Patents

Literature

65results about How to "Improve densification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

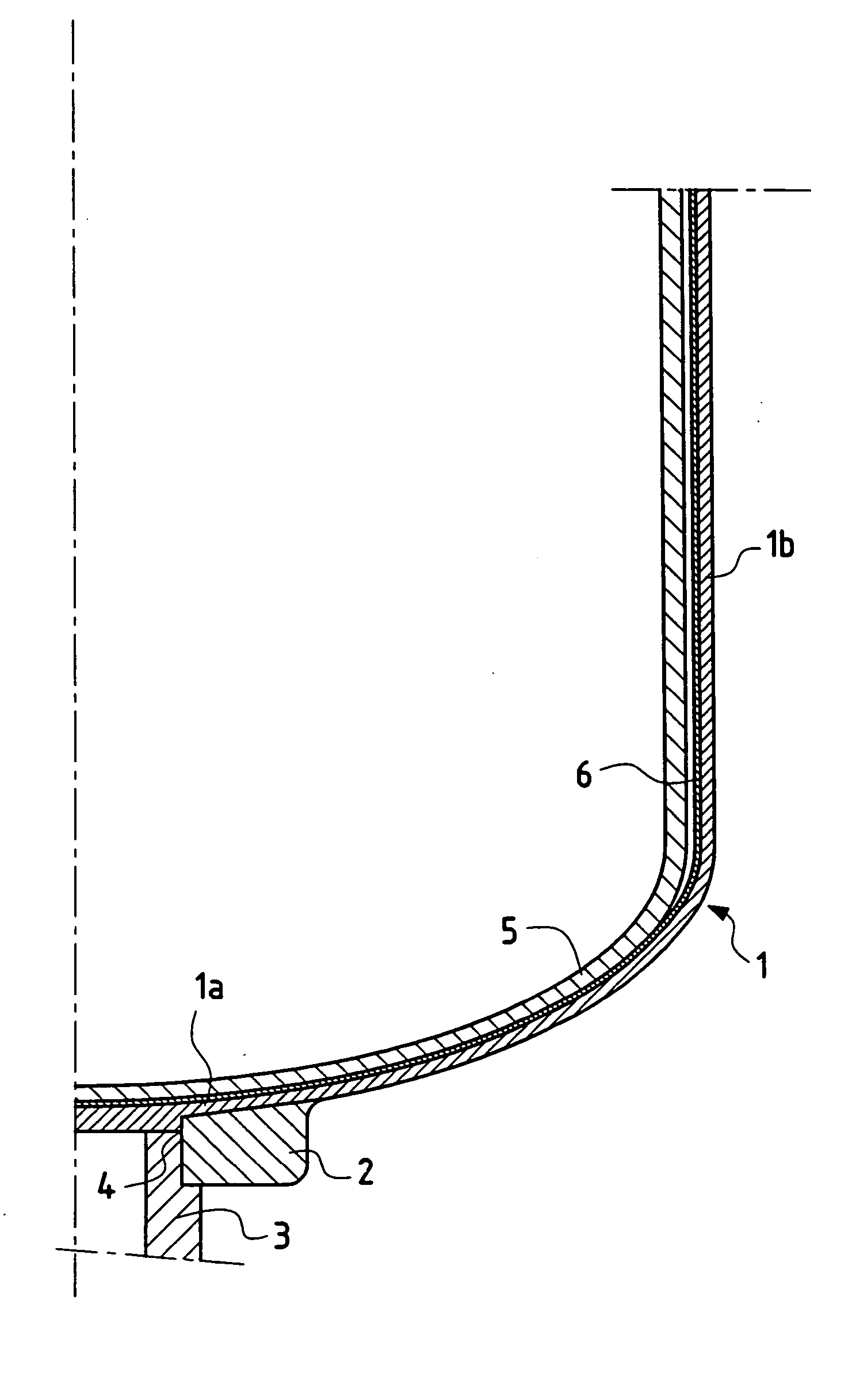

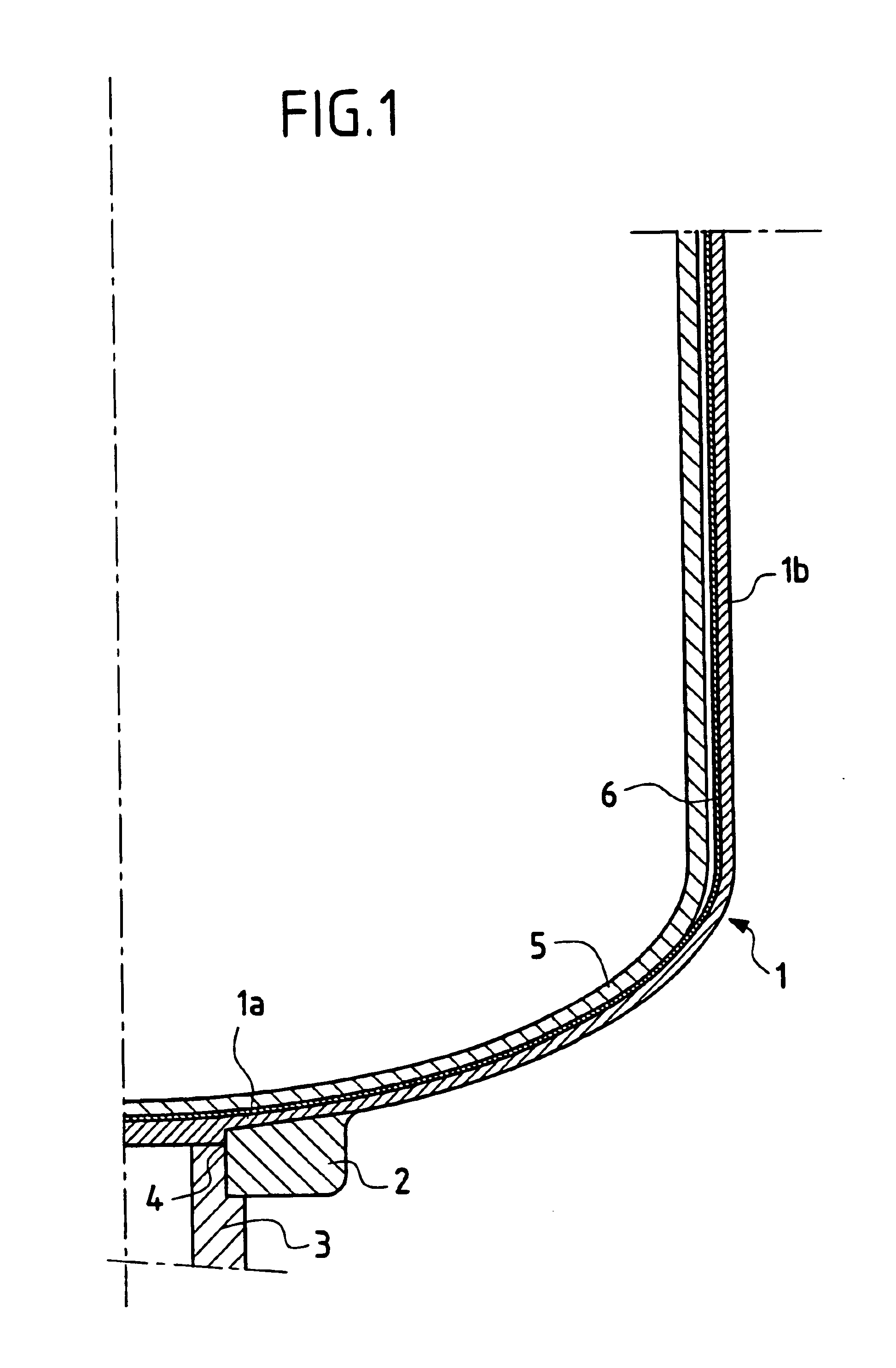

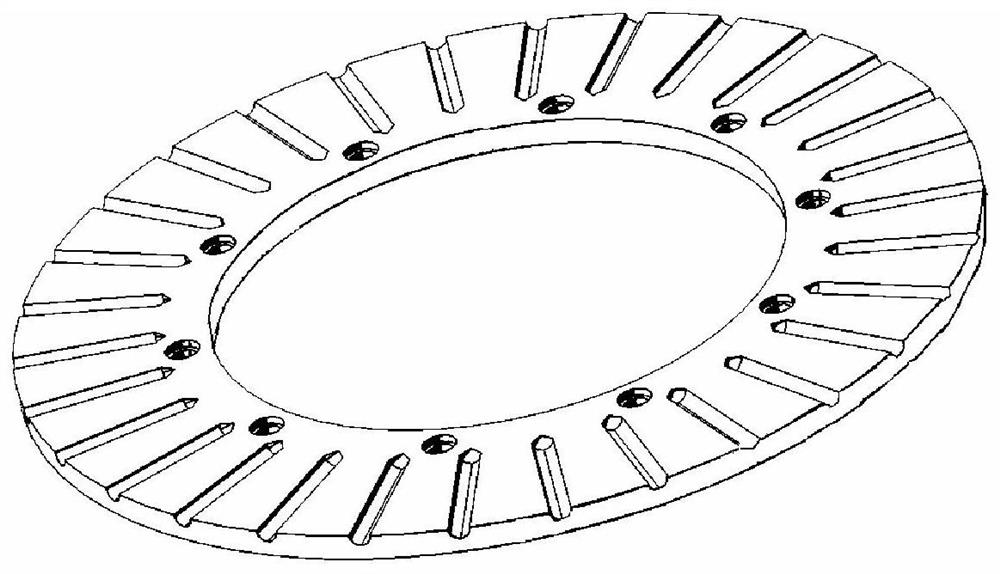

Thermostructural composite material bowl

A one-piece bowl of thermostructural composite material comprising fiber reinforcement densified by a matrix. The bowl is made by supplying deformable fiber in plies that are whole, being free from slots or cutouts, superposing said plies on a former of shape corresponding to the bowl to be made, deforming the plies, and bonding the superposed plies to one another by means of fibers extending transversely relative to the plies, e.g. by needling so as to obtain a bowl preform which is then densified. The bowl can be used as a support for a crucible in an installation for producing monocrystalline silicon.

Owner:GUIRMAN JEAN MICHEL +2

Rapid preparation method of low-cost carbon/carbon composite material

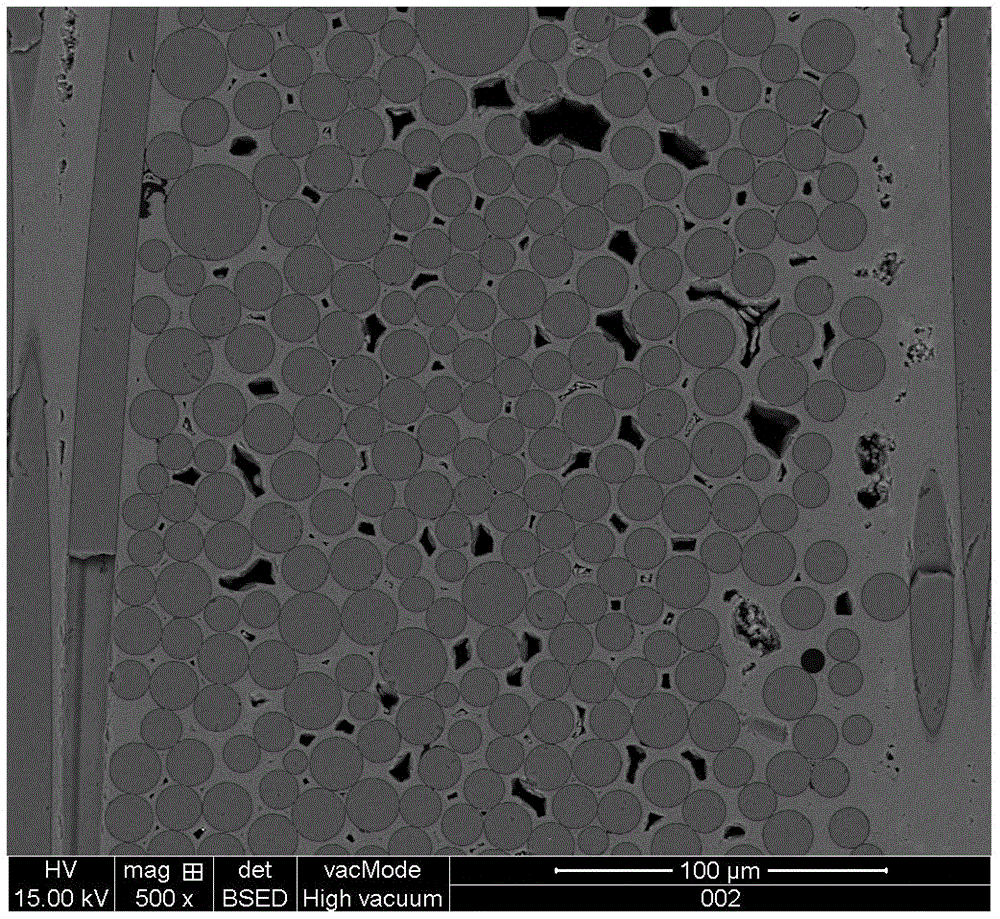

The invention relates to a rapid preparation method of a low-cost carbon / carbon composite material, and belongs to the field of composite materials. The method is mainly used for reducing the preparation cycle and the cost of the high-density carbon / carbon composite material. A low-density carbon / carbon composite material is formed through compounding fixed carbon fiber fabric in fiber bundles, the carbon fiber bundles are filled with carbon particles to make macro-pores become micro-pores, and low-pressure liquid impregnation carbonization or chemical vapor infiltration and high temperature thermal treatment are carried out to obtain the high-density carbon / carbon composite material. Compared with traditional methods, the preparation method of the carbon / carbon composite material, disclosed in the invention, has the advantages of greatly shortened preparation cycle and greatly reduced preparation cost.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for enhancing density of SiC/SiC ceramic matrix composite

The invention relates to a method for enhancing density of a SiC / SiC ceramic matrix composite. The method comprises the following steps: (1) a SiC / SiC ceramic matrix composite with a certain densification degree is immersed in slurry, in which an organic precursor and SiC powder are uniformly dispersed, and impregnation is carried out in an environment of 5-10 KPa vacuum degree for 20-50 min; (2) a material which has undergone vacuum impregnation is dried and the dried material undergoes cross-linking and curing; (3) the cross-linked and cured material undergoes pyrolysis treatment; and (4) the material which has undergone pyrolysis treatment further undergoes densification process in the atmosphere of a gaseous precursor containing Si and C elements by a chemical vapor infiltration technology while infiltration temperature is 850-1100 DEG C, pressure intensity is 10-20 KPa and infiltration time is 4-30 h. The method provided by the invention has advantages of simple operation, short densification time, good repeatability and high densification efficiency and has obvious advantages in the aspect of filling material voids. The method is a method with operability and development prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

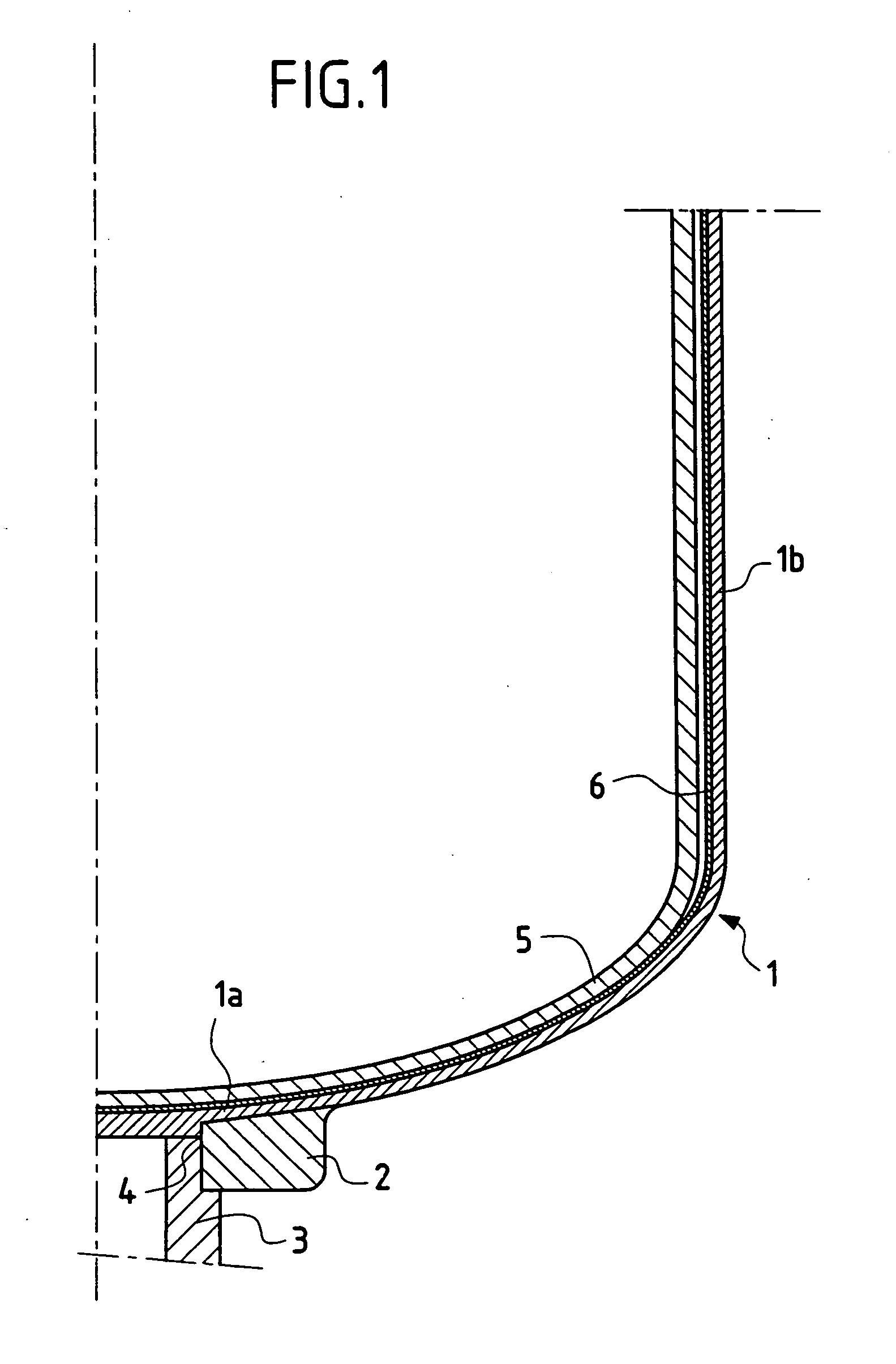

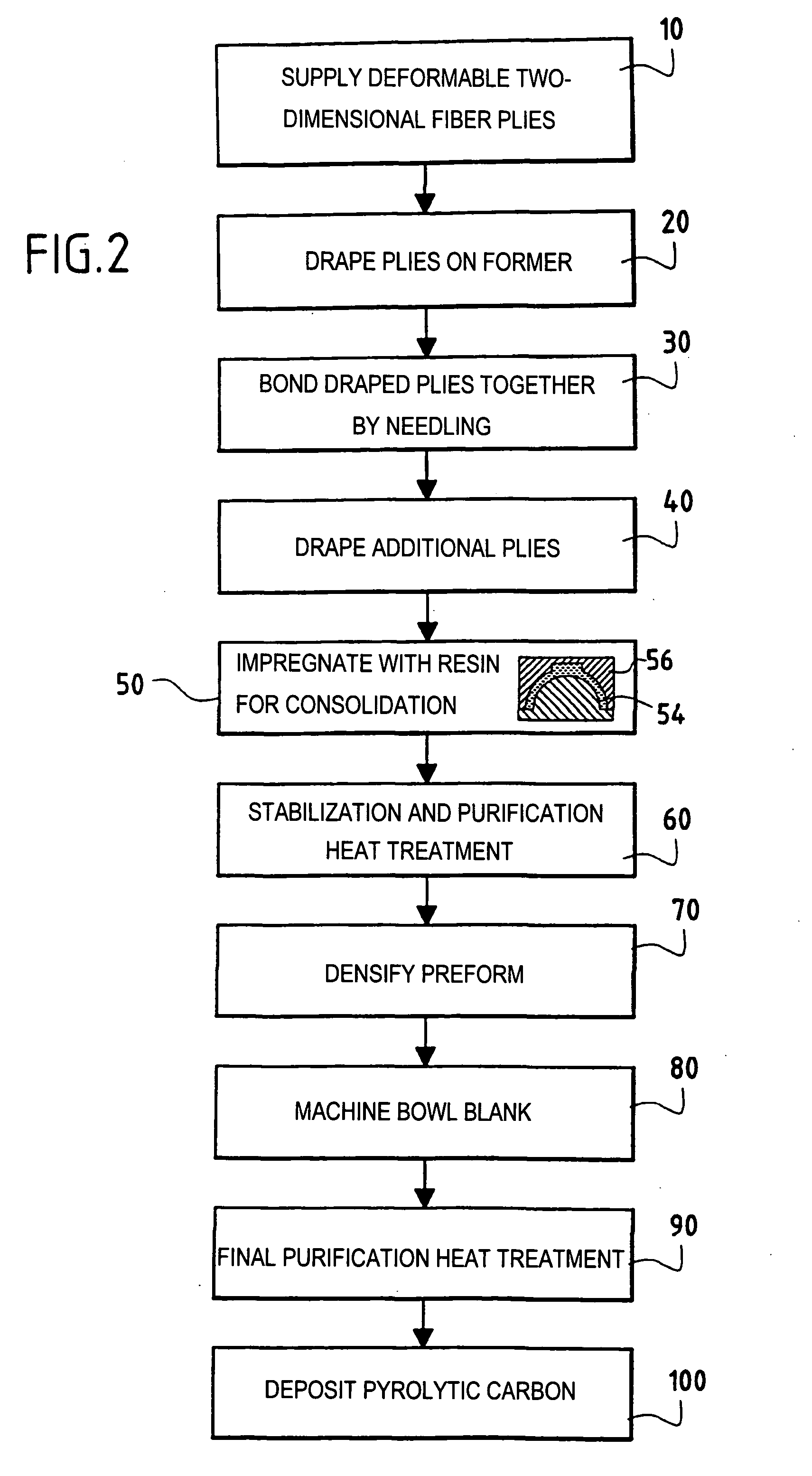

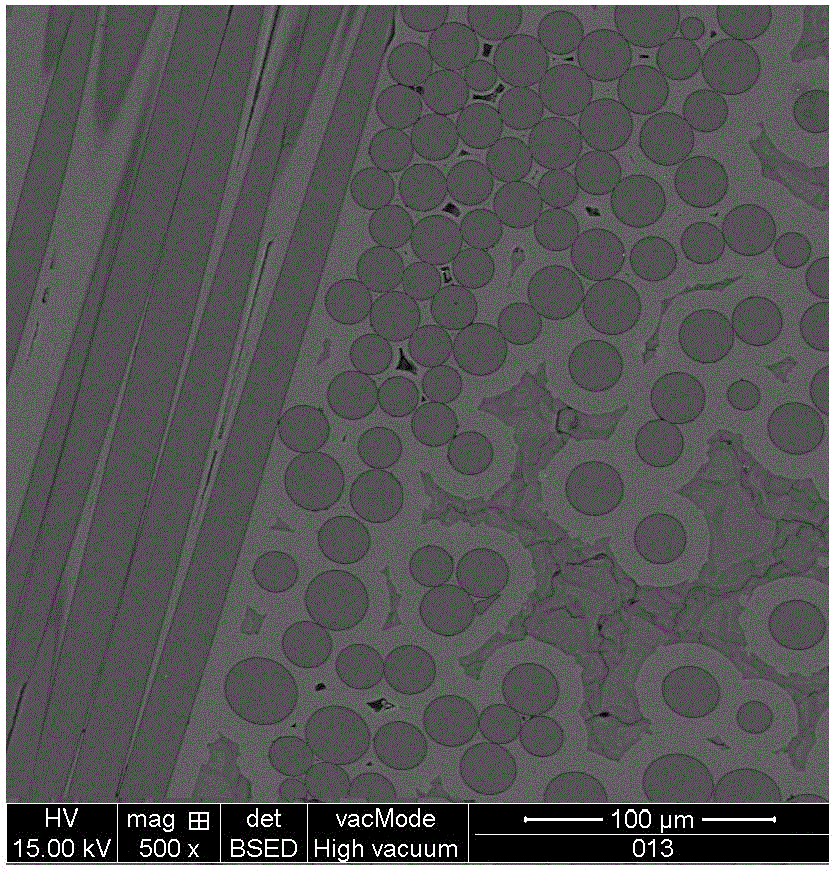

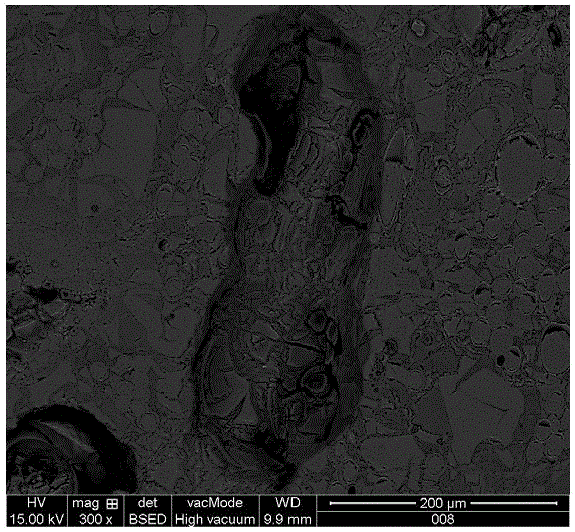

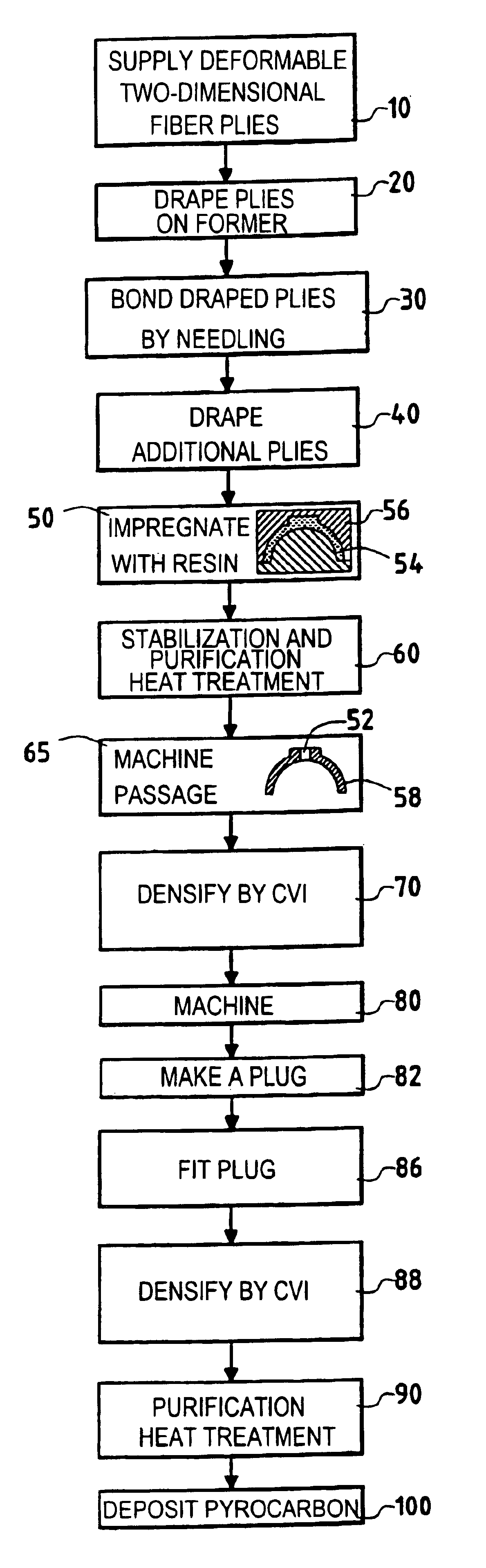

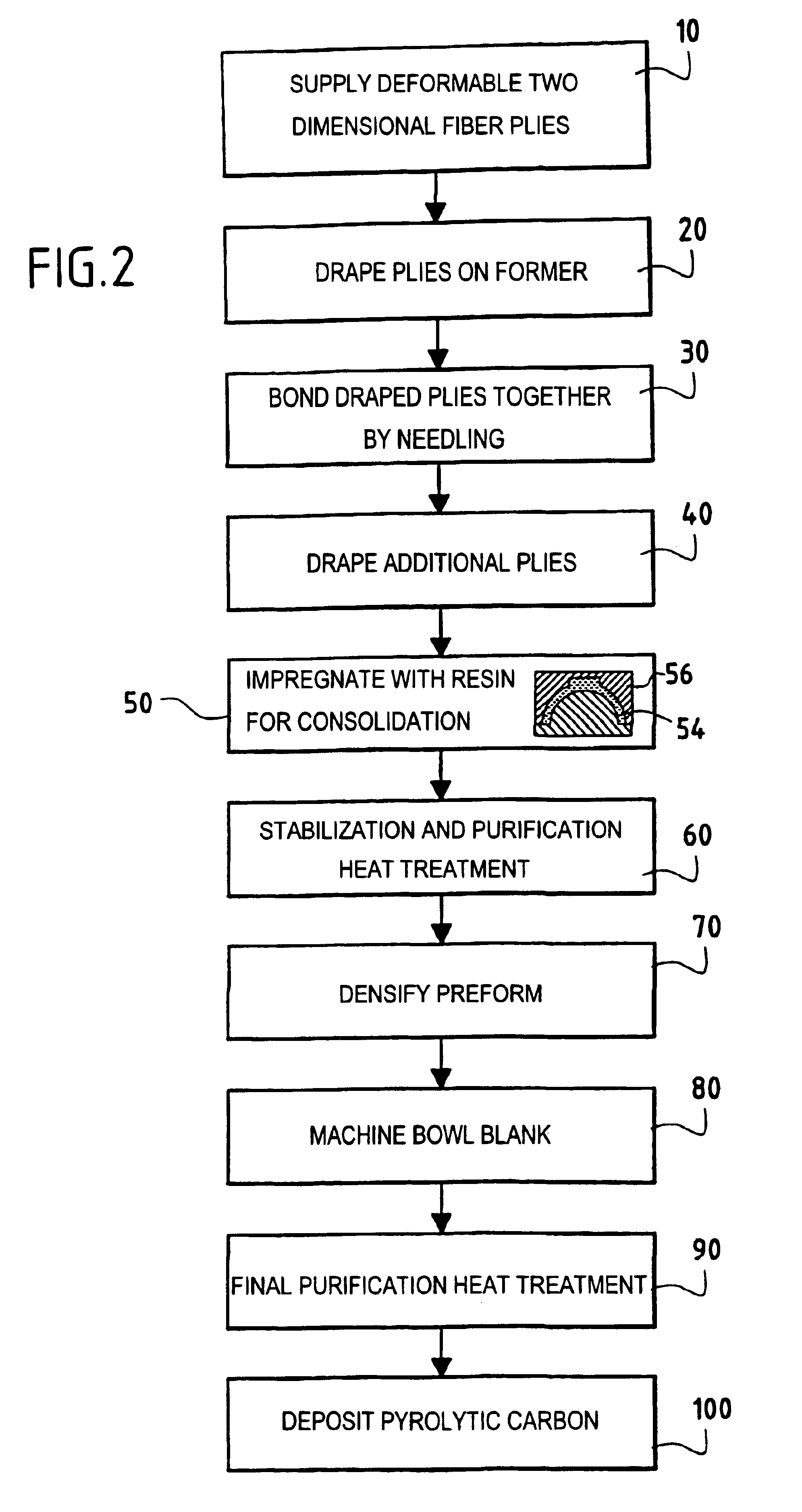

Method for making a bowl in thermostructural composite material

InactiveUS6837952B1Low costAvoid disadvantagesAfter-treatment apparatusLamination ancillary operationsThermoplastic compositesMaterials science

A method manufacturing a one-piece bowl of thermostructural composite material comprising fiber reinforcement densified by a matrix. The method comprises supplying deformable fiber plies that are whole, being free from slots or cutouts, superposing said plies on a former of shape corresponding to the bowl to be made, deforming the plies, and bonding the superposed plies to one another by means of fibers extending transversely relative to the plies, e.g. by needling so as to obtain a bowl preform which is then densified. The bowl (1) can be used as a support for a crucible (5) in an installation for producing monocrystalline silicon.

Owner:SNECMA MOTEURS SA

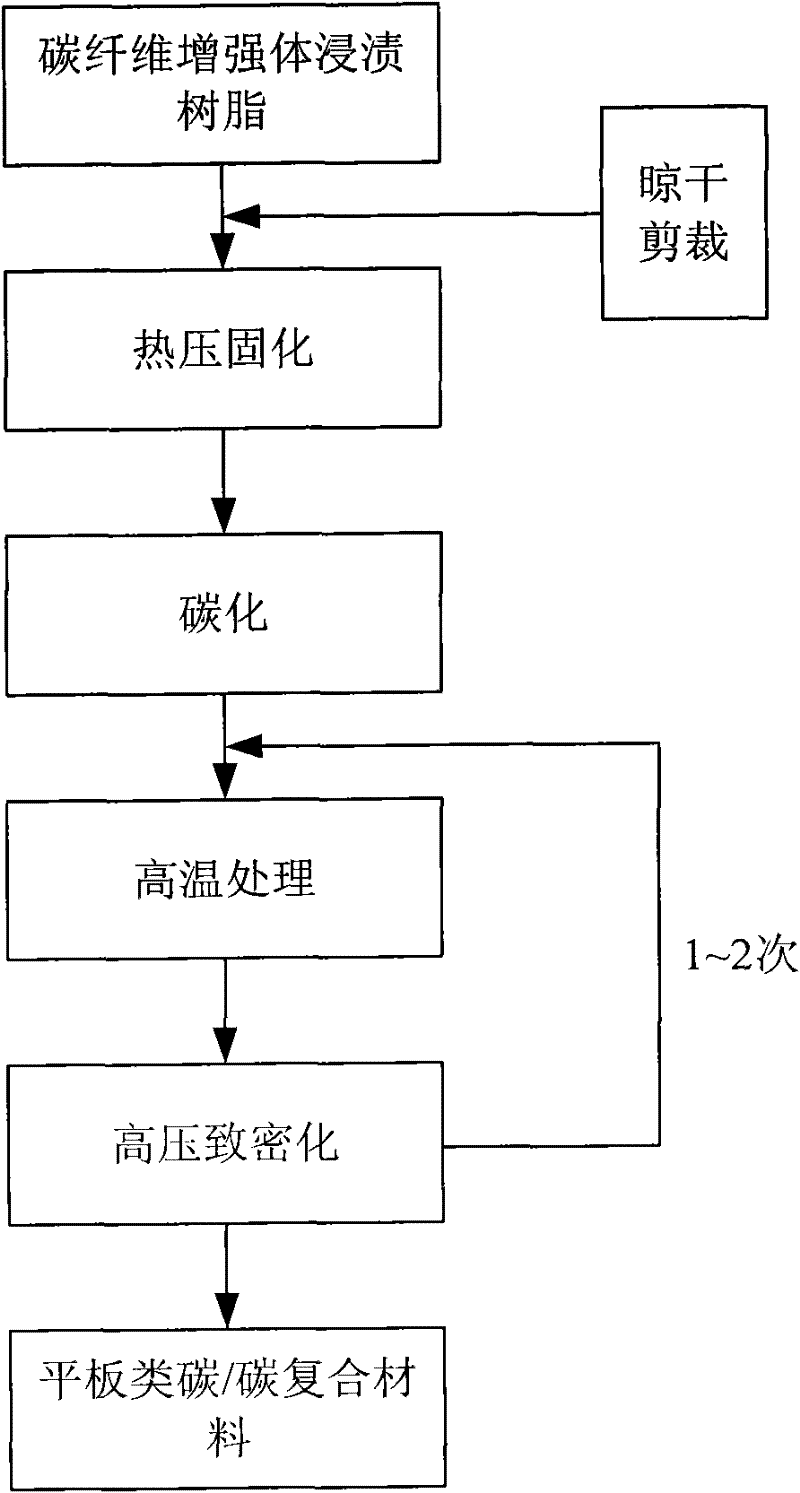

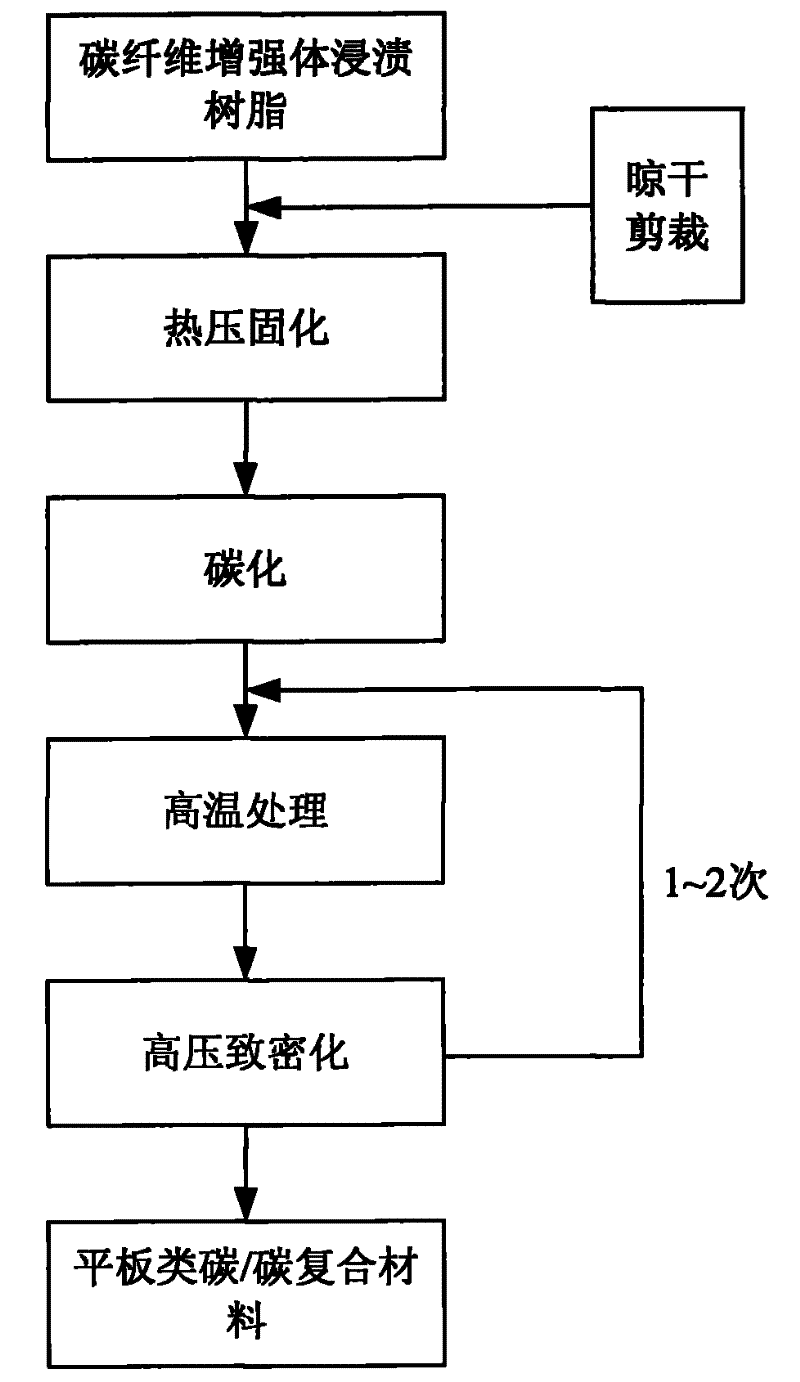

Method for rapidly forming flat plate carbon/carbon composite material

The invention aims at the problems of long preparation period, high cost and the like of a carbon / carbon composite material at present and provides a method for rapidly forming a flat plate carbon / carbon composite material. In the method, the thought of a resin-based composite material hot-pressing rapid forming process is adopted; and a carbon / carbon composite material carbonization process is combined with a high-pressure densification rapid densifying process. During preparation of the flat plate carbon / carbon composite material, the process is simple and is easy to control; the flat plate carbon / carbon composite material with large size and thick wall can be prepared; the flat plate carbon / carbon composite material has high density and high structural homogeneity; the preparation period can be greatly shortened; and cost of the material can be reduced.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Preparation method of carbon/carbon composite material

The invention provides a preparation method of a carbon / carbon composite material. The preparation method comprises the following steps of: a, preparing a carbon fiber preform; b, performing graphitization treatment on the carbon fiber preform to obtain a carbon fiber green body; c, carrying out CVD (Chemical Vapor Deposition) densification treatment on the carbon fiber green body, punching the carbon fiber green body after carrying out at least one CVD densification treatment to obtain a first intermediate, and repeatedly carrying out CVD densification treatment on the first intermediate until the density of the first intermediate reaches a first preset value to obtain a second intermediate; d, carrying out dipping curing-high-temperature heat treatment on the second intermediate until the density of the second intermediate reaches a target value, and obtaining a semi-finished product; and e, carrying out finish machining on the semi-finished product to obtain a finished product withthe target shape and size. The method is simple in process, low in production cost and high in product percent of pass, and large-batch preparation of the small-size carbon / carbon composite material can be realized.

Owner:HUNAN BOYUN NEW MATERIALS

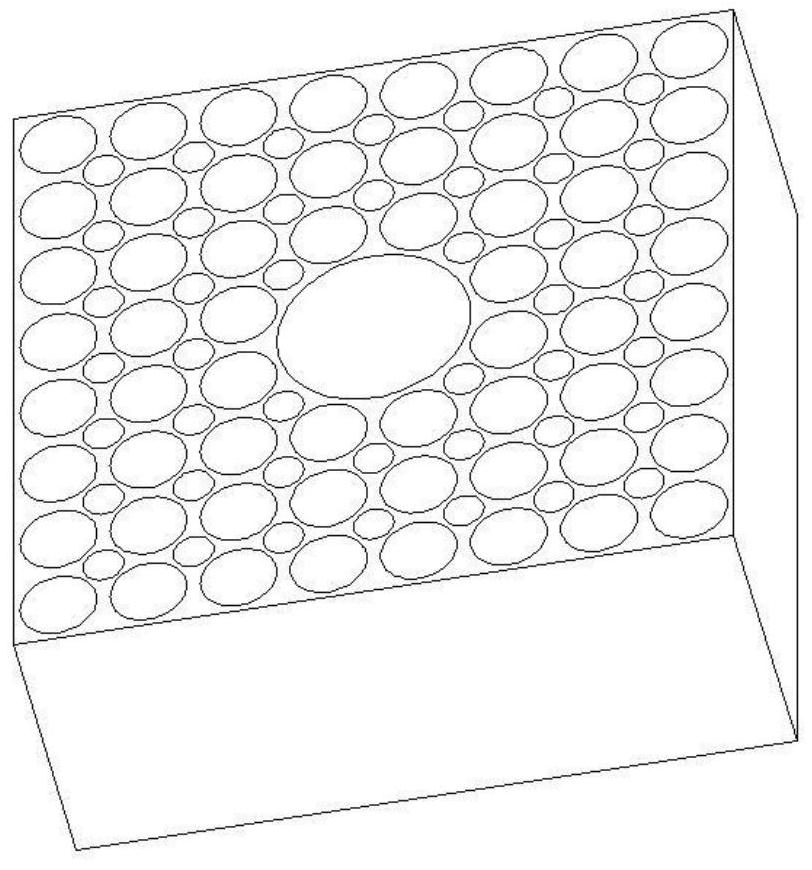

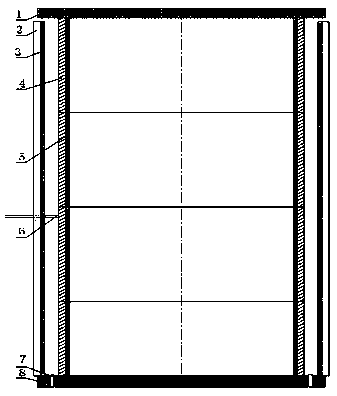

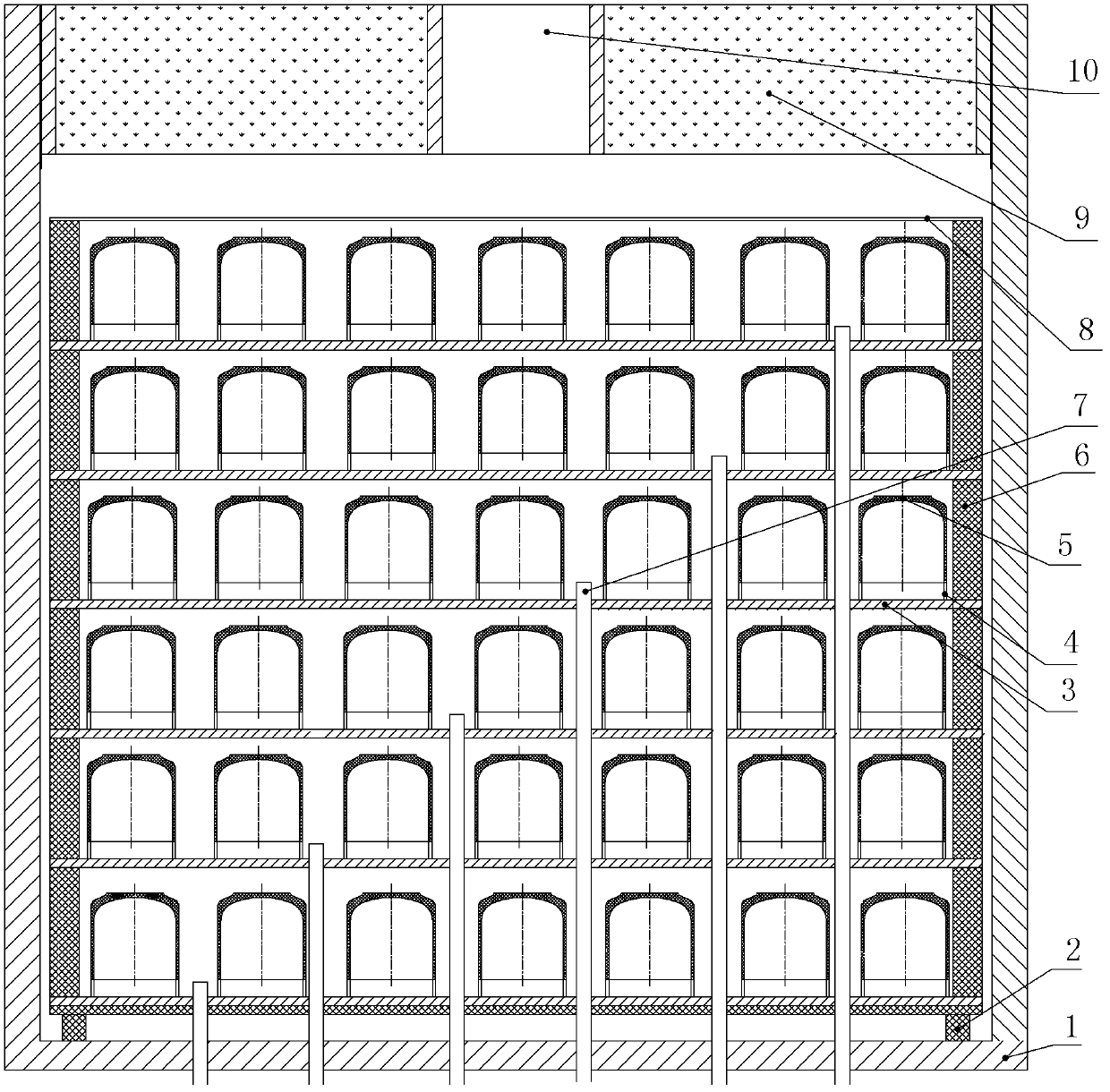

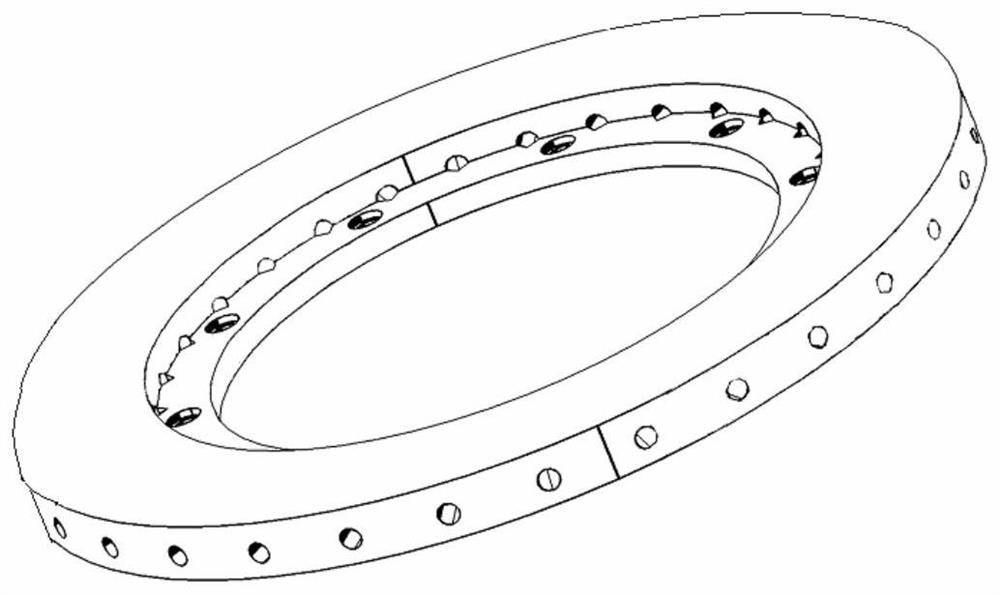

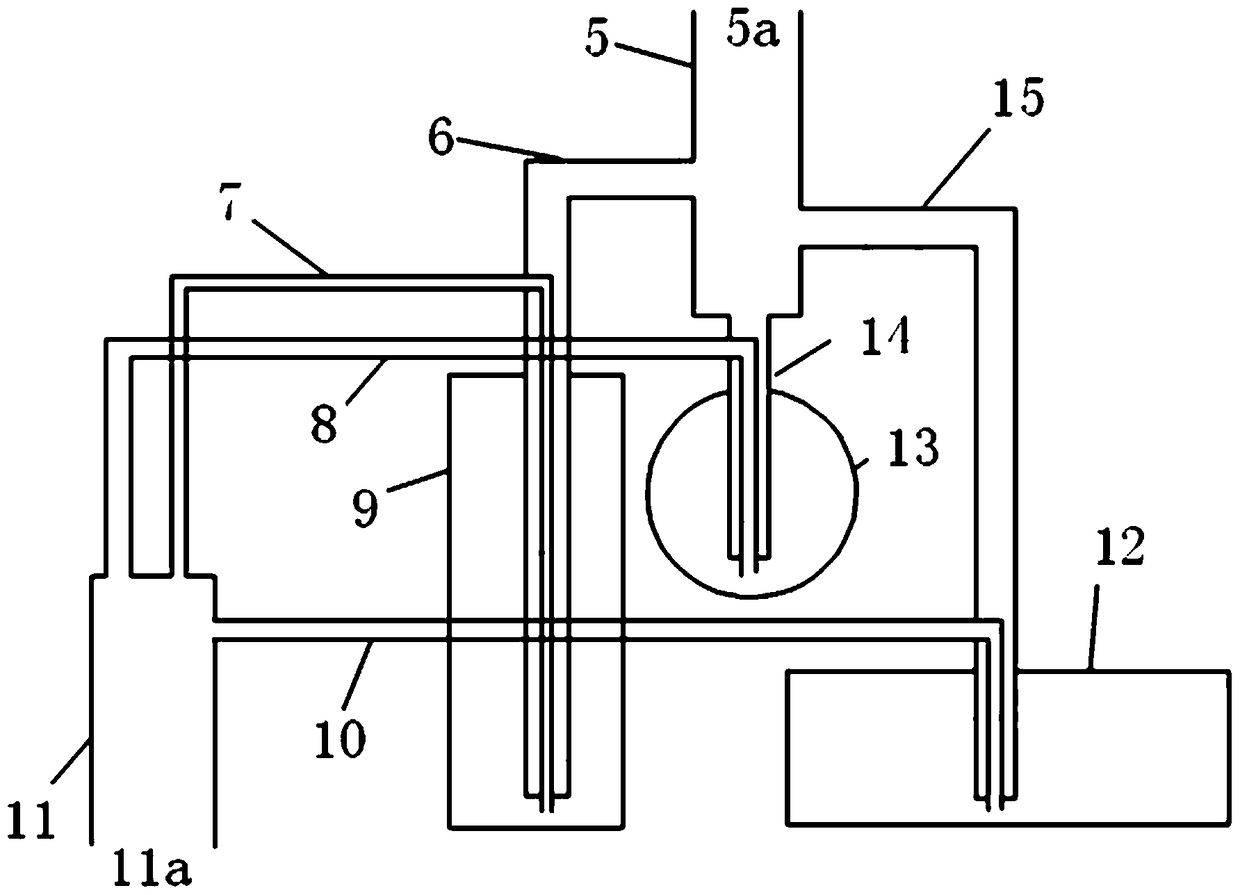

Multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting carbon/carbon crucible and method using same

ActiveCN102433543ASimple structureEasy to processBy pulling from meltChemical vapor deposition coatingCrucibleGraphite

The invention discloses a multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting a carbon / carbon crucible and a method using the same. The device comprises a chemical vapor deposition furnace consisting of an outer furnace tank and an inner furnace tank and also comprises multiple layers of graphite partition plates which are distributed in the inner furnace tank from bottom to top and multiple intake tubes which are inserted in the inner furnace tank from bottom to top; adjacent two layers of graphite partition plates are isolated by multiple graphite shores; the upper part of the graphite partition plate arranged on the most-top layer is provided with a gas-sealing plate; dependant deposition chambers are respectively formed between adjacent two layers of graphite partition plates and between the gas-sealing plate and the graphite partition plate arranged on the most-top layer; multiple deposition chambers are distributed from top to bottom; and the multiple intake tubes are respectively inserted into the multiple deposition chambers from bottom to top. The compacting method comprises the following steps: 1, charging of a crucible prefabricated body; and 2, compacting treatment. The device disclosed by the invention has simple structure, reasonable design, good use effect, good compacting effect, good density uniformity, large charging amount and the like, is convenient for assembling and easy to use and operate.

Owner:XIAN CHAOMA SCI TECH

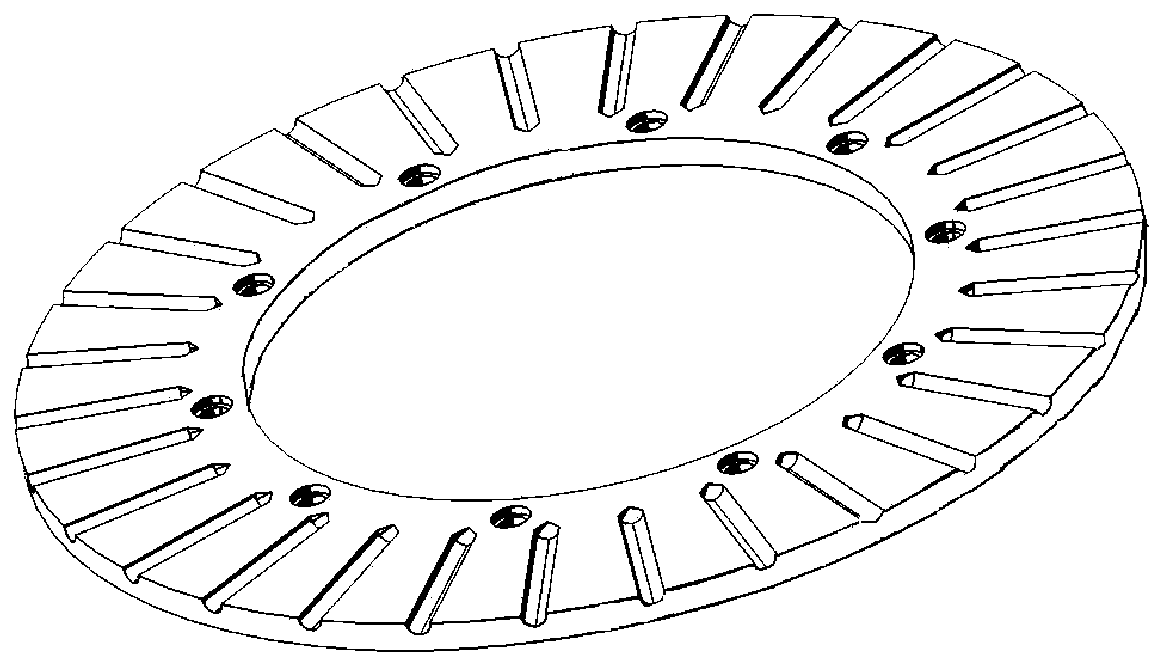

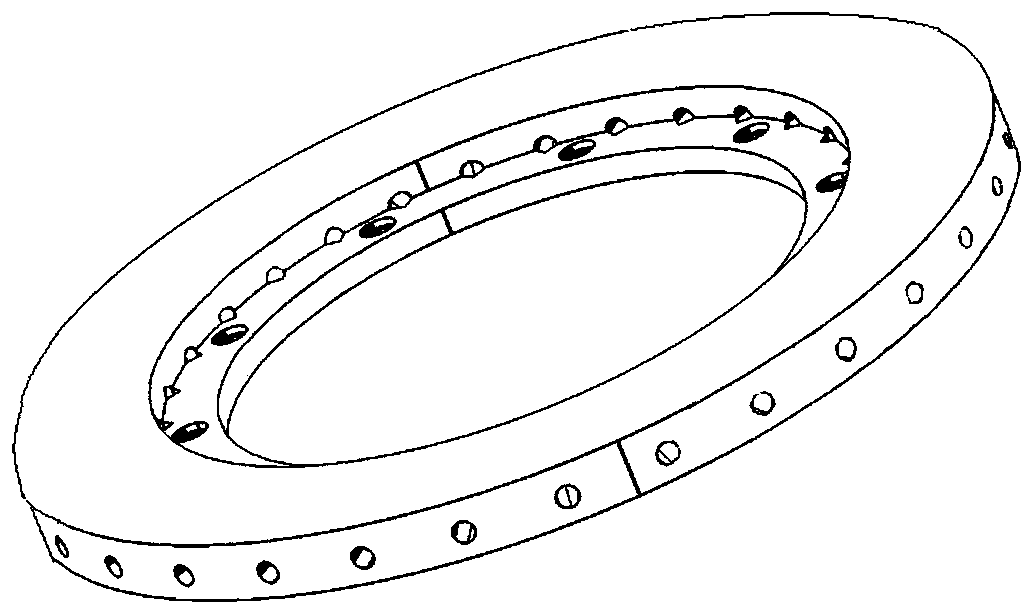

Carbon fiber enhanced carbon-silicon carbide friction material as well as preparation method and application thereof

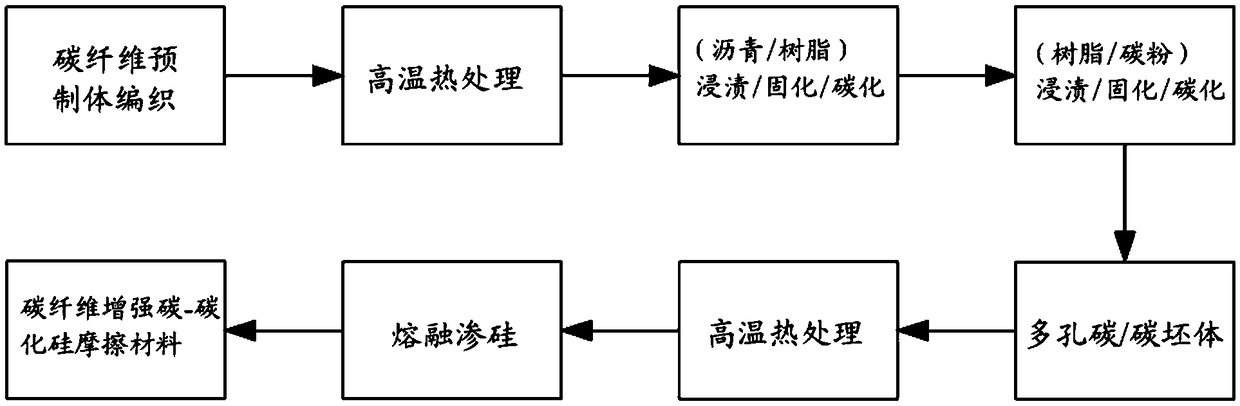

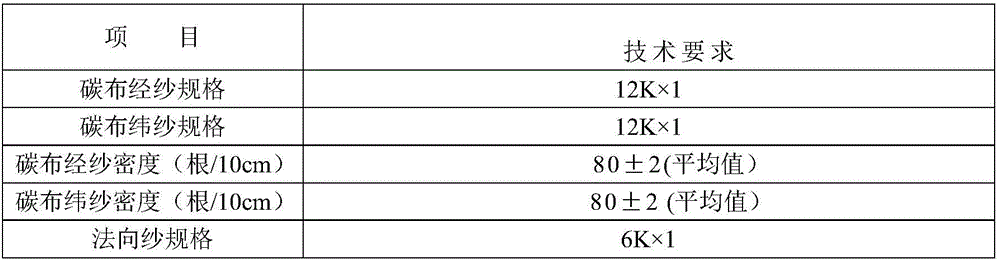

The invention discloses a preparation method of a carbon fiber enhanced carbon-silicon carbide friction material, belonging to the preparation field of carbon fiber enhanced carbon-silicon carbide composite materials. The preparation method comprises the following steps: (1) weaving a carbon fiber preform for formation; (2) carrying out high-temperature thermal treatment on the carbon fiber preform; (3) preparing an asphalt-resin mixed impregnant; (4) carrying out dipping, curing and carbonization on the asphalt-resin mixed impregnant; (5) preparing resin / carbon powder dipping precursor; (6) carrying out dipping, curing and carbonization on the resin / carbon powder dipping precursor; (7) carrying out high-temperature thermal treatment on a porous carbon / carbon blank; and (8) carrying out fusion siliconing on the porous carbon / carbon blank, so as to obtain the carbon fiber enhanced carbon-silicon carbide friction material. The preparation method is simple and controllable in process, short in preparation period and strong material structure designability, and the prepared friction material can be applied to automobile brake discs (pieces), high-speed train brake shoes and magnetically levitated train runners.

Owner:广州晶石创业投资管理合伙企业(有限合伙)

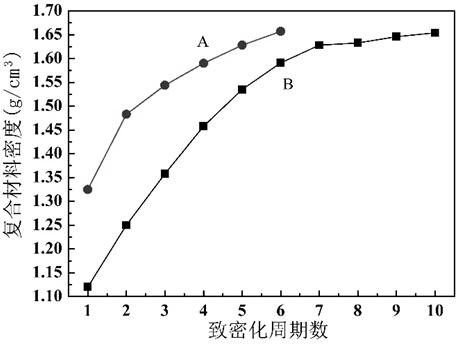

Rapid densification method of carbon/carbon composite material

ActiveCN104557097ADensification efficiency improvedReduce the temperatureMicrostructureCarbon composites

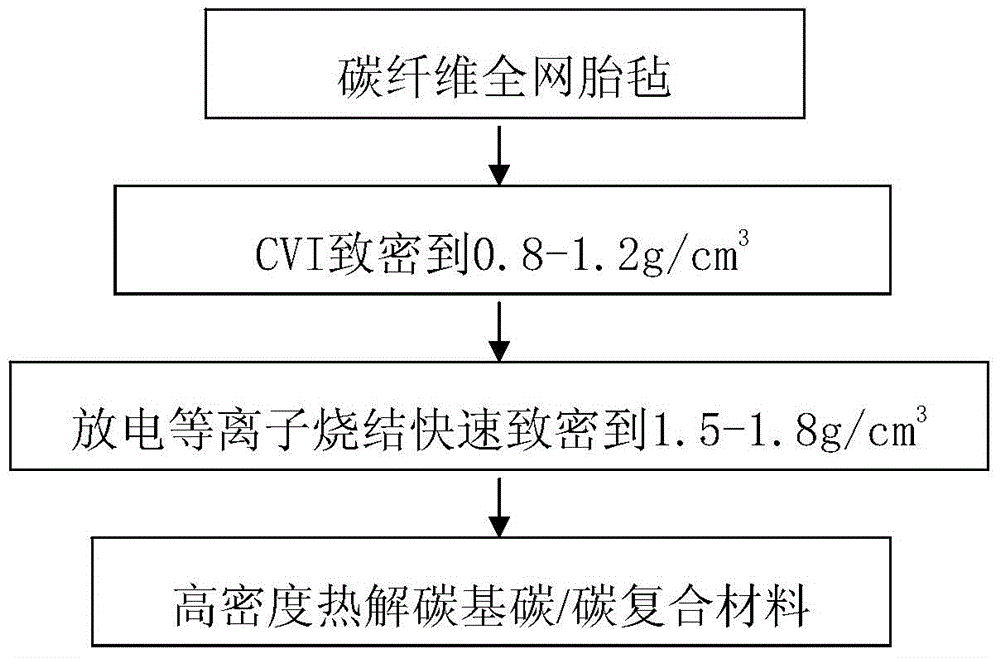

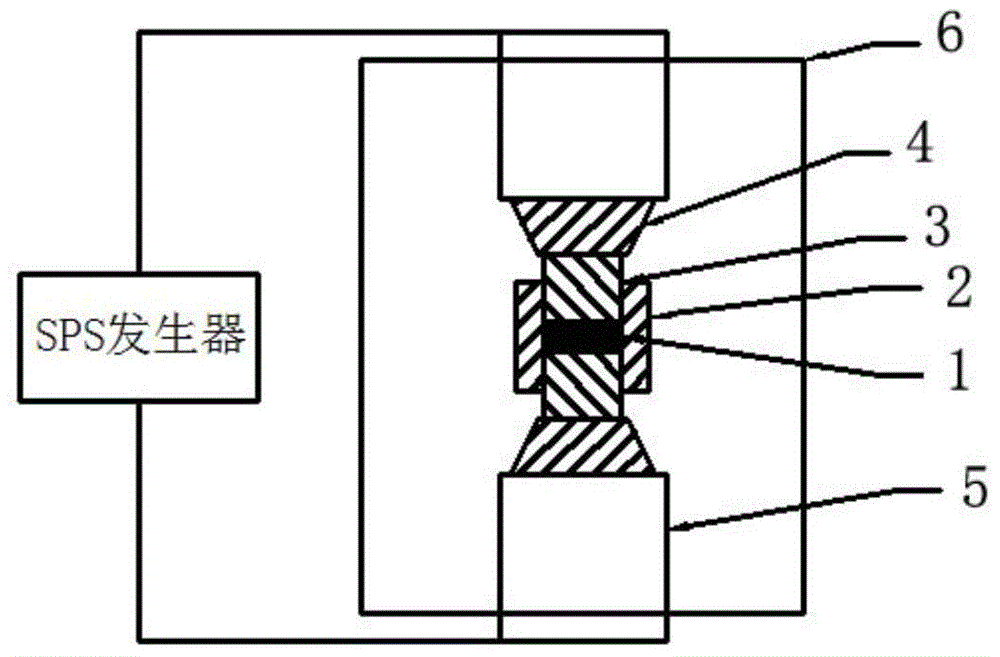

The invention discloses a rapid densification method of a carbon / carbon composite material. The rapid densification method comprises the following steps: (1) densifying a carbon fiber full-mesh felt with an initial density of 0.15-0.20 g / cm<3> to 0.8-1.5 g / cm<3>, and controlling the pyrolytic carbon microstructure of a matrix as a rough layer structure pyrolytic carbon; (2) vacuumizing to 10<-2> Pa by adopting an SPS furnace, rapidly heating the carbon / carbon composite material to 1600-2200 DEG C, slowly pressurizing to 30-40 MPa, controlling the heating speed within 100-200 DEG C / min and controlling the pressurizing speed within 0.5-1 MPa / min; (3) preserving the heat and the pressure for 10-30 min, cooling, releasing the pressure, controlling the cooling speed within 80-100 DEG C / min and controlling the pressure releasing speed within 1-2 MPa / min so as to finish the densification process of the carbon / carbon composite material and prepare a pyrolytic carbon-based carbon / carbon composite material with a density of 1.6-1.8 g / cm<3>.

Owner:CENT SOUTH UNIV

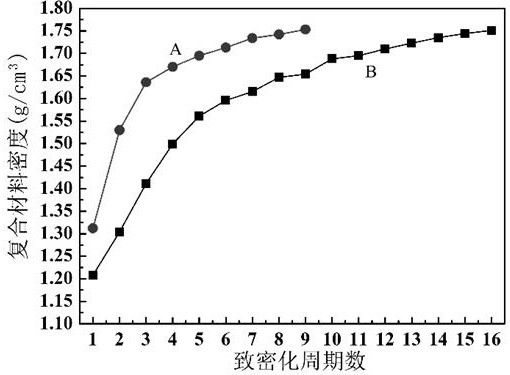

Method for rapidly preparing C/SIC ceramic composite material with pre-introduced matrix

The invention discloses a method for rapidly preparing a C / SIC ceramic composite material with a pre-introduced matrix, and relates to a ceramic matrix composite material and a preparing method thereof. According to the method, the structure of a fabric body is improved, mold pressing and matrix pre-introducing method are creatively provided, the period of the C / SIC ceramic composite material prepared with the PIP technology is greatly shortened, and therefore the aim that the preparing cost is reduced is achieved. The method includes the steps of fabric body processing, fabric body pretreating, precursor soaking, solidifying, mold pressing, high-temperature splitting, soaking, solidifying and splitting; after the increased mass is smaller than 1% of the raw mass, soaking and splitting are stopped, and material preparing is completed. According to the C / SIC ceramic composite material, on the premise that the production period is shortened by 30% to 50%, and the cost is reduced by 30% to 40%, the highest bending strength can reach 325 MPa, and the highest tensile strength can reach 180 MPa.

Owner:湖北三江航天江北机械工程有限公司

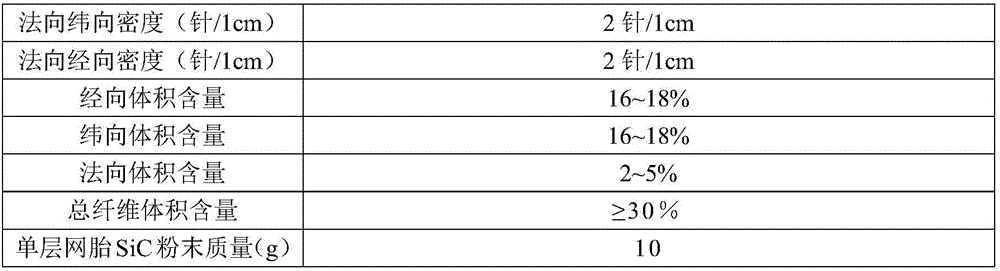

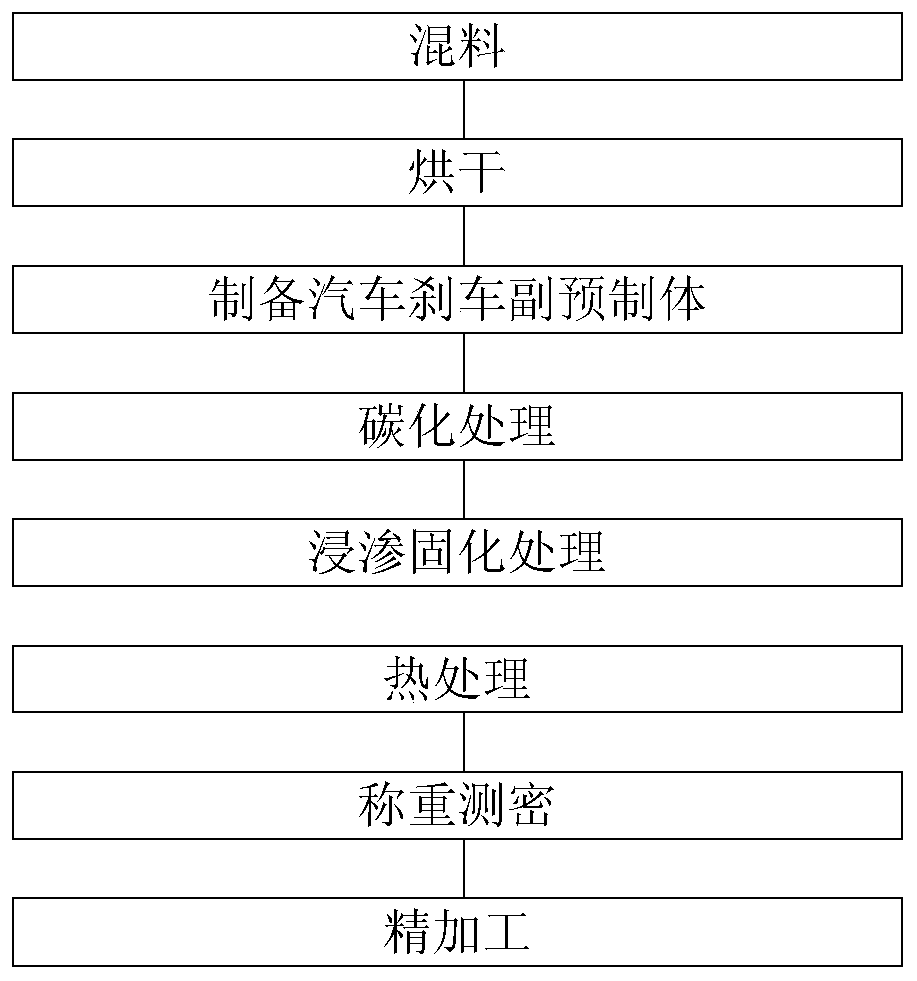

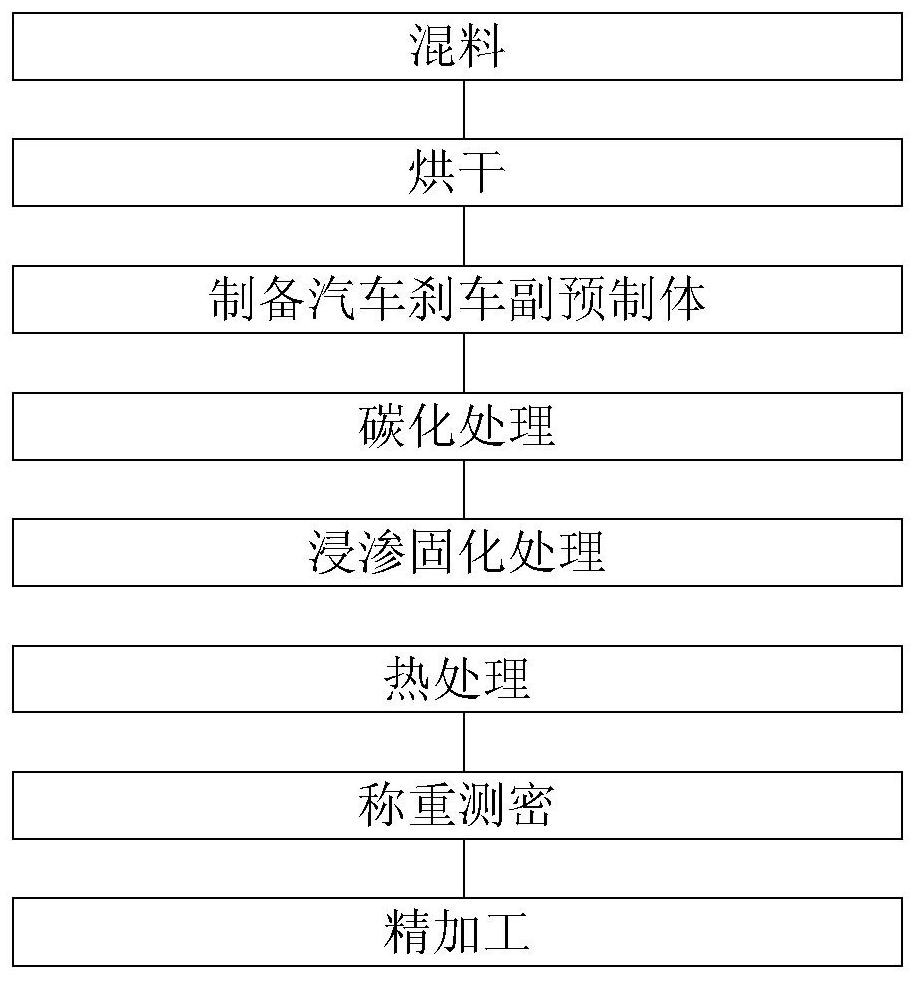

Fabrication method of automobile brake disc

ActiveCN110131343AImprove friction performanceHigh mechanical strengthOther chemical processesFriction liningCarbon fibersPolysilazane

The invention discloses a fabrication method of an automobile brake disc. An automobile brake pair pre-fabricated body is fabricated with carbon fiber prepreg through integrated molding pressing, anda polysilazane solution and a polycarbosilane solution are used as a ceramic precursor; the automobile brake pair pre-fabricated body is fabricated through an integrated molding pressing process, andthe density of the pre-fabricated body is larger than 1.4 g / cm3; a carbon fiber automobile brake pair pre-fabricated part is impregnated through the liquid ceramic precursor; the liquid precursor is subjected to high-temperature pyrolyzing after cross-linking and solidifying are finished and then is converted into a ceramic substrate; and then the impregnation-pyrolysis process is repeated, and finally a carbon fiber reinforced carbon-based / ceramic-based composite material is obtained. The production period is shortened greatly, the production cost is reduced, the densification efficiency is improved, and through adjustment of the impregnation proportion of polycarbosilane and polysilazane, the friction property and mechanical strength of an automobile brake pair can be optimized at the same time.

Owner:XIAN AVIATION BRAKE TECH

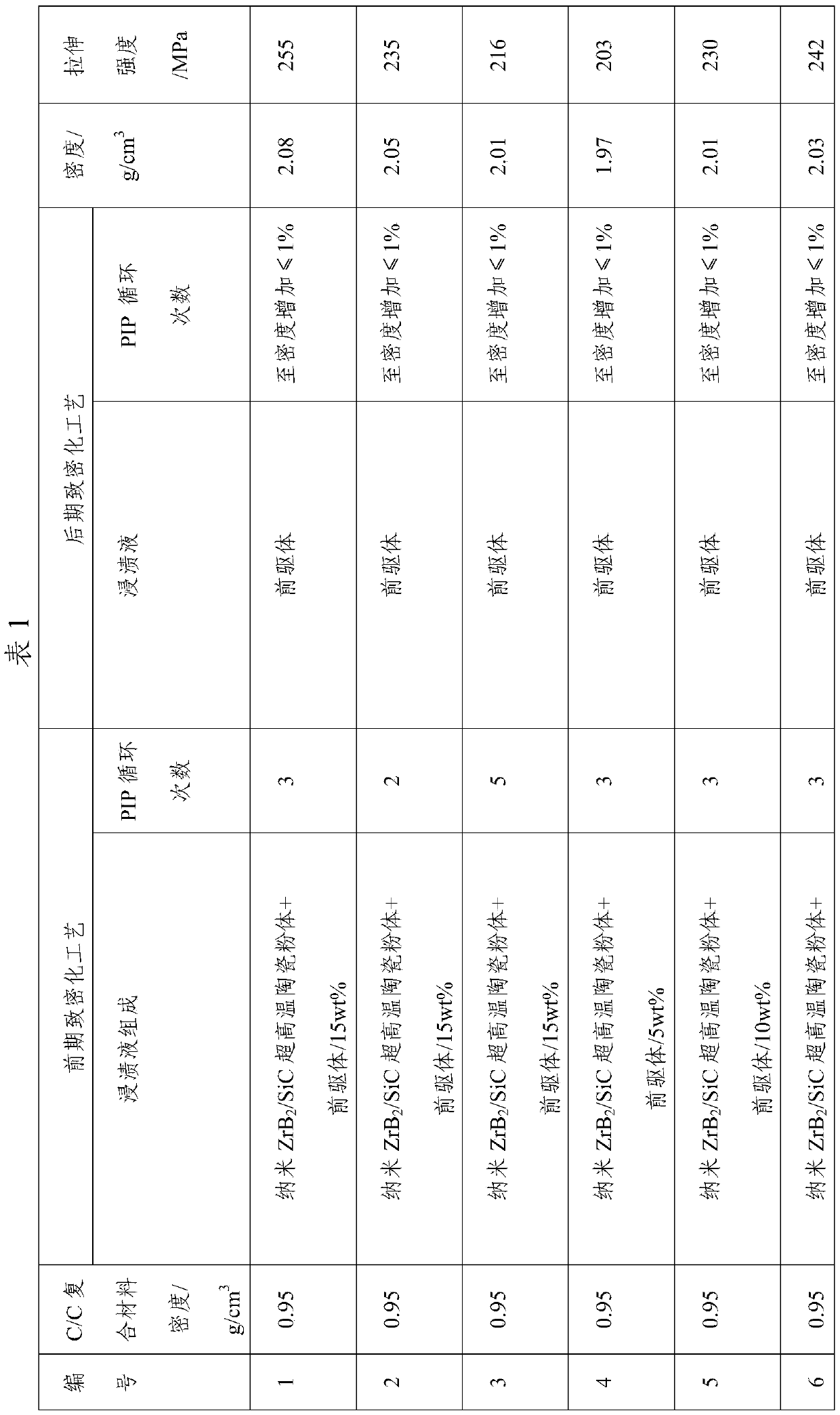

C/SiC-ZrB2 composite material and preparation method thereof

The invention relates to a C / SiC-ZrB2 composite material and a preparation method thereof. The preparation method comprises the following steps: curing and cracking a precursor to obtain nano ZrB2 / SiCcomplex-phase ultrahigh-temperature ceramic powder; mixing the ultrahigh-temperature ceramic powder with the precursor to prepare ultrahigh-temperature ceramic powder slurry; taking the slurry as animpregnation liquid, and carrying out earlier-stage densification treatment on a C / C composite material; and taking the precursor as an impregnation liquid, and carrying out later densification treatment on the composite material subjected to the early densification treatment to obtain the C / SiC-ZrB2 composite material. The wettability of the precursor, the carbon fiber and the matrix is relatively good, so that the penetration depth is favorably improved; slurry is adopted as impregnation liquid for early densification, the precursor is adopted for direct impregnation in the later stage, andthe uniformity and the densification degree of the composite material are improved on the basis that the impregnation efficiency and the impregnation depth are guaranteed.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for fabricating high performance carbon/carbon friction resistance material

InactiveCN1687291ARegulated contentContent up toOther chemical processesFibre treatmentHigh densityWear resistant

The present invention relates to a production method of high-performance carbon / carbon frictional resistance material which can be used in brake system of high-speed train, magnetic suspension train and racing automobile, etc. It is characterized by that said invention adopts laminated knitted carbon cloth as reinforced skeleton, and uses rough type pyrolytic carbon and wear-resistant high temperature resistant resin pyrolytic carbon to fill and compact the carbon-reinforced skeleton to form high-density wear-resistant carbon / carbon material, and adopts high-temperature reaction silconing method to add antioxidant SiC base body so as to raise high temperature frictional performance and surface frictional resistance performance of said carbon / carbon material.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material and preparation method thereof

The invention discloses a preparation method of a three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The preparation method ofthe three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material comprises the following steps of (1) stabilizing SiO2-ZrO2 composite sol;(2) impregnating three-dimensional silicon carbide fiber prefabricated members into the stabilized SiO2-ZrO2 composite sol; (3) drying the impregnated three-dimensional silicon carbide fiber prefabricated members; (4) performing thermal treatment; (5) repeating the impregnation-drying-thermal treatment process in the steps of (2) to (4) until the weight gain rate of a three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material intermediate in a current impregnation-drying-thermal treatment process relative to a previous impregnation-drying-thermal treatment process is smaller than 1% to obtain the three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The prepared three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material has the advantages of being high in high-temperature resistance and antioxidant and mechanical performance and the like.

Owner:NAT UNIV OF DEFENSE TECH

Three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material and preparation method thereof

ActiveCN107640976AImprove antioxidant capacityImprove high temperature resistanceCeramicwarePorosityFiber

The invention discloses a three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material. The composite material comprises a three-dimensional silicon carbide fiber preform and yttrium silicate, the yttrium silicate is a mixed crystalline phase of Y2Si2O7 and Y2SiO5, a crystalline phase of the Y2Si2O7 or a crystalline phase of the Y2SiO5, the pores of the three-dimensional silicon carbide fiber preform are uniformly filled with the yttrium silicate, and the porosity of the three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material is 10%-16%. A preparation method comprises the following steps: (1) preparing a Y2O3-SiO2 composite sol; (2) performing impregnating; (3) performing drying; (4) performing heat treatment; and (5)repeating processes including impregnating-drying-heat treatment in the steps (2)-(4). The three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material has the advantages of low porosity, a high compact degree, high-temperature resistance, oxidation resistance, excellent mechanical properties and the like; and the preparation efficiency of the preparation methodis high, and the compact degree and mechanical properties of the prepared composite material are remarkably improved.

Owner:NAT UNIV OF DEFENSE TECH

Quick low-cost CVD compacting method for carbon/carbon composite material

InactiveCN108220913AUniform and denseRapid densificationChemical vapor deposition coatingCarbon compositesOperability

The invention discloses a quick low-cost CVD compacting method for a carbon / carbon composite material. The method comprises the following steps: assembling a preform and an inner core mold tougher forhigh-temperature pre-treatment; placing the treated perform and inner core mold between upper and lower graphite electrodes of a deposition chamber of CVD equipment; and carrying out heating and introducing carbon source gas for 40-200h to prepare a carbon / carbon composite material product at one time. The method disclosed by the invention has the advantages and characteristics that 1, the methodintegrates advantages of a temperature differential method, a gas limiting method and a spontaneous heating characterized deposition process, so that influence of crusting of pyrolytic carbon on thesurface layer on deposition and compaction can be prevented effectively, the ability of the carbon source gas diffused to the perform is enhanced, and the deposition efficiency can be improved greatly; 2, the problem that density is not uniformly increased is solved, and the product quality is consistent; 3, the production energy consumption is low and the process and production cost is relativelylow; 4, the control degree of an air flow is high, and the utilization ratio of gas is high; 5, the perform and the graphite inner core mold are easily demolded, so that the operability is good; and6, the density state of the product can be controlled precisely, so that an accurate product effect is obtained.

Owner:AEROSPACE RUITIAN CARBON MATERIALS CO LTD

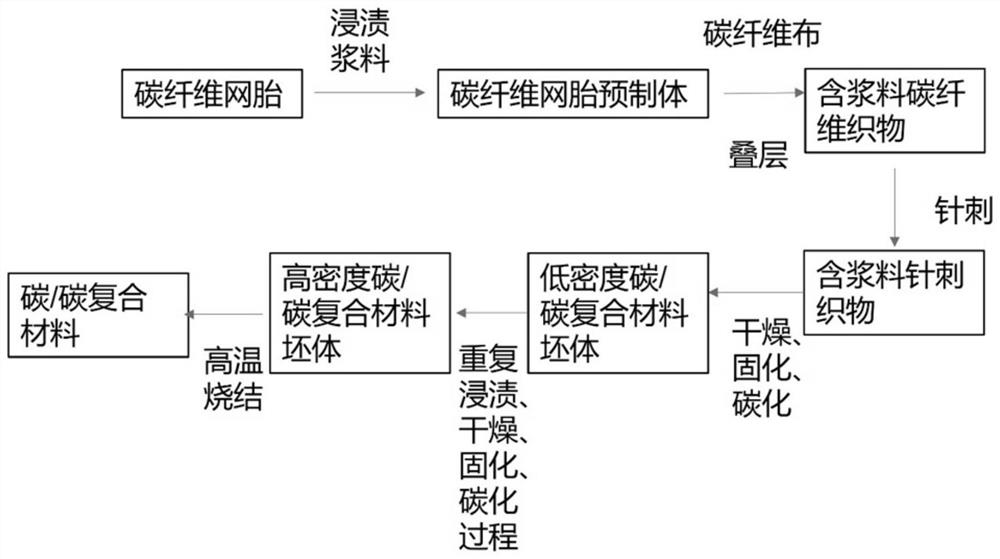

Wet needling process for preparing carbon/carbon composite material

The invention discloses a wet needling process for preparing a carbon / carbon composite material, and relates to the technical field of preparation of carbon / carbon composite materials. The process comprises the following steps: dipping a carbon fiber web in slurry to obtain a carbon fiber web preform; laminating the carbon fiber web preform and carbon fiber cloth to obtain a slurry-containing carbon fiber fabric; needling the slurry-containing carbon fiber fabric to obtain a slurry-containing needled fabric; sequentially carrying out heating, curing and carbonization treatment on the slurry-containing needle-punched fabric to obtain a low-density carbon / carbon composite material blank; the low-density carbon / carbon composite material green body is repeatedly subjected to the treatment processes of dipping, heating, curing and carbonizing, and a high-density carbon / carbon composite material green body is obtained; performing high-temperature heat treatment on the high-density carbon / carbon composite material green body to obtain a carbon / carbon composite material; the slurry is an ethanol suspension of asphalt and graphite powder. According to the process method, the preparation period of the carbon / carbon composite material prepared by a needling method is shortened.

Owner:富优特(山东)新材料科技有限公司

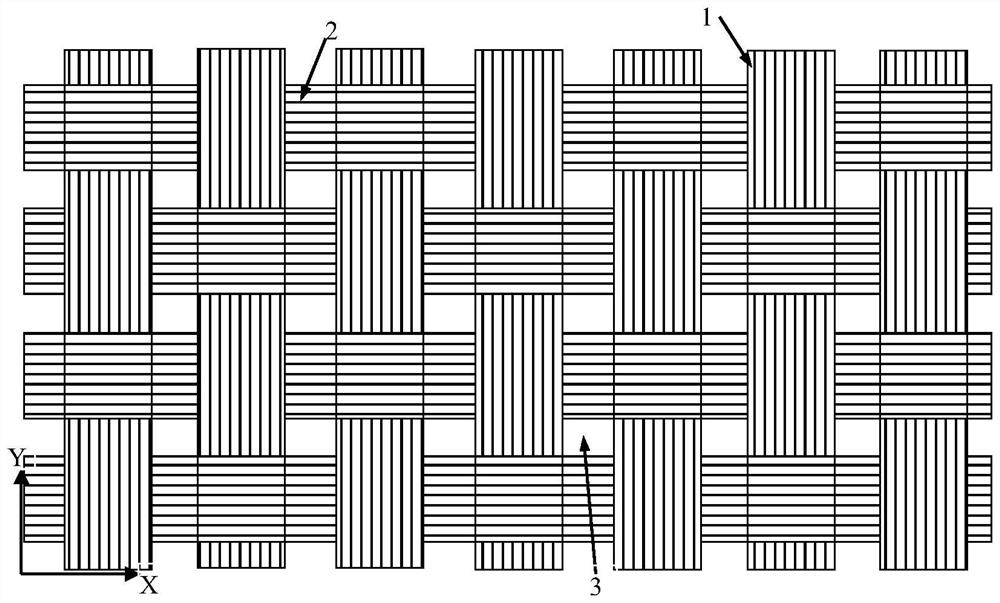

High-density flat carbon fiber gradient stitching preform and preparation method thereof

ActiveCN114407227AIncrease the number of layersImprove performanceWork-feeding meansLayered productsCarbon compositesCarbon fibers

The invention discloses a high-density flat carbon fiber gradient stitching preform and a preparation method thereof, and belongs to the field of equipment materials. According to the method, the flat carbon fiber bundles are adopted and woven into the light and thin single-layer flat carbon fiber plane prefabricated body, and then the flat carbon fiber gradient stitching prefabricated body is prepared through gradient lamination and stitching, so that the requirements of high layer density, high bearing capacity, strong interlayer and low stitching damage are met; and the problems of high porosity, high cost, long period, frequent processing and low mechanical property retention rate of the subsequent carbon / carbon composite material are thoroughly solved.

Owner:JIANGNAN UNIV

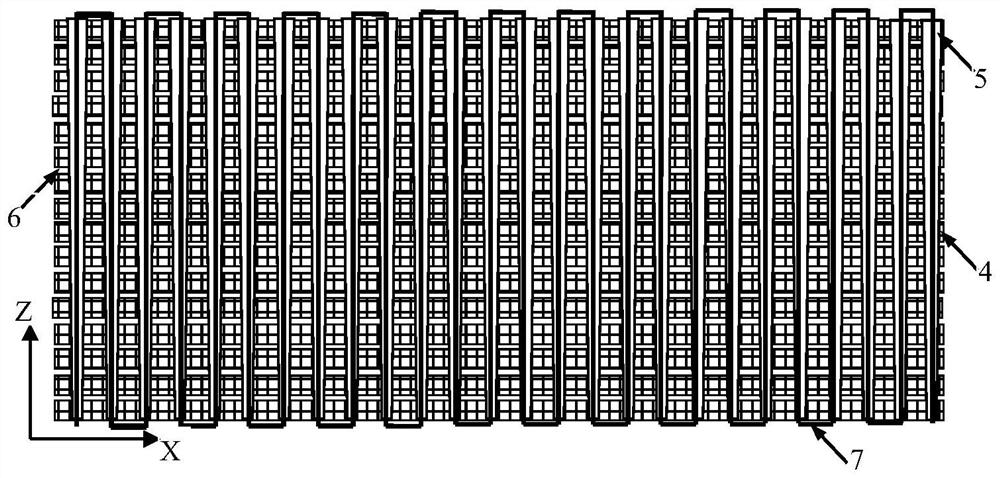

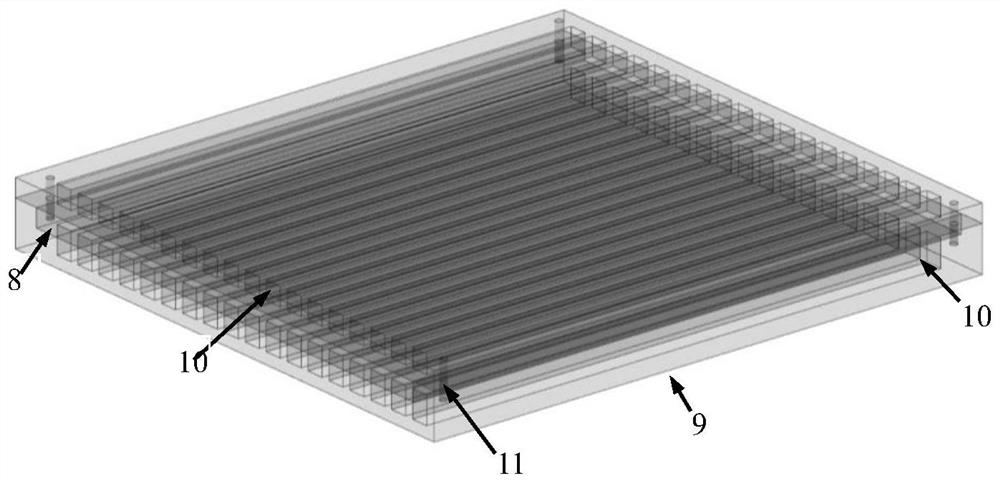

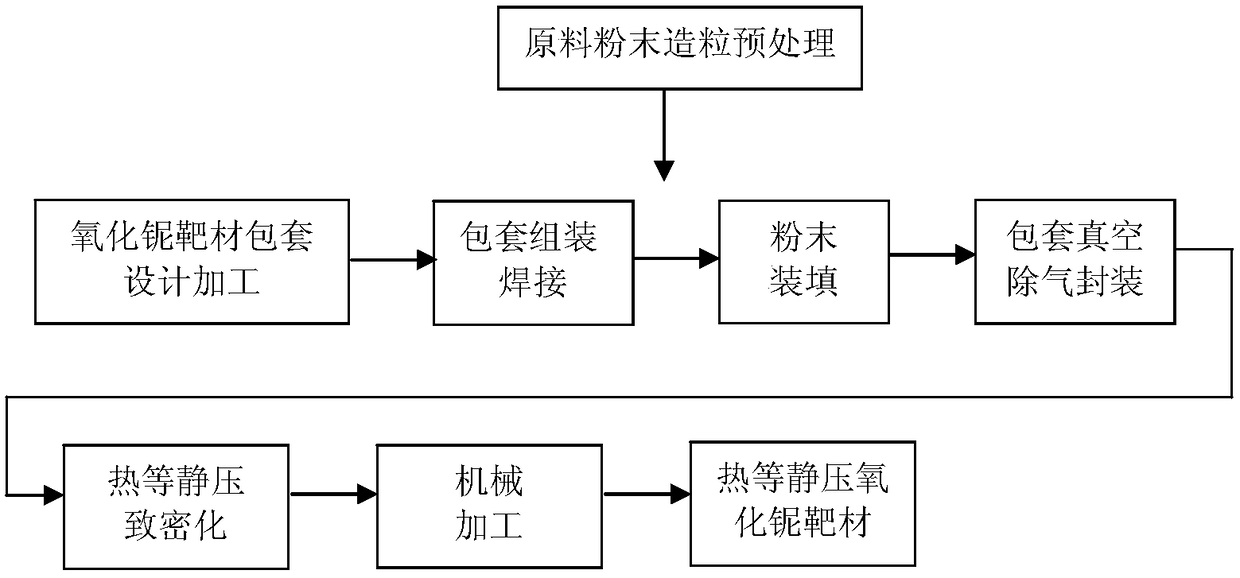

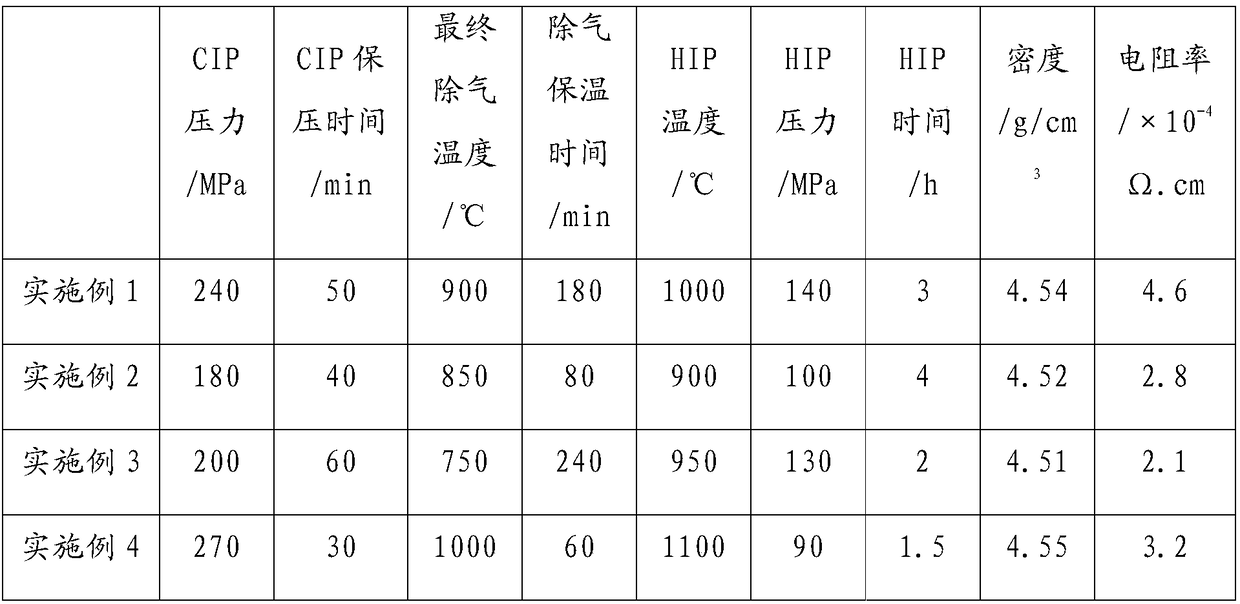

A method for preparing niobium oxide target material by hot isostatic pressing

ActiveCN105734506BAchieve densificationImprove densification efficiencyVacuum evaporation coatingSputtering coatingIntermediate frequencyPre treatment

The invention provides a method for preparing a hot isostatic pressing niobium oxide target material for a sputter coating. By means of the method, high-purity niobium pentoxide powder serves as a raw material, and the purity of the niobium pentoxide powder is not lower than 99.99%; the powder is packaged into a packaging sleeve after being pretreated; then vacuum thermal degassing is conducted on the powder, and the powder is pressed and molded in a hot isostatic pressing machine; and afterwards, a finished product is manufactured through machining. The niobium oxide target material prepared through the method has the beneficial effects that the density of the target material is high, and the density can reach 4.5 g / cm<3> or higher; and conductivity is good, the specific resistivity ranges from 2*10<-4> omega.cm to 5*10<-4> omega.cm, and the requirement for manufacturing niobium oxide films through an intermediate-frequency or direct current sputtering technology can be met.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material and preparation method thereof

The invention discloses a preparation method of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The preparation method of the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material comprises the following steps of (1) stabilizing SiO2-ZrO2 composite sol; (2) impregnatingthree-dimensional carbon fiber prefabricated members into the stabilized SiO2-ZrO2 composite sol; (3) drying the impregnated three-dimensional carbon fiber prefabricated members; (4) performing thermal treatment; (5) repeating the impregnation-drying-thermal treatment process in the steps of (2) to (4) until the weight gain rate of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material intermediate in a current impregnation-drying-thermal treatment process relative to a previous impregnation-drying-thermal treatment process is smaller than 1% to obtain the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The prepared three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material has the advantages of being high in high-temperature resistance and antioxidant and mechanical performance and the like.

Owner:NAT UNIV OF DEFENSE TECH

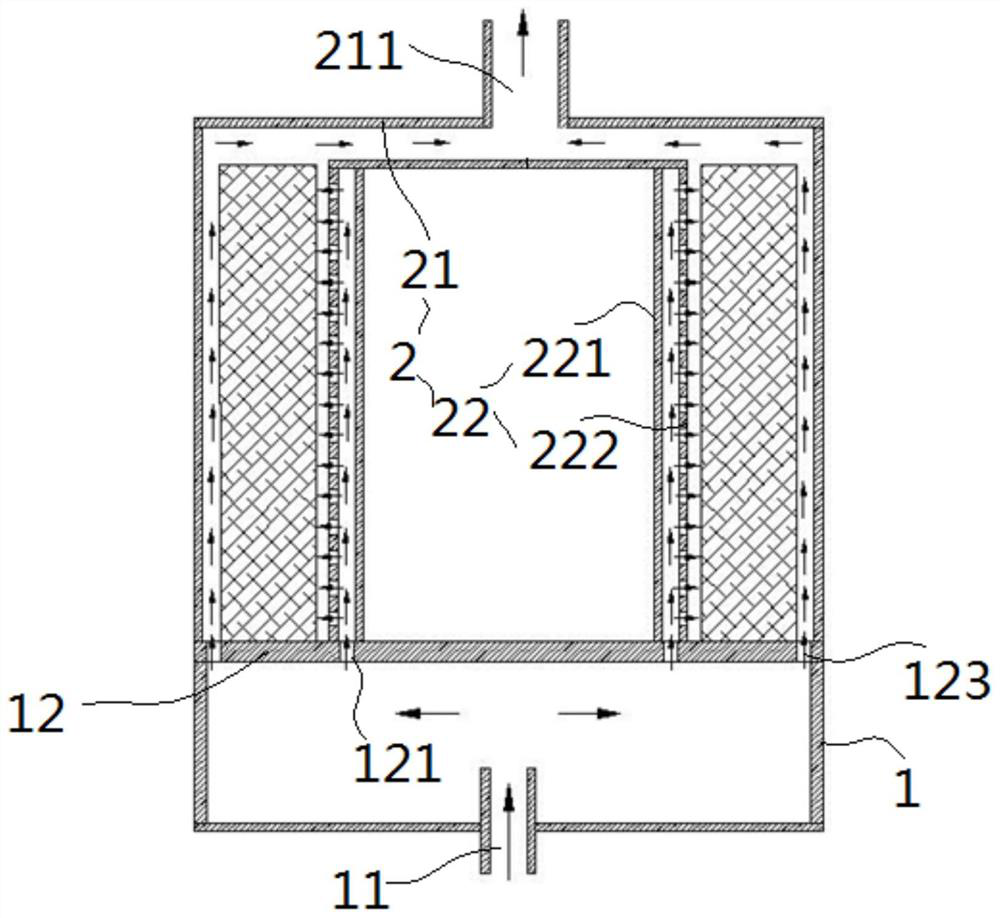

Multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting carbon/carbon crucible and method using same

ActiveCN102433543BSimple structureEasy to processBy pulling from meltChemical vapor deposition coatingCrucibleGraphite

The invention discloses a multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting a carbon / carbon crucible and a method using the same. The device comprises a chemical vapor deposition furnace consisting of an outer furnace tank and an inner furnace tank and also comprises multiple layers of graphite partition plates which are distributed in the inner furnace tank from bottom to top and multiple intake tubes which are inserted in the inner furnace tank from bottom to top; adjacent two layers of graphite partition plates are isolated by multiple graphite shores; the upper part of the graphite partition plate arranged on the most-top layer is provided with a gas-sealing plate; dependant deposition chambers are respectively formed between adjacent two layers of graphite partition plates and between the gas-sealing plate and the graphite partition plate arranged on the most-top layer; multiple deposition chambers are distributed from top to bottom; and the multiple intake tubes are respectively inserted into the multiple deposition chambers from bottom to top. The compacting method comprises the following steps: 1, charging of a crucible prefabricated body; and 2, compacting treatment. The device disclosed by the invention has simple structure, reasonable design, good use effect, good compacting effect, good density uniformity, large charging amount and the like, is convenient for assembling and easy to use and operate.

Owner:XIAN CHAOMA SCI TECH

Three-dimensional carbon fiber preform reinforced yttrium silicate composite material and preparation method thereof

ActiveCN107640973AImprove high temperature resistanceOvercoming brittlenessLayered productsNon-woven fabricsFiberPorosity

The invention discloses a three-dimensional carbon fiber preform reinforced yttrium silicate composite material. The composite material comprises a three-dimensional carbon fiber preform and yttrium silicate, the yttrium silicate is a mixed crystalline phase of Y2Si2O7 and Y2SiO5, a crystalline phase of the Y2Si2O7 or a crystalline phase of the Y2SiO5, the pores of the three-dimensional carbon fiber preform are uniformly filled with the yttrium silicate, and the porosity of the three-dimensional carbon fiber preform reinforced yttrium silicate composite material is 9%-14%. A preparation methodcomprises the following steps: (1) preparing a Y2O3-SiO2 composite sol; (2) performing impregnating; (3) performing drying; (4) performing heat treatment; and (5) repeating processes including impregnating-drying-heat treatment in the steps (2)-(4). The three-dimensional carbon fiber preform reinforced yttrium silicate composite material has the advantages of low porosity, a high compact degree,high-temperature resistance, oxidation resistance, excellent mechanical properties and the like; and the preparation efficiency of the preparation method is high, and the compact degree and mechanicalproperties of the prepared composite material are remarkably improved

Owner:NAT UNIV OF DEFENSE TECH

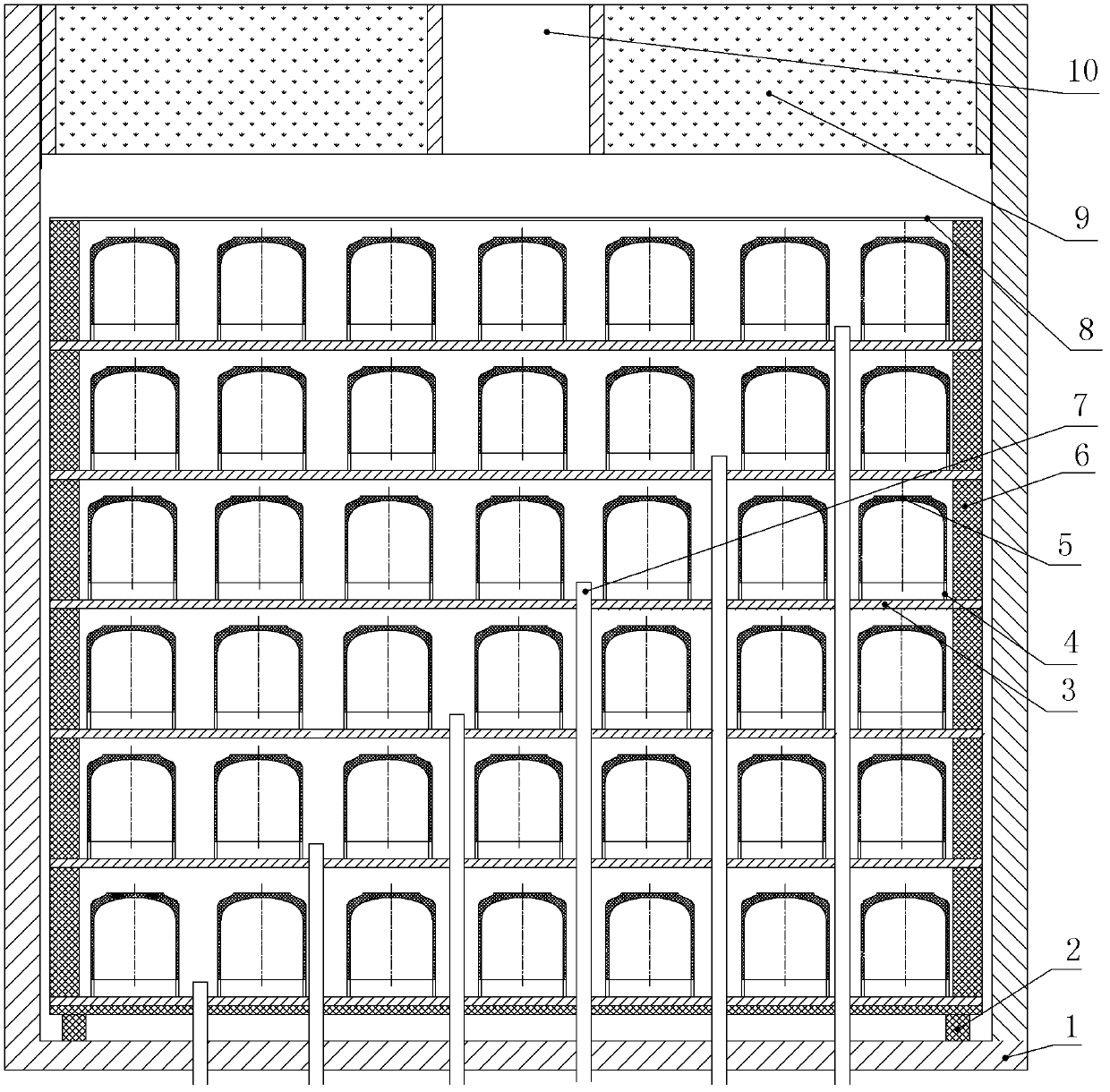

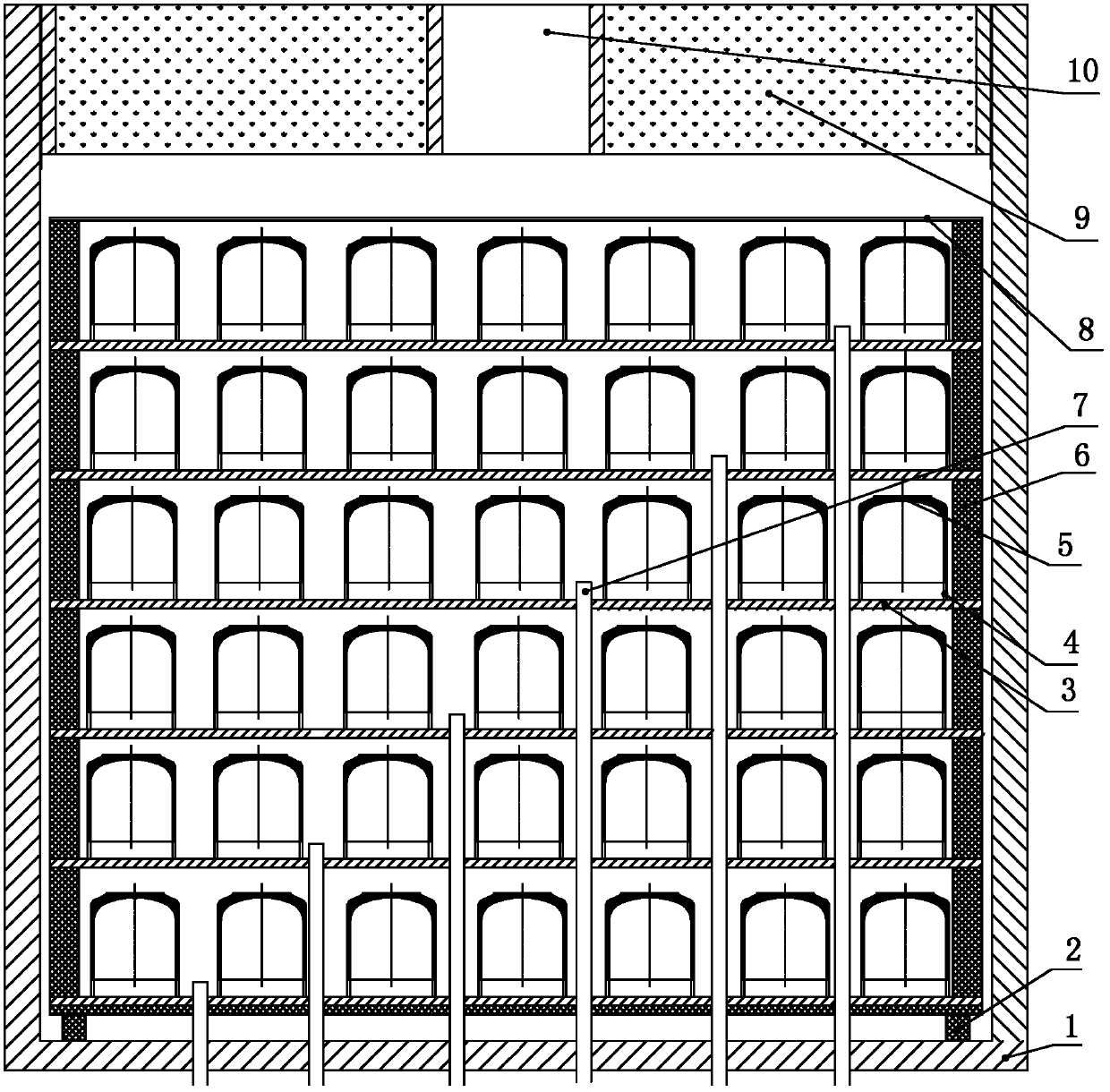

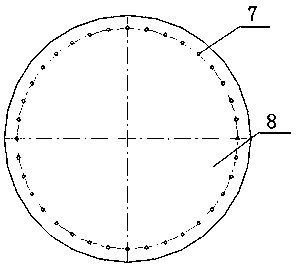

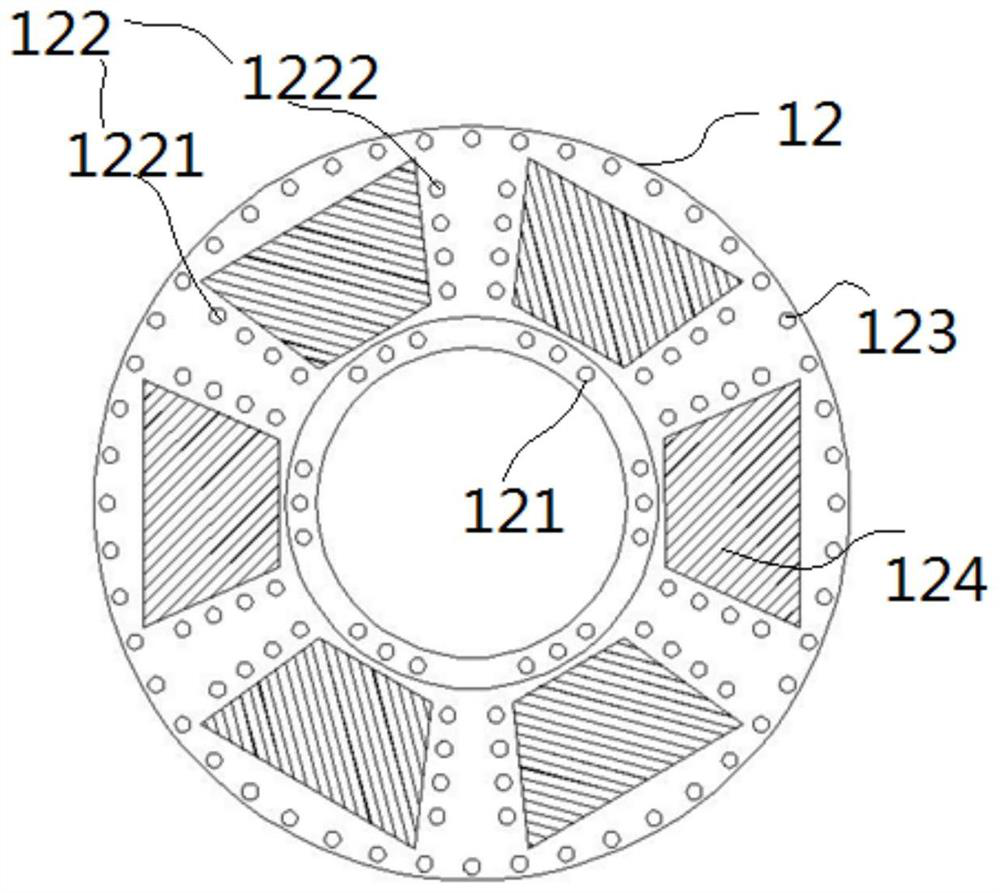

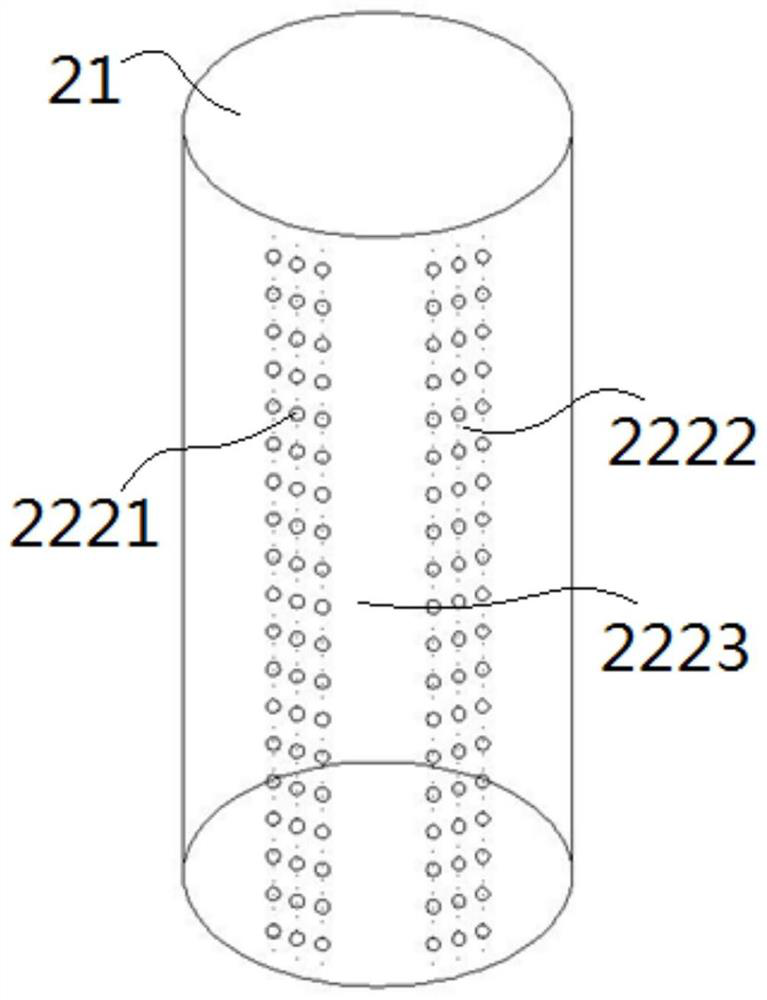

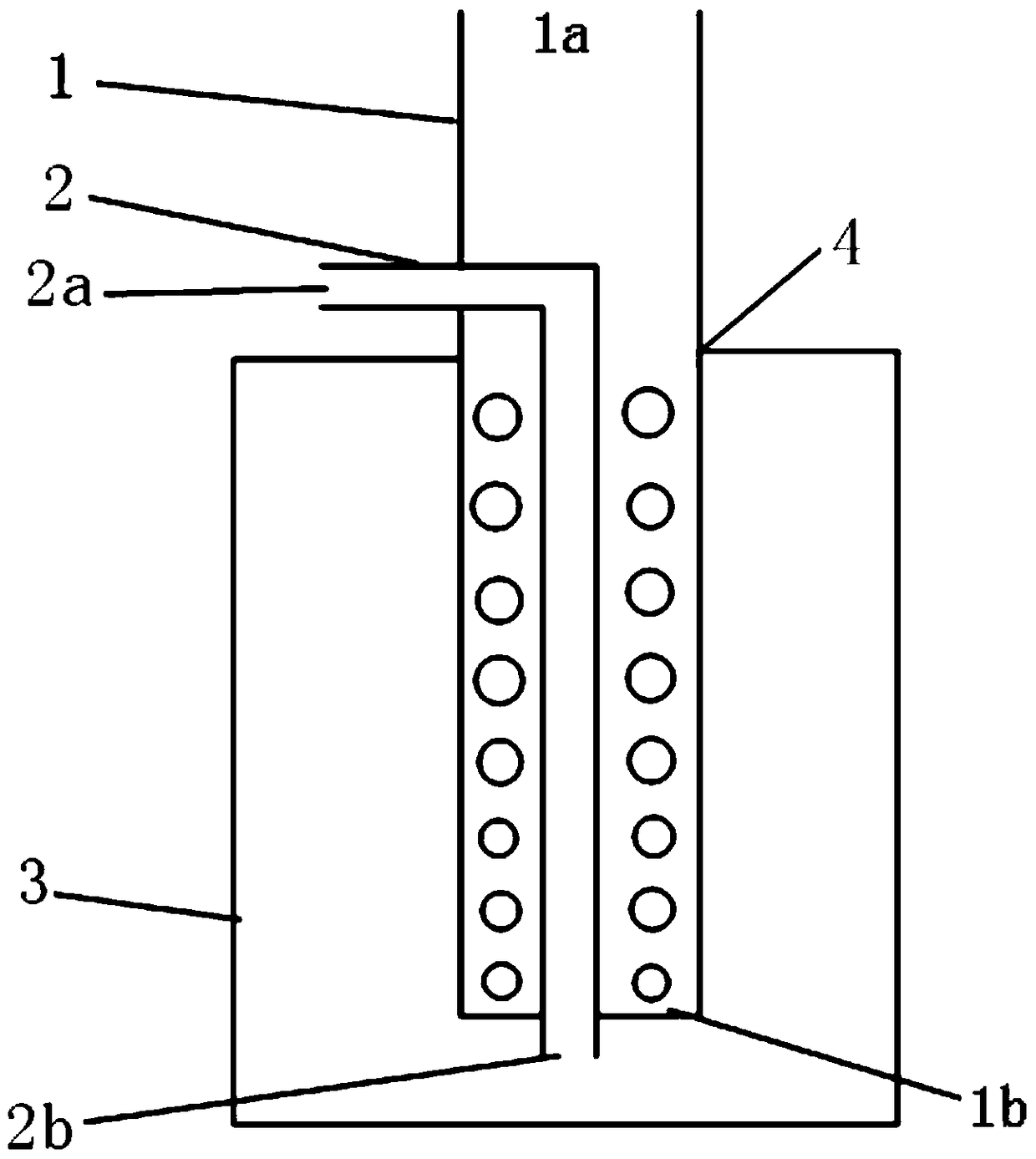

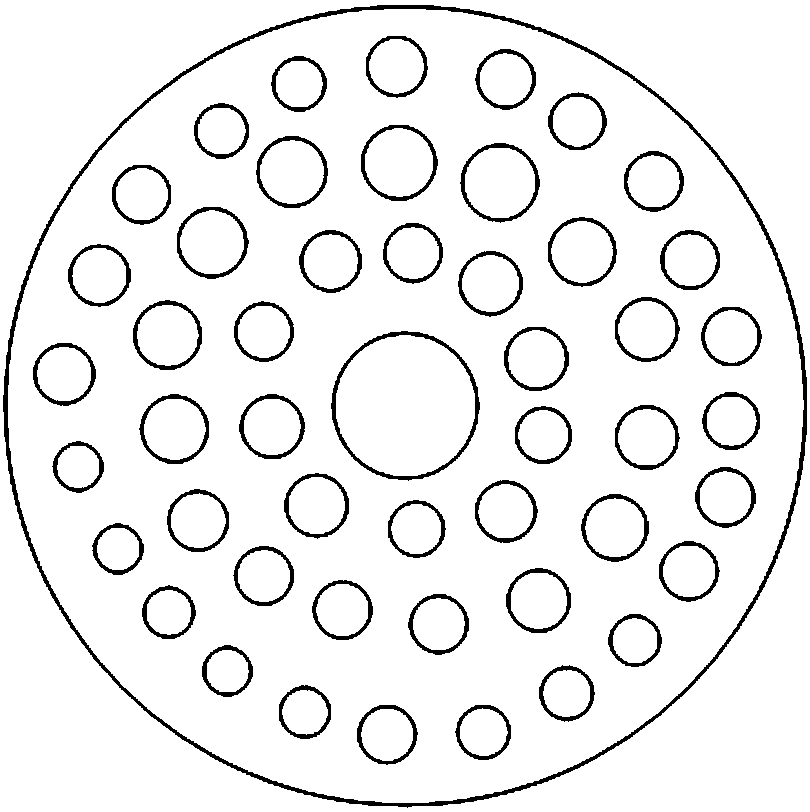

Vapor deposition device and preparation method of carbon/carbon composite material

ActiveCN112830807ASimple structureImprove densification efficiencyCarbon compositesDeposition process

The invention provides a vapor deposition device. The vapor deposition device comprises a base, a material plate and a deposition chamber, and the deposition chamber comprises an outer barrel, an exhaust port and an exhaust sleeve arranged in the outer barrel; the exhaust sleeve comprises an inner cylinder and a sleeve body arranged outside the inner cylinder in a sleeving mode, an airflow channel is defined by the inner cylinder and the sleeve body, and vent holes are formed in the side wall of the sleeve body; a first air inlet hole is formed in the material plate and is positioned between the sleeve and the inner cylinder; the material plate is further provided with an air inlet structure, the air inlet structure comprises an air inlet hole array, and the air inlet hole array is distributed in a radial shape with the exhaust sleeve as the center; and a fourth air inlet is formed in the side, away from the exhaust sleeve, of the air inlet array. The device can effectively control the flowing direction of gas in the deposition process, so that the gas is in full contact with a to-be-treated blank. In addition, the invention also provides a method for preparing a carbon / carbon composite material by using the device, and the method comprises the following step of determining the criterion of the flow of the carbon source gas and the principle that the flow is gradually reduced along with the increase of CVD (Chemical Vapor Deposition) times.

Owner:CENT SOUTH UNIV

Three-dimensional carbon fiber preform enhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material and preparation method thereof

ActiveCN107640975AImprove antioxidant capacityImprove high temperature resistanceCeramicwareFiberPorosity

The invention discloses a three-dimensional carbon fiber preform enhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material and a preparation method thereof. The composite materialcomprises a three-dimensional carbon fiber preform and yttrium oxide-aluminum oxide complex-phase ceramic, in the yttrium oxide-aluminum oxide complex-phase ceramic, the molar content of Al2O3 is 5%-95%, pores of a three-dimensional carbon fiber preform are uniformly filled with the yttrium oxide-aluminum oxide complex-phase ceramic, and the porosity of the three-dimensional carbon fiber preformenhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material is 10%-15%. The preparation method comprises the following steps; (1) preparing yttrium oxide-aluminum oxide composite sol; (2) carrying out dipping; (3) drying; (4) carrying out heat treatment; and (5) repeating a dipping-drying-heat treatment process in the step (2)-step (4). The composite material has the advantagesof low porosity, high compactness, high temperature resistance, oxidation resistance, excellent mechanical property and the like. The preparation method is high in preparation efficiency, and the compactness and mechanical property of the prepared composite material are improved remarkably.

Owner:NAT UNIV OF DEFENSE TECH

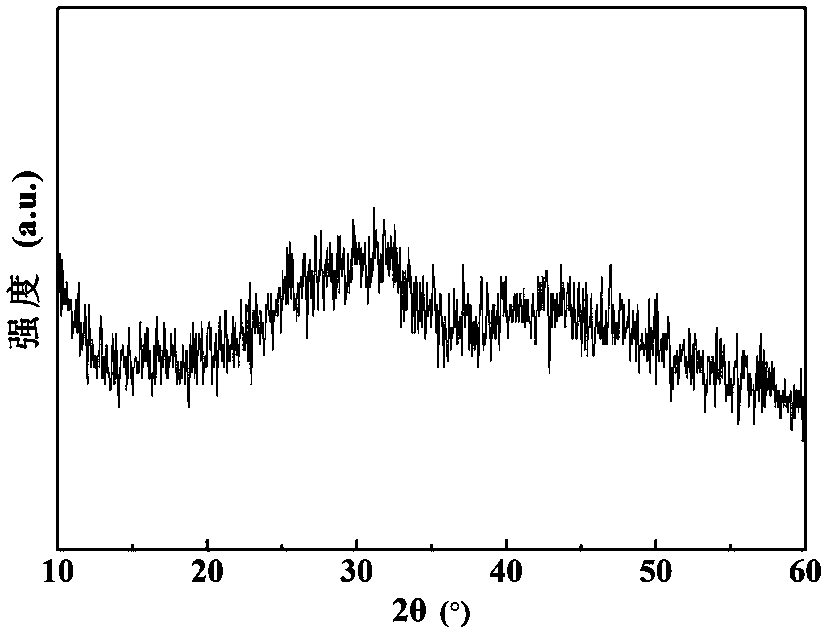

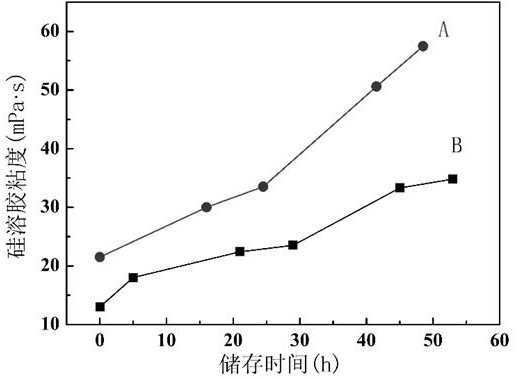

A kind of quartz fiber reinforced quartz-based composite material and its manufacturing method

The invention discloses a quartz fiber-reinforced quartz-based composite material and a manufacturing method thereof. The commercially available acidic silica sol is concentrated by vacuum rotary evaporation to obtain concentrated silica sol with a concentration of 30%-47%, and the concentrated Silica sol is divided into high-concentration silica sol and medium-concentration silica sol according to different concentration ranges, and a combined impregnation scheme with different concentrations of silica sol is designed for different densification cycles. Compared with the normal pressure heating and concentration method, the concentration efficiency of the vacuum rotary evaporation method is high, the obtained concentrated silica sol has good stability, and the size of the micelles contained is small, which is beneficial to the full impregnation of the fiber preform. The combined impregnation scheme adopted improves the densification efficiency, thereby achieving a SiO 2f / SiO 2 Efficient preparation of composite materials.

Owner:NINGBO SHUXIANG NEW MATERIAL

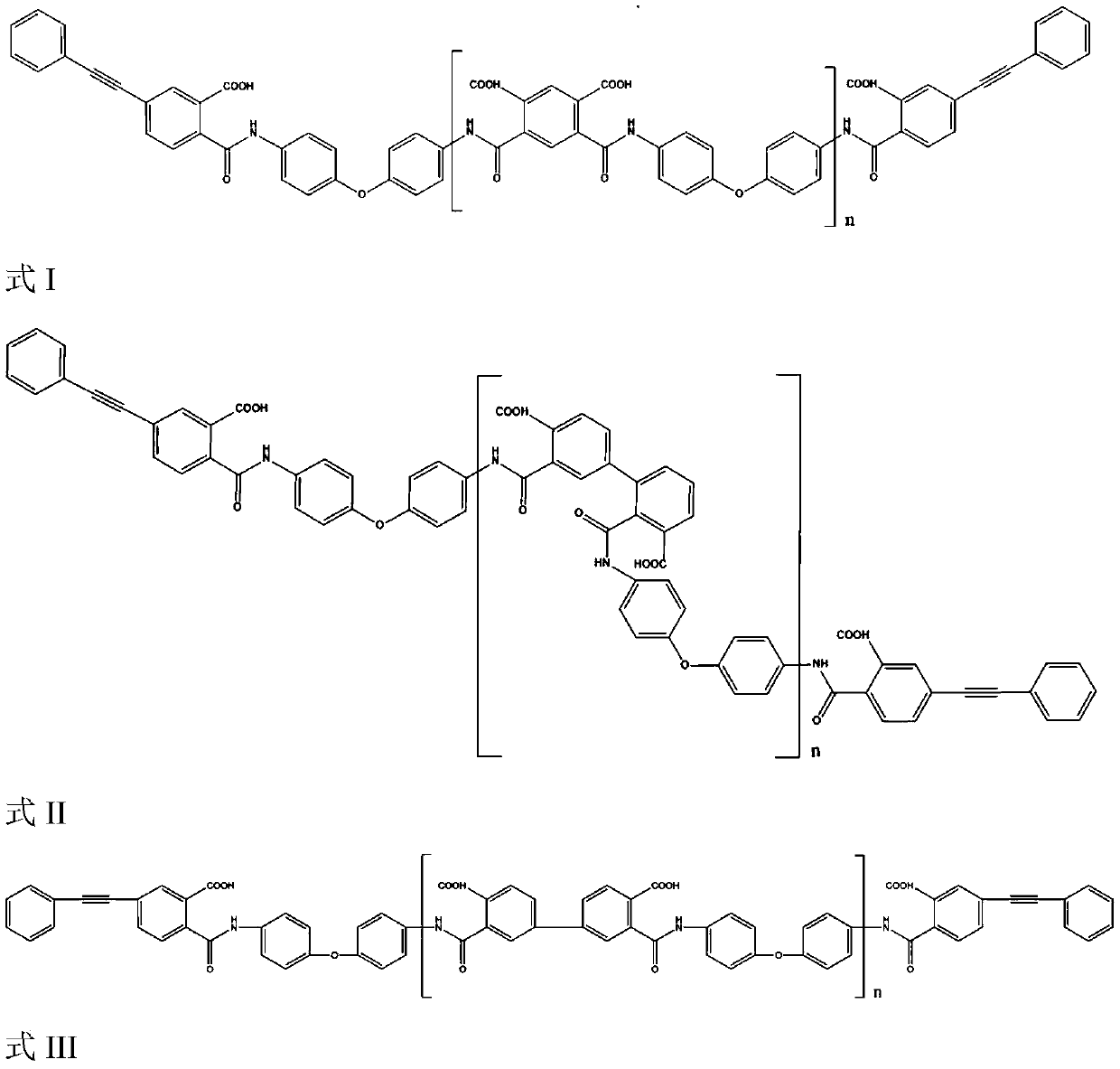

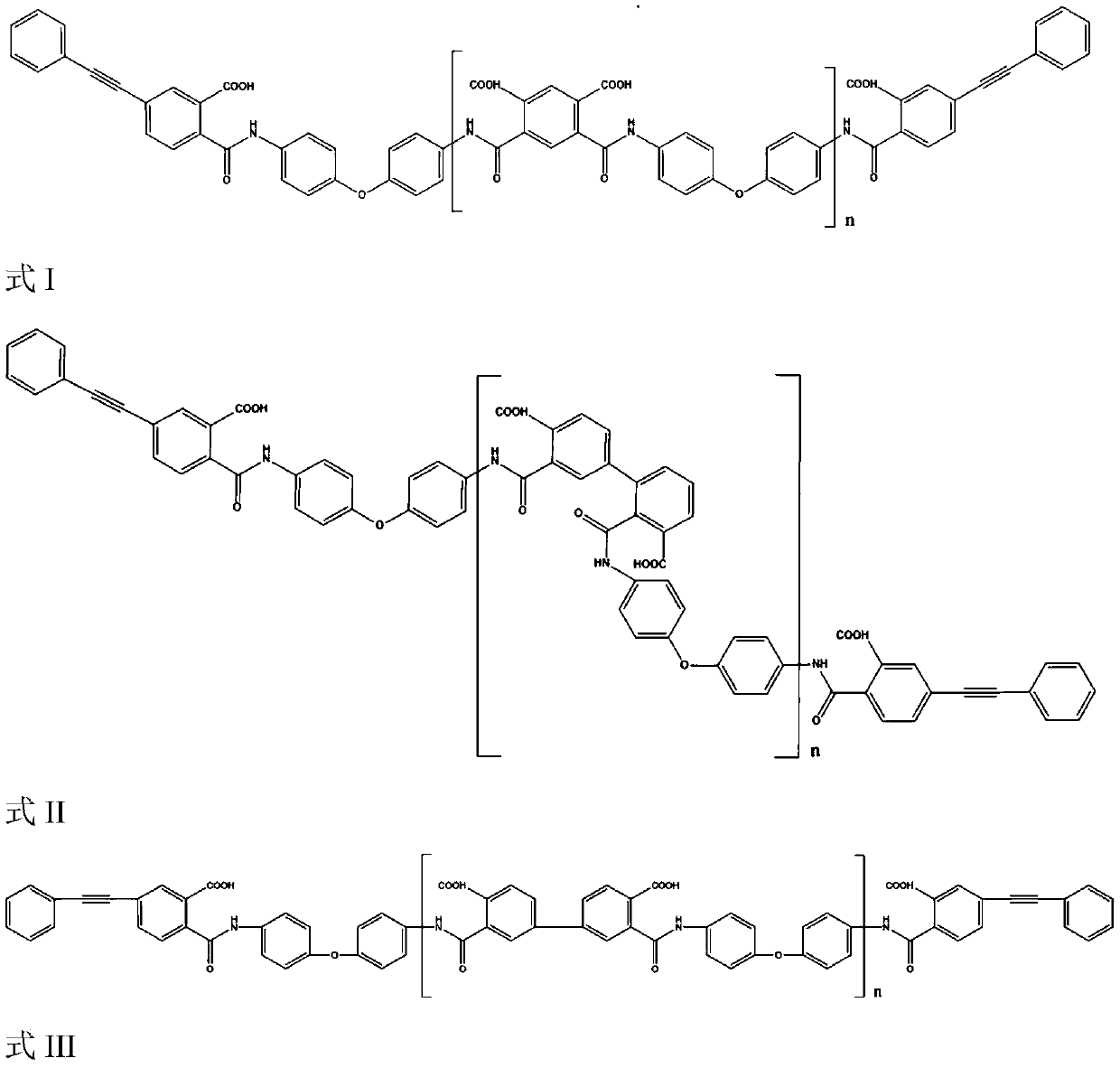

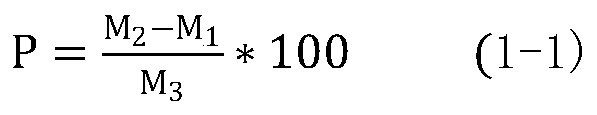

Preparation method of carbon fiber three-dimensional fabric enhanced polyimide-carbon based dual substrate composite material

The invention relates to a carbon fiber three-dimensional fabric enhanced polyimide-carbon based dual substrate composite material (PI-C / CF) which comprises carbon fiber three-dimensional fabric prefabricated bodies, carbon substrates and polyimide resin substrates. The carbon fiber three-dimensional fabric enhanced polyimide-carbon based dual substrate composite material prepared according to theembodiment has the advantages of excellent high-temperature resistance and excellent wear-resistant performance; the friction coefficient is small; the material belongs to a high-intensity high-temperature-resistant wear-resistant novel composite material, and the requirement in the fields of military science, aerospace and the like on the high-temperature wear-resistant structure element materials can be met.

Owner:SHANGHAI UNIV

A kind of preparation method of automobile brake disc

ActiveCN110131343BImprove friction performanceHigh mechanical strengthOther chemical processesFriction liningCarbon fibersPolysilazane

The invention discloses a fabrication method of an automobile brake disc. An automobile brake pair pre-fabricated body is fabricated with carbon fiber prepreg through integrated molding pressing, anda polysilazane solution and a polycarbosilane solution are used as a ceramic precursor; the automobile brake pair pre-fabricated body is fabricated through an integrated molding pressing process, andthe density of the pre-fabricated body is larger than 1.4 g / cm3; a carbon fiber automobile brake pair pre-fabricated part is impregnated through the liquid ceramic precursor; the liquid precursor is subjected to high-temperature pyrolyzing after cross-linking and solidifying are finished and then is converted into a ceramic substrate; and then the impregnation-pyrolysis process is repeated, and finally a carbon fiber reinforced carbon-based / ceramic-based composite material is obtained. The production period is shortened greatly, the production cost is reduced, the densification efficiency is improved, and through adjustment of the impregnation proportion of polycarbosilane and polysilazane, the friction property and mechanical strength of an automobile brake pair can be optimized at the same time.

Owner:XIAN AVIATION BRAKE TECH

A method for CVI densification of an open container and a gas pipeline structure

ActiveCN105463410BIncrease deposition rateImprove deposition qualityChemical vapor deposition coatingExhaust pipeVacuum pump

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

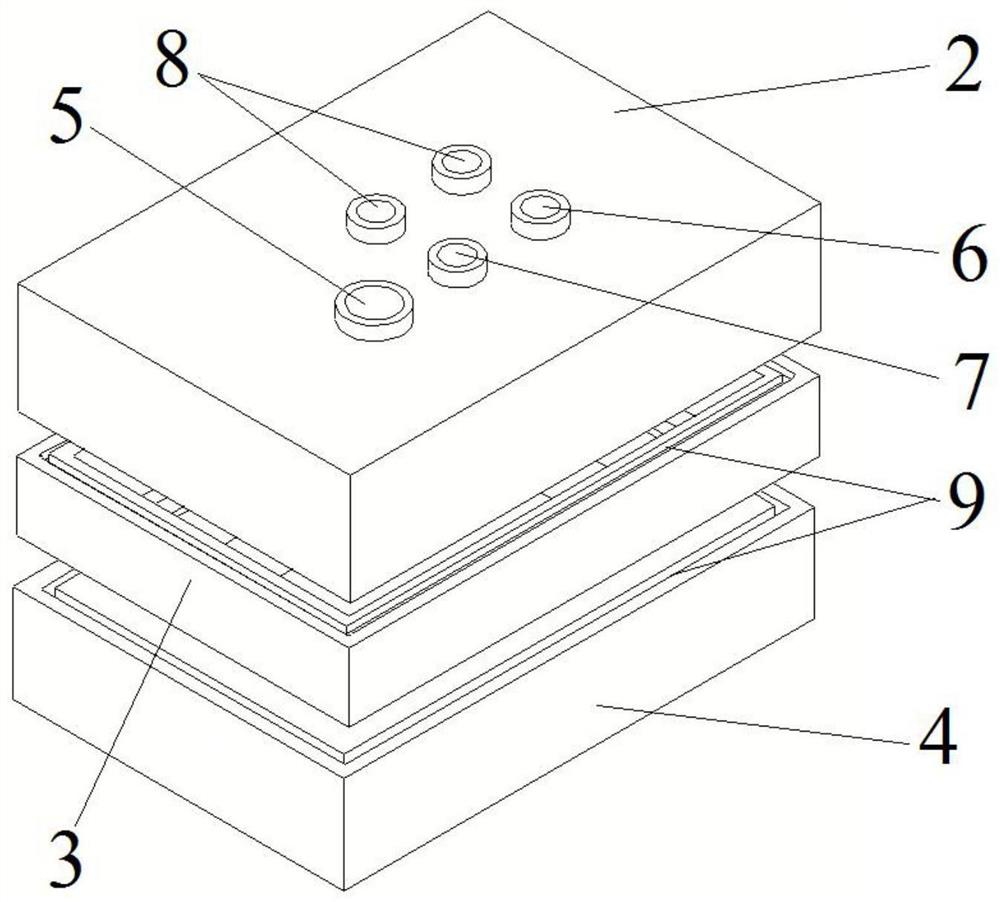

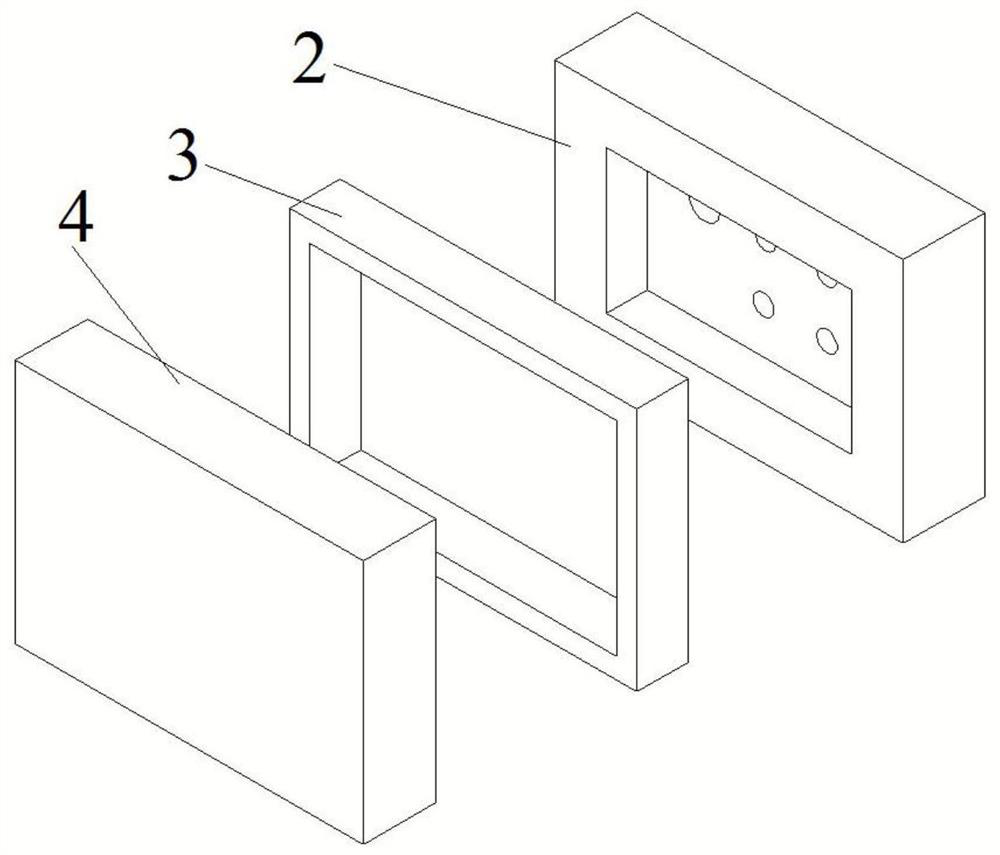

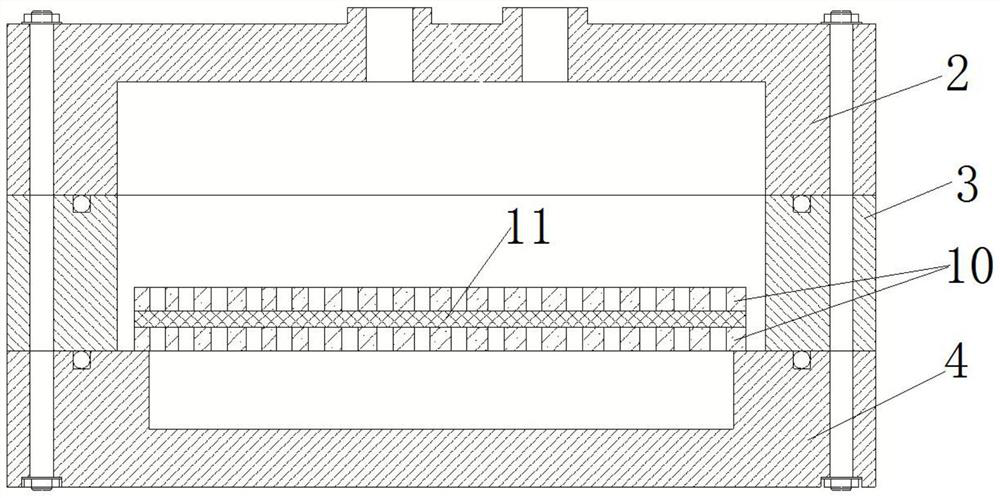

Densification tool mold and densification method for ceramic matrix composite matrix

The invention discloses a densification tool mold and densification method for ceramic matrix composite matrix, and the densification tool mold comprises a sealing end cover, a shape-preserving frame and a material storage base which are sequentially connected in a sealed mode; a flat-plate-shaped fiber prefabricated body is arranged between the shape-preserving frame and the sealing end cover, and a filling port and an air inlet are formed in the upper surface of the sealing end cover; the filling port is used for being communicated with a slurry feeding pipe, and the air inlet is used for being connected with an air pump. The upper surface of the sealing end cover is provided with an exhaust port and a connecting port used for connecting a pressure gauge and a safety valve, and the exhaust port is used for being connected with a vacuum pump. The flat-plate-shaped fiber prefabricated body is clamped through the shape-preserving frame, the size stability of the prefabricated body can be maintained, material deformation caused by external pressurization in the densification process can be effectively avoided, closed holes formed in the material in the impregnation process are effectively reduced, the repeated densification frequency can be reduced through pressurization of the air pump; therefore, the densification efficiency of the material is improved, and near-net forming of the ceramic-based composite material is realized.

Owner:BEIHANG UNIV

Preparation method of silicon carbide and silicon carbide composite material member

ActiveCN103387405BStrong process matchingShorten the manufacturing cycleCeramic matrix compositeNanotechnology

The invention relates to a preparation method of silicon carbide and silicon carbide composite material member, especially relates to a preparation method of deformed silicon carbide and silicon carbide composite material member, and belongs to the technology field of ceramic matrix composite material. The impregnation phase and the precursor used in the preparation method not only comprise the solid PCS, but also comprise the liquid PCS, which is more cheap, so the technology matching property of the member is stronger, the densification efficiency of the member is improved to some degree, the cost is reduced and the preparation period of the member is shortened. The impregnation phase has little harm to the environment and the operators, and only a general type ventilation device is needed.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com