Patents

Literature

1295results about How to "Improve inner quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst used for synthesis of vinyl acetate and its prepn. method

ActiveCN1903435AHigh activityReduce consumptionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidActivated carbon

A catalyst for synthesizing vinyl acetate from acetylene and acetic acid is prepared from activated carbon, zinc acetate and alkaline bismuth carbonate in mass ratio of 100: (27-40): 0.026 by excessive solution dipping method.

Owner:CHINA PETROCHEMICAL CORP +2

Method for preparing tobacco sheet and application thereof

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

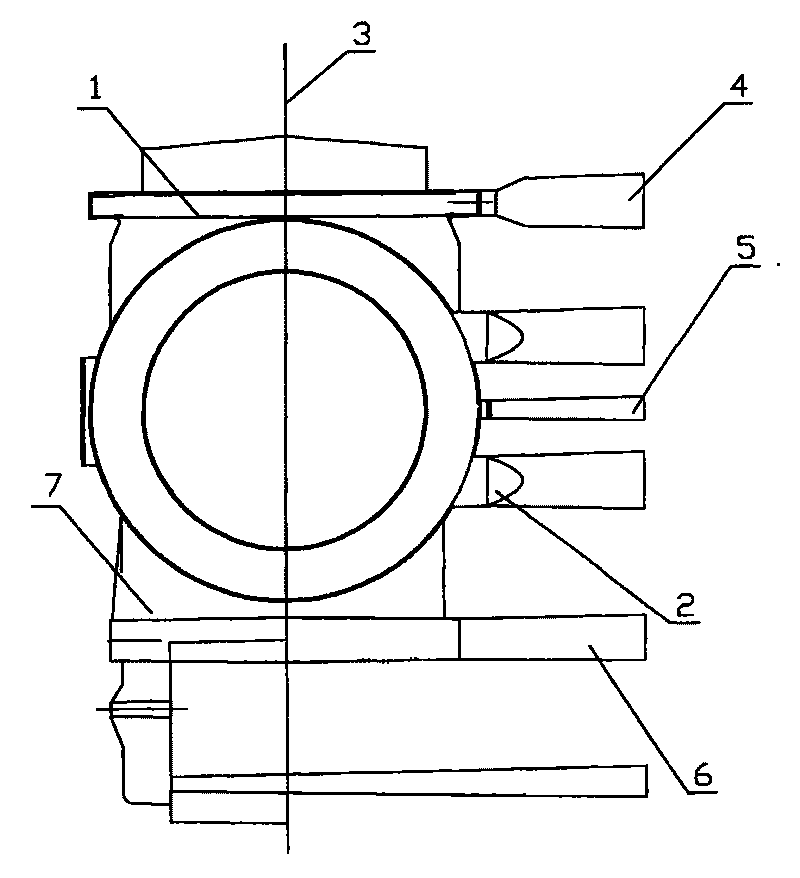

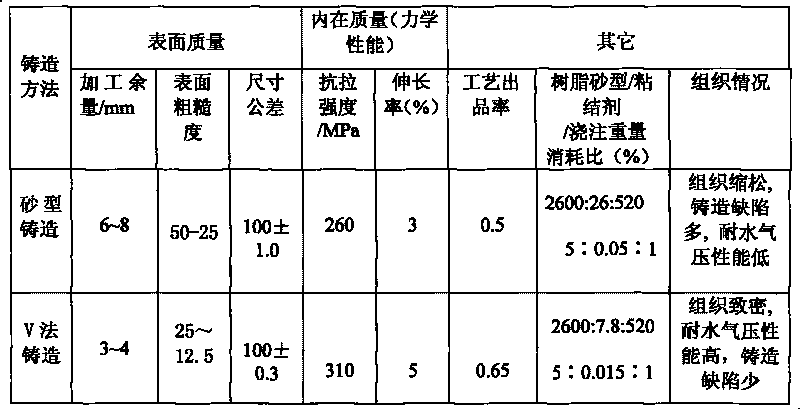

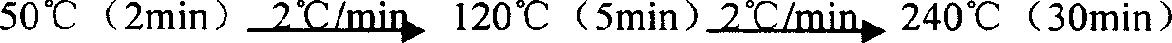

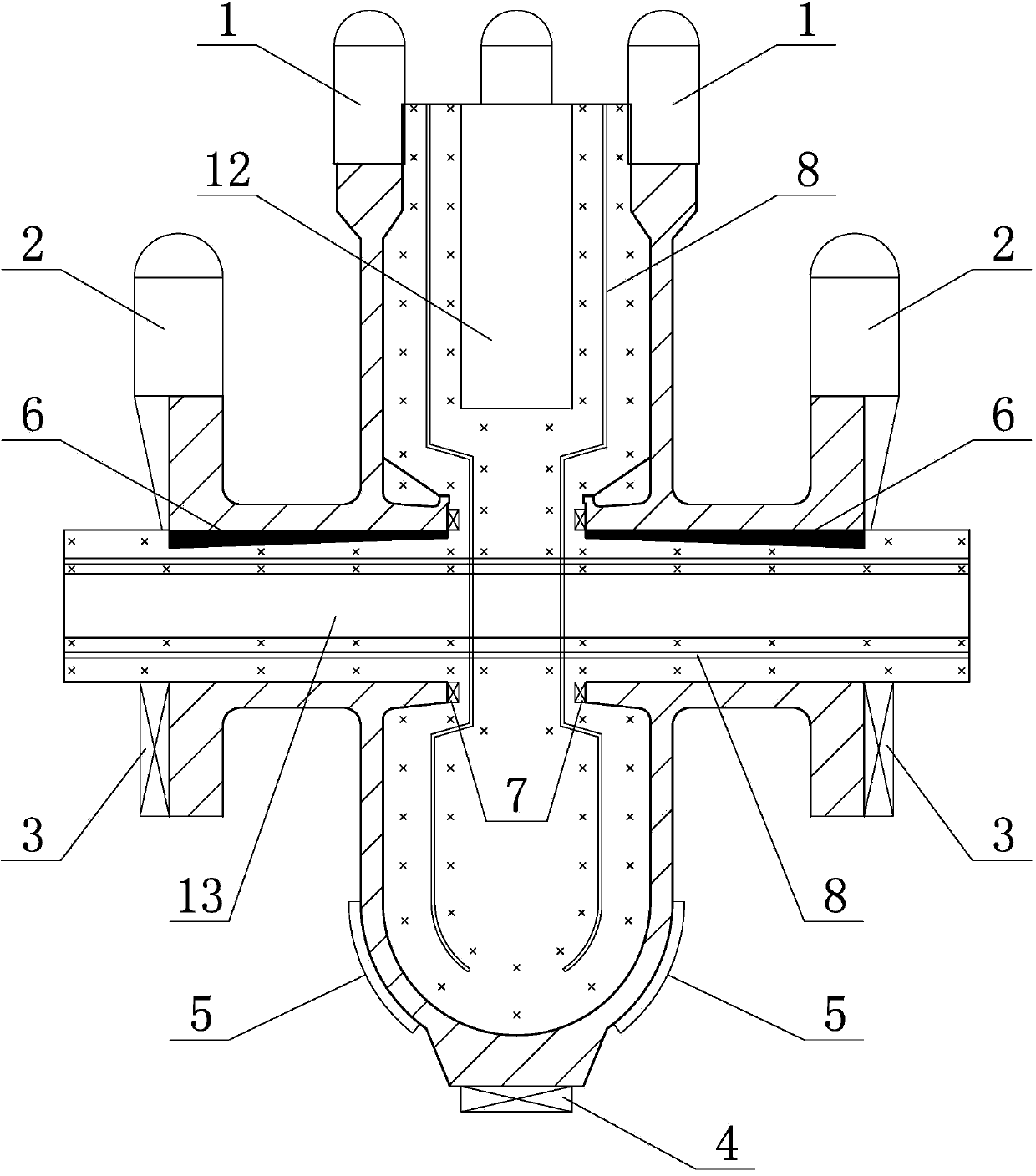

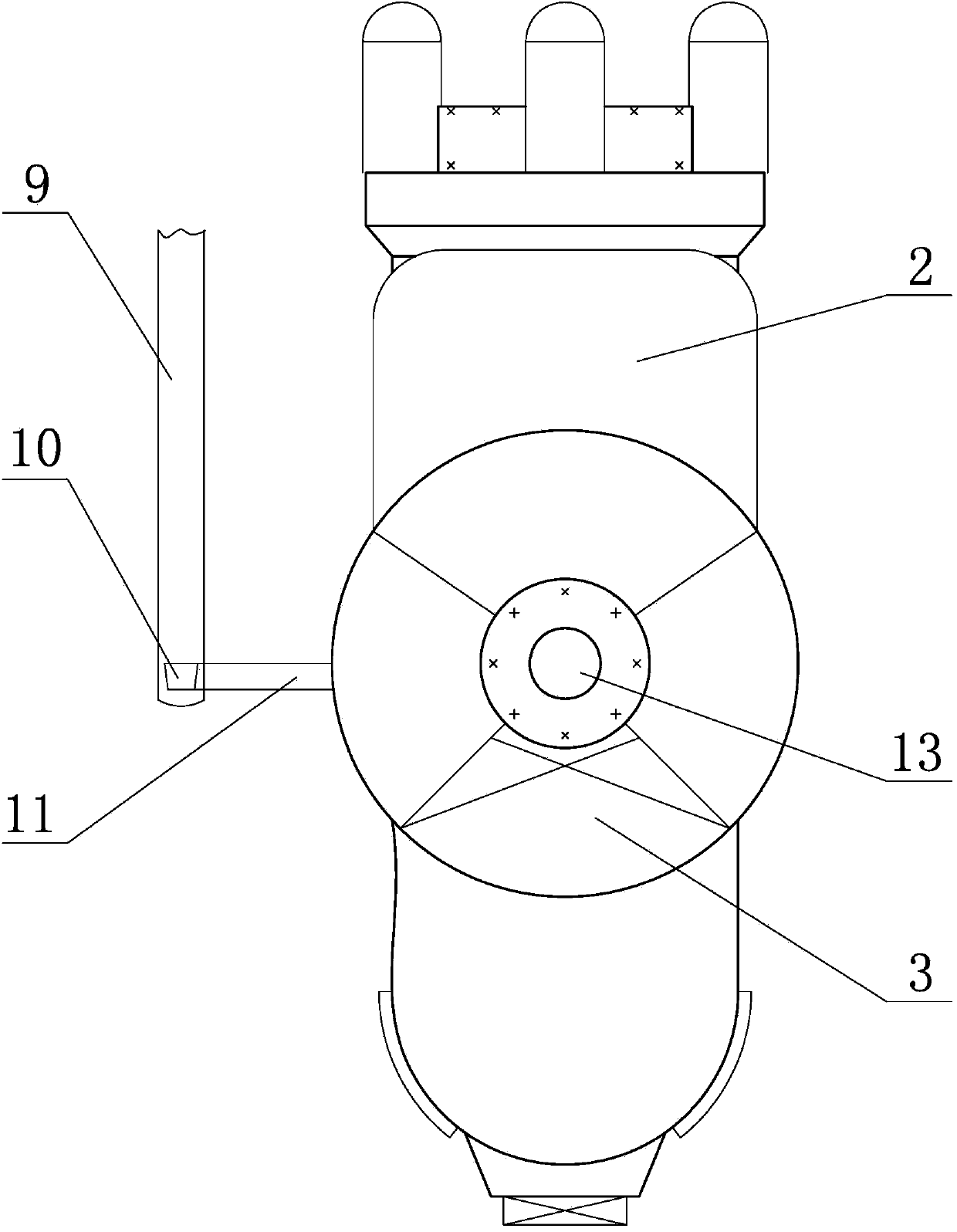

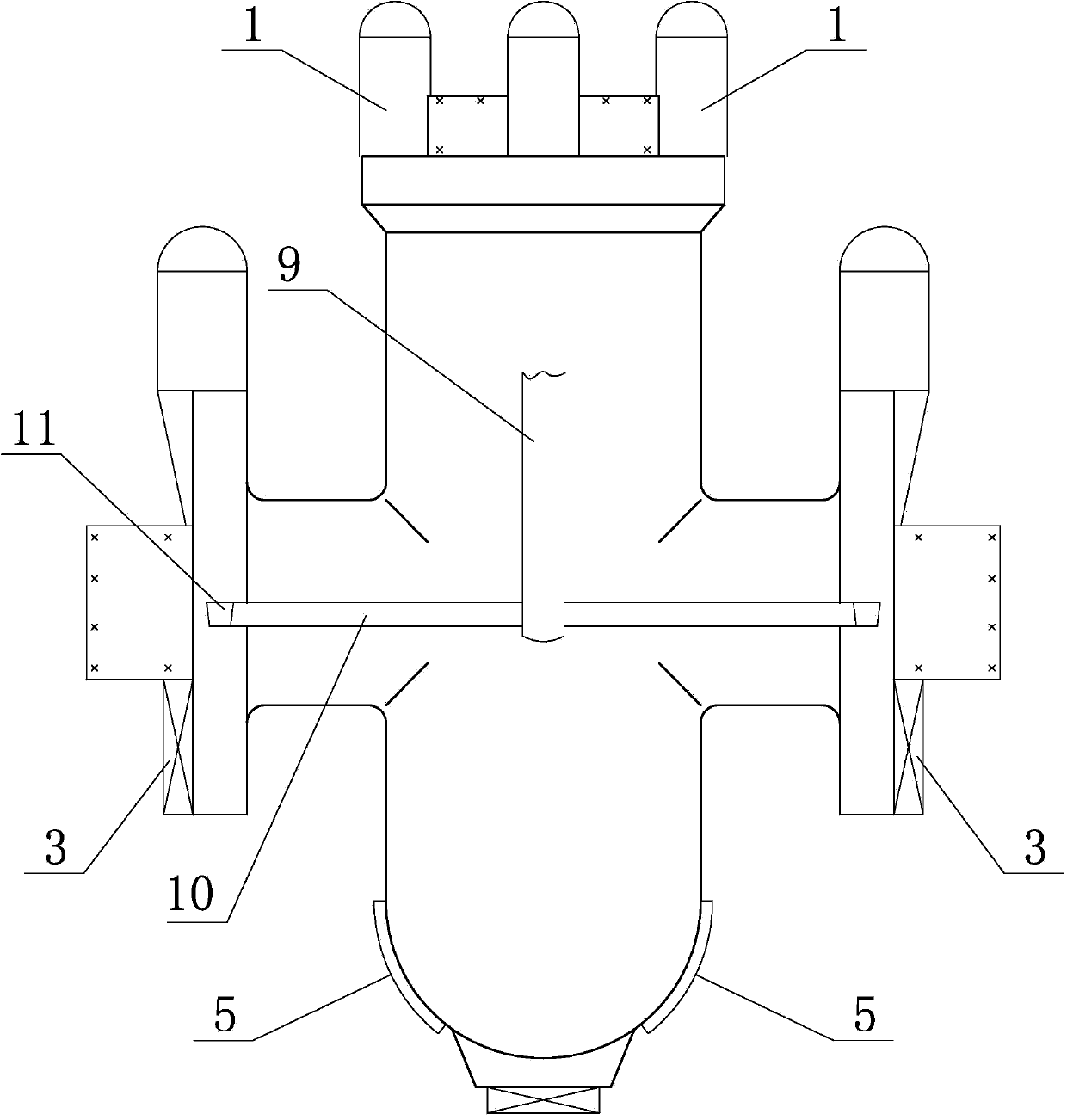

Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

ActiveCN101693282AImprove mechanical propertiesImprove quality levelFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a method for producing a voltage-bearing aluminum alloy tank body of an ultra-high voltage switch by a V-process, comprising the following steps: model making, thin film heating, thin film shaping (film absorbing), coating spraying, sandbox placing, ram-jolting by adding sand , back film covering, film loosening, core setting, box folding, pouring, removing box and shaking out. After the process is improved, an intermediate frequency furnace is utilized to melt and a crucible heat preserving furnace is utilized to modify and refine. When melting in the intermediate frequency furnace, microelements such as tombarthite and the like are replenished and a new non-stirring melting and refining technology is adopted so as to reduce oxide inclusion content in alloy liquid. Modification and refining treatment in the crucible heat preserving furnace ensures high purity degree and high component precision of aluminum liquid, and using pure aluminum alloy liquid can increase the ratio of acquiring qualified pressure-proof tank body foundry products.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

Method for extracting tobacco essence perfume

InactiveCN1899141AImprove qualityImprove inner qualityTobacco treatmentEssential-oils/perfumesFlavorReflux

The tobacco flavor extracting process includes the following steps: 1. crushing tobacco and setting in extracting tank; 2. adding solvent in 2-16 times the weight of tobacco to the extracting tank; 3. decompression reflux extracting at 20-60deg.c temperature and 0.020-0.098MPa vacuum degree for 1-8 hr; and 4. separating the liquid extract through filtering, and decompression concentrating the filtrate at vacuum degree of 0.020-0.098MPa to obtain the tobacco flavor of density 1.1-1.4g / ml. The extracting process is simple, safe, environment friendly, high in extracting efficiency and low in production cost, and the extracted tobacco flavor has the physical and chemical properties of natural tobacco components and may be added to cigarette to improve flavor, raise quality and lower tar.

Owner:宋光泉 +1

Composite amino acid ecological nutritious agent

InactiveCN1594232AApparently antiviralObvious antibacterialAnimal corpse fertilisersClimate change adaptationTrace elementFermentation

The invention provides a composite amino acid ecological nutritious agent, which comprises sea weed fermentation liquor, fermentation liquor of animal leftover bits and pieces, trace elements, and biological bacterium. The functions of the agent include stimulating growth, suppressing pathogenic agent and reinforcing immunization.

Owner:李长江

Wood-plastic formwork for construction engineering

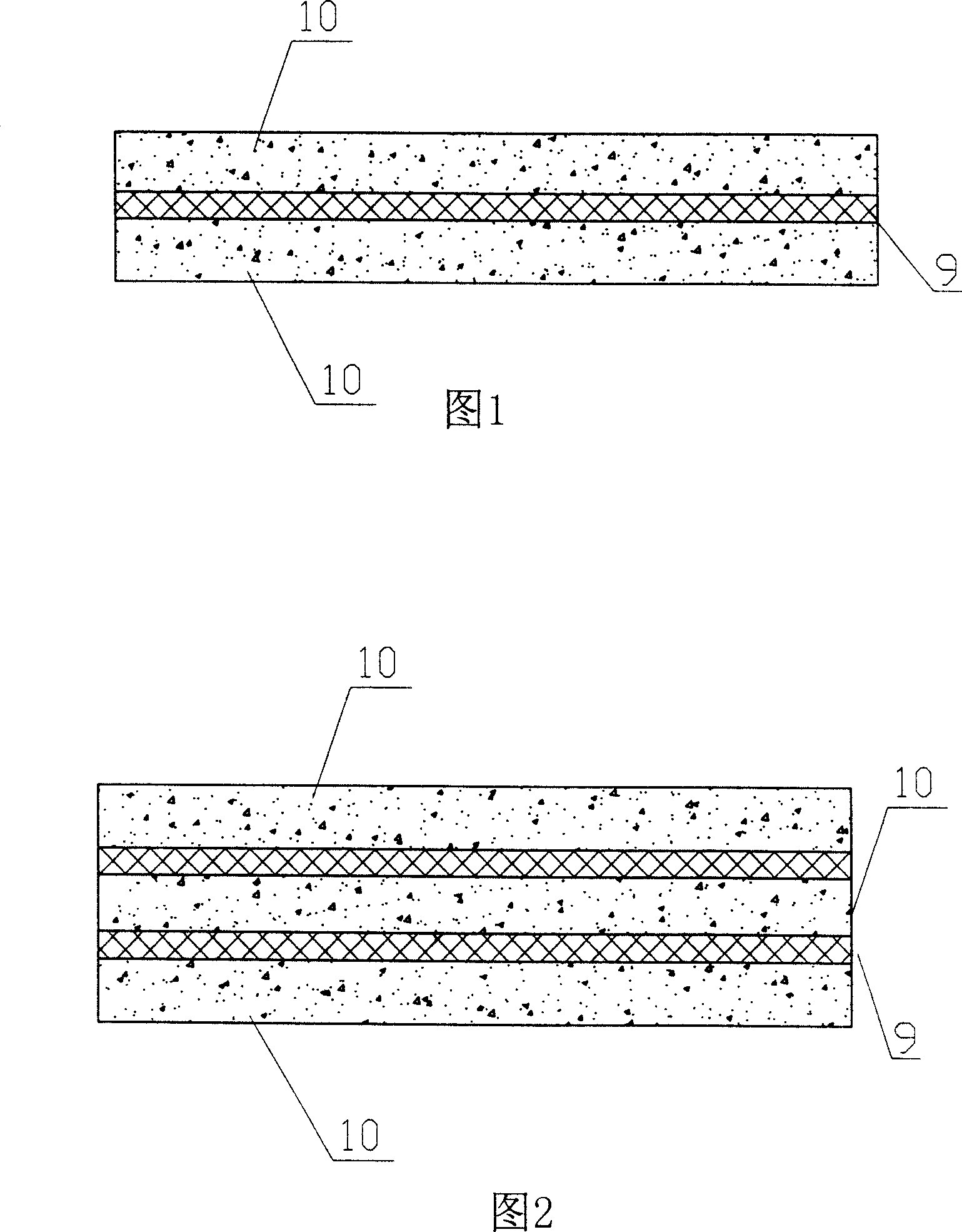

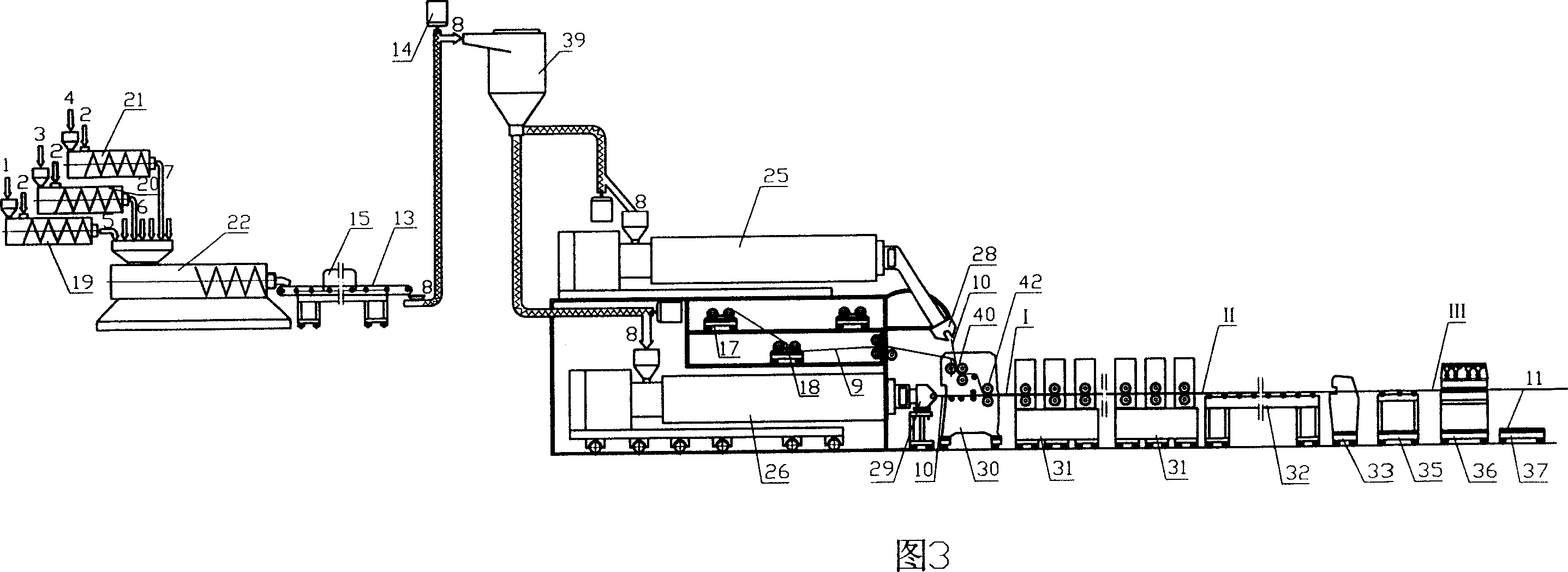

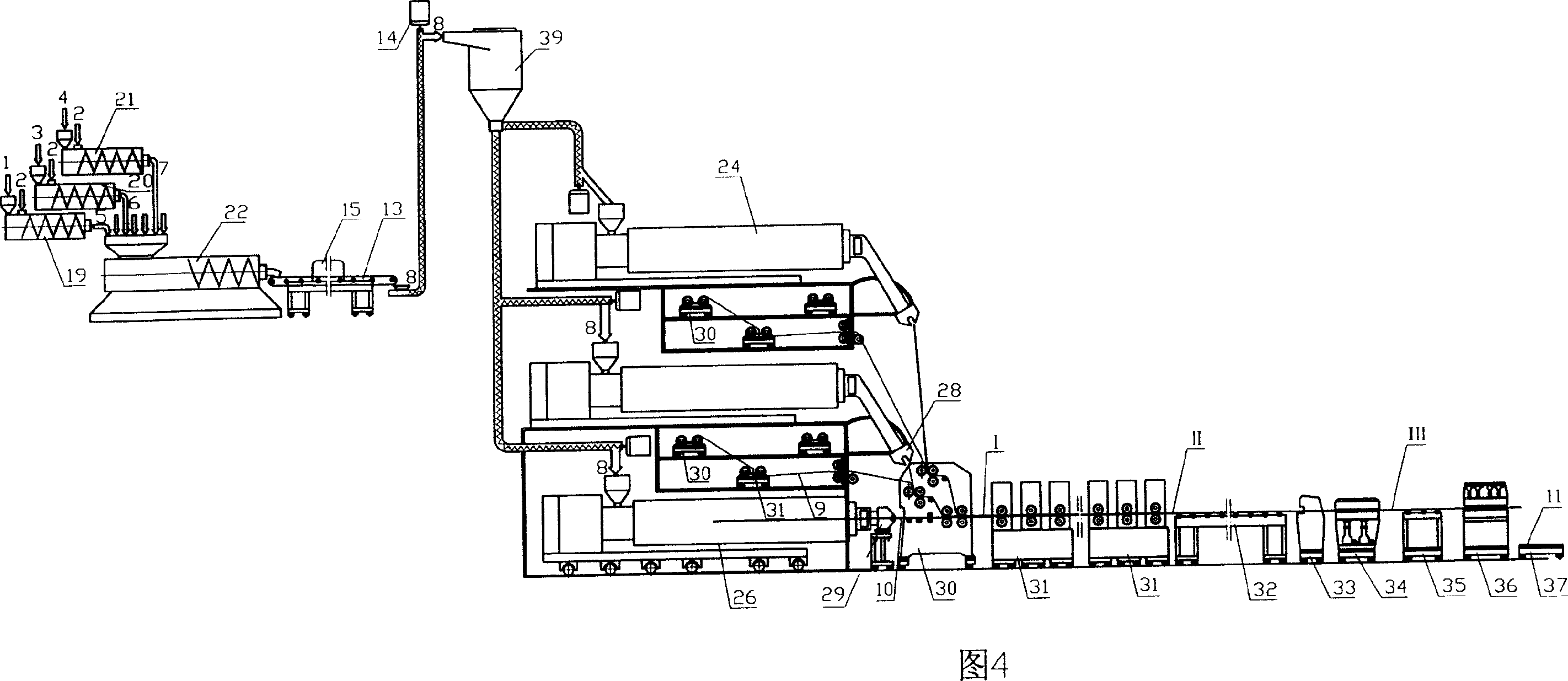

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

Casting and forging combined technique of aluminum alloy linkage rod

InactiveCN101486087AEnsure billet qualitySimplify the traditional die forging processEngine componentsRheniumRare-earth element

The invention discloses technology for casting and forging an aluminum alloy connecting rod, wherein an aluminum alloy composition of the connecting rod is adjusted by addition of rare earth element in casting technology, and the addition of the rare earth element is 2 to 5 percent of an aluminum liquid; the aluminum alloy connecting rod is guaranteed to comprise the following compositions: 88 to 94 percent of aluminum, 3.8 to 4.9 percent of copper, 0.5 to 1.5 percent of silicon, 0.4 to 1.2 percent of manganese, 0.4 to 1.0 percent of magnesium, 0.8 to 1.8 percent of rhenium and 0.4 to 0.14 percent of iron; and a casting head is not cut off and reheated in the casting technology and taken as one part or a scrapped part of a forged piece, and casting afterheat is utilized for forging. The technology simplifies the prior die forging technology, improves reasonable floatation, the streamline and mechanical properties of casting metals, improves a metallurgical structure close to the casting head on the forged piece, and has the effects of high technological utilization rate of materials, shortened technological process and energy conservation and consumption reduction. Moreover, the casting and forging technology can obviously improve the internal quality and the mechanical properties of casting blanks, and the production cost of the casting blanks is lower than that of the prior die forging.

Owner:DANYANG RONGJIA PRECISION MACHINERY

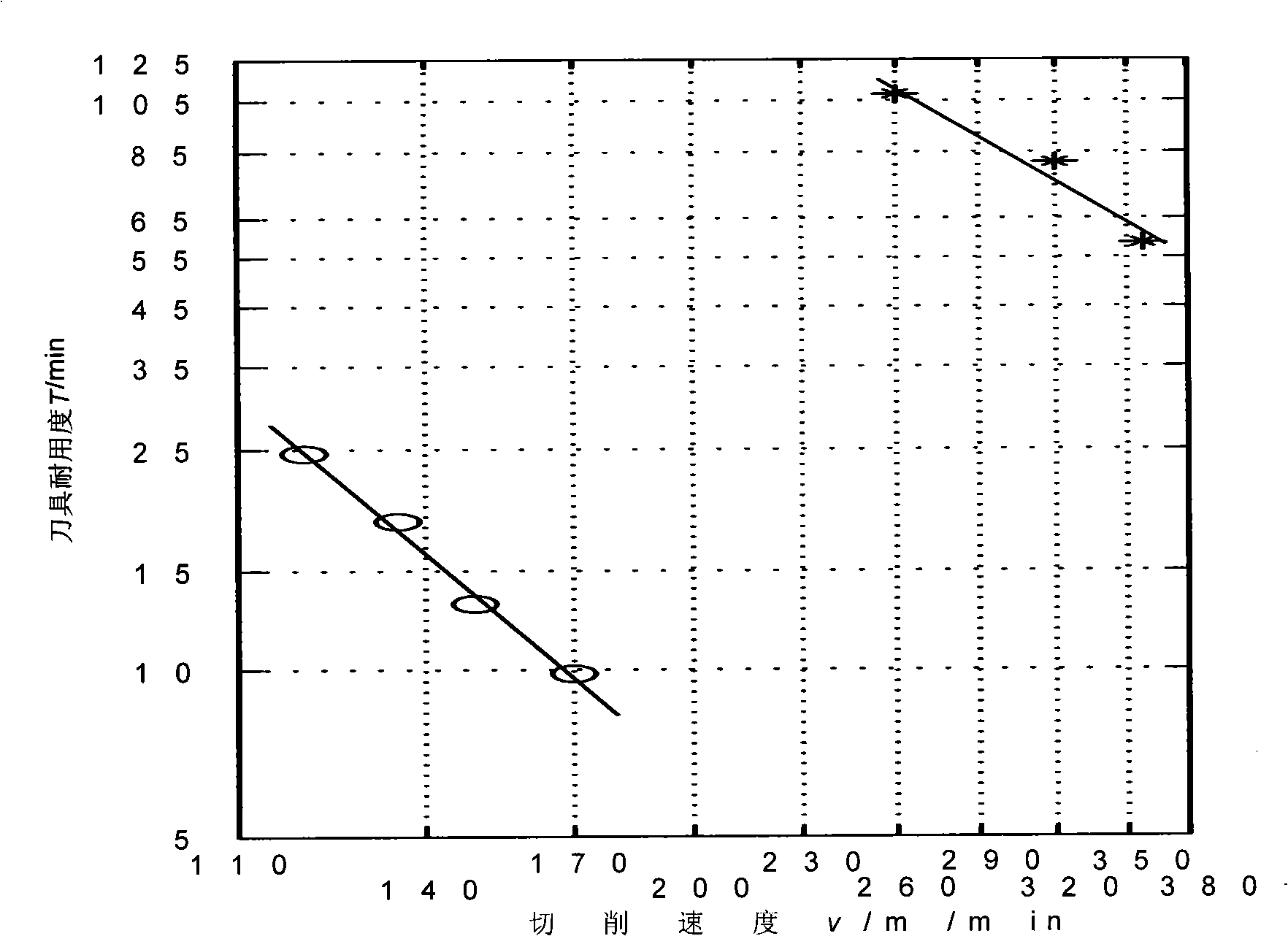

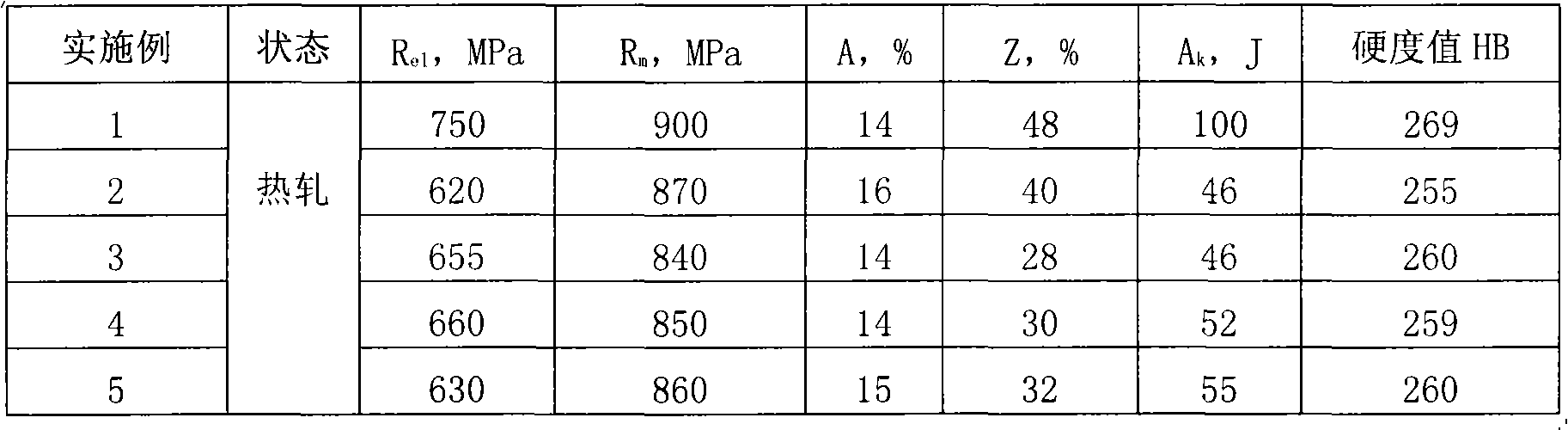

Easy-cutting untempered steel and method for manufacture thereof

InactiveCN101255535AEasy to shapeAdverse effects of improved mechanical propertiesProcess efficiency improvementElectric furnaceHeating timeHeating furnace

The invention discloses a Ca-S composite free-cutting non-quenched and tempered steel for cutting which has high cutting property and the manufacturing method thereof. The steel is composed of 0.44% to 0.49% of C, 0.30% to 0.60% of Si, 1.20% to 1.50% of Mn, 0.08% to 0.12% of V, no more than 0.30% of Cr, Ni and Cu, 0.040% to 0.065% of S, no more than 0.035% of P, 0.001% to 0.010% of Ca, 0.01% to 0.03% of Al, and the balance Fe and unavoidable impurity. According to the method, the compositions of inclusion in steel are controlled by ladle argon blowing and Ca-S composite processing, casting blank is poured by continuous casting, the average temperature for heating billet in a heating furnace is 1180 DEG C to 1220 DEG C, the heating time is 2 to 3 hours, the rolling starting temperature is 1100 DEG C to 1150 DEG C, the rolling finishing temperature is 850 DEG C to 1000 DEG C, the cooling speed of the rolled steel is 1.5 DEG C per second to 2.5 DEG C per second, the cooling bed cooing in pile temperature is 600 DEG C to 700 DEG C. The steel has superior mechanical property and free-cutting property.

Owner:SHANDONG IRON & STEEL CO LTD

Method for increasing yield and improving quality of continuously cropped flue-cured tobacco

InactiveCN102919038APromote decompositionSimple structureFertilising methodsHorticultureGreen manureIntermediate Grade

The invention provides a method for increasing yield and improving quality of continuously cropped flue-cured tobacco. The method combines planting and turning over and pressing green manure with applying decomposing agents and microbial fertilizer. When the green manure is turned over and pressed in spring, the decomposing agents are applied; a base fertilizer includes both special tobacco compound fertilizer and the microbial literalizer, so that green manure can give a full play in improving the soil, increasing yield and improving quality of tobacco. Therefore, the method is a simple, effective and practical method for increasing yield and improving quality of the continuously cropped flue-cured tobacco leaves. The yield of the tobacco leaves is increased by 15.2%-19.8%, both the appearance quality and the internal quality of tobacco leaves are improved, and the high and intermediate-grade tobacco yield is increased by 7.5%-10.5%.

Owner:SOUTHWEST UNIVERSITY

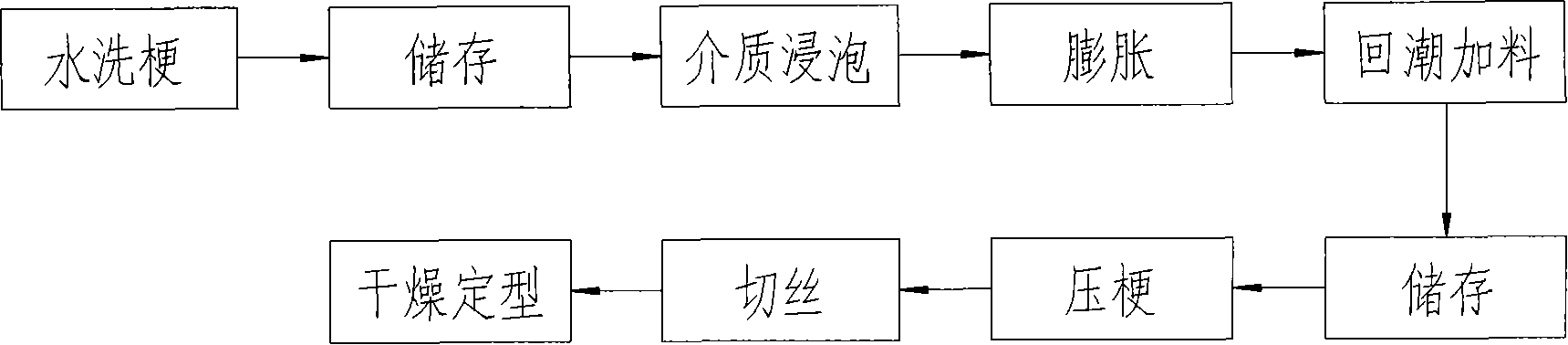

Technique of pre-expanding treating cabo

ActiveCN101108028AFully removedLarge specific surface areaTobacco preparationTobacco treatmentFilling materialsEngineering

A tobacco stalk pre-expending processing technics is provided, which is characterized in that: the technics comprises the following procedures: washing, storing, expanding in liquid and marinating with interface the tobacco stalk, expanding the stalk strips, moisture regaining and feeding, storing, pressing sticks and drying for shaping. The technics method of the invention changes the expanding of cut rolled stem into expanding the tobacco stick by using marinating with high temperature and low pressure and then expanding with high temperature and reduced preddure, thus sufficiently eliminating the bad flatus in the tobacco stick as the flatus of the wood or the corrupt straws; the tobacco stick after expanded has increased cells and remarkably enhanced ratio surface, thus the material liquid can filter into the tobacco sticks sufficiently to becoming a natural filling material and adaptation carrier for adjusting the cigarette fragrance and style; the cigarette stick after expanded is large in volume, which, after pressed, is easy being cut into silkiness (similar as the physical behavior of tobacco shred); after dried and shaped normally, the cut rolled stem can crisp naturally, thus increasing the filling capacity. The cut rolled stem processed by the technics method of the invention is basically similar with tobacco shred in color and shape and the alloying evenness of the tobacco shred is increased; besides, the tobacco shred has no bad aftertaste when smoking, but has strong filling capacity and enhanced internal quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Technique of preparing amlodipine besylate tablets

ActiveCN101161241AHigh dissolution rateImprove finenessOrganic active ingredientsPill deliverySolubilityAir volume

A preparation technology of amlodipine besylate is disclosed in the present invention, the technology is with amlodipine besylate, filler, disintegrating agent, lubricant etc. as main components. By using grinding and sieving; reasonably controlling particle water; repeatedly feeling fluidized bed granulating technology parameter, controlling spraying speed, spraying pressure and air quantity, under the situation of non-affecting tablet content and hardness, increasing the solubility of product greatly, thereby promoting the internal quality and curative effect of the product.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

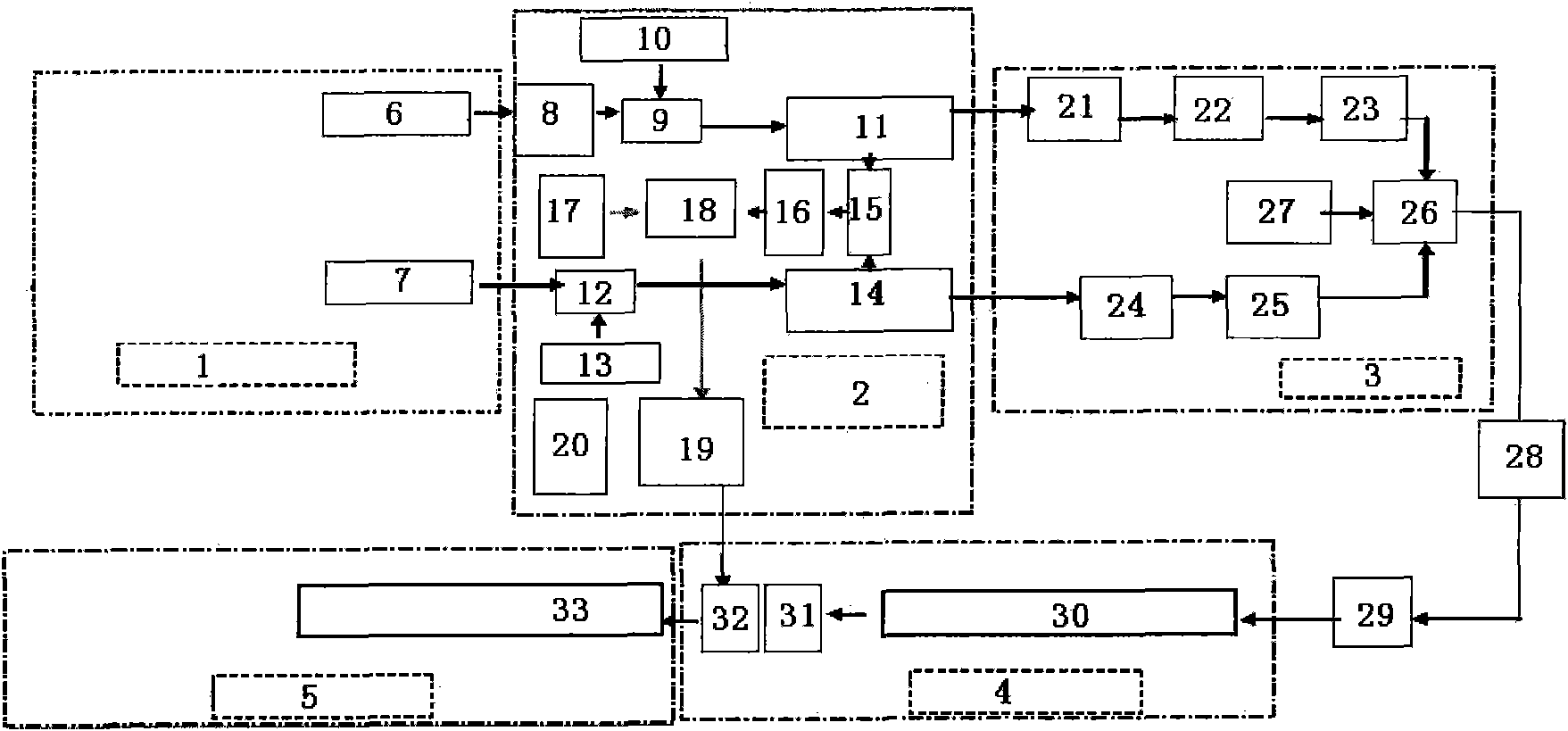

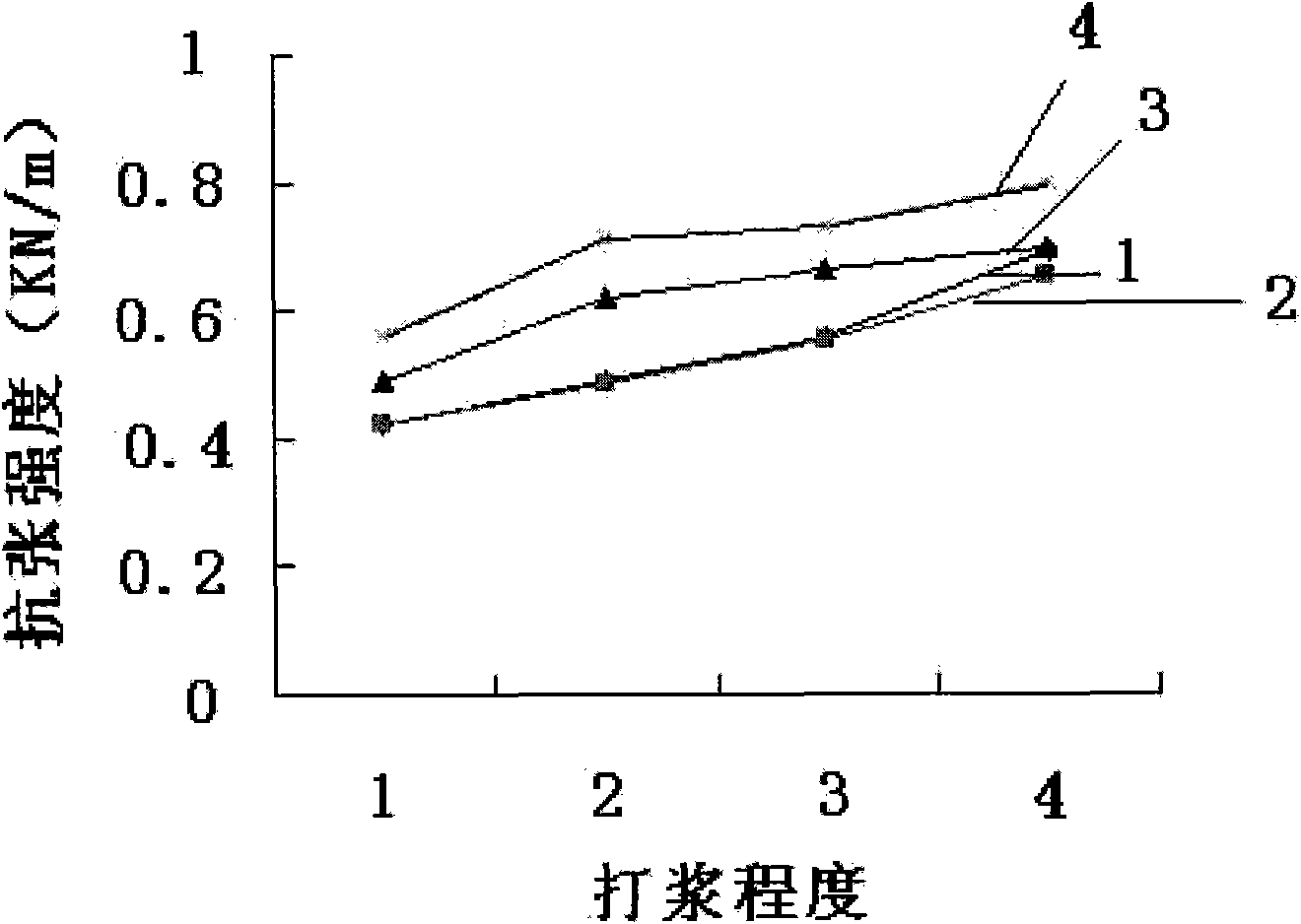

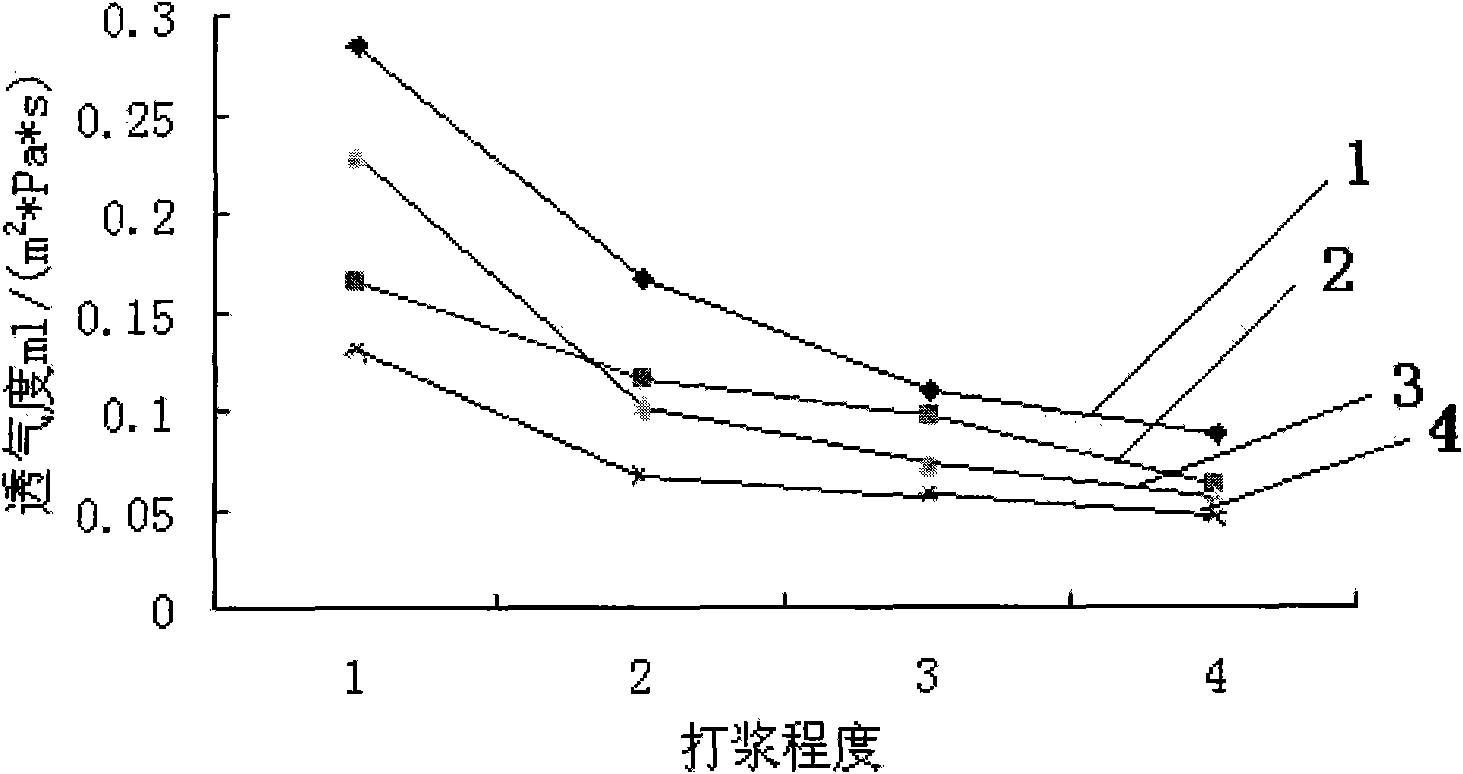

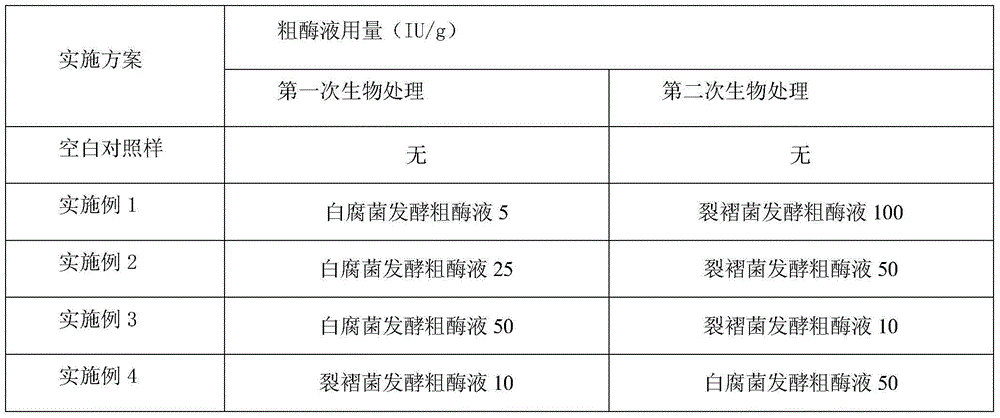

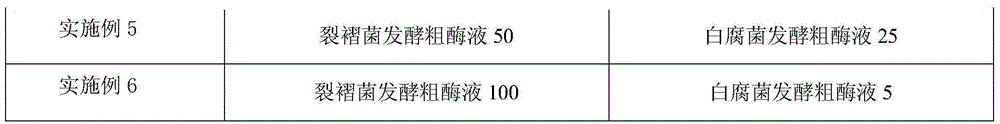

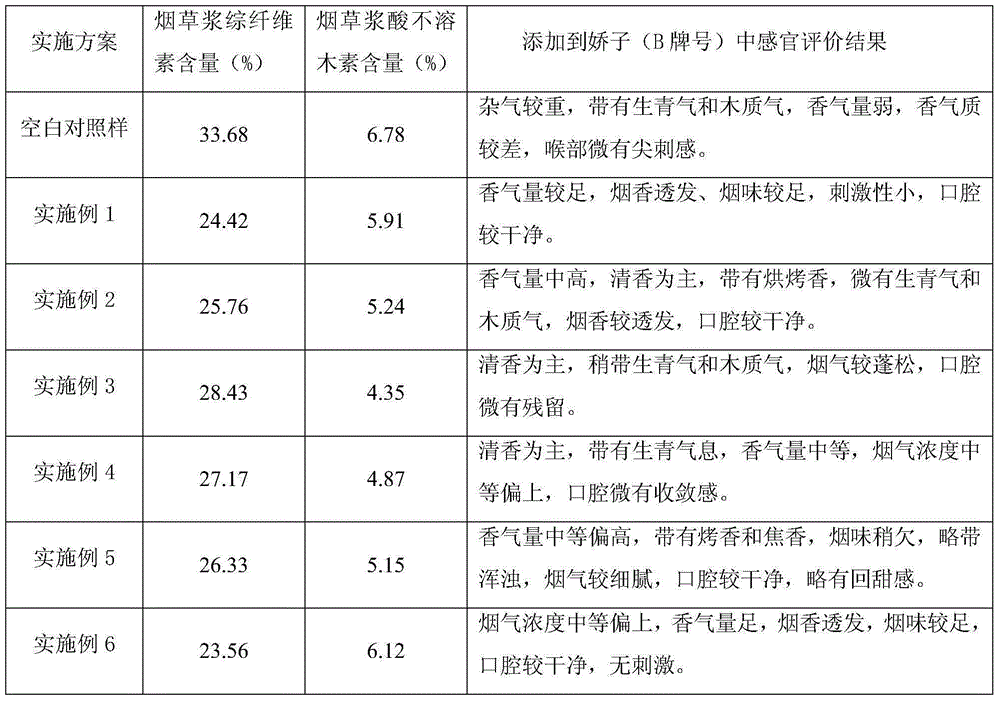

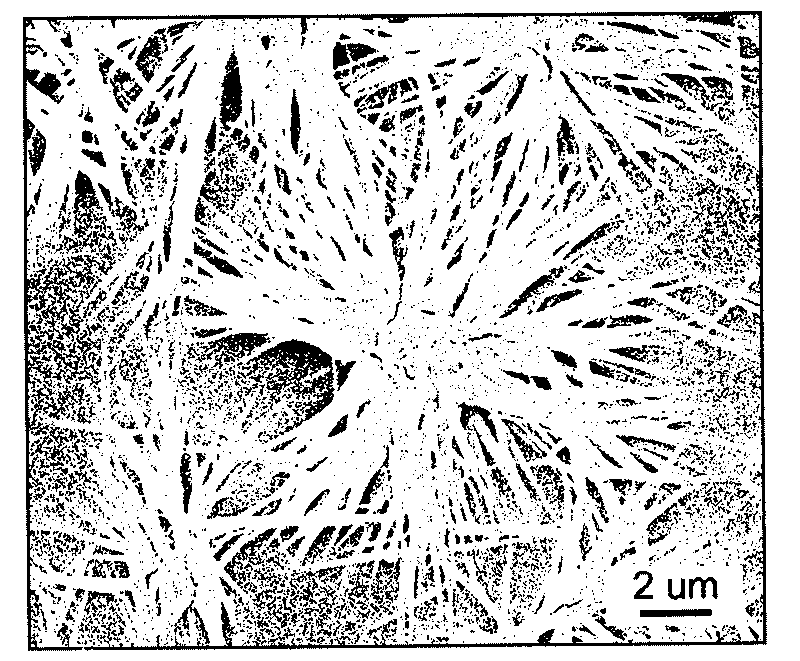

Biological treatment method of papermaking-method reconstituted tobacco raw materials and pulp

ActiveCN104957752AImprove inner qualityReduce mistTobacco preparationMacromolecular SubstancesChemistry

The invention discloses a biological treatment method of papermaking-method reconstituted tobacco raw materials and pulp, biological treatment is conducted twice on the papermaking-method reconstituted tobacco raw materials and pulp by means of the crude enzymes obtained through microbial fermentation, the object for the first biological treatment is materials which are extracted and tread rolled, and biological enzymes degrade cell wall substances and plays a role of enzymatic pulping; the second biological treatment is conducted in the potential elimination process after high consistency pulping is conducted and before low consistency beating is conducted, and the biological enzymes are acted on pulp fibers, further efficiently degrades macromolecular substances such as lignin, cellulose, hemicellulose, pectin and protein, conducts decoration or modification on the fiber surfaces, and plays the role of enzymatic beating. After the biological treatment is conducted twice, the cell wall substances in the materials and the pulp and undissolved macromolecular substances are degraded effectively, and the sensory quality of papermaking-method reconstituted tobaccos is promoted obviously.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +2

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

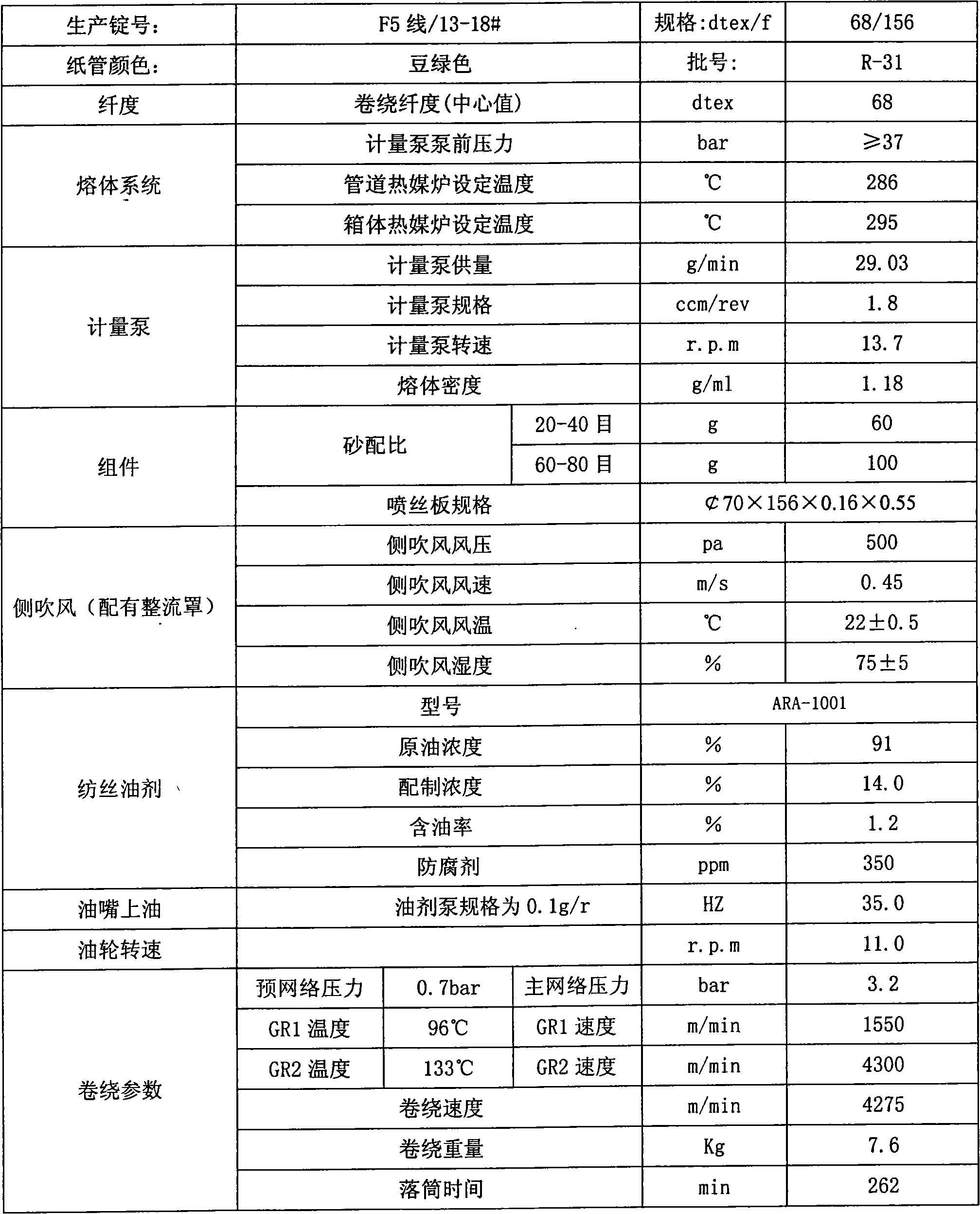

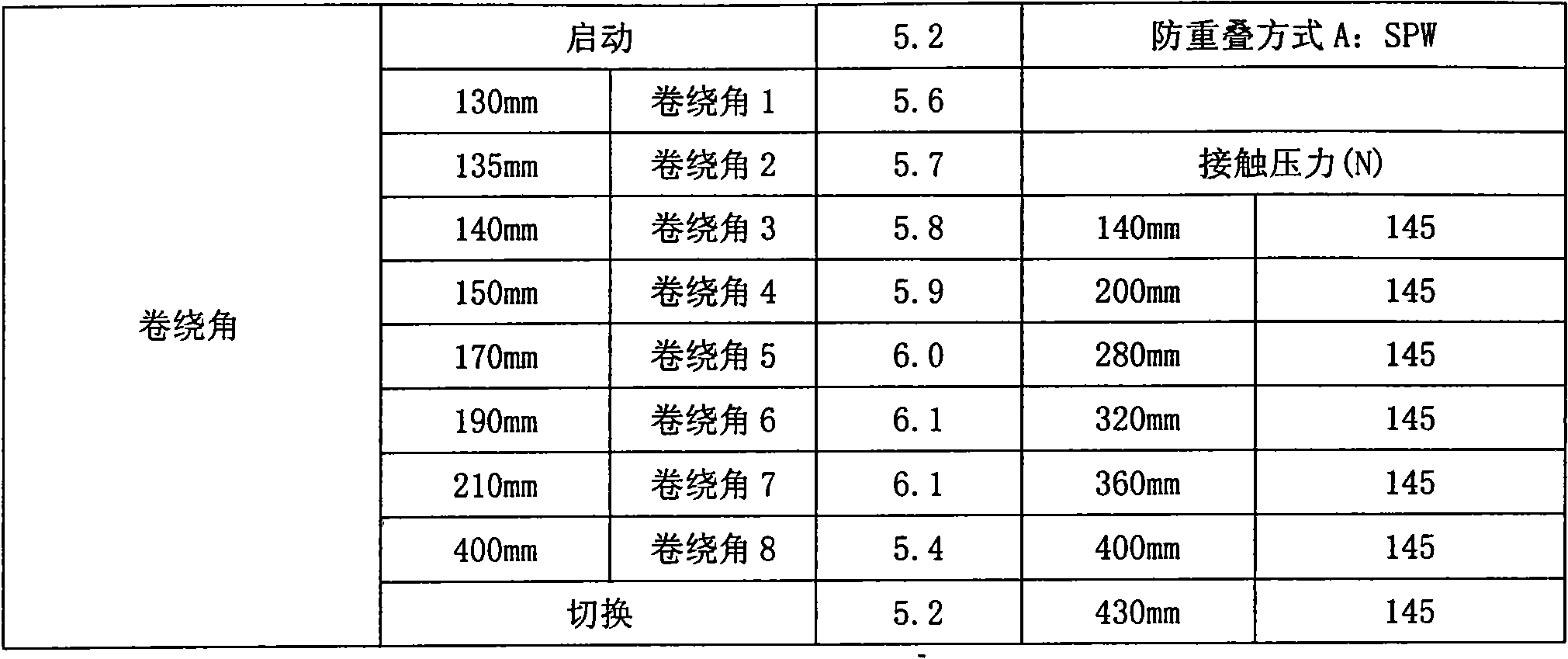

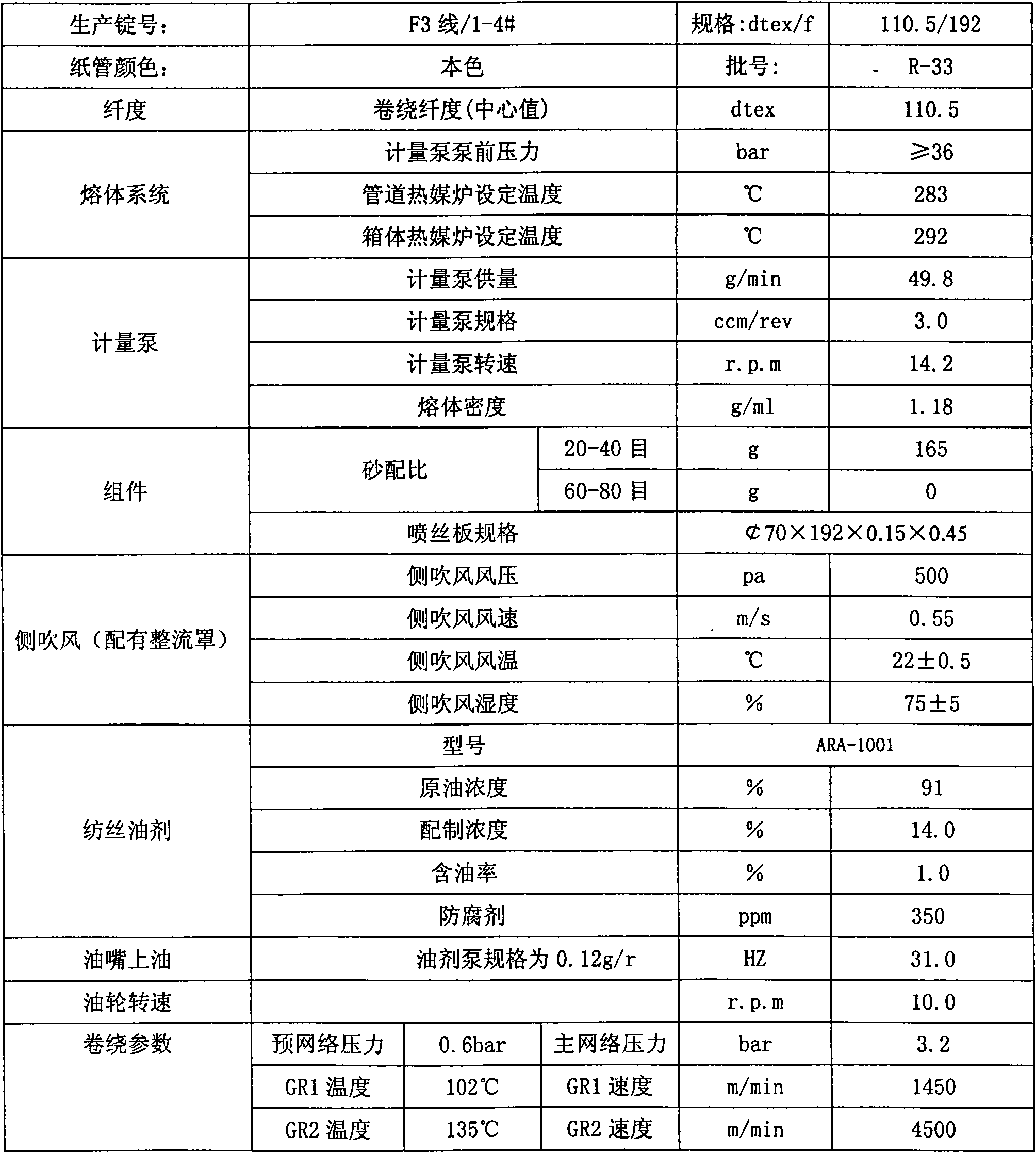

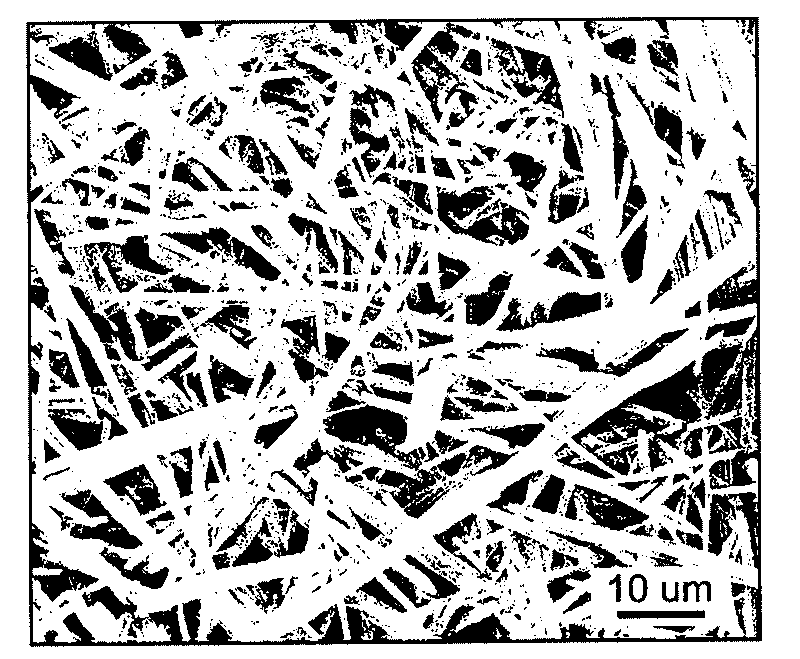

Melt direct spinning superfine denier terylene FDY filament and preparation process thereof

ActiveCN101634051ALow costIncrease productivitySpinning head liquid feederMelt spinning methodsFiberPolymer science

The invention discloses a melt direct spinning superfine denier terylene FDY filament and a preparation process thereof. The superfine denier terylene FDY filament is prepared by the following steps: adopting a production line of a melt direct spinning one-step method, using a spinning plate with the diameter of capillary of 0.15 to 0.2mm, L / D of 2.6 to 3.6 and diameter of plate surface of 70 to 90mm, installing fairing in a fiber cooling area and adopting a two-way oil feeding system to directly produce the superfine denier terylene FDY filament; and the obtained dpf (denier per filament) is 0.3 to 0.6, the number of orifices of one strand of filameter is 144F to 192F. The process routine can improve internal quality, simultaneously greatly reduces the processing cost, and has the capability of replacing imported similar products.

Owner:JIANGSU HUAYA FIBER

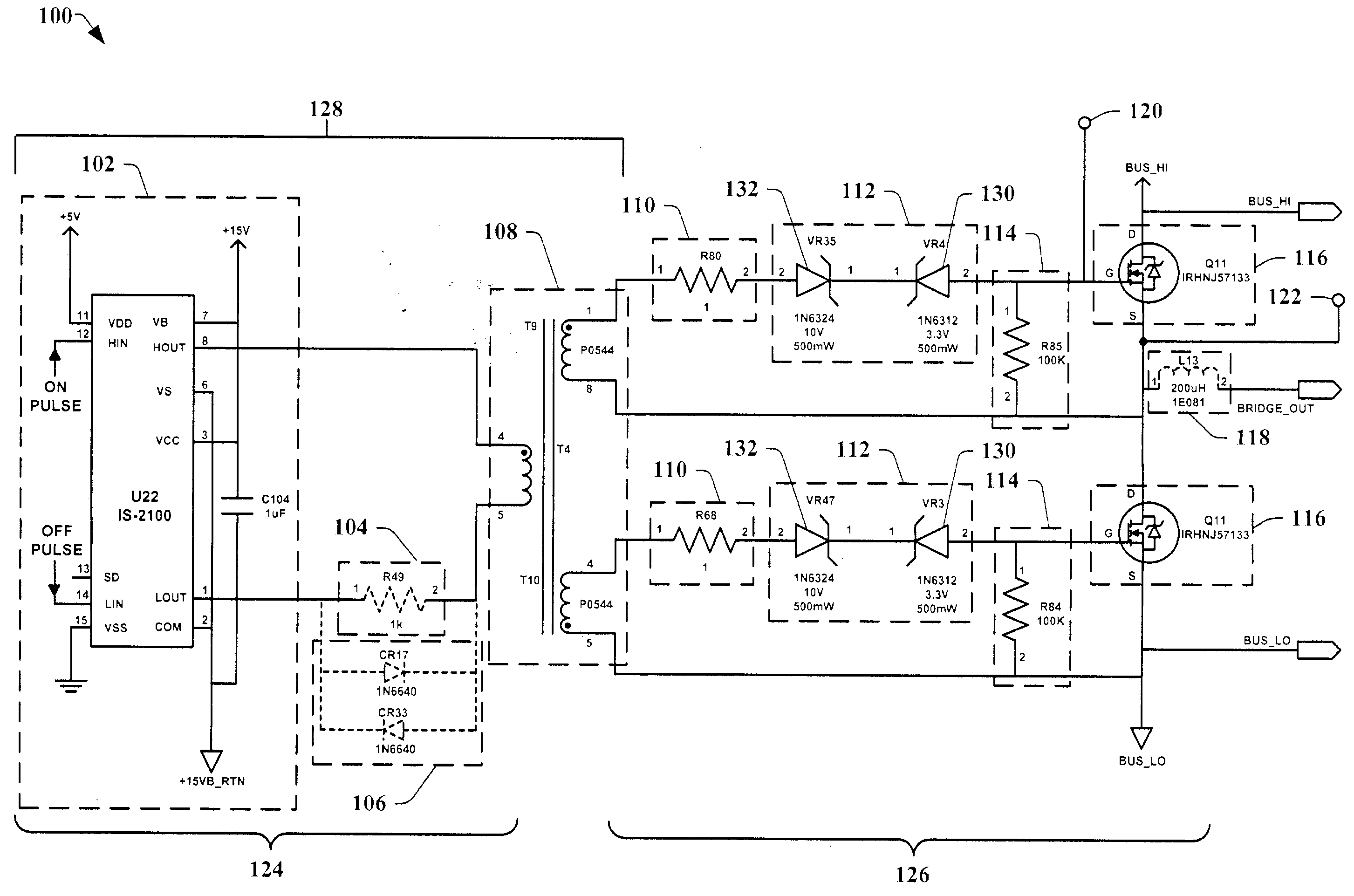

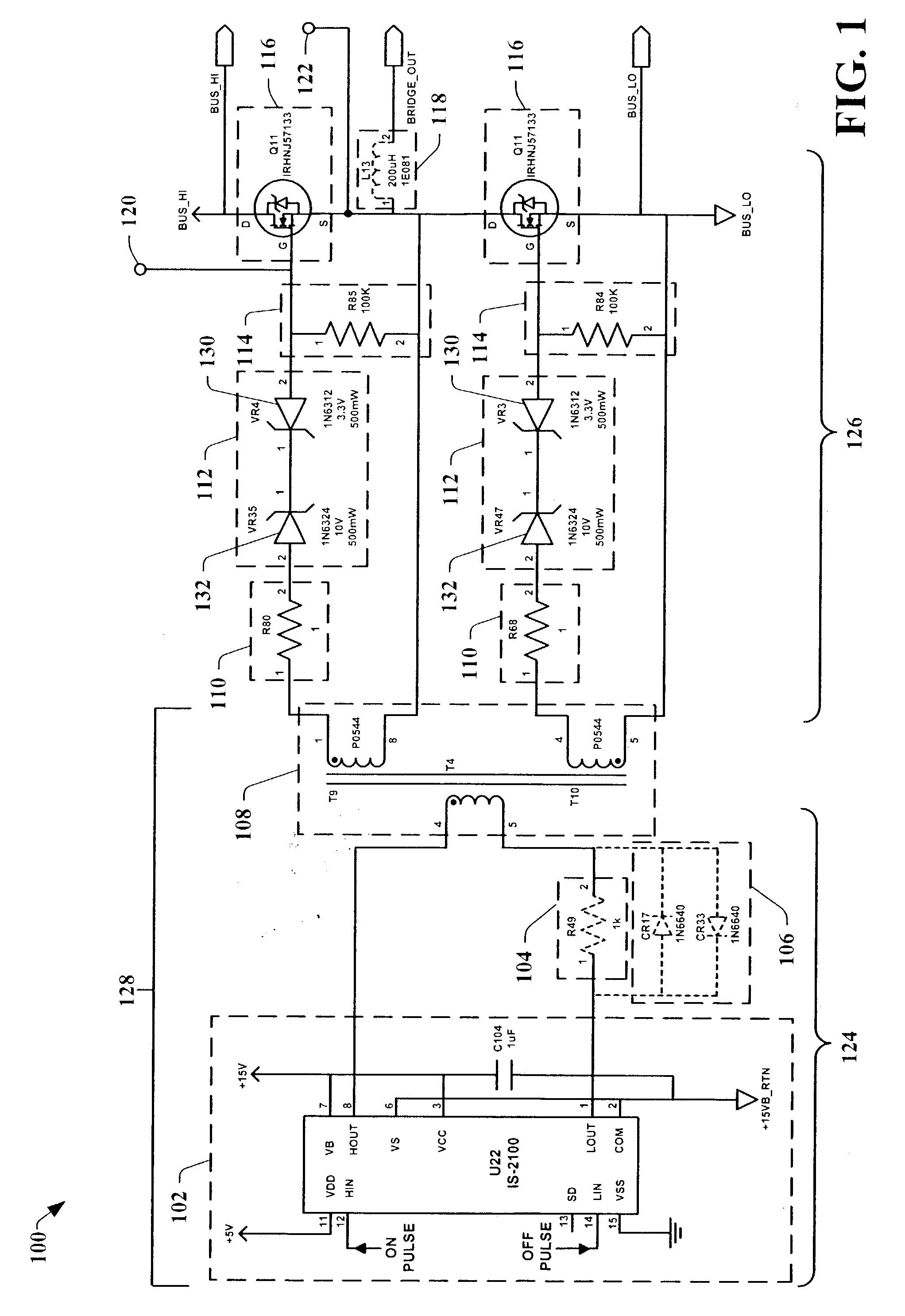

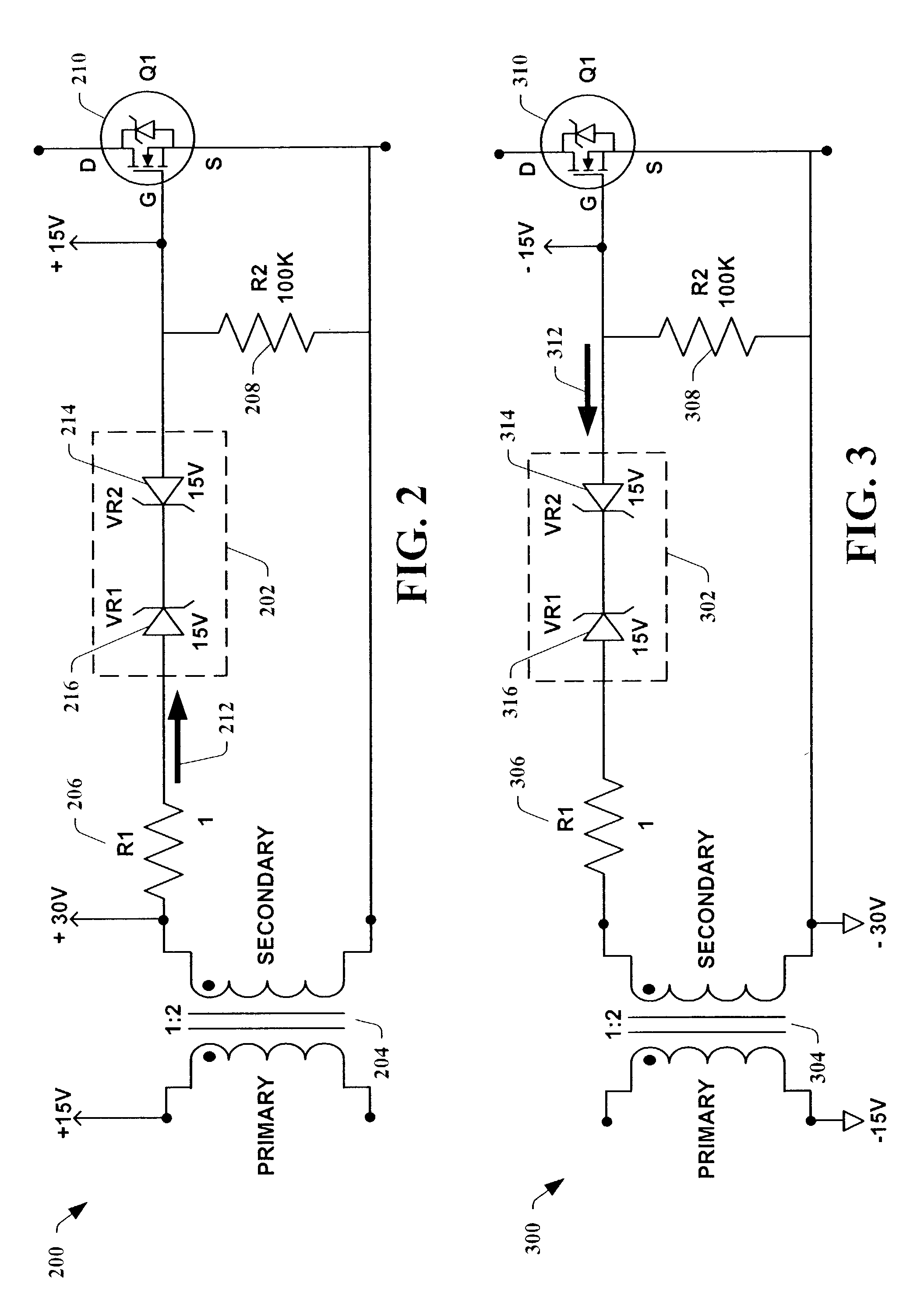

Isolated FET drive utilizing Zener diode based systems, methods and apparatus

InactiveUS20040251951A1Easy to controlImprove inner qualityElectronic switchingDiodeZener diodeEngineering

The present invention provides a system, apparatus and methodology for semiconductor device gate control utilizing a gate driver circuit 112 having opposing current inhibiting elements 130, 132 capable of controlling current flow until a predetermined voltage level is obtained across the current inhibiting element opposing the current flow. A difference of an isolated input voltage level and the predetermined voltage level approximates a gate voltage potential employed to drive a gate input of a semiconductor device. This is accomplished, in one instance of the present invention, by employing Zener diodes in an opposing fashion to produce the gate voltage potential. Zener diode breakdown voltages provide the predetermined voltage levels necessary to properly control the gated semiconductor device during gate charge and discharge cycles.

Owner:NORTHROP GRUMMAN SYST CORP

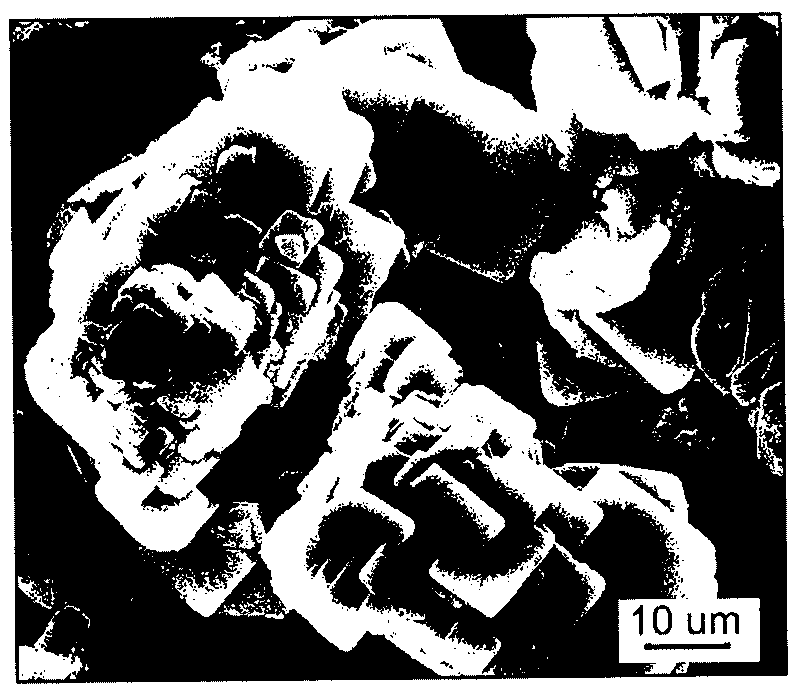

As-cast state high-carbon high-chromium cast iron and method for producing the same

InactiveCN101173340AIncrease productivitySimple processMolten metal pouring equipmentsWear resistantHigh carbon

The invention relates to an as-cast cast iron with high carbon and high chromium and a preparation method, which belongs to the technical field of metal wear-resistant material. The invention is characterized in that the composing components of the cast iron with high carbon and high chromium are (in weight percentage): 4.5 to 5.5 C, 22.5 to 30.8 Cr, 3.0 to 5.0 V, 0.7 to 1.2 Mn, 0.2 to 0.5 Nb, 0.5 to 1.0 Ti, 0.08 to 0.20 Mg, 0.05 to 0.20 Na, 0.05 to 0.20 RE, Si of less than 1.0 and Fe as well as unavoidable trace impurities for the rest, and Cr-to-C ratio is no less than 5.0 and no more than 5.6; the as-cast cast iron with high carbon and high chromium of the invention can be produced in an electric stove with the tapping temperature of 1440 to 1480 DEG C, and is inoculated with ferrovanadium particles after tapping; combined modification treatment is done with rare earth magnesium alloy and sodium salt; the casting temperature of hot metal is 1350 to 1380 DEG C; and the cast iron with high carbon and high chromium can be directly used after stress relief annealing treatment at the temperature of 200 to 280 DEG C. The invention has the advantages of no need of high-temperature heat treatment, low energy cost, short production period, good casting performance, high hardness and excellent abradability.

Owner:BEIJING UNIV OF TECH

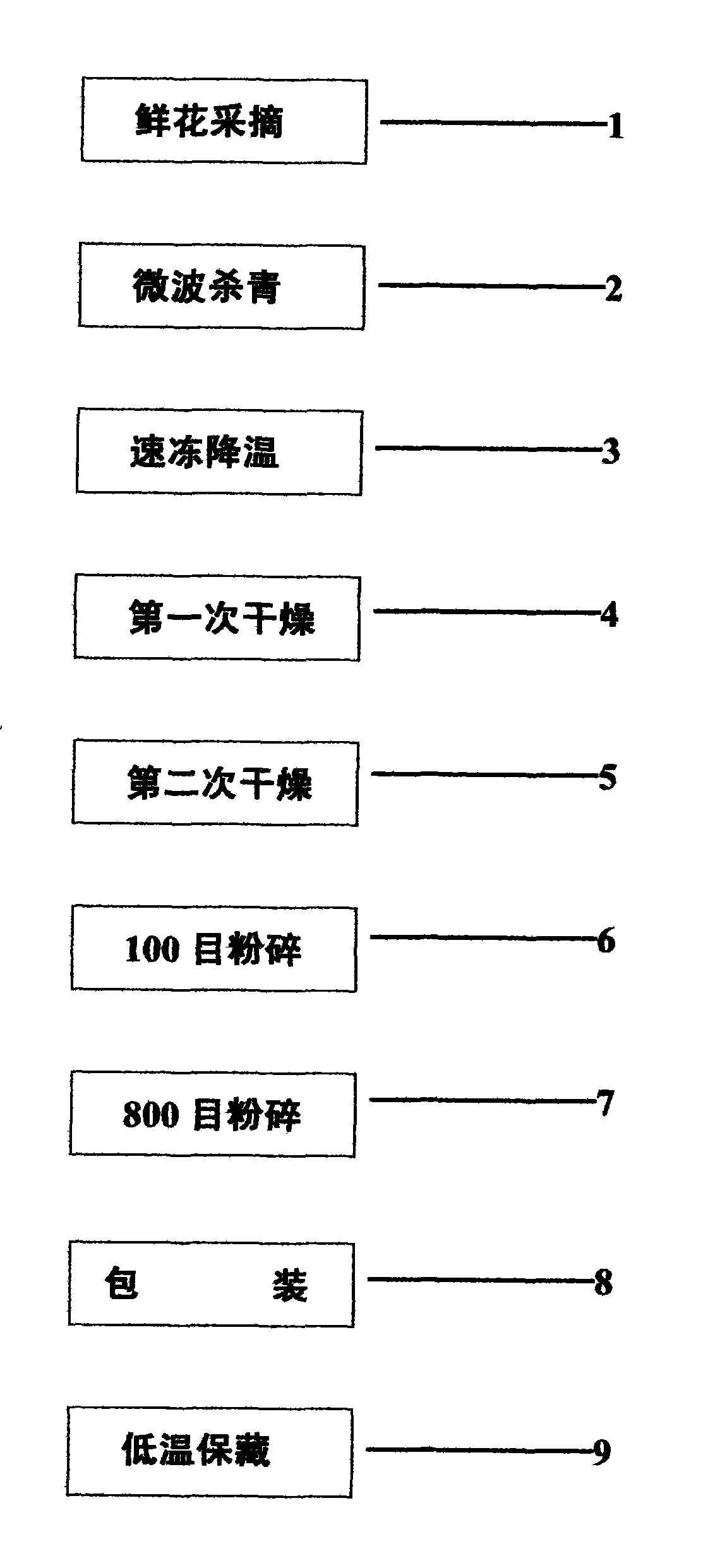

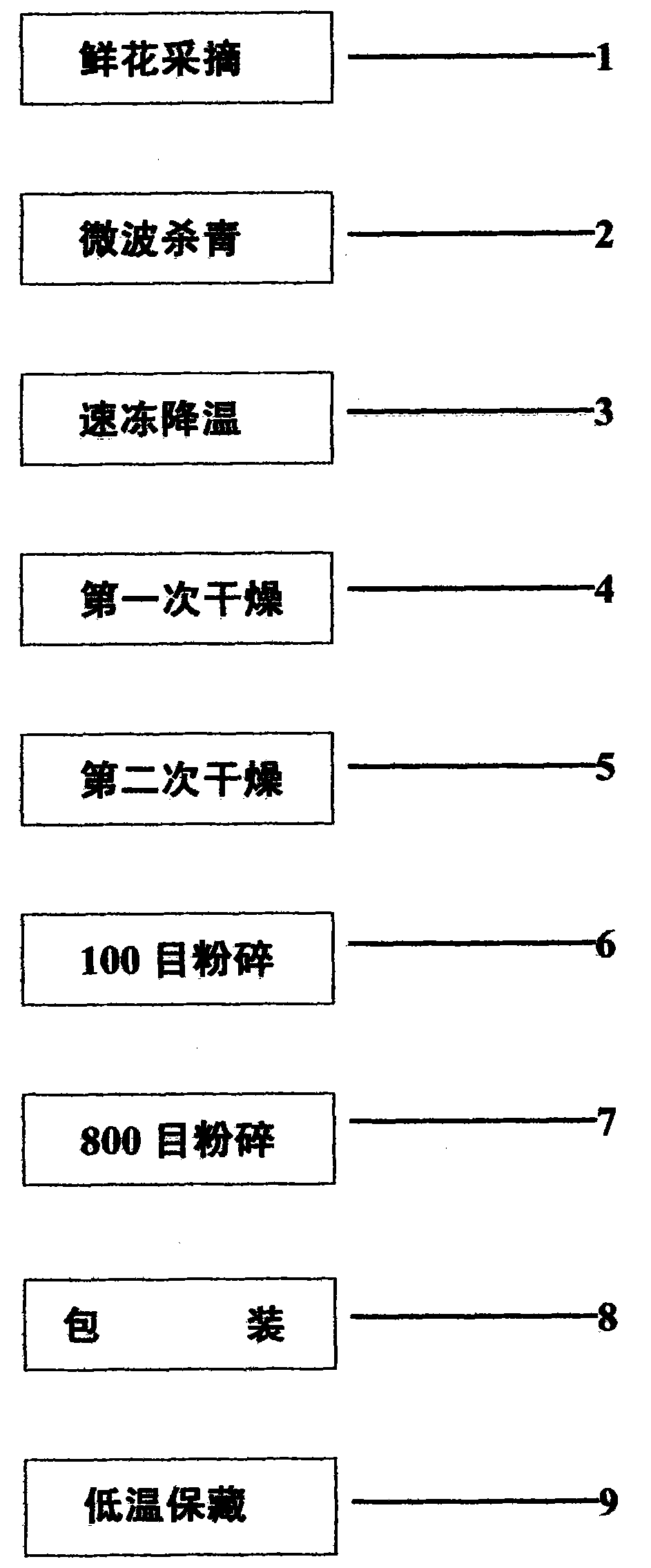

Honeysuckle micro powder tea

InactiveCN102113594ANo industrial pollutionNo pesticide residueTea substituesChlorogenic acidMicrometer

The invention relates to honeysuckle tea, in particular to honeysuckle micro powder tea, and provides honeysuckle micro powder tea with a particle size of 18 micrometers. The honeysuckle micro powder tea is characterized in that the tea contains as high as more than or equal to 5 percent of chlorogenic acid, has pale green color and faint scent smell, and avoids precipitates and granular sensation after being infused. A production method comprises the following steps of: picking fresh flowers, green-removing by using microwaves, quick freezing and cooling, performing secondary drying, crushing twice and refrigerating at low temperature. Due to the function of clearing heat and detoxicating and resisting bacteria in broad spectra, the honeysuckle micro powder tea has excellent inherent quality and shape characteristic.

Owner:李全才 +2

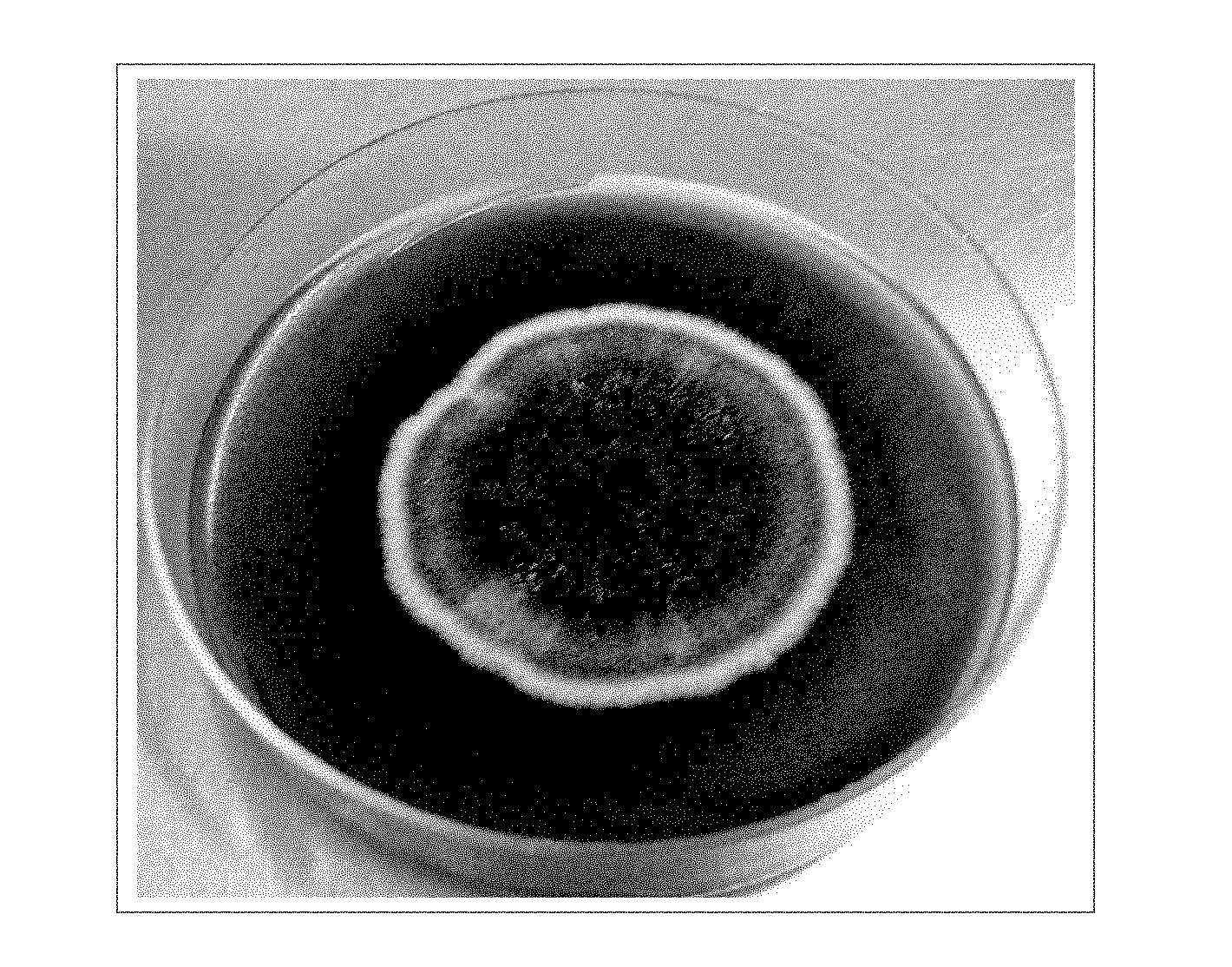

Preparation process of fungus-grown loosened green tea

ActiveCN102084903ABright golden colorGranular hypertrophyPre-extraction tea treatmentSporeAdditional values

The invention provides a preparation process of fungus-grown loosened green tea, which comprises the steps of: 1, purifying and separating eurotium cristatum; 2, preparing an eurotium cristatum spore suspension and determining the concentration thereof; 3, processing a green tea sample; 4, adding the eurotium cristatum suspension; 5, drying the tea, 6, controlling the humidity and temperature forfungus growing; 7, ageing and drying the fungus-grown loosened green tea; and 8, storing the fungus-grown loosened green tea. The invention can realize the fungus growing of the green tea by inoculating by using the golden flower fungus in Fuzhuan tea in a short period, and golden flower is generally flourish, bright and yellow in color, and large in particles, thus the fungus-grown loosened green tea inherits the impressions of the traditional green tea and can be endowed with the characteristics of the Fuzhuan tea, and the internal quality and the additional value of the green tea are improved.

Owner:HUNAN CITY UNIV

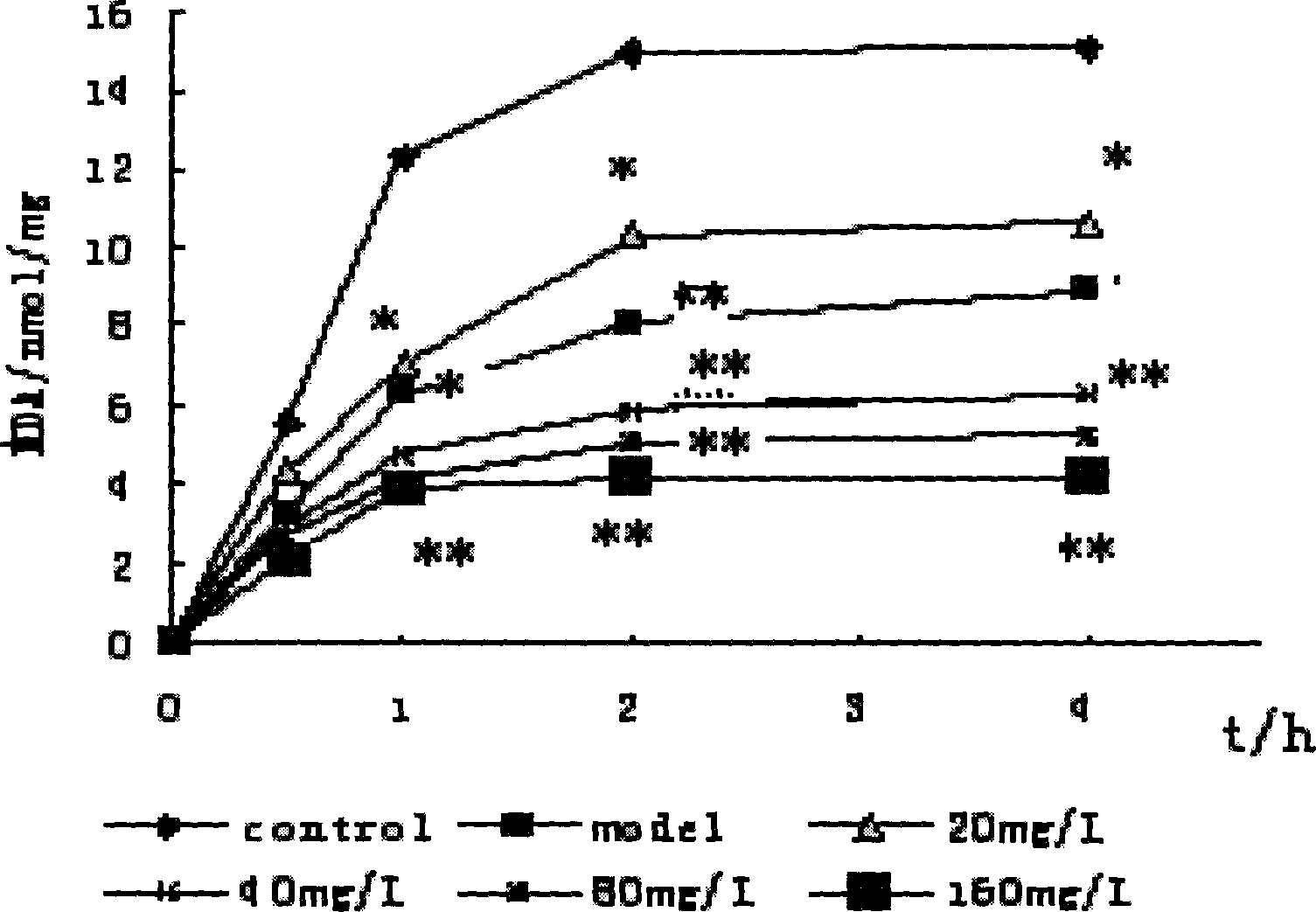

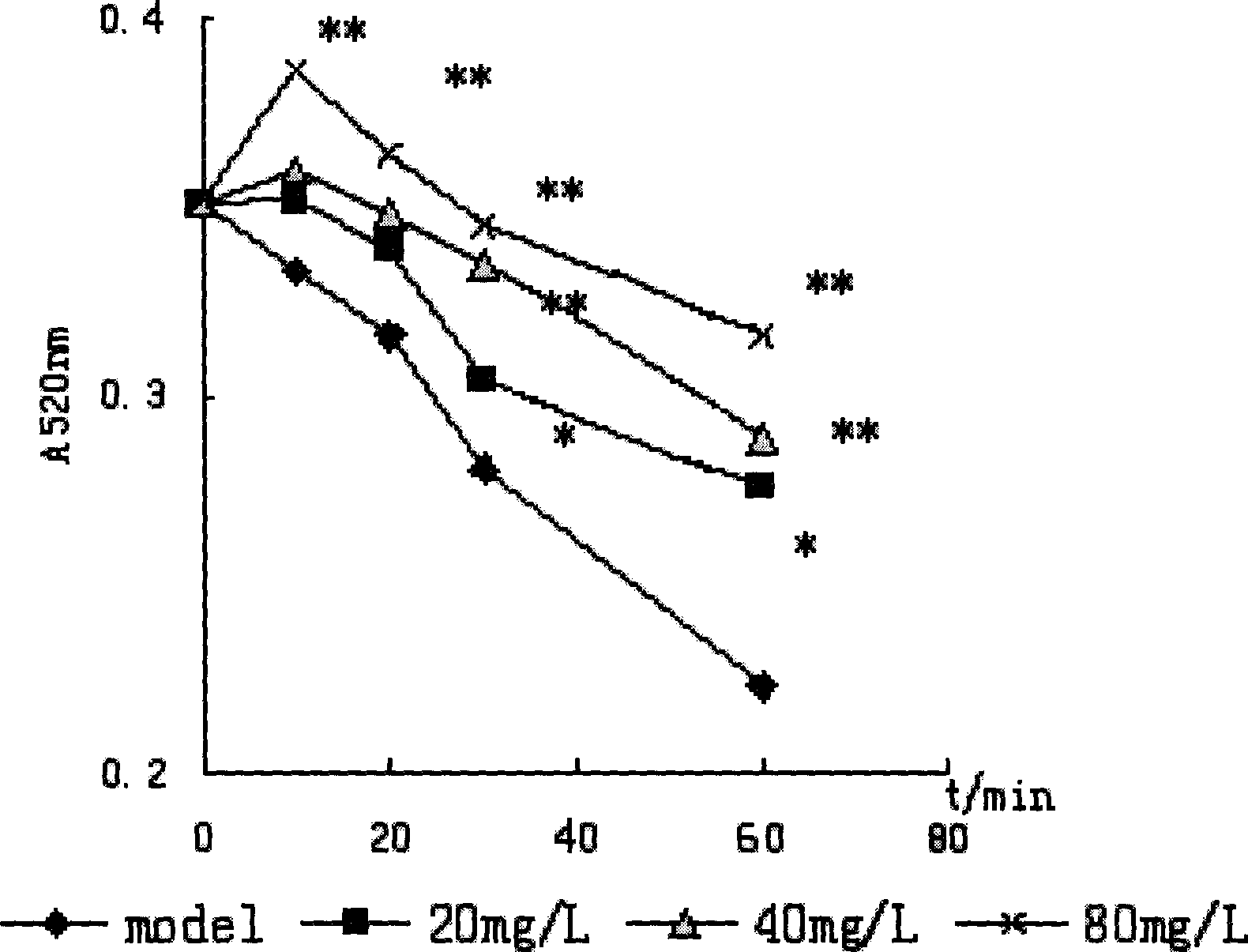

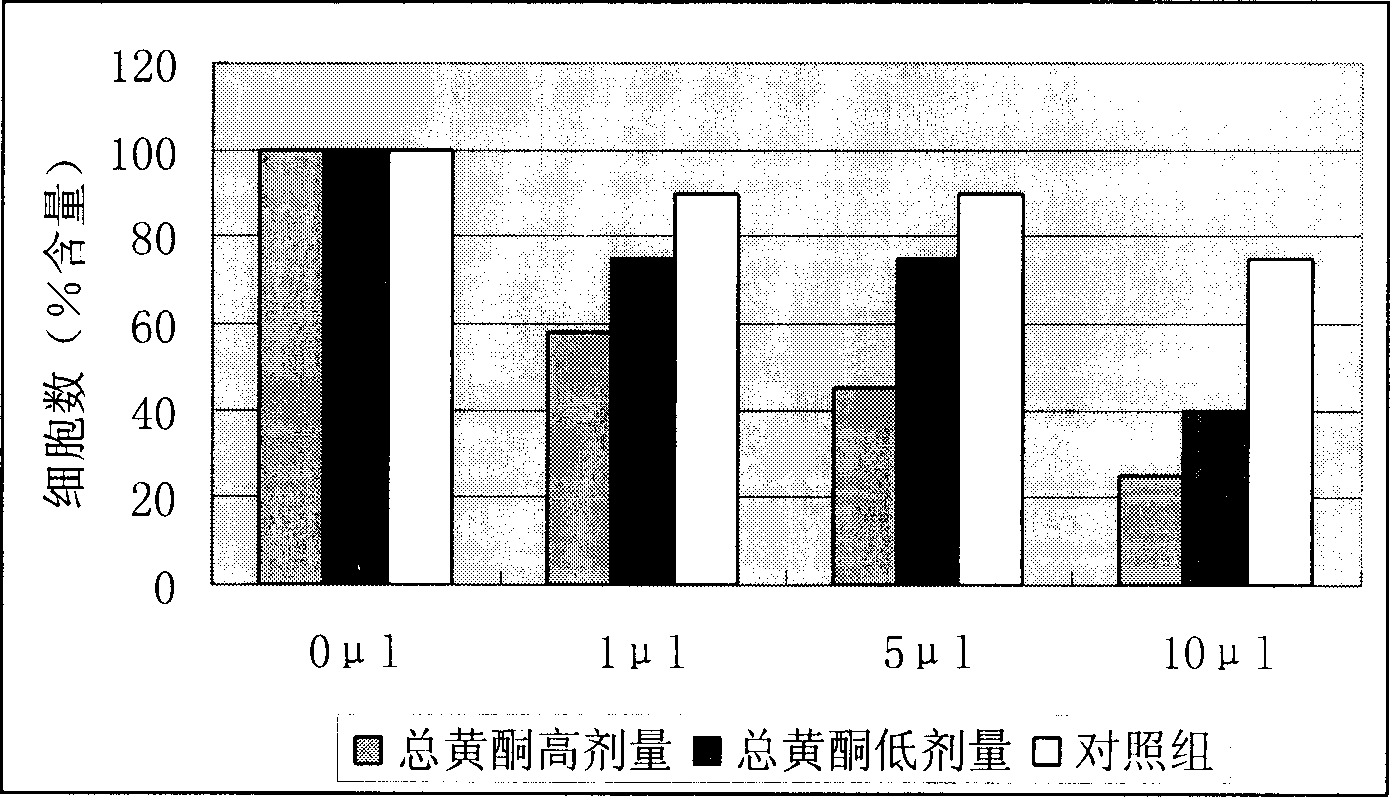

American goldenrod herb total flavone extract and its preparing method and use

InactiveCN1899341AEfficient enrichmentHigh in flavonoidsSugar derivativesSugar derivatives preparationDiseaseChlorogenic acid

The present invention relates to American goldenrod herb total flavone extract and its preparation process and use. The American goldenrod herb total flavone extract contains quercetin, quercetin-3-O-beta-D-heteroside, kaempferol-3-O-alpha-L-rhamnoside, chlorogenic acid, etc. capable of preventing and treating senile dementia, various inflammatory respiratory diseases, esophagus cancer, etc. The preparation process is simple, high extracting rate, and the extract has high pharmacological effect, stable property, low toxicity and controllable quality.

Owner:LINSAIJIAO BIOLOGICAL SCI & TECH DEV SHANGHAI

Method for producing high-elasticity bulked silk-cotton quilt

ActiveCN1743260APromote puffingPuffing treatment can ensure that cocoons are cooked evenly and promoteAnimal fibresUpholstery fillingBoiling processWadding

The invention relates to a method for producing a expanded silk wadding, which includes: sort cocoons, boil at high temperature, degelatinize, shuck the cocoons to remove silkworm, wash, loosen by drawing and make them into silk piece, dewater, dry and draw to make the silk wadding. The invention features that the cocoons before high temperature boiling process are vacuum soaked and expanded by a expanding liquor, concretely the cocoons before high temperature are suctioned into the expanding liquor heated by 80-95 degreeC under vacuum condition, soaked uniformly and expanded in slight boiling state. The said expand is made from amphoteric surfactant. The cocoons after being made into silk pieces and before dewatering are conducted an after finishing by a silk softening agent. Advantages: the patches and stem cubes resulted from un-uniform boiling or in-complete degelatinizing of cocoons are largely reduced; the silk floss is very soft because of full expanding.

Owner:NANTONG LOVER APPL +1

Alcoholization agent for tobacco leaf and application in technique of threshing and redrying, procedure

An alcoholizing agent of tobacco leaf for improving the biologic property and quality of tobacco leaf and shortening its alcoholizing period contains the enzyme chosen from proteniase, peptidase, cellulase and amylase, one or more of isopentanal, benzoic acid, 2,6,6-trimethyl cyclohexyl-1,3-dienyl formaldehyde, etc, acetic acid and / or 1-methyl-4-isopropylcyclohexyl-3-alcohol, and propanediol.

Owner:SHENZHEN BOTON FLAVORS & FRAGRANCES

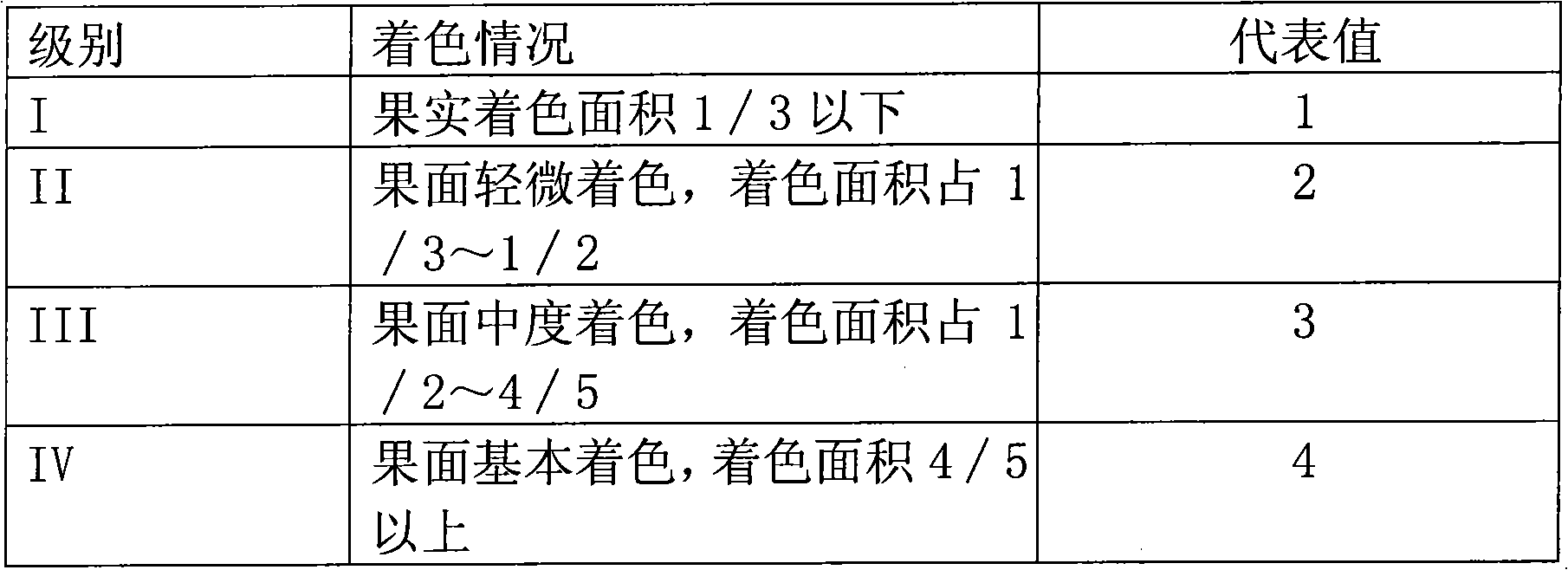

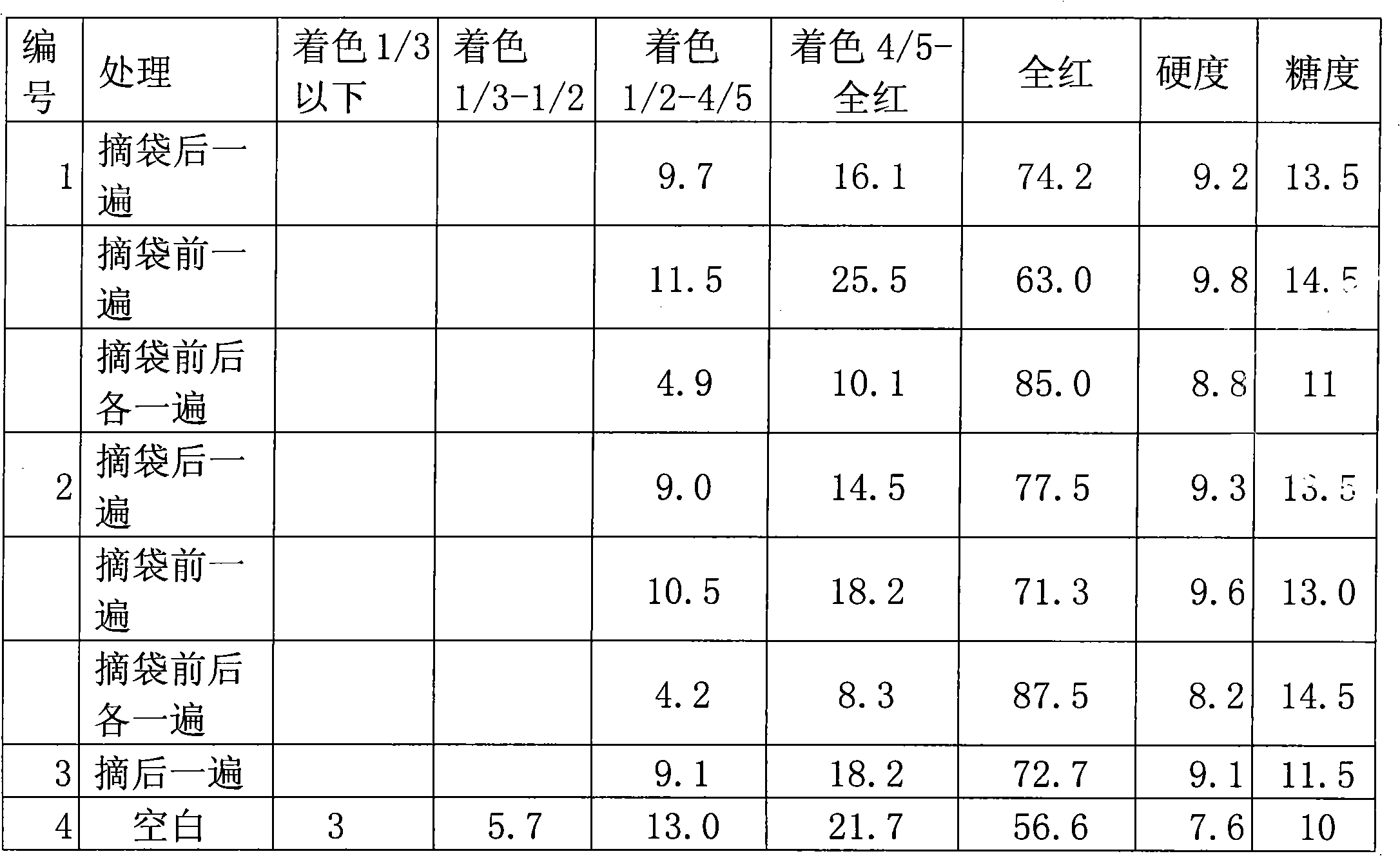

Fruit color enhancer and method for promoting fruit coloration by using same

InactiveCN102057953AGood colorGood lookingPlant growth regulatorsBiocidePhosphateHazardous substance

The invention discloses a fruit color enhancer and a method for promoting fruit coloration by using the same. The fruit color enhancer comprises photosynthetic bacteria, and also can comprise at least one of anthocyanin solution, chitin, chitosan, chitosan oligosaccharide, potassium dihydrogen phosphate, potassium sulfate and a wetting agent. The fruit color enhancer is sprayed on the surfaces of fruits or leaves for 1 to 5 times 1 to 45 days before the fruits are harvested, and the effect is more obvious when the fruit color enhancer is directly sprayed on the fruits instead of the surfaces of the leaves. By the method, harmful substances are not remained in the fruits, and sugar degree and hardness are improved to a certain extent. The method is suitable for the fruits of apples, grapes, cherries, tomatoes and the like, and has great significance for improving appearance and internal quality, and increasing the value and export yield of the fruits, and the income of peasants.

Owner:常大勇

Preparation method of hydroxy methionine salt and compound

The invention provides a preparation method of hydroxy methionine salt and a compound, comprising the following steps: a. feeding metal hydroxide or basic metal oxide or amphoteric metal oxide and 2-hydroxy-4-methylthiobutyricacid into a closed and corrosion resistant reaction kettle to react for 0.5-12h according to a stoichiometric ratio, taking the low-boiling polar organic solvent or the mixed solvent thereof with water as the reaction medium, stirring, separating the target product, washing and drying to obtain the products; and b. recycling the reaction medium. The preparation method of the invention has short route, no consumption of acid or alkali reagent, low cost, easily-controllable product quality, environmental friendliness and the like, thus being applicable to large-scale industrial production.

Owner:李宁 +1

Method for casting valve body of flat gate valve

ActiveCN103433434AReduced horizontal projected areaGravity feeding is easy to implementFoundry mouldsFoundry coresMiddle lineImpurity

The invention discloses a method for casting a valve body of a flat gate valve, and belongs to the technical field of valve body casting processes. The method is technically characterized in that a valve body cavity is vertically formed between a sand mold and a sand core; a plurality of valve body heat preserving risers are uniformly arranged at the open end of the valve body through the sand mold; a flange heat preserving riser is arranged at the upper end of a flange plate on each of two sides; a first external chill is arranged at the lower end of each flange plate; a plurality of second external chills are uniformly arranged at the periphery of a valve belly below the middle line of a flange; a third external chill is arranged on the outer bottom surface of the blind end of a main body of the valve body; process supplementary ion is arranged in an inner hole of the flange plate on each of the two sides; a fourth external chill is arranged on each of two end surfaces of a valve seat table in an inner cavity of the valve body. Therefore, the probability of occurrence of casting impurities and pore defects is reduced by using a vertical pouring method, gravity feeding is easy to implement so as to be matched with the chilling action of each external chill, and castings can be fed in sequence, so that the internal quality of the castings is well improved.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

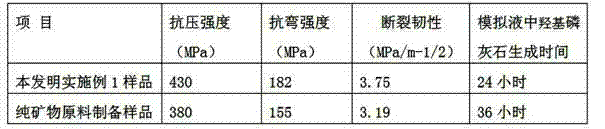

Biological microcrystalline glass prepared by utilizing phosphate tailings and preparation method thereof

The invention relates to biological microcrystalline glass prepared by utilizing phosphate tailings and a preparation method thereof. The biological microcrystalline glass comprises the following raw materials in parts by weight: 30 to 35 parts of the phosphate tailings, 15 to 25 parts of quartz sand, 10 to 16 parts of aluminium hydroxide, 20 to 28 parts of calcium hydrophosphate, 9 to 13 parts of calcium fluoride, 0 to 5 parts of magnesium oxide, 0 to 5 parts of zinc oxide and 0.5 part of sodium borate, wherein the utilization rate of the tailings reaches more than 30%. Compared with a product produced by utilizing conventional chemical raw materials, the biological microcrystalline glass has better physical and chemical properties and realizes reduction in the raw material cost by more than 30%. Based on the SiO2-Al2O3-P2O5-CaO-CaF2 system, the magnesium and the zinc are utilized to replace the partial calcium, so that a new magnesium-series wagnerite phase and a zinc-series zinc pointed crystal phase are generated, and therefore, the brittleness of the biological microcrystalline glass is improved while the mechanical strength is improved. In addition, the biocompatibility, the bioactivity and the chemical stability of the biological microcrystalline glass are improved.

Owner:CHINESE ACAD OF GEOLOGICAL SCI

Cold extrusion forming process for oil pump shaft for automobile

The invention discloses a cold extrusion forming process for an oil pump shaft for an automobile. The cold extrusion forming process comprises the following steps of: 1, blanking; 2, performing phosphorus saponification for the first time; 3, shaping and punching to form a guide positioning pit; 4, performing spheroidizing annealing; 5, performing shot blasting; 6, performing the phosphorus saponification for the second time; 7, performing backward extrusion to obtain a pre-cooling extrusion piece in which a bottom edge is reserved and which has a hollow straight wall; 8, annealing; 9, punching the bottom edge of the pre-cooling extrusion piece; 10, rectifying deviation and lathing an excircle, a flat head, a fillet and a tear strip; 11, performing the phosphorus saponification for the third time; and 12, performing forward extrusion, and pressing to form a cold extrusion piece for the oil pump shaft. By the cold extrusion forming process for the oil pump shaft for the automobile, the oil pump shaft for the automobile is subjected to extrusion forming once, so that the slight cutting or no cutting of complex pipe fittings is implemented.

Owner:上海久丰汽车零件有限公司

Plastic substrate film for food packing and machining process thereof

InactiveCN102380997AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention discloses a plastic substrate film for food packing. The plastic substrate film is formed by performing coextruding and blow molding on an inner layer, a middle layer and an outer layer, wherein the inner layer is made from low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE) and metallocene linear low-density polyethylene (mLLDPE); and both the middle layer and the outer layer are made from LDPE and LLDPE. The plastic substrate film for food packing has the characteristics of high barrier property, high airtightness, high pollution resistance, pressure resistance, impact resistance, high heat-sealing strength and high heat-sealing performance, and is accordant with the national food safety certification.

Owner:DALIAN RUIXIANDA PLASTIC CO LTD

Method of manufacturing halogenated rubber like polymer

ActiveCN1903892AMeet the needs of halogenation reactionIncreased macroscopic reaction ratePolymer scienceWastewater

The present invention relates to a method for preparing halogenated rubber polymer, including reaction of unsaturated rubber polymer and halogenating agent. It is characterized by that said halogenation reaction is implemented in a closed drying system with screw extrusion press by adding raw material and additive and making them undergo the processes of plasticization, deaeration, softening, multistage halogenation, stabilizing, removing volatile matter and discharging material.

Owner:江苏圣杰实业有限公司

Tobacco slice high-activity bio-enzyme regulator and method for improving the quality of the tobacco slice

The invention discloses a tobacco leaf quality biological enzyme composite adjuster and a biological enzyme adjuster for improving tobacco leaf quality and a relative method. The biological enzyme adjuster is made from preparing microbe composite enzymes which contains amylase, prolease, cellulose and pectic enzyme with polyzyme activity adjuster. The inventive biological enzyme adjuster can treat the low-quality tobacco leaf before and later initial bake, different from general enzyme liquid, to significantly improve the tobacco leaf quality whose total sugar, protein, nitrogen, nicotine and Smuco value are all improved, with increased volatile and semi-volatile smell components. Tests have proved that the invention can improve 1-2 levels of low-quality tobacco leaf, with simple process and low cost.

Owner:夏炳乐

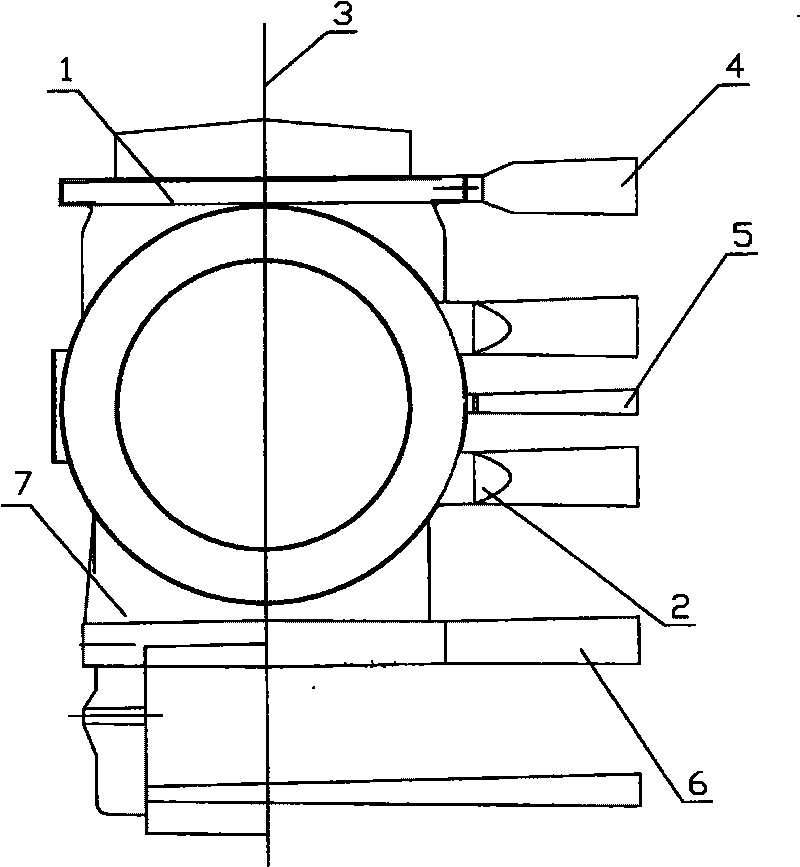

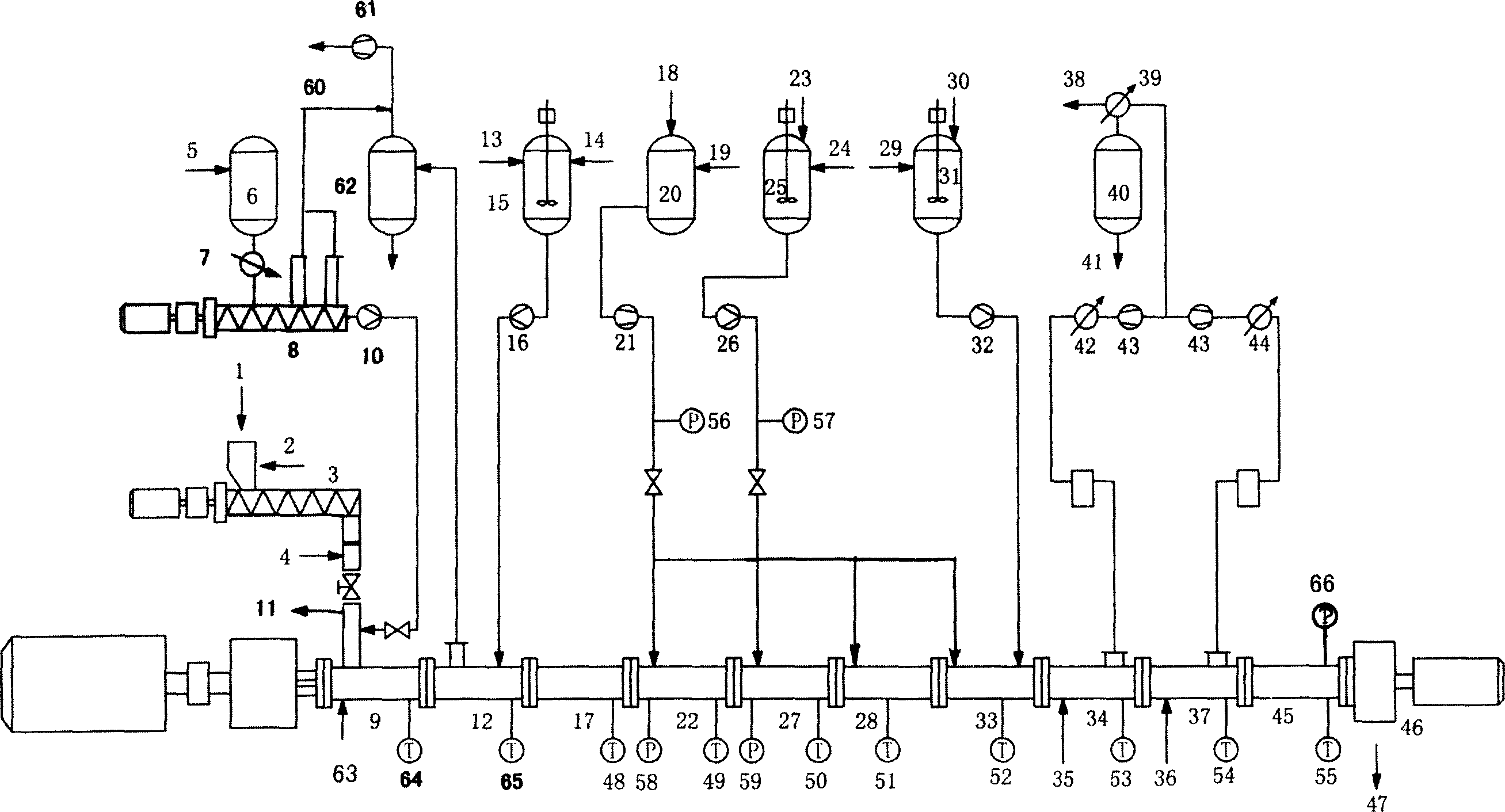

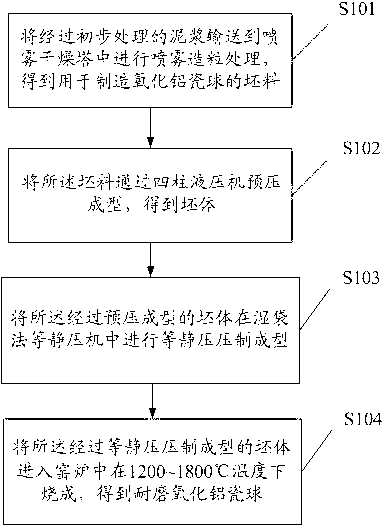

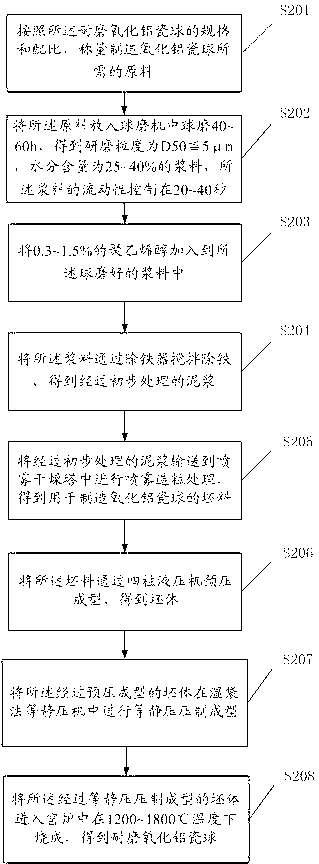

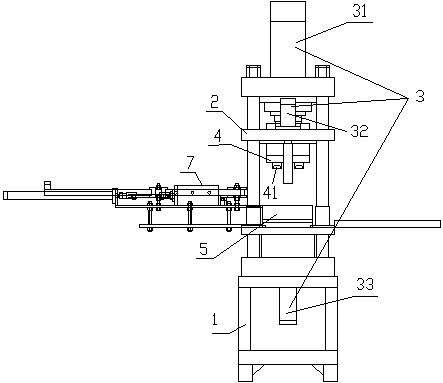

Wear-resisting aluminum oxide ceramic ball isostatic pressing process and special device

ActiveCN103171024AFacilitate automated productionImprove liquidityCeramic shaping apparatusSpray GranulationWorking environment

The invention discloses wear-resisting aluminum oxide ceramic ball isostatic pressing process. The process includes a first step of conveying slurry subjected to primary treatment into a spray drying tower for spray granulation treatment to obtain blanks for manufacturing aluminum oxide ceramic balls, a second step of carrying out prepressing molding on the blanks through a four-column hydraulic press to obtain green bodies, a third step of carrying out isostatic pressing molding on the green bodies subjected to prepressing molding in a wet-bag type isostatic pressing machine, and a fourth step of feeding the green bodies subjected to isostatic pressing molding into a kiln for burning under the temperature of 1200-1800 DEG C to obtain the wear-resisting aluminum oxide ceramic balls. The invention further discloses a special device for the wear-resisting aluminum oxide ceramic ball isostatic pressing process. The special device comprises the four-column hydraulic press. The wear-resisting aluminum oxide ceramic ball isostatic pressing process and the special device can improve appearance quality, enable specifications and sizes of products to be accurate, reduce wear rate of the products and improve the inherent quality of the products. Meanwhile, the wear-resisting aluminum oxide ceramic ball isostatic pressing process can improve production efficiency of the products, reduce labor intensity of workers, reduce dust pollution and improve working environment.

Owner:FOSHAN CERAMICS RES INST GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com