Patents

Literature

935results about How to "Save construction investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

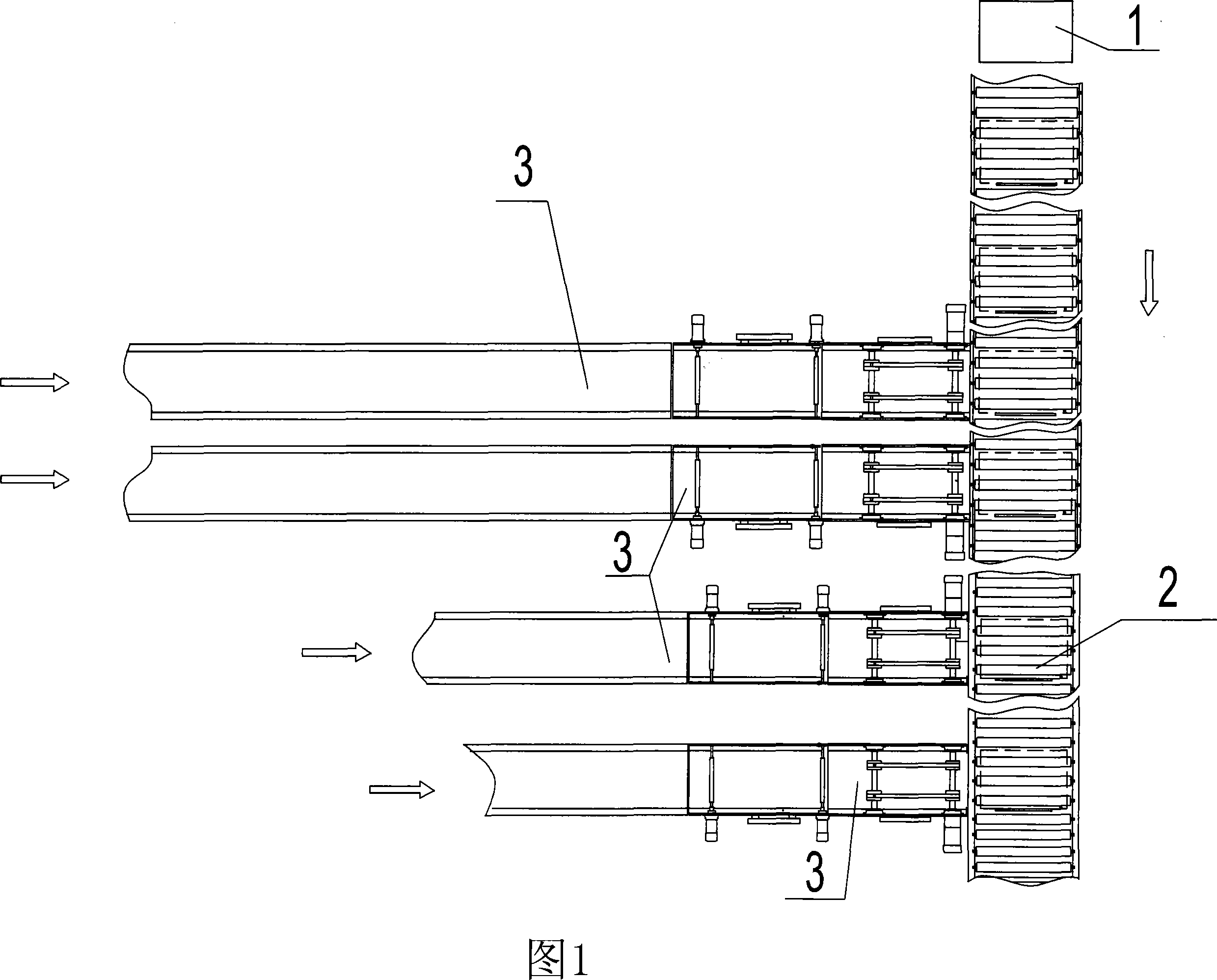

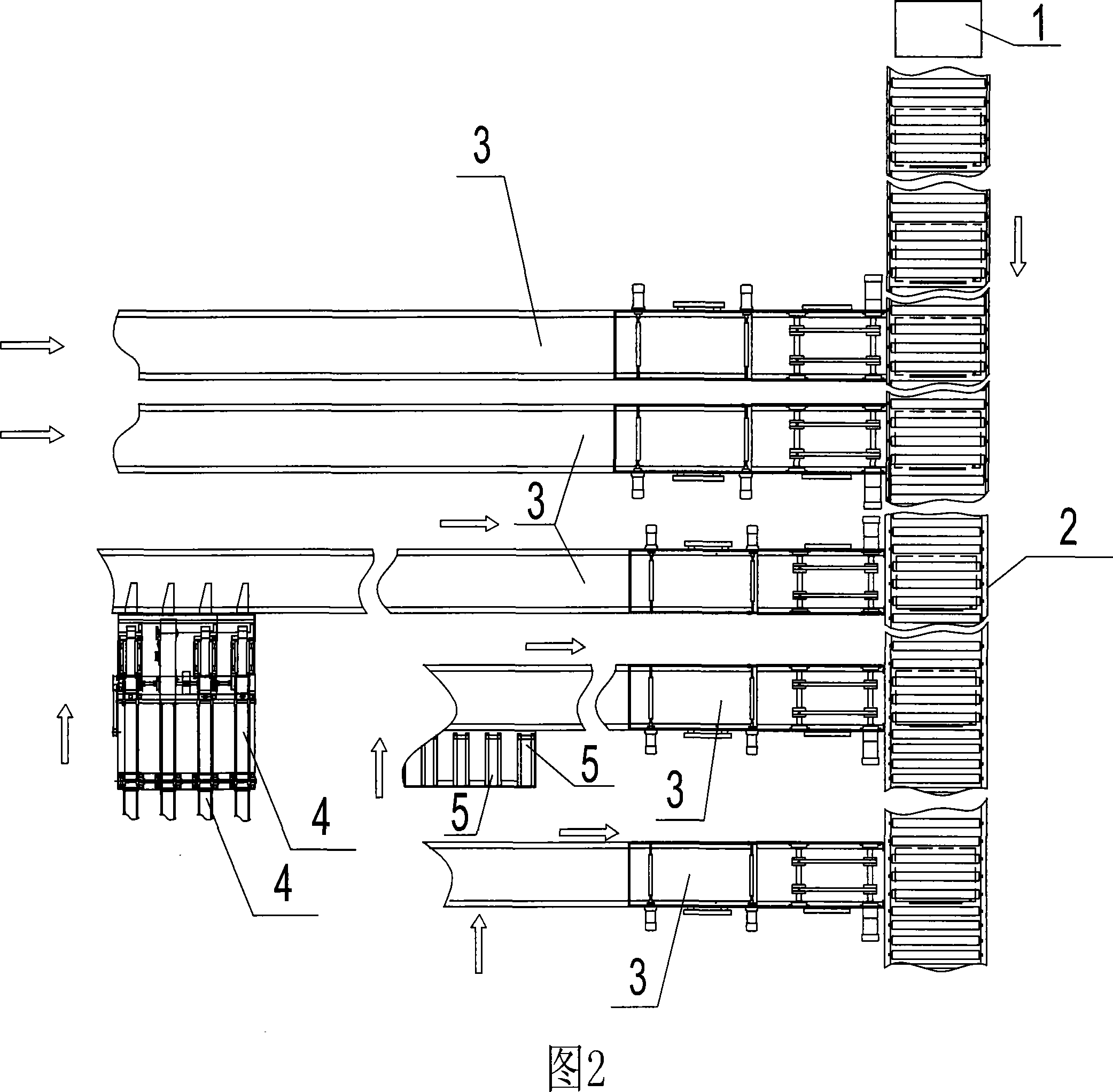

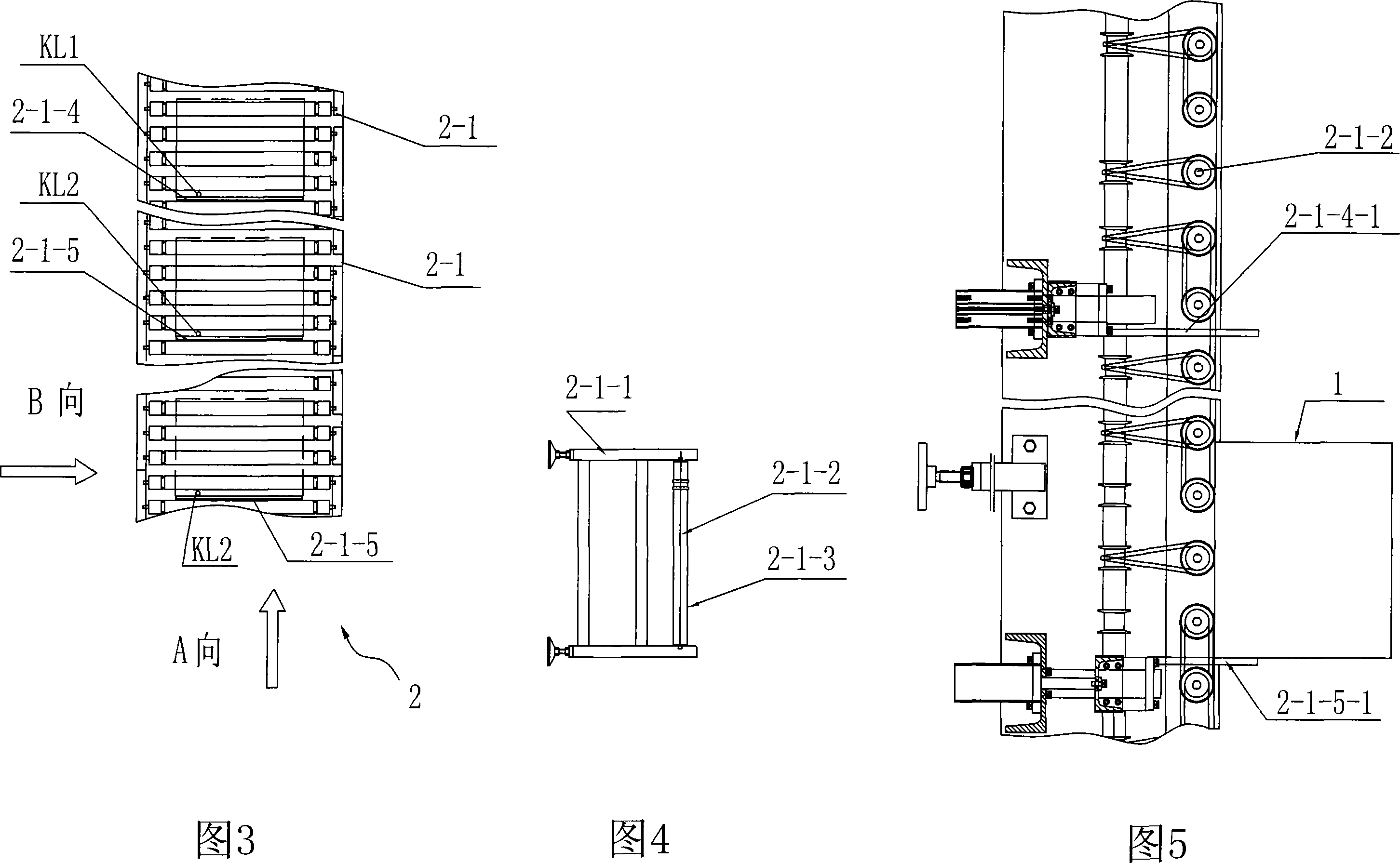

Goods sorting and split charging equipment and method thereof

InactiveCN101234677ASmall footprintReduce the number of employeesControl devices for conveyorsCo-operative working arrangementsElectronic control systemEngineering

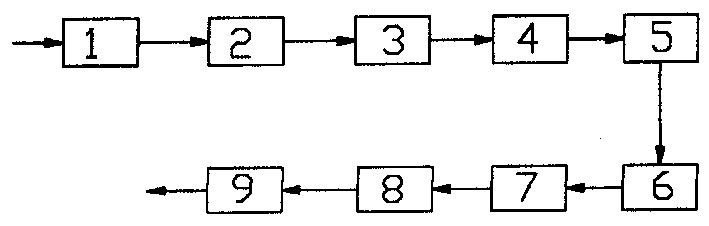

The invention discloses an equipment for sorting and packaging goods and a method thereof, wherein, the equipment comprises turning box baskets, a box basket transporting device, a goods-providing device, a radio frequency reader, a wireless radio frequency card, an electronic control system and a system of computer information management, wherein, each box basket box has the wireless radio frequency card; a side on a stopping position of a plurality of box baskets on the box basket transporting device is provided with the goods-providing device; the radio frequency reader is arranged near the stopping positions for the box backsets on the box basket transporting device. The method comprises the following steps: A. configuring devices for the whole line and determining the brands and specifications of goods to be delivered; B. setting the information of device configuration as well as the brands and specifications of the goods; C. setting the allocation proposal; D. preparing and implementing the allocation proposal; E. starting the whole line and pre-allocation; F. inputting empty box baskets; G. applying the box baskets for delivery and allocation; H. unloading the baskets. The equipment for sorting and packaging goods has the advantages of high speed, reliable work, low operation cost, compact structure, and small land occupancy, so the invention is applicable for various goods delivery centers with different delivery requirements and scopes.

Owner:姜广峻

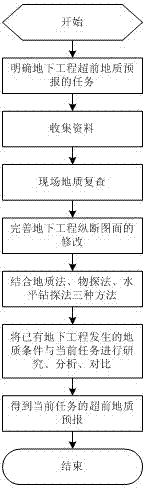

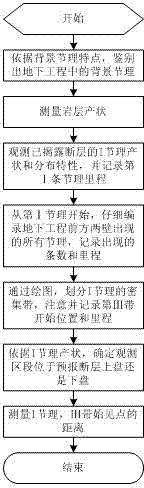

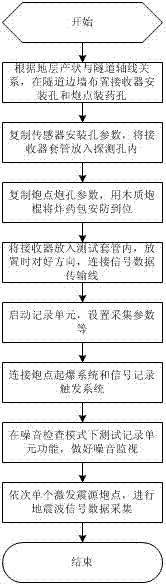

Advanced geological prediction method for underground engineering

InactiveCN102495434AEfficient use ofOptimizing the laws of objective cognitionGeological measurementsGeomorphologyApplicability domain

The invention discloses an advanced geological prediction method for underground engineering. With geology as pivot, the advanced geological prediction method for underground engineering comprises four stages of long-term advanced geological prediction, middle-term advanced geological prediction, short-term advanced geological prediction and impending advanced geological prediction. The advanced geological prediction method comprises the following steps of: (1) making advanced geological prediction tasks for underground engineering for the underground engineering clear; (2) collecting data; (3) carrying out field geological review; (4) perfecting the modification of a longitudinal section drawing of the underground engineering; and (5) adopting combined geological method, geophysical prospecting method and horizontal drilling method to obtain advanced geological prediction. The invention provides the advanced geological prediction method for underground engineering; with geology as pivot, comprehensive geological analysis is carried out in the whole process of advanced geological prediction for underground engineering and the long-term, middle-term, short-term and impending advanced geological predictions are closely combined together to implement combination of geological method, geophysical prospecting method and horizontal drilling method; the comprehensive application of the geophysical prospecting method is optimized; and the advanced geological prediction method for underground engineering, provided by the invention, has the advantages of improving the predication accuracy, reducing predication cost and obtaining wide application range, etc.

Owner:成都畅达通检测技术股份有限公司

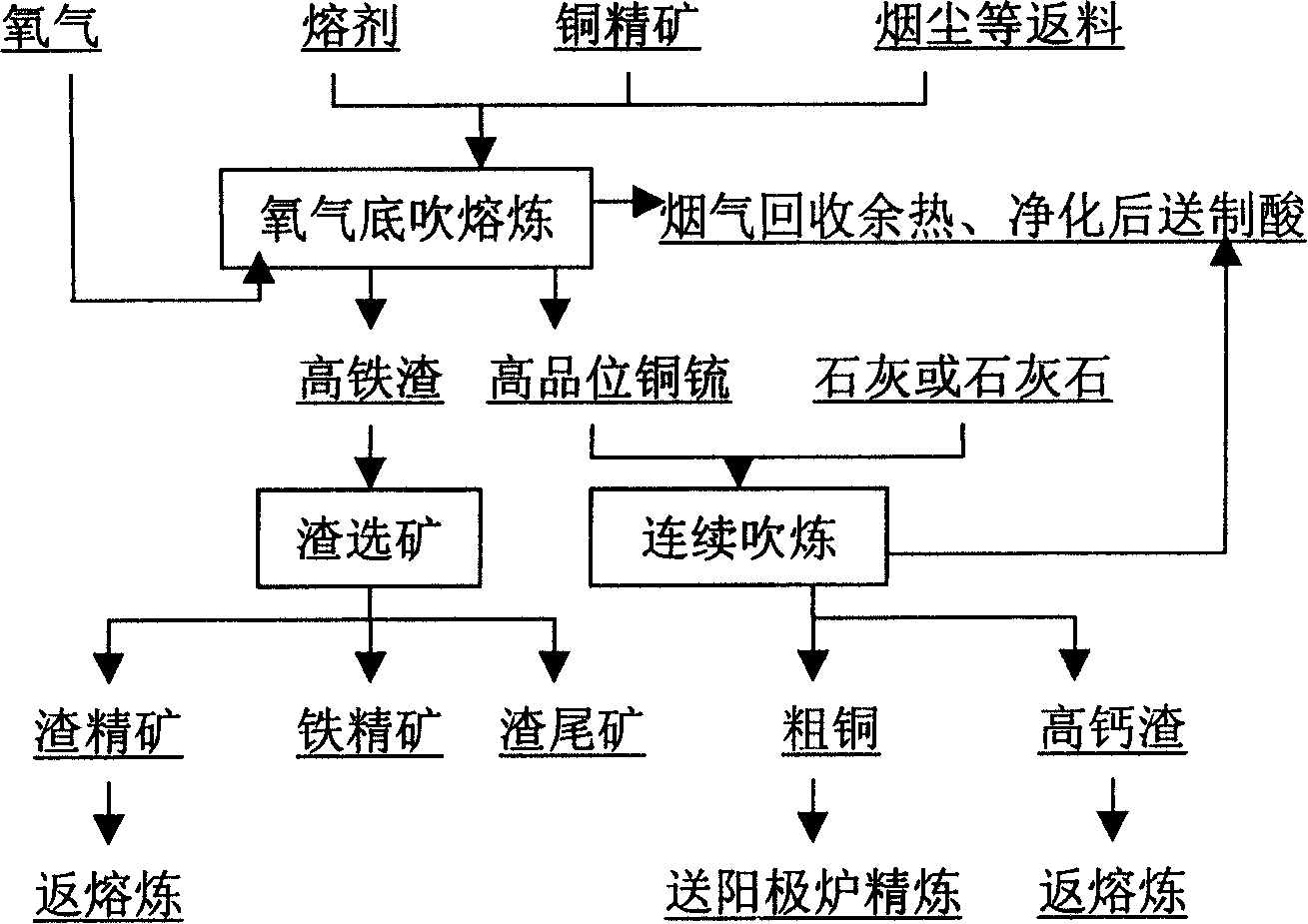

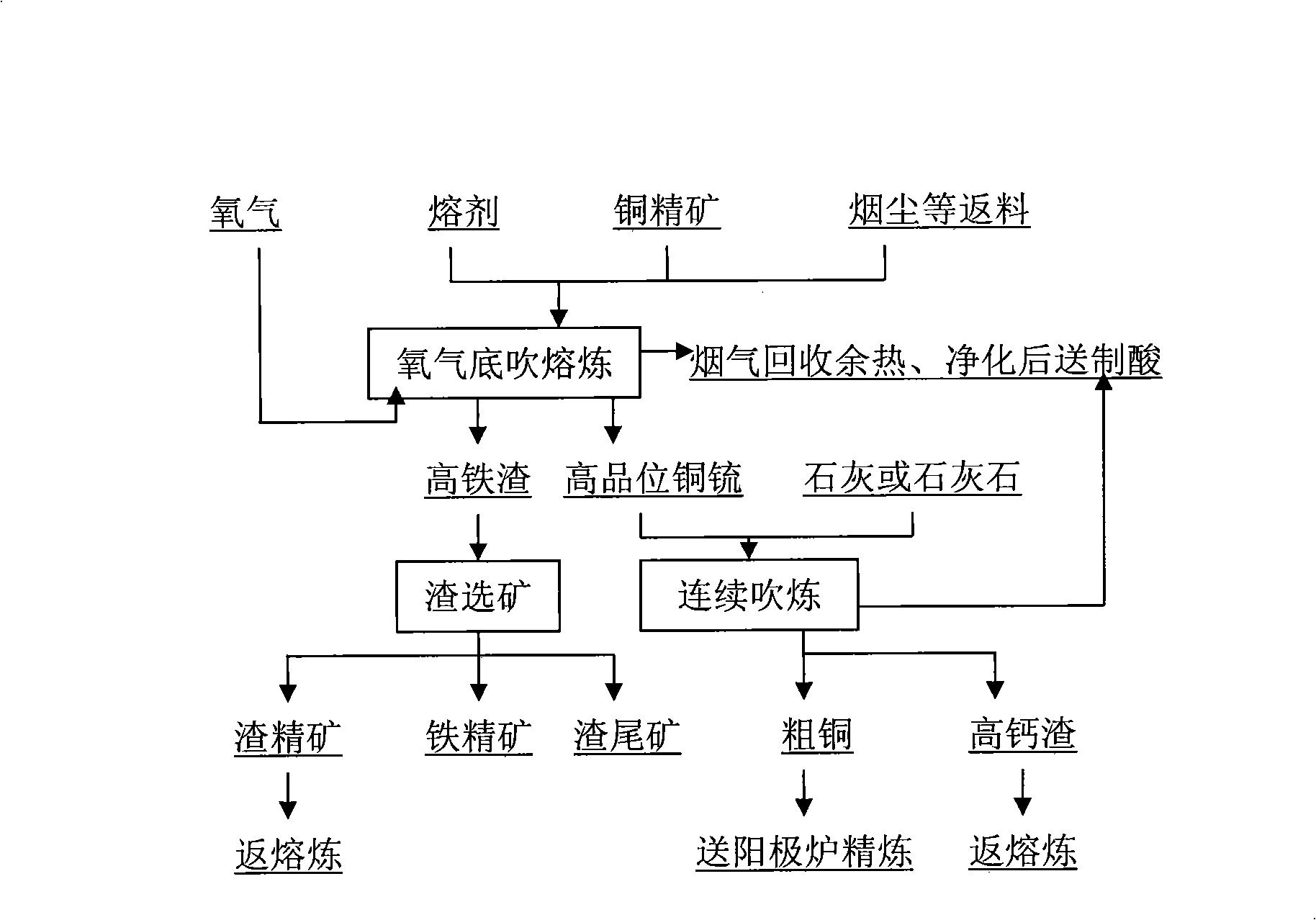

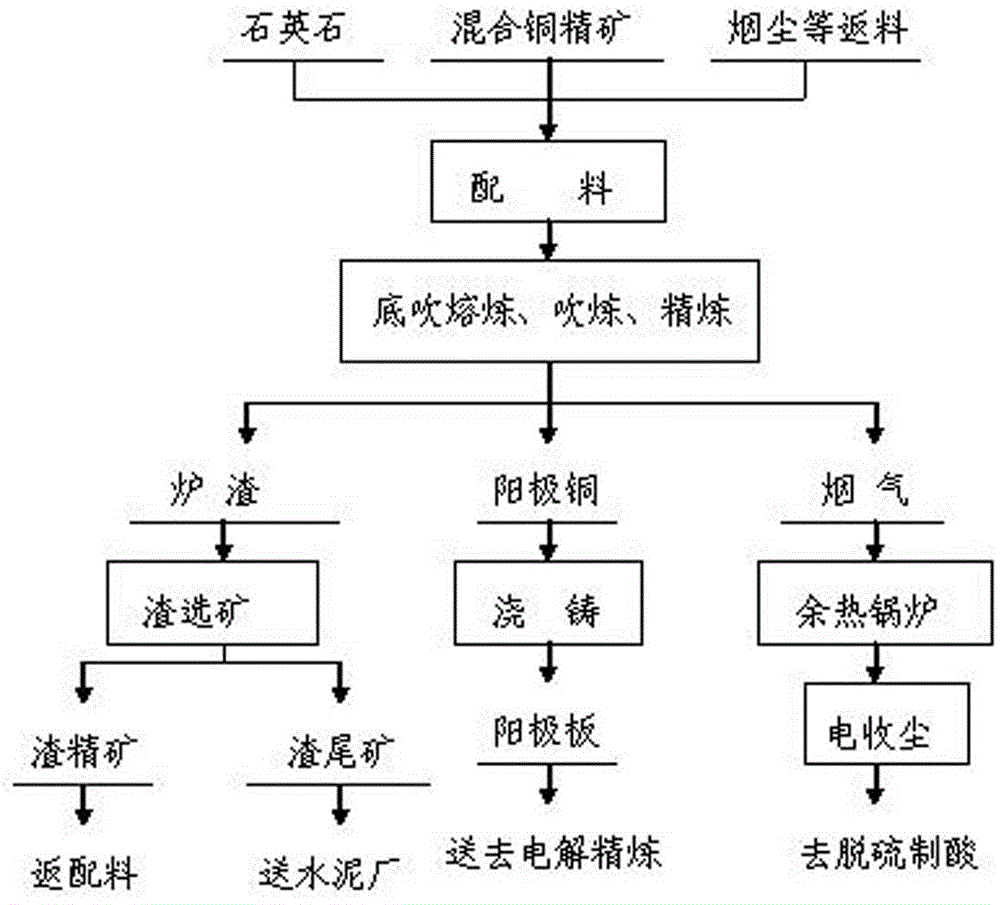

Technique for continuously smelting copper by employing oxygen bottom converter and device thereof

ActiveCN101165196AReduce loadHigh smelting yieldProcess efficiency improvementAutomatic controlSmelting process

The present invention relates to continuous copper-smelting oxygen bottom blowing furnace process and apparatus. The continuous copper-smelting process includes smelting high grade copper matte in an oxygen bottom blowing furnace, smelting coarse copper product with the high grade copper matte in one other bottom blowing furnace, producing high iron slag, dressing the furnace slag to obtain copper concentrate and returning to smelting furnace, separating out iron concentrate product and obtaining tailings. The process has short flow path, low investment, low power consumption, low cost, environment friendship and other advantages.

Owner:CHINA ENFI ENGINEERING CORPORATION

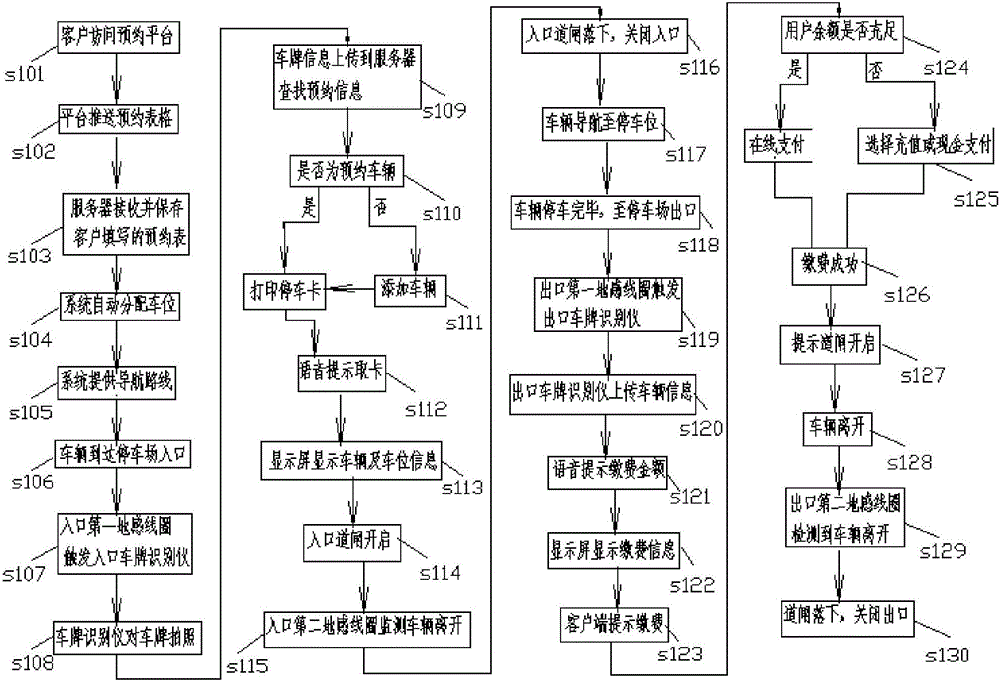

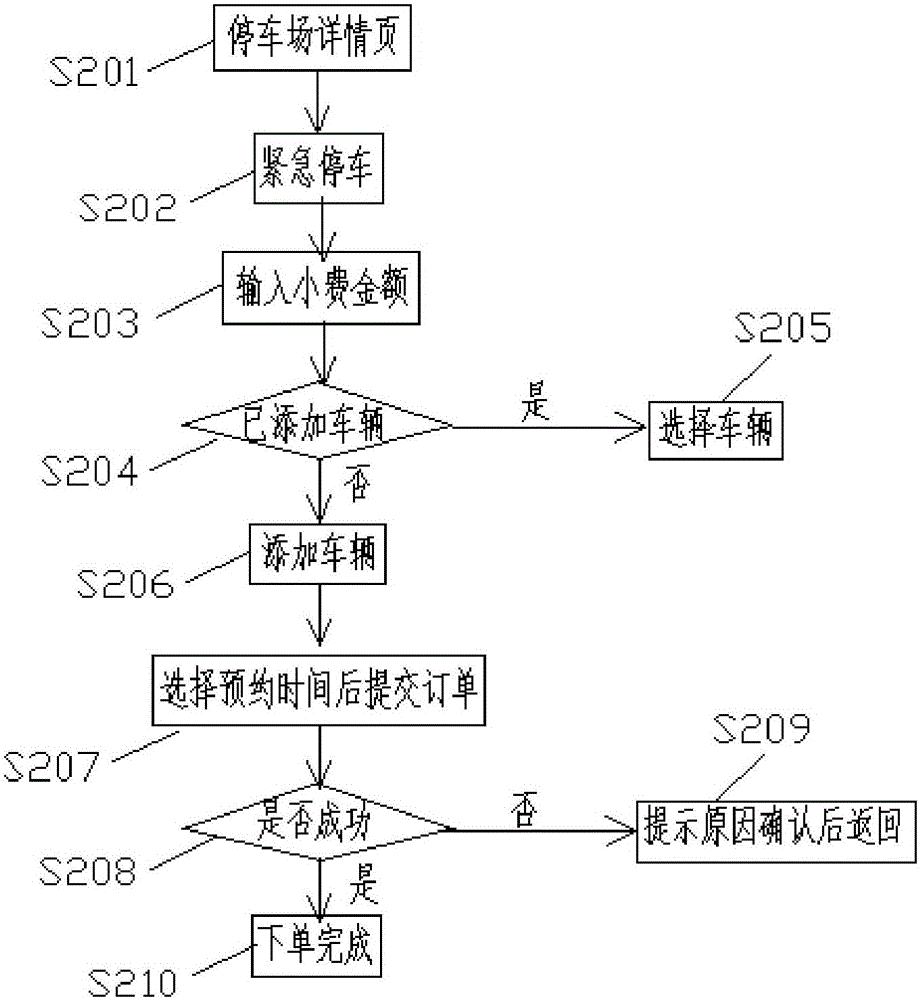

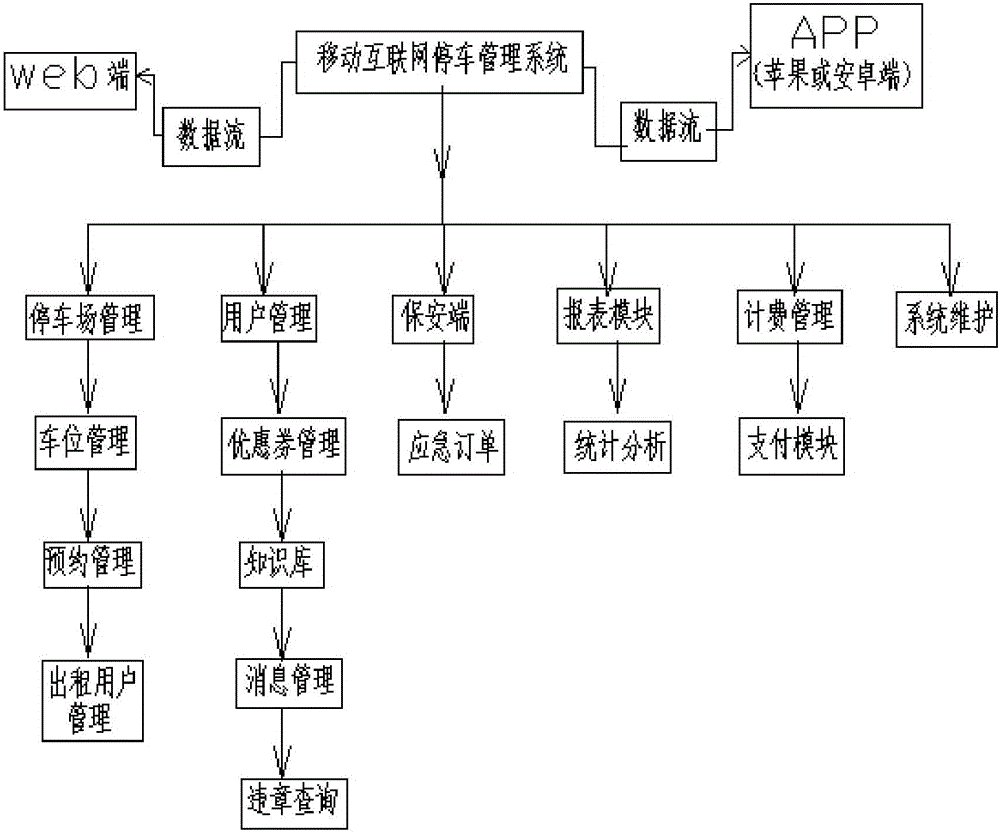

Mobile Internet parking management method and system

InactiveCN105825707AEasy dockingRealize data integration managementTicket-issuing apparatusReservationsPaymentSystem maintenance

The present invention relates to a mobile Internet parking management method and system. The mobile Internet parking management method includes the following steps that: a server receives a reservation parking request sent by a client and generates reservation information according to the reservation parking request and allocates a reserved parking space; when a reservation automobile arrives at the entrance of a parking lot according to a reservation, the server searches the reservation information according to automobile information uploaded by the entrance of the parking lot and instructs the entrance of the parking lot to carry out parking according to the reservation information; when the automobile leaves, the server calculates parking fees of the automobile and sends fee payment information to the client so as to prompt the user to pay the fees; and after the server receives online fee payment of the client, a current parking process is terminated. With the mobile Internet parking management system of the invention adopted, the user can carry out registration and make a reservation in advance, the registration and reservation are directly recorded through the system, an unoccupied parking space is reserved; and when an automobile is being parked, the system automatically identifies whether the automobile is a reservation automobile. With the mobile Internet parking management method and system adopted, a situation that a large number of parking space guidance and automobile searching devices are installed in a parking lot can be avoided, investment cost and system maintenance cost can be saved.

Owner:SINOFLEX OPTOELECTRONICS CHUZHOU

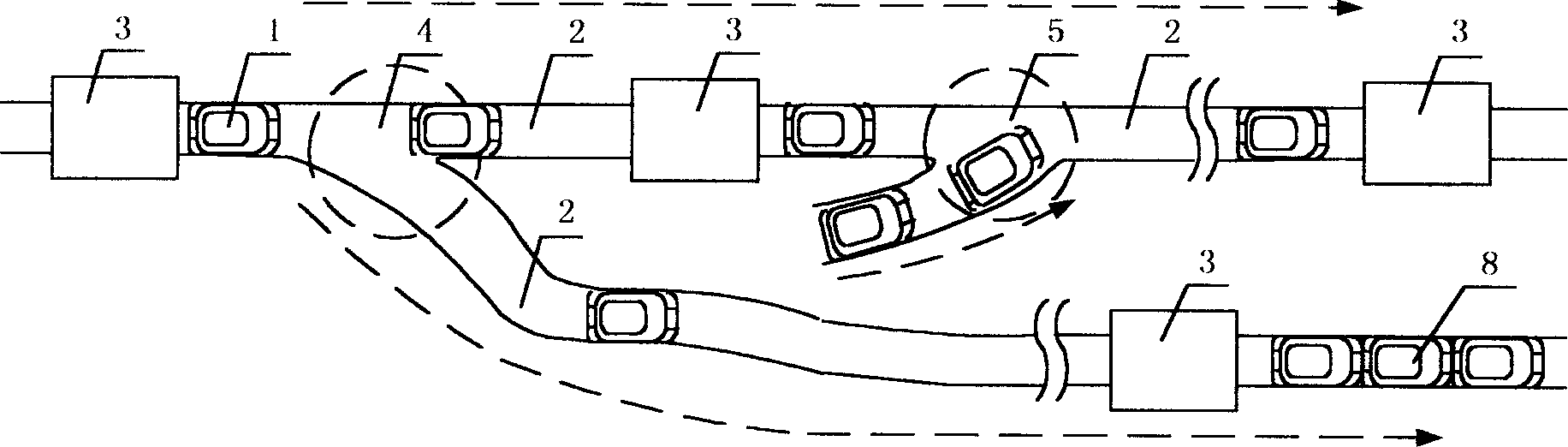

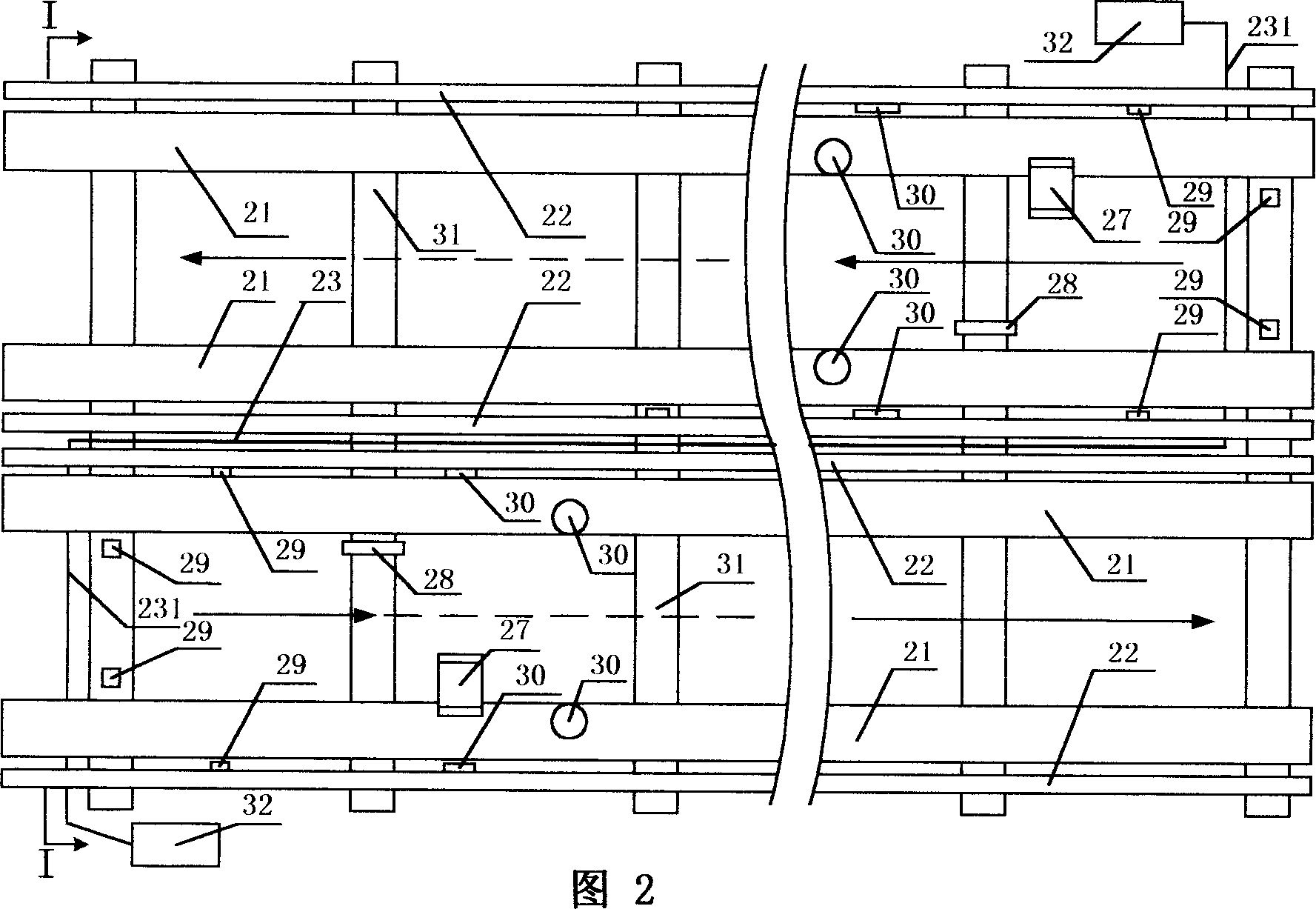

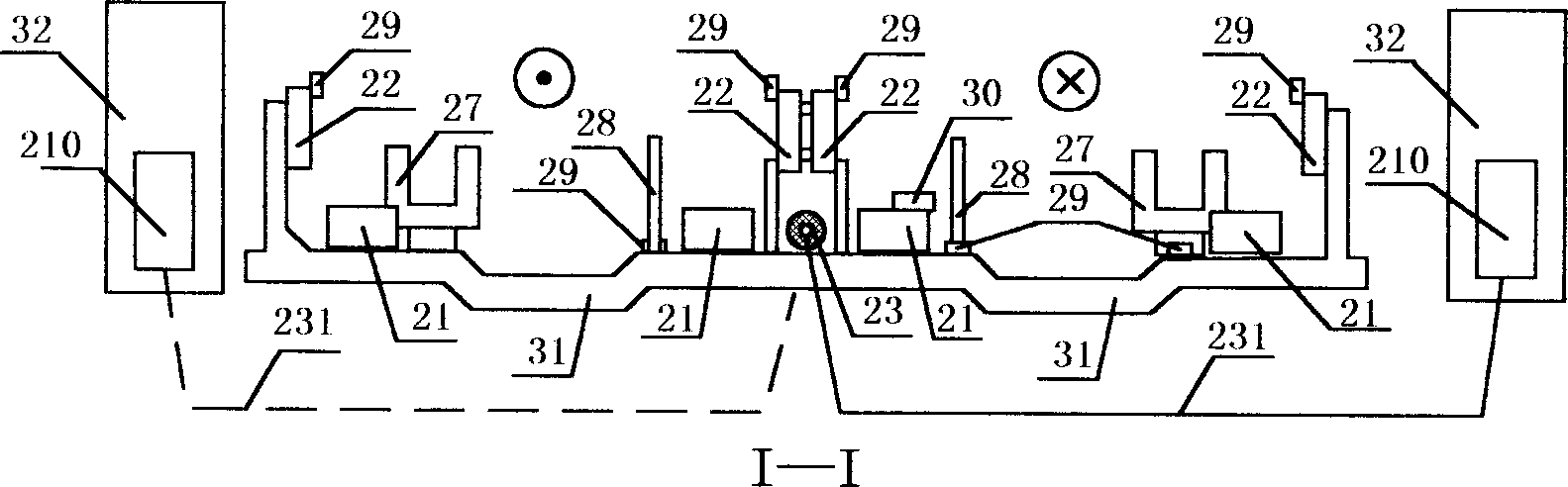

Rail transportation system of small vehicle

ActiveCN1526596ASave construction investmentReduce operating costsRailway componentsRailway stationLight railRail transit

The rail transportation system of small vehicles is used to replace available underground railway and light rail system, and has small driverless vehicles running in closed rail. The system consists of vehicles, closed rails and stations, the vehicles are computerized automatic ones, the closed rails is provided with vehicle controlling equipment, and the vehicles are started from stations randomly for express service from station to station. The present invention has the advantages of great traffic amount similar to that of main stem transportation, personalized service, low construction investment and low running expensive. It may be used for both passenger transport and cargo transport, and municipal rail transportation network may be constructed.

Owner:沈涌

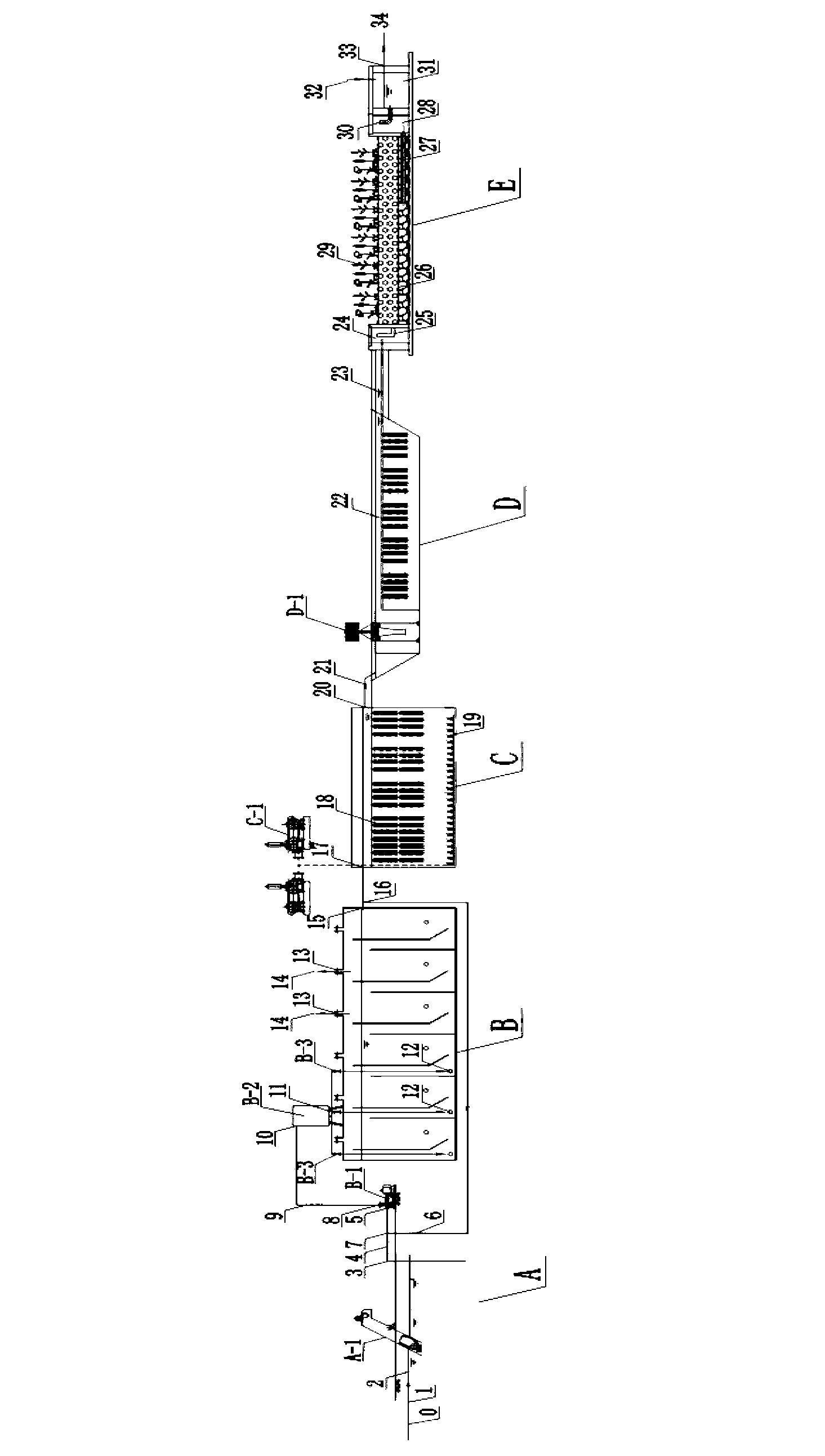

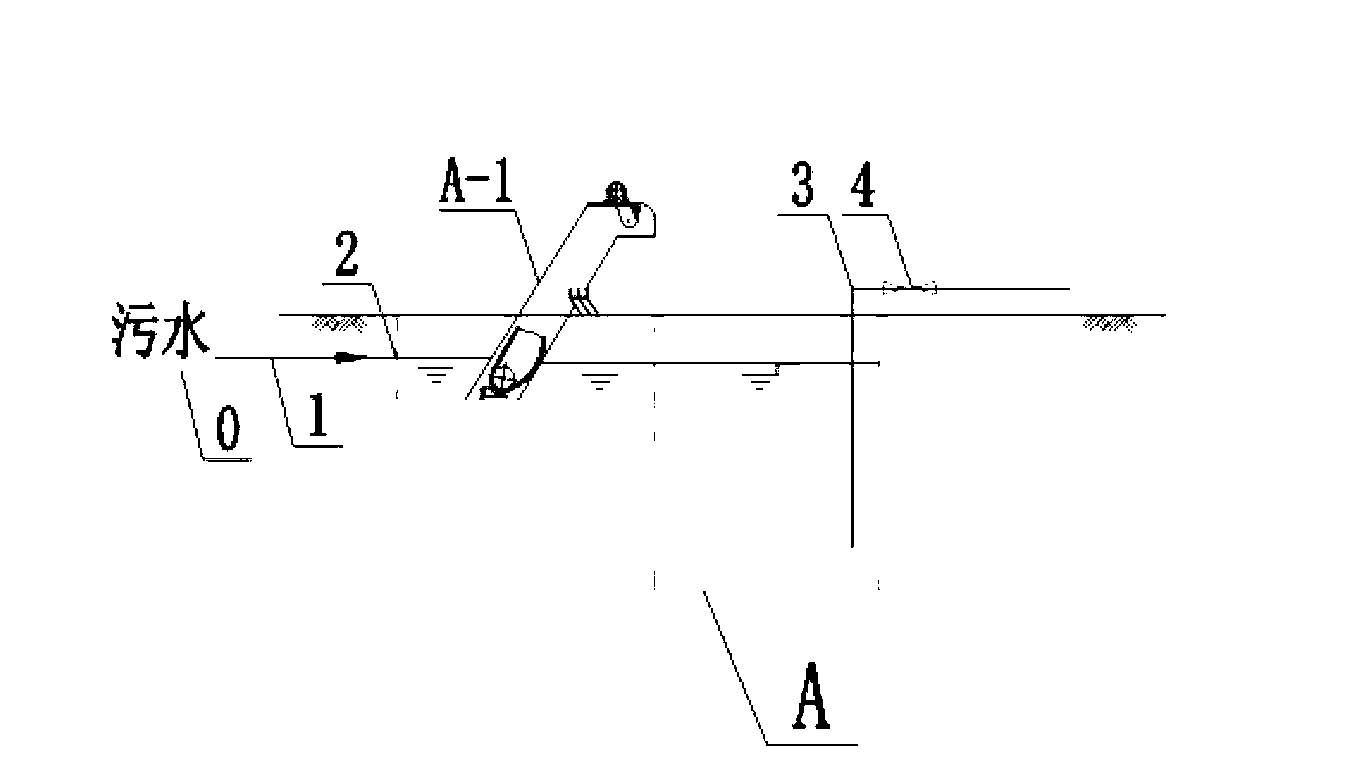

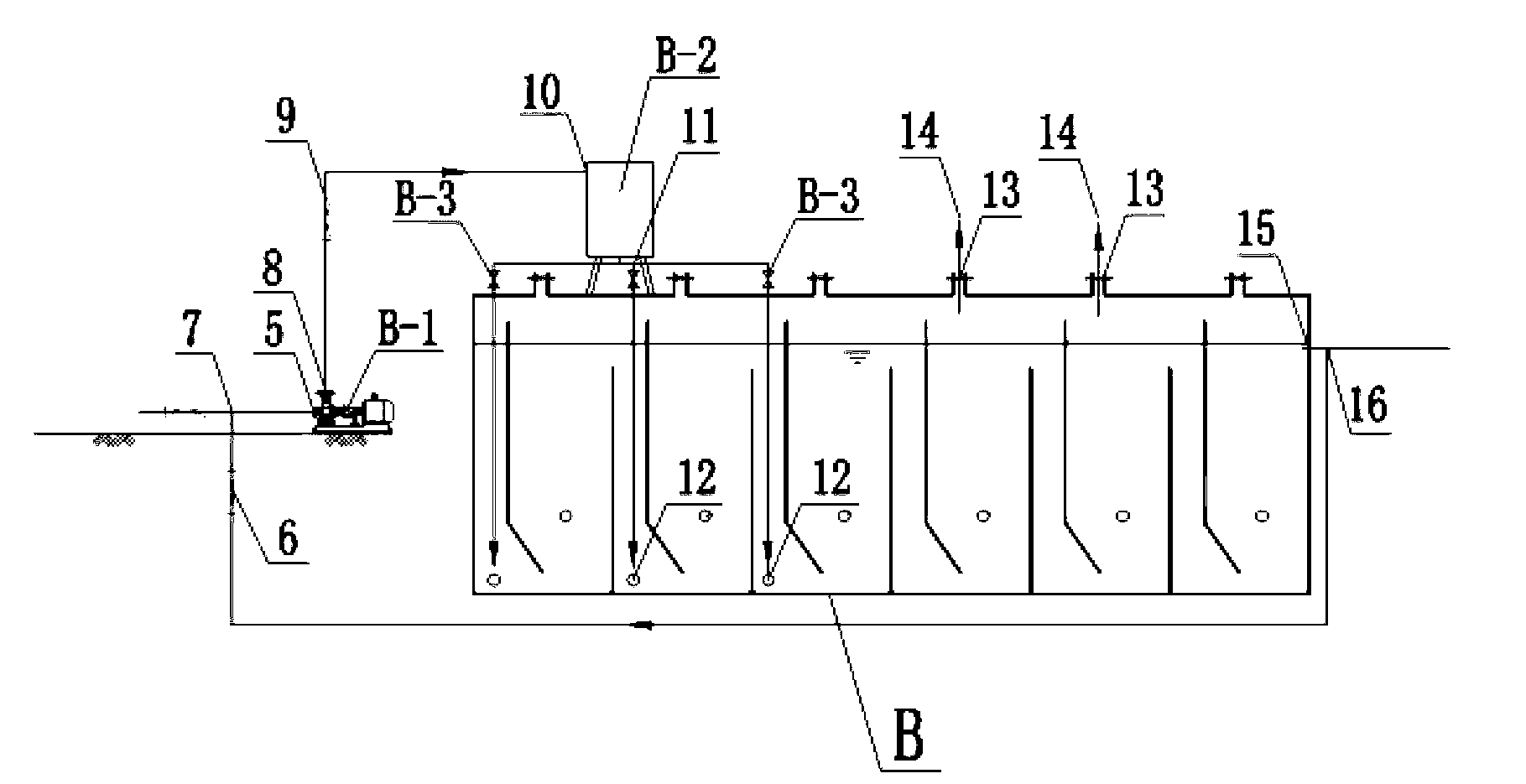

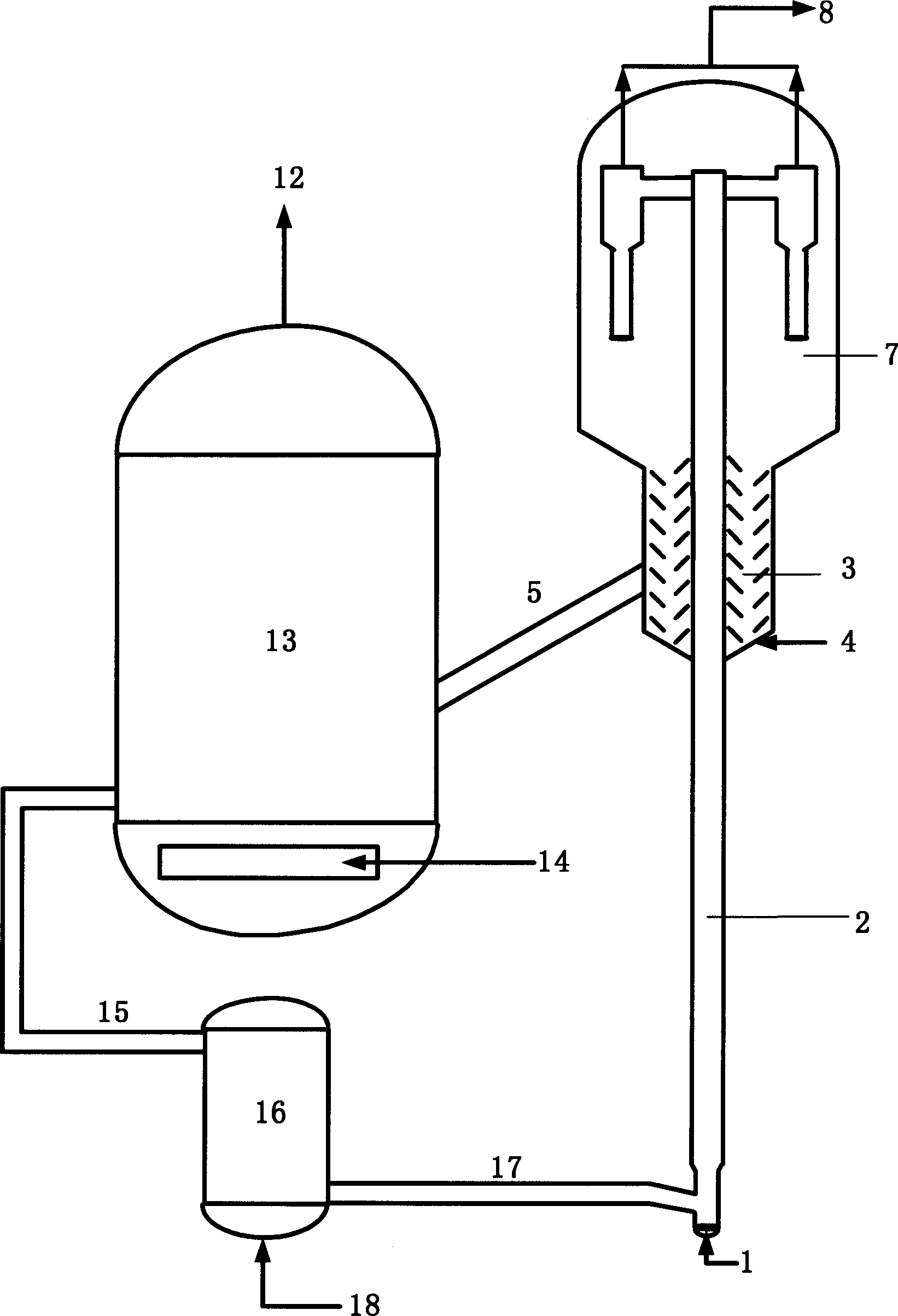

Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

ActiveCN102701521AEasy to handleReduce load ratioEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

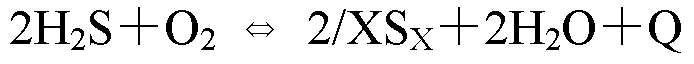

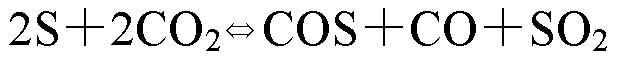

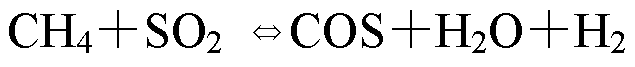

Zero-emission sulfur recovery technology combined with low-temperature methanol washing acid gas treatment

InactiveCN102631827ALow temperature methanol washing process has no effectThe process is not affectedDispersed particle separationClosed loopTower

The invention belongs to the technical field of sulfur recovery and particularly relates to a zero-emission sulfur recovery technology combined with low-temperature methanol washing acid gas treatment. In the zero-emission sulfur recovery technology, a low-temperature methanol washing acid gas treatment unit and a Claus sulfur recovery unit are set to a closed loop. The zero-emission sulfur recovery technology comprises the following steps: firstly, acid gas emitted from low-temperature methanol washing is subjected to sulfur production and recovery by the Claus sulfur recovery unit; sulfur production tail gas enters a low-temperature methanol washing unit after being subjected to hydrogenation reduction, cooling and compression; H2S in the tail gas is absorbed by low-temperature methanol and waste gas is exhausted from the top of a tower; methanol at the bottom of a hydrogen sulfide removal tower enters a methanol thermal regeneration tower; concentrated H2S acid gas is obtained at the top of the tower; and the concentrated H2S acid gas together with the H2S-containing acid gas produced in low-temperature methanol washing enters the Claus sulfur recovery unit for sulfur production. The zero-emission sulfur recovery technology is free of limitation by balance absorption of amine-method tail gas treatment, can obtain theoretic 100% sulfur recovery rate and has remarkable economical and environmental benefits; and the process is shortened greatly and the construction investment, operating cost and energy consumption are reduced by over 30%.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

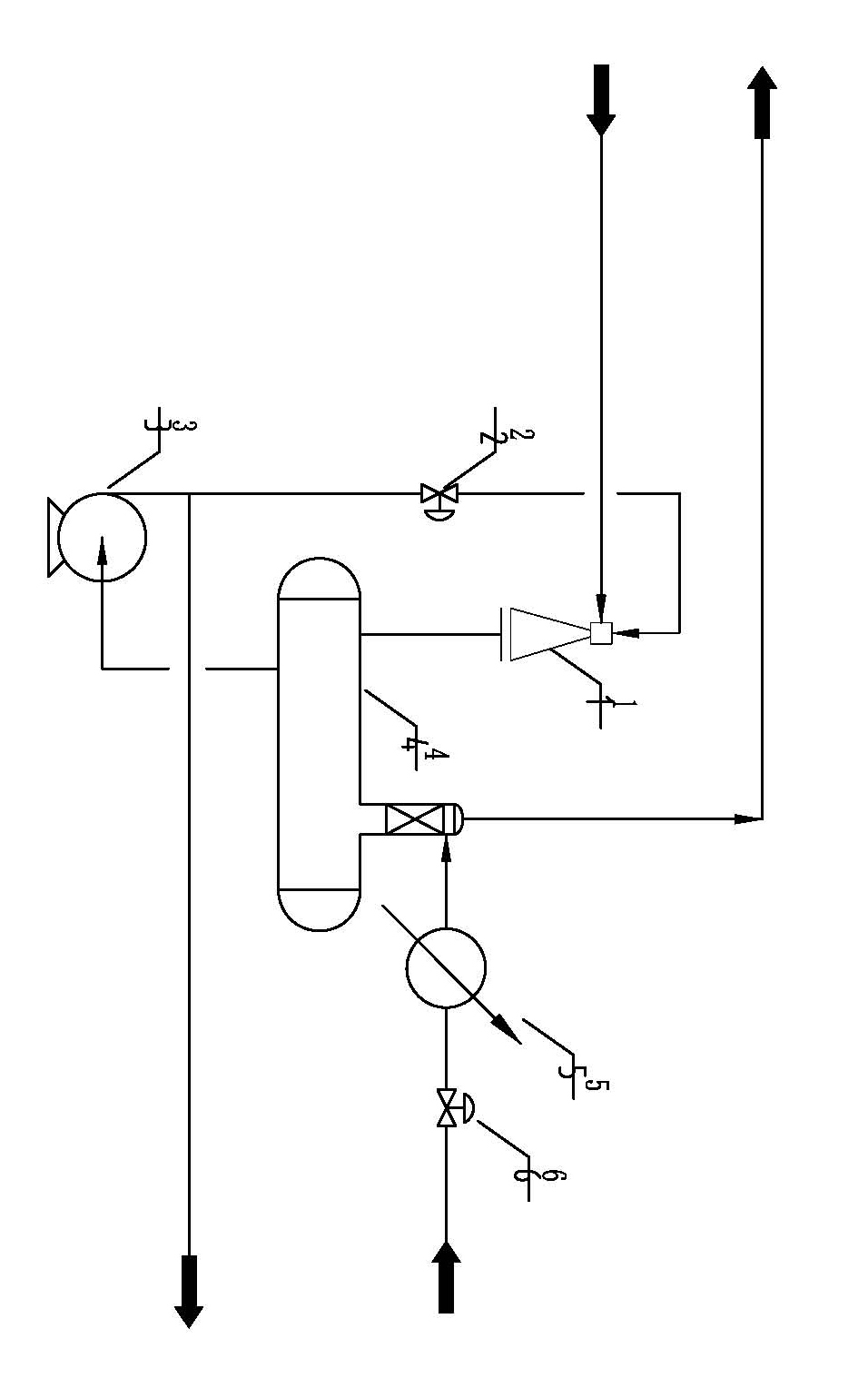

Pressure reduction gas desulfurization method

The invention relates to a pressure reduction gas desulfurization method which belongs to the technical field of chemical technology. The pressure reduction gas desulfurization method comprises the following steps of: firstly, performing injection desulfurization with an absorbent; secondly, performing absorption desulfurization with an absorbent in a recycling tank; and then performing absorption again with absorbing structured packing after absorption desulfurization. In the specific operations of the vacuum gas desulfurization method, the absorbent is recycled through a circulation line; a circulating pump and the recycling tank are connected to the circulation line; an injector is connected to an upstream circulation line of the recycling tank; sulfur-contained gas is connected to the injector; and the top of the recycling tank is provided with a clean gas outlet. The pressure reduction gas desulfurization method has the advantages of simple process, convenience of operation, low construction investment and low failure rate. Moreover, the content of hydrogen sulfide after gas desulfurization can be reduced to be less than 500ppm, thus the desulfurization and purification effects are good and the desulfurization efficiency is high.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

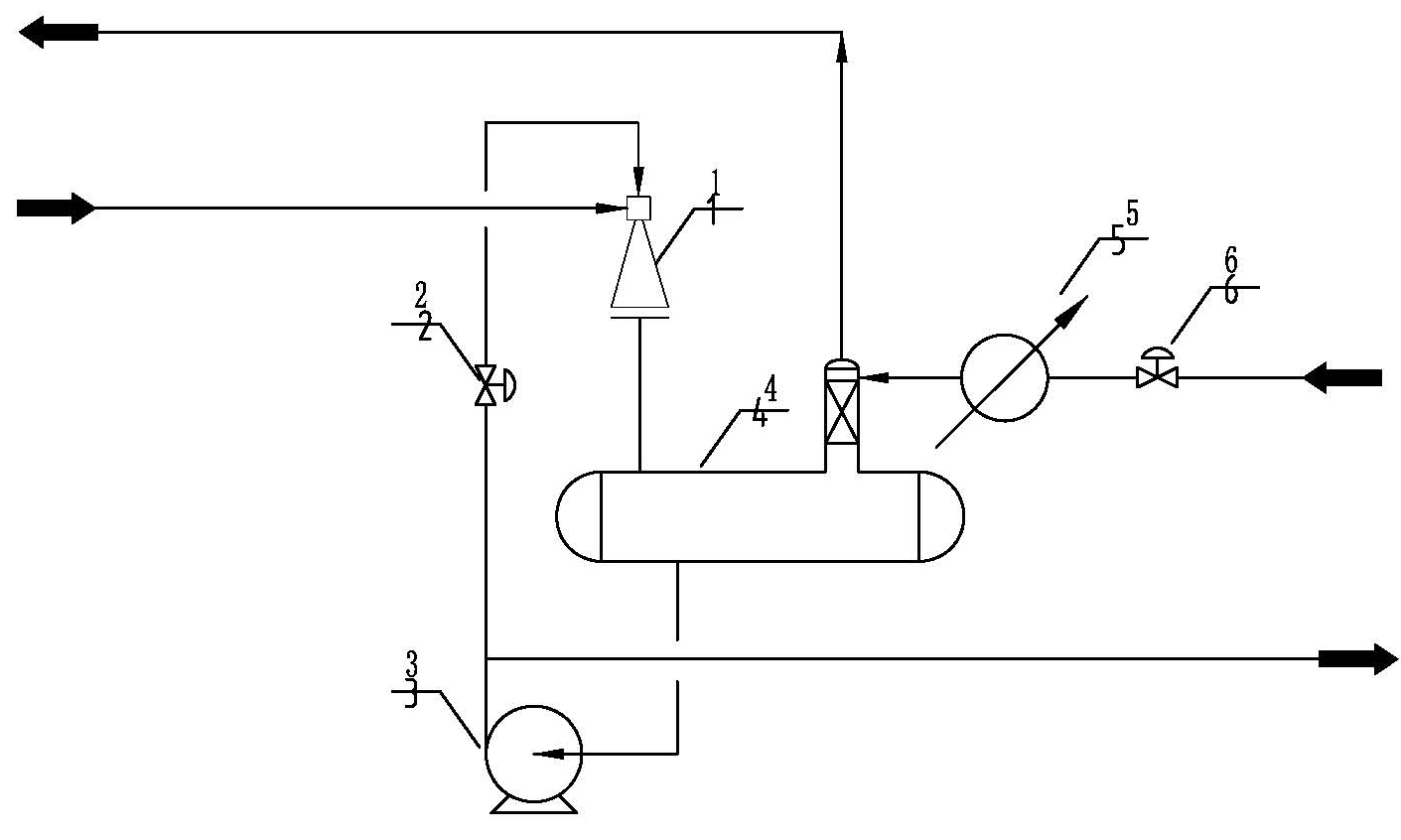

Liquid-phase treatment process of tail gas from sulfur recovery

ActiveCN102942162ASolve the capture problemHigh recovery rateSulfur preparation/purificationGeneration processWastewater

The invention belongs to the technical field of sulfur recovery, and particularly relates to a liquid-phase treatment process of tail gas from sulfur recovery. The liquid-phase treatment process comprises the following steps: recovering sulfur from acid gas through a Claus sulfur recovery device to generate sulfur production tail gas; introducing the sulfur production tail gas into a water film reactor, wherein all the sulfur dioxide and excessive hydrogen sulfide react to generate sulfur and H2S-containing tail gas; enabling the H2S-containing tail gas to be in direct contact with water to cool the H2S-containing tail gas, and discharging the condensed process waste water; oxidating the H2S-containing tail gas in an oxidation reactor to generate in-process gas; cooling the in-process gas through a sulfur cooler, and then further reacting in the water film reactor; and incinerating the waste gas, and then discharging. According to the process, the water film reactor is utilized to solve the problem on sulfur fog collection, and the water film reaction is used in the sulfur production tail gas treatment for the first time, thereby greatly improving the sulfur conversion rate, greatly shortening the process, and greatly reducing the construction investment, the operating cost and the energy consumption.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Method for decreasing sulfur content of hydrocarbon

ActiveCN1583972ABoost octaneSave construction investmentTreatment with plural serial refining stagesChemistryPetroleum

A method to reduce sulfur in hydrocarbon oil is that put the petroleum hydrocarbon and desulfuration agent into the fluid bed reactor and react with the fluid medium under following conditions: reaction temperature is 150-150 deg.C, heavy hourly space velocity is 0.1-60 per hour, the weight proportion of the desulfuration aget and cut fraction of gasoline is 3-40, and the reactive pressure is 130-1450 Kpa. The separate the production and desulfuration agent and transfer the production into downstream separation system. Moreover, transfer the desulfuration agent with carbon into regeneration equipment to regenerate after stripping and the regeneration temperature should be lower than 700 deg.C. Additionally, the desulfuration agent can be reused after being cooled down.

Owner:CHINA PETROLEUM & CHEM CORP +1

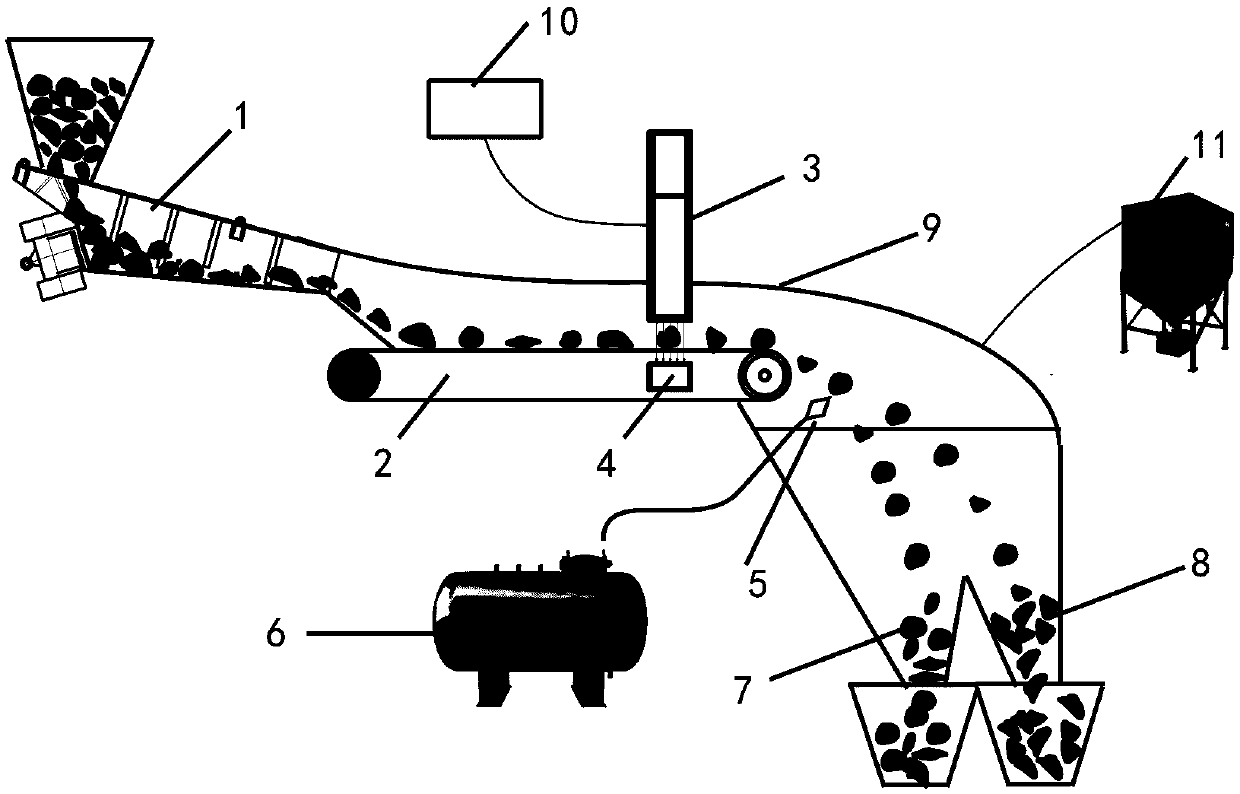

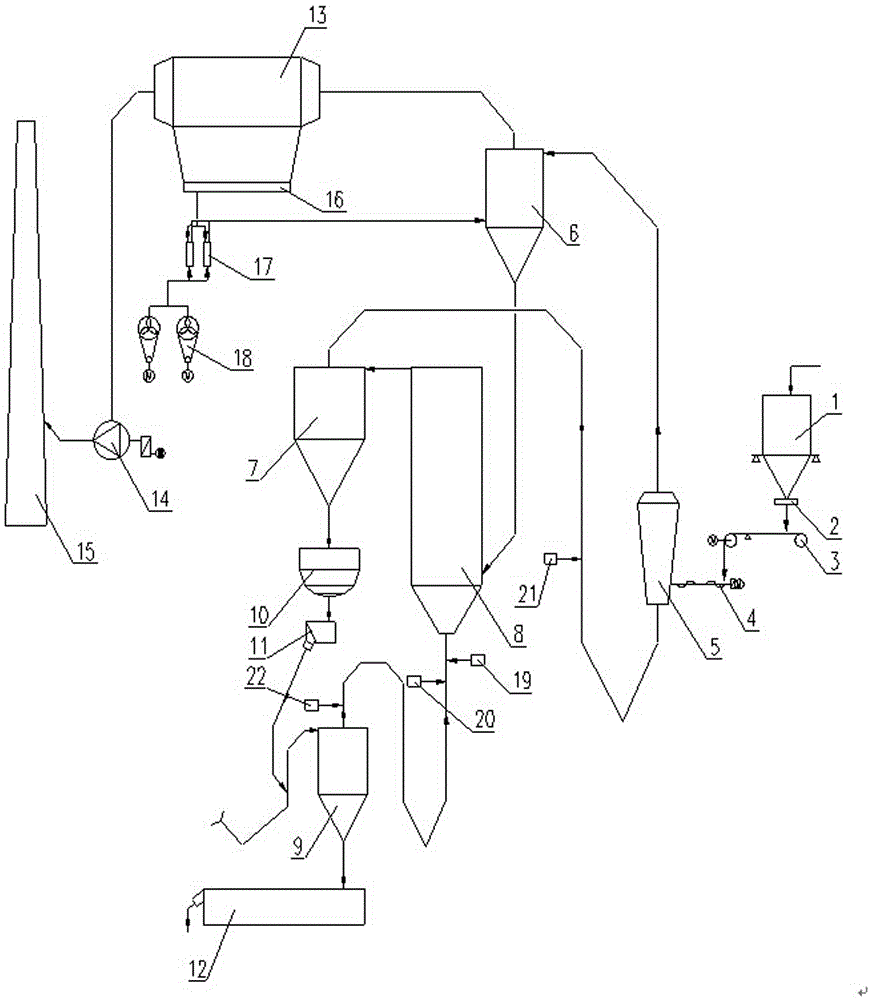

Telligent dry separator (TDS)

InactiveCN105499154AReduce in quantityLess-associative articulation pointSortingDust controlElectric control

The invention discloses a telligent dry separator (TDS). The telligent dry separator is characterized in that an intelligent identification method is adopted for establishing corresponding analysis models according to different characteristics of coal quality, through big data analysis, digitalized identification is conducted on coal and gangue, and finally the gangue is discharged through an intelligent execution system. The telligent dry separator (TDS) comprises four major systems, namely a feeding system, a material distribution system, an identification device and an execution mechanism, and three auxiliary systems, namely an air supplying system, a dedusting system and an electric control system. By means of the telligent dry separator (TDS), separation precision can be improved, the lower separation limit can be further lowered, and a condition is created for achieving the effect that all block raw materials ranging from 3mm to 300 mm adopt the intelligent dry separation process. Compared with traditional cleaning equipment, the telligent dry separator (TDS) has the advantages that on the aspect of construction investment, a system can be simplified, investment can be reduced, and the construction period can be shortened; on the aspect of separation effects, precision can be guaranteed, the heat value can be raised, and no coal slime is generated; on the aspect of production cost, consumption can be lowered, maintenance can be reduced, and manual work can be decreased.

Owner:TIANJIN MEITENG TECH CO LTD

Pulping and papermaking process through multiple-composition biological enzyme method

InactiveCN102345244AReduce consumptionImprove product qualityNon-fibrous pulp additionPaper/cardboardBlack liquorWastewater

The invention discloses a pulping and papermaking process through a multiple-composition biological enzyme method. The method is a biopulping method, which adopts a production process for preparing paper pulp through pulping and fermenting by using a multiple-composition biological enzyme method (phanerochaete, phanerochaete chrysosporium, xylanase, glucoamylase, yeast), adopts agricultural straws, rice and wheat straws, cotton stalks, rape stalks, reeds, bamboo, wood and the like as main raw materials, and comprises treatments of glass cutting, impurity removing, puffing, fermenting through multiple-composition biological enzyme, pulp washing, pulp selecting, defibrination and separation to form the pulp. According to the present invention, no black liquid is generated during the pulping process, the water from fermenting and pulping is recycled so as to achieve zero discharge of wastewater.

Owner:王凤忠

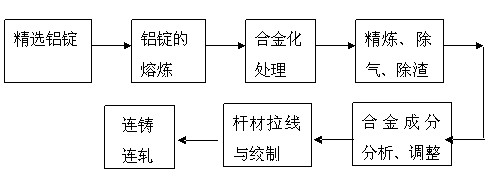

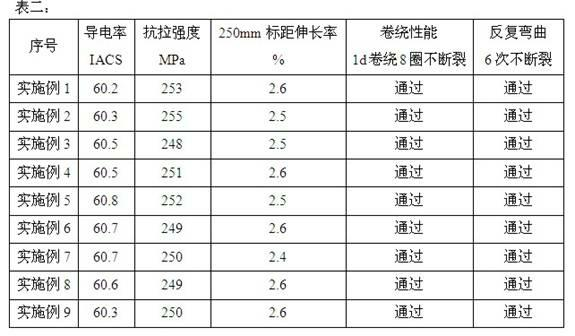

High-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and production method thereof

InactiveCN102634695ASave construction investmentImproved resistance to overloadIngotUltimate tensile strength

The invention discloses a high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and a production method of the high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire. The high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire is produced by finely selecting ingredients and contents of aluminum alloy and conducting process control. The specific steps are as follows: selecting Fe, Si, Mg, Cu and Re with different weight percents, melting aluminum ingot with the content not more than 0.03% in a vertical melting furnace, adding alloying elements in a heat insulation furnace, stirring, refining, conducting on-the-spot contents rapid analysis, carrying out content adjustment, and standing, enabling the aluminum ingot and the alloying element into a continuous casting machine for casting, rolling to be a circular aluminum alloy rod on a continuous rolling machine, pulling the circular aluminum alloy rod to be a circular aluminum alloy wire and twisting the circular aluminum alloy wire to be a conductor for aerial power transmission and distribution. According to the application of the aluminum alloy wire and the production method of the aluminum alloy wire, the aluminum alloy wire directly replaces the generally used aluminum conductor steel reinforced and is an energy-saving, environment-friendly and novel wire.

Owner:FAR EAST CABLE

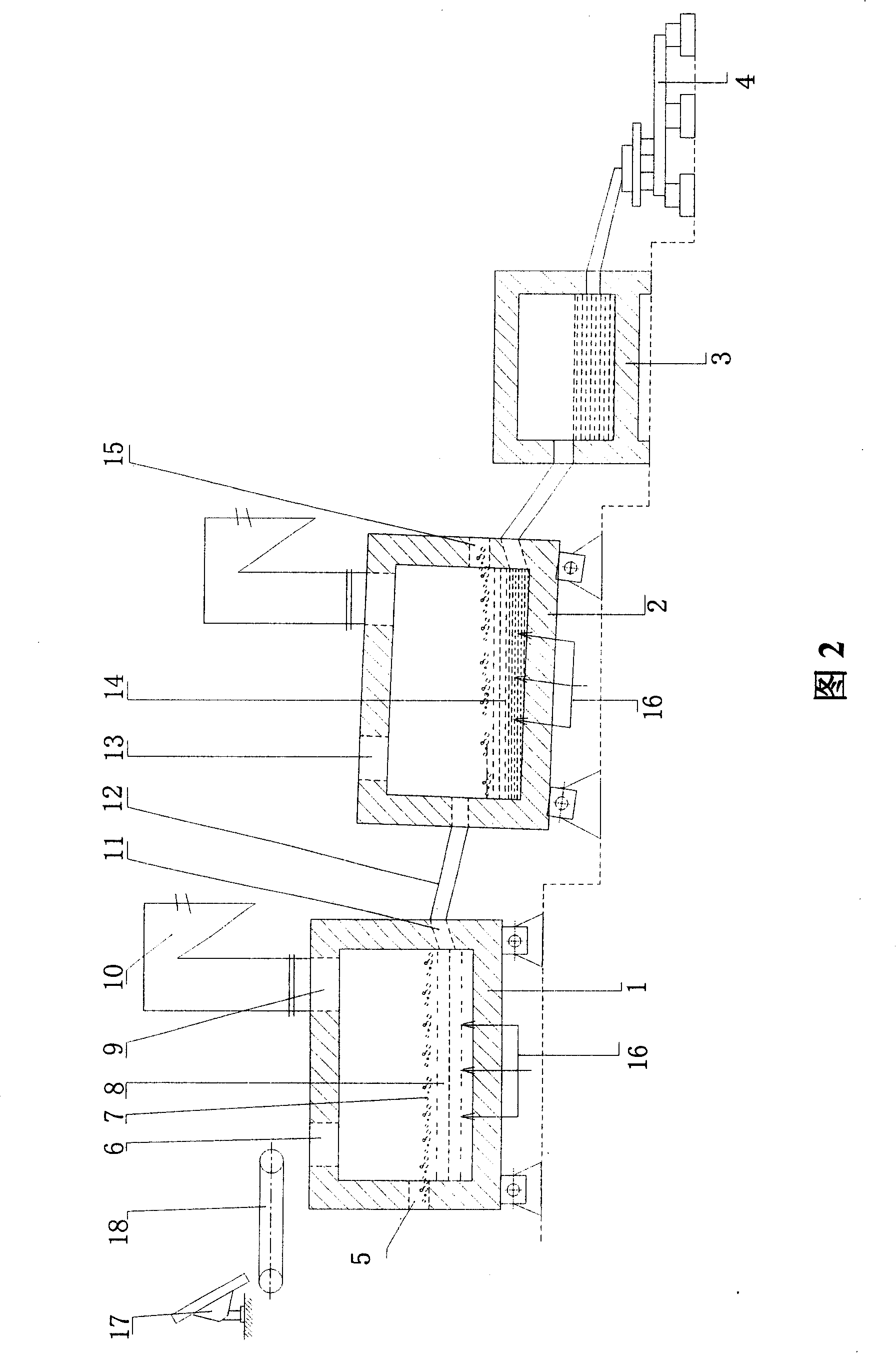

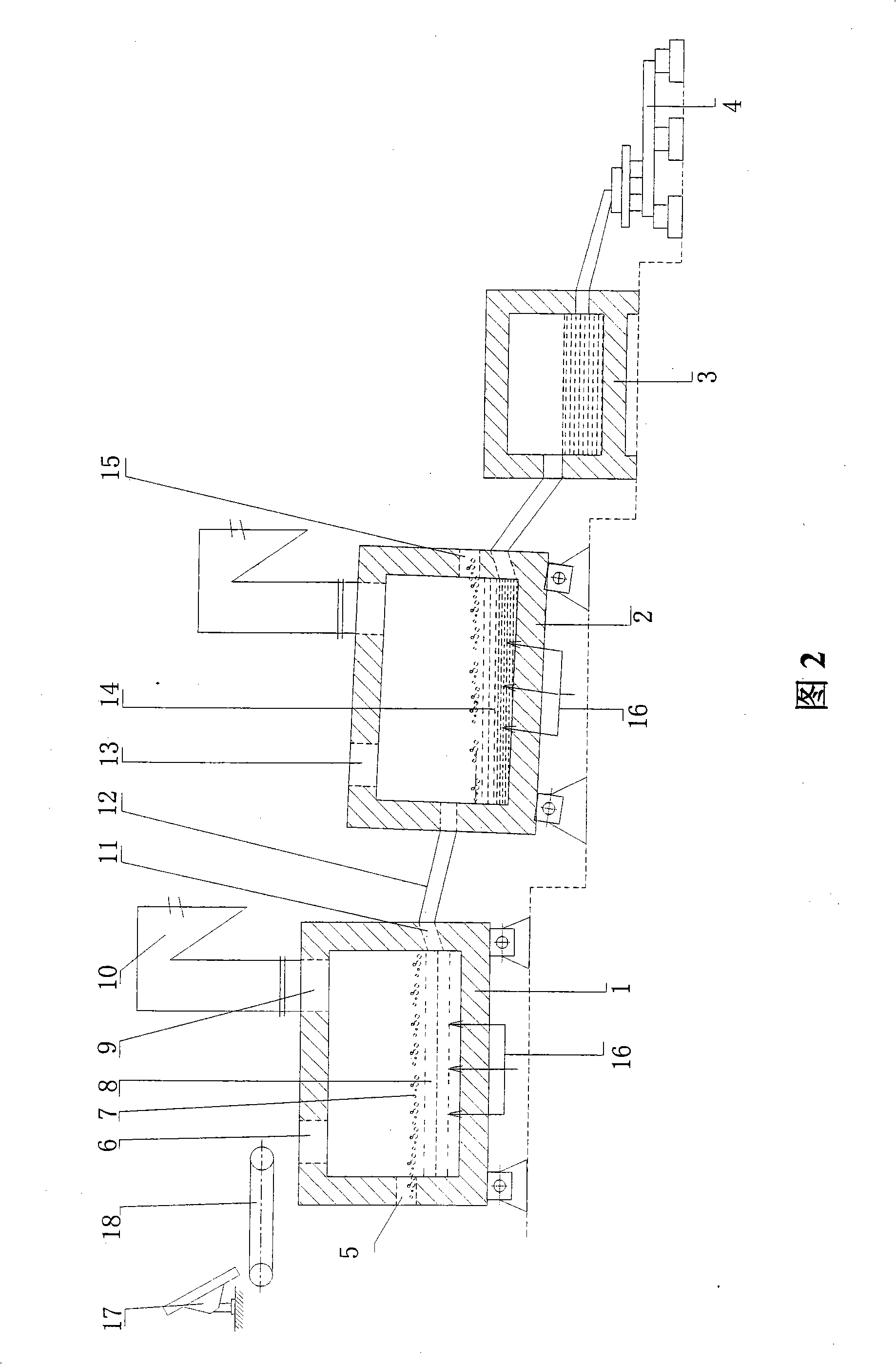

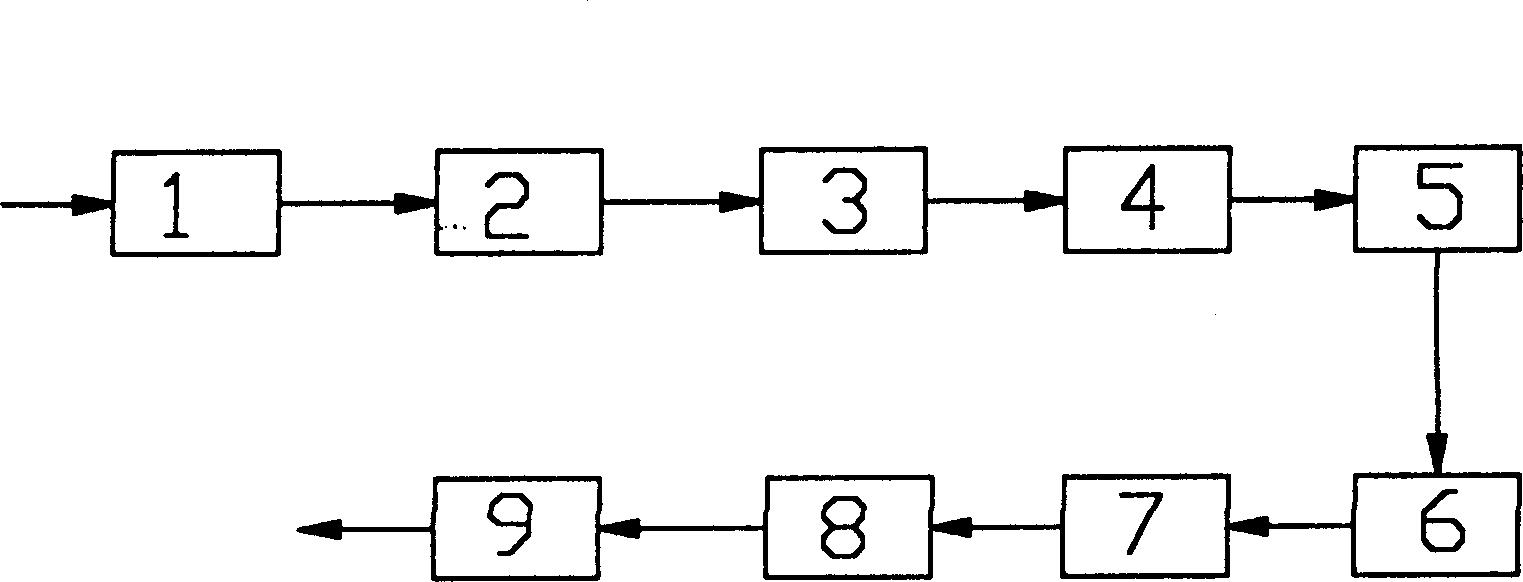

Oxygen bottom blowing continuous copper smelting apparatus

InactiveCN101328543ALess slagHigh yieldRotary drum furnacesCrucible furnacesSmelting processLiquid copper

The invention provides an oxygen bottom blowing continual copper smelting device used in the continual copper smelting process. The device is characterized in that the device comprises an oxygen bottom blowing smelting furnace, an oxygen bottom blowing converting furnace, an anode furnace and an anode plate casting machine, wherein the oxygen bottom blowing smelting furnace and the oxygen bottom blowing converting furnace are connected by a first chute, so that liquid copper matte smelted by the oxygen bottom blowing smelting furnace can be continuously injected into the oxygen bottom blowing converting furnace through the first chute to obtain coarse copper by the continuous converting of the oxygen bottom blowing converting furnace; the oxygen bottom blowing converting furnace and the anode furnace are connected by a second chute, so that the coarse copper can flow in the anode furnace through the second chute and is subjected to refining by the anode furnace to obtain anode copper; and the anode furnace and the anode plate casting machine are connected by a third chute, so that the anode copper can flow into the anode plate casting machine through the third chute and is subjected to casting by the anode plate casting machine to obtain the copper anode plate.

Owner:CHINA ENFI ENGINEERING CORPORATION

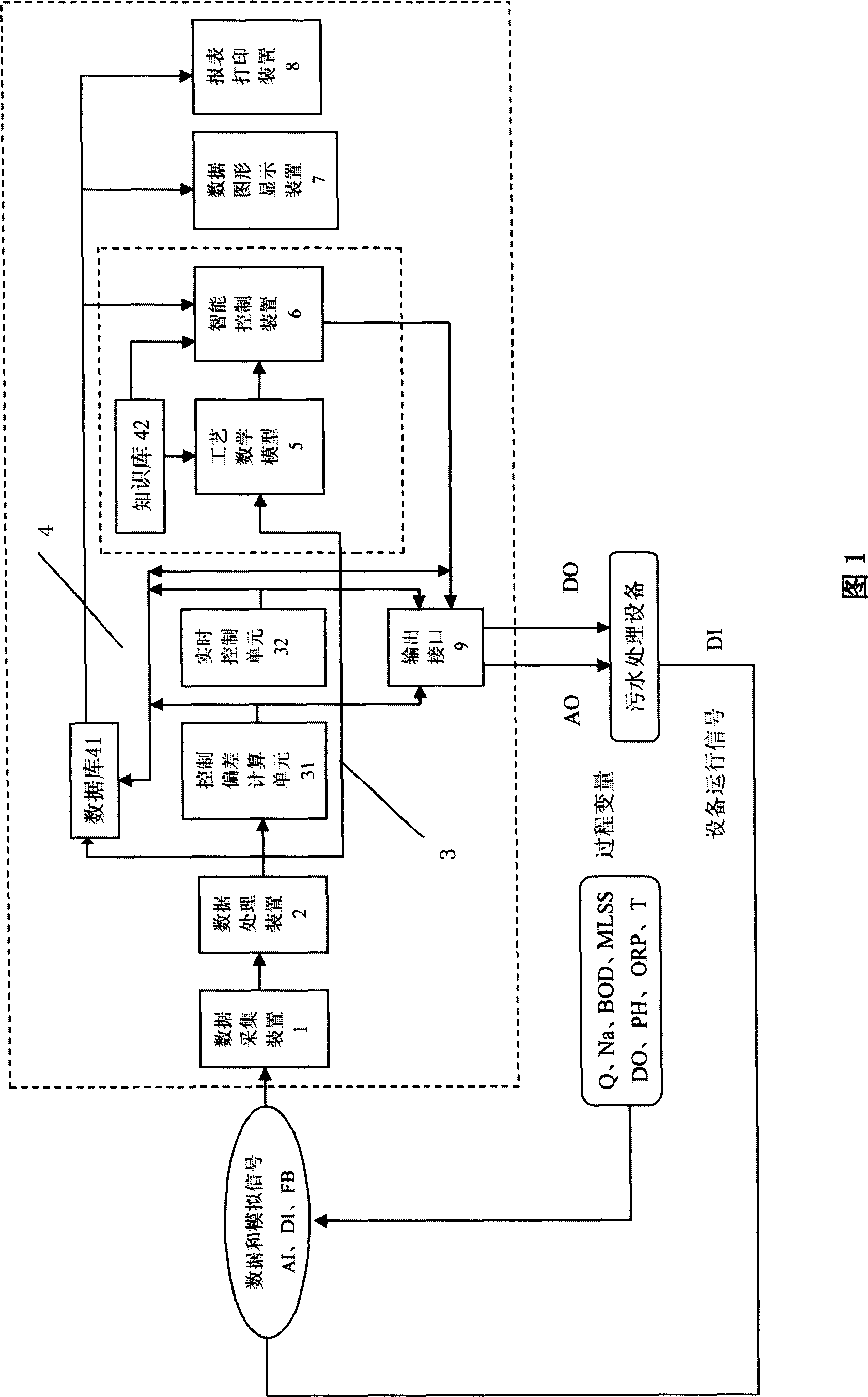

Sewage treatment intelligent management system

InactiveCN101369135ATo achieve the goal of reducing emissions in advanceSave construction investmentProgramme control in sequence/logic controllersData processingSewage treatment

The invention discloses an intelligent management system for sewerage processing, which comprises: a data-collecting device, a data-processing device, a real-time control device, a data-storing device, a technology mathematical model device and an intelligent control device; the data-storing device can store the data, the real-time control device can execute real-time control and calculation, the calculated regulating quantity can control operating devices in real time through an output port, and the calculated value can be imported in the data-storing device. The technology mathematical model device can execute the technology optimizing and improving calculation according to the processed data, the calculated optimization operating value can be sent to the intelligent control device to execute intelligent control calculation, the optimization control value can be calculated through taking knowledge and experience out from the data-storing device, and can be controlled and adjusted in the device corresponding to the output port , and the control value can be sent to the data-storing device for storage.

Owner:上海大地自动化系统工程有限公司 +1

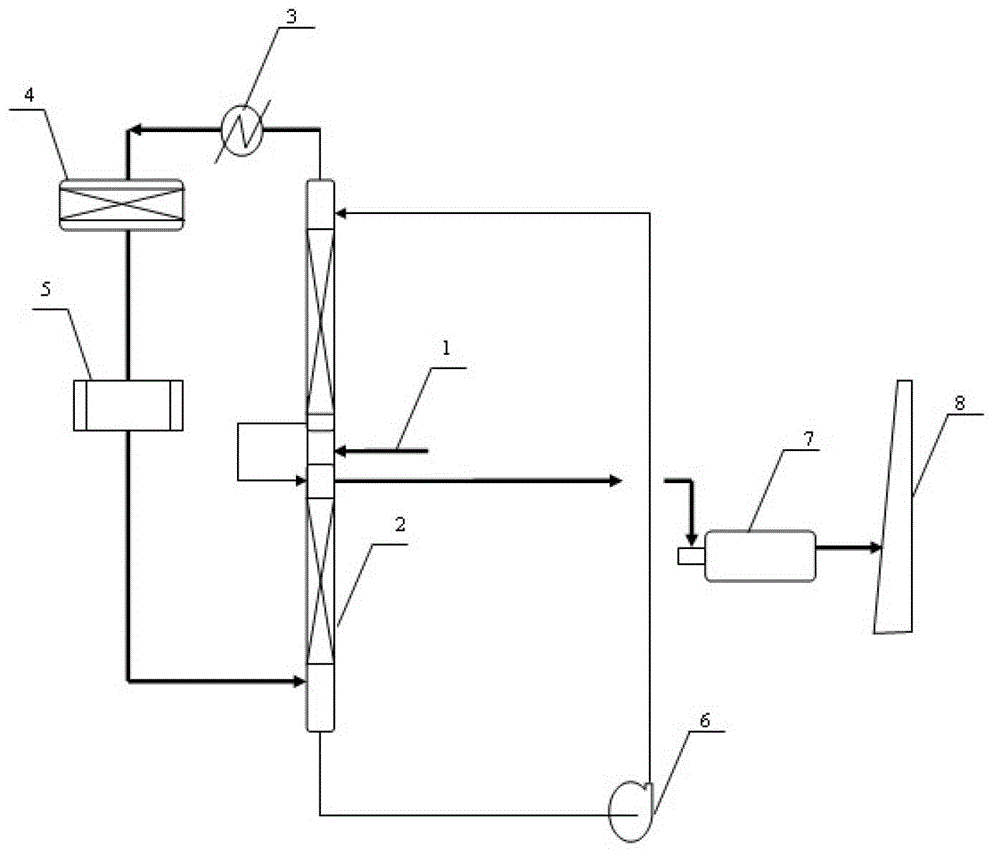

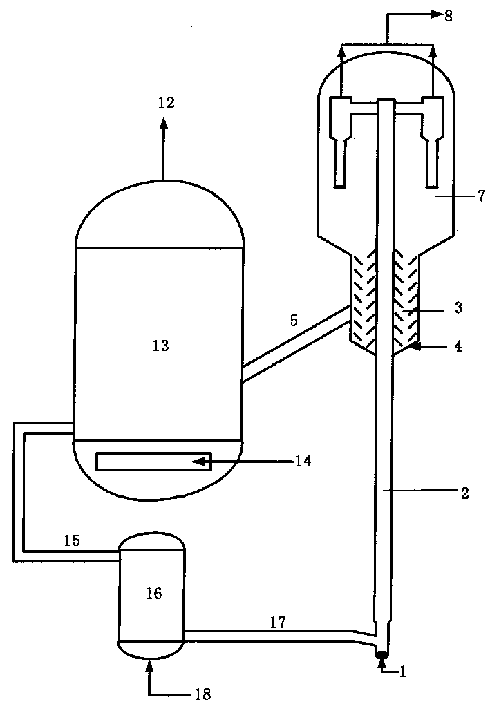

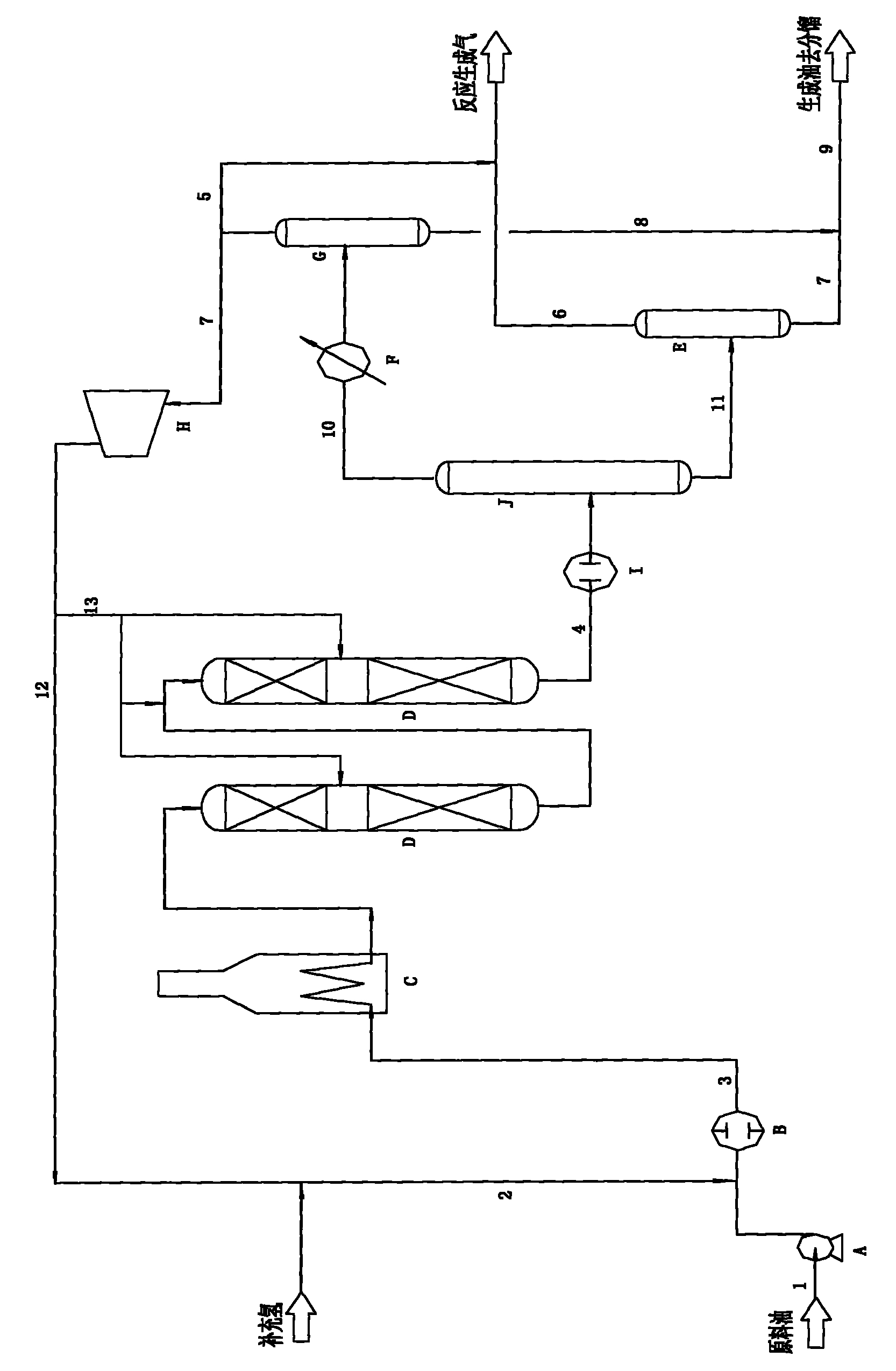

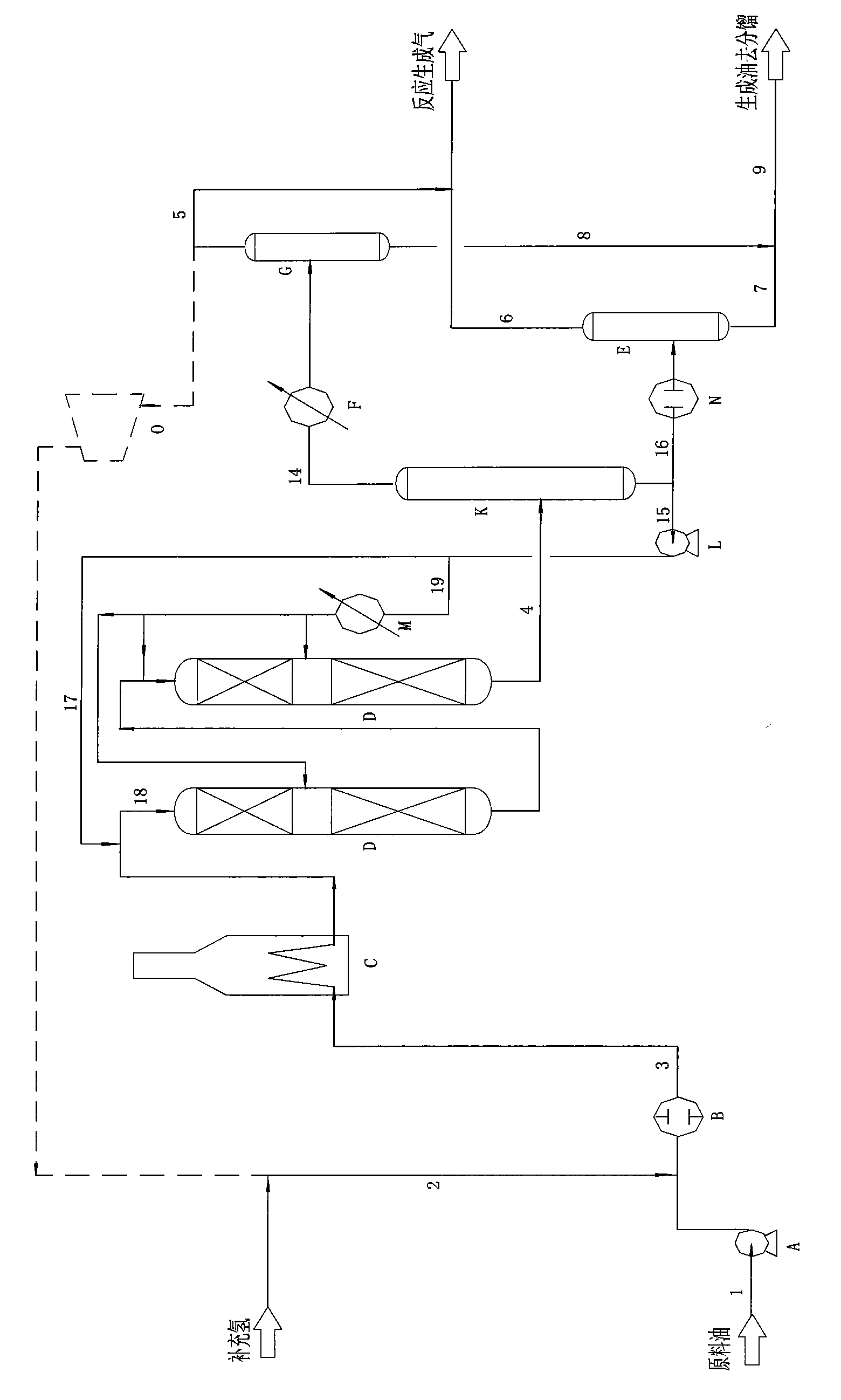

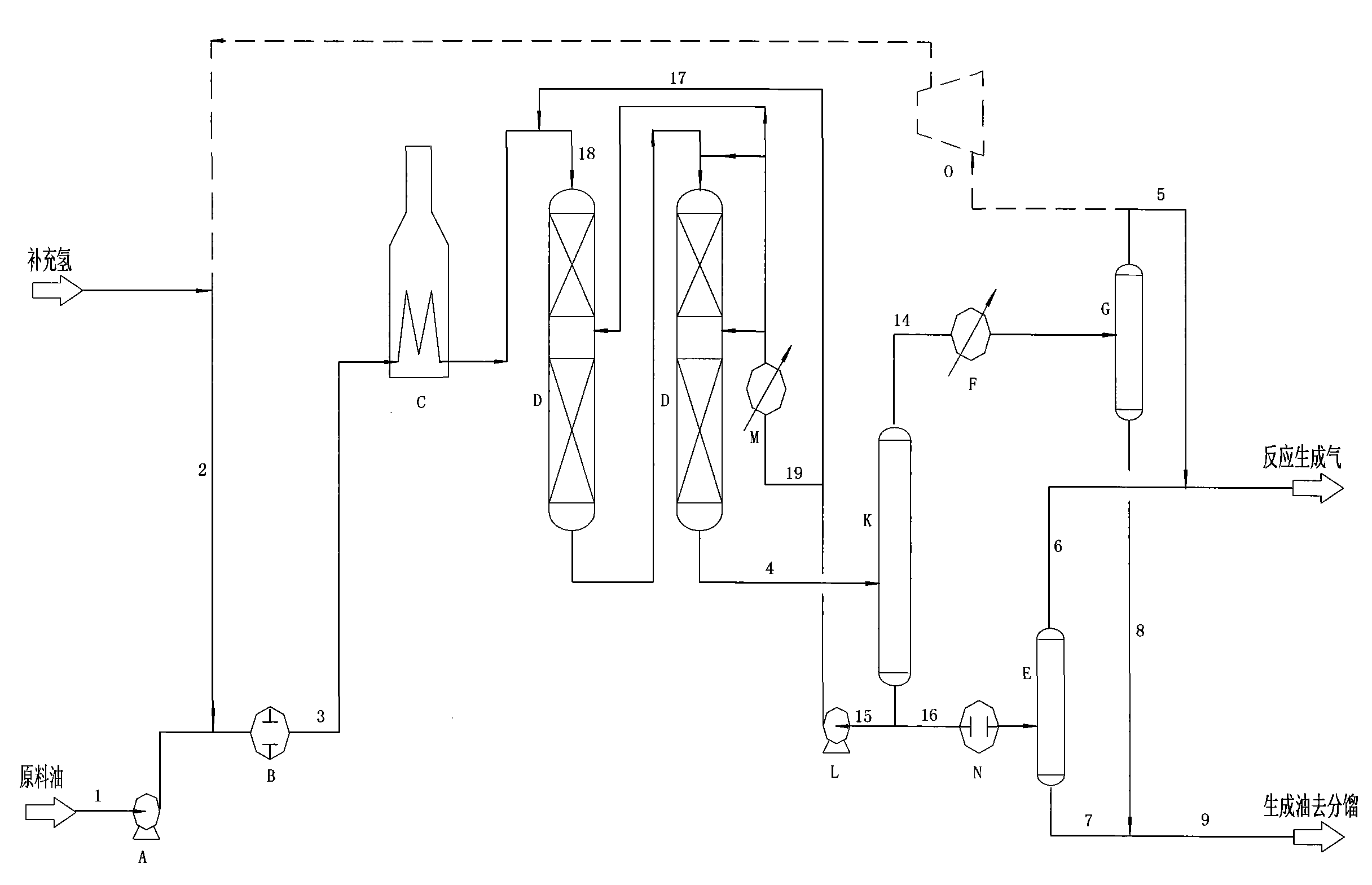

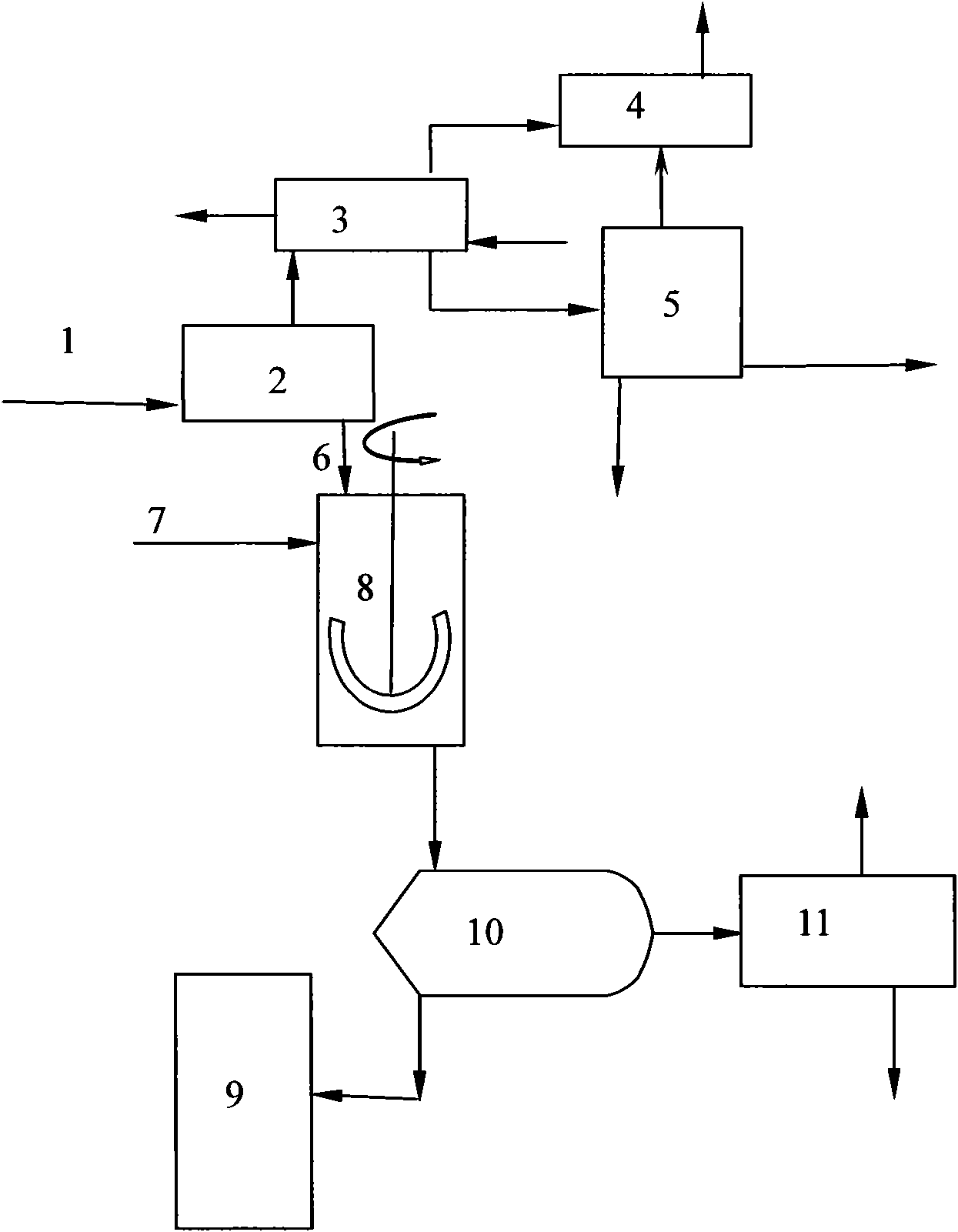

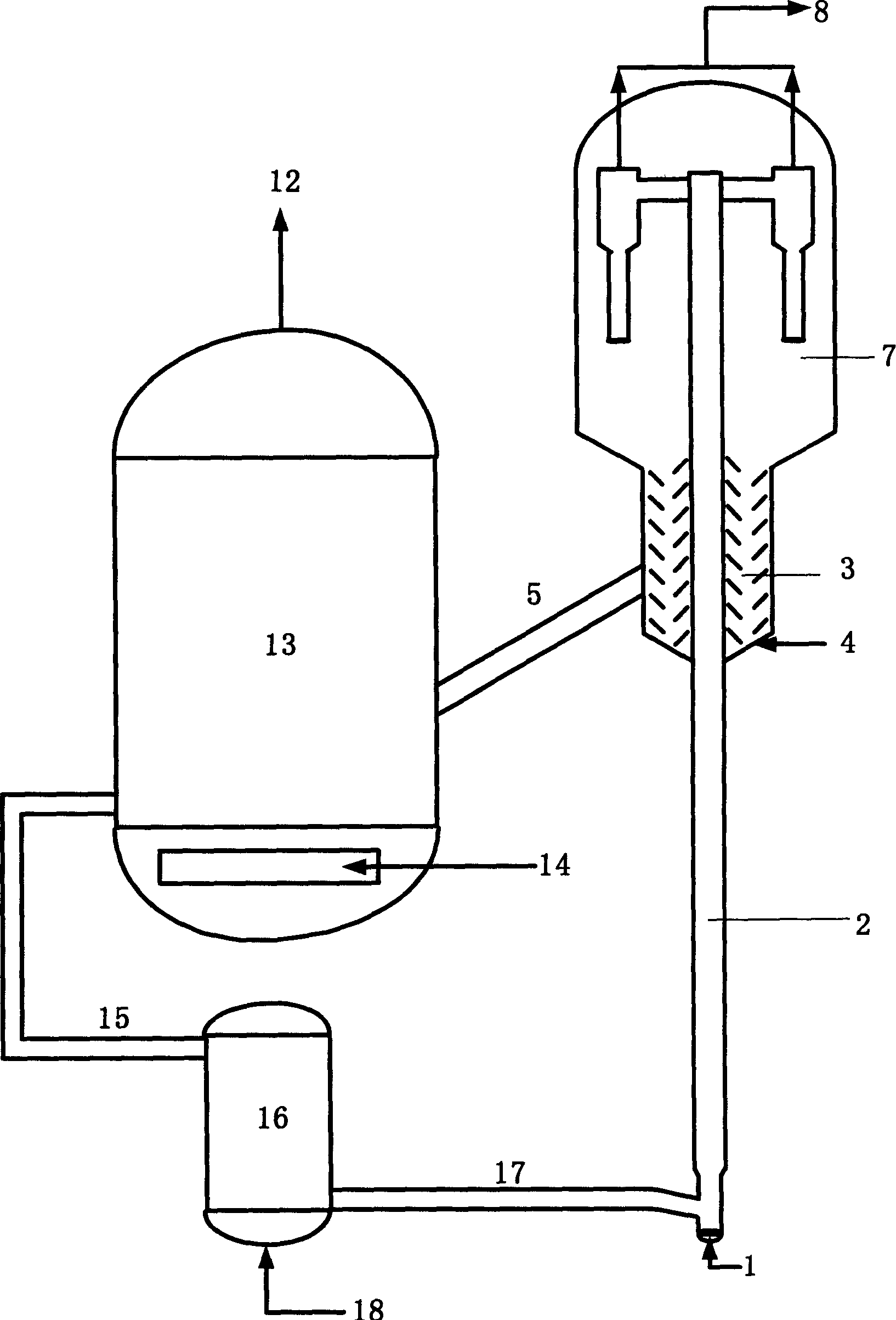

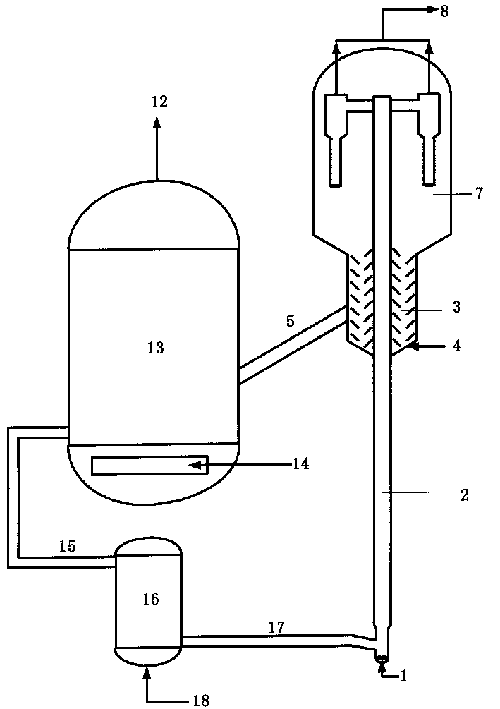

Circulating liquid phase hydrogenation method

ActiveCN102120934APipe size reductionSave construction investmentHydrocarbon oil crackingHydrocarbon oils refiningChemistryHigh pressure

The invention relates to a circulating liquid phase hydrogenation method which is characterized in that the hydrogenation reaction product is cooled by a heat exchanger or directly enters a thermal high-pressure separating tank; part of the liquid phase stream separated out from the thermal high-pressure separating tank is directly used as circulating oil or is further separated by the thermal high-pressure separating tank to be used as circulating oil, and the circulating oil returns to the inlet of each hydrogenation reactor and / or the inter-bed inlet space of the multi-bed hydrogenation reactor; the inlet of each hydrogenation reactor and / or the inter-bed inlet space of the multi-bed hydrogenation reactor are / is provided with or not provided with an circulating oil cooler; and after being subjected to cooling and liquid separation, the gas phase stream separated from the thermal high-pressure separating tank is sent out as the reaction generation gas or is compressed before returning to a hydrogen gas feed system. The method provided by the invention reduces the high-pressure gas passage system equipment in the existing hydrogenation method, the size of the pipeline and the energy consumption of the device, and achieves the purpose of saving the construction investment of the device.

Owner:CHINA PETROCHEMICAL CORP +1

Treatment method of oily sludge

ActiveCN102050556AReduce volumeReduce quality problemsThermal non-catalytic crackingSludge treatment by de-watering/drying/thickeningTherapeutic effectOil sludge

The invention relates to a treatment method of oily sludge, which is particularly suitable for oily sludge generated during the sewage treatment process of a refinery plant. The method comprises the following steps: after centrifugal dewatering, the oily sludge is dehydrated through rotary dehydration equipment under the control of a certain negative pressure and a certain temperature, so as to destroy the water, oil and solid stable system in the oily sludge; parts of oil and water in the oily sludge are distilled out; the coke generated after dehydration is extracted with a solvent; after extraction, the material undergoes the solid-liquid separation; the separated liquid phase is delivered to a delayed coking device; the separated solid phase is dehydrated to form the residues that meet the discharge standards for solids; and the wastewater generated during the process is biochemically treated and then discharged after reaching the discharge standards. The invention is mainly characterized in that the sludge treatment process is short, the speeds and the efficiencies of sludge dehydration and extraction are high, the effect is good, the operational condition is moderate, the energy consumption is reduced, the oily sludge treatment effect is good, and the operating maintenance of the equipment is simple.

Owner:PETROCHINA CO LTD

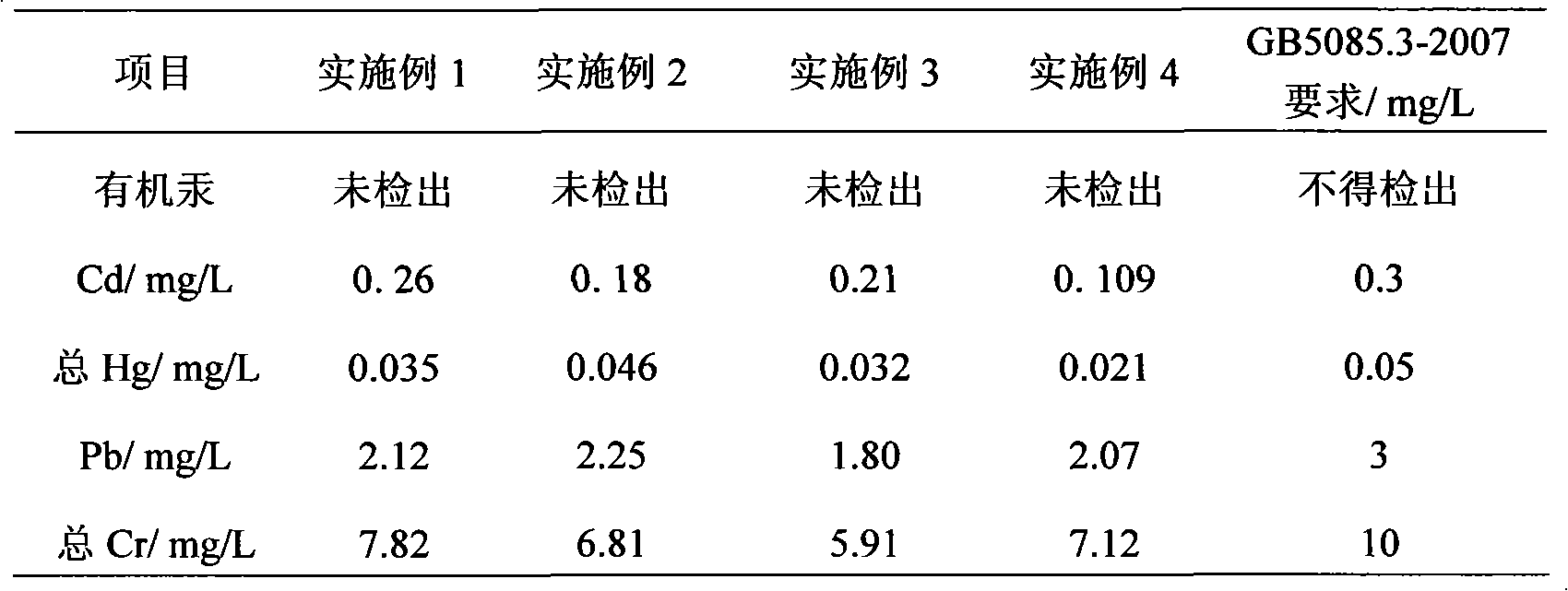

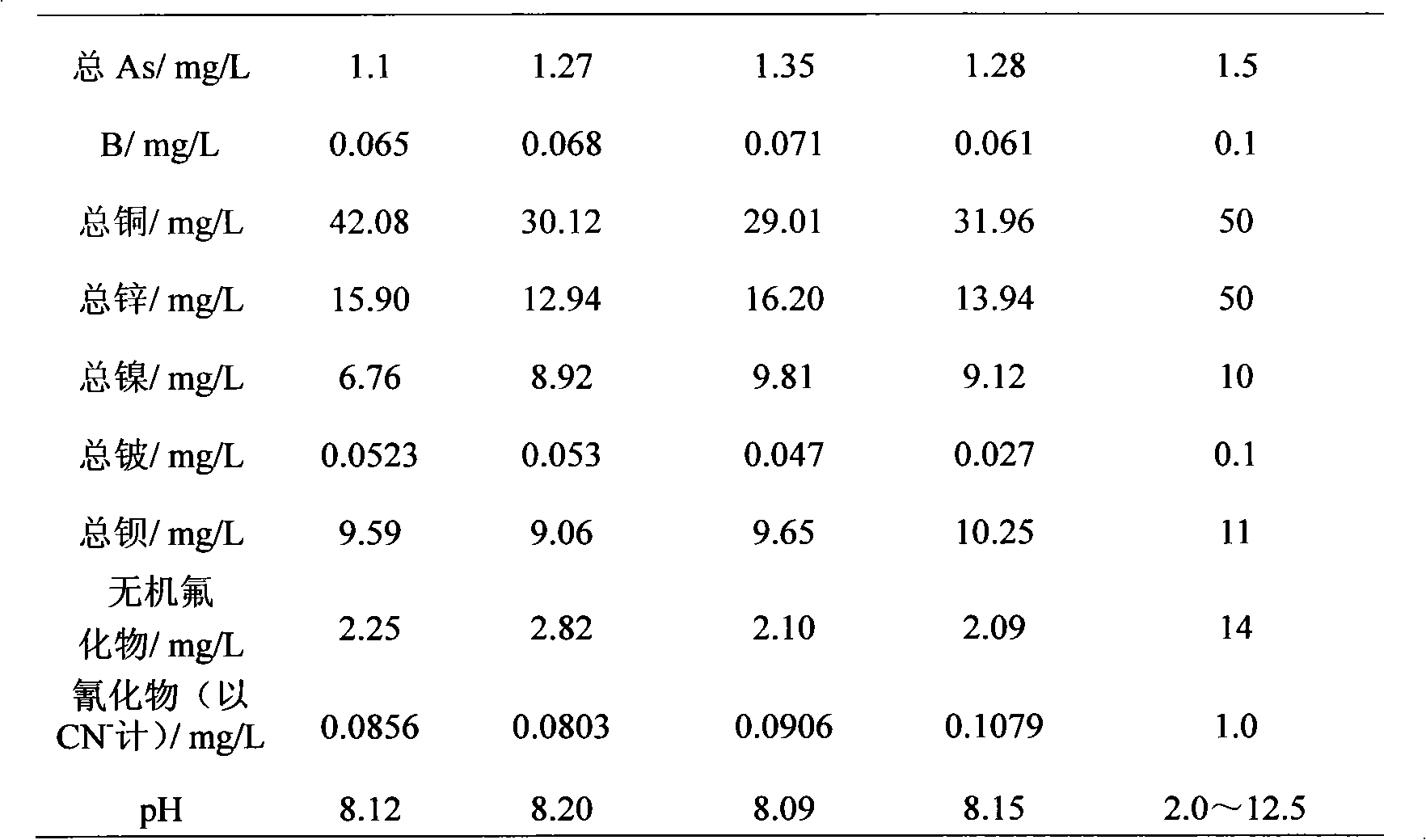

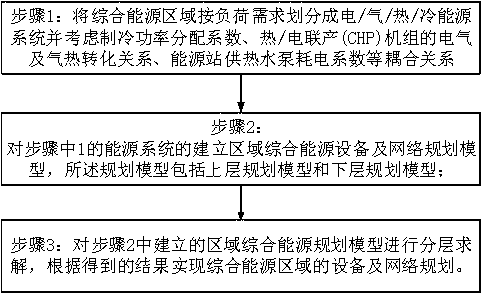

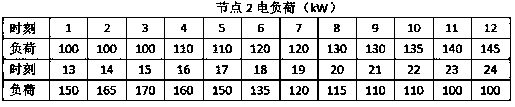

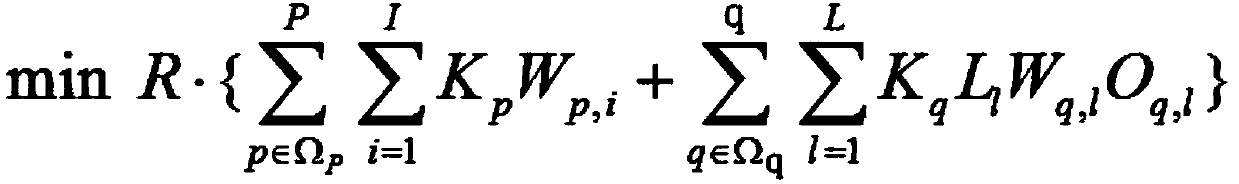

Regional comprehensive energy device and network dual-layer optimization configuration method

ActiveCN108446809ASave construction investmentNo capacity redundancyForecastingElectricityEngineering

The present invention discloses a regional comprehensive energy device and a network dual-layer optimization configuration method, belonging to the field of regional comprehensive energy planning. Themethod comprises the following steps that: comprehensive energy is divided into electrical / gas / thermal / cool energy systems according to load demands, coupling relations among different energy systemsare considered to establish a regional comprehensive energy device and a network planning model consisting of an upper layer planning model and a lower layer planning model, the lower layer planningis employed to perform decoupling solution of the electrical / gas / thermal / cool energy systems, maximum power of the device and the line is output, and feedback is performed to the upper layer; and theupper layer planning considers the device and network installation capacity constraint and performs solution, device capacity and line layout variables are output to regulate the lower layer, iteration solution is performed until convergence, and the device and network planning is achieve according to the obtained device capacity and a line layout result. The regional comprehensive energy device and the network dual-layer optimization configuration method have advantages of coupling planning of the electrical / gas / thermal / cool energy systems, reduction of establishing investment of the comprehensive energy area and reduction of system operation loss.

Owner:ECONOMIC TECH RES INST OF STATE GRID HENAN ELECTRIC POWER +2

Suspension roasting device and technology for producing multiform aluminum oxide

InactiveCN104692435AReduce production linksSave construction investmentAluminium oxide/hydroxide preparationAluminium hydroxideEngineering

The invention belongs to the technical field of metallurgy, and particularly relates to a suspension roasting device and technology for producing multiform aluminum oxide. The device is composed of a feeding system, a roasting system, a crystal separation system and a cyclone dust removal system, wherein the feeding system comprises a quantitative feeder, a spiral feeder and a drier, the roasting system comprises a cyclone preheater, a roasting furnace and a burning station, the crystal separation system comprises a cyclone separator, a crystallizer, a controllable material level valve, a cyclone cooler and a drying cooler, and the cyclone dust removal system comprises a dust remover, an induced draught fan and a chimney. During working, an aluminum hydroxide filter cake serves as the raw material, the roasting temperature of the roasting furnace and the time for materials staying in the crystallizer are adjusted according to different requirements of multiform aluminum oxide products, and finally obtained different aluminum oxide products are discharged out of the drying cooler. According to the device and technology, metallurgical aluminum oxide and high-temperature aluminum oxide are produced at the same time with one set of device and the same kind of material by adjusting operating parameters.

Owner:SHENYANG XINBO IND TECH

Method for decreasing sulfur content of hydrocarbon

InactiveCN1583973ABoost octaneSave construction investmentTreatment with hydrotreatment processesReaction temperatureGasoline

A method to reduce sulfur in hydrocarbon oil is that put the petroleum hydrocarbon and desulfuration agent into the fluid bed reactor and react with the fluid medium under following conditions: reaction temperature is 150-500 deg.C heavy hourly space velocity is 0.1-60 per hour, the weight proportion of the desulfuration agent and cut fraction of gasoline is 3-40, and the reactive pressure is 130-1450Kpa. Then separate the production and desulfuration agent and transfer the production into downstream separation system. Moreover, transfer the desulfuration agent with carbon into regeneration equipment to regenerate after striping and the regeneration temperature should be lower than 700 deg.C. Additionally, the desulfuration agent can be reused after being cooled down.

Owner:CHINA PETROLEUM & CHEM CORP +1

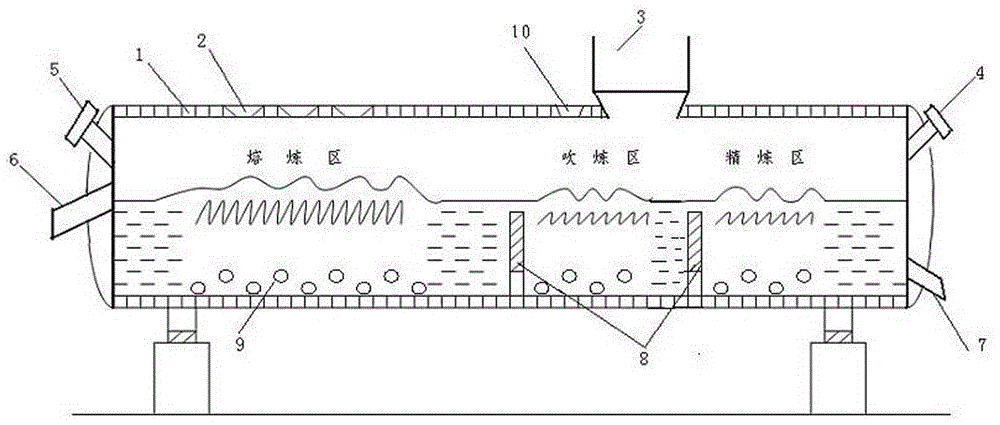

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

Deep purification and reclaiming device and method for dyeing waste water

InactiveCN1569694AImprove biochemical treatment efficiencyMeet process water requirementsMultistage water/sewage treatmentFiberChlorine dioxide

The invention discloses a deep purification and reclaiming device and method for dyeing waste water, wherein the device comprises a regulating reservoir, an naerobic tank, an aerobic aeration tank, a sedimentation tank, a chlorine peroxide oxidation tank, a medicament administration and coagulation tank, a biologically active charcoal tank and a fiber ball filter. The waste water treatment method integrates a biochemical treatment process and a physical-chemical treatment method.

Owner:东莞市天虹实业投资有限公司

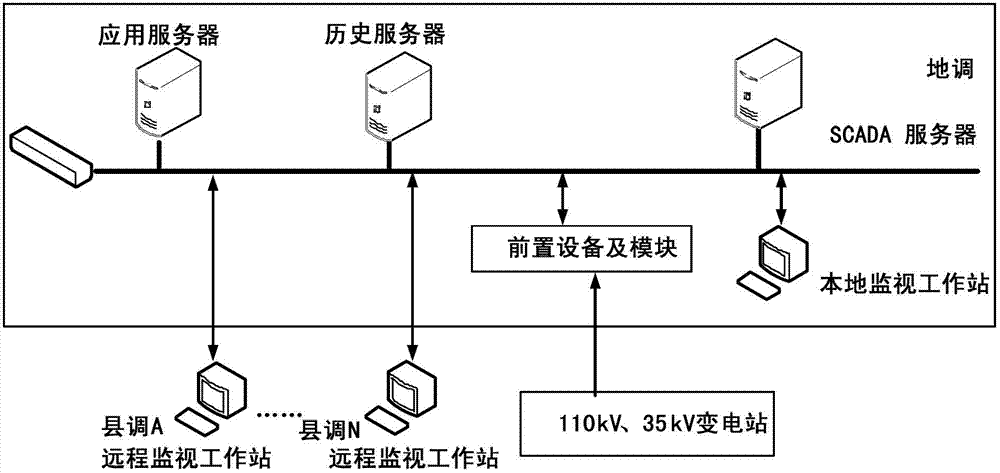

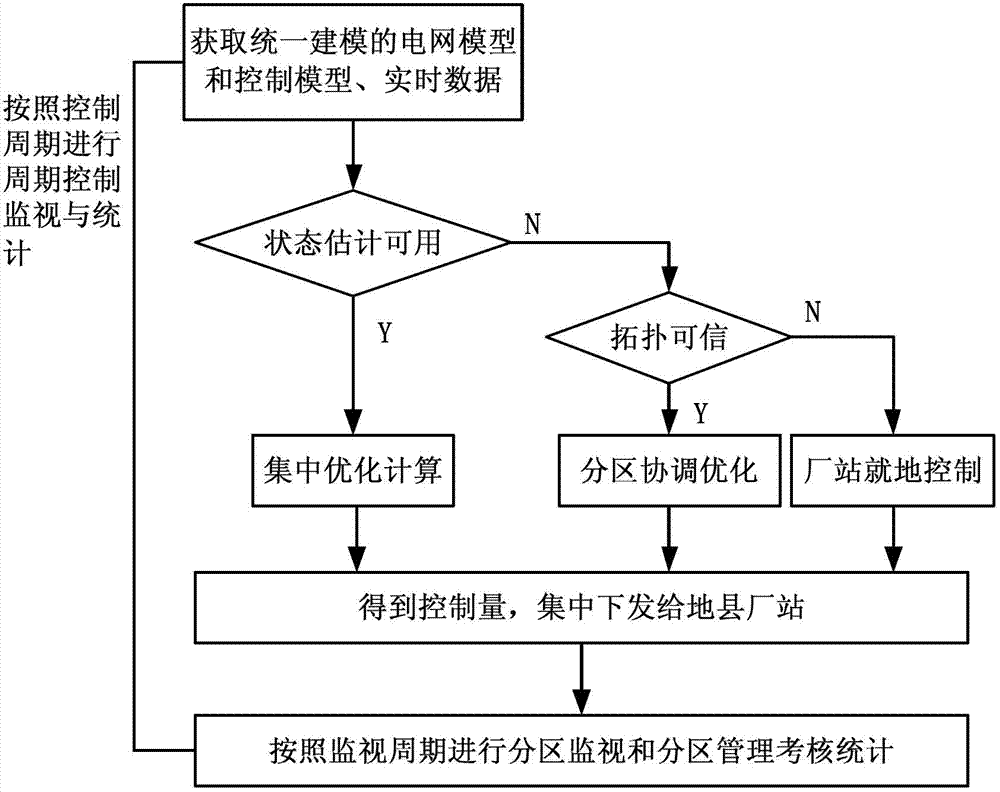

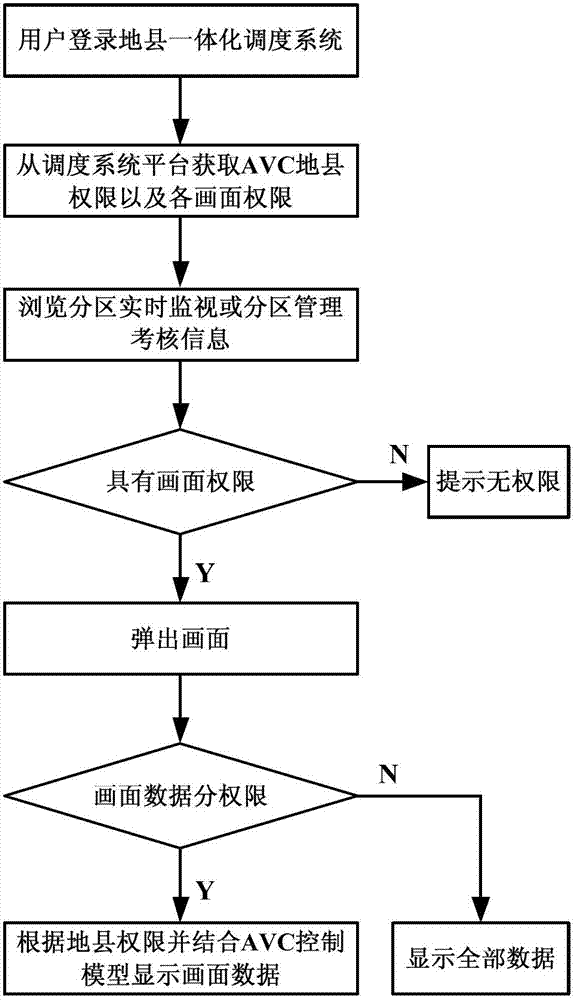

Prefecture-county integrated automatic voltage control method

ActiveCN102738800AReasonable useImprove reliabilityAc network voltage adjustmentReactive power compensationCycle controlReal-time data

The invention provides to a prefecture-county integrated automatic voltage control method. The control method comprises the following steps of: obtaining a power grid model, a control model and real-time data required for automatic voltage control; carrying out prefecture and county regional voltage idle work optimization calculation and constructing a control strategy system to obtain the controlling quantity of prefecture and county plant stations; distributing the obtained controlling quantity to a prefecture and county plant stations to be executed in a centralized manner through the prepositive communication of a scheduling automatic system; carrying out regional monitoring and regional management examining statistics; and returning for circulation so as to carry out periodic control monitoring and statistics when the voltage control period is reached. A prefecture-county shared automatic voltage control system more reasonably effectively utilizes various idle work adjustment and voltage control measures in a power grid, the construction investment of the system is reduced, and the system maintenance management is flexible and convenient.

Owner:CHINA ELECTRIC POWER RES INST +1

City ditch polluted water in situ ecological purifying processing device

InactiveCN101007674ARestoring ecological functionsReduce consumptionTreatment using aerobic processesSustainable biological treatmentWater wheelEngineering

The invention discloses an ecological purifying device of urban effluent, which comprises the following parts: biological earthworm reactor, biological rack, hydraulic aerating distributor, biological water-wheel type rotary disc, ecological purifying functional area and aeration filter purifying system, wherein the hydraulic aerating distributor connects biological earthworm reactor through overflow distributing board, which interconnects emergent aquatic plant area of ecological purifying functional area; the biological water-wheel type rotary disc is set in the outlet channel of biological earthworm reactor.

Owner:HEBEI AGRICULTURAL UNIV.

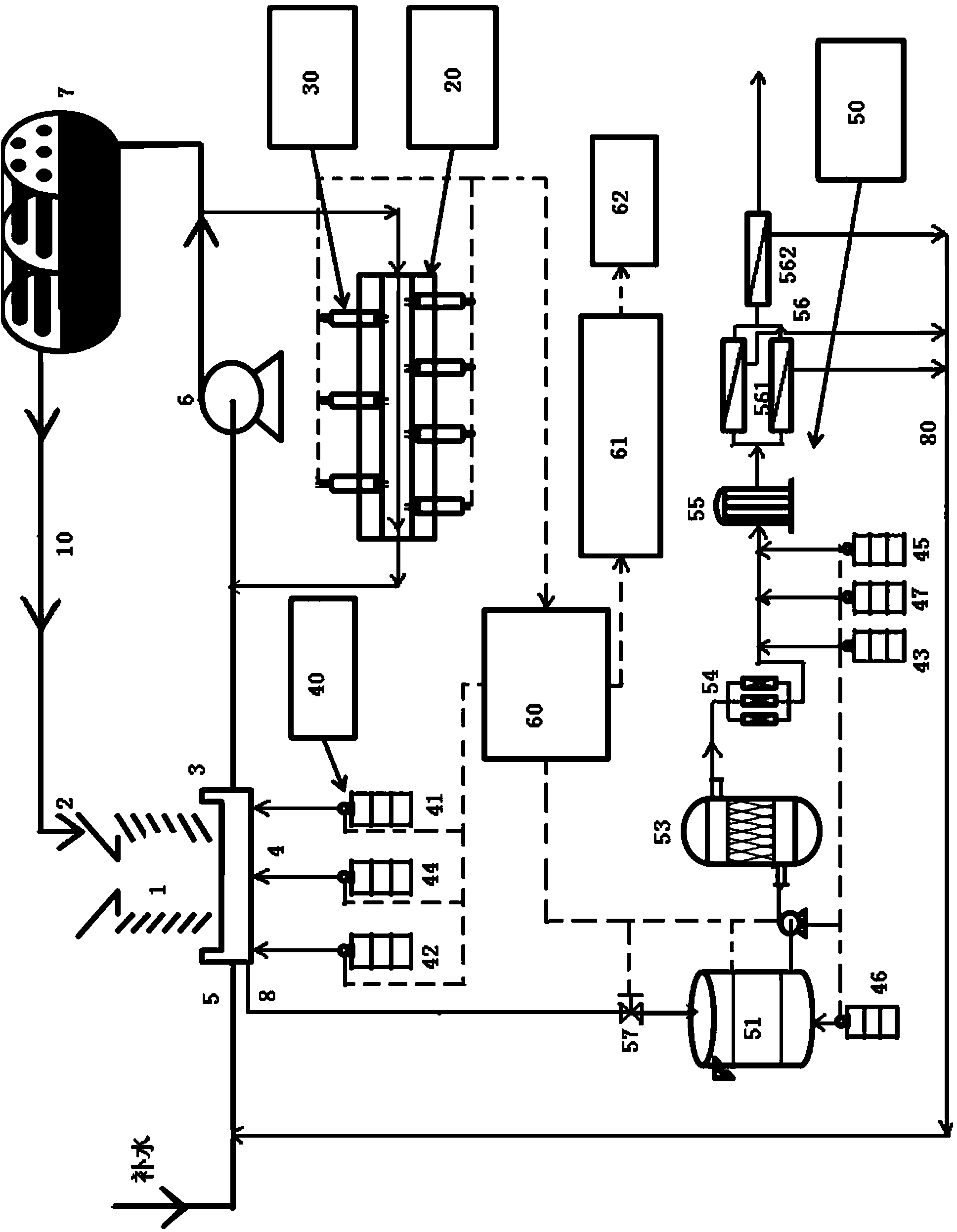

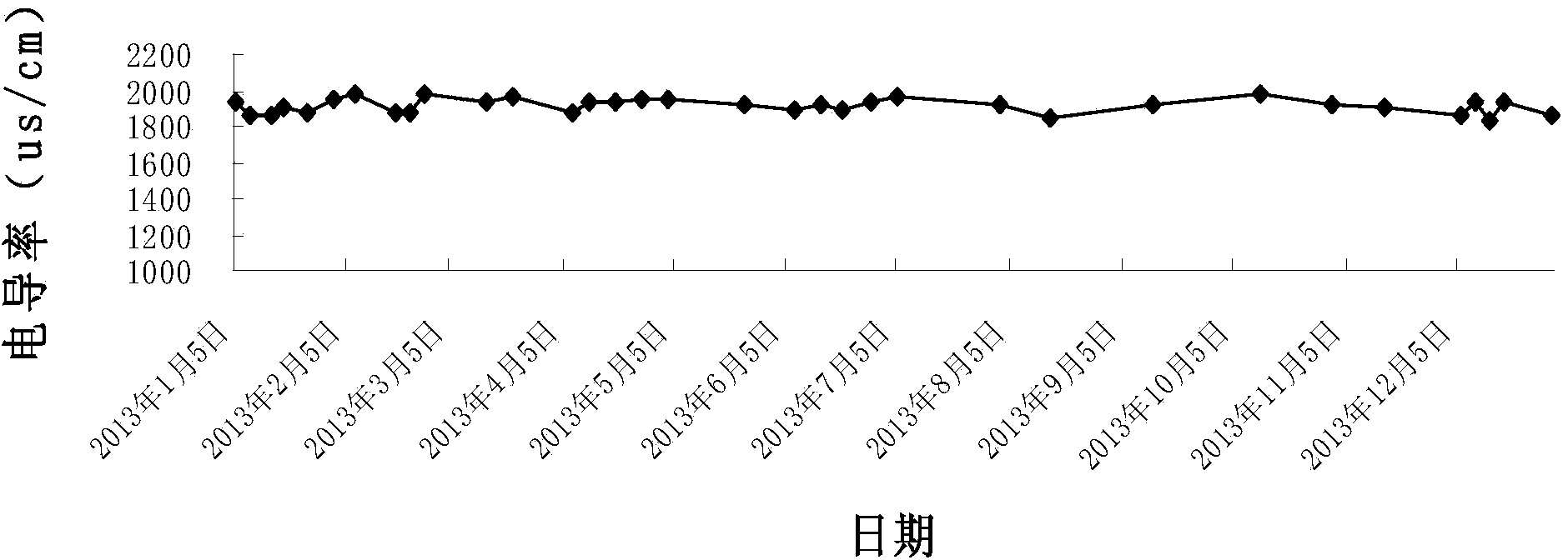

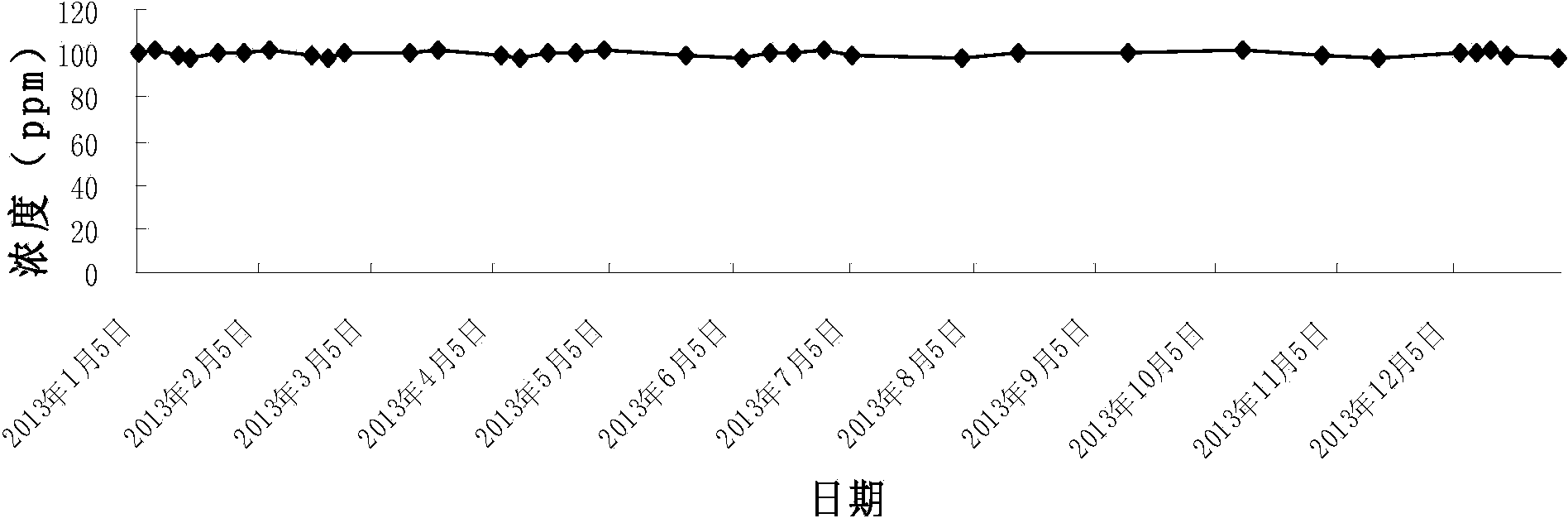

Integrated equipment and method for automatically treating circulating cooling water and recycling sewage water

ActiveCN104250042AManage water qualityImprove water qualityMultistage water/sewage treatmentWater useReverse osmosis

The invention discloses integrated equipment and a method for automatically treating circulating cooling water and recycling sewage water. The integrated equipment comprises an on-line cooling water quality monitoring device, a cooling water treatment effect monitoring device, a medicament feeding device, a water use amount and drug use amount counting device, an advanced cooling water treatment and recycling device and an on-site control device. The integrated equipment can effectively monitor the water quality of the circulating cooling water on line and automatically add and adjust medicines according to an actual condition of the water quality so as to solve the problems that the cooling water is scaled, eroded and deposited and generates microorganisms and ensures that the water quality of the cooling water can meet a requirement for advanced treatment on the water quality of recycled water; furthermore, the use amount of chemical products for treating the cooling water is reduced by 30 percent; when the water quality concentration factor of the cooling water reaches the maximum value permitted by the national standard, the advanced treatment and recycling device is switched on; a reverse osmosis system matched with a special scale inhibitor is used for performing advanced treatment on sewage water, so that 50-60 percent of sewage water can be recycled; calcium ions and bicarbonate radicals which are discharged by the cooling water are actually increased to 2,300 ppm (which is metered by calcium carbonate).

Owner:天津鲲飞环保科技有限公司

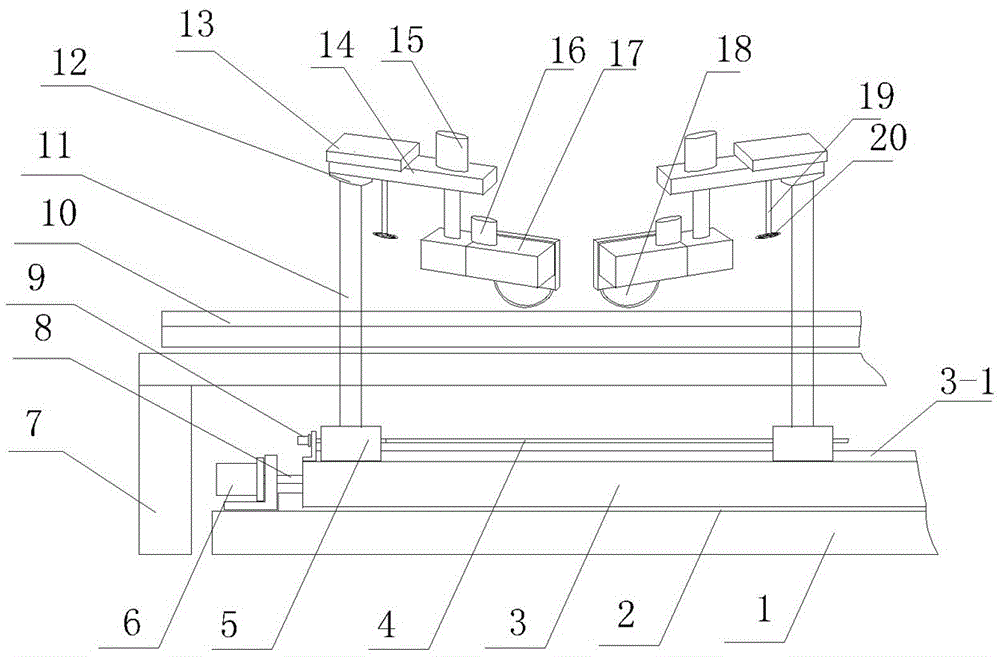

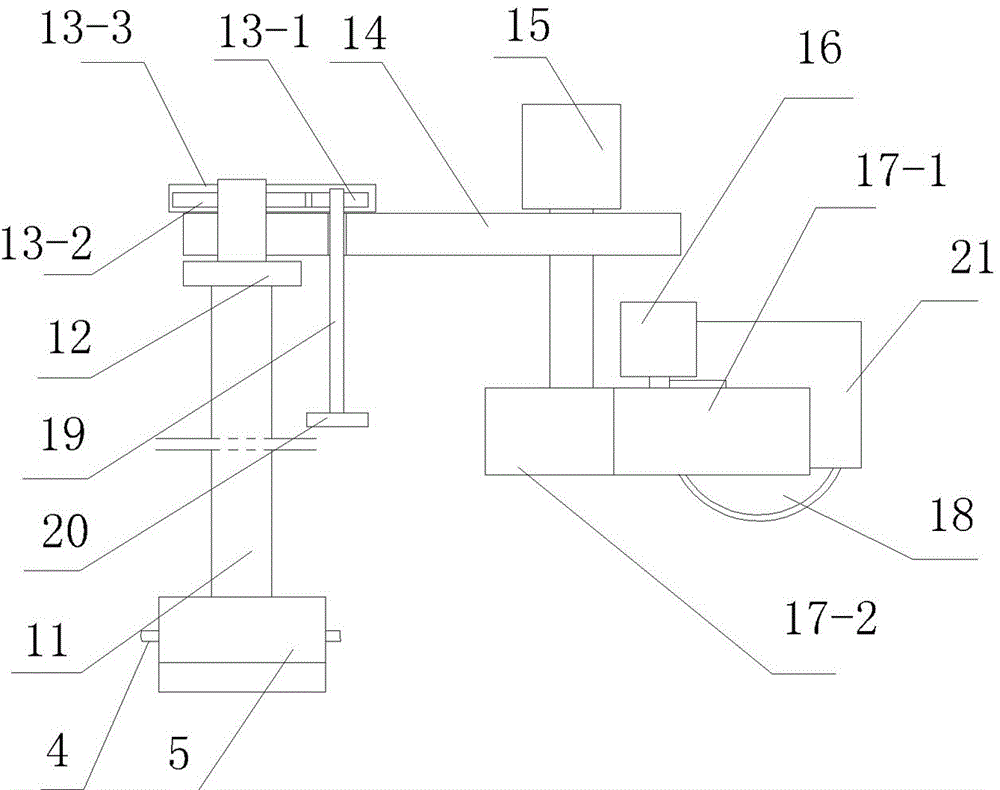

Pipeline elbow cutting device

InactiveCN105537681AReduce occupancyImprove cutting productivityMetal sawing devicesEngineeringMechanical engineering

The invention discloses a pipeline elbow cutting device which comprises two saw blade cutters and a connection elbow cutting module, wherein a saw blade distance adjusting mechanism and a saw blade moving mechanism are arranged under the saw blade cutters; each saw blade cutter comprises a base, an upright post and a rotating arm; a saw blade angle adjusting mechanism is arranged between each rotating arm and the corresponding upright post. The pipeline elbow cutting device adopts the two saw blade cutters and two saw blades to cut a plurality of connection elbow pipes, so that the cutting efficiency can be greatly improved, less operators are required, equipment and building investment is reduced, and the production cost is reduced.

Owner:王朝永

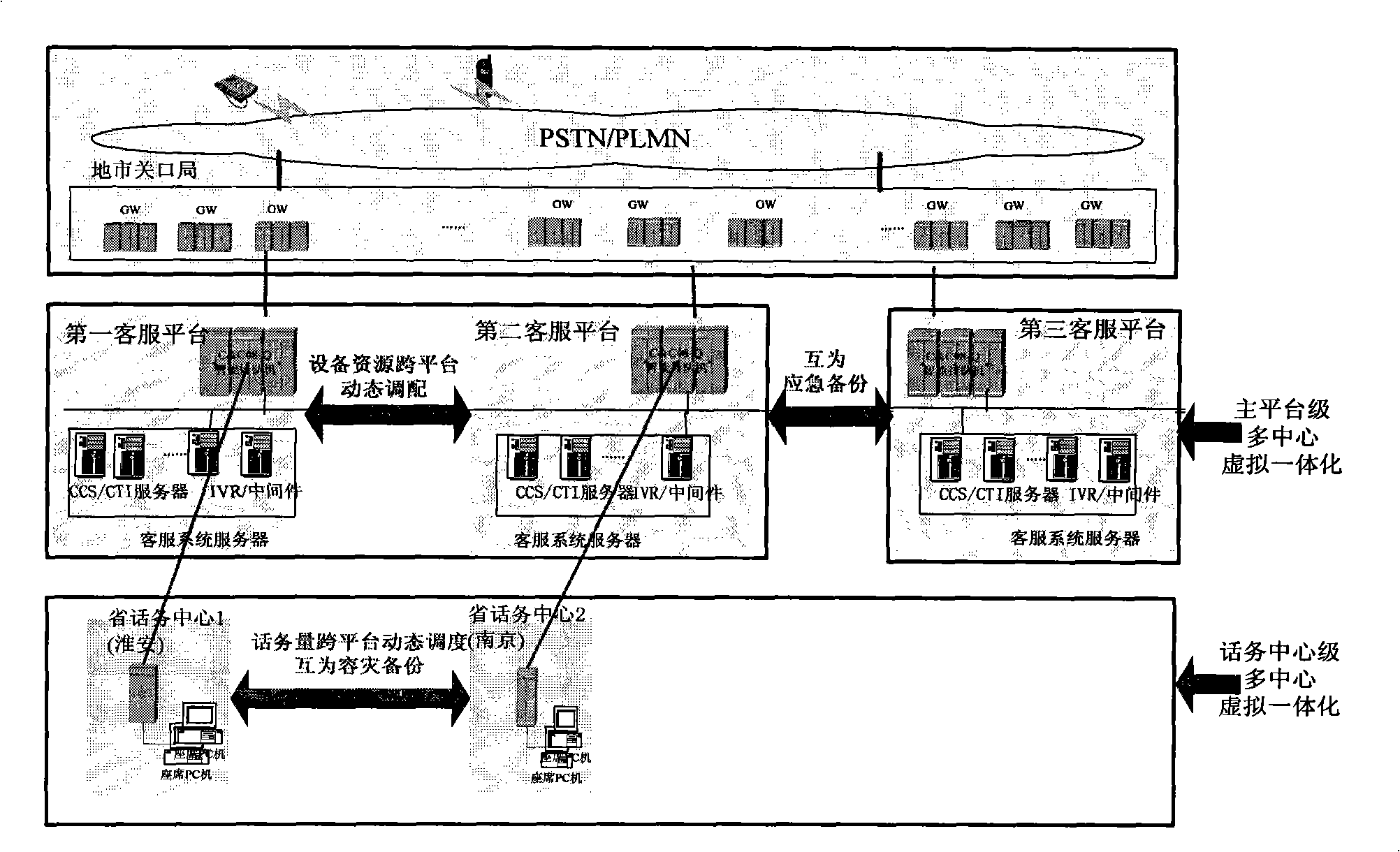

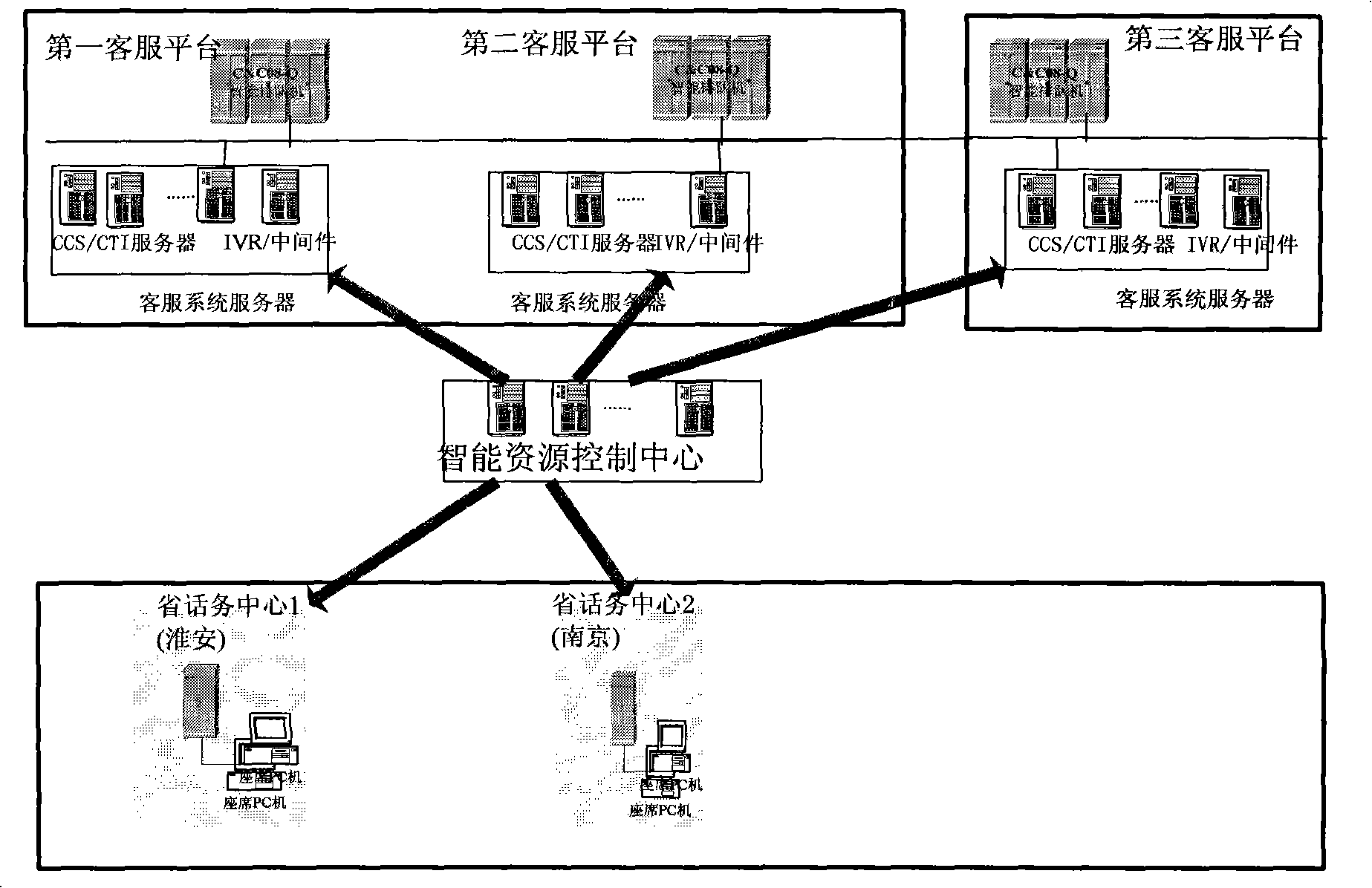

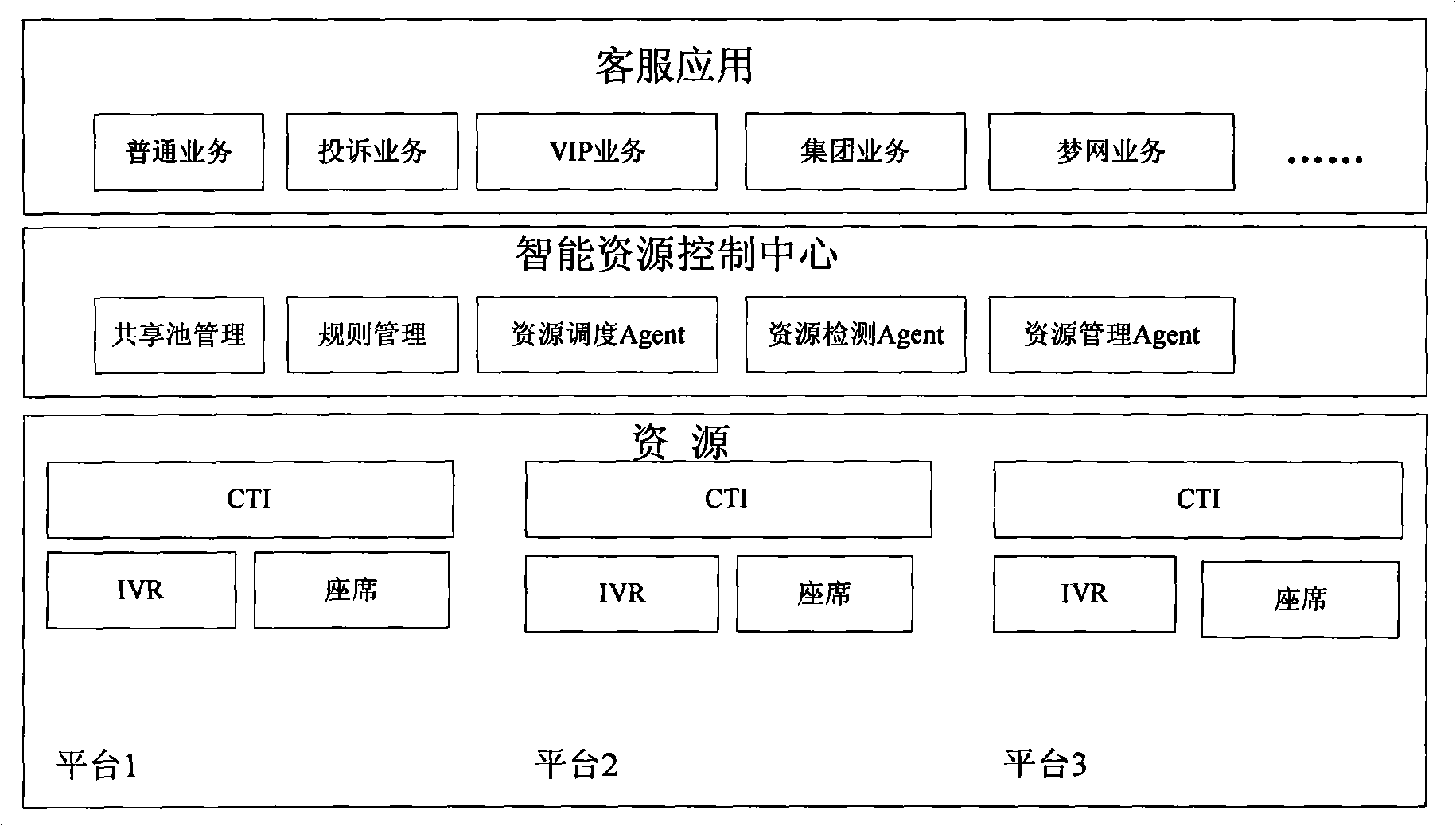

Method for implementing multi-center virtual integration of passenger service system

ActiveCN101330544ASave construction investmentReduce operating costsSpecial service for subscribersService systemOperating model

The invention discloses a method for realizing the multi-center virtual integration of a customer service system. The method realizes the functions of resource sharing and mutual emergency backup of two levels of a platform center and a call center; the platform center and the call center which are mutually independent isolated islands are transformed into a logically integrated customer service system, thereby realizing the function of cross-platform cross-region dynamic scheduling of IVR and call resources according to the platform loads and the operation situation of devices. In addition, the method utilizes a small amount of capacity expanding resources to build a third customer service platform, the backup resources of the original first and the second customer service platforms are released to be converted into the main resources, so the method can not only achieve the purpose of emergency backup of the first and the second customer service systems, but can also fully play the economic benefits of the third customer service platform which is taken as the backup resources; the multi-center virtual integration of seat resources breaks through the traditional dual-center independent operation mode and forms the dual-center collaborative operation mode.

Owner:CHINA MOBILE GROUP JIANGSU

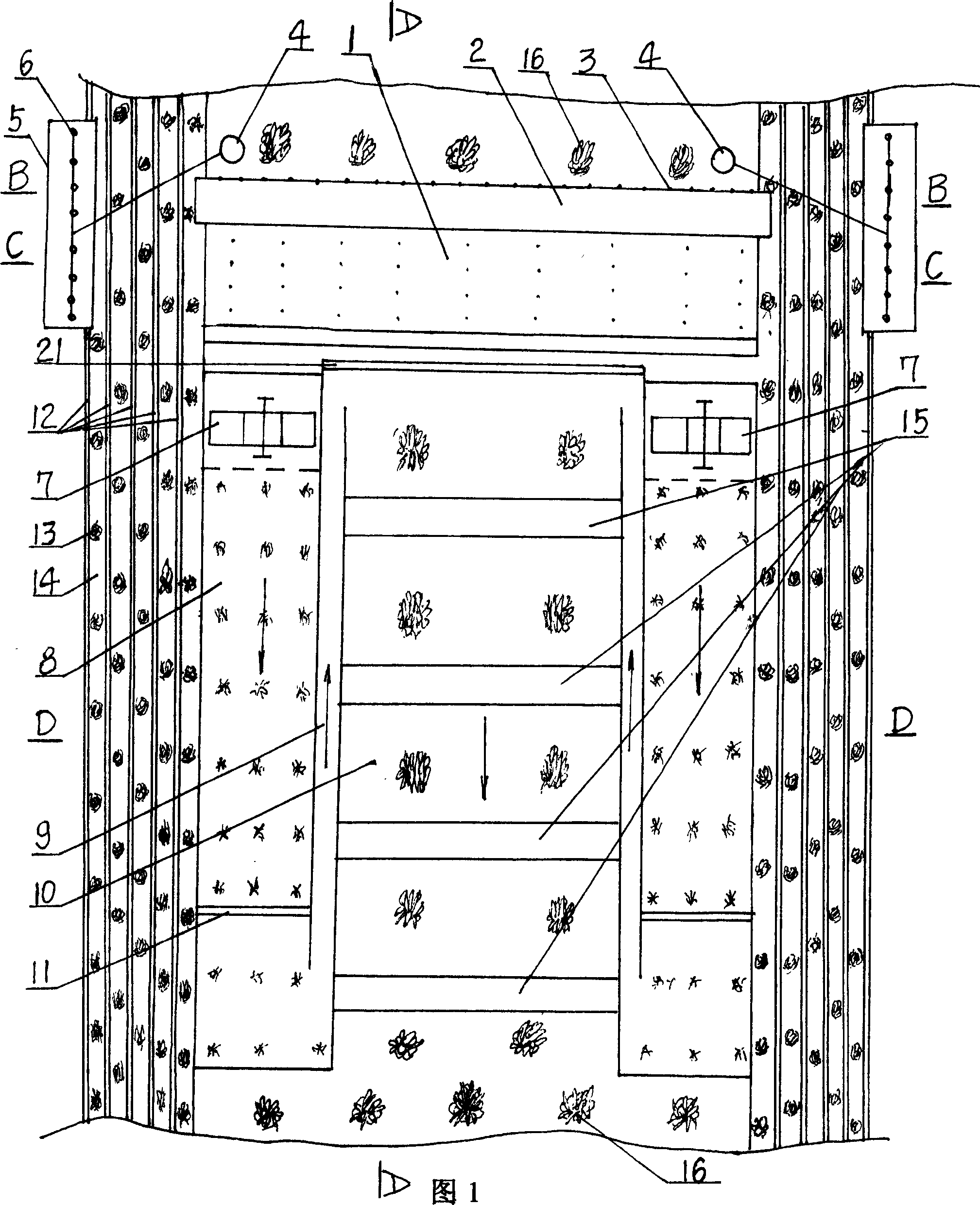

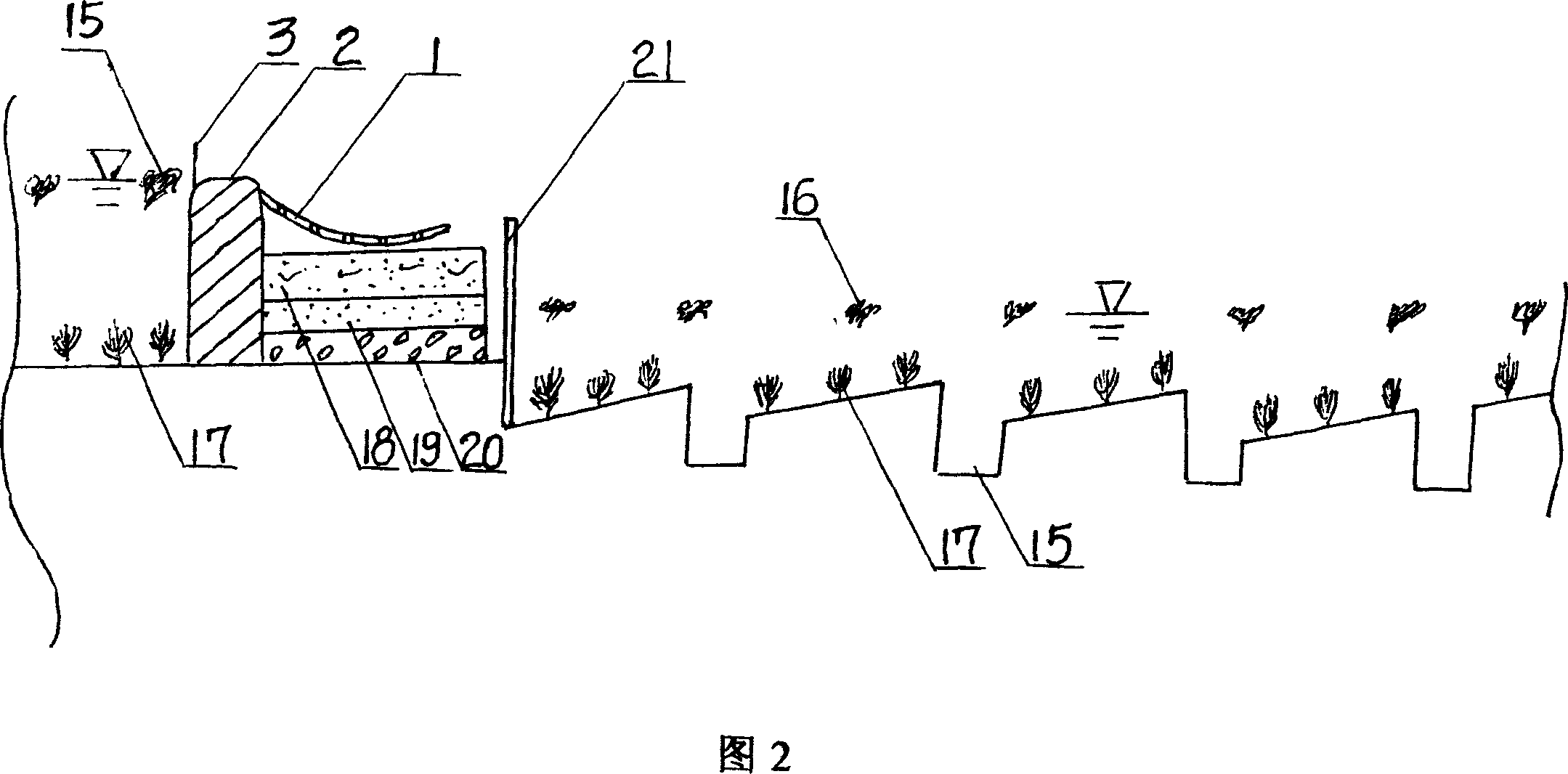

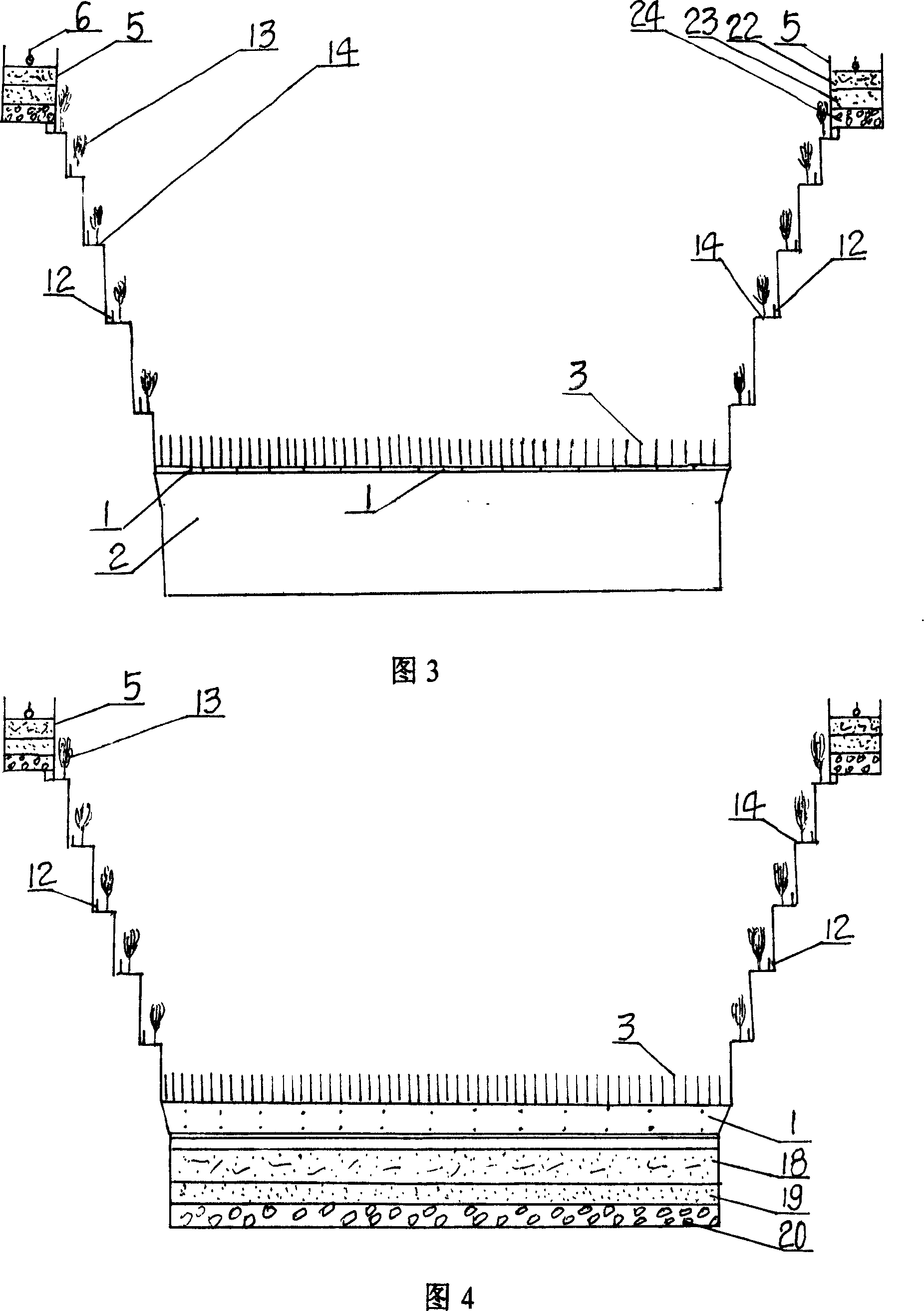

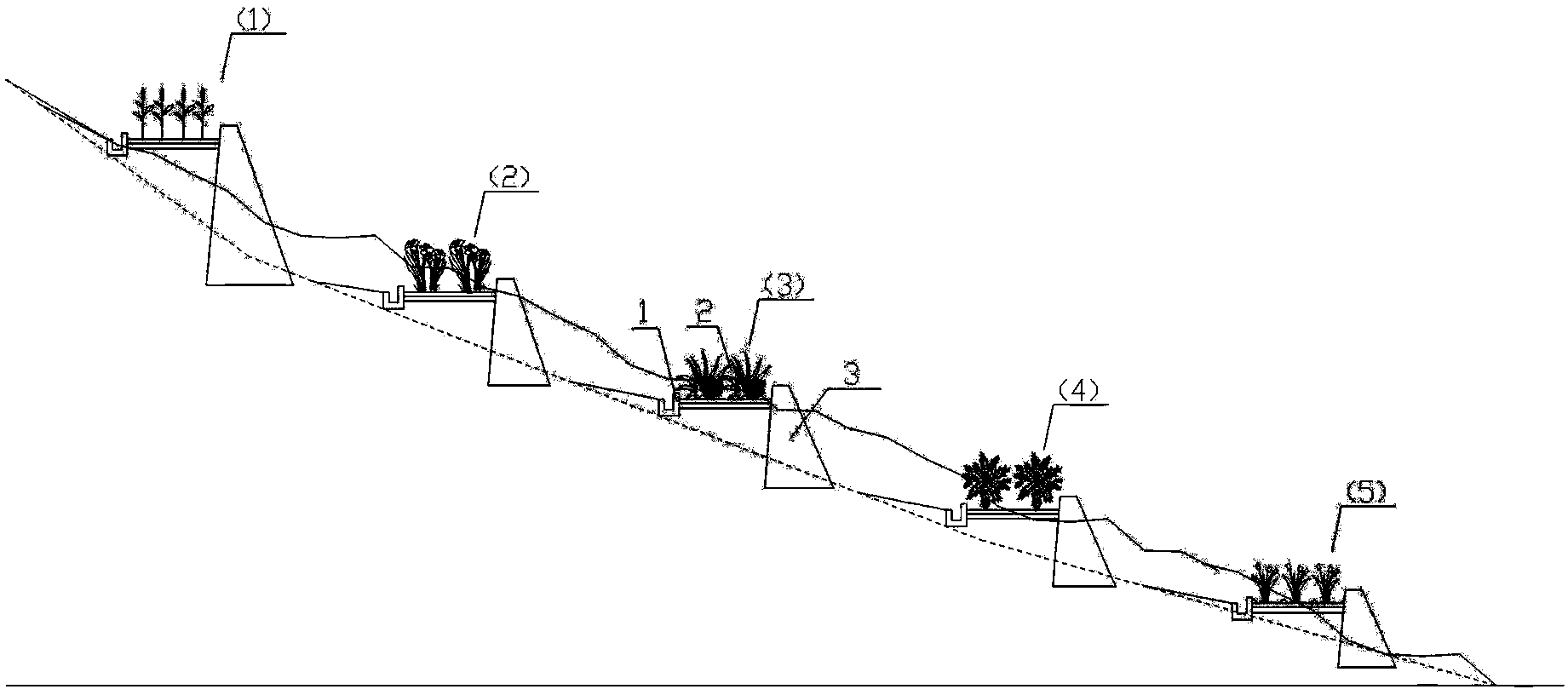

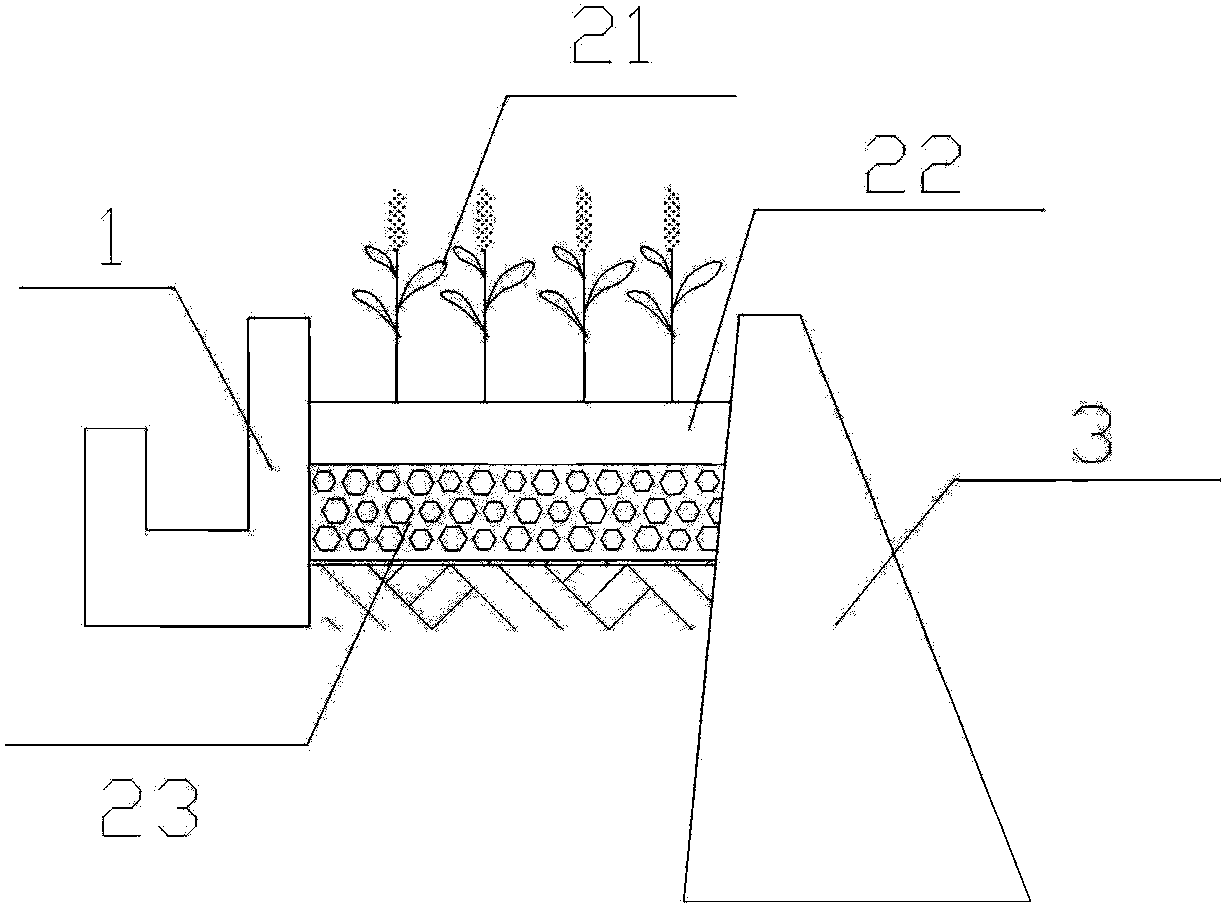

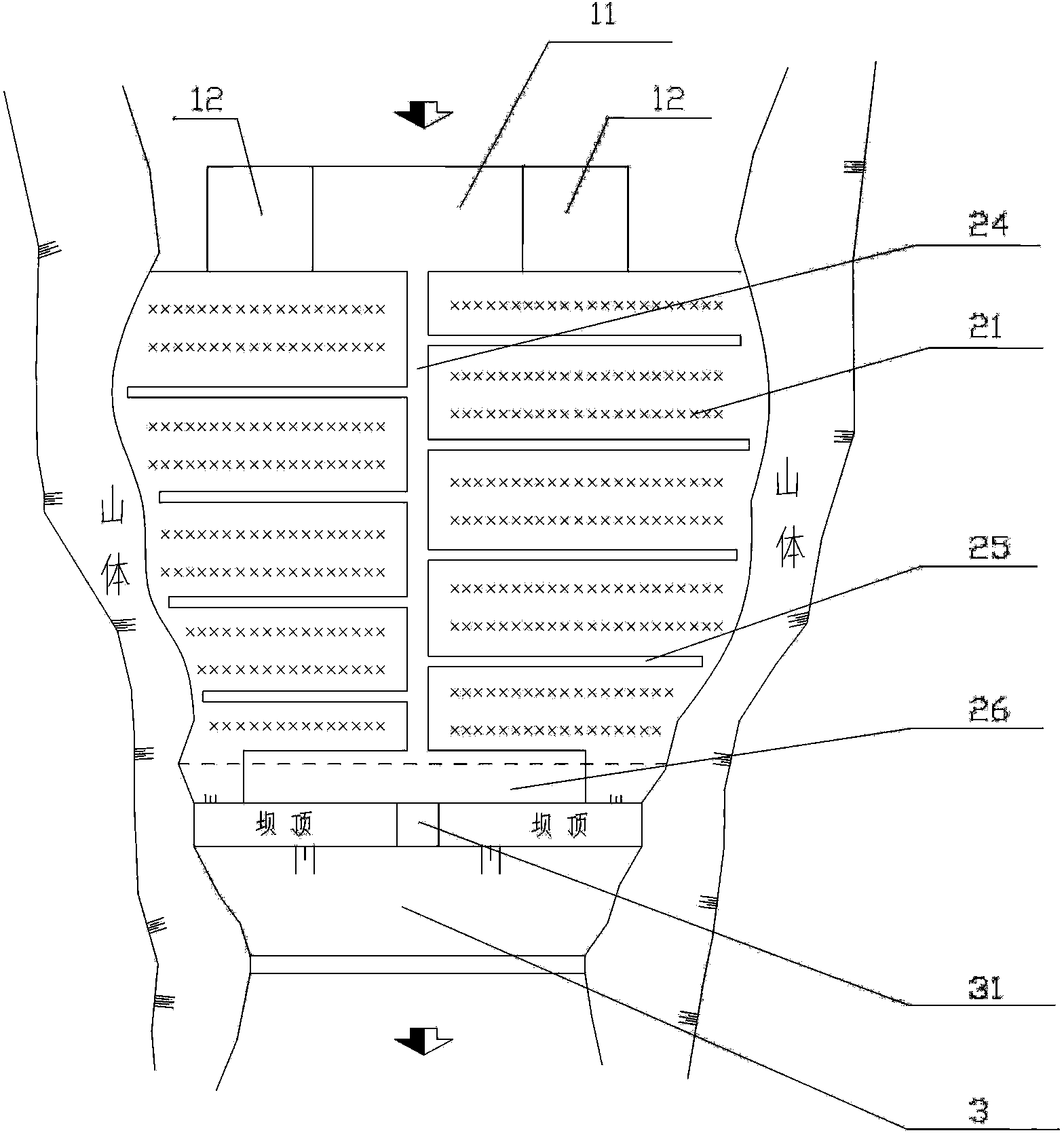

Ecological check dam prevention and control system for three gorges reservoir region hilly land ravine agricultural non-point source pollution

ActiveCN103588303ANo energy consumptionAvoid easy cloggingSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandEngineering

The invention relates to the fields of environmental engineering and ecological engineering. An ecological check dam prevention and control system for three gorges reservoir region hilly land ravine agricultural non-point source pollution is characterized in that multiple levels of ecological check dams are in trapezoidal distribution with natural fall from high to low along with the hilly land; each level of ecological check dam consists of a water storage regulating pond, a constructed wetland and a check dam main body, which are arranged sequentially according to the water flow direction; the water storage regulating pond is communicated with an overflow port in the previous level of the check dam main body. The system can effectively intercept and control the hilly land ravine agricultural non-point source pollution of the drainage basin, can reduce water and soil loss, can perform water-harvest irrigation, can reduce attenuation of channel nutrients before and after rainfall on sloping fields, and can realize ecological interception of agricultural non-point source pollutants.

Owner:WUHAN UNIV OF TECH

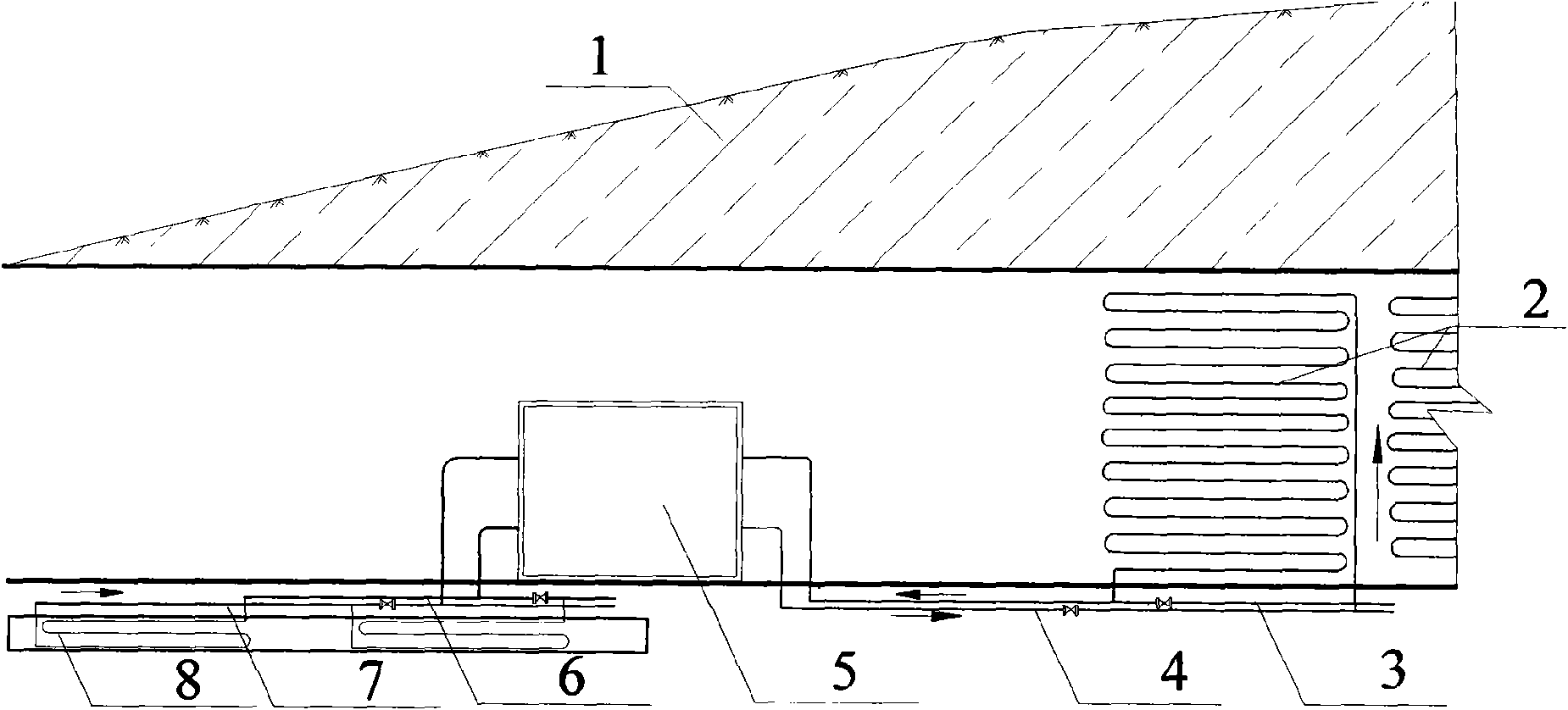

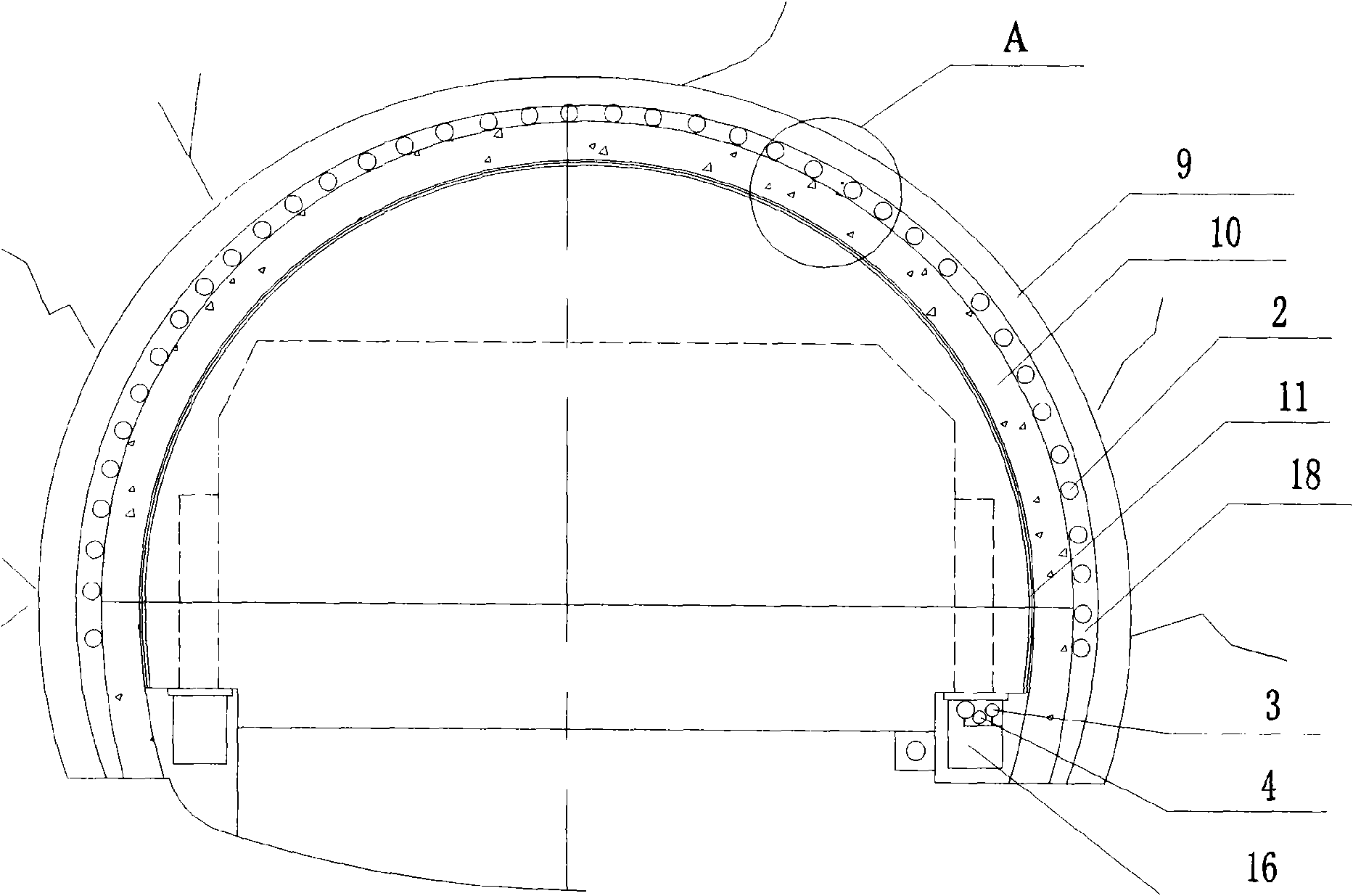

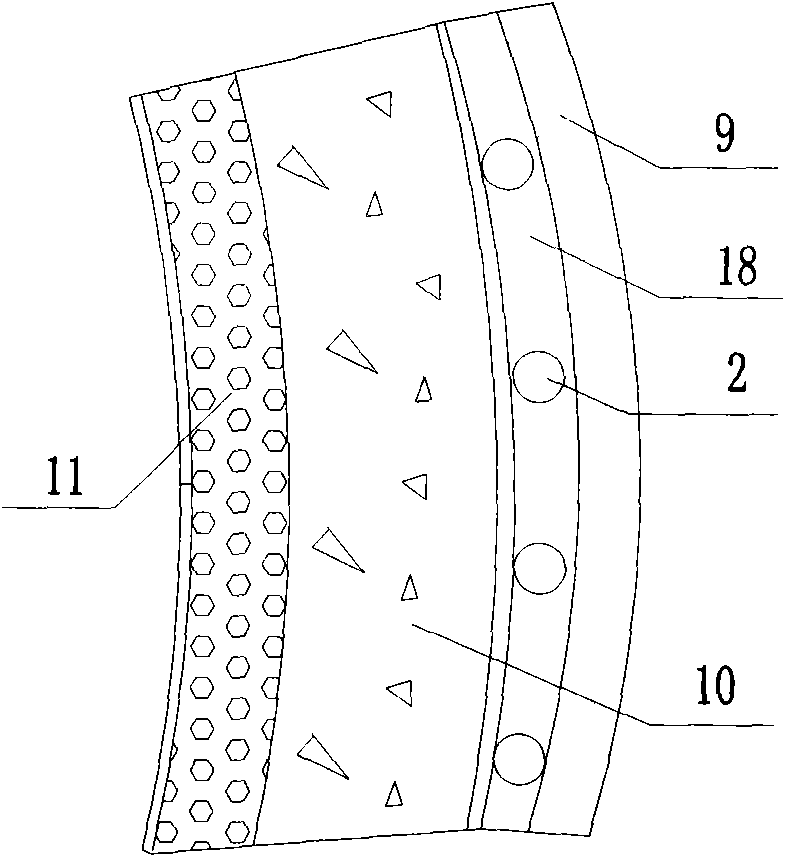

Ground source heat pump type heating system used for heat insulating ditch in tunnel

InactiveCN101672189ASave initial construction investmentSave construction investmentUnderground chambersTunnel liningThermal insulationHeat losses

The invention discloses a ground source heat pump type heating system used for a heat insulating ditch in a tunnel, comprising heat exchange tube circuits, a ground source heat pump and heating tube circuits. The heat exchange tube circuits are embedded in the tunnel, the heating tube circuits are laid on the wall and at the bottom of the heat insulating ditch, and the heat exchange tube circuitsand the heating tube circuits are respectively connected with the ground source heat pump. The heating system belongs to the active heating systems and can ensure the underground water in the heat insulating ditch to be drained out of the tunnel smoothly without being frozen. Compared with deep-buried ditches and cold-proof sluice culverts, the heating system has reliable freeze protection and thermal insulation effects. The system adopts the low temperature hot water heating mode, can not only ensure the underground water in the heat insulating ditch to be heated evenly but also reduce the heat loss, thus having good energy saving effect. Heat exchange tubes of the ground source heat pump are embedded between the primary lining and the secondary lining to replace underground boreholes required by the embedded tubes of the traditional ground source heat pumps, which can save part of the investment in the initial construction. Compared with the heating cable type heating systems used for the heat insulating ditches, the heating system can save 70% of the late operation and maintenance costs. The heating system exhausts no CO2 compared with the common fuel boilers.

Owner:TONGJI UNIV

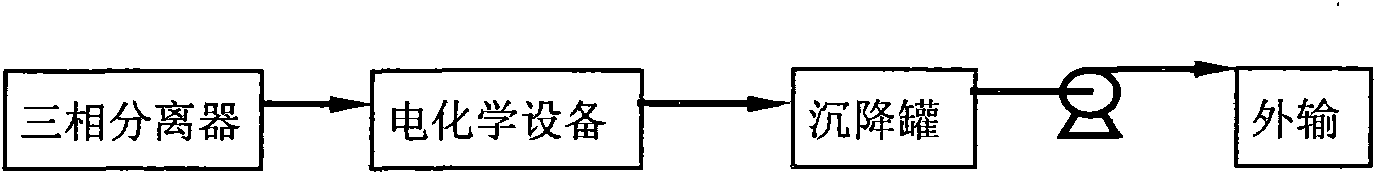

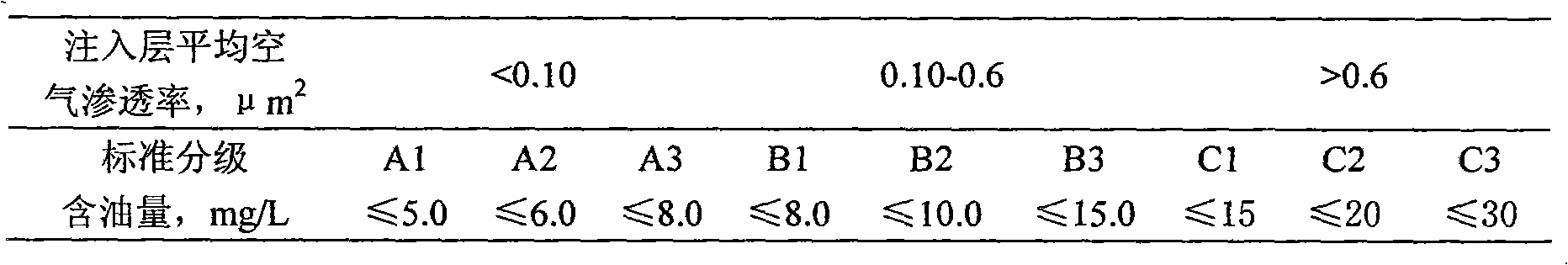

Electrochemical method of oil removal of wastewater produced in oil extraction by polymer flooding displacement

InactiveCN101602531AEasy to separateSave construction investmentWater/sewage treatment by flotationElectrolysisWater quality

The invention discloses an electrochemical method of oil removal by polymer flooding oil recovery wastewater, which comprises the following steps of: 1, electrolysis; 2, sedimentation. In the process of the electrolysis, tiny oil droplets in the wastewater lose electrons due to discharge on the surface of an anode, charges on the surface of the oil droplets are reduced, and electric potential of interface xi is decreased; and residual polymer pieces in the wastewater after the electrolysis are oxidized and degraded, viscosity of the wastewater is decreased, and water film intensity on the interface of oil / water is reduced. Therefore, the tiny oil droplets after the electrolysis are liable to be converged into large oil droplets and are rapidly separated from the wastewater under the action of cathode hydrogen. As treated by the method, crude oil in wastewater produced in oil extraction by polymer flooding displacement is quite easy for removal with no need for large use of sedimentation tanks, thus saving construction fund for oilfield; the invention has simple process, requires no drug, saves resource and cost and conforms to green chemistry process, quality of the wastewater after the oil removal is obviously crystal-clear; in addition, the device is convenient and safe in operation, easy to control and realize automation, extensively adapted to the amount of water, and convenient for popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com