Patents

Literature

235 results about "Centrifuge rotor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supporting applications ranging from clinical and blood banking, microbiology, tissue culture, molecular biology and genomics, drug discovery and proteomics, our centrifuge rotors are designed for maximum application flexibility and best-quality separations.

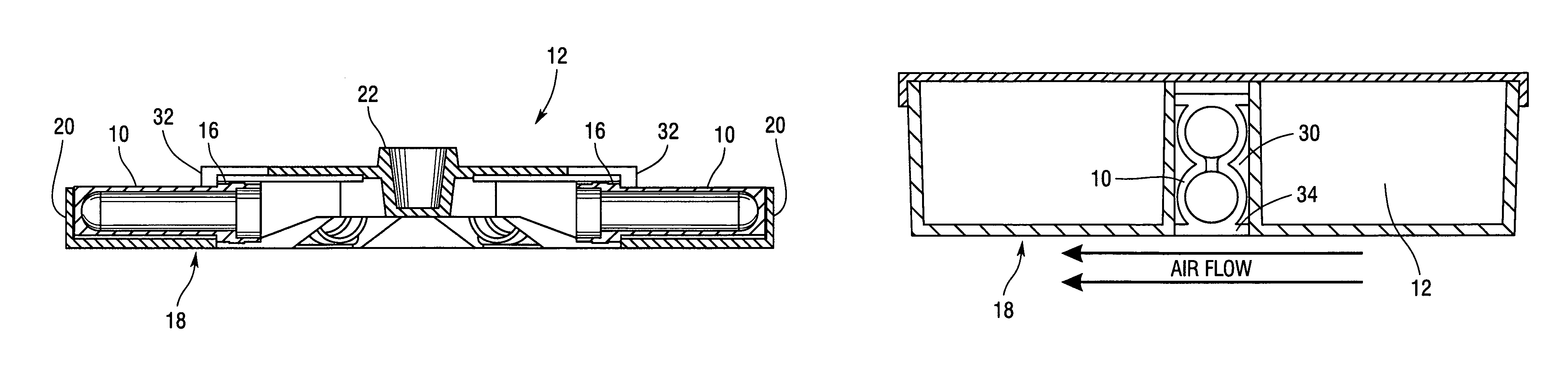

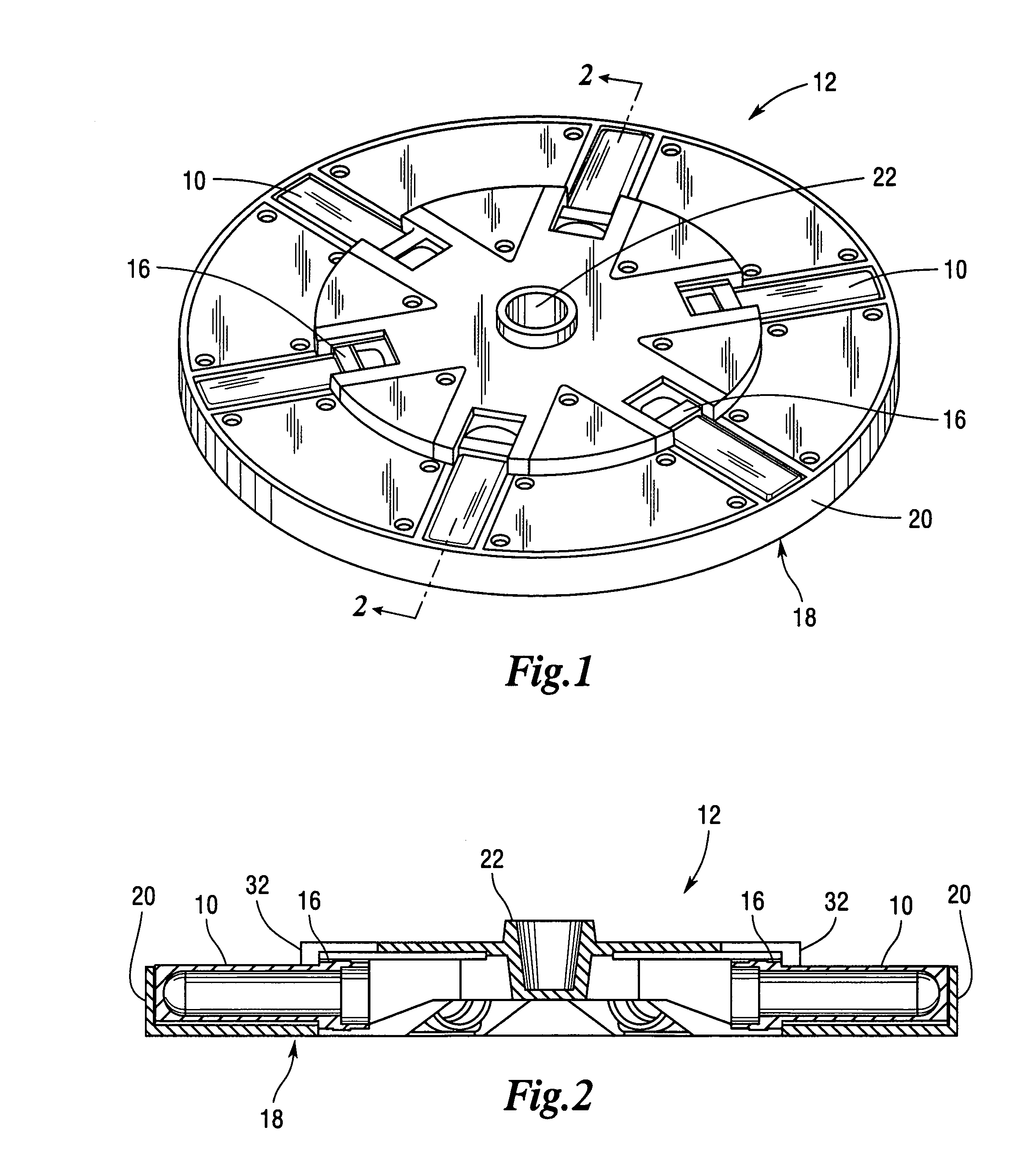

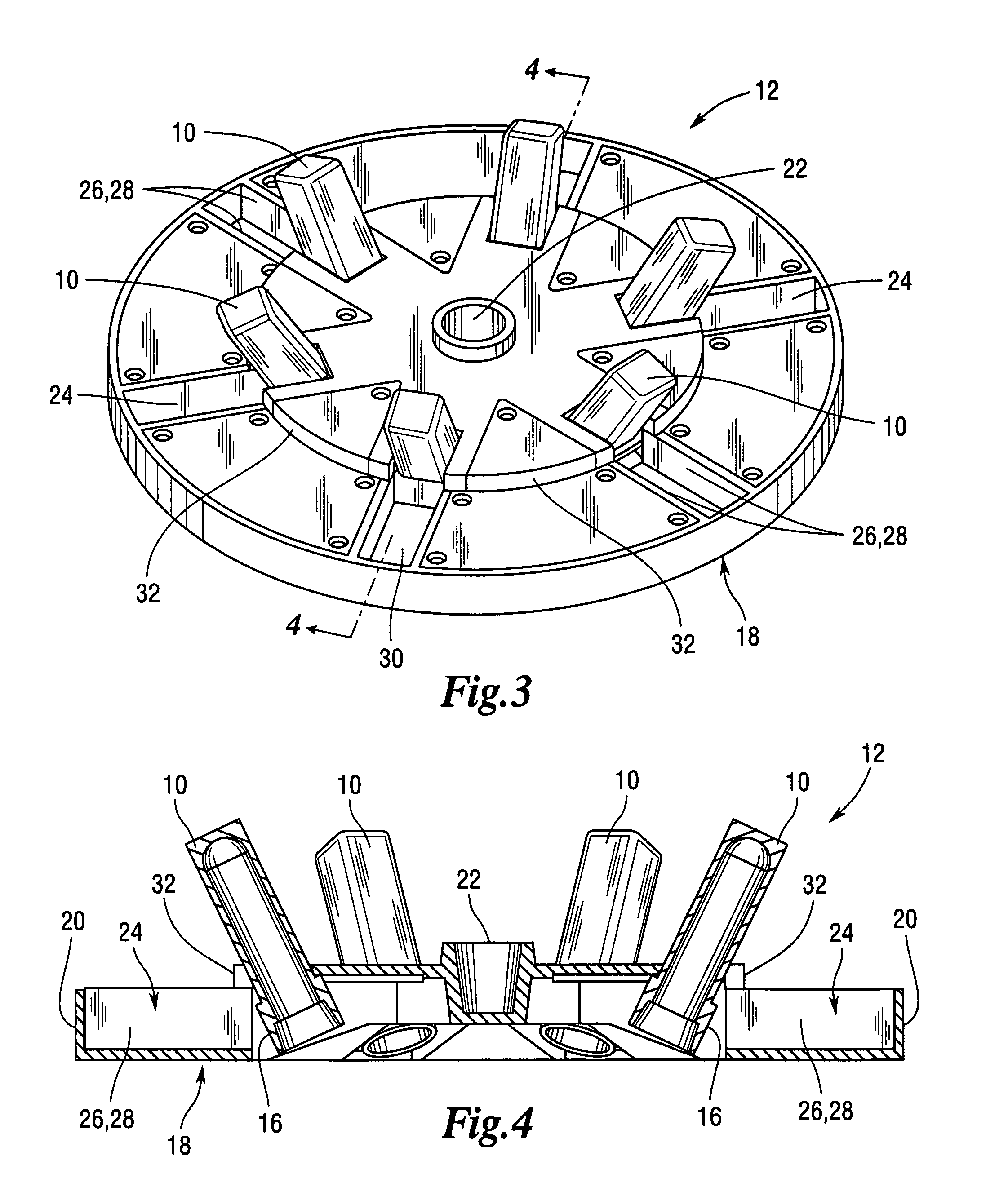

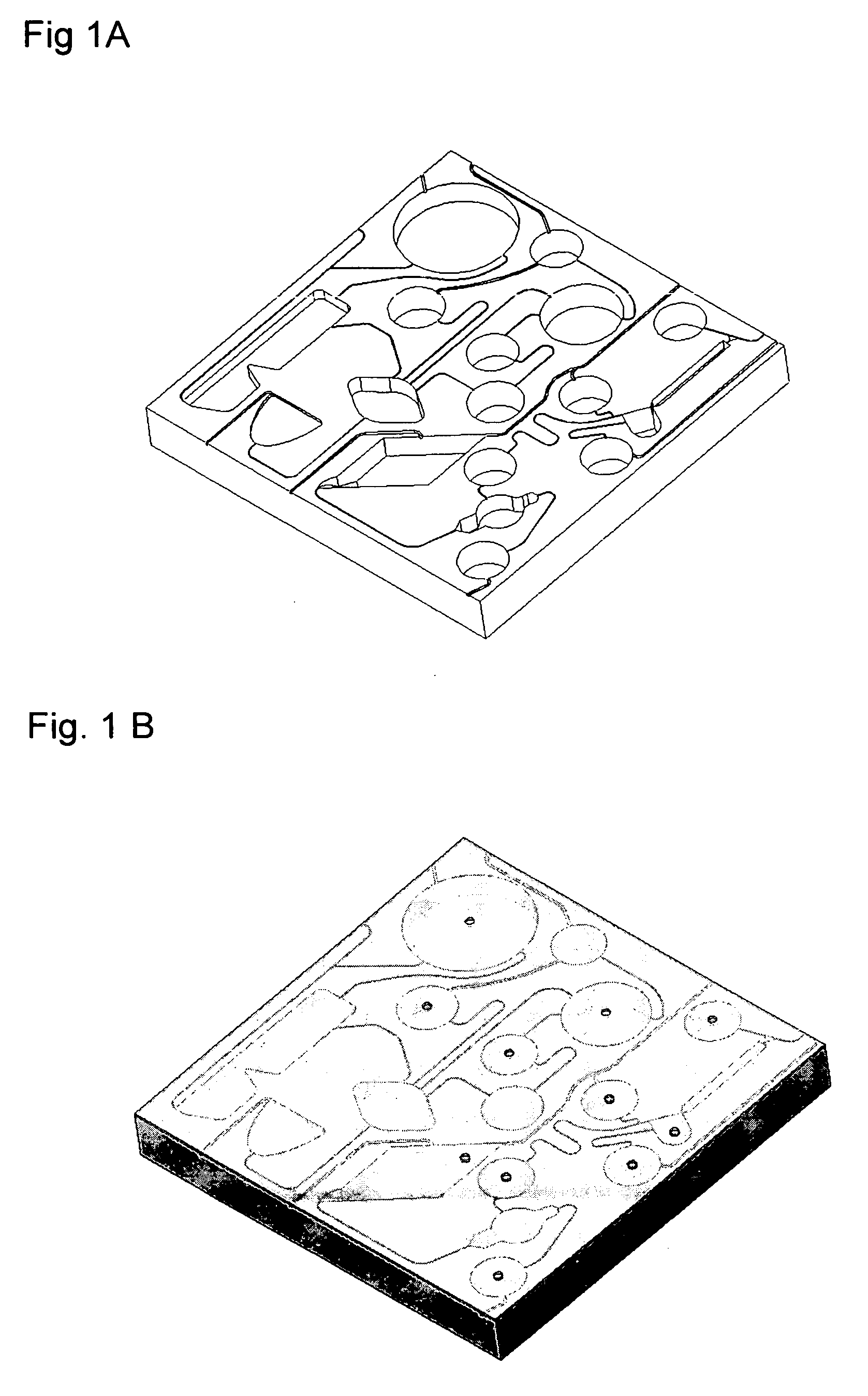

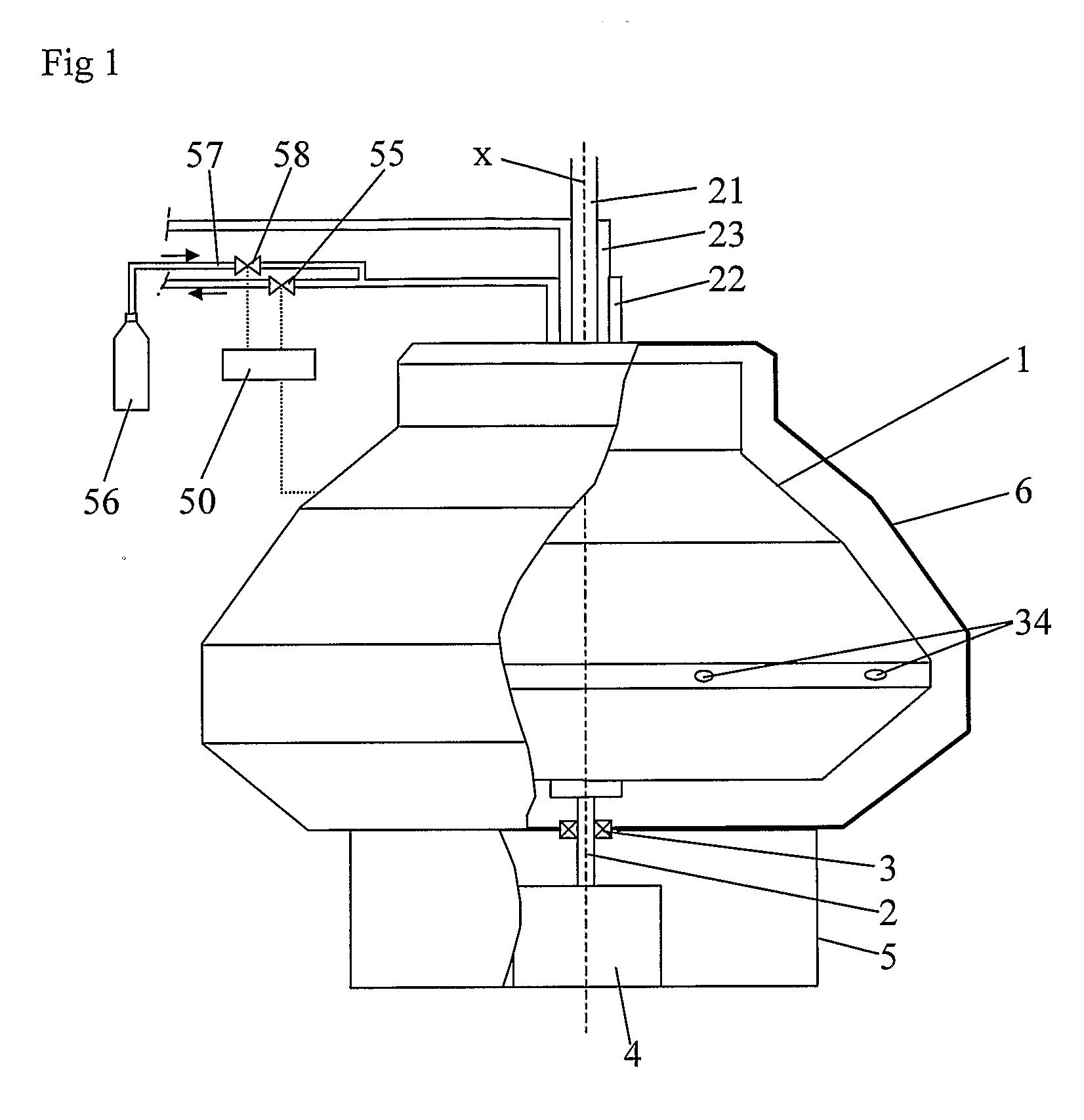

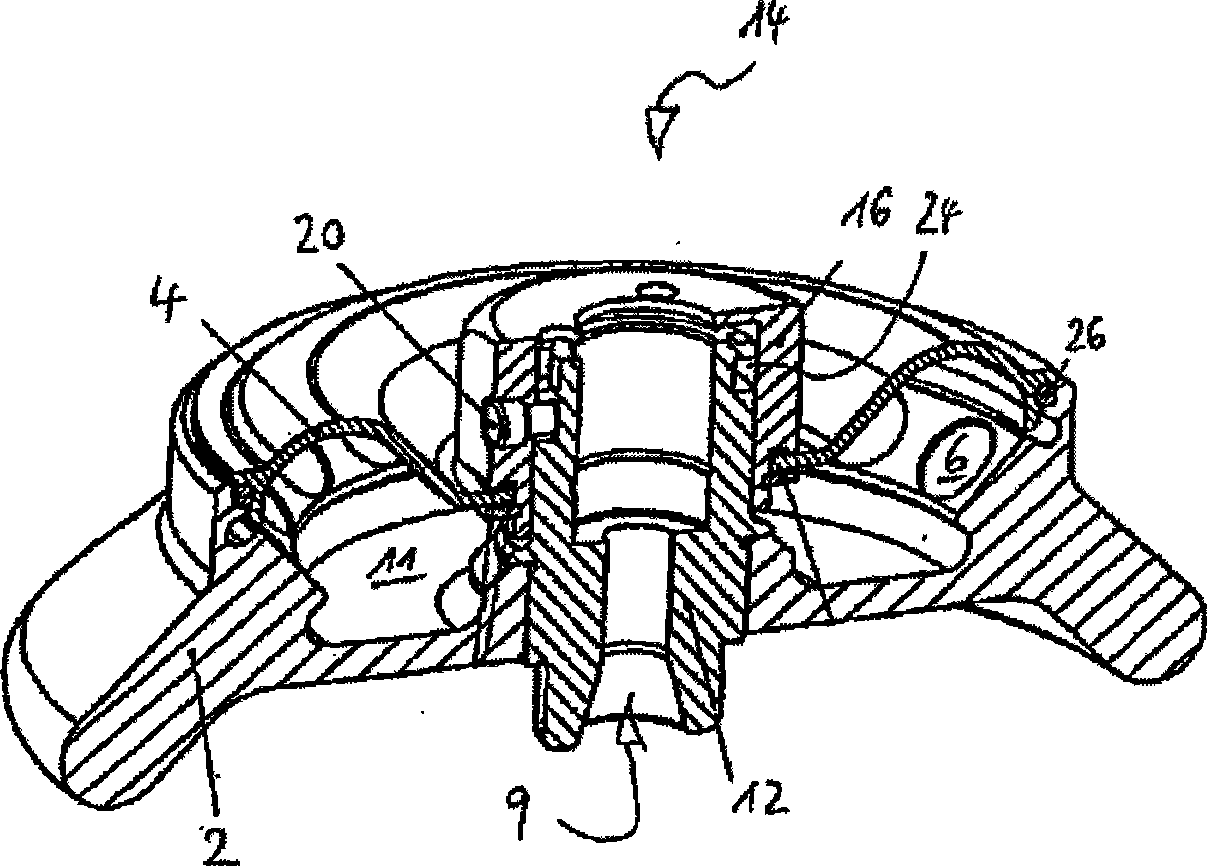

Centrifuge with aerodynamic rotor and bucket design

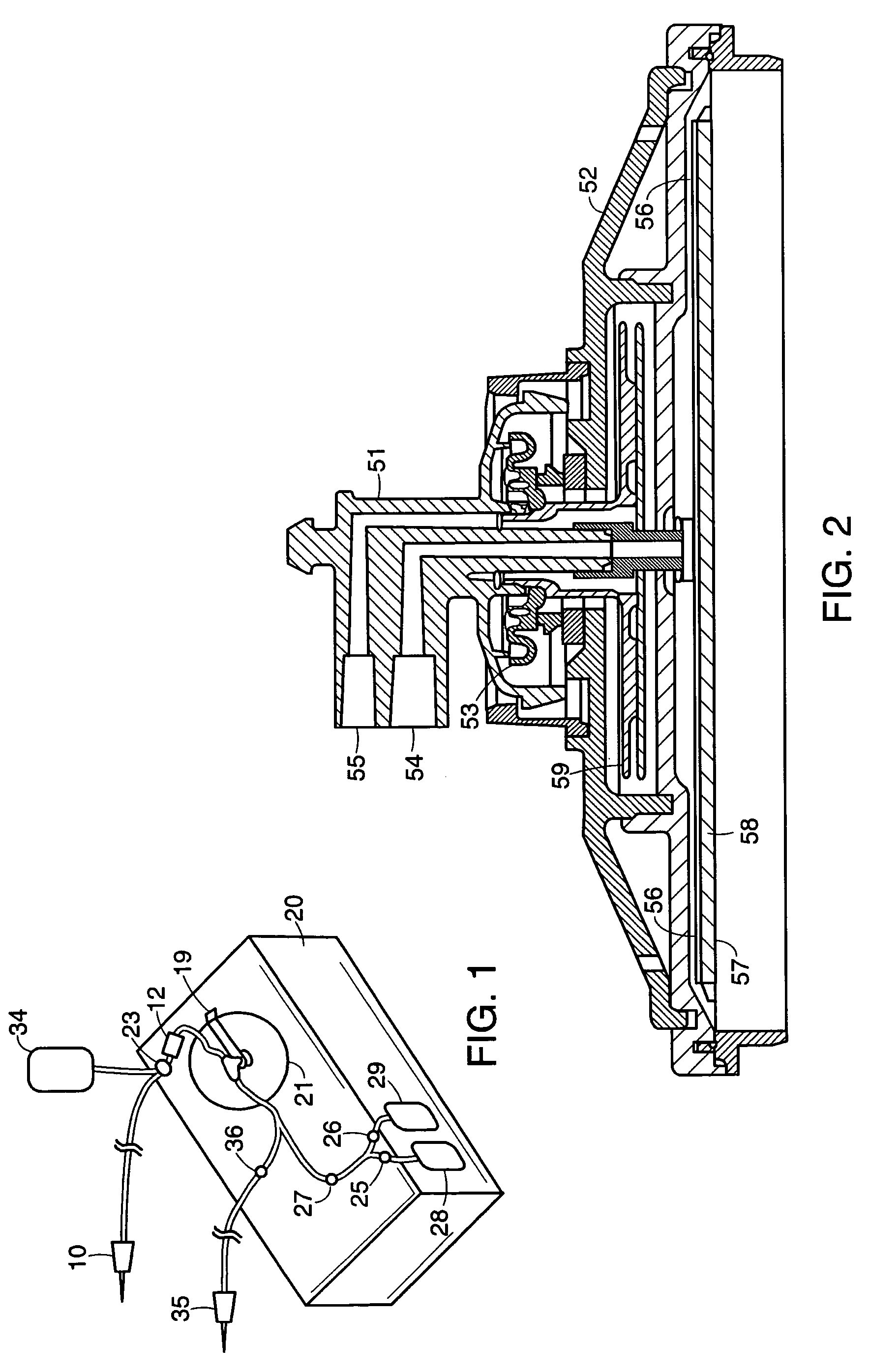

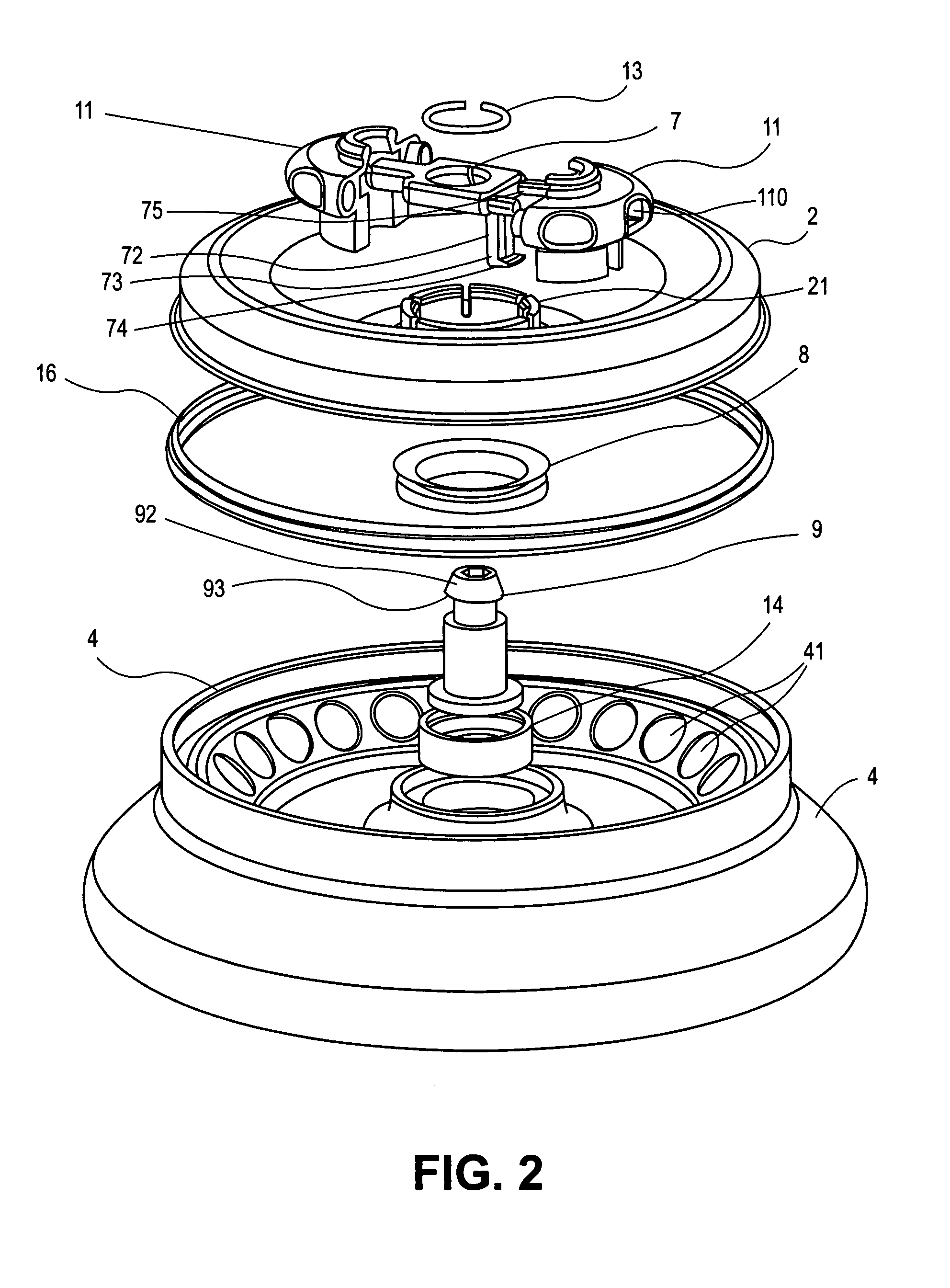

A rotor and specimen holder assembly for producing a relatively low power, low audible level, cool running centrifuge. The centrifuge rotor assembly is designed to enable a specimen holder to retract into the body of the rotor during centrifugation to produce aerodynamic features.

Owner:DRUCKER COMPANY INC THE

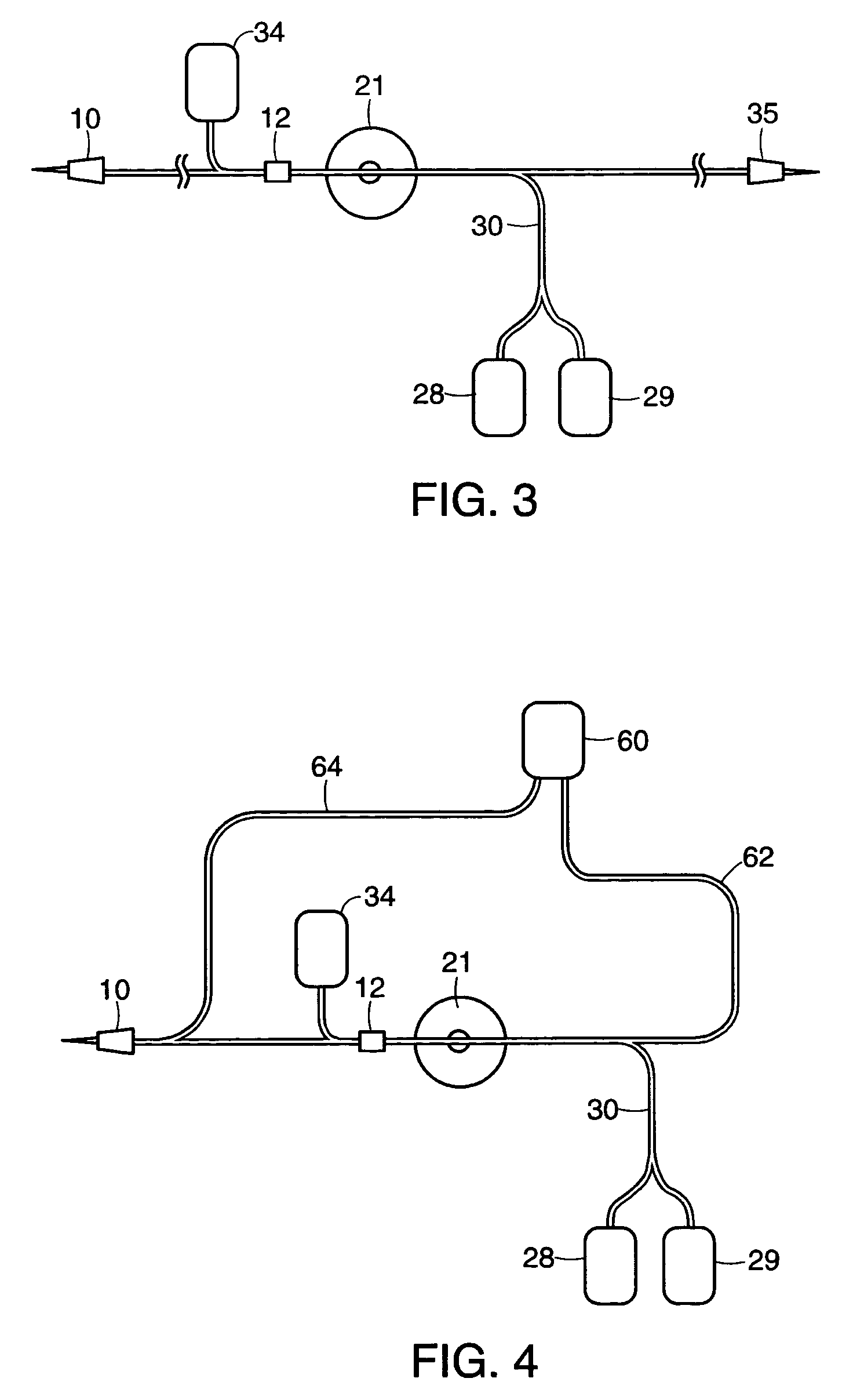

Method and apparatus for controlling fluid movement in a microfluidic system

InactiveUS20050026301A1Extension of timeLess attractiveAnalysis using chemical indicatorsWithdrawing sample devicesEngineeringCentrifuge rotor

The invention provides a method for moving a fluid sample within an open channel flow device by centrifugal force and specially adapted apparatus for practicing the method of the invention. The inventive method is a mechanically simple method for moving a fluid in a platform by changing the orientation of a platform relative to the direction of applied forces when the centrifuge rotor is at rest in order to move a fluid sequentially through a plurality of chambers, wherein movement of the fluid is controlled by the location or size of the passages connecting chambers relative to the direction of forces acting on the fluid.

Owner:PETITHORY HENRY

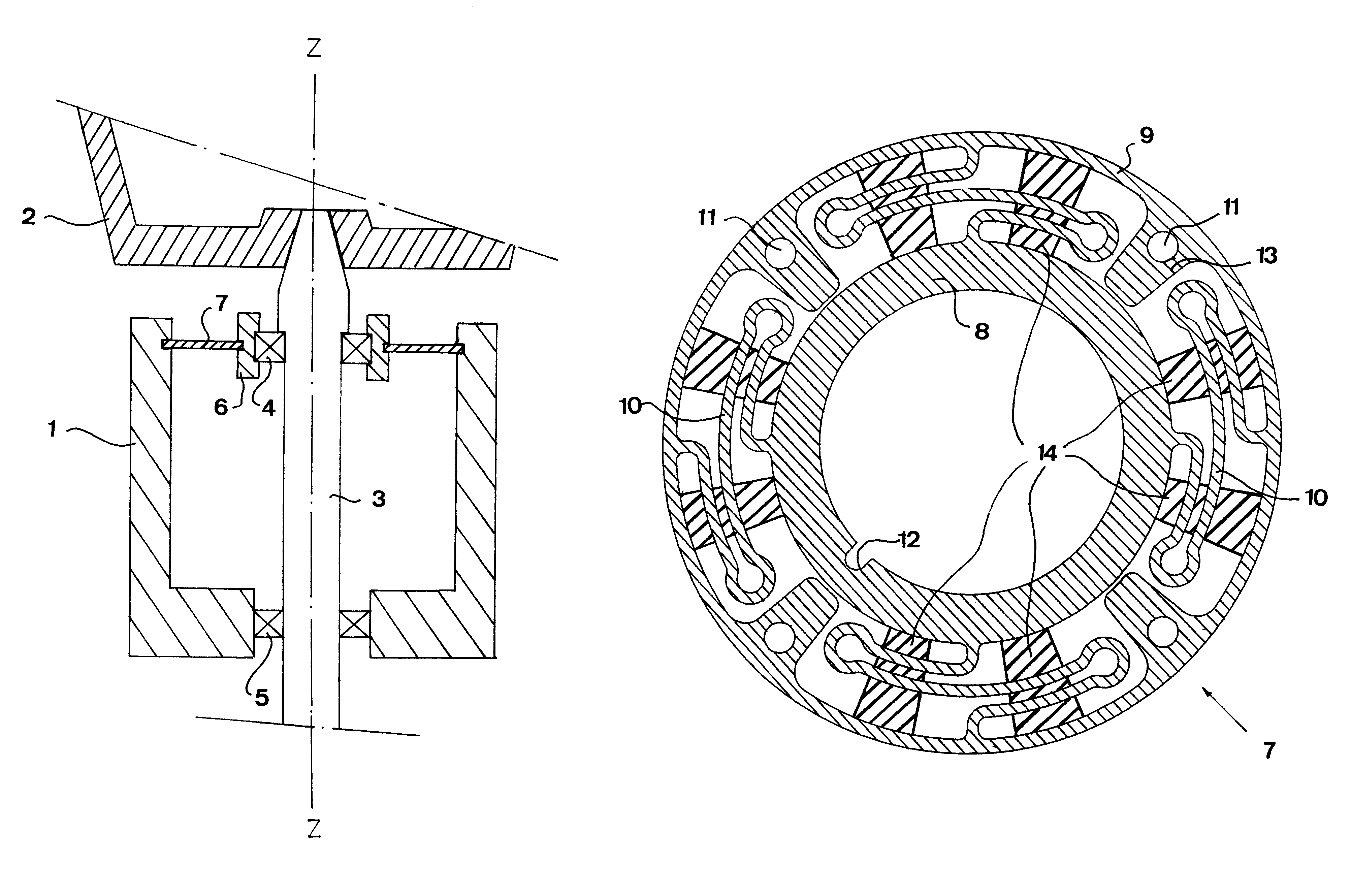

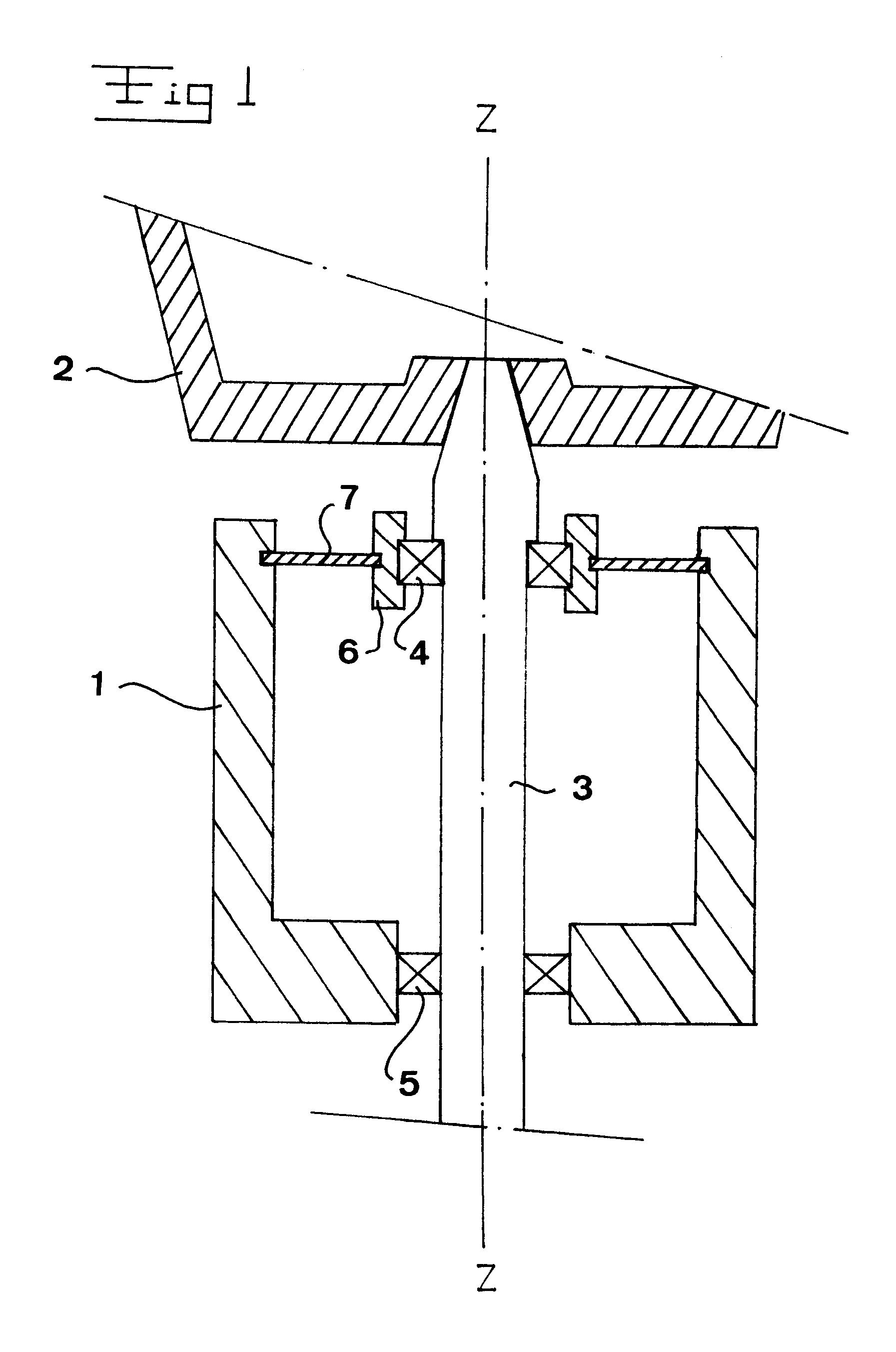

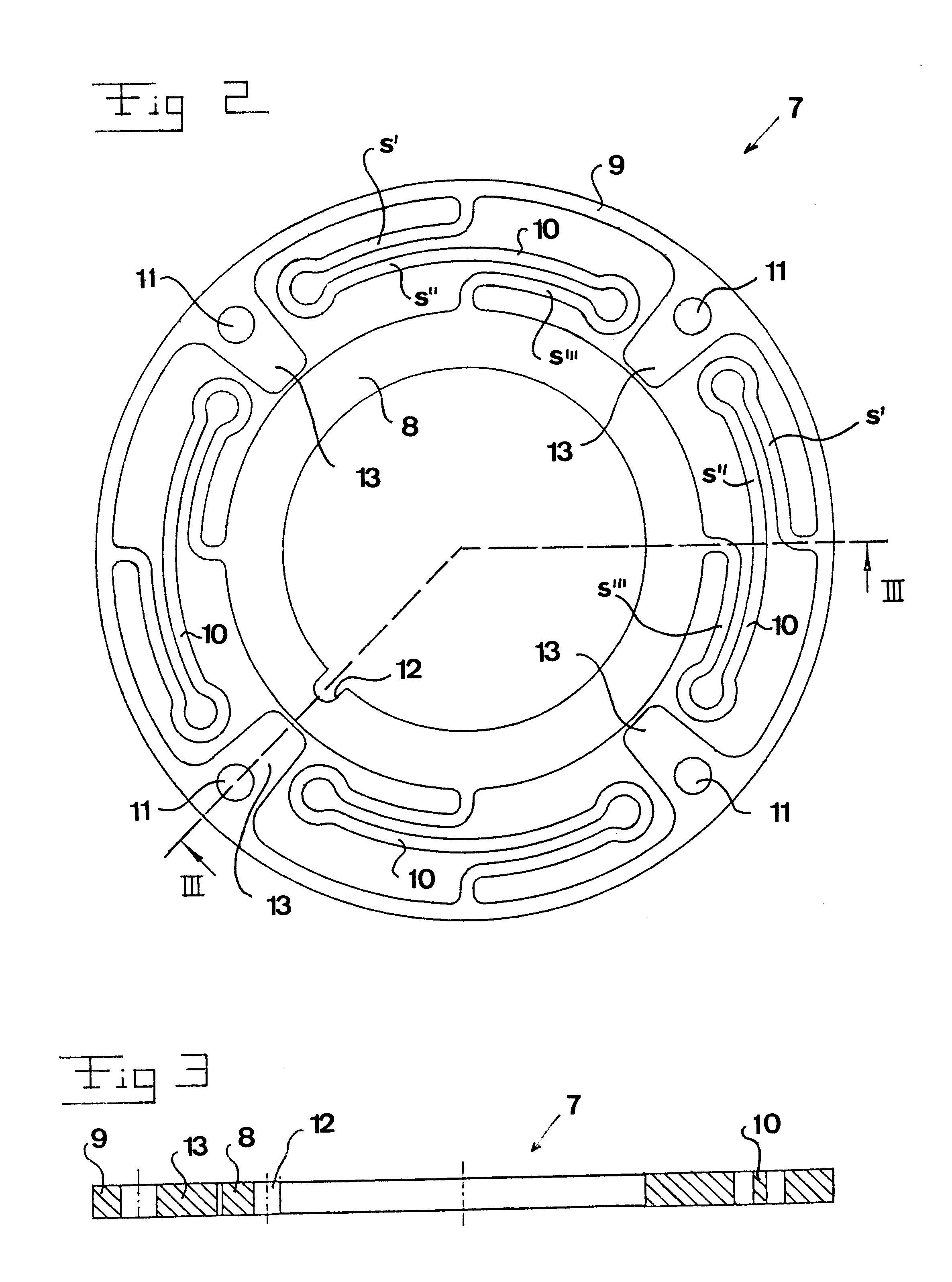

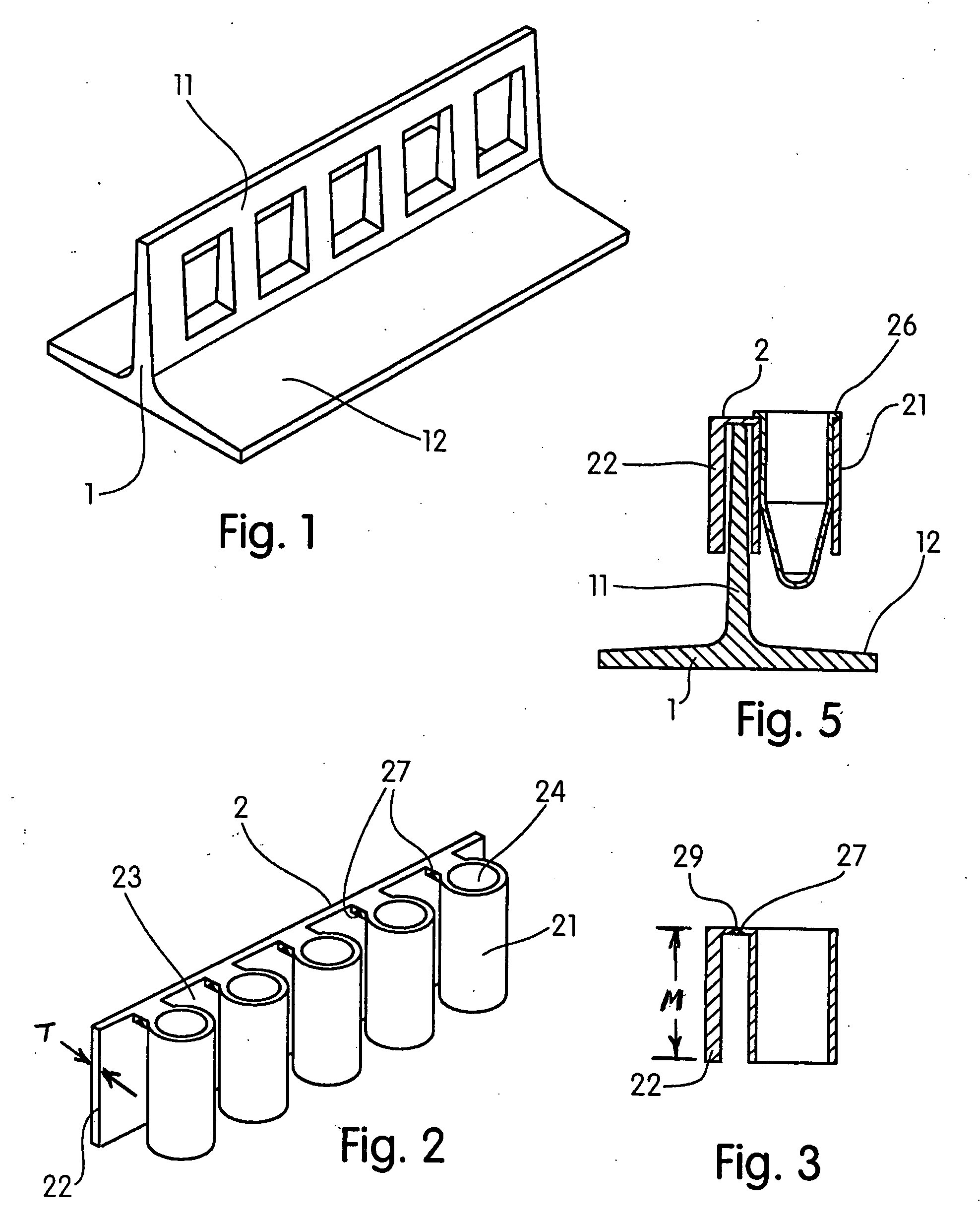

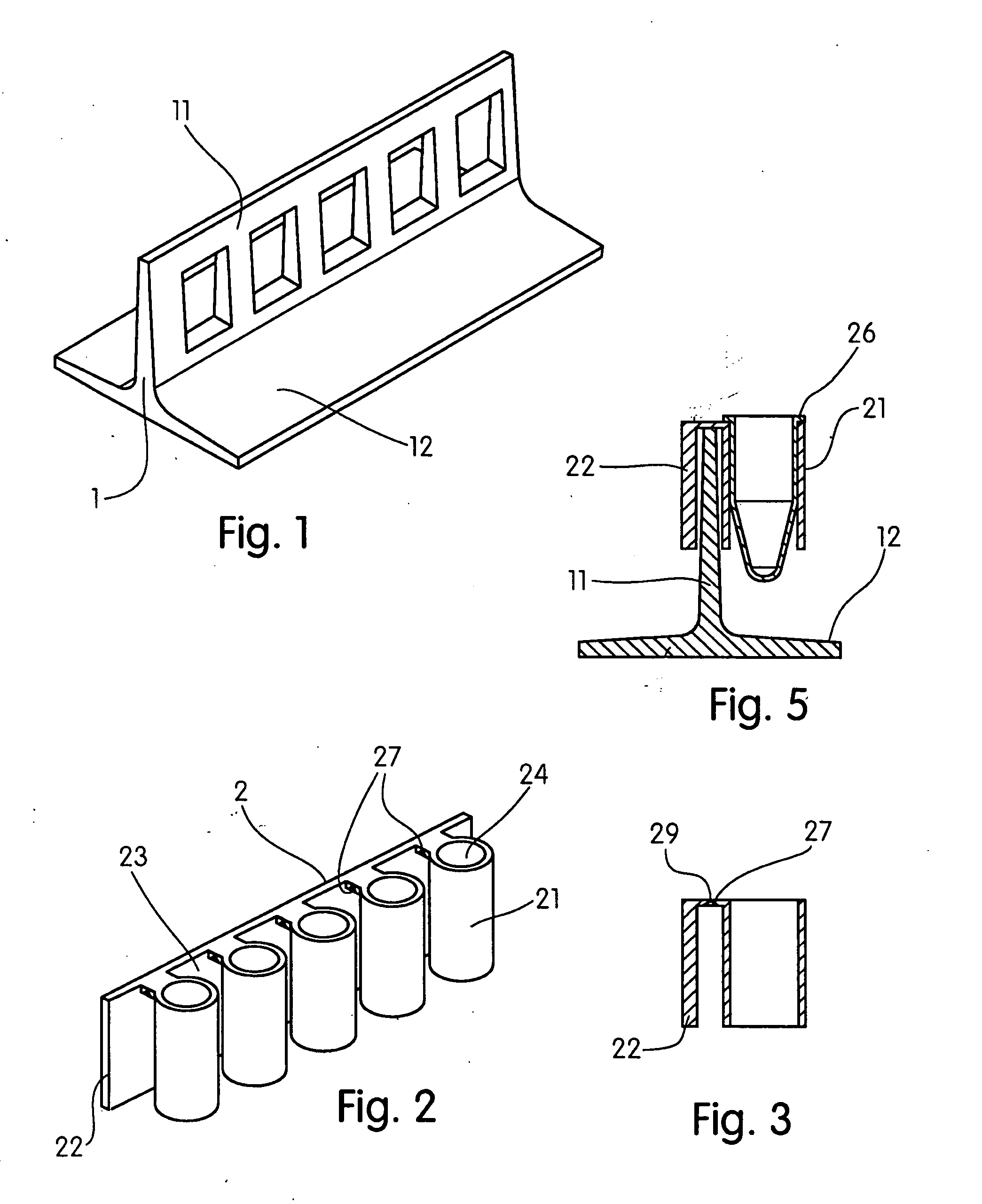

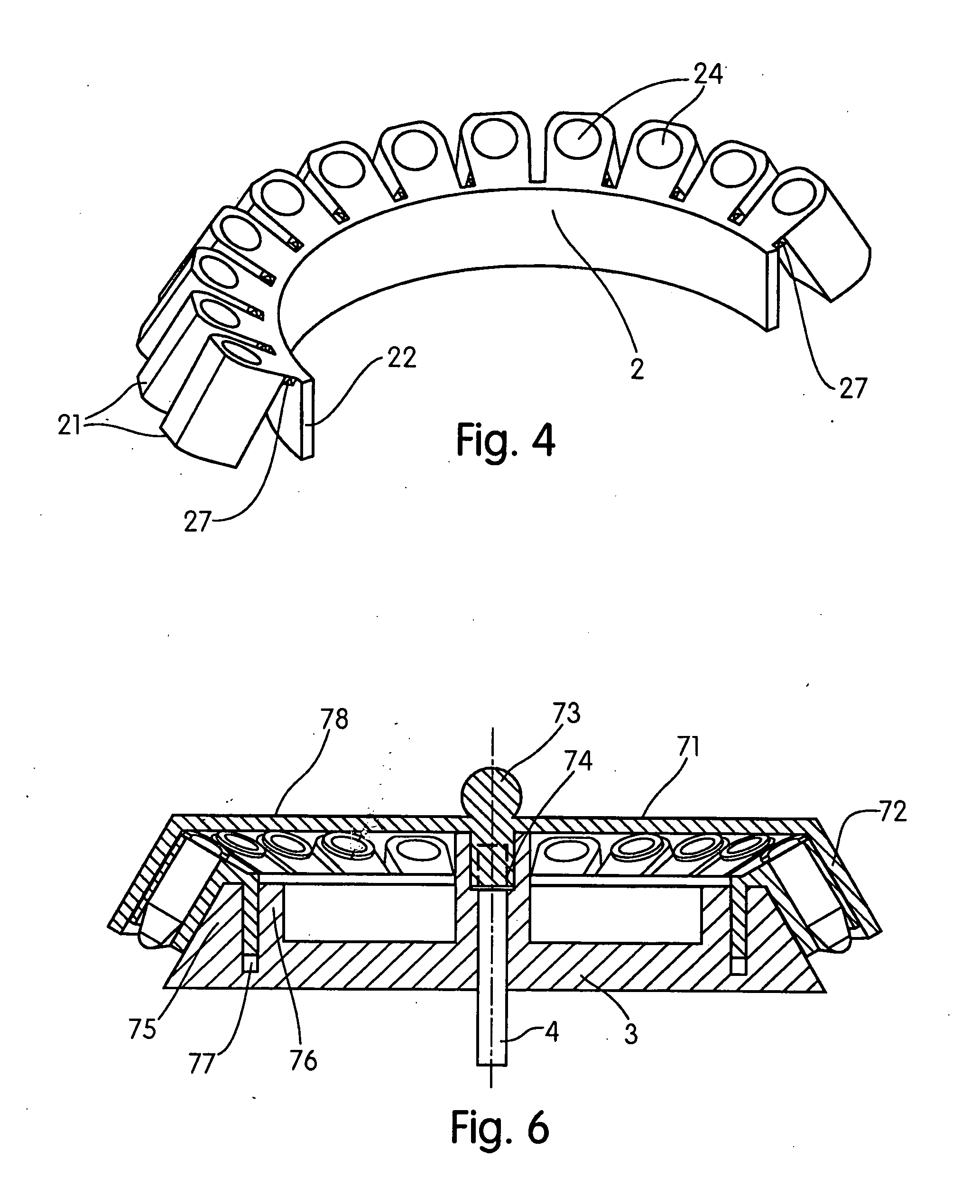

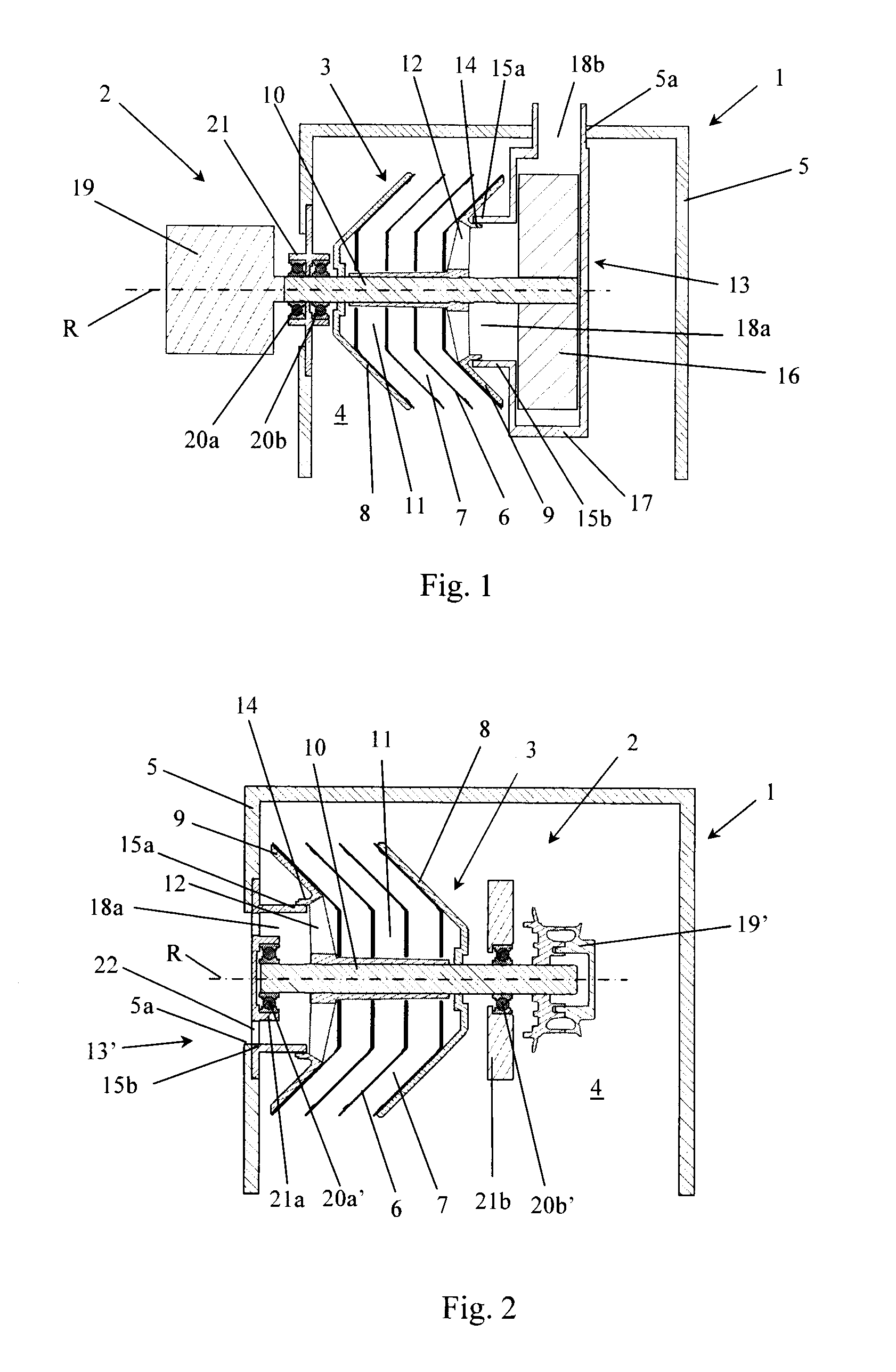

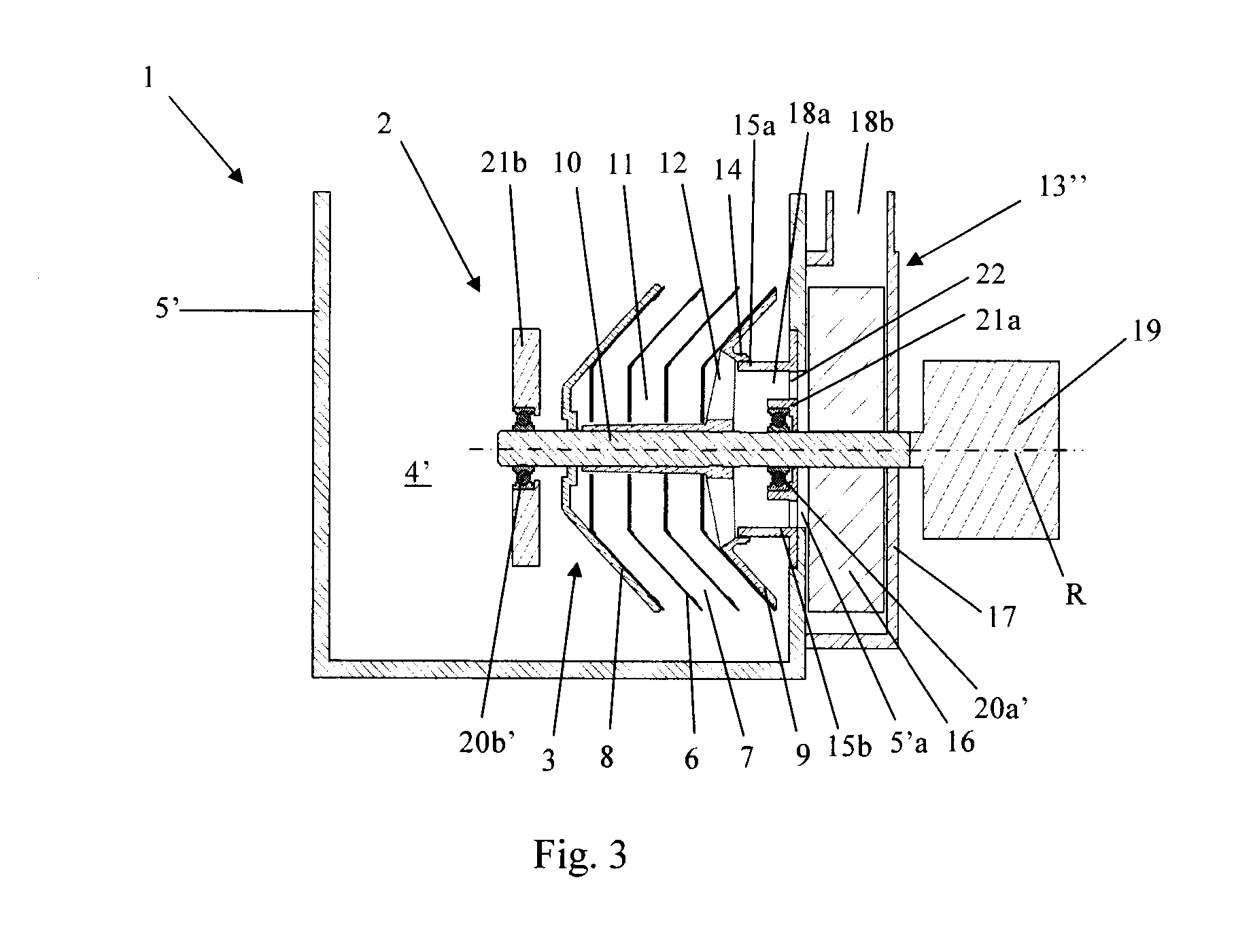

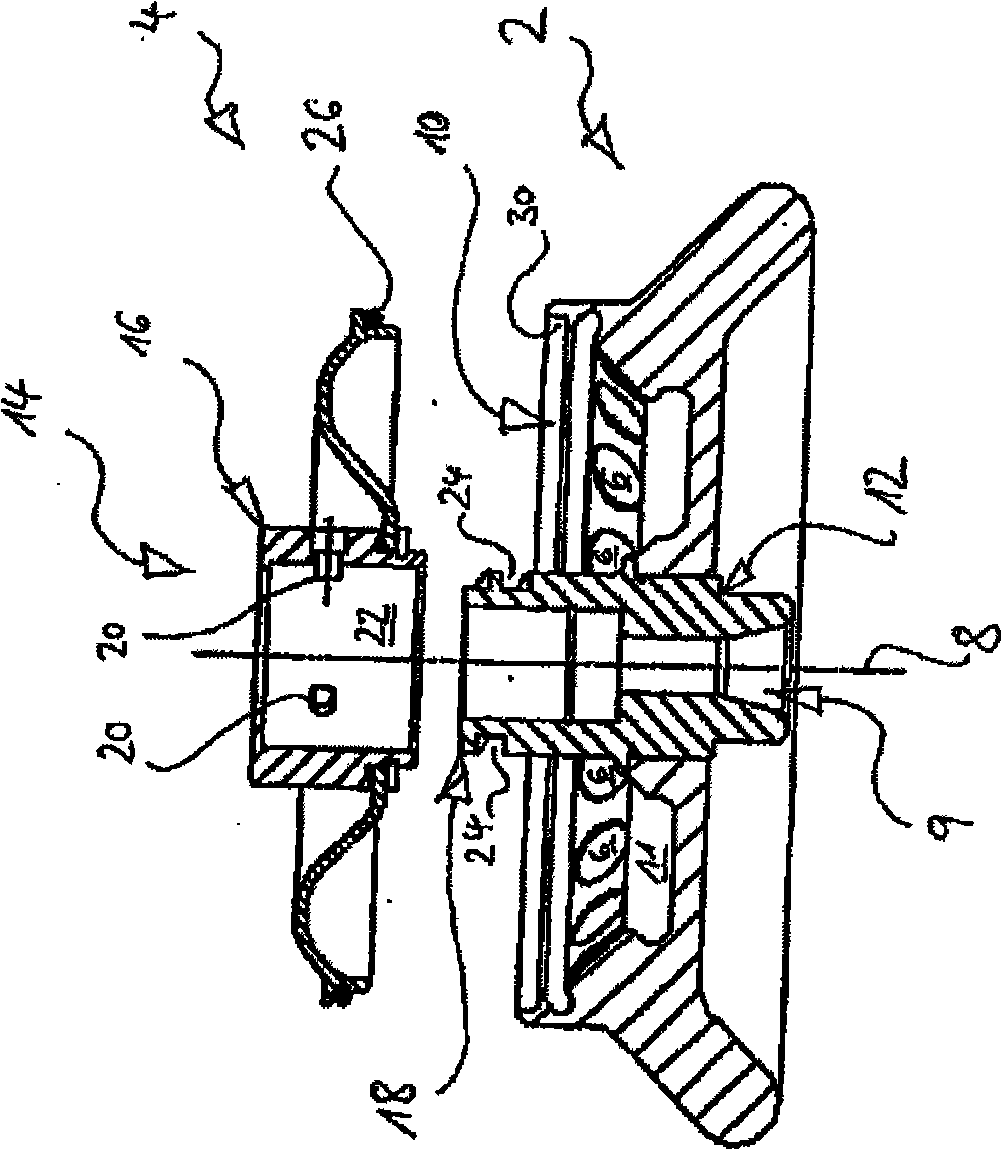

Flexible metal supporting device for a centrifugal separator

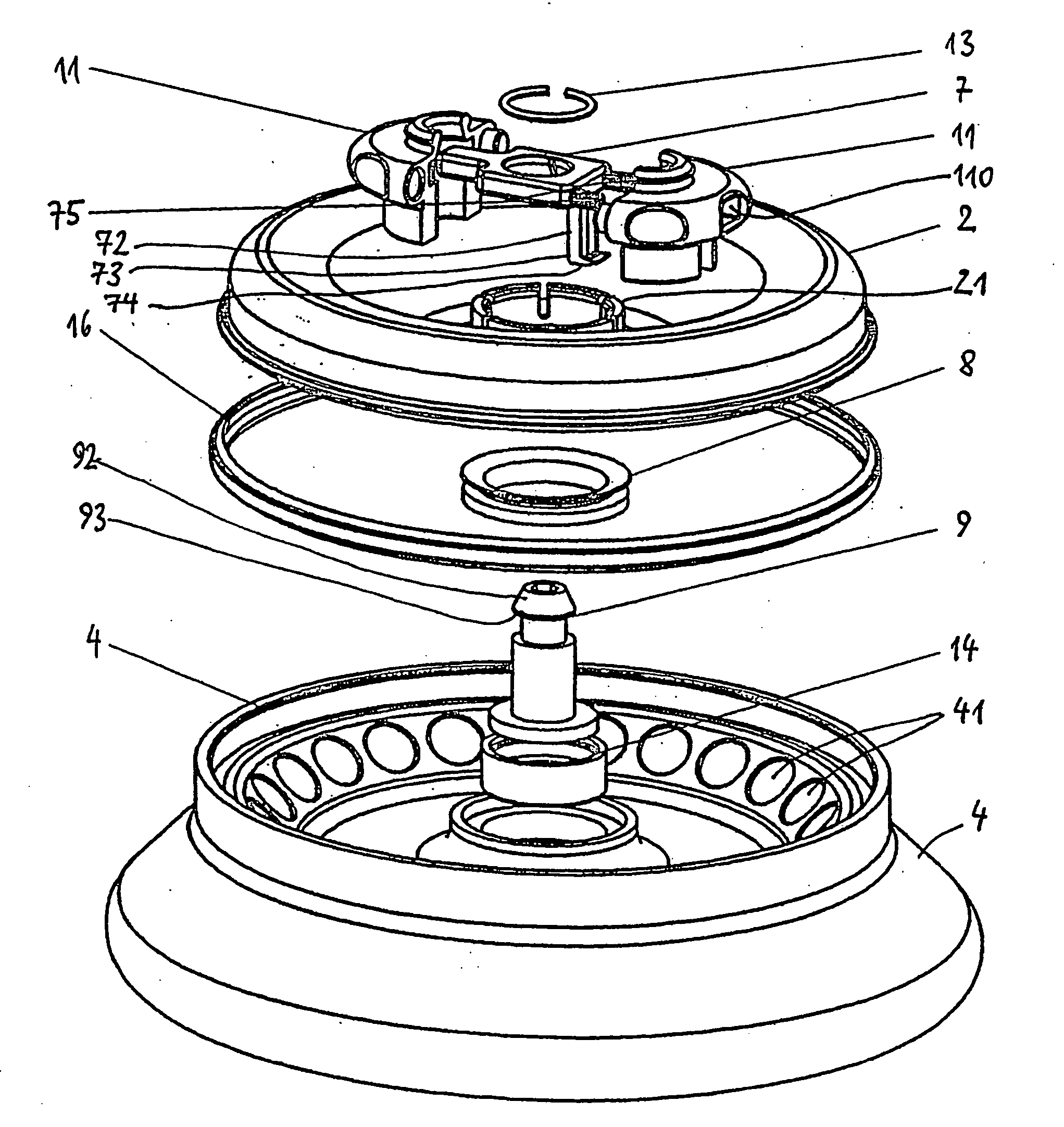

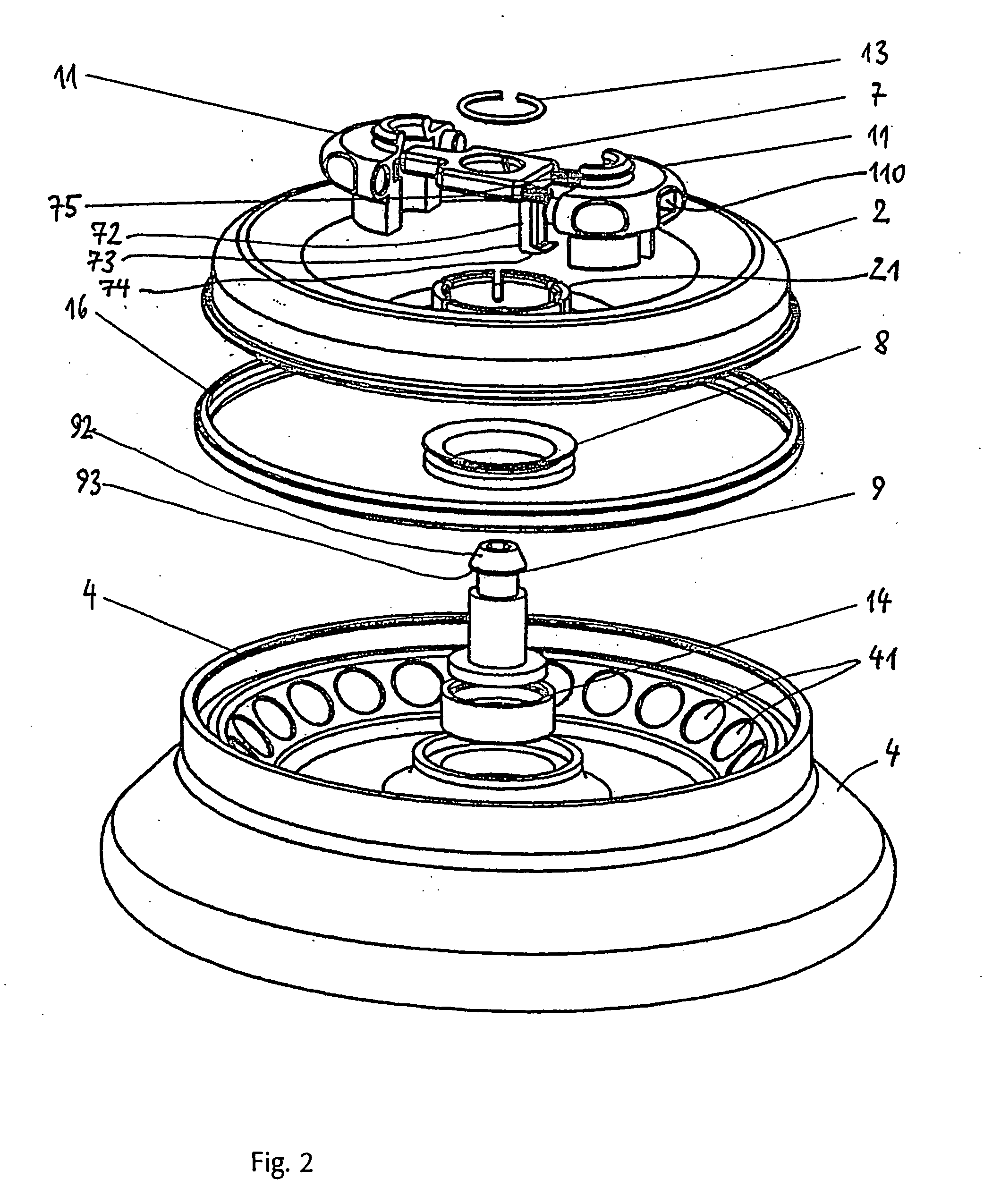

InactiveUS6224533B1Simple designSimple structureRolling contact bearingsCentrifugesCentrifuge rotorMetallic materials

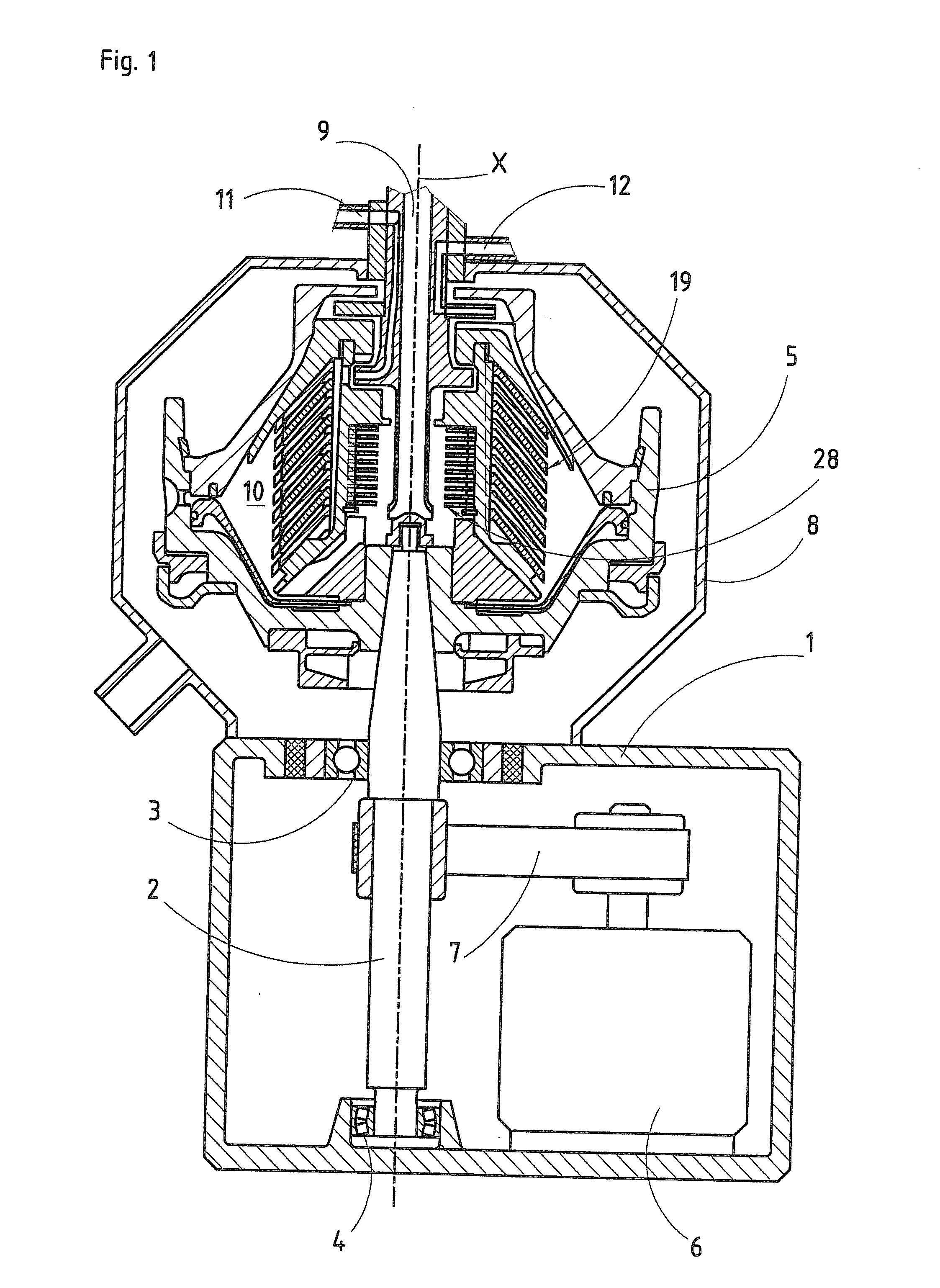

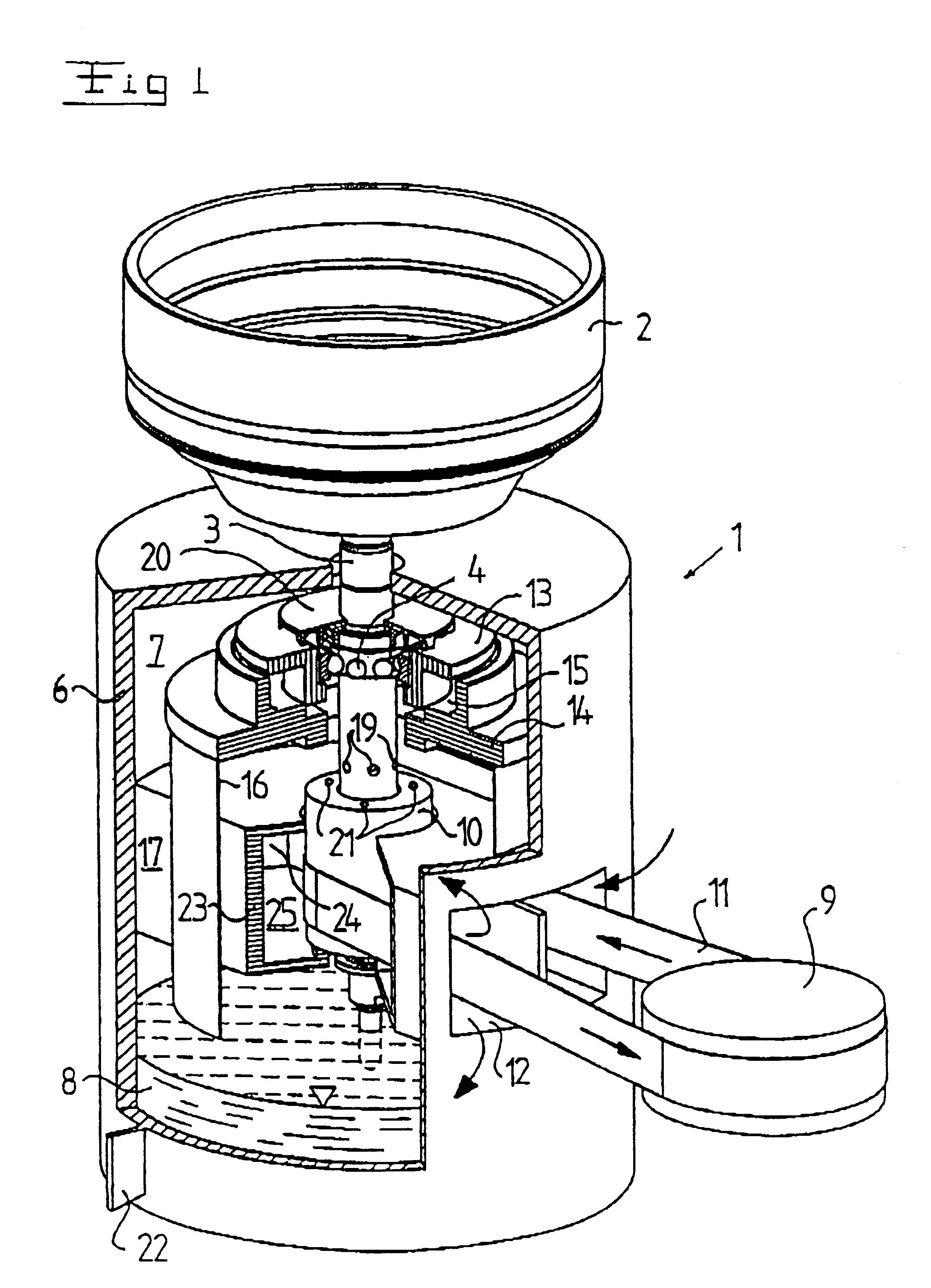

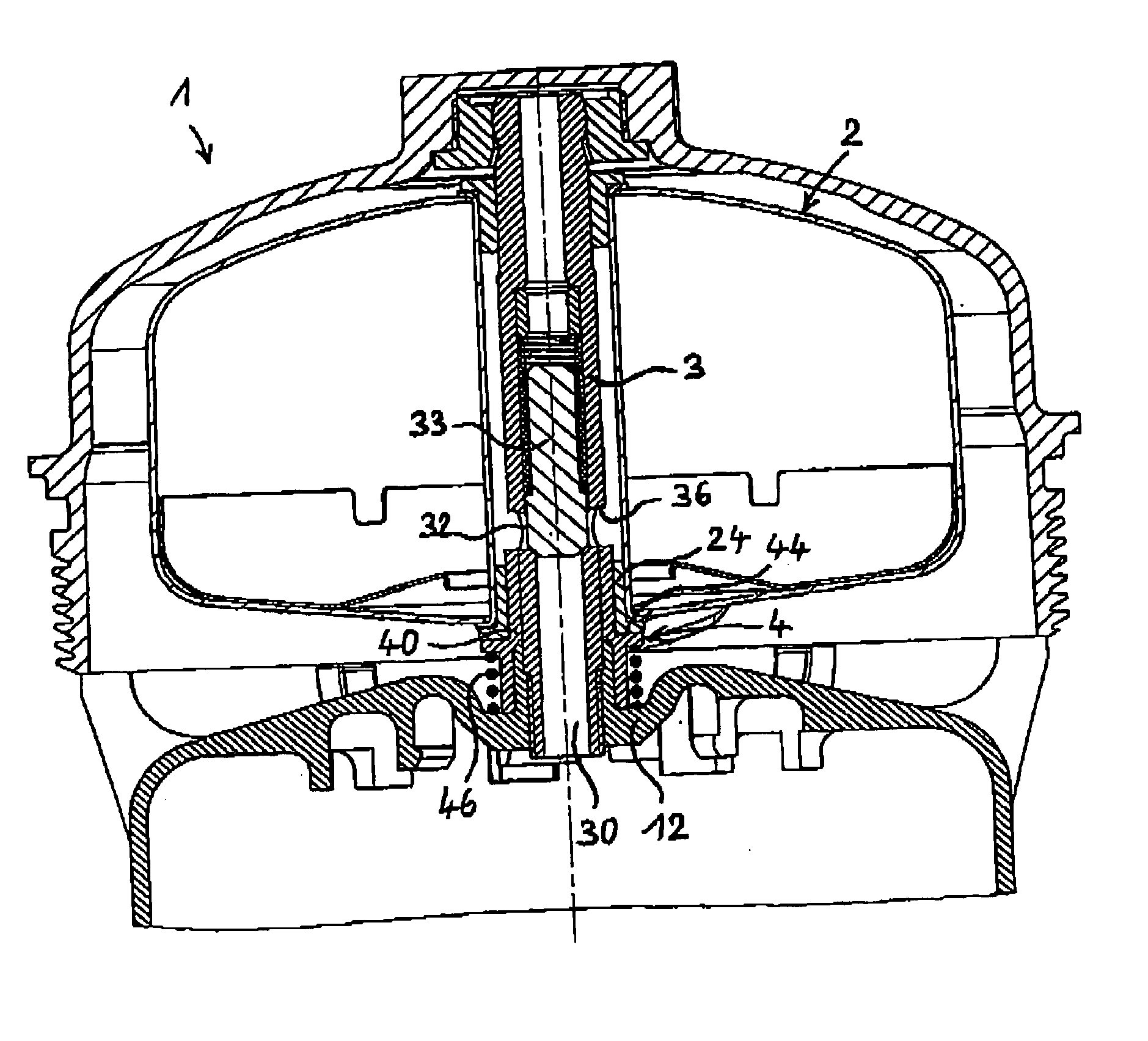

A flexible metal support device for a rotatable centrifuge rotor (2) provided in a frame member (1) by a bearing member (4). The support device comprises a support element (7) provided between the bearing member (4) and the frame member (1), and arranged to absorb relative movements between the centrifuge rotor and the frame member. The support element (7) comprises an inner mounting portion, essentially immovable in relation to the bearing member (4), and an outer mounting portion, essentially immovable in relation to the frame member (1). Moreover, the support element (7) comprises three flexible connecting portions which each extends between the inner and outer mounting portions and is arranged to absorb radial and axial relative movements between the centrifuge rotor and the frame member. Furthermore, the inner portion, the connecting portions and the outer portion form an integrated unit manufactured in one piece of metal material.

Owner:ALFA LAVAL AB

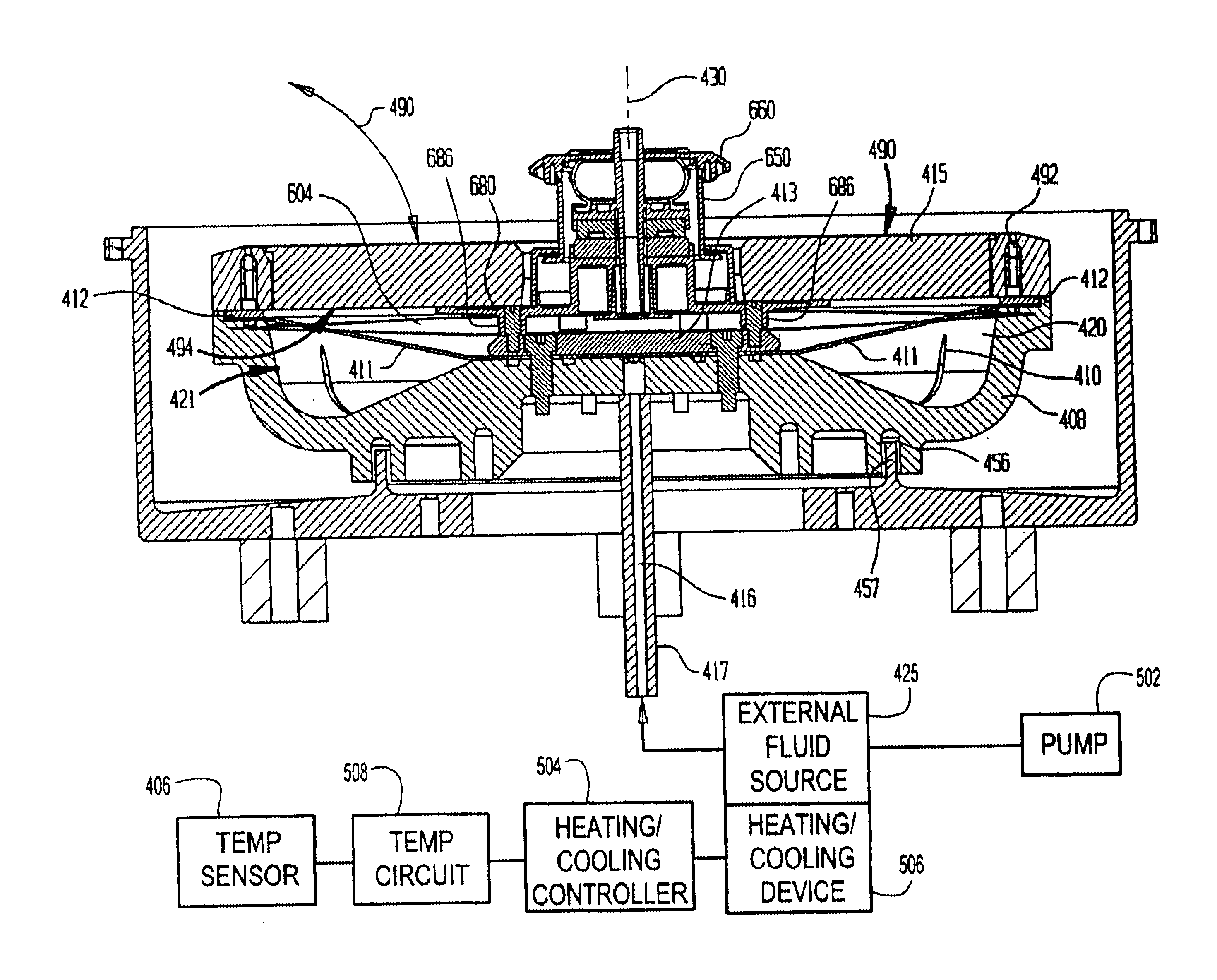

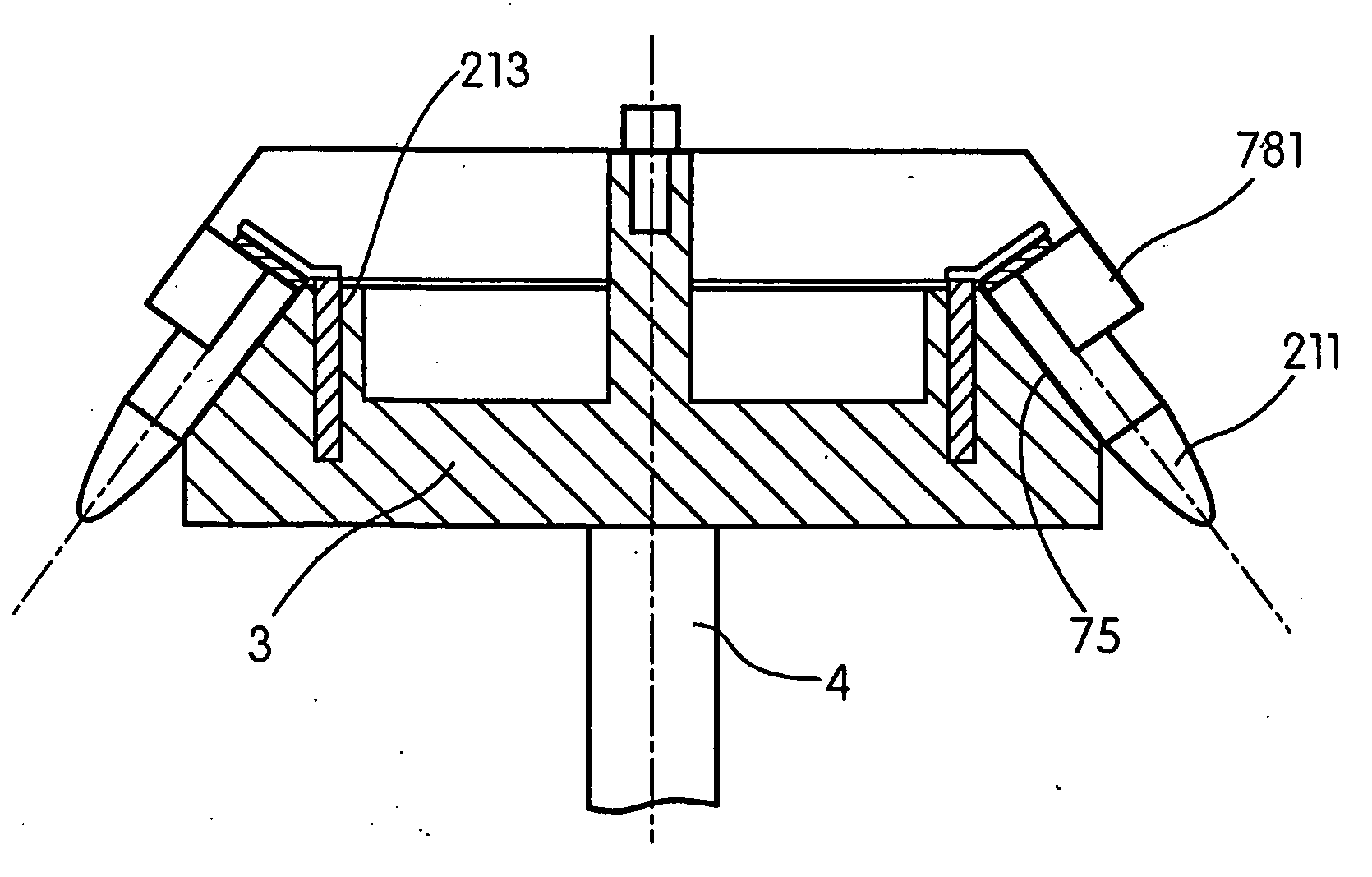

Biological processing apparatus for expressing fluid material

InactiveUS6852074B1Other blood circulation devicesMedical devicesCentrifuge rotorBiomedical engineering

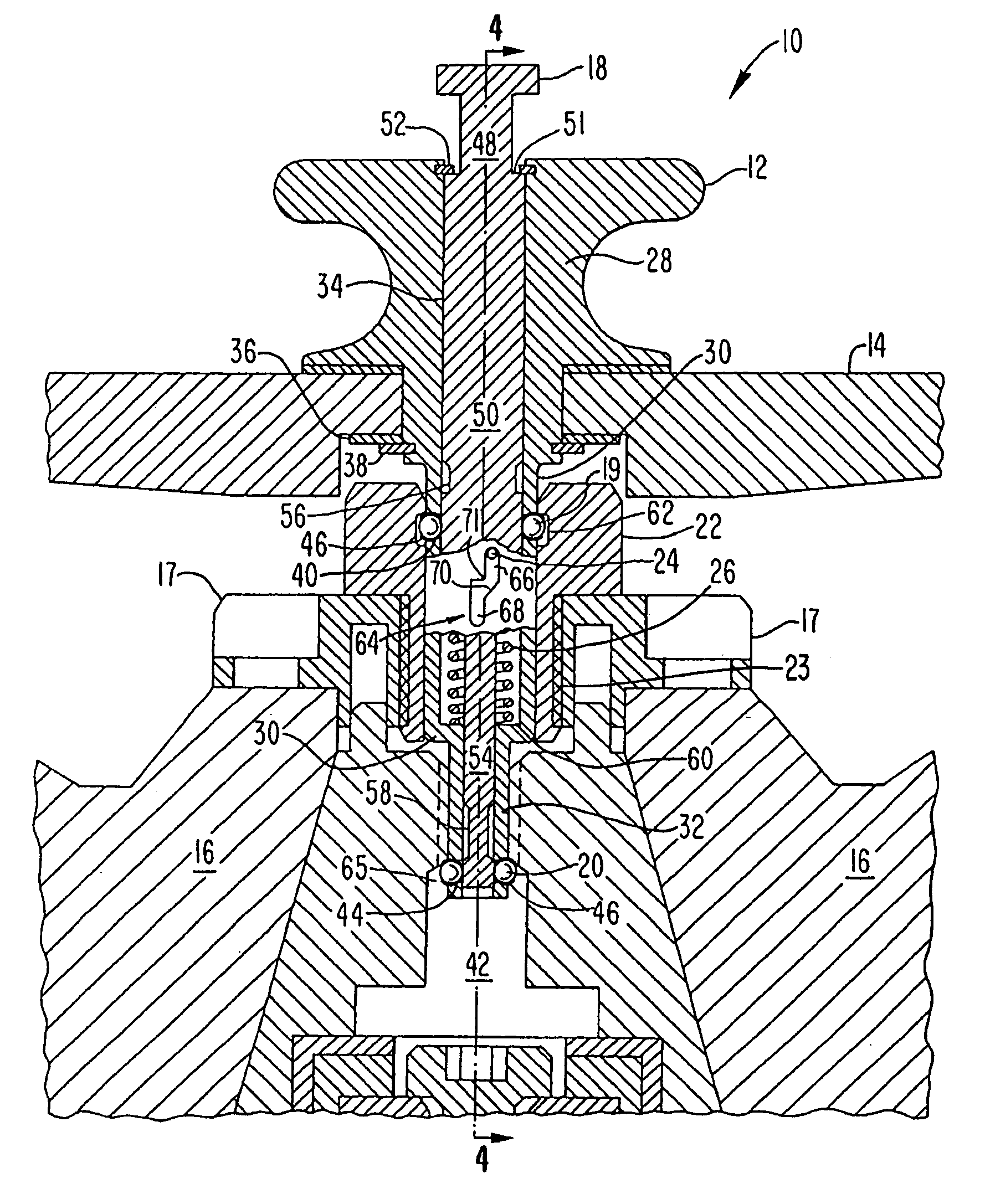

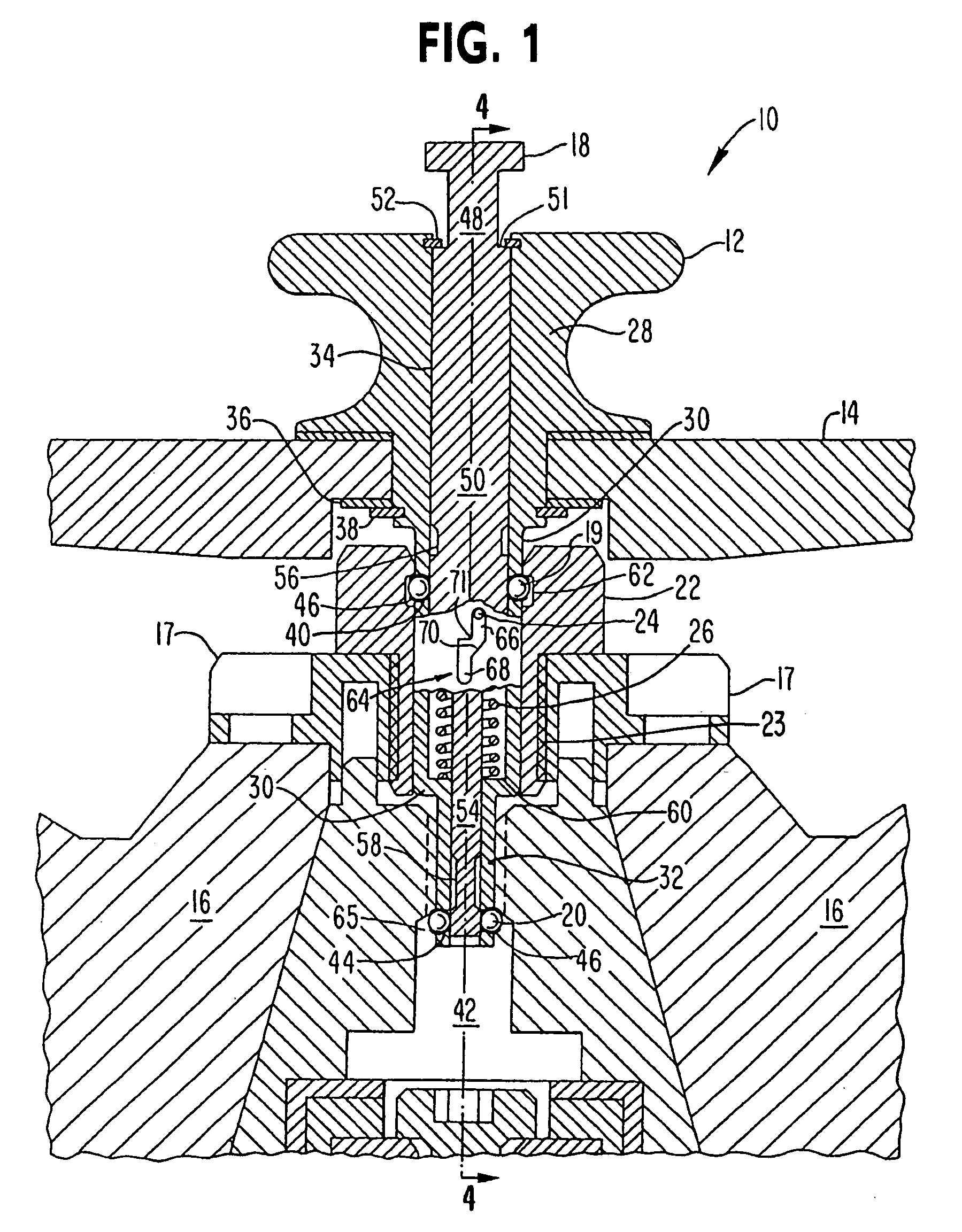

A method and apparatus for selectively expressing one or more selected fluid materials out of a fluid container, including a centrifuge rotor having a round centrifuge chamber of selected volume, a round expandable enclosure disposed within the centrifuge chamber having a rotation axis coincident with the central rotation axis and a flexible wall, a pump for controllably pumping a selected volume of expresser fluid into and out of the expandable enclosure wherein the fluid container is receivable within the centrifuge chamber, and a retaining mechanism for holding the fluid container within the centrifuge chamber in a coaxial position. The flexible wall of the fluid container is in contact with the flexible wall of the expandable enclosure.

Owner:VELICO MEDICAL

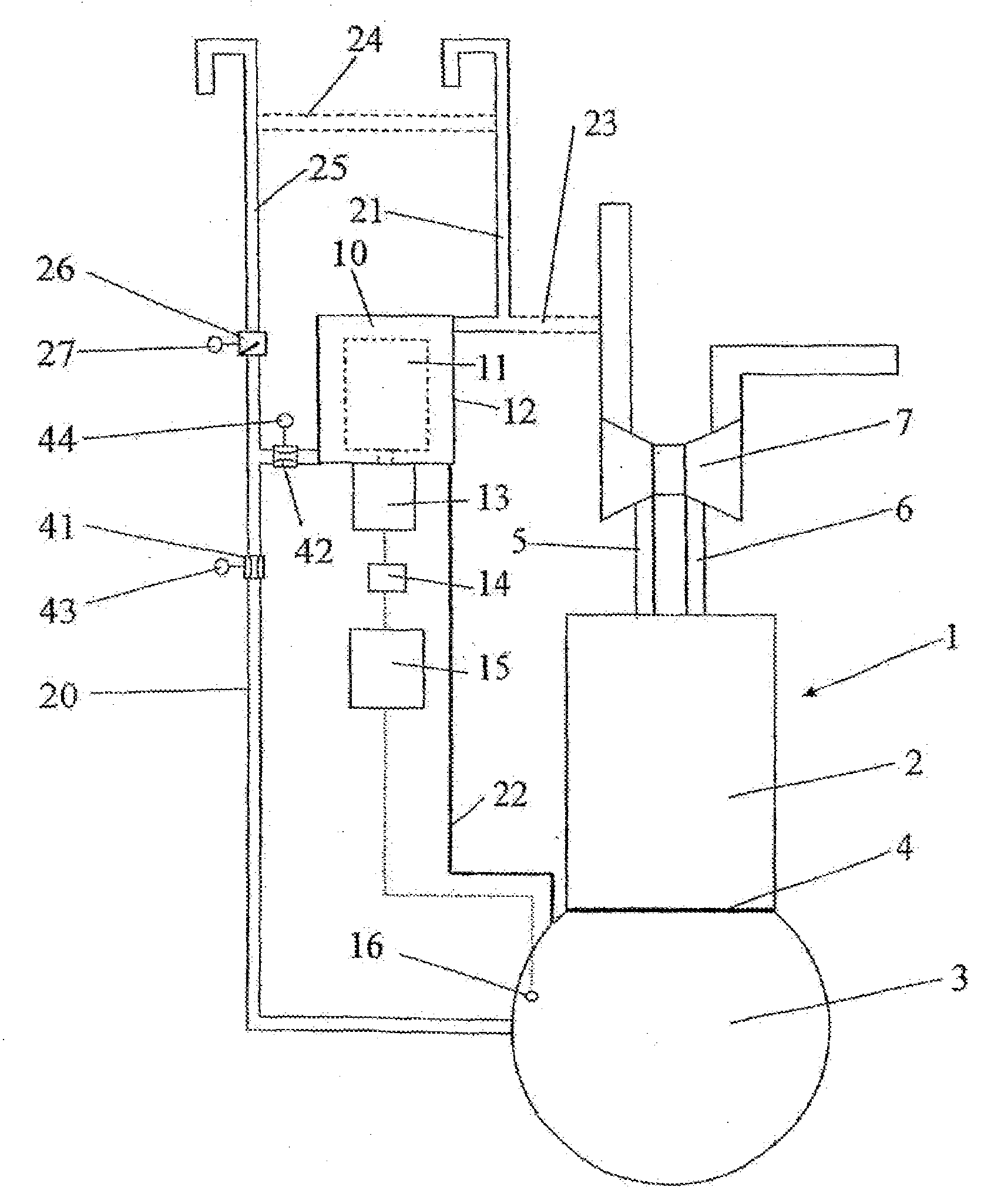

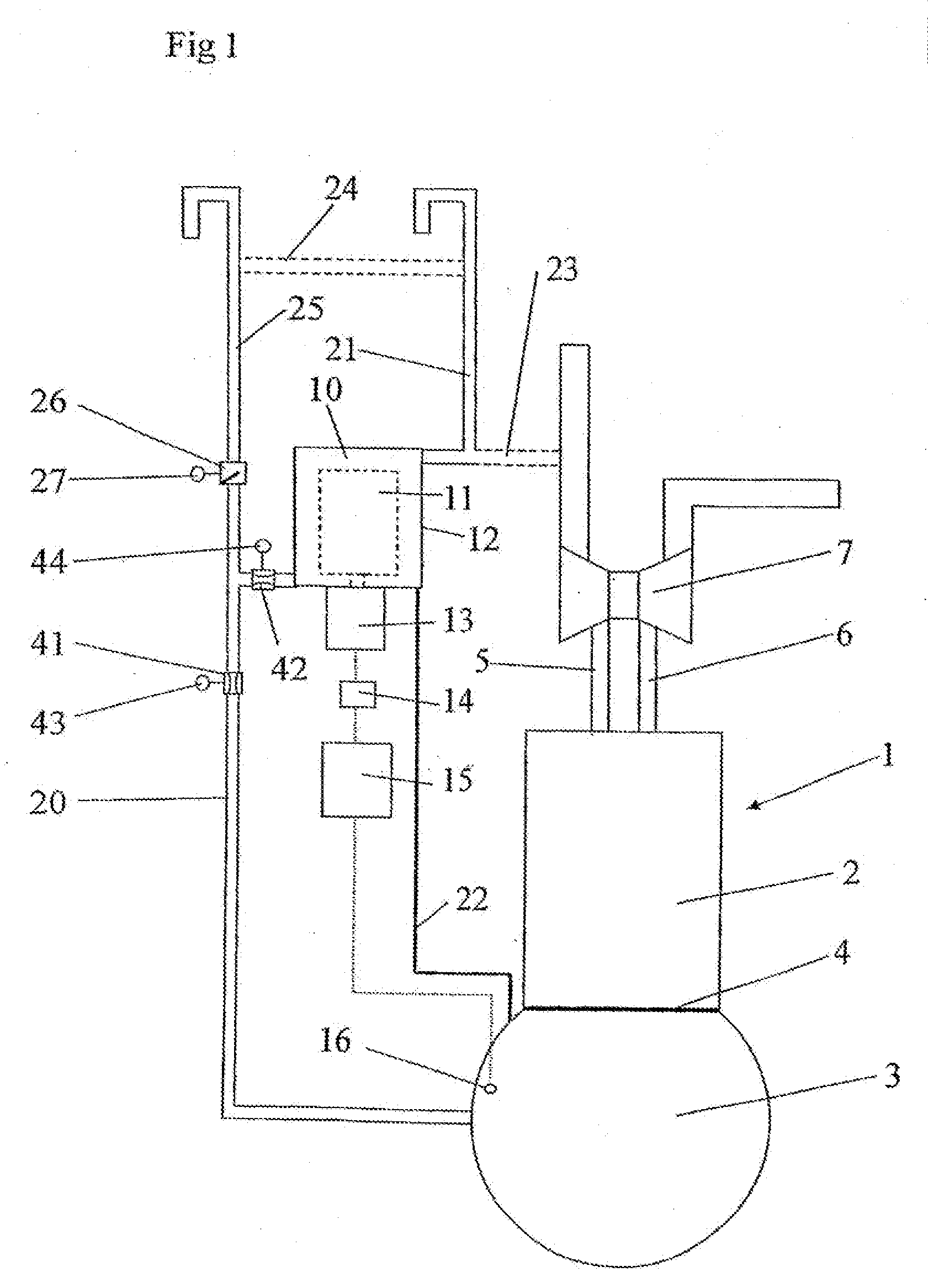

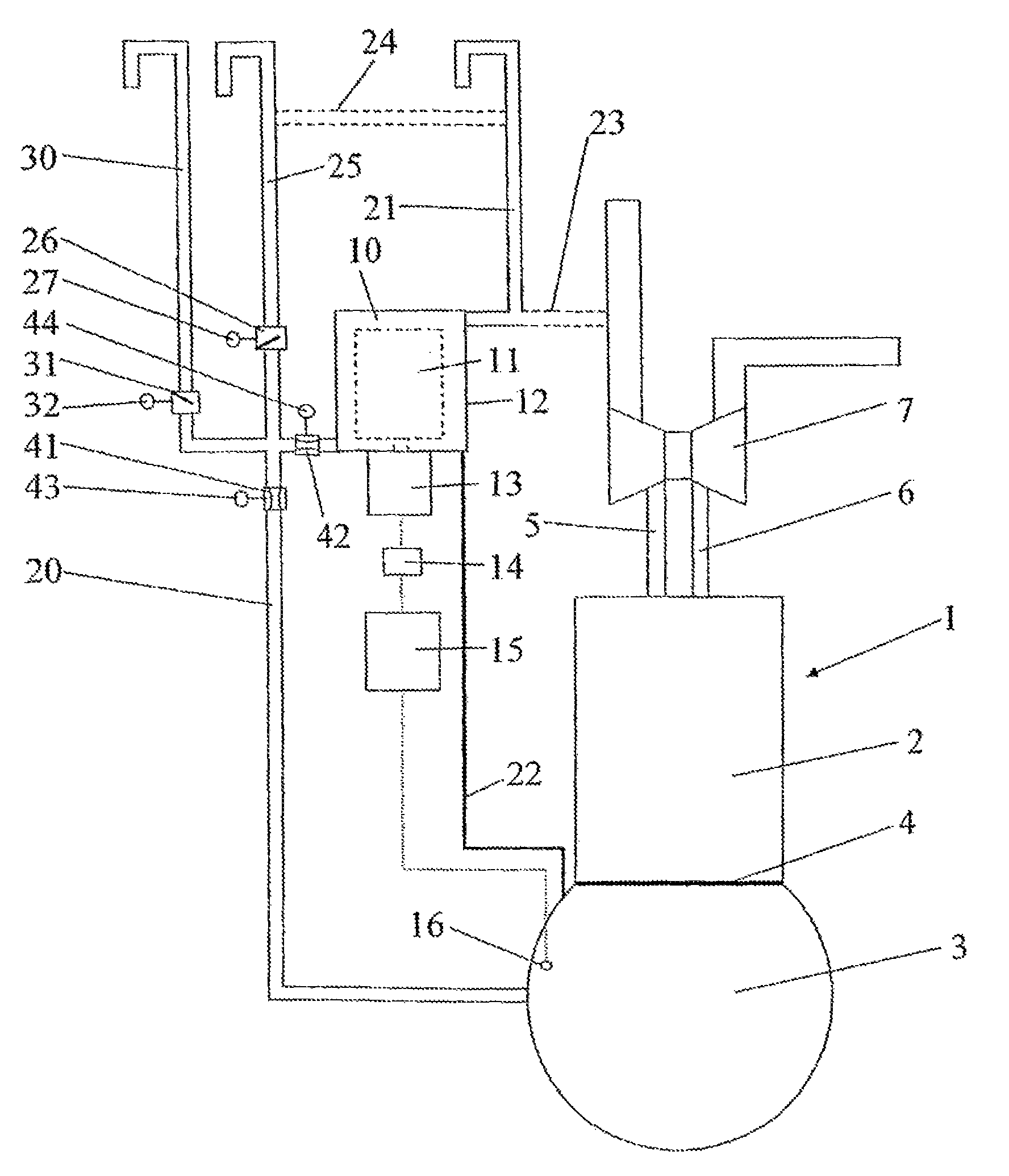

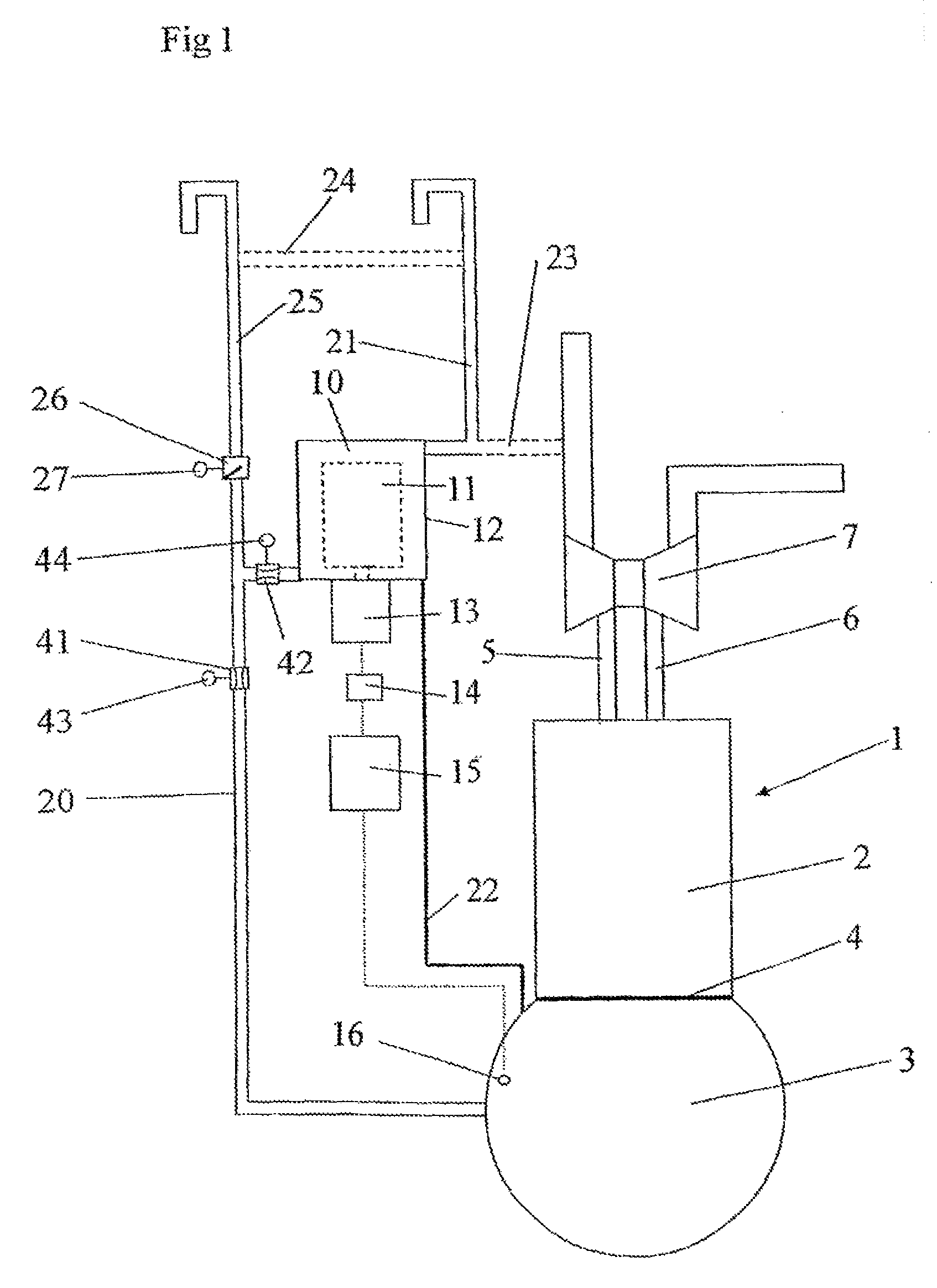

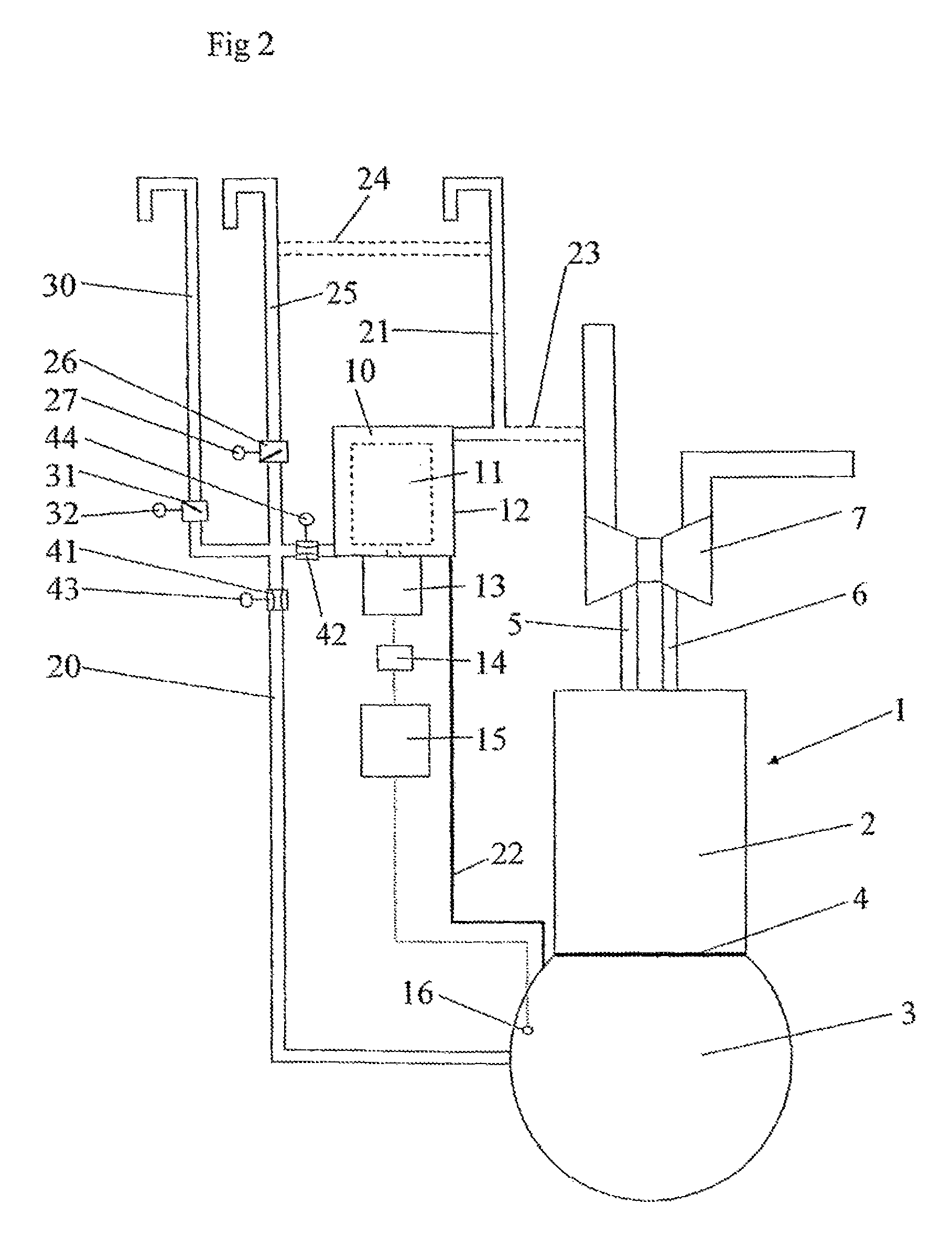

Device for cleaning of crankcase gases

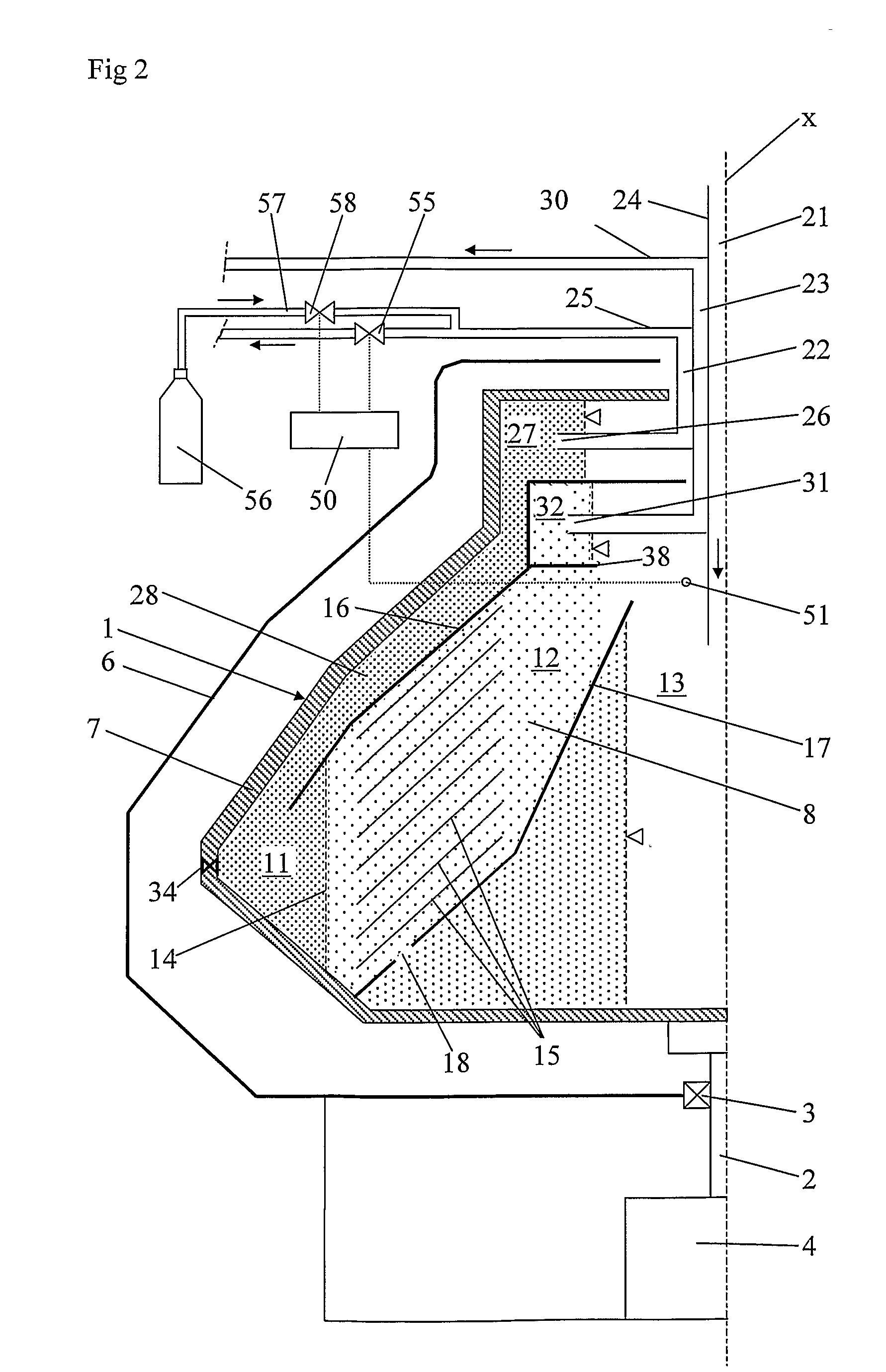

This document describes a device for cleaning of crankcase gases from a combustion engine, and a combustion engine having such a device. An inlet conduit is connected to a crankcase of the combustion engine. A centrifugal separator receives a flow of crankcase gases from the crankcase via the inlet conduit and comprises a routable centrifuge rotor for centrifuging the crankcase gases. A drive device drives the centrifuge rotor. An outlet conduit discharges cleaned crankcase gases from the centrifugal separator. The rotary speed of the drive device, and thus the rotary speed of the centrifuge rotor, is controllable depending on the gas pressure in the crankcase. An export conduit may be connected to the inlet conduit and adapted to enable discharge of a flow of crankcase gases from the crankcase by-passing the centrifugal separator depending on the gas pressure in the crankcase. An import conduit may be connected to the inlet conduit and adapted to enable feeding of a flow of air from the surroundings to the crankcase depending on the gas pressure in the crankcase.

Owner:ALFA LAVAL CORP AB

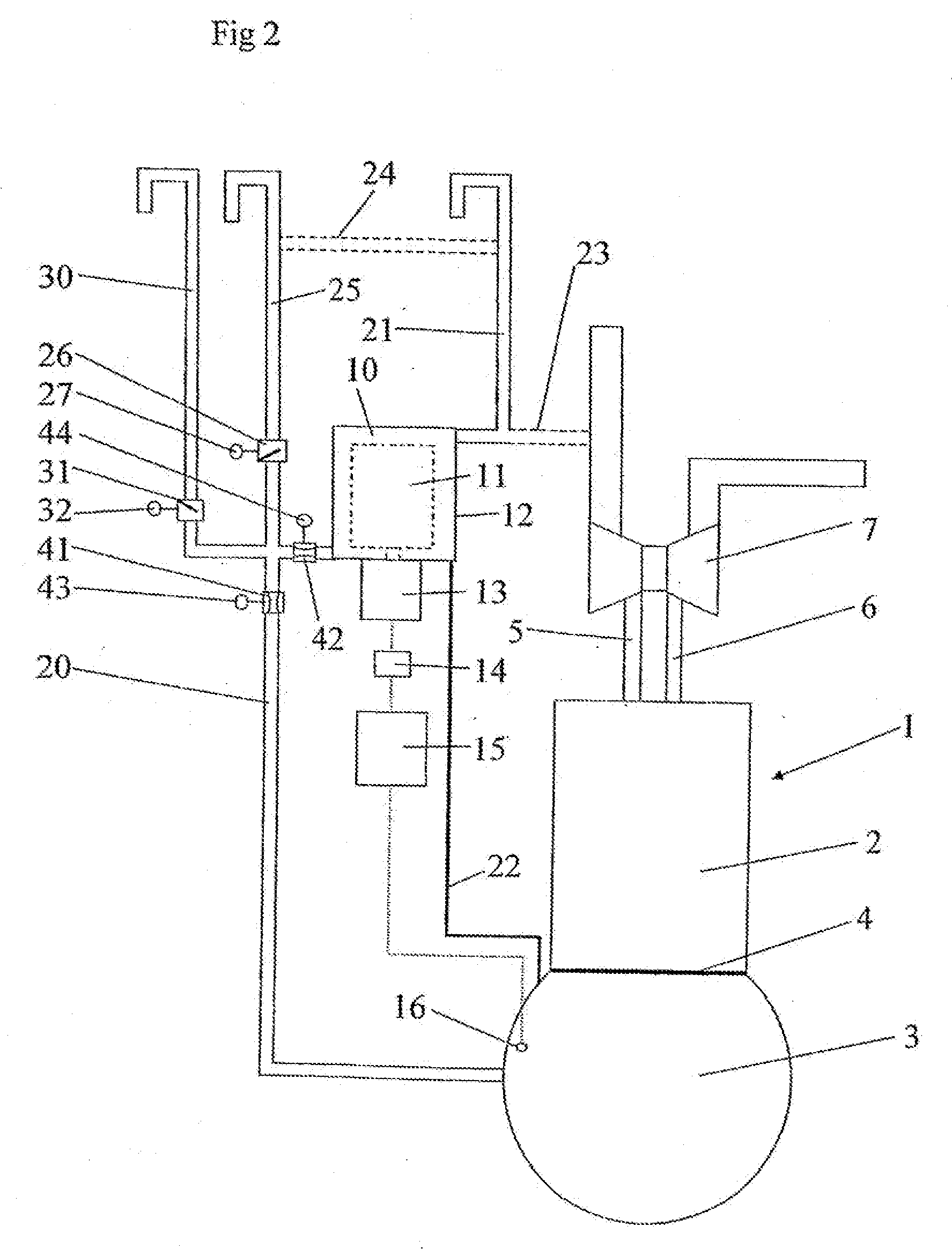

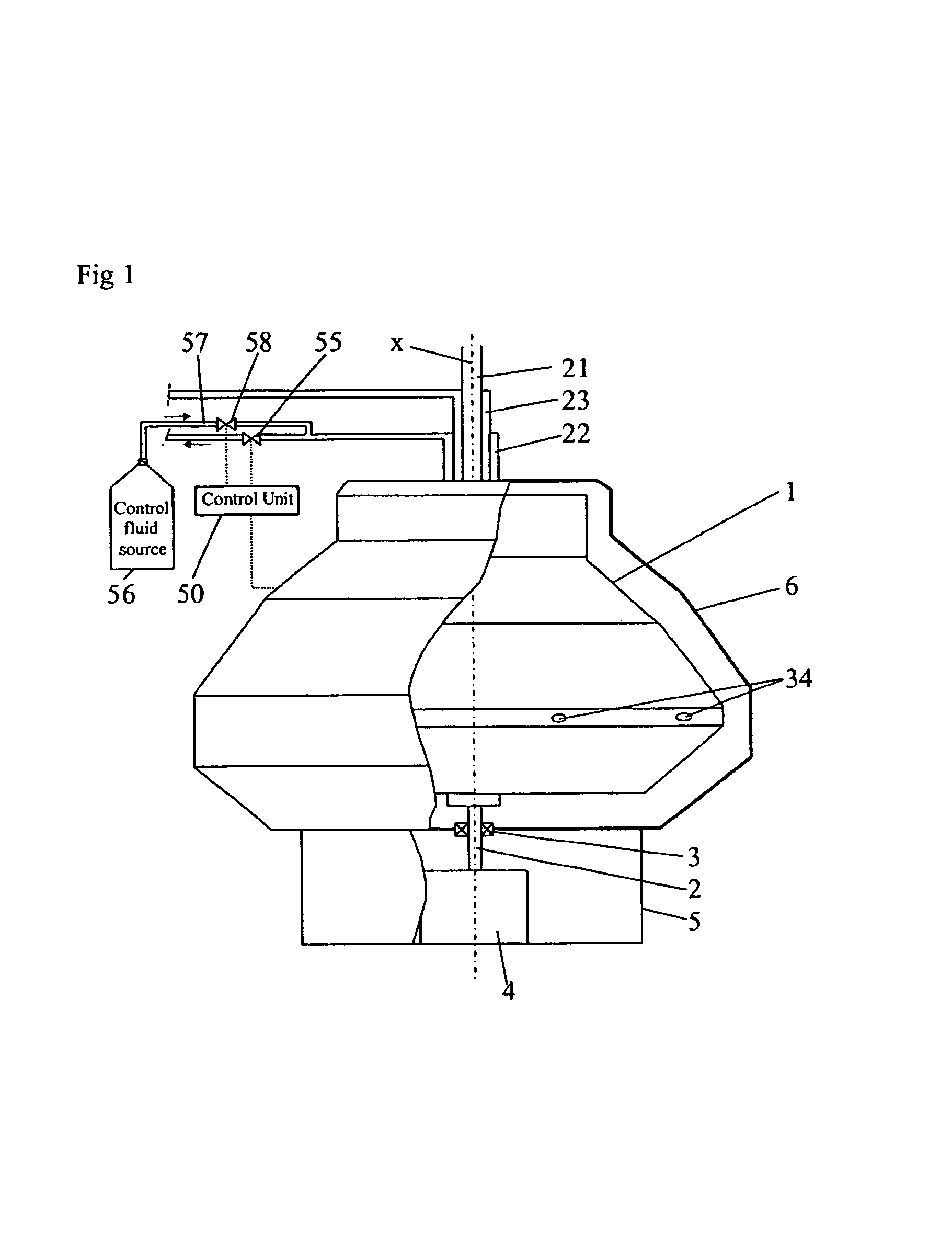

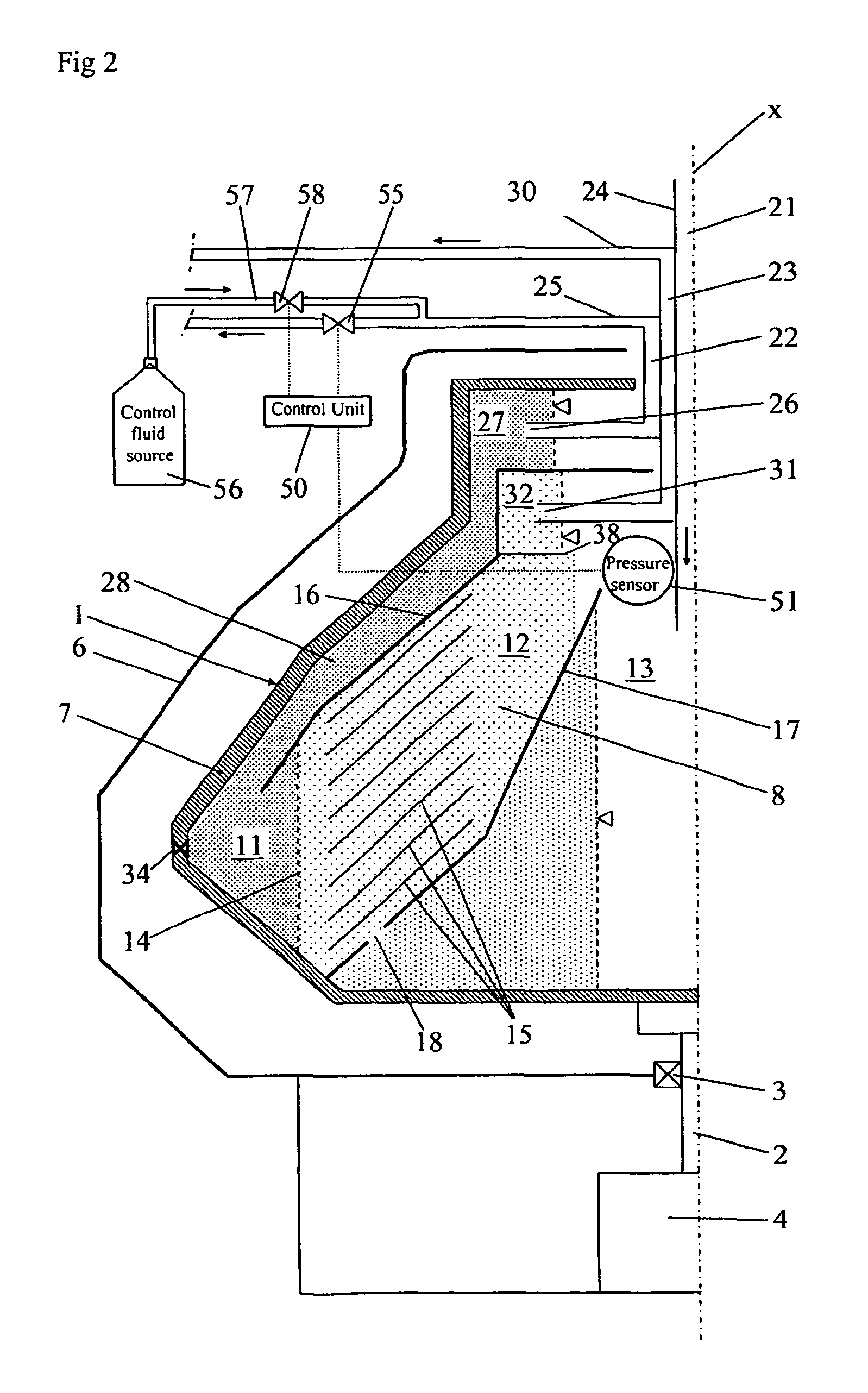

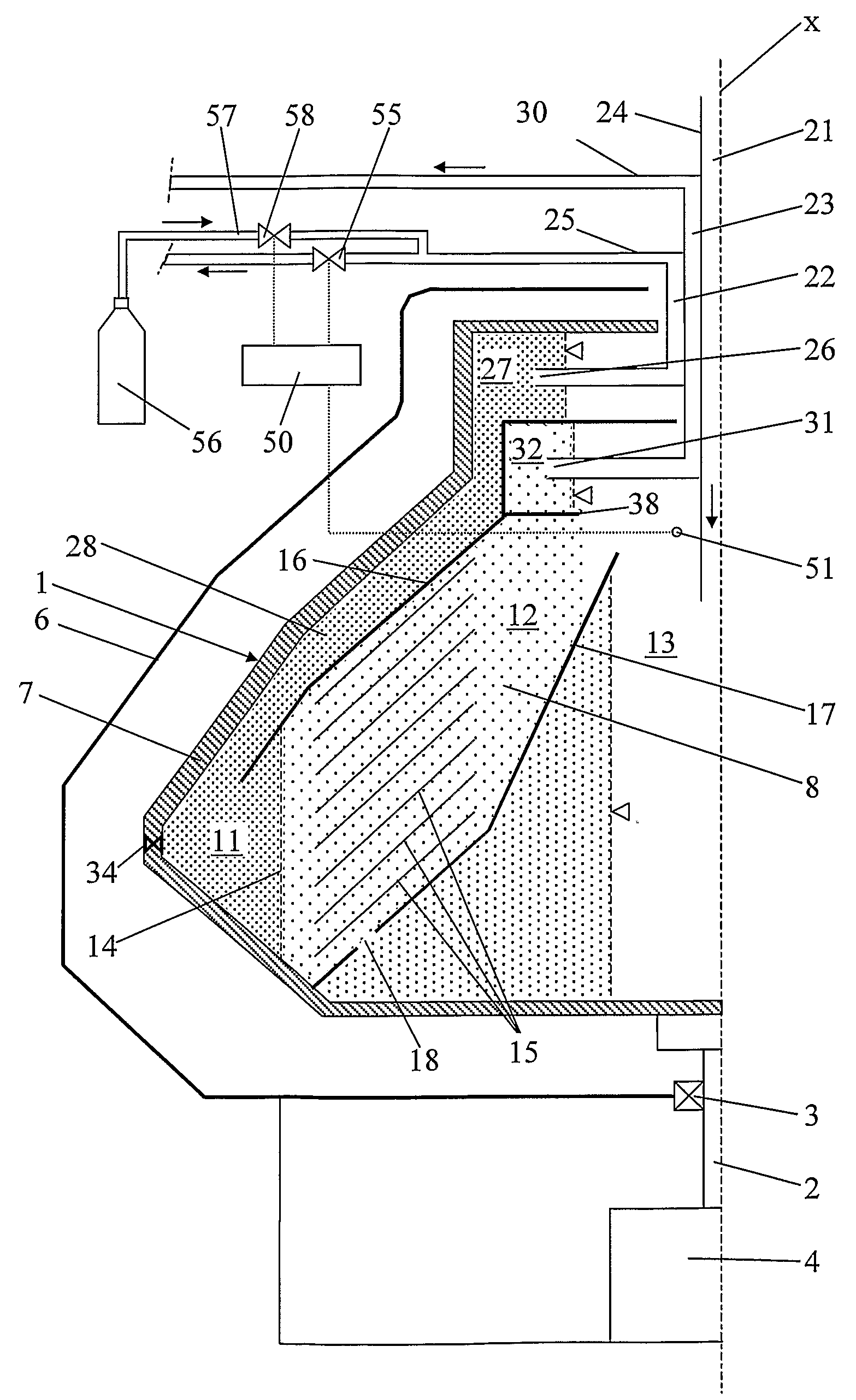

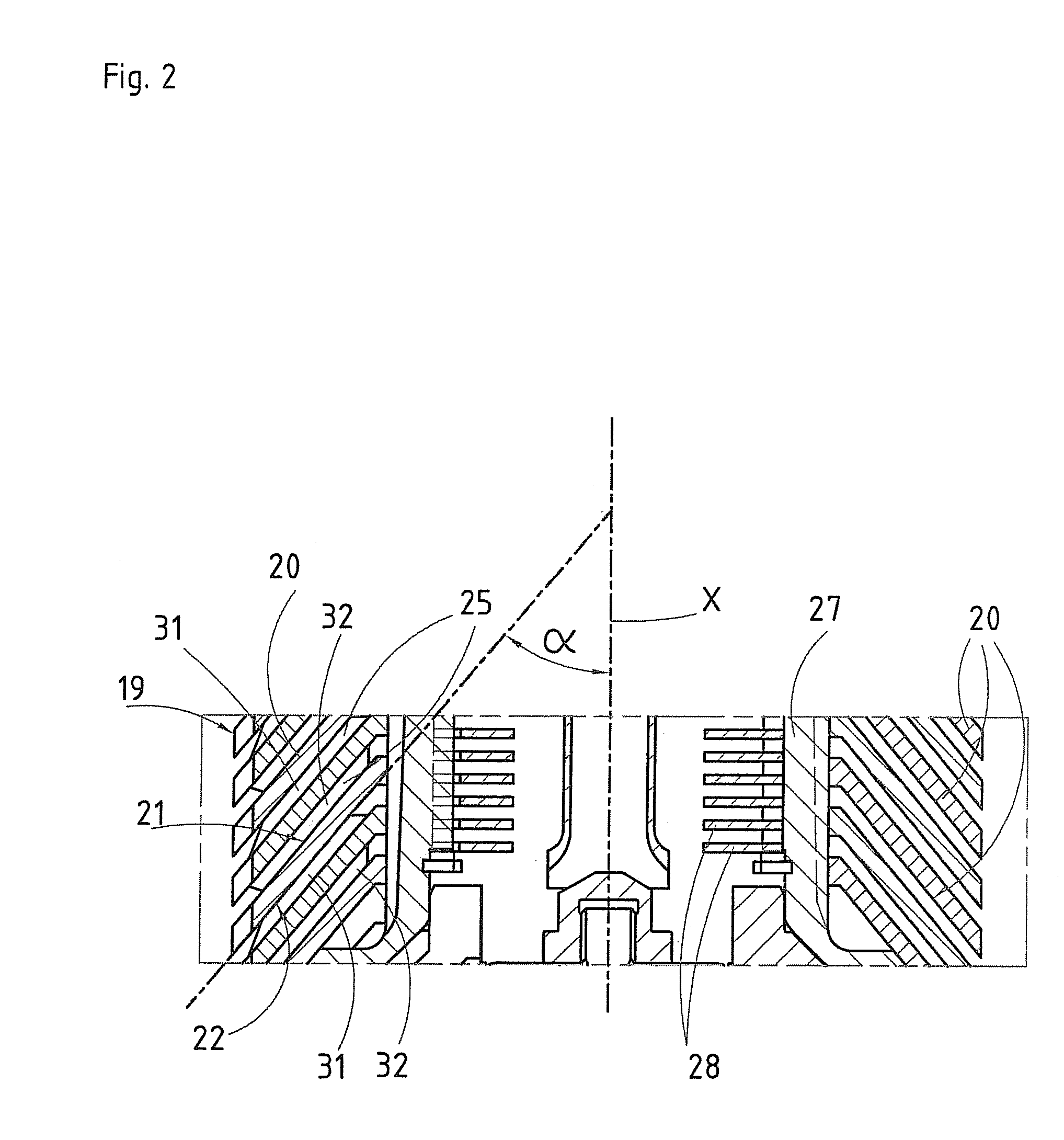

Apparatus and method for controlling the radial level of an interface in a centrifugal separator

ActiveUS7485084B2OptimalEasily realizedDispersed particle separationRotary centrifugesCentrifuge rotorRadial position

The invention refers to a centrifugal separator and a method of separating a product to a heavy phase and light phase. A centrifuge rotor encloses a closed separation space, which has a radially outer part for the heavy phase, a radially inner part for the light phase and a central gas-filled space. The radially outer part is separated from the radially inner part by a interface layer level. An inlet extends into the separation space for feeding the product. A first outlet extend from the radially outer part for discharge of the heavy phase. A second outlet extends from the radially inner part for discharge of the light phase. A control equipment permits control of the interface layer level to a desired radial position. A sensor senses a parameter related to the gas pressure in the central space. The control equipment controls the counter pressure in the first outlet in response to the sensed parameter for controlling the interface layer level to the desired radial position.

Owner:ALFA LAVAL CORP AB

Centrifugal Separator

ActiveUS20080171645A1OptimalEasily realizedDispersed particle separationRotary centrifugesCentrifuge rotorRadial position

The invention refers to a centrifugal separator and a method of separating a product to a heavy phase and light phase. A centrifuge rotor encloses a closed separation space, which has a radially outer part for the heavy phase, a radially inner part for the light phase and a central gas-filled space. The radially outer part is separated from the radially inner part by a interface layer level. An inlet extends into the separation space for feeding the product. A first outlet extend from the radially outer part for discharge of the heavy phase. A second outlet extends from the radially inner part for discharge of the light phase. A control equipment permits control of the interface layer level to a desired radial position. A sensor senses a parameter related to the gas pressure in the central space. The control equipment controls the counter pressure in the first outlet in response to the sensed parameter for controlling the interface layer level to the desired radial position.

Owner:ALFA LAVAL CORP AB

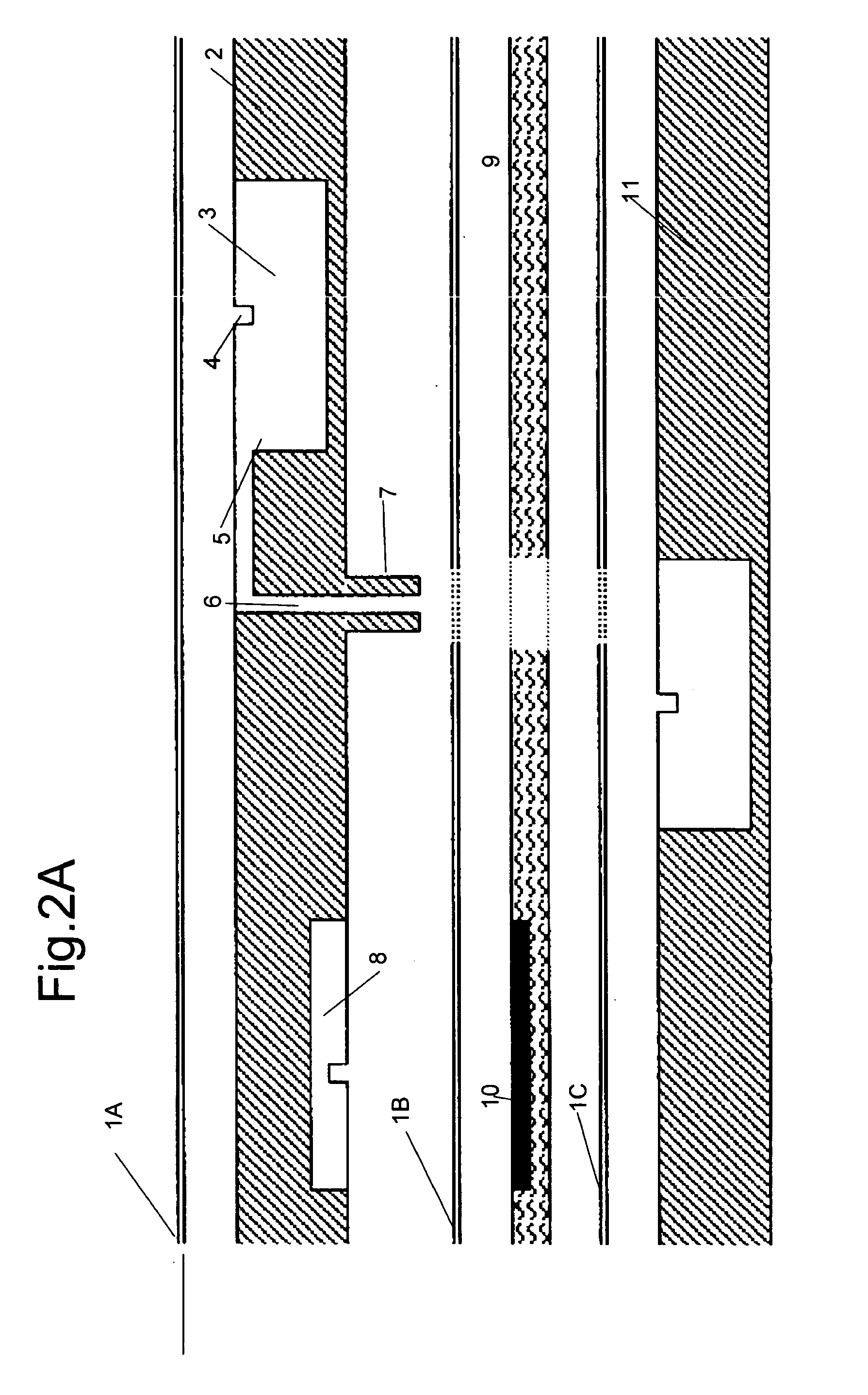

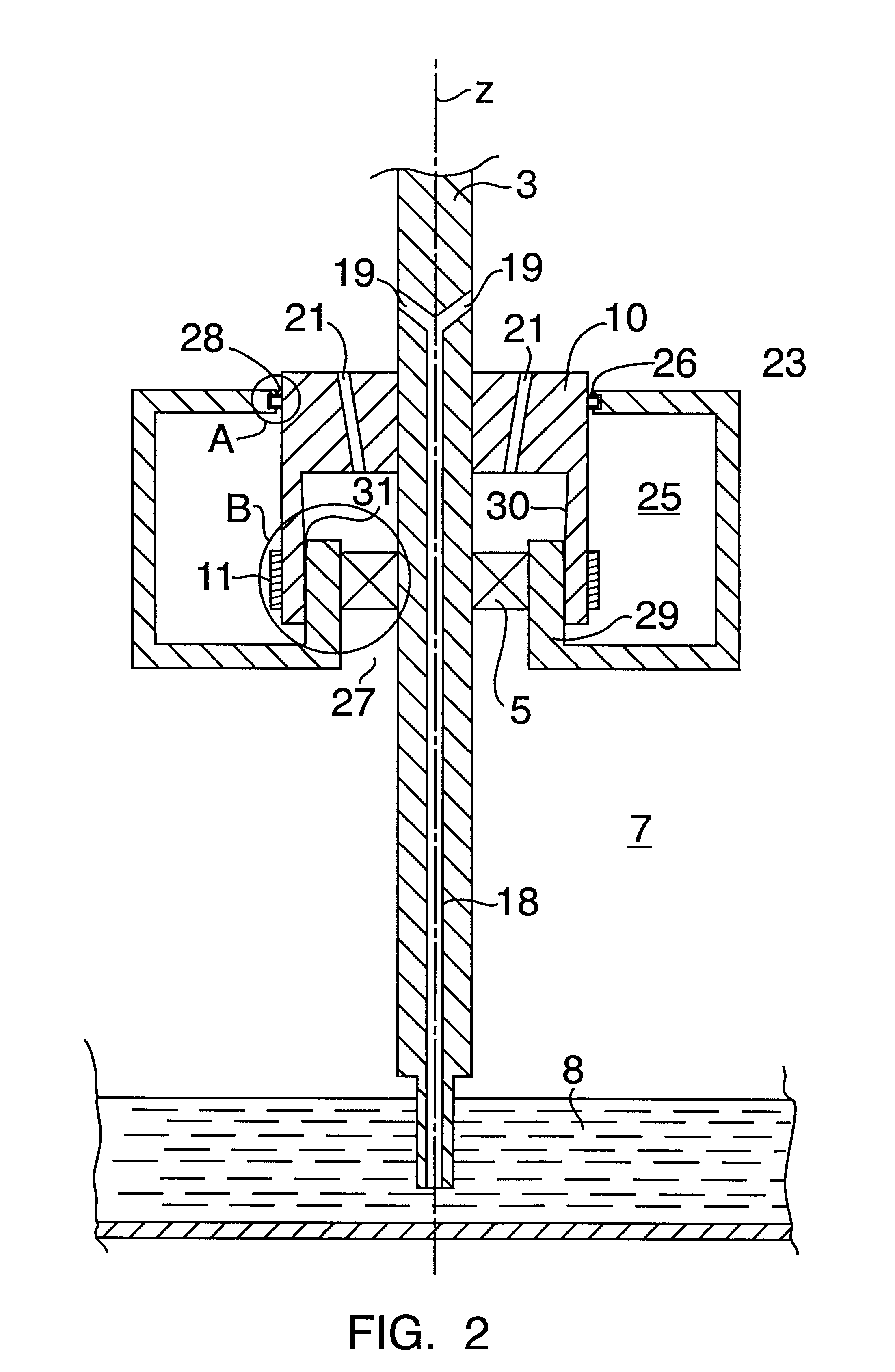

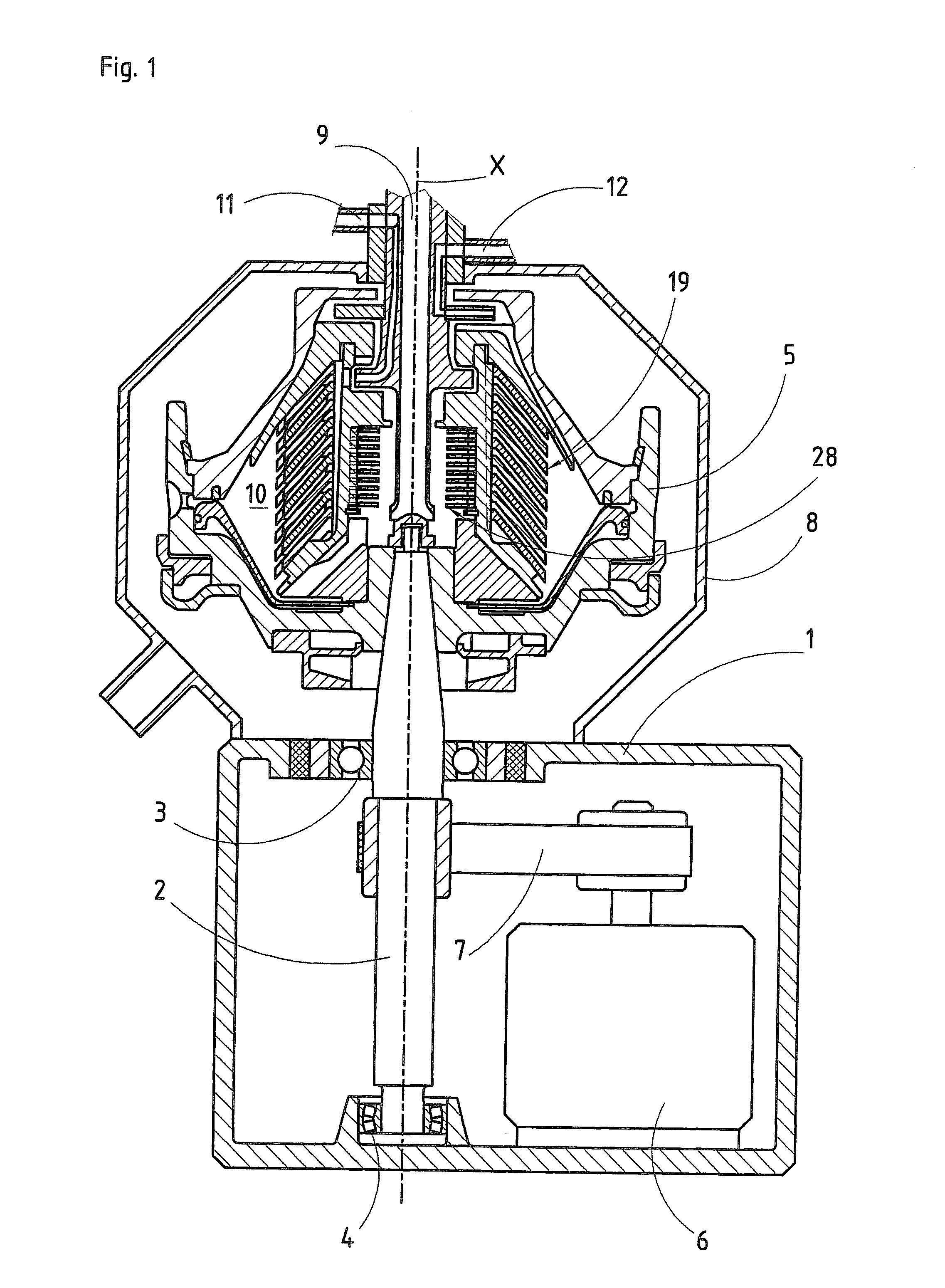

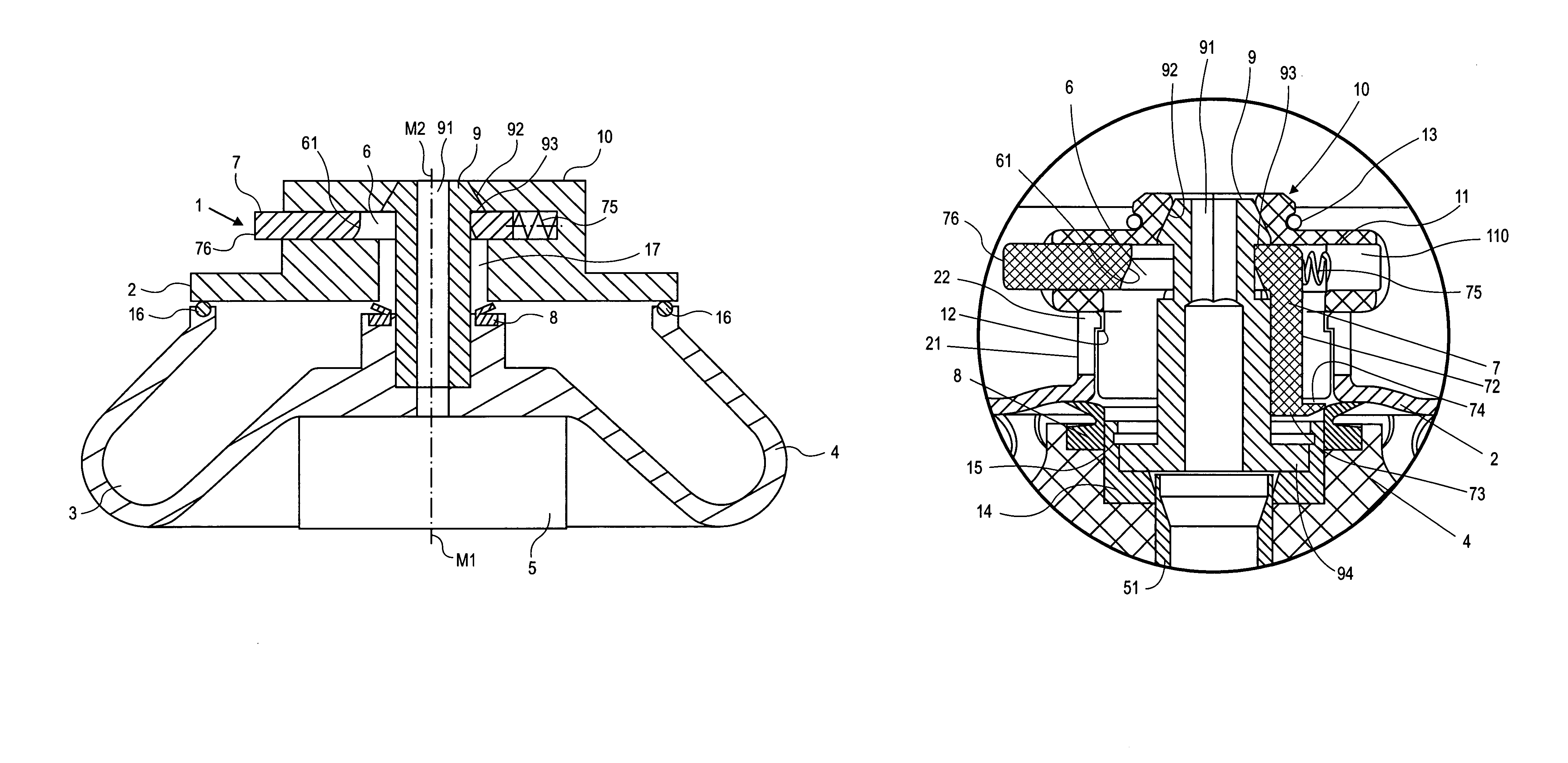

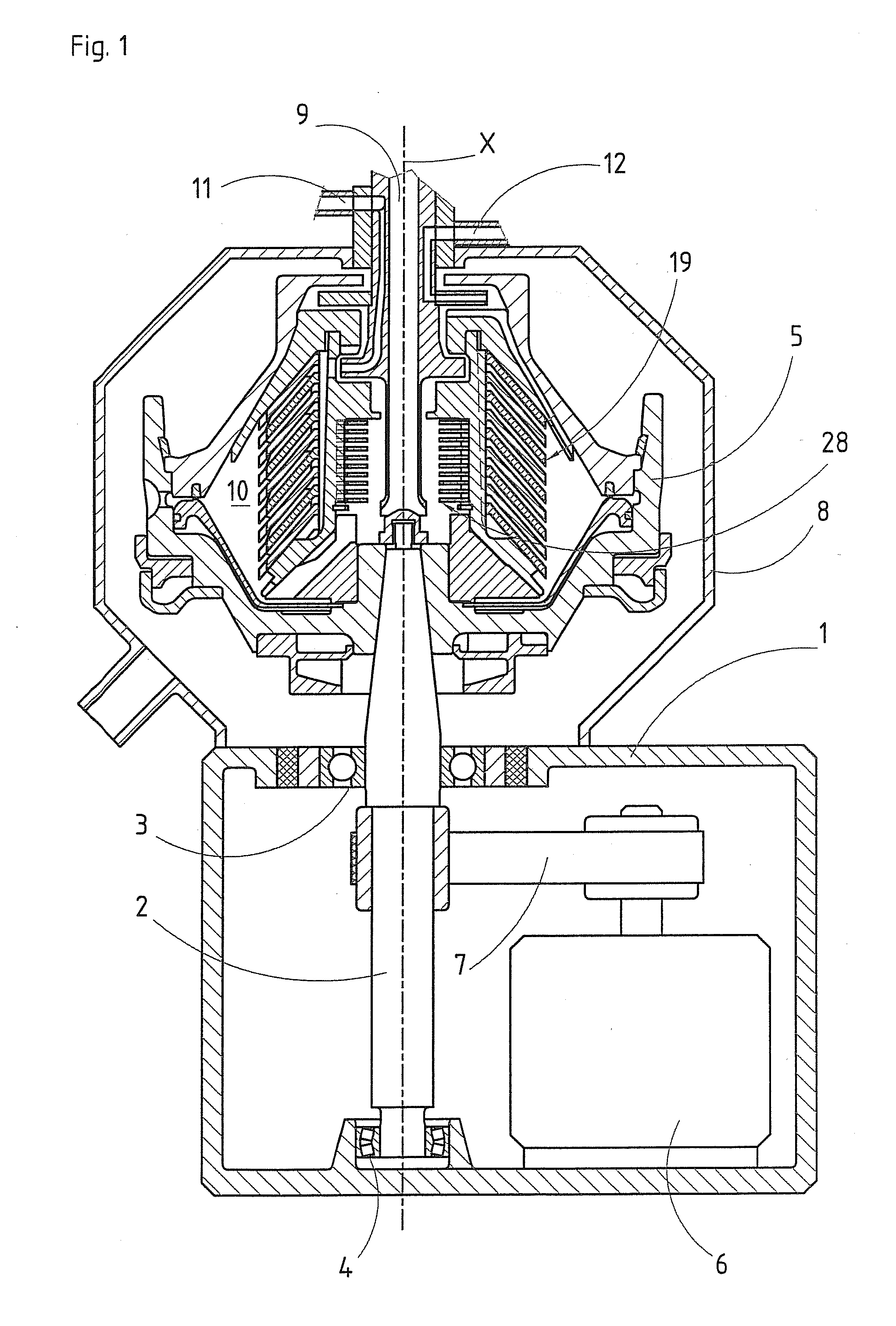

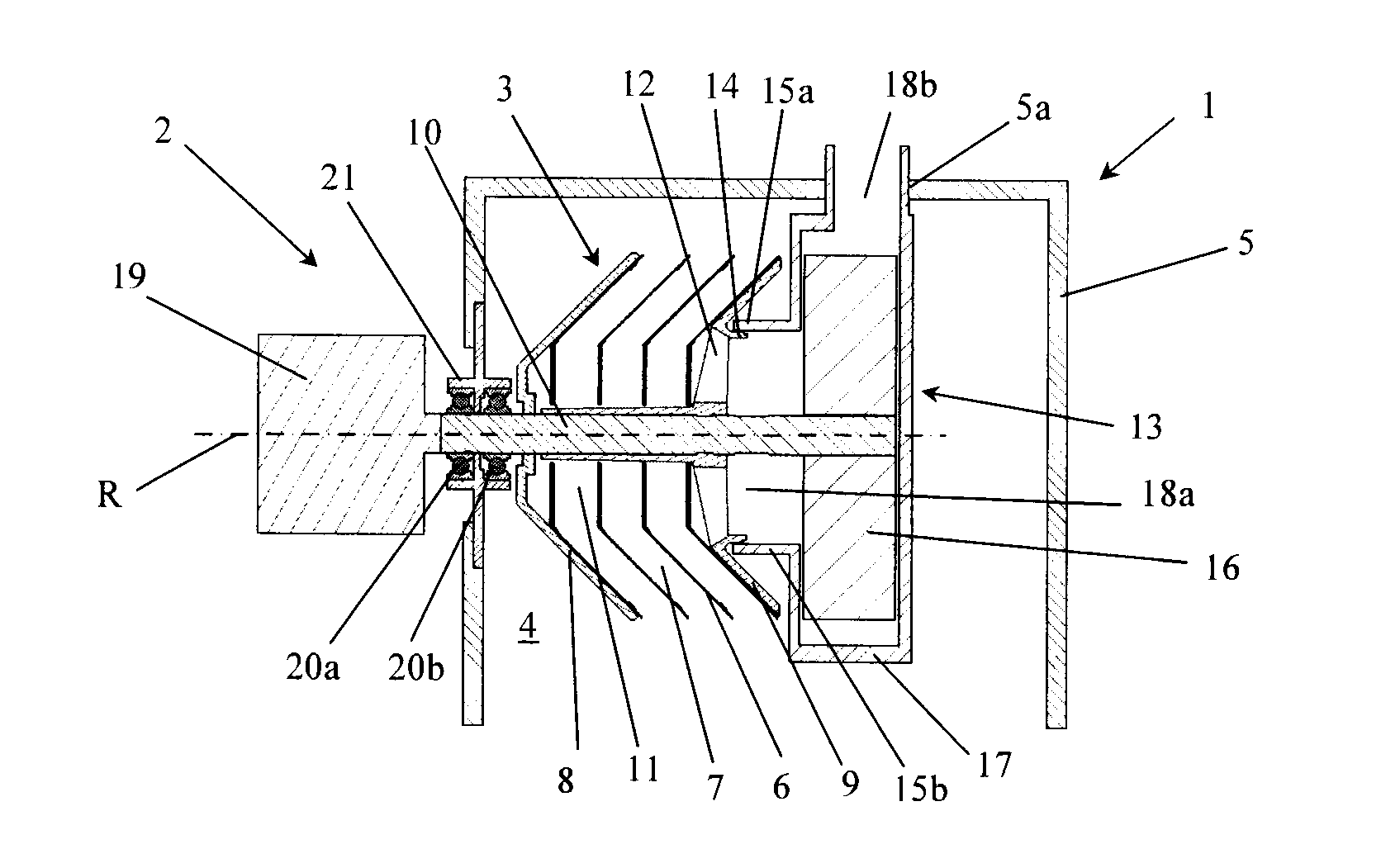

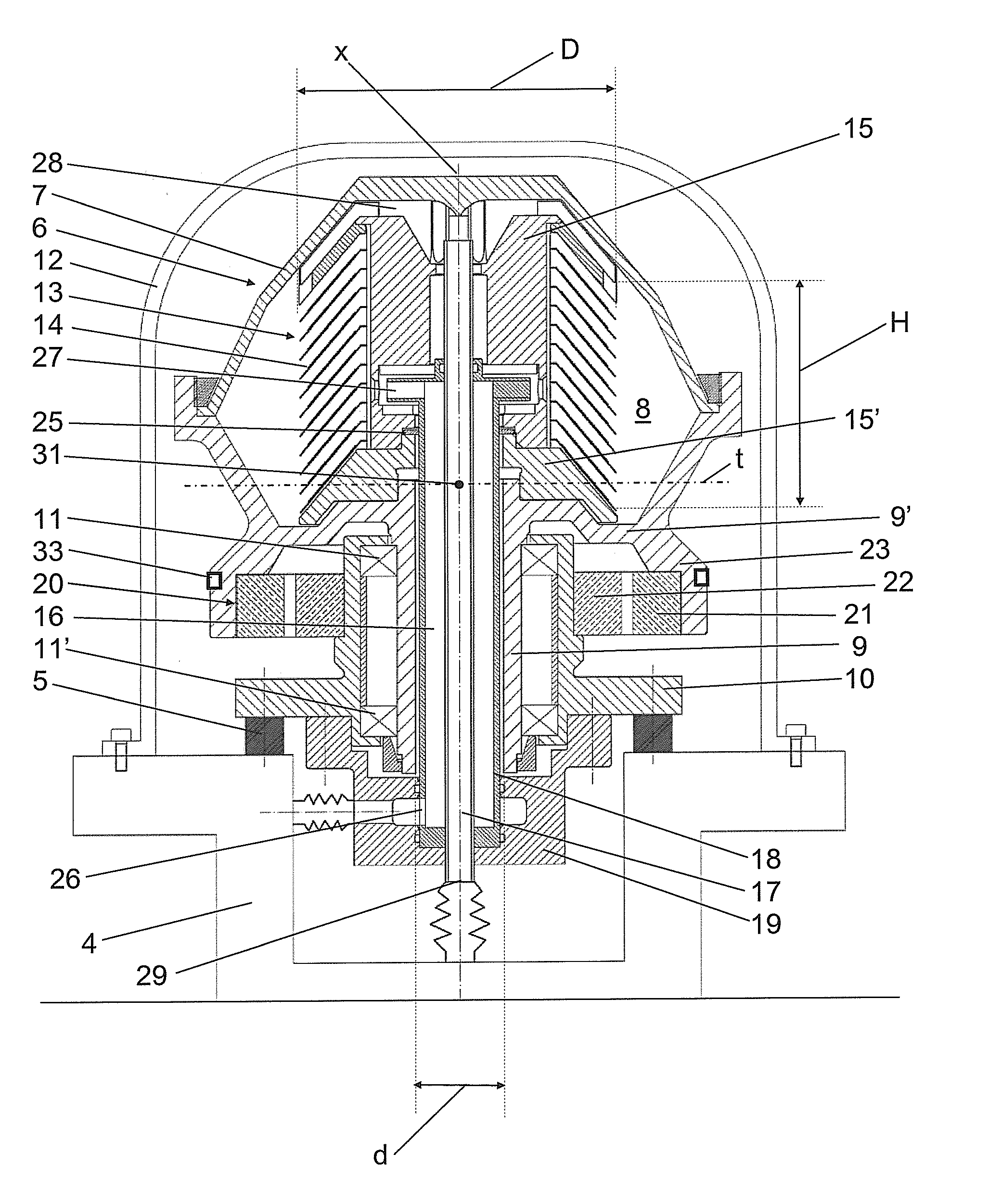

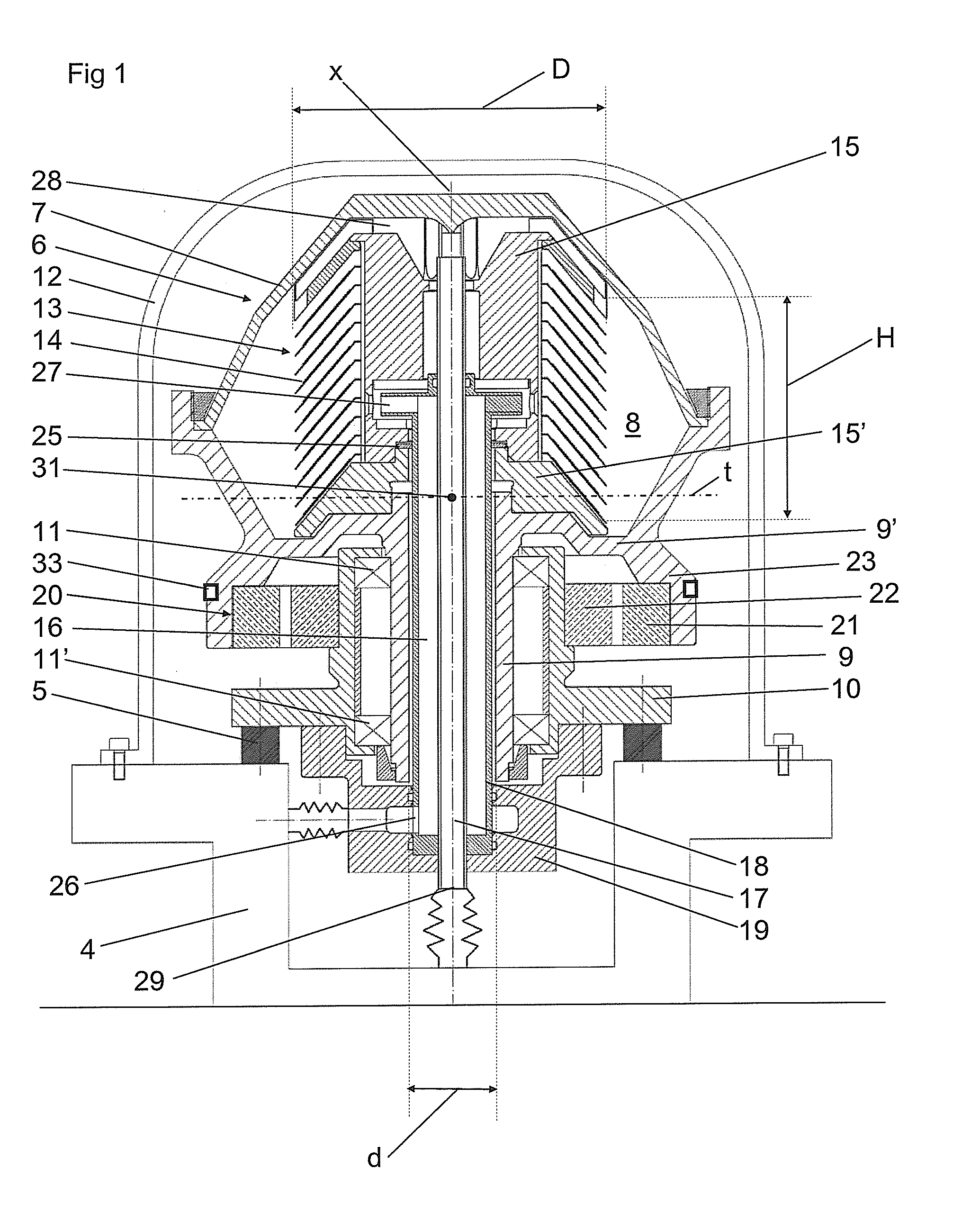

Drive unit for a centrifuge rotor of a centrifugal separator

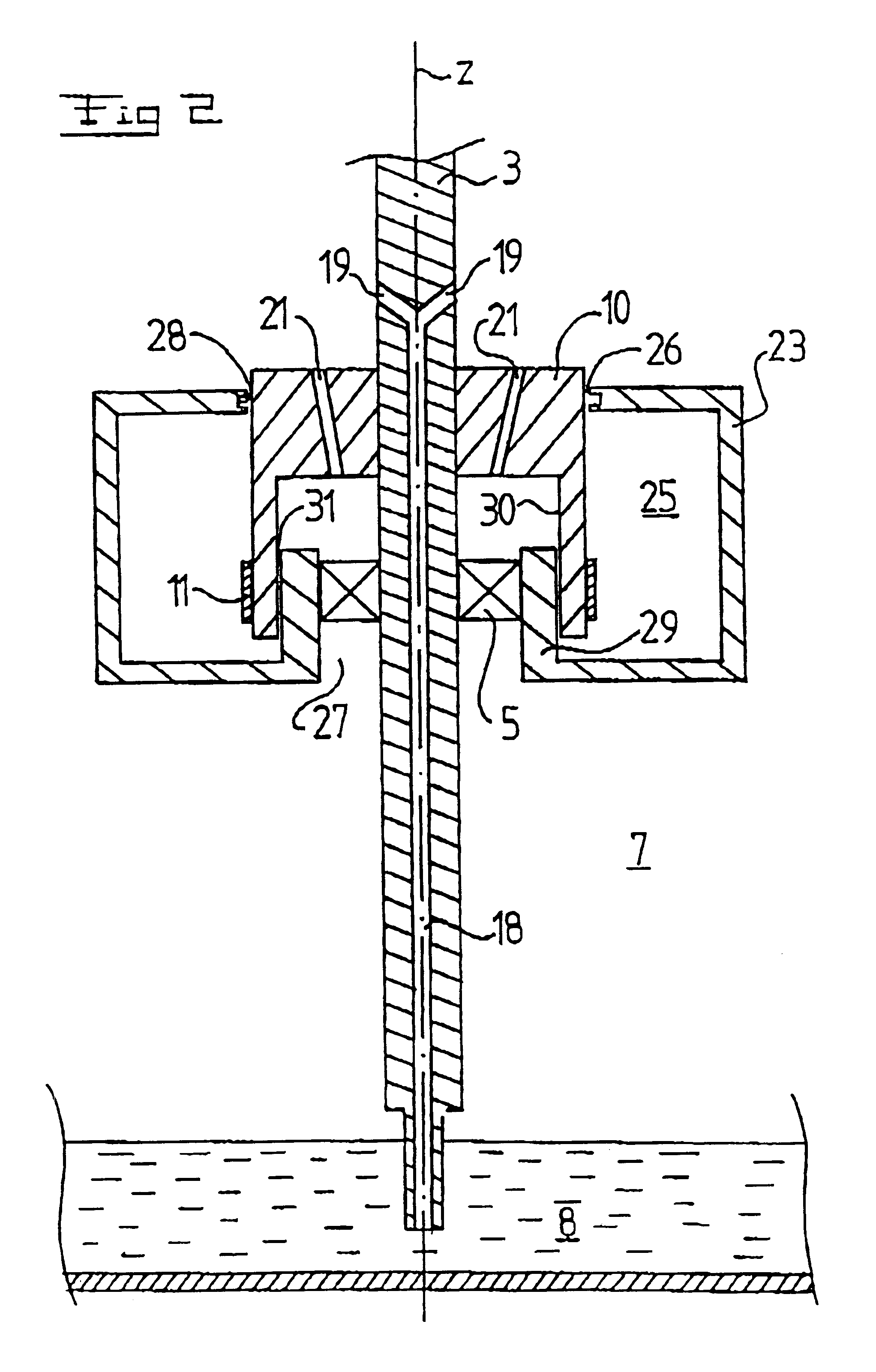

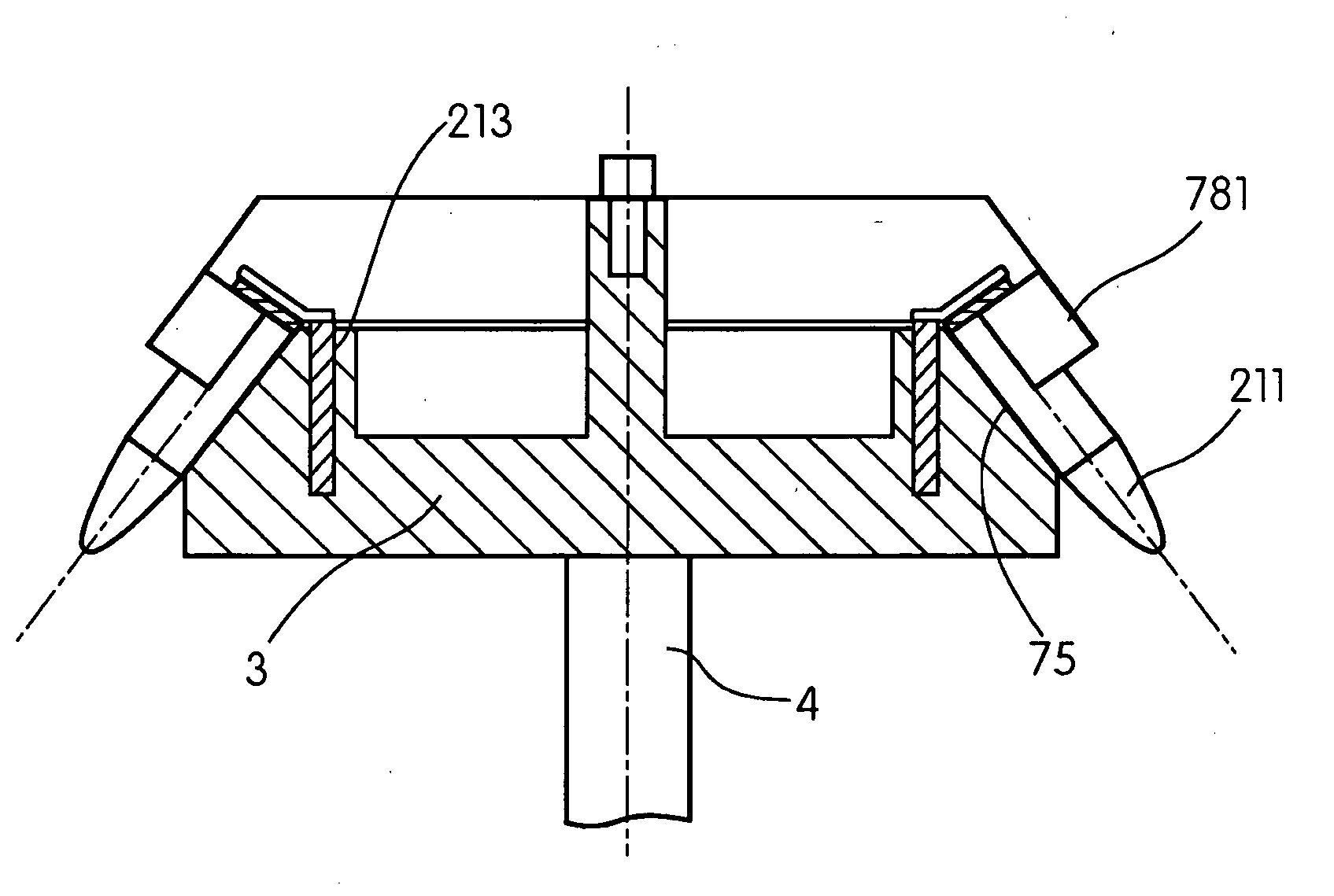

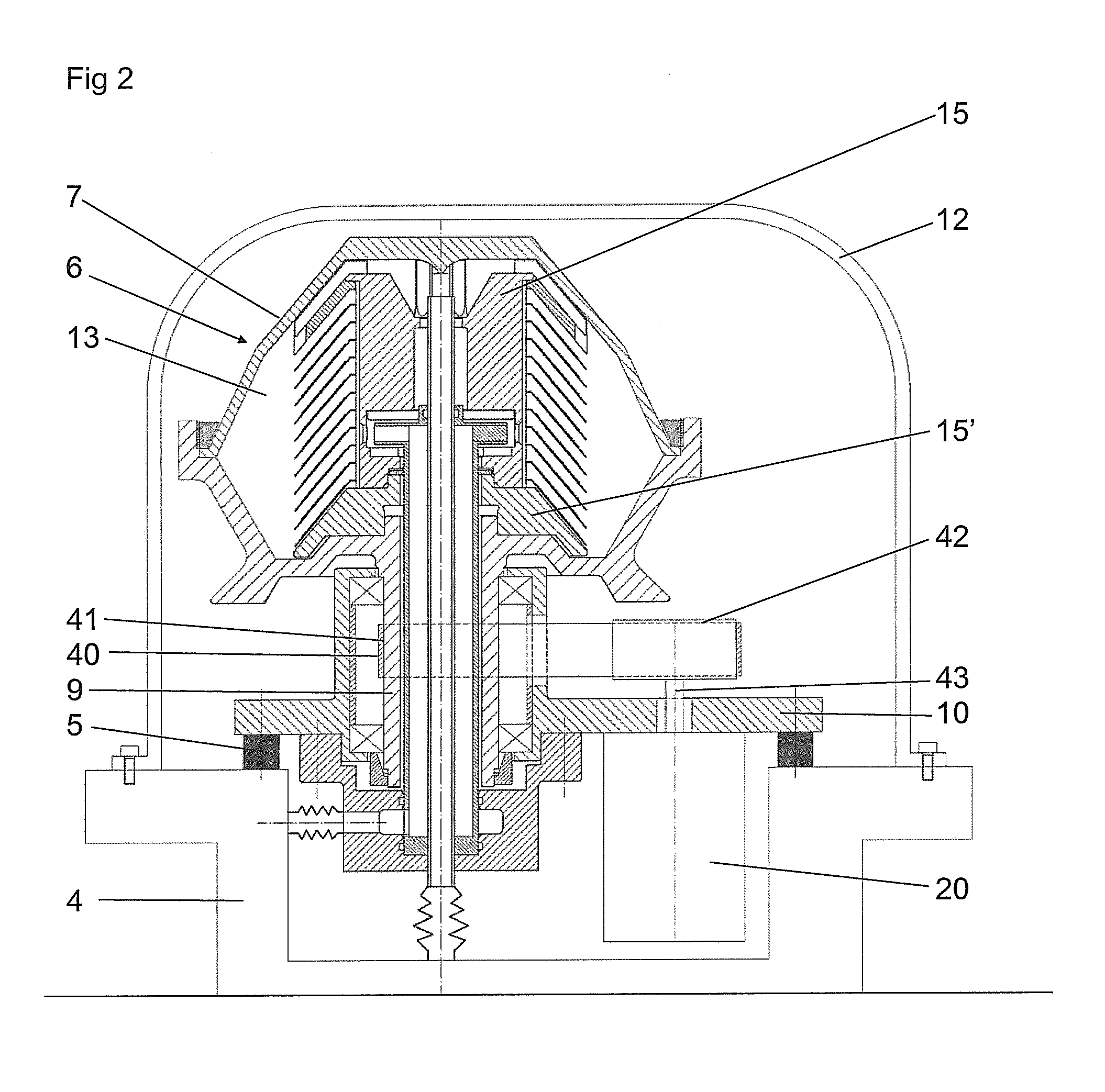

A drive unit for a centrifuge rotor of a centrifugal separator is provided that includes a drive shaft, arranged to support the centrifuge rotor and rotatably journalled around an axis (z) of rotation, a casing, which forms an inner space for the drive shaft, a drive motor shaft which is provided outside the casing and connected to the drive shaft by means of a transferring member extending through a passage in the casing, at least one shielding member, which is provided inside the casing in such a manner that the part of the transferring member which is located inside the casing is shielded from the inner space, and wherein the shielding member forms a channel, which extends through the casing and is shielded from the inner space of the casing.

Owner:ALFA LAVAL AB

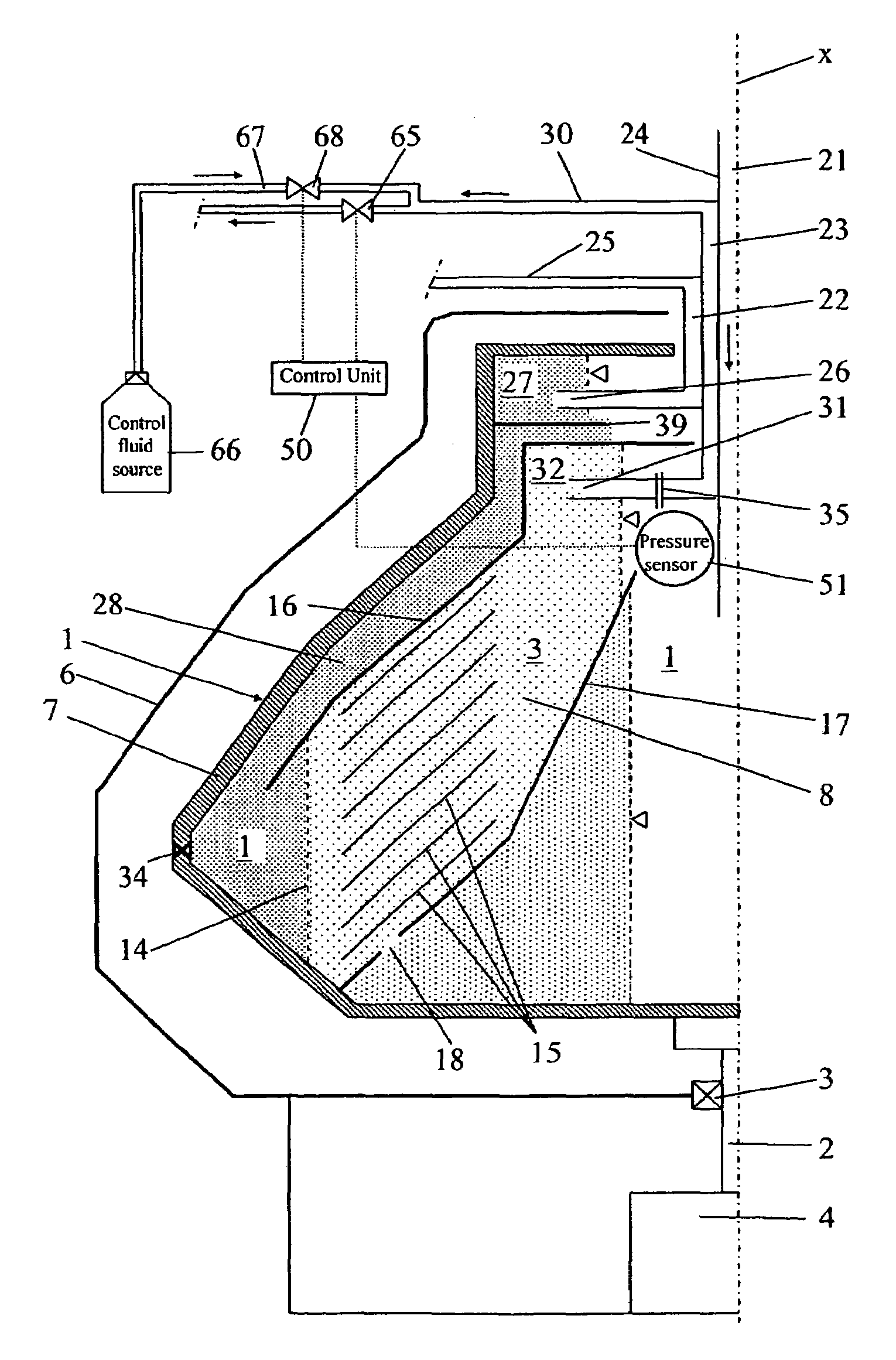

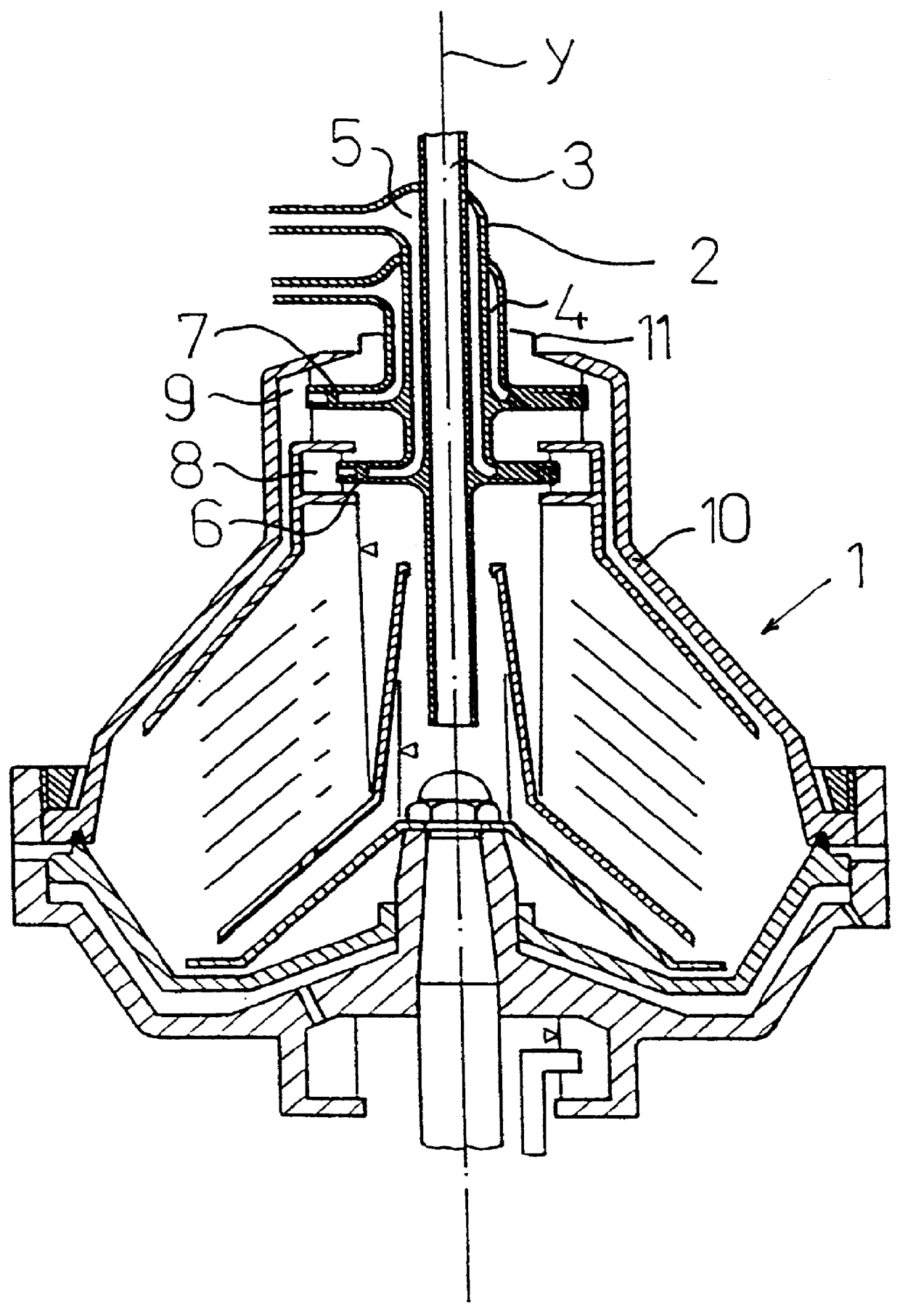

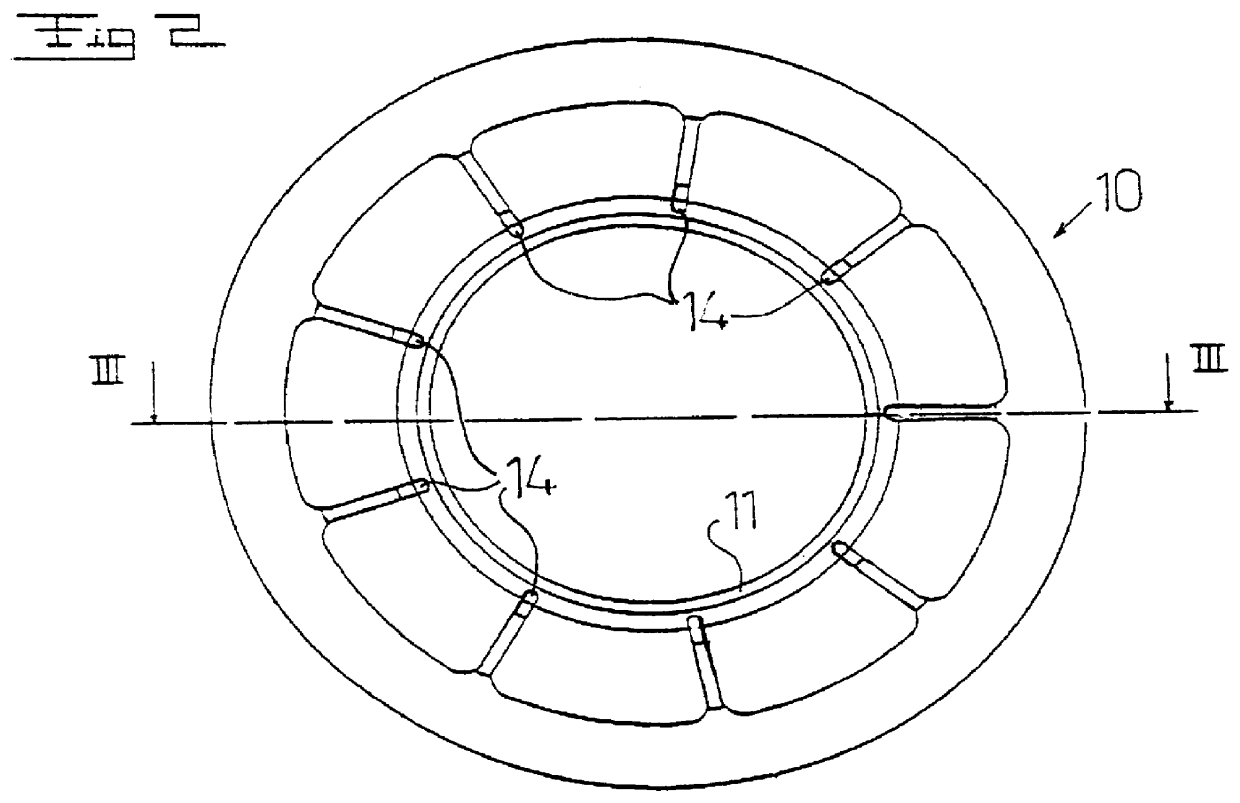

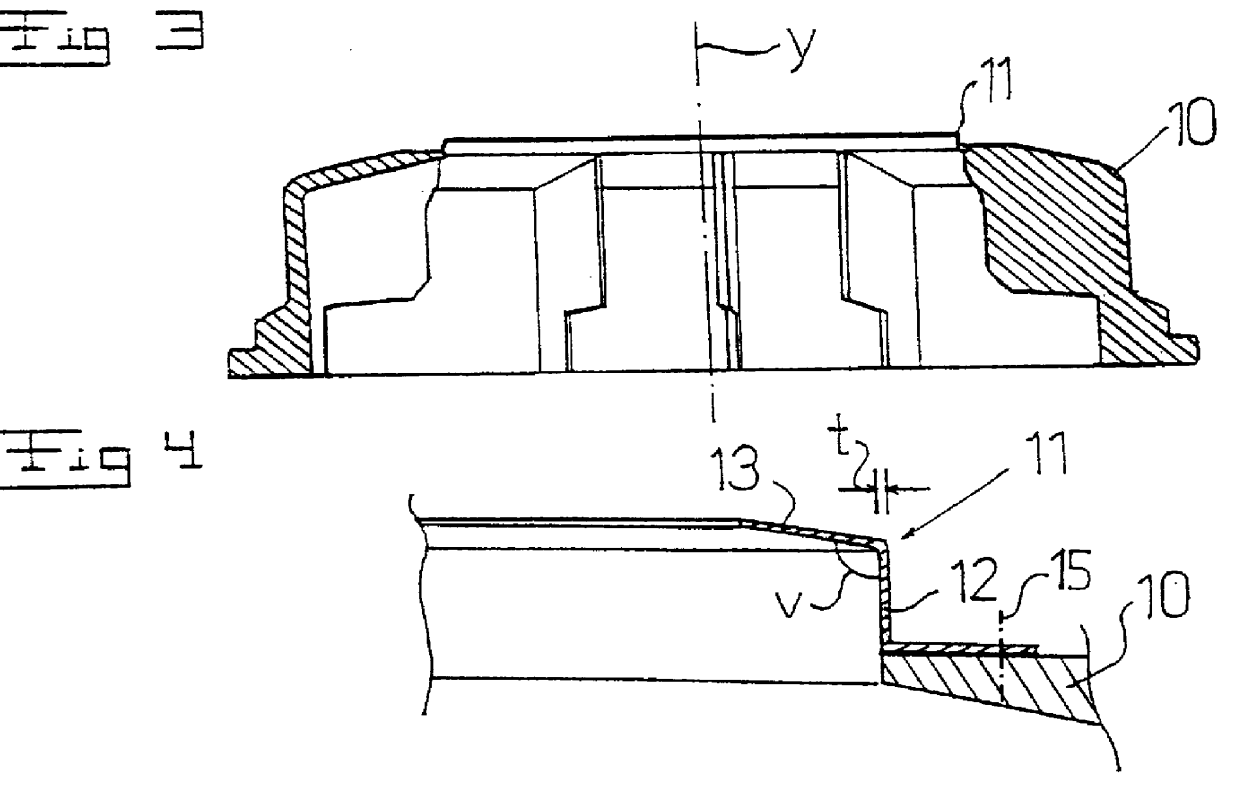

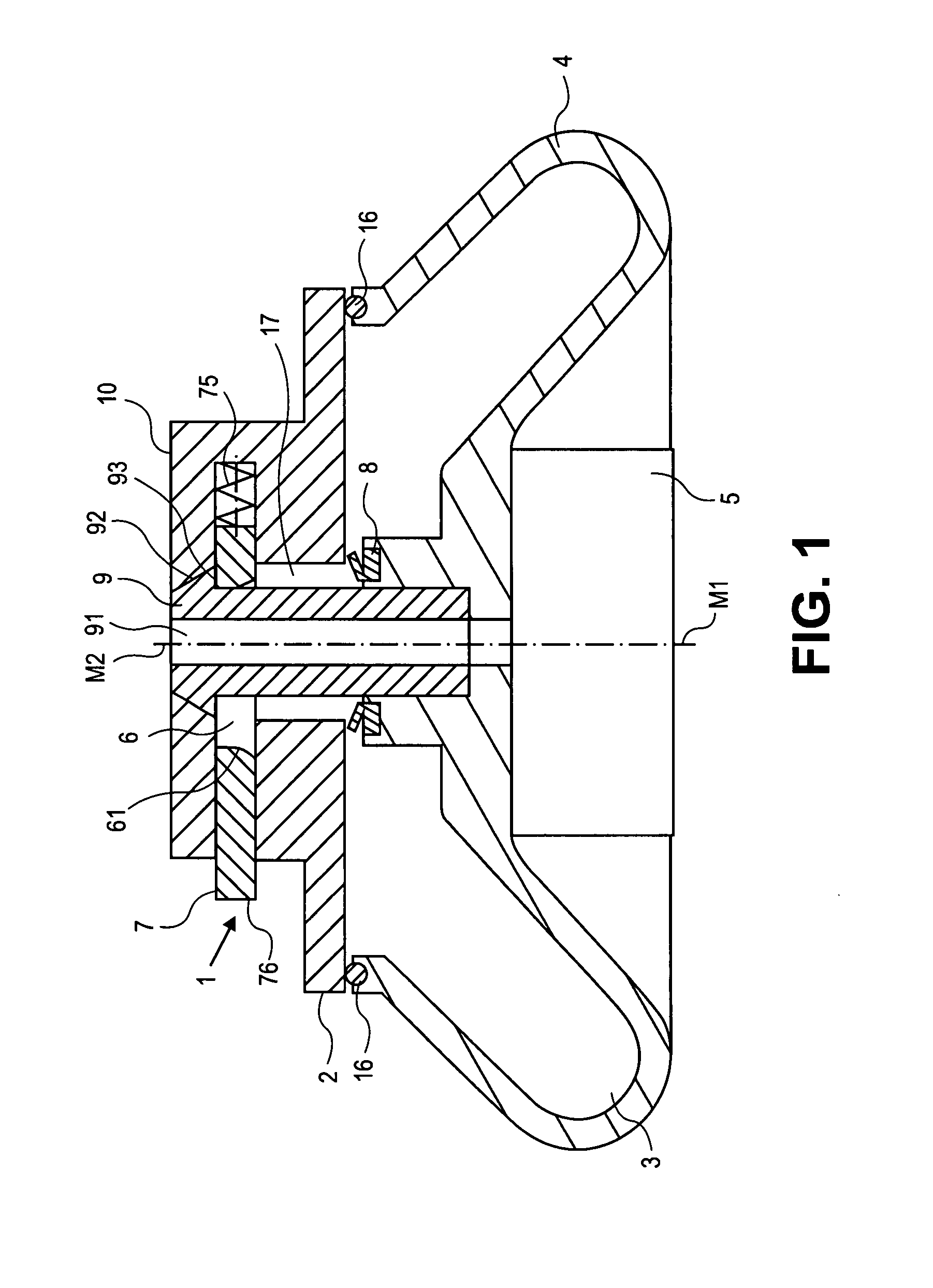

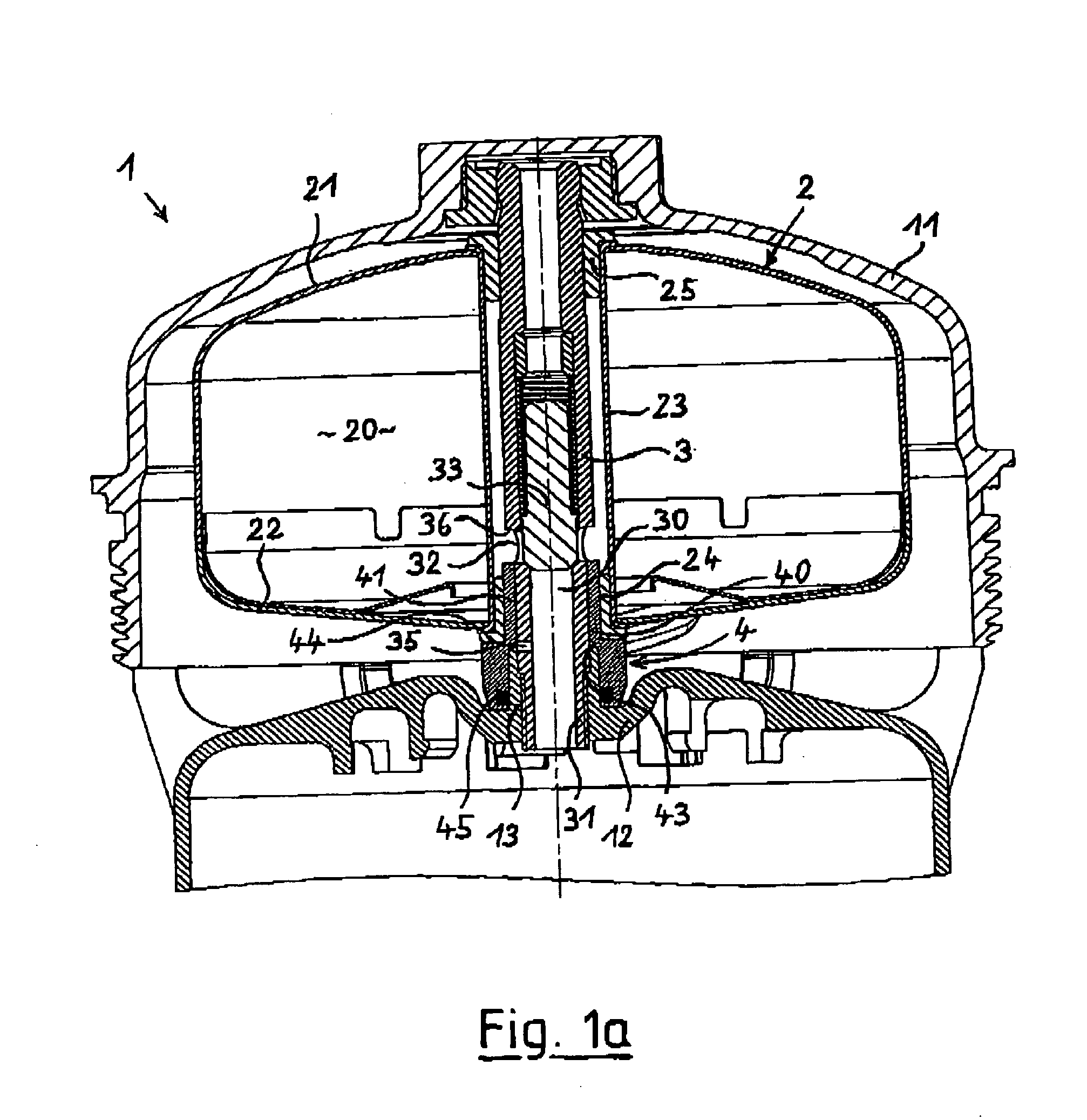

Centrifugal separator having a chamber with a deformable wall portion

A centrifugal separator comprises a centrifuge rotor (1), which has a wall (10) defining an interior of the rotor (1) and which during operation of the centrifugal separator is rotatable about a rotational axis (y) with respect to a stationary pipe member (2) comprising at least one passage for the transport of material. The pipe member (2) is provided to extend into the interior of the centrifuge rotor through an aperture of the rotor (1). A product separated during operation is collected in a chamber (9) provided in the proximity of said aperture and partly defined by an end wall portion (11) extending around said aperture and the pipe member (2) in such a manner that a clearance gap is formed between a radially inner edge of the end wall portion (11) and the pipe member (2). The end wall portion (11) is arranged to be deformable in the case that the pipe member contacts the end wall portion during the operation of the separator.

Owner:ALFA LAVAL AB

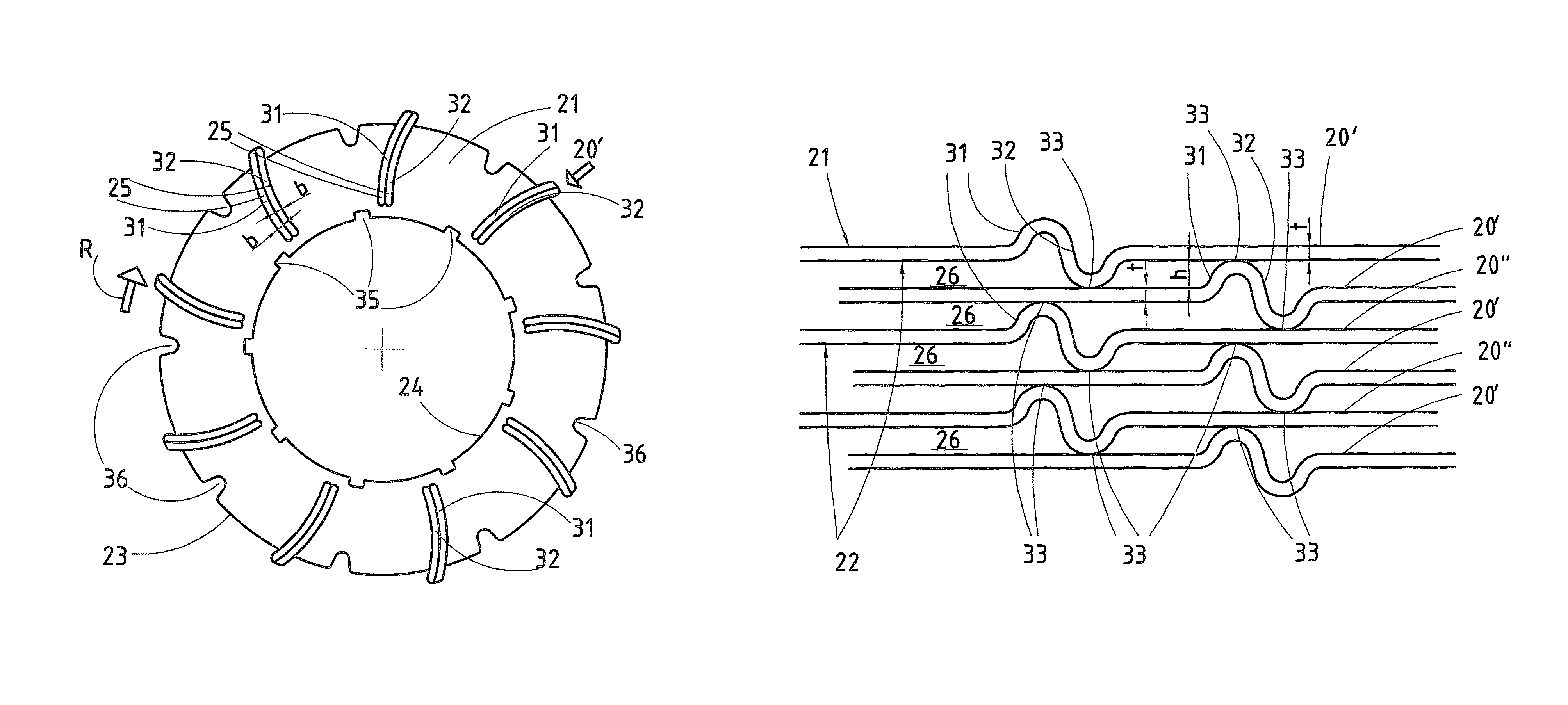

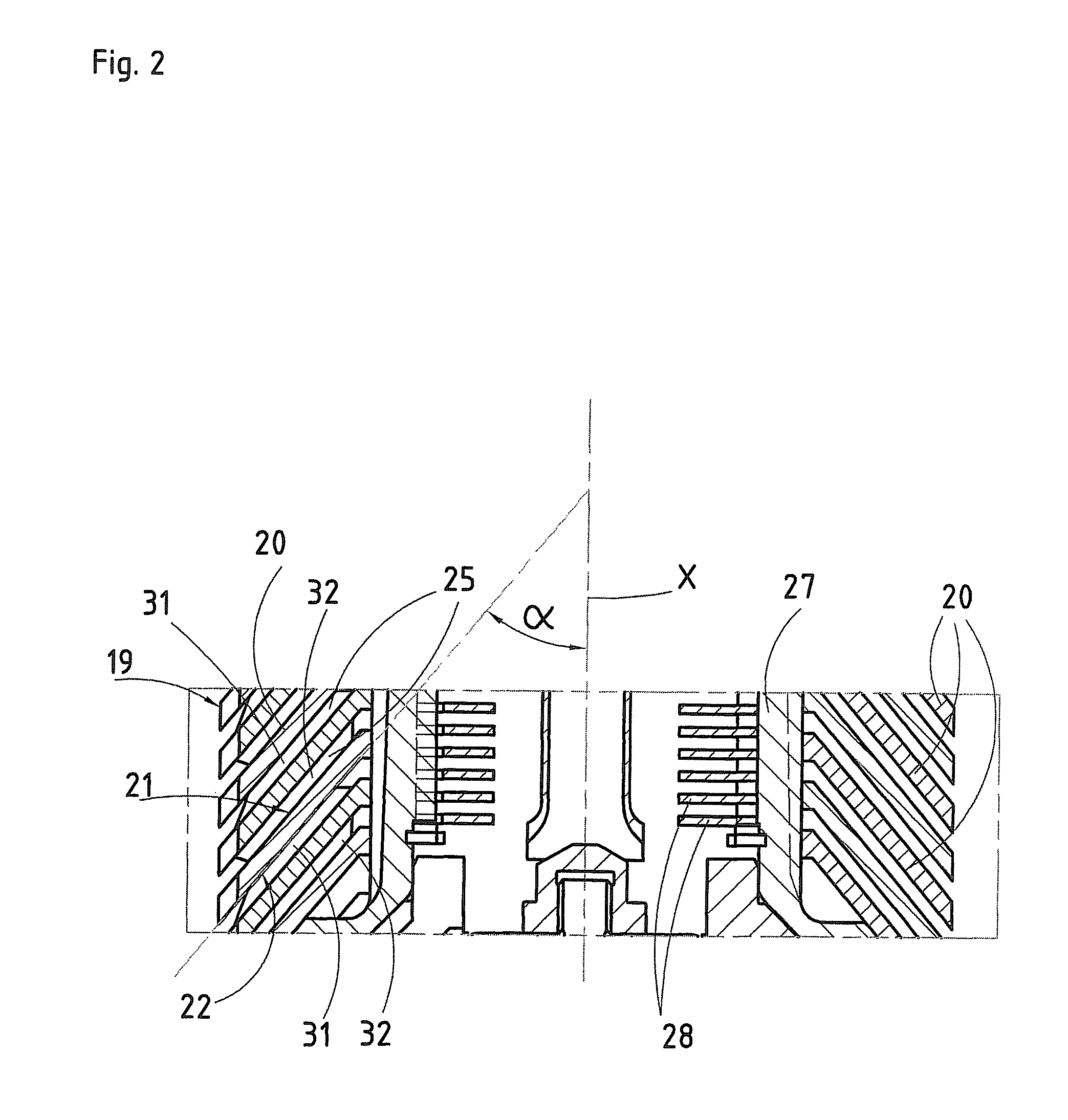

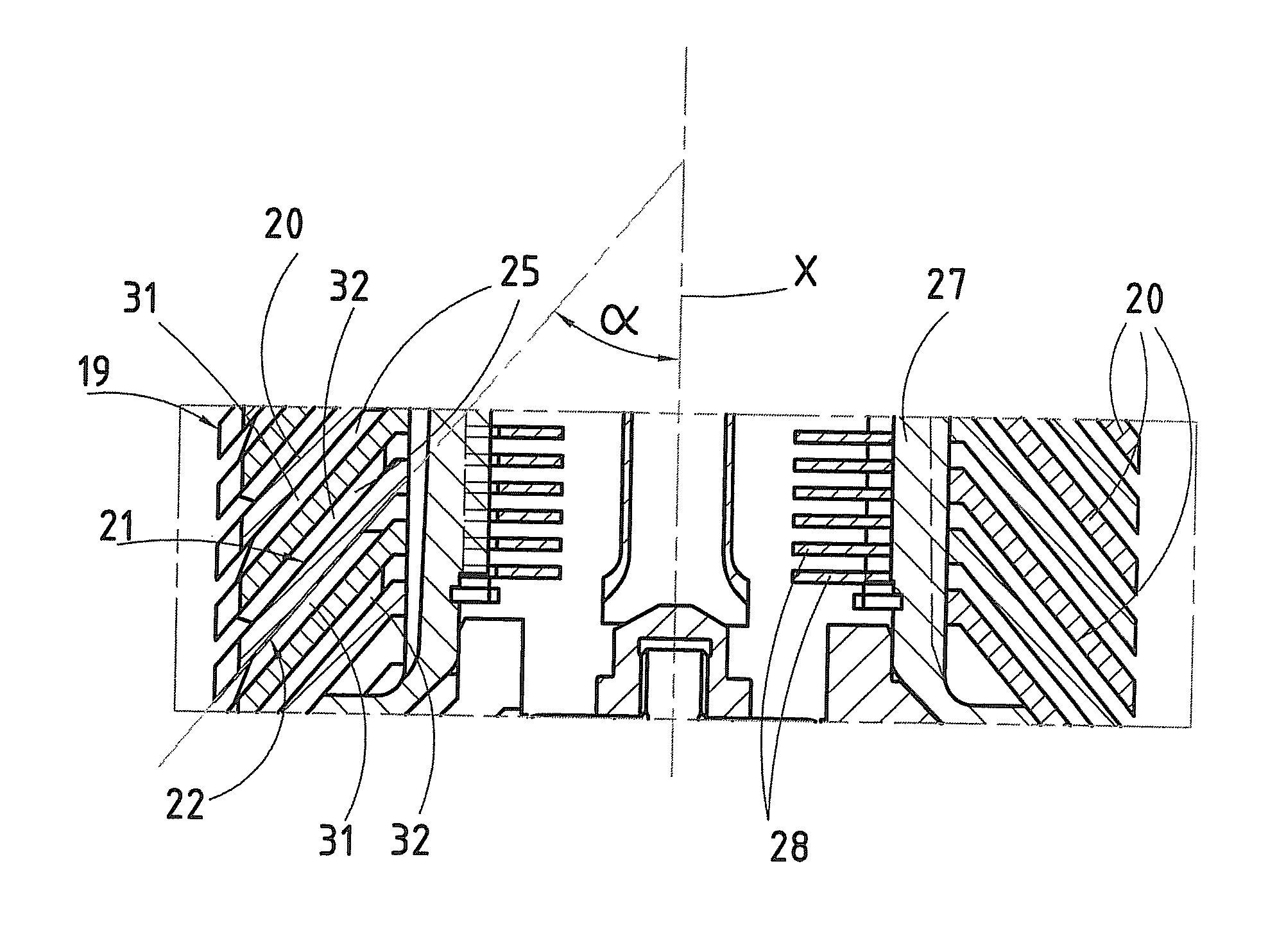

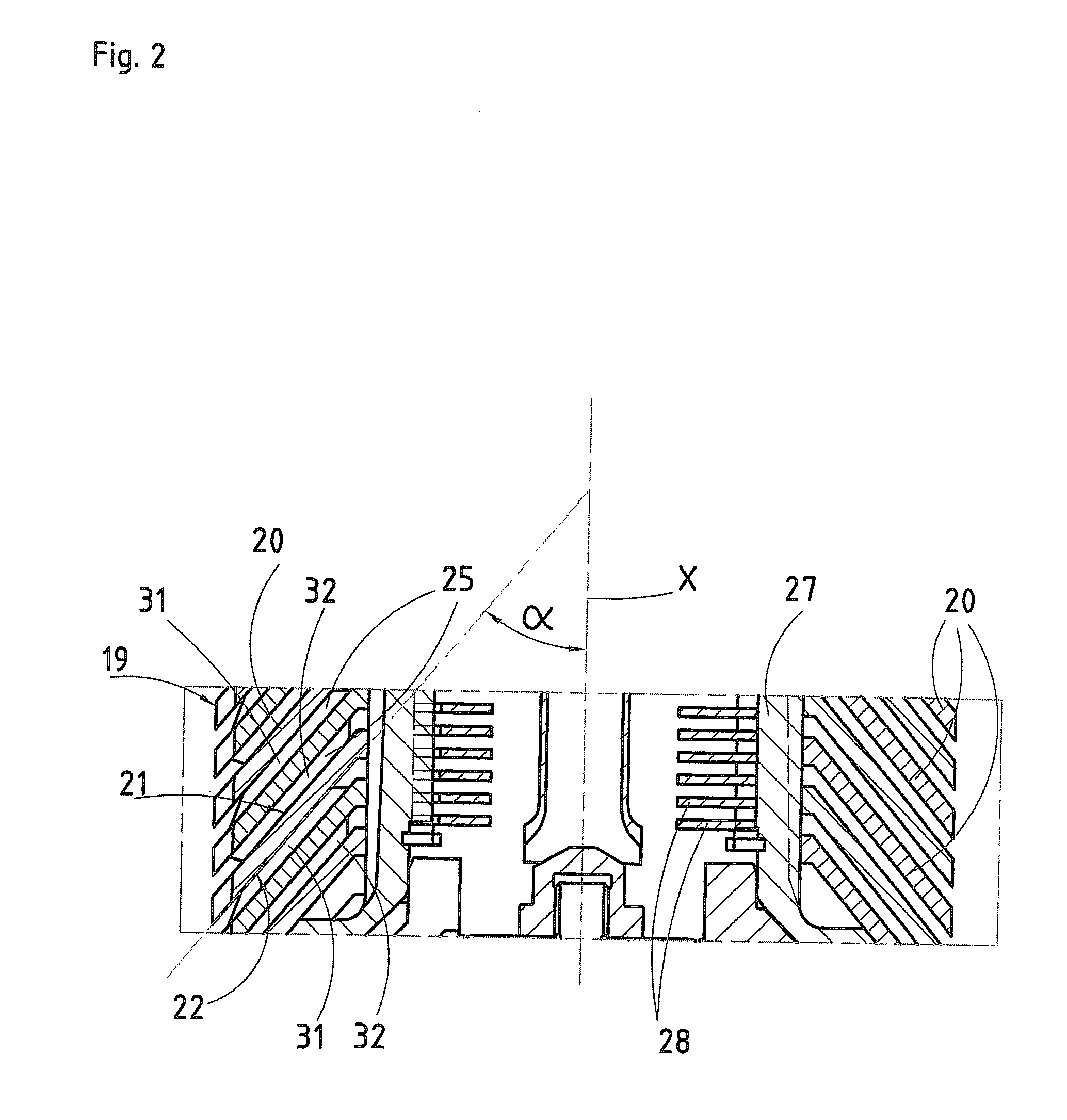

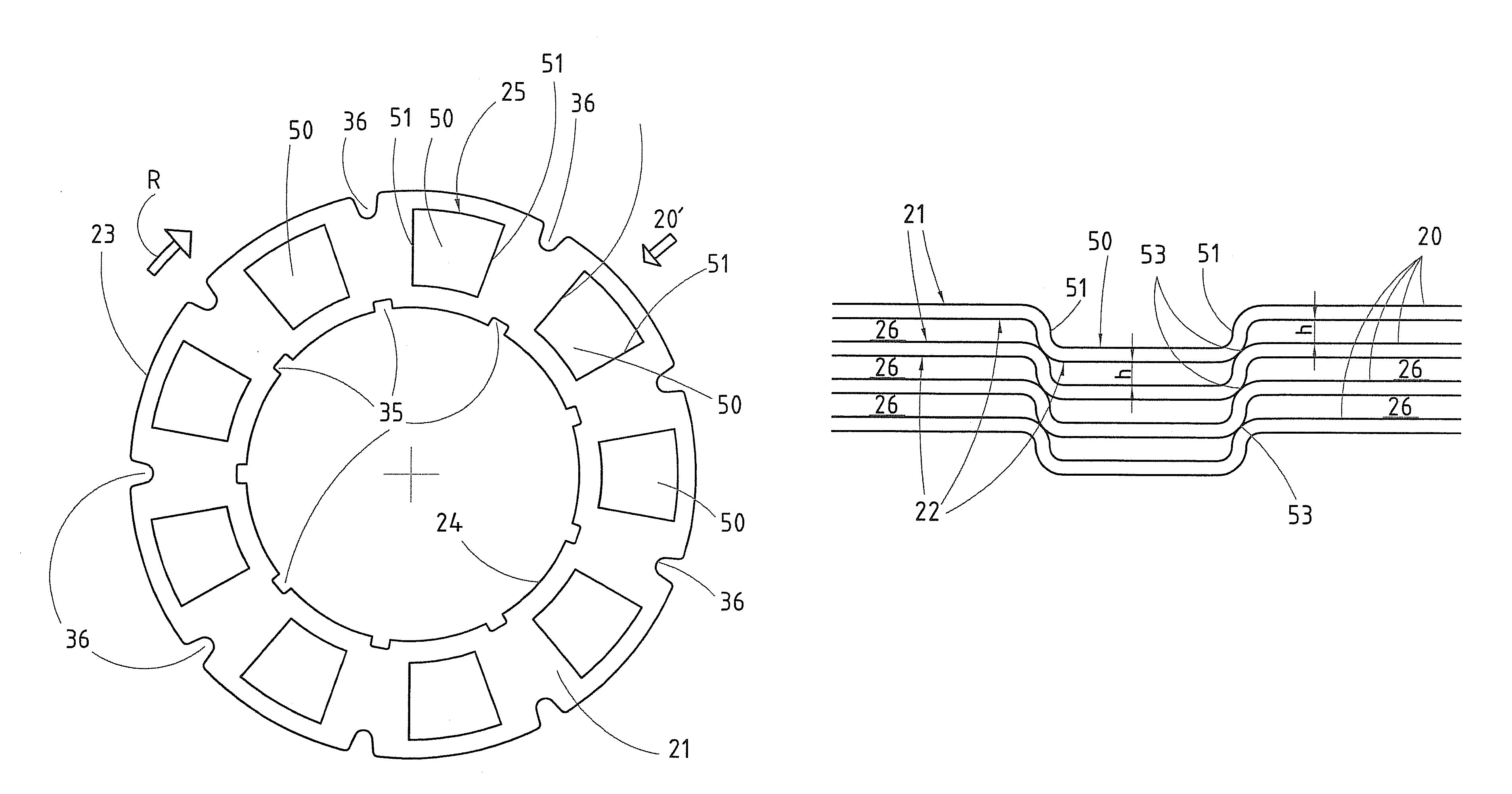

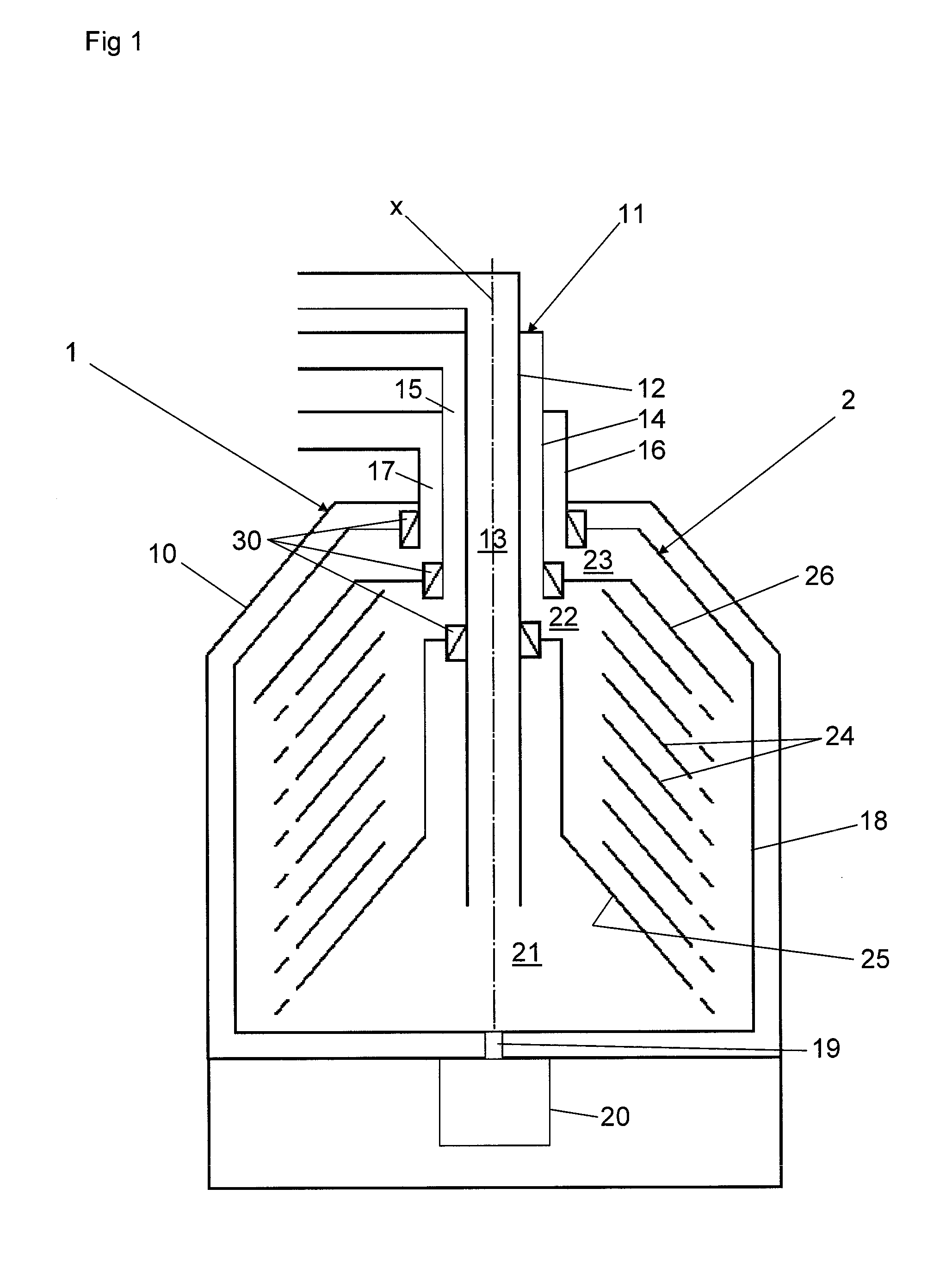

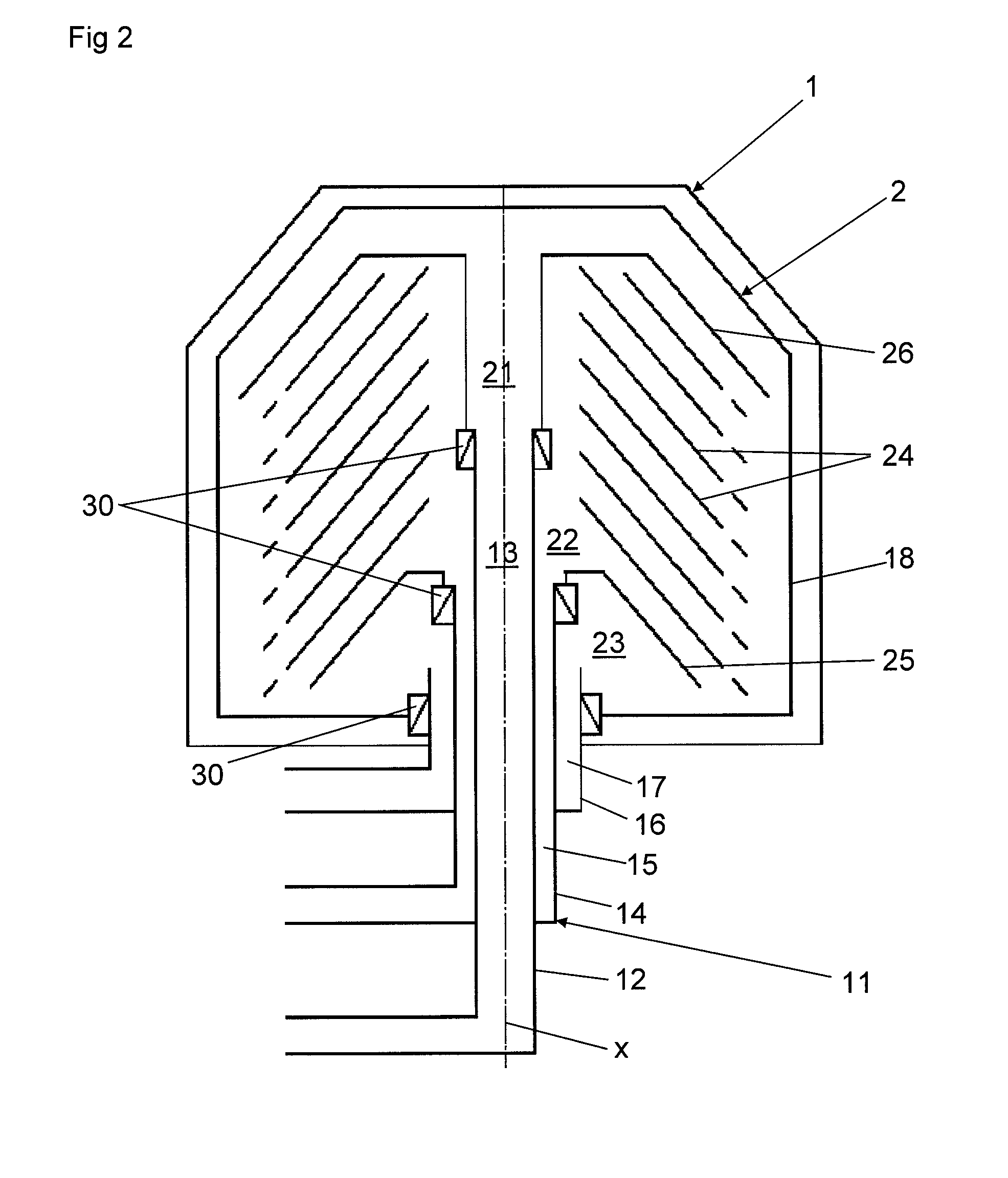

Centrifugal separator separating disc interspace configurations

A separating disk for a disk package of a centrifuge rotor of a centrifugal separator has a tapering shape and extends around an axis of rotation and along a tapering rotary symmetric surface along the axis of rotation. There is an interspace between the separating disk and an adjacent separating disk. The separating disc has first protrusions extending outwardly from the tapering rotary symmetric surface and second protrusions extending inwardly from the tapering rotary symmetric surface. Each of the first and second protrusion are after each other in a peripheral direction and define a contact zone adapted to abut an adjacent separating disk in the disk package. The contact zones of the first protrusions are displaced in relation to the contact zones of the second protrusions seen in a normal direction with regard to the outer surface. Each contact zone has a continuously convex cross sectional shape.

Owner:ALFA LAVAL CORP AB

System for transferance of test tubes from tube rack to centrifuge rotor

InactiveUS20100298108A1Significant effortSignificant timeRotary centrifugesLaboratory glasswaresCentrifuge rotorEngineering

A system including a flexible, removable tube holder that flexes to fit either a straight rack or a centrifuge rotor slot. The system provides for the elimination of manual recording of the individual tubes, and provides for the transference of the tubes from the rack to the centrifuge and back, as a group.

Owner:SHERMAN YURY +2

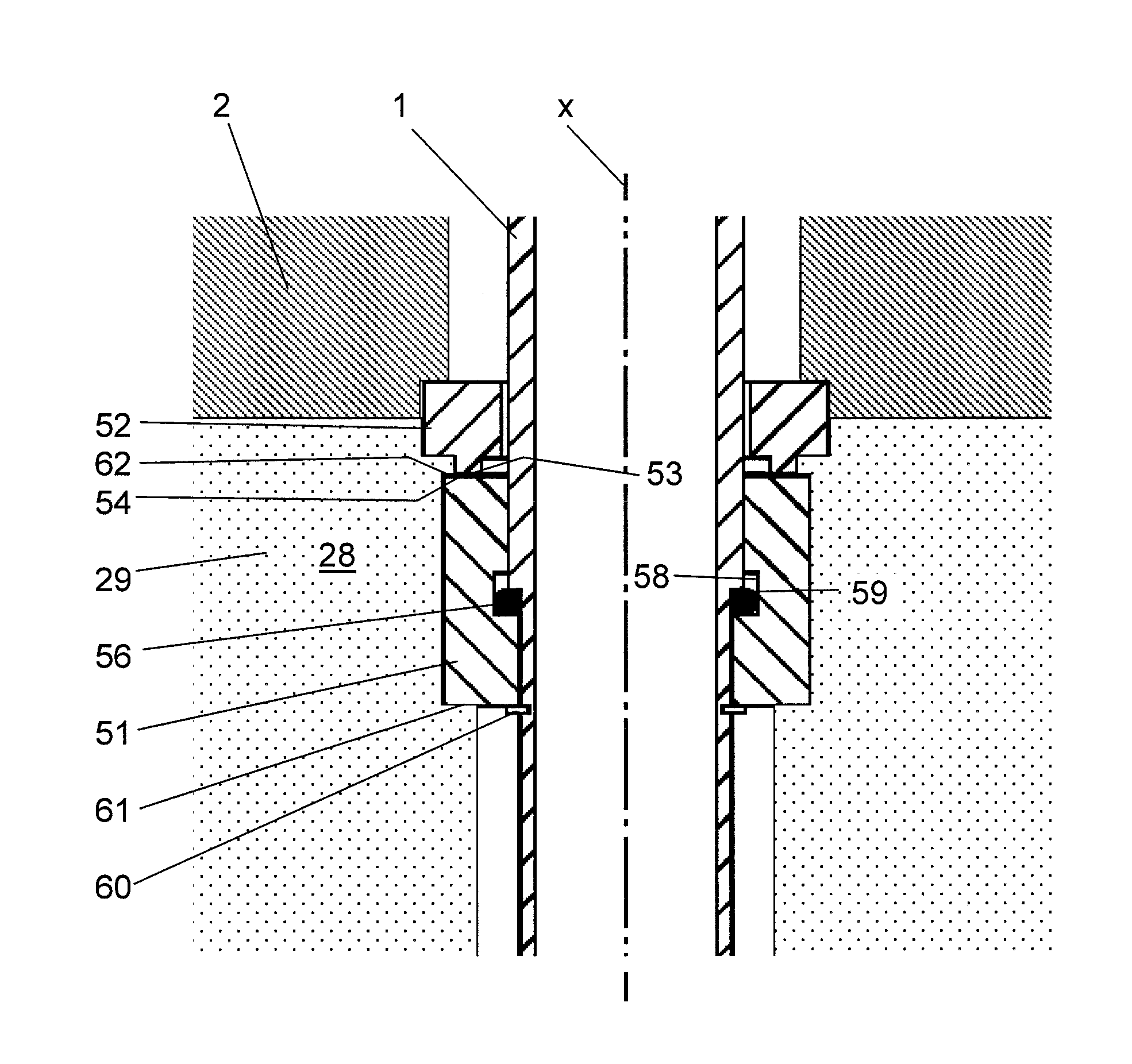

Separation disk for a centrifuge rotor, and a disk package

A separating disk for a disk package of a centrifuge rotor has a tapering shape and extends around an axis (x) of rotation, and along a rotary symmetric surface. The separating disk is configured in such a way that it creates an interspace between the separating disk and an adjacent separating disk in the disk package, and comprises first protrusions extending outwardly from the rotary symmetric surface and second protrusions extending inwardly from the rotary symmetric surface. Each first and second protrusion defines a contact zone adapted to abut the adjacent separating disk. The contact zone of the first protrusions is displaced in relation to the contact zone of the second protrusions. The first and second protrusions are provided after each other in the peripheral direction of the separating disk. The tapering shape and the protrusions of the separating disks have been provided though pressing of a blank of a material against a tool part having a shape corresponding to the tapering shape of the protrusions of the pressed separating disk.

Owner:ALFA LAVAL CORP AB

Methods and Apparatus for Hemolysis Detection in Centrifugal Blood Separator

ActiveUS20100267538A1ConfidenceOther blood circulation devicesDispersed particle separationCentrifuge rotorTest flow

A centrifugal blood processing apparatus comprising a centrifuge rotor, a separation chamber, a tubing set for conducting blood components and fluids and having an inlet line, and an outlet line. Apparatus tests flow conditions using a red light-green light sensor to detect non-recoverable hemolysis during priming by identifying a high R / G ratio, preferably a ratio of greater than or equal to fifty (50), prior to the beginning of the first return of blood components to a donor followed by identifying a R / G ratio at least as great as one and one tenth (1.1) together with a green signal less than a predetermined value, preferably less than or equal to one thousand (1000) reflectance units. If these conditions are detected, an alarm is given and the apheresis procedure is discontinued.

Owner:TERUMO BCT

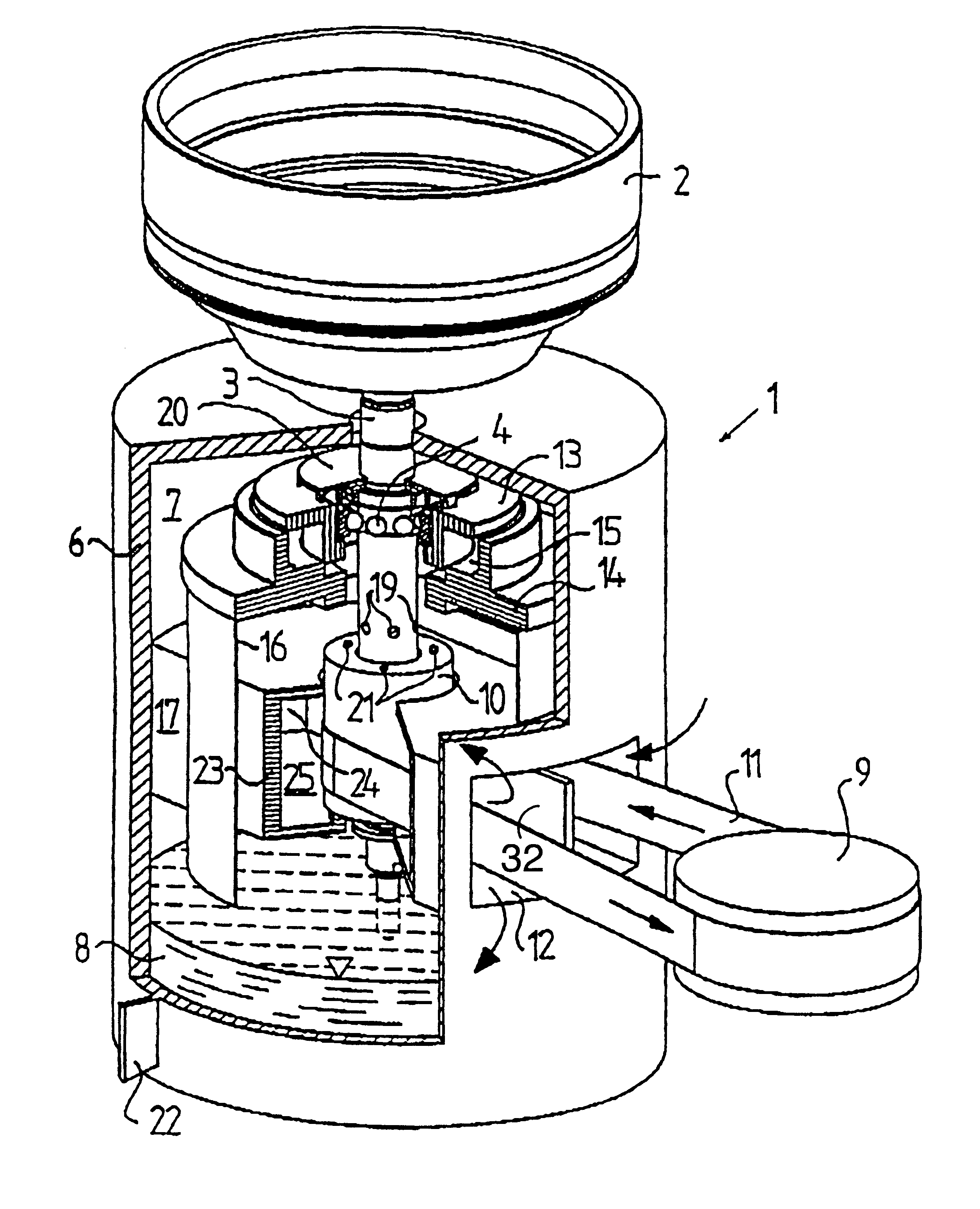

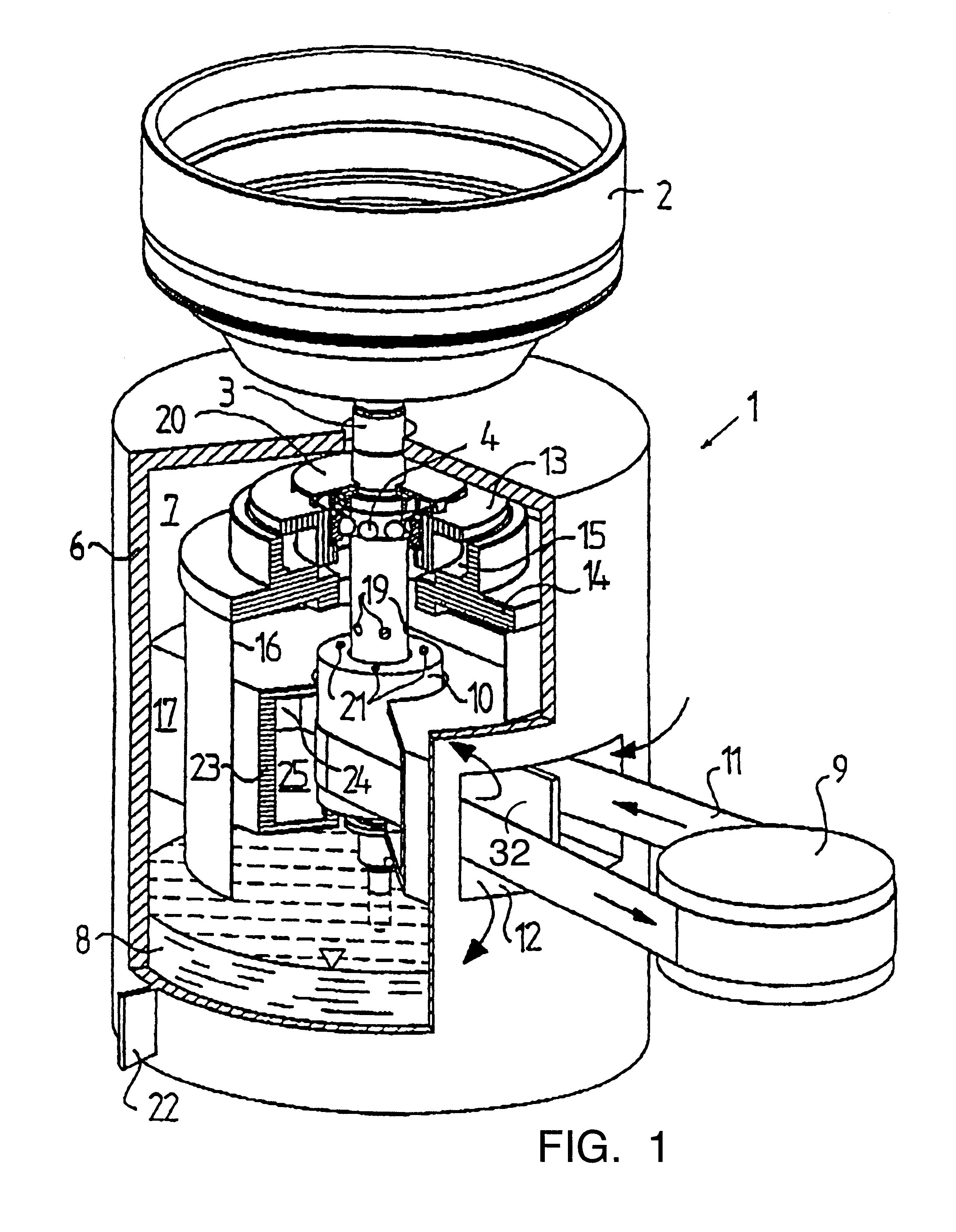

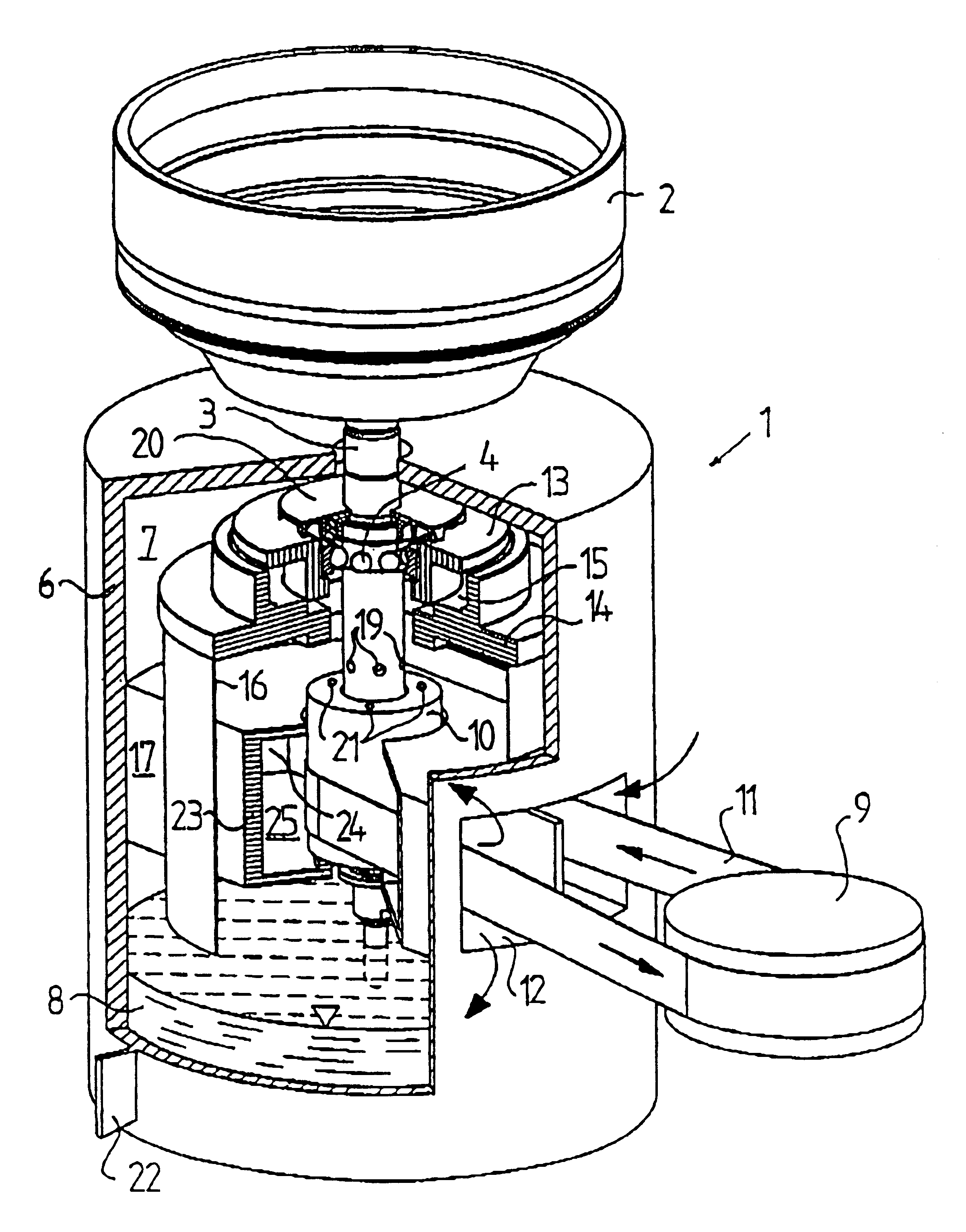

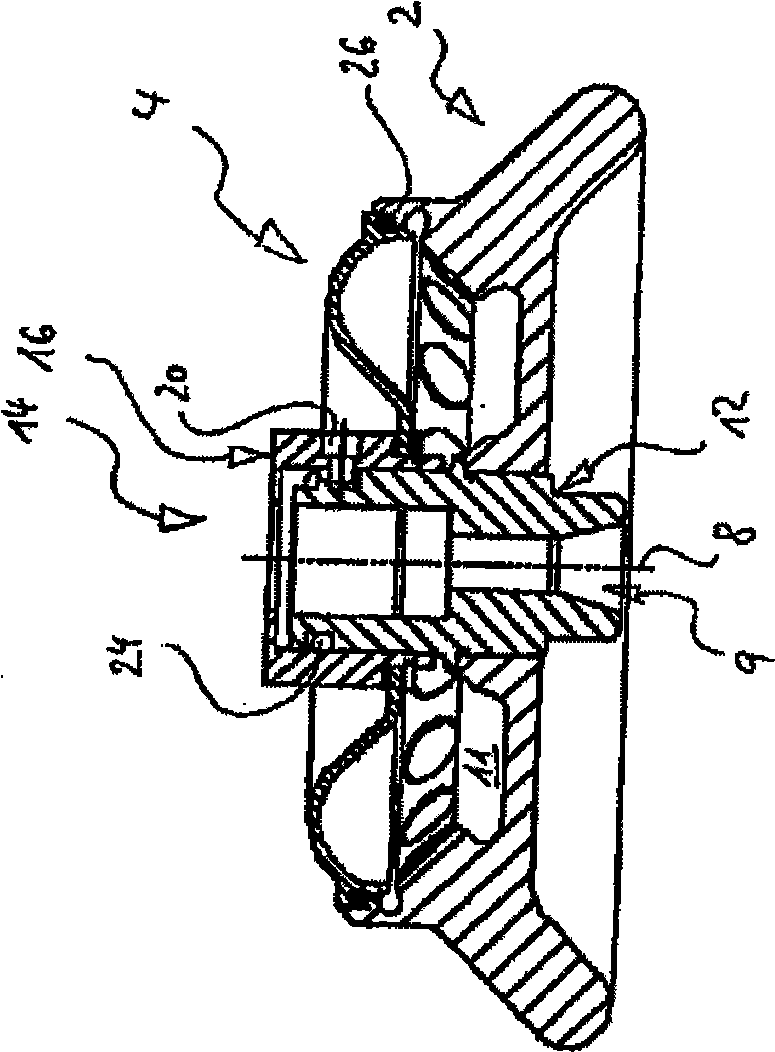

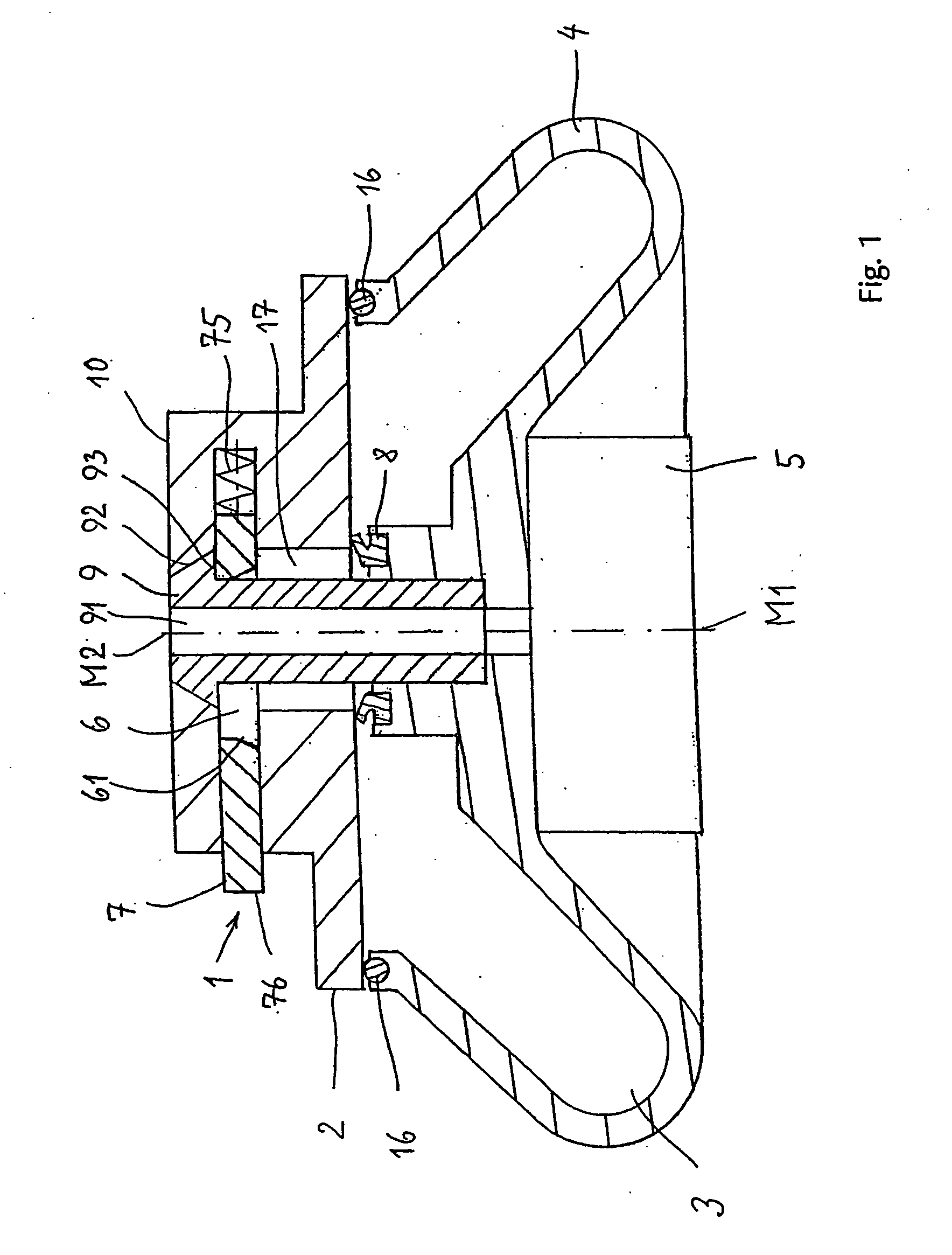

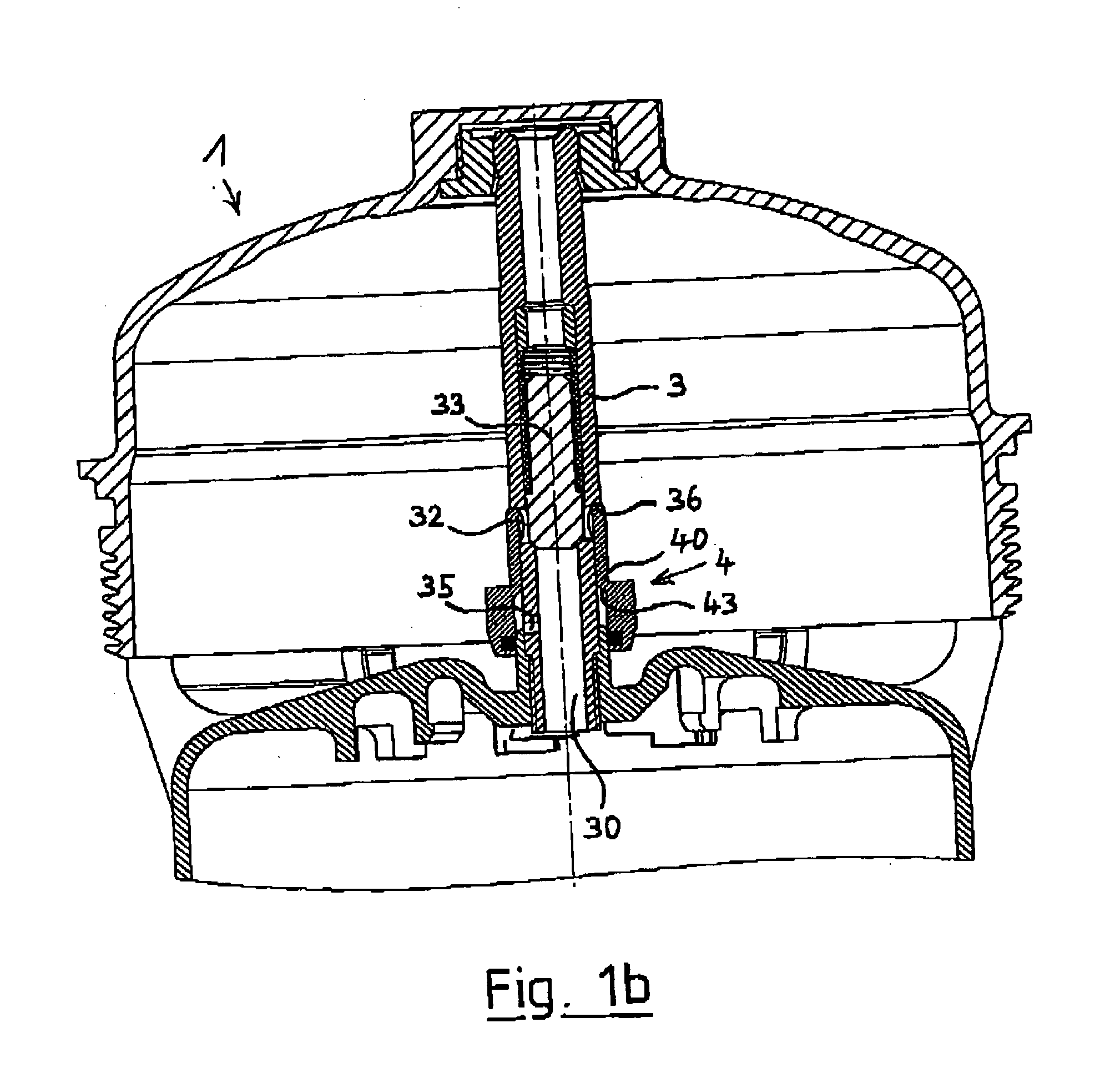

Drive unit for centrifuge rotor of a centrifugal separator

InactiveUS6578670B1Effective coolingCooling of the oil is improvedRolling contact bearingsShaftsCentrifuge rotorInterior space

The invention refers to a drive unit (1) for a centrifuge rotor (2) of a centrifugal separator. The drive unit (1) includes a drive shaft (3), which is arranged to support said centrifuge rotor (2) and is rotatably journalled around an axis (z) of rotation, a casing (6), which forms an inner space for the drive shaft (3), and a drive motor shaft (9), which is provided outside the casing (6) and connected to the drive shaft (3) by means of a transferring member (11) which extends through a passage (12) in the casing (6). A shielding member (23) is provided inside the casing (6) in such a way that the part of the transferring member (11), which is located inside the casing (6) is shielded from the inner space, wherein the shielding member (23) forms a channel, which extends through the casing (6) and is shielded from the inner space of the casing.

Owner:ALFA LAVAL AB

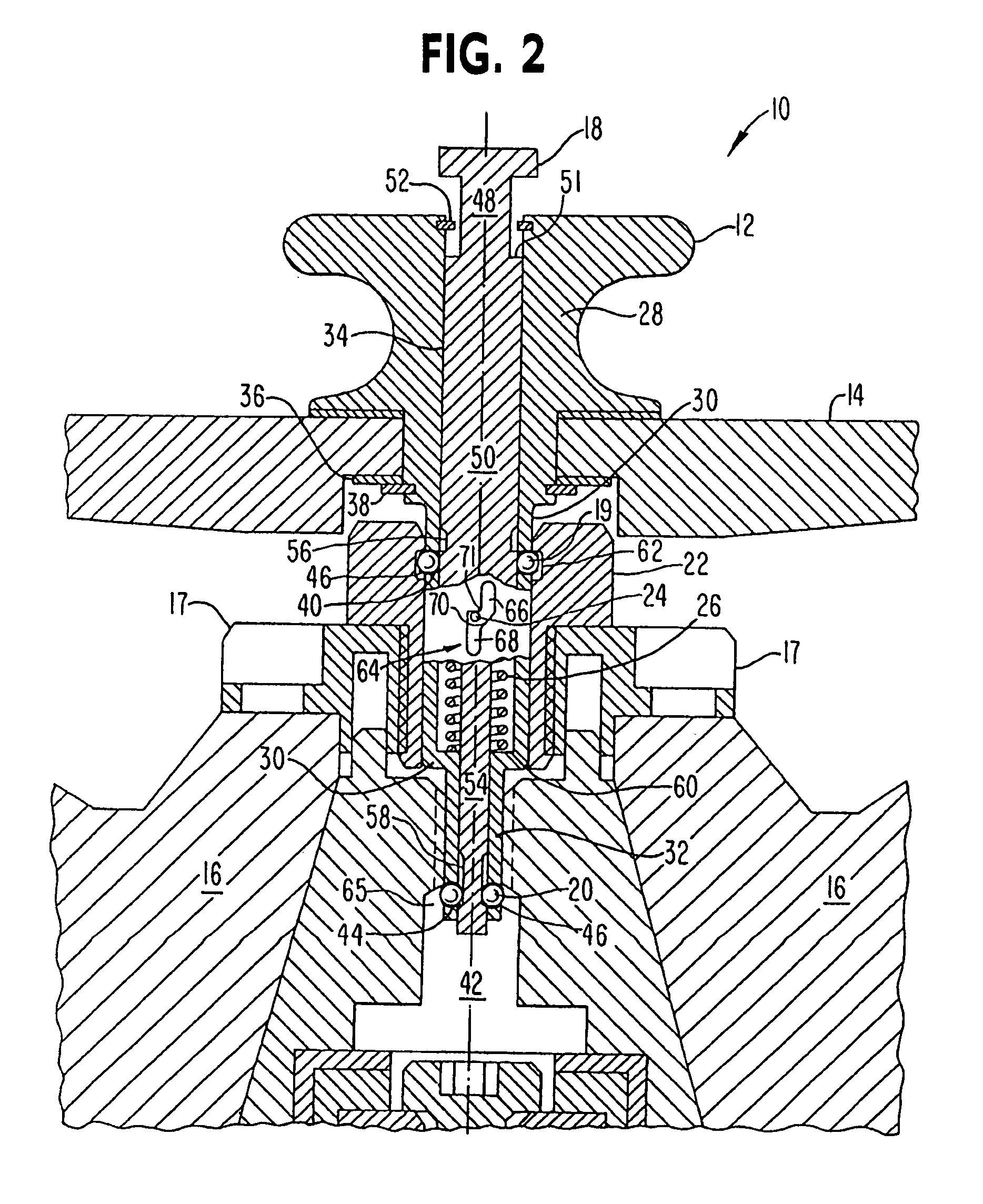

Attachment and release apparatus for a centrifuge rotor cover

An attachment and release apparatus for attaching a rotor to a centrifuge drive assembly and for attaching a cover to the rotor. The apparatus includes a knob, a cover wherein the knob has a plunger disposed therein. The apparatus also includes an adapter having detents and a drive spindle having detents. In addition, the apparatus has at least one adapter moveable element retained within a passage located on the knob and least one drive spindle moveable element retained within an additional passage located on the knob. The apparatus also includes a biasing element disposed around one end of the plunger.

Owner:KENDRO LAB PRODS

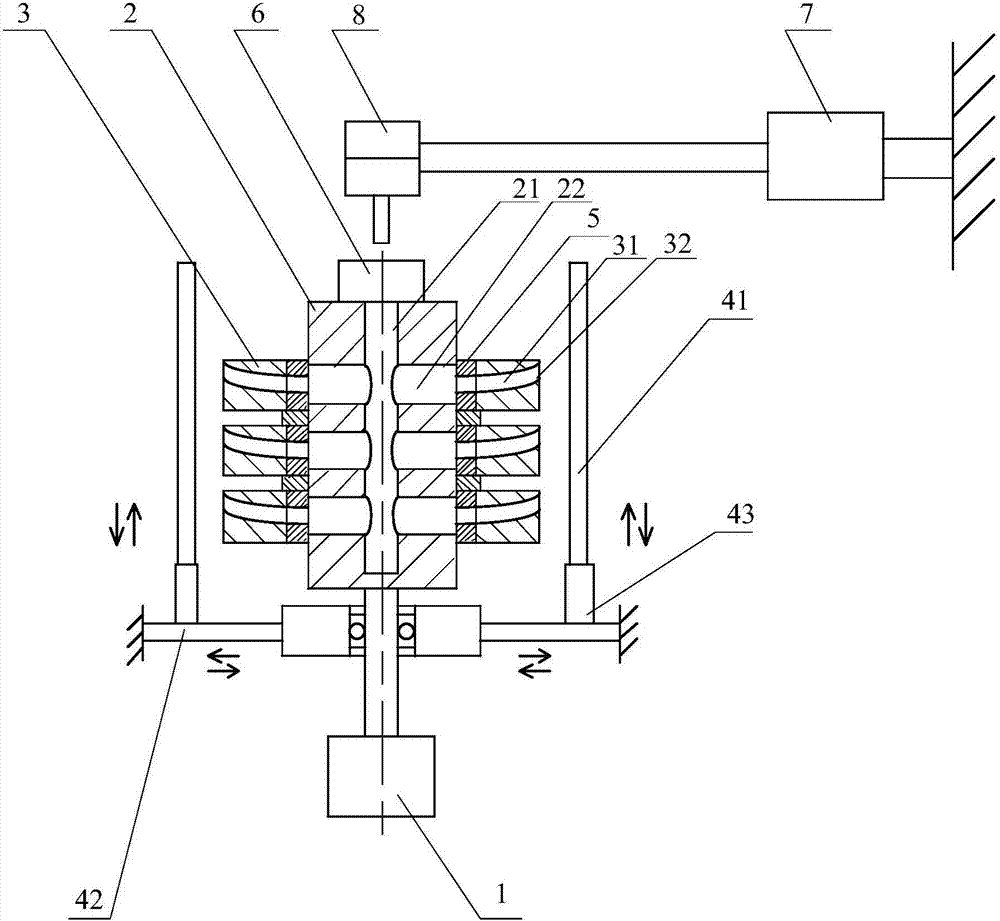

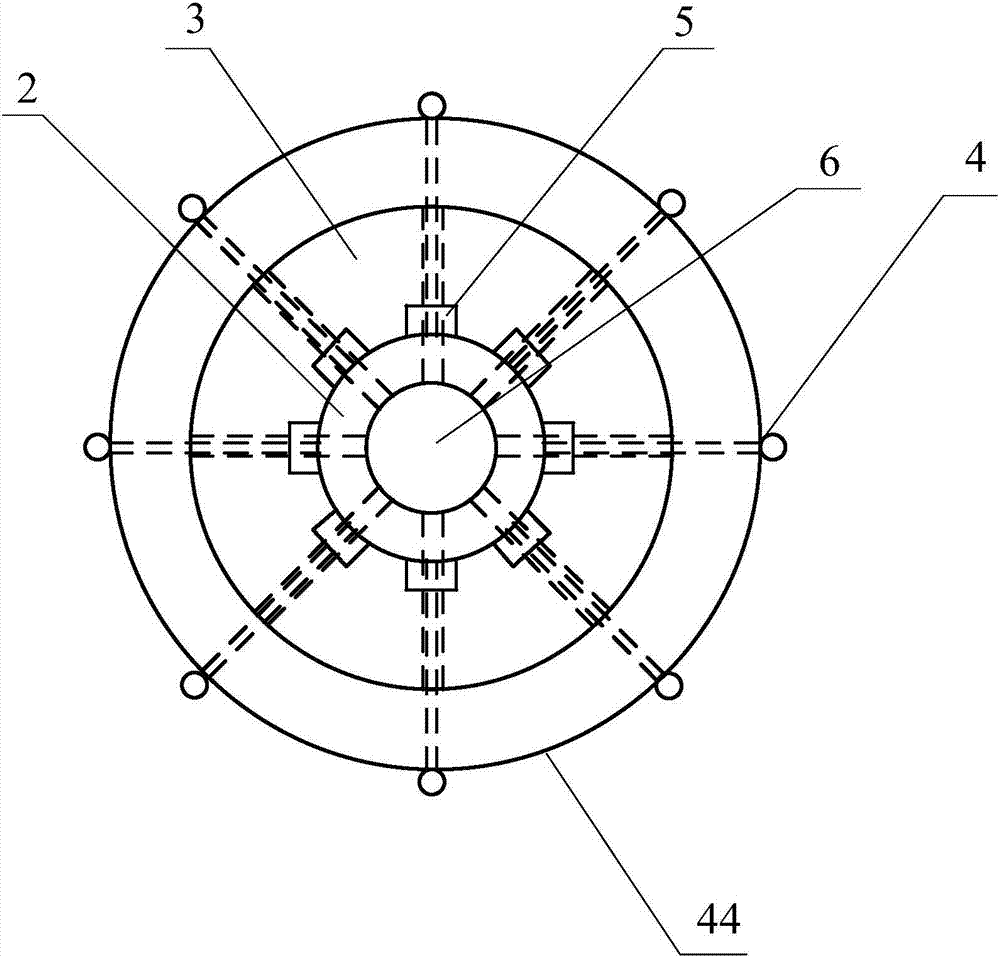

Reconfigurable centrifuge-rotor micro-nano spinning formation device

InactiveCN107059145AImprove spinning efficiencyReduce processing timeArtificial thread manufacturing machinesFilament/thread formingMicro nanoCentrifuge rotor

The invention relates to a reconfigurable centrifuge-rotor micro-nano spinning formation device. The device comprises a feeding device, a spinning device and a forming device. The feeding device is used for conveying spinning raw material to the spinning device. The spinning device comprises a driving device, a spinning rotary shaft and a spinning disc. The spinning rotary shaft is internally provided with a liquid storage tank and a discharge channel. The liquid storage tank is used for receiving and accommodating spinning raw material conveyed from the feeding device. An inlet of a discharge channel communicates with the liquid storage tank. An outlet of the discharge channel communicates with the outside of the rotary shaft. A spinning channel is arranged in the spinning disc. The spinning rotary shaft is axially provided with more than two groups of discharge channels. The forming device is used for collecting micro-nano fibers which are formed by curing of spinning raw material sprayed out by the spinning device. The reconfigurable centrifuge-rotor micro-nano spinning formation device has the following beneficial effects: the multiple spinning discs are installed in a matching manner; the spinning discs and the spinning rotary shaft are detachably connected; according to needs, the number of the spinning discs installed is determined; spinning efficiency is increased; furthermore, the formation device can move up and down so that fiber products of different shapes and structures are obtained.

Owner:WUHAN TEXTILE UNIV

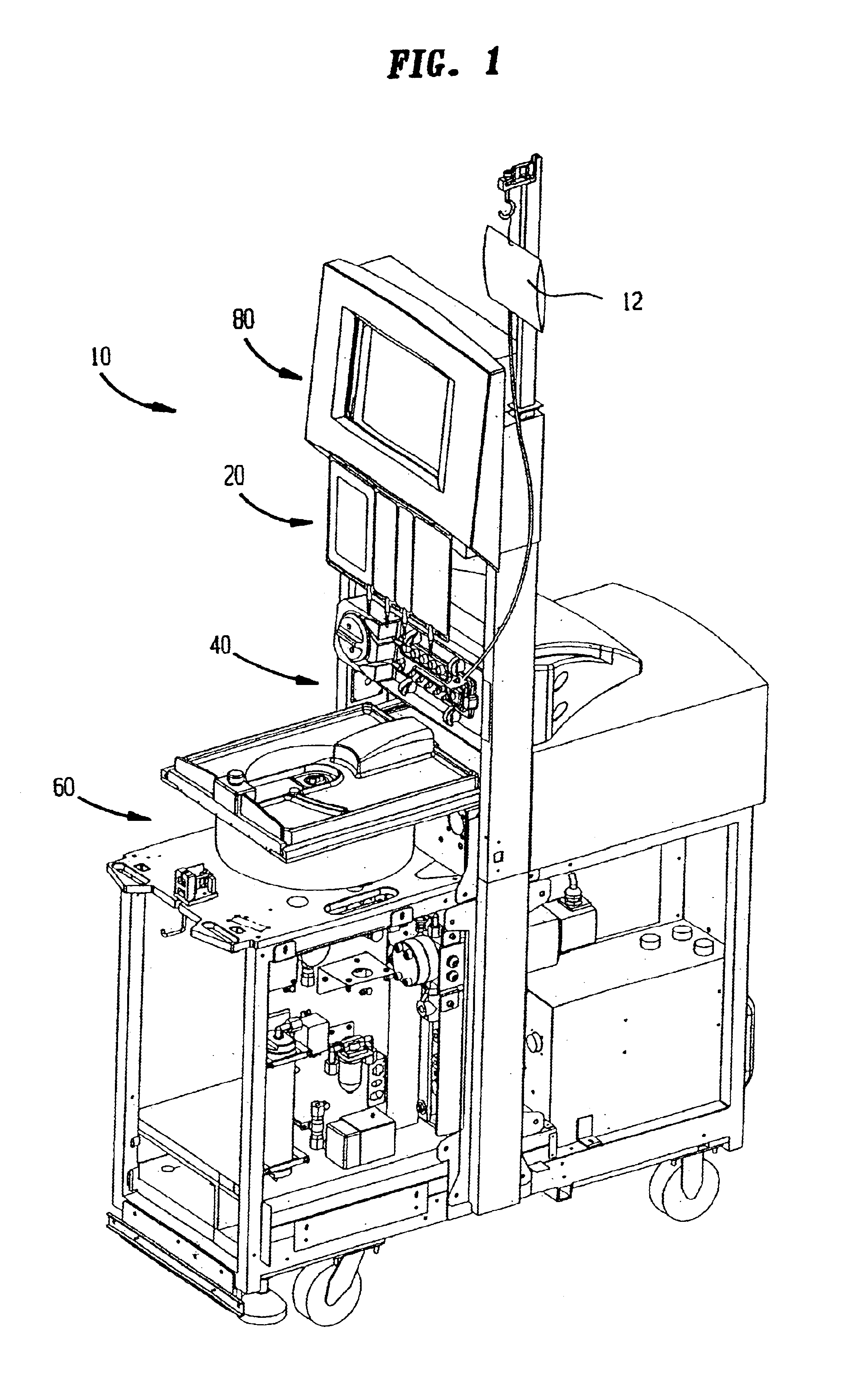

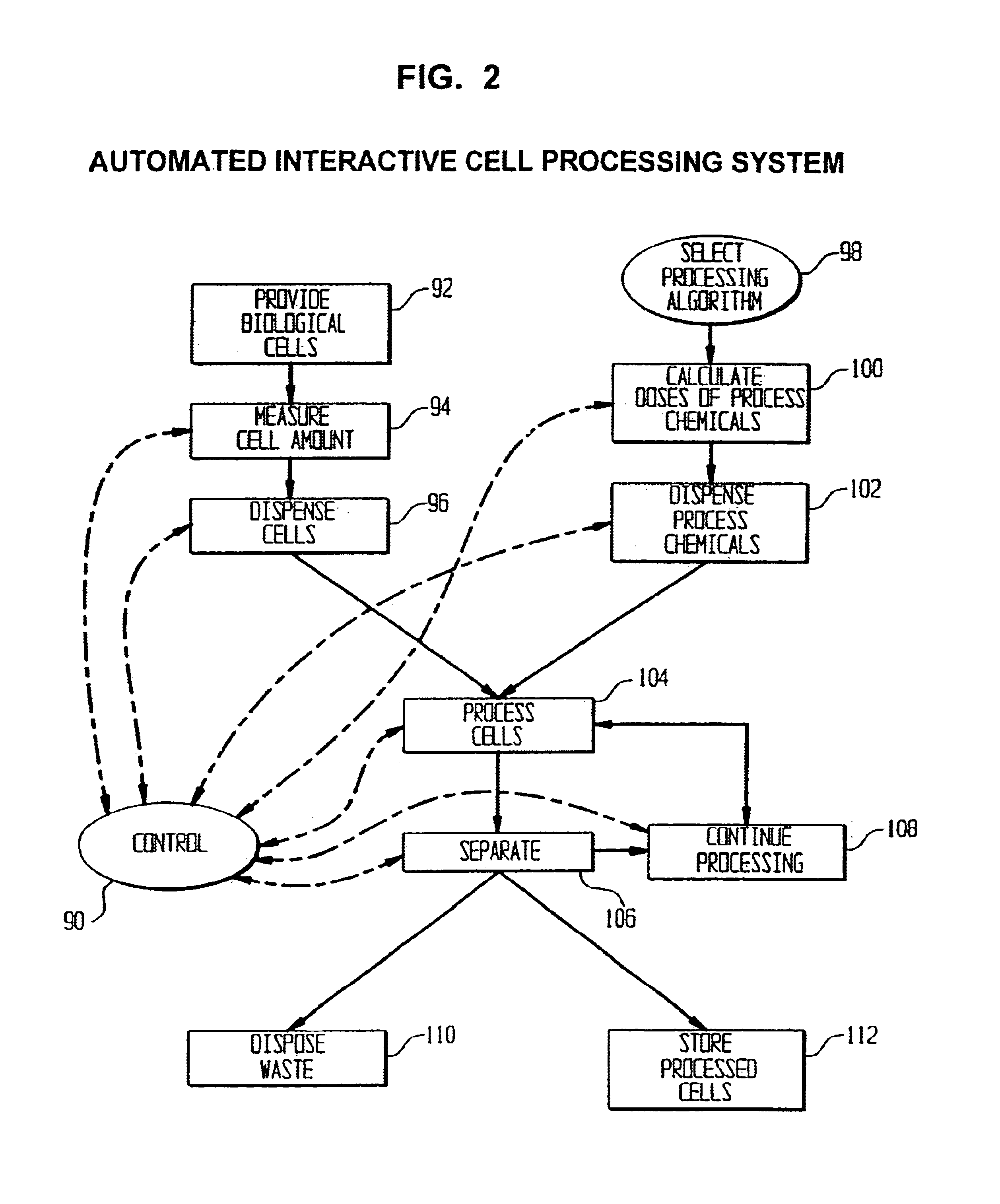

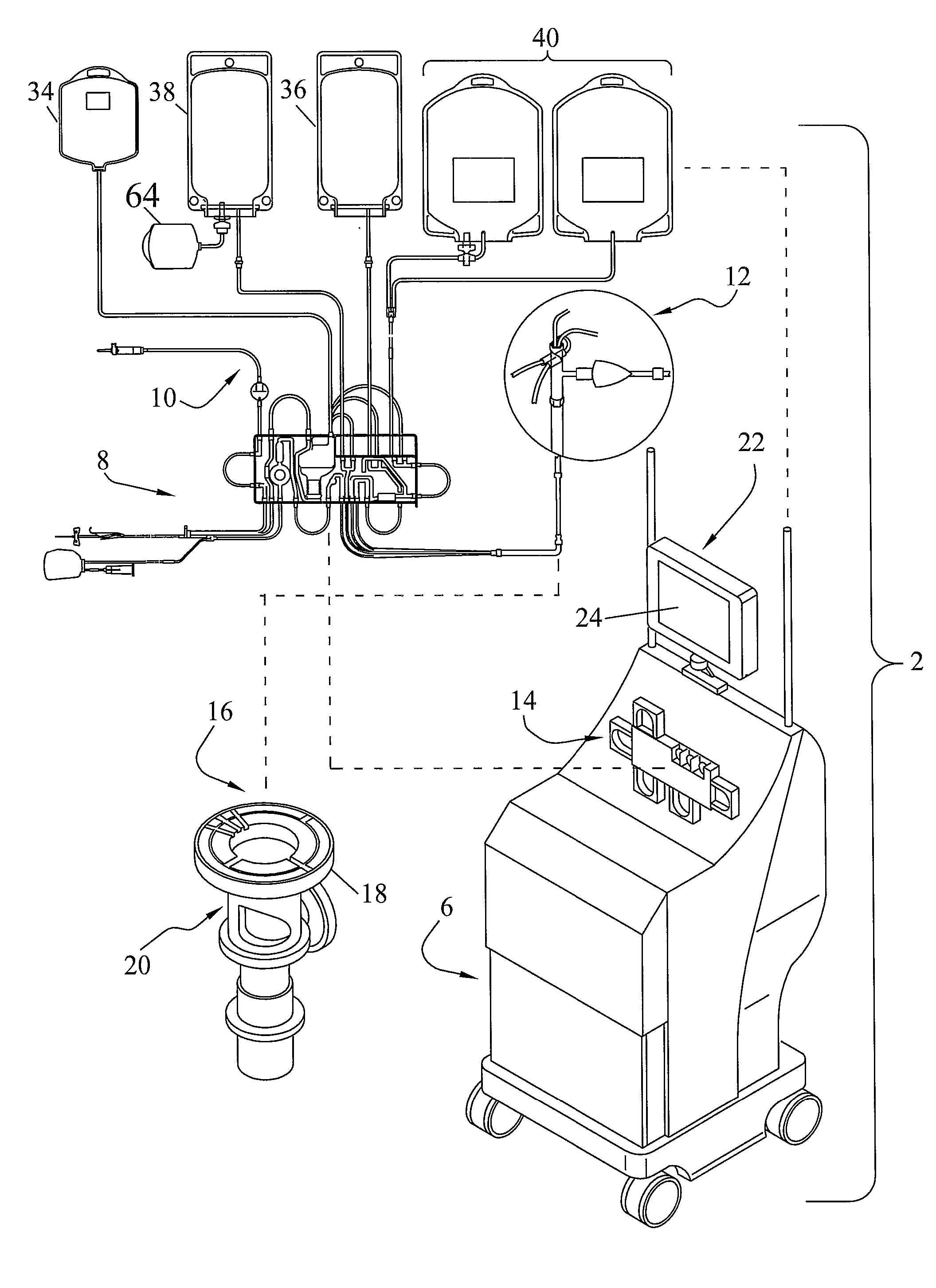

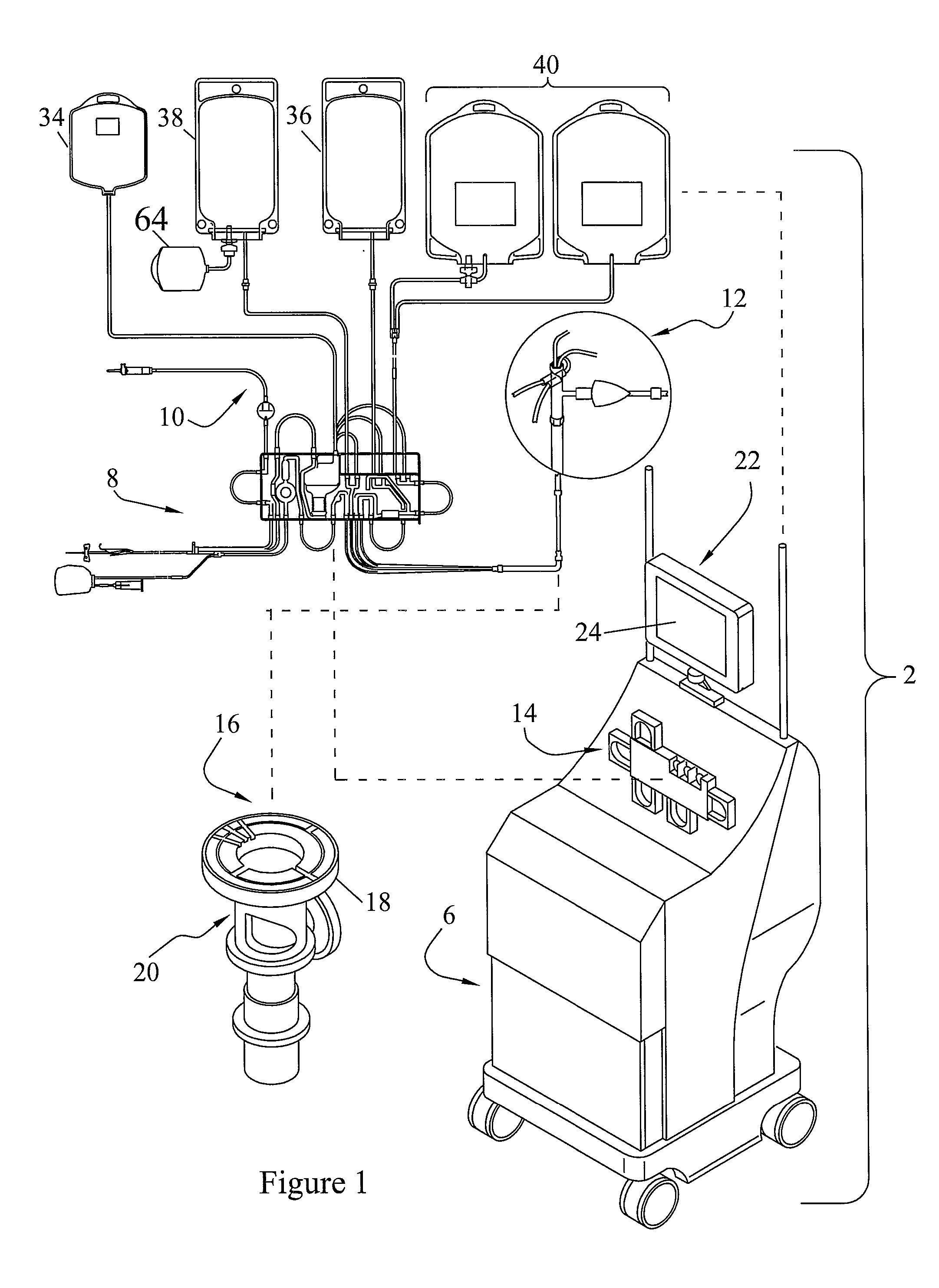

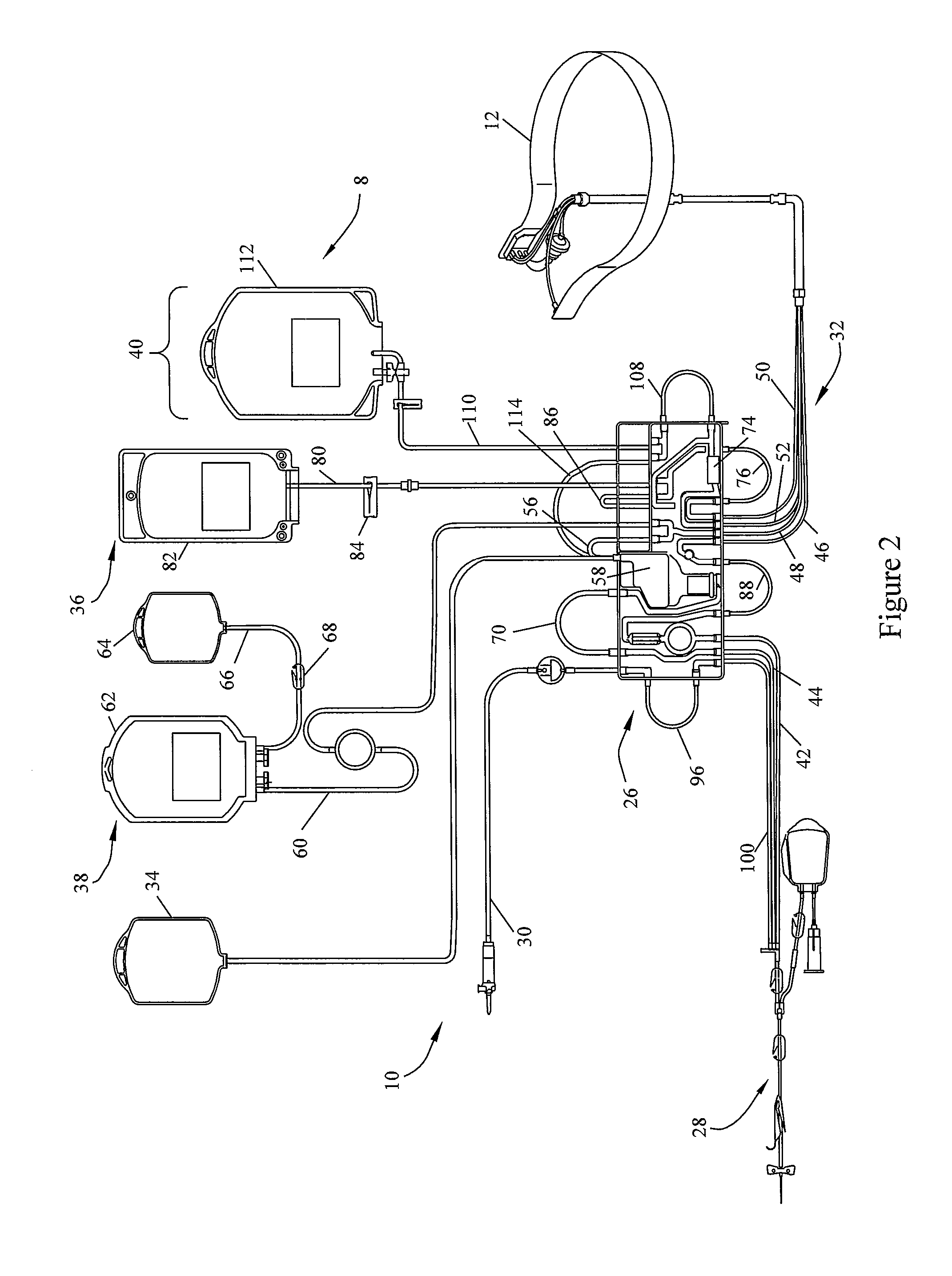

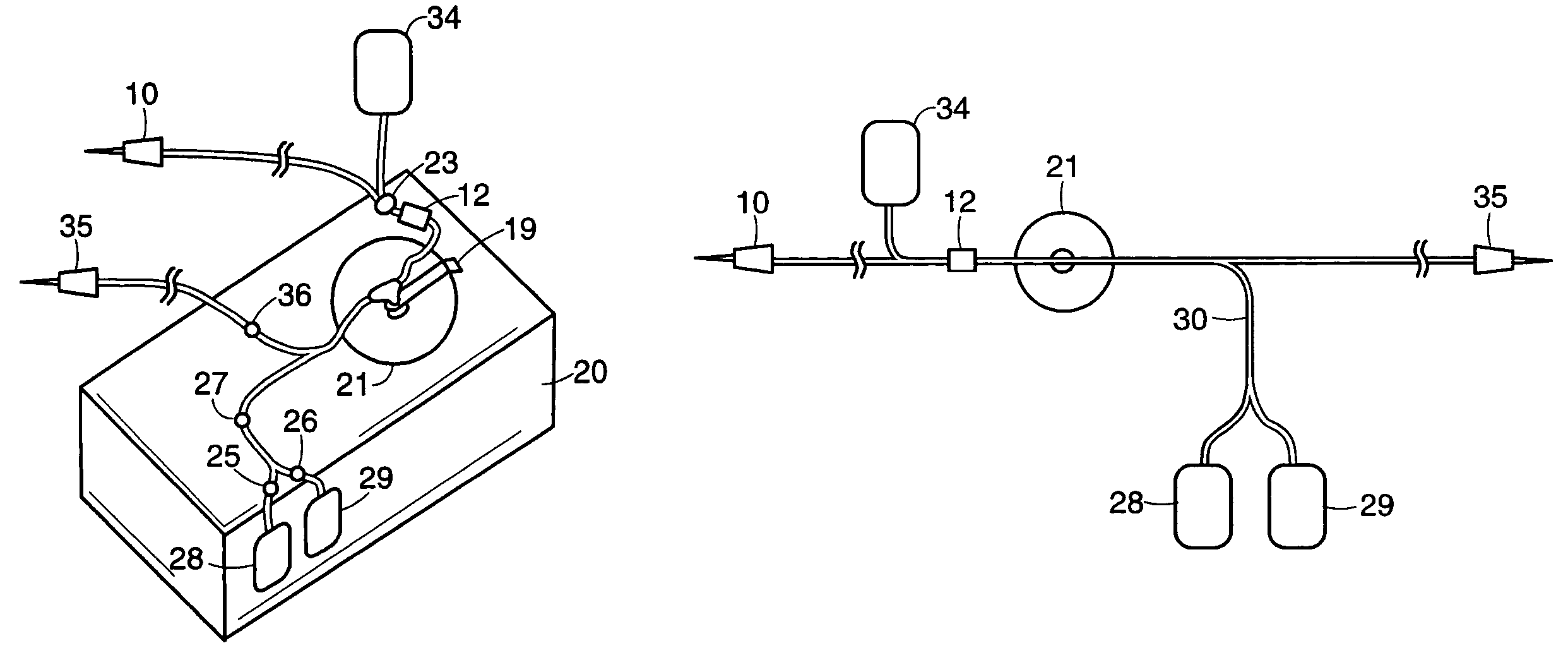

System and method for processing blood

InactiveUS7332125B2Reduce needEasy to useOther blood circulation devicesMedical devicesCentrifuge rotorControl flow

A system for filtering and processing blood that is simple to implement and that reduces the need for human intervention. The system may be used to collect red blood cells (RBCs). For such a system, a disposable set may be provided with an inlet port, an RBC container, a centrifuge rotor having a variable total volume, and a filter, along with tubing connecting the port, the container, the rotor and the filter. The filter is located in tubing between the inlet port and the rotor. A control unit is also provided and includes a spinner in which the rotor may be held, a flow-control arrangement for controlling flow among the various components of the disposable set, and an electronic controller. The whole blood is directed by the flow-control arrangement from the inlet through the filter to the rotor. The rotor includes an elastic diaphragm, and the control unit's flow-control arrangement includes a pump or other device for applying a positive and negative pressure to the rotor's elastic diaphragm. The spinner rotates the rotor so as to separate the whole blood into plasma and RBCs. Preferably, the plasma is urged out of the rotor first and returned to the donor, while the rotor is still being spun. After the plasma has been removed from the rotor, the RBCs are urged from the rotor to an RBC container. In preferred embodiments, the filter is a white blood cell filter, so that white blood cells are filtered from the blood before it reaches the rotor.

Owner:HAEMONETICS

Fixing device for a centrifuge rotor cover

The present invention relates to a fixing device of a cover for a centrifuge rotor, a receiving chamber of the centrifuge rotor, which is driven using a drive unit, for receiving samples to be centrifuged being closable aerosol-tight using the cover. The fixing device is provided with an opening so that the drive unit is accessible through the fixing device and the cover without removing the cover. The present invention has the advantage that the rotor may be removed from the centrifuge and the rotor remains closed aerosol-tight at the same time. In addition, simple, one-handed operation is made possible.

Owner:THERMO ELECTRONICS LED GMBH

System for transferance of test tubes from tube rack to centrifuge rotor

InactiveUS20100031760A1Saves significant effortShorten the timeAnalysis using chemical indicatorsLaboratory glasswaresCentrifuge rotorEngineering

The present invention includes a system and method for the management of specimens ordinarily manipulated via tubes. The invention may include a flexible, removable tube holder that is linear when placed in a rack and curved when placed into a centrifuge rotor. The system provides for the elimination of manual recording of the individual tubes, and also provides for the transference of the tubes from the rack to the centrifuge and back in a group.

Owner:SHERMAN YURY +2

Disk package for a centrifuge rotor

InactiveUS8562503B2Easy maintenanceImprove hygieneRotary centrifugesCentrifuge rotorMechanical engineering

Owner:ALFA LAVAL CORP AB

Centrifugal separator

ActiveUS20130067873A1Harmful oscillationHarmful vibrationCombination devicesRotary centrifugesCentrifuge rotorCombustion

A device for cleaning of polluted gas from a combustion engine, includes a centrifugal separator with a centrifuge rotor arranged to cause the polluted gas to rotate. The centrifuge rotor comprises a stack of truncated conical separating discs disposed at mutual spacing so they delimit intermediate spaces between them for the gas to flow through. An outlet chamber is disposed centrally within the stack of separating discs, whereby the centrifuge rotor is configured for counterflow separation. The centrifugal separator comprises a gas outlet which communicates with the outlet chamber. The stack of separating discs is disposed for rotation in a space formed within the combustion engine and arranged to receive the polluted gas, to which end the intermediate spaces between the separating discs communicate directly with the space, and the gas outlet is arranged to conduct the cleaned gas out from the space through a wall which delimits the space.

Owner:ALFA LAVAL CORP AB

Lid for closing a centrifuge rotor

The present invention relates to a lid for closing a centrifuge rotor, characterized by a positively locking rotation-activated closing mechanism, which, prepositioned on the centrifuge rotor, moves automatically into a closed position by virtue of the intrinsic weight of the lid.

Owner:EPPENDIRF AG

Fixing device for a centrifuge rotor cover

The present invention relates to a fixing device of a cover for a centrifuge rotor, a receiving chamber of the centrifuge rotor, which is driven using a drive unit, for receiving samples to be centrifuged being closable aerosol-fight using the cover. The fixing device is provided with an opening so that the drive unit is accessible through the fixing device and the cover without removing the cover. The present invention has the advantage that the rotor may be removed from the centrifuge and the rotor remains closed aerosol-fight at the same time. In addition, simple, one-handed operation is made possible.

Owner:THERMO ELECTRONICS LED GMBH

Blood Co-Processing For Contingent Autologous Leukocyte Transplantation

InactiveUS20070212674A1Strict controlHigh retention rateData processing applicationsOther blood circulation devicesWhite blood cellBlood plasma

A process for producing a leukocyte bank suitable for CAT therapy comprising the steps of providing a blood sample from a healthy donor individual; selectively separating and collecting leukocytes from the sample; selectively separating and collecting red blood cells and / or platelets and / or plasma from the sample; and cryogenically preserving the leukocytes (and optionally the red blood cells and / or platelets and / or plasma); wherein steps are conducted with an automated leukapheresis device comprising a separation device (e.g. a centrifuge rotor or filter), a leukapheresis tubing set and one or more pumps for conveying the sample through the tubing set and the separated leukocytes into a collection vessel.

Owner:LIFEFORCE GROUP

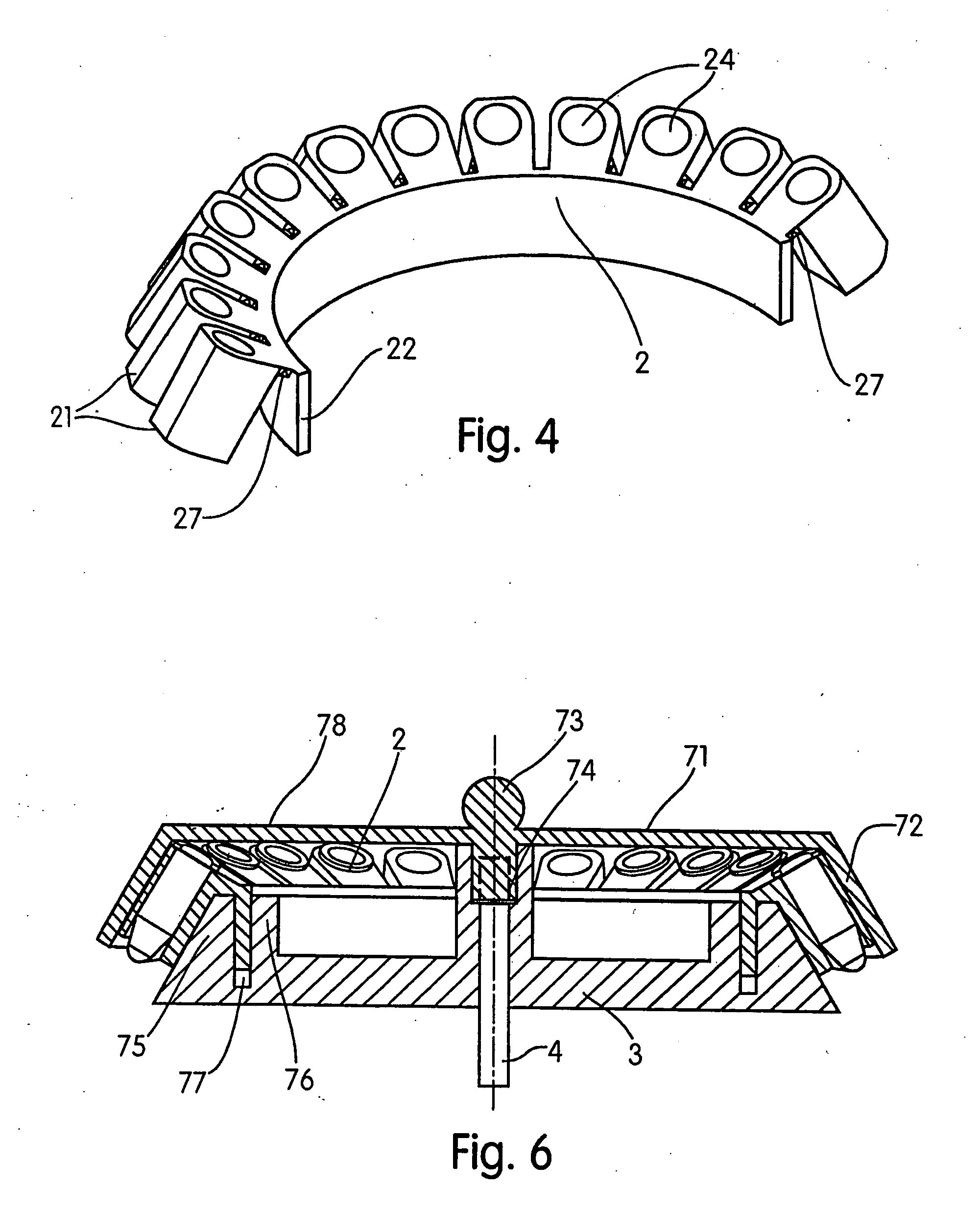

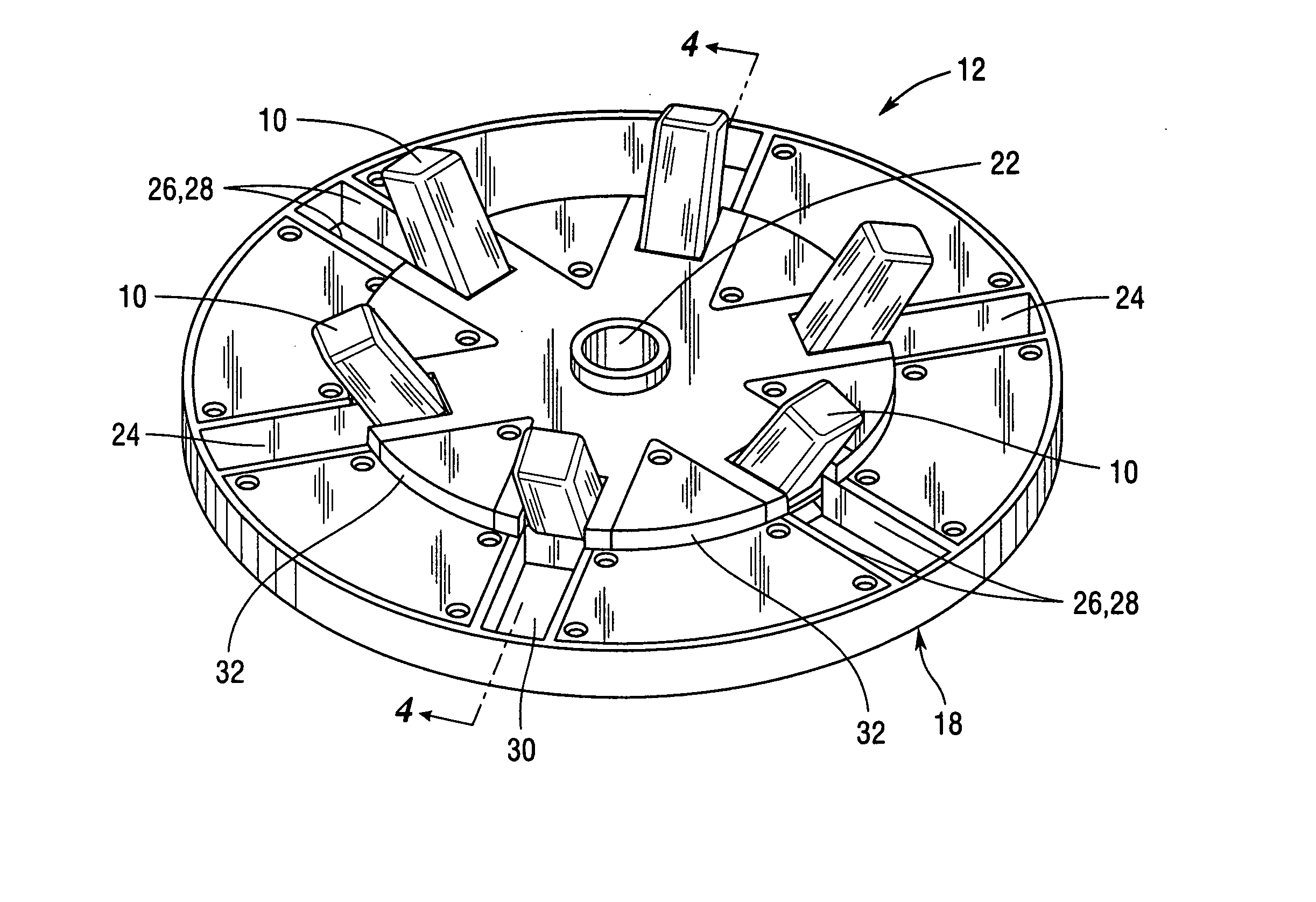

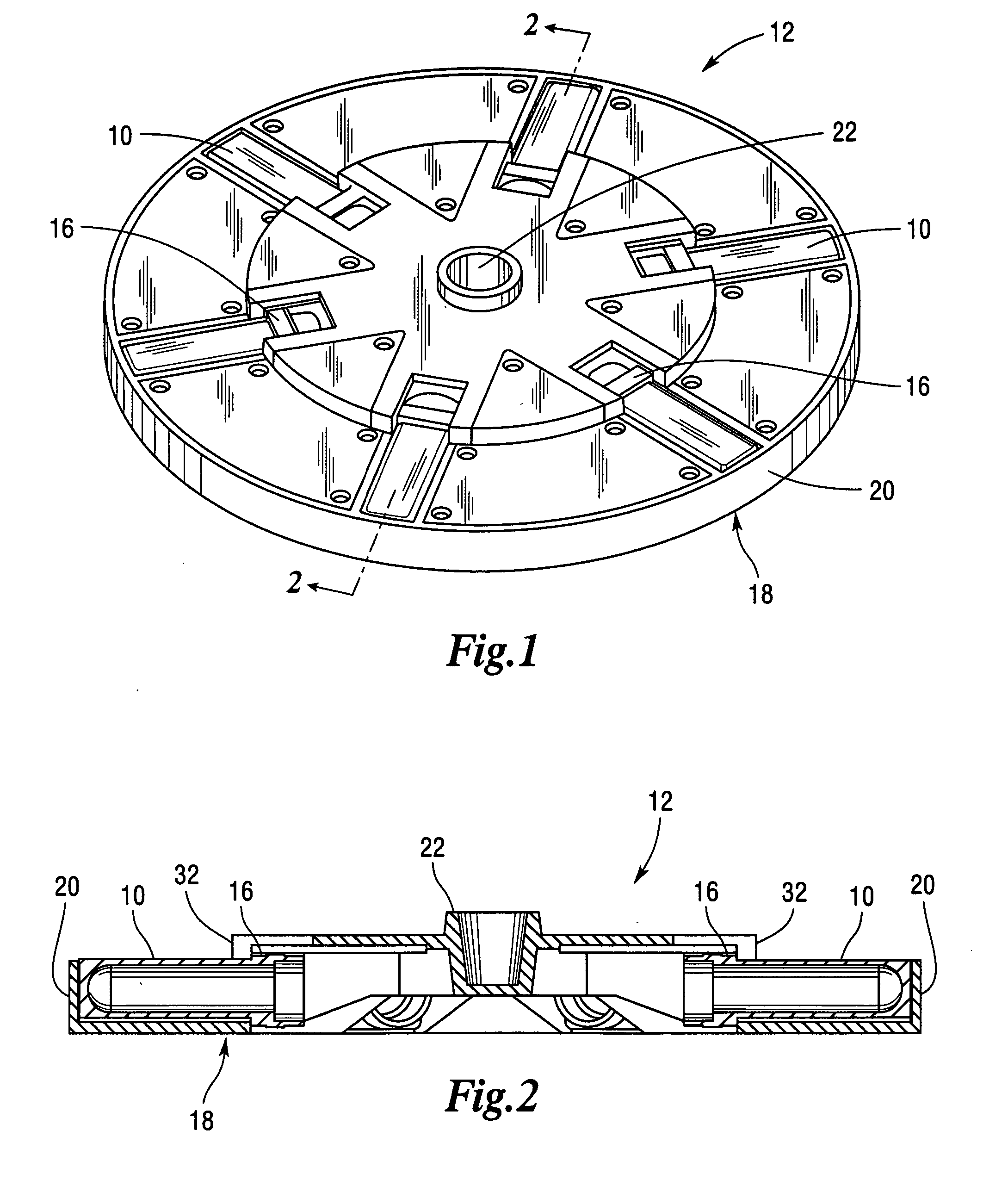

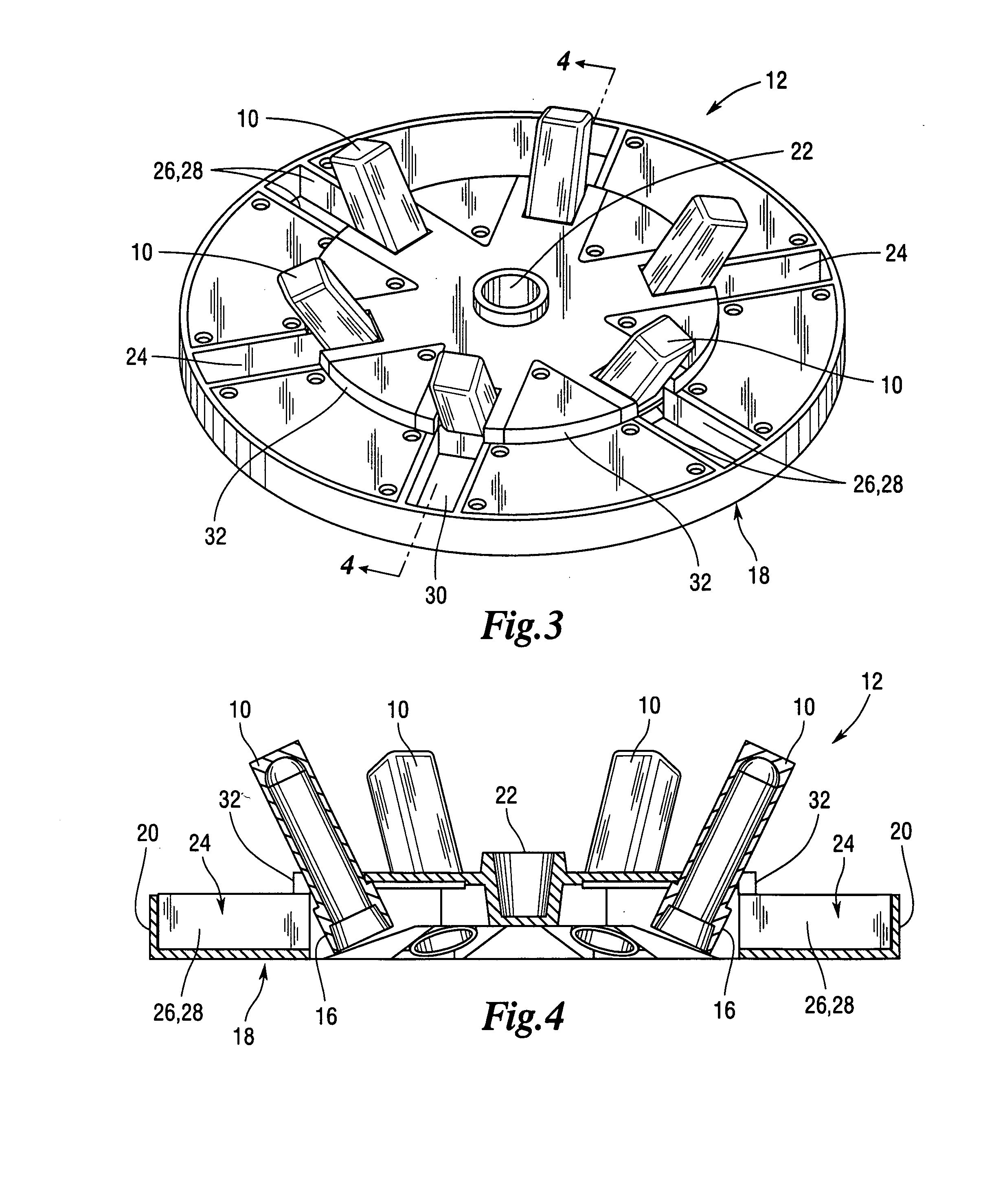

Centrifuge bucket design

A rotor and specimen holder assembly for producing a relatively low power, low audible level, cool running centrifuge. The centrifuge rotor assembly is designed to enable a specimen holder to retract into the body of the rotor during centrifugation to produce aerodynamic features.

Owner:DRUCKER COMPANY INC THE

Centrifugal separator

InactiveUS20090280974A1Improve mechanical sealingProlong lifeEngine sealsRotary centrifugesCentrifuge rotorMechanical engineering

In a centrifugal separator comprising a first and second separator part having a centrifuge rotor and rotates during operation relative to the first separator part. A space connecting the first and second separator parts houses a rotating liquid body during operation. A mechanical sealing device is provided at the space and includes a first sealing element on the first separator part having a first contact surface, and a second sealing element on the second separator part having a second contact surface. The liquid body on the first sealing element or the second sealing element and displaces the same axially so that the first and second contact surfaces are pressed against each other. A pre-tensioning element exerts force on the sealing element which acts to displace the first contact away from the second contact surfaces so that a gap is formed, forming a throttling.

Owner:ALFA LAVAL CORP AB

Centrifugal separator

In a centrifugal separator having a stationary part, a non-rotating part, is elastically connected to the stationery part, and a rotating part, rotates around an axis of rotation and comprises a centrifuge rotor and a rotating bearing-receiving element. The centrifuge rotor comprises a disk package with a plurality of separating disks. The rotating part is journalled in the non-rotating part so that the rotating part and the non-rotating part are commonly pivotable relative to the stationary part. A drive arrangement drives the rotating part about the axis of rotation within a range of revolutions. An inlet channel extends into the inner separation space for feeding of a medium to be separated. An outlet channel extends out from the inner separation space for discharge of a separated product. The bearing-receiving element is tubular. At least one of the inlet channel and the outlet channel extends through the bearing-receiving element.

Owner:ALFA LAVAL CORP AB

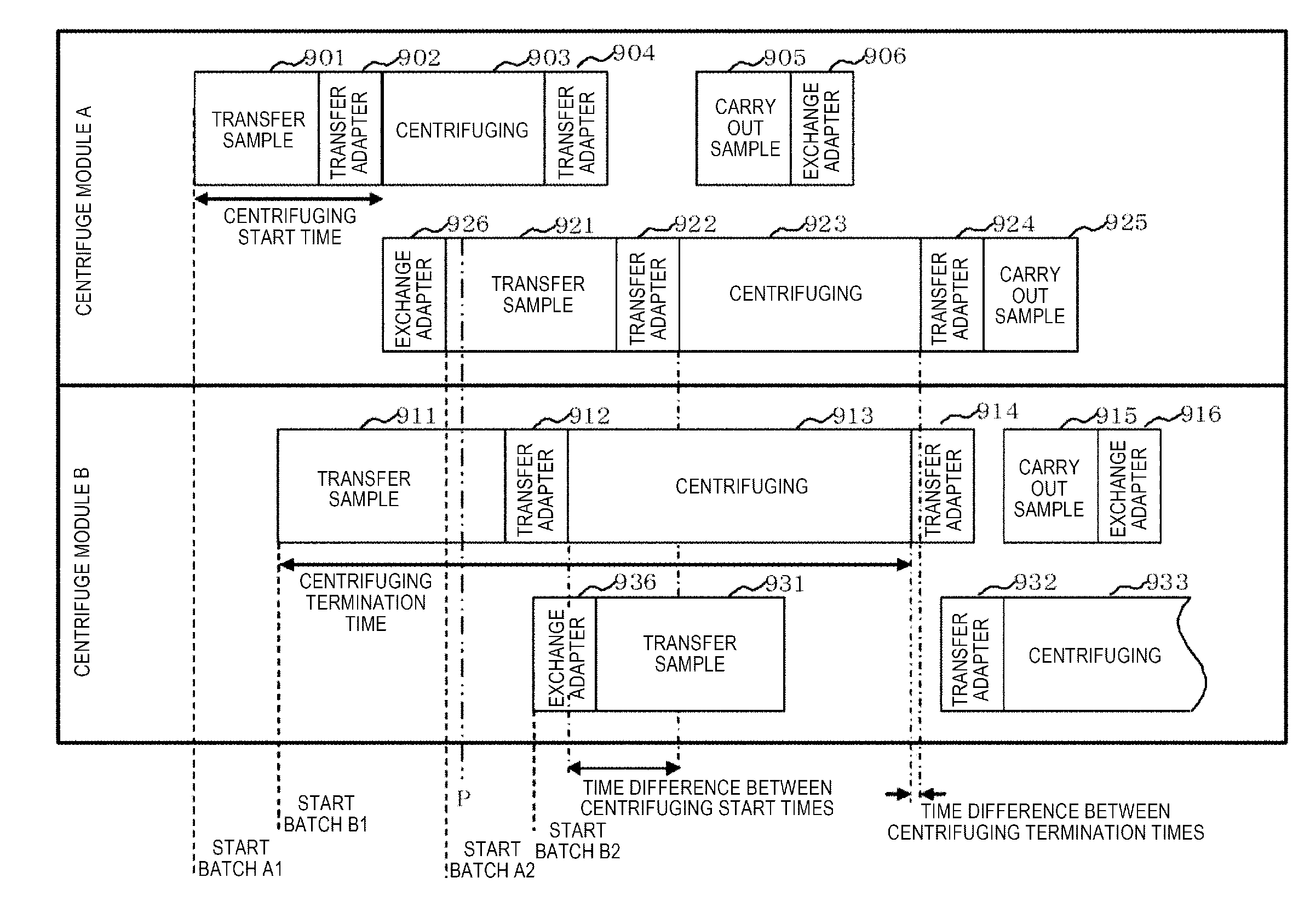

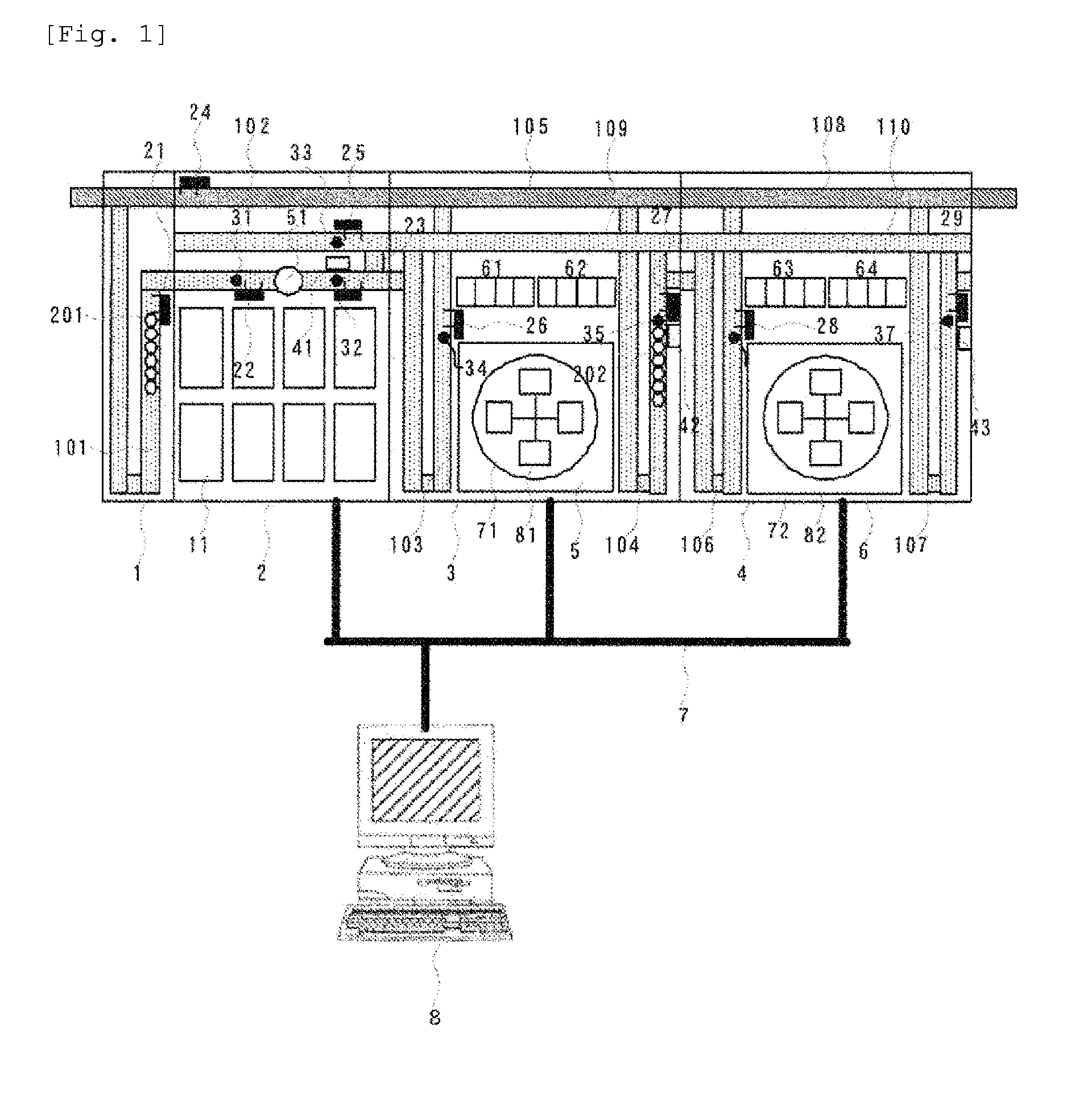

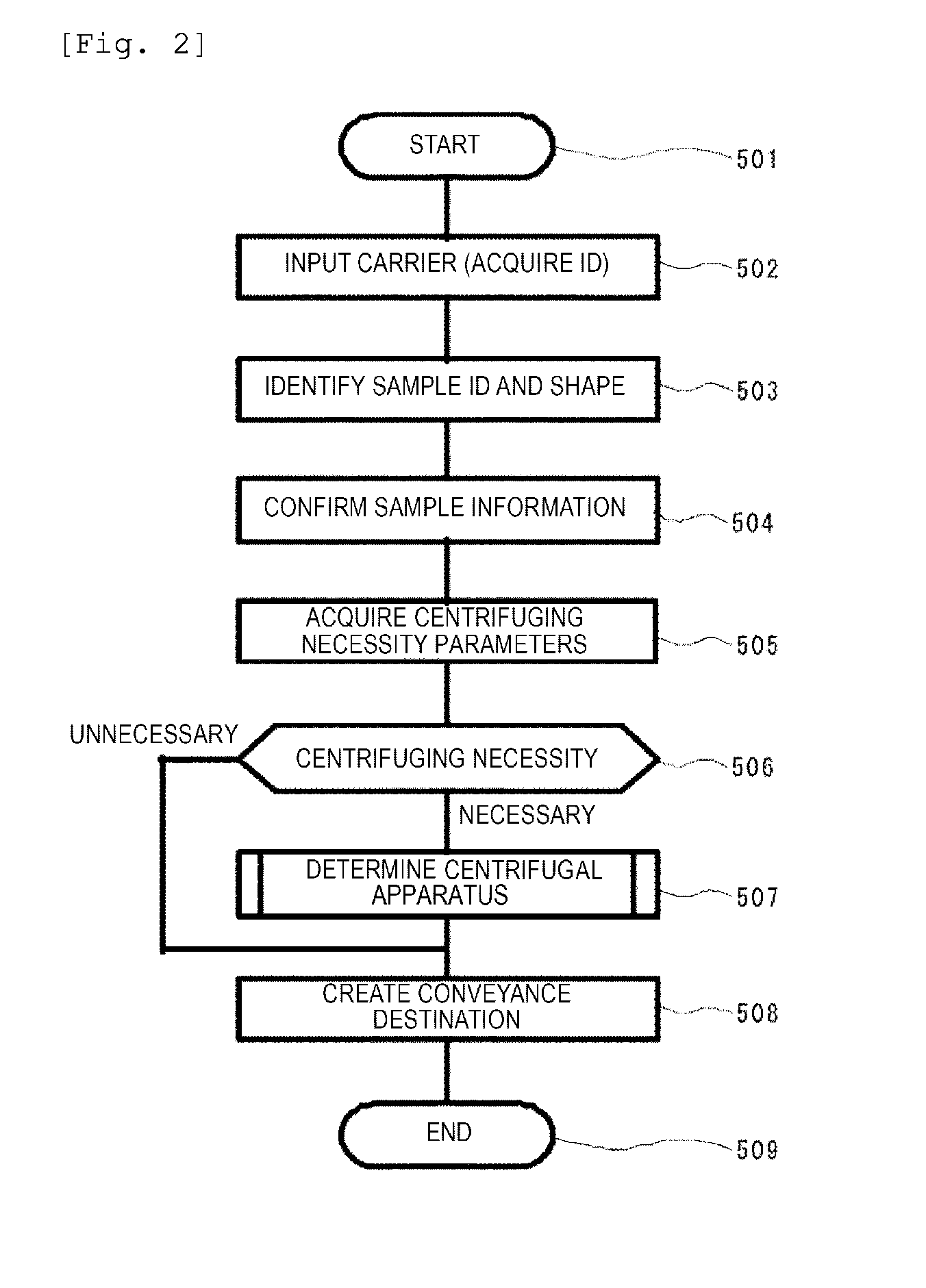

Centrifuging system, sample preprocessing system, and control method

ActiveUS20150360239A1Extended processing timeMinimize processing timeDispersed particle separationCentrifugal force sediment separationCentrifuge rotorStart time

A sample preprocessing system is capable of reducing centrifuging time, which accounts for the majority of time required for a preprocessing step, and at the same time, performing centrifuging under various conditions. A system management unit ascertains the states of a plurality of centrifuge devices, particularly comparing centrifuging start times and centrifuging termination times for the respective centrifuge devices, and selects the centrifuge device for which the processing time is shortest. Specifically, the system includes an adapter that forms a plurality of batches, sample transfer means for transferring a sample to the adapter, a plurality of centrifuge rotors that centrifuge the adapter in batch units, and calculation means for calculating in advance a start timing and a termination timing of the centrifuging in batch units, and the batch, into which samples are transferred, is controlled on the basis of at least one of the calculated start timing and termination timing.

Owner:HITACHI HIGH-TECH CORP

Device for cleaning of crankcase gases

This document describes a device for cleaning of crankcase gases from a combustion engine, and a combustion engine having such a device. An inlet conduit is connected to a crankcase of the combustion engine. A centrifugal separator receives a flow of crankcase gases from the crankcase via the inlet conduit and comprises a routable centrifuge rotor for centrifuging the crankcase gases. A drive device drives the centrifuge rotor. An outlet conduit discharges cleaned crankcase gases from the centrifugal separator. The rotary speed of the drive device, and thus the rotary speed of the centrifuge rotor, is controllable depending on the gas pressure in the crankcase. An export conduit may be connected to the inlet conduit and adapted to enable discharge of a flow of crankcase gases from the crankcase by-passing the centrifugal separator depending on the gas pressure in the crankcase. An import conduit may be connected to the inlet conduit and adapted to enable feeding of a flow of air from the surroundings to the crankcase depending on the gas pressure in the crankcase.

Owner:ALFA LAVAL CORP AB

Centrifuge for the purification of lubricating oil of an internal-combustion engine

ActiveUS20050020428A1Small amount of leakageGuaranteed uptimeMachines/enginesLubricant mounting/connectionCentrifuge rotorEngineering

A centrifuge for the purification of lubricating oil of an internal-combustion engine is provided which includes a housing with a removable cover, a housing-fixed shaft arranged in the housing and a centrifuge rotor which is rotatably mounted on the shaft and is replaceable. The shaft is hollow at least in its lower part and forms in its hollow inside a section of a lubricating oil supply canal, which canal is in flow connection with an inside of the centrifuge rotor mounted on the shaft over at least one orifice opening. The centrifuge also includes an adjustable valve plug arranged at the shaft and arranged to be held in an open position by the centrifuge rotor. The valve plug releases the orifice opening in the open position. The valve plug is also arranged to be transferred into a closing position and held in the closing position by a force created by at least one of a pressure of the lubricating oil and by a preloading component if the centrifuge rotor is missing. The valve plug plugs the orifice opening in the closing position.

Owner:HENGST WALTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com