Method for casting valve body of flat gate valve

A technology of flat gate valve and valve body, which is applied in the direction of casting molding equipment, casting mold, casting mold composition, etc. It can solve the problems of large wall thickness, difficult quality to meet the use requirements, long length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

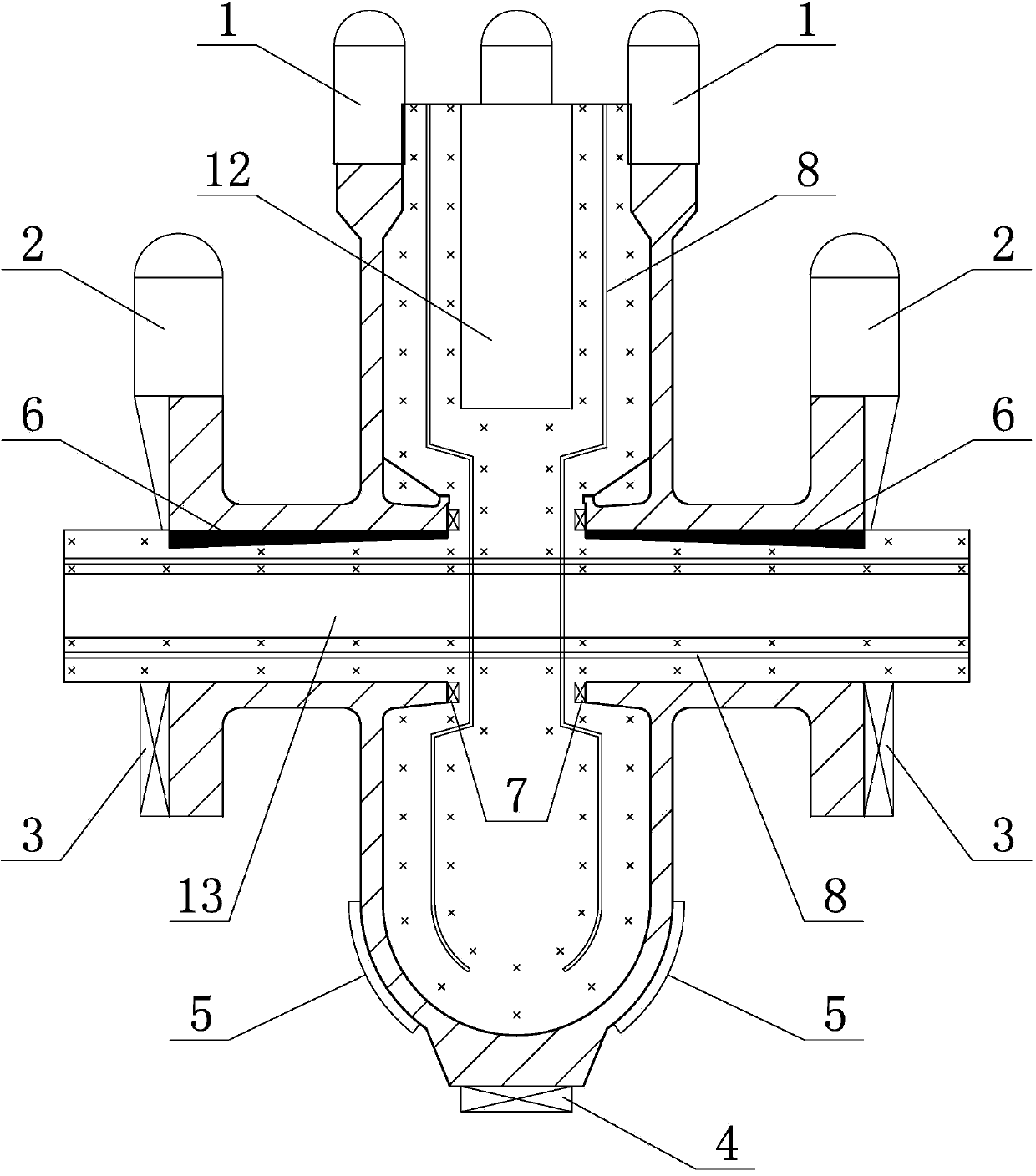

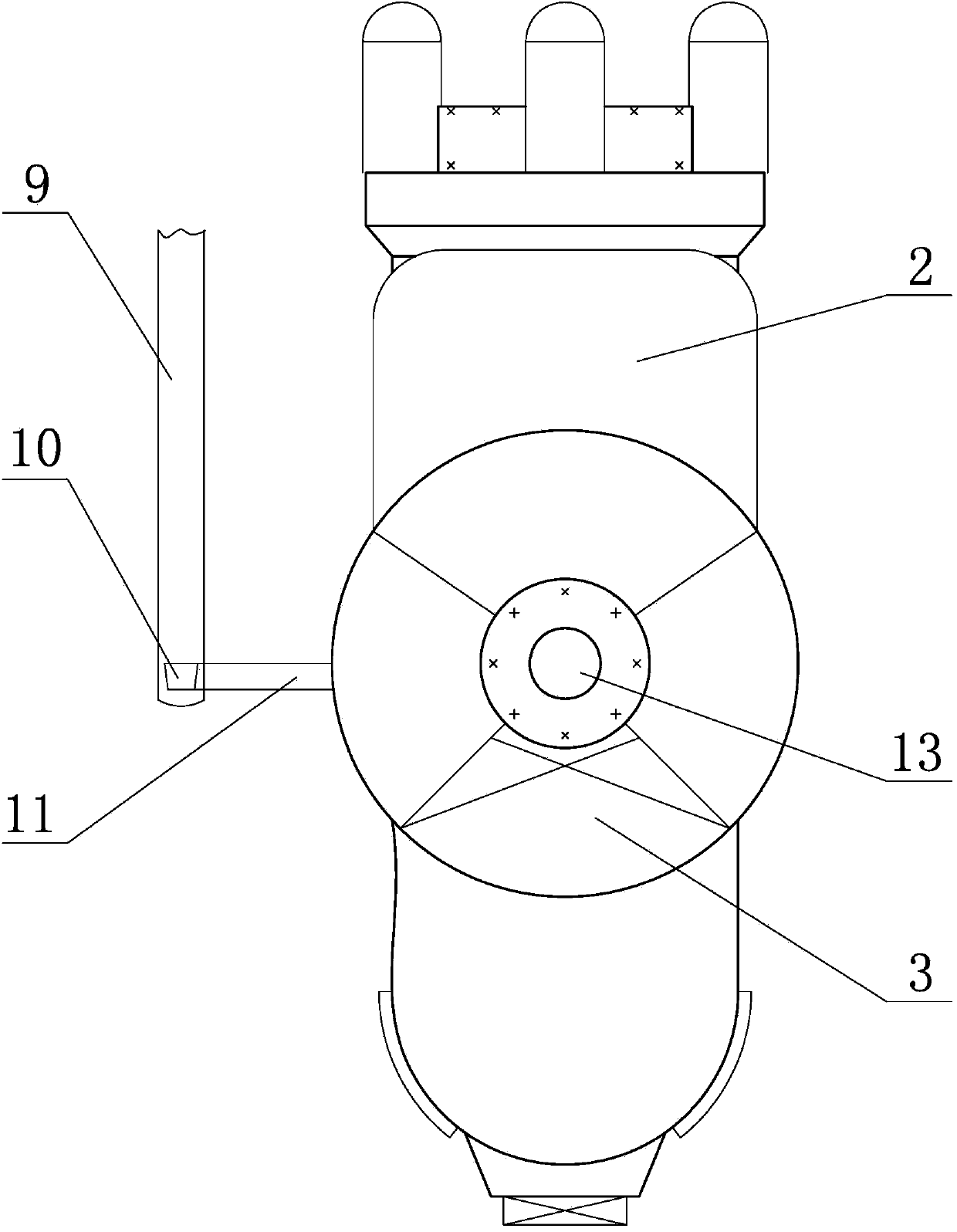

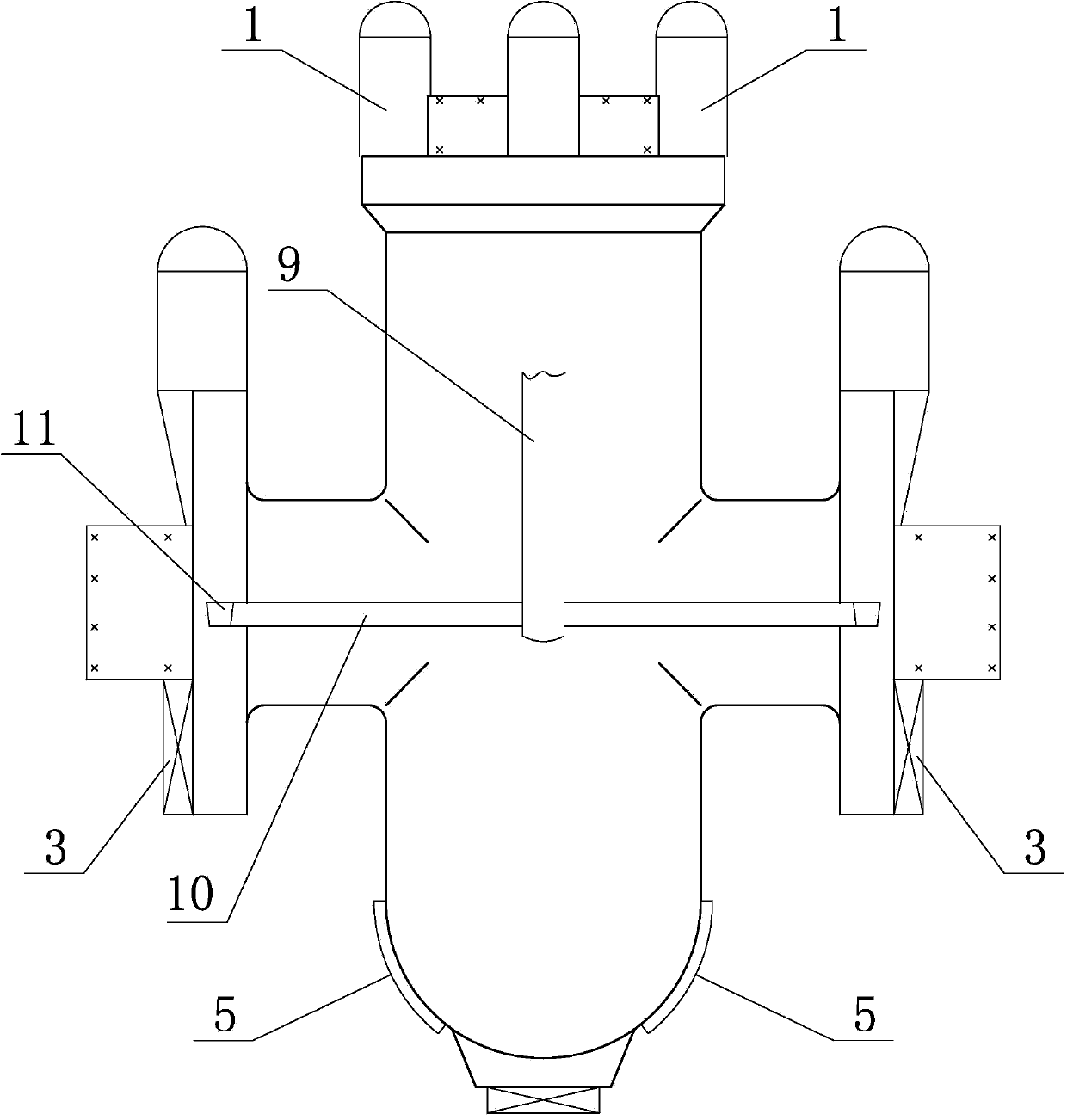

[0025] like figure 1 , figure 2 and image 3 Commonly shown, a casting method of a slab gate valve body, including the steps of using molding sand to make sand molds and using core-making sand to make sand cores, and then combining the prepared sand molds and sand cores together, said A vertical valve body cavity is formed between the sand mold and the sand core, that is, the open end of the valve body is upward, and the blind end of the valve body is at the bottom. The molding sand is carbon dioxide hardened water glass sand, and the core making sand is Cast steel resin sand is used, and cast steel resin sand has the characteristics of self-ignition after being burned by heat, so it greatly facilitates the sand cleaning work of the inner cavity of the blind end of the valve body, improves the efficiency of sand cleaning work, and also overcomes the problem caused by castings. The sand cleaning in the inner cavity is not clean, and it is washed away by the fluid during use,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com