Patents

Literature

755results about How to "Resolve the break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anionic water-based non-curing rubber asphalt waterproof coating and preparation method thereof

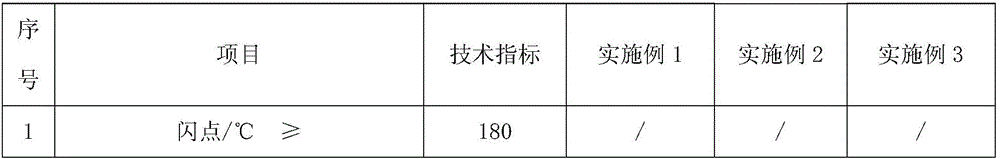

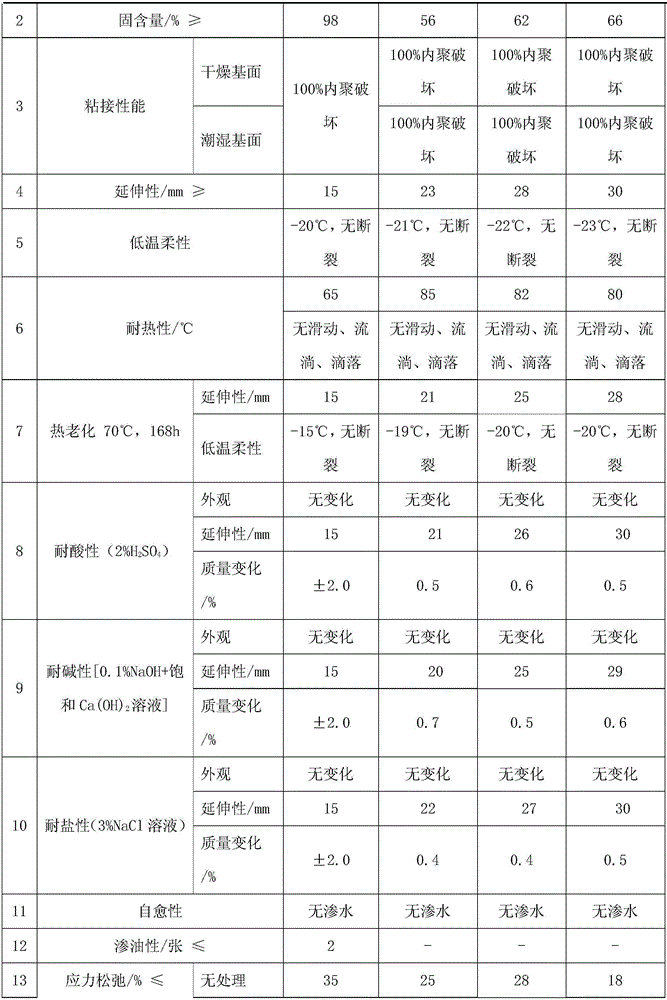

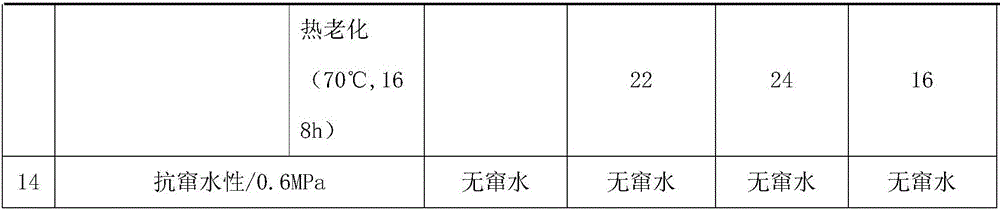

The invention discloses an anionic water-based non-curing rubber asphalt waterproof coating and a preparation method thereof. The preparation method comprises the steps that 85-95 parts by mass of anionic rubber modified asphalt emulsion, 2-5 parts by mass of anionic SBR latex, 4-7 parts by mass of anionic neoprene latex, 0.1-1 part by mass of hydrophobing agent and 0.5-2.5 parts by mass of permeability-reducing agent are stirred and mixed to be uniform to obtain a component A; inorganic salt is dissolved in water, an inorganic salt solution with the concentration being 10% to 30% is prepared, and a component B is obtained; the component A and the component B are sprayed and mixed through a spraying gun according to the mass ratio being (5-15):1, and the anionic water-based non-curing rubber asphalt waterproof coating is obtained, wherein the anionic rubber modified asphalt emulsion is prepared by emulsifying matrix asphalt, a tackifier, rubber elastomers, an anionic emulsifier, a stabilizer, a PH modifier and water through a colloid mill. The product is stable in storage, environmentally friendly, free of pollution, good in non-curing effect, high in waterproof performance and simple in process.

Owner:KESHUN WATERPROOF TECH CO LTD

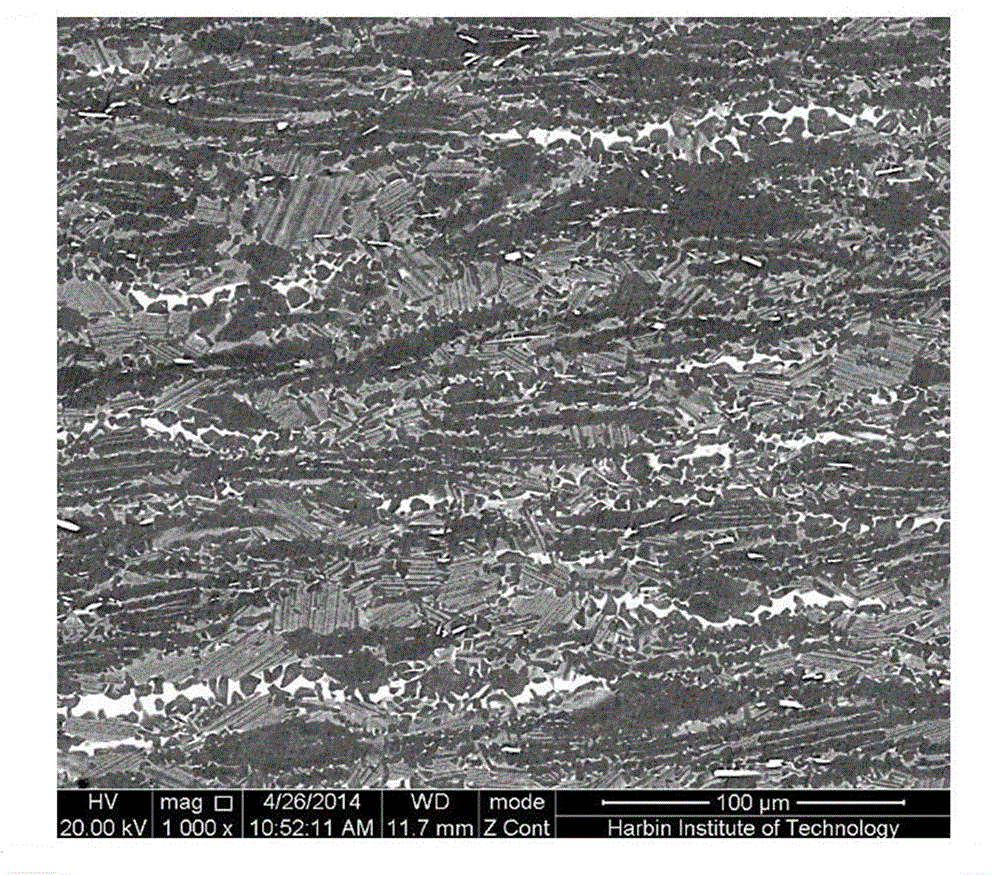

Preparation method for high-toughness nodular cast iron

The invention provides a preparation method for high-toughness nodular cast iron, which is a method for producing high-toughness nodular cast iron by utilizing a medium-frequency electric furnace and selecting materials such as cast iron which is low in sulfur, phosphor and manganese content, waste steel, and the like. The preparation method mainly comprises chemical component design, furnace burden selection, medium-frequency furnace smelting, a nodulizing agent selection and nodulizing treatment method, a nucleating agent selection and nucleating treatment method, and the like. The method disclosed by the invention does not need thermal treatment and desulfuration treatment, is less in processes, adopts a wet type sand production line to manufacture QT600-10 casting pieces, has casting efficiency higher than that of sand-lined iron type, and is low in cost. The produced nodular cast iron is high in strength, good in plasticity and toughness, can be used for components such as a transmission shaft, a rear axle shell, a differential mechanism shell, a bracket, and the like for a car and a tractor chassis.

Owner:HENAN POLYTECHNIC UNIV

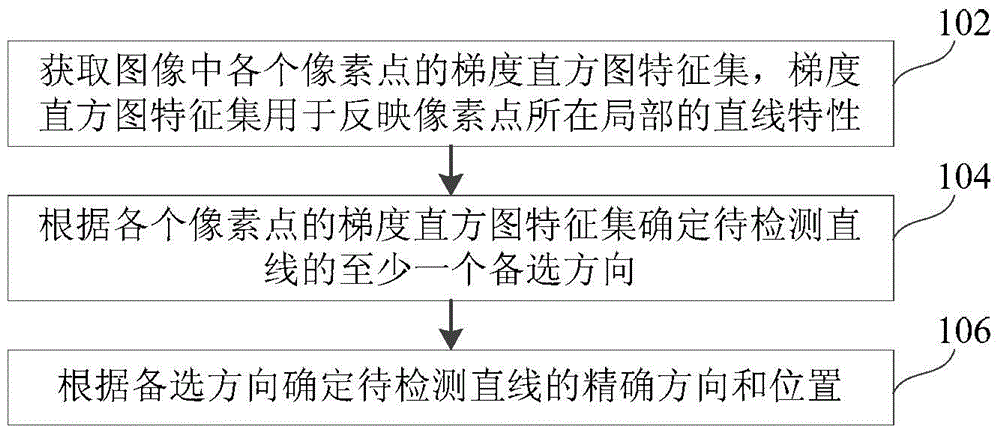

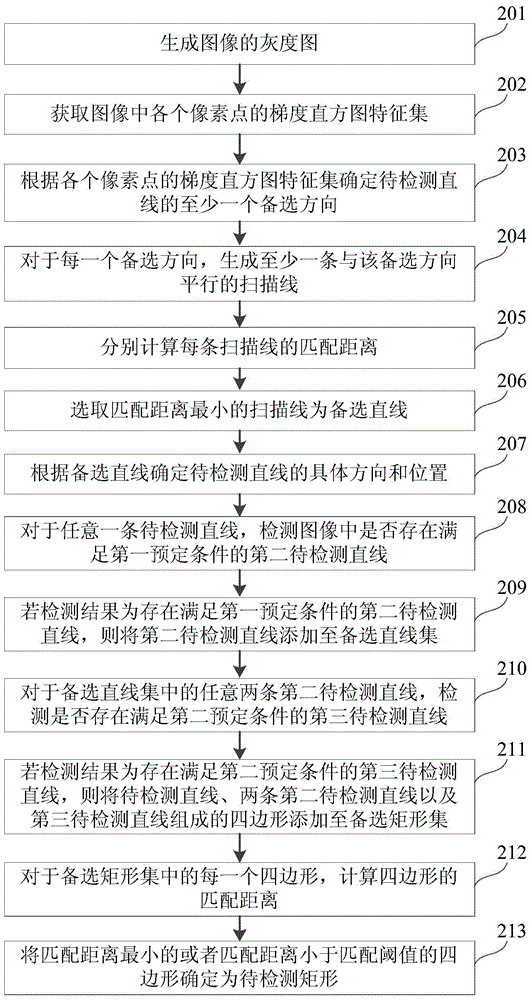

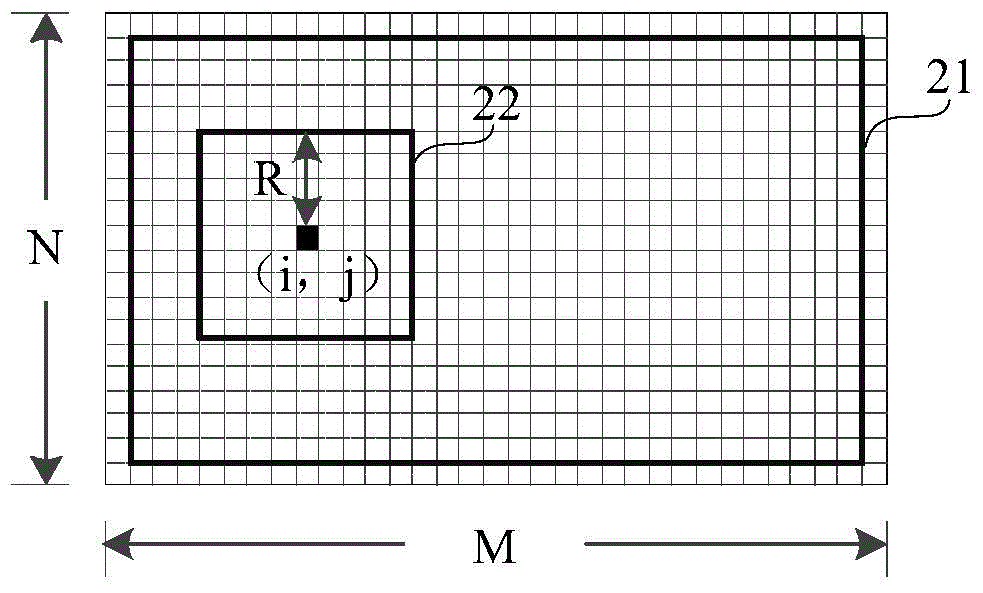

Straight line detection method and device

ActiveCN103914830AResolve the breakResolve accuracyImage enhancementDrawing from basic elementsHough transformImaging processing

The invention discloses a straight line detection method and device and belongs to the field of image processing. The straight line detection method comprises the steps that gradient histogram feature sets of all pixel points in an image are obtained, wherein the gradient histogram feature sets are used for reflecting straight line features of the part where the pixel points exist; according to the gradient histogram feature sets of all the pixel points, at least one alternative direction of a straight line to be detected is determined; according to the alternative direction, the accurate direction and position of the straight line to be detected are determined. The problems that according to a straight line detection method in the prior art, when edge strength is weak or noise interference exists, a straight line is broken, and a detection result is inaccurate are solved. According to the straight line detection method, Hough transfom is not adopted, and image binaryzation is not needed, so that the influence of errors produced by binaryzation is sufficiently avoided, and straight line detection accuracy is improved.

Owner:XIAOMI INC

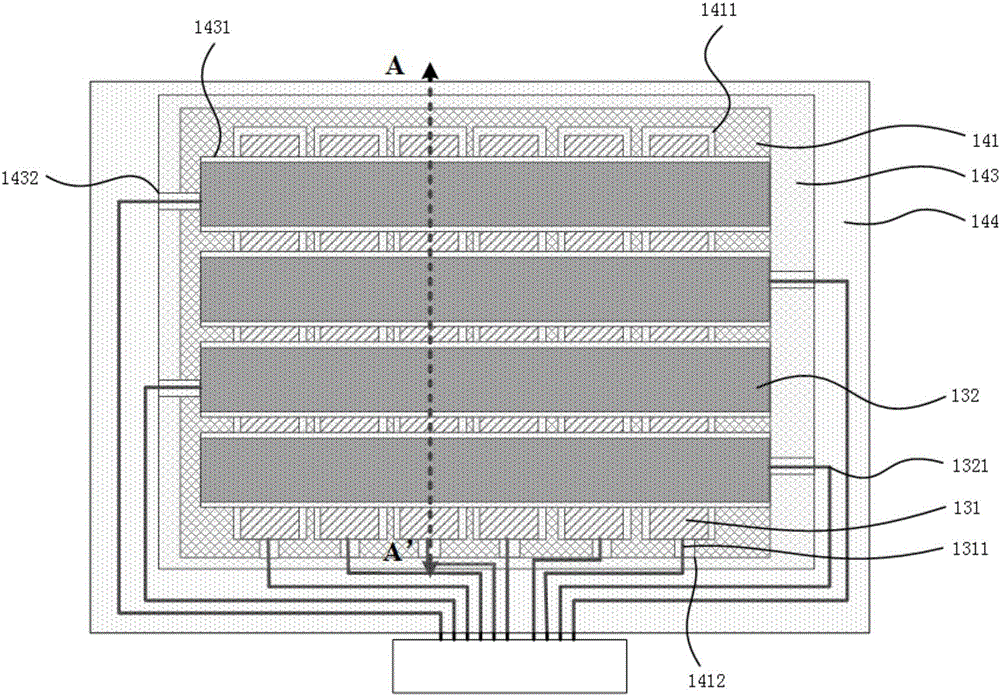

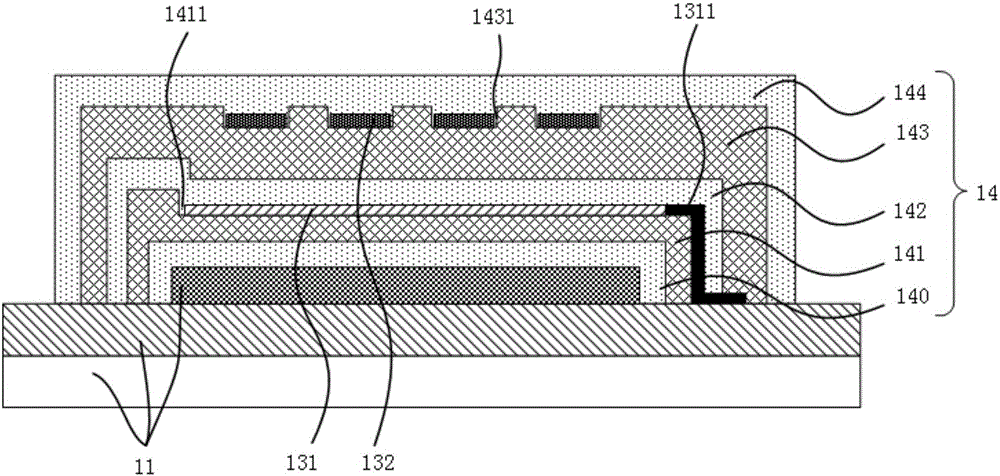

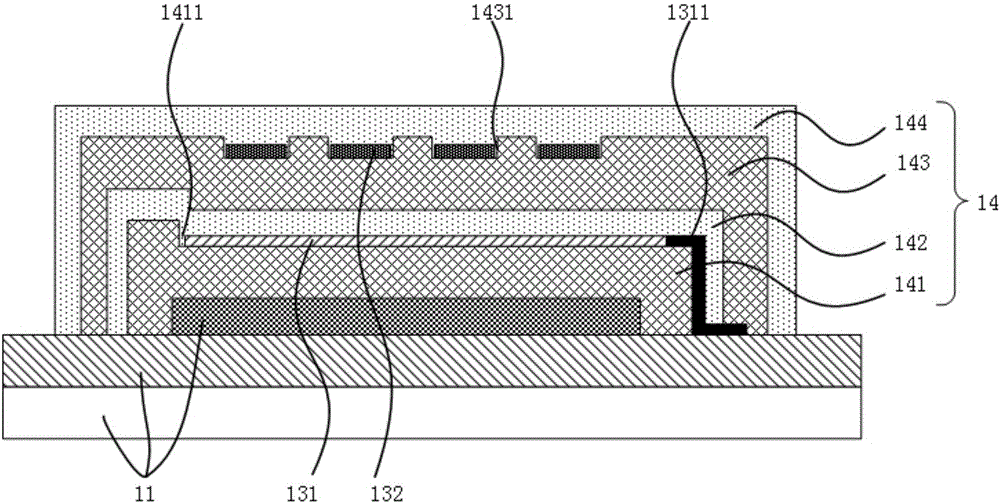

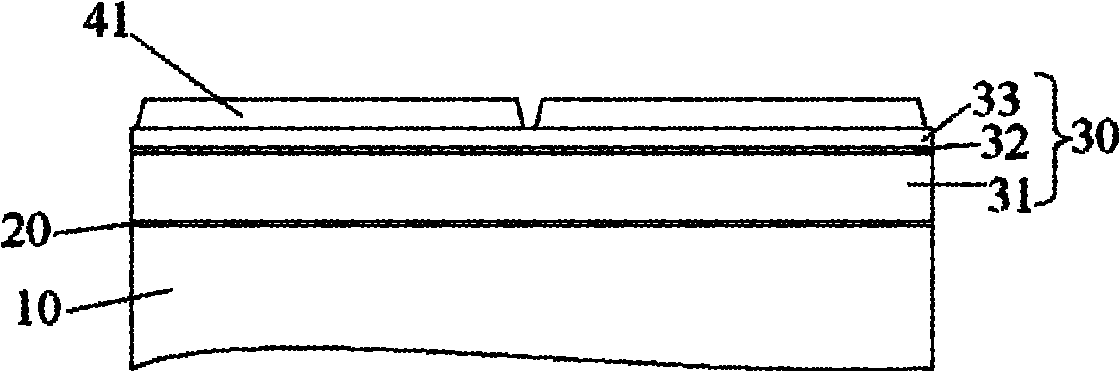

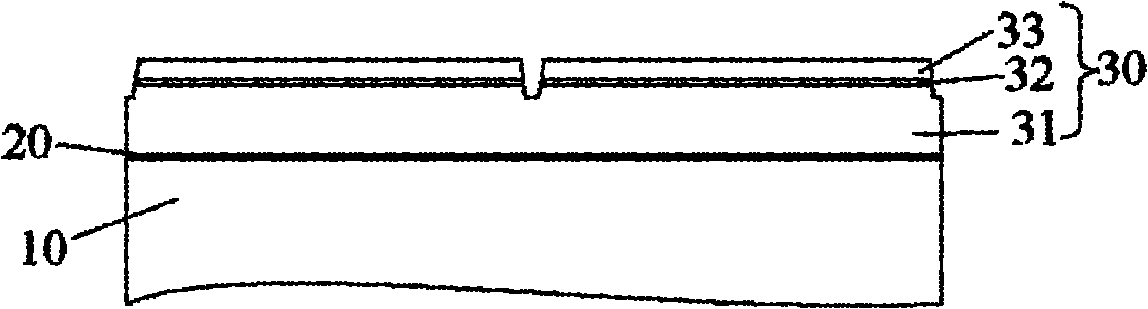

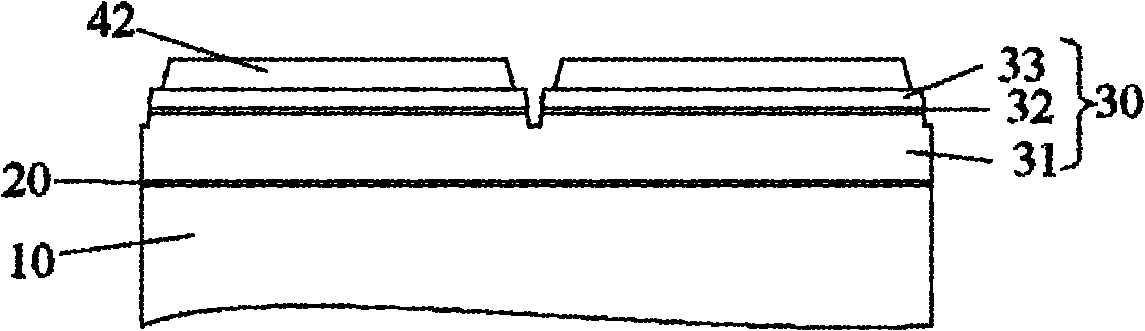

Organic light-emitting display panel

ActiveCN106293258AAvoid corrosionDoes not increase thicknessSolid-state devicesInput/output processes for data processingOrganic layerEngineering

The invention discloses an organic light-emitting display panel. The organic light-emitting display panel comprises an organic light-emitting element array substrate, a thin-film encapsulation layer covering the organic light-emitting element array substrate, a plurality of touch-control driving electrodes, a plurality of touch-control sensing electrodes, a plurality of first touch-control routing lines, and a plurality of second touch-control routing lines, wherein the first touch-control routing lines are electrically connected with the corresponding touch-control driving electrodes; the second touch-control routing lines are electrically connected with the corresponding touch-control sensing electrodes; the thin-film encapsulation layer comprises a first organic layer and a second organic layer; a plurality of first grooves and a plurality of second grooves are formed in the first organic layer, and a plurality of third grooves and a plurality of fourth grooves are formed in the second organic layer; the touch-control driving electrodes are located in the first grooves, and the first touch-control routing lines are located in the second grooves; the touch-control sensing electrodes are located in the third grooves, and the second touch-control routing lines are located in the fourth grooves; the first touch-control routing lines and the second touch-control routing lines are located in the thin-film encapsulation layer. The organic light-emitting display panel provided by the invention is used for meeting the requirement that the touch-control routing lines are not easy to corrode.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Monolithic multi-way valve body casting piece casting method

ActiveCN105903910ADefect control such as sticky sandAvoid overheatingFoundry mouldsFoundry coresCasting defectLinearity

The invention discloses a monolithic multi-way valve body casting piece casting method which comprises the following steps: preparing a core preparing mold, and checking and cleaning the mold; preparing a main core by mold sand, and after the shape of the main core is finalized, spraying a mold release agent, and demolding; preparing small cores, and drilling exhaust holes in the small cores; finishing to remove burrs on the main core and the small cores, and removing a transition jet nozzle on the main core; fixing the main core by a sand core bonding preparation tooling, firstly assembling the small core at one side, and then assembling the small core at the other side; mounting the assembled sand core into a shell body; and casting a valve body: performing a pouring process at two sides of a side thin gate at the same time, using an exothermic riser with the diameter of 120 mm and the height of 220 mm, and placing special cold iron at the bottom face of the shell body. The monolithic multi-way valve body casting piece casted by the casting method has the advantages that the linearity of a main valve hole casting blank is controlled to be less than or equal to 1.0 mm, and the valve hole linearity is ensured; the casting piece pore shrinkage, shrinkage porosity, internal gas holes and other casting defects, especially defects of micropores in the casting piece, are solved; and the compactness of the internal structure is improved.

Owner:南通华东油压科技有限公司

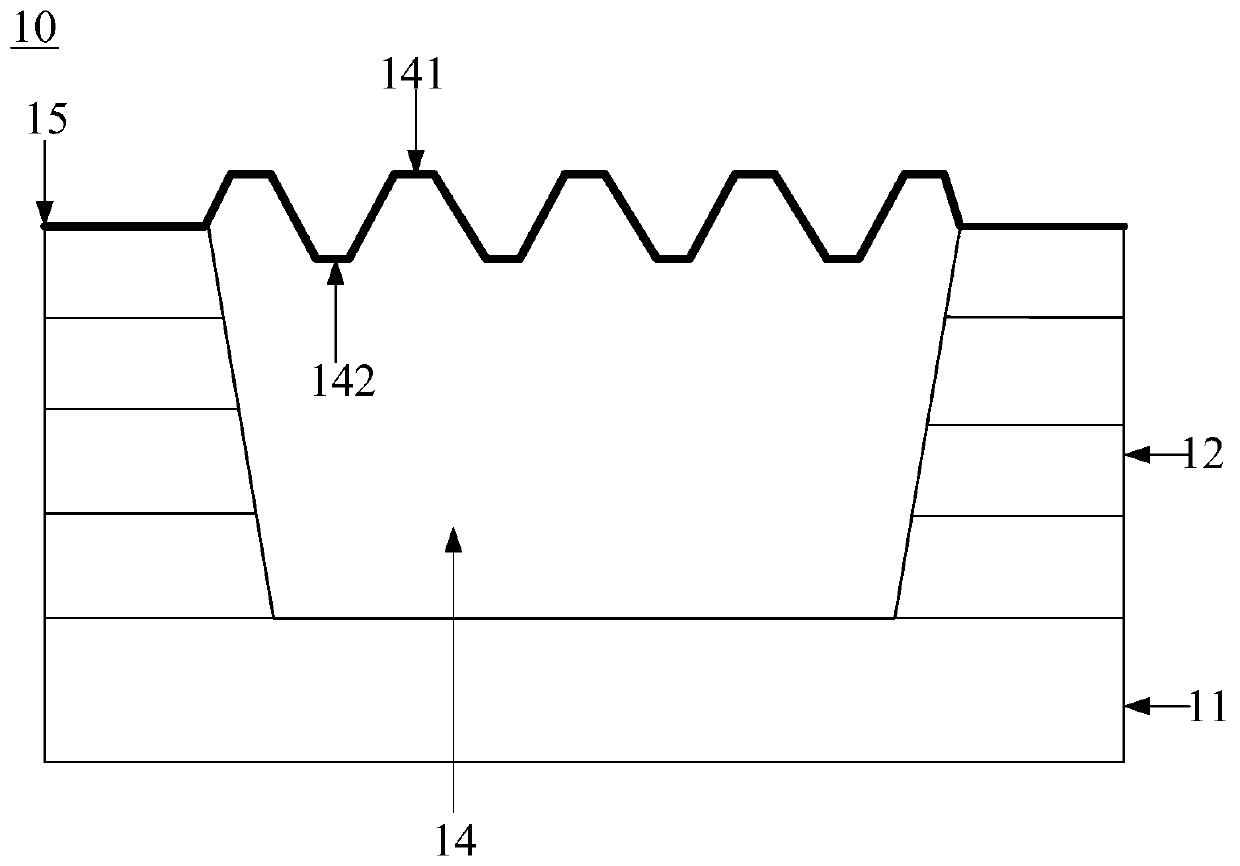

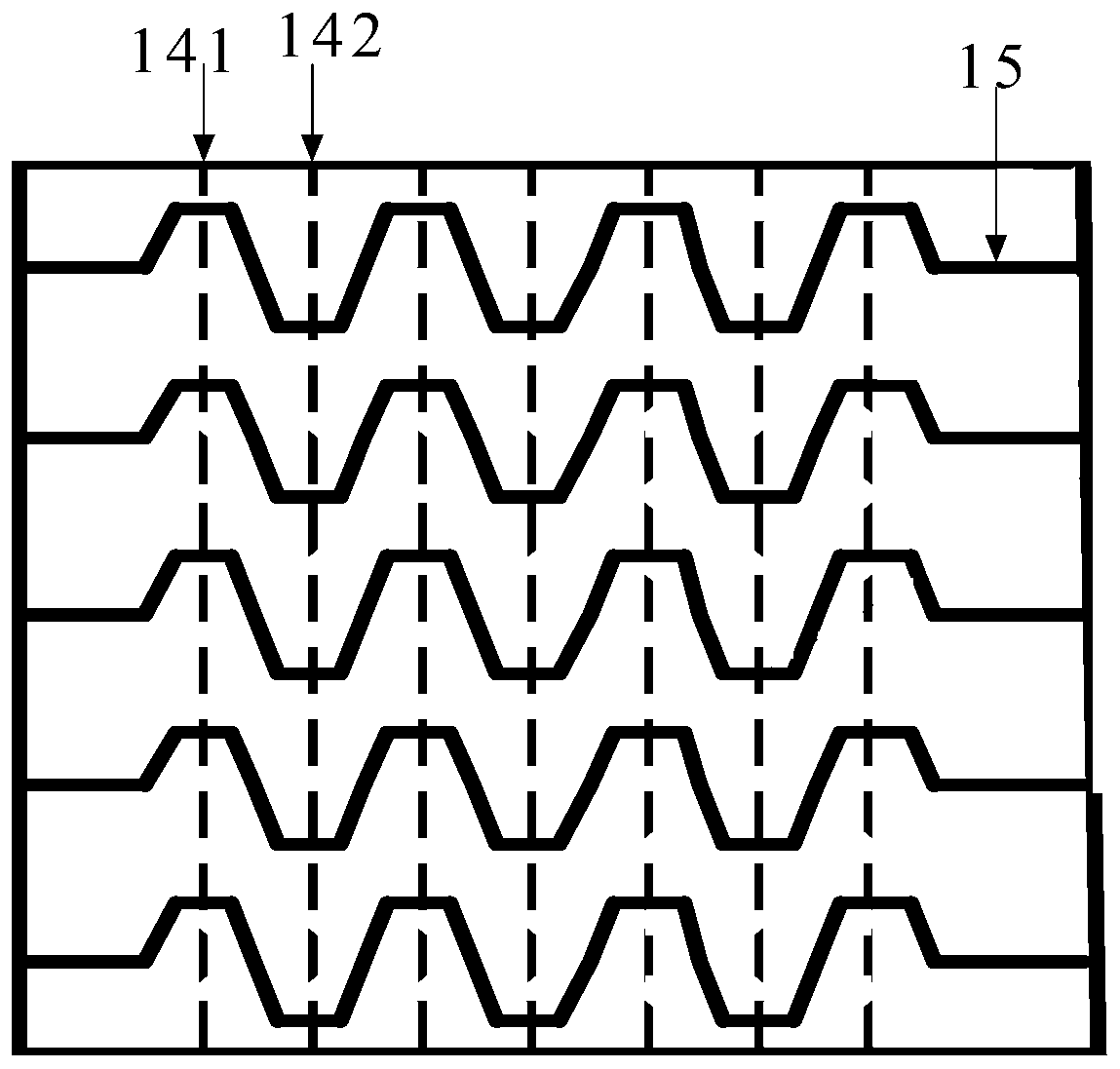

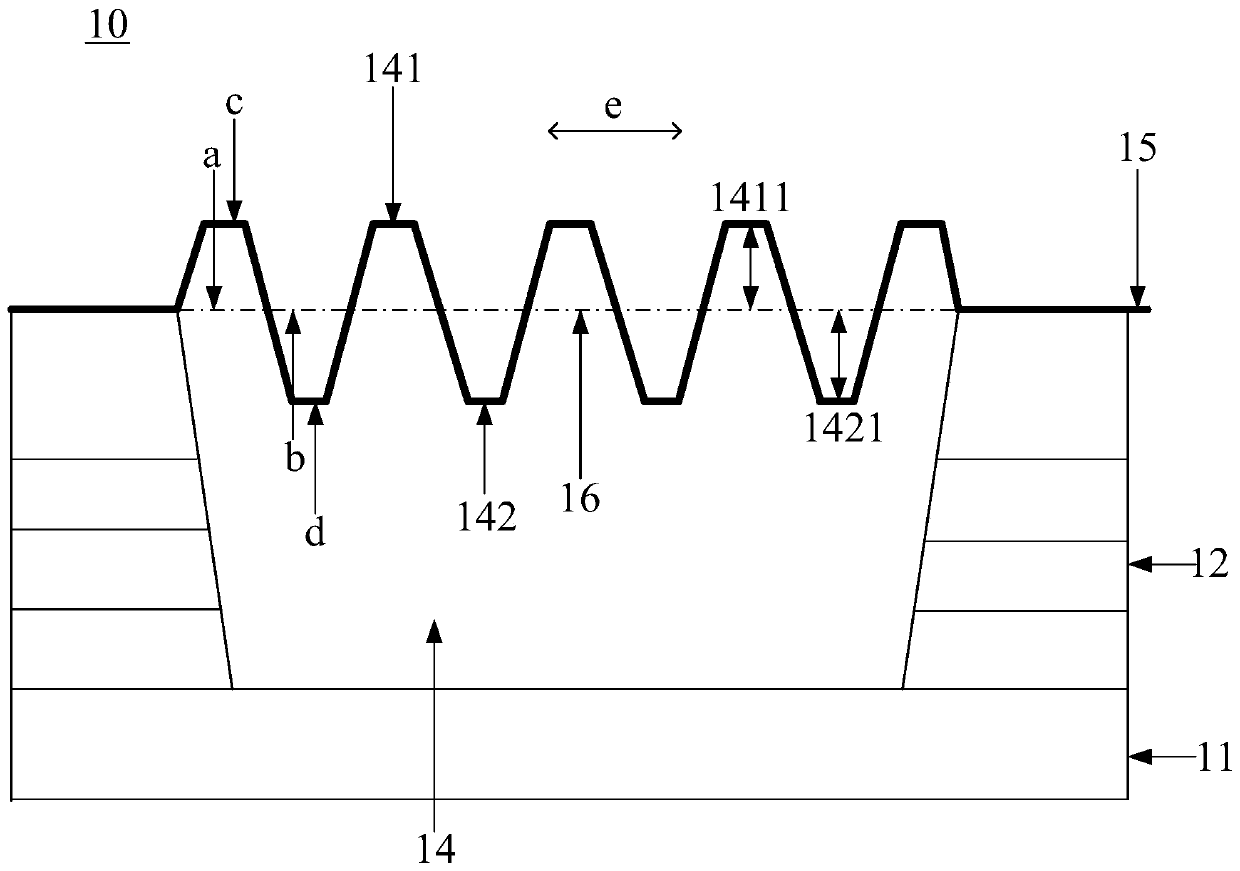

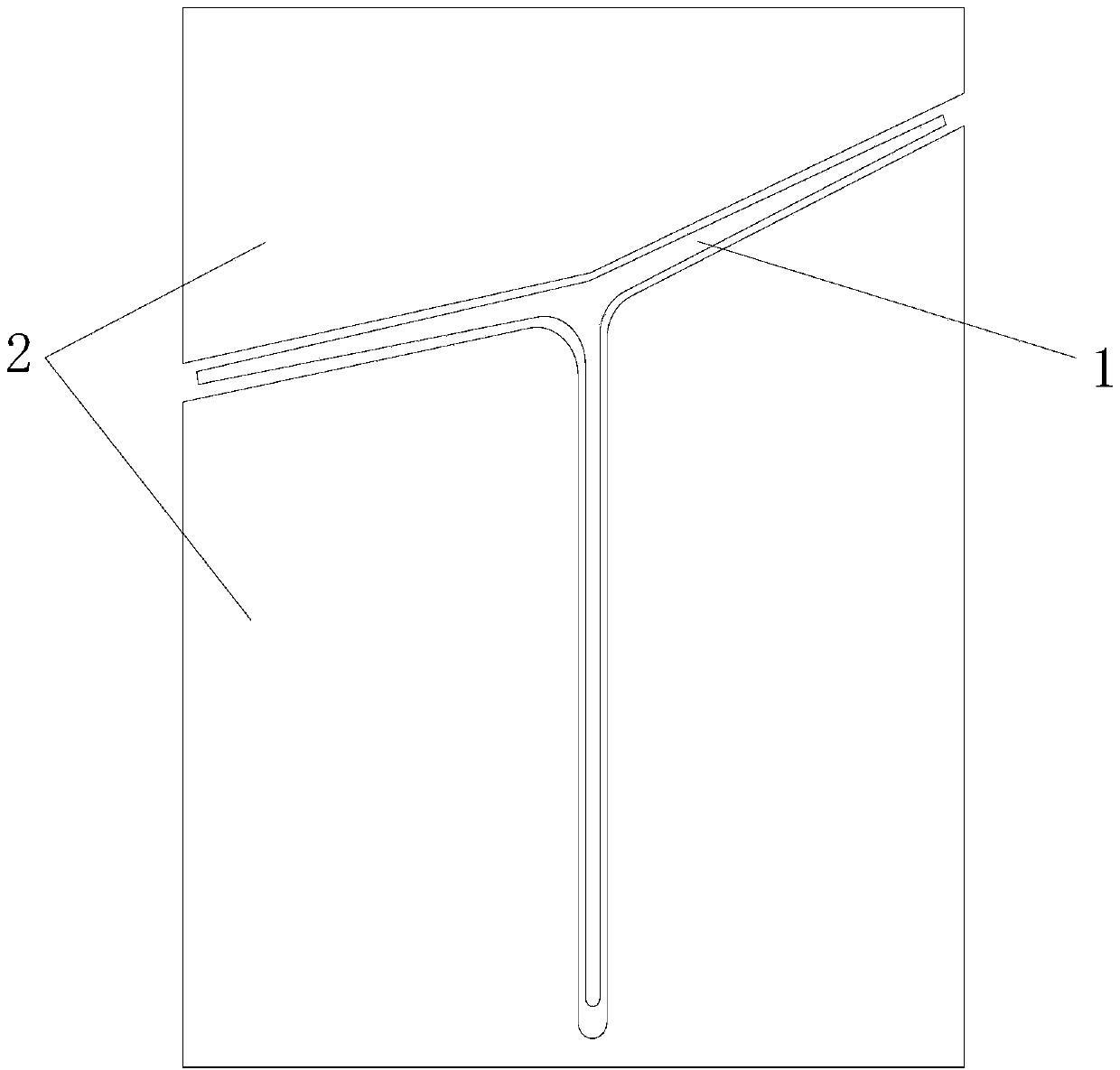

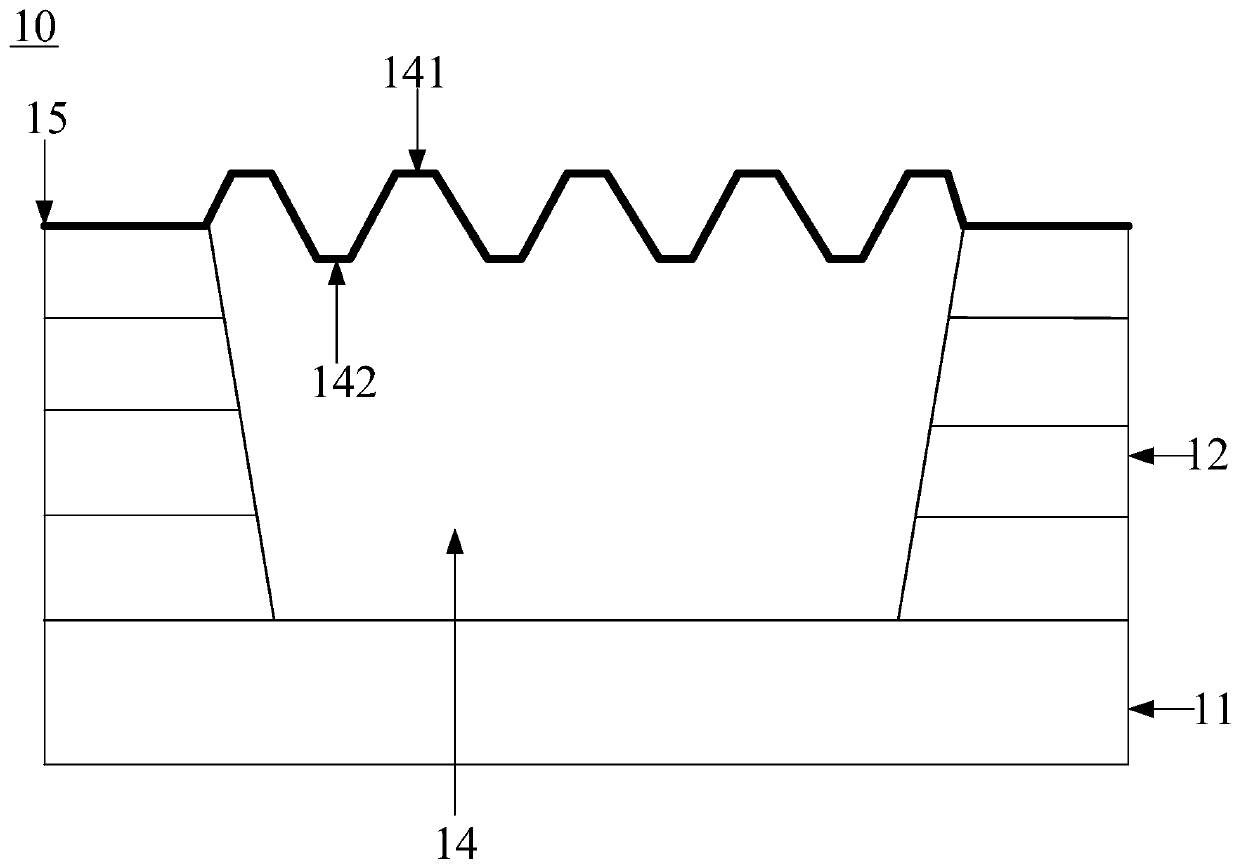

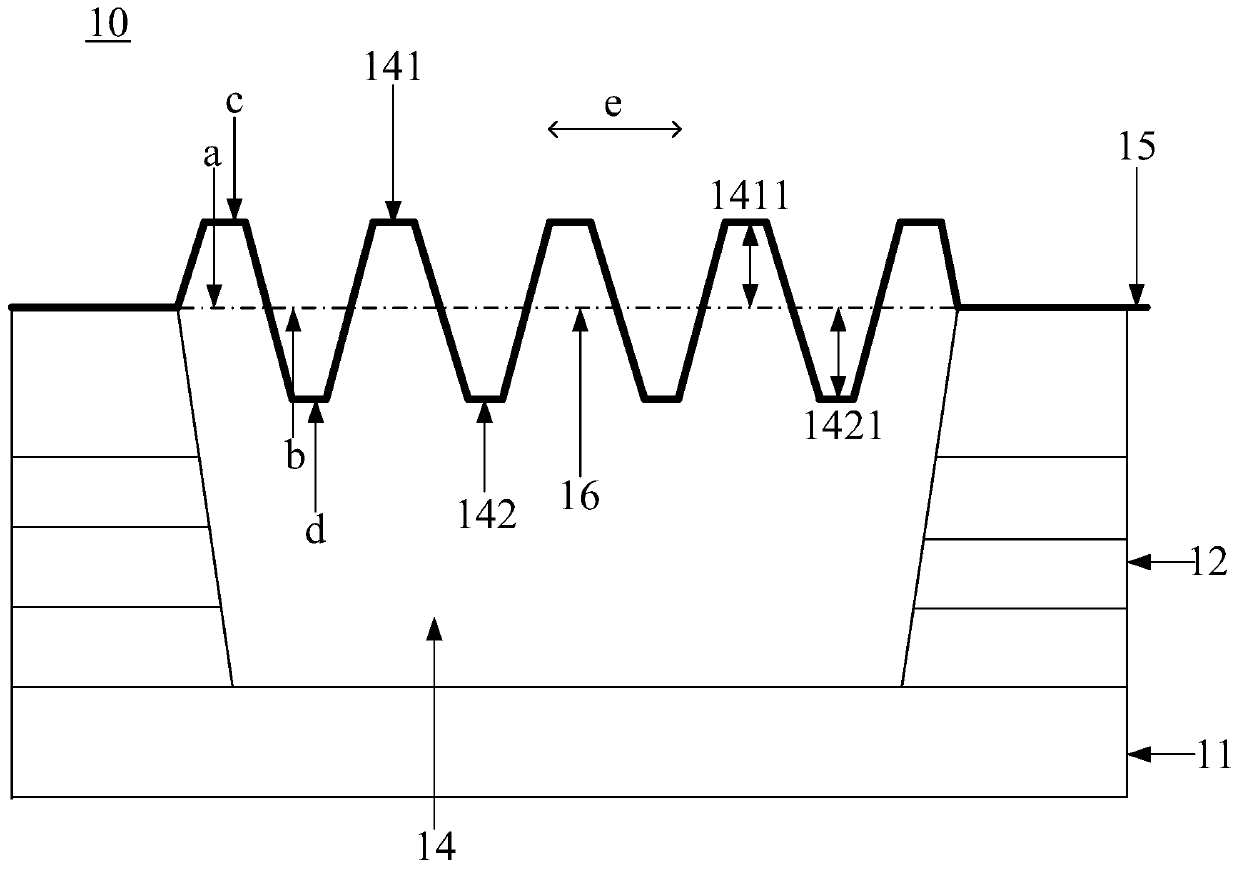

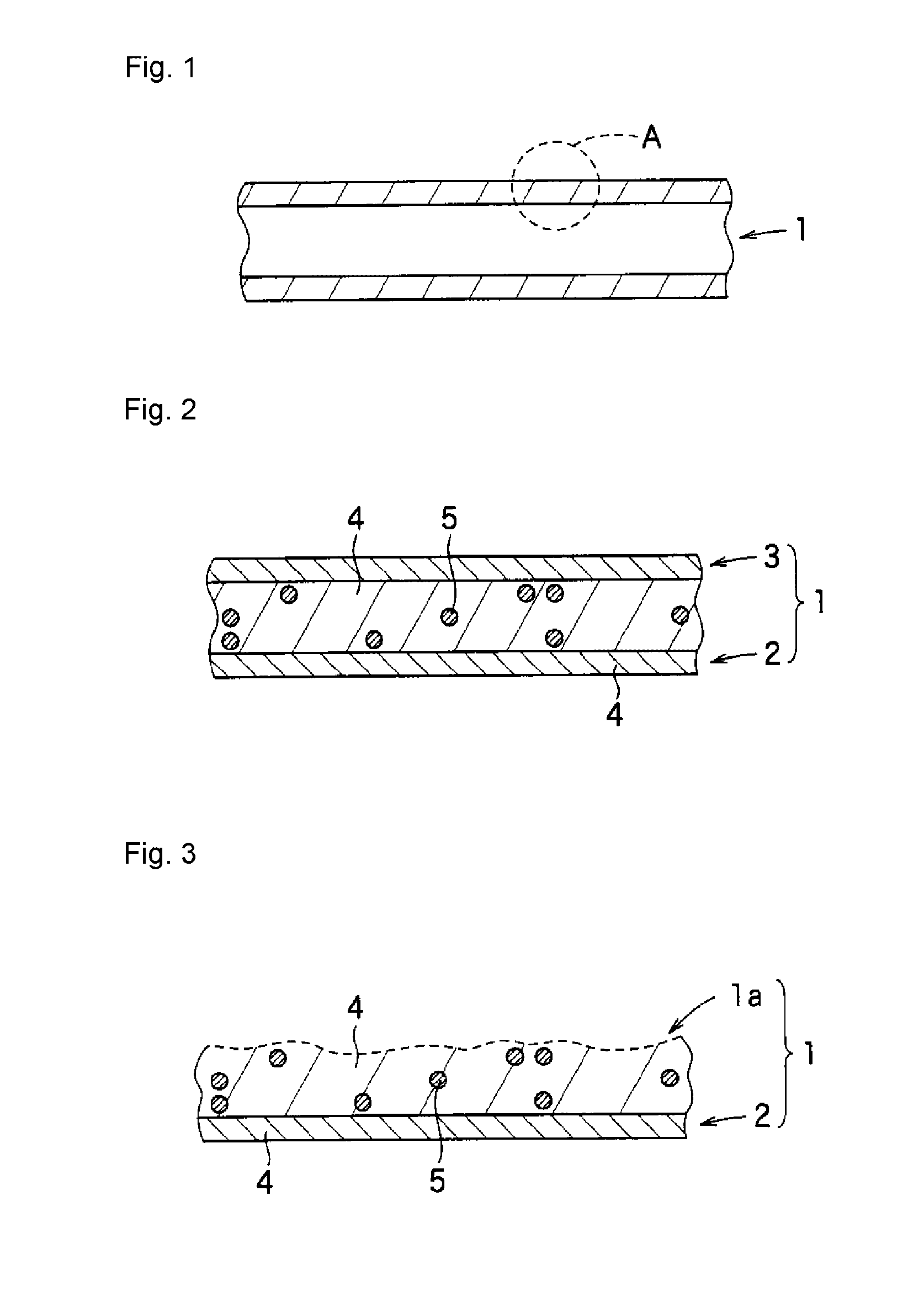

Flexible display panel and manufacturing method thereof

ActiveCN110444578AImprove performanceLow bendabilitySolid-state devicesSemiconductor/solid-state device manufacturingConvex structureState of art

The invention discloses a flexible display panel and a manufacturing method thereof, and belongs to the technical field of display. The flexible display panel comprises a base substrate, wherein the base substrate has an inorganic layer structure; the inorganic layer structure comprises a plurality of inorganic layers; the base substrate has a bent region; the inorganic layer structure has a groove in the bent region; the base substrate having the inorganic layer substrate is provided with a bent bearing structure located in the groove; a side of the bent bearing structure away from the base substrate has alternate convex structures and concave structures; the base substrate having the bent bearing structure has at least one wire; the orthographic projection of at least one wire on the base substrate is in a bent shape; and the wire is attached to the convex structures and the concave structures to form a bent structure with high bending performance. The flexible display panel solves the problem in the prior art that the wire is poor in bending performance, and is likely to break in the process of bending the display panel, and achieves an effect of improving the performance of thebent region.

Owner:BOE TECH GRP CO LTD +1

Composite cylinder jacket and manufacturing method

A composite cylinder jacket is featured as using alloy cast ¿C iron layer as internal layer of cylinder jacket and using cast ¿C steel layer as external layer, setting pure copper combination layer between alloy cast ¿C iron layer and cast ¿C steel layer for connecting these two layers. Its preparing method is the same to cold processing technology, heating and chemical treatment technique and outline size in method for preparing universal cylinder jacket in addition to casting technique.

Owner:WEICHAI POWER CO LTD

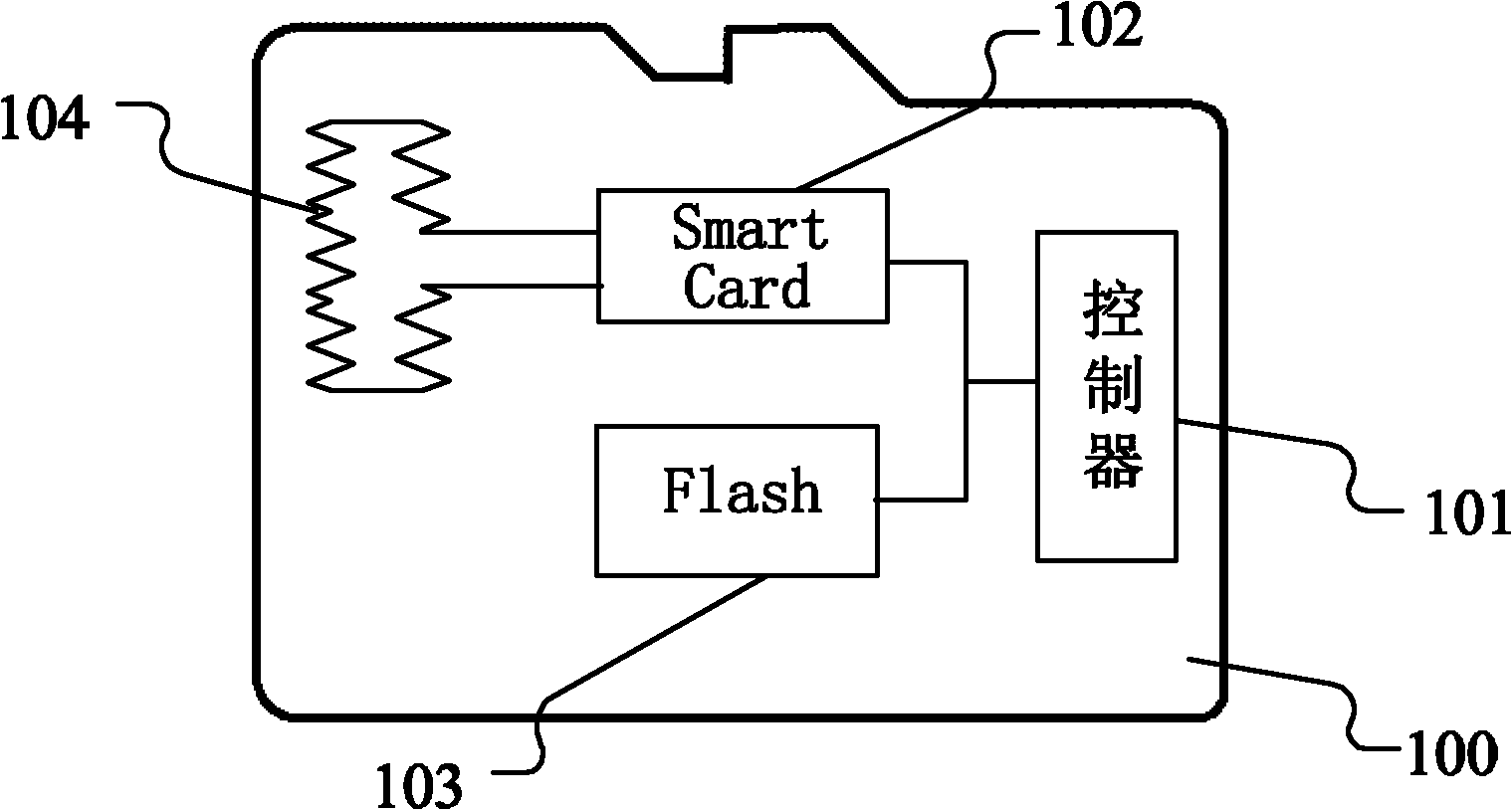

Dual-interface SD card

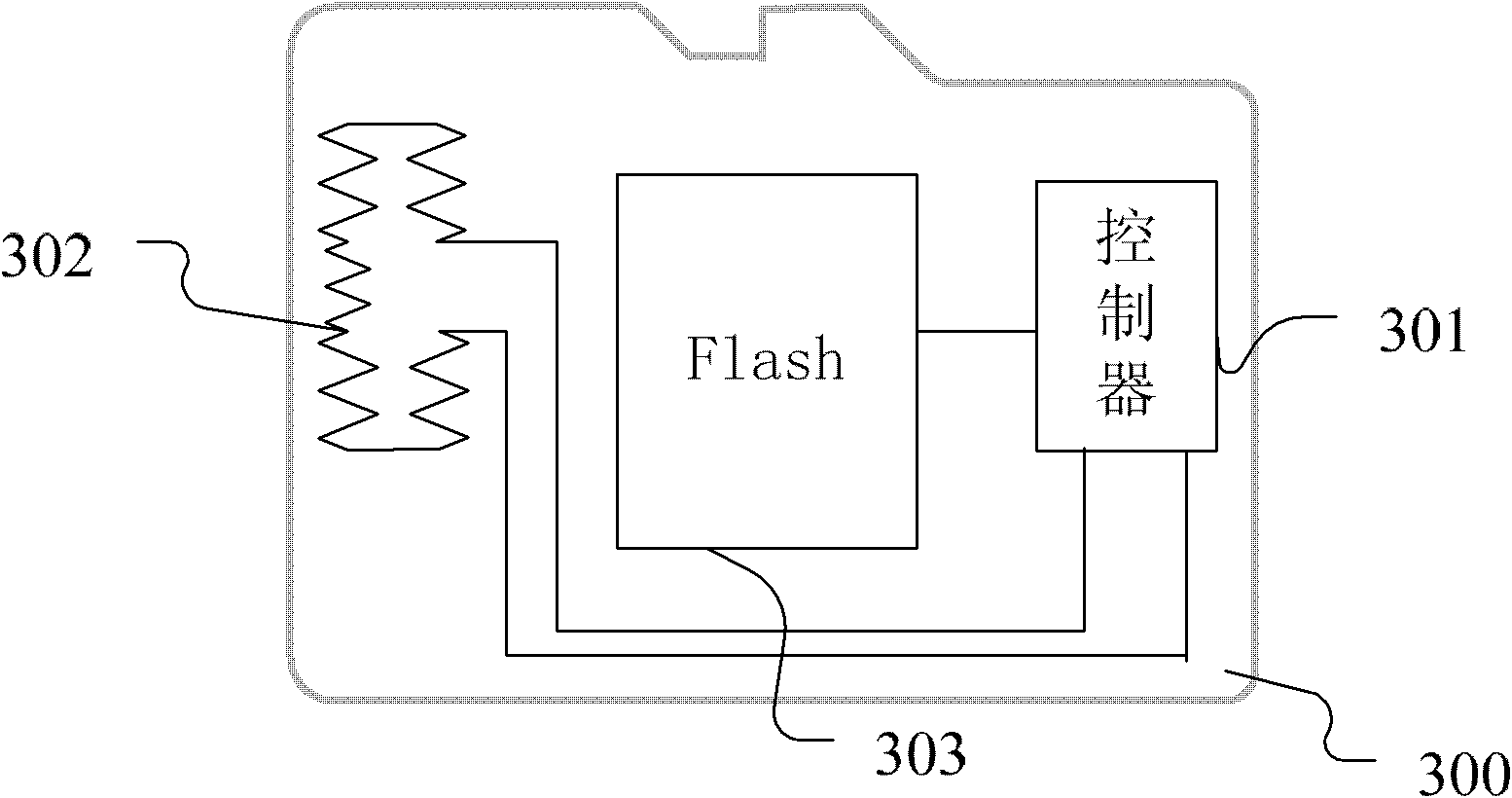

InactiveCN101853422ASecurity Information InteractionMiniaturizationAntenna supports/mountingsRecord carriers used with machinesMiniaturizationSmart card

The invention discloses a dual-interface SD card and belongs to the technical fields of mobile communication equipment and mobile payment. The dual-interface SD card comprises a card substrate, a controller, an intelligent card chip, a storage, and a micro antenna, wherein the intelligent card chip and the storage are connected with the controller respectively; the intelligent card chip is connected with the micro antenna through a corresponding antenna pin; and the controller, the intelligent card chip, the storage, and the micro antenna are embedded in the card substrate. By integrating a radio frequency antenna through low temperature co-fired ceramic, lamination, thin film and film coating, and other technology, and by embedding the antenna into the conventional SD card, the embedding and miniaturization of the antenna are realized.

Owner:BEIJING HUADA ZHIBAO ELECTRONICS SYST

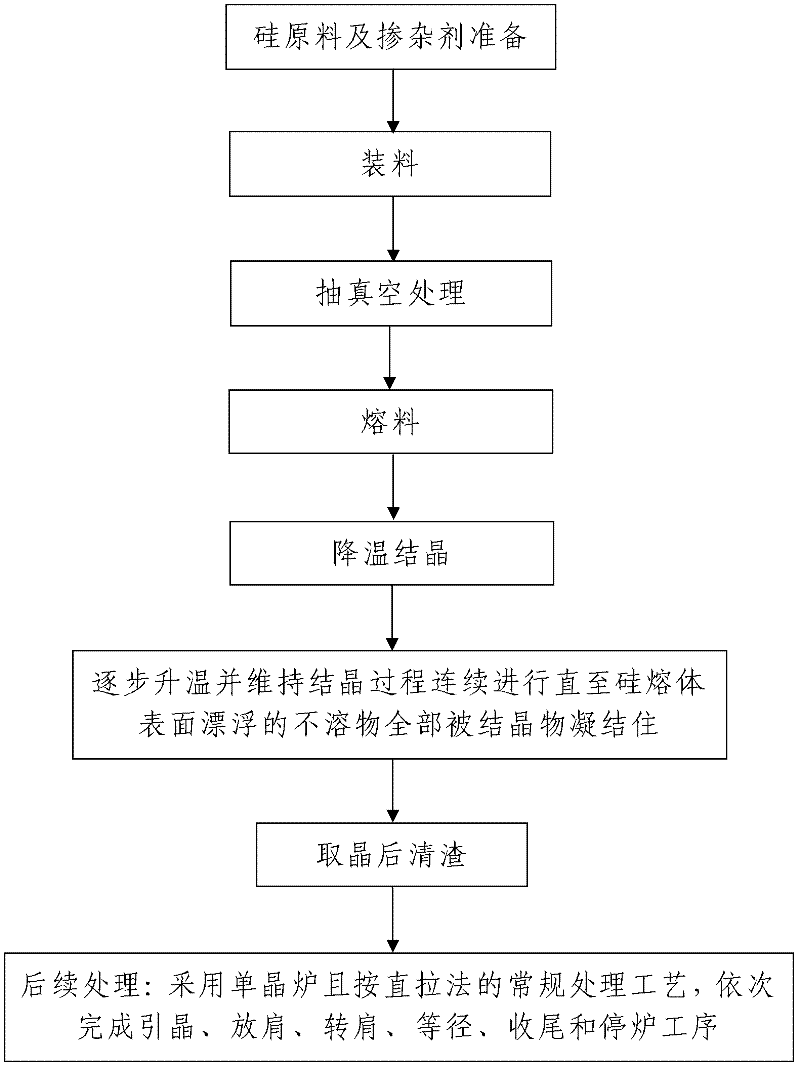

Process for producing Czochralski silicon single crystal

InactiveCN102242397AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltDopantSlag

The invention discloses a process for producing a Czochralski silicon single crystal, which comprises the following steps of: 1, preparing a silicon raw material and a doping agent; 2, charging; 3, vacuumizing; 4, melting; 5, extracting slag, namely 501, performing cooling crystallization, 502, gradually heating, and keeping the crystallization process continuously performed until insoluble substances floating on the surface of a silicon melt are completely condensed by the crystal, and 503, taking the crystal out, and removing the slag; and 6, performing subsequent treatment, namely finishing crystal leading, shoulder expanding, shoulder rotating, diameter equalizing, ending and blowing down processes in turn by using a single crystal furnace according to the conventional treatment process of a Czochralski method to obtain the finished silicon single crystal formed by pulling. The process is reasonable in design, simple in steps, convenient to implement, easy to master and good in using effect, can effectively ensure the quality of the produced silicon single crystal, and can solve the practical problems that slag removing time is difficult to master, the slag extracting effect is poor, the produced silicon single crystal has low purity, and the like.

Owner:XIAN HUAJING ELECTRONICS TECH

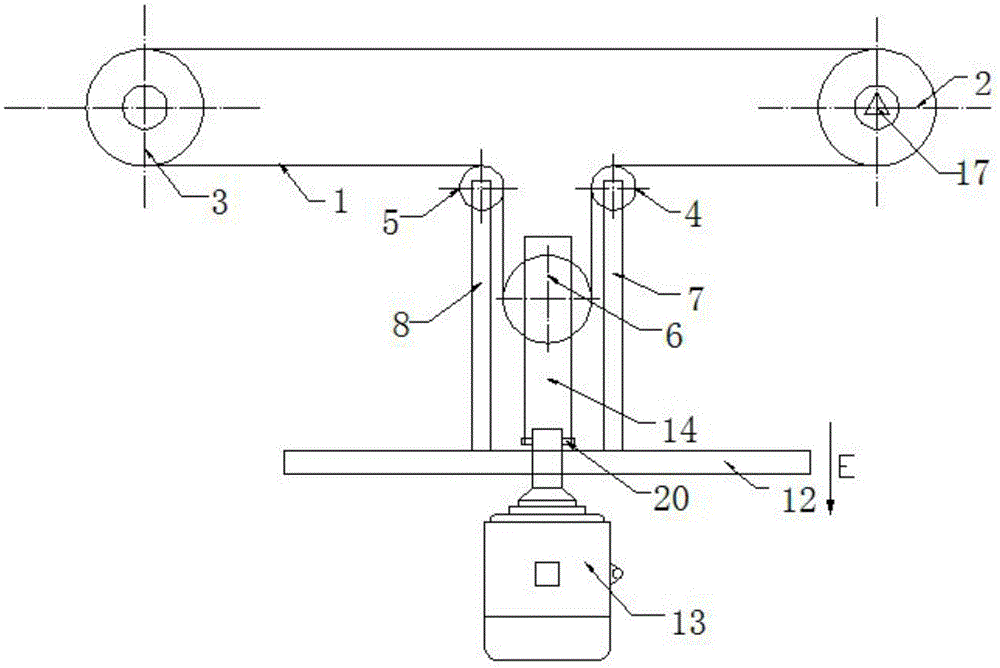

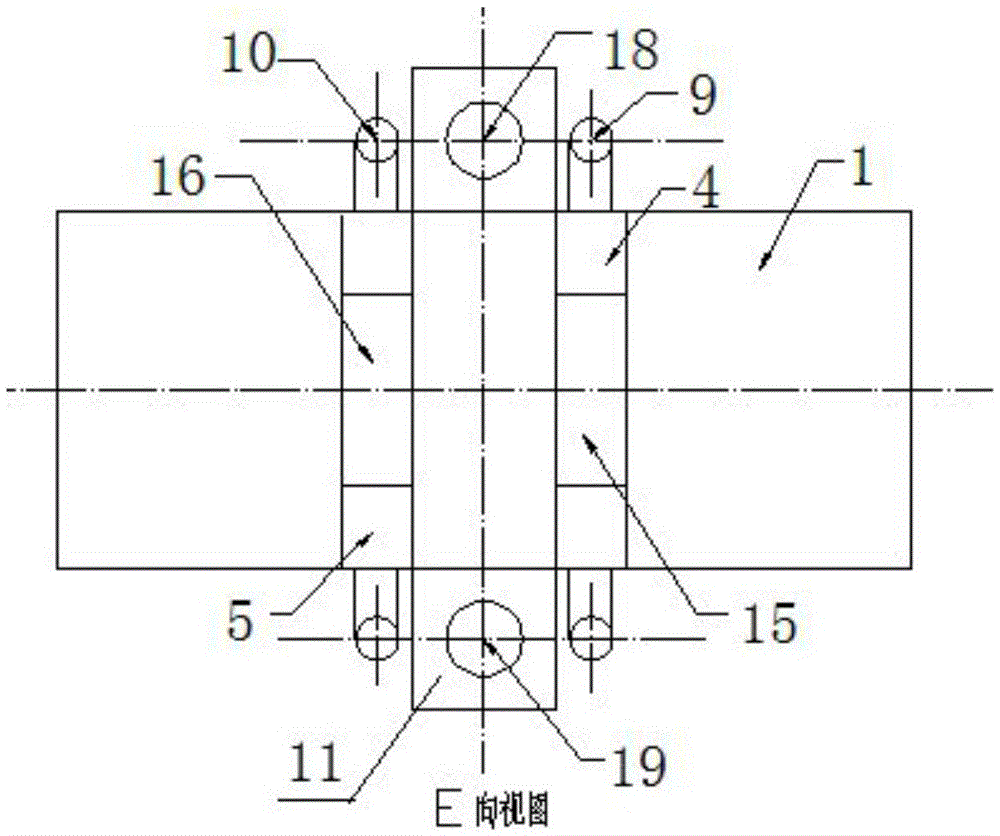

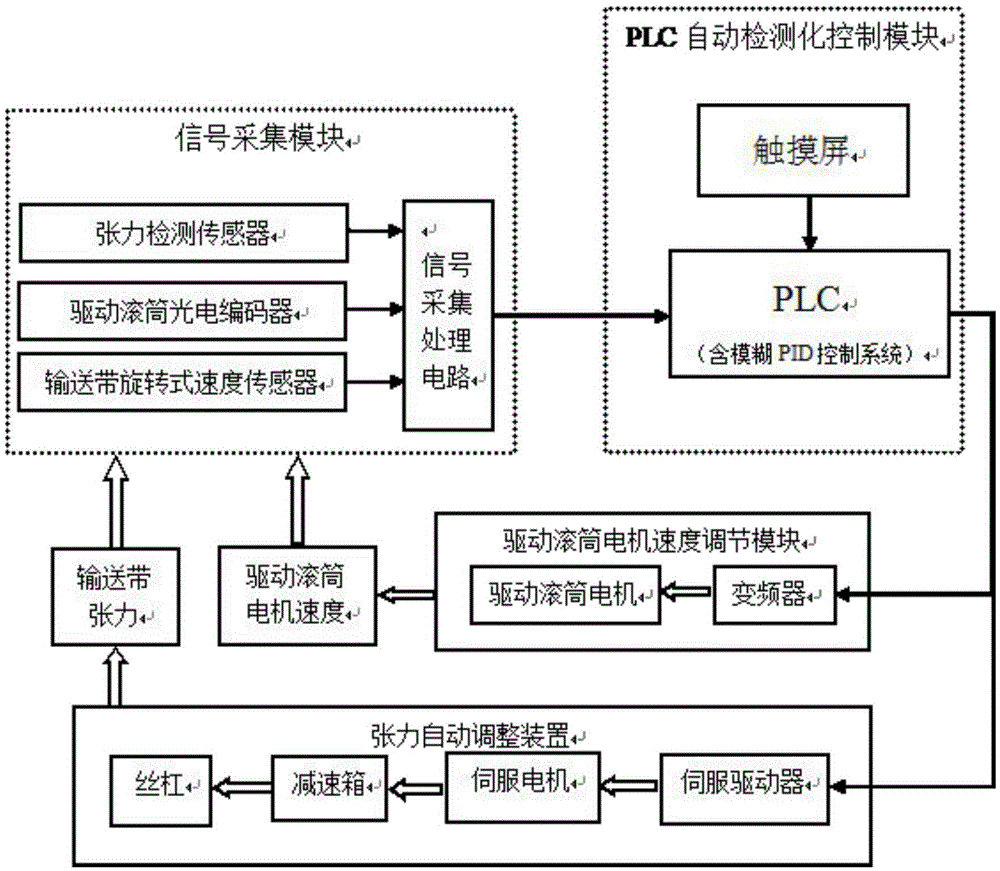

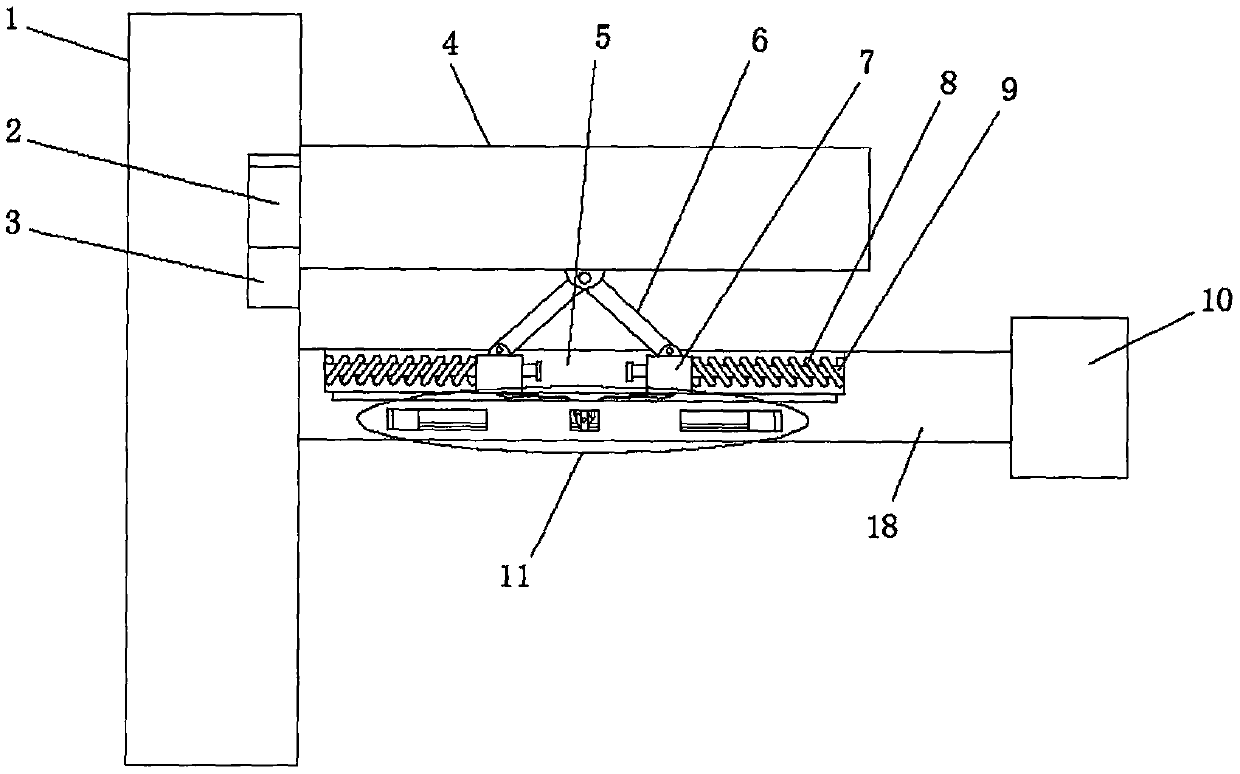

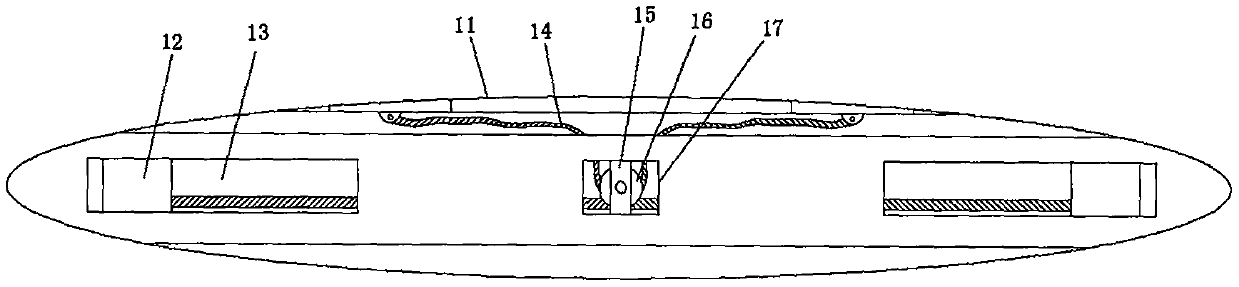

Automatic detection and adjustment device and method for preventing breakage and slippage of long-conveying-distance conveying belt

InactiveCN105600354AImprove real-time performanceImprove accuracyControl devices for conveyorsProgrammable logic controllerEngineering

The invention discloses an automatic detection and adjustment device and method for preventing breakage and slippage of a long-conveying-distance conveying belt. The device comprises a mechanical part and a measurement and control part, wherein the mechanical part comprises a conveying belt, a transmission system, a drive drum, a turnabout drum, a conveying belt tensioning mechanism, a supporting mechanism and an automatic tension adjustment device; the measurement and control part comprises a signal acquisition module and a PLC (Programmable Logic Controller) automatic detection and control module; the signal acquisition module is used for acquiring data signals of a tension of a conveying belt, a speed of the conveying belt and a speed of the drive drum and conveying the data signals to the PLC automatic detection and control module; the PLC automatic detection and control module sends an instruction to the automatic tension adjusting device and a motor of the drive drum and adjusts the tension of the conveying belt and the speed of the drive drum respectively. According to the automatic detection and adjustment device and method, a relationship between slippage and breakage faults of a conveying belt of a belt conveyor is established, the variation of the tension of the conveying belt is detected while the slippage is detected, and therefore the breakage problem caused by excessive adjustment of a tension adjustment device is avoided.

Owner:JIANGSU UNIV

Production process of ultrathin-wall aluminum alloy section for aviation

The invention discloses a production process of an ultrathin-wall aluminum alloy section for aviation. The production process comprises the following steps: 1) before extrusion, heating an aluminum alloy casting rod, an extrusion mold and an extrusion container; 2) extruding the section; 3) straightening; 4) carrying out sizing sawing on the straightened section; 5) heat treatment. According to the production process, the aluminum rod, the extrusion mold and the extrusion container are preheated before extrusion, so that the temperature of the section in the extrusion process can be kept stable, the mass defects of the section caused by an over-cold or over-heat condition are avoided, meanwhile, the end part of the section is completely wrapped and fixed by a clamp hole in the stretching and straightening processes, the contact area of the section and a clamp is large, the problem of rupture in the end part of the section in the stretching and straightening processes can be avoided, vertical quenching is carried out on the section by adopting quenching liquid of which the concentration is 8-10% and the temperature is 25-30 DEG C in the production process, the cooling speeds of various parts of the section are uniform, the quenching deformation can be greatly reduced, and the product quality is improved.

Owner:CHINA ZHONGWANG

Manufacturing method of LED chip

The invention discloses a manufacturing method of an LED chip, wherein a procedure of removing one part of an epitaxial layer comprises the following steps of: forming a first mask film layer on the epitaxial layer, wherein the first mask film layer comprises a plurality of mask film layer units isolated from one another, and a first clearance with a predetermined size is arranged among the maskfilm layer units; removing a second semiconductor layer, a lighting layer and one part of a first semiconductor layer from a region where the first clearance is located to form a groove; eliminating the first mask film layer; repeating the steps for N times to remove parts of the epitaxial layer and a buffer layer until reaching a substrate, reserving an Nth clearance with predetermined size among the mask film layer units, wherein the width of the Nth clearance is greater than that of a (N-1)th clearance; forming an isolating groove with N steps, wherein N is not smaller than 2. By applying the technical scheme of the invention, the isolating groove has smaller depth and greater width as well as a certain inclination degree, thereby being beneficial to the coverage of an insulating material and the adhesion of metal connection wires, and solving the problem of breakage probably caused when the metal connection wires cross a deeper groove.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

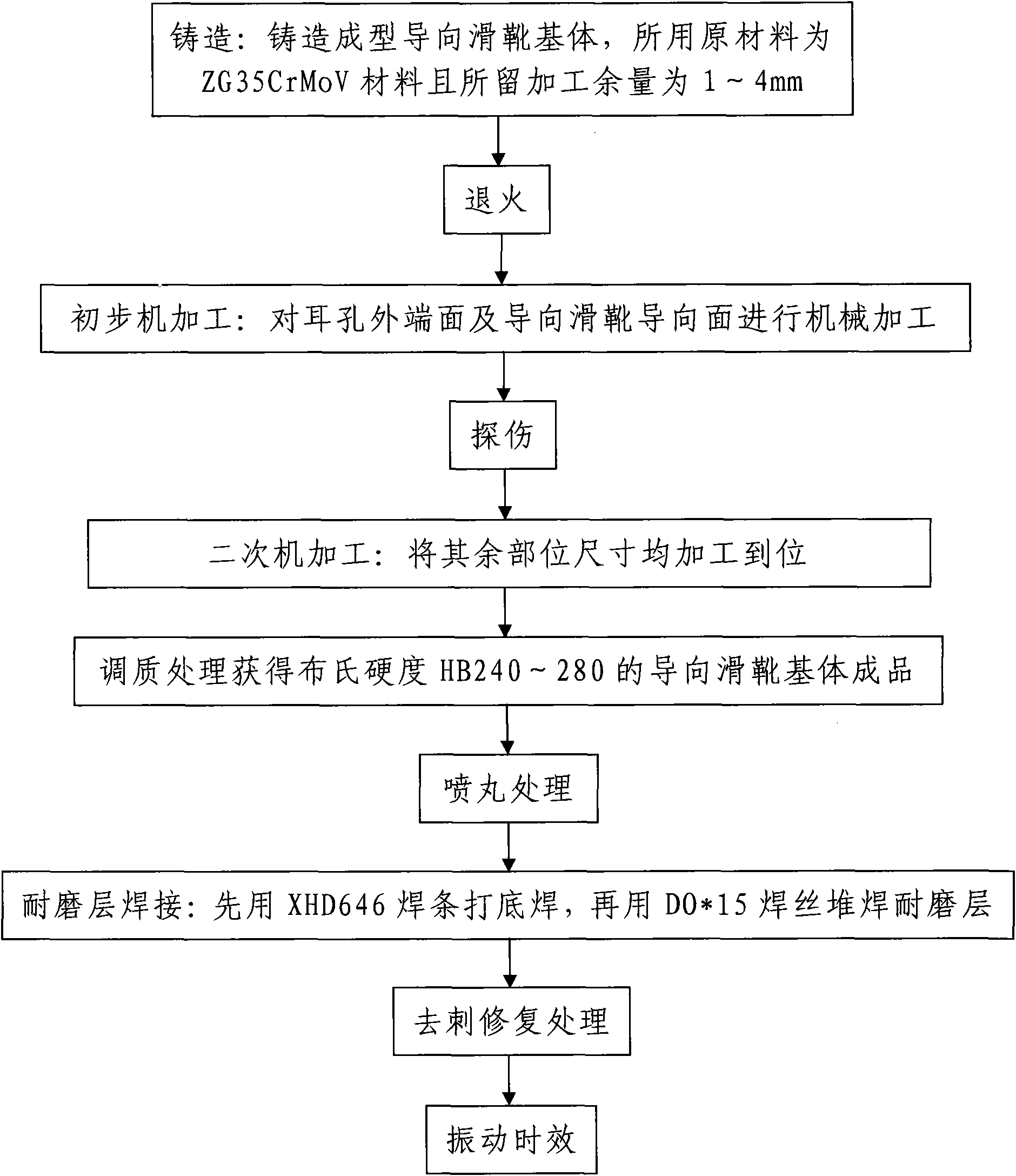

Processing technology for prolonging service life of guiding slide shoes

ActiveCN101608546AReasonable design of process stepsSimple and efficient operationFoundry mouldsSlitting machinesEngineeringHardness

The invention discloses a processing technology for prolonging the service life of guiding slide shoes. The processed guiding slide shoes consist of guiding slide shoe base bodies and wear-resisting layers, wherein the wear-resisting layers are welded on guiding surfaces. The technology comprises the following steps: firstly, casting: the guiding slide shoe base bodies are cast and shaped, the raw material is ZG35CrMoV, and the remained processing tolerance is from 1 mm to 4 mm; secondly, annealing; thirdly, primary machining: the outer end surfaces of lugs and the guiding surfaces are machined; fourthly, fault detection; fifthly, secondary machining: the rest part size is respectively machined; sixthly, quality regulation treatment: the finished guiding slide shoe base bodies with the brinell hardness of 240 to 280 are obtained; seventhly, peening treatment; eighthly, welding of wear-resisting layers: XHD646 welding bars are used for carrying out bottom welding firstly, and then DO*15 is used for carrying out surface welding on the wear-resisting layers; ninthly, deburring and repairing treatment; and tenthly, vibration aging. The invention has the advantages of reasonable design and convenient operation, and the processed guiding slide shoes have the advantages of high quality and long service life.

Owner:XIAN COAL MINING MACHINERY

Low-stress nickel plating technology

The invention provides a low-stress nickel plating technology which takes nickel salt as main salt and obtains a protective layer with low internal stress, high hardness, strong binding force and very superior ductility by checking a plating solution, removing the stress of a material to be plated, anode electrolytic oil removing, etching, nickel preplating, nickel plating and heat treatment. The technology is simple to operate and easy to maintain, has high work efficiency, less pollution to environment and simple sewage treatment, can be widely applied in the protective treatment of low alloy and high strength steel parts of aviation engines, and can be popularized and applied to the protective aspects of the low alloy and high strength steel parts of aviation and aerospace engines, civilian use products and the like and other parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Heat treatment process for water pump shaft connecting bearings

InactiveCN101445866AImprove performanceResolve the breakFurnace typesHeat treatment furnacesIntermediate frequencyQuenching

The invention relates to a heat treatment process for water pump shaft connecting bearings, which includes a quenching and tempering treatment and an intermediate-frequency inductive heat treatment, wherein, the quenching and tempering treatment comprises the steps that an inner shaft of a water pump shaft connecting bearing is positioned in a resistance furnace to have integral heat treatment at a heating temperature being 820 DEG C to 830 DEG C; then oil quenching is performed; and the water pump shaft connecting bearing after oil quenching is tempered at a temperature as high as 480 DEG C to 520 DEG C, kept for 2 hours, and then cooled quickly. The intermediate-frequency inductive heat treatment includes the following steps that the surface heat treatment of the inner shaft of the water pump shaft connecting bearing is performed after the quenching and tempering treatment is performed, the heating temperature is 880 DEG C to 900 DEG C, then water-quenched quenching is performed, the inner shaft of the water pump shaft connecting bearing is heated up to 160 DEG C to 180 DEG C and cooled at a normal temperature, the intermediate-frequency induction heating is performed at a high speed, austenite grains are difficult to grow, the martensite structure after quenching is also extremely tiny, the surface hardness is high, fine-granular carbide is distributed on the matrix of a rope prime body after the quenching and tempering treatment in a dispersion manner, and the hardness of the core thereof is HRC35-45; therefore, the strength and the toughness are good.

Owner:SHENGRUI TRANSMISSION

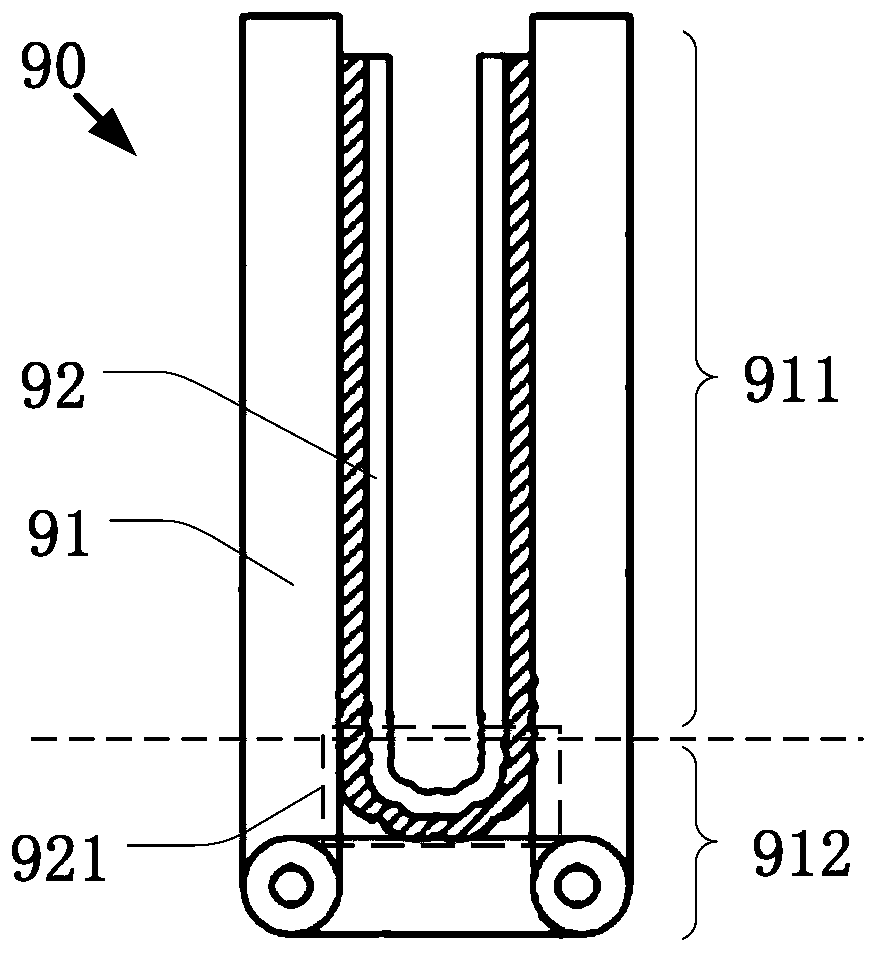

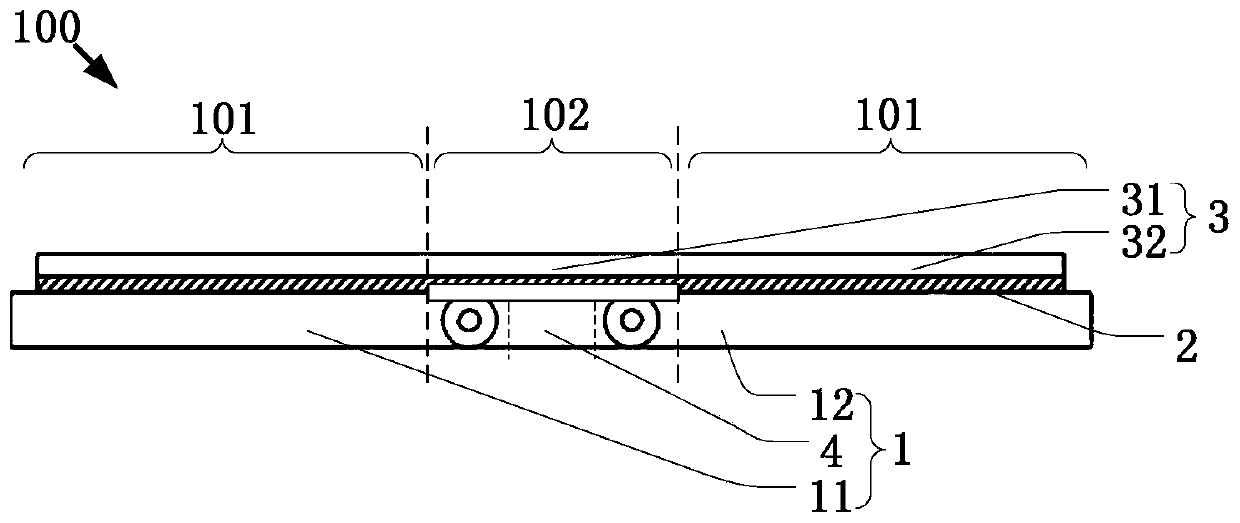

Folding display device

InactiveCN110718155AResolve the breakSmall bending radiusIdentification meansDisplay deviceEngineering

The invention provides a folding display device. The folding display device comprises a foldable module, sliding devices and a display panel. The foldable module comprises a first substrate, a secondsubstrate and a bending mechanism, wherein the first substrate and the second substrate are arranged oppositely, and the bending mechanism is arranged between the first substrate and the second substrate; the at least two sliding devices are arranged on the first substrate and the second substrate respectively; the display panel is mounted on the sliding devices; the display panel comprises a panel folding area and a non-folding area; the panel folding area is opposite to the bending mechanism; and when being bent, the display panel can slide relative to the foldable module through the slidingdevices. The folding display device solves the technical problem that breakage or wrinkling of the display panel is easily caused due to the fact that the stress of a bending area of the flexible display panel in the folding display device is excessively concentrated, so that the bending radius of the bending area is smaller.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

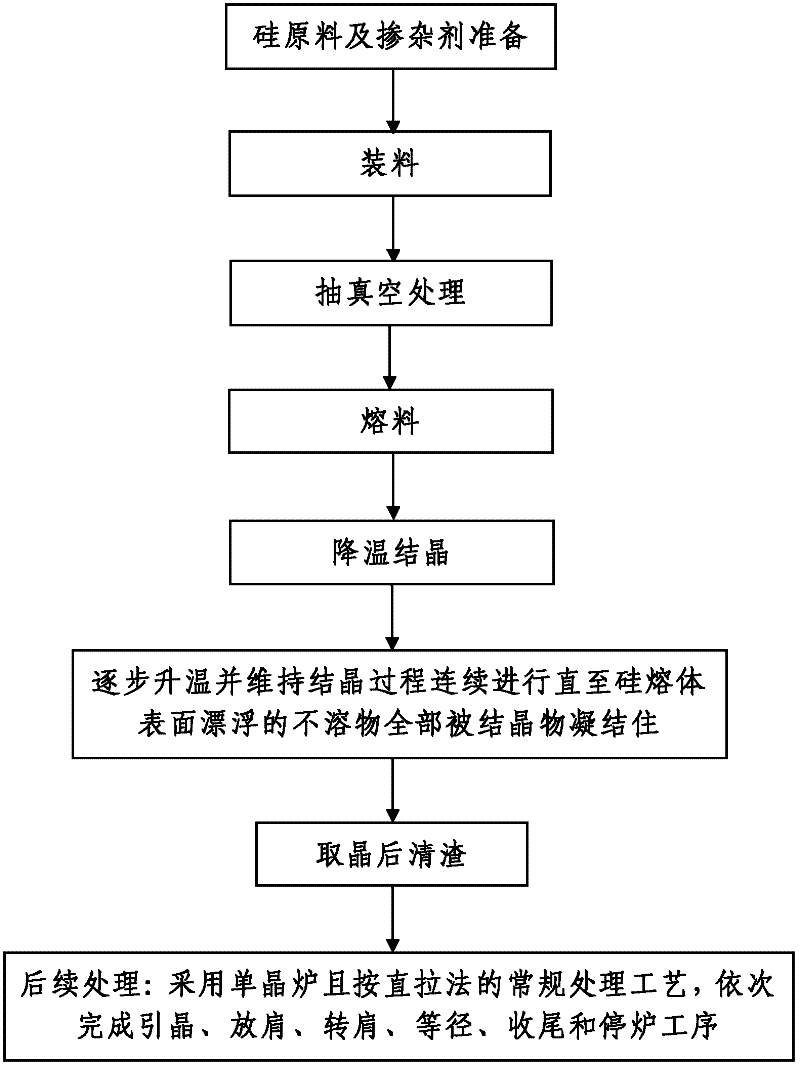

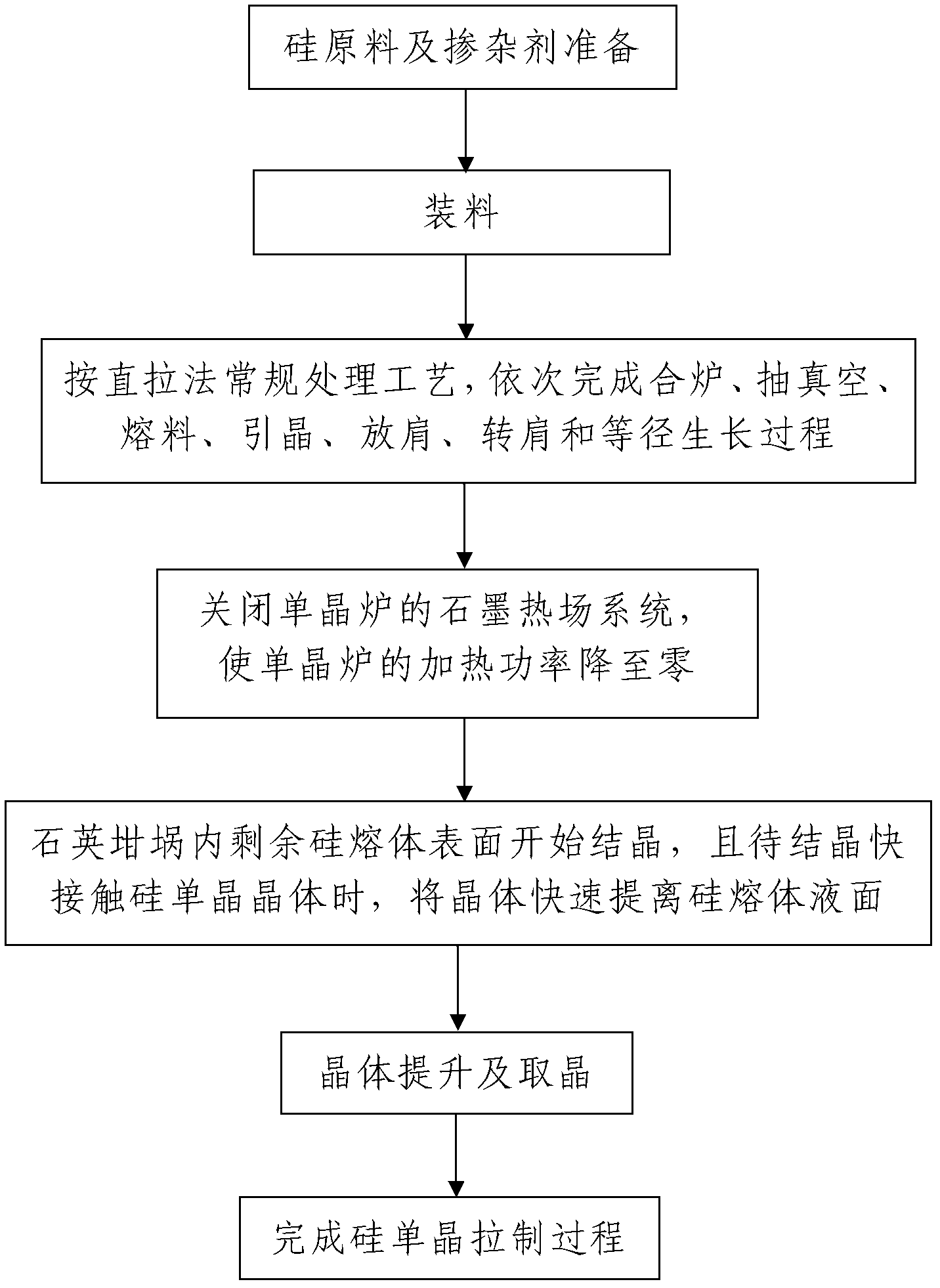

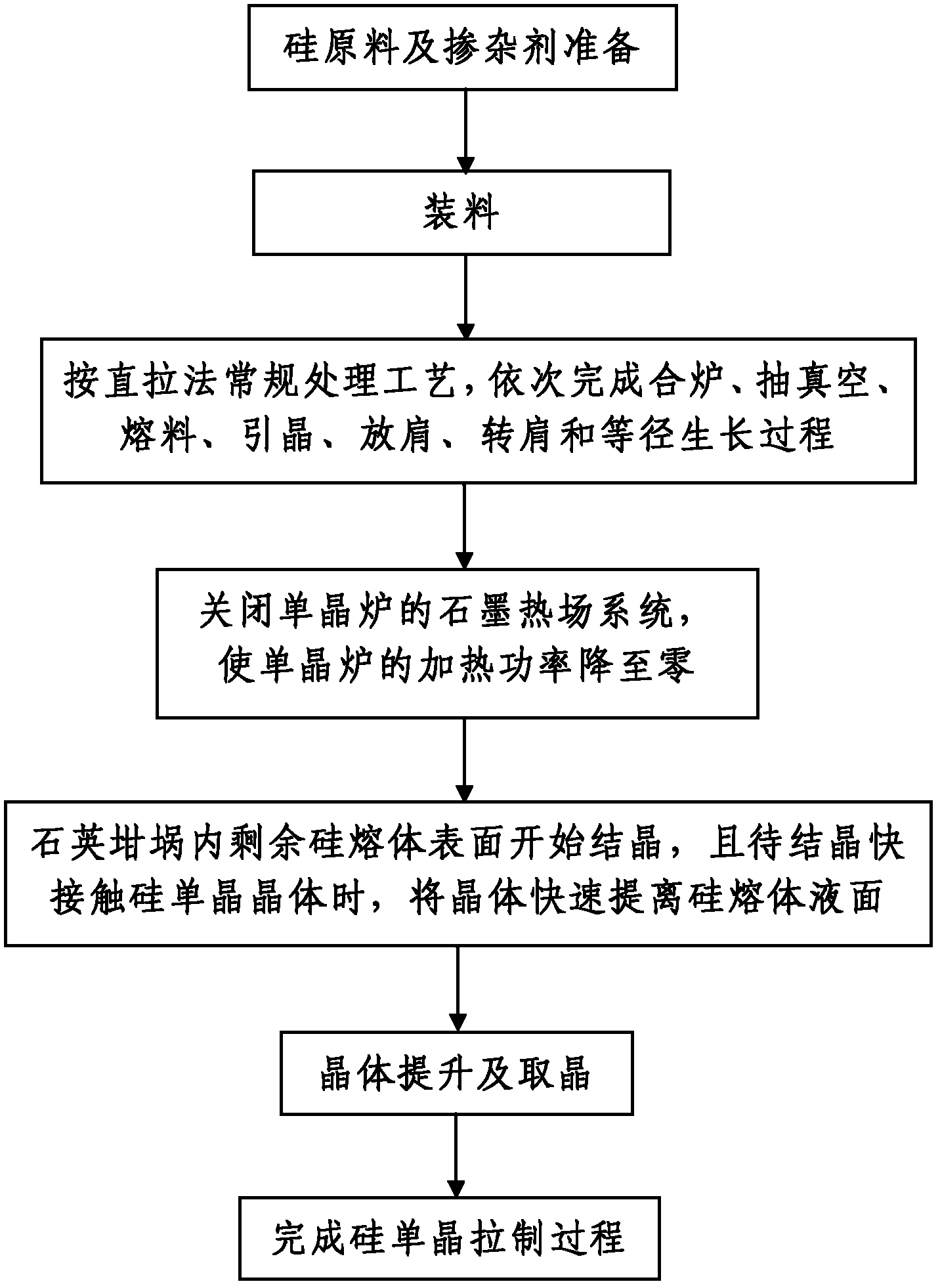

Method to raise production efficiency of czochralski silicon mono-crystal

InactiveCN102220634AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltVacuum pumpingDopant

The invention discloses a method to raise production efficiency of czochralski silicon mono-crystal. The method comprises the following steps: 1. preparation of silicon raw material and a doping agent; 2. charging; 3. processing in a mono-crystal furnace: completing processes of furnace mixing, vacuum-pumping, stock melting, seeding, diameter controlling, casting speed increase and equal diametergrowth, according to a routine processing technology of a czochralski method; 4. post processing: first, a graphite thermal field system of the mono-crystal furnace is closed to lower thermal power of the mono-crystal furnace to zero; then residual silicon melt surface in a quartz crucible begins to crystallize, and when the crystals are about to contact silicon mono-crystals, the mono-crystals are lifted from the silicon melt liquid surface rapidly; last, crystal lifting and crystal collection are carried out to obtain silicon mono-crystal finished product. The invention has the advantages of reasonable design, simple method steps, convenient realization, easy grasp, good usage effect. An ending process of crystal drawing is omitted to increase production efficiency, so as to solve the problem that czochralski silicon mono-crystal production efficiency is restricted by a demanded ending process in the silicon mono-crystal production process.

Owner:XIAN HUAJING ELECTRONICS TECH

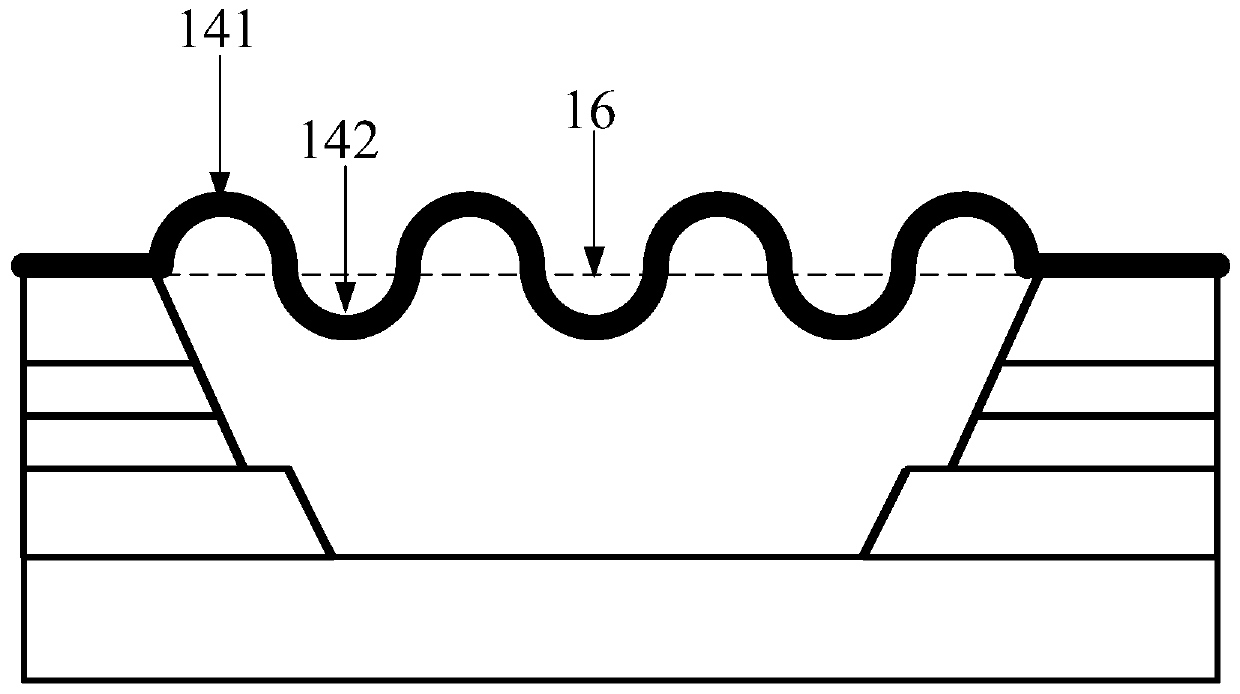

Flexible display panel and manufacturing method thereof

ActiveCN110444549AImprove bending performanceResolve the breakSolid-state devicesSemiconductor/solid-state device manufacturingConvex structureEngineering

The invention discloses a flexible display panel and a manufacturing method thereof, and belongs to the technical field of display. The flexible display panel comprises a base substrate, wherein the base substrate has an inorganic layer structure; the inorganic layer structure comprises a plurality of inorganic layers; the base substrate has a bent region; the inorganic layer structure has a groove in the bent region; the base substrate having the inorganic layer substrate is provided with a bent bearing structure located in the groove; a side of the bent bearing structure away from the base substrate has alternate convex structures and concave structures; the base substrate having the bent bearing structure has at least one wire; and the wire is attached to the convex structures and the concave structures to form a waved bent structure with high bending performance. The flexible display panel solves the problem in the prior art that the wire is poor in bending performance, and is likely to break in the process of bending the display panel, and achieves an effect of improving the performance of the bent region.

Owner:BOE TECH GRP CO LTD +1

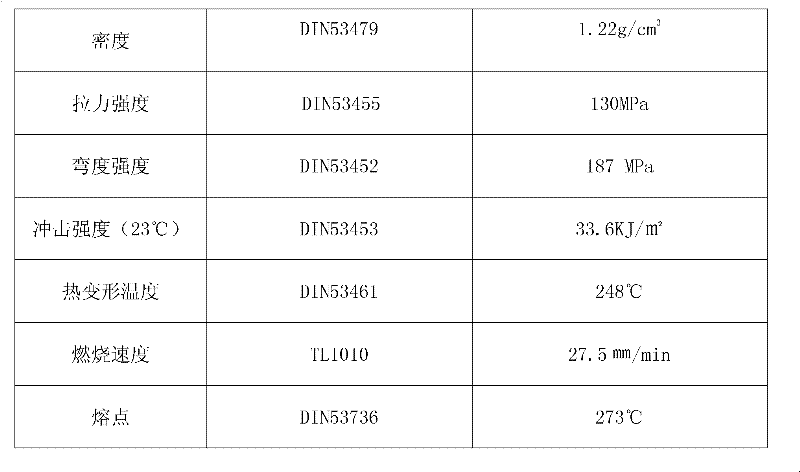

Abrasion-resistant plastic gear and manufacturing method thereof

The invention discloses an abrasion-resistant plastic gear and a manufacturing method thereof. The method mainly comprises the following steps of: adding dried and proportioned raw materials into a heated injection molding machine, setting injection pressure, speed, time and glue quantity of different stages of the injection molding machine, setting final protective pressure and protective pressure speed to achieve an optimal injection molding technology, and thus obtaining a final qualified product. The method overcomes the physical property defects of whitening, breakage, poor toughness, low strength and the like when the abrasion-resistant plastic gear is formed by injection molding; and the injection molding technology has stability, the obtained product is stable in quality, the production efficiency is improved, and the production cost is reduced.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

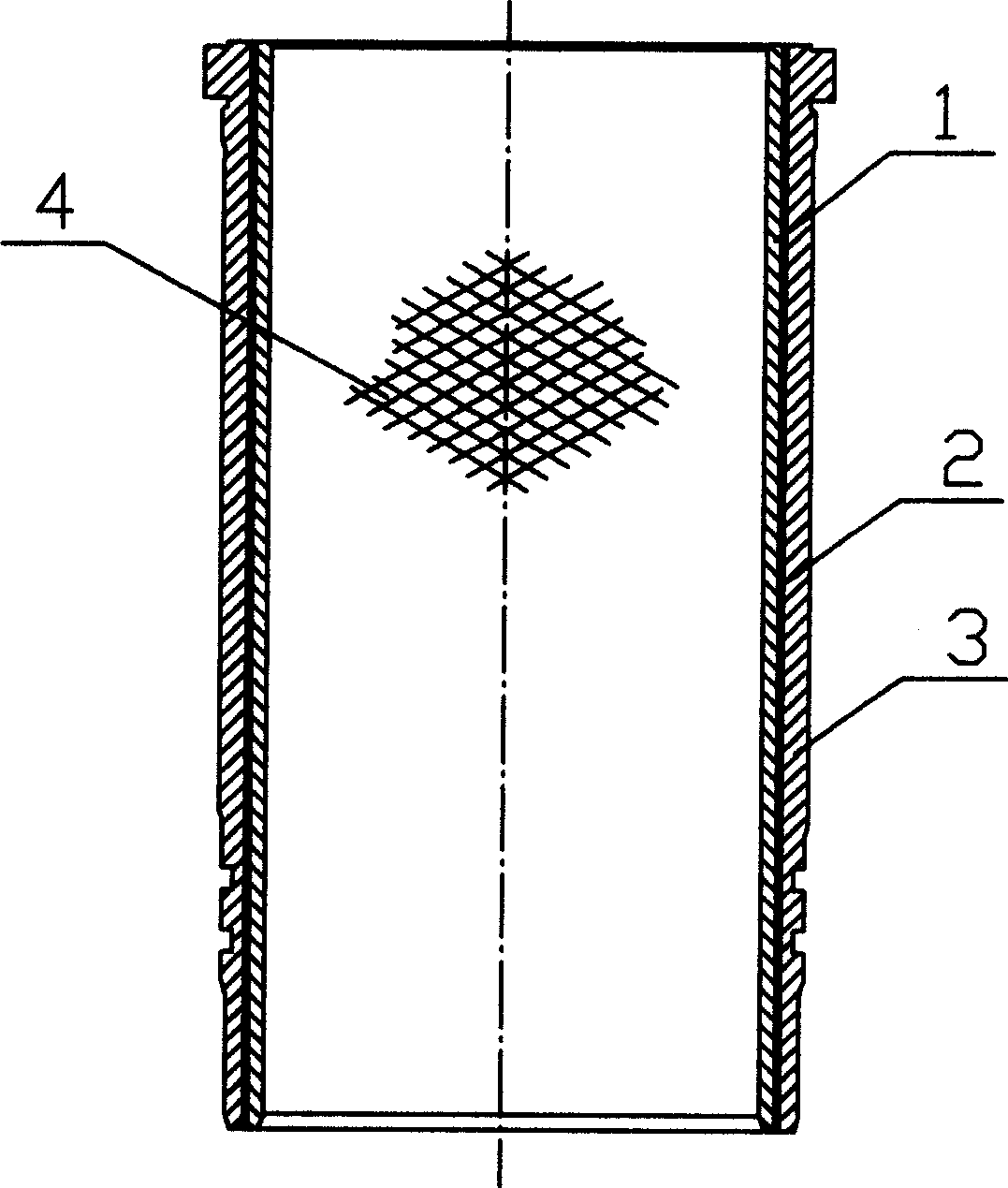

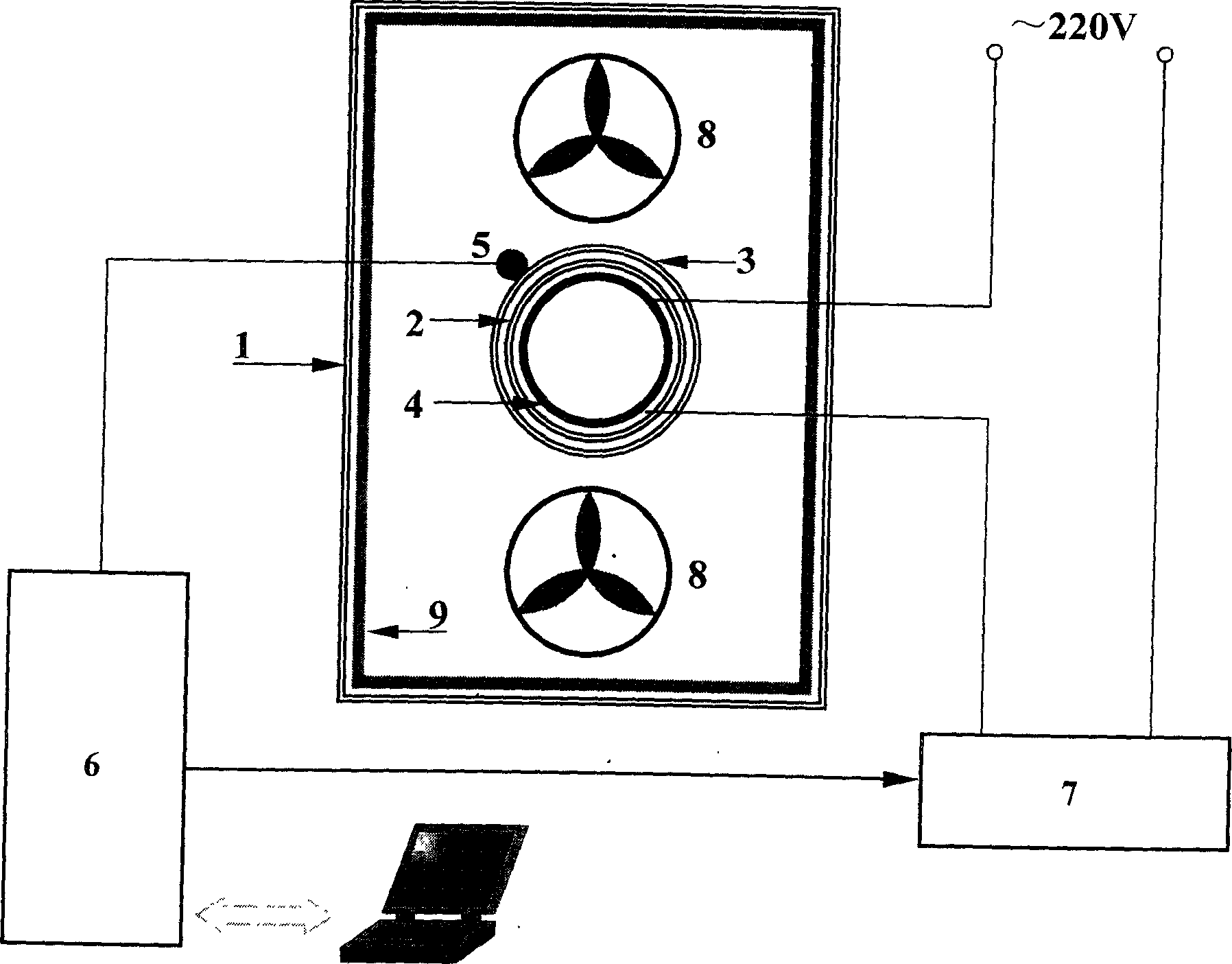

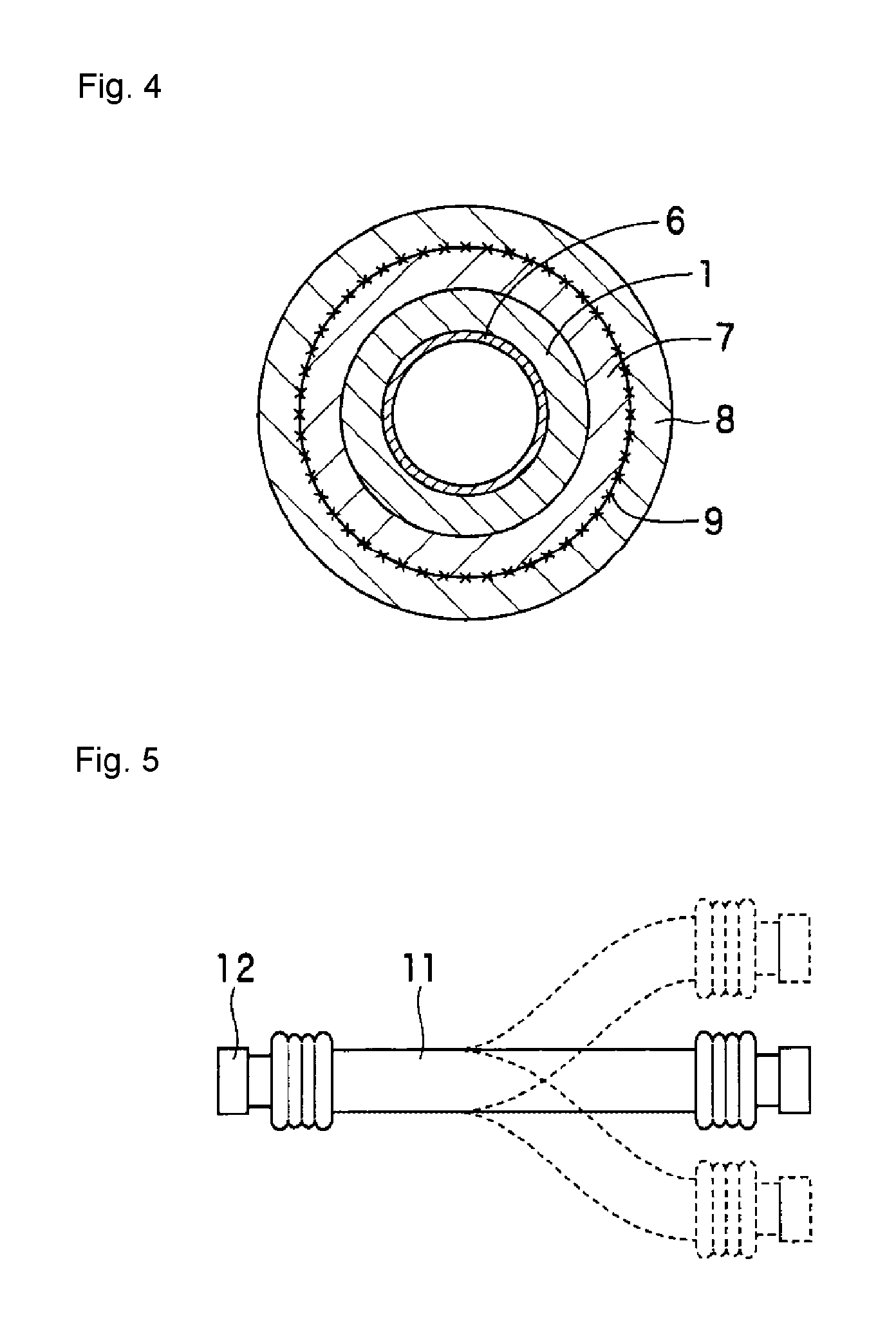

Minisize chromatographic column box with high precision temperature control system

InactiveCN1877319AImprove thermal conductivityImproved coefficient of thermal expansionComponent separationTemperatue controlTemperature controlControl system

The invention discloses a micro chromatographic column tank which comprises a tank body, capillary column heating frame set in the tank, capillary column bound around the frame, a heating device set on the inner wall of the frame, a precise thermo resistor and a temperature control system set out of the tank. The capillary column heating frame employs metal alloy material; the capillary column employs quartz material; the heating device is flexible electrical heating membrane coated on the inner wall of the frame; the temperature control system includes a temperature control module, the precise thermo resistor connects with the signal input terminal of the temperature control module, the output terminal of the temperature control module connects with the insulating single-phase alternative current modulator module of which one end of the output terminal connects with the heating device, and the other end of the output terminal connects with the input power.

Owner:张西咸 +3

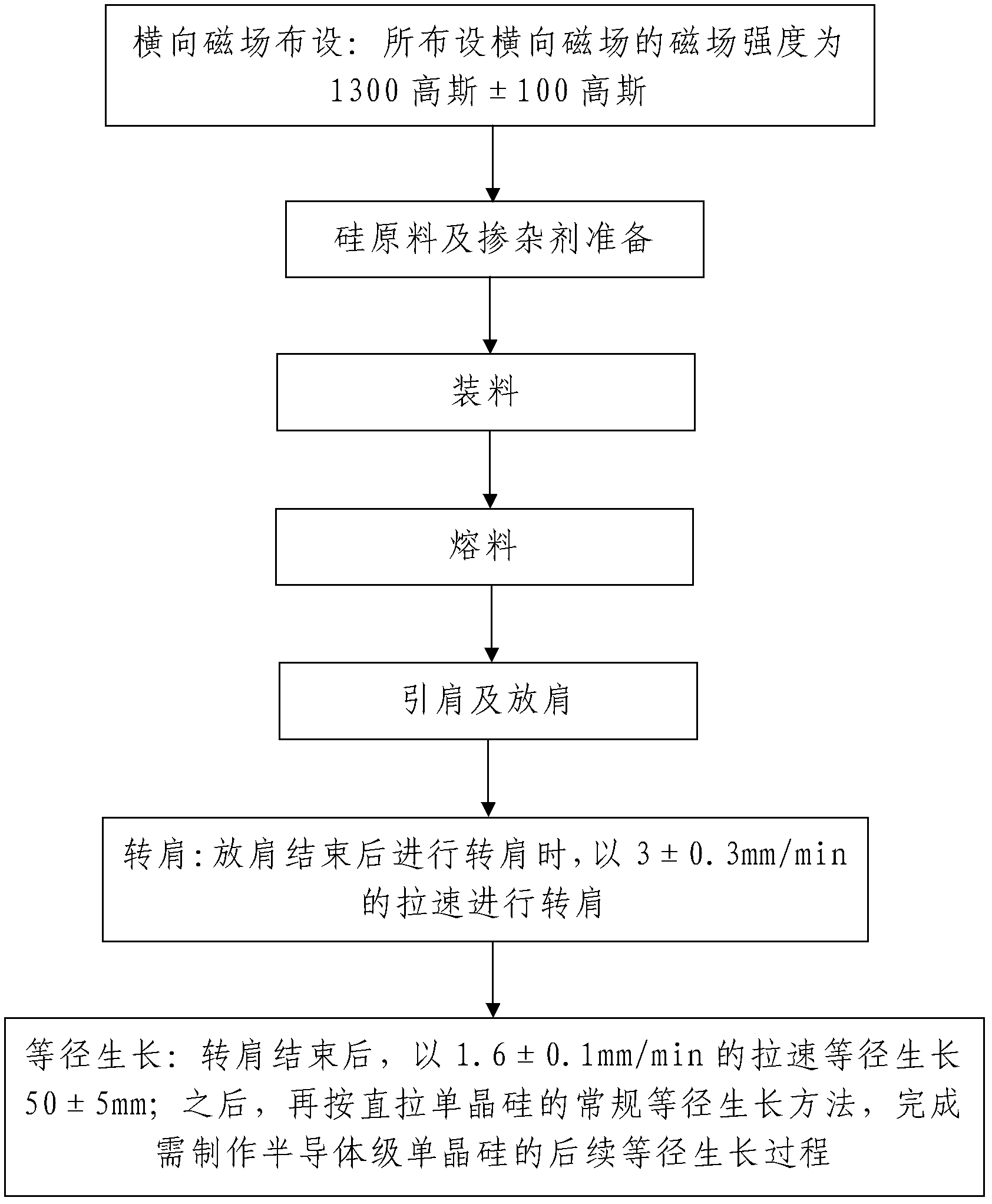

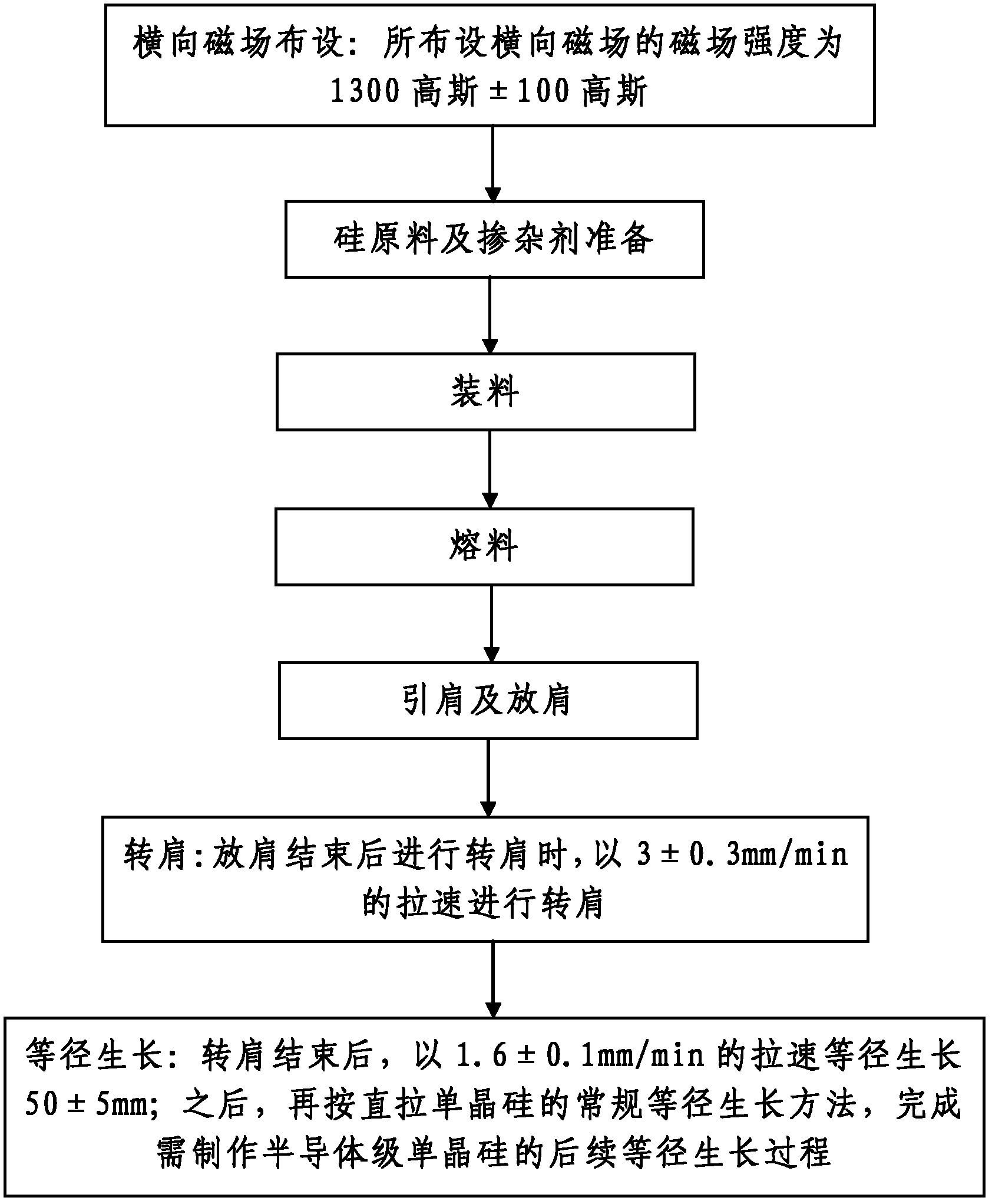

Production technology of semiconductor grade silicon single crystal

InactiveCN102220633AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltTransverse magnetic fieldSingle crystal

The invention discloses a production technology of semiconductor grade silicon single crystal, comprising the following steps: 1, arranging a transverse magnetic field: the magnetic field intensity of the transverse magnetic field is 1300 + / - 100 gausses; 2, preparing silicon material and doping agent; 3, charging; 4, melting material; 5, introducing shoulder and expanding shoulder; 6, rotating shoulder: after the step of expanding shoulder, the step of rotating shoulder is carried out with a casting speed of 3 + / - 0.3 mm / min; and 7, growing at the same diameter: after the step of rotating shoulder, the material grows up to 50 + / - 5 mm with a casting speed of 1.6 + / - 0.1 mm / min; then, a conventional method of growing at the same diameter for direct pulling silicon single crystal is used to complete the subsequent process of growing at the same diameter of the semiconductor grade silicon single crystal. The method has the advantages of reasonable design, simple steps, easiness in realization, easiness in mastering and good using effect, and is capable of effectively guaranteeing the quality of the produced semiconductor grade silicon single crystal. The produced semiconductor grade silicon single crystal has high uniformity of cross-section electric resistivity and no micro-defects such as swirl.

Owner:XIAN HUAJING ELECTRONICS TECH

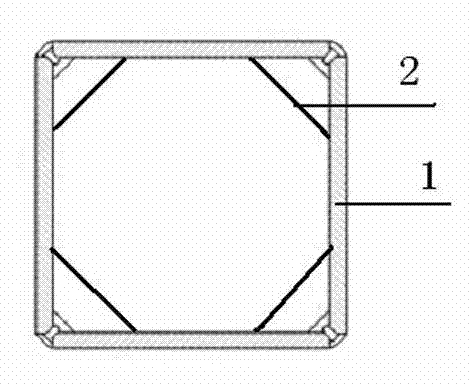

Small-section square girder and welding process thereof

ActiveCN102773590AResolve the breakSolve Weld CrackingElongated constructional elementsArc welding apparatusShear capacityWelding deformation

The invention discloses a small-section square girder and welding process thereof, belonging to welding technology and capable of solving the problem of low welding quality in case of small manual welding space. The small-section square girder has four girder plates with widths of 200-220mm and lengths smaller than or equal to 10m in paired arrangement to form a box-shaped inner cavity, in which are arranged reinforcement rib plates, flanges are welded at two ends of the girder plates, and inside and outside fillets are present between the girder plates and between the girder plates and the flanges. In welding, a to-be-welded part is cleaned before welding, a run-on plate and a run-off plate are assembled and welded, welding is carried out by use of an automatic welding cart, an inner cavity and an exposed welding seam alternate welding sequence is adopted during welding, an inner cavity backing welding seam is firstly formed, the backing welding seam for an exposed welding seam is then formed after the back gouging is strictly performed, the inner cavity and the exposed welding seam are sequentially formed, and a back-step welding method is adopted. According to the invention, welding deformation is controlled within an allowable range, torsion resistance and shearing resistance of the small-section square girder are improved, and stability and reliability of the girder are ensured.

Owner:SHANXI PINGYANG IND MACHINERY

Damping type steel structure node component

InactiveCN109667341AResolve the breakSolve the shock absorptionProtective buildings/sheltersShock proofingSteel columnsMaterials science

The invention relates to the field of steel structures and specifically discloses a damping type steel structure node component. The following scheme is proposed for solving the problems that the present steel structure node position has inferior damping property and is easy to cause bolt breaking. The damping type steel structure node component comprises a steel column, a box iron and a truss chord member; the box iron is jointed between the steel column and the truss chord member; a limiting slot is formed on one side of the steel column close to the box iron; a limiting block is in slidingconnection with the limiting slot; a damping steel plate is connected with one side of the limiting block away from the limiting slot; two symmetrically arranged hinge rods are hinged on the middle position of the bottom end of the damping steel plate; moveable blocks are hinged on the bottom ends of the hinge rods. When a shearing force is generated on the node position of steel structure connector according to the invention, effective buffering and damping protection can be realized, the damping steel plate can be prevented from direct collision with the box iron and the box iron can be protected, so that the structure at the steel structure node can be protected, the stability of steel structure can be guaranteed and the damping type steel structure node component is suitable for popularization.

Owner:SHIHEZI UNIVERSITY

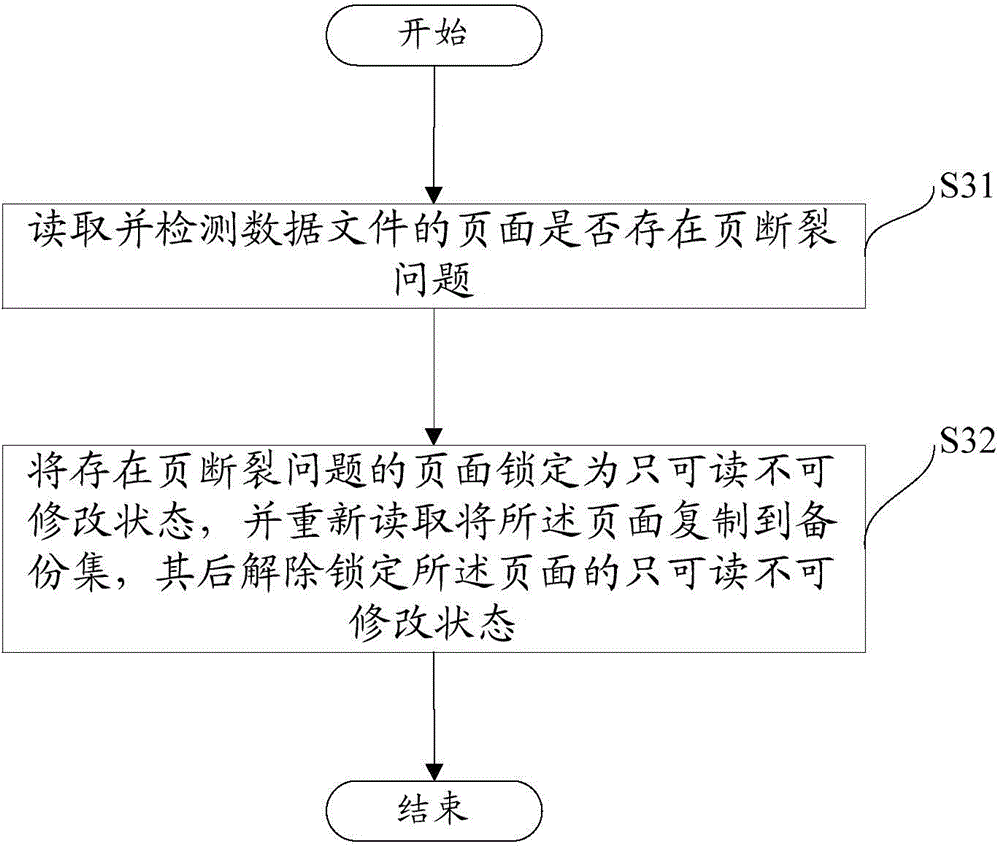

Method and equipment used for backing up data

ActiveCN106155839AResolve the breakImprove backup success rateRedundant operation error correctionData filePage break

The purpose of this application is to provide a method and device for backing up data. Specifically, read and detect whether the page of the data file has a page break problem; and lock the page with the page break problem into a readable and unmodifiable state, and re-read and copy the page to the backup set, and then release the page Locks the read-only, non-modifiable state of the page. Compared with the prior art, the method and device for backing up data described in the present application reads and detects whether a page of a data file has a page break problem, and uses a preemptive method to lock the page with the page break problem to be readable and unmodifiable. state to temporarily prevent subsequent data from continuing the writing process to the page. After the page quickly completes the writing process of the current data, the page is re-read and copied to the page in the backup set, so as to solve the problem well. The problem of page breakage in the backup process is eliminated, and the backup success rate is greatly improved.

Owner:ALIBABA GRP HLDG LTD

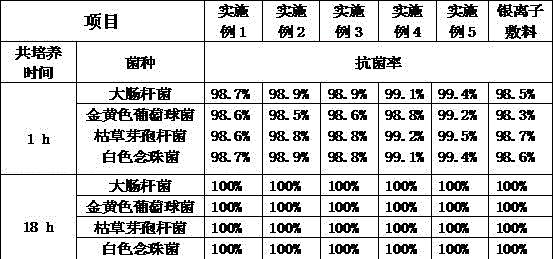

Method of Manufacturing Anti-Bacteria Polyamide Fiber via High Speed Spinning

InactiveUS20080164628A1Increase length diameter ratePromote swellingArtifical filament manufactureMonocomponent polyamides artificial filamentYarnLow speed

A method of manufacturing anti-bacteria polyamide fiber via high speed spinning disclosed a kind of method, which can make manufacturing anti-bacteria polyamide fiber via high-speed spinning realized, including the preparation of anti-bacteria particles and process of high-speed spinning. The preparation of anti-bacteria particles includes surface treatment of anti-bacteria agent and its process of preparation. Choose nano zeolite carrying silver ion as anti-bacteria agent, mix the anti-bacteria particles and polymer chips, after melting, produce anti-bacteria yarns via high speed spinning. The surface treatment to the anti-bacteria agent the invention can improve the spinnability of raw material and place foundation for realizing high speed spinning. Further more, for the spinning pack, adopt good quality mental powder as filtering and pressuring material and increase length diameter rate of hole of spinneret to lengthen the friction distance that the melt passing the spinneret holes in order to eliminate the inner energy of polymer, which prevent the melt from breaking cause by released inner energy while polymer bursting from the spinneret holes. The method described in the invention is simple and easy to implemented. High speed spinning realized by adopting this method, solve the problems of long process rout, low output and lower grade products caused by existing low-speed spinning and greatly increase the beneficial result of enterprise.

Owner:LIAONING YINZHU CHEMTEX GROUP

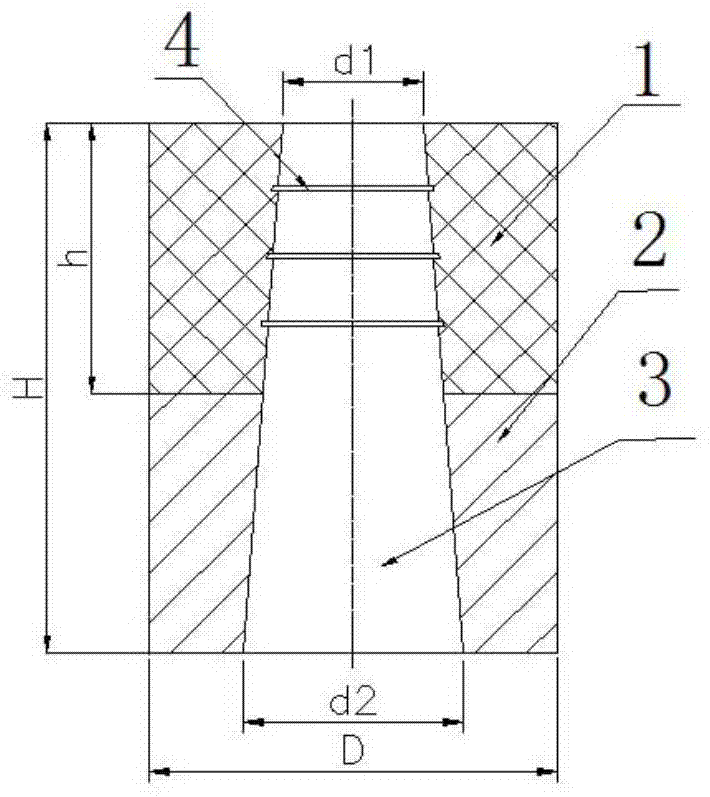

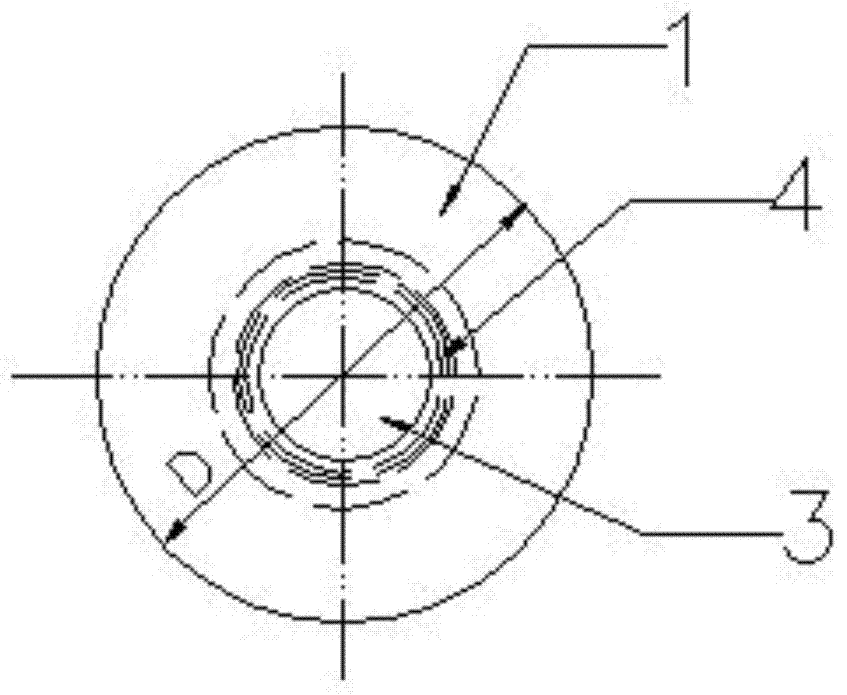

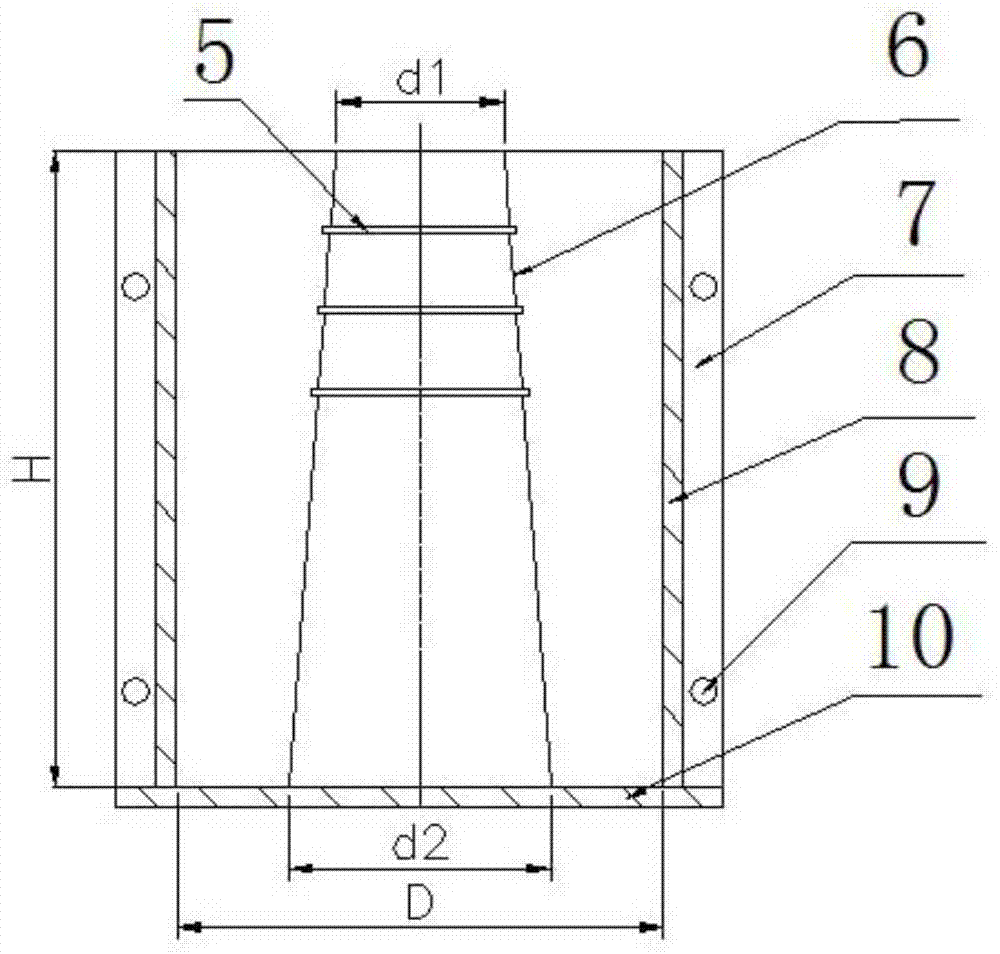

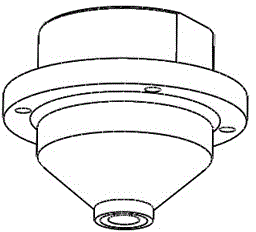

Composite long-life low-cost steel ladle air brick base brick and manufacturing method thereof

The invention relates to a composite long-life low-cost steel ladle air brick base brick. The composite long-life low-cost steel ladle air brick base brick comprises a base brick body, the base brick body comprises an upper body and a lower body which are molded by once casting of different cast materials. The upper body is 260 to 300 mm high, and the inner wall of the upper body is circumferentially provided with grooves uniformly distributed along the height direction. By the composite long-life low-cost steel ladle air brick base brick, cost performance is superior to that of an existing composite air brick base brick, corrosion speed is lower to more than 0.5 mm per furnace year on year, and service life is prolonged by more than ten times.

Owner:SHANDONG IRON & STEEL CO LTD

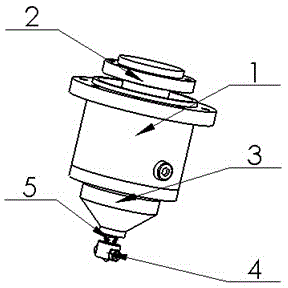

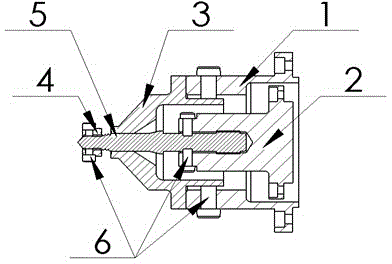

Withdrawable double-shaft-shoulder stirring head

InactiveCN104139240AAdjustable spacingResolve the breakNon-electric welding apparatusEngineeringMechanical engineering

The invention discloses a withdrawable double-shaft-shoulder stirring head. The withdrawable double-shaft-shoulder stirring head comprises a stirring-head upper shaft shoulder, a stirring-head lower shaft shoulder and a withdrawing stirring pin, the stirring-head upper shaft shoulder is connected with a stirring head sleeve through bolts which perpendicularly penetrate through the stirring head sleeve and are fixed to the stirring-head upper shaft shoulder, a stirring pin sleeve is installed in the stirring head sleeve, the withdrawing stirring pin fixed through a bolt is installed in the stirring pin sleeve, the other end of the withdrawing stirring pin and the stirring-head lower shaft shoulder are connected into a whole through threads, a bolt penetrates through the stirring-head lower shaft shoulder and is fixed to the withdrawing stirring pin, the withdrawing stirring pin is in clearance fit with the stirring-head upper shaft shoulder, and the diameter of an opening in the tail end of the stirring-head upper shaft shoulder is larger than the diameter of the stirring-head lower shaft shoulder. According to the withdrawable double-shaft-shoulder stirring head, the distance between the stirring-head upper shaft shoulder and the stirring-head lower shaft shoulder is adjustable, and the problems that the withdrawing stirring pin is broken, the stirring-head lower shaft shoulder falls off and tool setting is difficult in a welding process are solved.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD +1

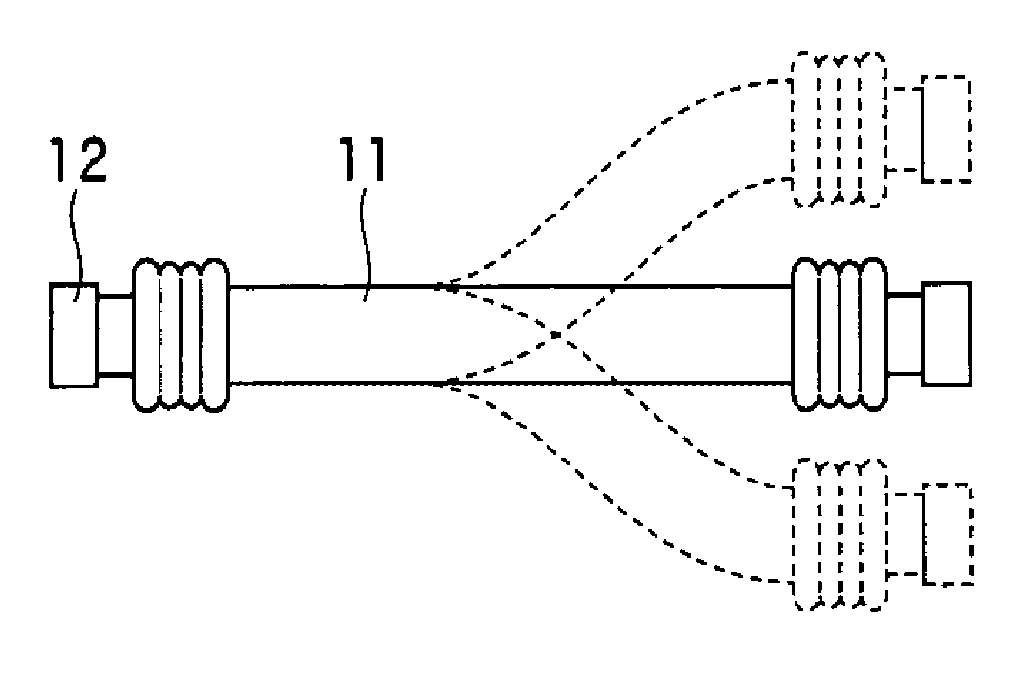

Hose for transporting refrigerant and method of producing the same

InactiveUS20120199237A1Reduce melt viscosityPromote meltingSynthetic resin layered productsLaminationElastomerPolyolefin

To provide a hose for transporting a refrigerant, a butyl rubber layer 7 is formed on outer periphery of a tubular resin layer 1, which is in contact with a refrigerant, and an ethylene-propylene rubber layer 8 is further formed on the outer periphery thereof. The resin layer 1 is composed of a material that contains, as a main component, a mixture of a polyamide resin and a modified polyolefin elastomer, a skin layer 6 is formed only on an inner peripheral surface of the resin layer, and tensile modulus (A) of the skin layer 6, tensile modulus (B) of the resin layer 1 excluding the skin layer 6, tensile modulus (C) of the butyl rubber layer 7, and tensile modulus (D) of the ethylene-propylene rubber layer 8 satisfy the relationship that is defined by the following formula (α):(A)>(B)>(C)>(D) (α).

Owner:SUMITOMO RIKO CO LTD

Method for preparing TiAl alloy plate without canning

The invention discloses a method for preparing a TiAl alloy plate without canning in order to solve the problems that an existing ingot metallurgy canning and rolling the TiAl alloy plate is complicated in process, high in machining cost and low in raw material utilization rate, and a TiAl alloy bar prepared through a powder metallurgy method is easy to introduce impurities and is high in cost. The method comprises the specific steps of 1, weighing all raw material ingredients; 2, preparing a casting ingot through induction skull melting of a water-cooling copper crucible and melted model precision casting; 3, carrying out blank pre-treatment; 4, carrying out a first plate extrusion stage; 5, carrying out a second plate extrusion stage, thus obtaining the TiAl alloy plate. According to the method for preparing the TiAl alloy plate without canning, disclosed by the invention, the surface of the obtained plate is smooth and has no cracks, and the TiAl alloy plate is uniformly organized, is small in crystal grain and has excellent mechanical performance.

Owner:TAIYUAN UNIV OF TECH

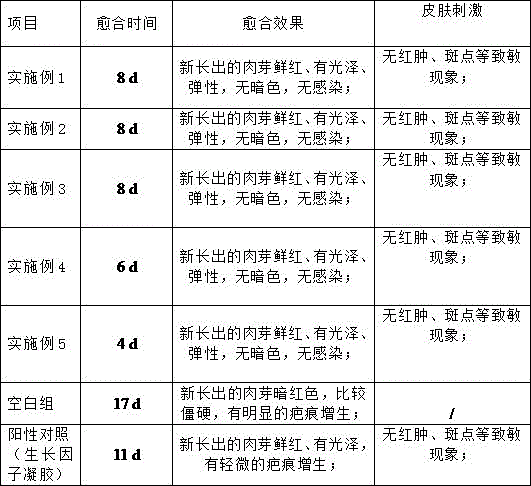

Bamboo alginate functional dressing and preparation method thereof

The invention belongs to the field of medical dressings, and particularly relates to a bamboo alginate functional dressing and a preparation method thereof. The dressing comprises the following components in parts by weight: 1-4.2 parts of sodium alginate, 0.05-0.4 part of sodium hyaluronate, 0.25-2 parts of collagen, 4.5-31 parts of bioactive glass powder and 62-95 parts of bamboo fiber. The dressing can quickly promote healing of a wound surface, and healed wound surface is smooth and resilient and is less prone to scar proliferation; and the dressing has the functional characteristics of antisepsis, imbibition, hemostasis, adhesion prevention, no cytotoxicity and the like, and can satisfy various requirements for wound surface healing. According to the preparation method of the bamboo alginate functional dressing, the problem that the alginate medical dressing is cracked after exudate imbibition is solved, thereby facilitating dressing change by medical personnel.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com