Patents

Literature

33results about How to "Low processing and running costs" patented technology

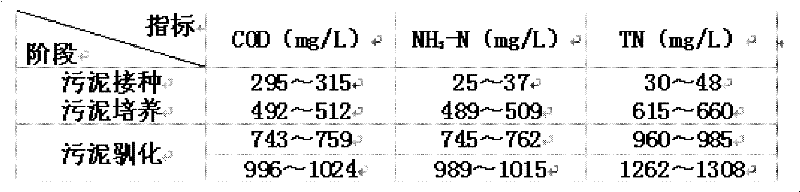

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

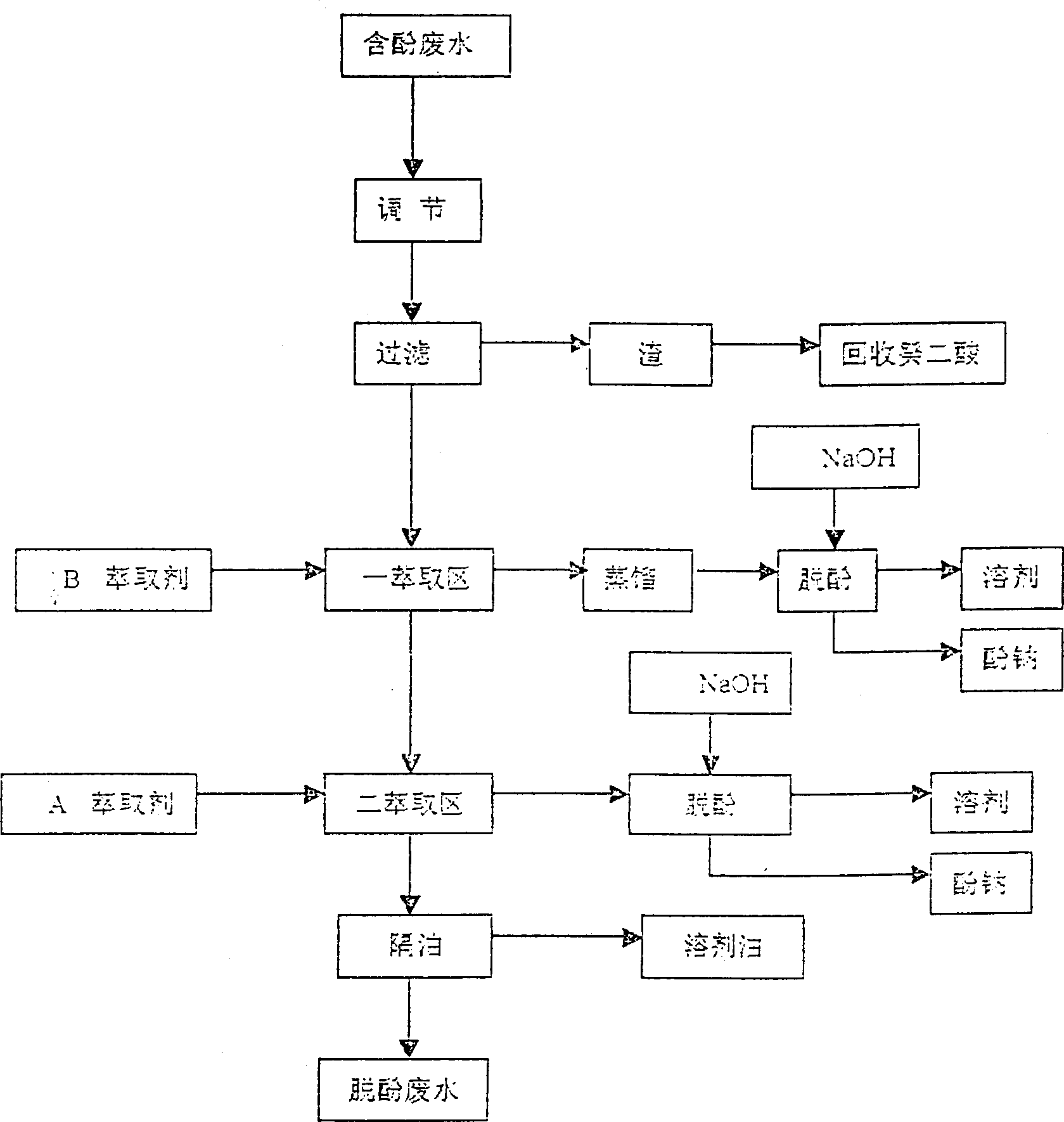

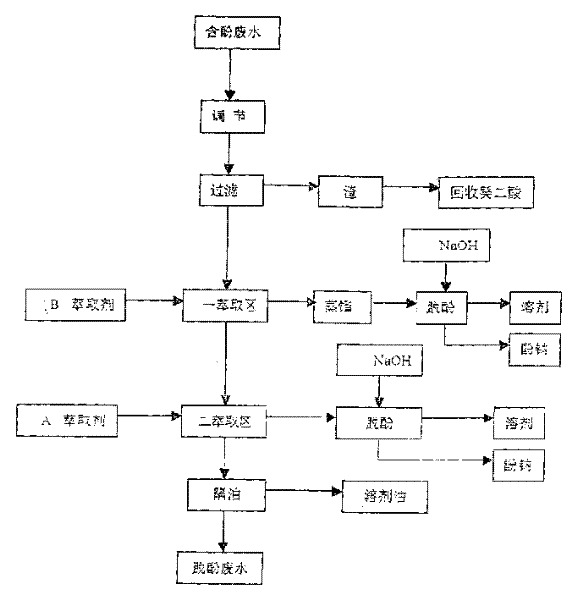

Treatment of phenol containing decanedioic acid waste water by extractive distillation

InactiveCN1450006AAvoid SaponificationLow processing and running costsMultistage water/sewage treatmentPhosphoric Acid EstersPhosphate

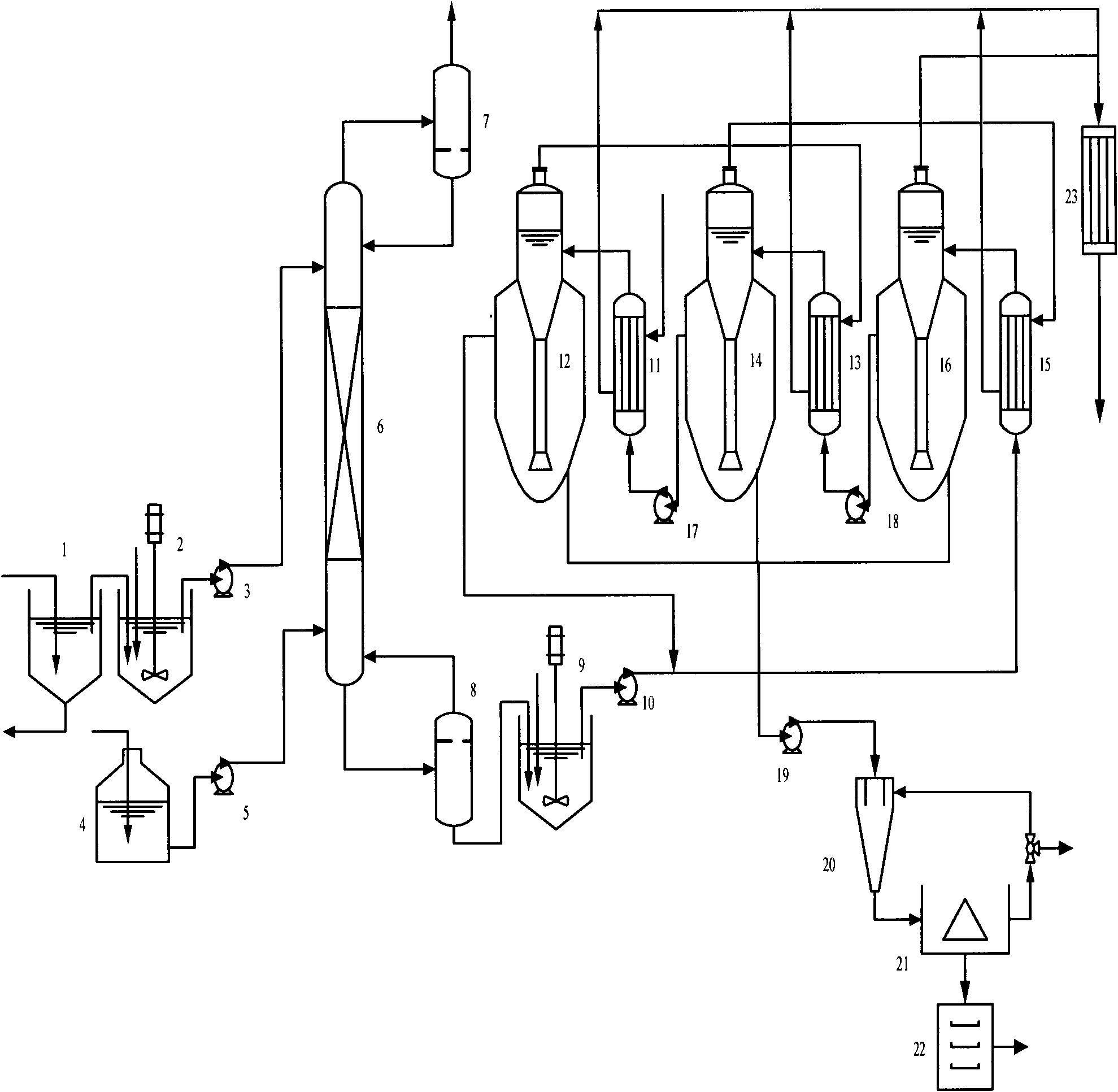

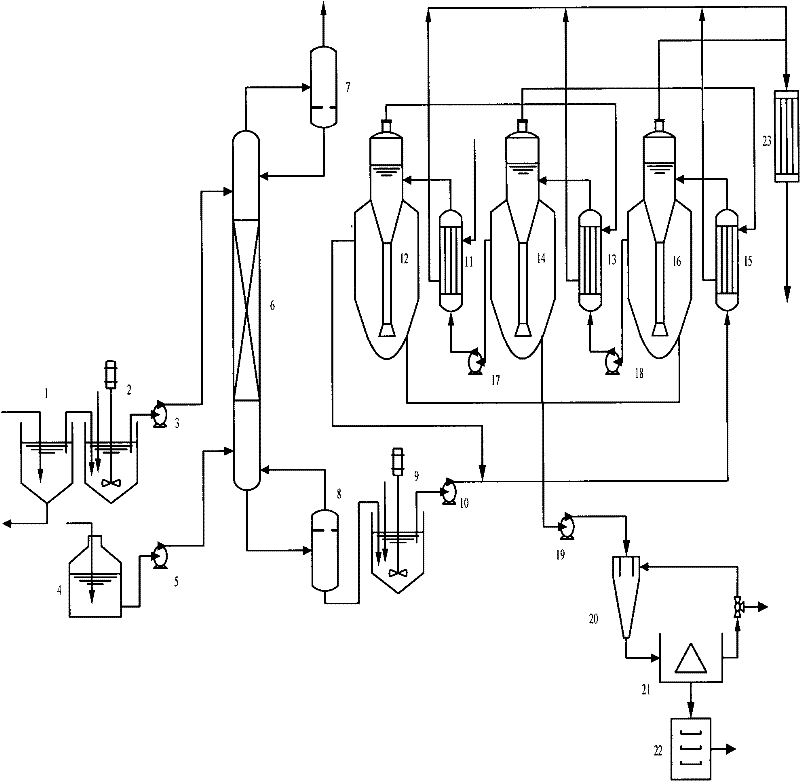

The method for treating waste water containing phenol which is produced in the course of producing sebacic acid includes five steps: regulation, filtration, extraction, removing phenol and isolating oil. After the phenol-containing waste water is filtered and its insoluble material is removed, in first extraction zone the high carbon alcohol is used as extraction agent to remove the organic material from waste water and effectively reduce content of phenol, the load extraction agent is fed into distillation procedure, the distilled high carbon alcohol can be reextracted and can be circularly used, and the organic material being in the waste water can be recovered in the form of high-boiling material, and the second extraction zone the mixture of phosphate and kerosene is used as extraction agent to make counter-current extraction with the phenol-containing waster water.

Owner:HAIHUA TIANHE ORGANIC CHEM SHANDONG

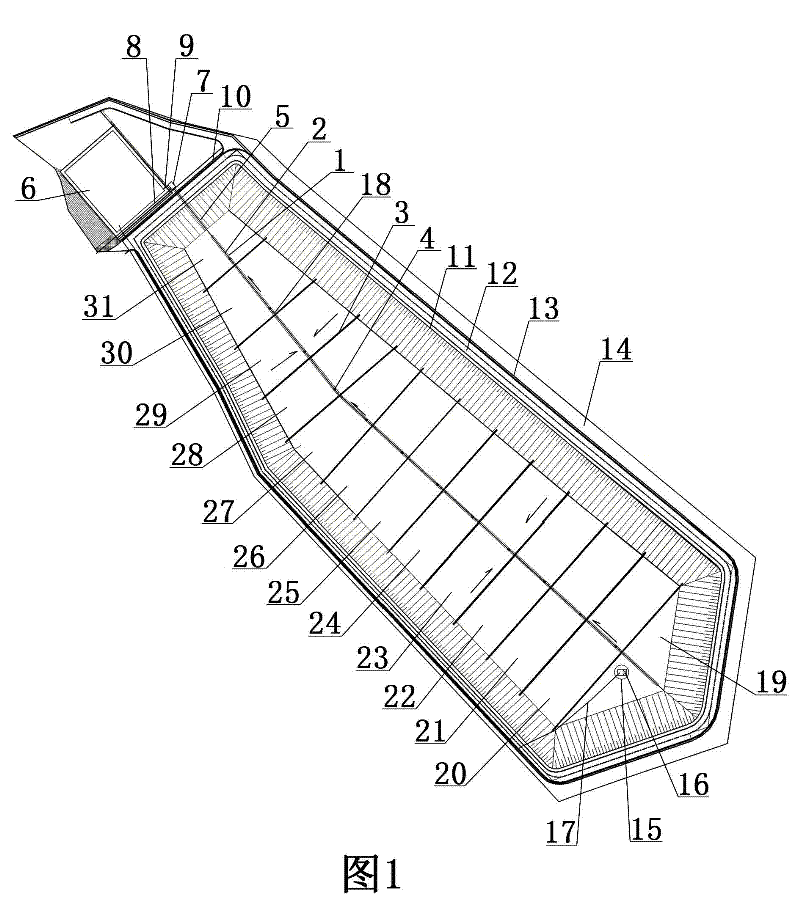

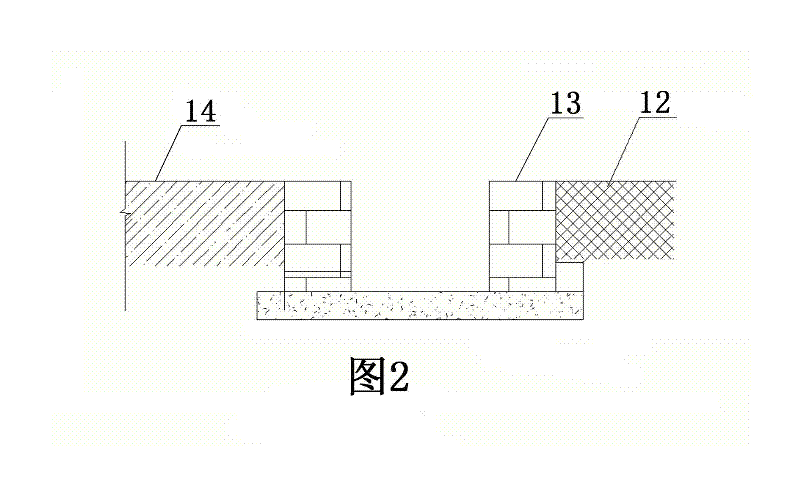

Valley-type refuse landfill series multi-partition rain and sewage shunting device and method

Owner:青岛市环境卫生科研所

Method for treating polymer-containing sewage of oil field

ActiveCN101993177AEasy to separateExtend the filter cycleMultistage water/sewage treatmentSludgeBacillus cereus

The invention relates to the improvement of a method for treating polymer-containing sewage of an oil field. The method is characterized in that microorganisms are formed by mixing bacillus cereuses, bacillus megateria, bacillus subtilis, candida lipolytica, bacillus brevis and pseudomonas fluorescens; after microorganism aerobic degradation, post filter treatment is carried out; obligate microorganisms are used for degrading oil and organic pollutants bonded on polymers, thereby improving the separability of surplus inorganic substances and polymer-containing substances; and meanwhile, the degradation of the oil and the organic pollutants creates a condition for subsequently prolonging the filter period of a filter material. The invention has the advantages of simple process, simplified flows, convenient running and management, good treatment effect, low treatment and running cost (0.65-0.7yuen / ton of water, which is 2 / 3 of that of conventional treatment), no need of adding any drug,no treatment secondary pollution and stable treatment effect, can guarantee that treated yield water can stably reach 5.5.2, has small sludge quantity and does not need a sludge treatment system, thereby solving the treatment problem of polymer-containing sewage of an oil field.

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

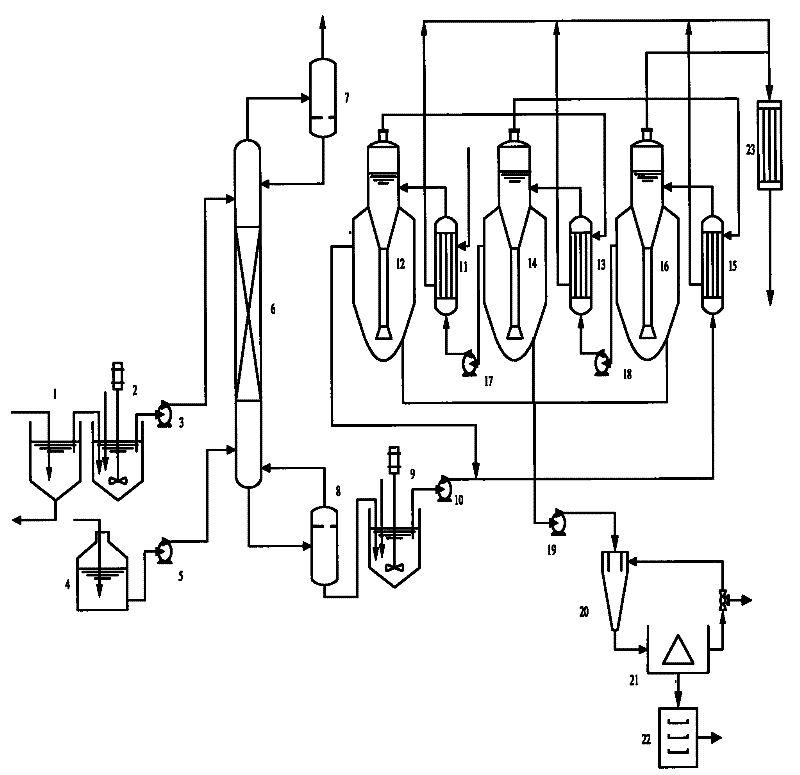

Process for changing phenolic nitrate effluent into useful material by extracting, evaporating, crystallizing and coupling

InactiveCN101654305ASolve bottlenecksSolve the miscibility problemEvaporationSolution crystallizationPhenolSodium sulfate

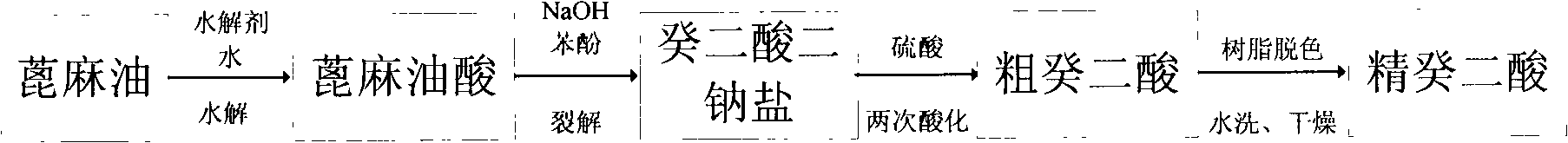

The invention discloses a process for changing phenolic nitrate effluent into useful material by extracting, evaporating, crystallizing and coupling, belonging to the field of changing waste water into useful materials. The process comprises the steps of pre-treating waste water, extracting phenol, performing triple effect evaporation and recycling sodium sulfate. Phenol is extracted with ricinoleic acid and is recycled, so the industrial usage of the phenol is decreased. The oil-water mutual solving problem is efficiently solved by utilizing the salting-out effect of the sodium sulfate highlycontained in the waste water. By adopting triple effect evaporation of counter-current operation under a basic condition, the phenol is efficiently prevented from secondarily returning into air, so the phenol contained in the treated waste water is less than 0.5mg / l and can be used as the scouring water for preparing process or can be directly discharged. The by-product sodium sulfate solid is efficiently recycled and the purity of the sodium sulfate is above 99.9%. The produced sodium sulfate makes up for the steam consumption during the evaporation process. Furthermore, the process has theadvantages of low treating cost, economic benefit and obvious environmental benefit.

Owner:TSINGHUA UNIV

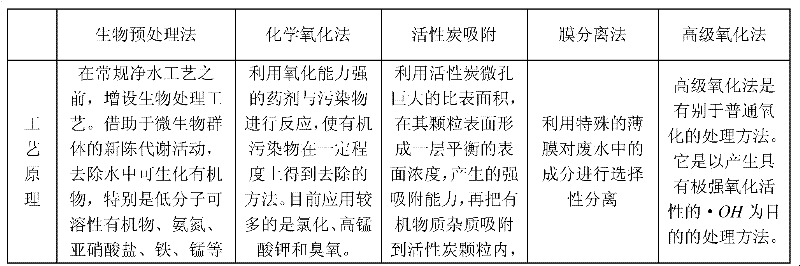

Method for removing hard biodegradable organic matters from sewage

InactiveCN103073105ATo achieve the purpose of degrading organic matterLow processing and running costsWater contaminantsWater/sewage treatment by oxidationFerric hydroxidePtru catalyst

The invention relates to a method for removing hard biodegradable organic matters from sewage. According to the method, the hard biodegradable organic matters can be removed from the sewage. An essential difference between the method and a present Fenton advanced oxidation process is that ferric hydroxide is taken as a catalyst, so that the defects that ferrous iron is continuously added as the catalyst and partial ferrous sludge is generated and is to be treated are overcome. The ferric hydroxide as the catalyst is recyclable and no ferrous sludge is generated. The process wholly has the advantages of simple structure, reliable running and low cost.

Owner:陈振选 +1

Method for treating landfill leachate

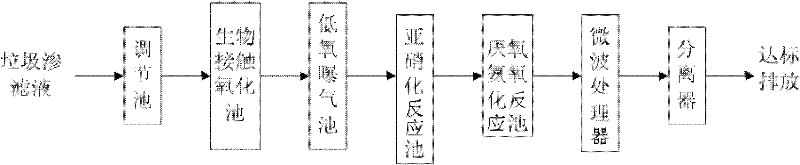

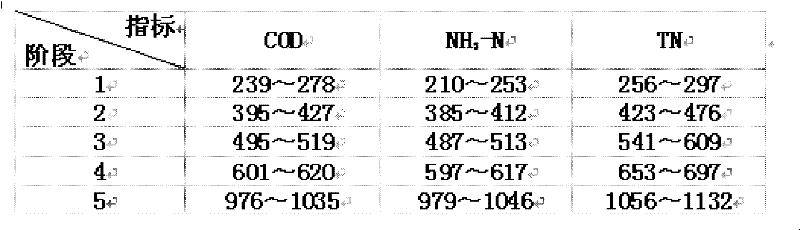

InactiveCN102674623APromote degradationEffluent water quality up to standardMultistage water/sewage treatmentWater/sewage treatment by oxidationOxidation pondLow oxygen

The invention discloses a method for treating landfill leachate. The method comprises the following steps of: feeding the landfill leachate into an adjustment tank first, sequentially feeding the landfill leachate into a biological contact oxidation pond, a low-oxygen aeration tank, a nitrosation reaction tank, an anaerobic ammonium oxidation reaction tank and a microwave treater, finally feeding the landfill leachate into a separator, performing precipitation separation to separate active carbon obtained after microwave treatment from the outlet water of the landfill leachate, and then discharging the outlet water which meets the standard. The technology for treating the landfill leachate saves energy and is high in efficiency and low in consumption; and by the method, pollutants such as organic pollutants, nitrogen (N) and phosphorus (P) can be effectively removed, and the environmentally acceptable treatment and discharge of the landfill leachate can be realized finally.

Owner:ARCHITECTURAL DESIGN RES INST OF GUIZHOU

Method for treating polymer-containing sewage of oil field

ActiveCN101993177BEasy to separateExtend the filter cycleBacteriaMultistage water/sewage treatmentSludgeTherapeutic effect

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

Advanced treatment device and method of micropolluted organic sewage

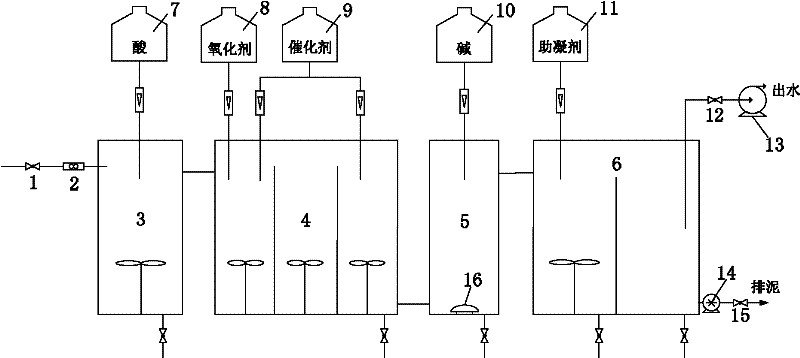

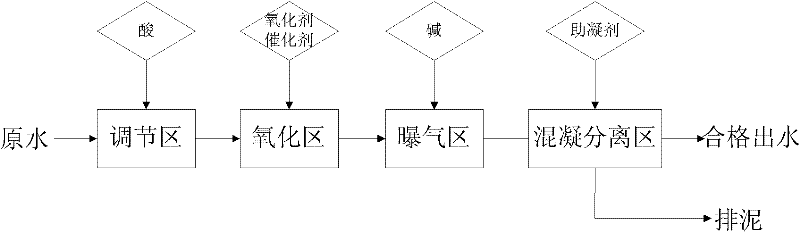

ActiveCN102390905AMeet the requirements of subsequent production processesReduce organic contentMultistage water/sewage treatmentCyclic processSludge

The invention discloses an advanced treatment device and method of micropolluted organic sewage. The advanced treatment device comprises an adjusting tank, an oxidization tank, an aeration tank and a coagulation and separation tank which are communicated, wherein the upper lateral wall of the adjusting tank is provided with a water inlet valve, and the top of the adjusting tank is communicated with an acid feeding pot; the top of the oxidization tank is respectively communicated with an oxidant feeding pot and a catalyst feeding pot; the top of the aeration tank is communicated with an alkaline feeding pot; the top of the coagulation and separation tank is respectively communicated with a coagulant aid feeding pot and a water outlet pump; and the lateral wall of the lower part of the coagulation and separation tank is communicated with a sludge discharge pump. The method comprises the following steps of: (1), discharging water or micropolluted water into the adjusting tank; (2) addingacid to the adjusting tank; (3) adding hydrogen peroxide to the oxidization tank, respectively adding catalysts and stirring; (4) feeding alkaline into the aeration tank for aeration; (5) adding a coagulant aid to the coagulation and separation tank; (6) separating water and flocculent bodies; and (7) removing sludge from the separated flocculent bodies and separating water for recycling to obtain the advanced treatment circulating process of the organic sewage. The invention has the advantages of simple structure, running reliability, low cost and convenience for operation.

Owner:西安瑞美德水业科技有限公司

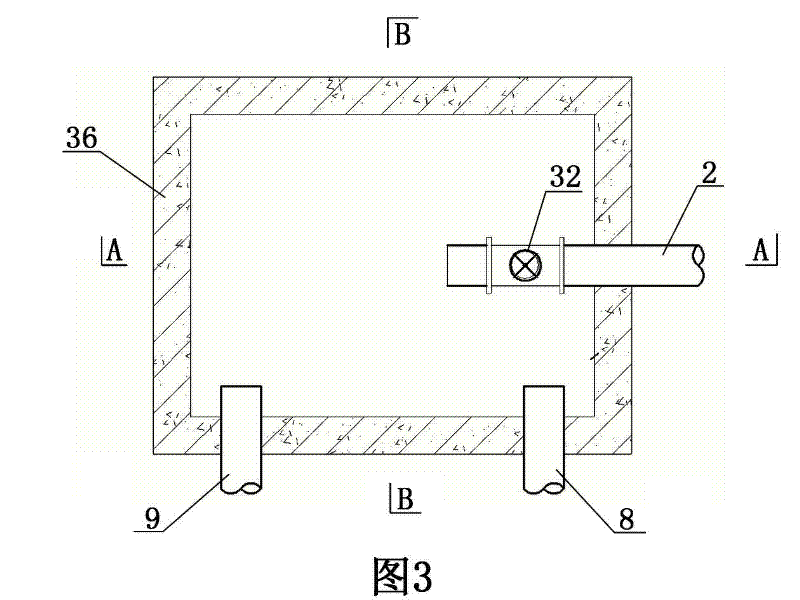

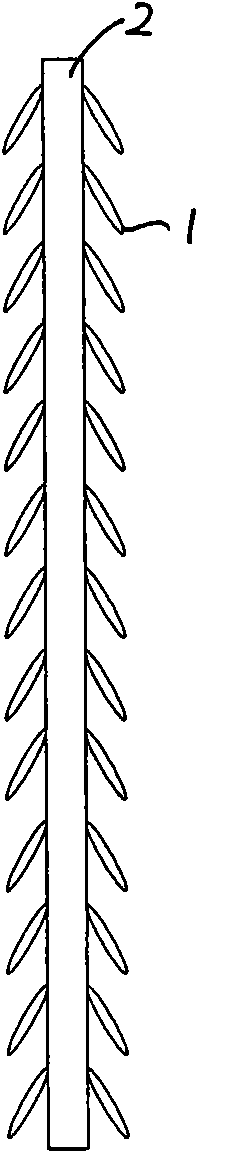

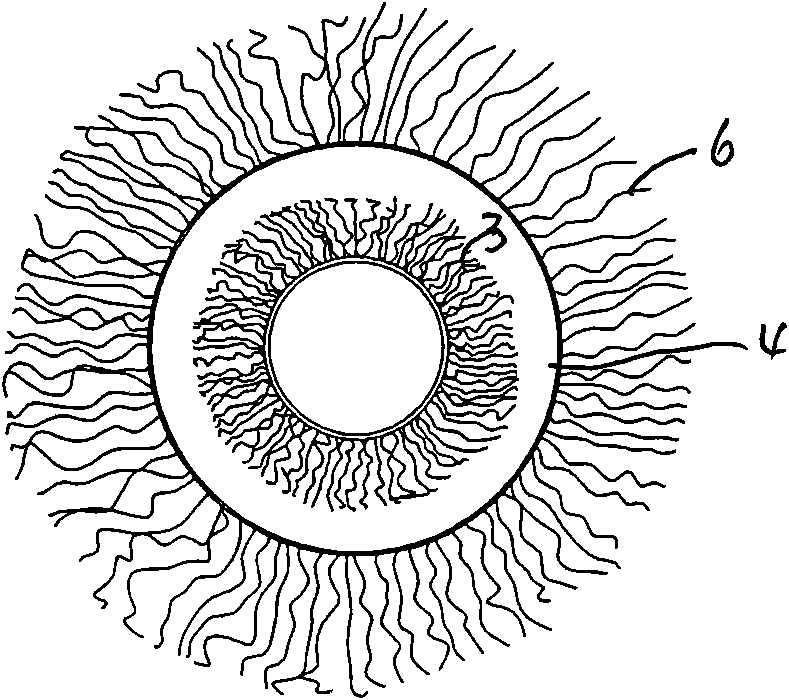

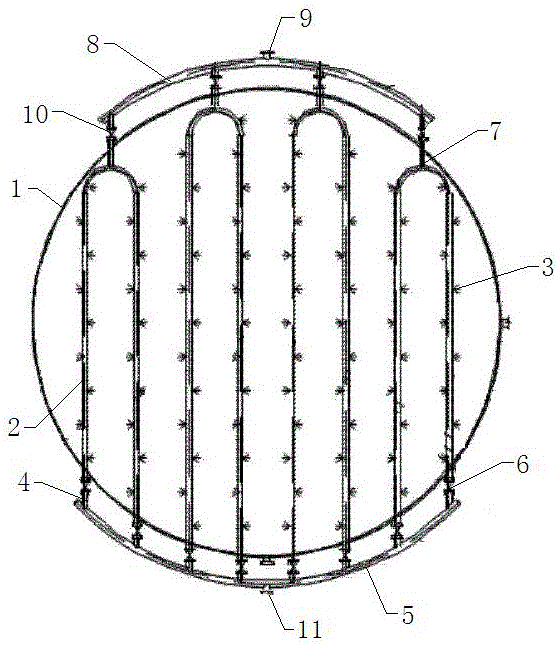

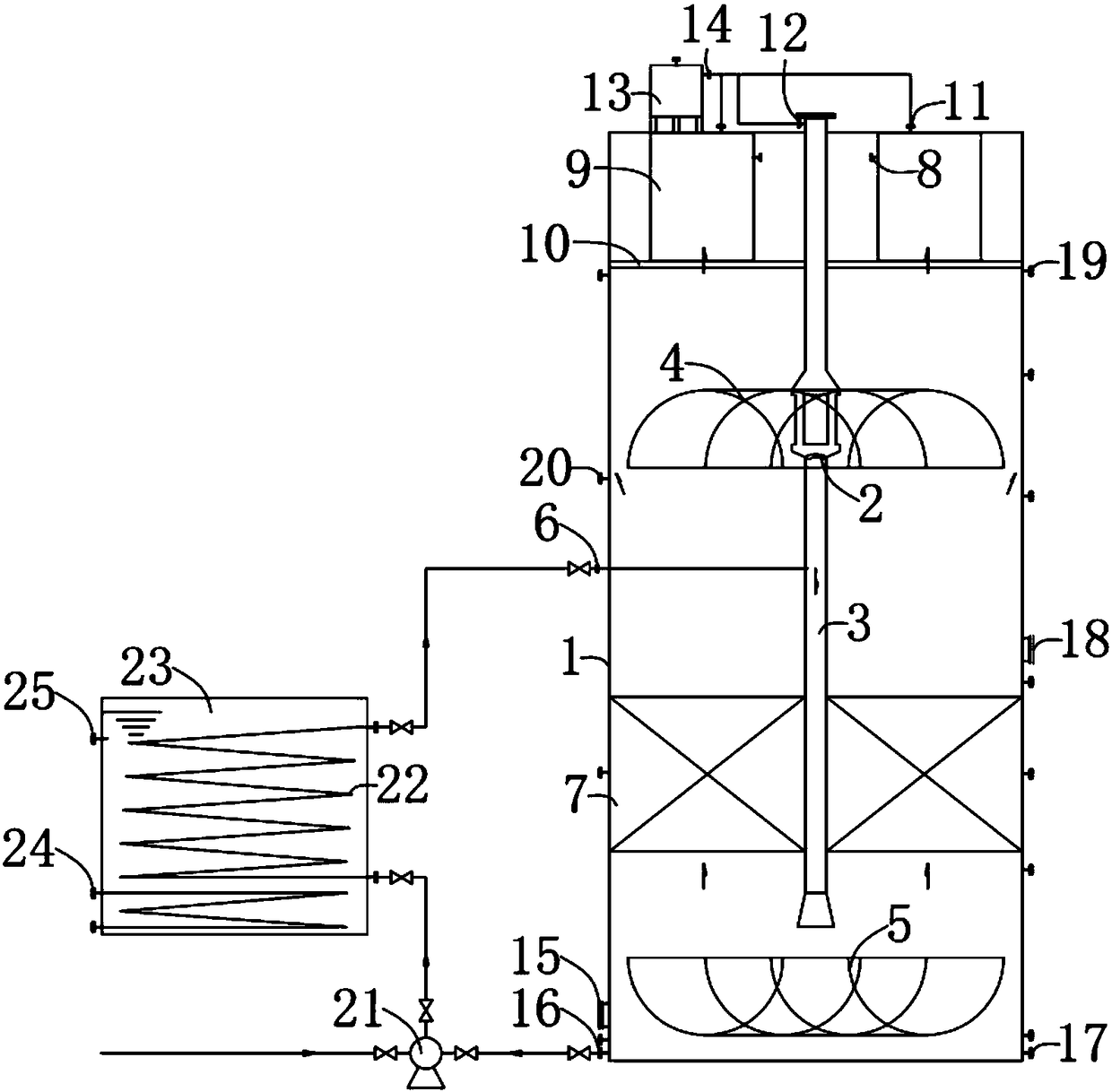

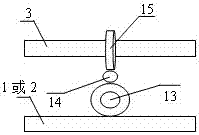

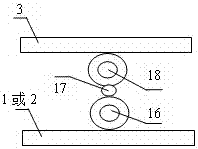

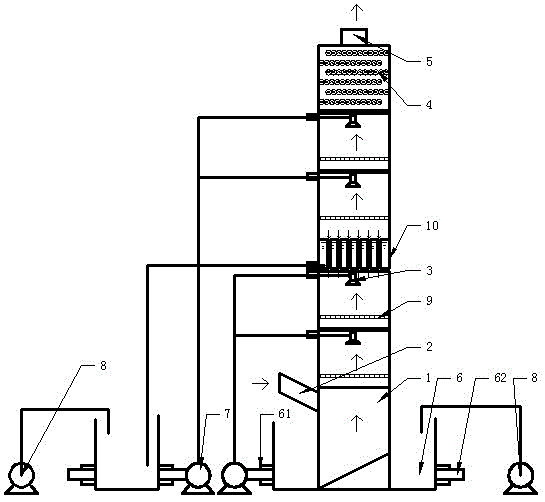

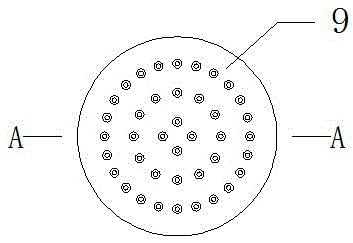

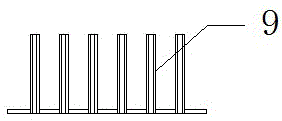

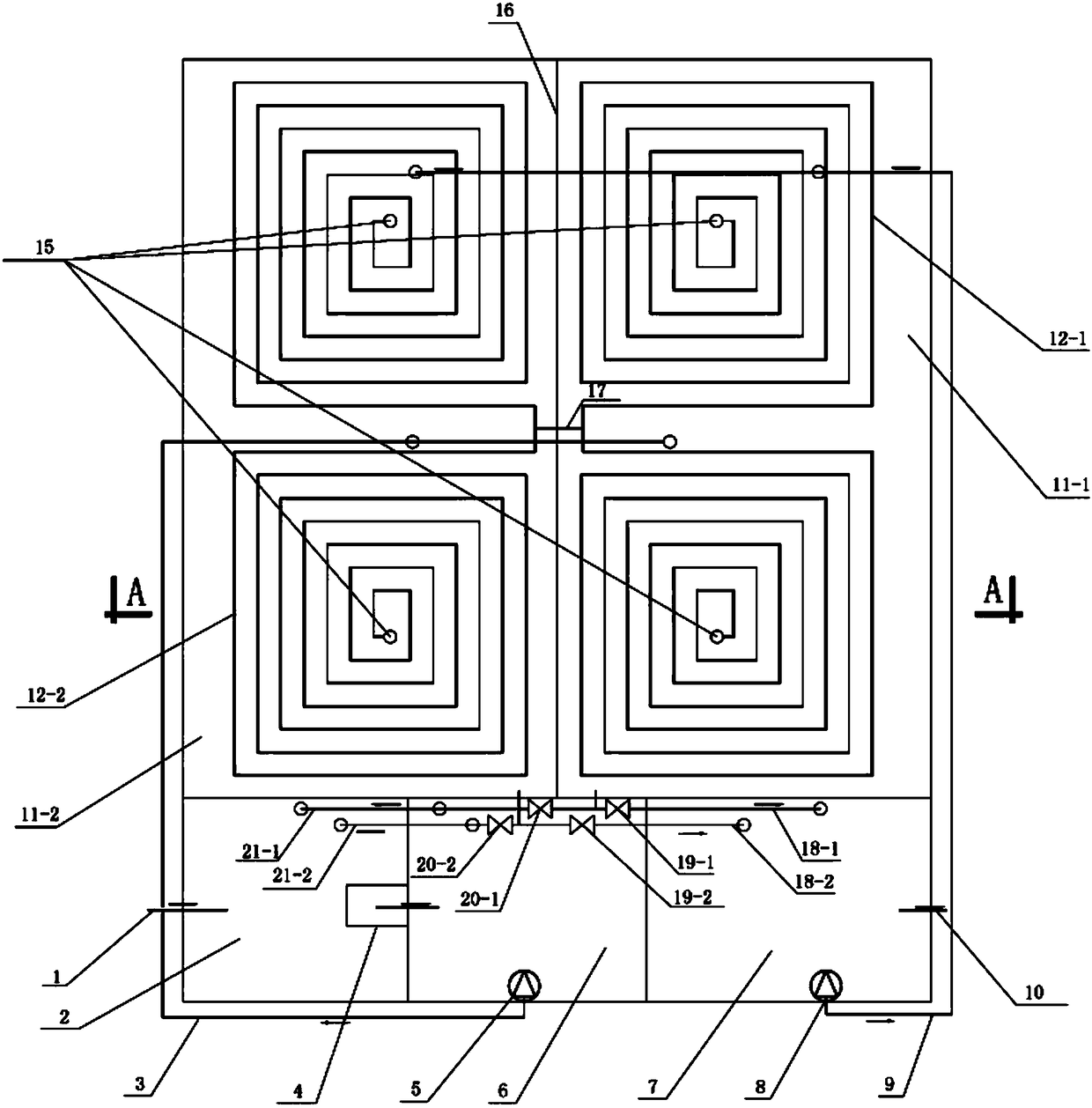

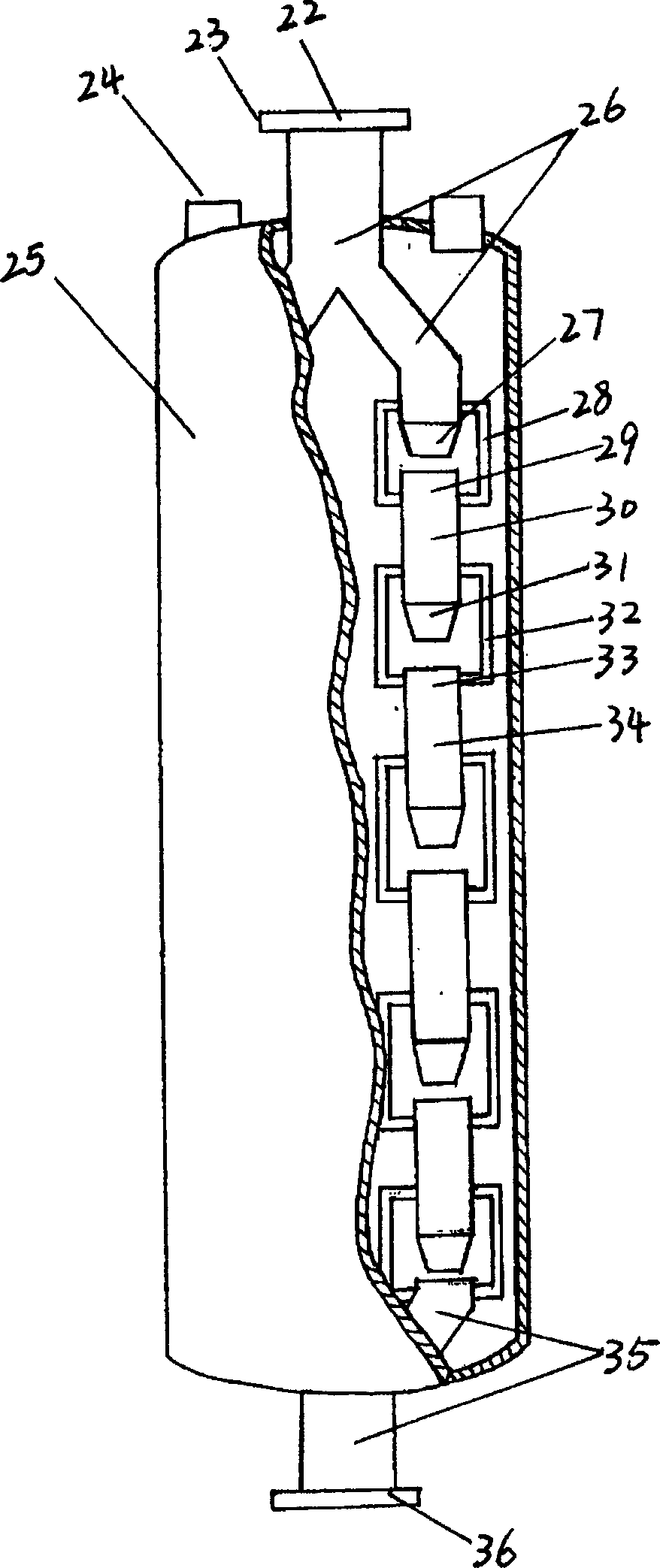

Water distribution system for anaerobic reactor

PendingCN106145342AHigh activityEliminate cloggingWater distributersTreatment with anaerobic digestion processesHigh concentrationEconomic benefits

The invention discloses a water distribution system for an anaerobic reactor, comprising a support (1). A plurality of U-shaped water distribution pipes (2) are disposed on the support (1) and provided with a plurality of nozzles (3), and two adjacent nozzles (3) on branch pipes of the U-shaped water distribution pipes (2) are always on two sides of the corresponding branch pipe; water inlets of the U-shaped water distribution pipes (2) are connected with an inflow master pipe (5) respectively through corresponding inflow branch pipes (4), and the inflow master pipe (5) distributes water for the U-shaped water distribution pipes (2) in mechanical constant-pressure distribution manner. The U-shaped water distribution pipes herein enable uniform water distribution with no dead corner and good mud bed activity; a pressure backflushing system is added, blockage of the water distribution system and mud bed dead corners that are formed are eliminated, high efficiency and low energy consumption are achieved, anaerobic treatment effect is improved, significant environmental and economic benefits are achieved in the field of treatment of high-concentration organic wastewaters, and wastewater treatment cost is decreased by 8%.

Owner:WUXI XINGSHENG ENVIRONMENTAL PROTECTION EQUIPCO

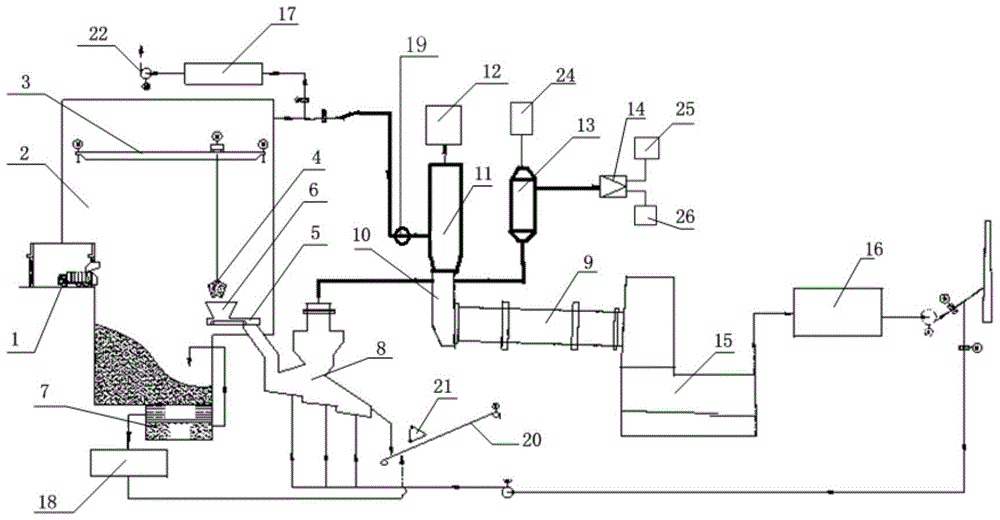

Power plant variable-load coal-fired furnace desulfurization wastewater zero discharge system

PendingCN112125463ASolve runnabilitySolve heat transferRecuperative heat exchangersSpecific water treatment objectivesFlue gasPower grid

The invention discloses a power plant variable-load coal-fired furnace desulfurization wastewater zero-discharge system which comprises an adjustable low-temperature flue gas waste heat recycling system device, a desulfurization wastewater evaporation and concentration system using waste heat as a heat source, a desulfurization wastewater pretreatment system and a system for finally treating concentrated desulfurization wastewater to zero discharge. The system has the beneficial effects that the influence of furnace load adjustment automatically performed by most power plant coal-fired furnaces along with power grid load change on a furnace tail flue gas waste heat recovery device and a desulfurization flash evaporation concentration system can be conveniently adapted through system adjustment, so that the waste heat recovery system and the low-temperature flash evaporation concentration system are integrally stable in operation; by automatically adjusting the temperature difference between the wall surface temperature of the waste heat recovery device and the temperature of the flue gas, the waste heat exchange amount is basically unchanged, a higher energy-saving effect is achieved, the waste heat of the flue gas is fully utilized, desulfurization wastewater does not need to be subjected to dosing pretreatment, and the wastewater treatment operation cost is reduced.

Owner:青岛润扬环境科技有限公司

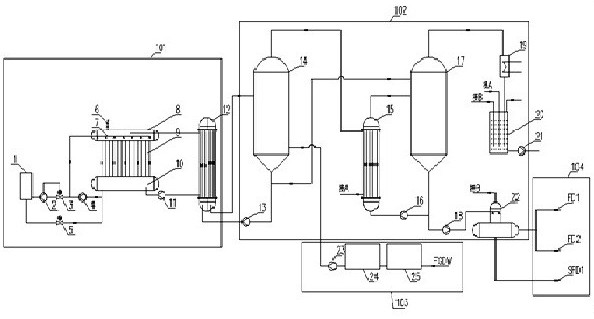

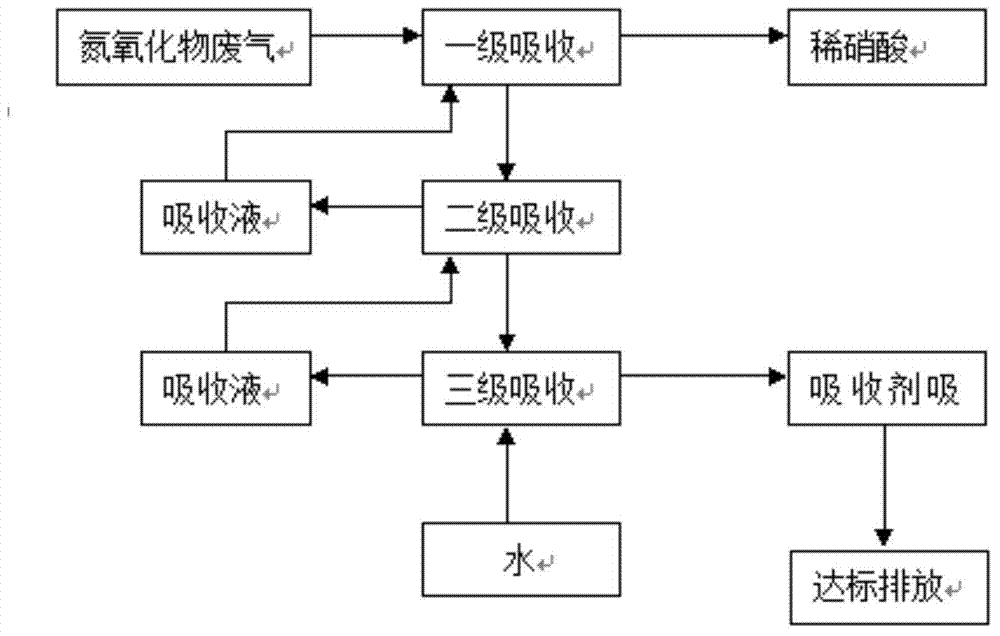

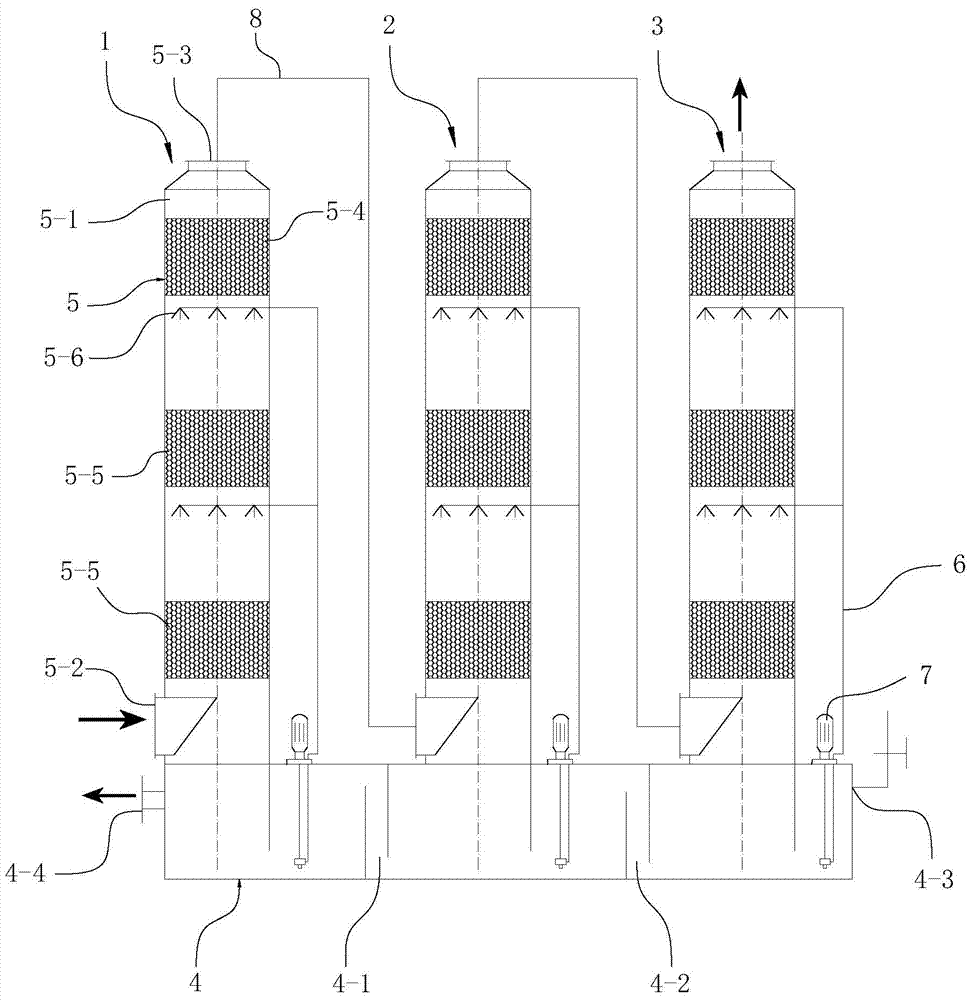

Nitric oxide waste gas pollution control process method and equipment

InactiveCN104258705AReduce concentrationLow processing and running costsDispersed particle separationHigh concentrationThree stage

The invention relates to a nitric oxide waste gas pollution control process method and equipment. The nitric oxide waste gas pollution control process method comprises a first-stage backwashing process, a second-stage backwashing process and a third-stage backwashing process; waste gas is sequentially washed through the first-stage backwashing process, the second-stage backwashing process and the third-stage backwashing process, dilute nitric acid can be recycled in the backwashing processes, and dry-method absorption is performed on the waste gas after subjected to three-stage backwashing. According to the nitric oxide waste gas pollution control process method, the concentration of nitric oxide in waste gas is substantially reduced on the premise that nitric acid is recycled, and waste gas is absorbed by virtue of a dry-method adsorbent so that emission of nitric acid on standard can be ensured; deficiencies of a known existing alkali absorption process method are overcome; nitric acid is recycled; alkali or additive is omitted, and the operation cost of waste gas treatment is lowered; the pollution control difficulty of high-concentration nitric oxide is reduced; the waste gas pollution control rate is guaranteed.

Owner:天津市嘉腾环保设备股份有限公司

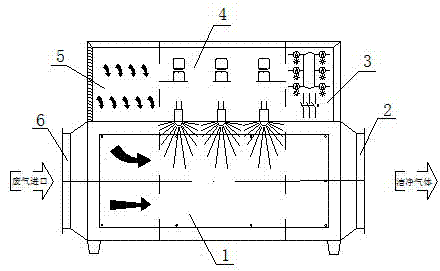

Collecting system for printing and coating waste gas

InactiveCN109045852AFull recoveryLow processing and running costsGas treatmentDispersed particle filtrationThermal energyAir volume

The invention relates to a collecting system for printing and coating waste gas. The collecting system comprises a fresh air intake system, a hot air drying system, a printing machine and a tail gas treatment system which are sequentially connected, wherein the tail gas treatment system is connected with the hot air drying system through a heat energy recycling system; the fresh air sucked by thefresh air intake system is sent into the printing machine via the hot air drying system, and carries the waste gas in the printing machine out of the tail gas treatment system; the high-temperature waste gas treated by the tail gas treatment system is performed with heat exchange by the heat energy recycling system, and the gas after heat exchange is exhausted out; the heat absorbed by the heat energy recycling device is recycled into the hot air drying system. The collecting system has the advantages that part or all of heat energy can be recycled by the heat energy recycling system; the hotair is directly recycled to a circulating drying air inlet of the printing machine by the hot air recycling system, so as to greatly reduce the air volume and fully recycle the heat energy; the running cost of tail gas treatment is greatly reduced, a large amount of heat energy is saved, and the higher social and economic benefits are realized.

Owner:青岛大拇指环境工程有限公司

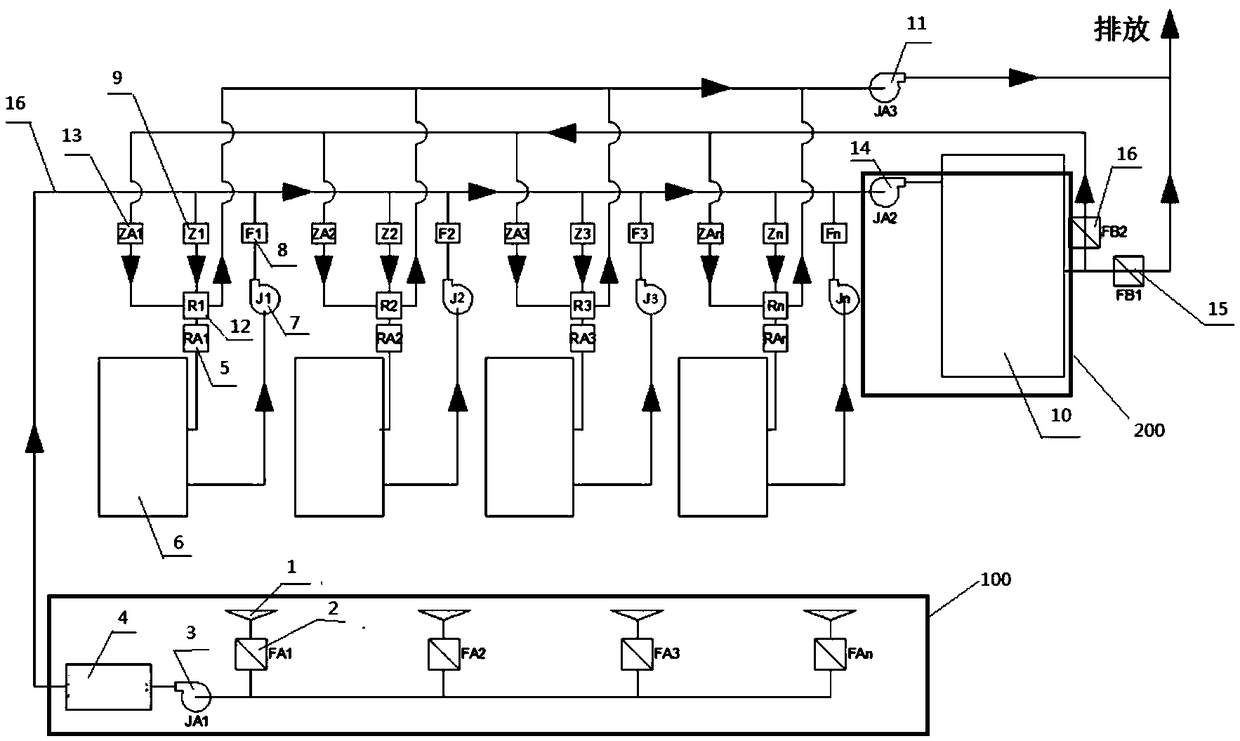

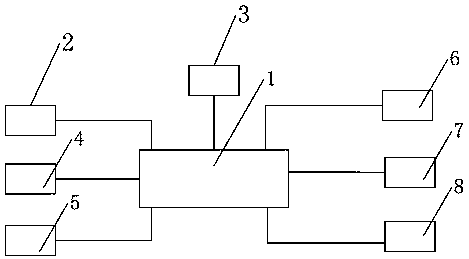

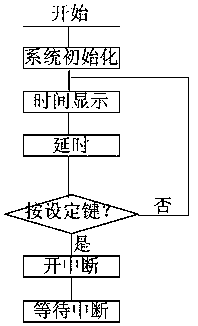

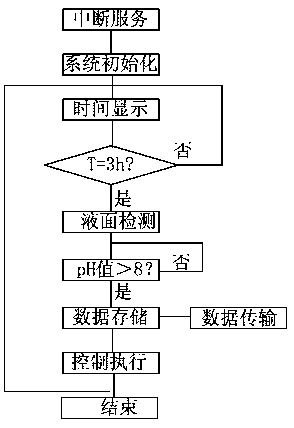

Complete set of online monitoring and control system for petrochemical wastewater

InactiveCN108051558AImprove performanceImprove reliabilityTesting waterMonitoring and controlStreamflow

The invention belongs to the technical field of monitoring of petrochemical wastewater and particularly relates to a complete set of online monitoring and control system for petrochemical wastewater.The system comprises a controller, a timing module and a detection module, wherein the timing module is coupled with the controller; the detection module comprises a chromaticity sensor, a flow sensor, a temperature sensor and a pH sensor, and the pH sensor is connected with the controller and transmits a pH value signal to the controller; the system also comprises a storage device, and the storage device stores flow, temperature, time and pH parameters detected by the detection module and is connected with the controller. Efficient treatment of the petrochemical wastewater is realized, the wastewater treatment process can be monitored, the performance, reliability, flexibility and operation efficiency for wastewater treatment can be improved according to monitoring results, and the wastewater treatment load is increased.

Owner:SHANDONG XINGHUO SCI TECH INSTITYTE

Quartz sand purification system without washing procedure

ActiveCN112678830ALow processing and running costsAvoid clumpingSilicaDrying solid materials with heatFluidized bed dryingWater use

The present invention discloses a quartz sand purification system without the washing procedure. The quartz sand purification system without the washing procedure comprises an acid pickling device, a filtering device, a drying device and a finish machining device, and quartz sand materials are sequentially transferred among the acid pickling device, the filtering device, the drying device and the finish machining device; the drying device comprises a fluidized bed dryer, a material inlet of the fluidized bed dryer is connected with a stock bin, and a material outlet is connected with a collecting bin. A hot air inlet of the fluidized bed dryer is sequentially connected with a heating furnace, an air blower and an air filter, a hot air outlet is sequentially connected with a cooler, a multi-stage dust removal device, a multi-stage water absorption device and an acid mist absorption tower through pipelines, and a gas outlet of the acid mist absorption tower is communicated with the atmosphere. According to the invention, deacidification in a washing process can be satisfied, a large amount of environmental protection and production investment are saved, water and wastewater treatment operation cost is saved, production cost is reduced, and an impurity removal effect can be further achieved in a fluidized bed drying process.

Owner:龙川县明昊石英新材料有限公司 +1

Anaerobic ammonia oxidation reactor

InactiveCN108609734ALow processing and running costsLess investmentWater contaminantsBiological treatment apparatusWater bathsLoad resistance

The invention discloses an anaerobic ammonia oxidation reactor. The anaerobic ammonia oxidation reactor comprises a reactor barrel body and a circular flow guiding barrel, wherein a liquid inlet is formed in the upper portion of a flow pushing assembly in the circular flow guiding barrel; an upper flow guider assembly is arranged on the upper portion of the liquid inlet; a lower flow guider assembly is arranged on the lower portion of the circular flow guiding barrel; a sewage inlet tube is arranged on one side of the reactor barrel body; an anaerobic ammonia oxidation mycoderm carrier fillerregion is arranged in the reactor barrel body; a plurality of three-phase separators are symmetrically arranged on the top of the upper flow guider assembly; a sewage outlet is formed in the bottom ofthe reactor barrel body, and communicates with a water inlet of a circulating pump; a water outlet pipe of the circulating pump communicates with a serpentine pipe in a water-bath pre-heating tank; and a water outlet pipe of the serpentine pipe communicates with a water inlet pipe. The anaerobic ammonia oxidation reactor is high in treatment efficiency, large in sewage impact load resistance, lowin running cost and high in equipment integration degree, and runs stably.

Owner:江苏金博源环保科技有限公司

Full valence state application integrated wastewater treatment method integrating catalysis, oxidation, reduction and coagulation

PendingCN109467215ALow running costReduced sludge productionMultistage water/sewage treatmentWater/sewage treatment by oxidationIonScrap

The invention discloses a full valence state application integrated wastewater treatment method integrating catalysis, oxidation, reduction and coagulation and belongs to the field of wastewater treatment. The invention aims at providing the full valence state application integrated wastewater treatment method integrating catalysis, oxidation, reduction and coagulation, which has the advantages oflow cost, simple operation and good treatment effect. The full valence state application integrated wastewater treatment method integrating catalysis, oxidation, reduction and coagulation, disclosedby the invention, comprises the following steps: adding iron scraps or other ferrous metal scraps into to-be-treated wastewater and adding an oxidant for catalytic oxidation; adding the iron scraps orother ferrous metal scraps again, and adjusting the pH value for flocculent precipitation. The full valence state application integrated wastewater treatment method integrating catalysis, oxidation,reduction and coagulation, disclosed by the invention, can control the addition of raw materials according to the demands of wastewater treatment, and adjust the yield of (ferrous) iron ions, so thatthe sludge yield is reduced to the greatest extent while the demands of treatment are met.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

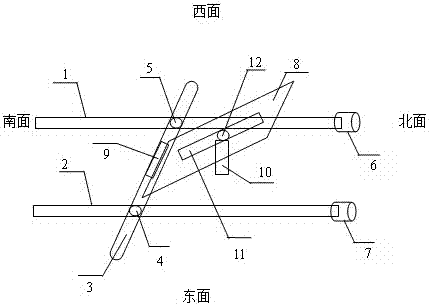

Double-axis tracking sun illumination device having symmetric linear slideways

PendingCN107065934ALow processing and running costsReduce processing costsControl using feedbackDual axisStructural unit

The invention relates to a double-axis tracking sun illumination device having symmetric linear slideways and aims to solve technical problems of small scale, high cost and low benefits existing in sun illumination tracking equipment in the prior art. The device is characterized in that a lighting device rack (8) and a bearing cross rod (3) are connected through a hinge (9), the cross rod (3) slides along the linear slideways through universal linkage mechanisms (4) and (5), driving devices (6) and (7) are further comprised, another slideway (11) on the lighting device rack (8) is connected with a column (10) through along a universal linkage mechanism (12), and the lighting device rack (8) is made to realize linkage change of longitude and latitude angles. The device is advantaged in that vertical tracking is driven through transverse tracking to realize integrated linkage, multiple rows of symmetric structure units are combined to realize simultaneous sun tracking of large-scale multi-set light acquisition racks, processing and operation cost is low, and the device is suitable for large structure making.

Owner:江苏戴日光控能源科技有限公司

Optical microwave waste gas purifier

InactiveCN104492236AShort process flowLow investment intensityDispersed particle separationControl systemSmall footprint

The invention relates to an optical microwave waste gas purifier which comprises a purifier body, wherein a waste gas inlet is formed in the left end of the purifier body; a clean gas outlet is formed in the right end of the purifier body; a control system panel is arranged at the upper part of the right end of the purifier body; a microwave emitting system is arranged at the upper middle part of the purifier body. Compared with the traditional waste gas treatment method, the optical microwave waste gas treatment method has the advantages that the unit investment strength for waste gas treatment low, the occupied area is small, a large-scale waste gas treatment project or small-scale dispersed waste gas treatment projects can be built, the waste gas treatment process flow is short, physico-chemical degradation reaction of pollutants in waste gas is fast, the comprehensive energy consumption of unit waste gas treatment is low, the operation cost of unit waste gas treatment is low, and the waste gas treatment process is free from the influence of environmental temperature and the concentration of original waste gas pollutants.

Owner:SUZHOU BOHAN ENVIRONMENTAL PROTECTION TECH

Device and method for simultaneously removing sulfur and mercury through paper-pulping black liquor

InactiveCN105457480AAchieve emission standardsAchieve modularityGas treatmentDispersed particle separationEnvironmental chemistryFlue gas

The invention relates to a device and method for simultaneously removing sulfur and mercury through paper-pulping black liquor. In a reaction tower, a screen plate is arranged in the position corresponding to the position below each atomizing nozzle; a perforated plate is further arranged in the reaction tower. The device cooperates with black liquor to remove sulfur and mercury in flue gas, in order to improve the sulfur and mercury removing efficiency, the black liquor can be quenched and tempered in advance, and an oxidization agent is added in the black liquor for dilution. On the screen plates, the flue gas makes contact with a liquid membrane to form bubbles, the liquid membrane is broken, small liquid drops are generated again, and the gas and liquid contact possibility is increased; when the flue gas passes a liquid inlet guide pipe, the gas and liquid contact area and the gas and liquid contact probability are further increased; when the flue gas makes contact with the black liquor, sulfur and mercury are diffused in a gas phase body without resistance and then enter the liquid membrane; sulfur and mercury are absorbed by the black liquor, gaseous sulfur and mercury become liquid sulfur and mercury, molecular diffusion is performed in the liquid membrane, Hgp is adsorbed by a solution, meanwhile, components in the black liquor are diffused to a gas phase from a liquid phase, soluble complex components of S2-, X2- and OH- are also transferred into the gas phase, and oxidizing separation is performed after contact.

Owner:CHINA UNIV OF MINING & TECH

Process for changing phenolic nitrate effluent into useful material by extracting, evaporating, crystallizing and coupling

InactiveCN101654305BSolve bottlenecksSolve the miscibility problemOrganic chemistryEvaporationPhenolSodium sulfate

The invention discloses a process for changing phenolic nitrate effluent into useful material by extracting, evaporating, crystallizing and coupling, belonging to the field of changing waste water into useful materials. The process comprises the steps of pre-treating waste water, extracting phenol, performing triple effect evaporation and recycling sodium sulfate. Phenol is extracted with ricinoleic acid and is recycled, so the industrial usage of the phenol is decreased. The oil-water mutual solving problem is efficiently solved by utilizing the salting-out effect of the sodium sulfate highly contained in the waste water. By adopting triple effect evaporation of counter-current operation under a basic condition, the phenol is efficiently prevented from secondarily returning into air, so the phenol contained in the treated waste water is less than 0.5mg / l and can be used as the scouring water for preparing process or can be directly discharged. The by-product sodium sulfate solid is efficiently recycled and the purity of the sodium sulfate is above 99.9%. The produced sodium sulfate makes up for the steam consumption during the evaporation process. Furthermore, the process has the advantages of low treating cost, economic benefit and obvious environmental benefit.

Owner:TSINGHUA UNIV

Filtering pipeline type septic tank reaching standards

PendingCN108218172AStubborn and flexibleAdd filter methodSludge treatment by de-watering/drying/thickeningToilet black water treatmentFiltrationSewage

In order to further improve the treatment efficiency of septic tanks reaching standards, the invention provides a filtering pipeline type septic tank reaching standards. The filtering pipeline type septic tank is mainly composed of an excrement residue tank, a water collecting tank, a clean water tank and a filtering pipeline tank, wherein the excrement residue tank is provided with pipeline typegrids; the water collecting tank is provided with a sewage lifting pump; the clean water tank is provided with a backwashing pump; the filtering pipeline tank is positioned above the excrement residuetank, the water collecting tank and the clean water tank; and the filtering pipeline tank is at least divided into two grids, each grid of the filtering pipeline tank is provided with a group of or multiple groups of filtering pipelines, and the filtering pipelines are mutually communicated through filtering pipeline connecting pipes. Pollutants in sewage are removed through biological contact oxidation, anaerobic biochemical reaction, aerobic biochemical reaction as well as filtration and precipitation action in the facilities.

Owner:邱学尧

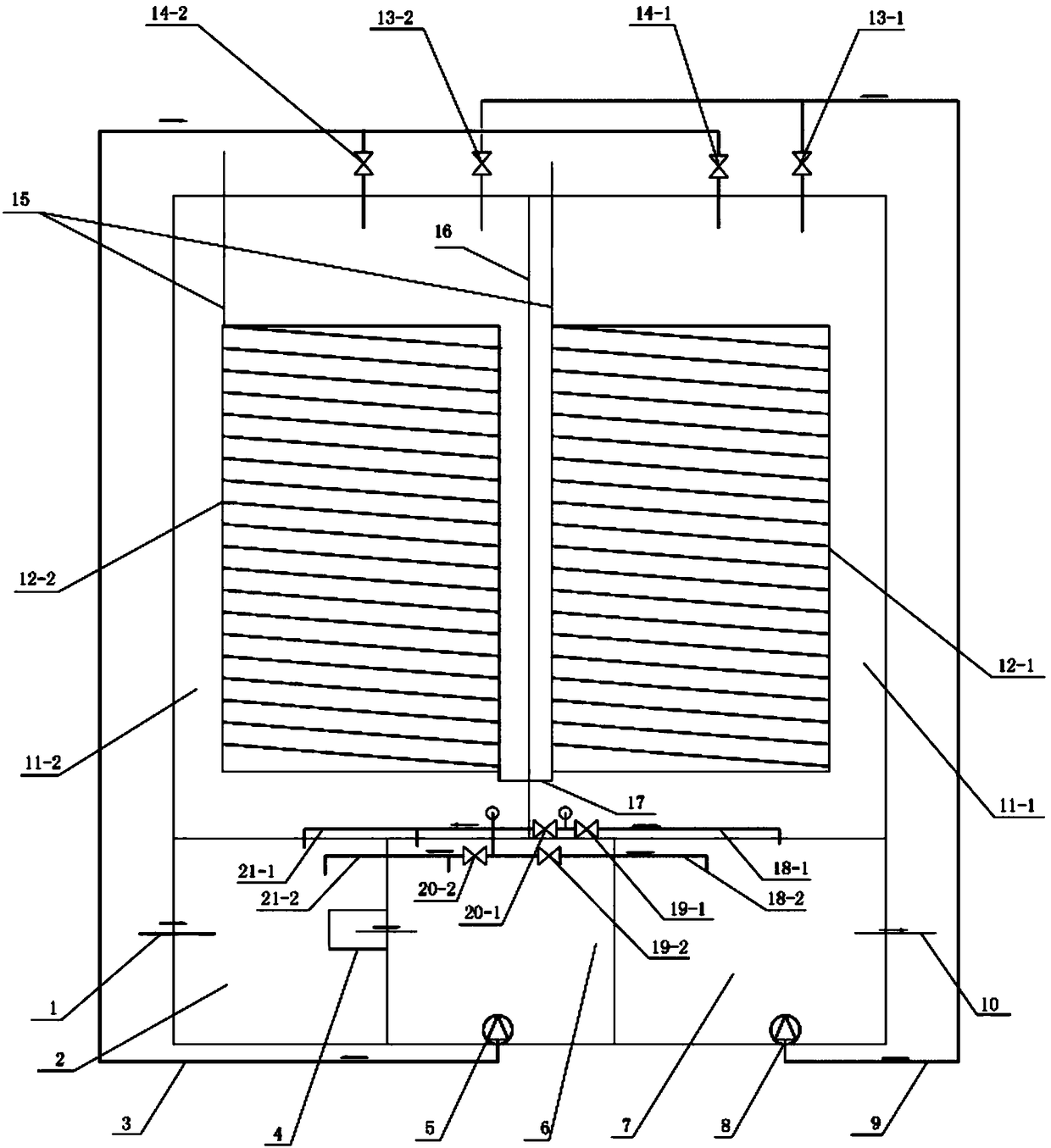

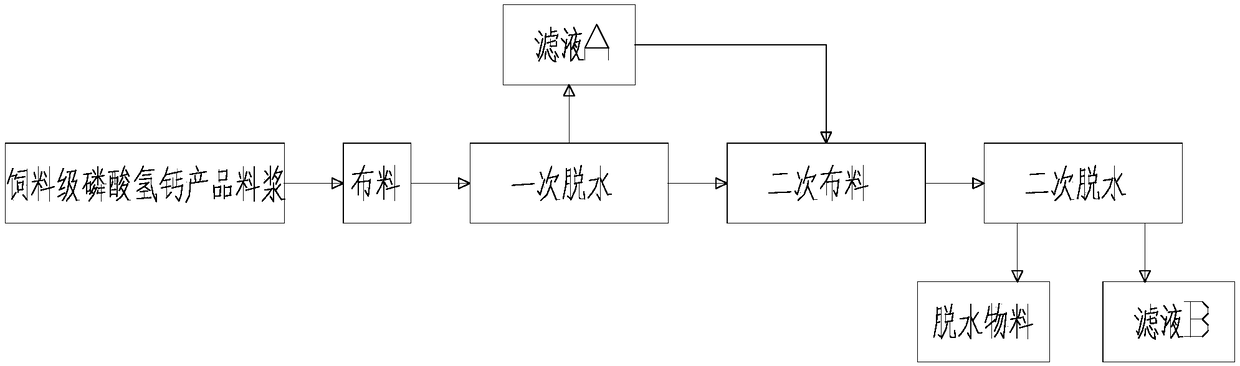

Dehydration method of calcium hydrogen phosphate product slurry

ActiveCN106395781BDehydration method is simpleImprove automation performancePhosphorus compoundsHydrogen phosphateMachine control

The invention discloses a novel dehydration method of calcium hydrogen phosphate product slurry. The method includes the following 4 steps: material distribution, first dehydration, second material distribution and second dehydration. The four steps are mainly carried out through an adhesive tape filter, which consists of a vacuum filtration box, an adhesive tape located above the vacuum filtration box and an adhesive tape machine controlling the adhesive tape rotation. Specifically, the adhesive tape thickness is greater than or equal to 40mm, the adhesive tape moving speed is 0.08-0.1m / s; the vacuum gas pumping amount of the vacuum filtration box is set at 7-8m<3> / m<2>, the vacuum degree is 0.06MPa, and the total length of the vacuum filtration box is 6-7m. The method provided by the invention has the advantages of good dehydration effect, simple operation, high automation performance, low production and running cost, and small safety risk, etc., thus being suitable for popularization and application.

Owner:金华

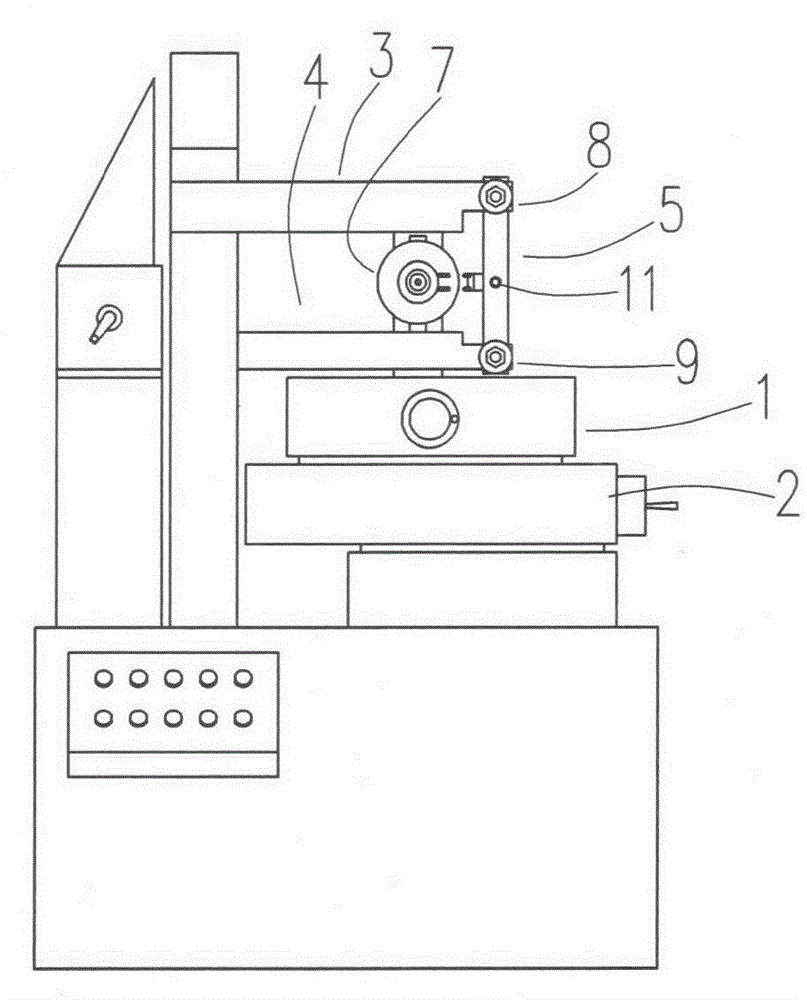

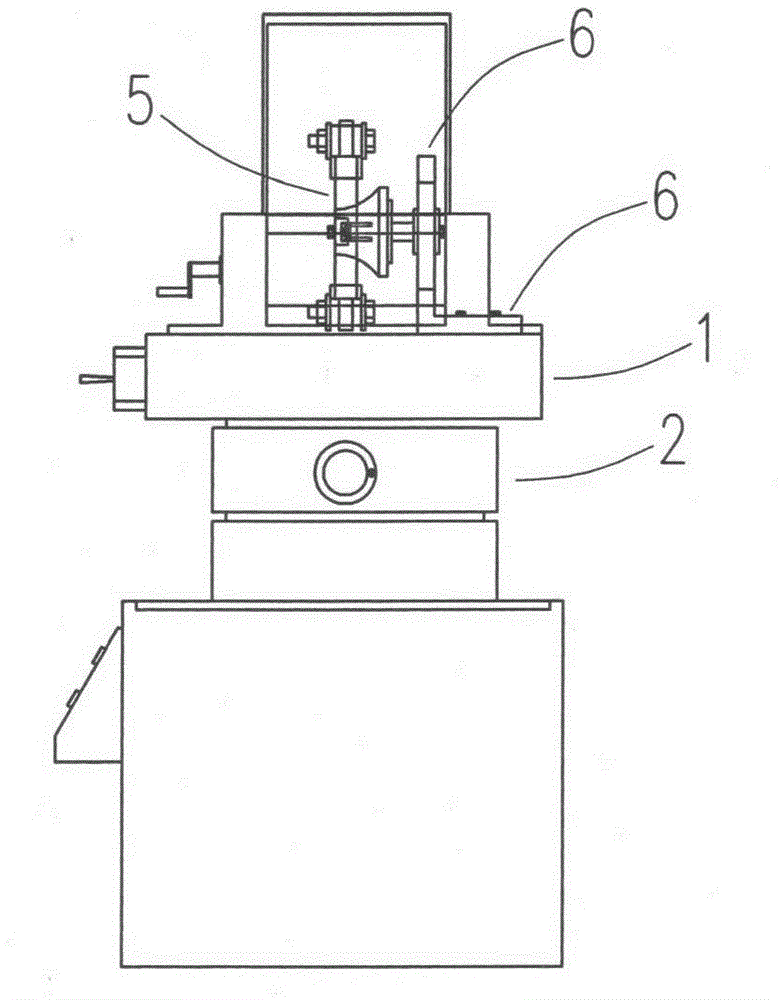

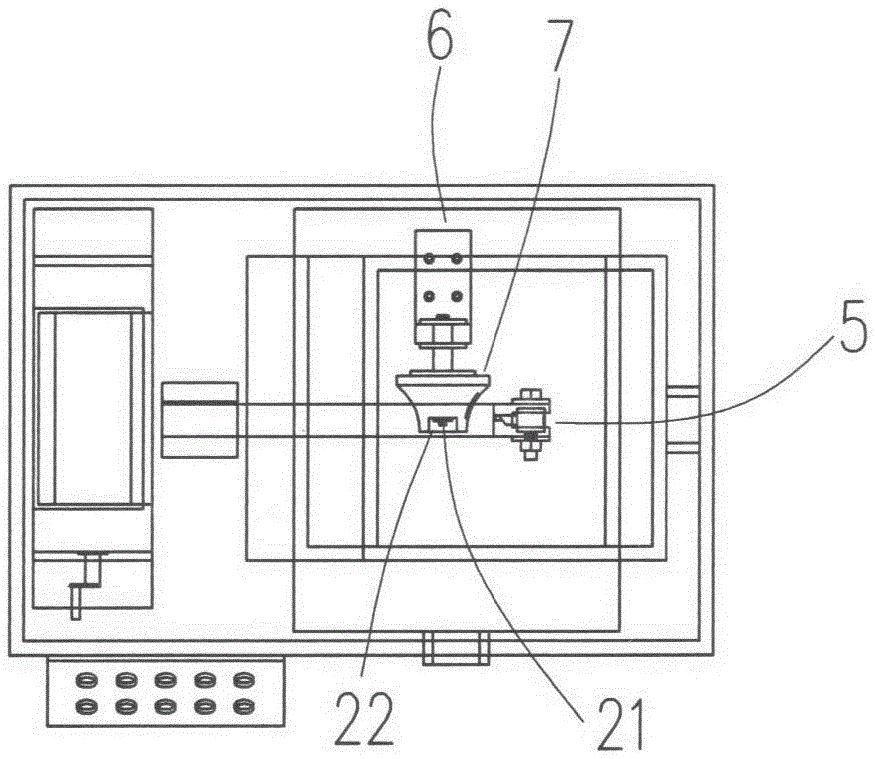

Improved structure of wire-cutting machine tool for graphite electrode curved surface projection precision machining

InactiveCN104441264BLow processing and running costsImprove machining accuracyWorking accessoriesStone-like material working toolsNumerical controlGraphite electrode

A linear cutting machine improved structure for graphite electrode curved surface projection precision machining comprises a program input and output device, a numerical control device, an X-axis workbench, a Y-axis workbench, an upper cantilever and a lower cantilever. The linear cutting machine improved structure for graphite electrode curved surface projection precision machining is characterized in that the linear cutting machine improved structure further comprises a blade clamp and a graphite electrode clamp, the two ends of the blade clamp are fixed to the end of the upper cantilever and the end of the lower cantilever respectively, and the graphite electrode clamp is fixed to the X-axis workbench. The linear cutting machine improved structure is simple, low in improvement cost, low in operation cost compared with a machining center and high in machining precision, and also has the advantages that operation is easy and machining efficiency is high.

Owner:GUANGYUAN FEIDA MOLD MFG

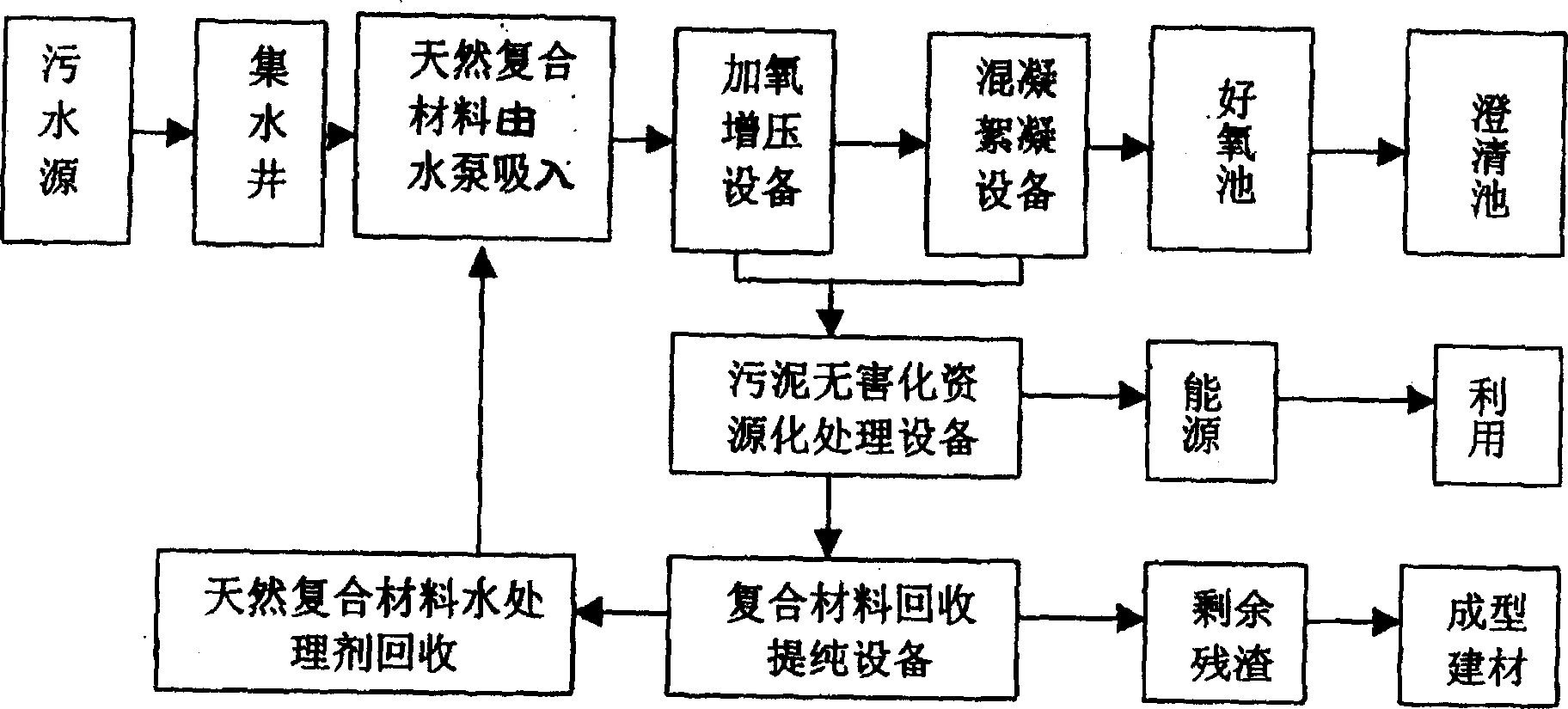

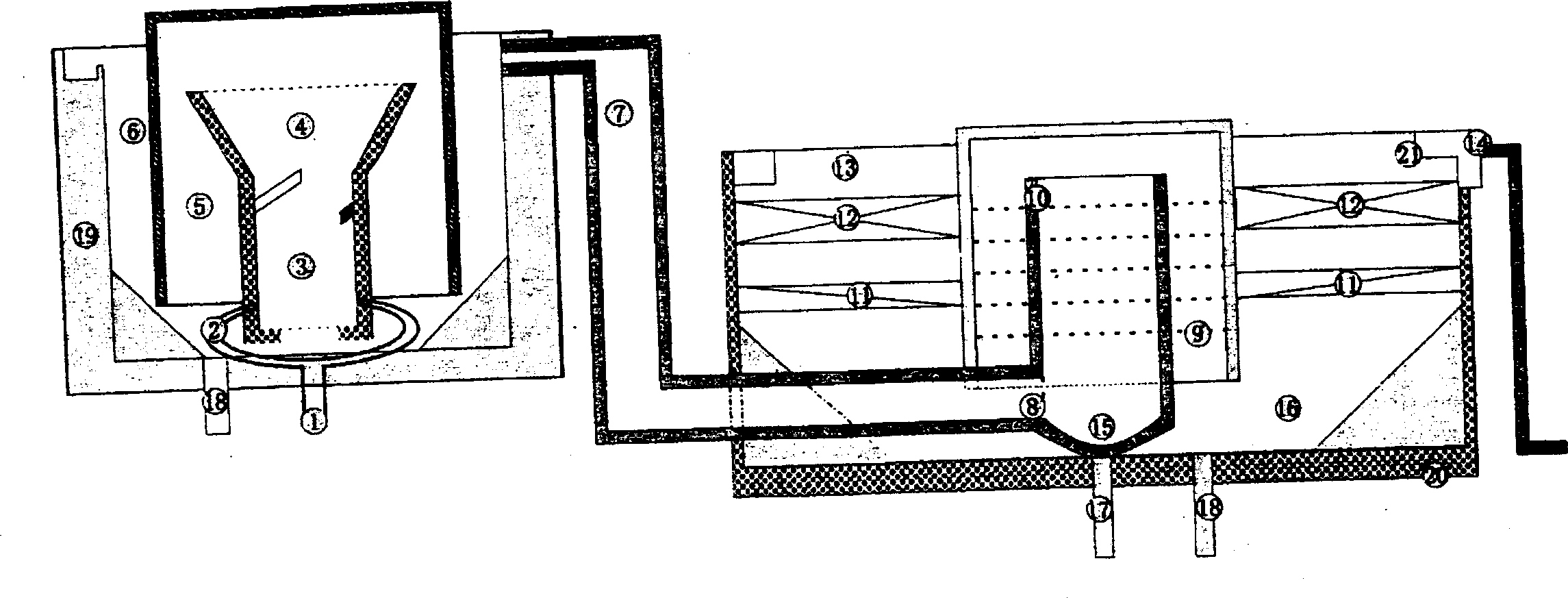

Treatment of industrial and domestic waste water as ecological resource

InactiveCN1140473CLarge specific surface areaEfficient removalMixing methodsMultistage water/sewage treatmentIndustrial waste waterDewatered sludge

The present invention discloses a wastewater treatment method, including the following steps: a. adding natural composite material water treatment agent; b. pressurizing and aeration treatment; c. coagulating and flocculation; d. bio-degrading in aerobic aeration tank; e. sludge dewatering treatment; and f. separating dewatered sludge and recovering natural composite material water treatment agent. Said invention not only can reduce cost for treating waterwater, but also possesses high efficiency for removing various pollutants, does not produce secondary pollution and can change sludge into resource to make utilization, and can recover natural composite material water treatment agent, so that it is applicable to purification treatment of industrial wastewater and domestic wastewater.

Owner:蒲重良

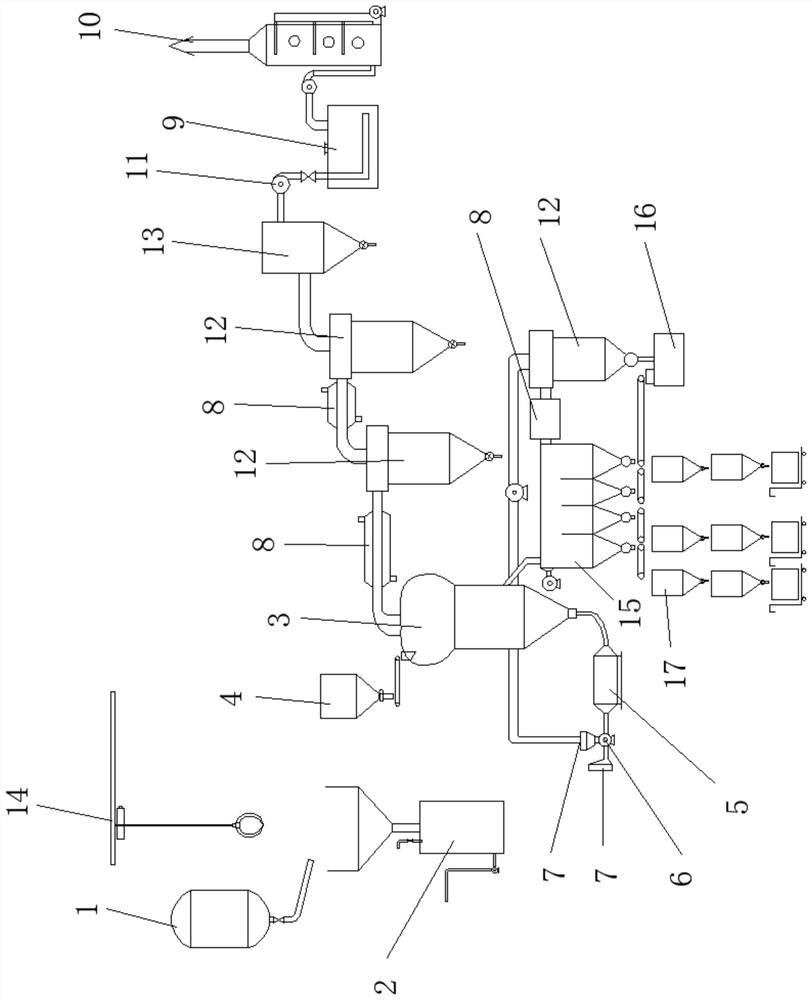

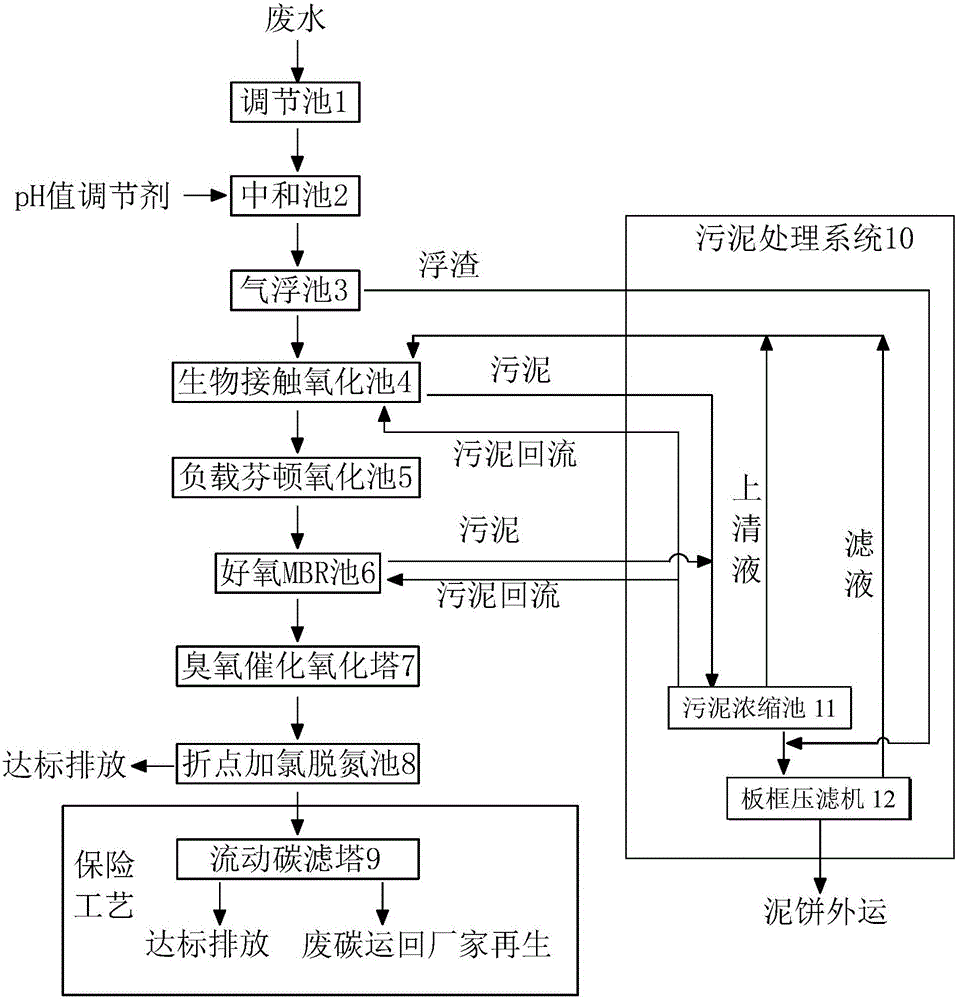

Synthetic rubber wastewater treatment system and its treatment method

ActiveCN104710077BAchieve emission standardsSolve the difficult problem of emission standardsMultistage water/sewage treatmentNature of treatment waterFiltrationSludge

The invention discloses a treatment system of synthetic rubber wastewater. The treatment system comprises a PLC system, an adjusting tank, a neutralizing tank, a floatation tank, a biological contact oxidation tank, a load Fenton oxidation tank, an aerobiotic MBR tank, a catalytic ozonation tower and a break point chlorination denitrification tank, wherein a sludge treatment system comprises a sludge storage tank, a sludge thickener and a plate-and-frame filter press; a water outlet B of the break point chlorination denitrification tank is connected to a flowing carbon filtration tower through a water pump B, the flowing carbon filtration tower further treats organic matters and ammonia nitrogen in sub-standard wastewater, and the wastewater is emitted after the emission standard is achieved. The treatment system disclosed by the invention can effectively remove the hardly degradable organic matters and the high-content ammonia nitrogen in water, and a load-type Fenton effect can improve the biodegradability of the wastewater and guarantees the effect of biochemical treatment; latter catalytic ozonation can further remove the hardly degradable organic matters in the water due to biochemical action; the flowing carbon filtration tower can guarantee the up-to-standard emission of the wastewater, and the CODCr of the wastewater after treatment is smaller than 60 mg / L.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

Quartz sand purification process without washing procedure

ActiveCN112624125ASignificantly progressiveLow processing and running costsSilicaFluidized bed dryingAcid washing

The invention relates to a quartz sand purification process without a washing procedure, which comprises the steps of deacidifying acid-washed and purified quartz sand until the mass of acid liquor in the quartz sand is less than 10%, feeding the deacidified quartz sand into a fluidized bed dryer, and drying at the temperature of 350-750 DEG C under a hot air condition, and cooling the dried quartz sand material to obtain the high-purity quartz sand material. According to the method, the washing procedure is omitted, a large amount of environmental protection and production investment are saved, the water utilization and wastewater treatment operation cost is saved, the production cost is reduced, and meanwhile, the impurity removal effect can be further achieved in the fluidized bed drying process.

Owner:HUANGGANG NORMAL UNIV +1

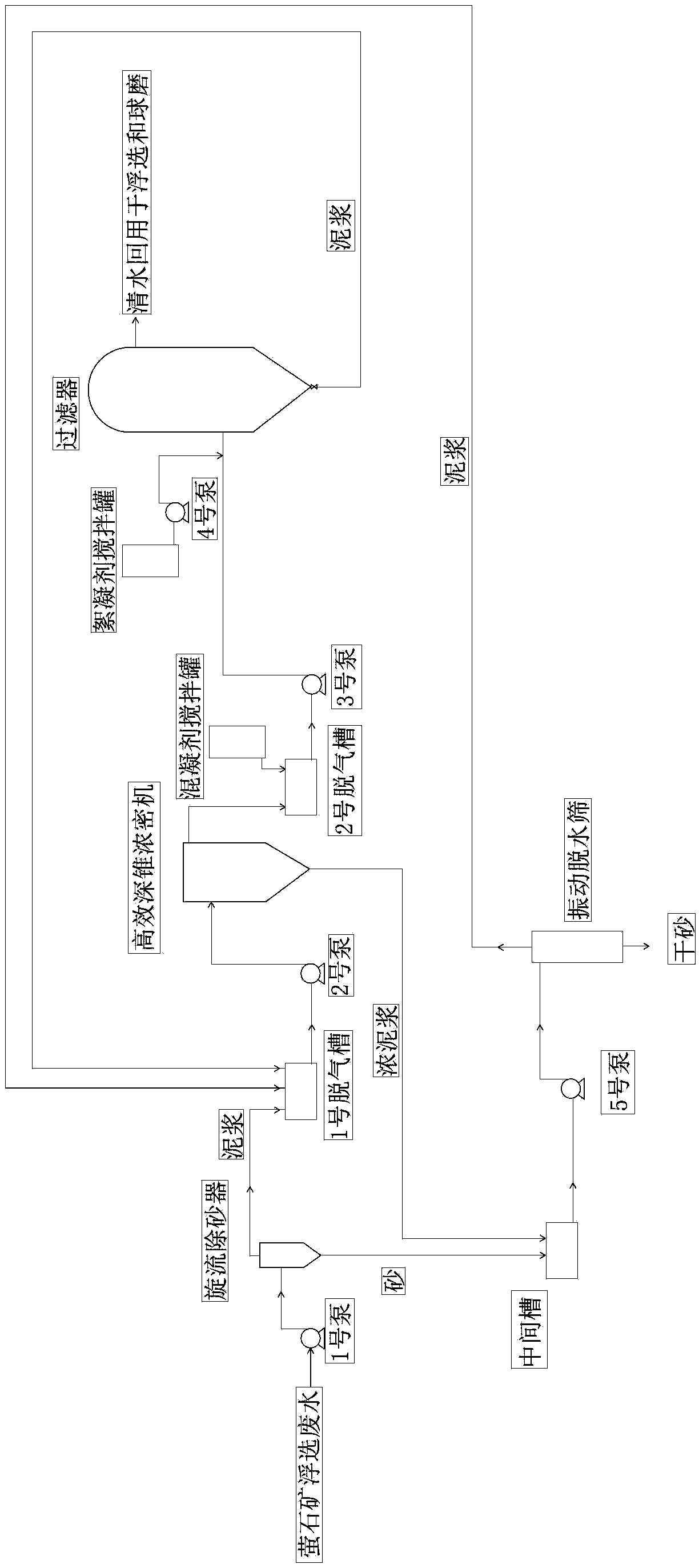

Technique for fluorite mine floatation sewage treatment

ActiveCN103058422BSave waterReduce usageMultistage water/sewage treatmentWater leakageSolid particle

The invention discloses a technique for fluorite mine floatation sewage treatment. The technique disclosed by the invention uses two deaerating tanks for removing air bubbles in mud, so that tiny solid particles are prevented from being adsorbed onto the air bubbles, and sedimentation and separation effects are improved. The technique disclosed by the invention needs no tailing pond, and by using the technique, the floor space can be reduced by more than 96% in comparison with the existing fluorite mine floatation sewage treatment technique according to a newly built fluorite mine floatation plant, so that land acquisition cost and tailing pond construction cost are saved, and the construction period is shortened; according to the existing floatation plant with tailing pond that is built, high investment for clearing the tailing pond or newly building the tailing pond after the tailing pond is full in future is saved. Compared with a waste water treatment technique using the tailing pond, the technique completely avoids potential environmental protection hazard about waste water leakage in the tailing pond and potential safety hazard about dam break of the tailing pond. The method disclosed by the invention realizes good separation effect, small floor space, low investment and low operation cost.

Owner:上海班德环保设备有限公司

A quartz sand purification system without water washing process

ActiveCN112678830BLow processing and running costsAvoid clumpingSilicaDrying solid materials with heatFluidized bed dryingWater use

Owner:龙川县明昊石英新材料有限公司 +1

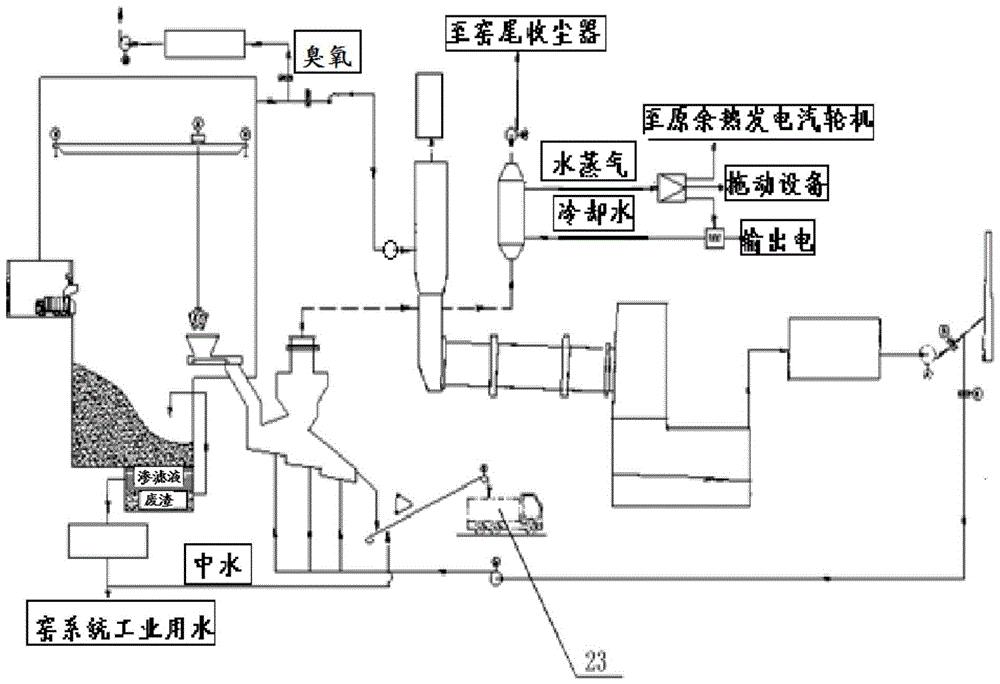

Cement rotary kiln co-processing domestic waste and energy comprehensive utilization system and method

ActiveCN105032884BLarge amount of processingLow processing and running costsConstruction waste recoverySolid waste disposalWater vaporDecomposition

Owner:坚构建材科技集团有限公司

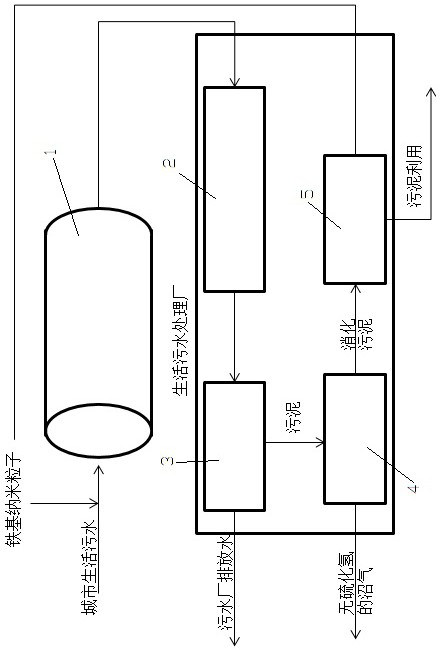

Sewage treatment method

PendingCN114716093AExtended service lifeReduce concentrationWaste based fuelMultistage water/sewage treatmentNanoparticleMunicipal sewage

The invention discloses a sewage treatment method, and aims to solve the problem that the concentrations of substances such as nitrogen, phosphorus, hydrogen sulfide and the like in sewage fed into a biochemical treatment tank are too high due to the fact that urban domestic sewage contains a large amount of organic matters and the organic matters are rotten and deteriorated in the process of being conveyed through an urban pipeline. The method comprises the following steps: chemical addition, biochemical treatment, precipitation, anaerobic treatment and iron recovery. The invention provides a'transfer type 'method for use of the iron-based nanoparticles in sewage treatment, and provides an example for single use mode conversion of other various sewage treatment chemicals. With the adoption of the application, the use amount of chemicals in the urban sewage system can be greatly reduced, so that great environmental and economic benefits are brought. Furthermore, by adopting the method, on one hand, the treatment operation cost is saved by reducing the use amount of chemicals, and on the other hand, the environmental negative effect possibly brought by the chemicals is also reduced.

Owner:四川文理学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com