Cold extrusion forming process for oil pump shaft for automobile

A molding process and oil pump shaft technology, applied in the field of processing technology, can solve the problems of increasing process steps and processing costs, difficult to control product accuracy, etc., and achieve the effects of saving raw materials and processing costs, improving internal quality, and reducing processing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

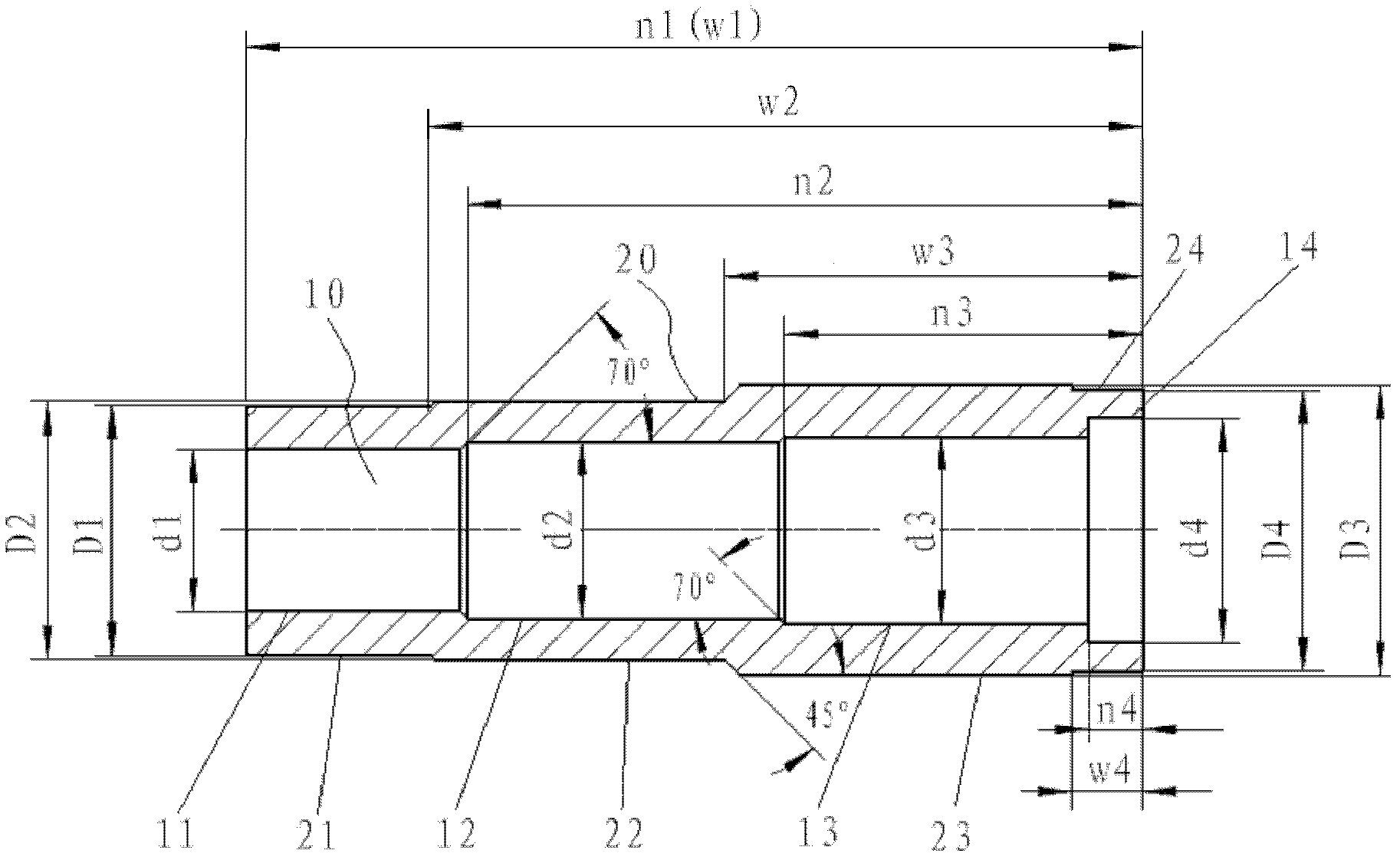

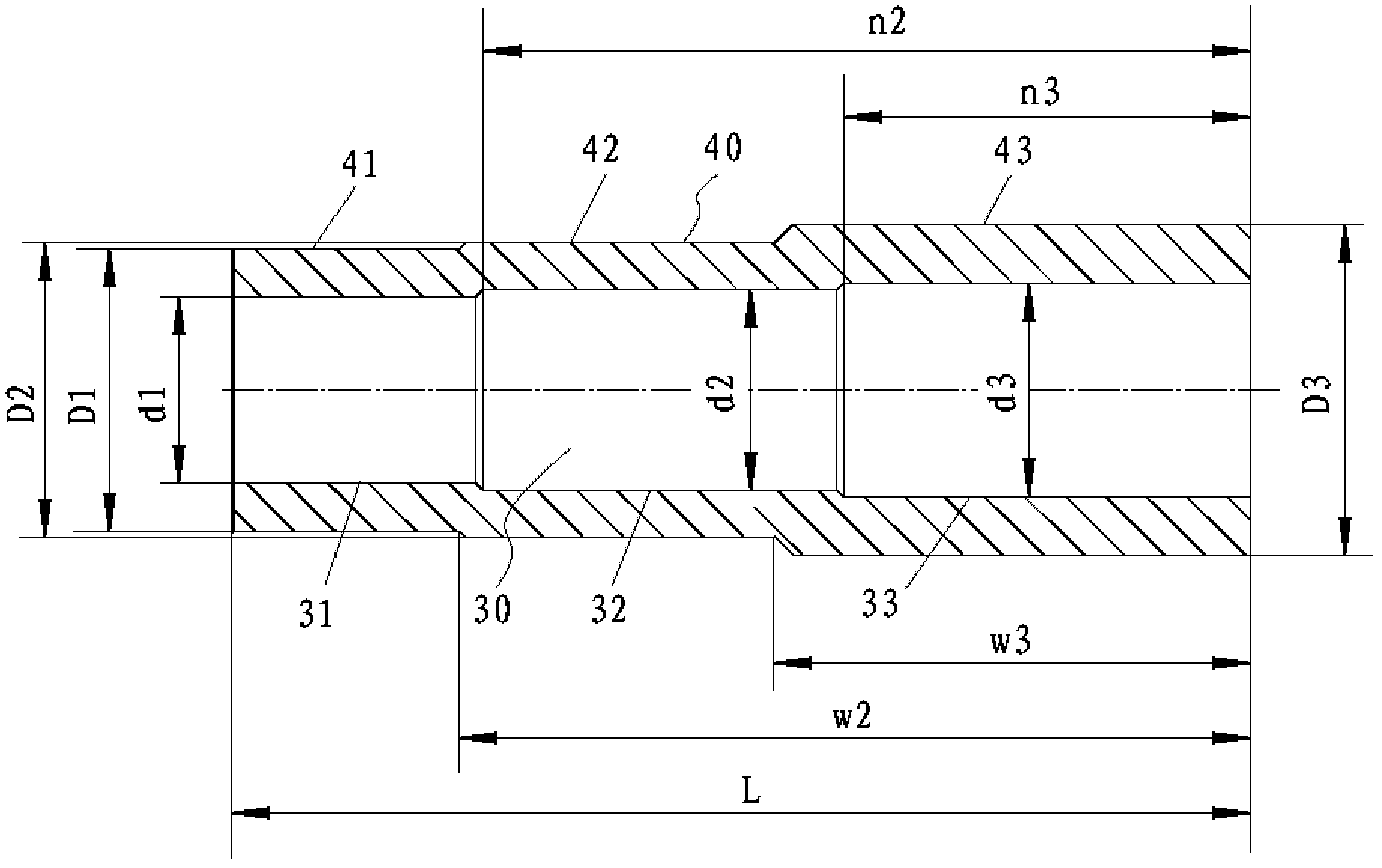

[0027] see Figure 3a to Figure 3g , the cold extrusion forming process of a kind of automobile oil pump axle of the present invention, comprises the following steps:

[0028] Step 1, saw a round bar blank 51 of required length on a disc according to product requirements (see Figure 3a ), to ensure that the length tolerance of the round bar blank is 0 to 0.1mm, and to make the perpendicularity between the two ends of the round bar blank and the outer peripheral surface of the round bar blank be 0.10mm;

[0029] Step 2, carry out the first phosphorus saponification treatment to the round bar blank 51 according to the conventional phosphorus saponification process;

[0030] Step 3, shaping the round bar blank through step 2 and punching guide positioning pits to make blank 52 (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com