Patents

Literature

2093 results about "Precision casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

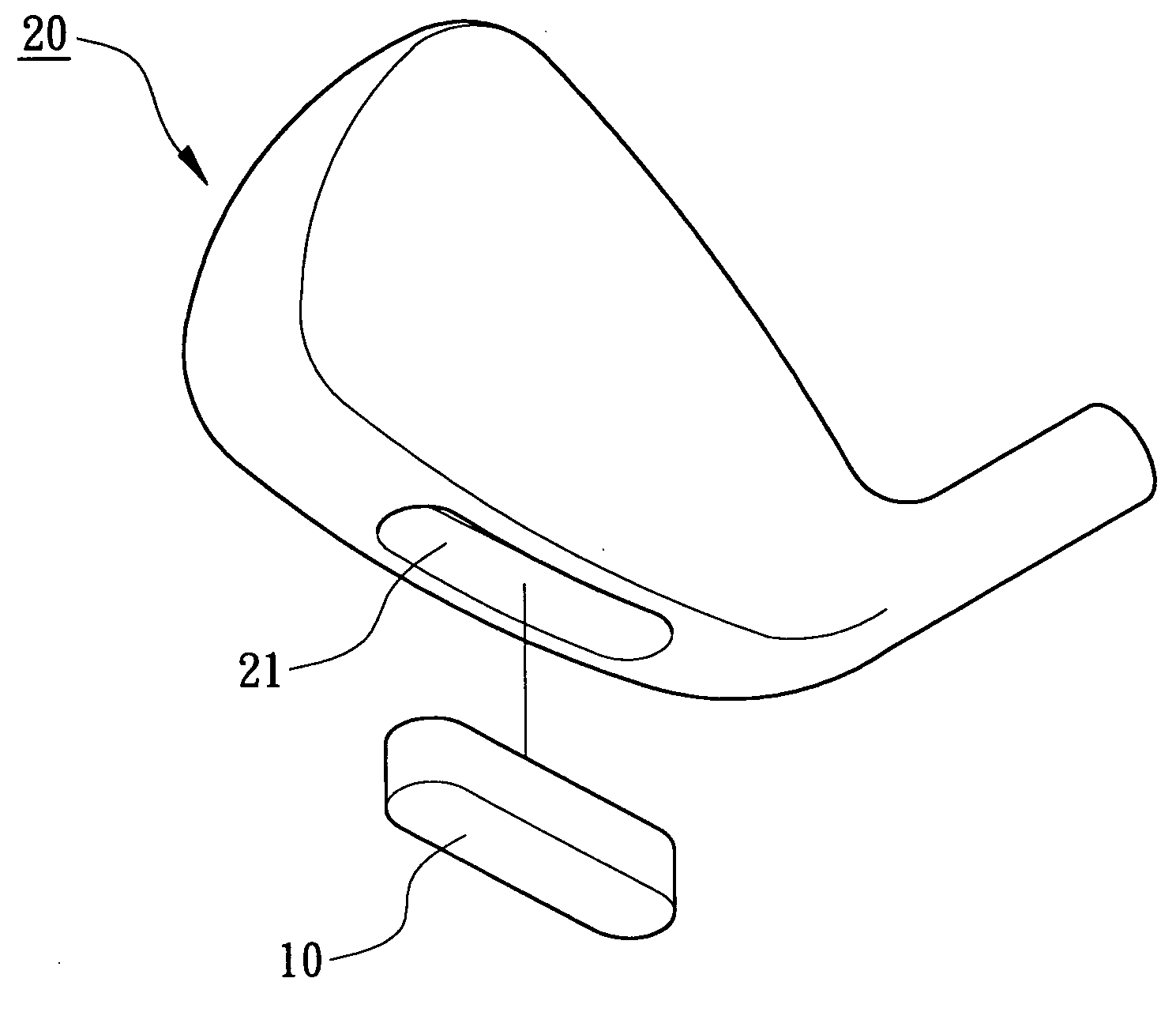

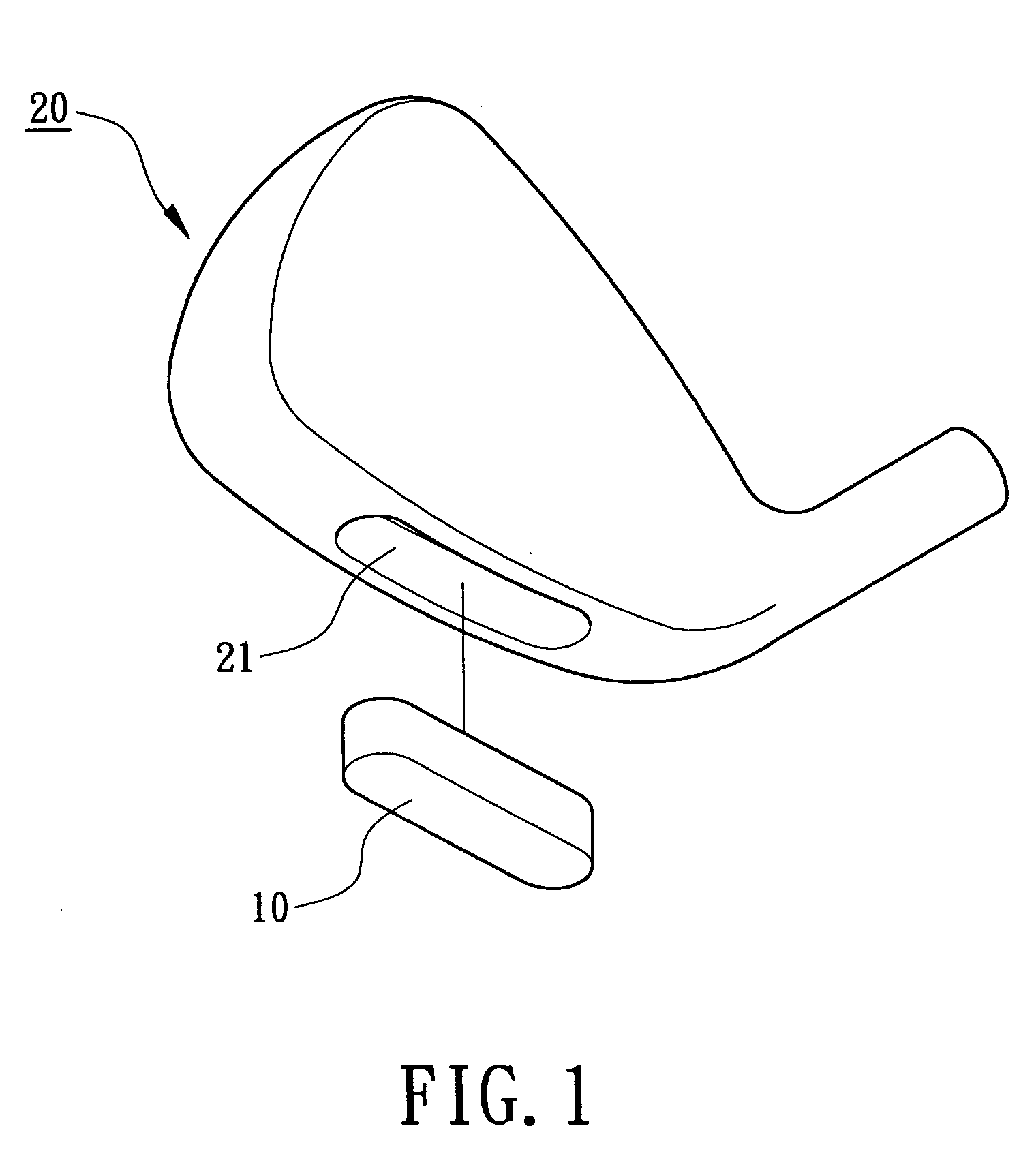

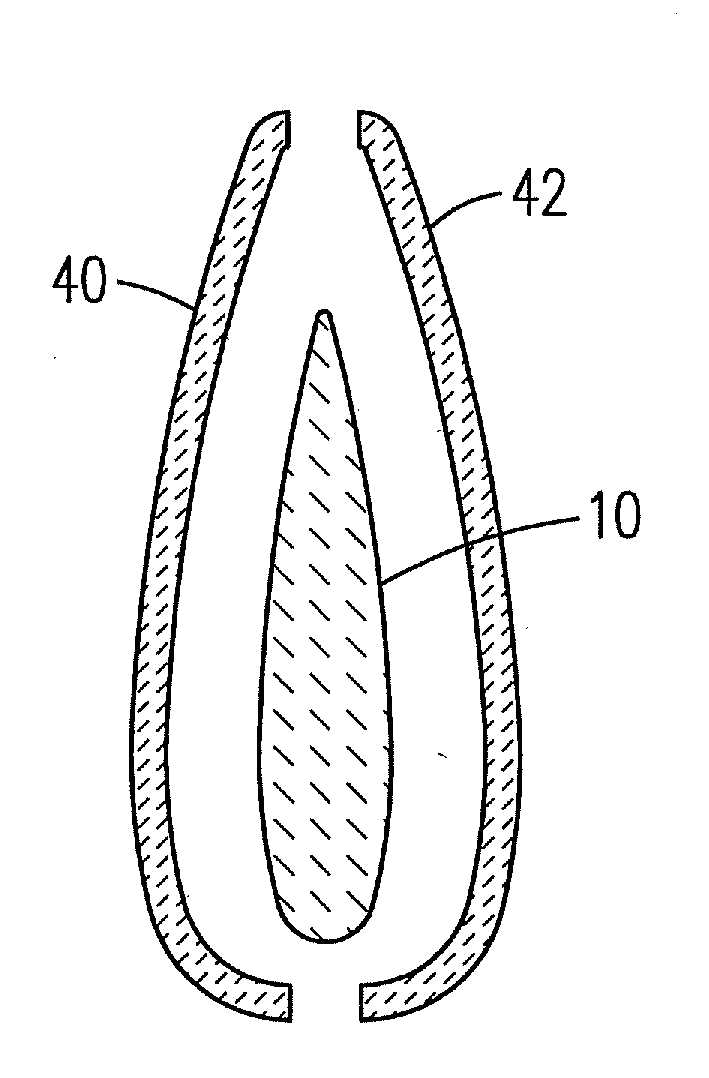

Weight member for a golf club head

A weight member for a golf club head is made of a WMoNi alloy by powder metallurgy or a precision casting process. The WMoNi alloy includes tungsten 1-70 wt %, molybdenum 4-55 wt %, and nickel 25-95 wt %. Molybdenum increases the density of the weight member and improves the rust-resisting property of the weight member. The tungsten, molybdenum, and nickel provide a uniform metallographic phase. Uniformity of shining finishing of the weight member is thus improved.

Owner:FUSHENG IND CO LTD

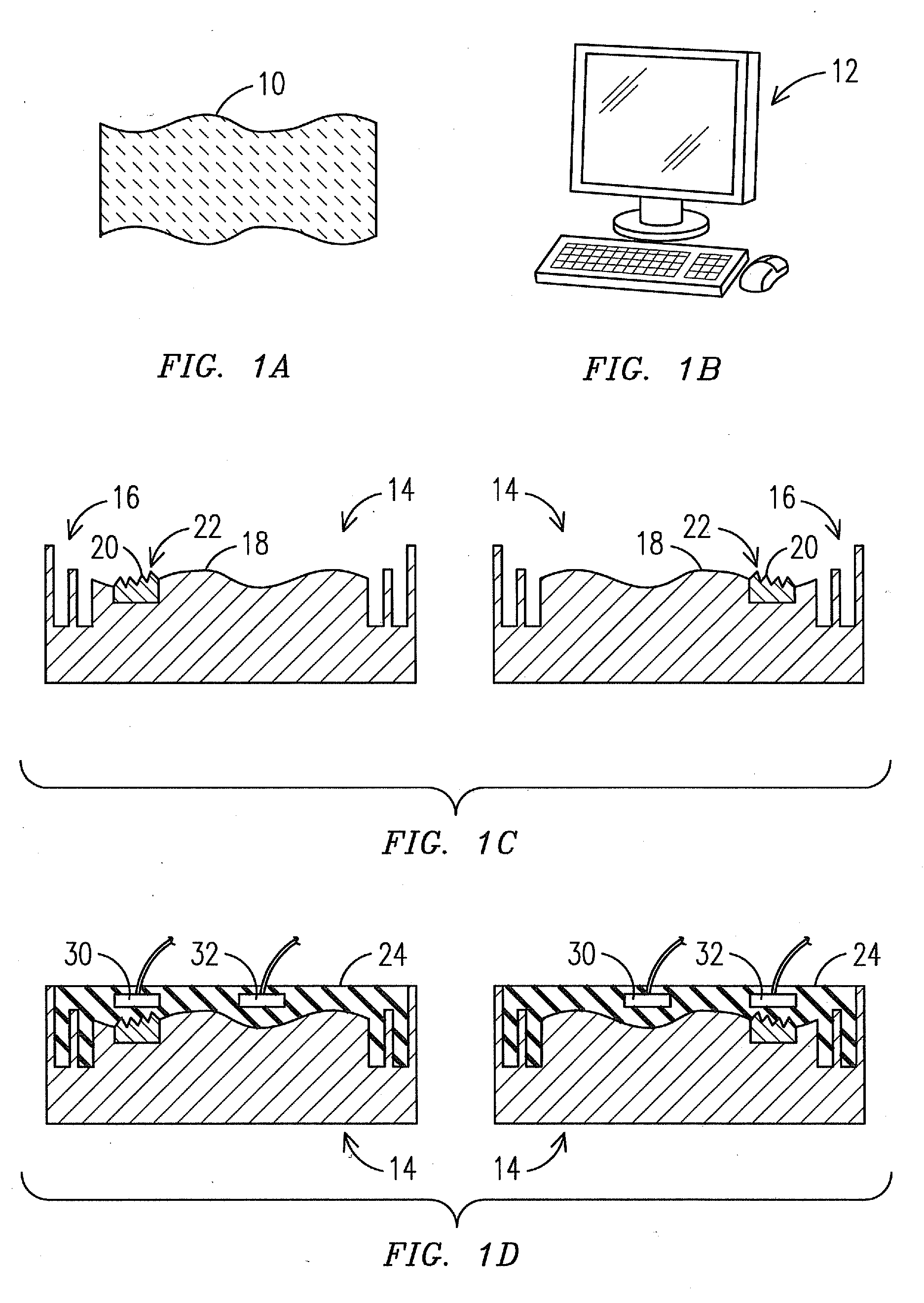

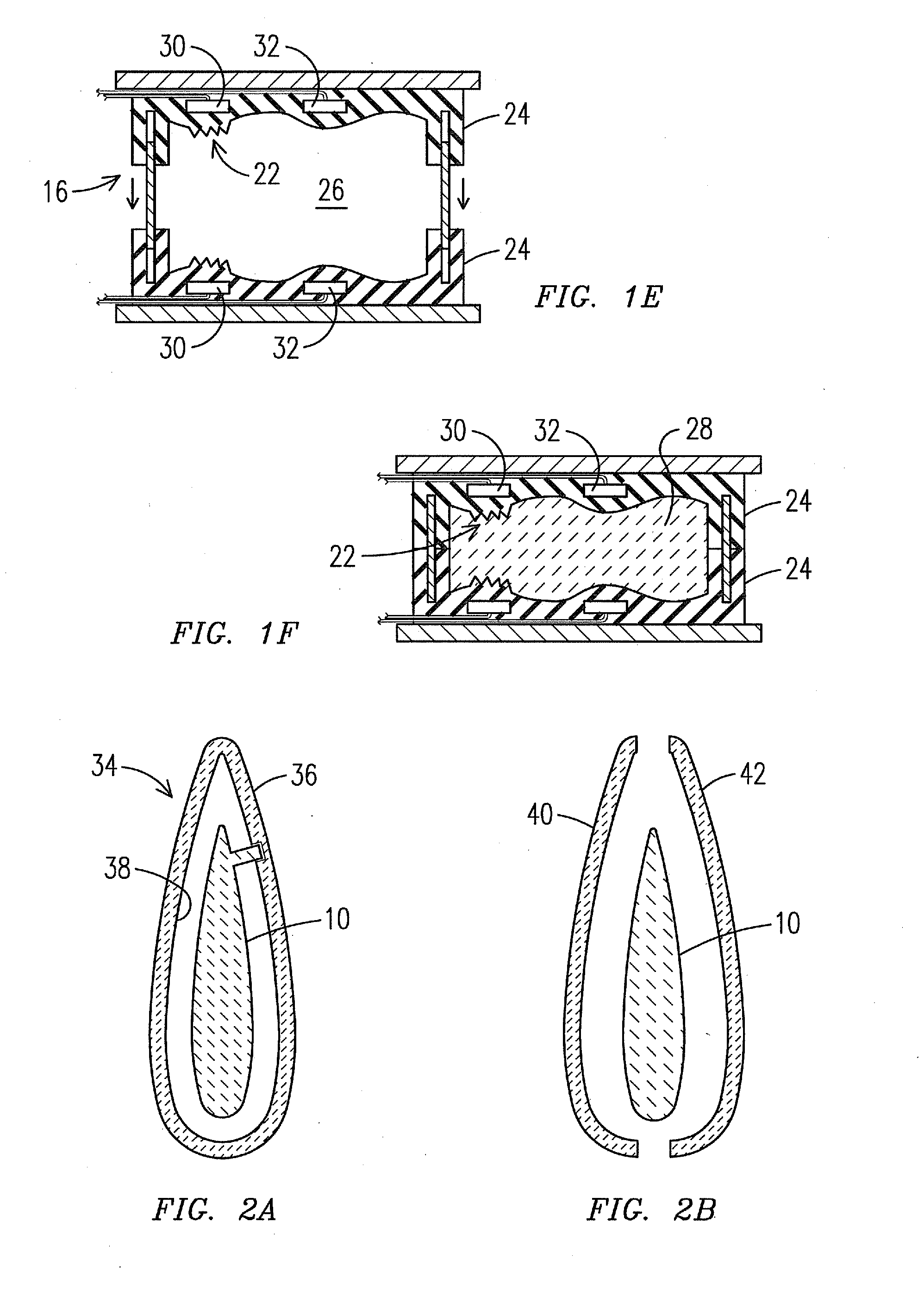

Waxless precision casting process

Alloy products are produced with a waxless casting process. A model of a ceramic casting vessel (34) defining a desired product shape is digitally divided into sections (10, 40, 42). Each section is translated into a soft alloy mater tool (14) including precision inserts (20) where needed for fine detail. A flexible mold (24) is cast from each master tool, and a section of the ceramic casting vessel is cast from the respective flexible mold. The vessel sections are assembled by aligning cooperating precision features (58, 60) cast directly into each section and the alloy part is cast therein. No wax or wax pattern tooling is needed to produce the cast alloy product. Engineered surface features (54) may be included on both the interior and exterior surfaces of the shell sections.

Owner:MIKRO SYSYTEMS INC +1

A low-cost precision casting method for titanium alloy and titanium-aluminum alloy

InactiveCN102294436AIncrease contentControl quality costFoundry mouldsFoundry coresPolyvinyl alcoholTitanium alloy

The invention relates to a method for precisely casting a titanium alloy and a titanium aluminum alloy with low cost, which relates to a method for precisely casting the titanium alloy and the titanium aluminum alloy, and solves the technical problem that cast pieces have low surface quality and internal quality in the conventional method for lowering the cost of precisely casting the titanium alloy and the titanium aluminum alloy by using electrically-fused alumina and silica sol. The method comprises the following steps of: preparing a surface layer binder from zirconium sol, silica sol, a wetting agent JFC, n-octyl alcohol, polyvinyl alcohol and latex; adding calcium carbonate, alumina, titanium dioxide and zirconia to prepare a surface layer coating; preparing a shell surface layer; preparing a shell back layer by a universal method for precisely casting the titanium alloy; dewaxing and sintering to obtain a shell; and casting the titanium alloy or the titanium aluminum alloy by using the shell so as to obtain a titanium alloy cast piece or a titanium aluminum alloy cast piece. Compared with a precise casting method by purely using a zirconium-based binder and a zirconia fireproof material, the method has the advantage that raw material cost is lowered by 30 to 70 percent and the method can be used for civil titanium alloy cast pieces and titanium aluminum alloy cast pieces for common aviation.

Owner:HARBIN SHITAI NEW MATERIAL TECH & DEV

Method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum

The invention provides a method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum, comprising the technological steps of purification, crystal transforming reaction, oriented crystallization, washing and separation, and drying and pulverization. The method concretely comprises the following steps of: enhancing the taste of calcium sulfate dlhy in the desulfurized gypsum to be greater than 95% through a purification treatment; dissolving and recrystallizing the desulfurized gypsum at 70 to 98 DEG C under the normal pressure through adding prepared habit modifiers, transforming into the alpha semi-hydrated gypsum and then carrying out oriented crystallization on the alpha semi-hydrated gypsum to form a short column-shaped alpha semi-hydrated gypsum crystal under the function of an oriented crystal type stabilizer, wherein the length-diameter ratio of the short column-shaped alpha semi-hydrated gypsum crystal is less than 1:3, the 2h breaking strength is greater than 6.5 MPa, the compression strength is greater than 23 MPa, the dry breaking strength is greater than 25 MPa, and the dry compression strength is greater than 53 MPa. The method can be widely used in the fields of ceramics, automobiles, precise casting, heterogenic casting and the like.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Preparation method of calcium-oxide-based ceramic core

The invention discloses a preparation method of a calcium-oxide-based ceramic core, and belongs to the technical field of precision casting of titanium alloy. The preparation method of the calcium-oxide-based ceramic core comprises the following steps of firstly preparing rare-earth-oxide-coated calcium oxide powder; secondly modeling and sintering the rare-earth-oxide-coated calcium oxide powder; and finally obtaining the calcium-oxide-based ceramic core, wherein the calcium-oxide-based ceramic core is prepared from the following raw materials in percentage by weight: 5-15% of plasticizer, 0.001-20% of mineralizer, and the balance of rare-earth-oxide-coated calcium oxide powder bodies, and the sum of the raw materials is 100% in percentage by weight. The calcium-oxide-based ceramic core prepared by the method disclosed by the invention has excellent mechanical properties and can effectively prevent the defect that calcium oxide is easy to hydrate when meeting water.

Owner:BEIHANG UNIV

Method for evaporative pattern precise composite casting

InactiveCN101590513APrevent shrinkageAvoid shrinkage defectsFoundry mouldsFoundry coresSurface layerPolystyrene

The invention discloses a method for evaporative pattern precise composite casting. The method comprises the following steps: making a mould by polystyrene foam to form a casting system; coating a surface modifying agent on the surface of the mould; preparing a mould shell including a surface layer mould shell, a transitional layer mould shell and a back layer mould shell; taking the mould out after placing the mould in a pre-wetting agent for 2 to 3s, dipping the mould in a container filled with surface layer coating, turning the mould so as to evenly coat the mould, sprinkling zircon sand on the mould, and drying the mould for 4 to 6h to prepare a surface layer mould shell; dip-coating the surface layer mould shell by a transitional layer coating, sprinkling and drying the sand for 8 to 12h; preparing the transitional layer mould shell and the back layer mould shell by the similar method; sealing pulp by the back layer coating, and drying for 14 to 18h; roasting the mould at a temperature of between 950 and 1,050 DEG C, and keeping warm for 30 to 60min; and pouring the molten metal in the mould shell to form a casting. The method has the advantages of preparing the metallic mould without the conventional precise casting, saving processing time, lowering cost and simultaneously ensuring the product quality.

Owner:郑州神牛铸造有限公司

Method for preparing TiAl-based alloy formwork by precision-investment casting

InactiveCN101462151AFast moisture absorptionGood hygroscopicityFoundry mouldsFoundry coresWaxOxide ceramic

The invention discloses a method for preparing a shuttering for a precision investment casting TiAl-based alloy, and relates to a method for preparing an oxide ceramic shuttering. The method solves the problems of slow drying for making the shuttering, longer production period for cast and high cost during production of a TiAl-based alloy precise cast. The preparation method comprises: firstly, adopting SLS technology to prepare a fusible pattern; secondly, coating polyvinyl alcohol on the surface of bauxite and grinding the bauxite into granules; thirdly, smearing a shuttering surface layer; fourthly, smearing a shuttering back layer; fifthly, removing wax from the shuttering, and roasting the shuttering; and sixthly, casting the TiAl-based alloy in vacuum to obtain the TiAl-based alloy cast. The method only needs 13 to 15 days to obtain the TiAl-based alloy precise cast from CAD design, but the prior method at least needs 45 to 60 days, so the method saves nearly two thirds of production period, and the manufacturing cost is correspondingly lowered.

Owner:HARBIN INST OF TECH

Preparing method of low-cost oxide ceramic shell for titanium alloy precision casting

A low-cost oxide ceramic mould for the precise casting of Ti-alloy is prepared through preparing paint and wax mould of casting, immersing the wax mould in paint for 10-20 min, leveling the paint, uniformly applying the white electro-corundum powder to the paint layer of wax mould, drying, and high-pressure dewaxing.

Owner:HARBIN INST OF TECH

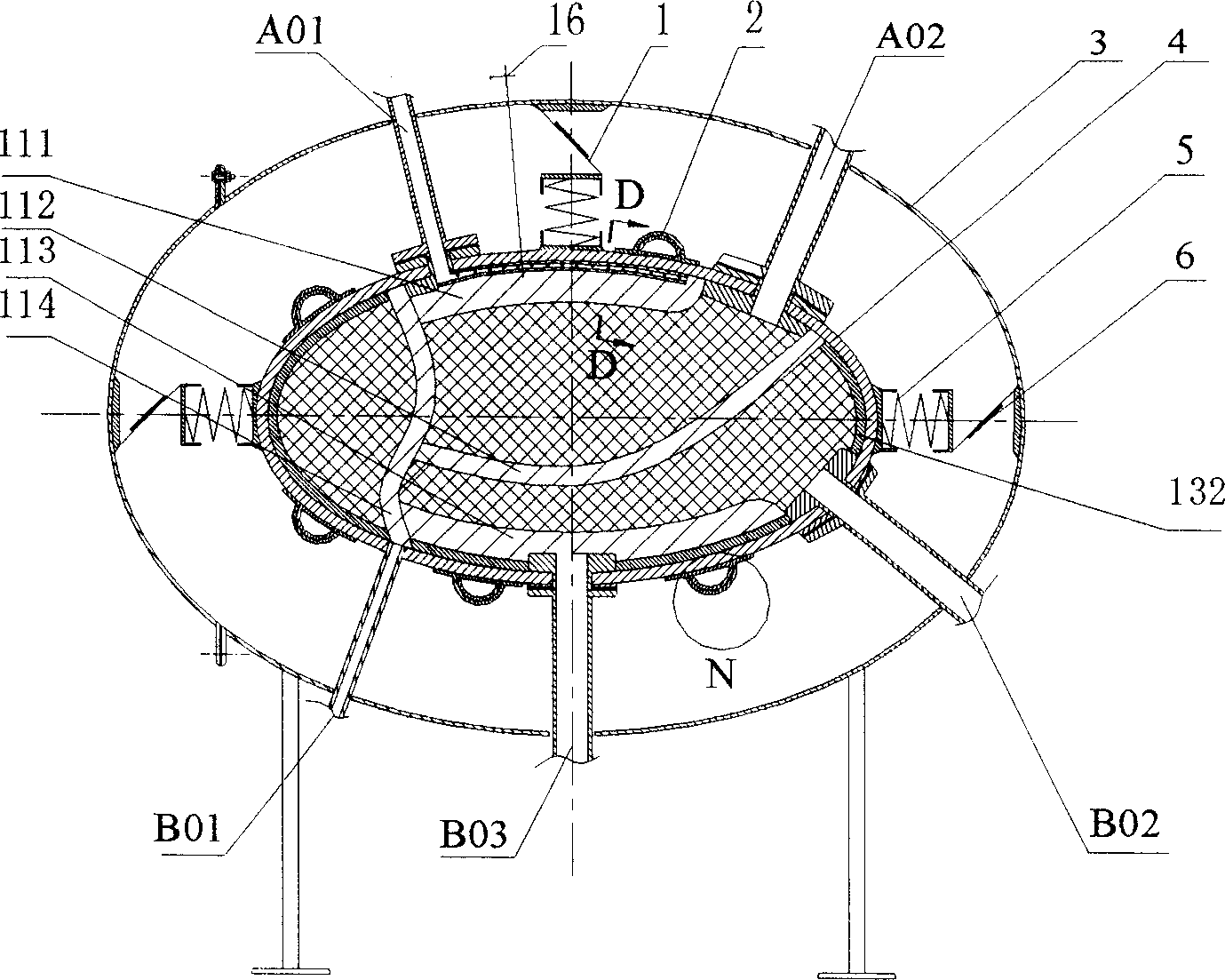

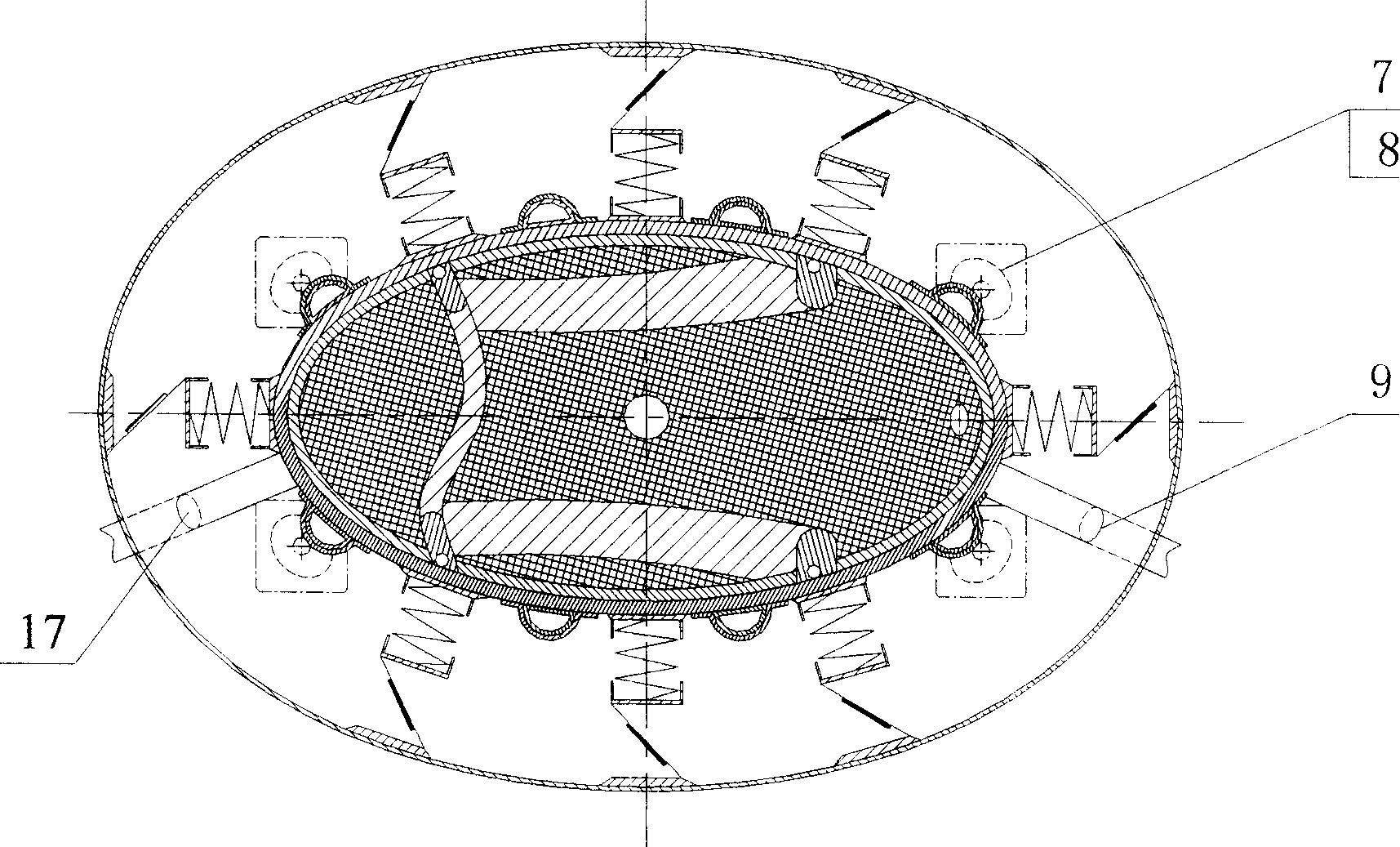

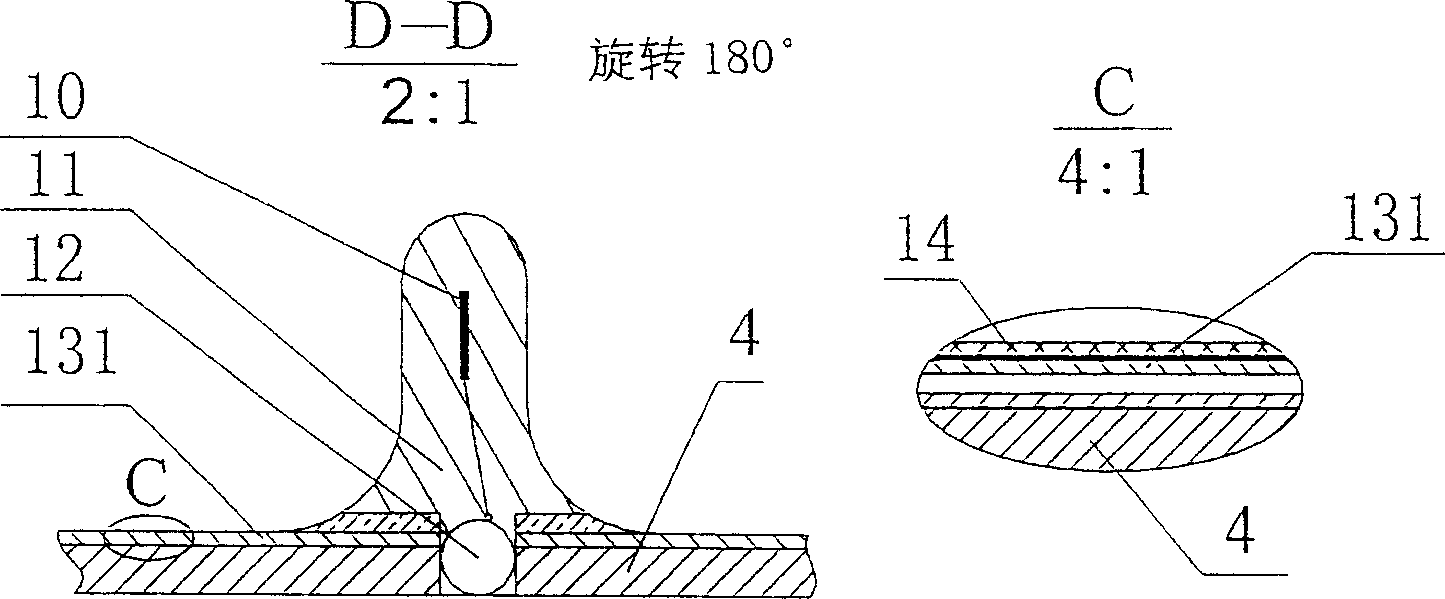

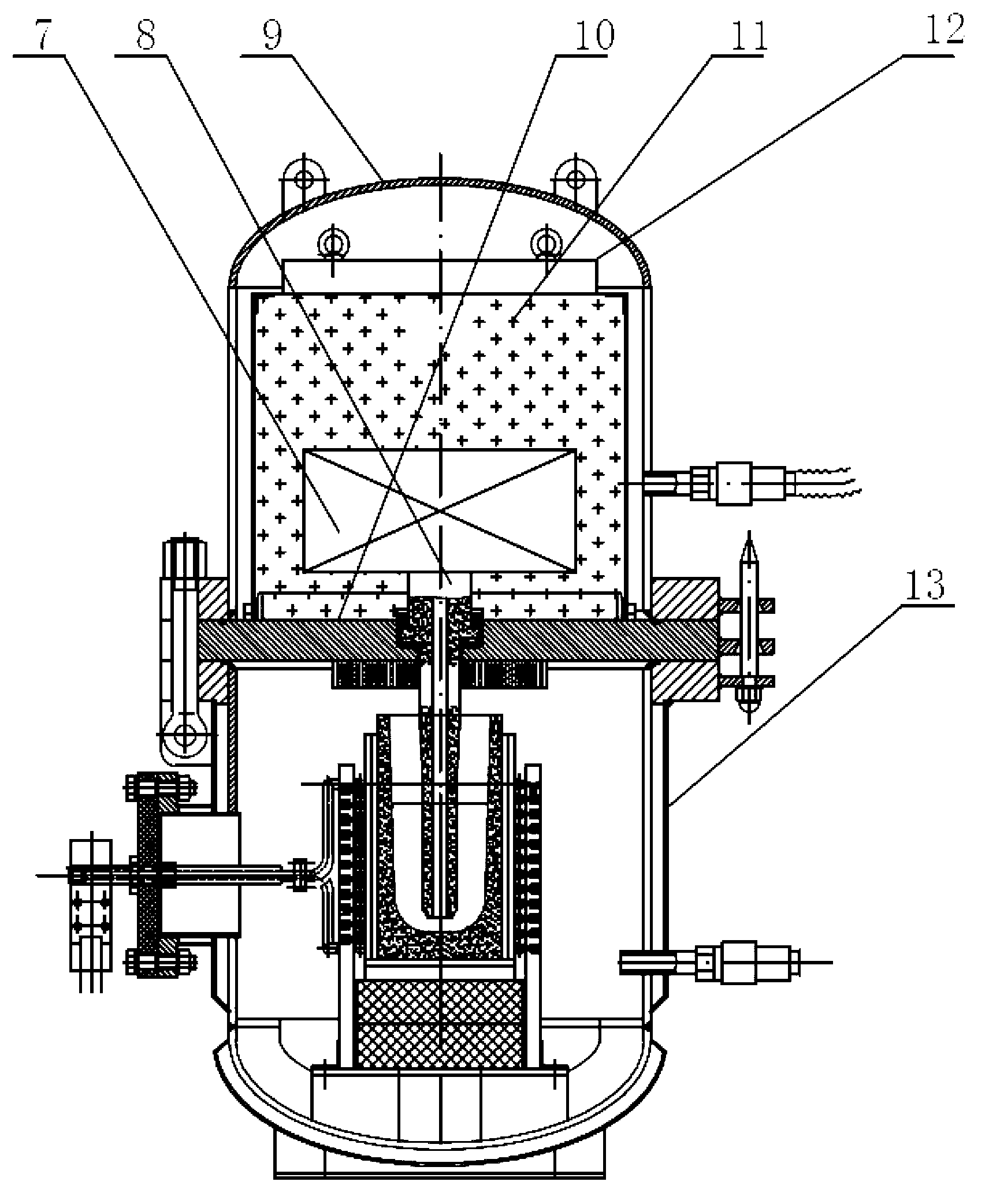

Fermentation tank

InactiveCN1904031AReduce concentration polarizationDegree of reductionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFermentation

The present invention relates to a fermentation tank, in particular it discloses a peristaltic type fermentation tank for solid matrix. Said fermentation tank includes the following several portions: tank body, supporting wall, flexible wall, heat exchange tube, culture medium liquor inlet pipe, material-feeding pipe, membrane diffusate outlet pipe, fermented product outlet pipe and residue-discharging pipe. Said invention also provides the concrete structure of above-mentioned every portion and connection mode of all the above-mentioned portions. Besides, said invention also provides its working principle and concrete operation method.

Owner:JILIN UNIV

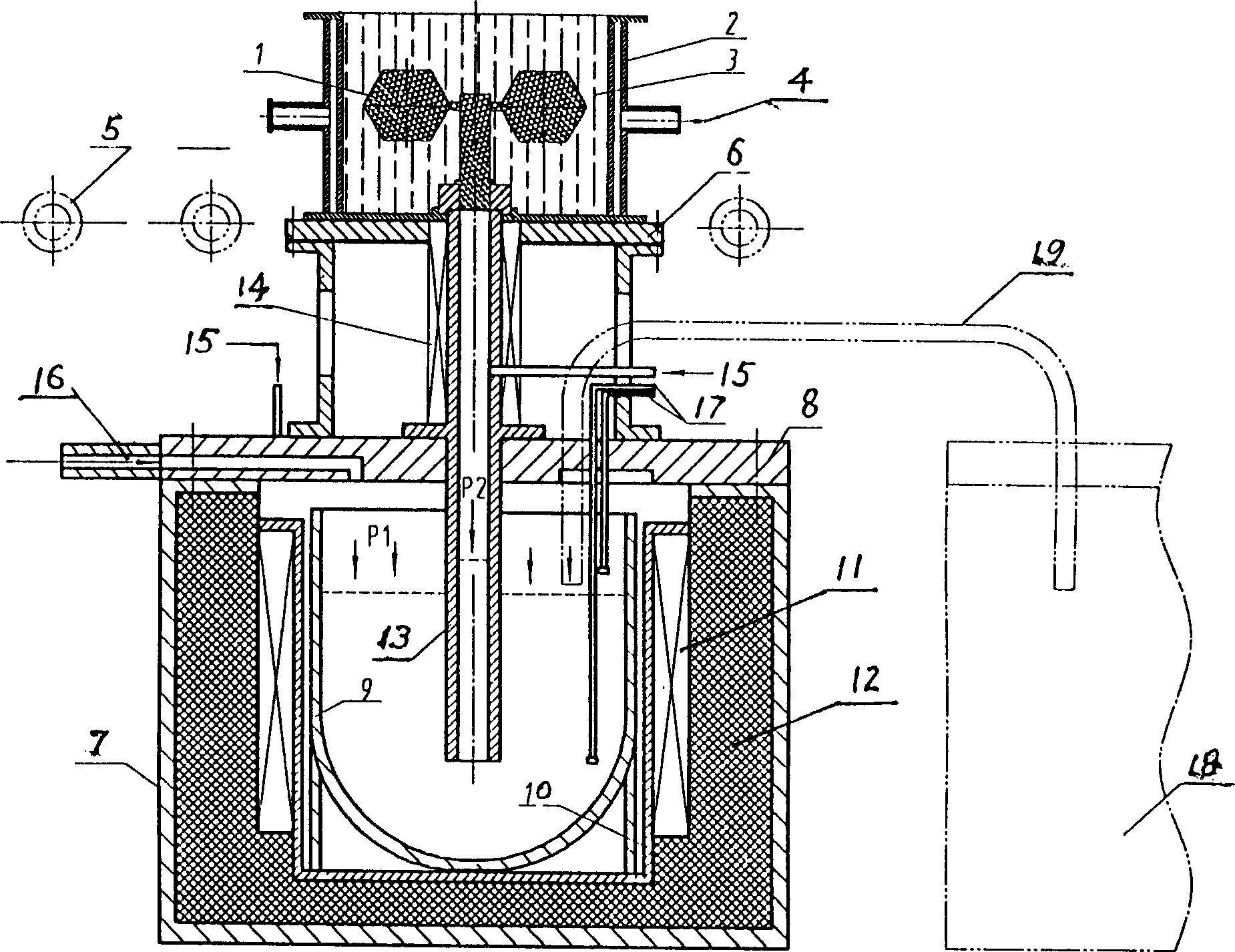

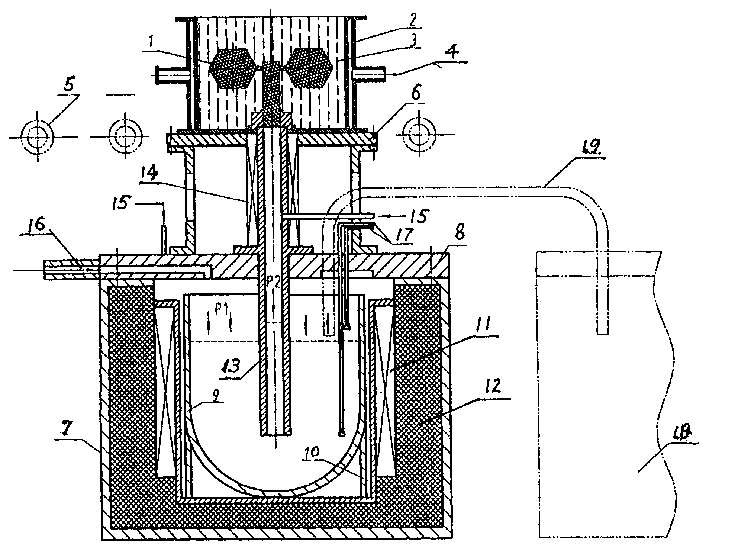

Antigravitational vacuum method and apparatus for asting Mg allor or Al alloy with lost mould

InactiveCN1382542ASuitable for mass productionImprove automationFoundry mouldsFoundry coresCrucibleShielding gas

An antigravitational casting technology includes putting a lost mould in a bottom running type sand box, adding sand, vibration compacting, loading molten MgAl alloy in filler while introducing protecting gas, introducing the pressure controllable inertial gas to the filler, and pouring the molten alloy into said sand box to gasify said list mould. Its apparatus is composed of filler, sand box, pouring pipe, crucible in the filler, and heating coil surrounding said pouring pipe. It is suitable for precision casting.

Owner:HUAZHONG UNIV OF SCI & TECH

Precisive ornament casting moulding material

ActiveCN101074320AHigh hardnessLow shrinkageFoundry moulding apparatusMINERAL WAXMicrocrystalline wax

A precision-casting mold material for ornament consists of hydrogenated microcrystalline wax, paraffin, petroleum resin, high-molecular polymer, mineral wax and animal and vegetable wax. It has better bending strength, surface hardness, thermal stability, fluidity, reutilization and less linear shrinkage rate. It can be used for gold and silver ornaments.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lost foam casting vibration clotting method

The invention relates to a vibration solidification method of lost mold casting, pertaining to the precision casting field, which aims at fining the organization of castings of the lost mold casting, reducing the cost and enhancing the performance of castings. The invention comprises three steps of: production of foamy mold, imbedding the foamy mold into a casting box for filling and compacting sand as well as casting of molten metal; the invention is characterized in that: before and during the period of casting molten metal, during the solidification period, or the solidification period after the period of casting molten metal, casting box filled with foamy mold and scattered sand is vibrated at the frequency ranging from 10 to 100Hz and the amplitude ranging from 0.1 to 3.0mm, and rotation speed of a vibration motor that drives the vibration is 750 to 3000 rpm, and the vibration is stopped after the solidification of casting is completed. The invention has the advantages of low cost, easy operation and control, obvious fining effect of casting organizations, greatly improving performance and no environmental pollution, which is both suitable for the casting of the lost molds of nonferrous metals components, such as aluminum alloy, magnesium alloy, copper alloy, etc., and is also suitable for the casting of the lost mold of ferrous metal components, such as cast iron, cast steel and so on.

Owner:HUAZHONG UNIV OF SCI & TECH

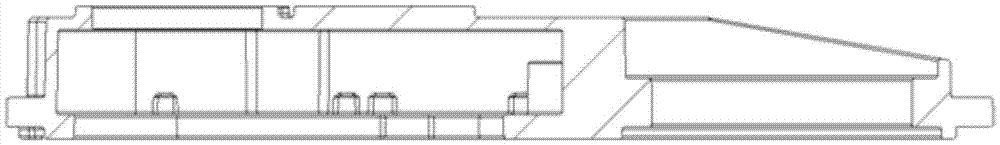

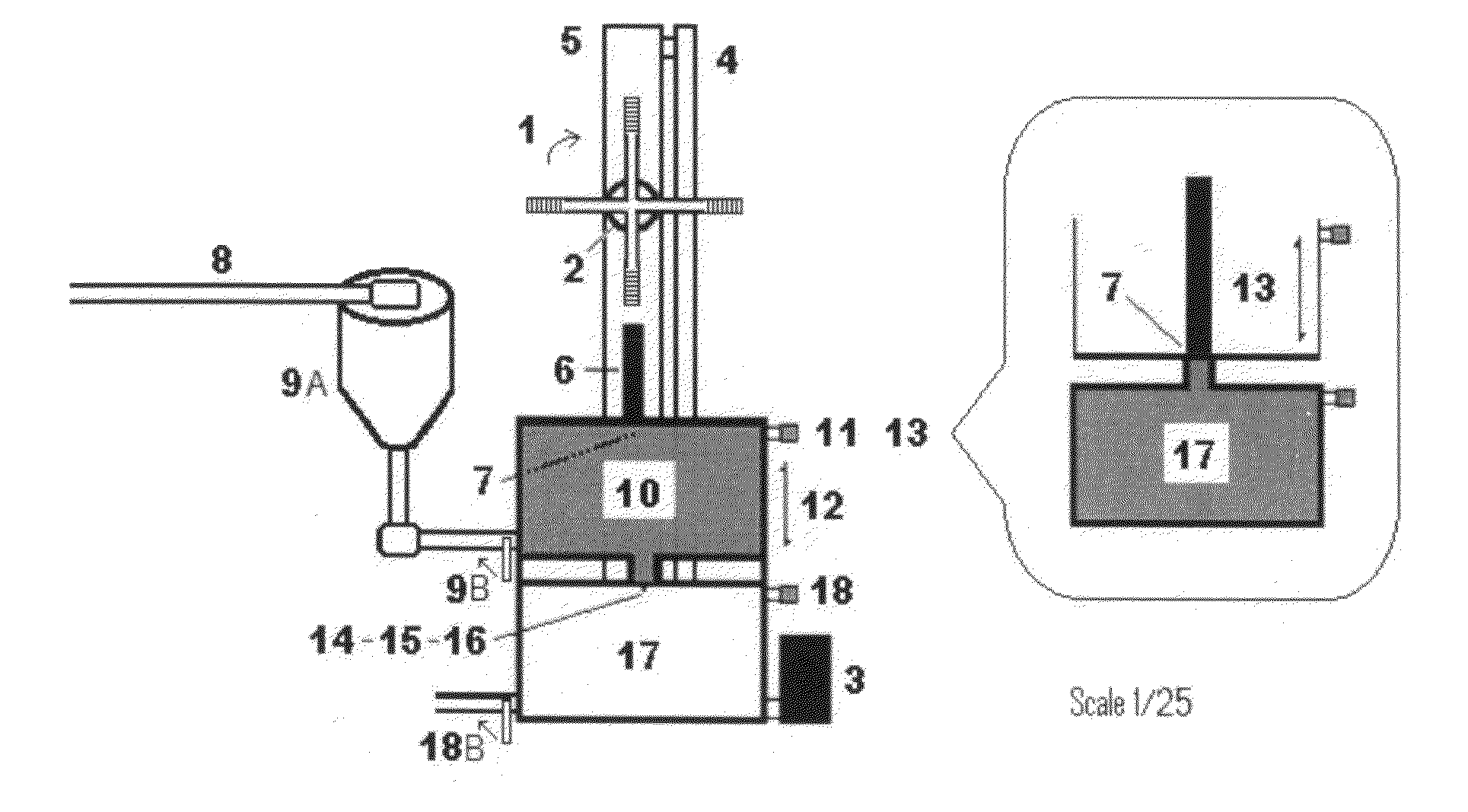

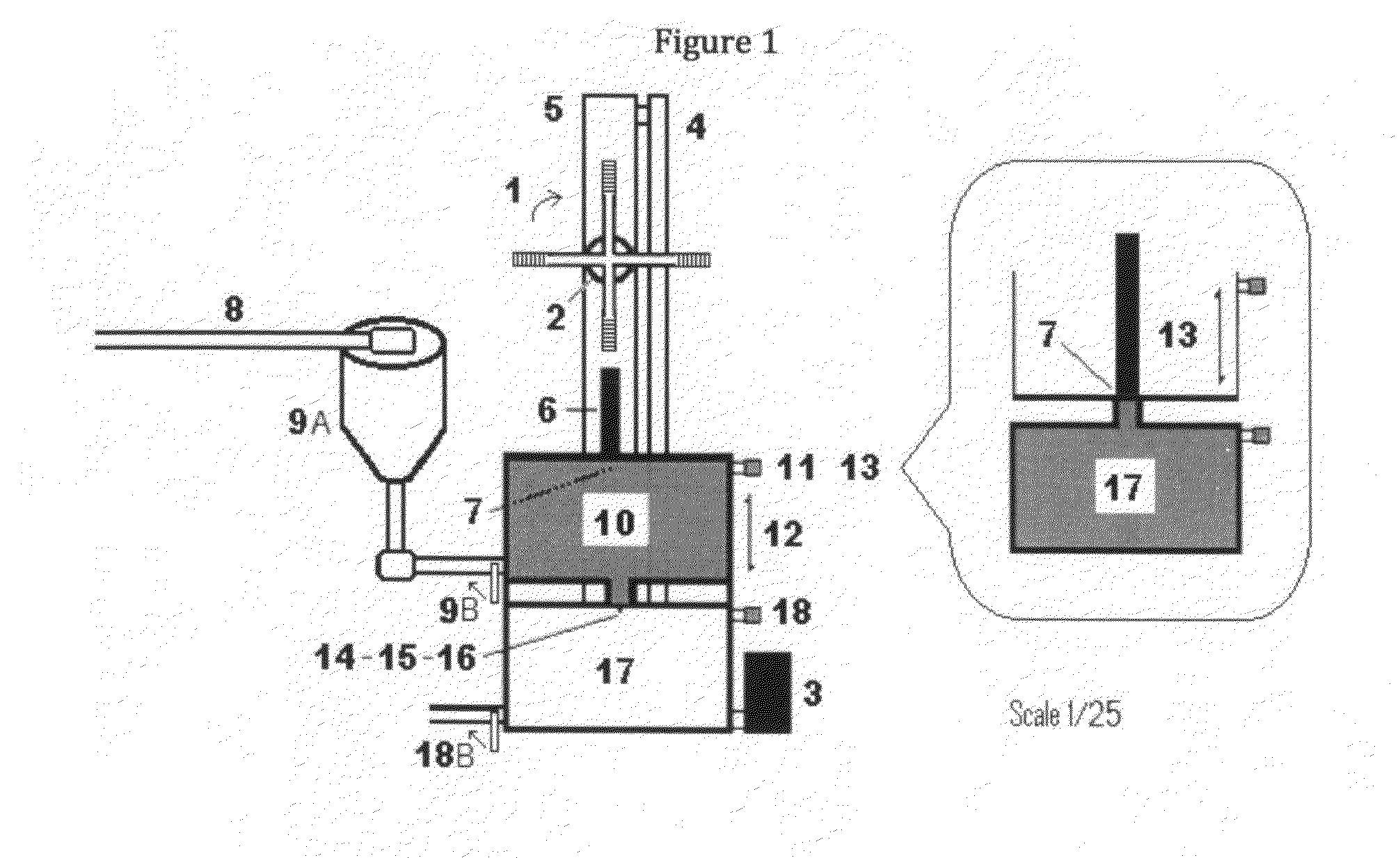

Precesion casting method for high temperature alloy complex thin-walled castings

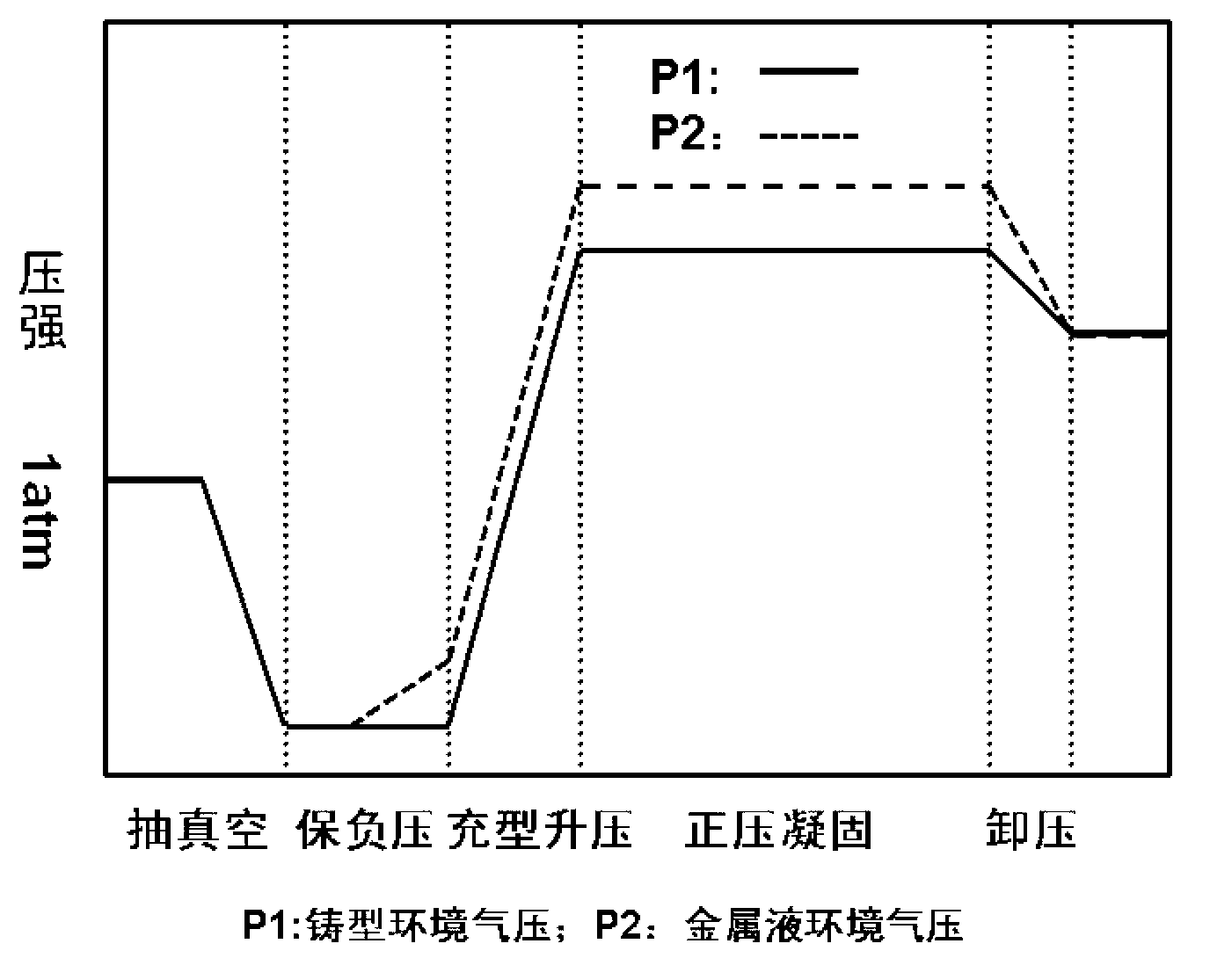

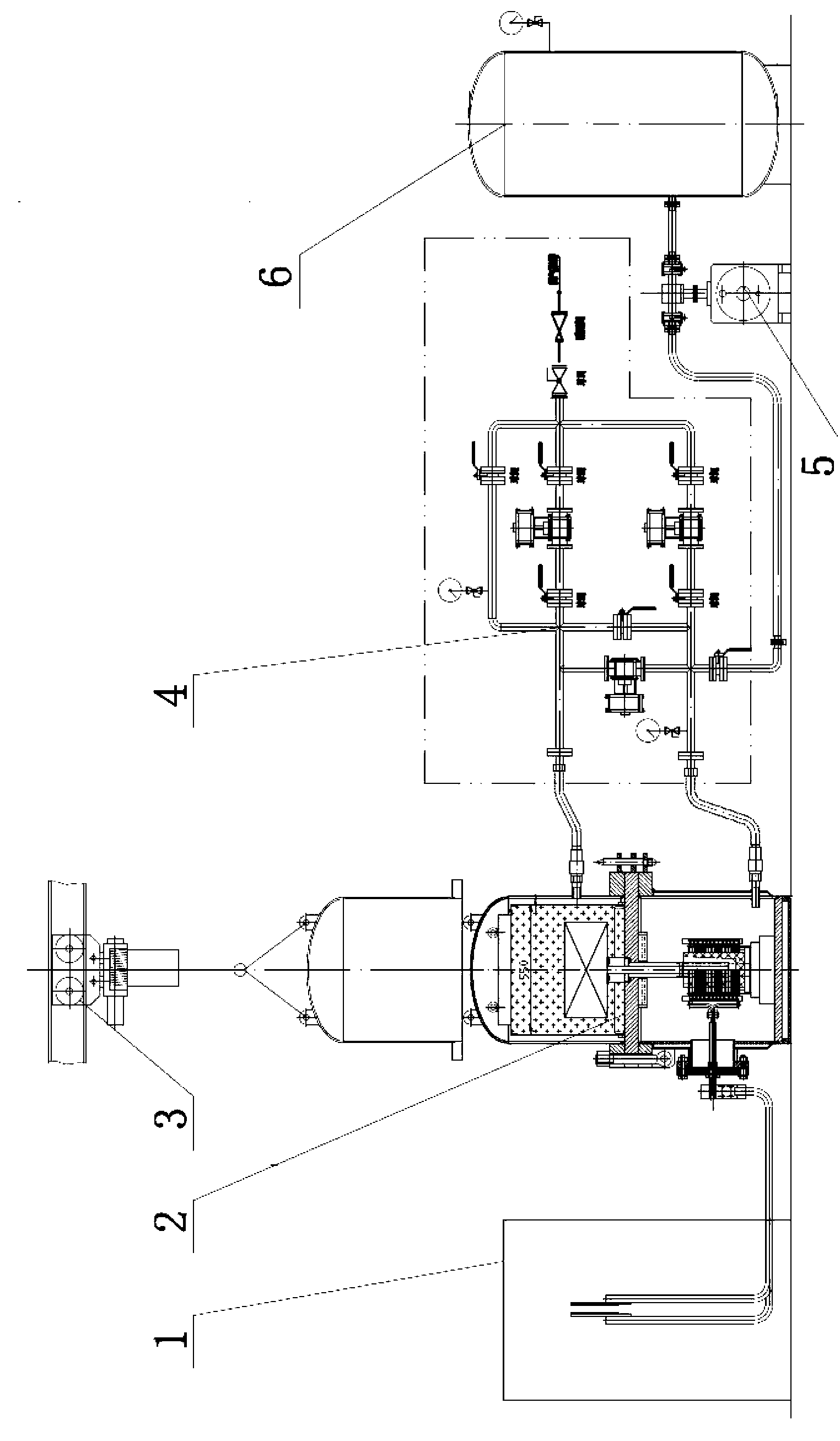

ActiveCN102699311ASolve filling problemsReduce air permeabilityFoundry mouldsFoundry coresIntermediate frequencyMold filling

The invention discloses a precision casting method for high temperature alloy complex thin-walled castings. The method comprises the following steps of: utilizing a medium frequency induction heating power supply to melt the alloy, utilizing a medium baffle to separate an upper tank and a lower tank, and utilizing an electric hoist to elevate the upper tank when a casting mold and a liquid rising tube are installed; after the installation is completed, utilizing a gas circuit control pipeline, a vacuum system and a gas tank to realize vacuum and pressure regulation in a pressure regulating furnace. By adopting the method disclosed by the invention, stable and efficient mold filling is realized, the castings is solidified sequentially, utilization efficiency of the material can be effectively improved, and the space for near-end net shape casting can be supplied; the complex, thin-walled and integral metal castings which are difficult to cast through other molding methods can be produced, so as to solve the filling problem in the pouring process of the complex thin-walled castings, and in particular, the filling capacity for the thin-walled castings with the wall thickness of less than 3mm is greatly improved. Accurate castings with high dimensional accuracy can be obtained through high temperature alloy pressure regulating investment precision casting, and the accuracy of the casting can reach between CT4 and CT6.

Owner:SHANGHAI JIAO TONG UNIV

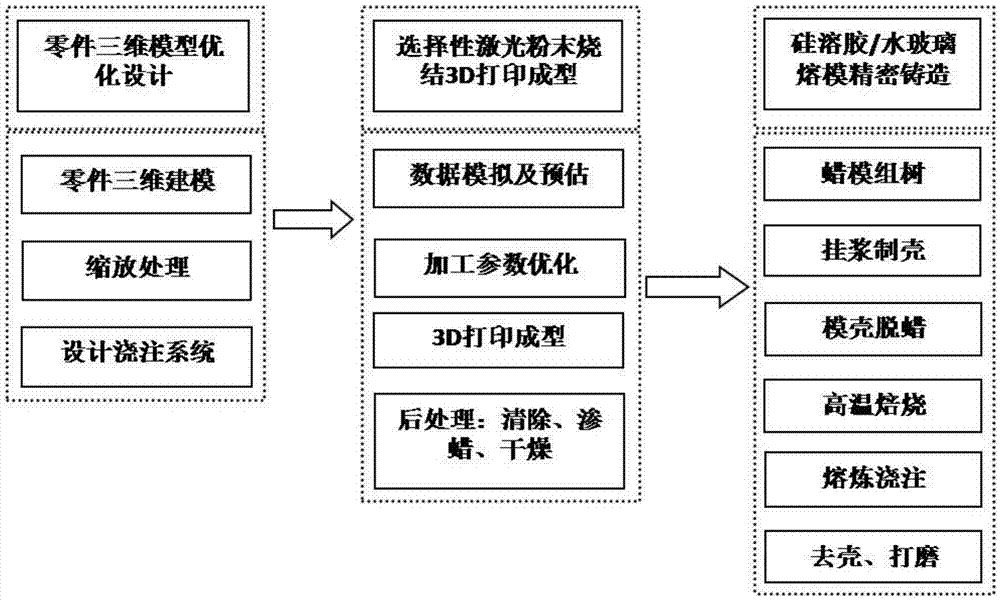

Precision lost wax casting technology based on selective laser powder sintering 3D printing

InactiveCN105436406AFast preparationCasting fastAdditive manufacturing apparatusFoundry mouldsInvestment castingOptimal design

The invention discloses a precision lost wax casting technology based on selective laser powder sintering 3D printing. The precision lost wax casting technology comprises the following steps that S101, a target part is subjected to optimal design of a CAD casting technology; S102, selective laser powder sintering 3D printing forming is carried out; and S103, silica sol / water glass precision investment casting is carried out. A wax mold of the part can be fast manufactured without molds, the metal part is fast manufactured, fast manufacturing of complex parts can be achieved, and integration, automation and fastness in the precision casting technology process can be achieved; and the development period of new products are greatly shortened, development cost is reduced, and the precision lost wax casting technology is especially suitable for production of single small-batch complex castings and trial-manufacturing of new products.

Owner:HUST WUXI RES INST +1

Shell making method for deep blind hole of precision casting

The invention discloses a shell making method for a deep blind hole of a precision casting. The method comprises the following steps of: making a wax pattern module; coating the module to make a shell; sequentially coating a surface layer, a transition layer, a third layer and a fourth layer; after coating the third layer or fourth layer, performing air drying until the shell is completely dried; stirring silica sol zircon powder slurry and mullite sand according to a mass ratio of 4:(6-6.5) into paste to obtain filling; pouring the filling into the position of the deep blind hole of the casting; then aligning the deep blind hole of the casting with a fan for forced air drying until the deep blind hole of the casting is completely dried; continuously reinforcing according to the casting size until the required layer number of the shell is obtained; and dewaxing to obtain a corresponding shell. The shell making method for a deep blind hole of a precision casting, disclosed by the invention, is simple and convenient to operate, effectively solves the difficulty in shell making for a shell deep blind hole of a precision casting, enhances the strength of the shell at the deep blind hole, greatly reduces the defects of breakage, deviation and the like of the shell at the deep blind hole, realizes an obvious effect and fundamentally guarantees the delivery time of the products for customers.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

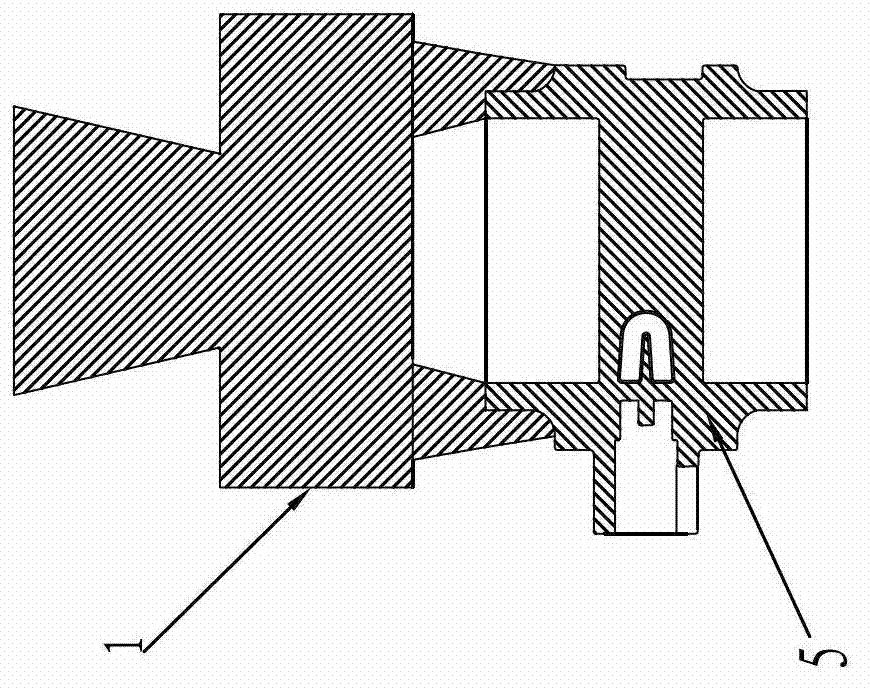

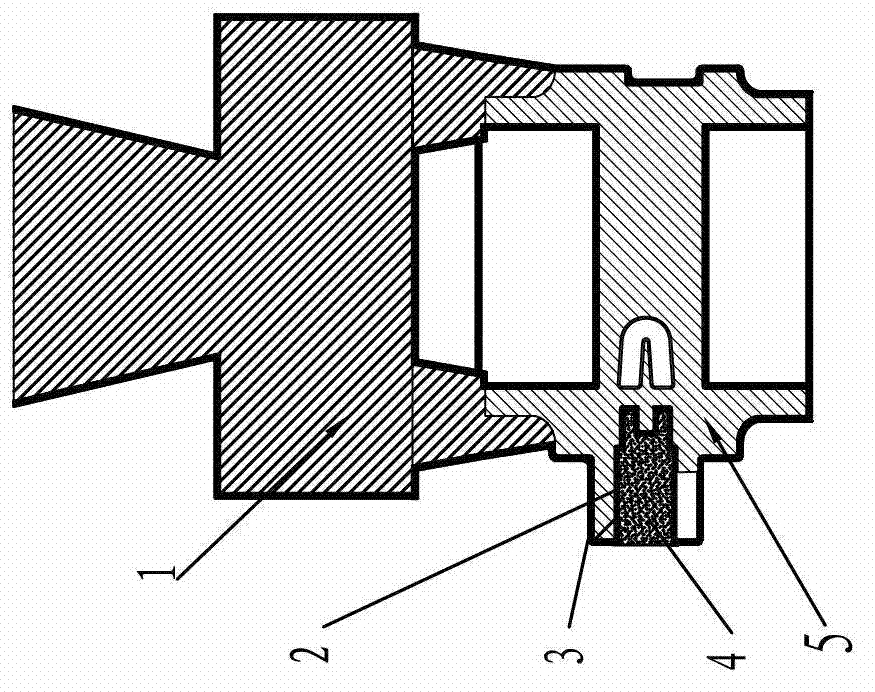

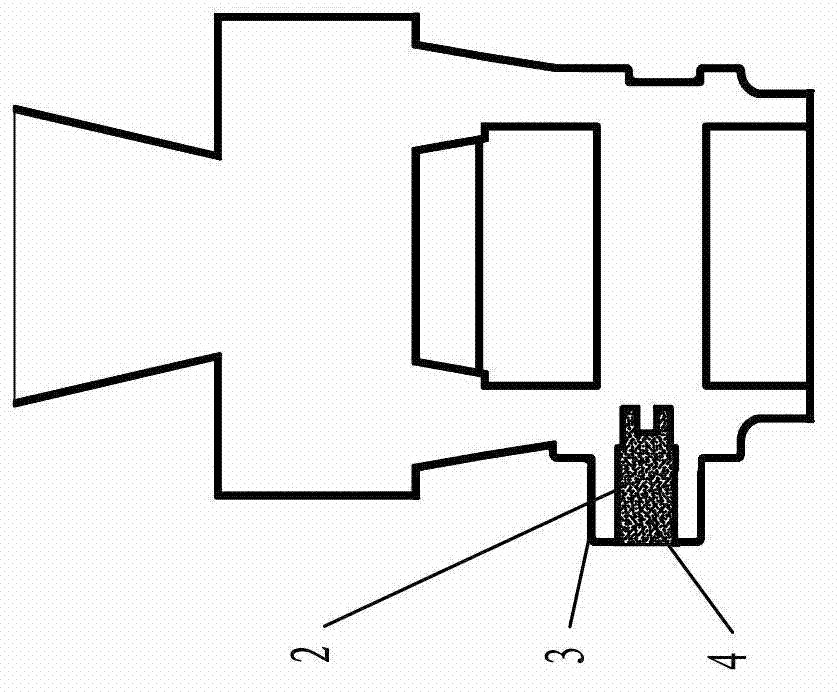

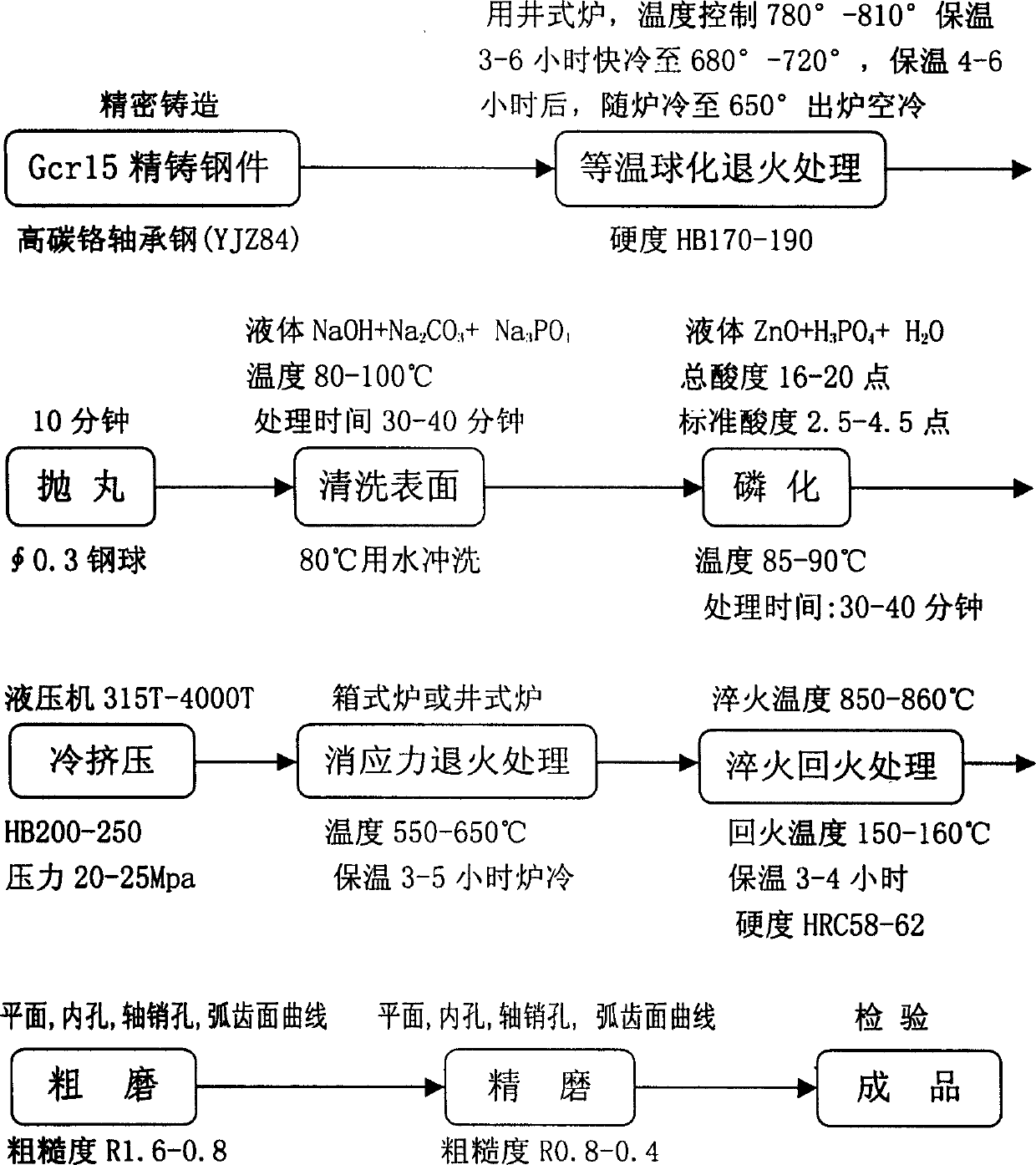

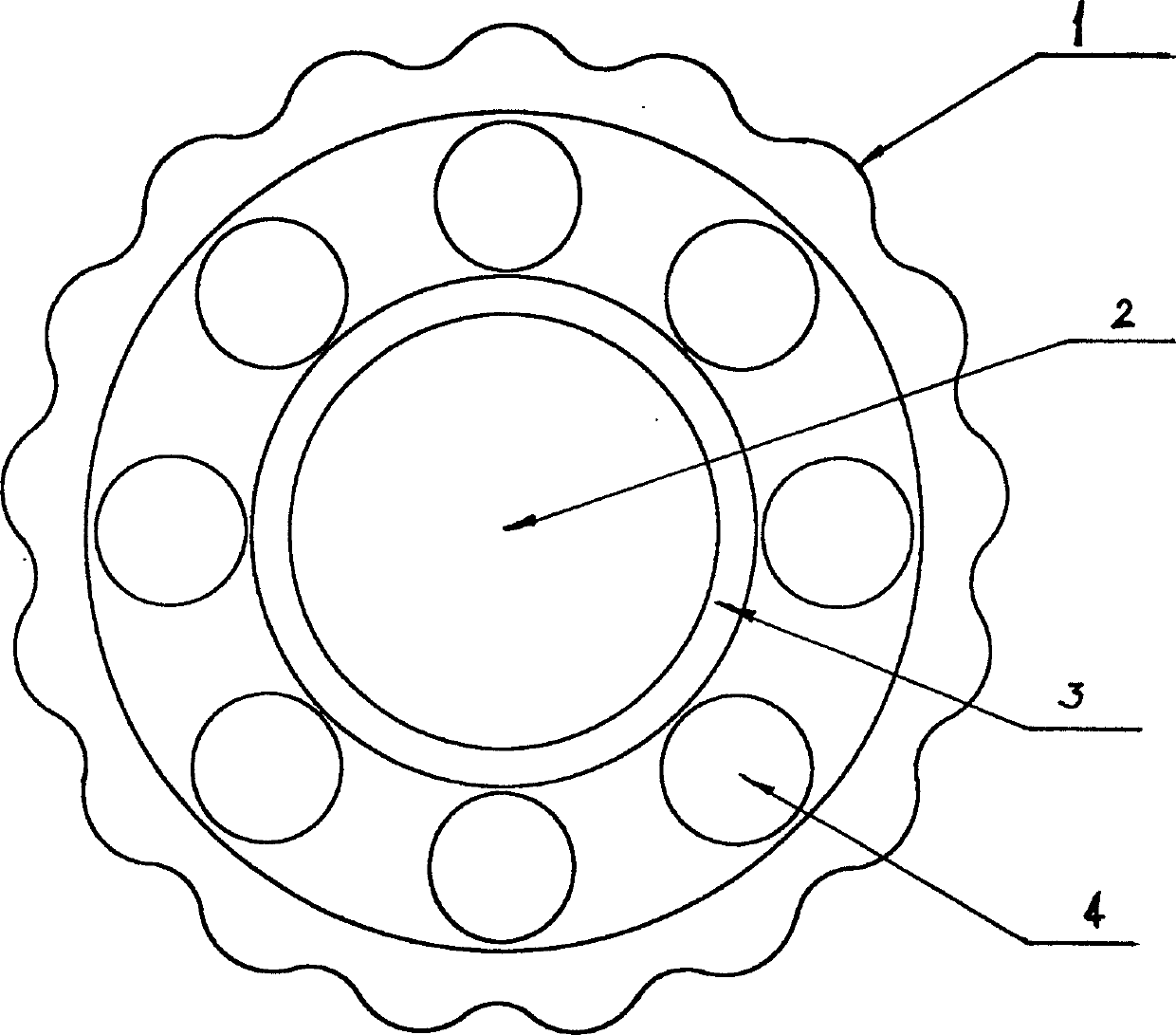

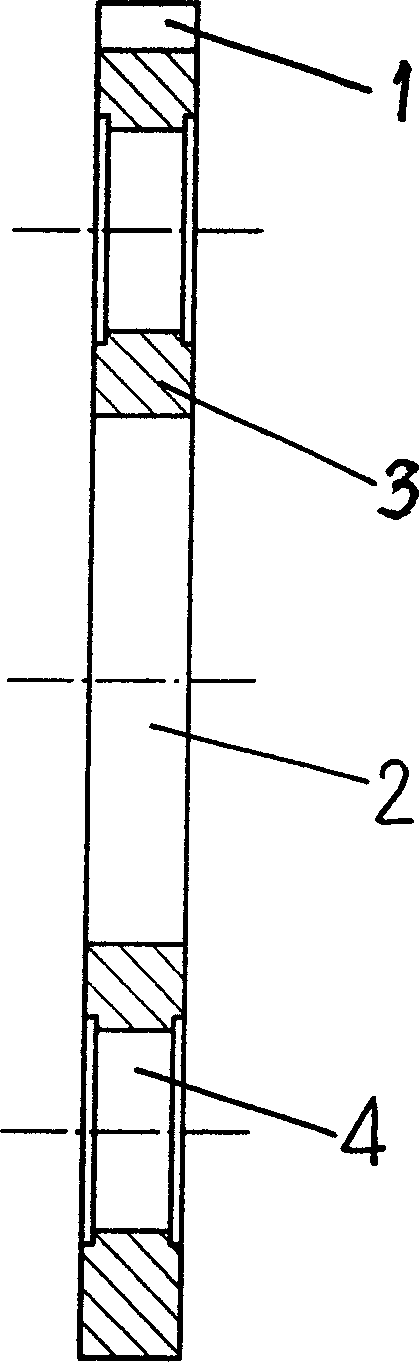

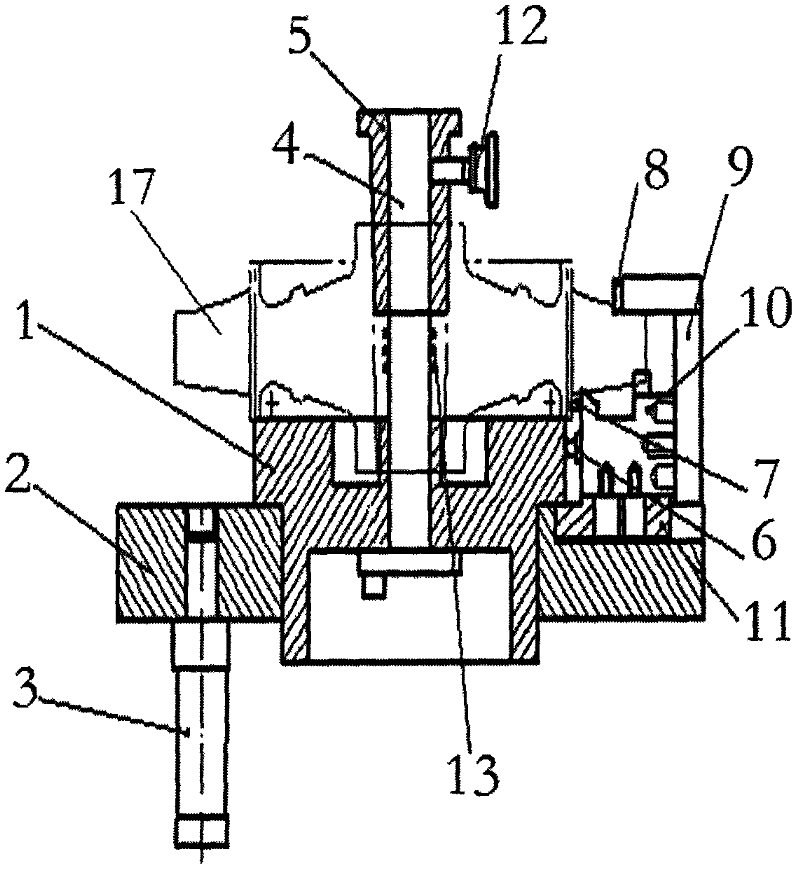

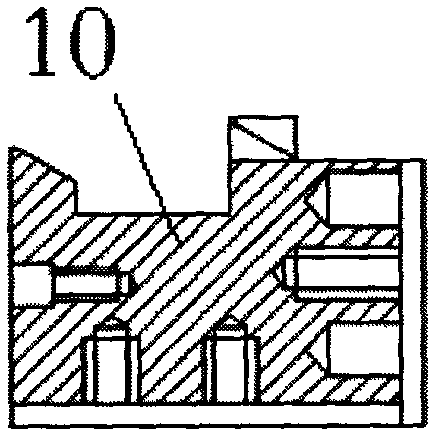

Precision casting and extrusion processing technique of high-carbon chromium bearing steel cycloid wheel

The invention relates to high-carbon chromium bearing steel cycloid wheel precision casting extrusion manufacturing technology. It is the critical component manufacturing technology in the spindle wheel swinging reducer. Its mainly technical features lie in its technological line that the first step, the high-carbon chromium bearing steel is precisely cast to many cycloid wheel blanks, and the remained forging envelope is from 0.3 millimeter to 0.5 millimeter. The second step, isothermal spheroidizing is practiced. The third step, shot blasting is practiced. The forth step, the surface is cleaned out. The fifty step, phosphorization is practiced. The sixth step, cold extrusion is practiced. The seventh step, stree-free annealing is practiced. The eighth step, quench tempering is practiced. The ninth step, the plane, inner hole, shaft pin hole, and curve tooth surface curve of the cycloid wheel are practiced coarse grinding. The tenth step, they are practiced fine grinding. The eleventh step, the cycloid wheel is tested after the fine grinding, and the finished product is put in storage. The technology can economize more than fifty percent of the raw material, sixty percent of the manpower; the economized energy is reached to twenty percent; the improved work efficiency is twice.

Owner:薛安志

Manufacture method of stainless steel, carbon steel precision casting surface shell

InactiveCN101362184AChange performanceImprove breathabilityFoundry mouldsFoundry coresSurface layerFoaming agent

The invention discloses a manufacturing method of a surface layer shell which is precisely cast by stainless steel and carbon steel, which is characterized by being completed by the following production steps of: (1) preparing a refractory coating; (2) preparing a surface layer shell; and (3) drying the surface layer shell. As mullite sand of 80 to 100 meshes instead of expensive imported zircon sand is adopted in an adhesive layer, the manufacturing method of a surface layer shell which is precisely cast by stainless steel and carbon steel reduces the production cost; as in the preparation of the refractory coating, appropriate wetting agents and anti-foaming agents are added into silicone liquid and zircon powder is used, the performance of the shell is changed and the shell is caused to be good in permeability; as the flow rate of the refractory coating is controlled to be 38 to 45s, the roughness value of a cast piece is low. By testing, performance indexes of cast products of the surface layer shell which are made in the precise casting by the method meet the standard requirements; the surface layer shell is not only high in size precision and low in surface roughness value, but also the production cost can be reduced by 10 to 20 percent.

Owner:山东燕山精密机械有限公司

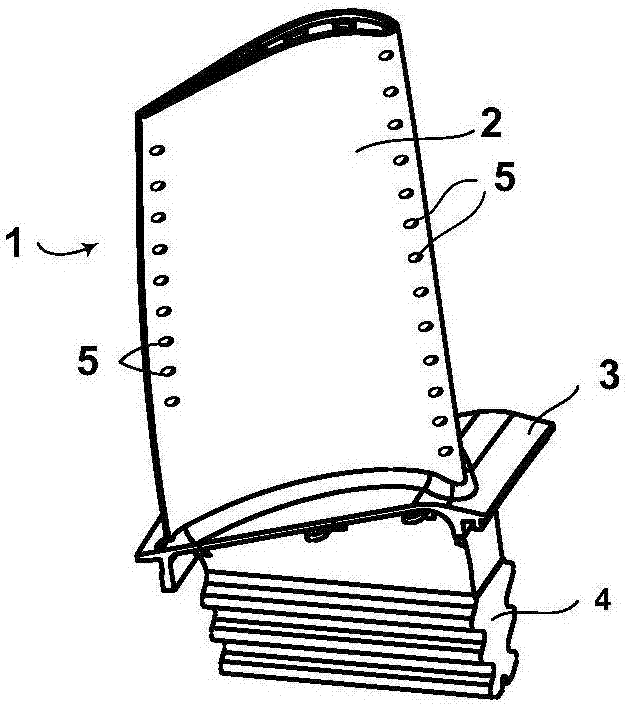

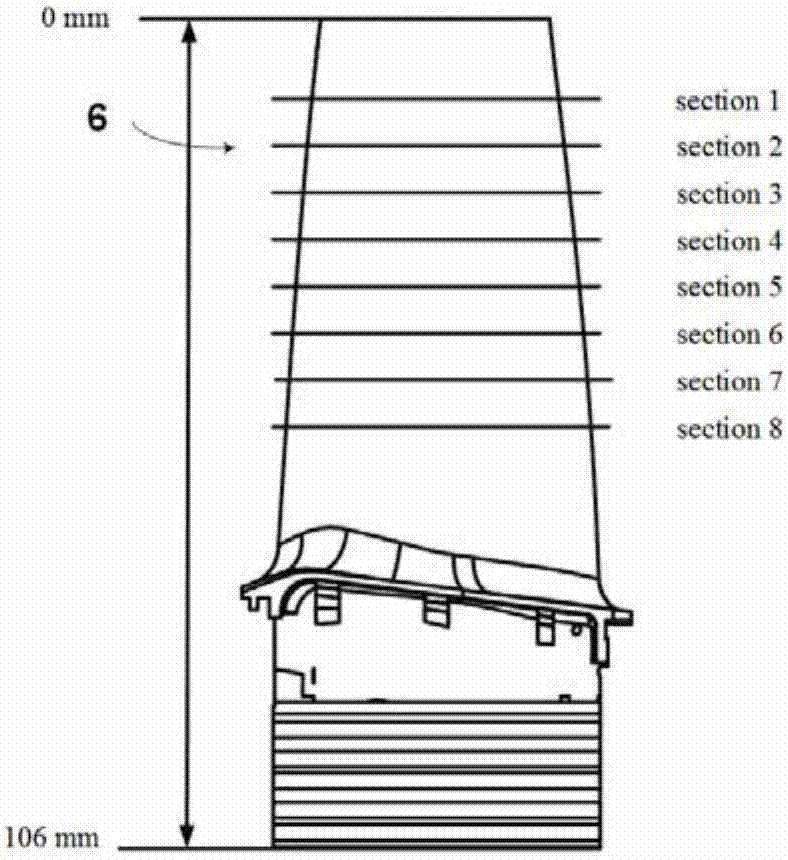

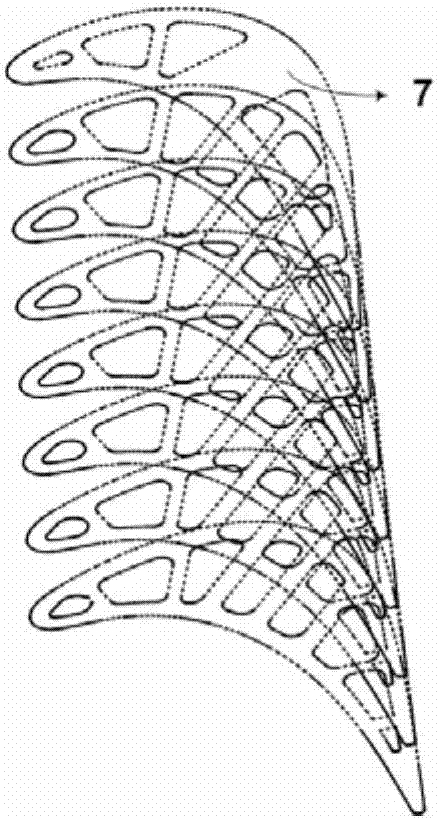

Production method of hollow turbine vane with shaped air film hole

InactiveCN101306465ASolve problems that are difficult to process and formLow viscosityFoundry mouldsFoundry coresTurbine bladeEngineering

A method for producing hollow turbine blades with special-shaped film holes is provided. The method comprises the following steps: adopting the stereo-lithography technology to produce a resin die comprising a hollow turbine blade prototype with the special-shaped film holes; pouring ceramic slurry into a die cavity of the resin die; padding the special-shaped film holes and the inner cooling channel of the hollow turbine blade surface; copying the inner and the outer structures of the hollow turbine blade prototype; in-situ forming the ceramic slurry under the action of a catalytic agent and an evocating agent to form a ceramic body; drying for ignition lost of the resin die and sintering; obtaining a ceramic mould comprising inner and outer mould cores; finally pouring the high-temperature metal liquid into the ceramic mould; removing the ceramic mould after freezing forming and cooling the metal; and obtaining the hollow turbine blades with the special-shaped film holes. The method is mainly suitable for producing the hollow turbine blade precision casting with the special-shaped film holes, solves the problem of difficulty in processing forming the special-shaped film holes, and provides the method for producing the precision casting with special-shaped holes formed on the surface thereof.

Owner:XI AN JIAOTONG UNIV

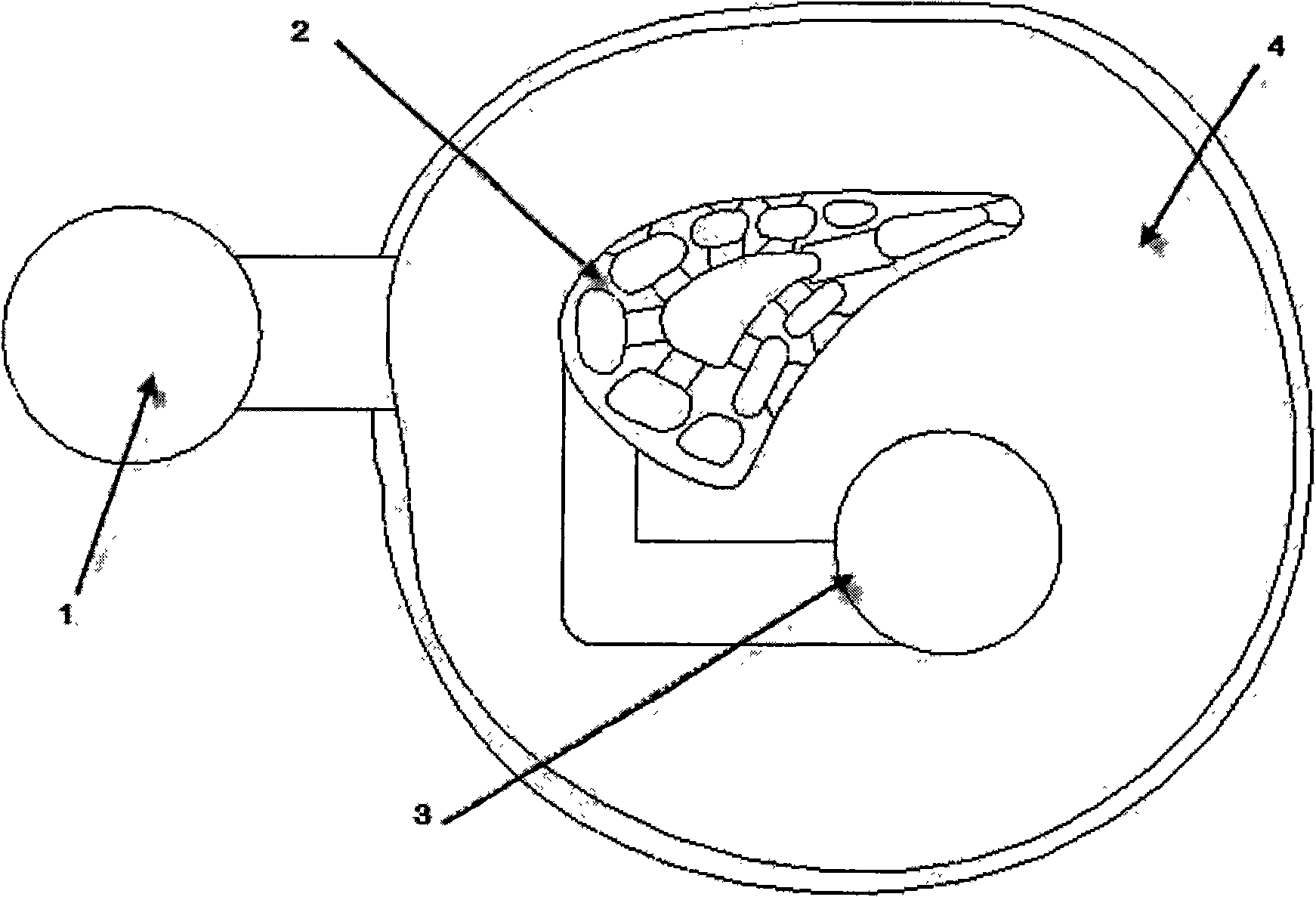

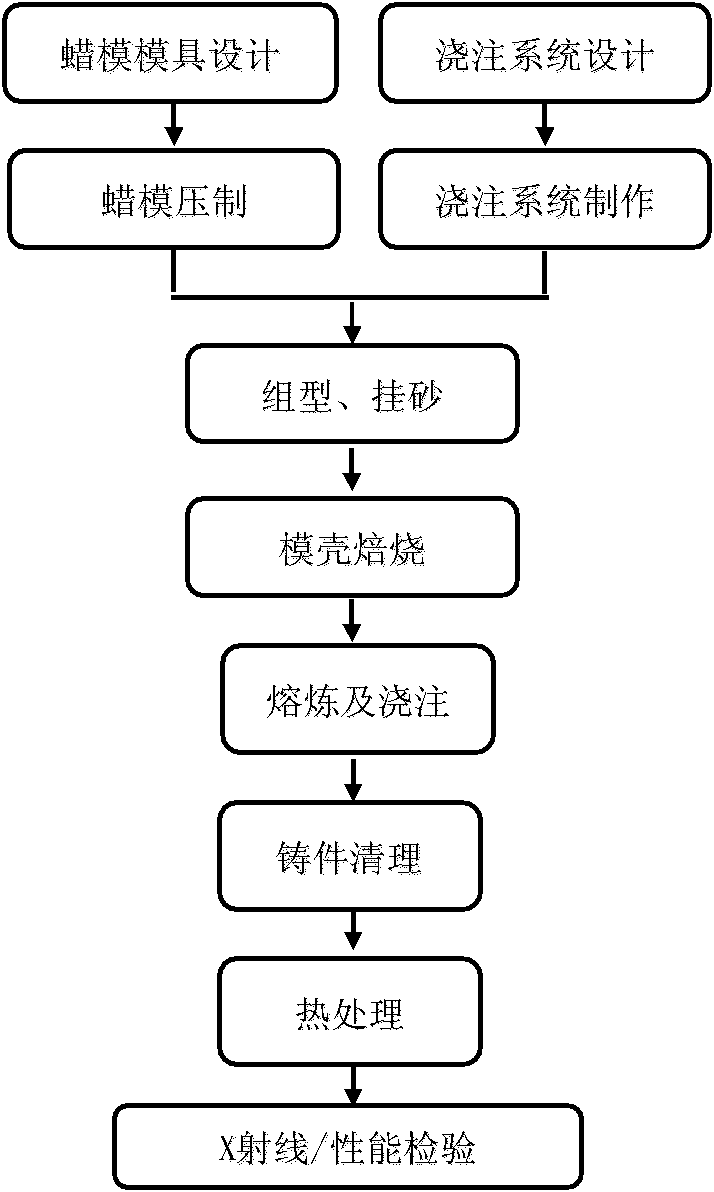

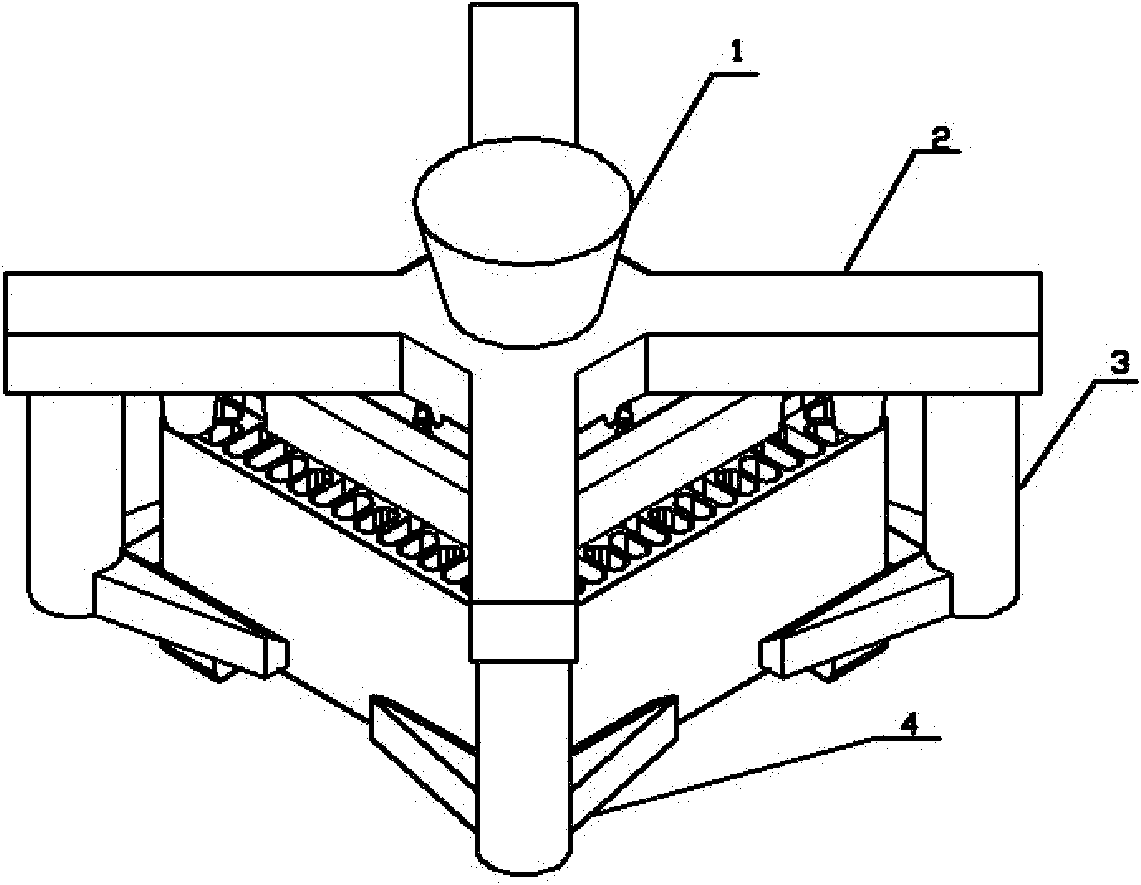

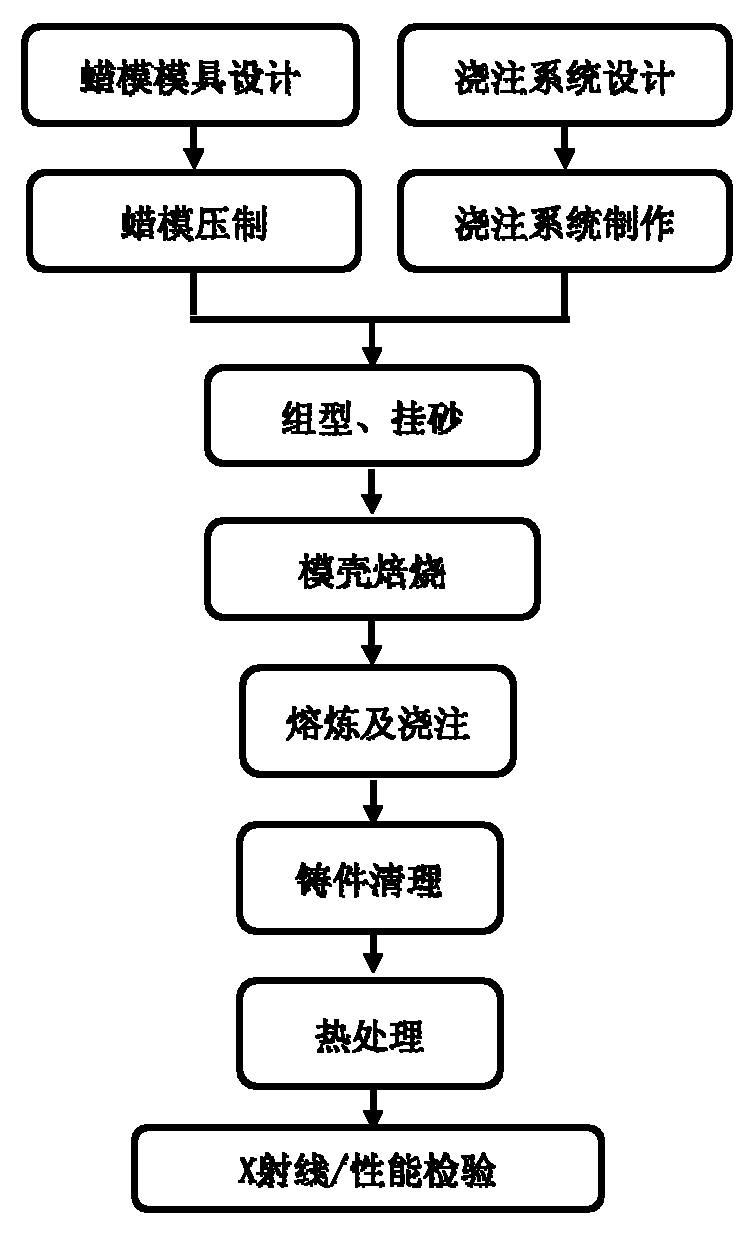

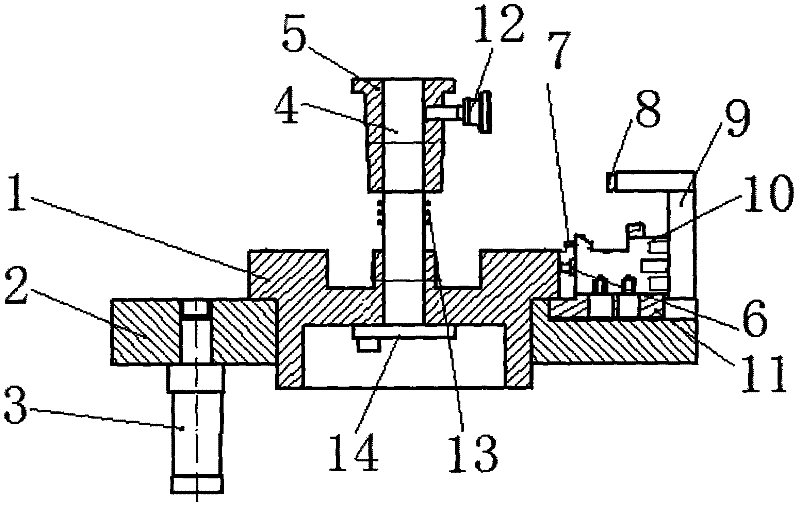

Precision casting molding method for complex thin-walled member

The invention discloses a precision casting molding method for a complex thin-walled member. The method comprises the following steps of: 1) manufacturing a wax die; 2) pressing the wax die; 3) designing and manufacturing a pouring system; 4) forming: bonding the wax die pressed in the step 2) and a sprue cup, a cross gate, a sprue and an in-gate pressed in the step 3) by adopting liquid wax to form a whole; 5) coating sand; 6) roasting a die shell: roasting the die shell in a box-type electric resistance furnace, taking out the die shell after the roasting is finished, and cleaning residues in the cavity of the die shell; 7) smelting and casting; 8) clearing a casting; and 9) obtaining a complex thin-walled member product after thermal treatment. A nuclear reactor tube seat close to the required geometric dimension is obtained by adopting a direct casting mode in the method; and the manufacture of the tube seat can be finished only by a little machining operation after the method is adopted, so the manufacturing cost of the tube seat is remarkably reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD +1

Method for preparing casting titanium and titanium-aluminum base alloy porous ceramic mould shell

InactiveCN101104195AQuality improvementReduce residual strengthFoundry mouldsFoundry coresHigh pressurePorous ceramics

Disclosed is a preparation method of a porous ceramic shell of cast titanium and titanium aluminum alloys, relating to the melt mould precise casting field. The invention solves the problem that cracks are caused when the thin-walled titanium and the titanium aluminum alloys castings are solidified and shrunk due to the large residual intensity of the present shell of cast titanium and titanium aluminum alloys. The method is as following: firstly, wax mould pressing; secondly, coating and hanging four surface layers, and the manufacturing processes of each layer are that coating and hanging coatings of the surface layer, sprinkling zirconic sand, drying in the room temperature, and then the next layer is coated and hung; thirdly, coating and hanging two transitional layers, whose differences from coating and hanging the surface layers lie in that each coated and hung transitional layer comprises a high polymer and a back coating of water latex, and bauxite sand of 50 to 70 orders is sprinkled; fourthly, coating and hanging four to eight reinforcing layers, whose differences from hanging and coating the transitional layers lie in that the bauxite sand of 30 to 40 orders is sprinkled; fifthly, coating and hanging the coatings of an outer layer , which will be dried in the room temperature; sixthly, dewaxing by high pressure steam; seventhly, roasting the shell. The invention can be widely applied in the manufacturing of the shell of titanium and titanium aluminum alloys castings for the national defense and domestic use.

Owner:HARBIN INST OF TECH

Precision casting method for thick-wall base aluminium alloy casting

ActiveCN102717030AQuality improvementImprove yieldFoundry mouldsFoundry coresEconomic benefitsThick wall

The invention discloses a precision casting method for a thick-wall base aluminium alloy casting. The precision casting method comprises the steps of designing a wax mould, making the wax mould, moulding, carrying out sand lining, dewaxing, roasting a mould shell, baking the mould shell, modelling, smelting and pouring, cleaning the casting and ageing. The precision casting method for the thick-wall base aluminium alloy casting disclosed by the invention provides a reliable technical scheme for production of the thick-wall aluminium alloy casting, and a casting meeting the requirements is made; meanwhile, product quality and rate of finished products are greatly improved by adopting a pressure regulating casting moulding method, production cost is reduced, and great economic benefit is created.

Owner:西安超晶科技股份有限公司

Manufacturing method and fixture of integral bladed-disk wax mold

ActiveCN102363199AImprove consistencyHigh dimensional accuracyFoundry moulding apparatusWaxPrimary standard

The invention discloses a manufacturing method and a fixture of an integral bladed-disk wax mold. According to the invention, an integral bladed-disk wax pattern is divided into single blades and a disk shaft. Processes of separated pressing, precise fixture positioning and wax mold welding assembling are adopted. The integral wax pattern is precisely cast. According to the invention, the disk shaft is fixed on an assembling fixture; the blades are sequentially positioned on positioning points on the fixture, and are welded onto the disk shaft. Blade bodies and channel inner walls with high precisions are adopted in the positioning of the blades, such that good consistency is provided for the blades. When the wax pattern is assembled, positioning points are positioned on the blade bodies;blade body positioning points are consistent with processing positioning points, primary standards of cold and hot processing are consistent, such that blade dimensional precision of the whole cast is optimally improved, throat areas between blades are ensured, and flow rate homogeneity is ensured. Positioning parts of the fixture can be adjusted according to measured dimensions of parts, such that the volume of flow rate can be changed according to directional positions of angles of the blades. Therefore, repairing or even rejecting risks caused by unqualified integral mold dimensions are avoided, production period is saved, and production cost is reduced. With the method provided by the invention, hard processes are turned easy, product precision is improved, and production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

Non ionic groups of amphoteric polysaccharide linear or branched alkyl or acid and base distillation reservoir liquid or gas mechanically refined and Nano particle dispersion and recovery basin in vacuum processing for Building Materials and High Wear-Heat Resistant Parts Brushes; Windings; Coils; Battery Cells; Brake Pads; Bushings; 2.5 Phase Extrusions Die Cast Molding; Refrigeration; Polarized Glass; and Central Processing Unit Processors.

Manufacture process scientific formula mechanically refined and nanoparticle dispersion preform slurry non ionic or electrolyte carbon nanofoam CNFs with or without ionic suspension elements manufactured, Preform slurry high wear-heat resistant parts electronic component composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension element enhanced composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, capacitors, battery cells, rheostats, electronic resistors, transformers, transducers, rectifiers, power supplies, or heat sinks, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, washers, spacers, and bushings, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts precision casting molds manufacturing highly pure metal, Super Alloy, acid-solid, alkaline, glass, acrylic, halide, alkalide, or ceramics specializing in 2.5 phase die cast molding.

Owner:MATTHEWS ROBERT RICHARD

Water-soluble ceramic core material and preparation method thereof

ActiveCN105693254AConsider surface qualityTaking into account the dimensional accuracySolubilityPrecision casting

The invention belongs to the precision casting technique and relates to a water-soluble ceramic core material and a preparation method thereof. The water-soluble ceramic core material comprises a high-temperature ceramic material, water-soluble inorganic salts, metallic oxides and at least one amorphous ceramic material. The preparation method comprises the following steps: raw material pretreatment, raw material weighing, mixing, mold core forming, degreasing, sintering and secondary sintering. According to the water-soluble ceramic core material and the preparation method, the properties of surface quality, dimensional precision, foaming level, mechanical strength, heat resistance, water solubility, environment friendliness and the like of the mold core can be considered, and scientific research and production requirements of aluminum alloy are met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for preparing TiAl-based alloy formwork by wax mold casting

The invention relates to the field of precision casting, in particular to a method for preparing a shuttering for an investment casting TiAl-based alloy with low cost and strong stability. The method comprises the following steps: preparing slurry of which flow cup viscosity is 10 to 25 seconds from Y2O3 powder of 200 to 400 meshes on granularity and silica sol according to a weight ratio of 2:1-3:1; then, coating the slurry on a wax mould, sprinkling electric melting Y2O3 sand of which sand granularity is 40 to 100 meshes on the wax mould, and drying the wax mould; preparing slurry of which flow cup viscosity is 10 to 30 seconds by adopting Al2O3 powder of 200 to 400 meshes on granularity and silica sol according to a weight ratio of 3:1-4:1, coating the second layer, sprinkling electric melting Al2O3 sand of which sand granularity is 40 to 80 meshes on the wax mould, and drying the wax mould; preparing slurry by adopting bauxite and silica sol according to a weight ratio of 3:1-4:1, and sprinkling coal gangue sand of which sand granularity is 16 to 24 meshes on the wax mould; after three layers, finally hanging the bauxite slurry, and drying the slurry; and then removing wax, and sintering the mould. The method has the advantages of simple shuttering preparation process and low cost of the shuttering, can effectively control reaction of a TiAl-based alloy cast and a shuttering surface material, reduce oxygen feeding amount of the alloy, and is suitable for casting a TiAl-based alloy cast.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

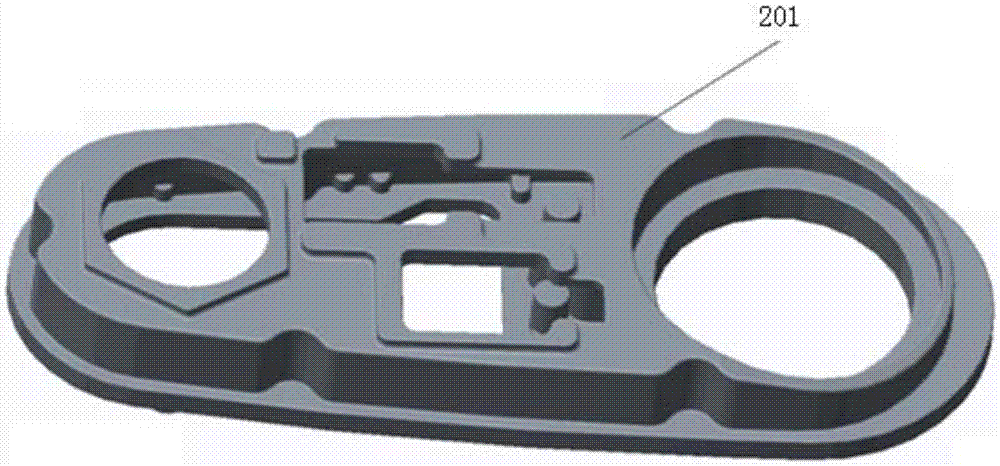

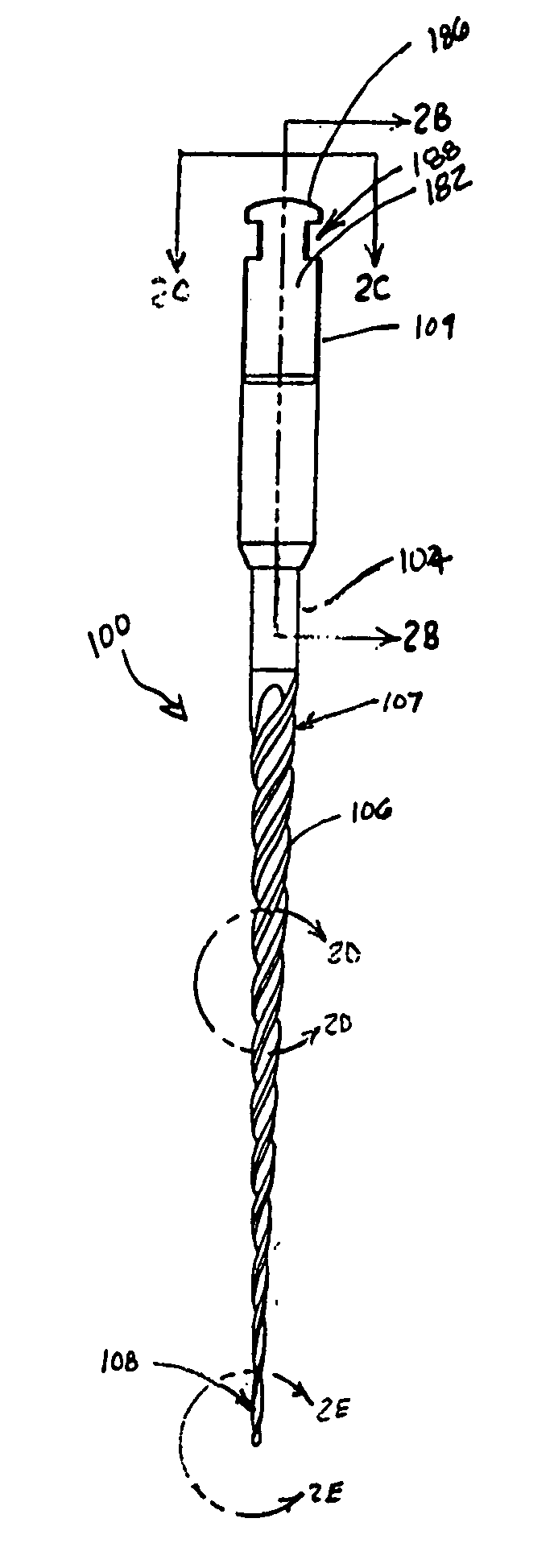

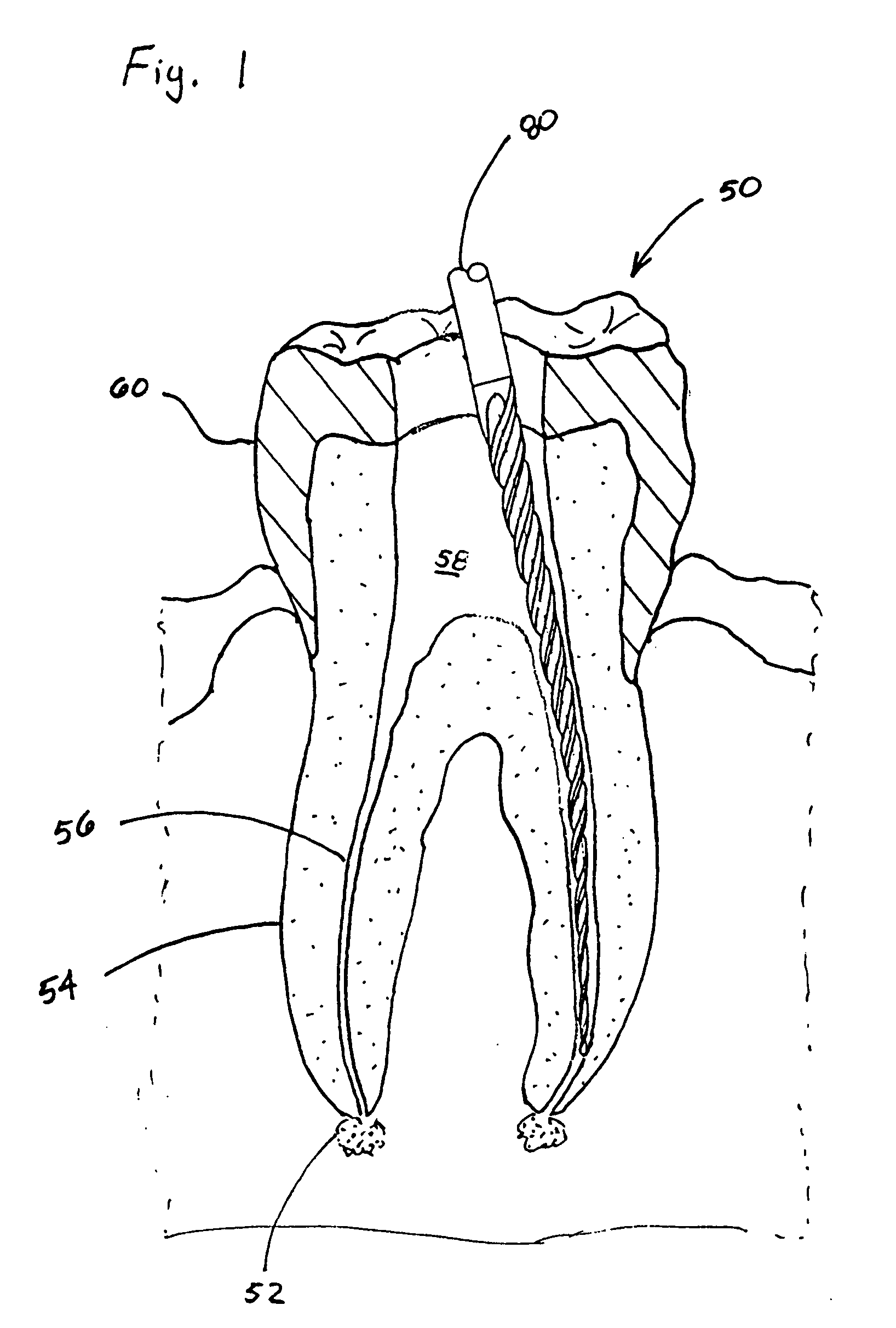

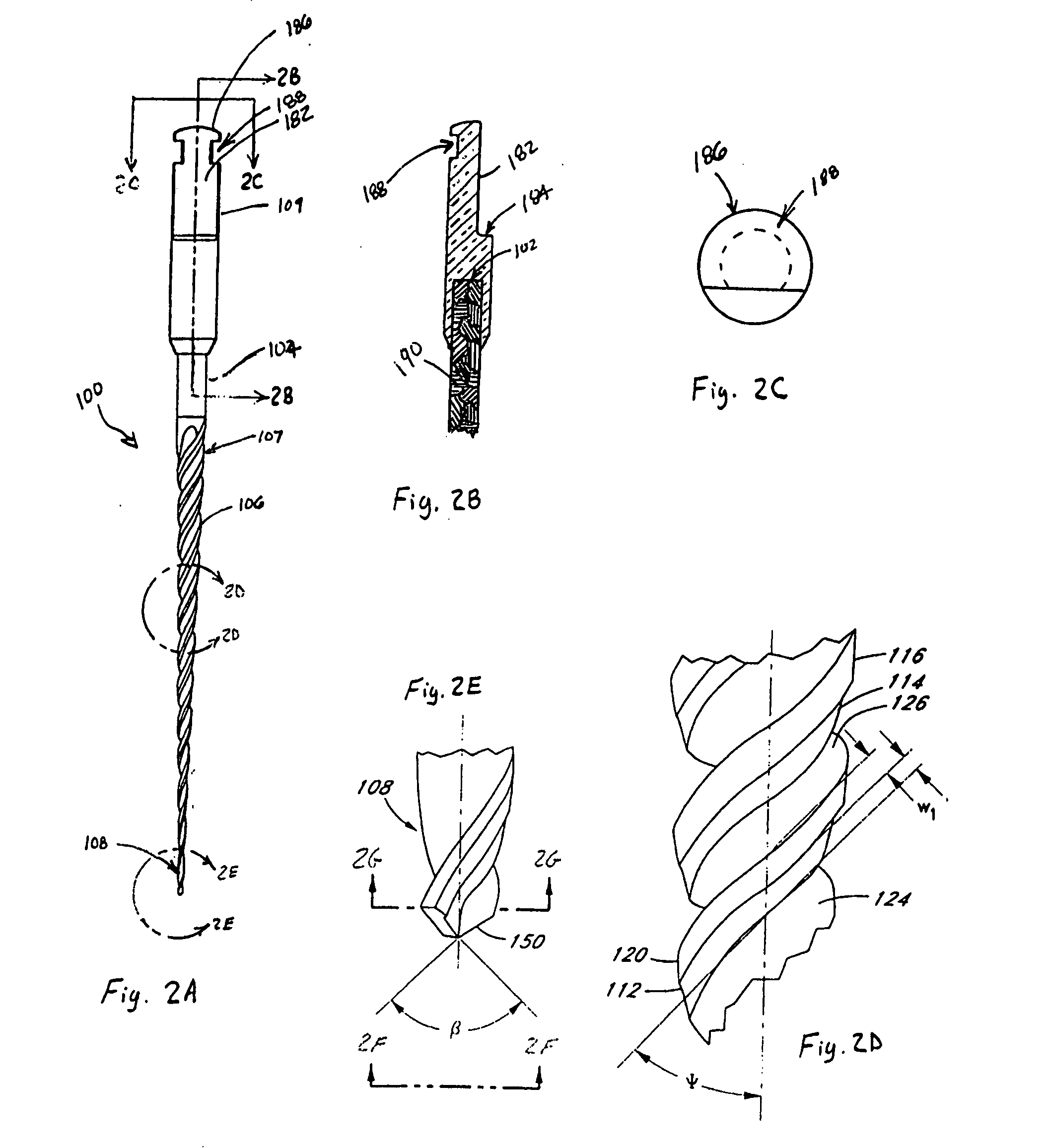

Precision cast dental instrument

InactiveUS20070184406A1Resistance to breakageResistance to wearTransportation and packagingWristbandsDental structureInstrumentation

An endodontic file (200) is provided particularly adapted for the removal of tooth structure, decayed or damaged nerve tissues or dentine material on the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The endodontic instrument includes a shaft (202) having a shank portion (204) and a generally elongated working portion (206). The working portion preferably includes cutting or abrading features (232) adapted upon rotation and / or reciprocation of the instrument to cut, abrade or remove tissue from the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The working portion extends from a proximal end (207) adjacent the shank portion to a distal end (208) terminating at a tip (250). The entire instrument and / or at least the working portion thereof is formed of an amorphous or essentially amorphous material having no or essentially no detectable crystalline structure and / or from a nanocrystalline material having an average crystalline grain size less than about 1 μm. The instrument may be formed by conventional grinding operations or by direct casting, forging or molding, in a manner producing an integral as-molded instrument having one or more sharp cutting edges. The instrument is inexpensive to manufacture and exhibits improved cutting-edge sharpness, wear resistance, lubriciousness and resistance to breakage.

Owner:CLOUDLAND INST

Grinding material for precision casting

The invention relates to a precise casting mold material, which comprises: petroleum wax, petroleum resin, high polymer, mineral wax and animal-plant wax. This product has high bending strength, superficial hardness, small linear shrinkage and ash, and well other properties, overcomes opposite in prior art, and fits to manufacture large-scale thin-wall integral fine-casting structure part.

Owner:CHINA PETROLEUM & CHEM CORP +1

Parametric machining method of air film cooling holes for precision casting turbine blades

ActiveCN107506519AImprove machining accuracyGuaranteed forming accuracyGeometric CADDesign optimisation/simulationTurbine bladeCooling effect

A parametric machining method of air film cooling holes for precision casting turbine blades relates to turbine blades. The method provides errors including casting deformation of components, positioning errors of clamps, and blade movement and deformation during small hole machining so as to achieve parametric accurate machining of hollow turbine blade air film holes. Through solving and calculating propagation and accumulation of error during air film machining, correcting design parameters of air film holes and processing the air film holes according to air film hole shape and location parameters which are the center point of the film hole, the normal of the film hole, and the hole depth of the air film hole after correction, the processing accuracy of the air film holes is increased and the cooling efficiency of turbine blades is increased. This method has important theoretical significance and application value for precise forming of hollow turbine blade, avoids the present situation of air cooling efficiency reduction in the field of air film hole processing, ensures the precision of air film hole forming and achieves the air cooling effect consistent with the design requirements.

Owner:XIAMEN UNIV +1

Packing mold material used in investment precision casting

InactiveCN102876054ALow linear shrinkageHigh strengthFoundry moulding apparatusWaxInvestment casting

The invention relates to a packing mold material used in investment precision casting, which comprises starch serving as a packing material, and further comprises petroleum wax, organic superpolymer, rosin and 5 to 20 percent by mass of tapioca. As tapioca is added in the packing mold material, the shrinkage ratio and the expansion ratio of the packing mold material can be controlled effectively, which is very important for controlling casting dimensional precision in investment precision casting. The tapioca is wide in source, and lower in cost than other packing mold materials, and does not react with an investment casting shell. The packing mold material has the advantages that the linear shrinkage ratio and the ash content are low and the strength, the smearing property and the flowability are better, thereby being suitable for manufacturing model wax of large thin-walled investment precision casting and ornamental article casting with higher surface quality requirements.

Owner:GUANGXI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com