Patents

Literature

747results about How to "Easy to vent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

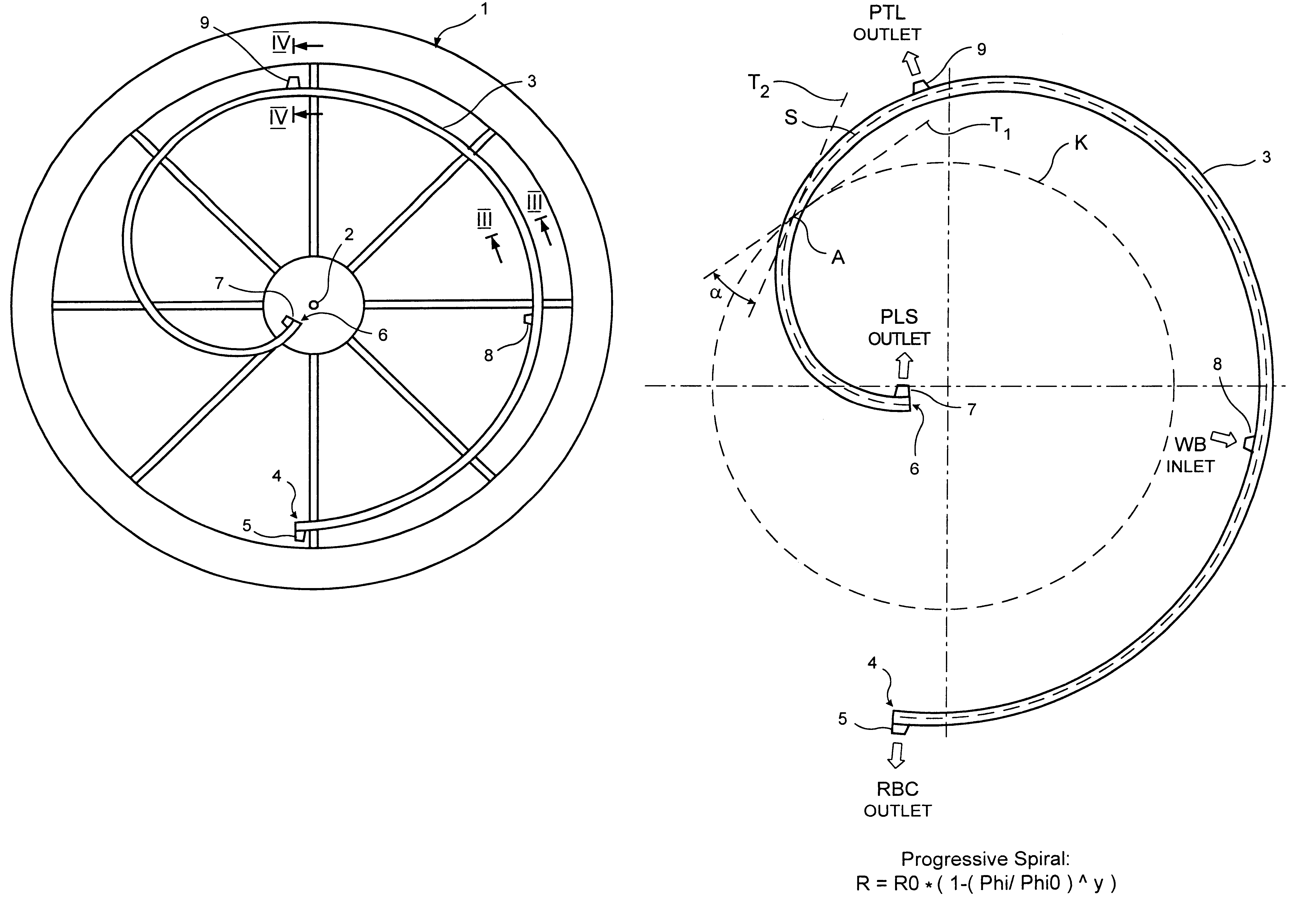

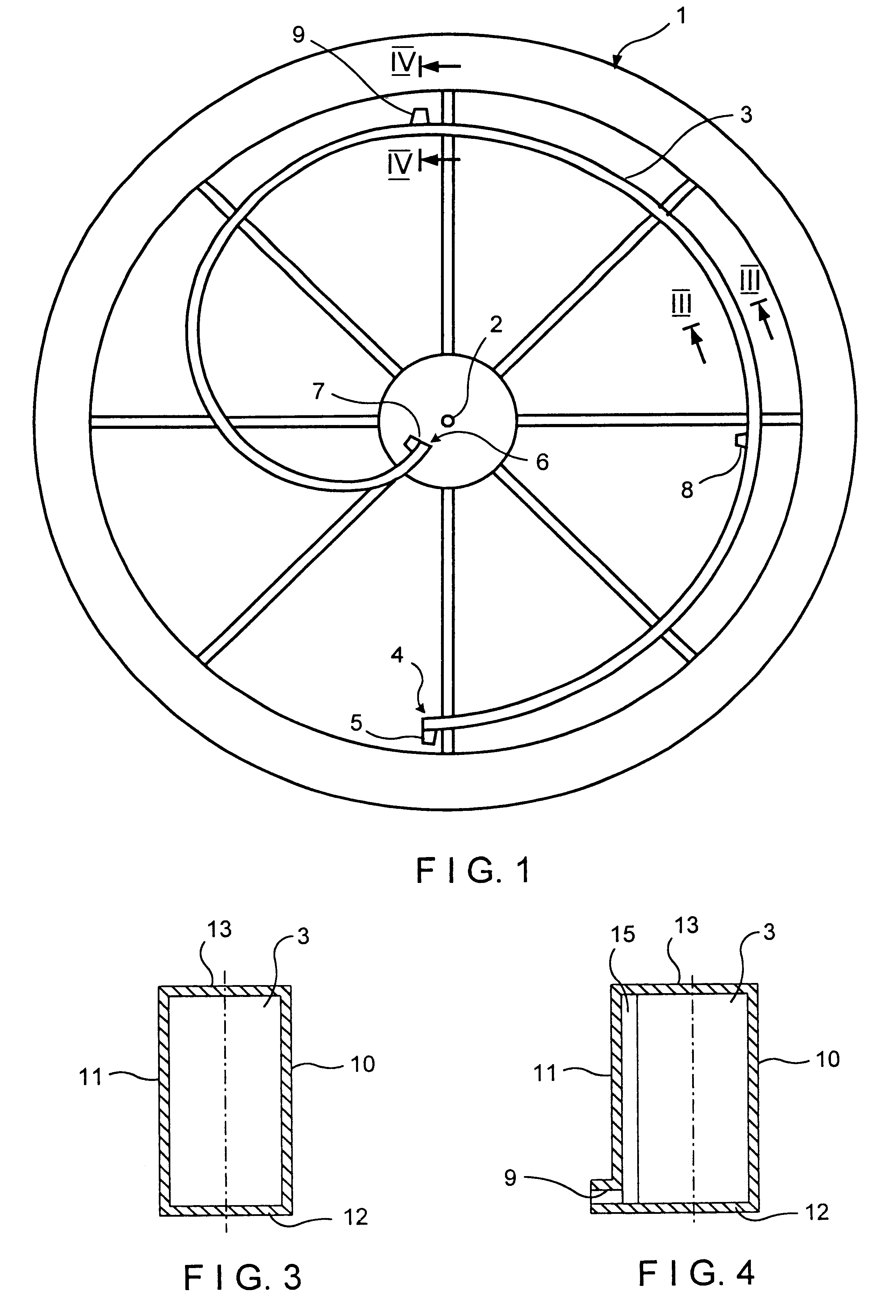

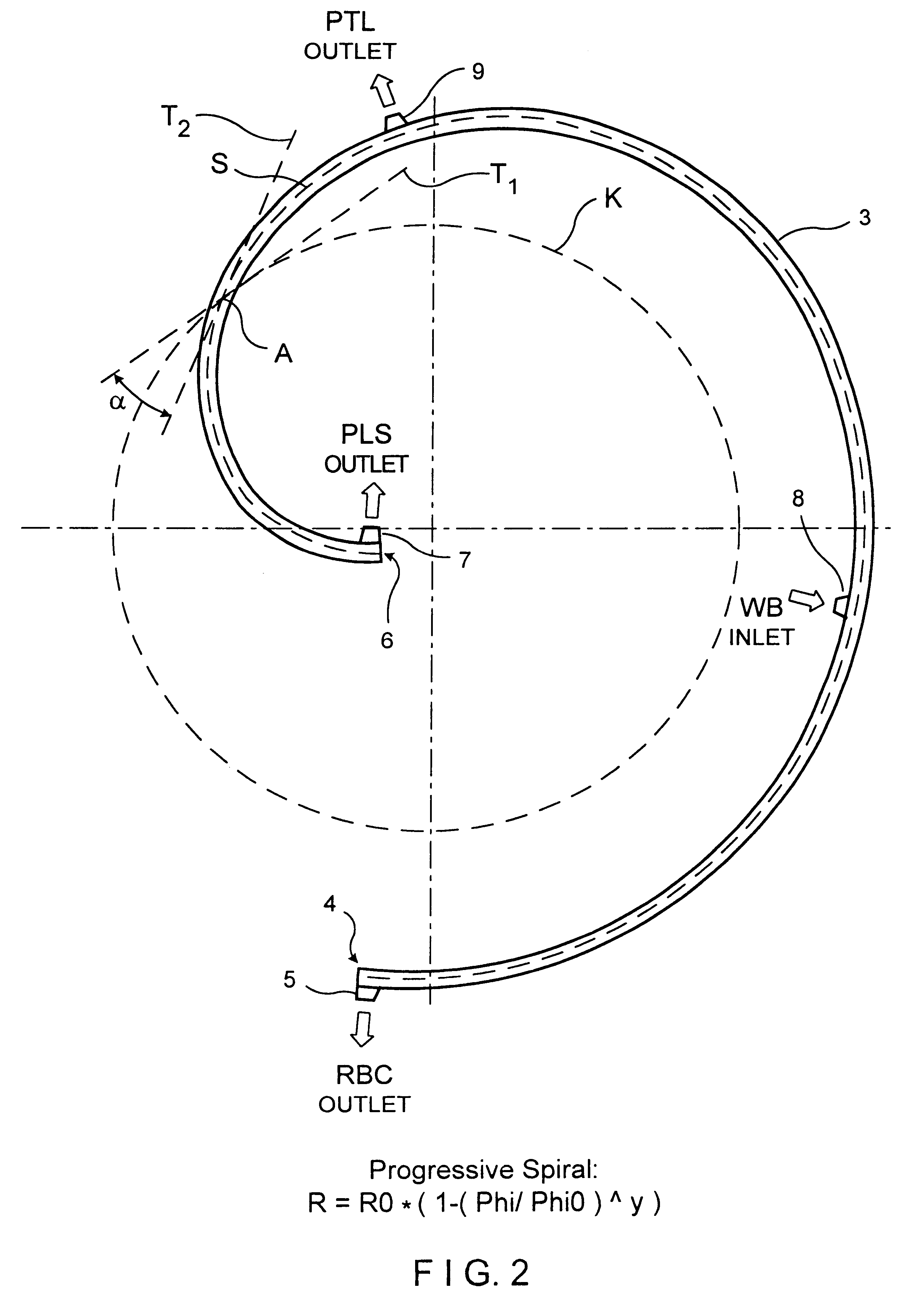

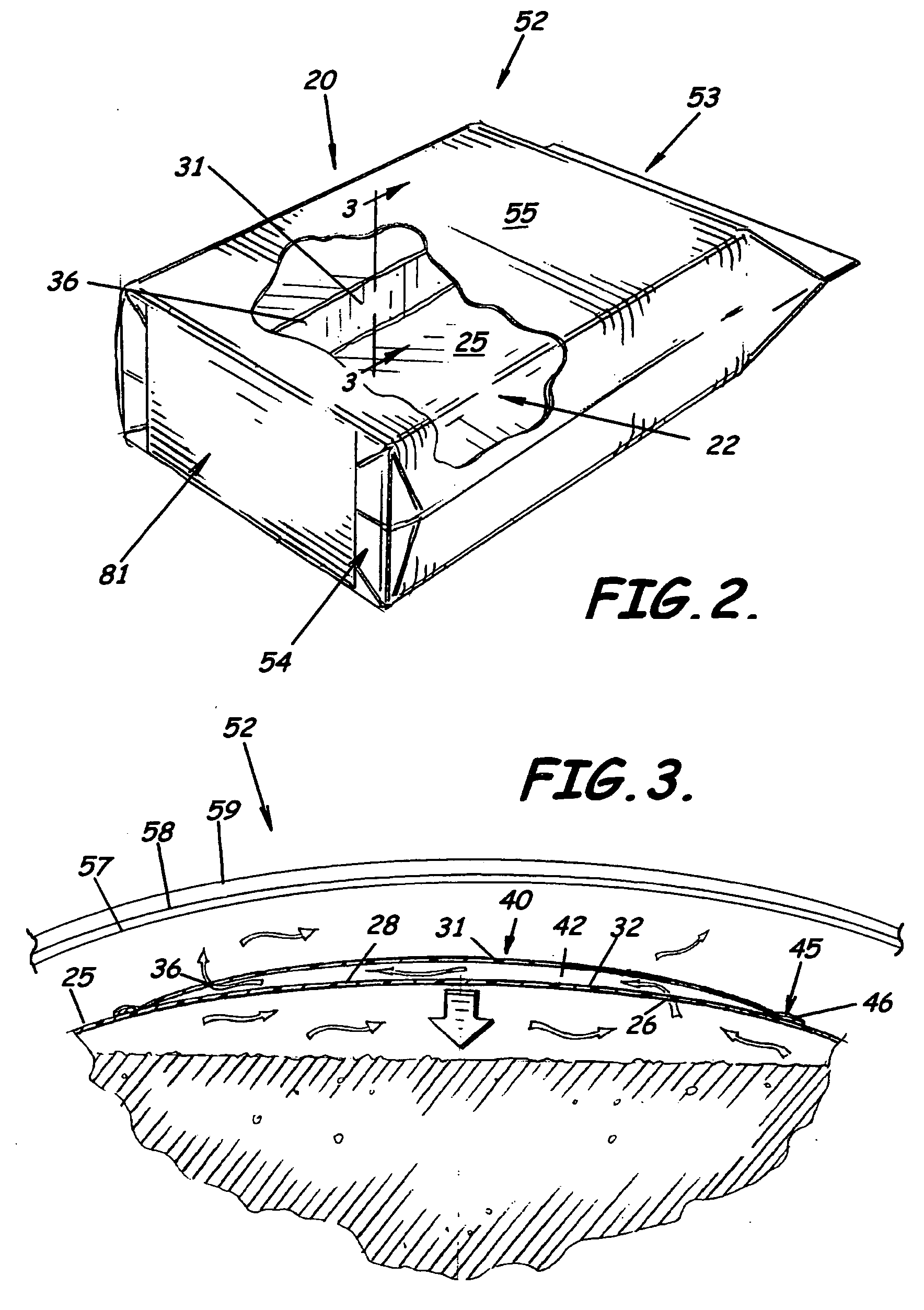

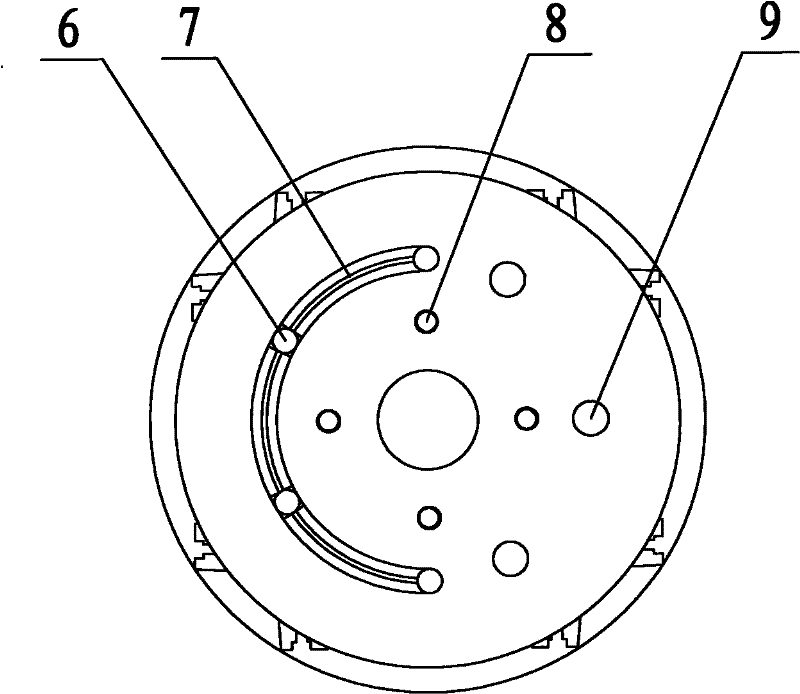

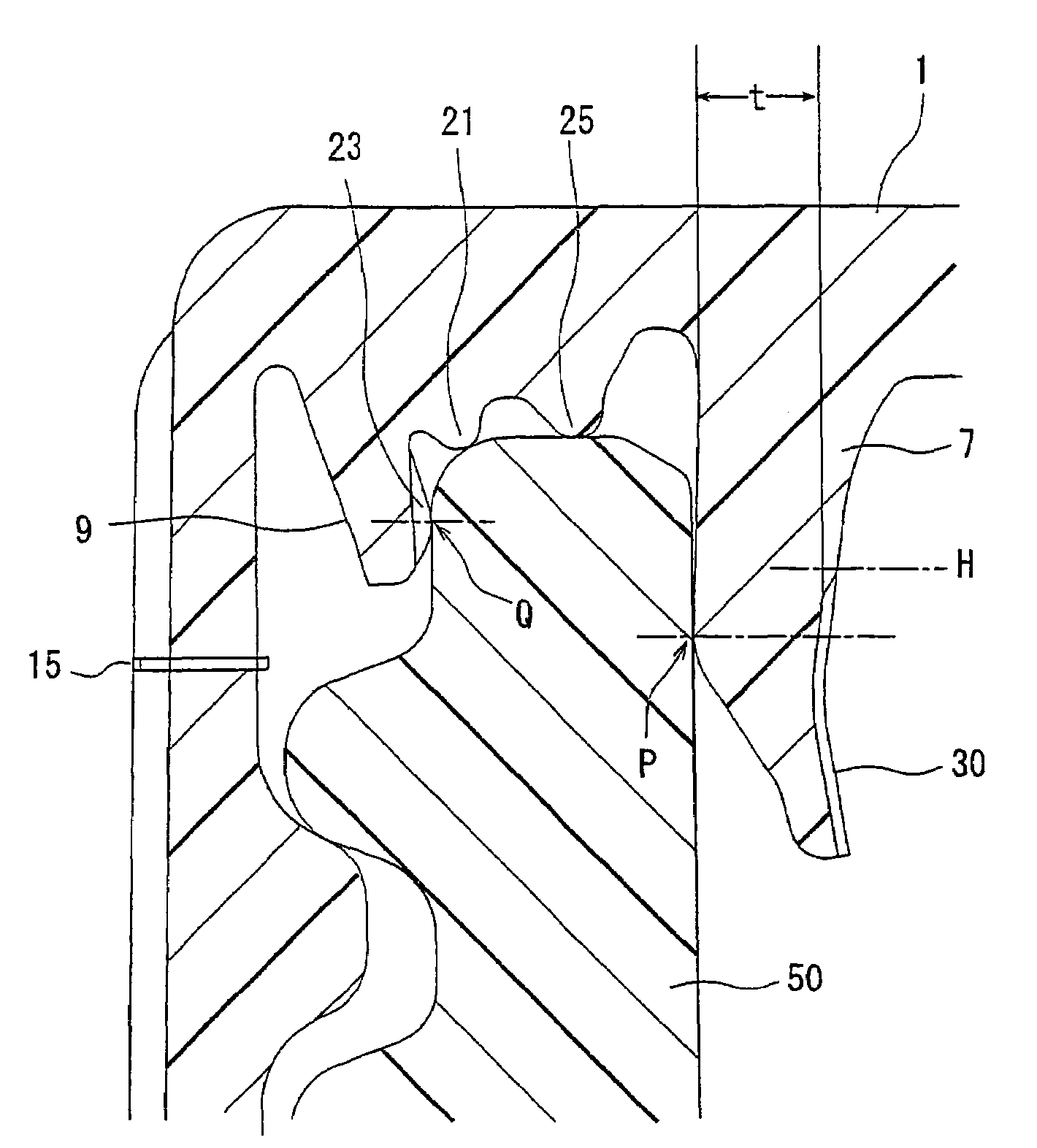

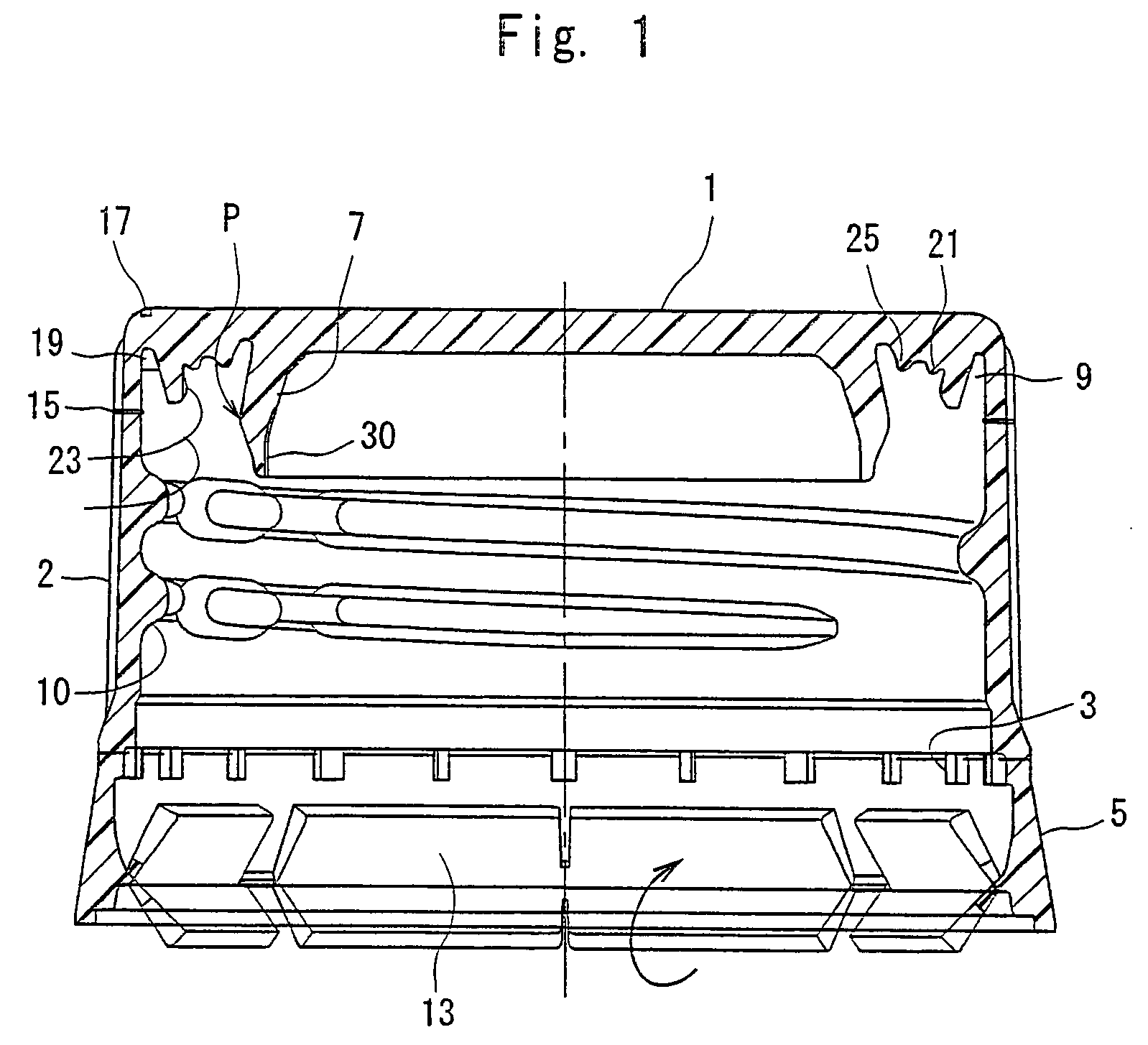

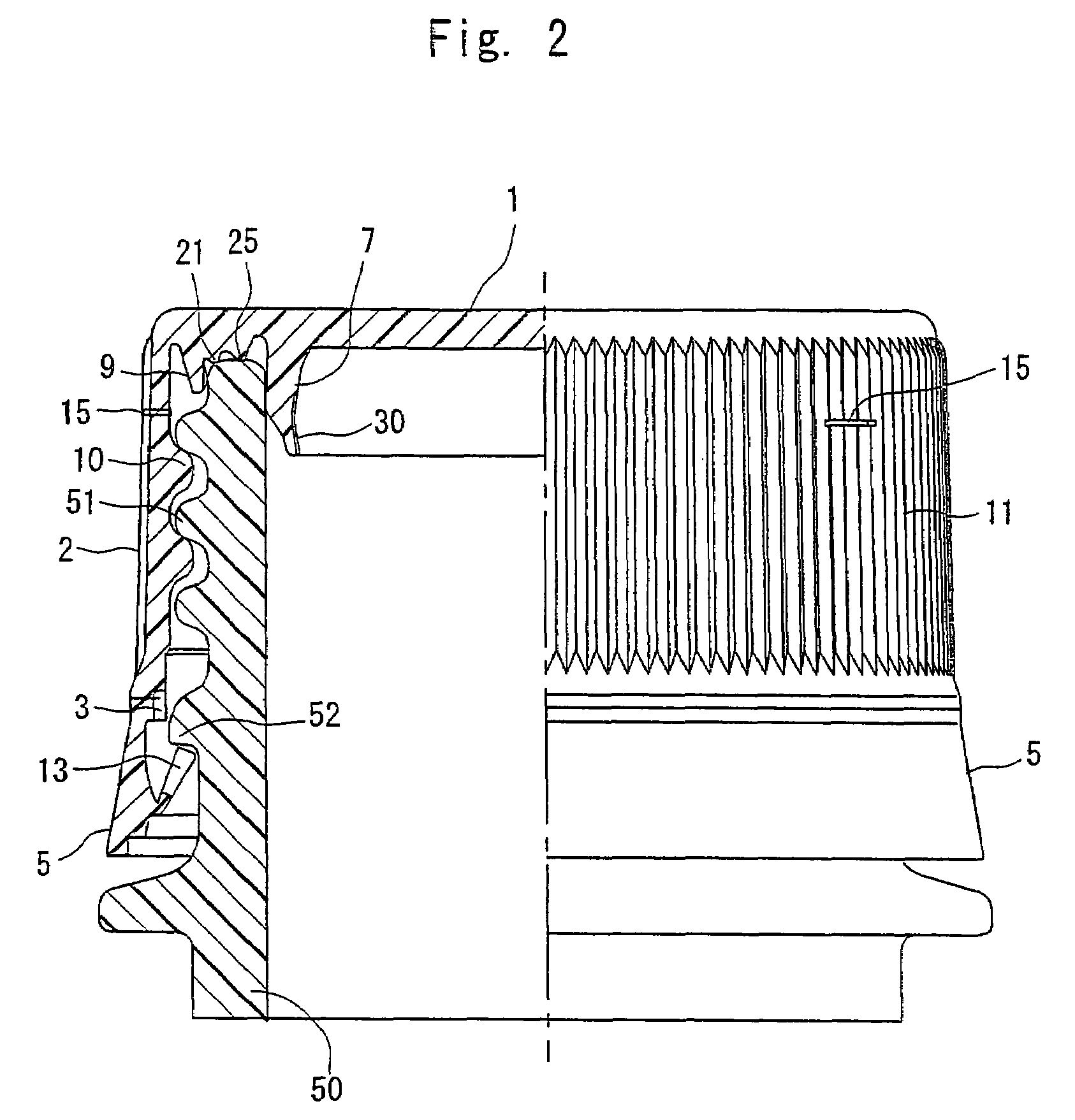

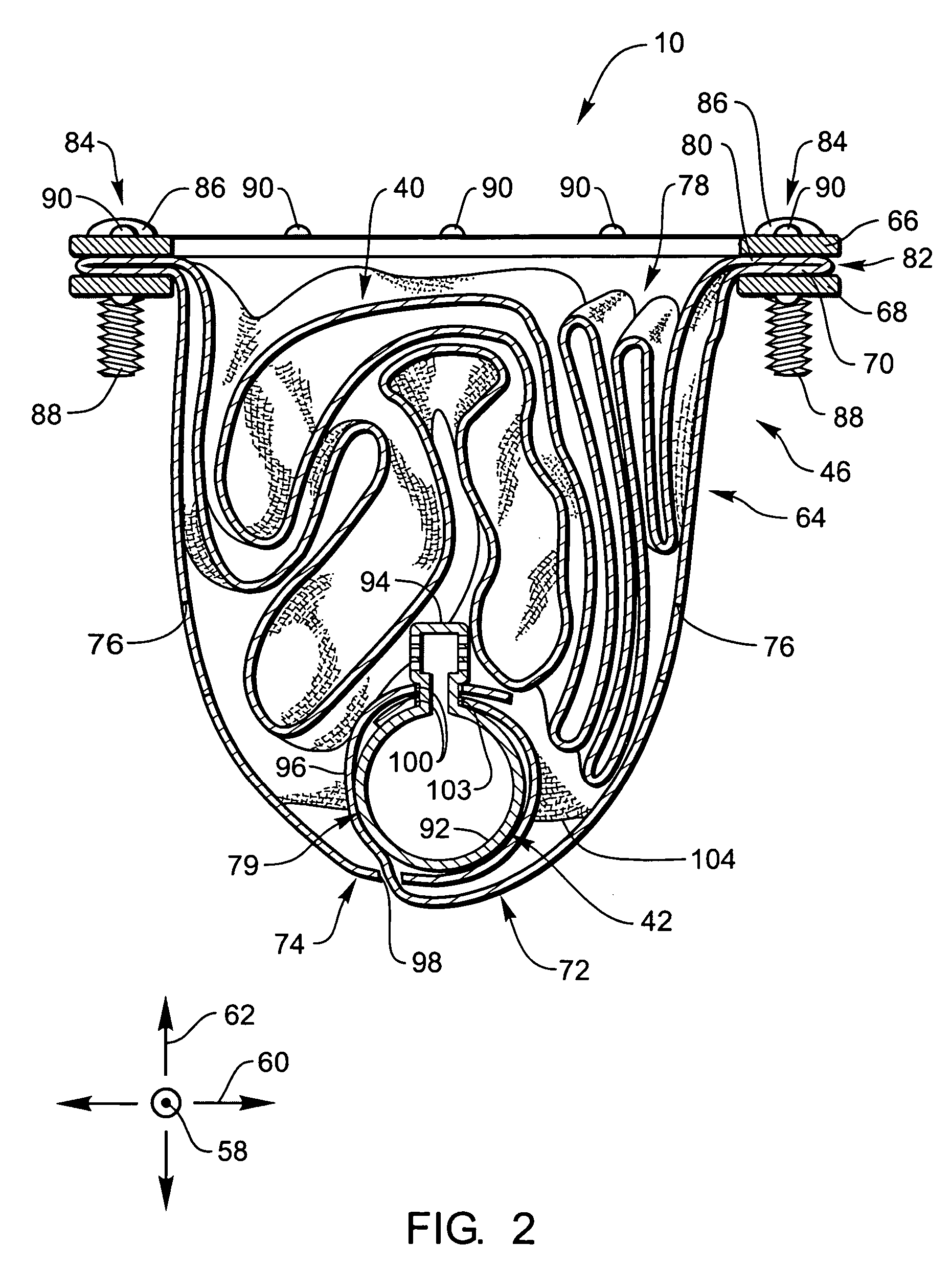

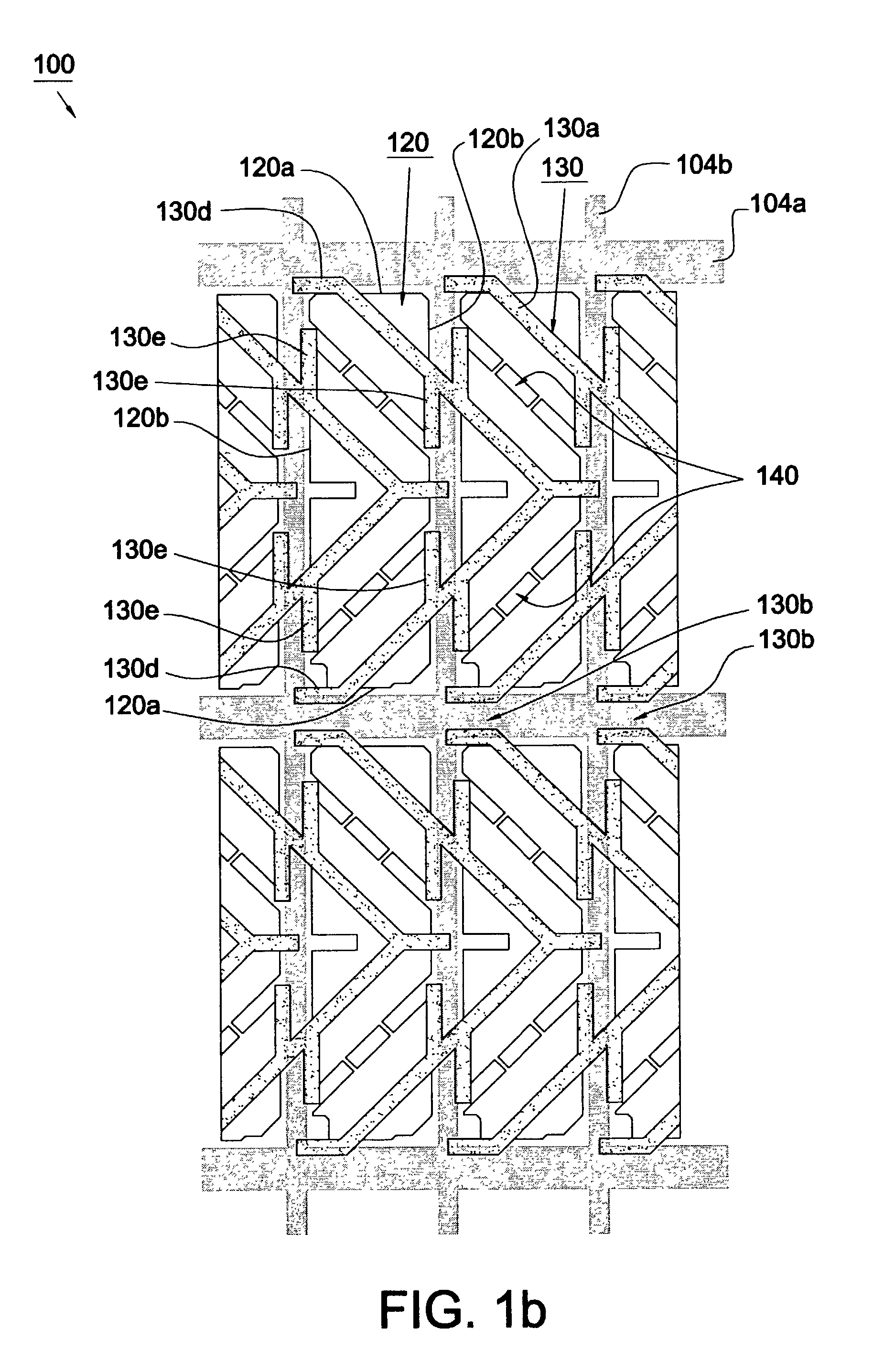

Centrifuge chamber for a cell separator having a spiral separation chamber

InactiveUS6277060B1Increase valueEasy to ventWithdrawing sample devicesDispersed particle separationEngineeringCell separation

A centrifuge chamber of a cell separator having a separation channel with an inlet to introduce the cell suspension and at least one outlet to withdraw a fraction of the cell suspension is described. The cell suspension can be blood. The separation channel is shaped like a spiral extending from the radially outer end of the channel to the radially inner end of the channel, with a progressive slope. The centrifuge chamber allows a uniform, contaminant free separation of the cell suspension into its components.

Owner:FRESENIUS AG

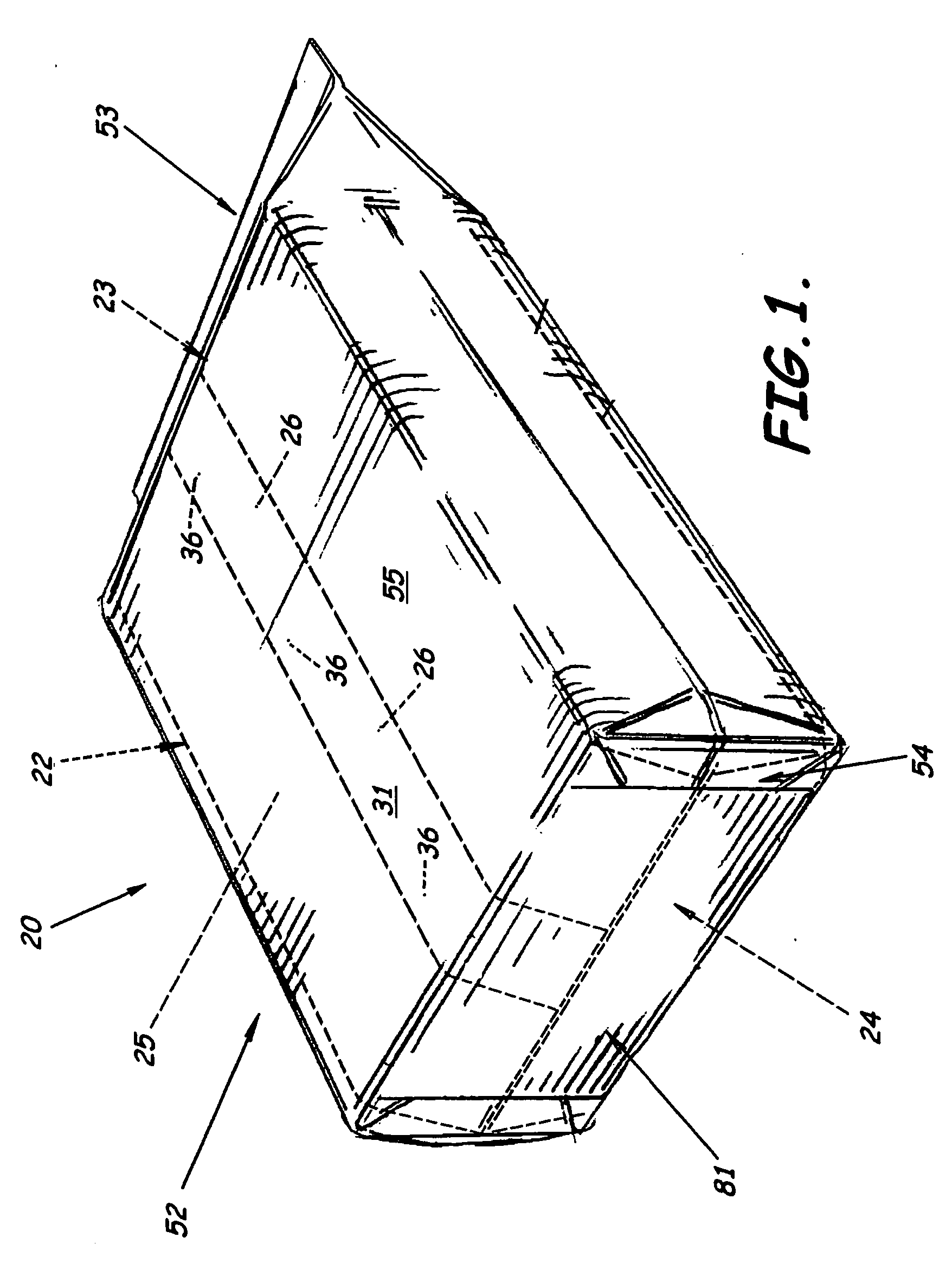

Method of forming a vented bag

Owner:EXOPACK TECH

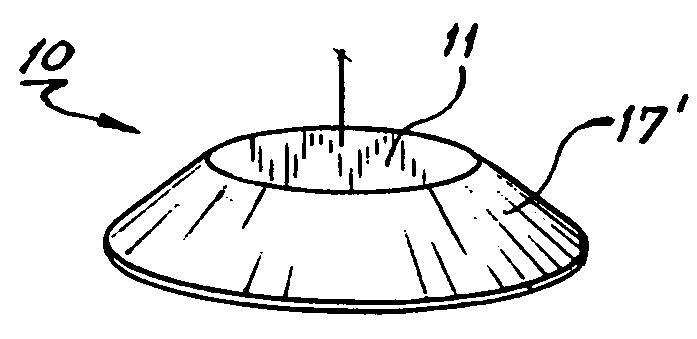

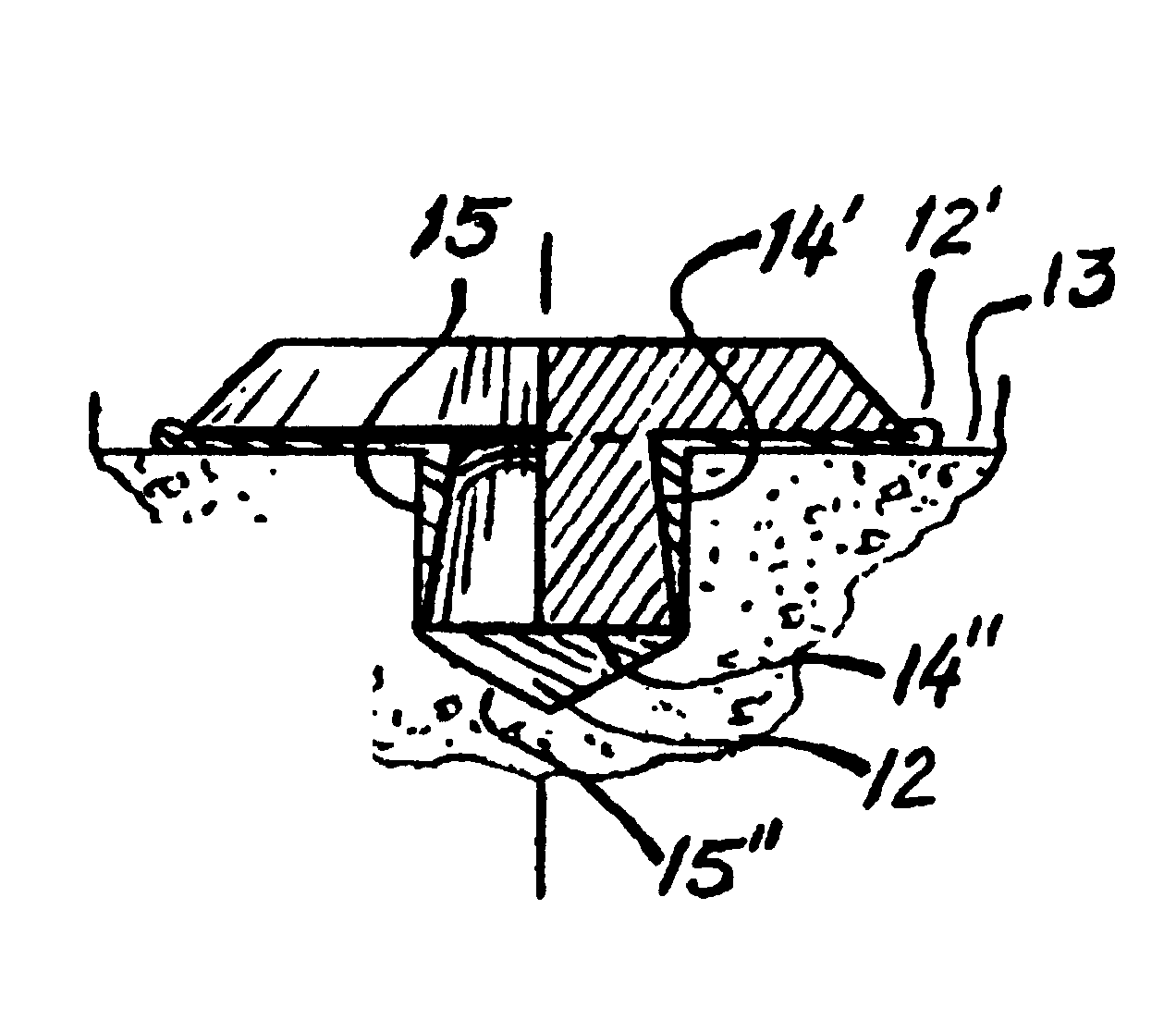

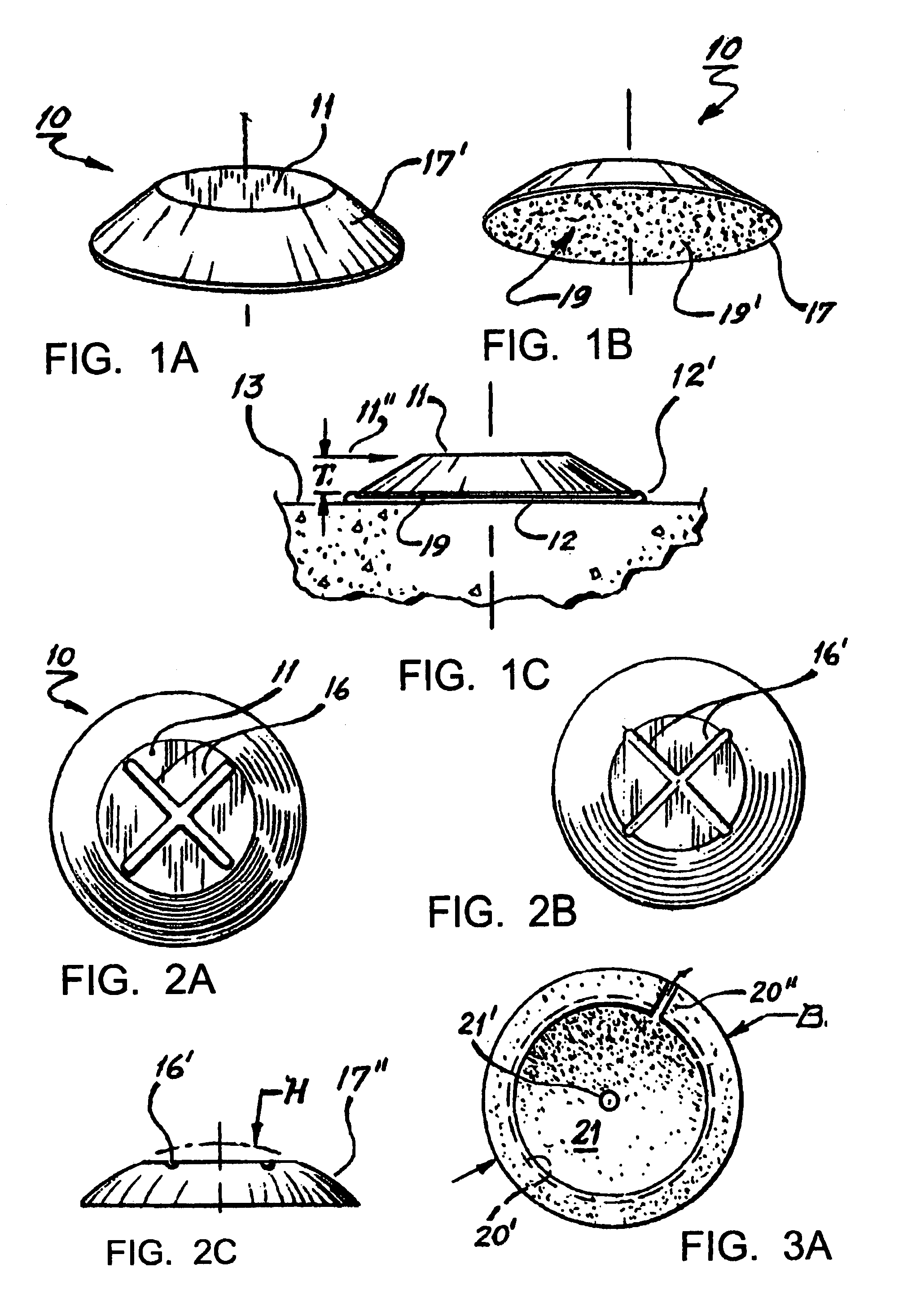

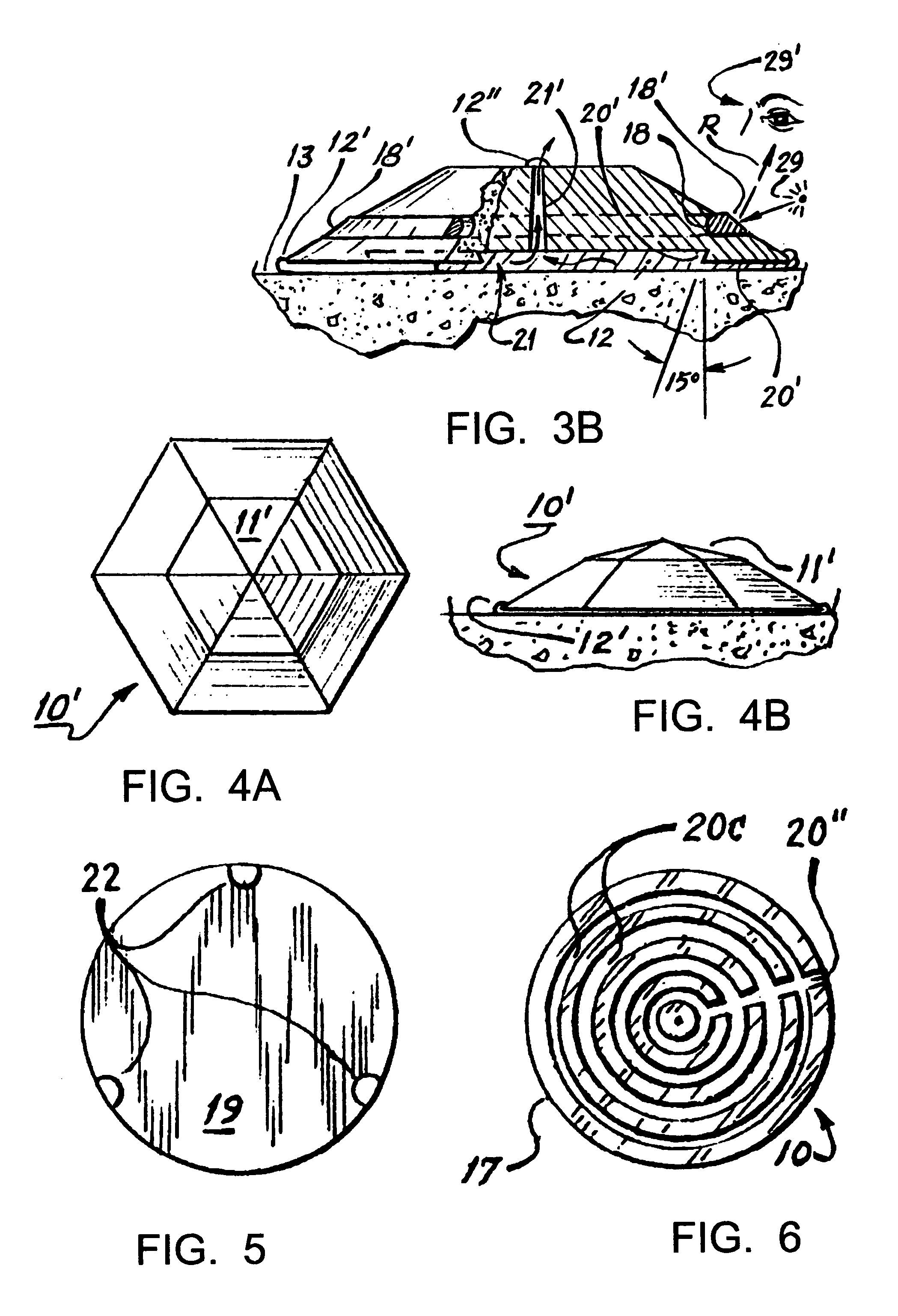

Detectable warning-dots demarkation for pedestrian safety

ActiveUS20060039752A1Improved pedestrian foot tractionImprove toughnessPaving detailsTraffic signalsTouch PerceptionWheelchair

A novel small quasi-hemispherical truncated-dome modular-dot like device, which can be readily affixed to pavement in a Federally-mandated pattern via a special hole / matrix-stencil;—the resulting demarkations thereby serving to alert the Legally-blind (as well as Guide-dogs, persons in wheelchairs, and otherwise pre-occupied non-handicapped individuals) their pedestrian-pathway is entering into a potentially dangerous transition area typically crossed by a motor-vehicle pathway. The individual so called DW-DOTS™ are resilient circular low-profile devices having an annular-ramp configuration, and thus standing out only sufficiently above a foot-surface as to enable foot-tactile detection, yet not pose the potential tripping hazzard known to embedded-mats. This novel safety-button offers a desired permanent contrasting-color, plus has a definition and rugged permanency not known to poured-dot installations. The disclosure sets forth various generic-variant structural embodiments, as well as the preferred method of attachment to a walkway-pavement surface.

Owner:HYAMS CHRISTOPHER A

Detectable warning-dots demarkation for pedestrian safety

ActiveUS7249911B2Great tractionImprove toughnessPaving detailsTraffic signalsWheelchairTouch Perception

A novel small quasi-hemispherical truncated-dome modular-dot like device, which can be readily affixed to pavement in a Federally-mandated pattern via a special hole / matrix-stencil;—the resulting demarkations thereby serving to alert the Legally-blind (as well as Guide-dogs, persons in wheelchairs, and otherwise pre-occupied non-handicapped individuals) their pedestrian-pathway is entering into a potentially dangerous transition area typically crossed by a motor-vehicle pathway. The individual so called DW-DOTS™ are resilient circular low-profile devices having an annular-ramp configuration, and thus standing out only sufficiently above a foot-surface as to enable foot-tactile detection, yet not pose the potential tripping hazzard known to embedded-mats. This novel safety-button offers a desired permanent contrasting-color, plus has a definition and rugged permanency not known to poured-dot installations. The disclosure sets forth various generic-variant structural embodiments, as well as the preferred method of attachment to a walkway-pavement surface.

Owner:HYAMS CHRISTOPHER A

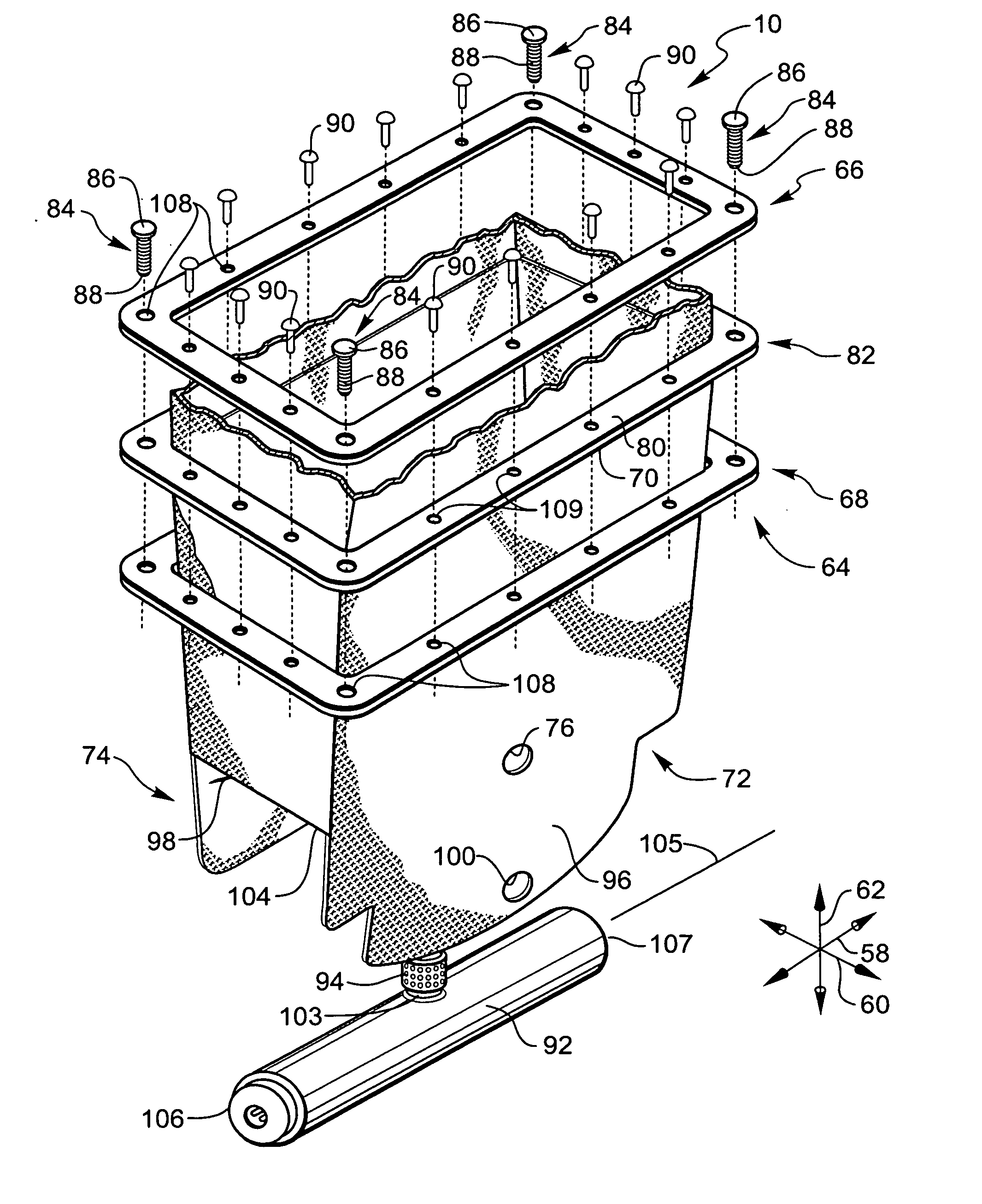

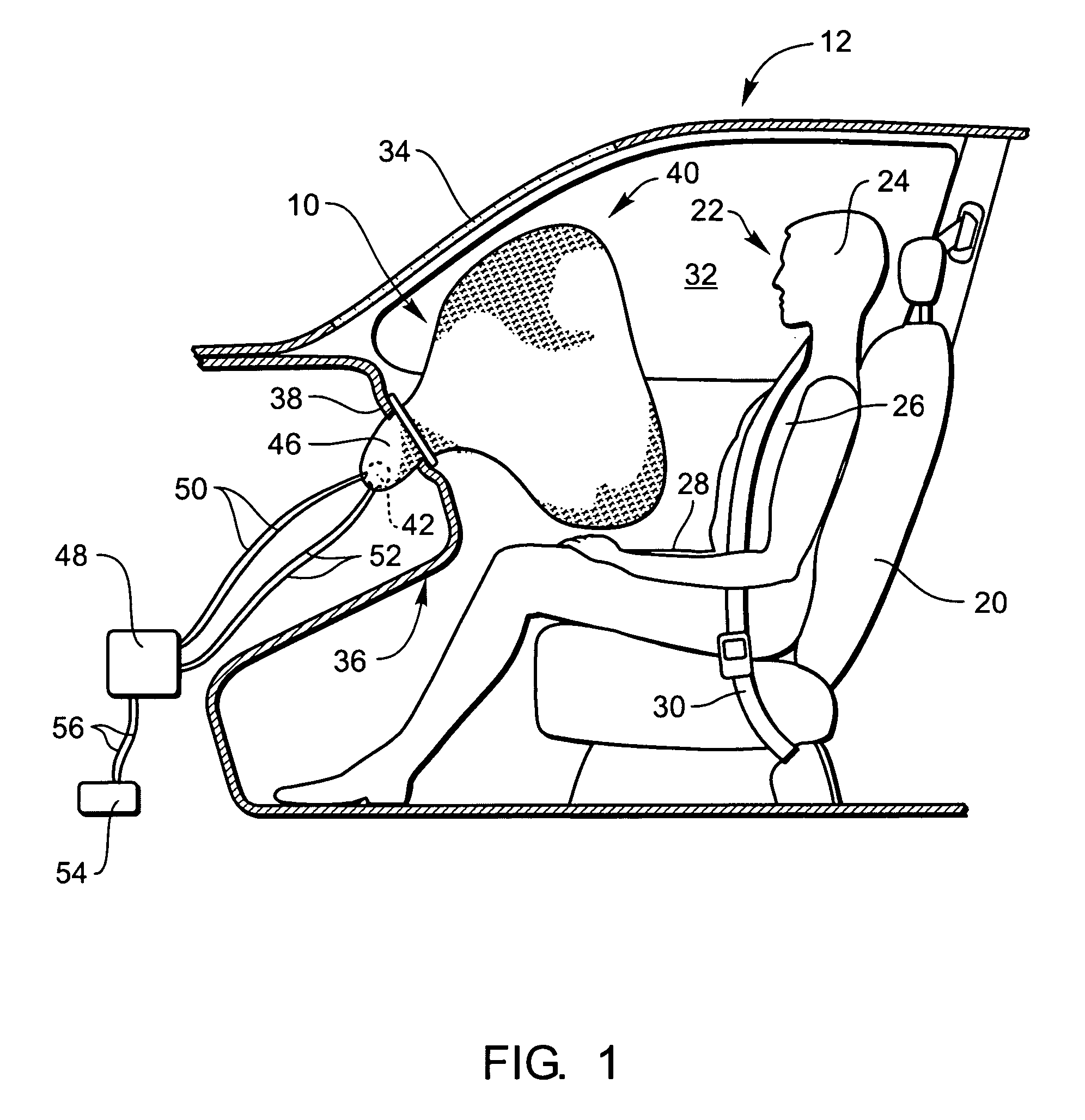

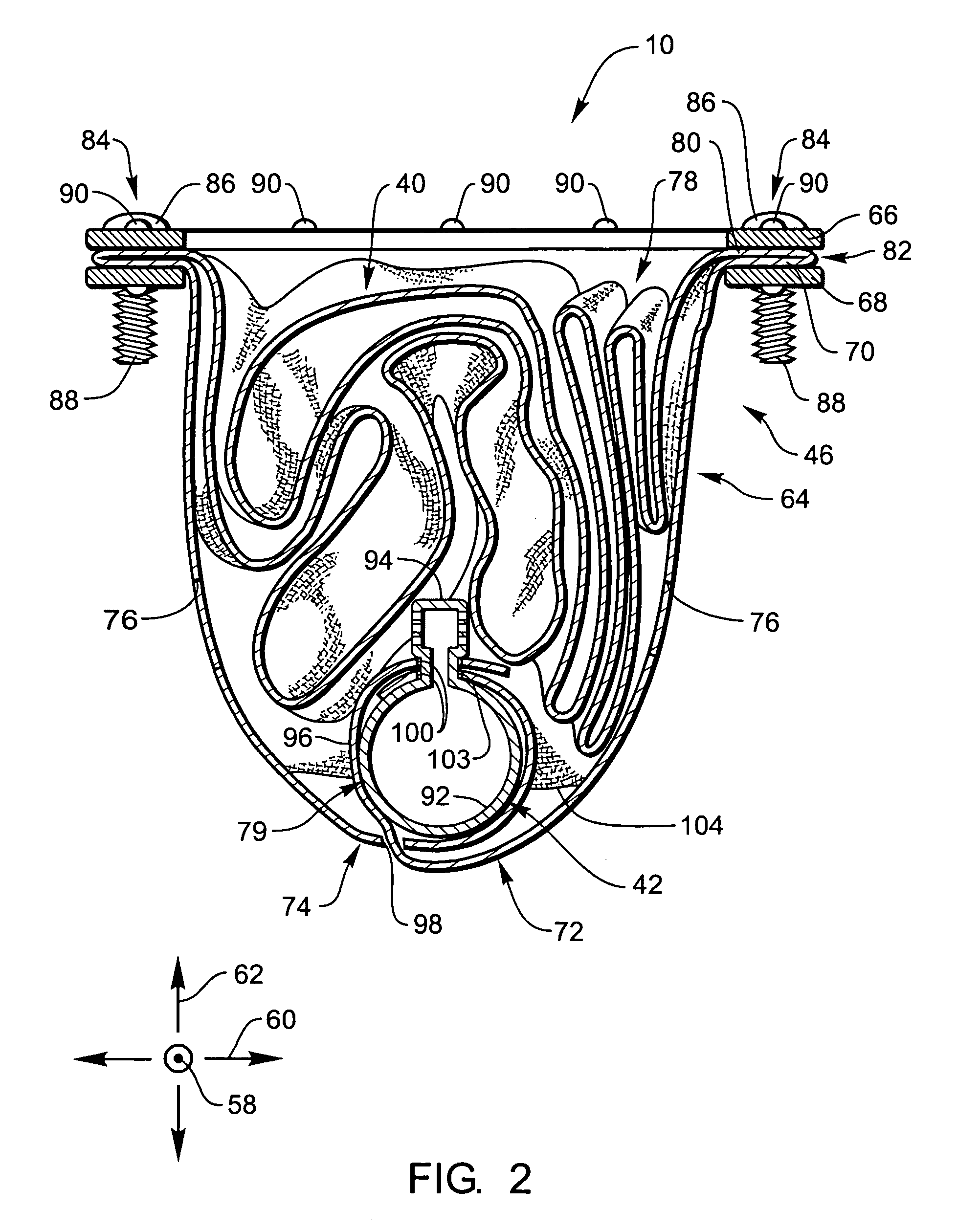

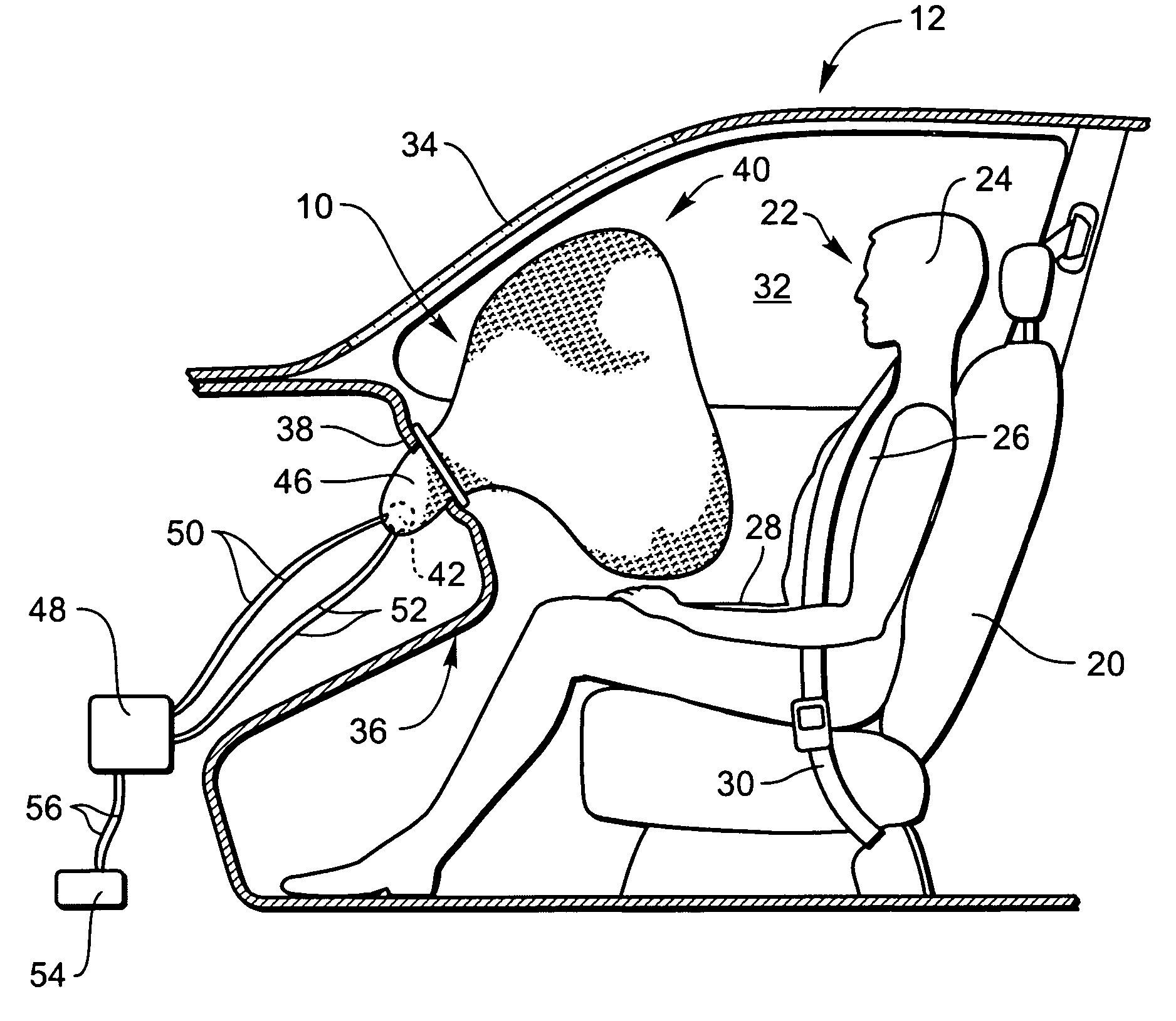

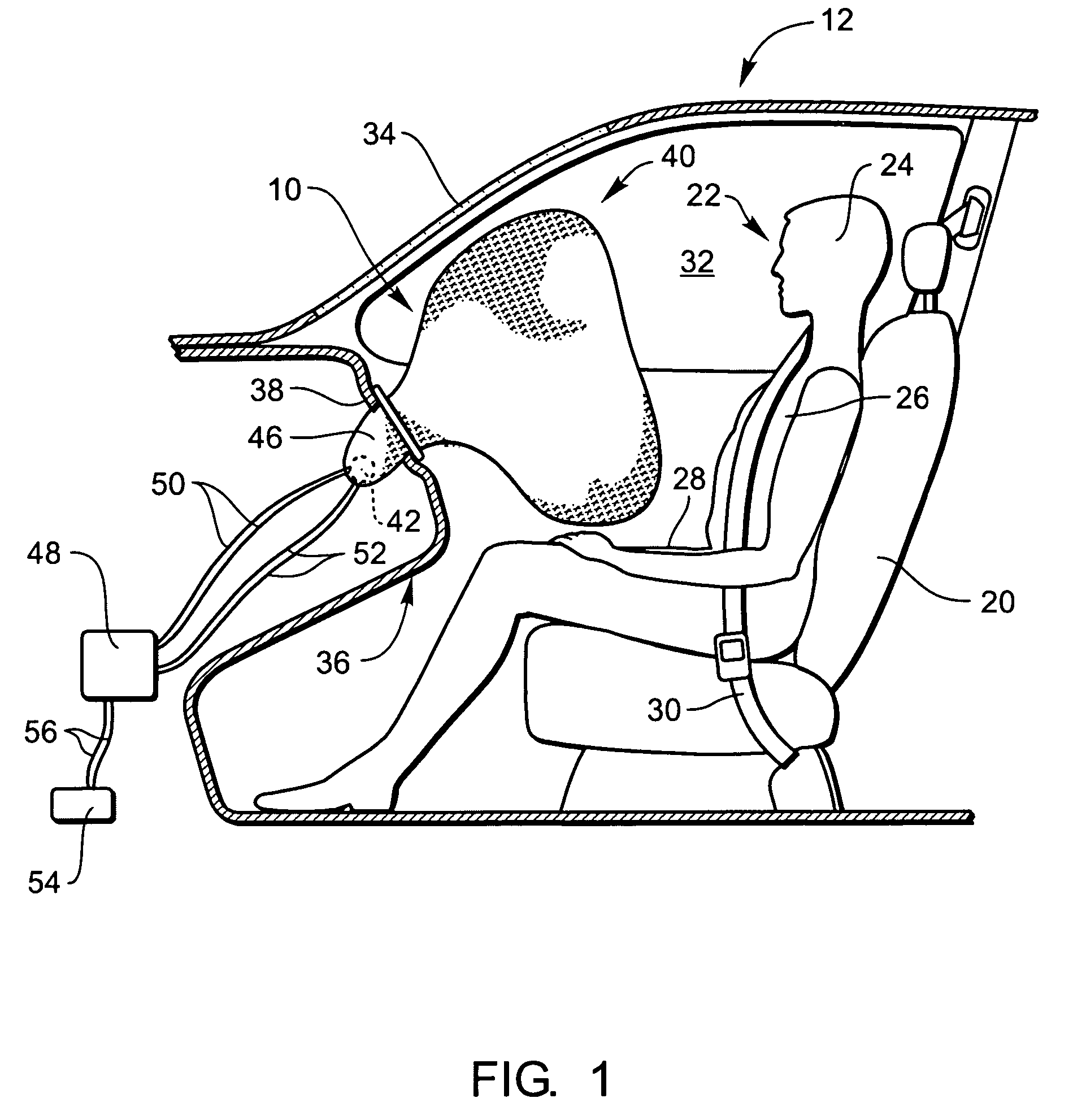

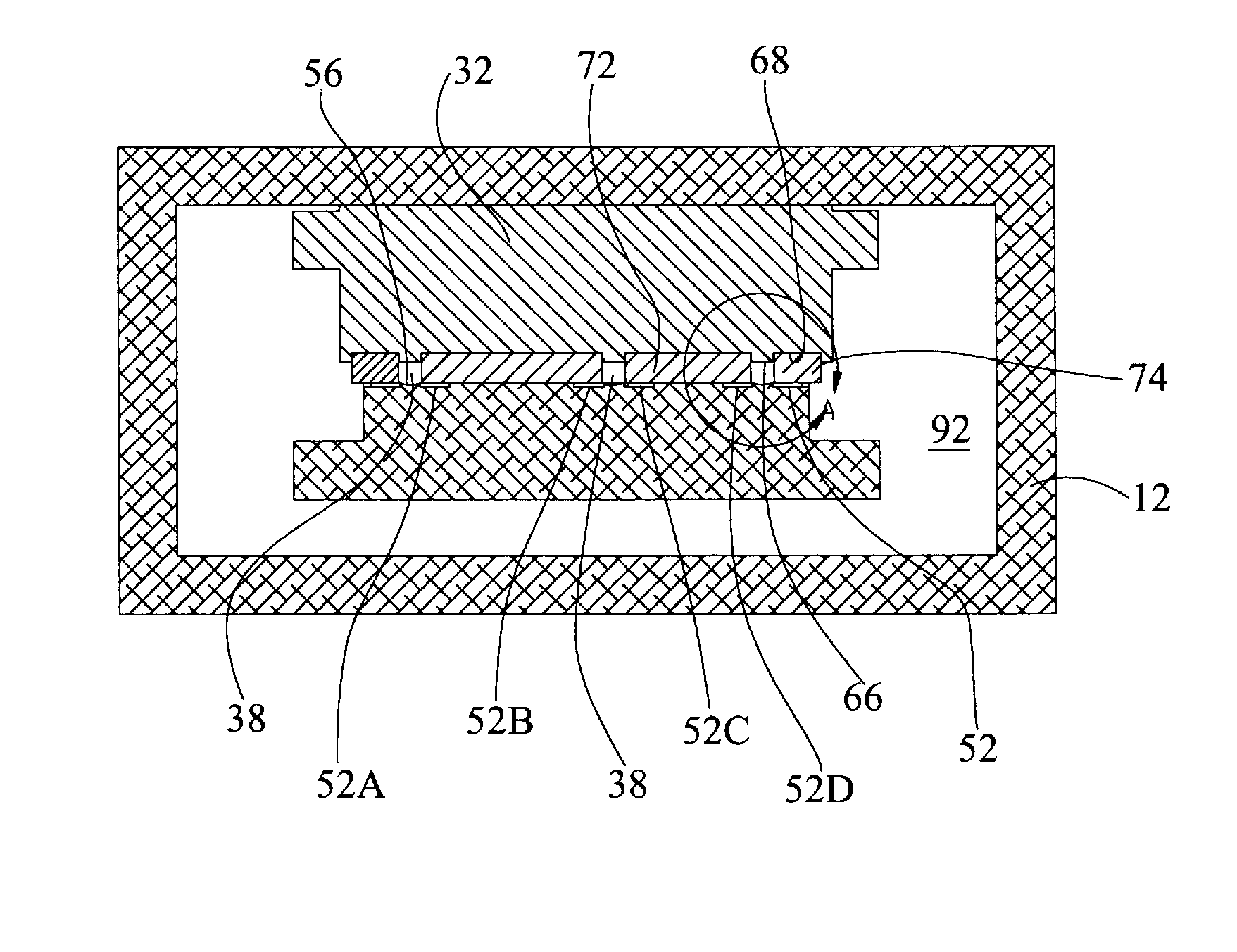

Flexible housing for an airbag module

ActiveUS20050225059A1Soften the inflated cushionPermit deflationPedestrian/occupant safety arrangementNutsEngineeringAirbag

An airbag module may have an inflator, a cushion, and a housing that contains the inflator and the cushion. The housing has an outer wall formed of a flexible material and a bracket designed to be attached to a vehicle. During deployment, the cushion is expelled out of the housing through the bracket. The inflator remains in the housing and inflation gas is conveyed to the cushion through the housing. The inflator may be retained by flaps wrapped around the inflator and secured to a perpendicularly oriented diffuser of the inflator. Alternatively, the diffuser may extend through an orifice formed in a fabric wall within the housing, and retention portions of the outer wall may be wrapped around the opposite side of the inflator. The airbag module may be mounted in an instrument panel to provide front seat, passenger's side impact protection without requiring a rigid module housing.

Owner:AUTOLIV ASP INC

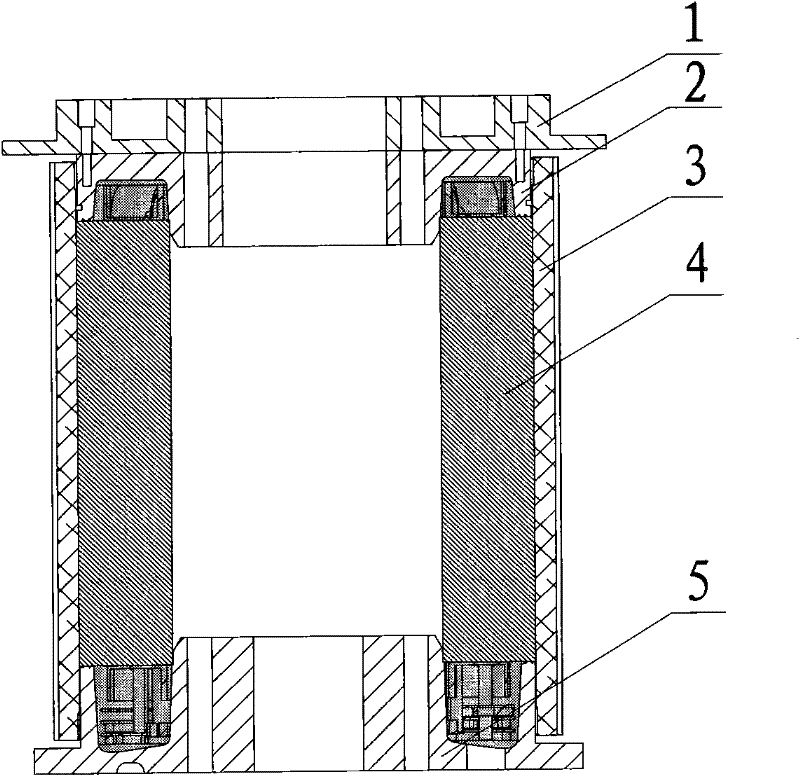

Motor stator core potting process

InactiveCN102280975AImprove potting efficiencyEasy to remove the moldManufacturing stator/rotor bodiesEpoxyEngineering

The invention provides a filling and sealing process of a motor stator core. The filling and sealing process comprises the following steps of: (1) preparing a filling and sealing material; (2) arranging an upper die filling and sealing die and a lower die filling and sealing die on a motor stator and positioning; (3) injecting the prepared filling and sealing material from an upper die plate; and (4) curing at 75-85 DEG C for 20-40 percent. The filling and sealing material is prepared from the following raw materials, such as epoxy resin, a diluting agent, a curing agent, a flexibilizer, silicon micropowder, and the like according to certain proportions. Compared with the prior art, the invention has the advantages that the filling and sealing time is greatly shortened, the operation is convenient, the filing and sealing efficiency of a motor is effectively improved, and energy consumption is saved; the stator has high surface finish quality and good insulation and waterproofing property; meanwhile, the mechanical property of the motor is improved, and the running stability of the motor is better ensured.

Owner:NANJING GAOQI ELECTRIC

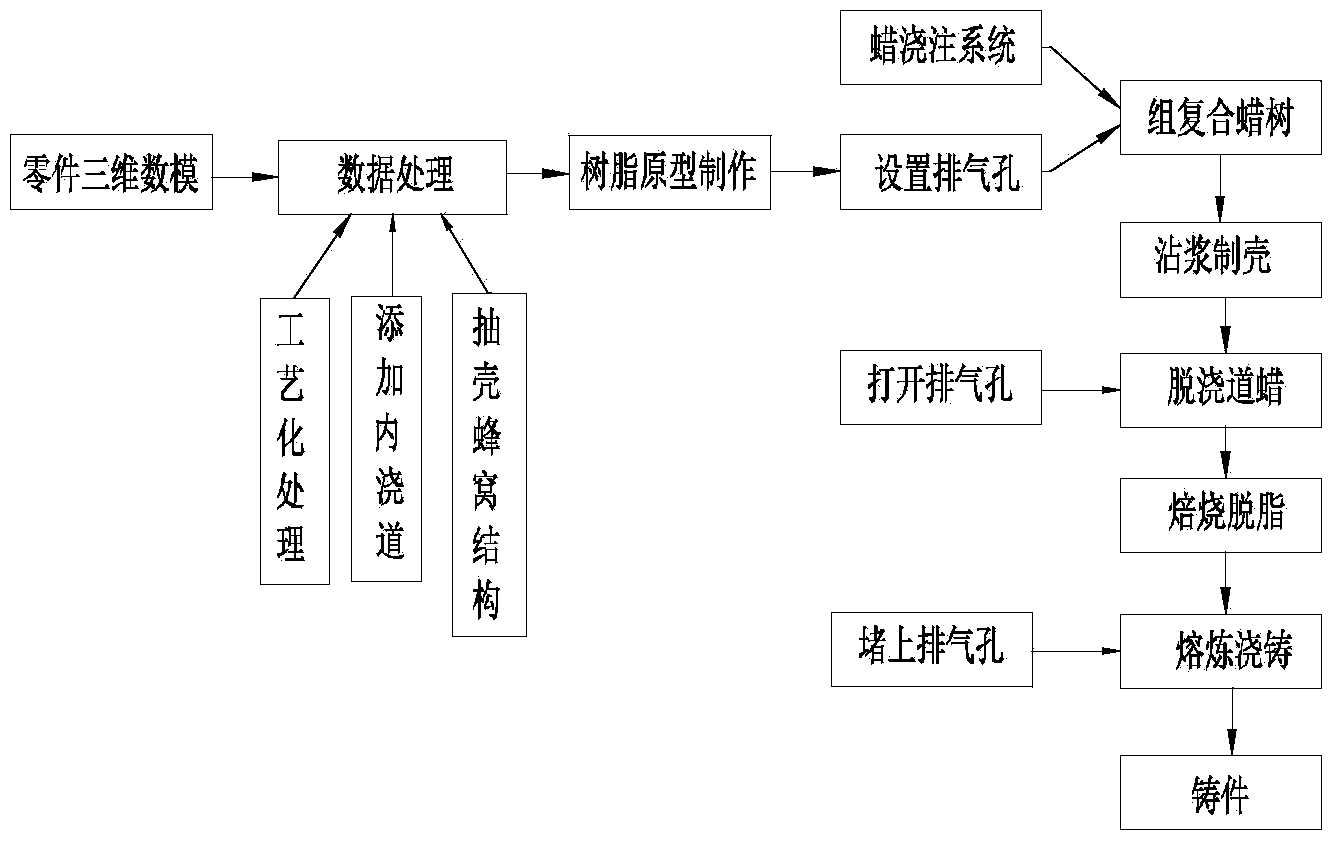

Rapid investment casting method based on stereolithography (SL)

Owner:无锡市交大增智增材制造技术研究院有限公司

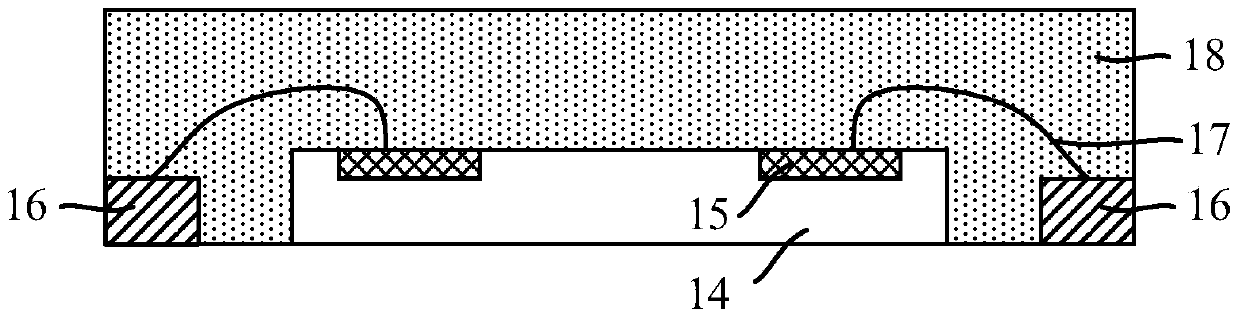

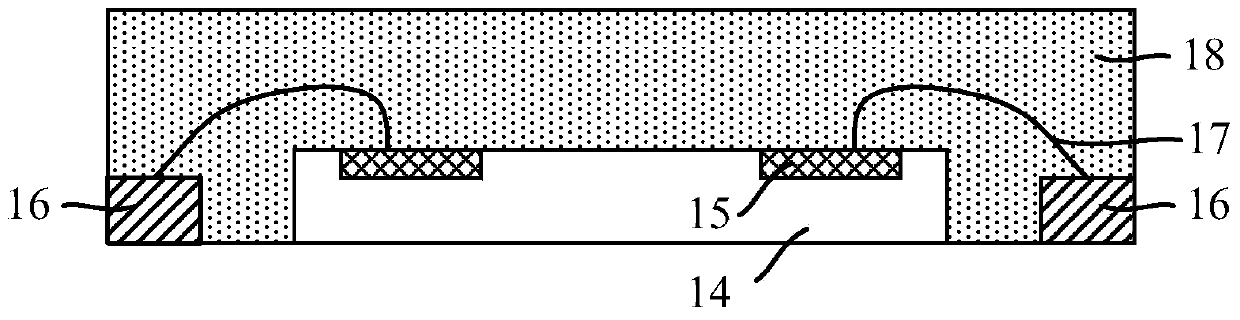

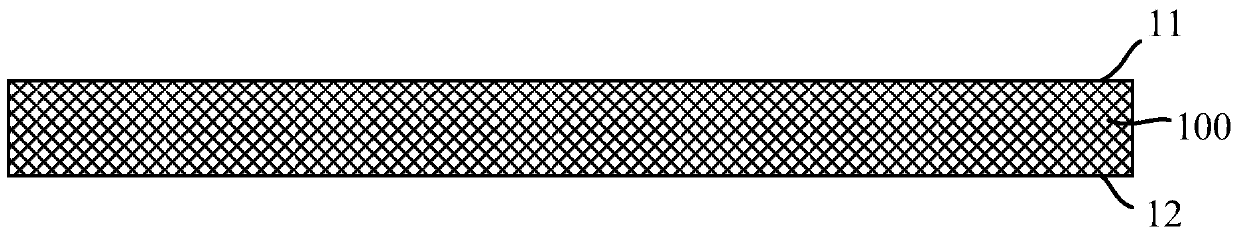

Packaging structure

ActiveCN103730429AHighly integratedImprove packaging efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A packaging structure comprises a lead frame, a pre-packaging face plate. The lead frame is provided with a plurality of bearing units distributed in a matrix mode and middle ribs used for fixing the bearing units, each bearing unit comprises a plurality of independent pins, and openings are formed between adjacent pins. The pre-packaging face plate comprises a first plastic-packaging layer, openings, and a second plastic-packaging layer, wherein a plurality of integration units distributed in a matrix mode are arranged in the first plastic-packaging layer, at least one semiconductor chip is arranged in each integration unit, a plurality of welding discs are arranged on the surface of the semiconductor chip, the welding discs are provided with metal protruding blocks, the pre-packaging face plate is inversely arranged on the first surface of the lead frame, the integration units correspond to the bearing units, the metal protruding blocks on the semiconductor pins are connected with the first surfaces of the pins in a welding mode. The openings are filled into the openings between the pins, the second plastic-packaging layer is filled into the space between the pre-packaging face plate and the first surface of the lead frame, and the second plastic-packaging layer is exposed of the second surfaces of the pins. The packaging structure is small in occupied space, and the integration level is improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

Plastic cap featuring excellent sealing and venting

A plastic cap comprising a top panel and a skirt hanging down from the peripheral edge of the top panel, the inner surface of the top panel forming an inner ring that forms a seal upon coming into intimate contact with the inner surface of the wall of the mouth of a container, and the inner surface of skirt forming a screw thread that comes into engagement with a screw thread formed on the outer surface of the wall of the mouth of the container, wherein a slender recessed portion is formed in a number of at least one in the inner surface of said inner ring extending upward from an end thereof. The cap features both excellent sealing and excellent venting.

Owner:TOYO SEIKAN KAISHA LTD +1

Flexible housing for an airbag module

ActiveUS7195273B2Soften the inflated cushionPermit deflationPedestrian/occupant safety arrangementNutsEngineeringSide impact

An airbag module may have an inflator, a cushion, and a housing that contains the inflator and the cushion. The housing has an outer wall formed of a flexible material and a bracket designed to be attached to a vehicle. During deployment, the cushion is expelled out of the housing through the bracket. The inflator remains in the housing and inflation gas is conveyed to the cushion through the housing. The inflator may be retained by flaps wrapped around the inflator and secured to a perpendicularly oriented diffuser of the inflator. Alternatively, the diffuser may extend through an orifice formed in a fabric wall within the housing, and retention portions of the outer wall may be wrapped around the opposite side of the inflator. The airbag module may be mounted in an instrument panel to provide front seat, passenger's side impact protection without requiring a rigid module housing.

Owner:AUTOLIV ASP INC

Low-viscosity epoxy resin system for resin transfer molding and preparation and using method thereof

The invention relates to a low-viscosity epoxy resin system for resin transfer molding and a preparation and using method thereof. The epoxy resin system consists of a component A and a component B, wherein in the component A, the weight ratio of epoxy resin to reactive diluent to antifoaming agent is 55-90: 10-45: 0.05-1; and the weight ratio of the component B (curing agent) to the component A is 100: 10-30. The preparation and using method comprises the following steps of: mixing and stirring the components A and B of the epoxy resin system uniformly in a ratio, pumping vacuum and removing bubbles at room temperature, and finally heating the components for 6 hours at the temperature of 80 DEG C to obtain a casting. The epoxy resin system can improve the gelling time and viscosity, meanwhile keeps good mechanical property and thermal property, and can be used for manufacturing large-sized composite structural members of automobiles, ships, wind-power blades, aerospace and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Berry can and processing method thereof

The invention relates to a new can processing method which is applicable to a berry raw material and a berry can processed through the method, and the can processing method is characterized in that the tissue improvement method in line with the characteristics of berry is adopted, a calcium preparation and the sugar impregnation are combined for treatment so as to increase the strength of the skin part and pulp part of the berry, and the complete and due taste of fruit granules can be maintained during the follow-up heat treatment process; a formula with special flavor and nutritional attributes is utilized for the preparation of canned soup, thereby greatly improving the health-care and beautifying effects of the product; according to the actual nutritional requirement of the berry raw material, a safe thermal sterilization way is adopted, the thermal degasification temperature and sterilization temperature in the traditional process are reduced by about 10 DEG C, the nutritional value and sensory quality of the product are better protected, the natural taste of the berry raw material is maintained, energy is saved, and the can processing method can be maturely applied to berry can products and is applicable to actual situations of the majority of can food production enterprises.

Owner:丹东美比食品有限公司

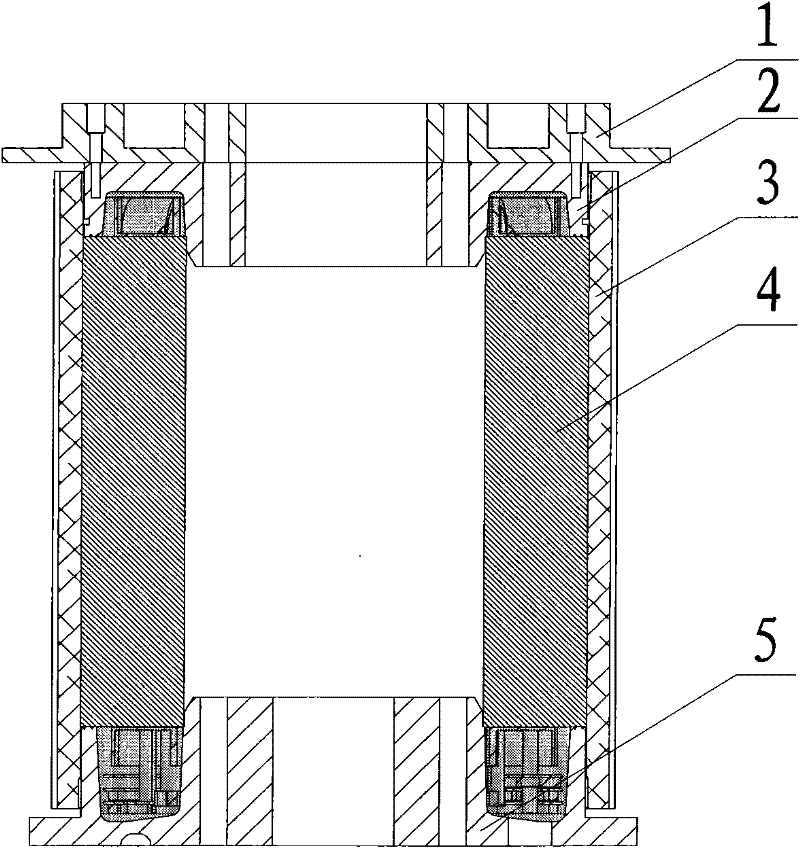

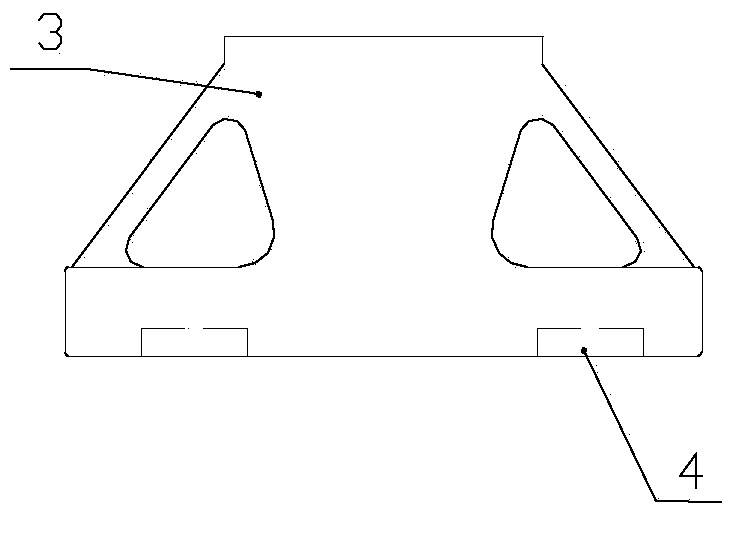

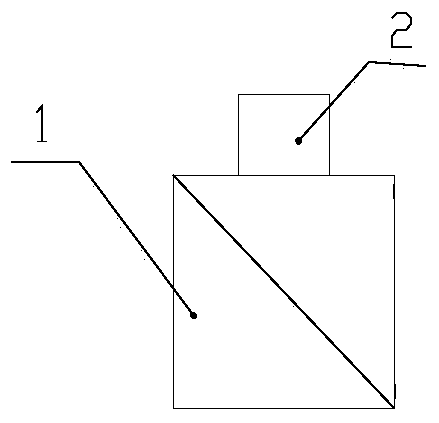

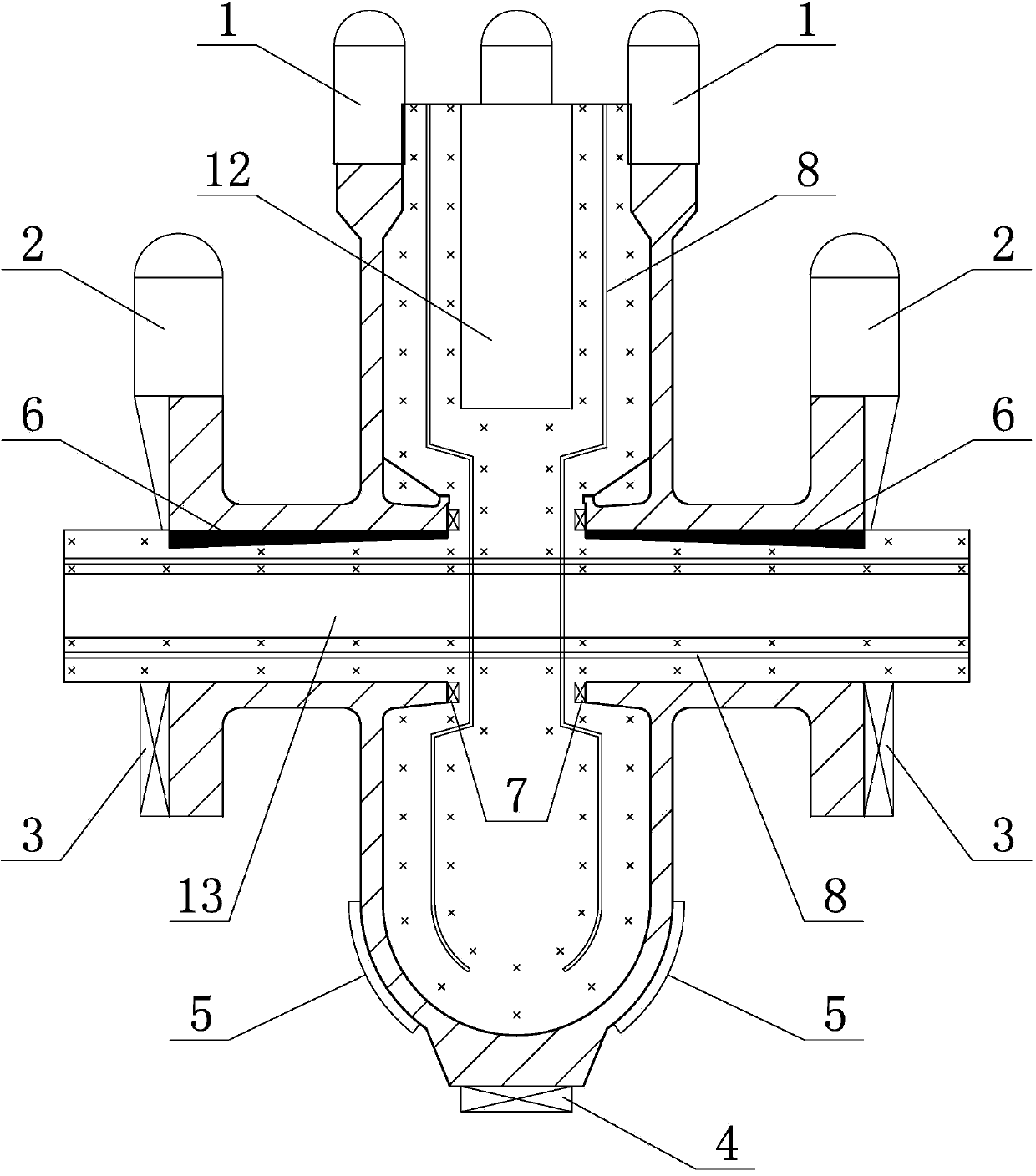

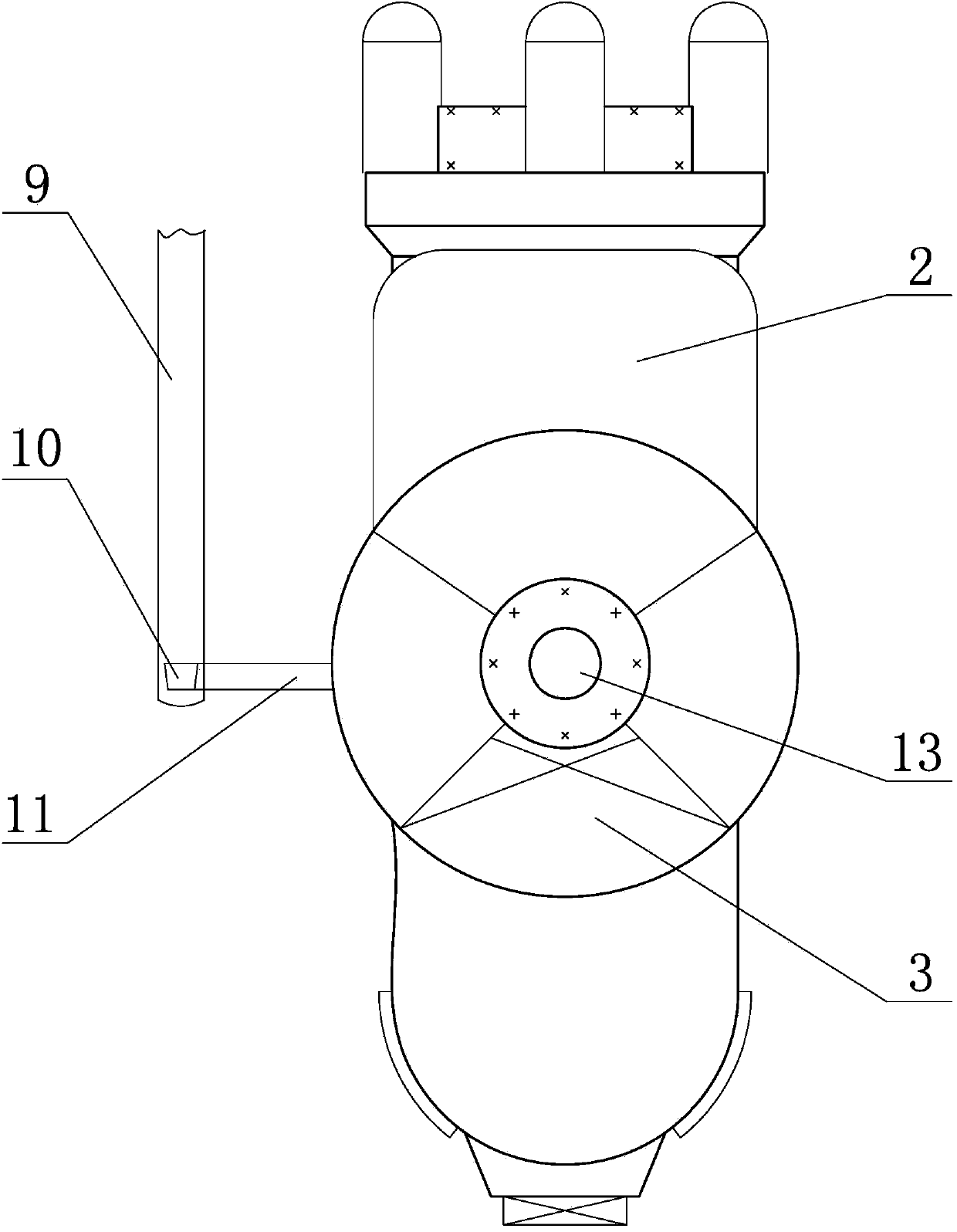

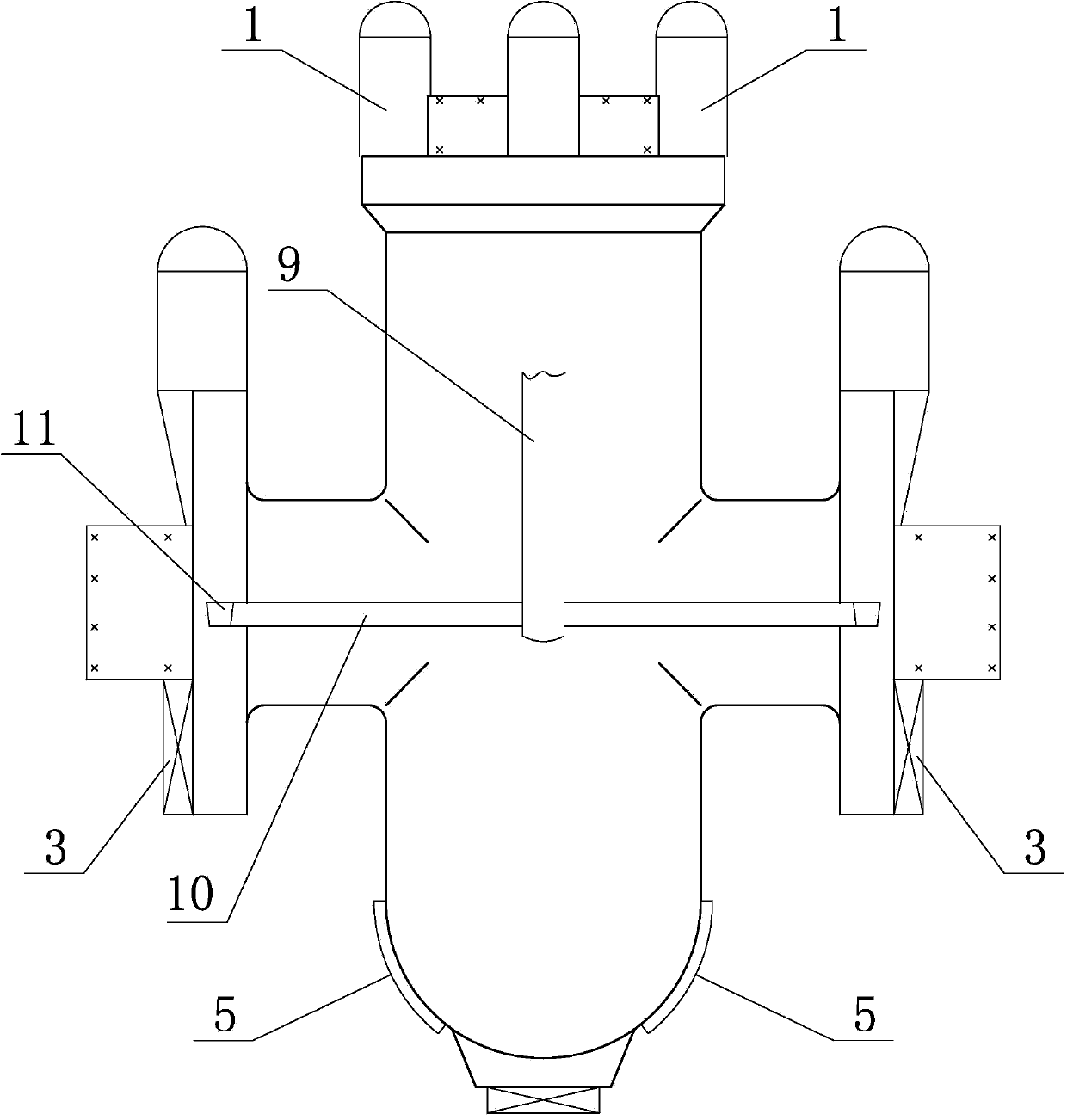

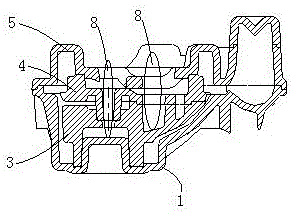

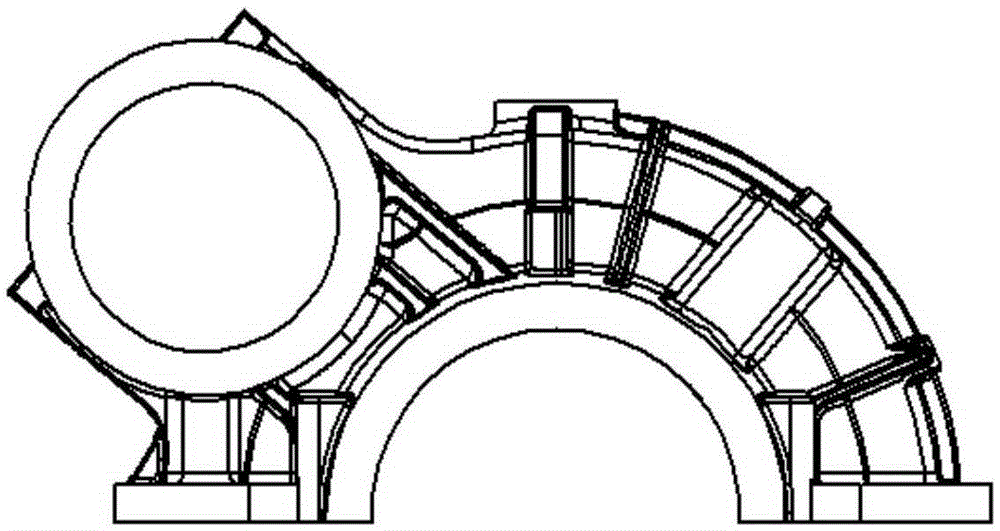

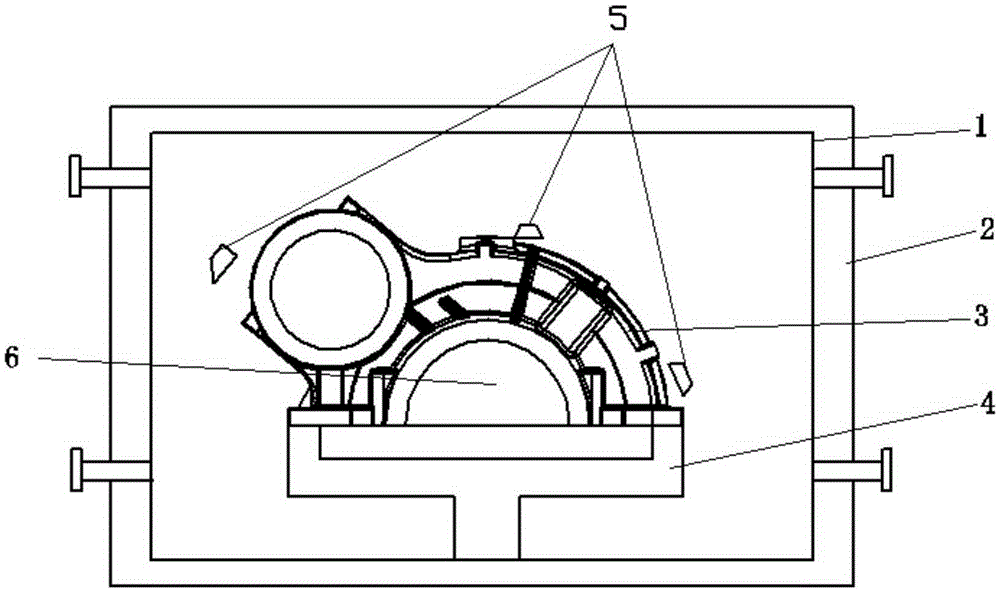

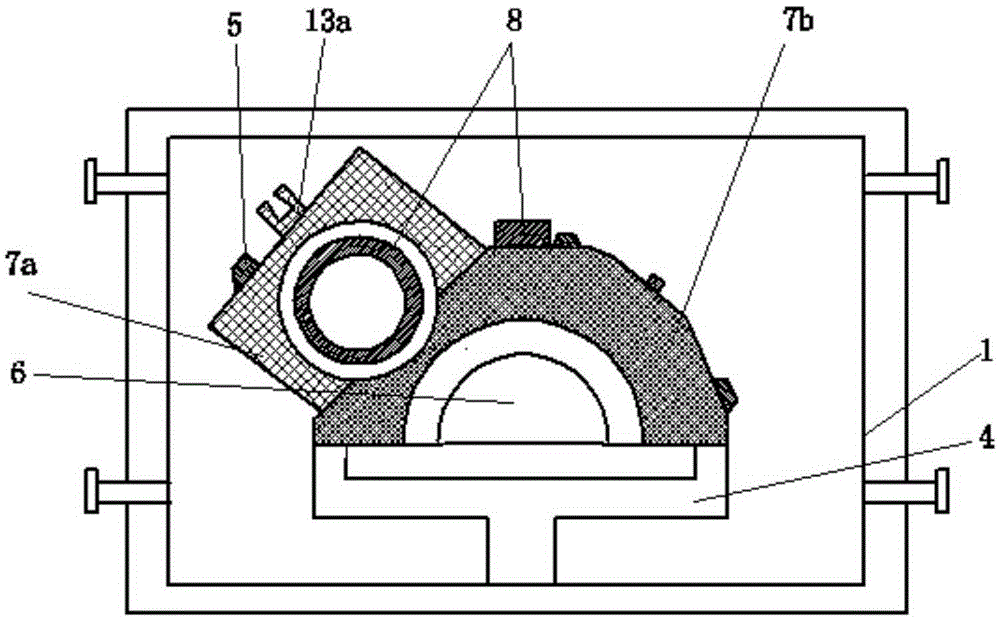

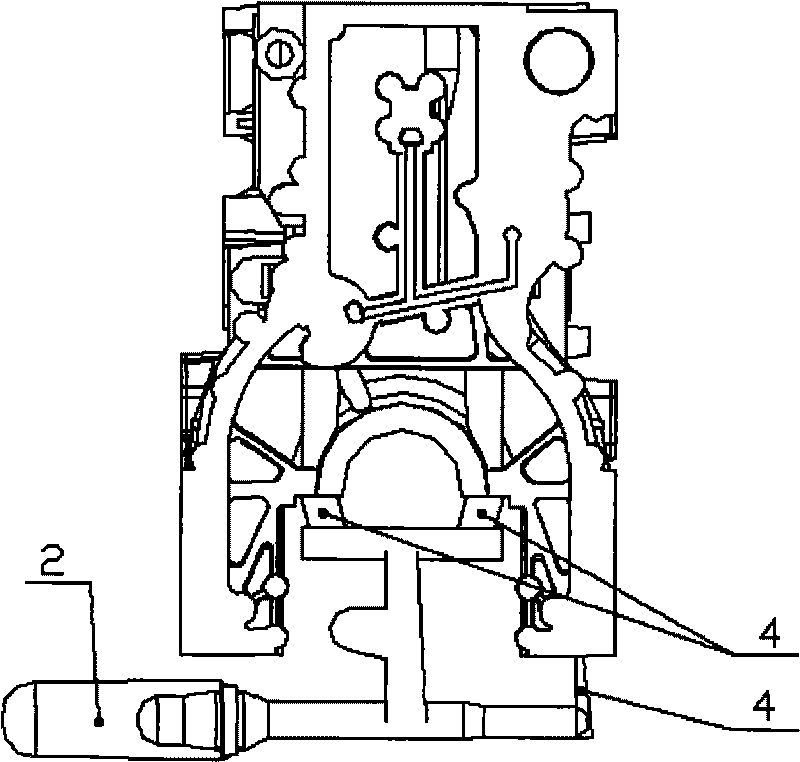

Alloy liquid extrusion casting forming device and process method thereof

The invention discloses an alloy liquid extrusion casting forming device which comprises a hammerhead (1), a static die (2), a movable die (3) and a pouring slot (4). The device adopts the technical scheme that a declined and downward funnel-shaped pouring slot occupied by both the movable die and the static die arranged respectively by half is arranged on the parting plane on one side of a vertical die casting mould; a cylinder chamber type feed liquid chamber and the piston type hammerhead with a sealing knife is arranged on the static die; the hammerhead is controlled to be pushed up, and simultaneously the sealing knife seals the pouring slot. Firstly, feed liquid is filled into the a die cavity at high speed with low pressure, then the semisolid feed filled into the die cavity is extruded at low speed with high pressure, and the semisolid feed is gradually condensed to be formed under high-pressure low-speed extrusion. The alloy liquid extrusion casting forming device and the process method thereof integrate full casting functions of low-pressure filling and high-pressure extrusion into a whole, ensure that forming of alloy casting achieves the purposes of no gas entrapment, no cast seam, no mis-run, no forging crack, no fash, compact texture, fine crystal grain, high mechanical property, capability of performing thermal treatment and sealing, high dimensional accuracy, energy saving and low cost.

Owner:中建投(绍兴)机械科技有限公司

Method for casting valve body of flat gate valve

ActiveCN103433434AReduced horizontal projected areaGravity feeding is easy to implementFoundry mouldsFoundry coresMiddle lineImpurity

The invention discloses a method for casting a valve body of a flat gate valve, and belongs to the technical field of valve body casting processes. The method is technically characterized in that a valve body cavity is vertically formed between a sand mold and a sand core; a plurality of valve body heat preserving risers are uniformly arranged at the open end of the valve body through the sand mold; a flange heat preserving riser is arranged at the upper end of a flange plate on each of two sides; a first external chill is arranged at the lower end of each flange plate; a plurality of second external chills are uniformly arranged at the periphery of a valve belly below the middle line of a flange; a third external chill is arranged on the outer bottom surface of the blind end of a main body of the valve body; process supplementary ion is arranged in an inner hole of the flange plate on each of the two sides; a fourth external chill is arranged on each of two end surfaces of a valve seat table in an inner cavity of the valve body. Therefore, the probability of occurrence of casting impurities and pore defects is reduced by using a vertical pouring method, gravity feeding is easy to implement so as to be matched with the chilling action of each external chill, and castings can be fed in sequence, so that the internal quality of the castings is well improved.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

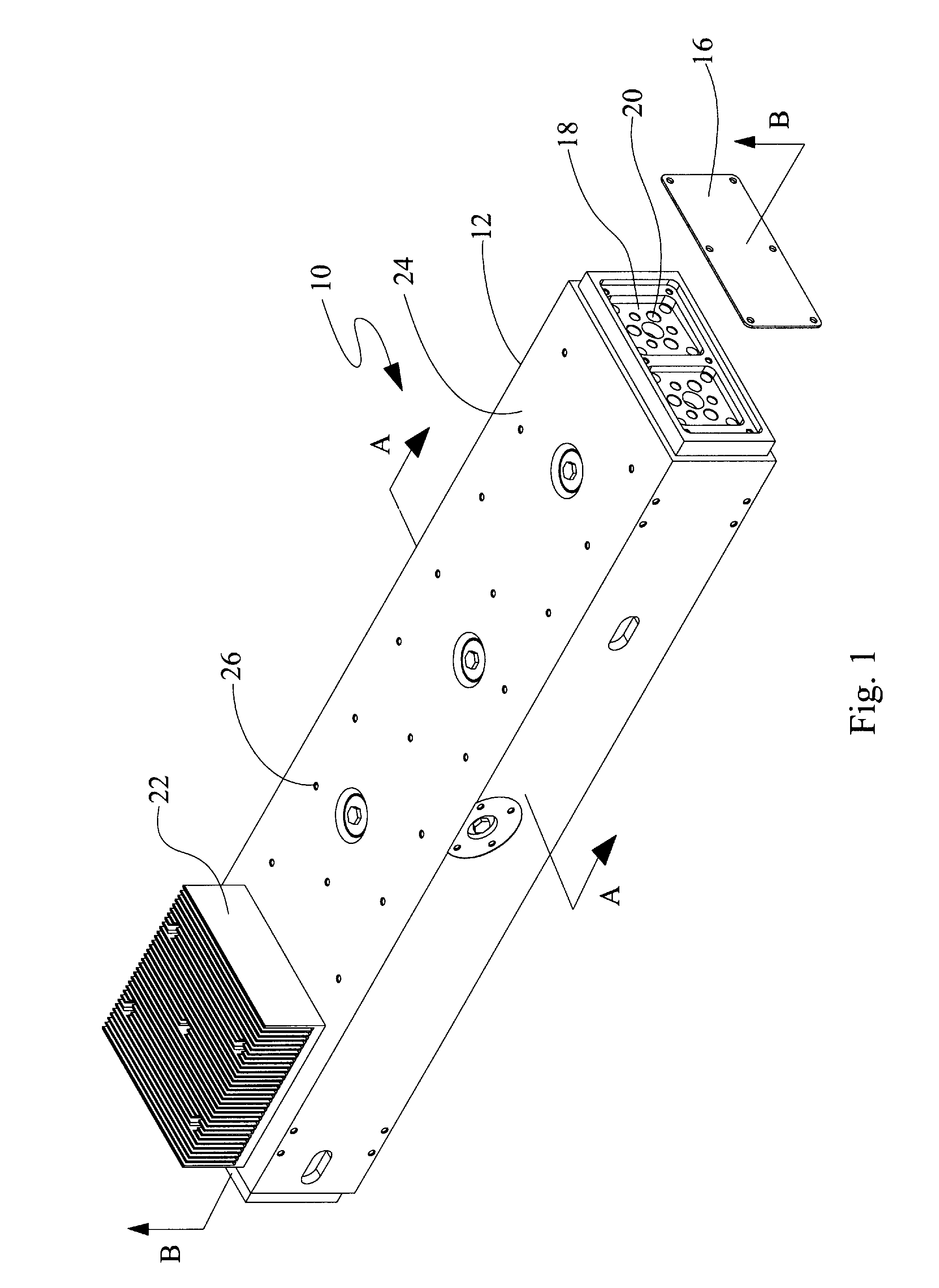

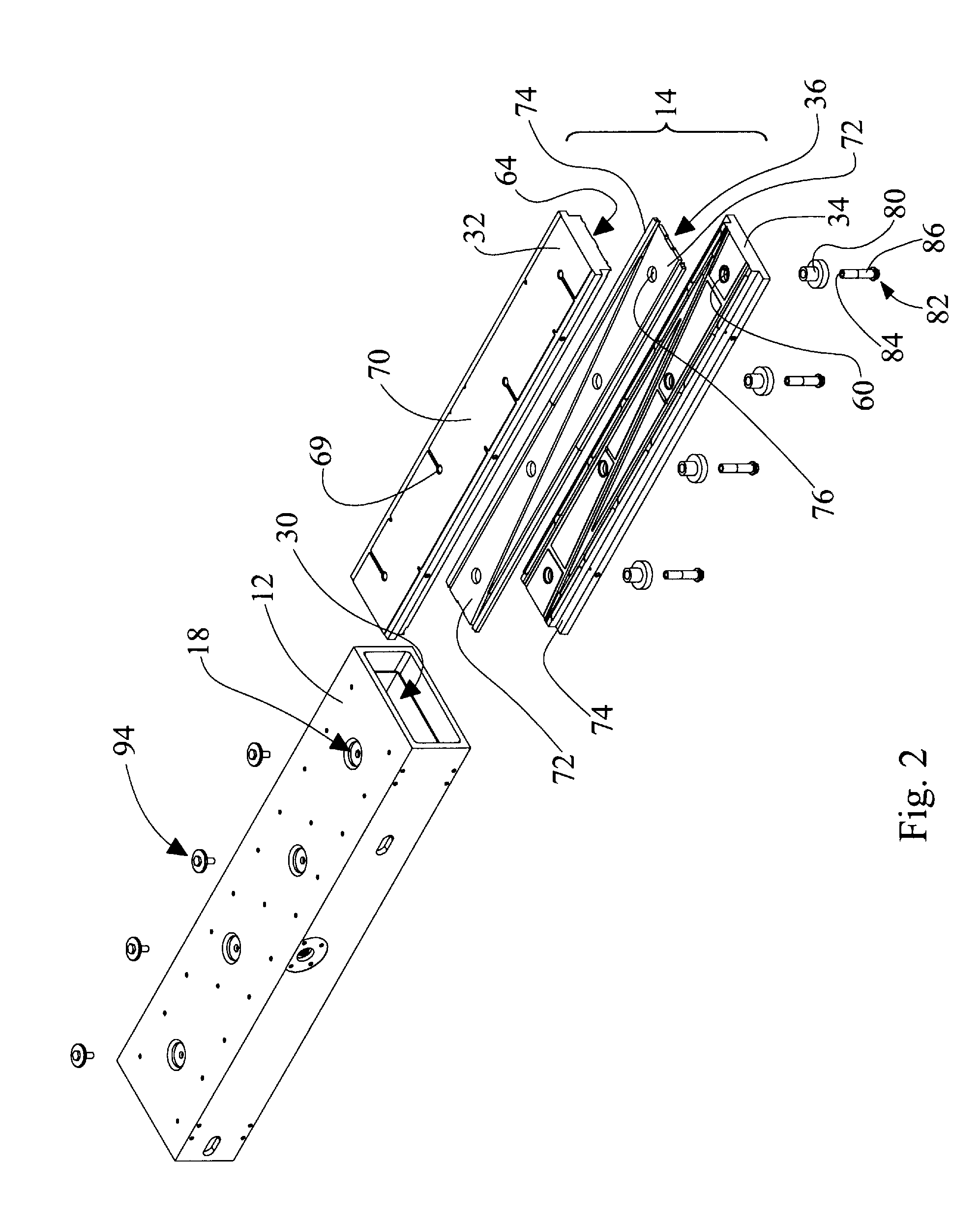

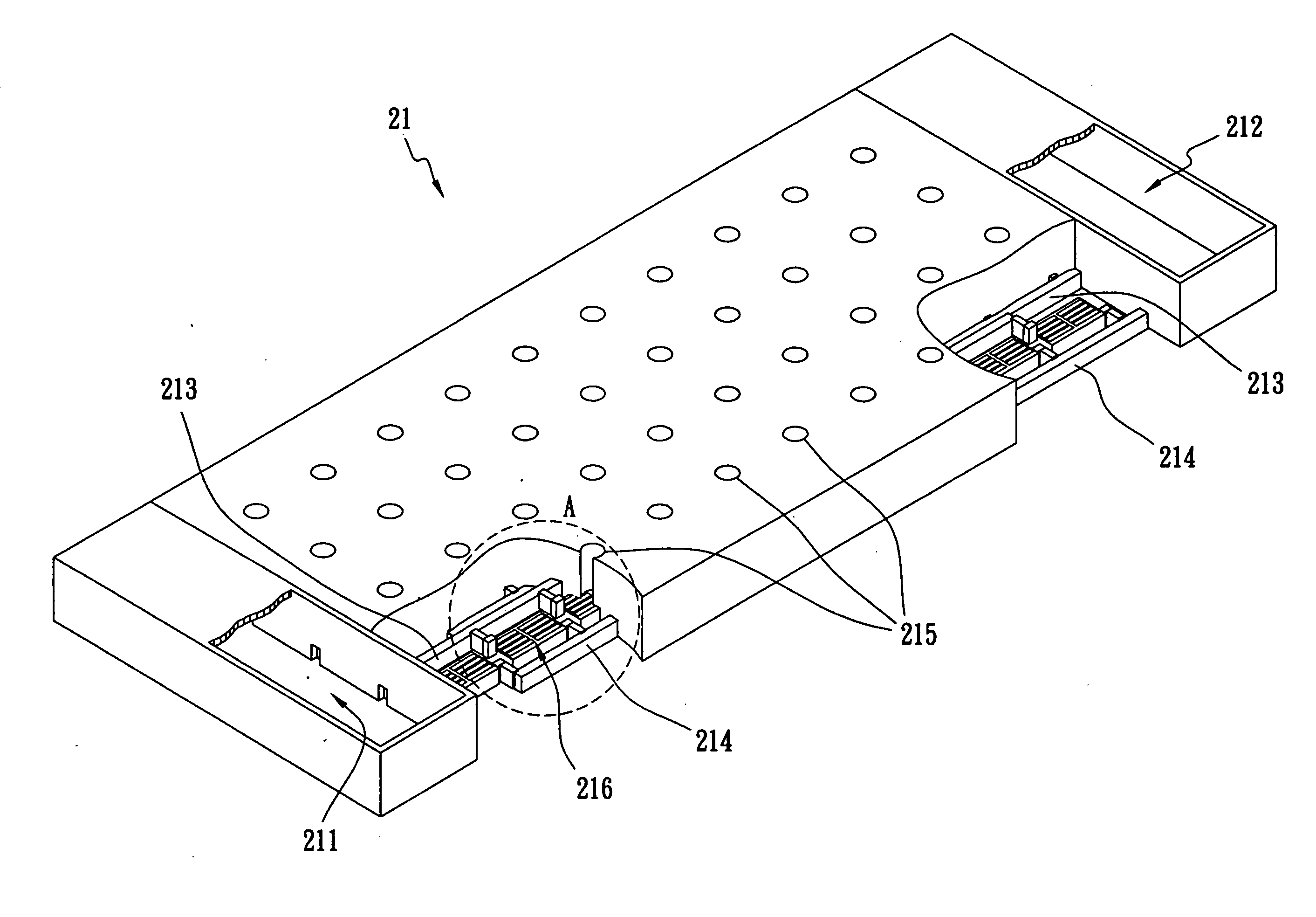

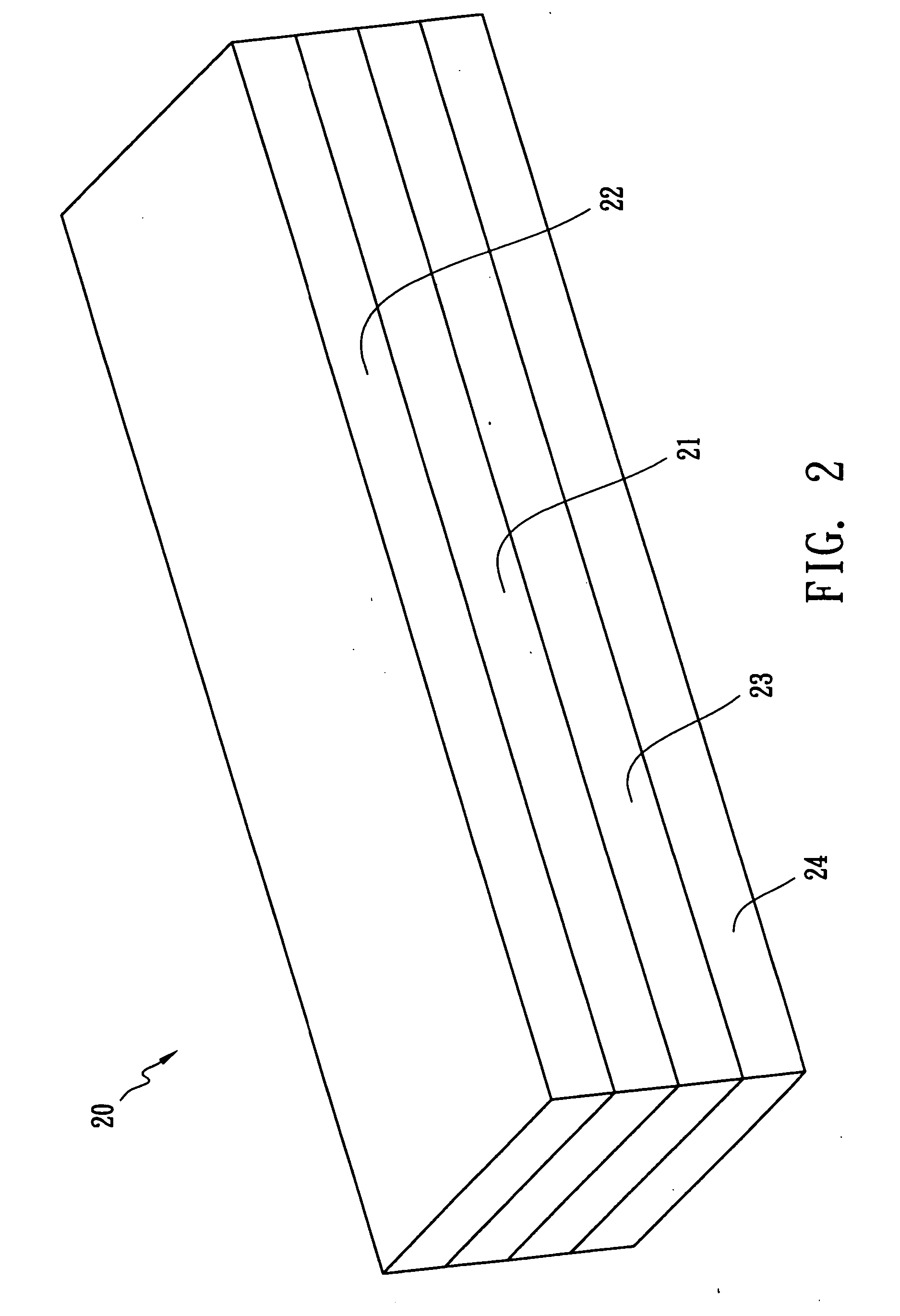

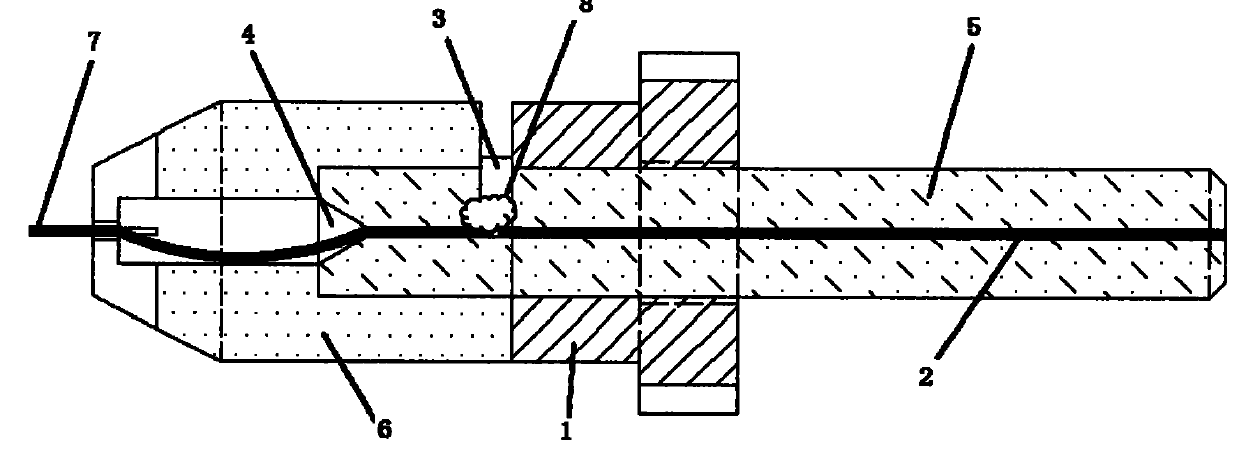

Waveguided laser channels for a gas laser

ActiveUS7570683B1Eliminate distortionGood plasma breakdownActive medium materialLaser cooling arrangementsDielectricOptical axis

An RF-excited waveguide laser module comprises a first electrode having a first elongate surface defining in part a waveguide laser channel extending along an optical axis, the first elongate surface having a substantially linear cross-section normal to the optical axis. A second electrode has a second elongate surface defining in part the waveguide laser channel extending along the optical axis. The second elongate surface has a non-linear cross-section normal to the optical axis. A dielectric insert may be provided between the electrodes defining in part the waveguide laser channel. A lengthwise gap may extend essentially an entire length of the waveguide laser channel between one of the first and second electrodes and the dielectric insert. The gap provides fluid communication between the waveguide laser channel and a volume outside the waveguide laser channel.

Owner:EPILOG CORP

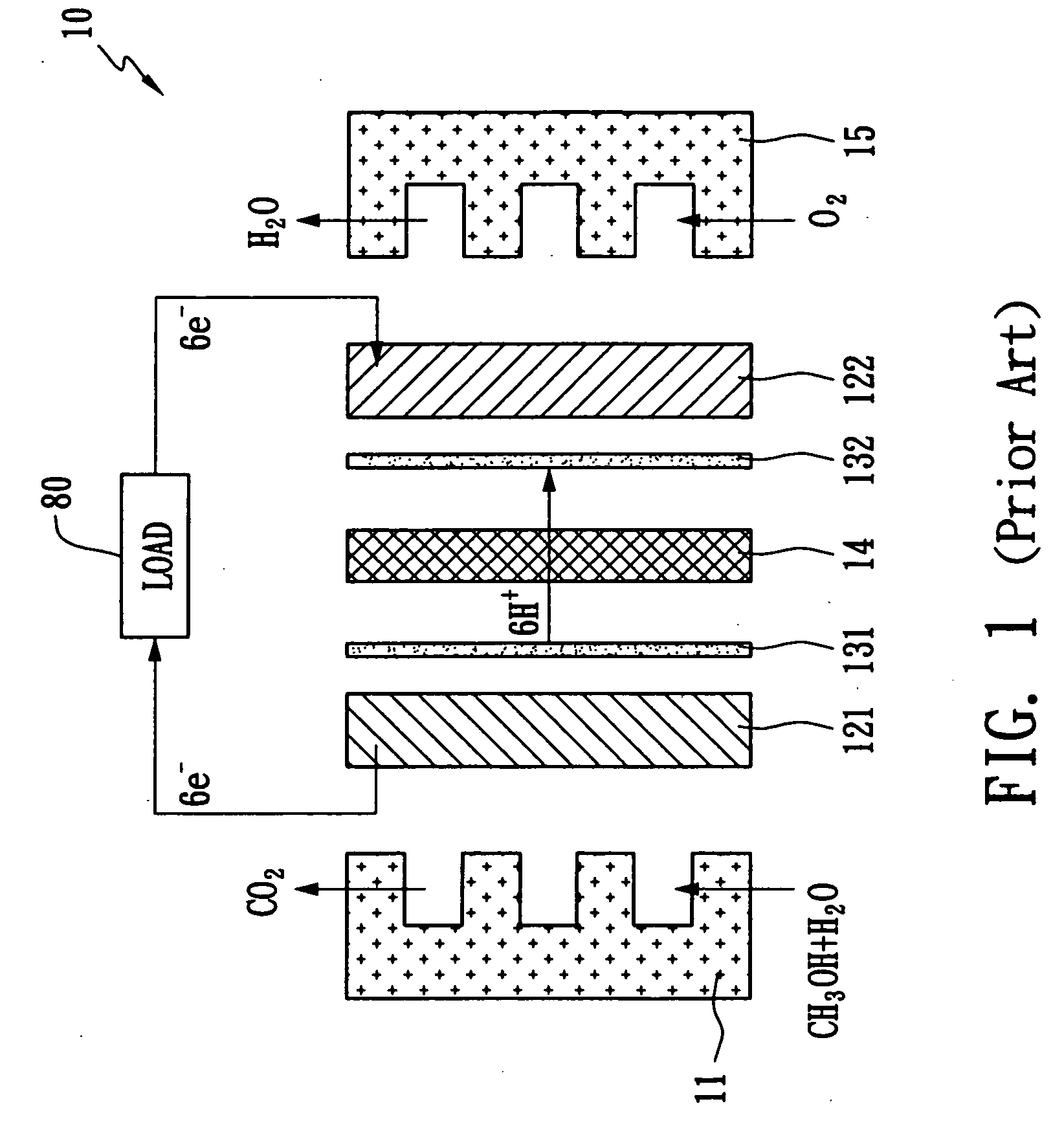

Passive micro fuel cell

ActiveUS20060183015A1Relieve stressStable power generationMaterial nanotechnologyReactant parameters controlFuel tankCarbon nanotube

An efficient and passive micro fuel cell includes an anode plate, a reaction plate, a cathode plate and a condensation plate. The anode plate draws a dilute solution of methanol from a fuel tank to delivery to a series of upper oxidation reaction room through micro-channels by thermal capillarity. The condensation plate separates carbon dioxide and vapor from each other. Meanwhile, the methanol solution is delivered to a plurality of lower oxidation reaction rooms. Protons pass through the inner walls of the reaction holes and a porous membrane layer and arrive in the lower reduction reaction rooms. The lower reduction reaction rooms and the lower oxidation reaction rooms have reaction holes whose inner walls have carbon nanotubes and catalysts. A plurality of upper reduction reaction rooms delivers oxygen for the reduction reaction and drains the reduced water at the same time.

Owner:NATIONAL TSING HUA UNIVERSITY

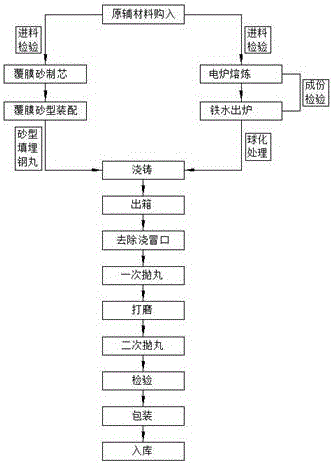

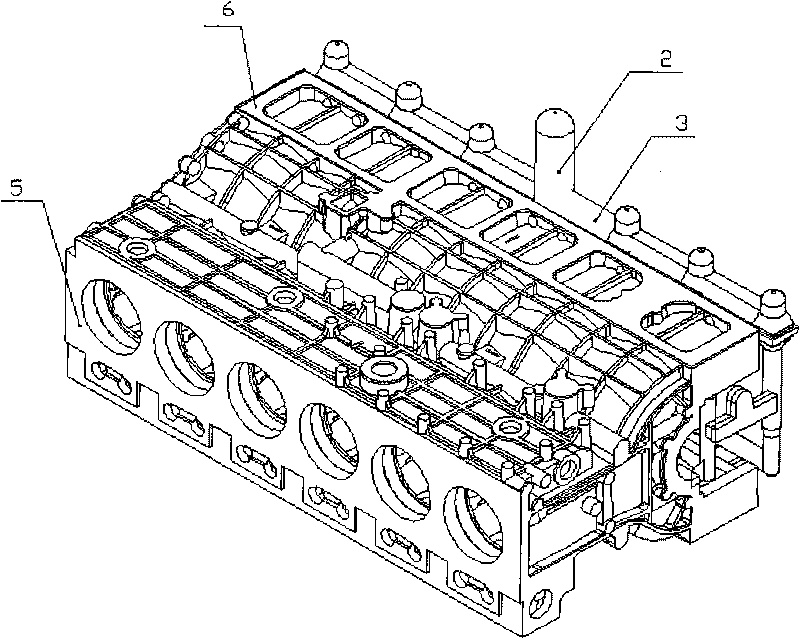

Casting method of main reducer housing

ActiveCN106825438AHigh dimensional accuracyHigh surface finishGearboxesFoundry mouldsPorositySurface finish

The invention relates to a casting method of a main reducer housing. The casting method includes: a precoated sand core forming process, a smelting ball iron process and a casting process, the precoated sand core forming process includes core-making of precoated sand, coated sand type assembly and sand-type steel shot filling; the smelting ball iron process includes electric-furnace smelting and charging of molten iron and treatment; the casting method is characterized by including casting, unboxing, de-gating, one-step shot blasting, grinding, secondary shot blasting and detecting. With the method, exhaust smoothness is guaranteed, generation of hole defects in the casting is avoided from the sand core exhaust process, sand hole and pore defective reject rate is controlled within 1%, shrinkage or porosity defect is avoided, the casting is stable in size and high in surface smoothness, the yield is higher as compared with that with a traditional casting method of the main reducer housing, the production process is easier to control, and production competitiveness has higher advantages.

Owner:抚州市羊易铸业有限公司

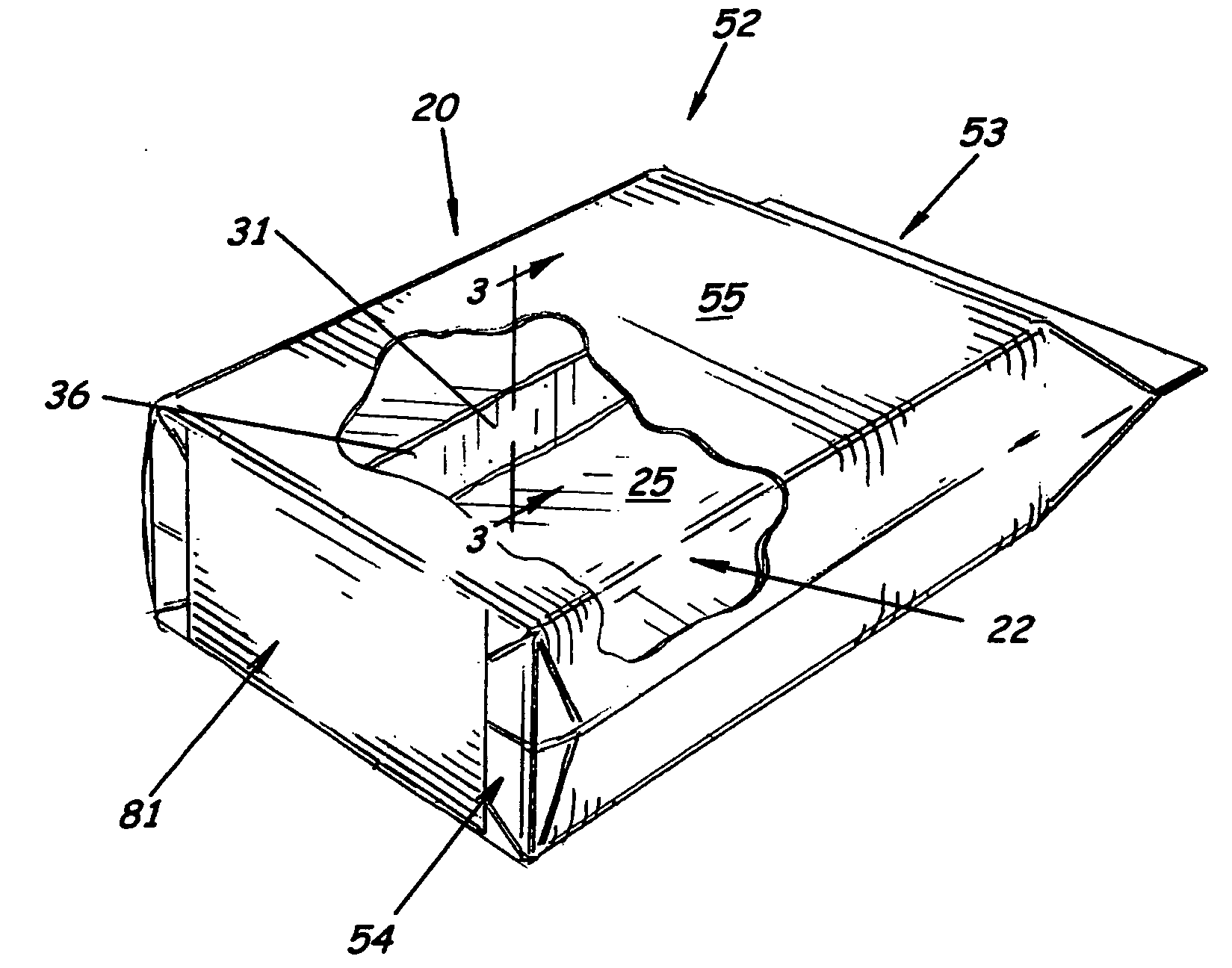

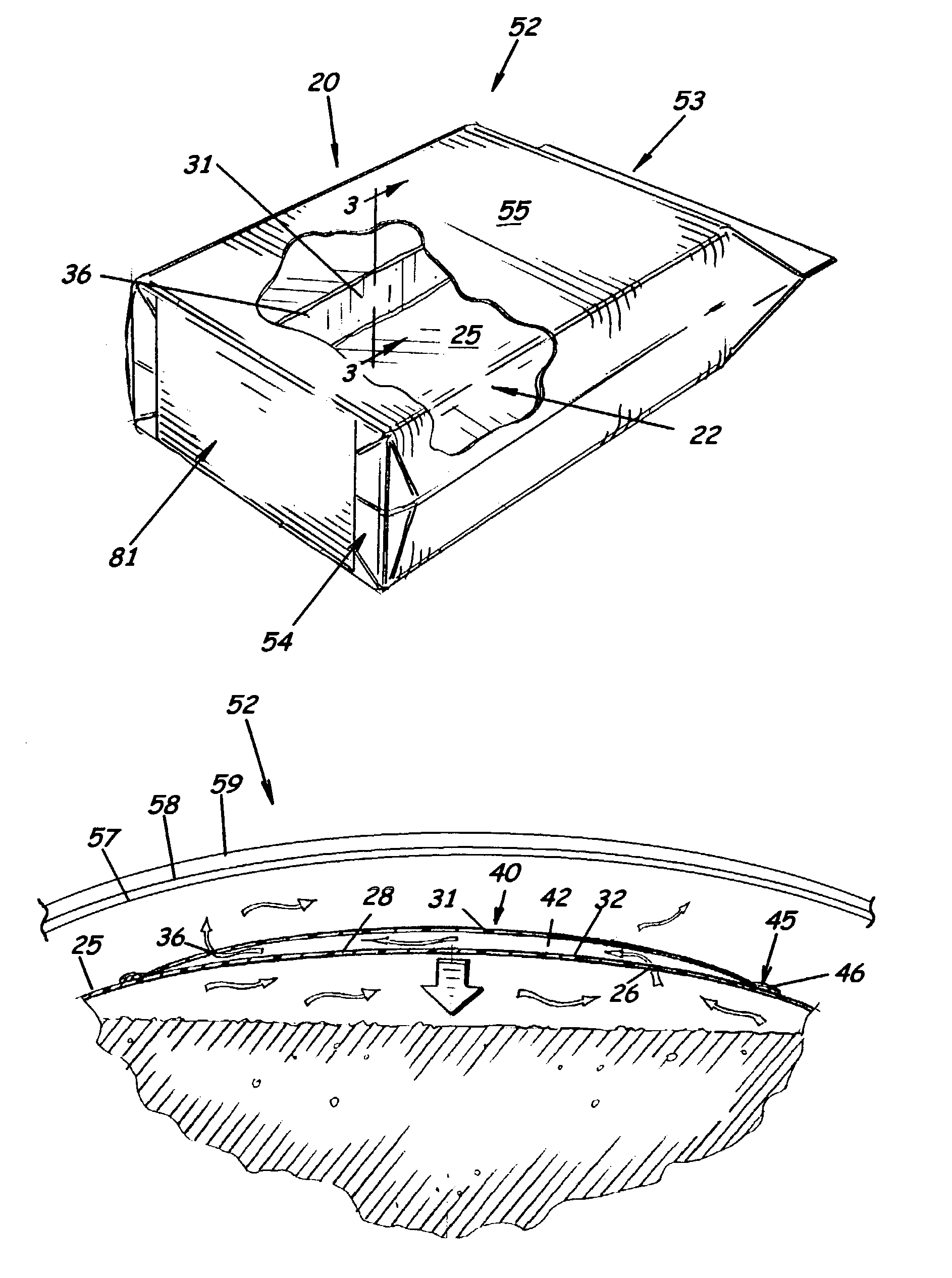

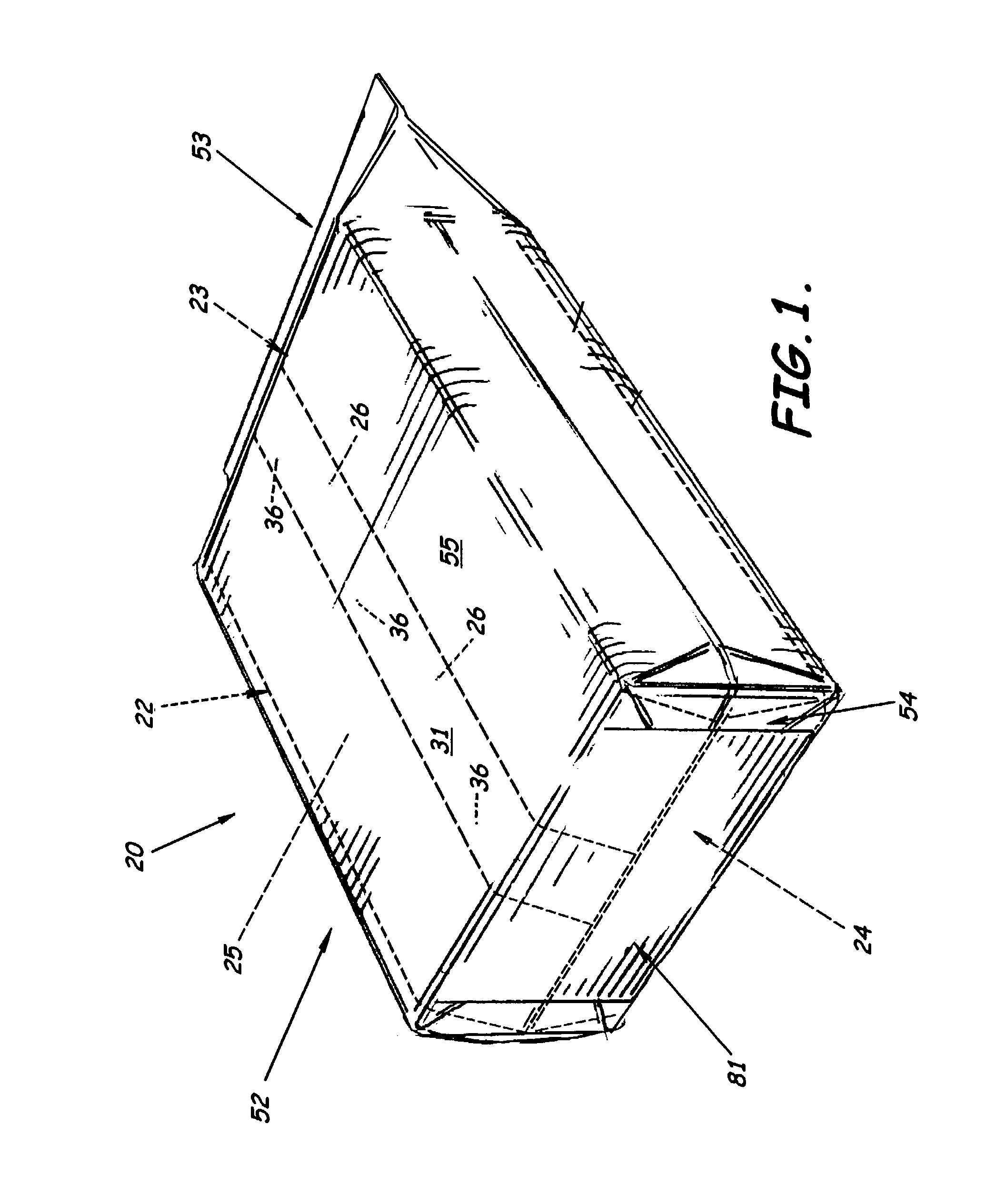

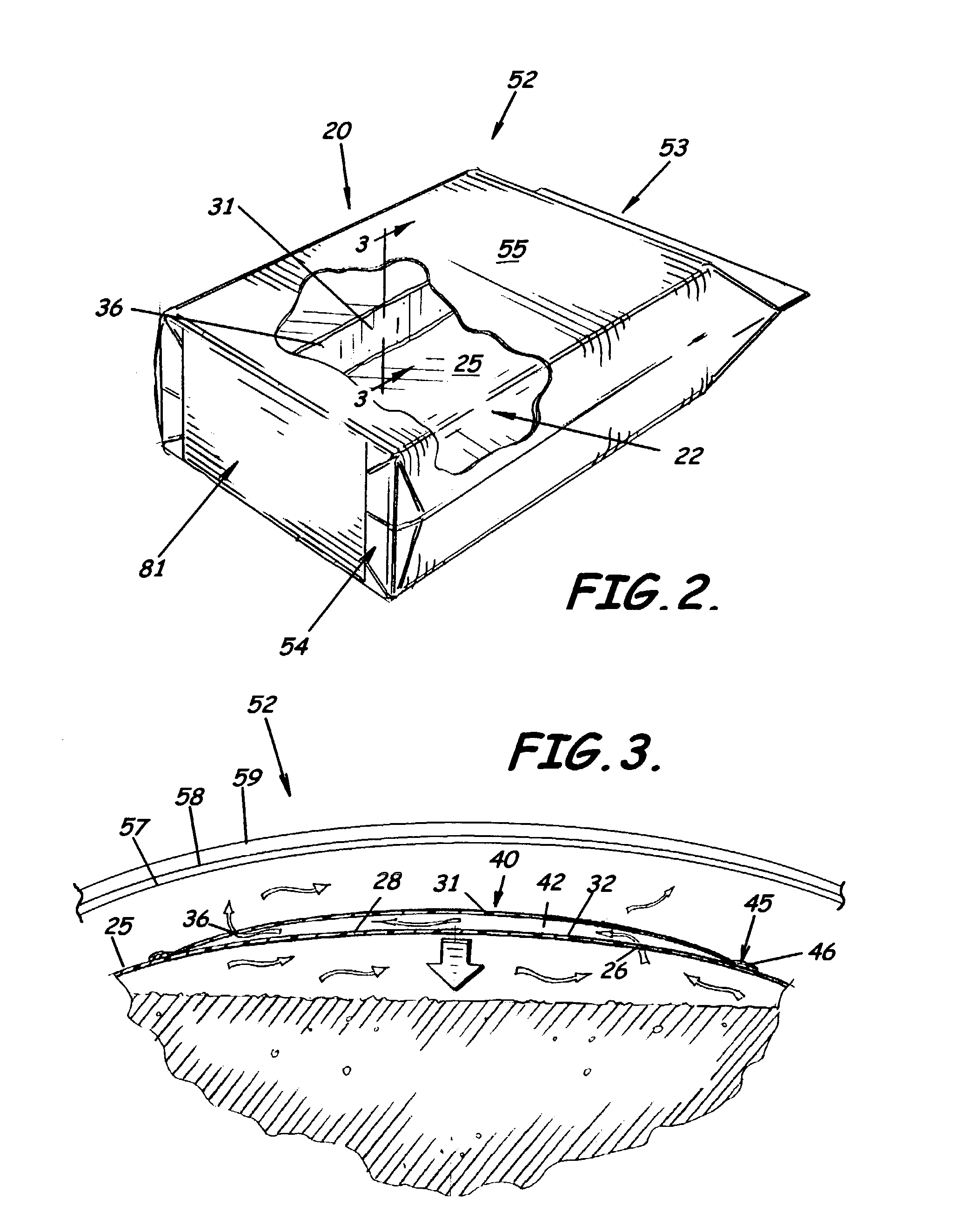

Multiwall vented bag, vented bag forming apparatus, and associated methods

Owner:HOOD PACKAGING

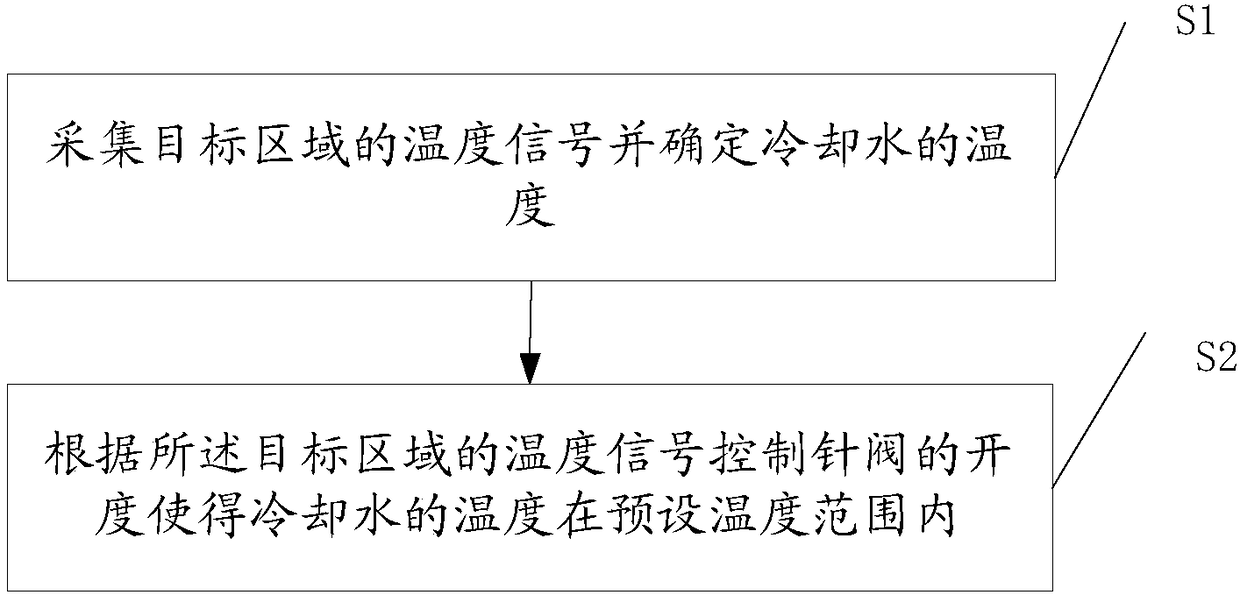

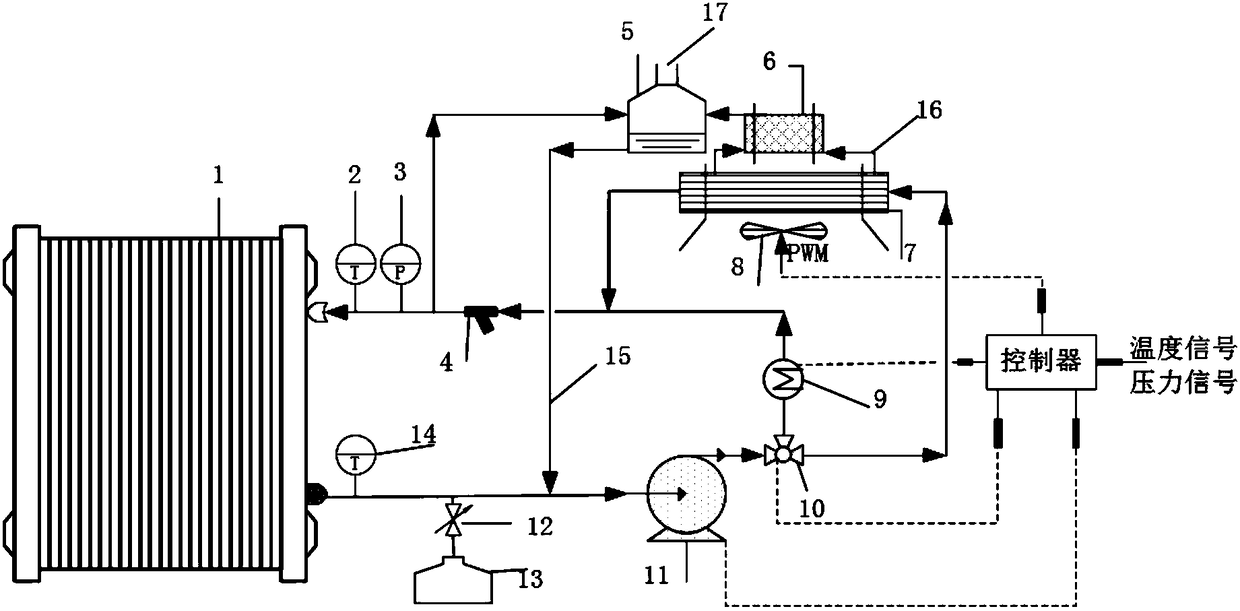

Thermal management device, system and method of fuel cell stack

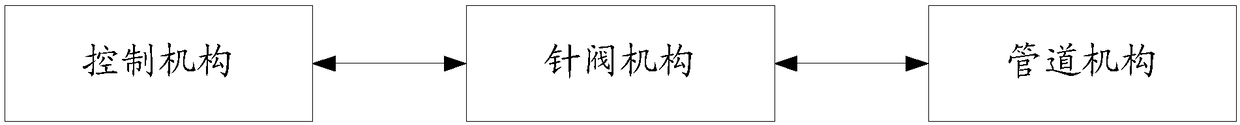

PendingCN108091903APrecise temperature controlEasy to fillFuel cell heat exchangeControl flowFuel cells

The invention proposes a thermal management device, system and method of a fuel cell stack. The device comprises a pipeline mechanism, a cooling liquid inlet, a control mechanism and a needle valve mechanism, wherein the pipeline mechanism penetrates through the fuel cell stack and is connected with a water box, a heat sink and a water pump, the cooling liquid inlet is used for circularly coolinga cooling liquid discharged out of a cooling liquid outlet of the fuel cell stack and then transmitting the cooling liquid to the fuel cell stack, the control mechanism is connected with a data acquisition device and is used for determining a temperature of the cooling liquid according to a temperature signal acquired by a data acquisition device and controlling opening degree of a needle valve according to the temperature signal so that the temperature of the cooling liquid is within a preset temperature range, the needle valve mechanism is arranged on a path between the water pump and the heat sink and is used for controlling flowing quantity of the cooling liquid of the heat sink according to a signal of the control mechanism, the pipeline mechanism comprises exhaust air ducts, the exhaust air ducts are respectively arranged on a path between the cooling liquid inlet of the fuel cell stack and the water box and on a path between a deionized water tank and the water box and are usedfor transmitting bubbles in the cooling liquid in the pipeline mechanism to the water box.

Owner:TSINGHUA UNIV

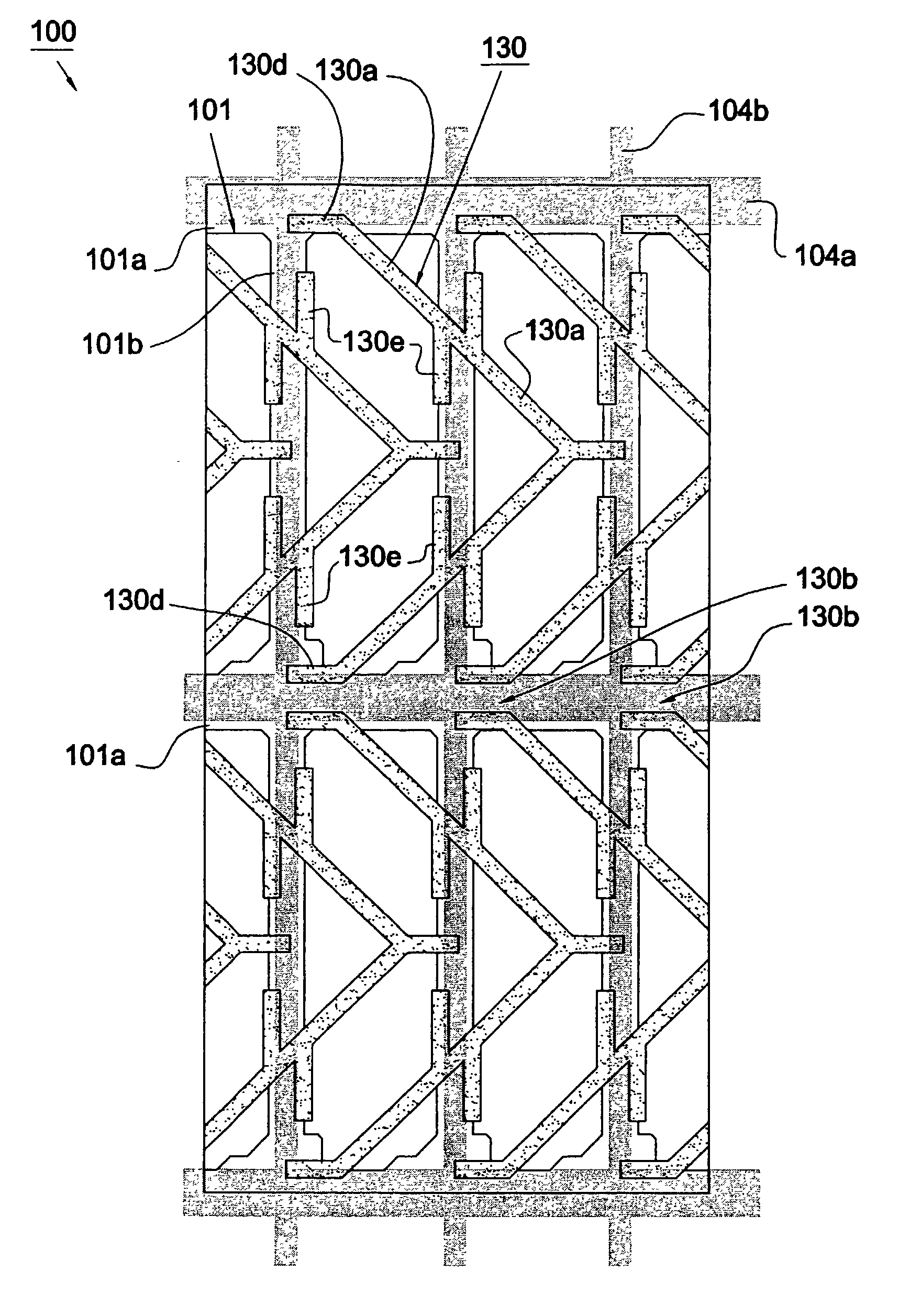

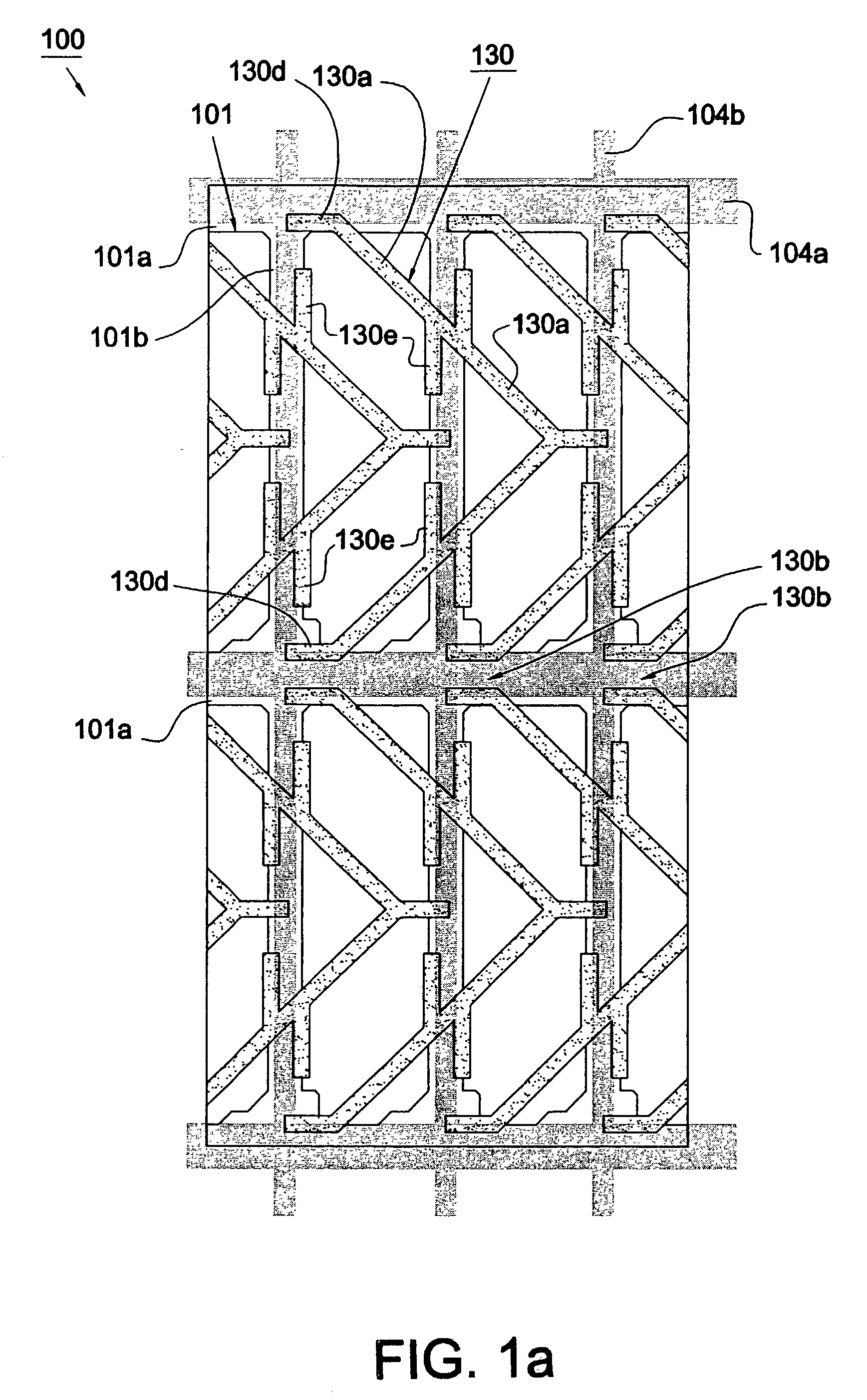

Liquid crystal display including array of protrusions in a broken zigzag pattern all formed within area of light-shielding matrix

A liquid crystal display mainly includes two substrates processed for vertical alignment and a liquid crystal having a negative dielectric constant anisotropy sealed between the two substrates. An array of slits is provided on pixel electrodes formed on one substrate. A light-shielding matrix and an array of protrusions is provided on the other substrate. Each of the first protrusions has a main body being arranged substantially in a zigzag pattern and in parallel to one another. The slits and the main bodies of the first protrusions are arranged alternately. The liquid crystal display is characterized in that the first protrusions have a plurality of breaks formed within the area of the light-shielding matrix.

Owner:INNOLUX CORP

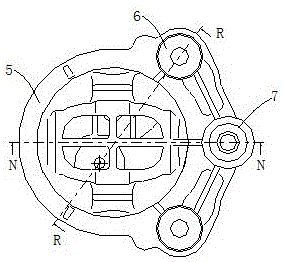

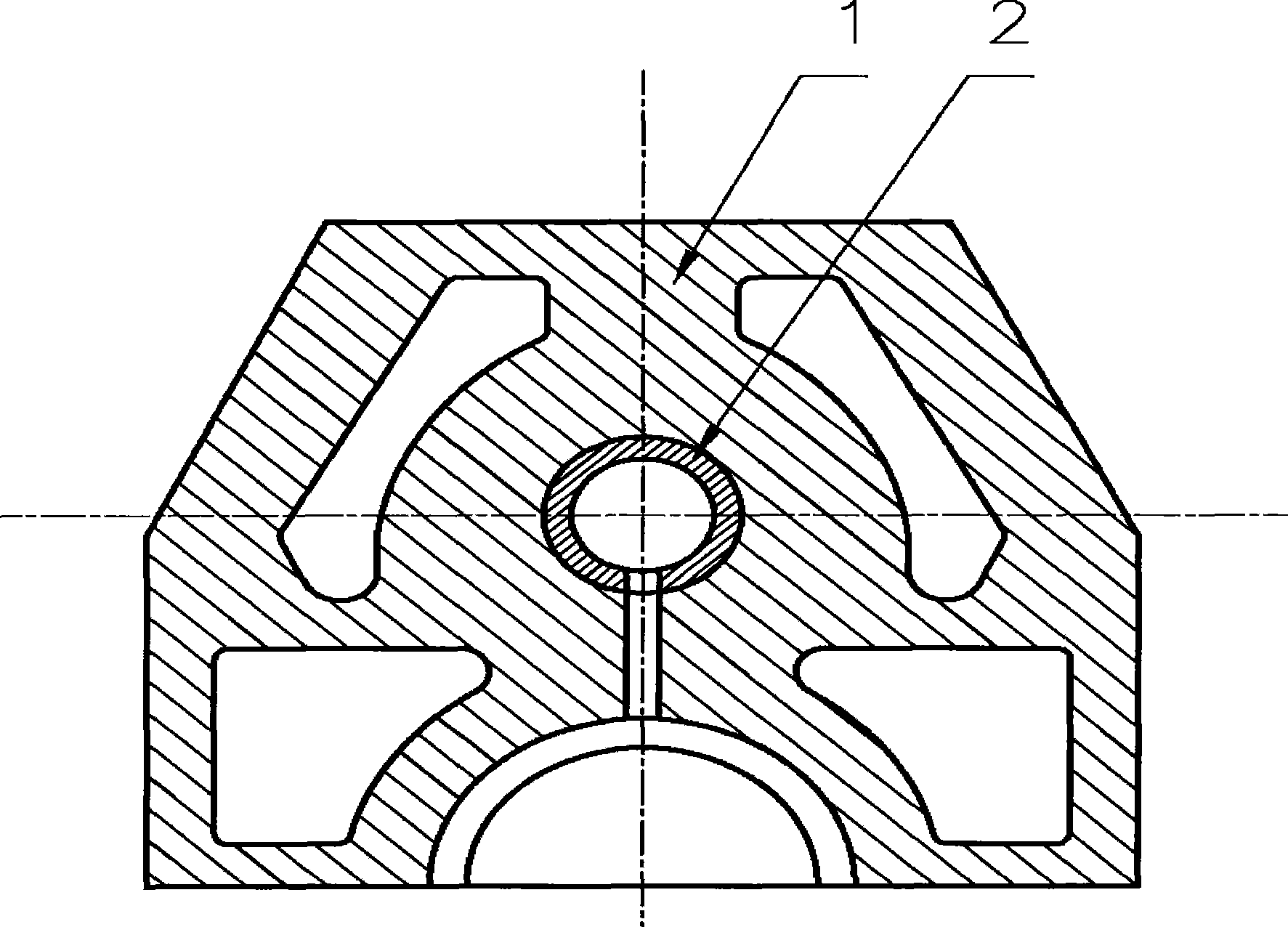

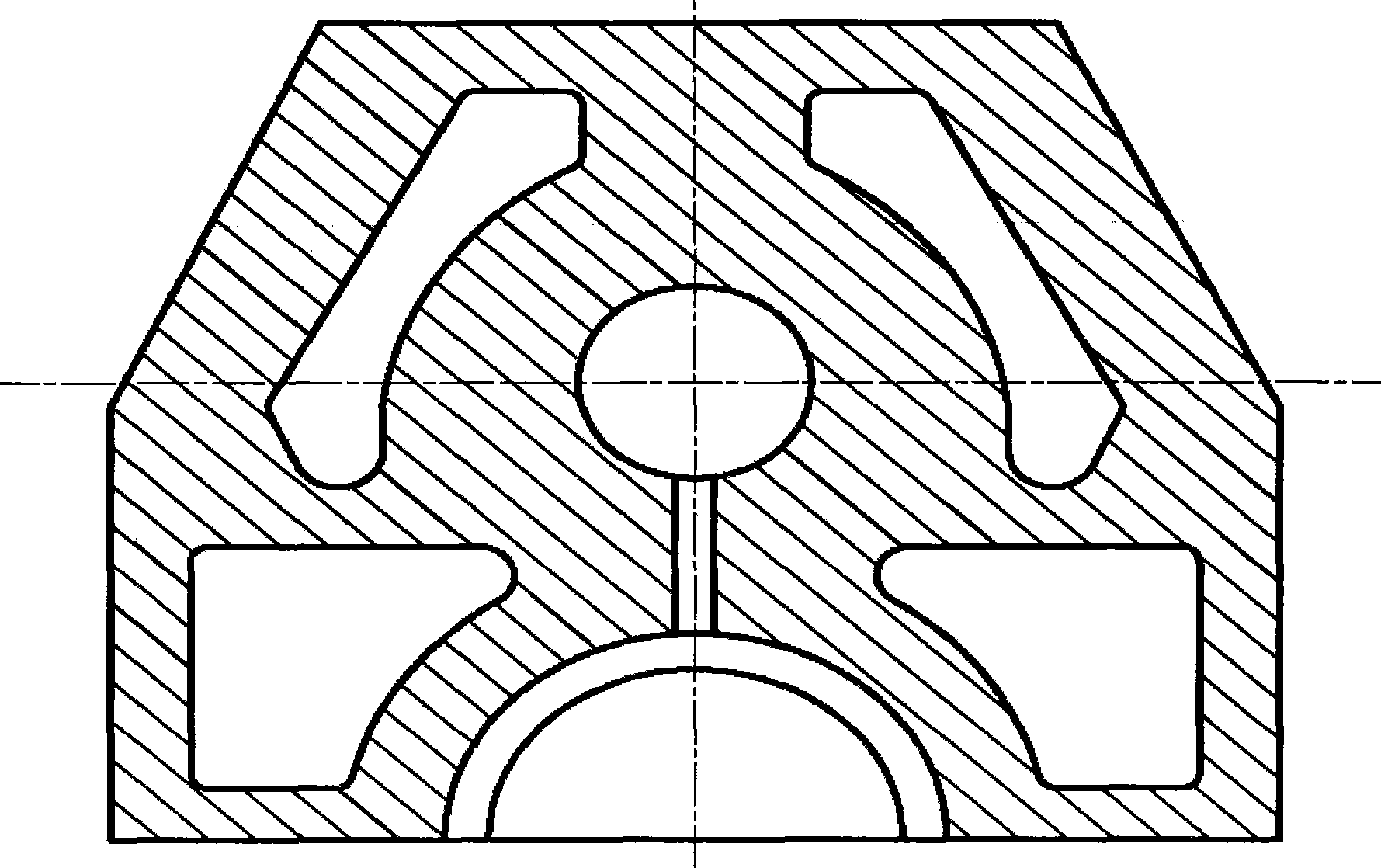

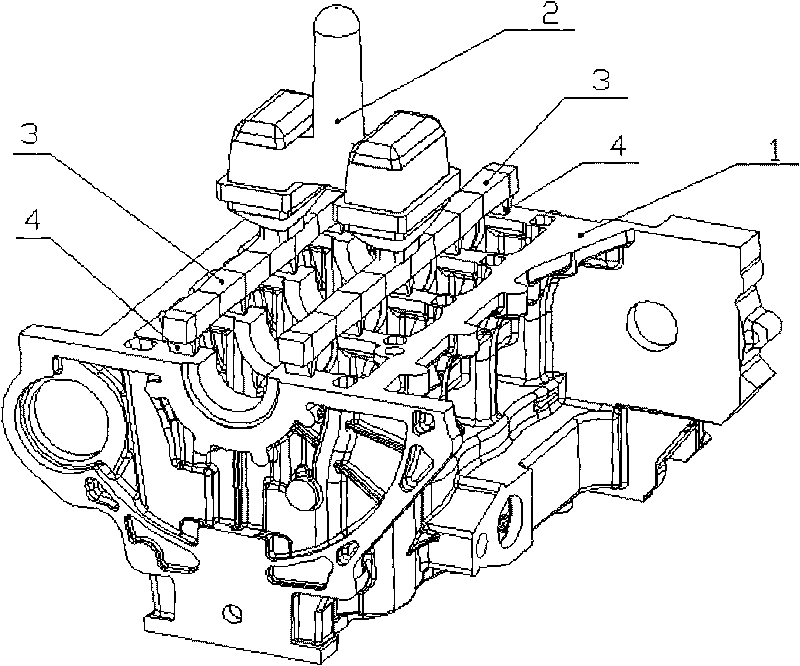

Casting mold and forming method for box body of gearbox

ActiveCN105382206AClear outlineFilled tightlyFoundry mouldsFoundry coresCasting moldMaterials science

The invention provides a casting mold and forming method for a box body of a gearbox and belongs to the technical field of liquid formation of metal. The forming method comprises the following steps that precoated sand is used for core shooting, so that precoated sand blocks are manufactured, then an outer precoated sand mold layer is formed by splicing the precoated sand blocks, and the outer precoated sand mold layer and a sand core are used for forming a casting cavity of the box body of the gearbox; and finally the box body of the gearbox is manufactured through the casting mold in a low-pressure casting way. According to the specific structure of the casting mold, the sand core is located in the center of the casting mold; the casting cavity is formed in the outer layer of the sand core and mainly formed by the sand core and the outer precoated sand mold layer; an outer resin sand mold layer is arranged on the outer layer of the outer precoated sand mold layer, and the outer precoated sand mold layer and a sand box are connected through the outer resin sand mold layer, so that the casting mold is formed. According to the casting mold and forming method for the box body of the gearbox, the cavity which is formed by the precoated sand and used for large complicated castings is used for low-pressure casting for the first time, the precoated sand blocks are subjected to core shooting under pressure, high-temperature sintering formation is conducted, filling is compact, and the situations that sand filling is incompact and sand adhesion defects are caused due to human factors during resin sand molding are avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

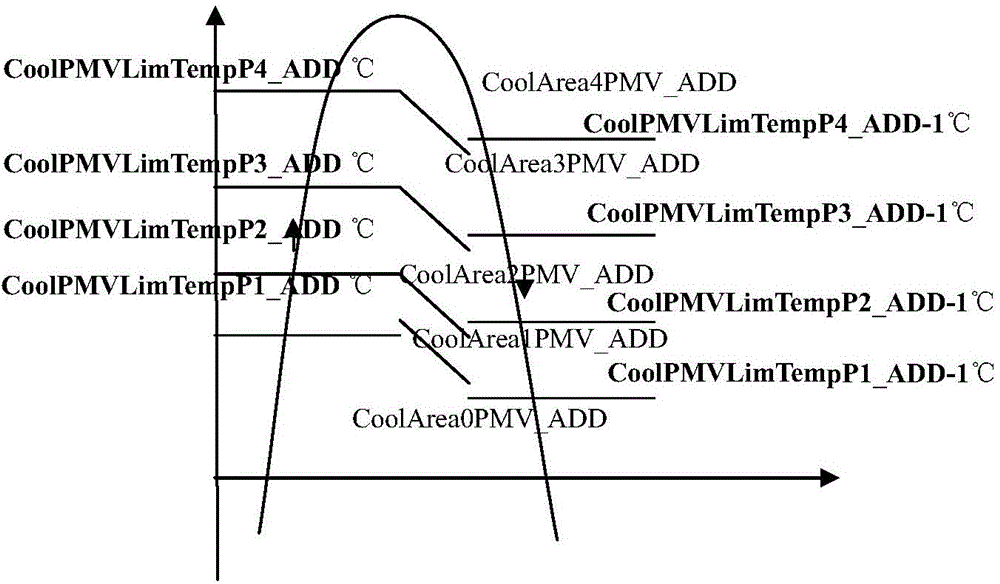

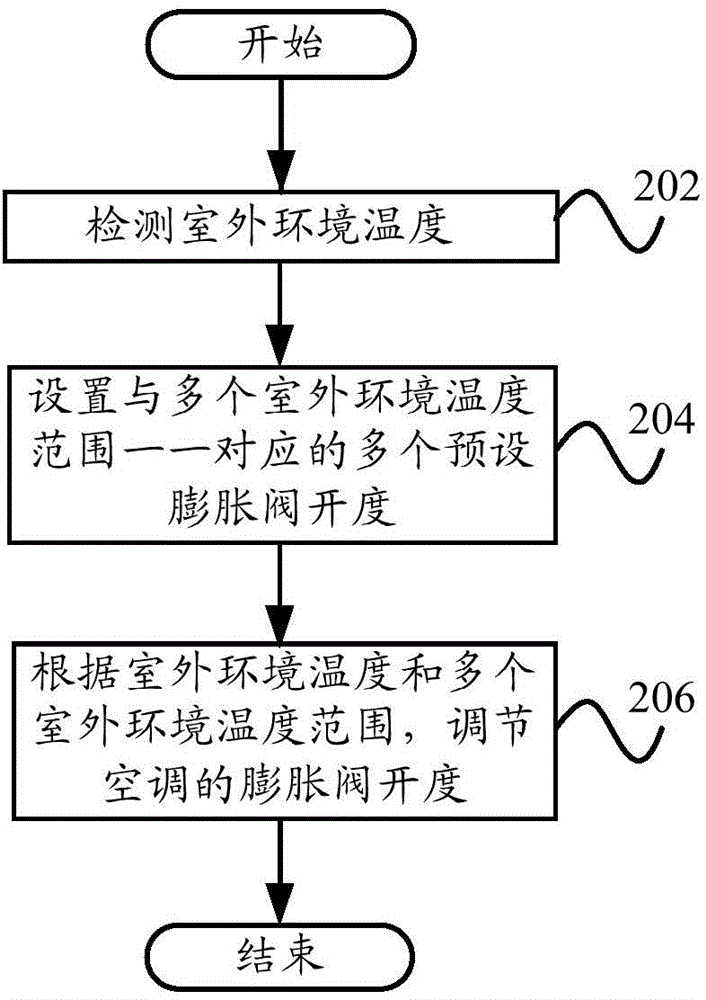

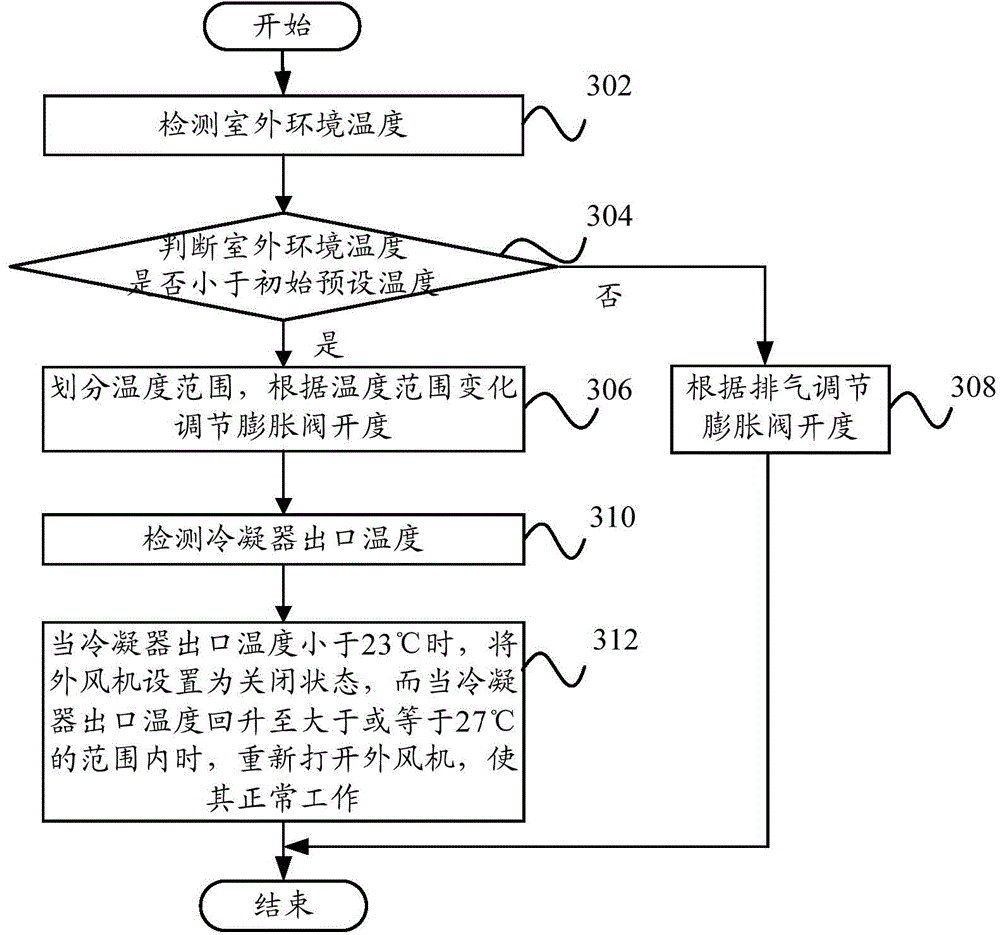

Refrigeration control method and system and air-conditioner

ActiveCN104132422ASolve the problem of difficult and efficient coolingEasy to ventSpace heating and ventilation safety systemsLighting and heating apparatusControl systemEngineering

The invention provides a refrigeration control method used for an air-conditioner. The method includes the steps that the outdoor environment temperature is detected; the opening degree of a plurality of preinstalled expansion valves corresponding to a plurality of outdoor environment temperature ranges one by one is set; the opening degree of the expansion valves of the air-conditioner is adjusted according to the outdoor environment temperature and the outdoor environment temperature ranges. Correspondingly, the invention further provides a refrigeration control system and the air-conditioner. According to the technical scheme, the opening degree of the expansion valves can be increased in time when the outdoor environment temperature is excessively low, so that the pressure of a condenser is improved, and the refrigerating capacity of the air-conditioner can be prevented from being lowered substantially.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

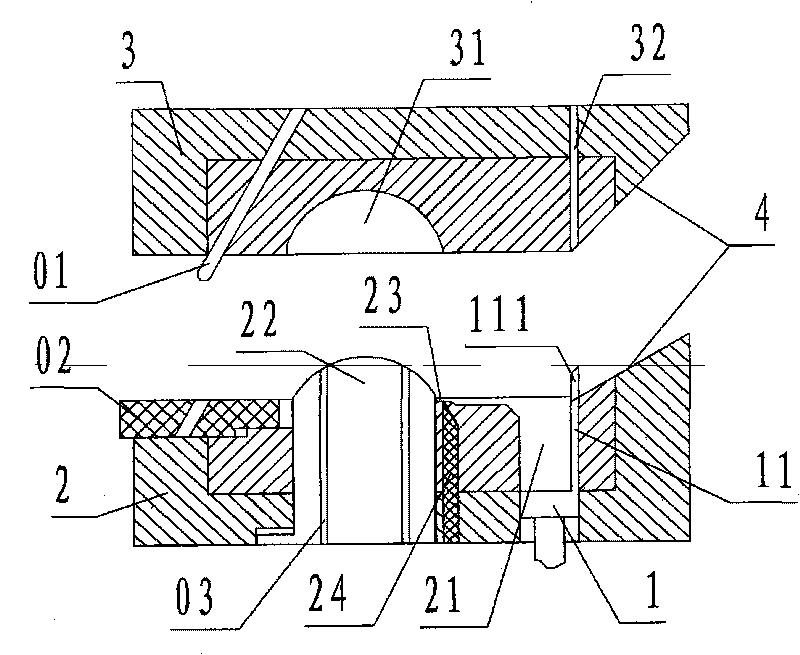

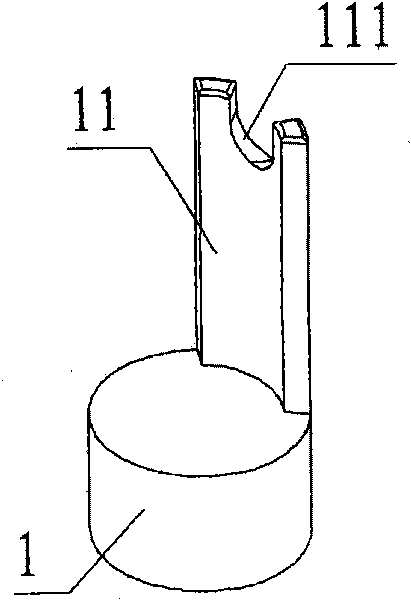

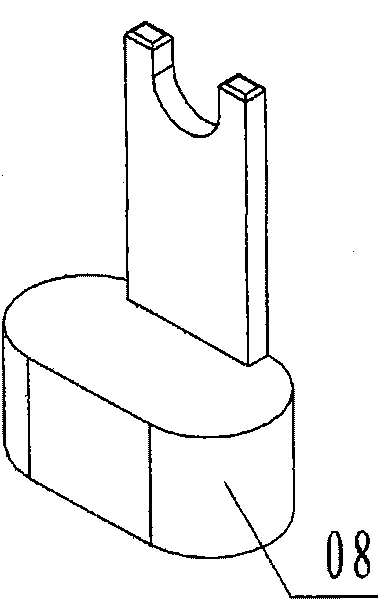

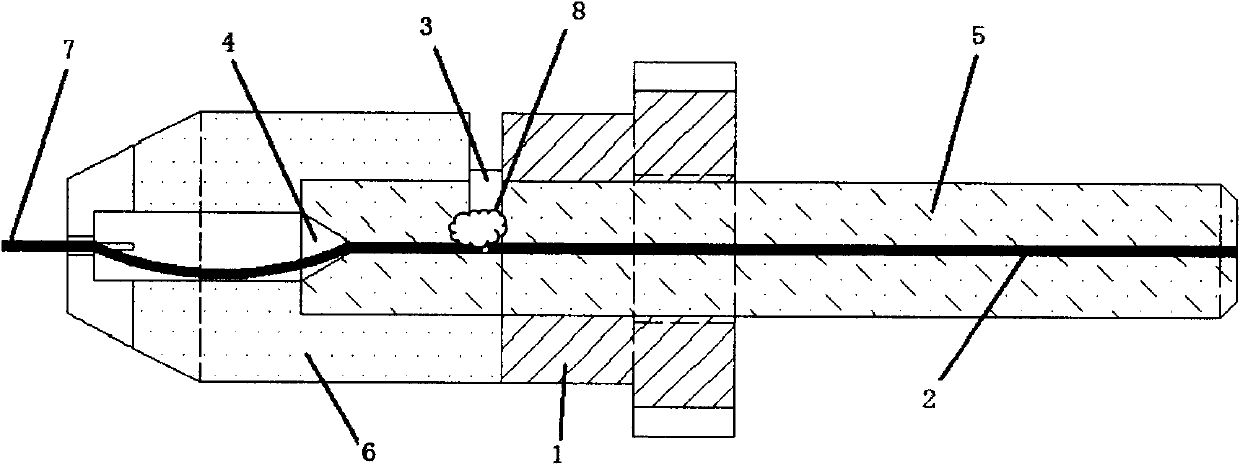

Quick pre-buried optical fiber connection device

InactiveCN102169212ALow machining accuracy requirementsImprove matchCoupling light guidesEngineeringOptical fiber cable

The invention relates to a quick pre-buried optical fiber connection device. The device comprises a wheel handle (1), a pre-buried optical fiber (2), a nominal aperture insertion core (5) and a bushing (6); an opening (3) is formed on the insertion core (5); a conical guide opening (4) is formed at one end of the opening (3); one end of the pre-buried optical fiber (2) is placed in the opening (3) of the insertion core (5) and butted with an optical fiber to be butted, and the other end of the pre-buried optical fiber (2) is placed on the end face of the insertion core (5) and polished to be a standby; a space retained in an inner hole of the bushing (6) is used for keeping a tiny bent state of the optical fiber to be butted and has a function of locking the optical fiber to be butted; and matching liquor (8) is prepared in the opening (3). During use, the optical fiber to be butted (7) enters the opening (3) of the insertion core (5), where the insertion core (5) and the pre-buried optical fiber (2) are butted, through the bushing (6). The connection device has a simple structure, low production cost and simple and quick operation, guarantees the butting precision of the optical fiber to be butted, effectively reduces insertion loss of joints and increases echo loss.

Owner:NANJING UNIV OF POSTS & TELECOMM

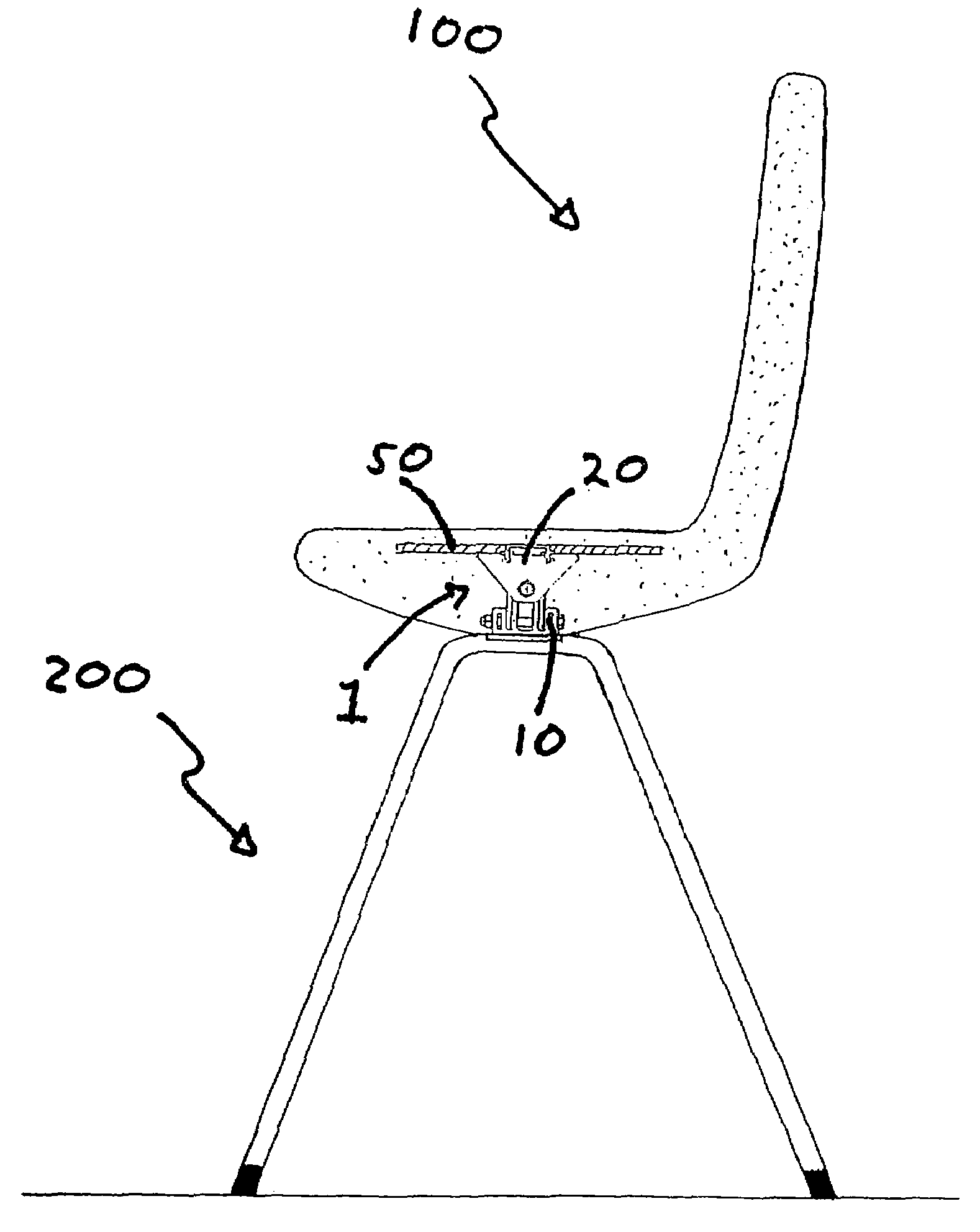

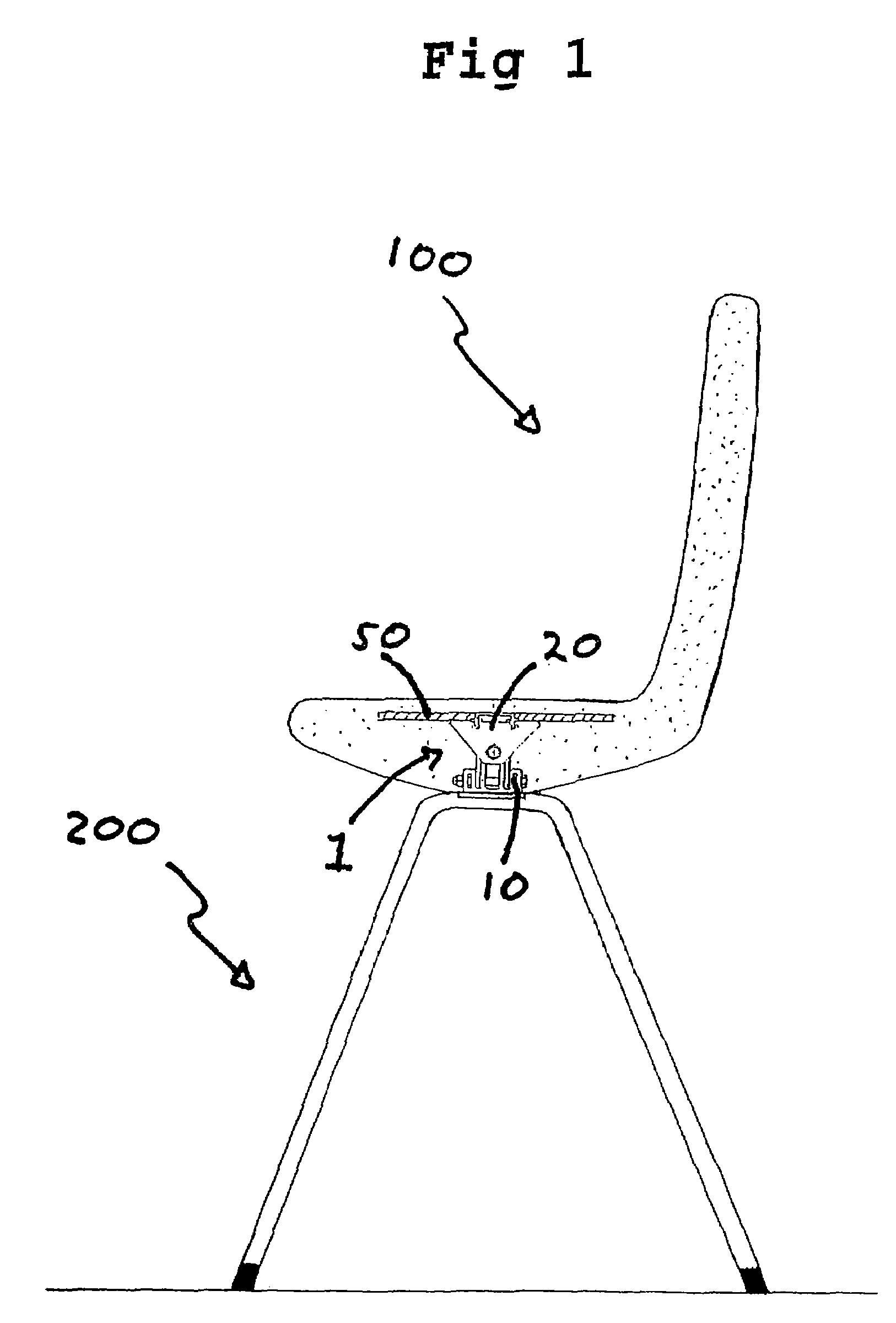

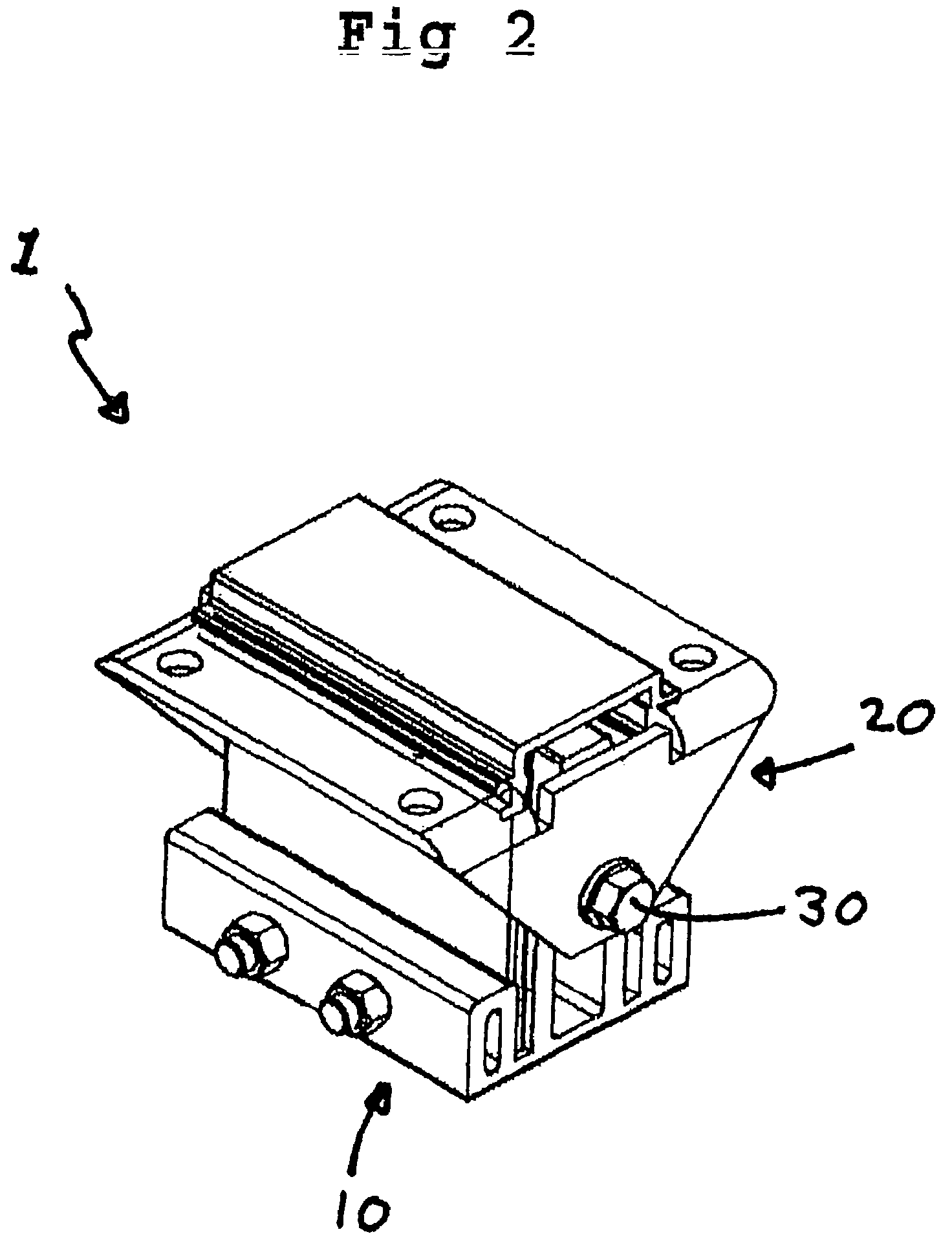

Mobile joint suitable for a sitting device

InactiveUS7434880B2Function increaseIncrease stiffnessOperating chairsDental chairsParallel plateEngineering

The present invention relates to a mobile joint (1) with spring resistance, suitable for a sitting device, comprising a first and a second joint element (10, 20), which are pivotally connected by a shaft (3), to allow tilting of the sitting device caused by the displacement of the users weight, comprising a first and a second parallel plate spring (18, 19) with first and second ends, with an intermediate blocking element (11), wherein each plate spring (18, 19) in the first end are connected to the first joint element (10), and in the second end are glidingly abutting the second joint element (20), the first and second plate spring (18, 19) each having an axis of rotation that is displaced in relation to each other and the shaft (3).

Owner:VARIER FURNITURE AS

Composite material used for casting aluminum alloy box body oil duct and method thereof

InactiveCN103480794AContinuous adjustment of thermophysical parametersAvoid the hidden danger of entering the oil passageFoundry mouldsFoundry coresBodies oilSurface finish

The invention belongs to the field of casting technologies, and particularly relates to a composite material used for casting an aluminum alloy box body oil duct and a method of the composite material used for casting the aluminum alloy box body oil duct. In order to solve the deep hole casting technical problem which is difficult to solve through an original casting technique, avoid the phenomenon that drilling is performed after hole-forming through an inlaying-cast steel pipe, and thus the oil duct is not homocentric and the aluminum base face is scratched, and solve the problem that a box body oil duct made of a common sand core can not meet the requirement for leakproofness, the composite material comprises metal pills, iron powder, roughing sand and a self-hardening resin sand binding agent, the oil duct core is made from the composite material to take place of an oil duct hole made of a steel pipe, interlayer defects can not be generated between the steel pipe and an aluminum substrate, and the potential hazard that steel scrapes enter the oil duct is avoided. According to the oil duct core made from the composite material, a compact chilling layer can be formed around the oil duct and meet the requirement for the leakproofness of the oil duct and is easy to scatter and low in gas forming, the surface of the oil duct is good in smoothness, and the oil duct can meet use requirements even if the oil duct is not subjected to machining.

Owner:STATE RUN NO 616 FACTORY

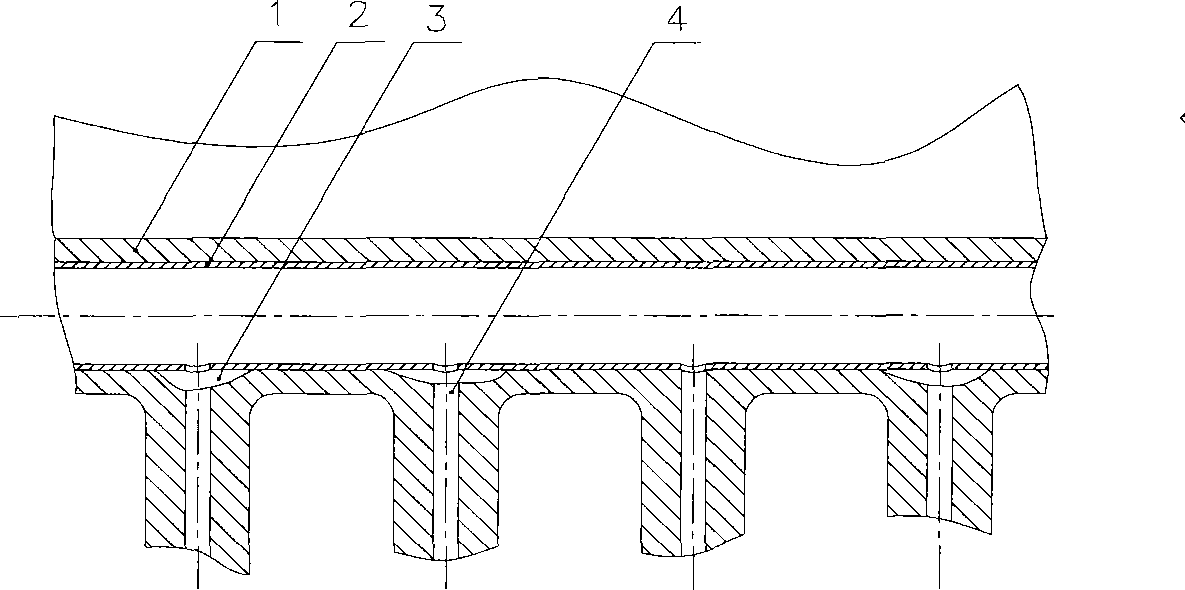

Cylinder block casting device and method

InactiveCN101733363ALiquid surface activePrevent floatingFoundry mouldsFoundry coresSlagCasting mold

The invention discloses a cylinder block casting device and a method, wherein the device comprises a cylinder block casting mold and a cylinder block casting; the cylinder block casting consists of a pouring gate, a sorue, a cross gate, an ingate and a cavity; and the cylinder block casting is horizontally arranged on the cylinder block casting mold when the cylinder top surface of the cylinder block faces downwards and the machine leg surface of the cylinder block faces upwards. The method comprises the following steps: by using the above cylinder block casting device, the casting liquid is injected into the cylinder block casting device from the pouring gate of the cylinder casting, flows through the sorue, the cross gate and the ingate in sequence and flows in the cavity of the cylinder block casting to complete the casting of the cylinder block. The device and the method in the invention can overcome the defects of poor effects of exhaust and slag dam, low casting yield, easily-damaged bland, uneven wall thickness and the like so as to realize the purposes of good effects of exhaust and slag dam, high casting yield, difficult damaged blank, even wall thickness and high product quality.

Owner:GUANGXI YUCHAI MASCH CO LTD

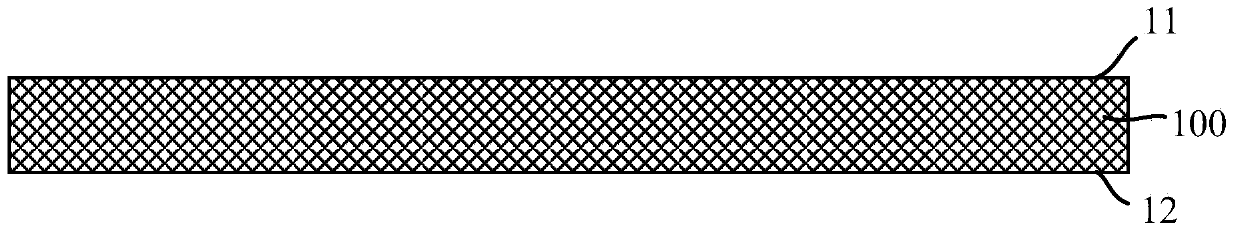

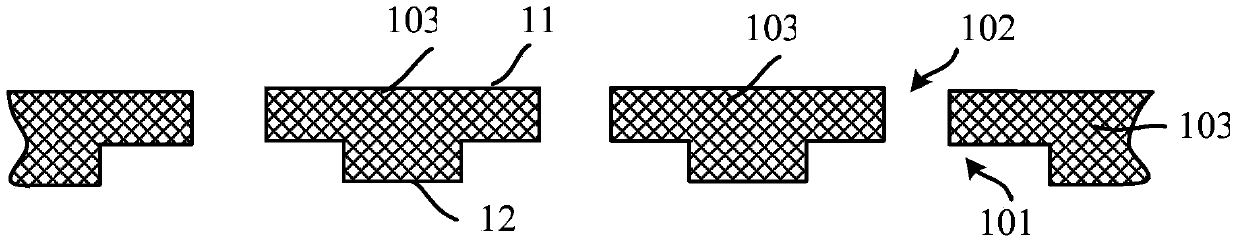

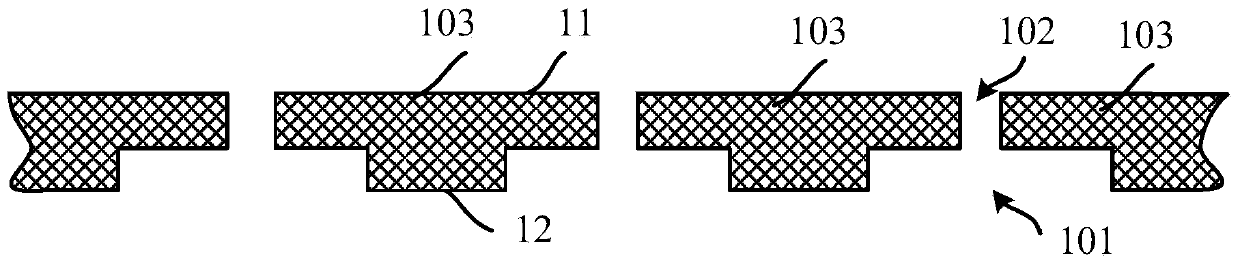

Lead frame and packaging structure forming methods

ActiveCN103745931AReduce areaAvoid short circuitSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

The invention discloses lead frame and packaging structure forming methods. The packaging structure forming method comprises the following steps: a lead frame is provided, wherein the lead frame comprises a first surface and a second surface which is opposite to the first surface, the lead frame is provided with a plurality of bearing units which are arranged in a matrix manner and medium-strength ribs for fixing the bearing units, each bearing unit comprises a plurality of discrete pins, and a first opening is formed between every two neighboring pins; a first plastic packaged layer for filling the first openings is formed; an insulating layer is formed on the first surface of the lead frame and the surface of the first plastic packaged layer, wherein second openings for exposing surfaces of the pins are formed in the insulating layer; a plurality of semiconductor chips are provided, wherein each semiconductor chip is provided with a plurality of bonding pads, and metal bumps are formed on the bonding pads; and the plurality of semiconductor chip are arranged on the lead frame in a flipping manner, and the metal bumps on the semiconductor chips and the surfaces of the pins exposed out from the second openings are soldered together to form a plurality of packaging units which are arranged in a matrix manner. According to the method of the invention, the packaging efficiency can be improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

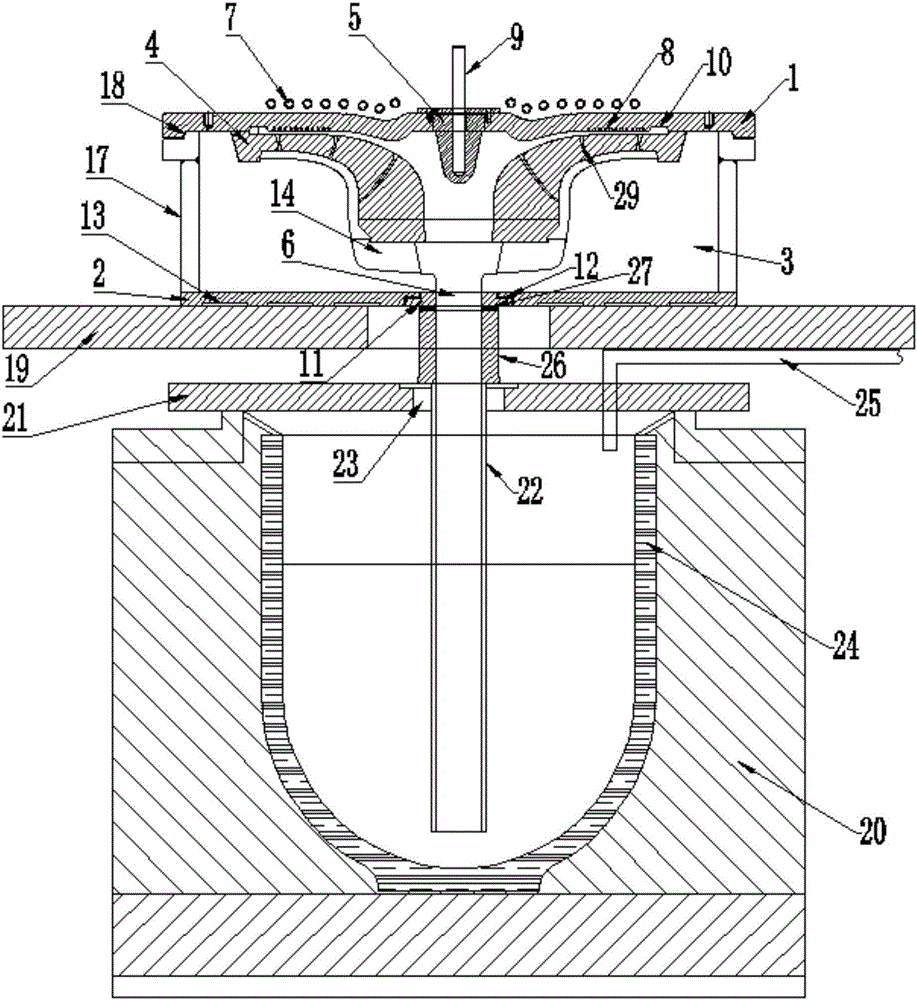

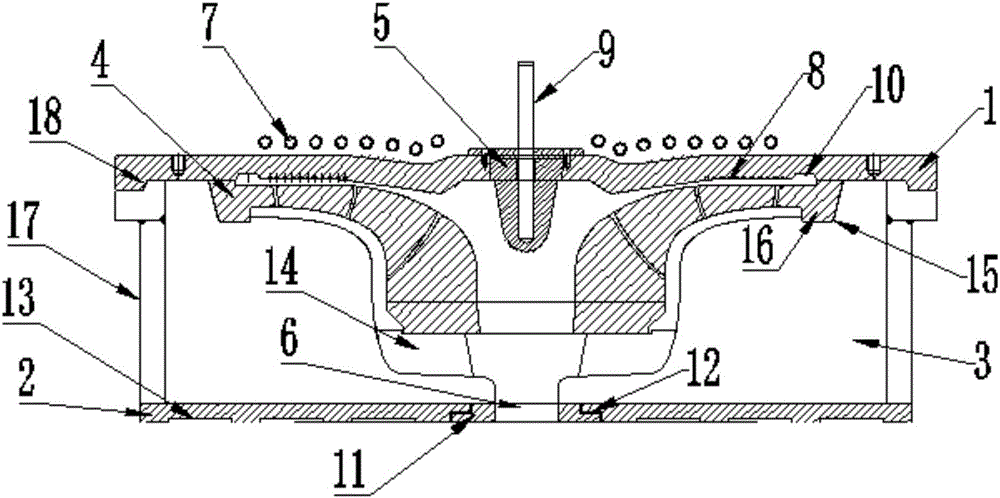

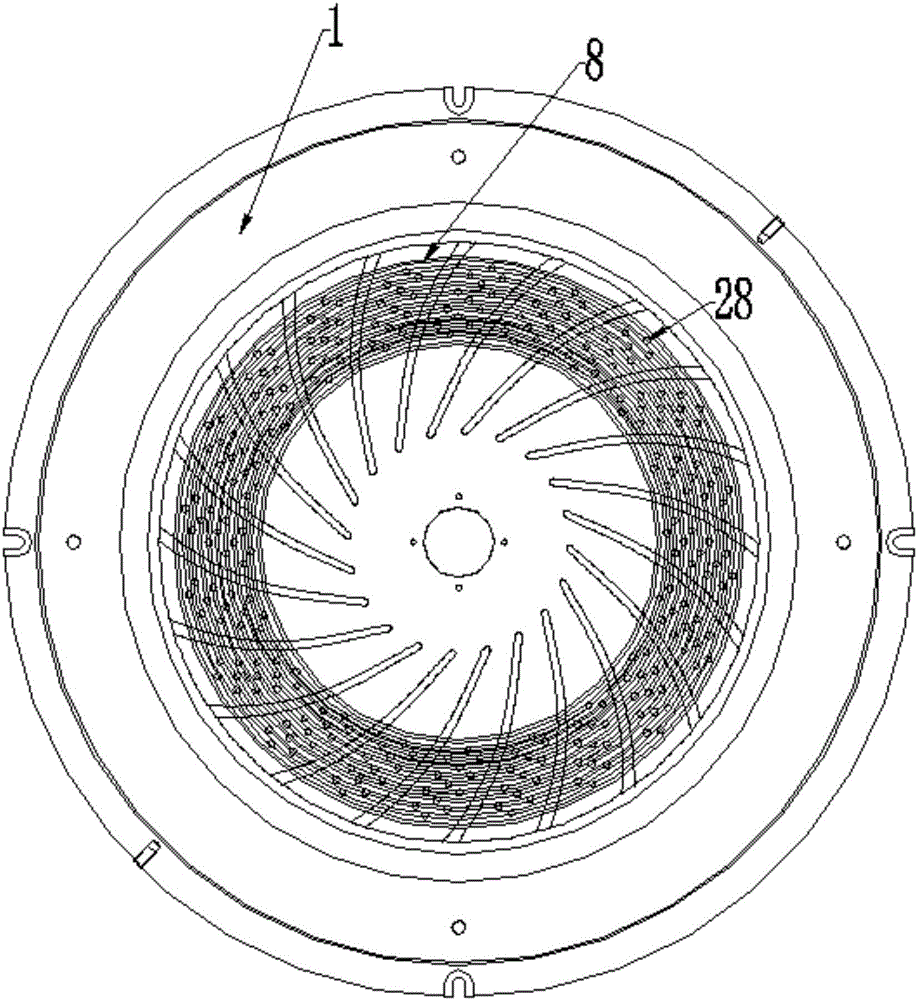

Low-pressure casting method, cooling control process and exhaust system of large impeller

The invention discloses a low-pressure casting method, a cooling control process and an exhaust system of a large impeller. The low-pressure casting method comprises the steps that a manufactured forming element and a manufactured mold core are dried, and a low-pressure casting mold of the impeller is preheated; a casting material is put in a casting device, heating and smelting are carried out to form a casting solution, and slag removal is carried out on the casting solution when the casting solution reaches the set temperature; the casting mold of the impeller is assembled, and the casting mold of the impeller and the casting device are connected to form an impeller casting system; the low-pressure casting device is subjected to low-pressure mold filling along a set pressure curve; after mold filling is finished, the low-pressure casting mold of the impeller is cooled; and after the temperature of the low-pressure casting mold of the impeller is reduced to the set temperature, the impeller is taken out to be cleaned. In the casting process, the pressure and the speed are adjusted, and therefore short run can be reduced; aluminum liquid oxidization can be controlled by adjusting the aluminum liquid temperature; and shrinkage porosity can be reduced by adjusting the cooling process.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

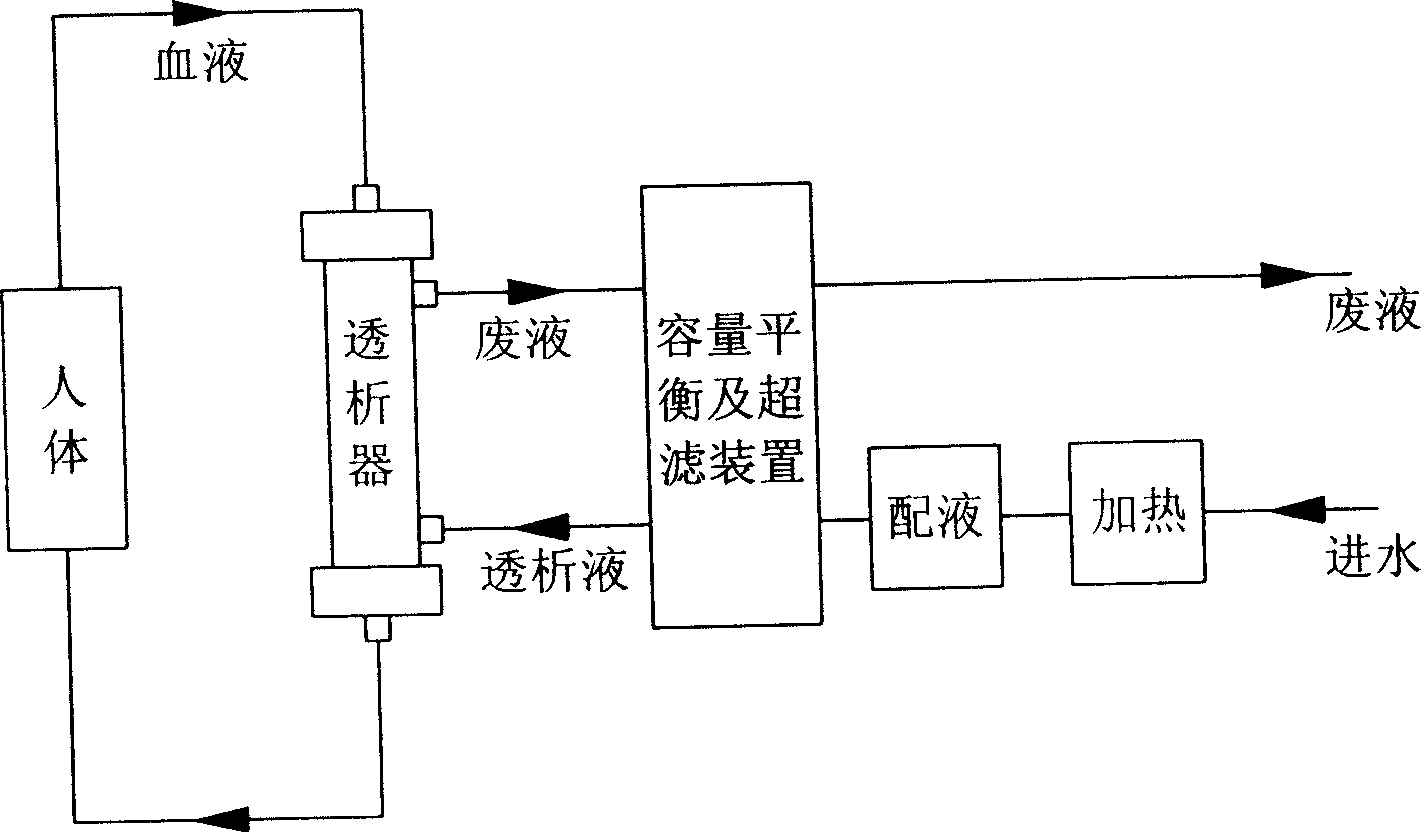

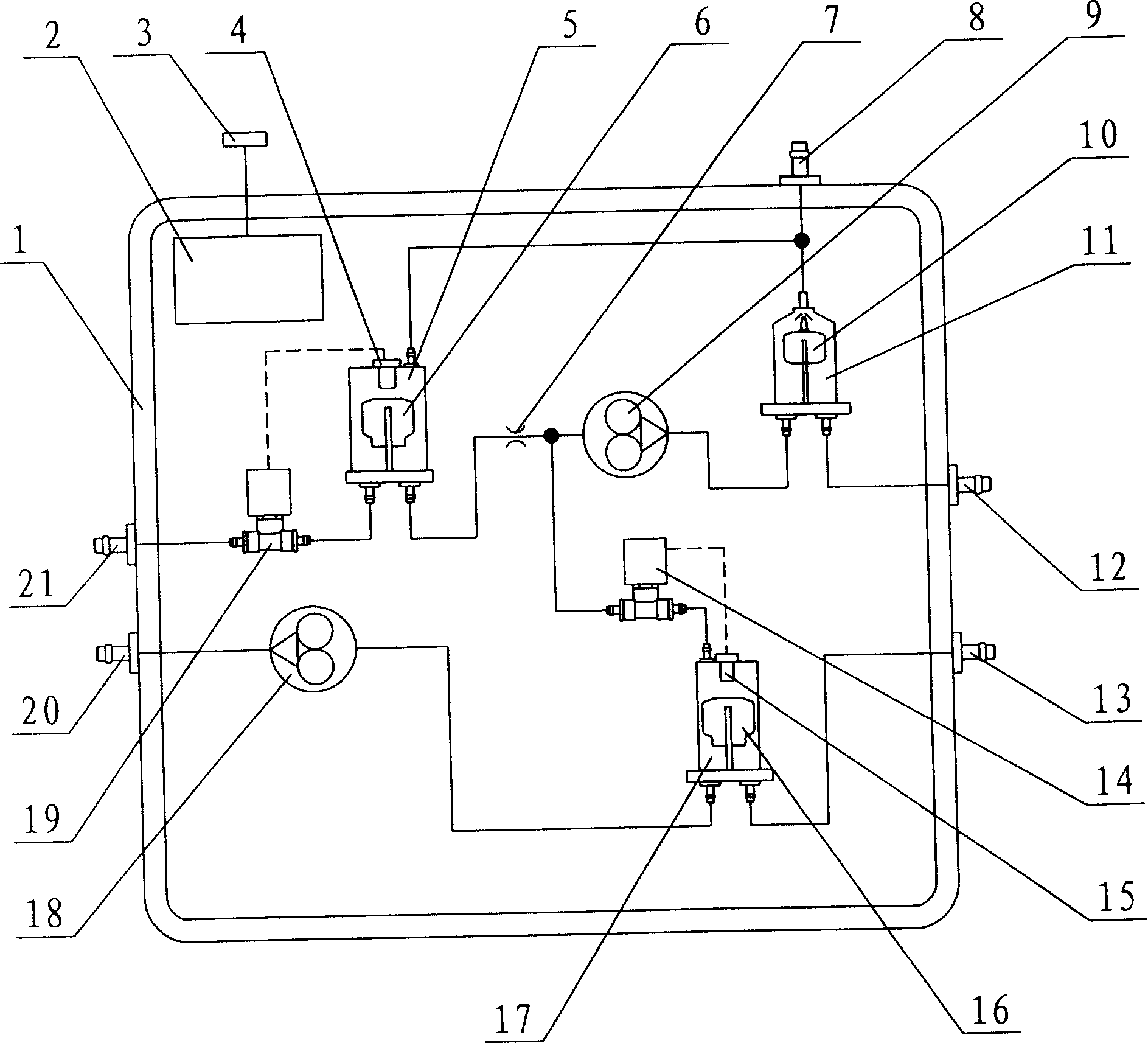

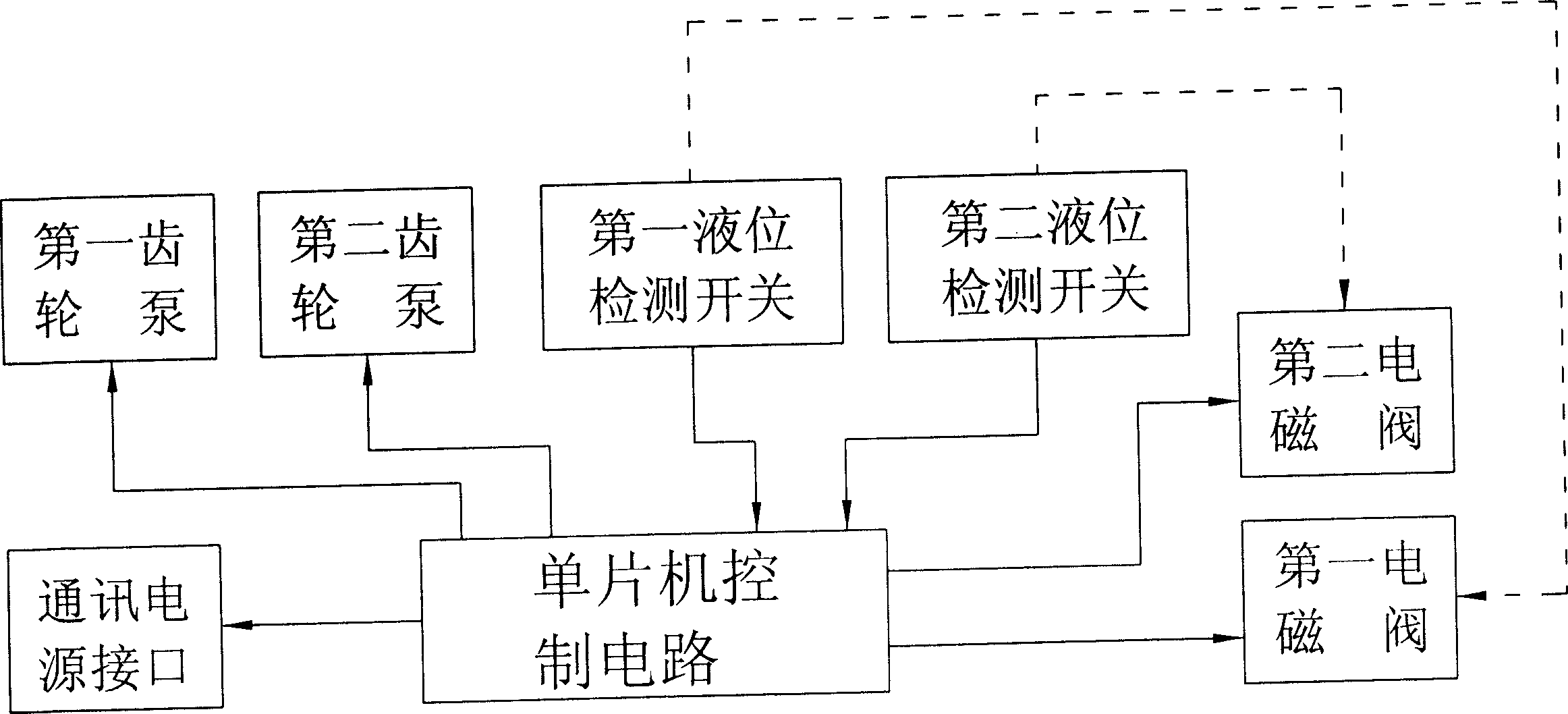

De-airing device for purifying blood

The de-airing device for purifying blood has one box with water inlet, water outlet, air exhaust, dialysate joint and waste liquid joint. The water inlet is connected to the liquid inlet of the flow controlling choke; the liquid outlet of the flow controlling choke is connected to two pipelines, including the first pipeline connected to the liquid inlet of the first de-airing tank via a gear pump and the second pipeline connected to the liquid exhaust of the second de-airing tank via a second solenoid valve; the liquid outlet and the air exhaust of the first de-airing tank are connected separately to the dialysis joint and the air exhaust joint pipeline; and the liquid inlet and the liquid outlet of the second de-airing tank are connected separately to the waste liquid joint pipeline and the water outlet joint via a second gear pump. The present invention can avoid air embolism to blood for normal dialysis treatment.

Owner:SWS HEMODIALYSIS CARE CO LTD

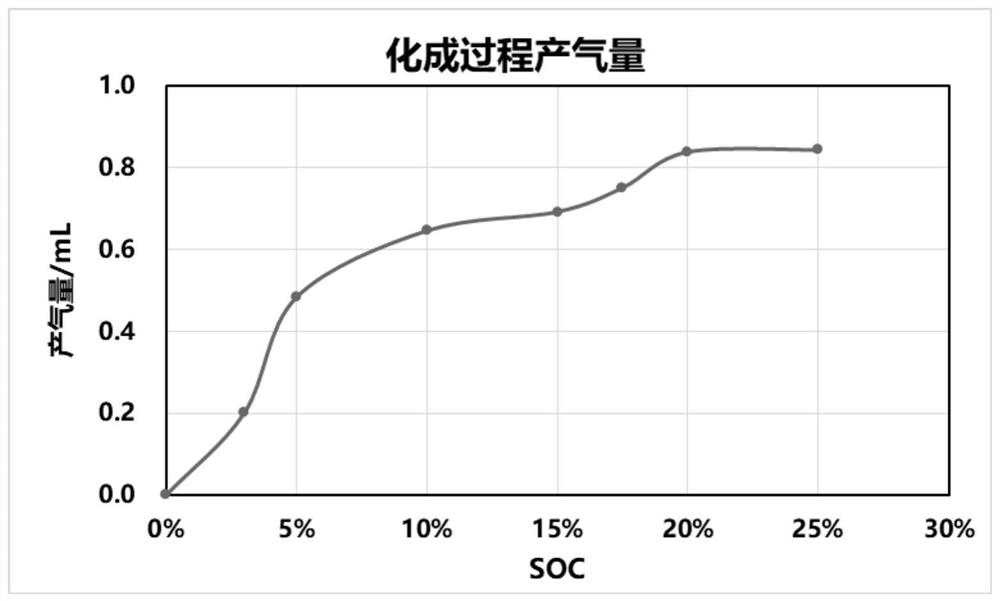

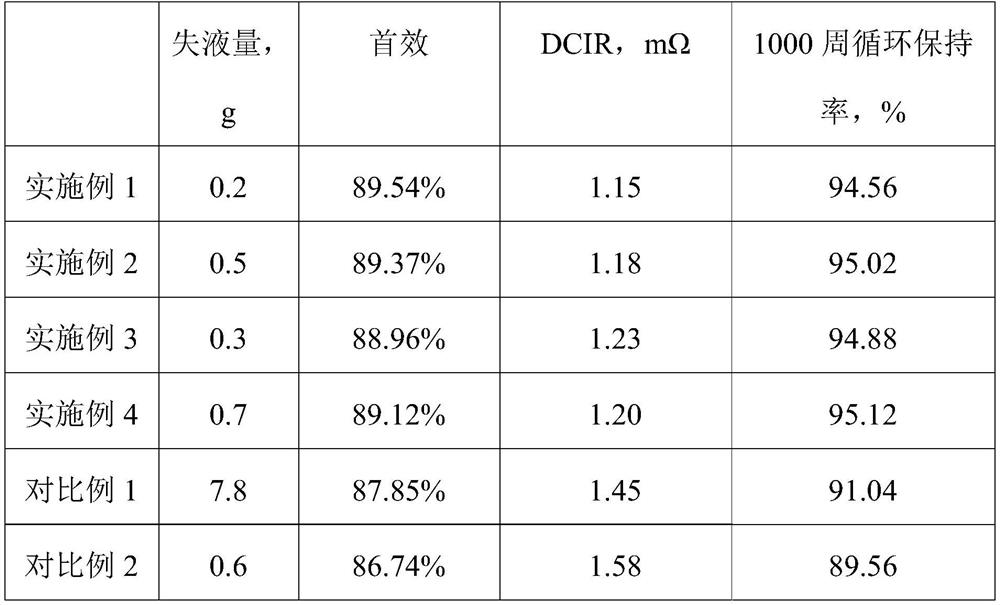

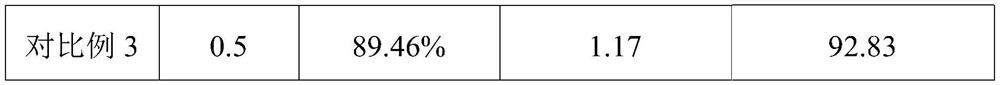

Lithium ion battery formation process and lithium ion battery obtained by same

ActiveCN111883866AReduce fluid lossAvoid cell swellingSecondary cells charging/dischargingPhysicsLithium electrode

The invention relates to a lithium ion battery formation process and a lithium ion battery obtained by the lithium ion battery formation process. The lithium ion battery formation process adopts a mode of combining segmented negative pressure and segmented current, and the formation process comprises three stages: in the first stage, the negative pressure is 20-60Kpa, and the lithium ion battery is charged to 5-15% SOC at a constant current of 0.05-1 C; in the second stage, the negative pressure is 80-90 Kpa, and the lithium ion battery is charged to 20%-30% SOC at a constant current of 0.1-0.3 C; in the third stage, the negative pressure is 20-40 Kpa, and the lithium ion battery is charged to a cut-off voltage at a constant current of 0.3-0.5 C. The formation process is beneficial to exhausting in the formation process, reducing the liquid loss, avoiding swelling of the battery cell and improving the formation interface; the process is simple and convenient to operate, short in formation time and convenient to produce, and meanwhile, the formation process adopts one-time full charge, so the interface side reaction of the electrode and the electrolyte is fully carried out, and thecapacity consistency and the self-discharge screening consistency are improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com