Patents

Literature

55results about How to "Good development and application prospects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

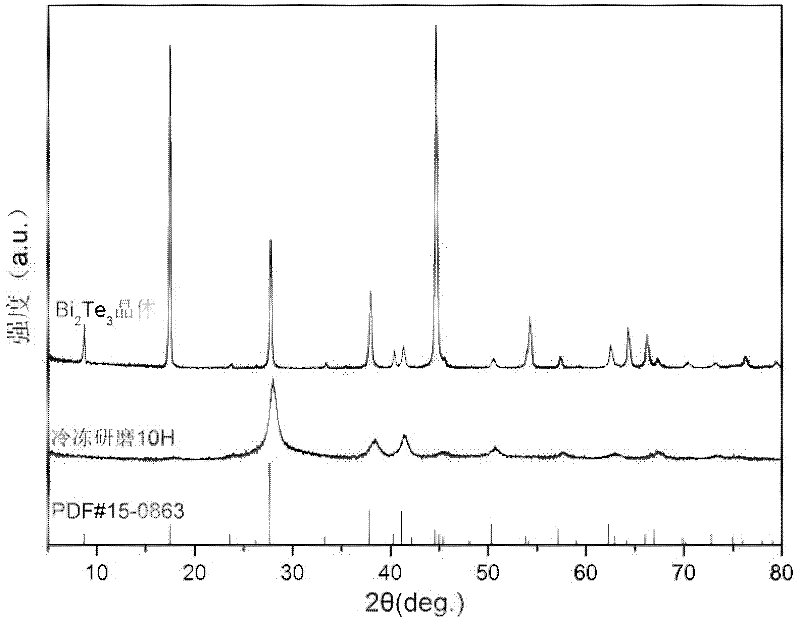

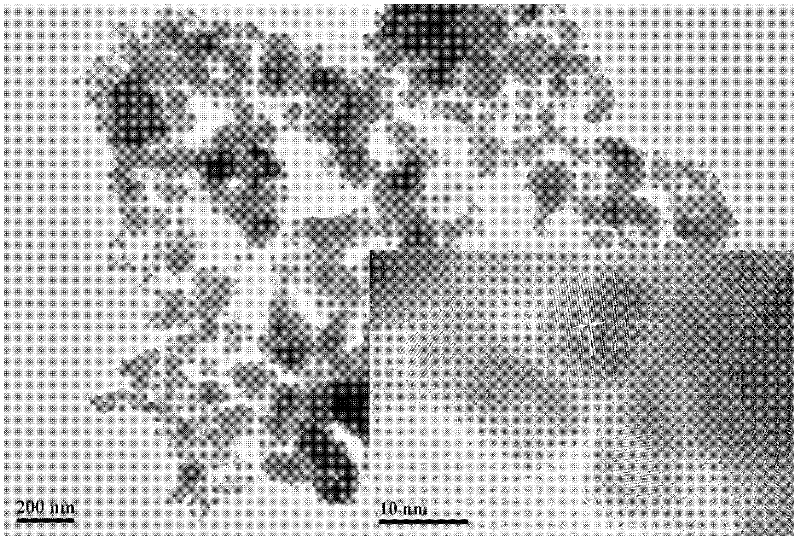

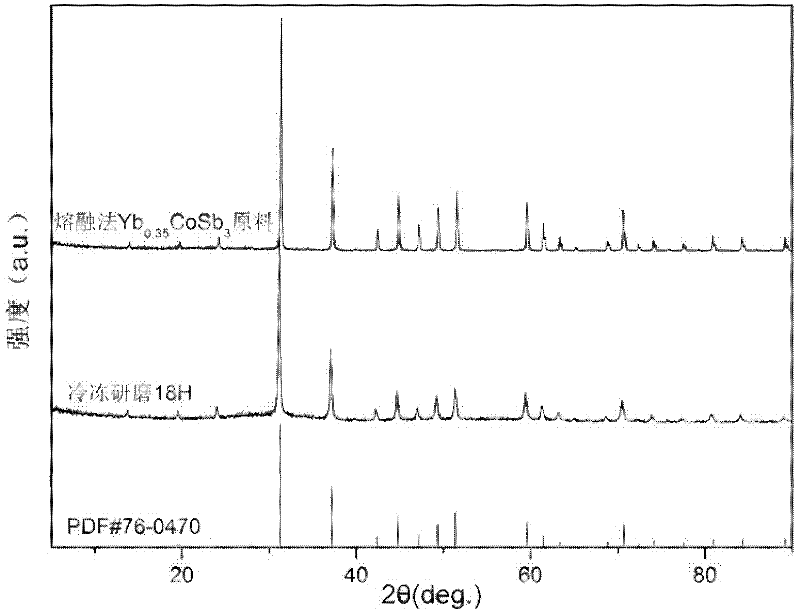

Nanometer thermoelectric powder material preparing method

InactiveCN102386321AGood lookingImprove performanceThermoelectric device manufacture/treatmentNanotechnologyThermoelectric materialsDecomposition

The invention relates to a nanometer thermoelectric powder material preparing method which comprises the following steps: crushing a thermoelectric material into 1mm-5mm of coarse powder; placing the coarse powder into a grinding tank, dipping liquid nitrogen and then precooling for 5-60min; and grinding the mixture in the liquid nitrogen environment for 1-30h, thus obtaining nanometer thermoelectric powder by vacuum drying after grinding. With the method, the nanometer thermoelectric powder which does not have phase change or decomposition is prepared, and the powder is ensured to have a good shape and performance, and has good controllability, high utilization rate, no pollution and the like, so that good developing and promoting prospect can be realized.

Owner:DONGHUA UNIV +1

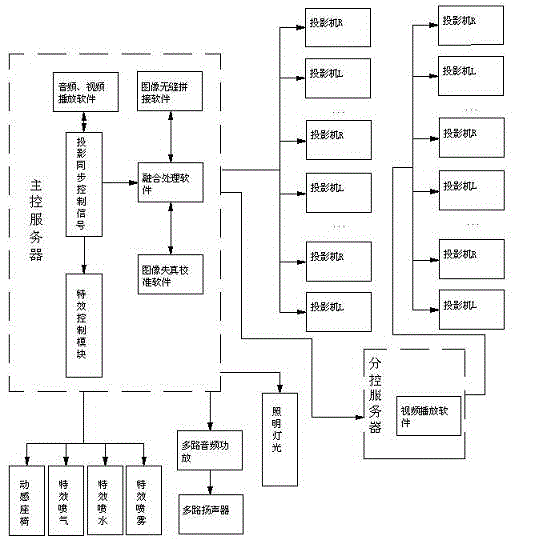

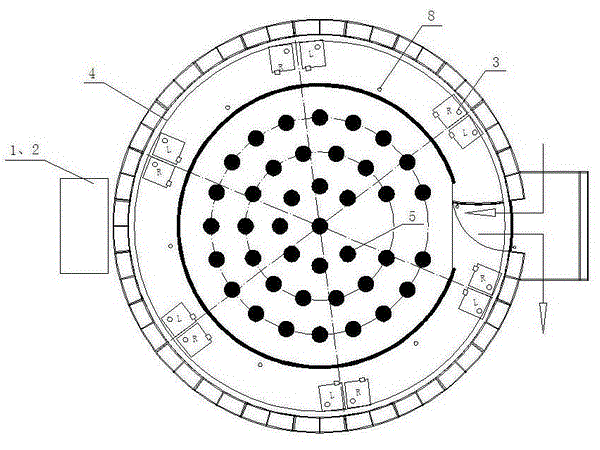

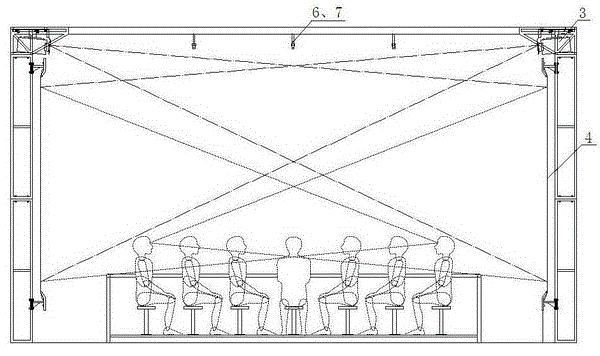

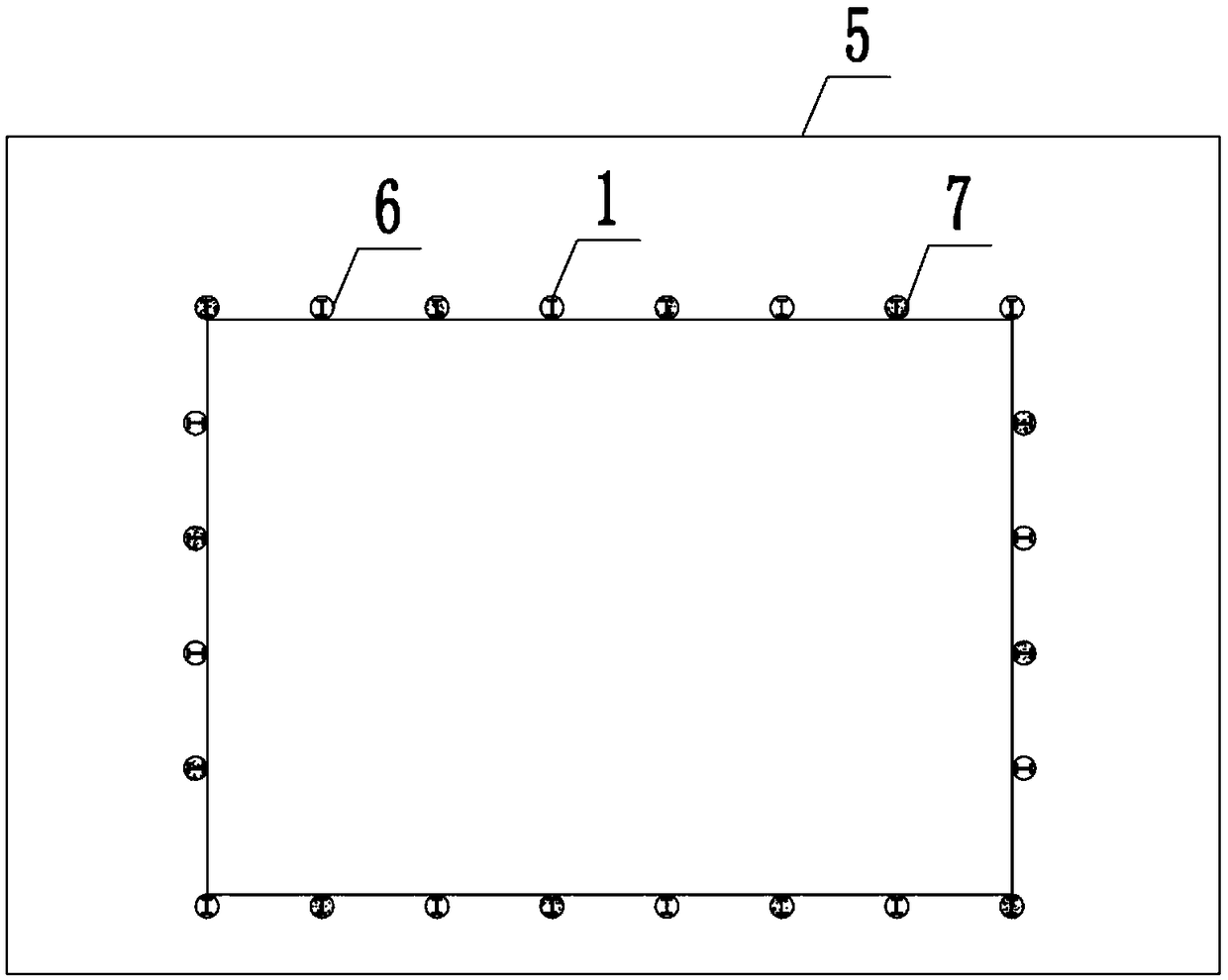

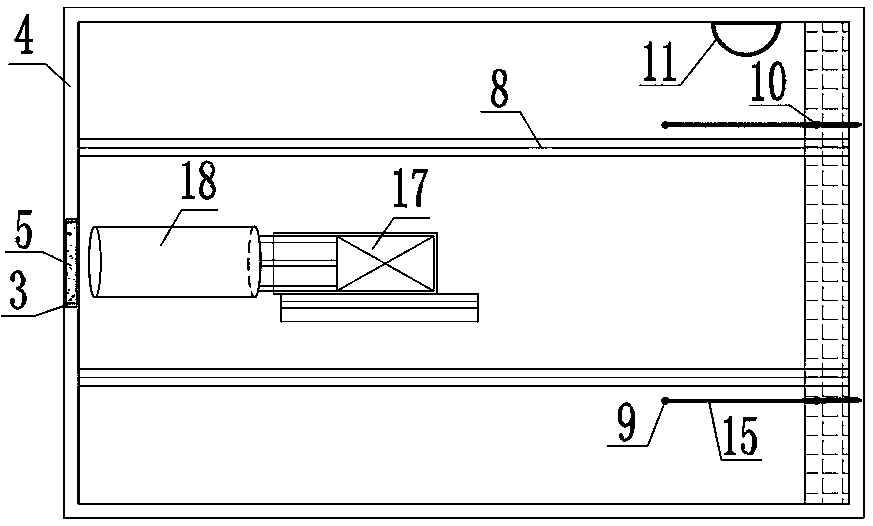

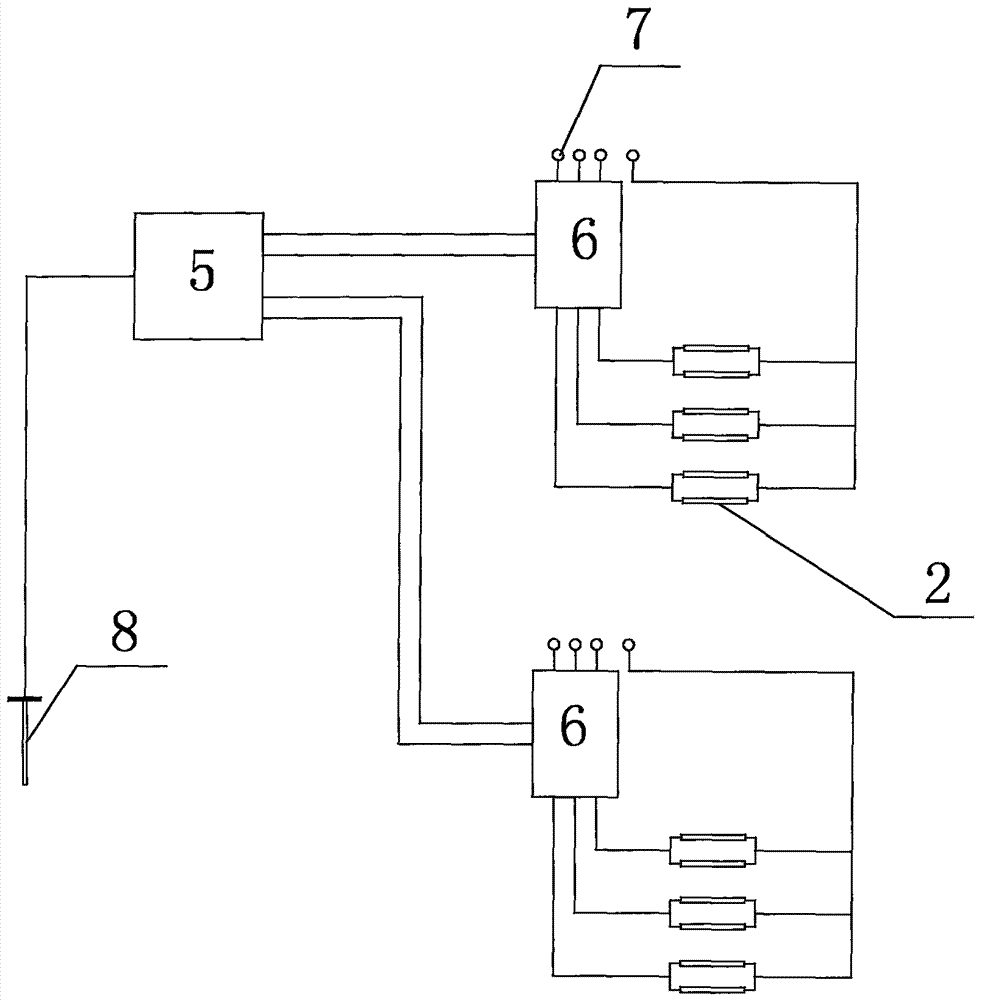

Five-dimensional (5D) 360-degree ring screen digital stereoscopic cinema system

ActiveCN103064245AShocking viewing experienceGood development and application prospectsTelevision system detailsColor television detailsComputer graphics (images)Image processing software

A five-dimensional (5D) 360-degree ring screen digital stereoscopic cinema system and a showing device thereof are characterized in that the 5D 360-degree ring screen digital stereoscopic cinema system comprises a main control server, a branch control server, projection equipment, watching equipment and a special effect generating device. The main control server comprises a control module, audio-video playing software and image processing software. According to the 5D 360-degree ring screen digital stereoscopic cinema system, a 5D movie and a 360-degree ring screen movie are combined into a whole, a video signal is output through the main control server, processed through the image processing software and displayed through the projection equipment, a shown stereoscopic image can surround audiences, the stereoscopic image rushes out of a ring screen and reaches to a position in front of eyes of the audiences, and passes through the audiences to a position behind the audiences, scenes provided by a movie and stereoscopic dynamic images surround and penetrate through the positions all around the audiences, the audiences can be personally on the scenes in a high-emulation mode, and the movie images are integral, continuous and lifelike.

Owner:SHANGHAI XINGYING DIGITAL TECH +1

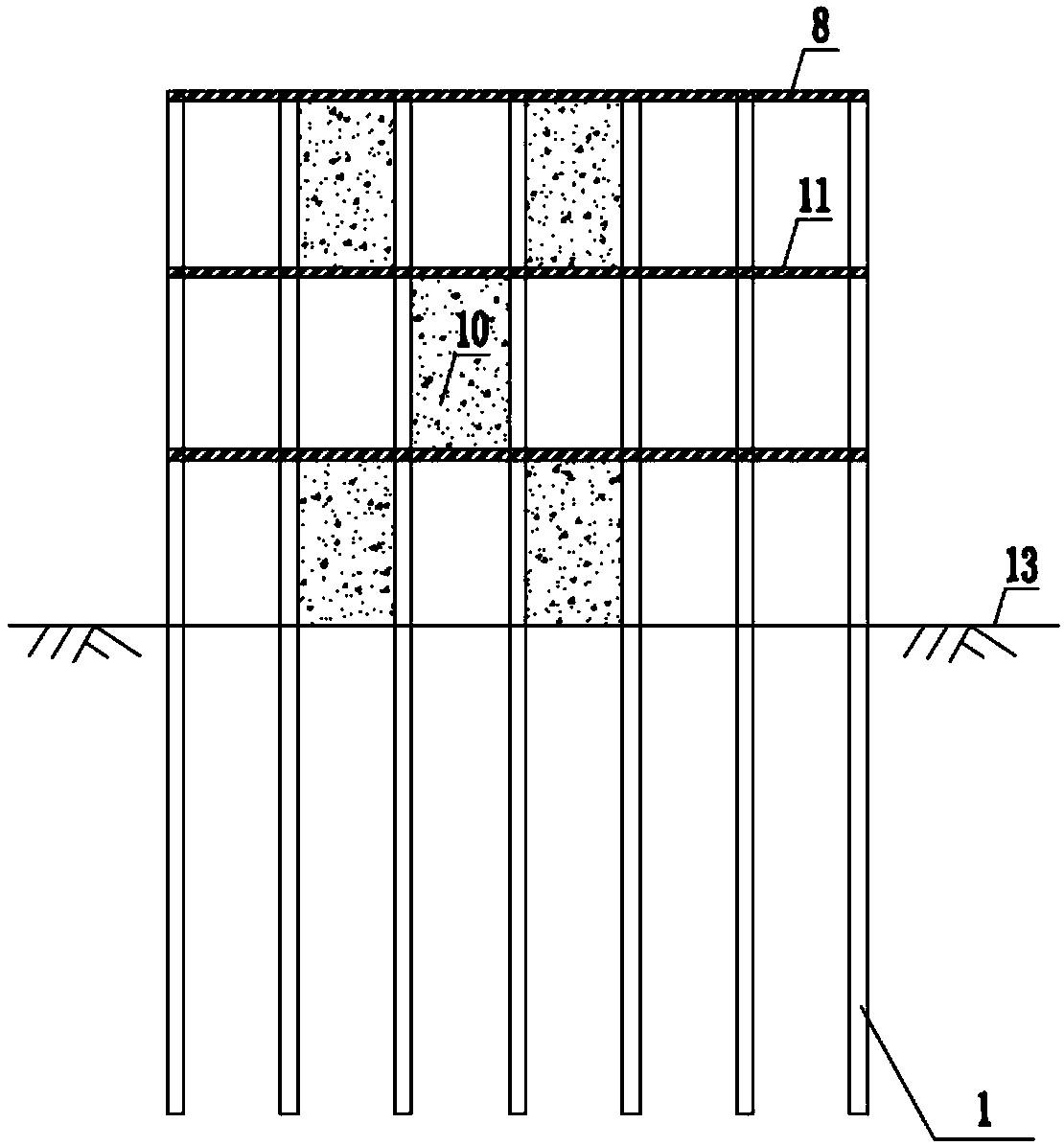

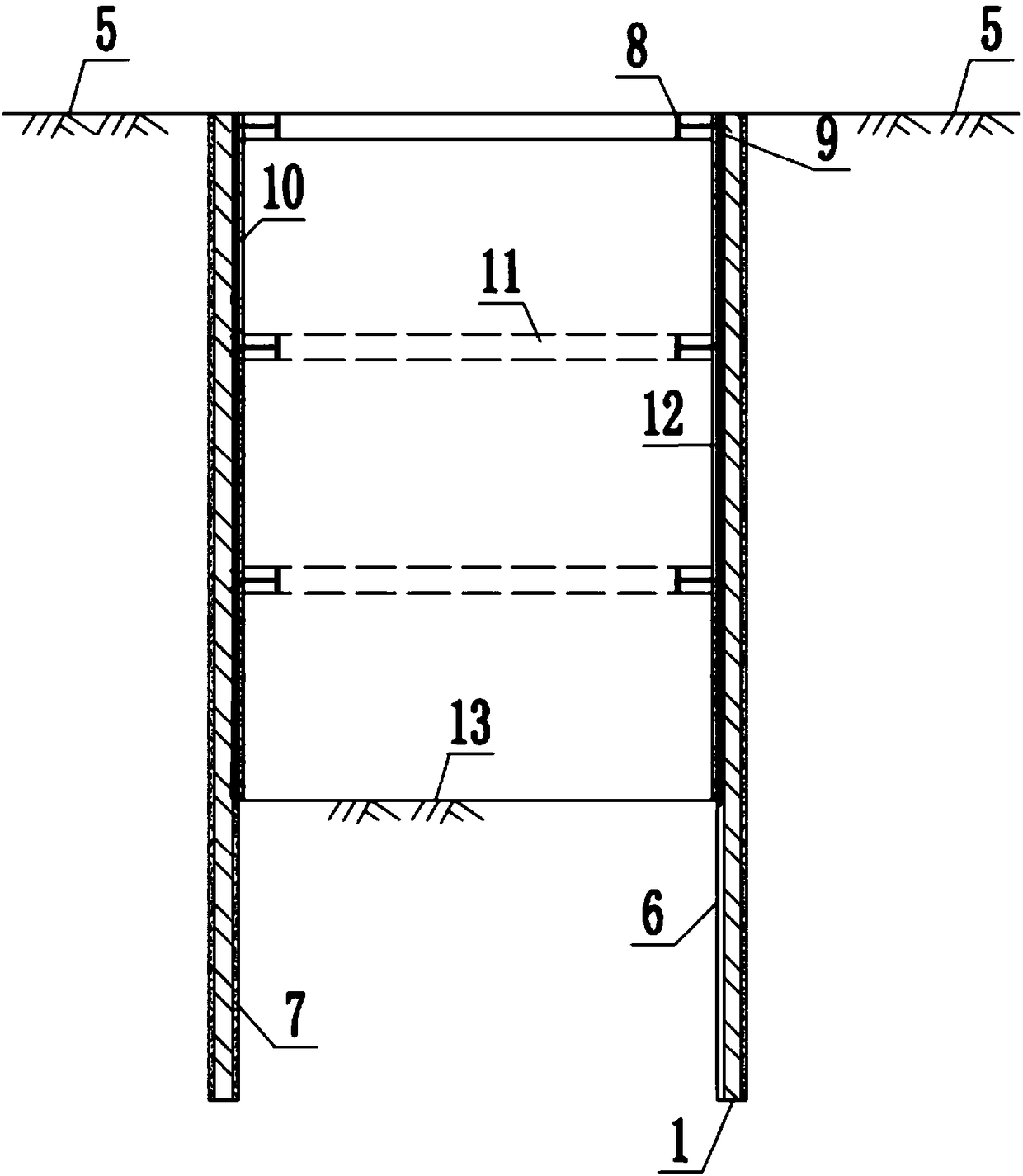

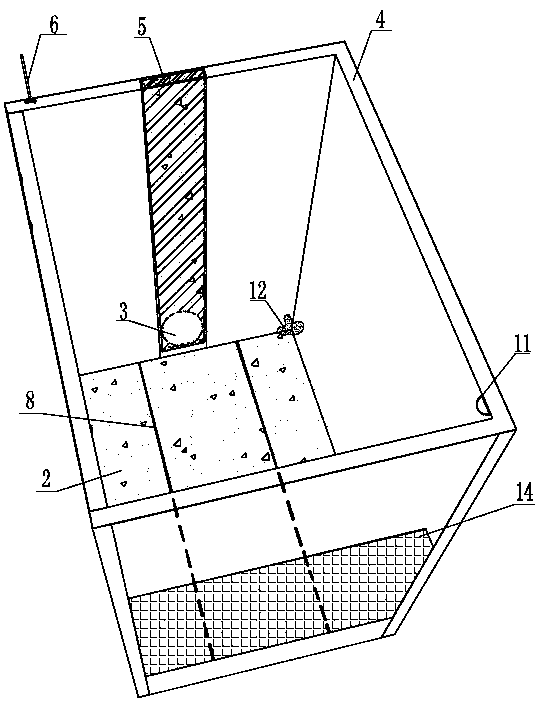

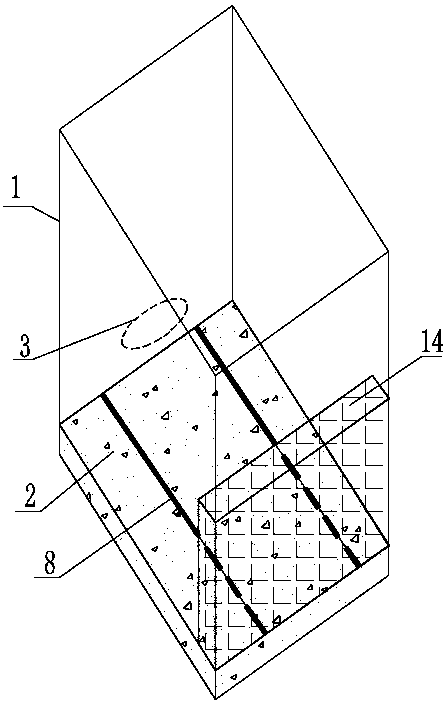

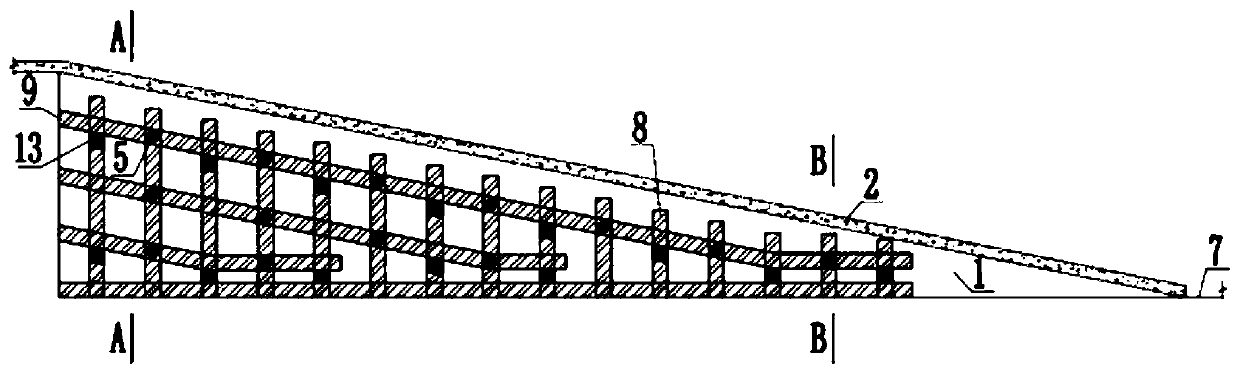

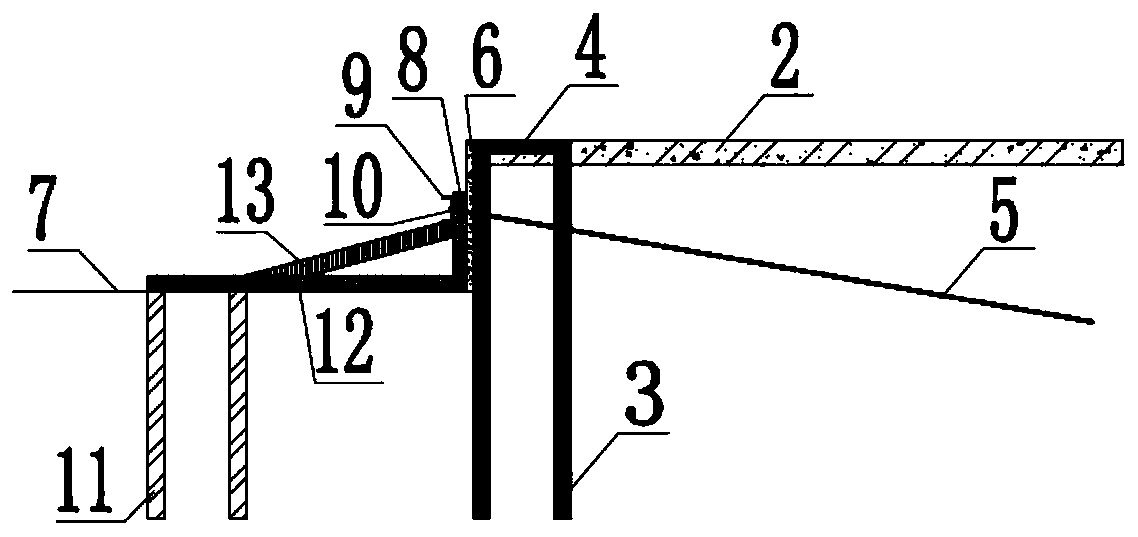

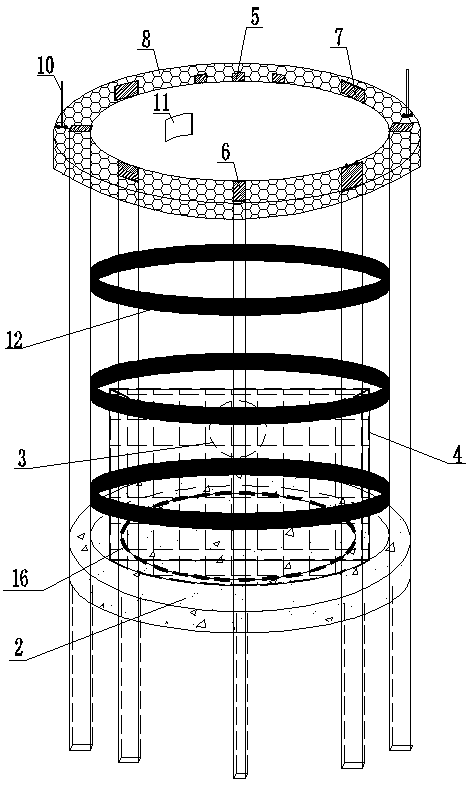

Design construction method of flexible compound fabricated recoverable rectangular working well supporting structure

InactiveCN109056746AMeet the positioning and installation accuracy requirementsAdvanced technologyExcavationsStructure systemHigh polymer

The invention relates to a standardized design construction method of a flexible compound fabricated recoverable rectangular working well supporting structure. The method comprises the following stepsthat (1) construction of minisize supporting piles is carried out; (2) construction of pile top crown beams; (3) a rectangular working well is excavated, panels and waist beams are installed, and high polymers are poured to side walls for sealing; (4) excavation is carried out layer by layer sequentially in the vertical direction, and the step (3) is carried out repeatedly till the design depth is met, that is, construction of the rectangular working well supporting structure is completed accordingly; and (5) after the supporting structure fulfills the usage function, the supporting structurerecovery work can be carried out as the backfilling work is started. Through standardized design construction of the established supporting structure system, one supporting structure can meet the construction requirement of most rectangular working wells in a region, the advantages of safety, reliability, quick and convenient construction, advanced technologies, high recoverability, superior economic indicators and the like are achieved, and the application and development prospects are considerable.

Owner:南方工程检测修复技术研究院

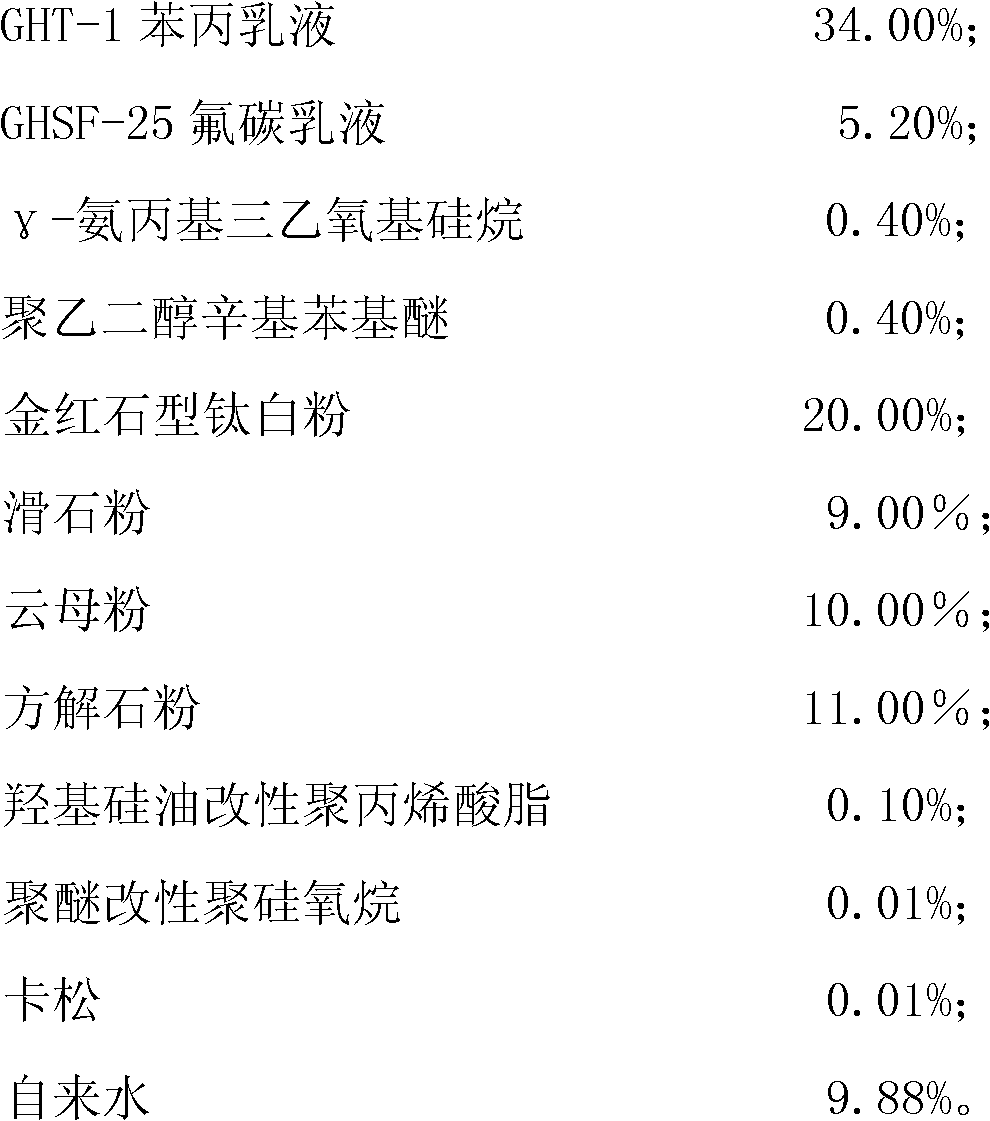

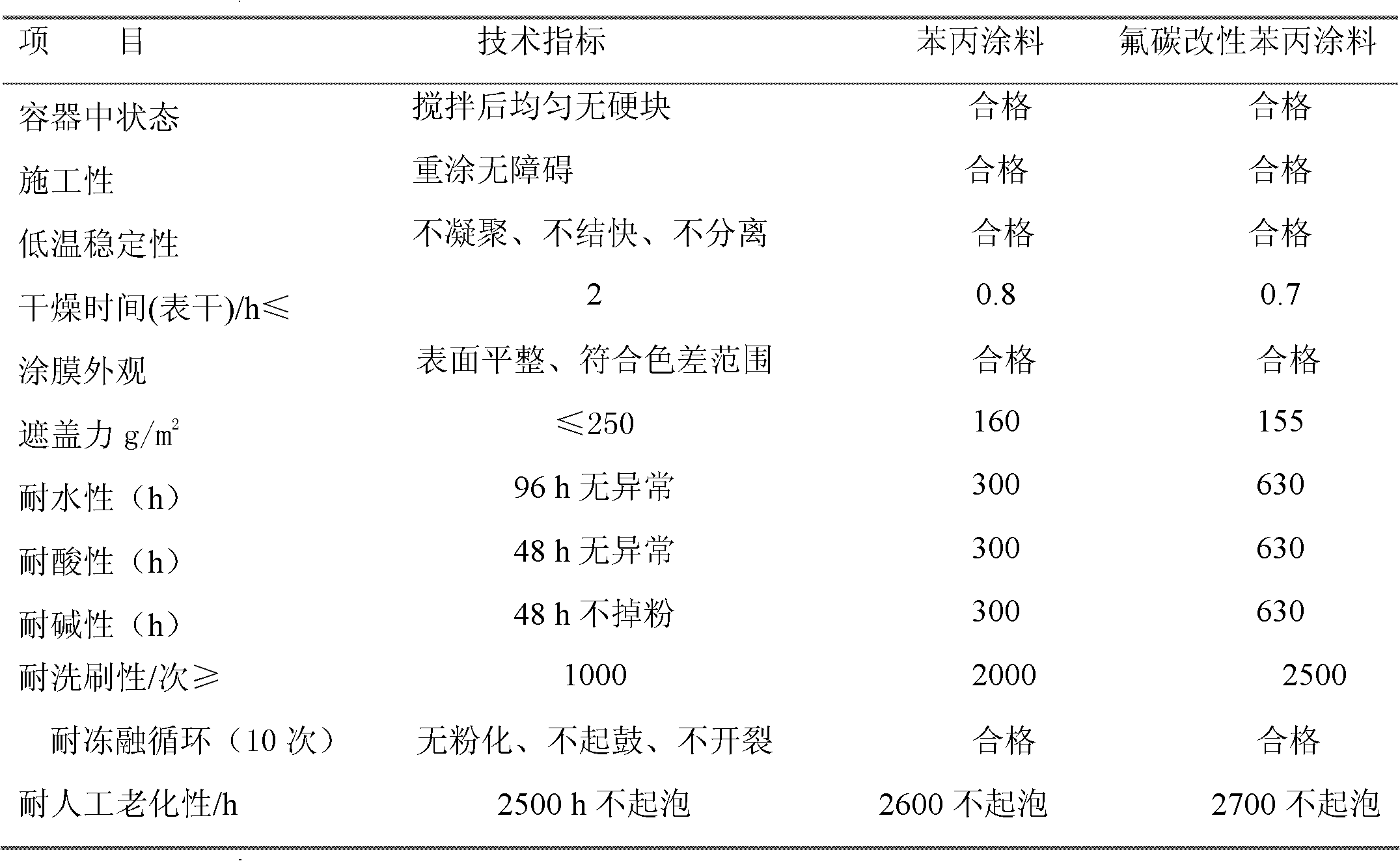

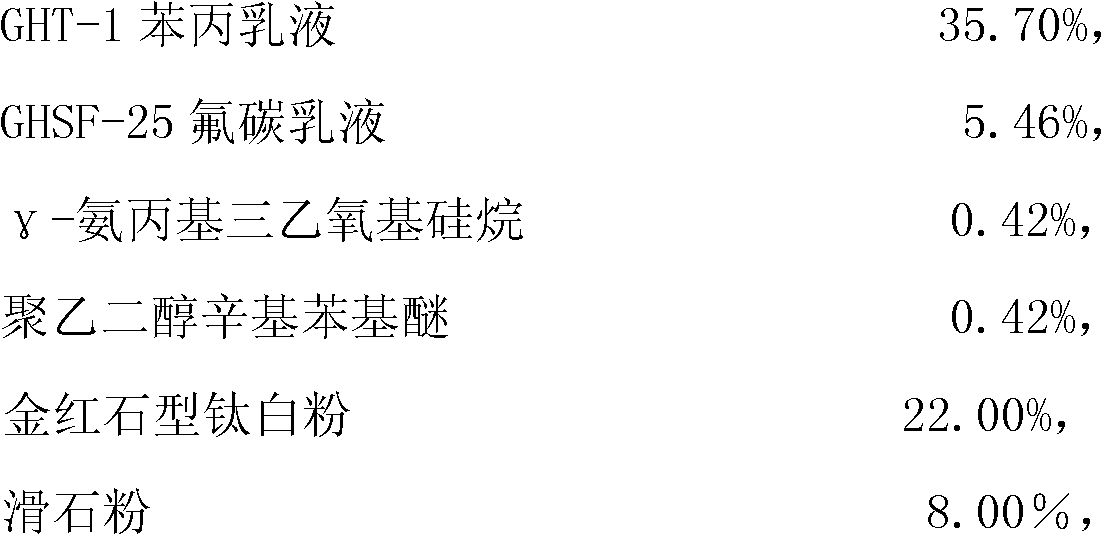

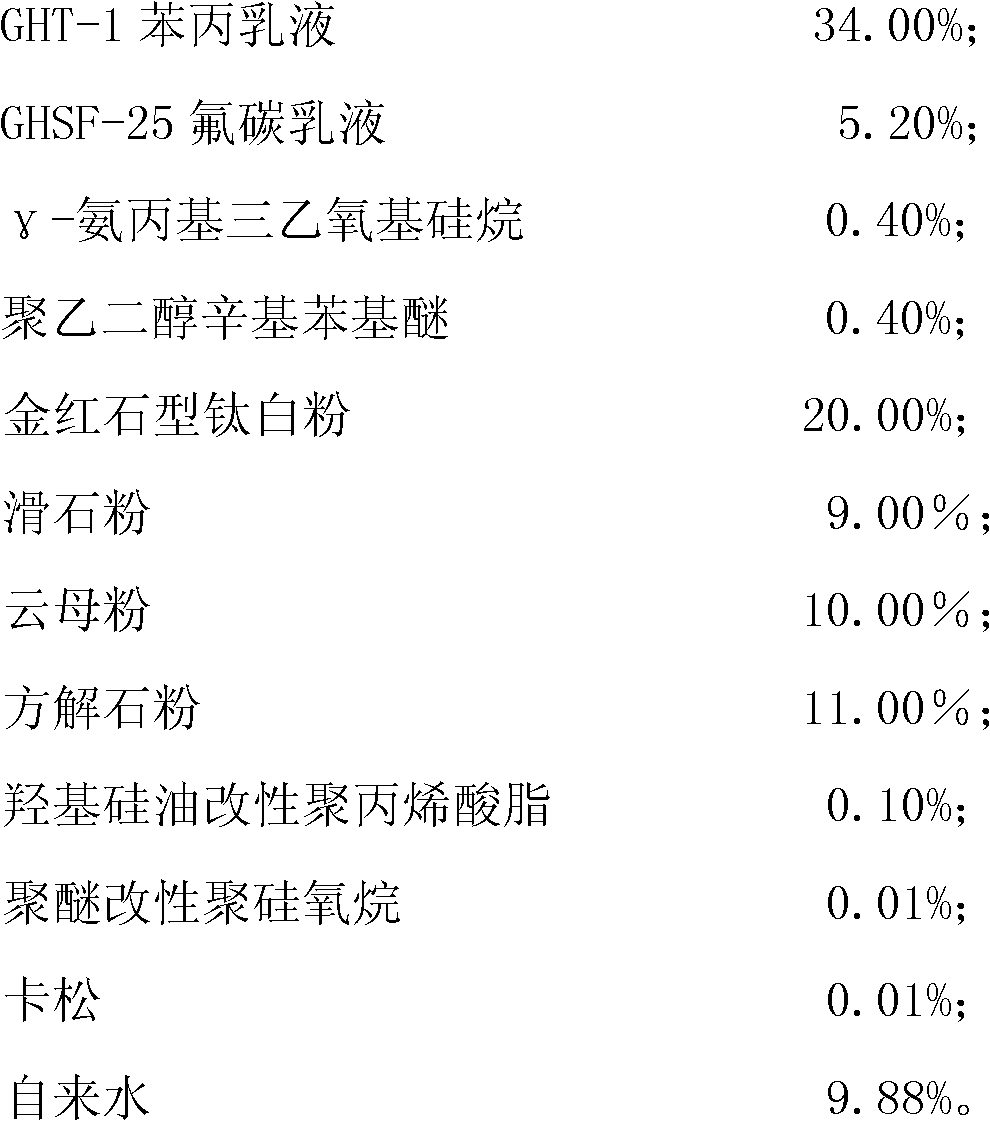

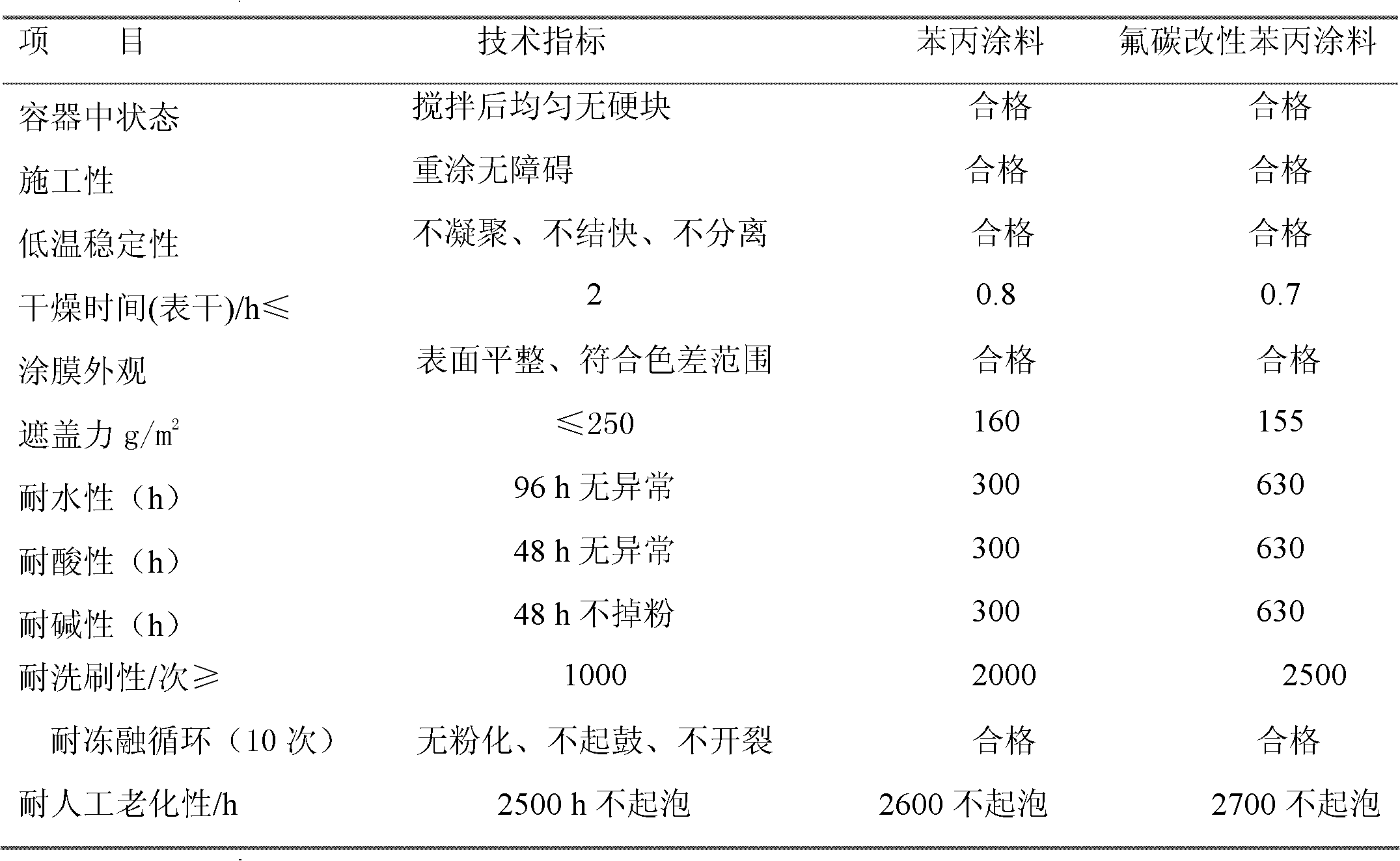

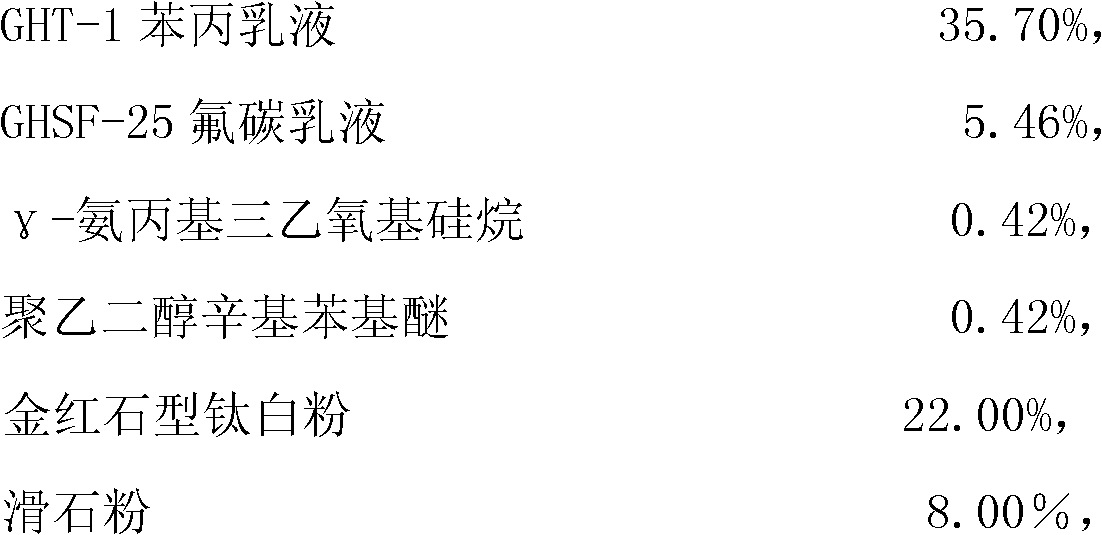

Fluorocarbon modified styrene-acrylic coating, and preparation method thereof

InactiveCN102585617AGood film formingImprove water resistanceAnti-corrosive paintsTriethoxysilanePhenyl Ethers

The invention discloses a fluorocarbon modified styrene-acrylic coating. The fluorocarbon modified styrene-acrylic coating consists of the following components in percentage by mass: 34 to 42.5 percent of GHT-1 styrene-acrylic emulsion, 5.2 to 6.5 percent of GHSF-25 fluorocarbon emulsion, 0.4 to 0.5 percent of gamma-aminopropyltriethoxysilan, 0.4 to 0.5 percent of polyethylene glycol phenyl ether, 18 to 22 percent of rutile type titanium dioxide, 8 to 10 percent of talcpowder, 8 to 10 percent of mica powder, 8 to 11 percent of calcite in powder, 0.1 to 0.15 percent of hydroxy silicone oil modified polyacrylate, 0.01 to 0.02 percent of polyether modified polysiloxane, 0.01 to 0.02 percent of kazon and the balance of water. A preparation method comprises the following steps of: modifying the styrene-acrylic emulsion by using the fluorocarbon emulsion, the gamma-aminopropyltriethoxysilan, and the polyethylene glycol phenyl ether at the temperature of between 76 and 80 DEG C, and preparing by using the modified fluorocarbon modified styrene-acrylic emulsion to obtain the fluorocarbon modified styrene-acrylic coating. The preparation process is simple, and low in investment and cost; and a product has the advantages of high weather fastness, chemical resistance, and water resistance, scrubbing resistance, and artificial aging resistance.

Owner:JIANGSU UNIV OF SCI & TECH

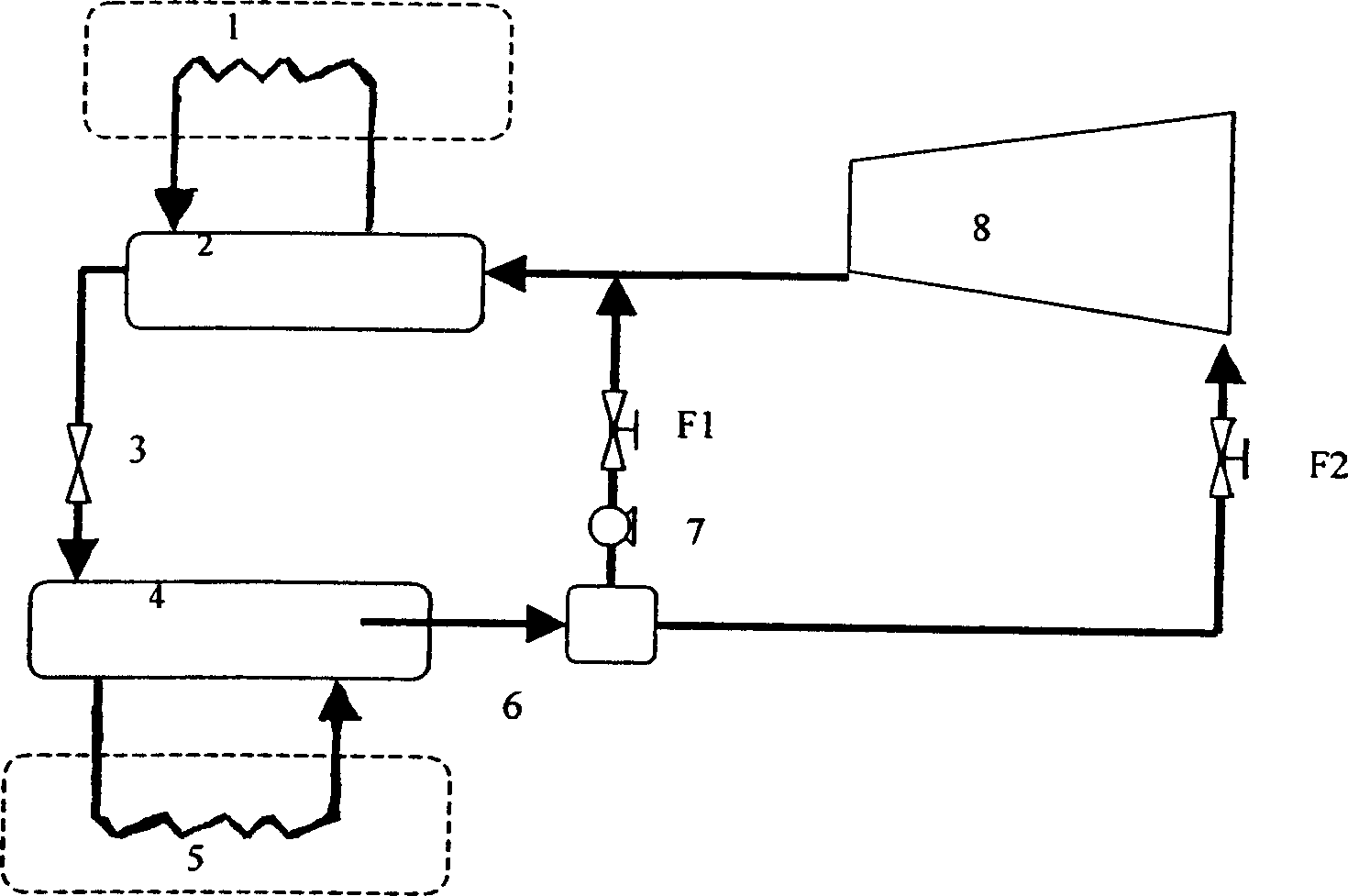

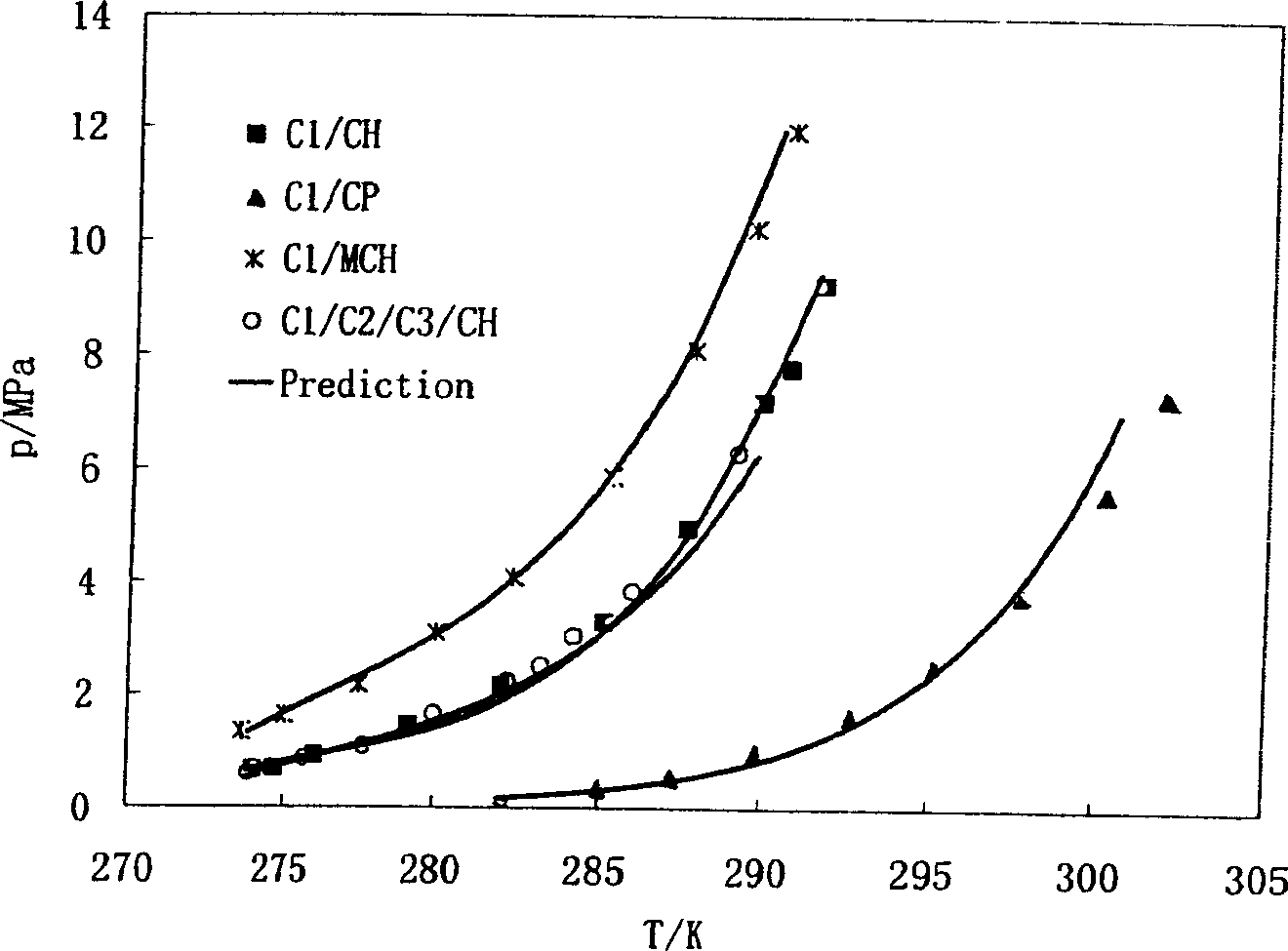

Refrigerating method using gas hydrate as medium and air conditioner refrigerator

InactiveCN1844801AGreat development and application prospectsGood development and application prospectsHeat-exchange elementsRefrigeration machinesVapor–liquid separatorProcess engineering

The invention discloses a refrigerating method for using hydrate as working medium and relative air conditioner. Said method comprises: generating high-pressure gas; generating gas hydrate; the slurry hydrate via the expand valve is depressurized to be fed to the decompose reactor (evaporator); the hydrate is decomposed into gas and water to adsorb heat; the gas and water are separated in gas-liquid separator to be fed to the compressor or generate reactor (condenser) to complete the cycle. Said air conditioner comprises a decompose reactor (evaporator), a expand valve, a compressor, a generate reactor (condenser), a water pump, and a gas-liquid separator connected to the valve via tubes, while the tube is filled with hydrate refrigerating working medium; the decompose reactor (evaporator) is connected to the cold end; the generate reactor (condenser) is connected to the hot end to discharge heat outside the room. The invention can save energy with high efficiency and wider application.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

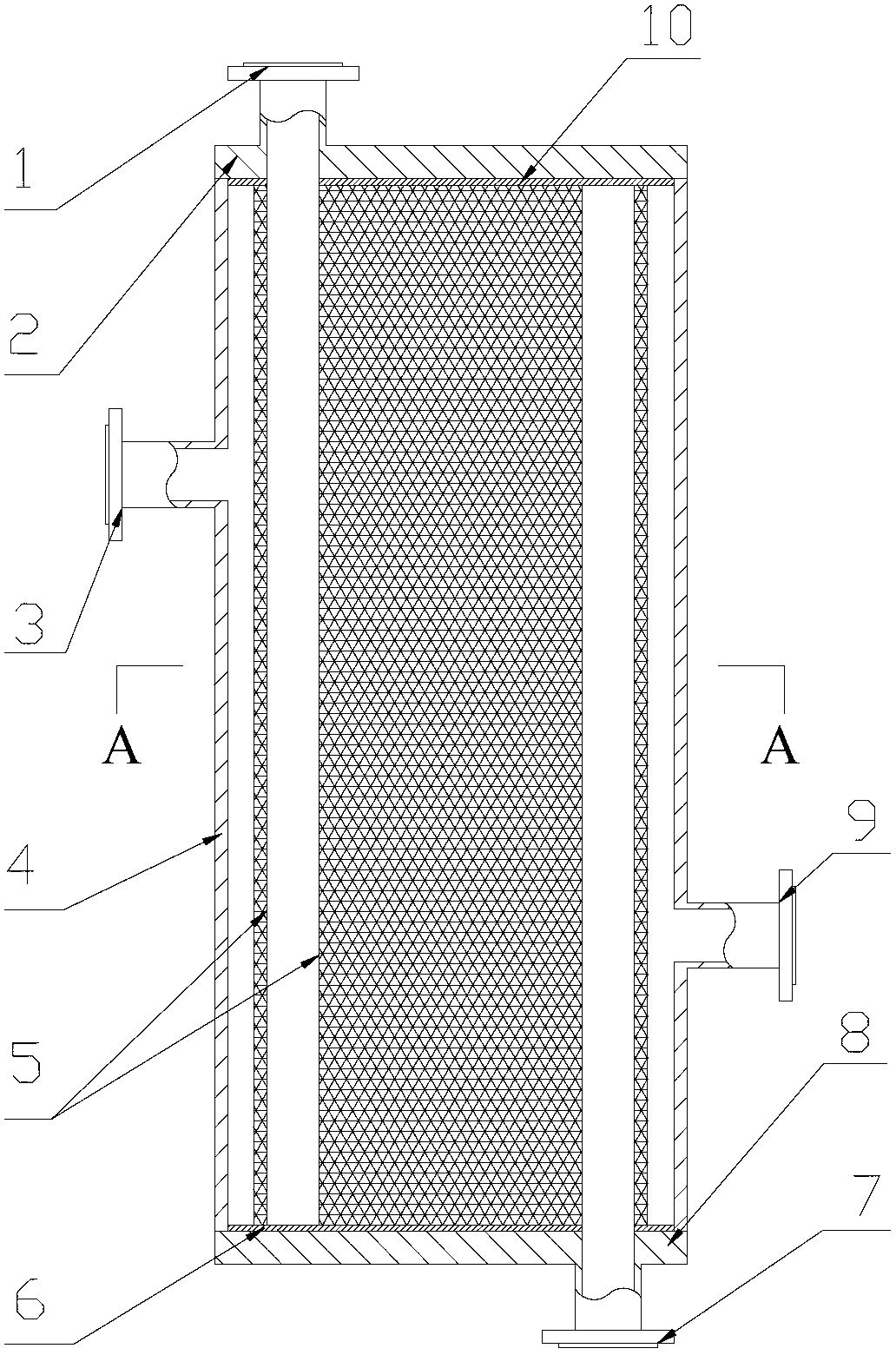

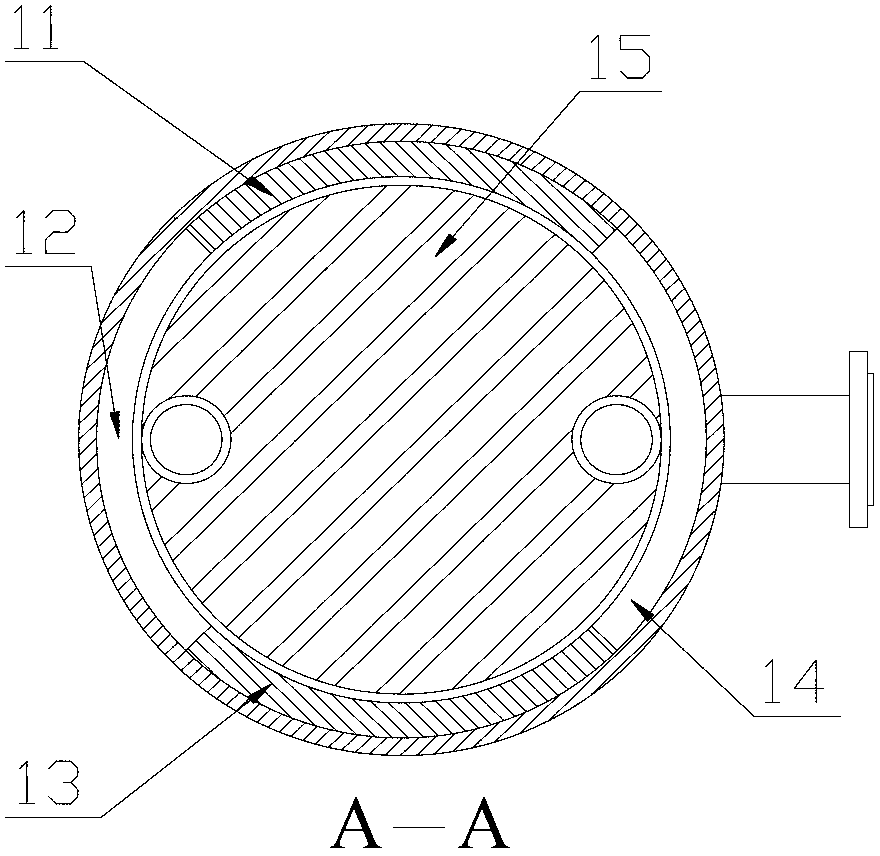

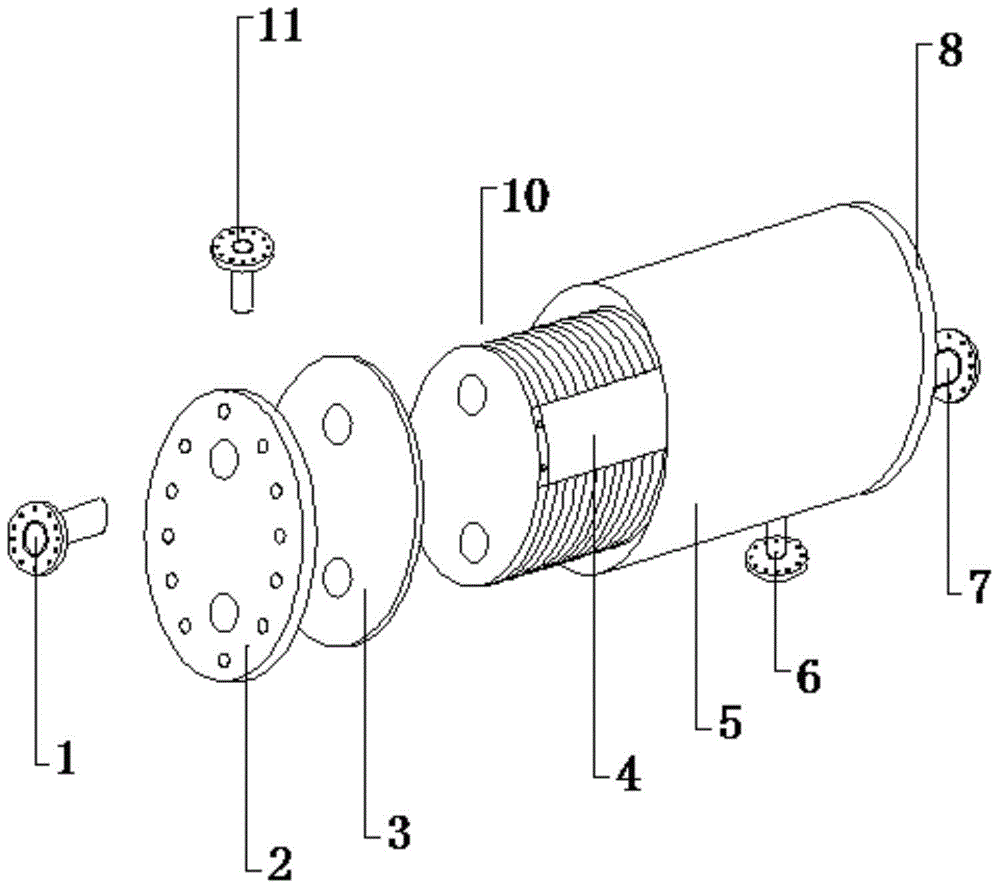

High-pressure resistant lamella heat exchanger adopting round corrugated plates

InactiveCN102706188AUniform stress distributionStrong pressure capacityLaminated elementsStationary plate conduit assembliesEngineeringHigh pressure

The invention aims to provide a high-pressure resistant lamella heat exchanger adopting round corrugated plates, which includes a shell, cover plates, a corrugated plate lathed bundle, flow guiding blocks and support plates, wherein the corrugated plate lathed bundle includes corrugated plates and is fixed in the shell through the support plates; the two ends of the shell are sealed by the cover plates; a shell side outlet and a shell side inlet are arranged in the shell; a plate side inlet and a plate side outlet are arranged in the cover plates; an annular zone between the shell and the corrugated plate lathed bundle is divided into a shell side inlet chamber and a shell side outlet chamber through the flow guiding blocks; the shell side inlet is communicated with the shell side inlet chamber; the shell side outlet is communicated with the shell side outlet chamber; angular holes are formed in the corrugated plate lathed bundle; and the plate side inlet is communicated with the plate side outlet through the angular holes in the corrugated plate lathed bundle. The high-pressure resistant lamella heat exchanger provided by the invention has the advantages of high pressure bearing capability, high heat exchange efficiency, compact structure, big heat transfer area in a unit volume, wide material selection range, wide application range, as well as simplicity in processing and installation.

Owner:HARBIN ENG UNIV

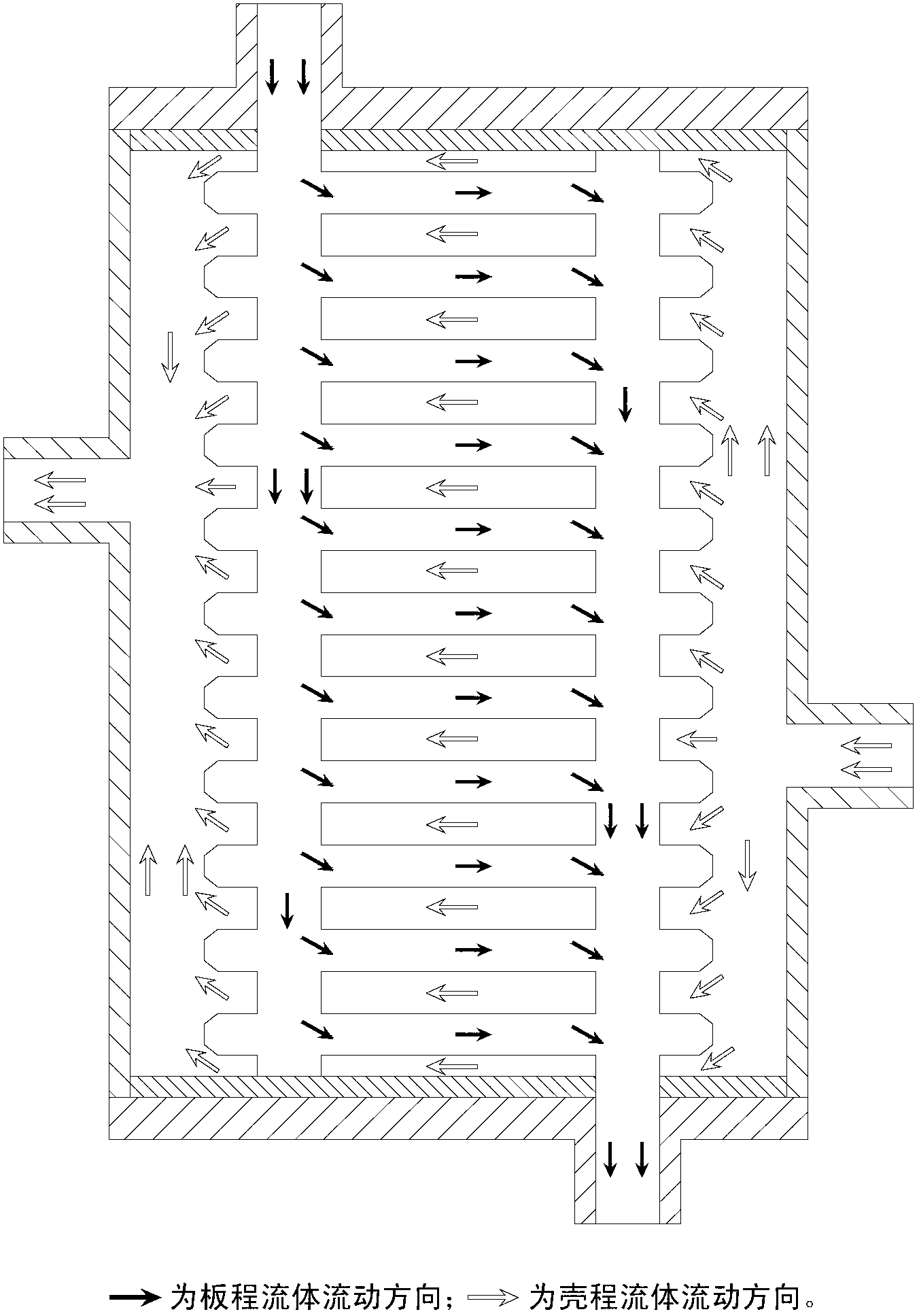

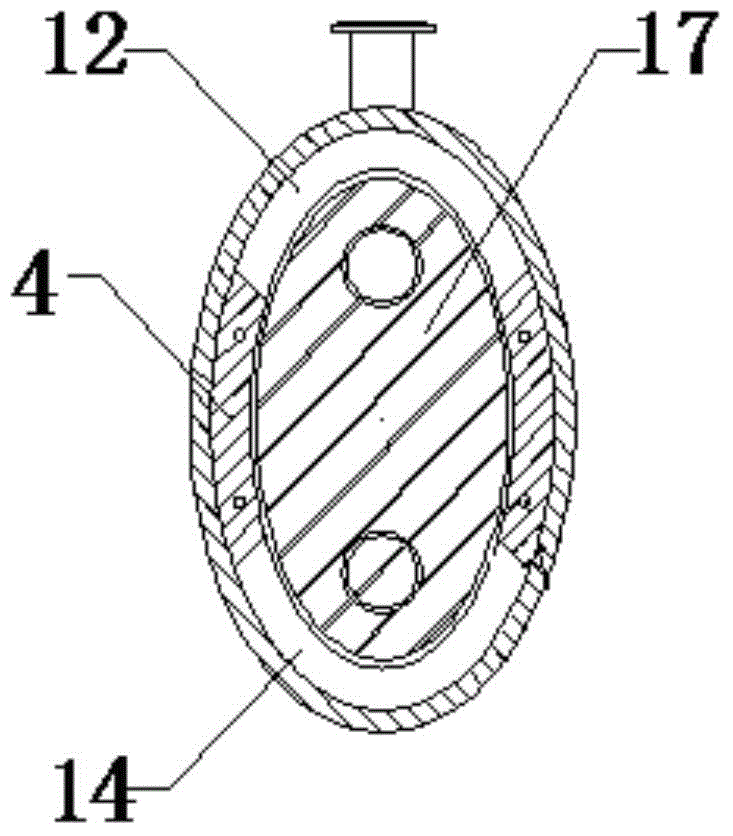

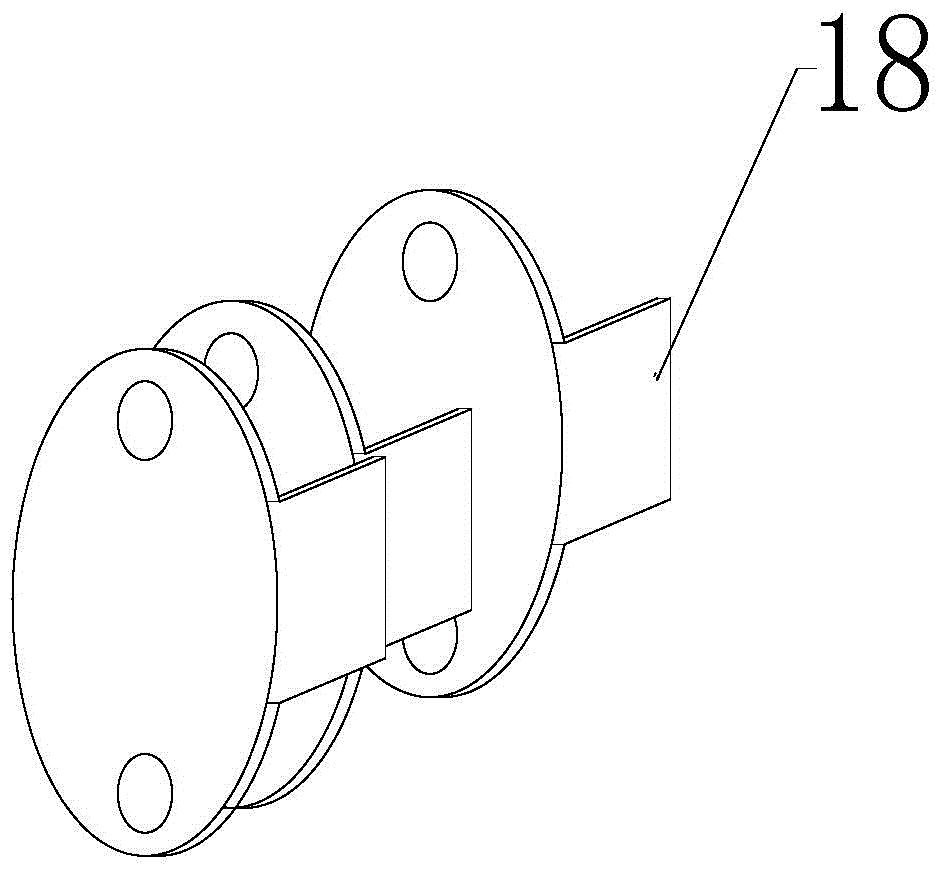

Plate-shell heat exchanger with oval corrugated plates

InactiveCN104089503AImprove heat transfer efficiencyReduce leakageLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

The invention relates to a plate-shell heat exchanger with oval corrugated plates. The multiple oval corrugated plates form a corrugated plate bundle, each corrugated plate is provided with two corner holes correspondingly, the corrugated plate bundle is arranged in a shell, the shell is provided with a plate pass inlet and a plate pass outlet, and the plate pass inlet and the plate pass outlet are communicated through the corner holes in the corrugated plates; a guide block is formed between the corrugated plate bundle and the shell and divides the annular area between the corrugated plate bundle and the shell into a shell pass inlet cavity and a shell pass outlet cavity; the shell is provided with a shell pass inlet and a shell pass outlet correspondingly. The plate-shell heat exchanger is characterized in that the corrugated plates are oval, and the two corner holes of each corrugated plate are formed in the upper portion and the lower portion of the corrugated plate respectively.

Owner:HARBIN ENG UNIV

Rectangular working well in water-rich stratum and preinstalling with pipe-jacking door opening and sliding-moving type rear-leaning wall and construction method of rectangular working well

ActiveCN110485470AShort construction periodOvercome construction difficultiesArtificial islandsProtective foundationThermal forceHydraulic engineering

The invention relates to a rectangular working well in a water-rich stratum and preinstalling with a pipe-jacking door opening and a sliding-moving type rear-leaning wall and a construction method ofthe rectangular working well. The construction method specifically comprises the following steps that (1) functional requirement design of the rectangular pipe-jacking working well is conduced; (2) maintenance structure open caisson construction of the rectangular pipe-jacking working well is conducted; (3) temporary limb protective structure construction is conducted; (4) in-well earth excavationis conducted; (5) bottom sealing of the rectangular pipe-jacking working well is conducted, and a sliding-moving type rail, a pulling ring and a rear-leaning wall anchoring part are pre-embedded; (6)a crawling well for entering into the rectangular pipe-jacking working well is mounted; (7) seam leakage treatment is conducted; (8) cave opening water-stop pressing plate mounting is conducted; (9)sliding-moving rear-leaning wall construction is conducted; (10) preinstalling door opening top sandwich concrete board wall lifting is conducted; and (11) pipe-jacking jacking construction is conducted. According to the rectangular working well and the construction method, the established structure system has the advantages that the functions are clear and definite, safety, fastness and convenience are achieved, and design is ingenious, especially, the problems that in the process of pipe-jacking in the water-rich stratum penetrating through the well wall, outburst of water and sand gushing safe hazards, and single well multi-direction pipe jacking construction are solved, and a novel method is provided for trenchless construction of underground pipelines such as hydraulic engineering, municipal administration, heating power and communication.

Owner:SAFEKEY ENG TECHZHENGZHOU

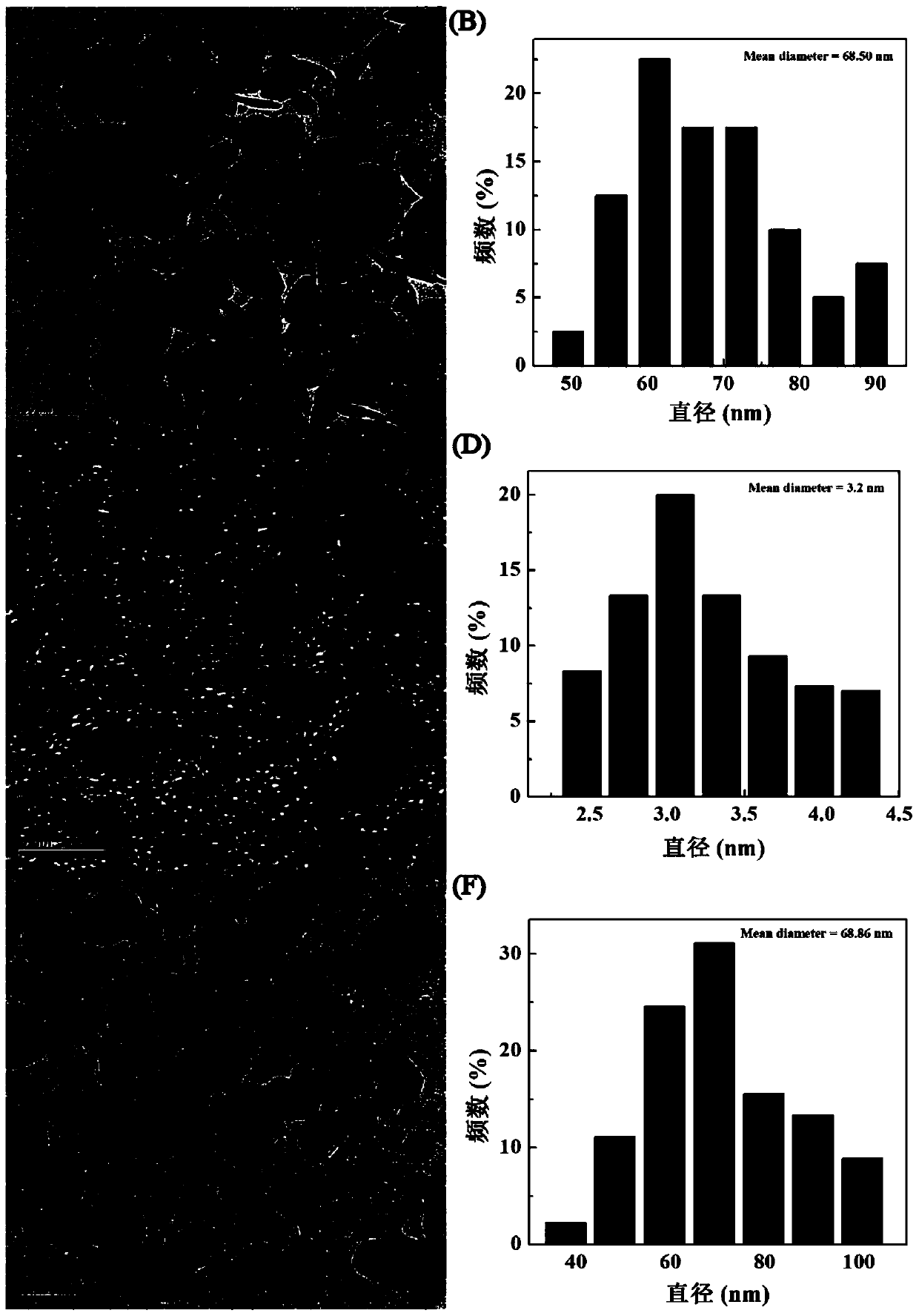

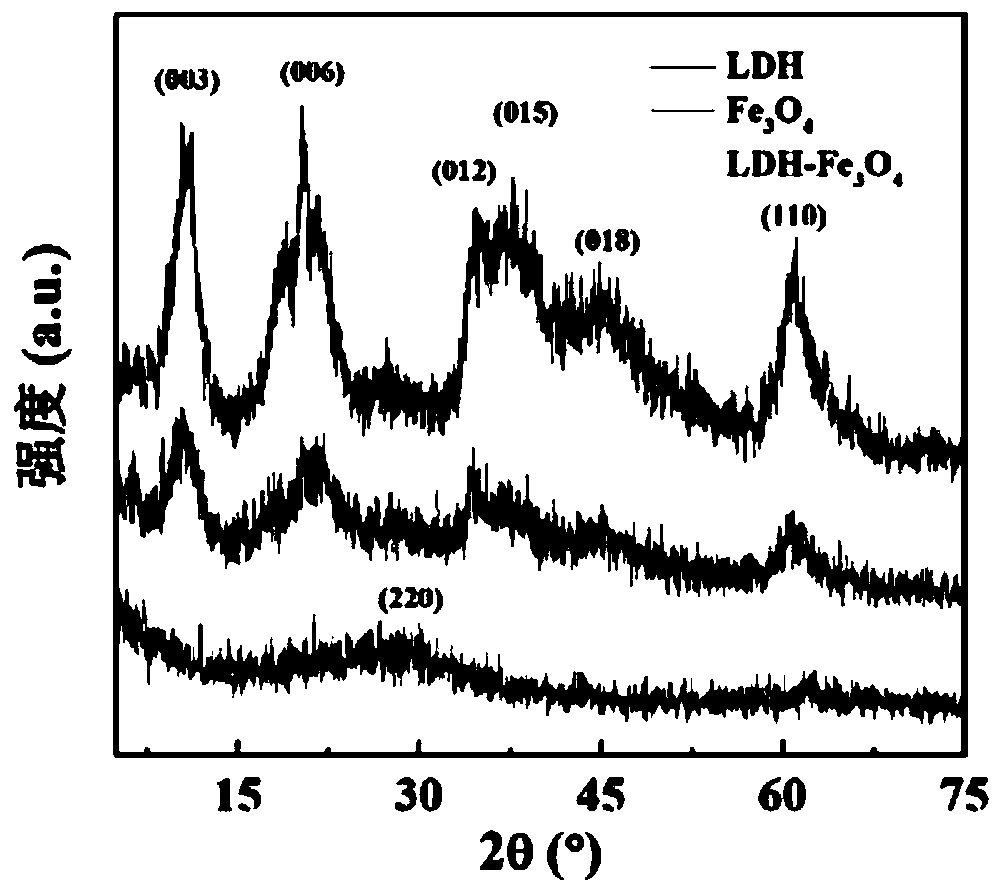

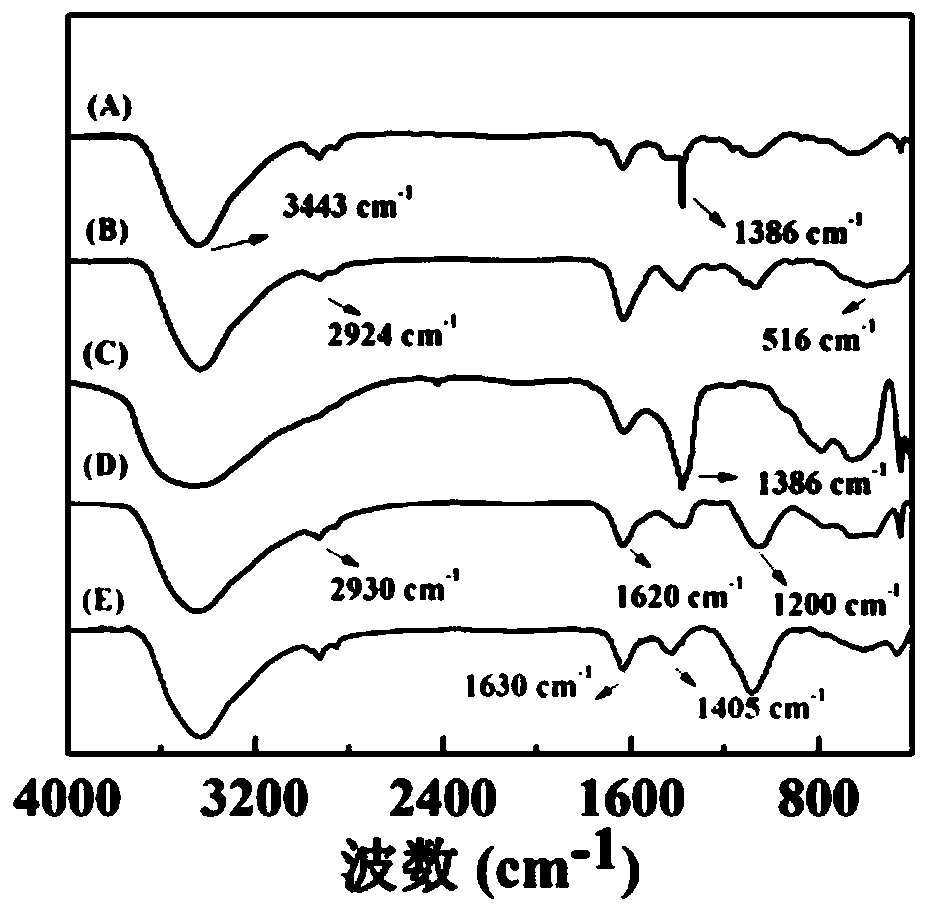

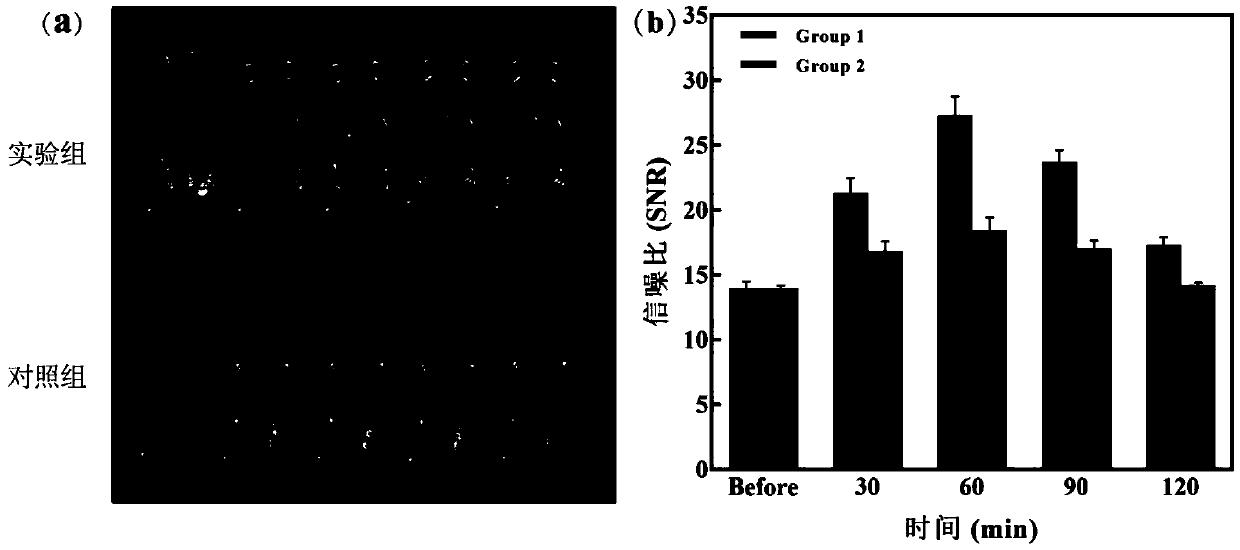

HA-targeted layered doubled hydroxide-ultrafine iron nano material and preparation and applications thereof

ActiveCN110013559AWide variety of sourcesSimple processOrganic active ingredientsPharmaceutical non-active ingredientsDoxorubicinMr imaging

The invention relates to a HA-targeted layered doubled hydroxide-ultrafine iron nano material and preparation and applications thereof. The preparation is as follows: synthesizing an LDH-Fe3O4 nano composite material by a coprecipitation method; covalently bonding activated hyaluronic acid on the surface of an LDH laminate through a silane coupling agent; and finally, carrying out surface loadingof an anticancer drug. The nano-material particles are uniformly distributed, and can enhance the MR imaging effect of the tumor part in an animal body. The LDH-Fe3O4-HA NPs is used as a carrier of ananticancer drug doxorubicin DOX, not only has sensitive pH response and release characteristics, but also can carry out specific recognition on tumor cells expressed by CD44 receptors so as to achieve the idealization effect of efficiently inhibiting tumors.

Owner:DONGHUA UNIV

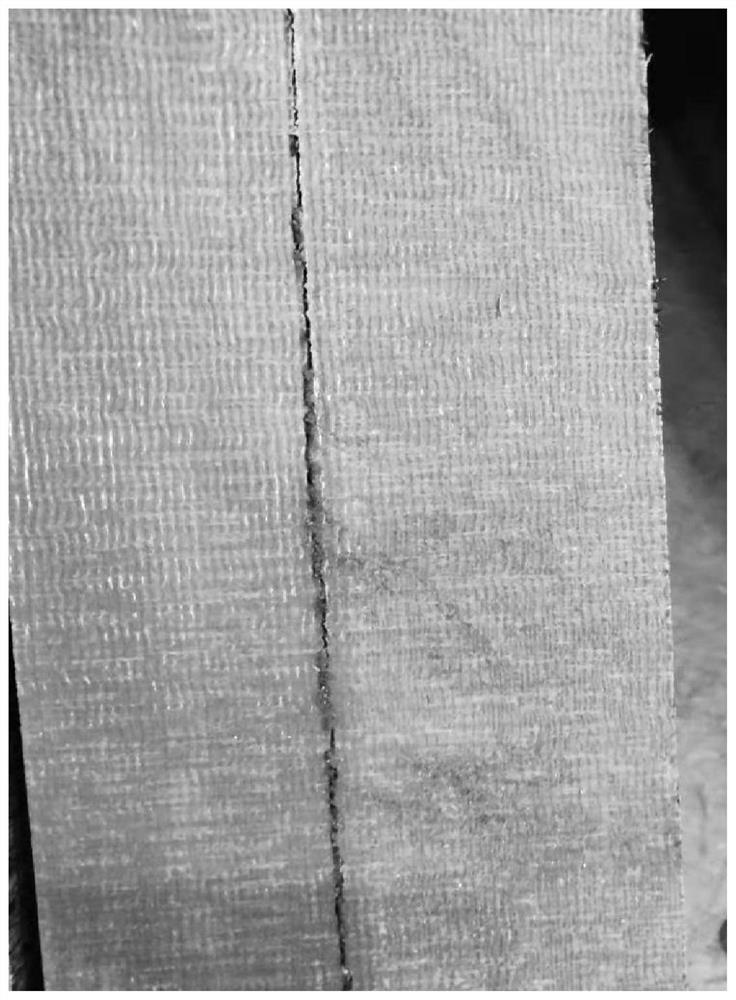

Preparation method of high-performance ultra-large and ultra-thick carbon/carbon composite material

PendingCN113024269AShorten the high temperature heat treatment cycleImprove product qualification rateCarbon compositesFiber

The invention provides a preparation method of a high-performance ultra-large and ultra-thick carbon / carbon composite material. The preparation method comprises the following steps: A, preparing a carbon fiber preform; B, performing primary graphitization treatment on the carbon fiber preform to obtain a carbon fiber blank; C, carrying out CVD densification treatment on the carbon fiber green body to obtain a CVD green body; D, carrying out secondary graphitization treatment on the CVD green body to obtain a graphitized green body; E, sequentially carrying out dipping curing treatment, carbonization treatment, high-temperature heat treatment and machining treatment on the graphitized green body; F, repeating the step E until the density of the graphitized green body reaches a target value to obtain a primary finished product; and G, performing finish machining on the primary finished product, and obtaining a finished product. The product prepared by the method is high in percent of pass and excellent in performance, and batch preparation of the high-performance ultra-large and ultra-thick carbon / carbon composite material can be realized.

Owner:CENT SOUTH UNIV

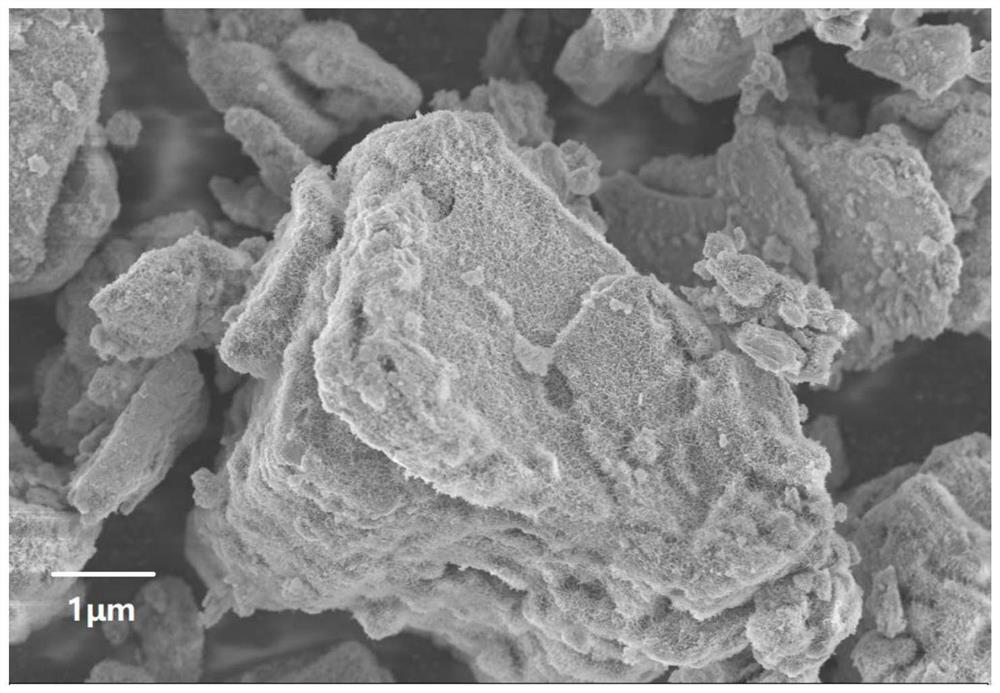

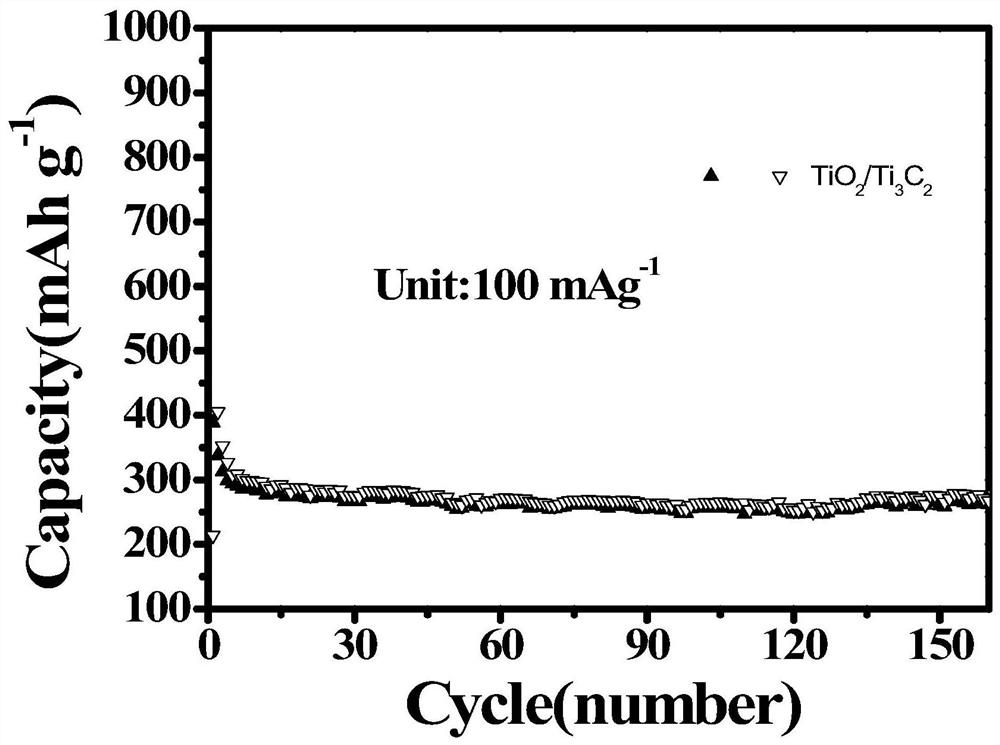

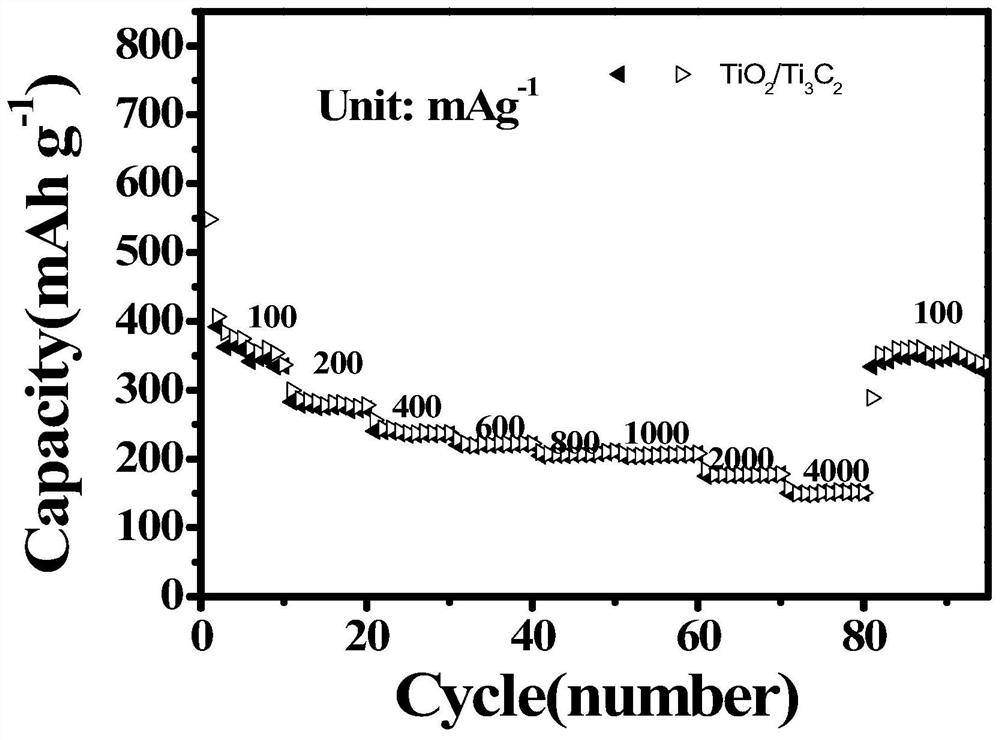

Preparation method of three-dimensional TiO2 nanowire/MXene composite material

The invention relates to a lithium battery negative electrode material, in particular to a preparation method of a three-dimensional TiO2 nanowire / MXene composite material. The method comprises the following steps: S1, adding Ti3AlC2 into hydrofluoric acid, and etching and stripping an aluminum layer; S2, carrying out the centrifugal drying on the reaction liquid obtained in the step S1 to obtain Ti3C2MXene; S3, ultrasonically dispersing the Ti3C2MXene obtained in the step S2 into a sodium hydroxide solution, and performing magnetic stirring to obtain a composite material precursor; S4, centrifuging and drying the composite material precursor obtained in the step S3 to obtain the composite material. Compared with the prior art, the preparation method has the advantages that MXene is alkalized through the sodium hydroxide solution, so that the interlayer spacing of MXene can be enlarged, the storage and transportation of lithium ions are facilitated, and the composite material has higher reversible capacity, better rate capability and good cycling stability and conductivity and is suitable for being applied to lithium ion batteries.

Owner:SHANGHAI INST OF TECH

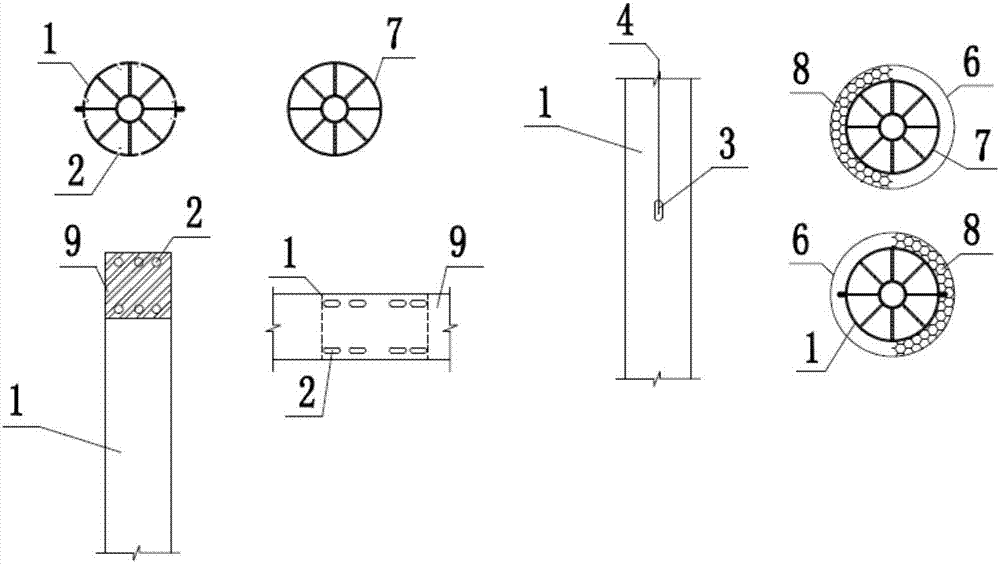

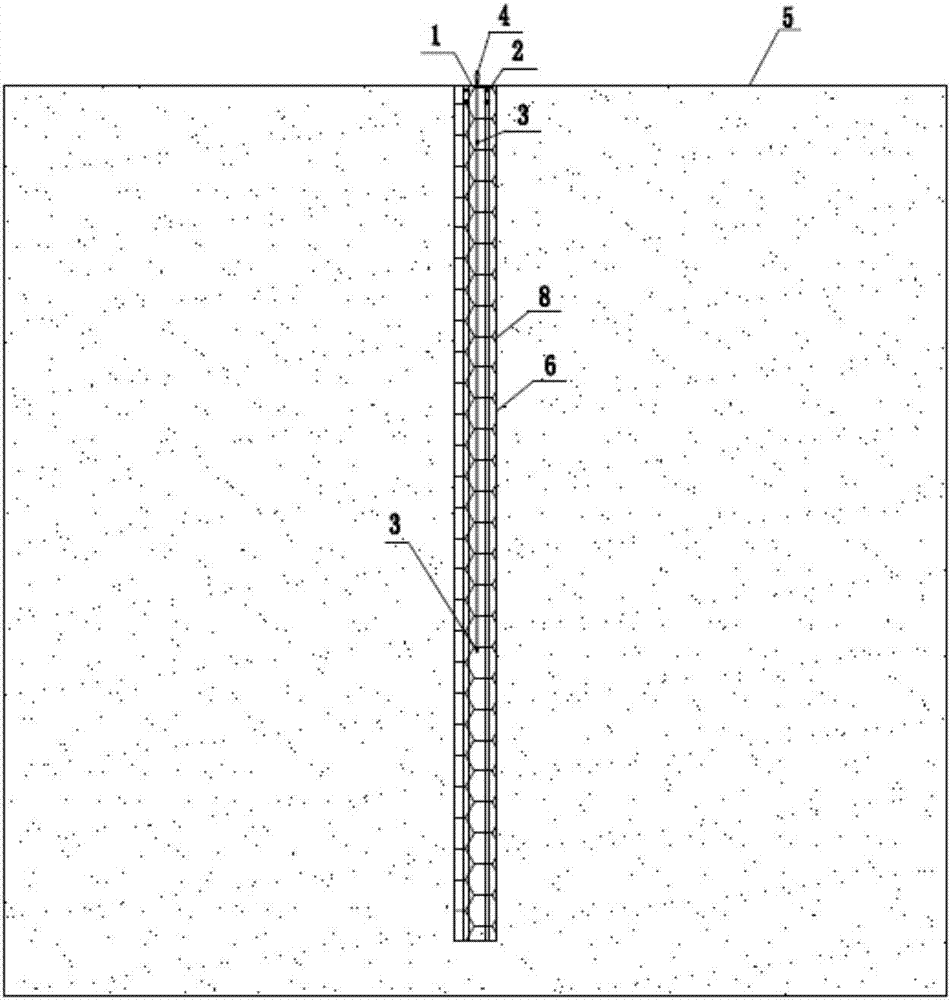

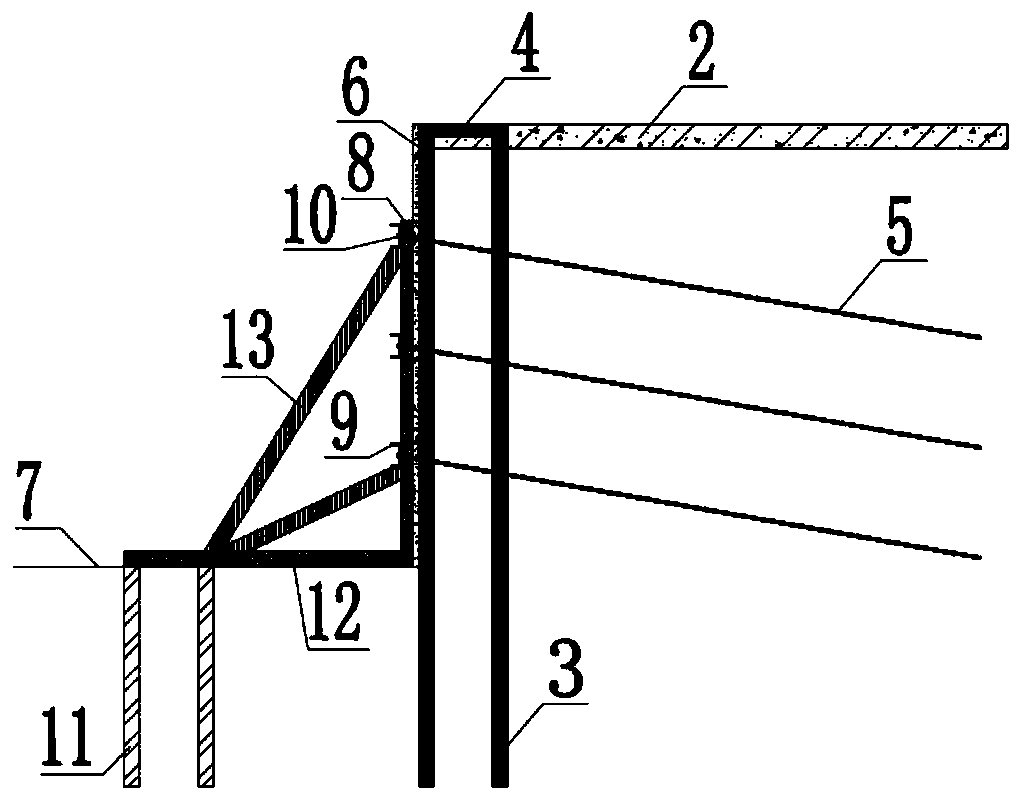

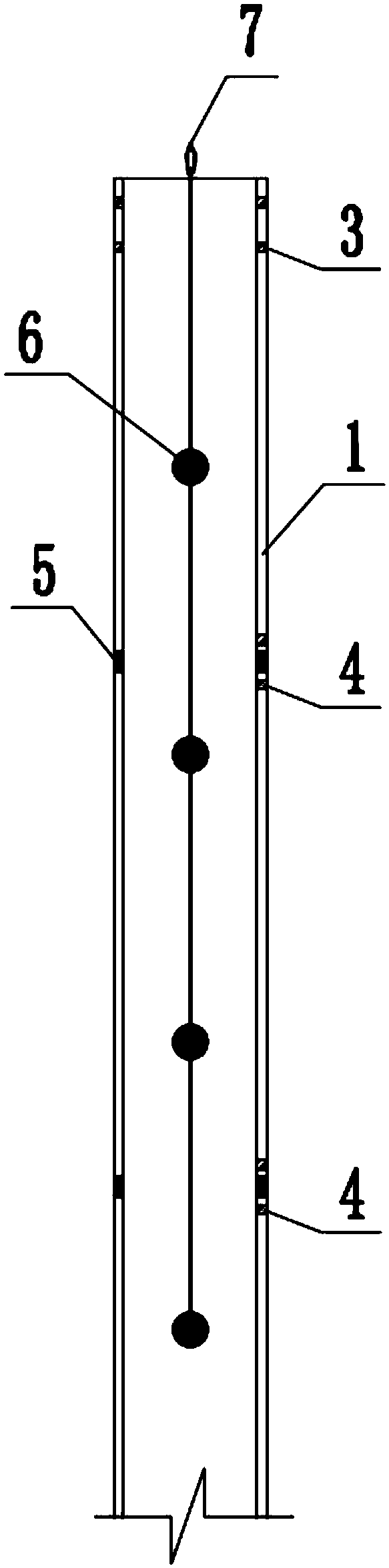

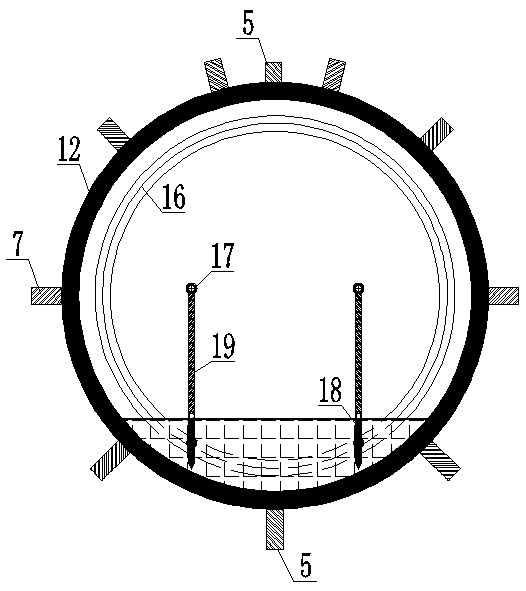

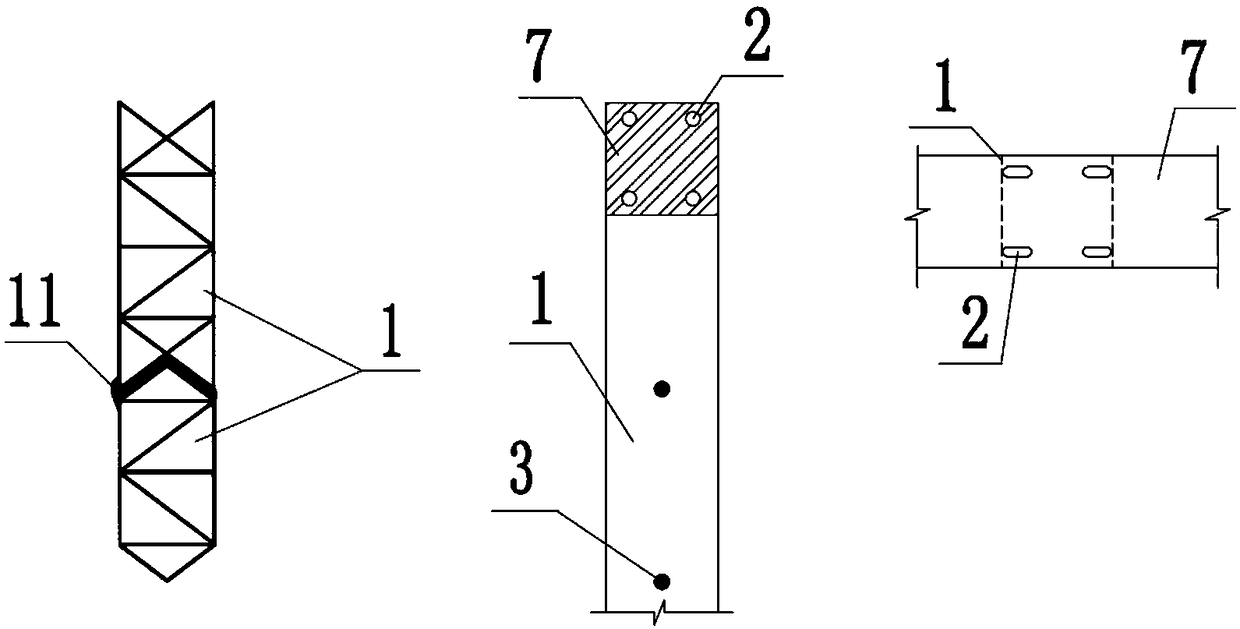

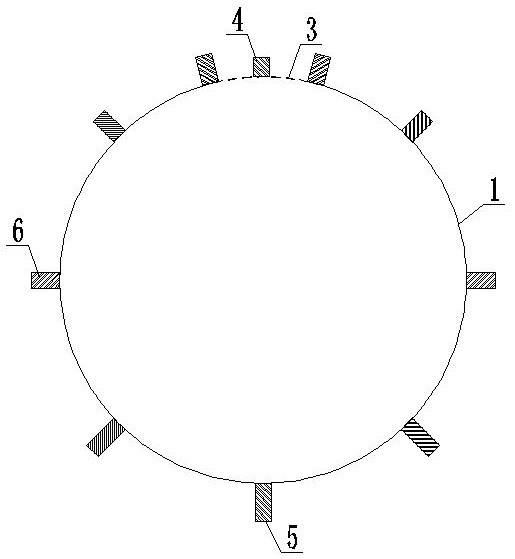

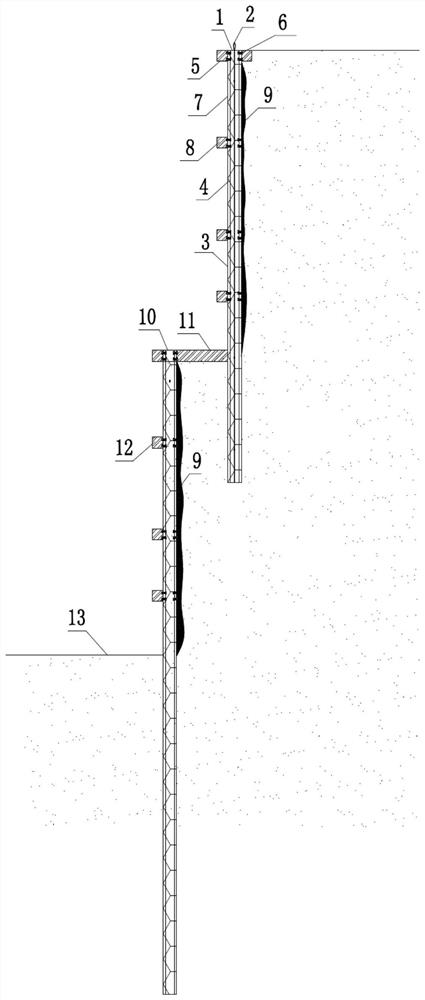

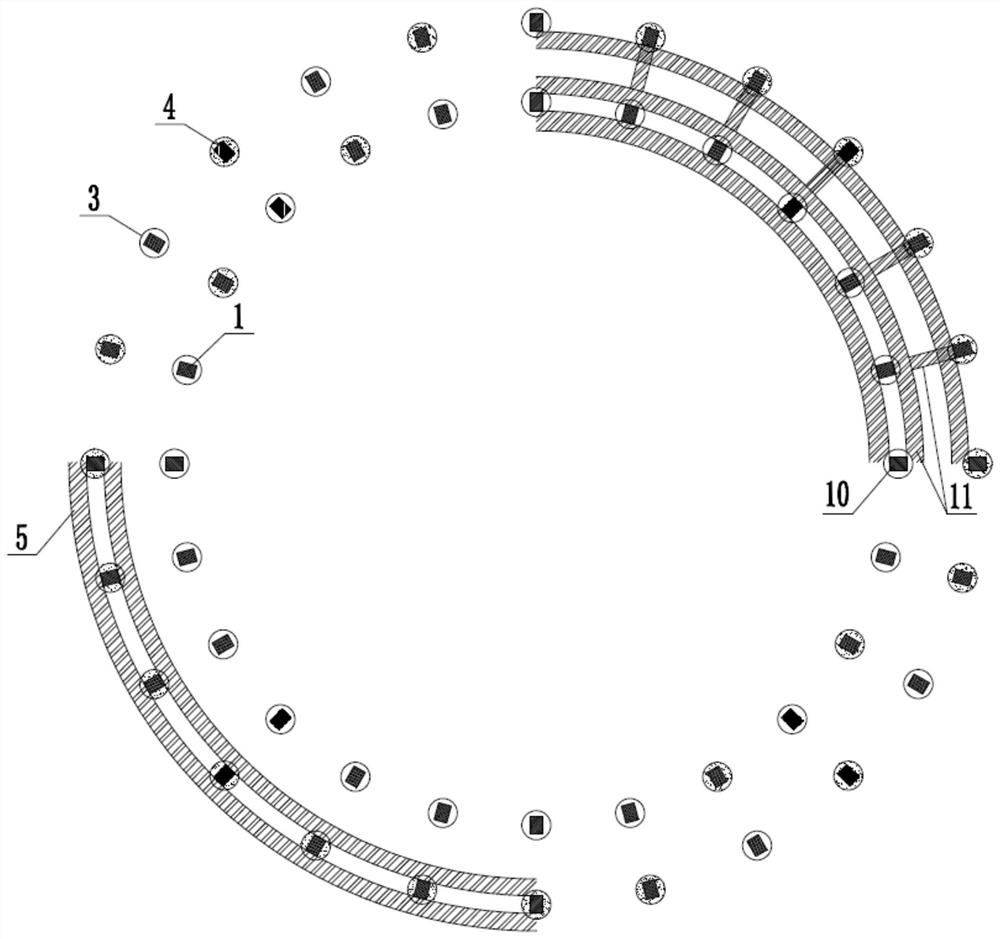

Design and construction method for flexible composite, seepage-proofing, fabricated and recyclable row pile supporting structure with circular cross section

ActiveCN107130611AMeet positioning accuracy requirementsAdvanced technologyExcavationsBulkheads/pilesReusabilitySubway station

The invention relates to a design and construction method for a flexible composite, seepage-proofing, fabricated and recyclable row pile supporting structure with a circular cross section. The design and construction method comprises the following steps: (1) constructing row piles with circular cross sections; (2) installing section steel top beams; (3) installing steel panels and performing post-grouting on the steel panels; (4) excavating in layers and sections sequentially in the vertical direction; (5) repeating the steps (3) and (4), and constructing up to the design depth; and (6) performing recycling step by step along with pit backfill after the supporting structure completes the using function. The flexible composite, seepage-proofing, fabricated and recyclable row pile supporting structure with the circular cross section constructed by adopting the design and construction method has the advantages that high safety and reliability are achieved, the construction is fast, the technology is advanced, high recyclability and reusability are achieved and the comprehensive economy and environmental protection indexes are superior, is a new method with advanced technology, high safety and reliability, high recyclability and reusability and superior comprehensive economy and environmental protection indexes for excavation and support of projects such as foundation pits, side slopes, subway stations, municipal pipelines and the like, and further has a considerable development and application prospect.

Owner:SAFEKEY ENG TECHZHENGZHOU

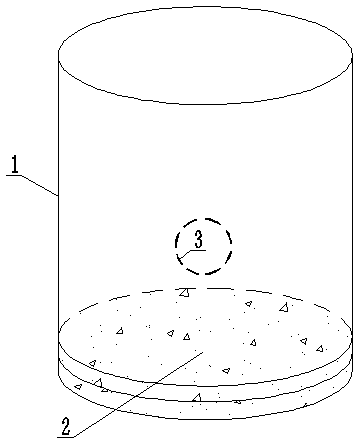

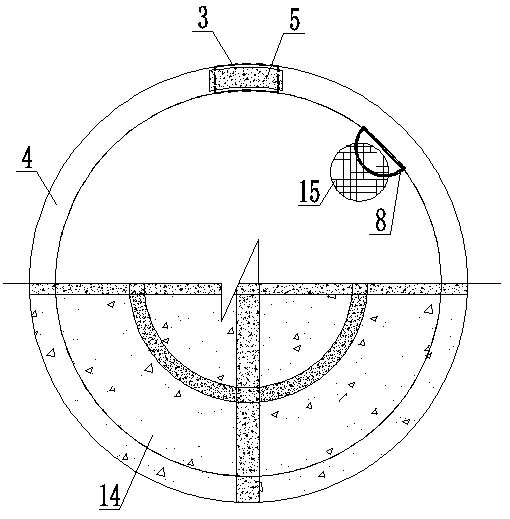

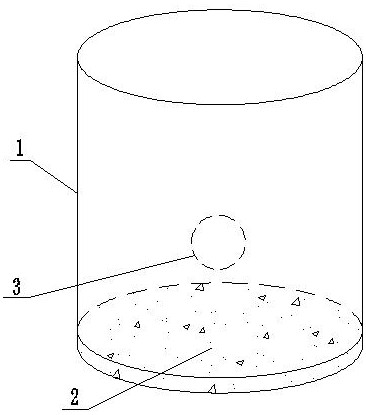

Permanent circular working well with preset pipe-jacking door opening in water-rich formation and construction method of permanent circular working well

ActiveCN110485468AAdvanced technical conceptAffordableArtificial islandsProtective foundationThermal forceFunctional requirement

The invention provides a permanent circular working well with a preset pipe-jacking door opening in a water-rich formation and a construction method of the permanent circular working well. The construction method specifically includes the following steps that (1) functional requirements of the circular working well are designed; (2) open caisson construction of a maintenance structure of the circular working well is conducted; (3) temporary border protection construction is conducted; (4) downhole earthwork is excavated; (5) the bottom of the circular working well is sealed; (6)a crawling ladder for entering the circular working well is mounted; (7) joint leakage is treated; (8) a wellhead water stopping pressing plate is mounted; (9) a sandwich concrete board wall at the top of the presetdoor opening is lifted; (10) jacking construction of pipe-jacking is conducted; (11) communication of downhole pipelines, mounting of valves and related work are implemented, checked and accepted; and (12) the temporary border protection is removed, the top of the circular working well is covered with a plate, a inspection well is mounted, and waterproof construction is conducted. According to the permanent circular working well and the construction method, a constructed structural system has many advantages of being clear in function, safe and quick, skillful in design and the like, the potential safety hazard of sudden water gushing and sand gushing in the process of the penetration of pipe-jacking through the well wall is particularly overcome, and a new method is provided for non-excavation construction of underground pipelines such as water conservancy, municipal administration, heating power and communication.

Owner:南方工程检测修复技术研究院

Construction method for reinforced supporting structure for foundation pit ramp under heavy-load passing condition

PendingCN110593266AAdvanced technologyRecycling can be efficientExcavationsShaping building partsRoad surfaceHeavy load

The invention provides a construction method for a reinforced supporting structure for a foundation pit ramp under a heavy-load passing condition. The construction method comprises the following steps: A, road surface construction for the foundation pit ramp; B1, sidewall supporting structure construction for the foundation pit ramp; B2, sidewall steel latticework installation for the foundation pit ramp; and B4, diagonal bracing beam installation. The construction method has the advantages of being safe and rapid, advanced in technology, capable of being efficiently recovered, green and economic, capable of saving resources, and the like in the aspects of design construction concept, structure system stress, construction manner, recovery value and the like of the reinforced supporting structure for the foundation pit ramp, and is capable of being successfully applied to a supporting project for the foundation pit ramp under the heavy-load passing condition, and considerable in development and application prospect.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

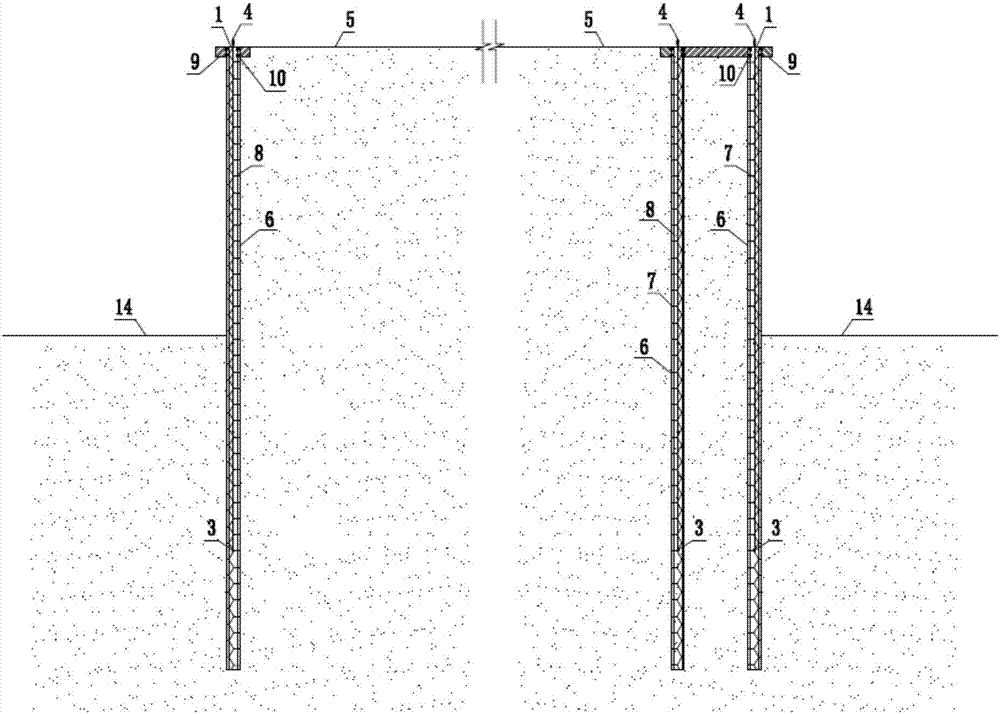

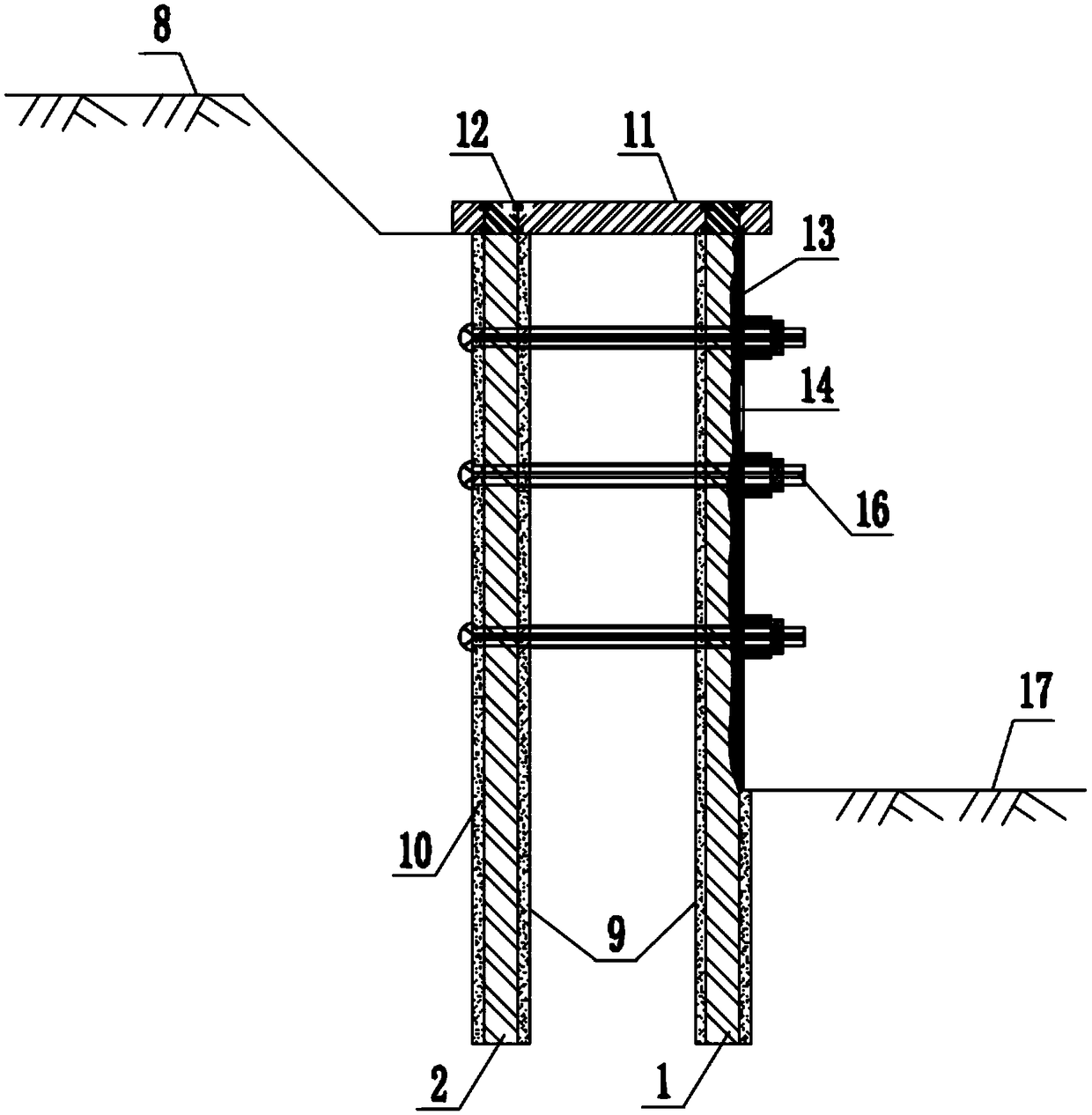

Design and construction method for flexible composite lattice type recyclable double-row pile supporting structure

InactiveCN109295986AMeet positioning accuracy requirementsReasonable force and safe and reliableExcavationsBulkheads/pilesStructure systemStructural stress

The invention relates to a design and construction method for a flexible composite lattice type recyclable double-row pile supporting structure. The method comprises the following steps that (1), a front pile row and a rear pile row are constructed; (2), profile steel crown beams are installed; (3), the earthwork is excavated in layers, panels are installed, and polymer grouting is carried out; (4), waist beams and contra-pull connecting rods are installed; (5), the earthwork is excavated vertically, hierarchically and sectionally in turn, the third step and the fourth step are repeated, the earthwork is excavated to the base elevation, and the construction of the flexible composite lattice type recyclable double-row pile supporting structure system is completed; and (6), after the supporting structure completes the use function, the supporting structure can be recycled step by step with the backfilling of a foundation pit. The constructed supporting structure system has the beneficialeffects of more reasonable structural stress, stronger resistance to lateral earth pressure, avoidance of crossing red lines, safety and reliability, quick construction, advanced technology, recyclability, superior economic and environmental protection indexes and the like and has considerable development and application prospects.

Owner:SAFEKEY ENG TECHZHENGZHOU

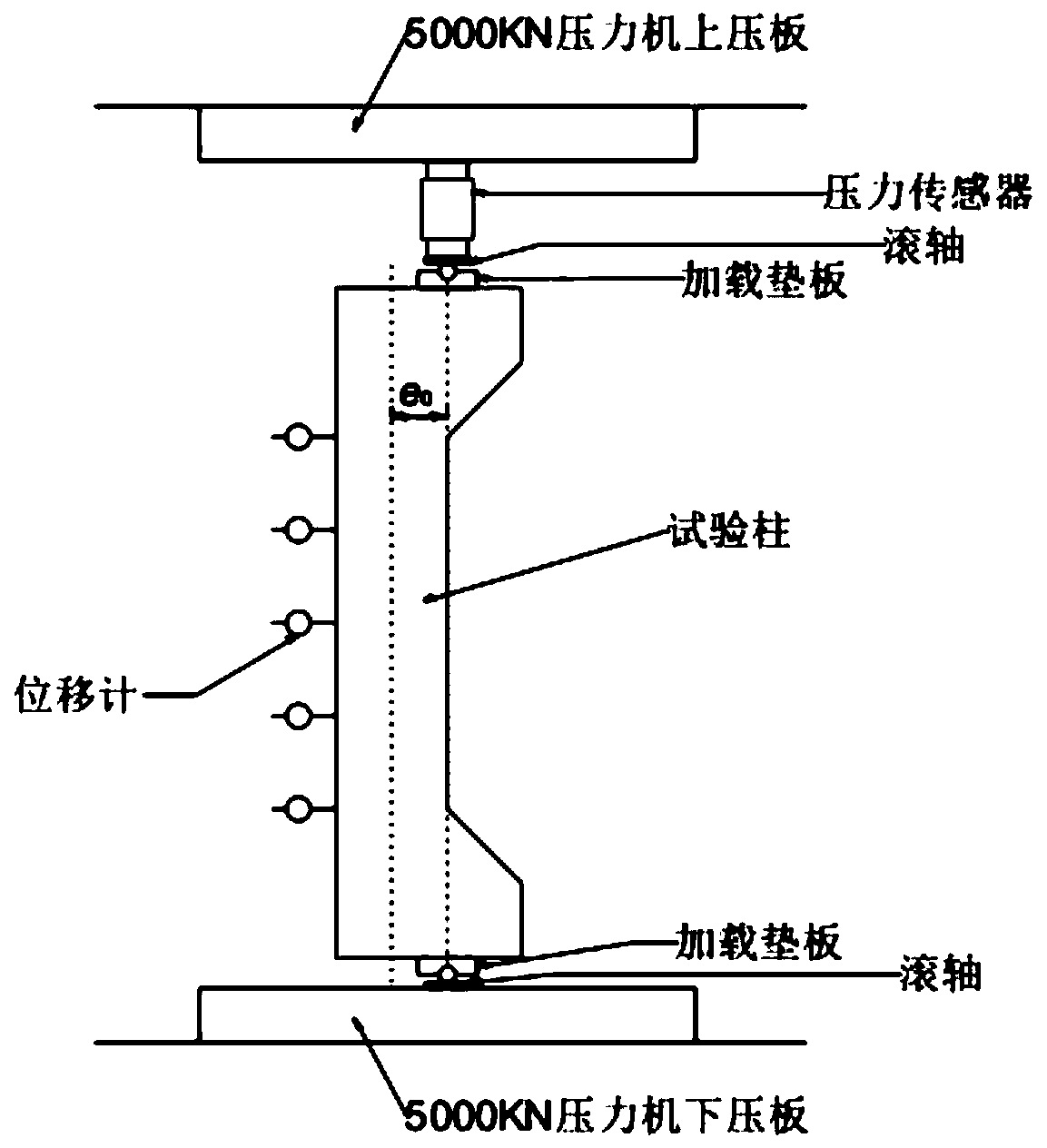

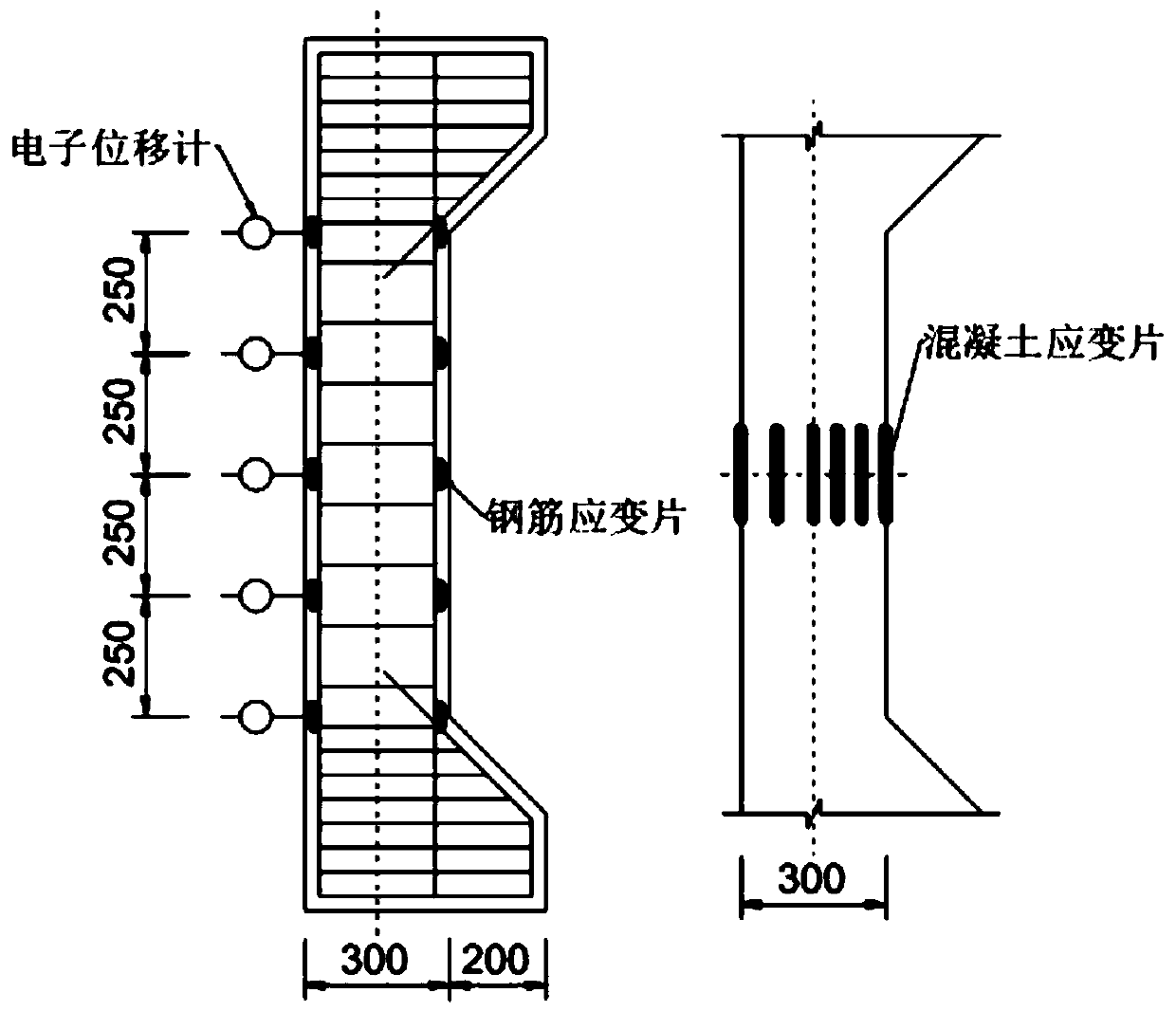

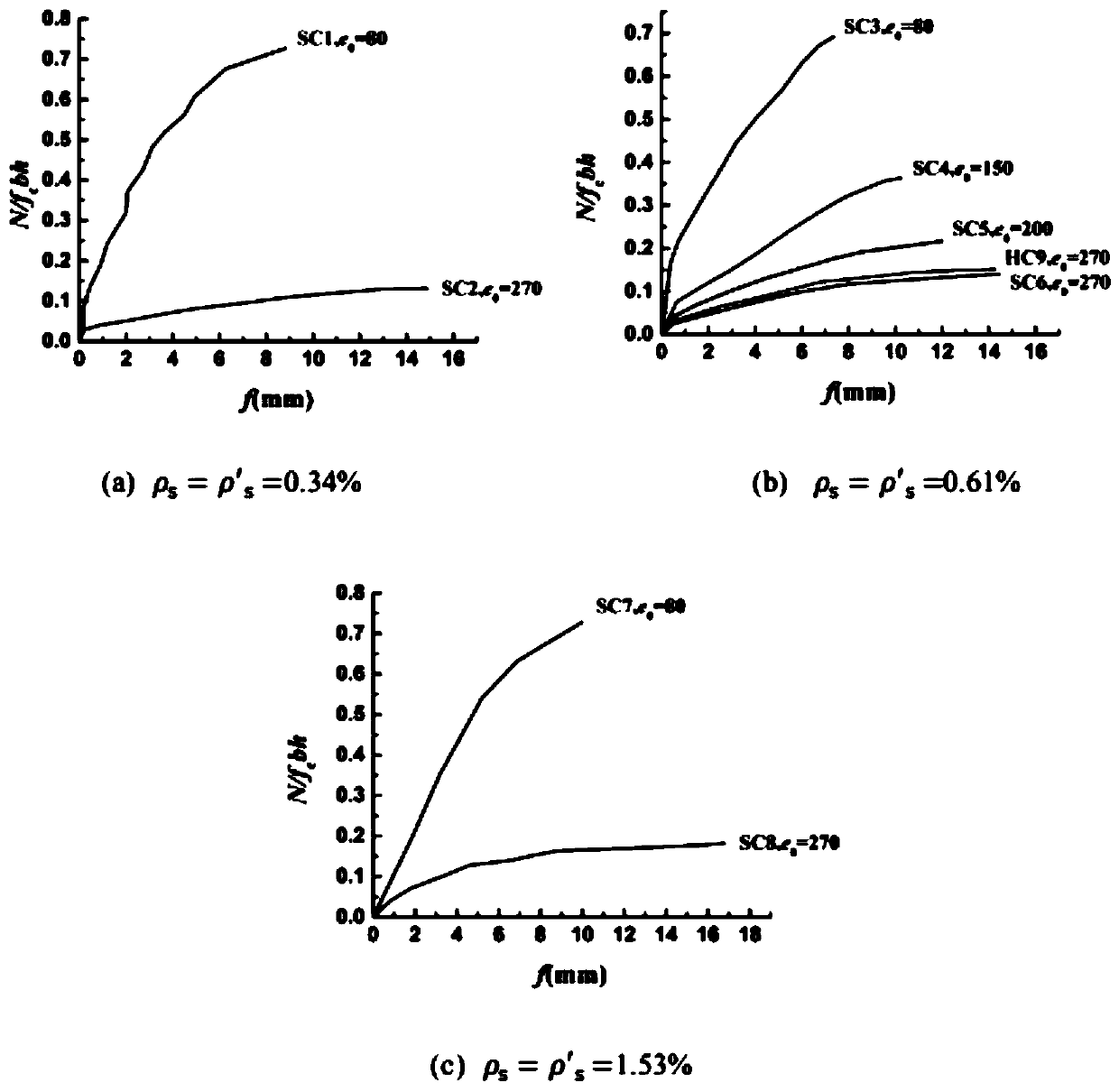

Analysis method for mechanical performance of stainless steel reinforced concrete column

ActiveCN110441140AGood development and application prospectsMaterial strength using tensile/compressive forcesRebarLateral deflection

The invention provides an analysis method for mechanical performance of a stainless steel reinforced concrete column, and the method comprises the following steps of establishing a mechanical performance test of a stainless steel reinforced concrete eccentric compression column; checking whether the flat section assumption of a stainless steel reinforced concrete eccentric compression member is true; analyzing the variation law of a deflection curve, a mid-span lateral deflection and a longitudinal steel strain; checking the theoretical formula of the bearing capacity of the stainless steel reinforced concrete eccentric compression column; and giving a calculation formula of an average crack spacing of a test piece of the stainless steel reinforced concrete eccentric compression column anda recommended value of the component characteristic coefficient. The analysis method provided by the invention compares the failure mode, deflection curve, crack development and longitudinal steel strain of the stainless steel reinforced concrete eccentric compression test piece under the change of the reinforcement ratio and the loading eccentricity, and discusses the calculation of the bearingcapacity and the crack width, so that a method of calculating the bearing capacity of the stainless steel reinforced concrete column is established to provide theoretical basis for the design of stainless steel reinforced concrete structures, having a good development and application prospect.

Owner:ZHENGZHOU UNIV

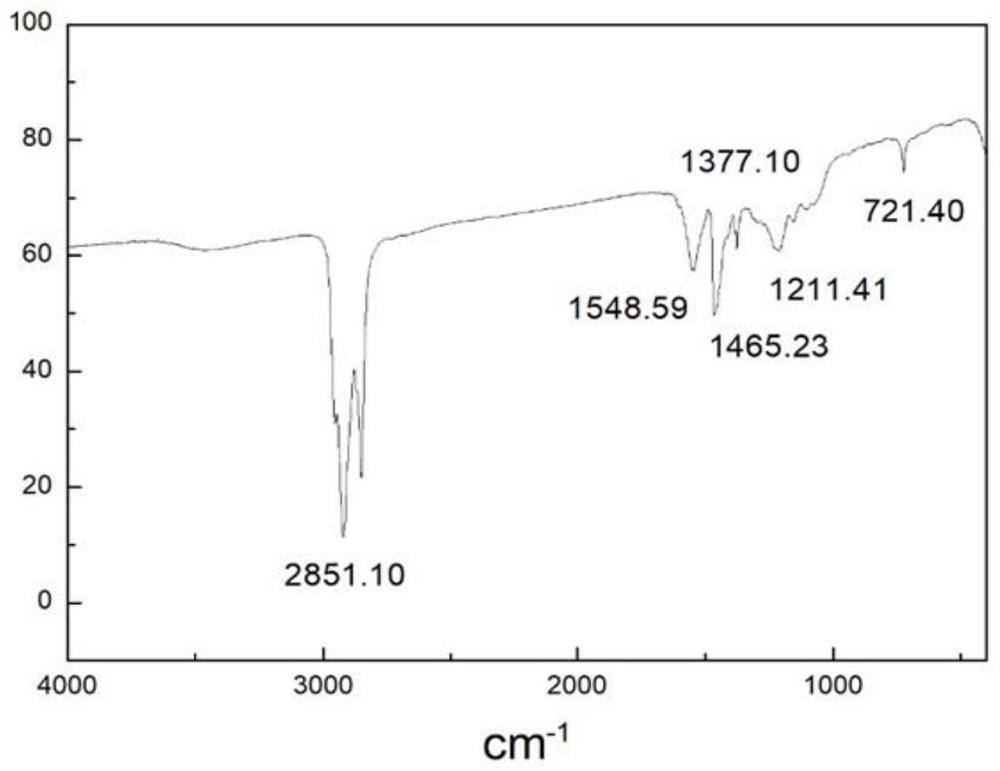

Rare-earth-based lubricating grease and preparation method thereof

The invention relates to the field of lubricants, and discloses rare-earth-based lubricating grease and a preparation method thereof. The rare-earth-based lubricating grease is characterized in that a thickening agent of the rare-earth-based lubricating grease is organic acid salt of rare earth elements, and the use amount of the thickening agent is 5-70 g relative to 100 g of base oil. Compared with the prior art, the lubricating grease disclosed by the invention does not need to introduce a third component such as polyurea or a rare earth compound in other forms as a thickening agent. The rare earth-based lubricating grease provided by the invention has the advantages of simple preparation process, excellent extreme pressure property, excellent wear resistance and the like, can be suitable for severe working conditions such as high temperature and high load, can be applied to various running equipment such as mechanical bearings, gears, transmission rods and the like in multiple industrial fields such as electric appliances, steel, automobiles and papermaking, and has a better application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

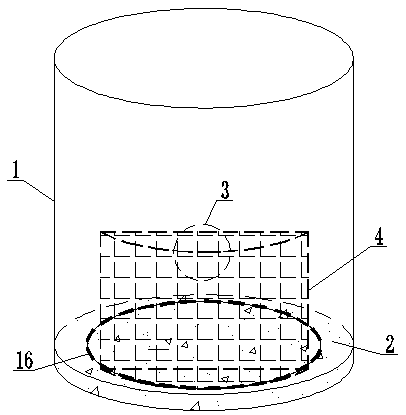

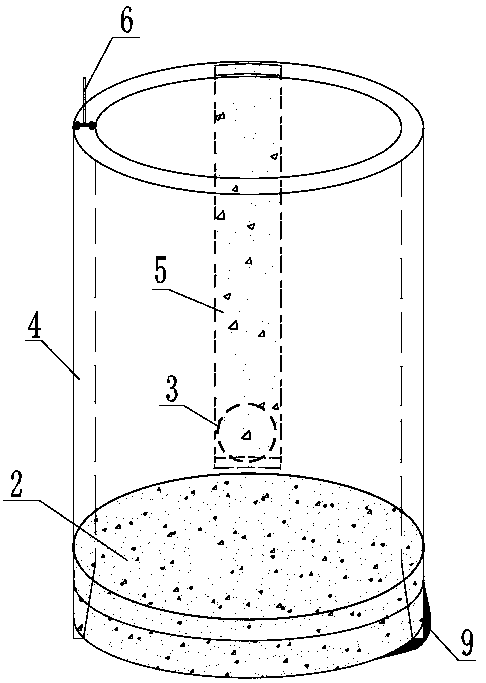

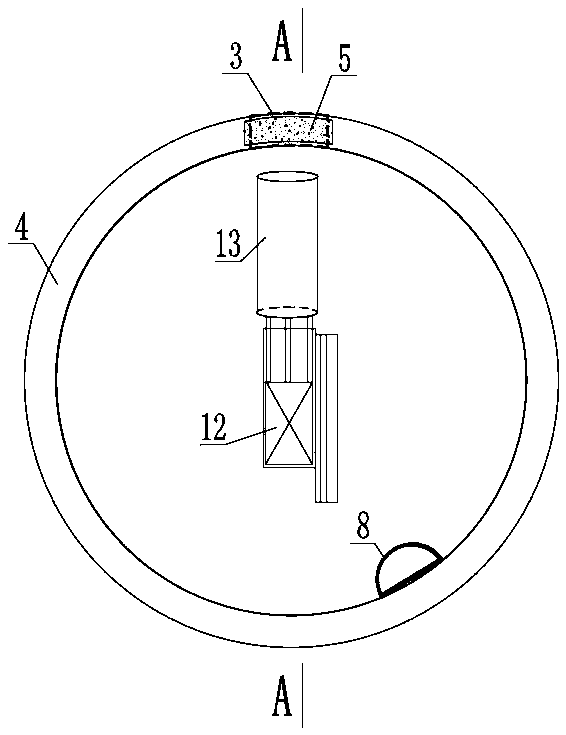

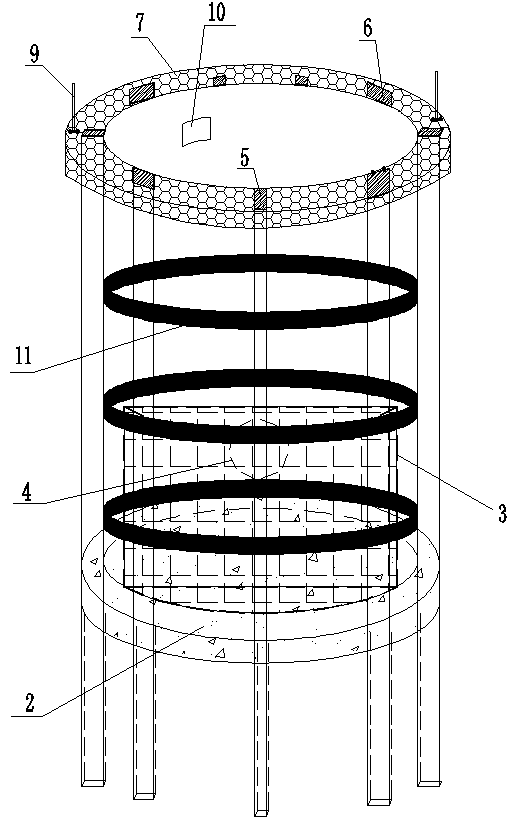

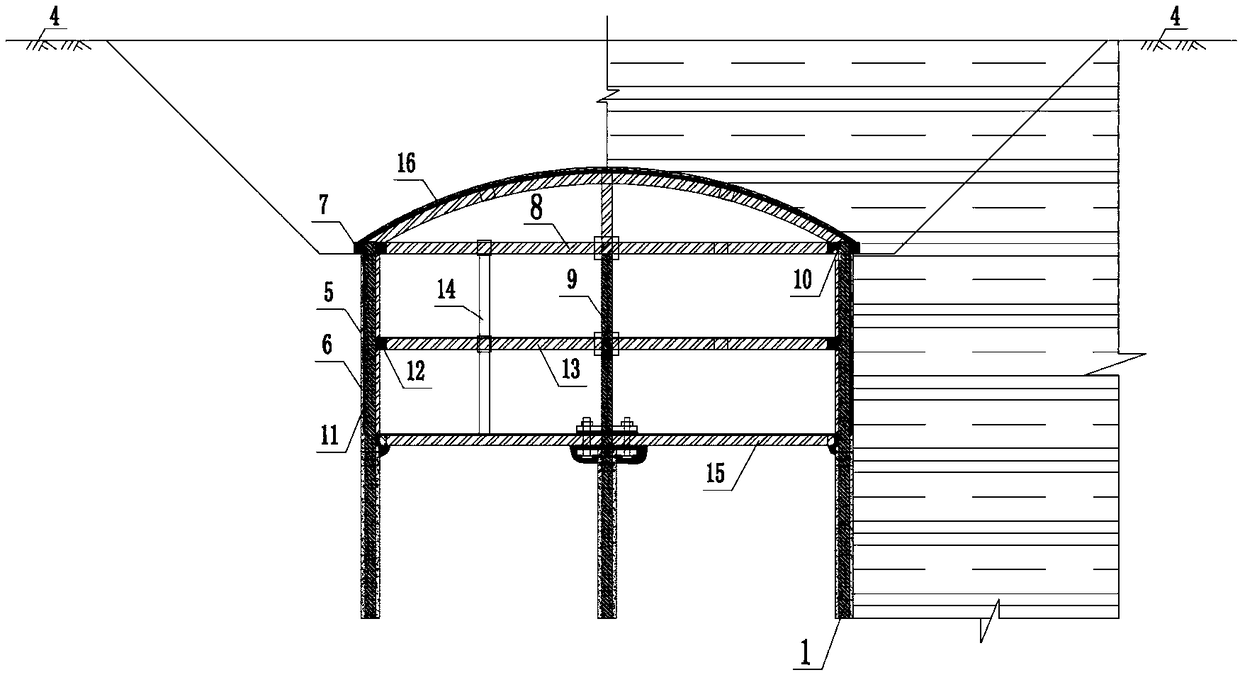

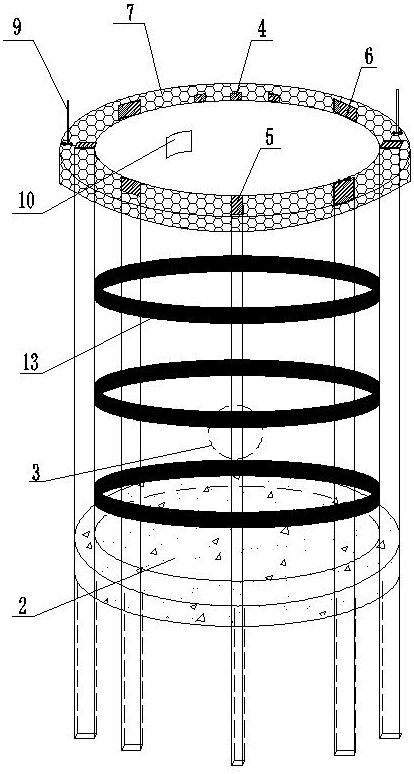

Fabricated recoverable circular working well of preset pipe-jacking door opening and rotary back leaning wall and construction method of fabricated recoverable circular working well

ActiveCN110485472AShort construction periodSave operating spaceArtificial islandsExcavationsPre embeddingStructure system

The invention relates to a fabricated recoverable circular working well of a preset pipe-jacking door opening and a rotary back leaning wall and a construction method of the fabricated recoverable circular working well. The construction method includes the following steps that (1) functional requirements of the circular working well are designed; (2) support pile construction is conducted; (3) a prefabricated crown beam is mounted; (4) border protection is conducted; (5) alternate construction ofearth excavation, a soil retaining panel and an annular inner support beam is conducted, and the door opening is synchronously reserved; (6) a crawling ladder for entering the circular working well is mounted; (7) the bottom of the circular working well is sealed, and a rotary track, a pull ring and a back leaning wall anchoring part are pre-embedded; (8) rotary back leaning wall construction is conducted; (9) after downhole operation is completed, in the process of backfilling, the members such as the back leaning wall, the soil retaining panel, the annular inner support beam, the crown beam and the support pile are recovered in an reverse sequence step by step. According to the fabricatedrecoverable circular working well and the construction method, a constructed structure system has many advantages of being clear in function, safe and rapid, recyclable in a fabricated mode, reusableand the like, and a new method is provided for non-excavation construction of underground pipelines such as water conservancy, municipal administration, heating power and communication.

Owner:南方工程检测修复技术研究院

Preparation method of low-cost ultra-large and ultra-thick carbon/carbon composite material

The invention provides a preparation method of a low-cost ultra-large and ultra-thick carbon / carbon composite material. The preparation method comprises the following steps: a, preparing a carbon fiber preform; b, carrying out graphitization treatment on the carbon fiber preform to obtain a carbon fiber blank; c, sequentially carrying out dipping curing treatment, carbonization treatment, high-temperature heat treatment and machining treatment on the carbon fiber blank; d, repeating the step c until the density of the carbon fiber green body reaches a target value to obtain a primary finished product; and e, carrying out finish machining on the primary finished product to obtain a finished product. The method is simple in process and low in production cost, the prepared product is high in percent of pass, the production cost is low, and low-cost batch preparation of the ultra-large and ultra-thick carbon / carbon composite material can be achieved.

Owner:HUNAN BOYUN NEW MATERIALS

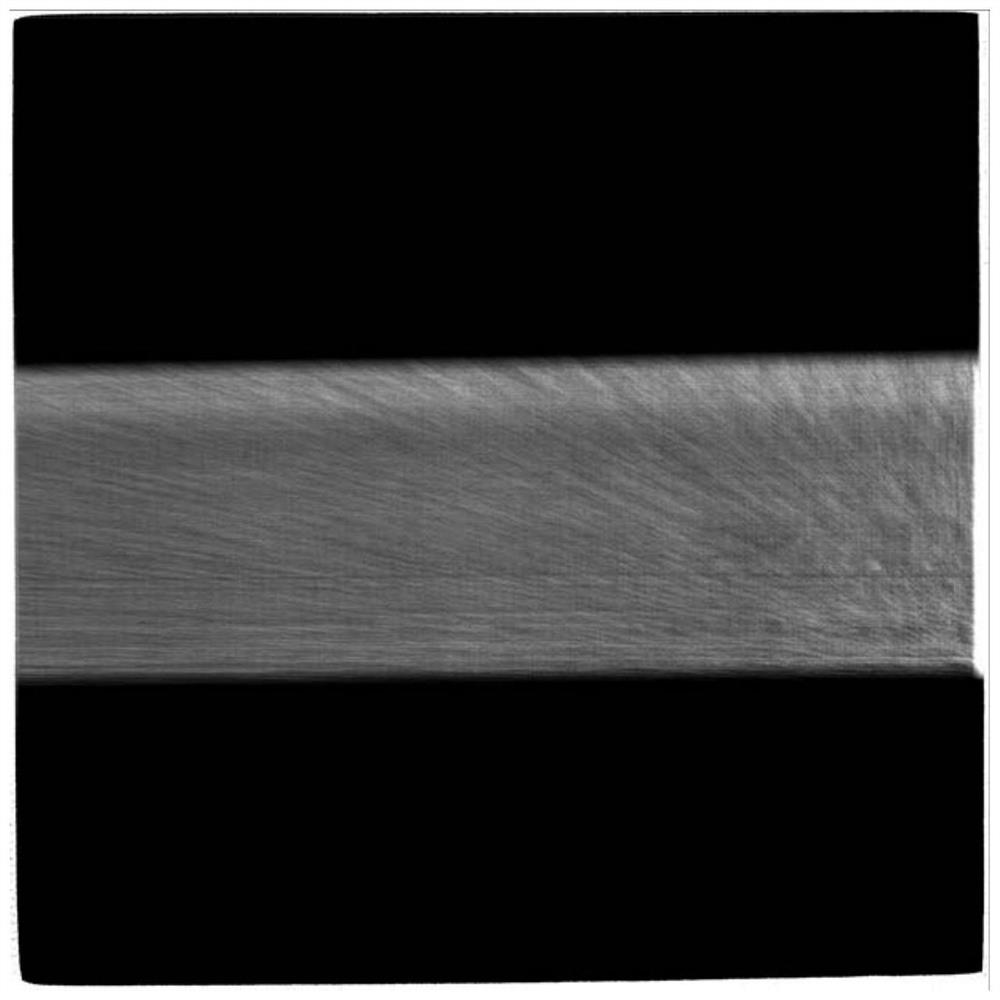

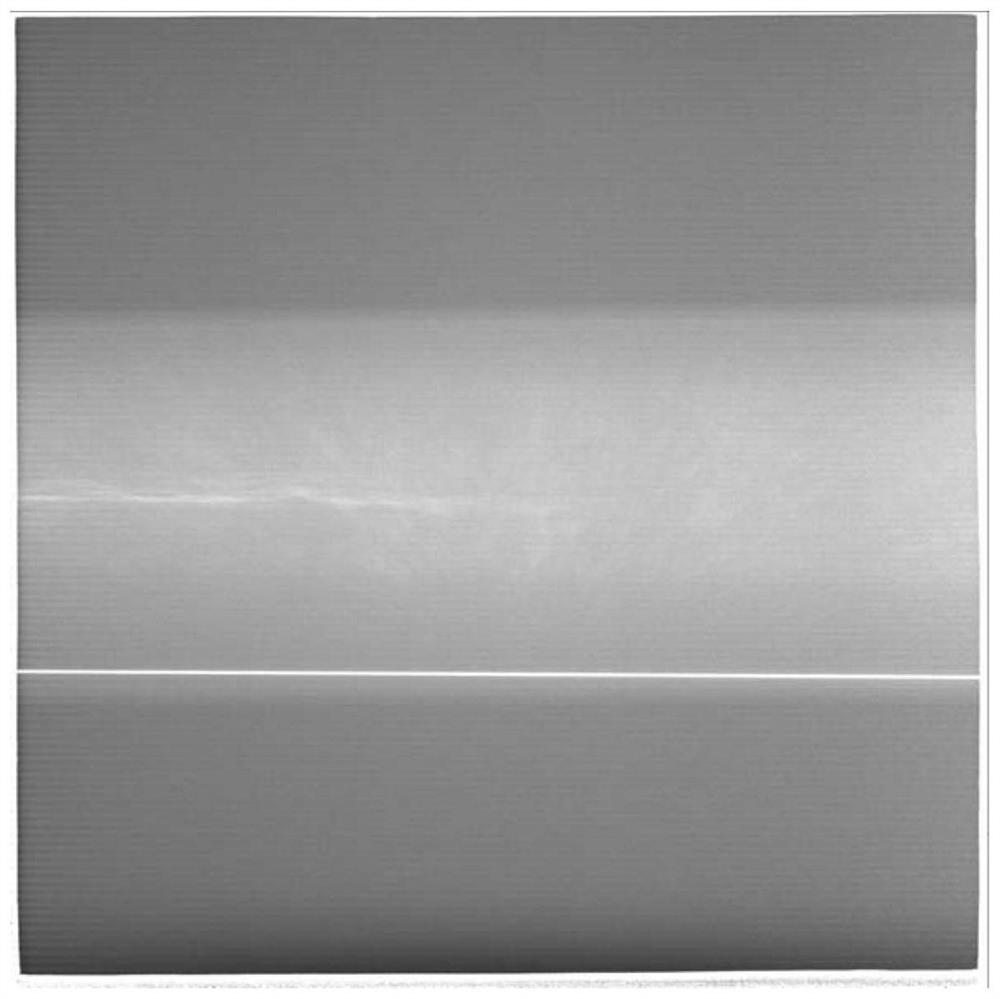

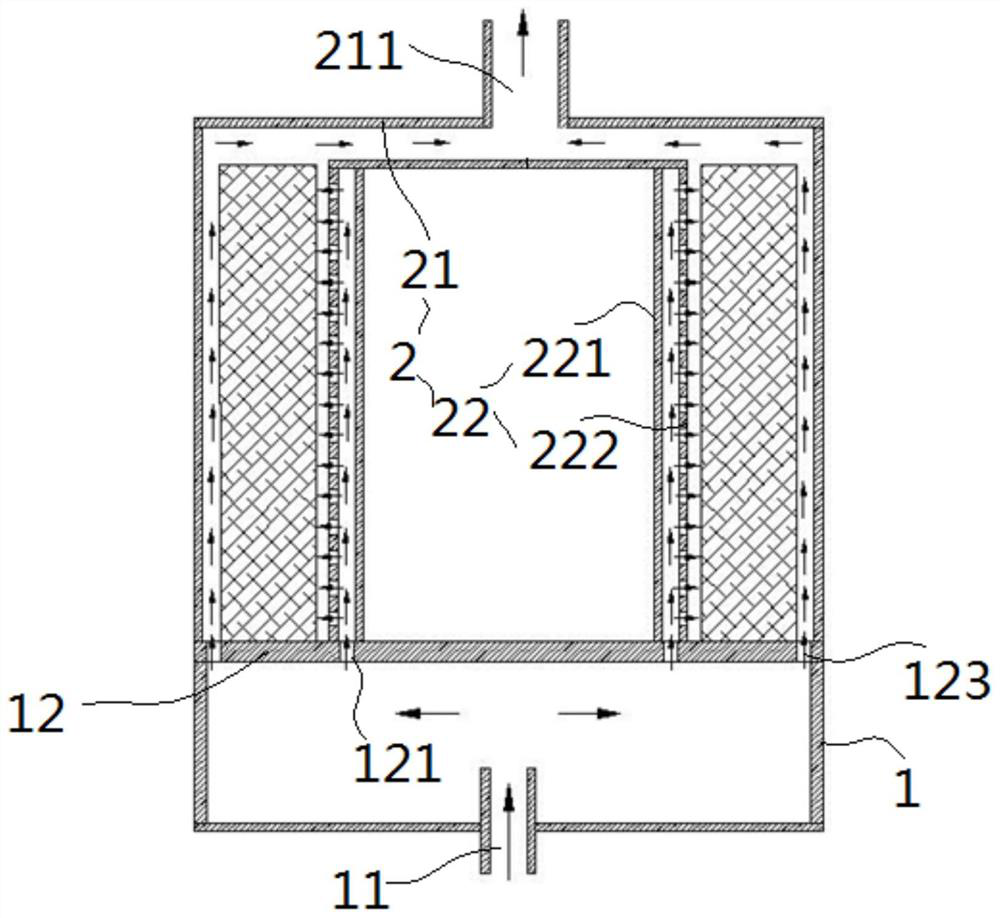

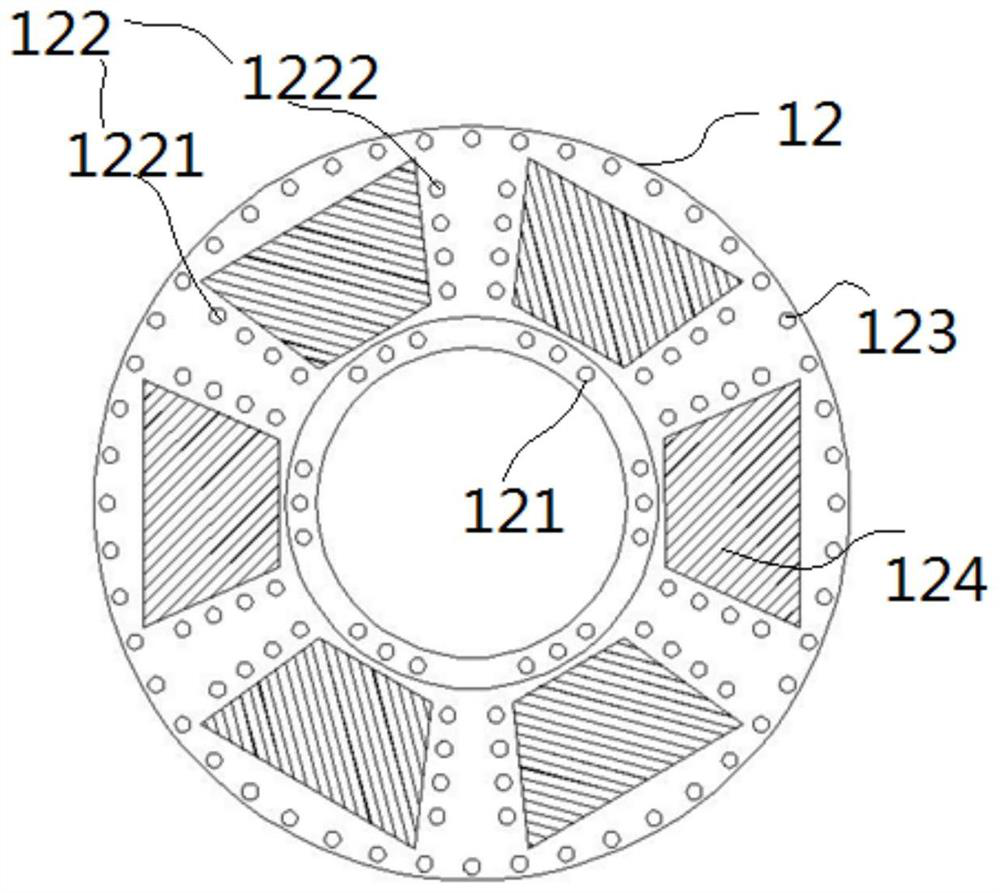

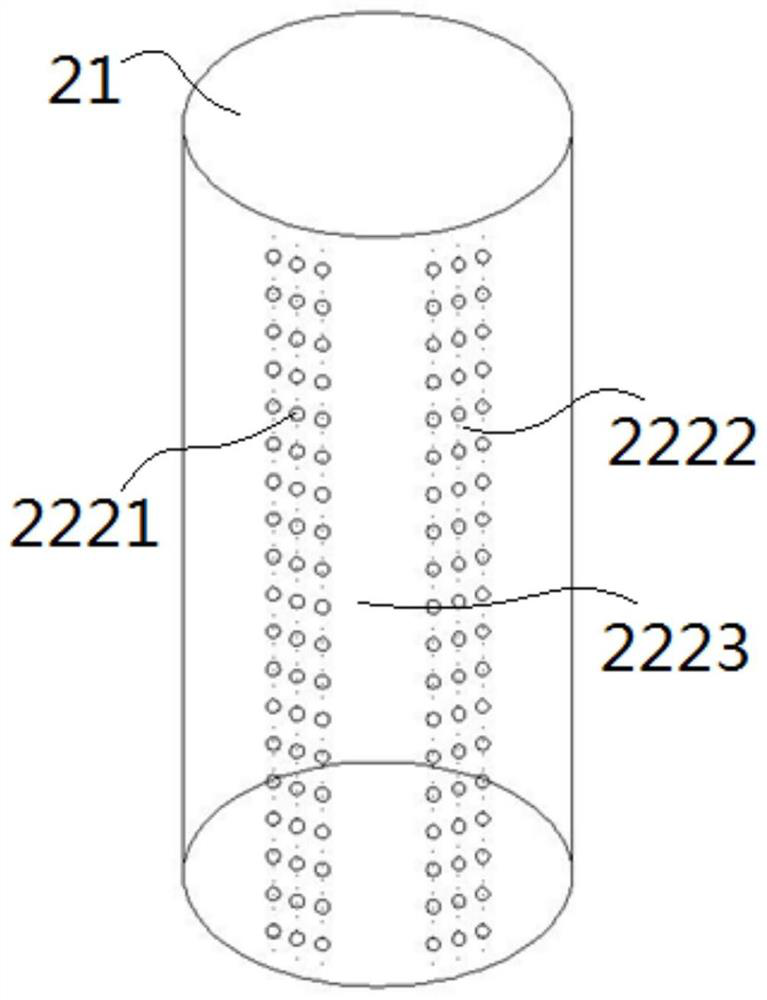

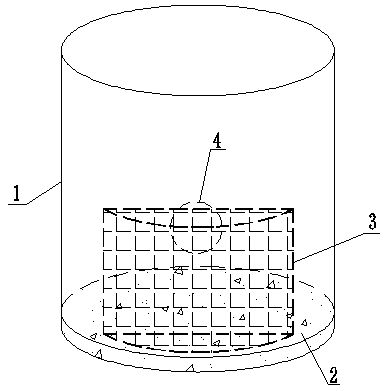

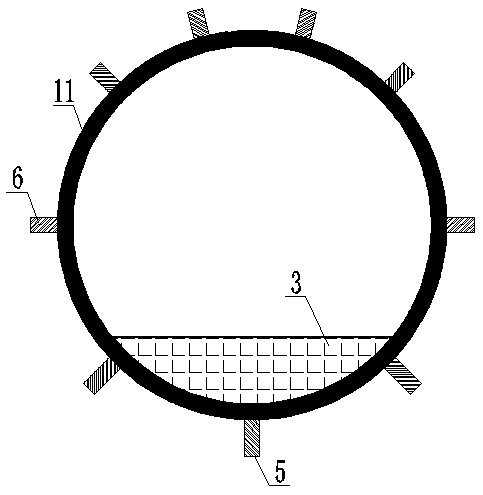

Vapor deposition device and preparation method of carbon/carbon composite material

ActiveCN112830807ASimple structureImprove densification efficiencyCarbon compositesDeposition process

The invention provides a vapor deposition device. The vapor deposition device comprises a base, a material plate and a deposition chamber, and the deposition chamber comprises an outer barrel, an exhaust port and an exhaust sleeve arranged in the outer barrel; the exhaust sleeve comprises an inner cylinder and a sleeve body arranged outside the inner cylinder in a sleeving mode, an airflow channel is defined by the inner cylinder and the sleeve body, and vent holes are formed in the side wall of the sleeve body; a first air inlet hole is formed in the material plate and is positioned between the sleeve and the inner cylinder; the material plate is further provided with an air inlet structure, the air inlet structure comprises an air inlet hole array, and the air inlet hole array is distributed in a radial shape with the exhaust sleeve as the center; and a fourth air inlet is formed in the side, away from the exhaust sleeve, of the air inlet array. The device can effectively control the flowing direction of gas in the deposition process, so that the gas is in full contact with a to-be-treated blank. In addition, the invention also provides a method for preparing a carbon / carbon composite material by using the device, and the method comprises the following step of determining the criterion of the flow of the carbon source gas and the principle that the flow is gradually reduced along with the increase of CVD (Chemical Vapor Deposition) times.

Owner:CENT SOUTH UNIV

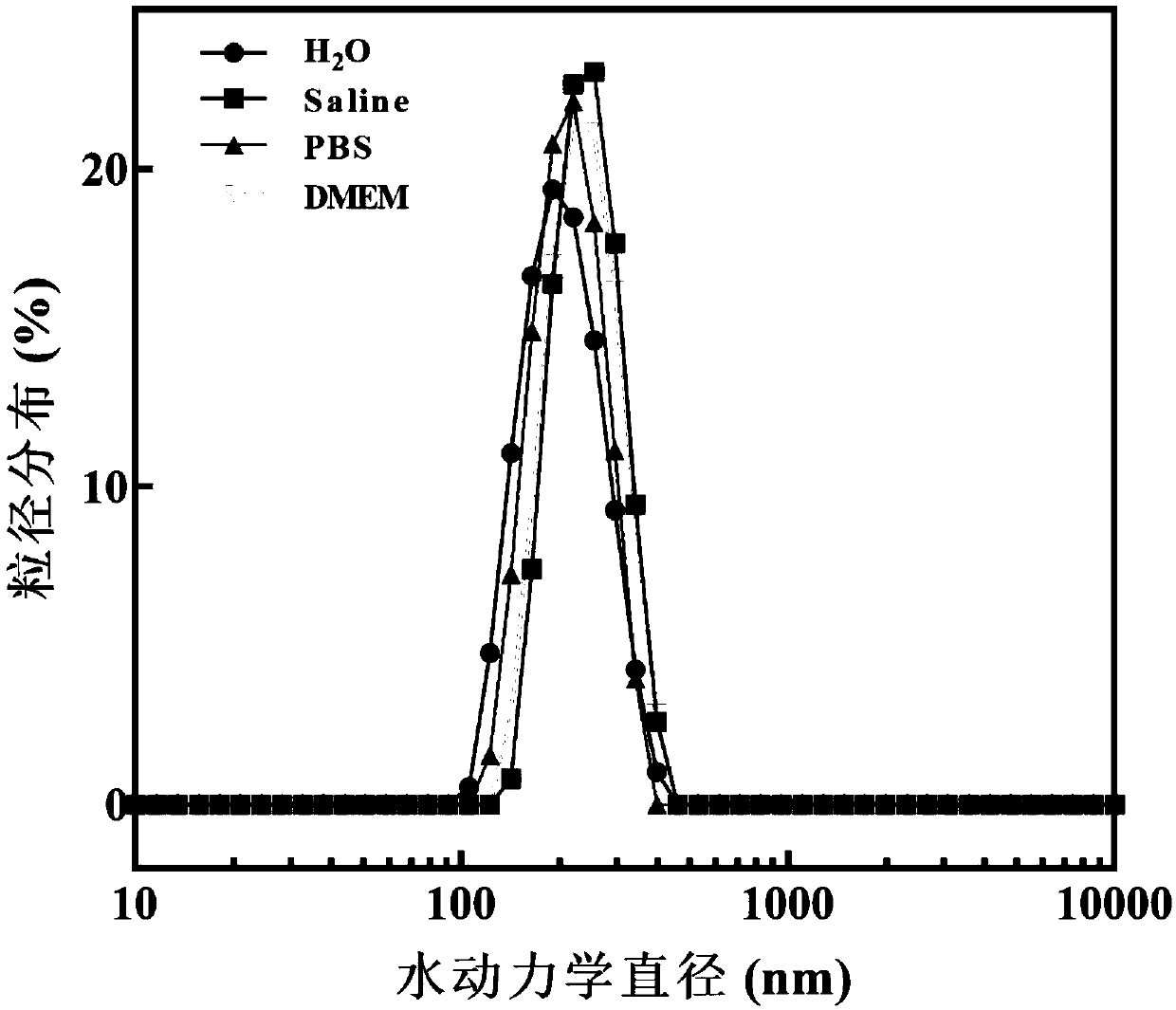

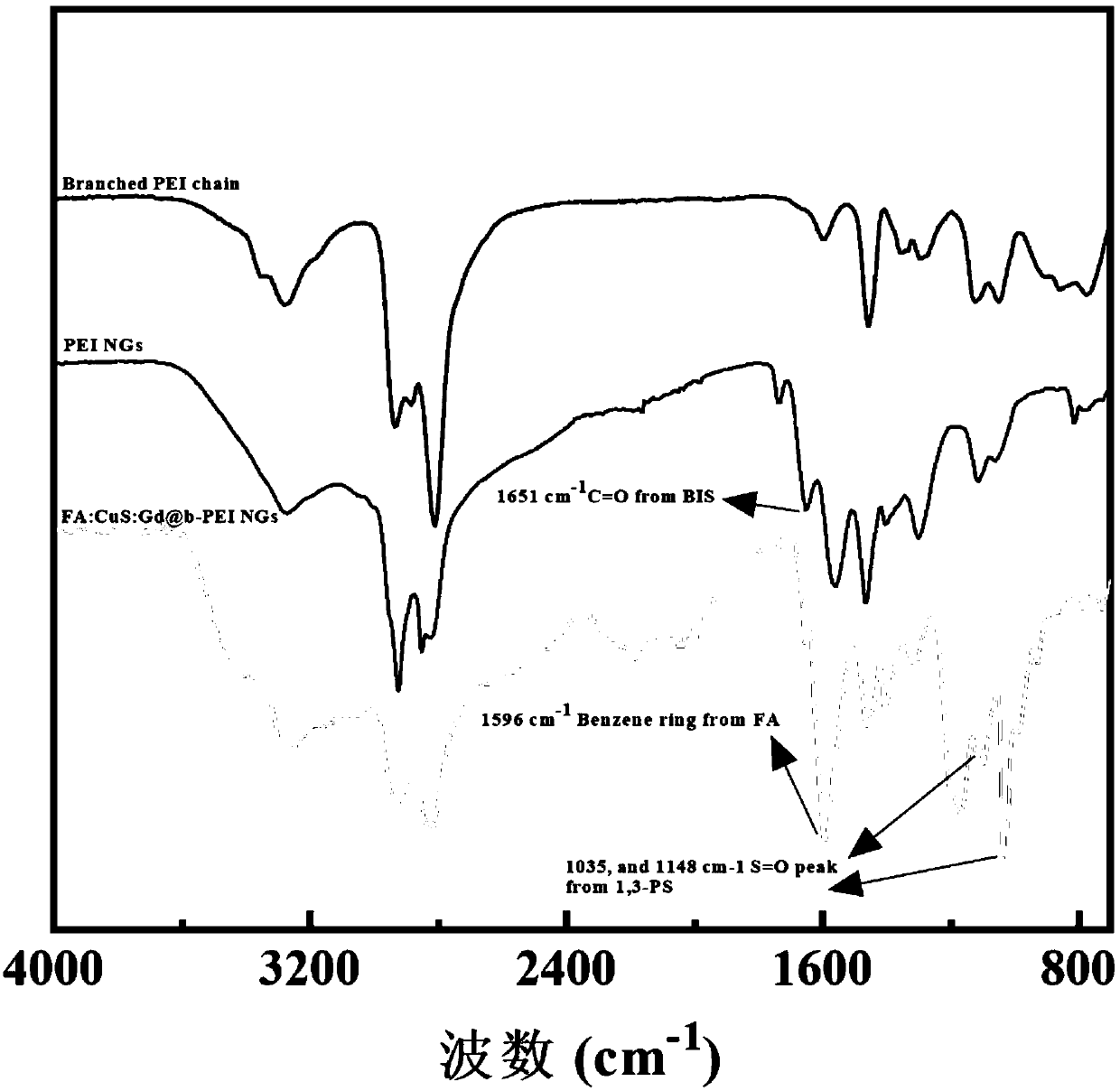

Gadolinium and copper sulphide loaded polyethyleneimine nanometer gel as well as preparation and application thereof

ActiveCN109568251AWide variety of sourcesSimple processEnergy modified materialsAerosol deliveryGd complexesIon

The invention relates to gadolinium and copper sulphide loaded polyethyleneimine nanometer gel as well as preparation and application thereof. The gel contains folic acid, DTPA-Gd compounds, 1,3-propane sultone, copper sulphide and polyethyleneimine nanometer gel. The preparation method comprises the following steps of preparing polyethyleneimine gel; preparing a gadolinium, folic acid and amphoteric ion modified polyethyleneimine nanometer gel compound; preparing gadolinium and copper sulphide loaded polyethyleneimine nanometer gel. The gel has the uniform dimension distribution; good solution dispersion performance and cell compatibility are realized; the r1 relaxation rate is obviously improved; good photothermal conversion efficiency is realized; the potential application value is realized in the fields of MR imaging and PTT.

Owner:DONGHUA UNIV +1

Fluorocarbon modified styrene-acrylic coating, and preparation method thereof

InactiveCN102585617BGood film formingImprove water resistanceAnti-corrosive paintsPhenyl EthersPolyethylene glycol

The invention discloses a fluorocarbon modified styrene-acrylic coating. The fluorocarbon modified styrene-acrylic coating consists of the following components in percentage by mass: 34 to 42.5 percent of GHT-1 styrene-acrylic emulsion, 5.2 to 6.5 percent of GHSF-25 fluorocarbon emulsion, 0.4 to 0.5 percent of gamma-aminopropyltriethoxysilan, 0.4 to 0.5 percent of polyethylene glycol phenyl ether, 18 to 22 percent of rutile type titanium dioxide, 8 to 10 percent of talcpowder, 8 to 10 percent of mica powder, 8 to 11 percent of calcite in powder, 0.1 to 0.15 percent of hydroxy silicone oil modified polyacrylate, 0.01 to 0.02 percent of polyether modified polysiloxane, 0.01 to 0.02 percent of kazon and the balance of water. A preparation method comprises the following steps of: modifying the styrene-acrylic emulsion by using the fluorocarbon emulsion, the gamma-aminopropyltriethoxysilan, and the polyethylene glycol phenyl ether at the temperature of between 76 and 80 DEG C, and preparing by using the modified fluorocarbon modified styrene-acrylic emulsion to obtain the fluorocarbon modified styrene-acrylic coating. The preparation process is simple, and low in investment and cost; and a product has the advantages of high weather fastness, chemical resistance, and water resistance, scrubbing resistance, and artificial aging resistance.

Owner:JIANGSU UNIV OF SCI & TECH

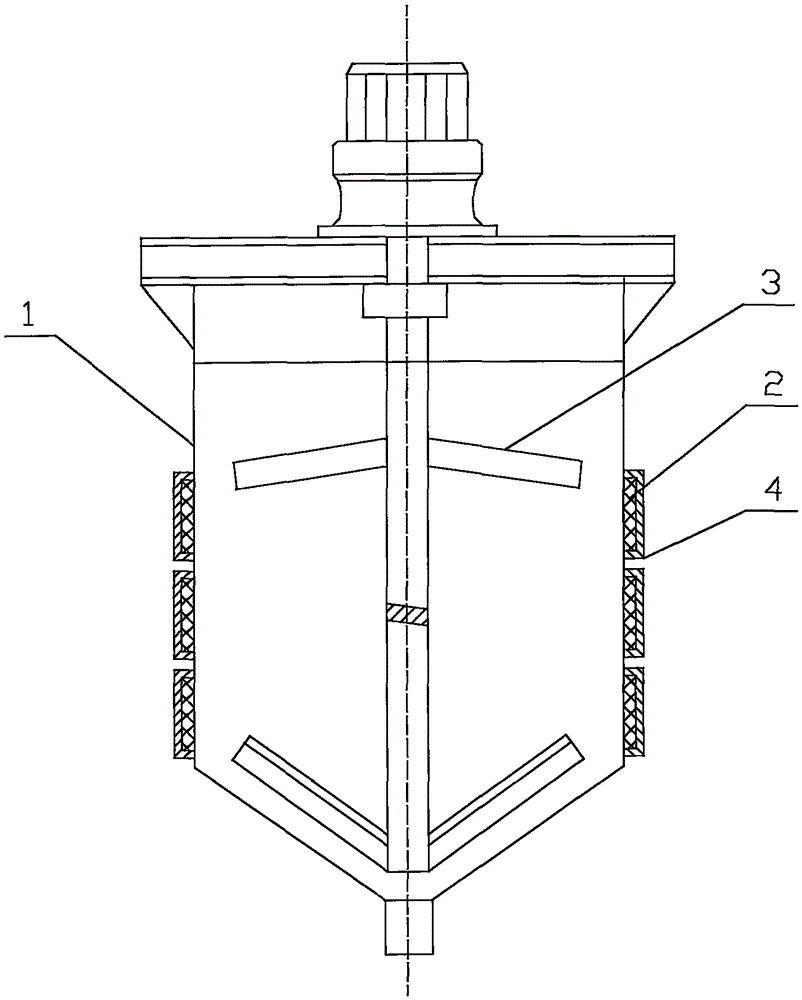

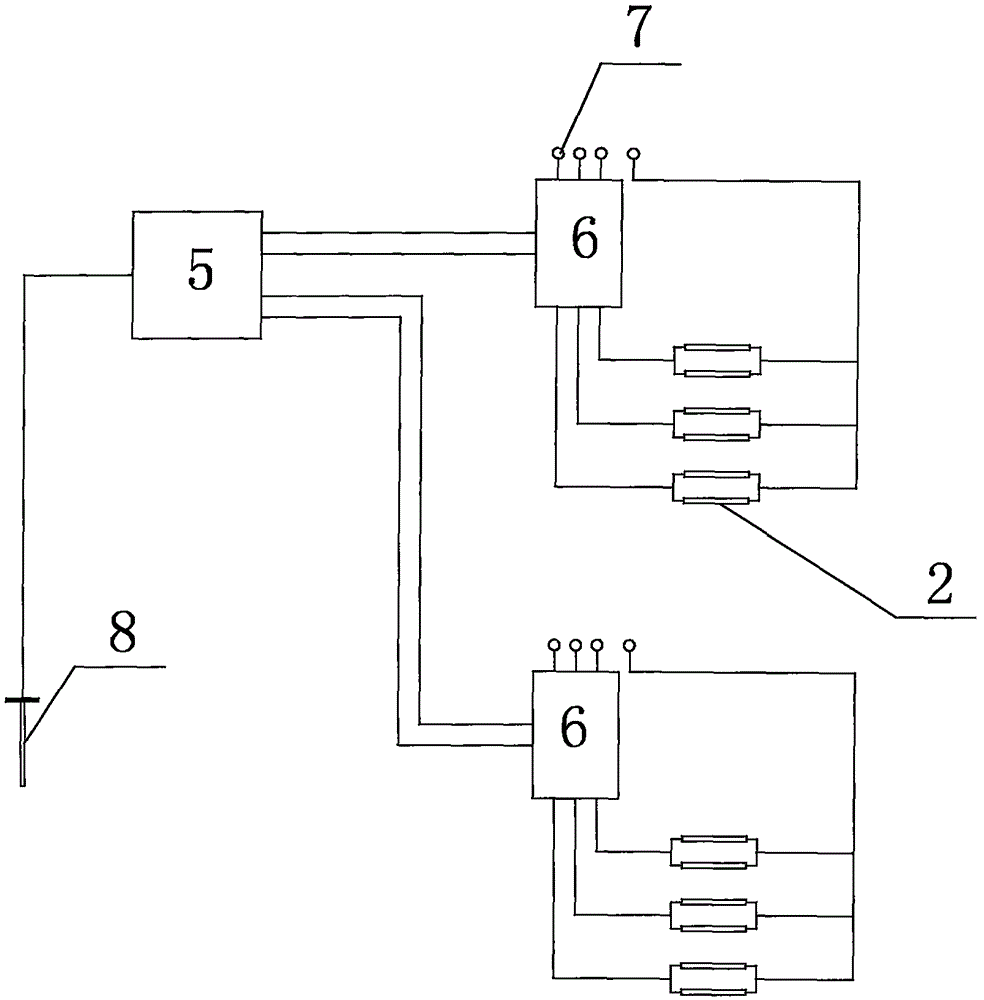

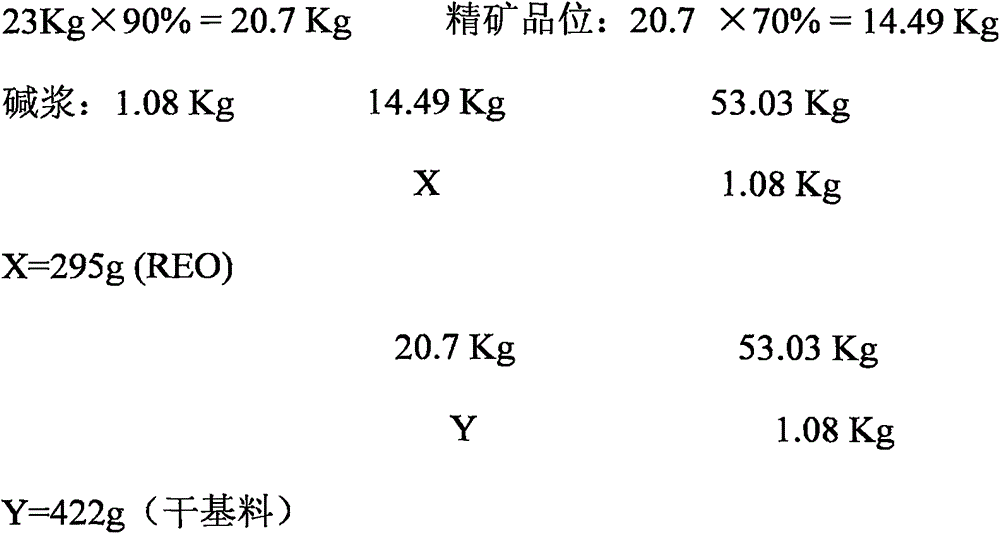

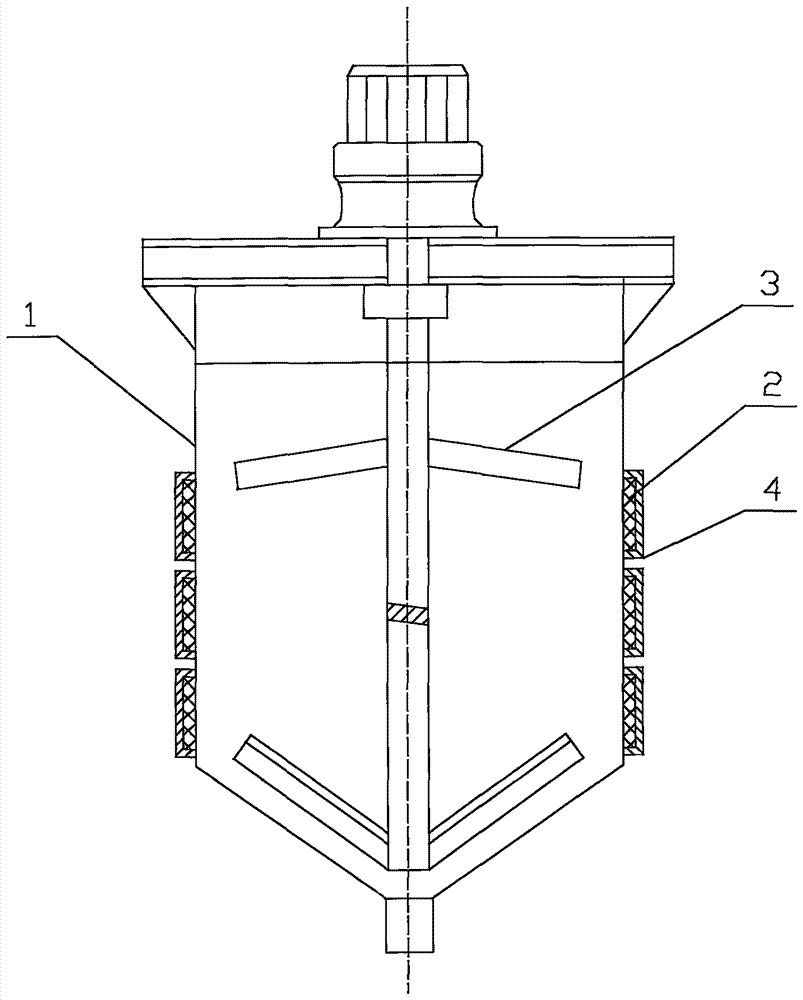

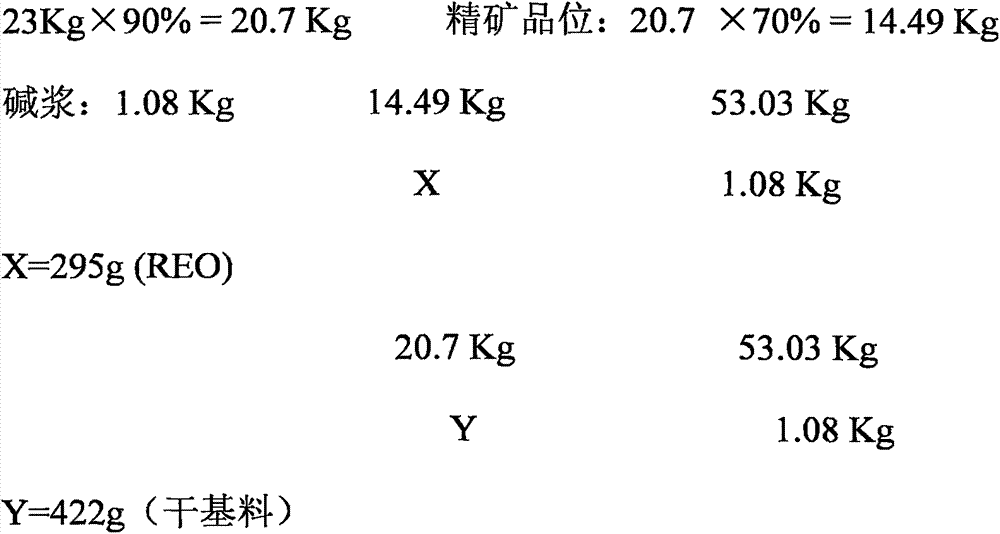

Novel alkaline hydrolysis tank and novel heating device and method for rare earth production

The invention discloses a novel alkaline hydrolysis tank and a novel heating device and method for rare earth production. The novel alkaline hydrolysis tank for rare earth production comprises an alkaline hydrolysis tank body which is wrapped with a ceramic heating element set, and the inner surface of the ceramic heating element set is attached to the outer wall of the alkaline hydrolysis tank body. The novel heating device for rare earth production comprises the alkaline hydrolysis tank body, a temperature control device, a pressure regulating device, a power source and a temperature measuring element. The novel heating method for rare earth production includes the following steps of (1) device preparation and connection and (2) temperature control program setting for heating. The novel alkaline hydrolysis tank and the novel heating device and method for rare earth production have the advantages that energy is saved, emission is reduced, comprehensive utilization of resources is achieved, economic benefits are good, and a good development and application prospect can be achieved.

Owner:内蒙古科学技术研究院

Circular jacking pipe work well of preset jacking pipe doorway in water-rich stratum and construction method thereof

ActiveCN110485465AAdvanced technical conceptAffordableArtificial islandsProtective foundationThermal forceFunctional requirement

The invention relates to a circular jacking pipe work well of a preset jacking pipe doorway in the water-rich stratum and construction method thereof. The construction method specifically comprises the following steps of (1) functional requirements design of a circular jacking pipe work well, (2) open caisson construction of a maintenance structure of the circular jacking pipe work well, (3) temporary edge protection construction; (4) earth excavation in the well, (5) sealing of the bottom of the circular jacking pipe work well, (6) installation of a ladder stand entering the circular jackingpipe work well, (7) joint leakage treatment, (8) installation of a water-stop pressing plate at an opening, (9) lifting of a sandwich concrete slab wall at the top of a preset doorway and (10) construction of jacking of a jacking pipe, and the design and construction of the circular jacking pipe work well of the preset jacking pipe doorway in the water-rich stratum is completed. The circular jacking pipe work well structural system of the preset jacking pipe doorway in the water-rich stratum has the advantages of clear function, safety, quickness, and smart design, especially overcomes the potential safety hazard of sudden water gushing and sand gushing in the process of the jacking pipe in the water-rich stratum penetrating the well wall, and provides a novel method for the non-excavationconstruction of underground pipes of water conservancy, municipal, thermal force, communication and the like.

Owner:南方工程检测修复技术研究院

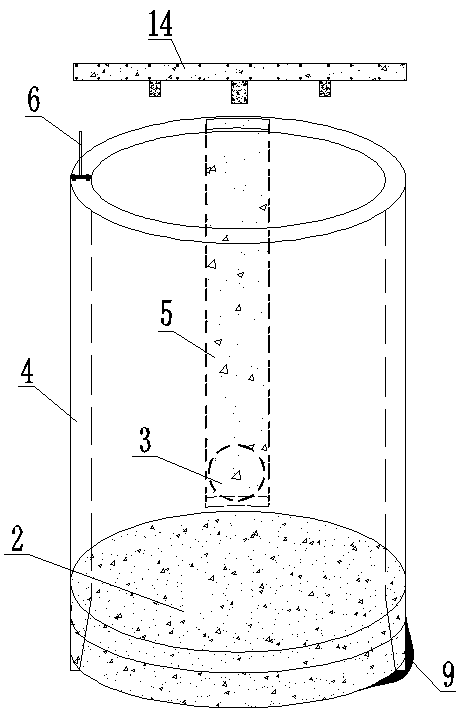

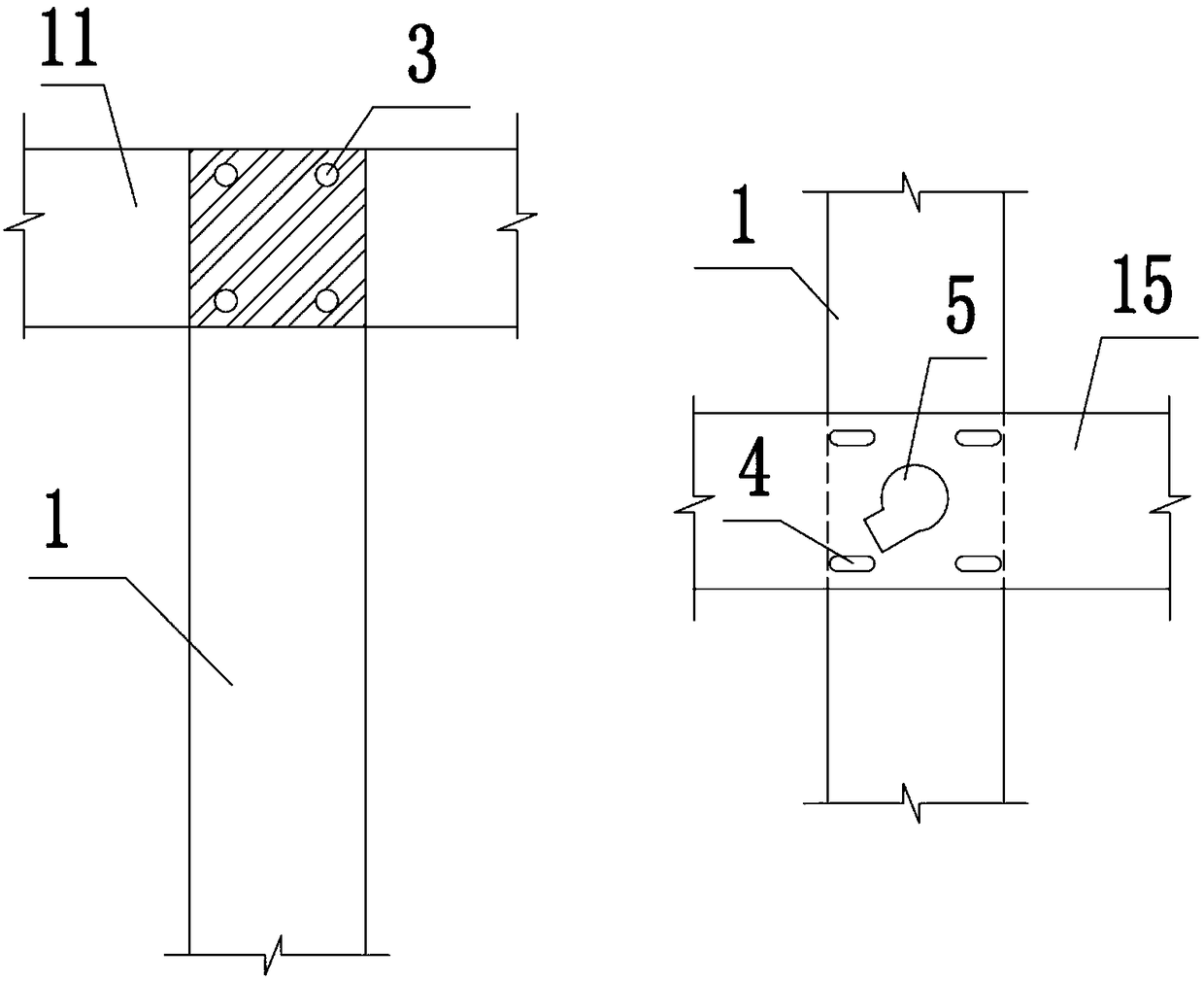

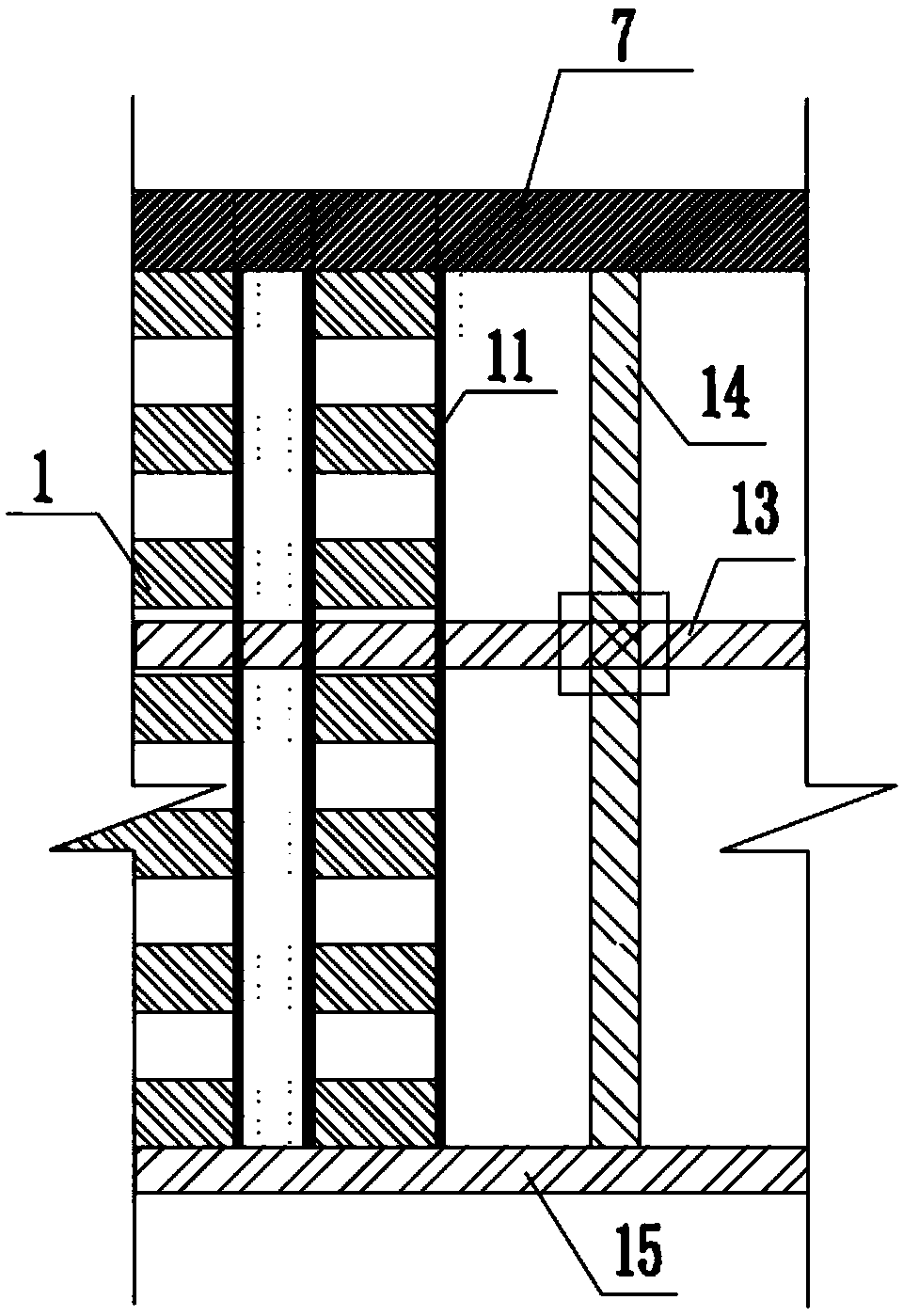

Rear-leaning-wall-integrated assembly type recoverable round working well and construction method thereof

ActiveCN110485469AOvercome the difficulties of separate constructionShort construction periodArtificial islandsExcavationsHydraulic engineeringFunctional requirement

The invention relates to a design construction method for integration of an assembly type recoverable round top pipe working well and a back leaning wall. The design construction method comprises thesteps that (1) functional requirements of the round top pipe working well are designed; (2) support piles are constructed; (3) precast top beams are installed; (4) near-edge protection construction isconducted; (5) alternate construction of earth excavation, soil retaining plates and annular inner support beams is conducted; (6) a ladder entering the round top pipe working well is installed; (7)the round top pipe working well is sealed; (8) a rear leaning wall is constructed, and thus integration construction of the assembly type recoverable round top pipe working well and the rear leaning wall can be completed; and (9) after in-well operation is completed, the rear leaning wall, the soil retaining plates, the annular inner support beams, the precast top beams, the support piles and other working well components are recovered step by step in a reversed order in the backfilling process. The constructed structural system has the advantages that functions are clear, and safe, fast, assembly type recoverable and recyclable effects are achieved, and a novel method is provided for non-excavation construction of underground pipelines of hydraulic engineering, municipal administration, heating power, communications and the like.

Owner:南方工程检测修复技术研究院

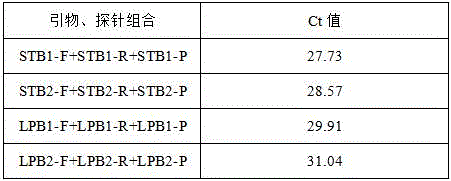

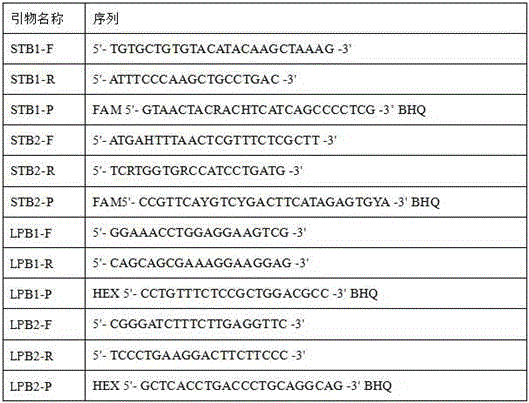

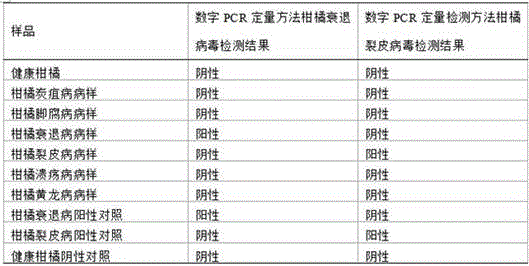

Citrus tristeza virus and citrus exocortis viroid dual detection kit and application thereof

ActiveCN106244732ASimple and reliable absolute quantificationAbsolute quantitative realizationMicrobiological testing/measurementDNA/RNA fragmentationPositive controlRNA extraction

The invention discloses a citrus tristeza virus and citrus exocortis viroid dual detection kit and application thereof, and designs a dual digital PCR quantitative detection reagent composition for citrus tristeza viruses and citrus exocortis viroids. The kit contains a virus sample RNA extraction reagent, a cDNA reverse transcription synthesis reagent, a digital PCR reagent, a citrus decline and citrus exocortis positive control sample template and a citrus decline and citrus exocortis negative control sample template. The kit has the advantages of high specificity, higher impurity interference resistance, convenience, high speed, detection sensitivity equivalent to that of an existing real-time fluorescent quantitative PCR detection method and the like when being used for detecting the citrus tristeza viruses and the citrus exocortis viroids, and can be used for early qualitative and quantitative detection of the citrus tristeza viruses and the citrus exocortis viroids, epidemiological survey and the like.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI

Integrated design construction method of flexible compound fabricated support and underground structure

The invention relates to an integrated design construction method of a flexible compound fabricated support and an underground structure. The method comprises the following steps that (1) side walls of the fabricated support structure are constructed; (2) a first layer of supporting system is installed; (3) earth excavation is carried out, and high polymers are poured to joints of the side walls of the fabricated support structure; (4) internal fabricated supporting systems are installed layer by layer; (5) excavation is carried out layer by layer and section by section sequentially in the vertical direction, and the step (3) and the step (4) are carried out repeatedly till the foundation base elevation is met; (6) a foundation pit of the underground space is sealed; and (7) the top of thefoundation pit is sealed, separated application of internal space capacities is improved, and accordingly construction is completed. The established underground space integrated structure has the various advantages of quick and convenient construction, recoverability, superior economic and environmental protection indexes and the like, the novel method which is safe, reliable, capable of achieving efficient recovery and superior in economic and environmental protection index is provided for construction of underground pipe galleries, underground space utilization and the like, and the application and development prospects are considerable.

Owner:南方工程检测修复技术研究院

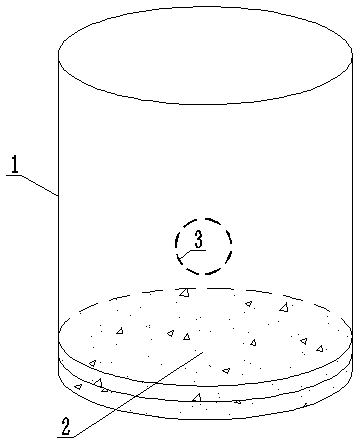

An assembled recyclable circular work pit with reserved door openings and its construction method

ActiveCN110485466BShort construction periodEnsure safetyArtificial islandsExcavationsArchitectural engineeringStructural system

An assembled recyclable circular working well with a reserved door opening and its construction method according to the present invention comprise the following steps: (1) functional requirement design of the circular working well; (2) construction of support piles; (3) prefabrication Crown and beam installation; (4) Border protection construction; (5) Earthwork excavation, soil retaining panels, and ring-shaped inner support beams are alternately constructed, and door openings are reserved simultaneously; (6) Ladder installation for entering the circular working well; (7) If the bottom of the circular working well is sealed, the construction of the prefabricated recyclable circular working well with reserved door openings can be completed; (8) After the operation in the well is completed, the retaining panels, annular inner support beams, crown beams and Working well components such as support piles. The prefabricated recyclable circular working well structure system with reserved door openings constructed by the present invention has many advantages such as clear function, safety and quickness, assembled recyclable, reusable, etc. Excavation construction and restoration provides a new method.

Owner:南方工程检测修复技术研究院

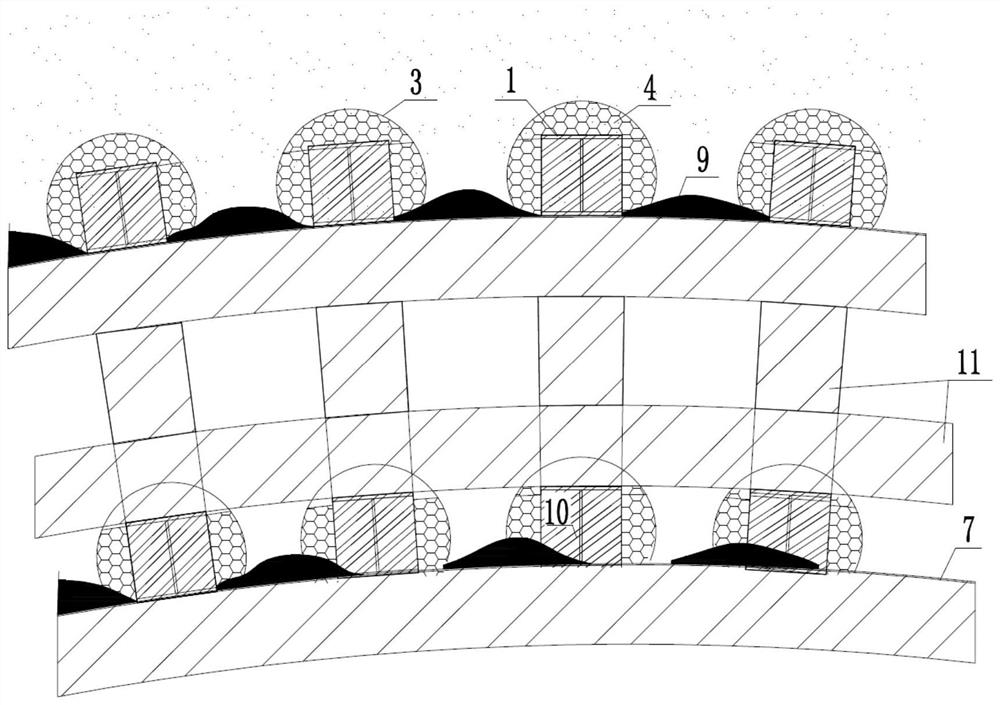

Design and construction method of a flexible compound ladder-shaped deep circular shaft assembled recyclable support structure

ActiveCN109356589BAdvanced technologyImprove economic indicatorsEmbankmentsExcavationsSupporting systemArchitectural engineering

The invention relates to a design construction method of a fabricated recyclable support structure of a flexible composite ladder-shaped deep circular vertical shaft. The design construction method comprises the following steps that (1) a first-layer annular supporting pile is constructed; (2) a first-layer pile top crown beam is mounted; (3) earthwork is excavated in layered and sectioned modes,and a panel and waist beams are mounted; (4) a second-layer annular supporting pile is constructed; (5) a second-layer crown beam and lower waist beam supporting system is mounted; and (6) the steps (3), (4) and (5) are repeated till the design base elevation is reached, and then the support structure is constructed. The support structure constructed by the design construction method has the multiple advantages of being safe and reliable, quick to construct, advanced in technology, large in excavation support depth, capable of being recycled and reused, superior in economic and environmental protection index and the like, a new method with the advantages of safety, reliability, efficient recycle and reuse, and superior economic and environmental protection indexes is provided for construction of projects such as underground space utilization, and the development and application prospects are considerable.

Owner:SAFEKEY ENG TECHZHENGZHOU

Novel alkaline hydrolysis tank, novel heating device and heating method for rare earth production

The invention discloses a novel alkaline hydrolysis tank for rare earth production, a novel heating device and a heating method, wherein the novel alkali hydrolysis tank for rare earth production comprises a main body of the alkali hydrolysis tank, and the outer wall of the main body of the alkali hydrolysis tank is wrapped There is a group of ceramic heating sheets, the inner surface of the group of ceramic heating sheets is attached to the outer wall of the main body of the alkaline hydrolysis tank. A new heating device for rare earth production, which includes an alkaline hydrolysis tank body, a temperature control device, a pressure regulating device, a power supply and a temperature measuring element. A novel heating method for rare earth production, comprising the following steps: (1) equipment preparation and connection; (2) setting temperature control program for heating. The invention has the advantages of saving energy and reducing consumption, achieving comprehensive utilization of resources, good economic benefits, and good development and application prospects.

Owner:内蒙古科学技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com