Treatment method of oily sludge

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the use limitation, affect the coke volatile content and ash index, and affect the petroleum Coke quality and other problems, to achieve the effect of lightening the load, reducing the number of equipment and equipment construction investment, and reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

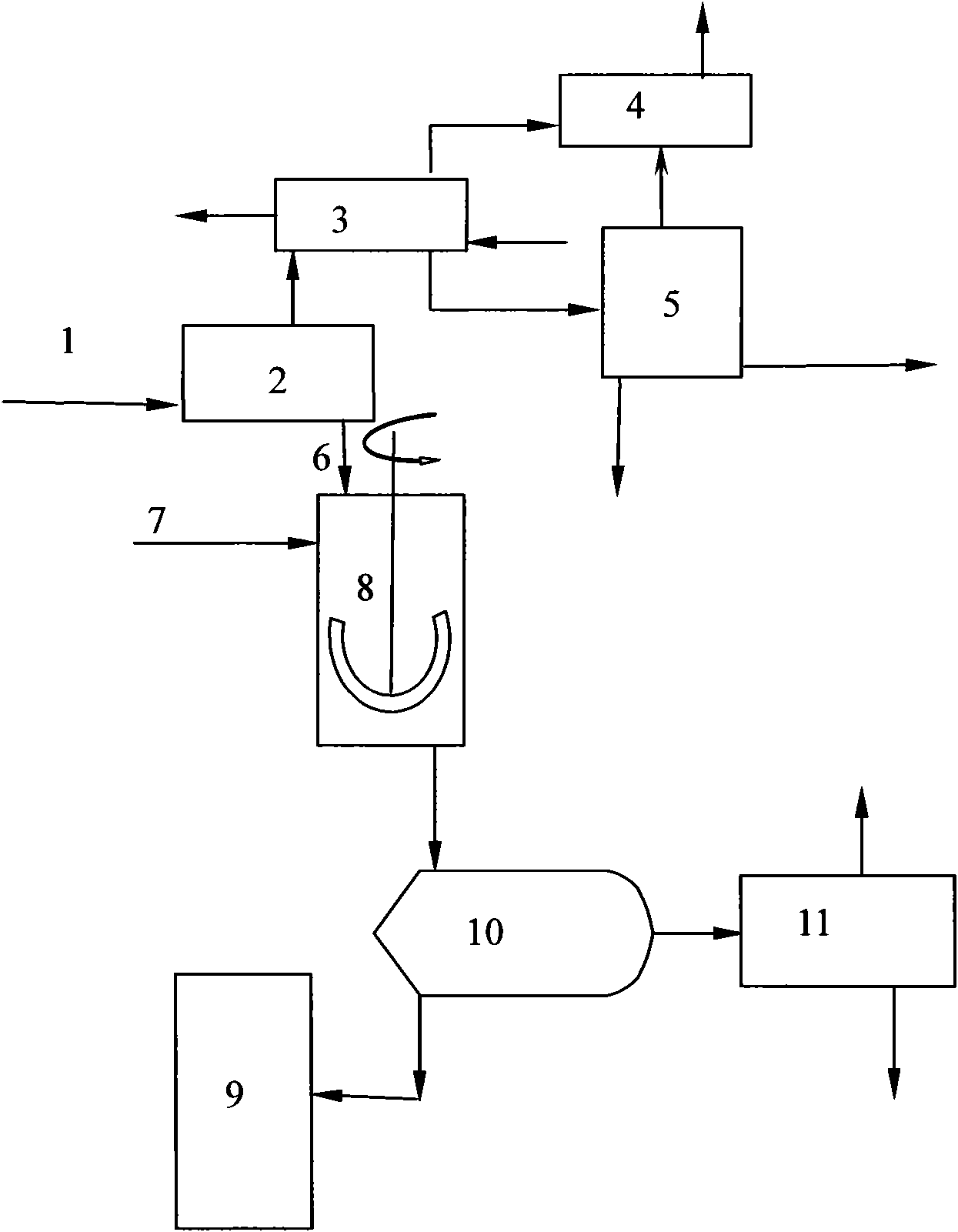

Method used

Image

Examples

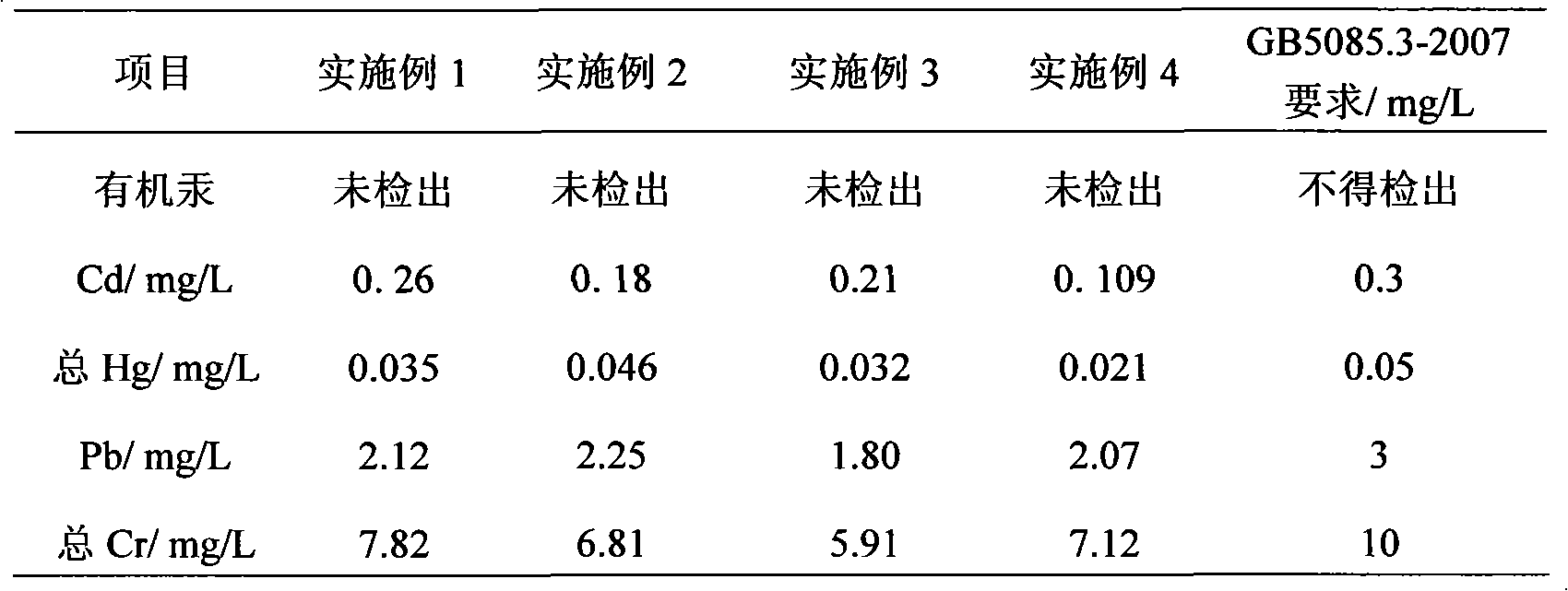

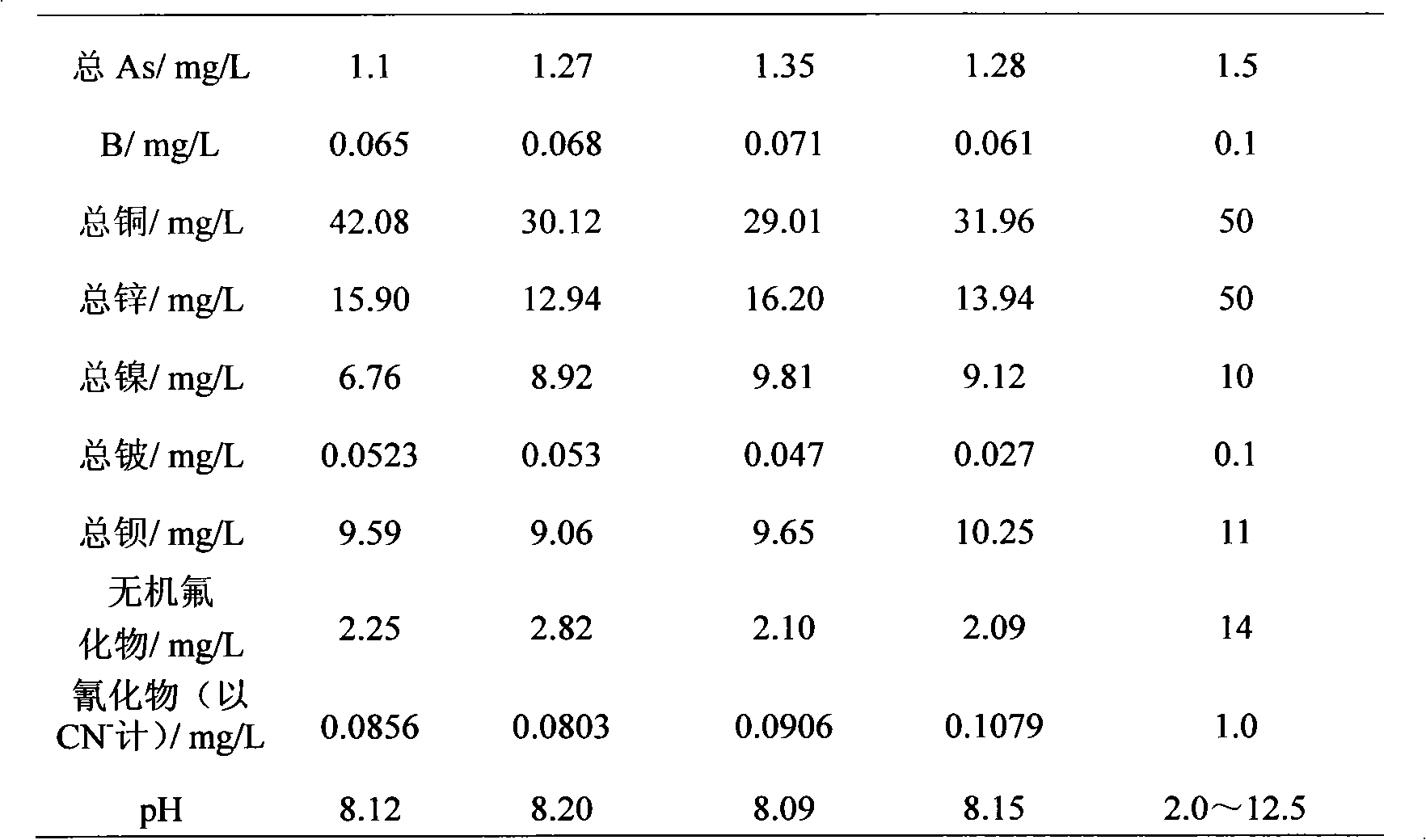

Embodiment 1

[0027] After mechanical dehydration, the oily sludge produced by a refinery sewage treatment plant has a moisture content of 74.3%, an oil content of 19.6%, and a solid content of 6.1%. The sludge is dried by a paddle-type sludge dryer (drying temperature 300°C, pressure 20kpa (absolute pressure)), and after drying for 85 minutes, the moisture content of the coke produced is 1.2%, which is mixed with butane at 1:95 Mix and extract for 30 minutes (at a temperature of 10°C). After the extraction is completed, the solid-liquid mixture is sent to the centrifugal separator, and the separated liquid phase enters the delayed coking device, and is heated to 340°C through heat exchange and the convection tube of the heating furnace, and enters the fractional distillation The lower part of the tower exchanges heat with the high-temperature gas from the top of the coke tower. After the light oil in the material is evaporated, the temperature of the material rises to 380°C, and at the same...

Embodiment 2

[0031] After mechanical dehydration, the oily sludge produced by a refinery sewage treatment plant has a water content of 79.5%, an oil content of 15.7%, and a solid content of 4.8%. After the sludge is dried (drying temperature 300°C, pressure 100kpa (absolute pressure), drying time 75min), the water content of coke is 58.5%, which is mixed with isooctane at 1:8 for extraction (temperature is 60 ℃, time 15min), after the extraction is completed, the solid-liquid mixture is sent to the centrifugal separator, and the liquid phase separated by centrifugation enters the delayed coking device, and is heated to 350 ℃ through heat exchange and heating furnace convection tube, and then enters the lower part of the fractionation tower, After exchanging heat with the high-temperature gas from the top of the coke tower, the light oil in the material is evaporated, and the temperature of the material rises to 400°C, and at the same time, the coke powder entrained in the high-temperature o...

Embodiment 3

[0035] After mechanical dehydration, the oily sludge produced by a refinery sewage treatment plant has a water content of 82.5wt%, an oil content of 15.7%, and a solid content of 4.8%. After the sludge is dried (drying temperature 160°C, pressure 40kpa (absolute pressure), time 60min), the water content of coke is 40.5%, which is mixed with diesel oil at a ratio of 1:20 (temperature is 20°C, time 10min ), after the extraction is finished, the solid-liquid mixture is sent to the centrifugal separator, and the separated liquid phase enters the delayed coking device, is heated to 346°C through heat exchange and the convection tube of the heating furnace, enters the lower part of the fractionation tower, and After the light oil in the material is evaporated, the temperature of the material rises to 395°C, and at the same time, the coke powder entrained in the high-temperature oil gas is washed. The raw material is drawn out from the bottom of the fractionating tower together with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com