Patents

Literature

409 results about "Decanedioic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decanedioic acid. decanedioic acid (ˌdɛkeɪndaɪˈəʊɪk) n (Elements & Compounds) a white crystalline carboxylic acid obtained by heating castor oil with sodium hydroxide, used in the manufacture of polyester resins and rubbers and plasticizers.

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly "all-natural" elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

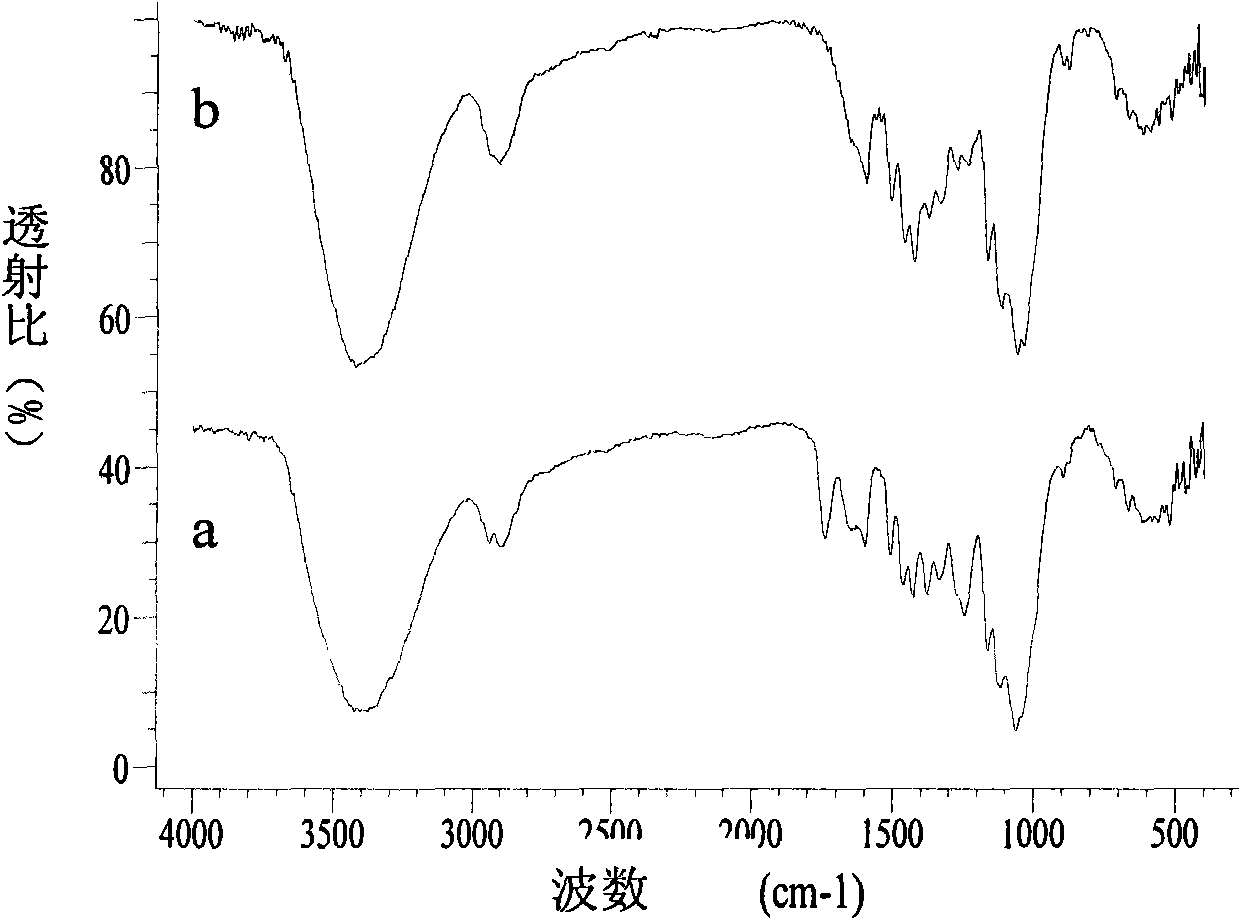

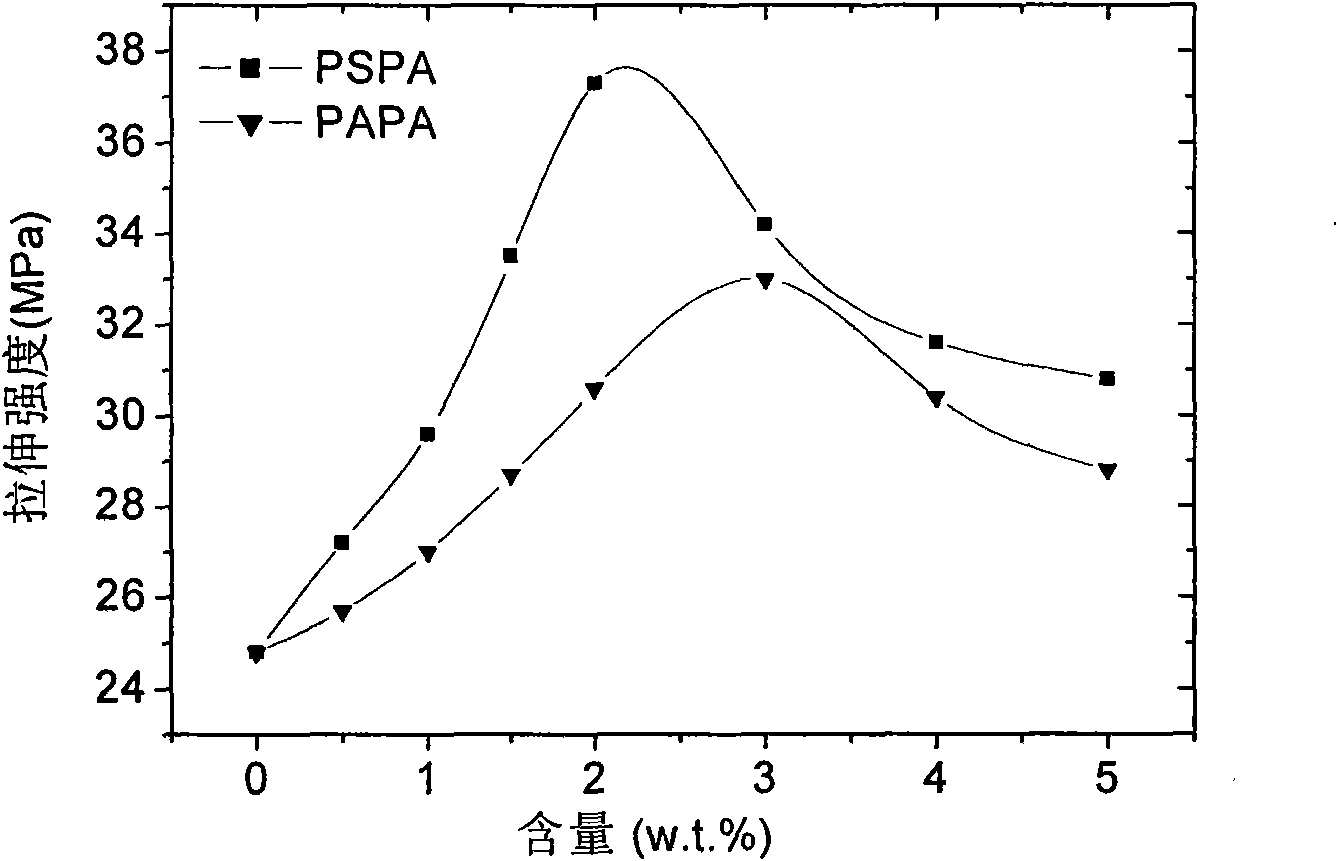

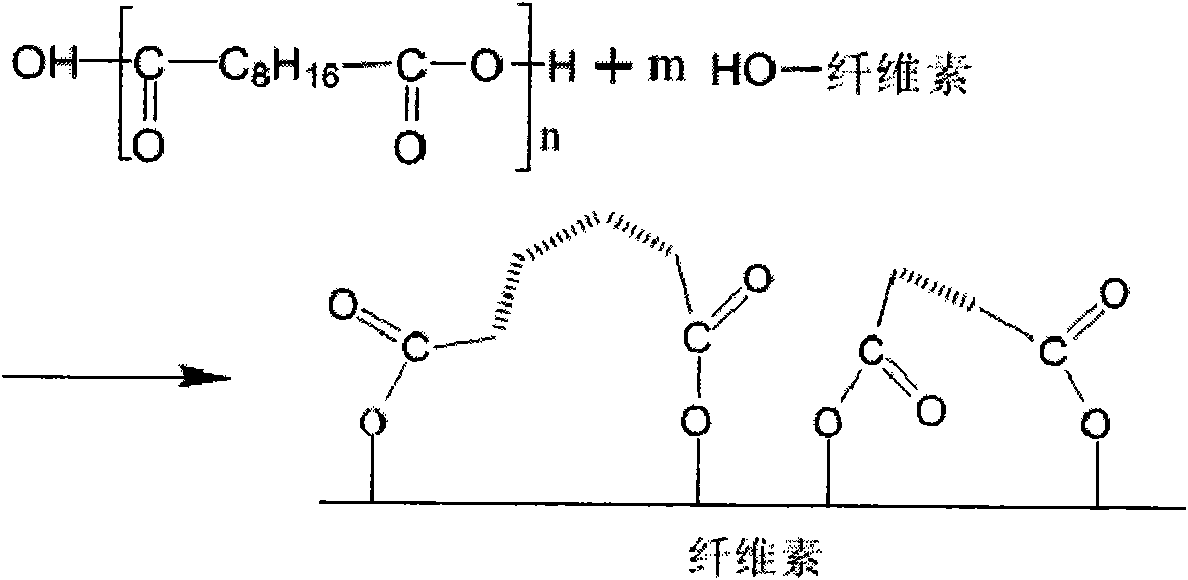

Water-resistant wood-plastic composite material and preparation method thereof

InactiveCN101613503AImprove interface compatibilityImprove composite effectPolyolefinPolymer substrate

The invention discloses a water-resistant wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-65% modified wood powder, 25-98% of polyolefin matrix and 1-10% compatilizer; wherein, the compatilizer is one of polysebacic polyanhydride (PSPA) and polyazelaic polyanhydride (PAPA) or both the two. The invention also discloses a preparation method of the water-resistant wood-plastic composite material. The method is as follows: PSPA and / or PAPA are / is utilized to carry out segmented surface grafting on the wood powder to improve the interface compatibility between the wood powder and polyethylene, and the wood powder is pretreated by alkali liquor to removing unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining the wood-plastic composite material with excellent mechanical property, low water absorption capacity and good dimensional stability; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV +1

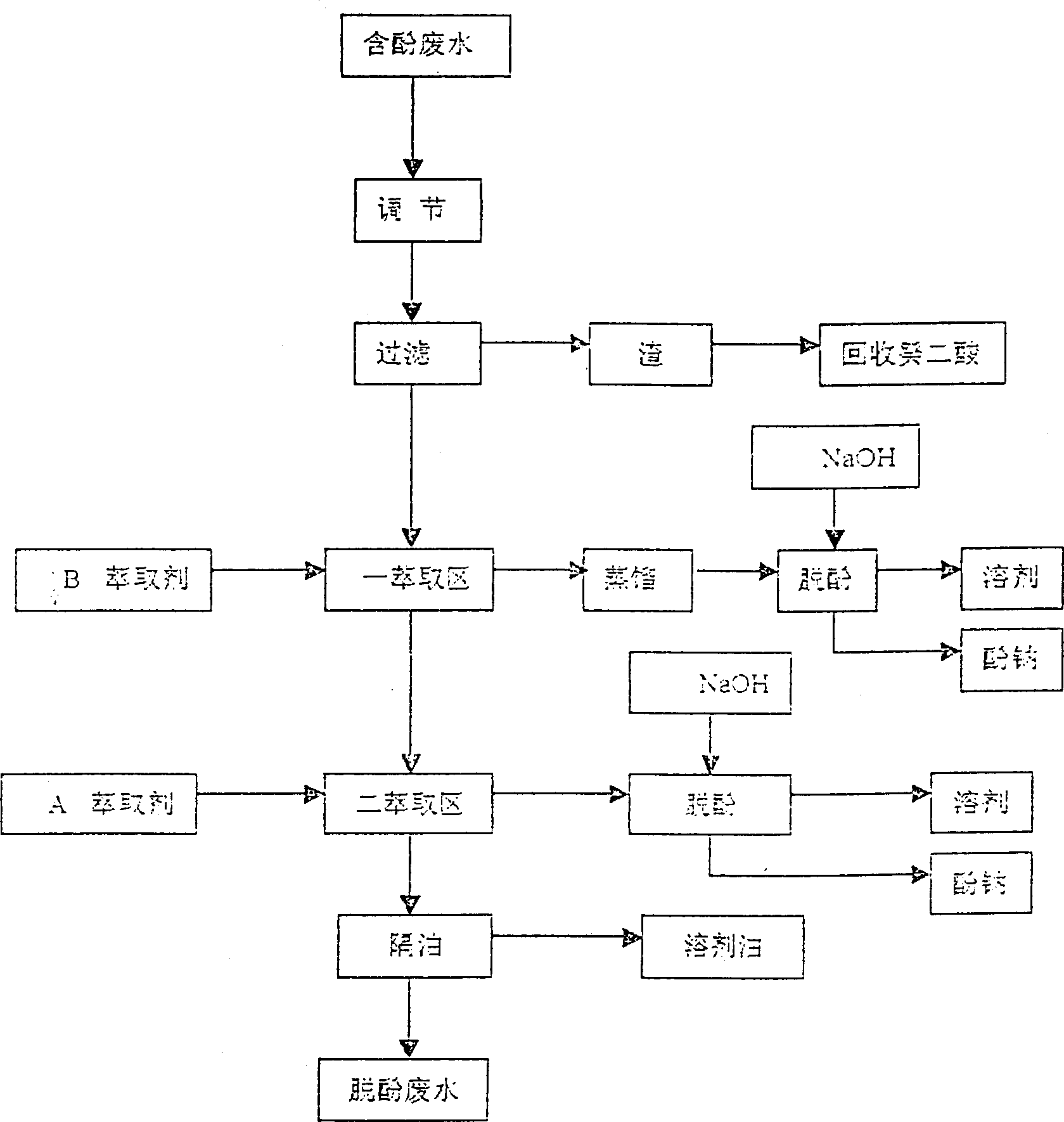

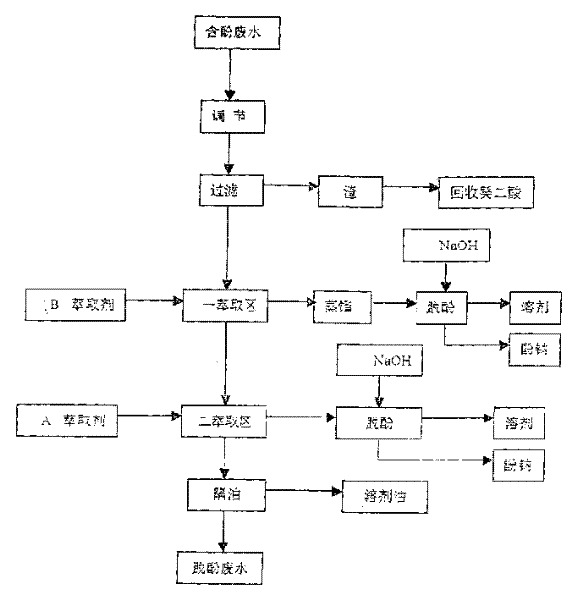

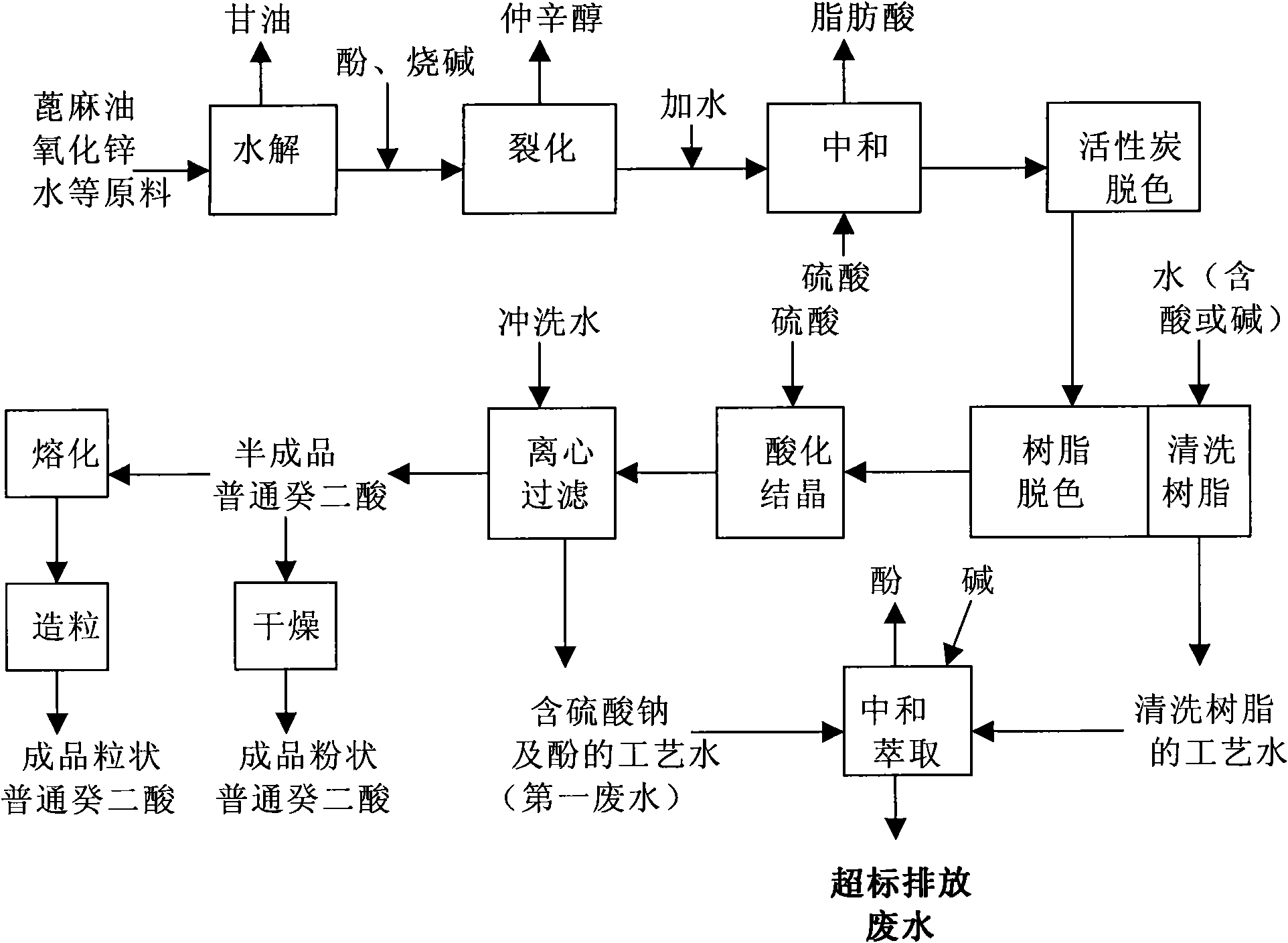

Treatment of phenol containing decanedioic acid waste water by extractive distillation

InactiveCN1450006AAvoid SaponificationLow processing and running costsMultistage water/sewage treatmentPhosphoric Acid EstersPhosphate

The method for treating waste water containing phenol which is produced in the course of producing sebacic acid includes five steps: regulation, filtration, extraction, removing phenol and isolating oil. After the phenol-containing waste water is filtered and its insoluble material is removed, in first extraction zone the high carbon alcohol is used as extraction agent to remove the organic material from waste water and effectively reduce content of phenol, the load extraction agent is fed into distillation procedure, the distilled high carbon alcohol can be reextracted and can be circularly used, and the organic material being in the waste water can be recovered in the form of high-boiling material, and the second extraction zone the mixture of phosphate and kerosene is used as extraction agent to make counter-current extraction with the phenol-containing waster water.

Owner:HAIHUA TIANHE ORGANIC CHEM SHANDONG

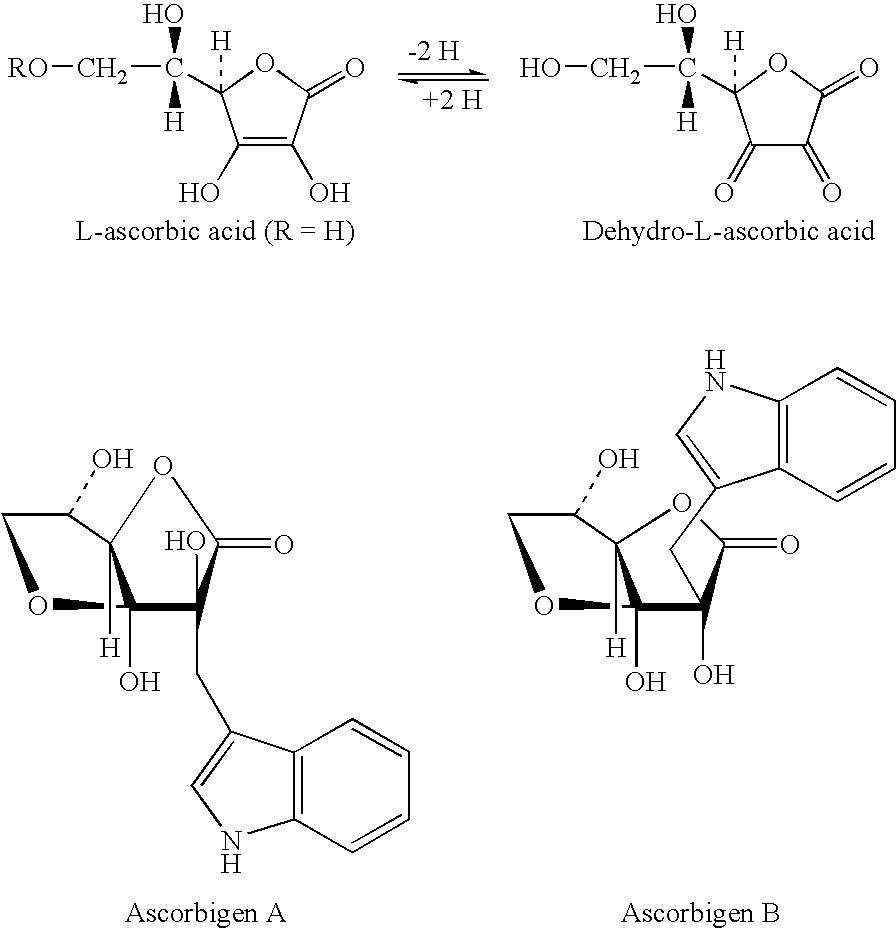

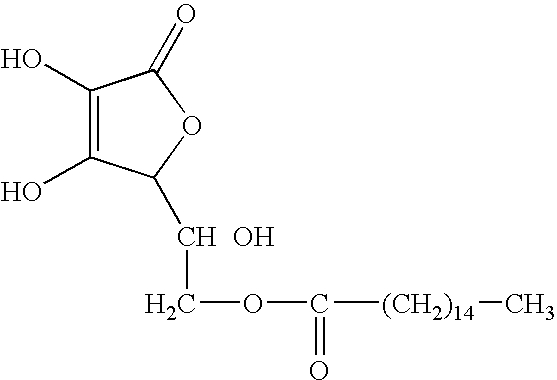

Skin-lightening compositions with an improved action

InactiveUS20080152604A1Lightening of skin colorLess visibleCosmetic preparationsOrganic active ingredientsCarboxylic acidDicarboxylic acid

Cosmetic or dermatological preparations are comprised of from 0.01 to 5% by weight of a dicarboxylic acid selected from the group consisting of 8-hexadecene-1,16-dicarboxylic acid decanedioic acid nonanedioic acid and combinations thereof and from 0.01 to 5% by weight of ascorbic acid, salts of ascorbic acid, ascorbic acid derivatives and combinations thereof. These preparations provide skin-lightening and / or hair-lightening preparations which inhibit melanin biosynthesis and do not damage hair and / or skin.

Owner:HENKEL KGAA

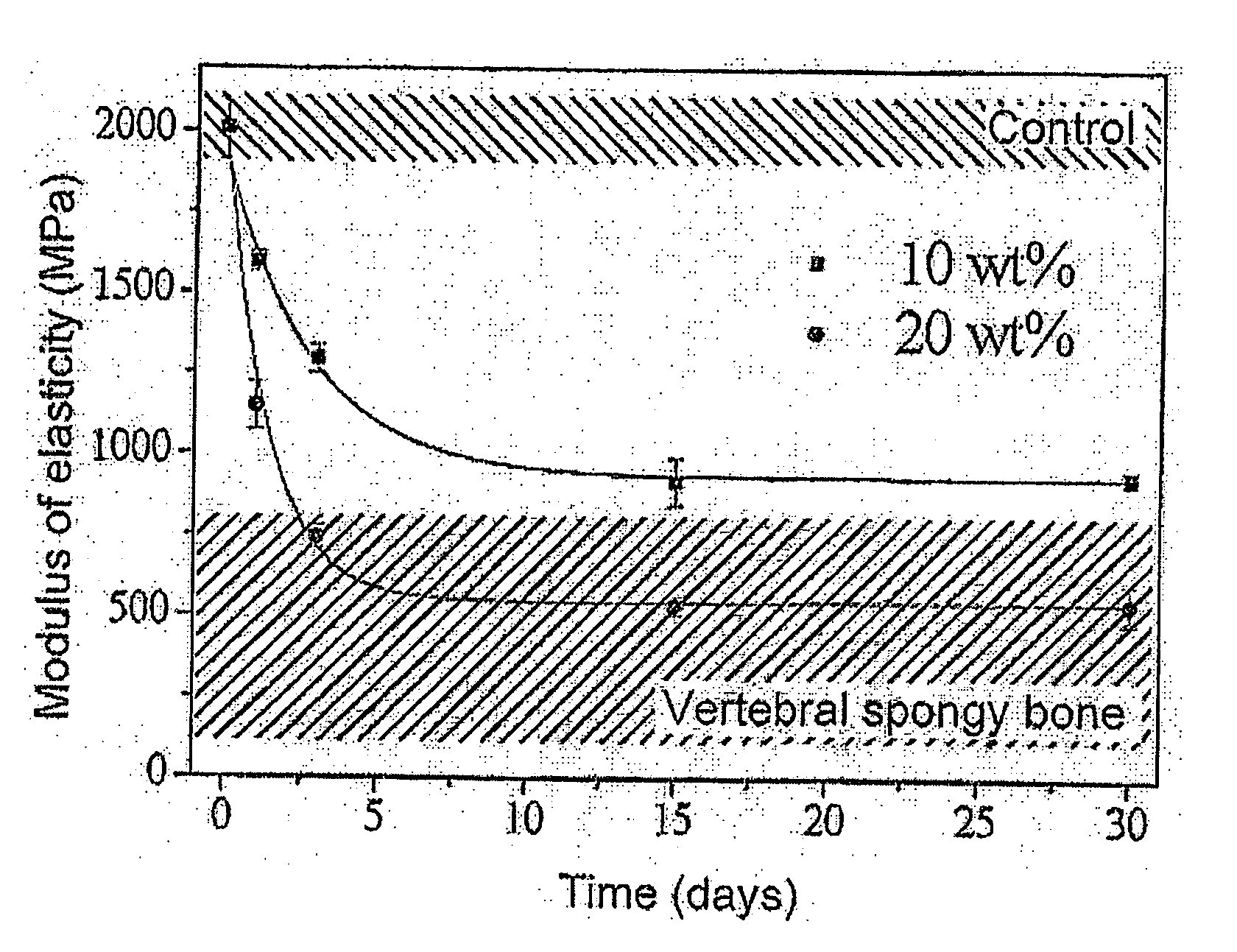

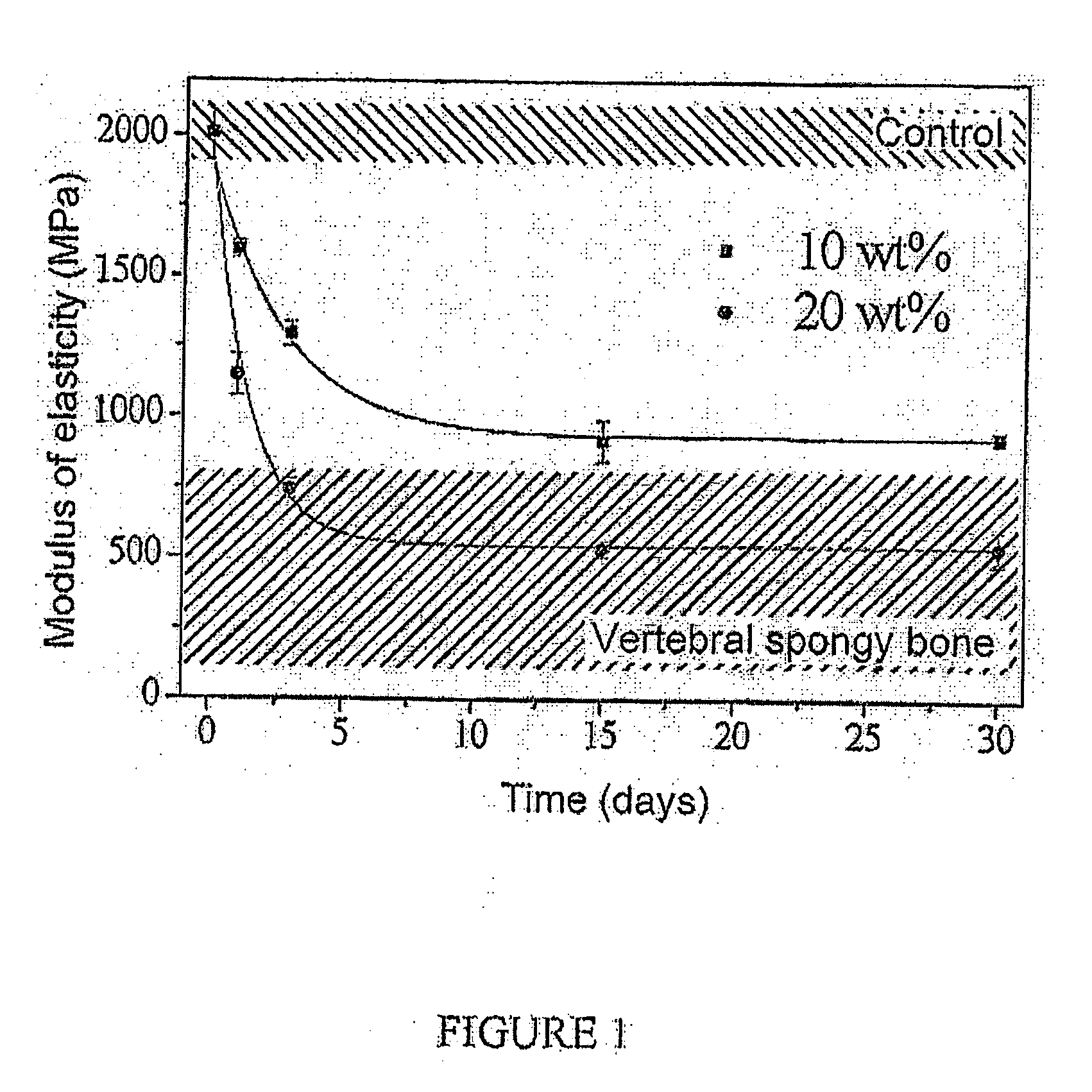

Bone filling cement

ActiveUS20100228358A1Impart stiffnessReduce stiffnessCosmetic preparationsImpression capsInjectable boneGlycerol

The present invention relates to an injectable bone cement for filling bones with mechanical properties equivalent to those of vertebral spongy bone comprising 70 to 99 wt. % of an acrylic polymer combined with an inorganic type radiopaque compound and 1 to 30 wt. % of calibrated hydrophilic flexible solid particles, said calibrated hydrophilic flexible solid particles being chosen from gelatin, poly(glycerol sebacate) or a mixture thereof.A bone cement according to the invention is particularly intended for vertebroplasty, kyphoplasty or cementoplasty.

Owner:TEKNIMED SAS

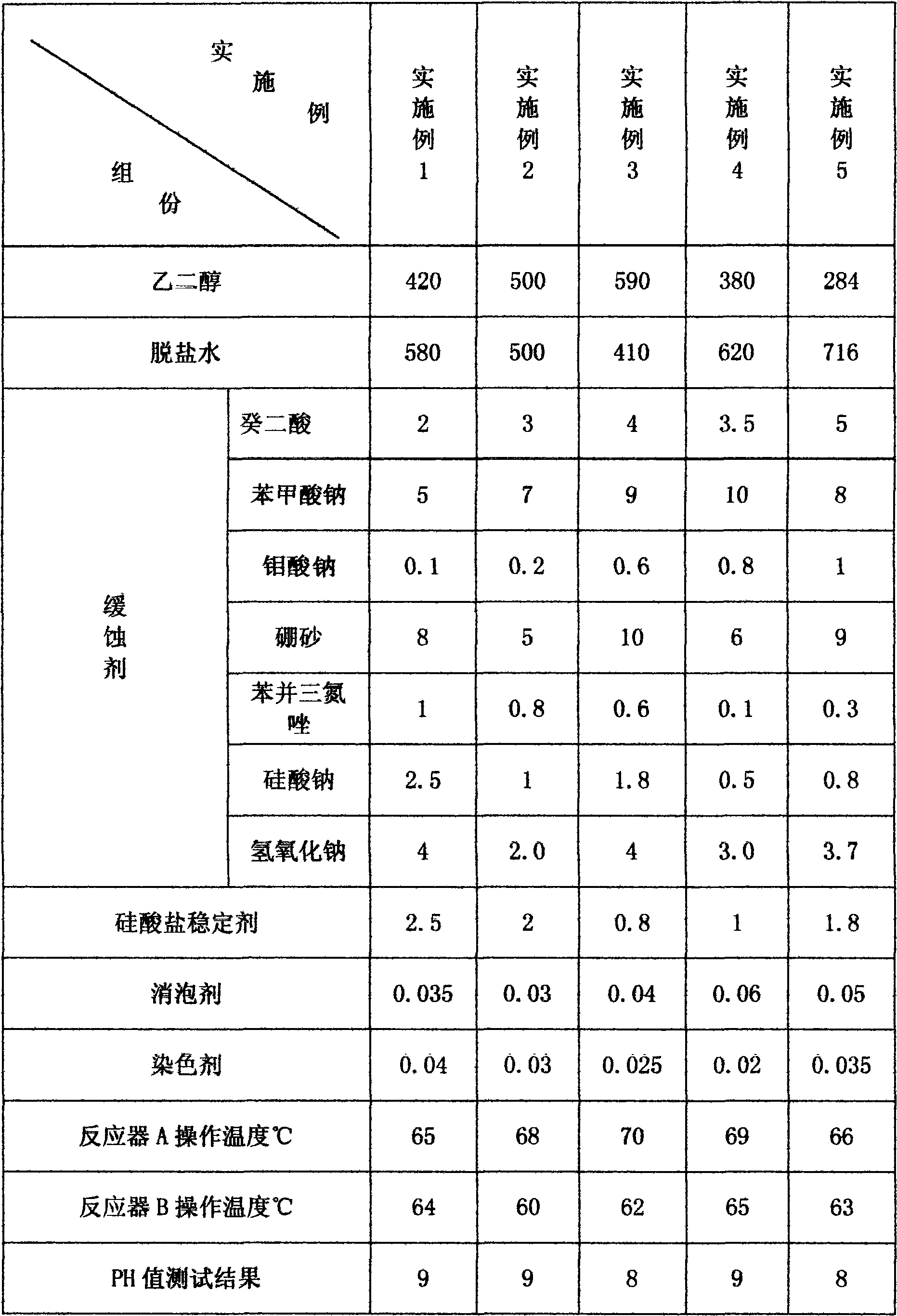

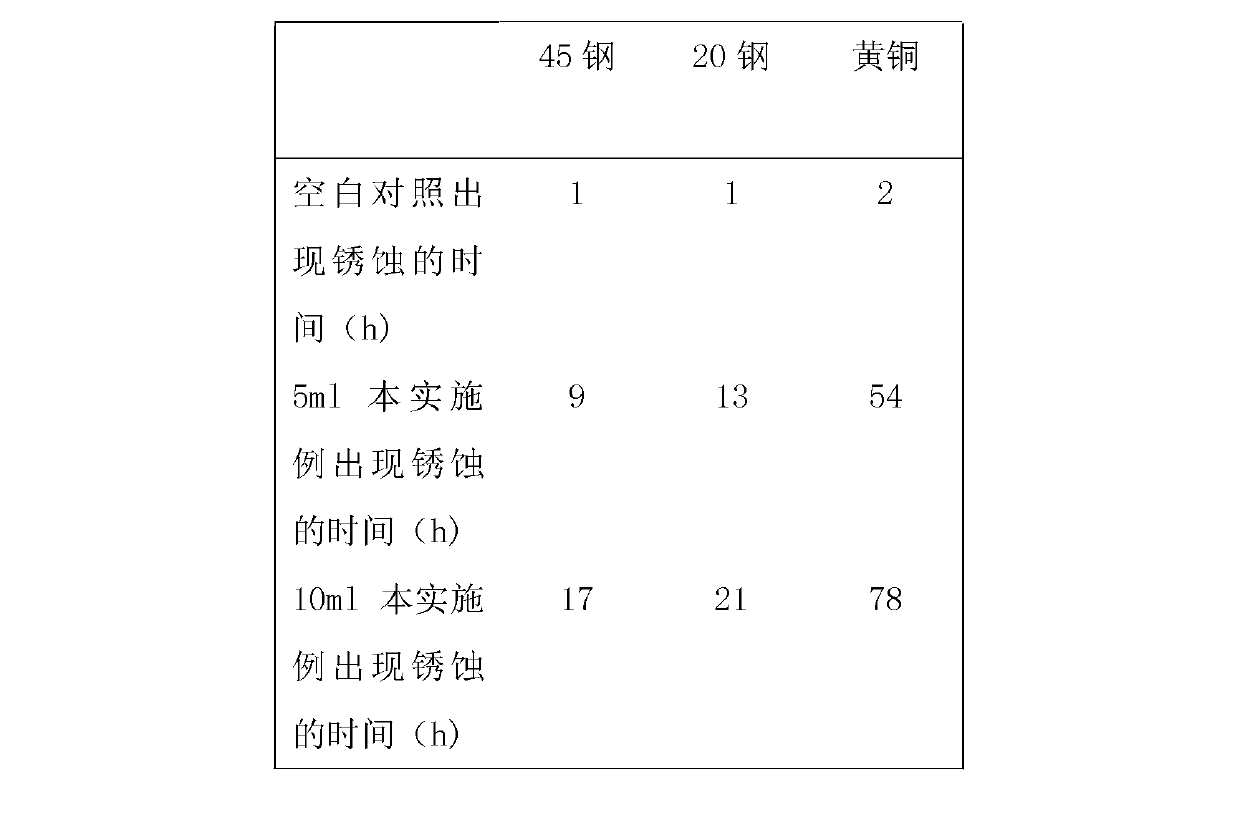

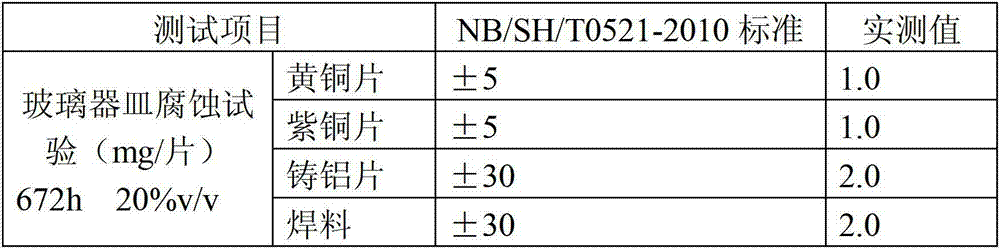

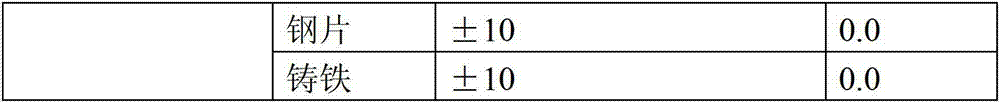

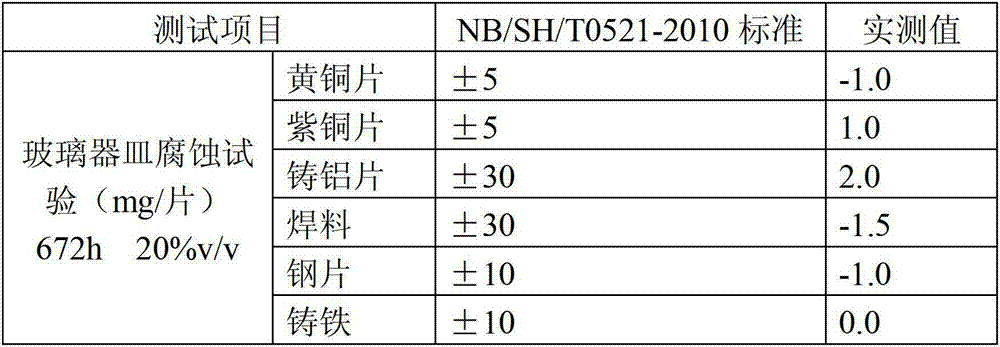

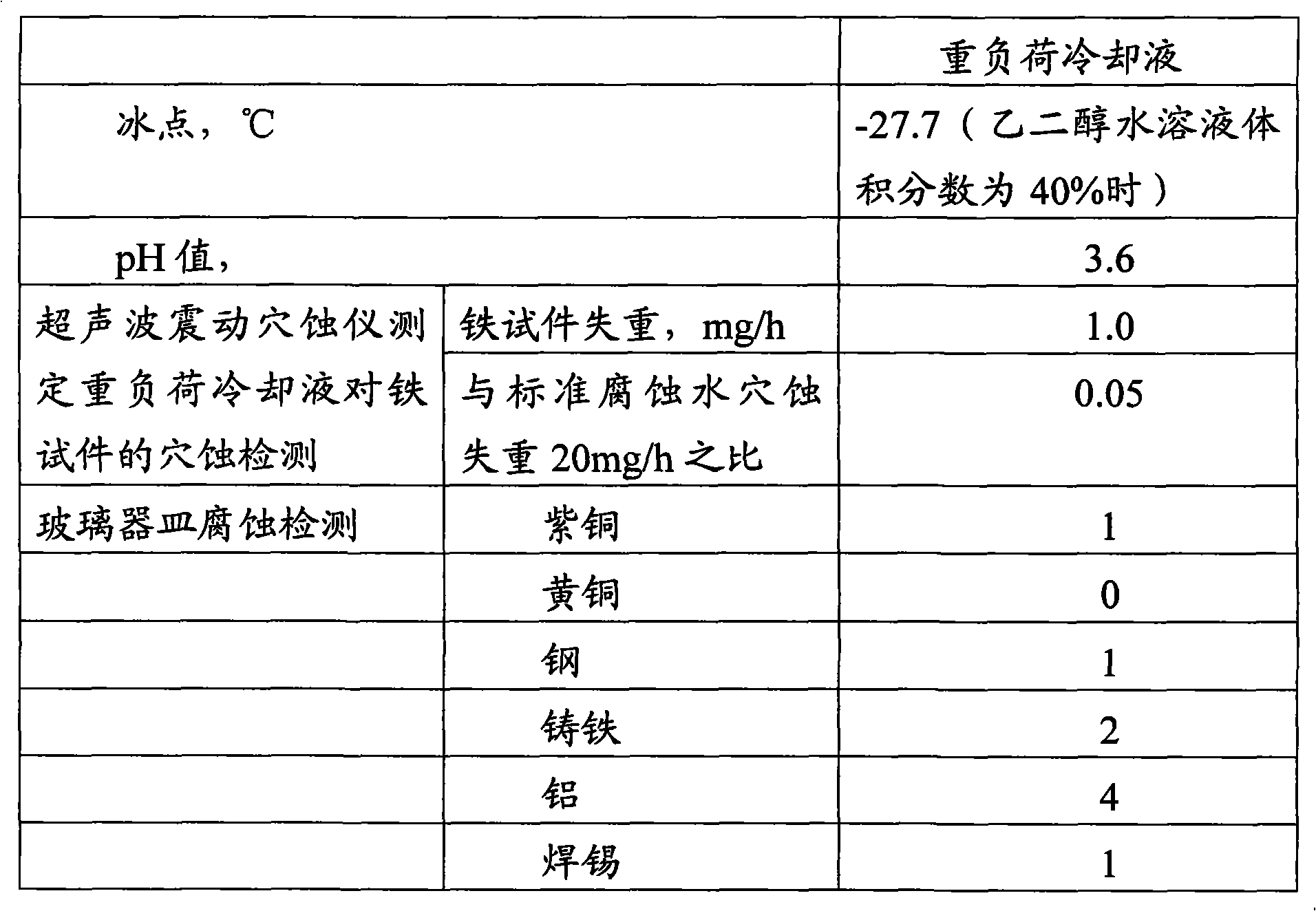

Environment-friendly type long-acting automobile cooling liquid formulation and producing technique thereof

InactiveCN101215460AImprove the protective effectExtend the life cycleHeat-exchange elementsSodium metasilicateHazardous substance

The invention discloses a formula of environmental friendly type long-term automobile coolant and a process for preparation, the formulation contains glycol, desalting water, decanedioic acid, sodium benzoate, sodium molybdate, borax, polybenzotriazole, sodium metasilicate, sodium hydroxide, metasilicate, stabilizing agent, defoaming agent and coloring agent, catalyst cases A, B and C are adopted to mix and react under normal temperature and normal pressure, the pH value of the coolant which is generated is controlled within 8-9, the automobile coolant of the invention has the efficiencies of anti-freeze, anti-boiling, anti-corrosion, anti-fouling and can diffuse heat fast, the cooling effect is good, the necessary raw materials can be easily bought on the market, the coolant has non hazardous substances such as sodium nitrite and the like, lowers the harm to environment and human bodies, generates non gelatin during storing periods, can not dilute any inhibitor, and has long-term performance, the manufacturing process of the product is simple, the using equipment is less, the operation is easy, the demanding energy consumption is low, the producing cost is low, the coolant is easy for industrial-scale production and has high promotion and application value and good market prospects.

Owner:吉化集团吉林市星云化工有限公司

Detergent for stainless steel and preparation method

A detergent for stainless steel contains proportionally nitric acid, hydrochloric acid, ammonium persulfate, water-soluble chloride, catalyst, corrosion inhibitor (the composition of triethanolamide decanedionate, tween and sodium tripolyphosphate), and water.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

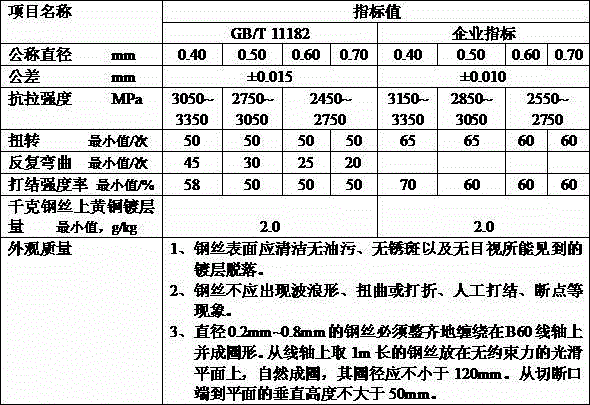

Ultra-high-pressure steel wire winding composite hose

ActiveCN104100783AImprove stress resistanceImprove pulse lifeFlexible pipesPolymer scienceMicrocrystalline wax

The invention discloses an ultra-high-pressure steel wire winding composite hose, which comprises an inner rubber pipe, a framework layer, a middle rubber layer and an outer rubber layer, wherein the framework layer is arranged outside the inner rubber pipe, the middle rubber layer and the framework layer are made into a whole, the outer rubber layer is arranged outside the middle rubber layer, inner rubber of the inner rubber pipe is prepared from the following ingredients including nitrile rubber, high styrene rubber, solution polymerized styrene-butadiene rubber, sulphur S, vulcanizing agents DTDM, vulcanization accelerators CZ, accelerators D, nanometer zinc oxides, stearic acid, scorch retarders CTP, flowing exhaust agents SC617, integral anti-aging agents 4020, anti-aging agents BLE, microcrystalline wax, carbon black, nanometer silicon dioxide, bonding agents RC, bonding agents RC-23, tackifying resin SP1068, dioctyl sebacate and polyolefin, and the middle rubber layer and the outer rubber layer are respectively made of different materials. The rubber pipe belongs to the ultra-high-pressure steel wire winding composite hose capable of bearing the pressure as high as 50 to 300 Mpa, and belongs to an ultra-high-pressure hydraulic rubber pipe meeting the requirements of engineering machinery and oil drilling.

Owner:河南亿博科技股份有限公司

Complex lithium-base lubricating grease and production technique thereof

The invention relates to a complex lithium-base lubricating grease and a production technique thereof. The complex lithium-base lubricating grease comprises the following components in parts by weight: 9-13.5 parts of 12 hydroxystearic acid, 3-4.5 parts of decanedioic acid, 2.6-3.9 parts of lithium hydroxide, 5-50 parts of compound calcium sulfonate lubricating grease, 22.8-78.3 parts of base oil, 0.5-1 part of thickener, 1-3 parts of multifunctional agent, 0.5-1 part of antioxidant and 0.1-0.3 part of metal deactivator. The production technique comprises the following steps: converting superhigh-base-number calcium sulfonate with a conversion agent at 60-100 DEG C for 20-60 minutes until the superhigh-base-number calcium sulfonate becomes obviously thickened, and heating to 140-180 DEG Cto remove water, thereby obtaining the complex calcium sulfonate lubricating grease. The invention has the advantages of long service life in the occasions of long grease-complementation period under long-term heavy load, slight oxidative stain at high temperature, excellent anti-rusting property in damp or sea occasions, and low loss in the occasions of substantive water flushing; and the invention has favorable lubricating property and can prolong the service life of the bearing in the occasions of dampness and heavy load.

Owner:辽宁海华科技股份有限公司

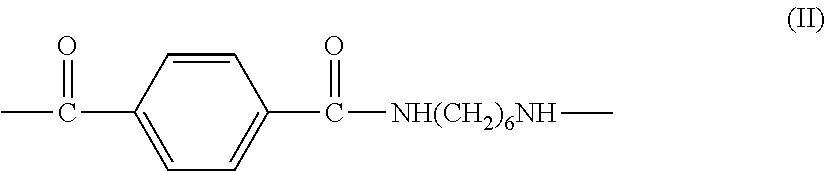

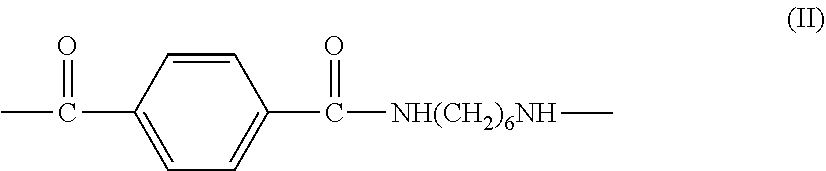

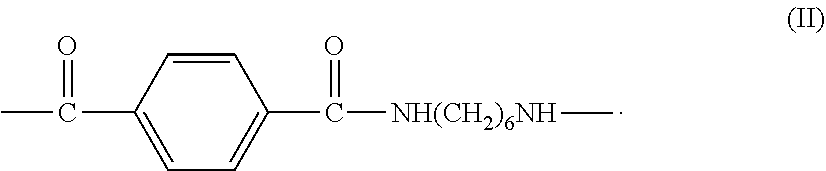

Salt resistant polyamide compositions

Polyamides made from 1,6-hexanediamine, and the dicarboxylic acids 1,10-decandioic acid, 1,12-dodecanedioic acid, or 1,14-tetradecanedioic acid and terephthalic acid in specified proportions are particularly resistant to salt stressed (induced) corrosion cracking. This makes them particularly useful as vehicular parts which may be exposed to salts. Particularly when these polyamides contain tougheners and / or plasticizers they are especially useful for hoses and tubes.

Owner:EI DU PONT DE NEMOURS & CO

Composition and method for diversion agents for acid stimulation of subterranean formations

InactiveUS6994166B2Effectively and temporarily divertLess permeableFluid removalFlushingCarboxylic acidSolid particle

It has been discovered that solid, particulate dicarboxylic acids are useful as diverting agents in methods for acidizing subterranean formations to improve the uniformity of the acid treatments (acid displacement) by diverting acid to intervals of relatively less permeability. Particularly suitable solid, particulate dicarboxylic acids include, but are not necessarily limited to, those insoluble in both aqueous and hydrocarbon liquids, but which are soluble in mutual solvents or alcohol blends. These acids may have melting points of from about 180 to about 300° F. (about 82 to about 149° C.), formula molecular weights of from 146 to 400, and mesh sizes of from about 20 mesh to about 400 mesh (about 841 to about 38 microns). Particular dicarboxylic acids that fit this description include, but are not necessarily limited to, dodecanedioic acid, undecanedioic acid, decanedioic acid, azelaic acid, suberic acid, and mixtures thereof.

Owner:SUPERIOR ENERGY SERVICES LLC

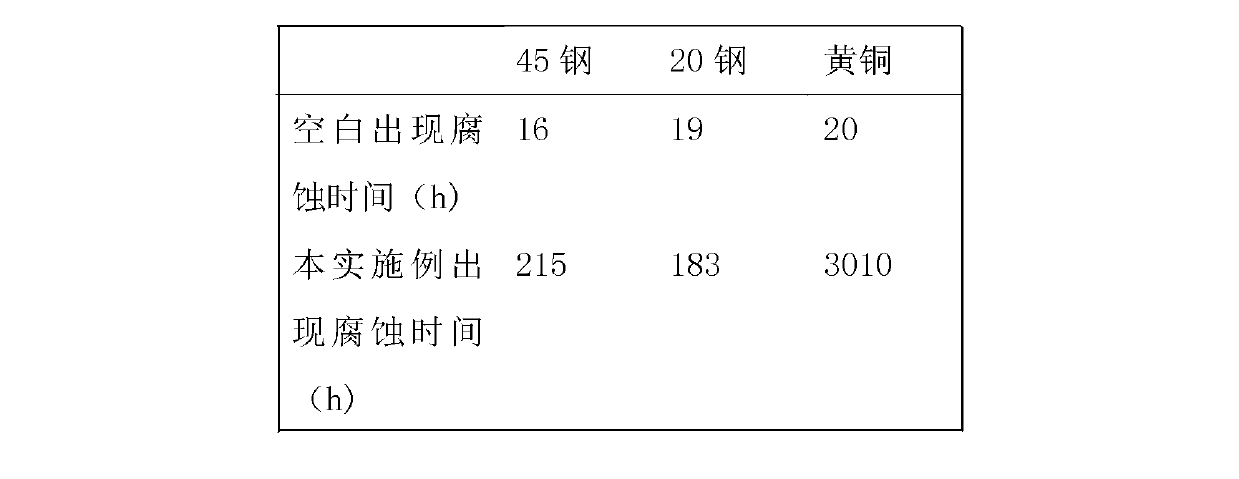

Metal antirust agent containing modified medical stone powder

ActiveCN103103528AGood gas phase anti-rust effectExcellent contact rust resistancePolyesterGas phase

The invention discloses a metal antirust agent containing modified medical stone powder. The antirust agent is prepared from the following raw materials in parts by weight: 100-105 parts of castor oil, 1.5-3 parts of ferrocene, 1-2 parts of polyisobutene, 0.6-1.2 parts of bitertanol, 0.5-1.5 parts of 2-aminoethyl heptadecenyl imidazoline, 0.8-1.6 parts of beta-naphthylamine, 1-2 parts of N-phenyl-2-naphthylamine, 0.6-1.1 parts of zinc dialkyl dithiophosphate, 1-2 parts of sodium dodecyl benzene sulfonate, 0.8-1.6 parts of propanediol sebacate polyester, 4.2-5.2 parts of film-forming resins and 1.3-2.1 parts of modified medical stone powder. The metal antirust agent has excellent contact antirusting performance and good gas-phase antirusting effect and has good gas-phase antirusting effect and contact antirusting effect on steels and brasses.

Owner:汕头市联达包装材料有限公司

Anti-freezing cooling liquid and preparation thereof

ActiveCN101376802AGood storage stabilityImprove stabilityHeat-exchange elementsAnti freezingSodium silicate

The invention provides an antifreezing cooling liquid which comprises glycol, water, decanedioic acid, sodium silicate and a foam killer; wherein, the cooling liquid also contains cinnamic acid and mannite. The invention also provides a preparation method of the antifreezing cooling liquid; wherein, the method includes the step of uniformly mixing the glycol, the water, the decanedioic acid, the sodium silicate and the foam killer. The storage stability of the antifreezing cooling liquid provided by the invention is better; besides, the antifreezing cooling liquid provided by the invention extensively improves the restraining effect to aluminum corrosion.

Owner:BYD CO LTD

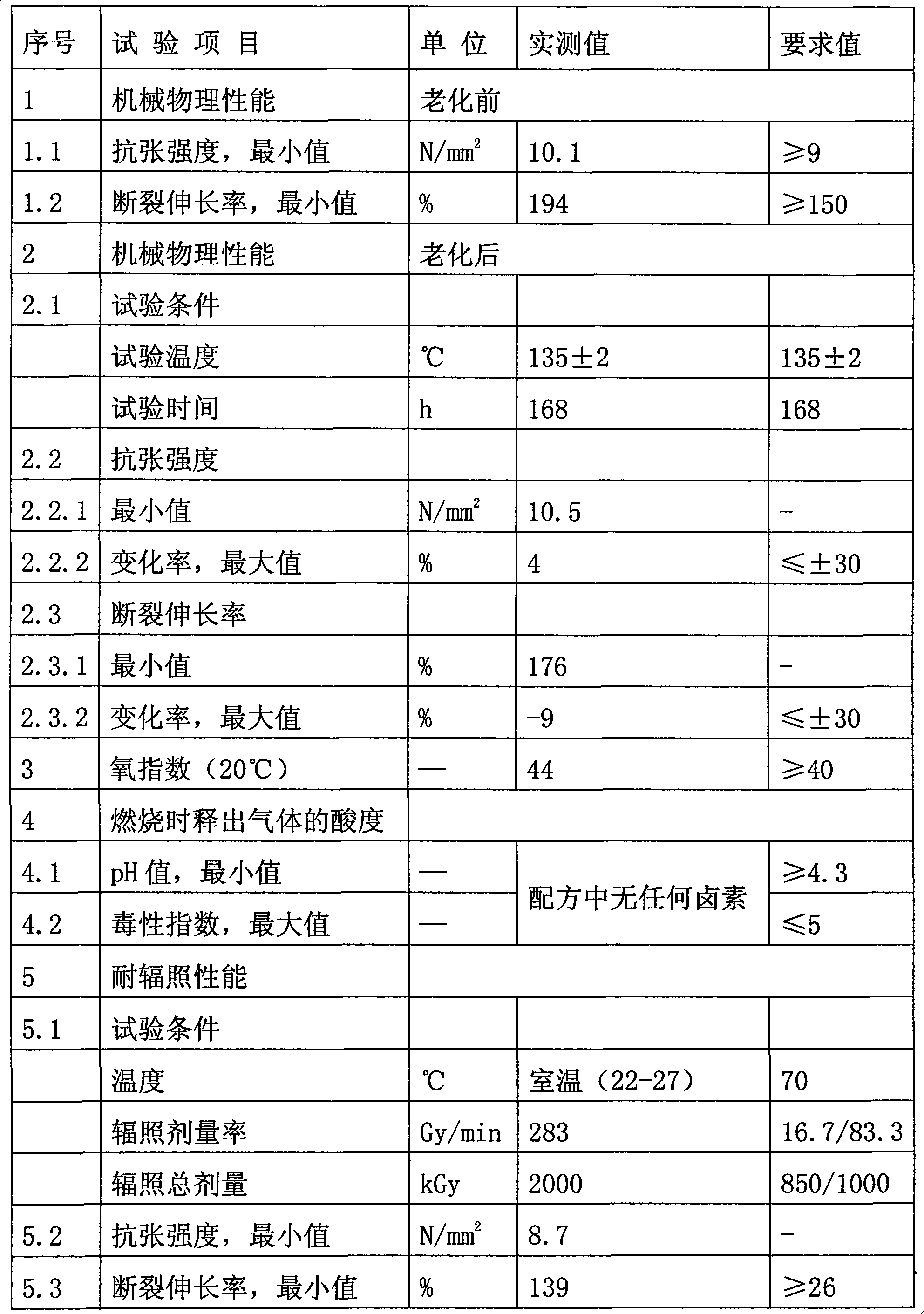

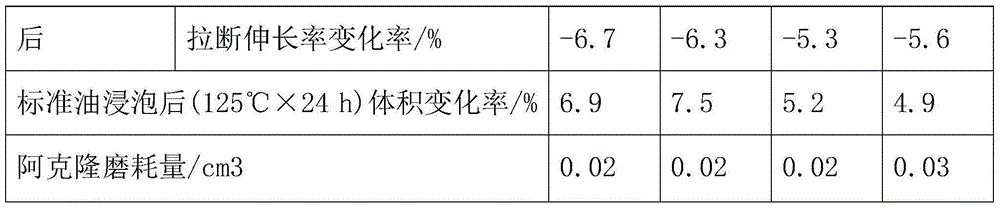

Irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and preparation method

ActiveCN101597397AImprove radiation resistanceThe ratio is scientific and reasonableInsulated cablesInsulated conductorsDi-tert-butyl peroxideNuclear power

The invention discloses an irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and a preparation method. The raw materials comprises ethane-vinyl acetate rubber, maleic anhydride stem grafting ethane-vinyl acetate rubber, magnesium hydroxide fire retardant, organic silicon fire retardant, nano cerium oxide, FEF, zinc stearate, stearic acid, vinyl trisilane, Aflux A-16, Aflux A-25, polycarbonate diimine(PCD-50), 2, 2, 4-trimethyl-1, 2-dihydride quinoline, antiager DDA, di-tert-butyl peroxide cumene, triene propylcyanide uric acid ester and decanedioic acid dioctyl, which are heated and mixed to obtain the materials of the invention. The invention features scientific and reasonable formula and proportion, and the process is advanced. The sheathing material features fine irradiation resistance, excellent mechanical properties and long service life, thus being a good irradiation resistant non-halogen low smoke and flame-retardant sheathing material applied to nuclear power stations.

Owner:BAOSHENG SCI & TECH INNOVATION

Anti-cancer sustained-released injection containing epothilone derivate

InactiveCN101396342AEasy to operateGood repeatabilityOrganic active ingredientsSolution deliveryPoly dl lactidePolyethylene glycol

The invention relates to an anti-cancer sustained release injection containing epothilone derivative, consisting of sustained microspheres and menstruum. The sustained microspheres comprise anti-cancer drugs selected from taxane, alkylating agent and / or plant alkaloid and the like, the epothilone derivative and sustained release auxiliary material. The menstruum is a special menstruum containing suspending agent. The epothilone derivative is selected from epothilone B, epothilone D, iso-epothilone D, BMS-247550, azaepothilone B, furan epothilone D or BMS-310705. The sustained release auxiliary material is selected from poly-dl-lactide, the glycolic acid copolymer of the poly-dl-lactide, polyethyleneglycol, the polylactide copolymer of the polyethyleneglycol, carboxyl terminated polylactide copolymer, fatty acid and decanedioic acid copolymer, etc. The suspending agent is selected from carboxymethyl cellulose and the like with the viscosity of 100cp to 3000cp (under the temperature of 25 DEG C to 30 DEG C). The sustained release microsphere can also be made into a sustained release implant. The sustained release injection is injected or arranged in or around the tumour and can release drug at partial position for 40 days approximately, therefore, the sustained release injection improves the local drug concentration selectively and enhances the treatment effect of non-operative treatments, such as radiotherapy, chemotherapy and the like at the same time.

Owner:JINAN SHUAIHUA PHARMA TECH

Anti-cancer sustained-released injection containing epothilone derivate

InactiveCN101396340AEasy to operateGood repeatabilityOrganic active ingredientsSolution deliveryPoly dl lactidePolyethylene glycol

The invention relates to an anti-cancer sustained release injection containing epothilone derivative, consisting of sustained microspheres and menstruum. The sustained microspheres comprise anti-cancer drugs selected from taxane, alkylating agent and / or plant alkaloid and the like, the epothilone derivative and sustained release auxiliary material. The menstruum is a special menstruum containing suspending agent. The epothilone derivative is selected from epothilone B, epothilone D, iso-epothilone D, BMS-247550, azaepothilone B, furan epothilone D or BMS-310705. The sustained release auxiliary material is selected from poly-dl-lactide, the glycolic acid copolymer of the poly-dl-lactide, polyethyleneglycol, the polylactide copolymer of the polyethyleneglycol, carboxyl terminated polylactide copolymer, fatty acid and decanedioic acid copolymer, etc. The suspending agent is selected from carboxymethyl cellulose and the like with the viscosity of 100cp to 3000cp (under the temperature of 25 DEG C to 30 DEG C). The sustained release microsphere can also be made into a sustained release implant. The sustained release injection is injected or arranged in or around the tumour and can release drug at partial position for 40 days approximately, therefore, the sustained release injection improves the local drug concentration selectively and enhances the treatment effect of non-operative treatments, such as radiotherapy, chemotherapy and the like at the same time.

Owner:JINAN SHUAIHUA PHARMA TECH

Water-mediated preparations of polymeric materials

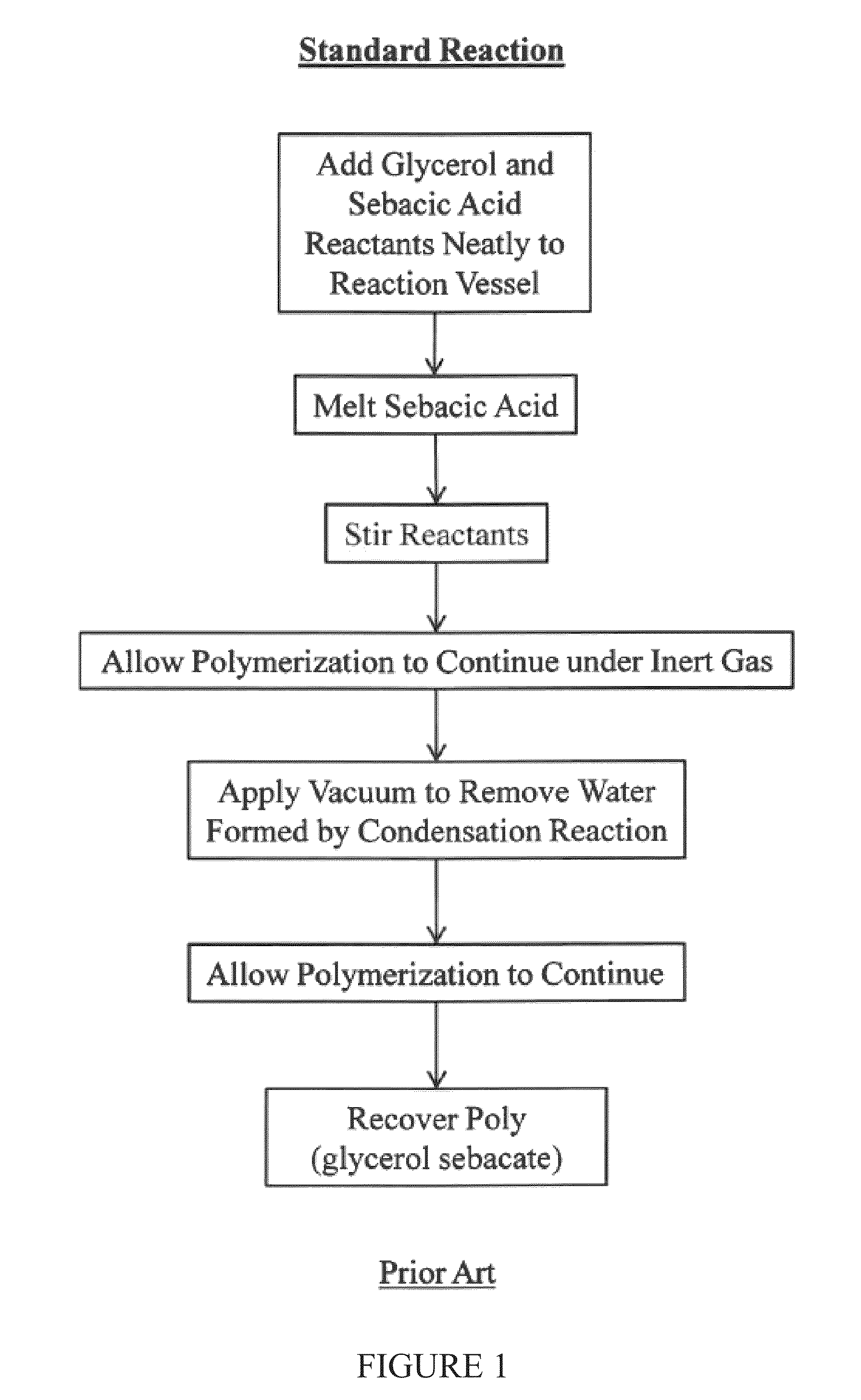

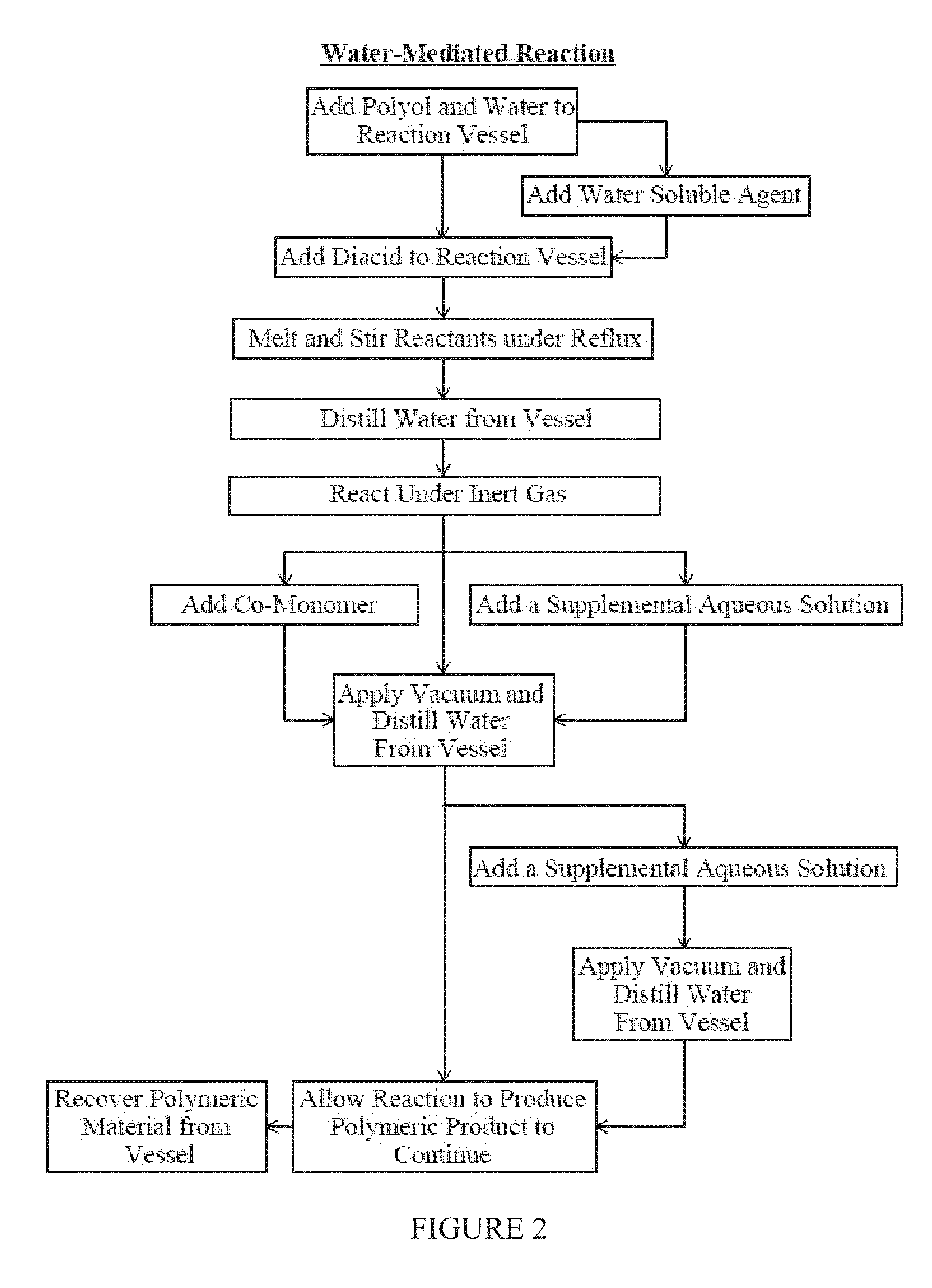

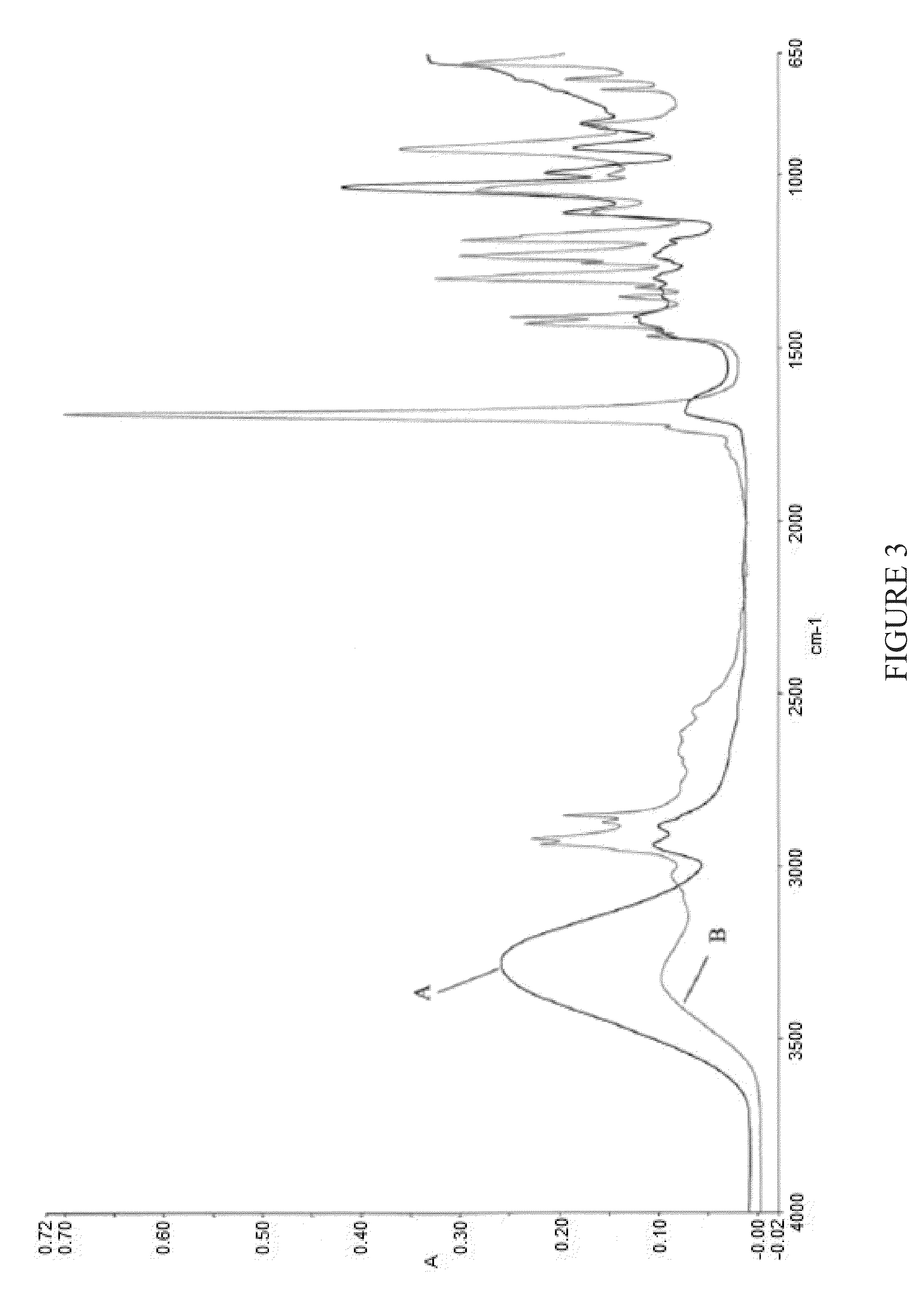

A process is provided for preparing a polymeric material through a water-mediated polymerization process that includes combining an alcohol monomer and an aqueous solution in a vessel, adding an acid monomer to the vessel, removing water from the vessel and producing the polymeric material from the vessel, wherein the polymeric material comprises a polyester of the alcohol monomer and the acid monomer. The methods described herein are particularly suitable for polymerization of poly(glycerol sebacate).

Owner:THE SECANT GRP

1,2-propanediol antifreezing cooling liquid

ActiveCN102732232AGood corrosion resistanceGood additionHeat-exchange elementsCooling towerCavitation

The invention discloses a 1,2-propanediol antifreezing cooling liquid which comprises the following components in percentage by mass: 0.5-3.0% of decanedioic acid, 0.25-1.5% of succinic acid, 0.1-0.9% of benzotriazole, 0.05-0.3% of hydroxypropyl methacrylate, 0.0004-0.005% of defoaming agent and the balance of 1,2-propanediol. The 1,2-propanediol antifreezing cooling liquid composite formula system disclosed by the invention has the characteristics of no water, persistent effect, environmental protection and durable corrosion resistance; the antifreezing agent is the non-toxic 1,2-propanediol capable of being naturally degraded; the formula technology mainly uses the organic acids; the 1,2-propanediol antifreezing cooling liquid can provide long-acting protection for the cooling system, and implement temperature rise of the antifreezing cooling liquid without pressurized conditions; and the 1,2-propanediol antifreezing cooling liquid can almost completely eliminate liner pitting corrosion, aluminum pump cavitation corrosion and other technical problems when being used in heavy-load engines, and can widely use automobiles, ships, large-size cooling towers, solar energy and the like as the heat-conducting media of the cooling system.

Owner:张家港迪克汽车化学品有限公司

Special fertilizer for single cropping rice and preparation method of special fertilizer

ActiveCN102815996AReduce invalid releaseIncrease the chelating structureFertilizer mixturesCellulosePesticide residue

The invention provides a special fertilizer for single cropping rice. The special fertilizer is prepared by the following raw materials by weight: 10-20 parts of cottonseed meal, 8-10 parts of coated nitrogen-phosphorus-potassium mixed fertilizer, 25-40 parts of calcium superphosphate, 8-10 parts of coated potassium chloride, 20-30 parts of plant ash, 1-2 parts of ferrous sulfate, 1-2 parts of zinc sulfate, 0.1-0.3 parts of borax, 10-12 parts of medical stone, 5-7 parts of peat, 3-4 parts of celastrus orbiculatus powder, 3-4 parts of oleander powder, 10-15 parts of bagasse, 10-15 parts of dolomite, 18-22 parts of chicken manure, 3-4 parts of carboxymethylcellulose, 15-20 parts of 30% of sulfuric acid, 5-10 parts of lime, 10-15 parts of chicken feather and 4-6 parts of propanediol sebacate polyester. A preparation method of the single cropping rice comprises the steps as follows: carrying out acidolysis on hairs to obtain amino acid; generating an amino acid chelated micro or medium fertilizer solution; sintering the dolomite to prepare a fertilizer carrier; fermenting an organic fertilizer; mixing the nitrogen-phosphorus-potassium mixed fertilizer and the carrier with the organic fertilizer and a plant insecticide; spraying the amino acid chelated micro or medium fertilizer solution; granulating; and finally coating with the propanediol sebacate polyester. According to the special fertilizer, the utilization rate of fertilizer efficiency can be remarkably increased, the slow release effect is achieved, the fertilizing amount is reduced, and the pesticide residues are reduced, so that the yield and the quality of the rice are improved.

Owner:MAANSHAN KEBANG ECO FERTILIZER

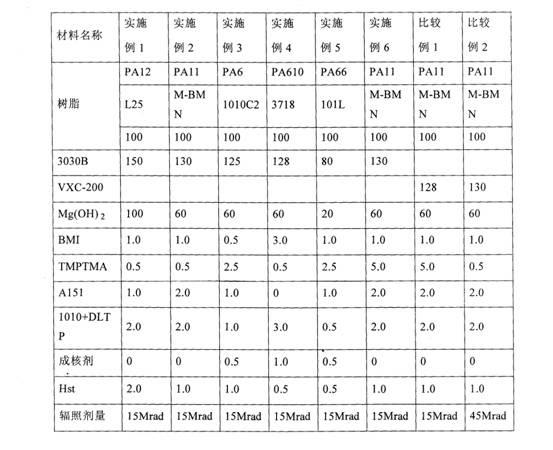

Base materials of PTC (Positive Temperature Coefficient) thermistor, PTC thermistor and preparation method thereof

InactiveCN102176361ANo sudden change in resistance valueLower resistancePositive temperature coefficient thermistorsAntioxidantMetal particle

The invention provides a base material of a PTC (Positive Temperature Coefficient) thermistor, a PTC thermistor and a preparation method thereof. The base material of a PTC themistor comprise the following components in parts by weight: 100 parts of polyamide resin, 80-150 parts of conducting particles, 20-100 parts of inert filter, 0.5-3 parts of cross-linking agent, 0-1 part of nucleating agent, 0.5-5 parts of sensitizing agent, 0.5-3 parts of antioxidant, 0.5-2 parts of lubricant, 0-2 parts of coupling agent; wherein the polyamide resin can be one of or a mixture of several of polyamide11, polyamide12, polycaprolactam, polycaprylamide, polypelargonamide, polyhexamethylene sebacamide, polydecamethylene sebacamide and polyhexamethylene adipamide; the conducting particle is carbon black, graphite, metal particle or conductive ceramics; the sensitizing agent is a polyfunctional acrylic ester reactive monitor. The PTC thermistor disclosed by the invention is mainly applied to overcurrent protection of an electrical motor in the automobile field in a harsh environment condition, as also can be applied to other special fields with higher ambient temperature.

Owner:深圳市长园维安电子有限公司

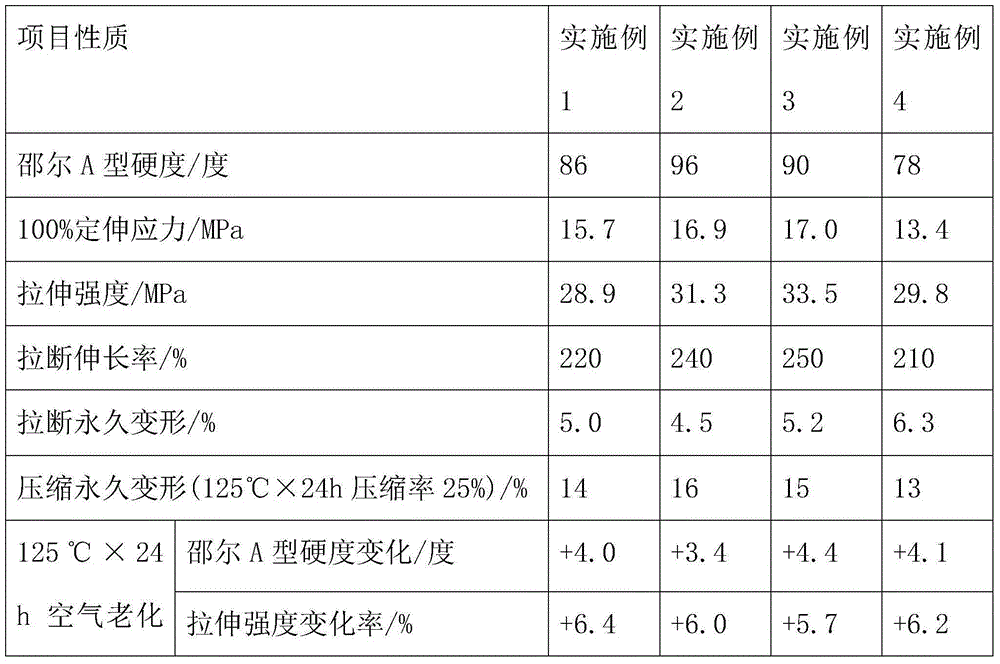

Leather cup rubber material for brake of automobile and preparation method thereof

Owner:WUHU HENGKUN AUTO PARTS

Ultraviolet-resistant three-proofing finishing agent

The invention relates to an ultraviolet-resistant three-proofing finishing agent and belongs to the technical field of textile auxiliaries. The ultraviolet-resistant three-proofing finishing agent comprises the following components in parts by weight: 12-16 parts of fluorocarbon emulsion, 8-12 parts of trifluoropropylmethylcyclotrisiloxane, 2-5 parts of a coupling agent, 1-3 parts of citric acid, 4-7 parts of 2-hydroxyl-4-methoxybenzophenone, 2-5 parts of bis-(2,2,6,6-tetramethyl-4-piperidyl)sebate, 3-5 parts of fat acid polyethenoxy ester and 120-150 parts of deionized water. The system of the ultraviolet-resistant three-proofing finishing agent provided by the invention is stable, and the ultraviolet-resistant three-proofing finishing agent not only has good water-proofing, oil-proofing and fouling-proofing functions, but also has a good ultraviolet-resisting function, and is easy to popularize and apply; a fabric finished by the ultraviolet-resistant three-proofing finishing agent touches better.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

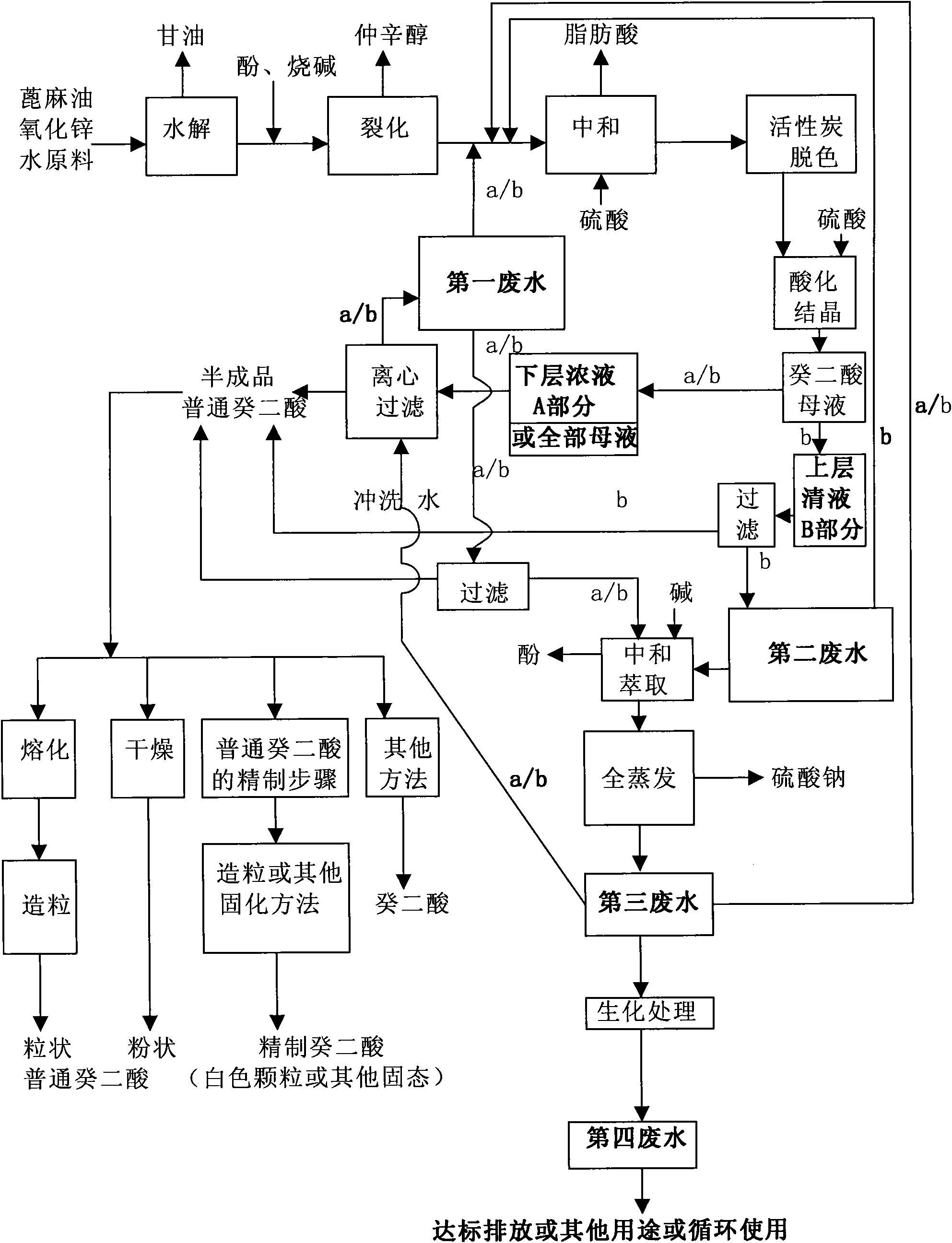

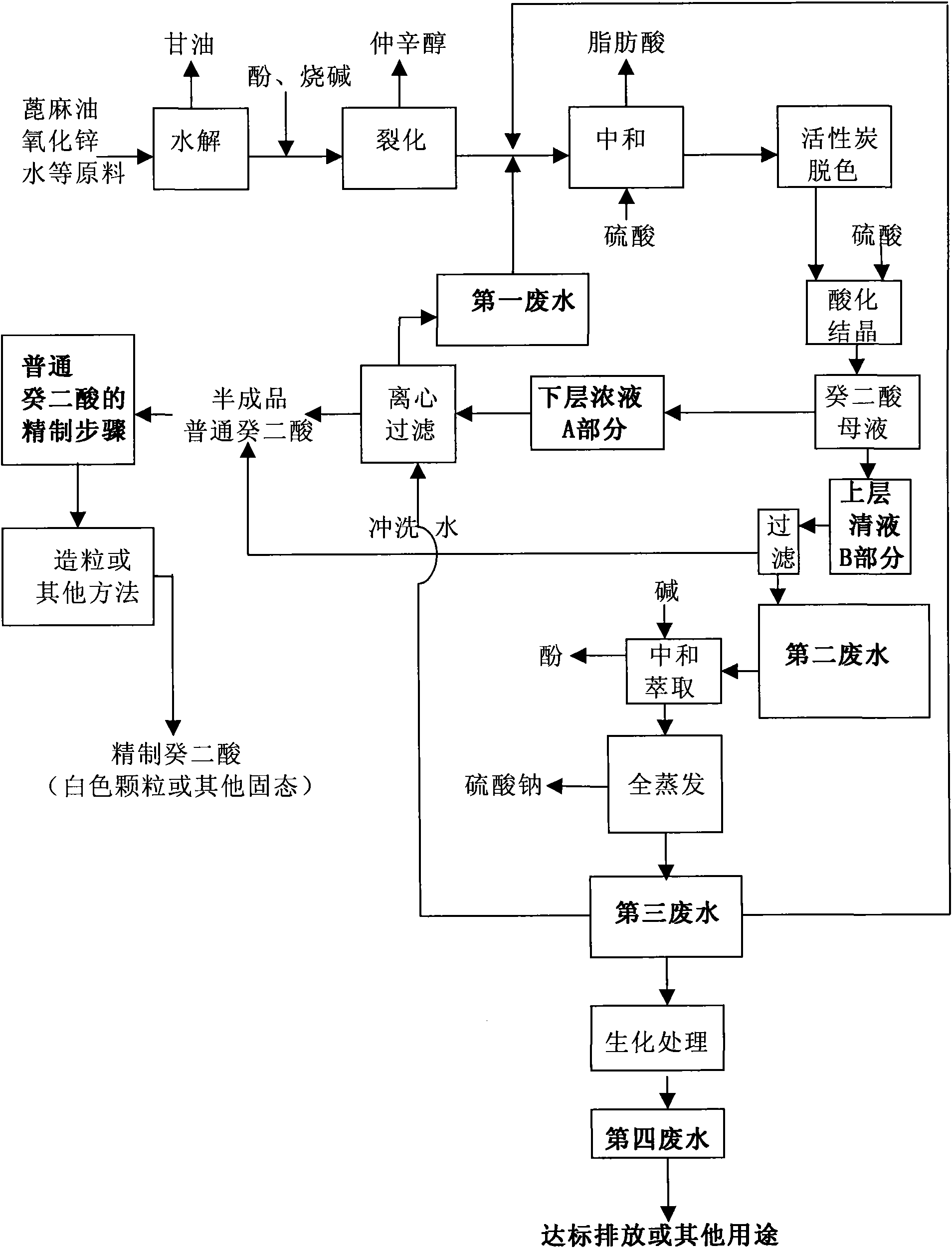

Reusable method of decanedioic acid phenol-containing wastewater

InactiveCN101575152AReduce water consumptionSave resourcesWater contaminantsMultistage water/sewage treatmentWastewaterPervaporation

The invention provides a reusable method of decanedioic acid phenol-containing wastewater, which comprises the following steps: providing decanedioic acid mother liquid which is prepared by neutralizing and acidating and crystallizing a sebacate solution; carrying out solid-liquid separation to the mother liquid to obtain a decanedioic acid solid and first wastewater, reusing the first wastewater, for example, part of the first wastewater is recycled to be used in a neutralization step; neutralizing and extracting balance of the first wastewater, removing phenol, performing pervaporation and removing by-product which is sodium sulfate to obtain third wastewater that is recycled to be used in the neutralization step or as flushing water in a centrifugal filtration step or is biologically treated to obtain fourth wastewater satisfying the discharge standard; or laminating the decanedioic acid mother liquid to obtain lower layer dope (part A) which contains crystallized decanedioic acid and upper clear solution (part B); carrying out solid-liquid separation to the lower layer dope (part A) which contains crystallized decanedioic acid to obtain the decanedioic acid solid and the first wastewater; carrying out solid-liquid separation to the upper clear solution (part B) to obtain the decanedioic acid solid and second wastewater; and reusing the first wastewater and the second wastewater.

Owner:上海芝东商务咨询有限公司

Cavitation corrosion resisting coolant used for heavy-duty engine and preparing method thereof

InactiveCN101550332AAvoid corrosionFormulation ScienceHeat-exchange elementsEngineeringSodium nitrite

The present invention relates to a cavitation corrosion resisting coolant used for heavy-duty engine, wherein the cavitation corrosion resisting coolant comprises the following components by weight: 10-90 parts of soft water, 10-90 parts of glycol, 0.1-1.4 parts of sodium borate, 0.3-2 parts of sodium benzoate, 0.2-2.5 parts of sebacic acid, 0.08-1 part of iodine arsenide, 0.2-3 parts of benzotriazole, 0.03-0.4 part of sodium molybdate, 0.04-0.4 part of sodium nitrite, 0.05-0.5 part of sodium hydroxide, 0.05-0.5 part of corrosion resisting stabilizing agent, 0.005-0.05 part of antifoaming agent and 0.001-0.01 part of colorant. The method of the invention comprises the following steps: (1) adopting a reaction still with mixing function in normal temperature, placing the soft water into the reaction still according to the ratio; (2) adding glycol according to the amount, mixing until the time when the glycol is totally dissolved; (3) weighting the sodium borate, sodium benzoate, sebacic acid, iodine arsenide, benzotriazole, JN-4 corrosion resisting stabilizing agent, sodium molybdate, sodium nitrite, sodium hydroxide, antifoaming agent and colorant, mixing for preparing a complexing agent; (4) adding the complexing agent into the reaction still and mixing to uniform; and (5) checking the freezing point, boiling point, pH value and color of coolant routinely, and then filtering and filling. The cavitation corrosion resisting coolant of the invention has the advantages of simple preparing and remarkable effect.

Owner:TIANJIN PORT (GROUP) COMPANY

High-performance modified carboxylated nitrile rubber material and preparation method thereof

The invention discloses a high-performance modified carboxylated nitrile rubber material. The material comprises the following raw materials by weight: 90 to 130 parts of modified carboxylated nitrile rubber, 15 to 30 parts of natural rubber, 20 to 40 parts of carbon black N-774, 5 to 10 parts of carbon black N-990, 5 to 10 parts of antimony trioxide, 3 to 5 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of sulfur, 0.5 to 3 parts of tetrabenzylthiuramdisulfide, 1 to 3 parts of N-tert-butyl-2-benzothiazole sulfonamide, 2 to 6 parts of dioctyl sebacate and 4 to 8 parts of an auxiliary. The modified carboxylated nitrile rubber blending material provided by the invention has higher comprehensive mechanical property, and heat and ageing resistant properties, high-temperature and oil resistant properties and low-compression and permanent-deformation properties.

Owner:合肥市再德高分子材料有限公司

Flexible polyvinyl chloride cable material and preparation method thereof

ActiveCN103589086AImprove flexibilityLow costPlastic/resin/waxes insulatorsPolymer sciencePolyvinyl chloride

The invention discloses a flexible polyvinyl chloride cable material which is characterized by being composed of the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 40-52 parts of plasticizer, 6-8 parts of secondary plasticizer, 15-25 parts of nano calcium carbonate, 1-2 parts of antioxidant, 1.5-2.5 parts of lubricant, 0.8-1.2 parts of pigment and 6-8 parts of composite heat stabilizer. By using the vinyl chloride-butyl acrylate resin, dioctyl phthalate and dioctyl sebacate mixed plasticizer, physical and mechanical properties of the prepared flexible polyvinyl chloride cable material completely conforms to a related product standard in China, the elongation at break is 1.43-1.53 times better than the national standard, and the flexibility of the cable material is greatly improved; and meanwhile, by using the low-cost vinyl chloride-butyl acrylate resin part instead of dioctyl sebacate plasticizer, the material cost can be reduced to some extent, thus increasing the market competitive power of the product.

Owner:南通市东风特种电线有限公司

Polyamide resin and polyamide composition composed thereof

The invention discloses a polyamide resin, which is composed of the following repeated unit components: a component A which is 80-99mol / % of a 10T unit formed by decamethylene diamine and terephthalic acid; and a component B which is 1-20mol / % of a 1010 unit formed by decamethylene diamine and sebacic acid, wherein the sebacic acid is substituted by m-phthalic acid or other aliphatic dicarboxylic acid containing 2-14 carbon atoms. A polyamide composition containing the polyamide resin comprises the following components in percentage by weight: 30-99.9% of polyamide resin, 0-60% of reinforcing filler, 0-50% of flame retardant, and 0.1 to 10% of other auxiliary agents. The polyamide resin and the composition composed thereof disclosed by the invention have the advantages that with the water saturated absorptivity lower than 0.8wt%, and the resin and the composition can be applied to situations in which the requirement on water saturated absorptivity is high, such as being applied to an engine oil pipe; with the melting point higher than 260 DEG C, and strong heat resistance, and the resin and the compositions can be applied to situations in which the reflow soldering temperature exceeds 260 DEG C; with the breaking elongation of 14-45%, and the notch impact strength of 6.9-12.0kJ / m2 (23 DEG C), the resin and the composition have high tenacity and can be applied to situations in which the requirement on water saturated absorptivity is high, such as being applied to an engine oil pipe.

Owner:KINGFA SCI & TECH CO LTD

Energy-saving cooling fluid

The invention relates to an energy-saving cooling fluid which takes glycol as a base material, and has the following components according to mass percentage: 92 to 95 of the glycol, 1 to 3 of deionized water, 0.5 to 1.5 of decanedioic acid, 0.6 to 2 of n-octanoic acid, 0.4 to 1.5 of potassium hydroxide, and 0.3 to 0.8 of methenamine. The cooling fluid has low freezing point, wide boiling spread, excellent heat conductivility at high temperature, and energy-saving efficiency, prevents frozen injury and occurrence of steam blocking layer when the engine works, improves the thermal equilibrium temperature when the engine works, with the fuel completely combusted, reduces tail gas discharge, and obviously promotes the power.

Owner:周振华

Non-ortho-benzene medical soft polyvinyl chloride plastic and preparation method thereof

InactiveCN101215398ARich sourcesEasy to process and modifySurgeryDIETHYLENE GLYCOL ADIPATEPolyvinyl chloride

The invention provides a non-o-benzene-type medical flexible polyvinyl chloride plastic and a process for preparation, and the components and the parts by weight are that polyvinyl chloride resin 100 parts, plasticizing agent 10-90 parts, stabilizing agent 1-10 parts, auxiliary stabilizing agent 1-10 parts, lubricating agent 0.2-5.0 parts and anti-oxidant 0-2 parts. The plasticizing agent is one and several of adipic acid propanediol ester, adipic acid diglycol ester, decanedioic acid butanediol ester, decanedioic acid propanediol ester, or adipic acid butanediol ester. The invention solves the bad effect which is caused by the dissolving out of phthalandione (2- ethylhexyl acrylate). The invention has the advantages that the invention not only keeps rich source of PVC material, but also the invention is easy to be processed and modified, and the products which are modified have excellent bioavailability, and the invention is applied in one time use, which can avoid cross-infection and the like. And the invention lowers the effects to environment, which belongs to environment-friendly-type products, and the performance of the products meets the existing standard requirements.

Owner:上海新上化高分子材料有限公司

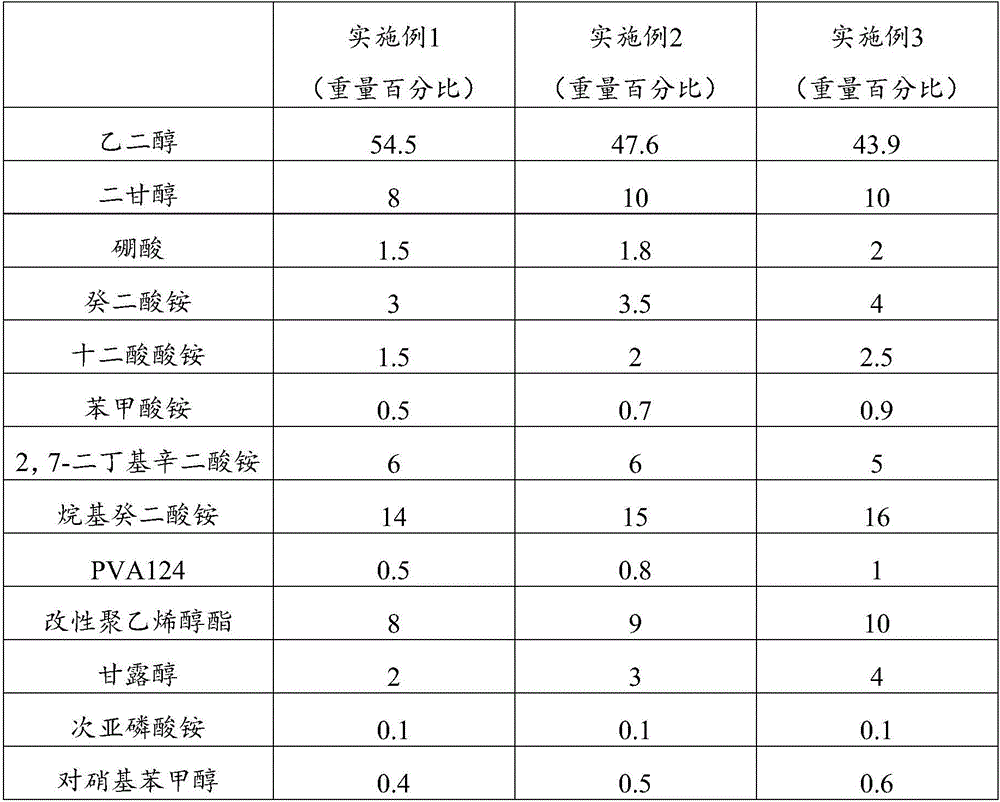

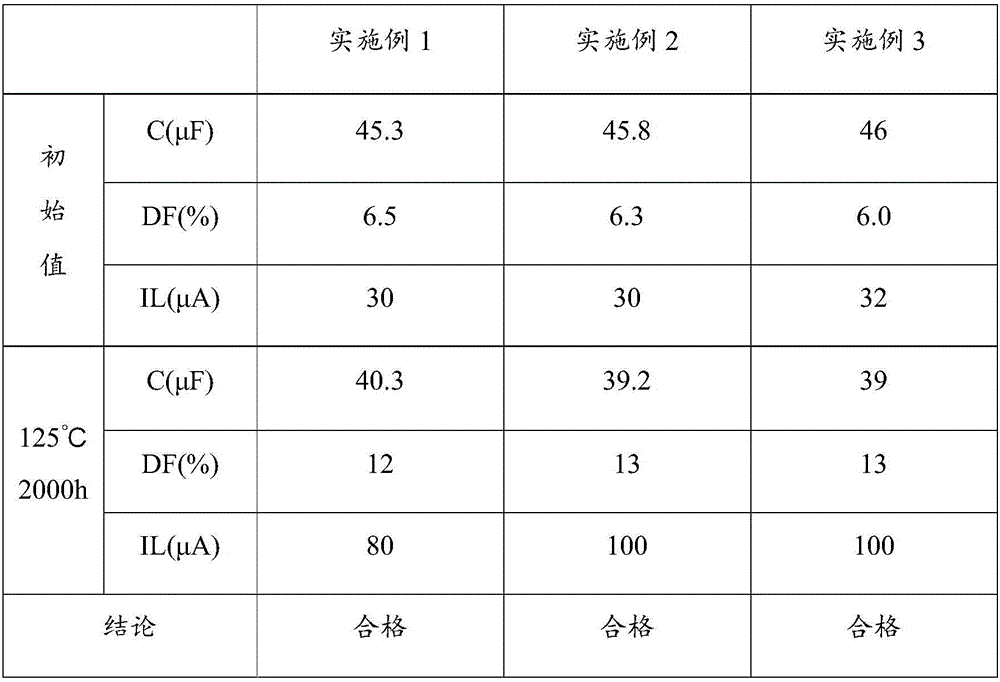

Electrolyte, electrolyte preparation method and aluminum electrolytic capacitor

ActiveCN106098379AImprove temperature resistanceImprove stabilityLiquid electrolytic capacitorsSolventTemperature resistance

The invention discloses an electrolyte, an electrolyte preparation method and an aluminum electrolytic capacitor. The electrolyte comprises, by weight percentage, 50-65w% of solvent, 23-33w% of solute, and 8-19w% of additive. The solute includes boric acid, ammonium benzoate, at least one material selected from ammonium dodecanedioate and 2,7-dibutyl octanedioic acid ammonium, and at least one material selected from ammonium sebate and alkyl ammonium sebate. Through the technical scheme, the temperature resistance performance and stability of the aluminum electrolytic capacitor are improved.

Owner:惠州市智胜新电子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com