Patents

Literature

2025 results about "Centrifugal separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A centrifugal water–oil separator, centrifugal oil–water separator or centrifugal liquid–liquid separator is a device designed to separate oil and water by centrifugation. It generally contains a cylindrical container that rotates inside a larger stationary container.

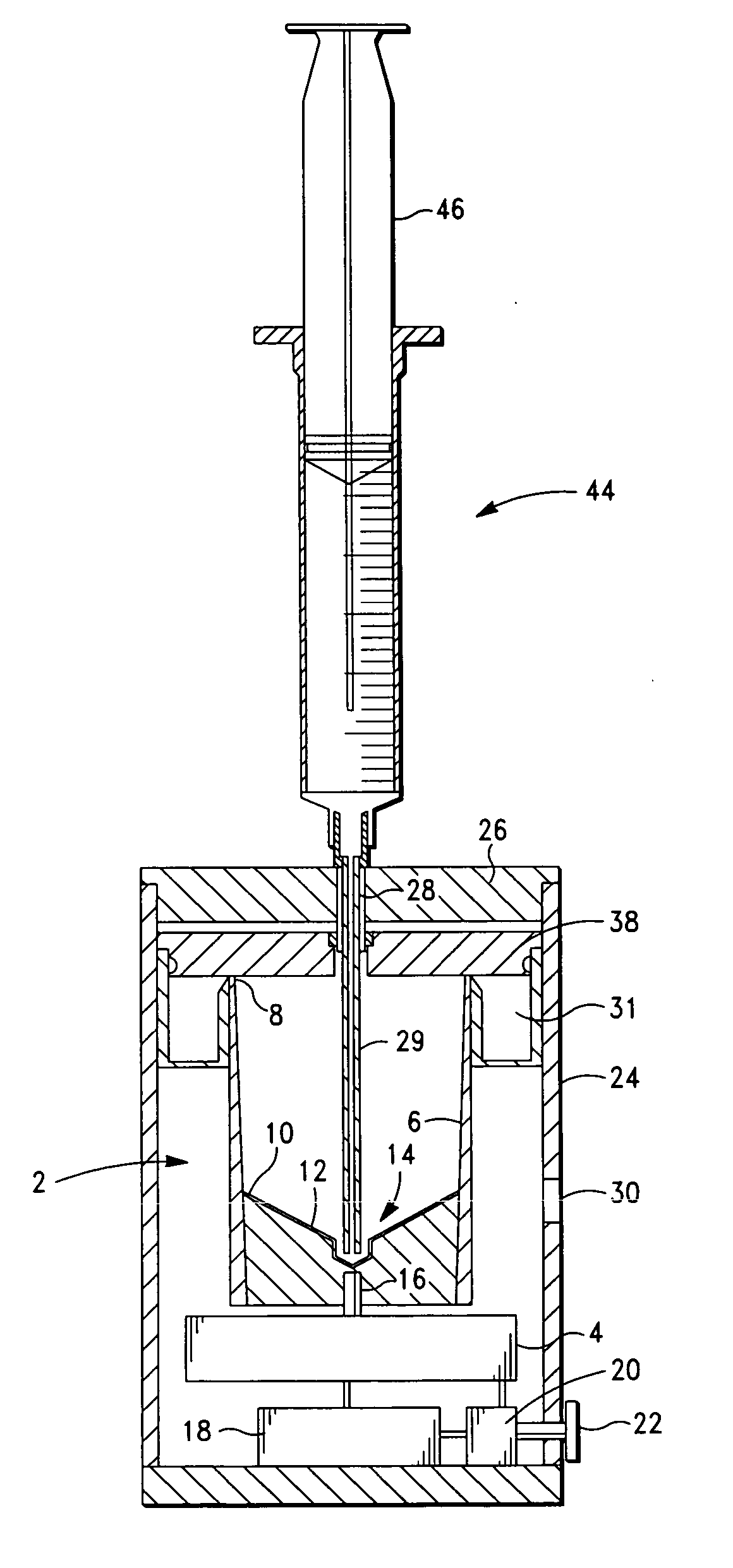

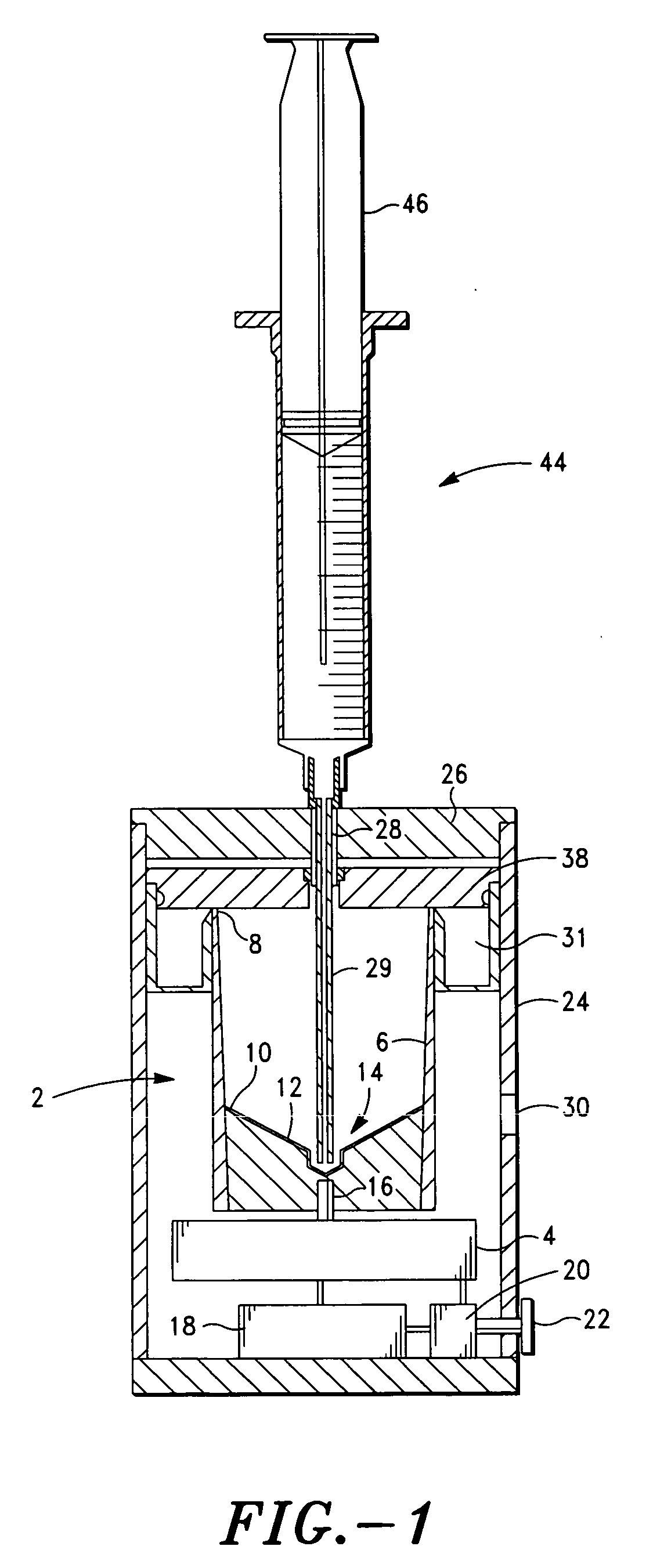

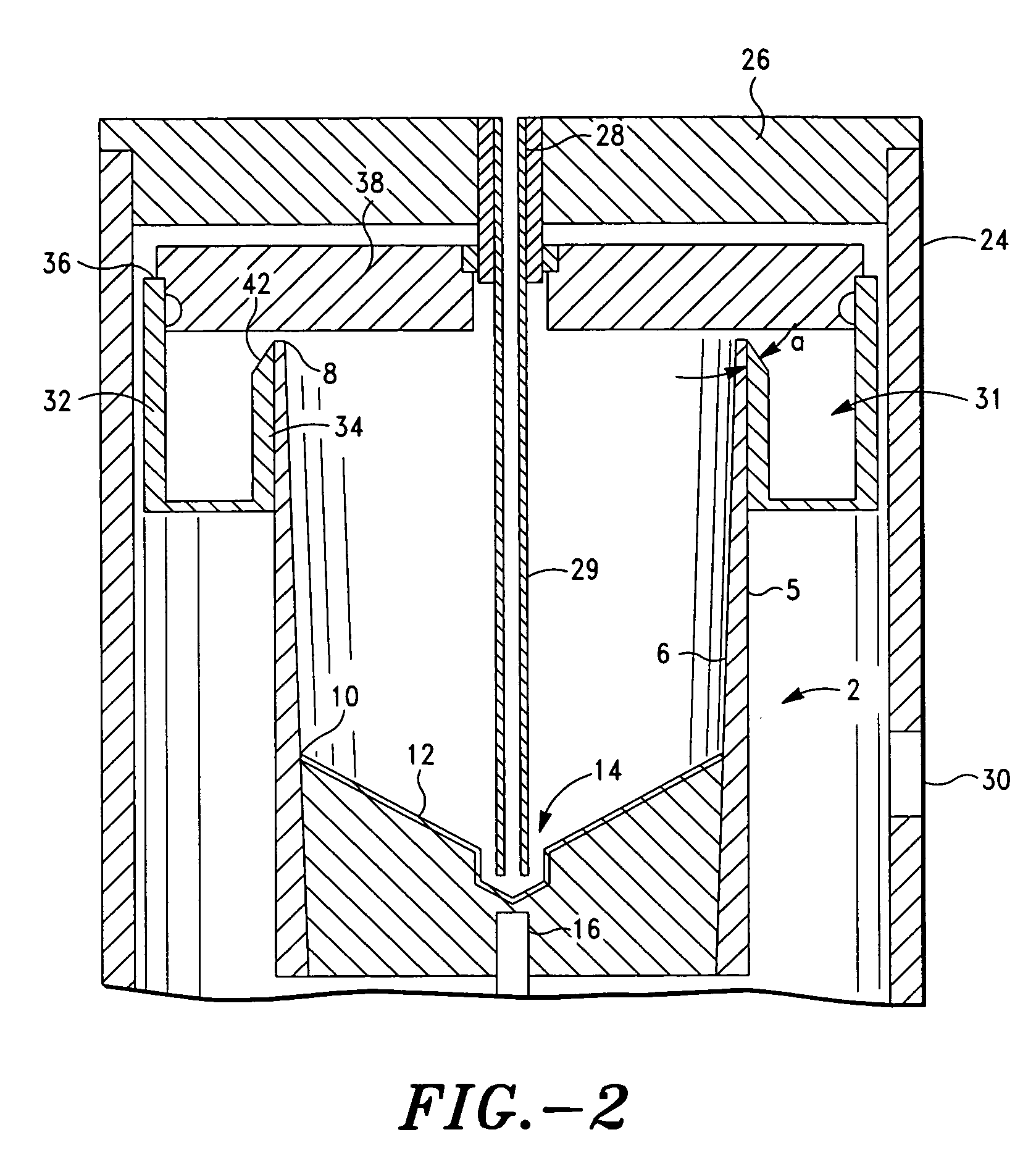

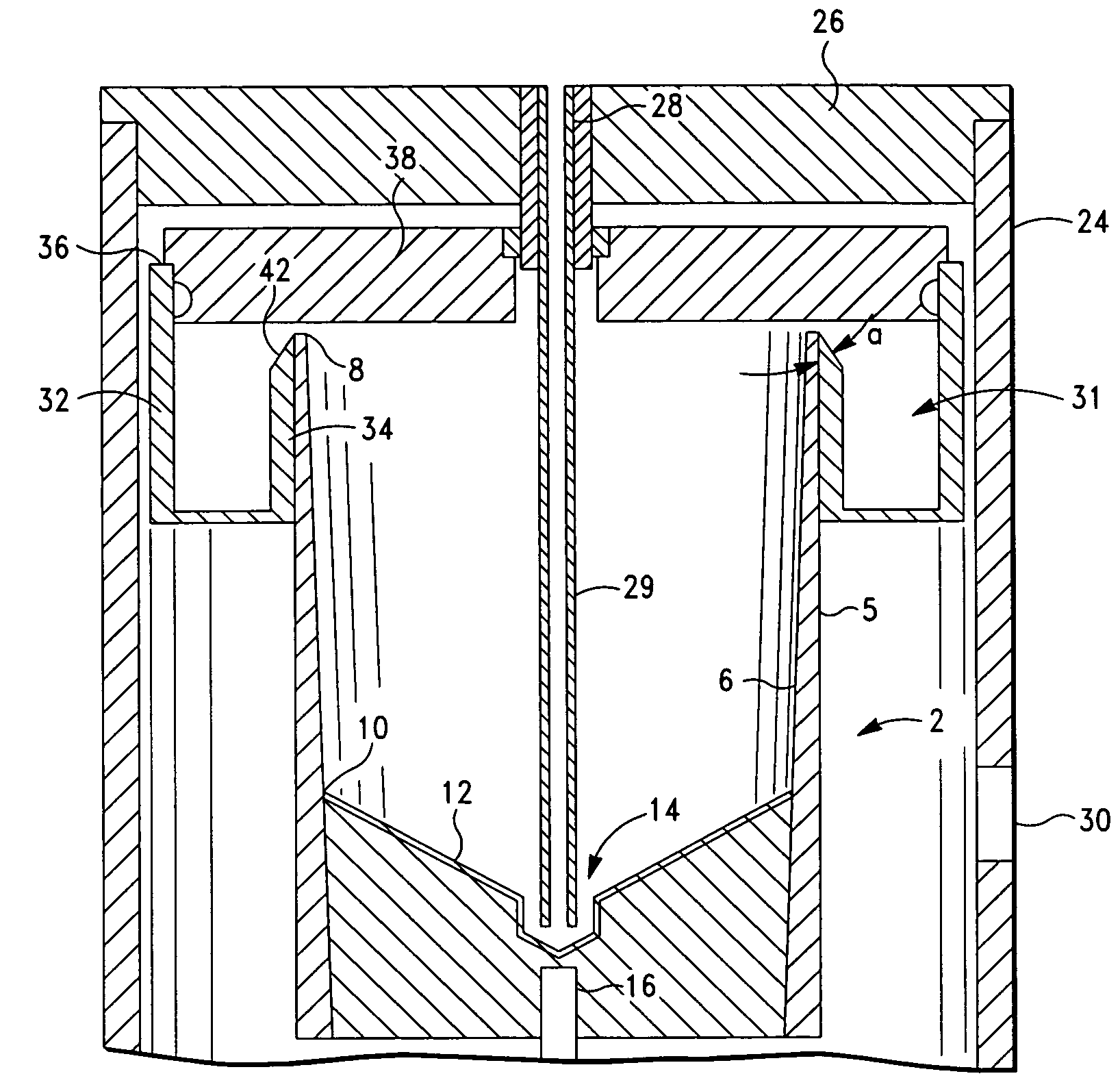

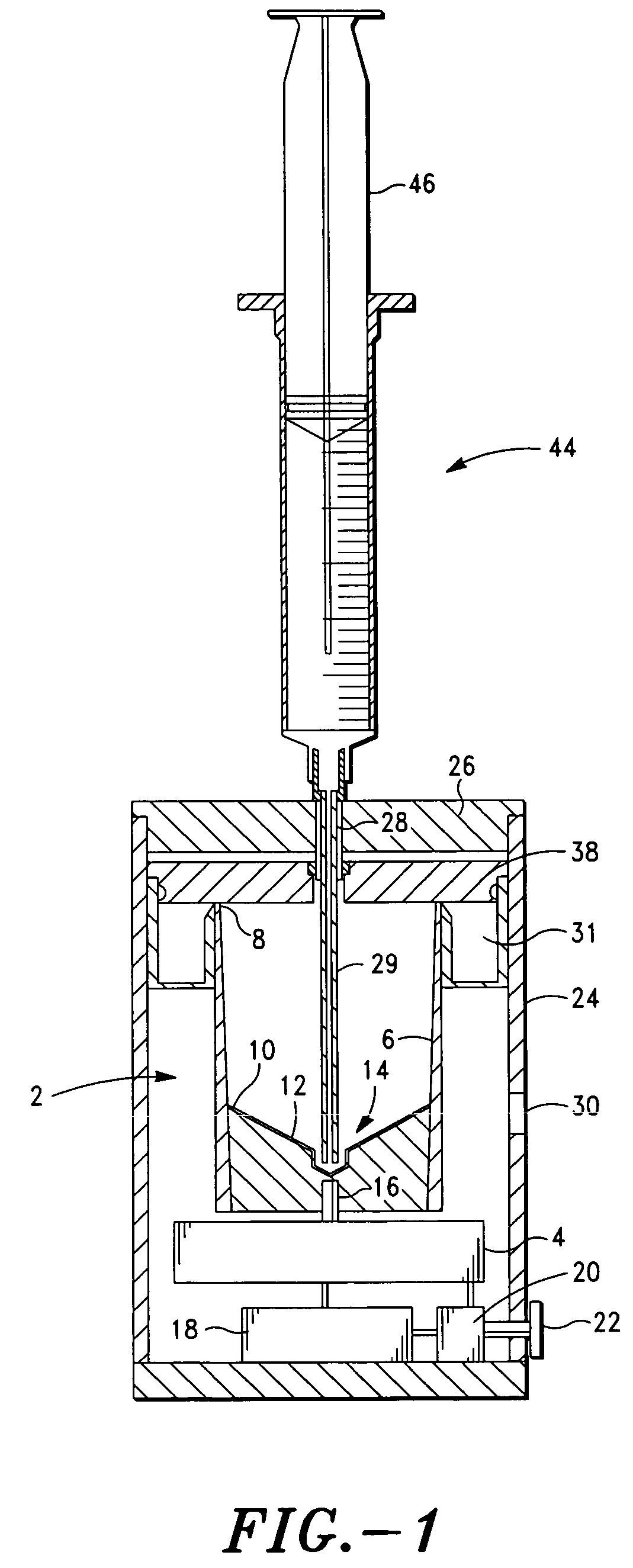

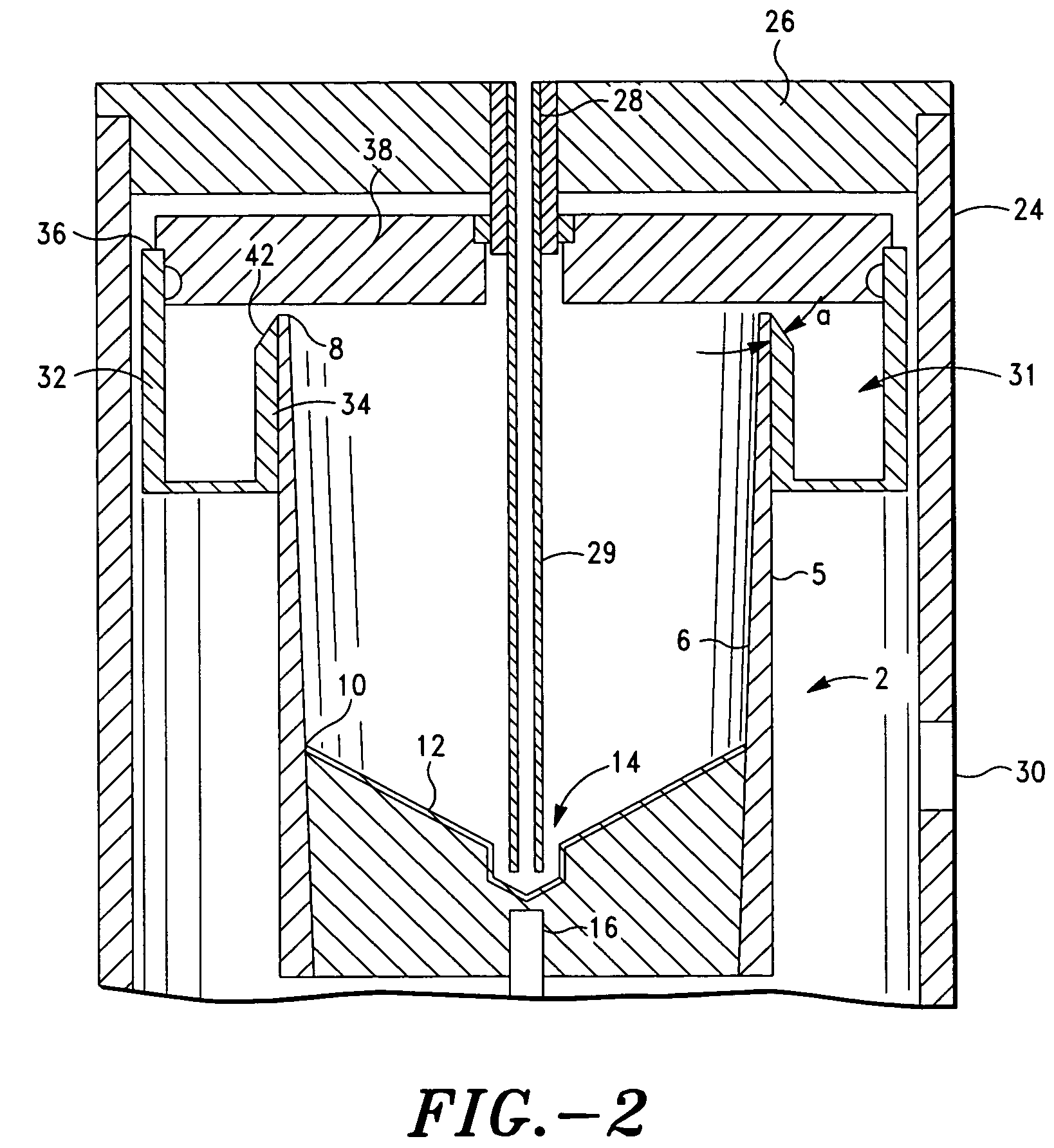

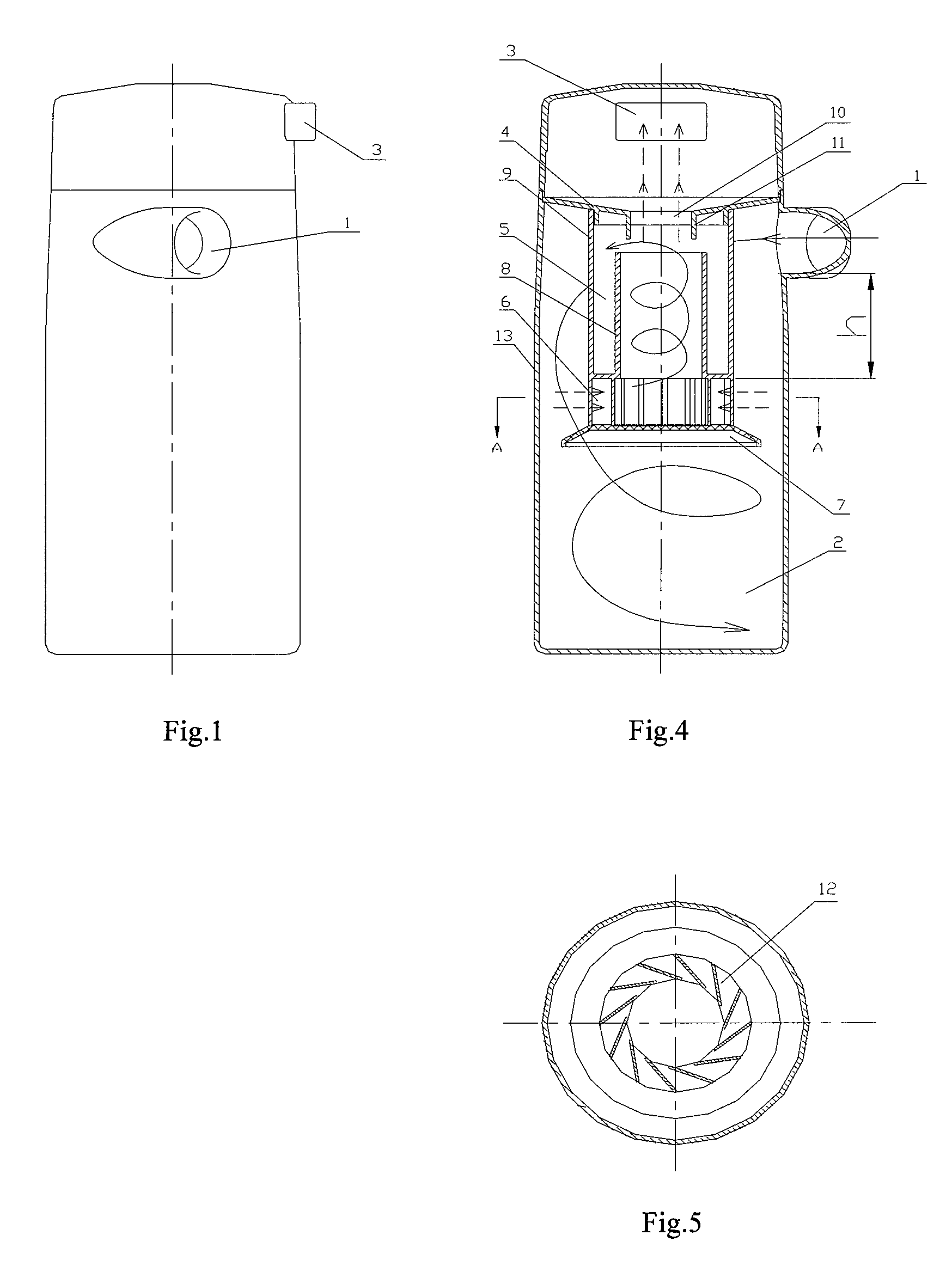

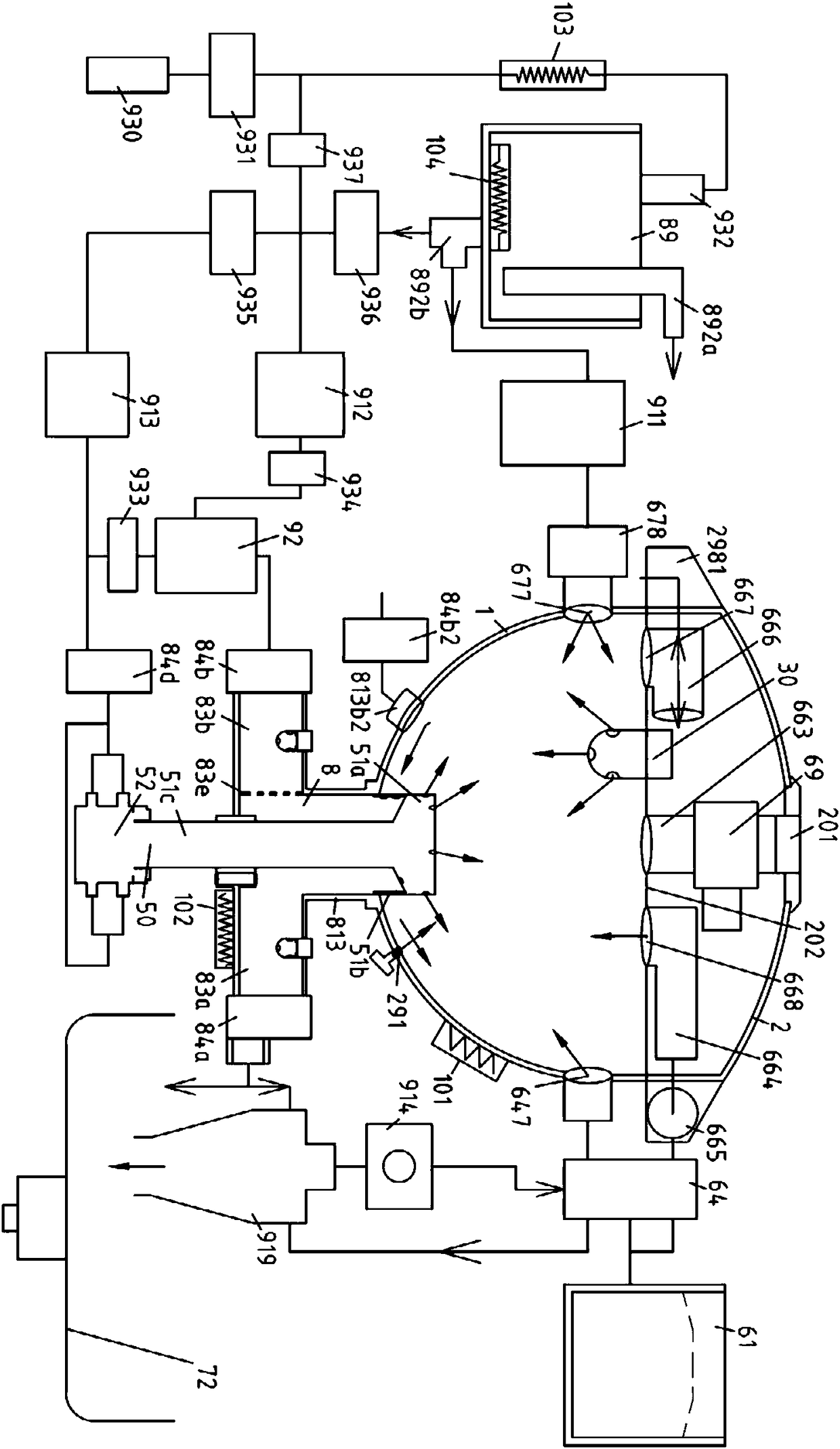

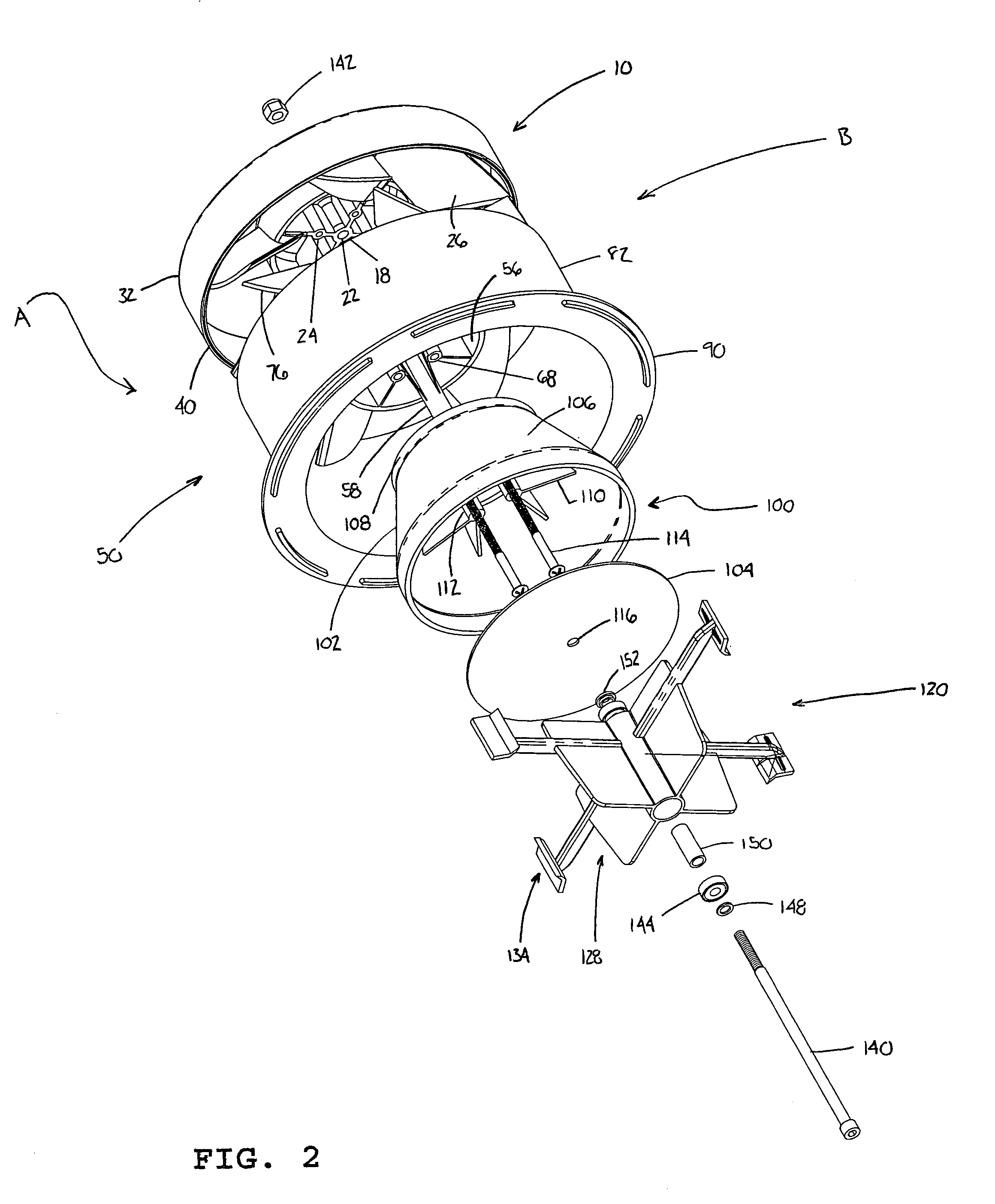

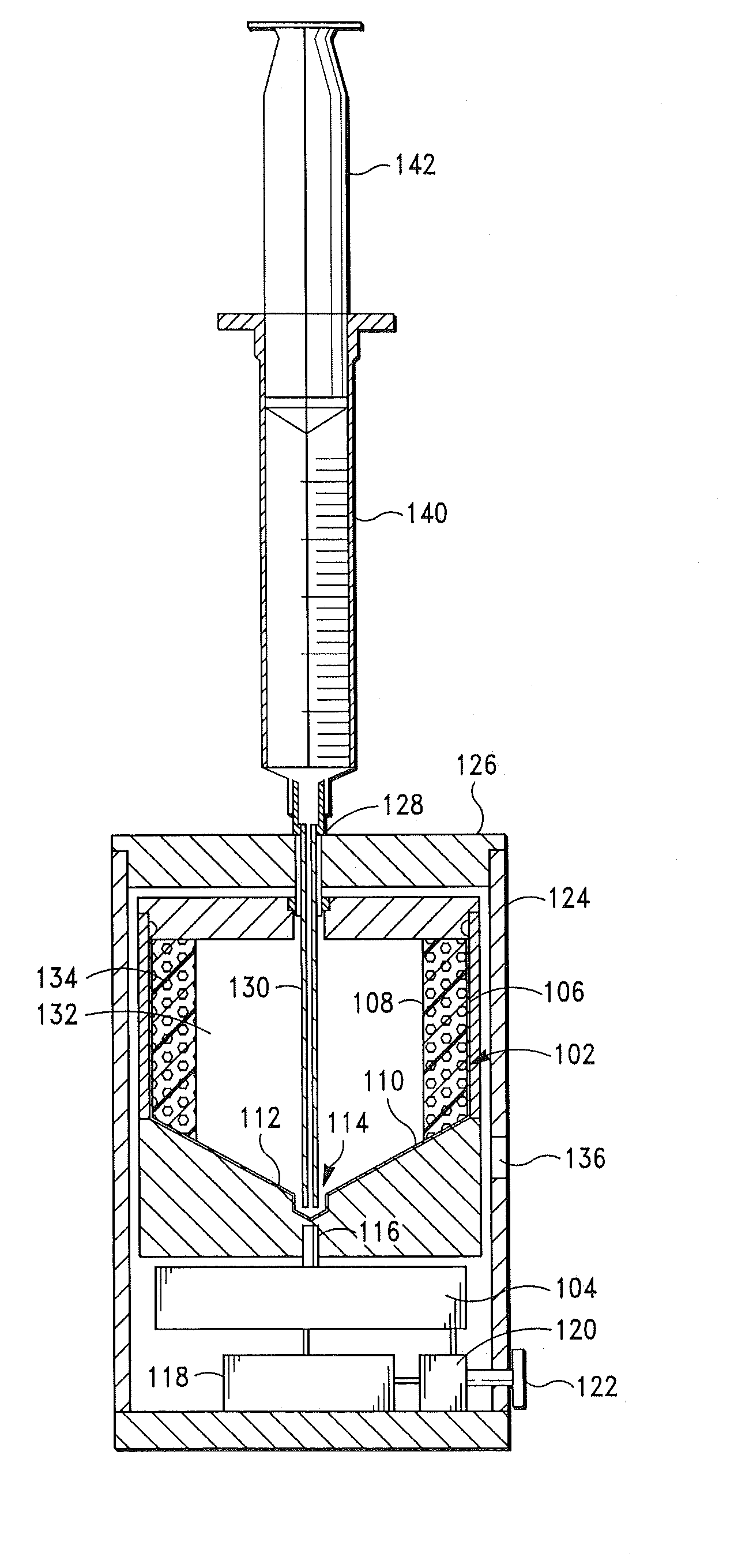

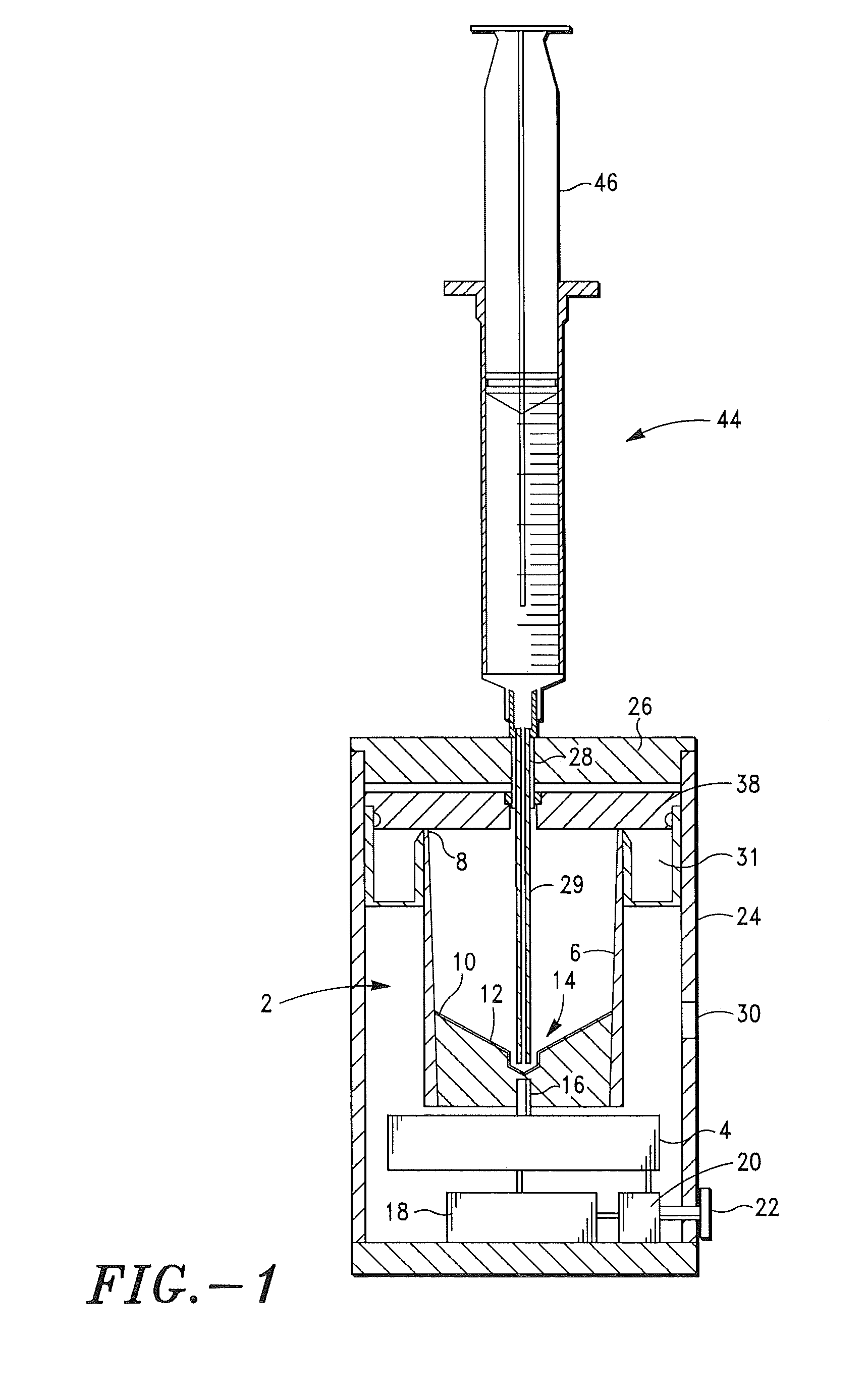

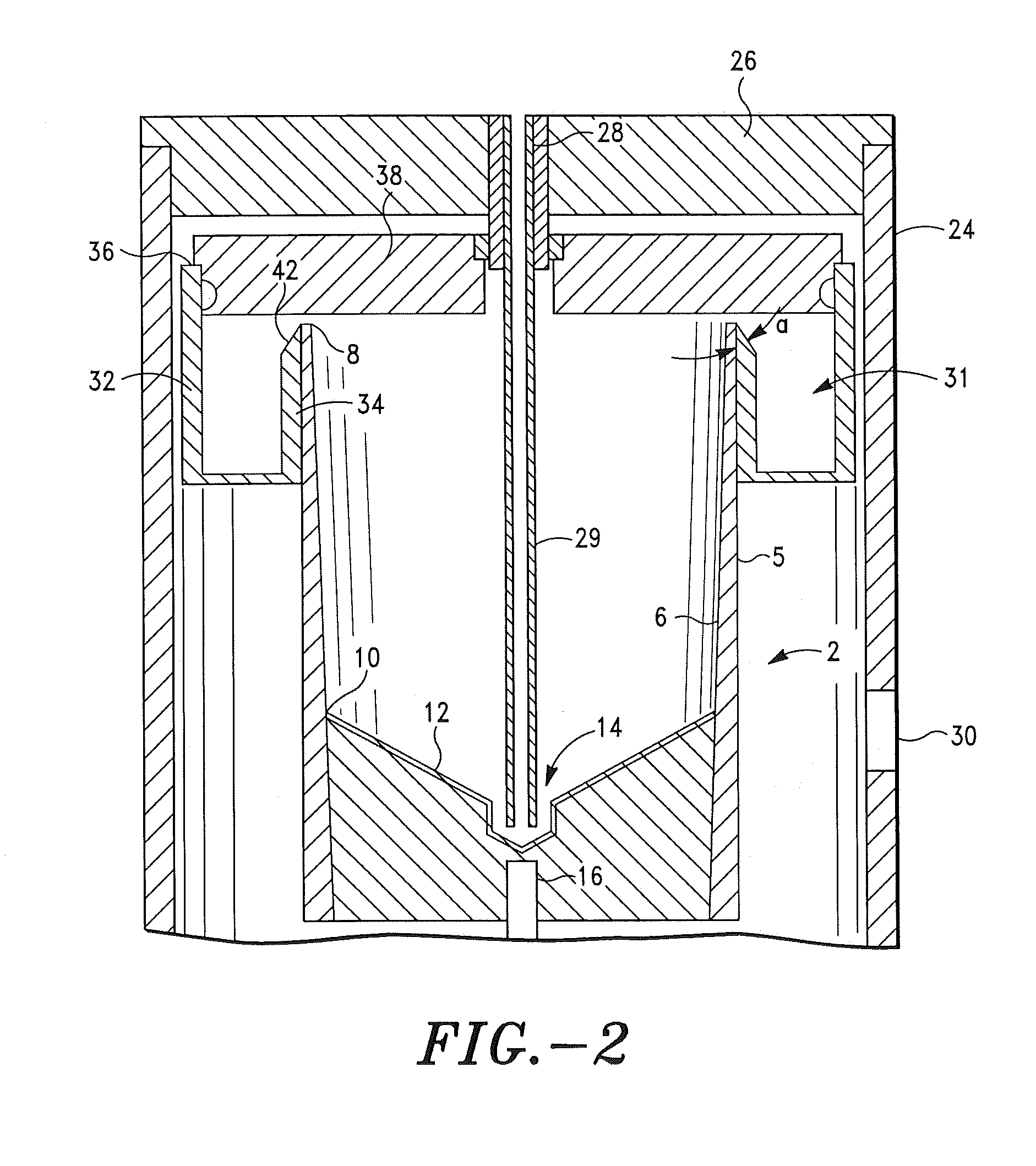

Method and apparatus for preparing platelet rich plasma and concentrates thereof

ActiveUS20060175242A1Shaking/oscillating/vibrating mixersTransportation and packagingFiberRed blood cell

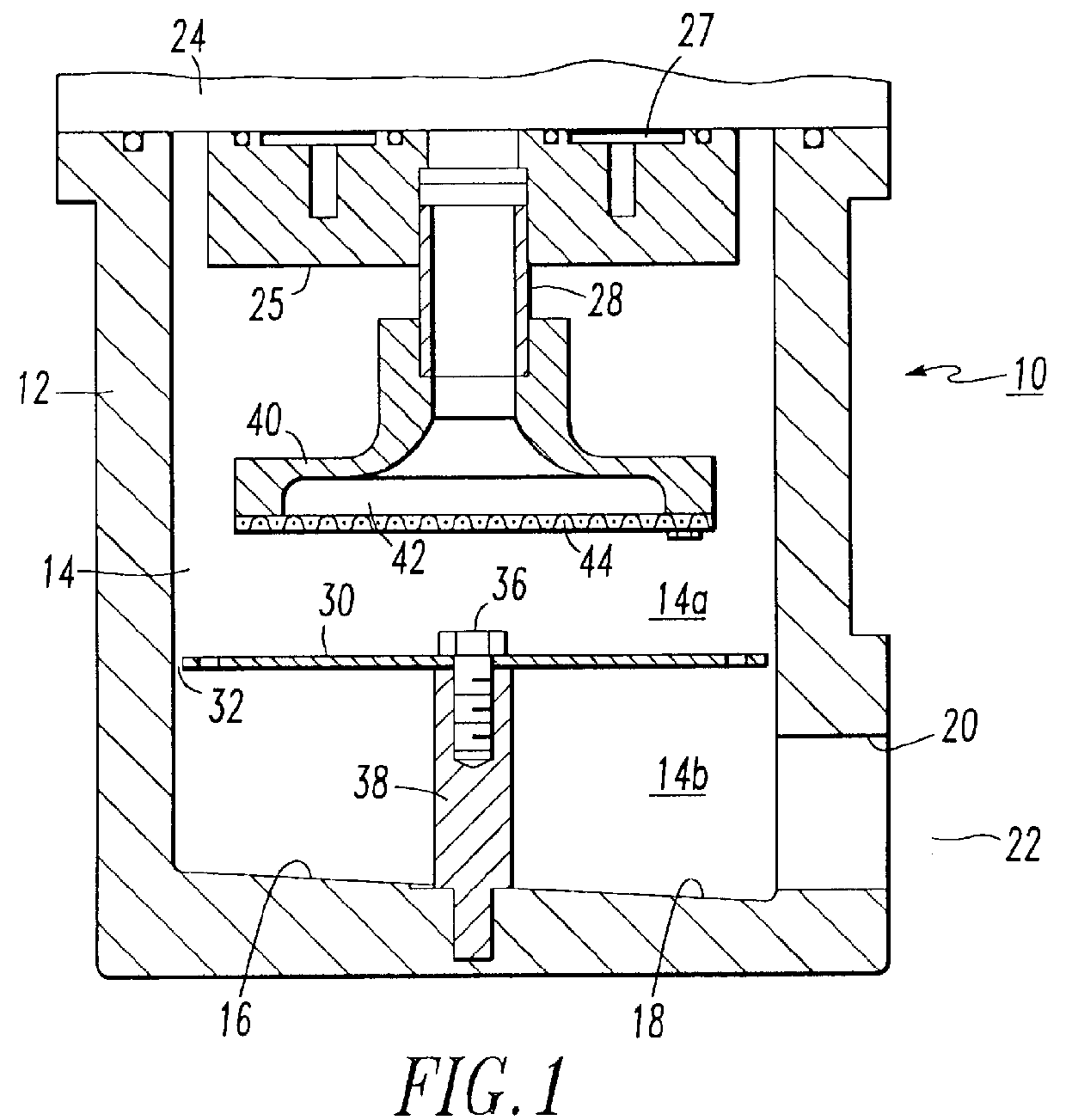

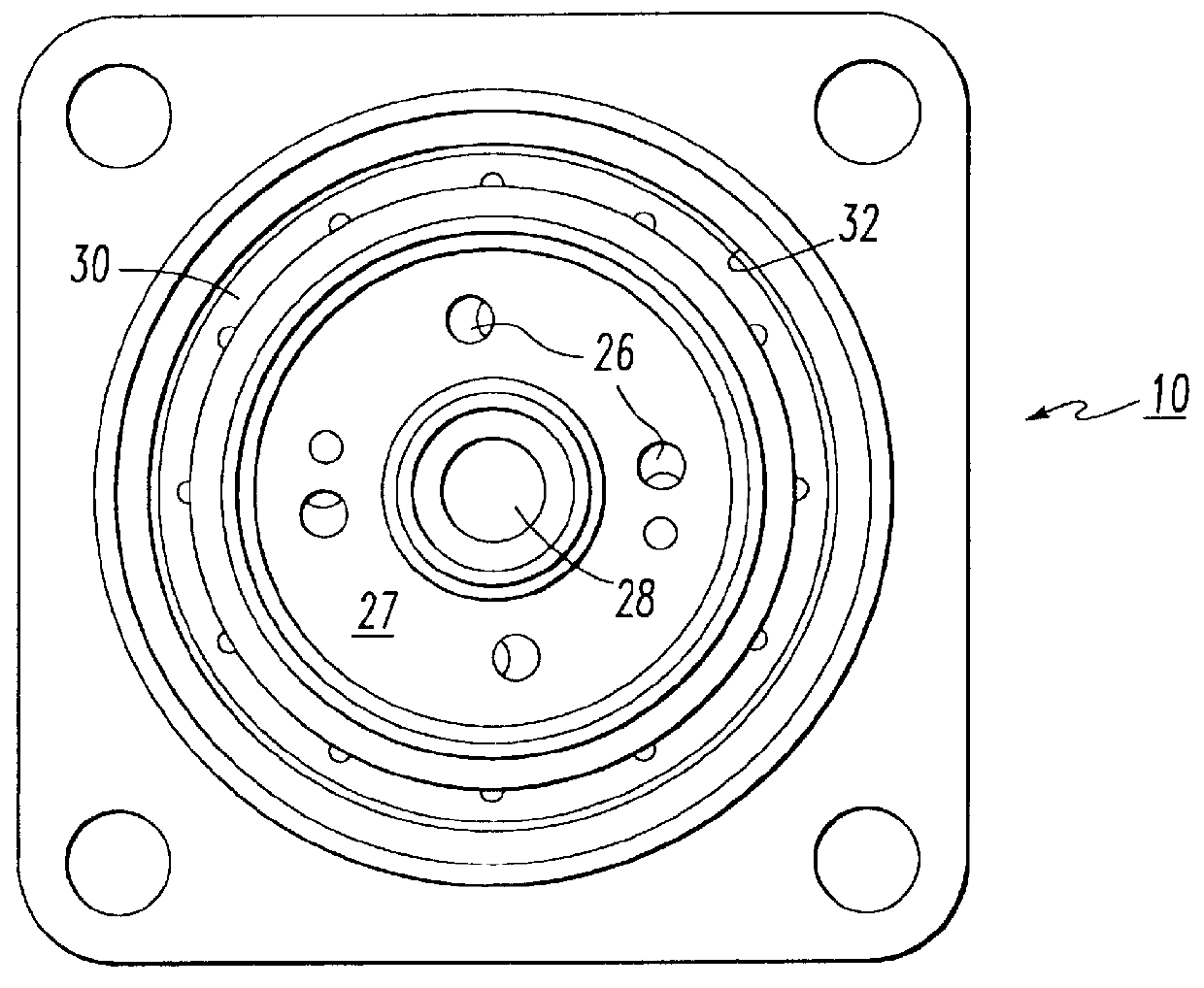

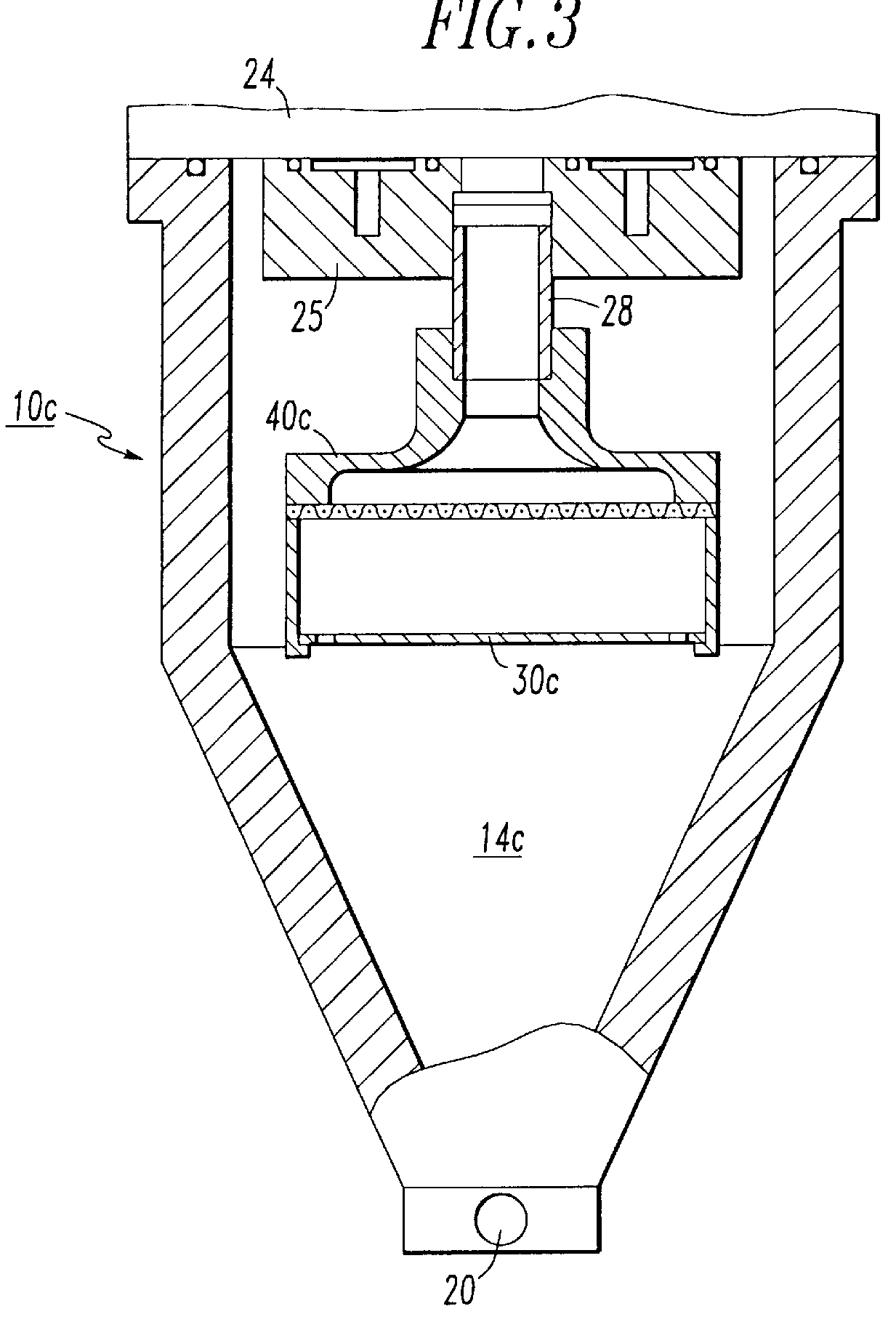

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

Method and apparatus for preparing platelet rich plasma and concentrates thereof

ActiveUS7708152B2Shaking/oscillating/vibrating mixersTransportation and packagingFiberRed blood cell

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

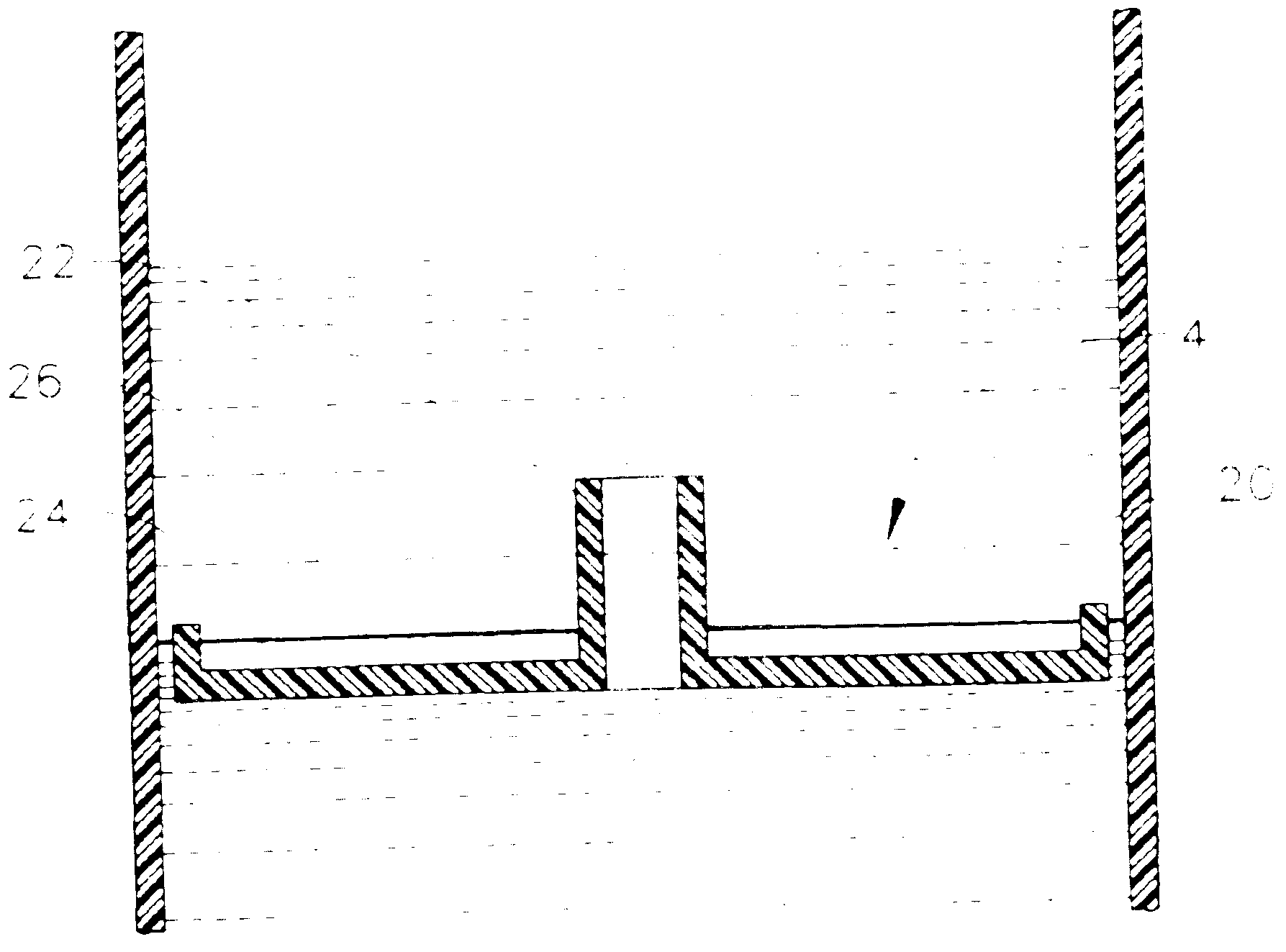

Blood component separator disk

InactiveUS7077273B2Improve processing efficiencyControl flowOther blood circulation devicesDispersed particle separationBlood component separatorRed blood cell

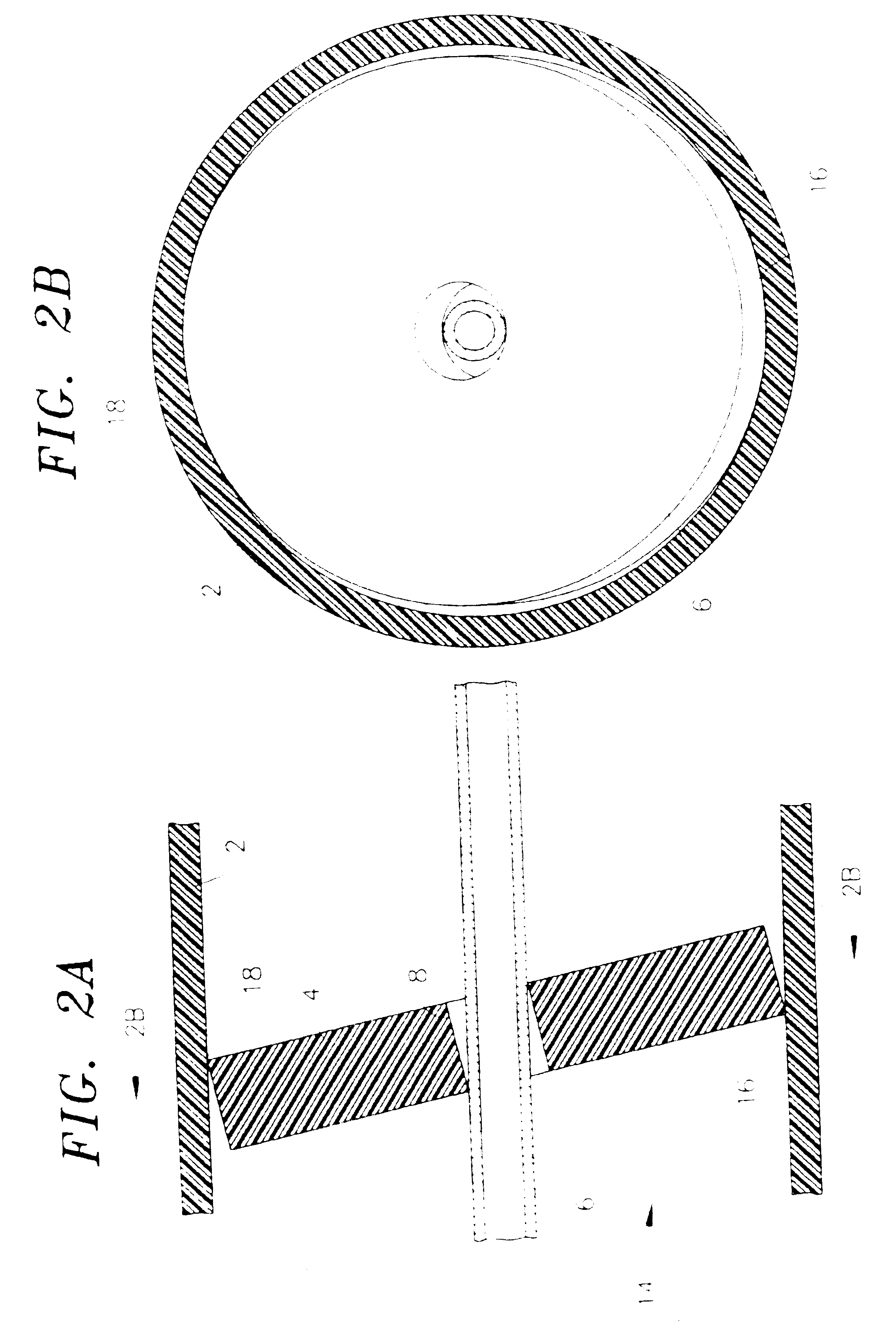

A separator disk (4) for use in centrifugal separation of components is designed to automatically position itself during separation at the interface between the supernatant and the remaining components. Preferably the interface is between plasma and red blood cells.

Owner:HARVEST TECH

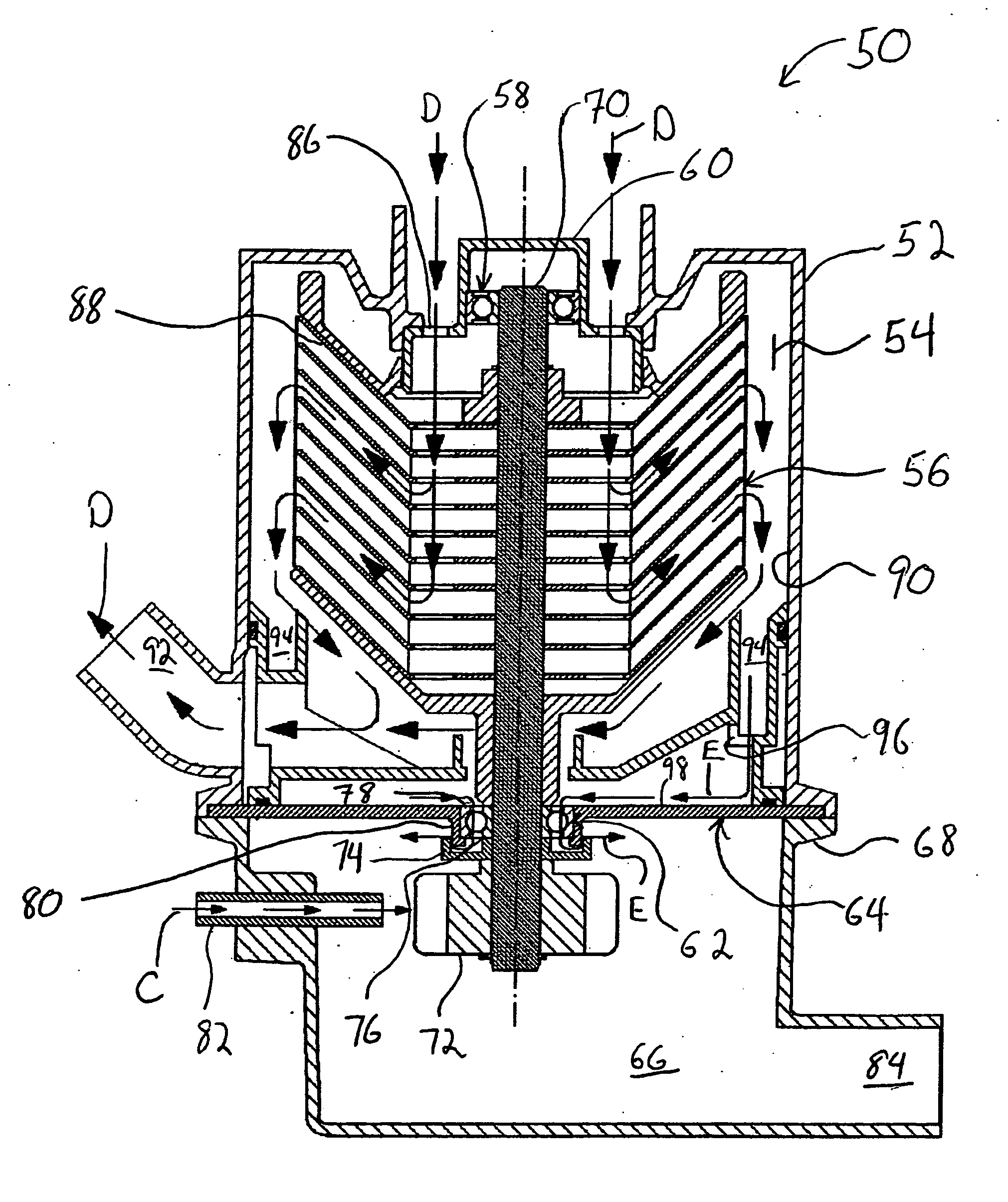

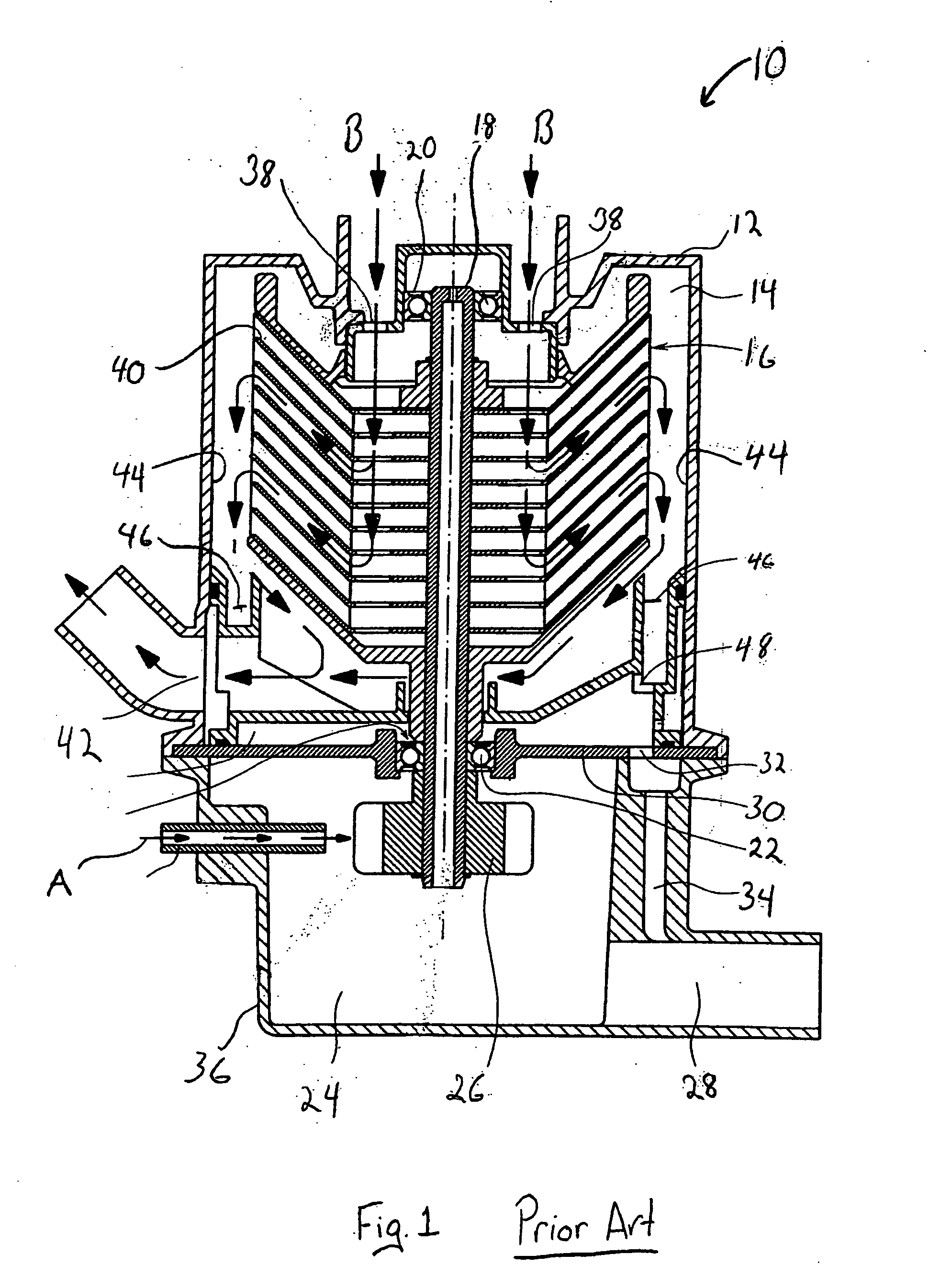

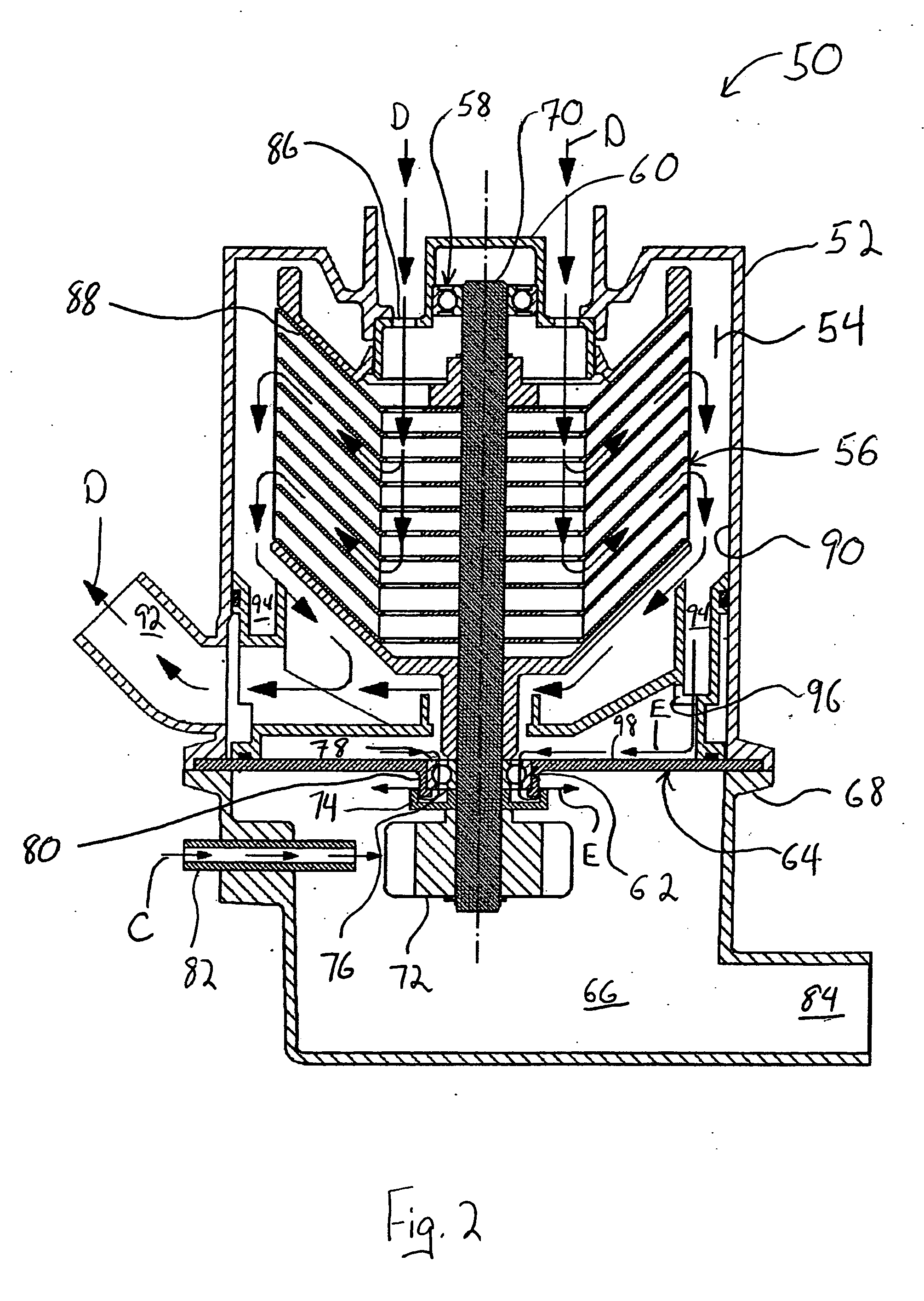

E-1 air dryer liquid separator with baffle

In a centrifugal separator for separating a liquid from a compressed gas, a baffle is provided to separate the centrifugal chamber into an upper sub-chamber and a lower sub-chamber but does not contact the walls of the chamber thereby being insufficient to prevent downward flow of separated liquid along the interior wall of the two sub-chambers, and insufficient to prevent flow of compressed gas from one sub-chamber to the other sub-chamber, the baffle nevertheless being sufficient to prevent turbulent gas flow in the lower sub-chamber when collected liquid is drained therefrom.

Owner:WESTINGHOUSE AIR BRAKE CO

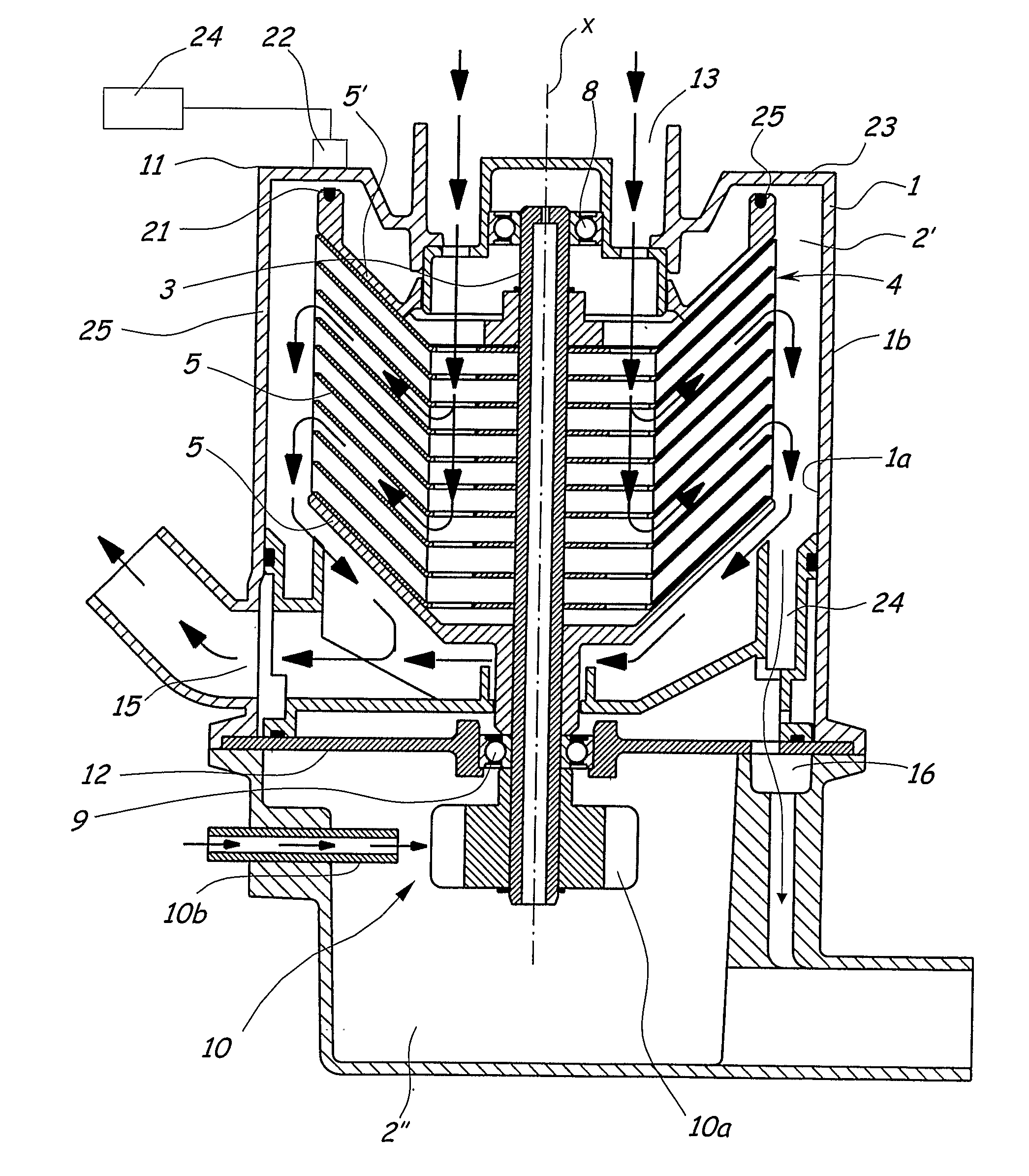

Method and a device for cleaning of crankcase gas

InactiveUS7152589B2Satisfy cleanlinessShorten speedDispersed particle separationCombustion enginesCombustionUnit of time

Owner:ALFA LAVAL CORP AB

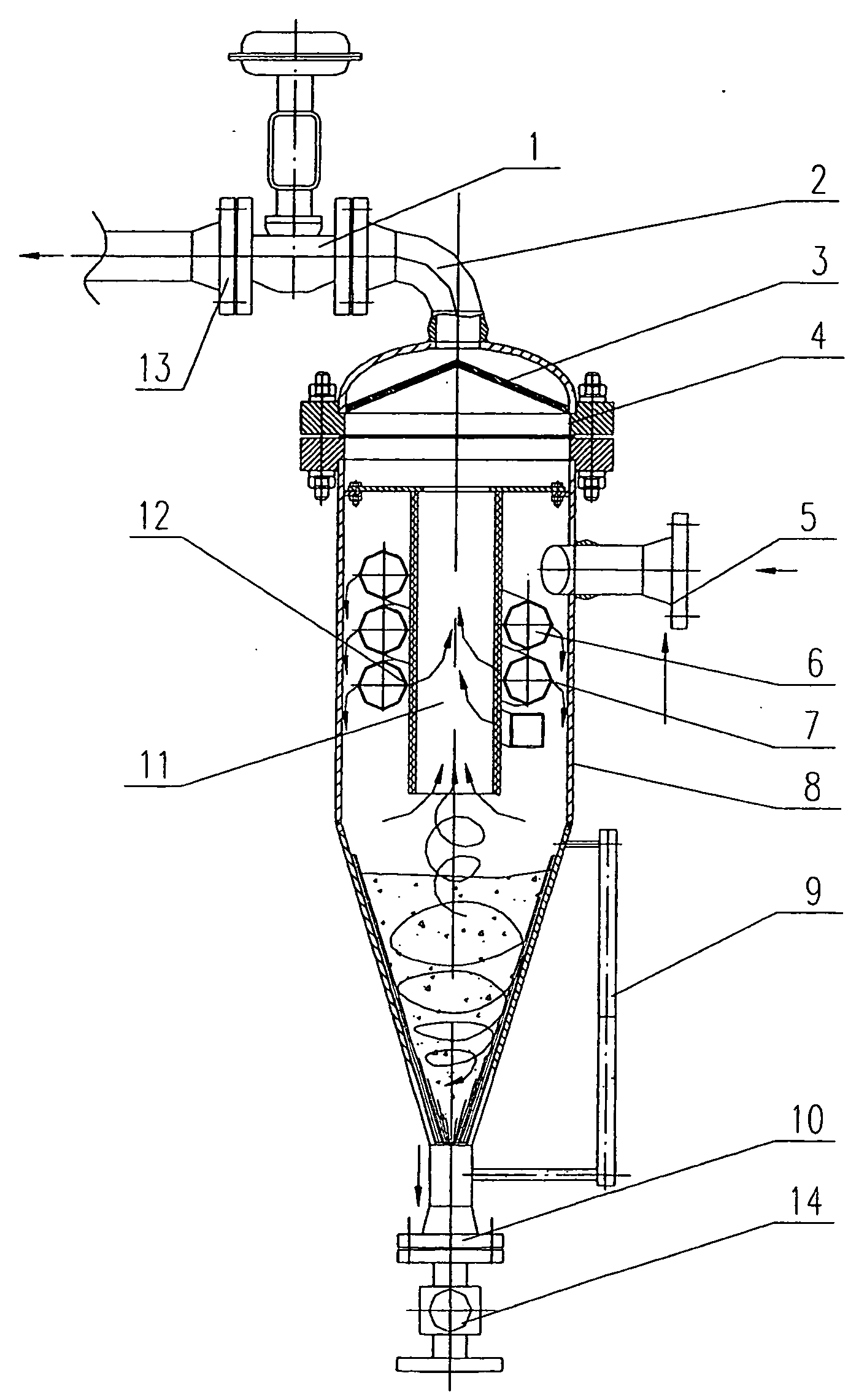

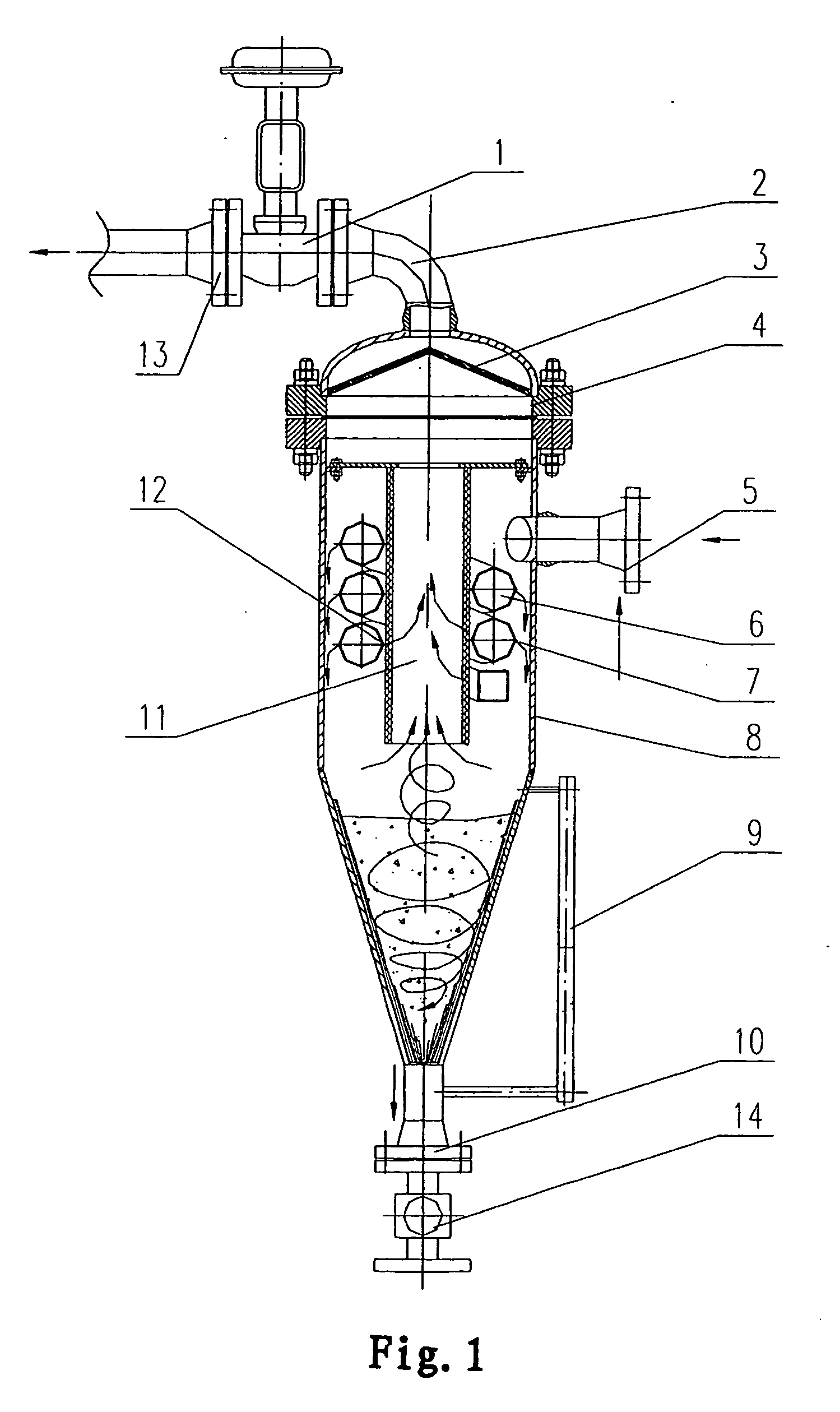

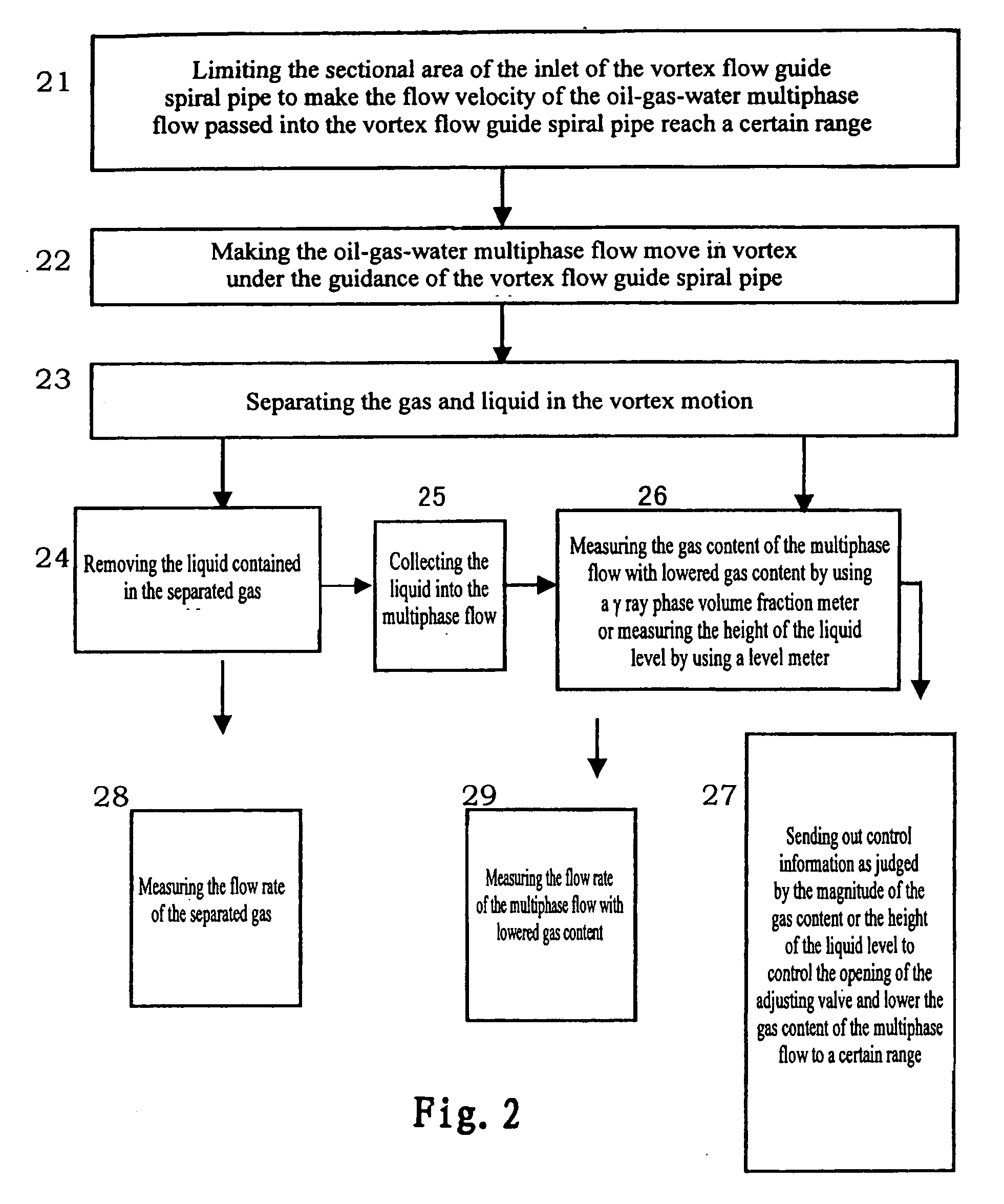

Adjustable gas-liquid centrifugal separator and separating method

ActiveUS20070084340A1Reduce gas contentSmall volumeCombination devicesLiquid degasificationEngineeringPhase volume

An adjustable type guide vortex gas-liquid separating apparatus is provided, it comprises a case, a vortex flow guide spiral pipe, a mist eliminator, an adjusting valve and a γ ray phase volume fraction meter. Its separating method is to make the oil-gas-water multiphase flow move in vortex, and thus to realize the gas-liquid separation, then to measure the gas content of the separated liquid phase by using the γ ray phase volume fraction meter and to send out control information as judged by the magnitude of the gas content in the liquid phase, so as to control the opening of the adjusting valve of the gas circuit, thus to achieve adjustment of the gas-liquid separation effects, and to control the gas content of the liquid phase to a certain range.

Owner:HAIMO TECH INC

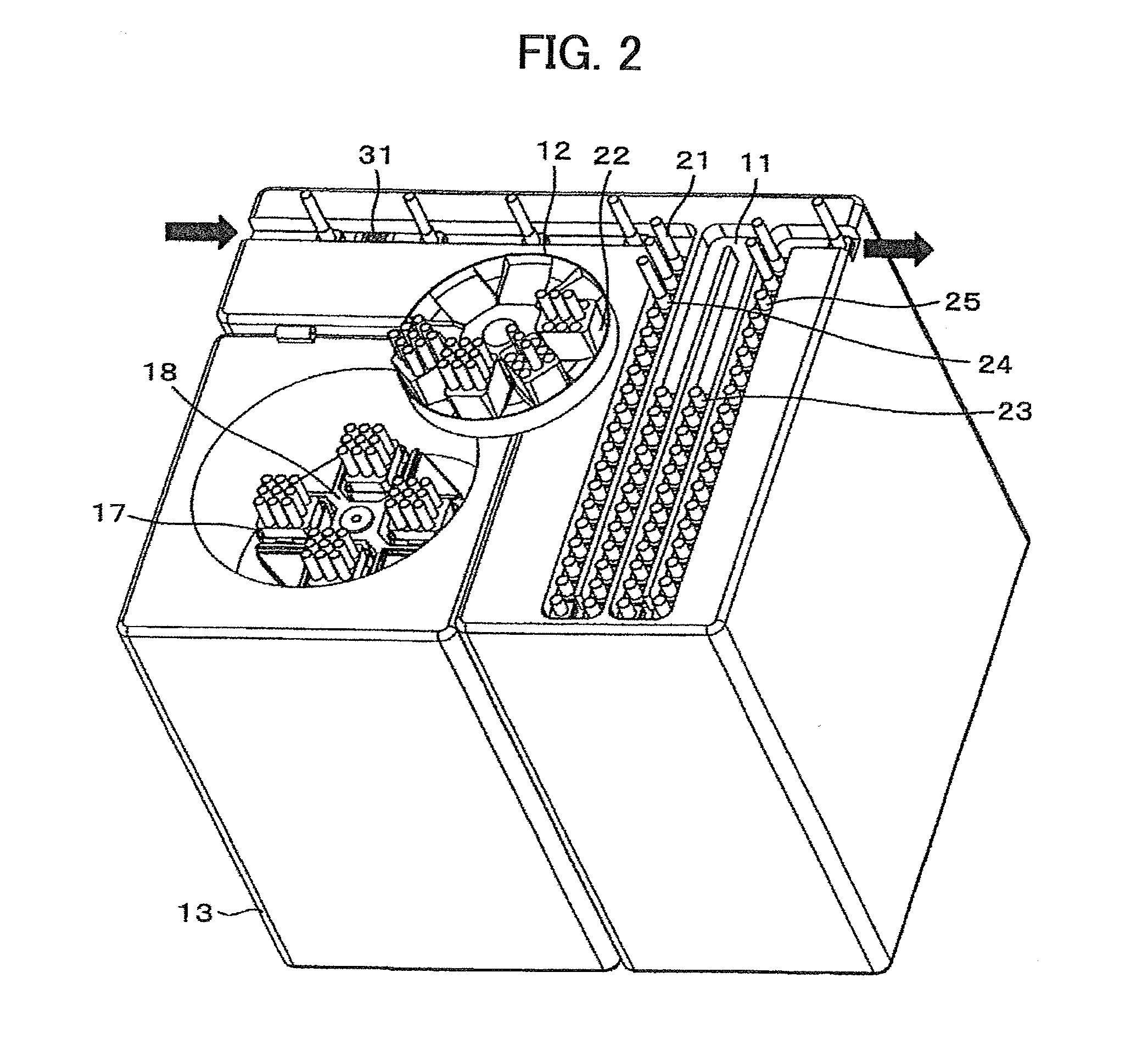

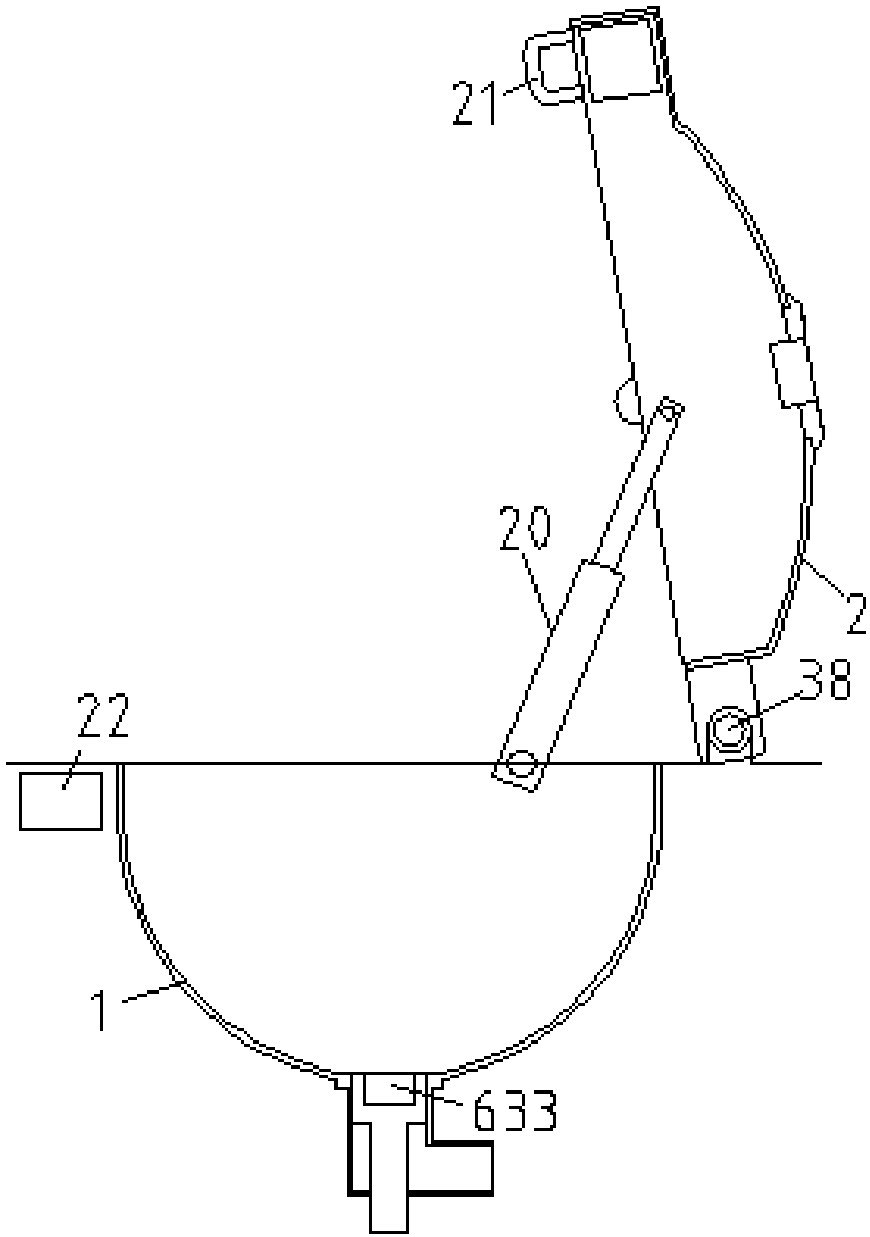

Centrifugal separator

The weight difference is limited between buckets (17) mounted at respective symmetrical positions with respect to a centrifugal separation rotational center and examination of samples is continuously performed in the order in which they are received. In particular, when a sample (21) is carried in a centrifugal buffer line (11), its weight is measured by weight measuring means (31). It is assumed that the names of two adaptors (22) placed at respective symmetrical positions with respect to the centrifugal separation rotational center are defined as an adaptor A and an adaptor B. A first sample is put on the adaptor A and a second sample is put on the adaptor B. Then, a third sample and subsequent ones are each put on the adaptor (22) lighter than the other adaptor after the total weights of samples put on the adaptors are computation-compared with each other.

Owner:HITACHI HIGH-TECH CORP

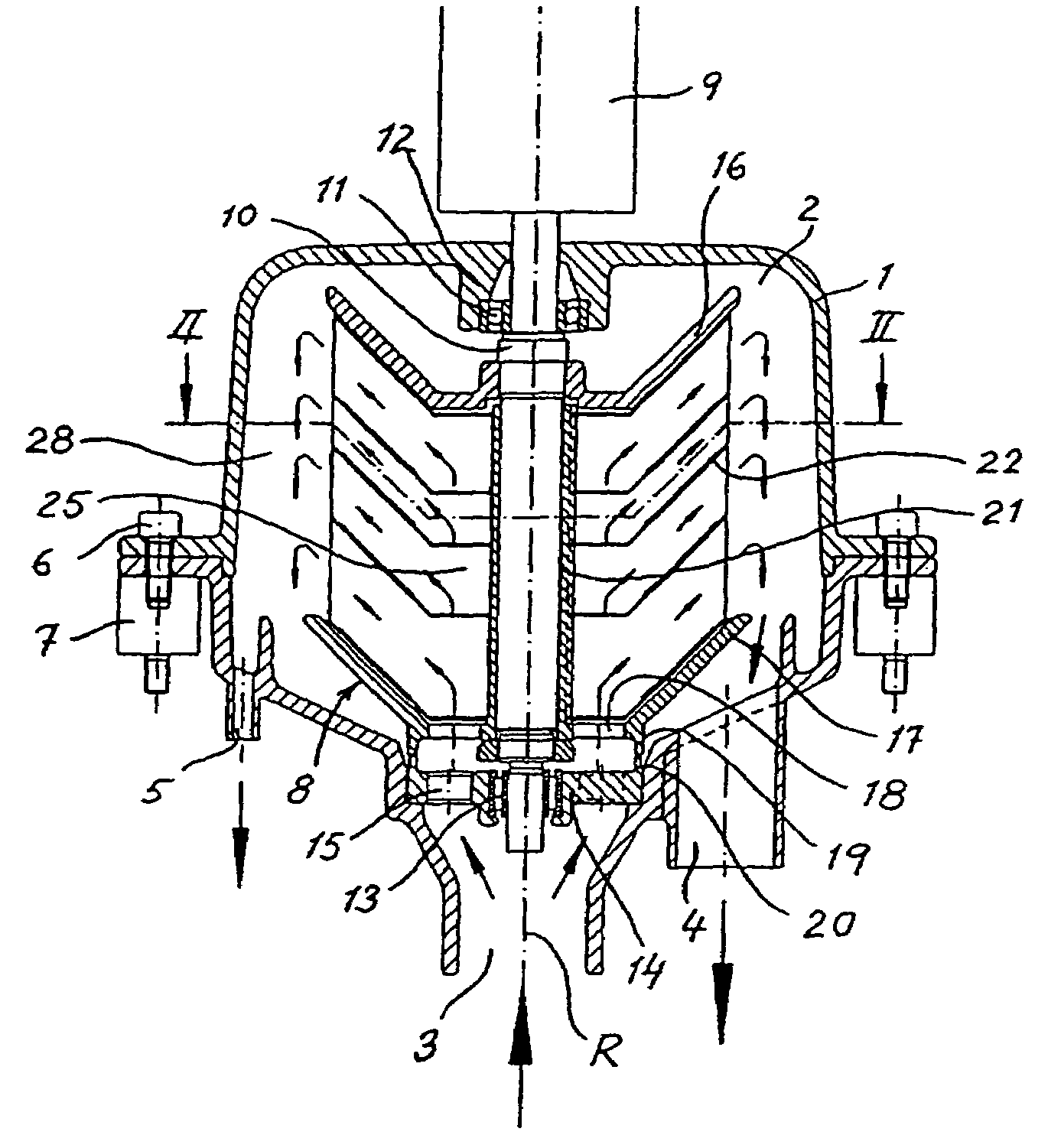

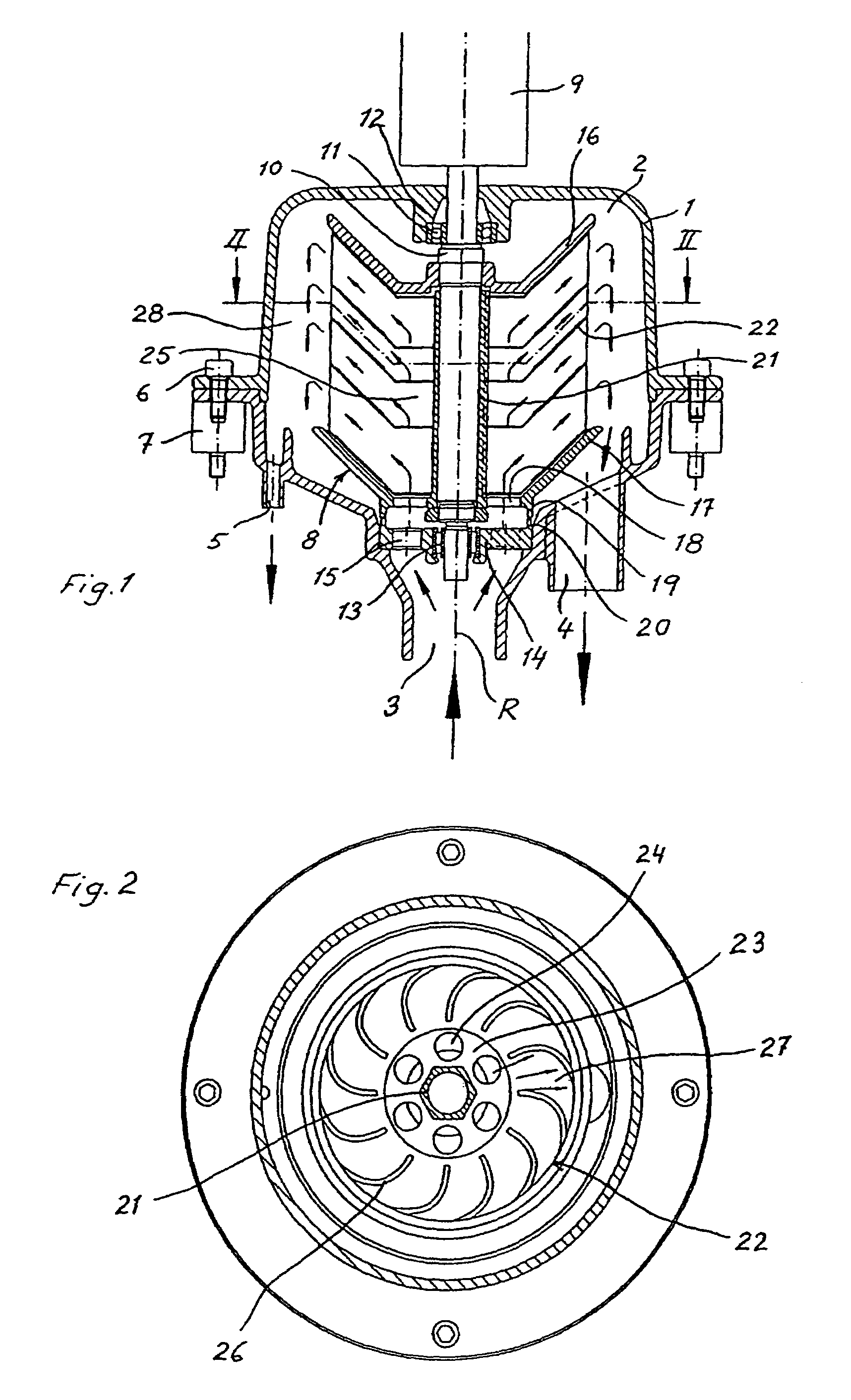

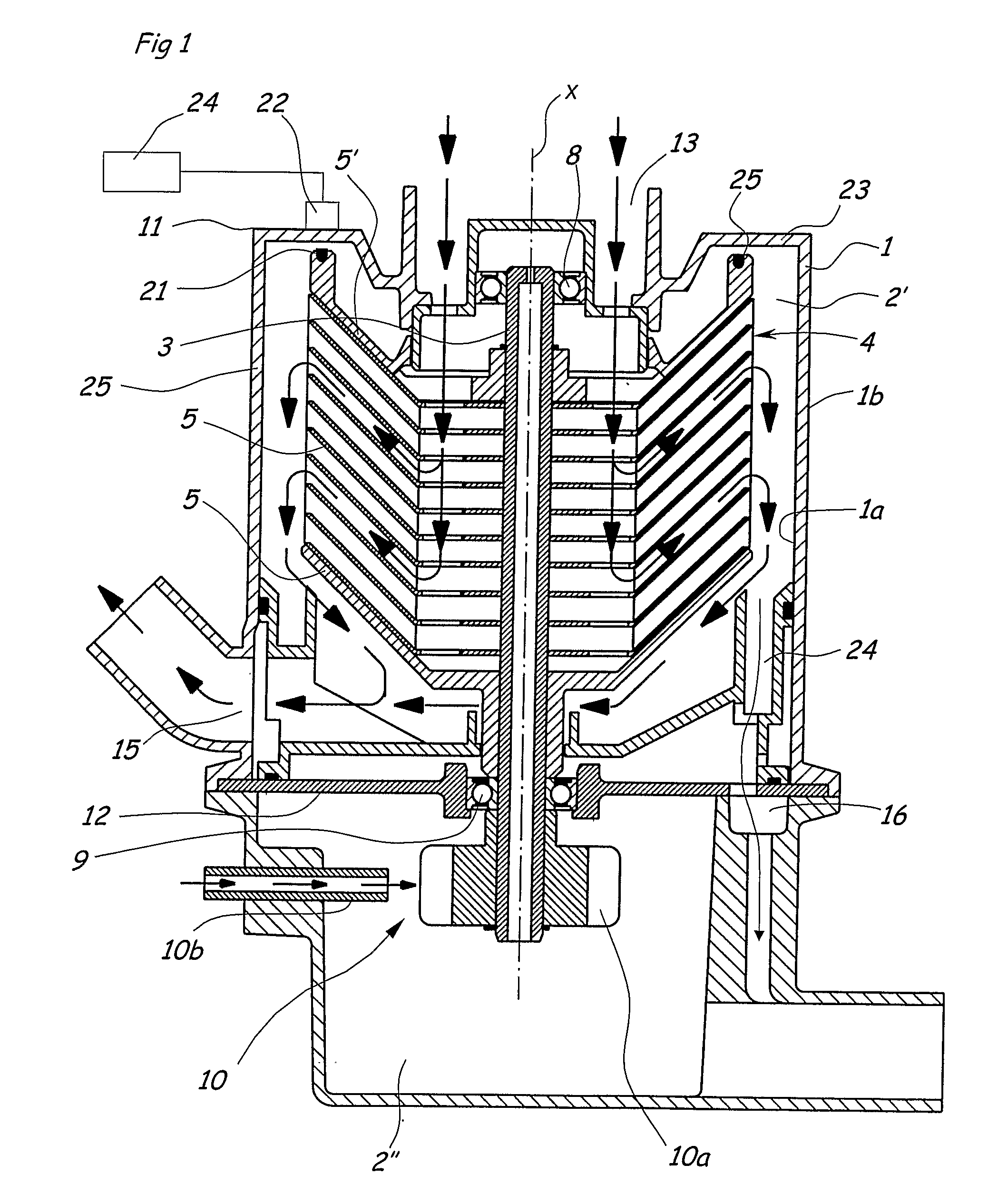

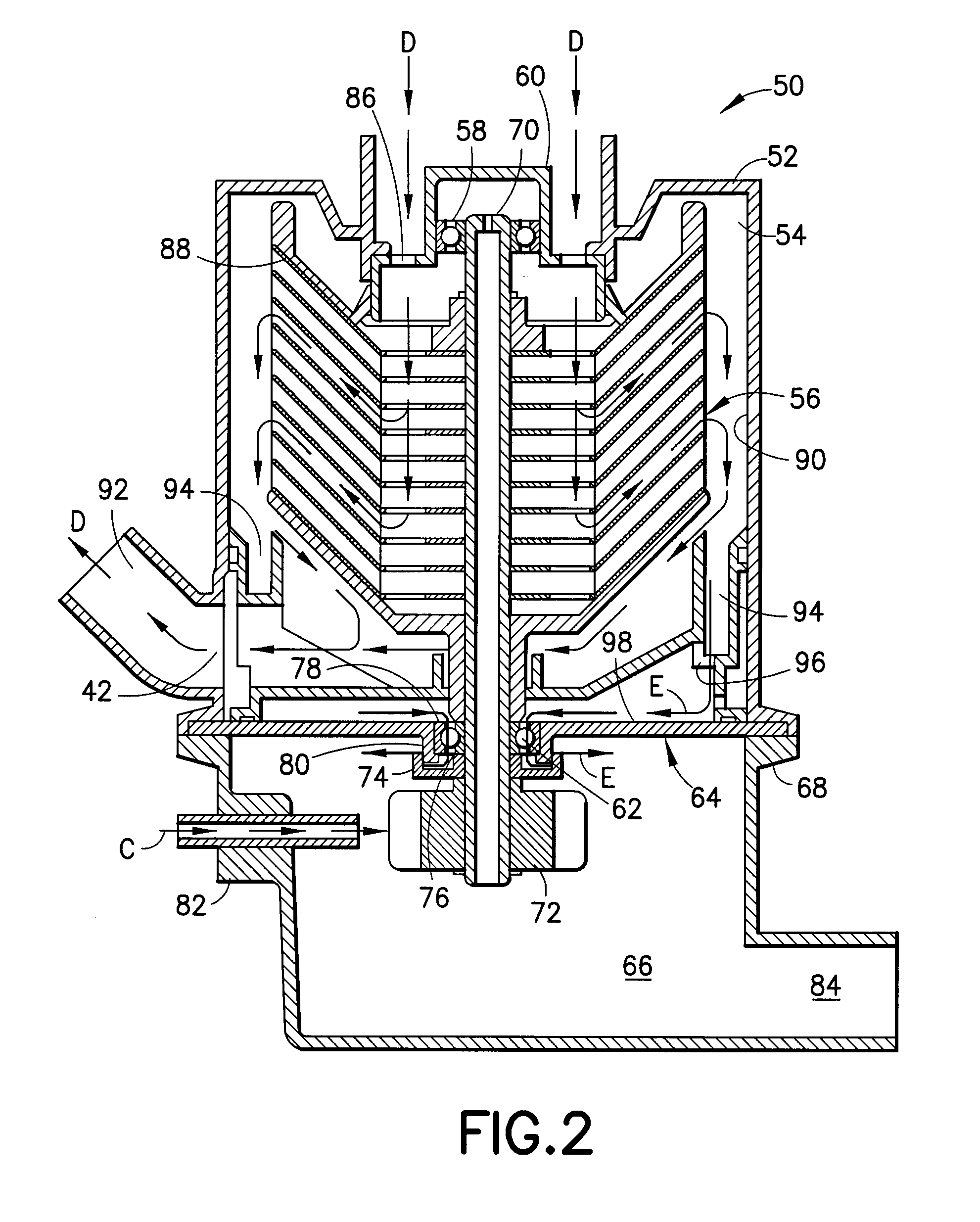

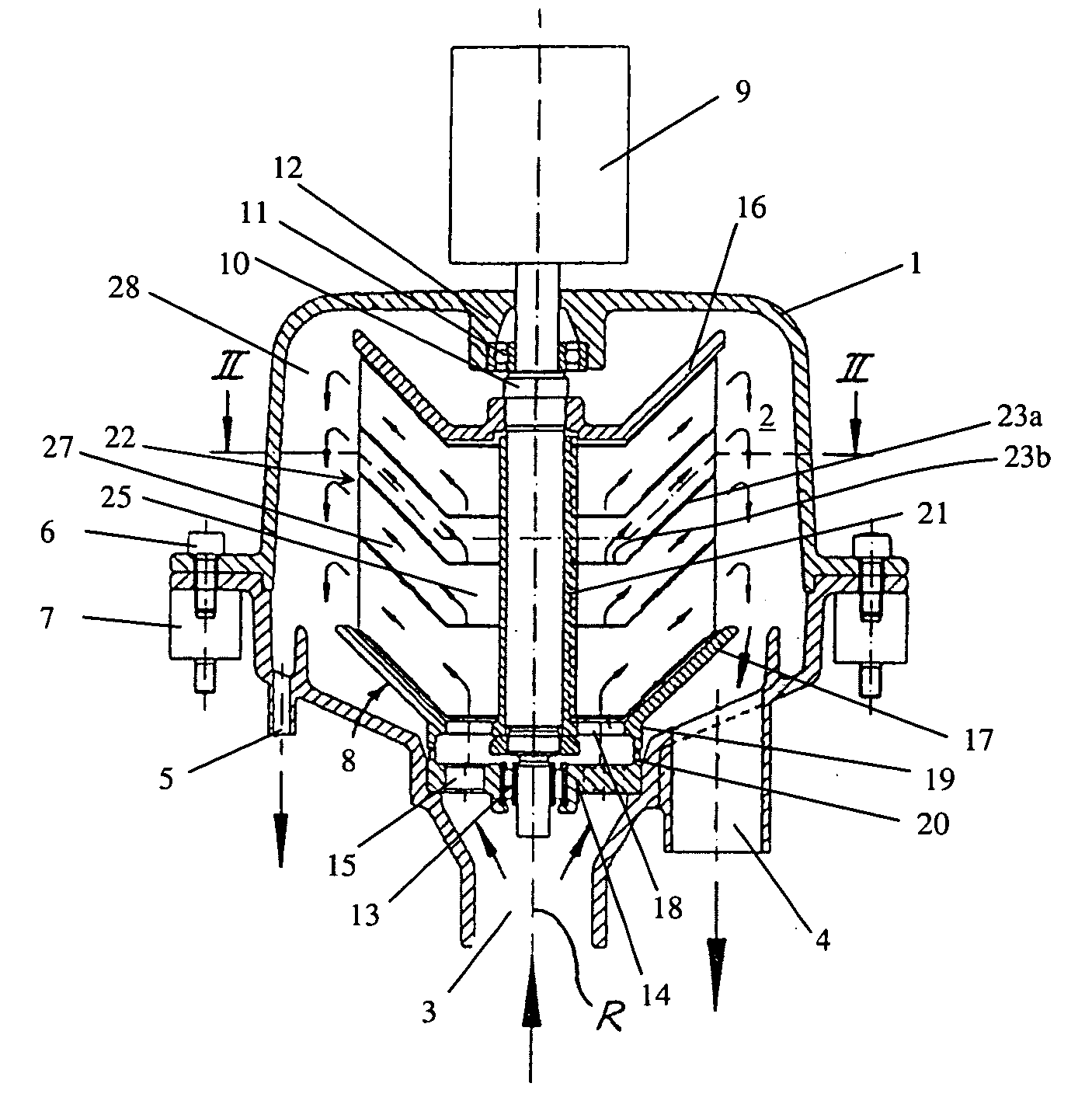

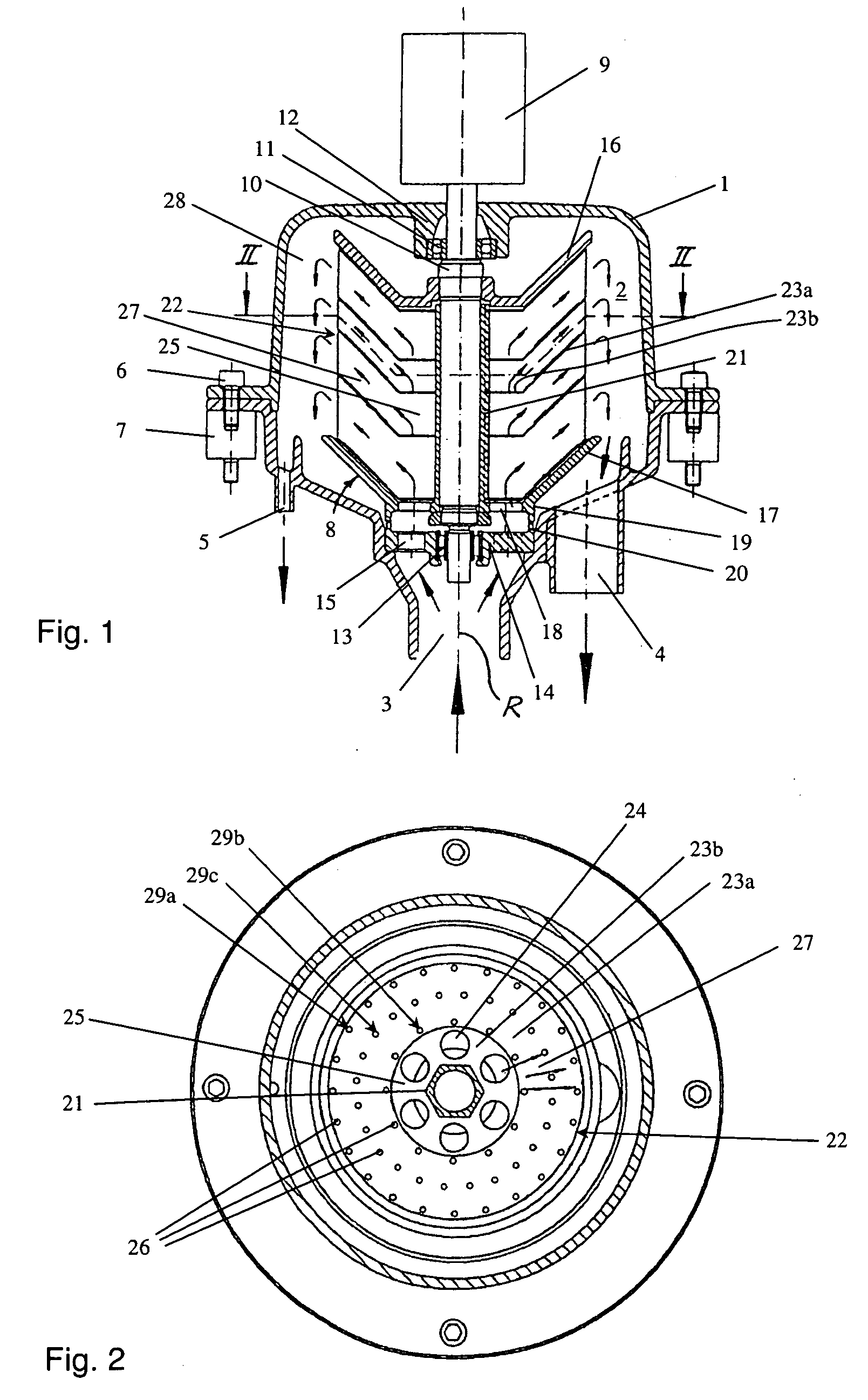

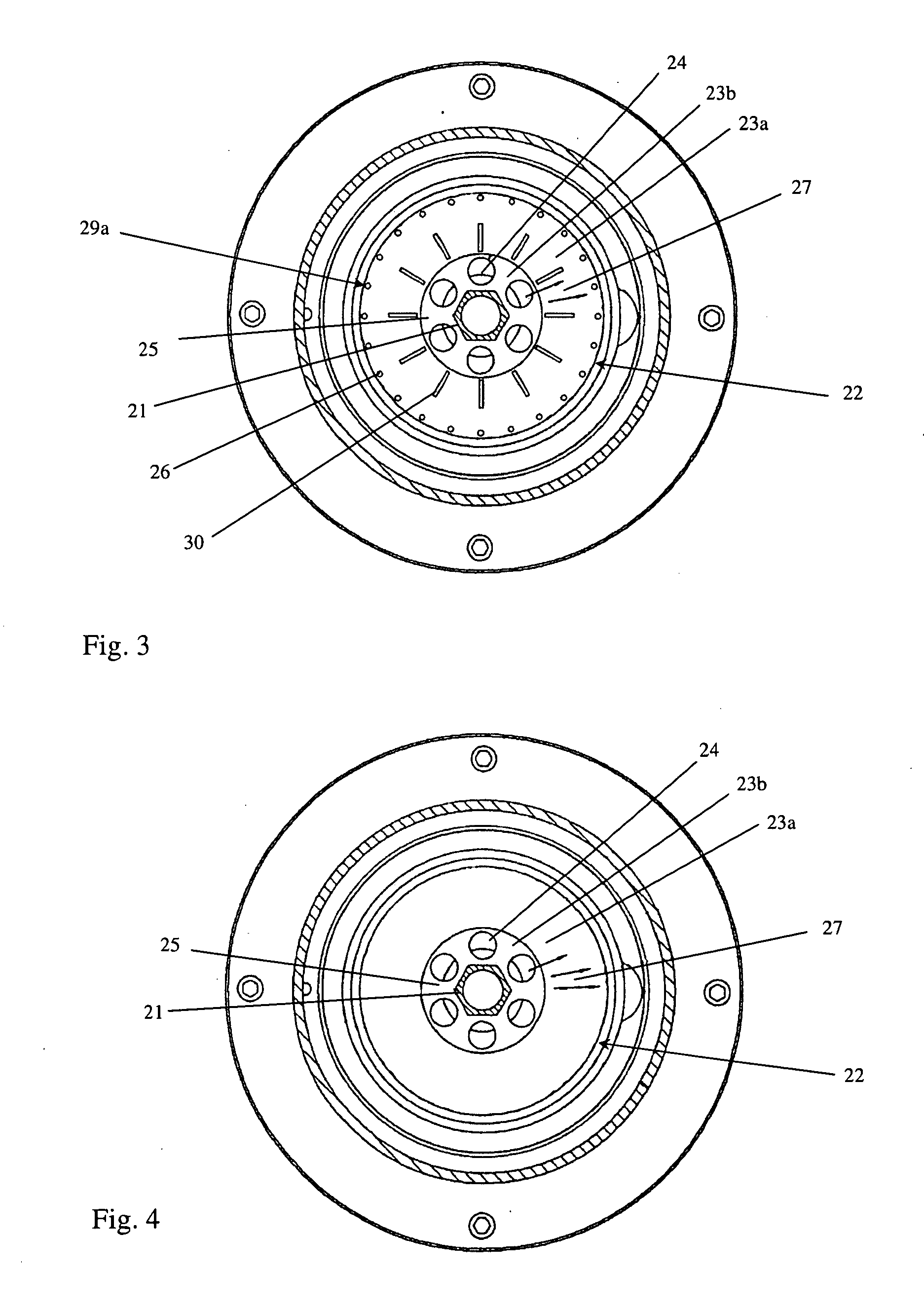

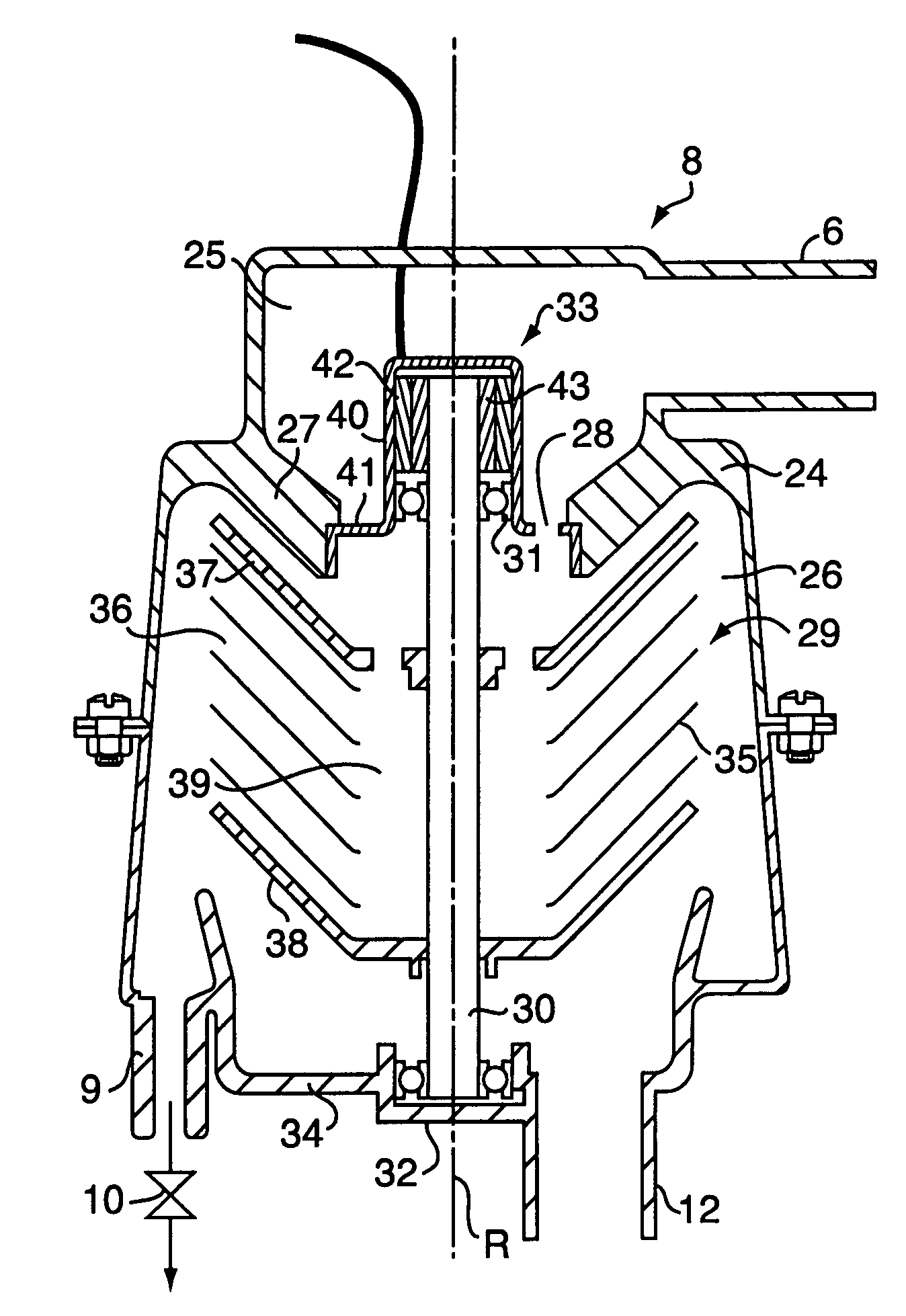

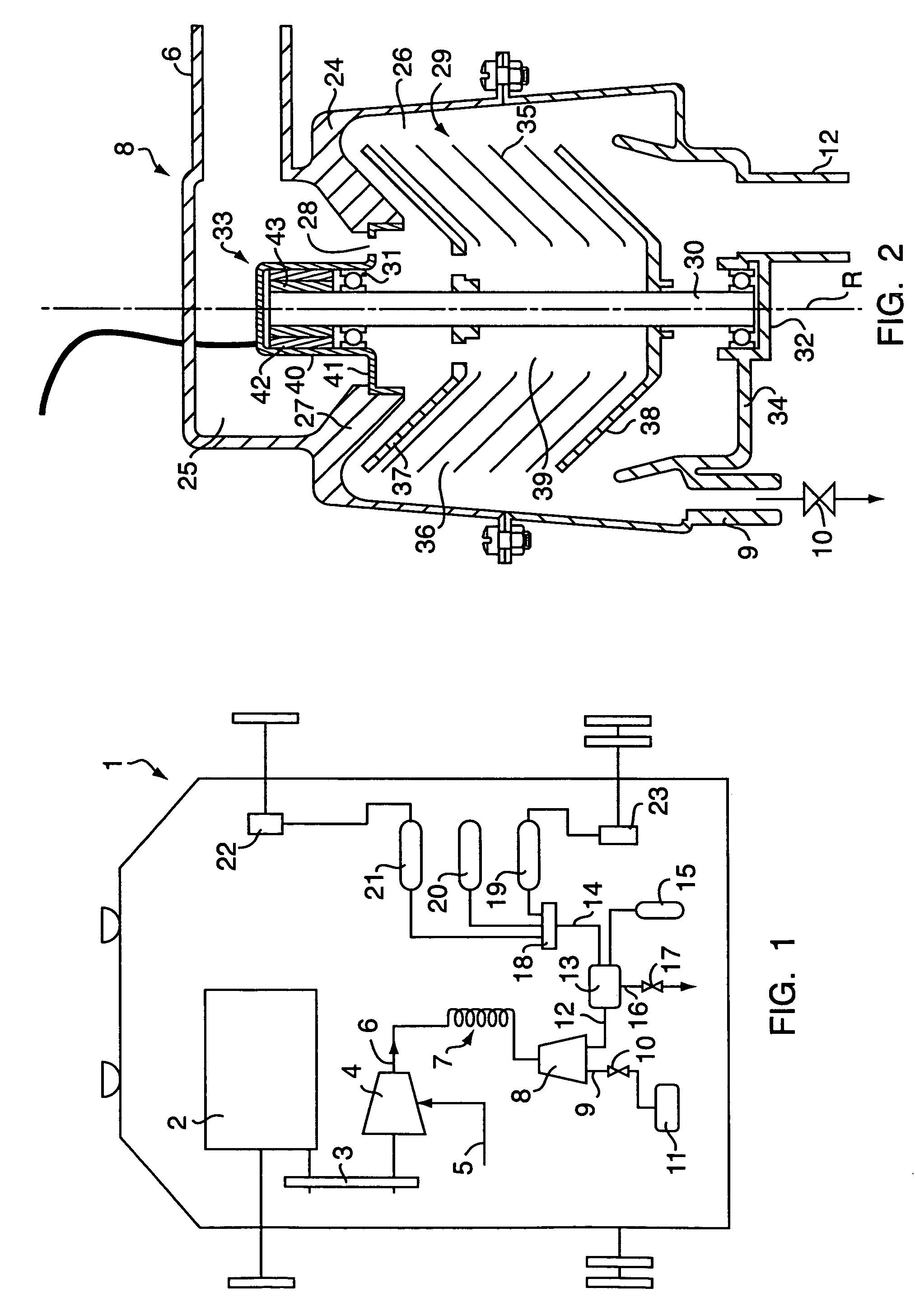

Centrifugal separator for cleaning gas generated by an internal combustion engine and a method for operating the same

ActiveUS20070249479A1Minimizes for egressMinimize potentialCombination devicesAuxillary pretreatmentEngineeringCentrifugal force

In a centrifugal separator for cleaning gases generated by an internal combustion engine a housing defines an interior separation chamber. A centrifugal rotor is coupled for rotation to the housing and extends into the separation chamber. A drainage chamber is positioned adjacent the separation chamber and is delimited therefrom by a partition wall. A flow path is provided through which oil, separated from gases generated by the internal combustion engine and collecting on the partition wall, can travel from the separation chamber to the drainage chamber. A pump wheel is coupled to a shaft portion defined by the rotor and extends radially outwardly therefrom. During operation the oil, upon exiting the separation chamber, contacts the pump wheel. Centrifugal forces generated due to the rotation of the pump wheel cause the oil to be thrown into the drainage chamber. The pump wheel also minimizes the potential for oil resident in the drainage chamber to re-enter the separation chamber.

Owner:ALFA LAVAL CORP AB

Centrifugal separator for cleaning of gas

ActiveUS20090025562A1Reliable and secure determinationReliable readCombination devicesAuxillary pretreatmentInterior spaceEngineering

The invention refers to a centrifugal separator comprising a stationary casing defining an inner space, a spindle and a rotating member, which is attached to the spindle and arranged to rotate around an axis of rotation with a rotary speed. The rotating member comprises a number of separating discs which are provided in the inner space. A drive member drives the spindle and the rotating member with said rotary speed. A sensor device senses the rotation of the rotating member in relation to the casing. The sensor device comprises at least one transmitter element which is provided in the inner space on the rotating member and a receiver element which is provided at the casing and arranged to sense the transmitter element. The receiver element is provided on the casing outside the inner space.

Owner:ALFA LAVAL CORP AB

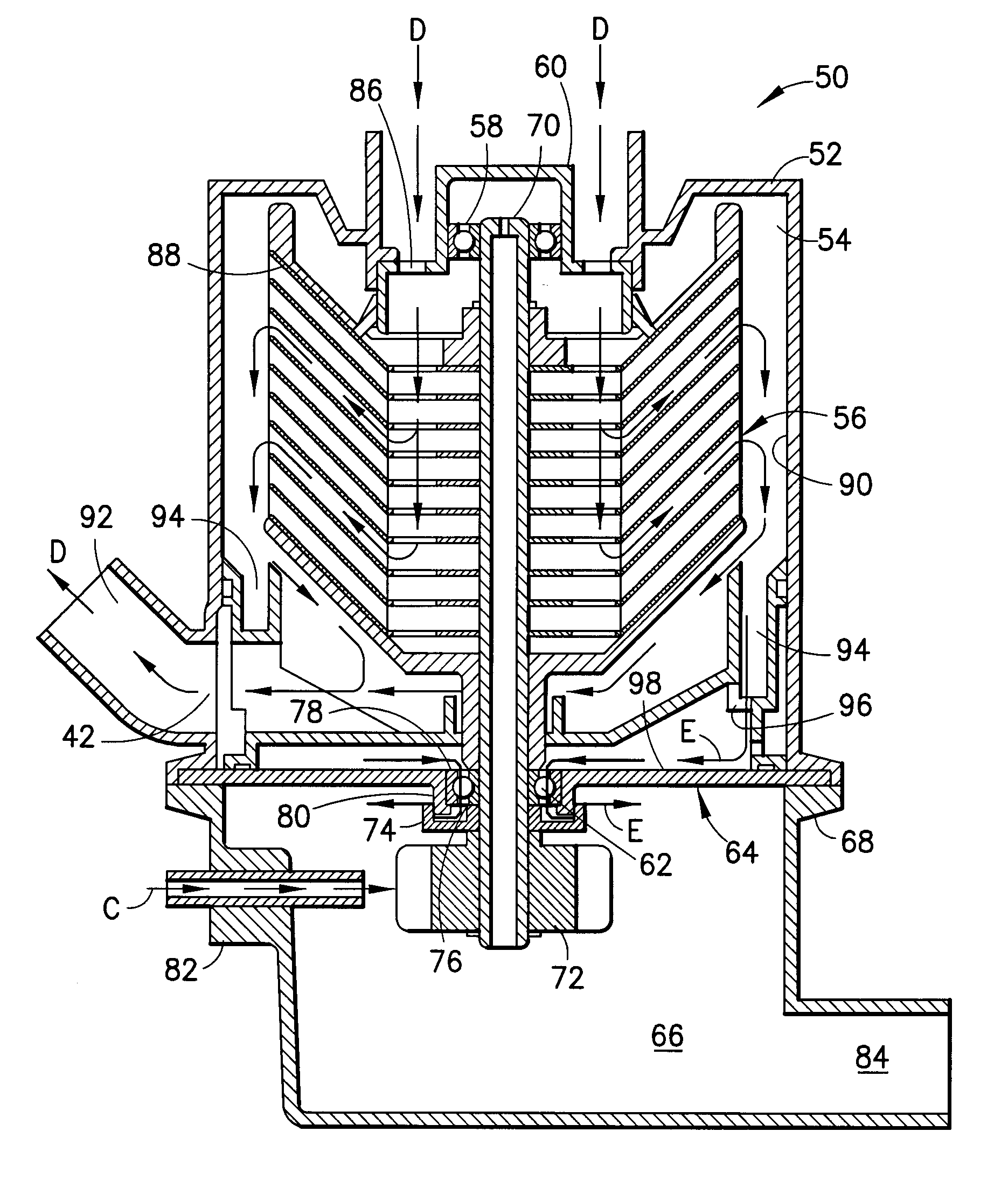

Centrifugal separator for cleaning gas generated by an internal combustion engine and a method for operating the same

ActiveUS7338546B2Minimize potentialUniform pressureCombination devicesAuxillary pretreatmentExternal combustion engineEngineering

In a centrifugal separator for cleaning gases generated by an internal combustion engine a housing defines an interior separation chamber. A centrifugal rotor is coupled for rotation to the housing and extends into the separation chamber. A drainage chamber is positioned adjacent the separation chamber and is delimited therefrom by a partition wall. A flow path is provided through which oil, separated from gases generated by the internal combustion engine and collecting on the partition wall, can travel from the separation chamber to the drainage chamber. A pump wheel is coupled to a shaft portion defined by the rotor and extends radially outwardly therefrom. During operation the oil, upon exiting the separation chamber, contacts the pump wheel. Centrifugal forces generated due to the rotation of the pump wheel cause the oil to be thrown into the drainage chamber. The pump wheel also minimizes the potential for oil resident in the drainage chamber to re-enter the separation chamber.

Owner:ALFA LAVAL CORP AB

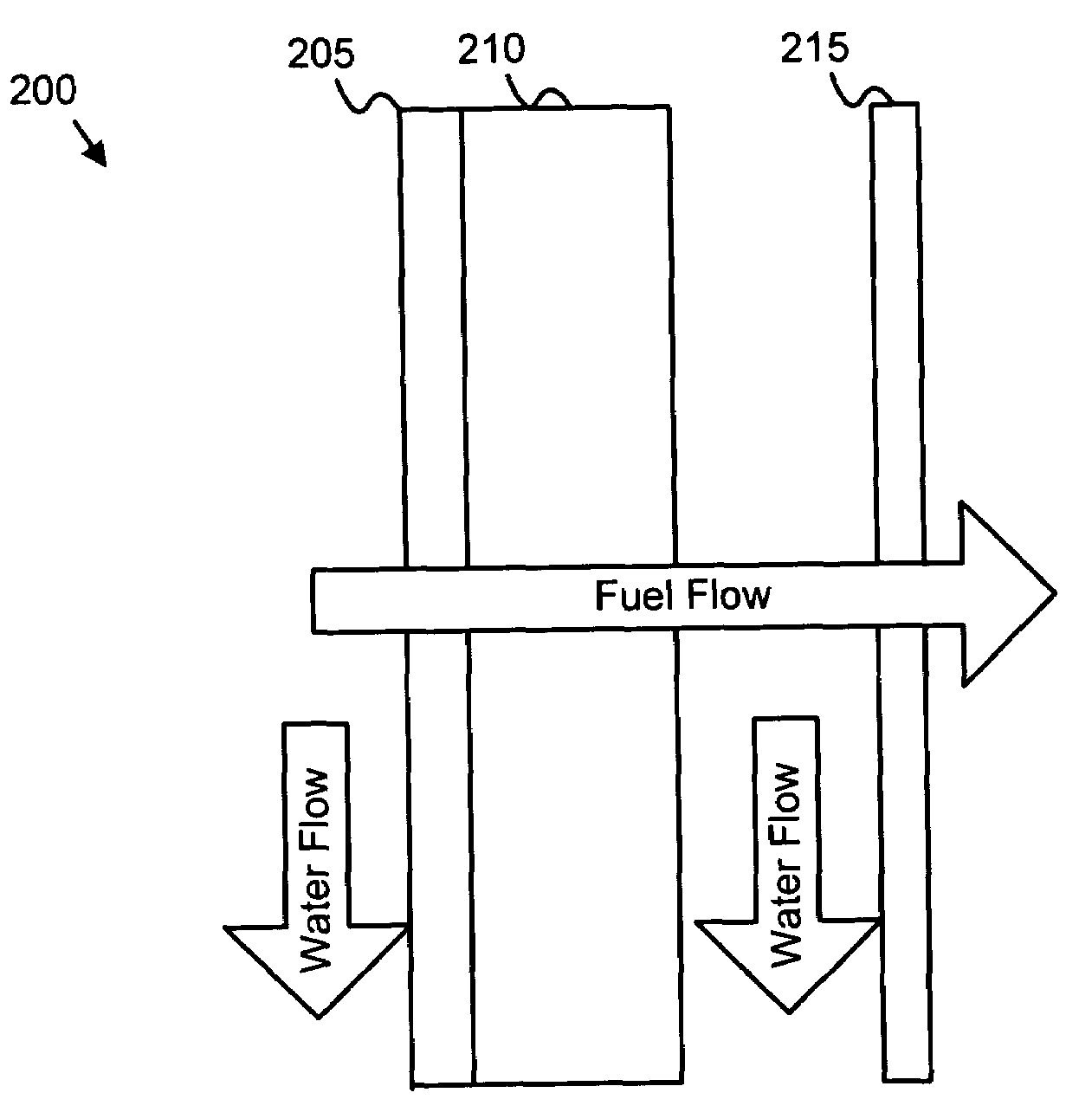

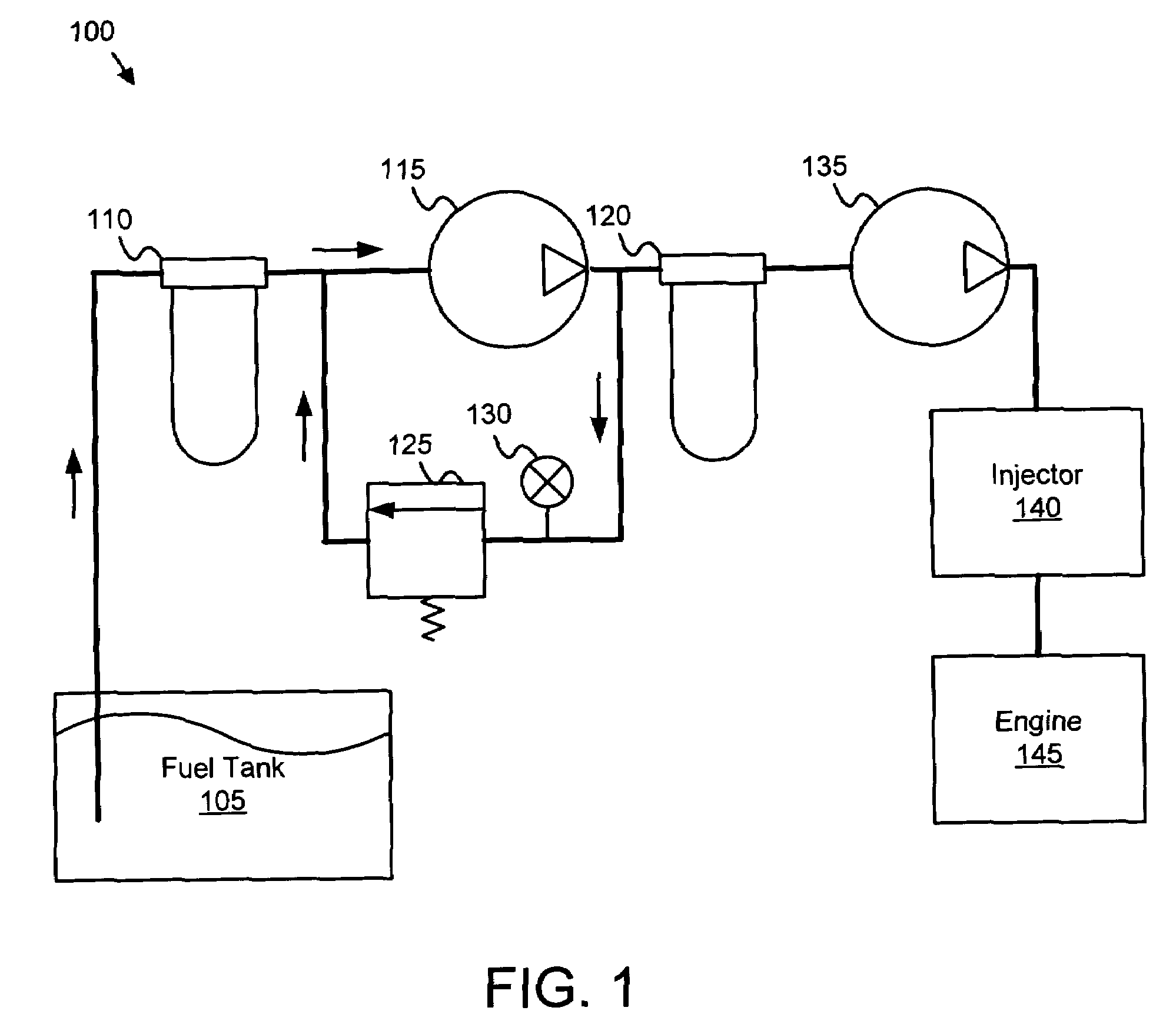

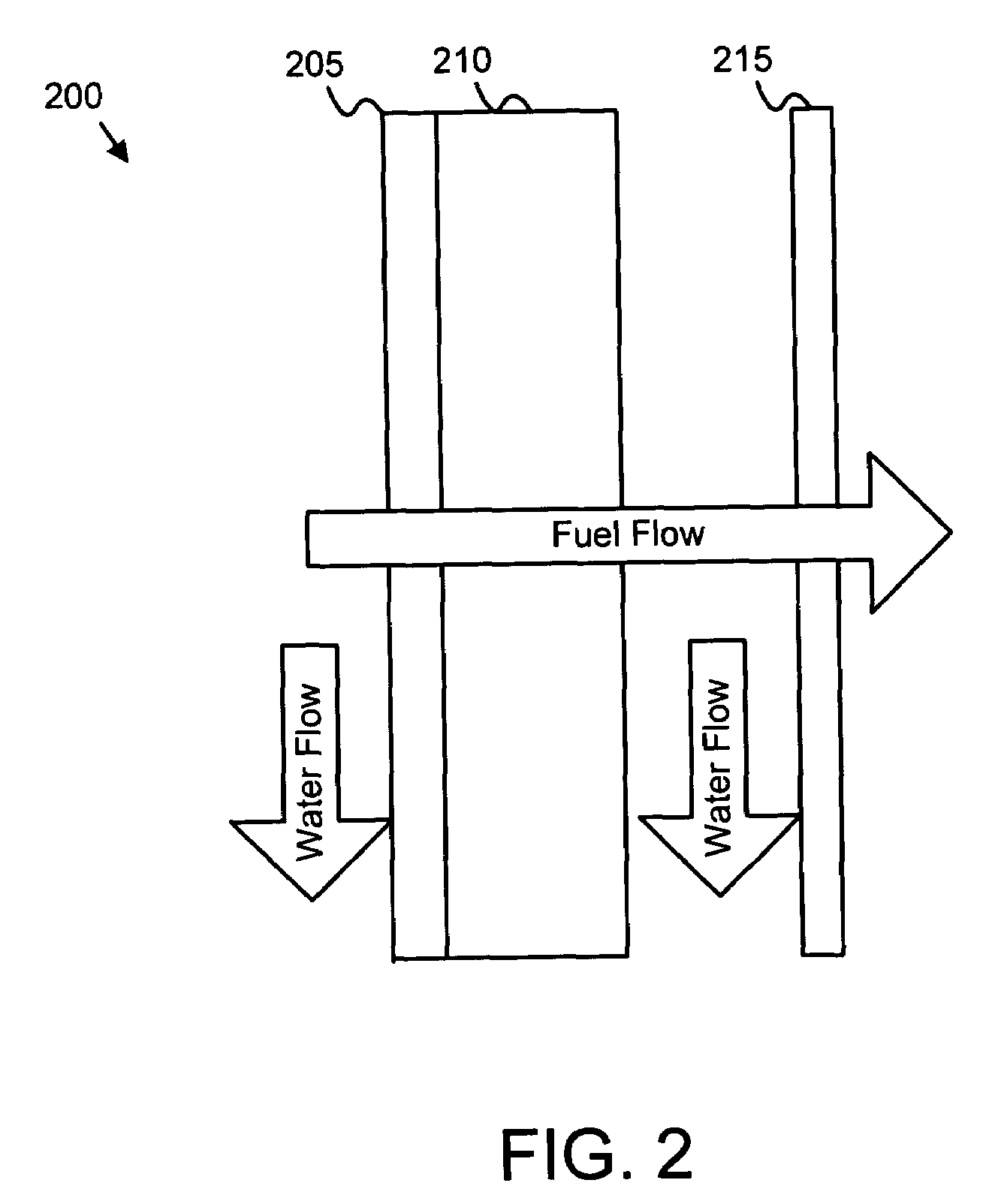

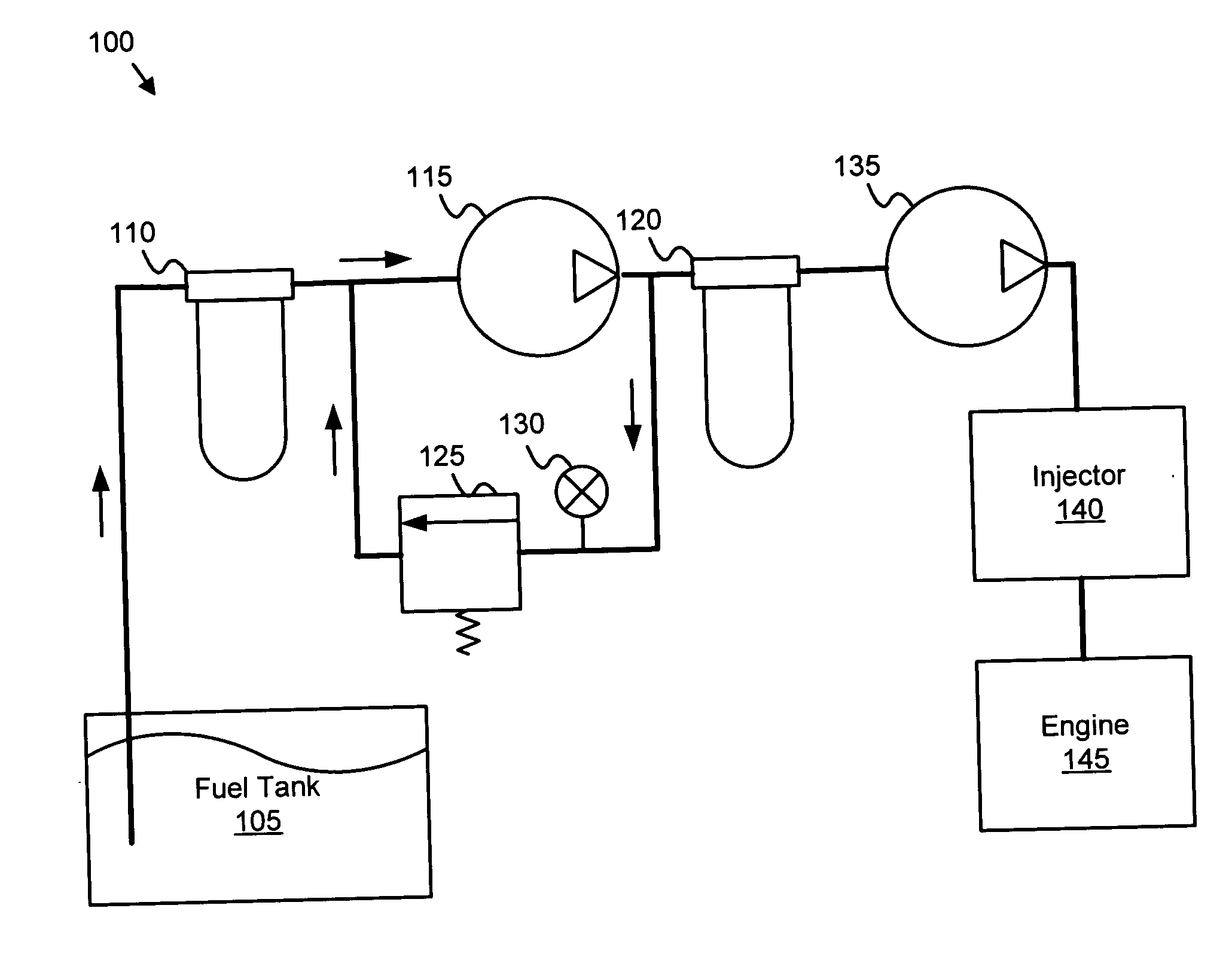

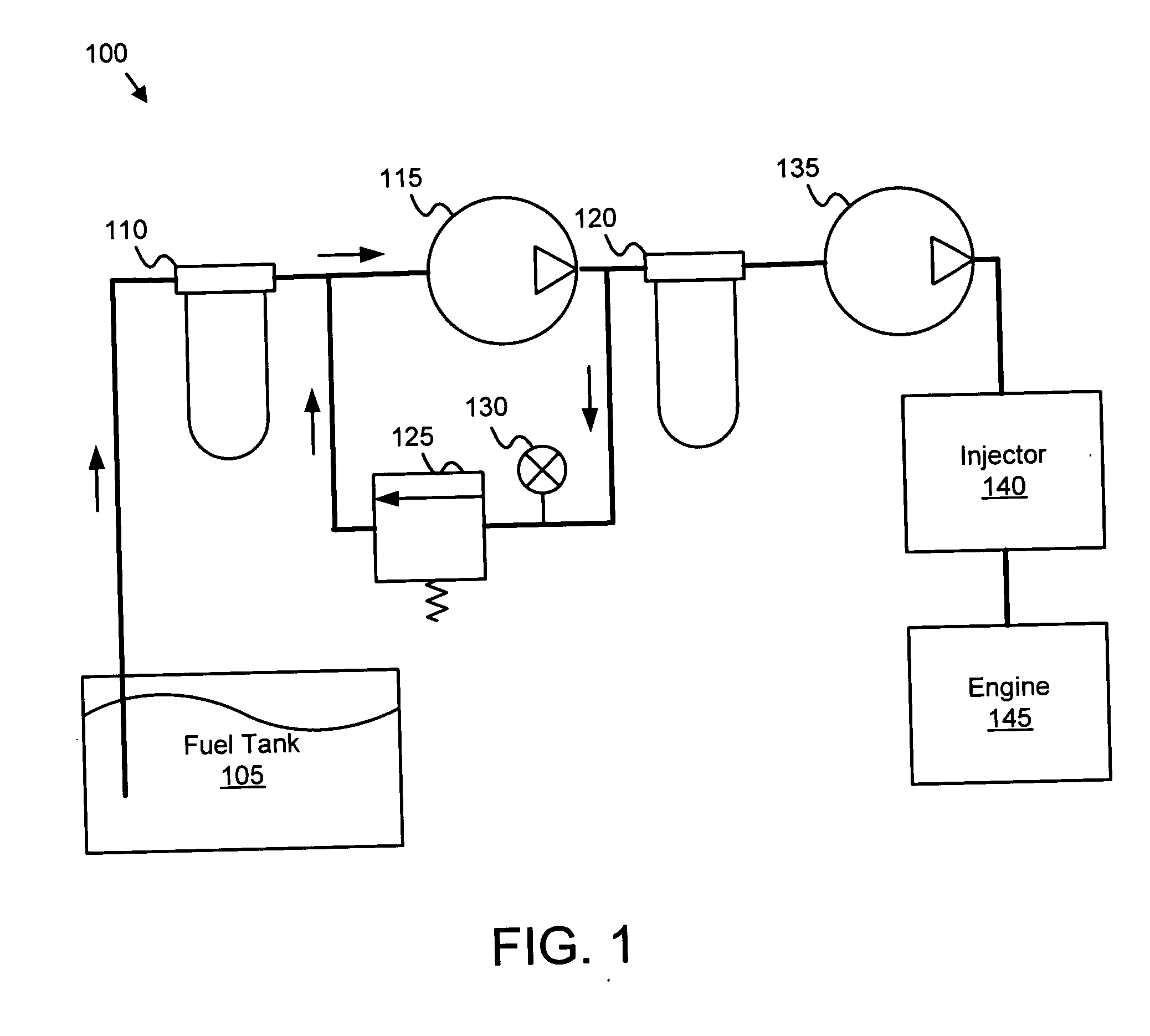

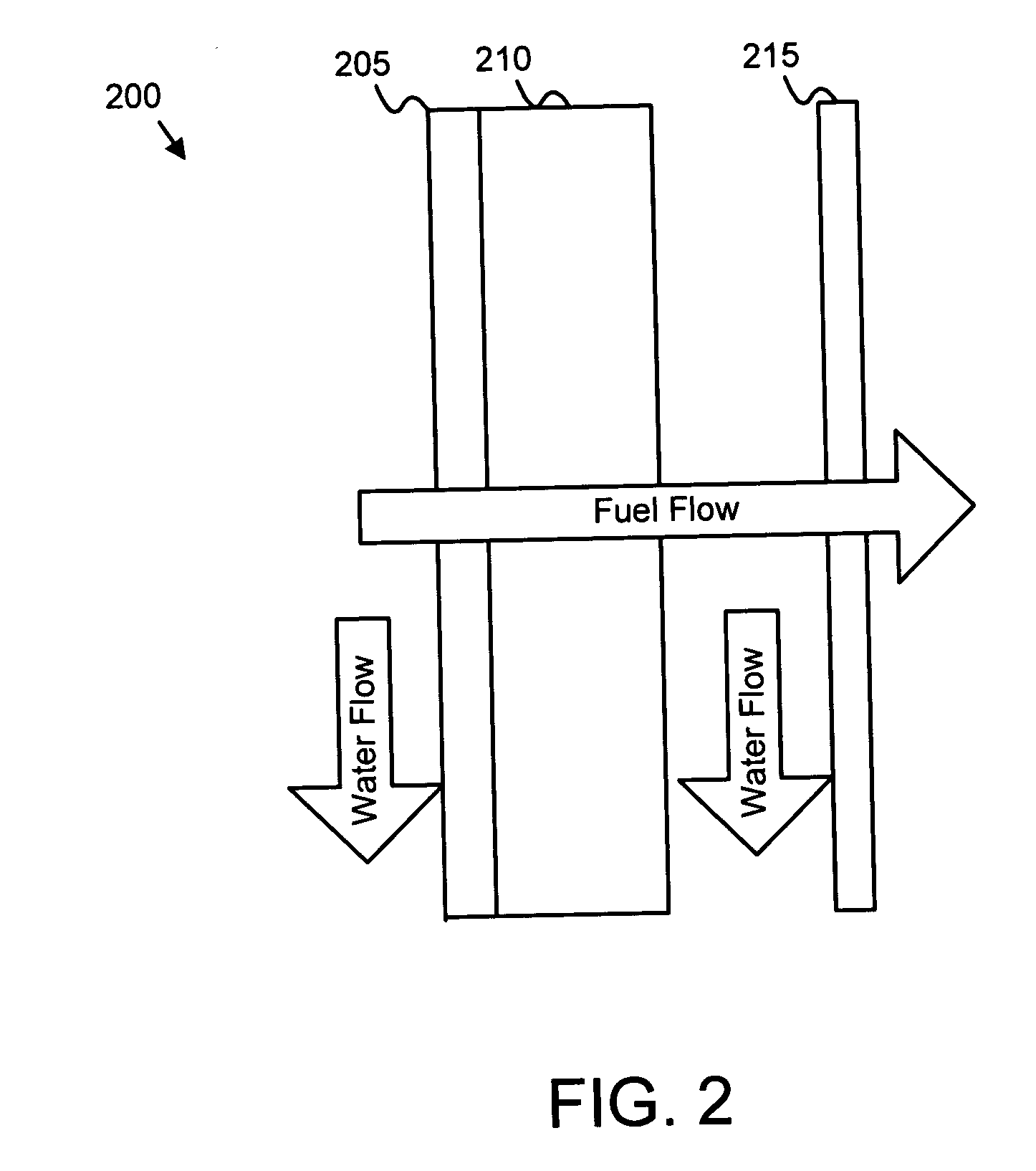

Apparatus, system, and method for multistage water separation

InactiveUS7527739B2Good removal effectLower overall pressure dropReversed direction vortexLoose filtering material filtersCentrifugal forceWaste management

An apparatus, system, and method are disclosed for multistage water separation. A first separation layer separates water droplets from a fuel flow by repelling the first water droplets. A coalescing layer may coalesce fine water droplets in the fuel flow. In one embodiment, a centrifugal separator directs the fuel flow tangentially to a filter wall and the centrifugal force of the fuel flow directed tangentially along the filter wall biases water droplets from the fuel flow. A second separation layer separates second water droplets from the fuel flow.

Owner:CUMMINS FILTRATION IP INC

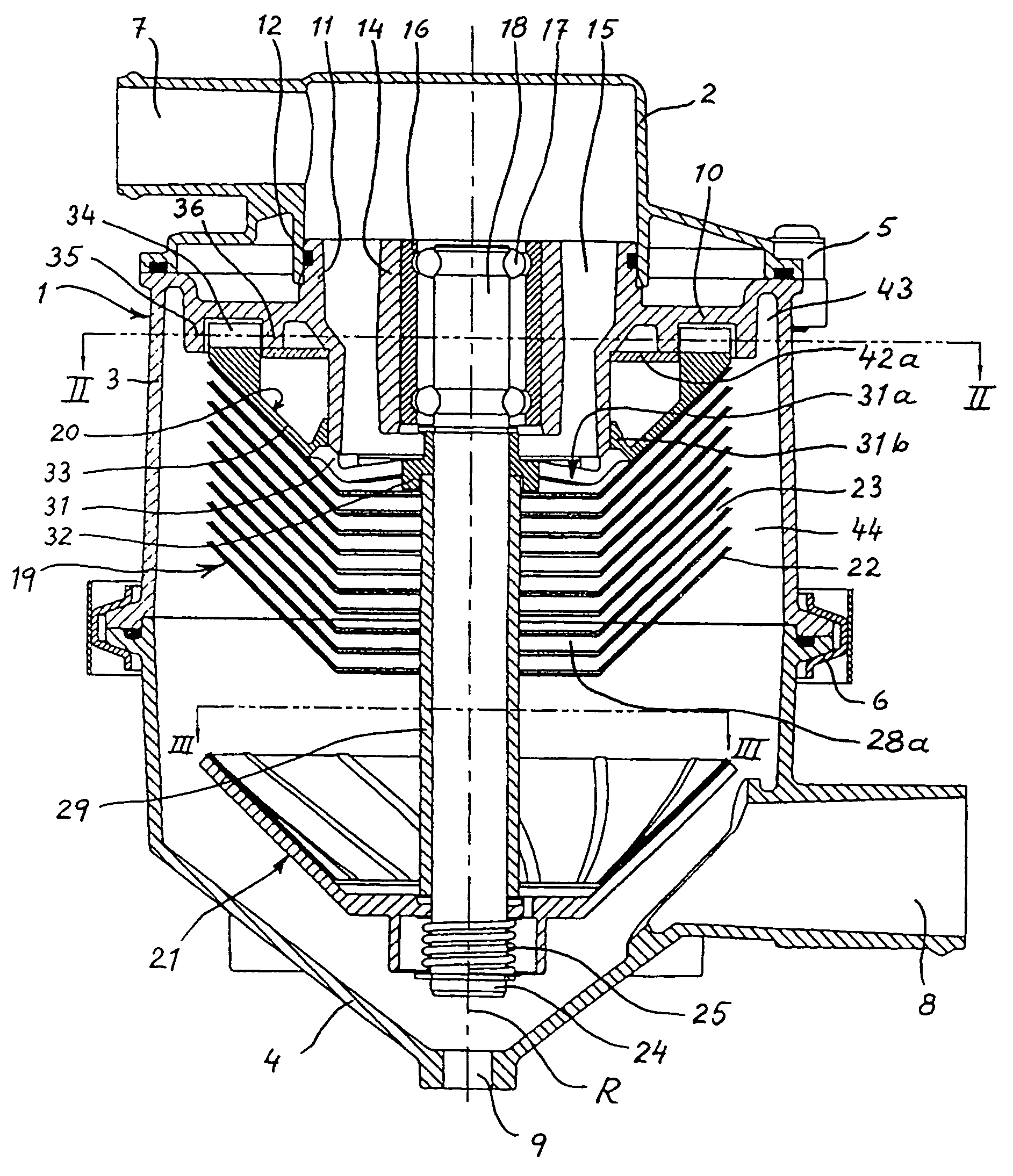

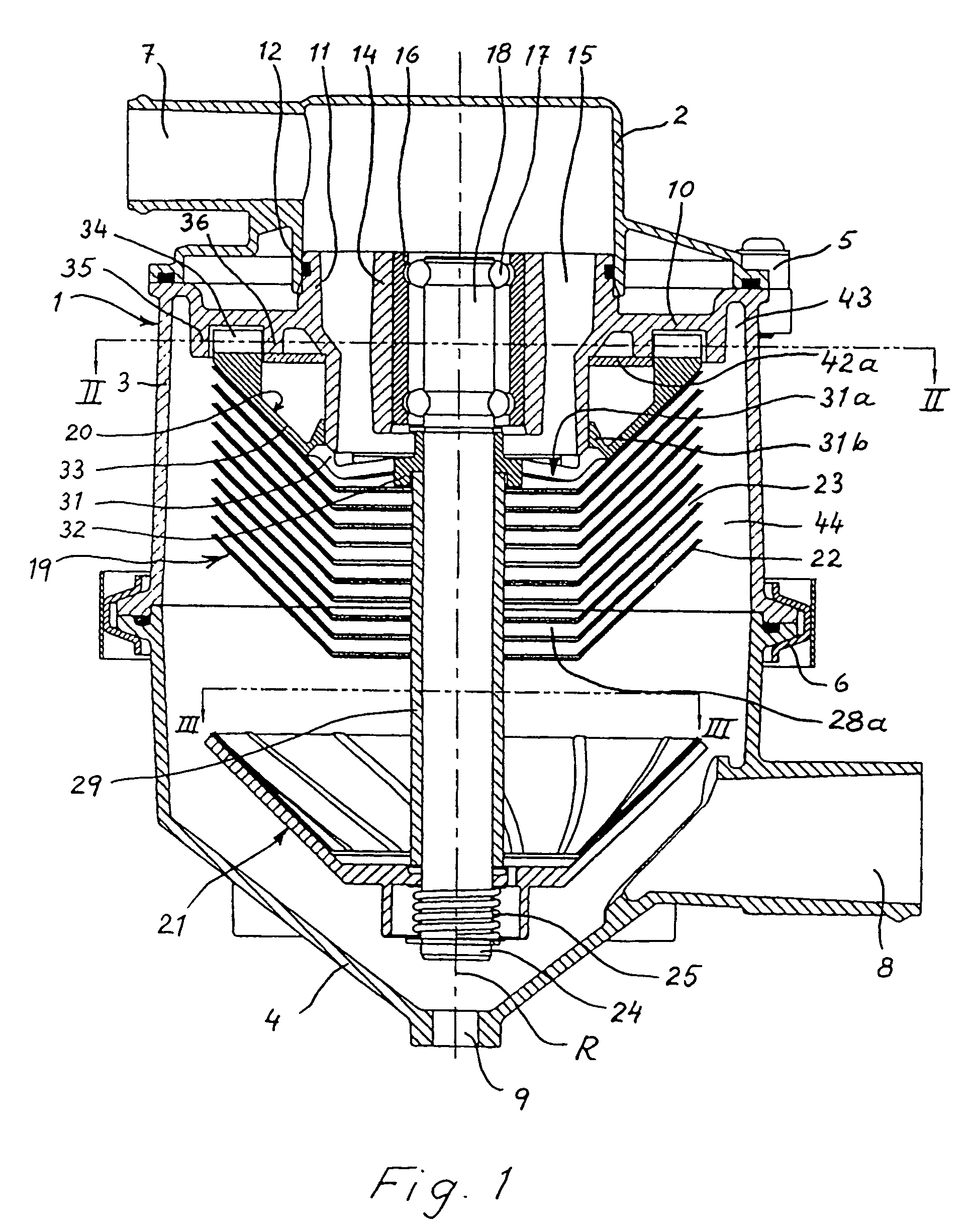

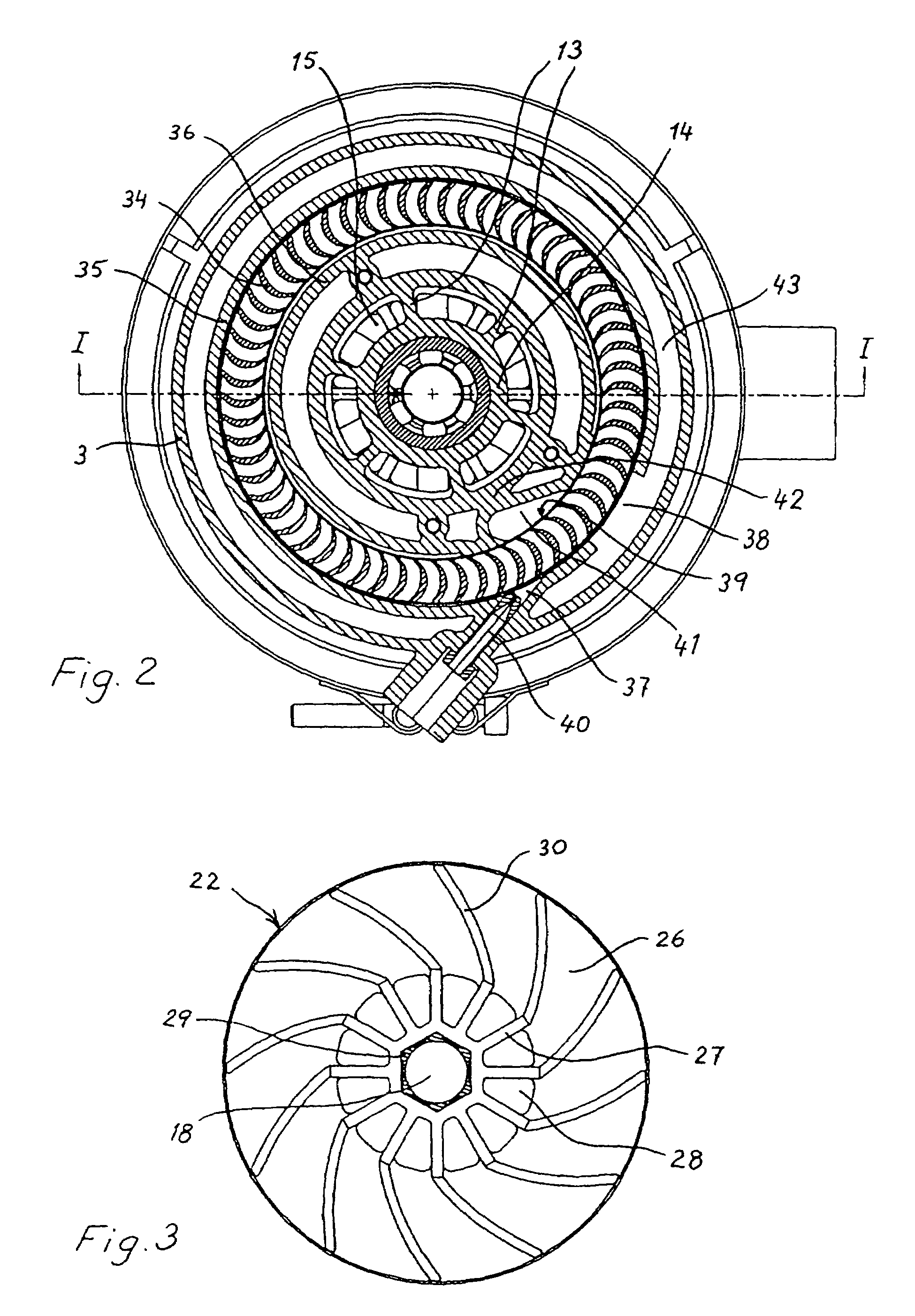

Centrifugal separator for cleaning gases

ActiveUS7396373B2Easy to cleanPrevent rotationCombination devicesDispersed particle filtrationFree formMechanical engineering

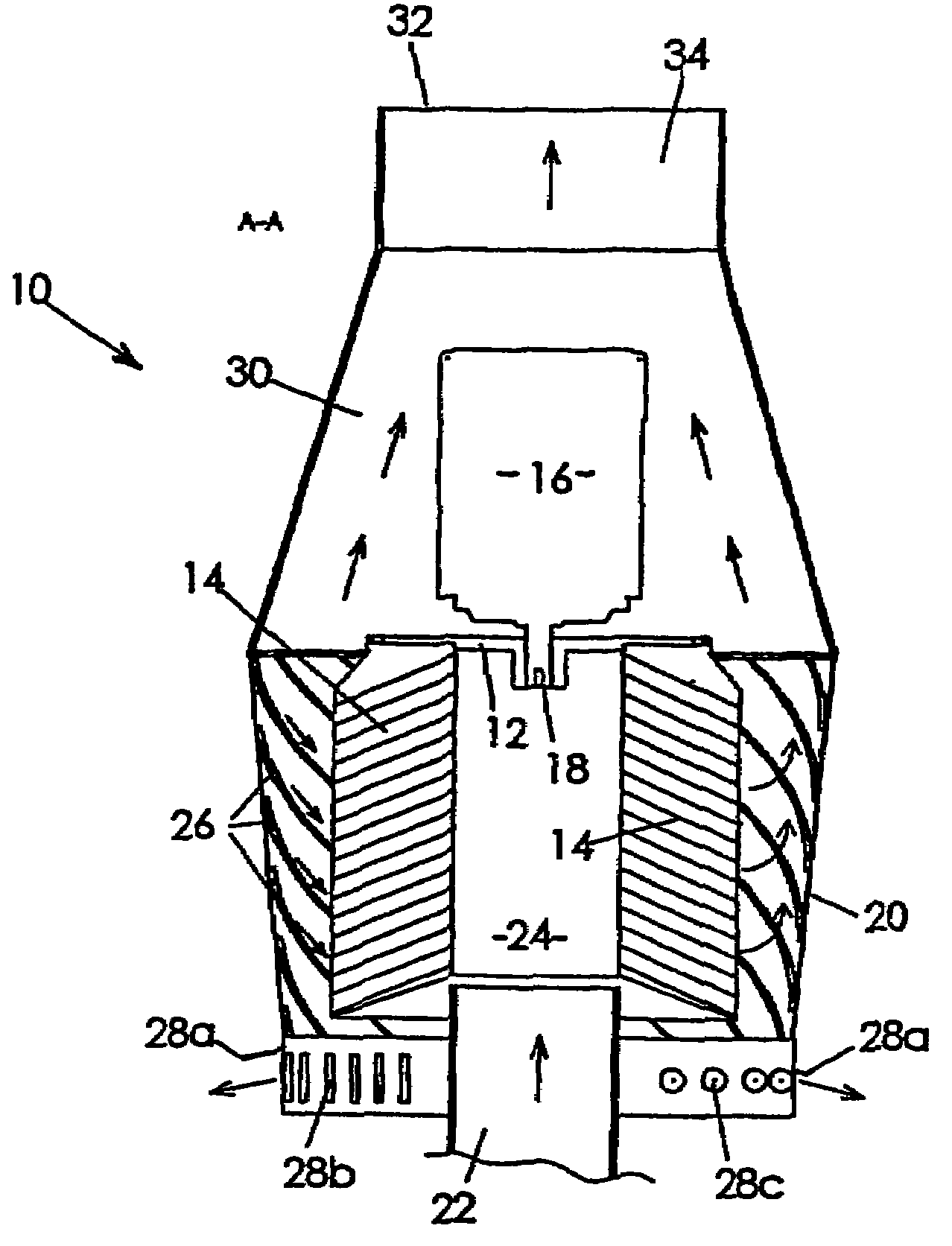

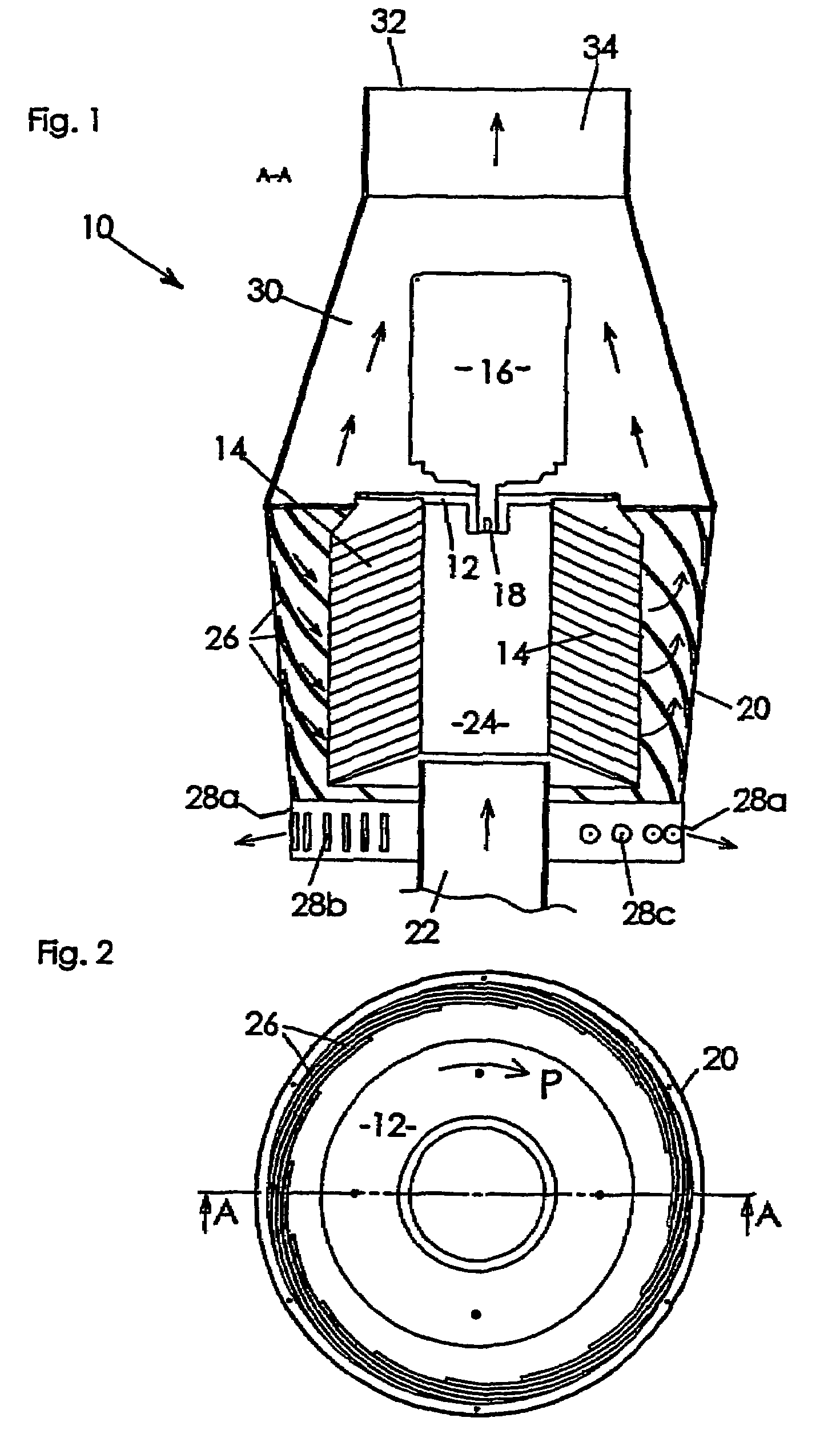

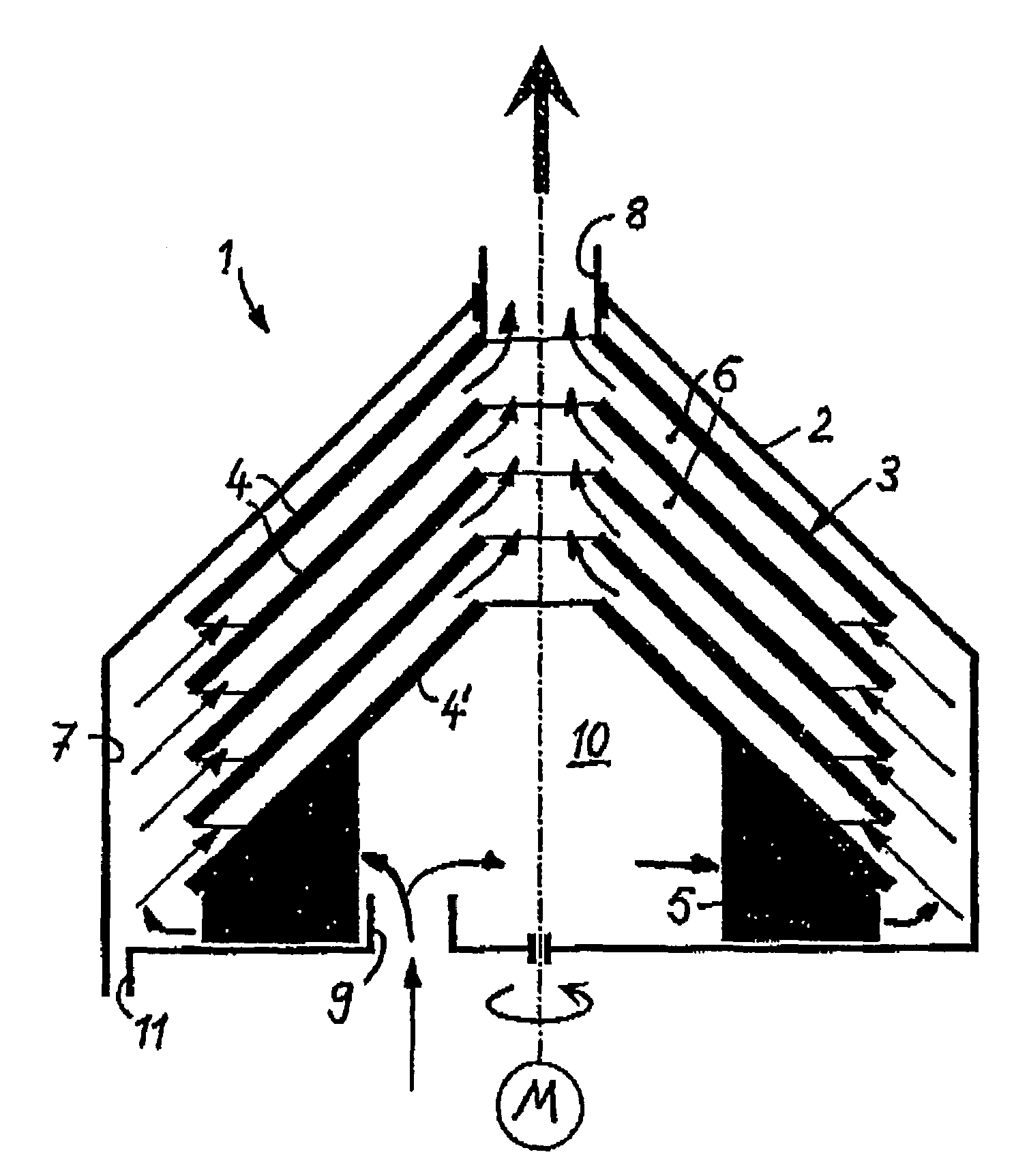

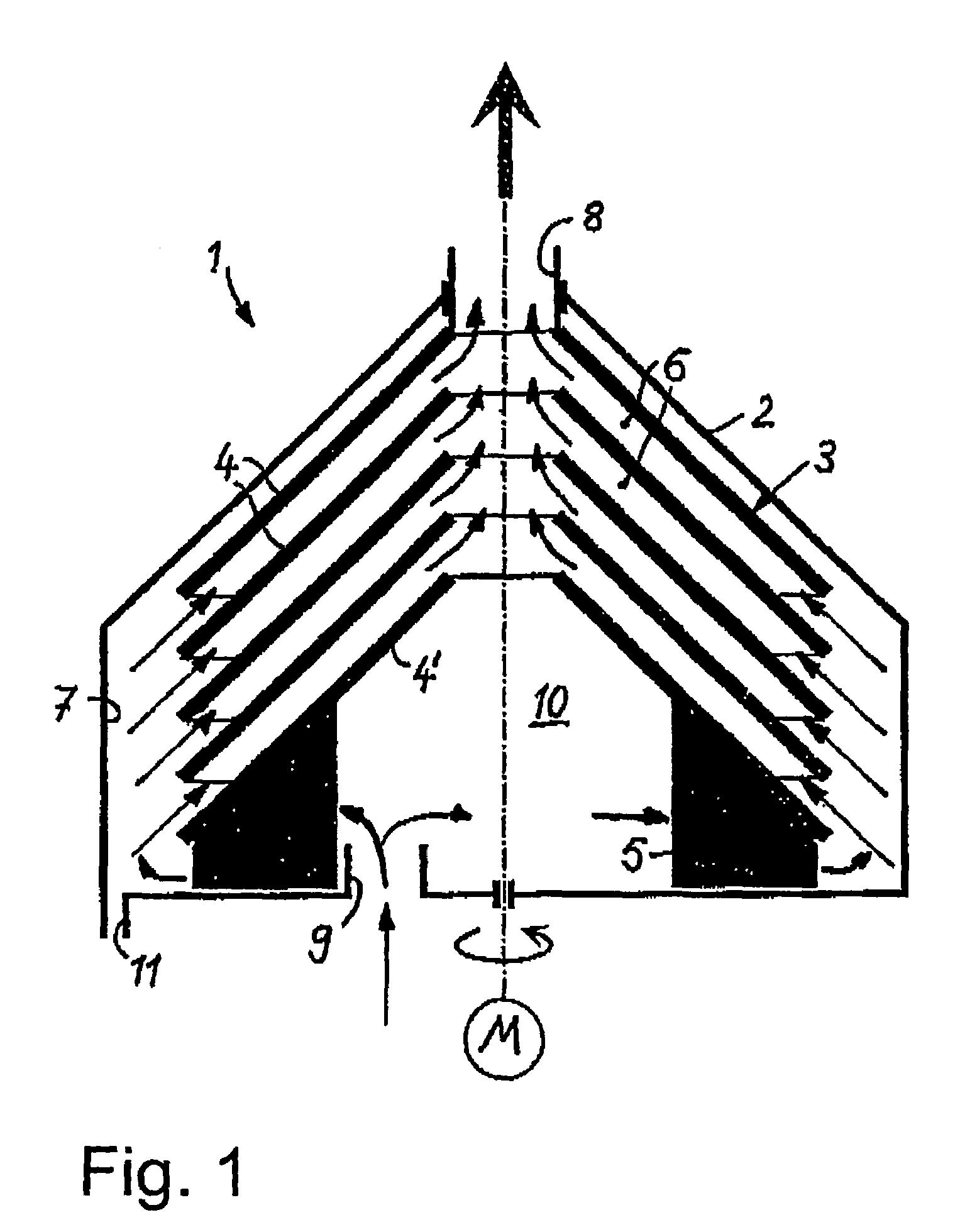

A centrifugal separator device (10) for separating solid and / or liquid particles which are suspended in gas media, which device comprises a rotor (12) which is provided sedimentation members (14), which is rotatably mounted in a surrounding stationary housing (20) and which has a central inlet for the gas medium which is to be cleaned. The housing (20) has, on the one hand, an outlet (32) for cleaned gas which, during its passage through the sedimentation members (14) in the rotor (12), has been freed form solid and / or liquid particles, and, on the other hand, an outlet (28 a-c) for solid and / or liquid particles which have been transferred onto the inner side of the housing. A number of parallel guide rails (26), which run helically, are arranged on the inner side of the housing and extends axially at least over a major part of the length of the rotor (12), and the outlet (32) in the housing for cleaning gas is located, with respect to the axis, at one end of the rotor (12) while the outlet (28a-c9 for the particles which have been collected on the housing wall is located at the opposite axial end of the rotor. The guide rails (26) are arranged in a direction on the inner side of the housing in relation to the direction of rotation of the rotor which is such that a peripherally outer of a gas vortex generated by the rotor is forced to entrain the particles which have been collected between the guide rails toward the particles outlet.

Owner:GRIMALDI DEV AB

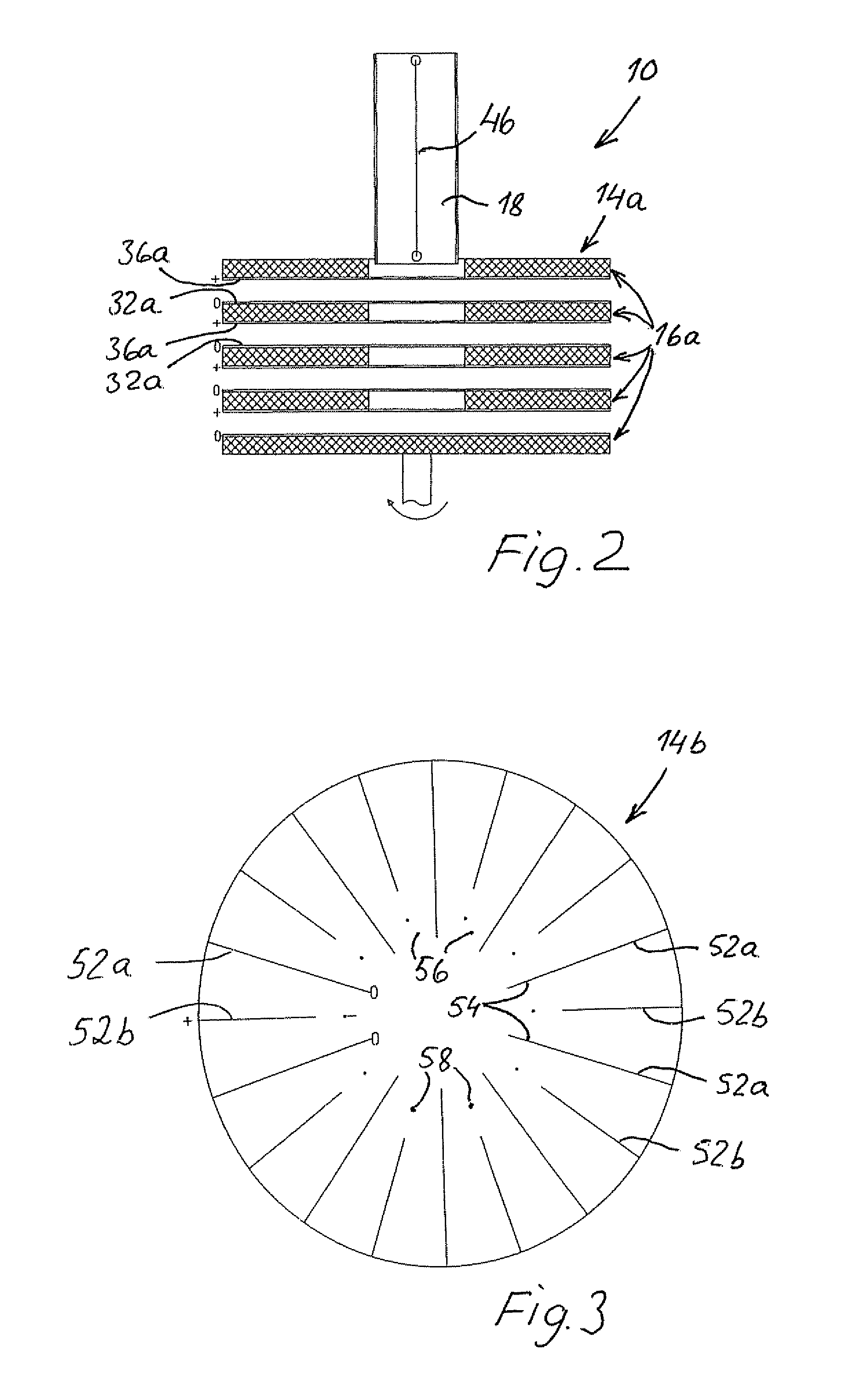

Method and Apparatus for Separation of Particles From a Flow of Gas

ActiveUS20090266231A1Increase capacityImprove efficiencyDispersed particle separationCentrifugesEngineeringCentrifugal force

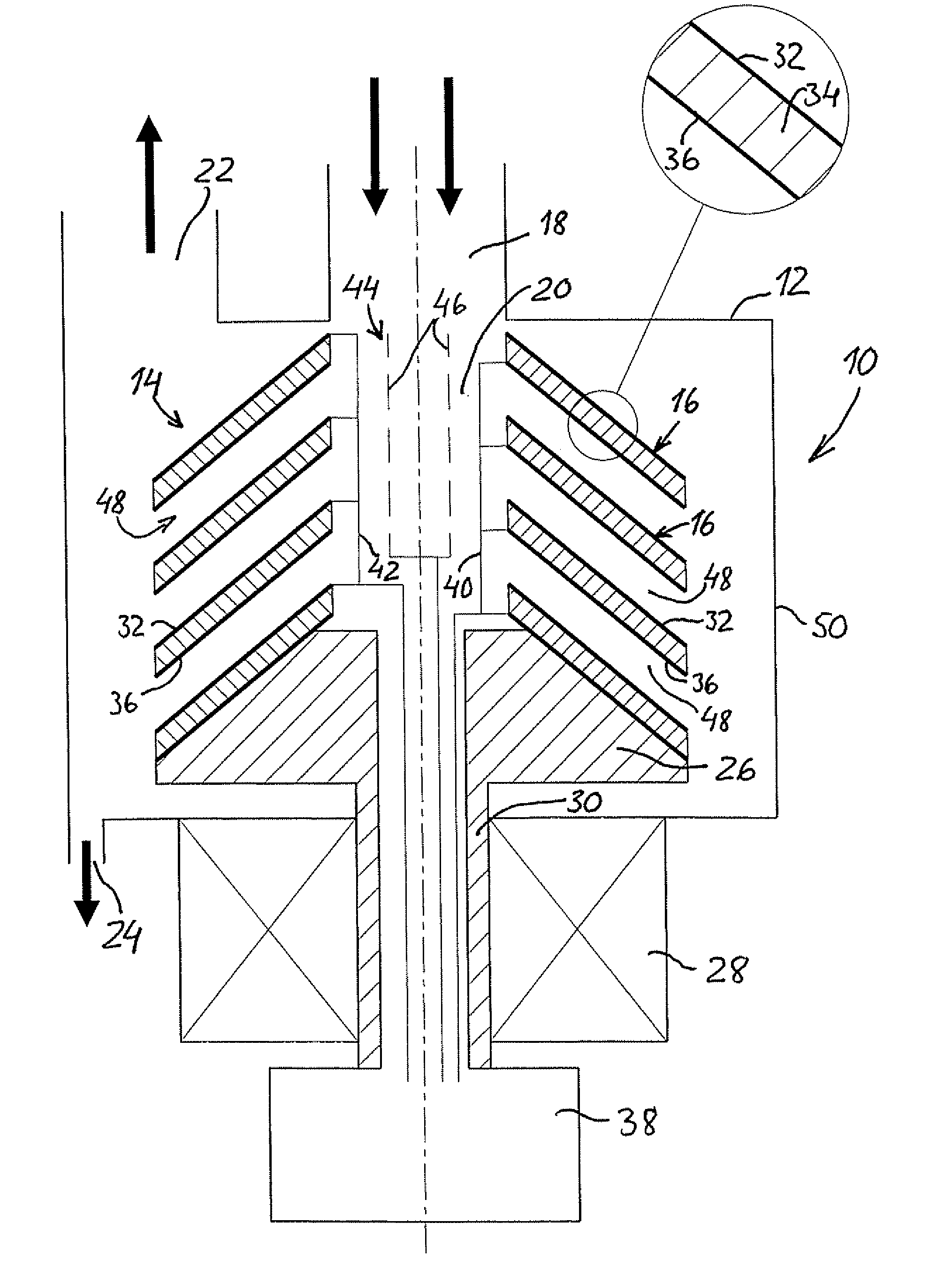

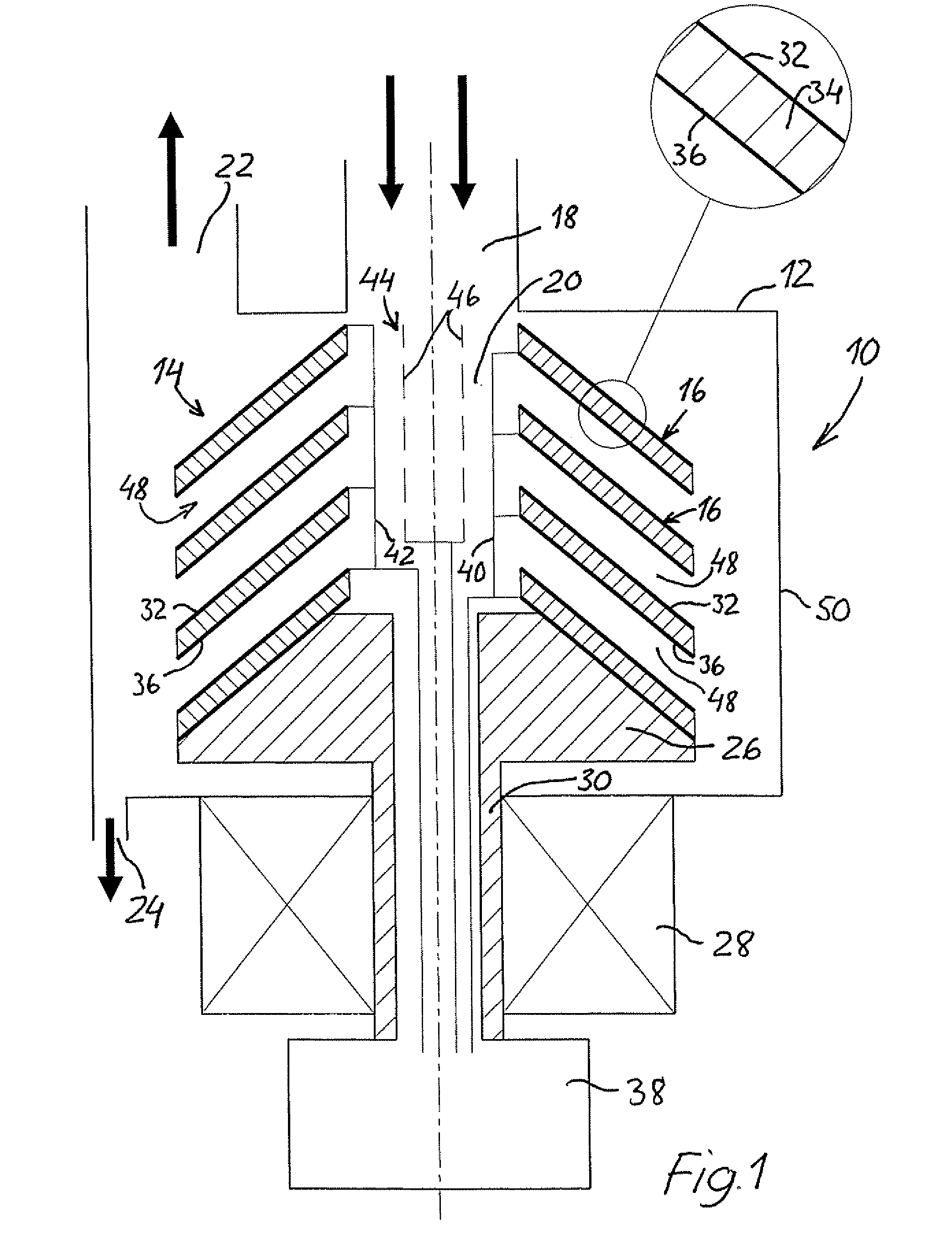

A method and apparatus for the separation of particles from a flow of gas, where both large, heavy and small, light particles can be separated off from the gas by means of the combined effect of an electrostatic attraction force and a centrifugal force in a centrifugal separator (10) of the type that comprises a rotor (14) that has a plurality of adjacent surface elements (16) with intermediate gas flow gaps (48) and that is mounted in such a way that it can rotate in a surrounding casing (12), which casing has an inlet (18) for unclean gas and an outlet (22) for clean gas and an outlet (24) for separated-of f particles. A charging unit (44) ionizes the particles upstream of the rotor (14). An electrical field is generated between adjacent surface elements (16) of the rotor in order to attract the ionized light particles towards a face of the surface elements by means of the electrostatic force. By means of the centrifugal force created by the rotor, the particles that have accumulated on the surface elements are thrown towards the inside of the casing and are led out through the outlet.

Owner:GRIMALDI DEV AB

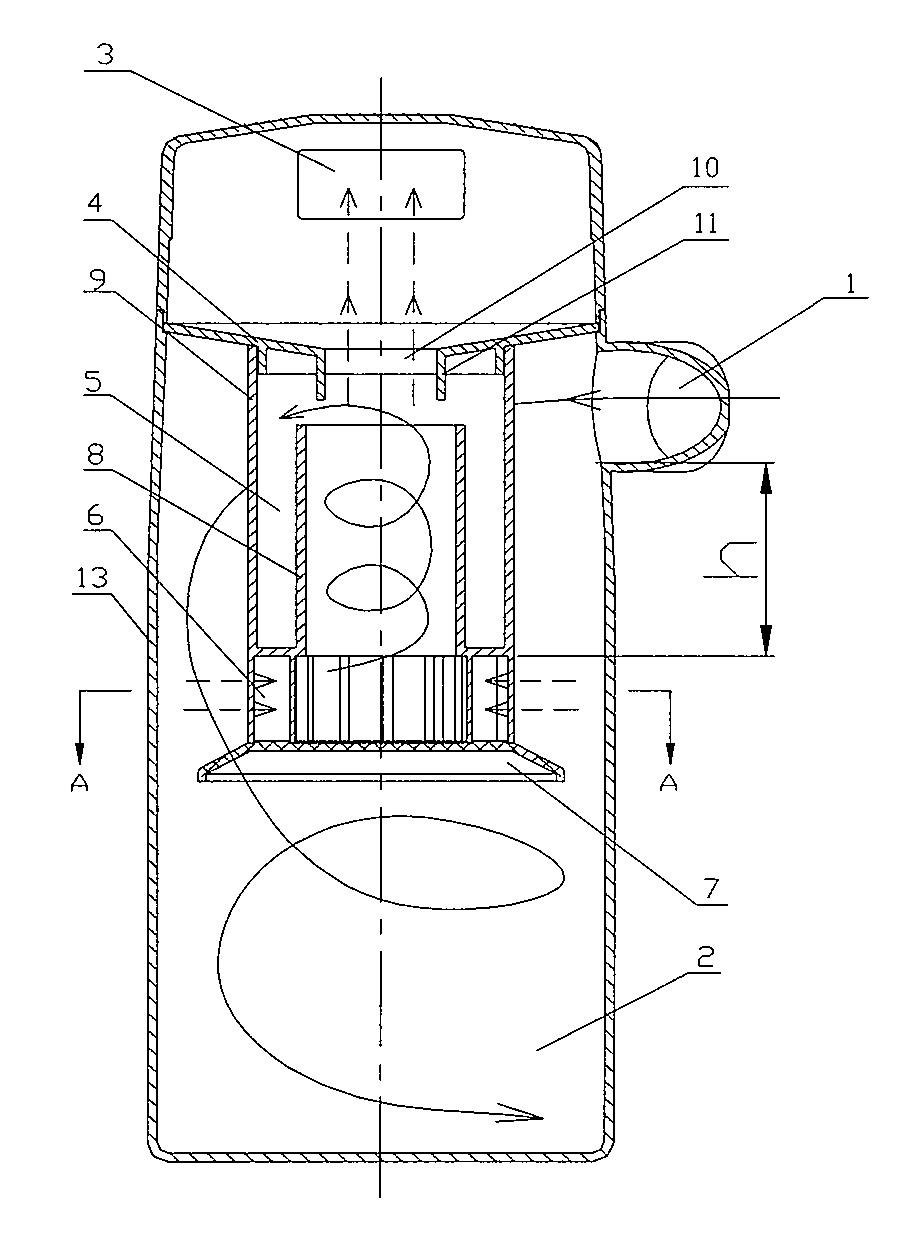

Dust collector cup of fall centrifugal separation type

InactiveUS7780753B2Optimize volumeWeight optimizationCleaning filter meansCombination devicesEngineeringDust collector

A dust collector cup working in the principle of fall centrifugal separation, consists of cup body (13), outlet (3) on the cup body (13), inlet (1) tangential to the circumferential wall of the cup body (13), and a separator settled in the cup body (13). The separator is composed of outlet tube (9), inlet (6) on the wall of the outlet tube (9), and the isolating shield (7) under the inlet (6) of the outlet tube (9), with the outlet tube (9) linked to the outlet (3) of the cup body (13). The fall between the horizontal positions of the lower end of inlet of the cup body (13) and the upper end of the inlet (6) of the outlet tube (9) is 0-140 mm.

Owner:WANG YUEDAN

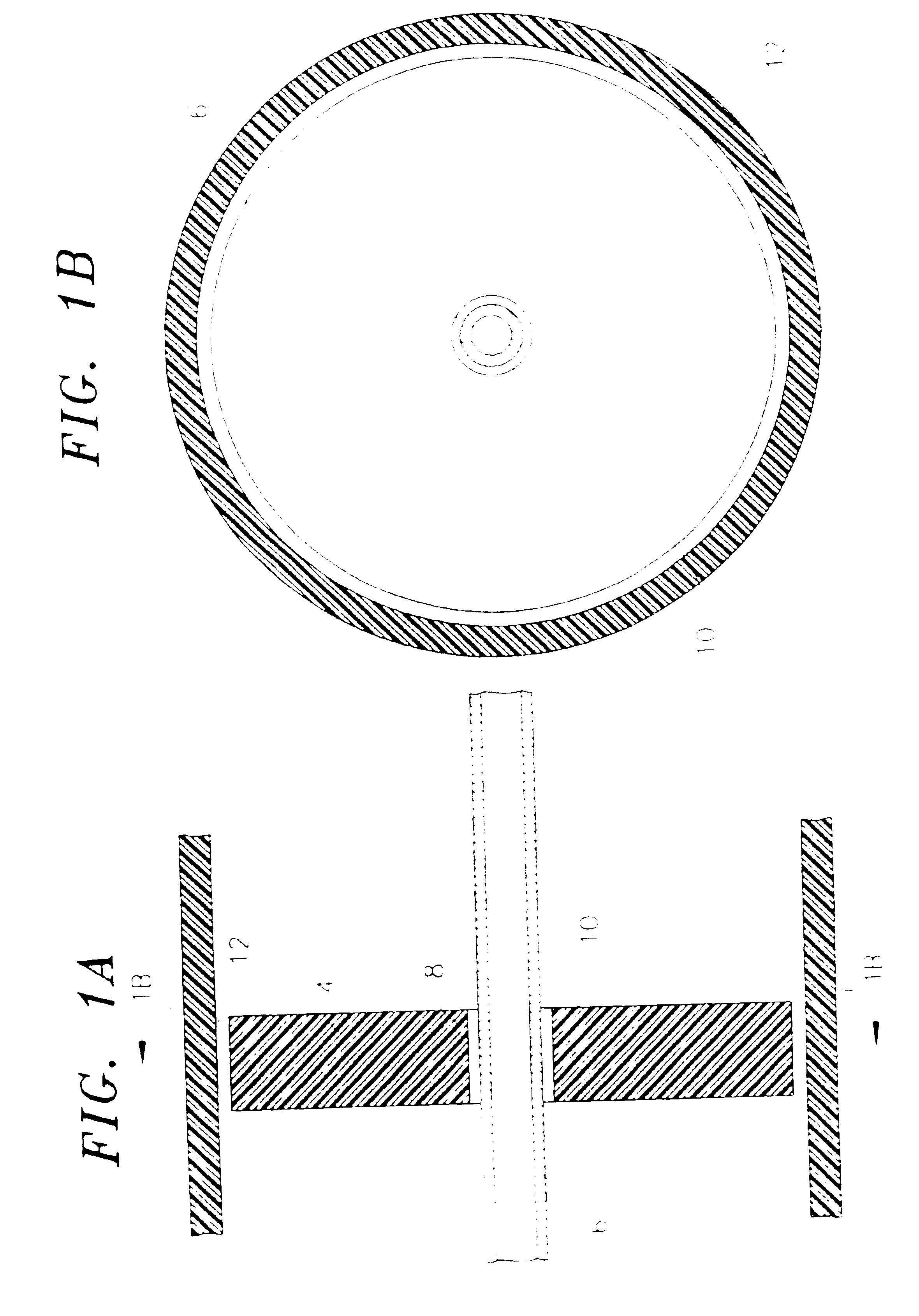

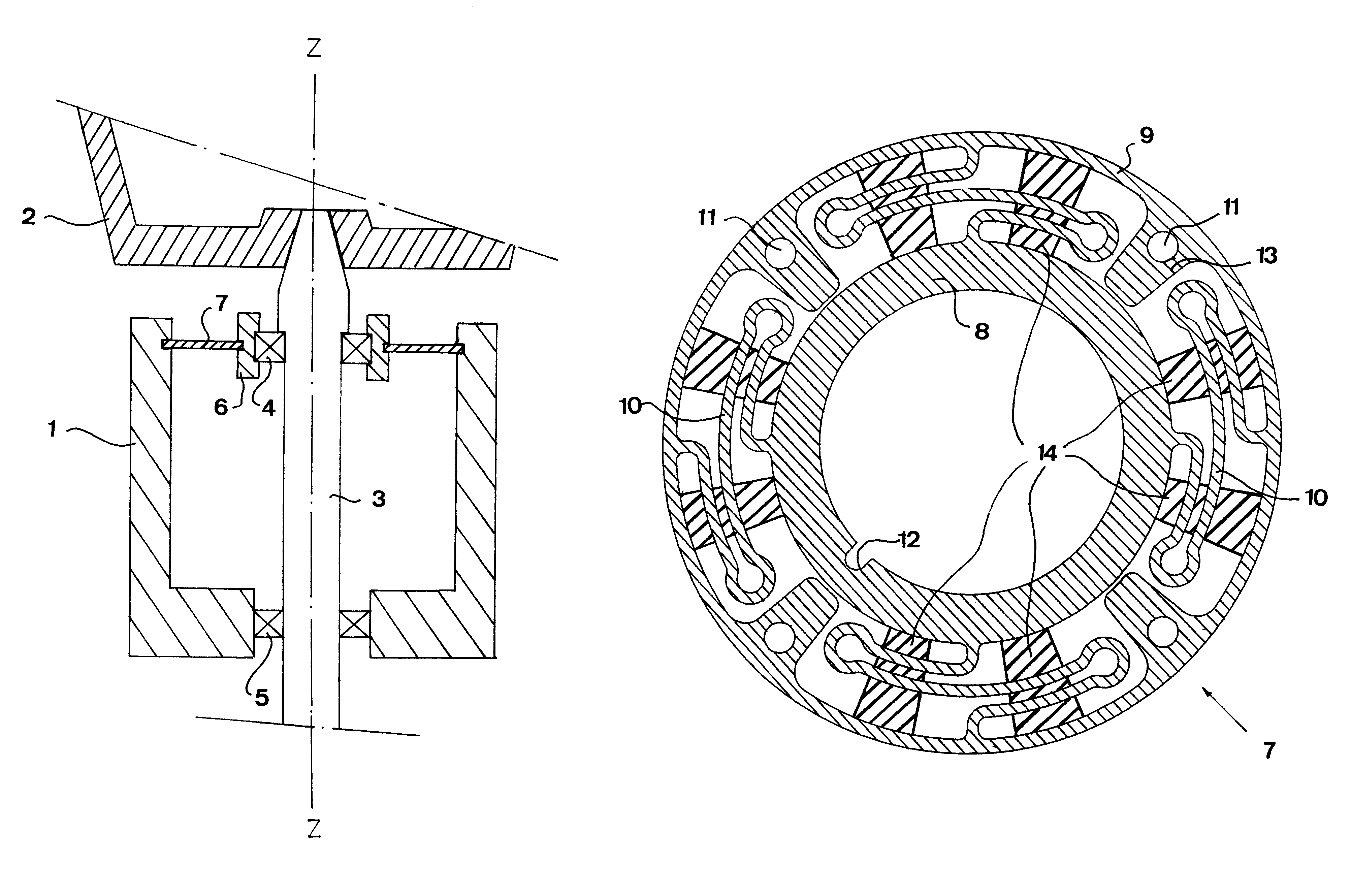

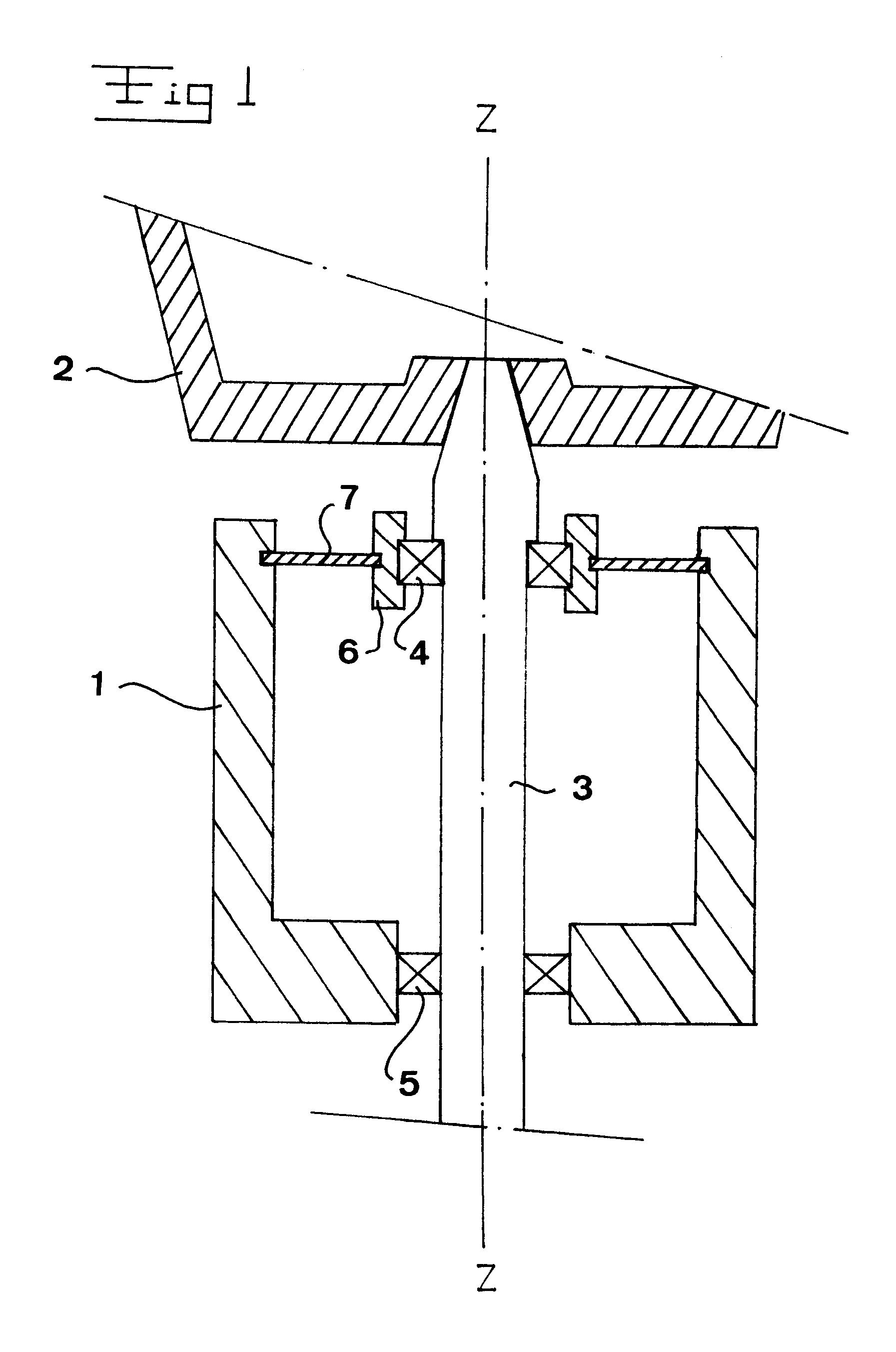

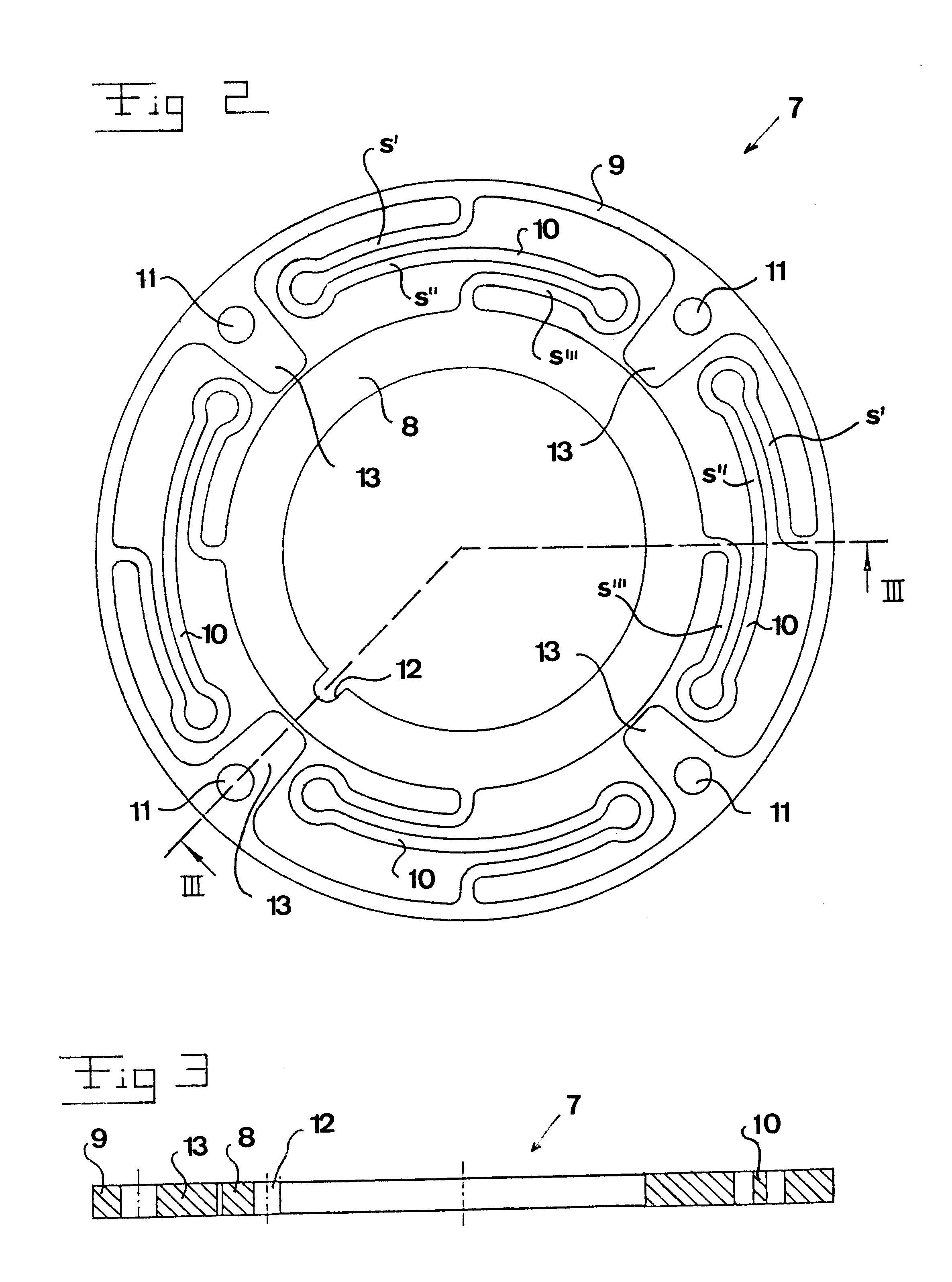

Flexible metal supporting device for a centrifugal separator

InactiveUS6224533B1Simple designSimple structureRolling contact bearingsCentrifugesCentrifuge rotorMetallic materials

A flexible metal support device for a rotatable centrifuge rotor (2) provided in a frame member (1) by a bearing member (4). The support device comprises a support element (7) provided between the bearing member (4) and the frame member (1), and arranged to absorb relative movements between the centrifuge rotor and the frame member. The support element (7) comprises an inner mounting portion, essentially immovable in relation to the bearing member (4), and an outer mounting portion, essentially immovable in relation to the frame member (1). Moreover, the support element (7) comprises three flexible connecting portions which each extends between the inner and outer mounting portions and is arranged to absorb radial and axial relative movements between the centrifuge rotor and the frame member. Furthermore, the inner portion, the connecting portions and the outer portion form an integrated unit manufactured in one piece of metal material.

Owner:ALFA LAVAL AB

Apparatus, system, and method for multistage water separation

InactiveUS20070039865A1Good removal effectLower overall pressure dropReversed direction vortexLoose filtering material filtersEngineeringCentrifugal force

An apparatus, system, and method are disclosed for multistage water separation. A first separation layer separates water droplets from a fuel flow by repelling the first water droplets. A coalescing layer may coalesce fine water droplets in the fuel flow. In one embodiment, a centrifugal separator directs the fuel flow tangentially to a filter wall and the centrifugal force of the fuel flow directed tangentially along the filter wall biases water droplets from the fuel flow. A second separation layer separates second water droplets from the fuel flow.

Owner:CUMMINS FILTRATION IP INC

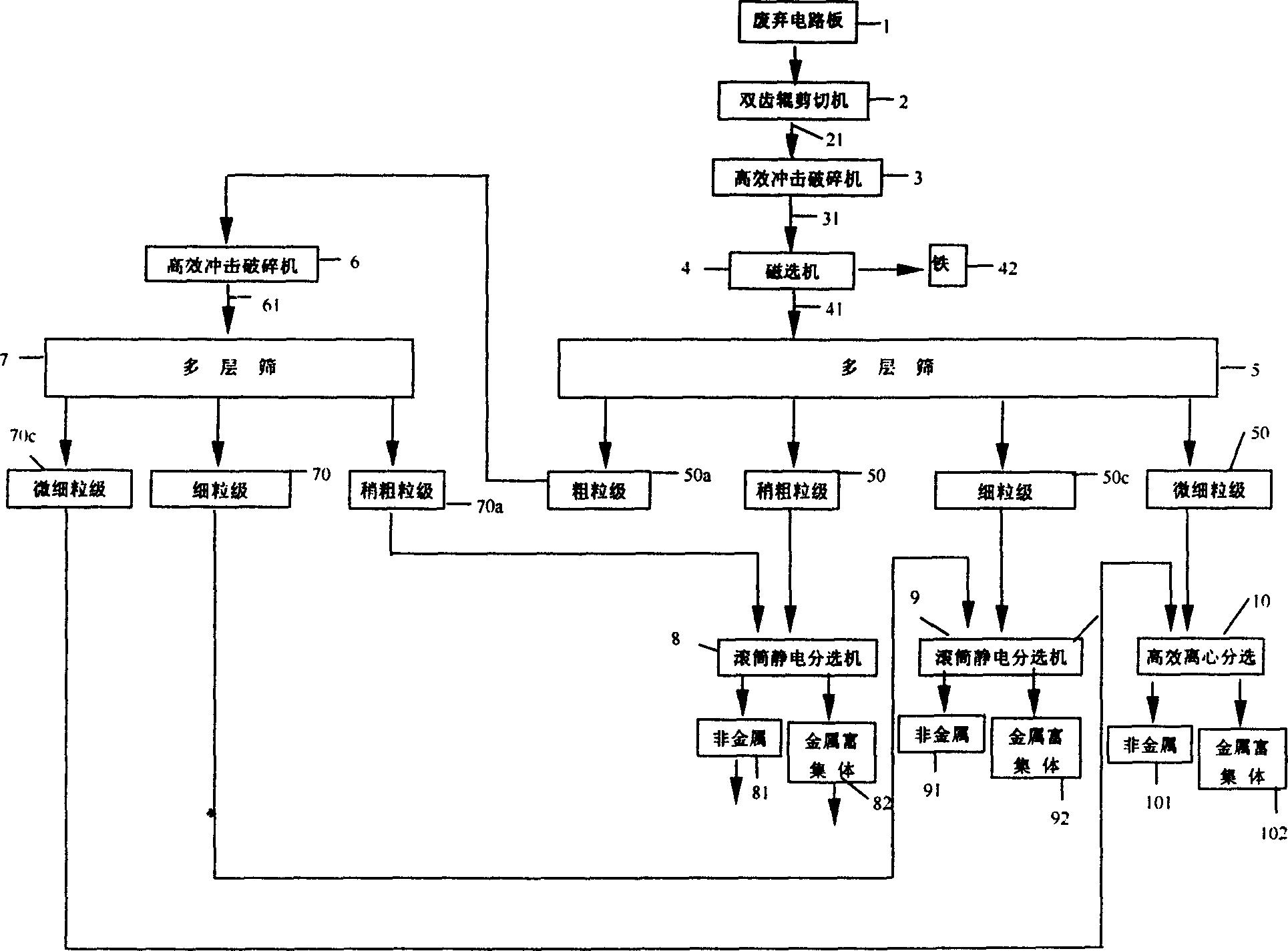

Techhnique for reclaiming metal concentrate in obsolete PCB physically

InactiveCN1563440ASolve resource problemsAchieve recyclingSolid waste disposalProcess efficiency improvementDouble teethMagnetic separator

A physical recovery technology of metal enriched materials from waste CB applies a mechnanical and physical sorting method to cut, crush, screen, sort and separate the waste CB by a double tooth roll shearer, a punch crusher, a magnetic separator, a separating screen, a rotary static separator, high efficient centrifugal separator to get a multicomponent of metal rich collection and a nonmetal enriched material to recover all valuable components from waste CB.

Owner:CHINA UNIV OF MINING & TECH

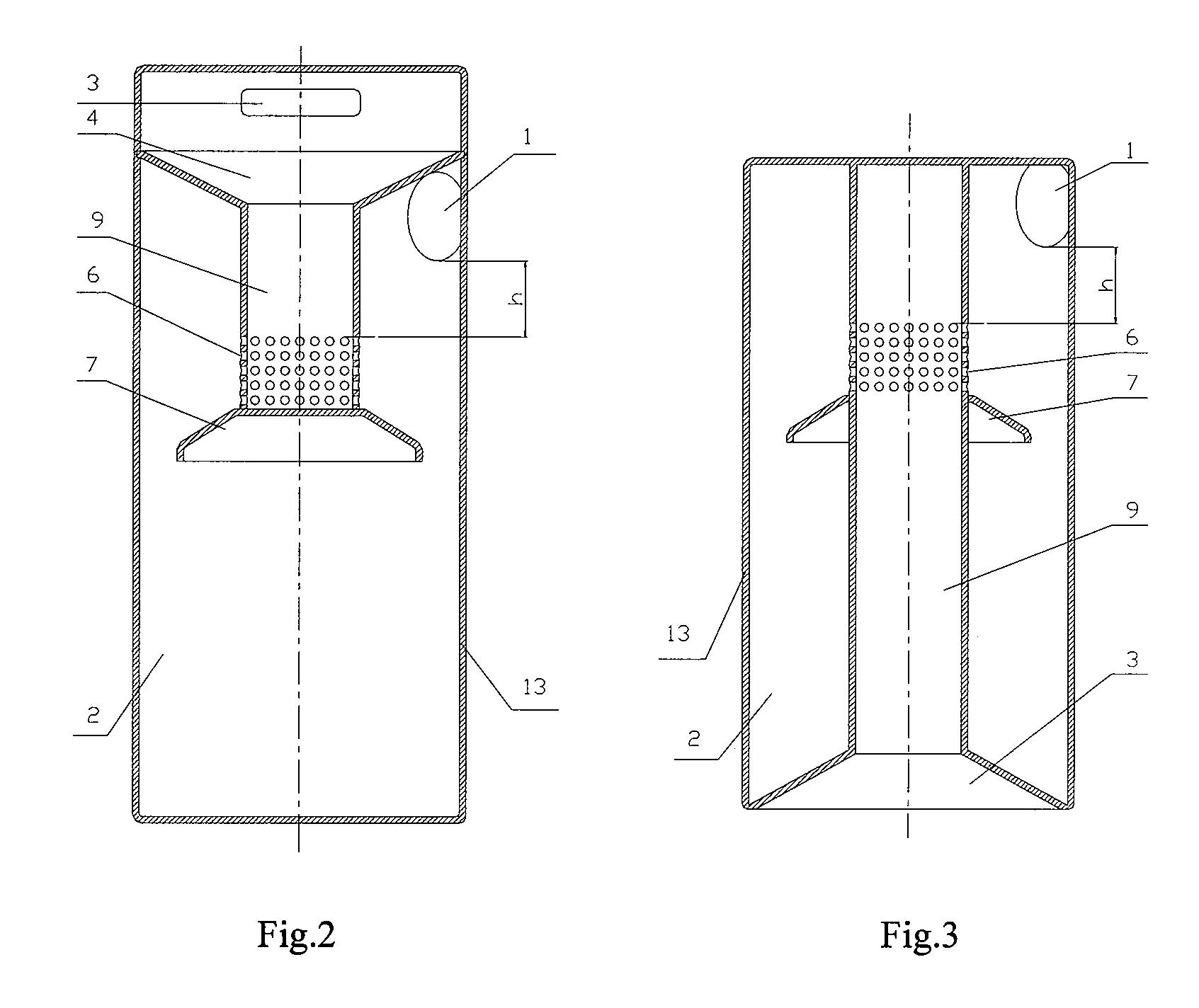

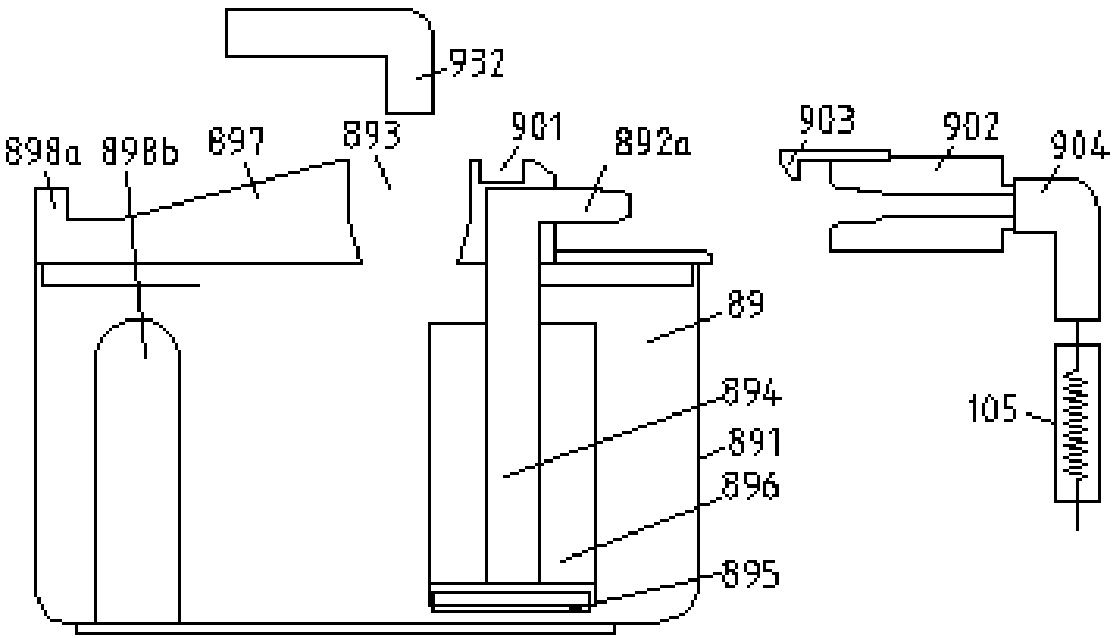

Intelligent rice cooker, integrated electric valve and filter screen pipe

ActiveCN108784446ATo achieve the purpose of saving waterCompact structureCooking-vessel lids/coversVessels with intergral heatingWater savingWater discharge

The invention discloses an intelligent rice cooker, an integrated electric valve and a filter screen pipe. The intelligent rice cooker comprises a bottom leakage spraying device, a water containing box and / or a feeding device; the feeding device comprises a worm rod and the filter screen pipe, the worm rod pushes rice grains to pass through the filter screen pipe, and a wind force, dust gravity and a centrifugal separator are used for removing dust in the rice grains; the rice cooker is provided with a filtering device for filtering rice washing water or cooker washing water discharged from the rice cooker for reuse; the rice cooker can achieve automatic addition of rice and water for cooking, and a rice cooker lid can be automatically opened or closed as needed. Through the technical scheme above, the intelligent rice cooker provided by the embodiment can save water in the processes of cooking rice and washing the cooker.

Owner:李亚锐

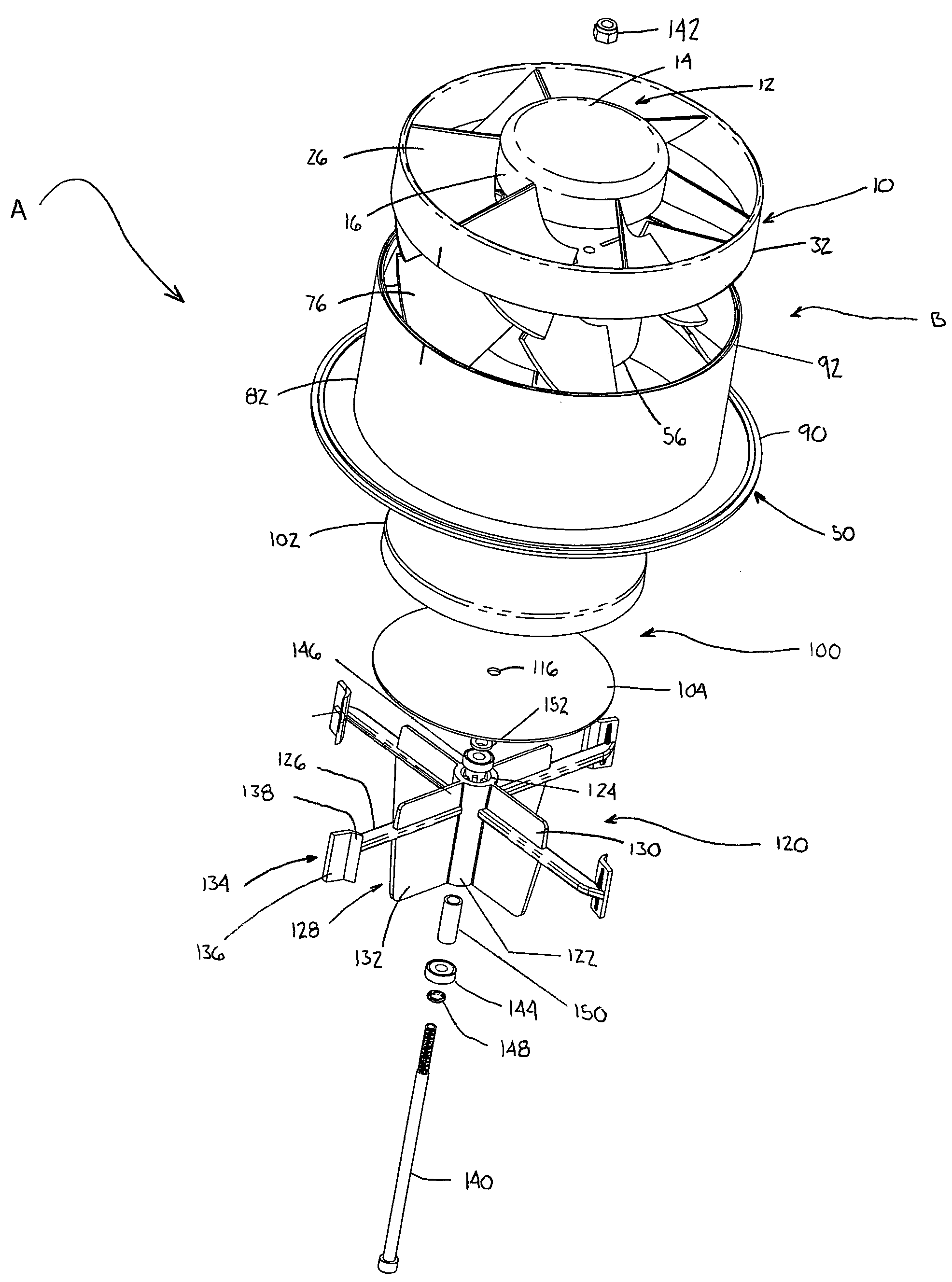

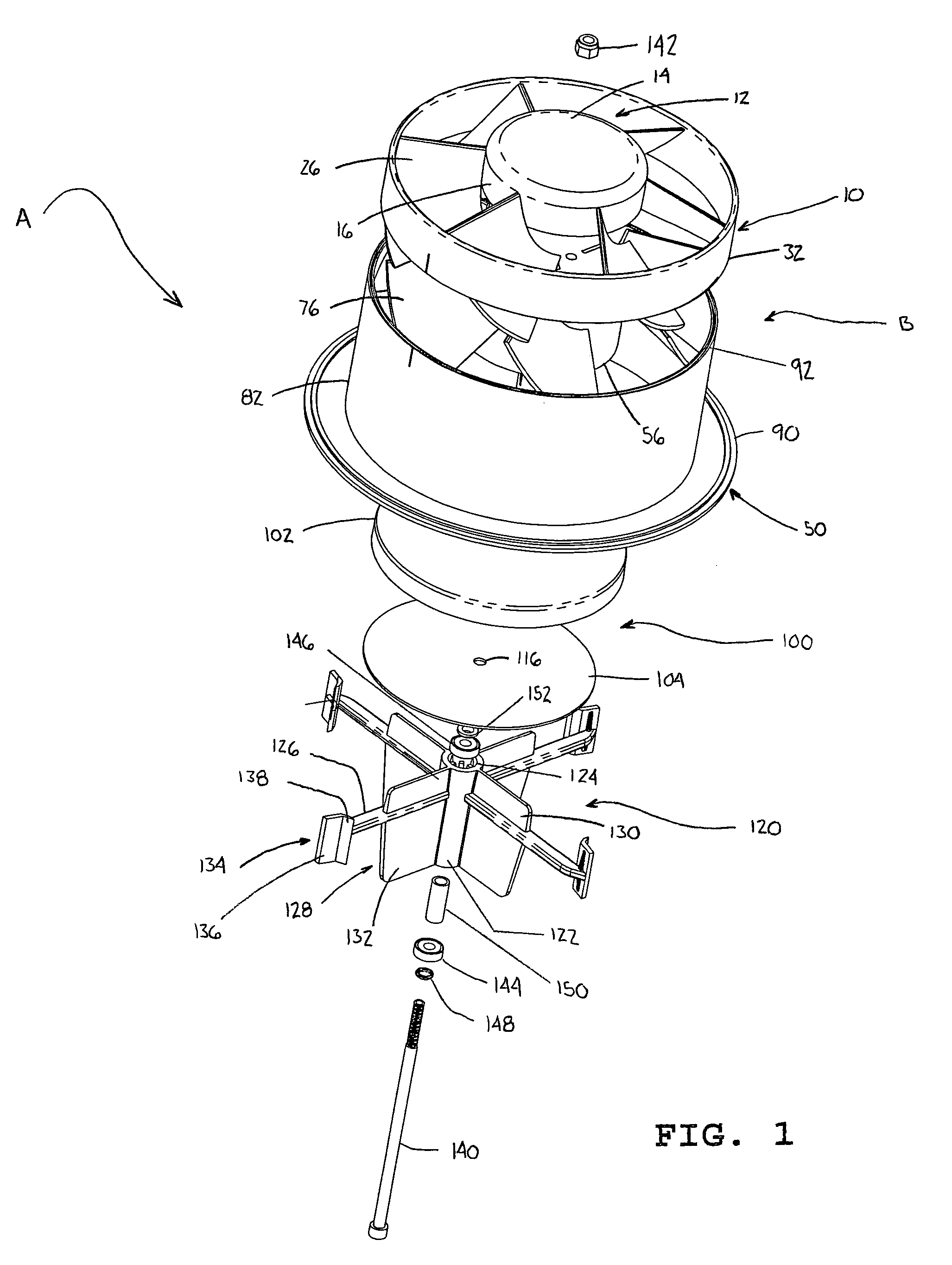

Inlet vane for centrifugal particle separator

A centrifugal particle separator includes a first vane assembly and a second vane assembly. The first vane assembly includes a centrally positioned hub, a collar encircling the hub and a plurality of first vanes. Each first vane can have an inner end connected to the hub and an outer end connected to the collar, wherein a trailing edge of at least one of the plurality of first vanes can extend past an edge of the collar. The second vane assembly includes a centrally positioned hub, a collar encircling the hub and a plurality of second vanes circumferentially disposed about the hub. Each second vane can have an inner end connected to the hub and an outer end connected to the collar, wherein a leading edge of at least one of the plurality of second vanes can extend past an edge of the collar. When the first and second vane assemblies are secured together, at least one of the plurality of first vanes protrudes into the second vane assembly.

Owner:DREISON INT

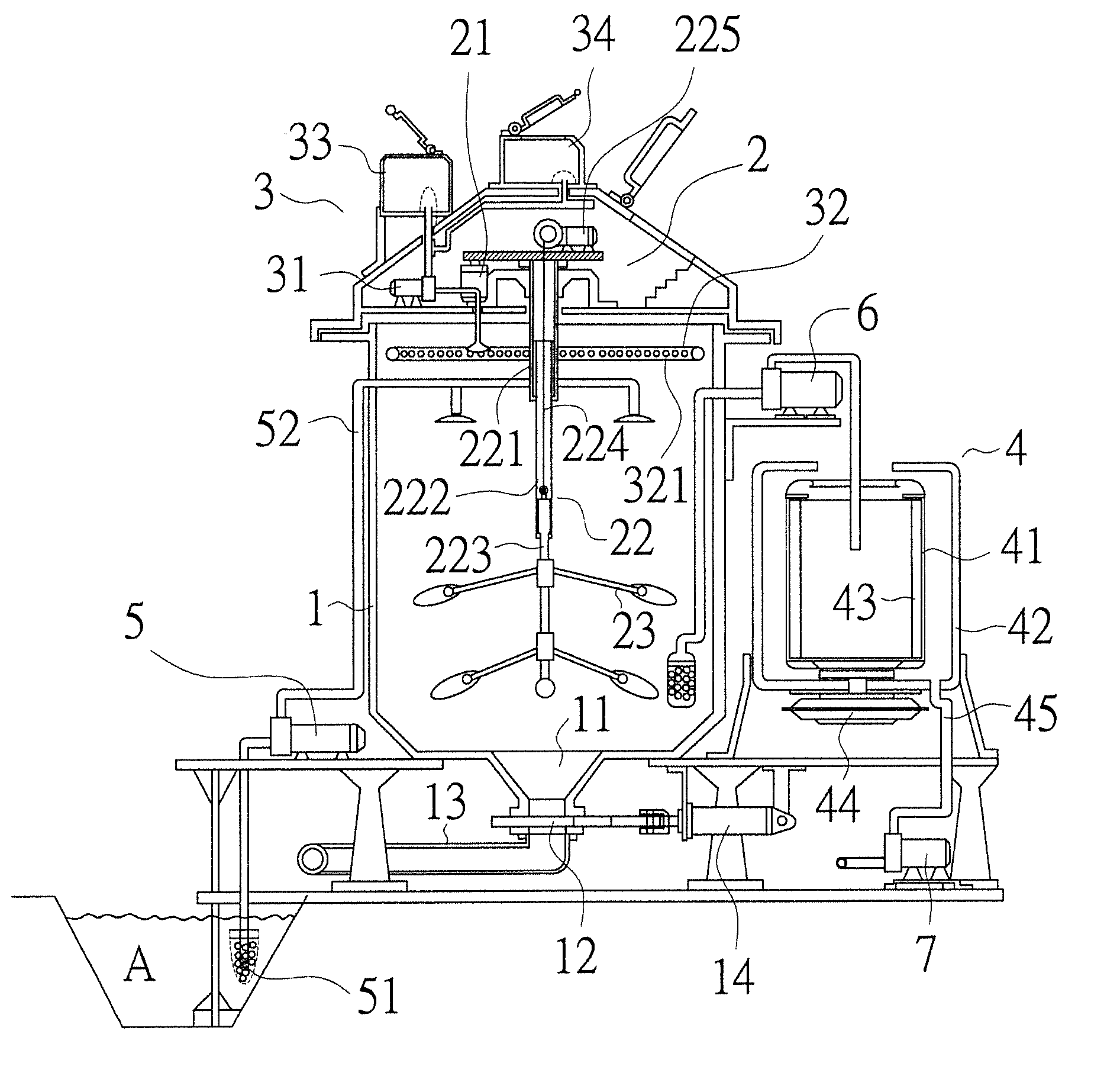

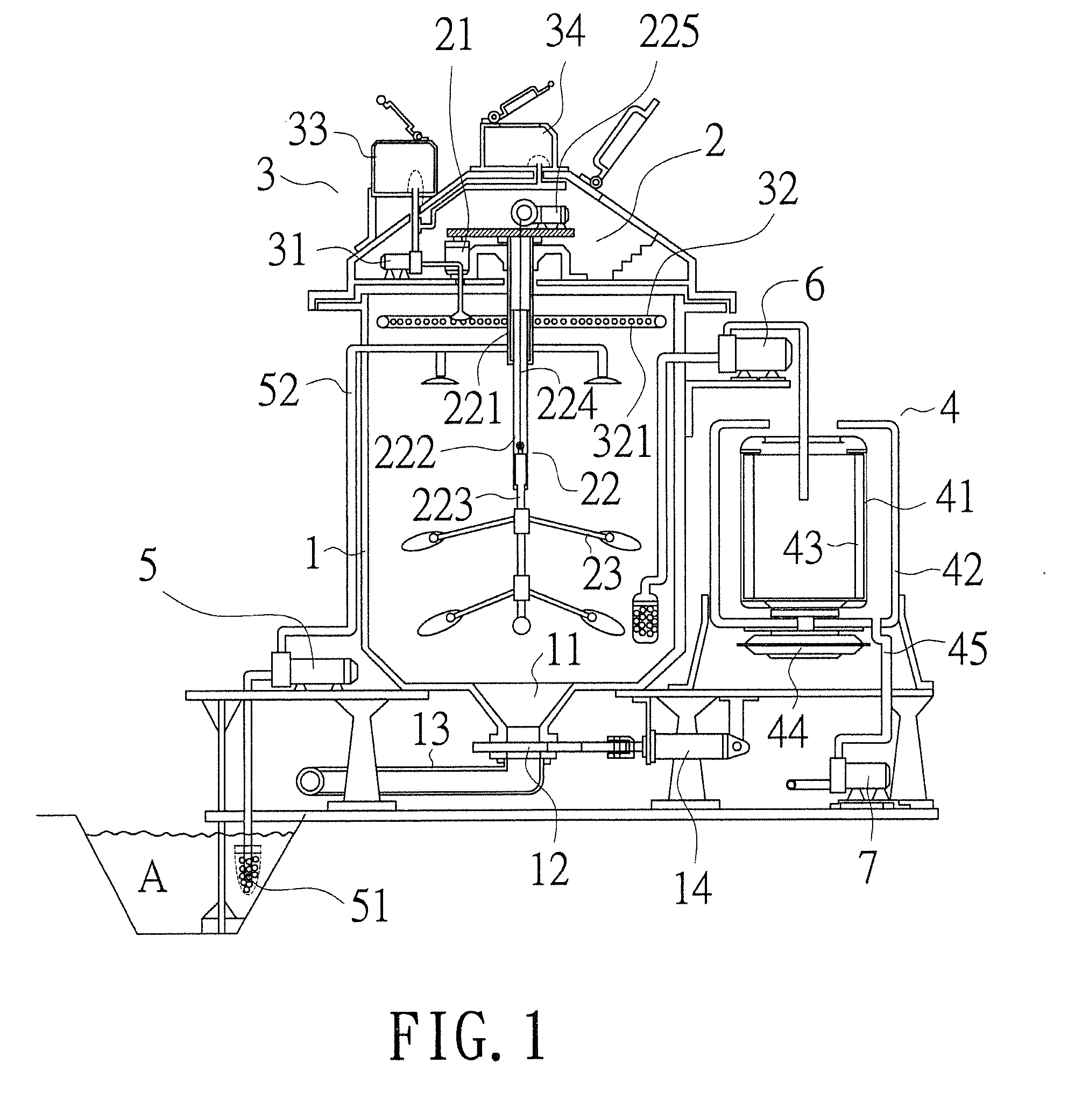

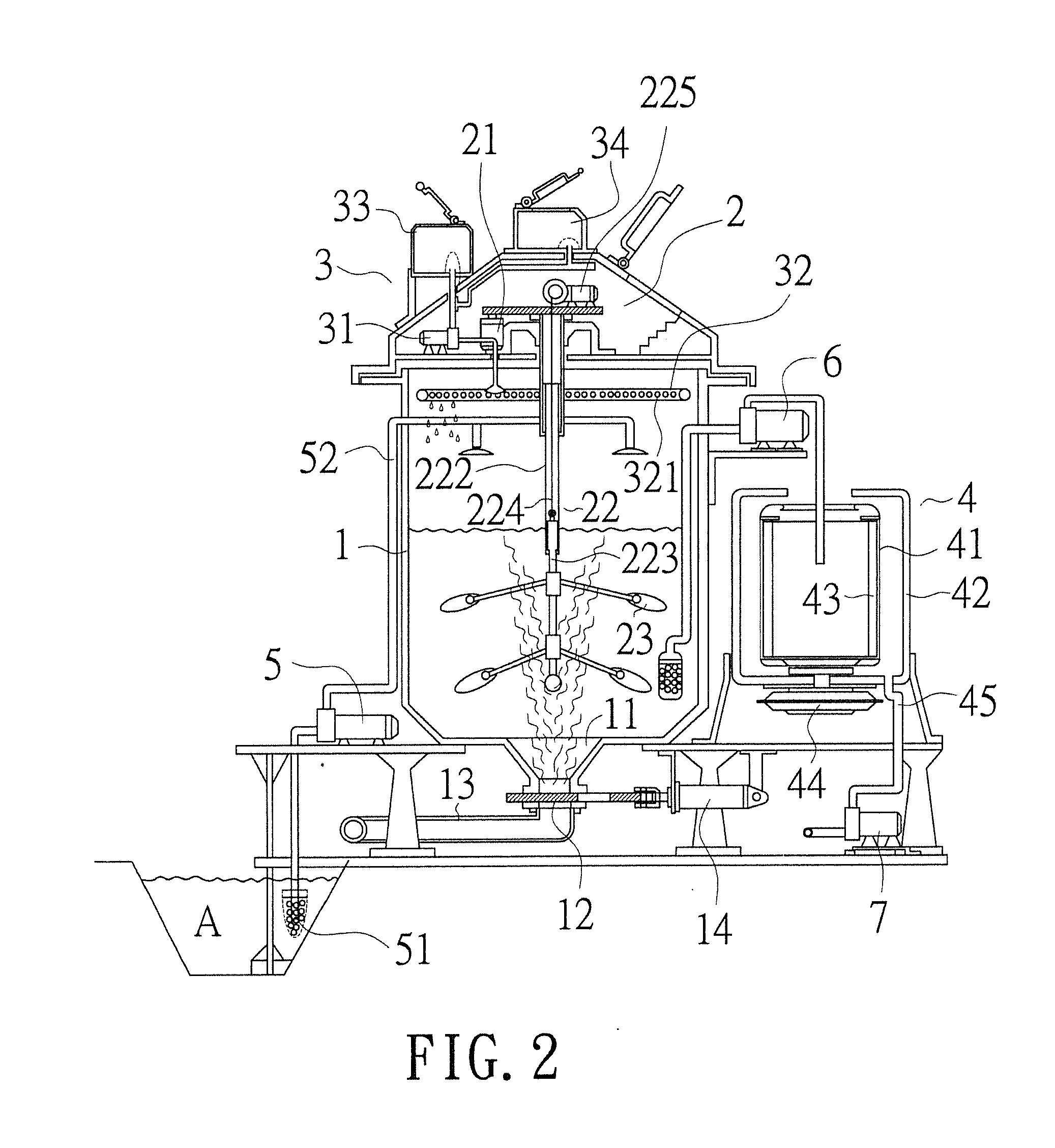

Sewage treatment system

ActiveUS20110226683A1Promote coagulationPromote flocculationWater/sewage treatment by centrifugal separationOther chemical processesComing outCentrifugation

A sewage treatment system is revealed. Water with contaminants is drawn from sources to the sewage treatment system for automatic and fast water purification. Thus clean drinking water is generated. The water with contaminants is sent to a treatment tank by a motor. Then non-toxic and odorless chemicals are sprayed in the treatment tank. By stirring and mixing of movable blades, the contaminants are coagulated and precipitated into a funnel under the treatment tank to be discharged. Next clean water in the treatment tank is sent to a centrifuge separator to be filtered and dehydrated by centrifugation. Water comes out from the centrifuge separator is drinking water. The sewage is converted into clean water. The system can provide clean safe drinking water to regions without water treatment plants.

Owner:RICHARD CHI HSUEH

Centrifugal separator

ActiveUS20100011723A1Evenly distributedImprove pumping capacityDispersed particle separationRotary centrifugesParticulatesProduct gas

The invention relates to a centrifugal separator for cleaning of gas from solid or liquid particles suspended therein which are of greater density than the gas. A main object of the present invention is to accomplish a centrifugal separator which does not have said inactive regions and thereby achieves efficient separation of particulate contaminants from a gas. This object is achieved by the centrifugal separator initially defined, which is characterised in that the interspaces between the separation discs at least at their radially outer parts are substantially open for flow of the gas in the circumferential direction and that mutually adjacent separation discs are arranged at mutual spacing such that rotation of the rotor causes a pumping action in the interspaces, which pumping action drives the gas from the gas inlet, through the interspaces between the separation discs and out via the gas outlet.

Owner:ALFA LAVAL CORP AB

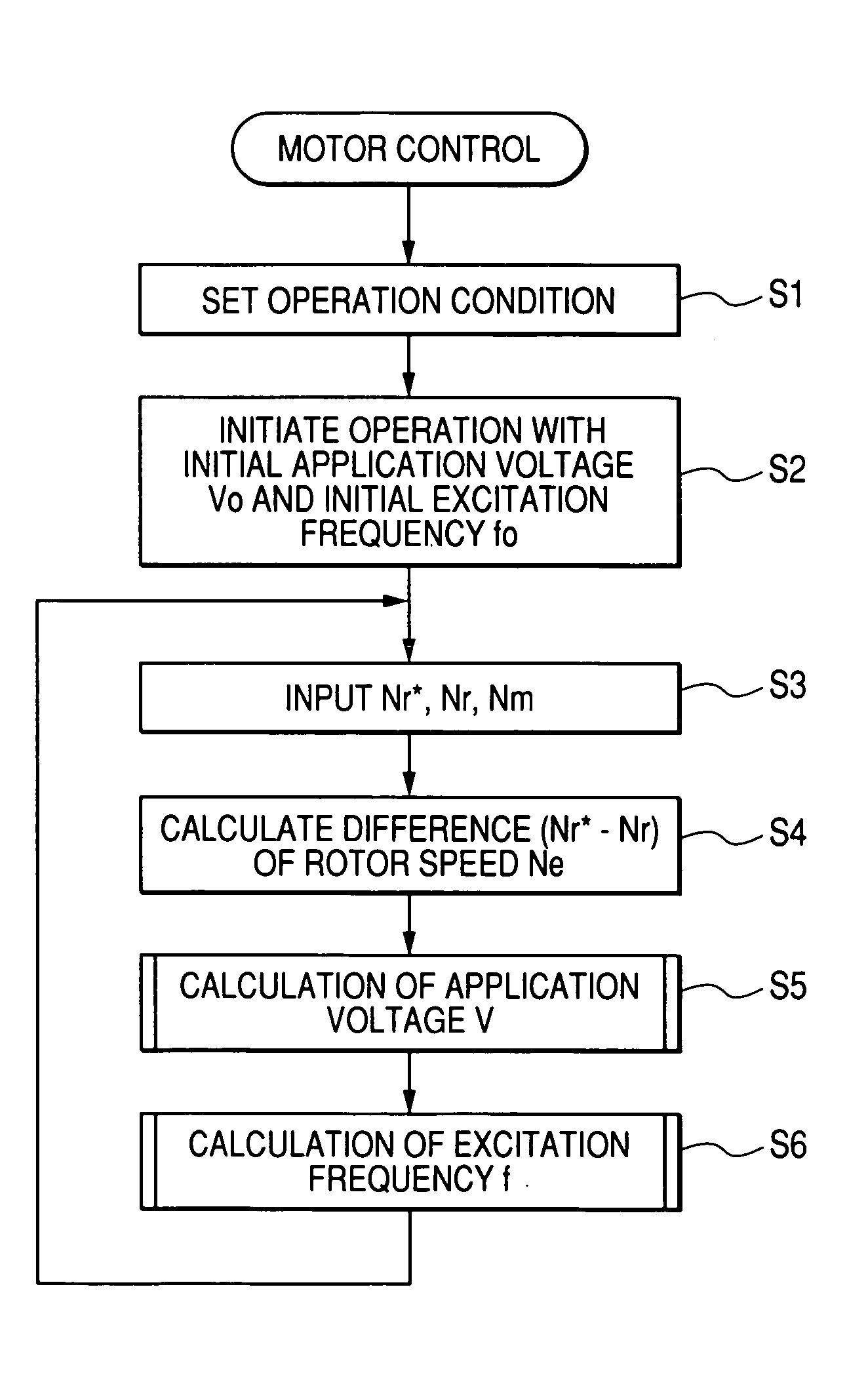

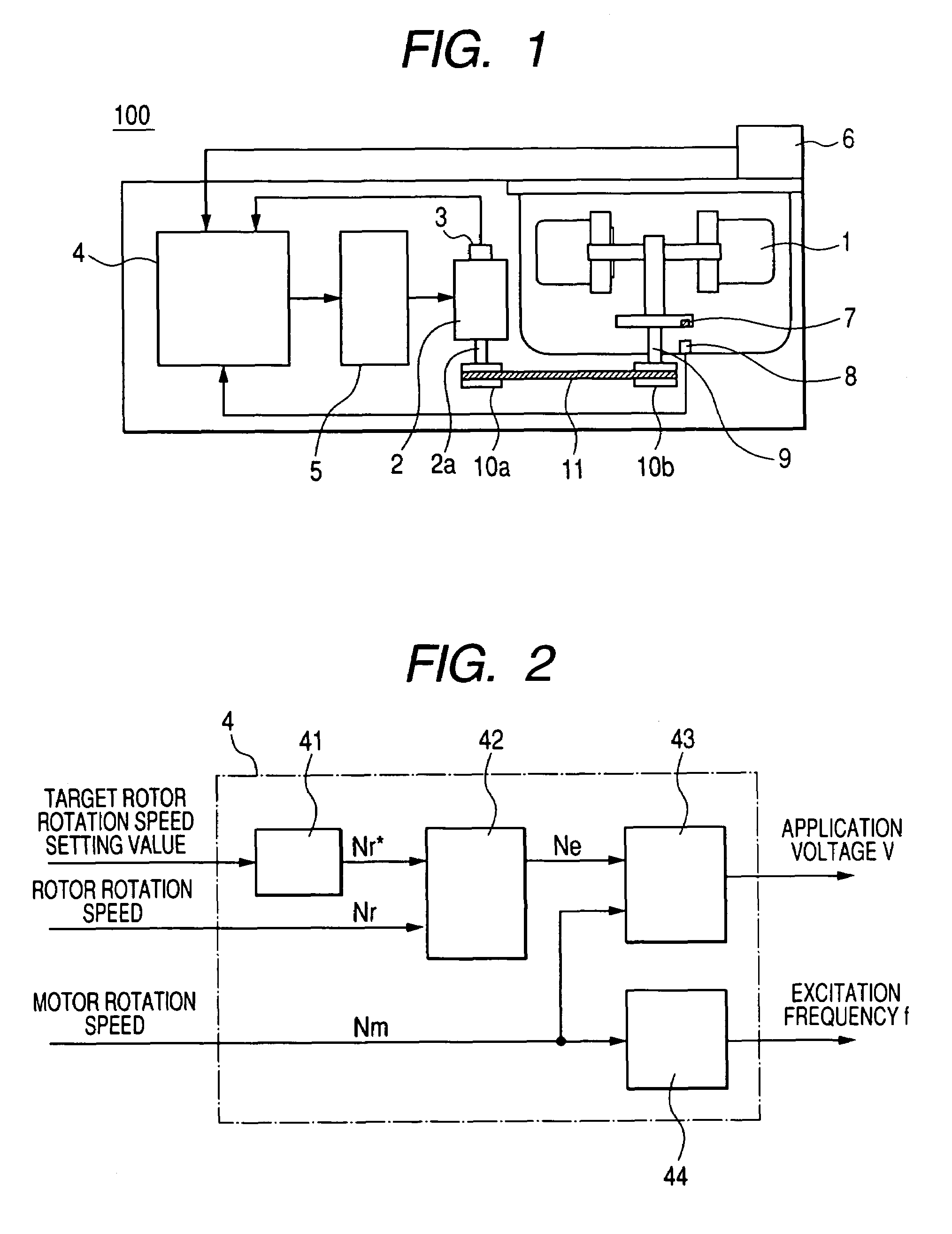

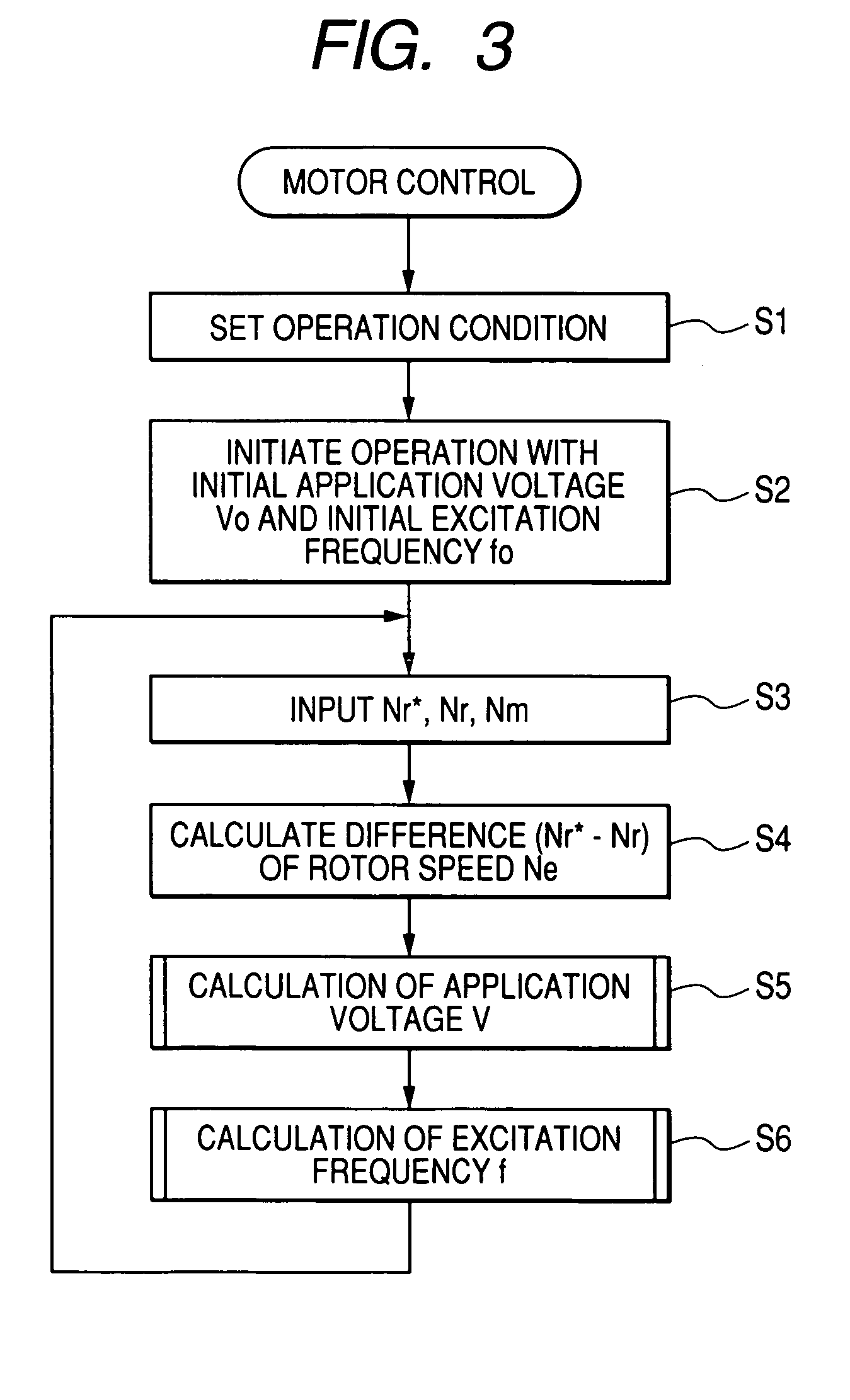

Centrifuge

InactiveUS7548034B2Easy to controlSingle motor speed/torque controlField or armature current controlMotor speedCentrifuge

A centrifuge including: a rotor rotating with a sample contained therein; a rotating shaft rotatably engaged with the rotor; a motor rotating the rotor and the rotating shaft; a belt transmitting rotational force of the motor to the rotating shaft; a rotor speed detecting unit detecting a rotation speed of the rotor; a motor speed detecting unit detecting a rotation speed of the motor; and a control unit controlling the motor, wherein the control unit calculates a signal for controlling the rotation speed of the rotor on the basis of a signal from the rotor speed detecting unit and controls the motor on the basis of a signal from the motor speed detecting unit and the calculated signal.

Owner:KOKI HLDG CO LTD

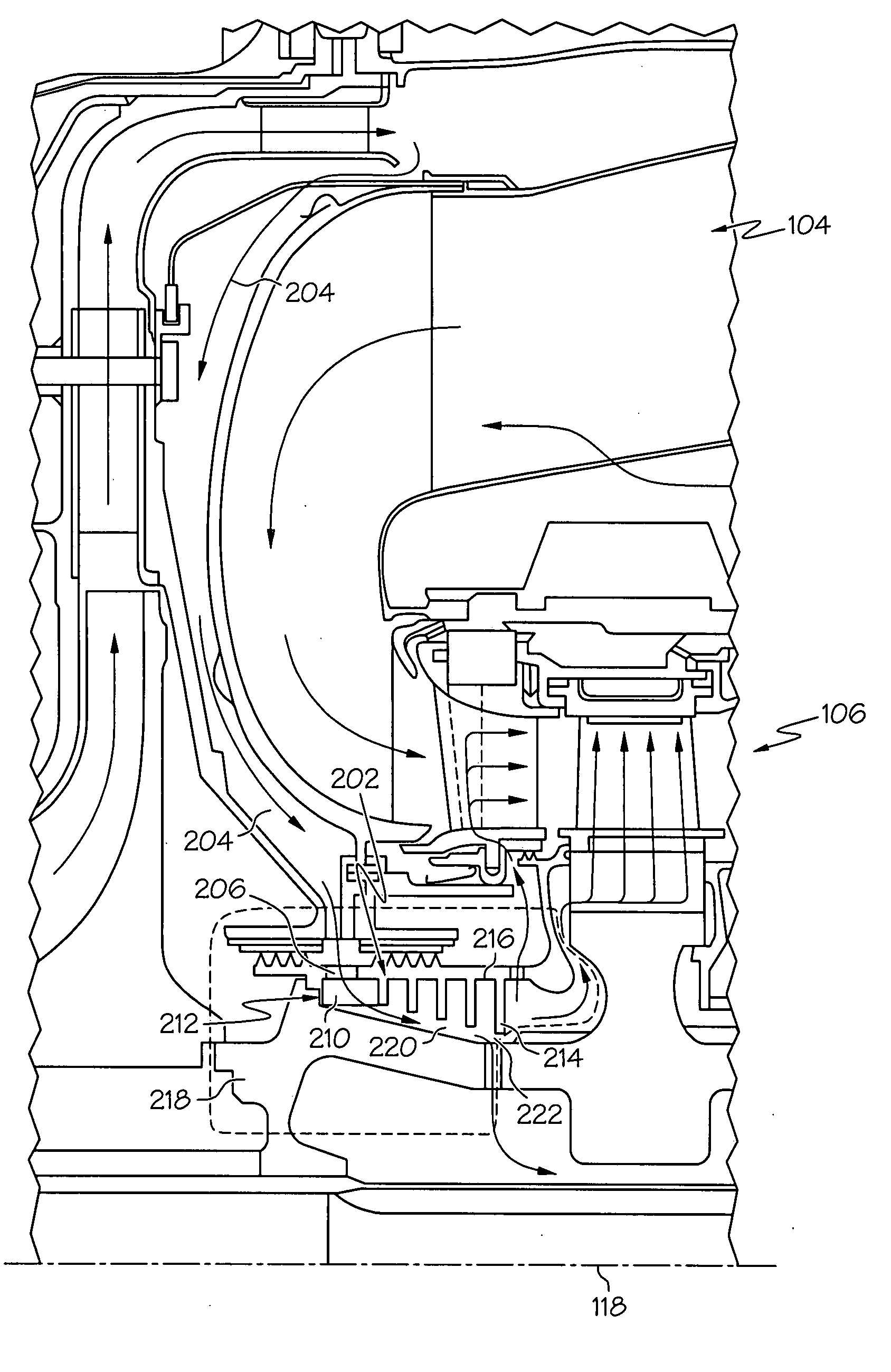

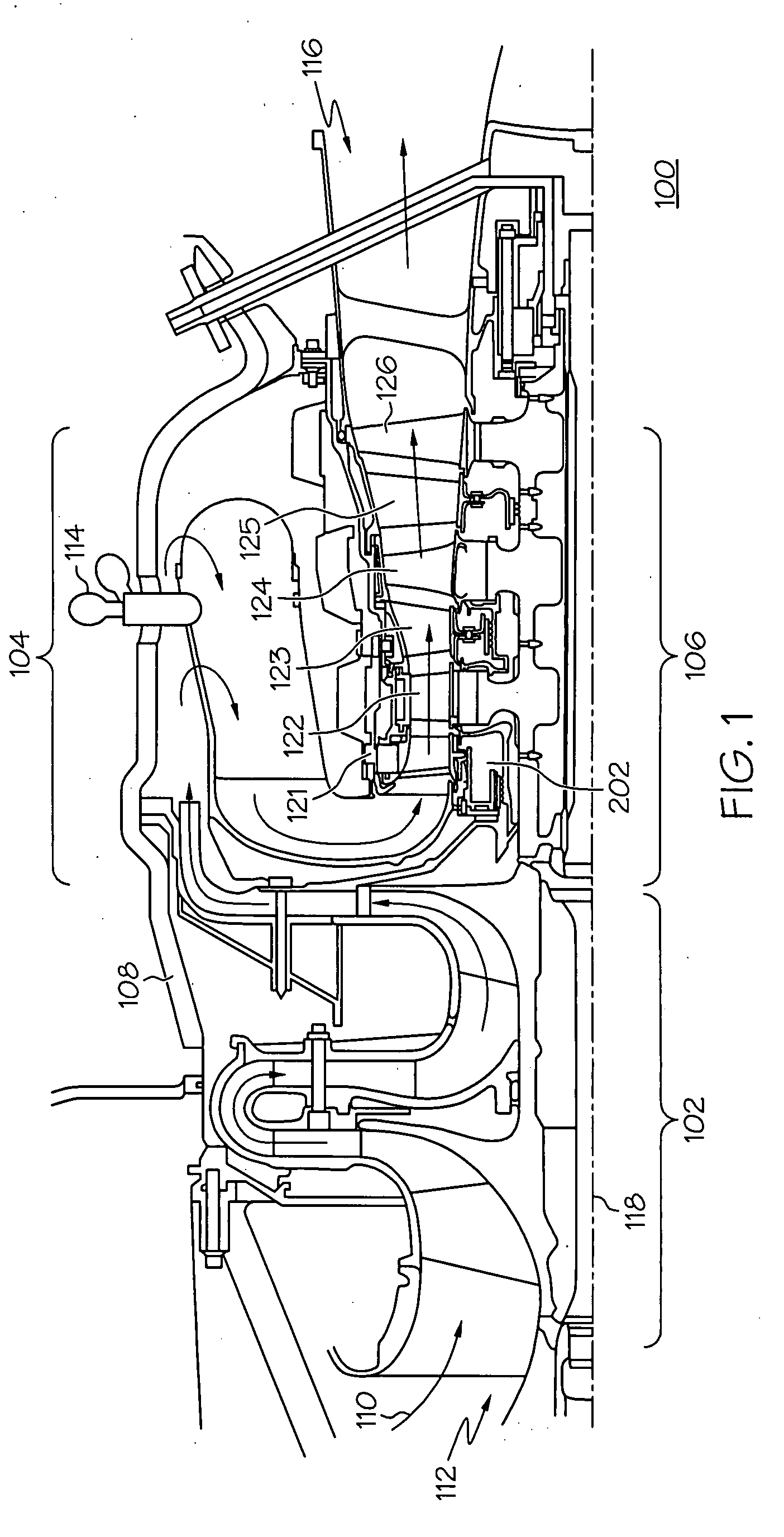

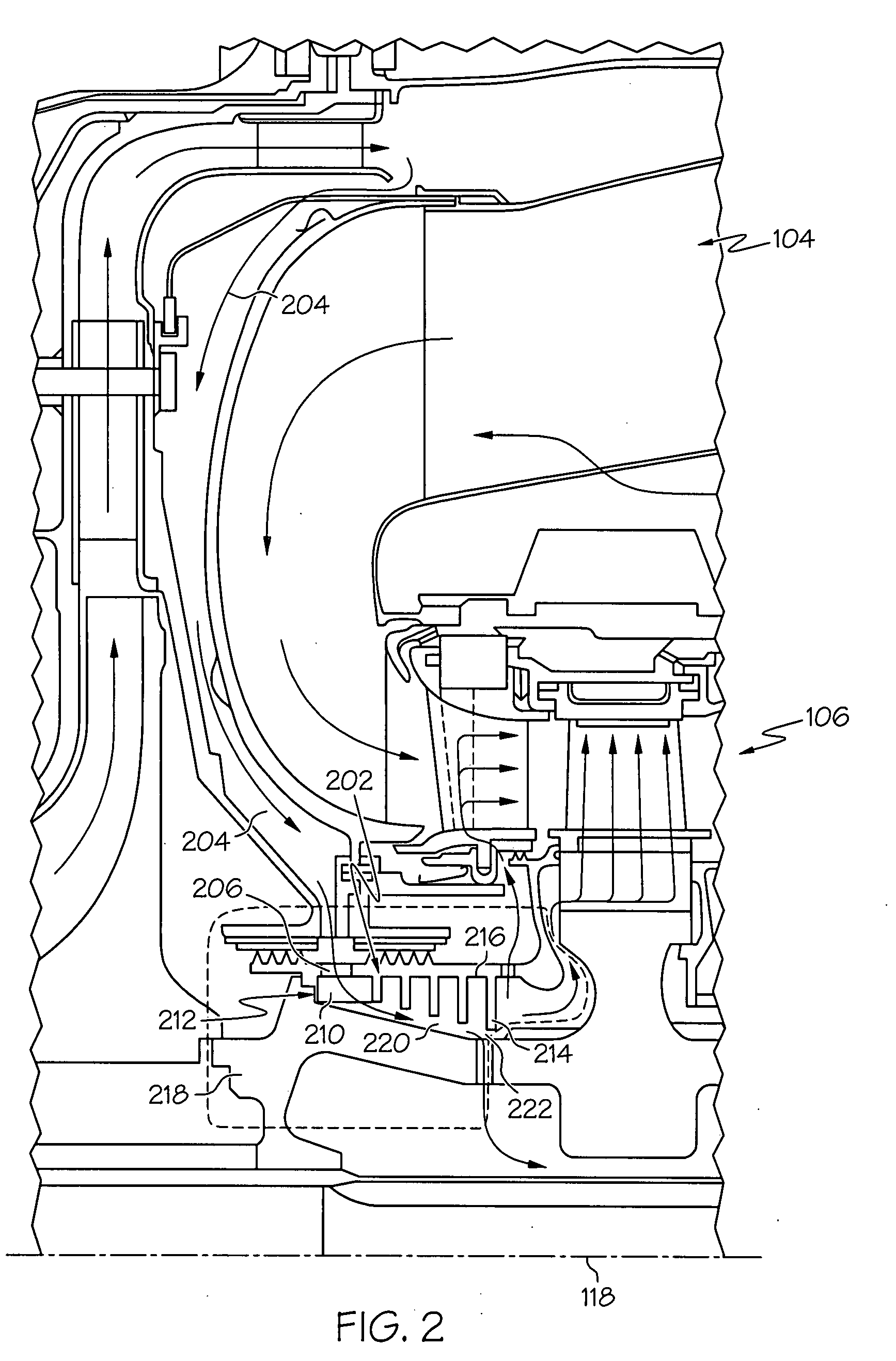

Turbine cooling air centrifugal particle separator

InactiveUS20080310951A1Efficient removalReduce the overall diameterPump componentsEngine fuctionsTurbine bladeCoupling

A centrifugal particle separator (202) is provided for removing particles such as dust particles from the compressed airflow (110) prior to reaching and cooling the turbine blades (122, 124, 126) of a turbine engine (100). A particle separator structure (208) has a side facing the axis (118) about which it rotates, the side including a plurality of pocket dividers (214) defining a plurality of pockets (216), and further defining an entrance cavity (206) for receiving the compressed air (110) containing particles. An inner flowpath coupling (218) includes a side opposed to the axis (118) that is positioned adjacent the particle separator structure (208) to define an airflow path (220) having an entrance communicating with the entrance cavity (212) and an exit (222), wherein the diameter (226) of the airflow outer flowpath (224) decreases from the entrance to the exit, and wherein a centrifugal force created by the centrifugal particle separator assembly (202) rotating around the axis (118) and the decreasing diameter (226) of the airflow path (224) which accelerates the rotational velocity of the air, forces the particles (228) to collect within the plurality of pockets (216) and the remaining compressed air is provided to cool turbine blades (122, 124, 126). A plurality of optional air accelerator fins (210) may be positioned within the entrance cavity (212). The combination of quickly accelerating air from non-rotating to rotating velocity, for example, by accelerator fins (210), and further subjecting the air and entrained particles to increasing rotational velocity resulting in an increasing centrifugal force field as particles (228) progress from the entrance (212) to the exit (222) of the separator assembly (202), efficiently removes the particles (228) from the air.

Owner:HONEYWELL INT INC

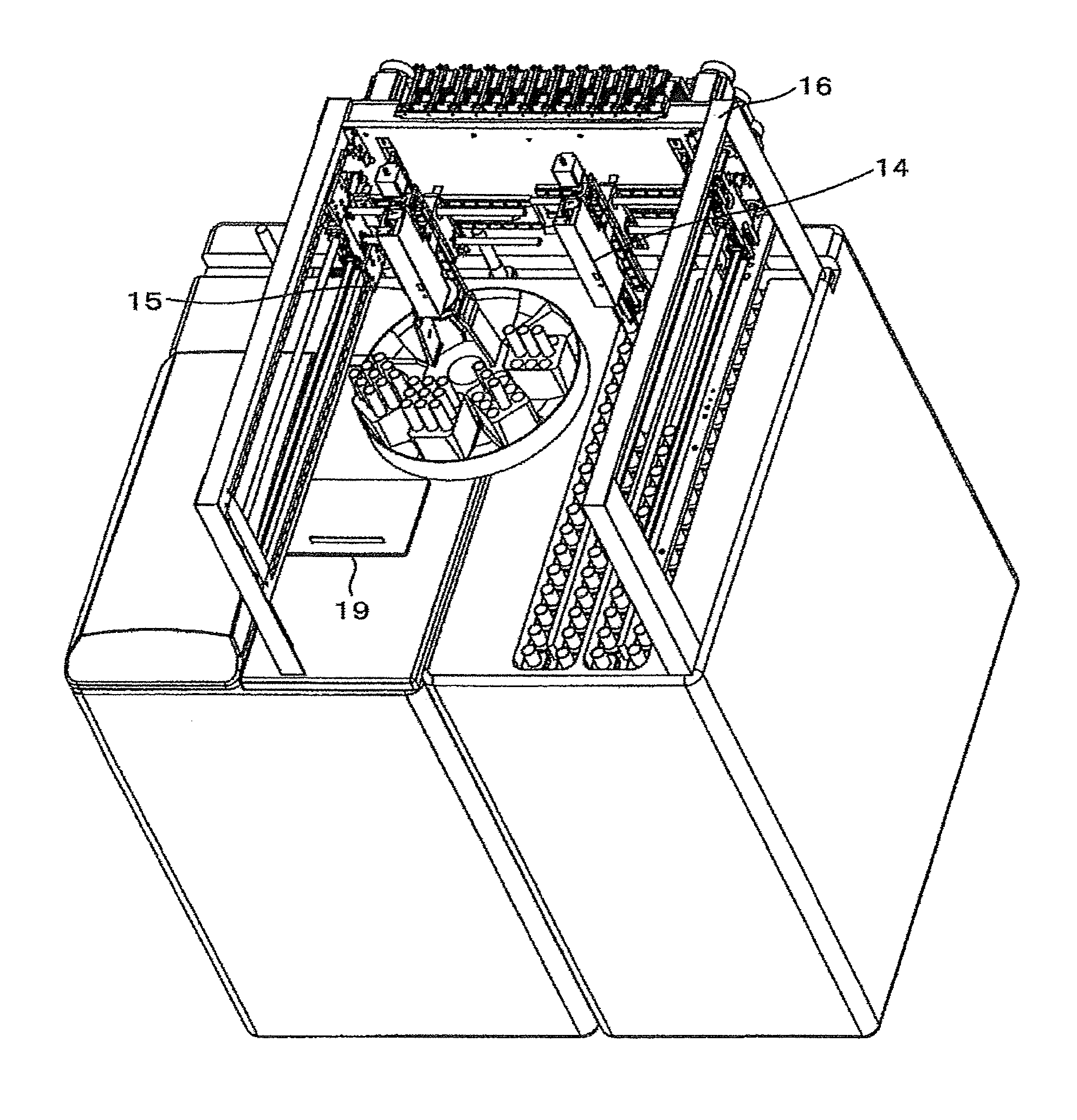

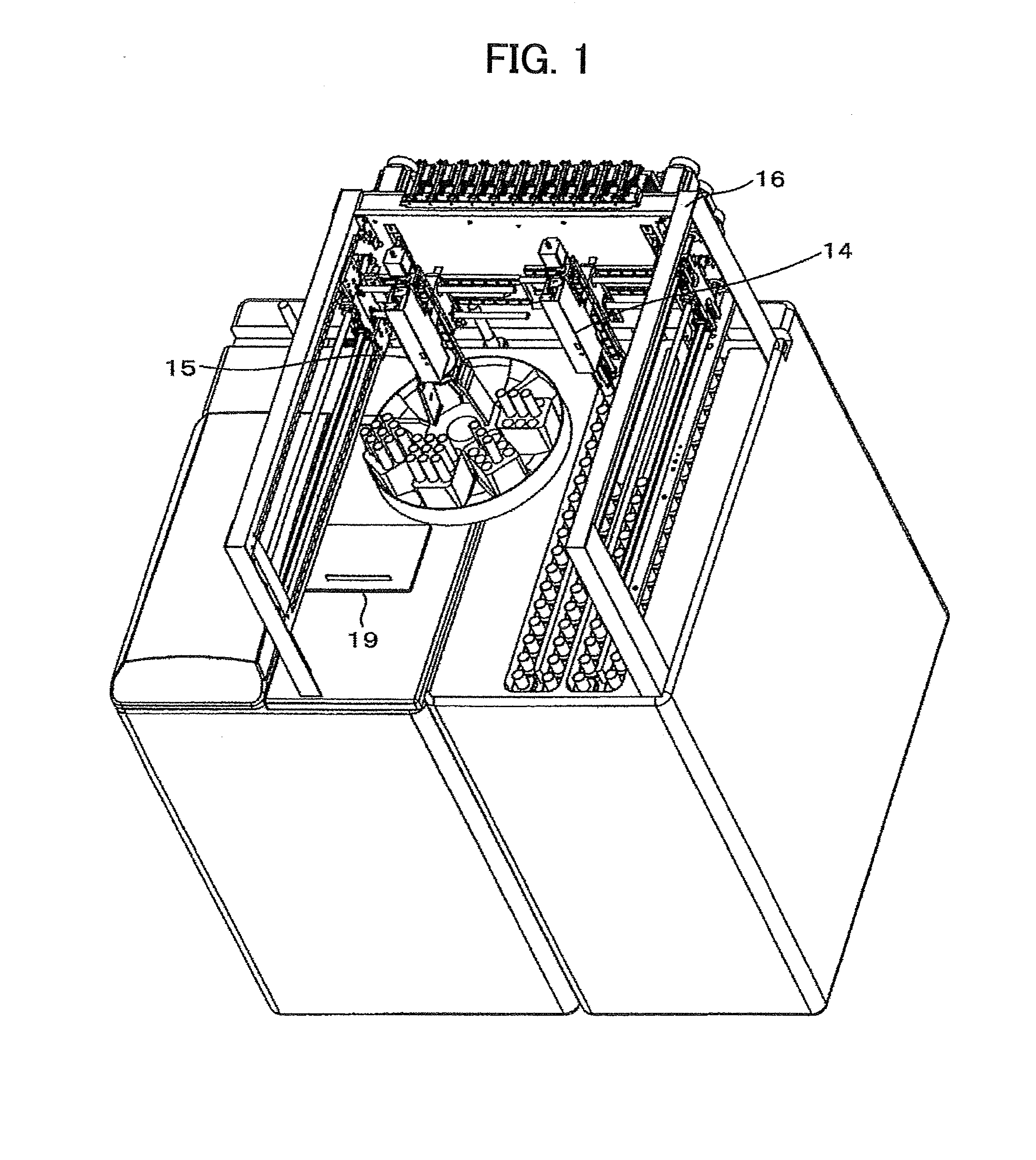

Method And Apparatus For Preparing Platelet Rich Plasma And Concentrates Thereof

ActiveUS20100206798A1Shaking/oscillating/vibrating mixersTransportation and packagingHollow fibreFiber

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

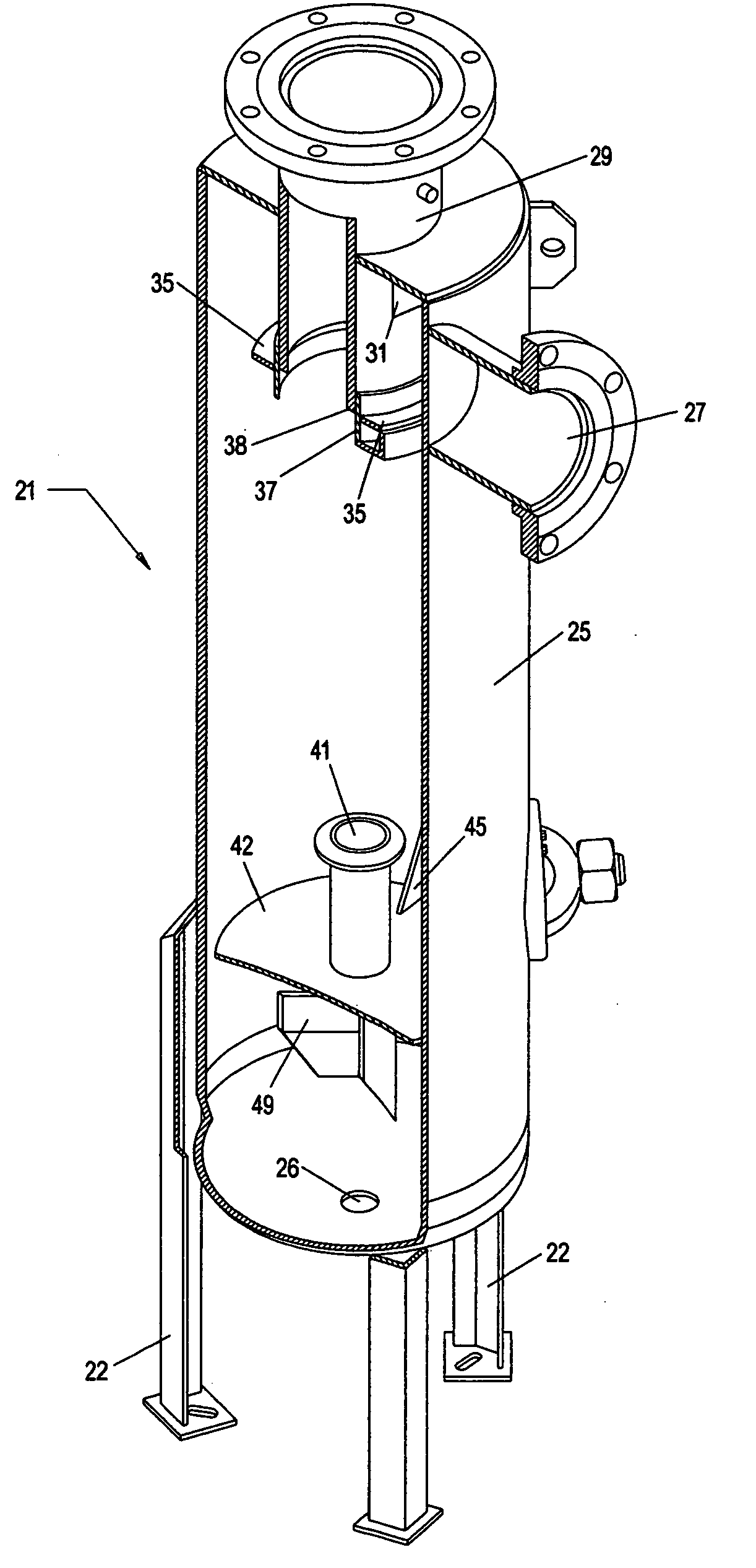

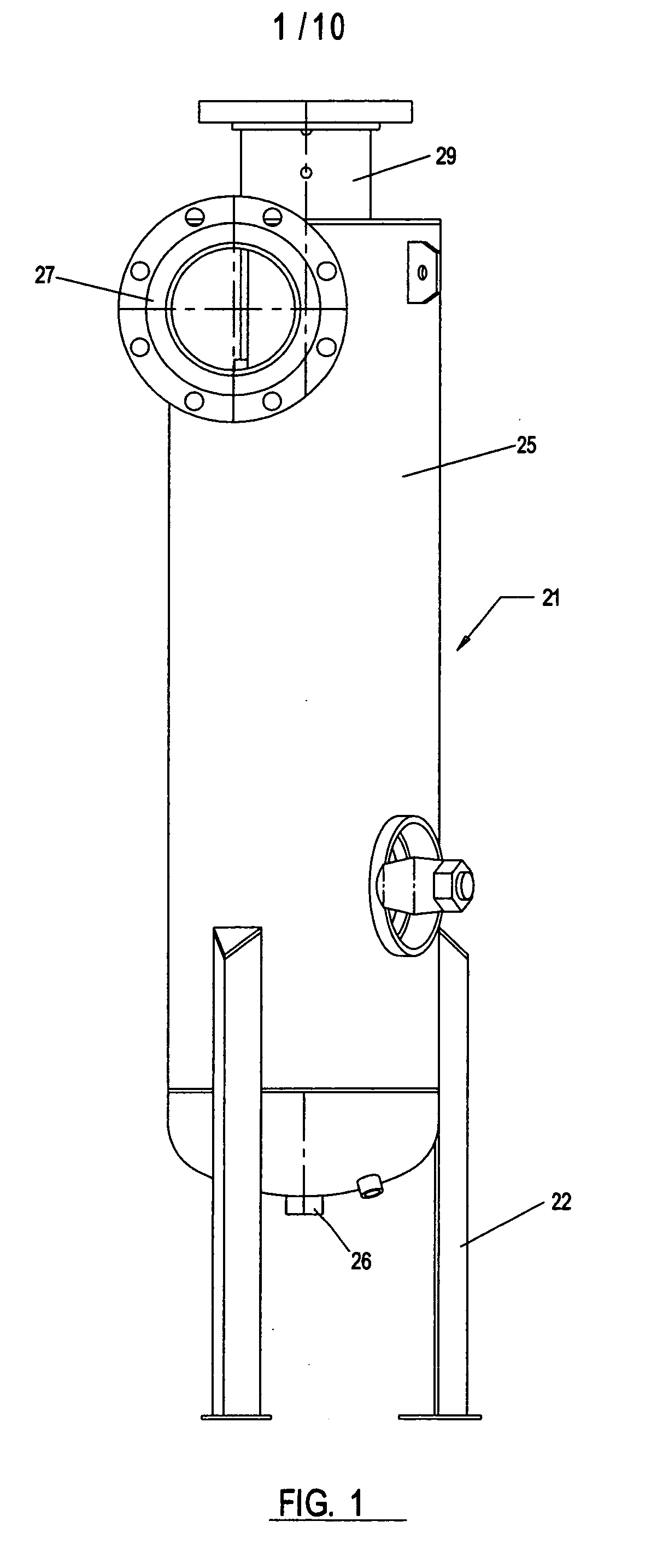

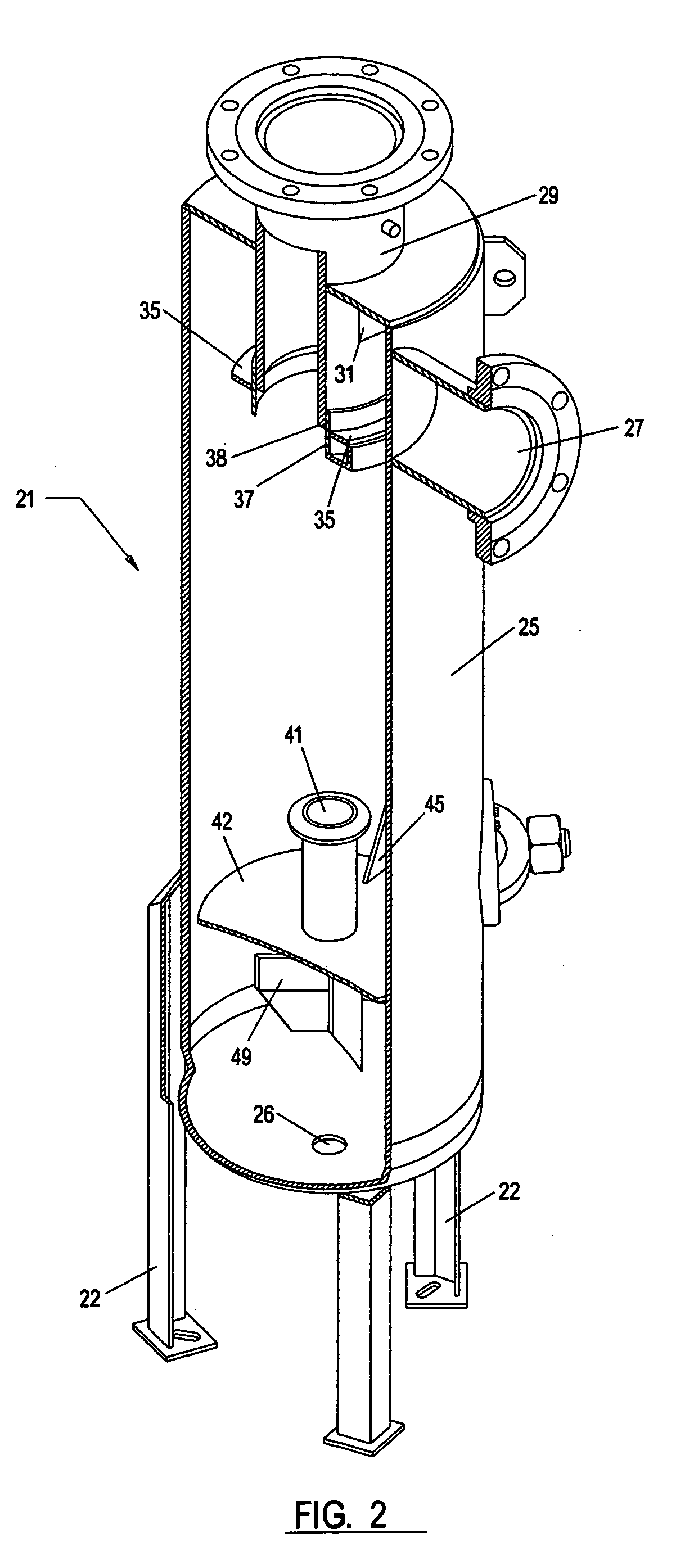

Dual stage centrifugal liquid-solids separator

InactiveUS7025890B2Reduce cavitationEasy to disassembleWater/sewage treatment by centrifugal separationLiquid degasificationDual stageSpins

Disclosed is a vortex-based centrifugal separator for removing solids from a liquid / solids fluid stream in two stages. A fluid stream under pressure is introduced at the top of the cylindrical separator at a tangential angle forming helical downward flow. The first stage uses a centrally-located spin plate for reversing the cleaner interior flow of the vortex back upward, while the heavier solids settle at the bottom of the chamber for periodic removal. In the second stage, a plurality of louvered slots in an upper discharge pipe remove finer solids from the exiting upward fluid flow prior to discharge.

Owner:GRISWOLD CONTROLS LLC

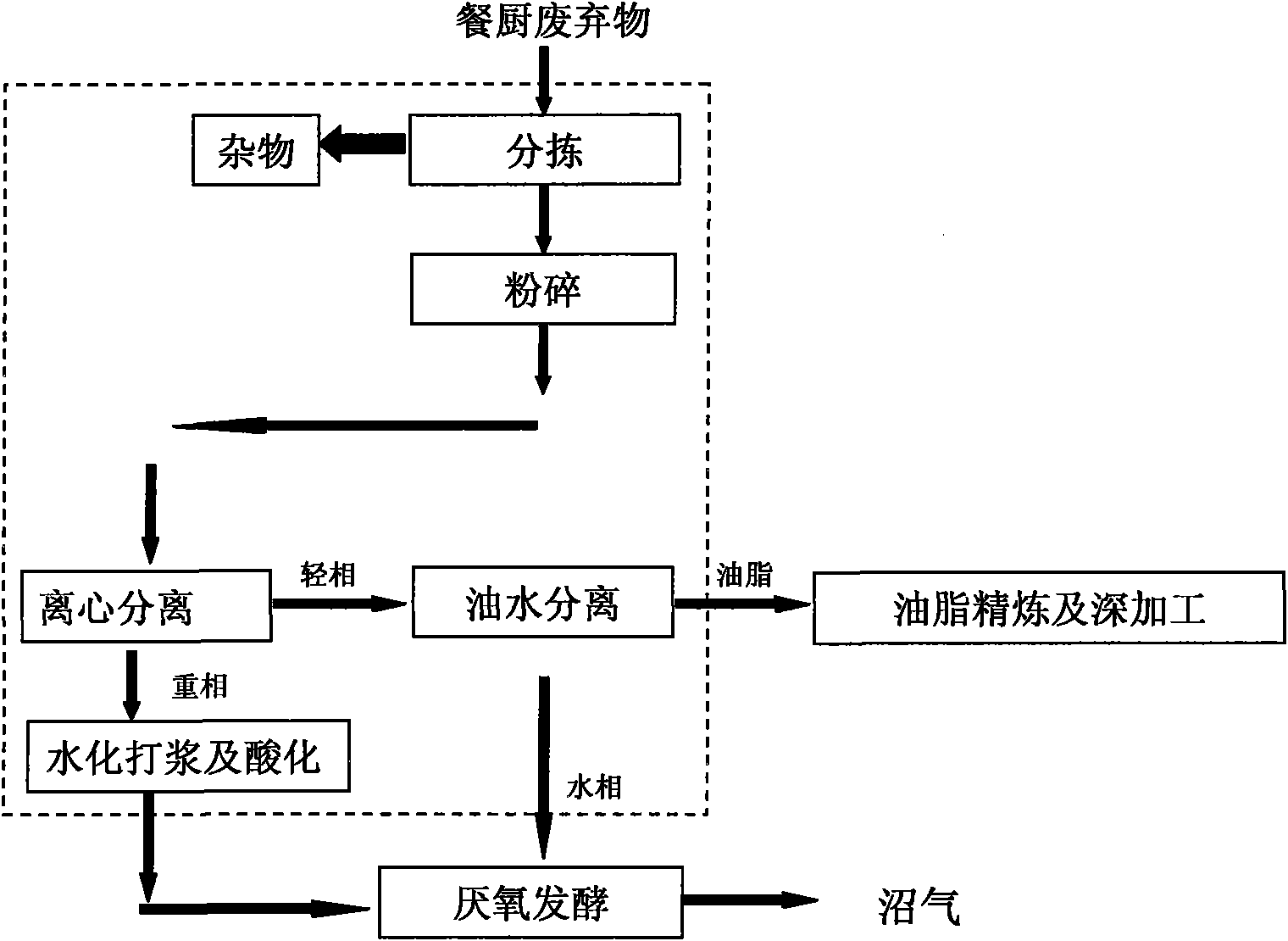

Kitchen waste disposal method

ActiveCN101921809AIncrease contentIncrease load factorWaste based fuelFermentationHigh concentrationSlurry

The invention relates to a kitchen waste disposal method which is characterized by comprising the following steps of: (1) sorting and removing impurities; (2) crushing a mixture the particle diameter of which is not greater than 8mm; (3) centrifugally separating to obtain a light phase and a heavy phase; (4) centrifugally separating the light phase into grease and a high-concentration solution; (5) hydrating for pulping and acidifying: carrying out water mill on the heavy phase and the high-concentration solution to prepare dense slurry and carrying out hydrolysis acidification on the dense slurry to obtain ground masses; and (6) carrying out anaerobic fermentation in an upflow anaerobic sludge bed to obtain methane. Compared with the prior art, the invention mainly improves the content of organic matter in the materials and greatly reduces the biogas residue yield through sorting, impurity removal and crushing; the grease which is not easy to acidified is removed through the centrifugal separation process and the oil and water separation process, which is beneficial to carrying out anaerobic fermentation; the insoluble organic matter is gradually converted into solvable organic matter through the hydration pulping process and the hydrolysis acidification process, and thereby, the anaerobic fermentation gas yield is improved, the sludge load factor is high and the biogas residue yield is very low.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

Processing method of sea cucumber glycopeptides chelated calcium

The invention relates to a processing method of sea cucumber glycopeptides chelated calcium. The method comprises the following steps: A. material treatment: cleaning sea cucumber mouthparts, cooking, soaking, beating, and homogenizing; B. biological enzymatic hydrolysis: choosing a variety of protease for composite segmented enzymatic hydrolysis; C. centrifugal separation: conducting continuous centrifugal separation on an enzymolysis liquid to obtain the sea cucumber glycopeptides solution and sea cucumber calcium precipitate; D. filtration, concentration and grading: subjecting the enzyme liquid to ultrafiltration fractionation concentration, and desalinating small peptide filtered solution by nanofiltration; E. preparation of sea cucumber calcium by organic acidolysis; G. chelating reaction: promoting the chelating of sea cucumber calcium and glycopeptides of sea cucumber by microwave assistance; and H. after the reaction, carrying out centrifuging separation, and drying the precipitate and supernatant respectively. The present invention comprehensively utilizes the sea cucumber processing waste to prepare sea cucumber autologous calcium and autologous glycopeptides for chelation. The method on the one hand is beneficial to playing their biological effects, and on the other hand can also obtain five products with different specific biological functions.

Owner:烟台参福元海洋科技有限公司

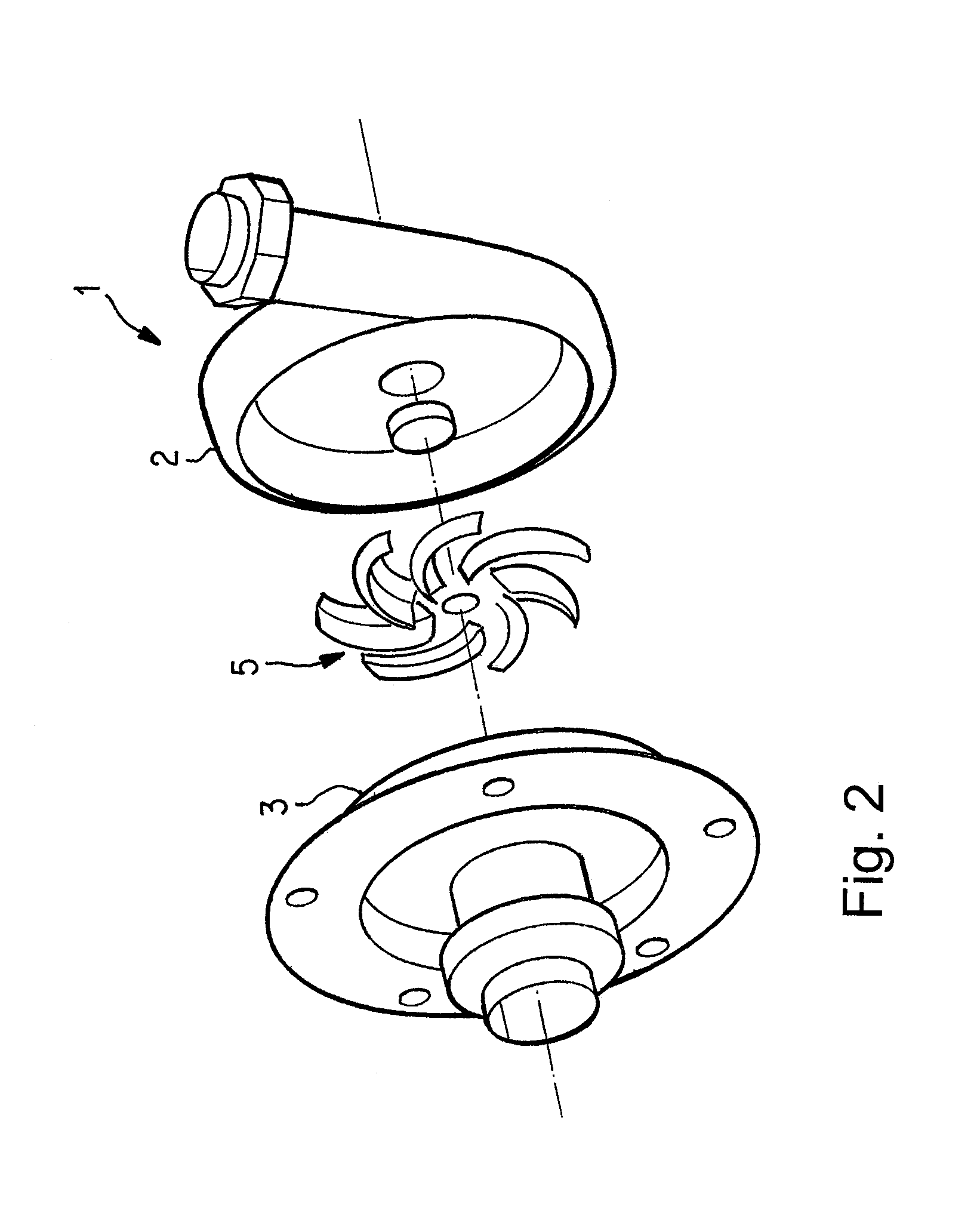

Centrifugal oil separator

InactiveUS7445653B2Minimized pressure dropCombination devicesLiquid degasificationImpellerEngineering

Owner:MANN HUMMEL GMBH

Centrifugal separator having a rotor and driving means thereof

InactiveUS7022150B2Available spaceEfficient use ofCombination devicesAuxillary pretreatmentRotational axisTurbine blade

In a centrifugal separator, the rotor of which is adapted to be driven by means of a gaseous driving fluid, the rotor itself supports a ring of turbine blades extending around the rotational axis of the rotor. A stationary nozzle is adapted to direct a flow of the driving fluid towards the ring of turbine members. After the driving fluid has passed between the turbine blades and has influenced them for driving of the centrifugal rotor, it enters a reversing chamber formed by a stationary reversing member. In the reversing chamber the driving fluid is caused to change its direction and is then conducted again towards the ring of turbine members in order to be utilized a second time for driving of the centrifugal rotor.

Owner:ALFA LAVAL CORP AB

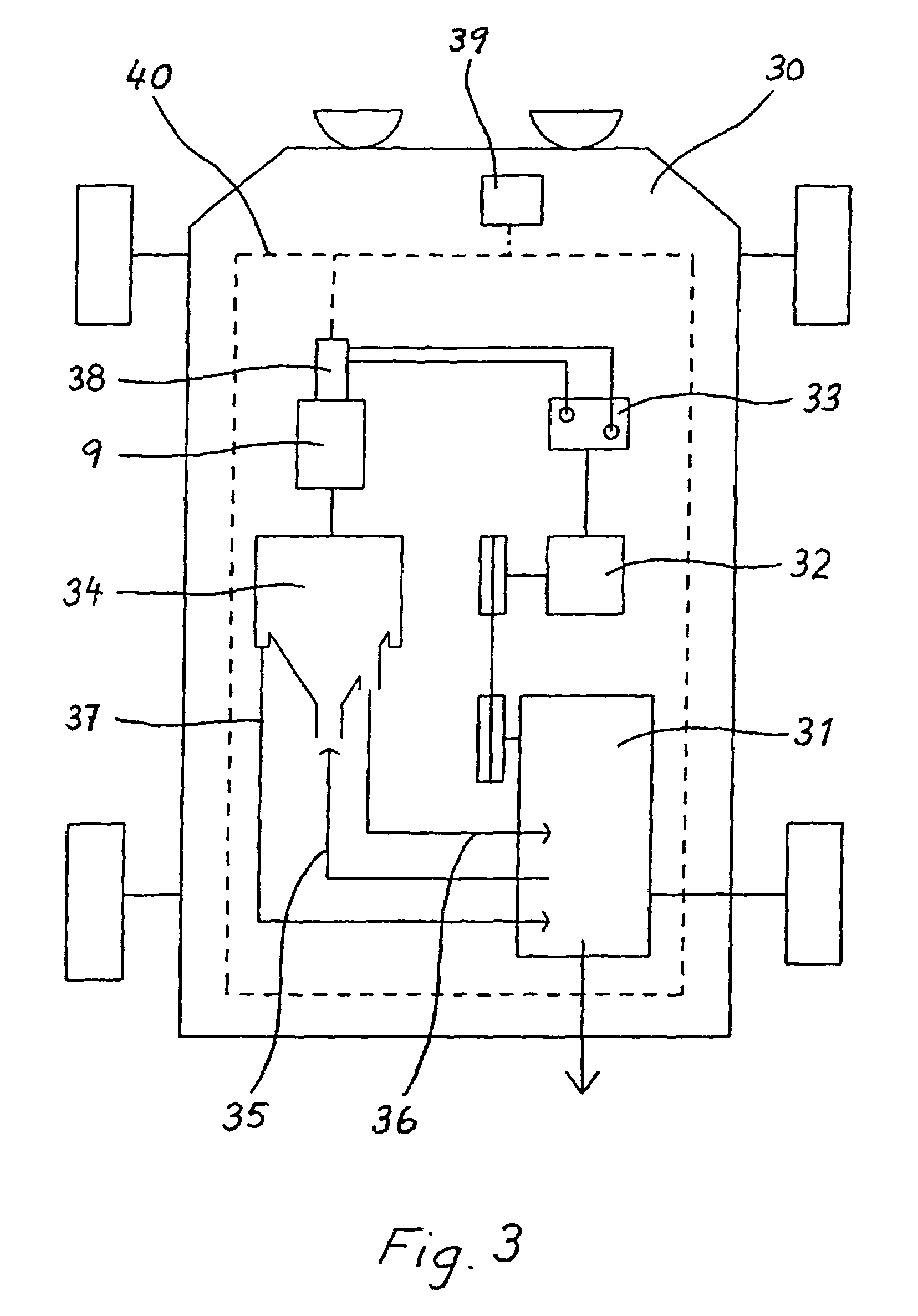

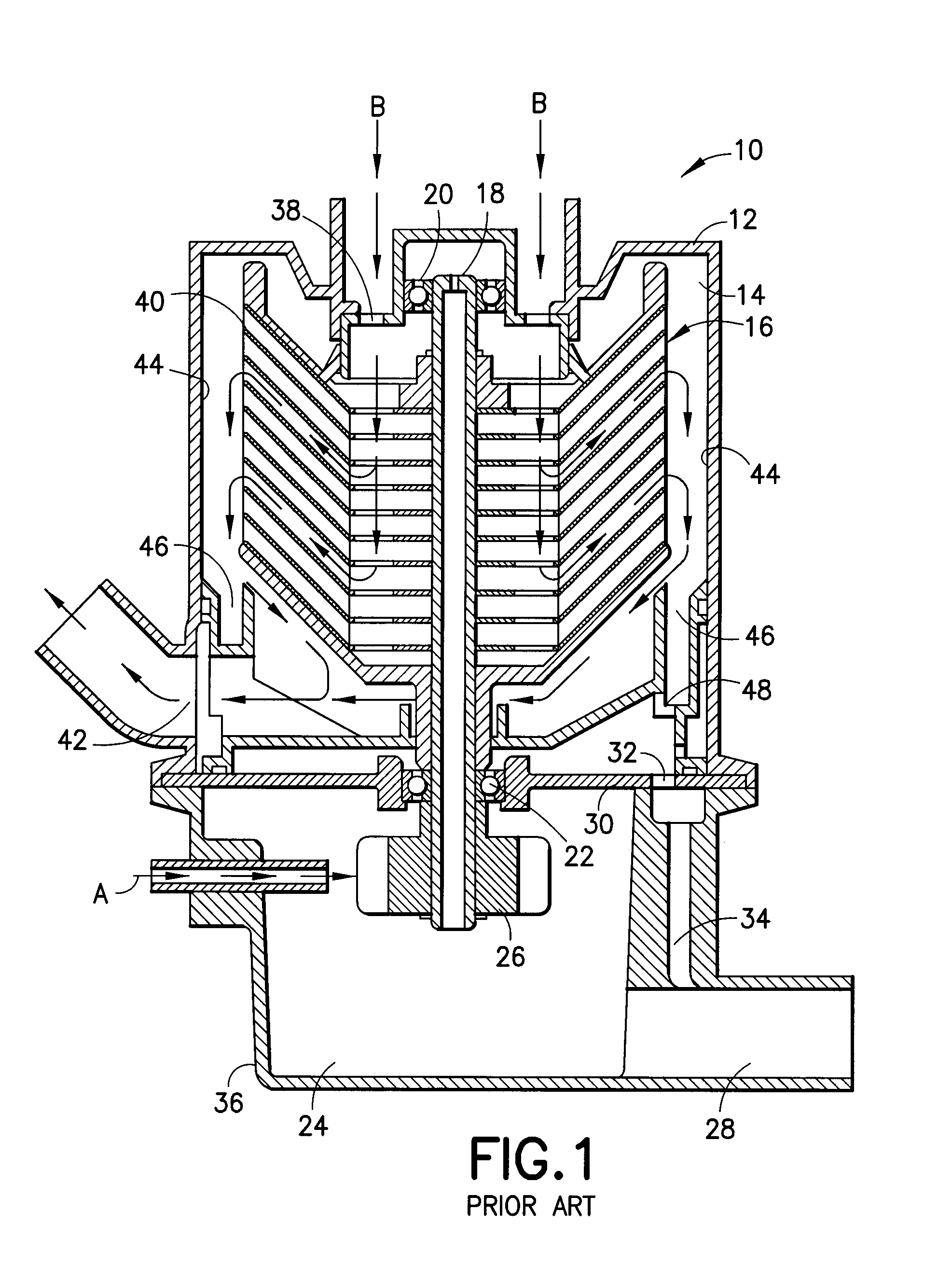

Method of treating air on board on a vehicle, and a device for use when performing the method

InactiveUS7022163B2Compact structureReduce manufacturing costHuman health protectionCombination devicesOn boardSolid particle

In a vehicle air is compressed for being used in the brake system of the vehicle, for instance. In the compressor, used for the compression, the air is contaminated with oil and solid particles. In order to be relieved from these particles, before the air is conveyed through a drying filter, the compressed is brought to rotation by means of a rotating member in a centrifugal separator. The rotating member may advantageously include a pile of conical separation discs forming flow passages between each other for the compressed air to be cleaned. By means of an efficient cleaning of the compressed air from particles the life time of the drying filter may be increased.

Owner:ALFA LAVAL CORP AB +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com