Patents

Literature

109results about How to "Reduce particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

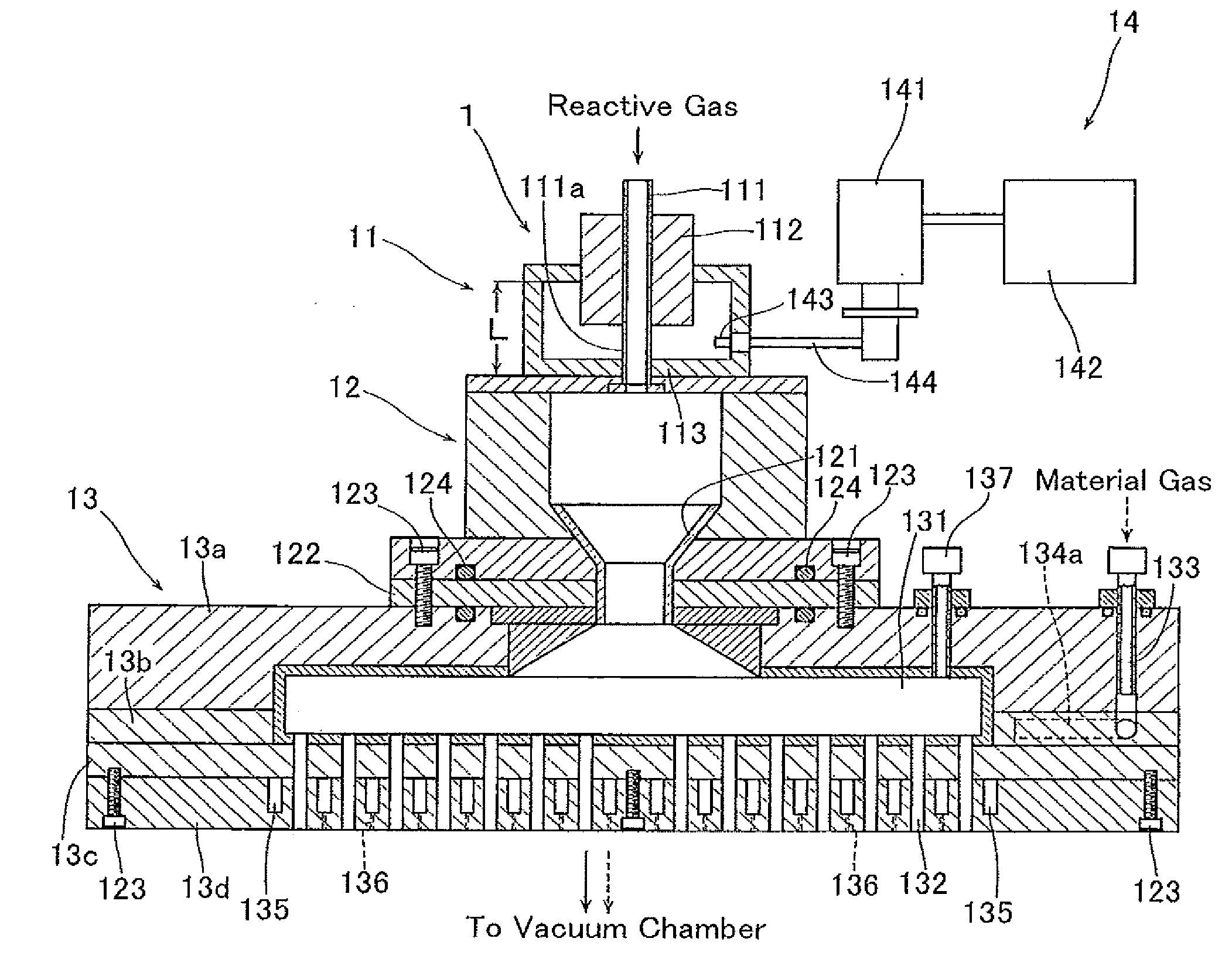

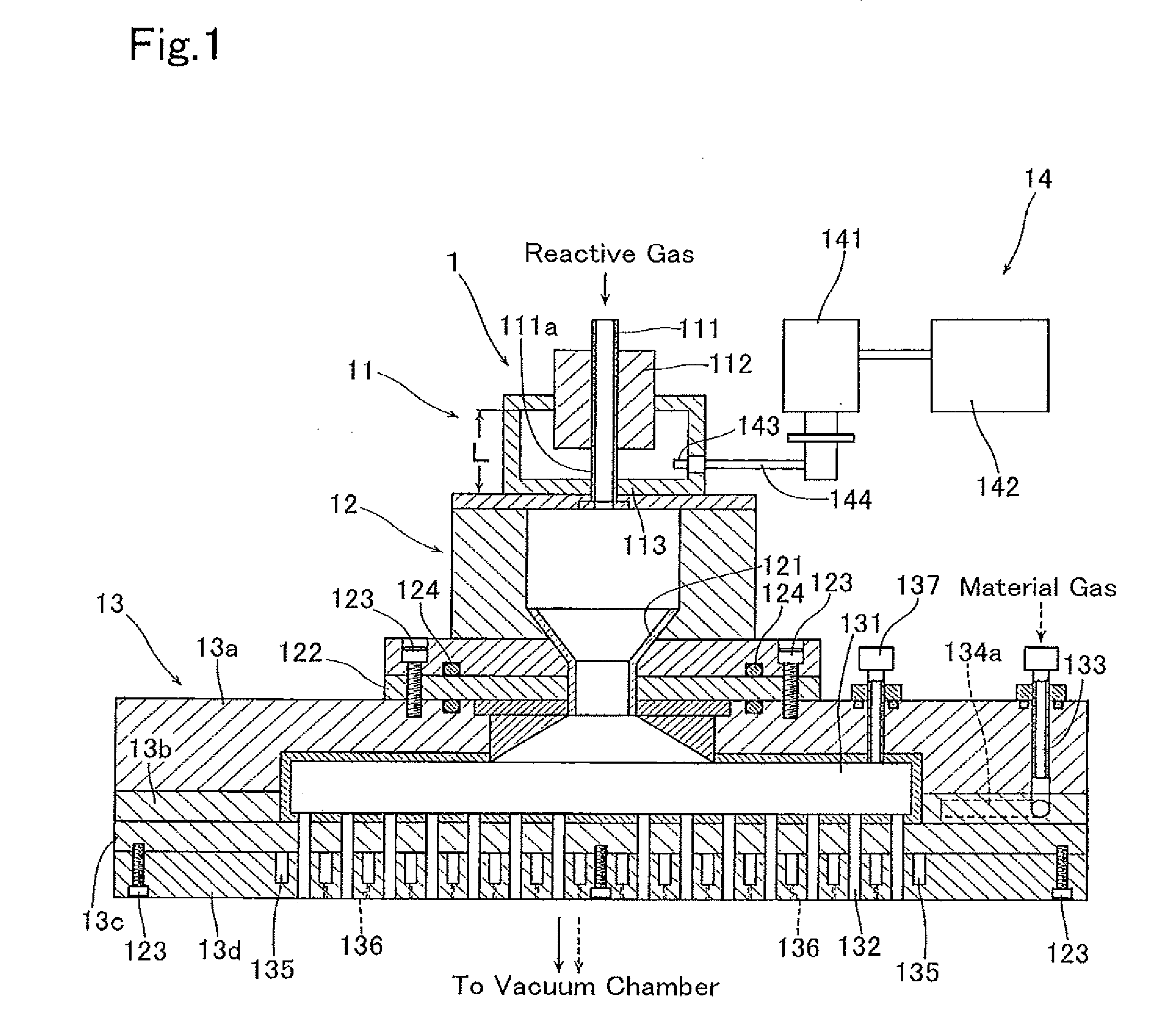

Method of forming barrier film

ActiveUS20100068891A1High aspect ratioReduce particleSemiconductor/solid-state device manufacturingChemical vapor deposition coatingResonant cavityMicrowave

A barrier film made of a ZrB2 film is formed by use of a coating apparatus provided with plasma generation means including a coaxial resonant cavity and a microwave supply circuit for exciting the coaxial resonant cavity, the coaxial resonant cavity including spaced apart conductors provided around the periphery of a nonmetallic pipe for reactive gas introduction, the coaxial resonant cavity having an inner height equal to an integer multiple of one-half of the exciting wavelength, the plasma generation means being constructed such that a gas injected from one end of the nonmetallic pipe is excited into a plasma state by a microwave when the gas is in a region of the nonmetallic pipe which is not covered with the conductors and such that the gas in the plasma state is discharged from the other end of the nonmetallic pipe.

Owner:ULVAC INC

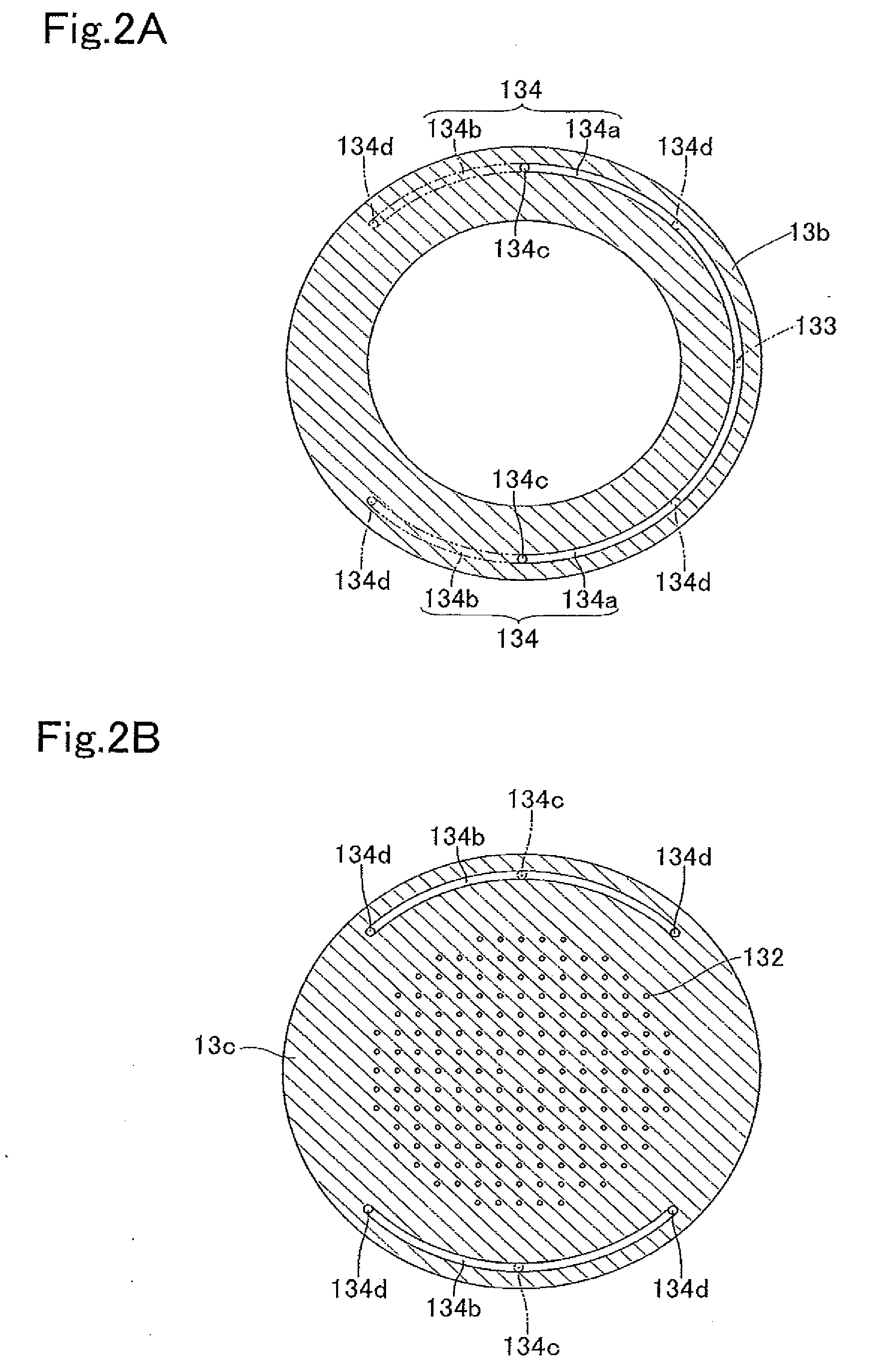

Hexagonal ferrite magnetic particle and method of manufacturing the same, and magnetic recording medium

ActiveUS20110244272A1Improve coercive forceReduce particlesMaterial nanotechnologyMagnetic materials for record carriersHeat treatedMaterials science

An aspect of the present invention relates to a method of manufacturing a hexagonal ferrite magnetic particle comprising melting an Al-containing starting material mixture to prepare a melt and quenching the melt to obtain an amorphous material; subjecting the amorphous material to heat treatment to cause a hexagonal ferrite magnetic particle to precipitate in a product obtained by the heat treatment; collecting a hexagonal ferrite magnetic particle by subjecting the product to treatment with an acid and washing, wherein the hexagonal ferrite magnetic particle collected has a particle size ranging from 15 to 30 nm, comprises 0.6 to 8.0 weight percent of Al, based on Al2O3 conversion, relative to a total weight of the particle, and Al adheres to a surface of the hexagonal ferrite magnetic particle.

Owner:FUJIFILM CORP

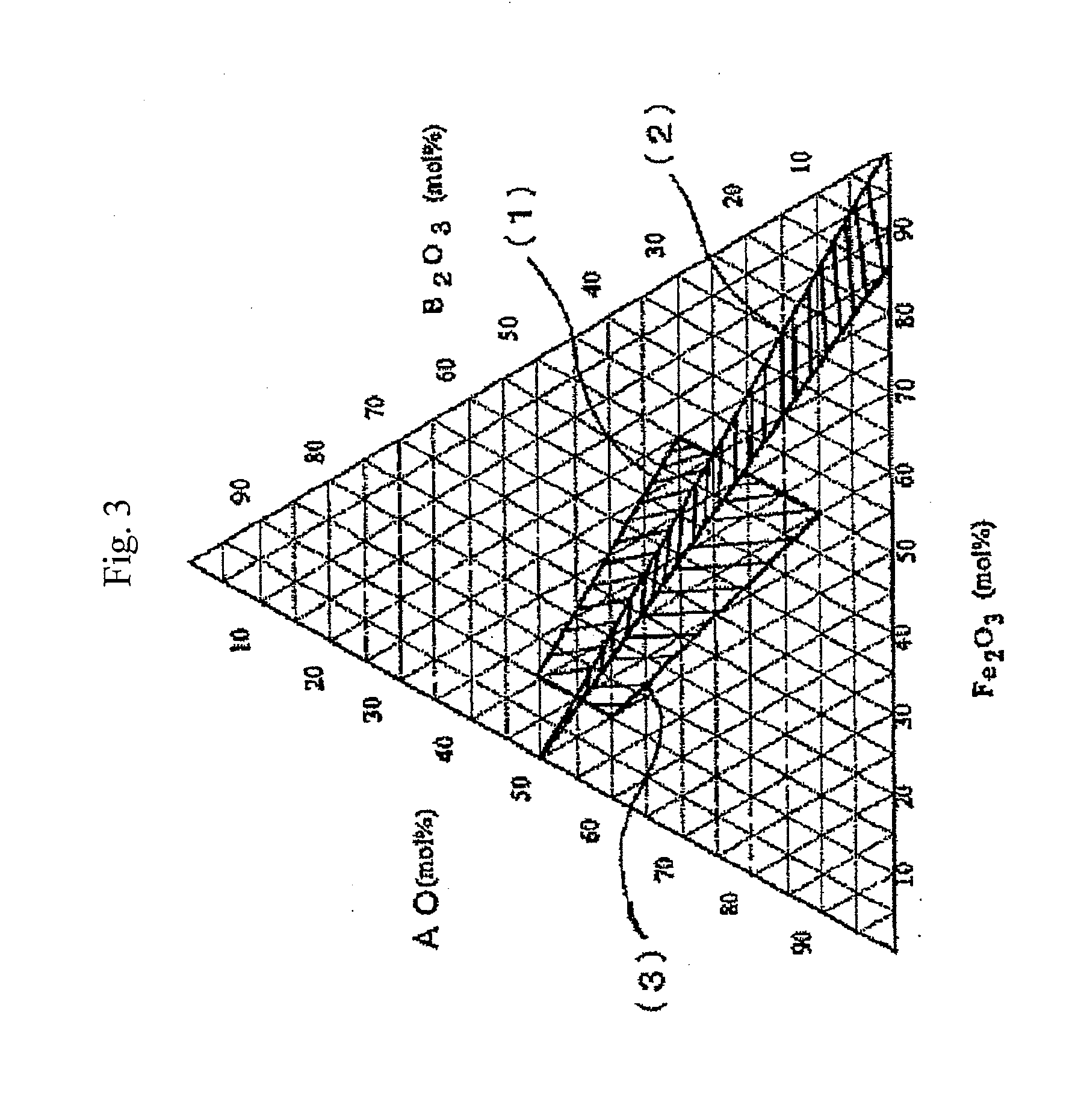

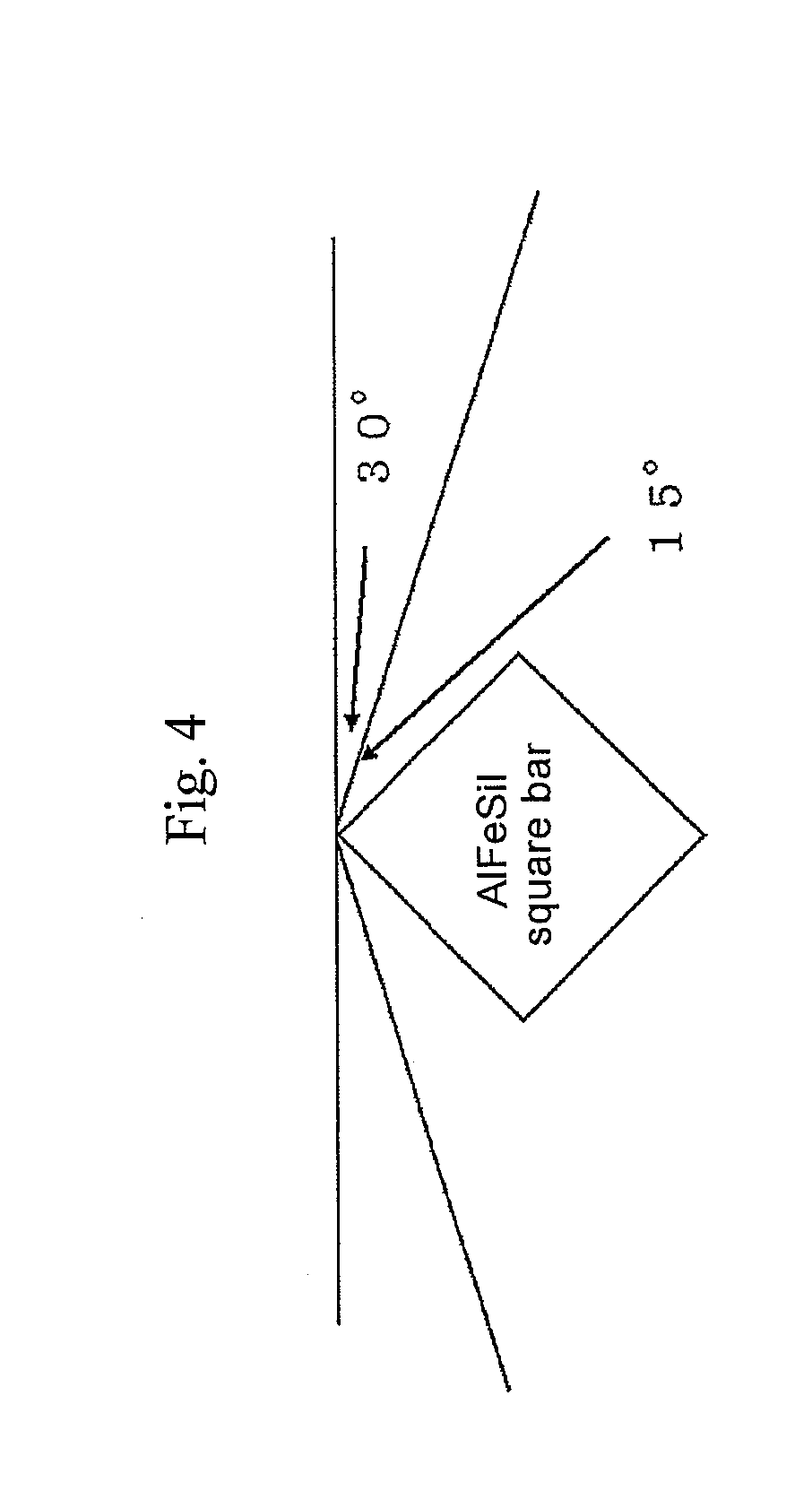

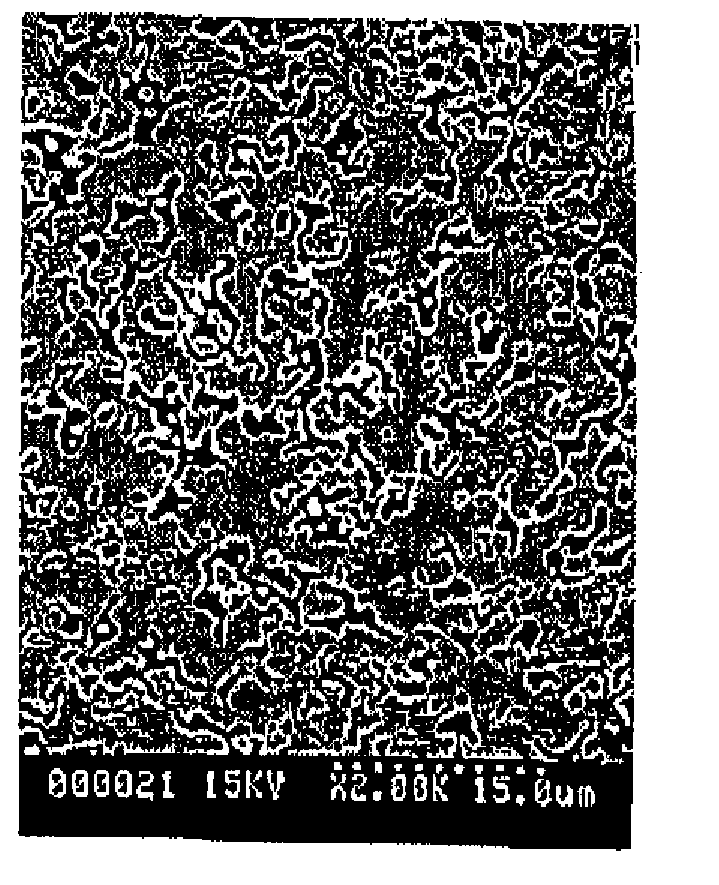

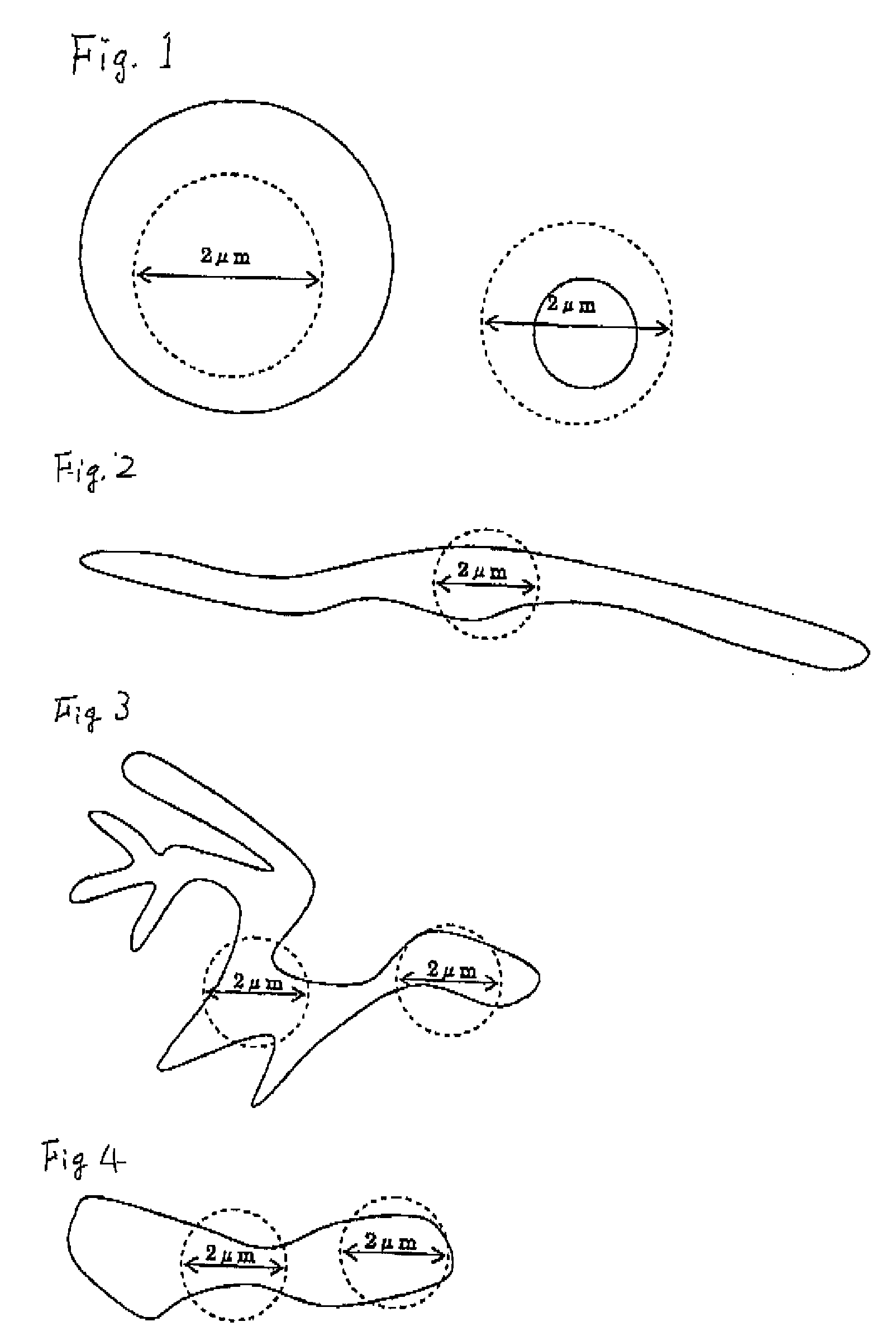

Nonmagnetic Material Particle Dispersed Ferromagnetic Material Sputtering Target

ActiveUS20090242393A1Good effectFast depositionCellsVacuum evaporation coatingProduction rateSputtering

Provided is a nonmagnetic material particle dispersed ferromagnetic material sputtering target comprising a material including nonmagnetic material particles dispersed in a ferromagnetic material. The nonmagnetic material particle dispersed ferromagnetic material sputtering target is characterized in that all particles of the nonmagnetic material with a structure observed on the material in its polished face have a shape and size that are smaller than all imaginary circles having a radius of 2 μm formed around an arbitrary point within the nonmagnetic material particles, or that have at least two contact points or intersection points between the imaginary circles and the interface of the ferromagnetic material and the nonmagnetic material. The nonmagnetic material particle dispersed ferromagnetic material sputtering target is advantageous in that, in the formation of a film by sputtering, the influence of heating or the like on a substrate can be reduced, high-speed deposition by DC sputtering is possible, the film thickness can be regulated to be thin, the generation of particles (dust) or nodules can be reduced during sputtering, the variation in quality can be reduced to improve the mass productivity, fine crystal grains and high density can be realized, and the nonmagnetic material particle dispersed ferromagnetic material sputtering target is particularly best suited for use as a magnetic recording layer.

Owner:JX NIPPON MINING& METALS CORP

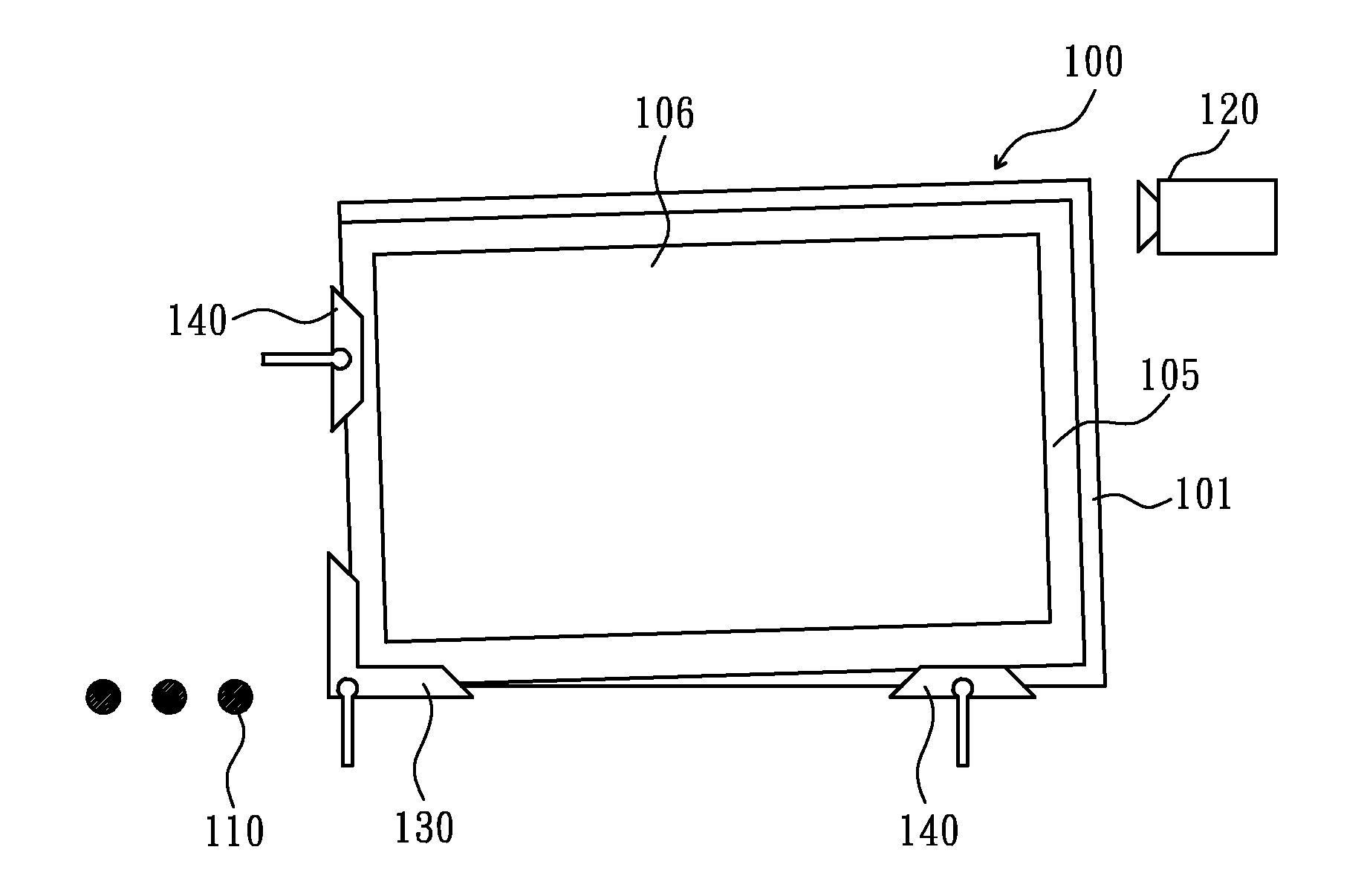

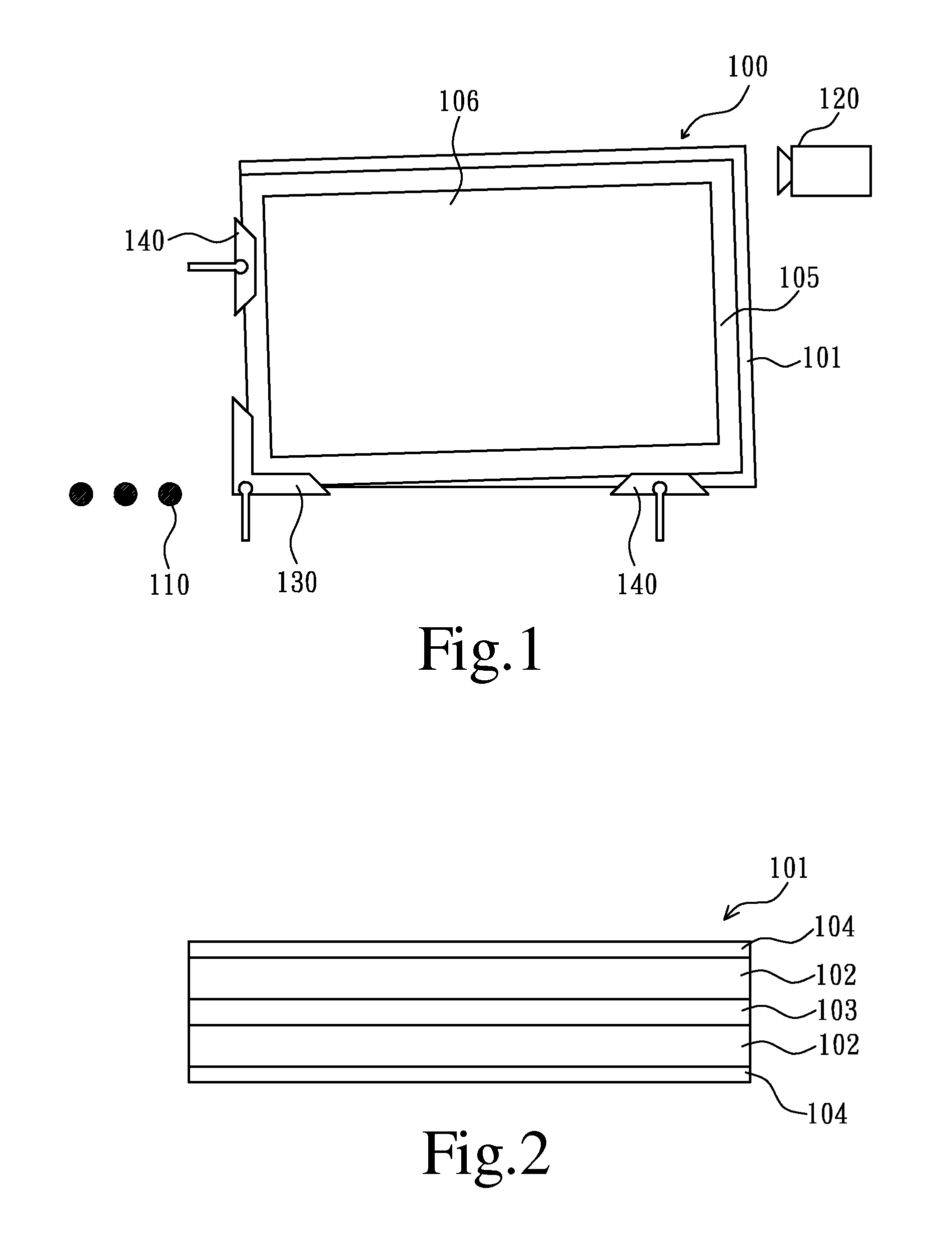

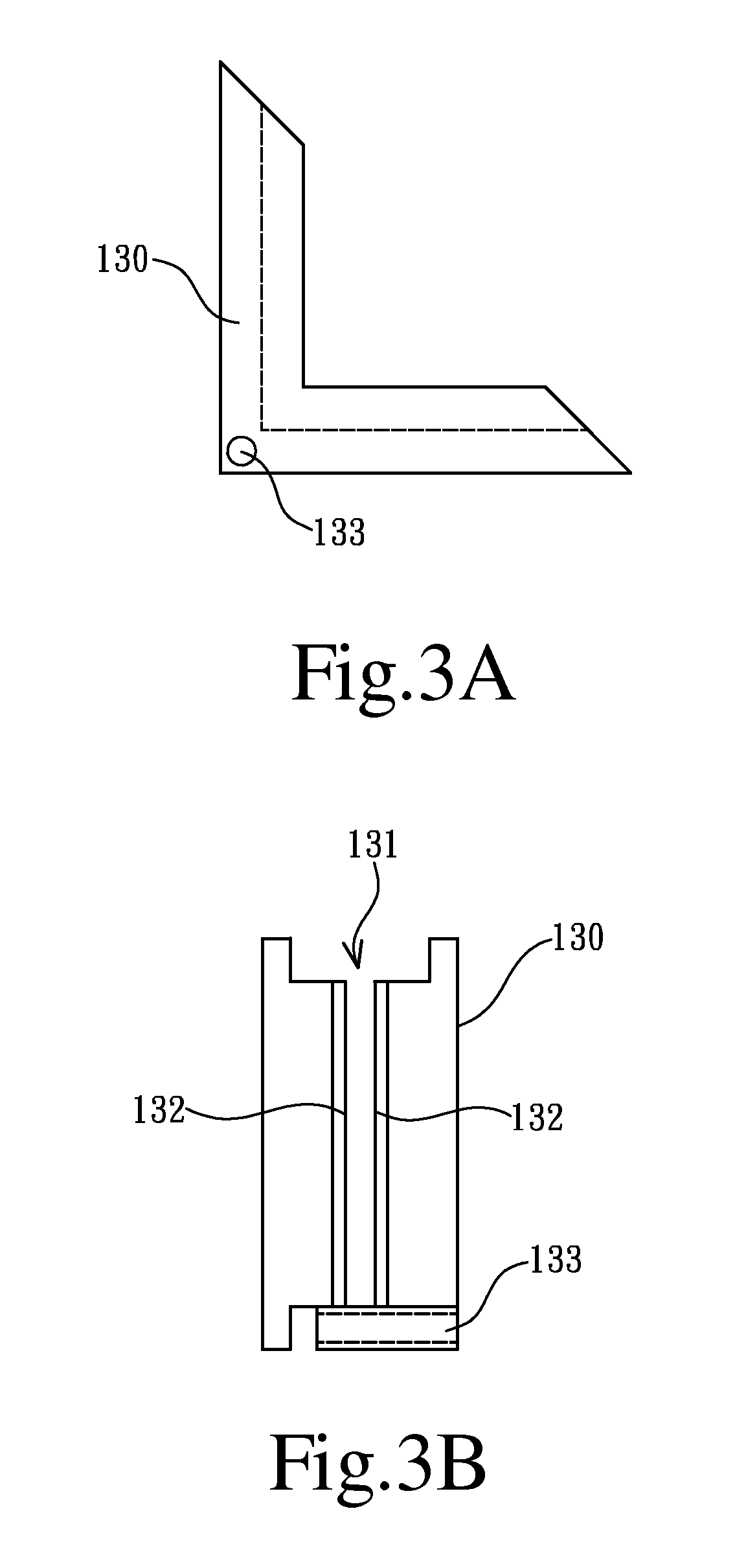

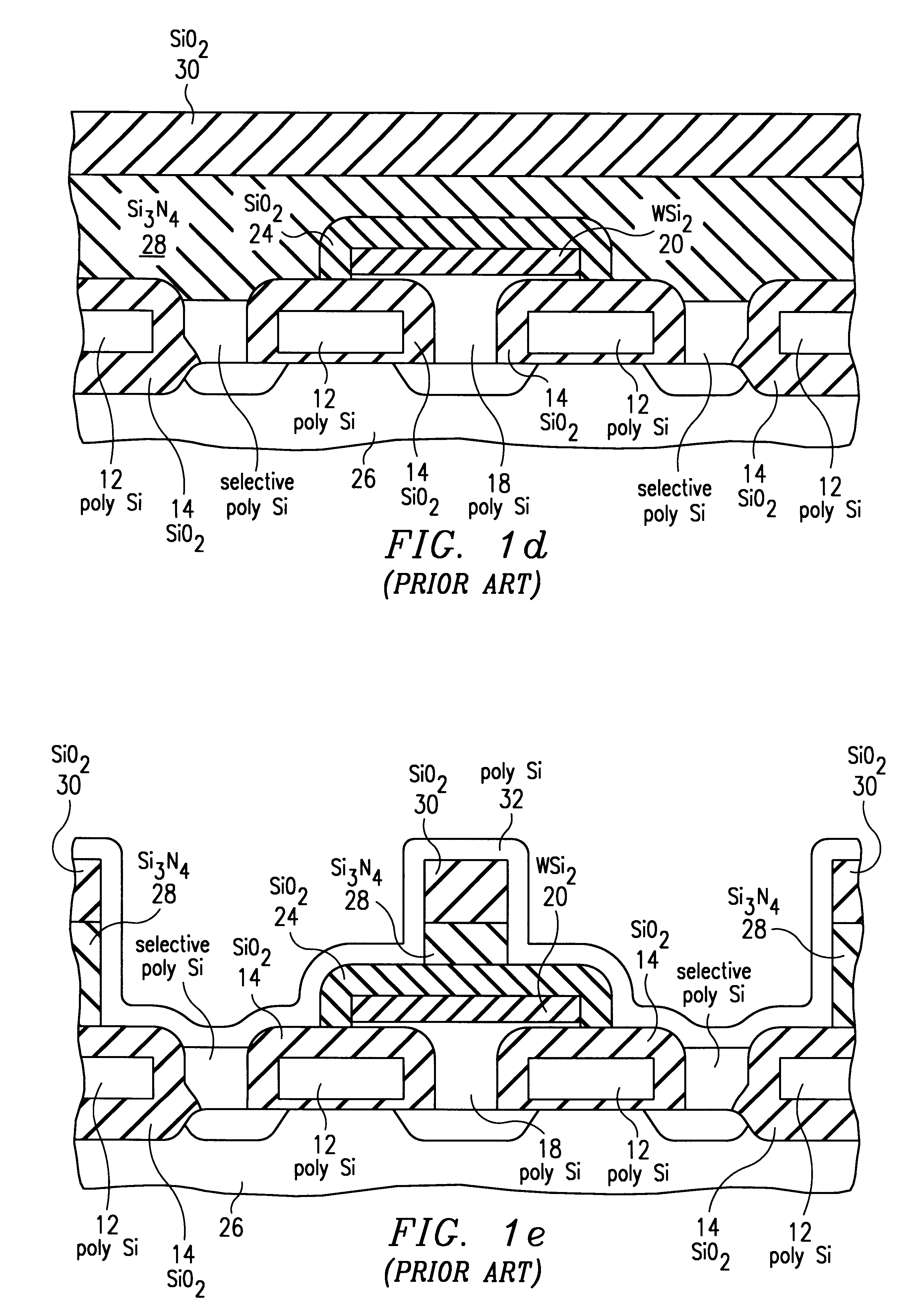

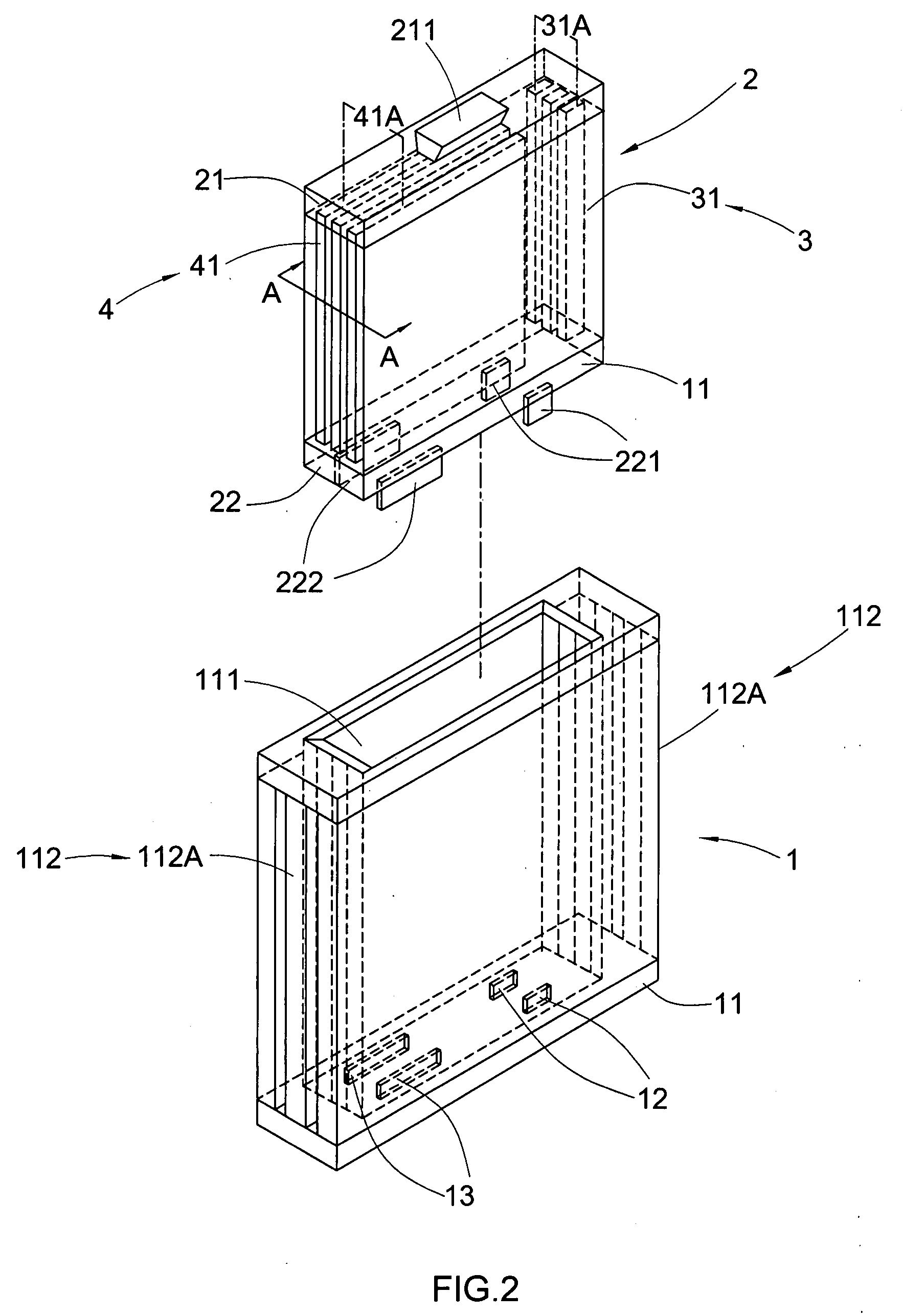

Panel alignment apparatus and panel alignment method

ActiveUS20120287260A1High positioning accuracyReduce particlesColor television detailsClosed circuit television systemsImage detectionEngineering

The present invention provides a panel alignment apparatus and a panel alignment method. The panel alignment apparatus comprises an image detection device and a first clamp. The method comprises the following steps: utilizing the image detection device to detect a position of a display panel, and to calculate a position adjustment value; and utilizing the first clamp to hold the standing display panel, and to rotate the display panel according to the position adjustment value for adjusting a position of the display panel. The present invention can utilize the clamps to precisely align the standing display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

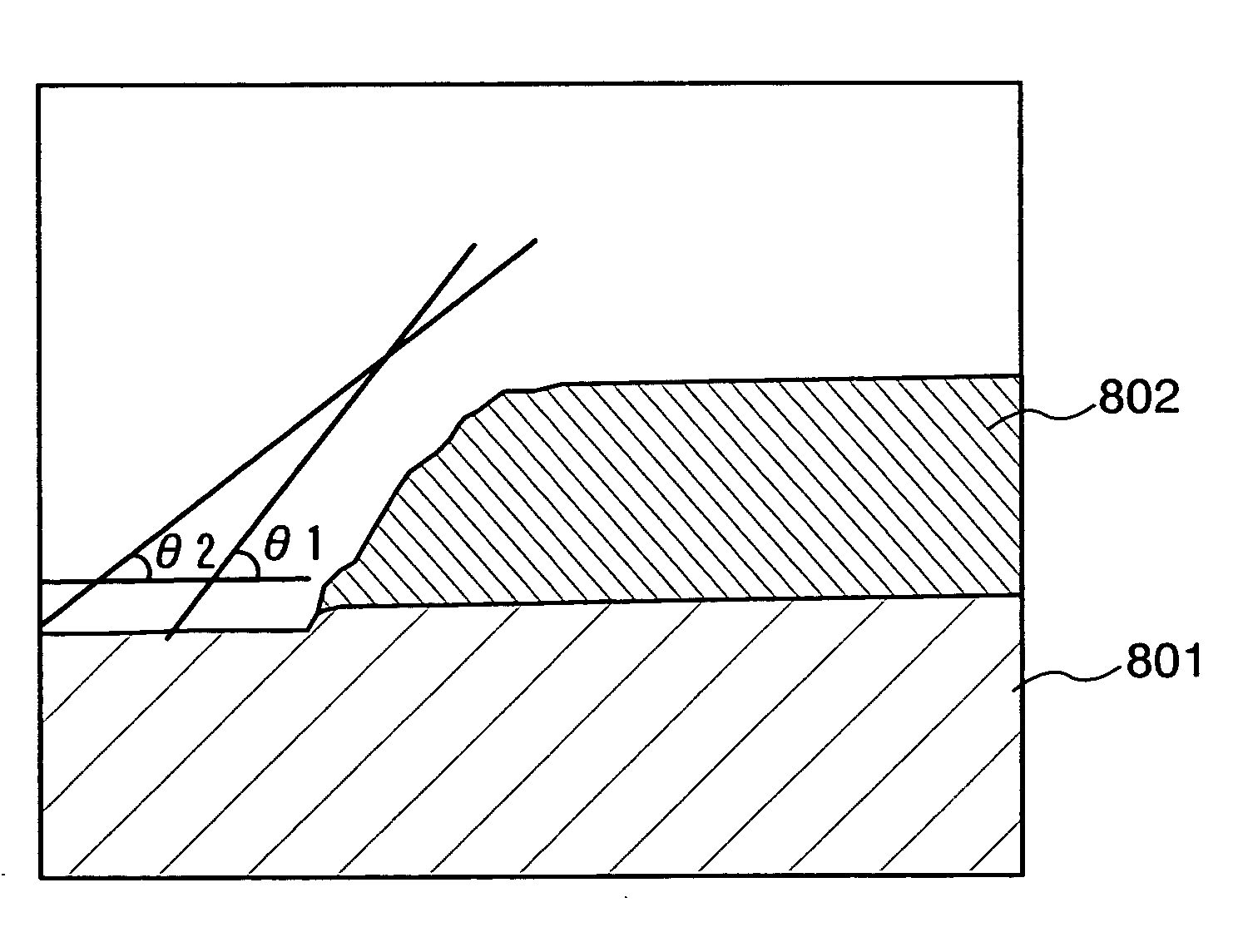

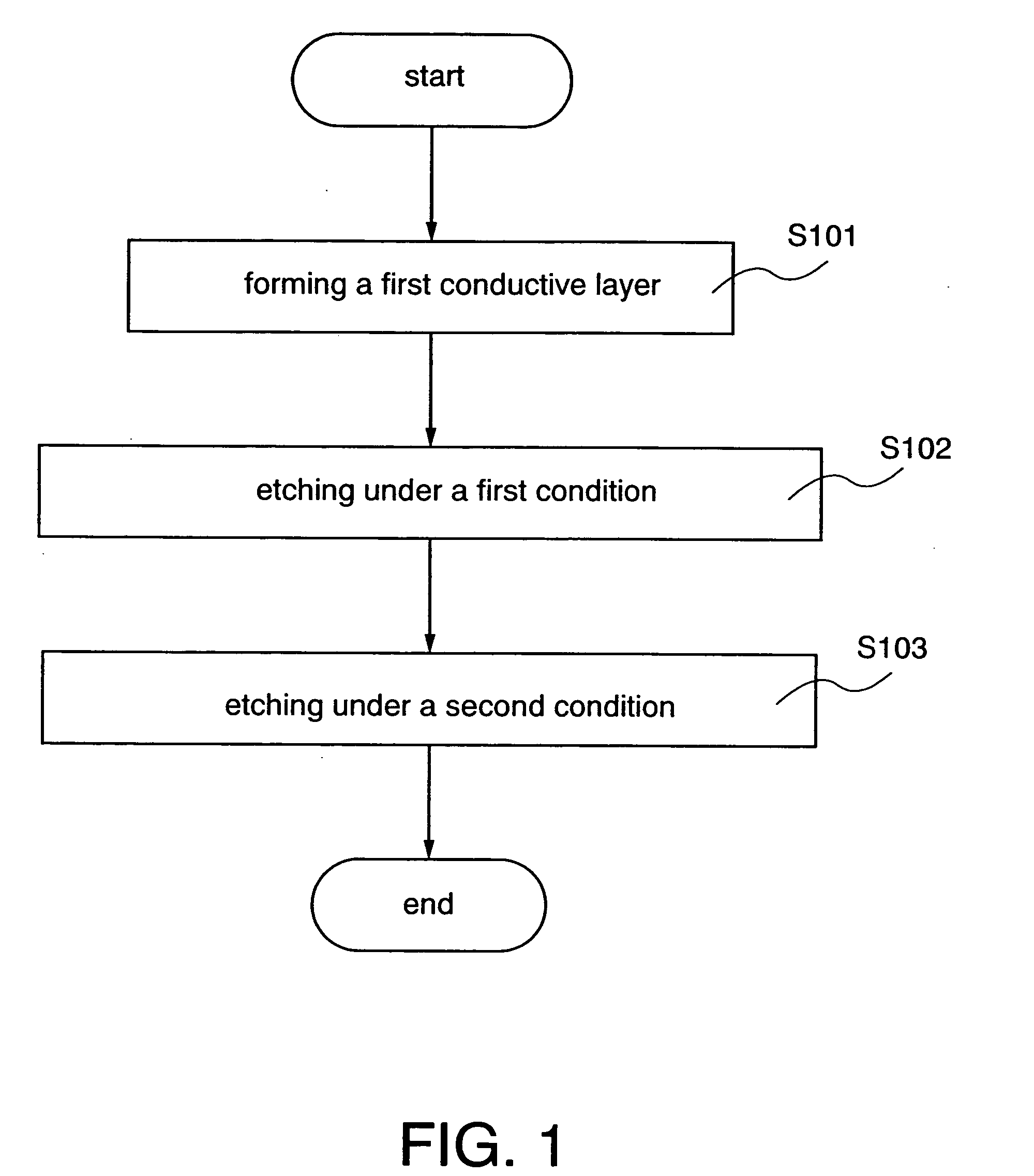

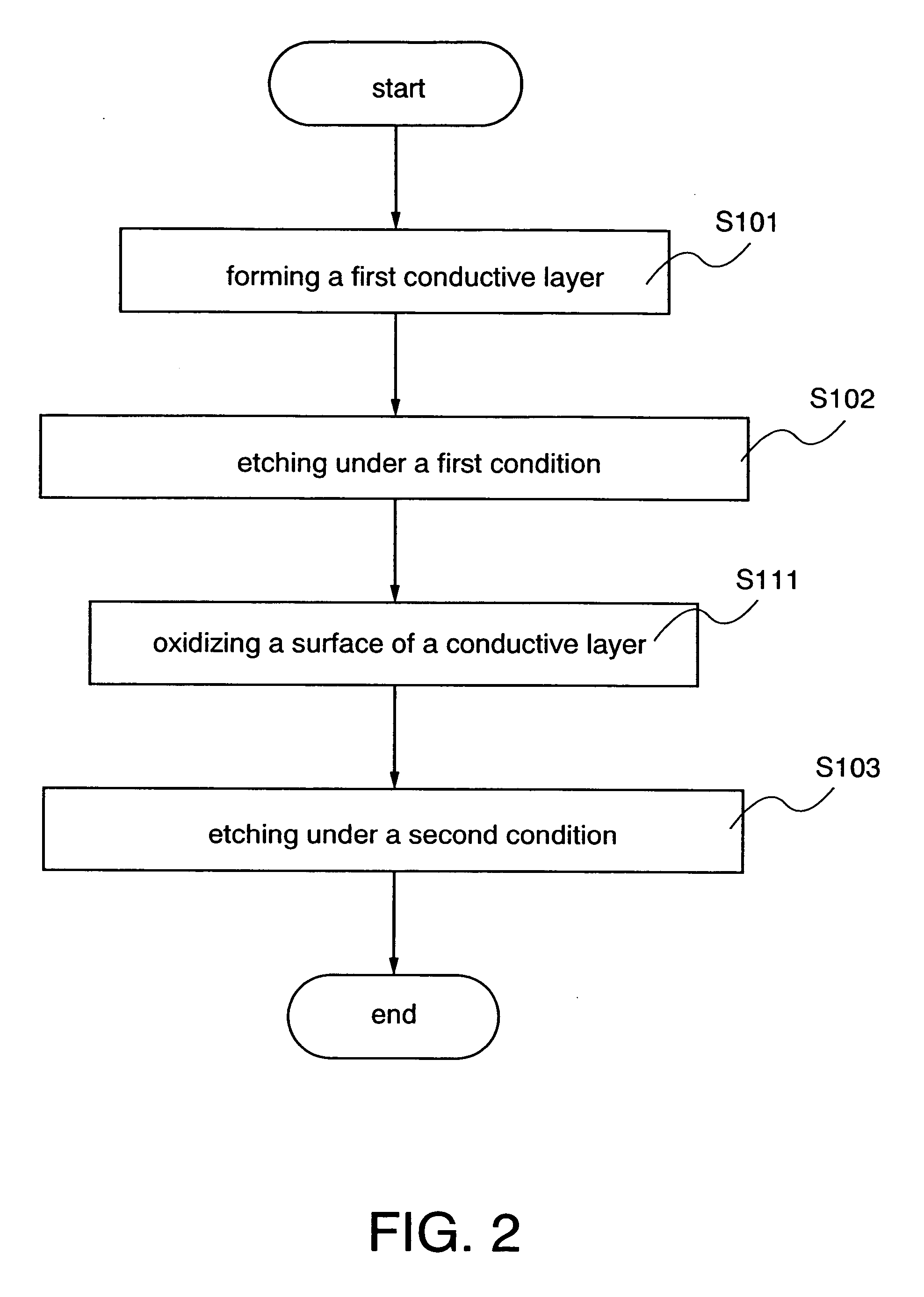

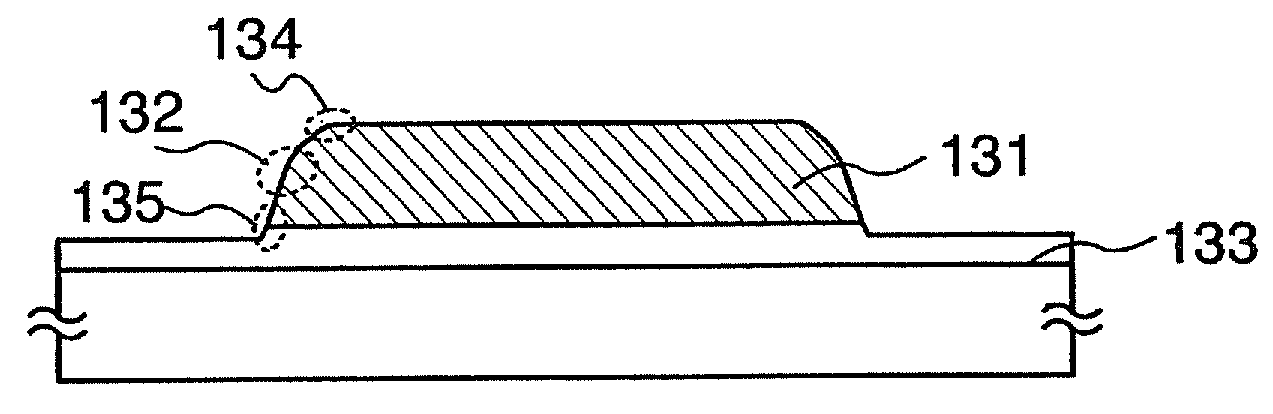

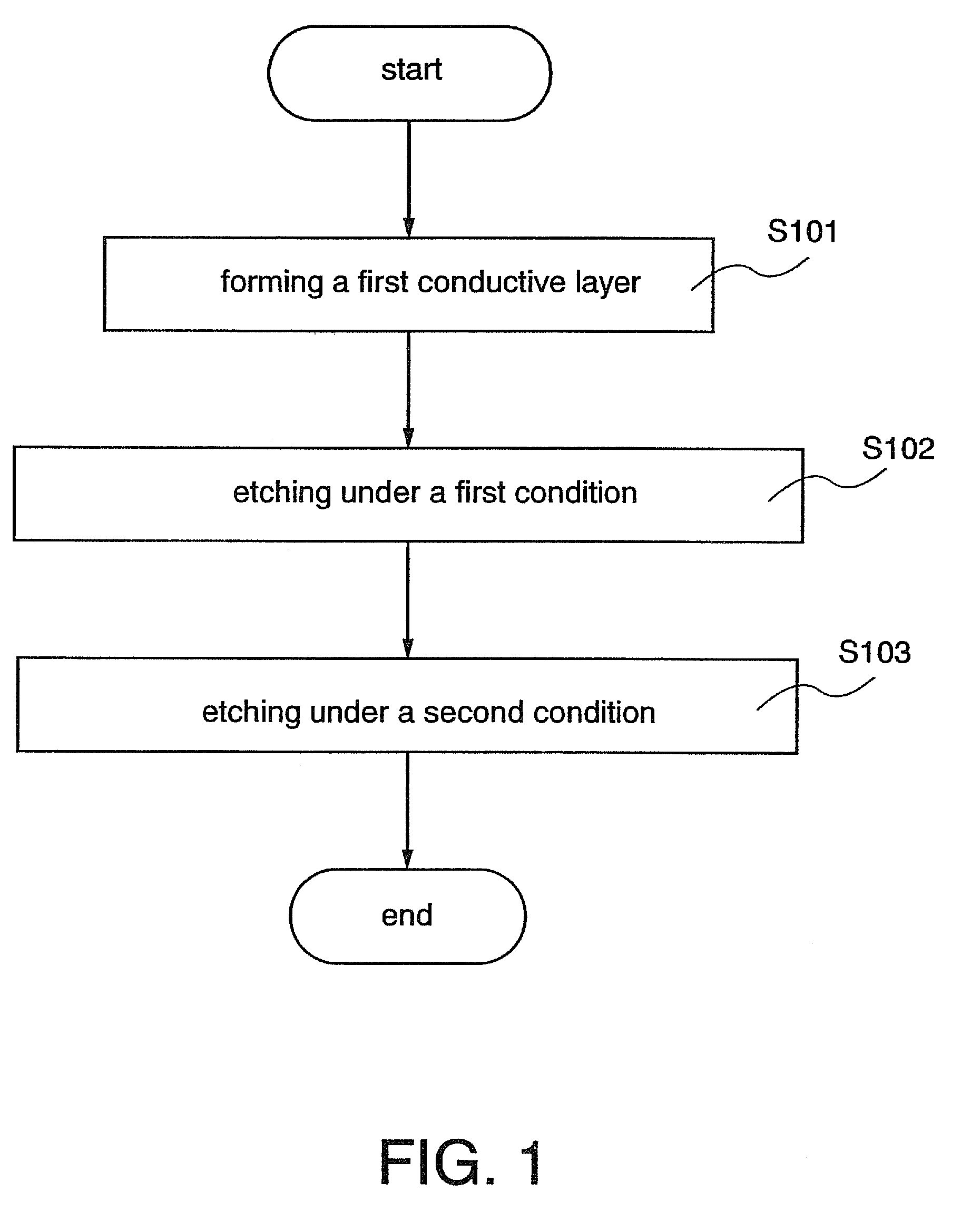

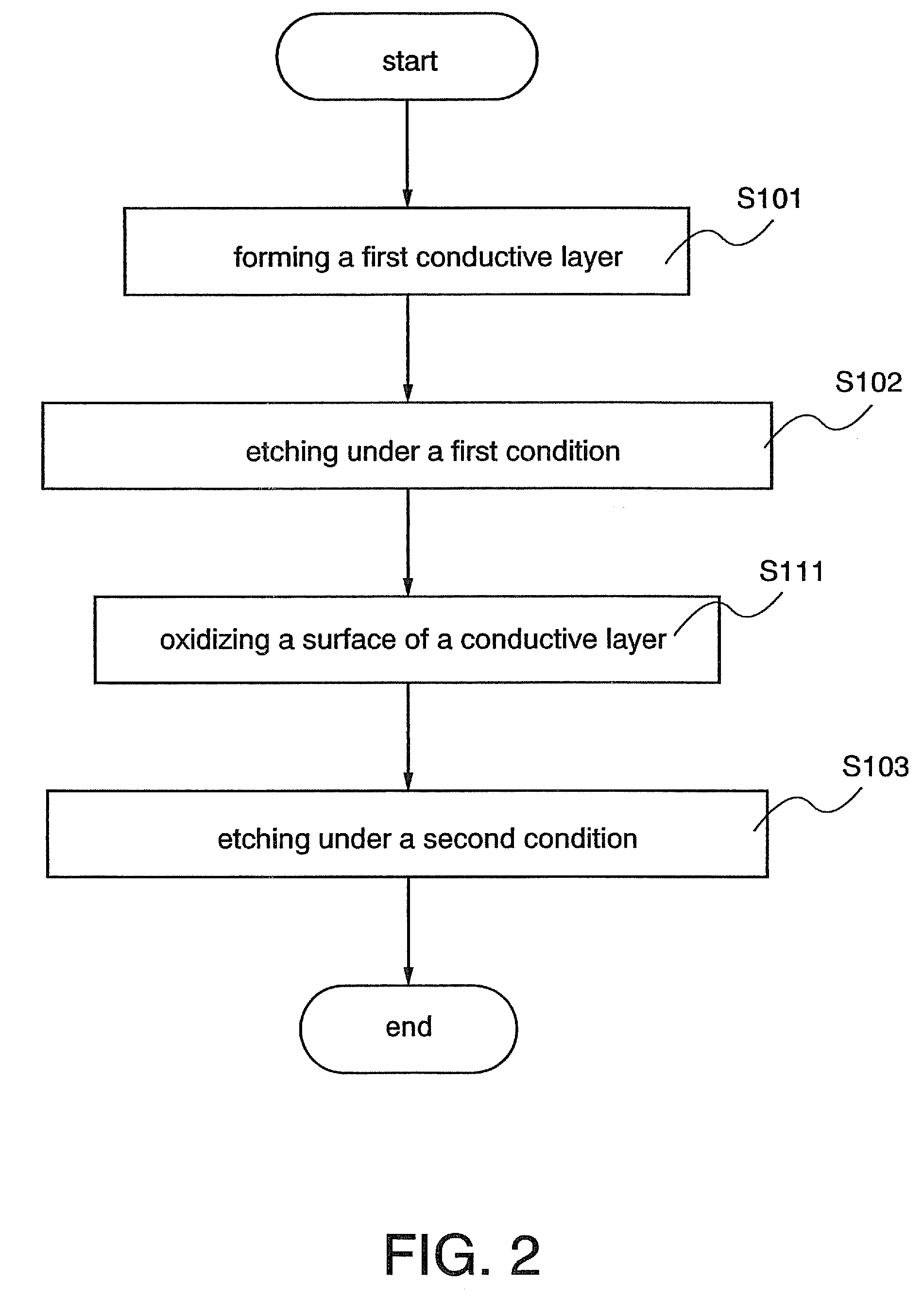

Wiring over substrate, semiconductor device, and methods for manufacturing thereof

InactiveUS20050245087A1Preventing short-circuitingAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A wiring over a substrate capable of reducing particles between wirings and a method for manufacturing the wiring is disclosed. A wiring over a substrate capable of preventing short-circuiting between wirings due to big difference in projection and depression between wirings and a method for manufacturing the wiring is also disclosed. Further, a wiring over a substrate capable of preventing cracks in the insulating layer due to stress at the edge of a wiring or particles and a method for manufacturing the wiring is also disclosed. According to the present invention, a method for manufacturing a wiring over a substrate is provided that comprises the steps of: forming a first conductive layer over an insulating surface; forming a first mask pattern over the first conductive layer; forming a second mask pattern by etching the first mask pattern under a first condition, simultaneously, forming a second conductive layer having a side having an angle of inclination cross-sectionally by etching the first conductive layer; and forming a third conductive layer and a third mask pattern by etching the second conductive layer and the second mask pattern under a second condition; wherein a selective ratio under the first condition of the first conductive layer to the first mask pattern is in a range of 0.25 to 4, and a selective ratio under the second condition of the second conductive layer to the second mask pattern is larger than that under the first condition.

Owner:SEMICON ENERGY LAB CO LTD

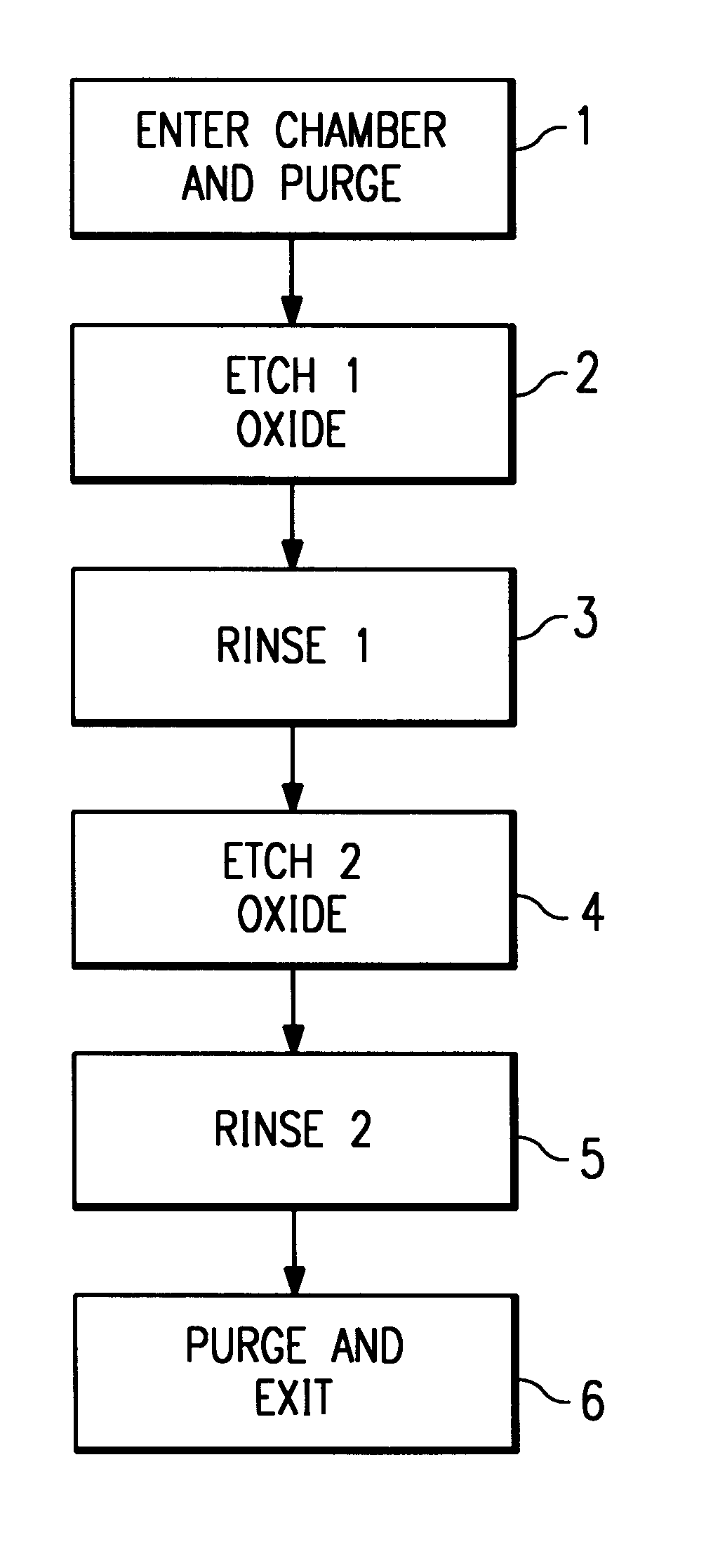

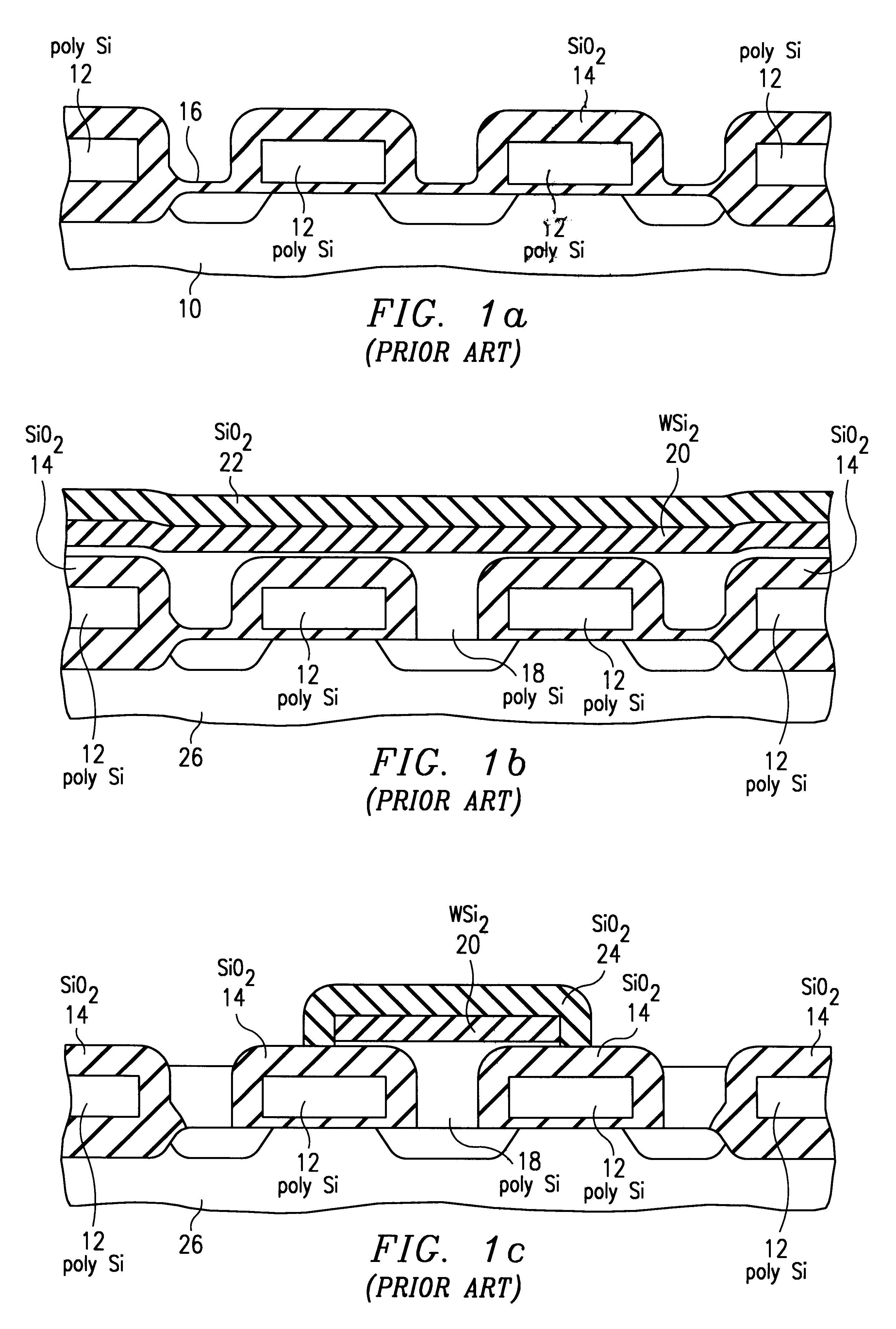

Two step oxide removal for memory cells

InactiveUS6174817B1Reduce particlesMinimizesTransistorSolid-state devicesHydrofluoric acidWater vapor

Hydrofluoric acid (HF) mixed with water and often buffered with ammonium fluoride is a standard silicon dioxide wet etchant which is followed by a rinse. An improved silicon dioxide etch is vapor HF which may be followed by a water vapor rinse. The invention discloses a further improved silicon dioxide etch. Following an initial exposure to vapor HF for oxide removal, a first insitu water rinse occurs. A second exposure to vapor HF then occurs and is followed by a second insitu water rinse. Water, rather than water vapor, aids in freeing particles from the wafer surface. During both the water rinses, the wafer may be rotated at increasing speeds to aid in sweeping particles from wafer surface. The process may be practiced in a commercially available reactor and is suitable for ULSI devices having complex topographies, such as, for example, 64 megabit DRAMs employing crown type memory cells.

Owner:TEXAS INSTR INC

PAM carrier

InactiveUS7503143B2Erosion minimizationStabilization of soil structureClimate change adaptationCultivating equipmentsBiology

A method for applying PAM to soil wherein said PAM is intermixed, impregnated and / or applied to solid carriers.

Owner:SKYLINE ENCAP HLDG LLC

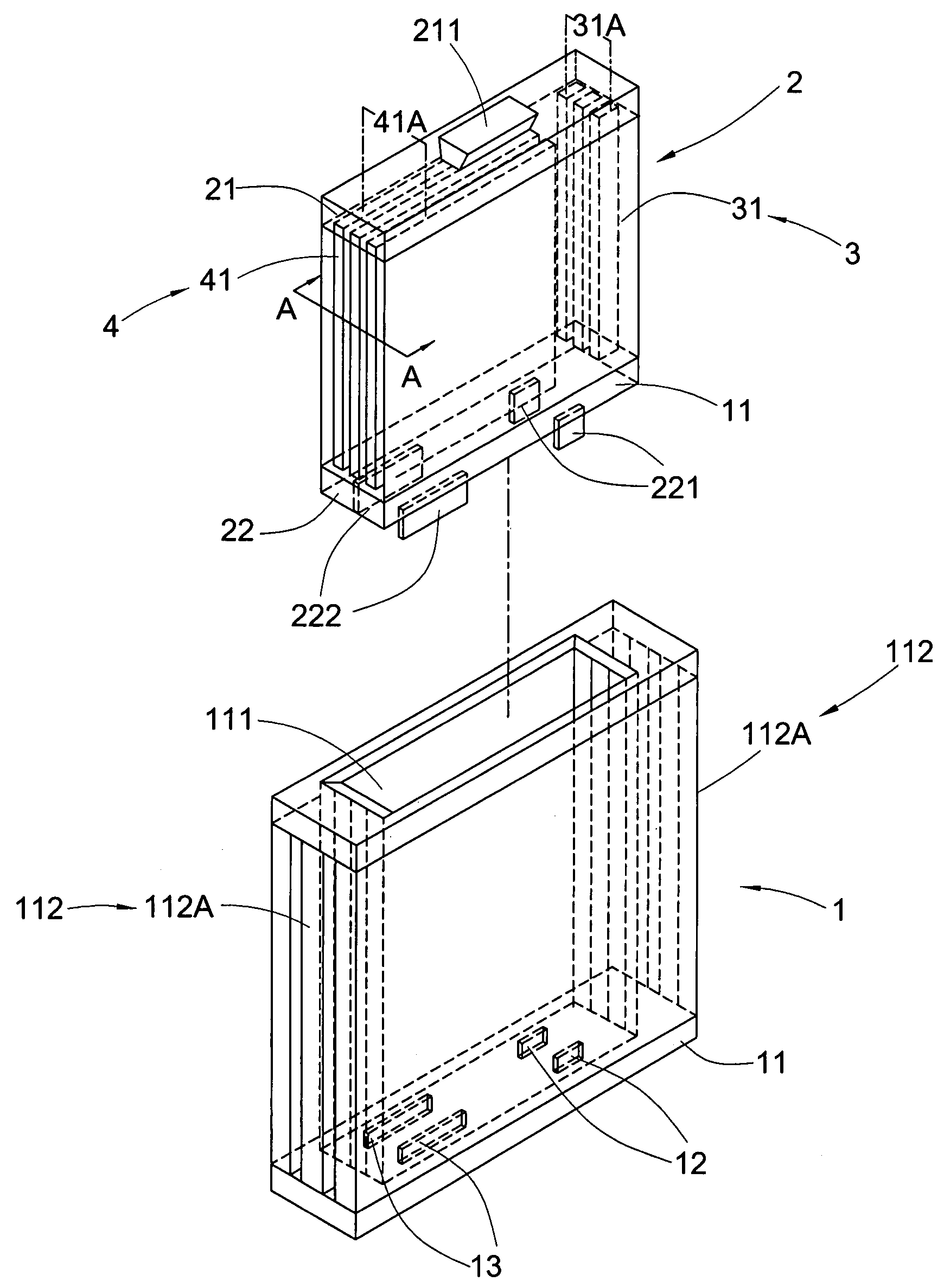

Compact Horizontal Air Purifier

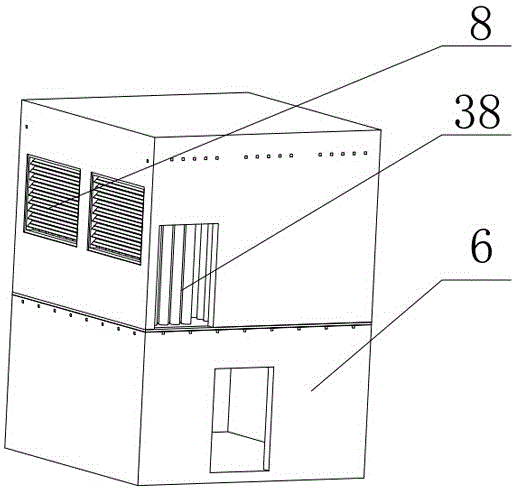

InactiveUS20090053113A1Reduce germsReduce odorMechanical apparatusLighting and heating apparatusAir filterAir purifiers

The present invention provides a compact horizontal air filter. The electrode array of the elements tending to be tainted with dust in the air filter is simple and convenient to generate clean and fresh air. The air filter comprises a case, a frame slidably inserted in and drew out of the case, a first array electrode fixed on the frame, a second array electrode fixed on the frame and being apart from the first array electrode, and a high voltage pulse generator. The electropositive particles in the air are attracted by the electronegative metal made collecting dust vane when they pass through a collecting dust chamber.

Owner:MAI CUIMEI

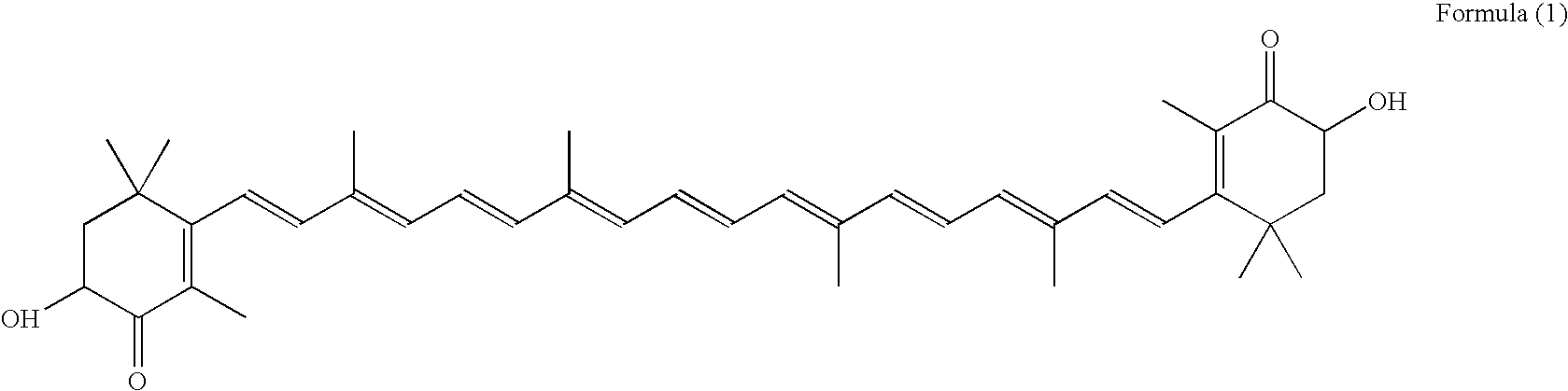

Carotenoid-containing emulsion composition, process for its production, and food and cosmetic product containing the same

InactiveUS20070286930A1Reduce particlesGood storage stabilityCosmetic preparationsToilet preparationsOil phaseWater soluble

A carotenoid-containing emulsion composition comprises carotenoid, wherein the composition further comprises: at least one water-soluble emulsifier in an aqueous phase; and tocopherol and lecithin in an oil phase.

Owner:FUJIFILM CORP

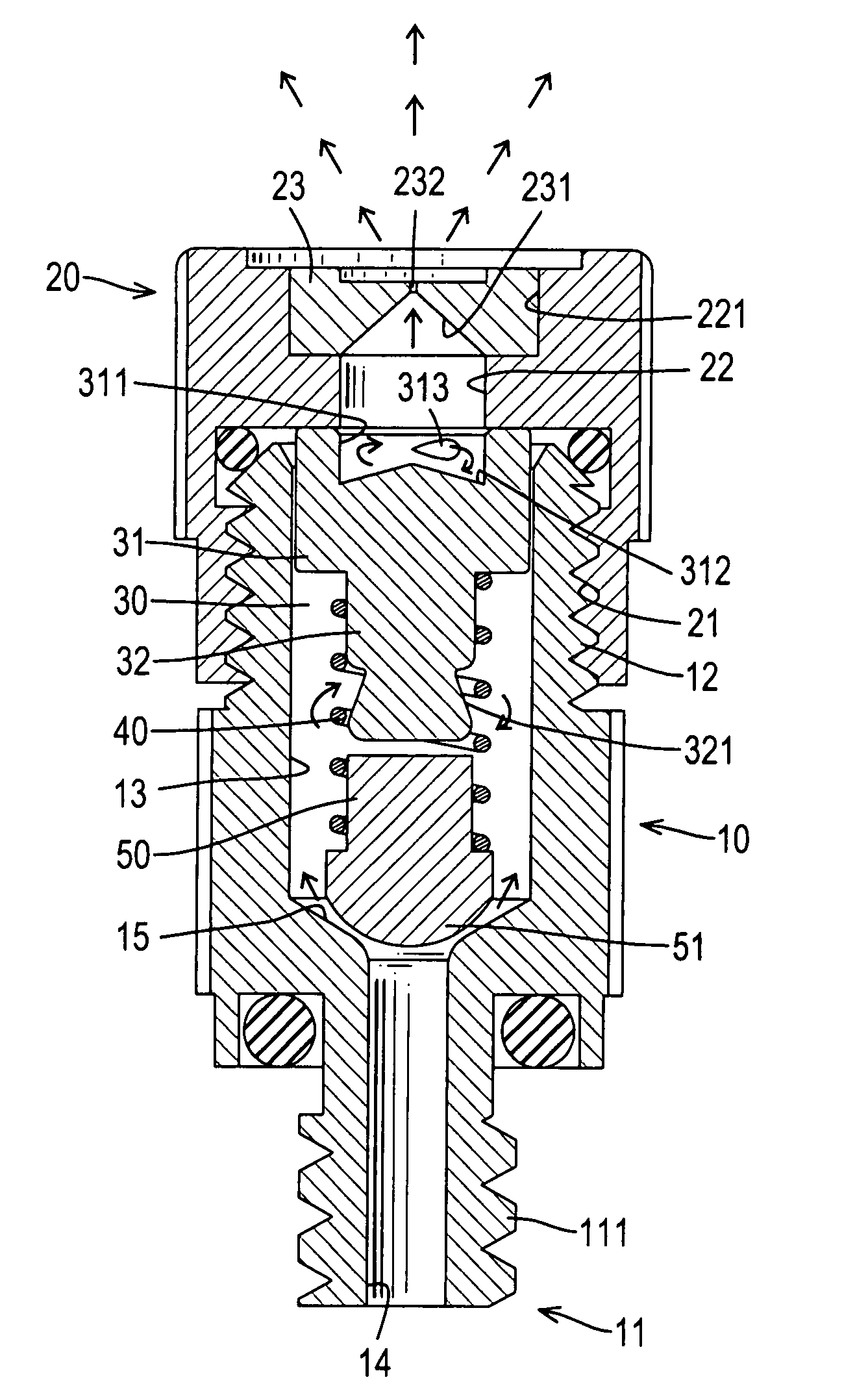

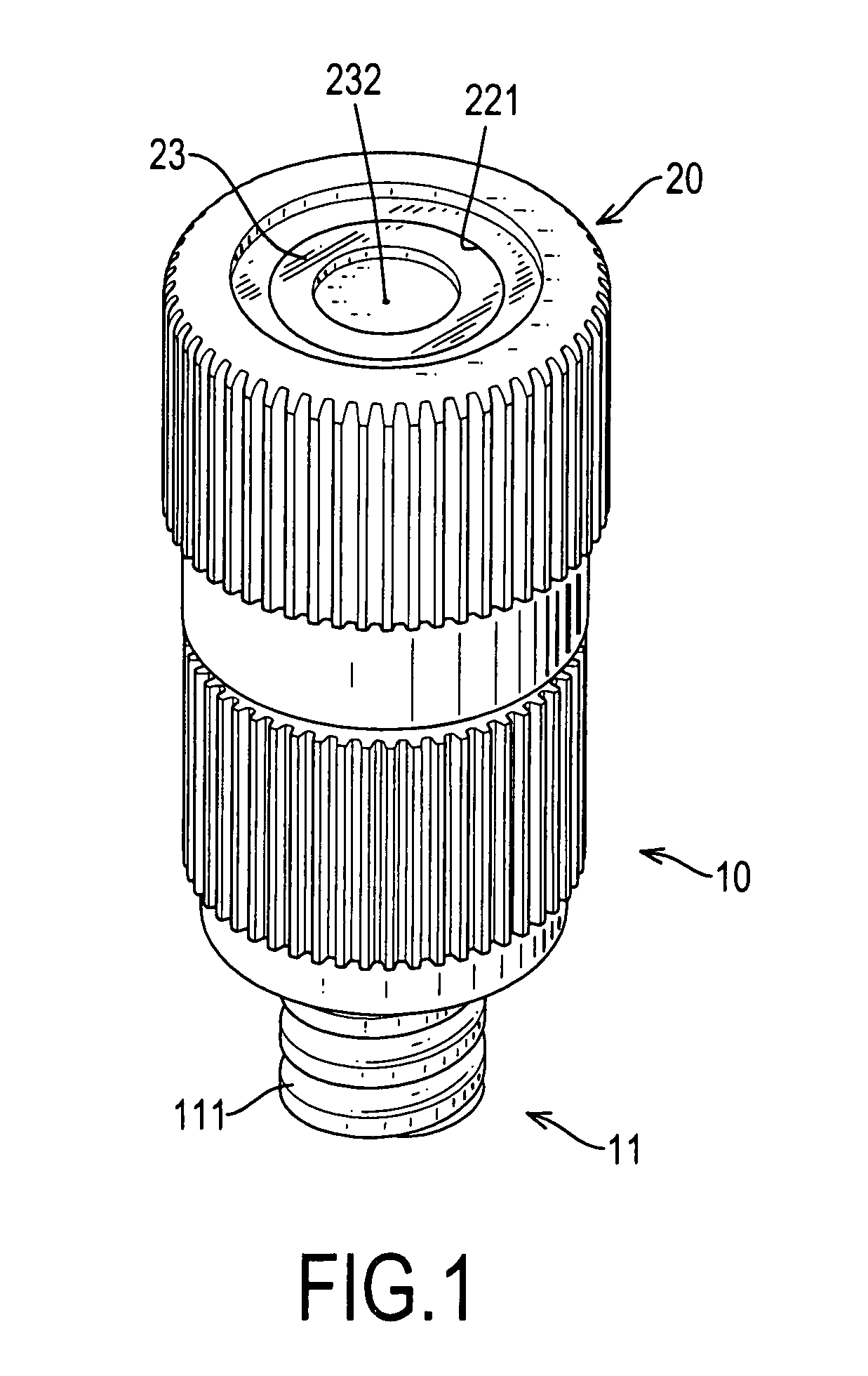

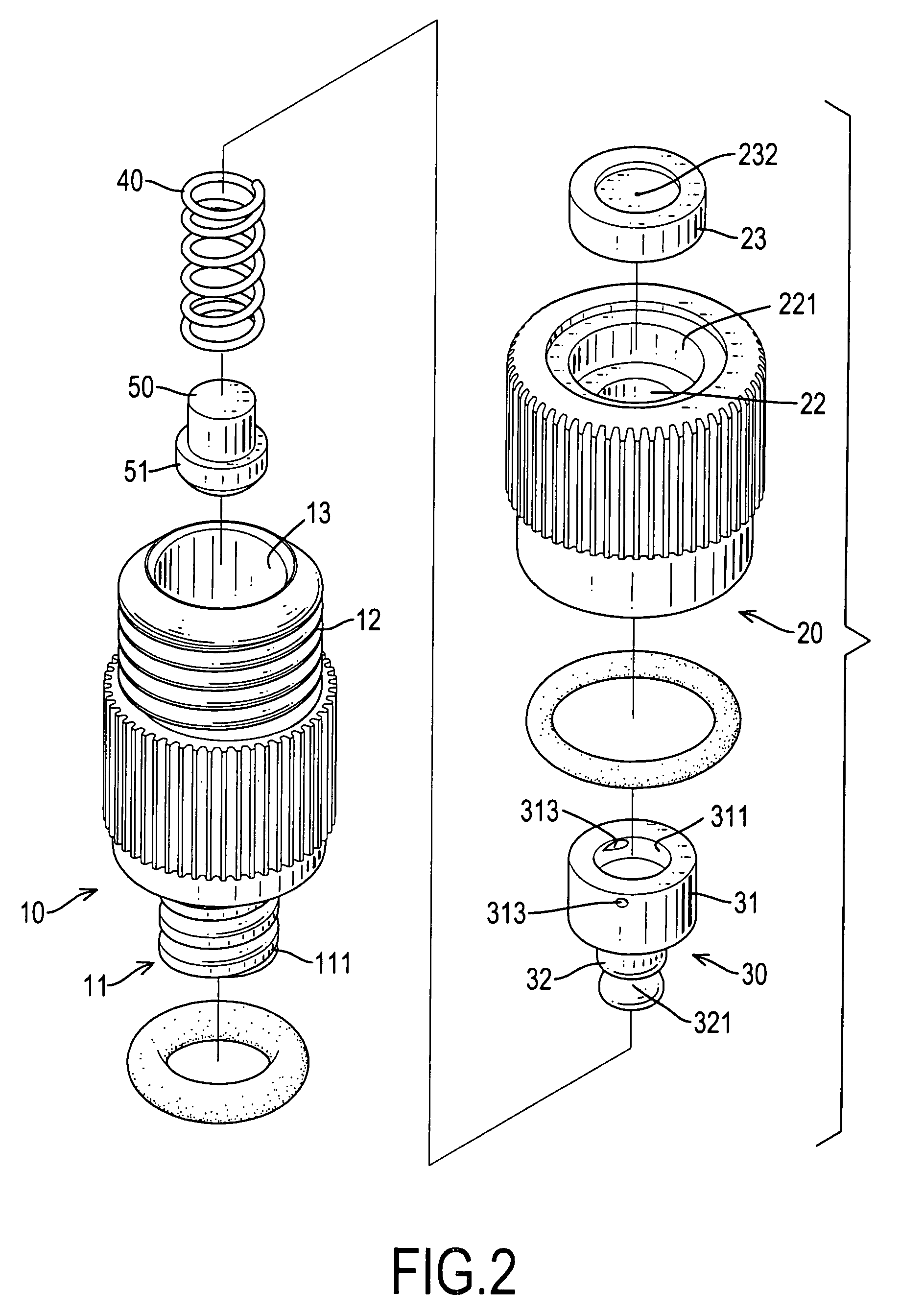

Spraying head assembly

InactiveUS7464885B1Reduce particlesIncrease distanceSpray nozzlesConical cavityMechanical engineering

A spraying head assembly has a tubular body, a cap, an upper plug, a lower plug and a spring. The cap is attached to the body and has a spraying channel, a conical cavity and a spraying hole. The conical cavity is defined inside the cap and communicates with the spraying channel and the spraying hole. The upper plug is held in the body and comprises a spraying end, a connecting end, a head and shaft. The head has a recess communicating with the spraying channel having a conical bottom. Multiple passages are defined in the head and communicate with the recess. The lower plug is mounted movably in the chamber in the body and is connected to the upper plug using the spring. In this arrangement, a liquid supplied to the connecting end forms vortexes in the body to reduce particles of liquid nebulization and raise ejection speed and therefore distance.

Owner:TANONG PRECISION TECH CO LTD

Particle reducing method and film deposition method

ActiveUS20130189849A1Reduce particlesElectric discharge tubesElectrostatic cleaningSusceptorEngineering

A particle reducing method includes a step of supplying a first gas to a vacuum chamber in which a susceptor, formed by an insulating object and the surface of which is provided with a substrate mounting portion, is rotatably provided; a step of generating plasma from the first gas by supplying high frequency waves to a plasma generating device provided for the vacuum chamber; and a step of exposing the substrate mounting portion, on which a substrate is not mounted, to the plasma while rotating the susceptor.

Owner:TOKYO ELECTRON LTD

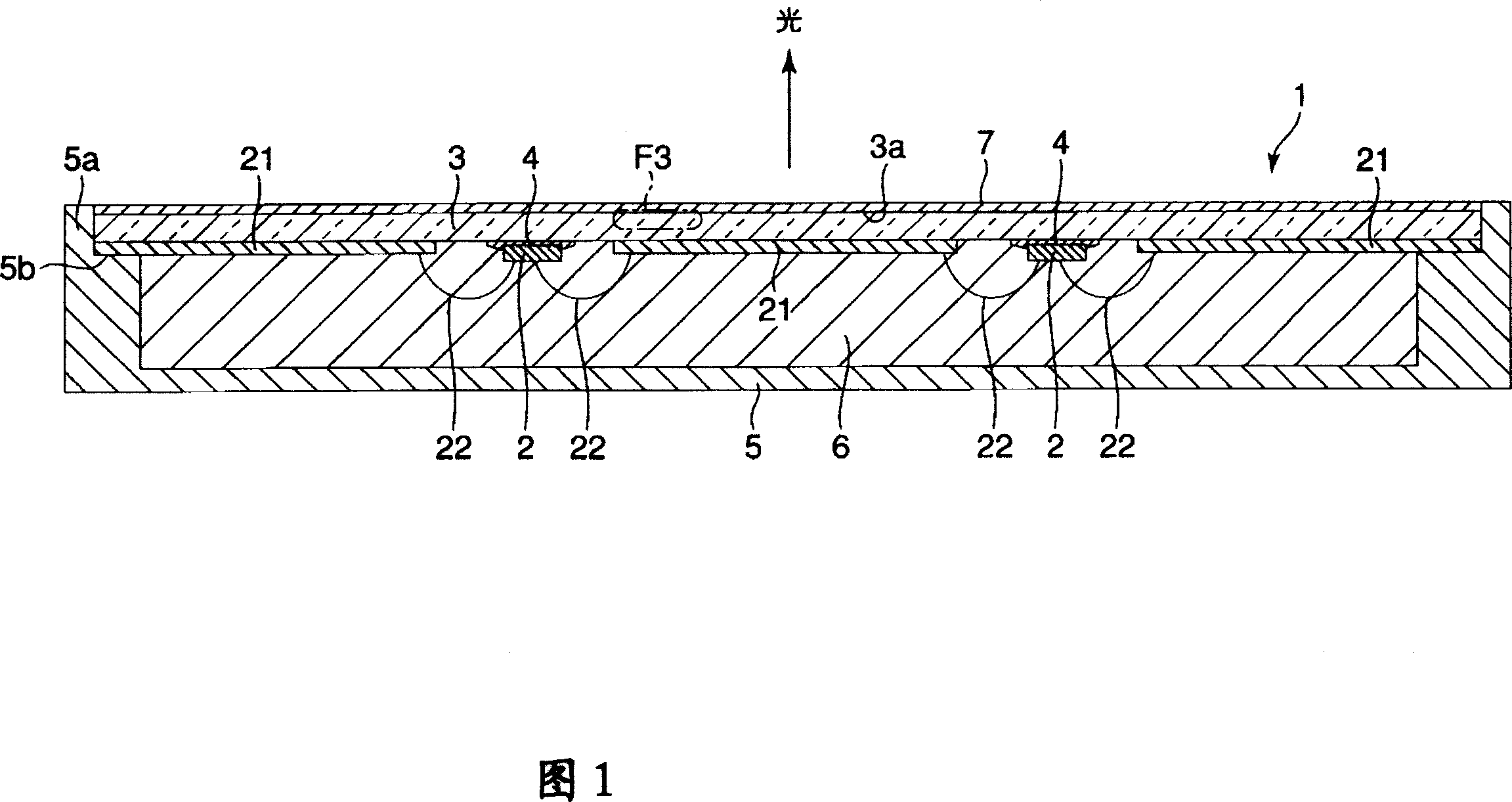

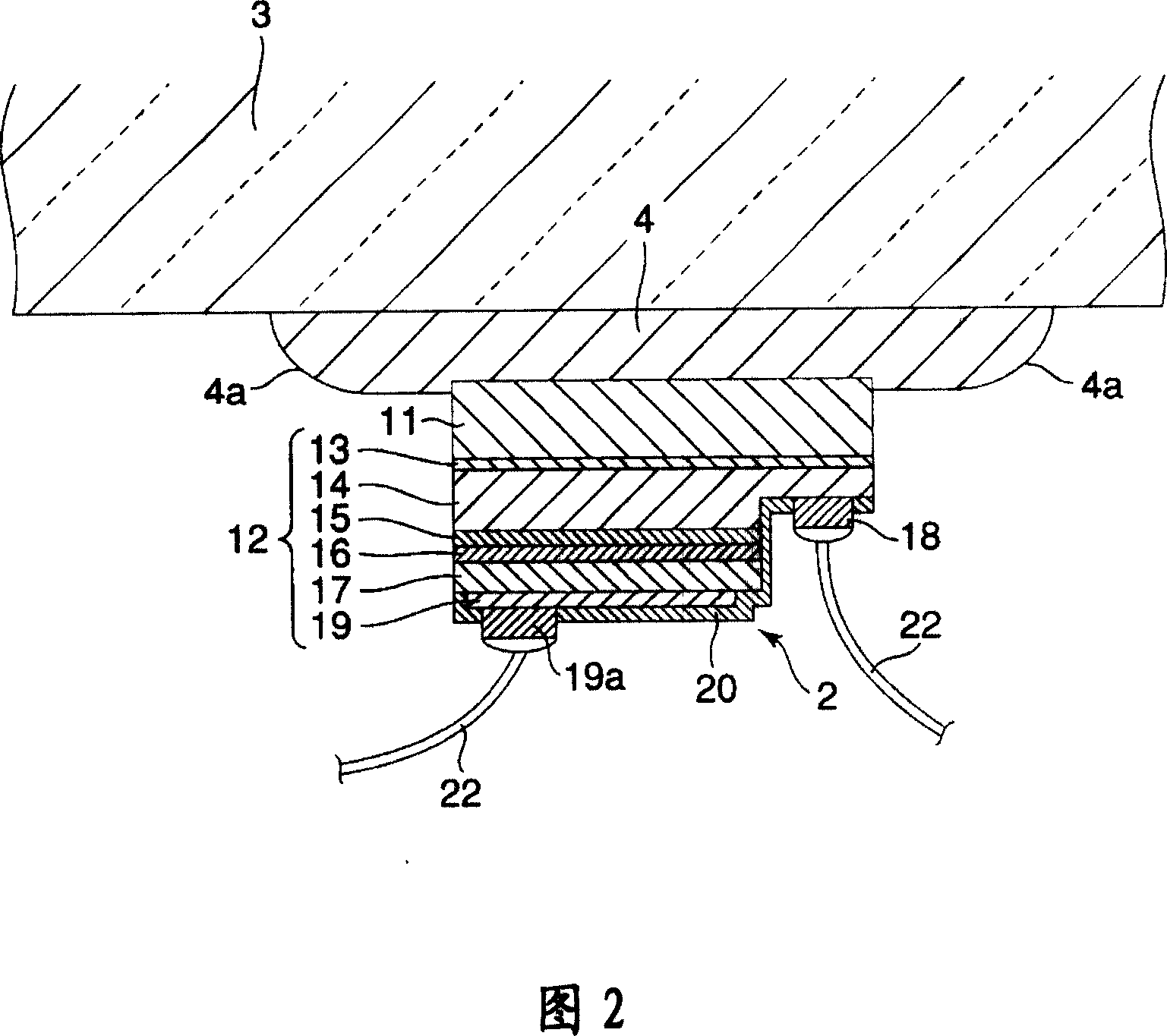

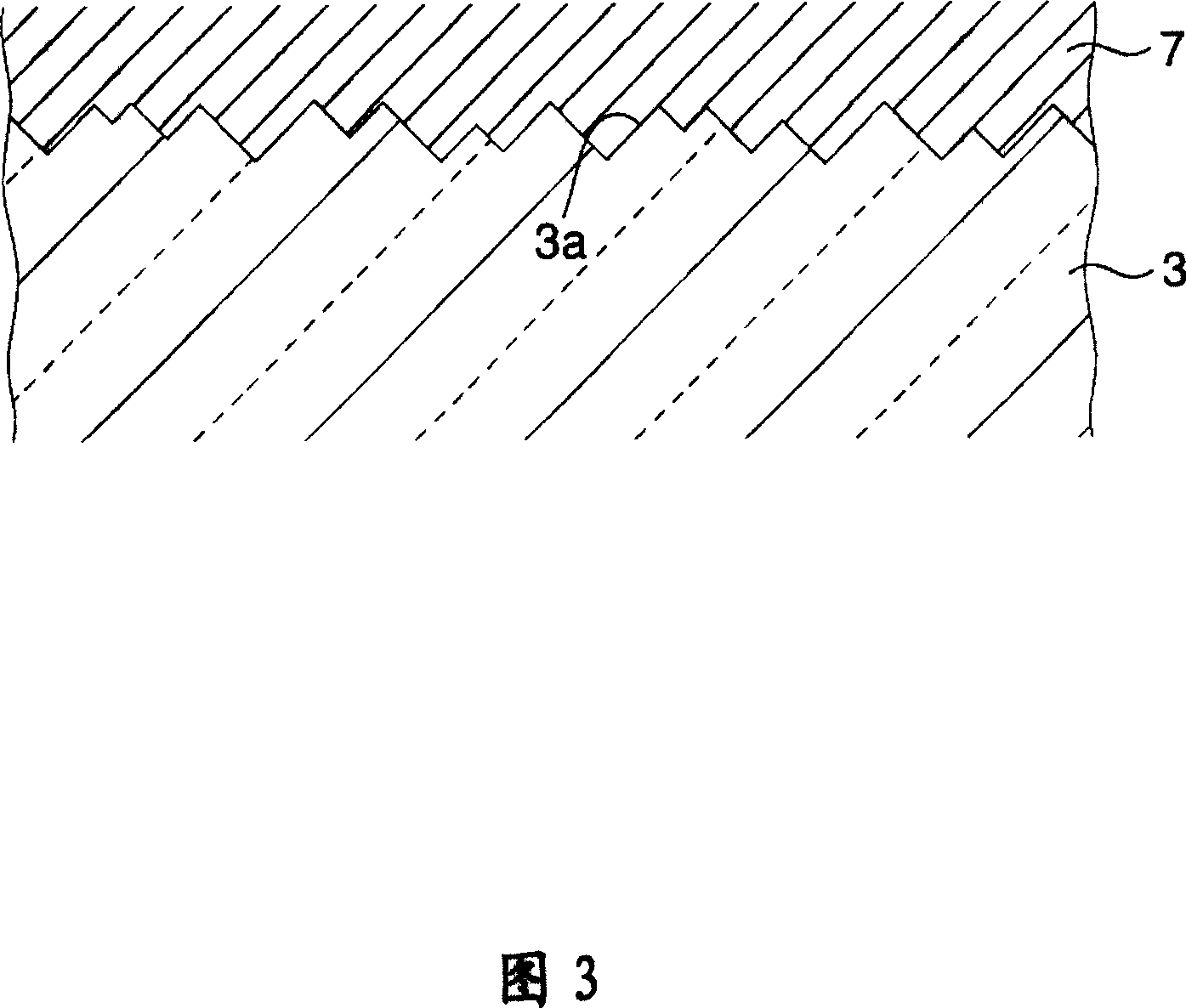

Illumination device

InactiveCN101034728AReduce graininessEfficient extractionSolid-state devicesSemiconductor devicesLuminophoreFluorescence

The present invention provides a lighting device which can high efficiently extract white light and reduce granular sensation about light source. The lighting device includes: plural semiconductor luminescent components, transparence substrate, transparence bonding layer, reflection member, transparence sealing member, luminophore layer. The luminescent components has semiconductor luminescent layer on back laminated layer of transparence component substrate and extracts the light emitted from the luminescent layer. Lead (conductive portion) of the transparence substrate is connected with p side and n side electrodes of the luminescent component. The backside of the transparence substrate is bonded with surface of component substrate of each luminescent component via the bonding layer. The seal member is arranged at back side of the transparence substrate to seal the luminescent component. The reflection member covers the seal member. The luminophore layer covers the surface of the transparence substrate. The luminophore layer includes luminophore for wavelength convertion of first light emitted by the semiconductor luminescent layer to second light with different wavelength.

Owner:TOSHIBA LIGHTING & TECH CORP

Soil stabilizer carrier

InactiveUS7730662B2Reducing fertilizer runoffReduce leachingClimate change adaptationCultivating equipmentsSoil scienceSoil stabilization

A method for applying a soil stabilizer, to soil wherein the soil stabilizer is intermixed, impregnated, and / or applied to solid carriers.

Owner:ENCAP LLC

Application of waterproof type emulsified olefin in use for production of fiberboard

A method to apply waterproof emulsified paraffin wax in fibreboard production includes emulsifying paraffin wax in water with emulsification additive to let paraffin wax solid content up to 40-50 % of being used as waterproofing agent, applying it in fibreboard production and drying all hydrophilic contents in emulsification agent off at drying process of 100-180 deg.C for achieving purpose of waterproof for fibre.

Owner:曾宪平

Transport roller of tobacco processing industry

InactiveCN102188046AReduce pollutionReduce loadCigarette manufactureShape objectPulp and paper industry

The invention relates to a transport roller (19) of tobacco processing industry, comprising a containing hopper (66) for containing rod-shaped objects (52, 54) of the tobacco processing industry, wherein the rod-shaped objects (52, 54) can be orderly, transversely and axially arranged into at least one row. The transport roller (19) is characterized in that the transport roller (19) at least partially comprises a sucking device (80) on the circumference thereof; furthermore, the invention also relates to a machine of the tobacco processing industry, in particular to a filter tip connecting and assembling machine.

Owner:HAUNI MASCHINENBAU AG

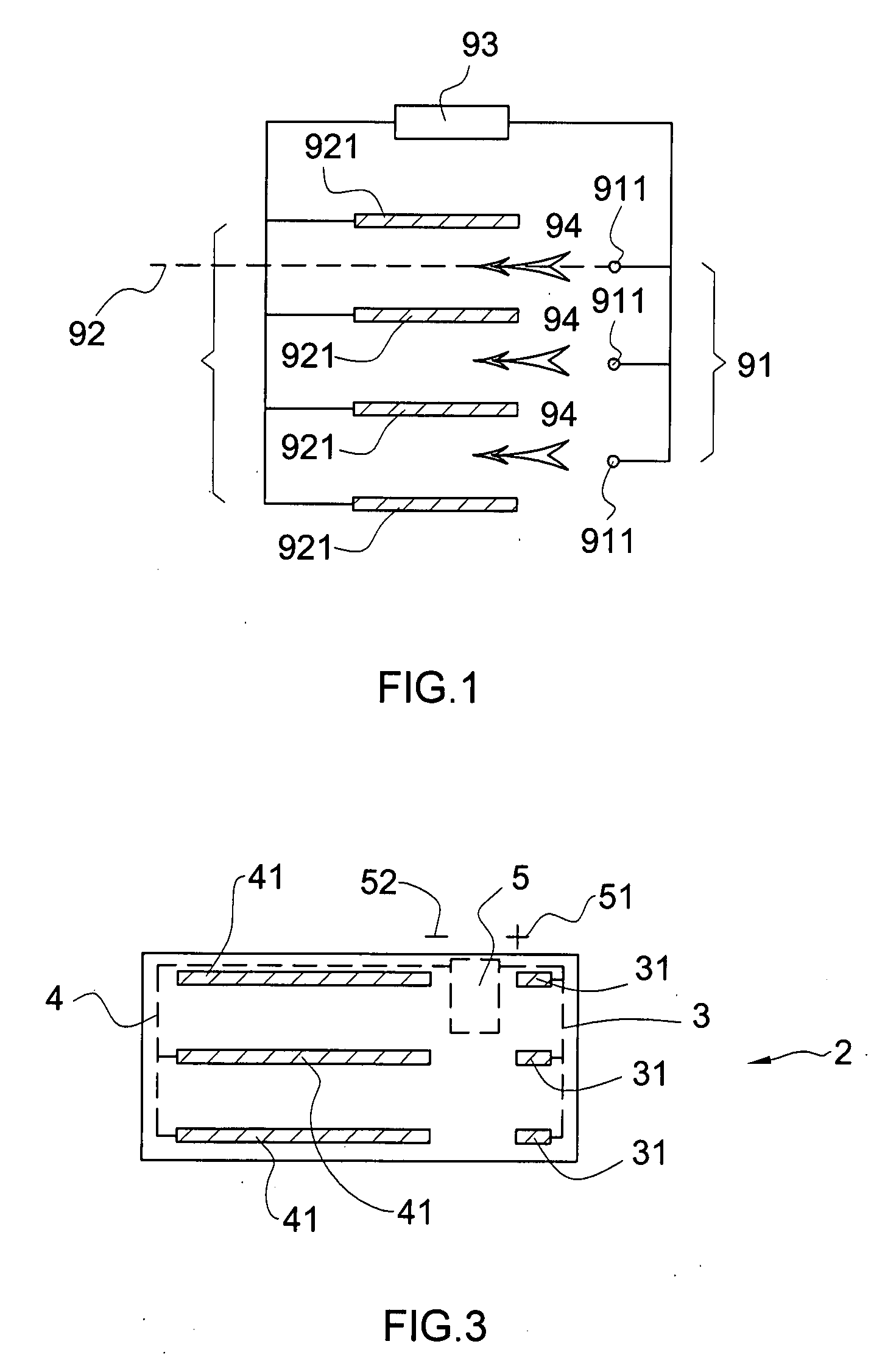

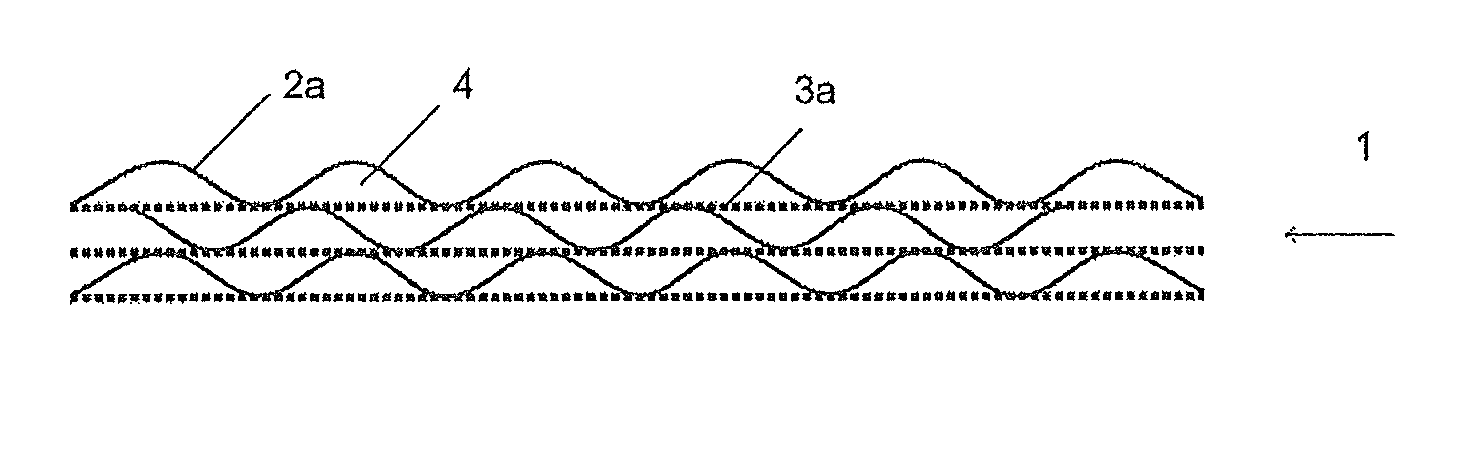

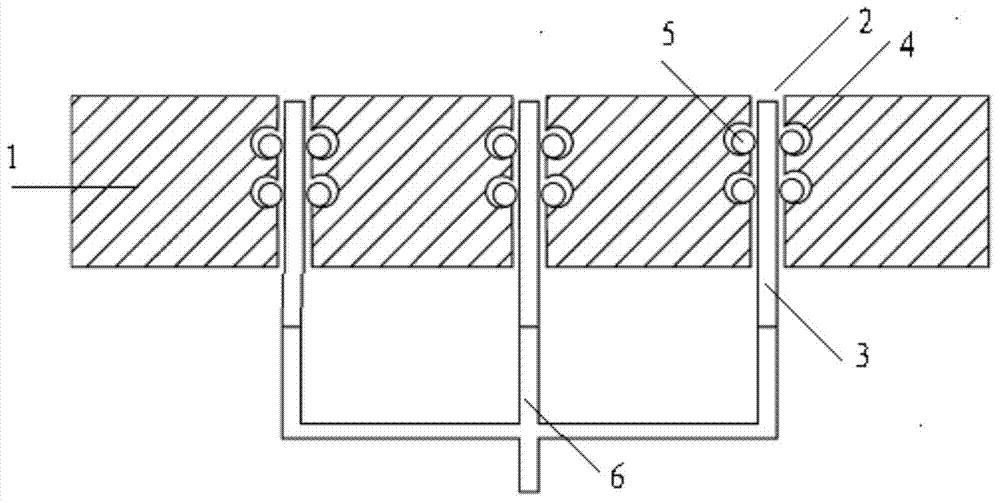

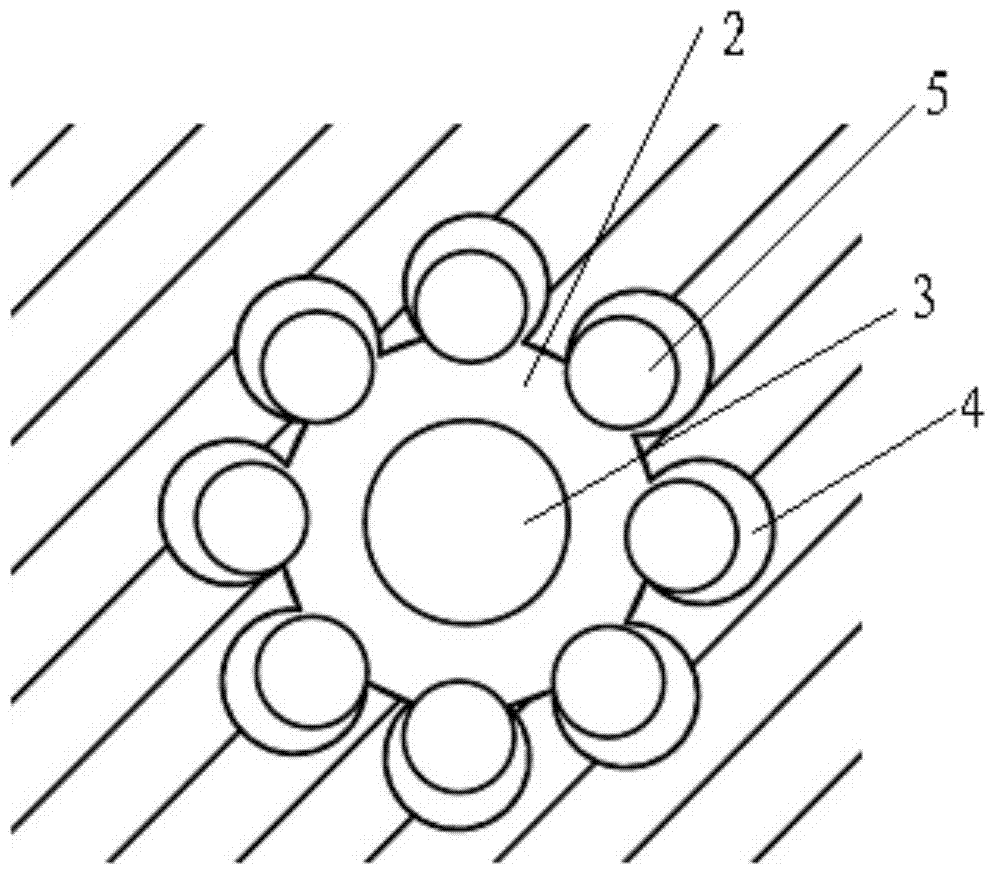

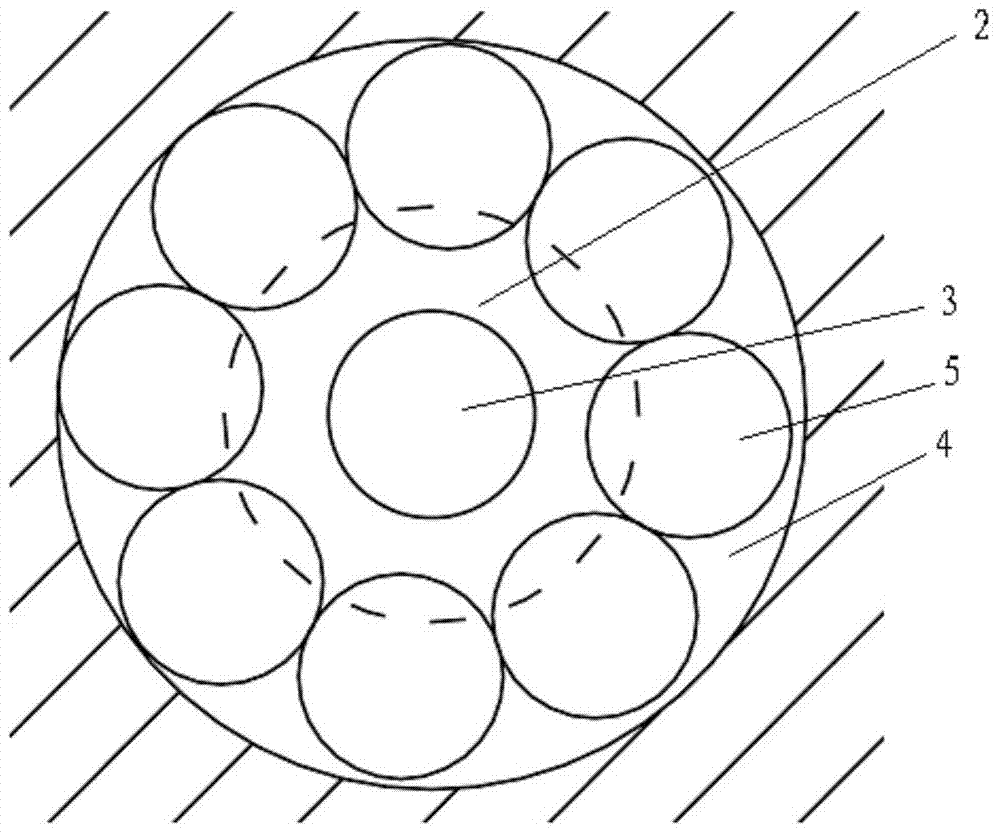

Cereal drying machine

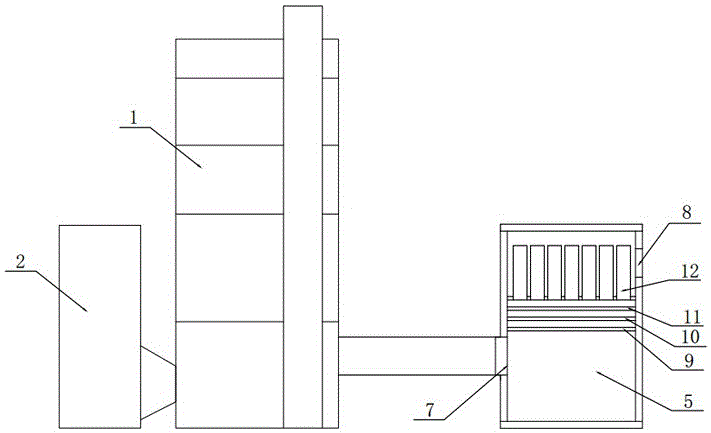

InactiveCN105104522AWill not affect healthWon't breakFood processingClimate change adaptationCold airPulp and paper industry

The invention relates to the field of cereal drying, and in particular relates to a cereal drying machine. The cereal drying machine comprises a drying tower (1) and a heat pump (2) which is communicated with the drying tower (1) and is used for providing hot air for the drying tower, wherein the heat pump (2) comprises a pump shell (3) and an evaporator (4) arranged in the pump shell; the cereal drying machine is characterized by further comprising a dust collection room (5) which is communicated with the drying tower (1) and is used for collecting waste air discharged by the drying tower; and a defrosting heating device is arranged on the evaporator (4). The cereal drying machine can efficiently filter the discharged waste air, and the phenomenon that cold air is generated at an air outlet where the evaporator is positioned during defrosting of the evaporator is avoided.

Owner:浙江天洲制冷机电有限公司 +1

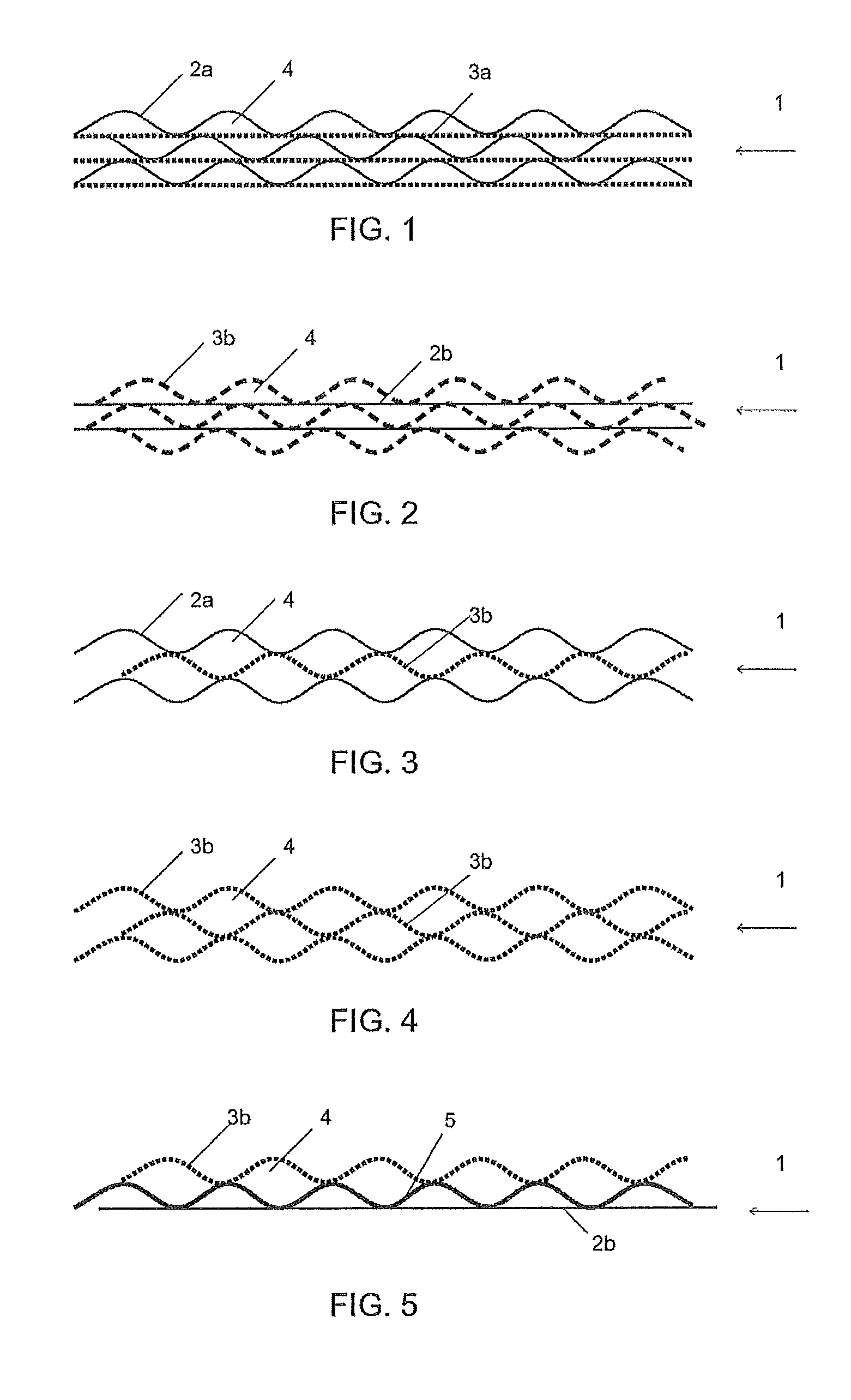

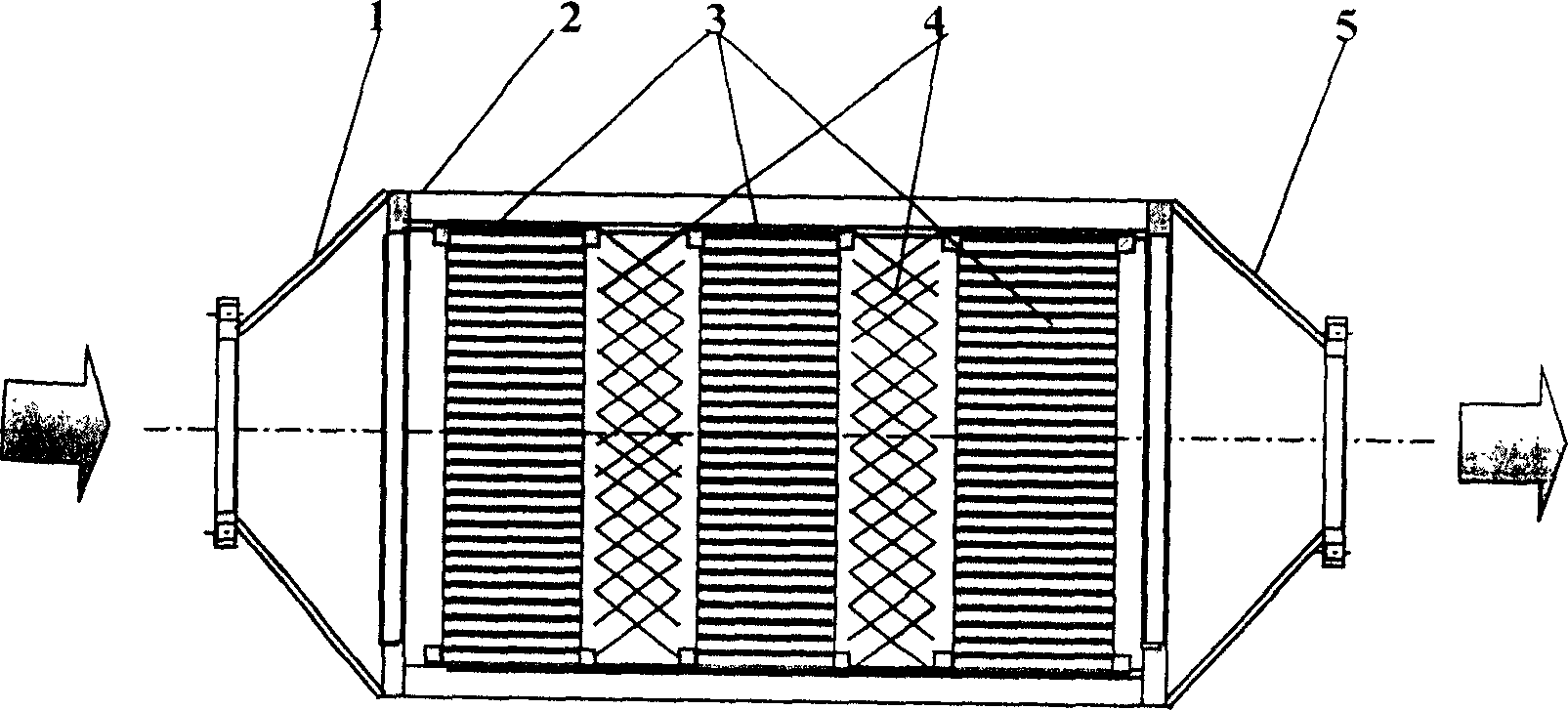

Substrate having porous sheet(s) for treating exhaust gases of combustion engines

ActiveUS8337762B2Reduce particlesCombination devicesMolecular sieve catalystsCombustionExhaust fumes

Owner:DINEX ECOCAT OY

Metal based diesel engine exhaust particles collector, exhaust treatment apparatus and reproduction method

InactiveCN1603586AImprove filtration efficiencyImprove thermal conductivityExhaust apparatusSilencing apparatusPorosityAlloy

The invention involves the metal and the diesel engine exhaust particle trap, the exhaust treating plant and regenerates the method. The trap for at least gathers the cylindrical block by 2 kind of different diameters which the gold thread mix briquetting becomes, dies the diameter is 0.05~0.4mm, opens the porosity is 70~80%, filterability good, the cost is low. In this exhaust treating plant for alternates with the particle trap and the oxidation catalysis which is closely packed, trap namely above trap. At least some 1 metal and particle trap and 2 oxidation catalyses. Exhaust through when, partial particles and CO, HC in oxidation catalysis surface catalytic combustion, partial particles by trap interception. When oxidation catalysis elevation of temperature between trap elevation of temperature, above particle burning, realization automatic regeneration. The equipment effectively eliminates the diesel engine exhaust pollution, the automatic regeneration, guaranteed the necessary power performance is good, is suitable for the diesel car, the ship and so on. The regeneration method for joins the micro liquid catalyst in the diesel oil and uses this installment, further enhanced the installment efficiency and the regeneration effect.

Owner:桂林利凯特环有限责任公司

Making and sterilizing method of polypropylene plastic infusion bottle

ActiveCN102247287AImprove product qualityHigh sterility assurance valuePharmaceutical containersPackage sterilisationInternal pressureBlow molding

The invention relates to a making and sterilizing method of a polypropylene plastic infusion bottle, comprising the following steps of: (1) an injection molding and blow molding process: melting medicinal-grade polypropylene granules at high temperature, extruding to make a bottle blank, blowing into a medicine bottle by using clean high-pressure air, wherein a blow molding control mode is a five-speed five-pressure method, and stretching foreblow is carried out before blow molding shaping; (2) a cleaning, filing and sealing process: cleaning the medicine bottle in a pumping way by using clean negative ion air, then filing medicine-containing liquid, controlling the medicine-containing liquid to be filled at the constant temperature of 50-75 DEG C, filling and then sealing a cover; (3) a high-temperature sterilizing process: placing the completely-filled and cover-sealed medicine bottle into a high-pressure sterilizing tank for sterilization, wherein inner pressure is controlled between 0.20 MPa and 0.35 MPa, sterilization temperature is 117-121 DEG C, and sterilization time is 20-12 minutes.

Owner:SHIJIAZHUANG NO 4 PHARMA

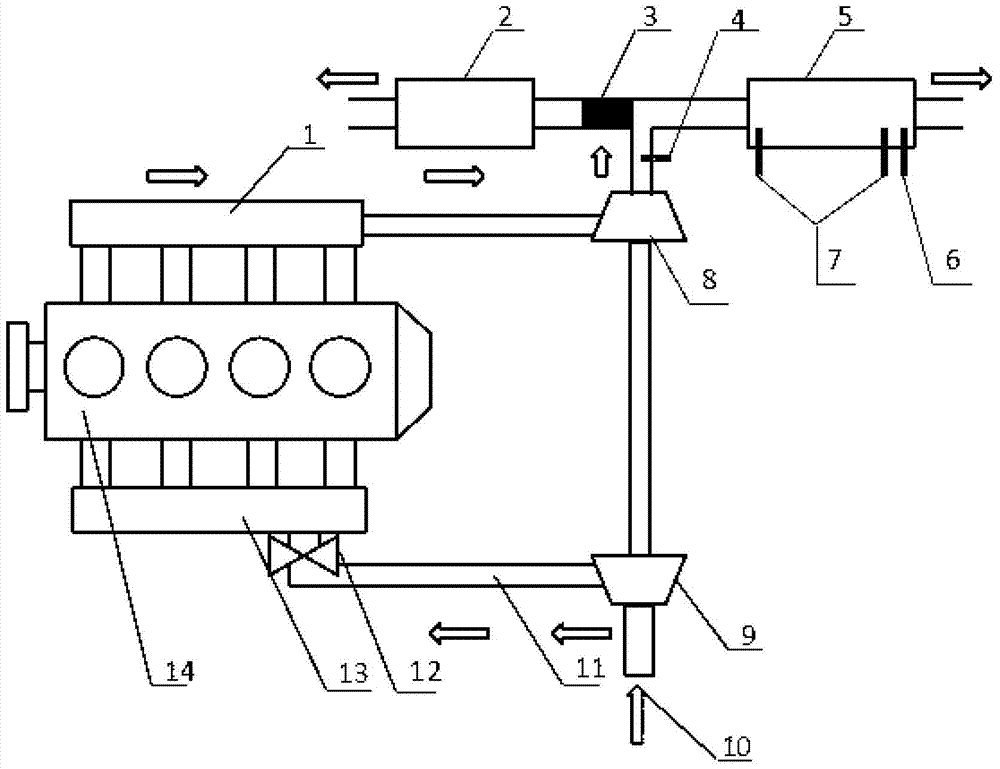

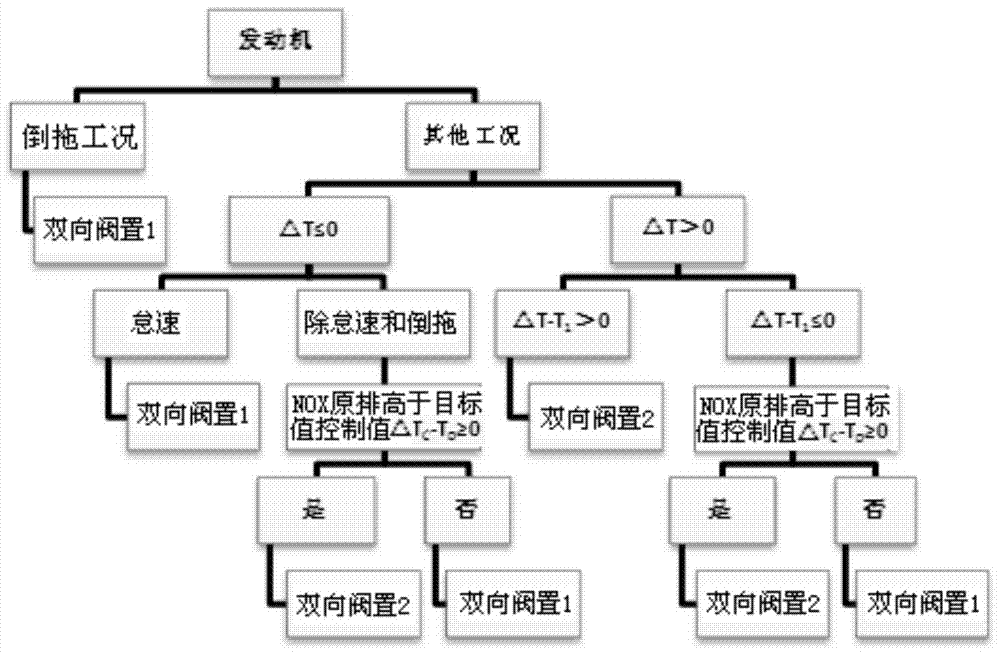

Engine SCR (Selective Catalytic Reduction) catalyst system and control method thereof

ActiveCN104775881AReduce smokeReduce particlesInternal combustion piston enginesExhaust apparatusHeat lossesTurbine

The invention discloses an engine SCR (Selective Catalytic Reduction) catalyst system and a control method thereof. The engine SCR catalyst system comprises an engine body, an SCR catalyst and a bypass pipe; a supercharger compressor, an intake pipe, an engine intake manifold and an intake throttling valve are arranged at the intake end of the engine body, and the intake throttling valve is located on the intake pipe; an engine exhaust pipe and a turbocharger turbine are arranged at the exhaust end of the engine body, and an exhaust temperature sensor is arranged on the engine exhaust pipe; an SCR upstream temperature sensor and an SCR downstream temperature sensor are arranged in the upstream and the downstream of the SCR catalyst respectively; the bypass pipe is connected at the front end of an inlet of the SCR catalyst in parallel, and a two-way bypass valve is arranged at an inlet of the bypass pipe. The engine SCR catalyst system can reduce heat loss of the SCR catalyst to the maximum extent, raise or keep temperature of the SCR catalyst and improve the conversion efficiency of the SCR catalyst.

Owner:GUANGXI YUCHAI MASCH CO LTD

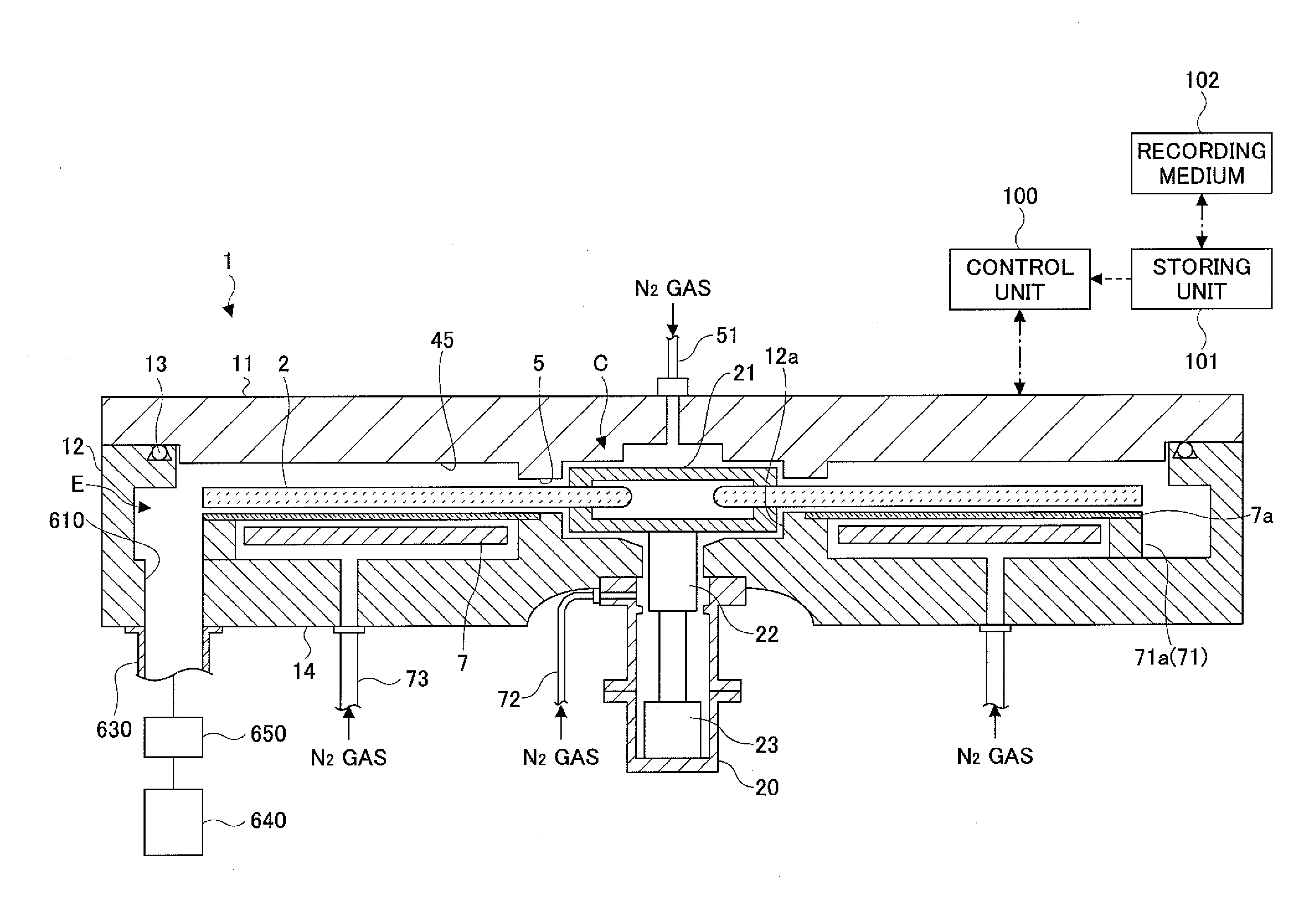

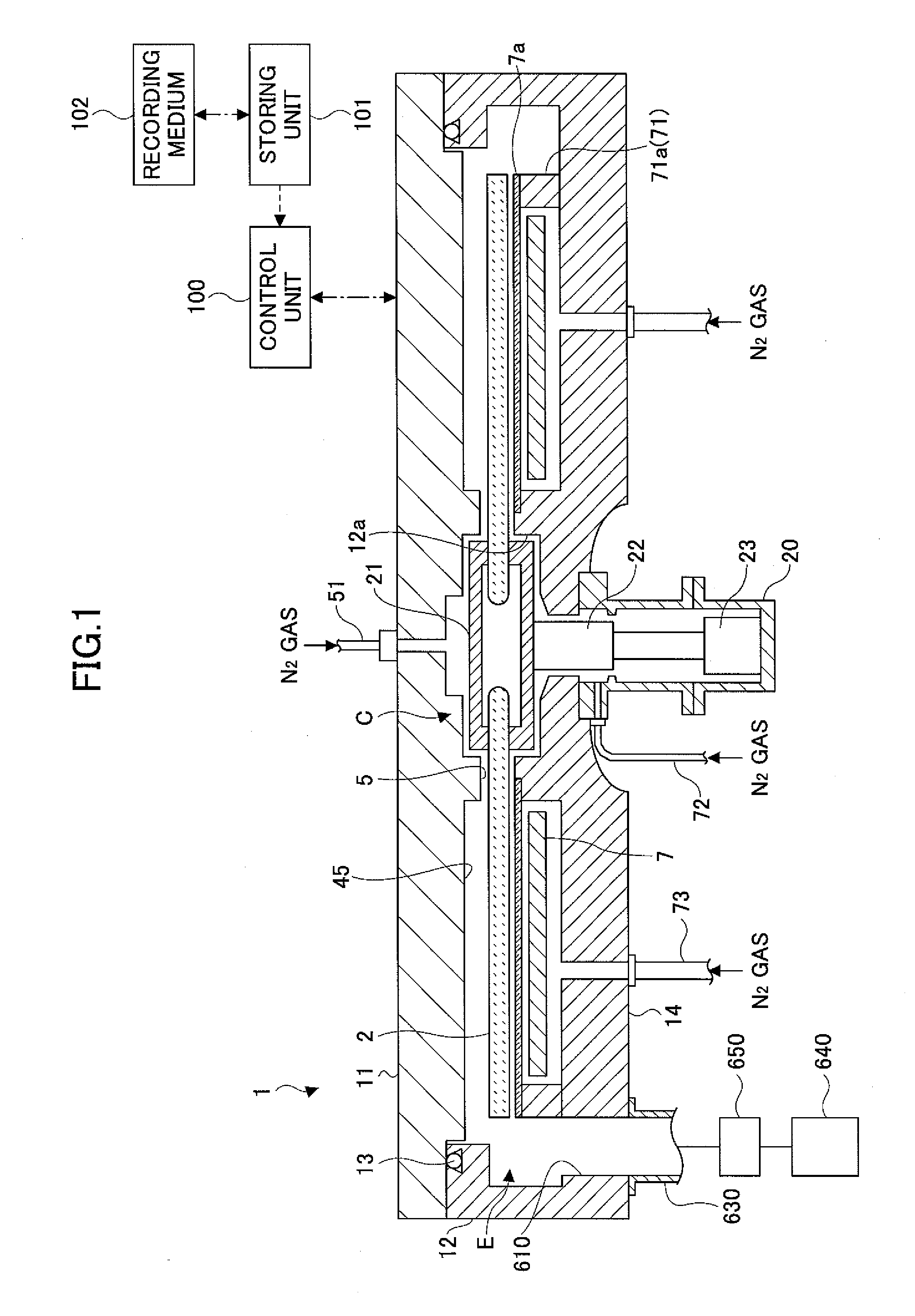

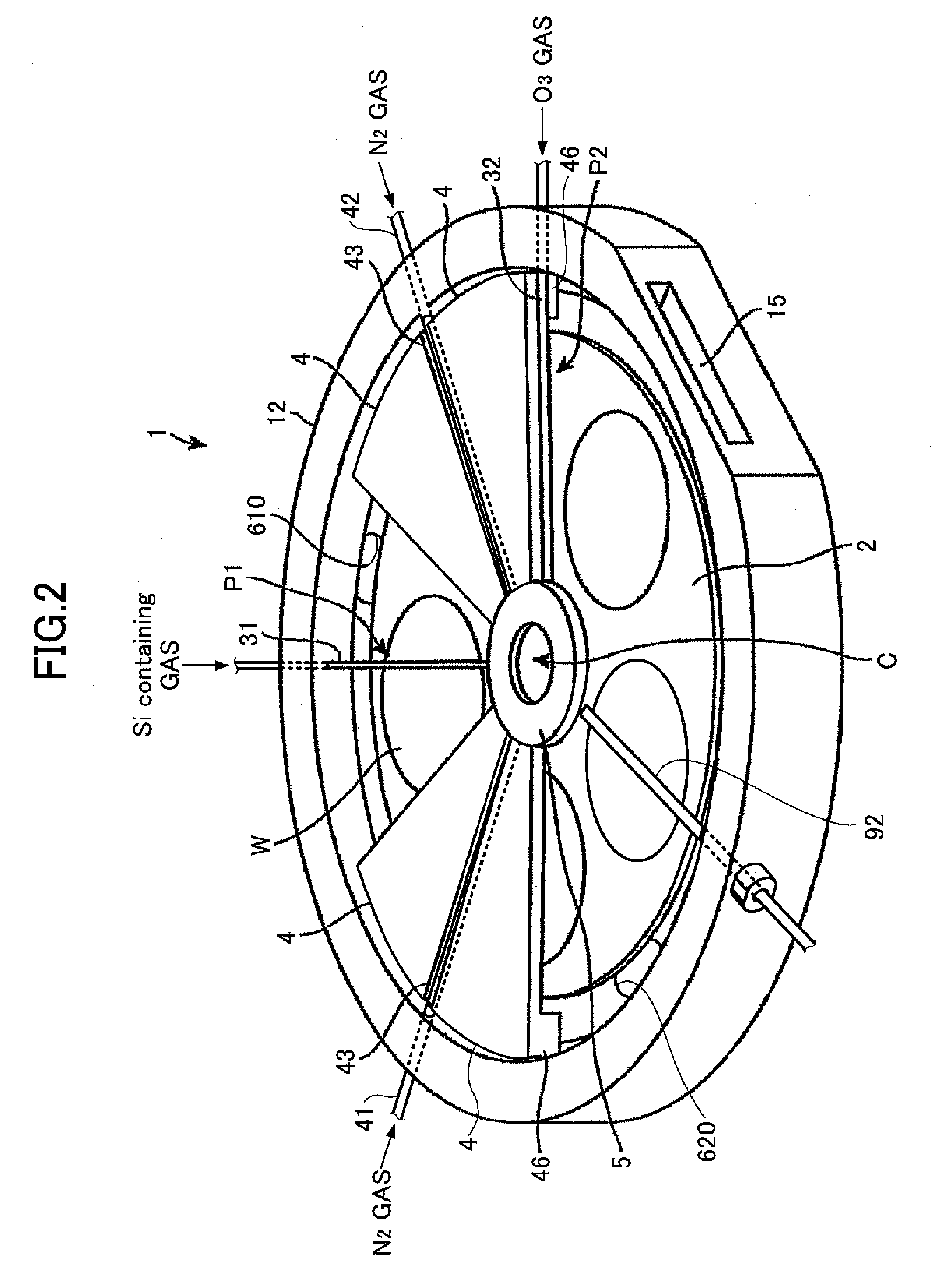

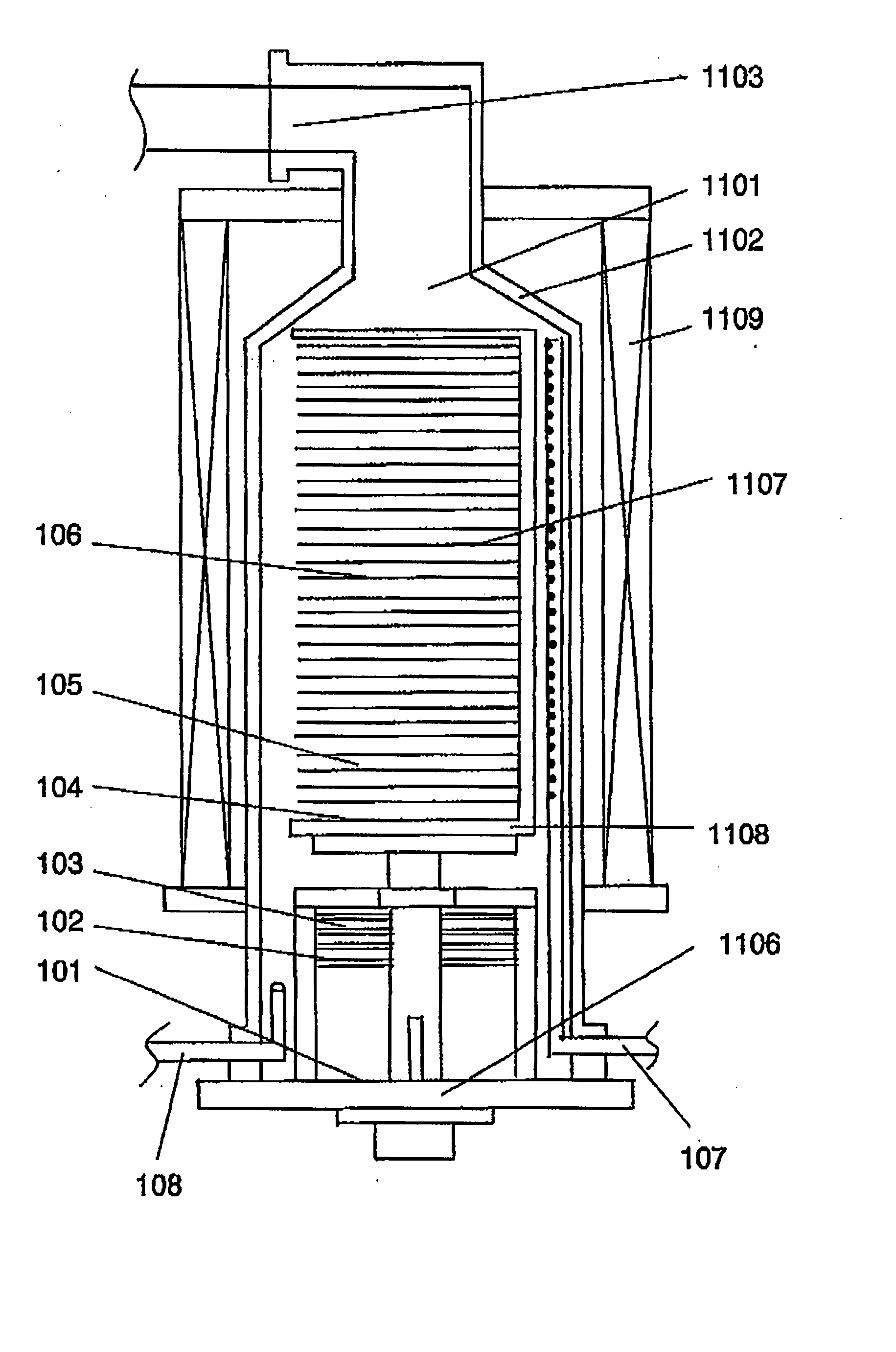

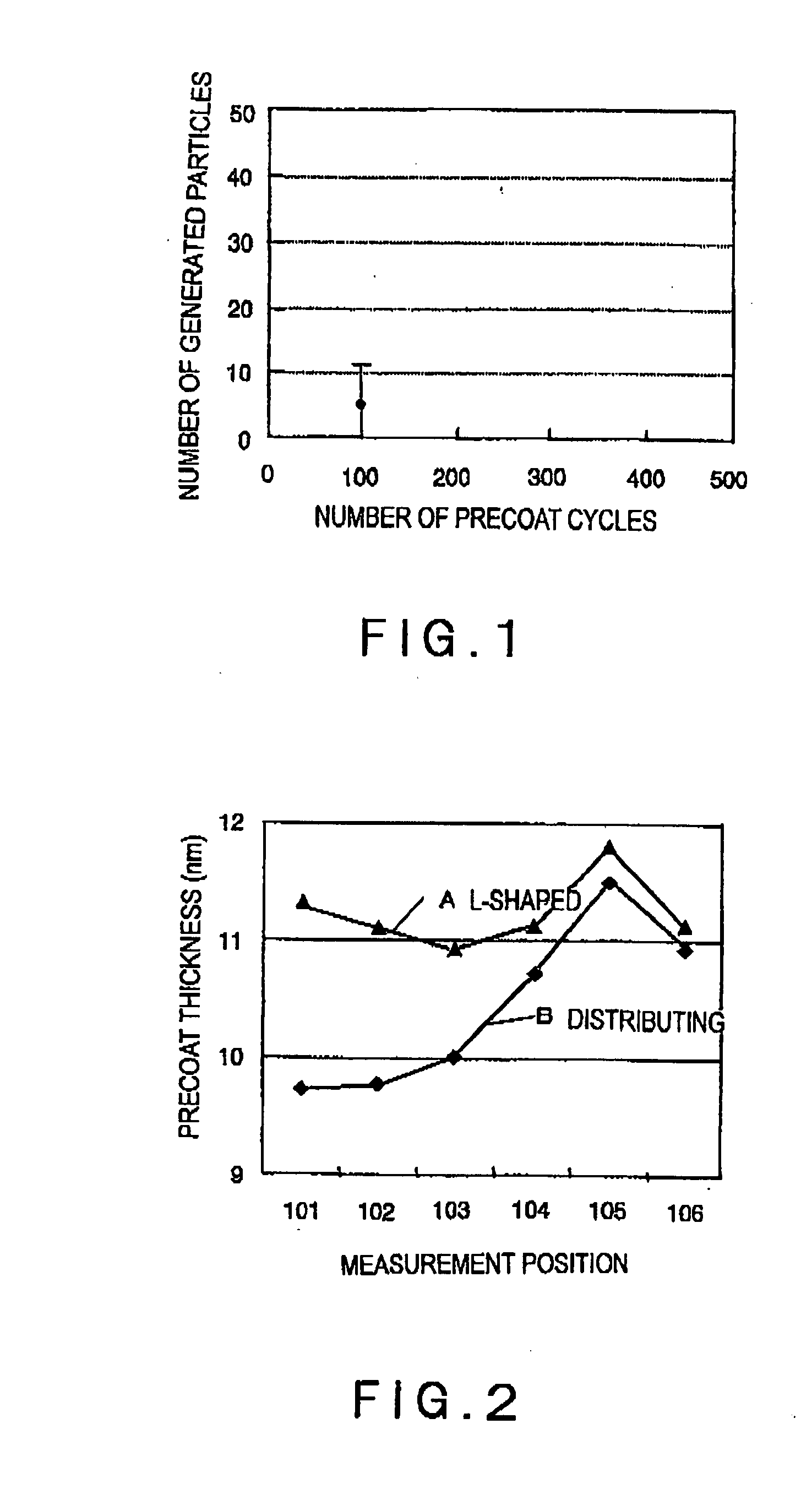

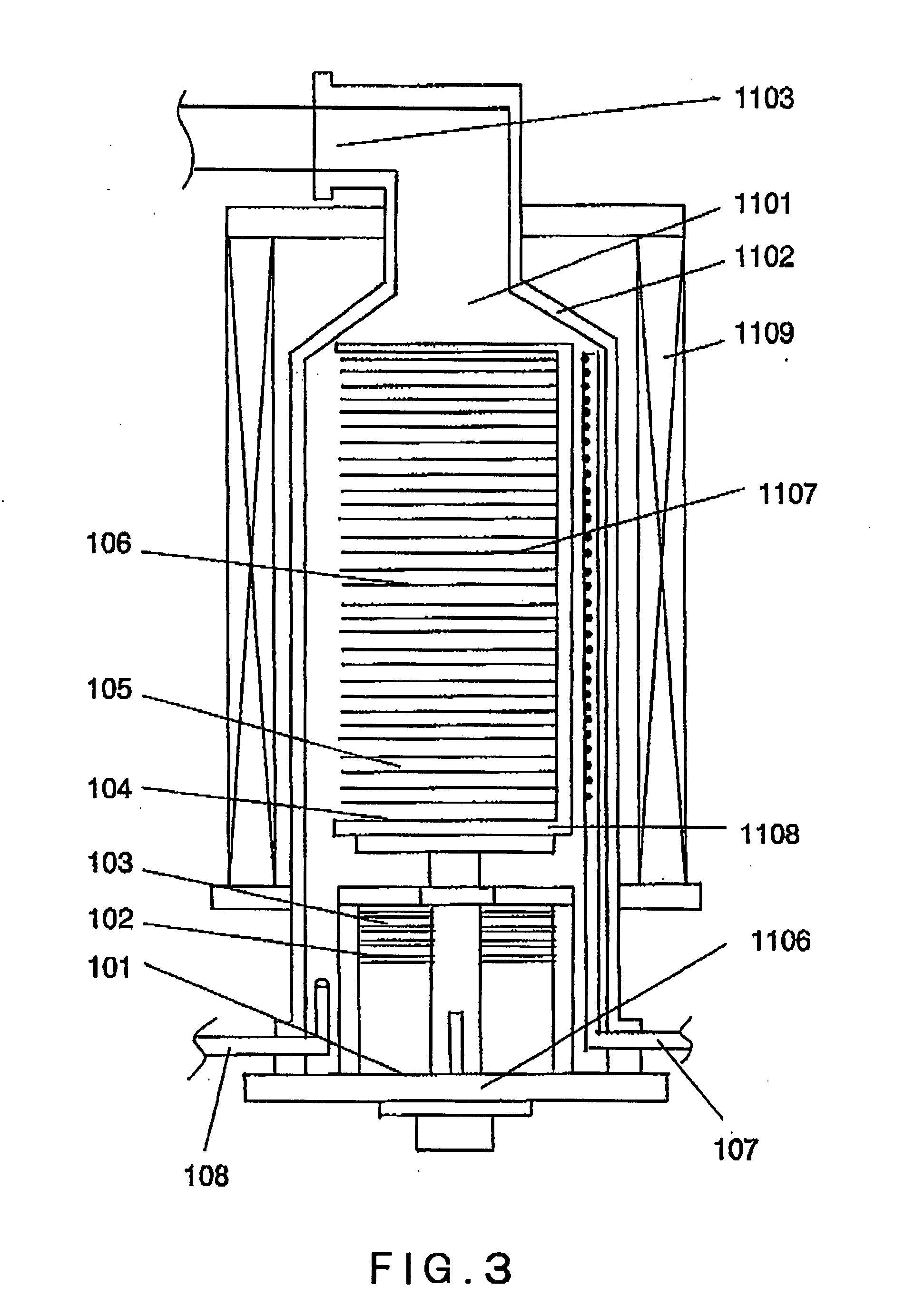

Semiconductor manufacturing system

InactiveUS20080066677A1Prevent particle generationEvenly distributedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForming gasEngineering

Disclosed is a technique for effectively suppressing the generation of particles resulting from peeling-off of unnecessary films that have unavoidably adhered to the inner surface of the reaction tube of an ALD film-forming apparatus. A precoating process utilizing ALD is performed to deposit a metal oxide film, e.g., an aluminum oxide film, onto the unnecessary films, in order to prevent peeling-off of the unnecessary films. The type and / or position of the nozzle for supplying ozone, as a precoat gas, into the reaction tube during the precoating process is different from that of the nozzle for supplying ozone, as a film-forming gas, into the reaction tube during forming of a film on a semiconductor substrate.

Owner:TOKYO ELECTRON LTD

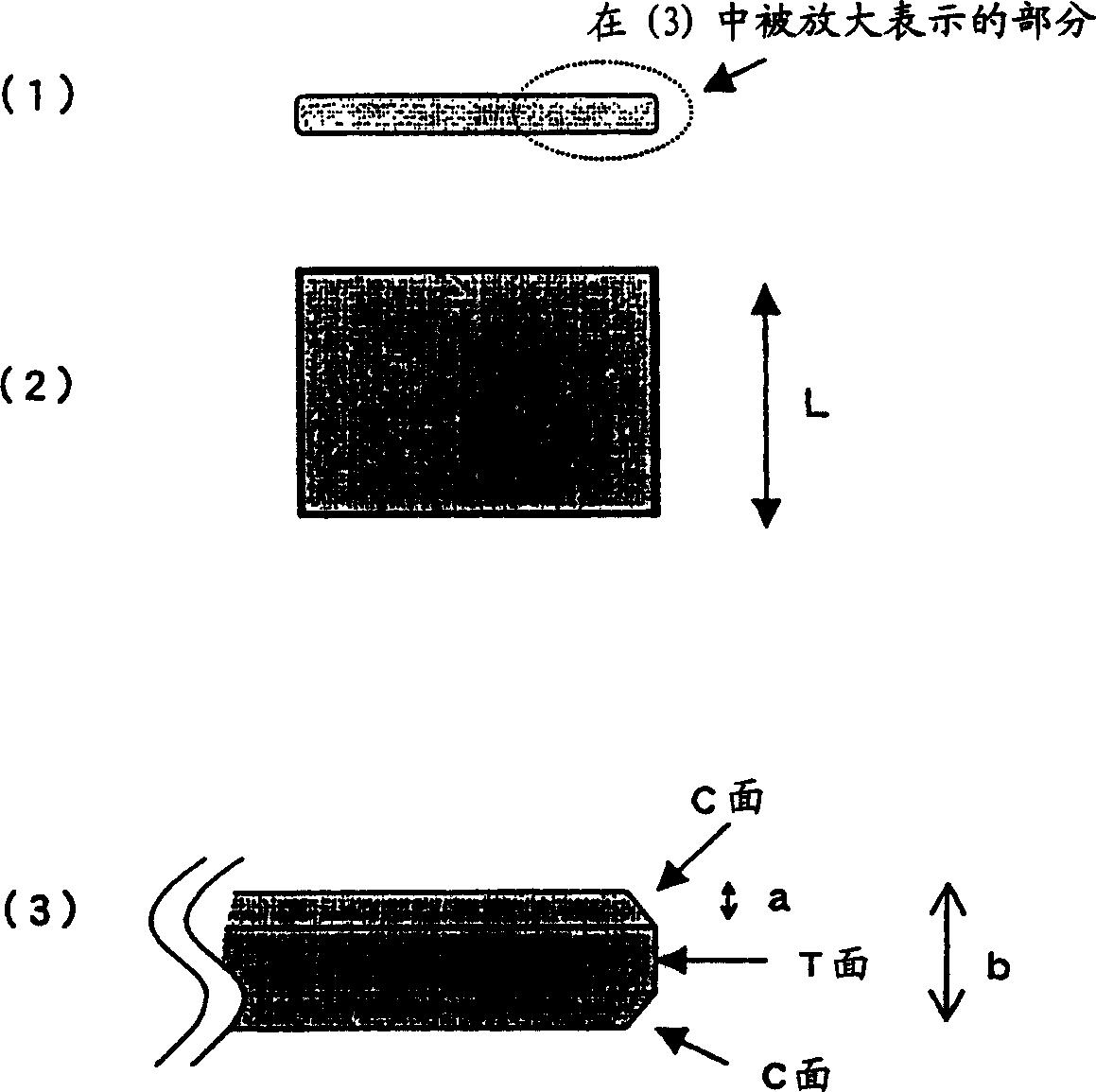

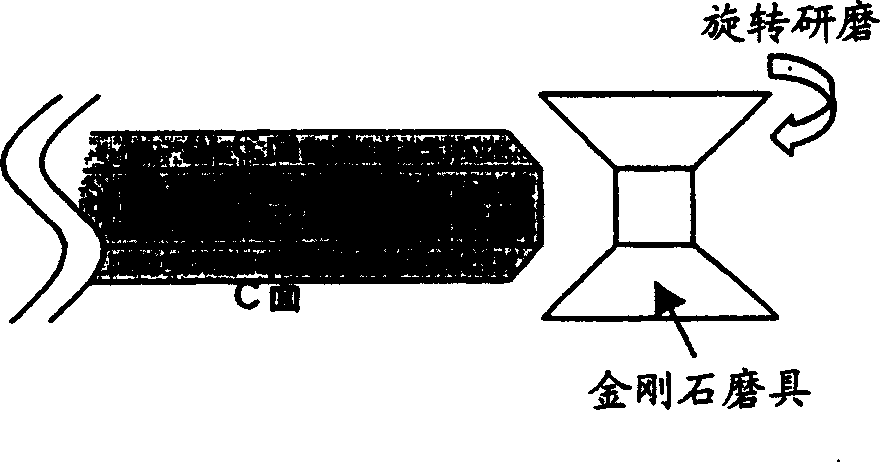

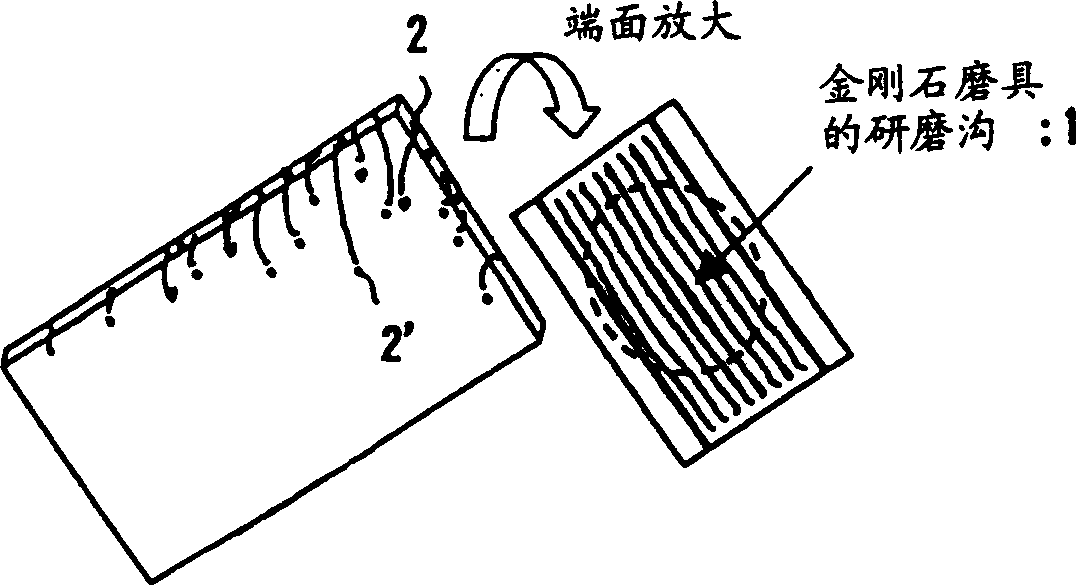

Base board for optical mask, optical mask blank and optical mask

ActiveCN1532631ANot easy to slipReduce particlesSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusSurface roughnessOptoelectronics

A substrate for photomask has a top surface and a back surface, the substrate being square in shape, an end surface formed along the thickness thereof and a chamfered surface formed on a perimeter edge region where the end surface and the top surface meet and another region where the end surface and the back surface meet, a size of the perimeter edge of the substrate is 300 mm or more on a side and the end surface and the chamfered surface each has a roughened surface having a surface roughness (Ra) ranging from 0.03 mum to 0.3 mum.

Owner:HOYA CORP

Wiring over substrate, semiconductor device, and methods for manufacturing thereof

InactiveUS20090206494A1Preventing short-circuitingAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Owner:SEMICON ENERGY LAB CO LTD

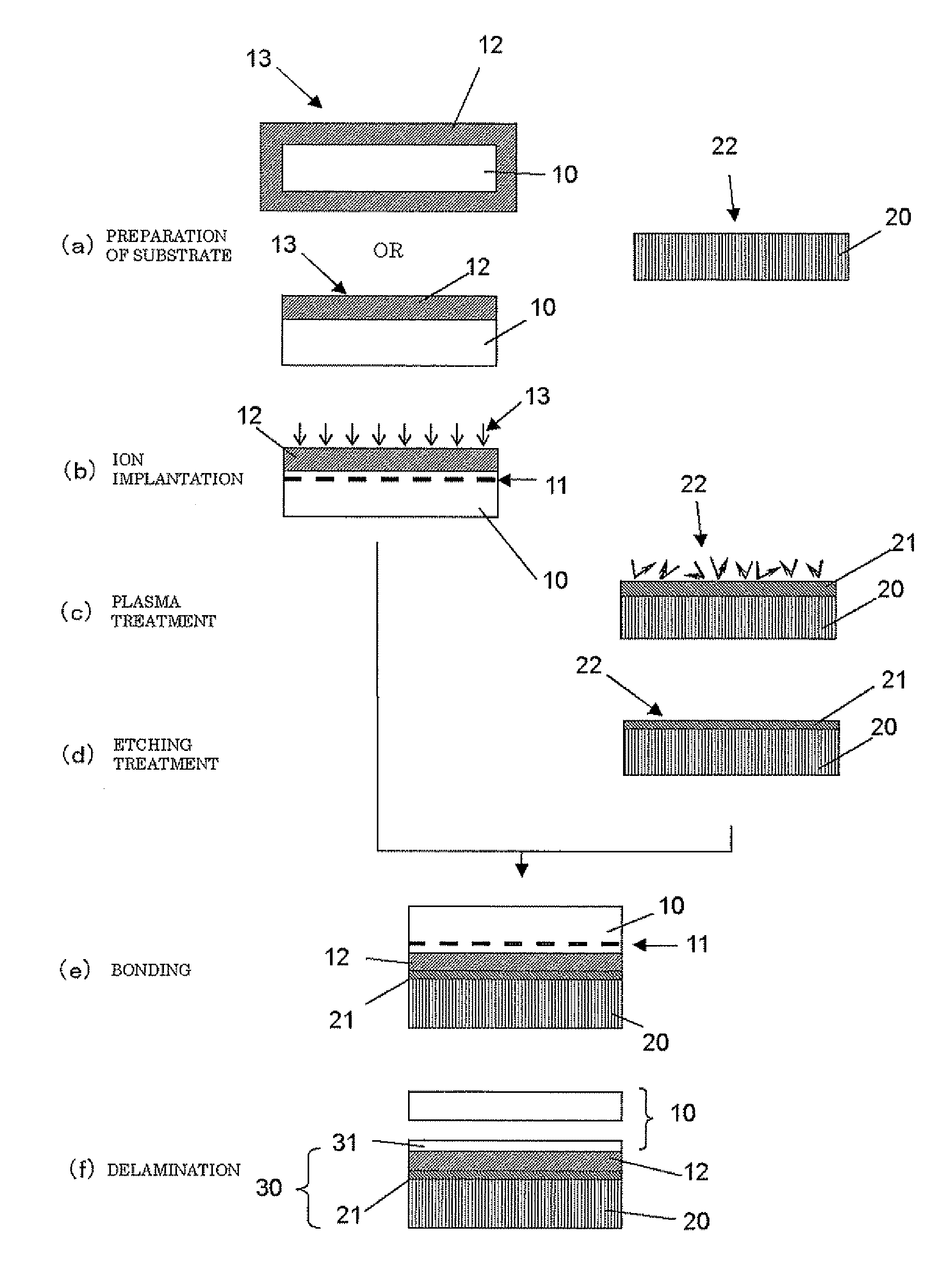

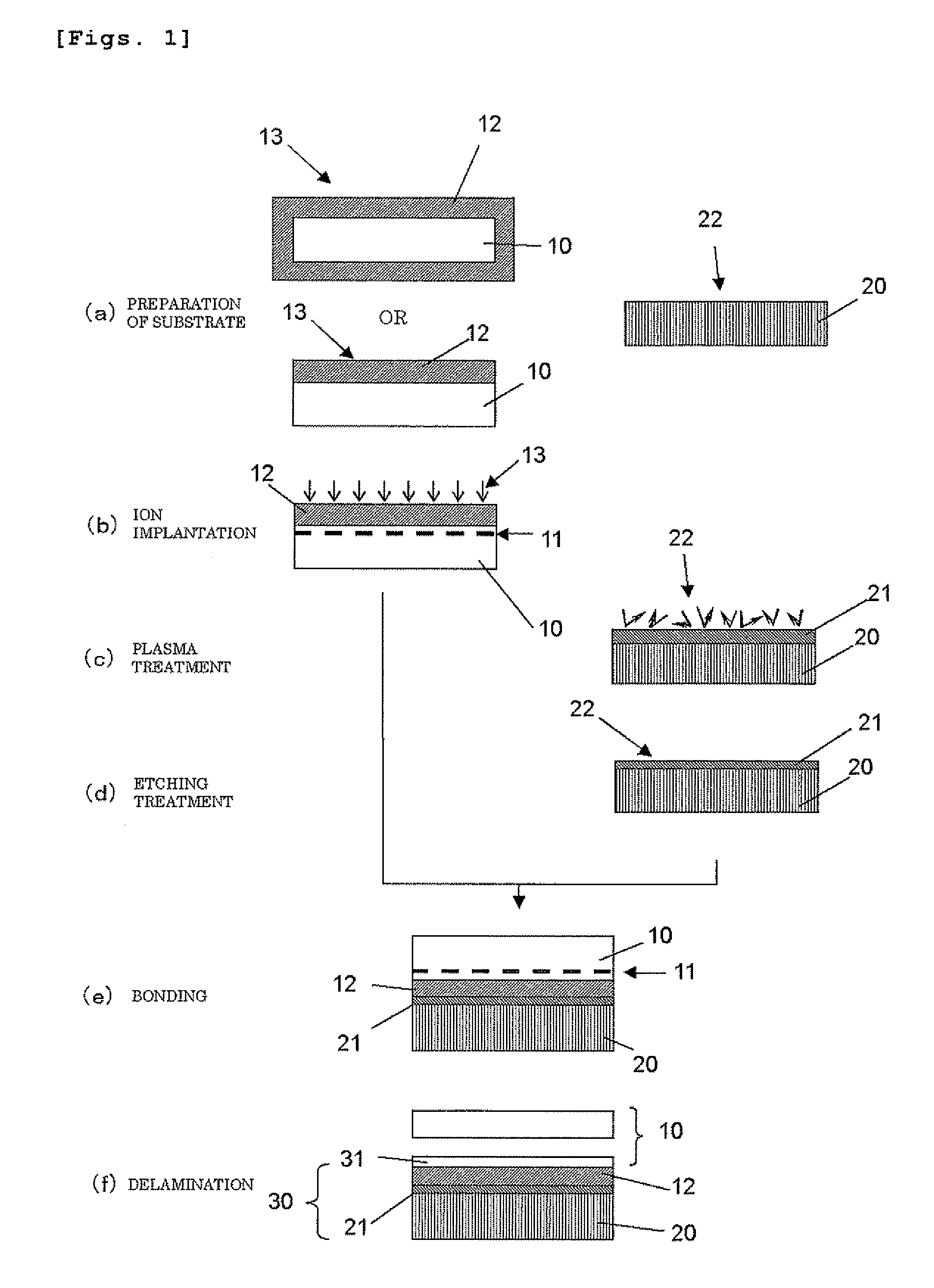

Method for manufacturing bonded wafer

ActiveUS20110104870A1Reduce particlesGood adhesionSemiconductor/solid-state device manufacturingIon implantationHydrogen ion

A method for manufacturing a bonded wafer, including at least implanting at least one type of gas ion selected from a hydrogen ion and a rare gas ion from a surface of a bond wafer to form an ion-implanted layer in the wafer, bonding an ion-implanted surface of the bond wafer to a surface of a base wafer directly or through an insulator film, and then delaminating the bond wafer at the ion-implanted layer to fabricate a bonded wafer. A plasma treatment is applied to a bonding surface of one of the bond wafer and the base wafer to grow an oxide film, etching the grown oxide film is carried out, and bonding to the other wafer is performed. The method enables preventing defects by reducing particles on the bonding surface and performing strong bonding when effecting bonding directly or through the insulator film.

Owner:SHIN-ETSU HANDOTAI CO LTD

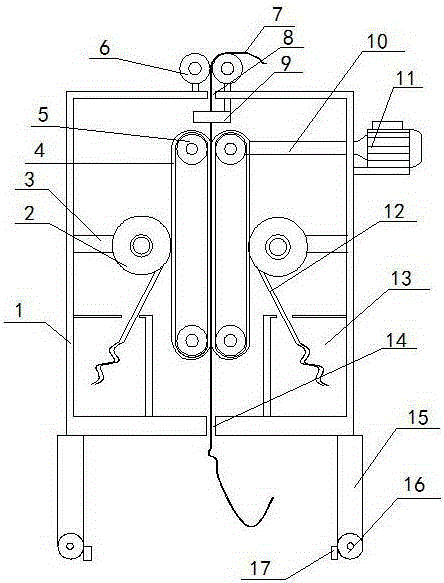

Automatic dedusting device for biodegradation film

InactiveCN105290052AQuick collection and recyclingEfficient removalCleaning processes and apparatusElectrostatic chargesSurface cleaningDrive shaft

The invention provides an automatic dedusting device for a biodegradation film. The automatic dedusting device comprises a machine body, a rotary dust collection paper sleeve, a supporting column, self-adhesive dedusting rubber belts, pulleys, rotary wheels, the biodegradation film, a biodegradation film inlet, an electrostatic dedusting device, a transmission shaft, a drive motor, dust collection paper rolls, waste paper collection tanks, a biodegradation film outlet, supporting legs, rolling wheels and brake devices. The number of the pulleys is four. The two pulleys at the upper end are connected with the drive motor through the transmission shaft. The electrostatic dedusting device is arranged at the upper end in the machine body. The biodegradation film is inserted into the electrostatic dedusting device in a penetrating manner. The waste paper collection tanks are arranged on the left side and the right side of the bottom end in the machine body. The rolling wheels are arranged at the lower ends of the supporting legs. The brake devices are arranged on the rolling wheels. By the adoption of a contact dedusting manner, dust, soft flocks and wee impurities on the surfaces of film materials can be removed quickly and efficiently, and the surface clearness of products is improved.

Owner:HUNAN KELAIBAO BIO ENERGY TECH CO LTD

Supporting machine table

InactiveCN103792707AReduce generationTo preventSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusLiquid-crystal displayRolling resistance

The invention relates to a supporting machine table. The supporting machine table comprises a plurality of pin holes, supporting pins which can move up and down are accommodated in the pin holes, at least one groove is formed in the walls of the pin holes, balls are accommodated in the grooves, freely roll in the grooves, and located around the supporting pins accommodated in the pin holes, and each ball can roll in the corresponding groove and a part of each ball always protrudes out of the walls of the pin holes due to the shape and the size of the grooves. According to the supporting machine table, the balls are arranged in the pin holes, when the supporting pins are deflected or bent, sliding friction between the supporting pins and the walls of the pin holes is converted into rolling friction between the supporting pins and the balls, generated particles can be reduced, particles adsorbed on a liquid crystal display panel are greatly reduced, Shell Mura is prevented from generating in the liquid crystal display panel, and the yield of products is increased.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

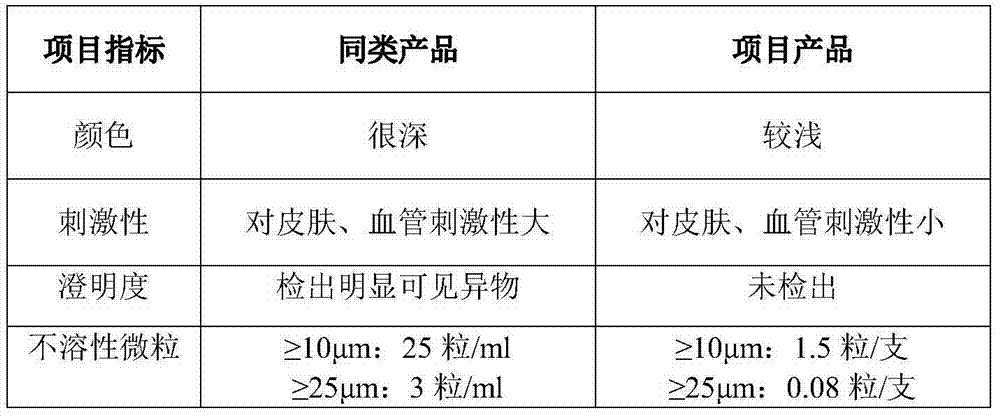

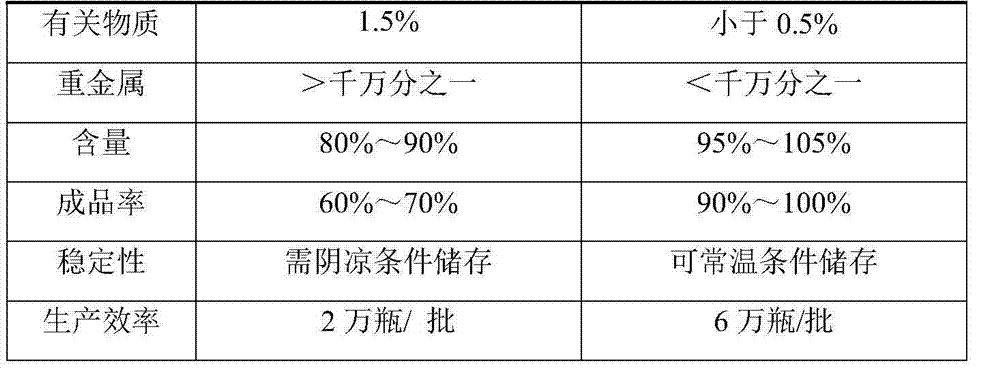

Method for preparing levofloxacin hydrochloride sodium chloride injection

InactiveCN103479522ASubstance reductionHigh clarityAntibacterial agentsOrganic active ingredientsWater bathsSodium Chloride Injection

The invention provides a method for preparing levofloxacin hydrochloride sodium chloride injection. By researching a liquid medicine preparation method, medicinal charcoal pretreatment and a terminal sterilization process, product quality is ensured by the aid of technologies of a concentrated solution and diluted solution method, charcoal slurry preparation from medicinal charcoal, water bath sterilization and the like, production is facilitated, obtained finished products have higher stability, so that the storage life of the finished products can be prolonged, and clinical use effects are better.

Owner:HAINAN HOTMED TIANYA PHARMA

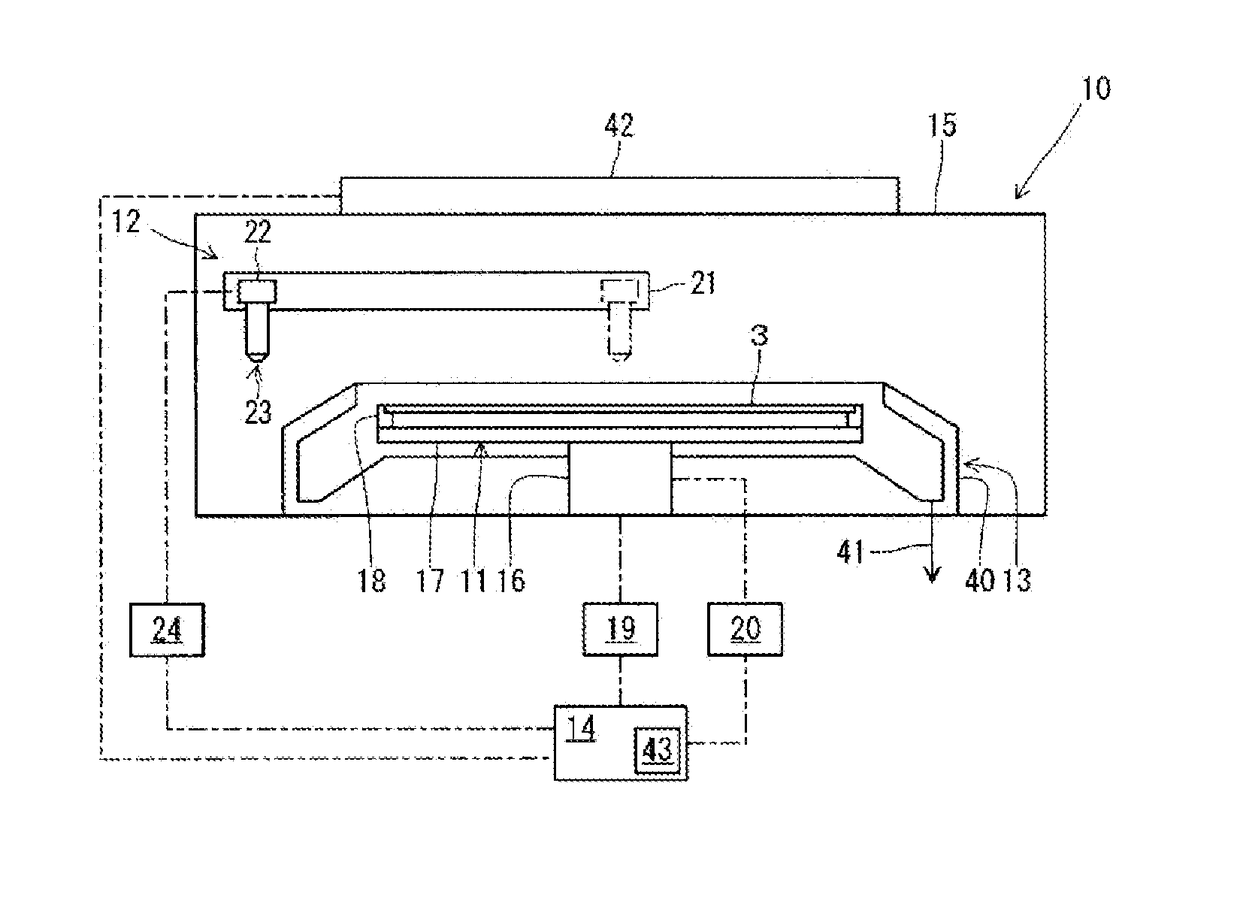

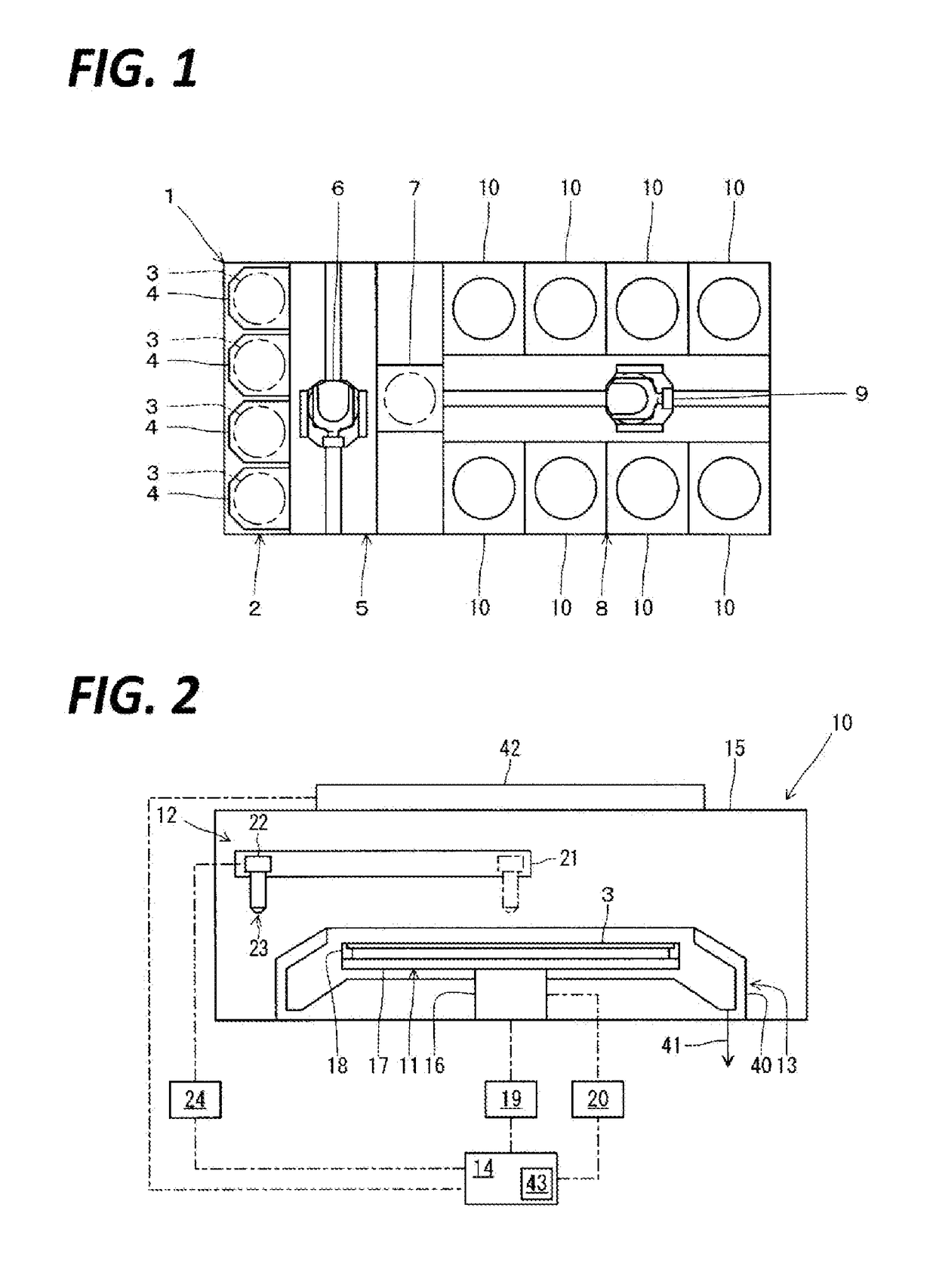

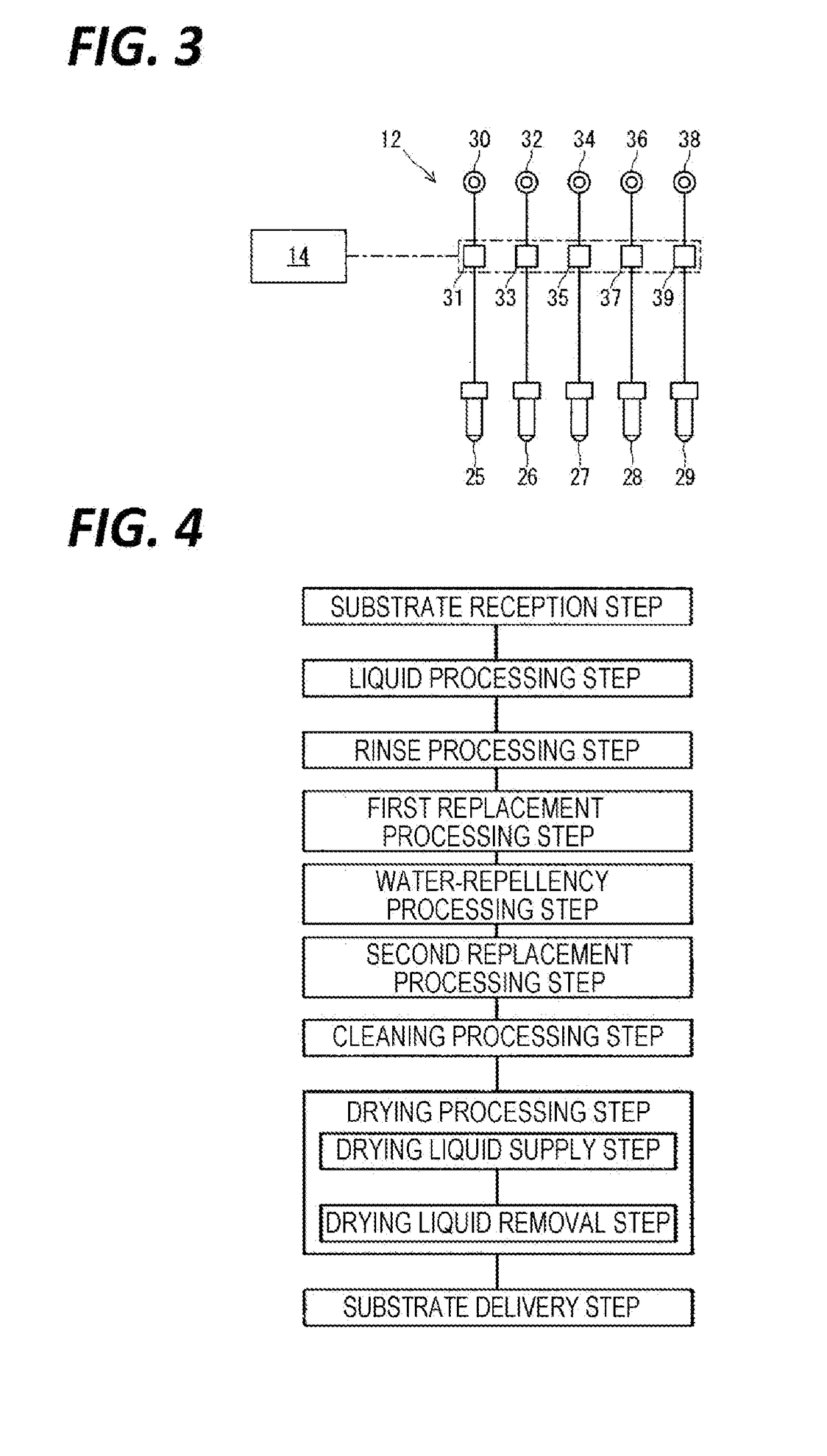

Substrate liquid processing method, substrate liquid processing apparatus, and computer-readable storage medium that stores substrate liquid processing program

InactiveUS20170301534A1Reduce decreaseReduce particlesSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringTreatment use

This liquid treatment method for substrates involves performing: a liquid treatment step for liquid-treating a substrate with a treatment liquid; a rinse treatment step for rinsing the liquid-treated substrate with a rinsing liquid; a water-repellency treatment step for subjecting the rinsed substrate to a water-repellency treatment using a water-repellency-imparting solution; next, a substitution treatment step for subjecting the substrate subjected to the water-repellency treatment to a substitution treatment acceleration liquid; a cleaning treatment step for cleaning the substrate subjected to the water-repellency treatment by using a cleaning solution; and thereafter, a drying treatment step for substituting the cleaning solution with a drying solution having a higher volatility than that of the cleaning solution, and removing the drying solution from the substrate. Thus, it is possible to prevent pattern collapse during the drying treatment, and to decrease particles caused by watermarks.

Owner:TOKYO ELECTRON LTD

Soil stabilizer carrier

InactiveUS20100166507A1Reduce lossesReduce particlesAmmonium nitratesClimate change adaptationSoil scienceWater soluble

A method for applying a water soluble soil stabilizer to soil wherein the soil stabilizer is added to a solid carrier.

Owner:SKYLINE ENCAP HLDG LLC

Motherwort injection

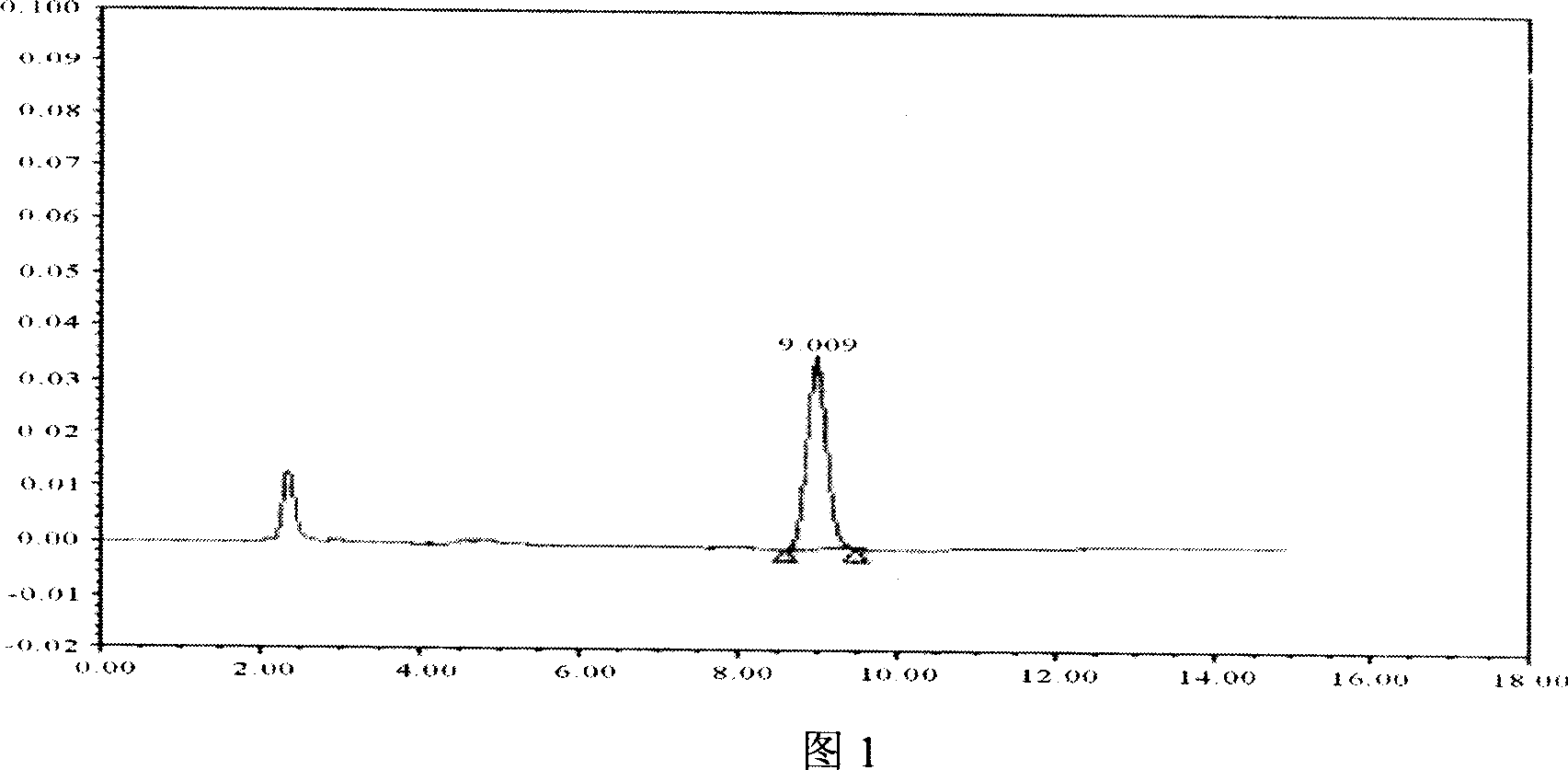

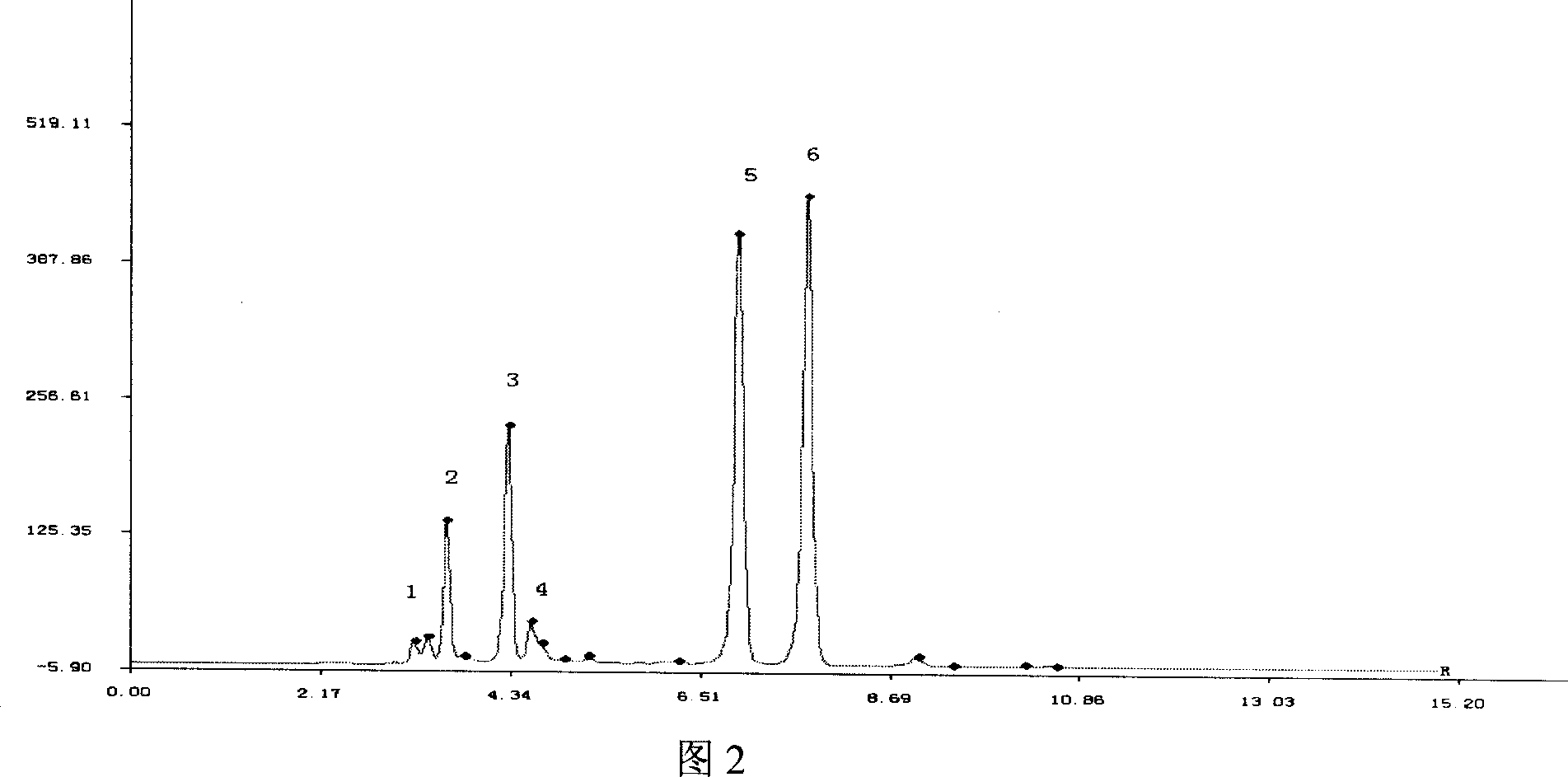

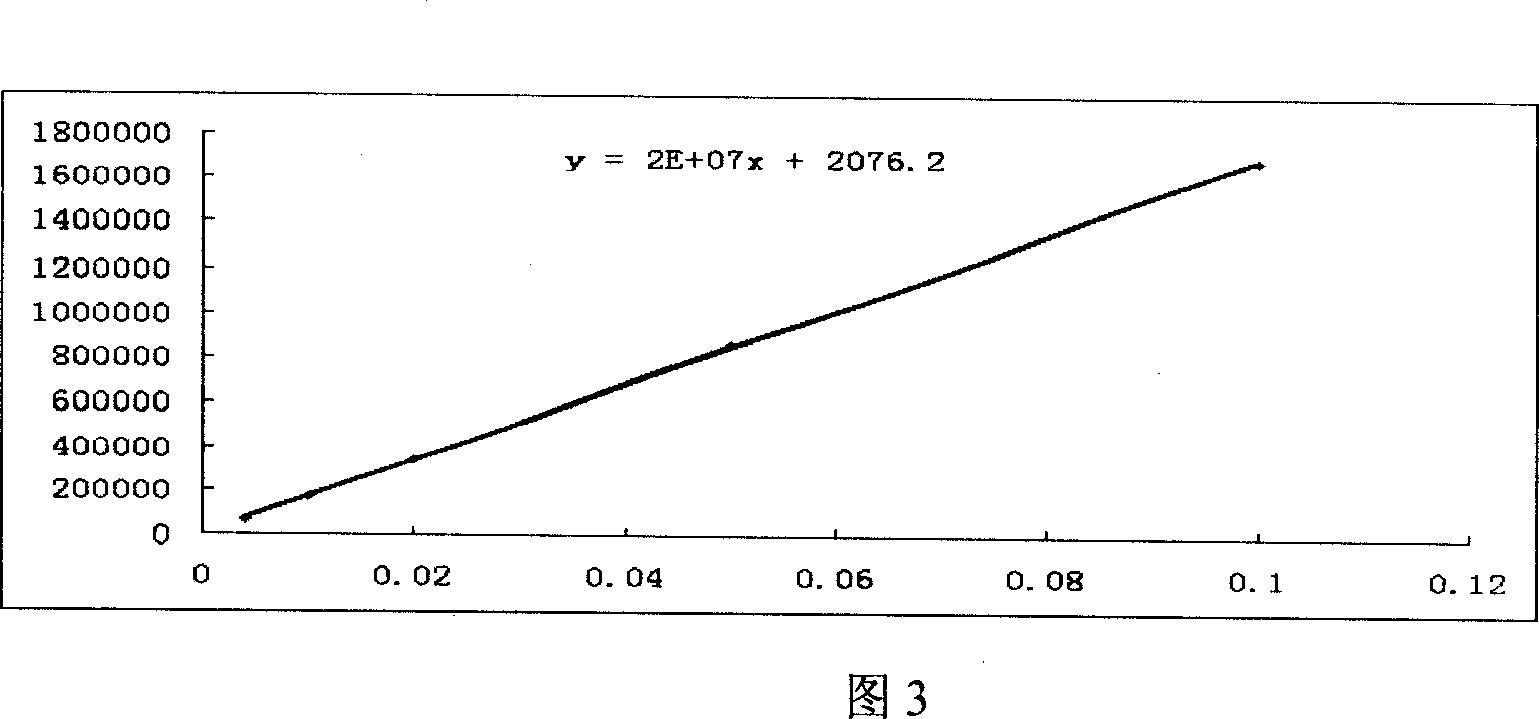

ActiveCN1973855ANot easy to removeThe content of effective components decreasedComponent separationPharmaceutical delivery mechanismHplc fingerprintMotherwort

The present invention relates to high quality motherwort injection and its preparation process. The present invention proposes the HPLC fingerprint standard, and has determined characteristic matters in motherwort injection, optimized technological process, raised injection consistency and high and stable product quality.

Owner:CHENGDU FIRST PHARMACEDTICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com