Patents

Literature

1925 results about "Spray Granulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for silicon carbide ceramic tube or rod

ActiveCN101560104AEvenly dispersedUniform moisture contentCeramic shaping apparatusClay processing apparatusShielding gasSlurry

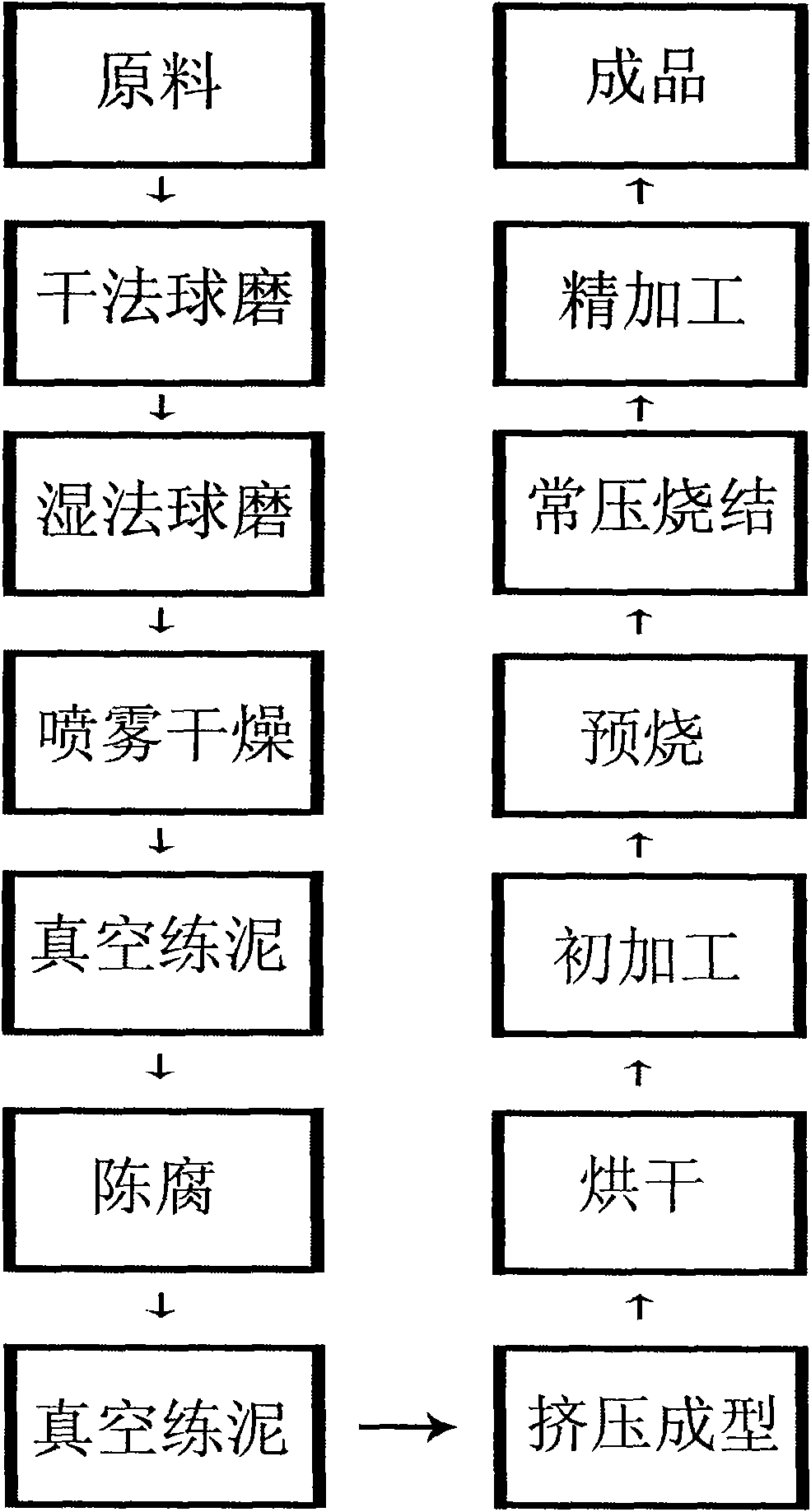

The invention relates to a preparation method for a silicon carbide ceramic tube or rod. An extrusion moulding method is adopted to form a blank body; a normal pressure sintering method is adopted for sintering; and submicron level silicon carbide powder and additives are taken as main raw materials. The preparation method comprises the following steps: 1) carrying out ball milling on the main raw materials by a dry method, adding water, a dispersant, a plasticizer, a lubricant and a liquid state binder, and then carrying out ball milling by a wet method; 2) adopting a spray granulation process to granulate silicon carbide slurry; 3) extruding the blank body by a one-shot direct extrusion moulding method after vacuum pug, corrosion, and vacuum pug; 4) drying the molded blank body by a stage drying mechanism; and 5) placing the blank body of the silicon carbide ceramic tube or rod in a vacuum furnace and carrying out sintering for two times by taking argon gas as protective gas. The high temperature resisting strength and the corrosion resistance of the silicon carbide ceramic tube or rod prepared by the method are both better than those of a reactive sintered product. Compared with a hot press sintering method, the method has lower limit on the product shape and size, and lower cost. The method is suitable for the industrialized production.

Owner:宁波欧翔精细陶瓷技术有限公司

Method for preparing organic sustained release fertilizer synergist

InactiveCN101591208AHigh calorific valueIncrease temperatureAgriculture gas emission reductionFertilizer mixturesMonosodium glutamateSodium Bentonite

The invention provides a method for preparing an organic sustained release fertilizer synergist. The synergist comprises the following components in portion by weight: 25 to 60 portions of organic component, 3 to 15 portions of synergistic component, 10 to 13 portions (solid) and 3.5 to 9 portions (liquid) of sustained release component, 0.5 to 5 portions of trace elements, 18 to 30 portions of inorganic nutrient, and 2 to 7 portions of additive. The synergist is prepared by the method of weighing, mixing, spray granulation and low-temperature drying, wherein the organic component contains 2 to 5 portions of humic acid, 25 to 45 portions of mature garbage or barnyard manure, and 2 to 5 portions of residue of monosodium glutamate and sugar; the synergistic component contains 1 to 3 portions of zeolite, 1 to 5 portions of fly ash, and 2 to 5 portions of synergistic agent; the sustained release component contains 10 to 13 portions of bentonite, 0.02 to 0.1 portion of nitrification inhibitor, and 4 to 8 portions of urease inhibitor (liquid); the trace elements contain 0.1 to 1 portion of zinc sulfate, 0.1 to 1 portion of manganese sulfate, 0.1 to 1 portion of borax, 0.1 to 1 portion of copper sulfate, and 0.1 to 1 portion of ferrous sulfate; the inorganic nutrient contains 6 to 9 portions of urea, 7 to 9 portions of ammonium phosphate, and 5 to 7 portions of potassium sulfate; and the additive contains 2 to 7 portions of plaster. The synergist is suitable for the planting of field crops and forest fruits.

Owner:新疆满疆红农资化肥科技有限公司

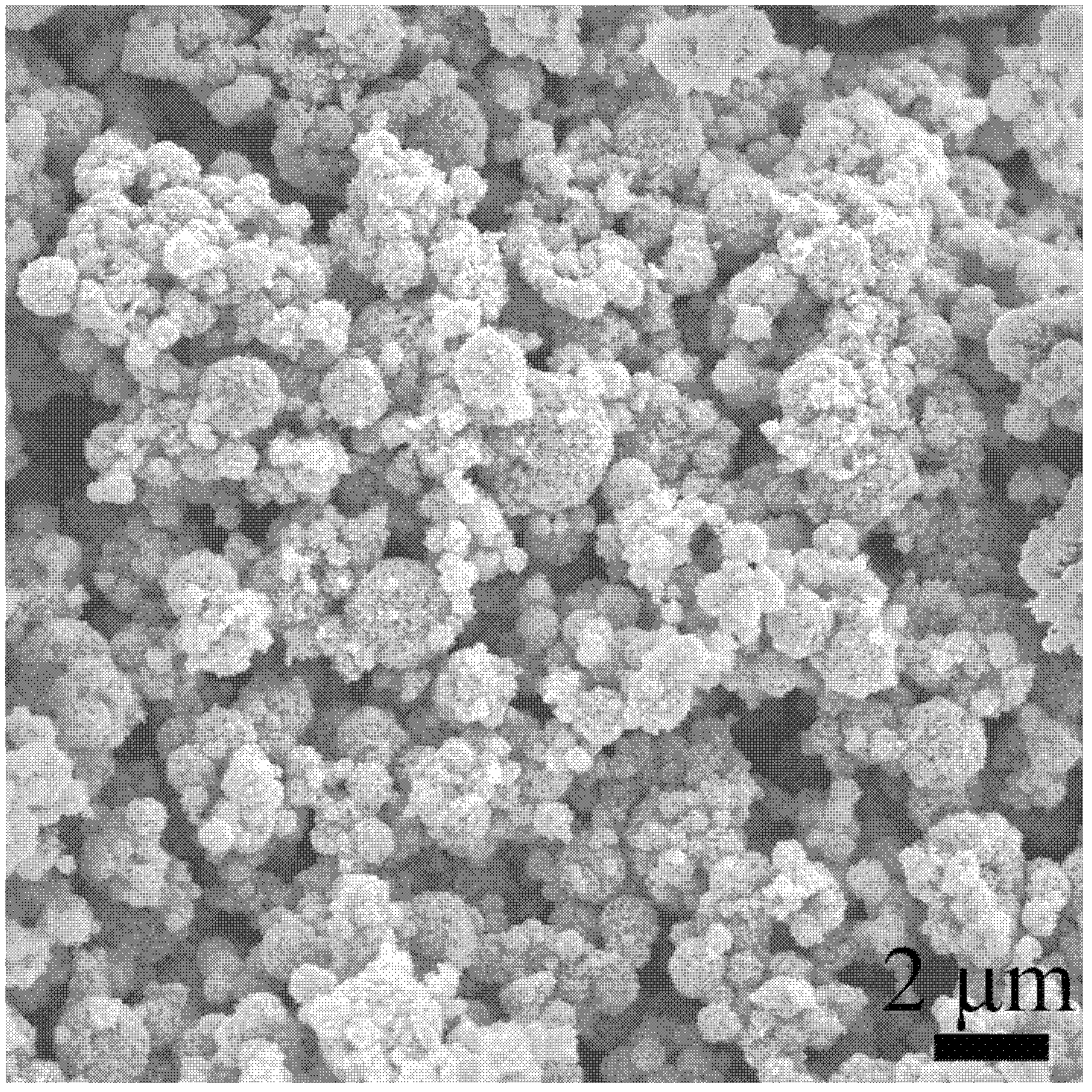

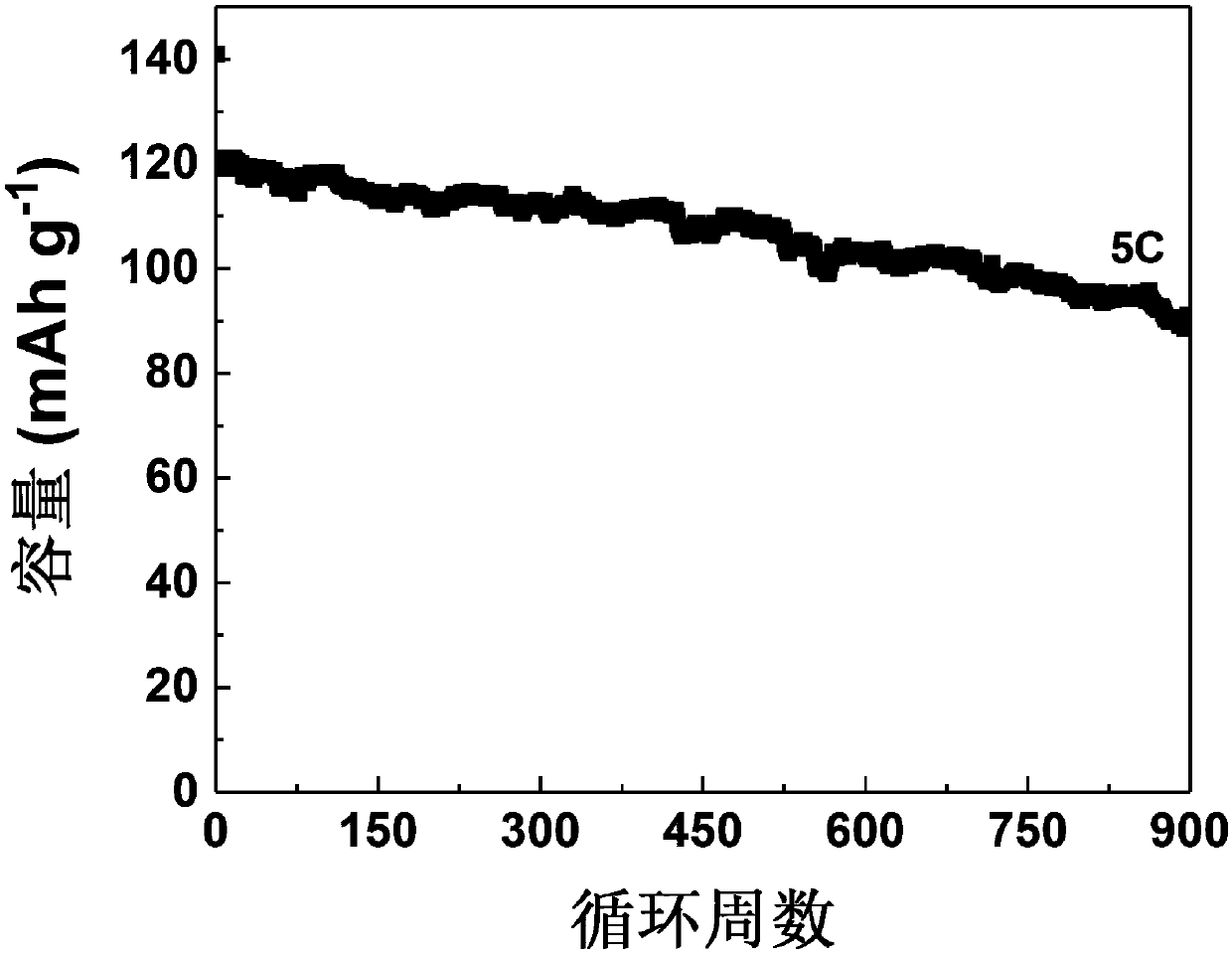

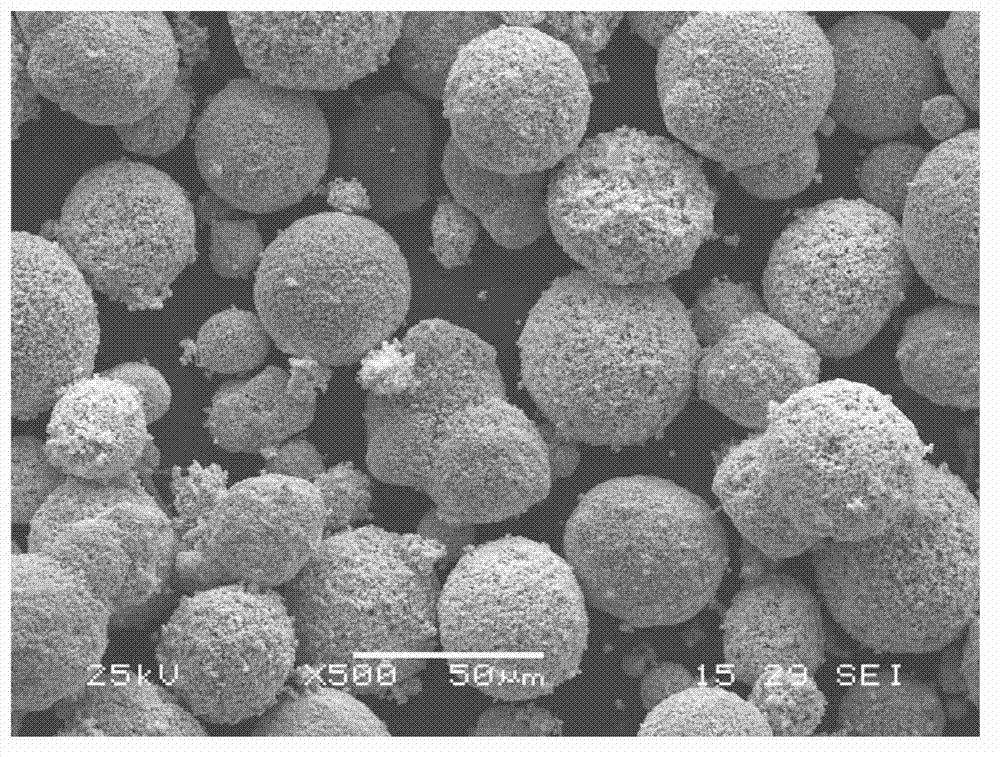

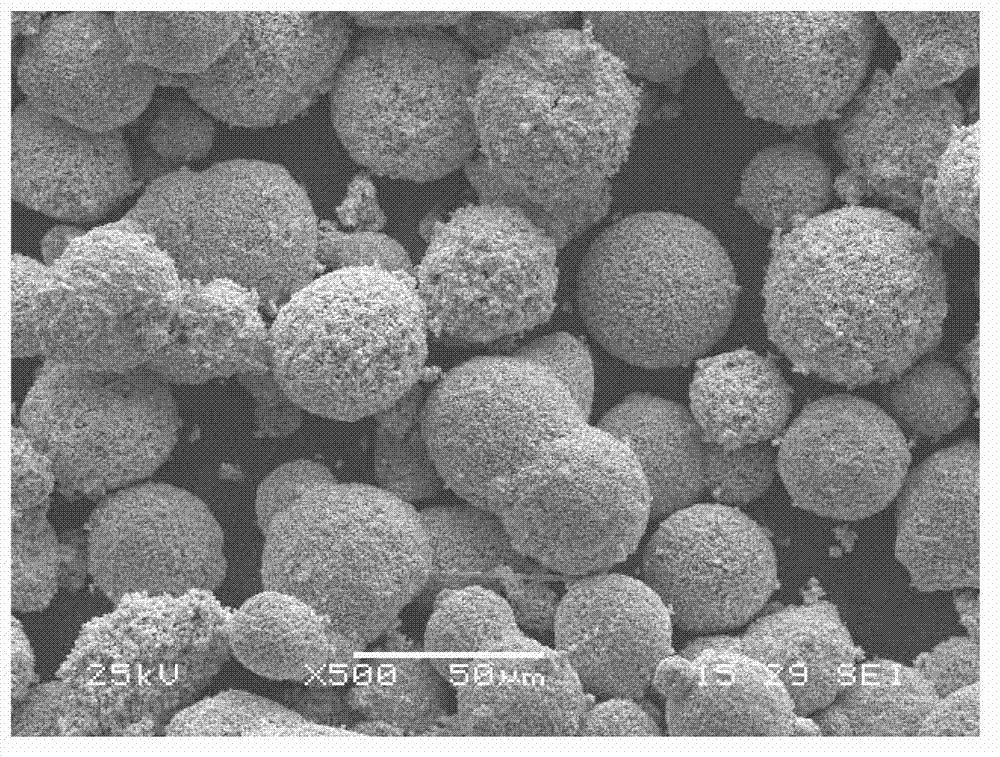

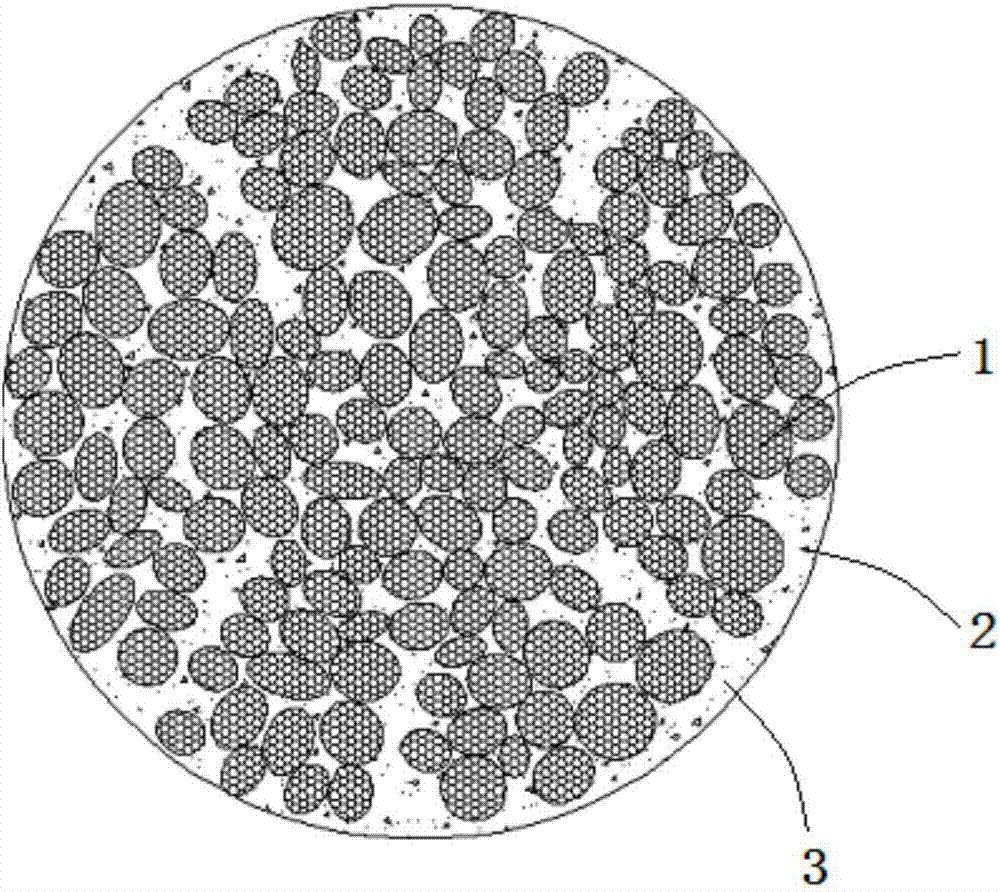

Spherical porous silicon/carbon composite material as well as preparation method and application thereof

InactiveCN106711461AHigh specific capacityPromote circulationCell electrodesCarbon compositesAdhesive

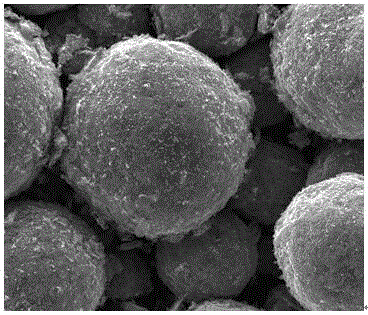

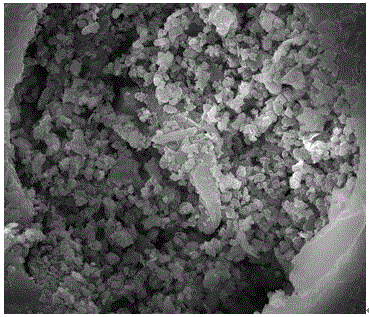

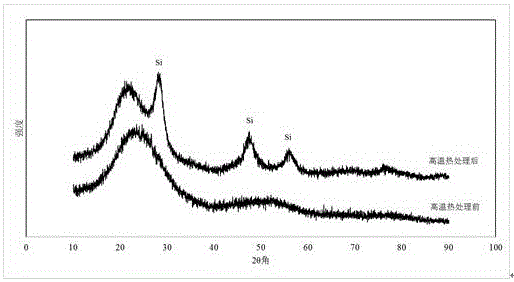

The invention discloses a spherical porous silicon / carbon composite material as well as a preparation method and application thereof. The spherical porous silicon / carbon composite material is structurally characterized in that a SiOx / C matrix, graphite with small particle size and a conductive agent are dispersed in porous amorphous carbon, wherein the average particle diameter is 12-25mu m; the method comprises the following steps of carrying out first coating on a SiOx raw material with powder pitch, and performing heat treatment so as to obtain a SiOx / C material; then performing ball milling by use of a wet method so as to reduce the particle diameter of powder, adding a carbon source adhesive, the graphite with the small particle diameter and the conductive agent, and performing high-speed dispersion, thereby obtaining pulp; and finally performing spray granulation and sintering on the pulp, thereby obtaining the final spherical porous silicon / carbon composite material. According to the invention, SiOx is dispersed in cracking carbon, the graphite and the conductive agent, so that SiOx volume expansion during a charge / discharge process is buffered, and the conductibility is enhanced; by virtue of the porous structure, the imbibition rate and cycle performance of the material can be effectively improved; by virtue of bitumencarb coating and high-heat treatment performed in advance, SiOx is prevented from being directly contacted with an electrolyte, and furthermore, the stability and first efficiency of the silicon / carbon material are improved.

Owner:ZHONGTIAN ENERGY STORAGE TECH

Material powder of manganese-zinc power soft magnet ferrite and its preparation method

InactiveCN1447356AExcellent physical and chemical propertiesReduce power consumptionInorganic material magnetismSpray GranulationSoft magnet

Manganese-zinc soft magnetic ferrite material powder is made through five working procedures: admixture, preburning, coarse cracking, sand mill and spraying-granulation by using Fe2O3, Mn3O4, and ZnOas main materials. The produced material powder has advantages of lower power consumption, high saturation induction density Bs, low cost and superior performances.

Owner:SHANGHAI BAOSTEEL MAGNETICS

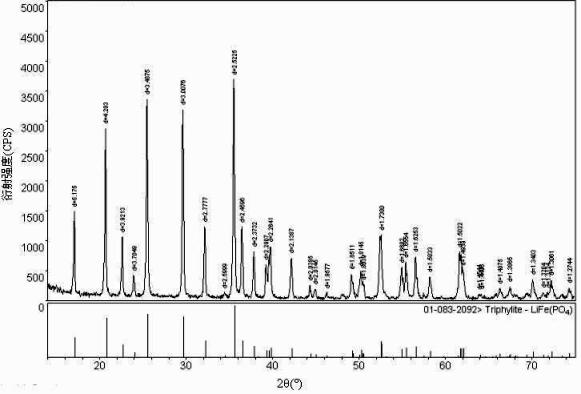

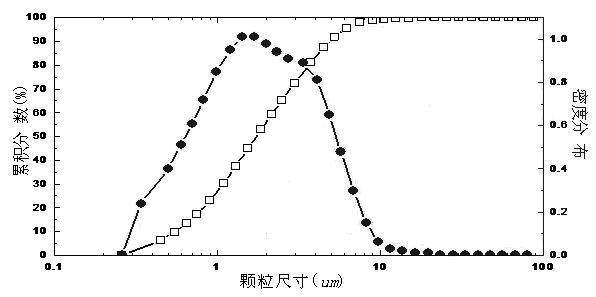

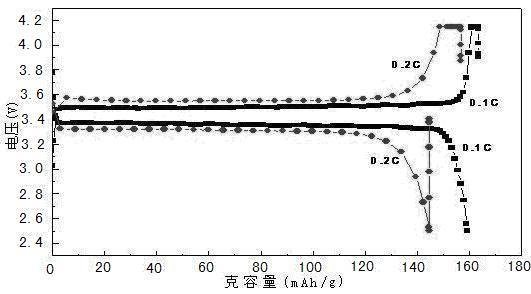

A kind of preparation method and product thereof of lithium iron phosphate material with high capacity and high compaction density

InactiveCN102275887ASolve the problem of impurityReduce manufacturing costCell electrodesPhosphorus compoundsElectrical batteryPhosphate

The invention belongs to the field of positive electrode materials for lithium ion batteries, and discloses a method for preparing lithium iron phosphate materials with high capacity and high compaction density, including (1) combining lithium source, Fe3+ source, phosphate, dopant and organic carbon source Mixing, and then spray granulation, (2) prepare calcined product, (3) mix and sand the calcined product and inorganic carbon source, and then spray dry to obtain secondary spray powder, (4) secondary spray The powder is heat-treated in vacuum or in a protective atmosphere, and sintered at a constant temperature; (5) After the above-mentioned sintered semi-finished product is passed through secondary ball milling or jet milling, a lithium iron phosphate product is obtained. The invention solves the defects of increased product cost, difficult coating and low compaction density of pole pieces caused by the use of divalent iron source, and has the characteristics of low production cost and good processability, electrical conductivity and electrochemical performance of prepared pole pieces .

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

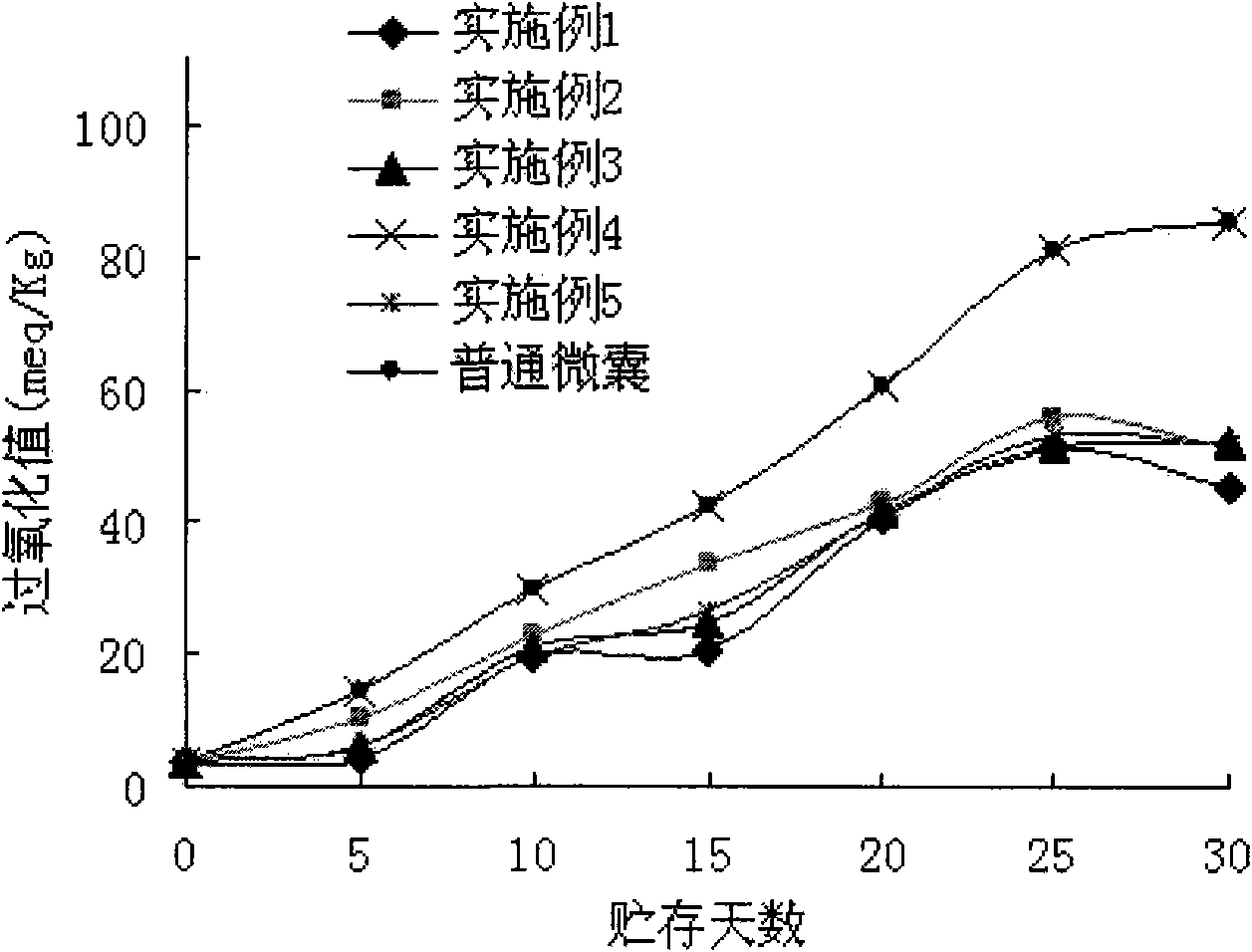

Strong anti-oxidation DHA microcapsule and preparation method thereof

InactiveCN101669920AImprove antioxidant capacityHigh yieldOrganic active ingredientsNervous disorderAntioxidantFish oil

The invention relates to a strong anti-oxidation DHA microcapsule. The microcapsule comprises the following components in percentage by weight: 10 to 30 percent of DHA fish oil, 0.02 to 0.2 percent ofantioxidant, 10 to 60 percent of wall material, and 5 to 30 percent of auxiliary wall material 5. The invention also relates to a method for preparing the strong anti-oxidation DHA microcapsule. On the basis of the prior process, the microcapsule is prepared by adding the antioxidant to oil phase and water phase respectively and performing emulsification, high-pressure homogenization, improved spray granulation and cold-air boiling-drying. The newly added antioxidant can produce better anti-oxidation effects and greatly improve the oxidation stability of the DHA microcapsule so as to prolongthe shelf life of products, and the improved spray granulation and the cold-air boiling-drying process can increase the yield of the DHA microcapsule. The DHA microcapsule can be used in the fields ofmedicines, foods, beverages and the like.

Owner:江苏怀仁生物科技有限公司

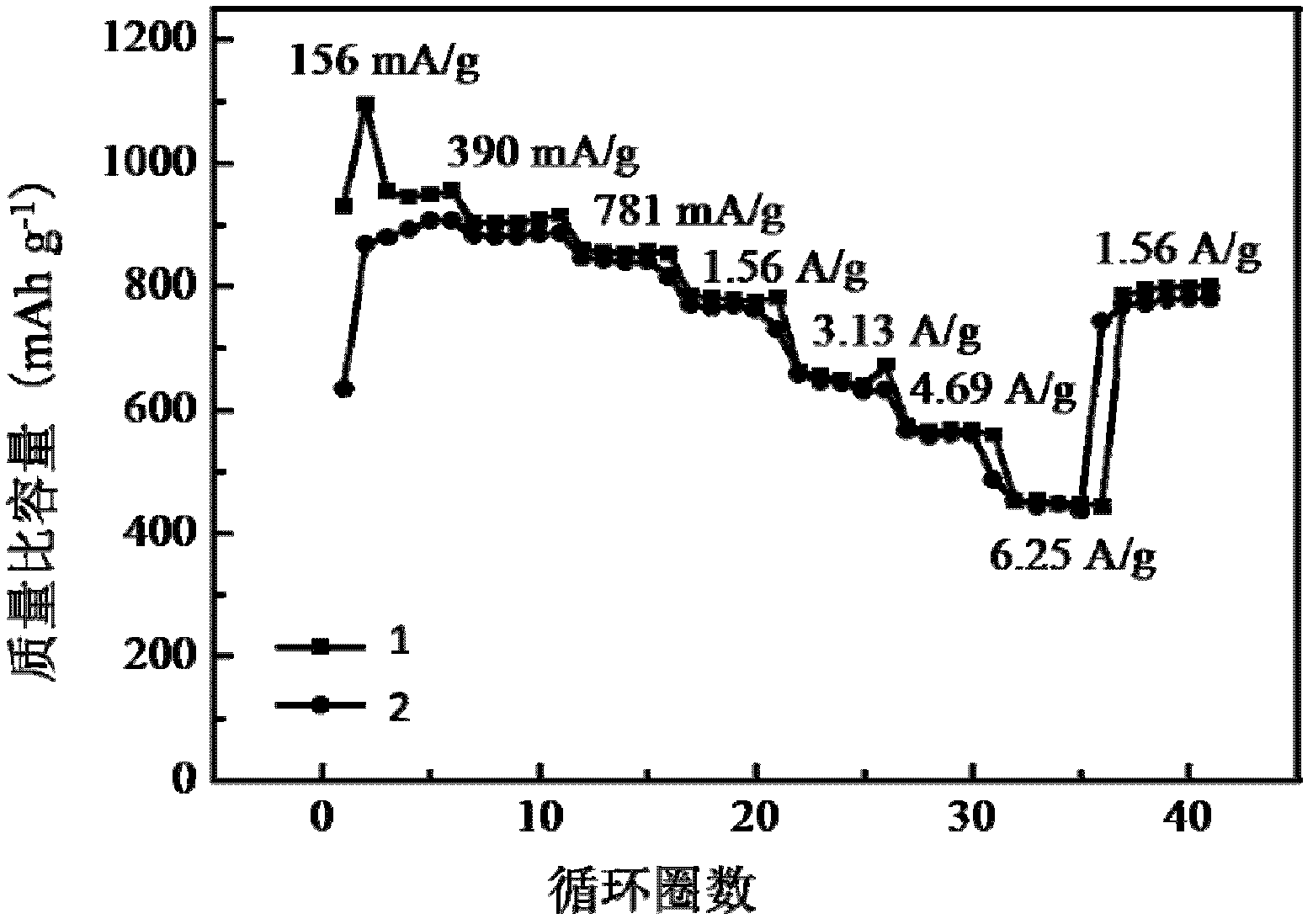

Method for preparing active electrode material of lithium ion battery

InactiveCN102593446AHigh tap densityIncrease energy densityCell electrodesSodium-ion batterySurface-active agents

The invention discloses a method for preparing an active electrode material of a lithium ion battery. The method comprises the following steps of: preparing a nano-crystal with electrochemical activity into an aqueous solution, and adding a carbon source and a surface active agent into the aqueous solution to form a uniform and stable mixture solution; and preparing the mixture solution into spherical particles under the condition that the temperature is between 200 and 900 DEG C through a spray granulation method, and performing heat treatment on the spherical particles in 400-900 DEG nitrogen gas so as to form the active electrode material of the lithium ion battery. Conductive networks are distributed in the active electrode material, and the active electrode material has a porous structure, so that the active electrode material has good lithium ion and electron transmission channels; and the lithium ion battery prepared from the active electrode material has high specific capacity, high-current charging and discharging and high cyclical stability. The method for preparing the electrode material of the lithium ion battery through a spraying method can be easily applied to mass production, and is generally used for preparing various high-performance electrode materials of the lithium ion battery.

Owner:TSINGHUA UNIV

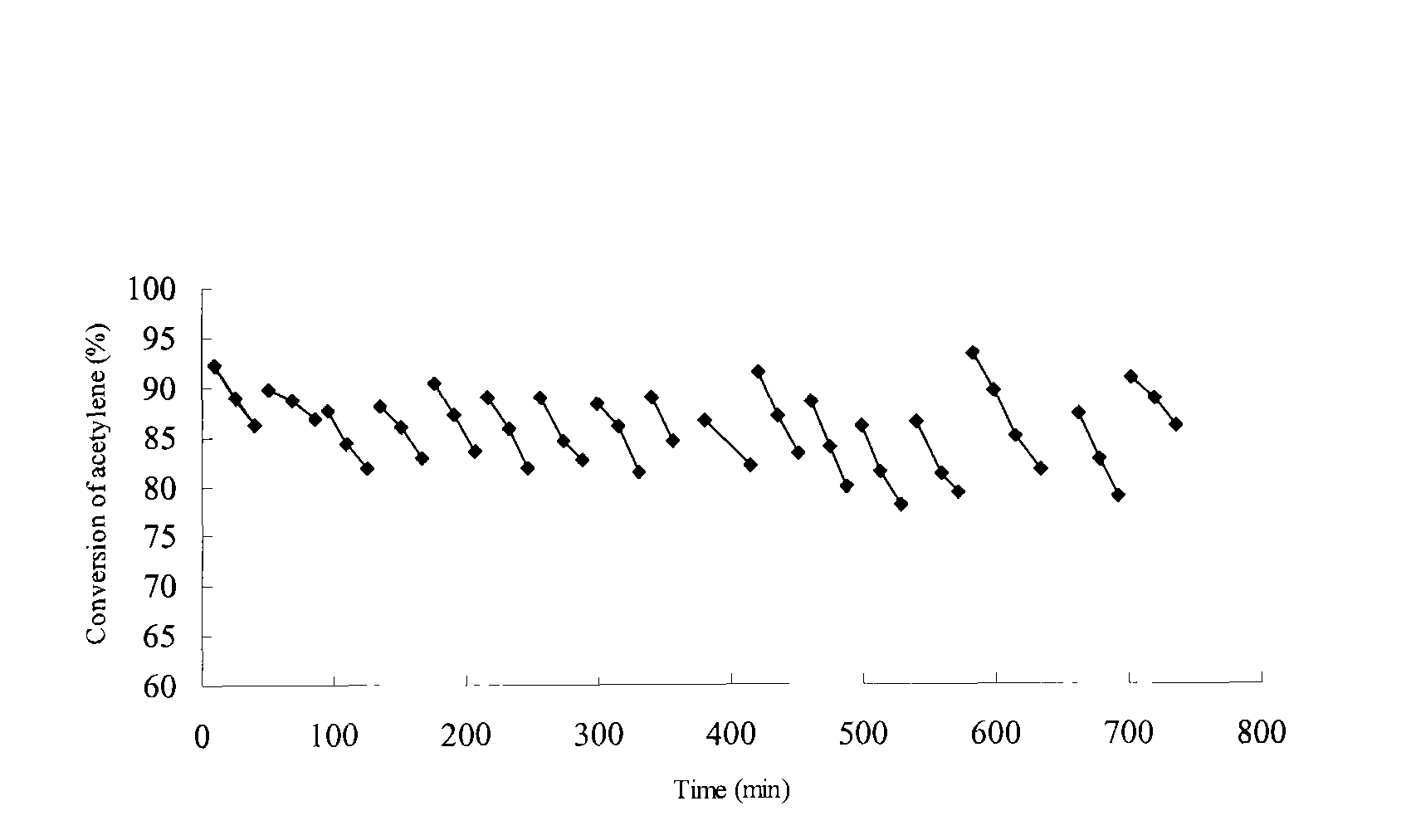

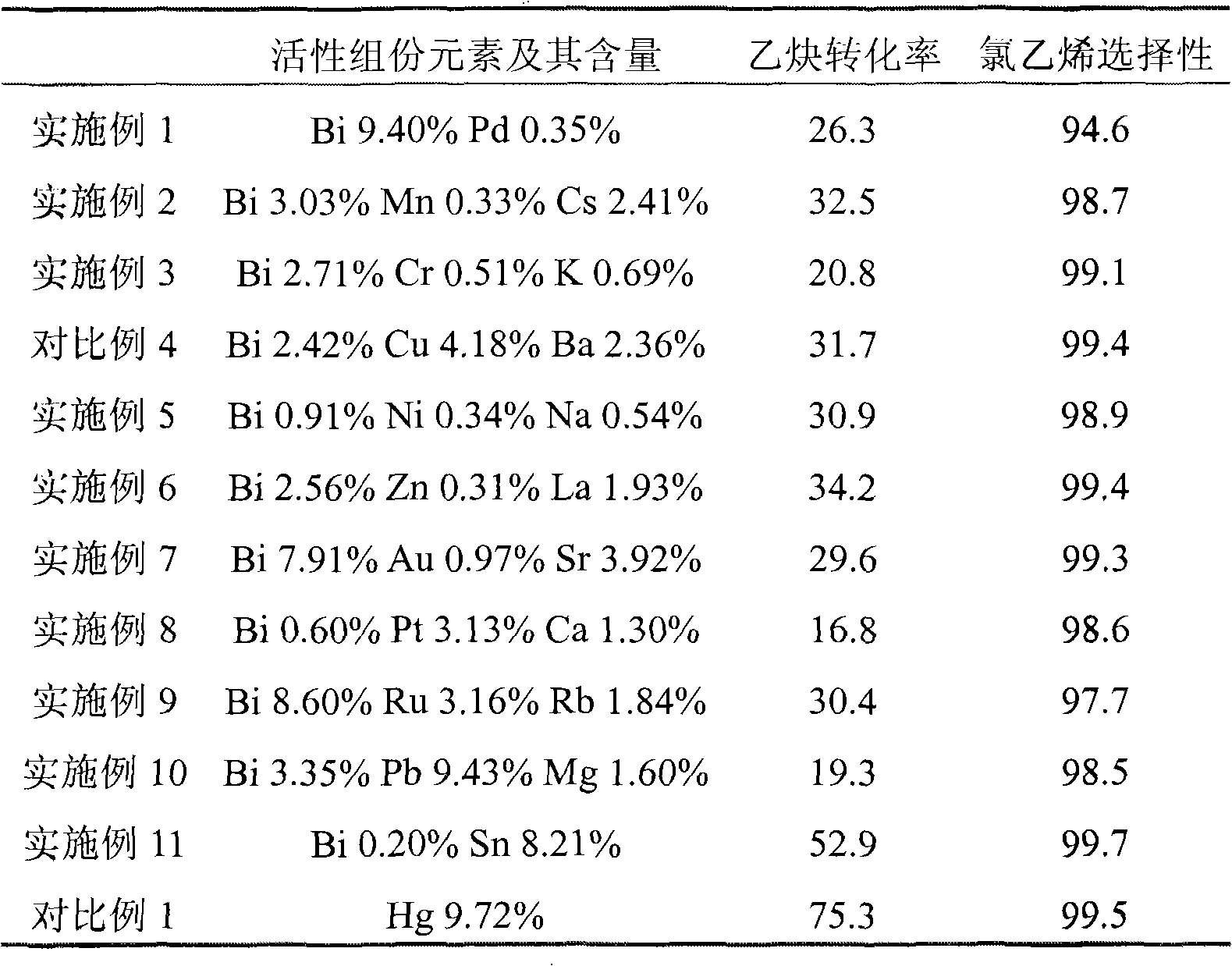

Method for synthesizing and regenerating mercury-free catalyst for hydrochlorination of acetylene and application thereof

InactiveCN101670293AHigh activityGood choicePreparation by halogen halide additionCatalyst regeneration/reactivationSpray GranulationHydrogen

The invention relates to a method for synthesizing and regenerating a mercury-free catalyst for hydrochlorination of acetylene and an application thereof, which belongs to the technical field of preparation of the mercury-free catalysts. The catalyst contains bismuth, phosphorous, a component for promoting catalysis and a carrier. The content of bismuth element accounts for 0.1-68.8wt% of the weight of the catalyst, the content of phosphorous element accounts for 0.1-40.8wt% of the weight of the catalyst, the content of the component for promoting the catalysis accounts for 0.1-63.6wt%, and the content of the carrier accounts for 50-99.5%. The coke-burning regeneration is carried out on the catalyst in hydrogen, water vapor, oxygen, air or other oxygen-containing oxidative atmosphere at the temperature of 300-600 DEG C after the inactivation. The catalyst is prepared by the impregnation method, the co-precipitation method or the spray granulation method. The catalyst provided by the invention has the advantages of good activity, high selectivity, high strength and regeneration, and can be used for producing vinyl chloride by the hydrochlorination of the acetylene.

Owner:TSINGHUA UNIV

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

The invention discloses a method for preparing a foamed ceramic insulation board by a waste glass ceramic wafer, belonging to the field of preparation technology of the foamed ceramic insulation board. The method comprises the steps of: washing the waste glass ceramic wafer with clear water, drying and grinding by ball milling to obtain waste glass ceramic powder with the fineness less than or equal to 100mu m; mixing the waste glass ceramic powder, pulverized fuel ash, furnace slag, coal gangue, ceramic tailings, foaming agent and modifying agent according to the mass ratio of (30-40):(10-15):(5-7):(10-18):(25-35):(1.8-2.2):(1.1-1.5); putting the mixture into a ball grinding mill, carrying out wet grinding and evenly mixing to form mixed slurry; drying by a pressure type spray granulation dryer and putting the dried product into a foaming refractory mould coated with aluminum oxide; heating to 1120-1150 DEG C in a heating furnace; and finally, annealing, cooling and cutting to obtain the foamed ceramic insulation board. The method is low in production cost and simple in technology, and can be used for continuously preparing the porous foamed ceramic insulation board with large size; and the product is good in performances.

Owner:ANSHENG SCI & TECH DEP

Preparation method of micro crystal wearable ceramic ball

A preparing method for a crystallite wear-resistant ceramic ball belongs to a technical field of abrasive media, which is characterized in that: firstly preparing a superfine material adopting wet ball milling, spraying and prilling; then rolling moulding; finally the crystallite wear-resistant ceramic ball with a diameter of 0.5-50mm after drying, firing and polishing. The inventive method has lots of advantages such as little equipment, low cost, large output and easy expansion; meanwhile, the ceramic ball is high-density, wear-resistant and stable.

Owner:淄博启明星新材料股份有限公司

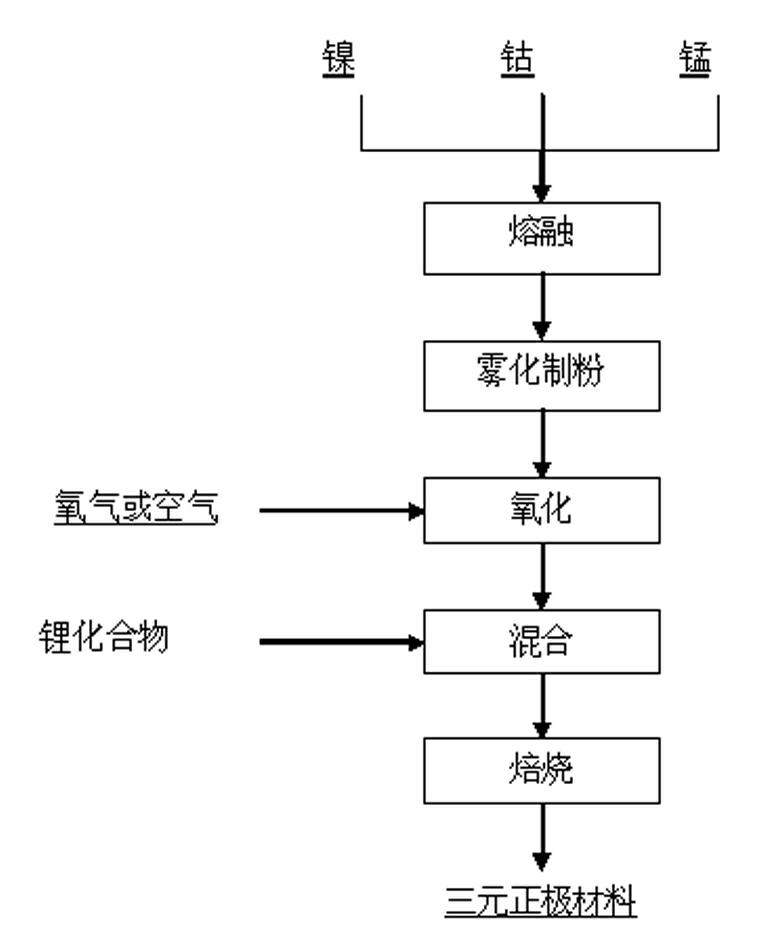

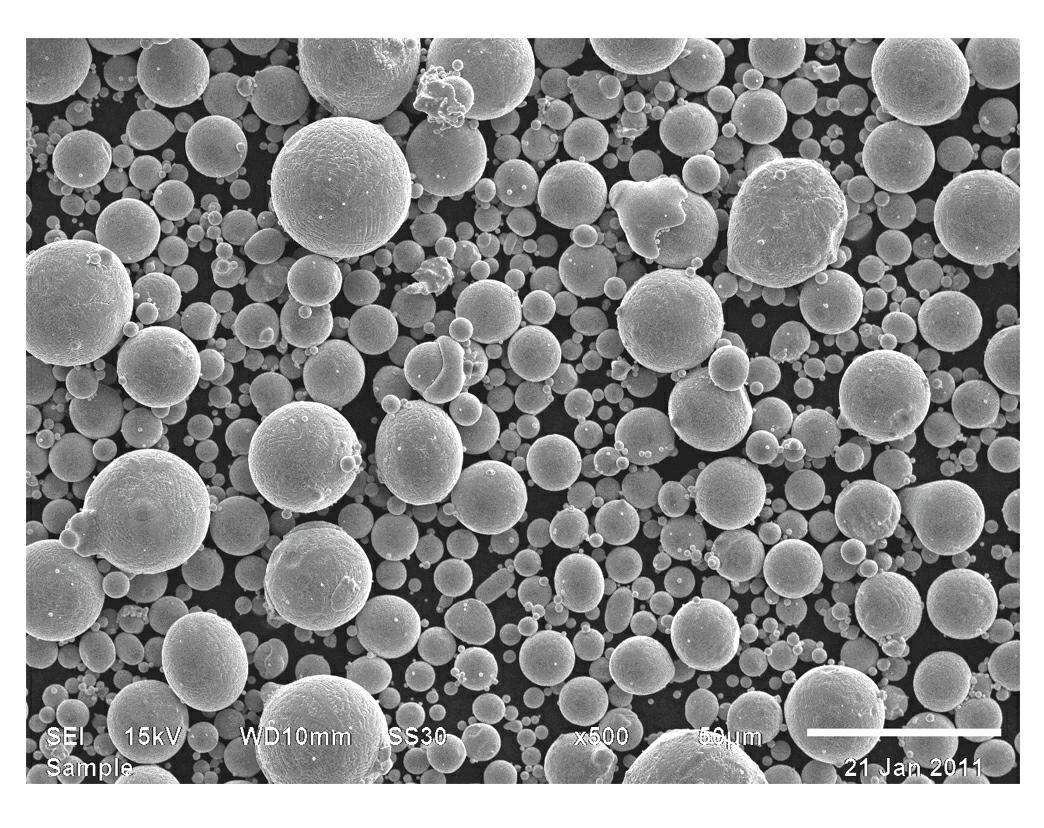

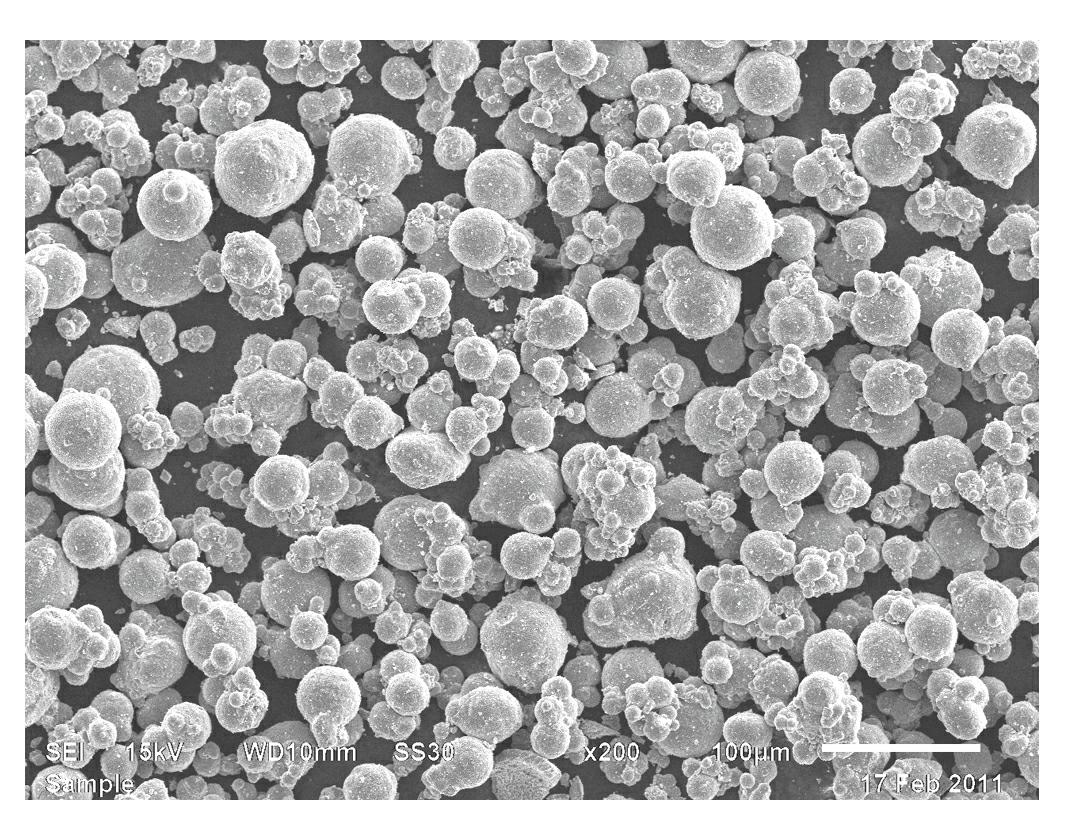

Ternary cathode material and production method thereof

The invention discloses a ternary cathode material and a production method thereof. The production method comprises the following steps of melting mixing materials of metallic nickel, cobalt and manganese at high temperature under the protection of inert gas or nitrogen; executing spray granulation after melting, and then oxidizing to obtain nickel, cobalt and manganese alloy oxide; and roasting the nickel, cobalt and manganese alloy oxide and a lithium compound at a temperature of 600-1050 DEG C after mixing according to the metallic element content mole ratio of (Ni+Co+Mn): Li=1:(1-1):1.15 to obtain the ternary cathode material, wherein the ternary cathode material is epigranular, regular spherical or similar to sphere, has large tap density, higher charge-discharge capacity and better electrochemical cycle performance. The ternary cathode material is prepared by adopting nickel, cobalt and manganese as raw materials and adopting full solid-phase reaction so as to completely avoid the environment pollution caused in the process of preparing a precursor by adopting a wet process. The invention has the advantages of simple process flow, convenience for operation and high production efficiency.

Owner:先进储能材料国家工程研究中心有限责任公司

Method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic

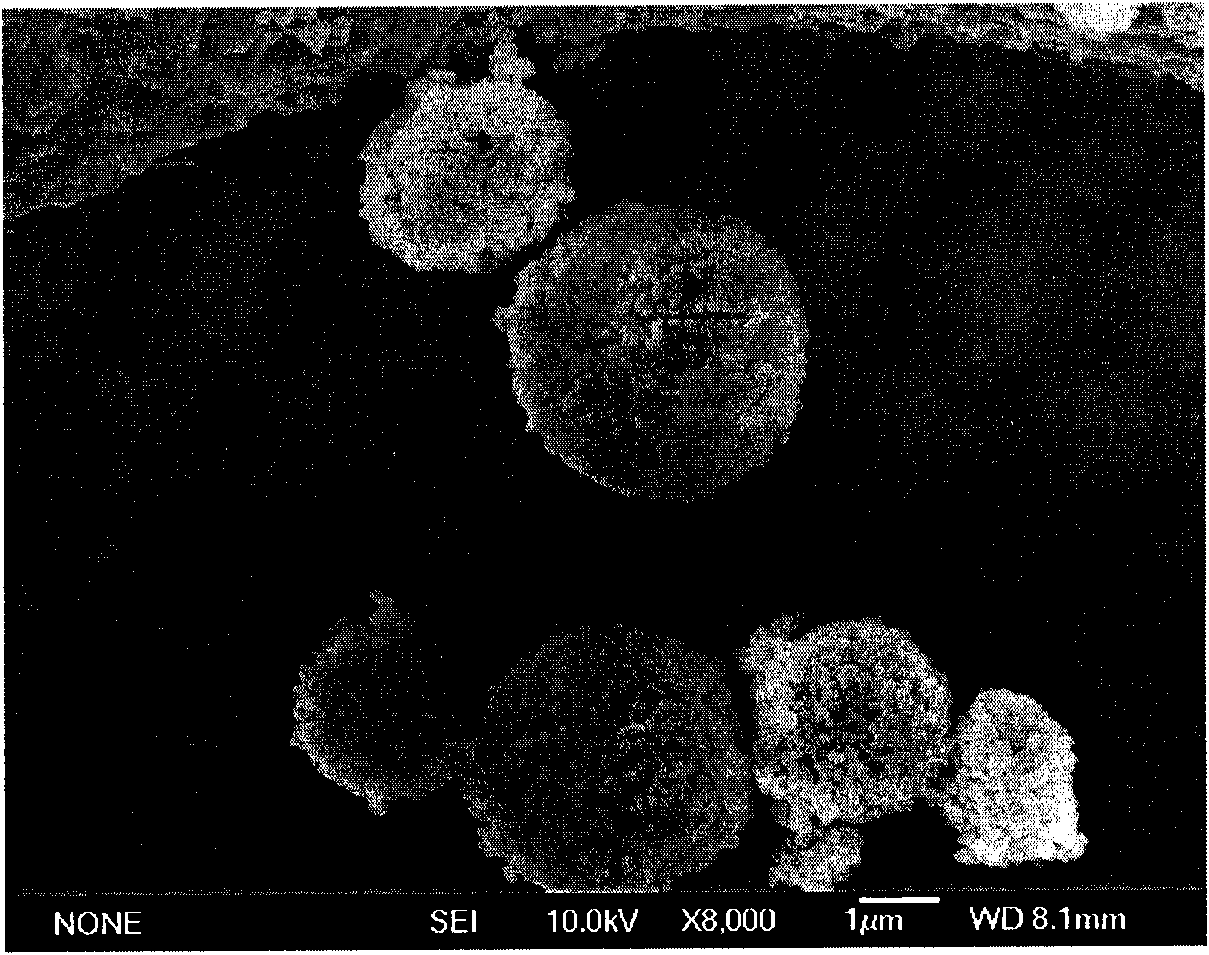

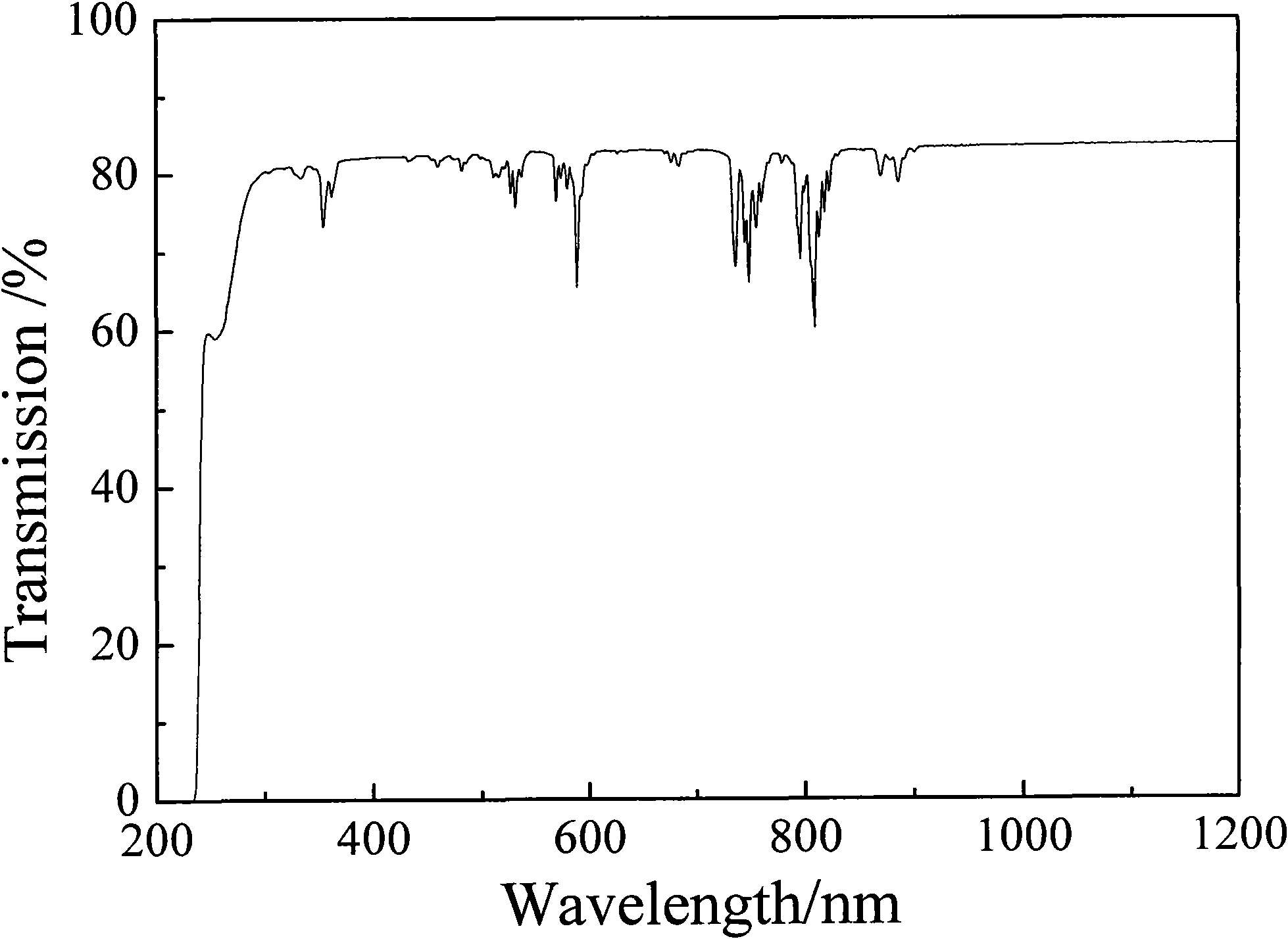

ActiveCN101985397AHigh linear transmittanceImprove mechanical propertiesRare-earth elementSpray Granulation

The invention relates to a method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic. In the invention, high-transparency polycrystalline ceramic is prepared by using commercial powdered Y2O3, Al2O3 and Re2O3, of which the purities are over 99.9 percent, as main raw materials and by spray granulation dry pressing molding process and vacuum reaction and sintering, wherein the Re may be one or several of trivalent rare earth elements such as Nd<3+>, Yb<3+>, Cr<3+>, Er<3+>, Ce<3+>, Sm<3+> and Eu<3+>; MgO or CaO or tetraethyl orthosilicate (TEOS) or SiO2 is used as a sintering assistant; a certain amount of bonding agent, plasticizer and dispersant is added; the oxides, sintering assistant and additive are mixed and added into a liquid medium, and the mixture is ball-milled and mixed for 0.5 to 100 hours; after the powder materials are mixed uniformly, the powder is made into spherical or approximately spherical grains; blanks formed by drying pressing isostatic forming are degreased; sintering the blanks in a vacuum sintering furnace; and annealing after sintering. The transmissivity at a laser wavelength of the rare earth-doped yttrium aluminum garnet transparent ceramic prepared by the method is more than or equal to 77 percent.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for preparing spherical active carbon employing water soluble bitumen

InactiveCN103693641ALow priceWide variety of sourcesCarbon compoundsSpray GranulationActivated carbon

The invention discloses a method for preparing spherical active carbon employing water soluble bitumen. The method comprises the following processes: washing commercial sulfonated asphalt to obtain a complete water-soluble material; preparing a bituminous solution from the obtained water-soluble material or water-soluble mesophase pitch and deionized water; carrying out spray granulation on the bituminous solution, so as to obtain a bituminous ball; carbonizing and activating the bituminous ball, so as to obtain the spherical active carbon. The method has the advantages that the commercial sulfonated asphalt and the water-soluble mesophase pitch are adopted, so that the spherical active carbon is low in price and wide in source, no organic solvent is added in the balling process, the bituminous ball is controllable in particle size distribution, the prepared spherical active carbon is large in specific surface area, and industrial production is easy to achieve.

Owner:TIANJIN UNIV

Ferrite magnetic core for network communication and method for producing the same

The invention relates to a manganese-zinc ferrite magnetic core for network communication and a method for preparing the same. The magnetic core comprises the following compositions in terms of mol ratio: 51 to 58 mol percent of Fe2O3, 23 to 38 mol percent of MnO, 6 to 14 mol percent of ZnO, 0.01 to 5 mol percent of NiO, and 0.01 to 3 mol percent of CuO. The method for preparing the magnetic core comprises the following steps sequentially: first time of material blending and ball milling, presintering, second time of material blending and ball milling, spraying granulation to obtain granule materials, pressing the materials into biscuits, and biscuit sintering. The sintering is performed in push board kiln in an N2 protective atmosphere, experiences different sintering temperature stages, and finally keeps the temperature for 3 to 8 hours in the N2 atmosphere until the temperature is cooled to room temperature. The magnetic core has the performances of high MU i, high superposition, broad band and low loss. The magnetic core is widely used in the fields of network communication and electronic power, in particular in an ADSL technical separator.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +2

Mxene-coated composite electrode material and preparation method therefor

ActiveCN107706372AReduce voidsImprove conductivityMaterial nanotechnologyCell electrodesElectrolytic agentSolvent

The invention provides an Mxene-coated composite electrode material and a preparation method therefor. The preparation method comprises the following steps of (1) adding an electrode material into a solvent to be stirred uniformly, and then adding Mxene to be stirred to obtain a uniform mixed solution; (2) performing spraying granulation on the obtained mixed solution by a spray dryer to obtain Mxene-coated electrode material powder; and (3) performing sintering on the obtained composite electrode material powder under inert gas protection, and then performing cooling. By adoption of the spraydrying method to enable Mxene to coat the electrode material, and by virtue of Mxene, contact between an electrolyte and the electrode material can be blocked, and ion dissolving in the electrolyte and a self-discharge effect can be lowered; in addition, the Mxene is uniformly distributed among the electrode material particles, so that gaps among the electrode material particles can be reduced and the conductivity of the electrode material can be reinforced; and the method is simple in operation, low in cost and the production efficiency can be improved.

Owner:SHANDONG UNIV

Method for preparing organic synergistic soil conditioner

ActiveCN101591543AIncrease organic matterSimple structureAgriculture tools and machinesOrganic fertilisersMonosodium glutamateAlkali soil

The invention provides a method for preparing an organic synergistic soil conditioner. The soil conditioner comprises the following components in portion by weight: 30 to 60 portions of organic component, 9 to 23 portions of synergistic component, 10 to 23 portions of conditioning component, and 15 to 30 portions of inorganic nutrient. The soil conditioner is prepared by the method of weighing, mixing, spray granulation and low-temperature drying, wherein the organic component contains 2 to 5 portions of humic acid, 25 to 45 portions of mature garbage or barnyard manure, and 2 to 5 portions of residue of monosodium glutamate and sugar production; the synergistic component contains 1 to 3 portions of zeolite powder, and 8 to 20 portions of synergistic agent; the conditioning component contains 2 to 10 portions of plaster, 9 to 13 portions of bentonite, 4 to 8 portions of polyvinyl alcohol (liquid), and 0.5 to 1.2 portions of starch (liquid); and the inorganic nutrient contains 4 to 7 portions of urea, 7 to 9 portions of ammonium phosphate, 5 to 7 portions of potassium sulfate, and 4 to 6 portions of ammonium sulfate. The preparation method is scientific, reasonable, simple and easy to operate; and the preparation method solves the synergistic effect of soil conditioners, and is suitable for the planting of field crops and forest fruits, in particular suitable for the conditioning of saline-alkali soil. By the determination of the national standard GB18877-2002, various indexes satisfy the national standard, and the content of the humic acid exceeds the standard requirement.

Owner:新疆满疆红农资化肥科技有限公司

Preparation method of tungsten carbide-cobalt or tungsten carbide-cobalt-chromium thermal spraying powder

ActiveCN102876907ANot easy to stick into blocksImprove performanceMolten spray coatingChemical industryThermal sprayingHigh energy

The invention relates to a preparation method of tungsten carbide-cobalt or tungsten carbide-cobalt-chromium thermal spraying powder. The preparation method includes: proportionally mixing tungsten carbide powder with cobalt powder or tungsten carbide powder, cobalt powder and chromium powder, compounding slurry, performing spray granulation, screening and degreasing granulated powder prior to rapidly sintering the granulated powder in a vertical high-temperature sintering furnace, enabling the powder to continuously and uniformly pass through a heating area and a cooling area in a free-falling motion mode, completing sintering in the heating area for 0.1-5s at the sintering temperature of 1000-1700 DEG C in the nitrogen protective atmosphere, and performing classified screening for the sintered powder as required finally. The preparation method solves the problems of long production cycle, low production efficiency, high energy consumption and the like when tungsten carbide based composite spherical thermal spraying powder is prepared by a traditional method, is simple in technological process, capable of achieving continuous production, energy-saving and environment-friendly and can be widely applied to the fields of aerospace, machine manufacturing, petrochemical engineering and the like, and the obtained powder is uniform in component, high in sphericity degree and good in fluidity.

Owner:CENT SOUTH UNIV

Acidating agent for newborn piglet feed and preparation method thereof

ActiveCN101715898AEasy feedingImprove protectionAnimal feeding stuffAccessory food factorsCelluloseAnti stress

The invention discloses an acidating agent for newborn piglet feed and preparation method thereof, relating to the feed additive field. The acidating agent is composed of the following raw materials by parts by weight: 40-55 parts of L-lactic acid, 20-25 parts of boletic acid, 2-4 parts of citric acid and 21-38 parts of auxiliary material, wherein the auxiliary material comprises the following components: 2-3% of dextrin, 7-8% of carboxymethyl cellulose cellulose sodium, the balance white carbon black; the raw materials added with water, mixing and spray granulation are carried out, so as to produce liquidity uniform granules. Pure organic acid composition is adopted, not only pH value of gastrointestinal tract can be reduced, but also sterilization anticorrosion can be realized, so as to regulate and control flora balance of gastrointestinal tract, thus being beneficial to breeding and growth of beneficial fungus such as lactic acid bacillus, inhibiting quantity of harmful fungus such as colibacillus and the like, improving animal anti-stress effect and improving animal immunity; and the acidating agent can directly participate in internal supersession, release energy, promote absorption of mineral substance, vitamin and nutritive material and improve animal production performance.

Owner:JINAN TIANTIANXIANG

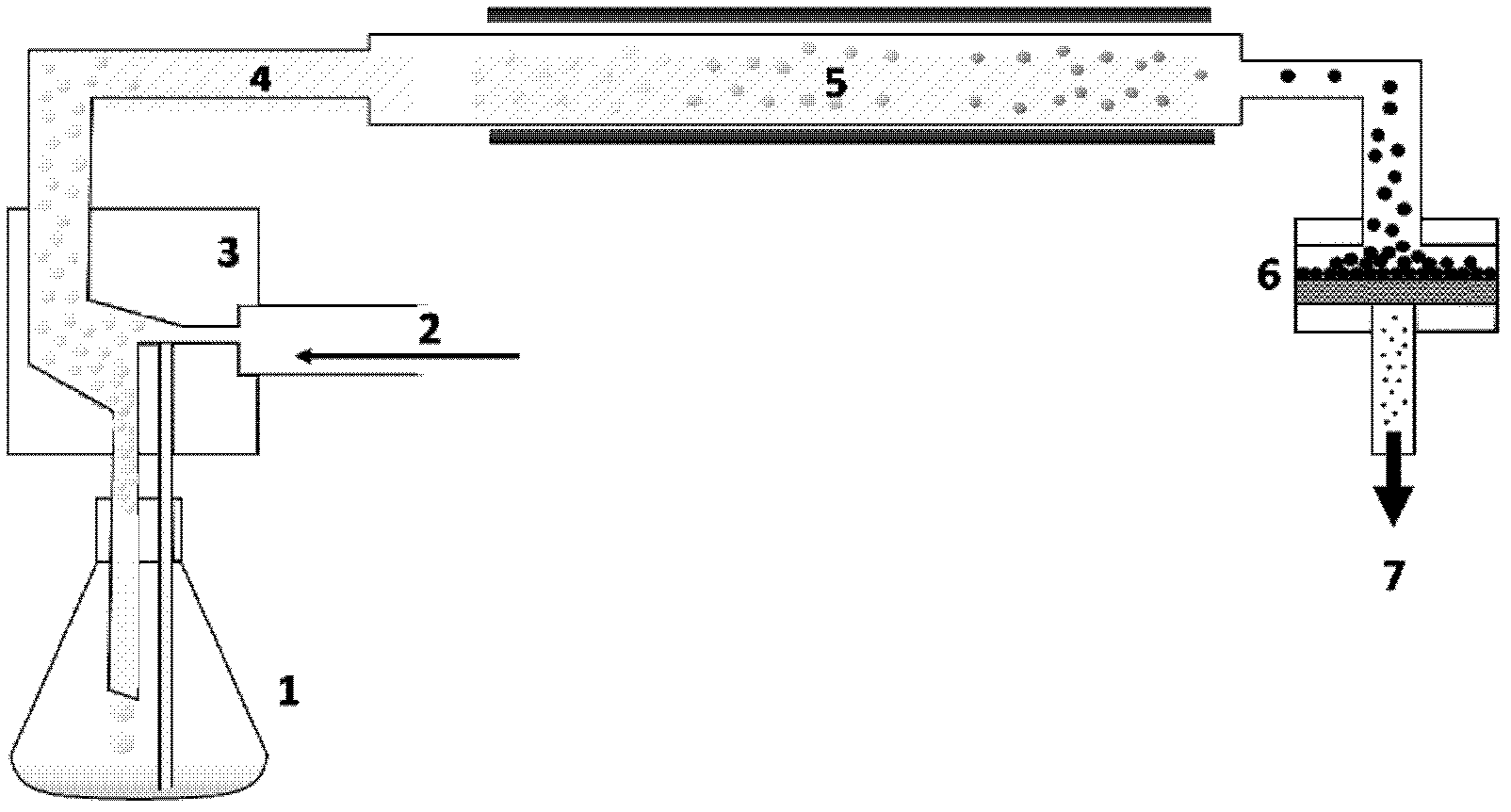

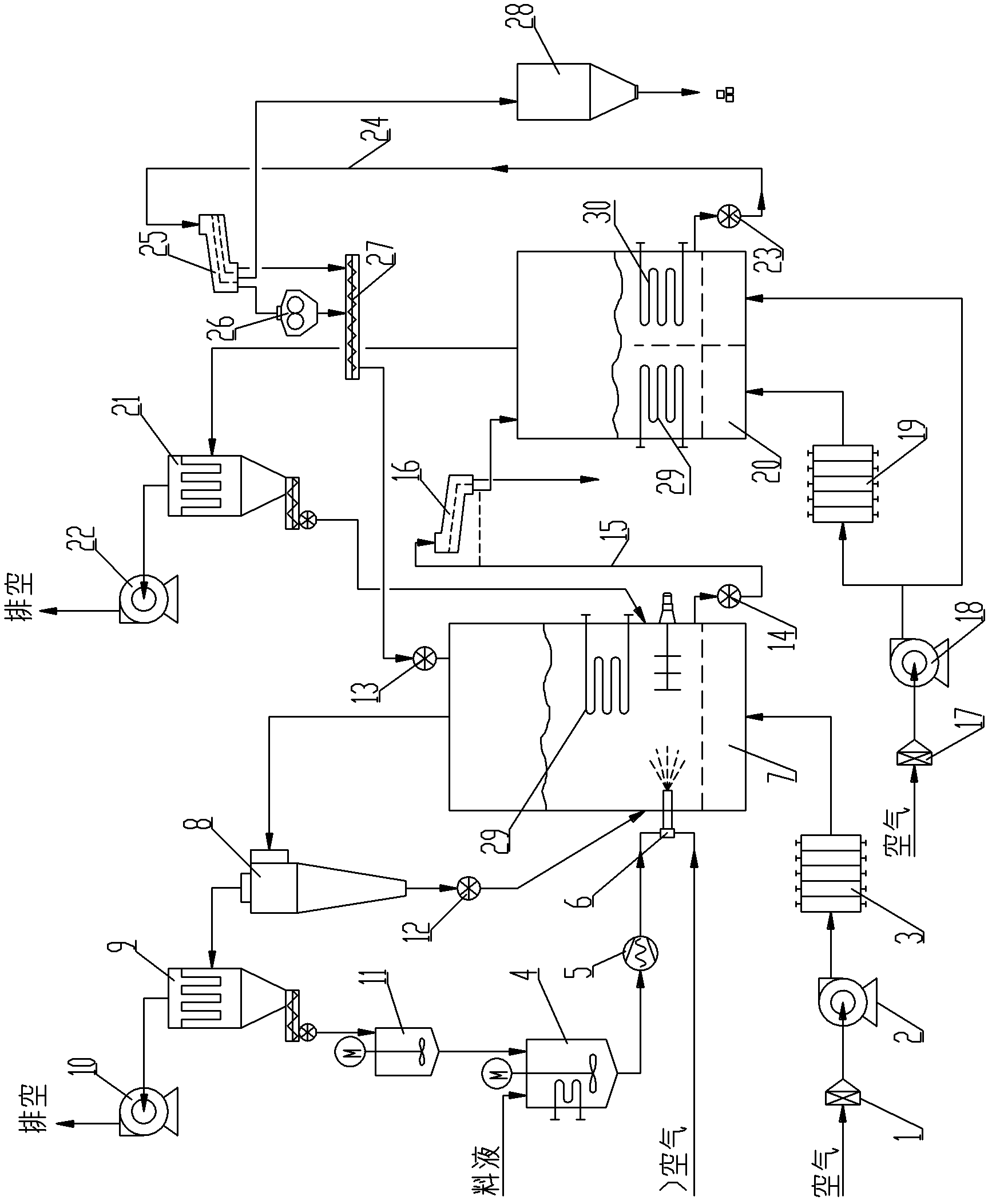

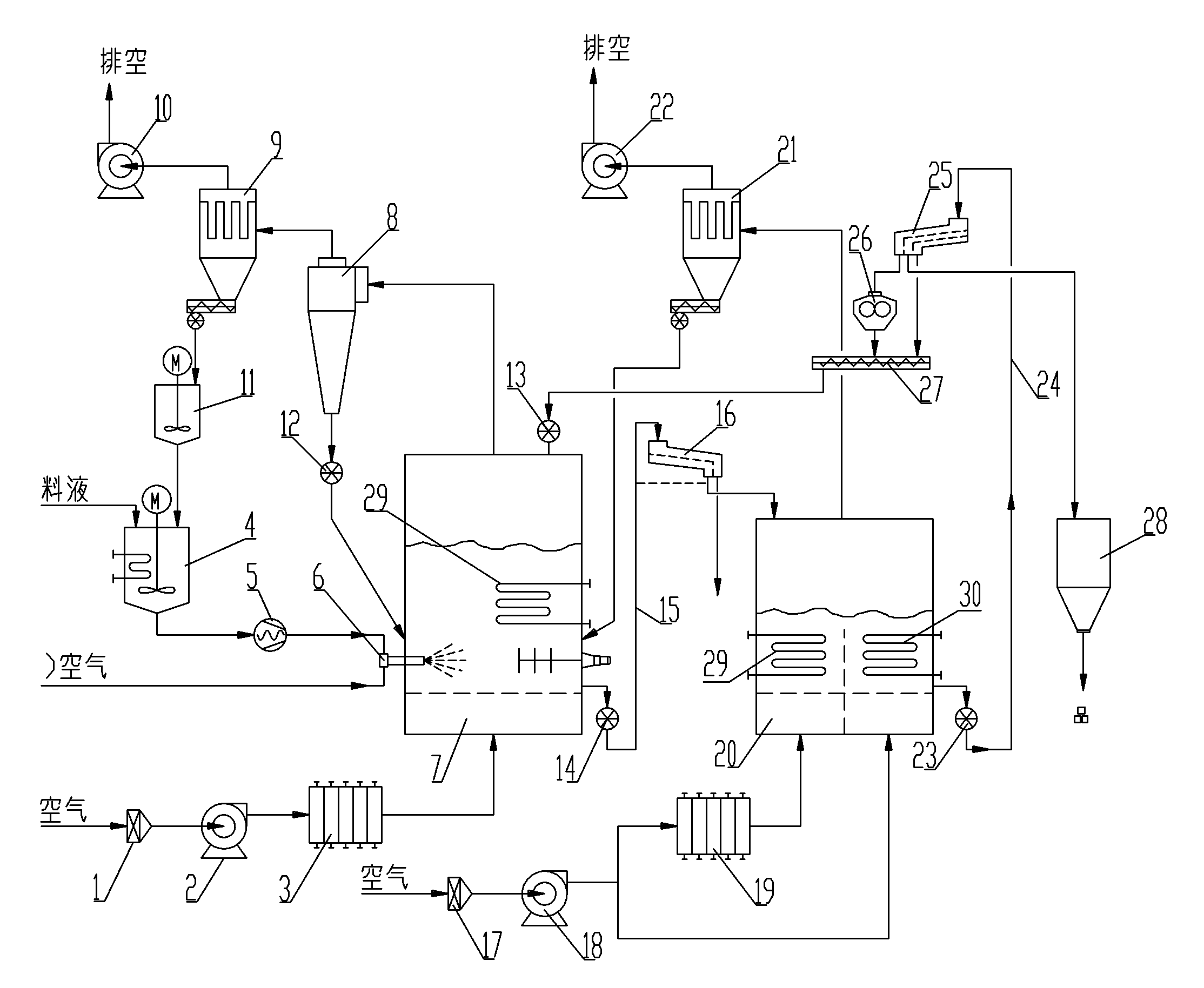

Large-scale continuous energy-saving fluidized bed spray granulation drying process

InactiveCN102274703AAdaptableNo pyrolysis problemsDrying solid materials with heatGranulation by liquid drop formationPrillEngineering

The invention discloses a large-scale continuous energy-saving fluidized bed spray granulation drying process, which belongs to the granulation drying technology. The surface of the seed crystal particles in the granulation fluidized bed is dried under the combined heating of the hot air and the built-in heater. The discharged materials are first screened out of lumps and oversized particles, and then sent to the cooling fluidized bed After the discharged materials are screened, the materials larger than the qualified particle size are crushed by the crusher, and then returned to the granulation fluidized bed together with the material smaller than the qualified particle size as crystal seeds for re-granulation, and the qualified particle size is sent to the into the finished product silo. The invention has strong material adaptability, can obtain granular products with large specific gravity, high strength, good sphericity, uniform particle size, and is not easy to absorb moisture, and realizes continuous large-scale production. Pollution and other characteristics.

Owner:山东奥诺能源科技股份有限公司

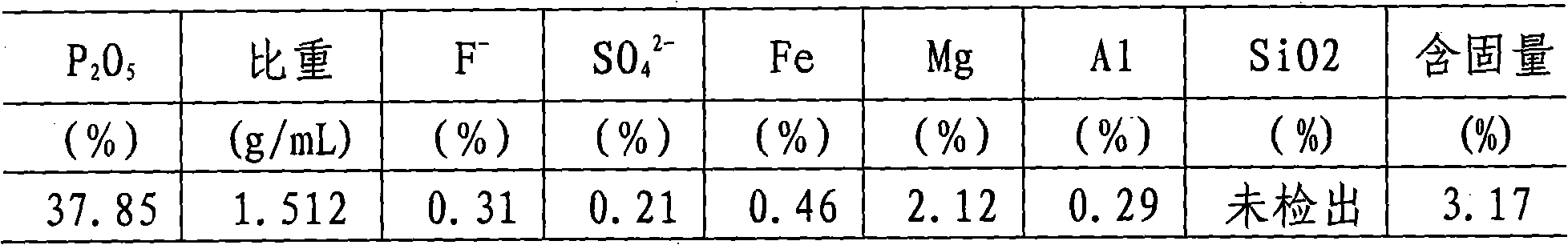

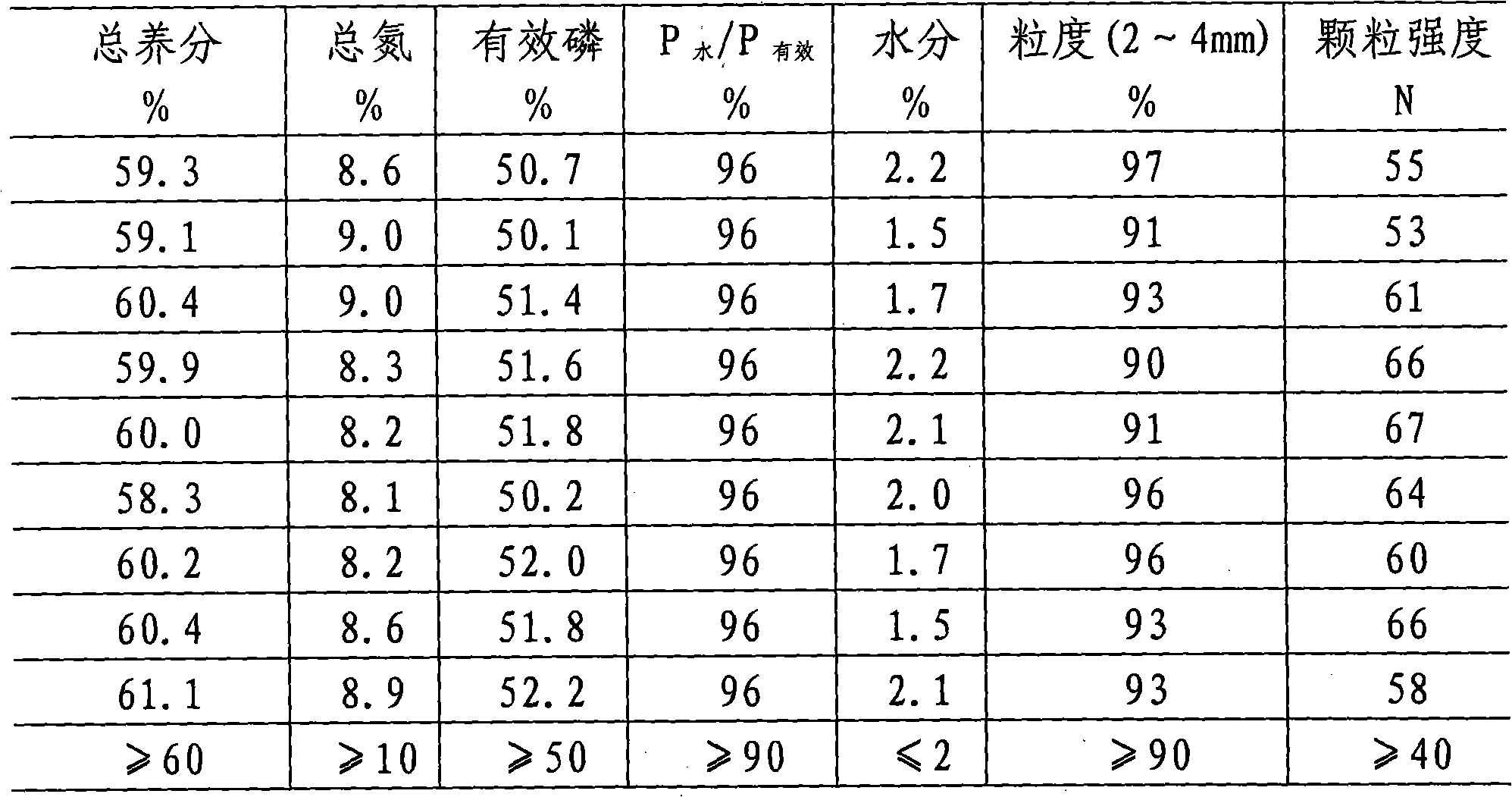

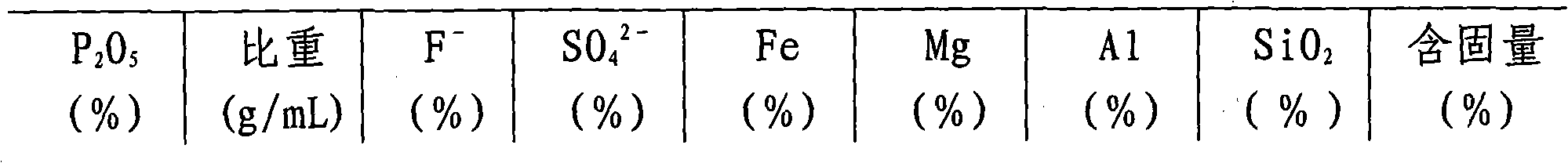

Method for producing granular monoammonium phosphate with raffinate

ActiveCN101891504ADigestive raffinateIncrease concentrationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSpray GranulationPhosphate

The invention provides a method for producing granular monoammonium phosphate with raffinate, wherein, ammonia is neutralized with phosphoric acid to obtain slurry, and the slurry is concentrated and then subjected to spraying granulation to obtain the granular monoammonium phosphate. The method comprises the following steps: (1) mixing wet-process phosphoric acid with the raffinate according to a certain ratio to obtain mixed phosphoric acid, and then lowering the metal ion content in the raw material mixed phosphoric acid; and (2) adjusting the neutralization degree of neutralization reaction between the mixed phosphoric acid and the ammonia to obtain monoammonium phosphate slurry. The granular monoammonium phosphate obtained by the method can meet the requirement for nitrogen nutrients in the product, reach the product strength of no less than 40N, digest the raffinate in a wet-process phosphoric acid purification device, conform to the requirement for the current global recycling economy. The method can improve the concentration of dilute phosphoric acid, reduce steam consumption of a slurrying system, and increase the product strength of the granular monoammonium phosphate.

Owner:WENGFU (GRP) CO LTD

Sintering preparation method of boron carbide ceramic

The invention discloses a sintering preparation method of boron carbide ceramic, which comprises the following steps: 1. sintering: carrying out mixing and ball milling on boron carbide powder, carbon powder, metal powder, a dispersant, an adhesive and deionized water to make a slurry, carrying out spray granulation, pressing into a biscuit, presintering for debonding, and carrying out thermal-insulation sintering at lower sintering temperature (slightly higher than the melting point of metal), thereby implementing primary shrinkage sintering of the product by utilizing the surface tension of the molten metal in the system; and 2. sintering: continuing enhancing the sintering temperature, carrying out in-situ reaction to generate metal carbide, metal boride or metal boro-carbide and nano B4C which have higher sintering activity, and forming a solid solution with boron carbide granules by using the metal carbide, metal boride or metal boro-carbide and nano B4C as sintering assistants to promote the further shrinkage sintering of the system, thereby obtaining the high-performance boron carbide ceramic. The method has the advantages of both the normal-pressure sintering technique and the reactive sintering technique.

Owner:NINGBO VULCAN TECH CO LTD

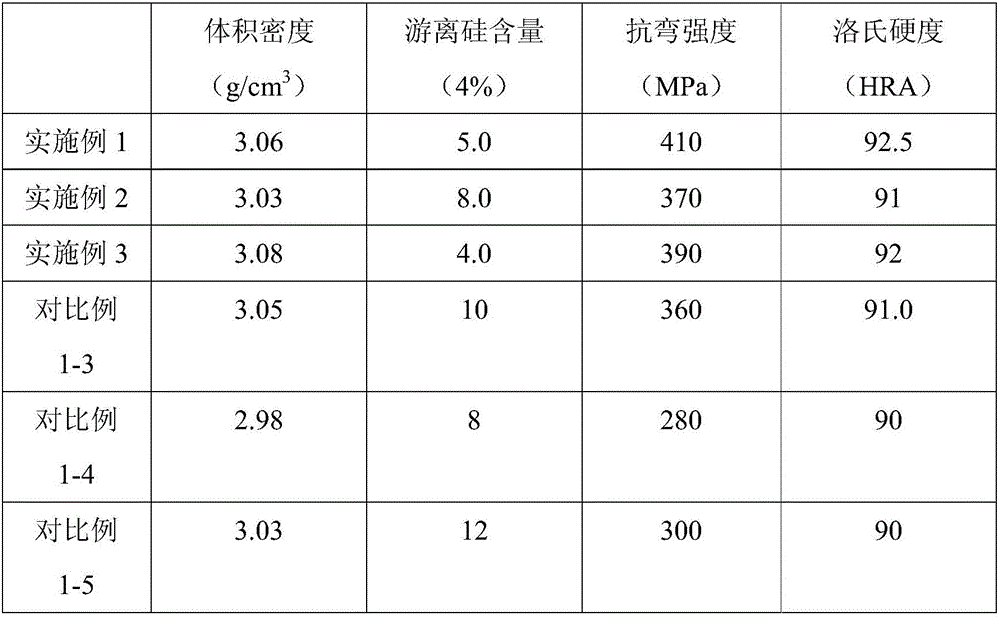

Method for preparing fine-grain silicon carbide ceramic through reaction sintering

The invention discloses a method for preparing fine-grain silicon carbide ceramic through reaction sintering. The method sequentially comprises the following steps: preparing a main material comprising 75-90wt% of silicon carbide micro-powder and 10-15wt% of active carbon powder; adding a dispersant and deionized water to the main material, sequentially adding an aqueous solution of organic matters containing high temperature carbon residue and a water-soluble polymer binder solution, and stirring and mixing above materials in a ball mill to prepare a uniformly-dispersed water-based silicon carbide slip; and sequentially carrying out spray granulation, dry press molding, dewaxing, vehicle working, high temperature siliconising sintering and alkali treatment desilication to obtain the silicon carbide ceramic.

Owner:浙江东新新材料科技有限公司

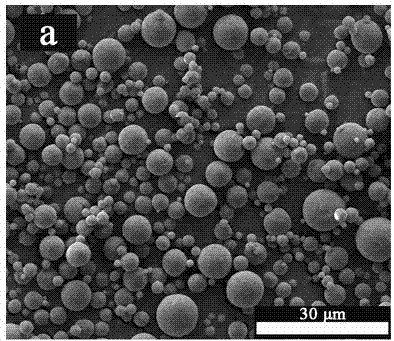

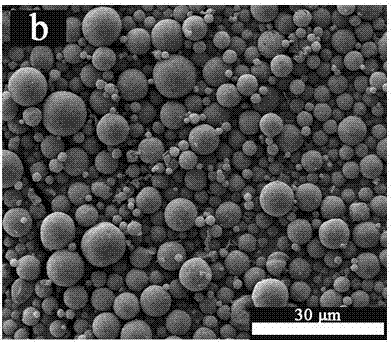

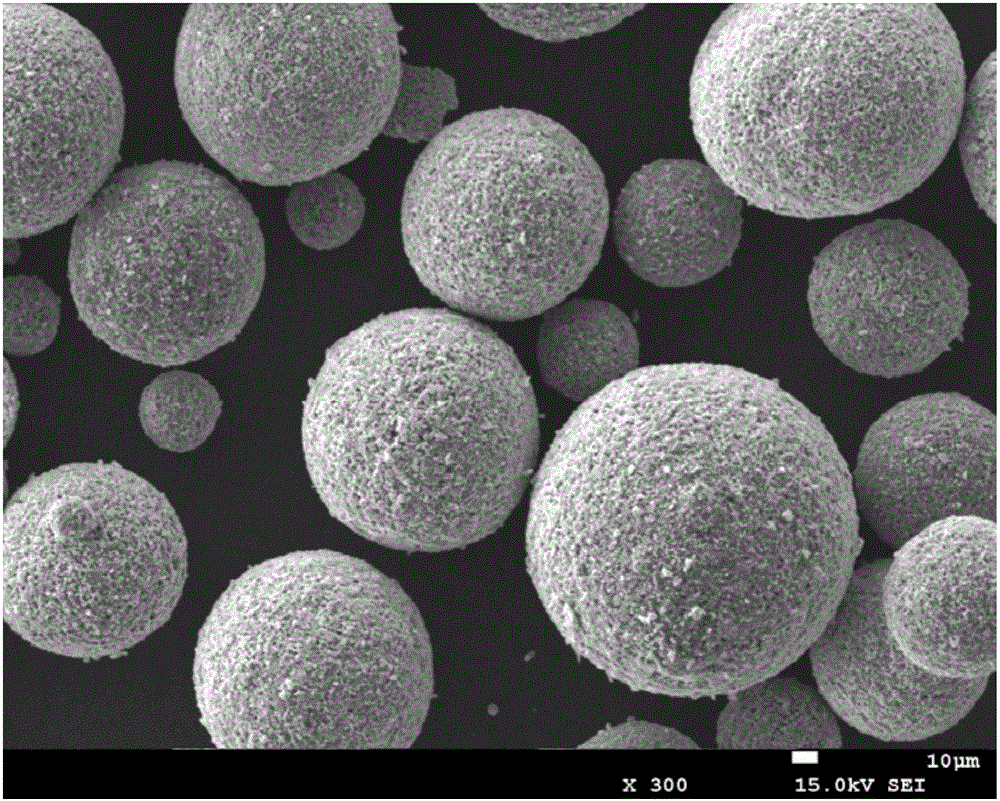

Metal ceramic composite alloy spherical powder and preparation method thereof

ActiveCN106270493AReduce composition segregationUniform microstructureAdditive manufacturing apparatusMolten spray coatingSpray GranulationMixed materials

The invention discloses metal ceramic composite alloy spherical powder and a preparation method thereof. The metal ceramic composite alloy spherical powder is TiCN-Co and at least one of Ni, Mo and Fe or (Ti, Me) CN-Co and at least one of Ni, Mo and Fe or TiCN-MxC-Co and at least one of Ni, Mo and Fe or (Ti, Me) CN-MxC-Co and at least one of Ni, Mo and Fe or (Ti, Me) CN-TiCN-MxC-Co and at least one of Ni, Mo and Fe. Mixed materials are dried, the powder is spherized by the aid of a roller spherizing method, a radio frequency plasma spherizing method or a spray granulation spherizing method, and the spherized powder is sintered to obtain the metal ceramic composite alloy spherical powder. The metal ceramic composite alloy spherical powder serves as a coating material, binding force between a coating and a substrate is improved, and the quality of 3D (three-dimensional) printing products can be improved when the spherical powder serves as a 3D printing material.

Owner:成都锦钛精工科技有限公司

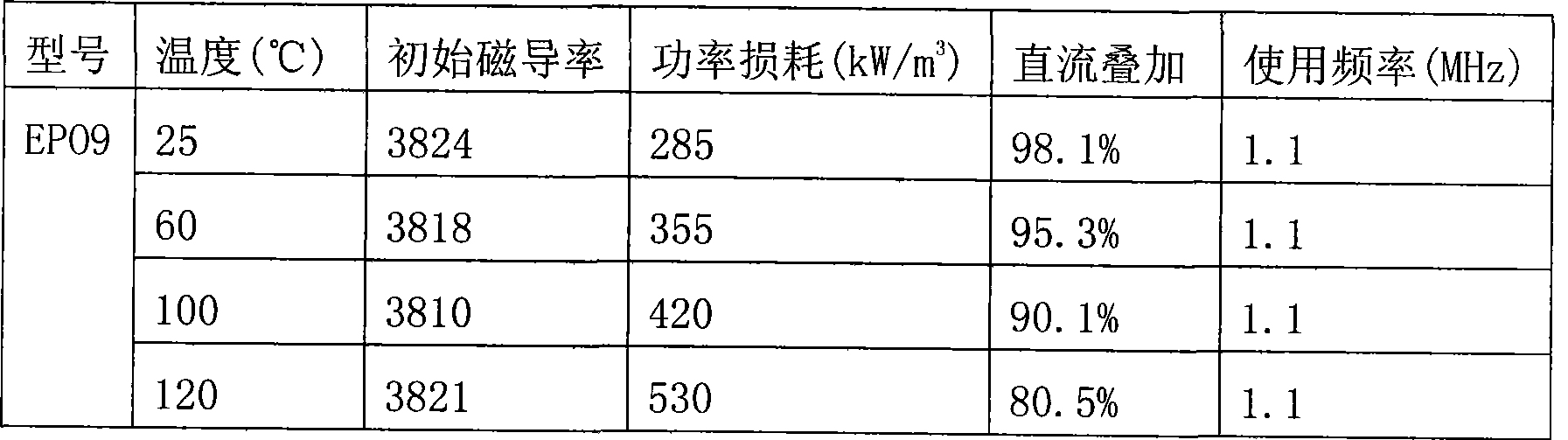

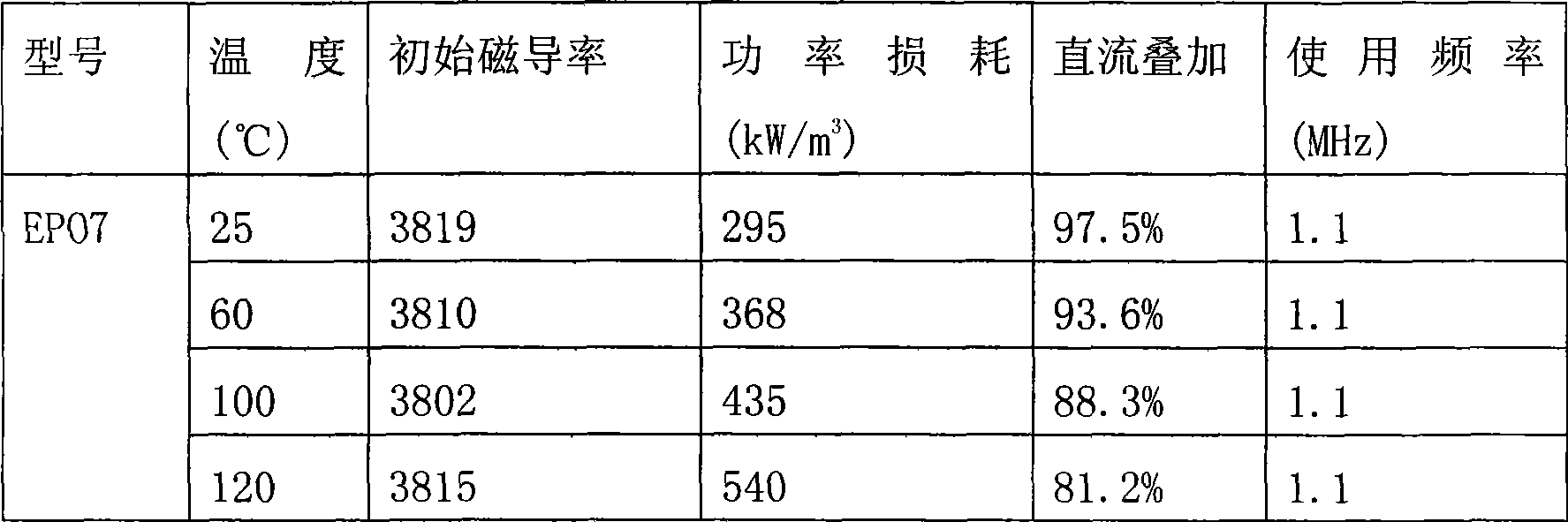

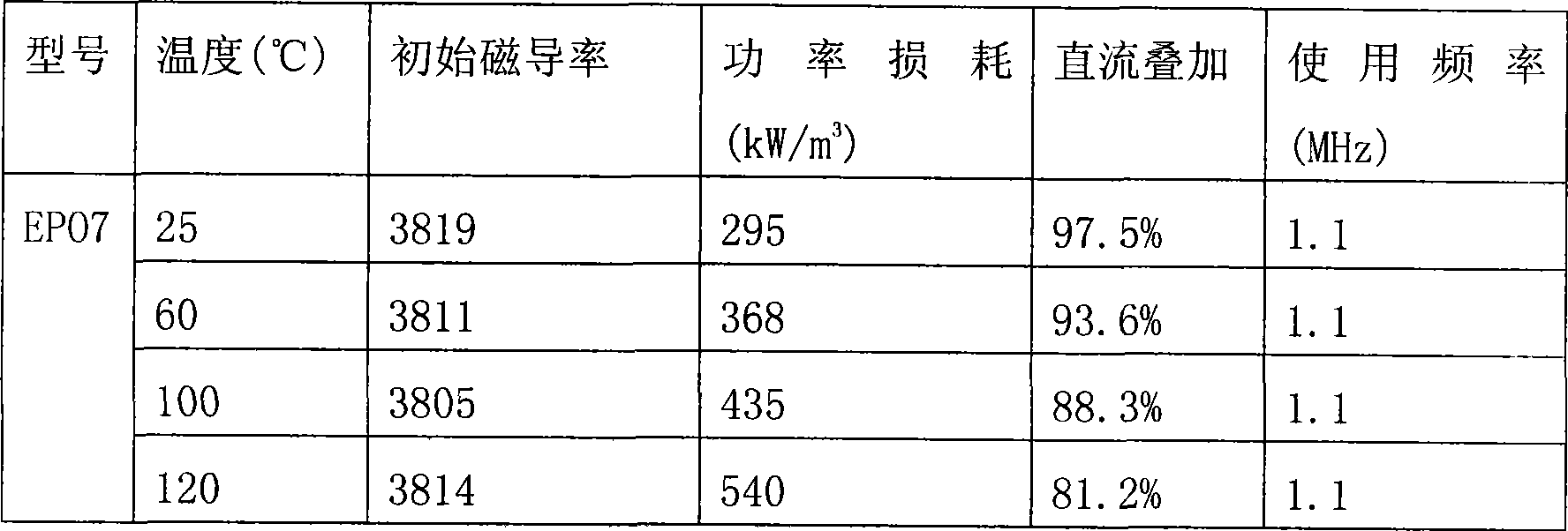

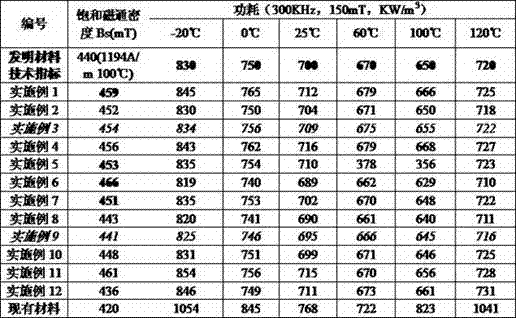

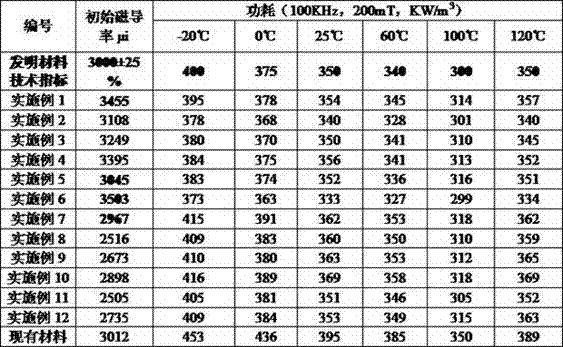

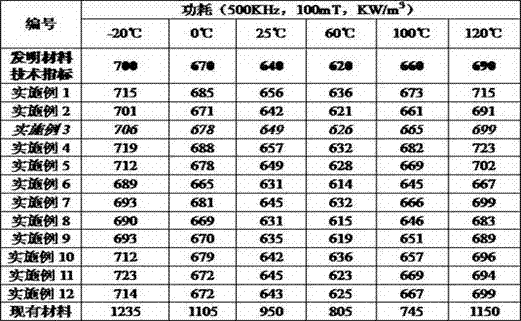

Broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material and preparation method thereof

ActiveCN107473727AImprove workabilityLow high frequency lossInorganic material magnetismSpray GranulationManganese

The invention discloses a broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material. The material comprises main ingredients, an auxiliary ingredient A and an auxiliary ingredient B, wherein the main ingredients comprise the following components in percentage by weight: Fe2O3, MnO and ZnO; based on the weight of the main ingredients, the auxiliary ingredient A comprises at least three of CaCO3, Nb2O5, NiO, SnO2 and Co3O4; and the auxiliary ingredient B comprises at least three of SiO2, Y2O3, K2CO3, Al2O3, CuO, MoO and Bi2O3. The preparation method of the material sequentially comprises the following steps: primary batching, primary sanding, pre-sintering, secondary batching, secondary sanding, performing component analysis, performing spray granulation, molding and sintering. The material disclosed by the invention has low loss in a temperature range from 20 DEG C below zero to 120 DEG C under the conditions of 100-500KHz and 100-200mT, and has high magnetic conductivity and high high-temperature saturation flux density. Compared with the conventional material, the material disclosed by the invention is energy-saving and can enable a switching power module to be miniature and efficient.

Owner:郴州市久隆旺高科电子有限公司

Super low-loss and small-line width microwave ferrite material and preparation method for microwave ferrite material

The invention relates to a super low-loss and small-line width microwave ferrite material and a preparation method for the microwave ferrite material and belongs to the field of microwave communication and magnetic materials. The main phase of the material is of a johnstonotite structure, and the chemical formula of the material is Y3-2x-yCa2x+yFe5-x-y-zVxZryAlzO12, wherein x is not less than 0.02 but is not more than 0.25, y is not less than 0.05 but is not more than 0.25, and z is not less than 0.01 but is not more than 0.25. The preparation method comprises the following steps of: calculating according to chemometry and weighing a raw material, vibratory milling, presintering, vibratory grinding and coarse crushing, sanding fine crushing, spray granulation, compression moulding and sintering. Proved by testing, the ferromagnetic resonance line width deltaH of the obtained material is not more than 1.27KA / m, the dielectric loss tgdeltae is not more than 0.5*10-4, and the insertion loss of an assembled microwave device is not more than 0.21dB, and thereby, the stability and the reliability of the obtained material are greatly enhanced, and the application range is broadened. The manufactured microwave ferrite device has the advantages of wide working band and low insertion loss.

Owner:TDG HLDG CO LTD

Composite organism slow release fertilizer product and producing method

InactiveCN101054314AOvercome the disadvantages of easy exceeding the standardOvercoming pollutionAgriculture gas emission reductionOrganic fertilisersMoisturePollution

The present invention relates to a chemical fertilizer and a manufacturing method thereof, specifically to a composite biological slow-release fertilizer product and its manufacturing method. Said composite biological slow-release fertilizer product in accordance with the present invention comprises granular fertilizer cores and coatings packing outside of the fertilizer cores, wherein said fertilizer cores are grains formed by a mixture of ternary compound fertilizer and the slow-release components which are mixture of urea and humic acids. Said coatings comprises at least animal oil and fat, bone meal and bacillus components. By replacing steam for heat spraying granulation with urea and humic acids melting complexing liquor, the manufacturing method in accordance with the present invention resolves the problem of moisture exceeding standard in 'three (organics, inorganics and bilogies) in one' fertilizer production and achieves the goal of nitrogen slow-release. At the same time, by adopting animal oil and fat and bone meal which can provide food such as lipids to animalcules and are easy to degrade as bacillus preparation carrier, said method overcomes the problems that the mixing of bacillus preparation and other fertilizer components leads to bacterial agent pollution and bacterium poisoning phenomenna. The present invention provides a 'three (organics, inorganics and bilogies) in one' composite biological slow-release fertilizer product which exhibits quick results, slow results and long results integrally, and a manufacturing method thereof.

Owner:王怀欣

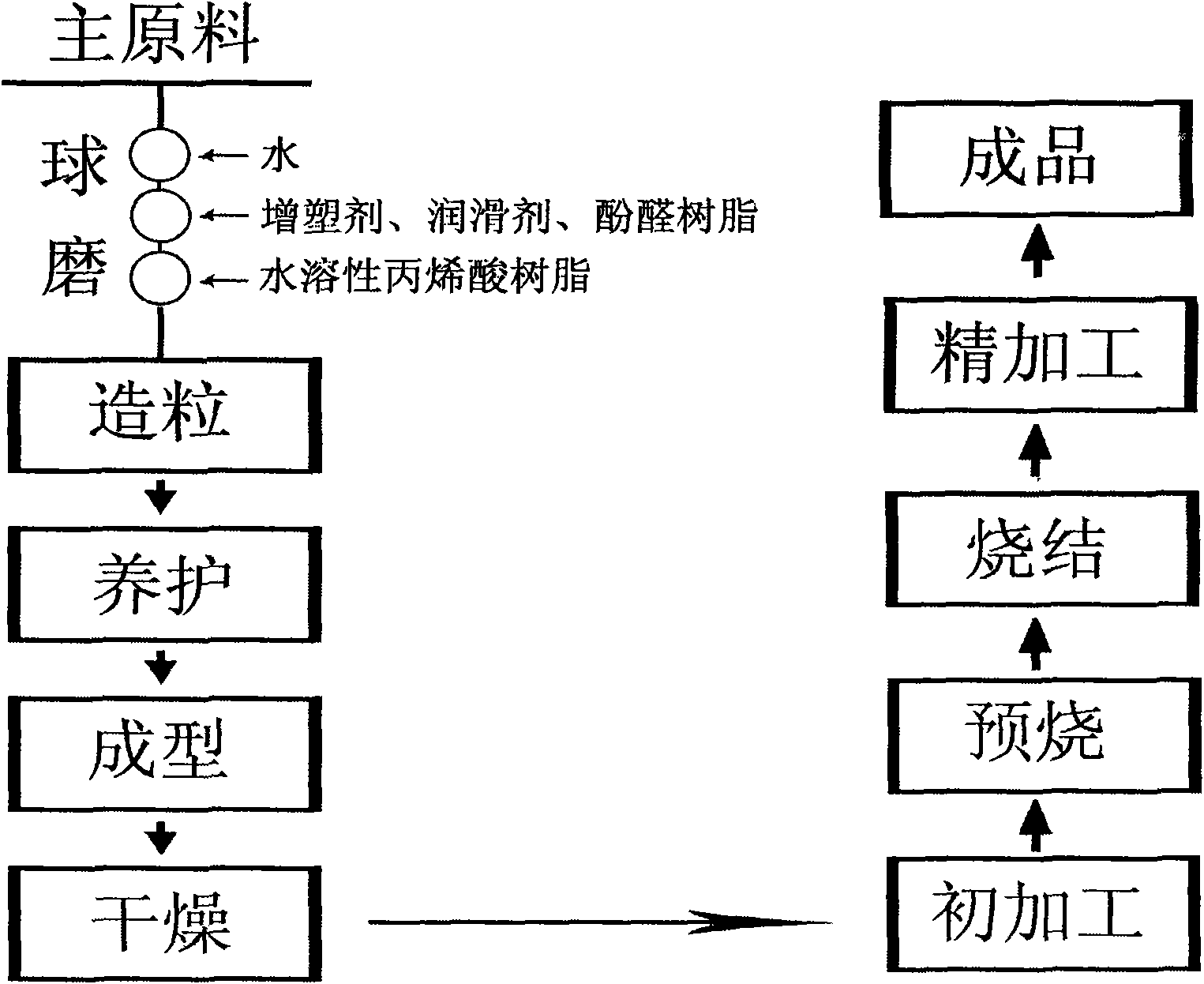

Preparation method of normal pressure-sintered silicon carbide ceramics

The invention discloses a preparation method of normal pressure-sintered silicon carbide ceramics, which adopts a solid normal pressure sintering method and takes submicro silicon carbide powder, graphite powder and boron carbide powder as main materials. The method comprises the following steps: 1) material grinding is carried out by adopting a staged ball milling mode, firstly, the main raw materials are ball-milled by adding water under the environment of the pH value being 10-12 to lead the agglomerated silicon carbide micro powder and other main raw materials to be evenly dispersed; then a plasticiser, a lubricant and water soluble phenol resin are added and ball-milled for a period of time; and finally a caking agent is added for ball milling; 2) spray granulation technology is adopted for carrying out granulation on the silicon carbide slurry; (3) the materials after granulation are maintained under constant temperature and humidity; (4) double-sided compression moulding is carried out on the maintained materials; (5) a staged drying mechanism is adopted for drying the molded body; and (6) the silicon carbide body is put in a vacuum firing furnace for being subjected to two times of sintering by taking the argon as protective gas. The silicon carbide ceramics prepared by the method have superior performance, corrosion resistance and long service life, and are applicable to commercial process.

Owner:宁波欧翔精细陶瓷技术有限公司

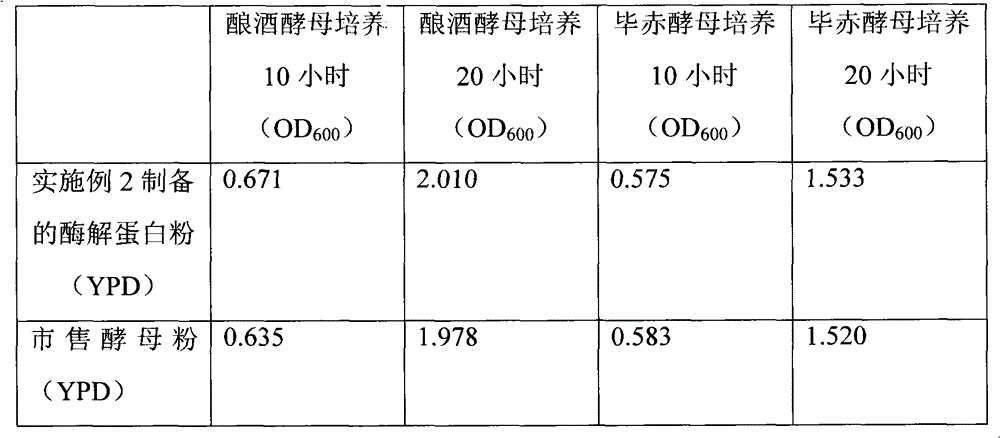

Amino acid fermentation bacteria utilization method

ActiveCN102719510AFacilitate efficient separationEasy to operateAnimal feeding stuffFermentationBiotechnologyMycoprotein

The invention discloses an amino acid fermentation bacteria utilization method, which belongs to the technical field of amino acid production. The method comprises the steps that by taking glutamic acid fermentation as an example and adopting the isoelectric point of fermentation broth, a disc separator is utilized to separate mycoprotein in the fermentation broth, and a moderate amount of compound enzyme is added into the mycoprotein serum, so that the walls of bacteria are broken and the bacteria are enzymetically hydrolyzed. The enzymatic hydrolysate is separated by the high-speed disc separator, and the cell walls are removed, the obtained clarified enzymatic hydrolysate is concentrated under low temperature to produce the enzymetically hydrolyzed mycoprotein extract, or the clarified enzymatic hydrolysate is dried by a gunite granulation fluidized bed drier, a spray granulation drier and the like to produce the enzymetically hydrolyzed mycoprotein powder. In the method, the utilization value of the mycoprotein is greatly increased, so that the mycoprotein is changed from cheap feed into high value-added yeast extract and yeast powder substitute, the product can be used as fermentation ingredient and in other fields, the resources can be sufficiently utilized in the whole process, the purposes of energy saving and consumption reduction are achieved, and the invention has a broad application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Method of preparing alumina ceramic prilling powder for sealed ring

The invention relates to a preparation method for alumina ceramic granulated powder used by a sealing ring, which is characterized in that the preparation process comprises: (1) weighting and mixing alpha alumina, silicon powder, light calcium carbonate, kaolin, burning talc magnesia and yttria, carrying out dry milling, crashing and uniformly mixing; (2) placing the uniformly mixed powder in a ball mill, diluting, adding a dispersant, a binder and a release agent and milling into slurry; (3) screening the milled slurry, removing iron, putting in a spray drying tower to carry out spray granulation; and (4) screening the spray granulated powder by a 40-mesh screen and a 200-mesh screen, taking the powder between the two screens as the finished product. The granulated powder prepared by the method of the invention has the advantages of solid granule, reasonably distributed granularity, large loose packed density, moderate strength, good fluidity and easy mold release. Moreover, the alumina sealing ring can be provided with microcrystalline structure only through the common dry pressing and sintering technology. The ceramic article has high tightness, and the surface of which has no pores found when being amplified by 20 times after abrasive polishing.

Owner:ZHENGZHOU HICER HIGH TECH CERAMICS

Improved acoustic material

The invention relates to an improved acoustic material which comprises zeolite particle, adhesive and nanocrystalline metal oxide. The zeolite particle, adhesive and nanocrystalline metal oxide are mixed and pelletized into sound-absorbing grain. The nanocrystalline metal oxide is selected from one or more of aluminum oxide, copper oxide, ferric oxide, zinc oxide, zirconium oxide and nickel oxide. The sound-absorbing grain is prepared according to the following steps: taking zeolite particle, adhesive and nanocrystalline metal oxide at certain mass ratio; mixing with water and then stirring and dispersing into a suspension; treating the dispersed suspension in the manner of spray granulation or titration granulation; screening and drying the prepared grain, thereby acquiring the sound-absorbing grain. According to the invention, the bonding strength of zeolite particle in the sound-absorbing grain is effectively increased, the phenomena of breaking and generating micro-powder of the sound-absorbing grain in the electrifying working process can be avoided and the problem of failure in the electrifying working process of the sound-absorbing grain can be effectively solved.

Owner:苏州夸克新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com