Patents

Literature

1149 results about "Metal deactivator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal deactivators, or metal deactivating agents (MDA) are fuel additives and oil additives used to stabilize fluids by deactivating (usually by sequestering) metal ions, mostly introduced by the action of naturally occurring acids in the fuel and acids generated in lubricants by oxidative processes with the metallic parts of the systems. Fuels desulfurized by copper sweetening also contain a significant trace amounts of copper.

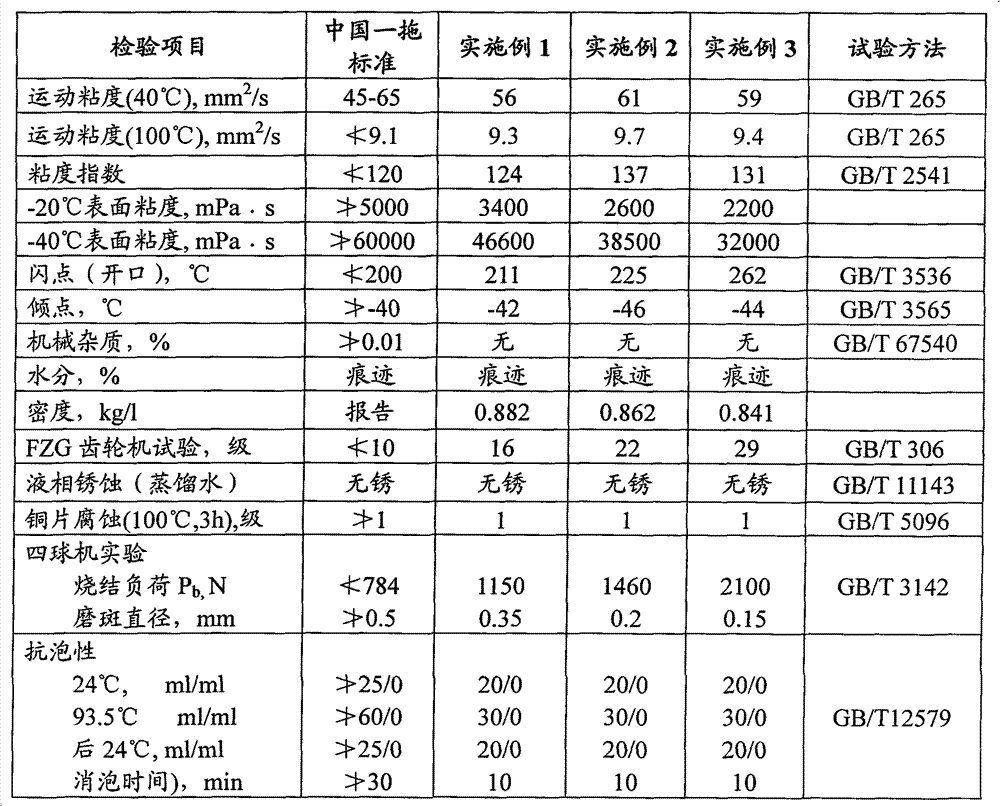

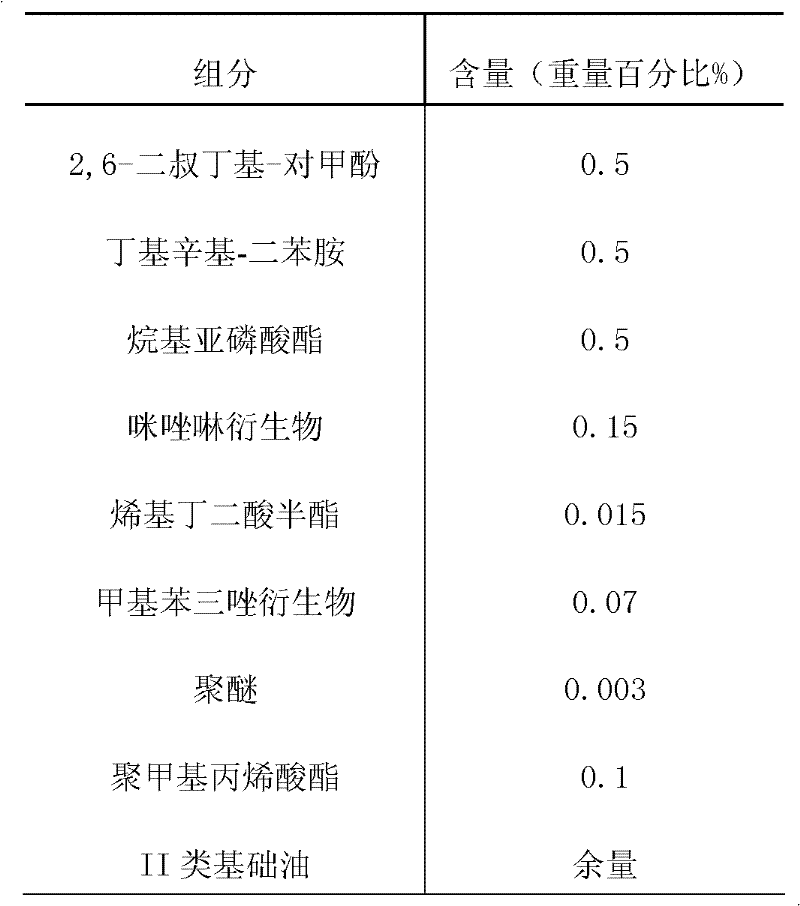

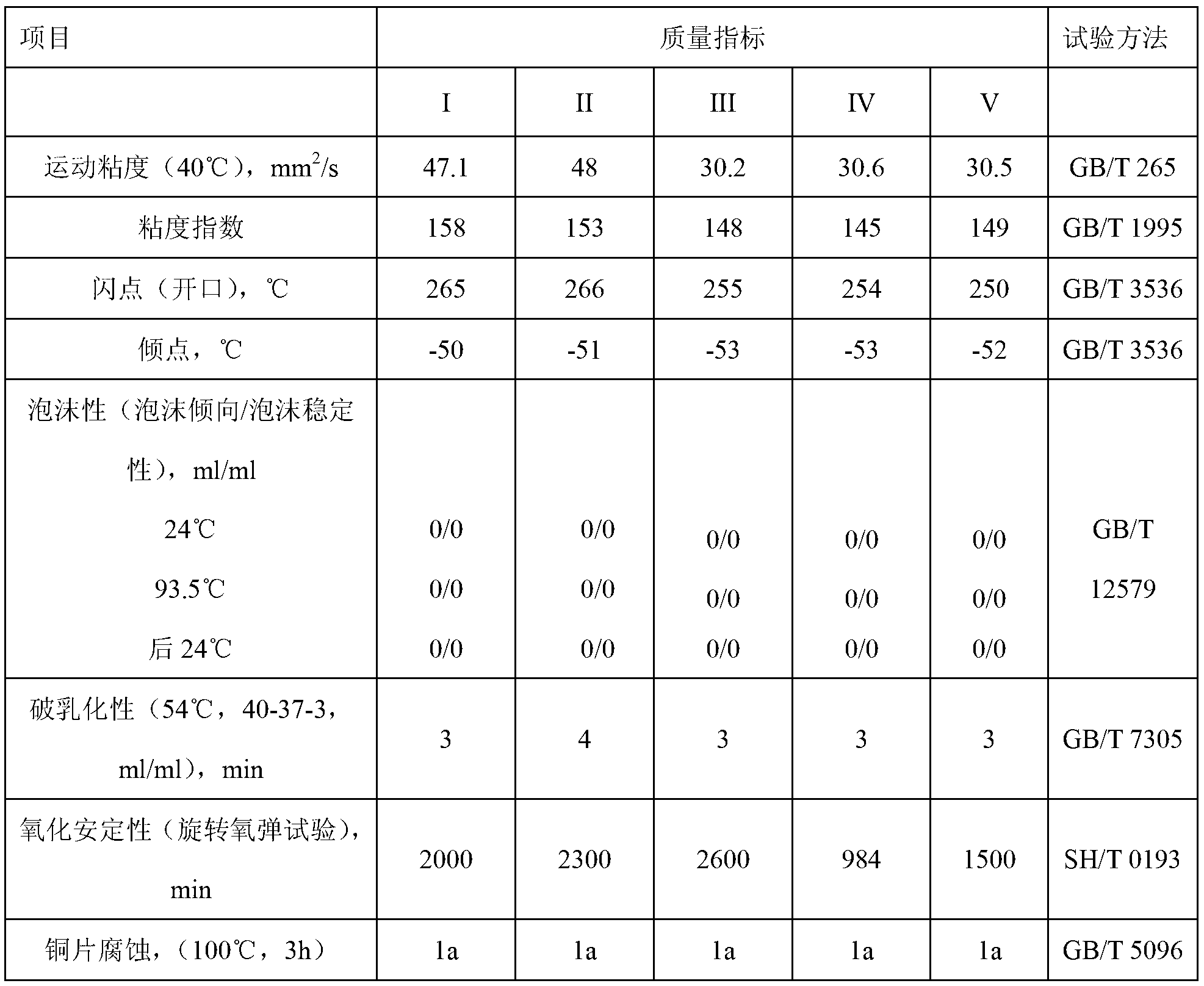

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

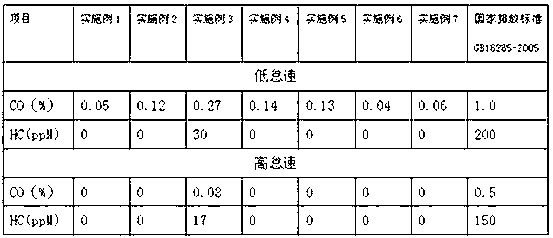

High-cleanness environment-friendly alcohol ether fuel for car

ActiveCN103275769AHigh chemical activityImproves resistance to phase separationLiquid carbonaceous fuelsFuel additivesMechanical engineeringMethanol

The invention provides a high-cleanliness environment-friendly alcohol ether fuel for a car. The fuel provided by the invention consists of the following raw materials: 600-800 parts of methanol, ethanol or a mixture of methanol and ethanol, 100-350 parts of an ether stabilizer, 1-6 parts of an anti-oxygen and anti-gum inhibitor, 2-5 parts of a metal deactivator, 1-3 parts of a corrosion inhibitor, 1-40 parts of a catalytic combustion improver, 2-4 parts of an antistatic agent, 10-100 parts of an antiknock stabilizer, 1-6 parts pf a purification dispersant, 1-6 parts of an anti-wear repair agent, 1-6 parts of a metal corrosion inhibitor, 2-6 parts of a rubber and plastic part corrosion and swelling inhibitor, 10-50 parts of a modified alcohol cosolvent, 0.2-0.8 part of a bactericide and 0.04-0.1 part of a recognition agent. The fuel provided by the invention has the advantages of stable performance, strong power, sufficient combustion, good seismic performance, good acceleration, easiness for starting up, no air lock, no separated layer, reduced fuel consumption, cleaner tail gas emission and no need of changing the structure of a spark ignition engine in the prior art and can be separately used, used instead of regular gasoline or used together with regular gasoline by co-combustion.

Owner:鲁家政

High temperature biobased lubricant compositions from boron nitride

InactiveUS20100105583A1Improve the lubrication effectEnhanced anti-wearBase-materialsBoron nitrideAlpha-olefin

This present invention discloses a method for the preparation of an improved high temperature engine lubricant composition comprising the steps of: 1) providing at least one biobased natural oil or biobased synthetic oil selected from the group consisting of natural or synthetic vegetable oil, natural or synthetic animal oil, genetically modified vegetable oil, genetically modified synthetic vegetable oil, natural or synthetic tree oil, and mixtures thereof; 2) providing at least one boron nitride; and 3) optionally, providing at least one base oil selected from the group consisting of a synthetic ester, solvent refined petroleum oil, a hydrocracked petroleum white oil, an all hydroprocessed synthetic oil, Fischer Tropsch oil, petroleum oil group I, group II, group III, a polyalphaolefin (PAO), and mixtures thereof; 4) optionally, providing at least one additive or combination of additives selected from the group consisting of anti-oxidant(s), corrosion inhibitor(s), metal deactivator(s), viscosity modifier(s), anti-wear inhibitor(s), friction modifier(s), and extreme pressure agent(s); 5) blending 1), 2), 3), and 4) in any sequence to form said composition.

Owner:RENEWABLE LUBRICANTS INC

Oil composition and its use in a transmission

Owner:THE LUBRIZOL CORP

Ethylene device quench oil viscosity reductant

InactiveCN101062880AEasy to useDoes not cause emulsificationHydrocarbon purification/separationHydrocarbonsVisbreakerLiquid viscosity

The invention discloses an ethylene device quench oil viscosity reductant in inhibiting liquid viscosity intensification technical domain, which is characterized by the following: comprising with inhibitor, disperser and metal deactivator; possessing the function of aggregation inhibition, aggregation prevention and metallic surface deactivation; decreasing erosion and incrustation of quench system device; possessing little adding quantity and good stability; non-generating side effect of oil water emulsion.

Owner:CHINA PETROLEUM & CHEM CORP +1

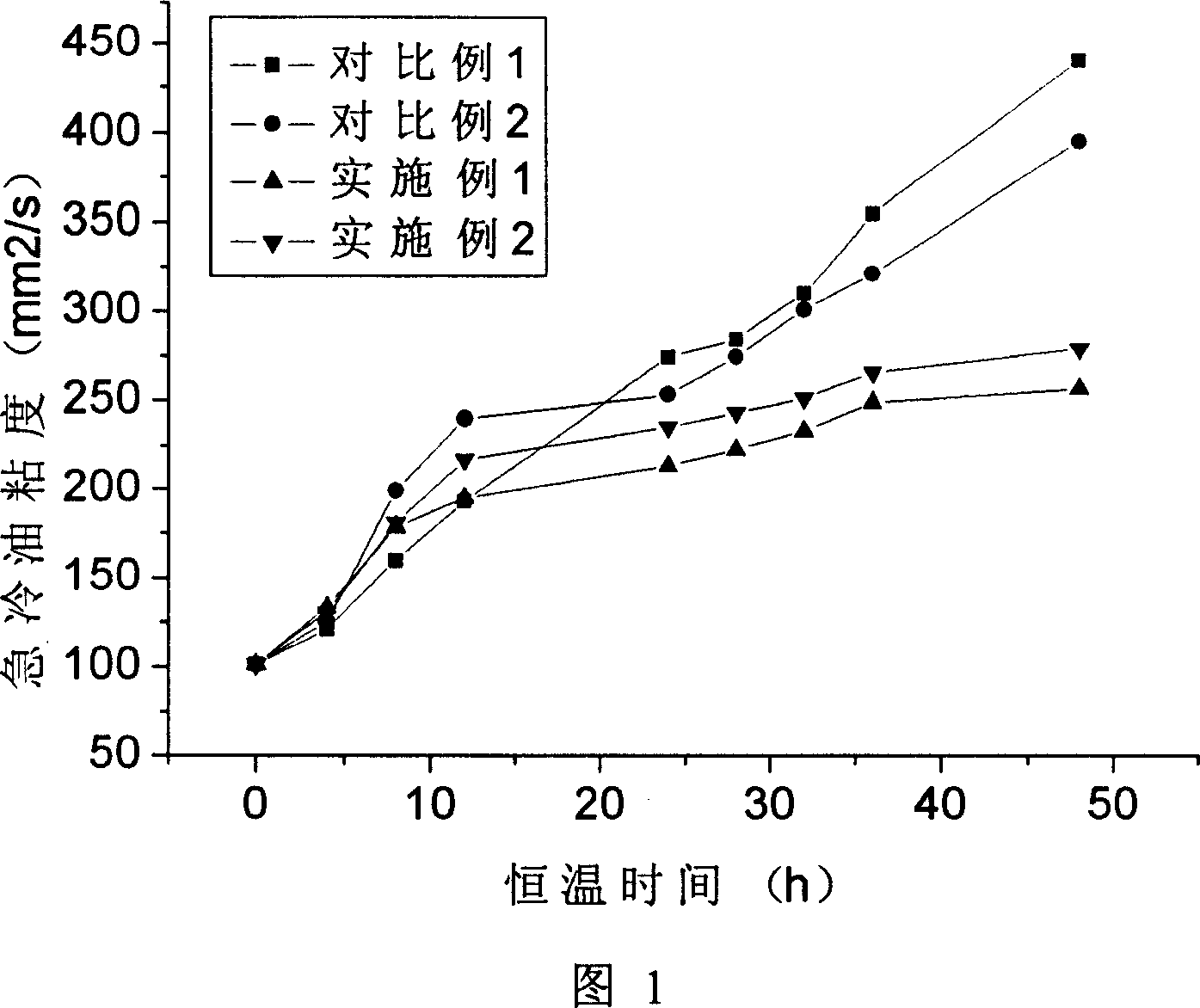

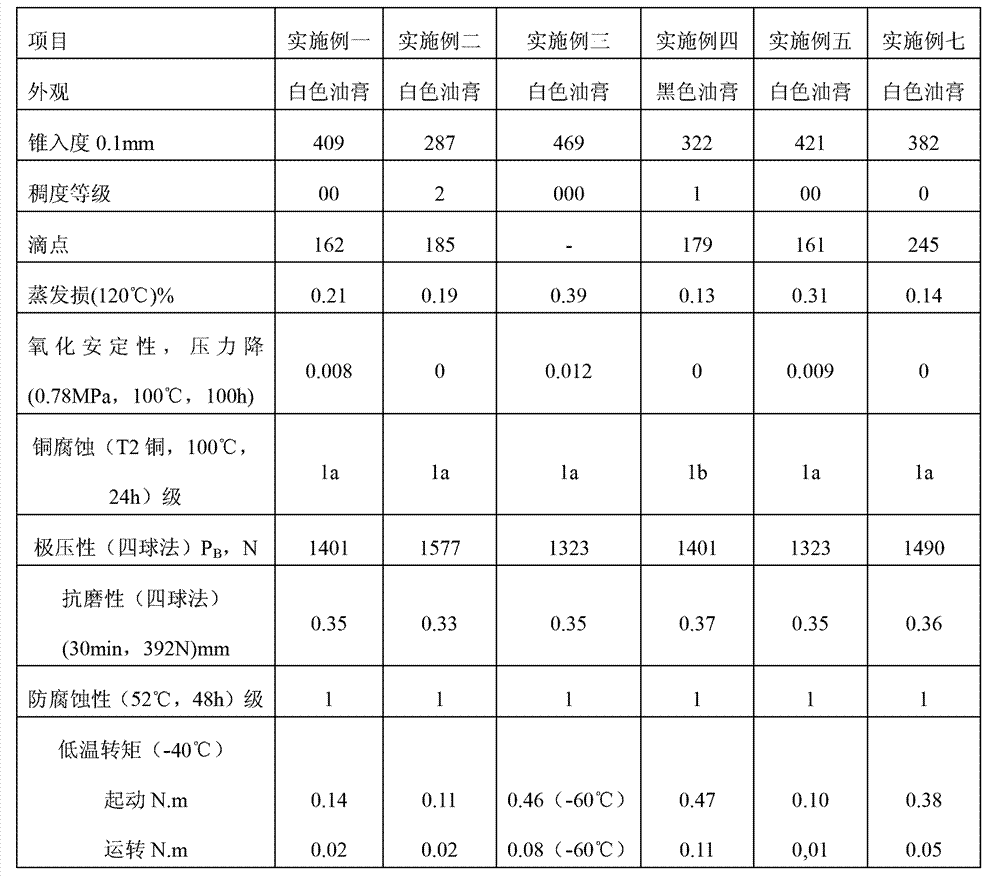

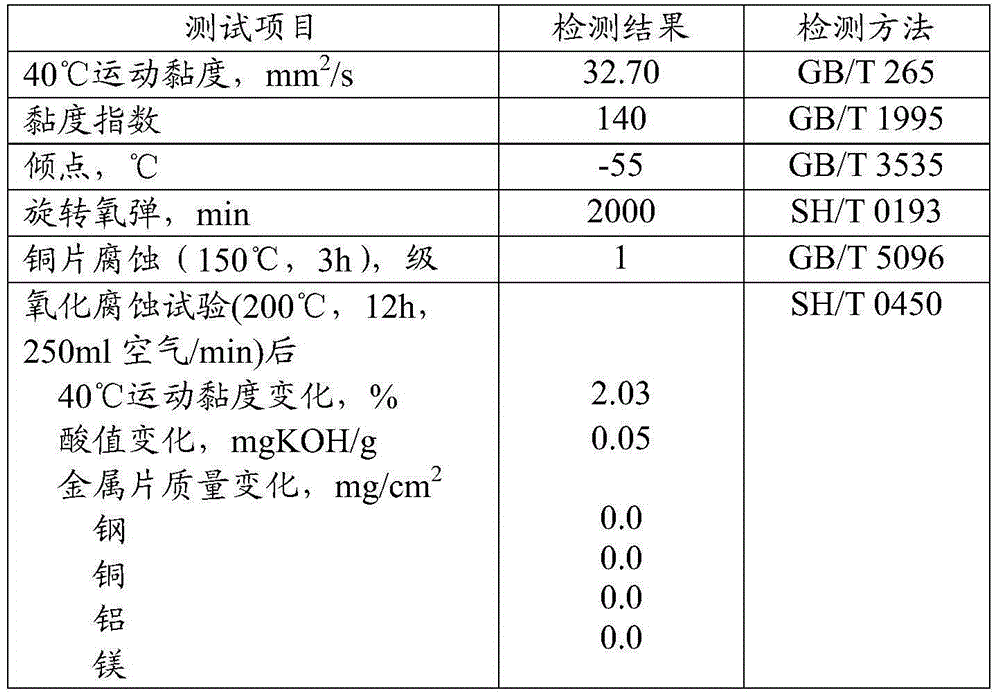

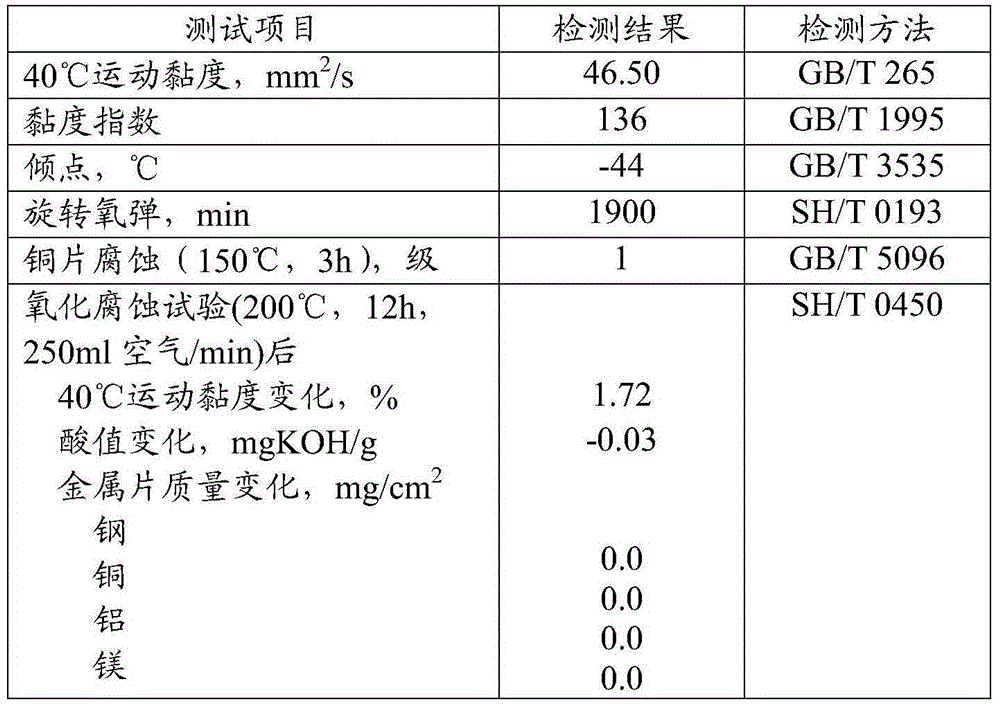

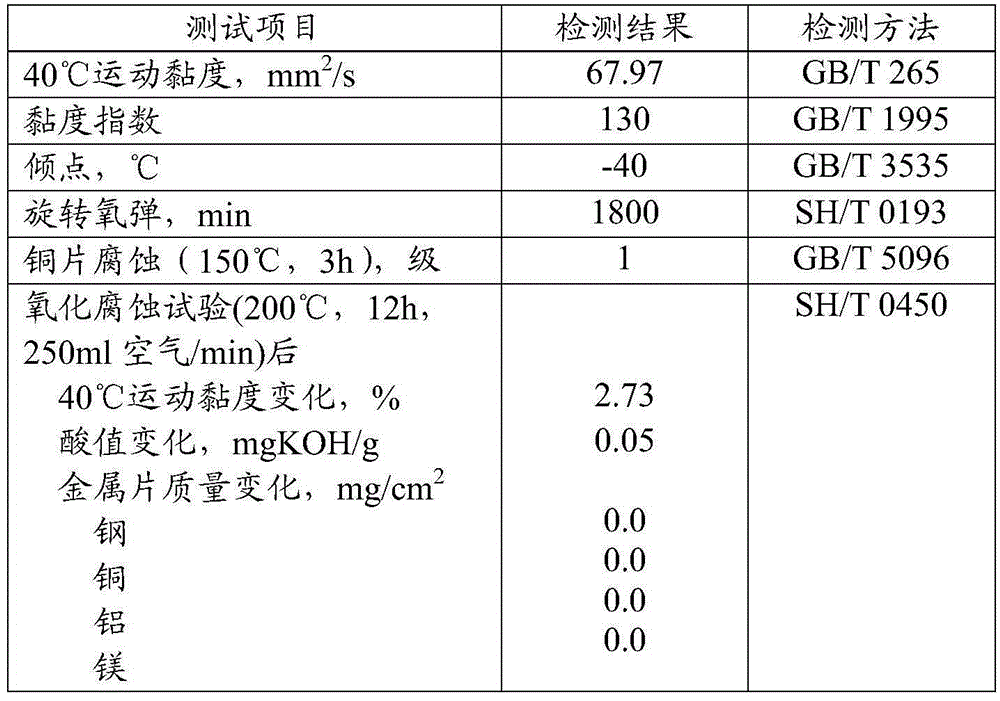

Low-temperature worm and gear lubricating grease composition and preparation method thereof

The invention provides a low-temperature worm and gear lubricating grease composition. The low-temperature worm and gear lubricating grease composition consists of the following components in percentage by weight: 40.5-94.55% of synthesis base oil, 2-20% of thickening agents, 2-20% of solid lubricants, 0.5-8% of extreme-pressure anti-wear reagents, 0.5-5% of friction improvers, 0.2-2% of antirust agents, 0.05-0.5% of metal passivator and 0.2-4% of antioxidants. The invention further provides a preparation method of the low-temperature worm and gear lubricating grease composition. The low-temperature worm and gear lubricating grease provided by the invention is prepared by refining low-middle-viscosity synthesis base oil, thickening agents and a plurality of additives and has the advantages that the starting torque and the low operation torque under a low-temperature environment equal to or lower than -40 DEG C are low, meanwhile, the extreme-pressure wear resistance, the antirust and anticorrosion properties and the leak resistance are excellent, the friction coefficient is low, the output efficiency is high, and the service life is extreme long.

Owner:武汉博达特种润滑技术有限公司

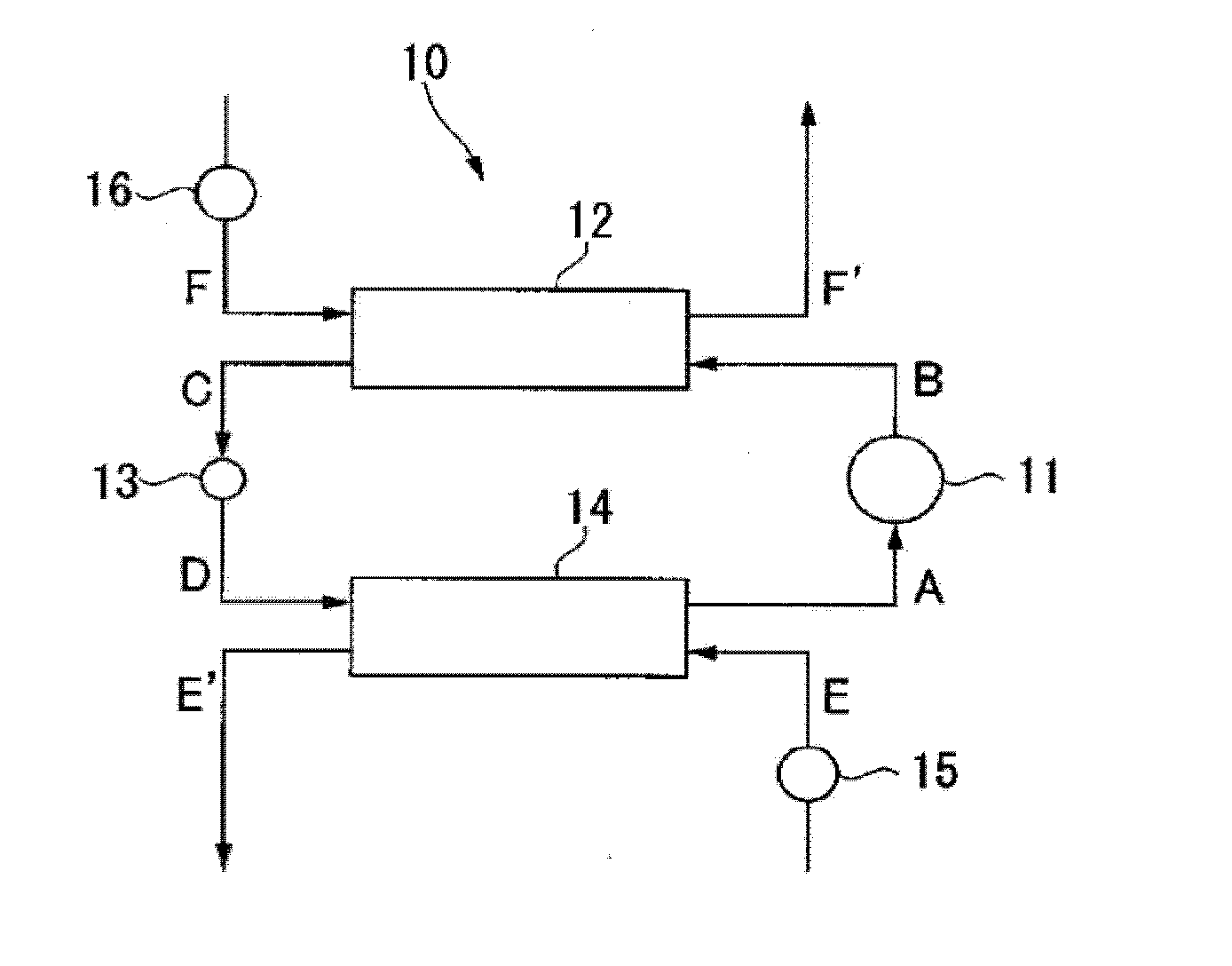

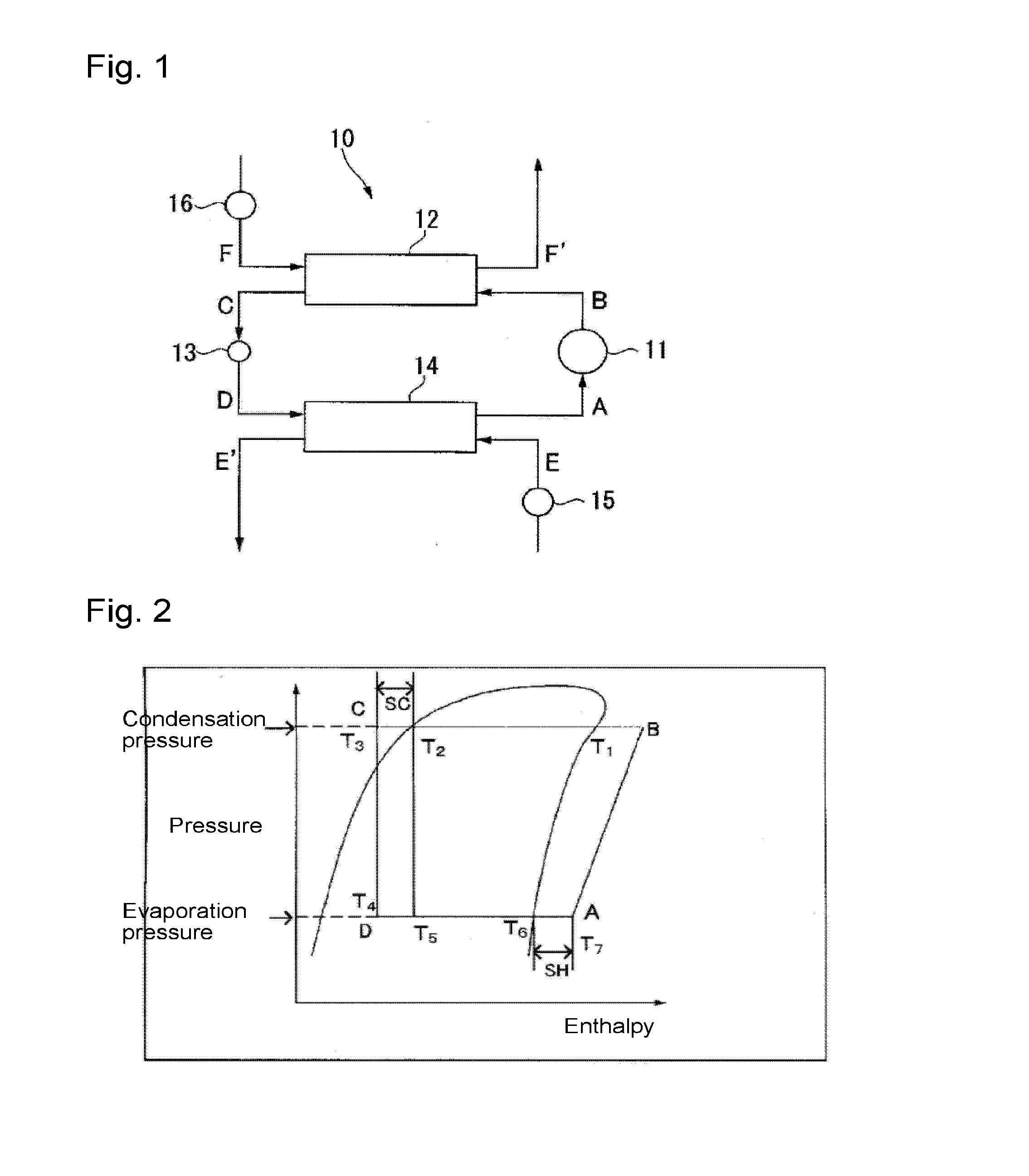

Composition for heat cycle system and heat cycle system

InactiveUS20170058174A1Low global warming potentialImprove cycle performanceCompressorCompression machines with non-reversible cycleWorking fluidHeat resistance

To provide a composition for a heat cycle system, which comprises a working fluid for heat cycle which has a low global warming potential and high stability, and which can replace R410A, and a heat cycle system employing the composition.A composition for a heat cycle system, which comprises a working fluid for heat cycle containing 1,2-difluoroethylene, and a stabilizer for preventing deterioration of the working fluid for heat cycle, such as an oxidation resistance-improving agent, a heat resistance-improving agent or a metal deactivator, and a heat cycle system employing the composition for a heat cycle system.

Owner:ASAHI GLASS CO LTD

Lubricating oil composition and use thereof

InactiveCN1594518AGood rolling lubricityImprove cooling effectAdditivesSolubilityChemical composition

The invention discloses a lubricating oil composition and use thereof, wherein the lubricating oil composition comprises 40-80 wt% of mineral oil, 10-50 wt% of oily agent, 4-10 wt% of emulsifying agent, 1-5 wt% of inhibitor, 2-5 wt% of antiwearing agent, 0.1-1.0 wt% of solubility promoter, 0.1-2.0 wt% of anti-oxidizing agent, and 0-0.5 wt% of metallic deactivator.

Owner:CHINA PETROCHEMICAL CORP +1

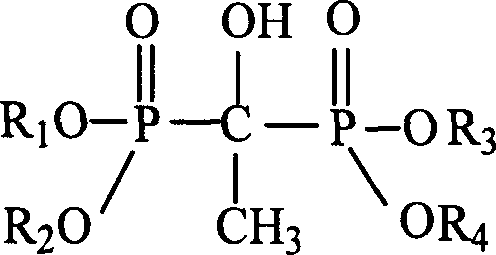

Combination of general gear oil

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

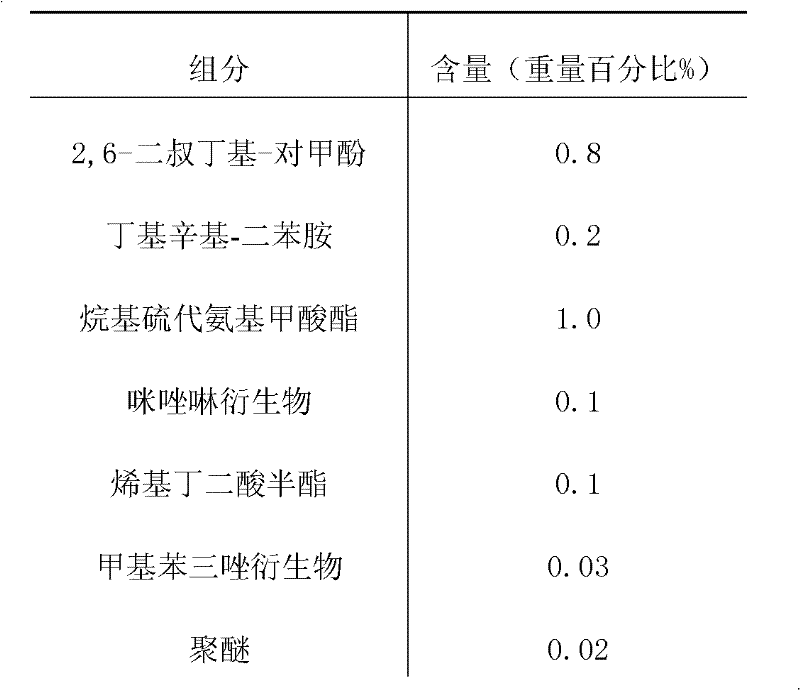

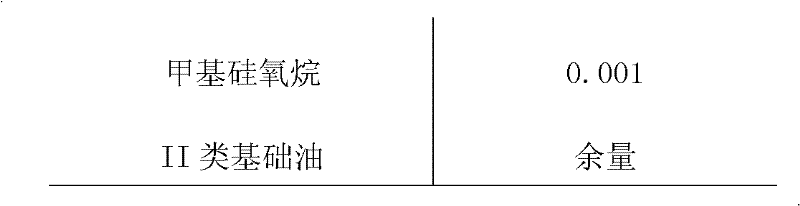

Air compressor oil composition

ActiveCN101724489AImprove anti-coking performanceImprove wear resistanceAdditivesBase-materialsTert butyl phenolFoaming agent

The invention relates to an air compressor oil composition, which comprises the following components in percentage by weight: 1.5 to 5 percent of antioxidant, 0.03 to 0.5 percent of ashless antirust agent, 0.01 to 0.5 percent of metal deactivator, 0.01 to 1 percent of ashless antiwear agent, 0.001 to 0.01 percent of anti-foaming agent and the balance of base oil, wherein the base oil is prepared by mixing poly alpha-olefin with ester oil in a weight ratio of 7-9:3-1 or mixing hydrogenated oil with the ester oil in the weight ratio of 7-9:3-1; and the antioxidant is the mixture of dialkylaniline, high-molecular thioether phenol and 4,4-methylenedi(2,6-di-tert-butyl phenol) in the weight ratio of 1:0.1-10:0.1-10. The air compressor oil composition has the advantages of excellent high-temperature anti-oxidation stability, anti-carbon deposition property, abrasive resistance, obvious energy-saving effect, good cost performance and low cost.

Owner:PETROCHINA CO LTD

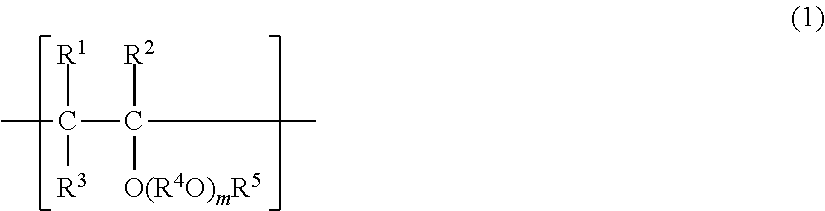

Composition of cold rolling sheet rolling oil

The invention discloses a cold-rolled sheet drawing oil composition to solve the defect of poor lubricating property nowadays, which is characterized by the following: this compositing includes 60-90 mass percent polyatomic alcohol ester oiliness agent, 0.5-5.0 mass percent non-ionic high molecular surfactant, 2.0-15.0 mass percent non-ionic ester ether type surfactant, 0.53-15 mass percent sulfide extreme pressure antiwear agent and 0.51-5 mass percent metal deactivator. This drawing oil possesses good lubricating property, milling train clean property and good annealing peace and quiet property.

Owner:CHINA PETROCHEMICAL CORP +1

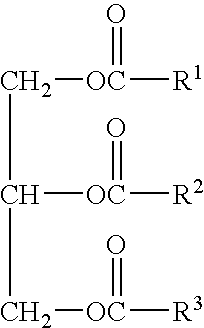

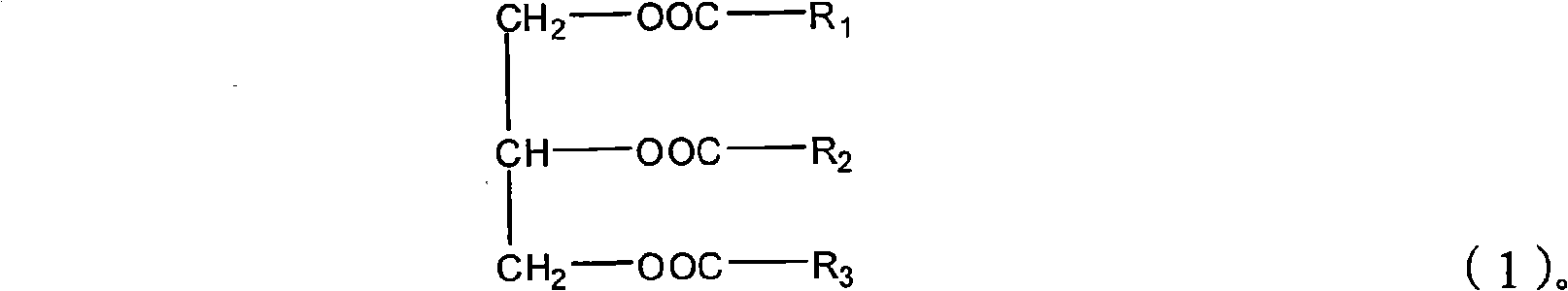

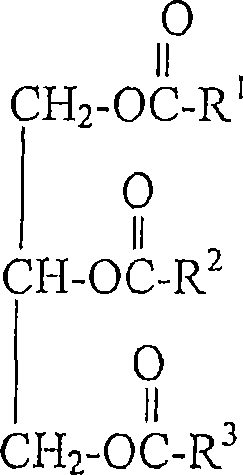

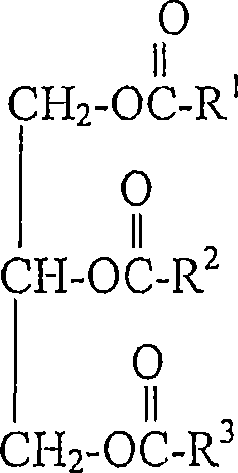

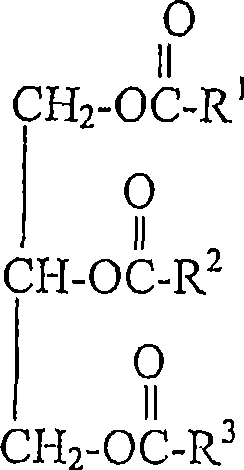

Environment-friendly insulating oil taking vegetable oil as raw material

InactiveCN101538505ACause some damagesRapid and complete biodegradationAdditivesVegetable oilAntioxidant

The invention provides environment-friendly insulating oil which takes vegetable oil as the raw material, and has high flash point and anti-oxidation stability, consists essentially of triglyceride and antioxidant, and also contains a metal deactivator in the further technical proposal. The environment-friendly insulating oil is prepared by refinement by taking vegetable oil as the raw material, does not contain toxic substances, dose not cause damage to environment and human body, and can be rapidly and thoroughly biodegraded, is environment-friendly insulating liquid, and can be applied in places with requirement of high fireproof performance as the flash point and the fire point thereof are both higher than 300 DEG C; the risk of fire and explosion is far lower than that of the traditional transformer oil; and all other performance indexes fully conform to the national standard GB 2536-90 of mineral transformer oil.

Owner:CHONGQING UNIV +1

Air compressor oil and preparation method thereof

InactiveCN104263481AGuaranteed safe operationAvoid cloggingLubricant compositionGas compressorAntioxidant

The invention provides air compressor oil which comprises the following components in parts by weight: 75-94 parts of synthetic hydrocarbon base oil, 5-20 parts of synthetic ester base oil and 1-5 parts of functional additive, wherein the functional additive comprises a purification dispersant, an antiwear agent, a metal deactivator, an antirust agent, an antioxidant, a pour point depressant, a demulsifying agent and an anti-foaming agent. The invention provides a preparation method of the air compressor oil. The preparation method comprises the step of mixing the synthetic hydrocarbon base oil, the synthetic ester base oil and the functional additive at the temperature of 60-80DEG C to obtain the air compressor oil. According to the air compressor oil provided by the invention, the synthetic oil is used as the base oil and the compound type functional additive is added, so that the air compressor oil provided by the invention has low oil sludge property. In addition, the air compressor oil provided by the invention also has the advantages of better thermal oxidation stability, low-temperature fluidity and higher viscosity index, and the use requirement of an air compressor is met.

Owner:CHINA PETROLEUM & CHEM CORP

Combination of oil for pair of gear worm

A composite oil for worm gear set contains mineral lubricating oil, at least one pour depressor and / or viscosity index improver chosen from polymethylacrylate, poly-alpha-olefin, alkylnaphthalene, etc, at least one S-contained extreme pressure agent and / or P-contained extreme-pressure antiwear agent, at least one oil agent or friction improver, at least one phenol-type or amine-type antioxidizing agent, at least one phenyltriazole or thiabiazole type metallic deactivator, and at least one poly-alcohol-ether type antiemulsifying agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

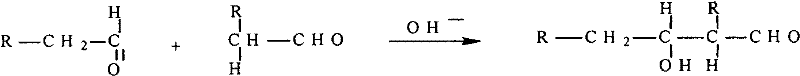

Aldehyde and ketone inhibitor for alkaline washing tower of ethylene unit

ActiveCN102531822AInhibition formationSuppress generationHydrocarbon purification/separationHydrocarbonsAntioxidantKetone

The invention relates to an aldehyde and ketone inhibitor for an alkaline washing tower of an ethylene unit, wherein the inhibitor comprises the components by mass percent: 10-25% of antioxidant, 10-20% of metal deactivator, 15-20% of polymerization inhibitor, 10-20% of dispersing agent and the balance of solvent. The aldehyde and ketone inhibitor can be used for effectively inhibiting the condensation reaction between aldehyde and ketone in oil phase and water phase in the alkaline washing tower with pertinence; the aldehyde and ketone inhibitor has antioxidant and polymerization inhibition functions at the same time, thus having an effective inhibition function for polymerization reaction caused by unsaturated hydrocarbon; the aldehyde and ketone inhibitor can be reacted with sulfide, so that polysulfide can further be prevented from being formed by the sulfide, and the generation of scaling substance can be inhibited; and the dispersing agent is added into the aldehyde and ketone inhibitor, so that the generated large polymers can be dispersed into small polymers; and therefore, the small polymers can be dispersed and dissolved in waste alkali liquid to be discharged, the blockage of equipment can be reduced, and the operation cycle of the equipment can be prolonged.

Owner:天津市瑞德赛恩新材料开发有限公司

Compressor Lubricant Compositions and Preparation Thereof

InactiveUS20090181871A1Reduce energy consumptionReduce volatilityLiquid carbonaceous fuelsAdditivesAlkaneFoaming agent

A compressor lubricant composition providing energy savings and exhibiting excellent oxidation stability is provided. The composition comprises (i) 80 to 99.999 weight percent of an isomerized base oil; and (ii) 0.001-20 weight percent of at least an additive selected from an additive package, oxidation inhibitors, pour point depressants, metal deactivators, metal passivators, anti-foaming agents, friction modifiers, anti-wear agents, and mixtures thereof; wherein the isomerized base oil has consecutive numbers of carbon atoms, less than 0.05 wt. % aromatics, a ratio of molecules with monocycloparaffinic functionality to molecules with multicyloparaffinic functionality greater than 2. In one embodiment, compressors employing the lubricant composition with isomerized base oil consumes at least 1% less power than compressors employing the lubricant compositions of the prior art.

Owner:CHEVROU USA INC

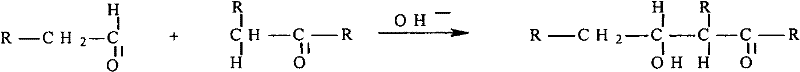

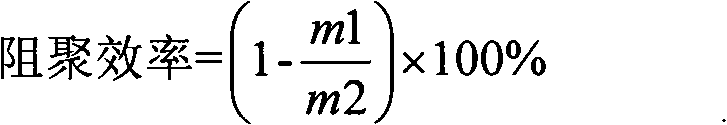

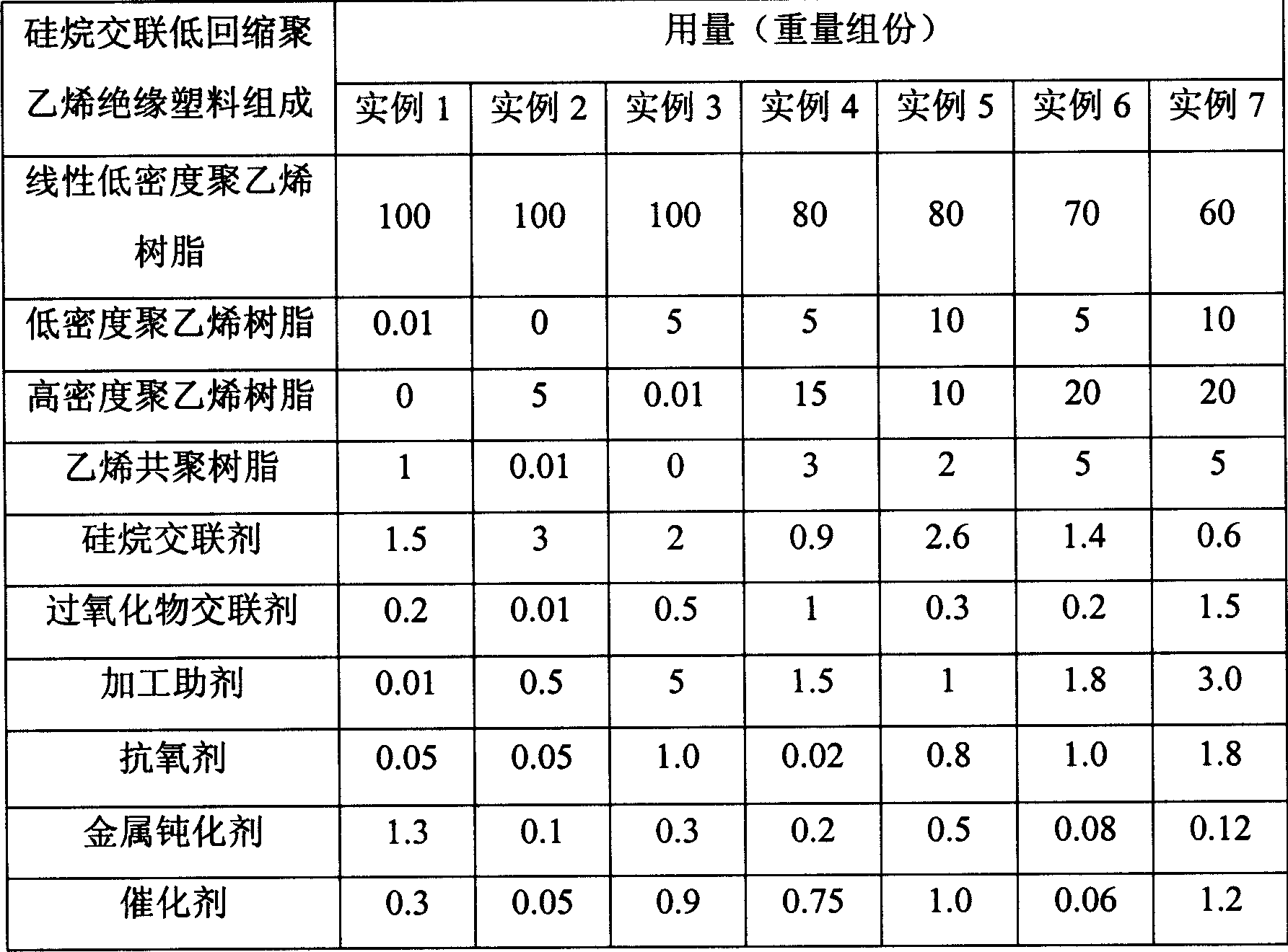

Silicane crosslinked low-retraction polyethylene plastic and its preparation method and use

InactiveCN1699457AImproving Insulation Shrinkage Test PerformanceInsulation shrinkage test index qualifiedLow-density polyethyleneLinear low-density polyethylene

The invention discloses a silicane crosslinked low-retraction polyethylene plastic and its preparation method and use, wherein the constituents include linear low density polyethylene, low density polyethylene, high-density polyethylene, ethylene copolymerized resin, silicane cross linking agent, hydroperoxides cross linking agent, processing auxiliary agent, anti-oxidant, metal deactivator and catalyst.

Owner:上海新上化高分子材料有限公司

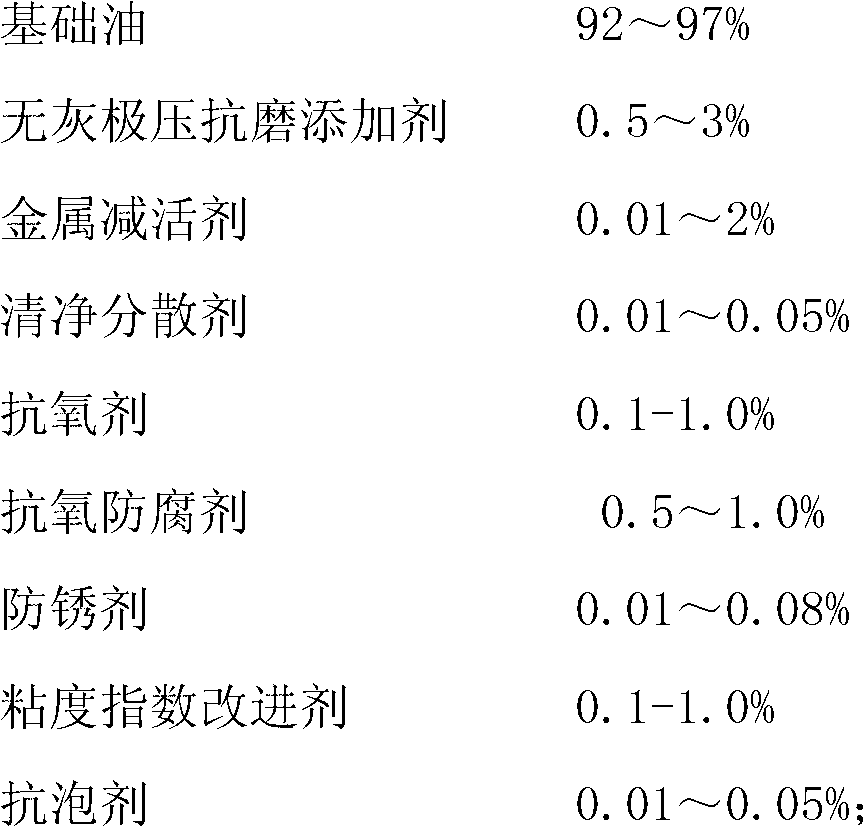

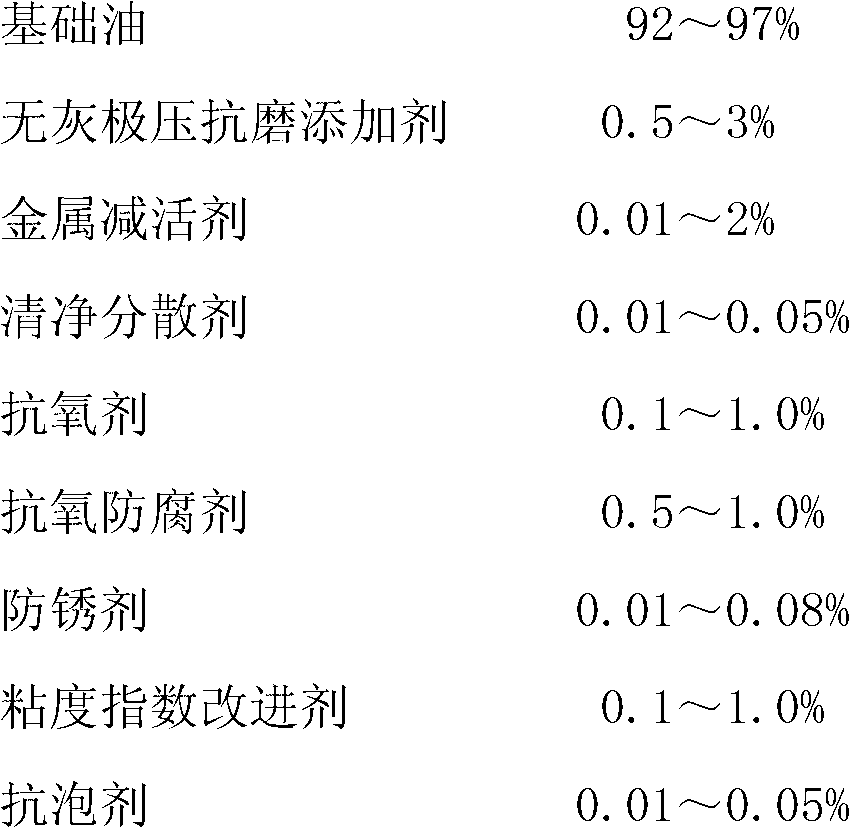

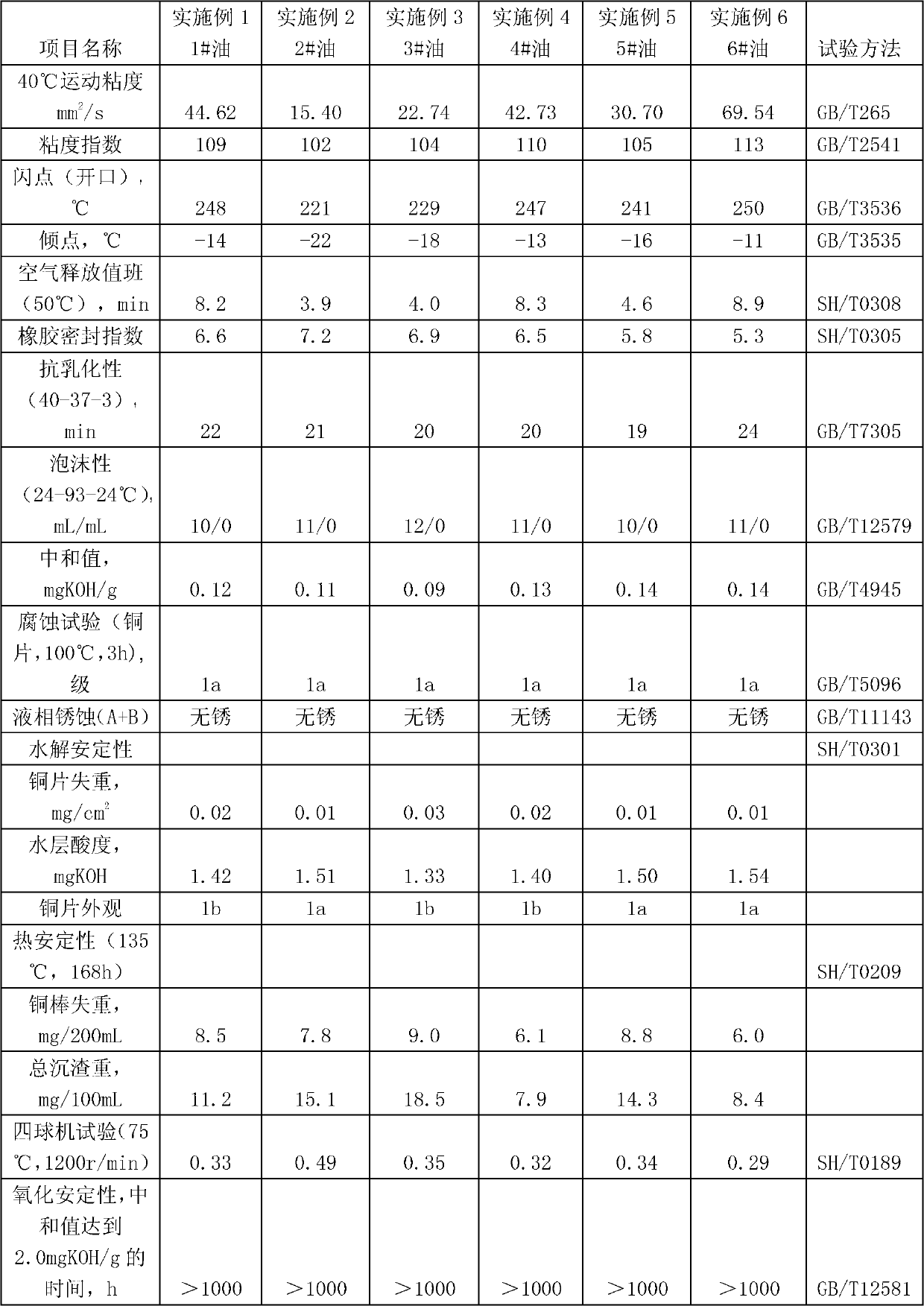

Ash-free anti-wear hydraulic oil

The invention discloses ash-free anti-wear hydraulic oil. The ash-free anti-wear hydraulic oil consists of the following components in percentage by weight: 92 to 97 percent of base oil, 0.5 to 3 percent of ash-free extreme-pressure anti-wear additive, 0.01 to 2 percent of metal deactivator, 0.01 to 0.05 percent of purification dispersant, 0.1 to 1.0 percent of antioxidant, 0.5 to 1.0 percent of antioxidant preservative, 0.01 to 0.08 percent of antirusting agent, 0.1 to 1.0 percent of viscosity index improver and 0.01 to 0.05 percent of anti-foaming agent, wherein the base oil is steam turbine oil with relatively high oxidation stability and emulsification resistance; the ash-free extreme-pressure anti-wear additive is at least one of S-P-N, S-P and P type ash-free extreme-pressure anti-wear additives; and the purification dispersant is DT-6 sulfurized calcium alkyl phenolate. The ash-free anti-wear hydraulic oil has high wear resistance, oxidation resistance, hydrolytic stability and rust resistance, can meet the requirement of high abrasion resistance of vane pumps, and can also meet the requirement of low corrosivity of plunger pumps.

Owner:上海福岛新材料科技有限公司

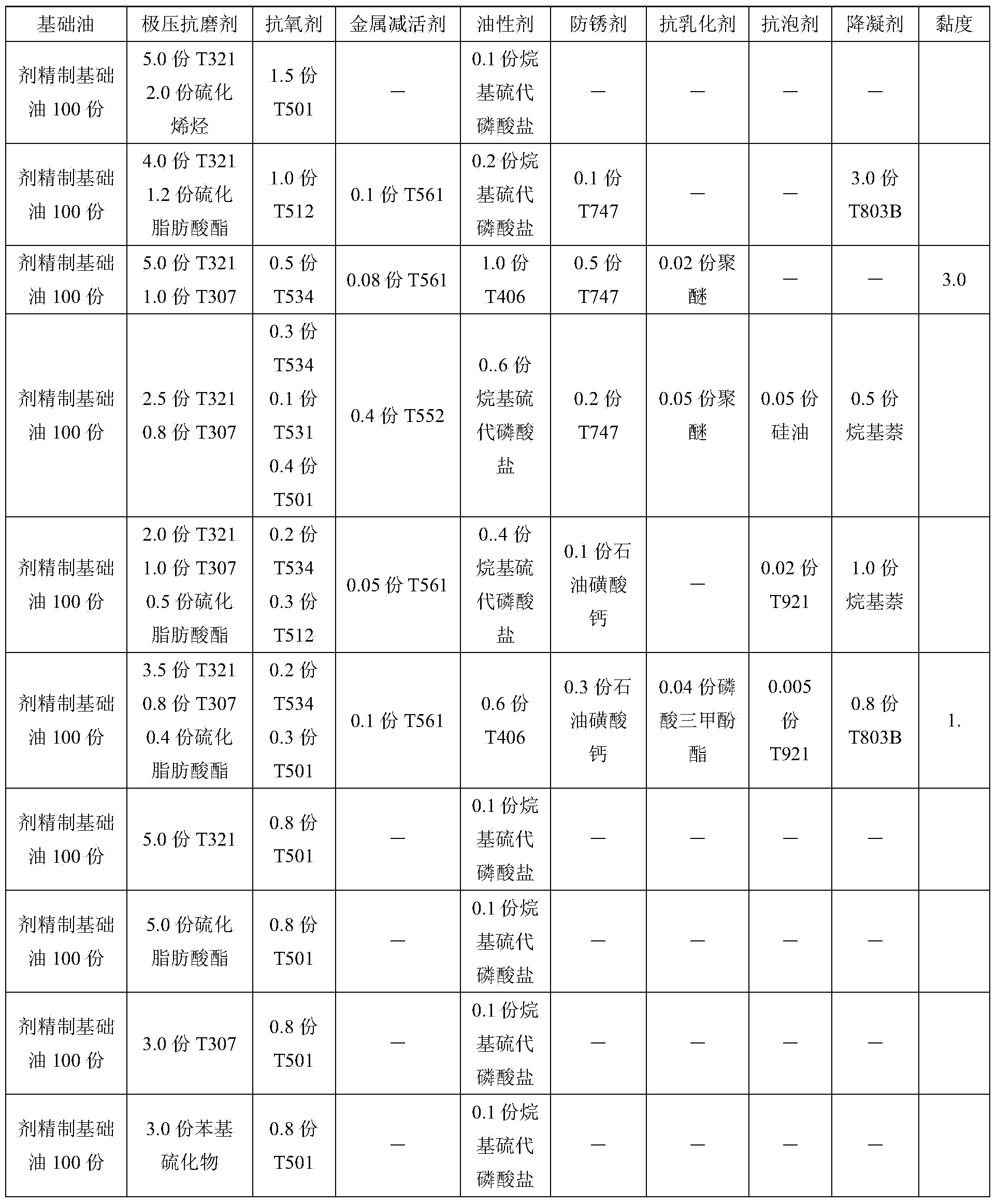

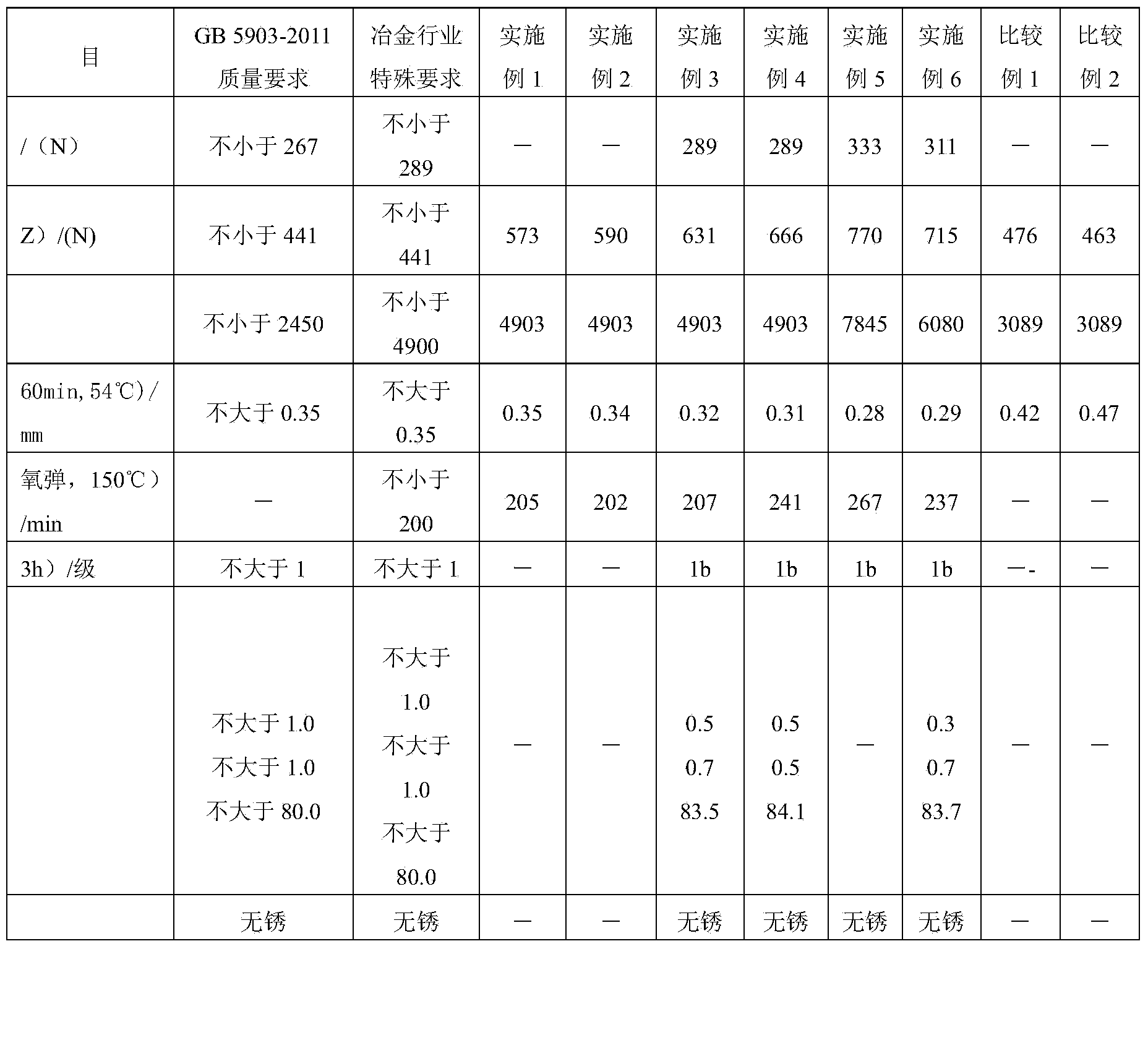

Gear oil composition and applications thereof

The invention relates to a gear oil composition and applications thereof, mainly solving problems of abnormal gear wear and poor oxidation stability of an oil product which are caused by that the extreme pressure property of industrial gear oil in the prior art fails to satisfy a part of using requirements of the metallurgy industry. According to the technical scheme adopted by the gear oil composition, the gear oil composition comprises following components by weight: a) 100 parts of mineral base oil; b) 0.1-10.0 parts of an anti-wear reagent at extreme pressure; c) 0.01-2.0 parts of an antioxidant; d) 0.01-0.5 part of a metal deactivator and e) 0.01-1.5 parts of an oiliness agent, wherein the anti-wear reagent at extreme pressure is a mixture of sulfurized isobutylene and at least one selected from sulfurized olefin, phenyl sulfide, sulfurized aliphatic ester or amine thiophosphate diester; and the antioxidant is at least one selected from 2,6-di(tertbutyl)-p-cresol, 3.5-di(tertbutyl)-4-hydroxy phenyl acrylate, pentaerythrite tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], N-phenyl-1-naphthylamine or alkylated diphenylamine. By the technical scheme, the problems are solved well and the gear oil composition can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

Screw air compressor oil composition and preparation method thereof

InactiveCN105176650AGuaranteed safe operationNot easy to oxidize and deteriorateLubricant compositionGas compressorAntioxidant

The invention provides a screw air compressor oil composition. The screw air compressor oil composition comprises the following components in percentage by weight: 75wt%-94wt% of synthetic hydrocarbon base oil, 5wt%-20wt% of synthetic ester base oil and 1wt%-5wt% of functional additives, wherein the functional additives include one or more of an anti-wear agent, a metal deactivator, a rust inhibitor, an antioxidant, a pour point depressant, a demulsifying agent, an anti-foaming agent and an acid scavenger. By taking mixed hydrocarbon oil of the synthetic hydrocarbon base oil and the synthetic ester base oil as the base oil and simultaneously adding functional additives, the obtained screw air compressor oil composition is not easily oxidized and degraded in a use process, and the changes of the dynamic viscosity and the acid value are relatively small, so that the corrosion to units of an air compressor can be reduced, and the safe operation of the screw air compressor is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP

Compressor oil composition

ActiveCN101397521AHigh viscosity indexImprove the lubrication effectAdditivesBase-materialsPhenolic antioxidantViscosity index

The invention provides a compressor oil compound which comprises the following materials on the basis that the weight of base oil is 100 percent: (1) a main amount of hydrogenization mineral oil base oil; (2) 1 to 15 weight percent of ashless dispersant; (3) 0.01 to 1 weight percent of the combination of half-hindered phenolic antioxidant or amine antioxidant and half-hindered phenolic antioxidant; (4) 0.05 to 2 weight percent of antiwear additive; (5) 0.01 to 0.5 weight percent of friction modifier; (6) 0.01 to 0.2 weight percent of metal passivator; and (7) 0 to 1000ppm of antifoamer. The compressor oil has the advantages of high viscosity index, excellent lubricating property and good oxidative stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricant and functional fluid additive package, and lubricants and functional fluids containing same

InactiveUS20120088704A1Stable storageLow lubricantOther chemical processesAdditivesPolyolefinAntioxidant

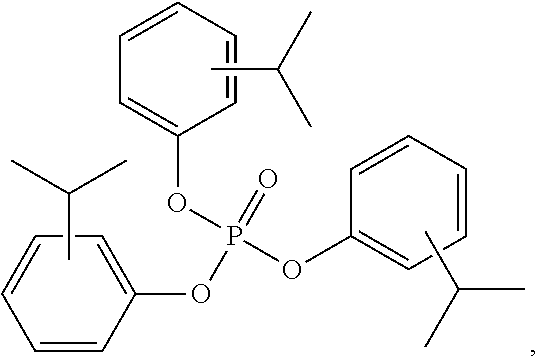

The present invention is a lubricant or functional fluid additive for a polyolefin oil blend, comprising a mixture of: (a) an anti-wear component consisting essentially of 95% isopropylated triarylphosphate and 5% dodecyl phosphate, the dodecyl phosphate being only partially esterified, the anti-wear component present in the polyolefin oil blend in a range of from about 0.75 percent to about 2.00 percent by weight; (b) an antioxidant component selected from the group consisting of alkylated phenyl-alpha-naphthylamine, phenyl-alpha-naphthylamine and mixtures thereof, and present in the polyolefin oil blend in a range of from about 0.75 percent to about 2.00 percent by weight; (c) an anti-rust component comprising an alkylated succinic acid ester anti-rust agent, and present in the polyolefin oil blend in a range of from about 0.050 percent to about 0.125 percent by weight; and (d) a metal deactivator component comprising a tolytriazole derivative, and present in the polyolefin oil blend in a range of from about 0.050 percent to about 0.125 percent by weight.

Owner:MATERIALS ENG & TECHN SUPPORT SERVICES CORP METABS CORP

Electrodepositable coating compositions and methods related thereto

InactiveUS20060042949A1Increased durabilityElectrolysis componentsVolume/mass flow measurementHydrogenMetal

The invention provides a curable electrodepositable coating composition that has improved durability in the presence of metal ions. The coating composition includes one or more ungelled, active hydrogen-containing ionic salt group-containing resins which are electrodepositable on an electrode, one or more curing agents, and one or more metal deactivators.

Owner:PPG IND OHIO INC

High temperature biobased lubricant compositions comprising boron nitride

This present invention discloses a method for the preparation of an improved high temperature engine lubricant composition comprising the steps of: 1) providing at least one biobased natural oil or biobased synthetic oil selected from the group consisting of natural or synthetic vegetable oil, natural or synthetic animal oil, genetically modified vegetable oil, genetically modified synthetic vegetable oil, natural or synthetic tree oil, and mixtures thereof; 2) providing at least one boron nitride; and 3) optionally, providing at least one base oil selected from the group consisting of a synthetic ester, solvent refined petroleum oil, a hydrocracked petroleum white oil, an all hydroprocessed synthetic oil, Fischer Tropsch oil, petroleum oil group I, group II, group III, a polyalphaolefin (PAO), and mixtures thereof; 4) optionally, providing at least one additive or combination of additives selected from the group consisting of anti-oxidant(s), corrosion inhibitor(s), metal deactivator(s), viscosity modifier(s), anti-wear inhibitor(s), friction modifier(s), and extreme pressure agent(s); 5) blending 1), 2), 3), and 4) in any sequence to form said composition.

Owner:RENEWABLE LUBRICANTS INC

Self-repairing multi-soap based composite bearing lubricating grease and preparation method thereof

ActiveCN1804016AAvoid underperformanceStable structureDrill bitsAdditivesStructural ModifierPetroleum

The related composite poly-soap self-repair bearing lubricating grease comprises the basic liquid, composite calcium sulfonate, composite Ca-Li-base thickener, non-oxidizing anti-corrosion additive, metal deactivator, tungsten disulfide extreme pressure additive, wear-well additive, self-repair additive, and structural modifier; has well anti-oxidation ability and bearing capacity, can repair wore part on condition of extreme pressure and high temperature to supply the silver-plating lacking on bearing radial surface effectively, prolongs bearing service time on maximum limit, and has special application in oil drilling exploration.

Owner:SINOPEC OILFIELD EQUIP CORP +1

Ship steam turbine lubricating oil composition

InactiveCN102676279AImprove rust resistanceAnti-emulsification time is smallLubricant compositionAntioxidantWear resistant

The invention relates to a ship steam turbine lubricating oil composition. The ship steam turbine lubricating oil composition is characterized by comprising the following components in weight percent: 0.3-1.5% of antioxidant, 0.03-0.2% of rust inhibitor, 0.03-1% of wear-resistant agent, 0.003-0.1% of demulsifier, 0.001-0.1% of anti-foaming agent, 0.02-0.1% of metal deactivator and base oil in balancing amount. Through a direct liquid rustiness test (synthetic seawater, 24 h), the ship steam turbine lubricating oil composition is rustless; after distilled water is added at 90 DEG C and stirred for half an hour, the direct liquid rustiness test (synthetic seawater, 24 h) is further performed on a separated oil layer, and the ship steam turbine lubricating oil composition is still rustless; the anti-emulsification time in a steam method is less than 180 s; the FZG invalid level is greater than 12; the viscosity level is ISOVG68, anti-foaming performance is less than 65-65-65 / 0 (mL / mL); air is released for less than 8min; and the TOST oxidation life is longer than 10,000 h.

Owner:PETROCHINA CO LTD

Complex lithium-base lubricating grease and production technique thereof

The invention relates to a complex lithium-base lubricating grease and a production technique thereof. The complex lithium-base lubricating grease comprises the following components in parts by weight: 9-13.5 parts of 12 hydroxystearic acid, 3-4.5 parts of decanedioic acid, 2.6-3.9 parts of lithium hydroxide, 5-50 parts of compound calcium sulfonate lubricating grease, 22.8-78.3 parts of base oil, 0.5-1 part of thickener, 1-3 parts of multifunctional agent, 0.5-1 part of antioxidant and 0.1-0.3 part of metal deactivator. The production technique comprises the following steps: converting superhigh-base-number calcium sulfonate with a conversion agent at 60-100 DEG C for 20-60 minutes until the superhigh-base-number calcium sulfonate becomes obviously thickened, and heating to 140-180 DEG Cto remove water, thereby obtaining the complex calcium sulfonate lubricating grease. The invention has the advantages of long service life in the occasions of long grease-complementation period under long-term heavy load, slight oxidative stain at high temperature, excellent anti-rusting property in damp or sea occasions, and low loss in the occasions of substantive water flushing; and the invention has favorable lubricating property and can prolong the service life of the bearing in the occasions of dampness and heavy load.

Owner:辽宁海华科技股份有限公司

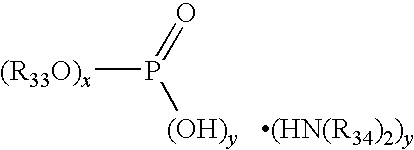

Multiple metal corrosion inhibitor

Disclosed is a lubricant composition comprising a) a lubricant, b) a triazole metal deactivator, c) a borate ester and optionally d) an amine phosphate. The lubricants, e.g. engine oils or functional fluids exhibit low corrosion of lead, copper, iron and zinc. The metal deactivators are 1,2,4-triazoles, for example 1-(di-isooctylaminomethyl)-1,2,4-triazole or 1-(di-(2-ethylhexyl)aminomethyl)-1,2,4-triazole, or are benzotriazoles, for example 1-(2-methoxyprop-2-yl)tolyltriazole, 1-(1-cyclohexyloxypropyl)tolyltriazole, 1-(1-cyclohexyloxyheptyl)tolyltriazole or 1-(1-cyclohexyloxybutyl)tolyltriazole or 1-[bis(2-ethylhexyl)aminomethyl-4-methylbenzotriazole. The borate esters are for example triethyl borate, tripropyl borate, triisopropyle borate, tributyl borate, tripentyl borate, trihexyl borate, tricyclohexyl borate, trioctyl borate, triisooctyl borate, tridecyl borate, tri(C8C10) borate, tri (C12-C15) borate or oleyl borate. The amine phosphate are for examplewherein R33 is n-hexyl and R34 is C11-C14 branched alkyl, and when x=1 then y=2; when x=2 then y=1.

Owner:CHASAN DAVID E +1

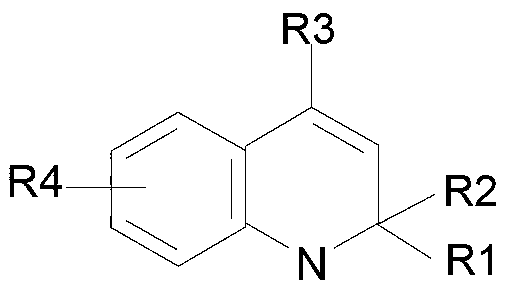

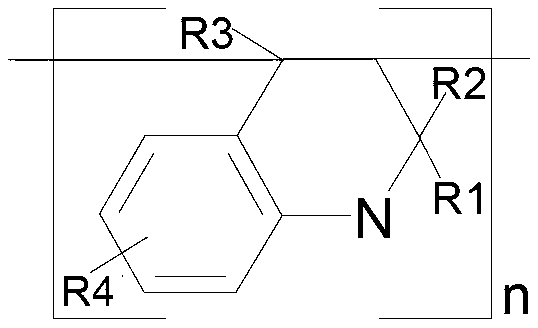

Air compressor oil composition and preparation method thereof

ActiveCN103194303AExtended service lifeImprove performanceHeat-exchange elementsLubricant compositionAntioxidantOxidation stability

The invention provides an air compressor oil composition and a preparation method thereof. The air compressor oil composition comprises polyether oil base oil or polyether oil and ester oil mixture base oil, a 2,2,4-trialkyl-1,2-dihydroquinoline antioxidant and a metal deactivator. Compared with the known air compressor oil composition, the air compressor oil composition has excellent oxidation stability, excellent comprehensive performance and a simple preparation method, and is particularly suitable for a screw air compressor.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

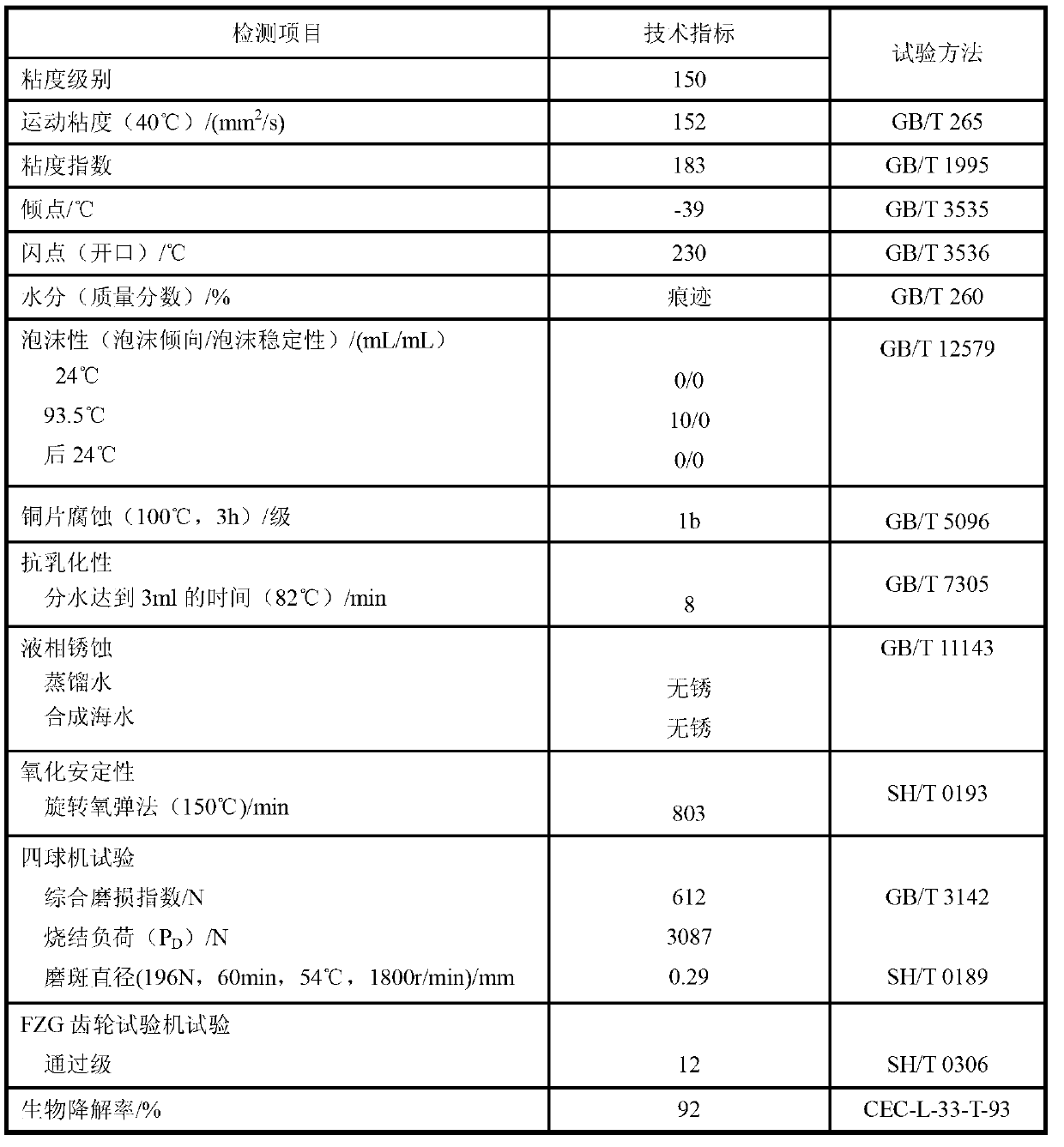

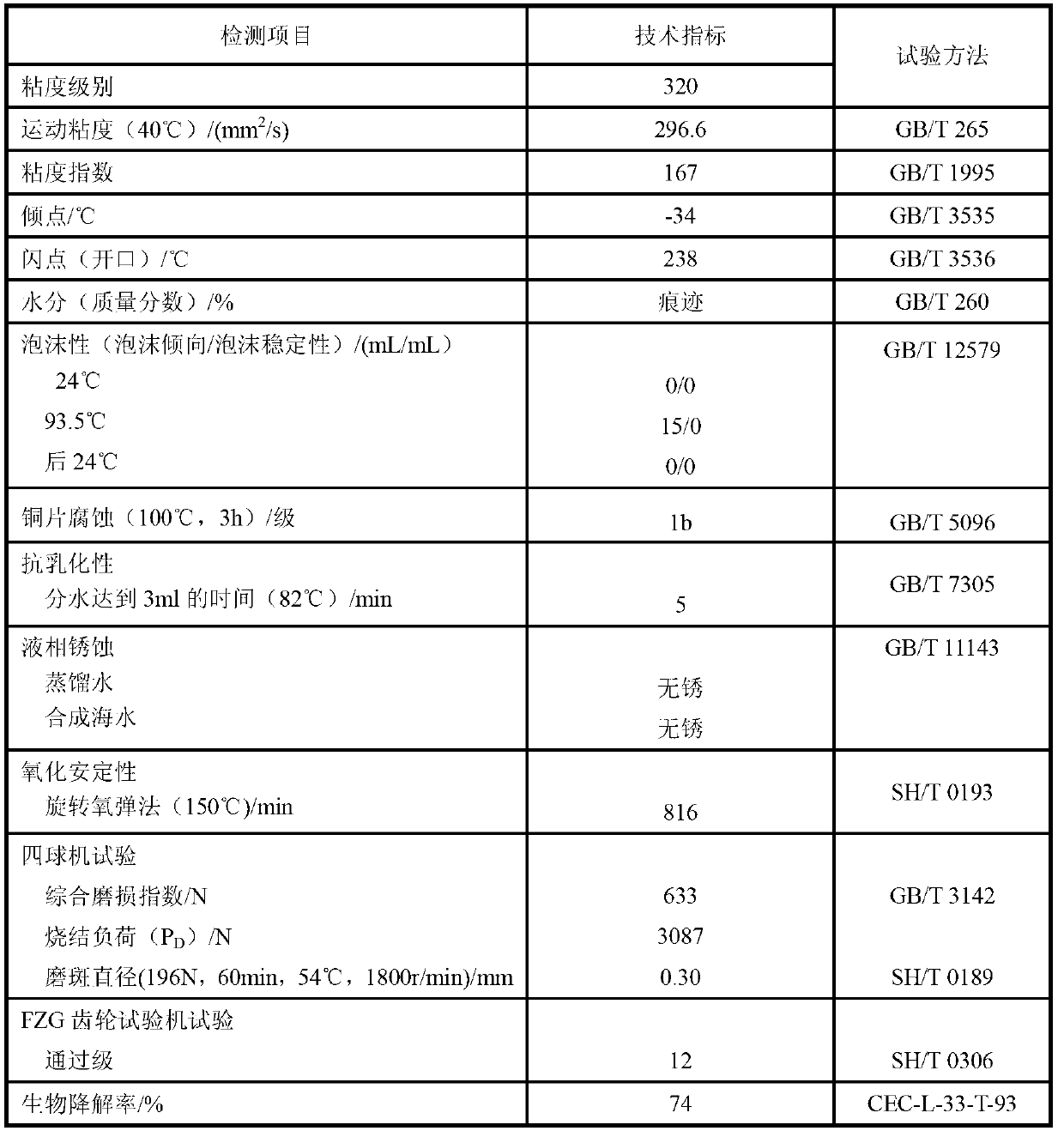

Special castor-oil-based gear oil for wind power generation

InactiveCN103131525AExtended service lifeReduce the number of oil changesLubricant compositionFoaming agentEngineering

The invention provides special castor-oil-based gear oil for wind power generation. The special castor-oil-based gear oil for wind power generation is formed through combination of castor-oil-based base oil and other additives. The special castor-oil-based gear oil comprises the following components in percentage by mass: 0-30% of other types of base oil, 0.1-2% of friction modifier, 0.1-3% of extreme pressure anti-wear agent, 0.01-0.3% of metal passivator, 0.1-2% of antioxidant agent, 0.001-0.5% of demulsification agent, 0.01-0.5% of anti-rust agent, 0.001-0.3% of anti-foaming agent and the balance of castor-oil-based base oil. The special castor-oil-based gear oil provided by the invention has the advantages of having excellent biological degradability, being capable of being decomposed under the effect of microorganisms even if leaking into environments, having no pollution to environments, and having excellent extreme pressure anti-wear performance, good thermal oxidation stability, low-temperature performance, viscosity-temperature performance, anti-emulsification property and long service life.

Owner:TIANJIN NANKAI UNIV CASTOR ENG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com