Patents

Literature

2443 results about "Catalytic combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic combustion is a chemical process which uses a catalyst to speed desired oxidation reactions of a fuel and so reduce the formation of undesired products, especially pollutant nitrogen oxide gases (NOₓ) far below what can be achieved without catalysts. The process was discovered in the 1950's by Catalytic Combustion LLC.

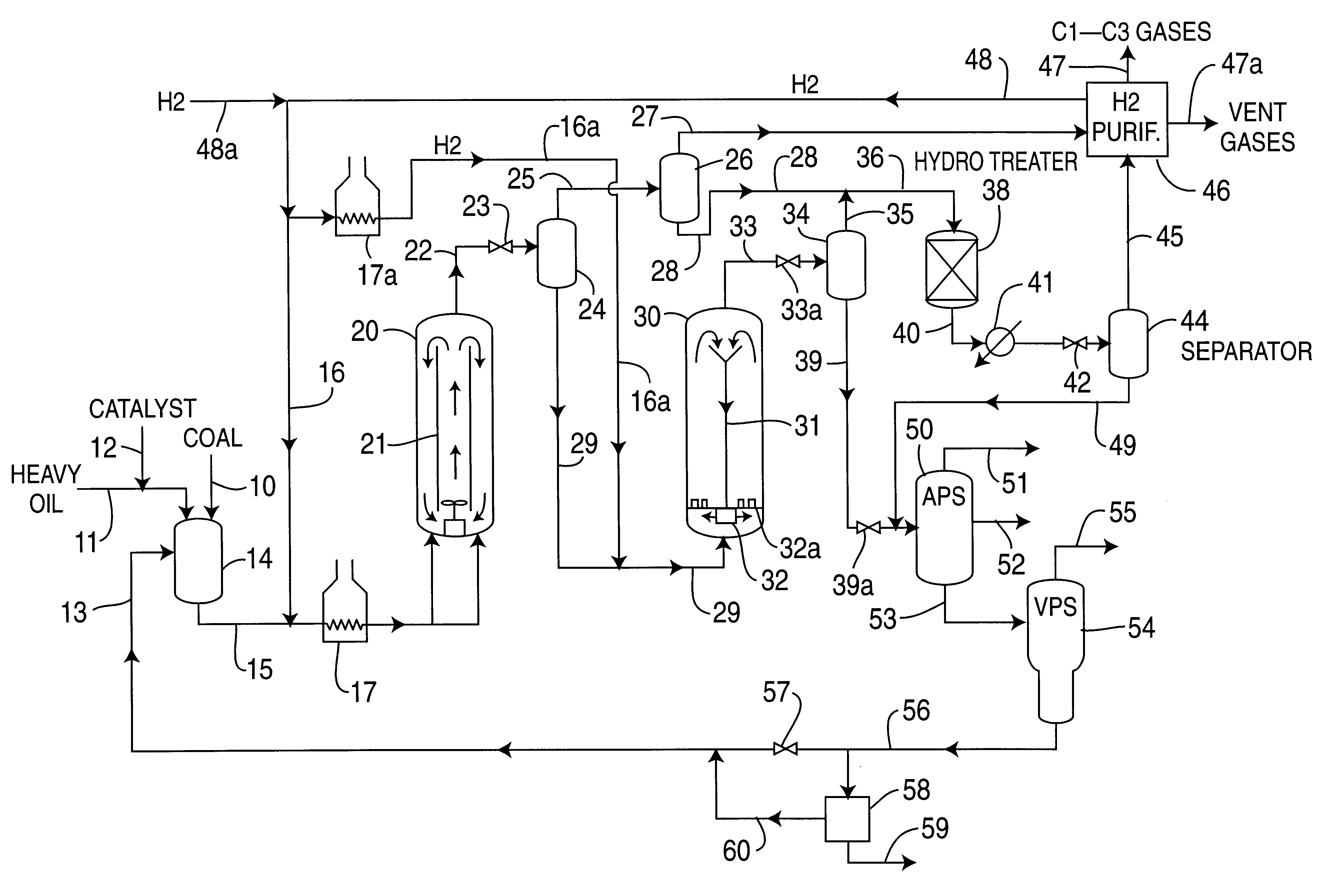

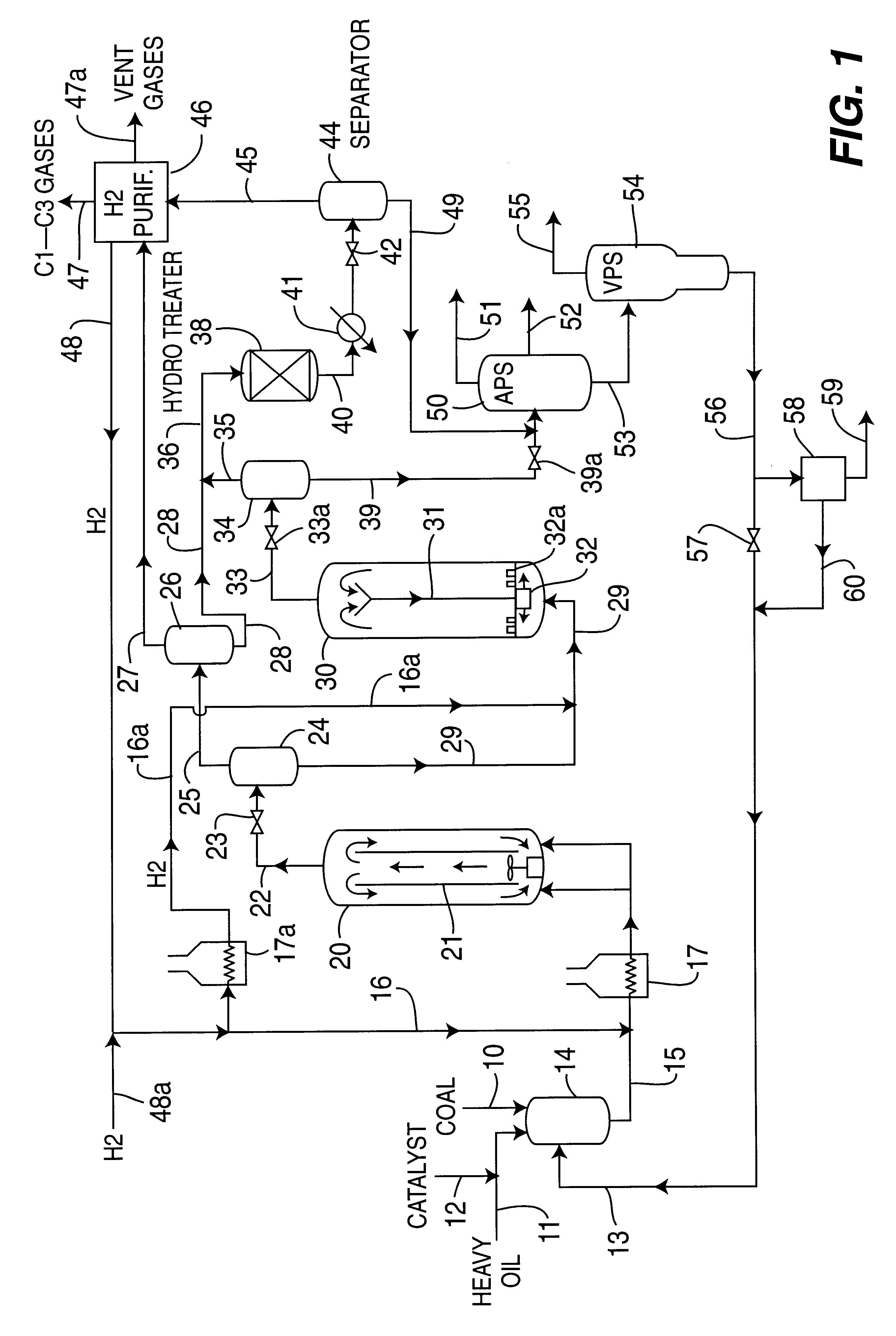

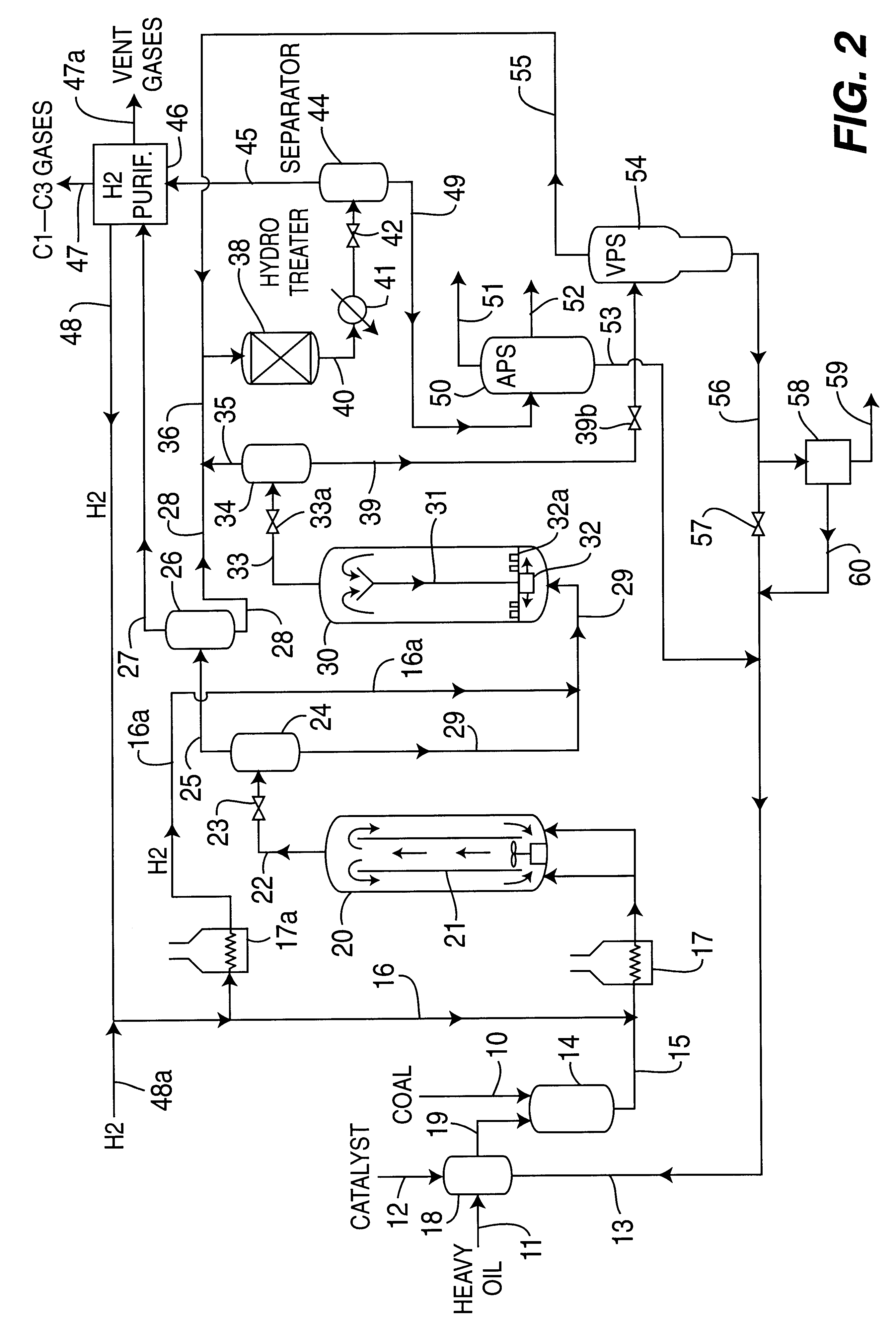

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

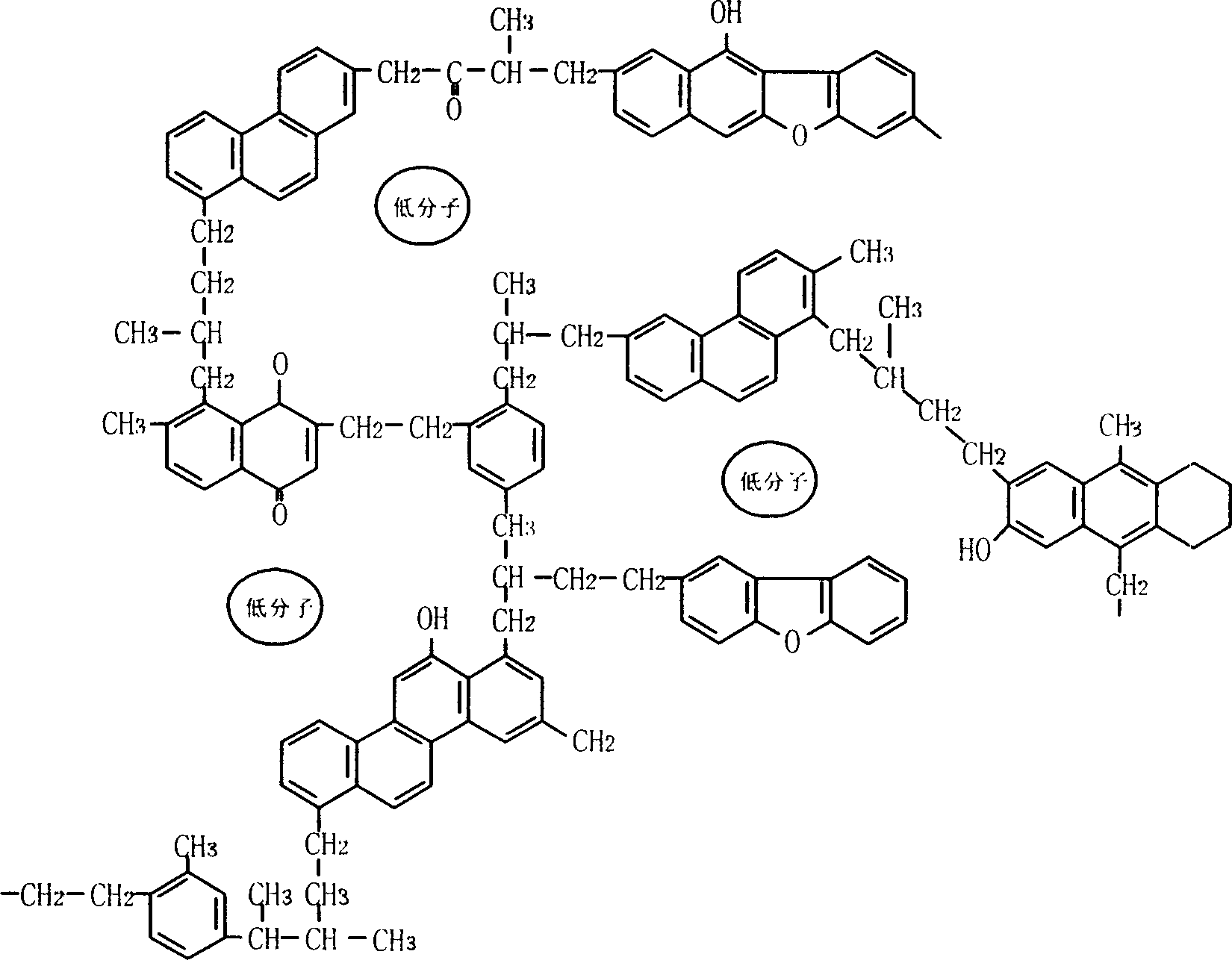

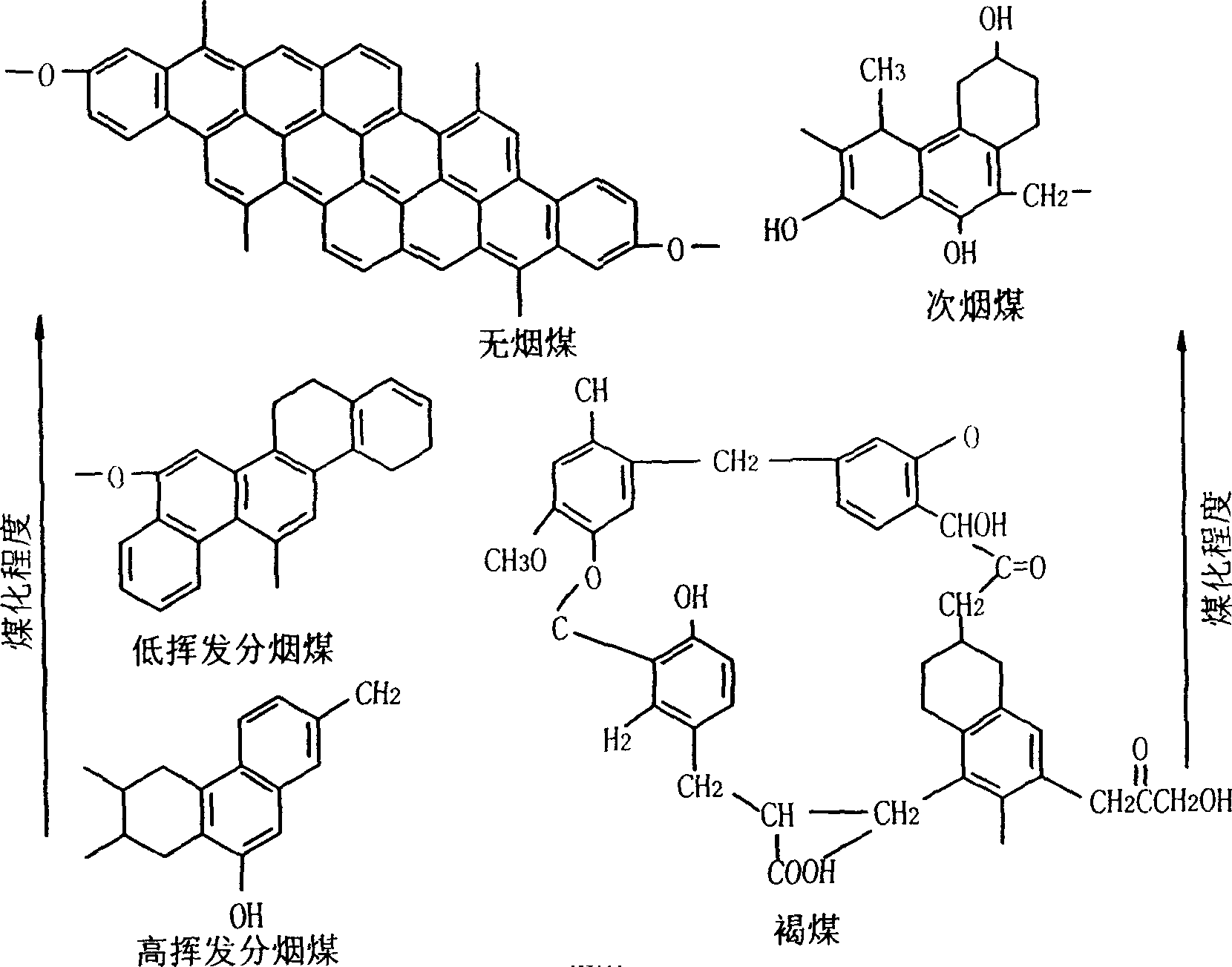

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

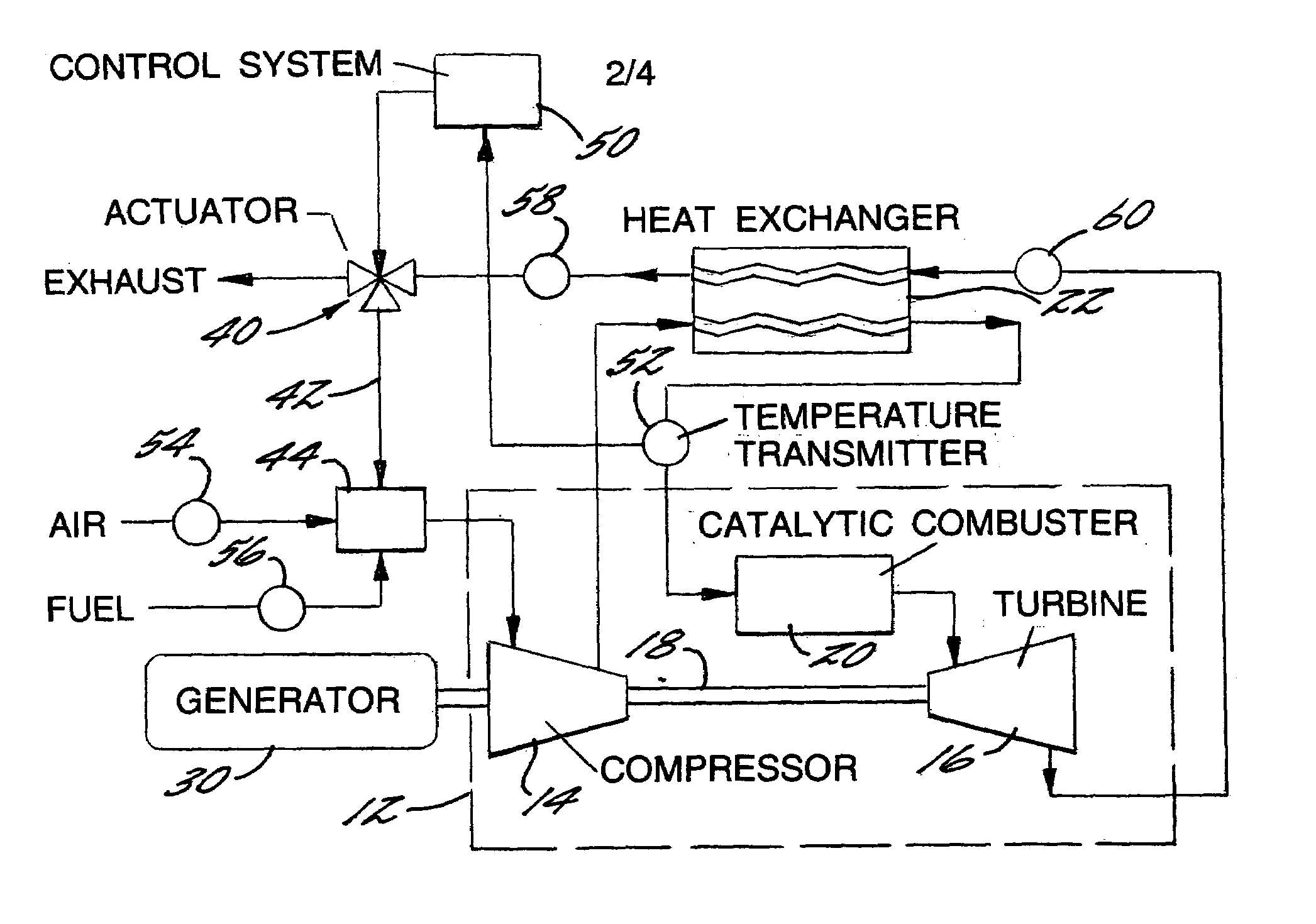

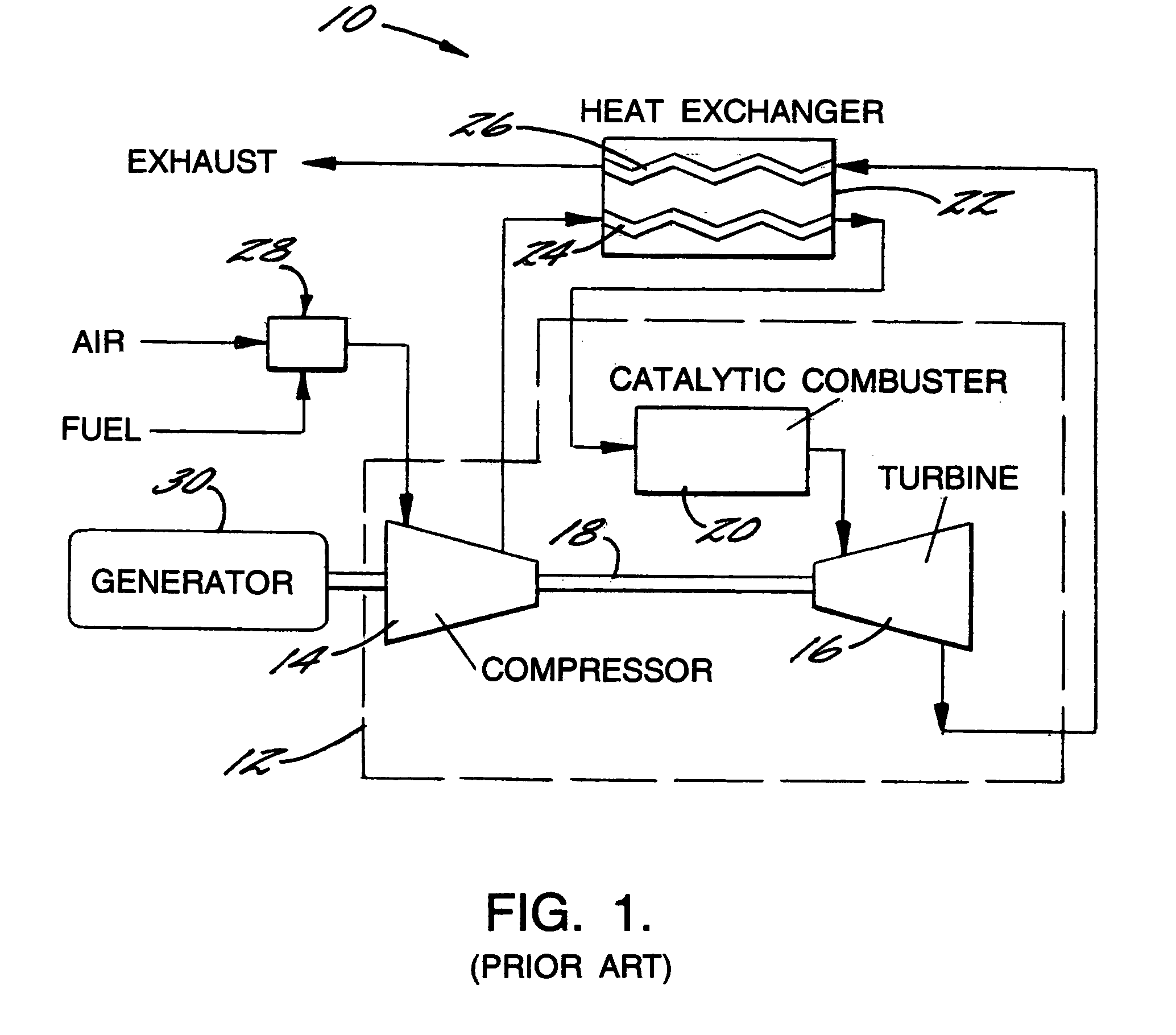

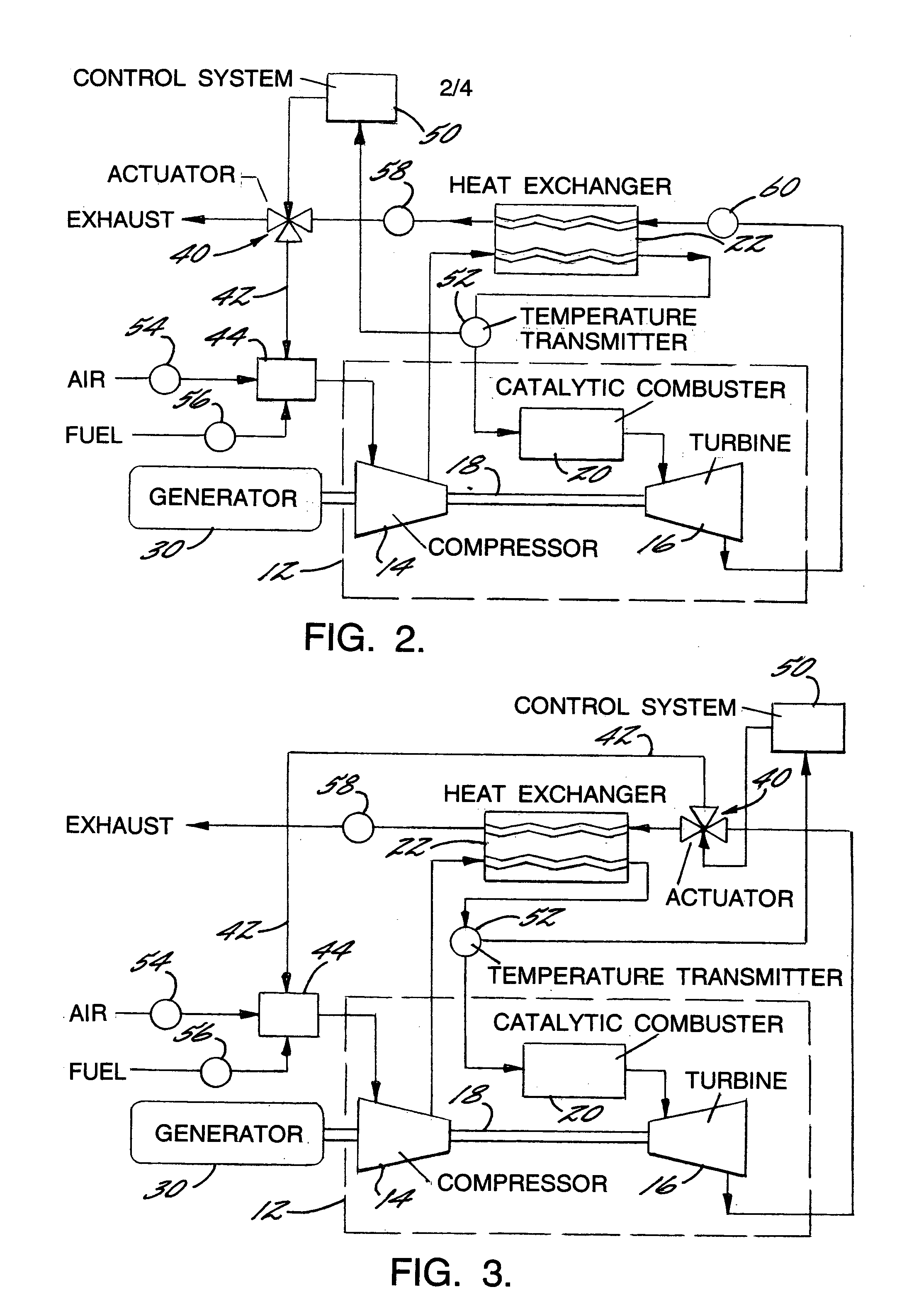

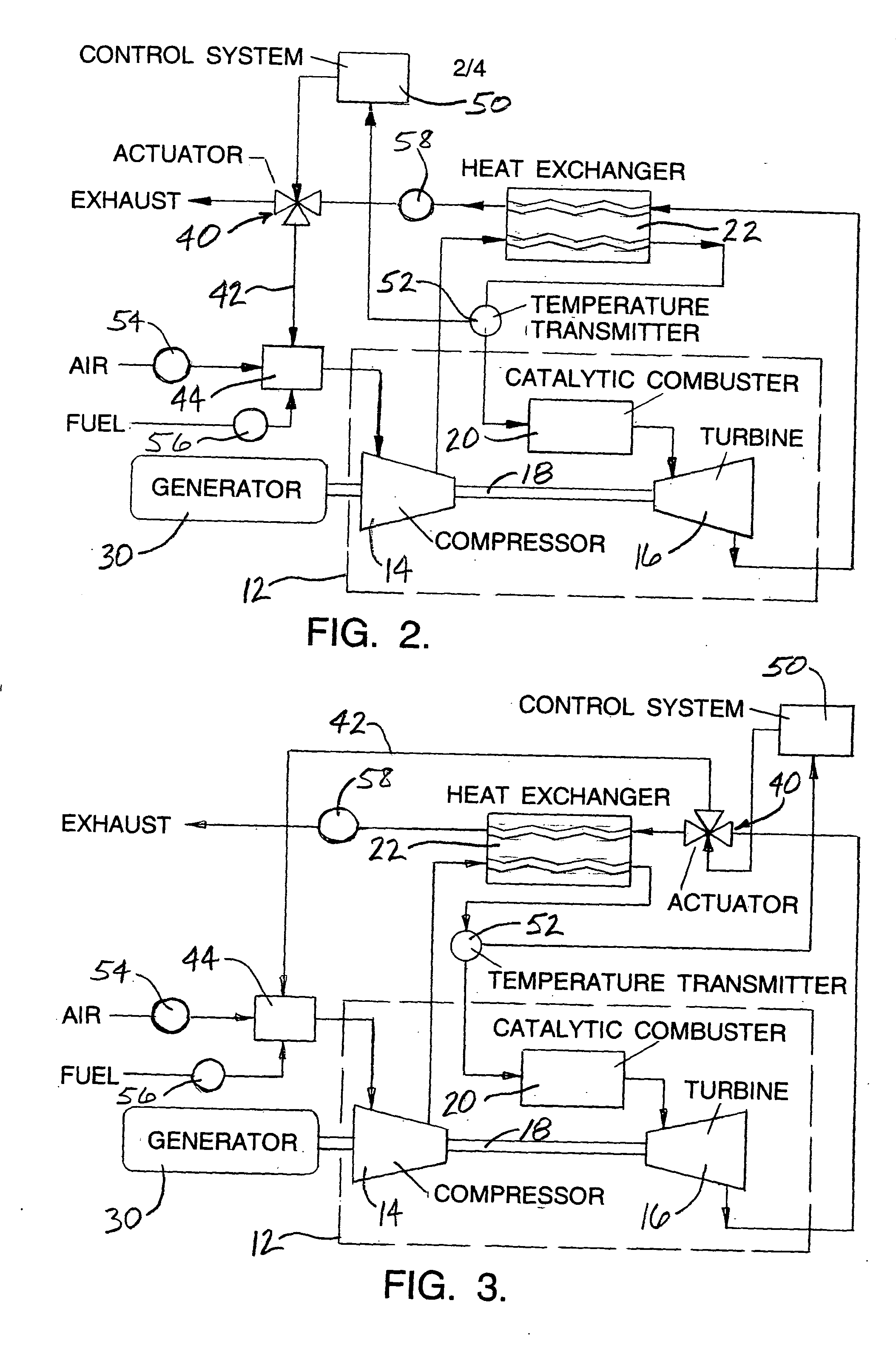

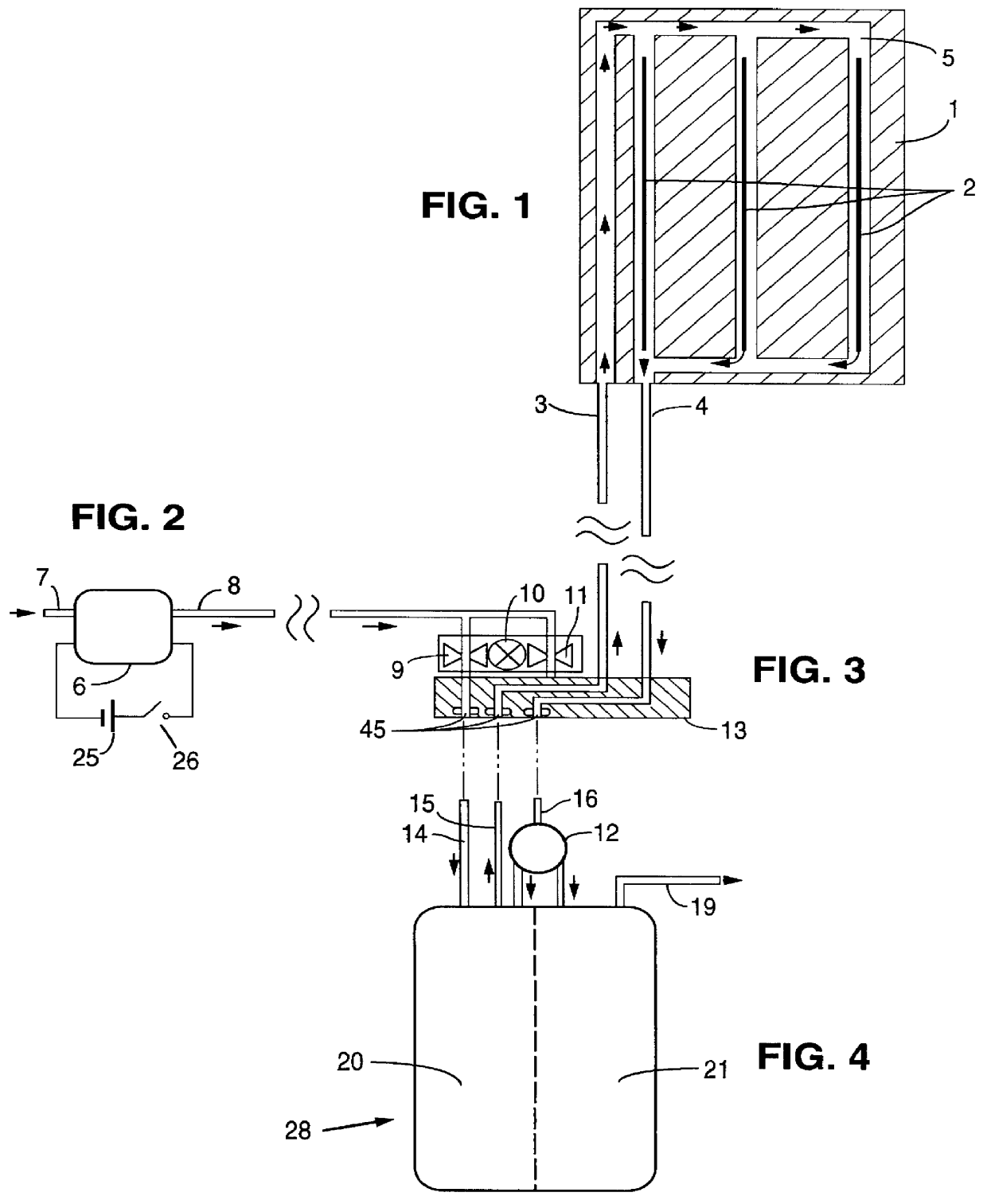

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

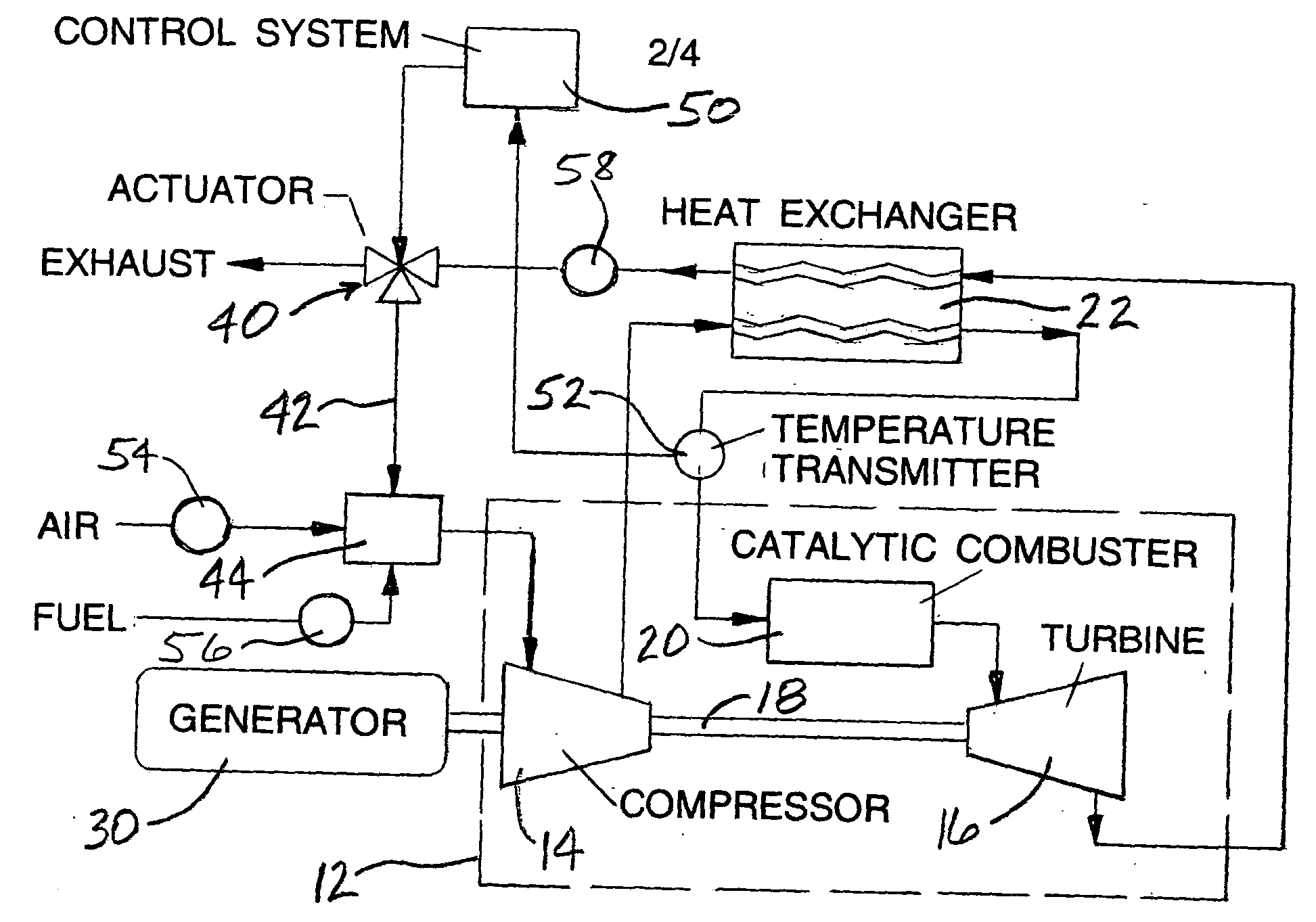

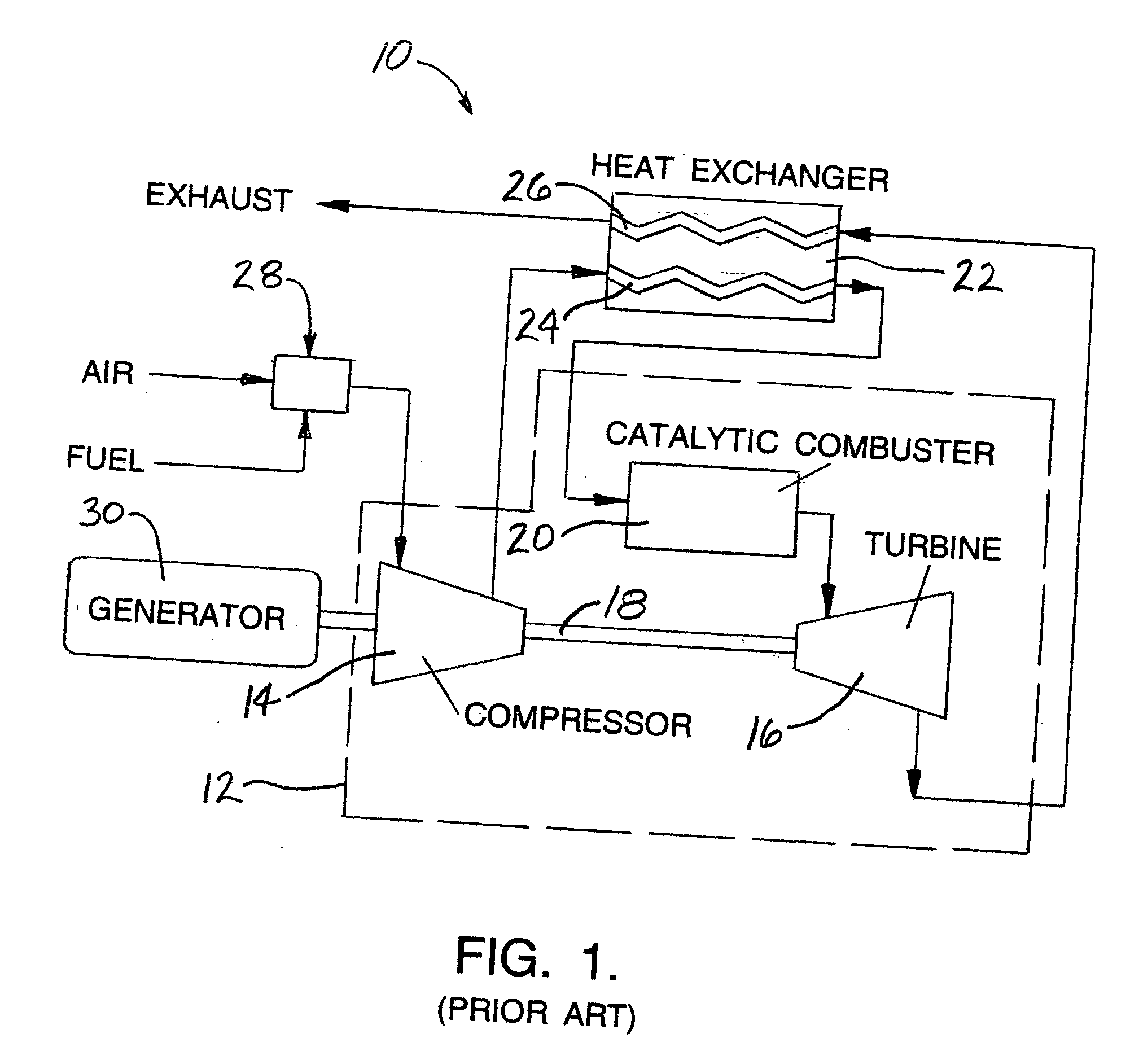

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

Fuel compositions employing catalyst combustion structure

InactiveUS20050044778A1Degradation of combustionReduce controlLiquid carbonaceous fuelsGas phaseGasoline

Metallic vapor phase fuel compositions relating to a broad spectrum of pollution reducing, improved combustion performance, and enhanced stability fuel compositions for use in jet, aviation, turbine, diesel, gasoline, and other combustion applications include co-combustion agents preferably including trimethoxymethylsilane.

Owner:OCTANE INT +1

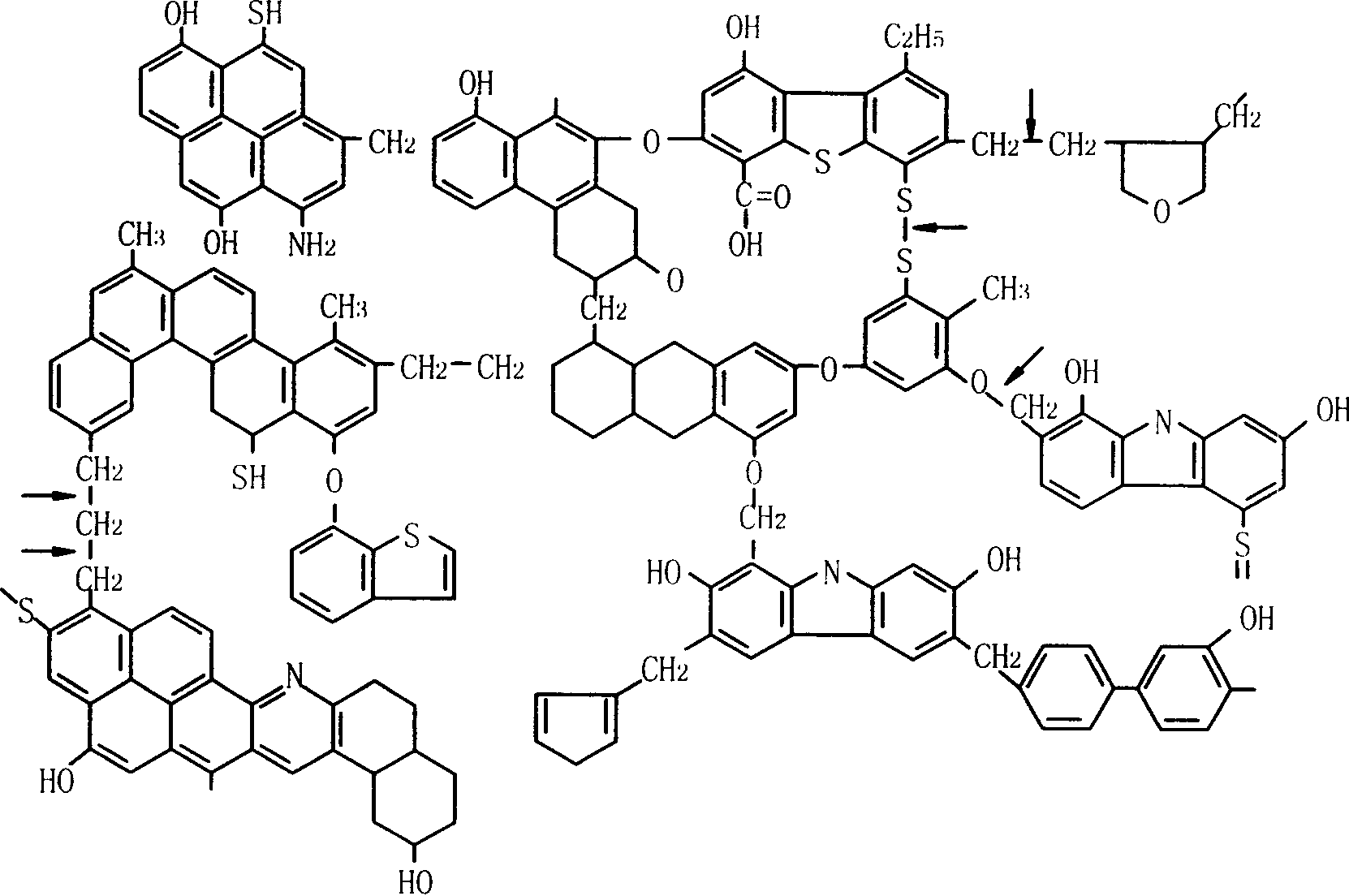

Catalytic combustion adjuvant for coal

A catalytic combustion improver of coal for increasing combustion efficiency and decreasing the exhaust of SO2, CO and NOx is composed of the primary raw materials chosen from 17 salts of organic acid, including acetate, oxalate, succinate, etc, the organic compound prepared by reaction between 17 organic acids and ore, metal, metallic oxide, or compound, chloride, etc, and the secondary raw materials chosen from high-caloricity agent, surface coating agent, solvent, assistant, emulsifying disperser, sulfur fixating agent and filler.

Owner:尹小林

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS20050022499A1Increase flow rateReduce the temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

Highly heat integrated reformer for hydrogen production

InactiveUS20100178219A1Improve distributionEasy to introduceCatalytic gas-gas reactionHydrogenCatalytic reformingSteam reforming

Described herein is a highly heat integrated steam reformer / combustor assembly that can be used in a fuel processor for hydrogen production from a fuel source. The assembly comprises a reforming section and a combustion section separated by a wall. Catalyst able to induce the reforming reactions is coated on the wall facing the reforming section. Catalyst able to induce the combustion reactions is coated on the wall facing the combustion section. A steam and fuel mixture is supplied to the reforming section where it is reformed to product hydrogen. A fuel and air mixture is supplied to the combustion section where it is combusted to supply the heat for the reformer. Catalytic combustion takes place on the combustion catalyst coated on one side of the wall while catalytic reforming takes place on the reforming catalyst coated on the other side of the wall. Heat transfer is very facile and efficient across the wall. Multiple such assemblies can be bundled to form reactors of any size.

Owner:HELBIO HYDROGEN & ENERGY PRODN SYST

Catalytic converter for cleaning exhaust gas

InactiveUS6261989B1Reduce and preventEasy to cleanNitrogen compoundsInternal combustion piston enginesCeriumCe element

A catalytic converter for cleaning exhaust gas includes a heat-resistant support, and a catalytic coating formed on the heat-resistant support. The catalytic coating contains Pd-carrying particles of a cerium complex oxide, Pt & Rh-carrying particles of zirconium complex oxide, and particles of a heat-resistant inorganic oxide.

Owner:DAIHATSU MOTOR CO LTD +1

Catalyzer for catalyzing combustion and its preparing method

InactiveCN1415410AReduced activityAvoid overwritingCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidActive component

A catalyst for the catalytic combustion of combustible waste gas is prepared by dipping the Pt as active component on the coated layer of cellular ceramics as carrier. The said coated layer contains Al2O3 (20-80 wt.%), TiO2 (10-40 wt.%), CeO2 (5-30 wt.%) and ZrO2 (5-20 wt.%). Its advantages are high utilization rate of Pt, and high distribution uniformity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for catalytic conversion of carbon monoxide in a hydrogen-containing gas mixture

InactiveUS6723298B1High activityHigh selectivityHydrogenCombustible gas catalytic treatmentHydrogenOperating temperature

A method for catalytic conversion of carbon monoxide with water to carbon dioxide and water in a hydrogen-containing gas mixture (carbon monoxide conversion) by passing the gas mixture over a shift catalyst that is at an operating temperature for the carbon monoxide conversion. The method is carried out with a shift catalyst based on noble metals that is applied to an inert support element in the form of a coating.

Owner:DMC2 DEGUSSA METALS CATALYSTS CERDEC

Catalytic converter for cleaning exhaust gas

InactiveUS6881384B1High catalytic activityEffectively its catalytic activityCombination devicesInternal combustion piston enginesCeriumCe element

A catalytic converter for cleaning exhaust gas includes a heat-resistant support, and a catalytic coating formed on the heat-resistant support. The catalytic coating contains zirconium complex oxide on which Pt and Rh are coexistently carried, and cerium complex oxide on which Pt and Rh are coexistently carried. The Pt- and Rh-carrying zirconium complex oxide and the Pt- and Rh-carrying cerium complex oxide are contained in a same layer of the catalytic coating.

Owner:DAIHATSU MOTOR CO LTD

High-cleanness environment-friendly alcohol ether fuel for car

ActiveCN103275769AHigh chemical activityImproves resistance to phase separationLiquid carbonaceous fuelsFuel additivesMechanical engineeringMethanol

The invention provides a high-cleanliness environment-friendly alcohol ether fuel for a car. The fuel provided by the invention consists of the following raw materials: 600-800 parts of methanol, ethanol or a mixture of methanol and ethanol, 100-350 parts of an ether stabilizer, 1-6 parts of an anti-oxygen and anti-gum inhibitor, 2-5 parts of a metal deactivator, 1-3 parts of a corrosion inhibitor, 1-40 parts of a catalytic combustion improver, 2-4 parts of an antistatic agent, 10-100 parts of an antiknock stabilizer, 1-6 parts pf a purification dispersant, 1-6 parts of an anti-wear repair agent, 1-6 parts of a metal corrosion inhibitor, 2-6 parts of a rubber and plastic part corrosion and swelling inhibitor, 10-50 parts of a modified alcohol cosolvent, 0.2-0.8 part of a bactericide and 0.04-0.1 part of a recognition agent. The fuel provided by the invention has the advantages of stable performance, strong power, sufficient combustion, good seismic performance, good acceleration, easiness for starting up, no air lock, no separated layer, reduced fuel consumption, cleaner tail gas emission and no need of changing the structure of a spark ignition engine in the prior art and can be separately used, used instead of regular gasoline or used together with regular gasoline by co-combustion.

Owner:鲁家政

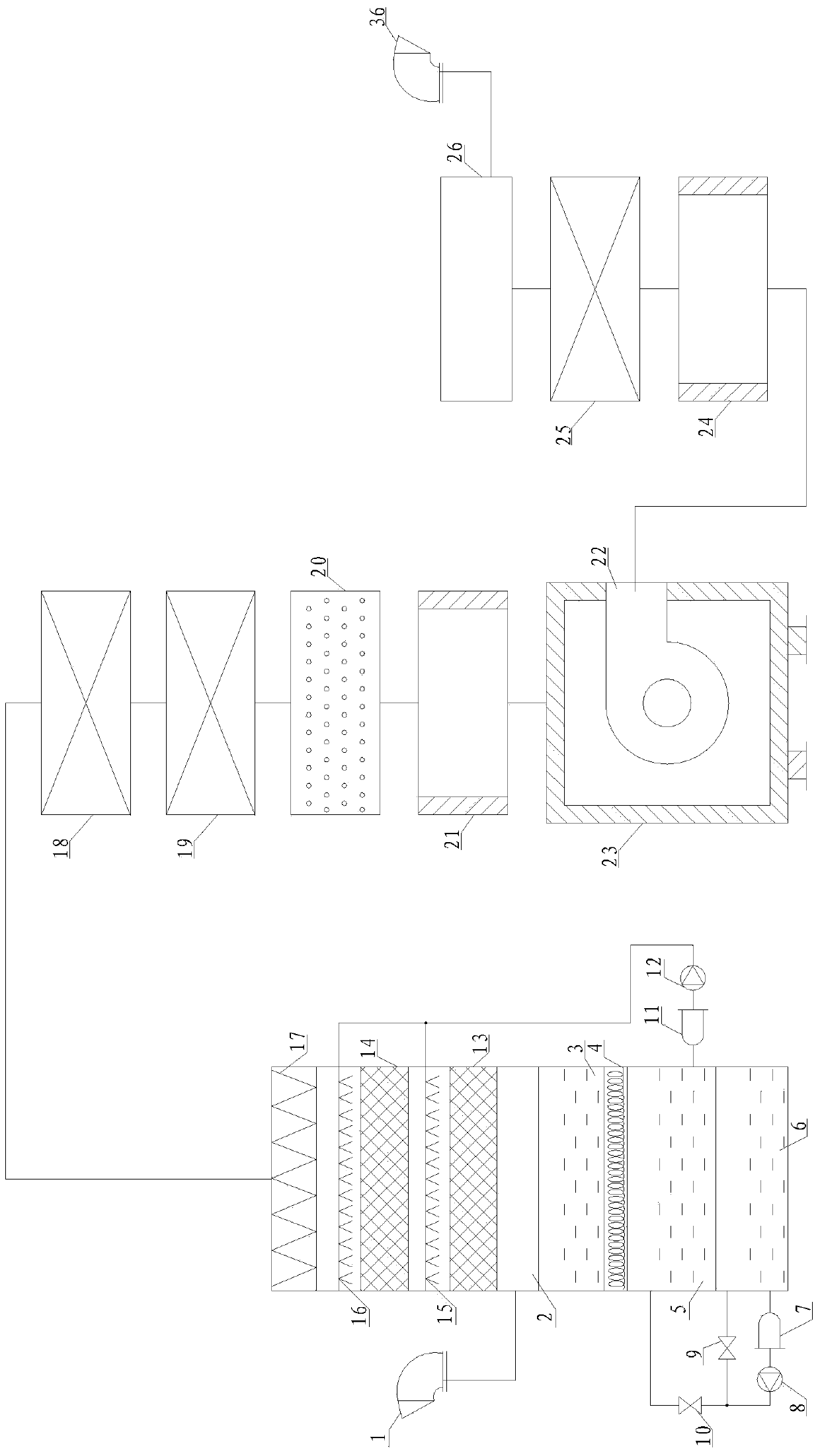

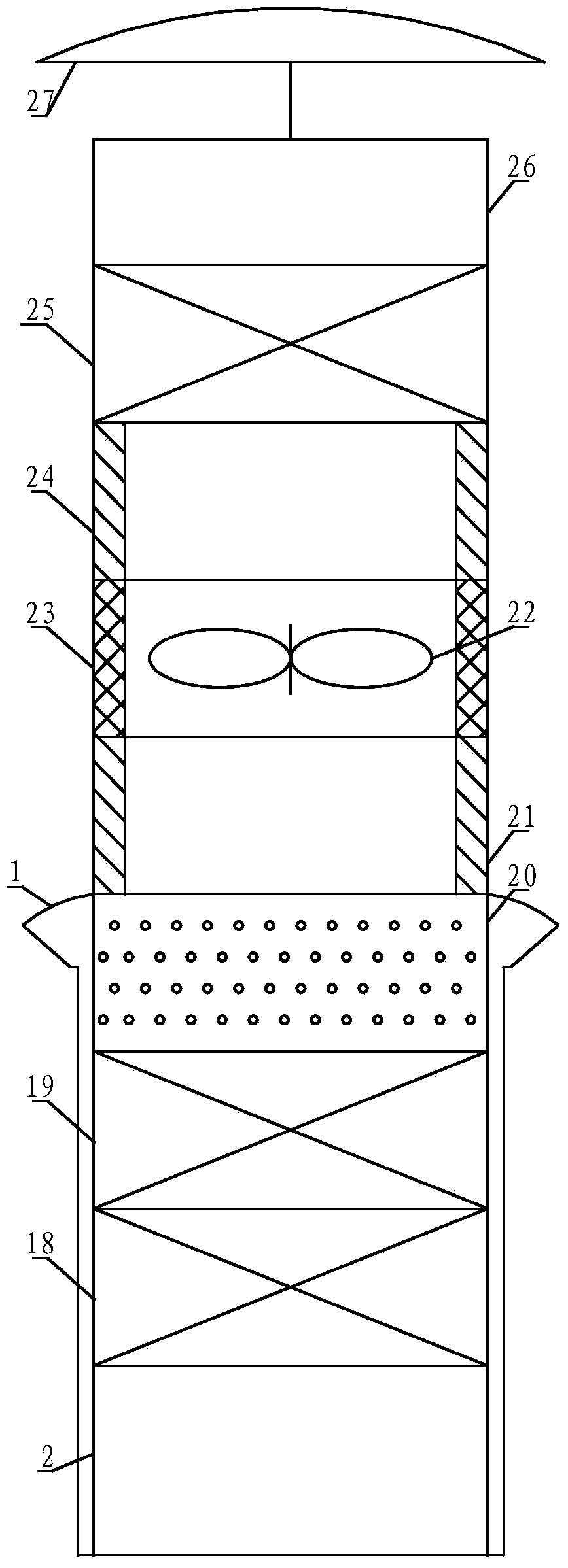

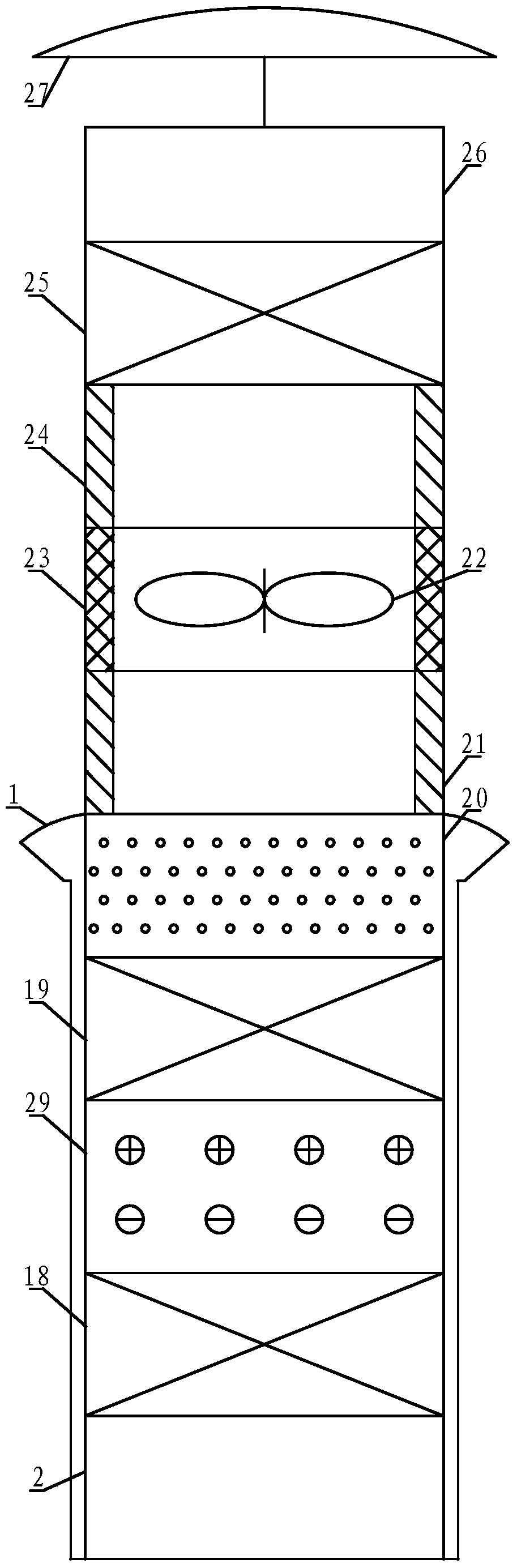

Haze pollutant removing device

ActiveCN103542473AQuick eliminationImprove air qualityCombination devicesLighting and heating apparatusAir filtrationAtmospheric air

The invention relates to the field of air pollutant removing devices, in particular to a haze pollutant removing device which comprises a ventilation system with a fan, an air filter device, purification devices and silencers. The ventilation system with the fan comprises a rainproof haze air inlet, an air pressure equalizing chamber, the fan and an air cleaning static pressure tank type spherical jet air outlet; the air filter device comprises a primary filter, an intermediate filter and a high-efficiency filter; the purification devices include one or a plurality of devices including an alkaline aqueous solution spray washing device, an activated carbon adsorption device, a negative ion purification device, a catalytic combustion purification device, an electrostatic dust collection device, an ultraviolet disinfection device, a photonic hydrogen ion purification device, a biological purification device and a three-way catalytic purification device; the silencers include one or a plurality of devices including a silencer at an induce draft end of the fan, a vibration damping muffler device and a silencer at an exhaust end. The haze pollutant removing device has the advantages that clean air can be exhausted to the atmosphere under the filter effects of filters and purification treatment effects of the various purification devices, and accordingly the purpose of quickly removing haze pollutants can be achieved.

Owner:王全龄

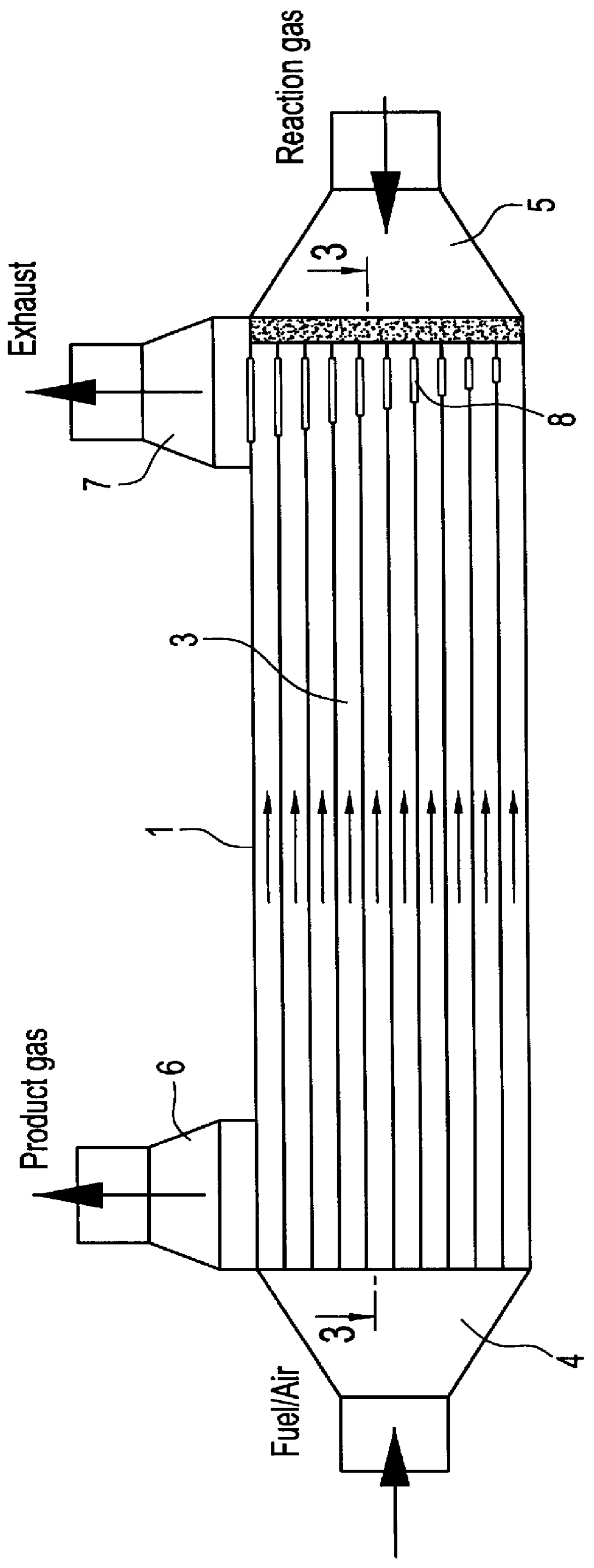

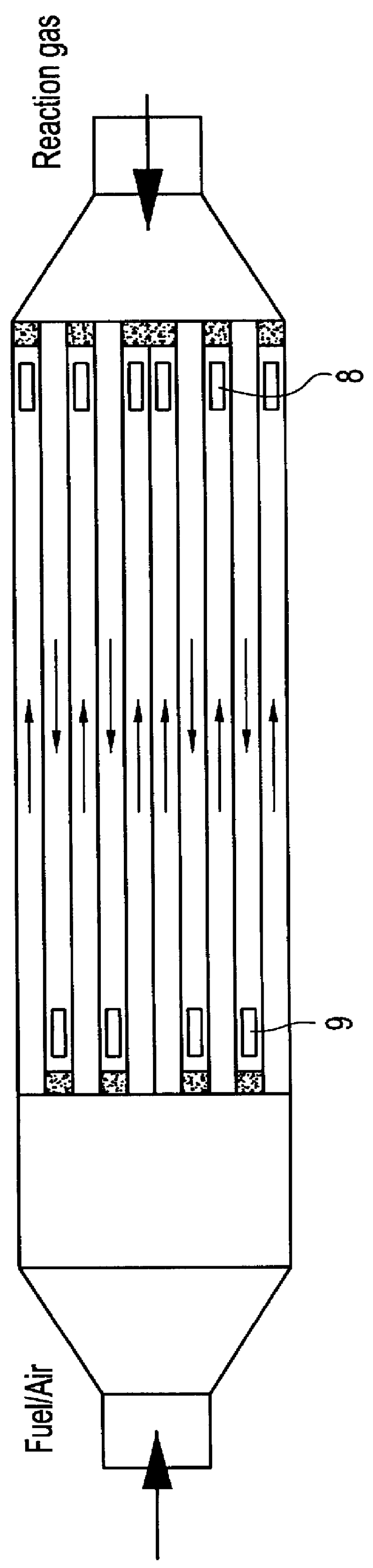

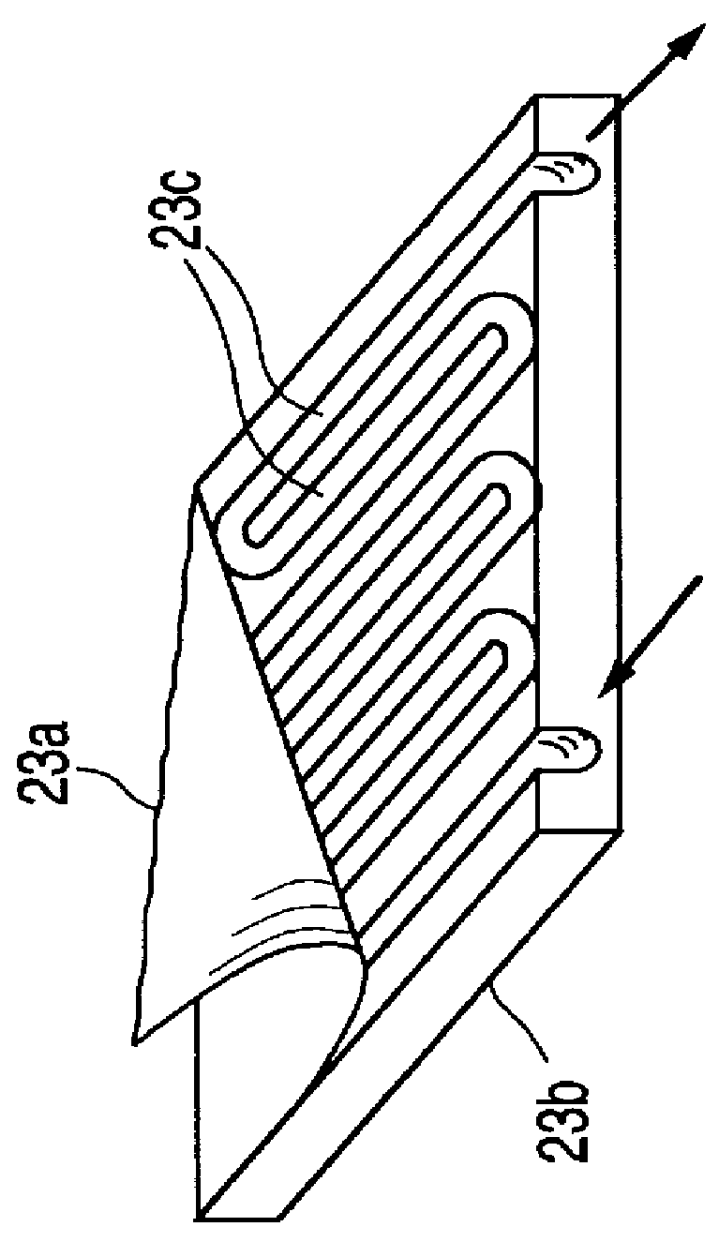

Reactor for performing endothermic catalytic reactions

InactiveUS6056932ACatalytic gas-gas reactionPhysical/chemical process catalystsOrganic chemistryCatalytic combustion

A reactor for performing endothermic catalytic reactions is disclosed formed of a monolithic counterflow reactor with parallel heating and reaction channels. The internal walls of the reaction channels are coated with a catalyst for the catalytic reaction to be performed, while the internal walls of the heating channels have a catalyst for the catalytic combustion of a fuel gas / air mixture.

Owner:DEGUSSA AG

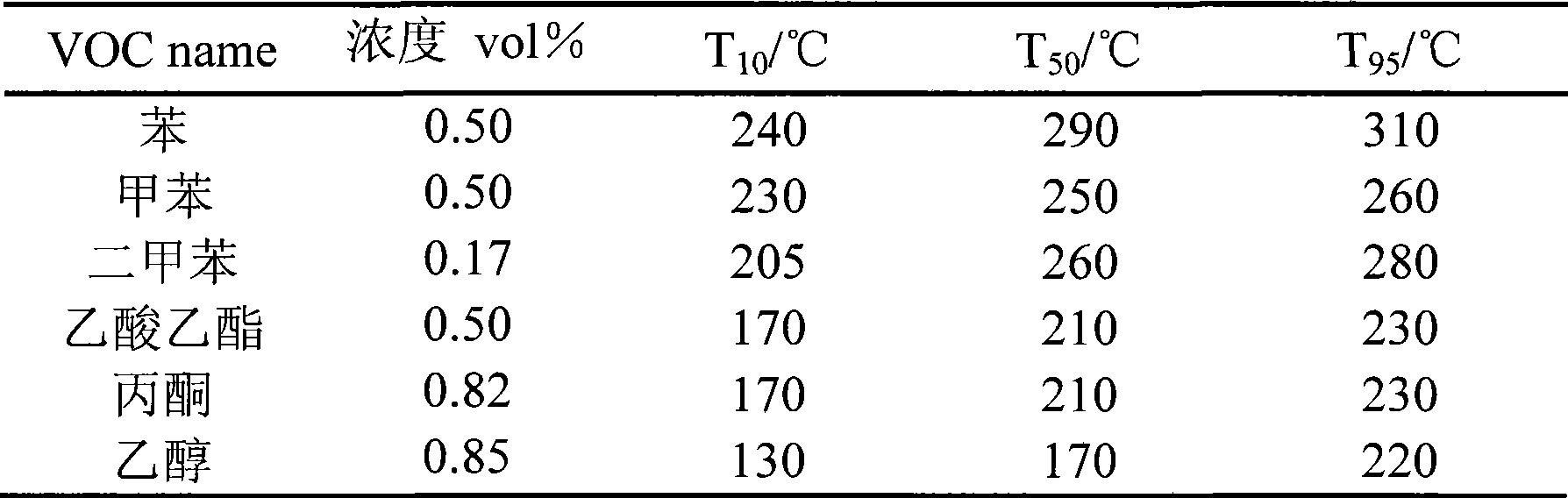

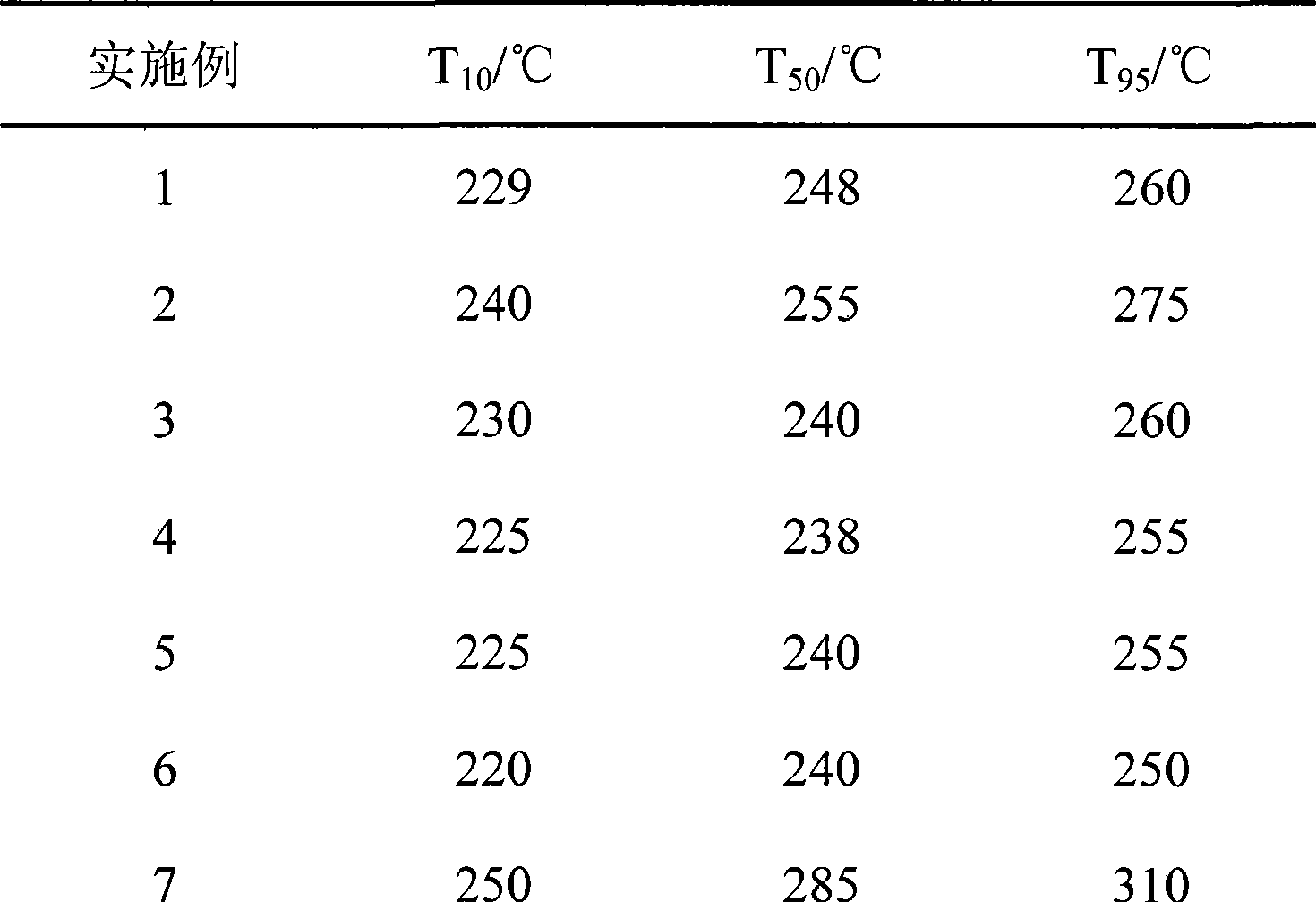

Cellular ceramic type catalyst for catalytic combustion of perovskite as well as preparation and application thereof

InactiveCN101439290AHigh activityImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioManganese

The invention discloses a honeycomb ceramics perovskite catalytic combustion catalyst; the honeycomb ceramics with a metal oxide coating is used as a carrier; the catalytic activity components disclosed in formula (I) are loaded; wherein, La, Sr, Co, and Mn respectively represent lanthanum, strontium, cobalt, and manganese; x is equal to 0 to 0.7 and y is equal to 0 to 0.7; the honeycomb ceramics with a metal oxide coating is to load a metal oxide coating of gamma-Al2O3, CemZr1-mO2, LaMnAl11O19, BaMnAl11O19 or Sr12Al14O21 on the surface of the honeycomb ceramics of a dichroite material; wherein, m is equal to 0.1 to 0.8; the mass ratio of the honeycomb ceramics, the metal oxide coating and the catalytic activity components is 1.0 : 0.03 to 0.2 : 0.05 to 0.15. The invention also relates to a preparation method for the catalyst and the applications of the catalytic combustion thereof to eliminate the waste gases of volatile organic compound; the dichroite honeycomb ceramics carrier and the catalytic activity components of the prepared honeycomb ceramics perovskite catalytic combustion catalyst are combined by one metal oxide coating with high adhesiveness and thermal stability, thus leading the catalyst to have the advantages of high mechanical intensity, high activity and good thermal stability. The catalyst provided by the invention is simple in preparation method, is low in the price of the used materials, and has excellent industrial application prospect. La1-xSrxCoyMn1-yO3 (I).

Owner:ZHEJIANG UNIV OF TECH

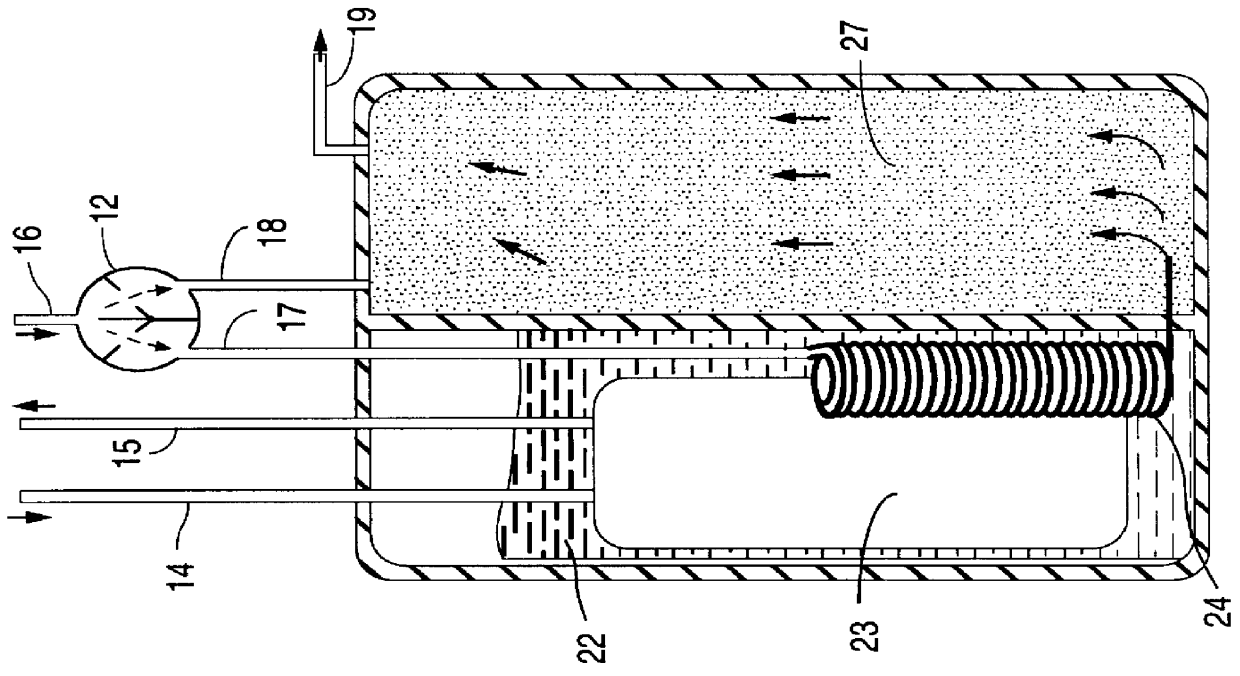

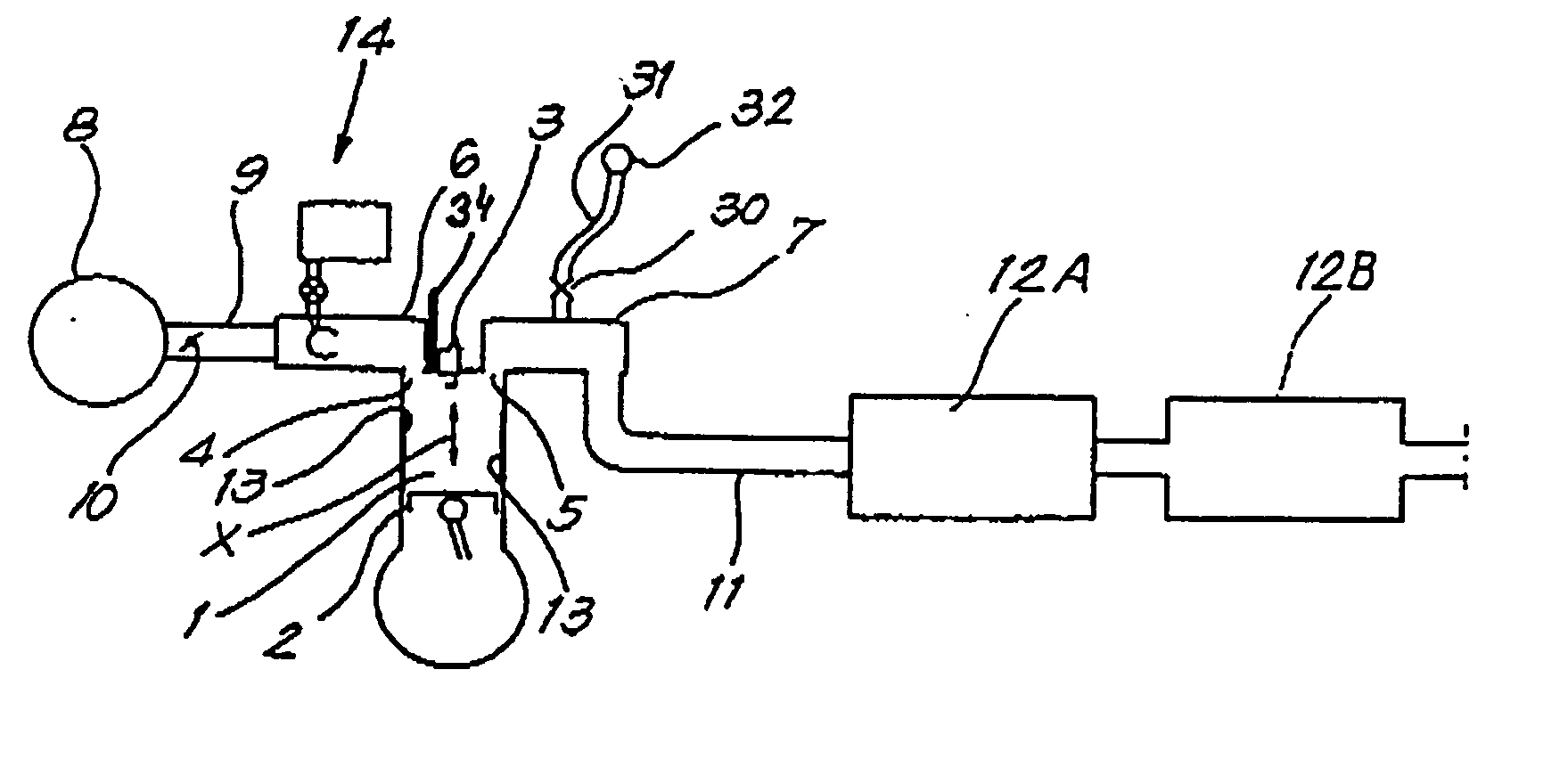

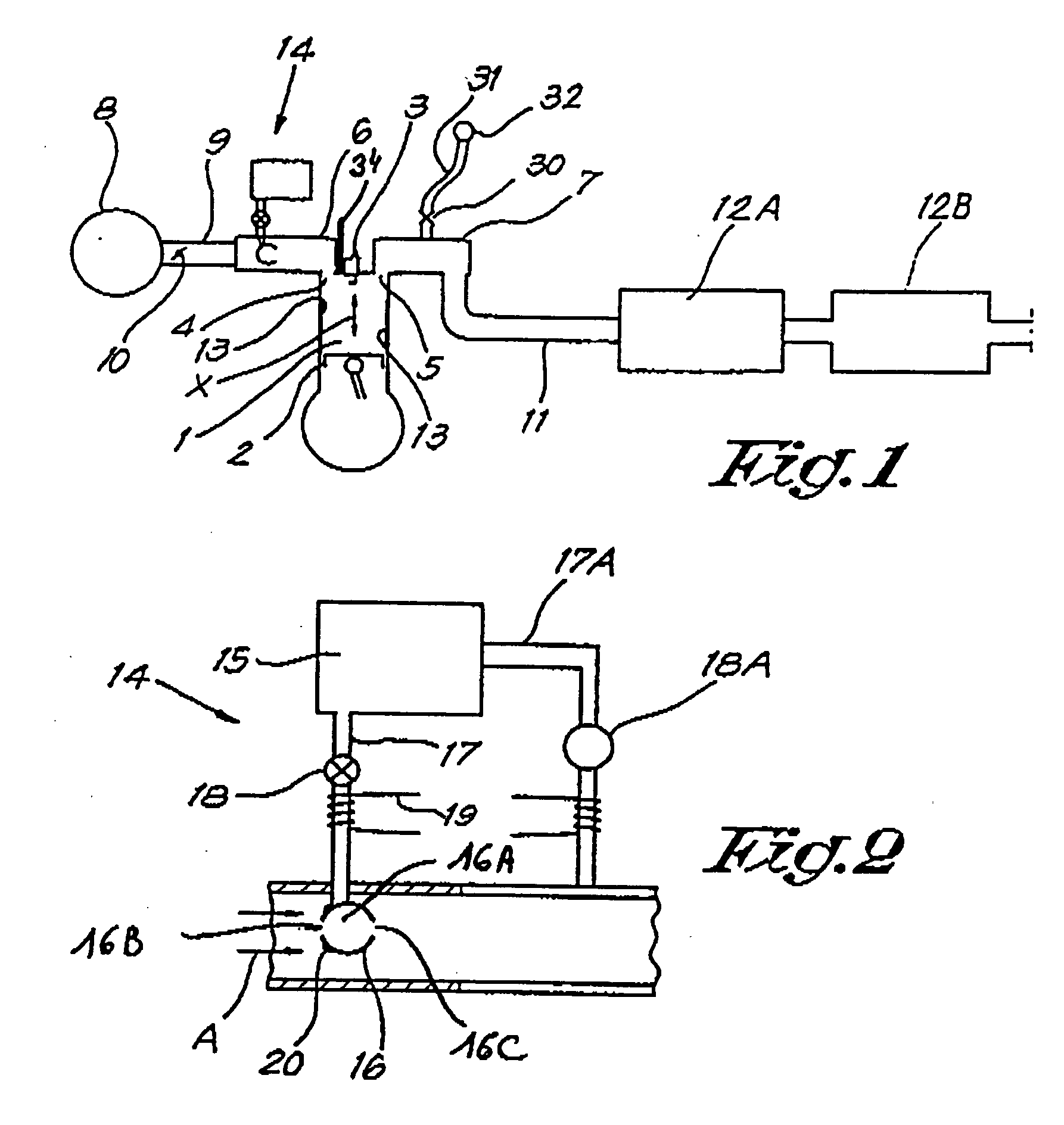

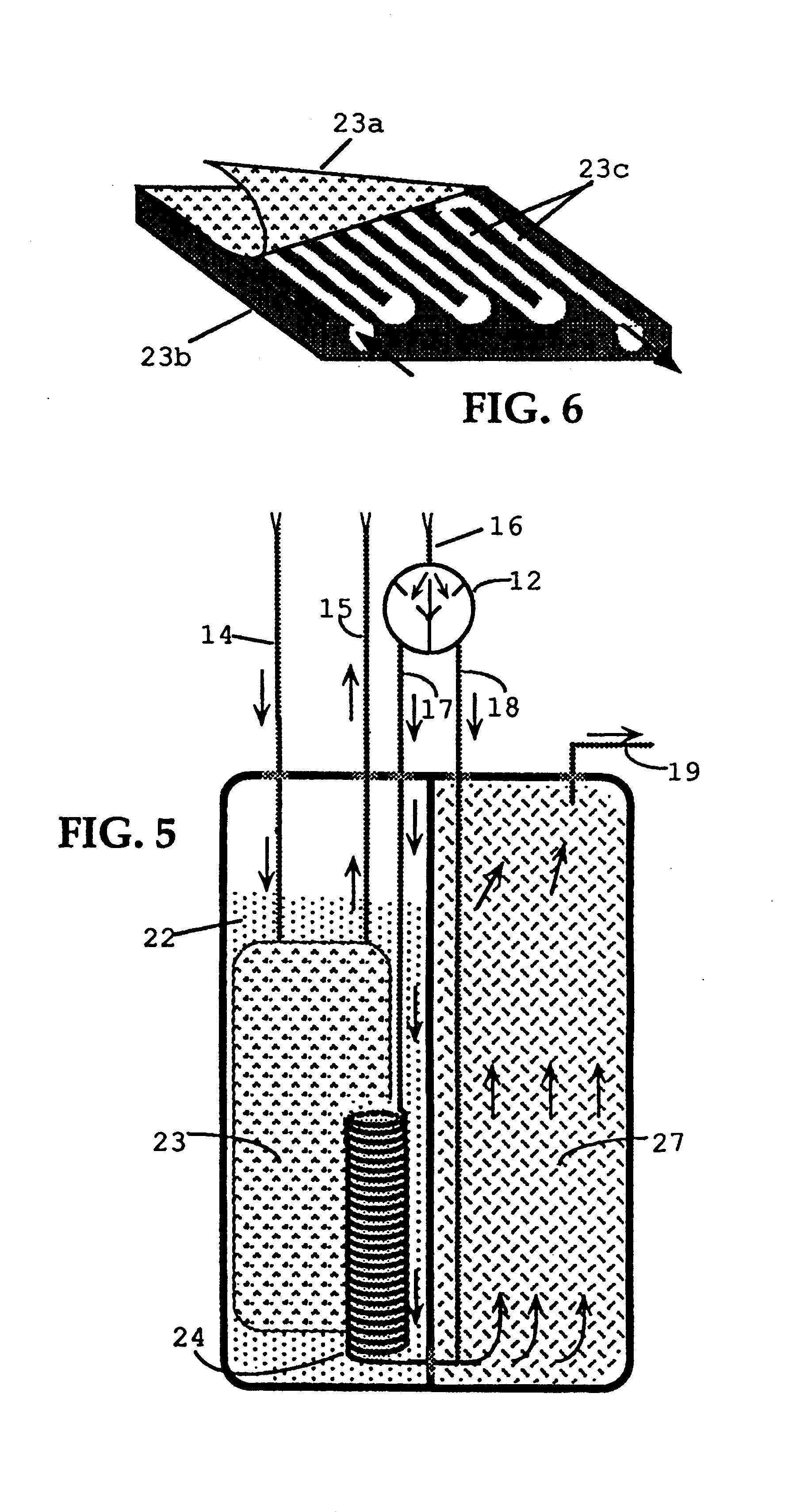

Portable heat generating device

InactiveUS6062210APromotes spontaneous flameless combustionReduce necessityExothermal chemical reaction heat productionOther heat production devicesElastomerThermal energy

A portable heat generating device in which fuel vapor and an oxygen supply (e.g. air) are directed through channels contained within a thin, flexible and compliant elastomeric sheet of material. Elongated catalytic heat elements, placed strategically within the channels, spontaneously interact with the fuel-air stream liberating heat energy. Means and methods are defined that permit flameless catalytic combustion to be uniformly extended over the length of each heat element, lowering power density but maintaining the overall power generated, permitting the use of many types of low temperature materials like plastics, polymers, and elastomers in the construction of the heater. The heat generation process is started by pumping an air stream into a reservoir containing a fuel source (e.g. methanol) thereby saturating the air stream with fuel vapor. The fuel vapor is mixed with a another stream of air to achieve a particular fuel / air ratio and directed into channels within the elastomeric sheet, reacting with the catalytic heat elements to produce flameless combustion. The warm exhaust gas is directed to a thermally controlled diverter valve. The valve senses the temperature of the liquid fuel supply and diverts some or all of the warm exhaust gas, as necessary, to heat the fuel and keep its temperature within a specified range. Exhaust by-products are passed into a miniature scrubber module adjacent to the fuel module. The scrubber absorbs any noxious components in the exhaust stream that may occur during start-up or rapid changes in operating condition.

Owner:CLIFFORD G WELLES

Method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion

InactiveCN104230615AGood dehydrogenation performanceInhibition of partial polymerizationHydrocarbonsPreparation from heterocyclic compoundsLiquid productReaction temperature

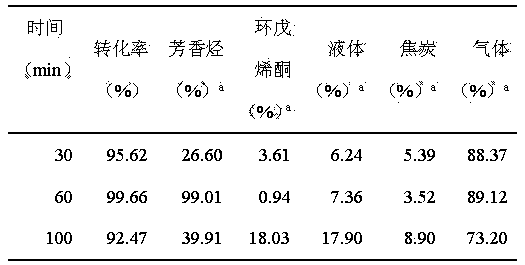

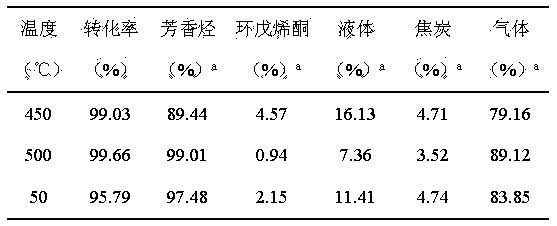

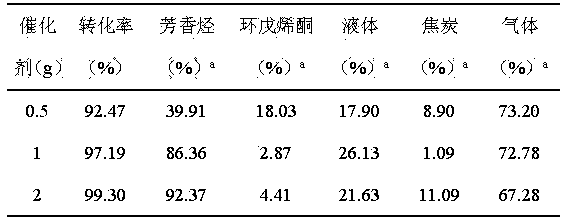

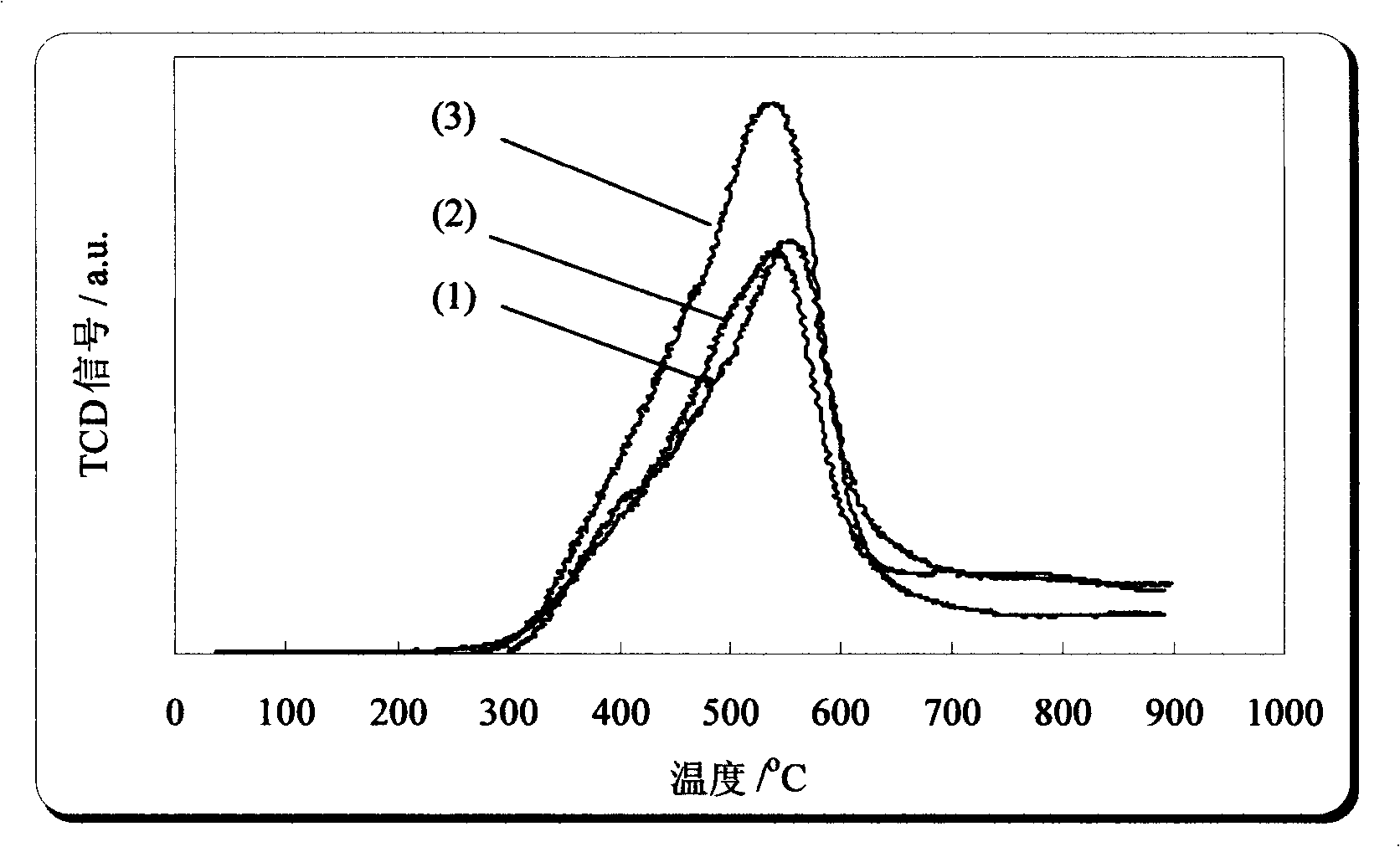

The invention relates to a method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion, which comprises the following steps: (1) using biomass derivative gamma-valerolactone as a raw material, which is prepared by carrying out hydrogenation reaction on levulinic acid; (2) introducing one or more transition metals into a zeolite molecular sieve, and preparing a reaction catalyst at the reaction temperature of 350-550 DEG C by using a fixed bed or fluid bed as a reactor; (3) in an inert or reducing atmosphere, carrying out contact reaction on the raw material gamma-valerolactone and catalyst under the reaction pressure of 0-10 MPa; and (4) after the pyrolysis gas is condensed, collecting the liquid product in the condensation receiver, thereby obtaining the aromatic hydrocarbon product (of benzene, toluene and xylene) and the cyclopentenone product. By using the renewable biomass derivative gamma-valerolactone as the raw material, the method has the advantage of milder reaction conditions, and the catalyst is simple to prepare and easy to recover and reuse.

Owner:湖南清欣绿色环保有限公司

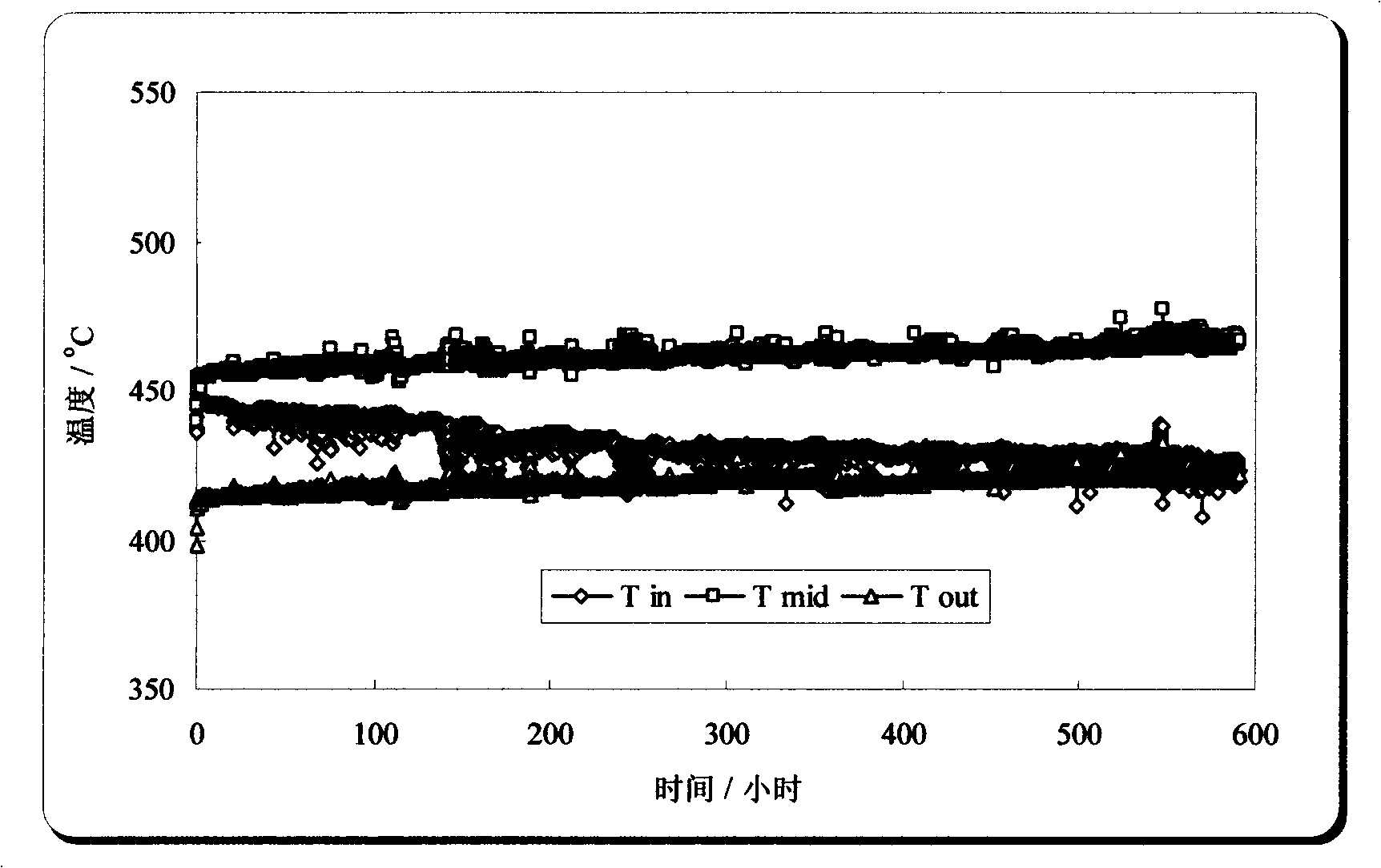

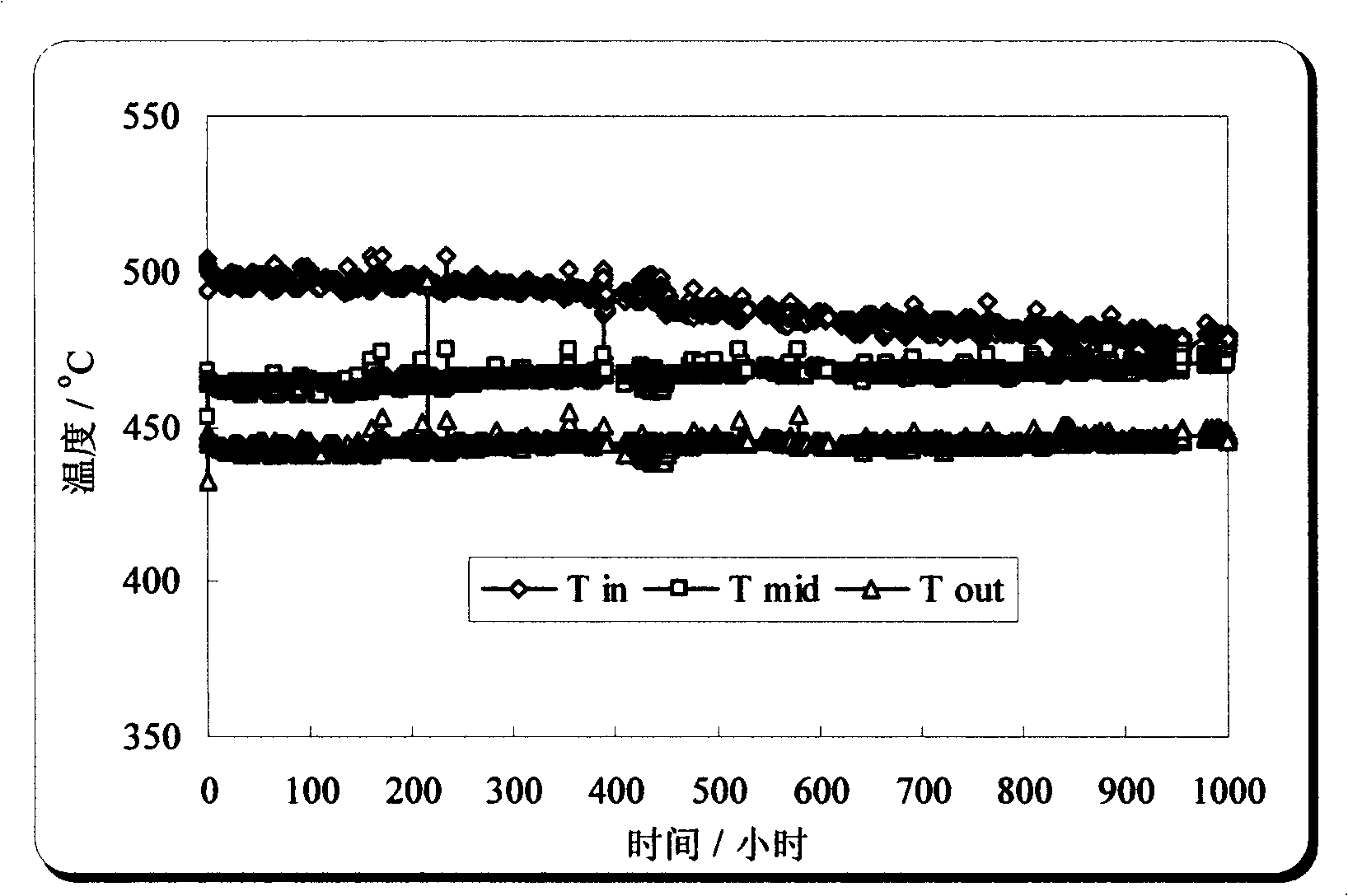

Coal bed gas deoxidation catalyst as well as preparation method and application thereof

InactiveCN101664679AExtend your lifeElimination of active oscillationsGas purification by catalytic conversionCatalyst activation/preparationRare-earth elementAlkaline earth metal

The invention relates to a coal bed gas deoxidation catalyst as well as a preparation method and the application thereof. The coal bed gas deoxidation catalyst takes one or the combination of severalplatinum group noble metals, i.e. Pd, Pt, Ru, Rh and Ir, as main catalyzing active components and takes one or the combination of several alkali metal / alkaline-earth metal oxides, i.e. Na2O, K2O, MgO,CaO, SrO and BaO, and multi-element compound oxides of CeO2, lanthanide series rare earth elements, i.e. Pr, Nd, Sm, Eu, Gd, and the like, or / and transition elements, i.e. Y, Zr, La, and the like, or / and gamma-Al2O3 as auxiliary catalysts, and the catalyzing components are loaded on an inert carrier in a coating way so as to prepare an integral catalyst. The coal bed gas deoxidation catalyst hasthe advantages of low igniting temperature, stable combustion process, high activity, long service life, and the like, is suitable for the methane catalyzing and combustion process taking coal bed gasdeoxidation purification as a purpose and can also be extensively applied to the catalyzing and combustion process of CO and low-carbon hydrocarbon under fuel-rich and oxygen-poor reducing atmosphere.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalytic burning reaction

Catalytic system combining an aluminium or iron containing catalytic support, a rare earth containing porous deposit, carbon nanoparticles and a carbon containing structure making bonds between carbon nanoparticles.

Owner:BOSTEELS DOMINIQUE

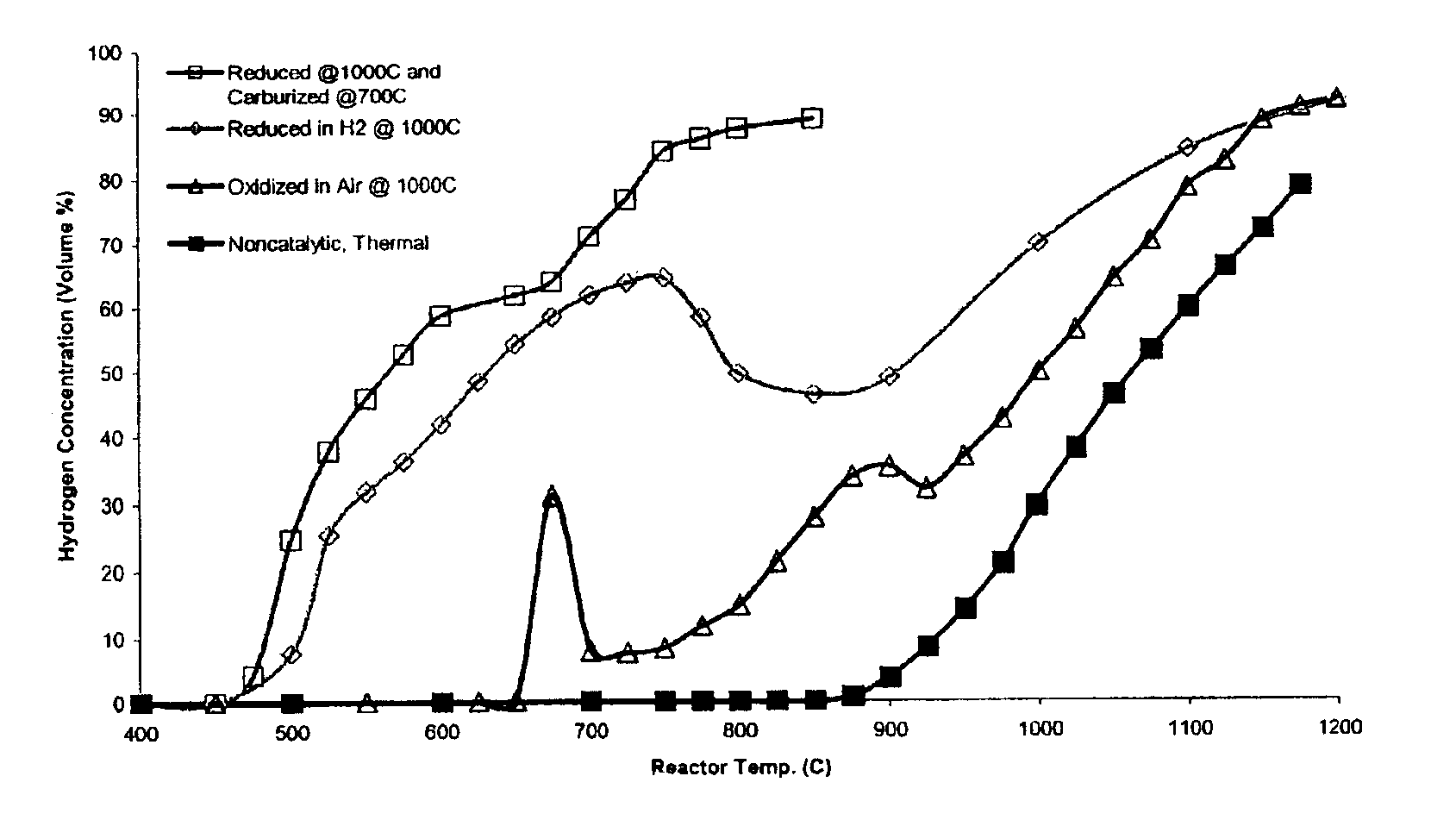

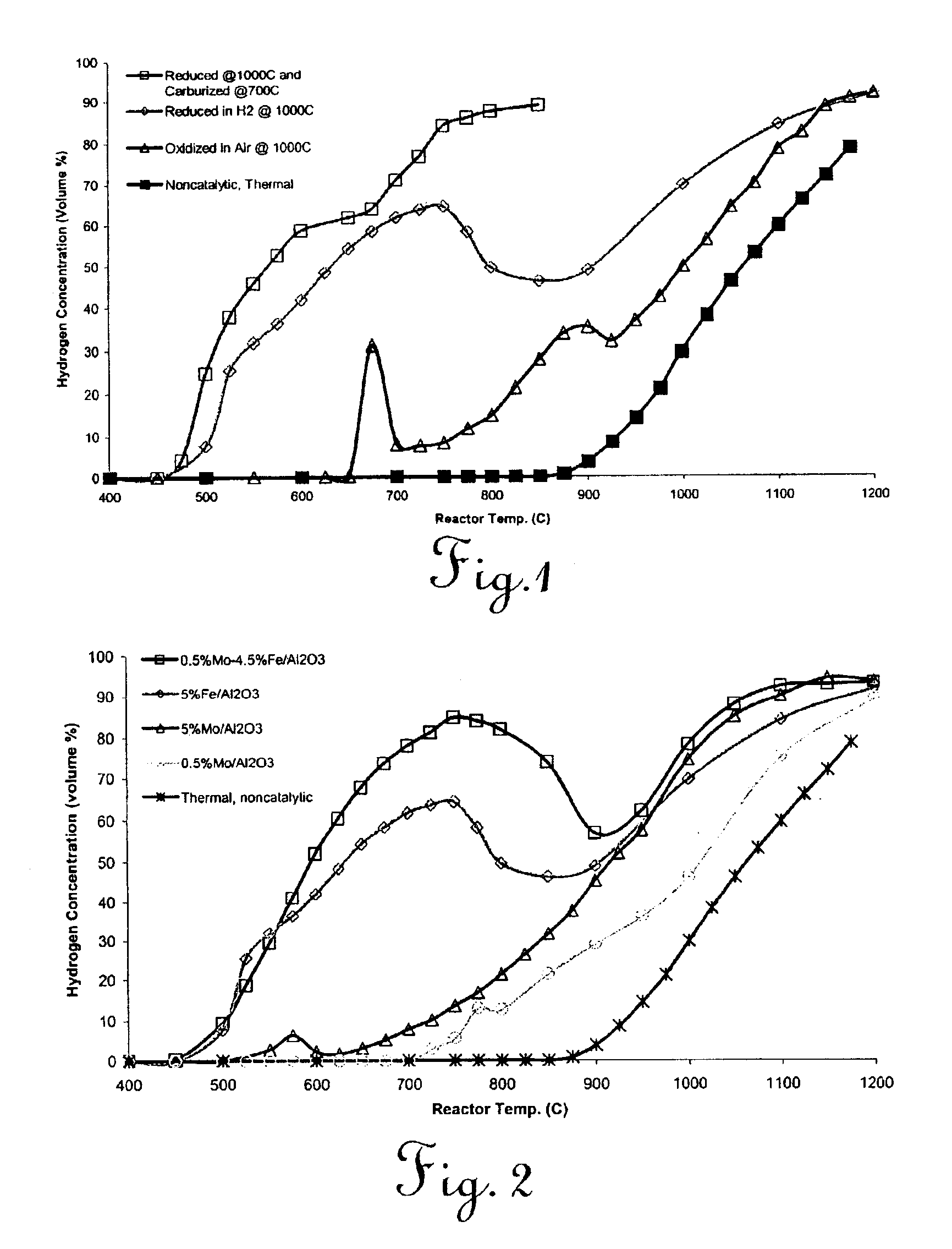

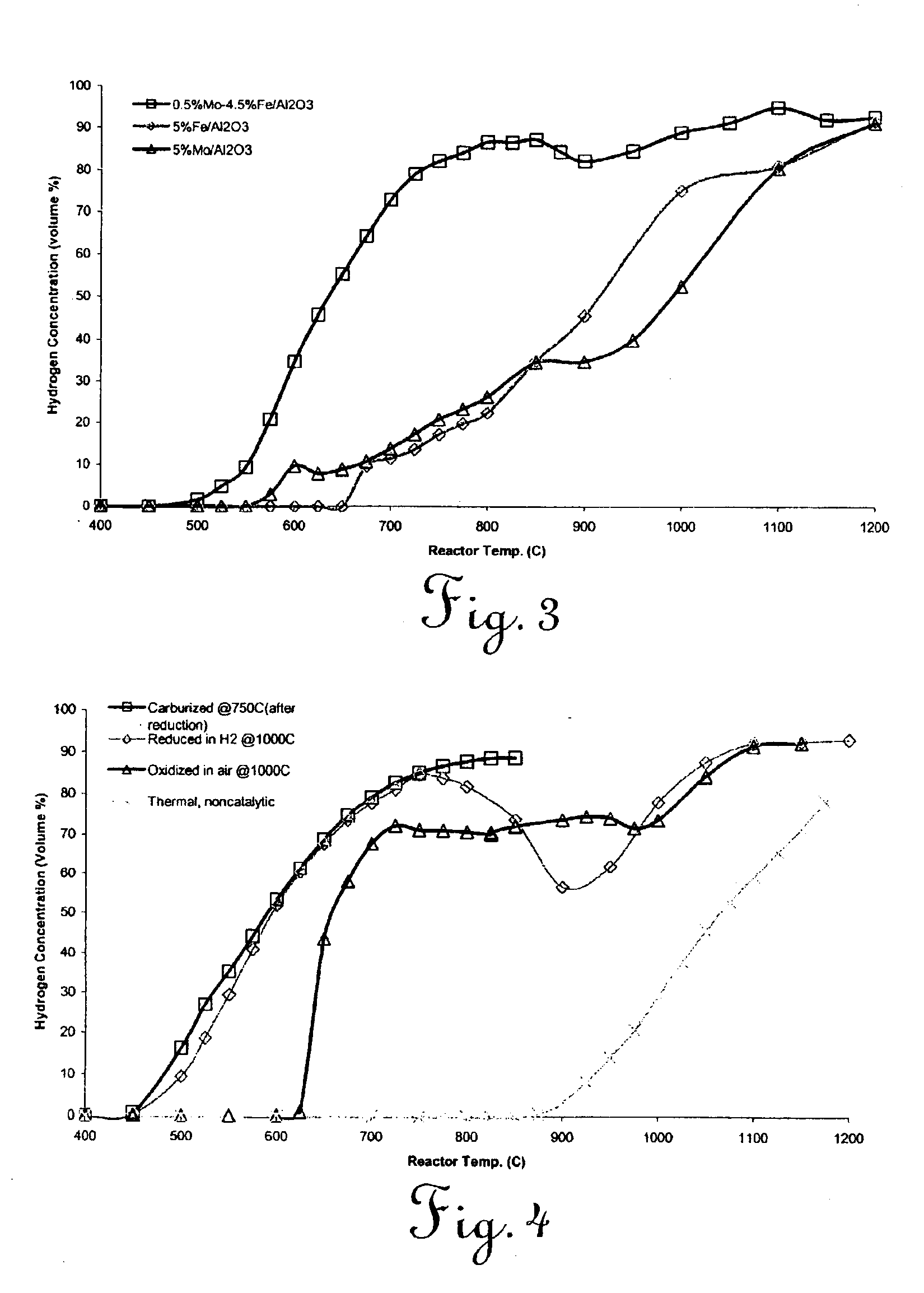

Catalytic conversion of hydrocarbons to hydrogen and high-value carbon

The present invention provides novel catalysts for accomplishing catalytic decomposition of undiluted light hydrocarbons to a hydrogen product, and methods for preparing such catalysts. In one aspect, a method is provided for preparing a catalyst by admixing an aqueous solution of an iron salt, at least one additional catalyst metal salt, and a suitable oxide substrate support, and precipitating metal oxyhydroxides onto the substrate support. An incipient wetness method, comprising addition of aqueous solutions of metal salts to a dry oxide substrate support, extruding the resulting paste to pellet form, and calcining the pellets in air is also discloses. In yet another aspect, a process is provided for producing hydrogen from an undiluted light hydrocarbon reactant, comprising contacting the hydrocarbon reactant with a catalyst as described above in a reactor, and recovering a substantially carbon monoxide-free hydrogen product stream. In still yet another aspect, a process is provided for catalytic decomposition of an undiluted light hydrocarbon reactant to obtain hydrogen and a valuable multi-walled carbon nanotube coproduct.

Owner:KENTUCKY UNIV RES FOUND OF

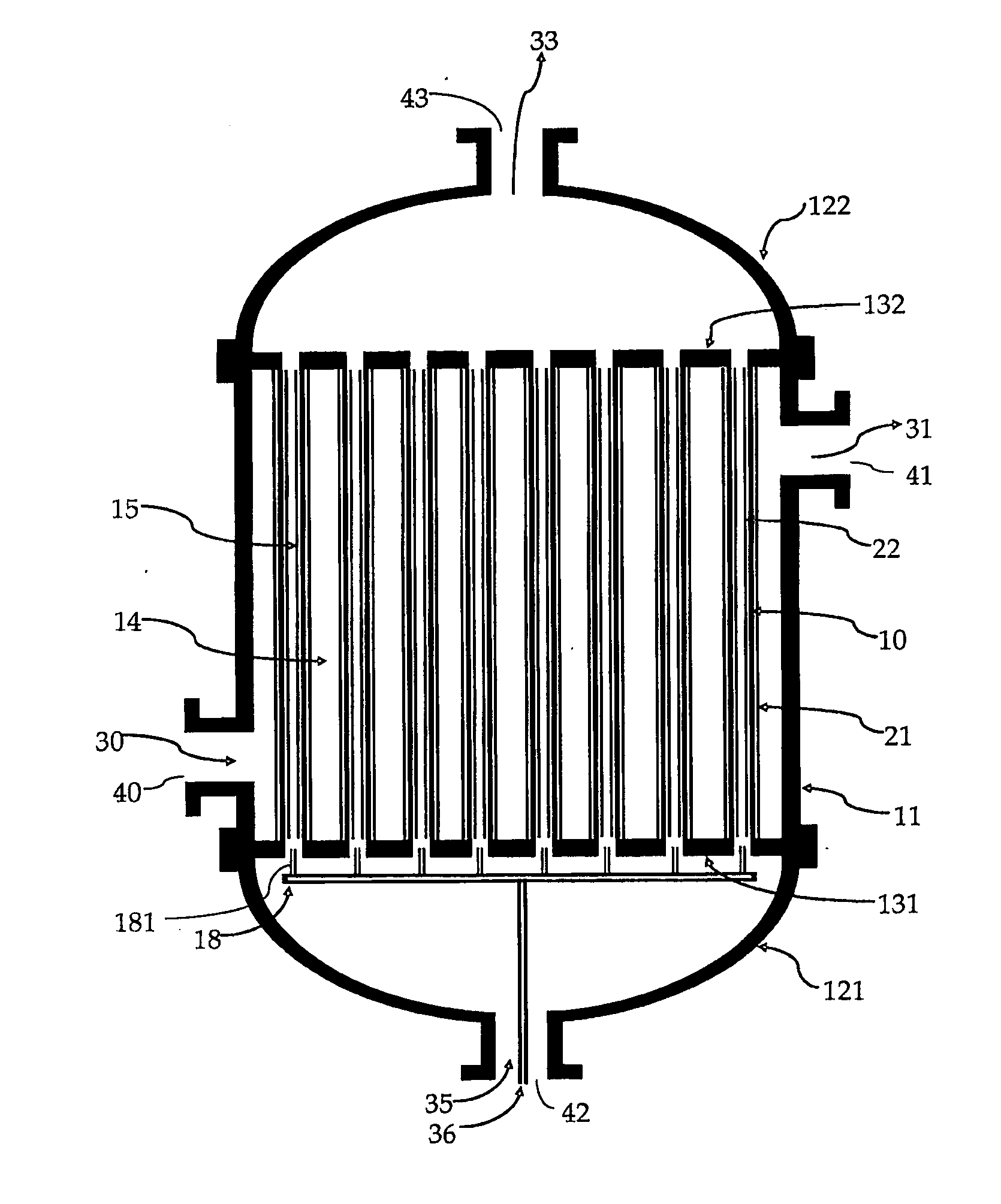

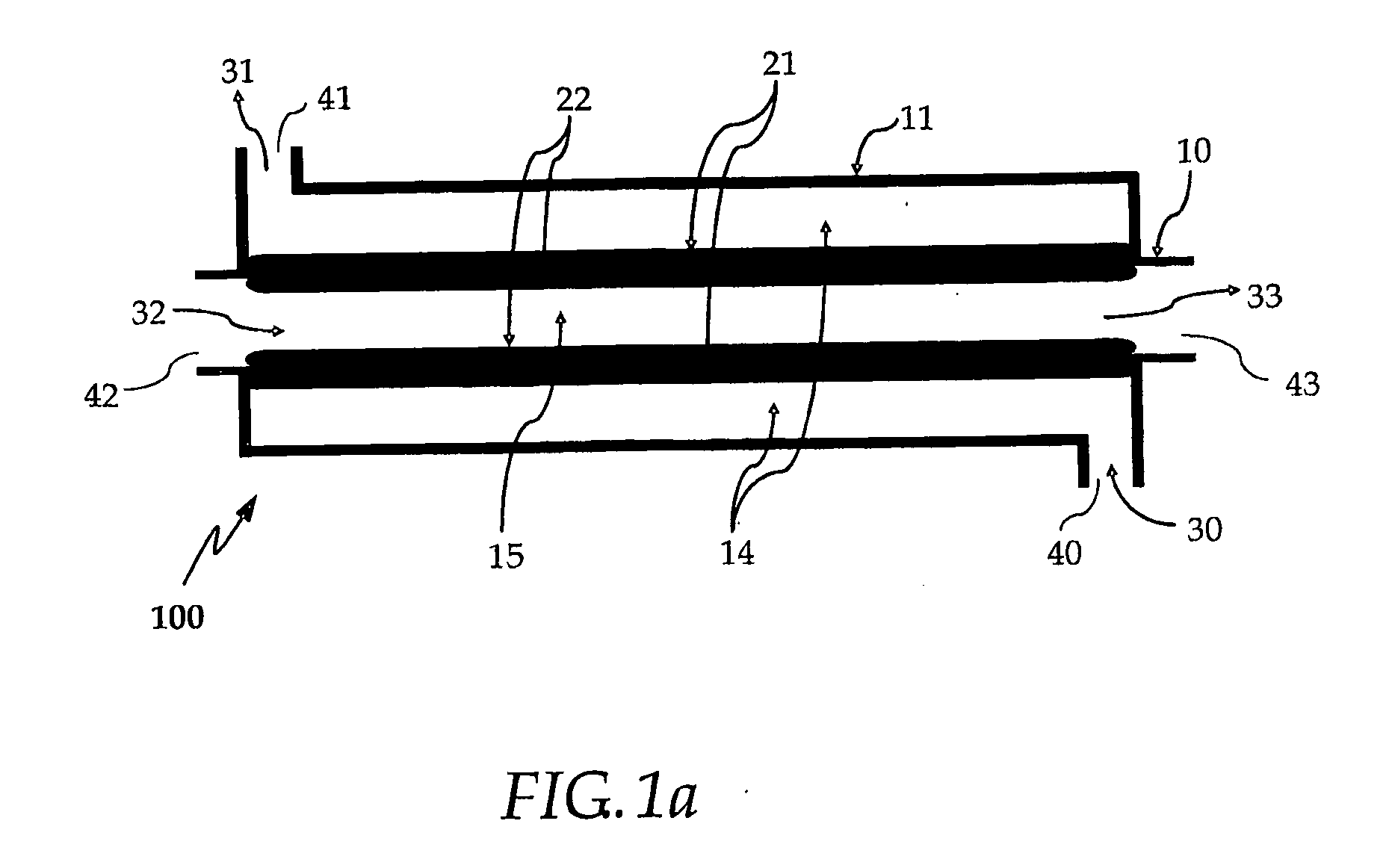

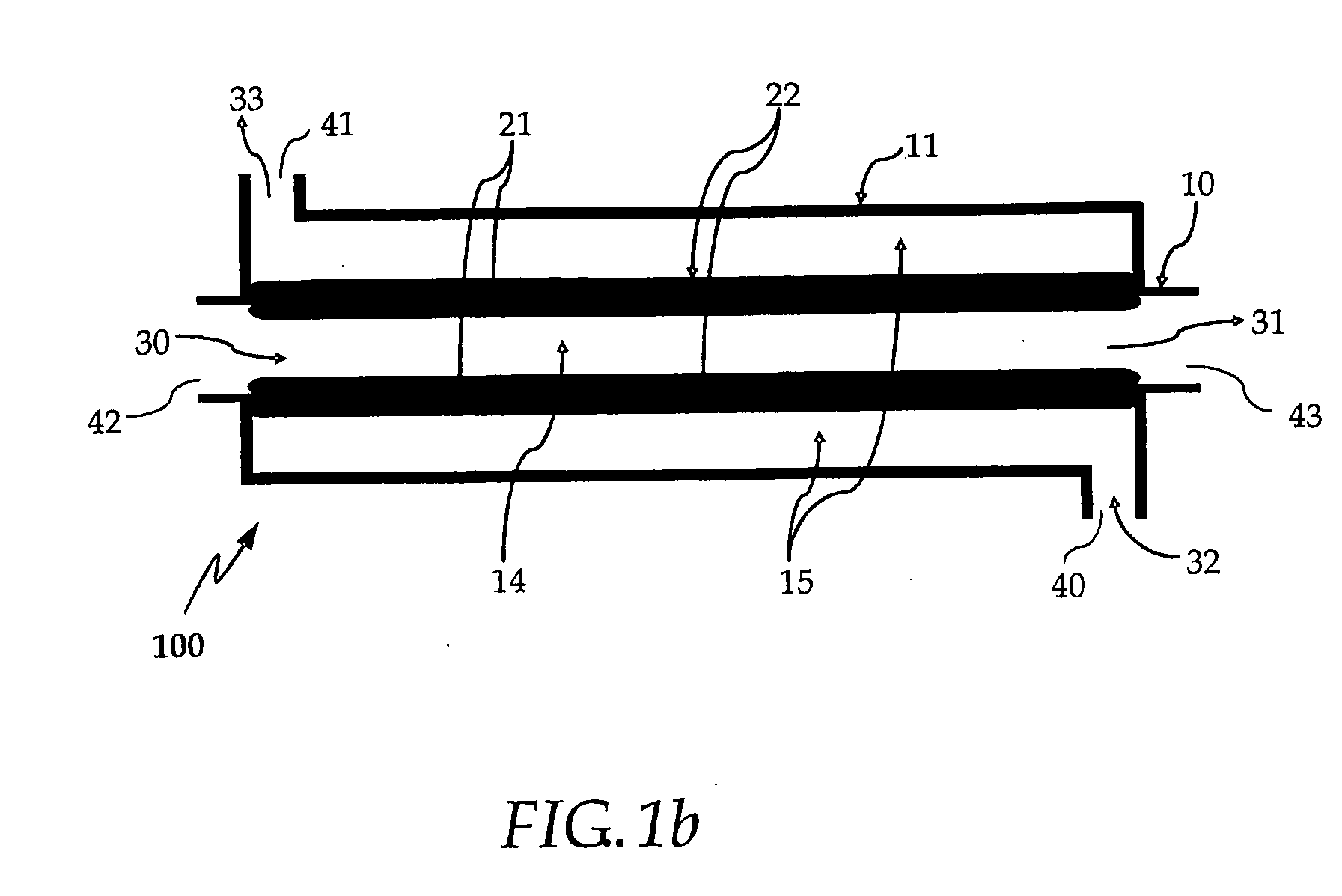

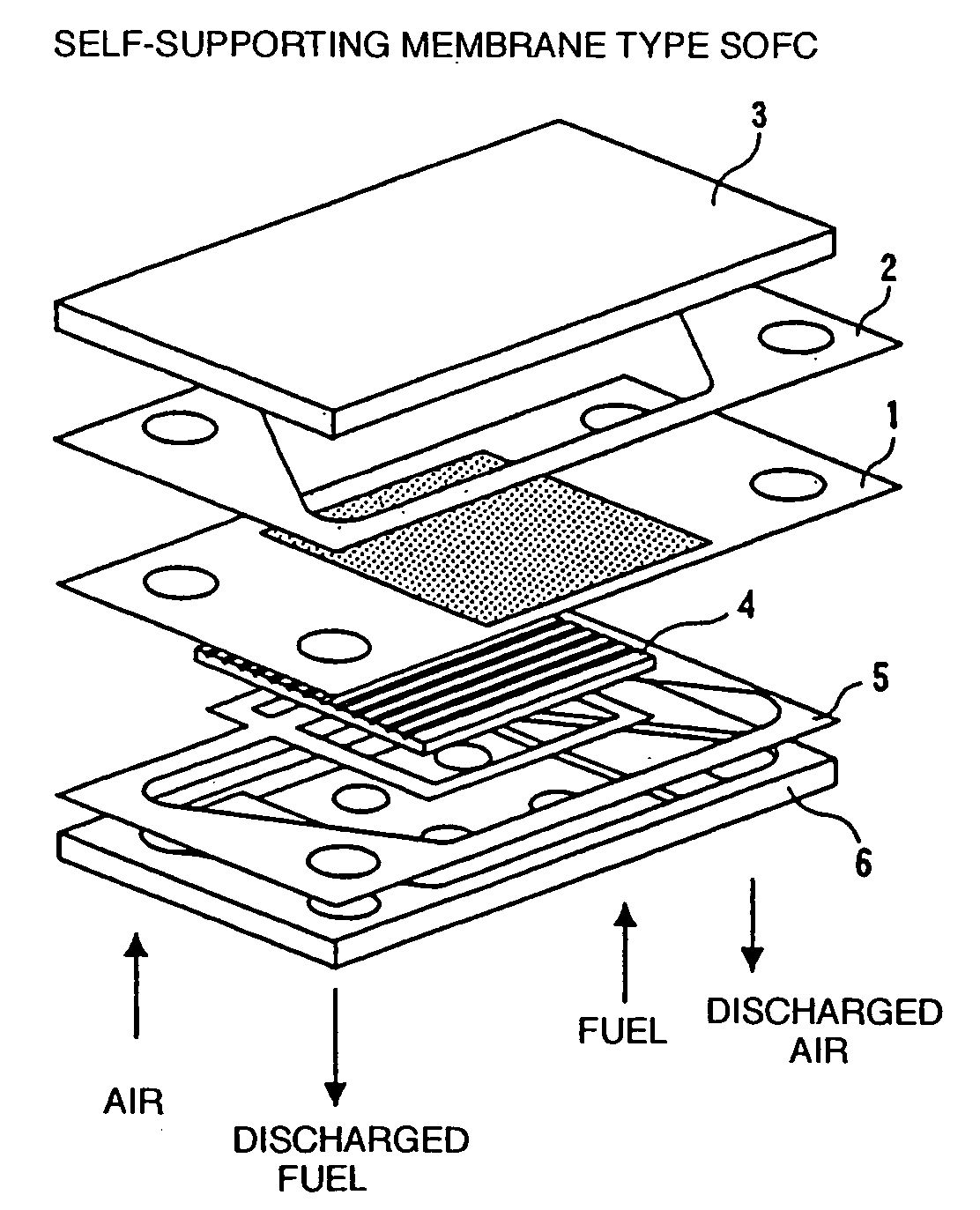

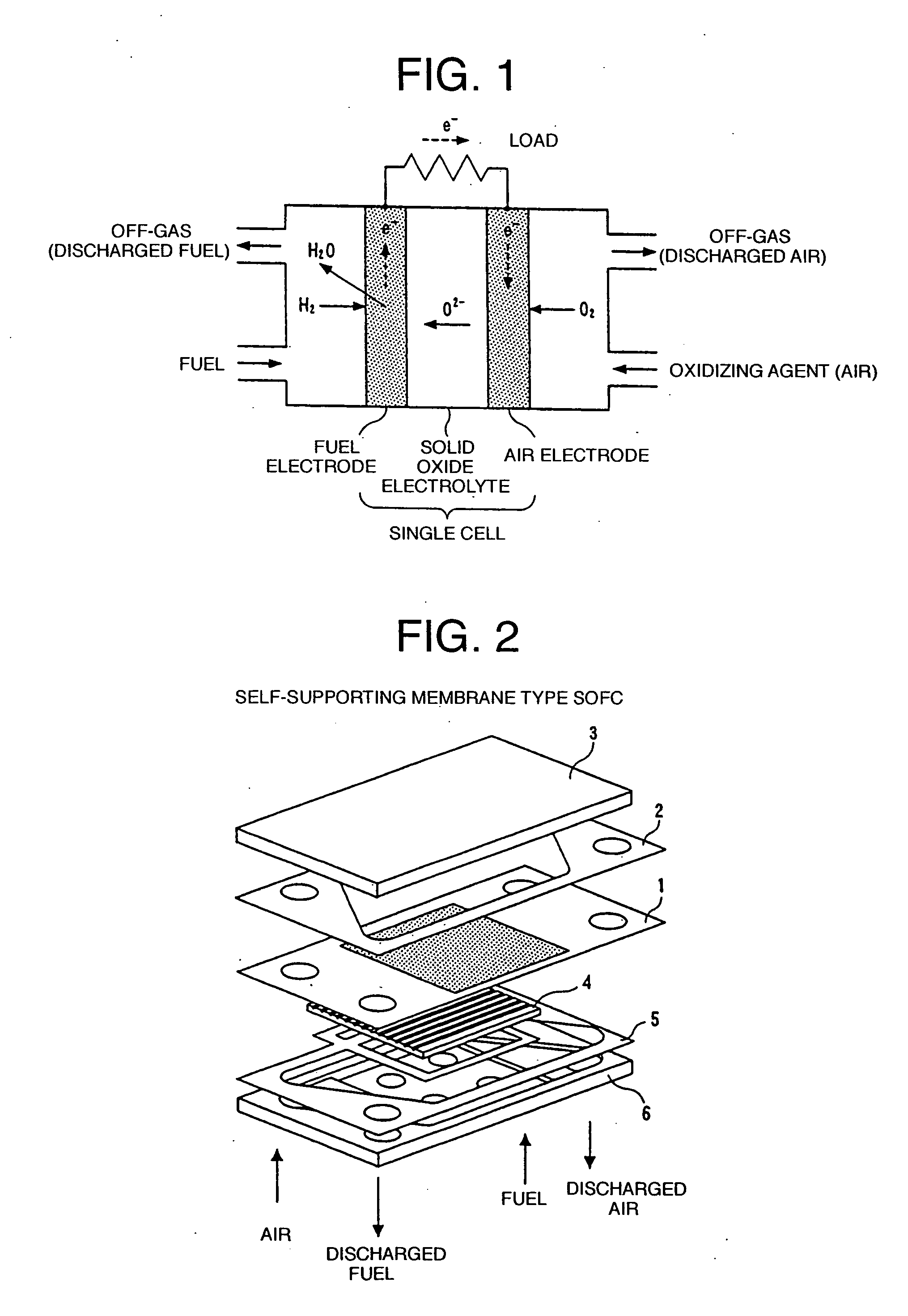

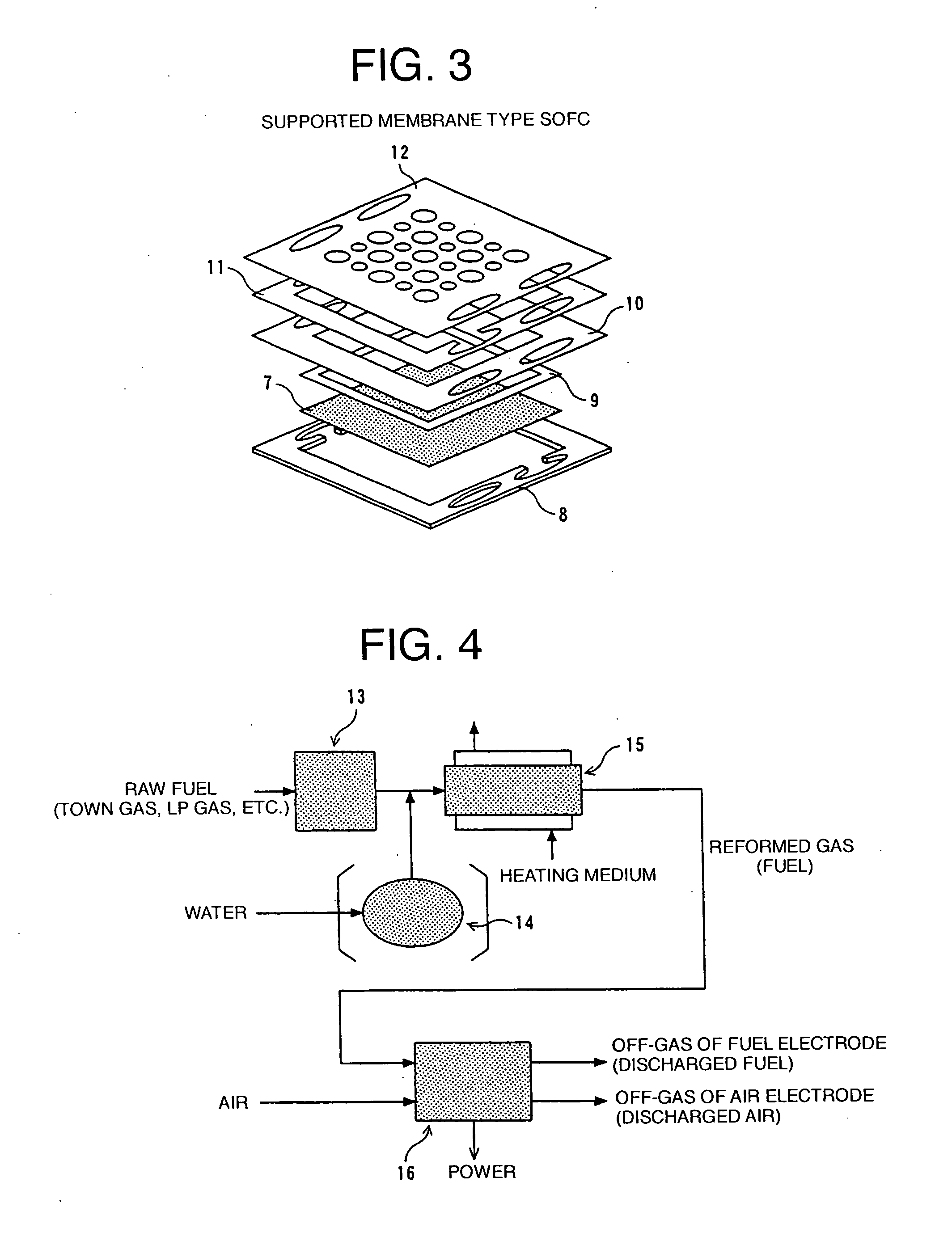

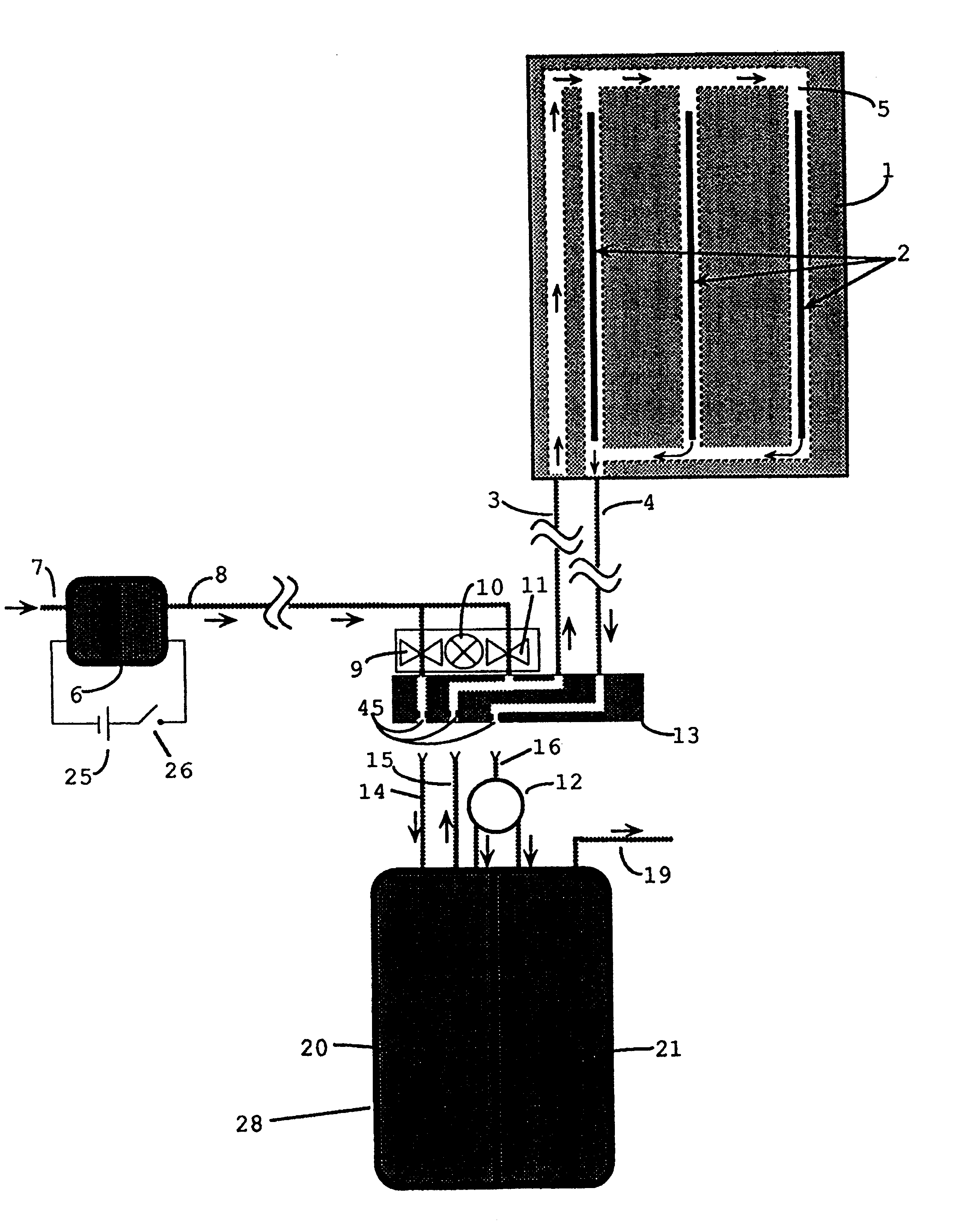

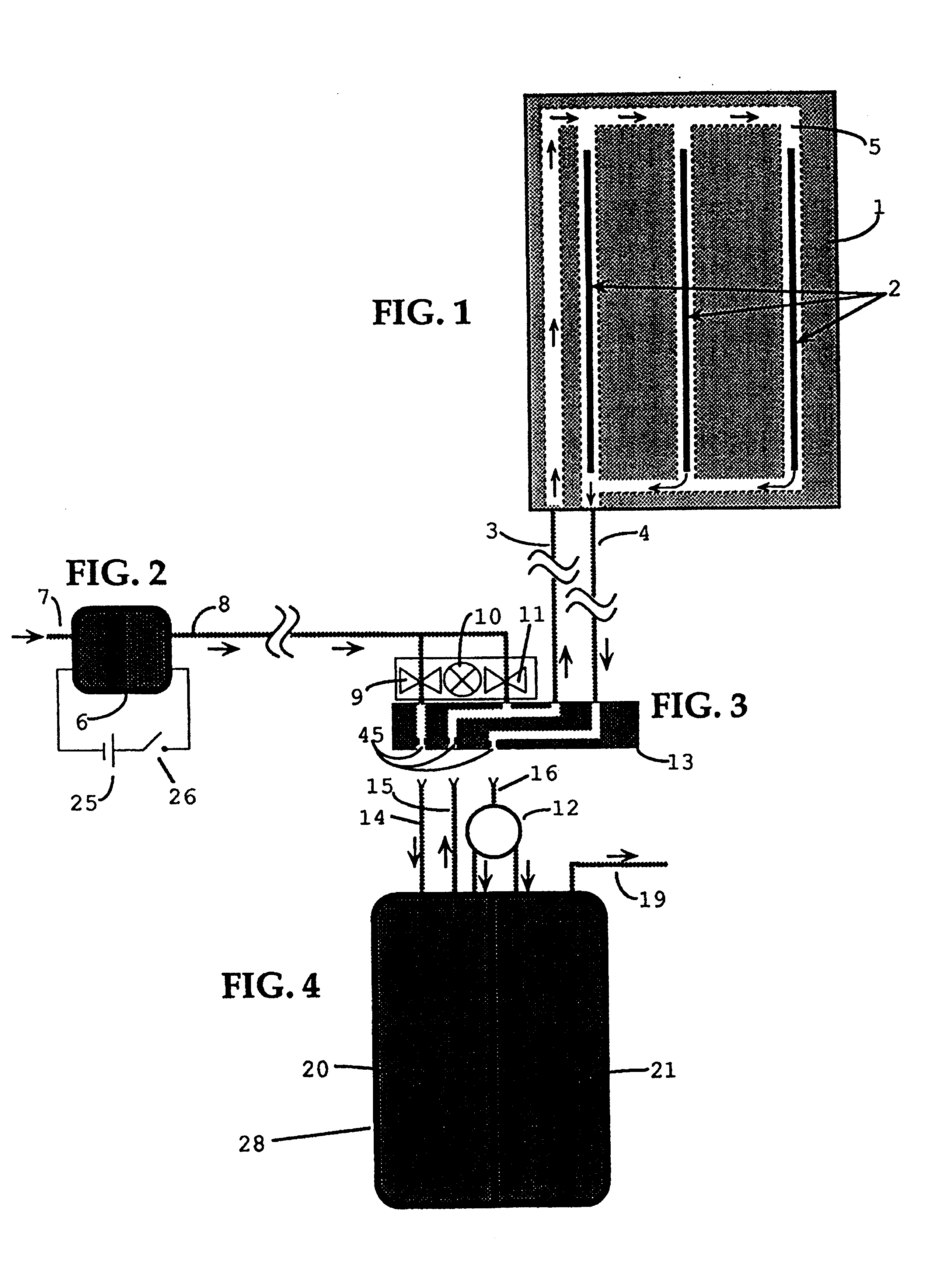

Solid oxide fuel cell system

There are provided a solid oxide fuel cell system comprising (a) a solid oxide fuel cell stack, (b) a preliminary reformer for removing hydrocarbons having two or more carbon atoms from a hydrocarbon fuel by converting the hydrocarbons having two or more carbon atoms into methane, hydrogen, and carbon monoxide, and (c) an integrated heat exchanger for catalytic combustion for heating either air or fuel, or both the air and fuel, to be guided to the solid oxide fuel cell stack, by use of a combustion gas formed by combusting discharged fuel with the use of discharged air, wherein component equipment described above are disposed in an adiabatic vessel and the integrated heat exchanger for catalytic combustion for use in the solid oxide fuel cell system. With the invention, an advantage of the preliminary reformer in combination with that of the integrated heat exchanger for catalytic combustion can be obtained, and heat loss of the SOFC system is eliminated or reduced as much as possible. In addition, with the integrated heat exchanger for catalytic combustion according to the invention, since air and / or fuel, to be fed to the SOFC stack, can be heated by controlling the maximum temperature achieved thereof, it is quite useful as an heat exchanger for an SOFC with operation temperature on the order of 850° C. or lower, particularly, for a supported membrane type SOFC, and further, the same is quite useful in making up an SOFC system because an inexpensive material can be used as a constituent material of a component equipment of the system, the system in whole can be reduced in size, and so forth.

Owner:TOKYO GAS CO LTD

Catalyst with Cu being loaded for taking off waste gas containing HCN and its preparing method as well as application

InactiveCN1462652AGood dispersionGive full play to the catalytic advantagesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTarMixed gas

A carried Cu catalyst for removing the HCN contained waste gas contains Cu and Al2O3 in Wt ratio of (2.96-5.92):100. Its preparing process includes adding Cu(NO3)2 solution to Al2O3 carrier, immersing, drying, calcining and H2 reducing. Its application method includes loading said catalyst into reaction furnace, heating to 150-300 deg.C, introducing the mixed gas containing HCN, NH3, tar and air to said reaction furnace, and catalytic combustion. Its advantages are simple operation etc.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

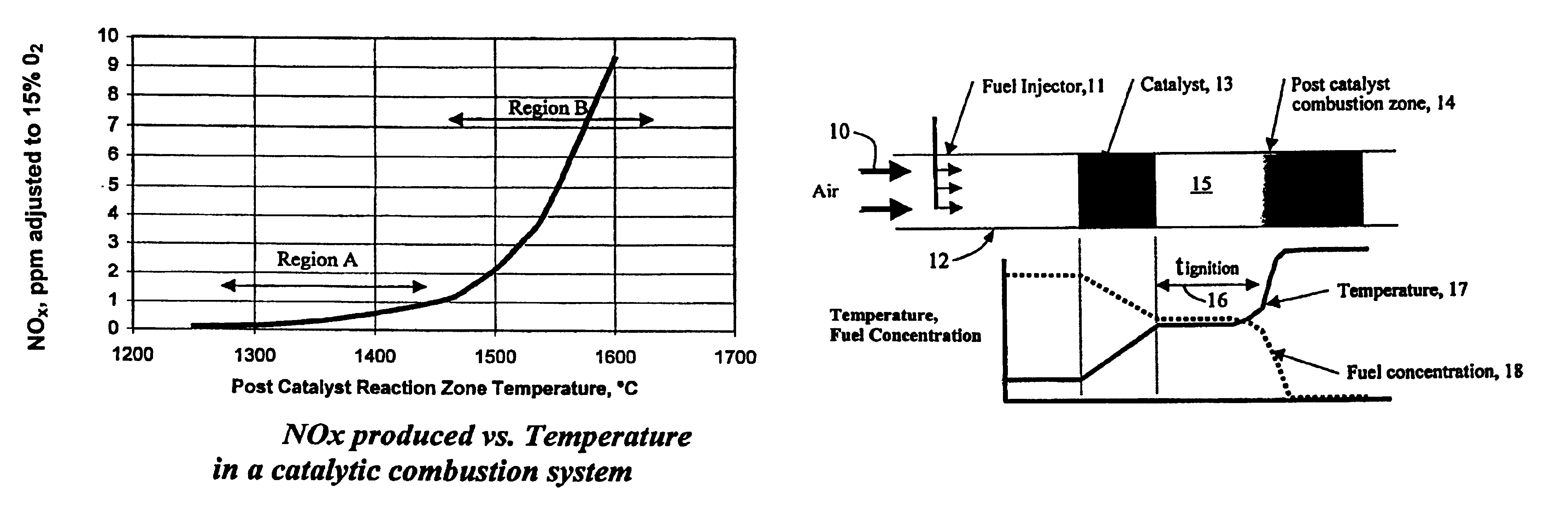

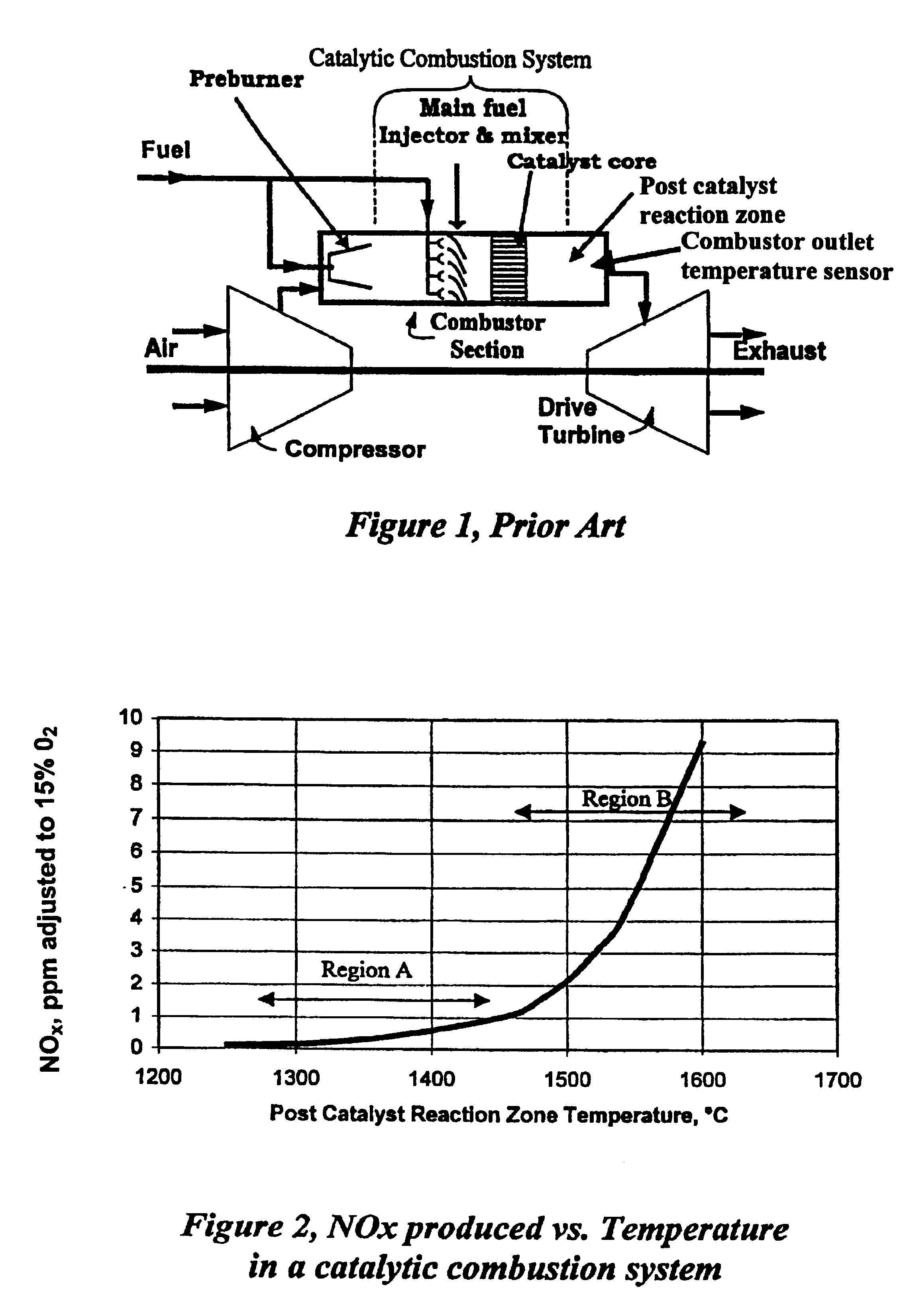

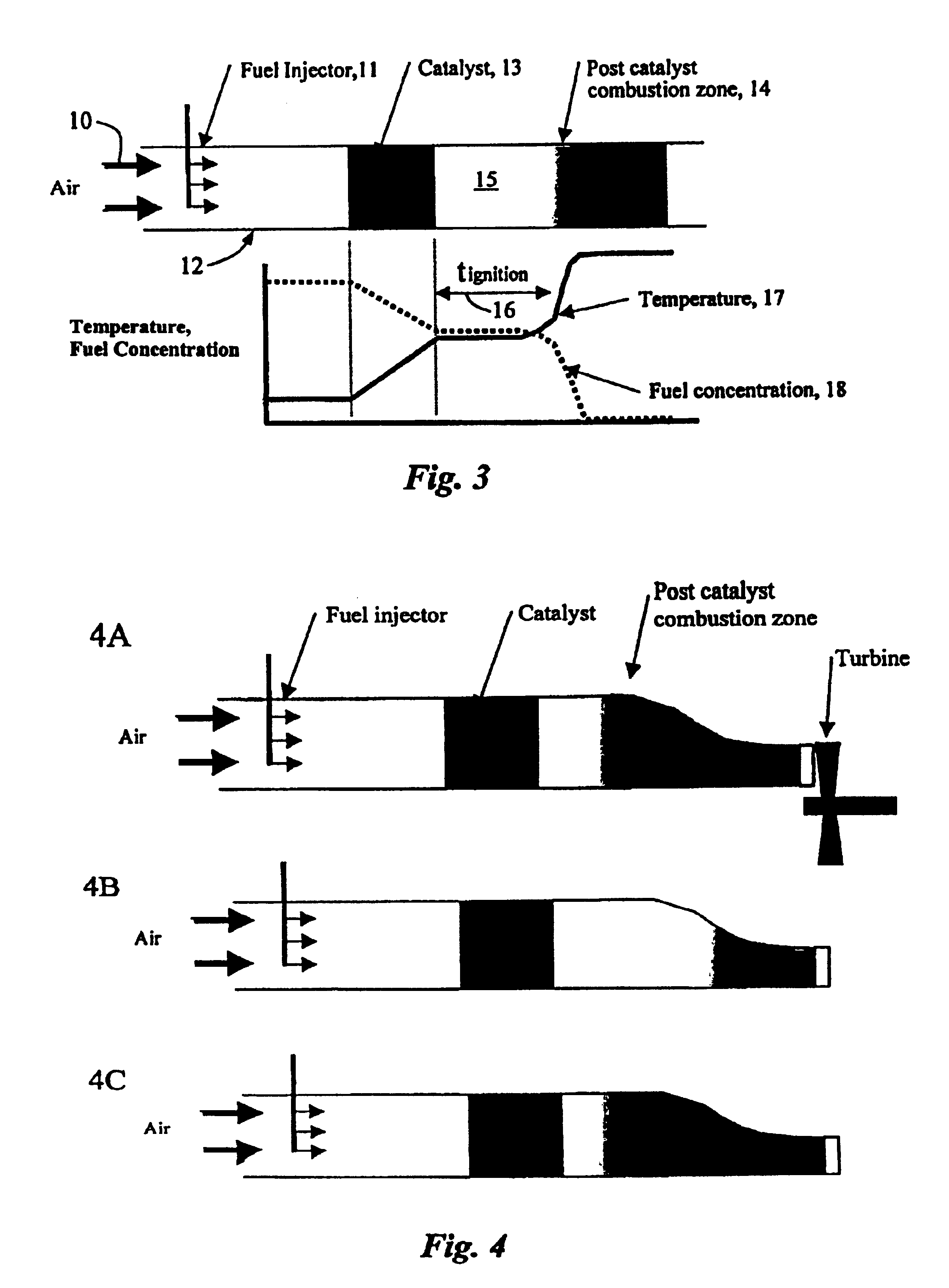

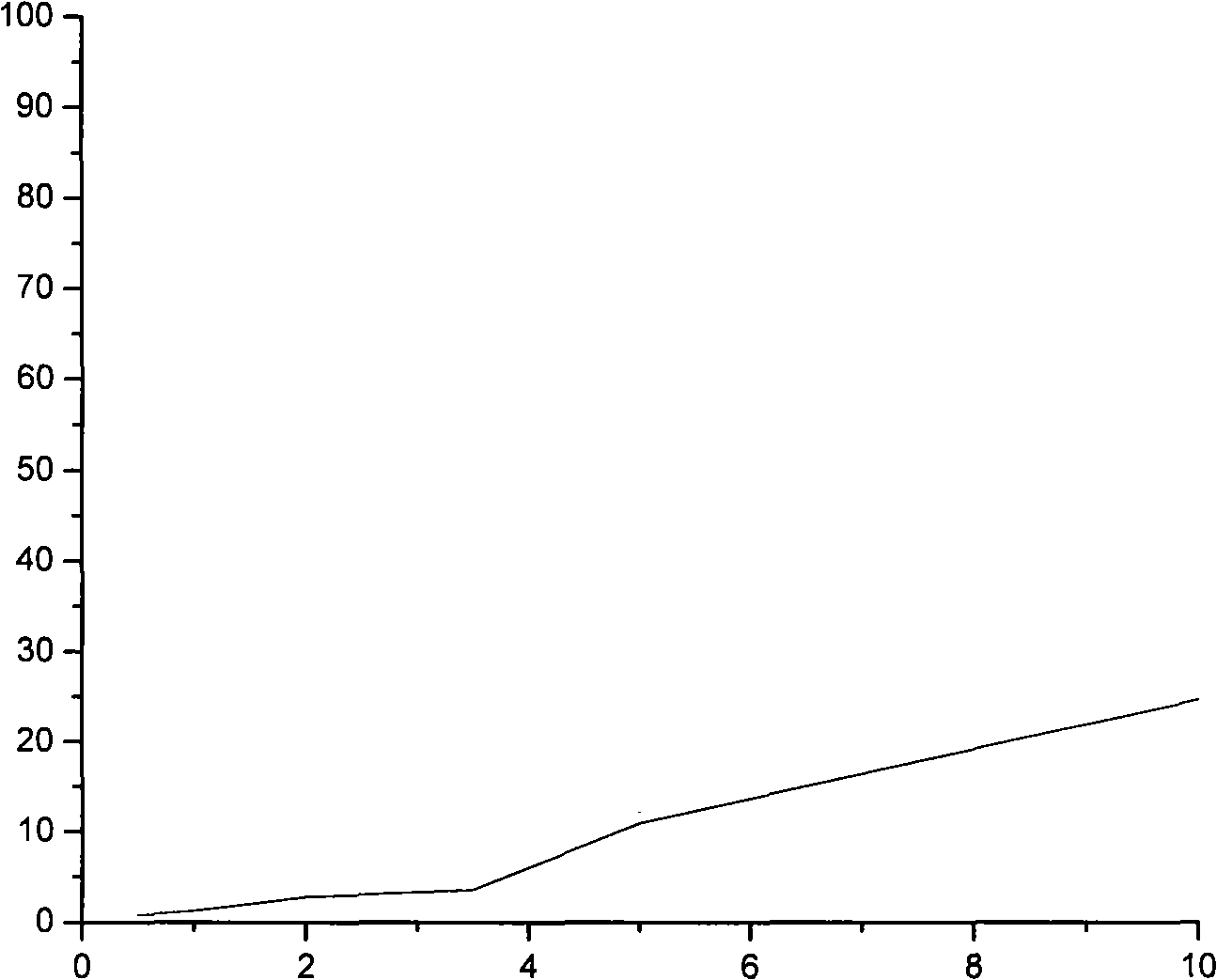

Method of thermal NOx reduction in catalytic combustion systems

InactiveUS6718772B2Shorten the timeLower Level RequirementsContinuous combustion chamberTurbine/propulsion fuel supply systemsIgnition delayProduct gas

Methods and apparatus, both devices and systems, for control of Zeldovich (thermal) NOx production in catalytic combustion systems during combustion of liquid or gaseous fuels in the post catalytic sections of gas turbines by reducing combustion residence time in the HC zone through control of the HC Wave, principally by adjusting the catalyst inlet temperature. As the fuel / air mixture inlet temperature (to the catalyst) is reduced, the HC Wave moves downstream (longer ignition delay time), shortens the residence time at high temperature, thereby reducing thermal NOx production. The countervailing increase in CO production by longer ignition delay times can be limited by selectively locating the HC Wave so that thermal NOx is reduced while power output and low CO production is maintained. NOx is reduced to on the order of <3 ppm, and preferably <2 ppm, while CO is maintained <100 ppm, typically <50 ppm, and preferably <5-10 ppm.

Owner:KAWASAKI HEAVY IND LTD

Portable heat generating device

InactiveUS6289888B1Promotes spontaneous flameless combustionReduce necessityExothermal chemical reaction heat productionOther heat production devicesThermal energyElastomer

A portable heat generating device in which fuel vapor and an oxygen supply (e.g. air) are directed through channels contained within a. thin, flexible and compliant elastomeric sheet of material. Elongated catalytic heat elements, placed strategically within the channels, spontaneously interact with the fuel-air stream liberating heat energy. Means and methods are defined that permit flameless catalytic combustion to be uniformly extended over the length of each heat element, lowering power density but maintaining the overall power generated, permitting the use of many types of low temperature materials like plastics, polymers, and elastomers in the construction of the heater. The heat generation process is started by pumping an air stream into a reservoir containing a fuel source (e.g. methanol) thereby saturating the air stream with fuel vapor. The fuel vapor is mixed with a another stream of air to achieve a particular fuel / air ratio and directed into channels within the elastomeric sheet, reacting with the catalytic heat elements to produce flameless combustion. The warm exhaust gas is directed to a thermally controlled diverter valve. The valve senses the temperature of the liquid fuel supply and diverts some or all of the warm exhaust gas, as necessary, to heat the fuel and keep its temperature within a specified range. Exhaust by-products are passed into a miniature scrubber module adjacent to the fuel module. The scrubber absorbs any noxious components in the exhaust stream that may occur during startup or rapid changes in operating condition.

Owner:CLIFFORD G WELLES

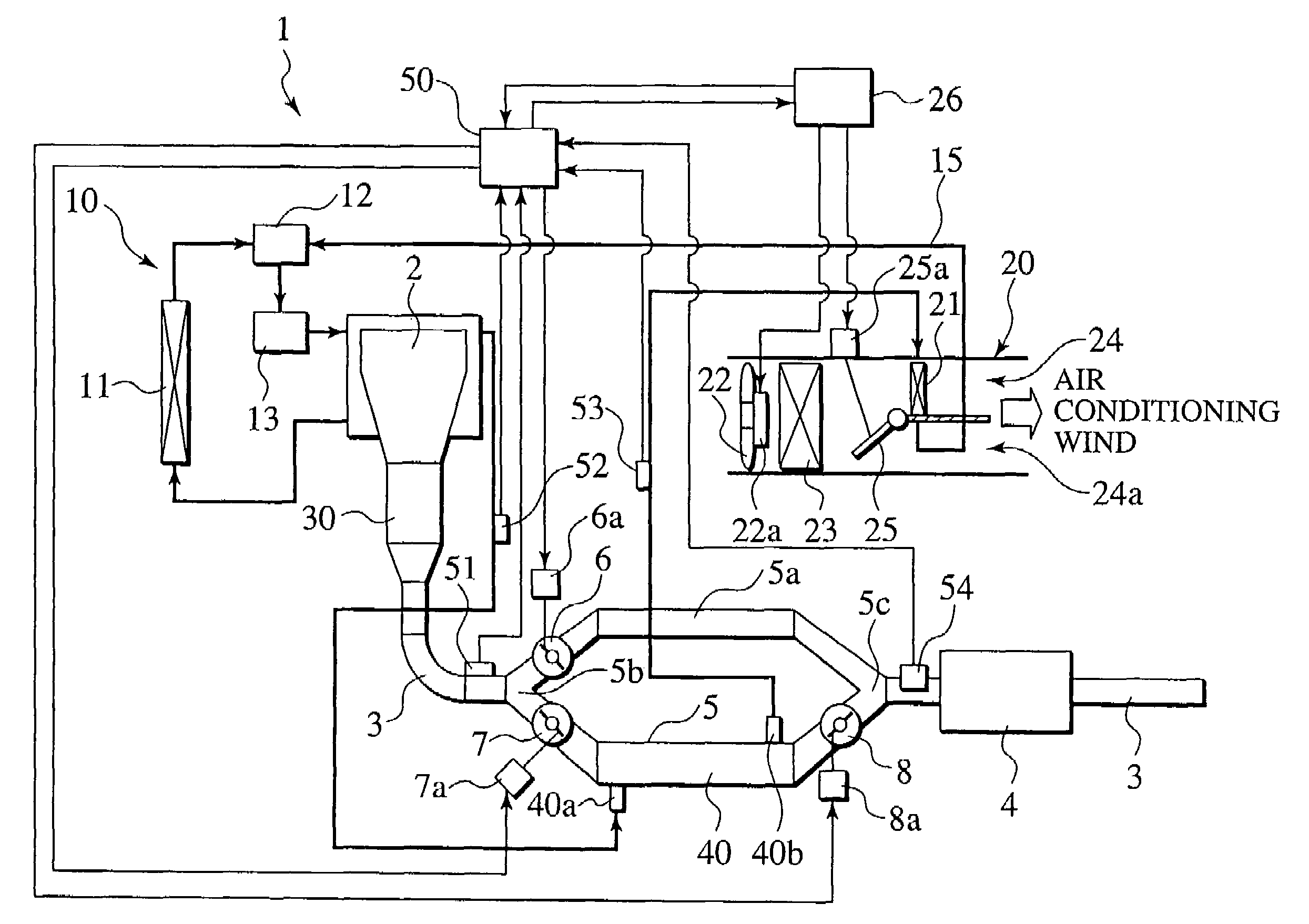

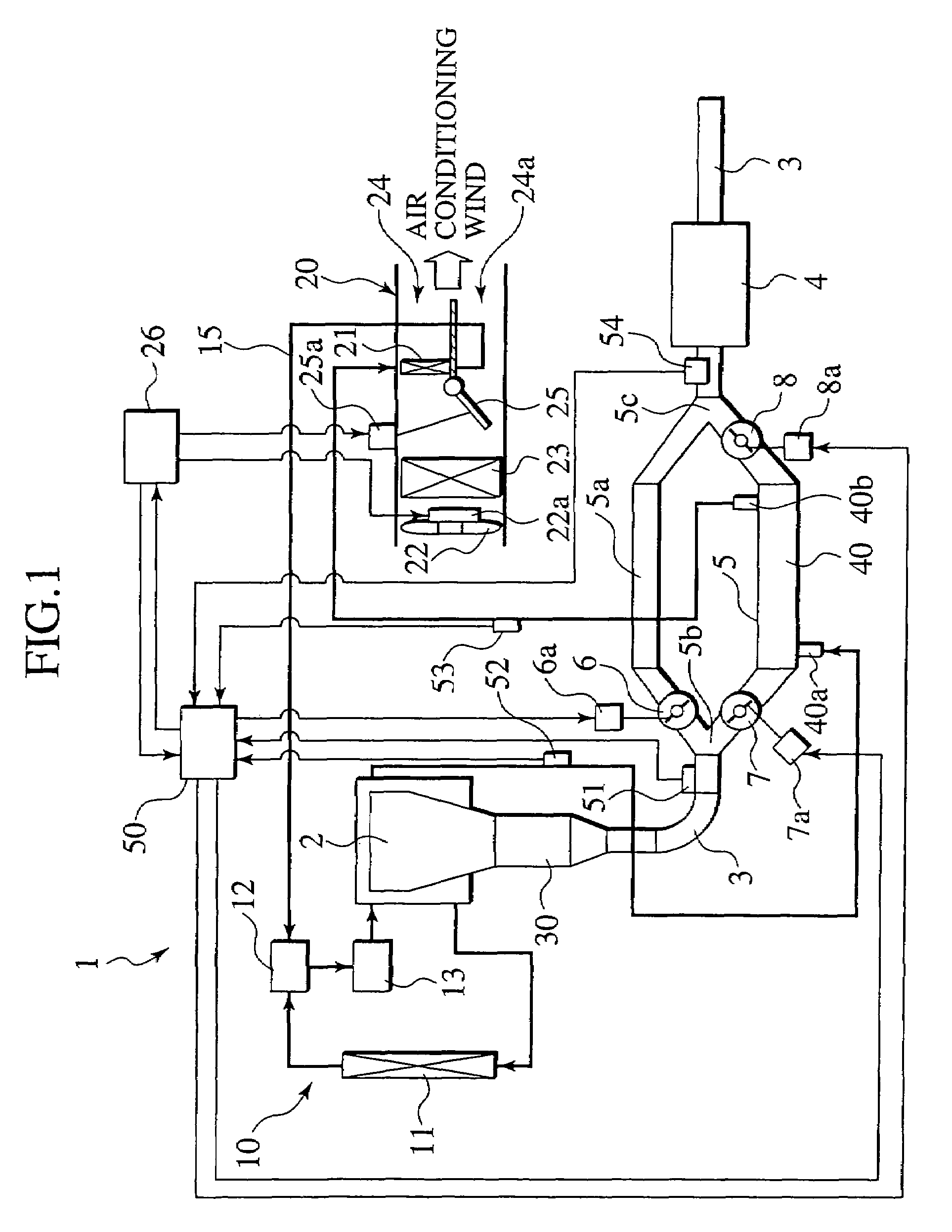

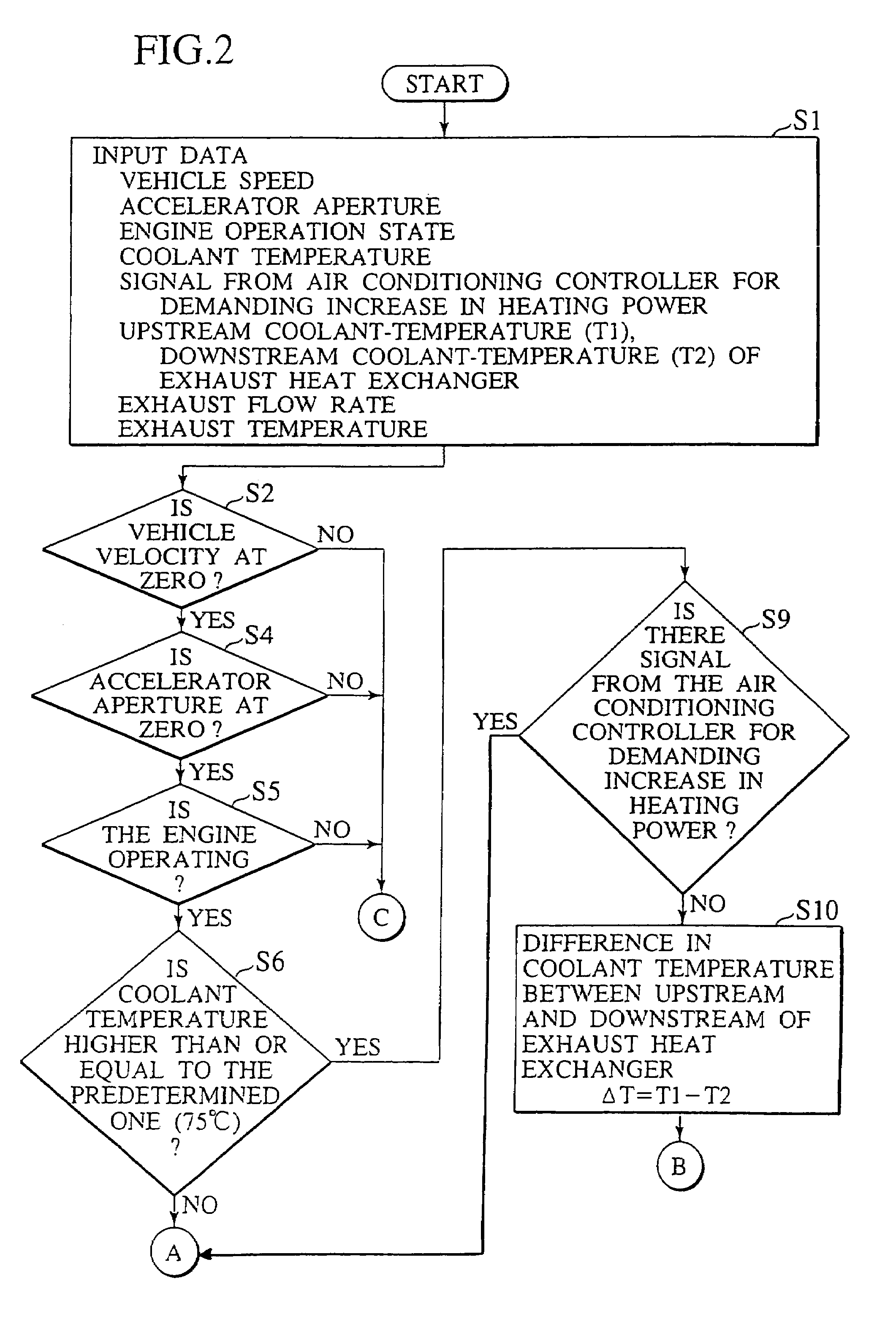

Exhaust-heat recovery system for engine

InactiveUS7246487B2Heat quantity can be increasedEffective temperatureAir-treating devicesElectrical controlExhaust fumesAir conditioning

An exhaust-heat recovery system includes a catalytic converter, an exhaust heat exchanger, an air conditioner and an engine controller. The catalytic converter is such that exhaust discharged from an engine passes therethrough and combustible components in the exhaust are catalytically burned therein. The exhaust heat exchanger induces heat exchange between the exhaust having passed through the catalytic converter and a coolant having passed through the engine. The air conditioner generates a heating wind by means of the heat exchange between the coolant having passed through the exhaust heat exchanger and an air conditioning wind. The engine controller controls incrementally the combustible components in the exhaust to be burned in the catalytic converter when a prescribed heating condition is unsatisfied.

Owner:CALSONIC KANSEI CORP

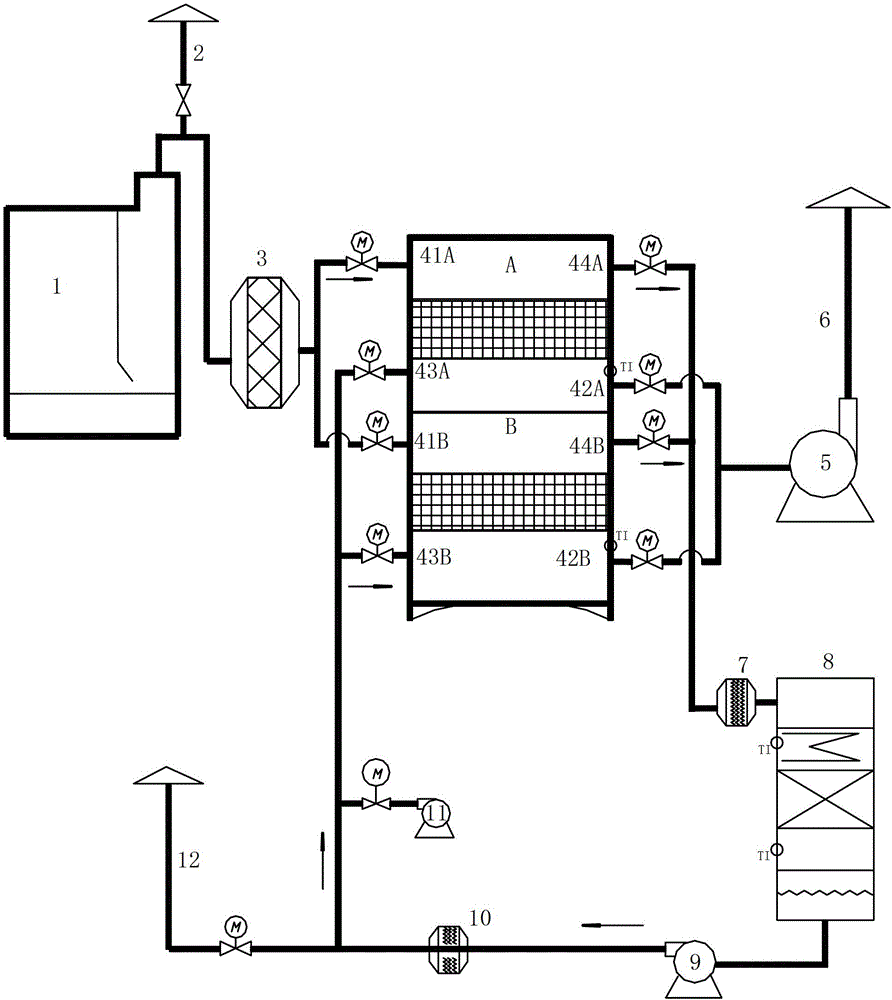

Organic waste gas multifunctional integral processing device

InactiveCN102941000AExtended service lifeLow running costDispersed particle separationIncinerator apparatusActivated carbonProgrammable logic controller

The invention discloses an organic waste gas multifunctional integral processing device, which comprises a programmable logic controller (PLC) control system, a dust filter device, active carbon adsorption beds A and B which are connected in parallel and a catalytic combustion bed. When organic waste gas is adsorbed, the organic waste gas firstly enters into the dust filter device to remove suspended solid; then enters into the active adsorption beds to remove organic substances; finally the purified waste gas is pumped through an adsorption exhaust fan and discharged on standard through an adsorption high-altitude discharge branch. When active carbon is desorbed and regenerated, the hot gas generated by the catalytic combustion bed is pressurized through a desorption fan, and then enters into the active absorption beds to reversely desorb and regenerate the saturated active carbon; the desorbed waste gas enters into the catalytic combustion bed; organics are burned to generate water and carbon dioxide; the hot gas generated at the same time is used for desorbing the active carbon. The processing device is controlled by the PLC, thereby realizing automatic switch between the two absorption beds, so that adsorption and desorption are carried out at the same time. The invention combines two technologies of adsorption and catalytic combustion organically and has complementary advantages.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

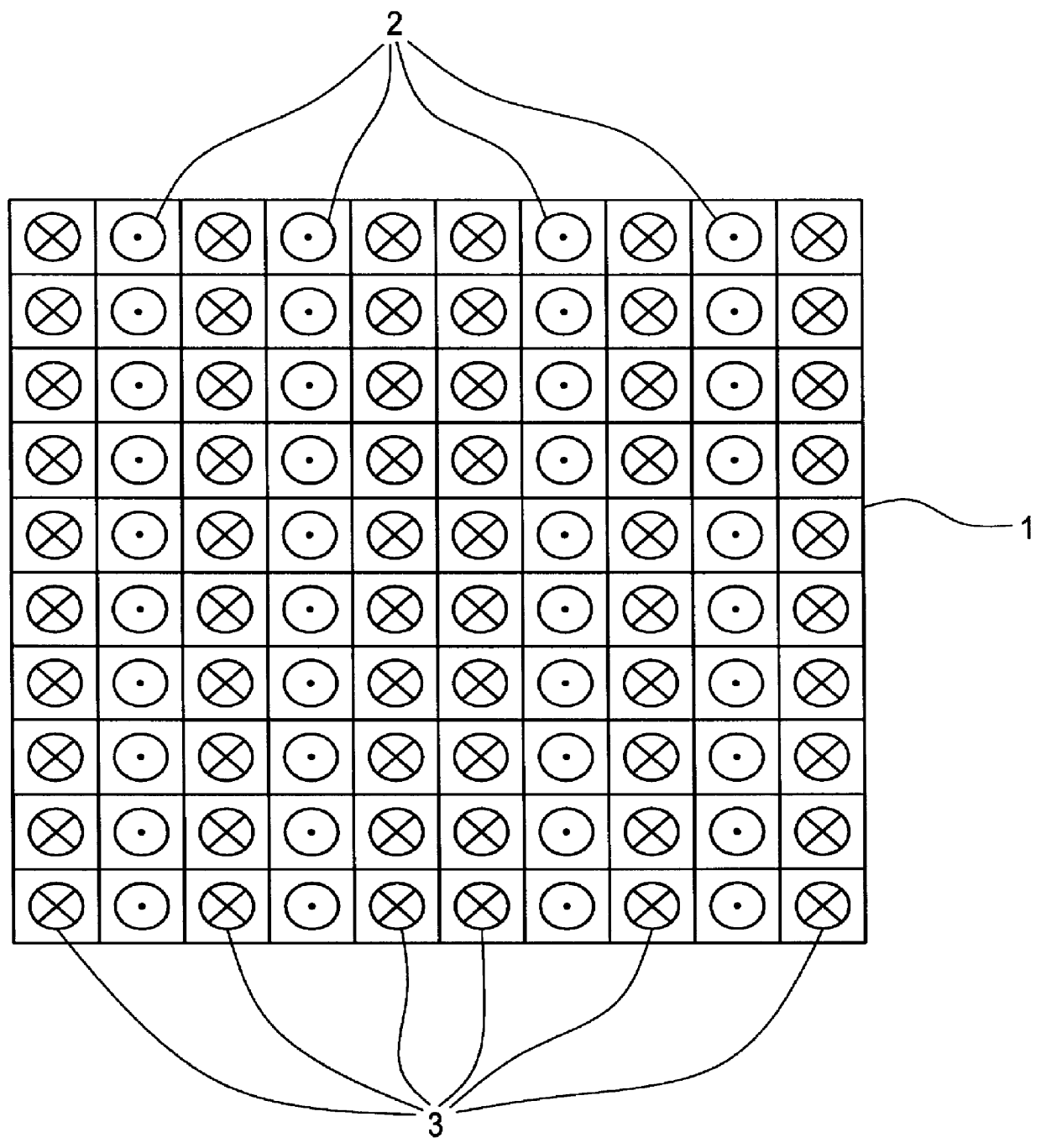

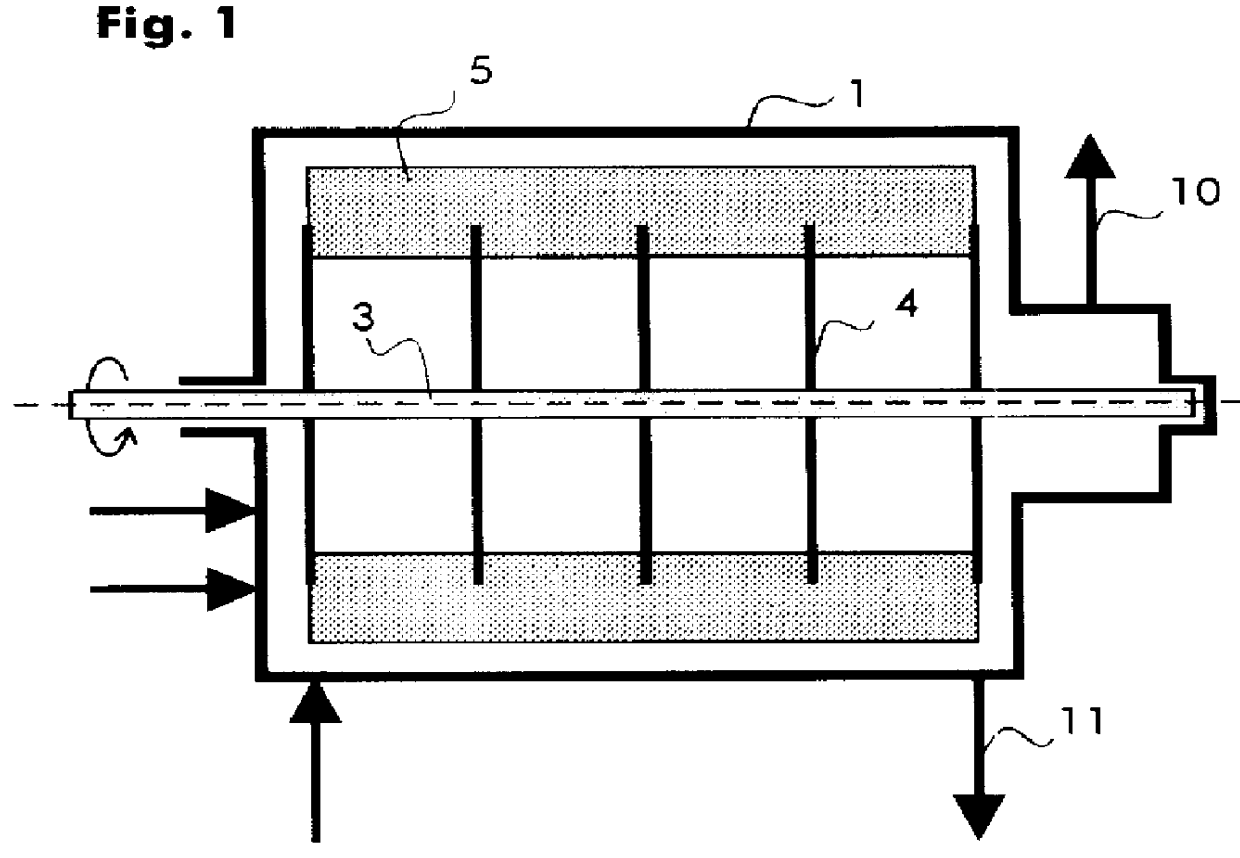

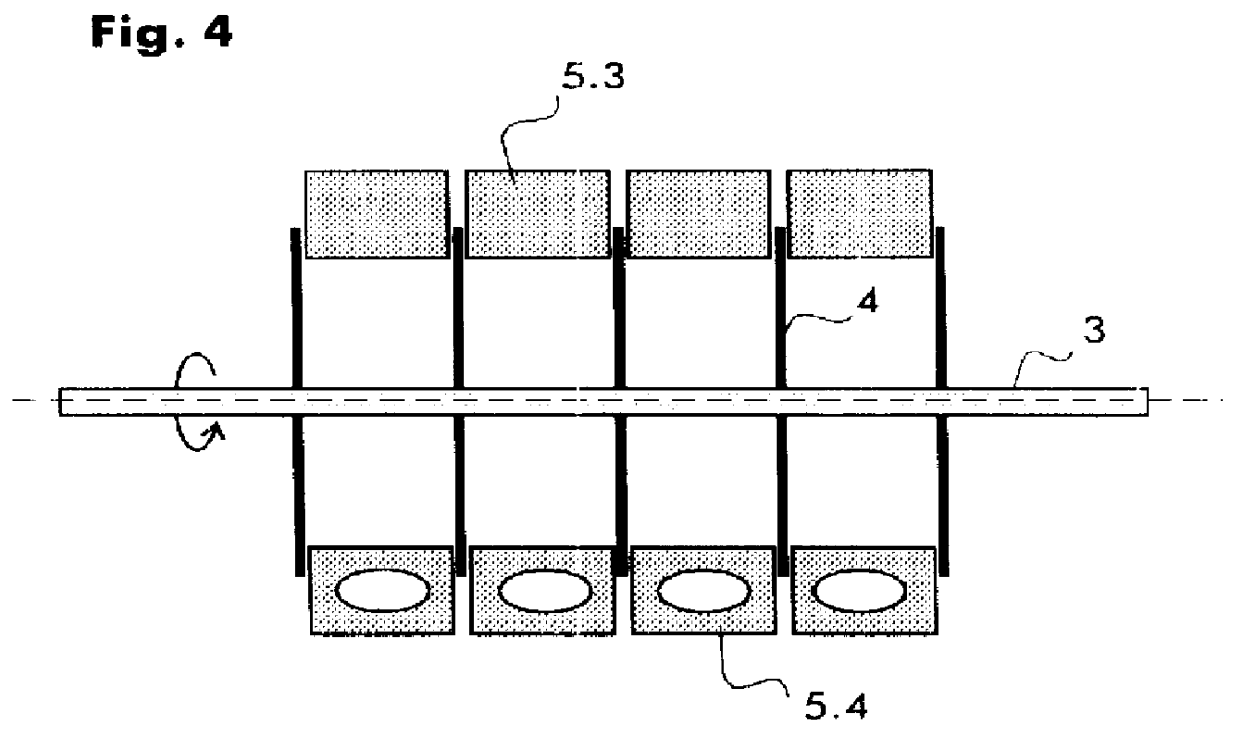

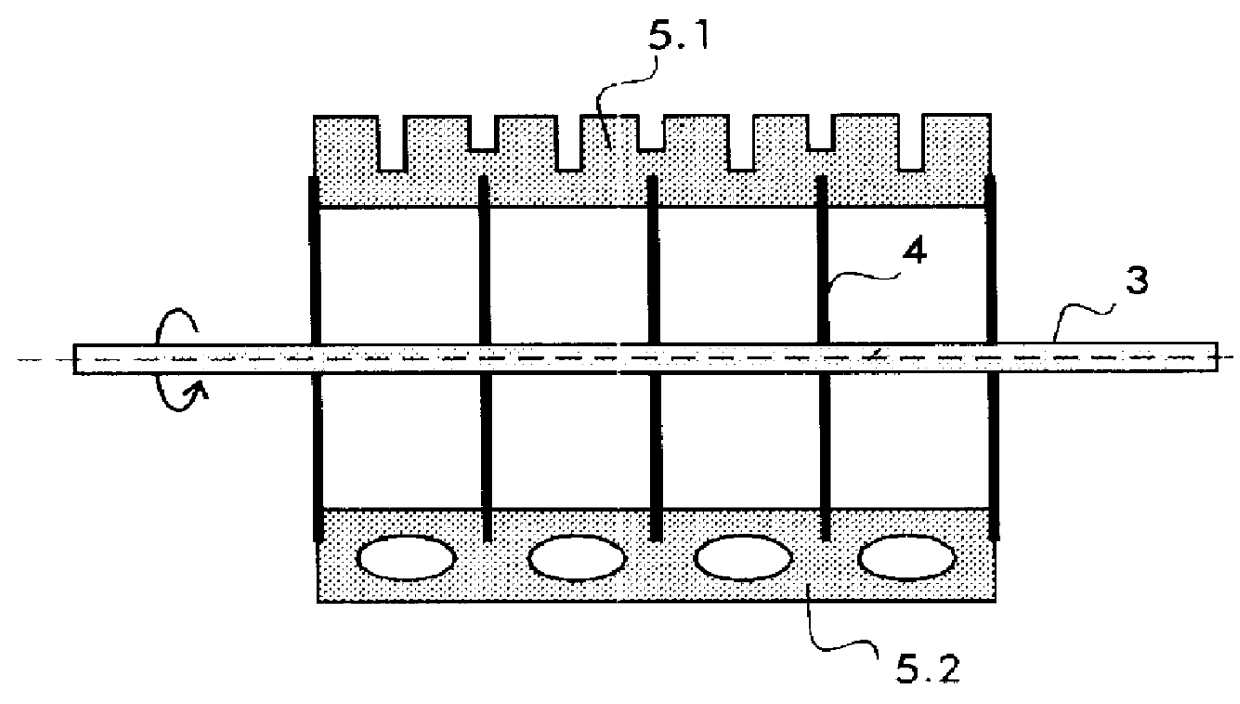

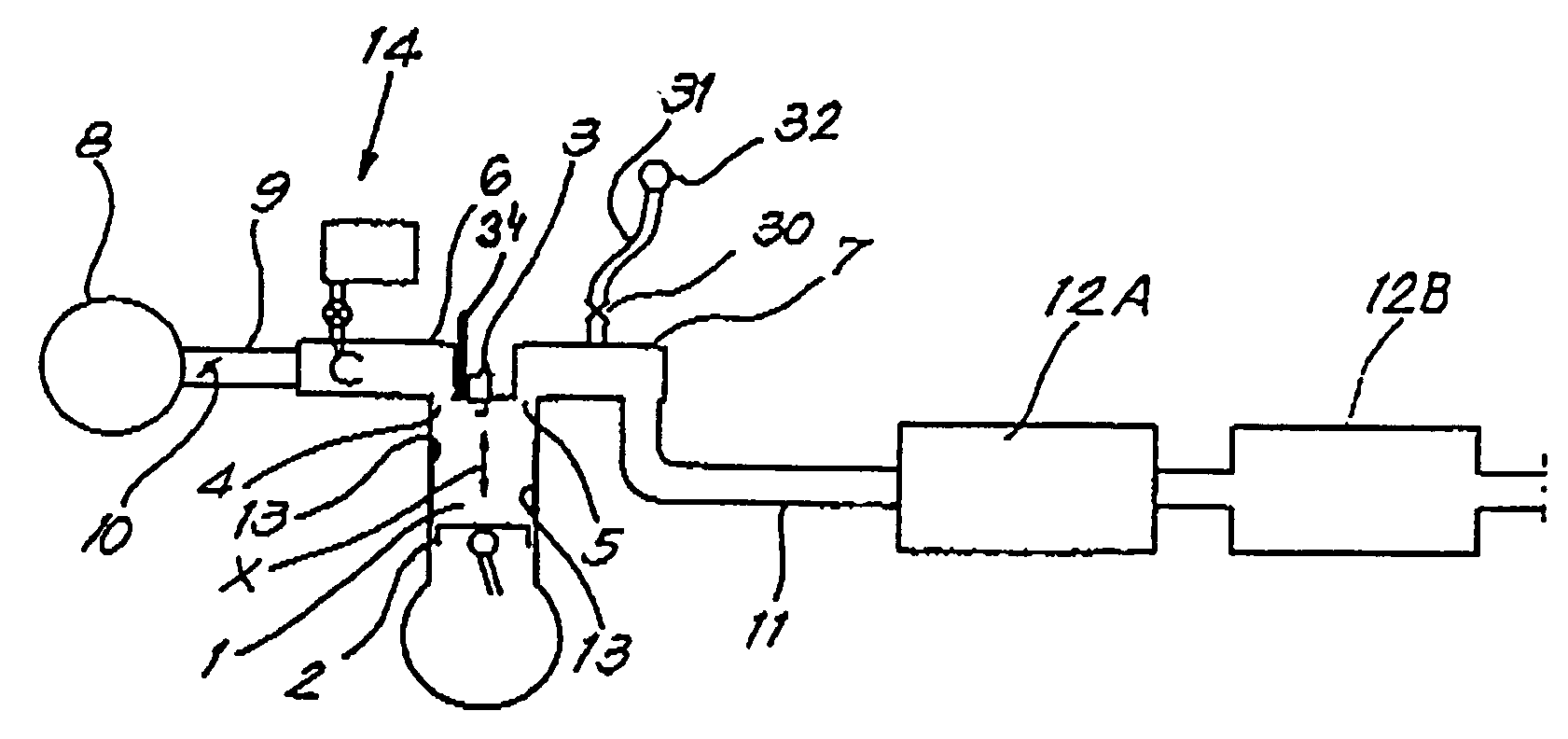

Process for thermal and/or catalytic decomposition and/or depolymerization of low-grade organic substances and device for carrying out the process

InactiveUS6165349AImprove economyEfficient processingCatalytic crackingSolid waste disposalDepolymerizationLower grade

PCT No. PCT / SK97 / 00006 Sec. 371 Date Jun. 1, 1999 Sec. 102(e) Date Jun. 1, 1999 PCT Filed Jul. 4, 1997 PCT Pub. No. WO98 / 39368 PCT Pub. Date Sep. 11, 1998The nature of the process consists in that the low-grade organic substances are subject, at a temperature of 150 DEG C. to 700 DEG C. and at a pressure of 0.1 MPa to 2.5 MPa, to the action of a moving bed of solid particles of a substance which perform whirling motion, whereby the solid particles of a substance constituting the moving bed are set to whirling motion by intensive agitation. The device consists of a reaction chamber (1) with a rotation mechanism (2) which rotation mechanism (2), located rotably in the faces of the reaction chamber (1), consists of a shaft (3) to which vanes (5) are symetrically attached by means of driving discs (4). The vanes (5) may be arranged in 3 to 10 rows, and they may be provided with openings (5.1) or cut-outs (5.2) of various geometrical shapes, and they may be divided into individual segments (5.3). Also the driving discs (4) may be provided with openings (4.1) of various geometrical shapes.

Owner:MADAR IVAN

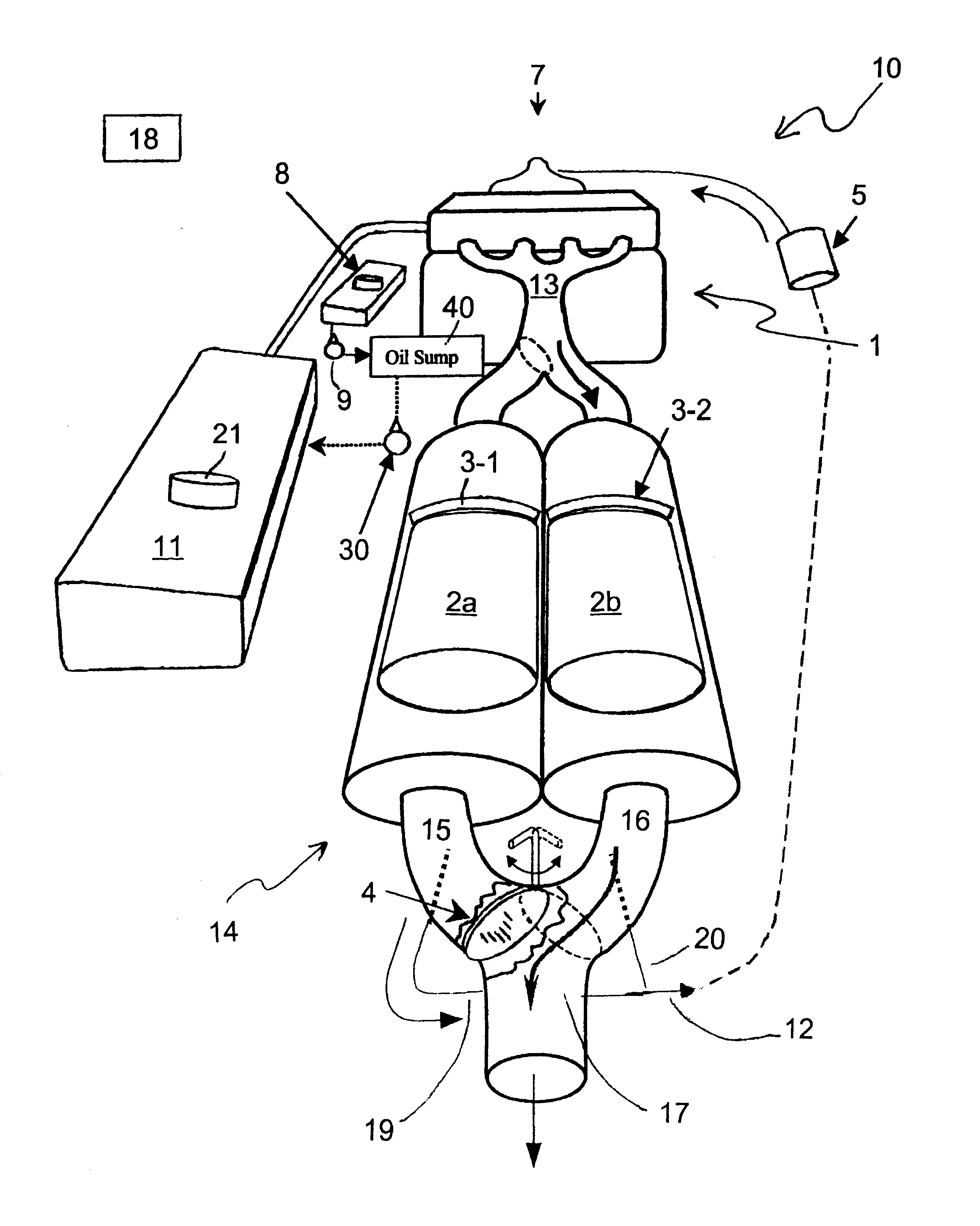

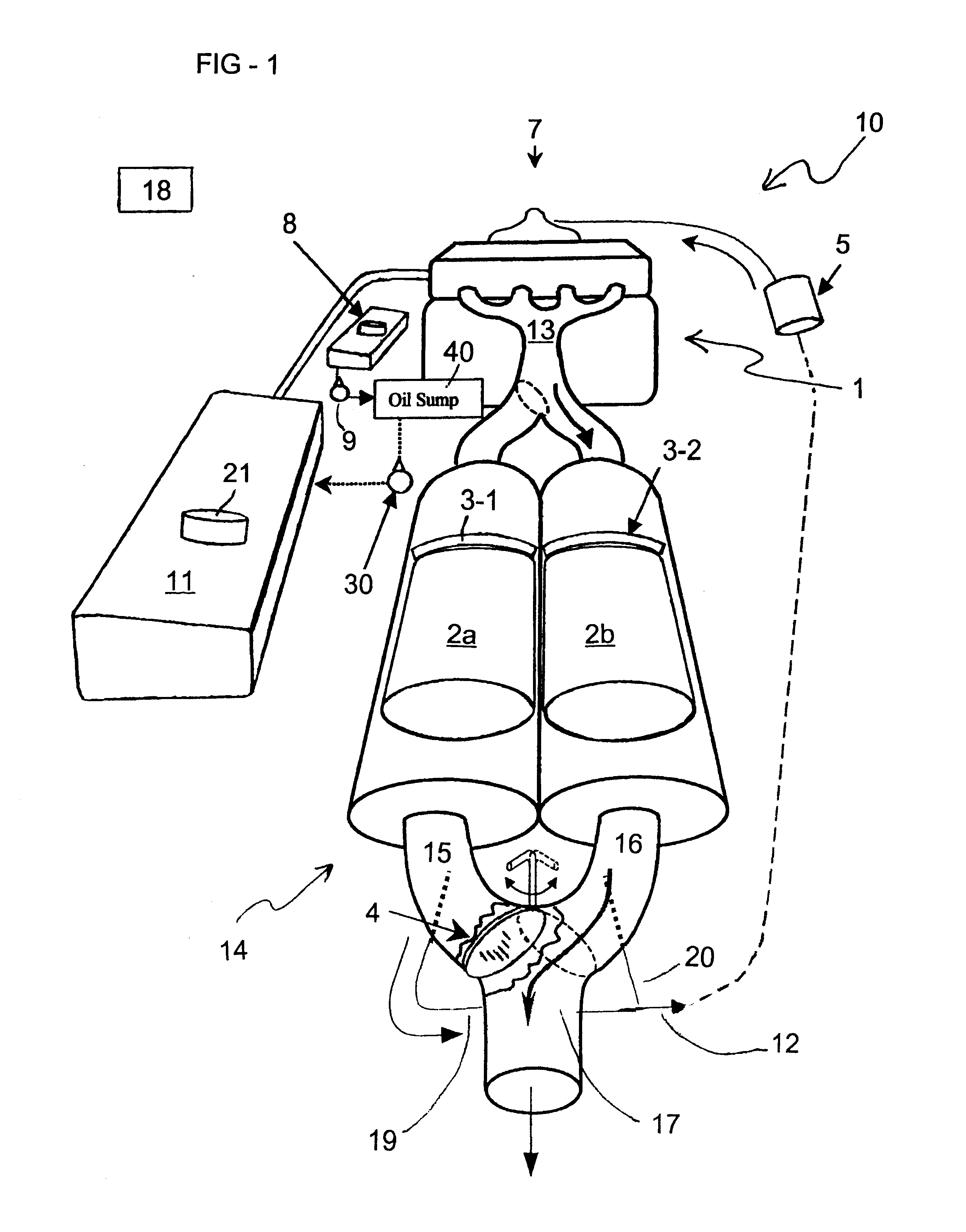

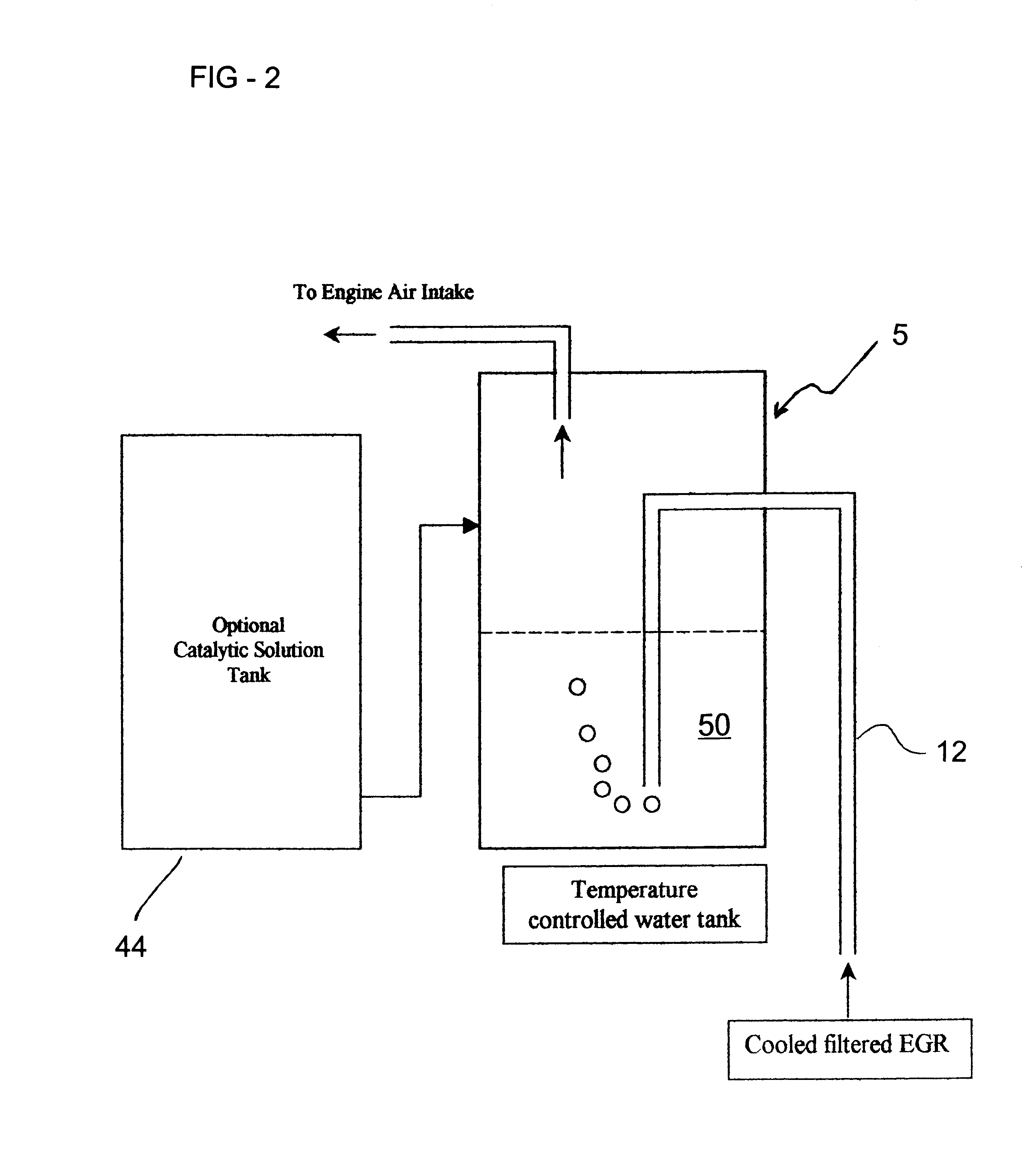

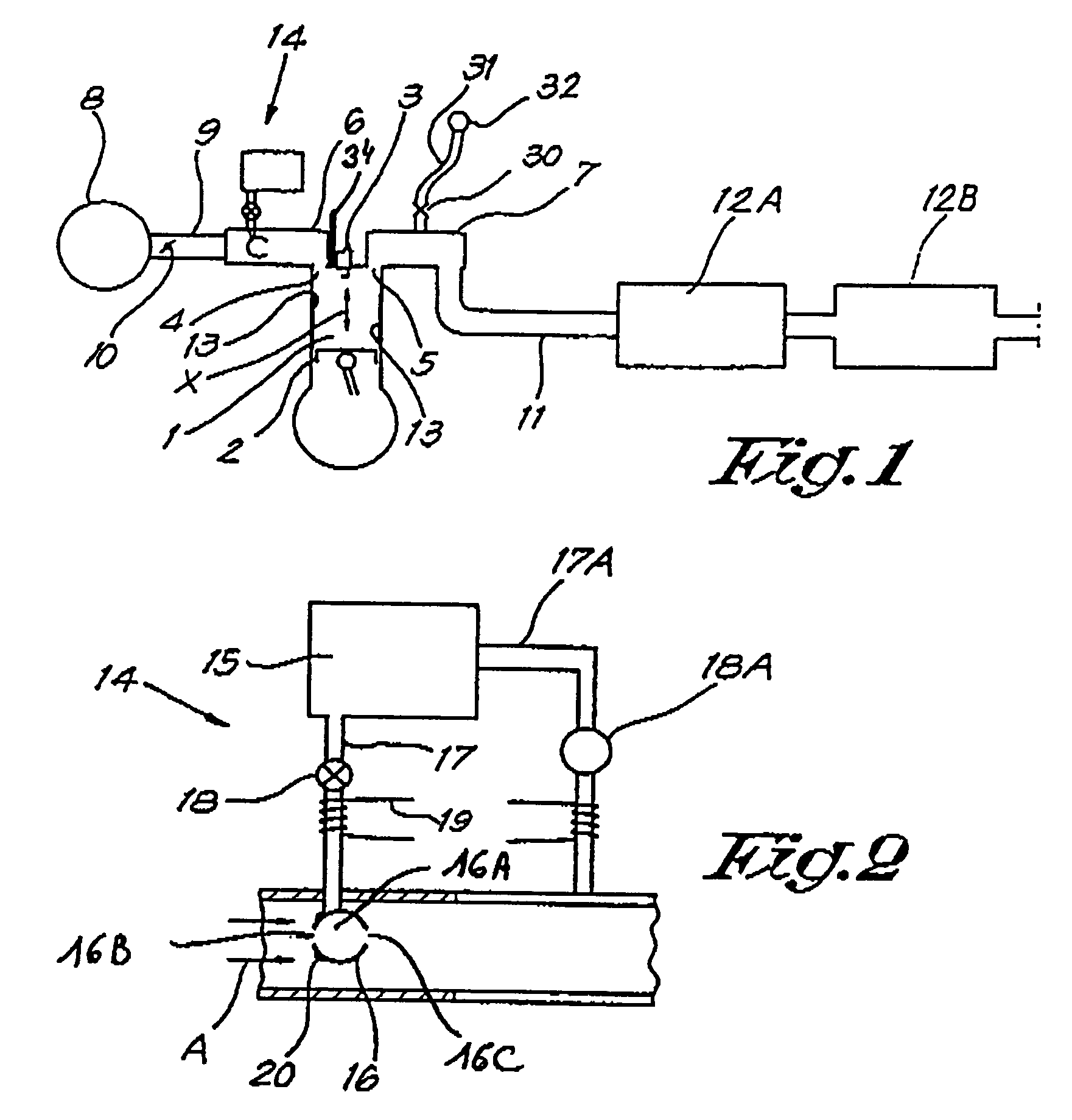

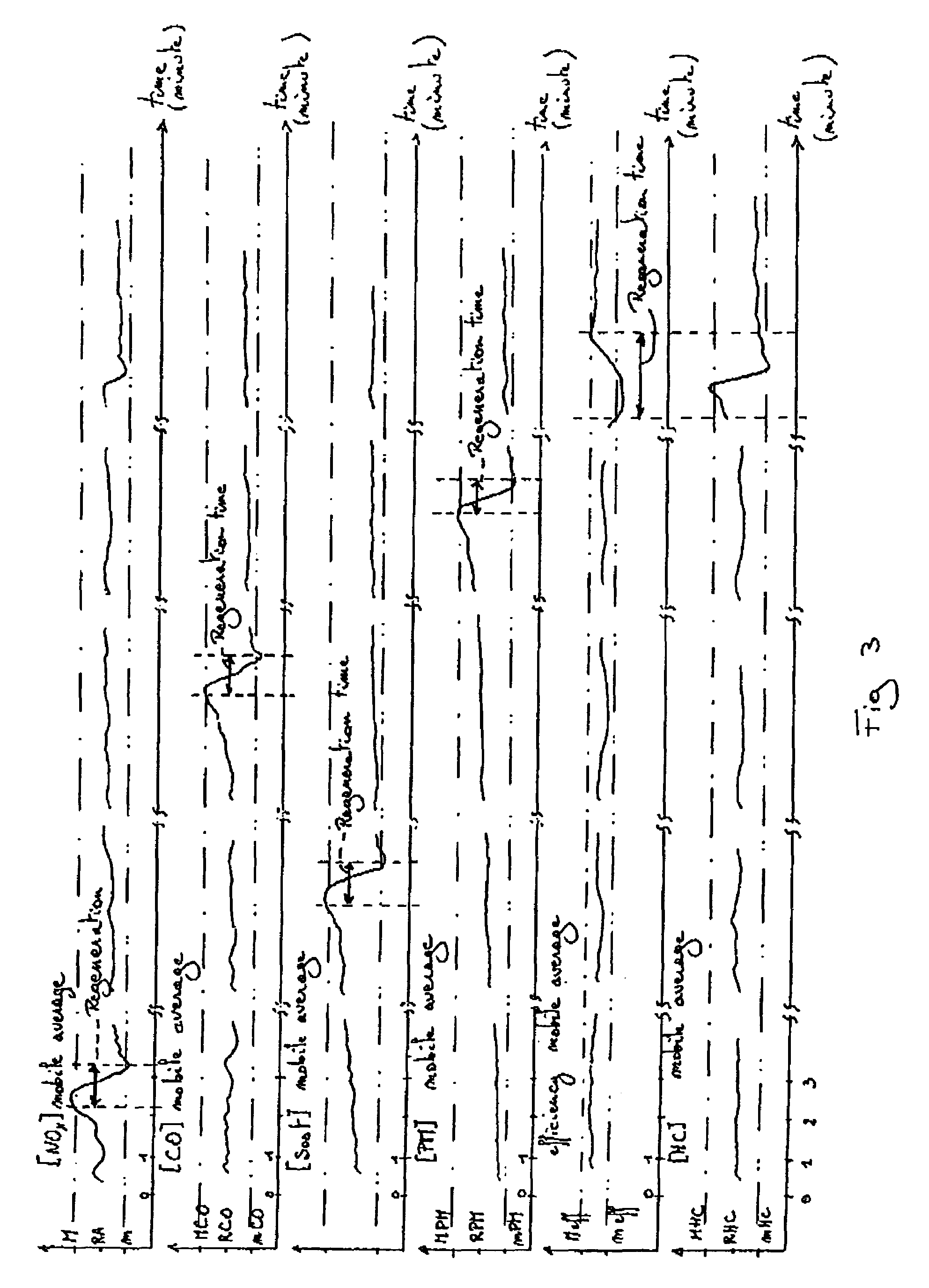

System for and methods of operating diesel engines to reduce harmful exhaust emissions and to improve engine lubrication

InactiveUS6892531B2Promote regenerationAnti-wear propertyInternal combustion piston enginesNon-fuel substance addition to fuelExhaust gas emissionsFuel tank

A Diesel engine anti-wear lubricant oil additive composition that includes organo-metallic compounds of Cu, Ce, etc., is used to catalytically burn-off diesel particulate matter (PM) collected by diesel particulate filter (DPF). A fuel borne catalyst (FBC) of Cu,Ce,Fe etc., required for regenerating the DPF is made by blending a predetermined quantity of used engine oil, removed from the engine crankcase oil system, with fuel in the fuel tank of a diesel engine equipped with DPF and EGR systems. A method of fumigating water and catalytic compounds of Cu, Fe, Ce, etc., into the air-intake system of a diesel engine in the EGR gases from the DPF or air, to reduce both PM and NOx emissions from a diesel engine, with improved engine lubrication performance, is also disclosed.

Owner:RIM JULIUS J

Catalytic burning reaction

ActiveUS7482303B2The process is stable and efficientRaise the ratioBurnersNitrogen compoundsRare earthCarbon Nanoparticles

Catalytic system combining an aluminium or iron containing catalytic support, a rare earth containing porous deposit, carbon nanoparticles and a carbon containing structure making bonds between carbon nanoparticles.

Owner:BOSTEELS DOMINIQUE

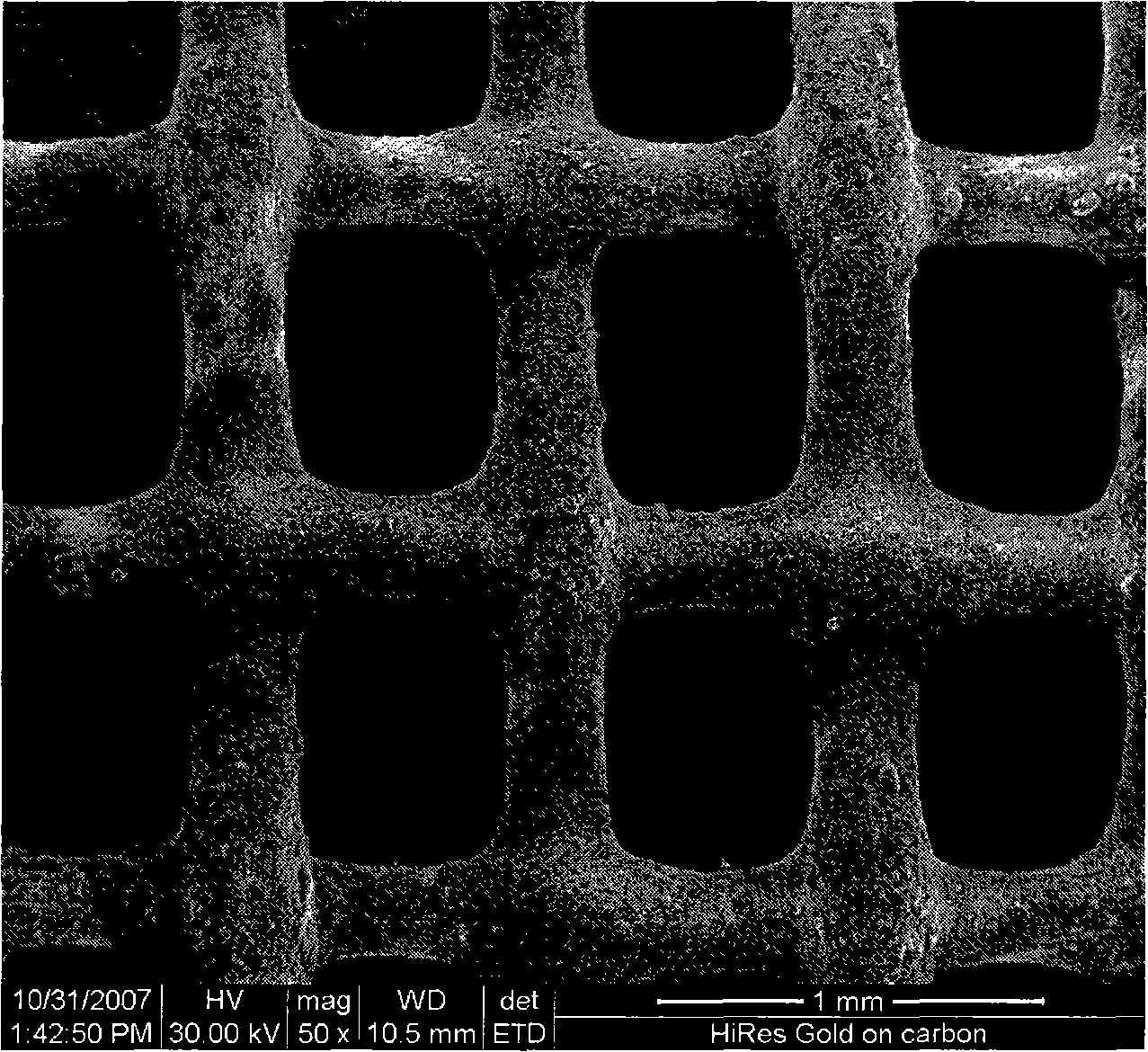

Method for covering aluminum oxide coating on honeycomb shaped wire mesh carrier

InactiveCN101274291AStrong adhesionNo crackCatalyst carriersCatalyst activation/preparationHoneycomb likeThermal shock

The invention discloses a method for coating an alumina coating layer on a faviform metal wire mesh carrier, which belongs to the technical field of the preparation of the coating layers of metal carriers, and is characterized in that after the faviform metal wire mesh carrier is molded, a pretreatment is implemented on the metal surface, and then the faviform metal wire mesh carrier is soaked in a sizing agent that contains Gamma-Al2O3 powder and aluminum powder, the Gamma-Al2O3 powder and the aluminum powder are sedimentated on the surface of the faviform metal wire mesh carrier through the electrolytic deposition method, and finally the faviform metal wire mesh carrier coated with the coating layer is roasted, wherein, the faviform metal wire mesh carrier takes the material of a stainless metal wire mesh that contains aluminum, the coating layer is distributed evenly on the surface of the faviform metal wire mesh carrier and does not chap, the thickness of the coating layer is 30 to 80Mum; the addition of the aluminum powder improves the thermal shock resistance and the mechanical vibration resistance of the coating layer, as well as the conglutination degree between the coating layer and the faviform metal wire mesh. The method for coating the alumina coating layer on the faviform metal wire mesh carrier of the invention has the advantages that the method is applicable to the preparation of the coating layers of the catalyst carriers which are used in the gas-solid catalytic reactions that are related to the environmental protection field such as the fields of the tail gas burning of motor vehicles and fixed sources and catalytic burning.

Owner:DALIAN UNIV OF TECH

Method for catalytic conversion of carbon monoxide in a hydrogen-containing gas mixture with improved cold start behavior

InactiveUS6555088B1Realize the operationHigh activityHydrogen separation using solid contactFuel cell auxillariesHydrogenPartial oxidation

A method for conversion of carbon monoxide to carbon dioxide and hydrogen with water in a gas mixture containing hydrogen and other oxidizable components. An oxidation-active noble metal shift catalyst is the catalyst. The necessary operating temperature of the catalyst is established and optionally maintained by partial oxidation of the oxidizable components of the gas mixture.

Owner:UMICORE AG & CO KG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com