High-cleanness environment-friendly alcohol ether fuel for car

An alcohol fuel, high-definition technology, applied in fuels, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of engine anti-wear, repair, poor lubrication effect, unsatisfactory corrosion inhibition effect, and inability to achieve clean emissions, etc. , to achieve the effects of not being easy to work rough, overcoming low-temperature starting and acceleration, and excellent ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

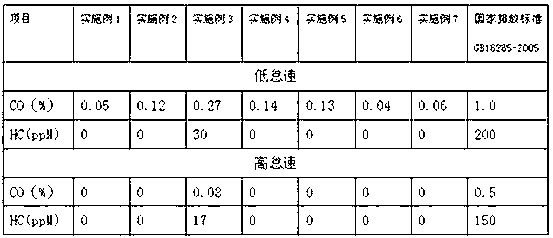

Examples

Embodiment 1

[0064] 600 parts of methanol, 300 parts of alcohol fuel ether stabilizer, 4 parts of anti-oxidation and anti-adhesive agent, 2.4 parts of metal passivator, 2 parts of corrosion inhibitor, 30 parts of catalytic combustion improver, 3 parts of antistatic agent, antiknock stabilizer 31 parts, 4 parts of cleaning and dispersing agent, 3 parts of anti-wear repair agent, 4 parts of alcohol fuel metal corrosion inhibitor, 4 parts of rubber and plastic parts corrosion swelling inhibitor, 12 parts of alcohol modified auxiliary solvent, alcohol fuel bactericide 0.54 parts, 0.06 parts of alcohol fuel identification agent.

[0065] The alcohol fuel ether stabilizer is prepared by mixing dimethyl ether and diisopropyl ether in a weight ratio of 4:2; Phenol, 2,4,6-tri-tert-butylphenol and N,N-diisopropyl-p-phenylenediamine are prepared by mixing at a weight ratio of 5:2:3; the metal deactivator is N,N '-disalicylidene-1,2-propanediamine; the corrosion inhibitor is prepared by mixing trialk...

Embodiment 2

[0067] 700 parts of methanol, 200 parts of alcohol fuel ether stabilizer, 4 parts of anti-oxidation and anti-adhesive agent, 3 parts of metal deactivator, 2 parts of corrosion inhibitor, 28 parts of catalytic combustion improver, 3 parts of antistatic agent, antiknock stabilizer 32 parts, 4 parts of cleaning and dispersing agent, 3 parts of anti-wear repair agent, 4 parts of alcohol fuel metal corrosion inhibitor, 4.4 parts of rubber and plastic parts corrosion swelling inhibitor, 12 parts of alcohol modified auxiliary solvent, alcohol fuel bactericide 0.54 parts, 0.06 parts of alcohol fuel identification agent.

[0068] The alcohol fuel ether stabilizer is prepared by mixing dimethyl ether and diethyl ether at a weight ratio of 35:1; It is prepared by mixing with p-hydroxydiphenylamine at a weight ratio of 2:1; the metal deactivator is N, N'-disalicylidene-1,2-propanediamine; the corrosion inhibitor is composed of phosphoric acid Tributyl ester, dibutyl phosphite and isoprop...

Embodiment 3

[0070] 800 parts of methanol, 150 parts of alcohol fuel ether stabilizer, 3 parts of anti-oxidation and anti-adhesive agent, 2 parts of metal deactivator, 2 parts of corrosion inhibitor, 10 parts of catalytic combustion improver, 3 parts of antistatic agent, antiknock stabilizer 10 parts, 3 parts of cleaning and dispersing agent, 2 parts of anti-wear repair agent, 3 parts of alcohol fuel metal corrosion inhibitor, 3.4 parts of rubber and plastic parts corrosion swelling inhibitor, 8 parts of alcohol modified auxiliary solvent, alcohol fuel bactericide 0.53 parts, alcohol fuel identification agent 0.07 parts.

[0071] The alcohol fuel ether stabilizer is prepared by mixing dimethyl ether, diethyl ether, and methyl tert-amyl ether in a weight ratio of 5:2:3; the antioxidant and anti-adhesive agent is composed of 2, 6-di-tert-butyl-p-cresol, N,N-diisopropyl-p-phenylenediamine and N-n-butyl-p-anilinophenol are prepared by mixing at a weight ratio of 5:2:3; the metal passivation T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com