Metal based diesel engine exhaust particles collector, exhaust treatment apparatus and reproduction method

A technology of exhaust gas treatment device and particle trap, which can be applied to exhaust devices, mufflers, machines/engines, etc. The effect of promotion and application, low cost and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

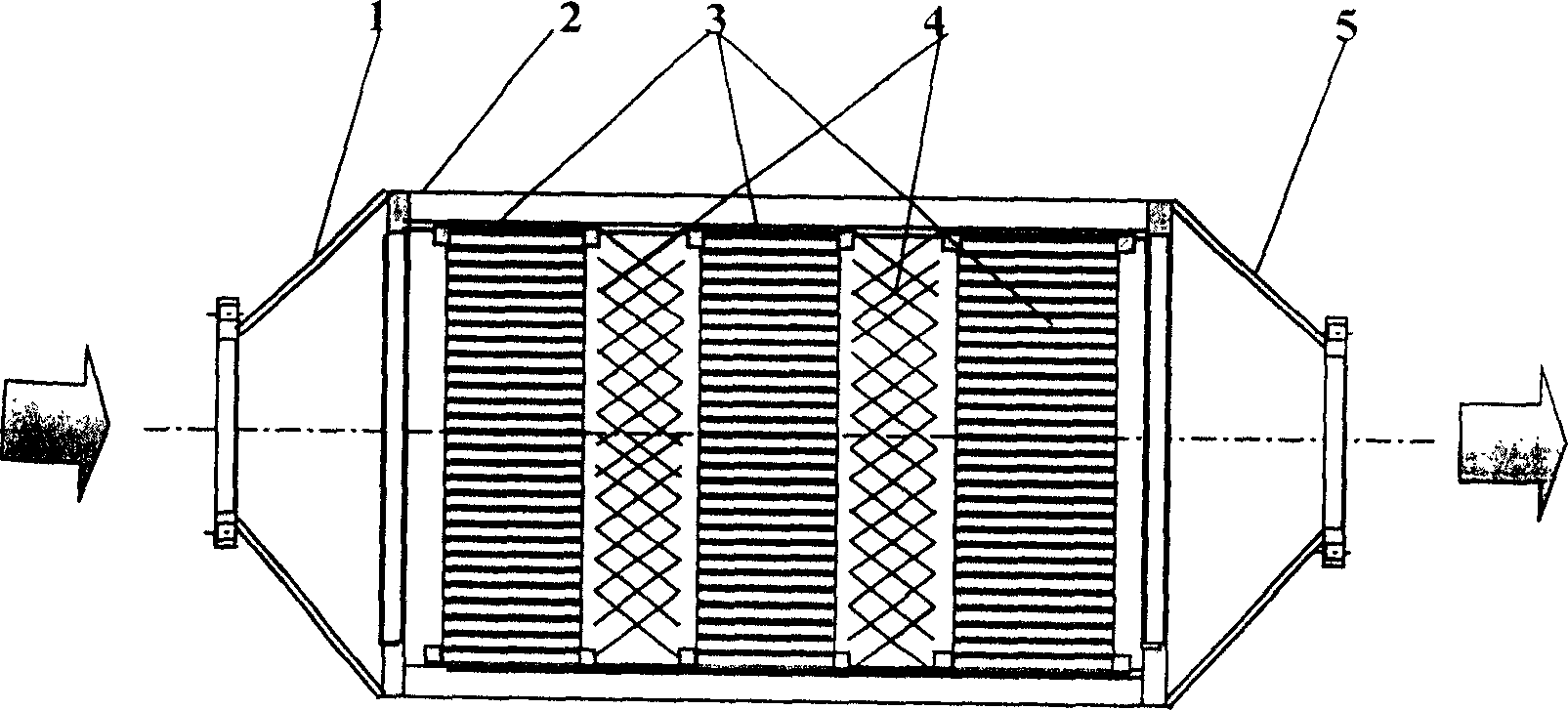

[0027] The structure of the metal-based diesel engine exhaust catcher of the present invention is as follows: figure 1 As shown, it is a columnar block pressed by at least two kinds of metal alloy wires with different diameters and high temperature resistance above 1000 °C in different proportions. The diameter is 60-200 mm, and the thickness is 3-20 mm. and the bottom surface is flat. The above-mentioned metal alloy wire has a diameter of 0.05-0.4 mm, and FeCrAl alloy wire can be used. According to different engine conditions and fuel and diesel conditions, the ratio of metal wires with different diameters is different. The opening ratio of the trap is 70-80%. In order to promote the oxidation of the particles on the metal-based particle trap 4, the above-mentioned metal alloy wires may be coated with an oxidation catalyst. The oxidation catalyst is a rare earth-transition metal-noble metal composite oxidation catalyst, which can effectively reduce the ignition point of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com