder particles with diameter being smaller than 1mu m; 3) the rapid-hardening flake is put into heavy rare earth compound turbid liquid to carry out ultrasonic coating; 4) the coated rapid-hardening flake is put into a sintered furnace filled with Ar2 to carry out positive pressure thermal diffusion; 5) ball milling, powder processing, orientation shaping, isostatic pressing and vacuum sintering are adopted to prepare the strip-casting flake after the heat treatment into a magnet. The chemical formula of the Nd-Fe-B permanent magnetic material is NdxFe(100-x-y-z-xl)ByCozCuxl, and the mass percent is as follows: x is 30-31.5, y is 0.95-1, z is 1-1.2, and xl is 0-0.06. The magnet prepared by the invention improves the intrinsic coercivity on the basis of keeping the current magnetic energy product.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

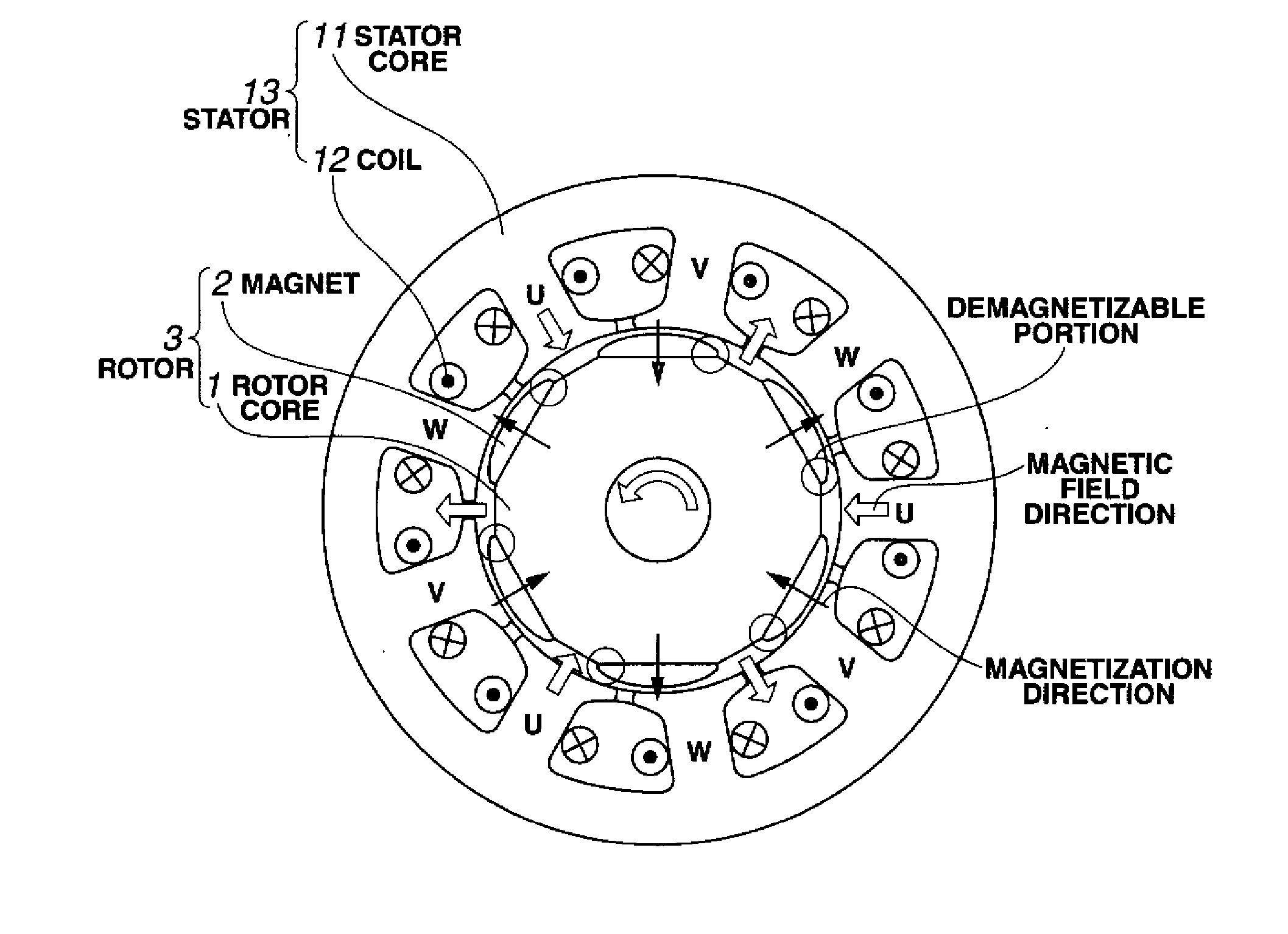

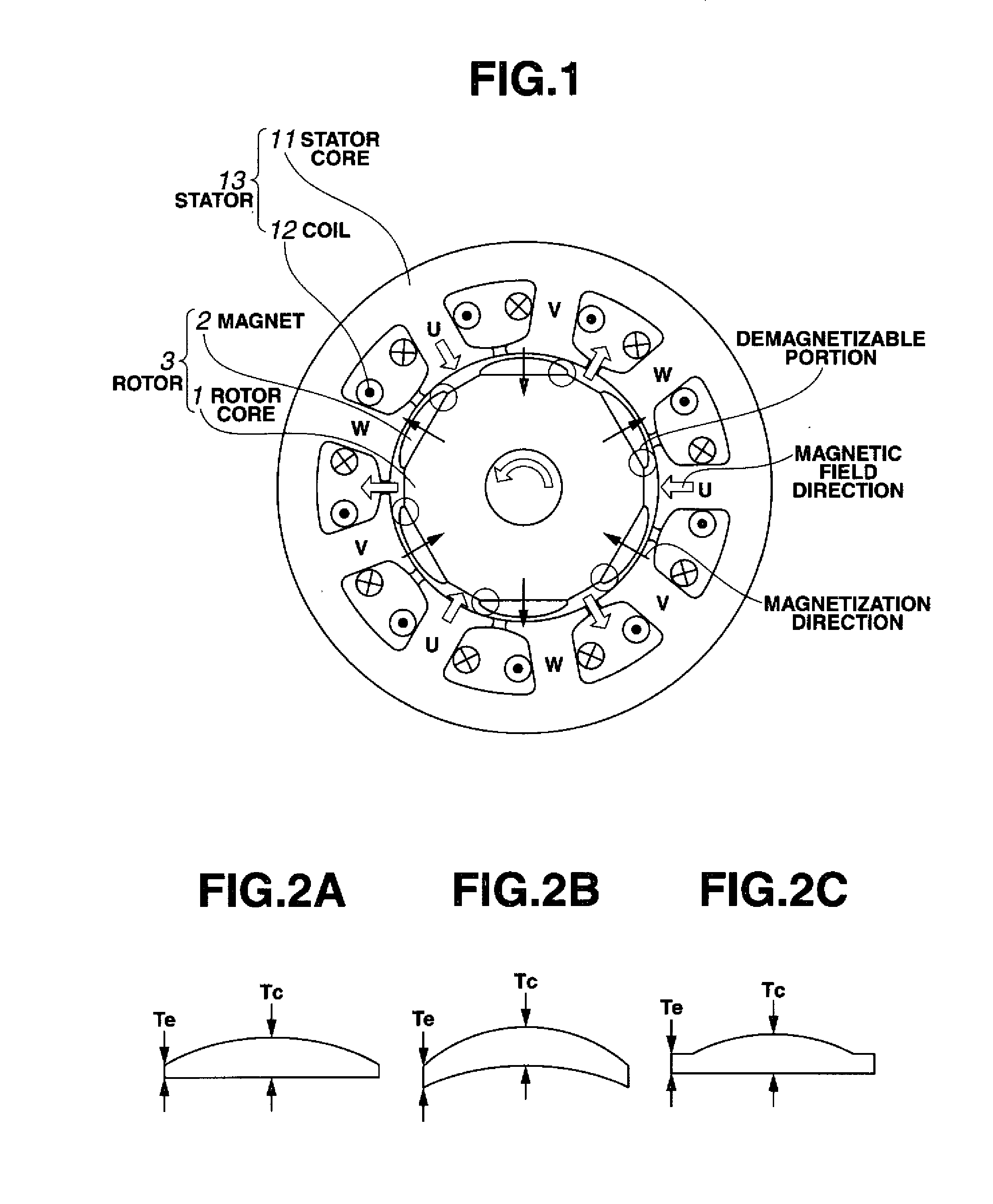

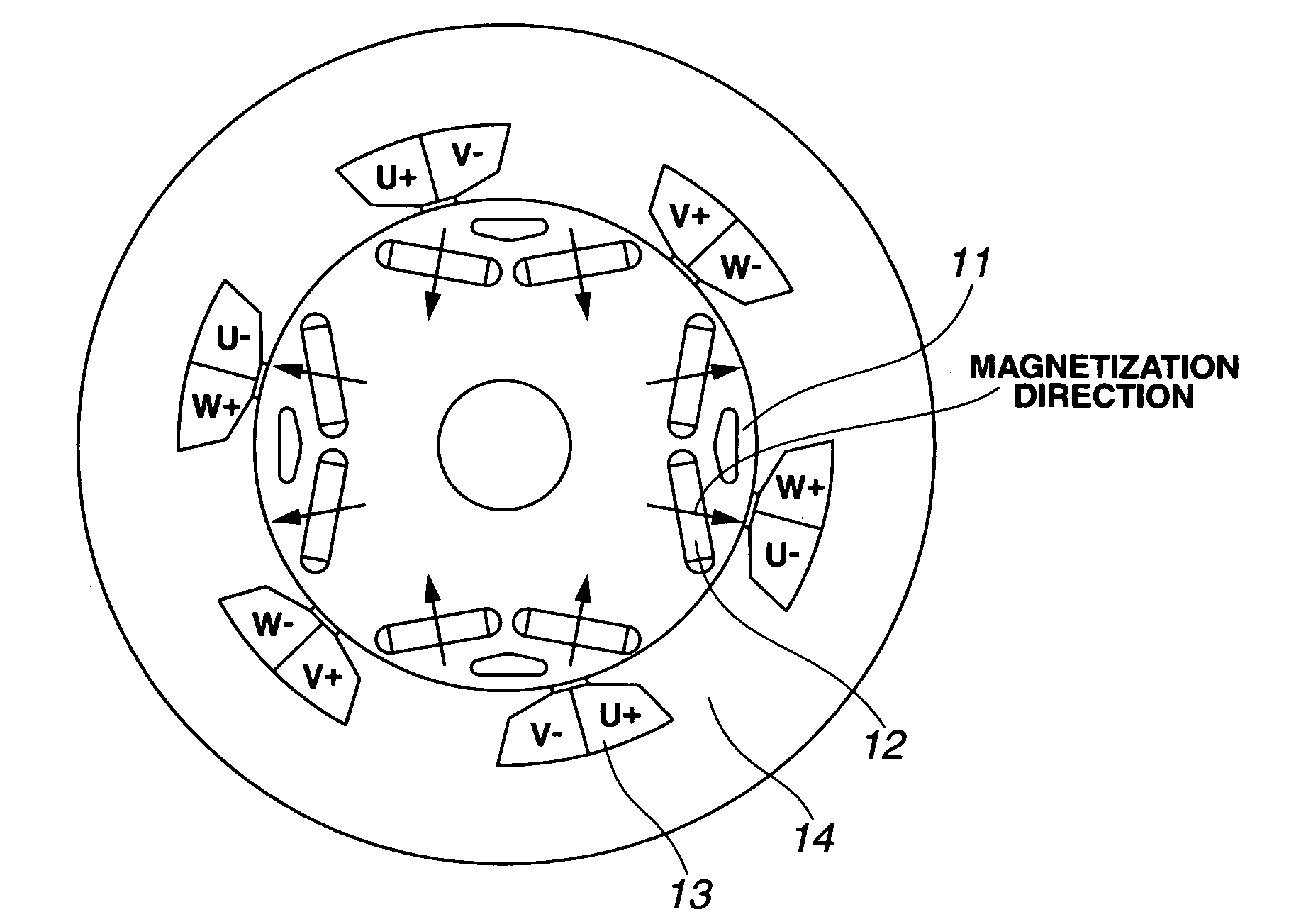

Permenent magnet rotating machine

ActiveUS20080054736A1Improve remanenceImprove coercive forceMagnetic circuit rotating partsManufacturing dynamo-electric machinesRare-earth elementSintered magnets

In a rotating machine comprising a rotor including a rotor core and a plurality of permanent magnet segments, and a stator including a stator core and windings, the permanent magnet segment is obtained by disposing a powder comprising an R2 oxide, R3 fluoride or R4 oxyfluoride on a sintered magnet body of R1—Fe—B composition, wherein R1 to R4 are rare earth elements, and heat treating the powder-covered magnet body. The permanent magnet segment of a cross-sectional shape which is tapered from the center toward opposed ends has a higher coercive force at the ends than at the center.

Owner:SHIN ETSU CHEM IND CO LTD

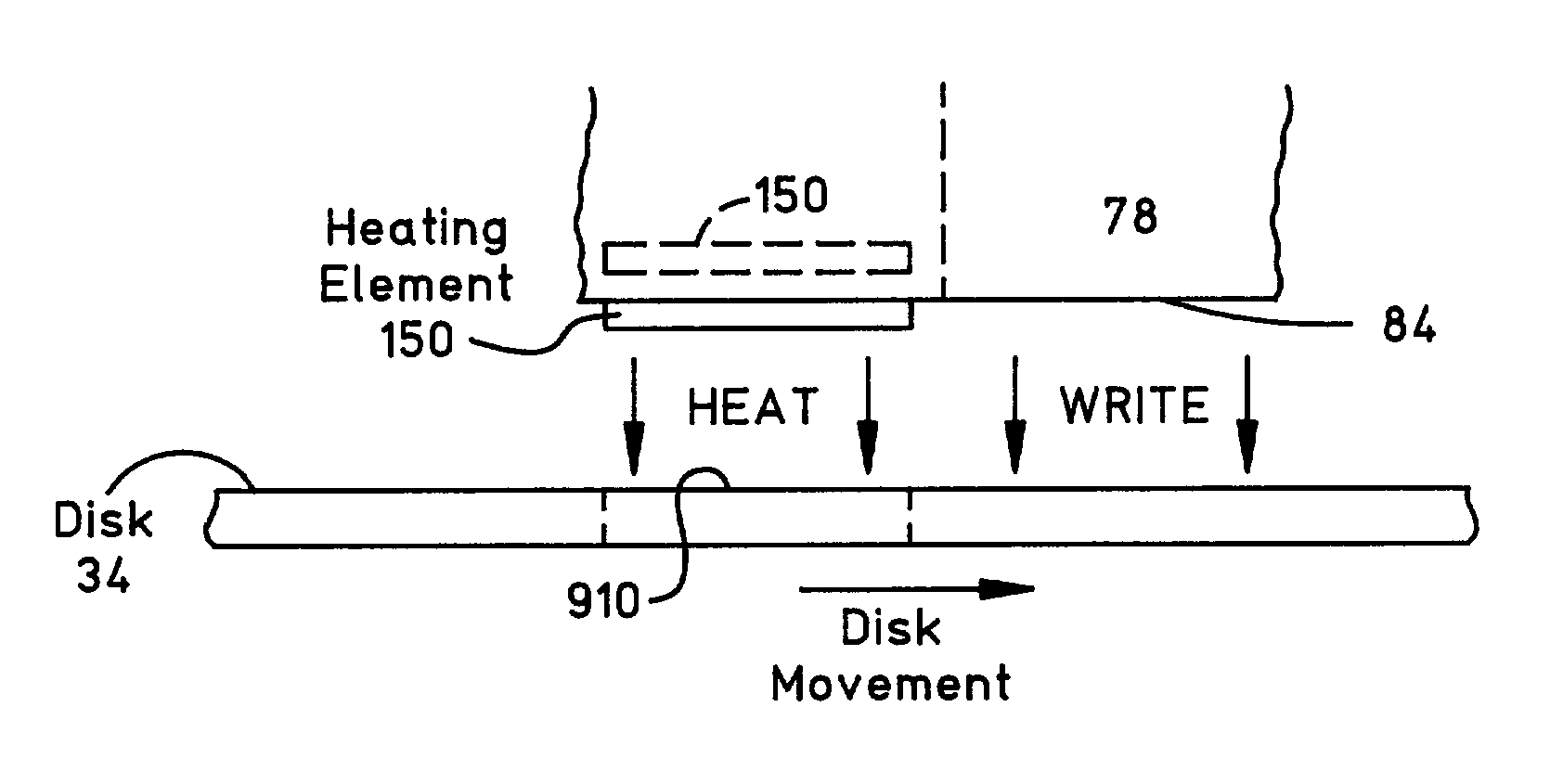

Magnetic head having a heater circuit for thermally-assisted writing

InactiveUS7006336B2Facilitates writing of dataImprove coercive forceConstruction of head windingsHeads using thin filmsEngineeringHeating element

A magnetic head for thermally-assisted writing of data to a disk is disclosed. In one illustrative example, the magnetic head includes a write head element and a heating element which is a resistive infared radiator. The heating element is coupled to at least one via pad which is exposed on an outer surface of the magnetic head. This via pad may be the same pad utilized for the write head element or for a read sensor. The heating element is formed beneath or within the pole tip such that it is able to transfer heat to a portion of the disk before the write head element can write data to it Advantageously, the heater facilitates the writing of data to high coercivity media.

Owner:INT BUSINESS MASCH CORP

Rare earth permanent magnet, making method, and permanent magnet rotary machine

ActiveUS20070017601A1Minimized eddy currentImprove remanenceMagnetic circuitInorganic material magnetismRare-earth elementSintered magnets

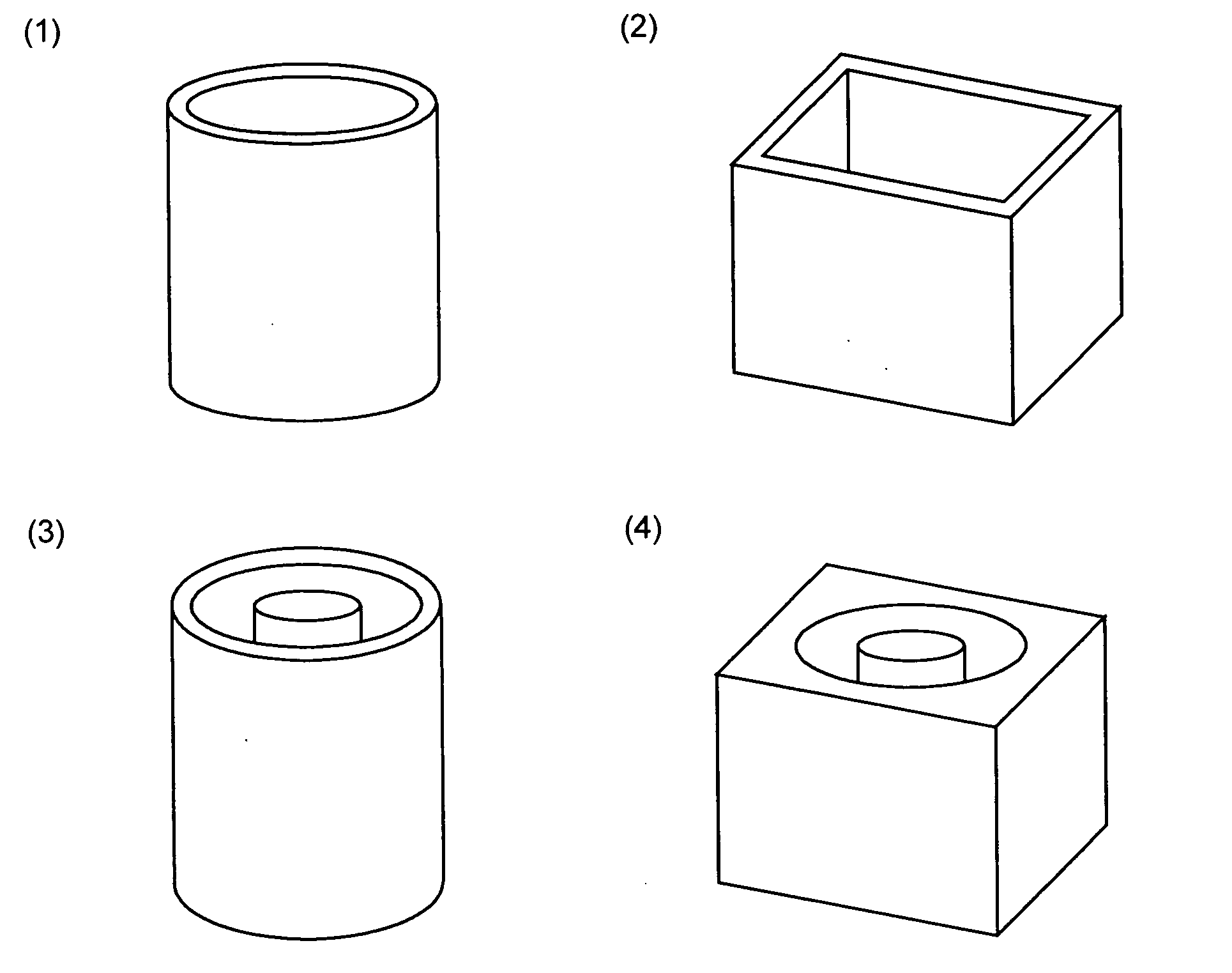

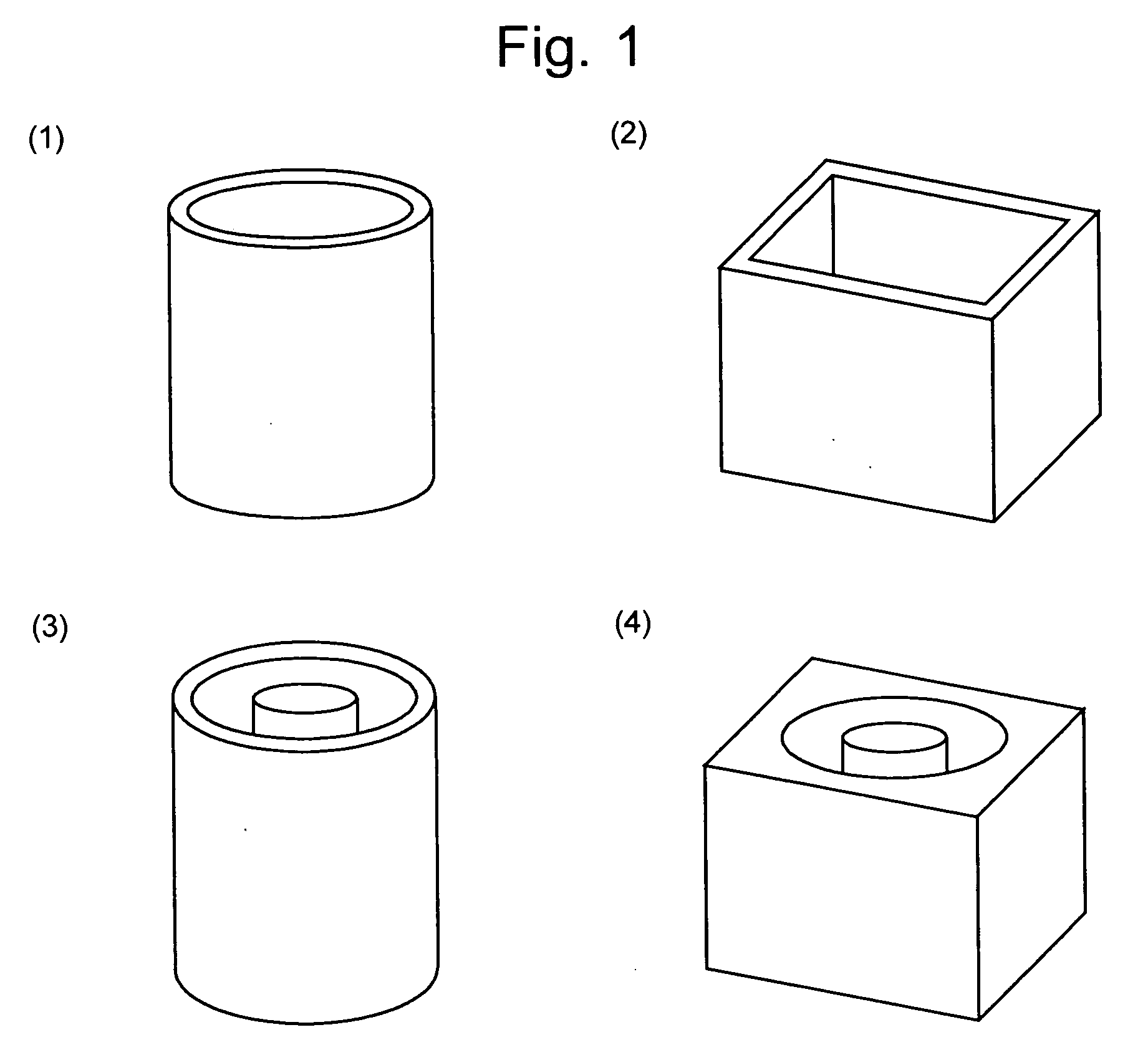

A rare earth permanent magnet is prepared from a sintered magnet body of a R1—Fe—B composition wherein R1 is a rare earth element inclusive of Y and Sc, by forming a plurality of slits in a surface of the magnet body, disposing a powder on the magnet body surface, the powder comprising an oxide of R2, a fluoride of R3, or an oxyfluoride of R4 wherein each of R2, R3, and R4 is a rare earth element, and heat treating the magnet body and the powder below the sintering temperature in vacuum or in an inert gas.

Owner:SHIN ETSU CHEM IND CO LTD

Rare earth permanent magnet and method of manufacturing the same

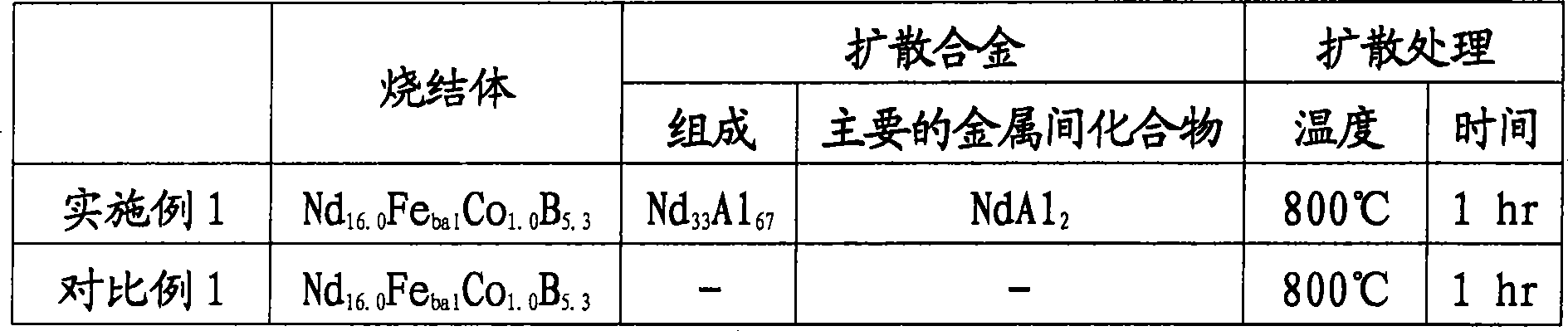

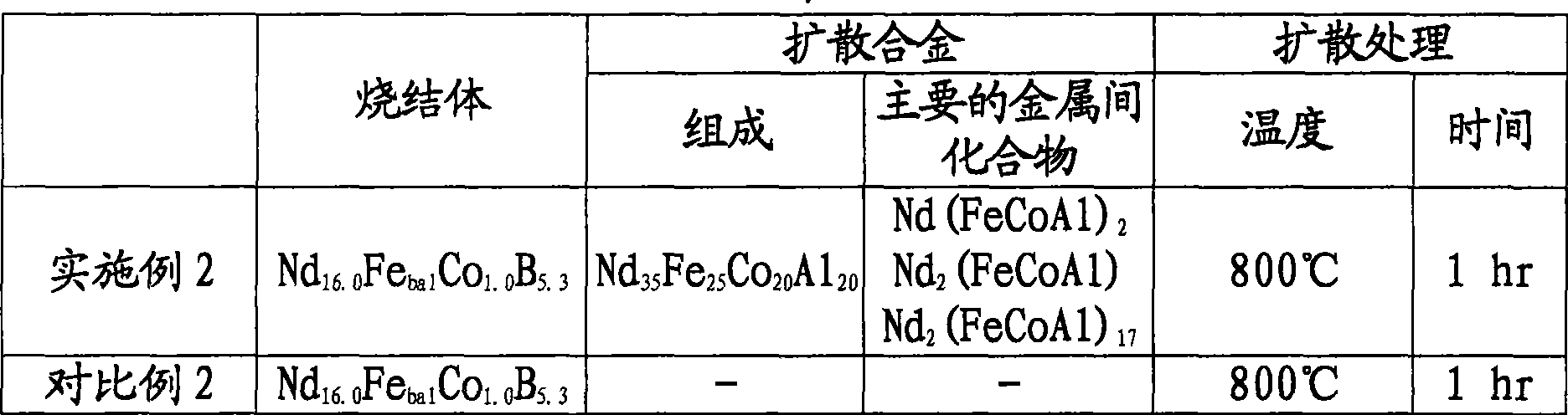

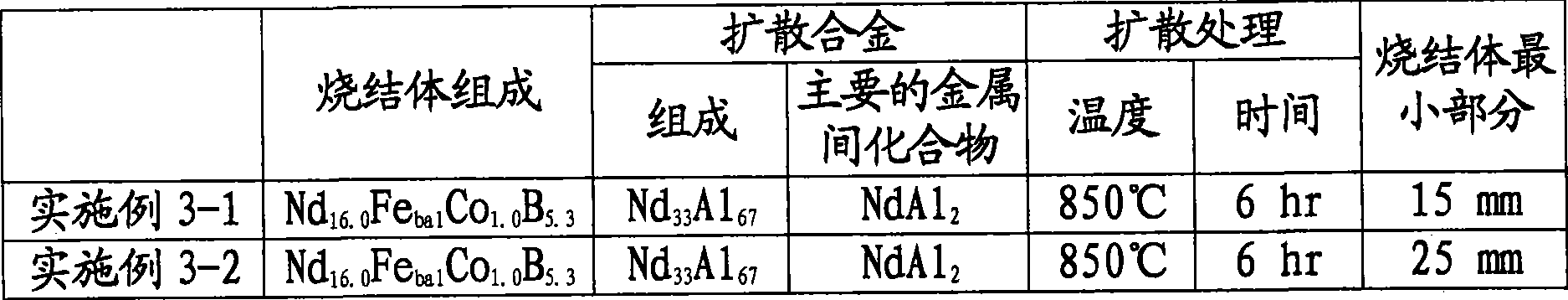

ActiveCN101521068AImprove productivityStrong magnetismInorganic material magnetismInductances/transformers/magnets manufactureProduction rateMetal alloy

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol% of an intermetallic compound phase on a sintered body of R-Fe-B system, and heating the sintered body having the powder disposed on surface thereof below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM IND CO LTD

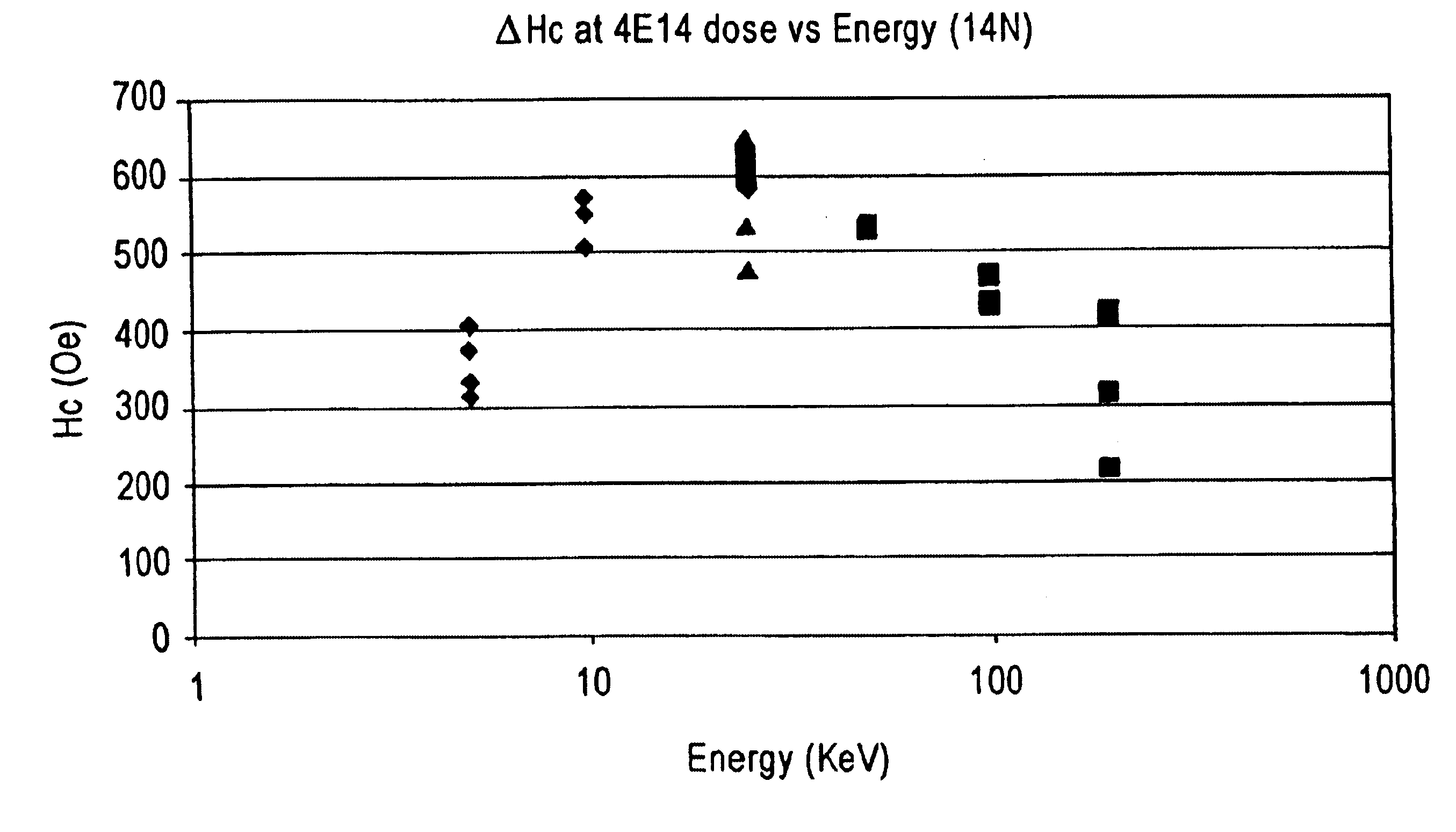

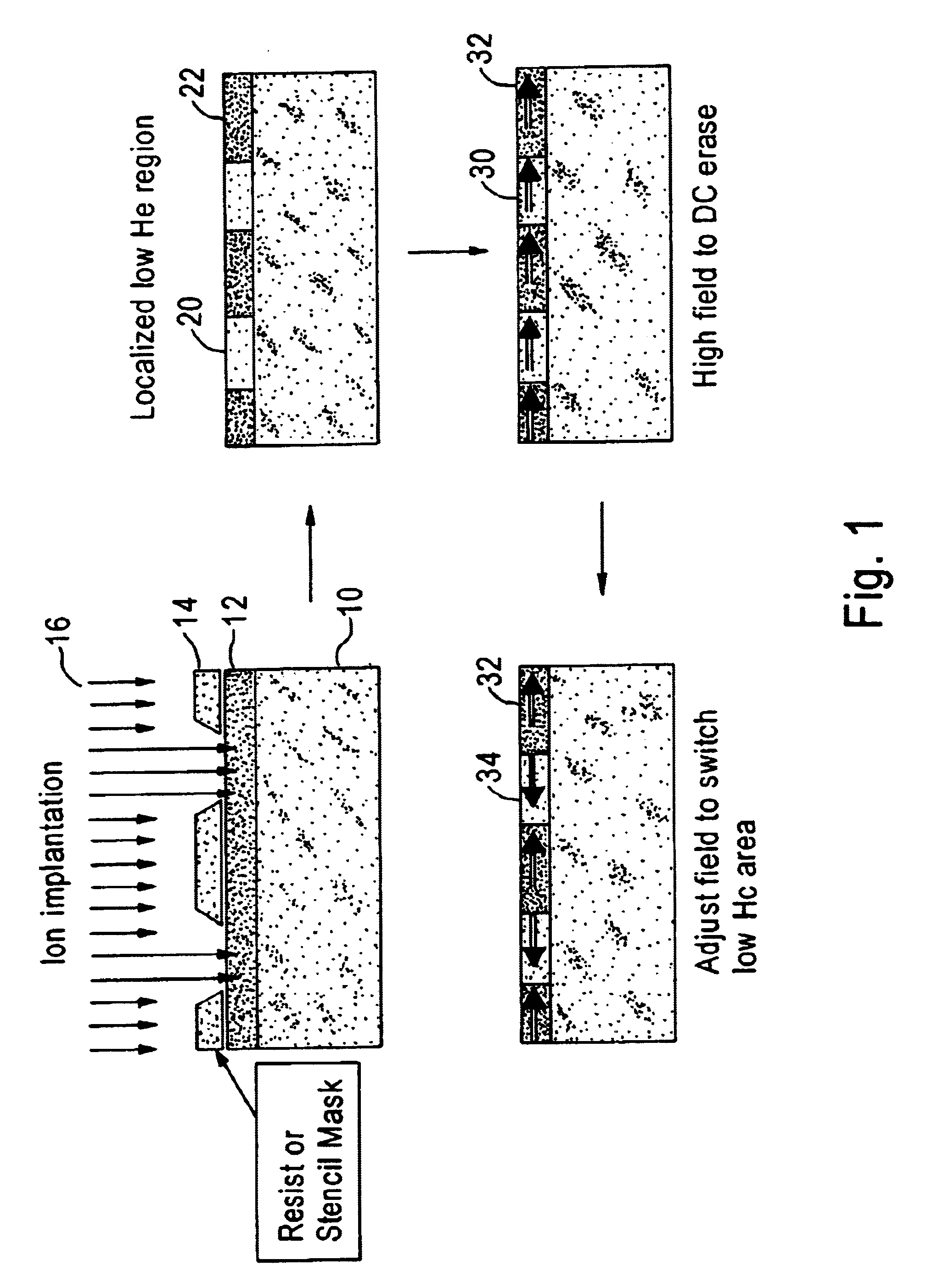

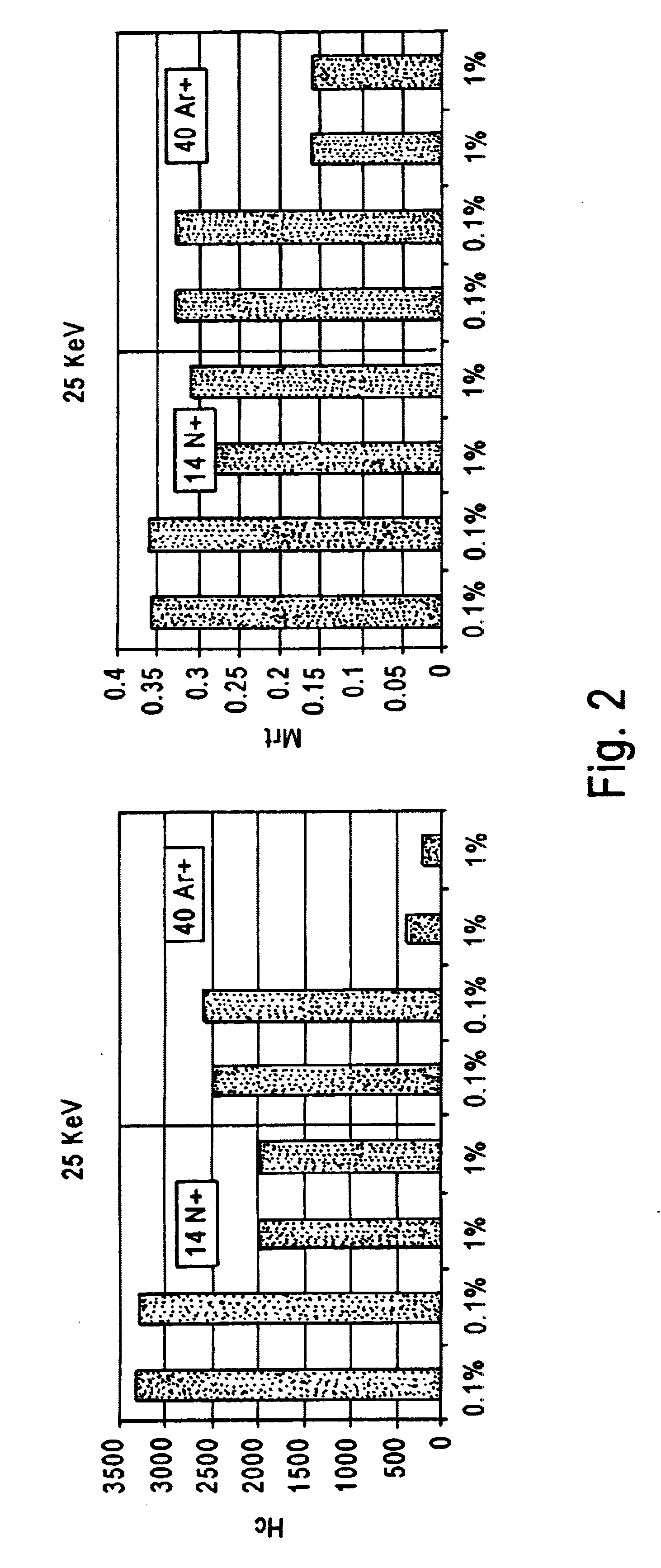

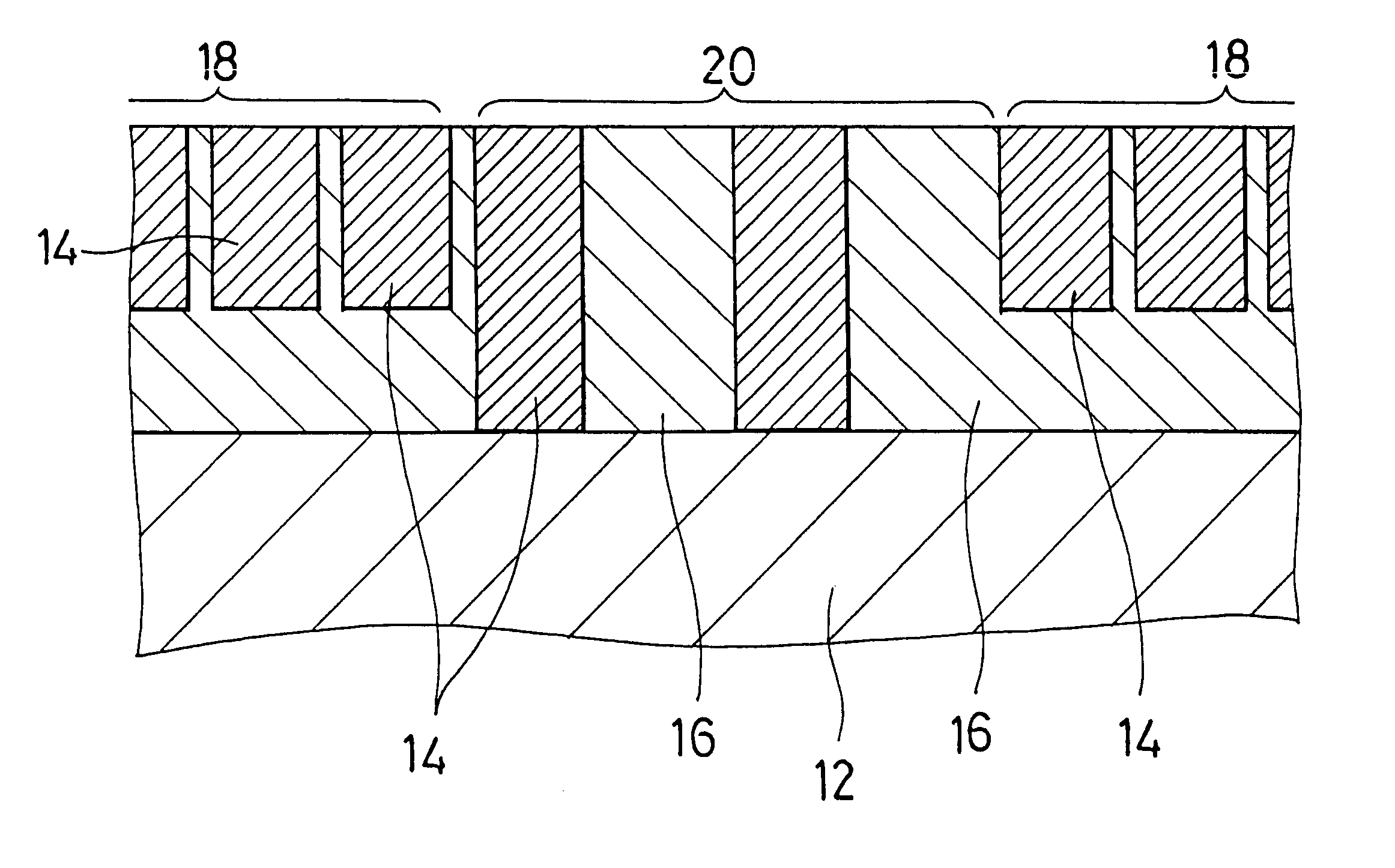

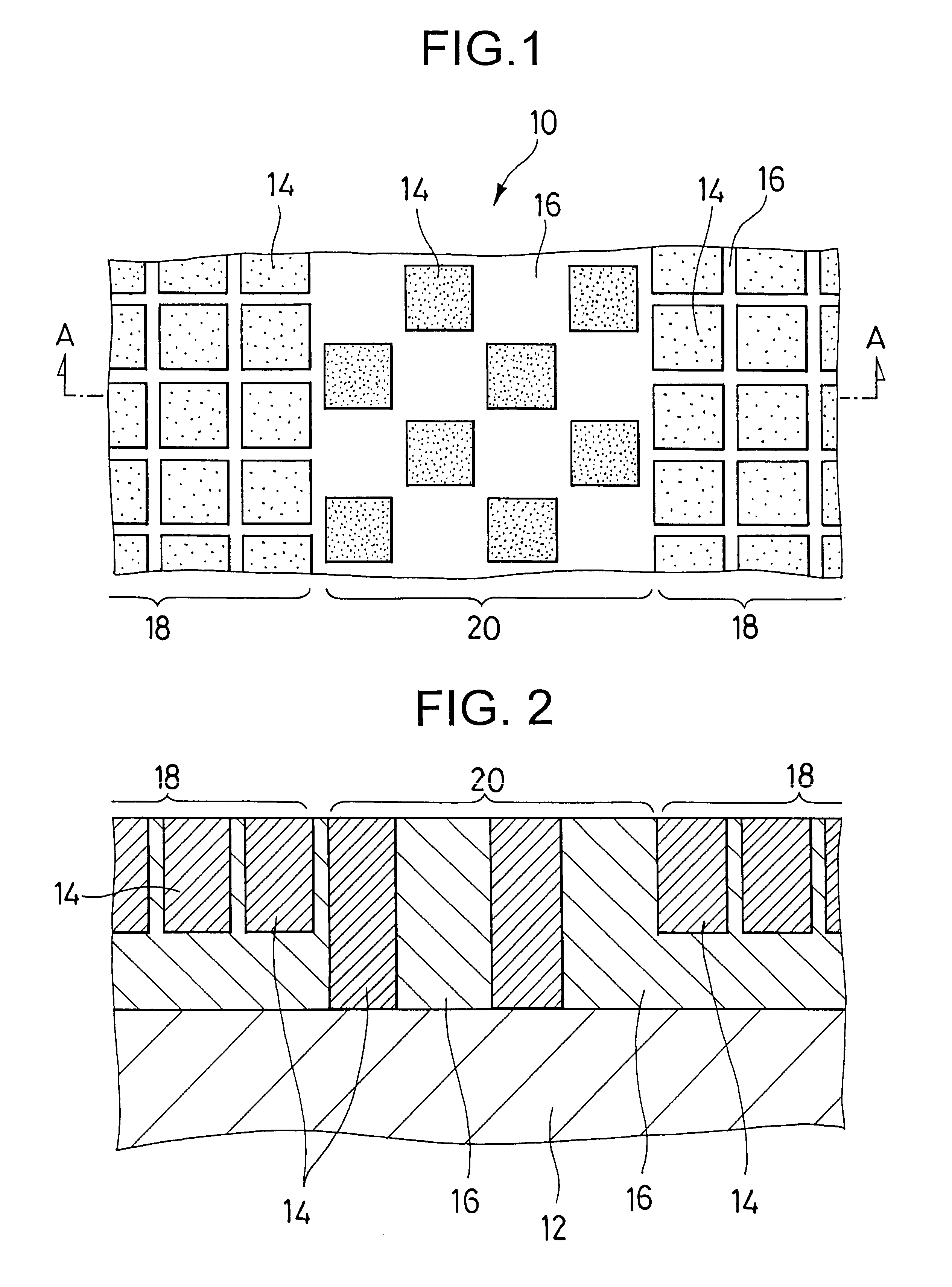

Patterning longitudinal magnetic recording media with ion implantation

InactiveUS6864042B1Increased areal recording densityUniform surfaceNanoinformaticsPatterned record carriersIon bombardmentTopography

A magnetic recording medium is formed with a distribution of low coercivity regions functioning as a transition pattern for servo information capable of being sensed by a read / write head by exposing a masked magnetic layer to ions to change the coercivity of the exposed magnetic layer without substantially affecting the topography of the magnetic layer.Embodiments of the present invention include forming a series of substantially radially extending low coercivity regions used to divide the magnetic layer into a plurality of sectors comprising substantially concentric circumferentially extending data tracks by exposing a masked magnetic layer having a high coercivity, i.e. from about 2000 Oe to about 10000 Oe, to one or more heavy atom ion bombardments of gaseous ions, e.g. argon ions, at a dose of about 1×1013 atoms / cm2 to about 9×1015 atoms / cm2 having an implantation energy of about 10 KeV to about 50 KeV.

Owner:SEAGATE TECH LLC

Thin-film magnetic head with near-field-light-generating layer

ActiveUS7911882B2Improve reliabilityLow coercivityRecording by magnetic meansArm with optical waveguideMagnetic mediaEngineering

A thin-film magnetic head that has a configuration in which the element-formed surface and the opposed-to-medium surface are perpendicular to each other, and a light source is sufficiently distanced from the medium surface is provided. The head comprises at least one near-field-light-generating layer for heating a part of a magnetic medium during write operation by generating a near-field light, having a shape tapered toward a head end surface on the opposed-to-medium surface side, and comprising a near-field-light-generating portion having a light-received surface and a tip reaching the head end surface on the opposed-to-medium surface side, and the light-received surface being sloped in respect to the element-formed surface and being provided in a position where an incident light propagating from a head end surface opposite to the opposed-to-medium surface can reach at least a part of the light-received surface.

Owner:TDK CORPARATION

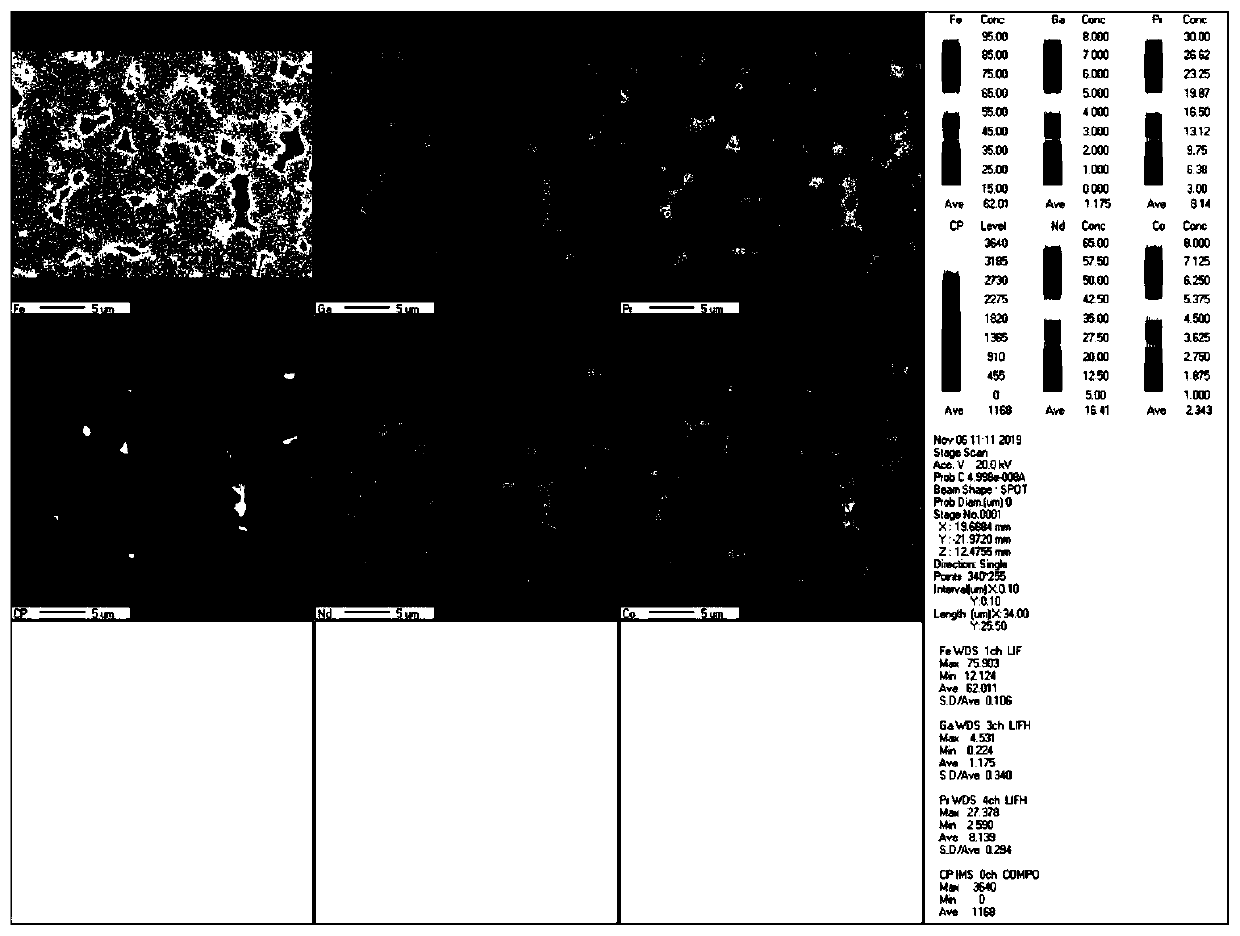

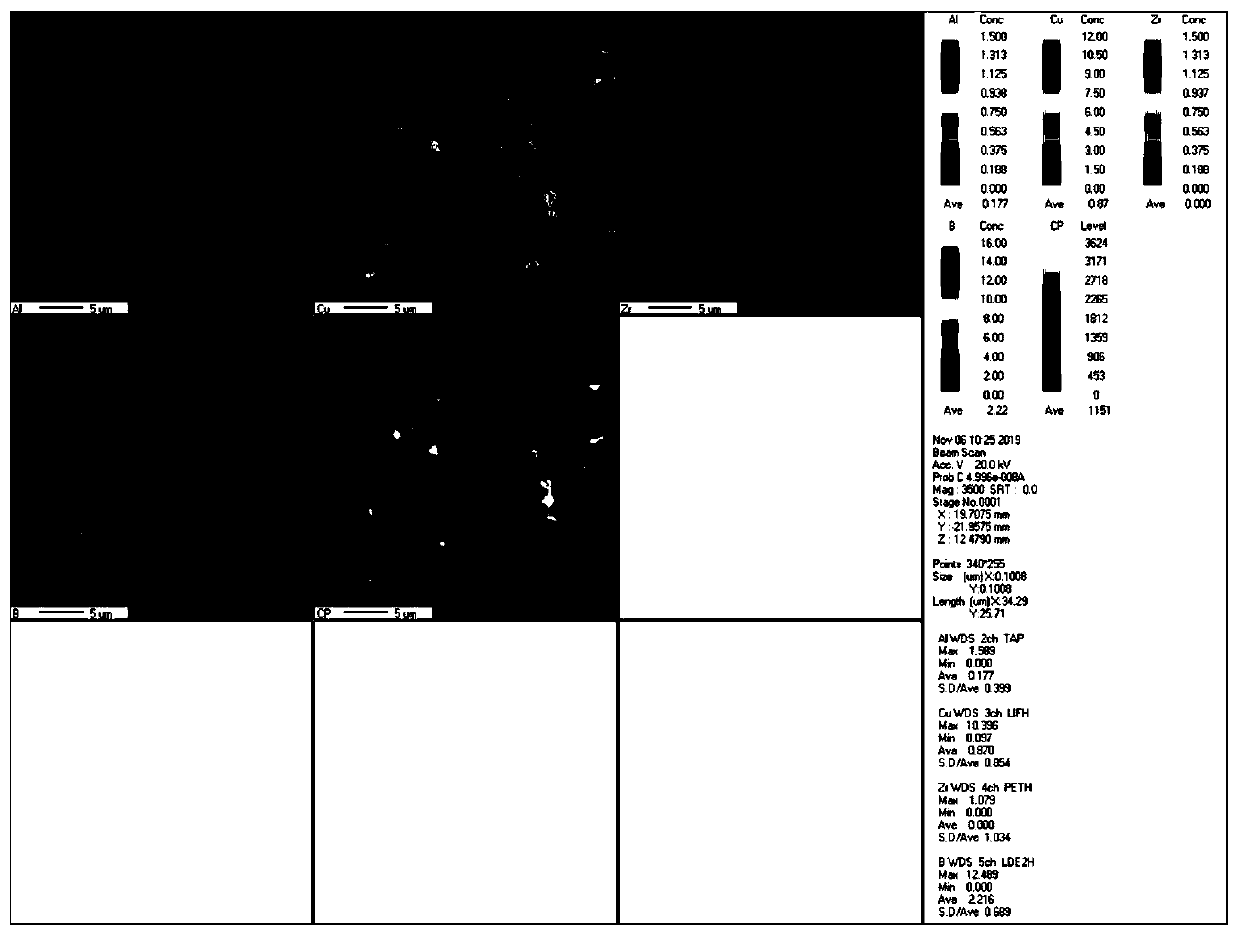

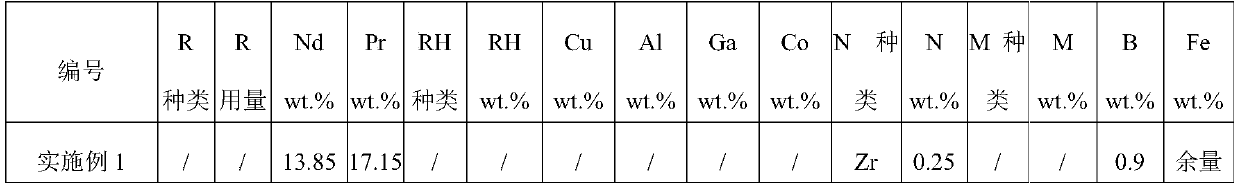

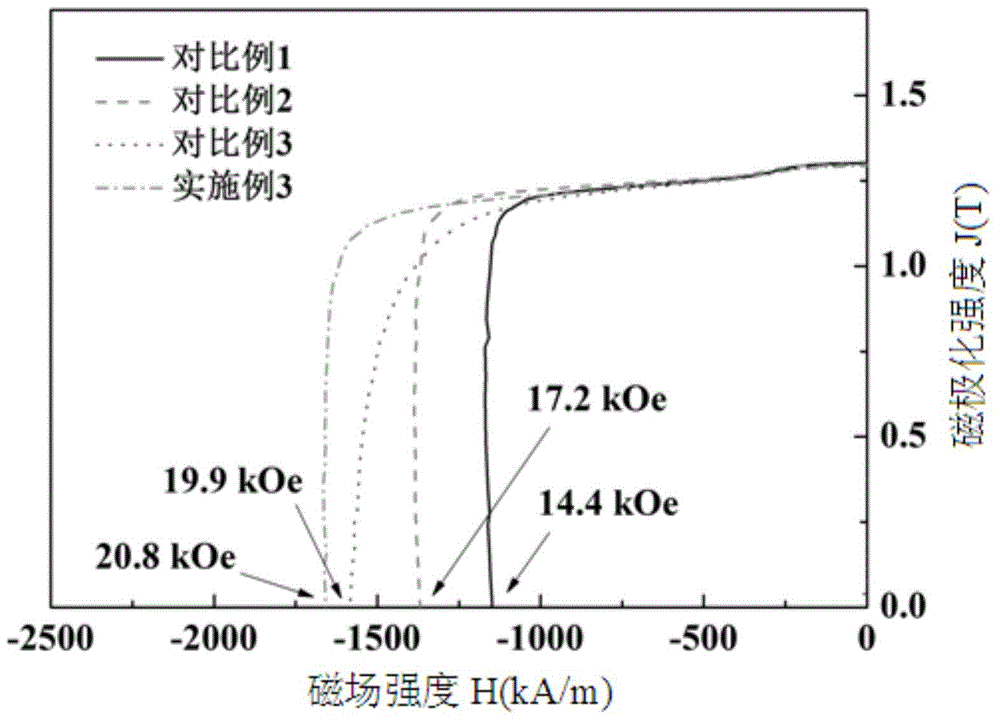

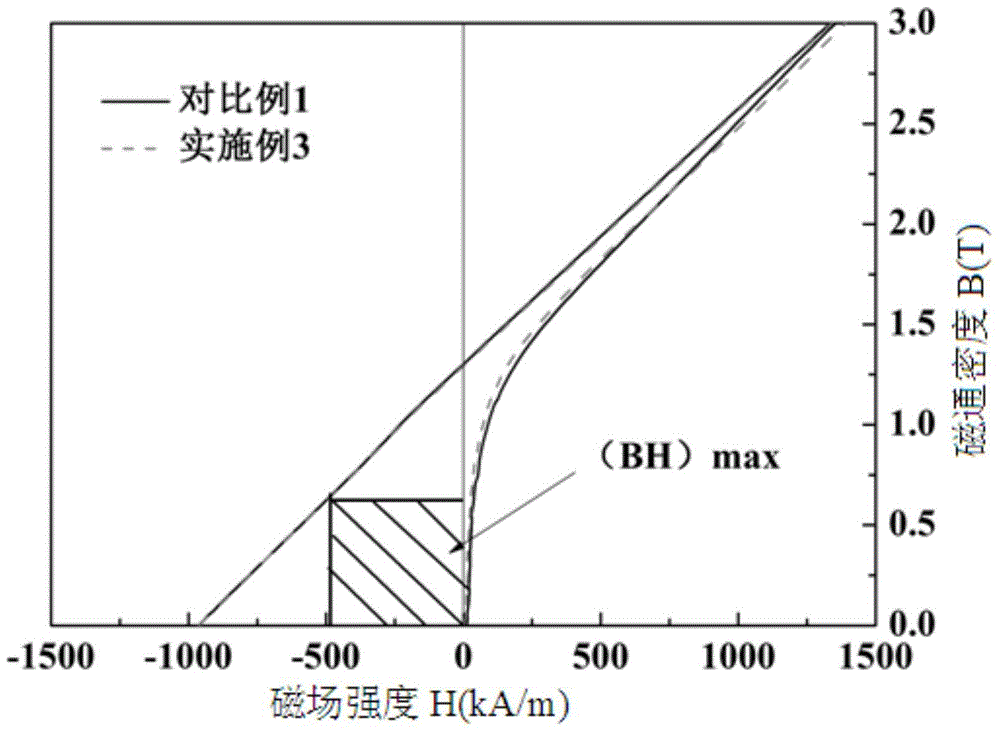

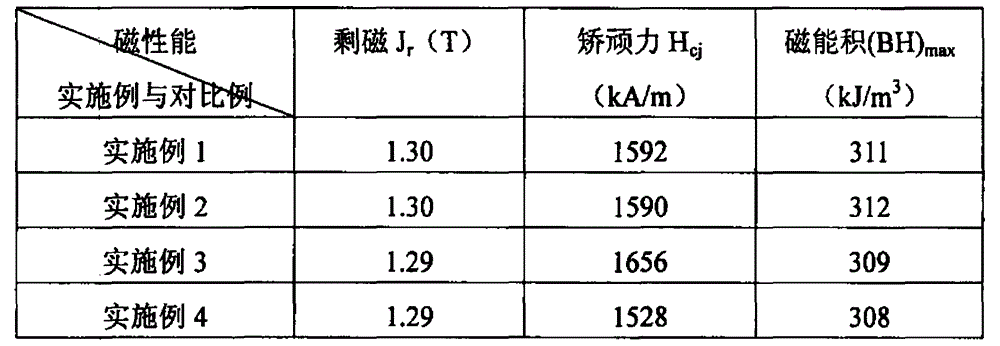

R-T-B series permanent magnet material and preparation method and application thereof

ActiveCN110853855AImprove coercive forceImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementComposite material

The invention discloses an R-T-B series permanent magnet material and a preparation method and application thereof. The R-T-B series permanent magnet material comprises components of 29.5-33.0 wt.% ofR', N, B and Te, wherein the R' comprises R, Pr, Nd, the R is a rare earth element except Pr and Nd, the content of Pr is greater than or equal to 8.85 wt.%, a mass ratio of Nd to R' is less than 0.5, the N is greater than 0.05 wt.% and is not greater than 4.1 wt.%, the N is Ti, Zr or Nb, the B is 0.90-1.2wt.%, and the Fe is 62.0-68.0wt.%. The R-T-B series permanent magnet material is advantagedin that a sintered permanent magnet product with high coercive force and a stable temperature coefficient is prepared by adopting a formula with high Pr content, advantages of Pr can be exerted to themaximum extent by adopting the formula disclosed by the invention, and production cost is effectively reduced.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Magnetic recording medium

InactiveUS6420058B1Improve coercive forceAvoid erasureProtective coatings for layersMagnetic materials for record carriersNon magneticPatterned media

The invention aims to prevent inadvertent rewriting or erasure of servo information in a patterned medium based on the perpendicular recording mode. The magnetic recording medium of the invention includes recording tracks each having an array of unit minute recording portions of a magnetic material separated by non-recording portions of a nonmagnetic material. The recording tracks include data regions and servo regions. The unit minute recording portions in the data regions have substantially the same surface area as the unit minute recording portions in the servo regions. The invention satisfies ARS / ARD>=1.5 provided that the unit minute recording portion has an aspect ratio which is the thickness divided by the square root of the surface area, the unit minute recording portion in the data region has an aspect ratio ARD, and the unit minute recording portion in the servo region has an aspect ratio ARS.

Owner:TDK CORPARATION

Method for preparing heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet

ActiveCN101521069AImprove coercive forceNot easily oxidizedInorganic material magnetismRare-earth elementDehydrogenation

The invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the residual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powder doping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidly solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, and performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sintered magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalent coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.

Owner:BEIJING UNIV OF TECH

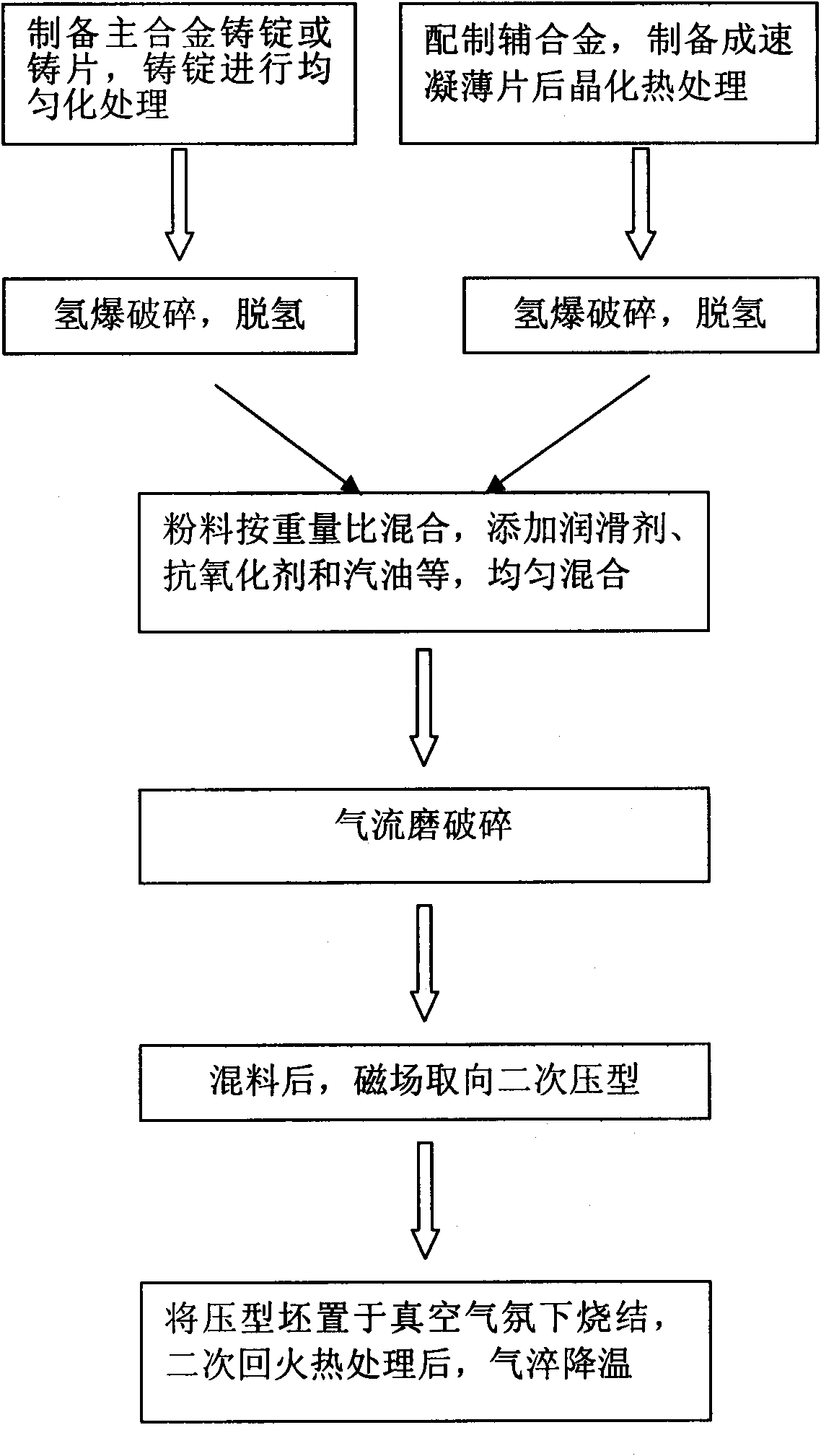

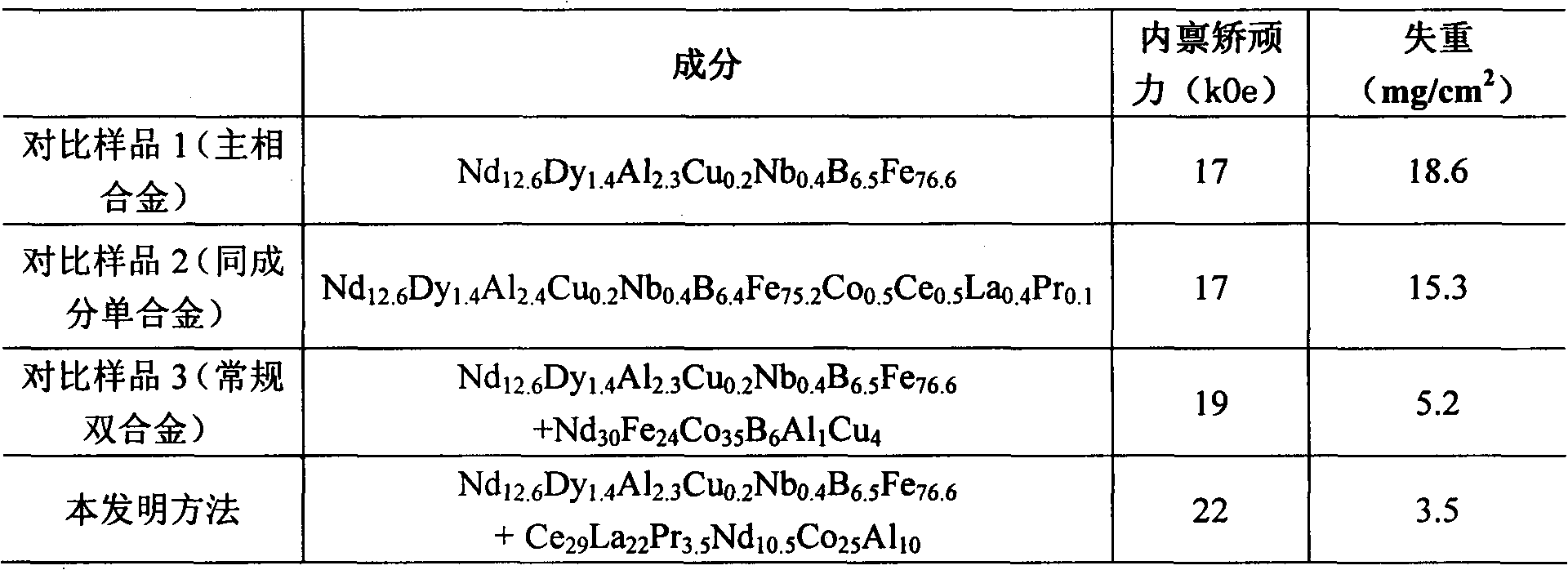

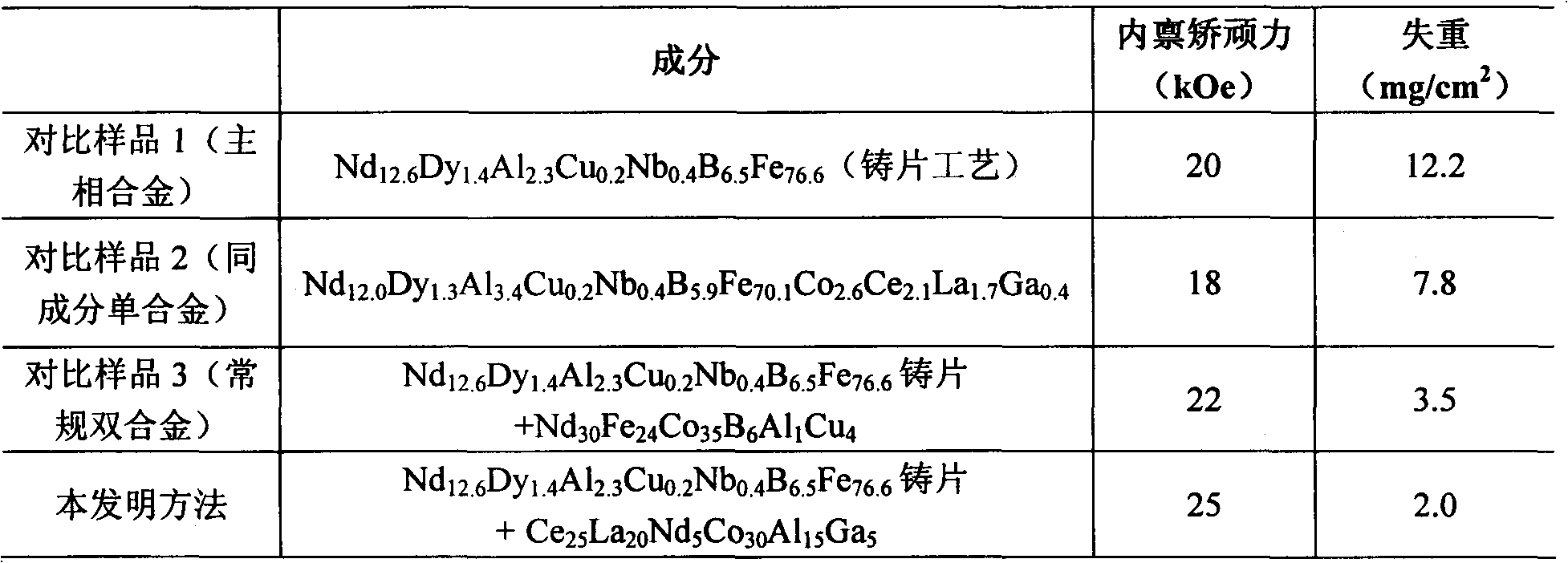

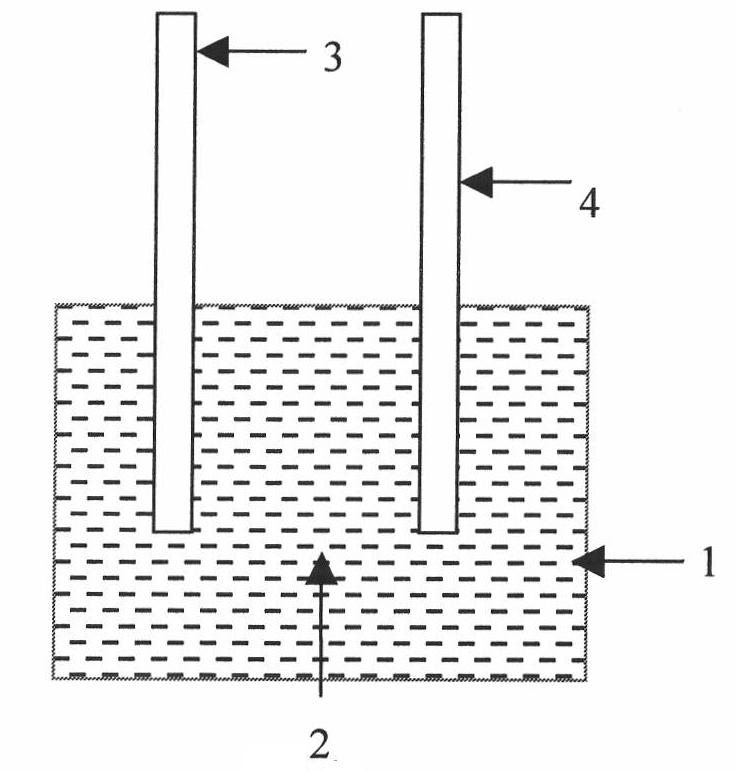

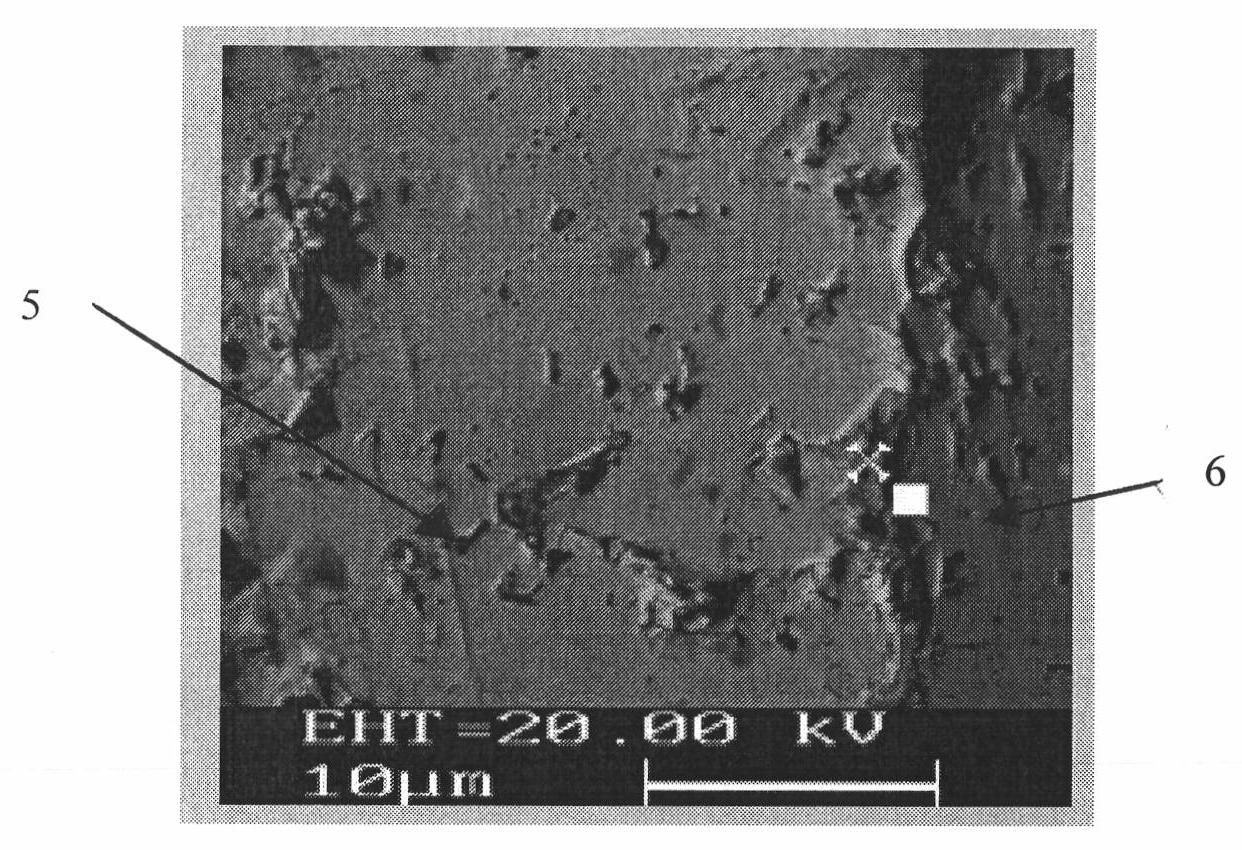

Sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance

ActiveCN102220538ALow cooling rate requirementsEnhanced Amorphous Formation AbilityInorganic material magnetismAlloyGas quenching

The invention discloses a sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance. On the basis of a double-alloy preparation process, Ce-enriched multicomponent rare-based alloy with high amorphous forming ability is used as an auxiliary alloy, and the decrystallizatoin of crystal boundary phase structure is realized by gas quenching cooling in a sintering tempering process. In the invention, the intrinsic coercivity is obviously improved, the anticorrosive weight loss is greatly reduced, the magnetic performance and anticorrosive performance are high, and the method can be widely used in the field of production of high-performance anticorrosive sintered neodymium-iron-boron material.

Owner:NANJING UNIV OF SCI & TECH +1

Preparation method of neodymium iron boron magnet

ActiveCN102103916AReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

InactiveUS7163591B2Improve coercive forceReduce manufacturing costInorganic material magnetismRare earthContamination

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50–500 μm sized magnet powders, which are then mixed with 1–10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500–1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1–20 μm, and the powders have an average size of 50–500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

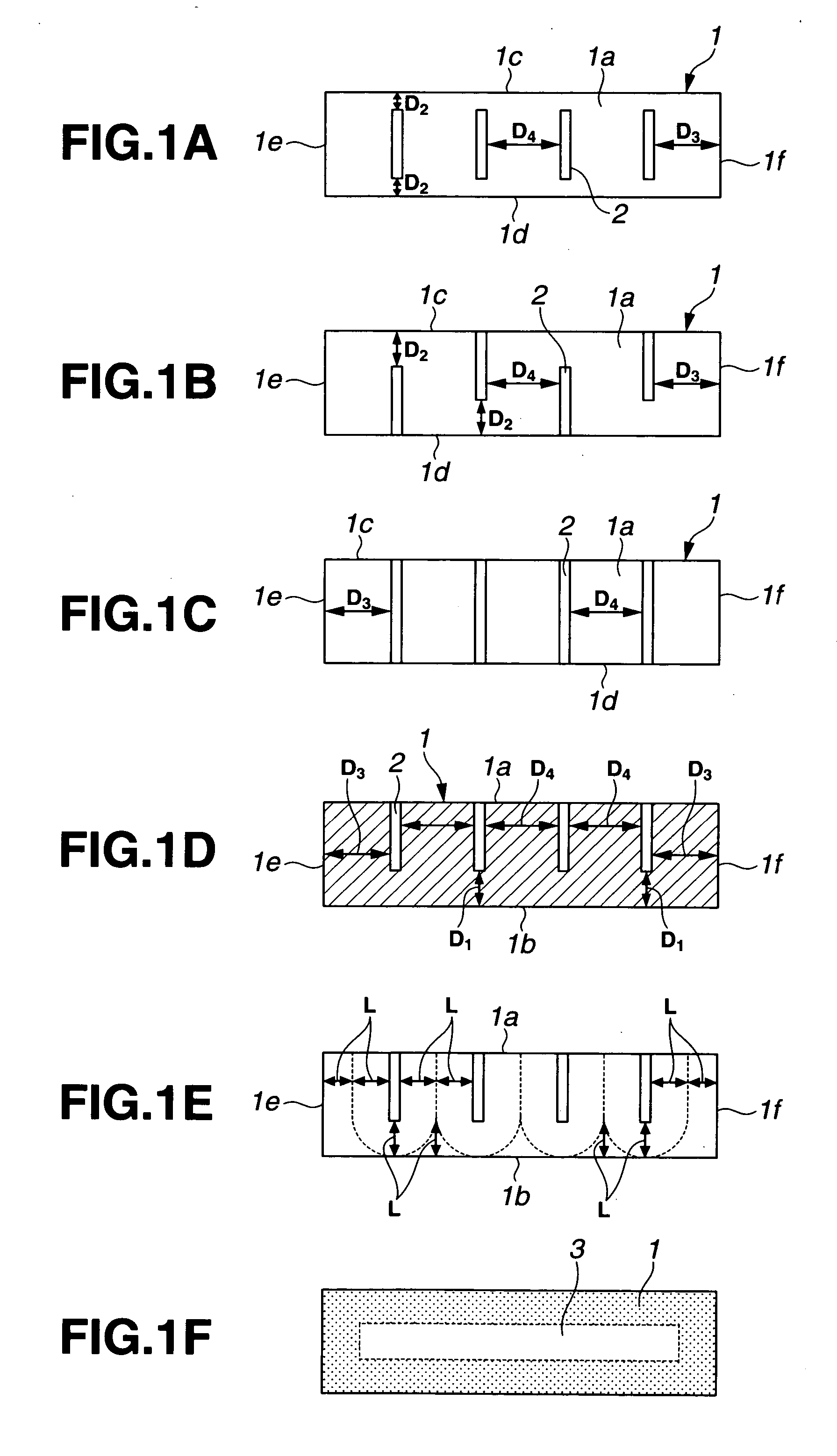

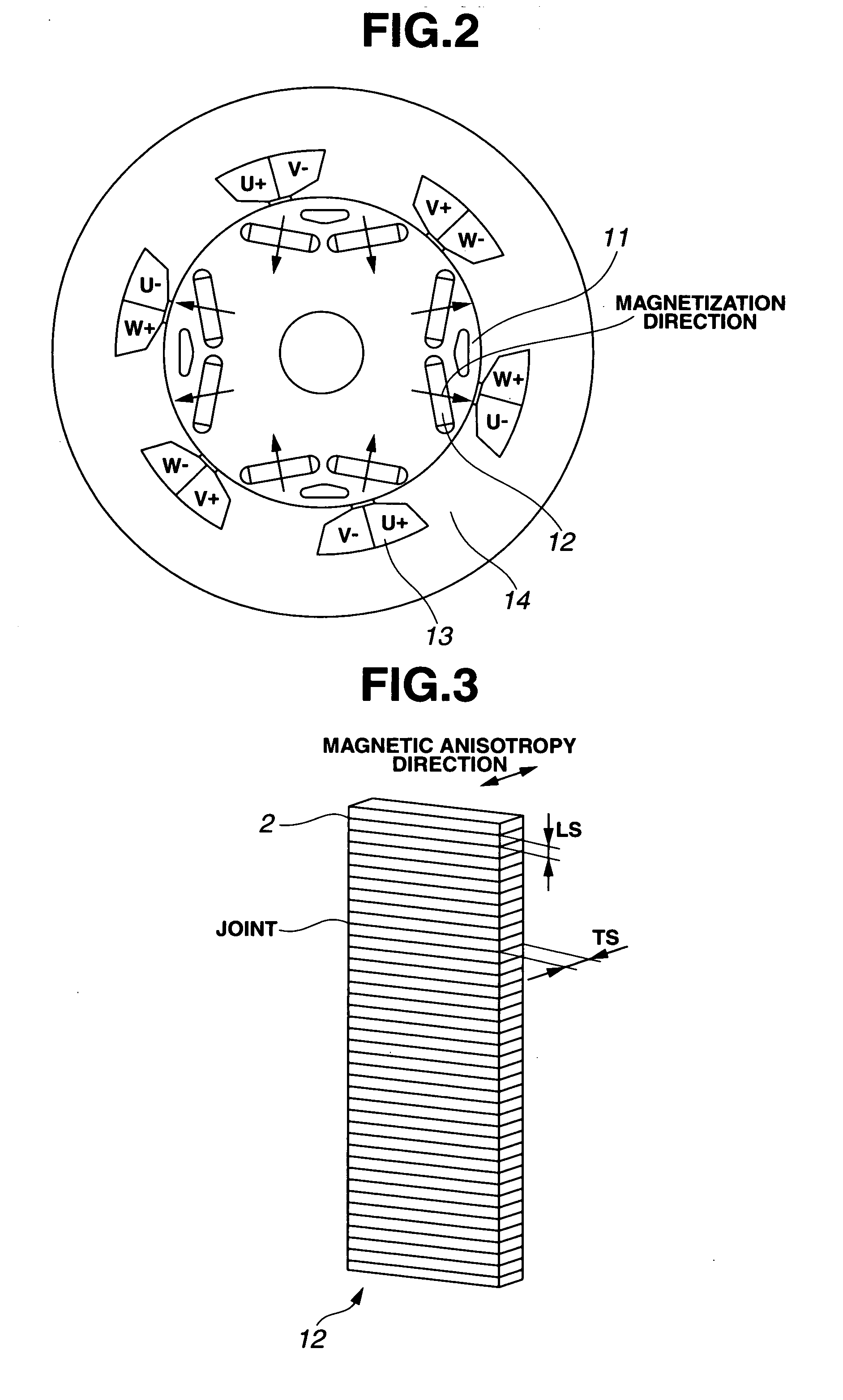

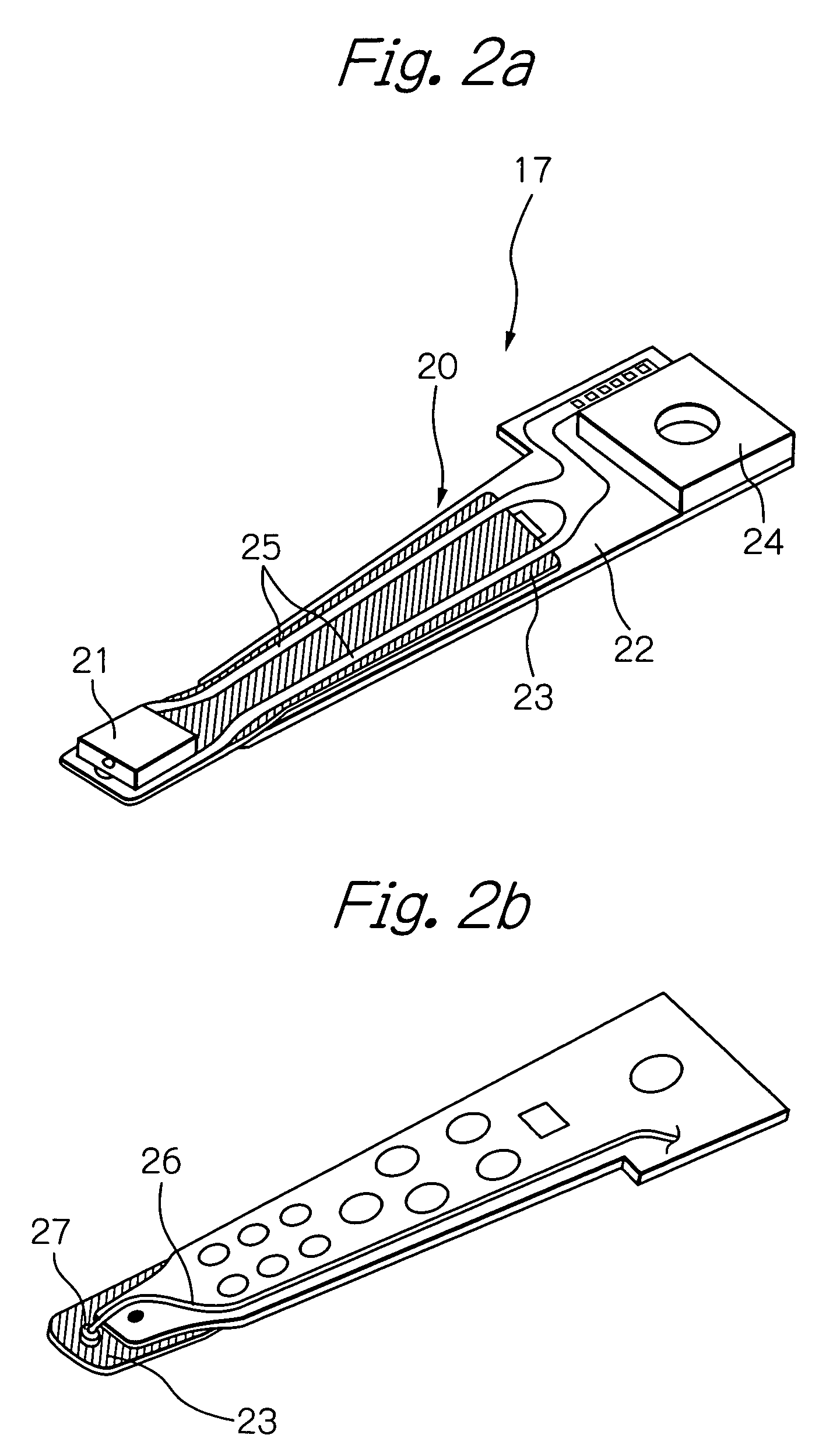

Method and System for Manufacturing Sintered Rare-Earth Magnet Having Magnetic Anisotropy

ActiveUS20070245851A1Improve coercive forceEfficient productionFoundry mouldsInorganic material magnetismManufacturing efficiencyCrystallite

To improve the performance of a rare-earth magnet, it is effective to use a low-oxidized powder having a small grain size. One objective of the present invention is to provide a method for manufacturing a sintered rare-earth magnet having a magnetic anisotropy, in which a very active powder having a small grain size can be safely used in a low-oxidized state. Another objective is to provide a method capable of efficiently manufacturing products having various shapes. In a weighing and loading section 41 and a high-density loading section 42, a fine powder as a material of the sintered rare-earth magnet having a magnetic anisotropy is loaded into a mold until its density reaches a predetermined level. Then, in a magnetic orientation section 43, the fine powder is oriented by a pulsed magnetic field. Subsequently, the fine powder is not compressed but immediately sintered in a sintering furnace 44. The present method enables the mass-producing machine to be simple in its operation and its housing to be accordingly smaller, so that it will be possible to eliminate the danger of oxidization or burning of the powder, which has been a serious problem for a conventional method that uses a large-scale die-pressing machine. Furthermore, the manufacturing efficiency can be improved by using a multi-cavity mold for manufacturing a sintered rare-earth magnet having an industrially important shape, such as a plate magnet or an arched plate magnet.

Owner:DAIDO STEEL CO LTD

Samarium-cobalt permanent magnet material and preparation method thereof

The invention provides a samarium-cobalt permanent magnet material, which consists of the following components in percentage by mass: 23 to 25.5 percent of samarium, 44 to 50 percent of cobalt, 14 to 20 percent of iron, 3 to 8 percent of copper, 2 to 4 percent of zirconium and 0.5 to 2 percent of heavy rare earth element. The invention also provides a method for preparing the samarium-cobalt permanent magnet material, which comprises the following steps of: mixing; smelting alloys; preparing magnetic power; orienting and forming; sintering and performing solid solution; and ageing. The samarium-cobalt permanent magnet material has the characteristic of high coercive force and can effectively meet the requirement of the field of high and new technology on the high coercive force of a rare earth permanent magnet material.

Owner:NINGBO STAR MATERIALS HI TECH

Preparation method of flexible anisotropy bonding rare earth permanent magnet material

InactiveCN101800106AAbundant resourcesReduce manufacturing costInorganic material magnetismInductances/transformers/magnets manufactureMagnetizationRare earth

The invention discloses a preparation method of flexible anisotropy bonding rare earth permanent magnet material, belonging to the field of magnetic materials. The material is prepared by combining the two-step approach accompanying temperature magnetic field orientation technology of which the calendaring process and the accompanying temperature magnetic field orientation process are separated. A certain quantity of anisotropy magnetic powder which is performed with surface treatment by the processing agent in advance, binder and processing agent are evenly mixed; the mixed material is calendered into flaky flexible bonding magnetic body by the calendaring technology; then, the flaky flexible bonding magnetic body is cut into parts which are heated at certain temperature under the condition of heat preservation for certain time, after that, the obtained product is put into an orientation magnetic field for accompanying temperature magnetic field orientation; and the direction of the orientation magnetic field is parallel to the plane normal direction of the flaky flexible bonding magnetic body. In the preparation technology, magnetic powder can overcome the constraint of a bonding system and rotates under the action of magnetic field force to ensure that the direction of easy magnetization of the magnetic powder generally points to the orientation direction, and the magnetic property of prepared flexible anisotropy bonding rare earth permanent magnet material can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

Grain boundary diffusion method for improving properties of sintered NdFeB magnets

ActiveCN104388951AIncreased diffusion kinetic energyLow melting pointInorganic material magnetismRare-earth elementDiffusion methods

The invention relates to a grain boundary diffusion method for improving properties of sintered NdFeB magnets. The grain boundary diffusion method comprises the following steps of stacking sintered NdFeB magnets and diffusion alloy sheets together and placing in a hot-pressing furnace; vacuumizing the hot-pressing furnace until the vacuum degree reaches a set value, heating the hot-pressing furnace, and when the temperature of the hot-pressing furnace reaches a set value, beginning to exert a pressure and maintaining the pressure and putting the diffused sample into a high-vacuum furnace for annealing, wherein the diffusion alloy sheets are low-melting-point eutectic diffusion alloys and are represented by R-TM, R is one or more of Sc, Y, La, Ce, Pr or Nd and TM is one or more of Ti, V, Cr, Mn, Fe, Co, Ni, Cu and Zn. Compared with the prior art, the sintered NdFeB magnets modified by the pressure diffusion method, which is provided by the invention, have the advantages of large diffusion depth of a diffusion agent, uniform distribution of grain boundary phases, high coercivity and the like, especially, low-melting-point diffusion alloys designed by the invention are free of expensive heavy rare earth element dysprosium and thus the cost of the raw materials is relatively low, the diffusion temperature is low and the energy consumption in the diffusion process is small.

Owner:SHANGHAI JIAO TONG UNIV

Current-perpendicular-to-the-plane (CPP) magnetoresistive sensor with improved ferromagnetic free layer structure

InactiveUS20080117553A1Good symmetryReduce sensitivityRecord information storageManufacture of flux-sensitive headsInterface layerSpin valve

A current-perpendicular-to-the-plane (CPP) magnetoresistive (MR) sensor has an improved free layer structure that includes a first ferromagnetic interface layer on the sensor's nonmagnetic spacer layer, a first electrically conductive interlayer on the first interface layer, a central ferromagnetic NiFe alloy free layer on the first interlayer, a second electrically conductive interlayer on the central free layer, and a second ferromagnetic interface layer on the second interlayer. The first ferromagnetic interface layer, central ferromagnetic free layer, and second ferromagnetic interface layer are ferromagnetically coupled together across the electrically conductive interlayers so their magnetization directions remain parallel. The free layer structure may be used in single or dual CPP sensors and in spin-valve or tunneling MR sensors.

Owner:WESTERN DIGITAL TECH INC

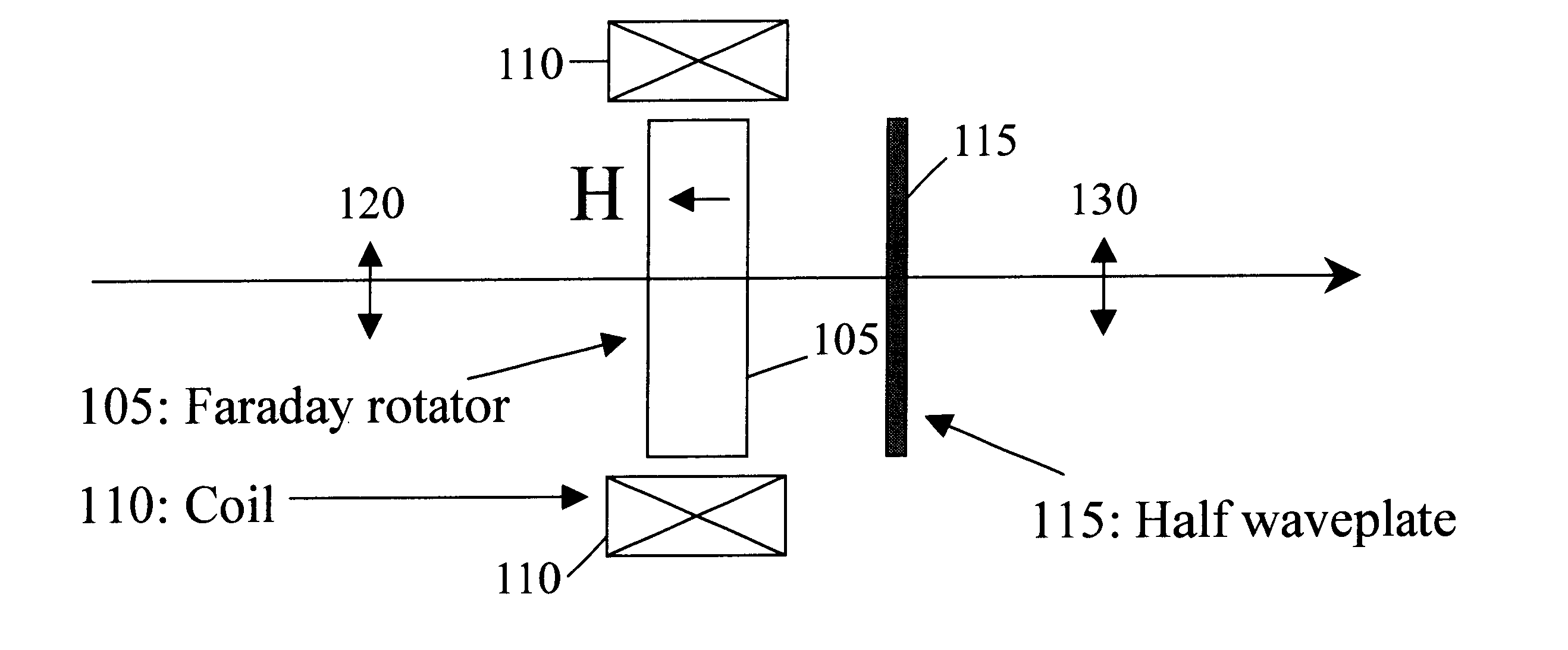

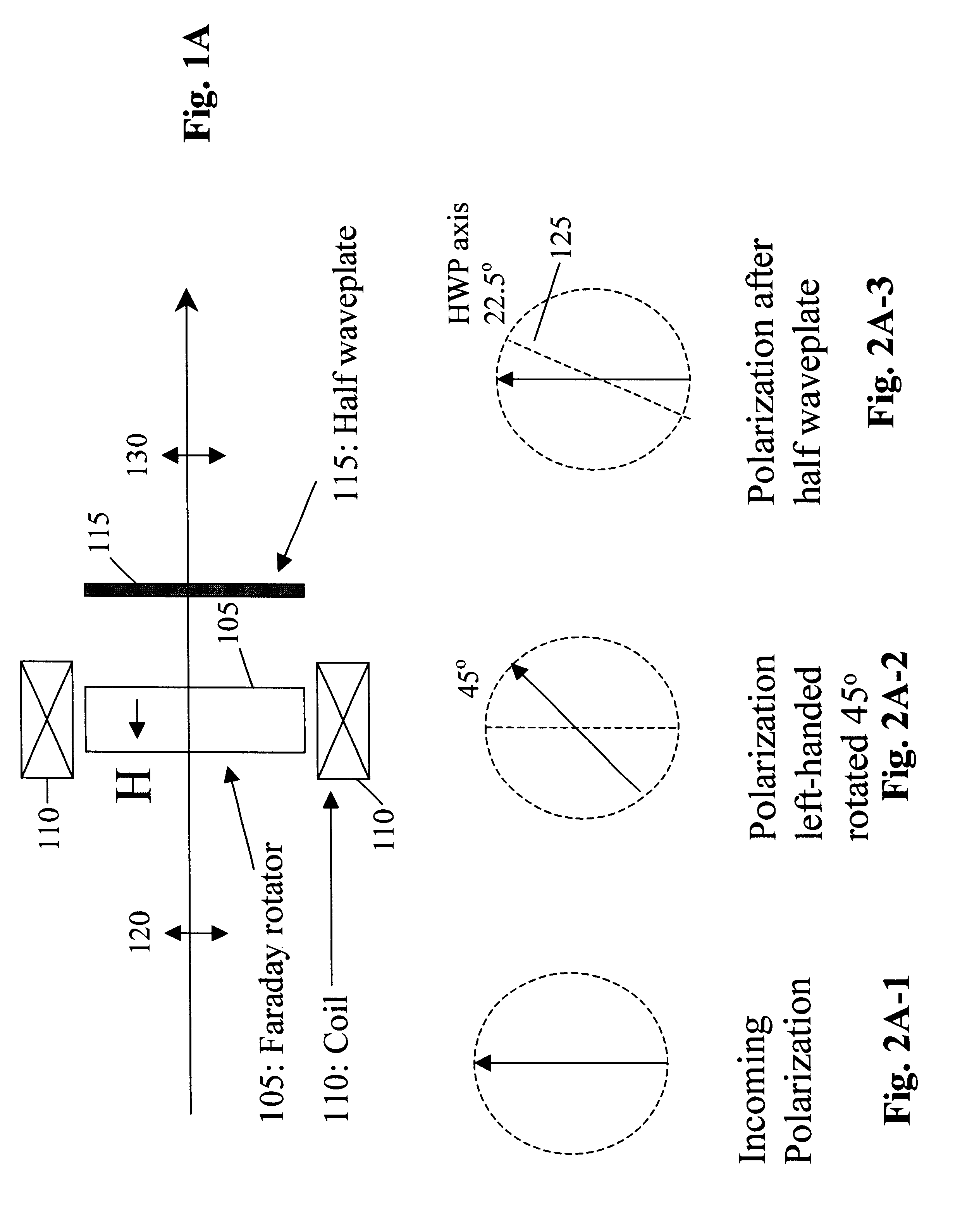

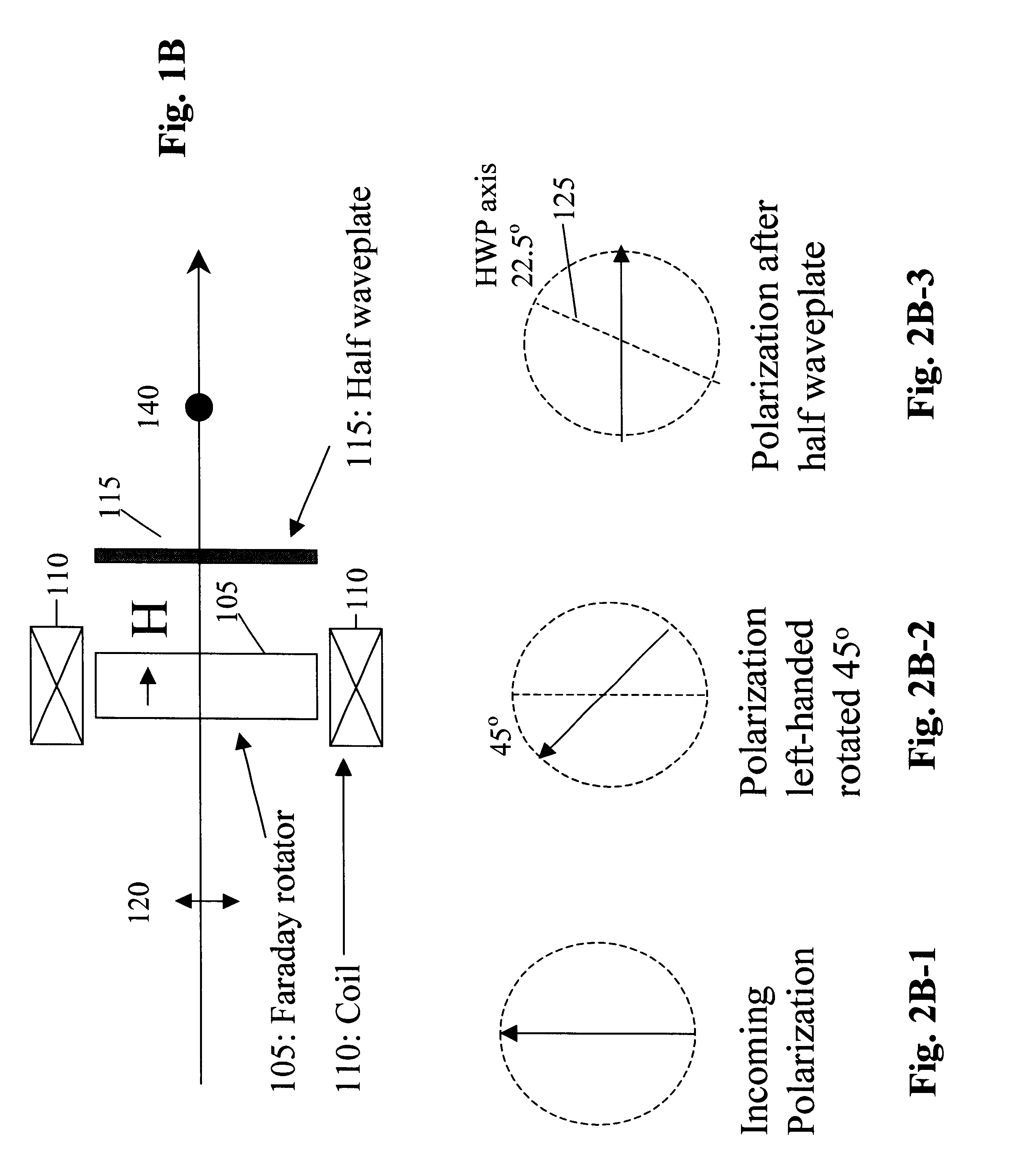

High switching speed digital faraday rotator device and optical switches containing the same

InactiveUS6594068B2Fast rise timeShort durationLaser detailsRadiation pyrometryMagnetizationEngineering

In all-optical networks, high speed optical switching and routing becomes one of the most important issues for interconnecting the transport network layers. This invention describes novel polarization-independent high speed optical switches using a digital Faraday rotator, which can also be used for various other optical switching devices. The basic digital Faraday rotator device is composed of (a) a semi-hard or hard iron garnet based magneto-optic crystal having bi-stable magnetization states at zero external magnetic field. (b) a wire winding around the crystal for changing the magnetization states by pulsed current having both fast rise time and short duration. (c) a circuit generating the required current pulses with both polarities. After a driving current pulse excitation to set the magnetization direction, the high coercive force and high remnant squareness in the garnet-based crystal will maintain the saturation magnetization state in the crystal without the need of any external current or magnetic field to sustain the remnant state. The apparatus and the method disclosed in this invention effectively reduces the overall power consumption. By using this digital Faraday rotator device, the polarization independent 1x2 and 2x2 optical switches are designed and fabricated.

Owner:SUI ZHIFENG

Sintered magnet

ActiveUS20150170810A1Improve coercive forceUse amount of heavy rare earth elements is reducedPermanent magnetsMagnetic materialsRare-earth elementSintered magnets

A sintered magnet of a preferred embodiment has a composition comprising: R (R is a rare earth element that must contain any one of Nd and Pr.): 29.5 to 33.0 mass %; B: 0.7 to 0.95 mass %; Al: 0.03 to 0.6 mass %; Cu: 0.01 to 1.5 mass %; Co: 3.0 mass % or less (provided that 0 mass % is not included.); Ga: 0.1 to 1.0 mass %; C: 0.05 to 0.3 mass %; O: 0.03 to 0.4 mass %; and Fe and other elements: a balance, and wherein a content of heavy rare earth elements in total is 1.0 mass % or less, and wherein the following relations are satisfied: 0.29<[B] / ([Nd]+[Pr])<0.40 and 0.07<([Ga]+[C]) / [B]<0.60, where [Nd], [Pr], [B], [C] and [Ga] represent the numbers of atoms of Nd, Pr, B, C and Ga, respectively.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com