Method for preparing TiAl alloy plate without canning

An alloy sheet and alloy technology, applied in the field of preparing TiAl alloy sheet without sheath, can solve the problems of low utilization rate of raw materials, high processing cost, easy introduction of impurities, etc., and achieve the effect of solving reaction melting, avoiding surface oxidation and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

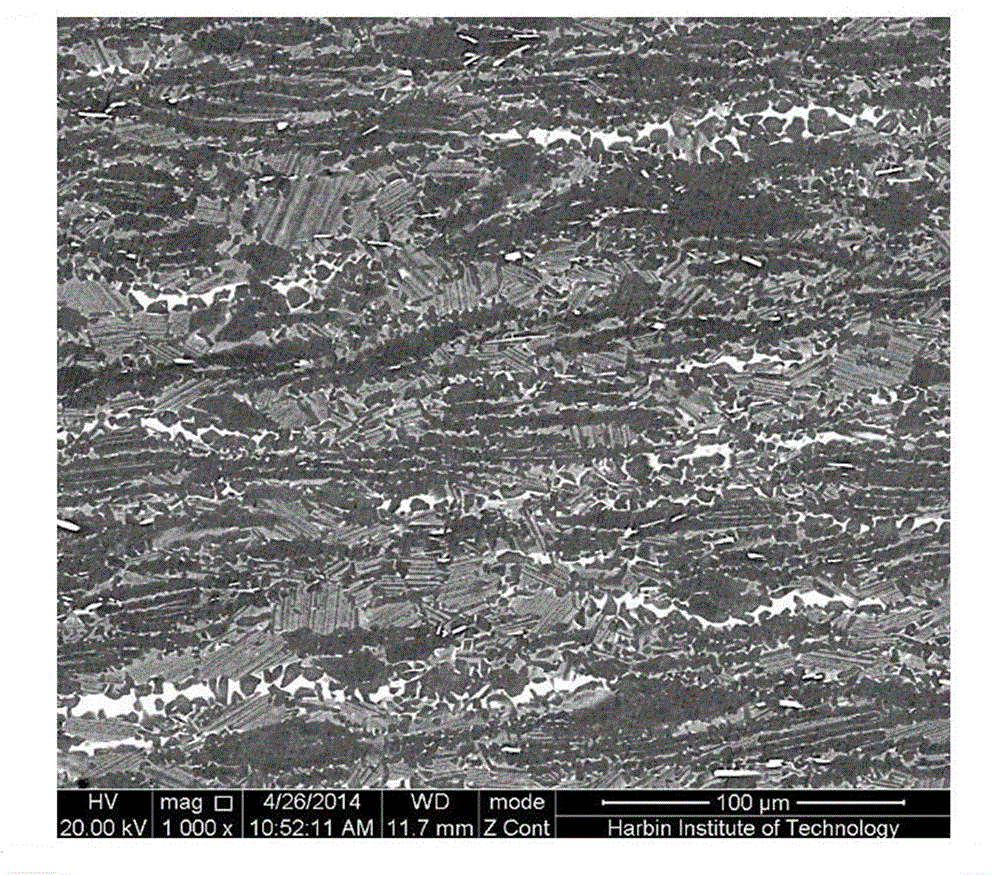

Image

Examples

Embodiment 1

[0037] The preparation method of Ti-45Al-8Nb alloy plate is as follows:

[0038] (1) Weighing raw materials: according to the atomic percentage of each element, it is composed of 45% Al, 8% Nb, and the balance is Ti and unavoidable impurities. A total of 10,000 g of titanium sponge, pure aluminum, and an aluminum-niobium alloy (with a Nb content of 54.56%) were weighed as raw materials.

[0039] (2) Melting ingots: Add the sponge titanium, pure aluminum and aluminum-niobium alloy weighed in step 1 into a water-cooled copper crucible induction melting furnace for melting, and the vacuum degree is 3.0×10 -3 mbar; then poured into ZrO preheated at 600°C 2 In the ceramic mold, a rectangular ingot is obtained.

[0040] (3), billet pretreatment:

[0041] a. Remove the riser from the TiAl alloy ingot and perform hot isostatic pressing treatment. The treatment process is 1260 ° C, 150 MPa, protected by argon atmosphere, kept for 4 hours, and cooled out of the furnace with the furna...

Embodiment 2

[0053] The preparation method of Ti-43Al-9Nb-0.3Y alloy plate is as follows:

[0054] (1) Weighing raw materials: according to the atomic percentage of each element, the composition is 43% Al, 9% V, 0.3% Y, the balance is Ti and unavoidable impurities. Sponge titanium, pure aluminum, aluminum yttrium alloy (Y content is 87.3%) and aluminum vanadium alloy (V content is 52.12%) totaling 10000g were weighed as raw materials.

[0055] (2) Melting ingots: Add the sponge titanium, pure aluminum and aluminum-niobium alloy weighed in step 1 into a water-cooled copper crucible induction melting furnace for melting, and the vacuum degree is 1.0×10 -3 mbar; then poured into ZrO preheated at 500°C 2 In the ceramic mold, a rectangular ingot is obtained.

[0056] (3), billet pretreatment:

[0057] a. Remove the riser from the TiAl alloy ingot and perform hot isostatic pressing treatment. The treatment process is 1250 ° C, 150 MPa, protected by argon atmosphere, kept for 4 hours, and cool...

Embodiment 3

[0069] The preparation method of Ti-44Al alloy plate is as follows:

[0070] (1) Weighing the raw material: 44% Al according to the atomic percentage of each element, and the balance being Ti and unavoidable impurities. A total of 10,000 g of titanium sponge and pure aluminum were weighed as raw materials.

[0071] (2) Melting ingots: Add the sponge titanium, pure aluminum and aluminum-niobium alloy weighed in step 1 into a water-cooled copper crucible induction melting furnace for melting, and the vacuum degree is 2.0×10 -3 mbar; then poured into 300℃ preheated Al 2 o 3 In the ceramic mold, a rectangular ingot is obtained.

[0072] (3), billet pretreatment:

[0073] a. Remove the riser from the TiAl alloy ingot and perform hot isostatic pressing treatment. The treatment process is 1250 ° C, 160 MPa, protected by argon atmosphere, kept for 4.5 hours, and cooled with the furnace;

[0074] b. Perform near-γ treatment on the ingot, and place the ingot in a vacuum heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com