Patents

Literature

413 results about "Nanocrystalline material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

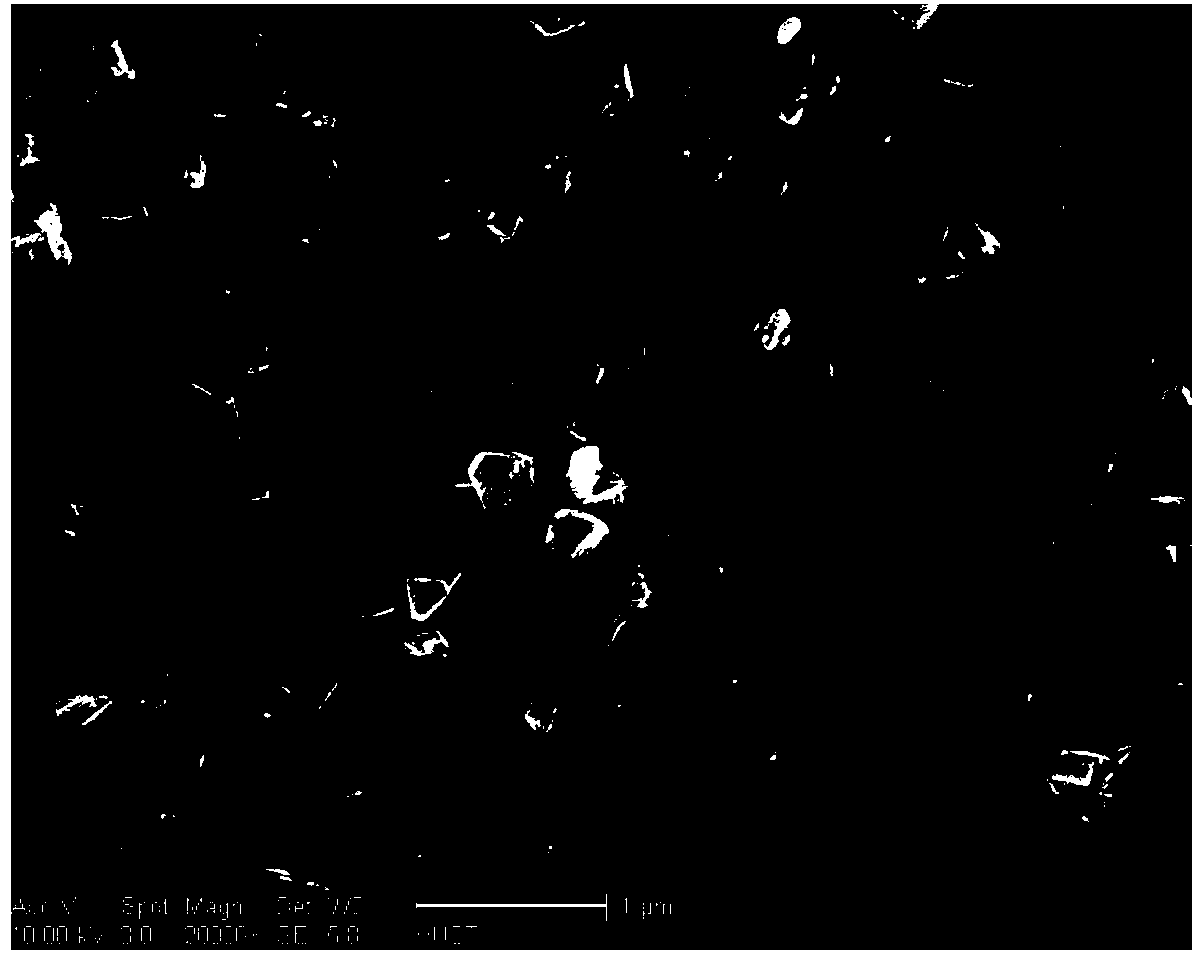

A nanocrystalline (NC) material is a polycrystalline material with a crystallite size of only a few nanometers. These materials fill the gap between amorphous materials without any long range order and conventional coarse-grained materials. Definitions vary, but nanocrystalline material is commonly defined as a crystallite (grain) size below 100 nm. Grain sizes from 100–500 nm are typically considered "ultrafine" grains.

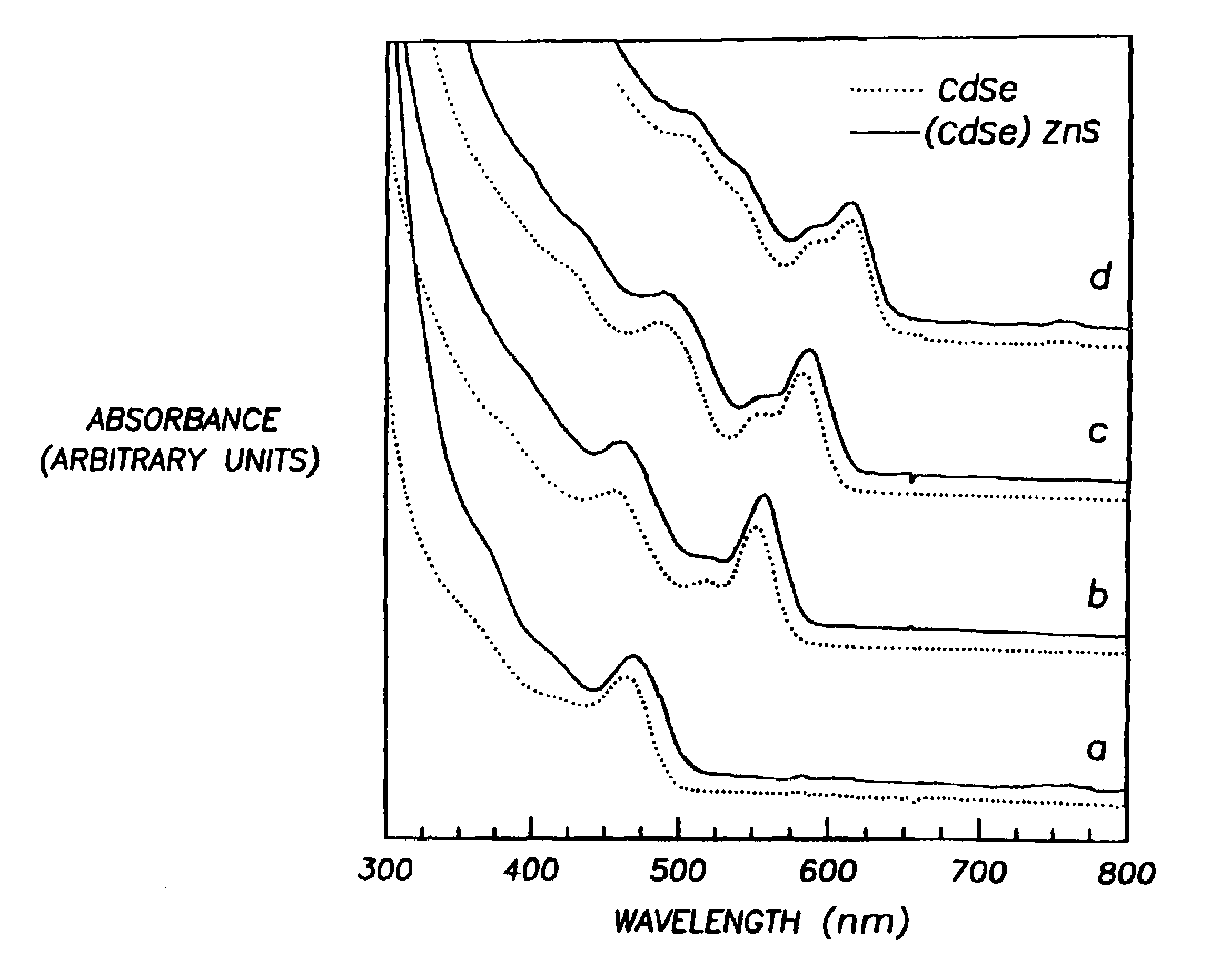

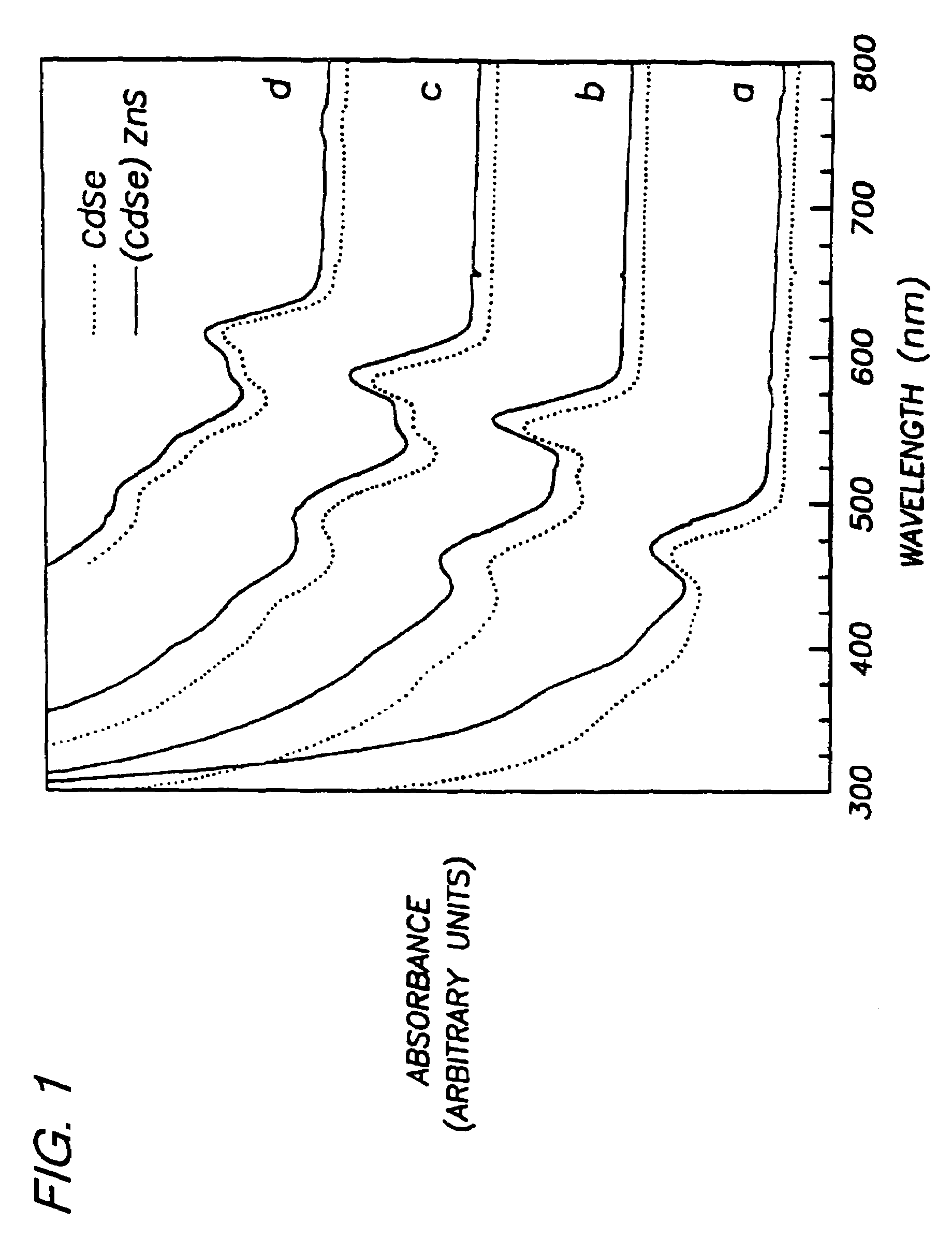

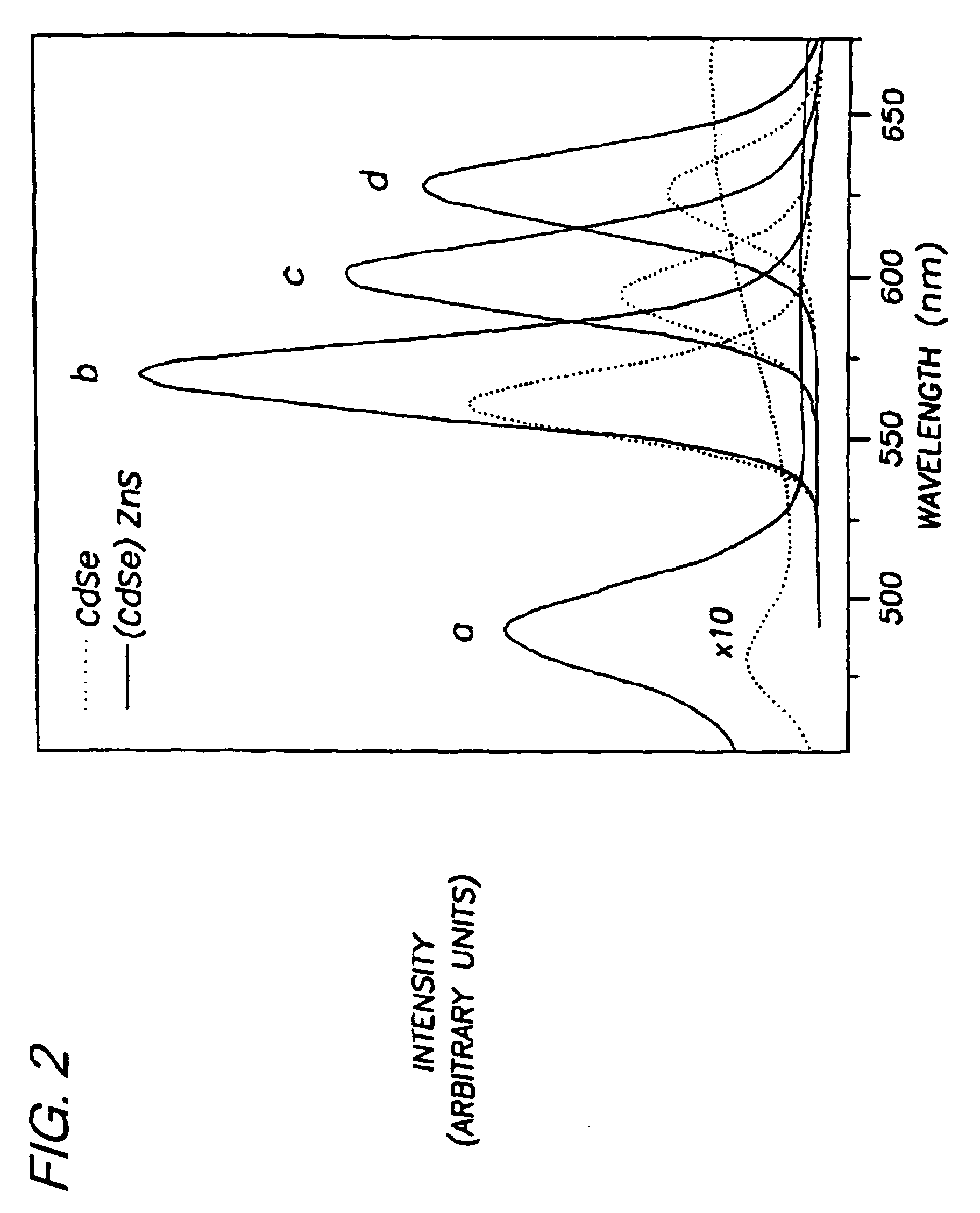

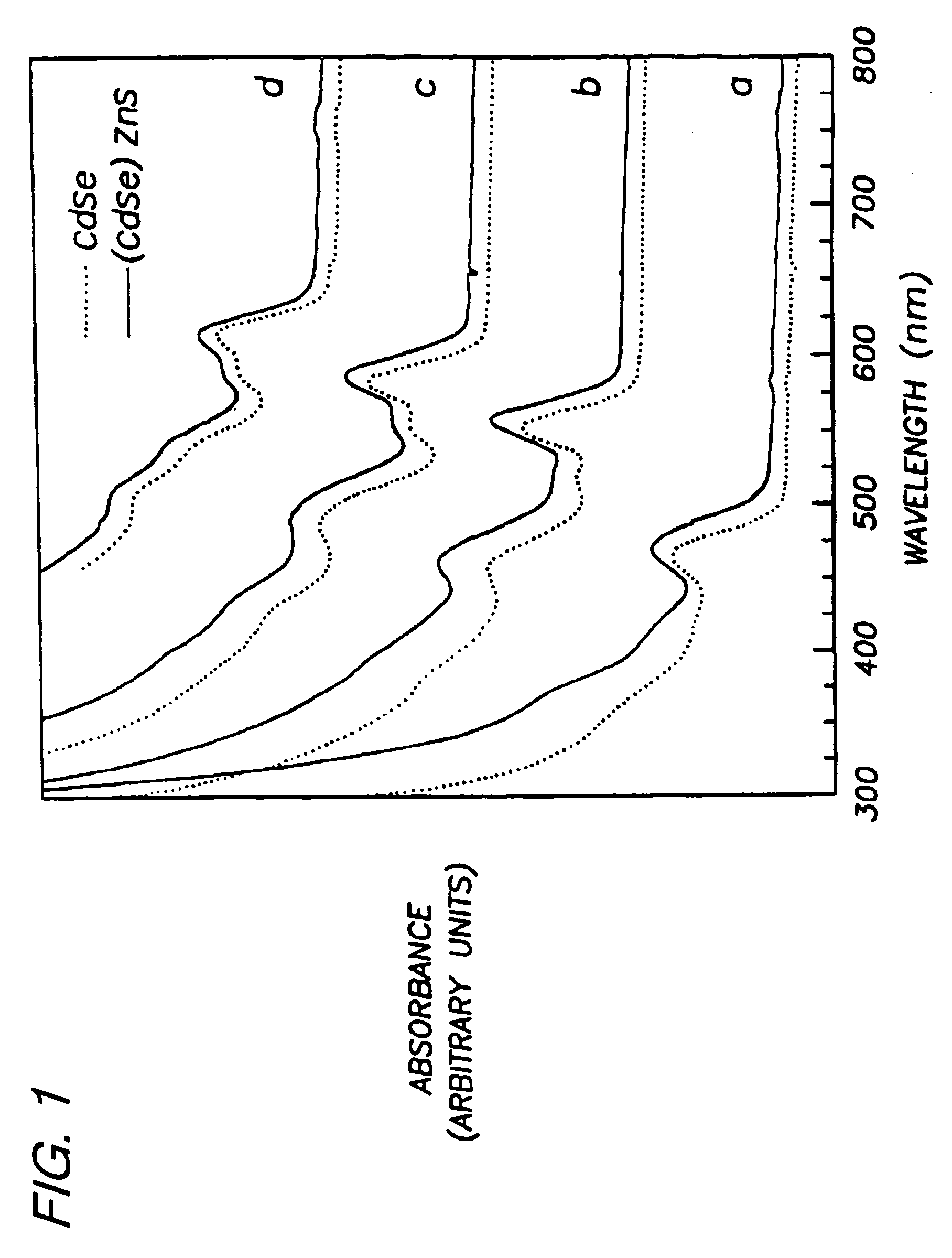

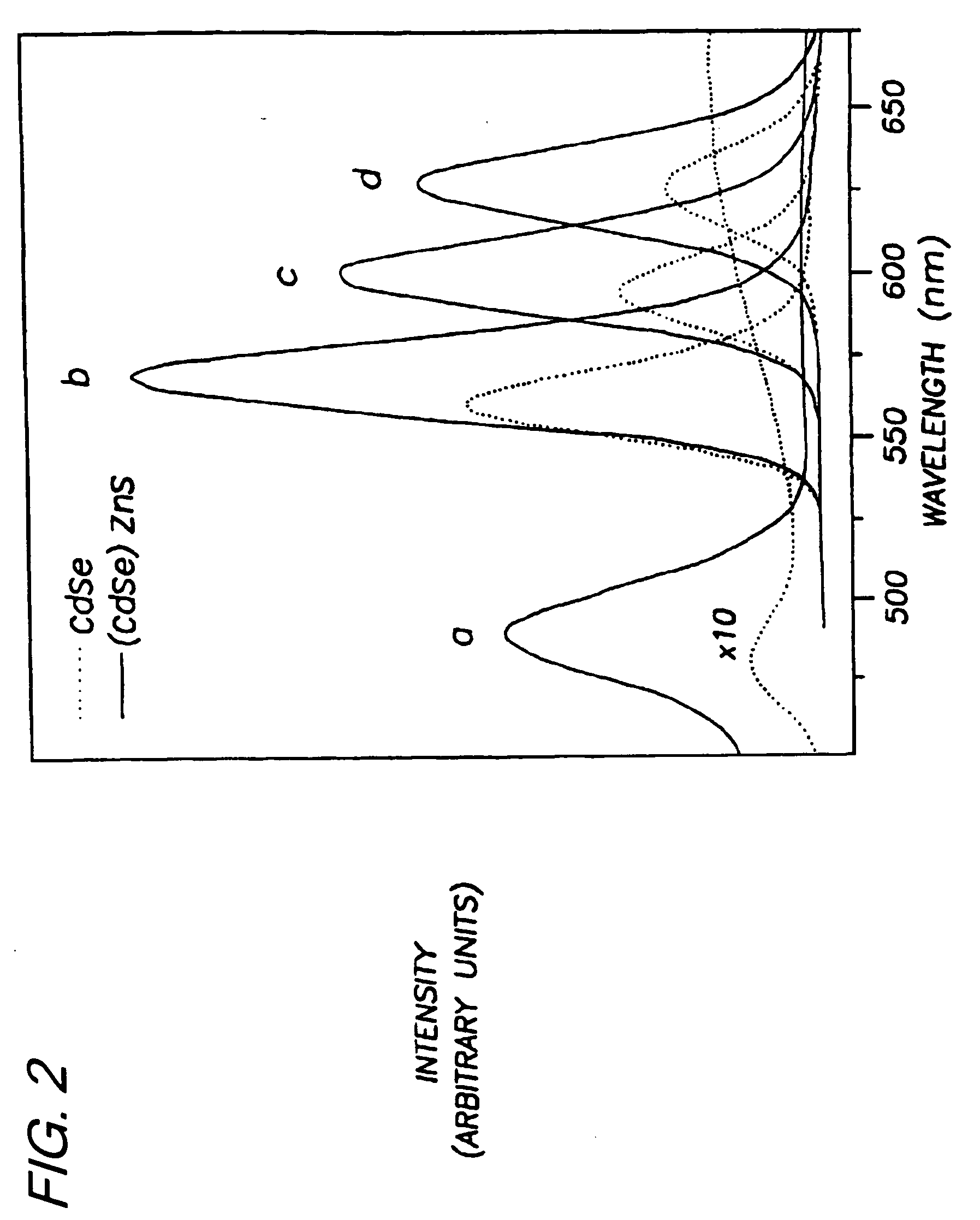

Highly luminescent color selective nanocrystalline materials

InactiveUS6861155B2Improve coordinationMaterial nanotechnologyFrom normal temperature solutionsQuantum yieldPhotoluminescence

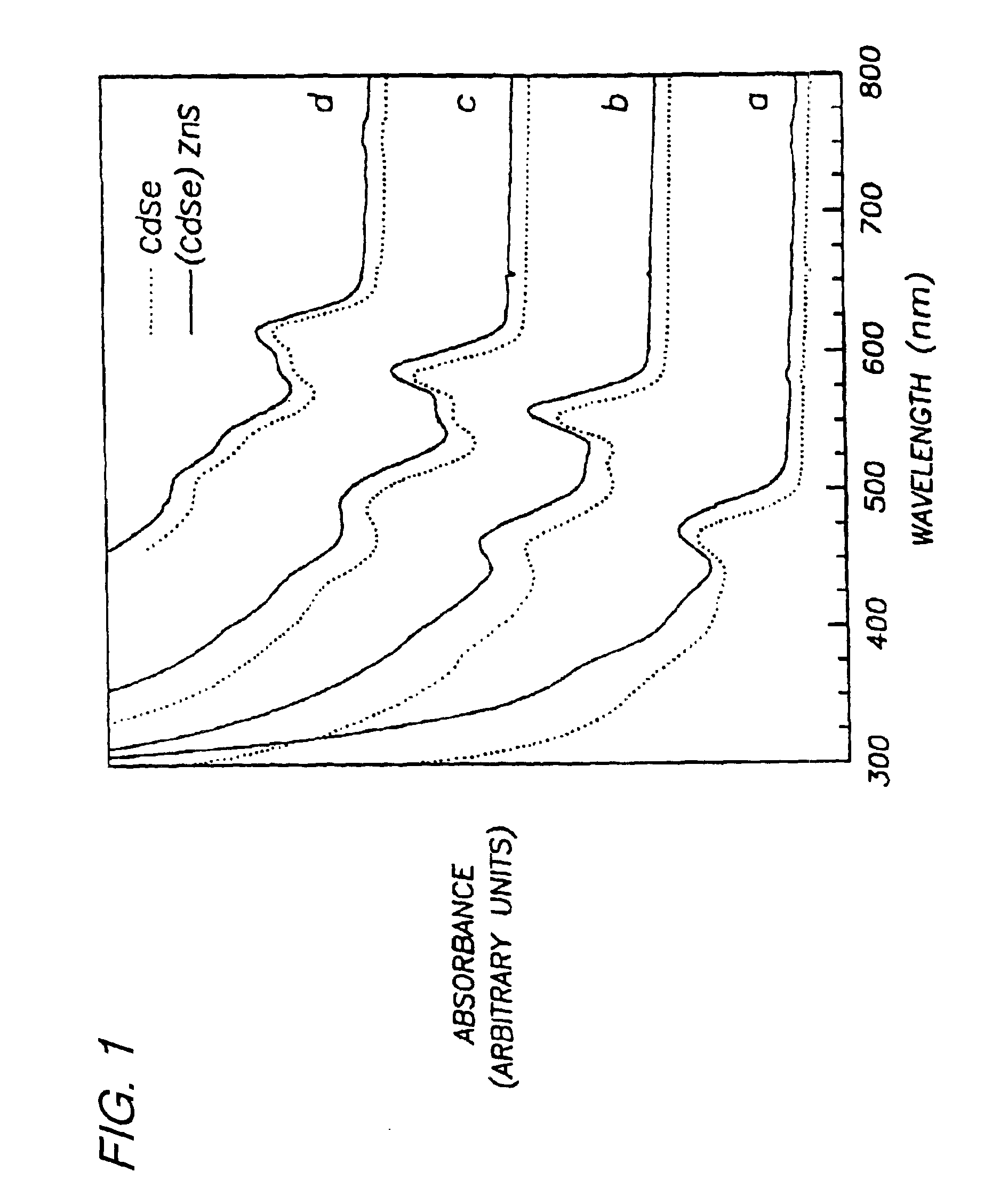

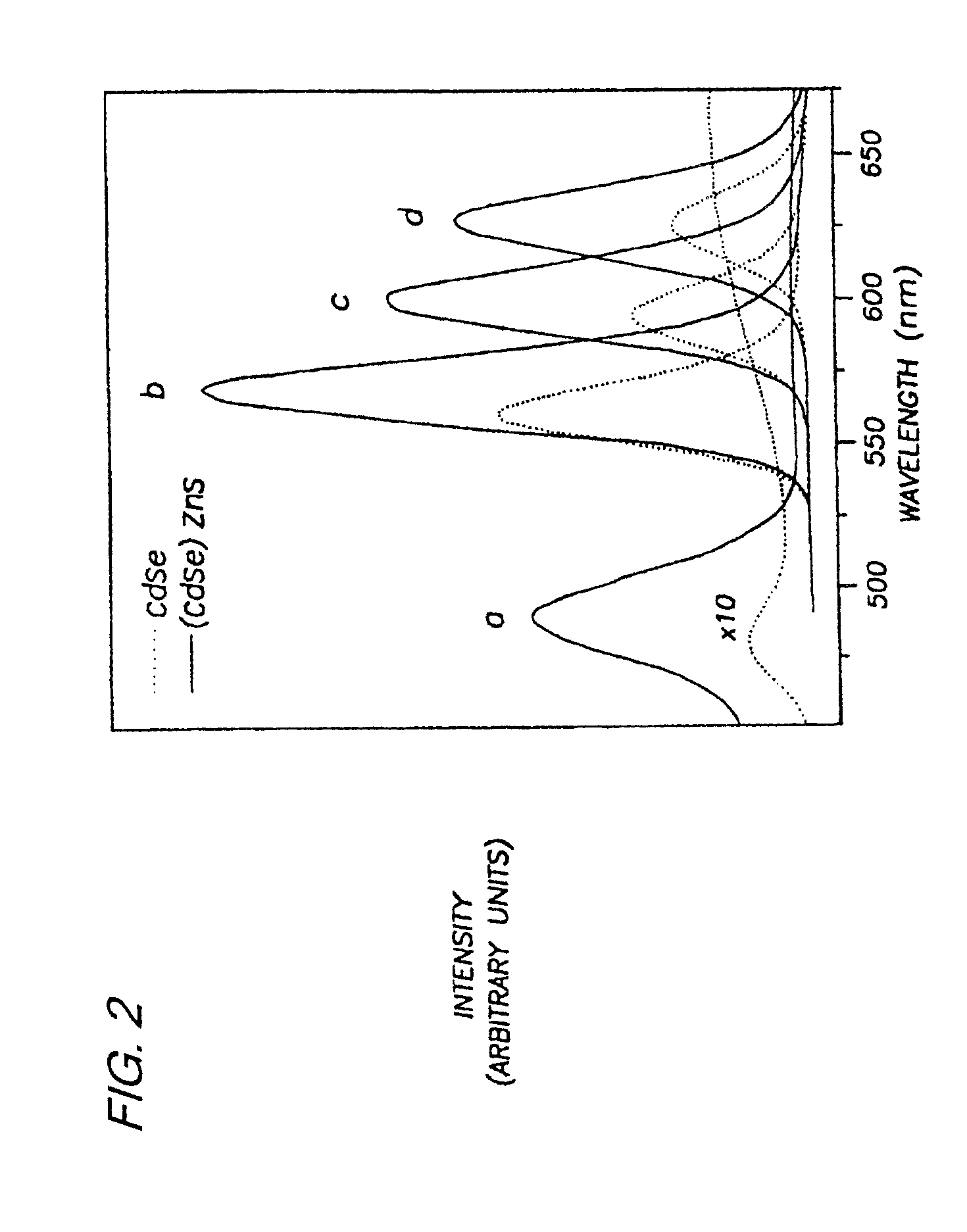

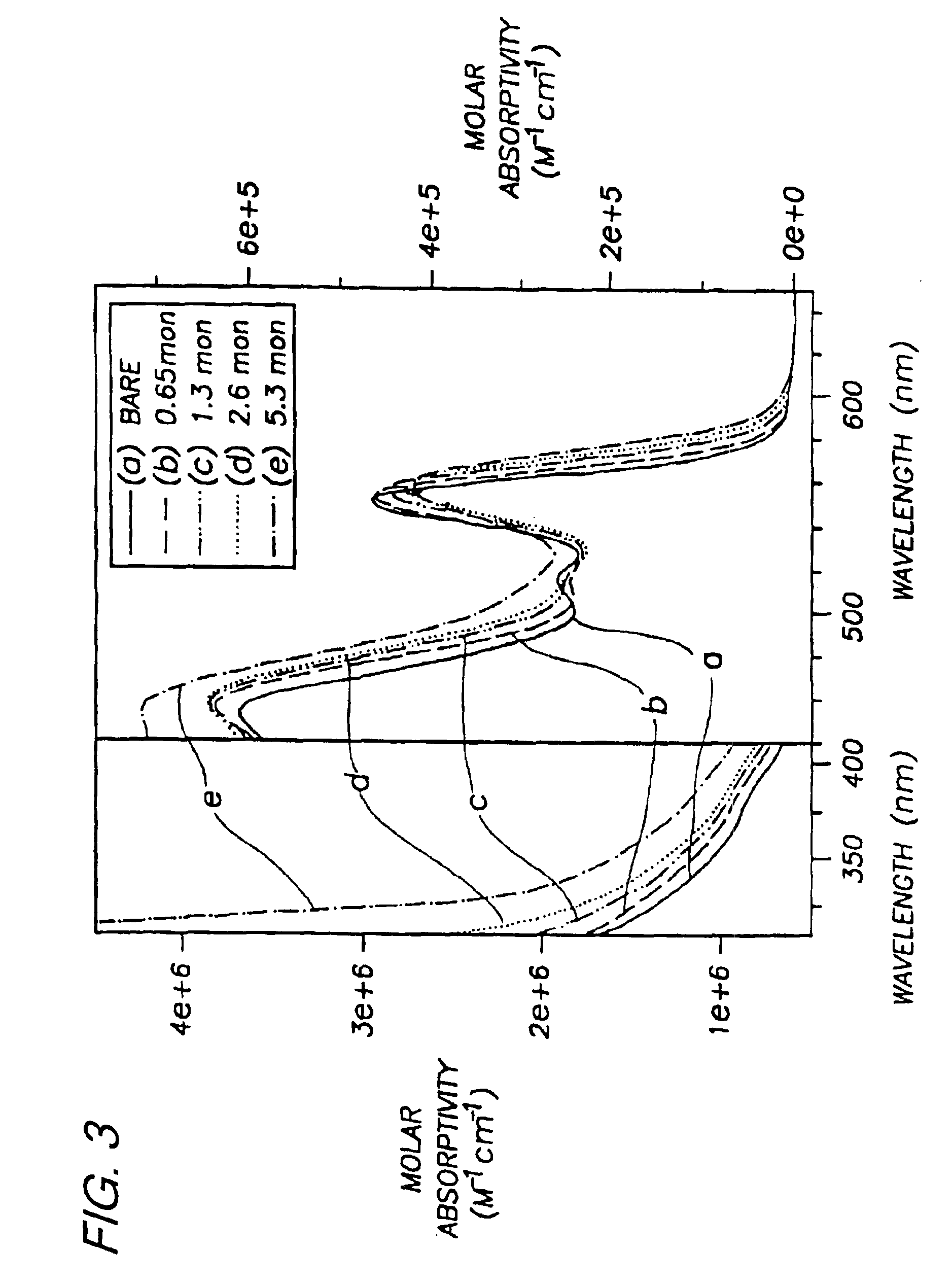

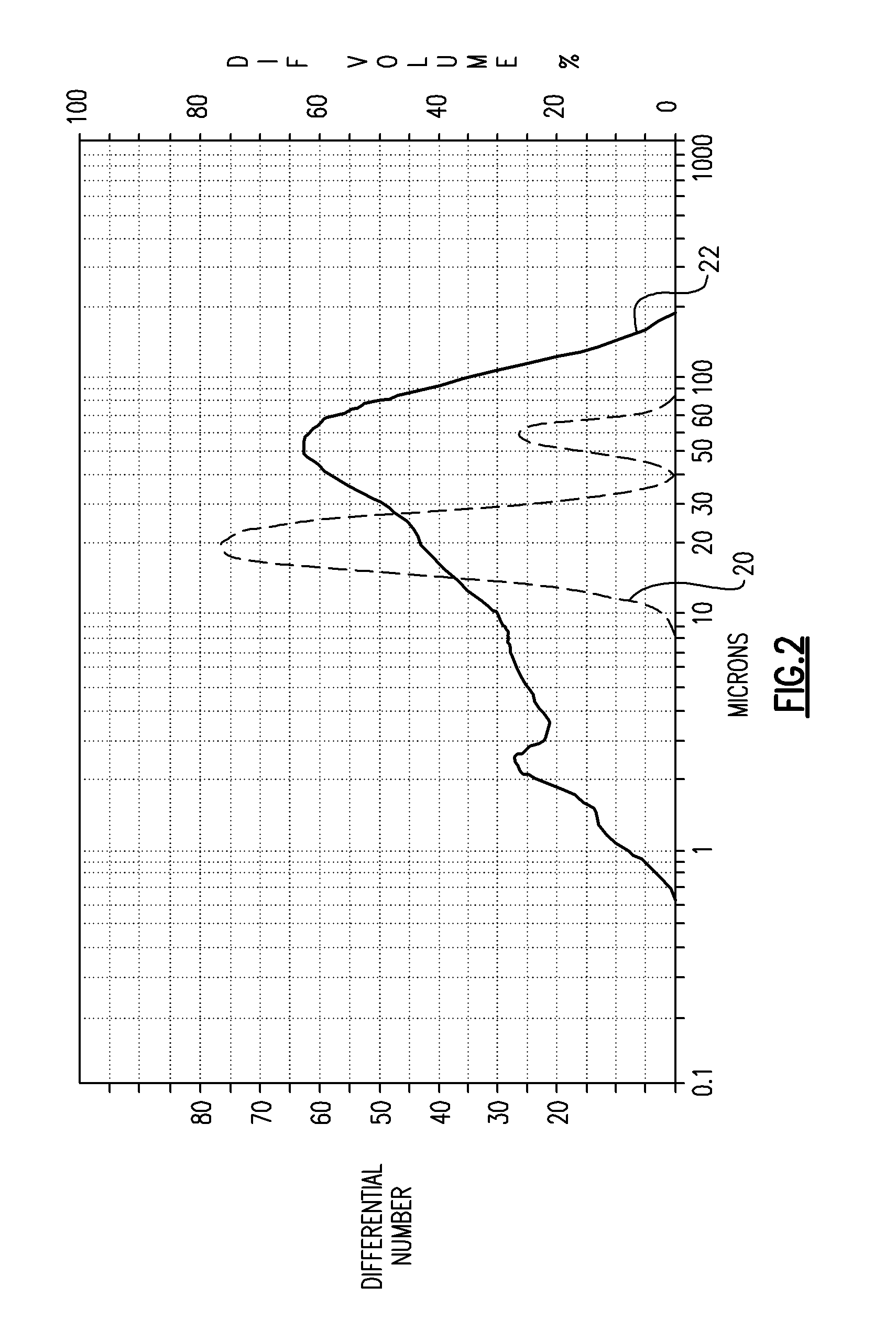

A coated nanocrystal capable of light emission includes a substantially monodisperse nanoparticle selected from the group consisting of CdX, where x=S, Se, Te and an overcoating of ZnY, where Y=S, Se, uniformly deposited thereon, said coated nanoparticle characterized in that when irradiated the particles exhibit photoluminescence in a narrow spectral range of no greater than about 60 nm, and most preferably 40 nm, at full width half max (FWHM). The particle size of the nanocrystallite core is in the range of about 20 Å to about 125 Å, with a deviation of less than 10% in the core. The coated nanocrystal exhibits photoluminescence having quantum yields of greater than 30%.

Owner:MASSACHUSETTS INST OF TECH

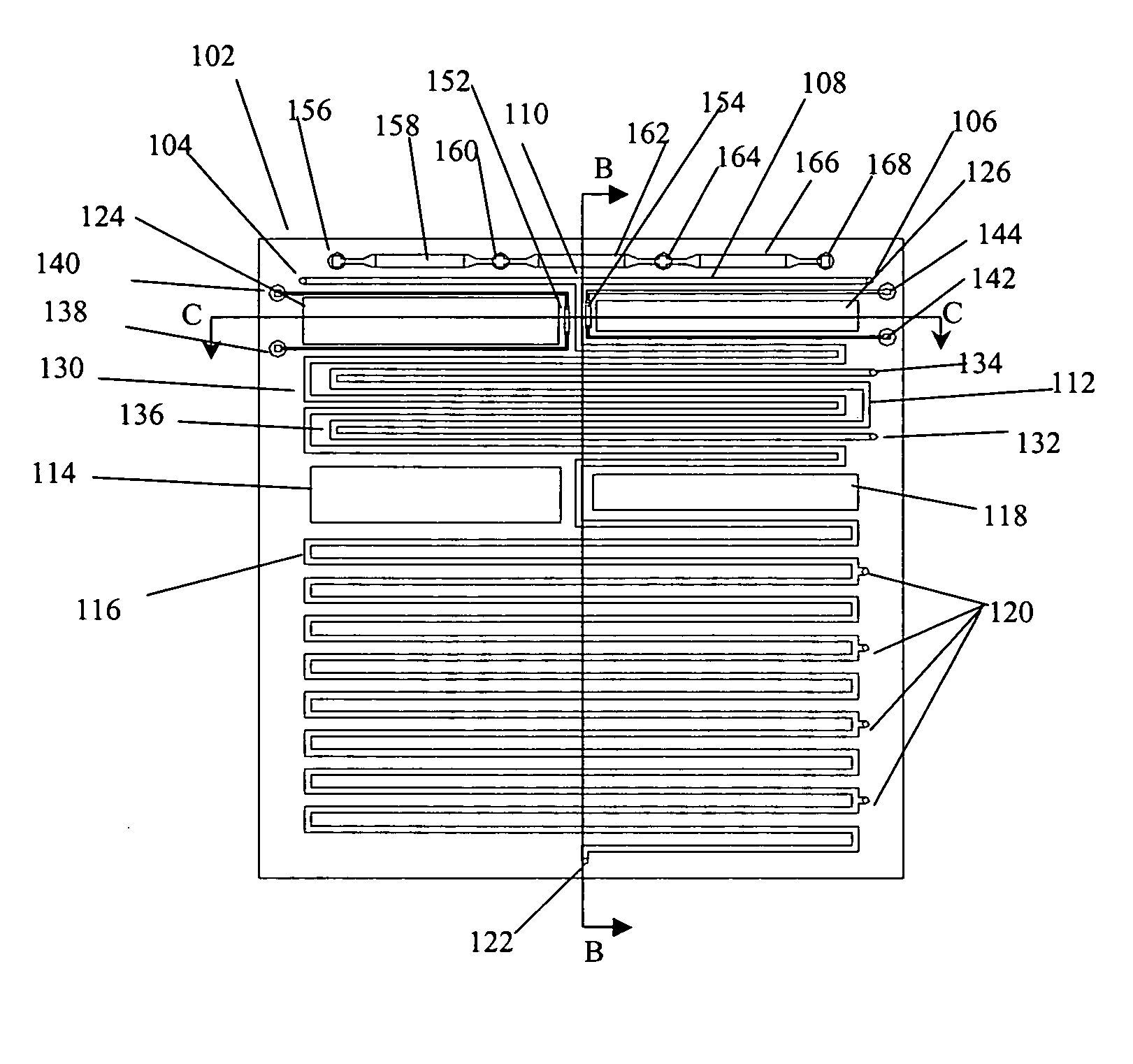

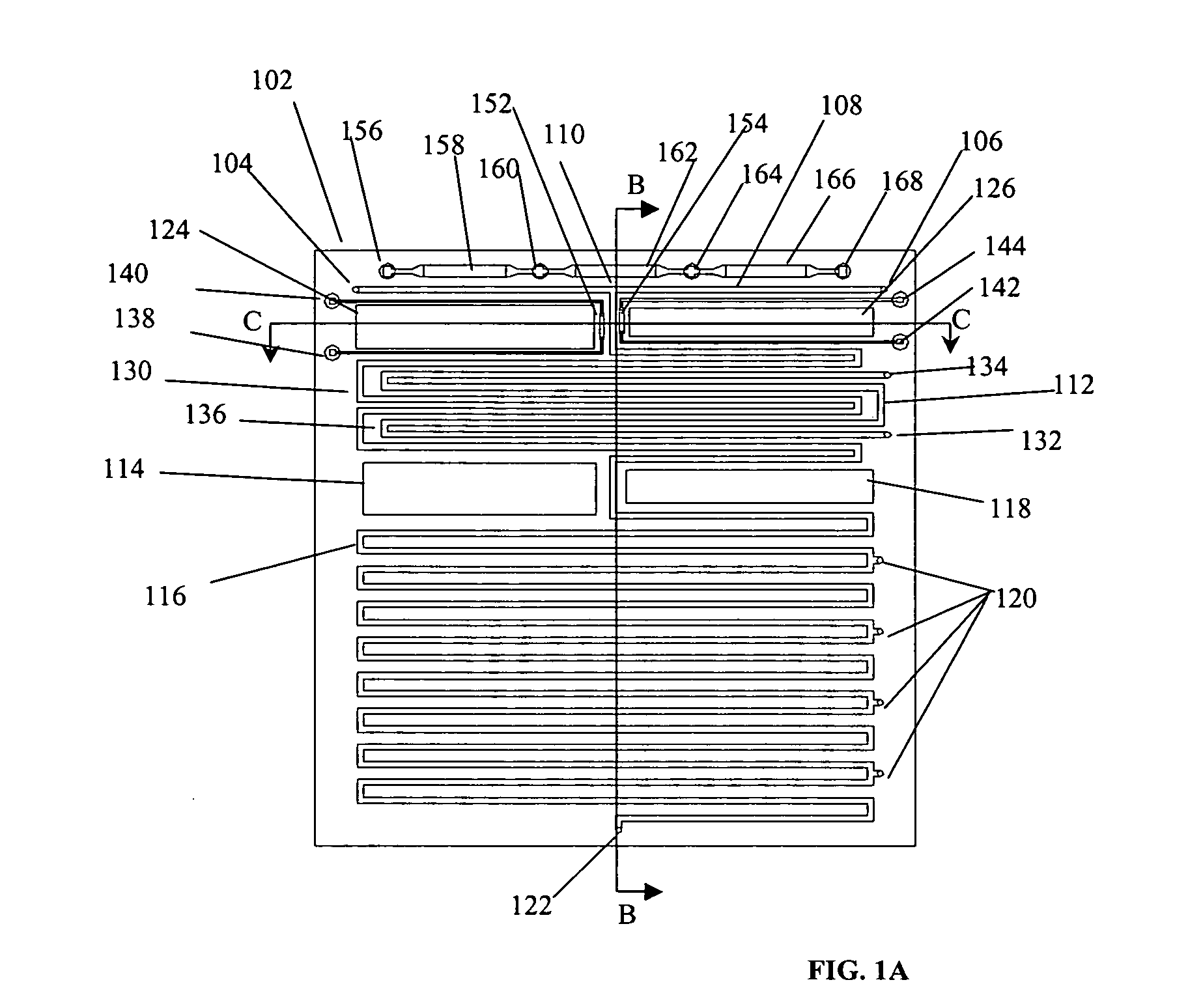

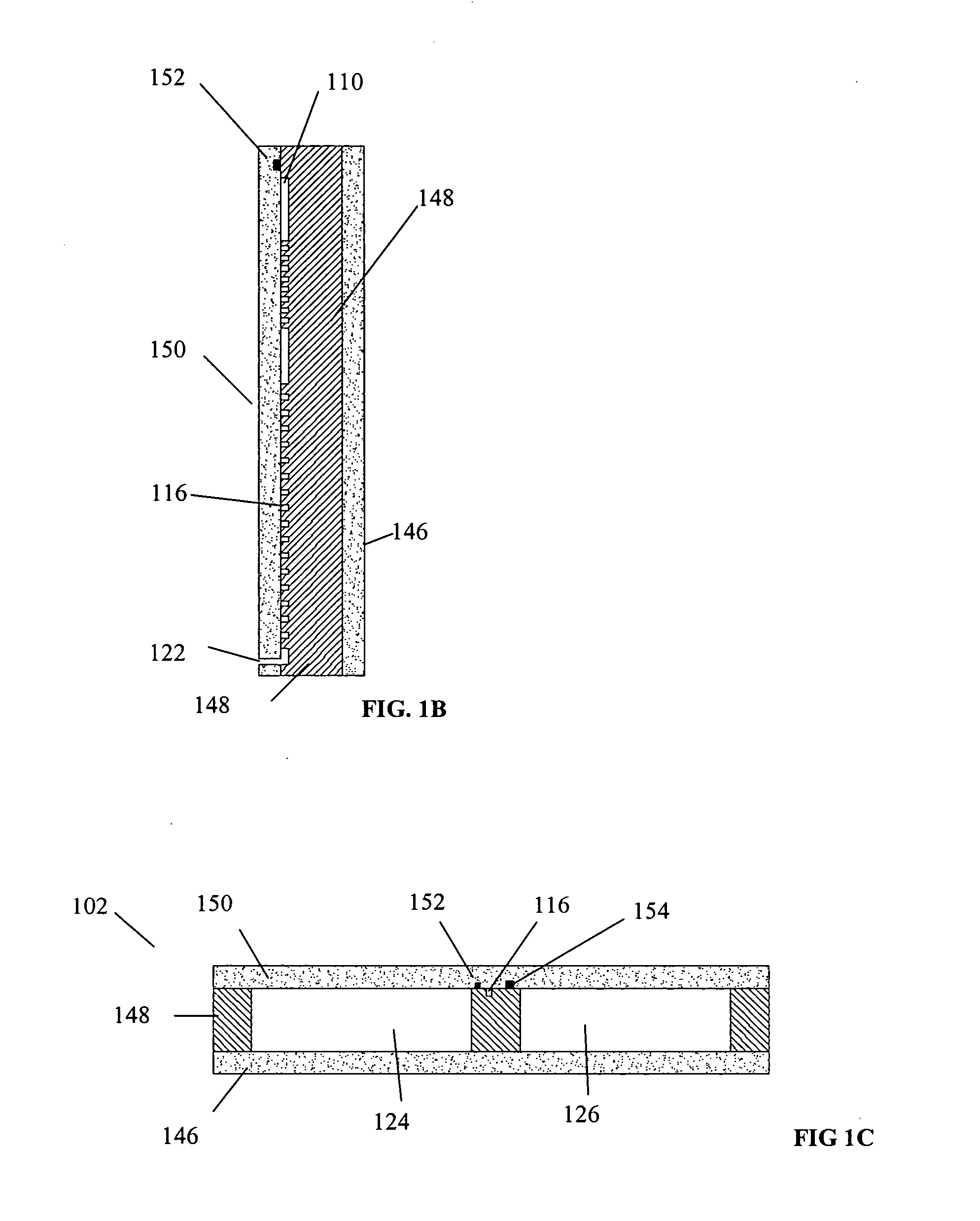

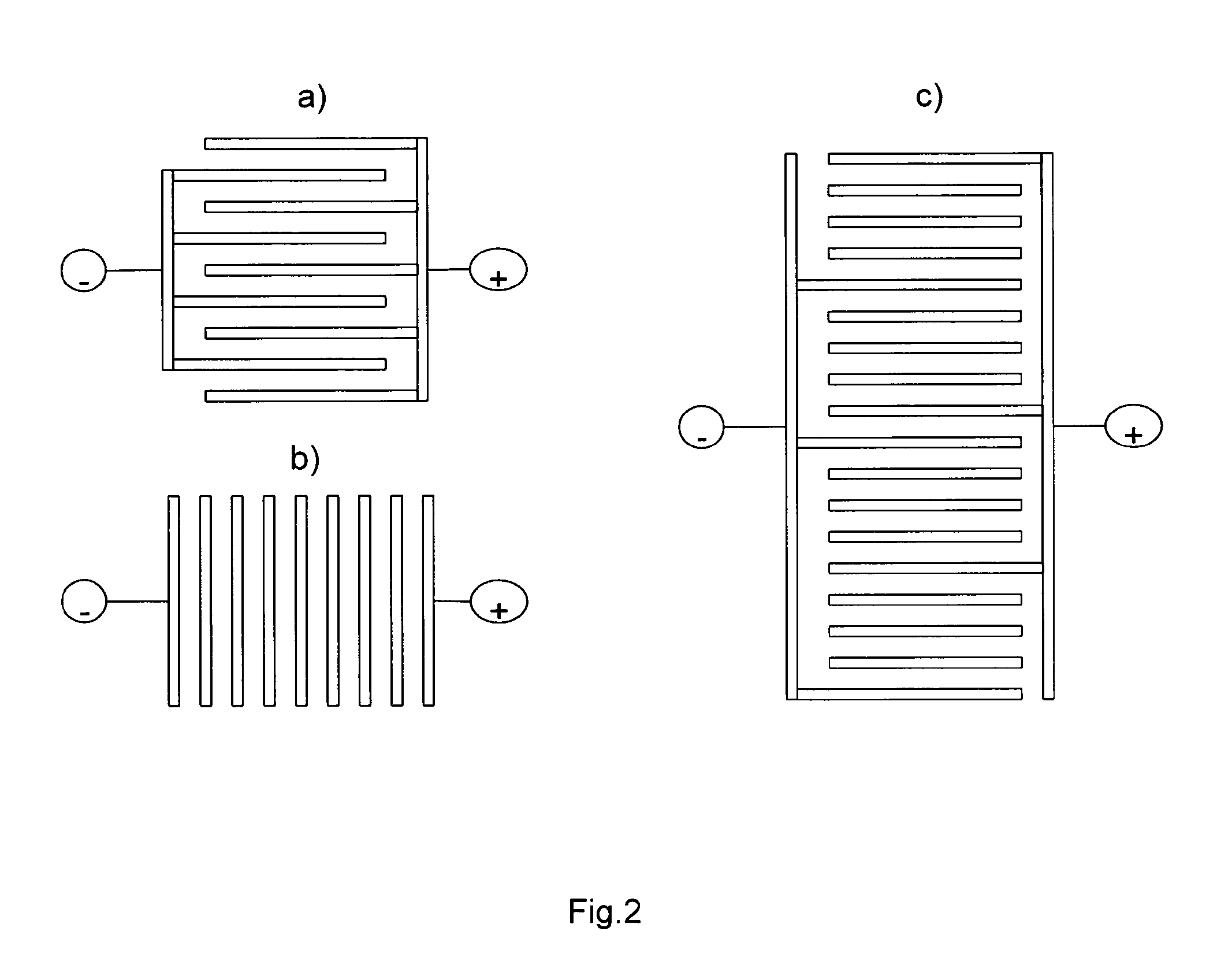

Microfluidic chemical reactor for the manufacture of chemically-produced nanoparticles

InactiveUS20050129580A1Maintain propertiesMaterial nanotechnologyPolycrystalline material growthProcess functionNanoparticle

The present invention discloses microfluidic modules for making nanocrystalline materials in a continuous flow process. The microfluidic modules include one or more flow path with mixing structures and one or more controlled heat exchangers to process the nanocrystalline materials and reagents in the flow path. The microfluidic modules can be interconnected to form microfluidic reactors that incorporate one or more process functions such as nucleation, growth, and purification.

Owner:LAKE SHORE CRYOTRONICS INC

Highly luminescent color-selective nanocrystalline materials

InactiveUS7125605B2Improve coordinationMaterial nanotechnologyFrom normal temperature solutionsQuantum yieldPhotoluminescence

A nanocrystal capable of light emission includes a nanoparticle having photoluminescence having quantum yields of greater than 30%.

Owner:MASSACHUSETTS INST OF TECH

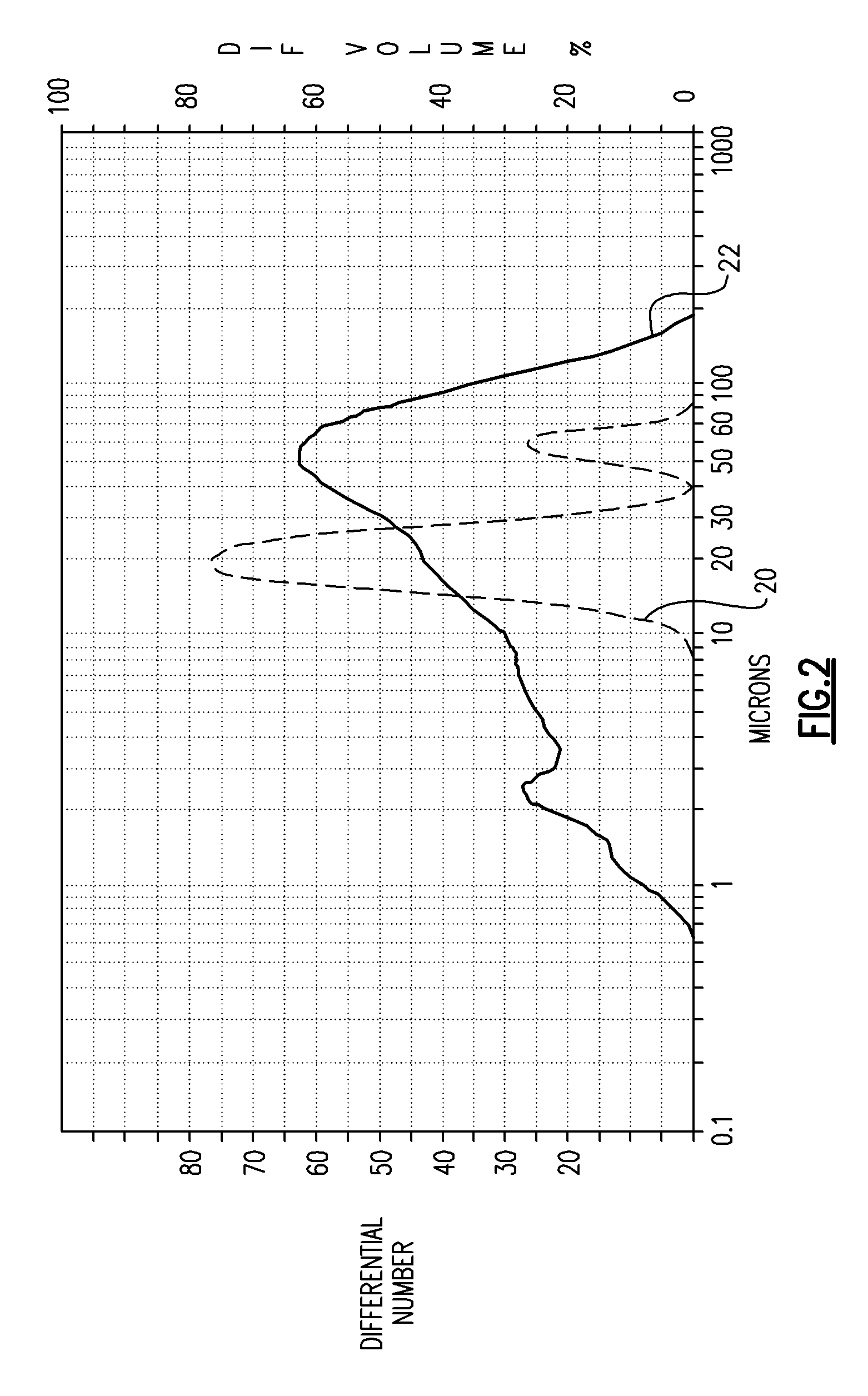

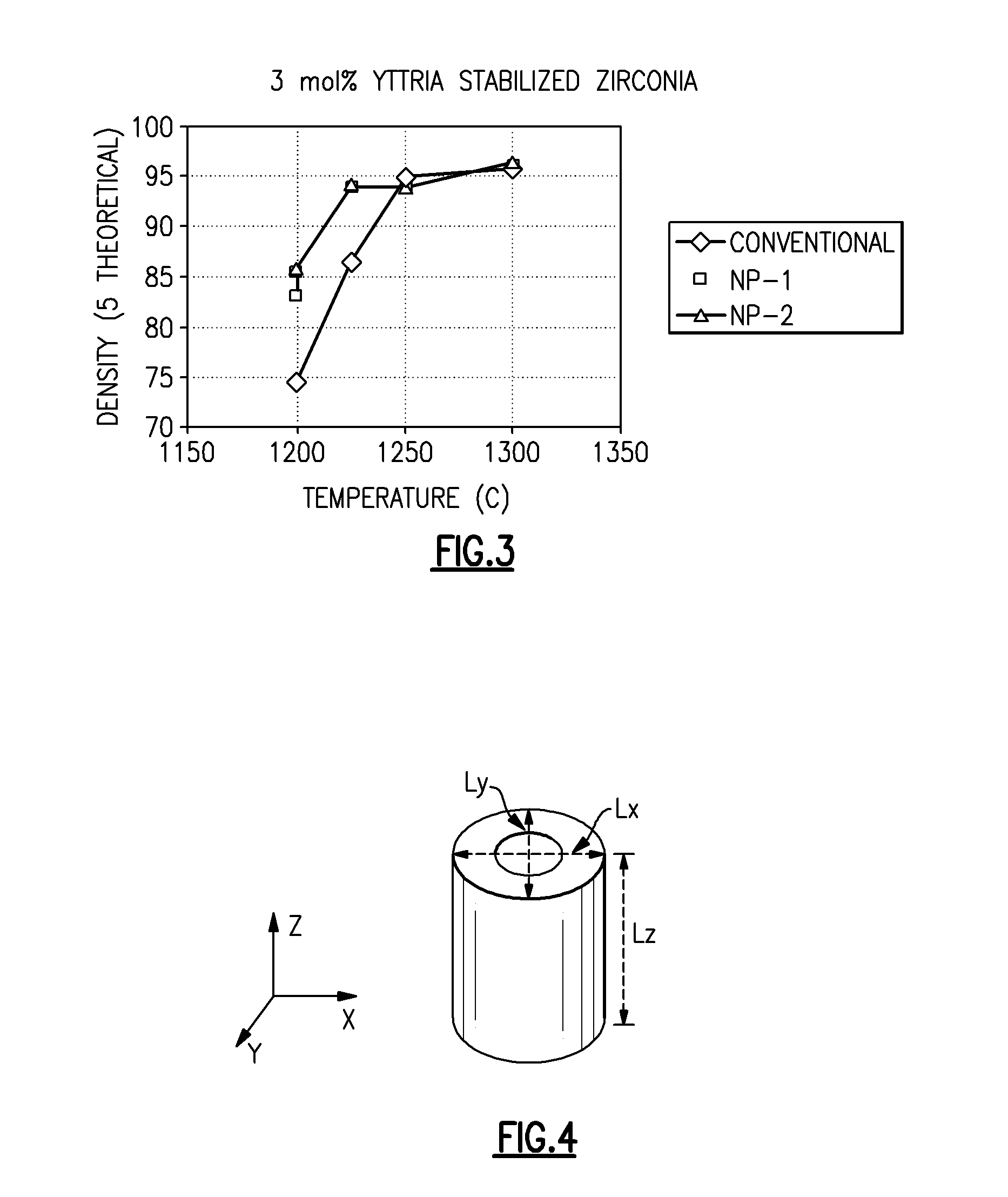

Dental restorations using nanocrystalline materials and methods of manufacture

Dental articles are produced using relatively low sintering temperatures to achieve high density dental articles exhibiting strengths equal to and greater than about 700 MPa. Ceramic powders comprised of nanoparticulate crystallites are used to manufacture dental articles. The ceramic powders may include sintering agents, binders and other similar additives to aid in the processing of the ceramic powder into a dental article. The ceramic powders may be processed into dental articles using various methods including, but not limited to, injection molding, gel-casting, slip casting, or electroforming, hand, cad / camming and other various rapid prototyping methods. The ceramic powder may be formed into a suspension, pellet, feedstock material or a pre-sintered blank prior to forming into the dental article.

Owner:IVOCLAR VIVADENT AG

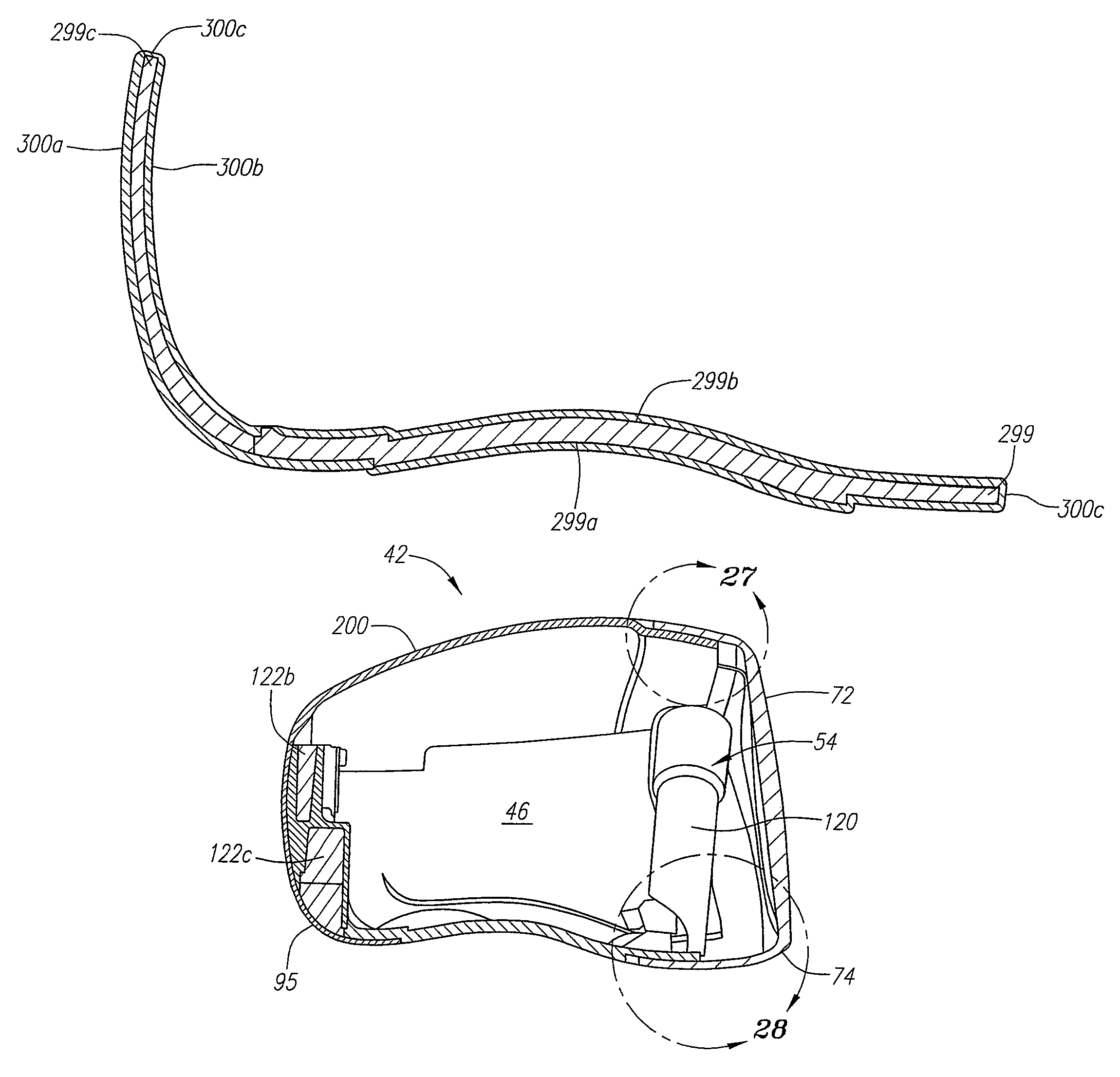

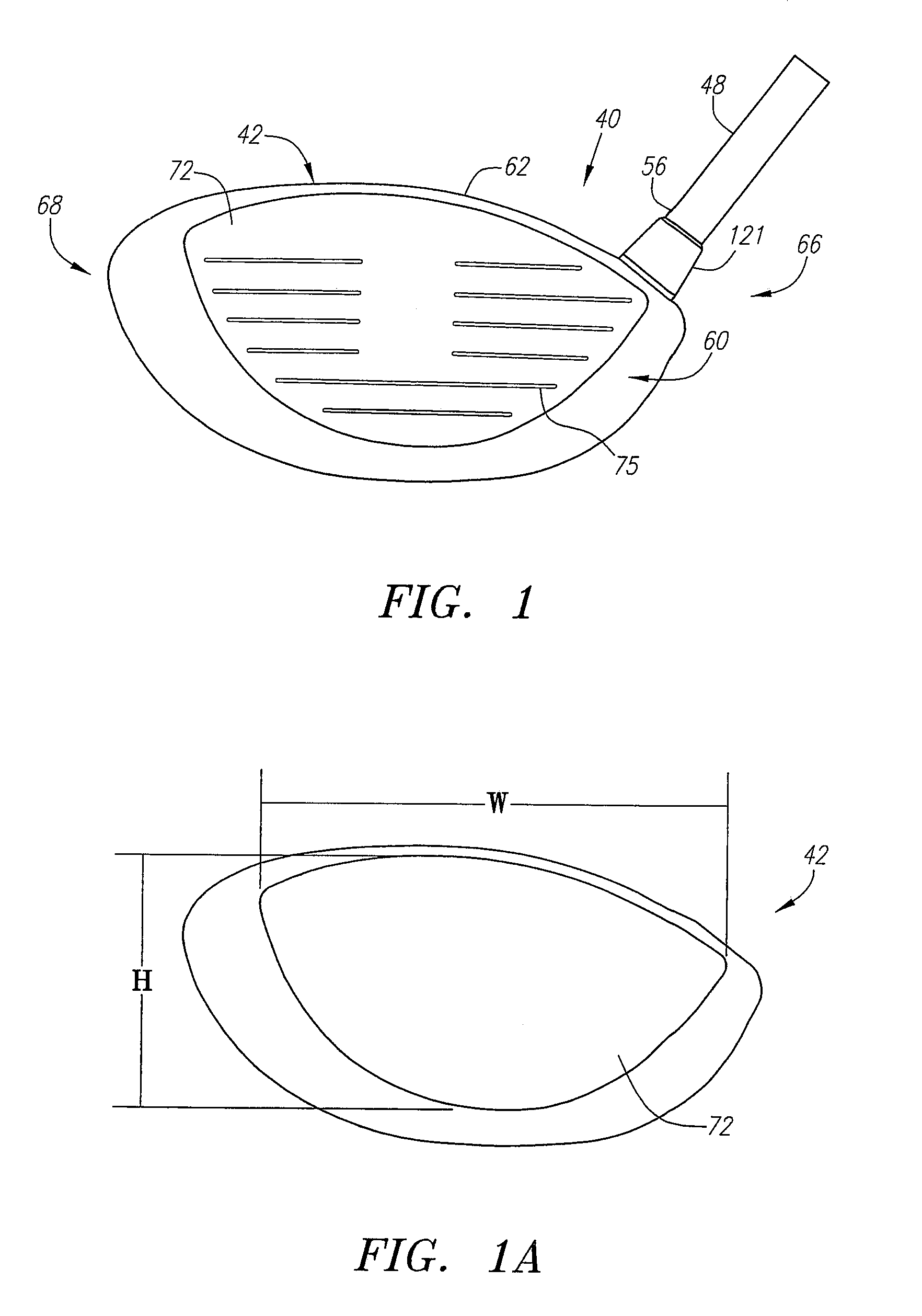

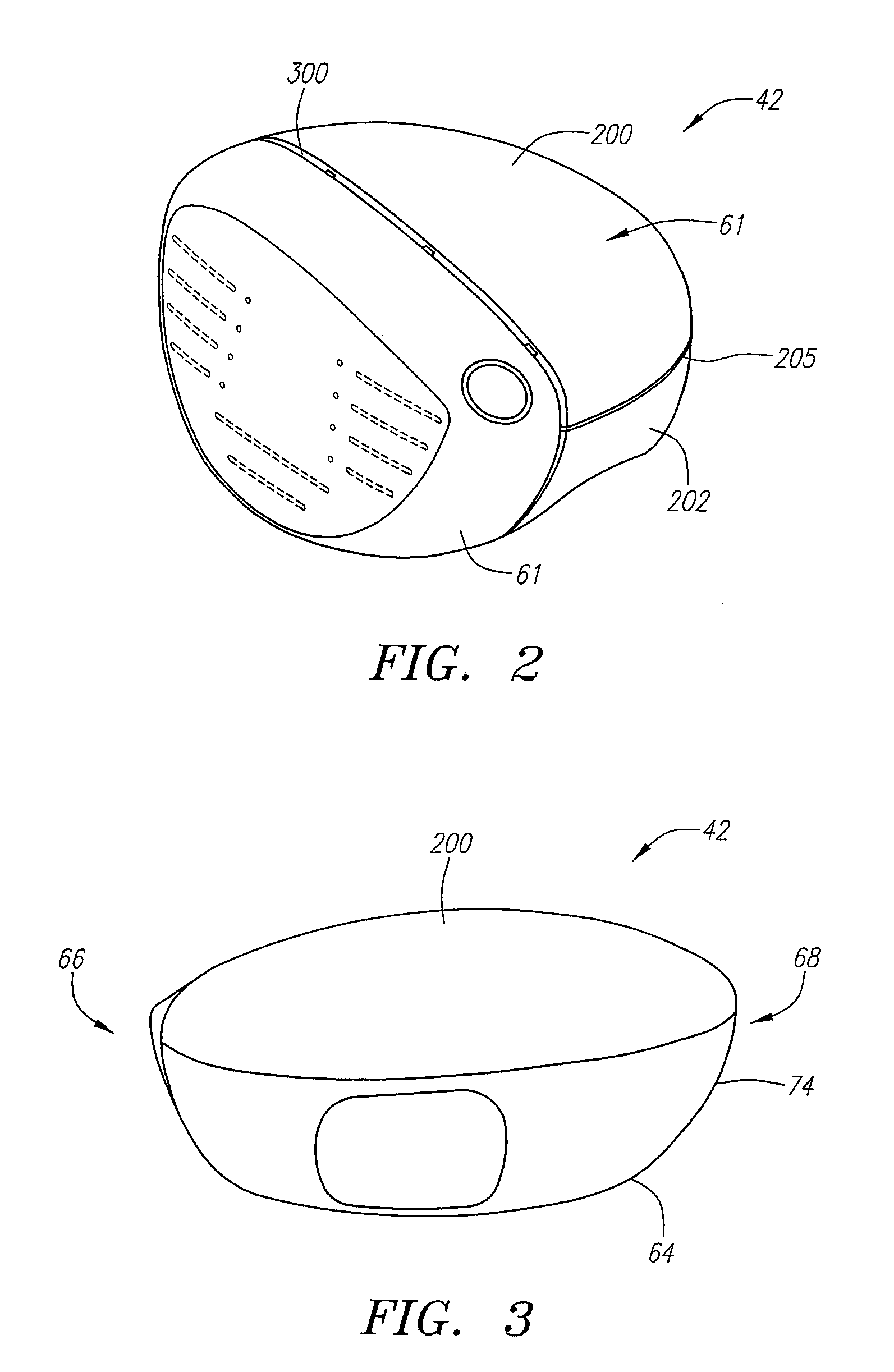

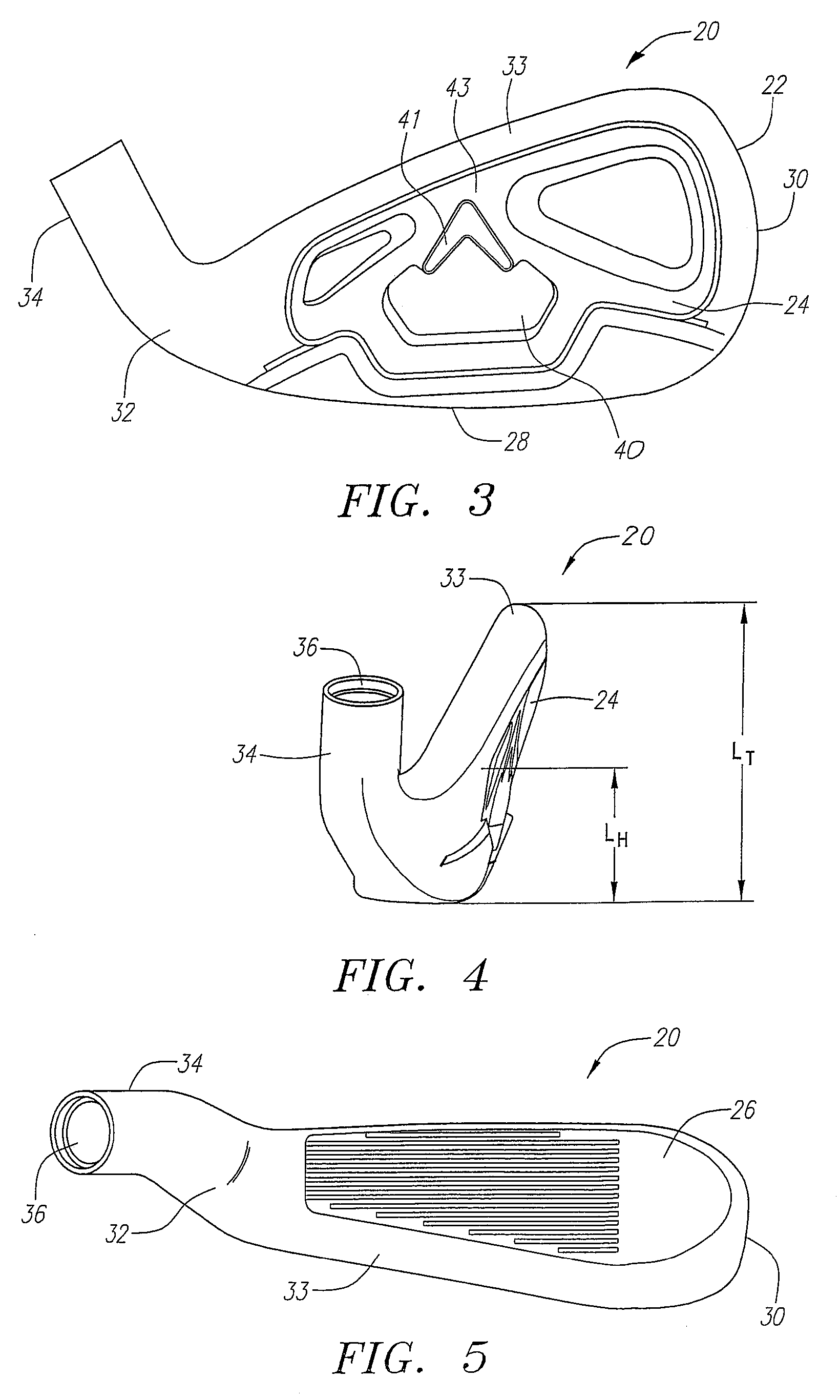

Nanocrystalline plated golf club head

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of an injectable polymer material such as a nylon. A plating layer (300) is disposed on at least a portion of the aft-body (61). The plating layer (300) preferably comprises a nanocrystalline material. The club head (42) preferably has a volume in the range of 290 cubic centimeters to 600 cubic centimeters.

Owner:TOPGOLF CALLAWAY BRANDS CORP

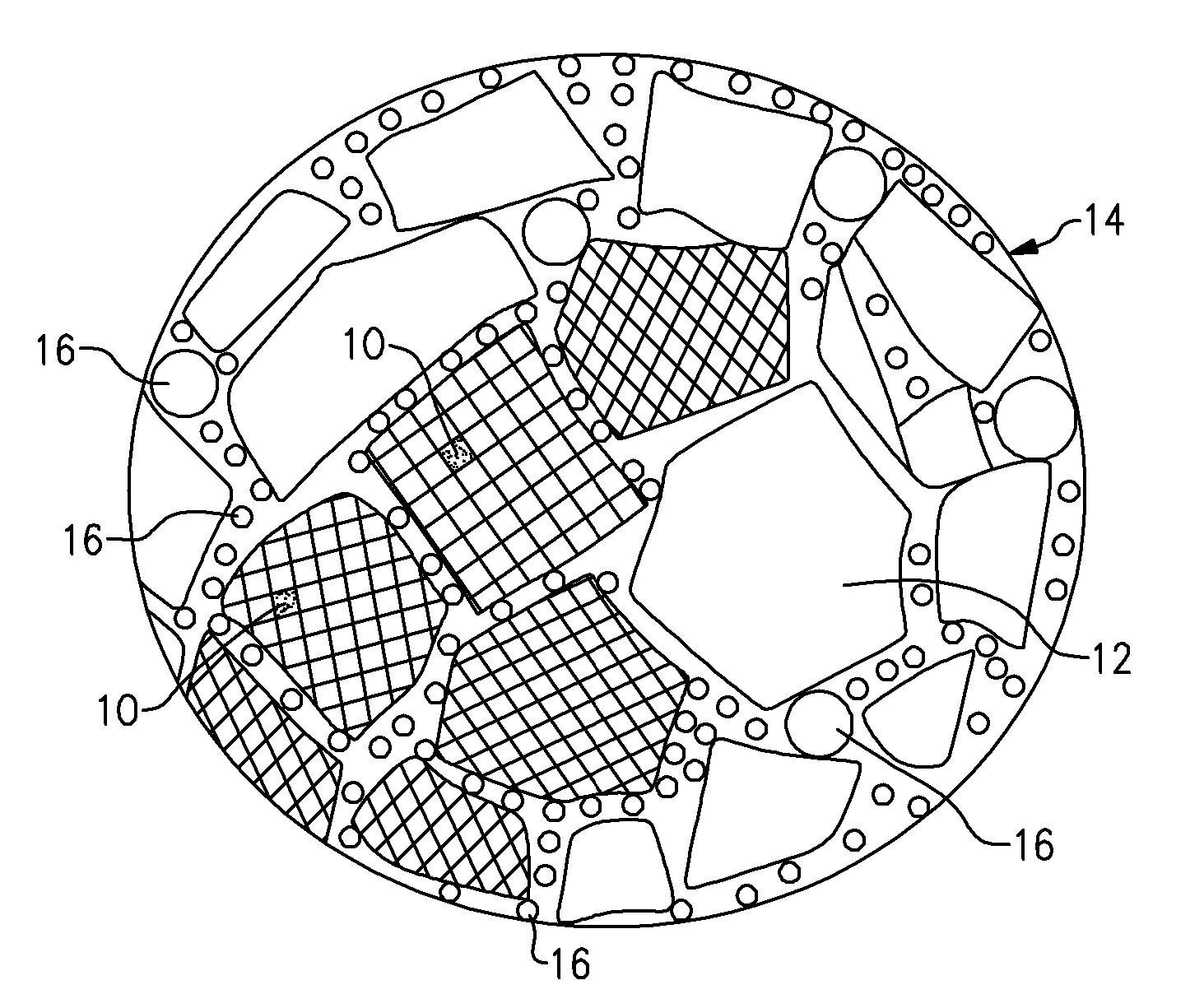

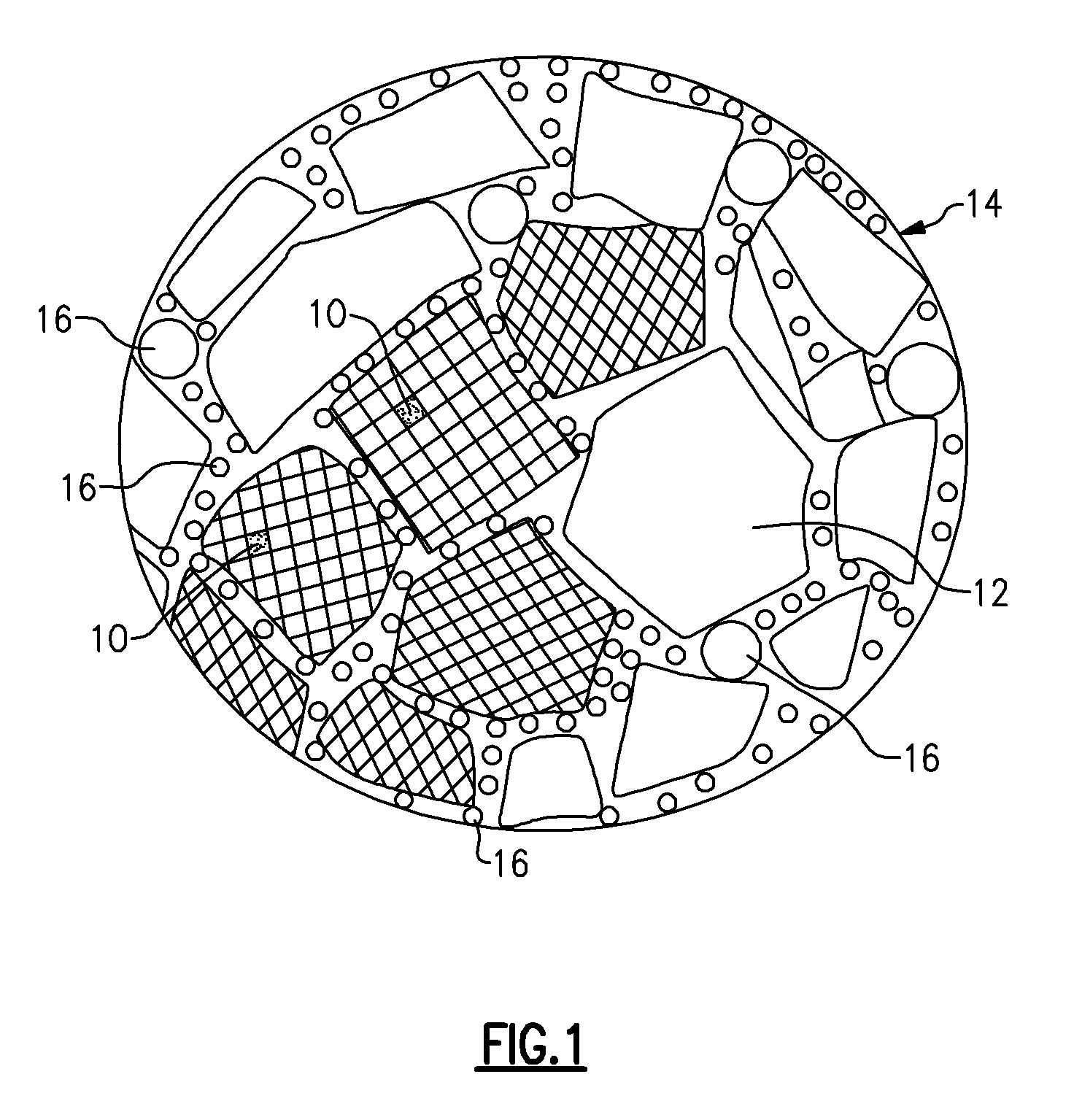

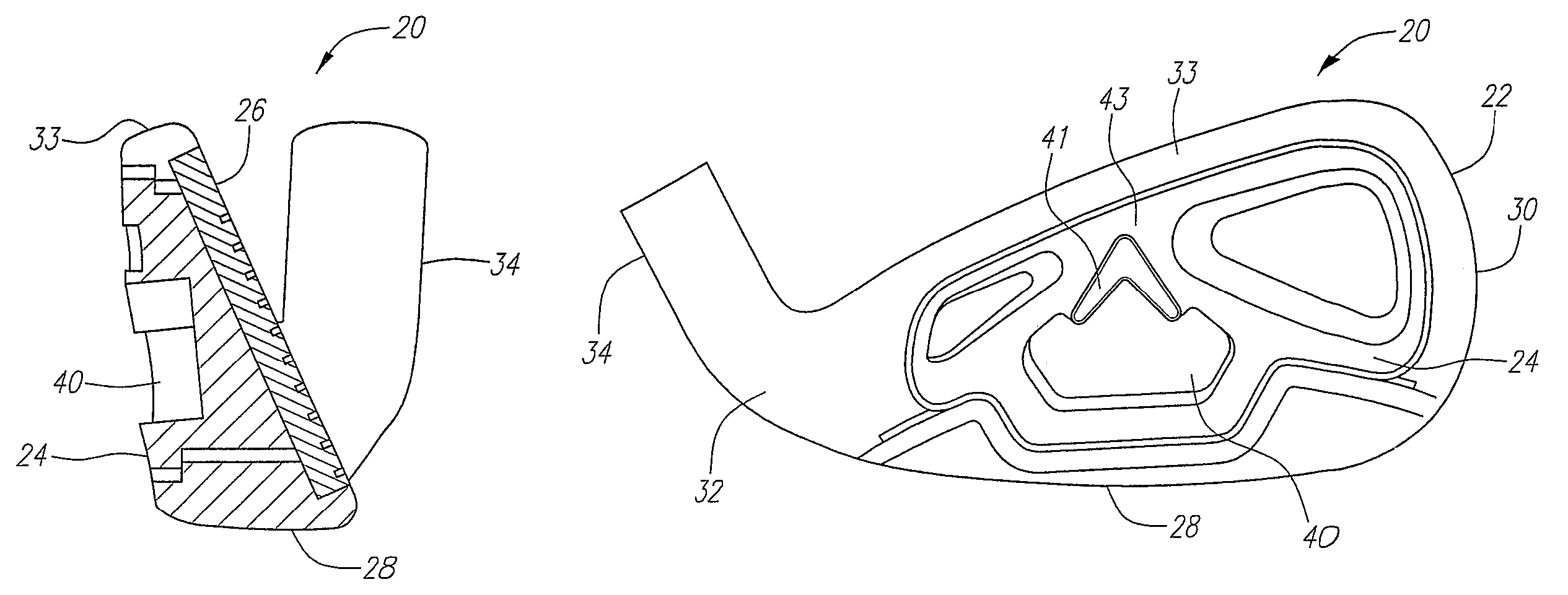

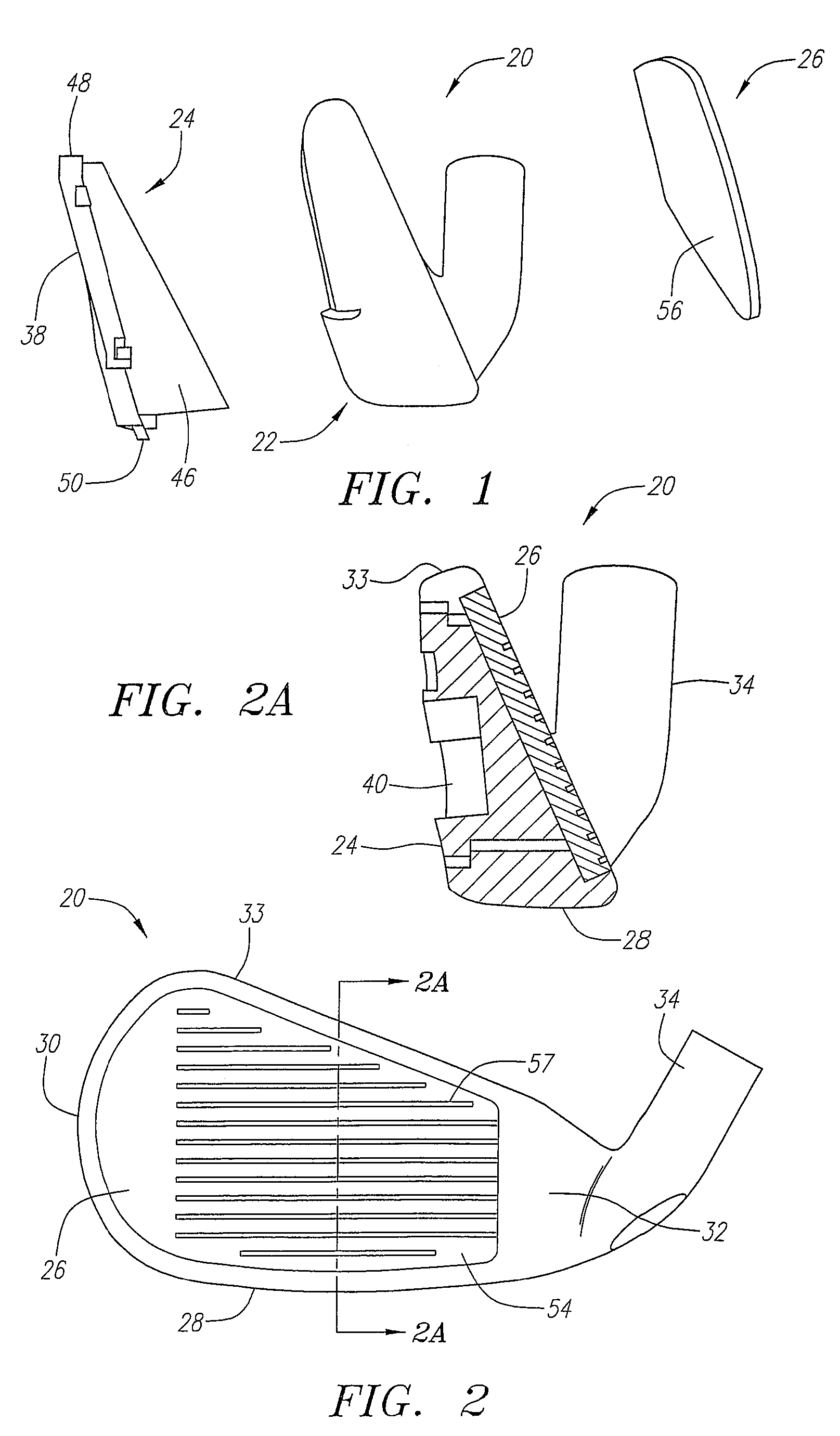

Iron golf club with nanocrystalline face insert

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a nanocrystalline plated face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a non-metal material plated with a nanocrystalline material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Methods of Manufacturing Dental Restorations Using Nanocrystalline Materials

Dental articles are produced using relatively low sintering temperatures to achieve high density dental articles exhibiting strengths equal to and greater than about 700 MPa. Ceramic powders comprised of nanoparticulate crystallites are used to manufacture dental articles. The ceramic powders may include sintering agents, binders and other similar additives to aid in the processing of the ceramic powder into a dental article. The ceramic powders may be processed into dental articles using various methods including, but not limited to, injection molding, gel-casting, slip casting, or electroforming, hand, cad / camming and other various rapid prototyping methods. The ceramic powder may be formed into a suspension, pellet, feedstock material or a pre-sintered blank prior to forming into the dental article.

Owner:IVOCLAR VIVADENT AG

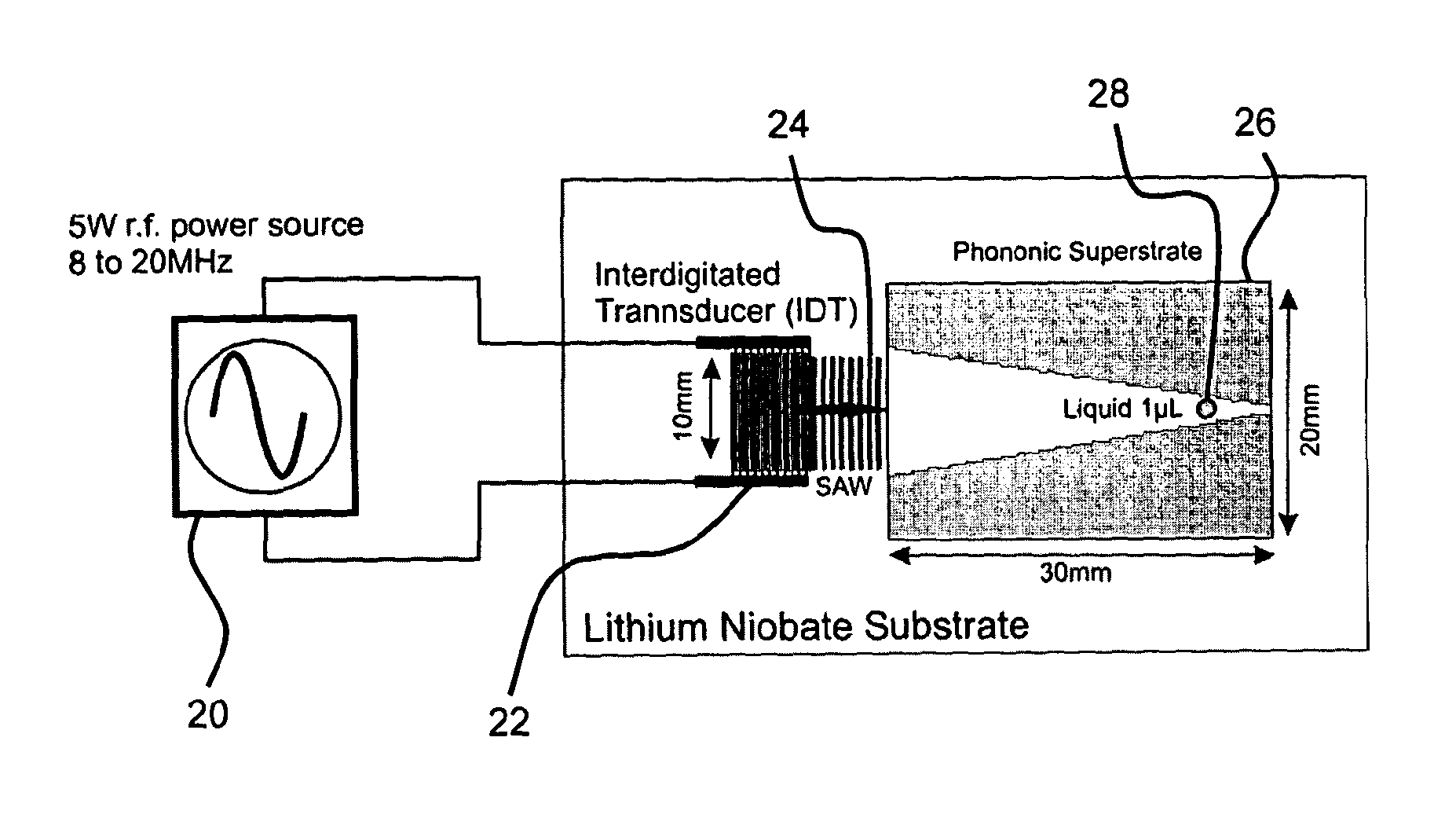

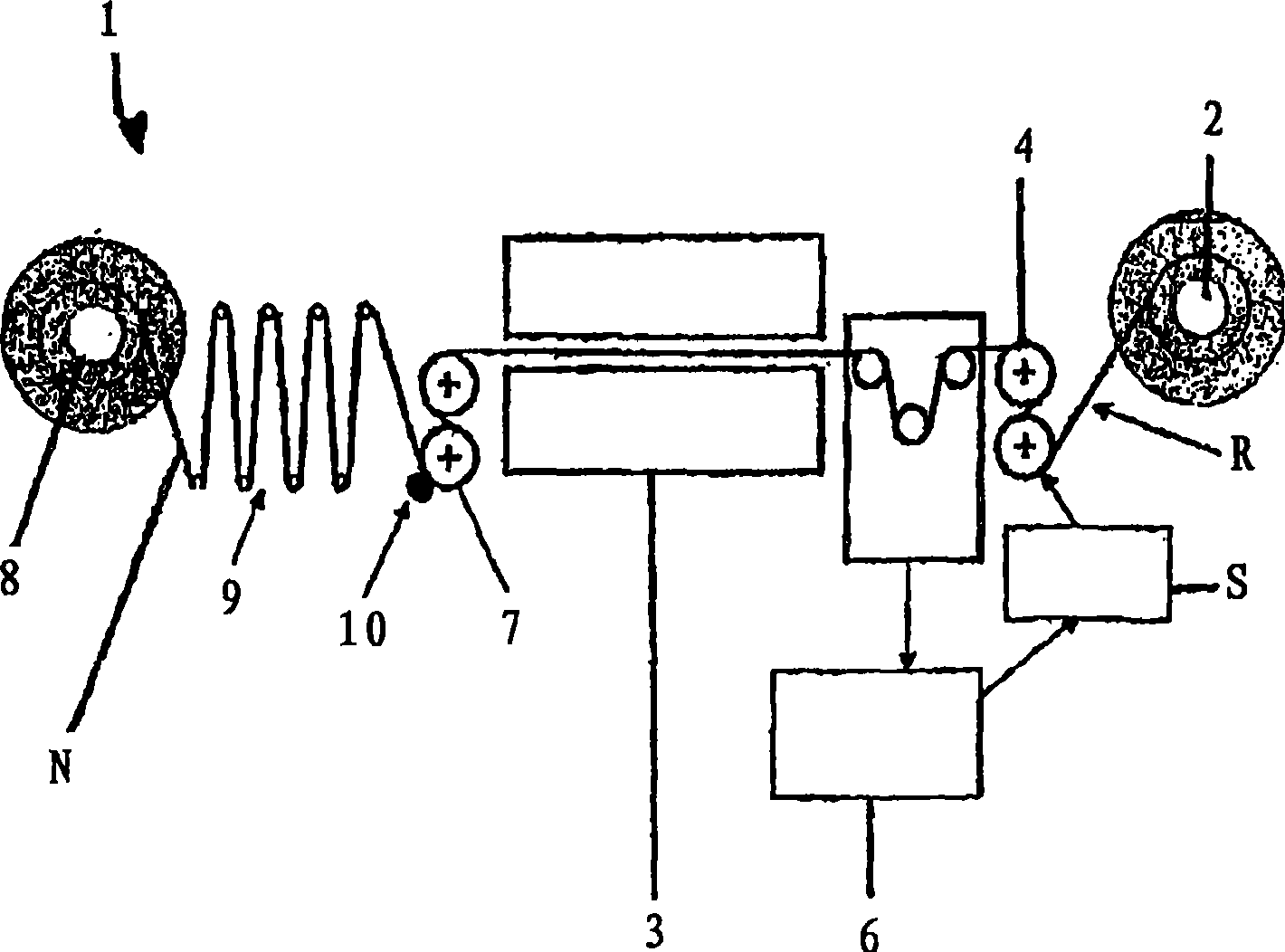

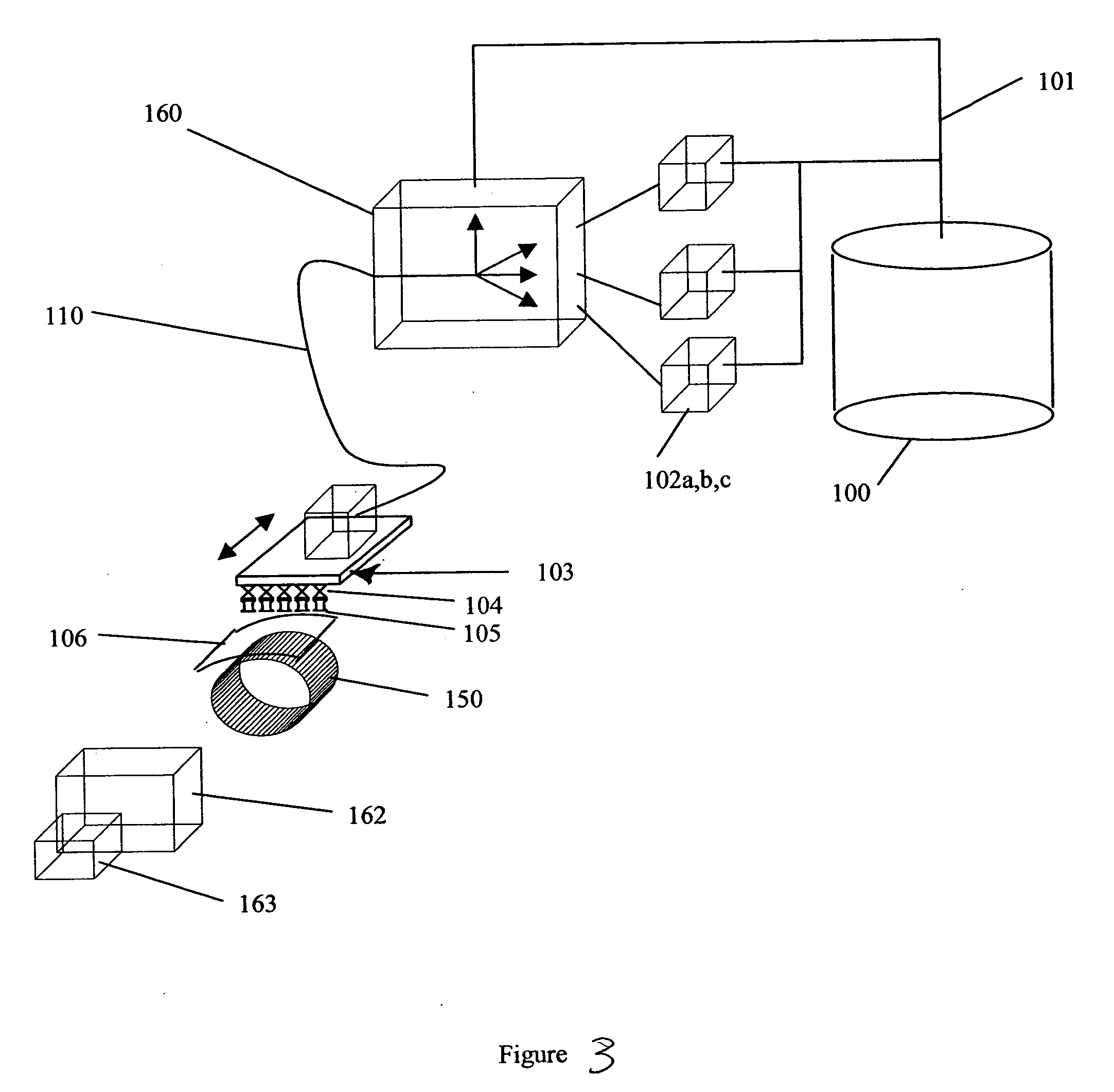

Fluidics Apparatus for Surface Acoustic Wave Manipulation of Fluid Samples, Use of Fluidics Apparatus and Process for the Manufacture of Fluidics Apparatus

ActiveUS20130330247A1Cost-effectiveEfficient preparationElectrolysis componentsVolume/mass flow measurementFluidicsTransducer

A fluidics apparatus for manipulation of at least one fluid sample is disclosed. A manipulation surface locates the fluid sample. A surface acoustic wave (SAW) generation material layer is provided. This is a polycrystalline material, textured polycrystalline material, biaxially textured polycrystalline material, microcrystalline material, nanocrystalline material, amorphous material or composite material. A transducer electrode structure arranged at the SAW generation material layer provides SAWs at the manipulation surface for interaction with the fluid sample. The manipulation surface has a phononic structure, for affecting the transmission, distribution and / or behaviour of SAWs at the manipulation surface. The apparatus is typically manufactured by reel-to-reel processes, to reduce the unit cost to a level at which the apparatus can be considered to be disposable after a single use.

Owner:THE UNIV COURT OF THE UNIV OF GLASGOW

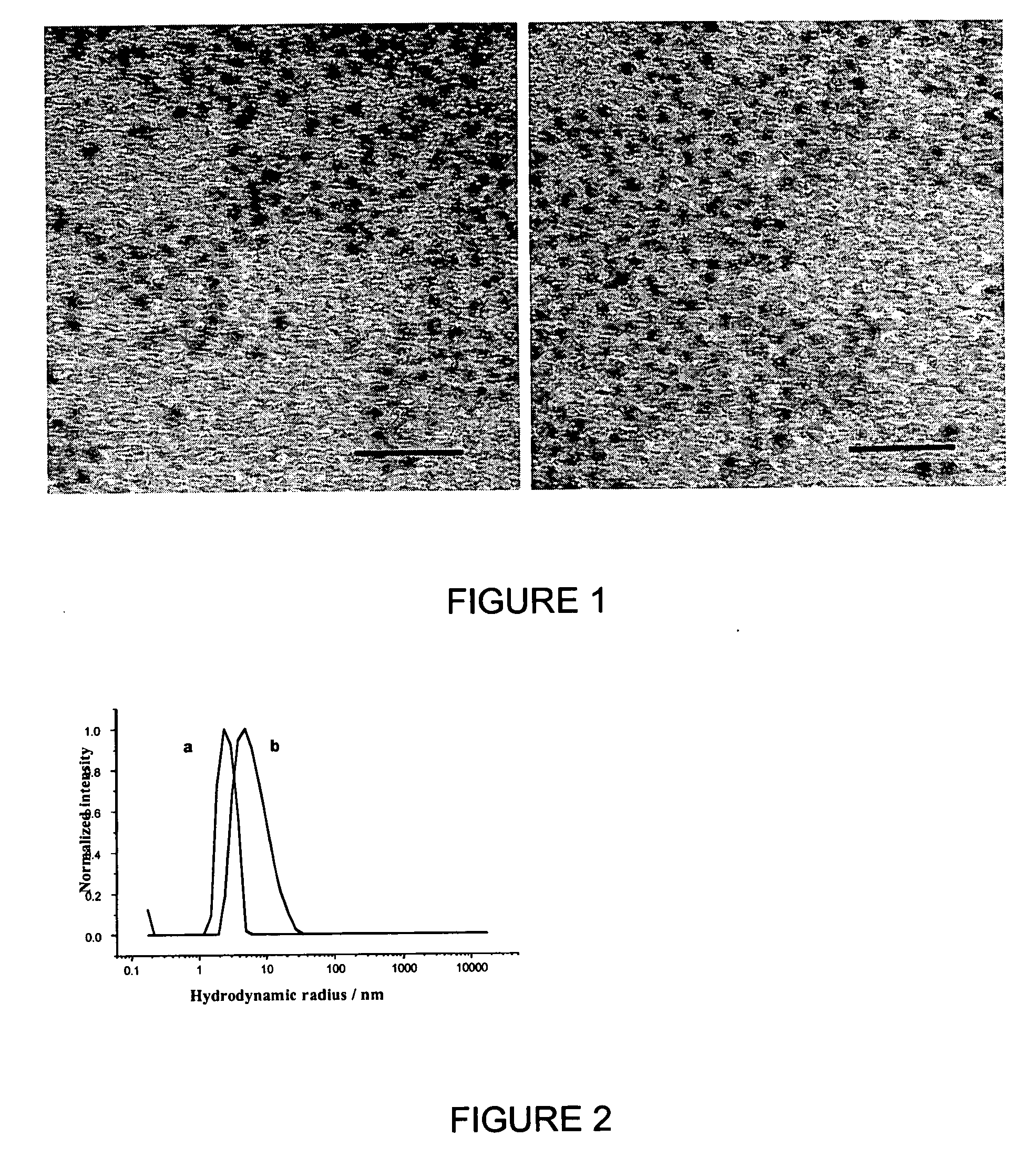

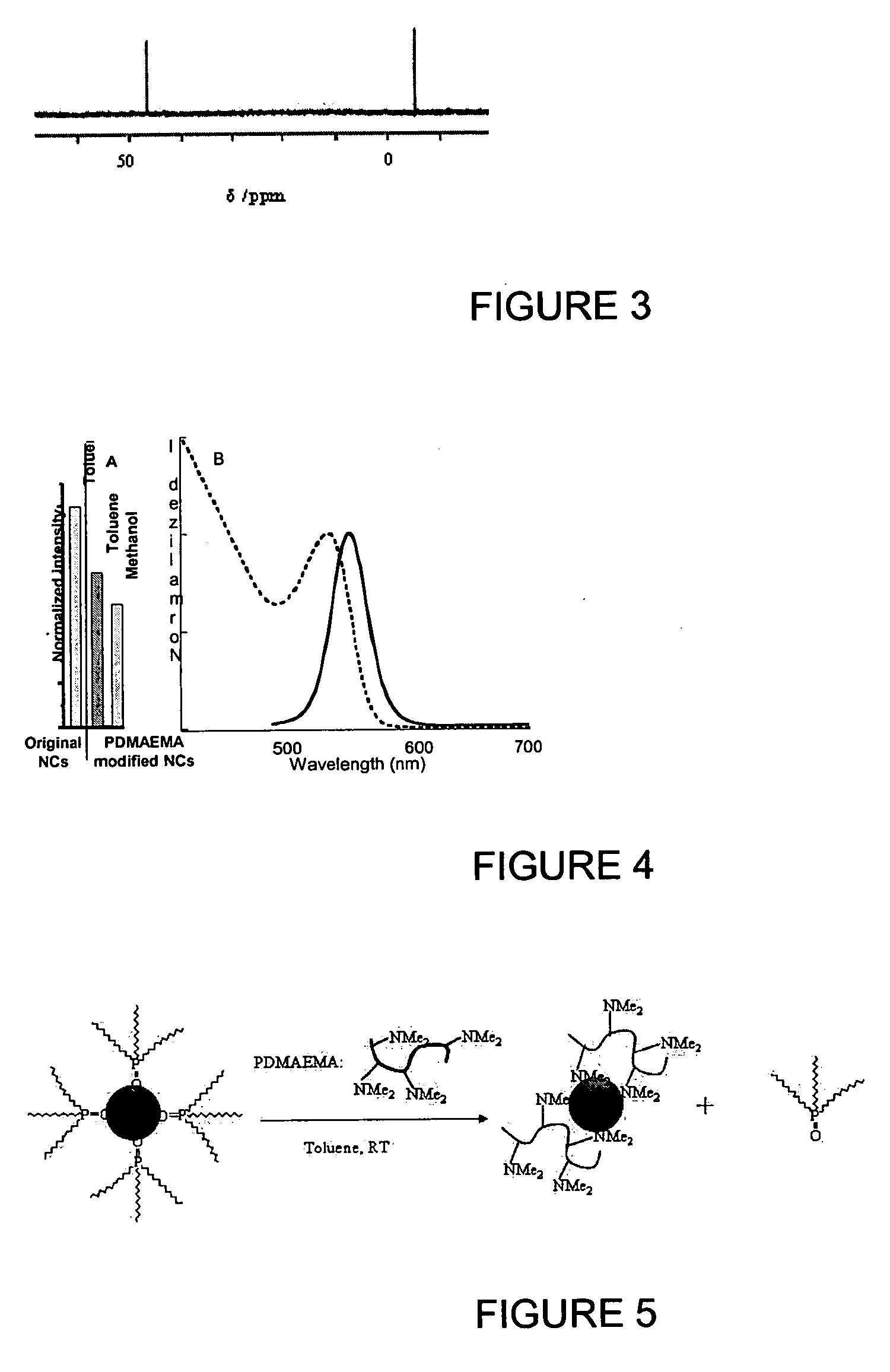

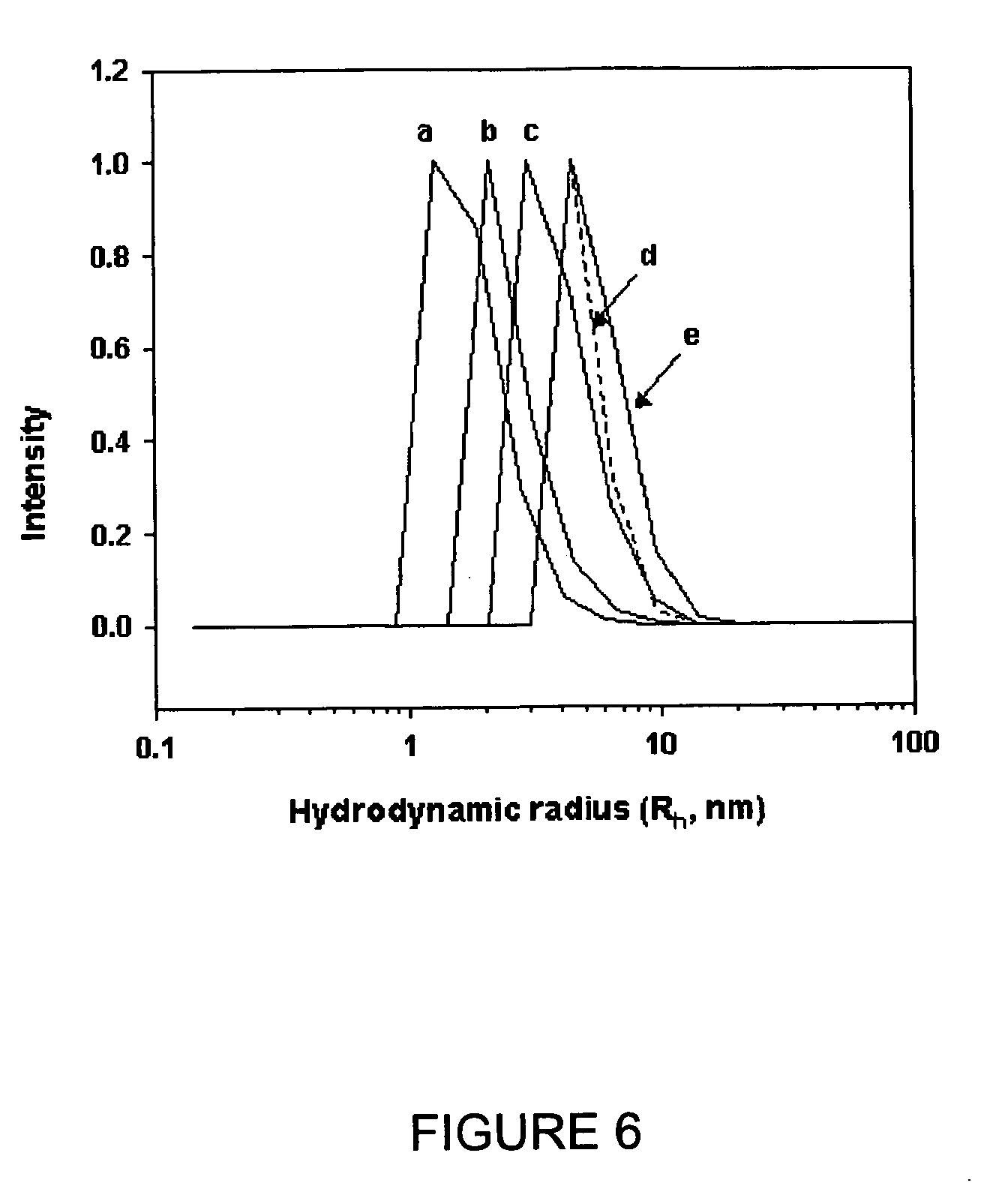

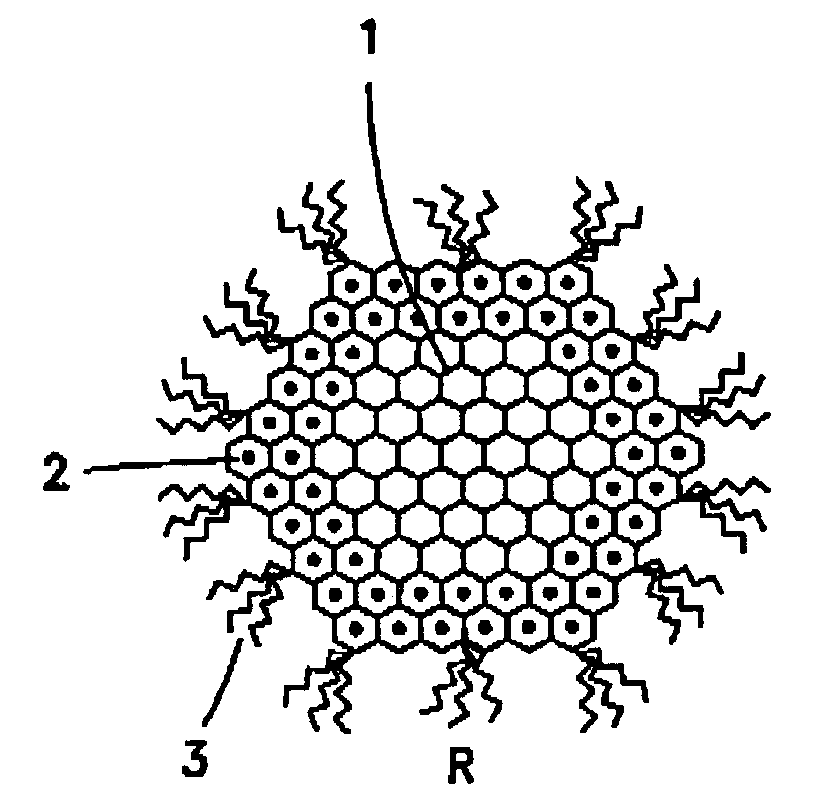

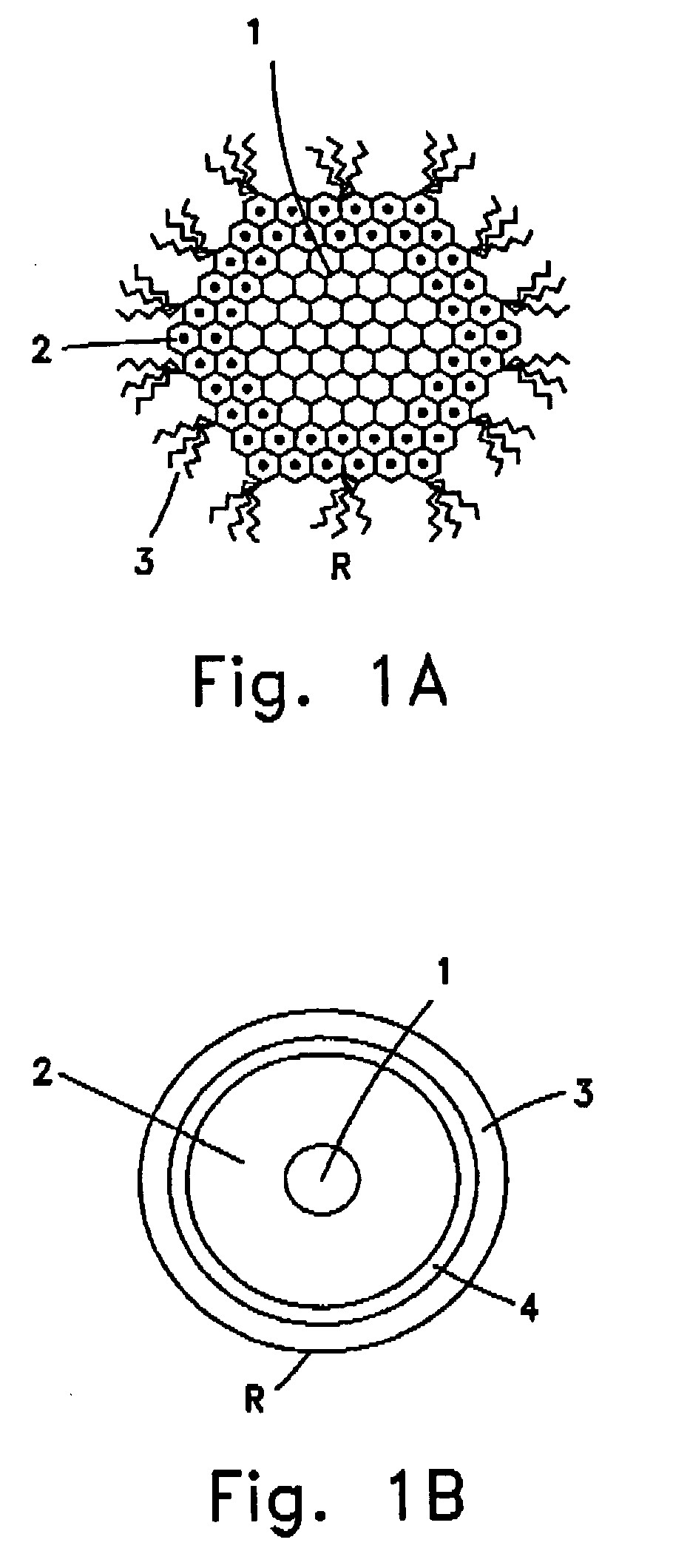

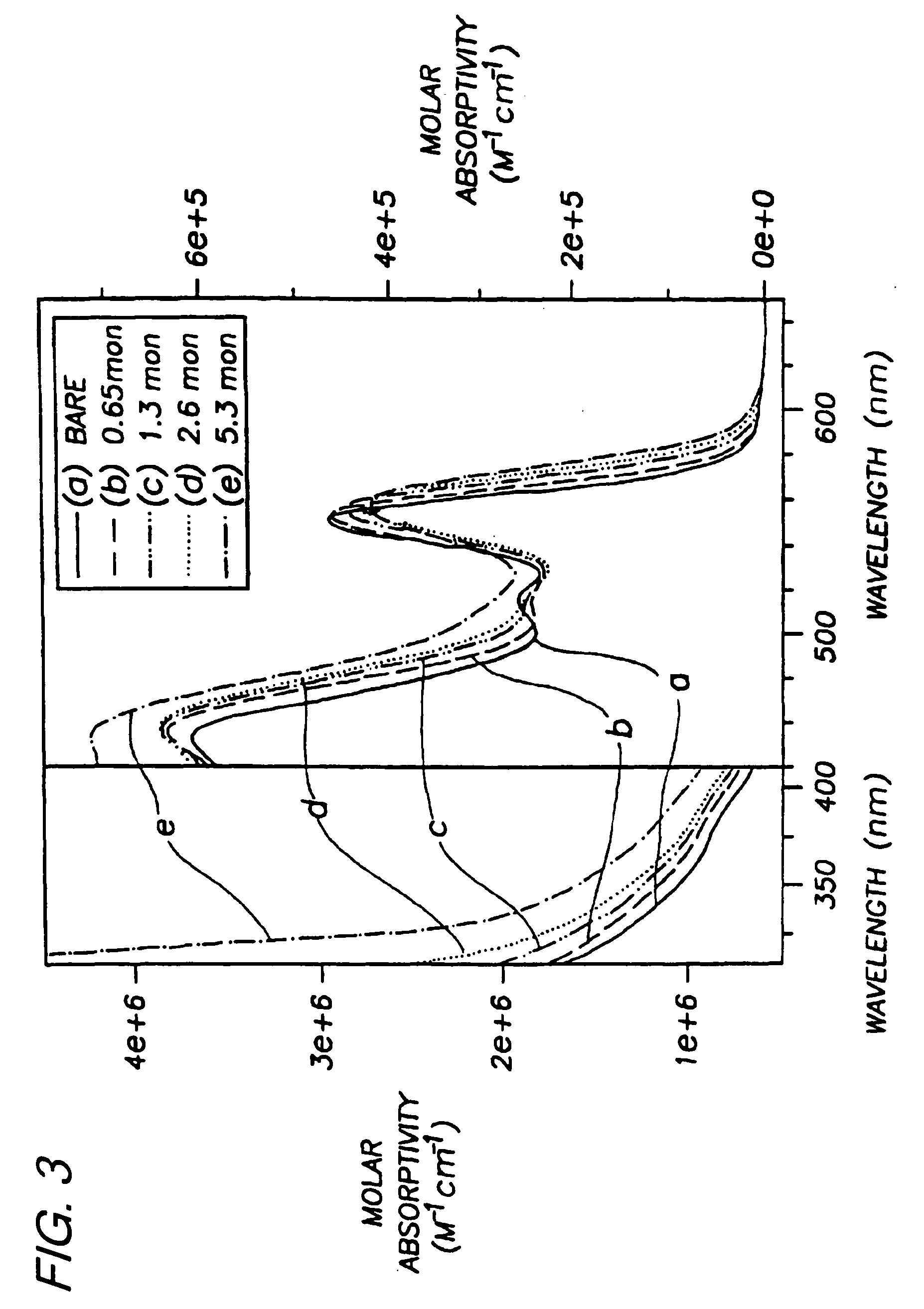

Surface modification of nanocrystals using multidentate polymer ligands

InactiveUS20060088713A1Colloidal stabilityStabilizing quantum size-dependent propertyMaterial nanotechnologyPigmenting treatmentSolventComputational chemistry

The present invention provides a method of surface passivation of colloidal nanocrystalline materials using a ligand exchange process in which quantum nanoparticles of pre-selected size and shape has polymer multidentate ligands bound at the surface of the nanocrystals for stabilizing quantum size-dependent properties of nanocrystals and providing colloidal stability of the nanoparticles in solvents. The method includes preparing a colloidal dispersion of nanoparticles, preparing a suitable polymer multidentate ligand and dissolving said suitable polymer multidentate ligand in a fluid, the polymer multidentate ligand having first portions which can bind to a surface of the nanoparticles and a second portion which does not bind to the surface of the nanoparticles, and mixing the fluid containing the suitable polymer with the colloidal dispersion of nanoparticles under conditions suitable to induce binding of at least some of the first portions of the polymer multidentate ligand onto the surface of the nanoparticles, the suitable polymer multidentate ligand being selected so that the at least some of the first portions which bind to the surface to stabilize quantum size-dependent properties of the nanocrystals, and the second portion which does not bind to the surface provides colloidal stability of the nanoparticles in a desired fluid.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO +6

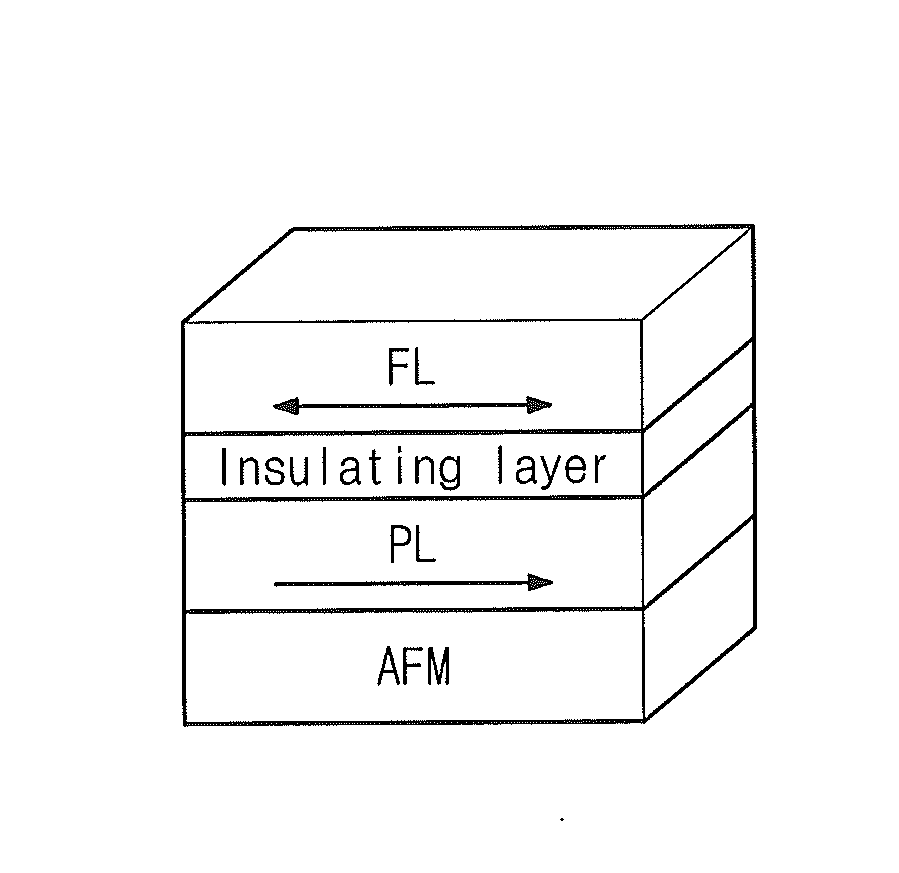

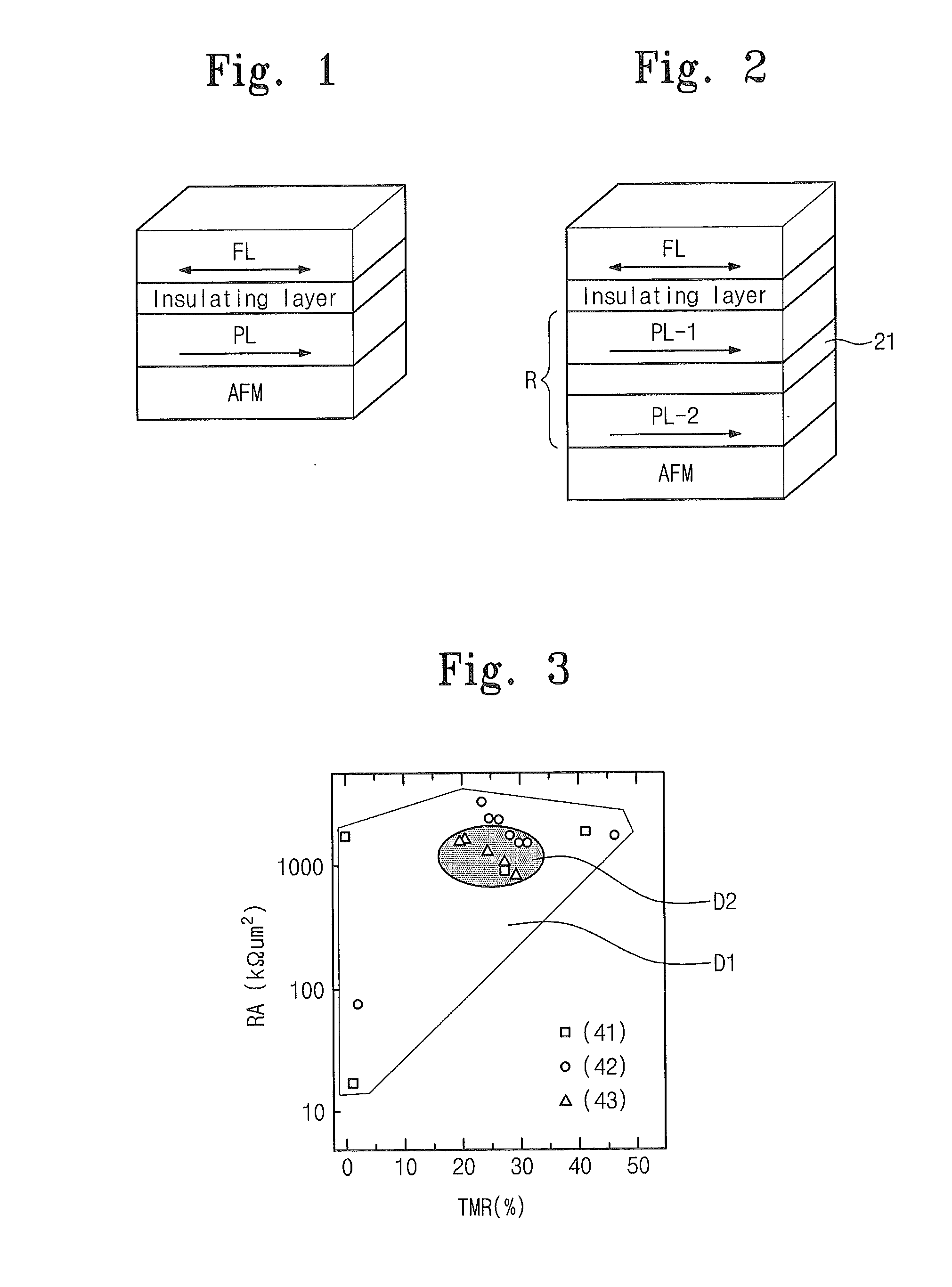

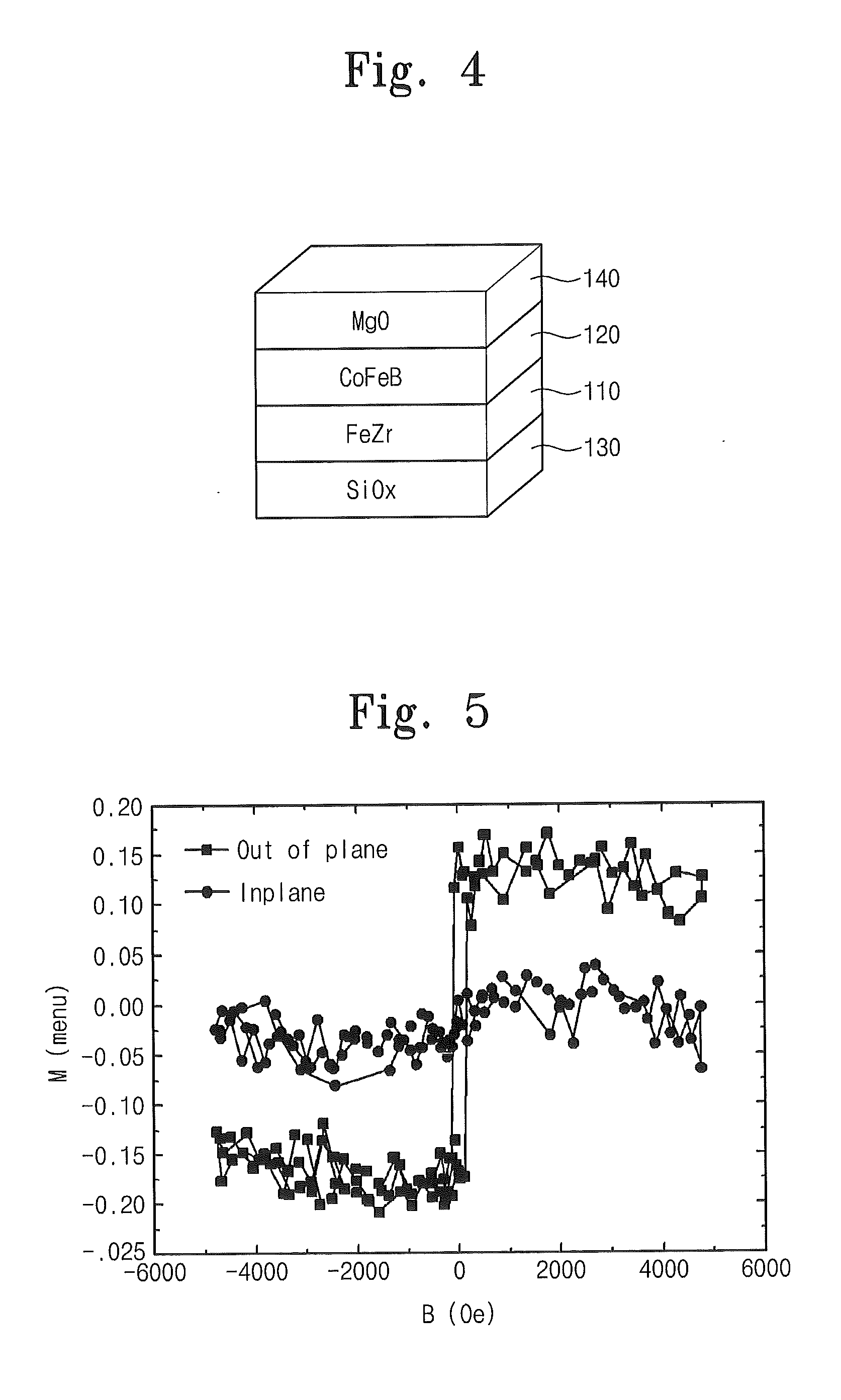

Magnetic Tunnel Junction Device Having Amorphous Buffer Layers That Are Magnetically Connected Together And That Have Perpendicular Magnetic Anisotropy

ActiveUS20130313665A1Improve uniformityIncreased junctionNanomagnetismGalvano-magnetic material selectionMagnetizationNanometre

According to a first embodiment of the present invention, a magnetic tunnel junction device comprises: a free layer having a magnetization in a variable direction; a pinned layer having a magnetization in a pinned direction; and a tunnel insulation film formed between the free layer and the pinned layer, wherein the pinned layer includes a ferromagnetic film and an amorphous metal film. In addition, a magnetic device according to a second embodiment of the present invention comprises: an amorphous or nanocrystal material layer; and a perpendicular magnetic anisotropic material layer formed on the amorphous or nanocrystal material layer. The amorphous or nanocrystal material layer is a predefined amorphous material or nanocrystal material layer serving as a lower layer, and the perpendicular magnetic anisotropic material layer is formed on the amorphous or nanocrystal material layer.

Owner:SAMSUNG ELECTRONICS CO LTD

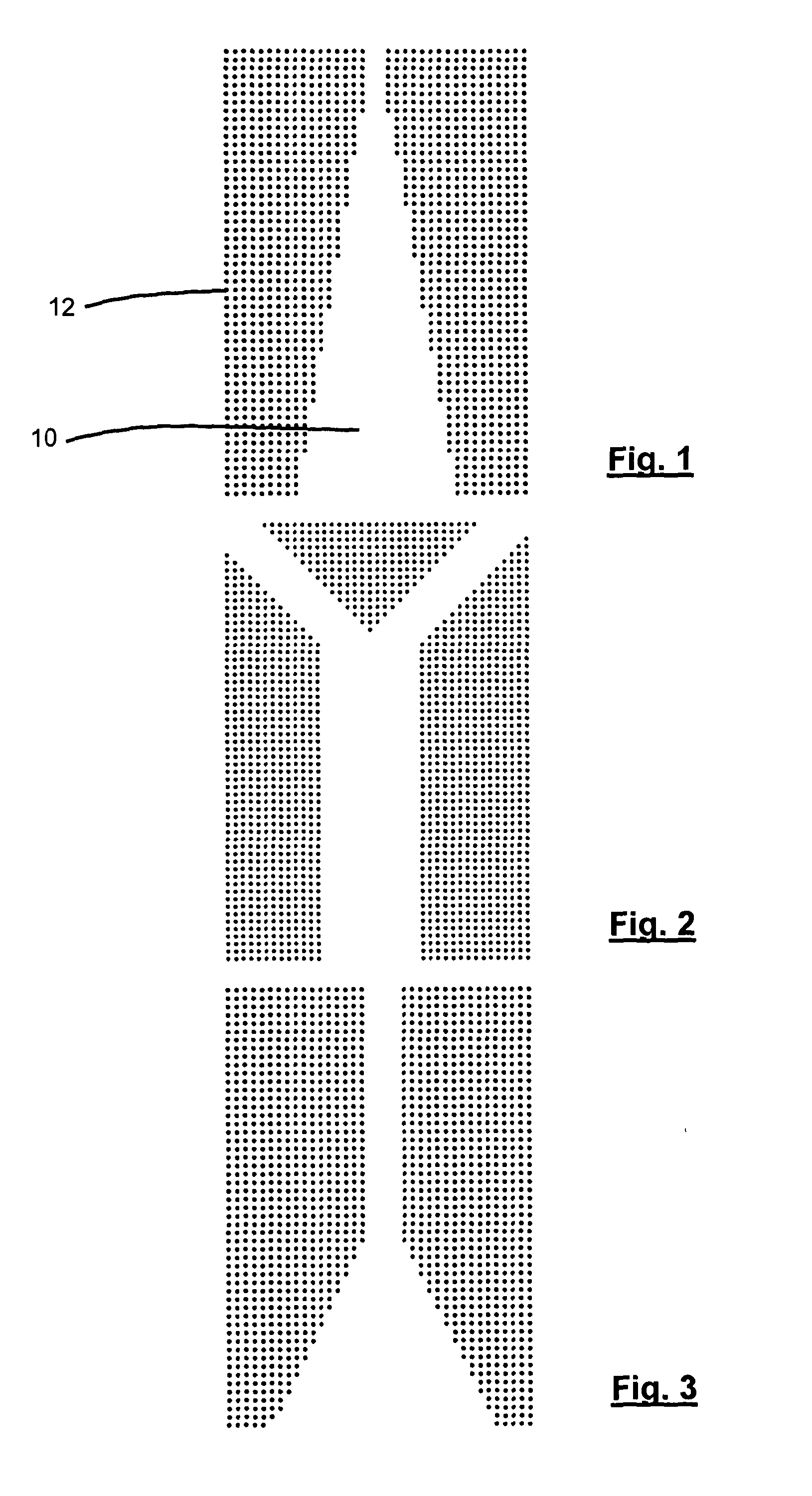

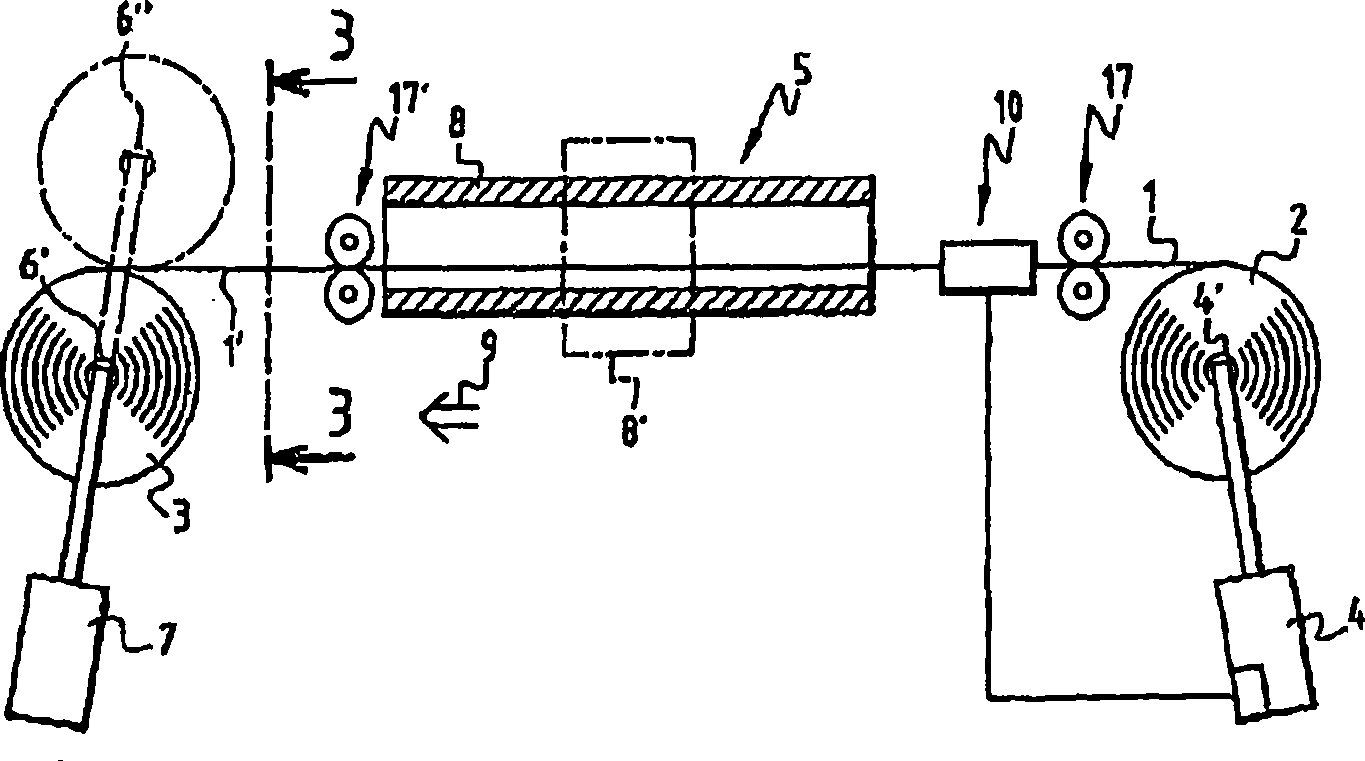

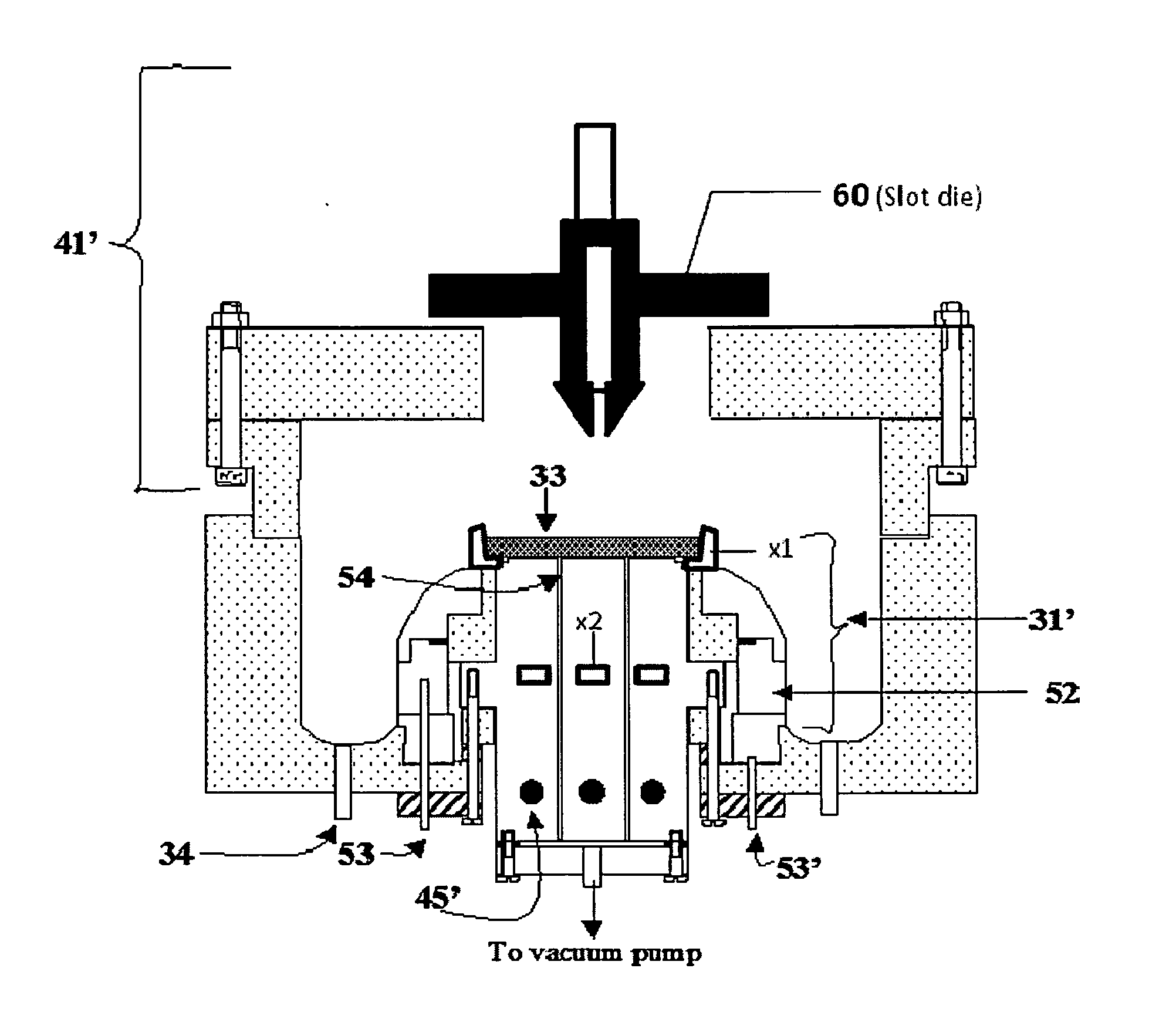

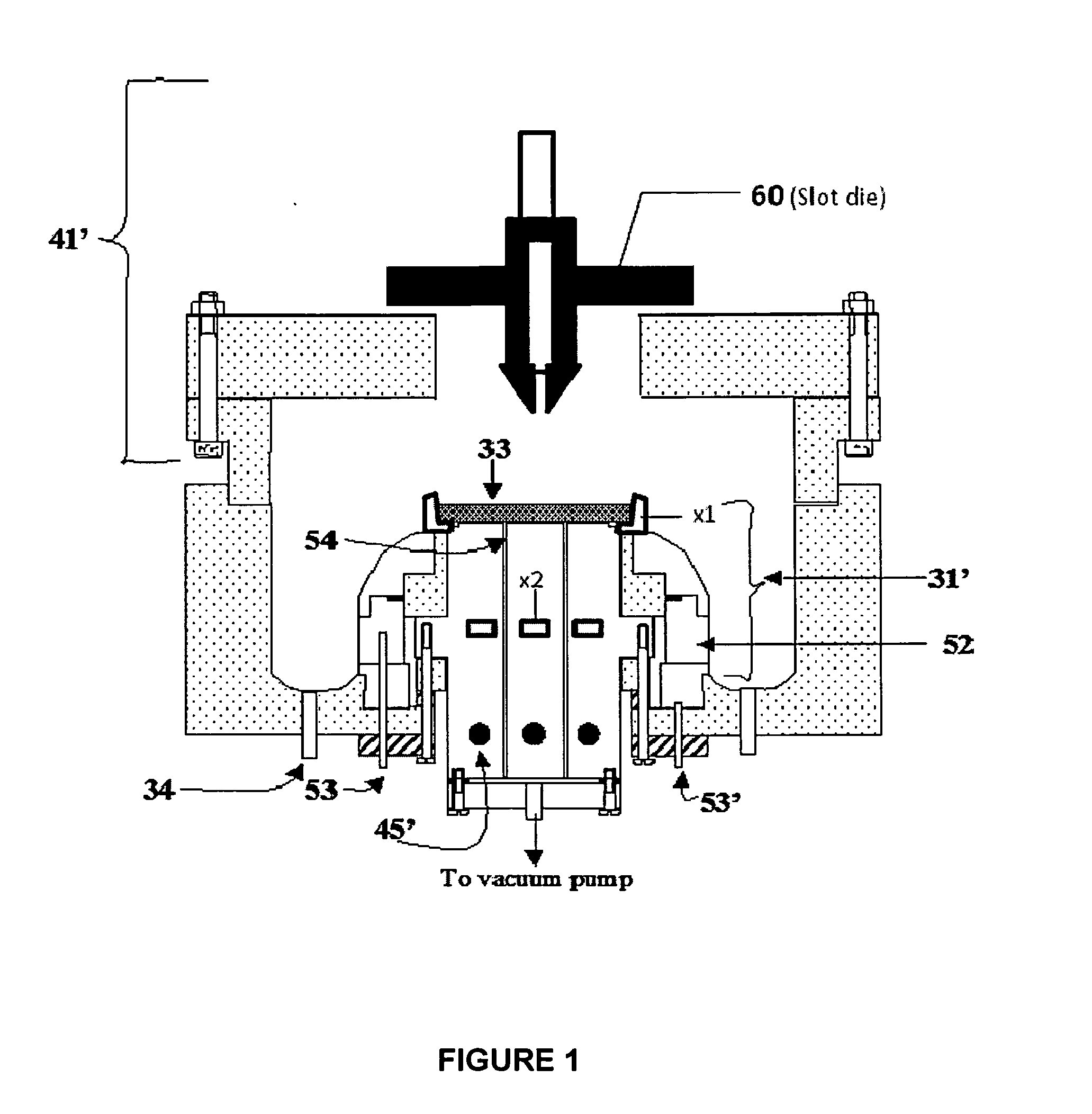

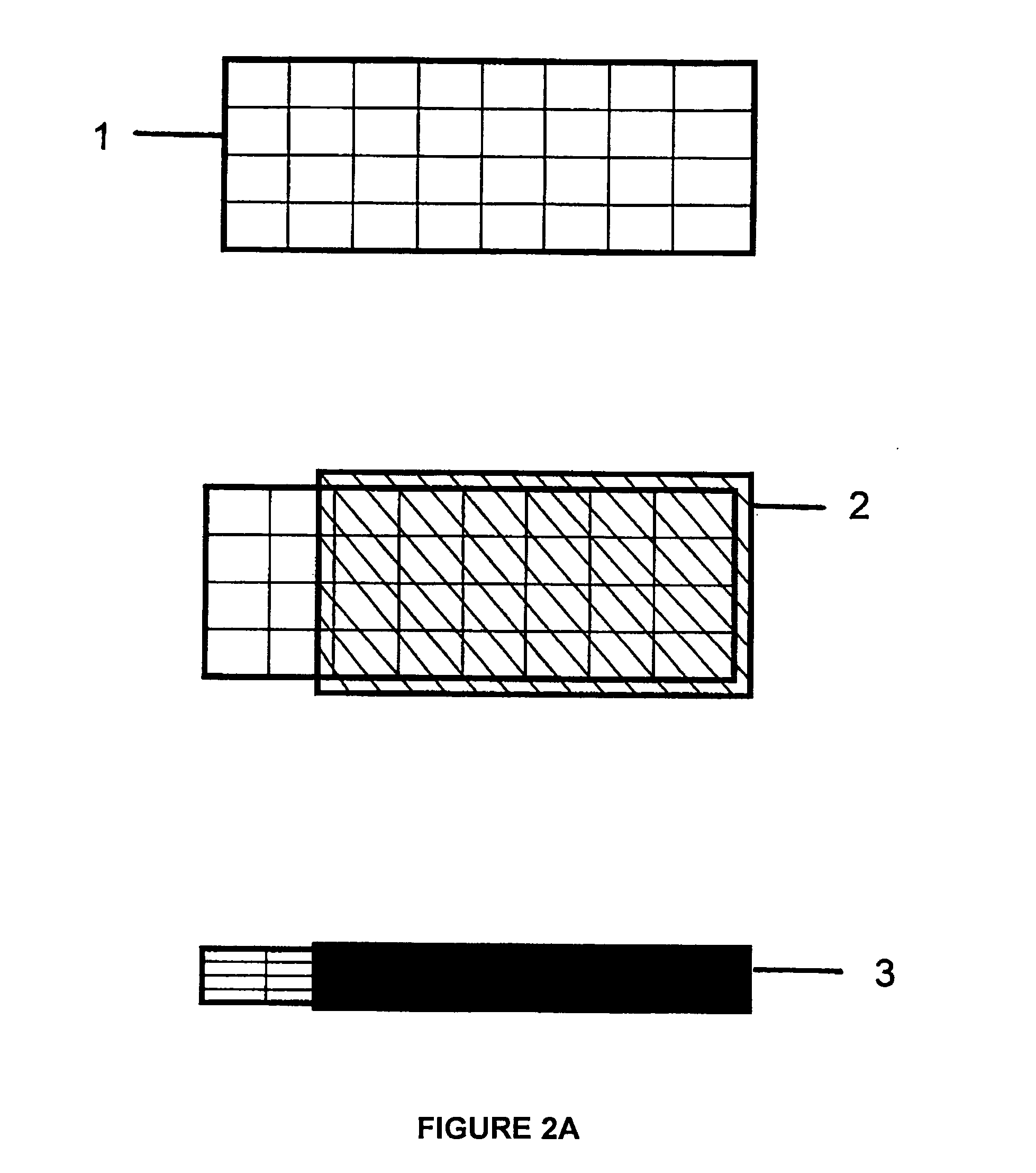

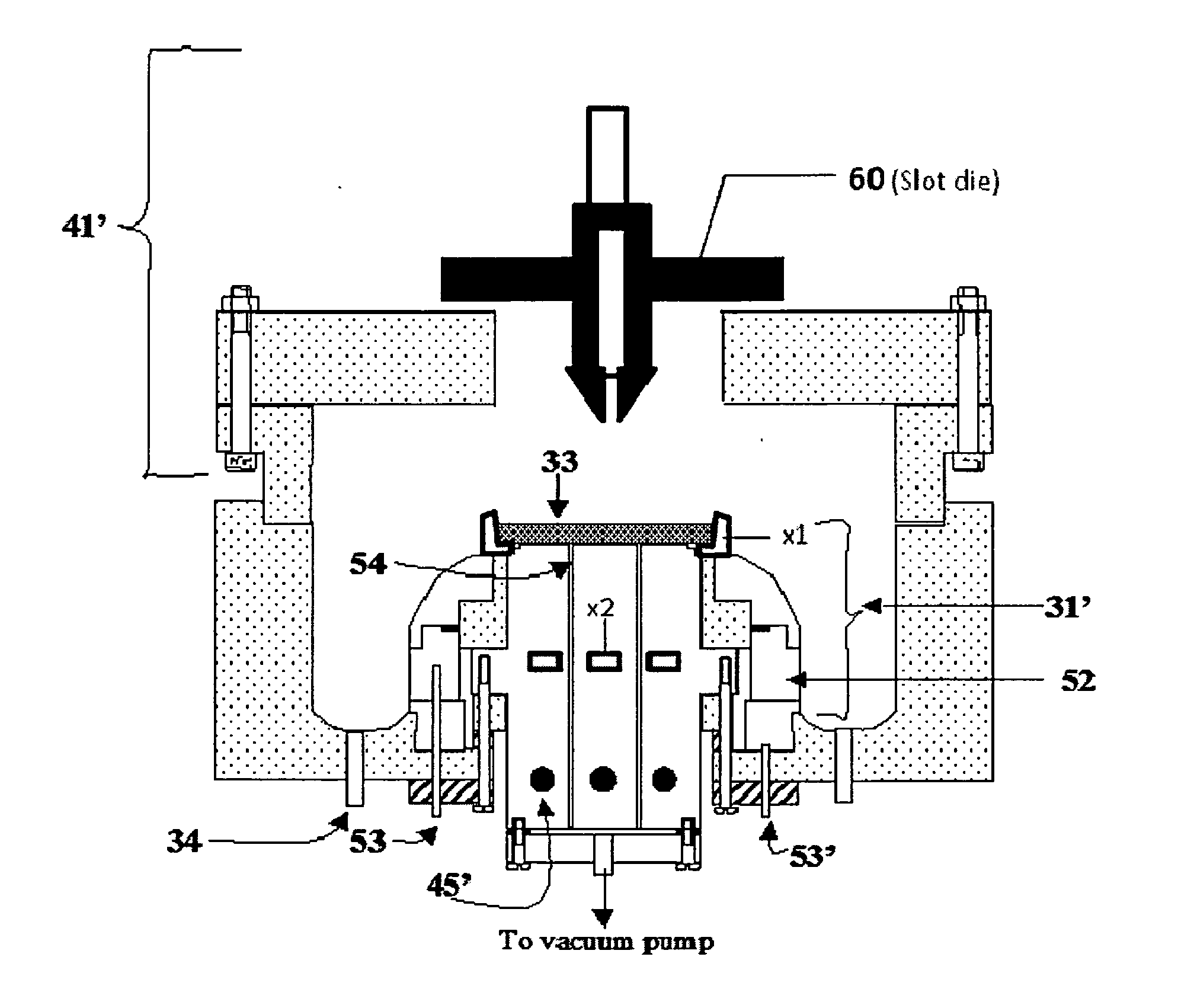

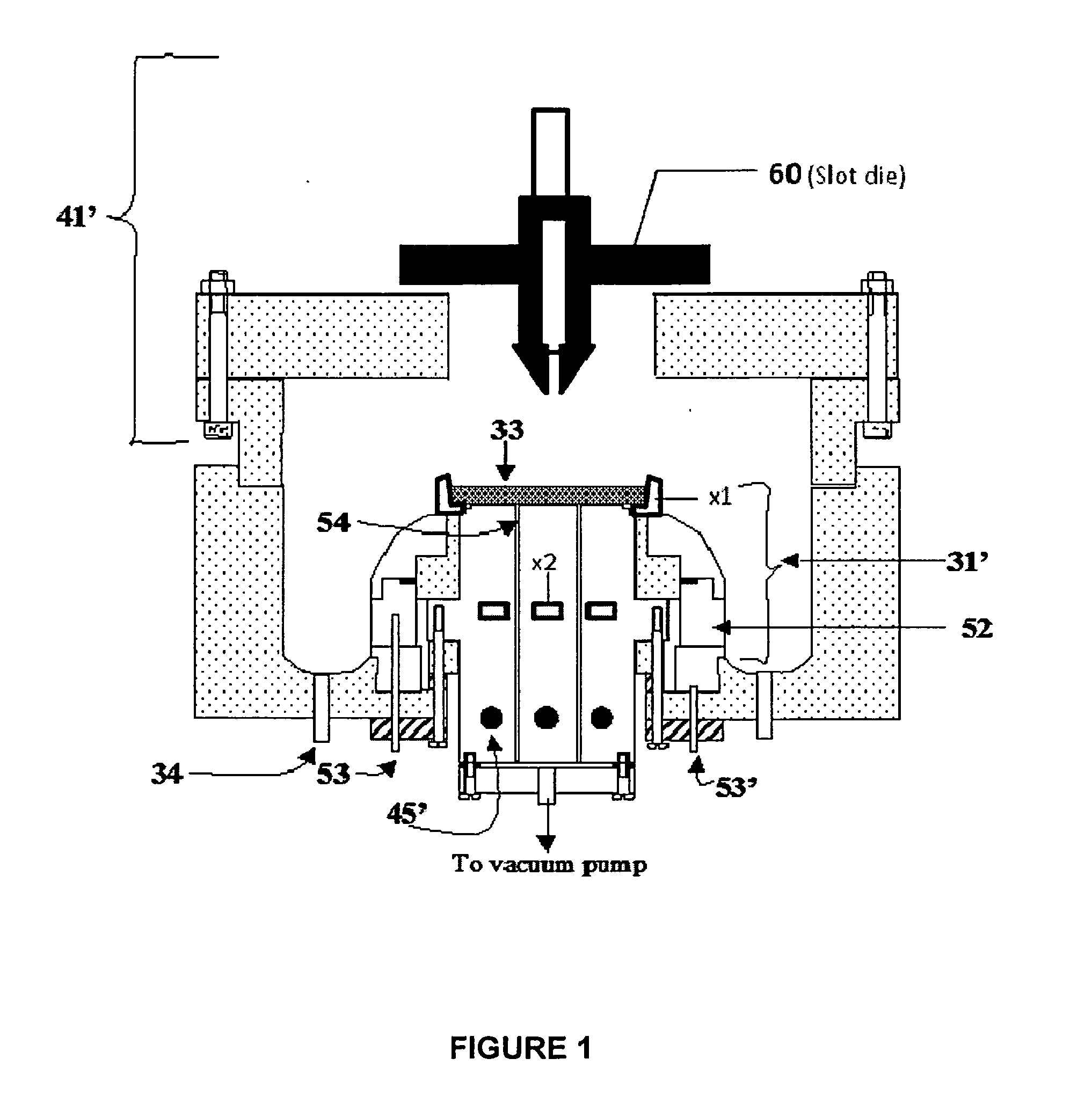

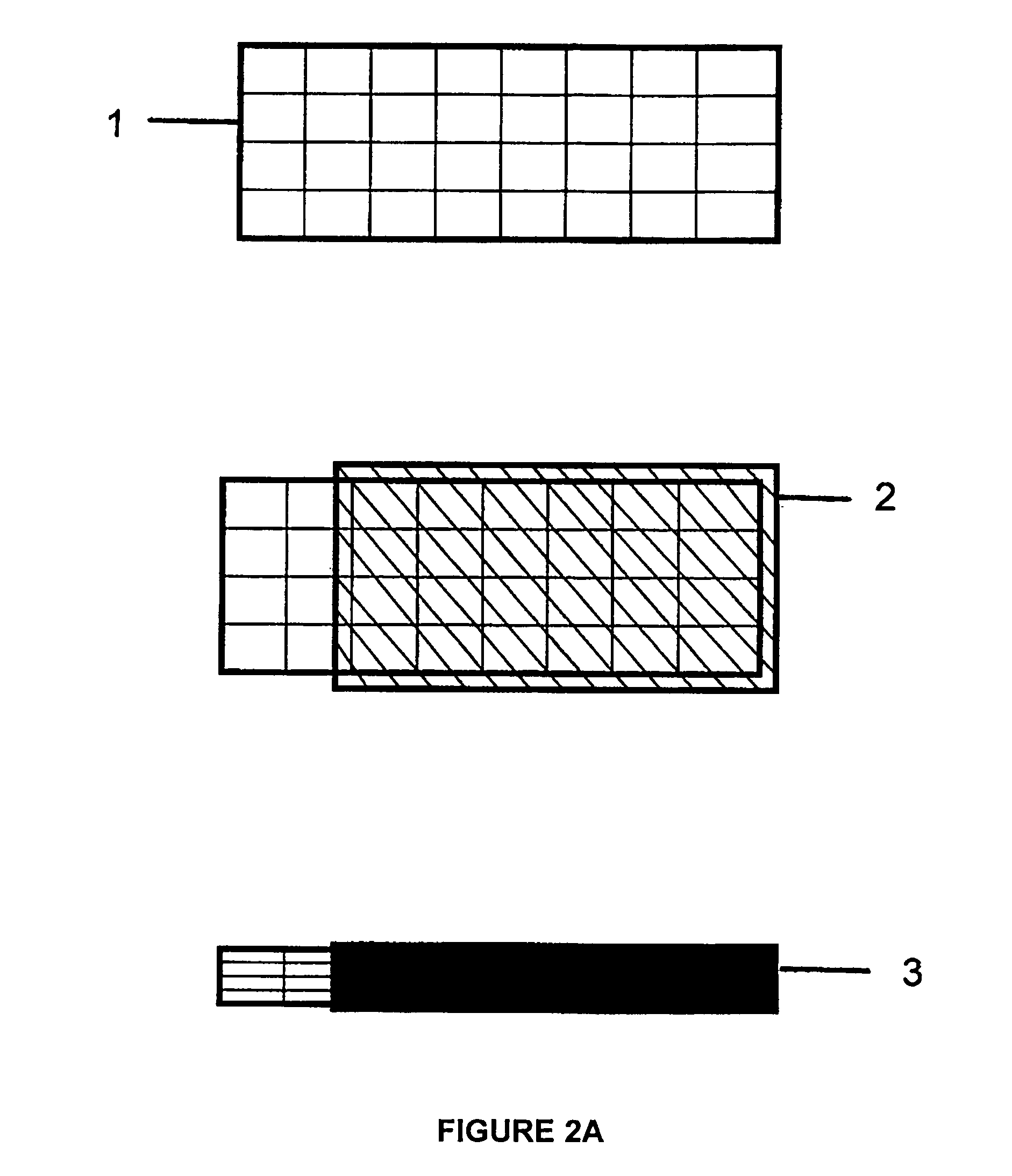

Method of producing a strip of nanocrystalline material and device for producing a wound core from said strip

The invention relates to a method of producing a strip of nanocrystalline material which is obtained from a wound ribbon that is cast in an amorphous state, having atomic composition [Fe1-a-bCoaNib]100-x-y-2-alpha-beta-gamma Cu<x>Si<y>BzNbalphaM'betaM''gamma, M' being at least one of elements V, Cr, Al and Zn, and M being at least one of elements C, Ge, P, Ga, Sb, In and Be, with: a <= 0.07 and b = 0.1, 0.5 <= x <=1.5 and 2 <= a <= 5, 10 <= y <= 16.9 and 5 <= z <= 8, beta <= 2 and gamma <= 2. According to the invention, the amorphous ribbon is subjected to crystallisation annealing, in which the ribbon undergoes annealing in the unwound state, passing through at least two S-shaped blocks under voltage along an essentially longitudinal axial direction of the ribbon, such that the ribbon is maintained at an annealing temperature of between 530 DEG C and 700 DEG C for between 5 and 120 seconds and under axial tensile stress of between 2 and 1000 Mpa. The tensile stress applied to the amorphous ribbon, the displacement speed of the ribbon during annealing and the annealing time and temperature are all selected such that the cross-section profile of the strip is not in the form of Omega and the maximum deflection of the cross-section of the strip is less than 3% of the width of the strip and preferably less than 1% of the width. The invention also relates to the strip and the core thus obtained and to the device used to implement the method.

Owner:IMPHY ALLOYS

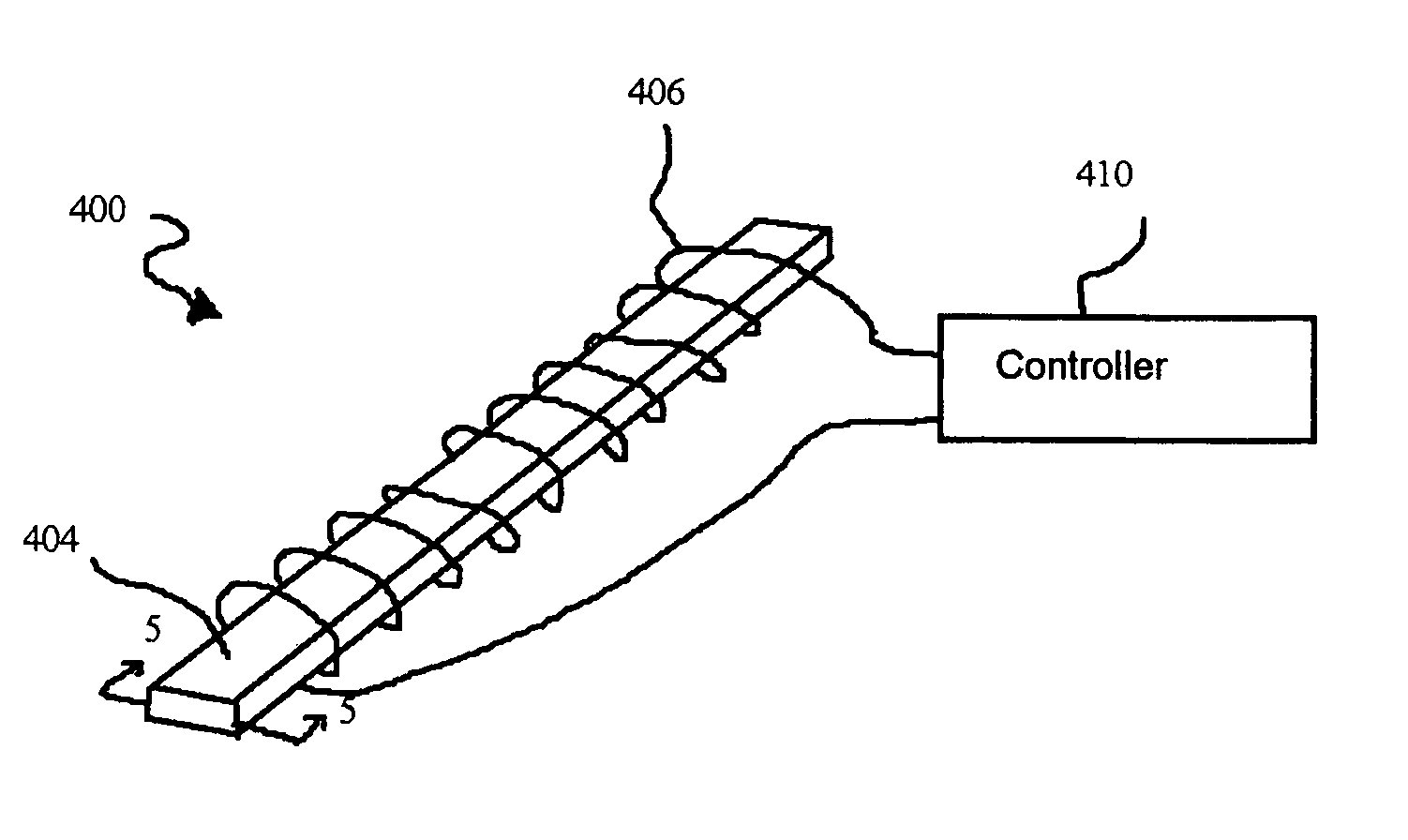

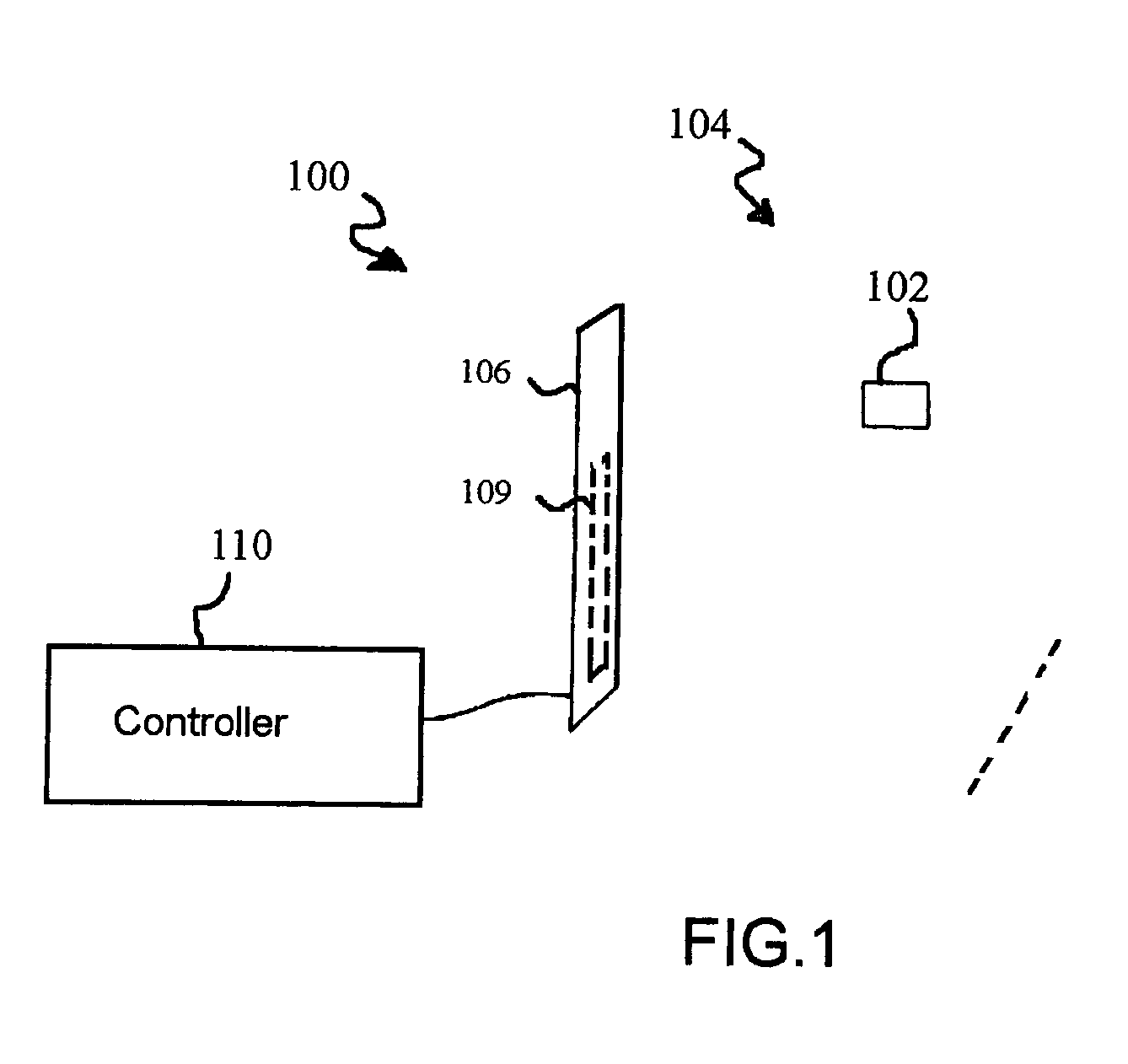

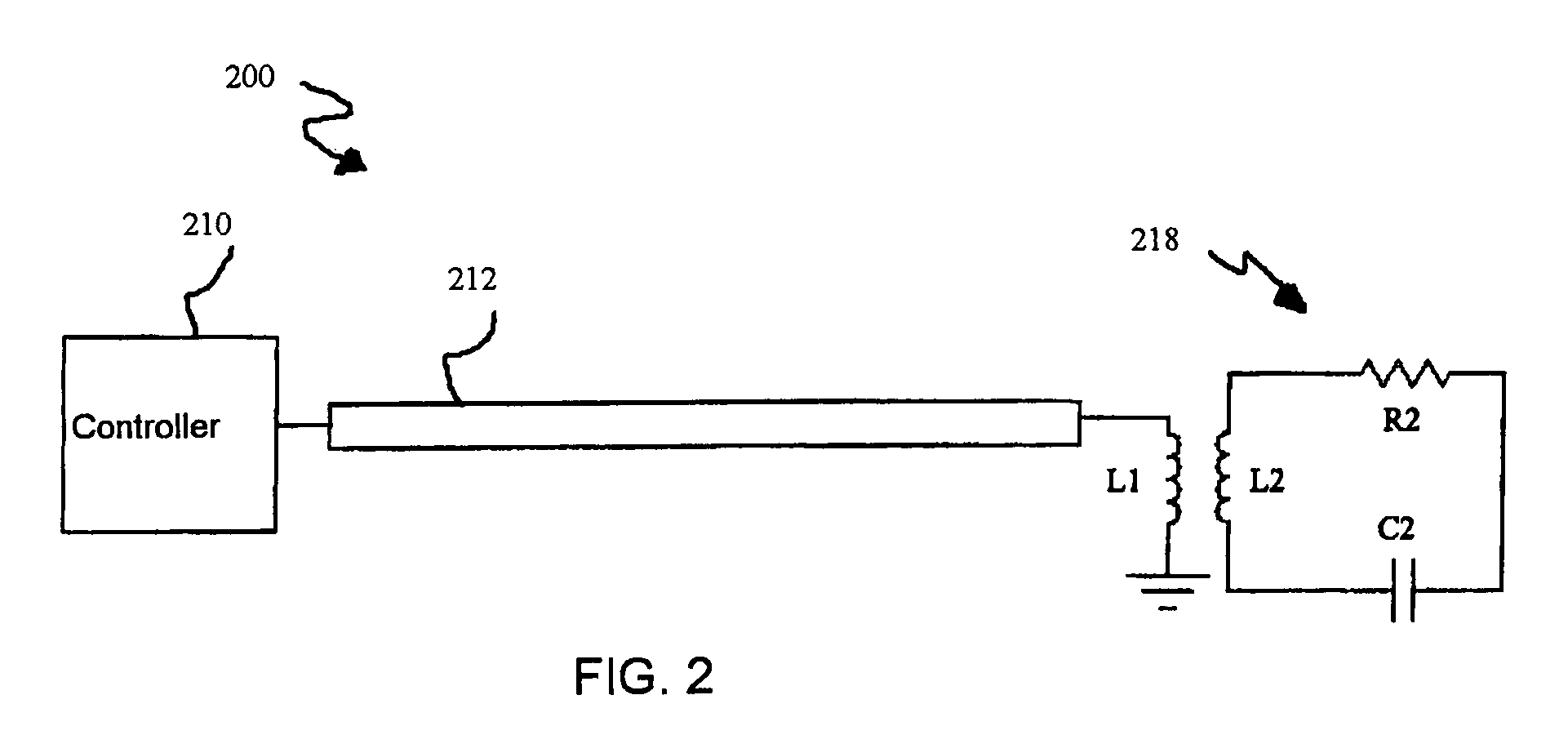

Nanocrystalline core antenna for EAS and RFID applications

ActiveUS7154447B2Expand the scope of detectionLoop antennas with ferromagnetic coreMaterial nanotechnologyCore antennaNanocrystal

A nanocrystalline core antenna for use in electronic article surveillance (EAS) and radio frequency identification (RFID) systems. The nanocrystalline antenna is constructed from nanocrystalline material and exhibits improved detection range in EAS and RFID systems compared to conventional antenna configurations.

Owner:SENSORMATIC ELECTRONICS CORP

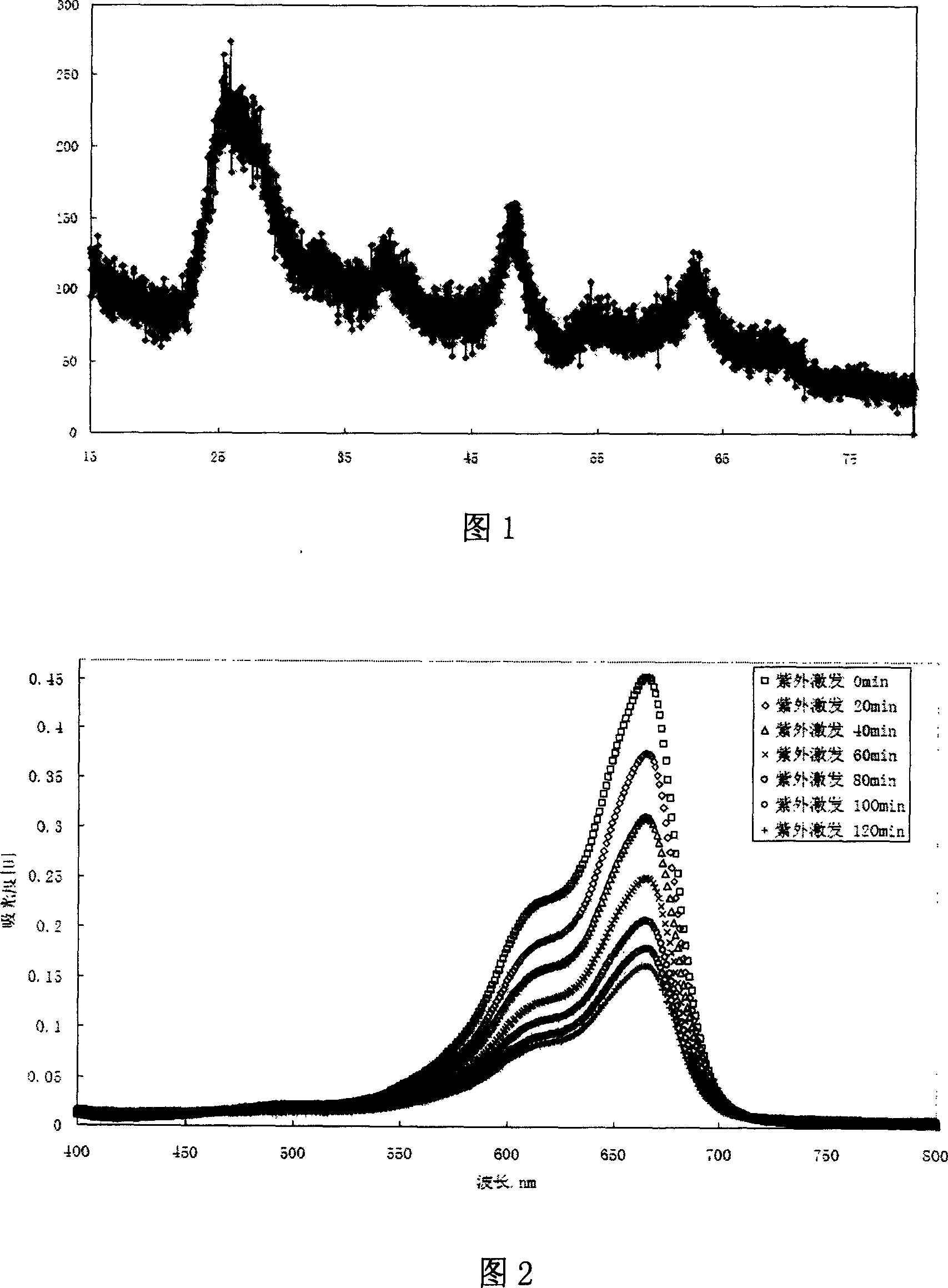

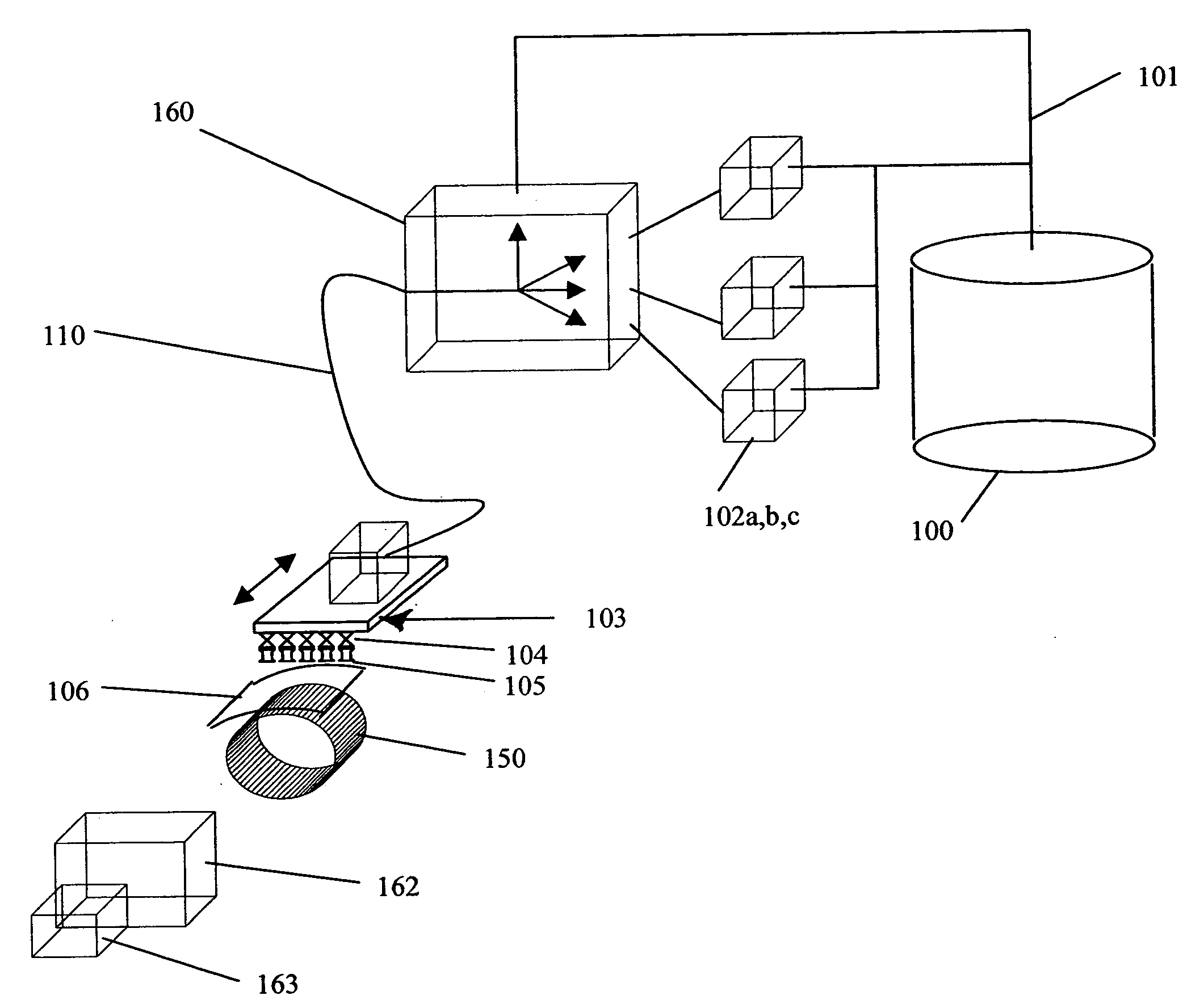

Low temperature crystallized nano titanium dioxide powder and sol synthesizing method

InactiveCN1935669AImprove photocatalytic activityStable storageTitanium dioxideNanocrystalTitanic acid

The invention belongs to an organic metal oxide-TiO2 photocatalyst preparing process, especially relating a synthesizing method of low temperature-crystallizing nanometer TiO powder and sol with high catalytic activity. And it obtains n-titanic acid deposit by making alkali neutralization and dilution hydrolyzation or heating hydrolyzation on titanic solution, and implements synthesizing related system nano crystal materials with normal-pressure and low-temperature liquid phases by such a processing process of re-dispersing the deposit by oxydol. And it largely reduces the cost of raw materials and avoids using titanium tetrachloride with strong corrosivity, reducing equipment requirements.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

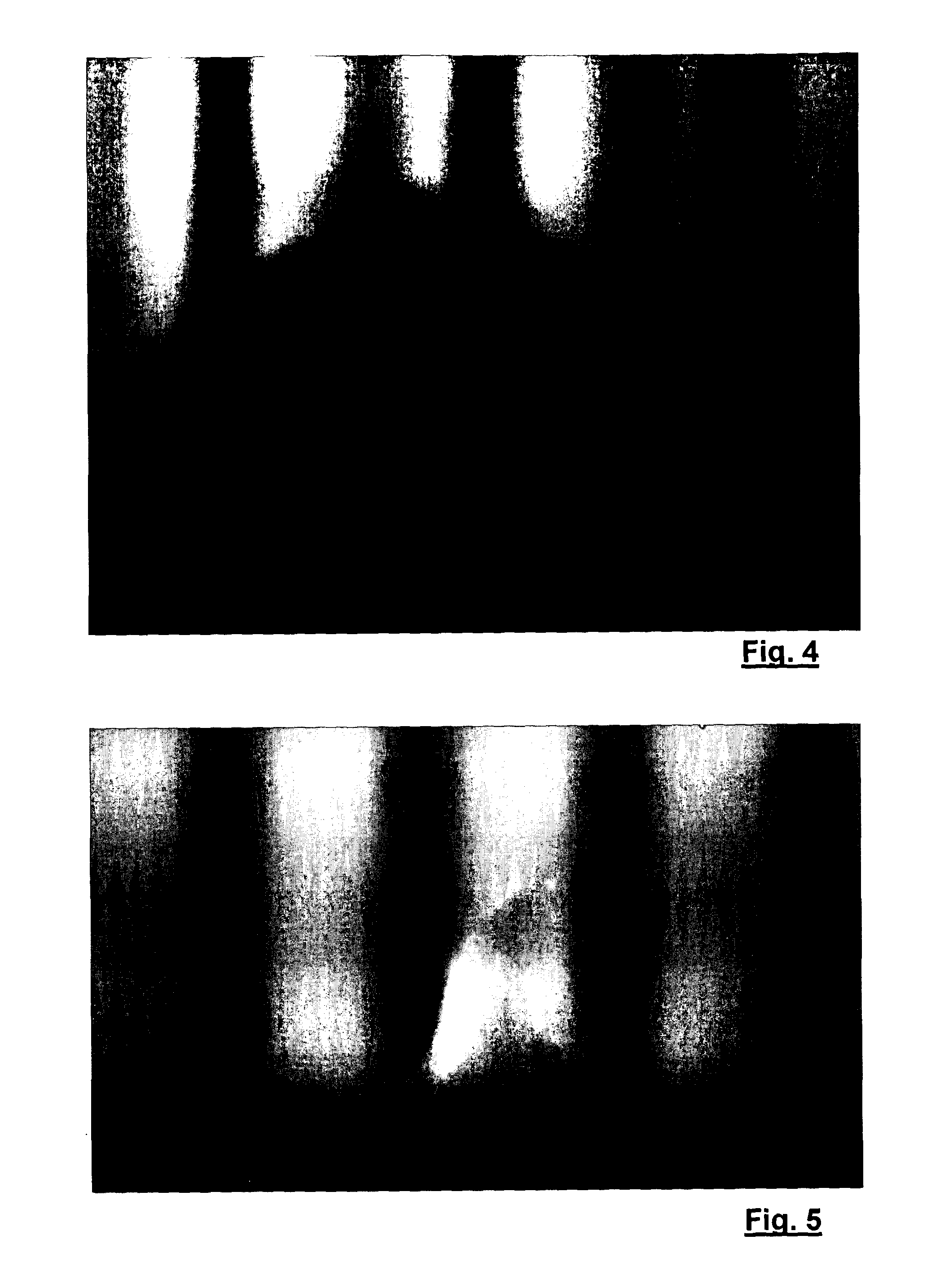

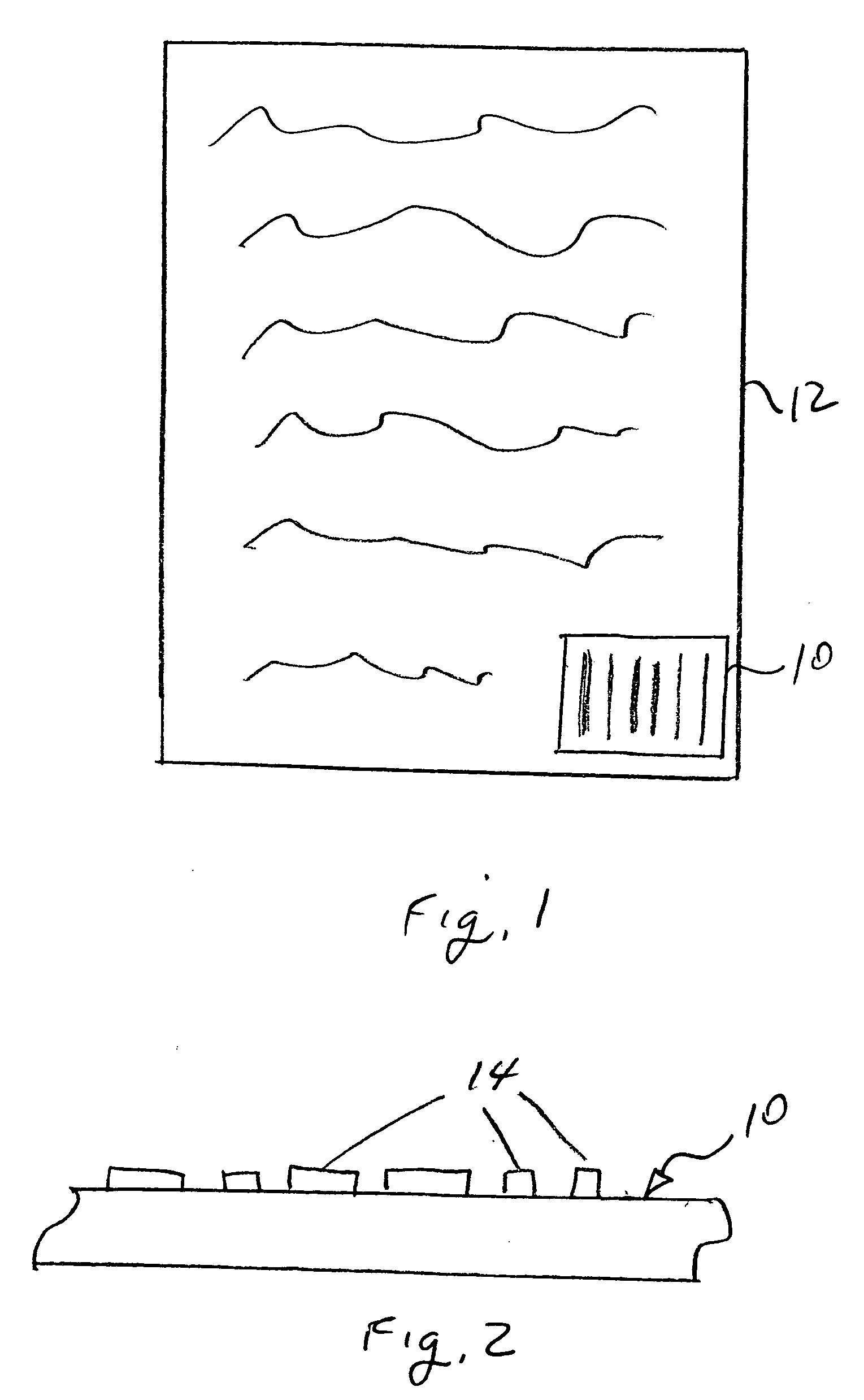

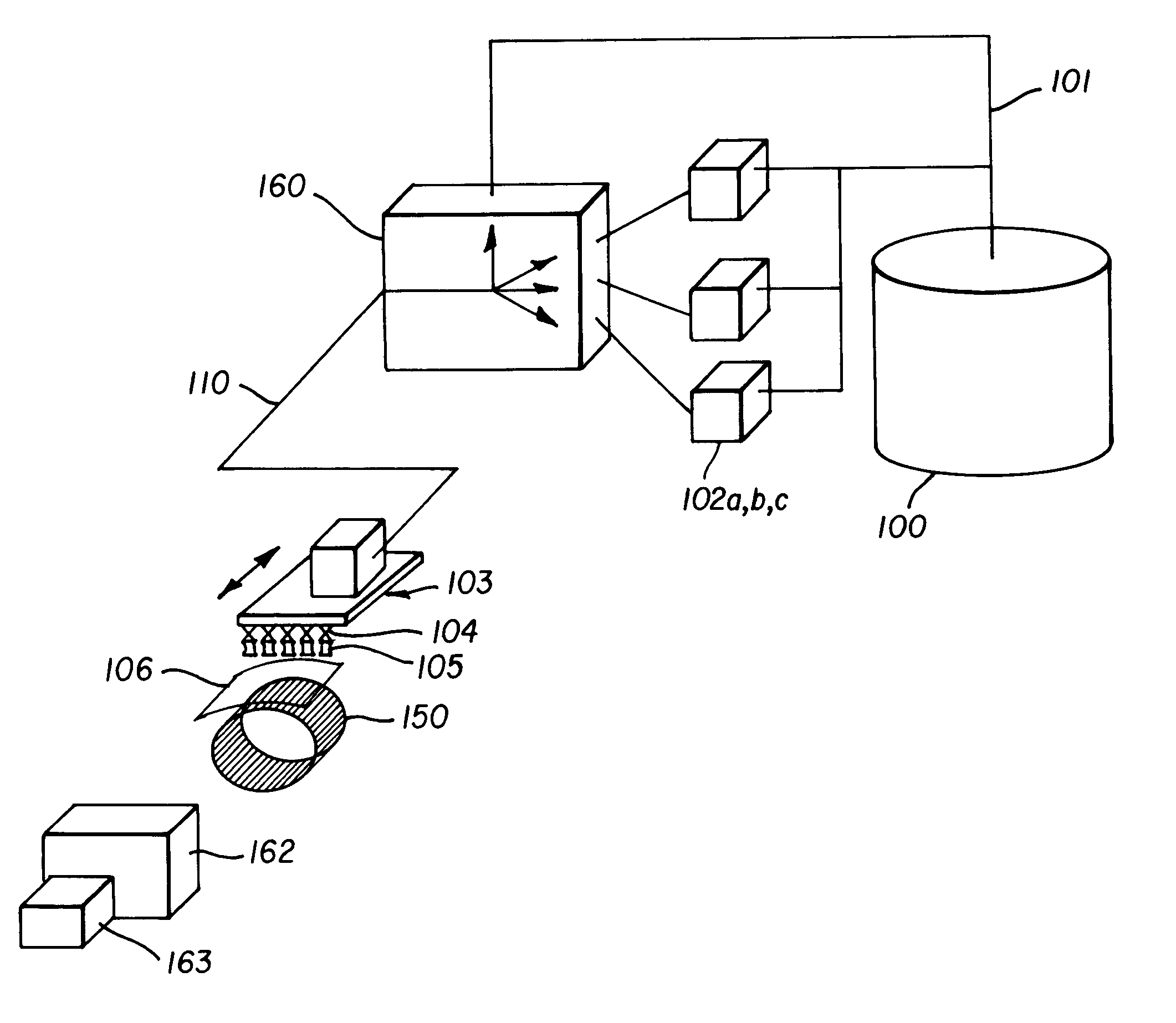

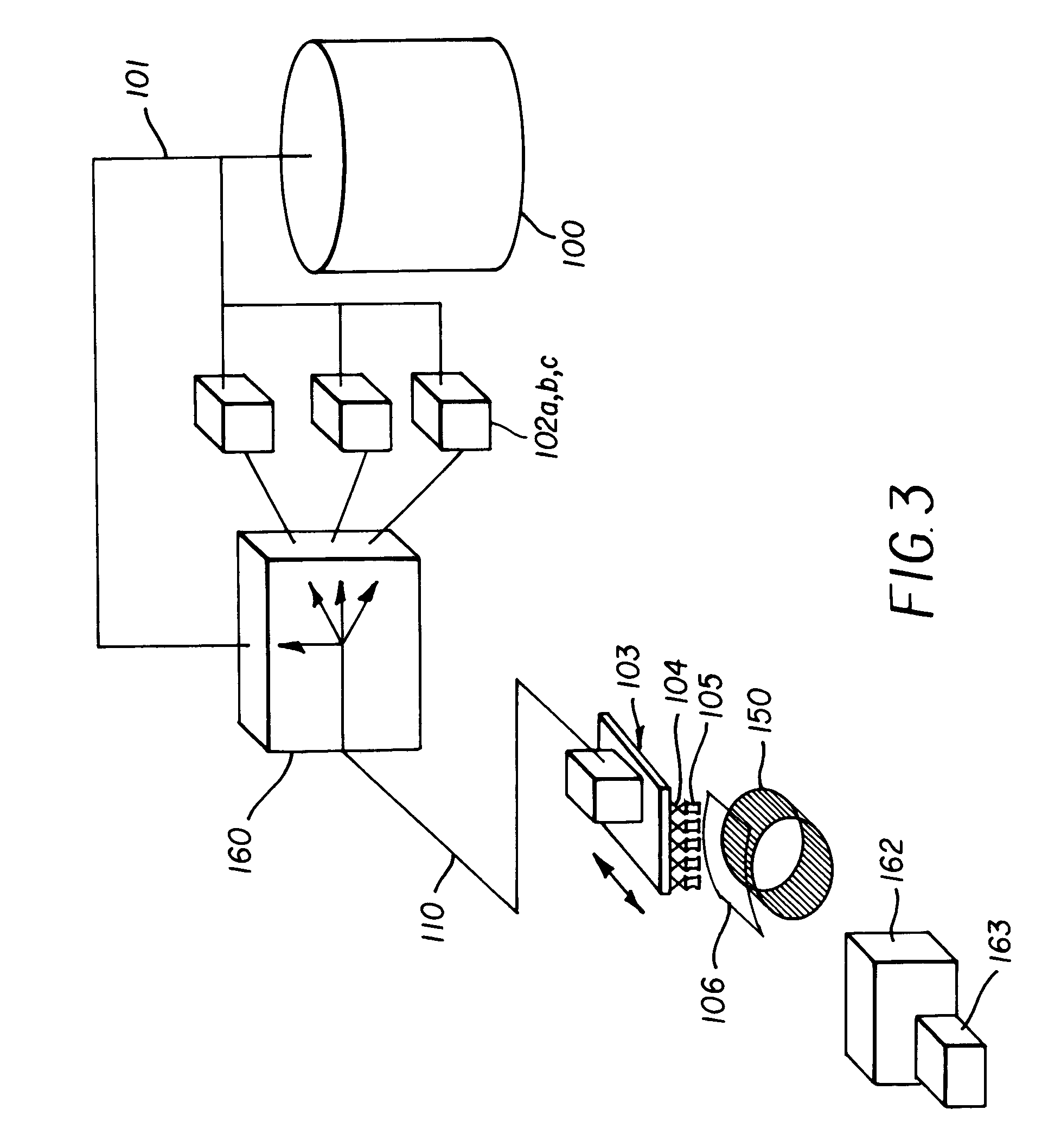

Authentication method and apparatus for use with compressed fluid printed swatches

InactiveUS20050018013A1Digital marking by photographic/thermographic registrationPrintingCompressed fluidEngineering

Authentication systems, apparatus, and methods authenticate an identification marking including a nanocrystalline material. One or more properties of the marking are ascertained to provide a measured profile. The measured profile is compared to at least one member of a closed set of reference profiles. Each reference profile has predetermined values of one or more properties. Each reference profile is unique within the set. At least one reference profile is characteristic of an indicator material in a nanocrystalline morphology and non-characteristic of the same indicator material in a bulk morphology.

Owner:EAPEIRON SOLUTIONS INC

Composite electrodes for lithium ion battery and method of making

InactiveUS20130108802A1Electrode rolling/calenderingElectrode thermal treatmentPorosityElectrical battery

A method for making a composite electrode for a lithium ion battery comprises the steps of: preparing a slurry containing particles of inorganic electrode material(s) suspended in a solvent; preheating a porous metallic substrate; loading the metallic substrate with the slurry; baking the loaded substrate at a first temperature; curing the baked substrate at a second temperature sufficient to form a desired nanocrystalline material within the pores of the substrate; calendaring the cured composite to reduce internal porosity; and, annealing the calendared composite at a third temperature to produce a self-supporting multiphase electrode. Because of the calendaring step, the resulting electrode is self-supporting, has improved current collecting properties, and improved cycling lifetime. Anodes and cathodes made by the process, and batteries using them, are also disclosed.

Owner:QUANTUMSCAPE CORP

Authentication method and apparatus for use with compressed fluid printed swatches

InactiveUS7044376B2Digital marking by photographic/thermographic registrationPrintingCompressed fluidEngineering

Authentication systems, apparatus, and methods authenticate an identification marking including a nanocrystalline material. One or more properties of the marking are ascertained to provide a measured profile. The measured profile is compared to at least one member of a closed set of reference profiles. Each reference profile has predetermined values of one or more properties. Each reference profile is unique within the set. At least one reference profile is characteristic of an indicator material in a nanocrystalline morphology and non-characteristic of the same indicator material in a bulk morphology.

Owner:EAPEIRON SOLUTIONS INC

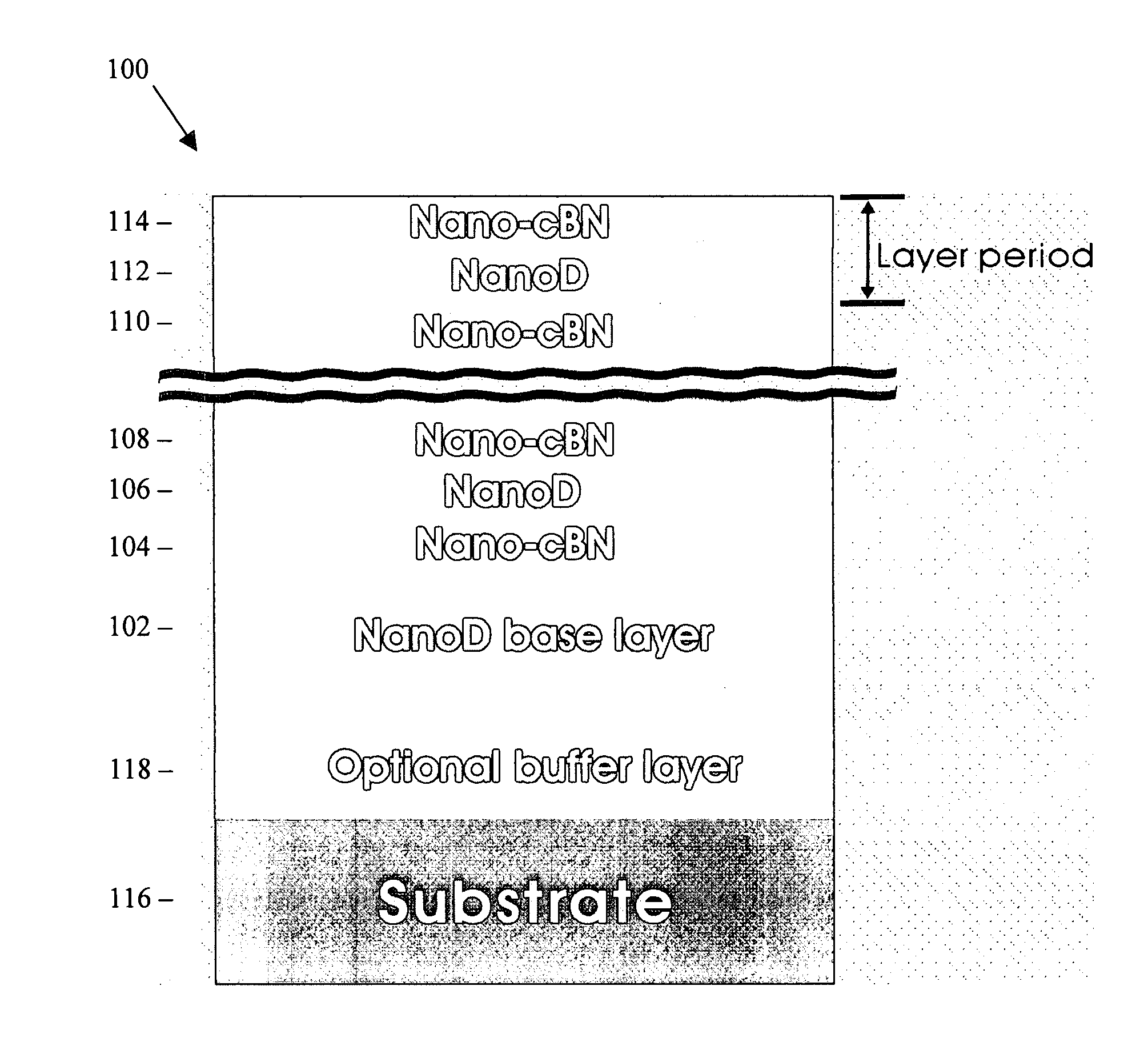

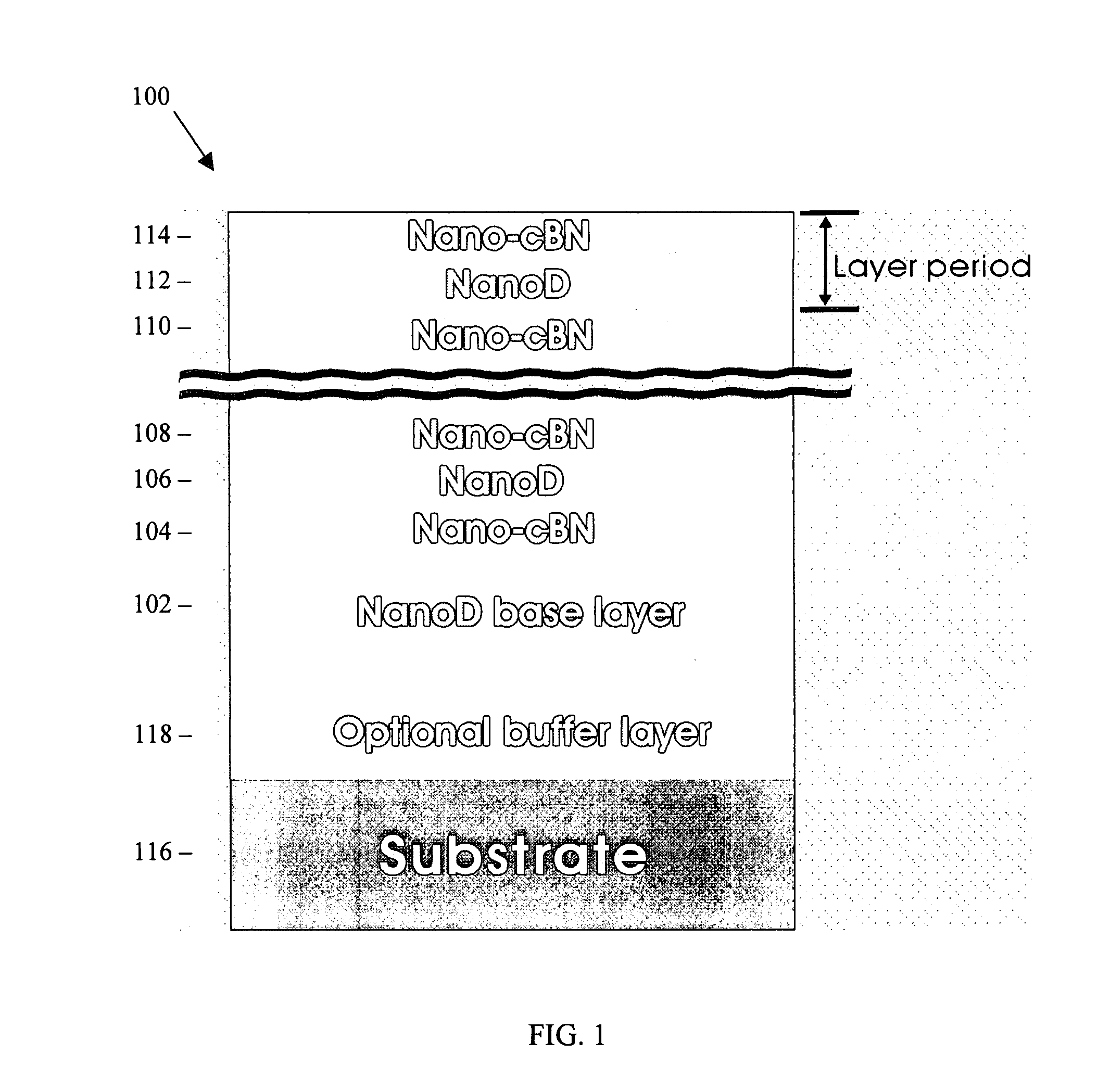

Ultrahard multilayer coating comprising nanocrystalline diamond and nanocrystalline cubic boron nitride

A multilayer coating (MLC) is composed of two chemically different layered nanocrystalline materials, nanodiamond (nanoD) and nano-cubic boron nitride (nono-cBN). The structure of the MLC and fabrication sequence of layered structure are disclosed. The base layer is preferably nanoD and is the first deposited layer serving as an accommodation layer on a pretreated substrate. It can be designed with a larger thickness whereas subsequent alternate nano-cBN and nanoD layers are typically prepared with a thickness of 2 to 100 nm. The thickness of these layers can be engineered for a specific use. The deposition of the nanoD layer, by either cold or thermal plasma CVD, is preceded by diamond nucleation on a pretreated and / or precoated substrate, which has the capacity to accommodate the MLC and provides excellent adhesion. Nano-cBN layers are directly grown on nanodiamond crystallites using ion-assisted physical vapor deposition (PVD) and ion-assisted plasma enhanced chemical vapor deposition (PECVD), again followed by nanodiamond deposition using CVD methods in cycles until the intended number of layers of the MLC is obtained.

Owner:CITY UNIVERSITY OF HONG KONG

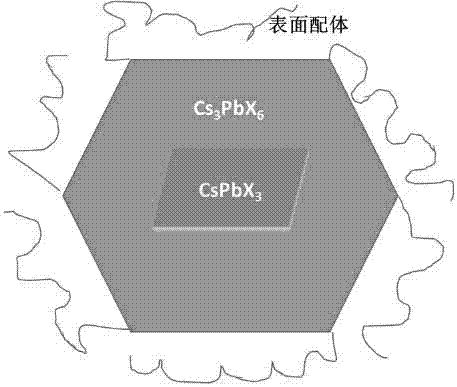

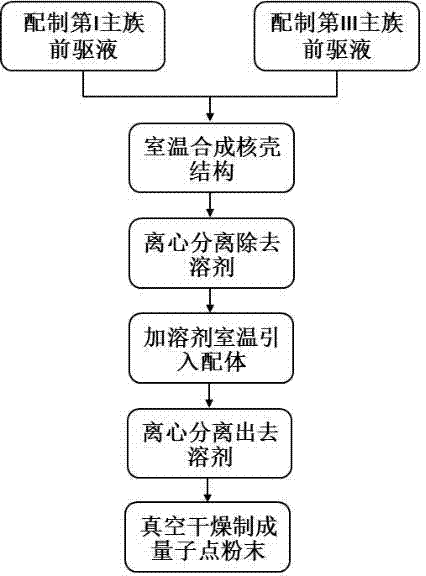

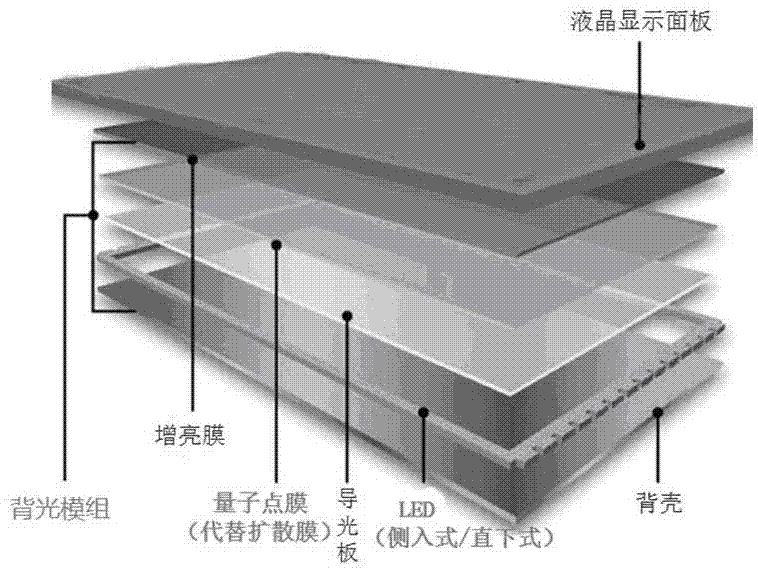

Preparation method of core-shell structural perovskite quantum dot

The invention discloses a preparation method of a core-shell structural perovskite quantum dot, which includes steps of configuring CsX and PbX2 precursor solutions respectively, mixing CsX precursor solution with PbX2 precursor solution, and generating a structure of coating CsPbX3 nano-crystal by Cs4PbX6 micro-crystal; separating and washing the compounded sediment; then dispersing the sediment in the solvent and introducing a ligand; performing membrane treatment on the solution after introducing the ligand to be a perovskite nanometer membrane; or separating again and vacuum-drying to be perovskite nanometer crystal powder. The core-shell structural perovskite nanometer crystal material can be dispersed in the organic solvent and prepared to be a quantum dot optical membrane; the quantum dot optical membrane is applied to a lighting diode liquid crystal display device and has stability to water, oxygen, heat, light and others.

Owner:向爱双 +1

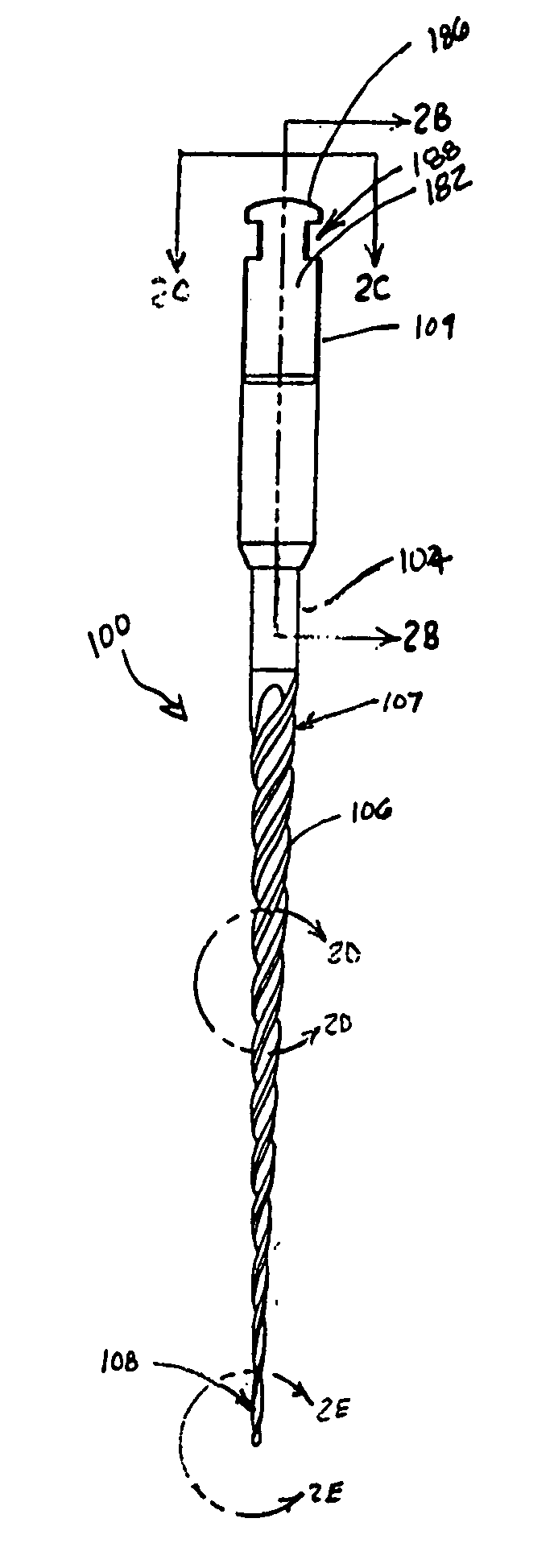

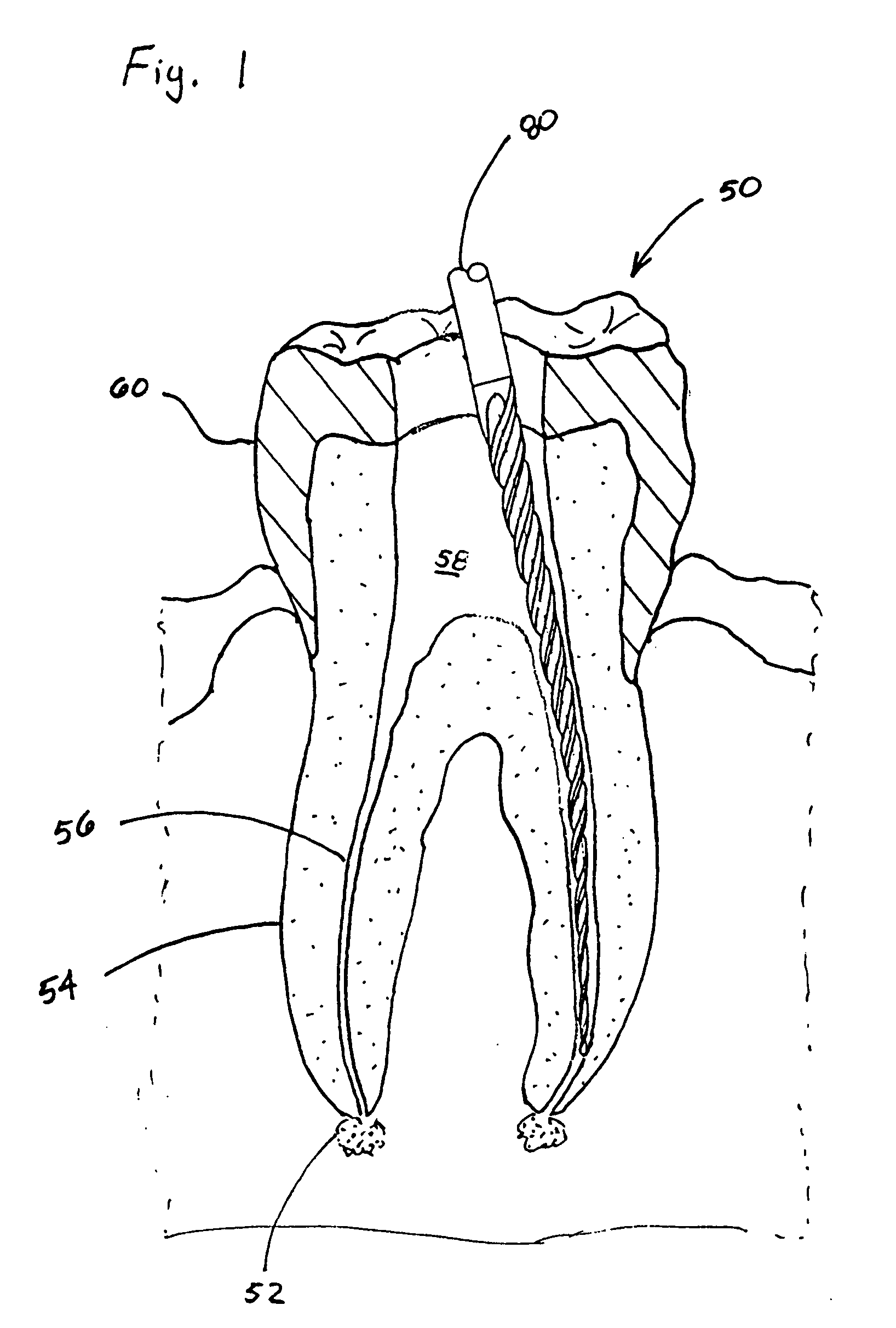

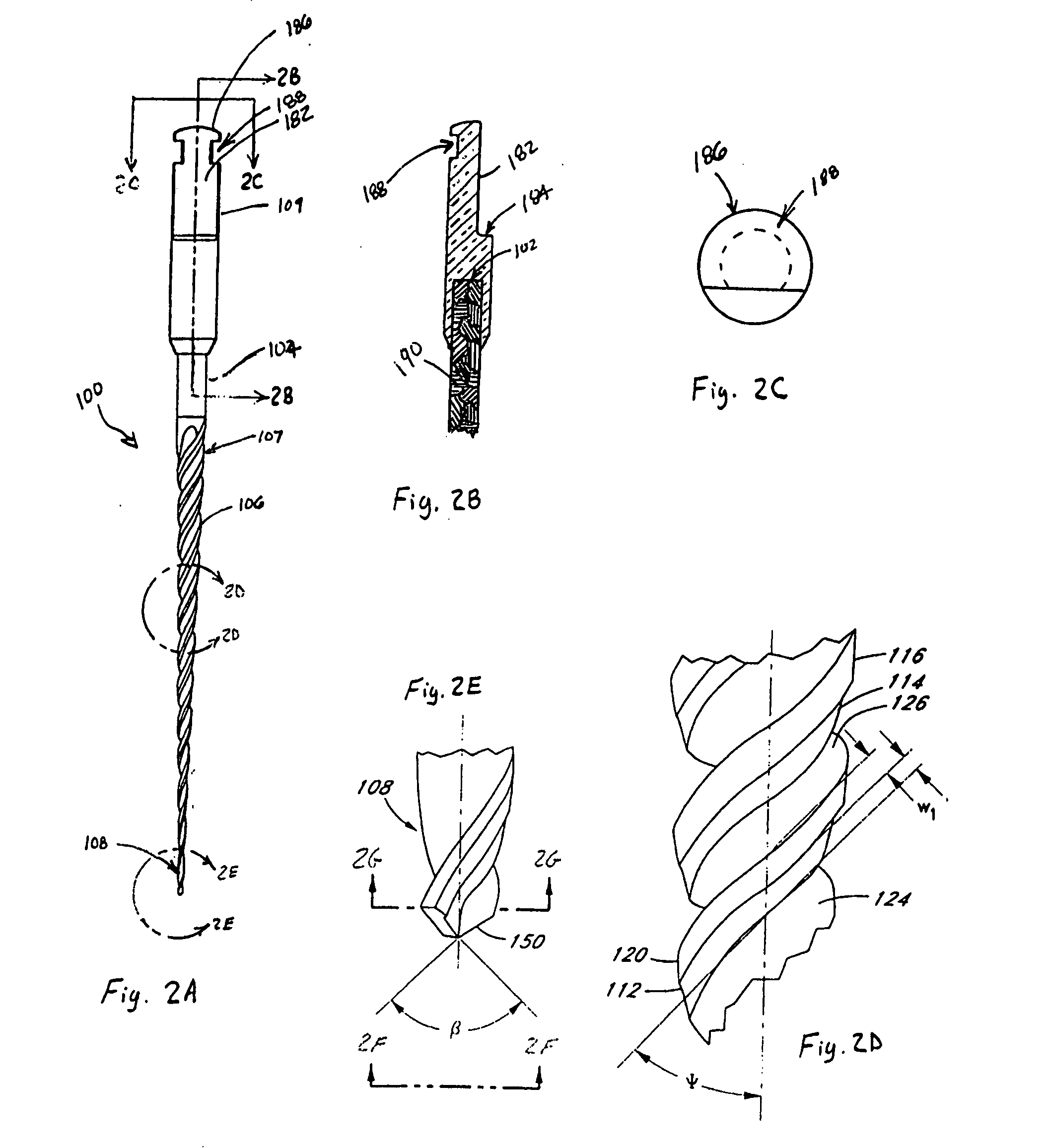

Precision cast dental instrument

InactiveUS20070184406A1Resistance to breakageResistance to wearTransportation and packagingWristbandsDental structureInstrumentation

An endodontic file (200) is provided particularly adapted for the removal of tooth structure, decayed or damaged nerve tissues or dentine material on the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The endodontic instrument includes a shaft (202) having a shank portion (204) and a generally elongated working portion (206). The working portion preferably includes cutting or abrading features (232) adapted upon rotation and / or reciprocation of the instrument to cut, abrade or remove tissue from the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The working portion extends from a proximal end (207) adjacent the shank portion to a distal end (208) terminating at a tip (250). The entire instrument and / or at least the working portion thereof is formed of an amorphous or essentially amorphous material having no or essentially no detectable crystalline structure and / or from a nanocrystalline material having an average crystalline grain size less than about 1 μm. The instrument may be formed by conventional grinding operations or by direct casting, forging or molding, in a manner producing an integral as-molded instrument having one or more sharp cutting edges. The instrument is inexpensive to manufacture and exhibits improved cutting-edge sharpness, wear resistance, lubriciousness and resistance to breakage.

Owner:CLOUDLAND INST

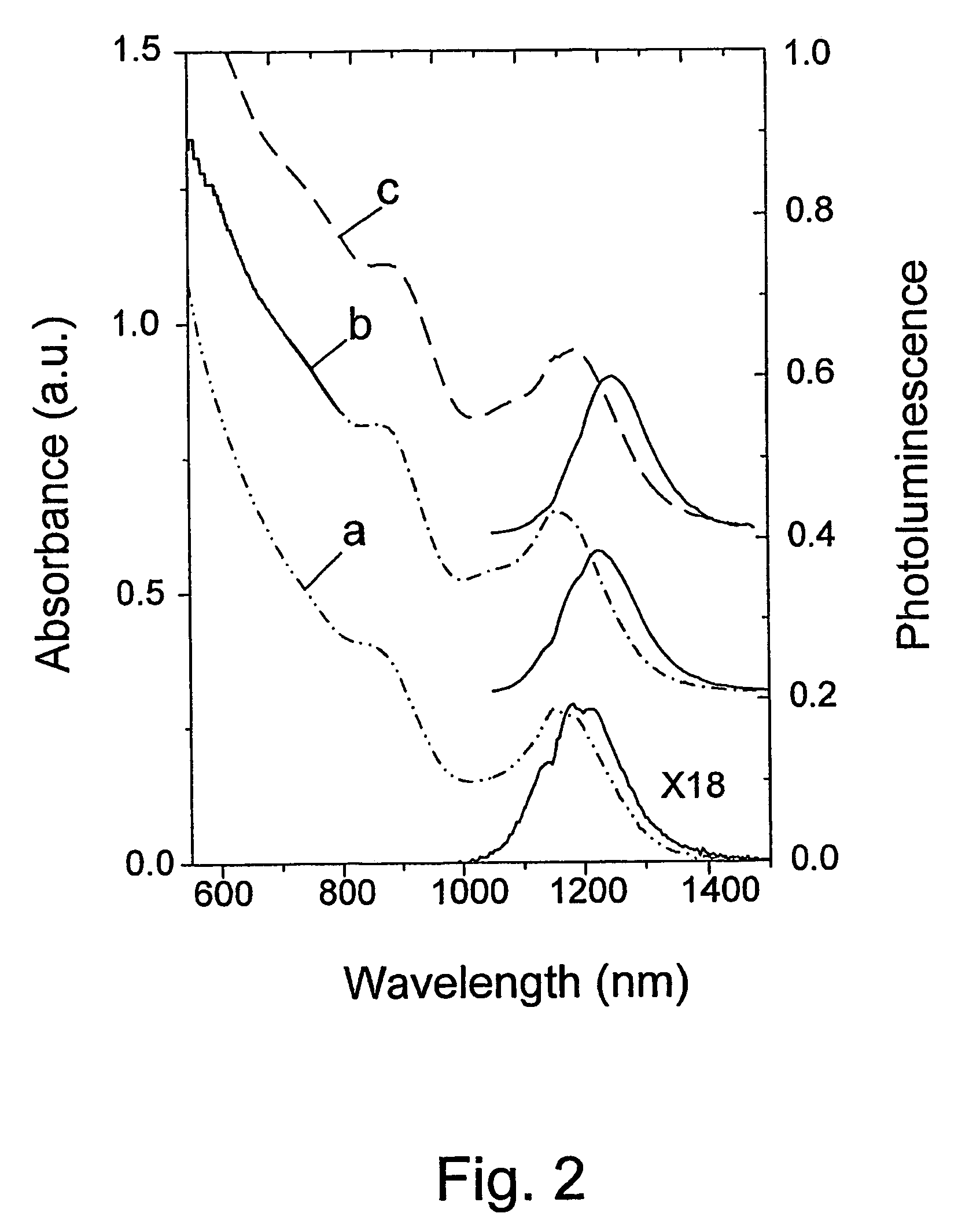

Near infra-red composite polymer-nanocrystal materials and electro-optical devices produced therefrom

InactiveUS7200318B2Energy efficiencyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhotodetectorAbsorbed energy

The invention comprises a composite material comprising a host material in which are incorporated semiconductor nanocrystals. The host material is light-transmissive and / or light-emissive and is electrical chargetransporting thus permitting electrical charge transport to the core of the nanocrystals. The semiconductor nanocrystals emit and / or absorb light in the near infrared spectral range. The nanocrystals cause the composite material to emit / absorb energy in the near infrared (NIR) spectral range, and / or to have a modified dielectric constant, compared to the host material. The invention further comprises electro-optical devices composed of this composite material and a method of producing them. Specifically described are light emitting diodes that emit light in the NIR and photodetectors that absorb light in the same region.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

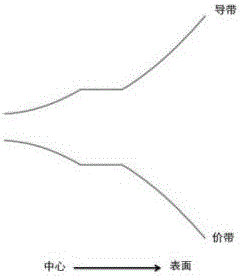

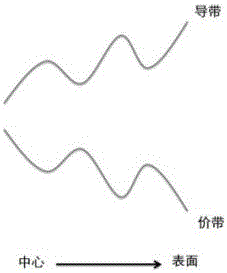

Nanocrystal with quantum well energy level structure and preparation method thereof, and semiconductor device

ActiveCN106601886AMeet the comprehensive performance requirementsEfficient luminous efficiencySemiconductor/solid-state device manufacturingNanoopticsQuantum wellQuantum dot

The present invention discloses a nanocrystal with a quantum well energy level structure and a preparation method thereof, and a semiconductor device. The nanocrystal comprises S central structural units located at the center of the nanocrystal and N surrounding structure units arranged in order located at the outer side of the center of the nanocrystal, wherein S is not smaller than 1, and the N is not smaller than 1, the central structural units and the surrounding structure units are the quantum dot structural units, and are the gradually changing structures with energy level width changing in the vertical direction or the uniform component structures with the consistent energy level width in the vertical direction. The novel nanocrystal provided by the invention can realize the higher-efficiency nanocrystal luminous efficiency and satisfy the integrated performance requirement of the semiconductor device and the corresponding display technology for the nanocrystal, and is the ideal nanocrystal material being suitable for the semiconductor device and the display technology.

Owner:TCL CORPORATION

Composite electrodes for lithium ion battery and method of making

InactiveUS20130108920A1Reduce internal porosityElectrode rolling/calenderingElectrode thermal treatmentPorositySodium-ion battery

A method for making a composite electrode for a lithium ion battery comprises the steps of: preparing a slurry containing particles of inorganic electrode material(s) suspended in a solvent; preheating a porous metallic substrate; loading the metallic substrate with the slurry; baking the loaded substrate at a first temperature; curing the baked substrate at a second temperature sufficient to form a desired nanocrystalline material within the pores of the substrate; calendaring the cured composite to reduce internal porosity; and, annealing the calendared composite at a third temperature to produce a self-supporting multiphase electrode. Because of the calendaring step, the resulting electrode is self-supporting, has improved current collecting properties, and improved cycling lifetime. Anodes and cathodes made by the process, and batteries using them, are also disclosed.

Owner:QUANTUMSCAPE CORP

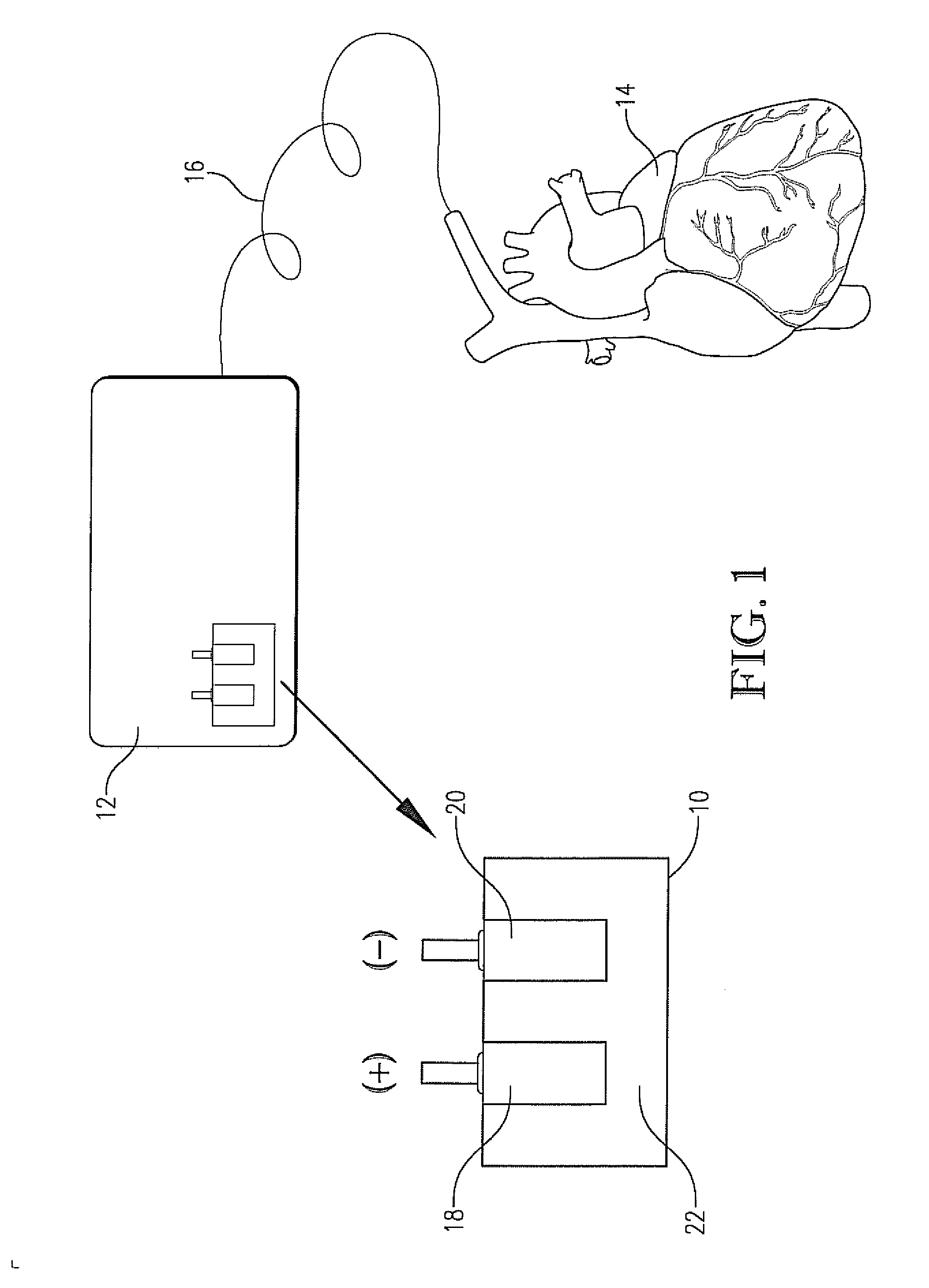

Synthesis of high surface area nanocrystalline materials useful in battery applications

InactiveUS20070286796A1Alkaline earth titanatesMaterial nanotechnologyElectrochemical cellMedical device

An improved mixed metal oxide material suitable for use in electrochemical cells is provided. The mixed metal oxide material generally exhibits high surface area and pore volume than conventionally manufactured materials thereby imparting improved electrochemical performance. Batteries manufactured using the mixed metal oxide material are particularly suited for use in implantable medical devices.

Owner:TIMILON TECH ACQUISITIONS LLC

Method for preparing nanocrystalline metal material containing nano-sized precipitates within crystal

The invention provides a method for preparing a nanocrystalline metal material containing nano-sized precipitates within a crystal. The method comprises the following steps of firstly, performing high-temperature solution treatment on a coarse crystalline metal material, thereby obtaining single phase solid solution with supersaturated and dissolved alloy element, wherein the coarse crystalline metal material contains alloy element in a matrix, and the solid solubility is reduced as the temperature is reduced; then, performing severe plastic deformation and high-pressure reverse processing at or below the room temperature, thereby obtaining single phase solid solution nanocrystalline material composed of nanocrystalline grains with supersaturated and dissolved alloy element; and finally, ageing the obtained nanocrystalline material at a pressure of 3-25 GPa and at a temperature of 100-800 DEG C, and holding the temperature for 5-8 h, thereby obtaining a nanocrystalline metal material containing nano-sized precipitates within a crystal. The method provided by the invention is wide in suitable material component range, and can be used for effectively avoiding severe plastic deformation to produce microcrack in a material, and the prepared nano-sized precipitates in the nanocrystalline material are distributed uniformly.

Owner:YANSHAN UNIV

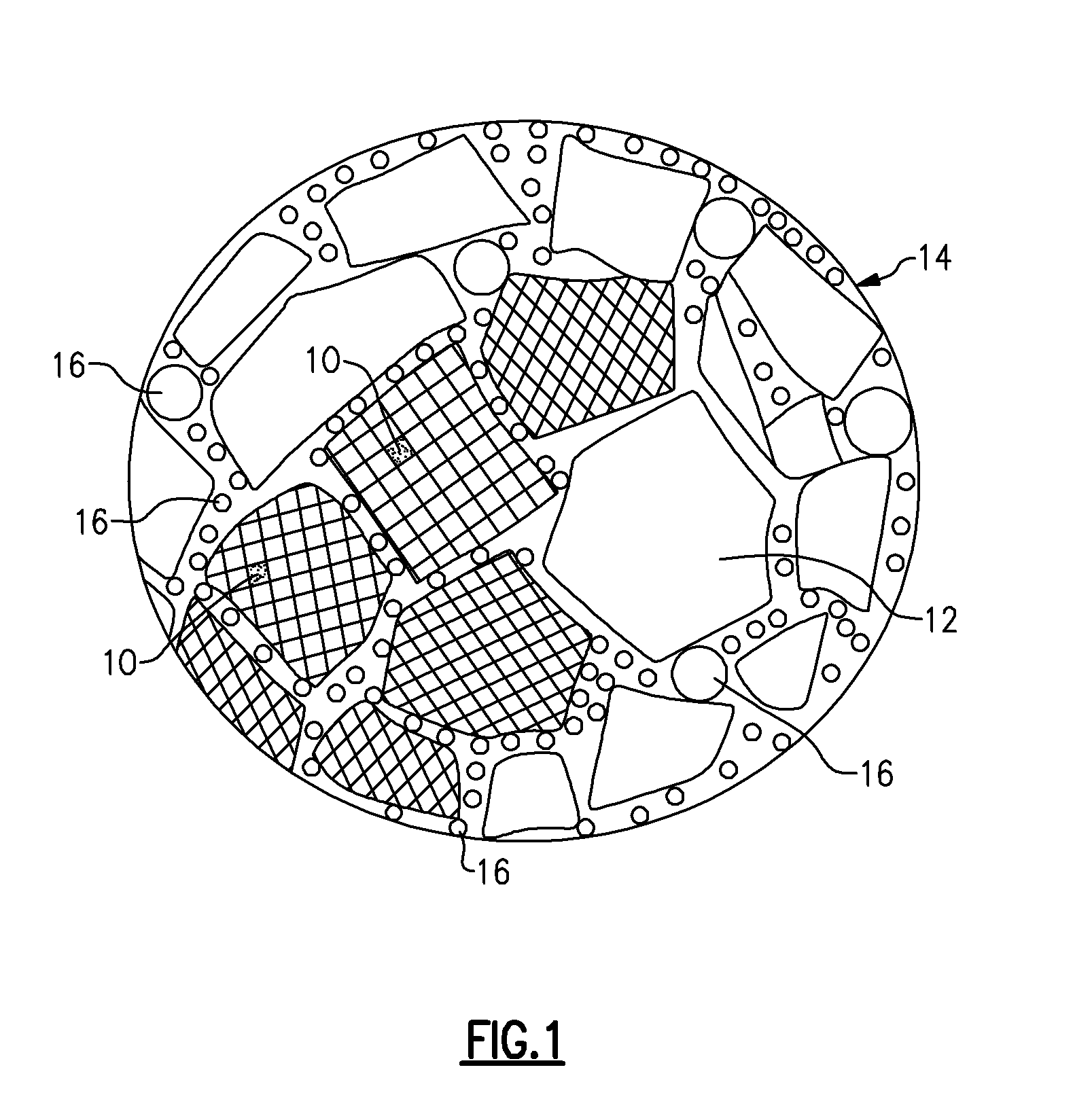

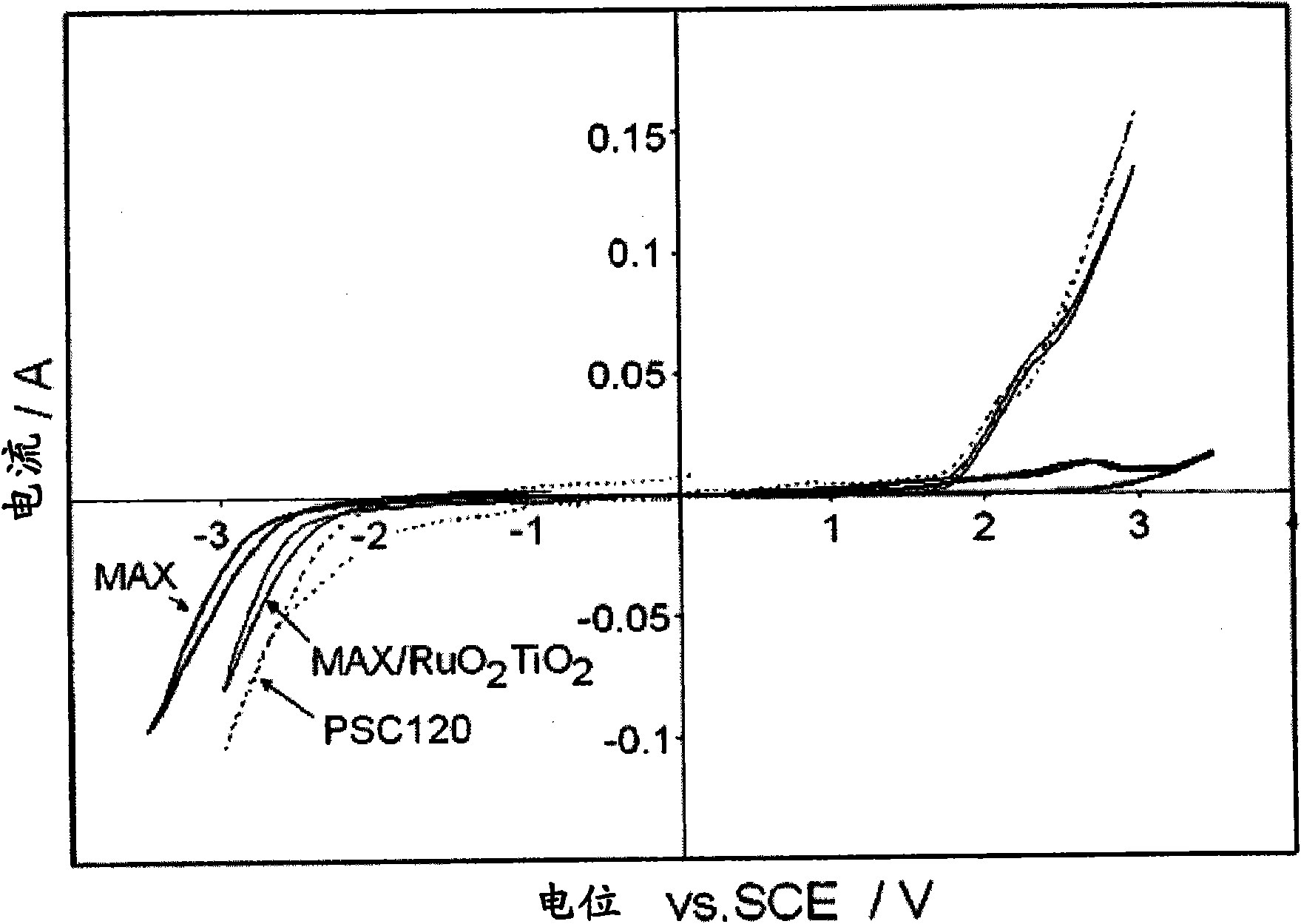

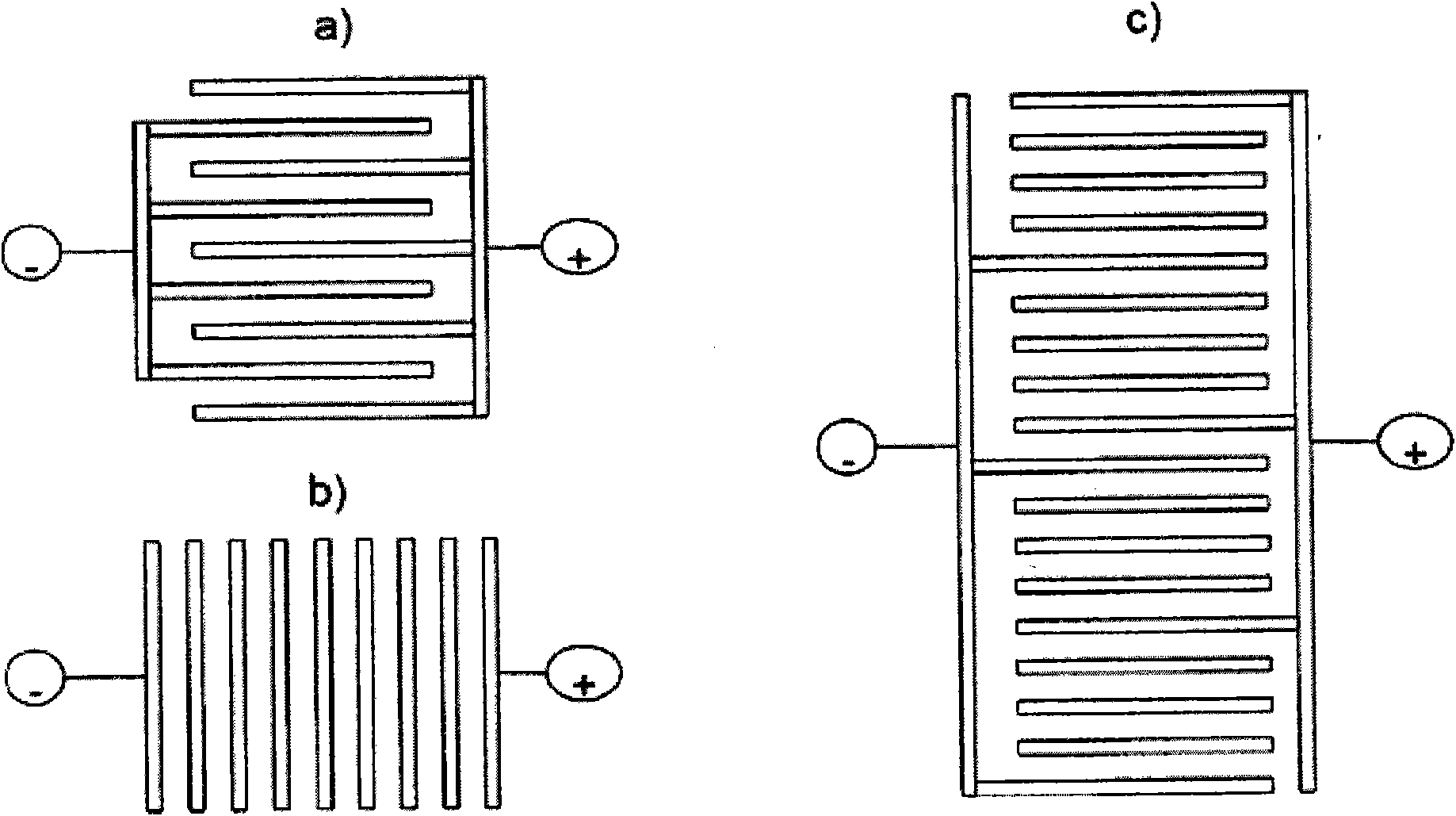

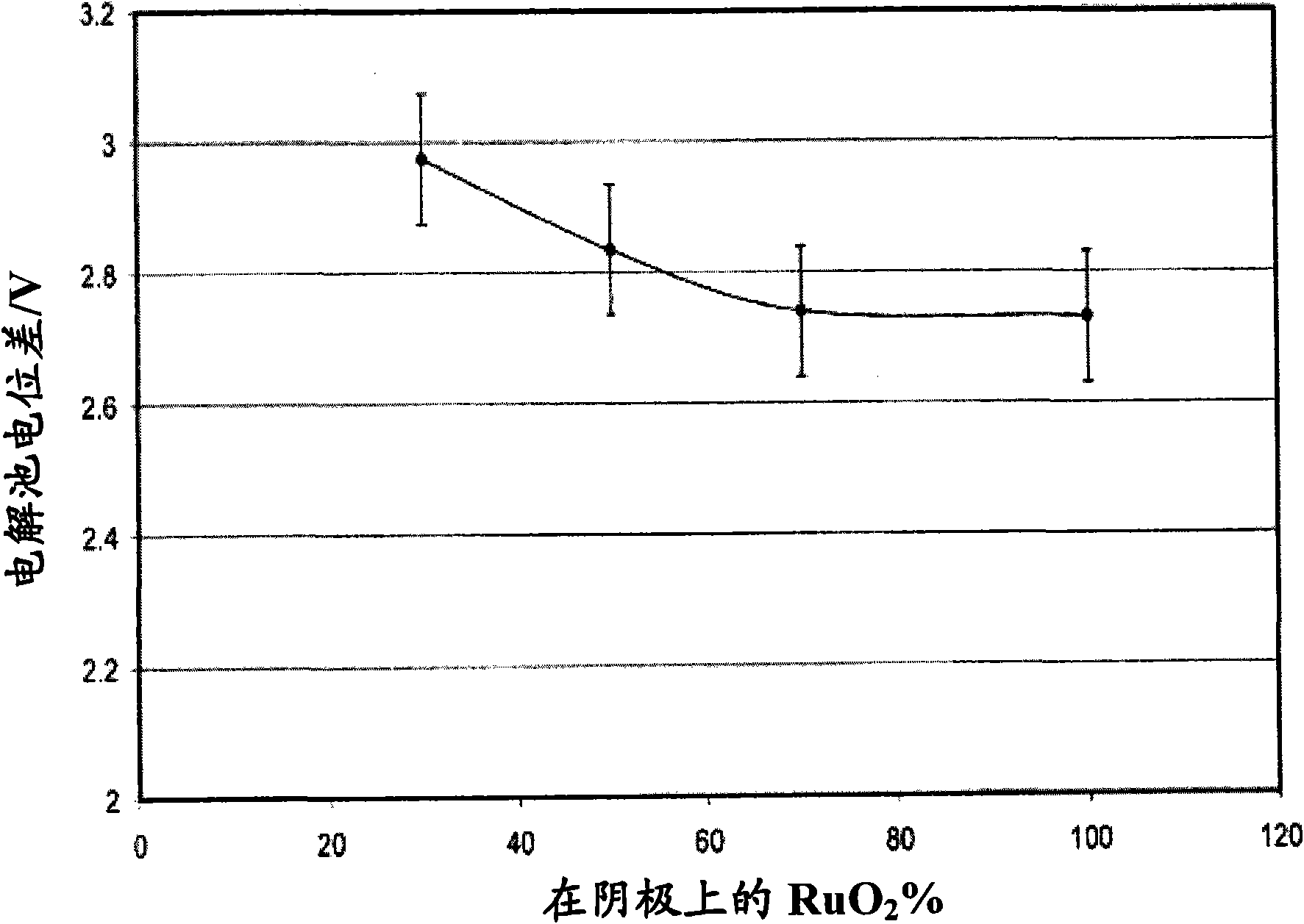

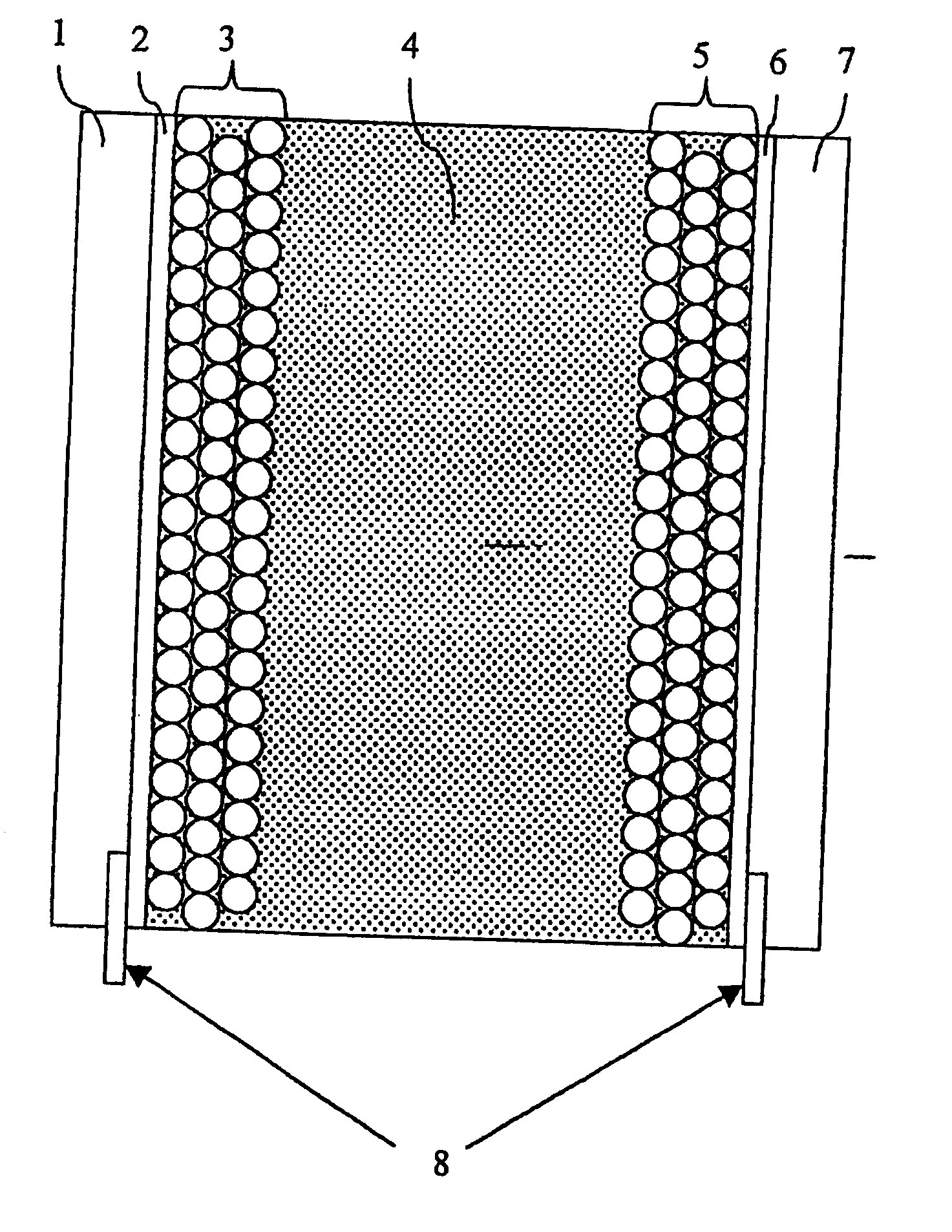

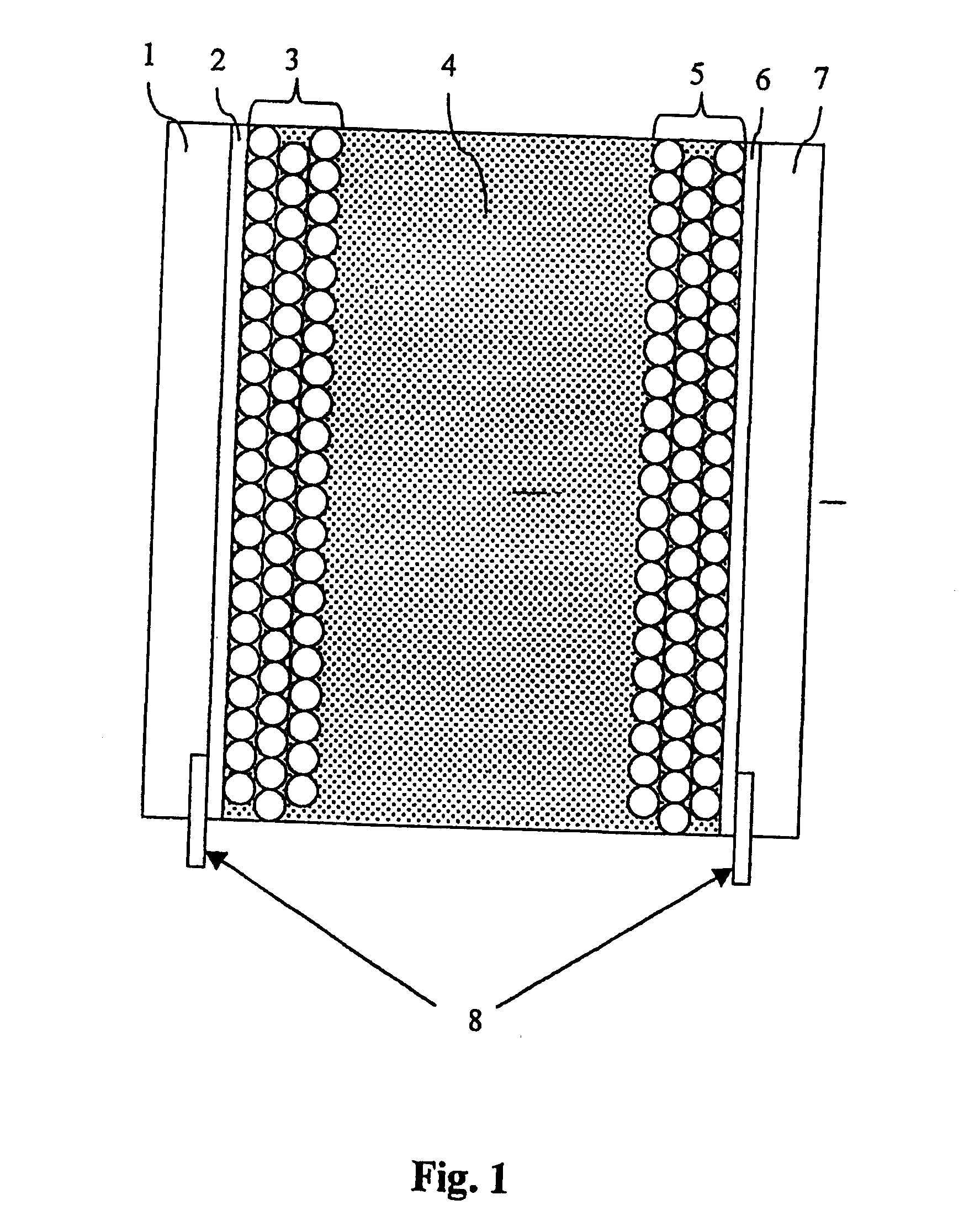

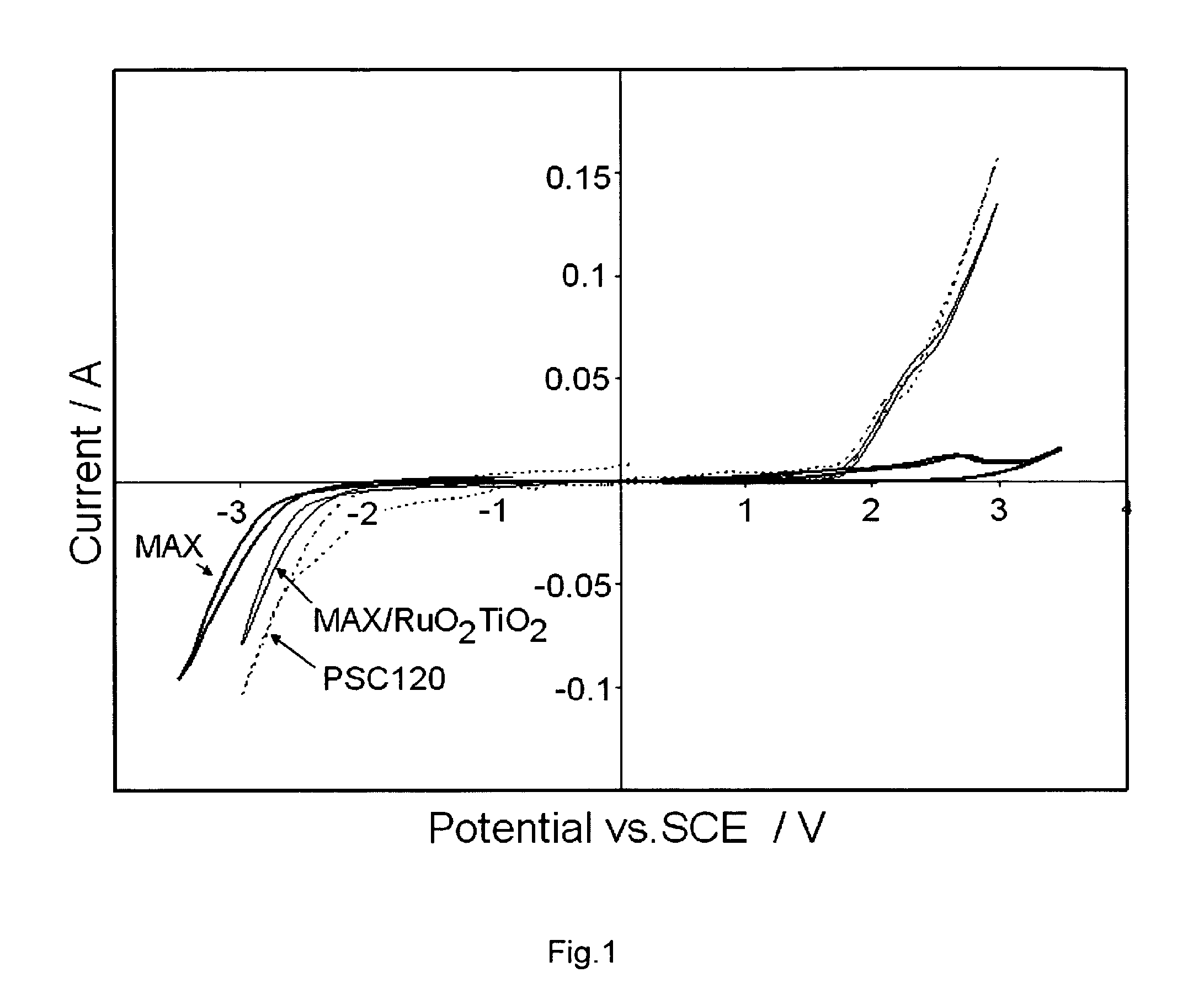

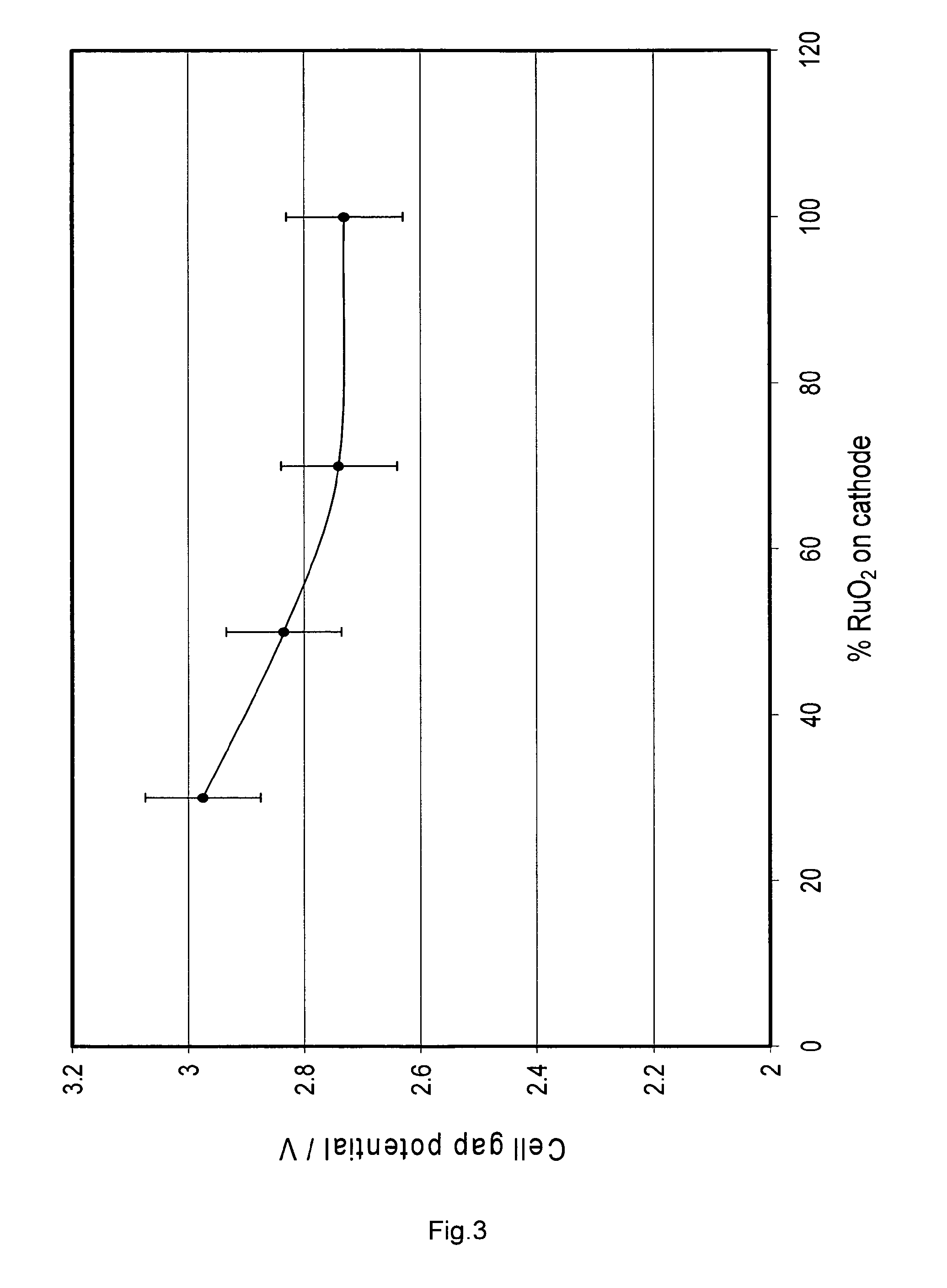

Electrode

An electrode substrate comprising M(n+1)AXn, where M is a metal of group IIIB, IVB,VB,VIB or VIII of the periodic table of elements or a combination thereof, A is an element of group IIIA, IVA, VA or VIA of the periodic table of elements or a combination thereof, X is carbon, nitrogen or a combination thereof, where n is 1, 2, or 3; and b) an electrocatalytic coating deposited on said electrode substrate, said coating being selected from at least one of b.1 ) a metal oxide and / or metal sulfide comprising ByC(1-y)Oz1Sz2, wherein B is at least one of ruthenium, platinum, rhodium, palladium, iridium, and cobalt, C is at least one valve metal, y is 0.4-0.9, 0 <= z1, z2 <= 2 and z1+z2=2; b.2) a metal oxide comprising BfCgDhEi, wherein B is at least one of ruthenium, platinum, rhodium, palladium, and cobalt, C is at least one valve metal, D is iridium, E is Mo and / or W, wherein f is 0-0.25 or 0.35-1, g is 0-1, h is 0-1, i is 0-1, wherein f+g+h+i=1; b.3) at least one noble metal; b.4) any alloy or mixture comprising iron-molybdenum, iron-tungsten, iron-nickel, ruthenium-molybdenum, ruthenium-tungsten or mixtures thereof; b.5) at least one nanocrystalline material. The electrode is used in an electrolytic cell for the production of alkali metal chlorate.

Owner:NOURYON CHEM INT BV

Highly luminescent color-selective nanocrystalline materials

InactiveUS20050048283A1Improve coordinationMaterial nanotechnologyFrom normal temperature solutionsQuantum yieldPhotoluminescence

A nanocrystal capable of light emission includes a nanoparticle having photoluminescence having quantum yields of greater than 30%.

Owner:MASSACHUSETTS INST OF TECH

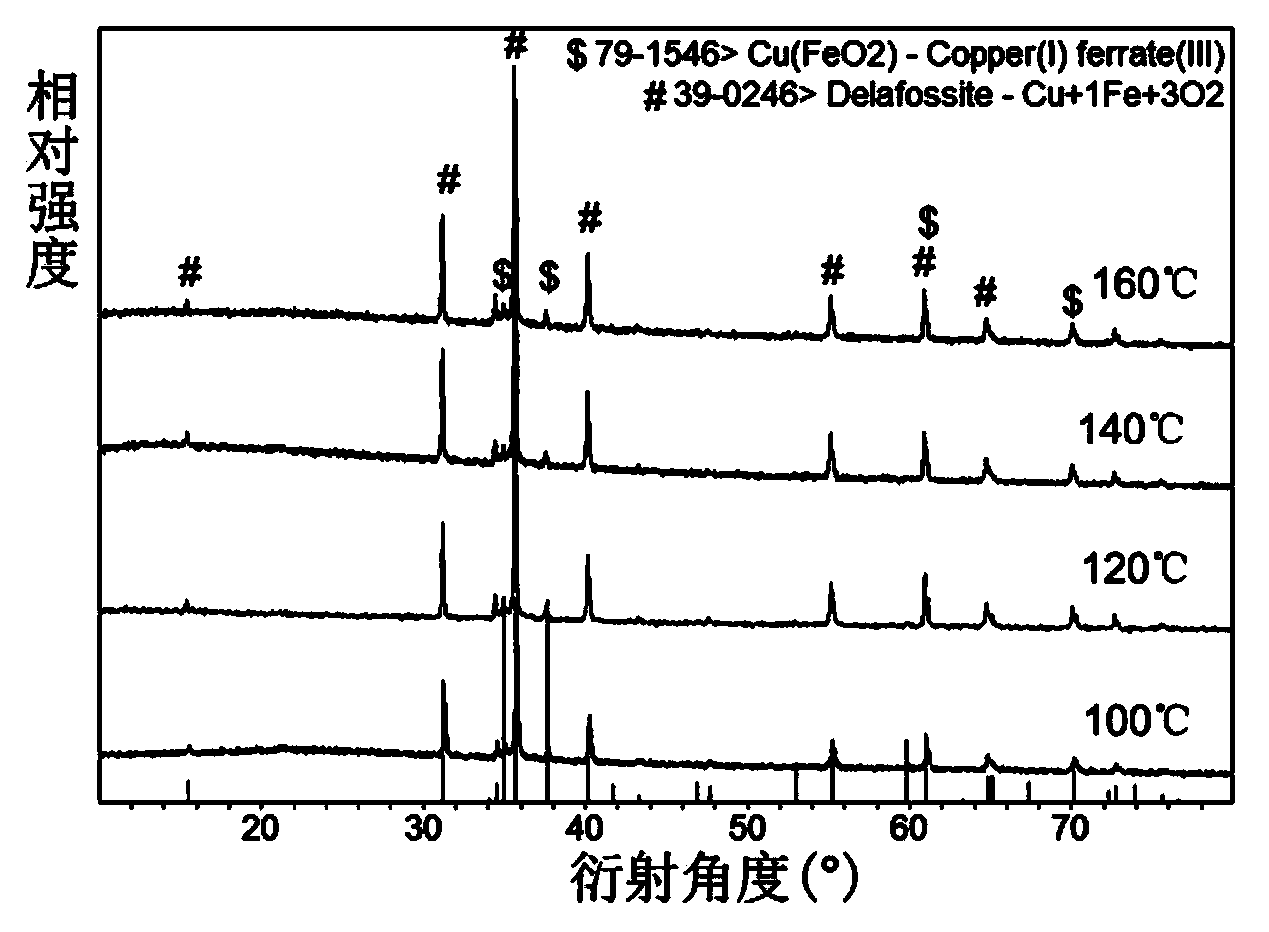

Low-temperature preparation method for CuFeO2 crystal material of delafossite structure

ActiveCN104058461APromote application developmentLow costMaterial nanotechnologyIron compoundsFilling rateReaction temperature

The invention discloses a low-temperature preparation method for a CuFeO2 crystal material of a delafossite structure, in particular to a low-temperature hydrothermal synthesis method for rapidly preparing the CuFeO2 nanocrystalline material of the delafossite structure. The method comprises the steps that parameters including reaction precursor components, the reaction temperature and the filling rate of a reaction solution in a hydrothermal reaction kettle are regulated and controlled through a low-temperature hydrothermal reaction, reactants including Cu(NO3)2 and FeCl2 react for 12 hours to 48 hours at the temperature ranging from 100 DEG C to 160 DEG C, and then, after a reaction product is processed through centrifugal cleaning and dried, the nanoscale CuFeO2 crystal material is obtained. The low-temperature preparation method for the CuFeO2 crystal material of the delafossite structure is easy to operate, the technological parameters are easy to control, no pollution is caused, the yield is high, and the method can be widely used for photoelectricity functional devices such as transparent conducting oxide.

Owner:WUHAN UNIV OF TECH

Electrochromic device based on nanocrystalline materials

InactiveUS20050104136A1Change color quicklyEnhance memoryTransistorSolid-state devicesPotential differenceEngineering

An electrochromic device, comprising a first electrode (3), a second electrode (5) and an electrolyte (4) separating the electrodes (3, 5), where at least one of said first and second electrodes includes an electrically active structure which have an at least dual state visual appearance depending on the potential difference between the first and the second electrode.

Owner:NTERA LTD (IE)

Electrode

An electrode substrate comprising M(n+1)AXn, where M is a metal of group IIIB, IVB, VB, VIB or VIII of the periodic table of elements or a combination thereof, A is an element of group IIIA, IVA, VA or VIA of the periodic table of elements or a combination thereof, X is carbon, nitrogen or a combination thereof, where n is 1, 2, or 3; and b) an electrocatalytic coating deposited on said electrode substrate, said coating being selected from at least one of b.1) a metal oxide and / or metal sulfide comprising ByC(1−y)Oz1Sz2, wherein B is at least one of ruthenium, platinum, rhodium, palladium, iridium, and cobalt, C is at least one valve metal, y is 0.4-0.9, 0<=z1, z2<=2 and z1+z2=2; b.2) a metal oxide comprising BfCgDhEi, wherein B is at least one of ruthenium, platinum, rhodium, palladium, and cobalt, C is at least one valve metal, D is iridium, E is Mo and / or W, wherein f is 0-0.25 or 0.35-1, g is 0-1, h is 0-1, i is 0-1, wherein f+g+h+i=1; b.3) at least one noble metal; b.4) any alloy or mixture comprising iron-molybdenum, iron-tungsten, iron-nickel, ruthenium-molybdenum, ruthenium-tungsten or mixtures thereof; b.5) at least one nanocrystalline material. The electrode is used in an electrolytic cell for the production of alkali metal chlorate.

Owner:AKZO NOBEL CHEM INT BV

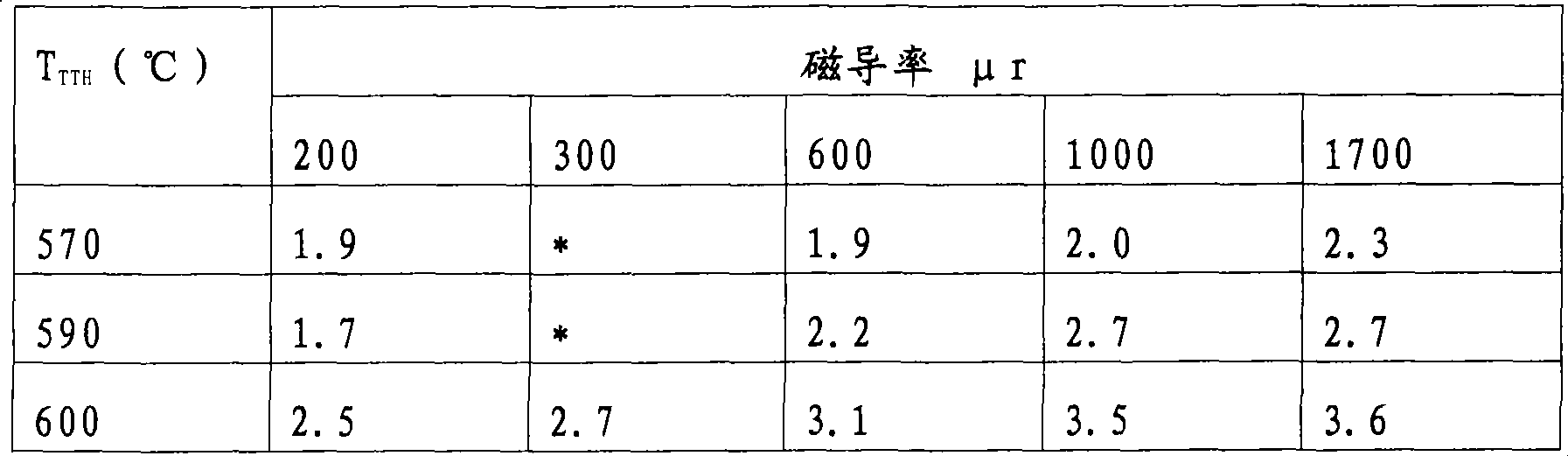

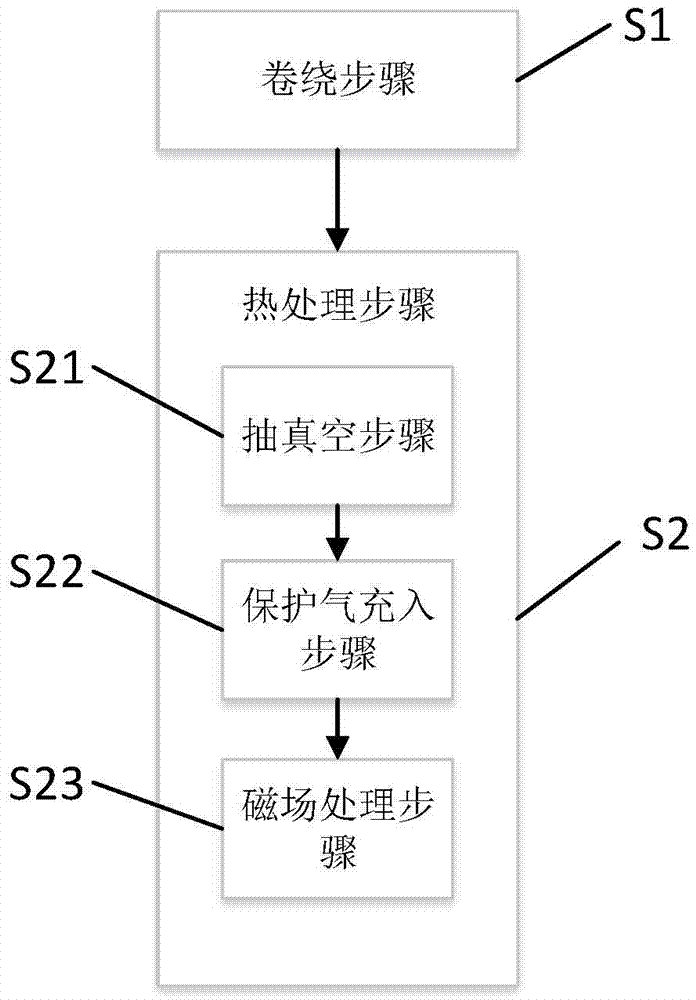

Heat treatment method for amorphous material or nanocrystalline material for magnetic shield sheet

InactiveCN106916928AImprove shielding effectReduce the saturation magnetostriction coefficientUnwanted magnetic/electric effect reduction/preventionMagnetic shieldAmorphous metal

The invention provides a heat treatment method for an amorphous material or a nanocrystalline material for a magnetic shield sheet. The heat treatment method comprises the following steps: a winding step of winding the amorphous strip material or the nanocrystalline strip material into magnetic cores with the needed dimensions, and a heat treatment step of arranging the amorphous magnetic cores or the nanocrystalline magnetic cores in a heat treatment furnace according to a certain rule and carrying out heat treatment, wherein magnetic field treatment is carried out during the heat treatment process. The shield performance of the magnetic shield sheet can be improved by virtue of a magnetic field-applied heat treatment process. In addition, a saturation magnetostriction constant is lowered after the magnetic field-applied heat treatment, so that the influence of stress is reduced, the magnetic conductivity is increased, the loss is reduced, and the charging efficiency is increased.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com