Improved acoustic material

A sound-absorbing material and an improved technology, applied in the field of electro-acoustic products, can solve the problems of sound-absorbing particles such as power-on failure, achieve the effect of large surface energy, solve failure, and enhance bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

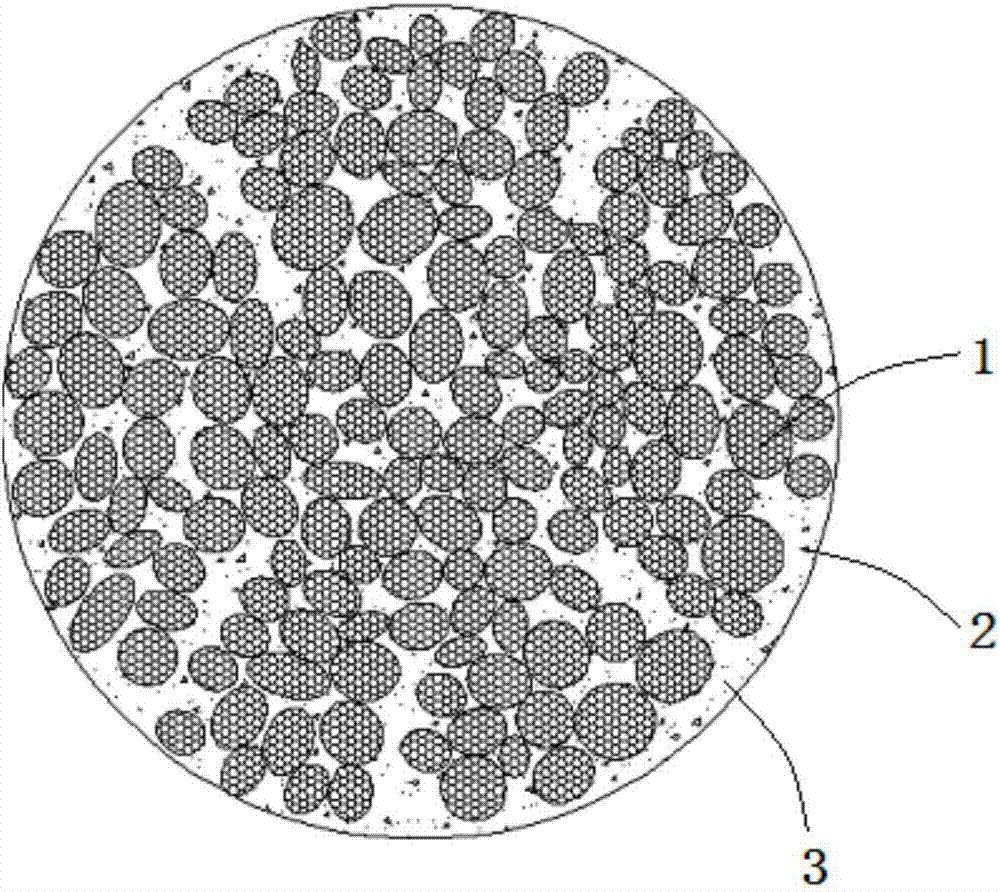

[0026] Embodiment 1, see attached figure 1 , an improved sound-absorbing material, including zeolite particles 1, adhesive 2 and nano-metal oxide 3, zeolite particles, adhesives and nano-metal oxides are mixed and granulated to form sound-absorbing particles; zeolite particles are pure SiO 2 Modified, when the speaker diaphragm vibrates up and down, the zeolite particles can absorb and desorb the gas in the inner cavity, increase the acoustic compliance of the air in the rear cavity, reduce the resonance frequency of the enclosed space, and improve the low-frequency performance. In this embodiment, There are uniform micropores in the zeolite particles, and the micropores absorb and desorb air molecules under the action of sound pressure, which can increase the volume of the virtual acoustic cavity.

[0027] The nano metal oxide is one or more of aluminum oxide, copper oxide, iron oxide, zinc oxide, zirconium oxide or nickel oxide. In this embodiment, alumina is selected as th...

Embodiment 2

[0037] Embodiment 2, an improved sound-absorbing material, including zeolite particles, adhesives and nano-metal oxides, zeolite particles, adhesives and nano-metal oxides are mixed and granulated to form sound-absorbing particles; the zeolite particles are pure SiO 2 Modified. Alumina is selected as the nanometer metal oxide, and the particle size of the nanometer metal oxide is 50 nanometers; the adhesive is an organic polymer binder, and the organic polymer binder is polyacrylate.

[0038] Zeolite particles, adhesives and nano metal oxides are mixed and granulated to form sound-absorbing particles, and the sound-absorbing particles are spherical or quasi-spherical; the mass ratio of the zeolite particles in the sound-absorbing particles ranges from 90% to 99%; the nano-metal The mass proportion of the oxide in the sound-absorbing particles ranges from 20 ppm to 20000 ppm; the mass proportion of the adhesive in the sound-absorbing particles ranges from 1% to 10%. The averag...

Embodiment 3

[0045] Embodiment 3, an improved sound-absorbing material, including zeolite particles, adhesives and nano-metal oxides, zeolite particles, adhesives and nano-metal oxides are mixed and granulated to form sound-absorbing particles; the zeolite particles are pure SiO 2 Modified. The nanometer metal oxide is nickel oxide, and the particle size of the nanometer metal oxide is 80 nanometers; the adhesive is an organic polymer binder, and the organic polymer binder is polyurethane.

[0046] Zeolite particles, adhesives and nano metal oxides are mixed and granulated to form sound-absorbing particles, and the sound-absorbing particles are spherical or quasi-spherical; the mass ratio of the zeolite particles in the sound-absorbing particles ranges from 90% to 99%; the nano-metal The mass proportion of the oxide in the sound-absorbing particles ranges from 20 ppm to 20000 ppm; the mass proportion of the adhesive in the sound-absorbing particles ranges from 1% to 10%. The average parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com