Patents

Literature

2574results about "Centrifugal force sediment separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for sample use maximization

InactiveUS20120309636A1Increase in sizeImprove accuracyImage enhancementBioreactor/fermenter combinationsPoint of careAnalyte

The present invention provides systems, devices, and methods for point-of-care and / or distributed testing services. The methods and devices of the invention are directed toward automatic detection of analytes in a bodily fluid. The components of the device can be modified to allow for more flexible and robust use with the disclosed methods for a variety of medical, laboratory, and other applications. The systems, devices, and methods of the present invention can allow for effective use of samples by improved sample preparation and analysis.

Owner:THERANOS

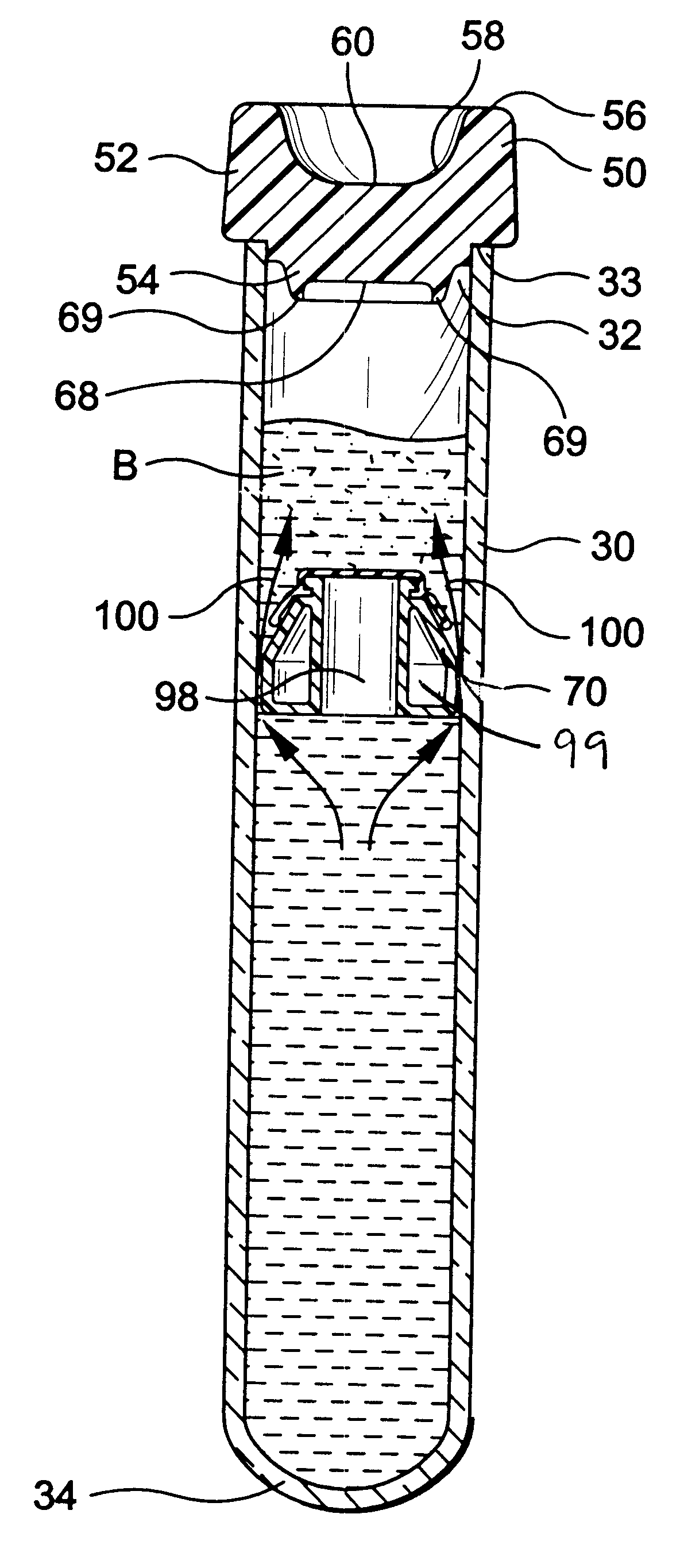

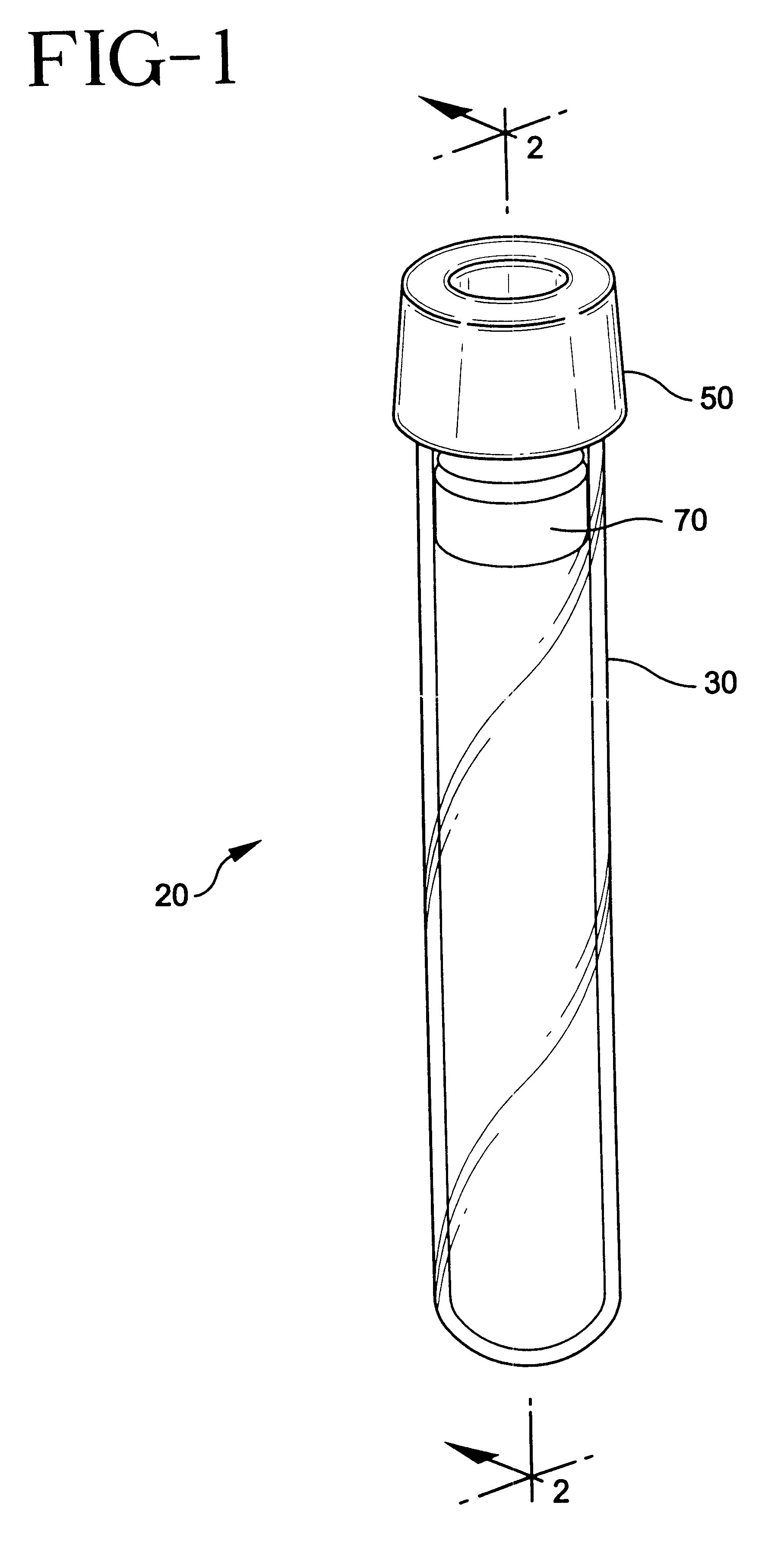

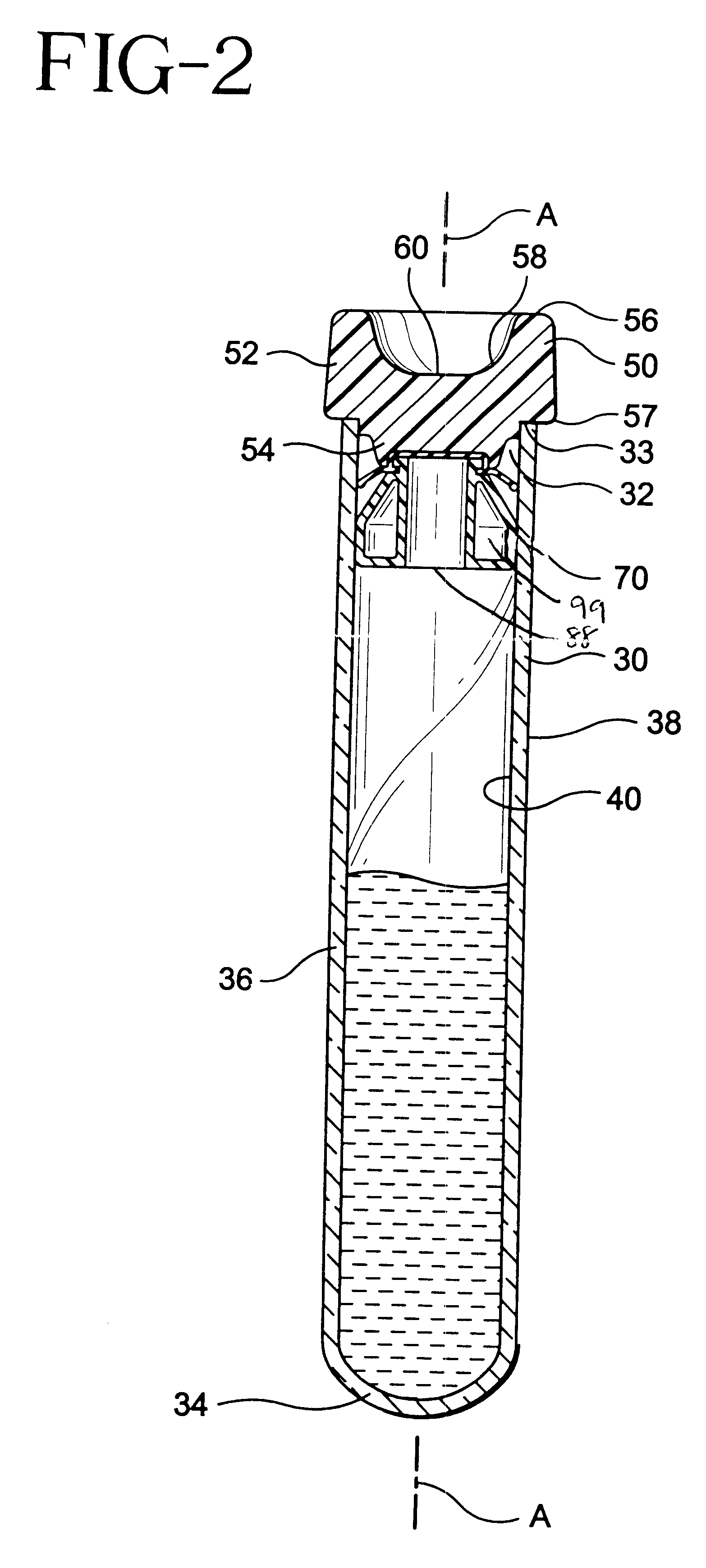

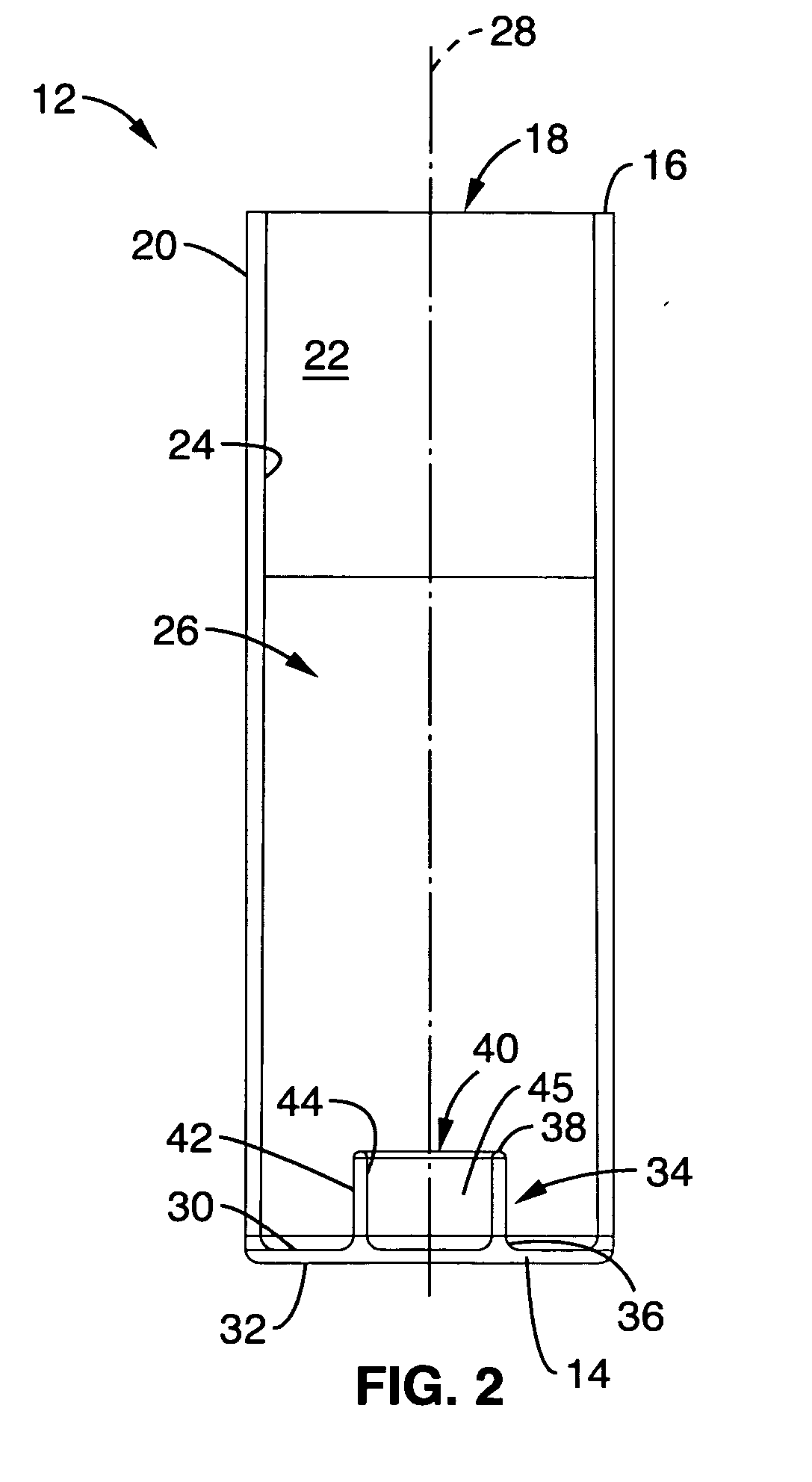

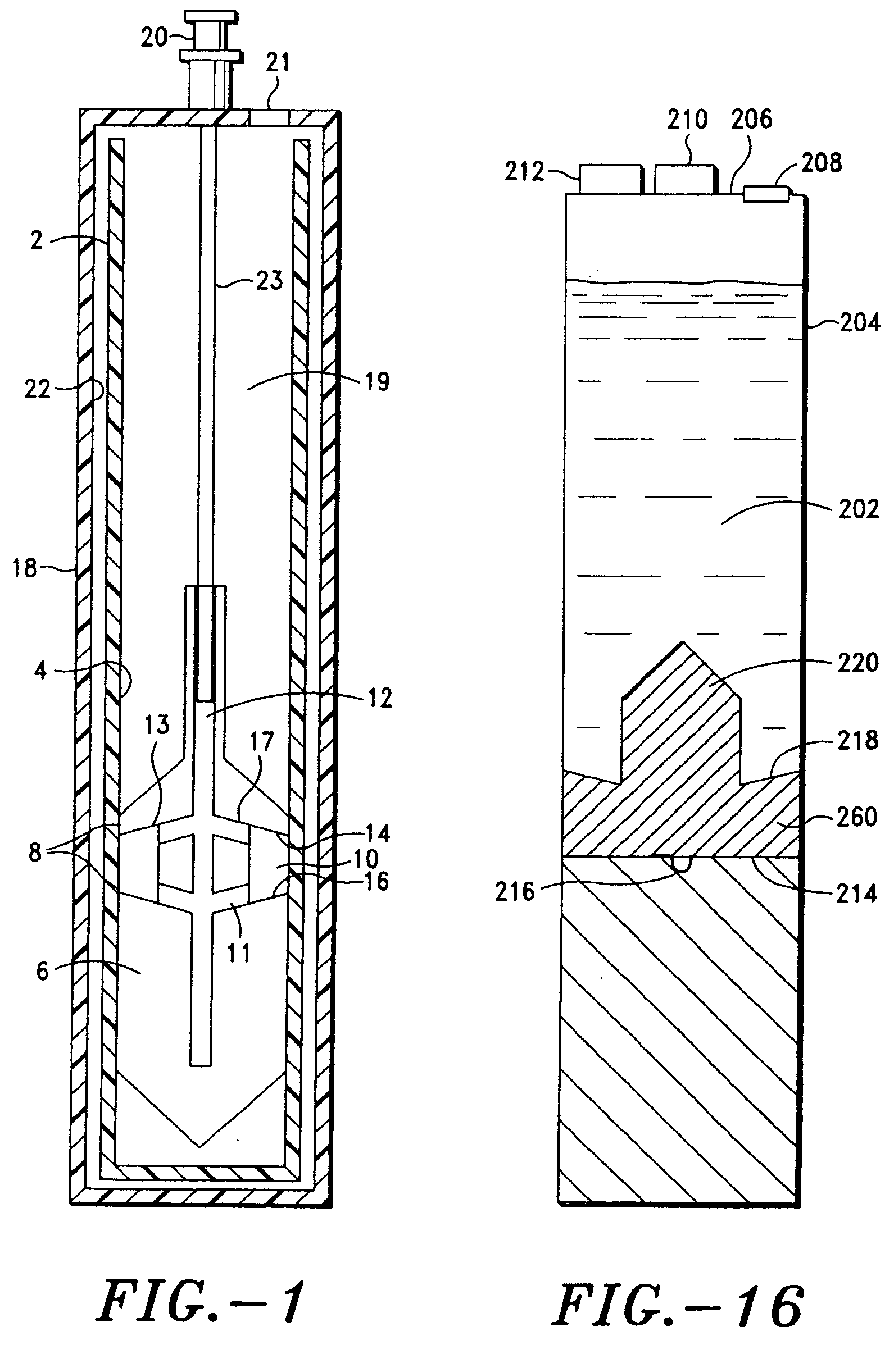

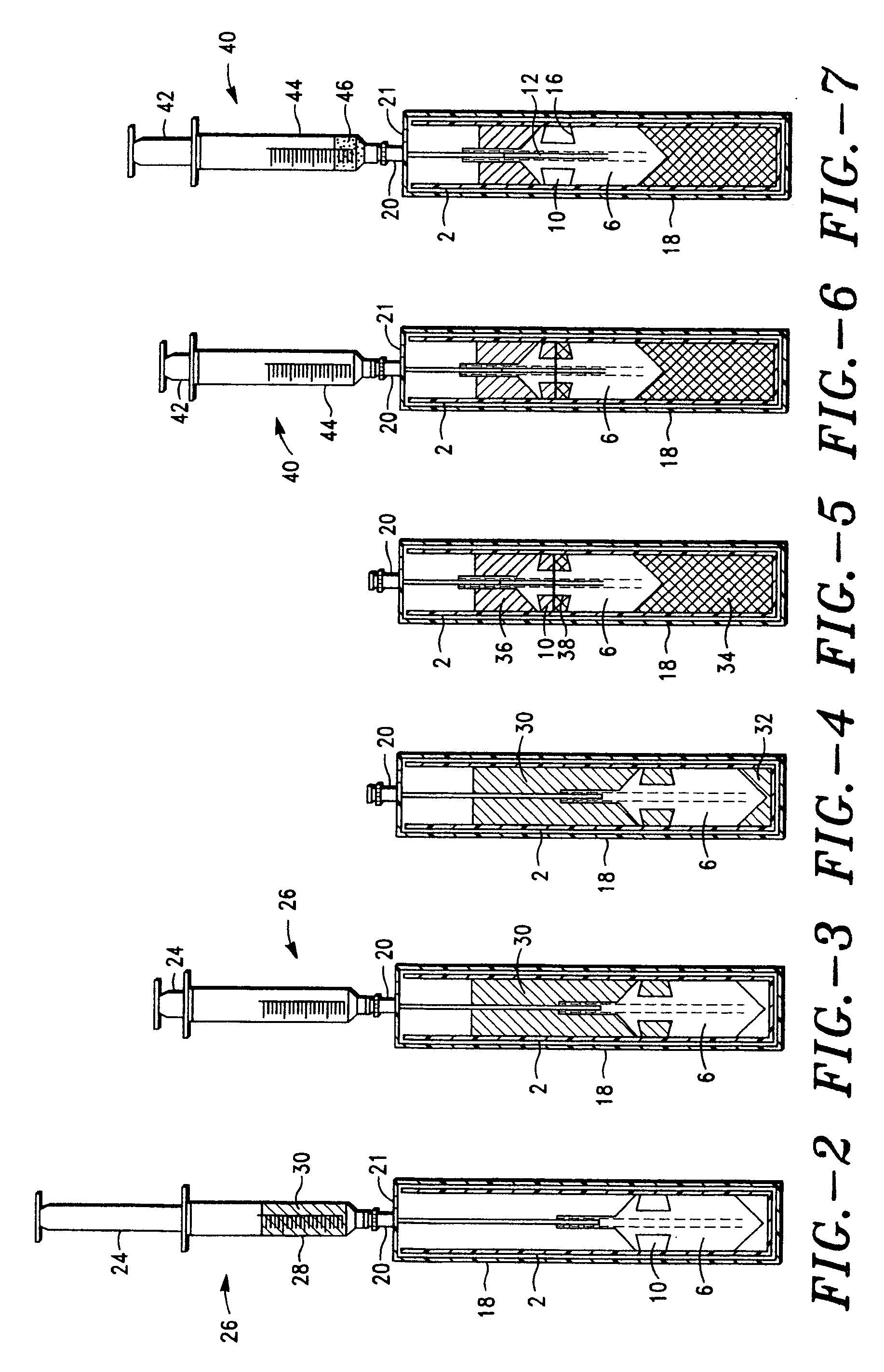

Device and method for separating components of a fluid sample

A device and method is provided for separating heavier and lighter fractions of a fluid sample. The device includes a plurality of constituents comprising a container and a composite element in the container. The composite element is a separator comprising at least two components and more particularly an elastic portion and a plug member. A fluid sample is delivered to the container and the device is subjected to centrifugation whereby the centrifugal load causes the elastic portion of the separator to deform so that the separator migrates into the fluid sample and stabilizes between the heavier and lighter fractions of the fluid sample. The elastic portion of the separator will resiliently return to its initial configuration upon termination of the centrifugal load such that the elastic portion sealingly engages the container and separates the heavier and lighter fractions of the fluid sample.

Owner:BECTON DICKINSON & CO

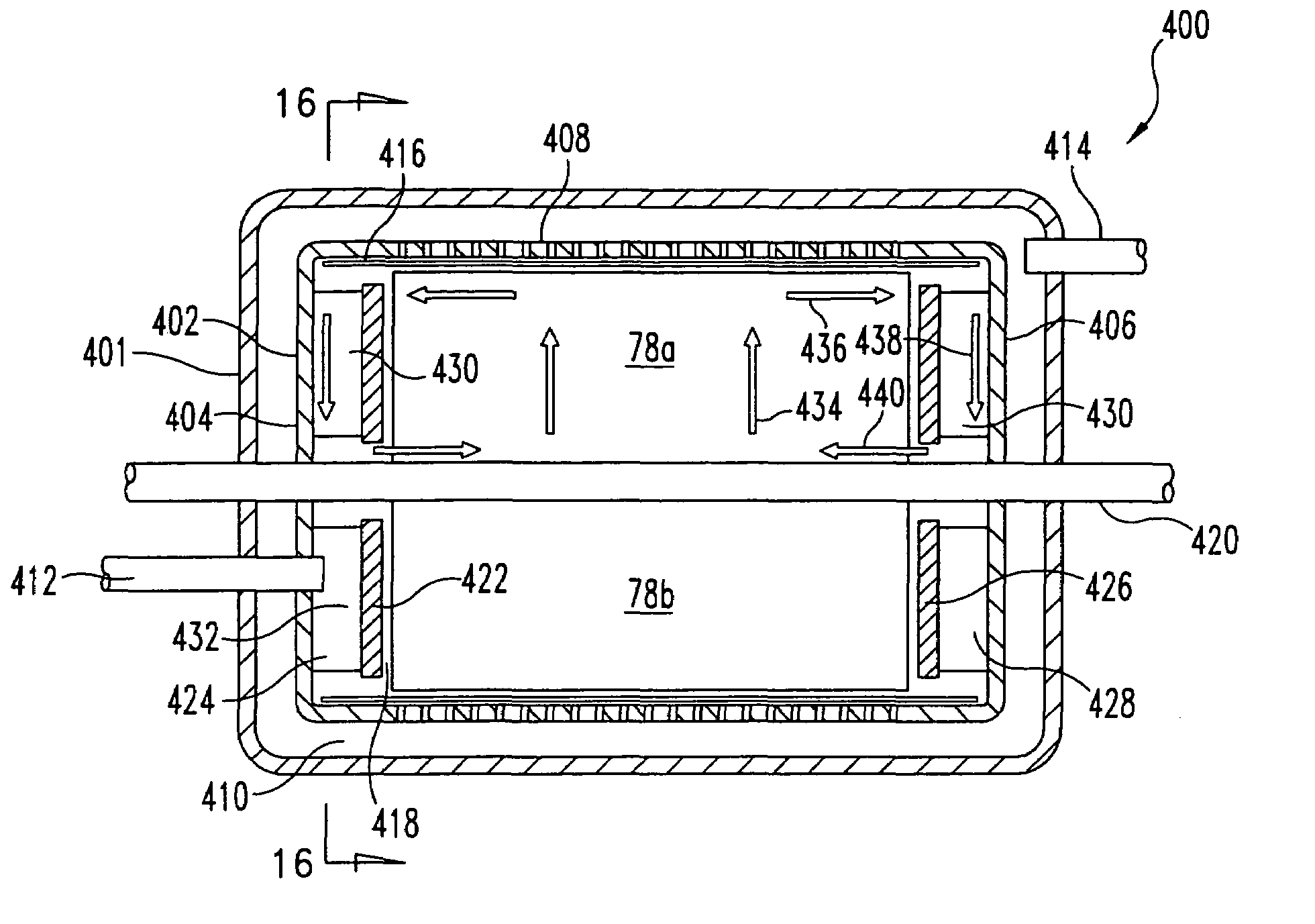

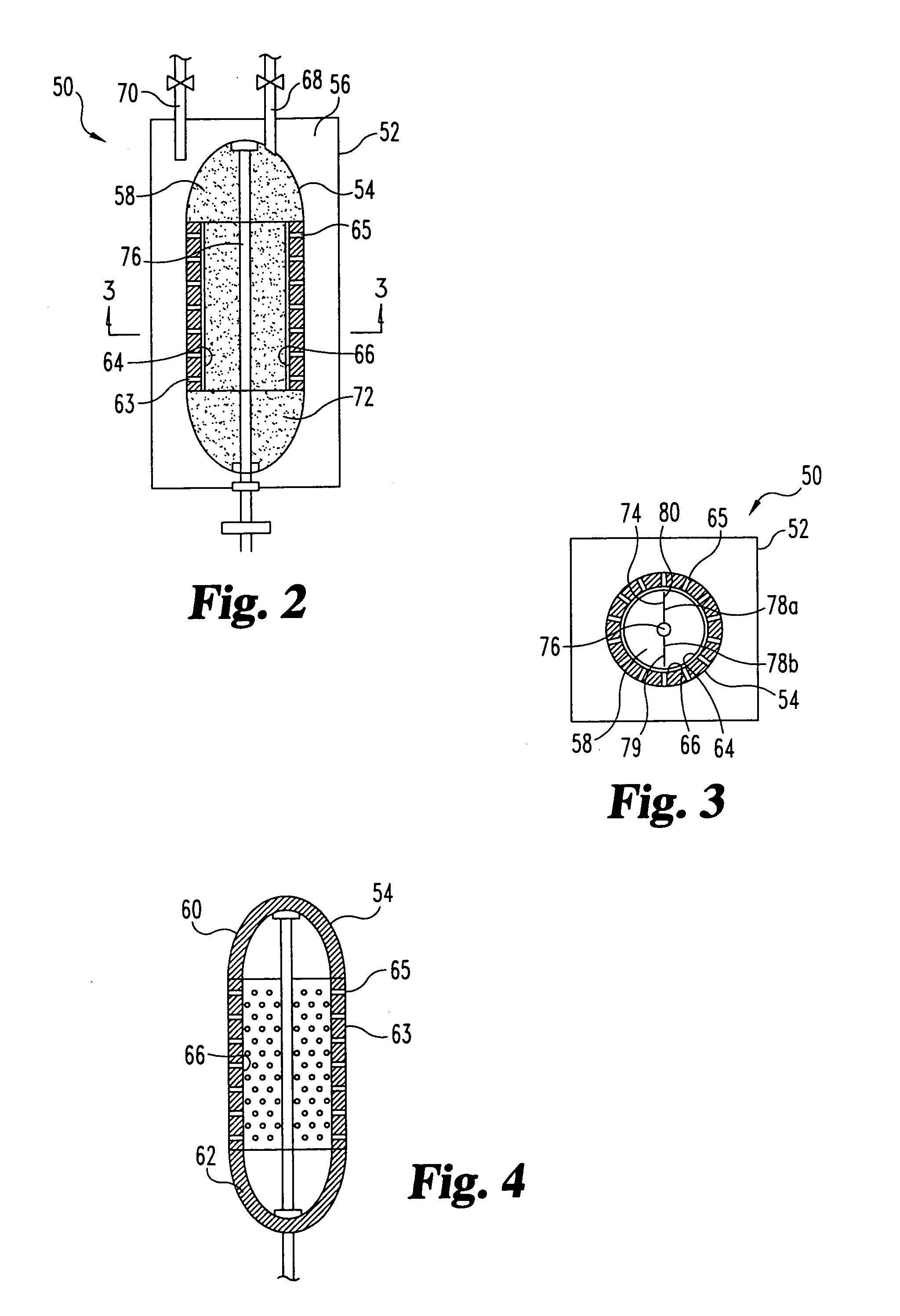

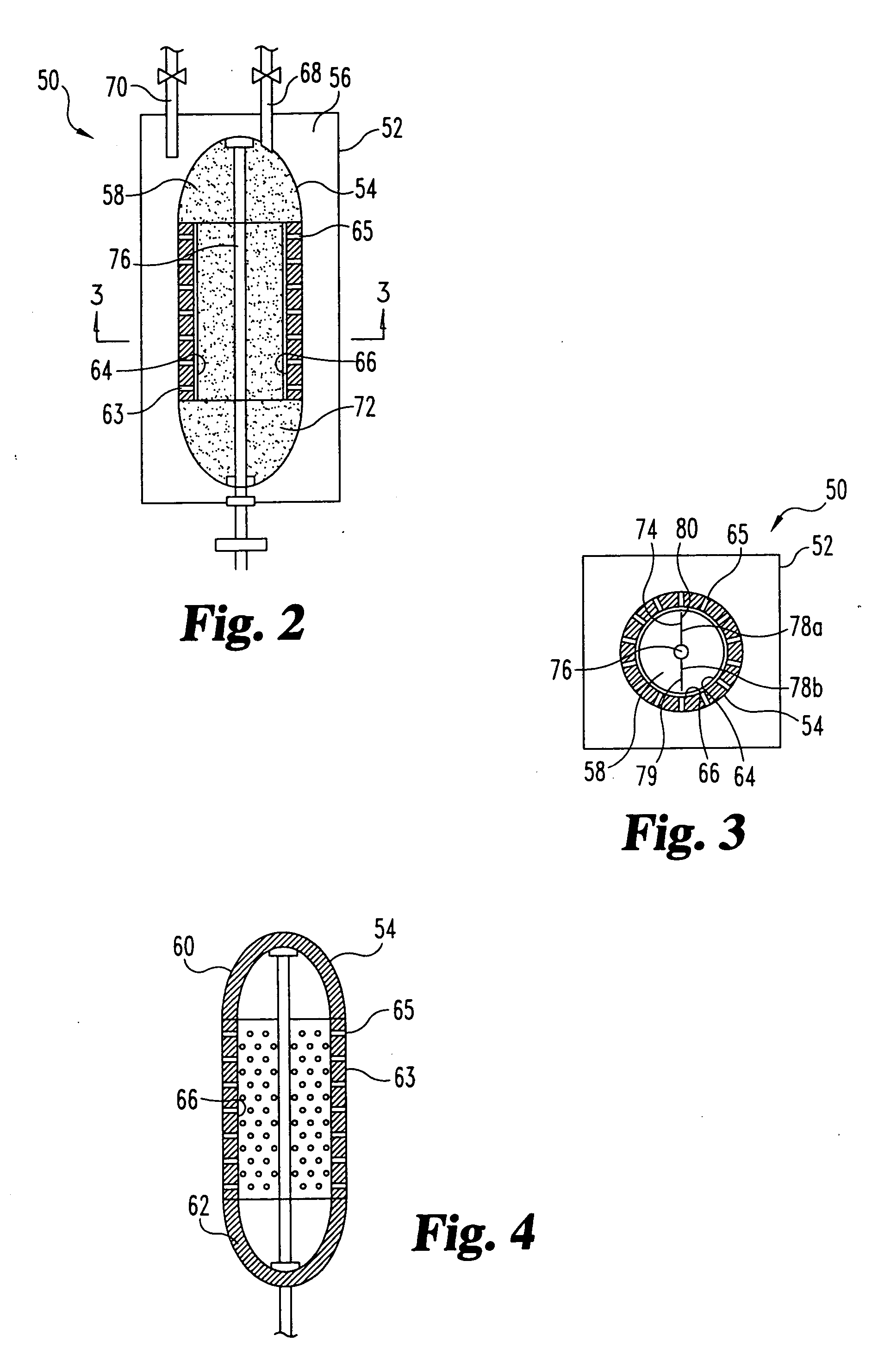

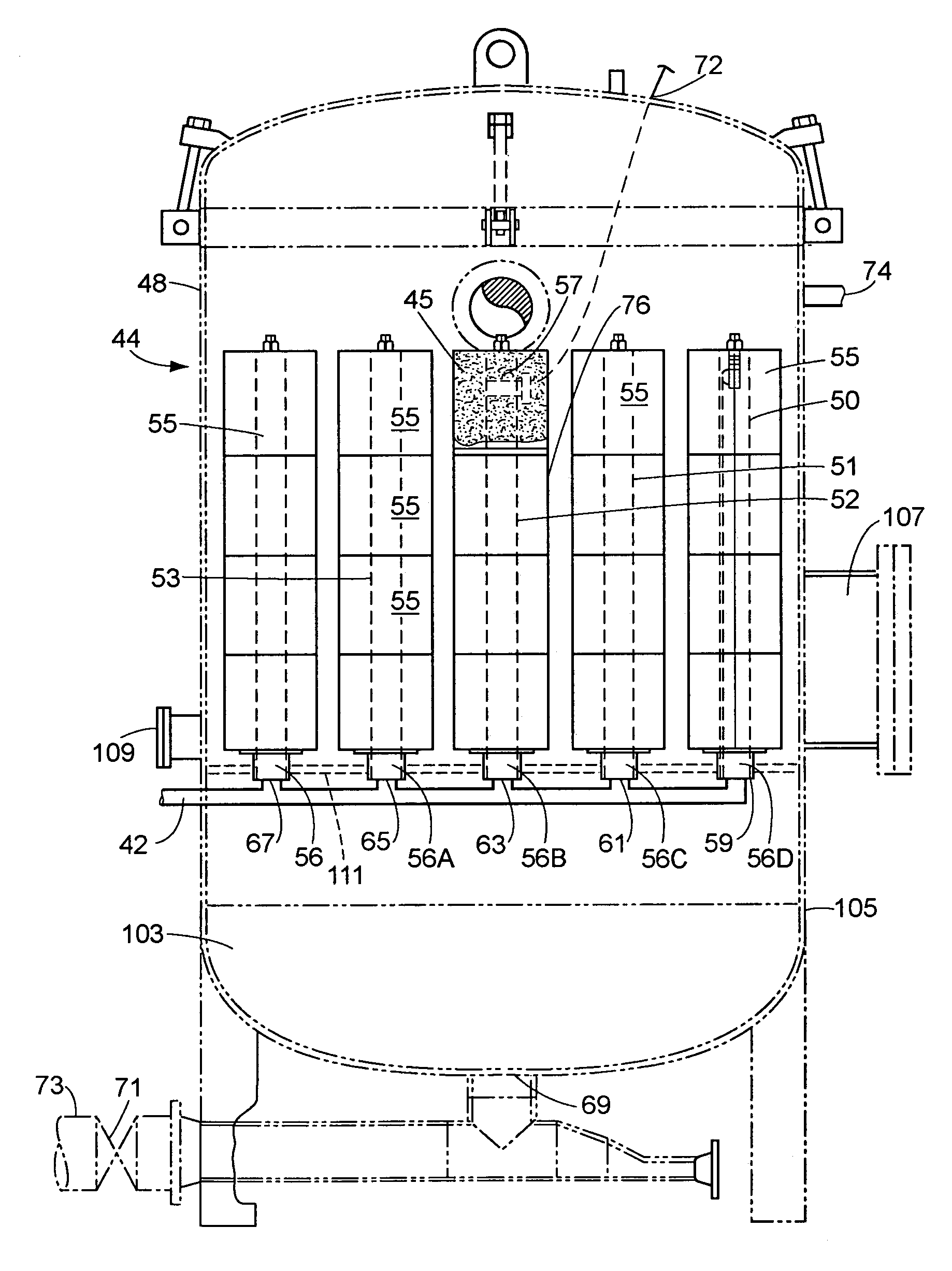

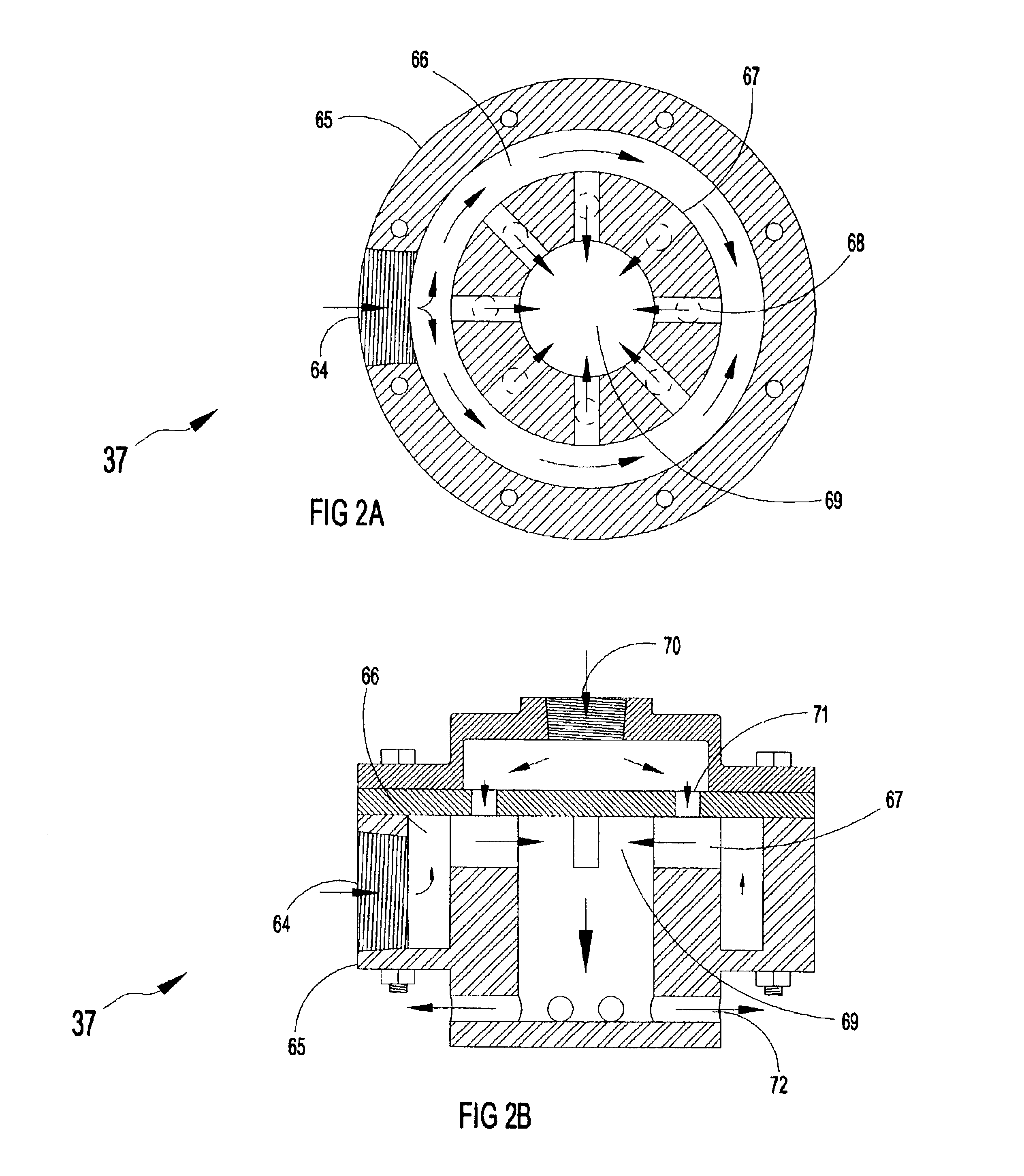

Sorbent reactor for extracorporeal blood treatment systems, peritoneal dialysis systems, and other body fluid treatment systems

InactiveUS7169303B2Facilitate homogeneous suspensionReduce probabilitySolvent extractionHaemofiltrationFluid balancePeritoneal dialysis

Systems and methods for extracorporeal processing of blood or other body fluid for the treatment of conditions, such as sepsis, autoimmune disease, or toxemia related to kidney failure, liver failure, or drug overdose are provided. In an extracorporeal treatment system, a fraction of a body fluid is passed into a treatment fluid, at least a portion of which is then passed through a sorbent suspension reactor for treatment by a sorbent suspension. The treatment fluid circuit can be maintained at a fixed volume, which enables accurate fluid balance between the patient and the extracorporeal circuit. Some or all of the treatment fluid, optionally also containing nutrients and / or therapeutic agents, is returned to the patient. In a peritoneal dialysis system, dialysate is passed into a patient's peritoneal cavity, recovered from the cavity, passed through a sorbent suspension reactor in accordance with the invention, and returned to the cavity.

Owner:HEMOCLEANSE TECH

Method and apparatus for collecting hyperconcentrated platelets

InactiveUS6022306AOther blood circulation devicesDispersed particle separationParticle flowPlatelet product

The instant invention relates to a method and the apparatus for collecting a hyperconcentrated platelet product. A fluid containing platelets and other particles flows into a fluid chamber at a flow rate. The flow rate of the fluid is selected to retain the majority of the platelets in the fluid chamber in a saturated bed. The platelets are collected from the fluid chamber without collecting the other particles to form a hyperconcentrated other particle reduced platelet product.

Owner:CARIDIANBCT

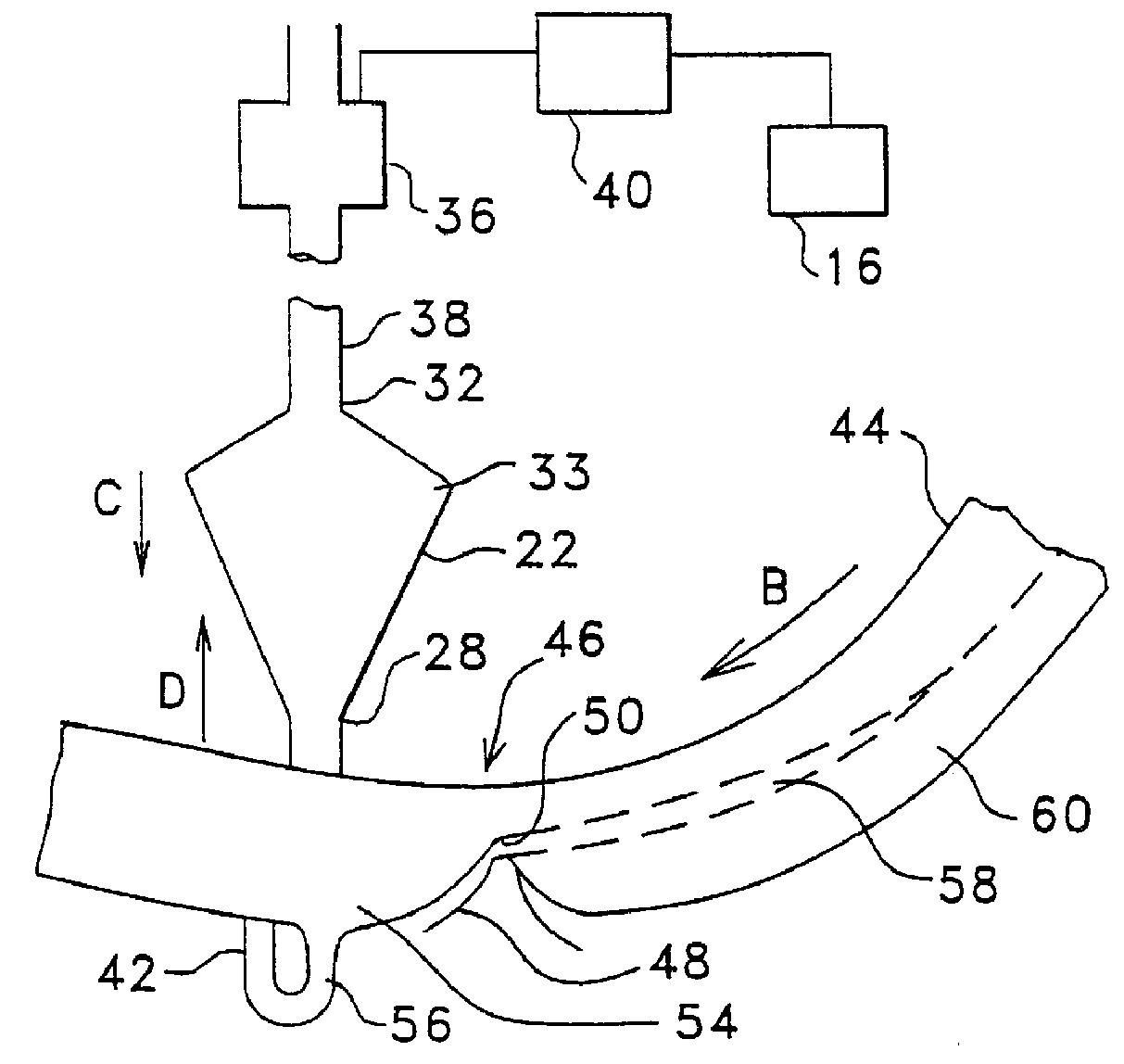

Monitoring and control system for blood processing

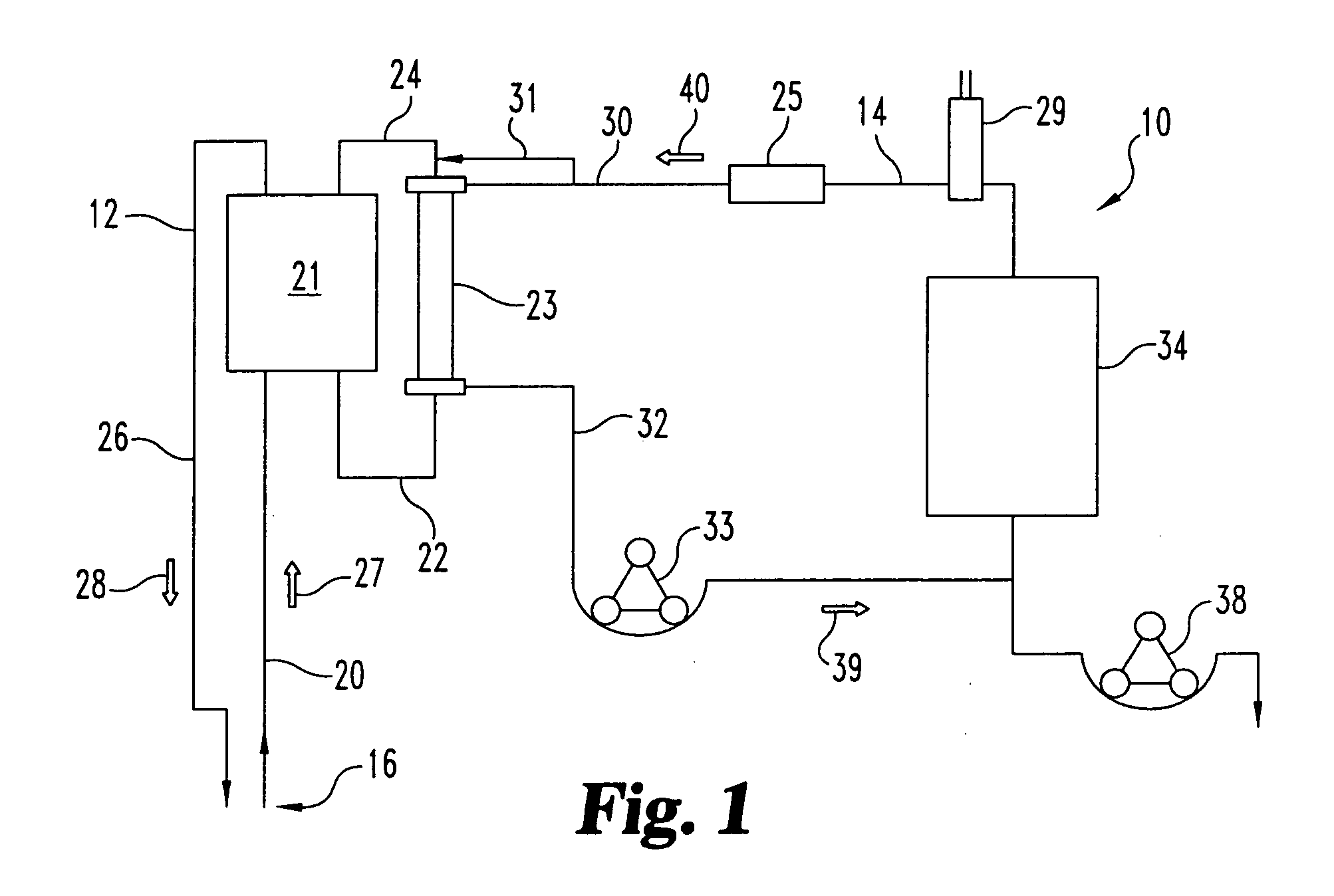

ActiveUS20050051466A1Speed up the processMinimize occurrenceLiquid separation auxillary apparatusWater/sewage treatment by centrifugal separationControl systemCentrifugation

The invention relates generally to methods of monitoring and controlling the processing of blood and blood samples, particularly the separation of blood and blood samples into its components. In one aspect, the invention relates to optical methods, devices and device components for measuring two-dimensional distributions of transmitted light intensities, scattered light intensities or both from a separation chamber of a density centrifuge. In embodiment, two-dimensional distributions of transmitted light intensities, scattered light intensities or both measured by the methods of the present invention comprise images of a separation chamber or component thereof, such as an optical cell of a separation chamber. In another aspect, the present invention relates to multifunctional monitoring and control systems for blood processing, particularly blood processing via density centrifugation. Feedback control systems are provided wherein two-dimensional distributions of transmitted light intensities, scattered light intensities or both are measured, processed in real time and are used as the basis of output signals for controlling blood processing. In another aspect, optical cells and methods of using optical cells for monitoring and control blood processing are provided.

Owner:TERUMO BCT

Sorbent reactor for extracorporeal blood treatment systems, peritoneal dialysis systems, and other body fluid treatment systems

InactiveUS20050006296A1Facilitate homogeneous suspensionReduce probabilityWater treatment parameter controlSemi-permeable membranesFluid balancePeritoneal dialysis

Systems and methods for extracorporeal processing of blood or other body fluid for the treatment of conditions, such as sepsis, autoimmune disease, or toxemia related to kidney failure, liver failure, or drug overdose are provided. In an extracorporeal treatment system, a fraction of a body fluid is passed into a treatment fluid, at least a portion of which is then passed through a sorbent suspension reactor for treatment by a sorbent suspension. The treatment fluid circuit can be maintained at a fixed volume, which enables accurate fluid balance between the patient and the extracorporeal circuit. Some or all of the treatment fluid, optionally also containing nutrients and / or therapeutic agents, is returned to the patient. In a peritoneal dialysis system, dialysate is passed into a patient's peritoneal cavity, recovered from the cavity, passed through a sorbent suspension reactor in accordance with the invention, and returned to the cavity.

Owner:HEMOCLEANSE TECH

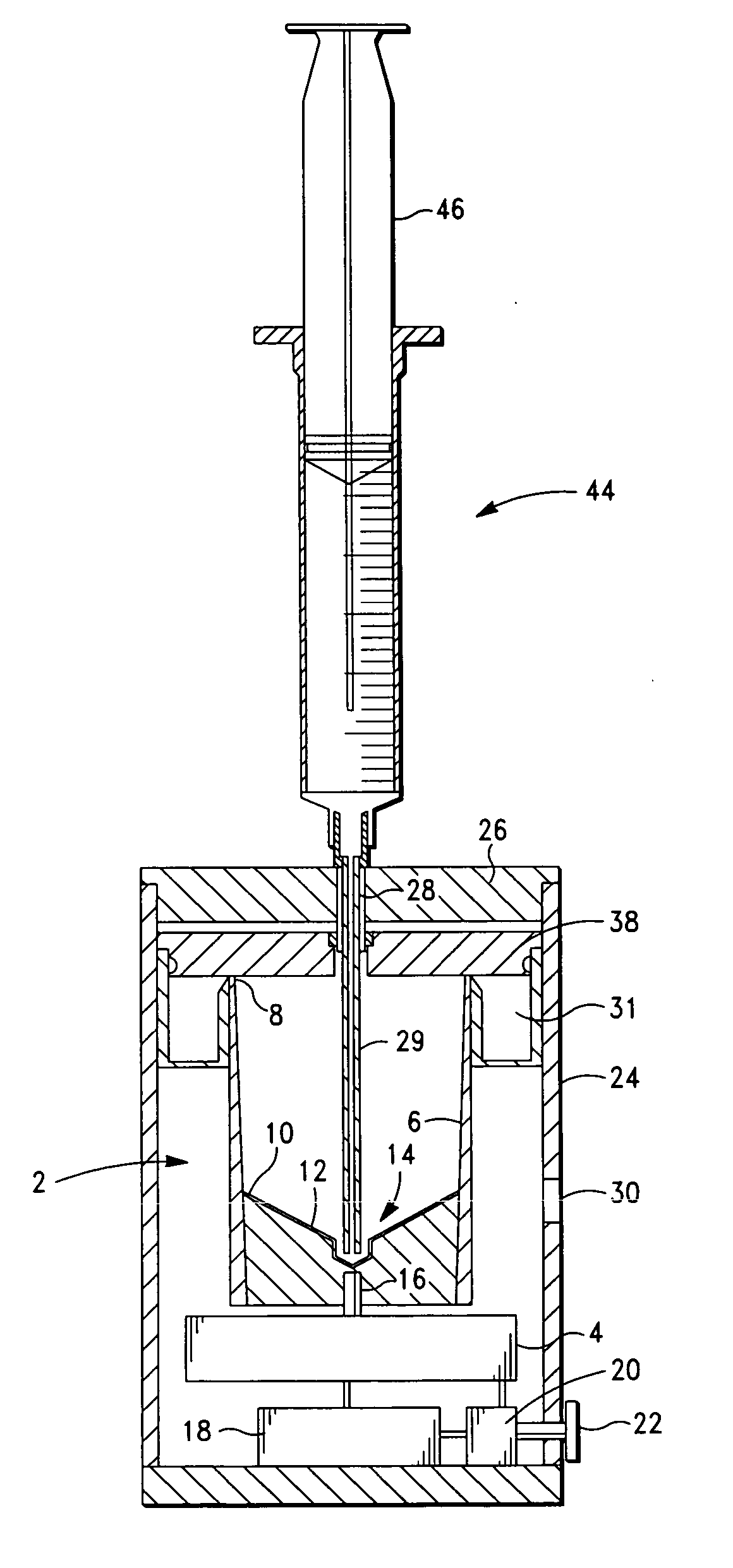

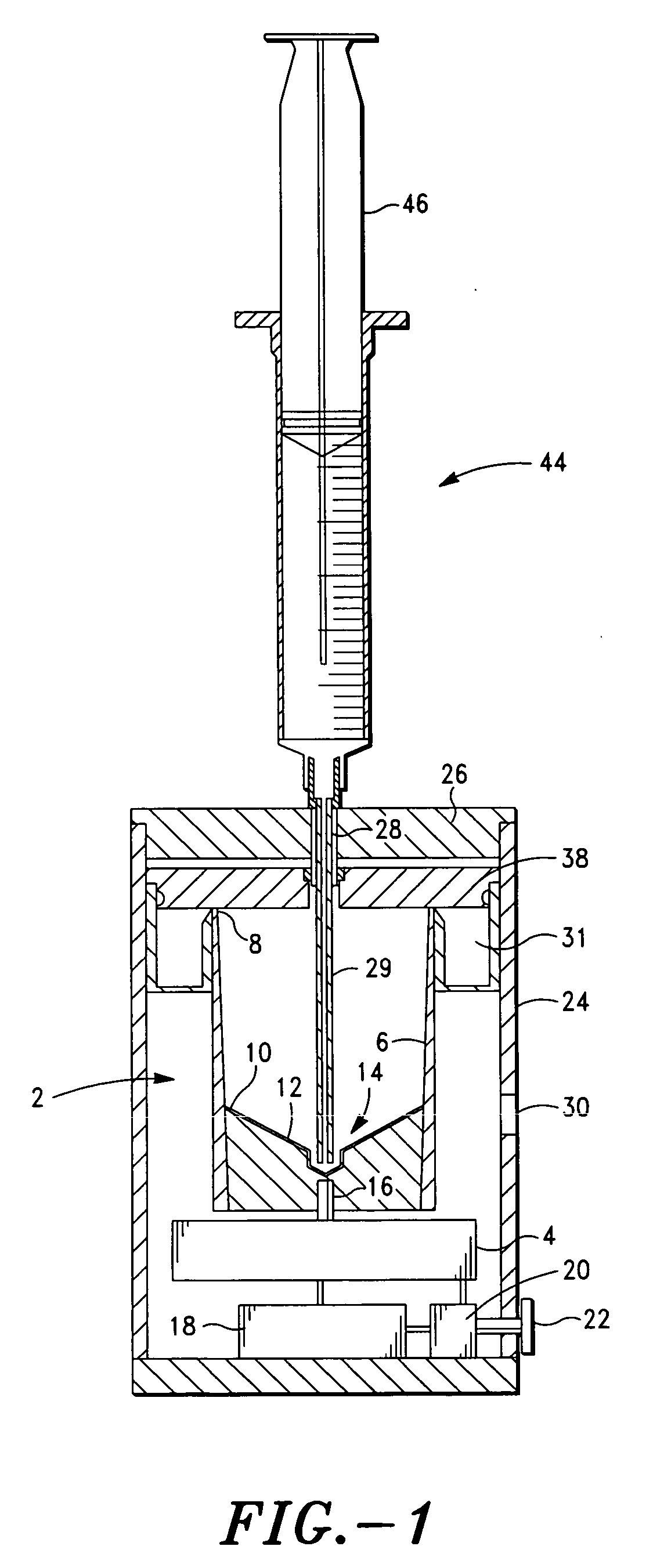

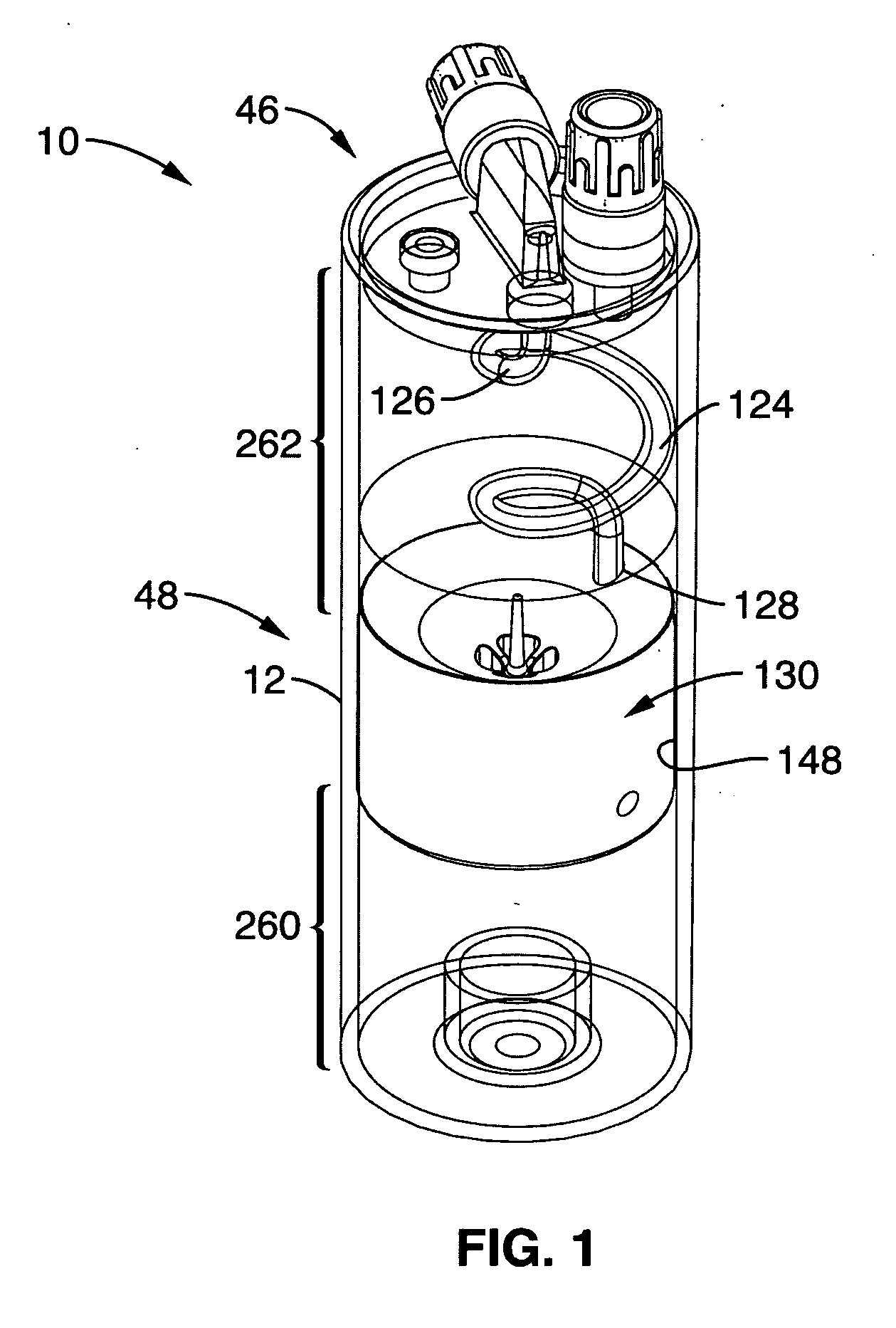

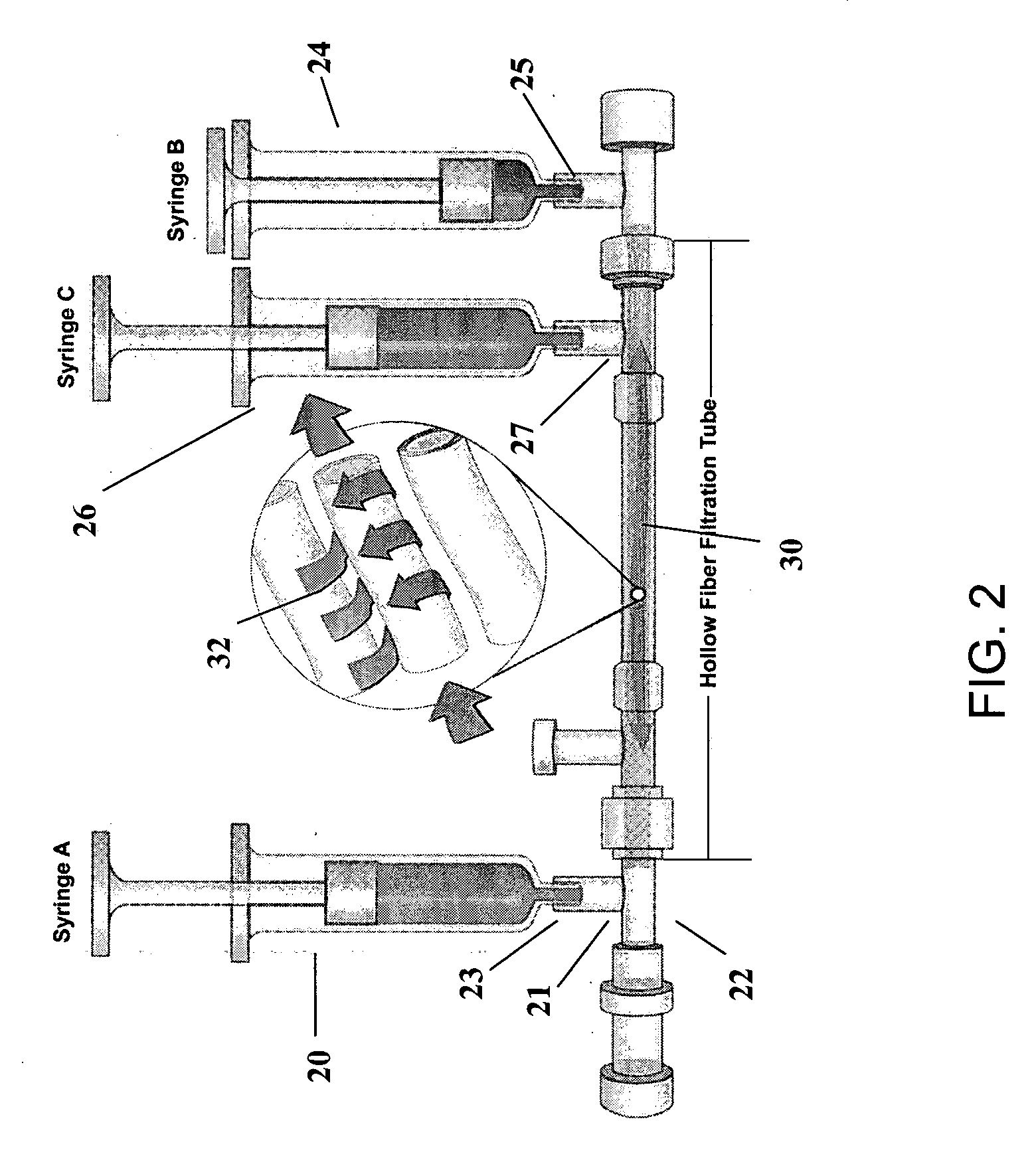

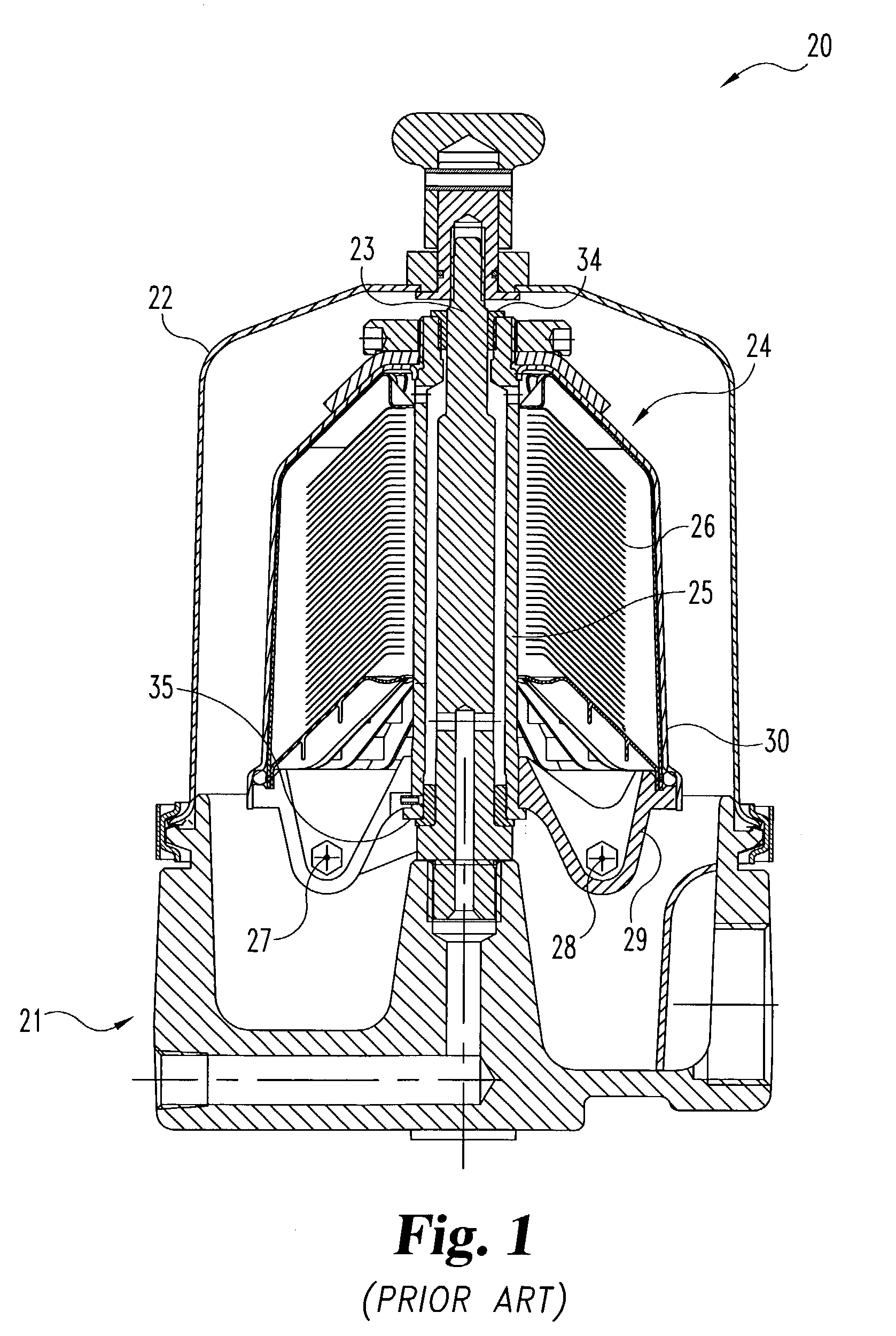

Method and apparatus for preparing platelet rich plasma and concentrates thereof

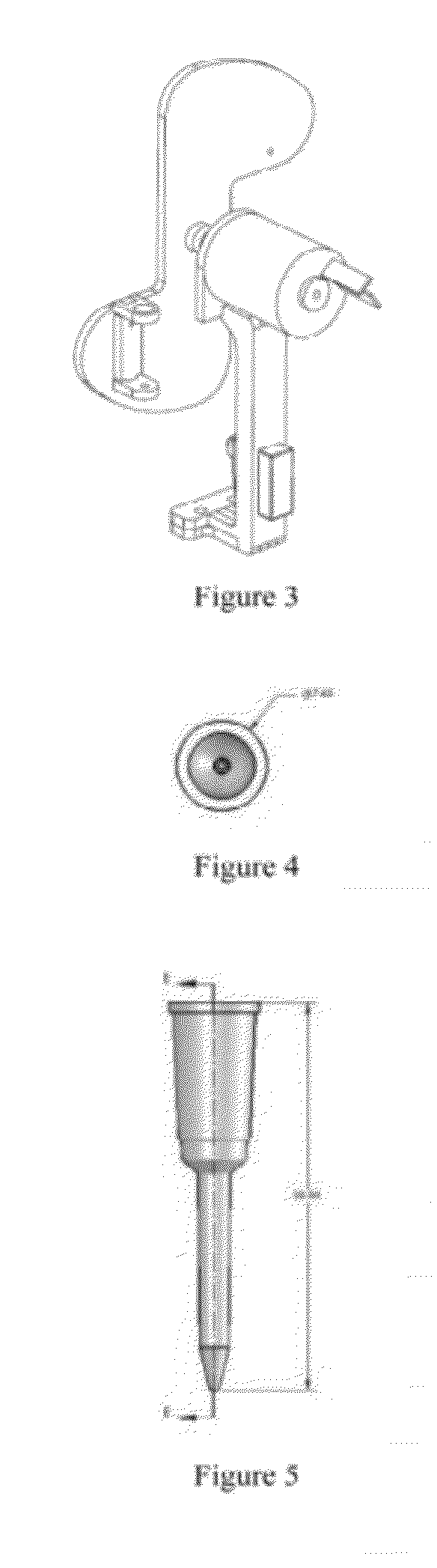

ActiveUS20060175242A1Shaking/oscillating/vibrating mixersTransportation and packagingFiberRed blood cell

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

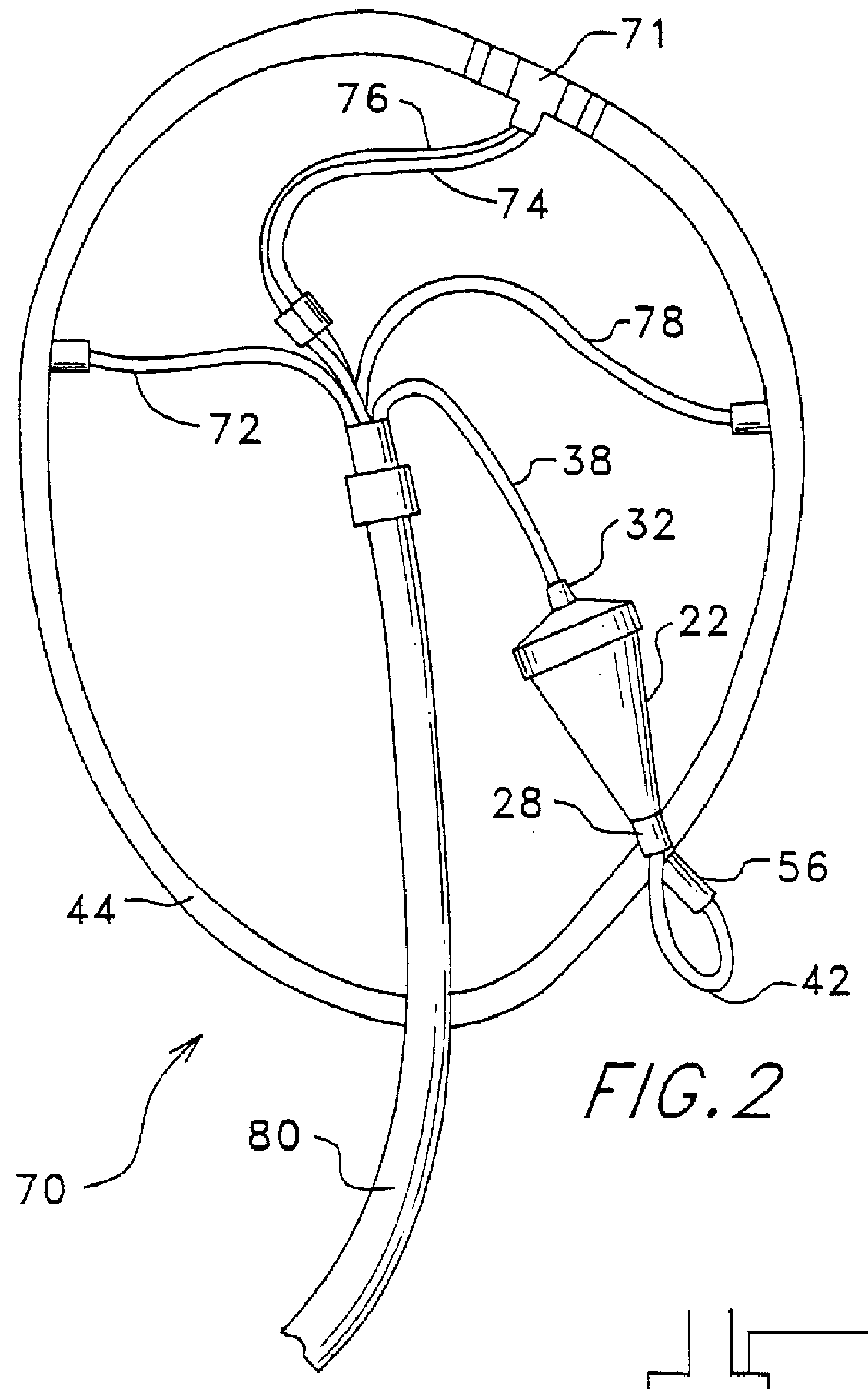

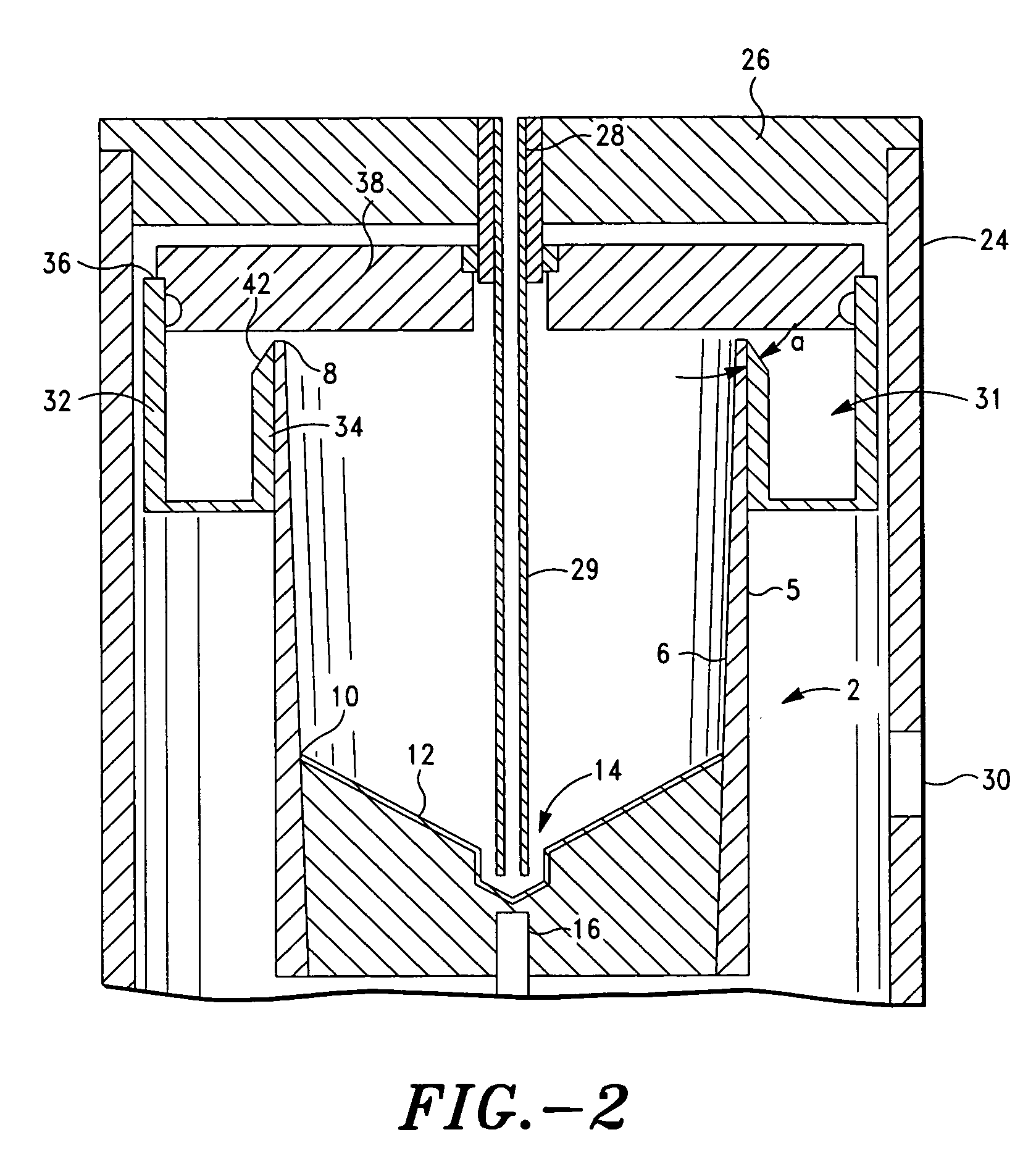

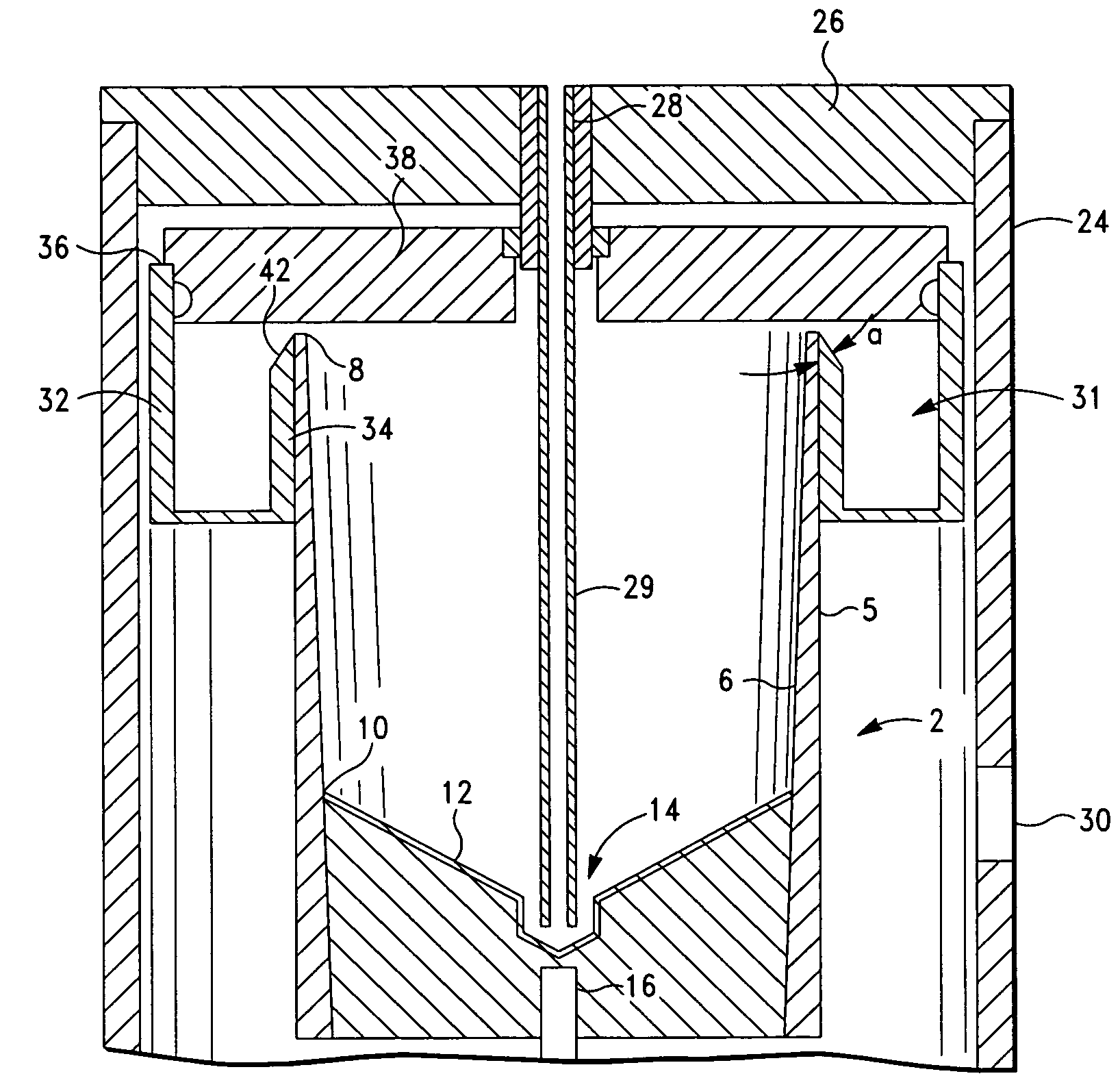

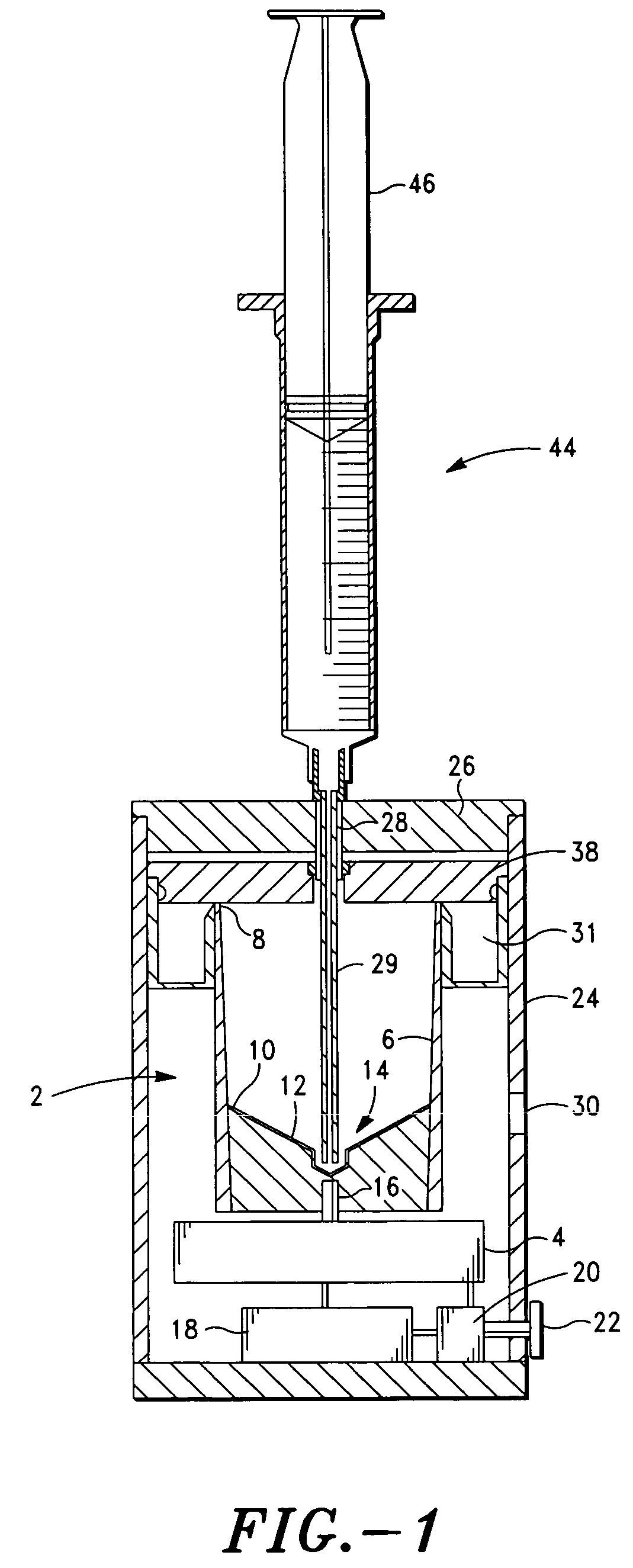

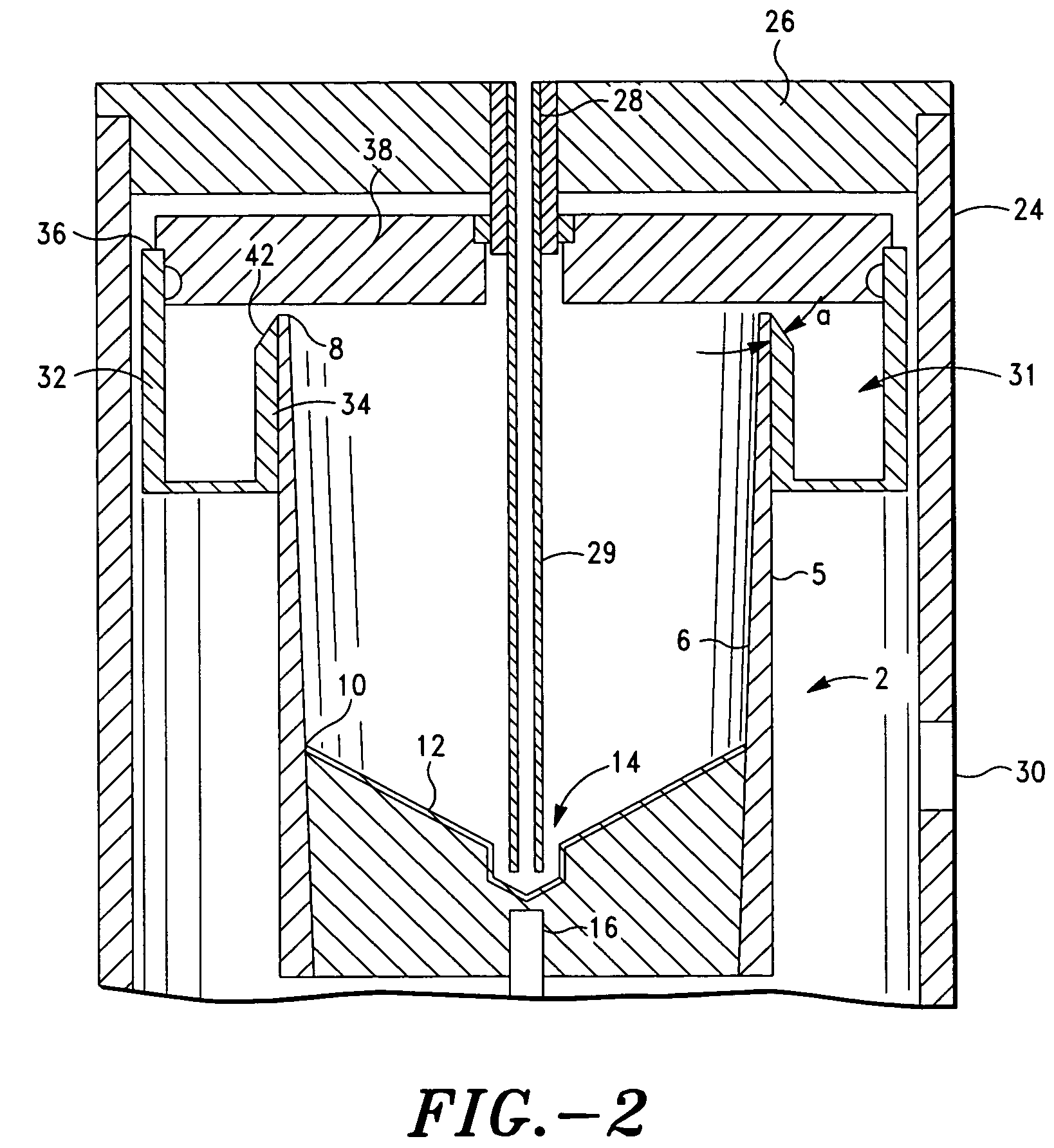

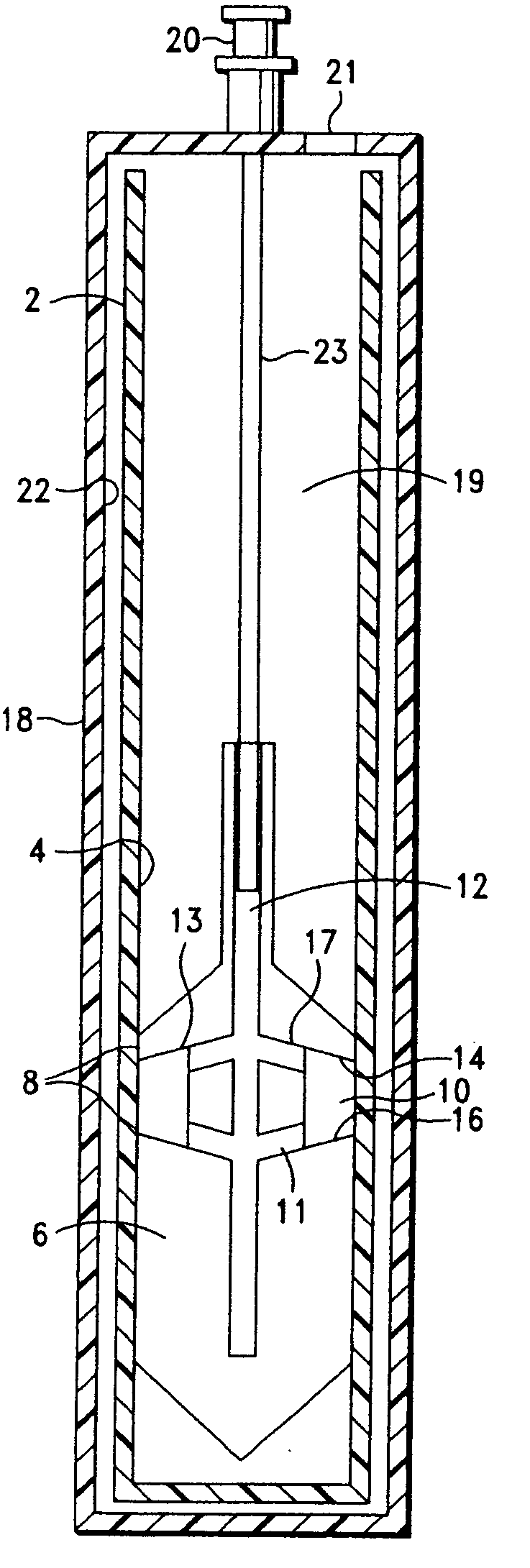

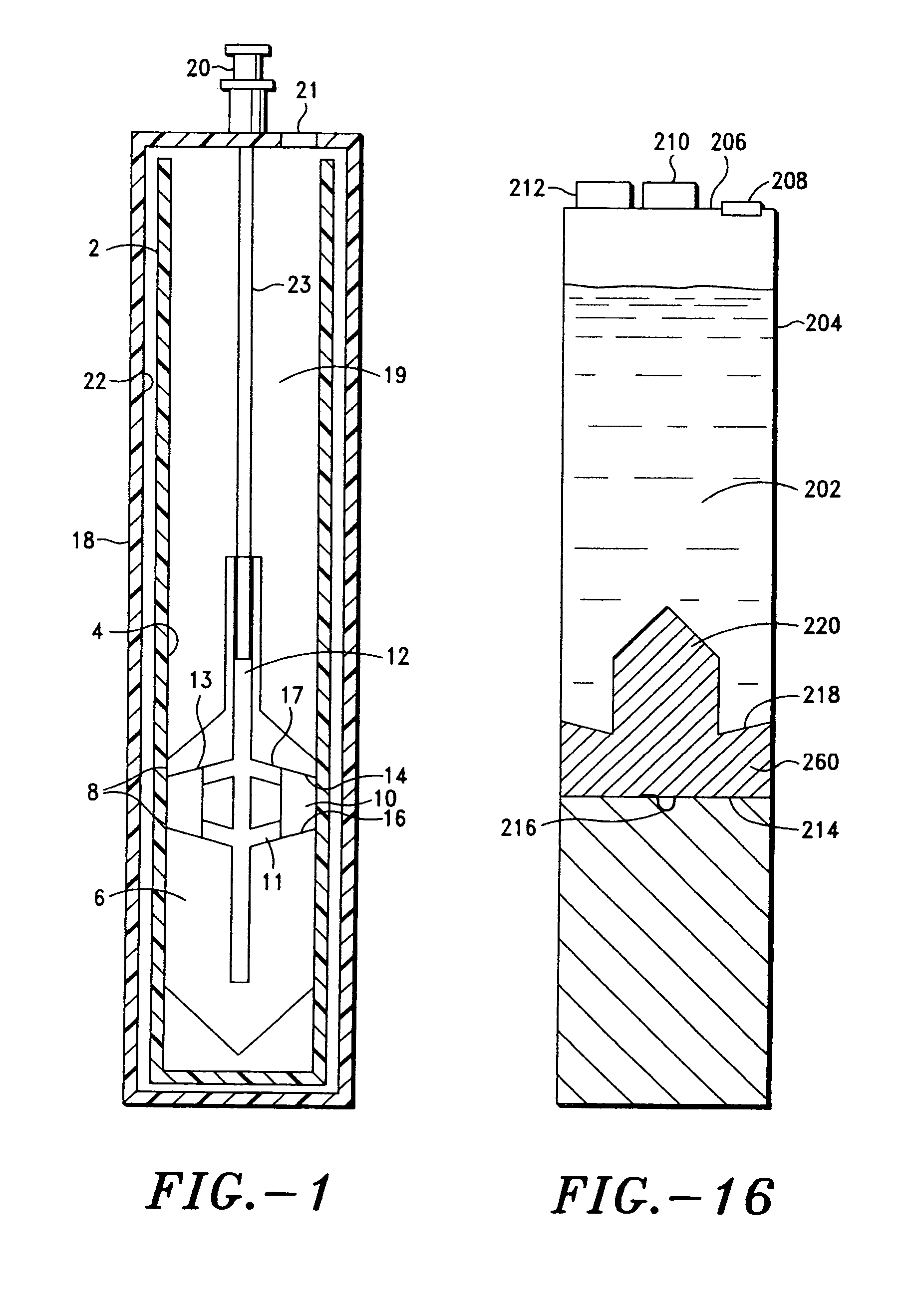

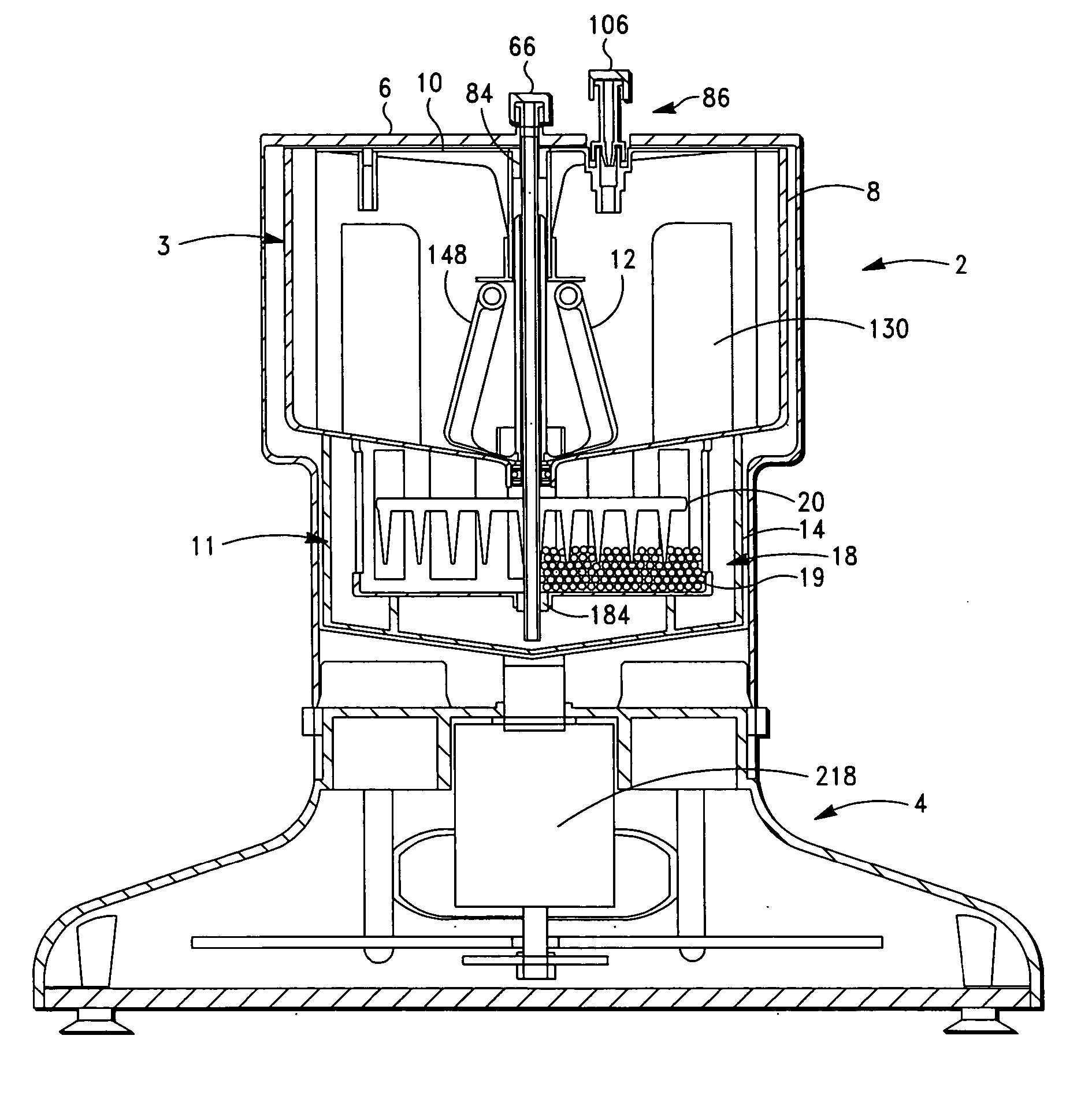

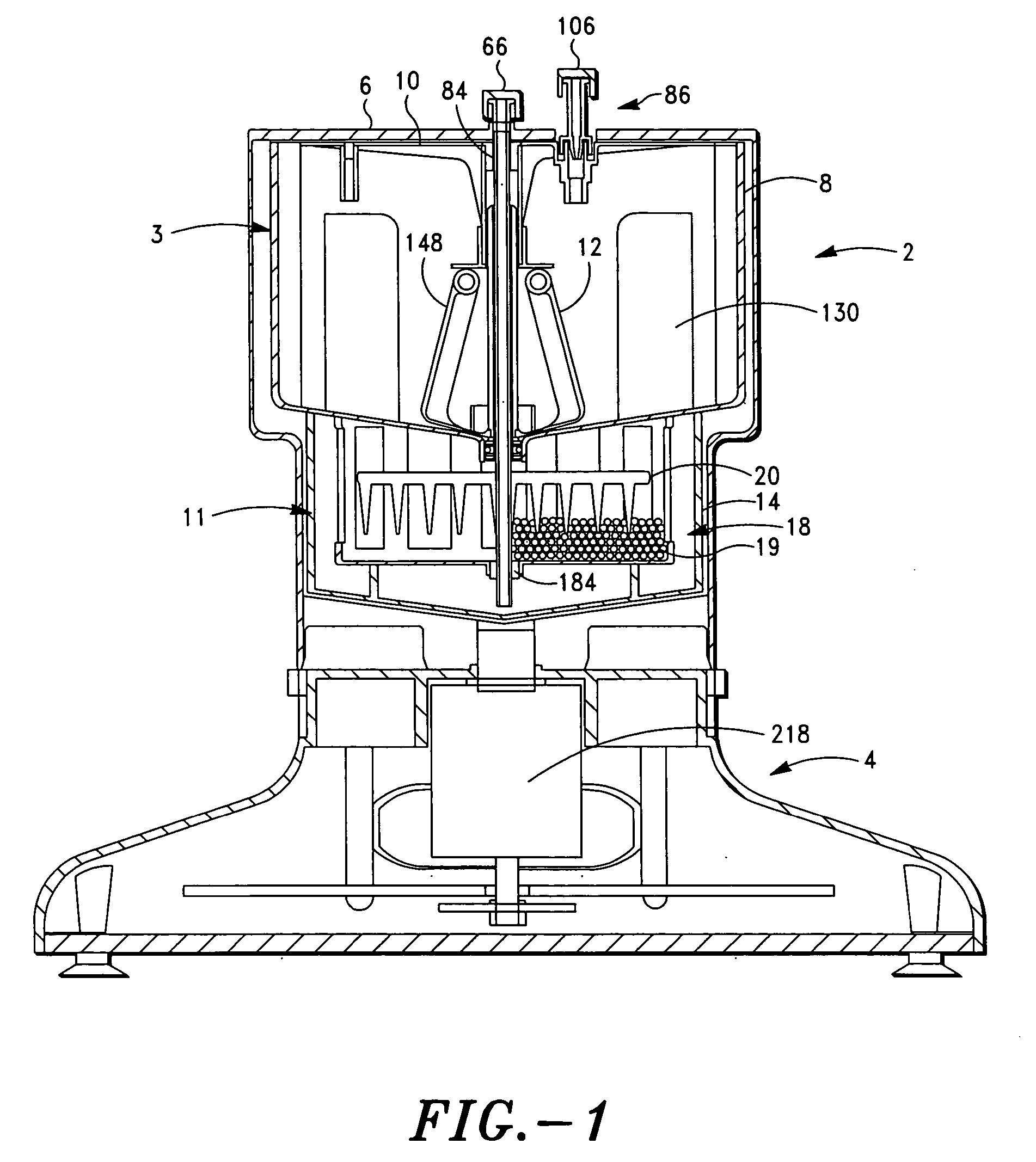

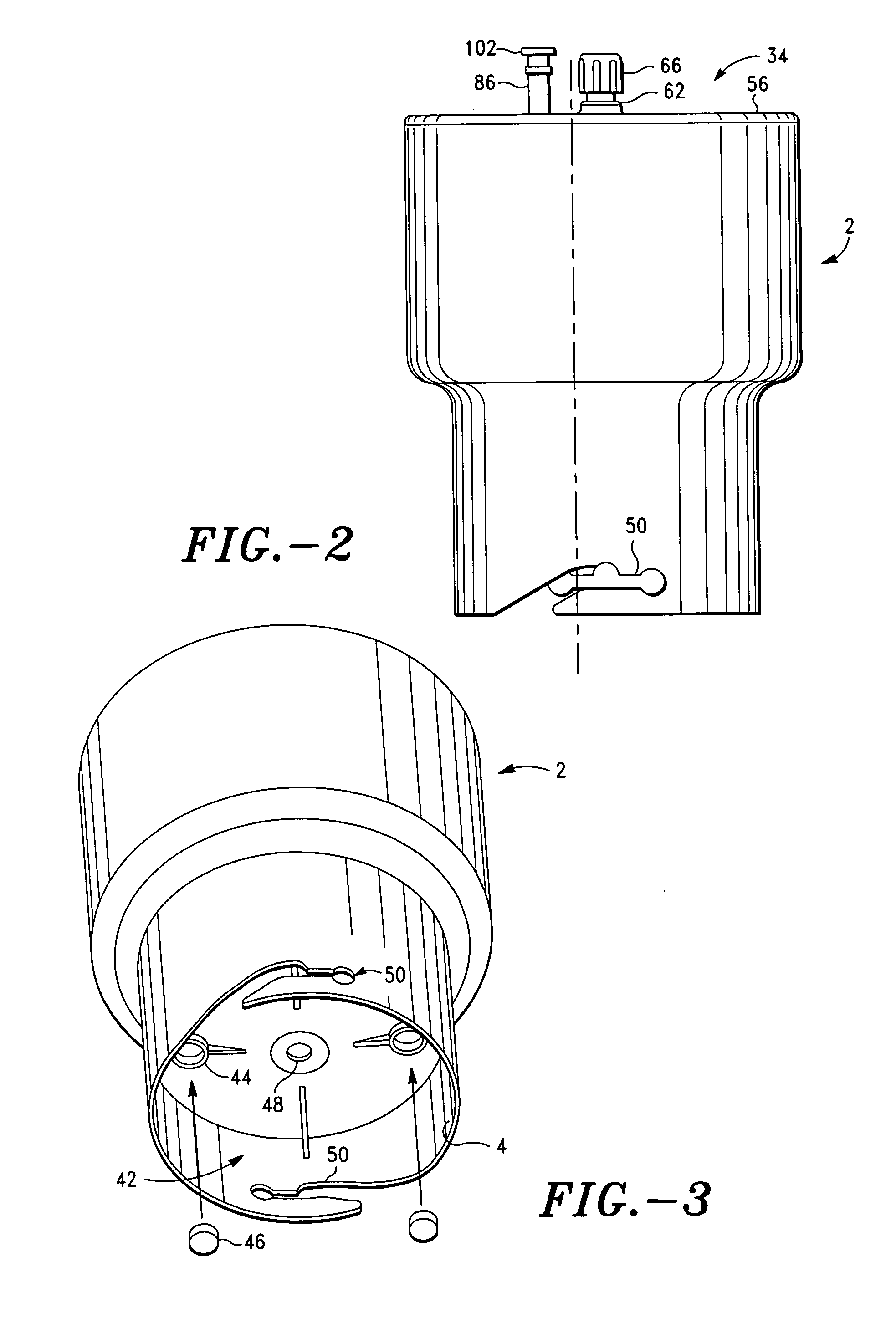

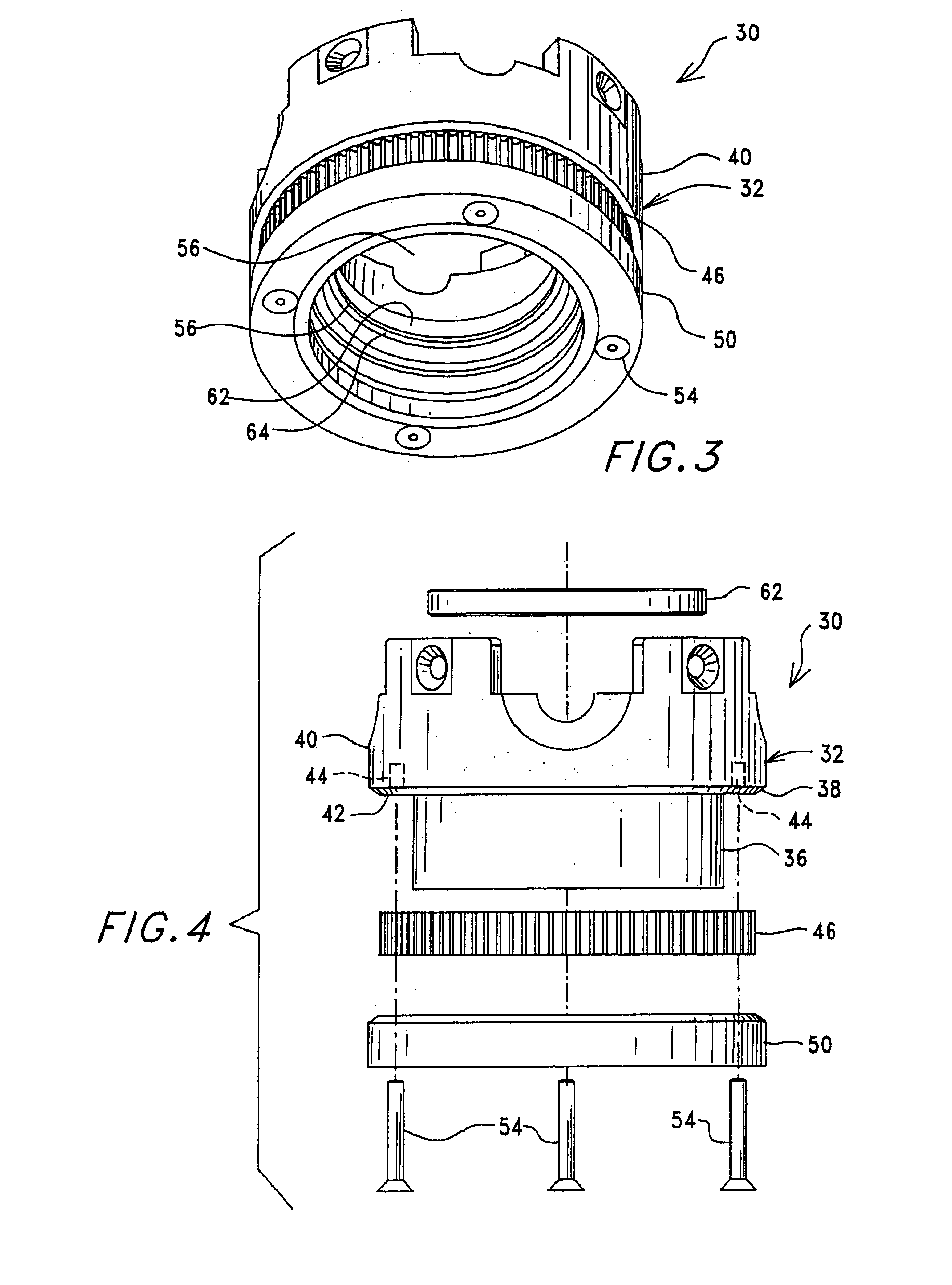

Apparatus and method for separating and isolating components of a biological fluid

A device for separating and isolating components of a biological fluid comprising a container for containing the fluid to be processed, a tube cap assembly for closing the container while providing filling and extraction communication therewith, a float assembly disposed within the container for funneling and controlling biological fluid flow into an inverted domed shaped isolation chamber within the float and controlling the biological fluid flow out of the isolation chamber for effecting an encapsulation or a sealed isolation of at least one component or fraction of the biological fluid flow within the isolation chamber during a centrifugation process. The device further comprising a flexible tube for connecting an extraction passageway disposed within the float assembly and an extraction valve of the tube cap assembly for allowing extraction of at least the one component or fraction encapsulated or isolated within the chamber.

Owner:THERMOGENESIS HLDG INC

Method and apparatus for preparing platelet rich plasma and concentrates thereof

ActiveUS7708152B2Shaking/oscillating/vibrating mixersTransportation and packagingFiberRed blood cell

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

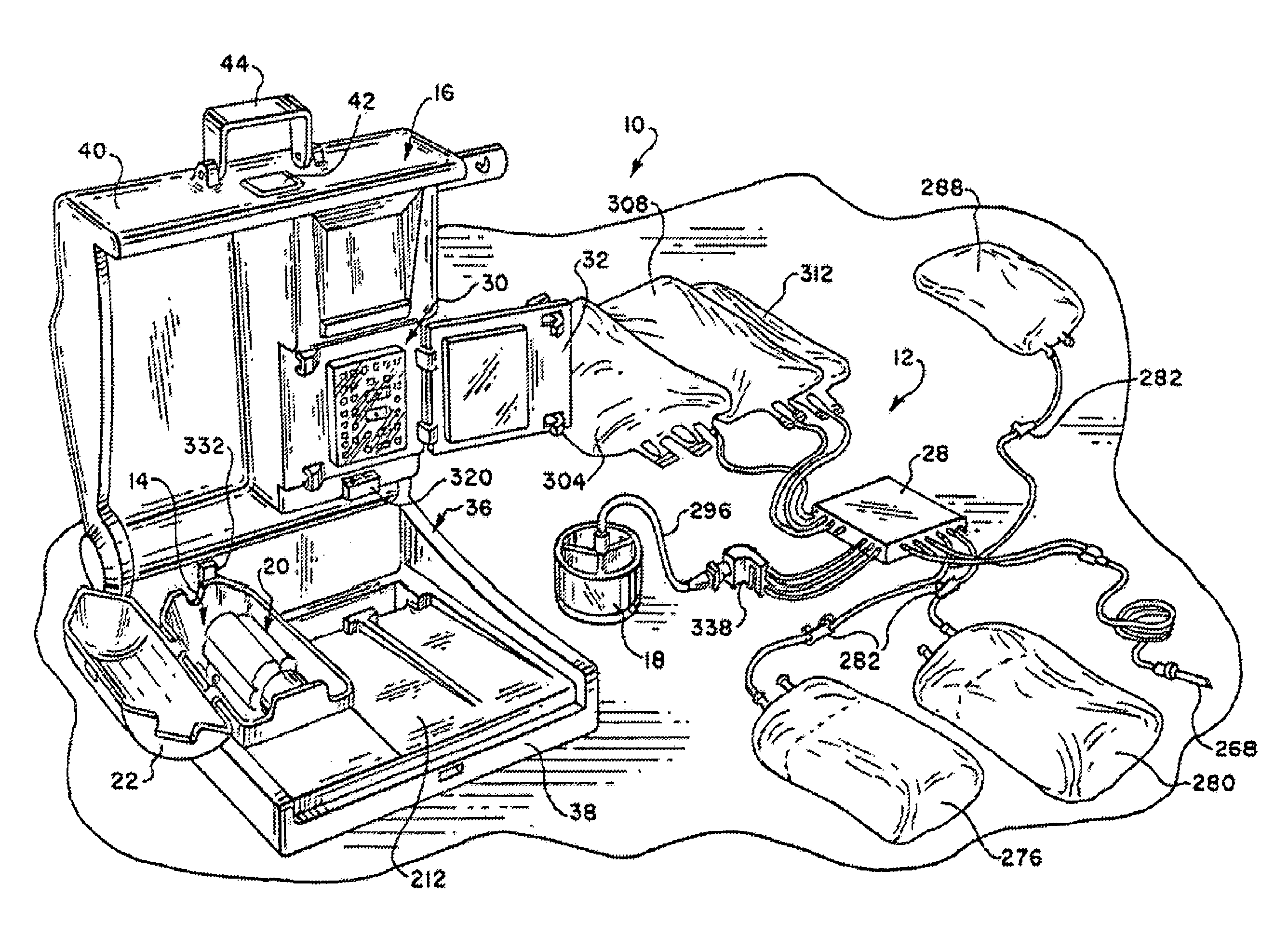

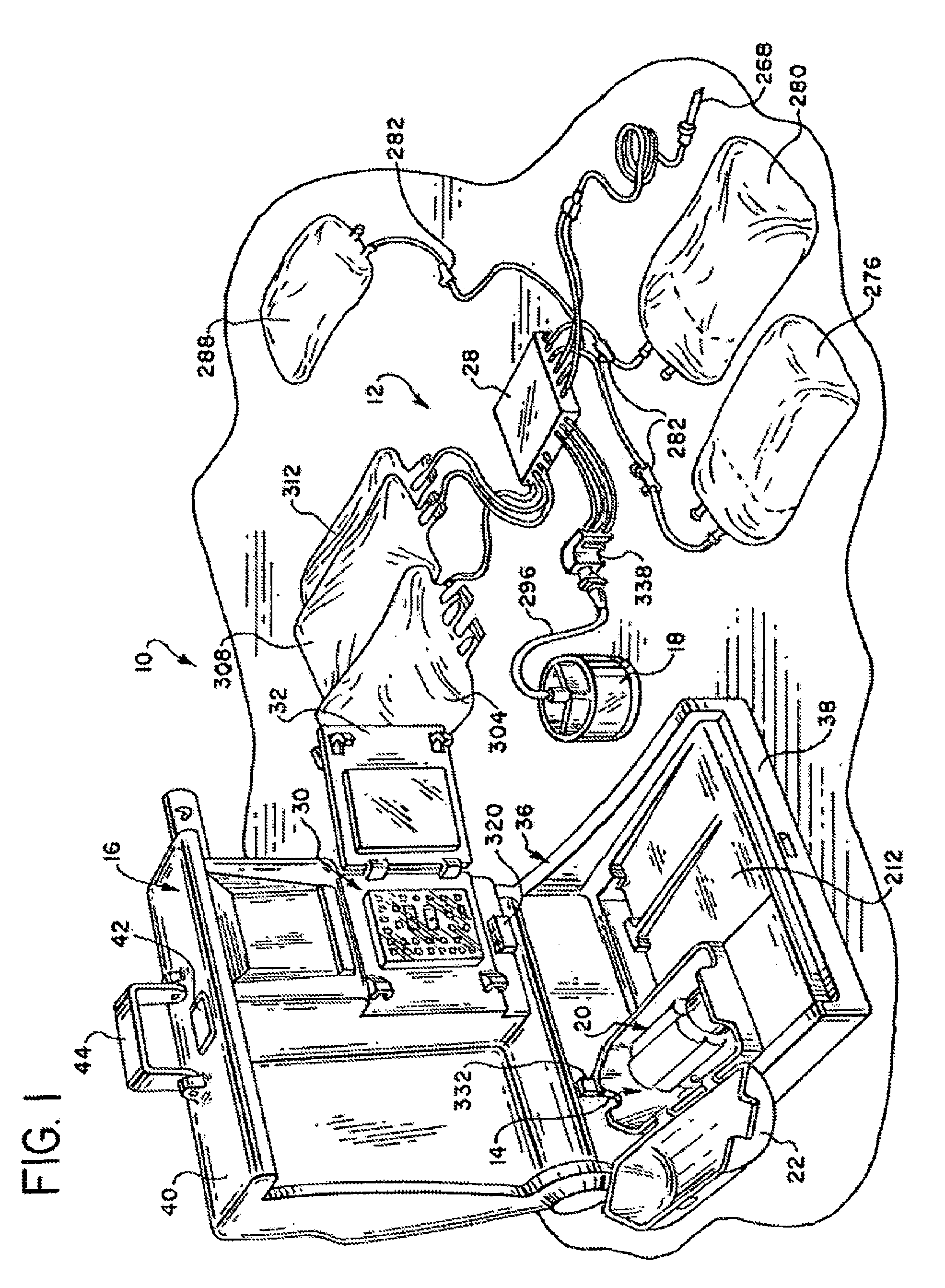

Blood separation systems and methods using a multiple function pump station to perform different on-line processing tasks

InactiveUS7041076B1Straightforward and accurate control functionReduce complexityOther blood circulation devicesRotary centrifugesBlood componentWhite blood cell

A multiple function pump station performs different on-line processing tasks. The pump station can be operated in one mode to draw blood from a donor can, in another mode, be operated to return blood to the donor. The pump station used to draw blood from a donor can also be used to perform subsequent blood processing tasks, such as mixing processing or additive fluids with the blood, or transfering a harvested blood component to a storage container, or finishing the processing of a harvested blood component, e.g., by passage through a filter to remove leukocytes.

Owner:FENWAL

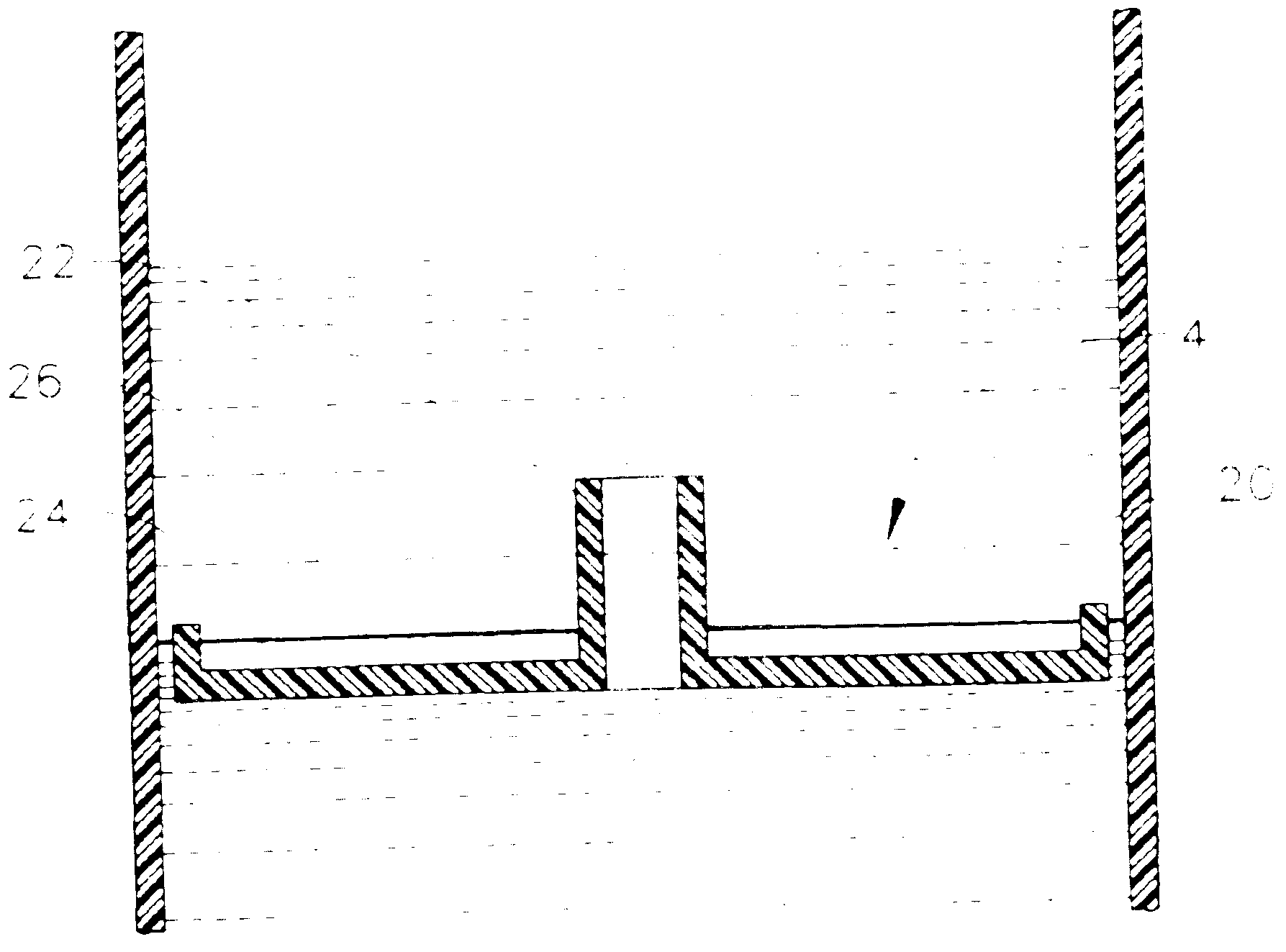

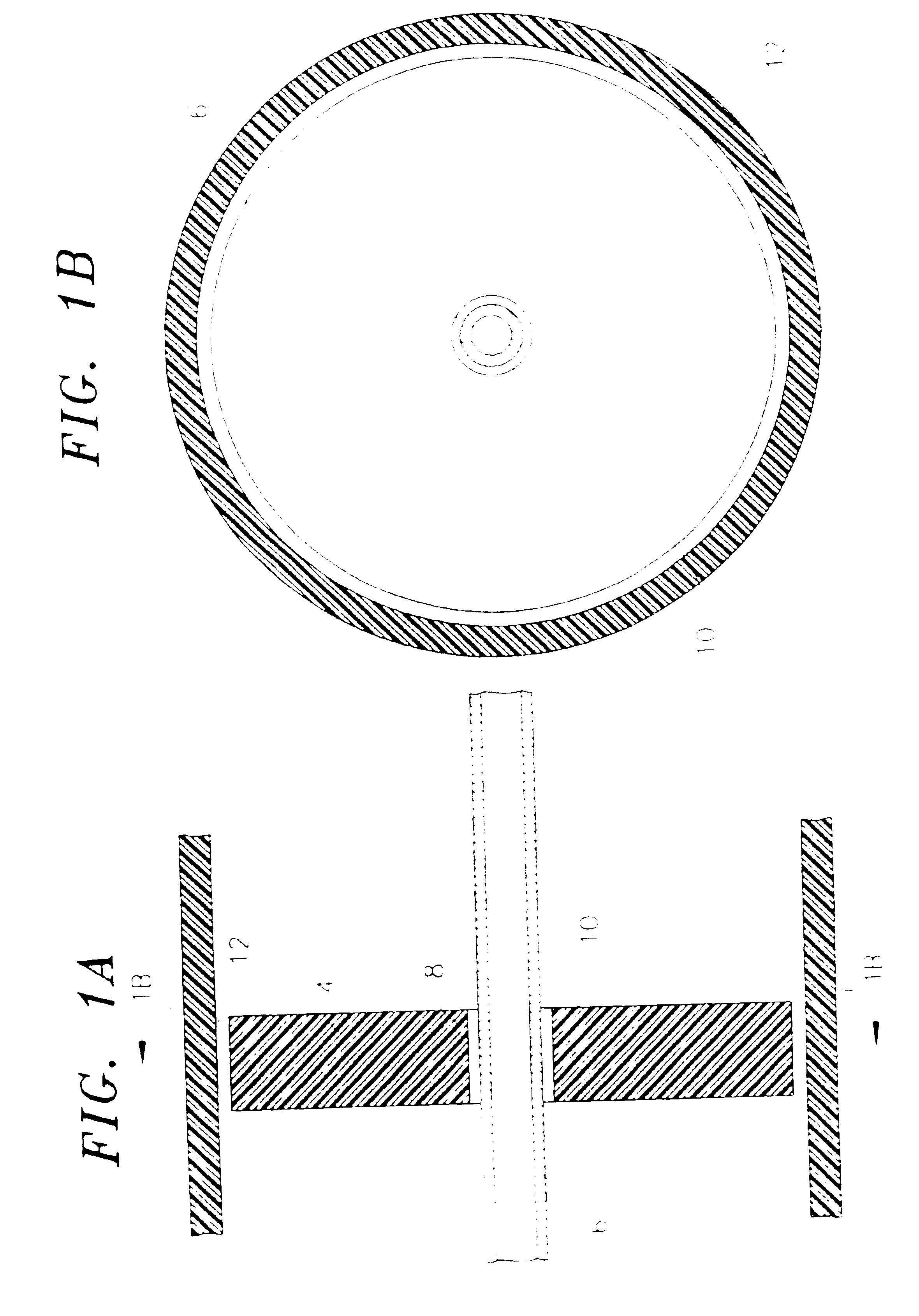

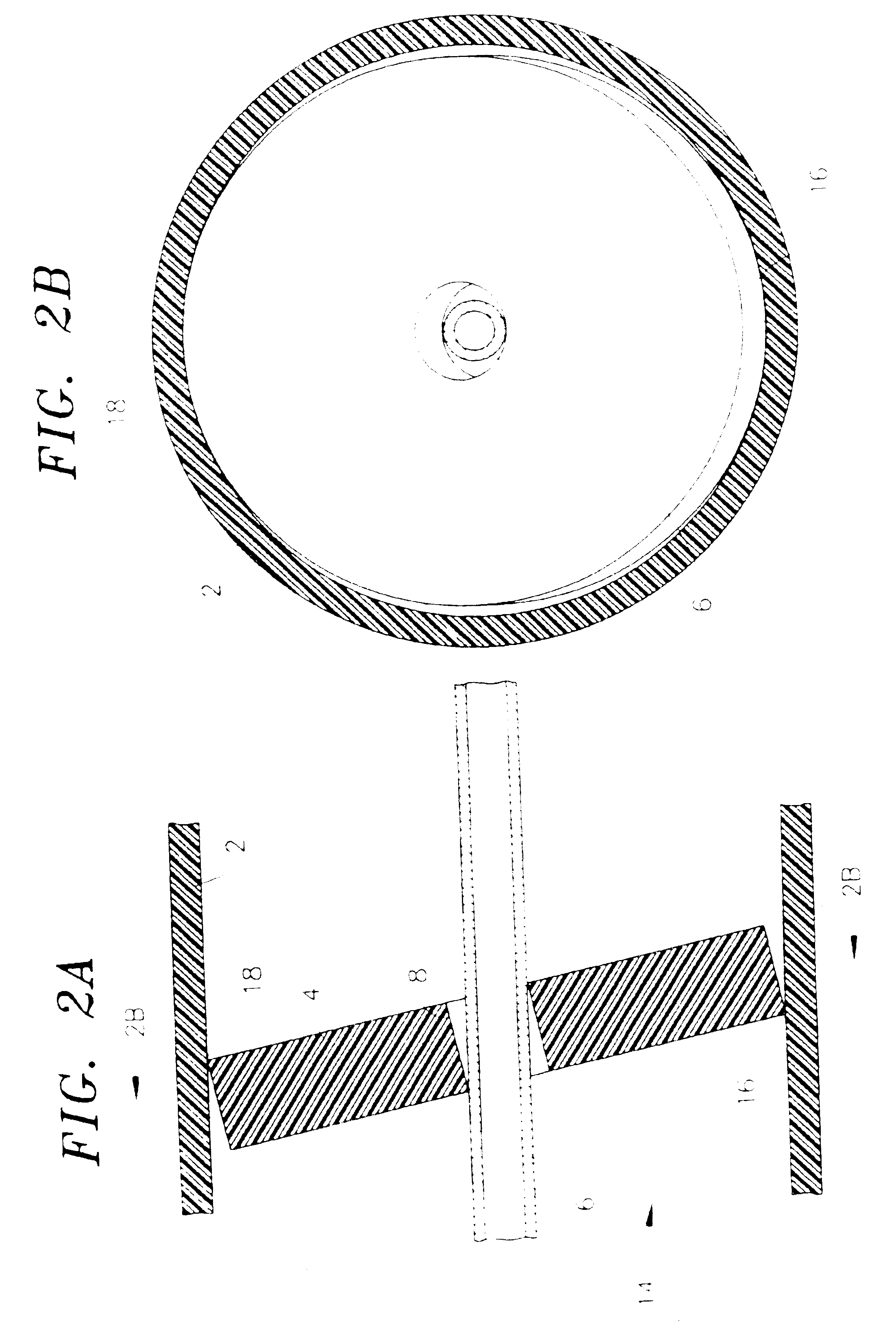

Blood component separator disk

InactiveUS7077273B2Improve processing efficiencyControl flowOther blood circulation devicesDispersed particle separationBlood component separatorRed blood cell

A separator disk (4) for use in centrifugal separation of components is designed to automatically position itself during separation at the interface between the supernatant and the remaining components. Preferably the interface is between plasma and red blood cells.

Owner:HARVEST TECH

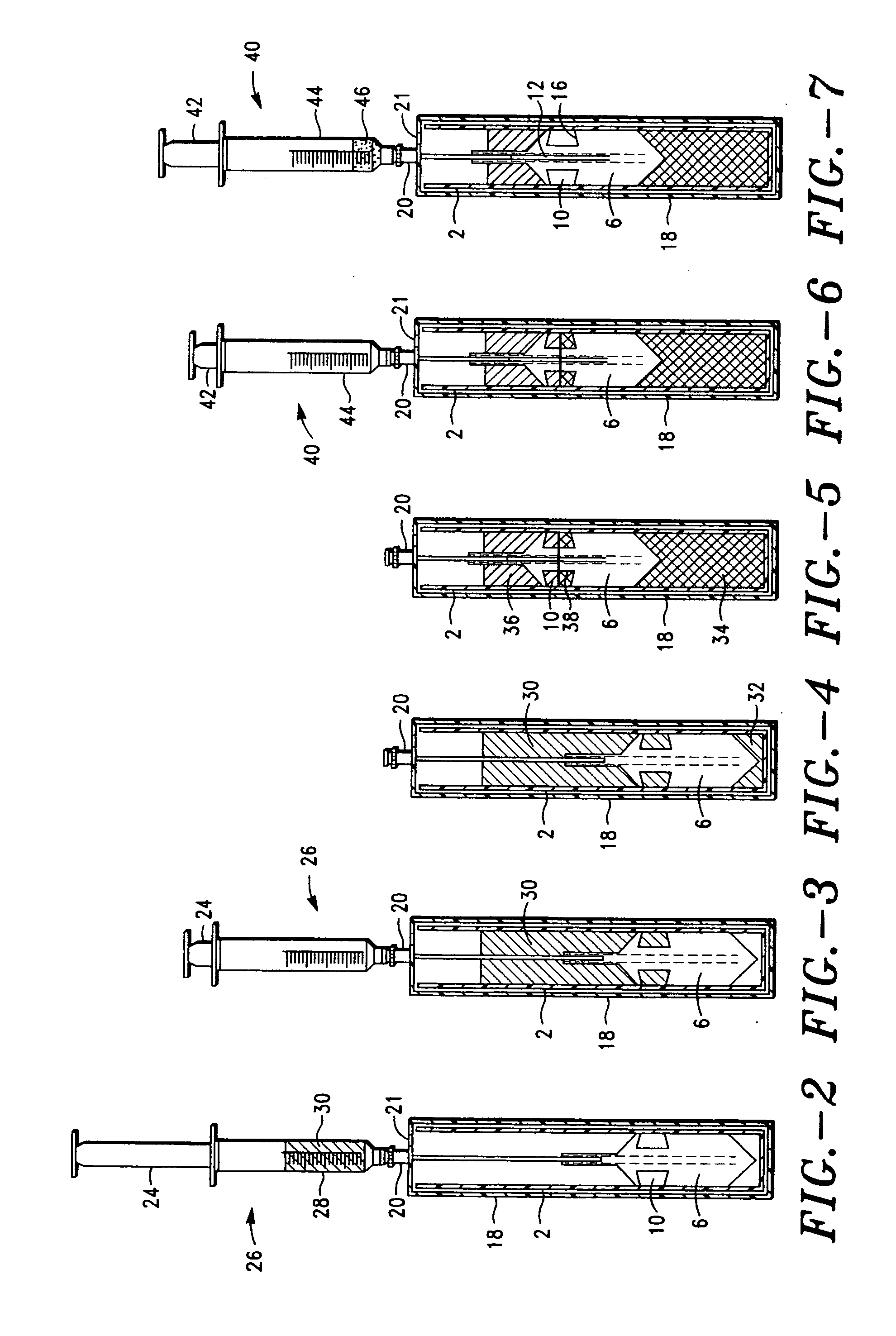

Methods and apparatus for isolating platelets from blood

InactiveUS20050186120A1Simple and fast preparationIncrease productionMedical devicesLaboratory glasswaresMedicineRed blood cell

A platelet collection device comprising a centrifugal spin-separator container with a cavity having a longitudinal inner surface. A float in the cavity has a base, a platelet collection surface above the base, an outer surface. The float density is below the density of erythrocytes and above the density of plasma. The platelet collection surface has a position on the float which places it below the level of platelets when the float is suspended in separated blood. During centrifugation, a layer of platelets or buffy coat collects closely adjacent the platelet collection surface. Platelets are then removed from the platelet collection surface. Movement of a float having a density greater than whole blood through the sedimenting erythrocytes releases entrapped platelets, increasing the platelet yield.

Owner:DORIAN RANDEL +2

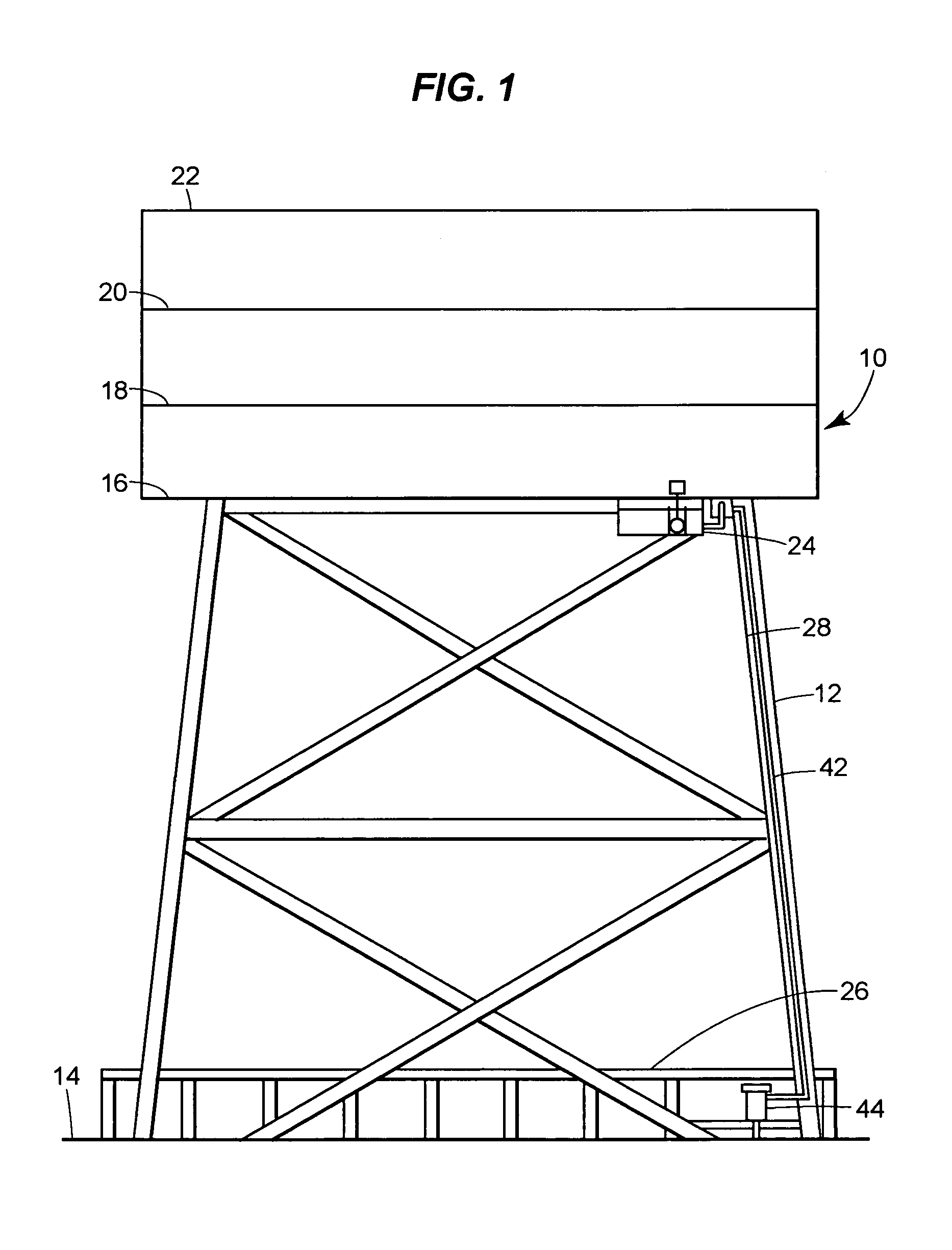

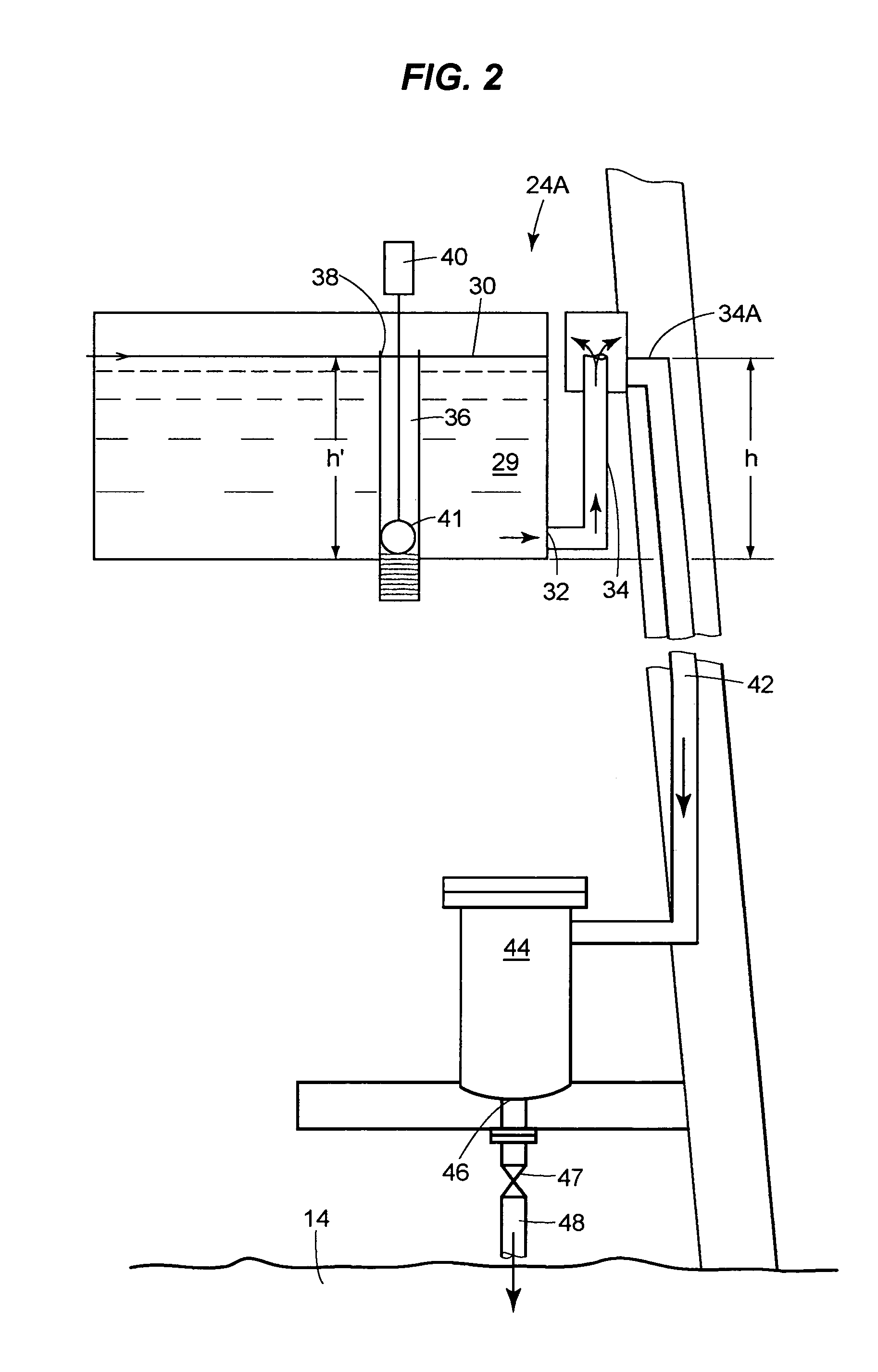

Method for removing oil from water coalescing in a polymer particle/fiber media

ActiveUS7297279B2Increase the liquid flow rateBig contactLiquid suspension thickening by filtrationSolid sorbent liquid separationFiberWater flow

Apparatus in fluid communication with a water leg portion of a hydrocarbon-contaminated water, e.g., a water leg portion of a produced water stream or an offshore drilling or production platform sump tank for conveying water, separated from oil, into contact with non-woven fiber / particulate polymer coalescing media-containing canisters such that the hydrocarbon droplets and other organic material droplets commingled with the sump tank or produced water will be coalesced by passage through the coalescing media. The canisters preferably are provided in a plurality of stacks in each vessel. Solids that do not pass through the canisters are accumulated at the bottom of the vessel and easily drained through a drain port. The water and hydrocarbons will pass through the coalescing media within the canisters and will be separated easily from each vessel, e.g., by gravity separation, sot that the water can be conveyed back to the ocean water without contamination.

Owner:AMCOL INTERNATIONAL CORPORATION

Methods and apparatus for isolating platelets from blood

InactiveUS20050196874A1Simple and fast preparationIncrease productionSurgeryVaccination/ovulation diagnosticsMedicineRed blood cell

A platelet collection device comprising a centrifugal spin-separator container with a cavity having a longitudinal inner surface. A float in the cavity has a base, a platelet collection surface above the base, an outer surface. The float density is below the density of erythrocytes and above the density of plasma. The platelet collection surface has a position on the float which places it below the level of platelets when the float is suspended in separated blood. During centrifugation, a layer of platelets or buffy coat collects closely adjacent the platelet collection surface. Platelets are then removed from the platelet collection surface. Movement of a float having a density greater than whole blood through the sedimenting erythrocytes releases entrapped platelets, increasing the platelet yield.

Owner:HANUMAN

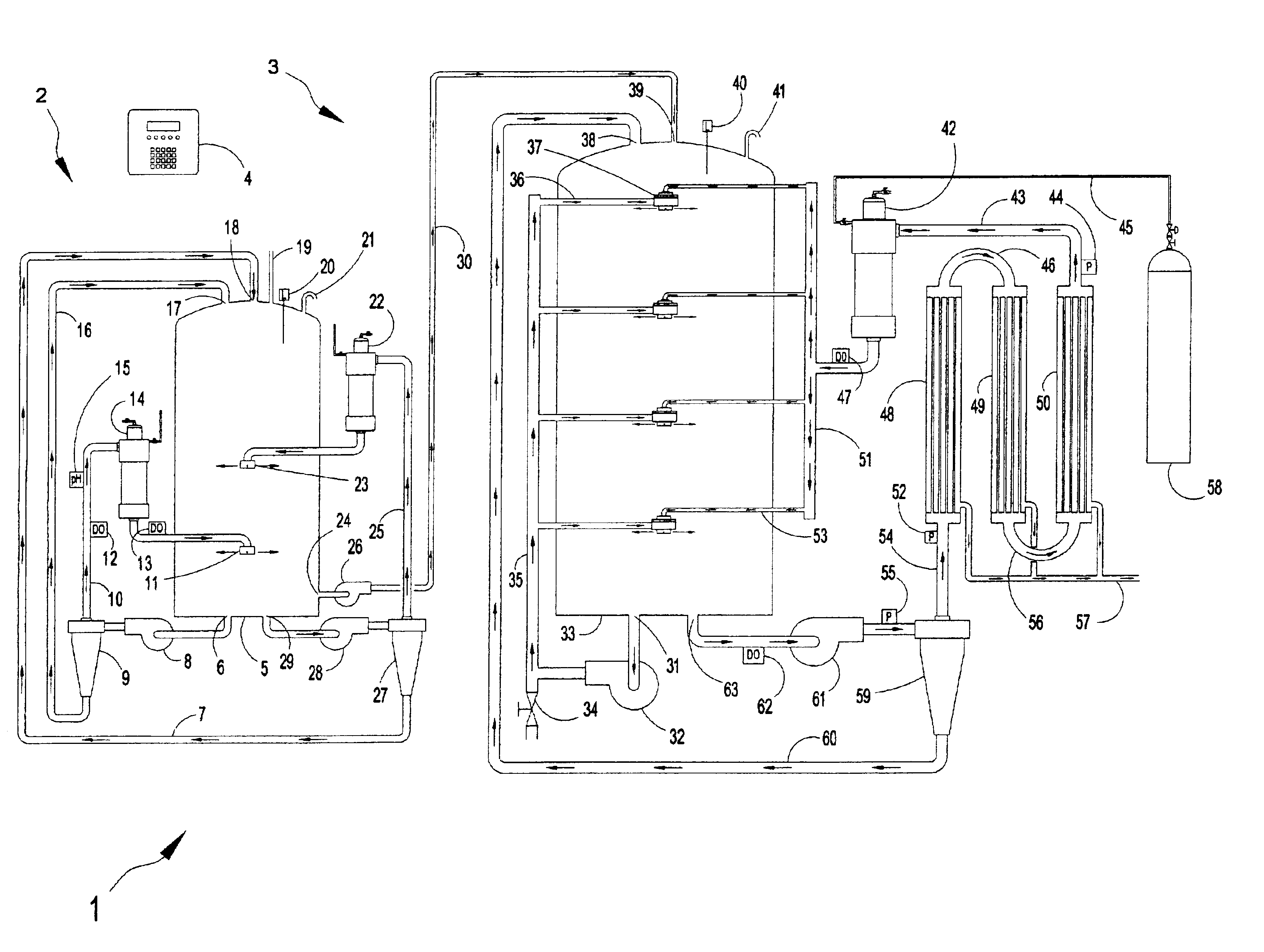

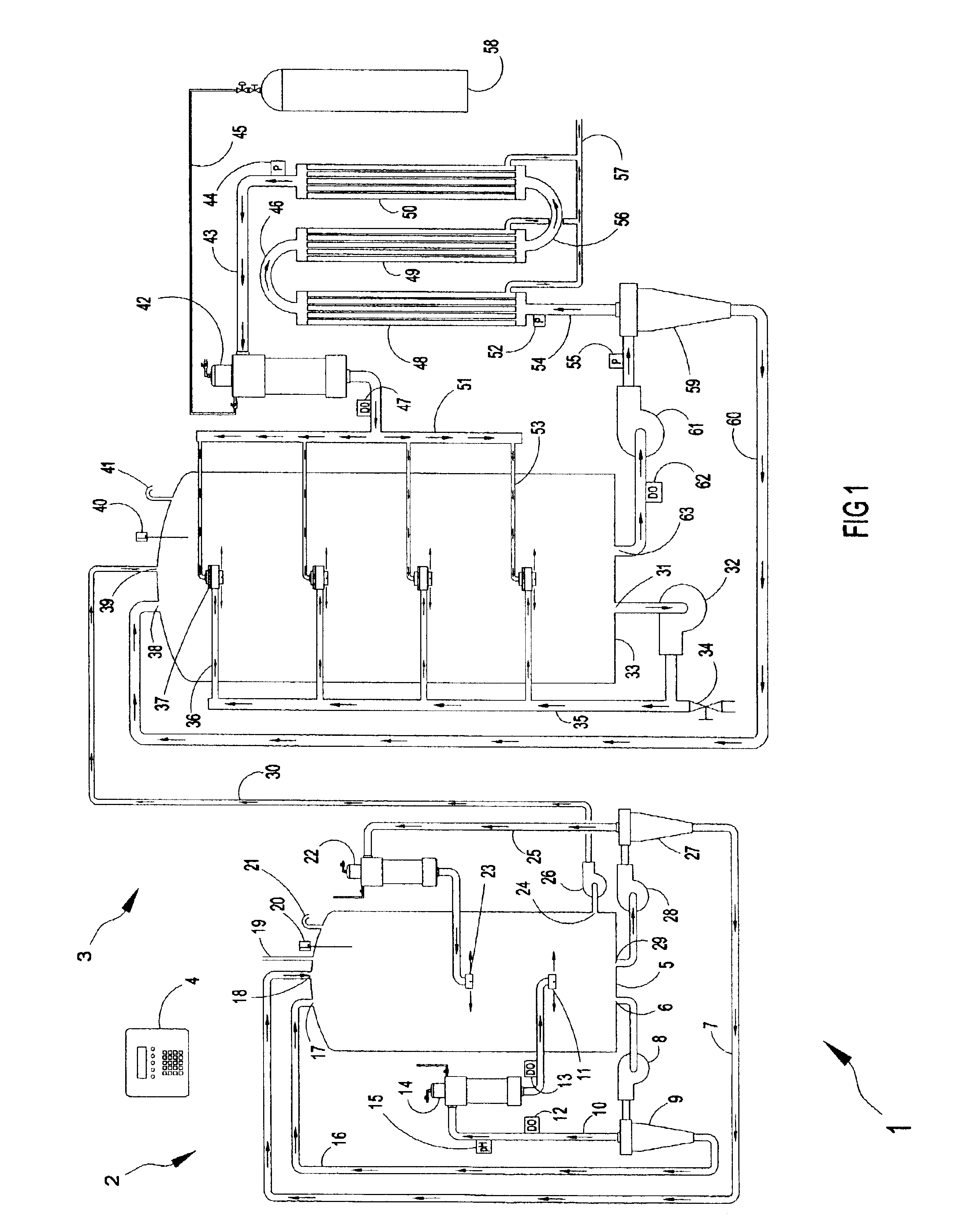

Method and apparatus for treatment of wastewater employing membrane bioreactors

InactiveUS6805806B2Accelerates the biodegradation processAvoid cloggingLiquid separation auxillary apparatusTreatment using aerobic processesAeration systemFiltration

Methods and apparatus employing membrane filtration in biodegradation processes for treatment of wastewater are described. A bioreactor system is described having an equalization system, a membrane bioreactor system, and a controller. Aeration systems for a membrane bioreactor, such as a mixer, and an ultrafilter subsystem are also described, as is a rotary membrane ultrafilter.

Owner:HYDROTREAT

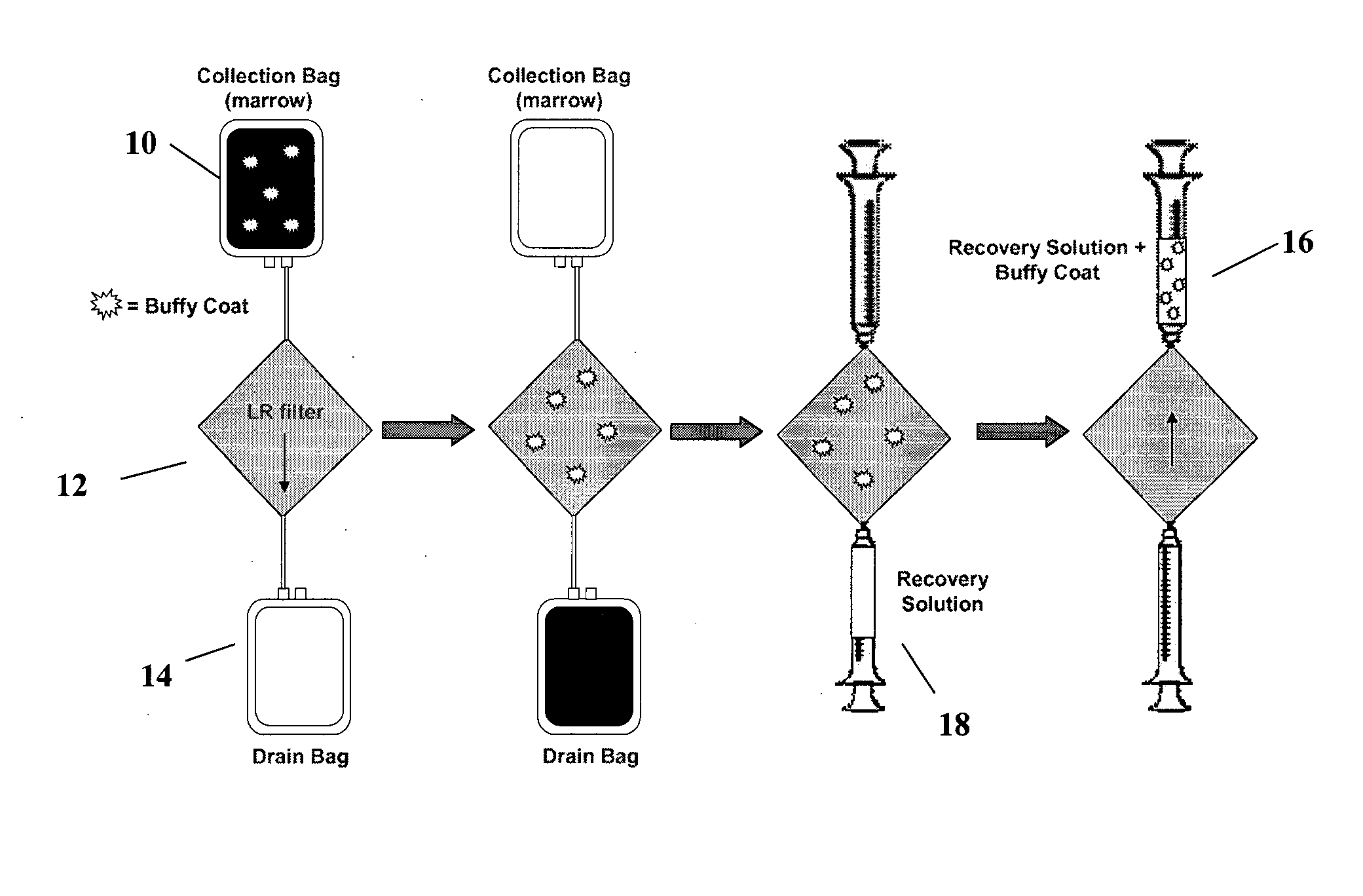

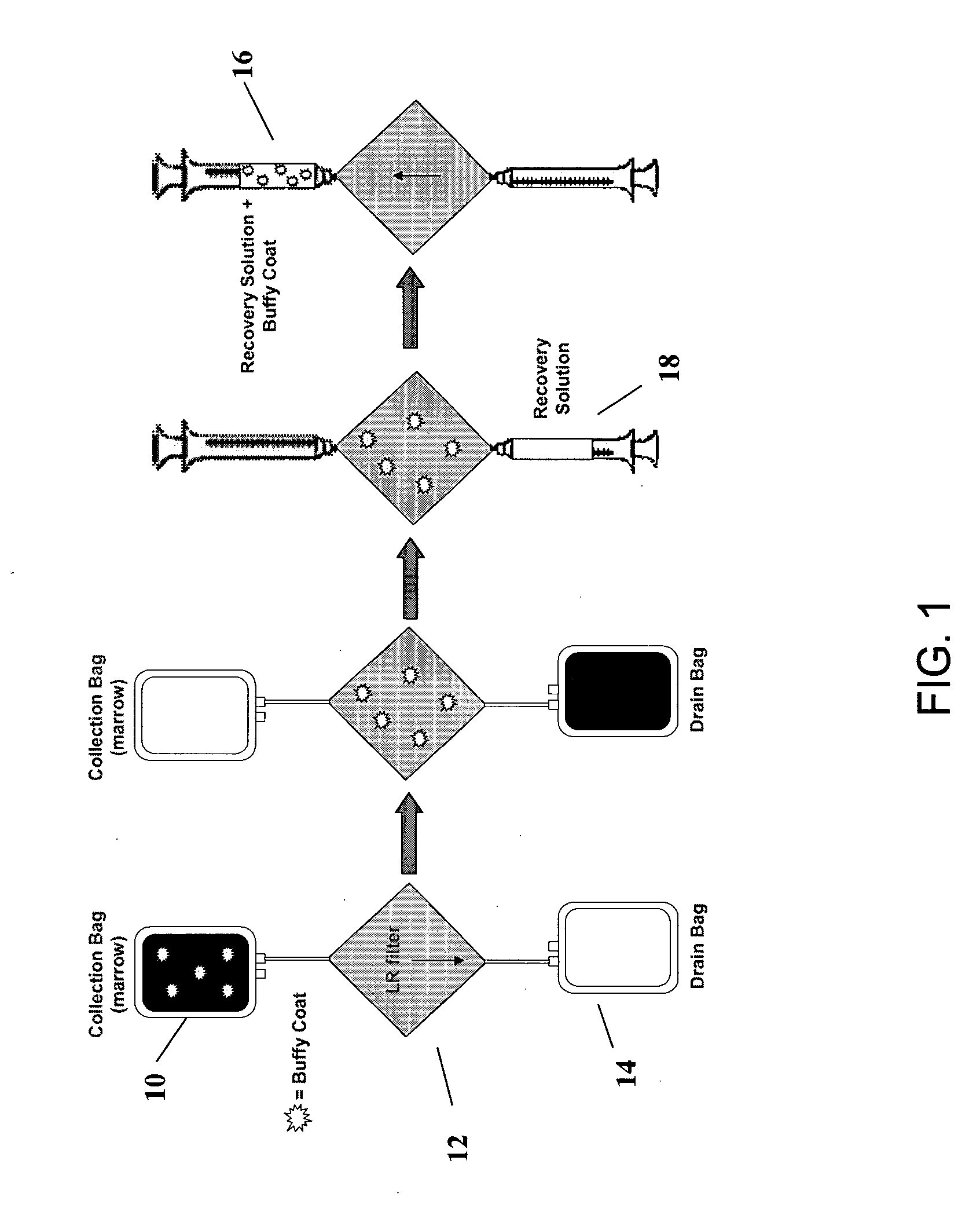

Preparation of a cell concentrate from a physiological solution

The present invention is directed to methods and compositions regarding the preparation of an cell concentrate, such as, for example, an osteogenic cell concentrate, from a physiological solution, such as bone marrow aspirate, blood, or a mixture thereof. In specific embodiments, the invention provides methods and compositions utilizing two physiological solution-processing techniques, particularly in a point of care environment, wherein centrifugation is not employed.

Owner:SMITH & NEPHEW INC +1

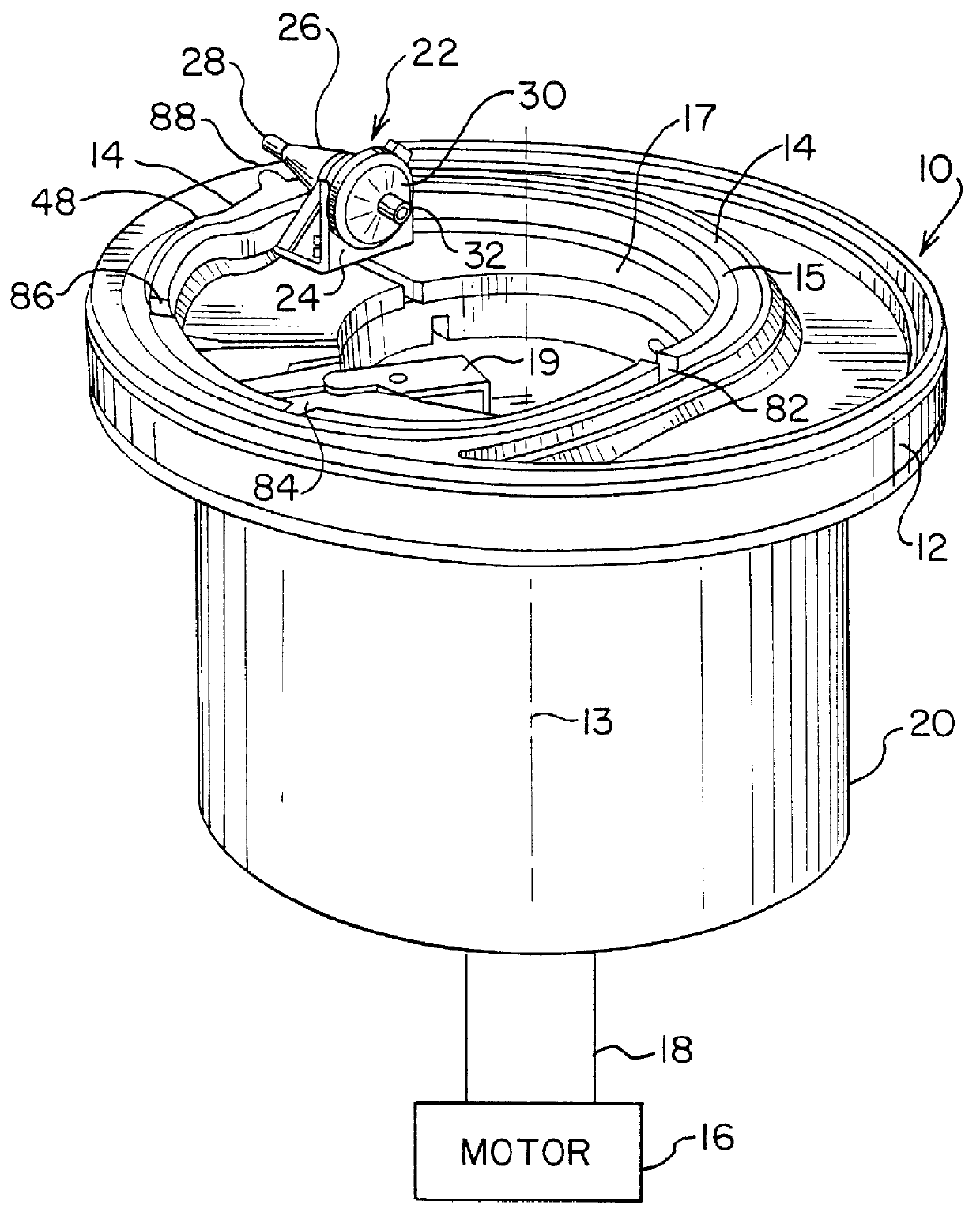

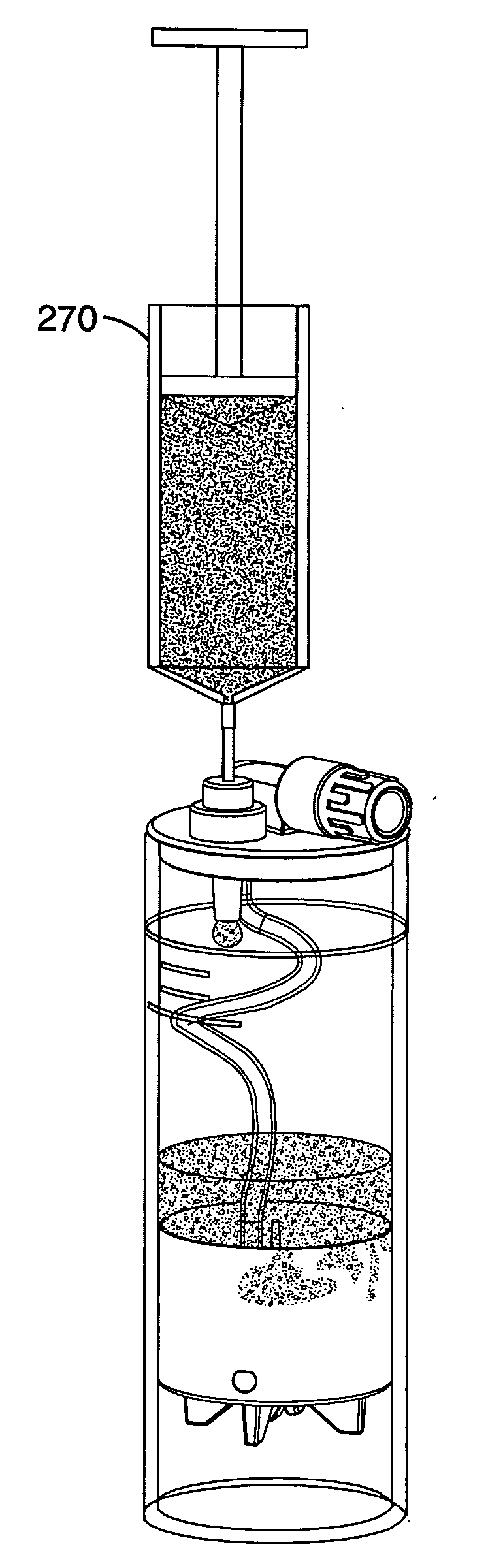

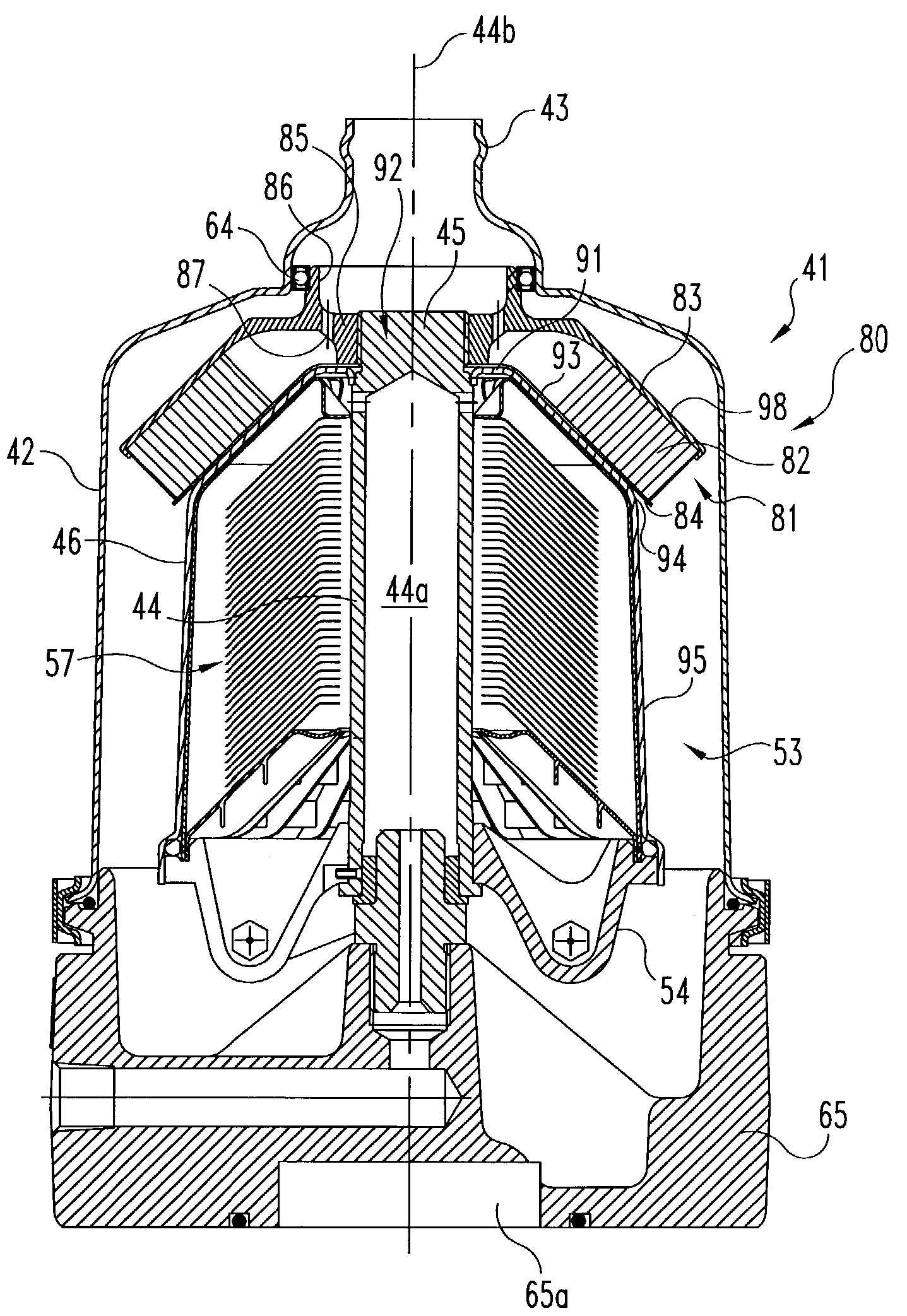

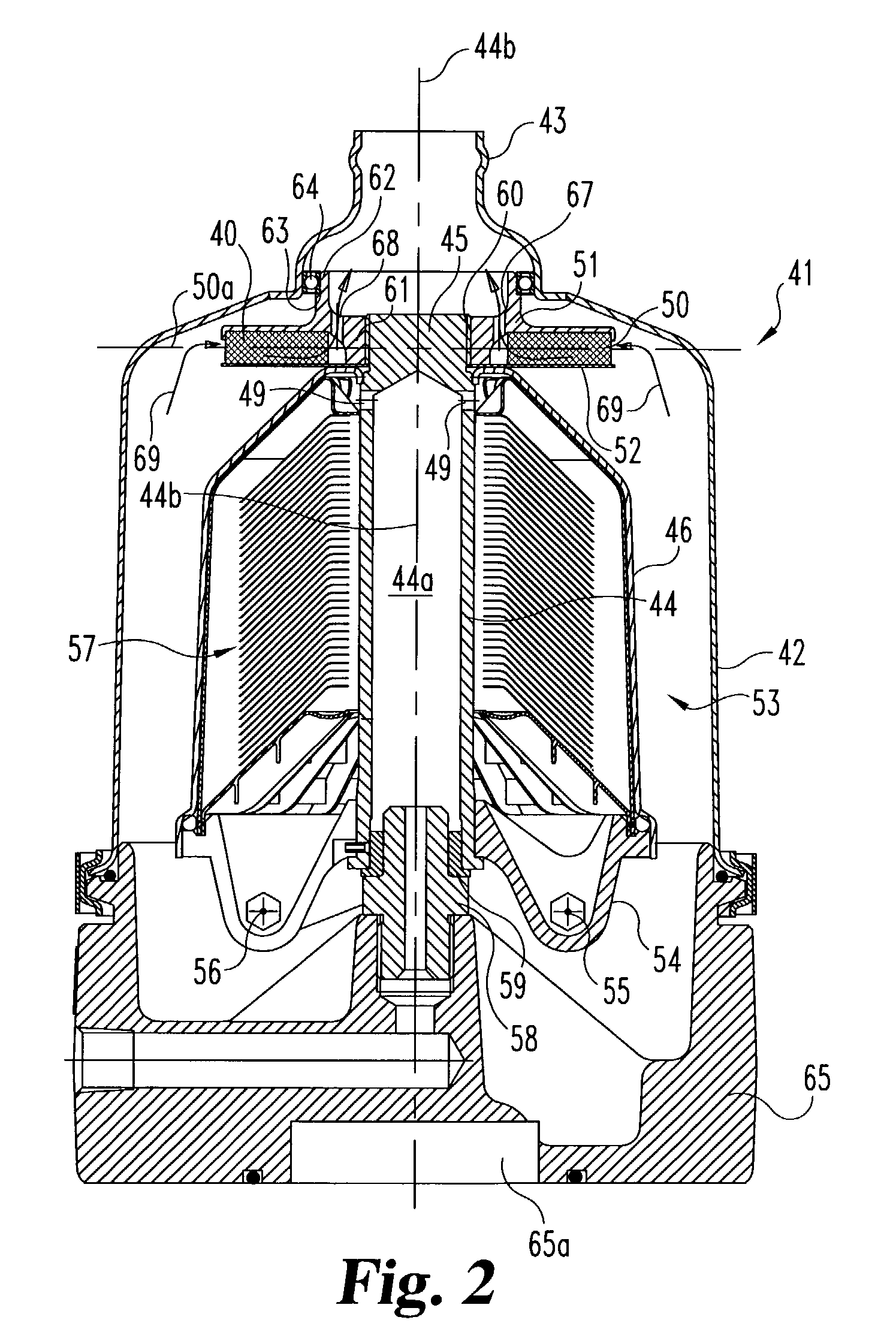

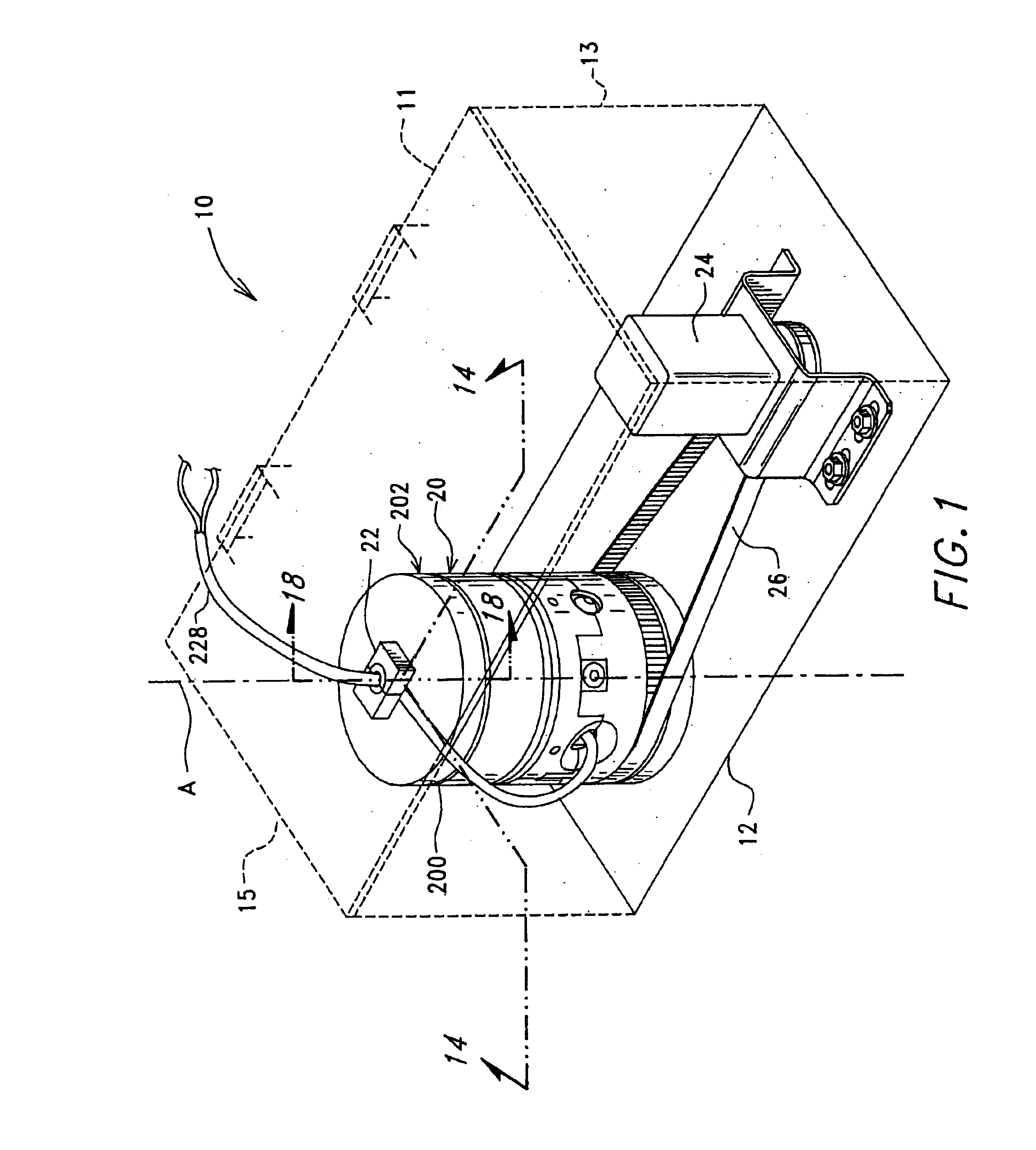

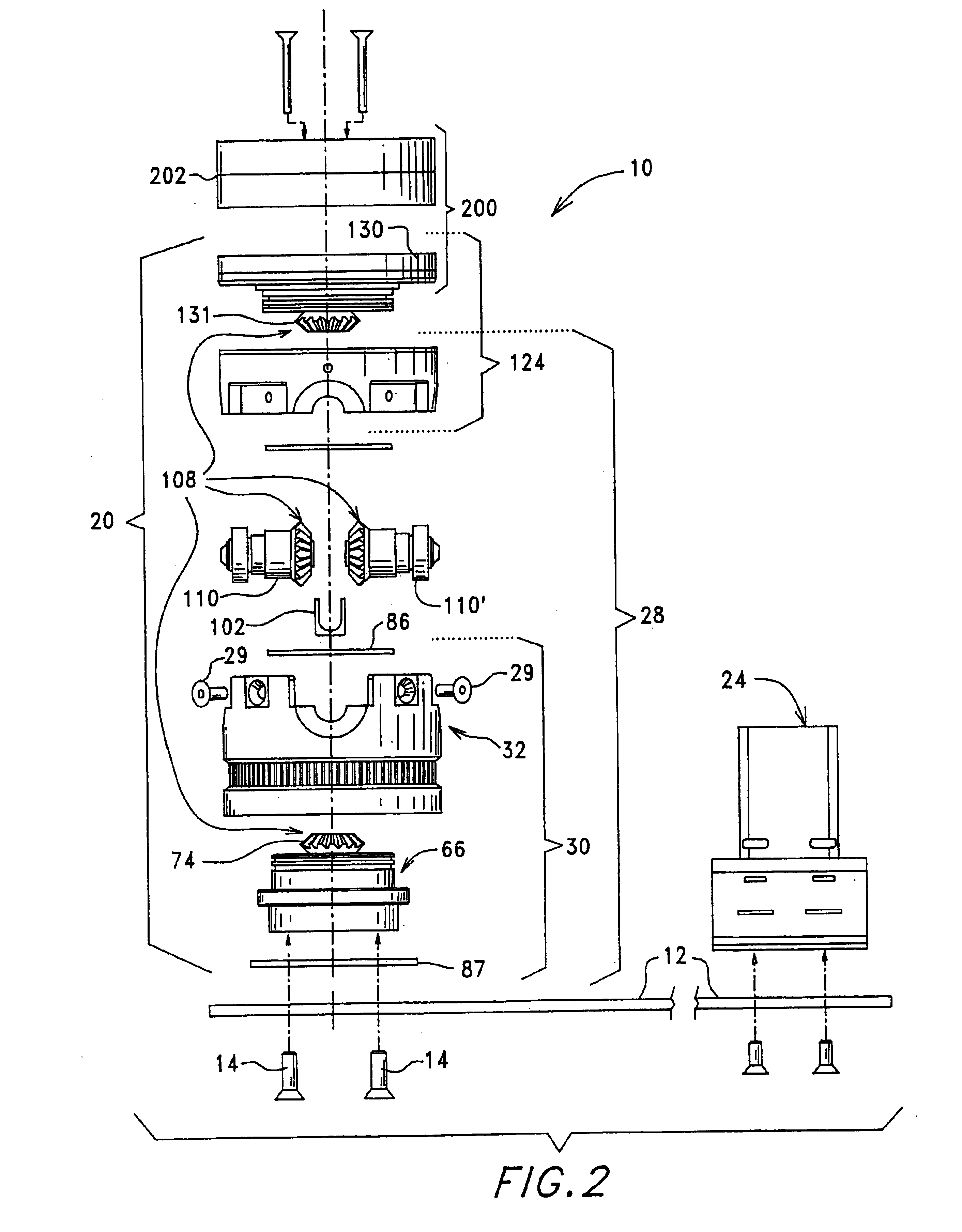

Apparatus and method for preparing platelet rich plasma and concentrates thereof

ActiveUS20060175244A1Increase in platelet levelAvoid assemblyRotary centrifugesMedical devicesRed blood cellEngineering

A PRP separator-concentrator comprising a housing, a separation assembly, and a concentration assembly. The concentration assembly has a concentration sump. An axially concentric rigid stationary outlet tube is secured to the housing and extends through the separation assembly to the sump. The separation assembly is attached to and positioned above the concentration assembly to form a combined separator-concentrator assemblage that is rotatable about the outlet tube. The separation assembly includes a separation chamber lined with a depth filter having pores and passageways that are sized to receive and entrap erythrocytes during centrifuging. The concentration chamber has a floor for supporting desiccated beads and a wall with at least one opening closed with a screen. The concentrator can have a distribution of upright screen supports, the upright screen supports having an inner surface and an outer surface, the cylindrical screen being supported on the outer surface of the upright screen supports. A stationary bead rake can be secured to the stationary tube and extend outward therefrom, the rake having distal ends that are spaced at a distance from the upright screen supports. The rake can comprise a longitudinal body, the center of which is secured to the rigid outlet tube. The separator-concentrator includes a valve assembly connecting the separation chamber and the concentration chamber. PRP concentrate is produced by contacting PRP with desiccated beads while the beads are stirred with a stationary rake, and rotating the concentration chamber at centrifugal speeds to separate PRP concentrate from the beads.

Owner:BIOMET BIOLOGICS +1

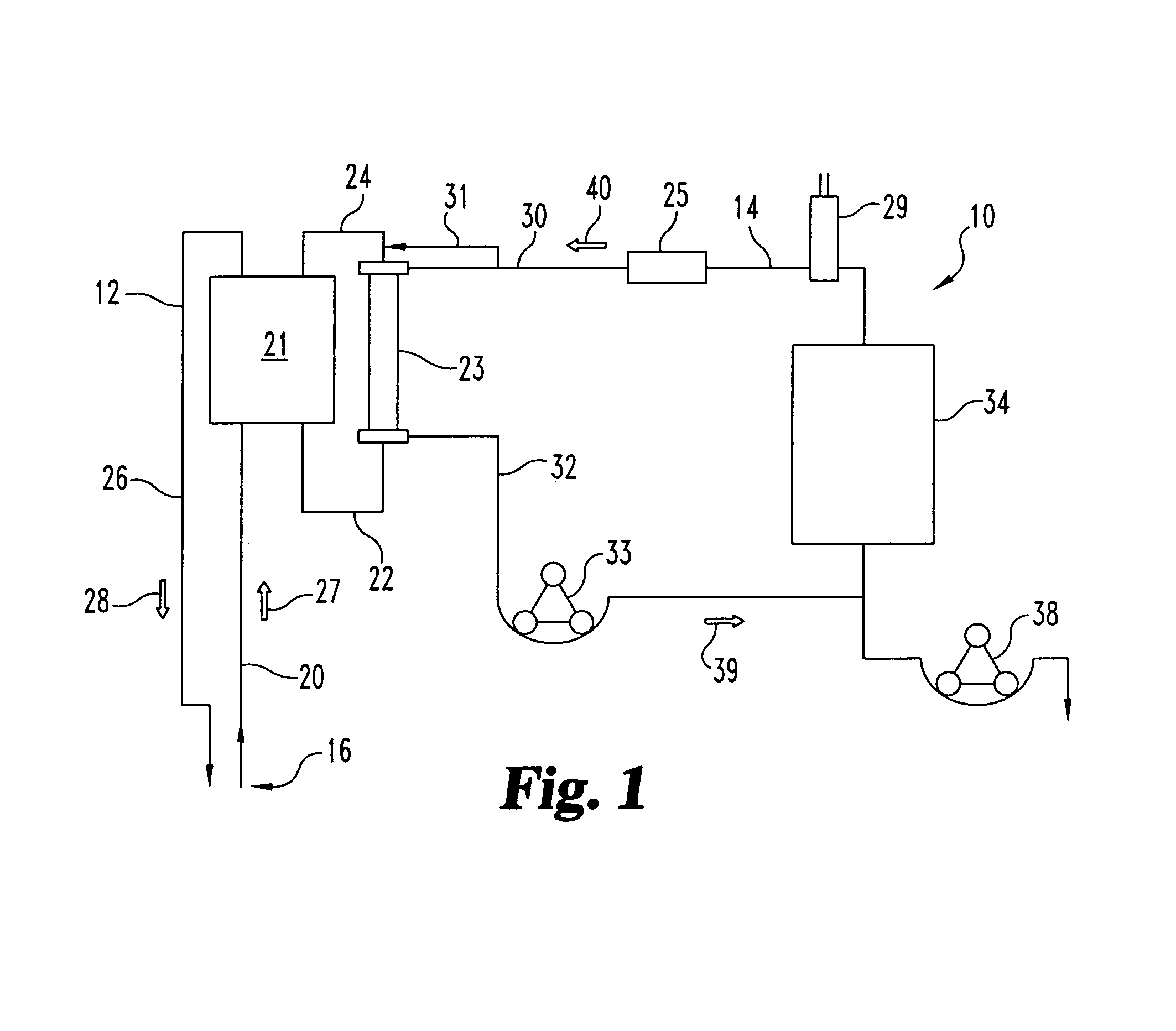

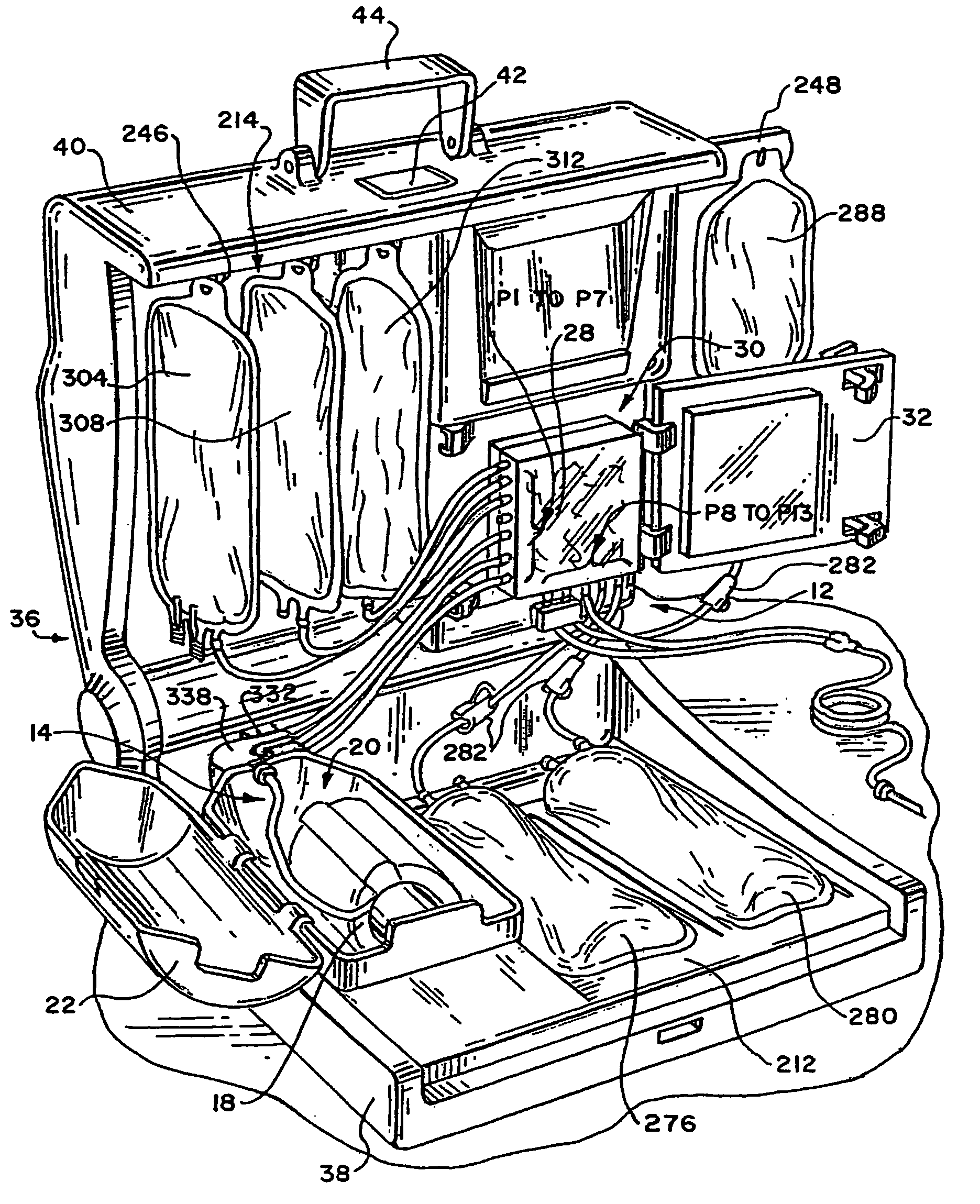

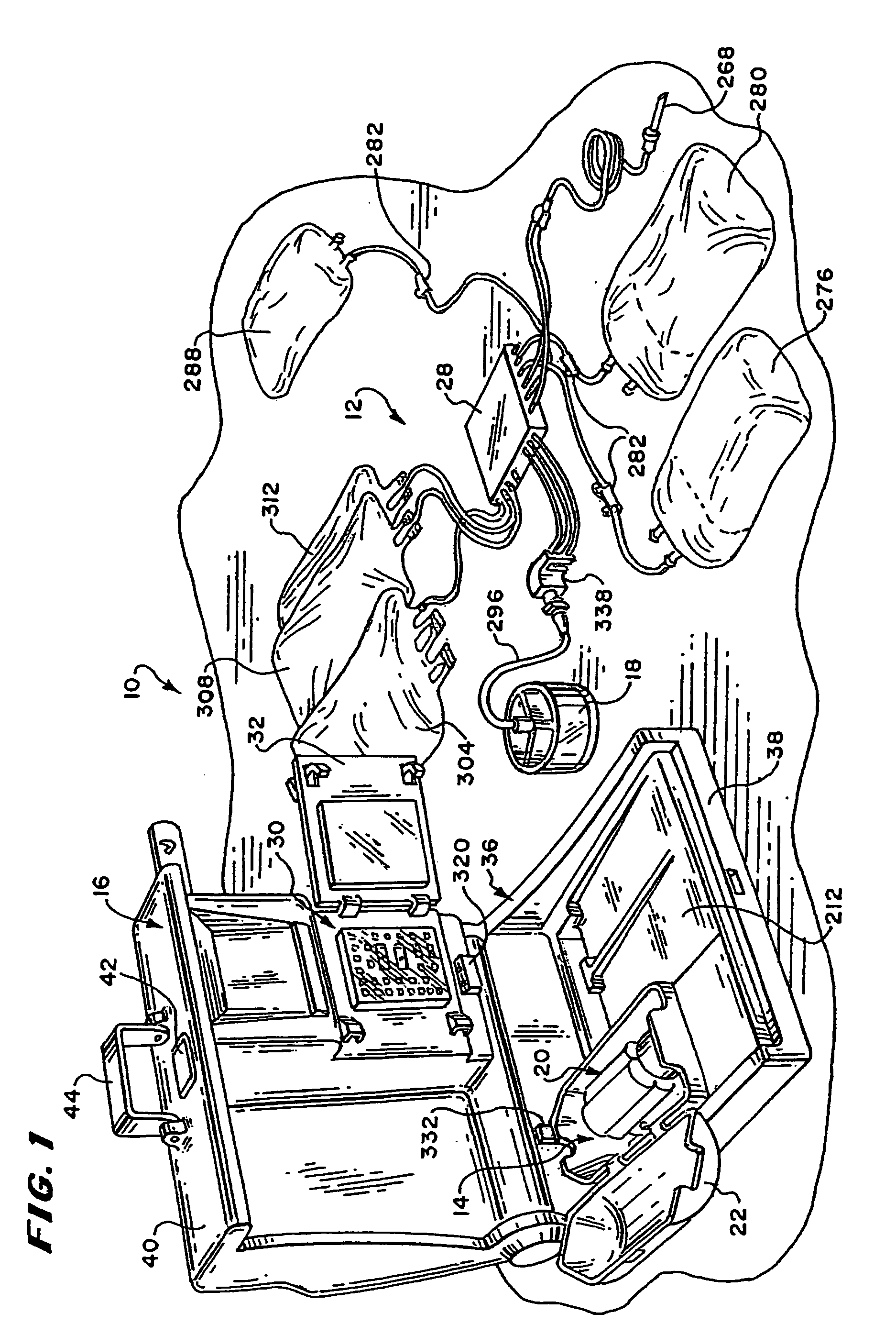

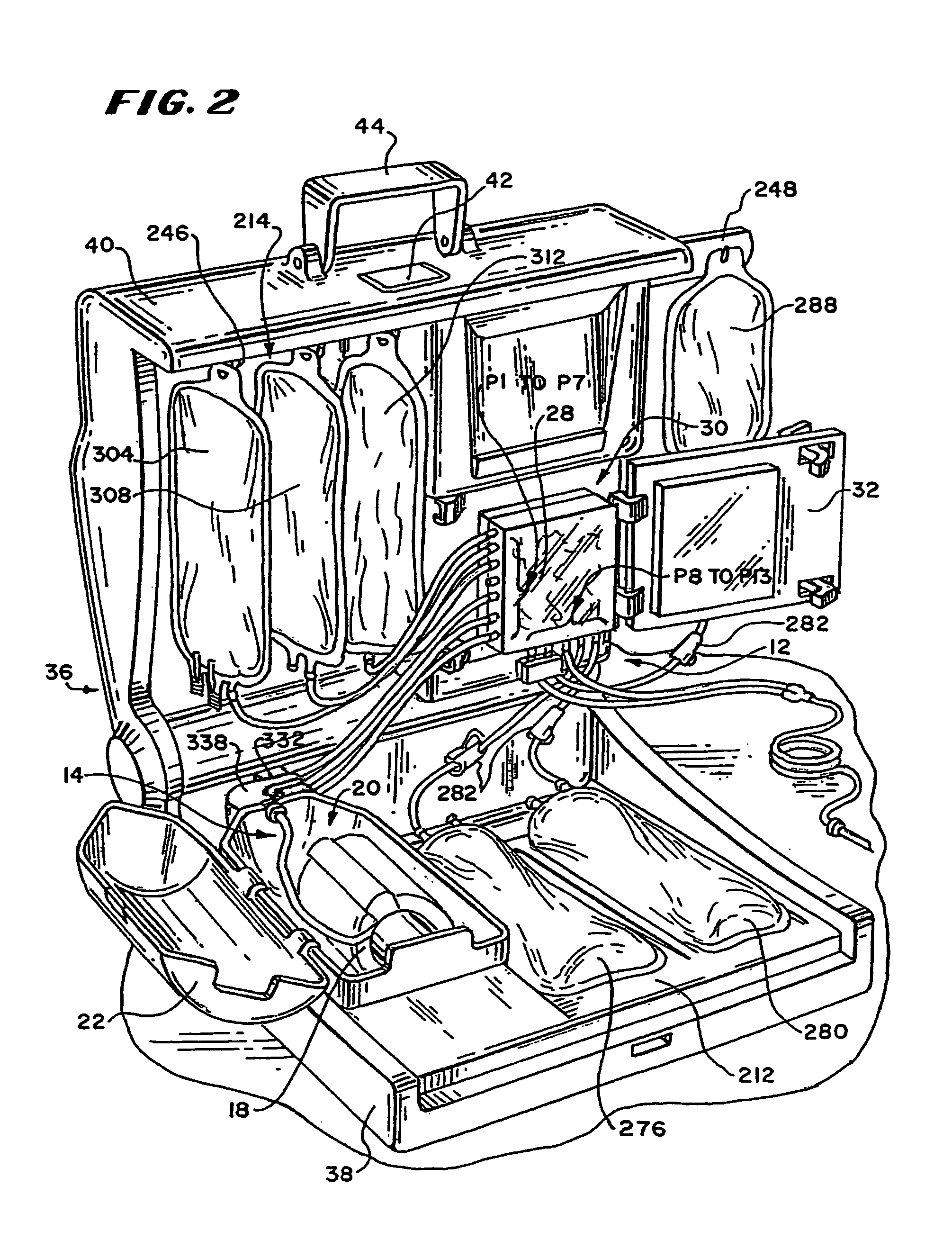

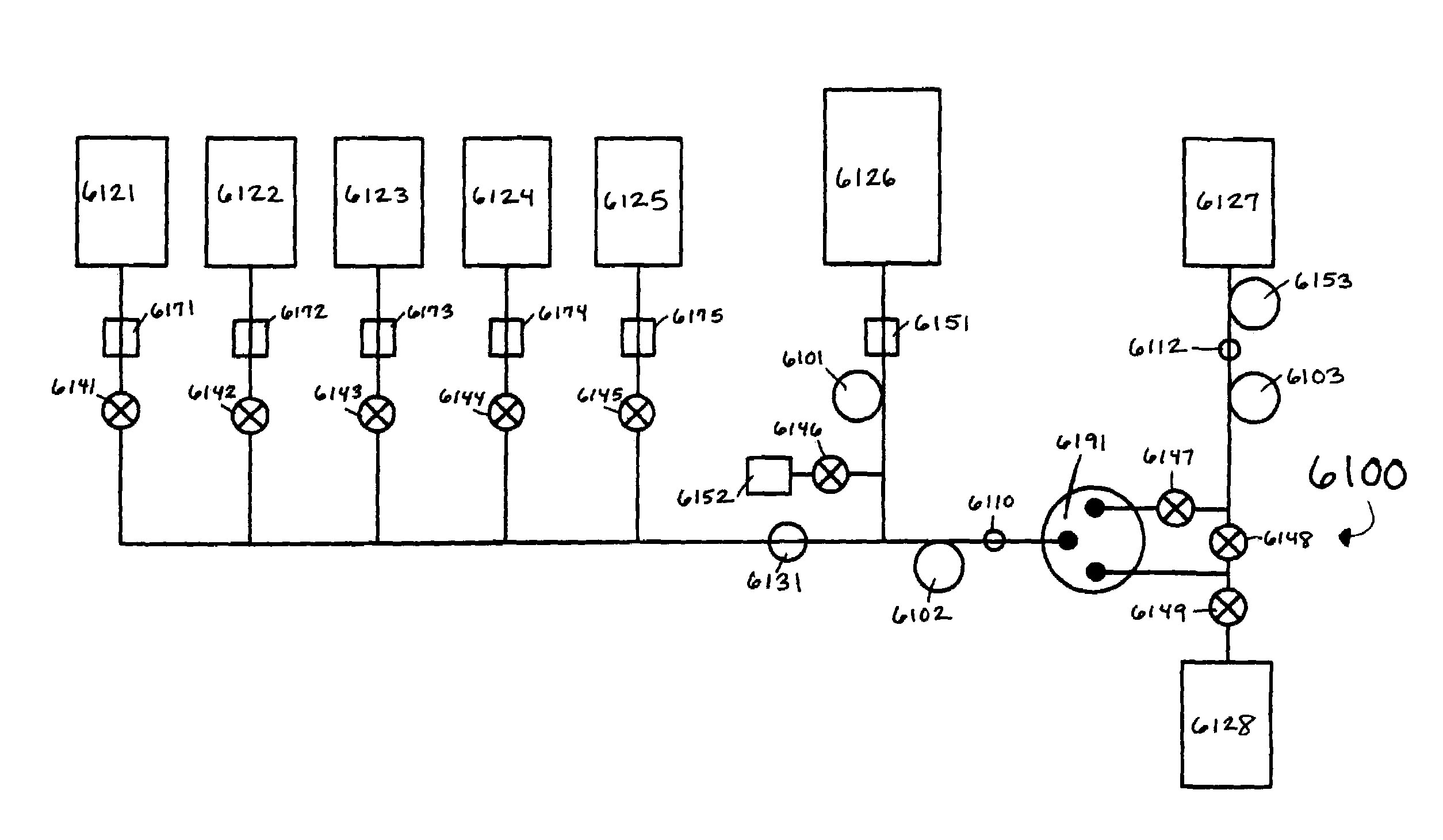

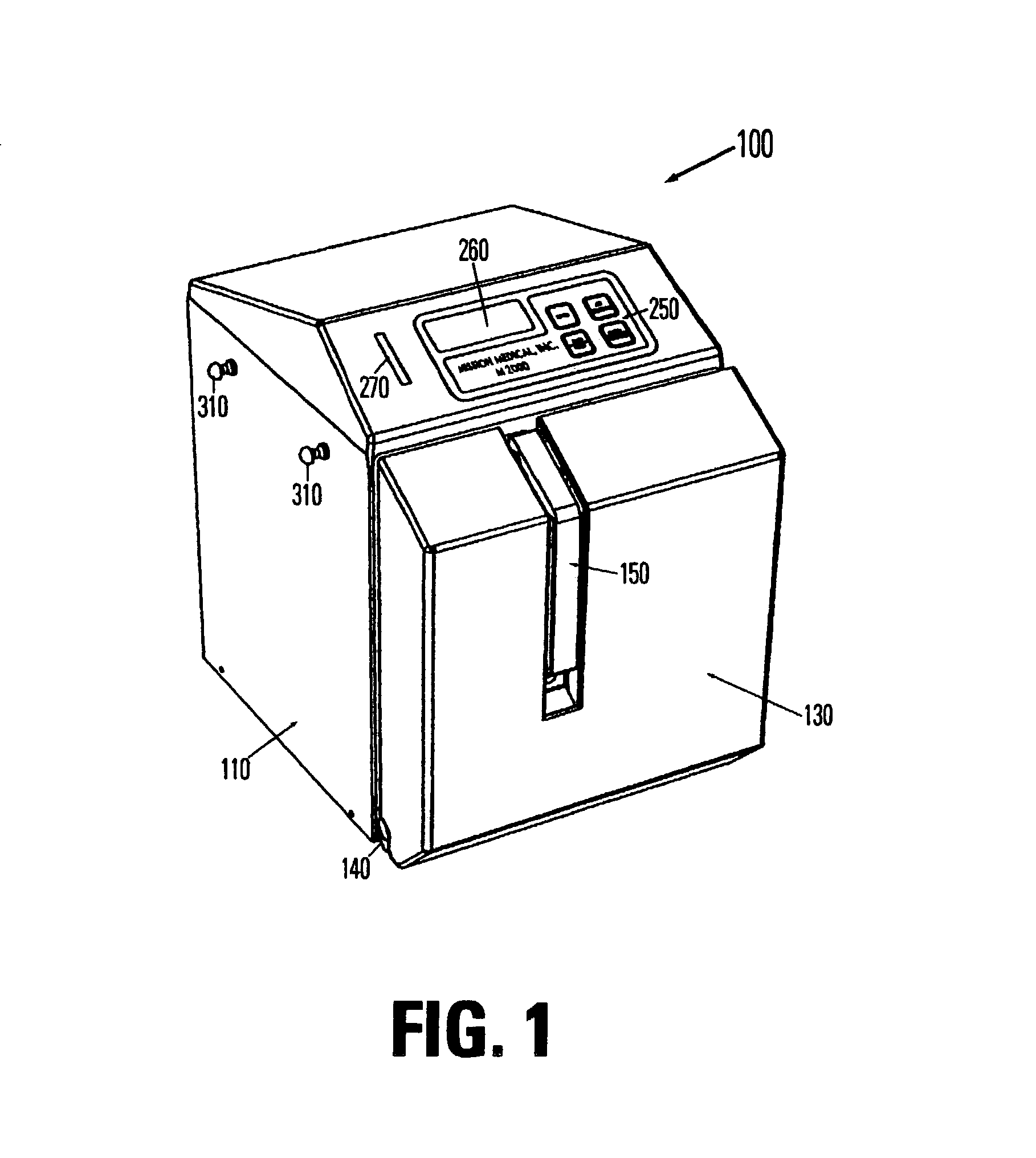

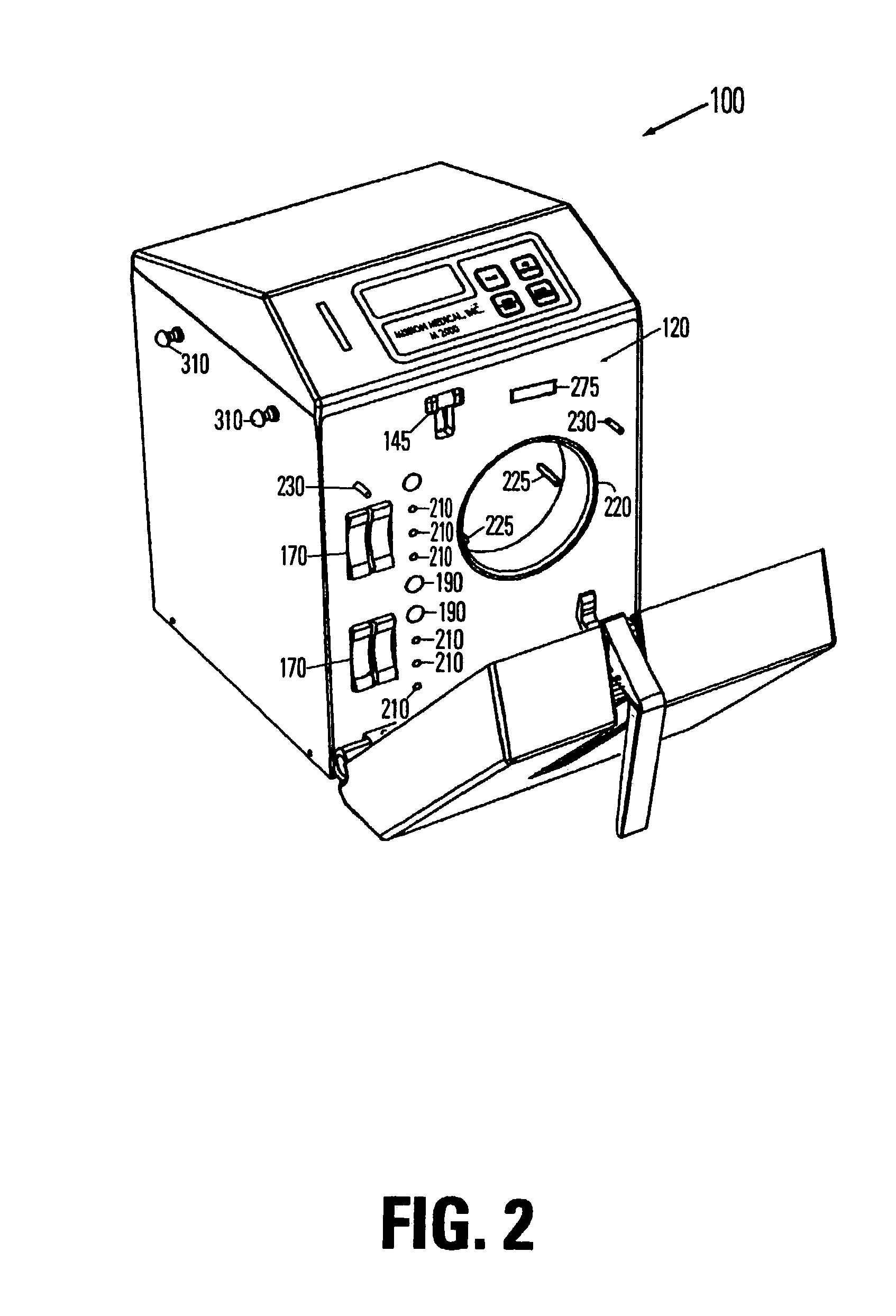

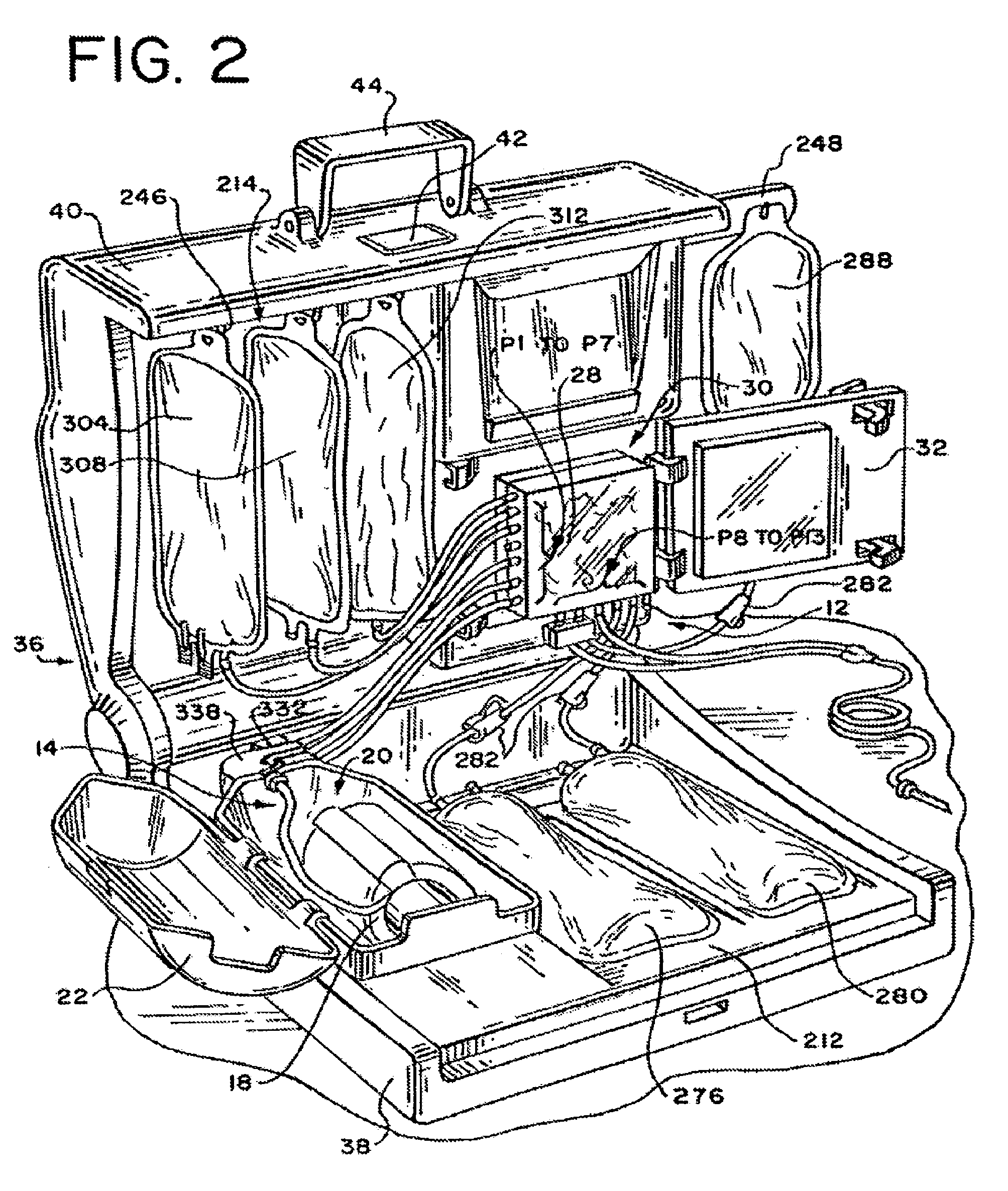

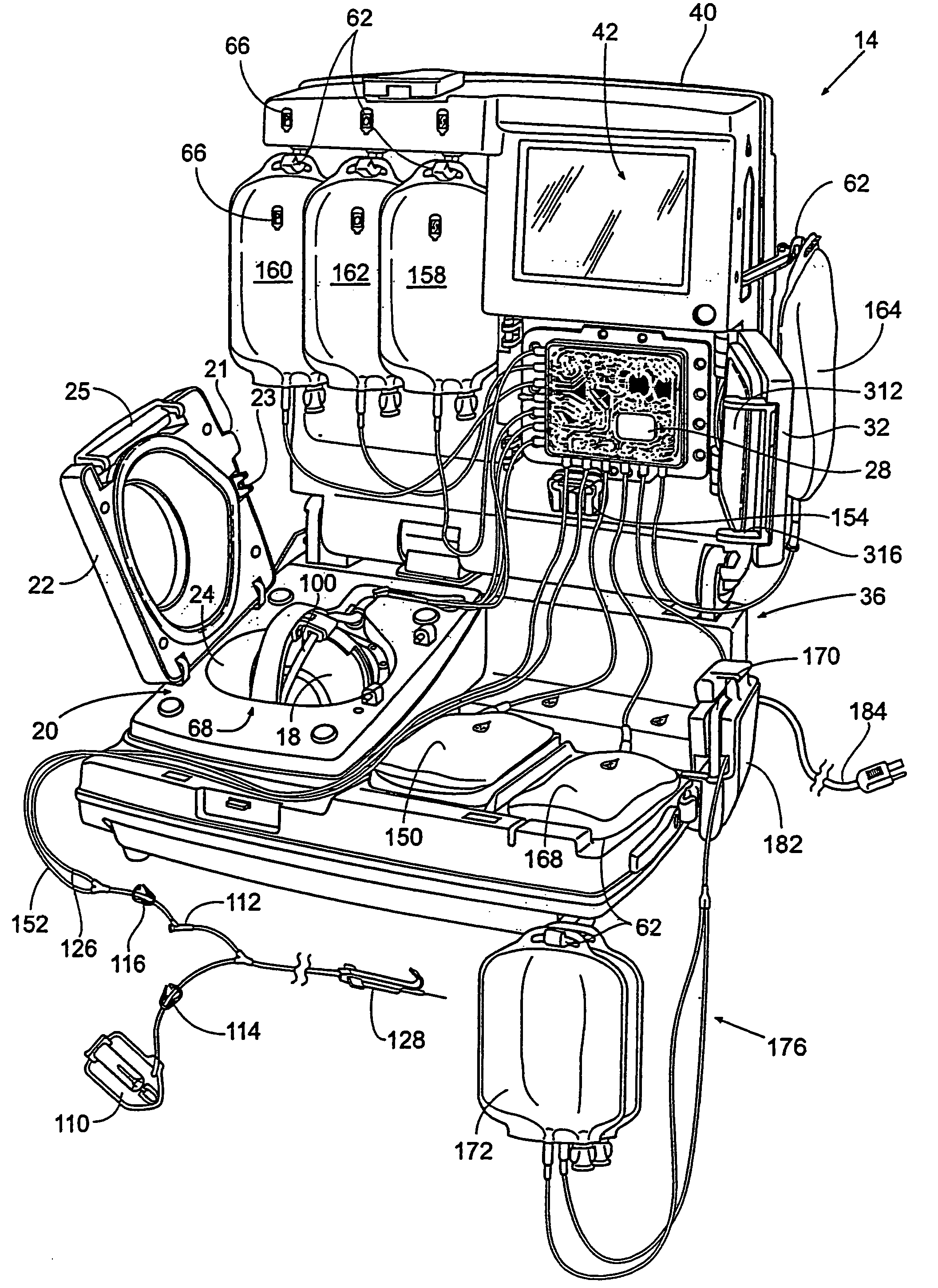

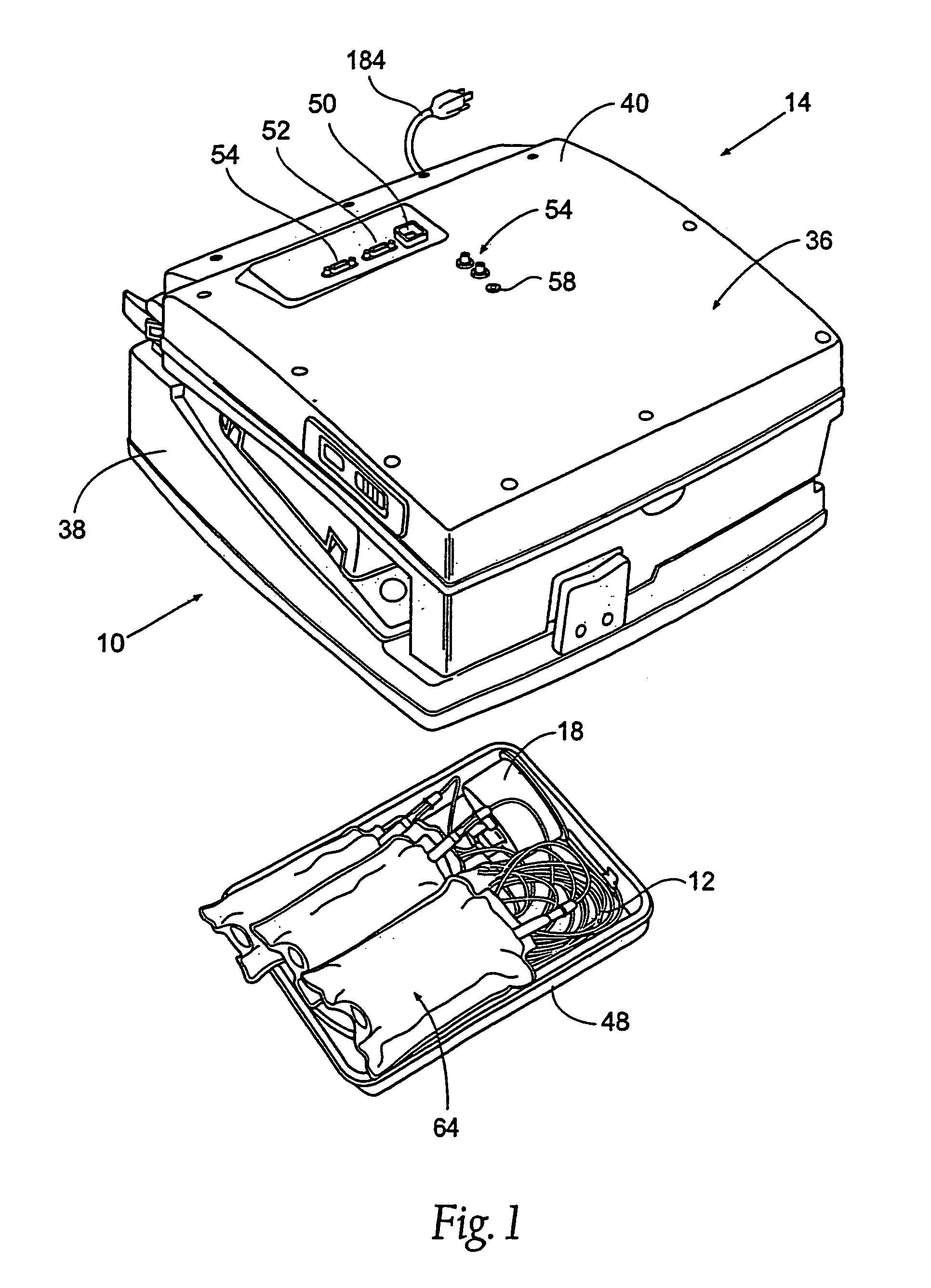

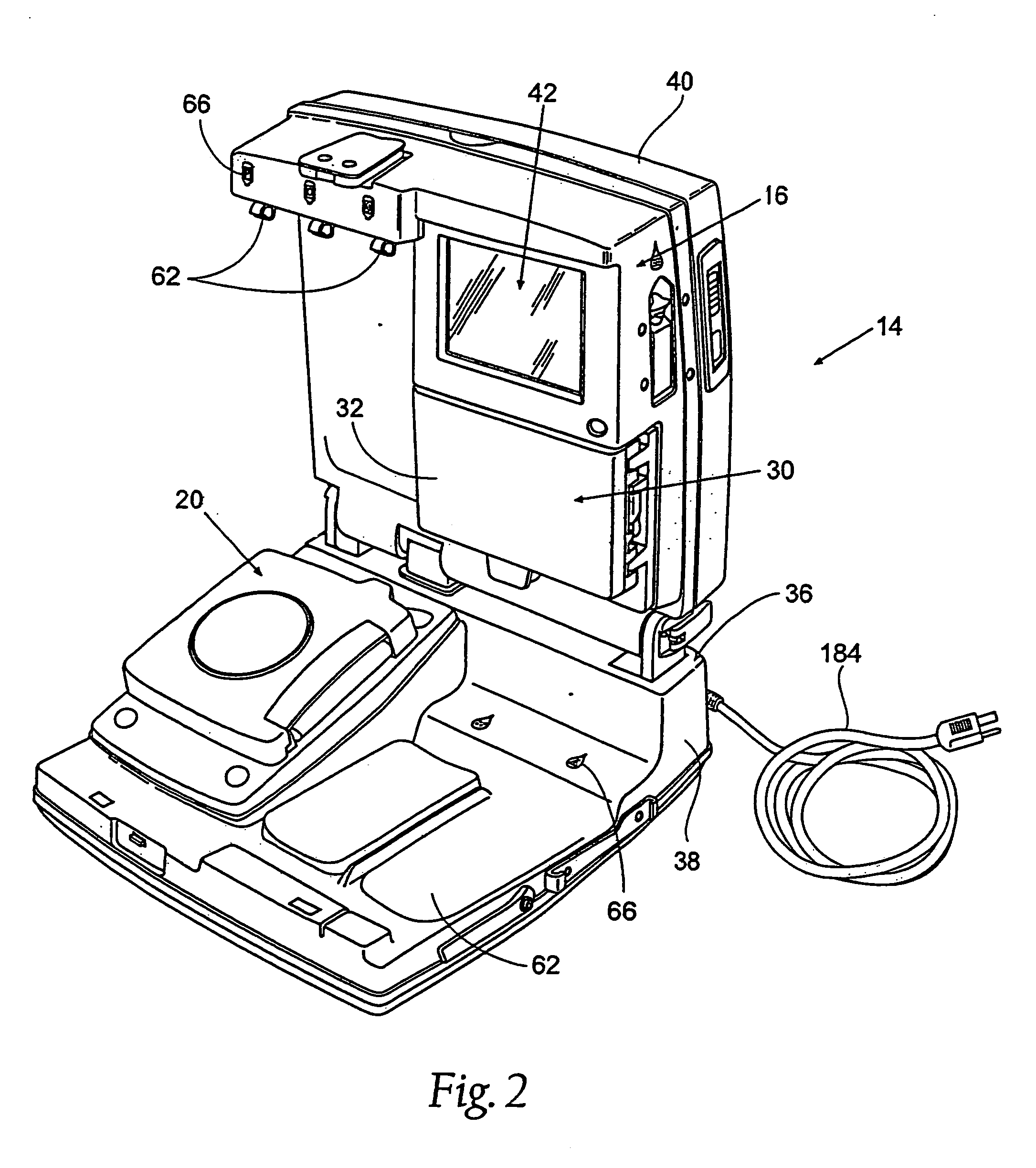

Integrated automatic blood processing unit

InactiveUS7037428B1Improve efficiencyFunction increaseWater/sewage treatment by centrifugal separationOther blood circulation devicesBlood componentMagnetic tape

A system for automatically processing blood components is described. The system includes a console, which contains all motors, pumps, sensors, valves and control circuitry, and a unique disposable set that includes a cassette supporting a centrifuge with an improved design, pump interfaces with an improved design, component and solution bags, and tubing. Various processes are implemented using a specific disposable set for each process which allows automatic identification of the process to be performed the console.

Owner:ZENON TECH PARTNERSHIP +1

Systems and methods for mid-processing calculation of blood composition

Blood separation methods are provided for mid-processing calculation of blood composition. Blood is conveyed into a device having an outlet line and the device is spun to separate platelets from the blood. A flow of platelets is conveyed from the device by the outlet line and the platelets in the outlet line are optically measured. With said optical measurement, a current platelet yield, a platelet pre-count, the volume of blood to process to collect a target amount of platelets, and / or the processing time required to collect a target amount of platelets is calculated. The optical measurement can also be used to calculate an amount of storage fluid to convey into a collection container with the platelets.

Owner:FENWAL

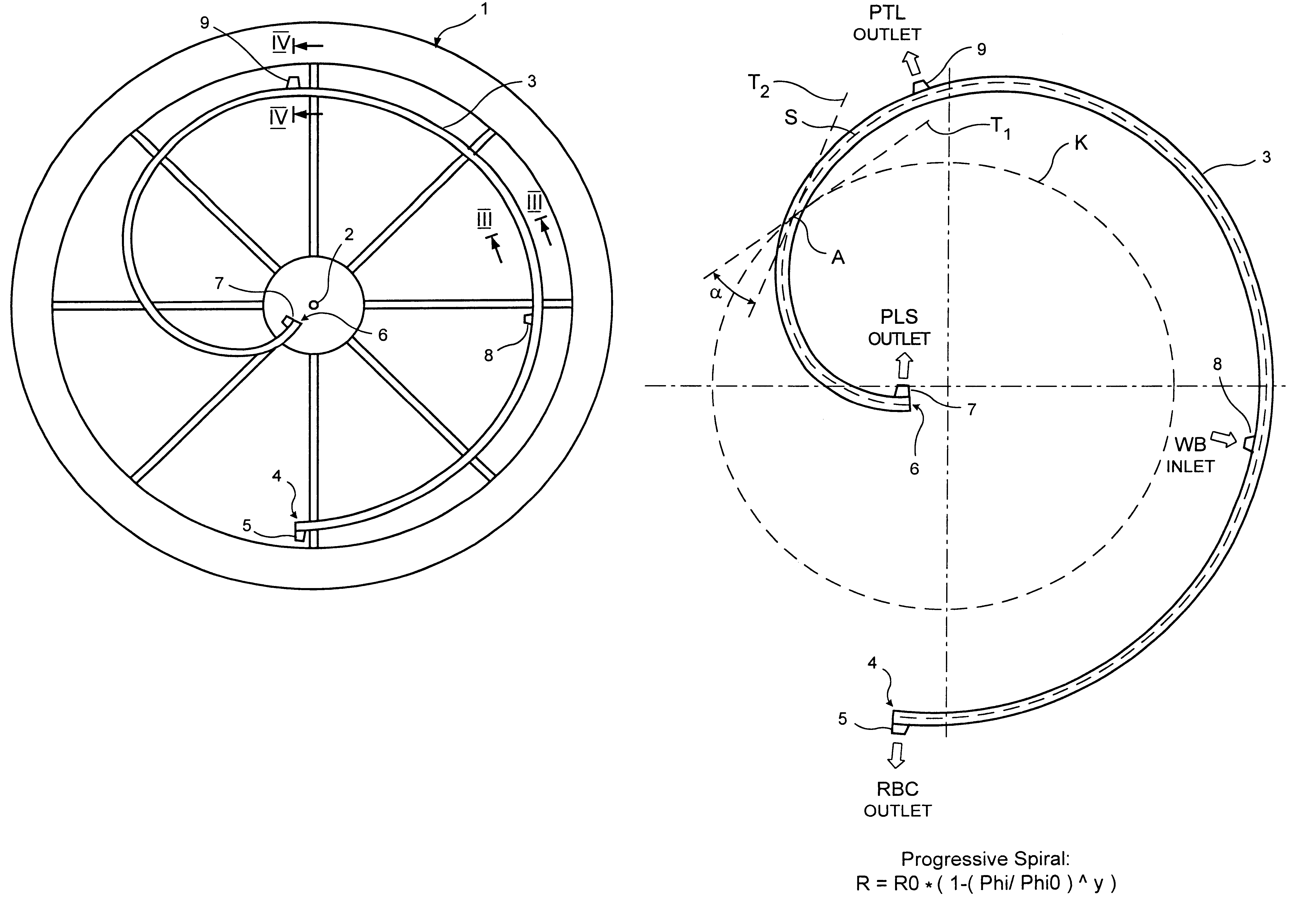

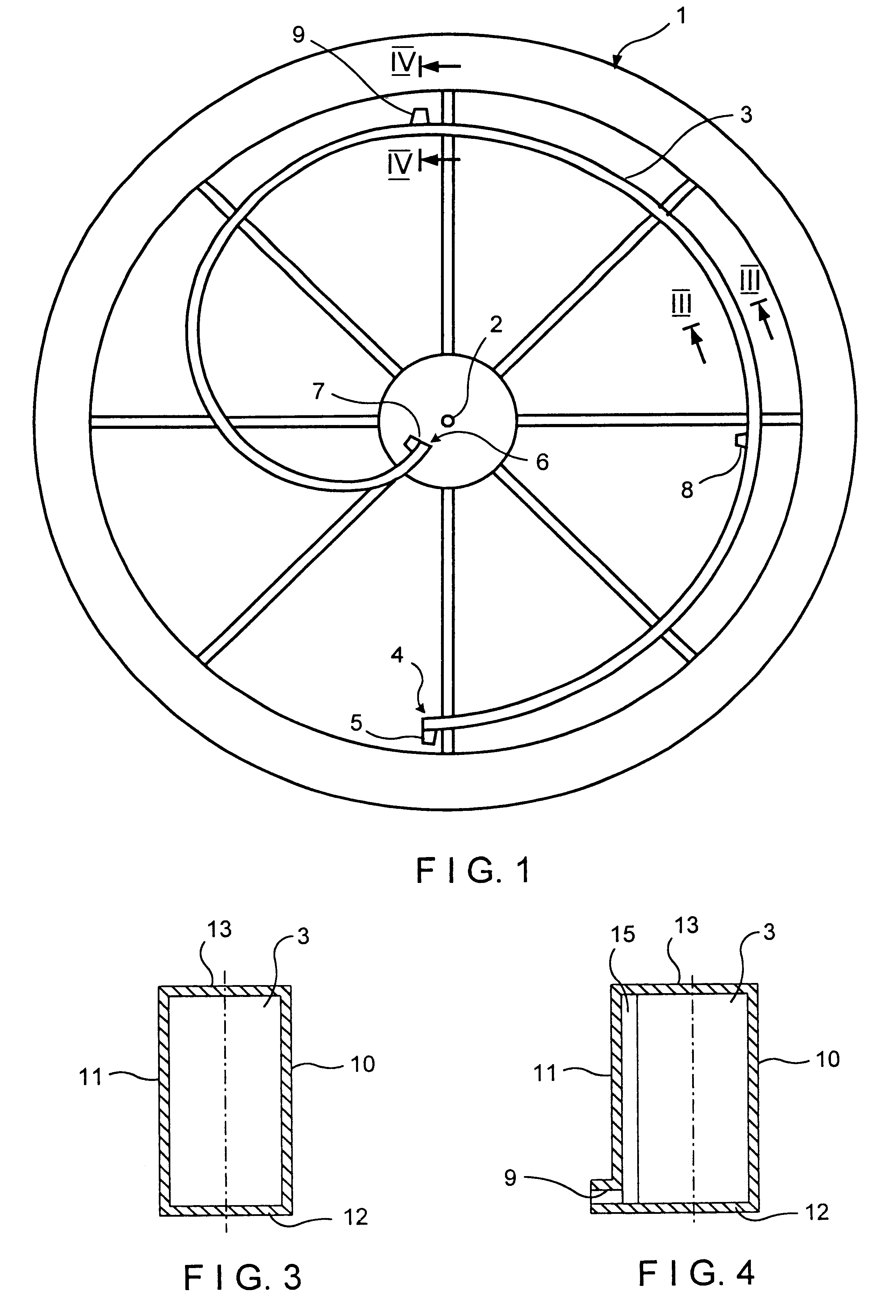

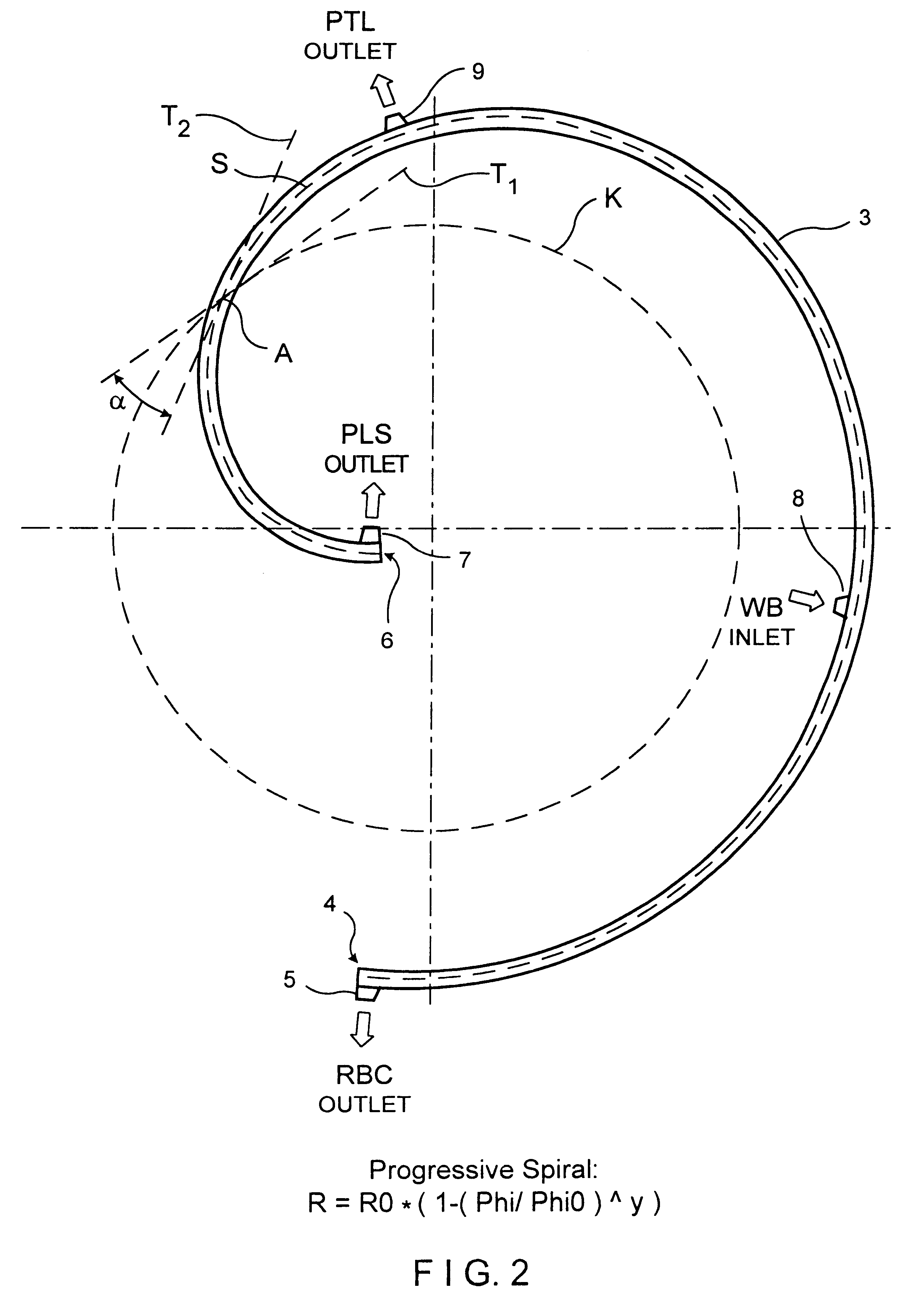

Centrifuge chamber for a cell separator having a spiral separation chamber

InactiveUS6277060B1Increase valueEasy to ventWithdrawing sample devicesDispersed particle separationEngineeringCell separation

A centrifuge chamber of a cell separator having a separation channel with an inlet to introduce the cell suspension and at least one outlet to withdraw a fraction of the cell suspension is described. The cell suspension can be blood. The separation channel is shaped like a spiral extending from the radially outer end of the channel to the radially inner end of the channel, with a progressive slope. The centrifuge chamber allows a uniform, contaminant free separation of the cell suspension into its components.

Owner:FRESENIUS AG

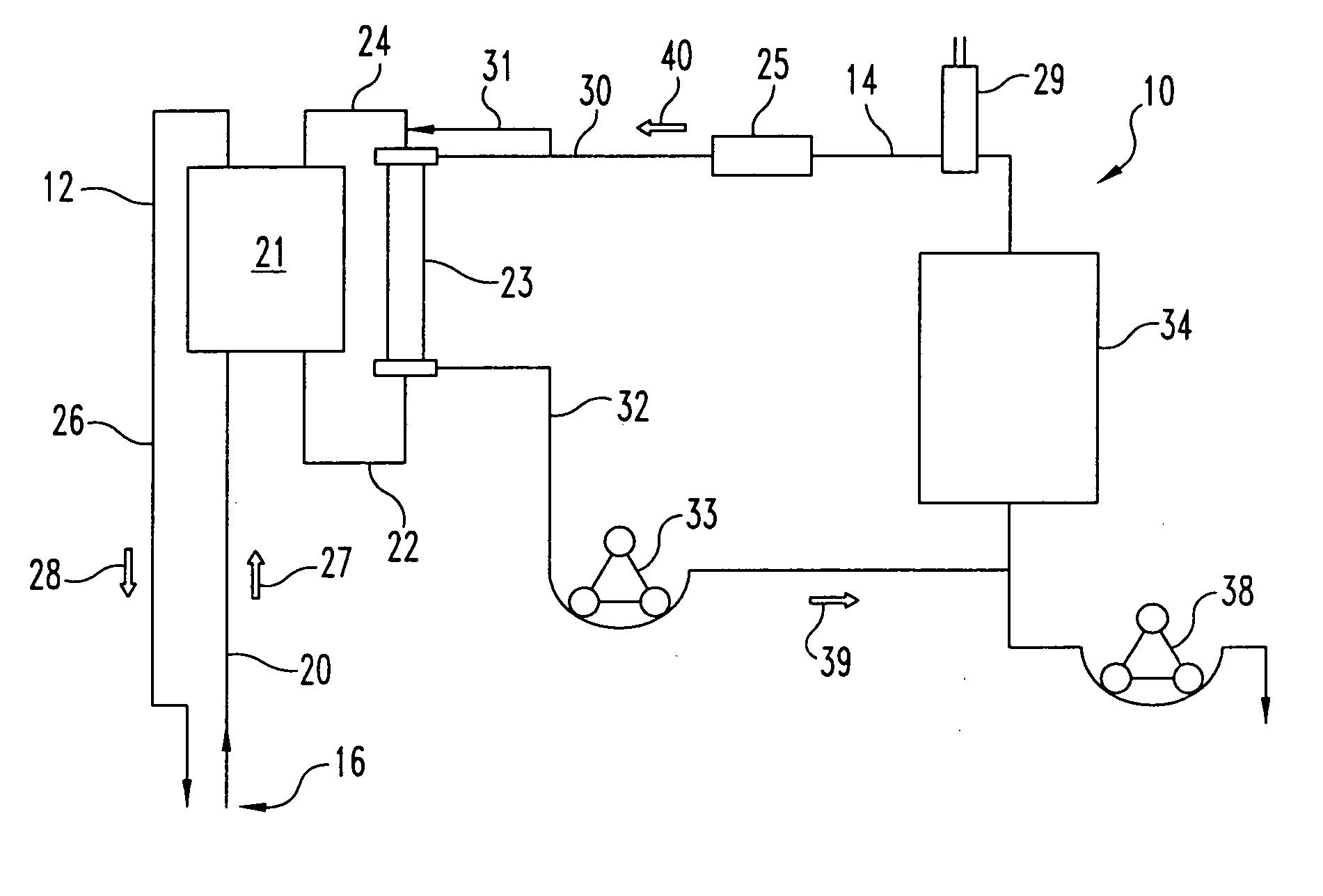

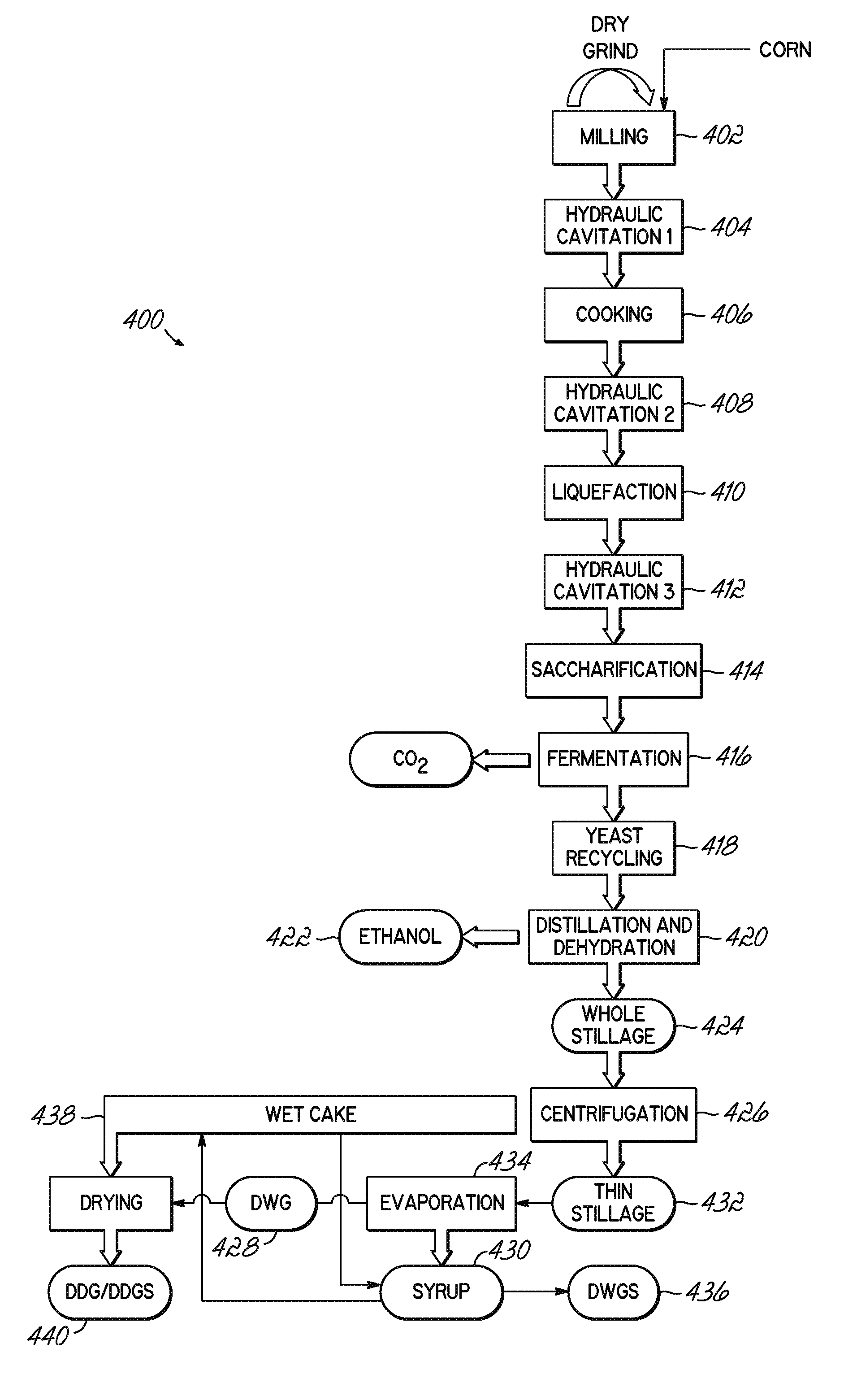

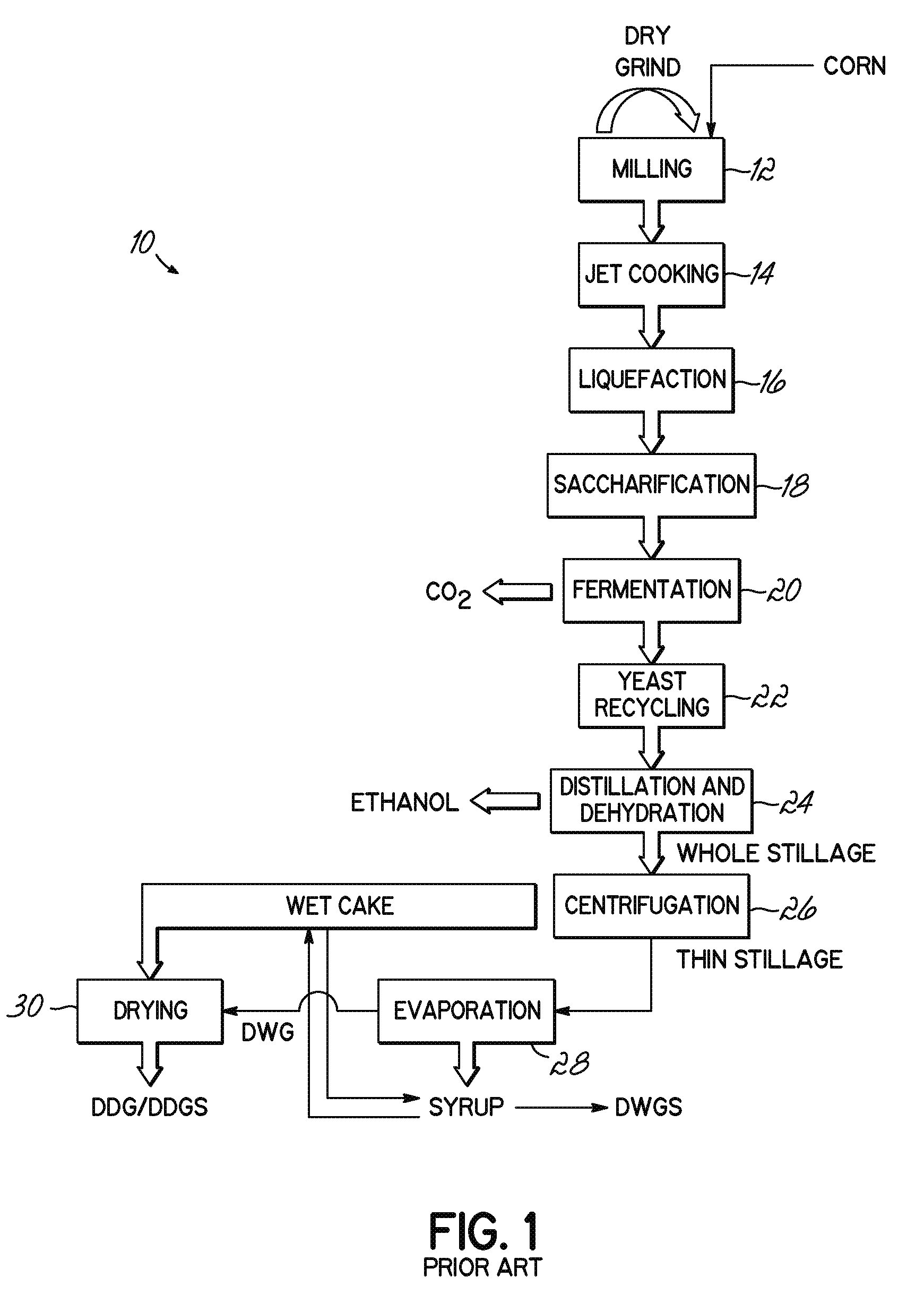

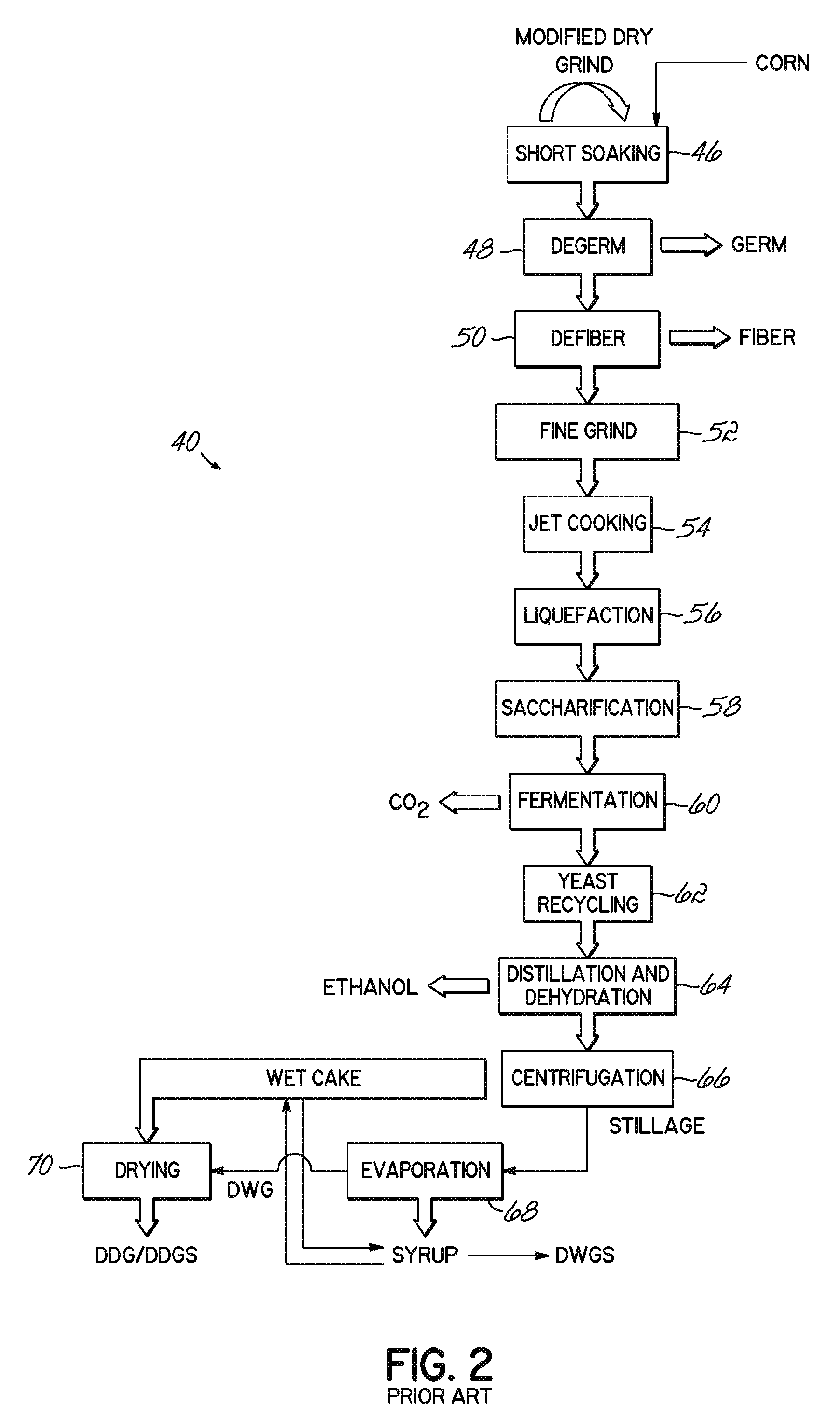

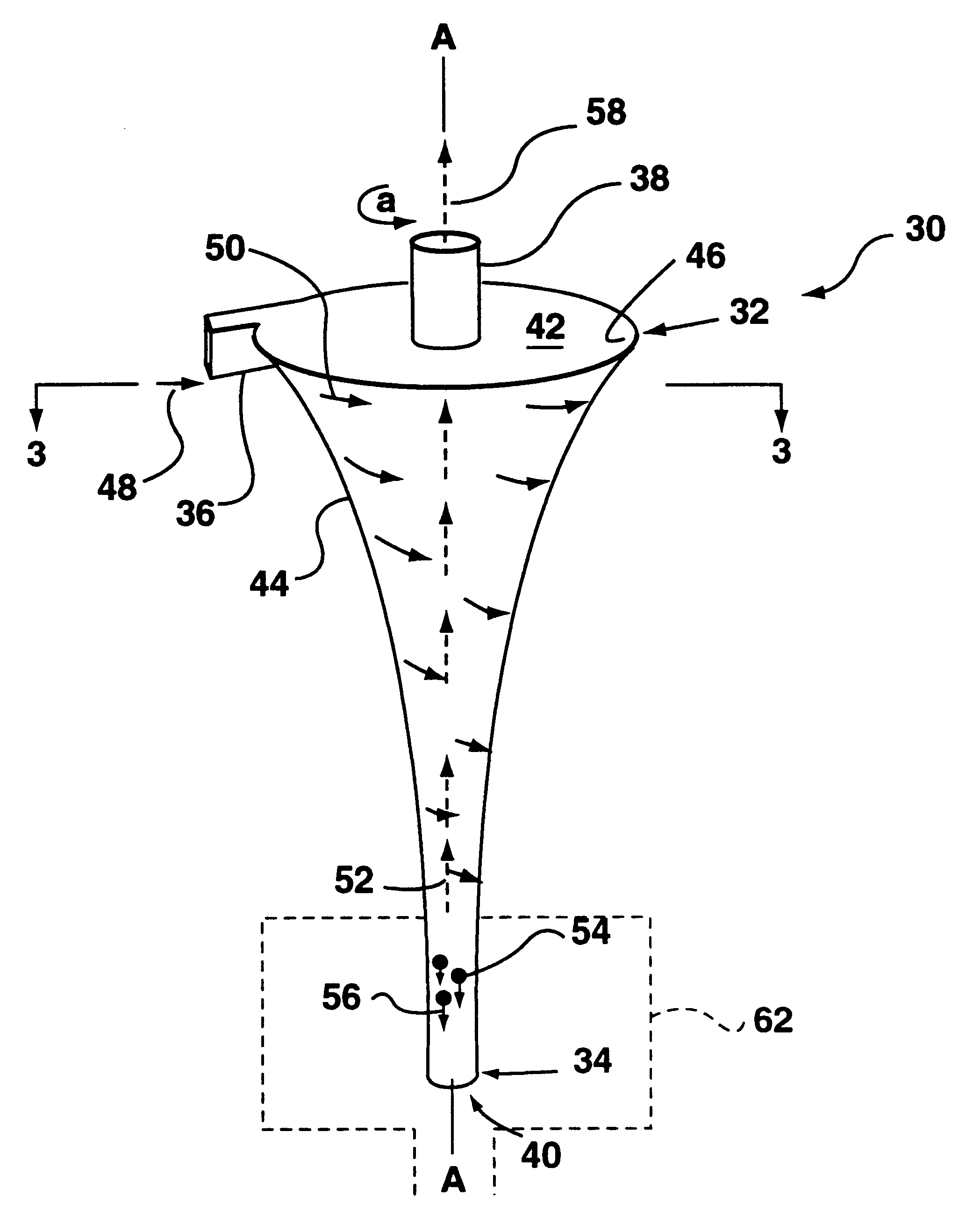

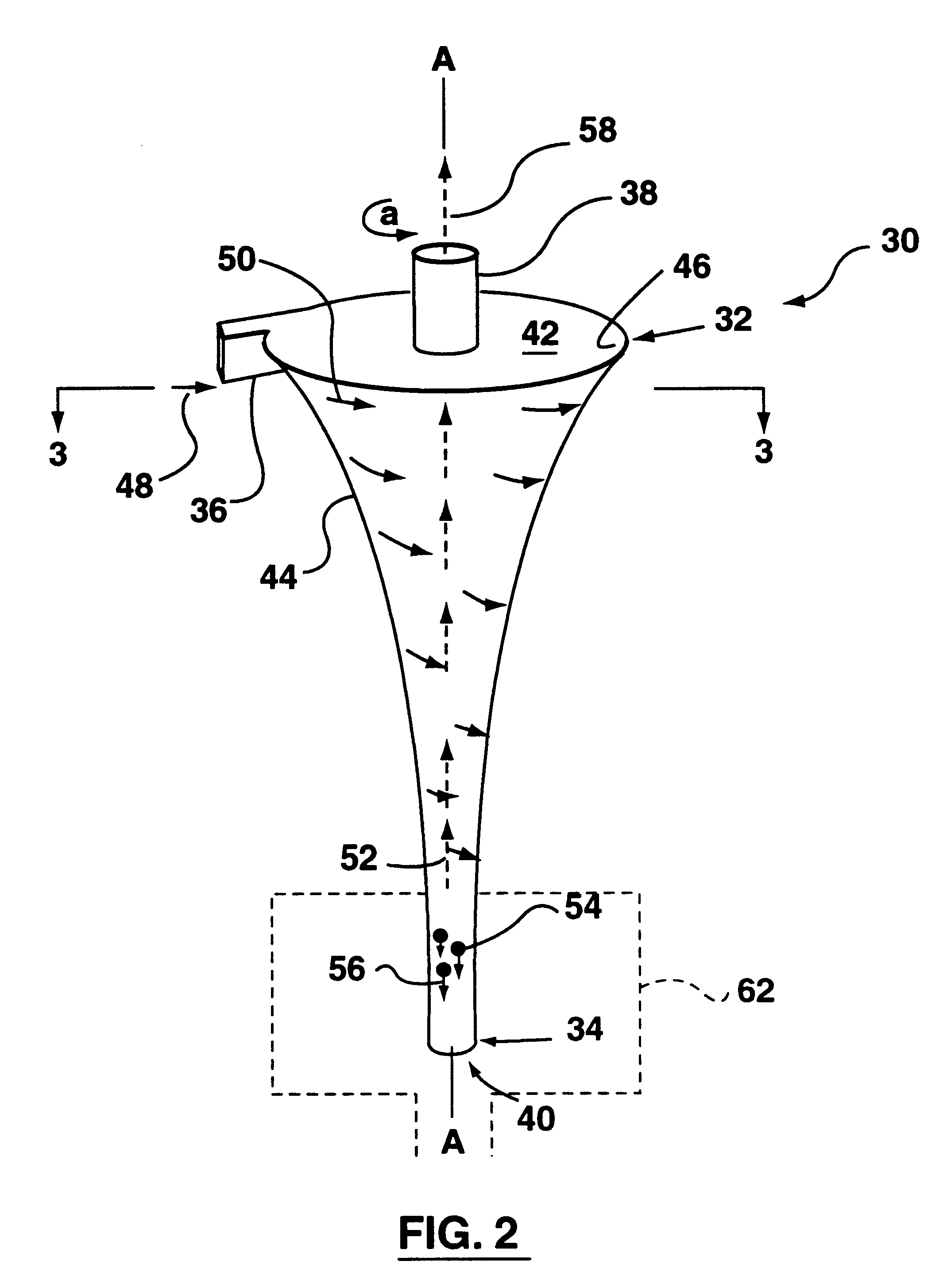

Alcohol production using hydraulic cavitation

InactiveUS20080277264A1Increase speedHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsCavitationLiquid medium

A system and method is provided which includes using a liquid treatment apparatus, which is equipped with cyclonettes, for example, to subject a liquid medium processing stream in an alcohol production process to hydraulic cavitation, i.e., to shear under vacuum, at one or more locations. The liquid treatment apparatus, in one embodiment, is directed to the formation of a central axial jet and a vacuum chamber that can be sealed by the exiting jet. Cavitation is generated by directing a high velocity jet of liquid medium processing stream through a volume of vapor under a vacuum created in the chamber through which the jet travels. This can reduce the production cost of alcohol, such as ethanol, by improving alcohol yield per bushel, among other benefits. In one embodiment, the alcohol production process is a dry grind process, a modified dry grind process, or a wet mill process. In one embodiment the alcohol production process utilizes grain as a starting material.

Owner:FLUID QUIP INC

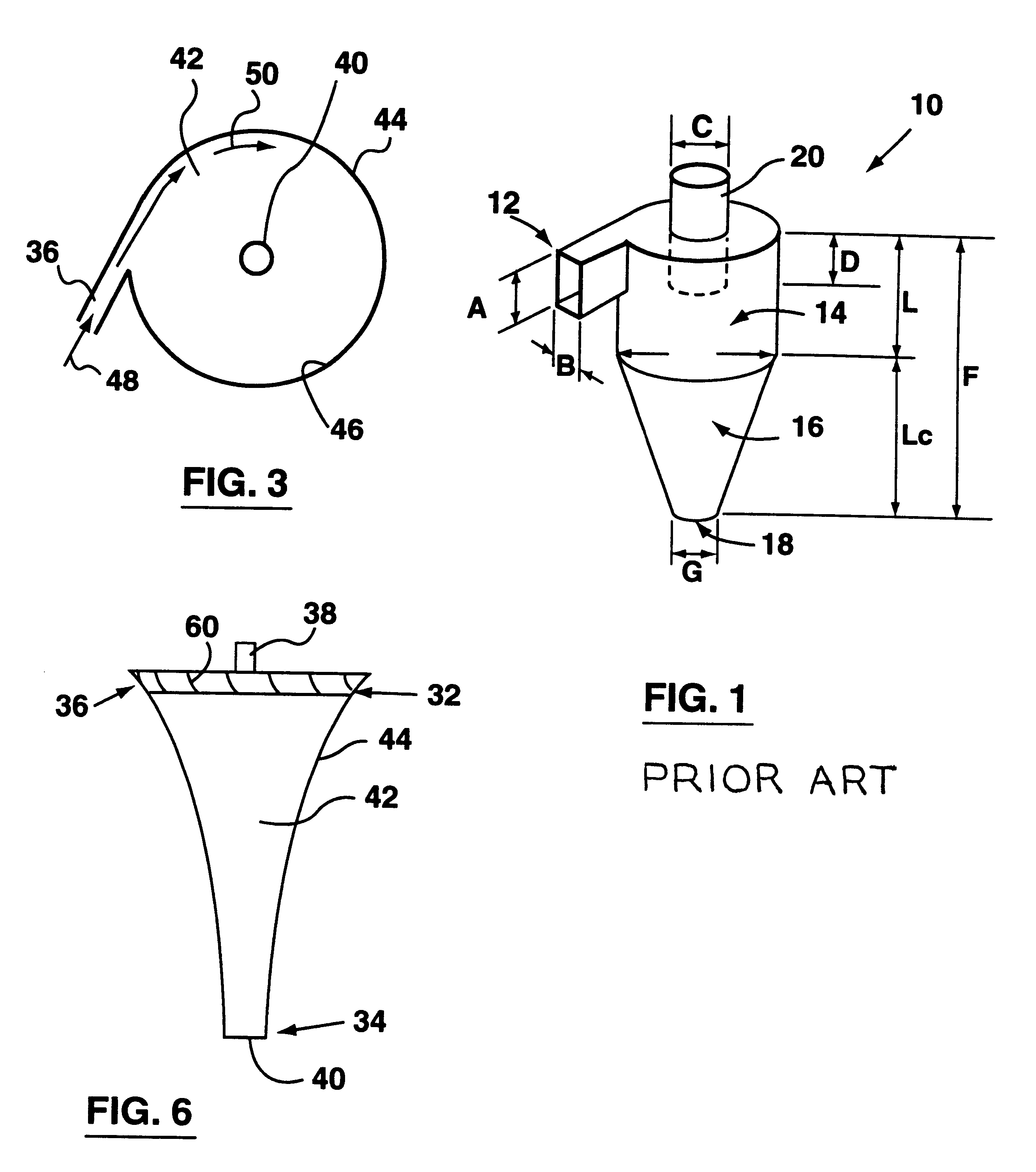

Cyclone separator having a variable longitudinal profile

InactiveUS6277278B1Reduce the numberEasy to separateReversed direction vortexDispersed particle filtrationCycloneEngineering

Owner:OMACHRON INTPROP

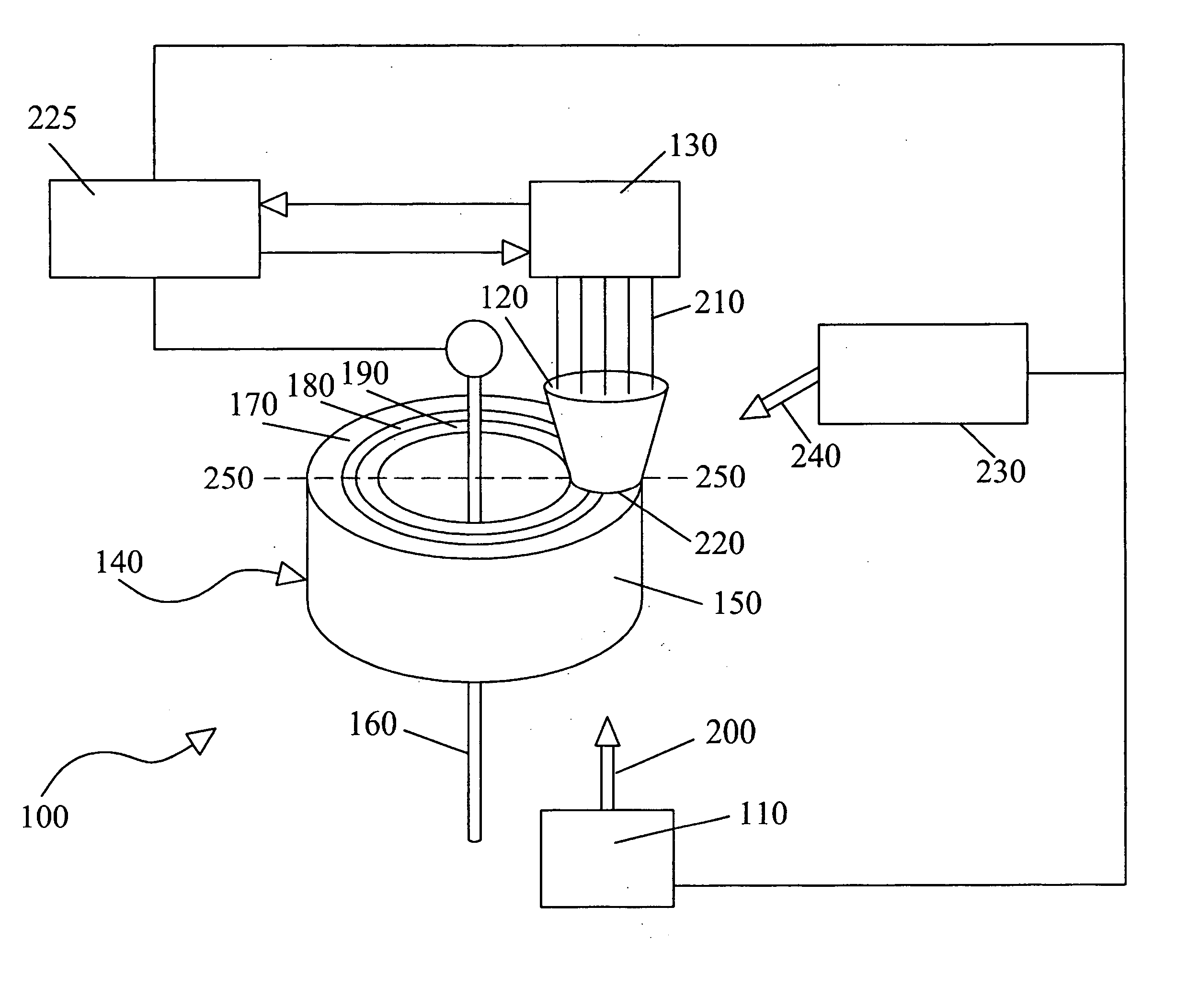

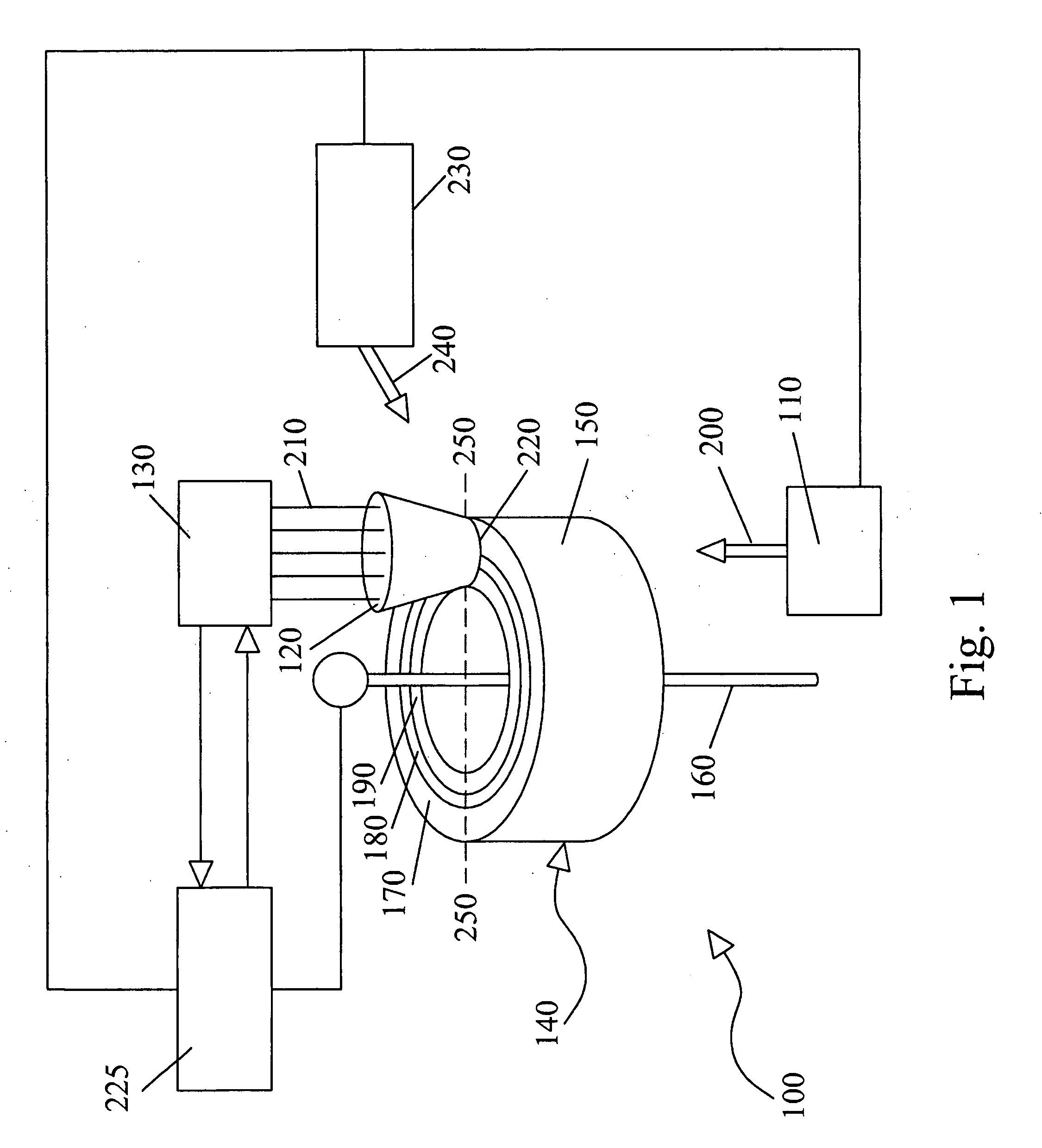

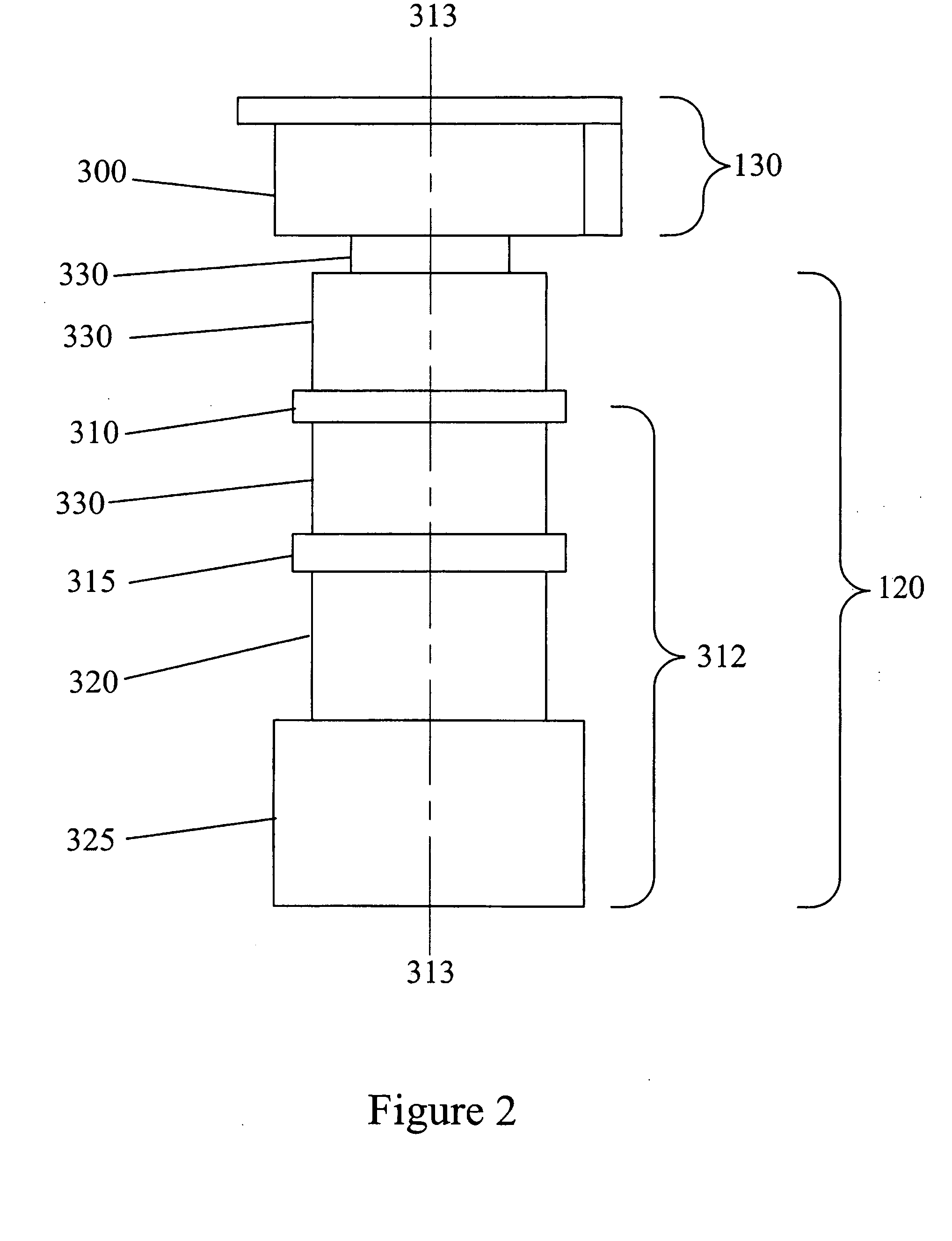

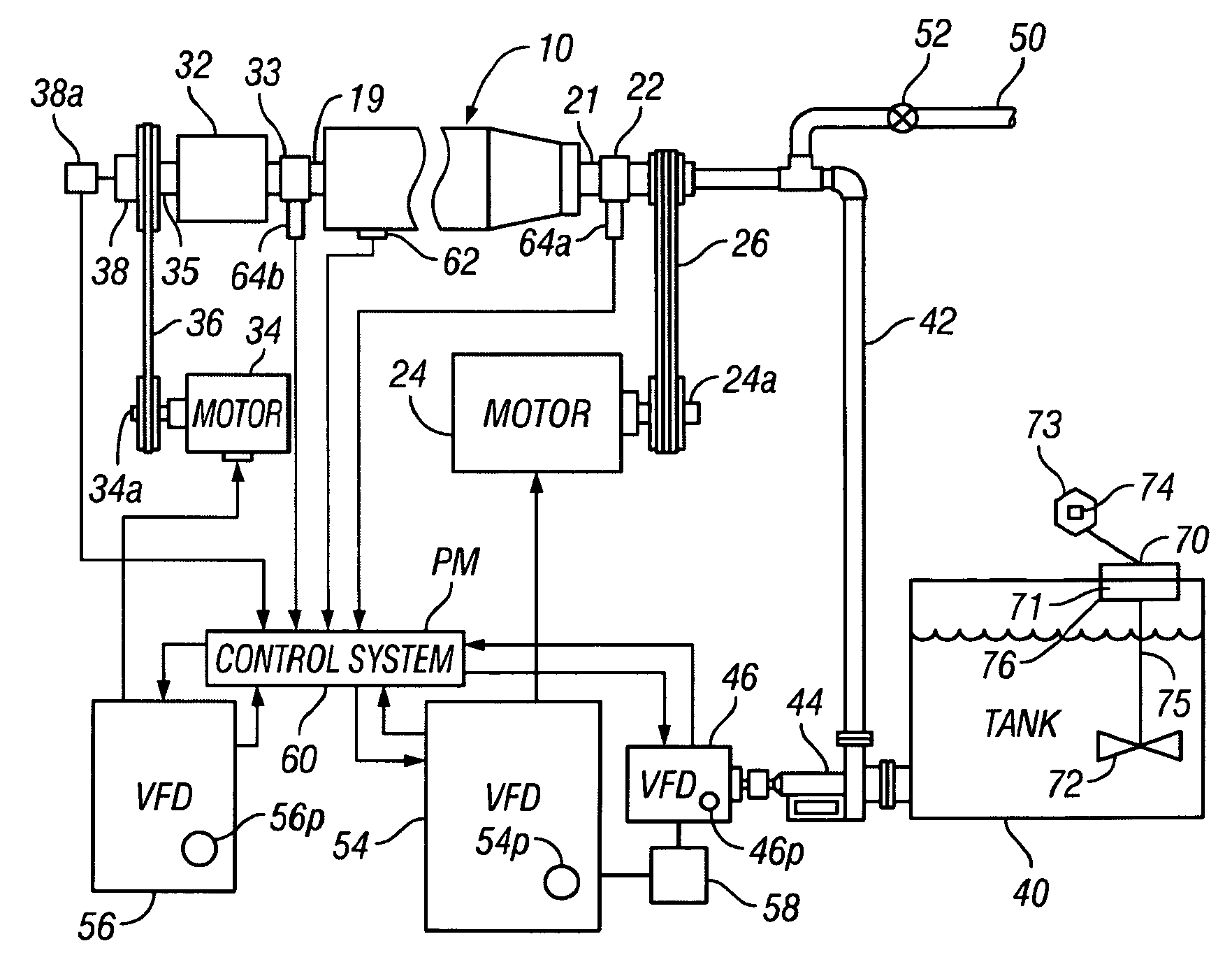

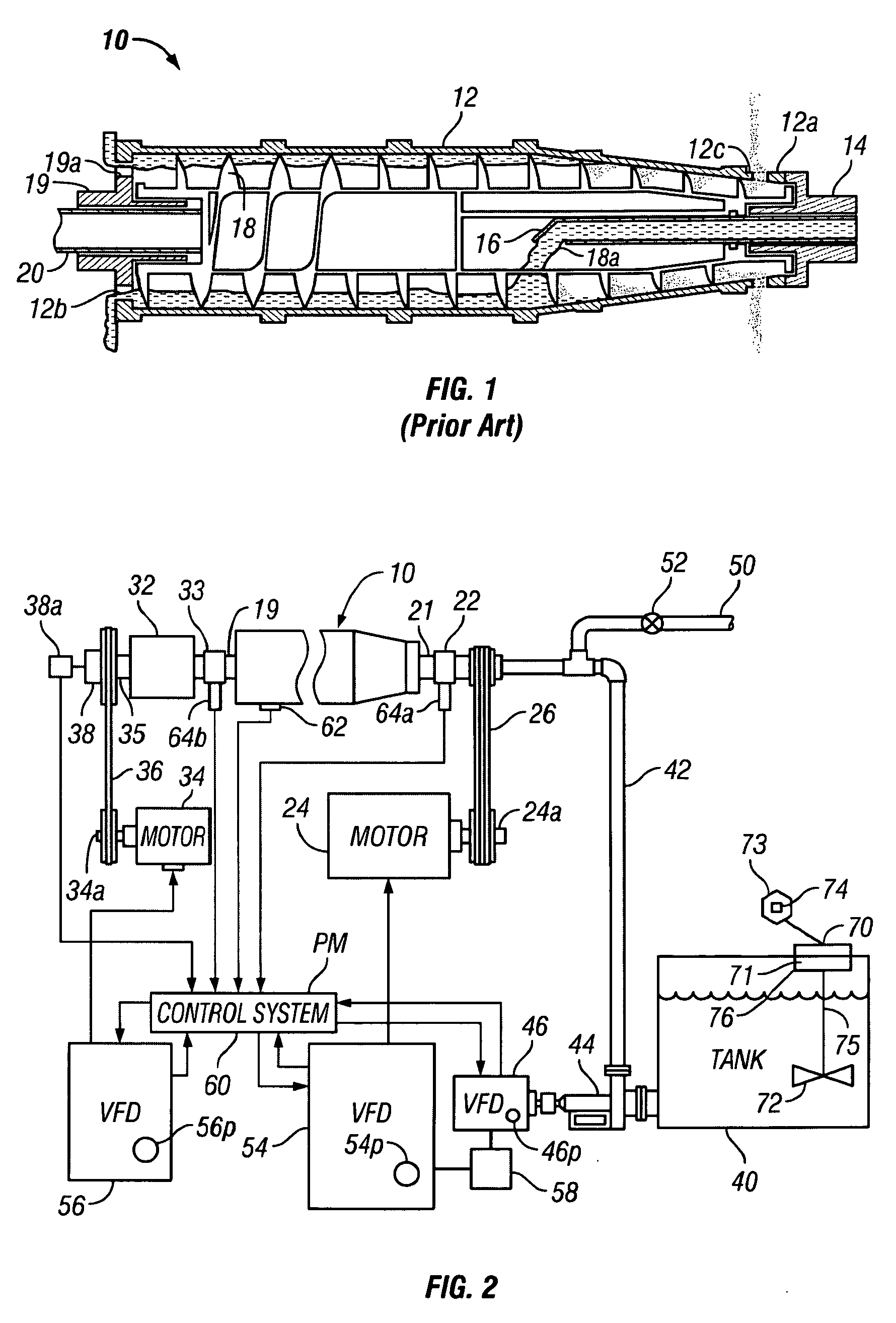

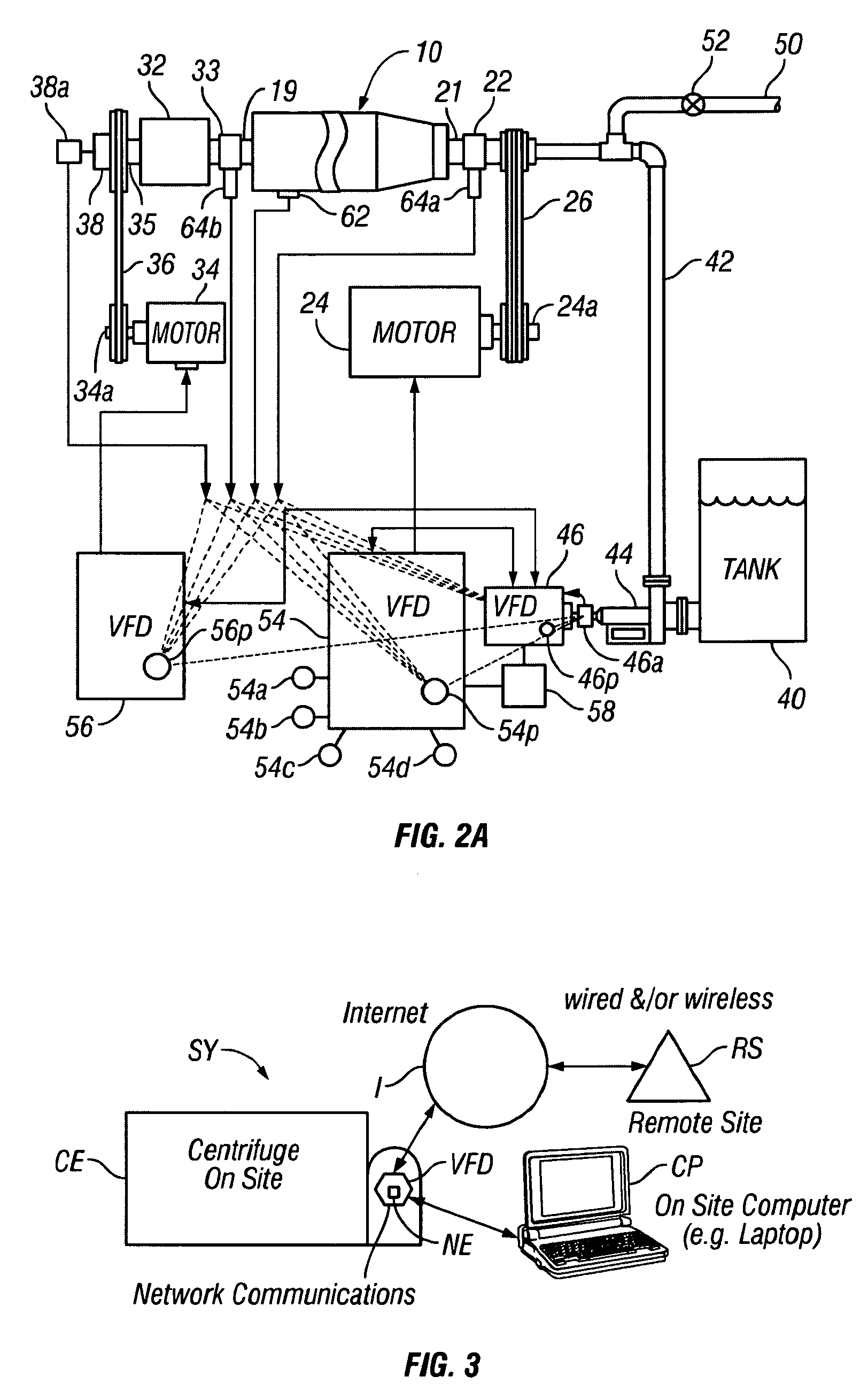

Controlled centrifuge systems

ActiveUS20090105059A1Sampled-variable control systemsDispersed particle separationSubject matterEngineering

Centrifuge systems and methods for controlling centrifuge systems, the systems in certain aspects for processing material, e.g., but not limited to drilling fluids with solids therein. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

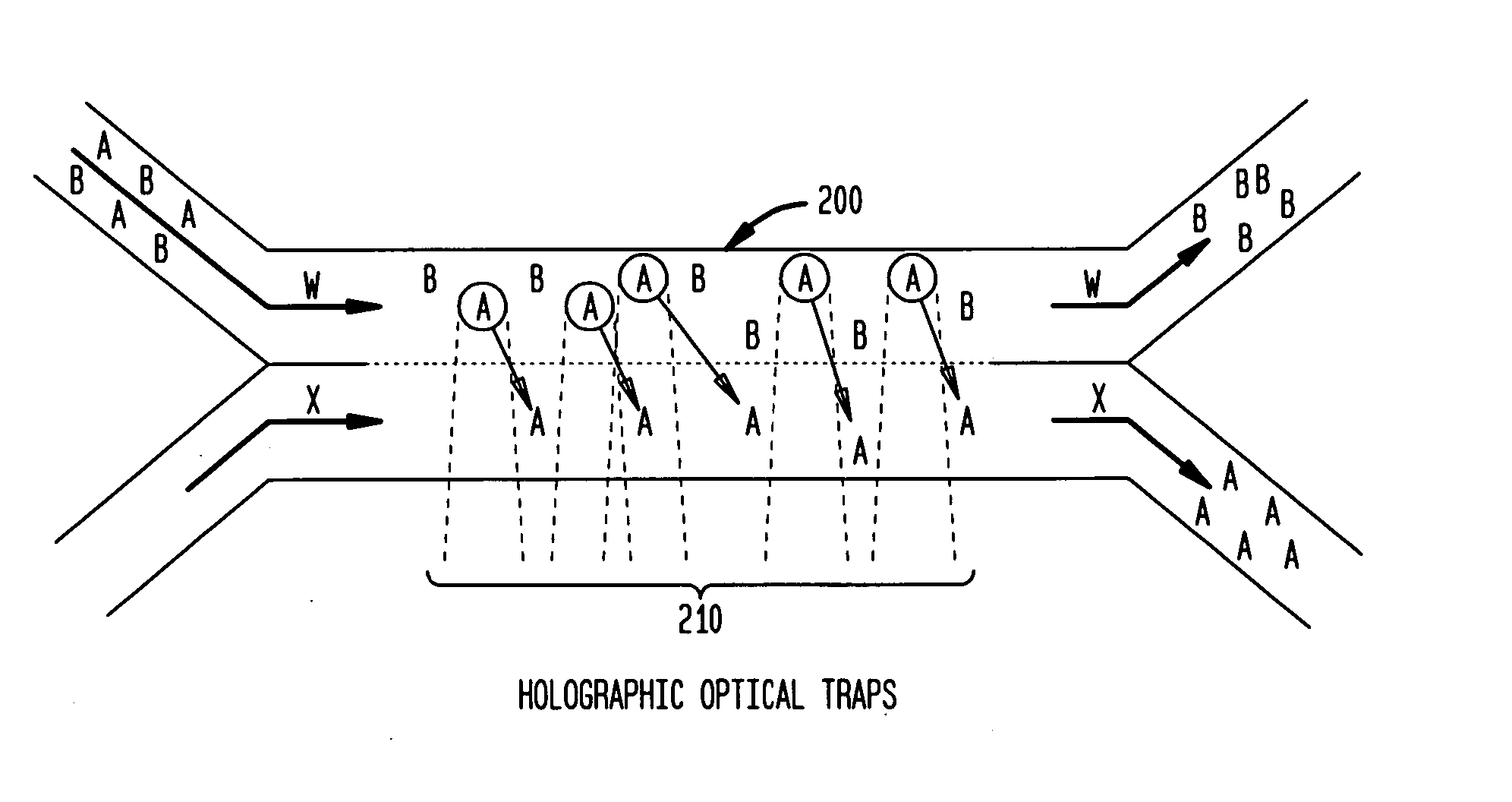

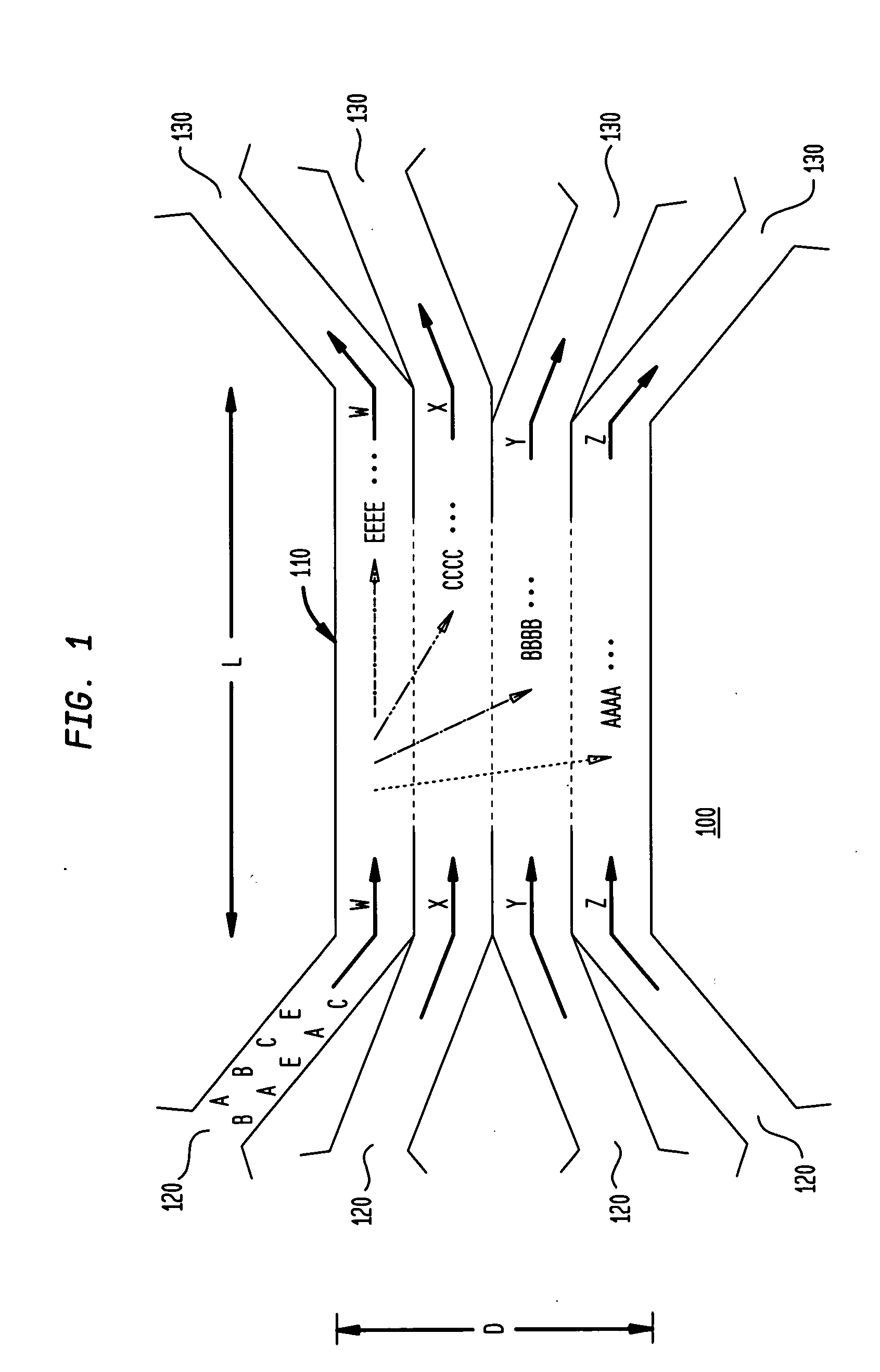

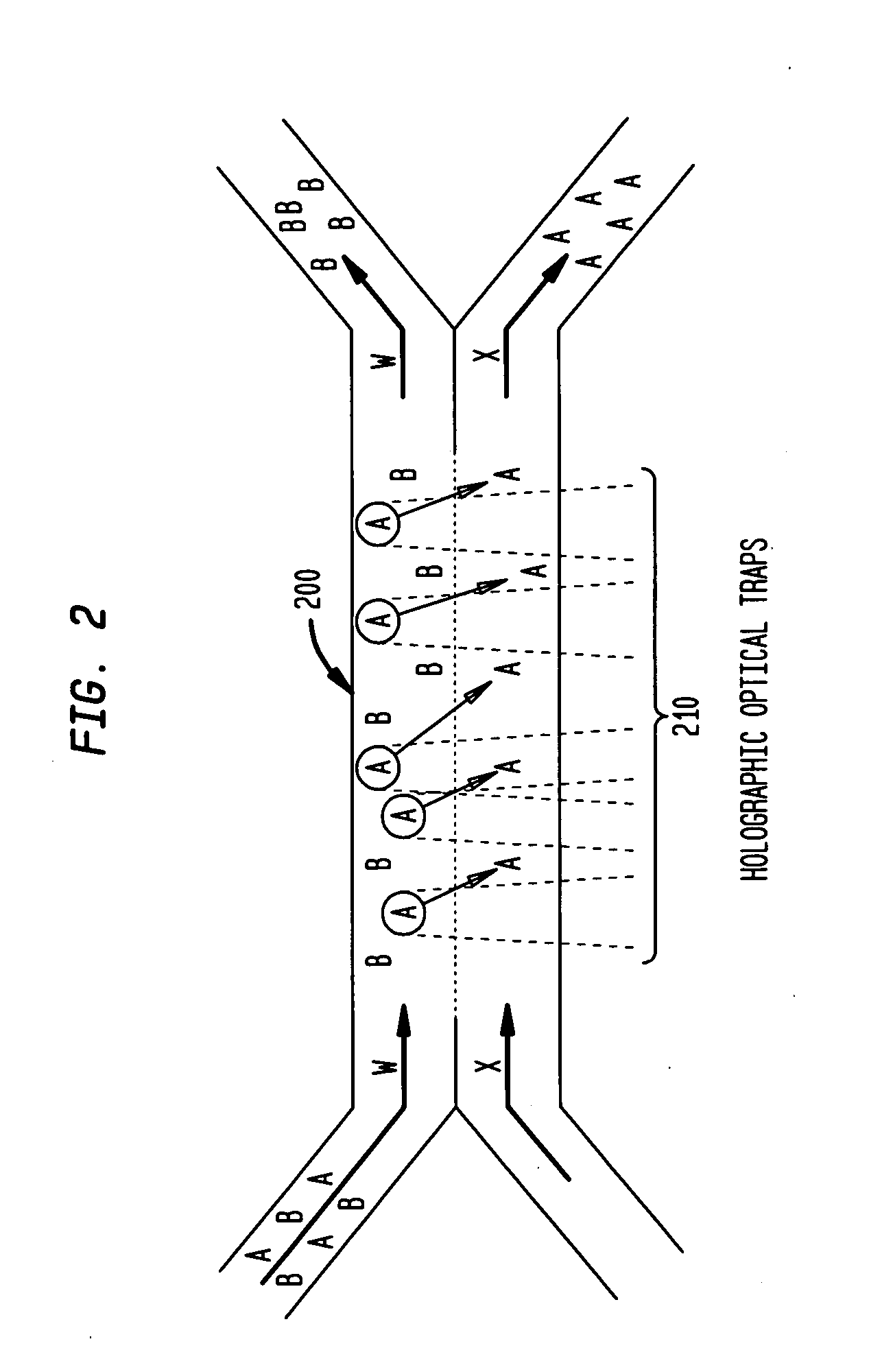

Multiple laminar flow-based rate zonal or isopycnic separation with holographic optical trapping of blood cells and other static components

ActiveUS20050061962A1Improve throughputSave a lot of timeDielectrophoresisOther blood circulation devicesCellular componentBlood component

The invention provides a method and apparatus for separating blood into components, may be expanded to include other types of cellular components, and can be combined with holographic optical manipulation or other forms of optical tweezing. One of the exemplary methods includes providing a first flow having a plurality of blood components; providing a second flow; contacting the first flow with the second flow to provide a first separation region; and differentially sedimenting a first blood cellular component of the plurality of blood components into the second flow while concurrently maintaining a second blood cellular component of the plurality of blood components in the first flow. The second flow having the first blood cellular component is then differentially removed from the first flow having the second blood cellular component. Holographic optical traps may also be utilized in conjunction with the various flows to move selected components from one flow to another, as part of or in addition to a separation stage.

Owner:ABS GLOBAL

Red blood cell processing systems and methods which control red blood cell hematocrit

InactiveUS7011761B2Optimize procedure timeAvoid adjustmentLiquid separation auxillary apparatusWater/sewage treatment by centrifugal separationMedicineHandling system

Processing systems and methods comprise a separation device that, in use, performs a separation process including separation of red blood cells from blood or a suspension containing red blood cells. The systems and methods include an outlet line coupled to the separation device to remove red blood cells from the separation device, at least in part, while the separation process occurs. A sensor associated with the outlet line senses hematocrit of red blood cells removed from the separation device and generates a sensed hematocrit output. A controller is coupled to the separation device to control removal of red blood cells from the separation device based, at least in part, upon the sensed hematocrit output.

Owner:FENWAL

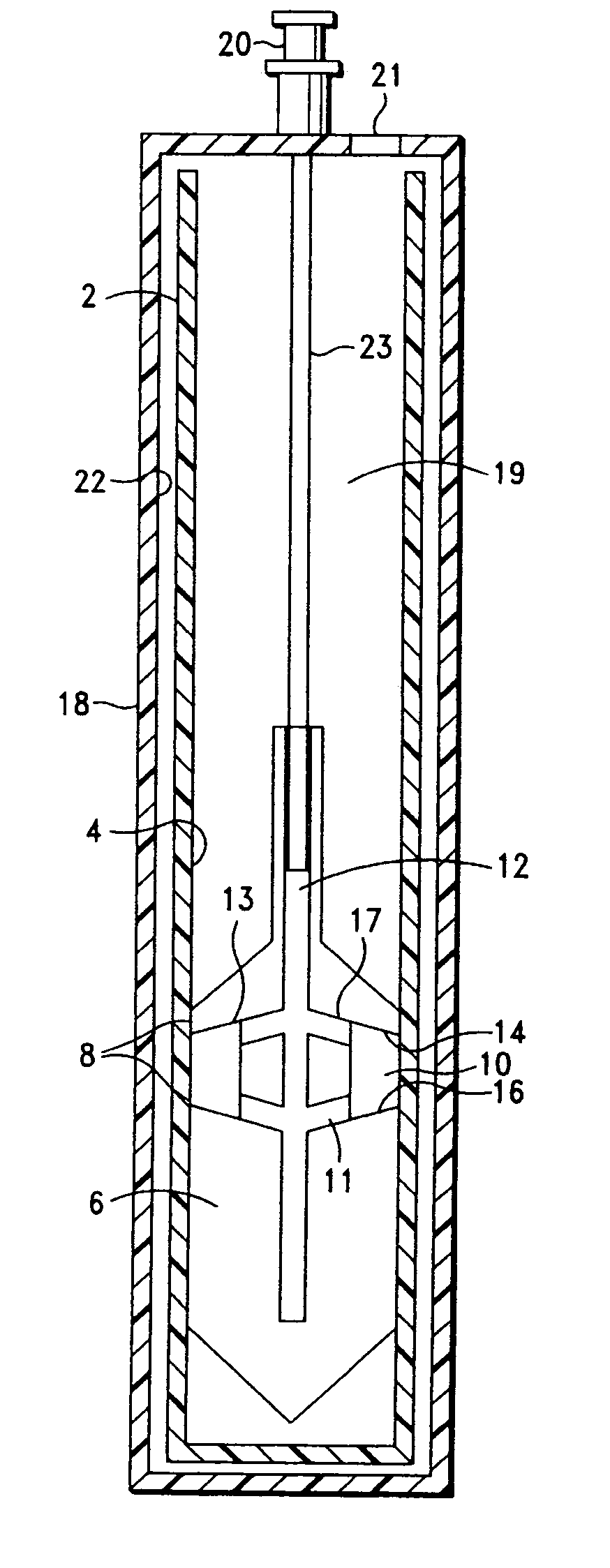

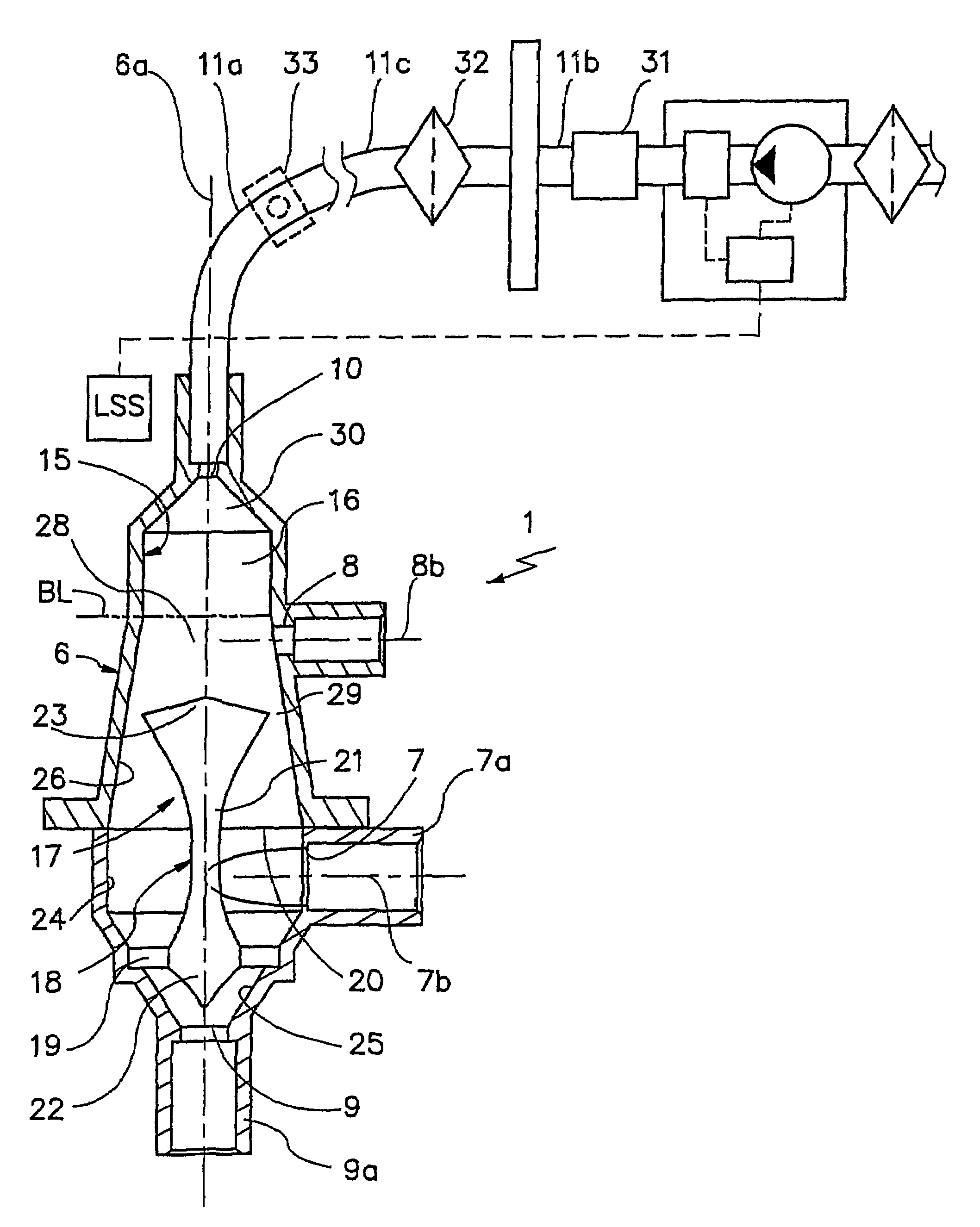

Gas separation devices

ActiveUS7517387B2Minimized volumeEasy to operateLiquid degasificationReversed direction vortexPhysiological fluidEffective surface

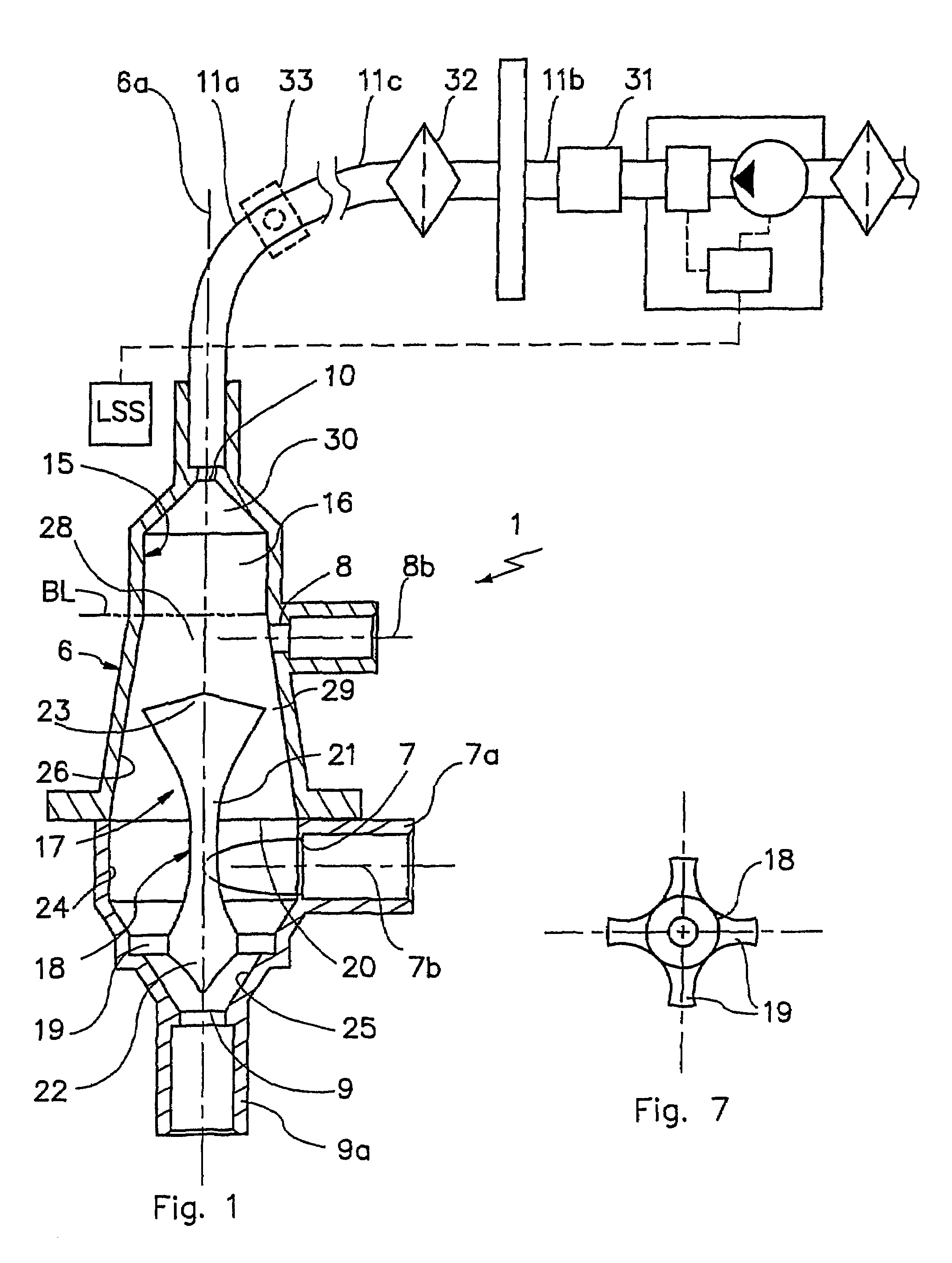

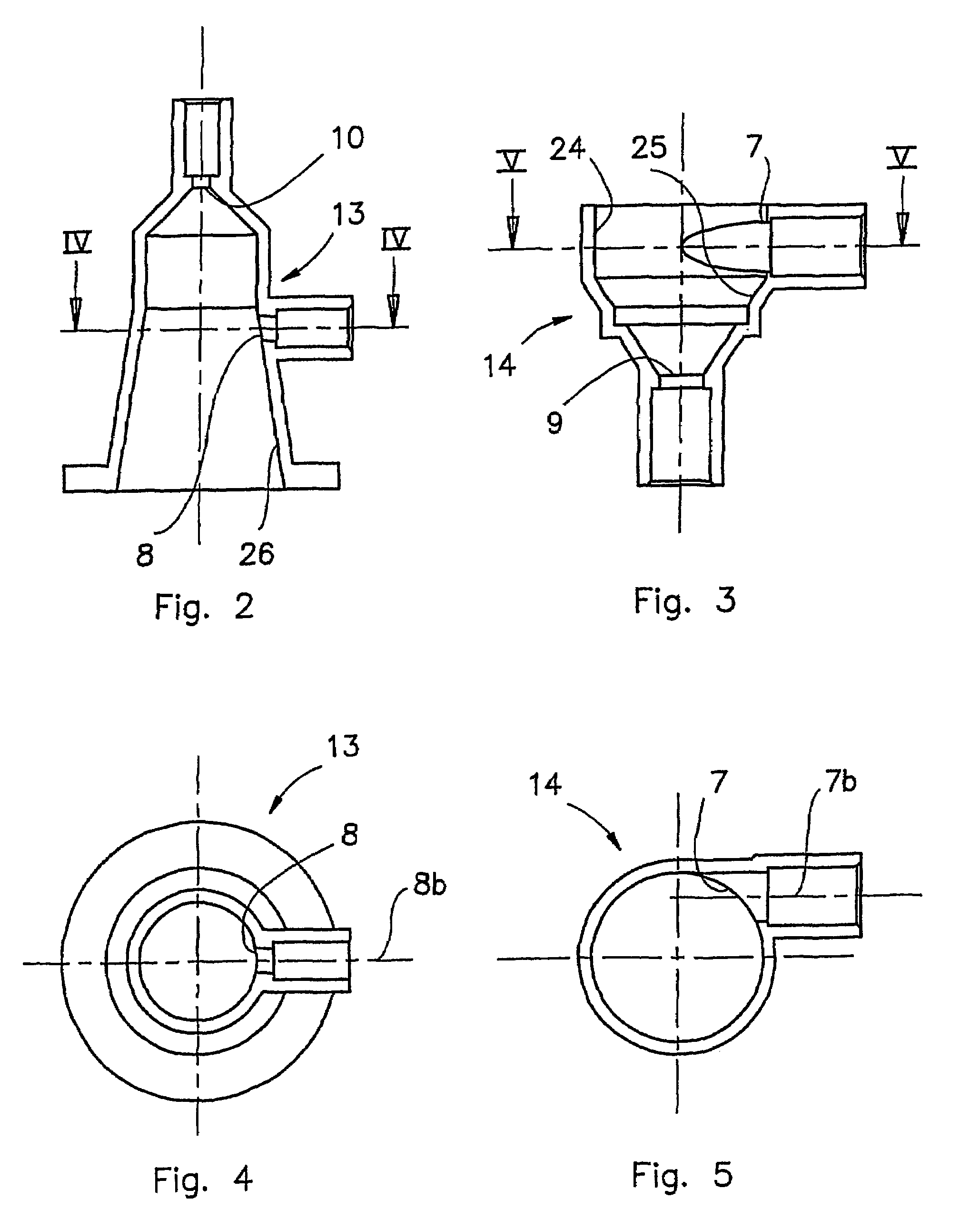

A description is given of a gas separation device for a physiological fluid, comprising a containing body (6) having at least a first inlet aperture (7) for a physiological fluid, positioned with a tangential direction of access, at least one outlet aperture (9) for the said fluid, spaced apart from the said inlet aperture, and a guide element (17) housed within the said body. The guide element (17) has a continuous active surface (15) designed to contact and guide the said fluid and delimits, together with the containing body (6), a first annular chamber (20) into which the first inlet aperture (7) opens directly.

Owner:GAMBRO LUNDIA AB

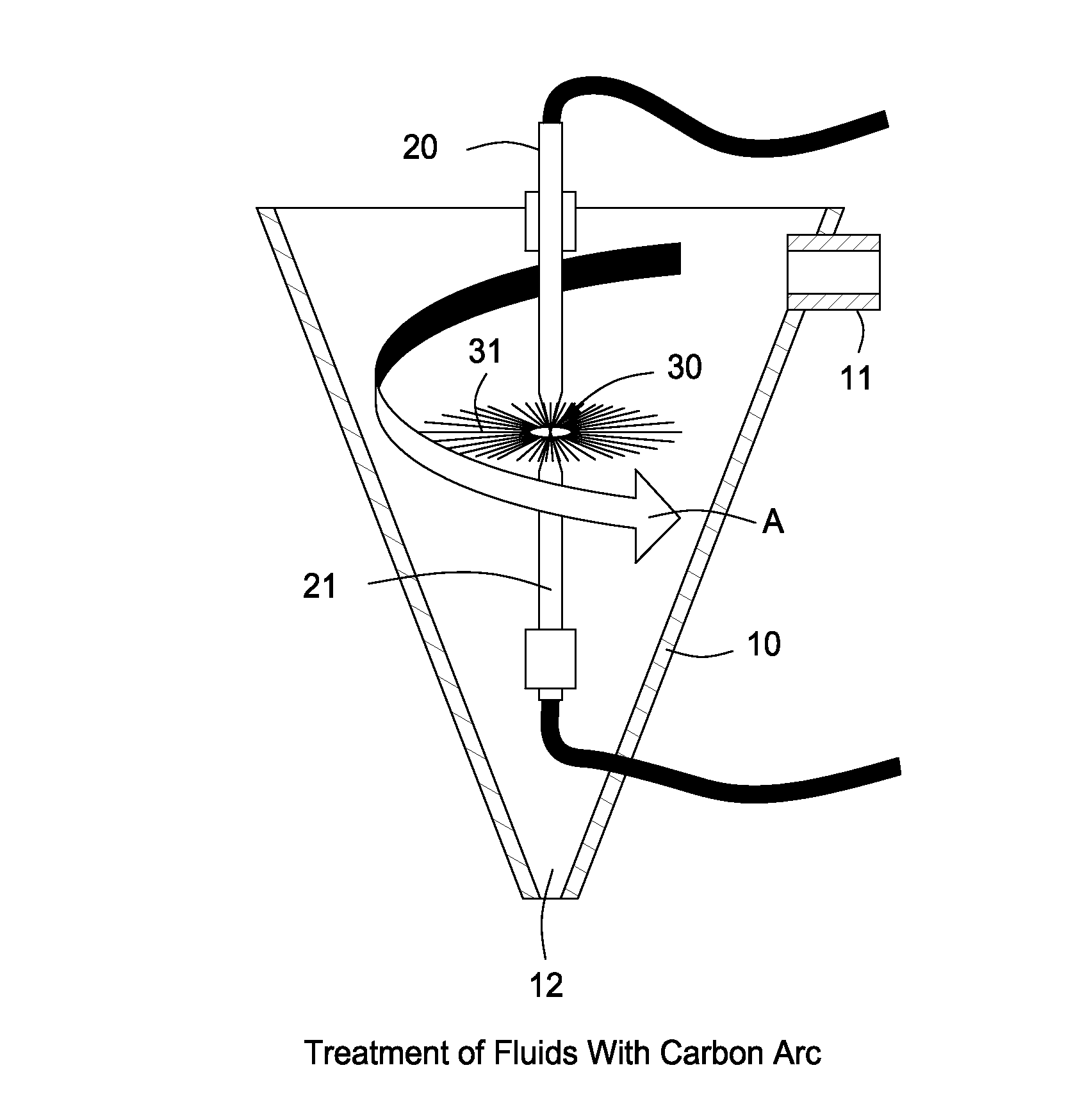

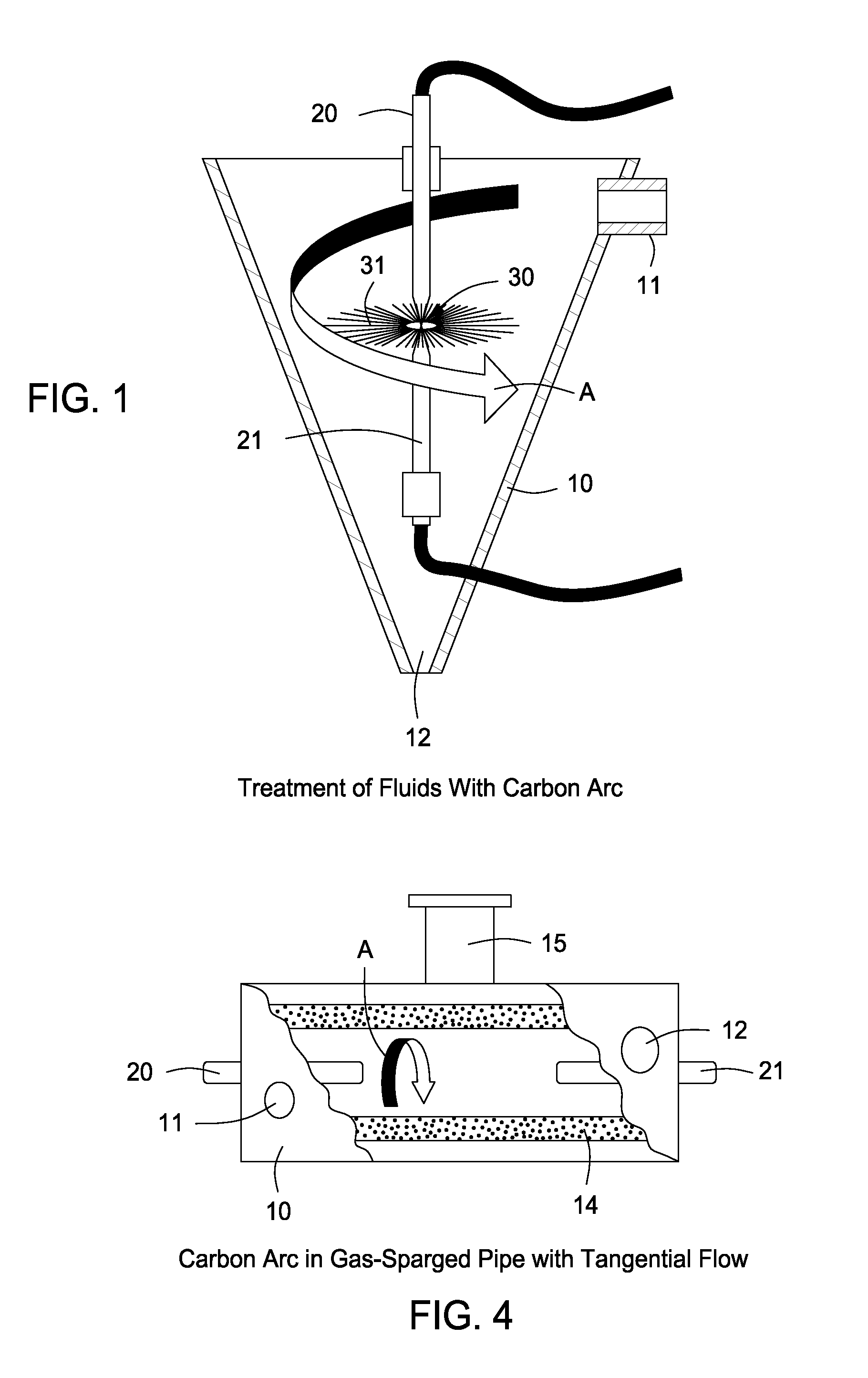

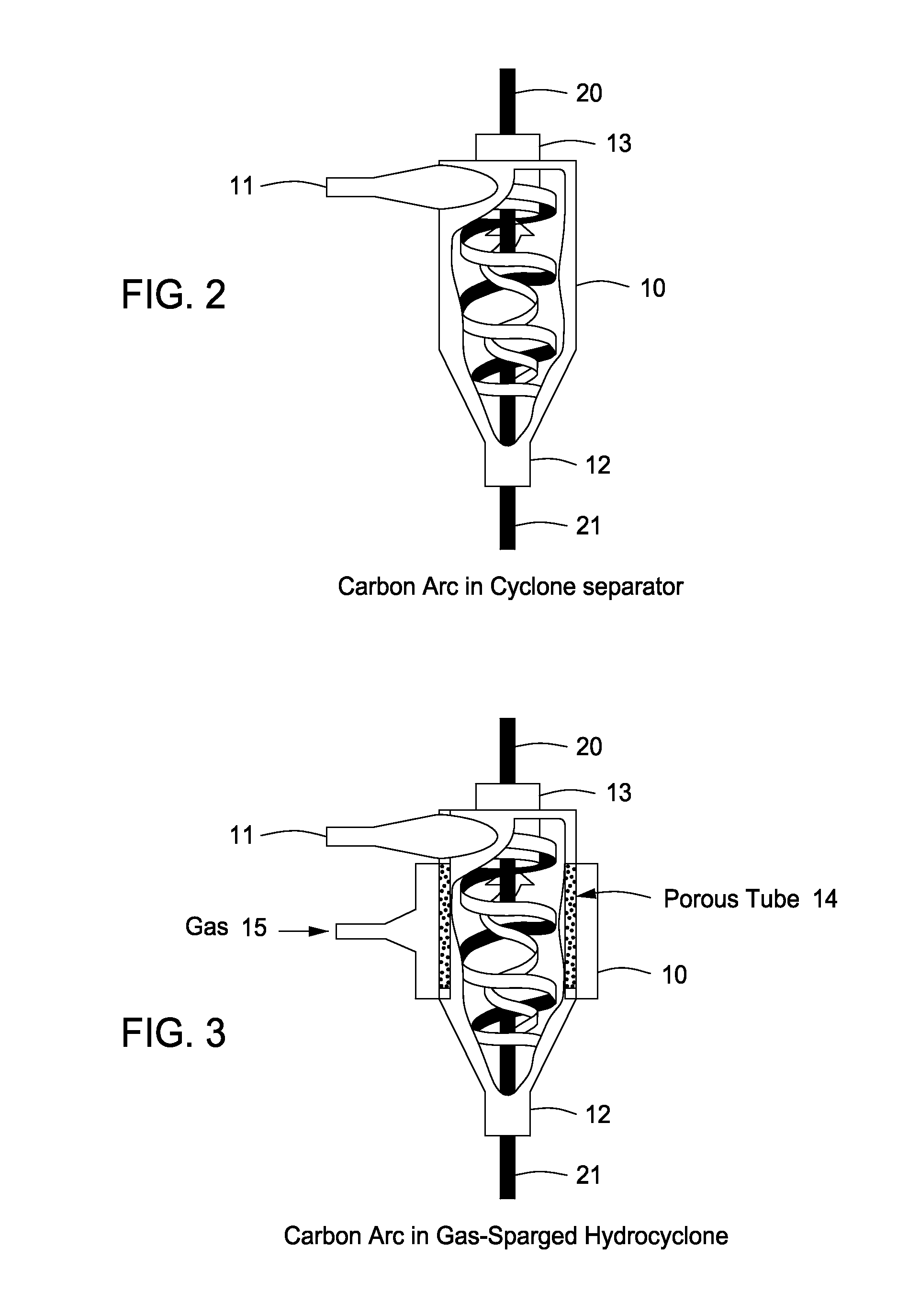

Treatment of fluids with wave energy from a carbon arc

ActiveUS7422695B2Superior wave energy deliveryEffective treatmentWater/sewage treatment by centrifugal separationReversed direction vortexCavitationPhysics

A method of and apparatus for treating liquids flowing in a thin film around a source of wave energy to directly expose the liquid to the wave energy, preferably generated in whole or part by an electrical arc between carbon electrodes. In addition to the wave energy generated by the electrical arc, energy generated by cavitation of the flowing liquid may be used in treating the liquid.

Owner:FORET PLASMA LABS

Integral air/oil coalescer for a centrifuge

InactiveUS7235177B2Combination devicesDispersed particle filtrationParticulatesMechanical engineering

A centrifuge for separating particulate matter from circulating fluid includes a centrifuge enclosure including a housing and a base joined together so as to define a hollow interior. A rotor is positioned in the hollow interior and is supported by the base in a manner to permit rotary motion of the rotor relative to the centrifuge enclosure. A coalescing filter assembly is secured to the rotor and is constructed and arranged for removing oil aerosol from a blowby gas which is introduced into the centrifuge. A roller bearing, press fit into the centrifuge housing, receives a portion of the coalescing filter assembly.

Owner:FLEETGUARD INC

Method for the production of a blood component composition

InactiveUS6899813B2Small sizeQuantity maximizationSurgical adhesivesOther blood circulation devicesBlood componentSpray nozzle

A system for the production of a blood component composition is provided. The system includes a centrifuge having a blood reservoir for receiving and separating a blood sample into multiple components; a dispenser disposed outside of the centrifuge having a first collection chamber containing an activation agent and a second collection chamber containing one or more medicinal agents; means for removing a first portion at least one separated blood component from the centrifuge to the first container and a second portion to the second collection chamber, wherein the first collection chamber activates the first portion and stores the resulting clot and thrombin; a filter for separating the thrombin from the clot; and a nozzle for entraining and mixing the thrombin with the second portion containing the one or more medicinal components.

Owner:ARTERIOCYTE MEDICAL SYST

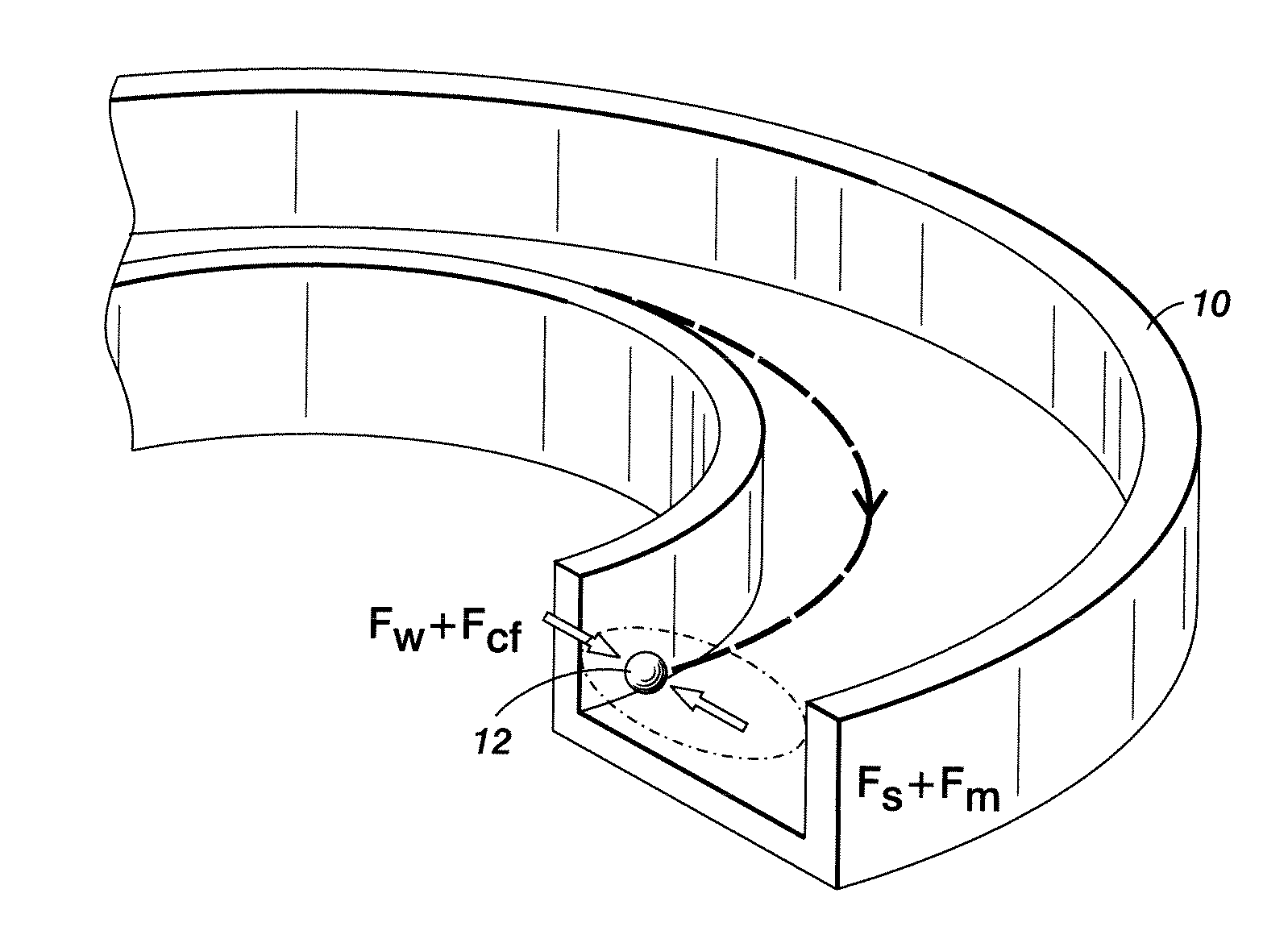

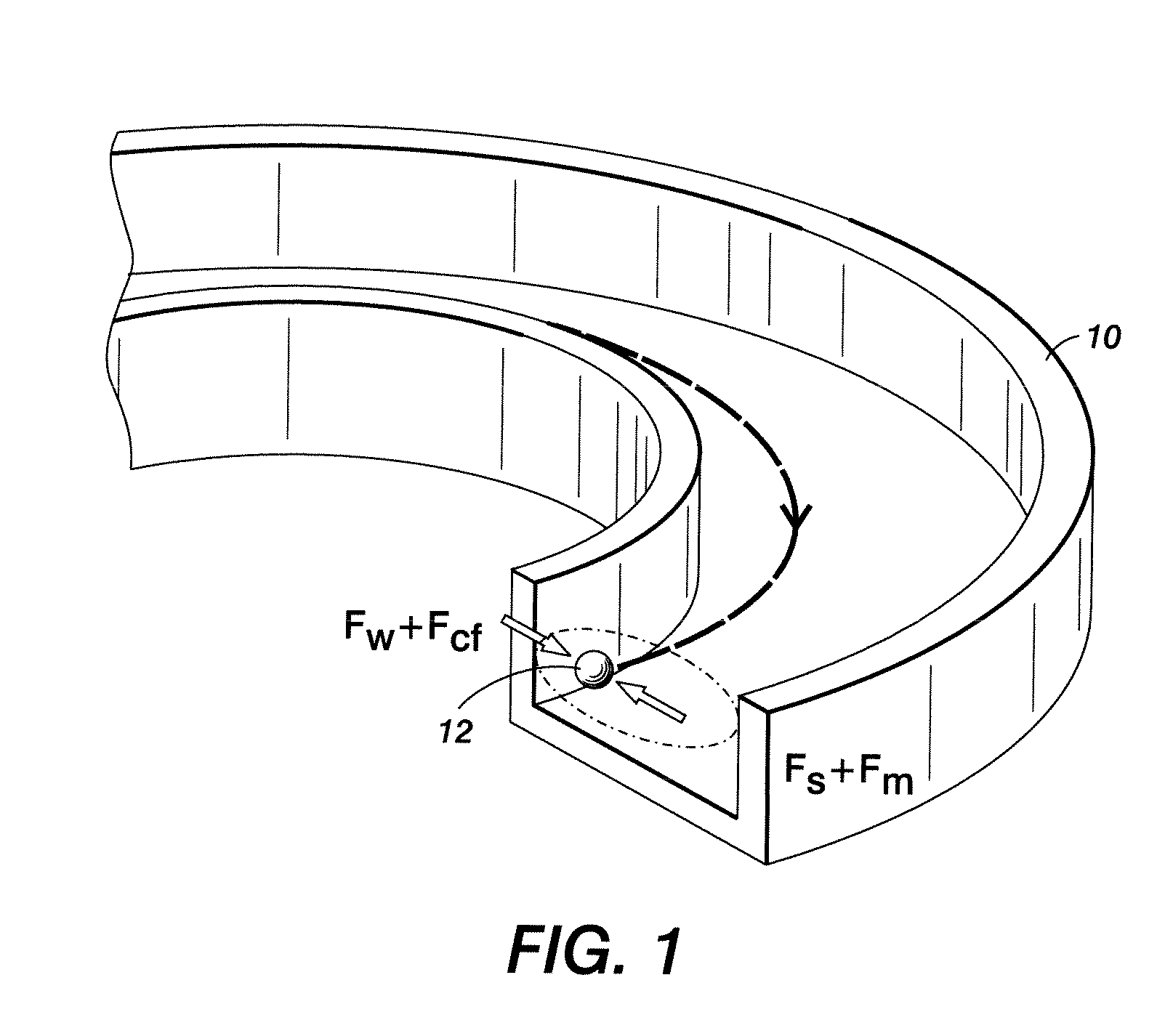

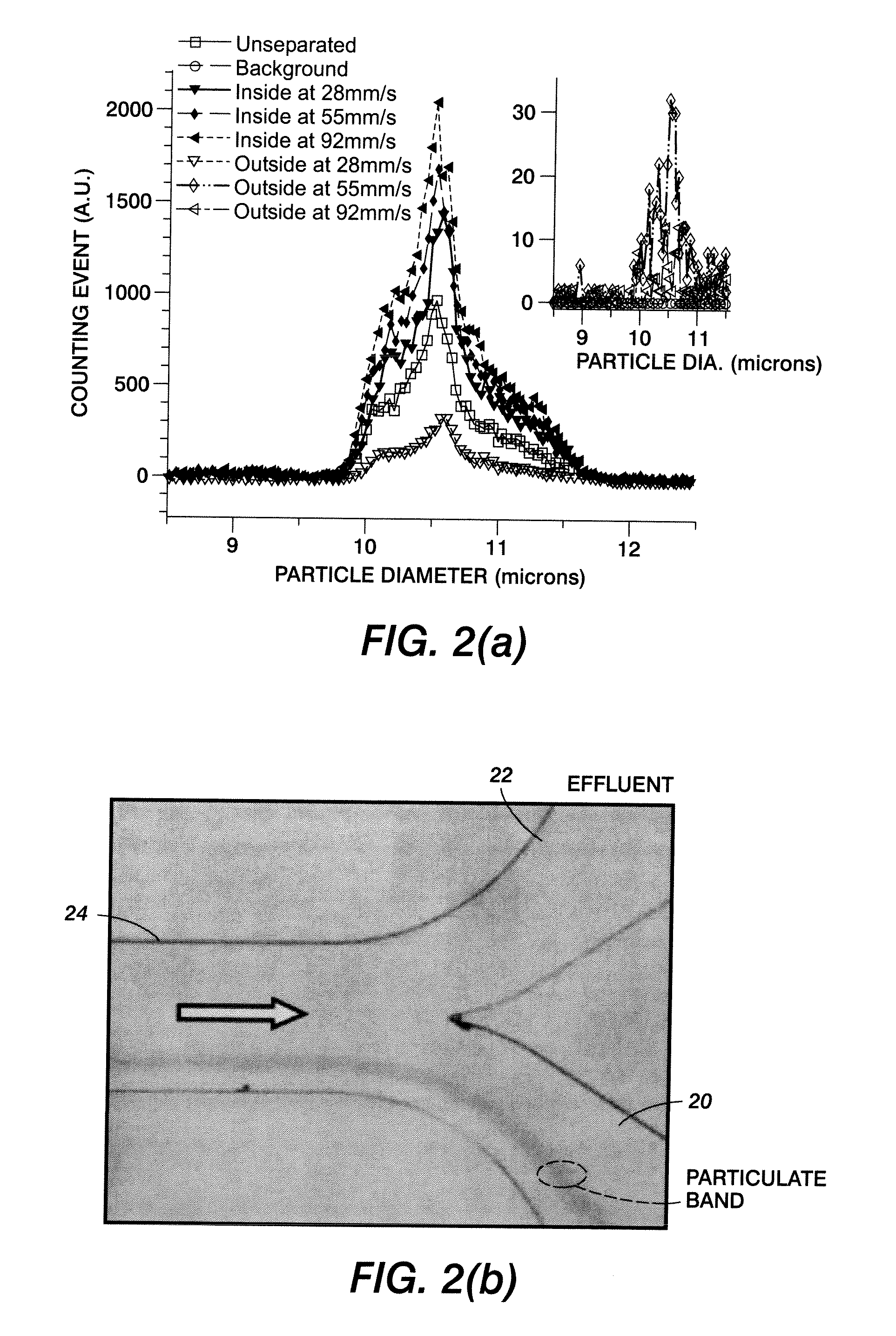

Fluidic Device and Method for Separation of Neutrally Buoyant Particles

ActiveUS20090114607A1Promote early formationWater/sewage treatment by centrifugal separationReversed direction vortexParticulatesParticle flow

A technique using a curved channel of a spiral device to introduce a centrifugal force upon neutrally buoyant particles flowing in a fluid, e.g. water, to facilitate improved separation of such particles from the fluid is provided. As these neutrally buoyant particles flow through the channel, a tubular pinch effect causes the particles to flow in a tubular band. The introduced centrifugal force perturbs the tubular band (e.g. forces the tubular band to flow in a manner offset from a center of the channel), resulting in an asymmetric inertial migration of the band toward the inner wall of the channel. This allows for focusing and compaction of suspended particulates into a narrow band for extraction. The separation principle contemplated herein implements a balance of the centrifugal and fluidic forces to achieve asymmetric inertial equilibrium near the inner sidewall.

Owner:XEROX CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com