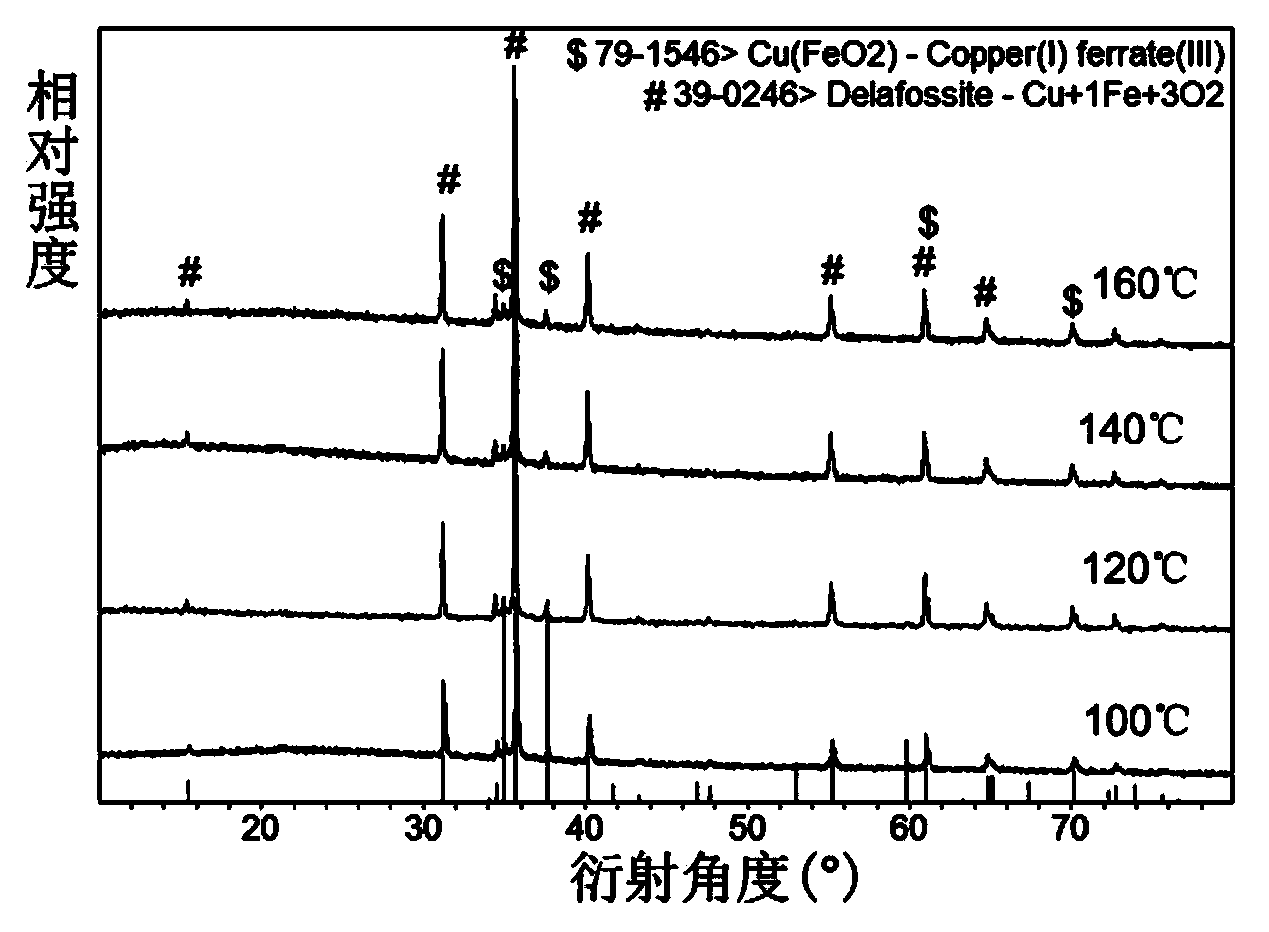

Low-temperature preparation method for CuFeO2 crystal material of delafossite structure

A technology of crystalline materials, delafossite, applied in the fields of nanotechnology, chemical instruments and methods, iron compounds, etc. for materials and surface science, which can solve the problem that the nanometer effect of photoelectrochemical properties has not been fully reflected, and the nanometer effect has not been reached. scale and other issues, to achieve the effect of easy control of process parameters, low price, and good experimental repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh Cu(NO 3 ) 2 and FeCl 2 Finally, add deionized water and stir it with a magnetic stirrer for about 10-15 minutes. After it is completely dissolved, add 4 times the molar amount of NaOH that acts as a mineralizer, and continue stirring for about 10-15 minutes until it is completely dissolved and forms water. Thermally reactive precursor. Transfer the above reaction precursor to a hydrothermal reaction kettle (generally polytetrafluoroethylene), and control the filling rate of the reaction liquid to about 65%. After sealing the kettle body, place it in a programmed temperature-controlled oven for hydrothermal reaction, set the reaction temperature to 160°C, and the reaction time to 12 to 48 hours.

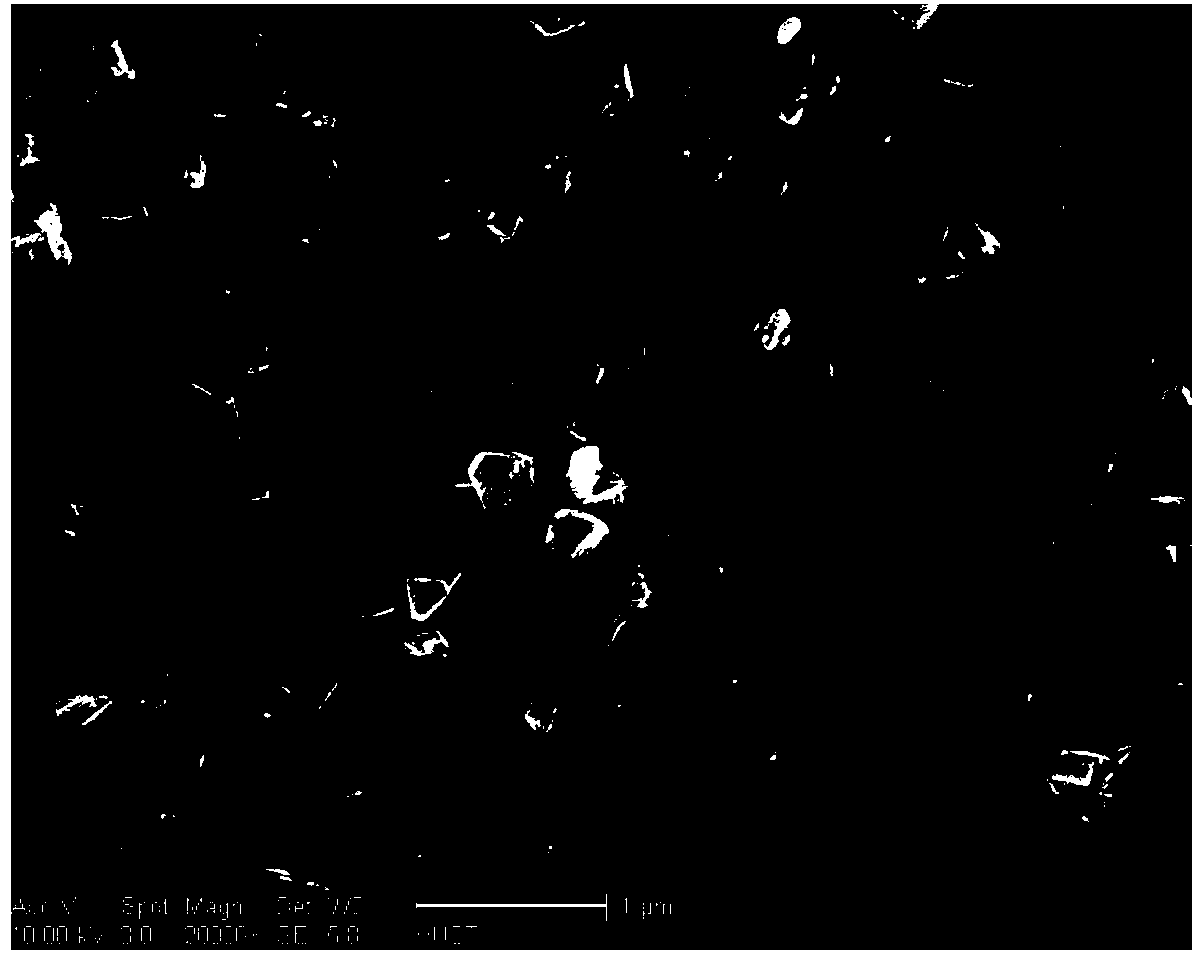

[0031] After the reaction, the kettle body was naturally cooled to room temperature, and the kettle body was opened to take out the reaction product. Use deionized water, dilute NH 3 ·H 2 O, deionized water, absolute ethanol, etc., were centrifuged and washed severa...

Embodiment 2

[0033] Weigh Cu(NO 3 ) 2 and FeCl 2 Finally, add deionized water and stir it with a magnetic stirrer for about 10-15 minutes. After it is completely dissolved, add 6 times the molar amount of NaOH that acts as a mineralizer, and continue stirring for about 10-15 minutes until it is completely dissolved and forms water. Thermally reactive precursor.

[0034] The above-mentioned reaction precursor is transferred to a hydrothermal reaction kettle (generally polytetrafluoroethylene), and the filling rate of the reaction liquid is controlled to be about 65-75%. After sealing the kettle body, place it in a programmed temperature-controlled oven for hydrothermal reaction, set the reaction temperature to 160° C., and the reaction time to 36 hours.

[0035] After the reaction, the kettle body was naturally cooled to room temperature, and the kettle body was opened to take out the reaction product. Use deionized water, dilute NH 3 ·H 2 O, deionized water, absolute ethanol, etc., w...

Embodiment 3

[0037] Weigh Cu(NO 3 ) 2 and FeCl 2 Finally, add deionized water and stir with a magnetic stirrer for about 10 to 15 minutes. After it is completely dissolved, add 4 to 10 times the molar amount of NaOH that acts as a mineralizer, and continue stirring for about 10 to 15 minutes until it is completely dissolved. Formation of hydrothermal reaction precursors.

[0038] Transfer the above reaction precursor to a hydrothermal reactor (generally polytetrafluoroethylene), and control the filling rate of the reaction solution to about 70%. After sealing the kettle body, place it in a programmed temperature-controlled oven for hydrothermal reaction, set the reaction temperature to 100°C, and the reaction time to 12 to 48 hours.

[0039] After the reaction, the kettle body was naturally cooled to room temperature, and the kettle body was opened to take out the reaction product. Use deionized water, dilute NH 3 ·H 2 O, deionized water, absolute ethanol, etc., were centrifuged and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com