Patents

Literature

1527results about How to "Small mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength chemical-physical dual-network hydrogel with self-recovery capability, and preparation method and application of hydrogel

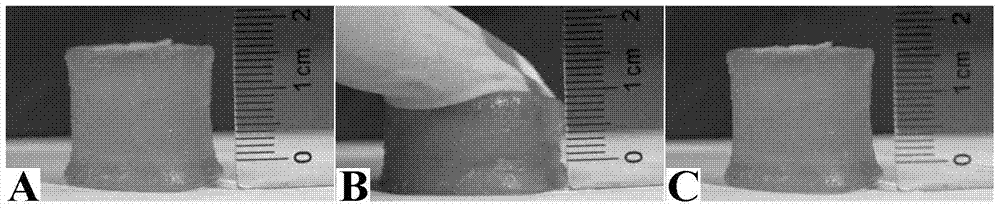

The invention discloses high-strength chemical-physical dual-network hydrogel with self-recovery capability, and a preparation method and application of the hydrogel. The high-strength chemical-physical dual-network hydrogel with the self-recovery capability is prepared from a first chemical network formed by the polymerization of hydrophilic monomers or by enabling hydrophilic macromolecules to be mixed and have a reaction, and a second physical network formed by carrying out physical crosslinking on polysaccharide and derivatives thereof, wherein the first chemical network and the second physical network are arranged in a way of being interspersed with each other. The dual-network hydrogel has high compressive strength and tensile strength, high toughness as well as good self-recovery property and fatigue resistance, and can maintain higher tensile strength and breakage elongation under the condition of having a notch. The prepared hydrogel has good mechanical property and biocompatibility, can be widely applied to the field of biological medicine, and can be used as a surface coating of a scaffold for tissue engineering, medical sponge or a medical implant.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Three-dimensional printing molding preparation method for porous ceramic for filtration

InactiveCN107098717ALoose connectionHigh precisionAdditive manufacturing apparatusDispersed particle filtrationShrinkage rateFiltration

The invention discloses a three-dimensional printing molding preparation method for a porous ceramic for filtration. The method comprises the following steps: S1 preparing a ceramic material for printing in a three-dimensional printer; S2 printing a porous ceramic green body through the three-dimensional printer by using the prepared printing ceramic material; and S3; conducting drying, rubber discharging and sintering on the printed porous ceramic green body to obtain a porous ceramic with a specific shape structure. The three-dimensional printing molding preparation method has the beneficial effects that ceramic particles are loose in connection, the density of the ceramic green body is low, the shrinkage rate after sintering is large, and the defects such as deformation and cracking are easy to occur, and the mechanical properties of the prepared products are lower; and a generated loose porous structure has larger pore size in pores, and the pore size and porosity are difficult to control through a molding process parameter. The ceramic material for printing according to the invention fully mixes solid powder with liquid additive, the ceramic particles are connected closely and the components are uniform, and the printed ceramic green body has high precision and good mechanical performance.

Owner:WUHAN UNIV OF TECH

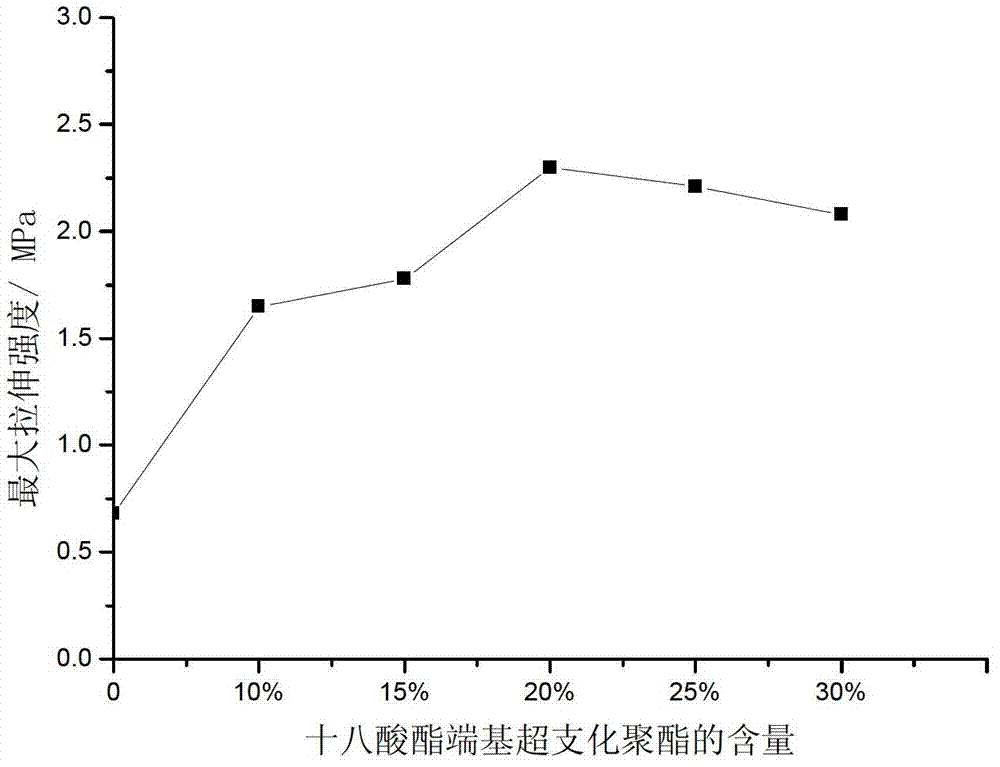

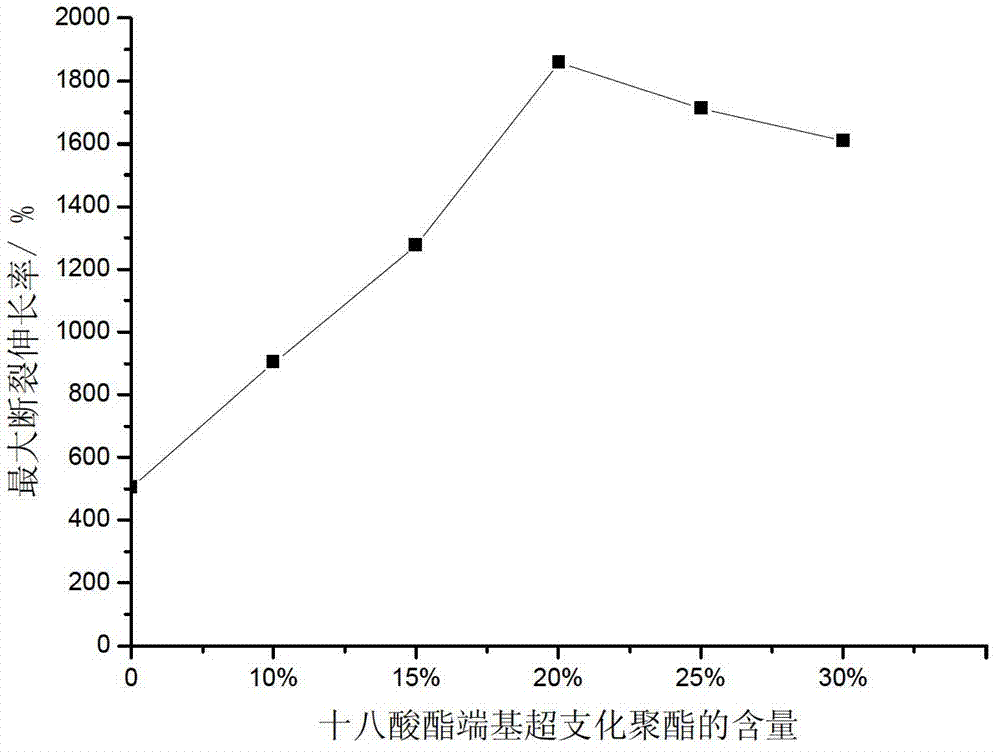

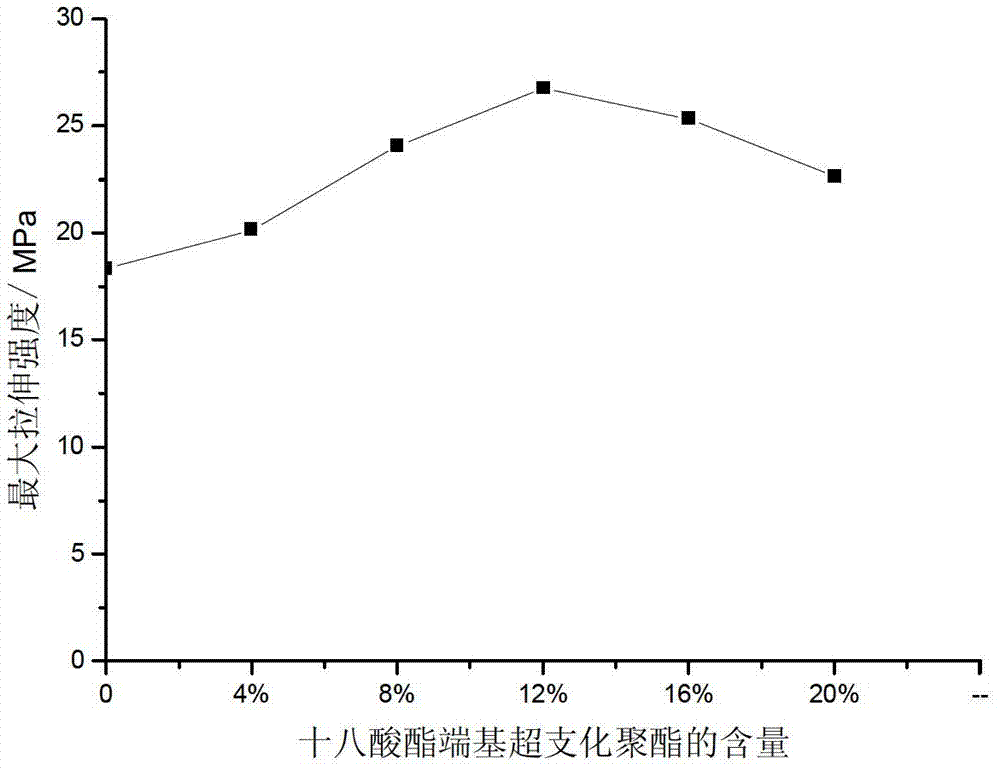

Application of fatty acid ester end group hyperbranched polyester as high polymer material viscosity reducing and toughening agent

InactiveCN103242627ASmall mechanical propertiesObvious viscosity reduction and toughening effectEpoxyPolyolefin

The invention discloses application of fatty acid ester end group hyperbranched polyester as a high polymer material viscosity reducing and toughening agent. According to the application disclosed by the invention, the fatty acid ester end group hyperbranched polyester is added into a thermosetting polyurethane prepolymer, an epoxy resin prepolymer, thermoplastic polyolefin or polyester for blending, and the viscosity and strength of the blending material are adjusted by adjusting the content of the fatty acid ester end group hyperbranched polyester. Viscosity tests prove that the viscosity of the blending material is reduced along with the increase of the content of the added fatty acid ester end group hyperbranched polyester at a processing temperature, and simultaneously, the mechanical property of the blending material is greatly improved.

Owner:东莞市鸿英新材料科技有限公司

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

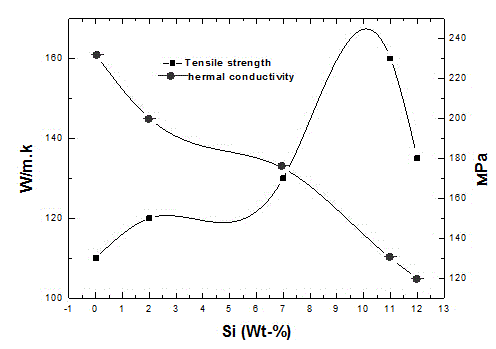

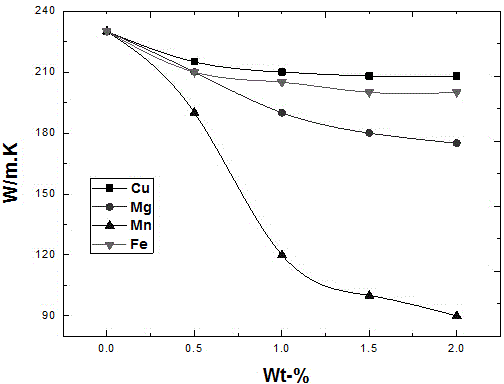

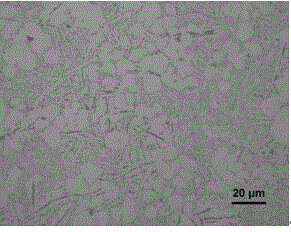

Hypoeutectic aluminum-silicon alloy with excellent thermal conductivity, preparation method and application thereof

ActiveCN104630576AReduce burning lossMeet the needs of casting long-term productionConductive materialMetal/alloy conductorsSilicon alloyCastability

The invention discloses a hypoeutectic aluminum-silicon alloy with excellent thermal conductivity. The alloy comprises the following chemical components: 5-9 wt% of Si, smaller than 0.5 wt% of Mg, smaller than 0.5 wt% of Cu, smaller than 0.7 wt% of Fe, smaller than 0.3 wt% of Mn, inevitable impurity elements and the balance of Al, a single inevitable impurity element is not less than 0.05 wt%, and the total amount of the inevitable impurity elements is lower than 0.25 wt%. The hypoeutectic aluminum-silicon alloy with thermal conductivity of 170-200 W / (m.K) can be obtained in a preparation process by such technical means as controlling the chemical components of the alloy and casting, and thermal treatment and the like. Good castability and mechanical properties of the aluminum-silicon alloy are guaranteed, and excellent thermal conductivity of the aluminum-silicon alloy is guaranteed at the same time.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

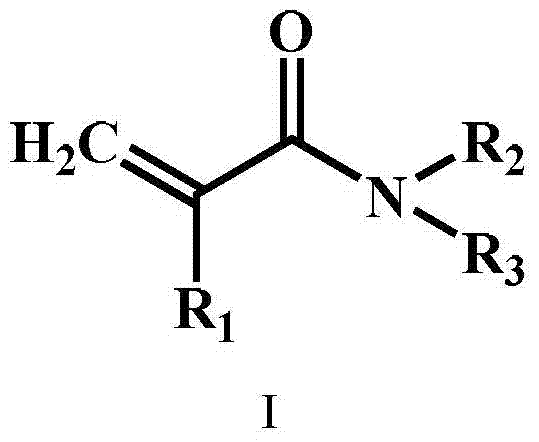

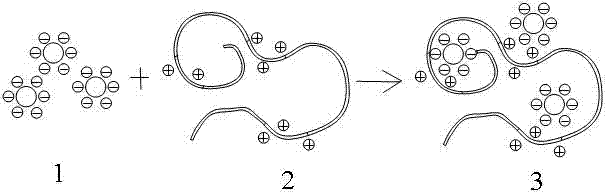

Quantum dot/acrylate polymer nanocrystal complex, preparation method of quantum dot/acrylate polymer nanocrystal complex, and colored conversion coating

ActiveCN103772872AGood dispersionEvenly dispersedPhotomechanical coating apparatusPhotosensitive materials for photomechanical apparatusPhotoluminescenceResin matrix

The invention discloses a quantum dot / acrylate polymer nanocrystal complex, a preparation method of the quantum dot / acrylate polymer nanocrystal complex, and a colored conversion coating, wherein the quantum dot / acrylate polymer nanocrystal complex is prepared by virtue of electrostatic interaction between an annion acrylate polymer and quantum dots with opposite charges. According to the invention, the quantum dots are pre-dispersed into the acrylate polymer, so as to prepare quantum dot / acrylate polymer nanocrystal complex. By virtue of similar composition of an acrylate polymer protection layer and acrylics as well as an acrylics modified photoresist resin matrix, the quantum dots can be easily dispersed into photoresist, are not easy to separate and are uniformly dispersed without aggregation, and thus the photoluminescent characteristic of the quantum dots is ensured. After the colored conversion coating prepared from the quantum dot / acrylate polymer nanocrystal complex is applied to a display, the colors of sub-pixel units of R / G / B colors corresponding to the colored conversion coating are relatively pure and have the relatively high saturability, energy of a backlight is sufficiently utilized, and the luminous efficiency is relatively high.

Owner:TCL CORPORATION

Heat resisting low expansion silumin and preparation thereof

The invention belongs to the field of non-ferrous materials and preparation and formation thereof, and relates to heat-resisting low-expansion high-silicon cast aluminum alloy. The alloy comprises the following compositions in percentage by mass: 18 to 25 percent of silicon, 1.0 to 2.5 percent of copper, 0.2 to 0.8 percent of magnesium, 0.5 to 2.5 percent of nickel, 0.3 to 0.6 percent of manganese, 0.3 to 1.0 percent of misch metal RE (the content of cerium is more than 40 percent), 0.006 to 0.04 percent of phosphorus, and the balance of aluminum. The production method comprises: firstly, melting raw materials of copper, nickel, silicon and aluminum into an aluminum silicon alloy fused mass; secondly, re-superheating the aluminum silicon alloy fused mass to the temperature of between 850 and 870 DEG C, adding manganese raw materials, and obtaining a mixed fused mass after uniform melting; thirdly, adjusting the temperature of the mixed fused mass to between 780 and 800 DEG C and adding the magnesium into the mixed fused mass; fourthly, adding rare earth raw materials into the mixed fused mass, maintaining at the temperature for 10 to 15 minutes, and raising the temperature to between 820 and 840 DEG C; fifthly, performing refining; and sixthly, raising the temperature of the refined mixed fused mass to between 830 and 850 DEG C, adding phosphorus raw materials into the mixed fused mass for modification, maintaining at the temperature for 15 to 20 minutes after modification, and performing casting, wherein the casting temperature is between 790 and 830 DEG C. Castings can well meet the performance requirements of peripheral materials of automobile engines after T6 heat treatment.

Owner:HUAZHONG UNIV OF SCI & TECH

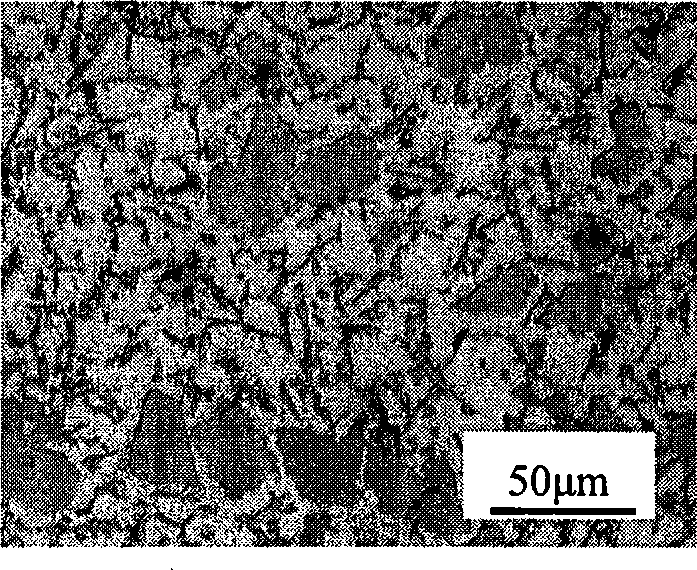

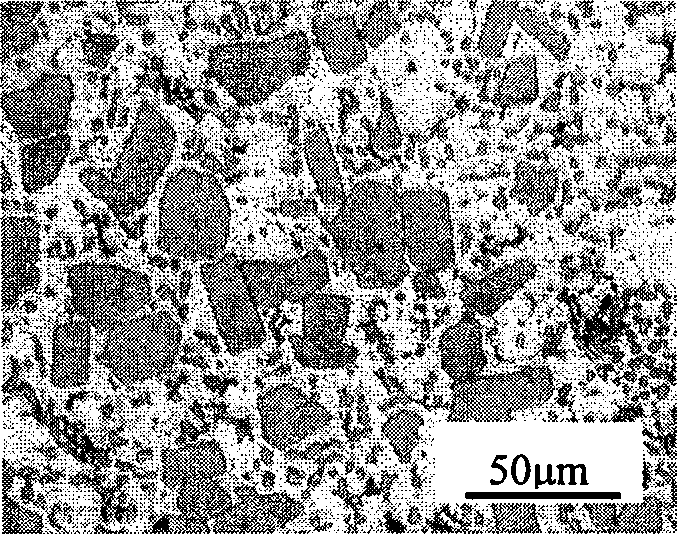

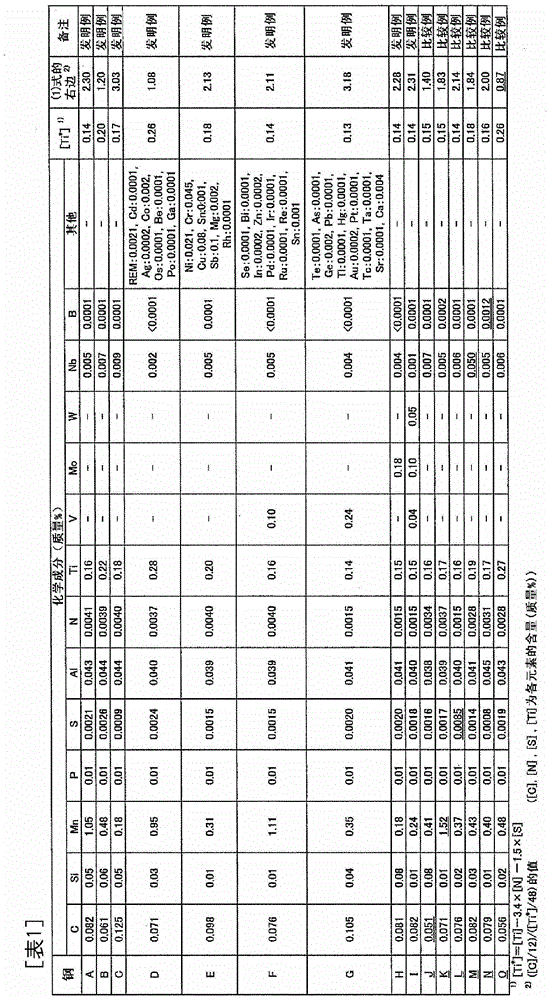

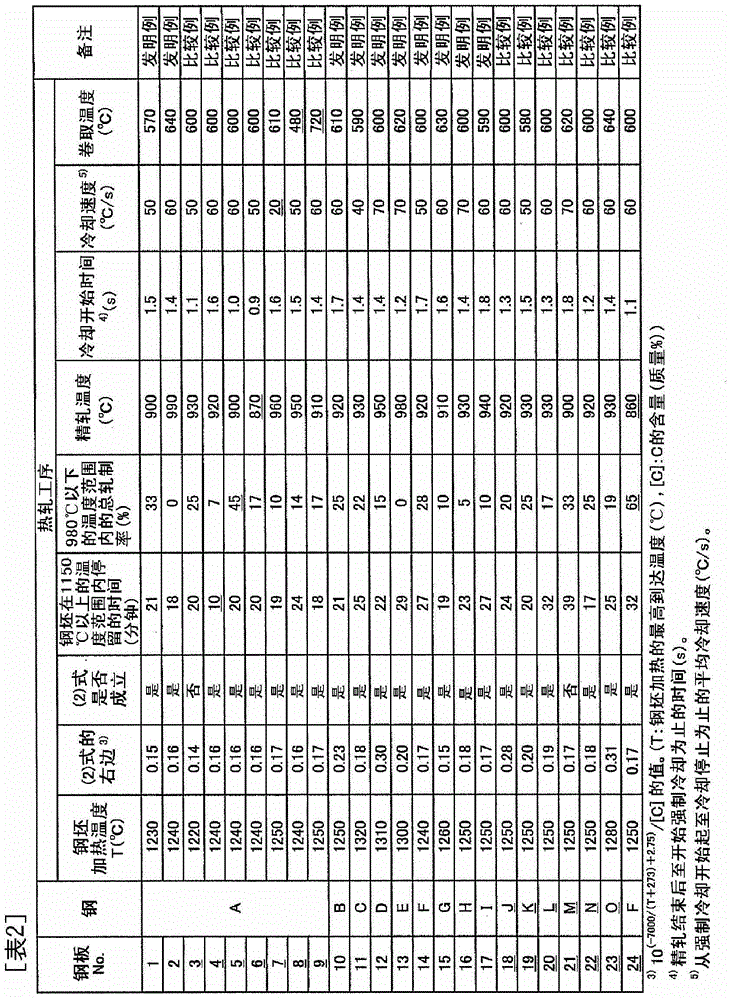

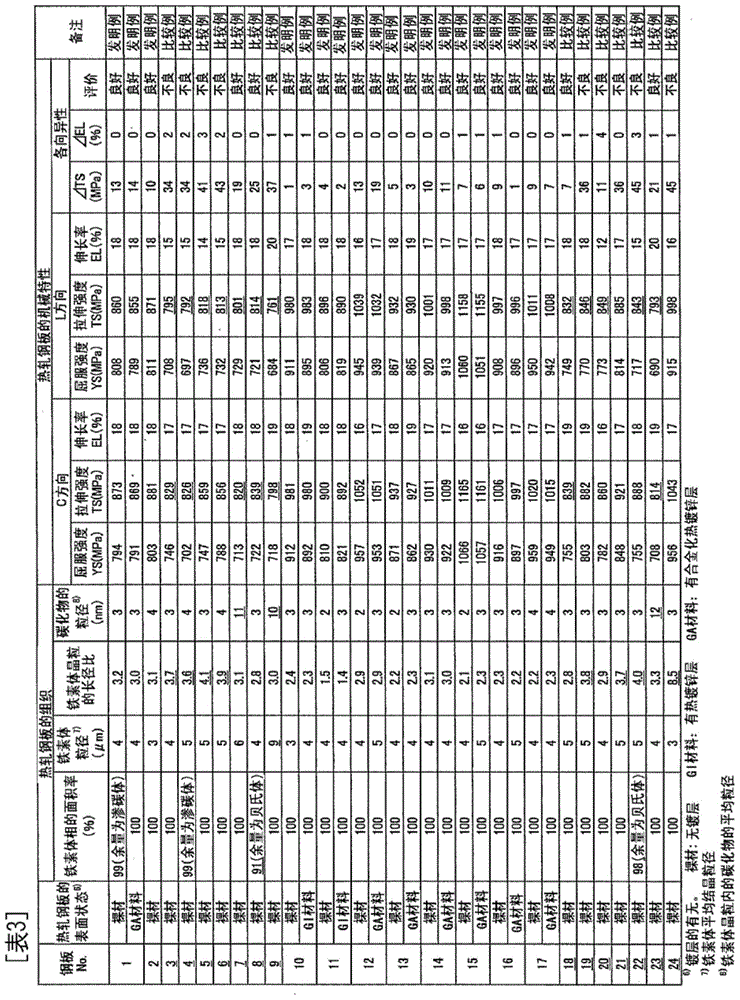

Hot-rolled steel sheet and process for manufacturing same

ActiveCN104011234ALow tensile strengthSmall mechanical propertiesHot-dipping/immersion processesFurnace typesSheet steelHot rolled

The present invention pertains to a process for manufacturing a hot-rolled steel sheet which comprises: heating a steel raw material that contains, in mass%, 0.055 to 0.15% of C, at most 0.2% of Si, at most 1.3% of Mn, at most 0.03% of P, at most 0.007% of S, at most 0.1% of Al, at most 0.01% of N and 0.14 to 0.30% of Ti so as to satisfy the relationship 1.0 <= ([C] / 12) / ([Ti*] / 48) (wherein [Ti*] = [Ti]-3.4[N]-1.5[S]) to a temperature (T) ( DEG C) which is equal to or higher than 1150 DEG C and which satisfies the relationship [Ti*] < 10{-7000 / (T+273)+2.75 / [C]; keeping the steel raw material in a temperature range down to 1150 DEG C for at least 15 minutes; subjecting the resulting steel raw material to hot rolling wherein the total rolling reduction in a temperature range up to 980 DEG C is 40% or less and the finish rolling temperature is 880 DEG C or higher; cooling the hot-rolled steel sheet at a cooling rate of 40 to 200 DEG C / s within three seconds after the completion of the finish rolling; and winding up the cooled steel sheet in a temperature range of 500 to 680 DEG C.

Owner:JFE STEEL CORP

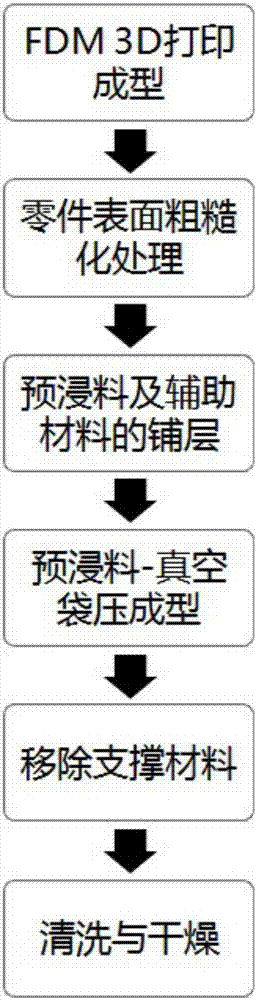

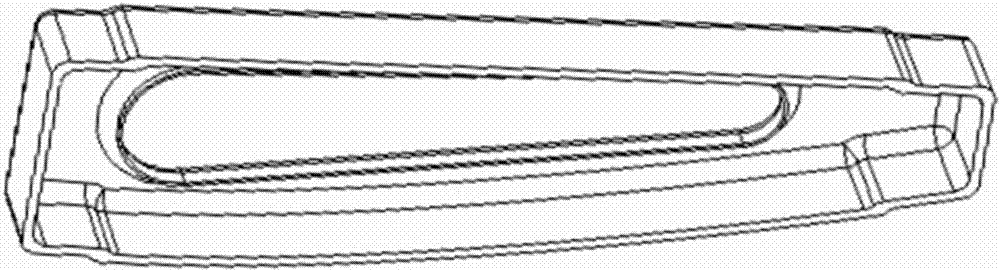

3D printing assisted forming method for fiber reinforced composite material

ActiveCN107187020AImprove surface roughnessIncrease mechanical bite forceAdditive manufacturing apparatus3D object support structuresFiber-reinforced compositeInvestment material

Provided is a 3D printing assisted forming method for a fiber reinforced composite material. An FDM 3D printing forming method and a continuous fiber composite material forming method are combined, a prepreg coating and an assisting material are laid on the surface of a part in a prepreg-vacuum bag molding composite material forming mode with an FDM 3D formed part as a forming mold, curing of prepreg is completed under a certain degree of temperature and pressure, and a supporting material is removed, cleaned and dried. By integrating the advantages of the flexibility and high precision of FDM 3D printing forming and the advantages of low weight and high strength of the composite material, the defects that FDM 3D printing forming is low in strength while the composite material is can not be separated from the mold easily are overcome, and the fiber reinforced composite material of a complex structure can be formed and manufactured into parts.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Non-halogen fire-retardant polypropylene and production thereof

Non-halogen fire-retardant polypropylene and its production are disclosed. The polypropylene consists of homopolymer polypropylene particle and fire-retardant agent. The fire-retardant agent consists of aluminum hydroxide, magnesium hydroxide and polyammonium phosphate. The process is treating aluminum hydroxide and magnesium hydroxide from coupling agent, coating polyammonium phosphate from cyanurotriamide -formaldehyde resin, dispersing treated nanometer particle on polypropylene matrix, premixing for polypropylene powder, nanometer aluminum hydroxide, magnesium hydroxide and polyammonium phosphate microcapsule proportionally in high-speed mixer from single-screw extrude and blend method, adding into single-screw extruder at normal feed rate, temperature and rotation speed, extruding, cooling and granulating. It achieves smokeless, non-toxic, good fire-retardant performance and less pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Metakaolin-based polymer foam concrete and preparation method thereof

The invention relates to metakaolin-based polymer foam concrete and a preparation method thereof. Metakaolin, coal ash and a coagulation accelerating agent are added into a mixing machine in proportion to be mixed to be uniform, an alkali excitant and water are added in proportion, and mixing is carried out to prepare slurry; while the slurry is prepared, a foaming agent is diluted with water in proportion of 1: 15, a high-speed mixing machine or a vacuum foaming machine is adopted for preparing fine and stable foam; and according to density design requirement, the prepared foam is blended into the uniformly mixed slurry in volume ratio to be mixed and foamed, wherein the volume ratio of the foam to the slurry is (1-4):1, and mixing is carried out for 2.5-3min until the foam is uniformly dispersed in the slurry, thus freshly blended metakaolin-based polymer foam concrete is prepared. Compared with the traditional cement-based foam concrete taking silicate cement as a main cementing material, the metakaolin-based polymer foam concrete has the characteristics of environmental friendliness, higher strength, low thermal conductivity, good heat insulating property and the like, and can be used for producing various foam concrete products.

Owner:CHONGQING UNIV

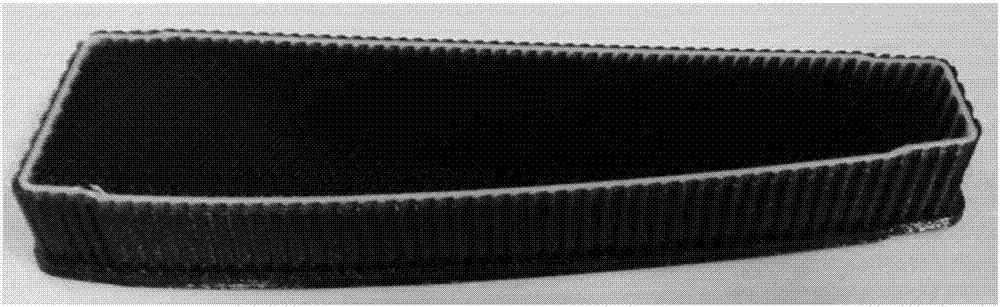

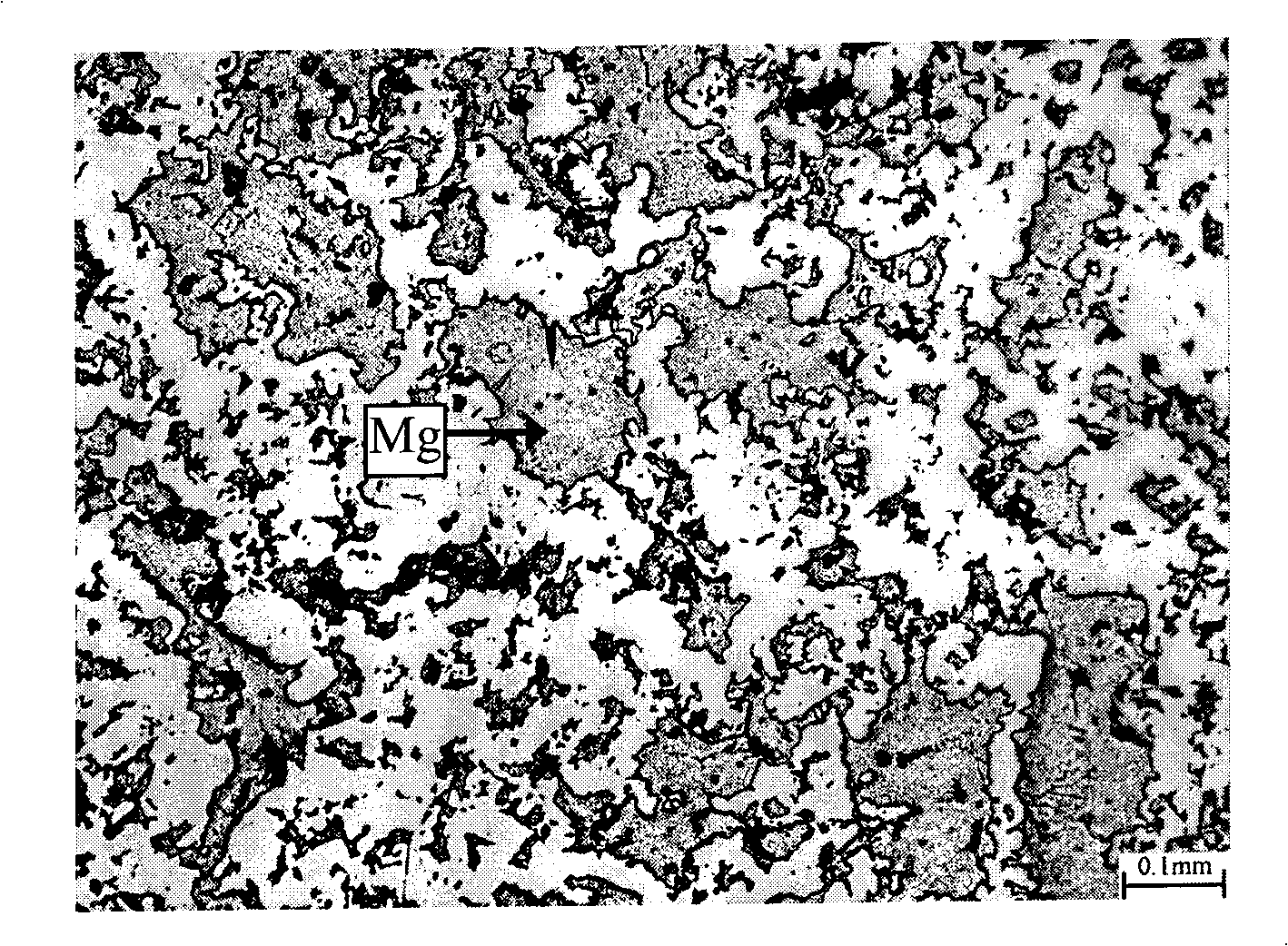

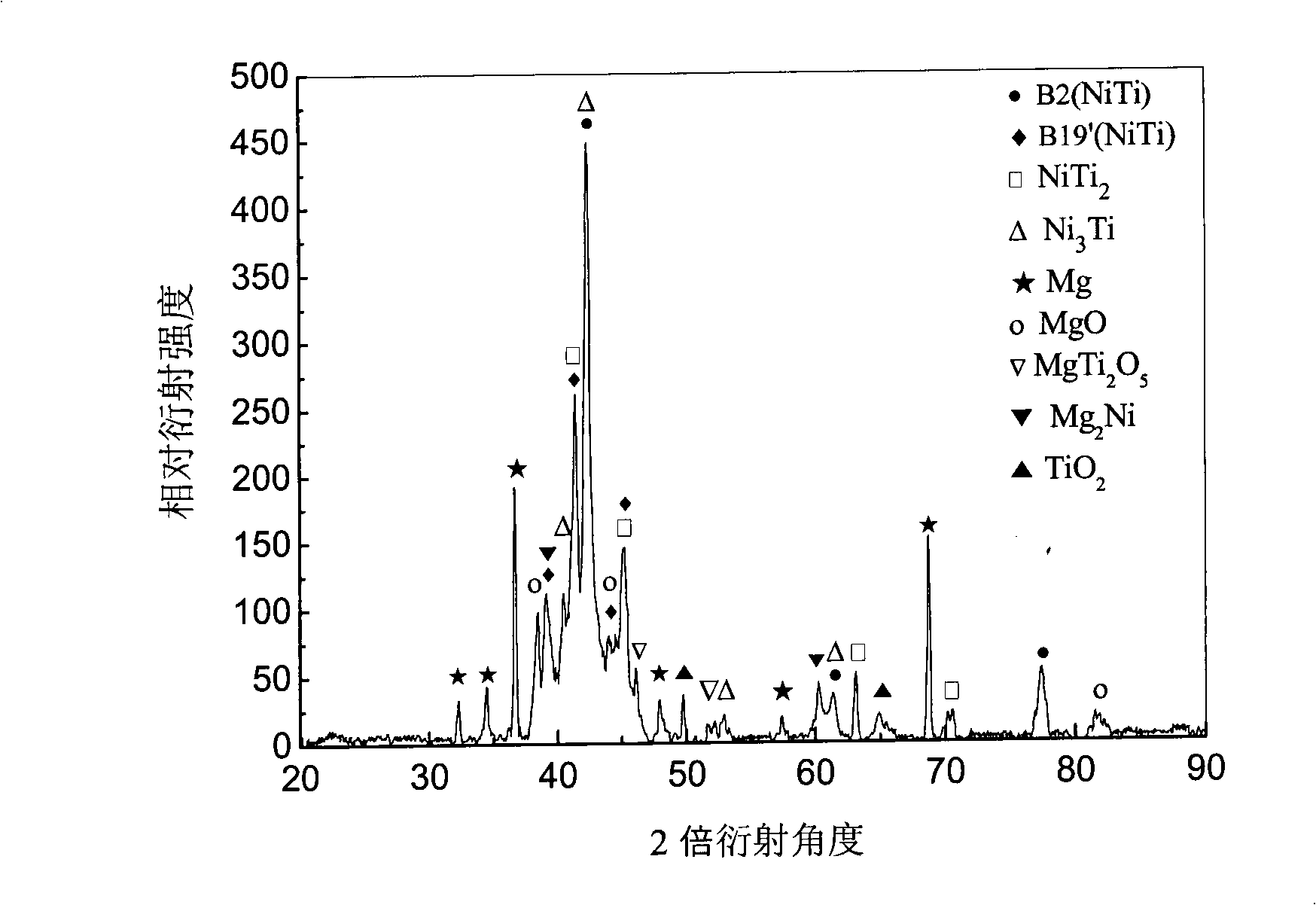

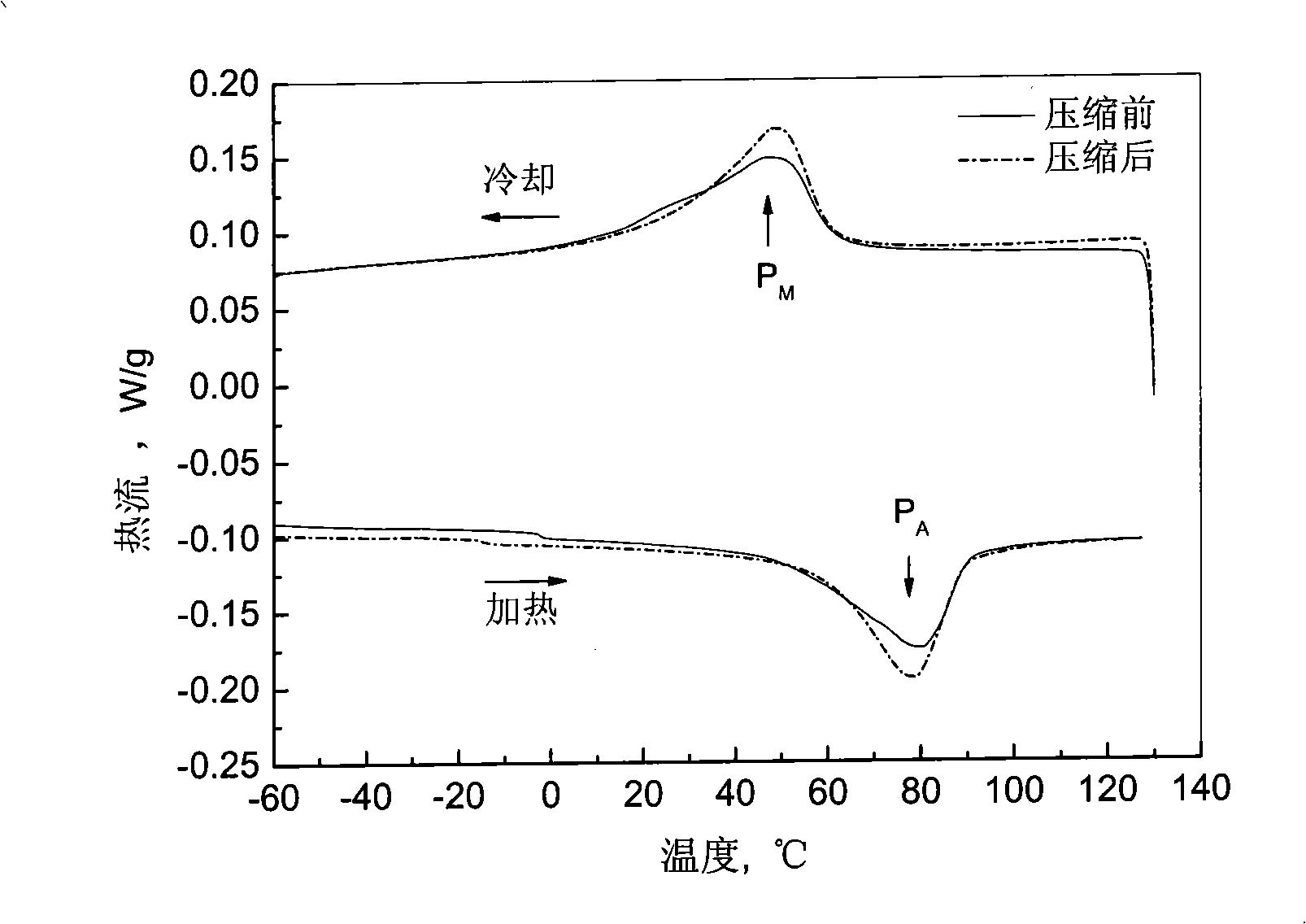

Preparation of composite type light high-strength nickel-titanium memory alloy-based high damping material

The invention discloses a preparation method of a compound type light-weight high-intensity nickel-titanium memorial alloy base high damping material. In the method, a powder sintering method is mainly used as a foundation and a pressureless infiltration technology is used as assistance; a pore-creating technology is firstly adopted; and a unit metal powder cascade sintering method is used for preparing a porous nickel-titanium alloy the holes of which are uniformly distributed; and then the pressureless infiltration technology is adopted for inducing the pure magnesium or magnesium alloy phase with high intrinsic damping, low density and micron scale into the porous nickel-titanium alloy, thereby preparing the high-damping magnesium(or magnesium alloy) / nickel-titanium memorial alloy base compound material the damping control phase of which is magnesium or the magnesium alloy. The compound nickel-titanium memorial alloy prepared by the invention still has the shape memory effect and the superelasticity action as well as has weight lighter than that of the compact nickel-titanium memorial alloy and intensity and damping capacity more excellent than that of the common porous nickel-titanium memorial alloy. The preparation method has good technical suitability, simple preparation process and low cost, and can be used for manufacturing the light-weight high-intensity compound damping materials, damping structures and apparatuses.

Owner:SOUTH CHINA UNIV OF TECH

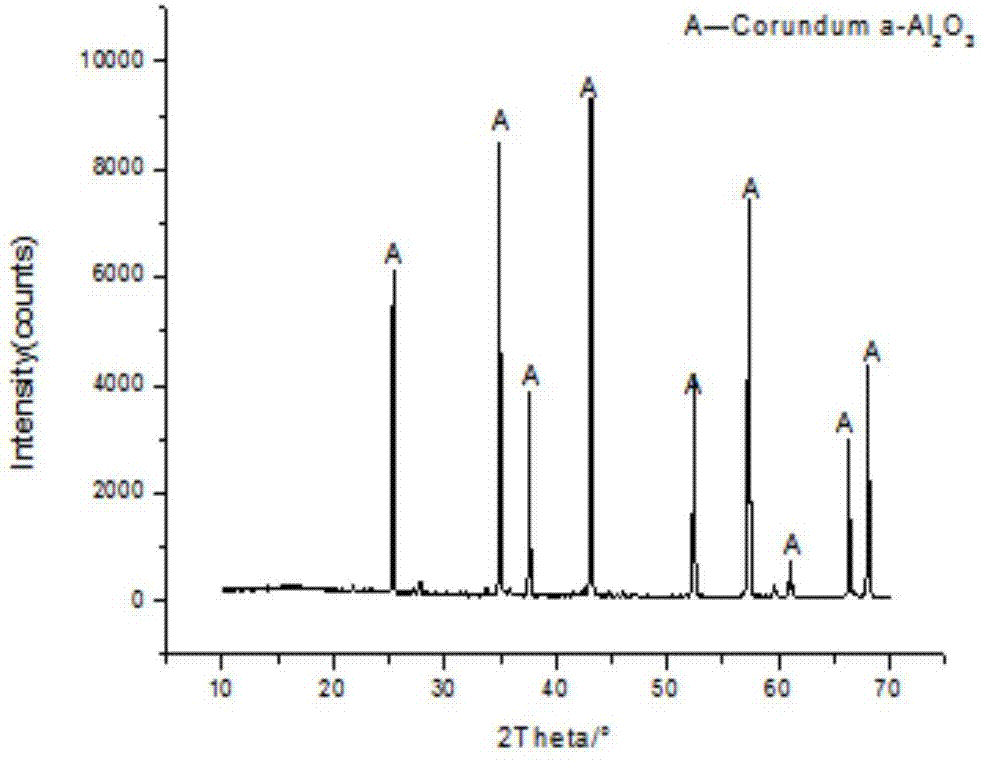

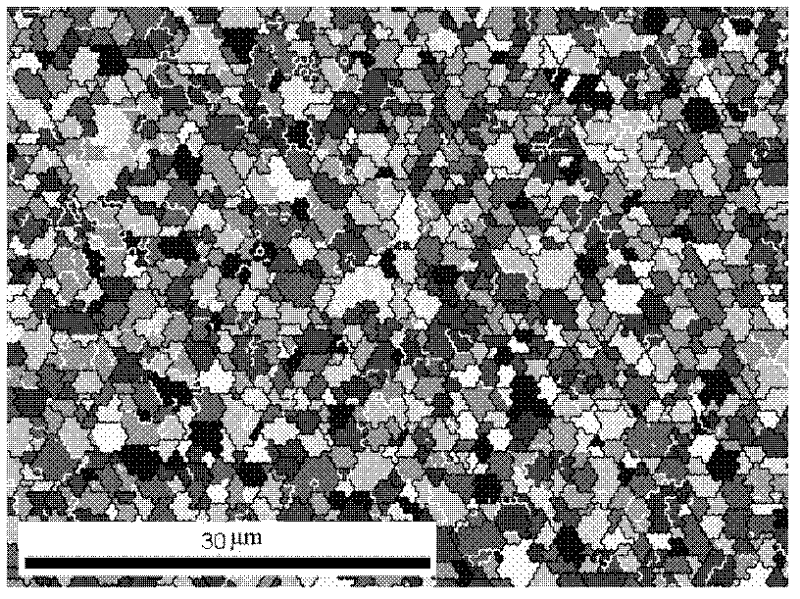

Submicron transparent crystal alumina ceramic possessing high linear transmittance

The present invention belongs to the field of transparent ceramic material technology, and is especially preparation process of submicron transparent crystal alumina ceramic possessing high linear transmittance. The transparent alumina ceramic is prepared with high purity alumina and nanometer zirconia additive, and through drying pressing and cold isostatic pressing or gel injecting to form, low temperature pre-sintering and hot isostatic pressing sintering. It has ceramic body relative density greater than 99.95 %, average crystal size not greater than 0.5 micron, Vickers hardness of 2200, bending strength of 650-800 MPa and linear transmittance at 600 nm greater than 60 %. It is suitable for use in making transparent bulletproof armoring, high temperature observation window, false teeth, etc.

Owner:韩敏芳 +1

Grapheme modified polypropylene master batch and preparation method thereof

InactiveCN103819815AKeep the cladding structureThere will be no local unevennessHeat conductingAntioxidant

The invention provides a grapheme modified polypropylene master batch and a preparation method thereof. The grapheme modified polypropylene master batch comprises the following raw materials in parts by weight: 100 parts of polypropylene particles, 0.01 to 5 parts of grapheme dry powder, 0.01 to 1 part of an antioxidant, 0.1 to 10 parts of a plasticizer, 1 to 10 parts of a light stabilizer, 1 to 10 parts of a lubricant, and 0 to 40 parts of a filler. The preparation method comprises the following steps: performing spraying modification on the polypropylene particles through the grapheme dry powder with static electricity, uniformly mixing the modified polypropylene particles with the rest of constituents, then feeding the mixture into a double-screw extruder for fusing and mixing, and finally extruding for granulation. The method enhances the mechanical property of the polypropylene material under the condition that the heat-conducting property of the polypropylene material is greatly improved.

Owner:北京纳新天地科技发展有限公司

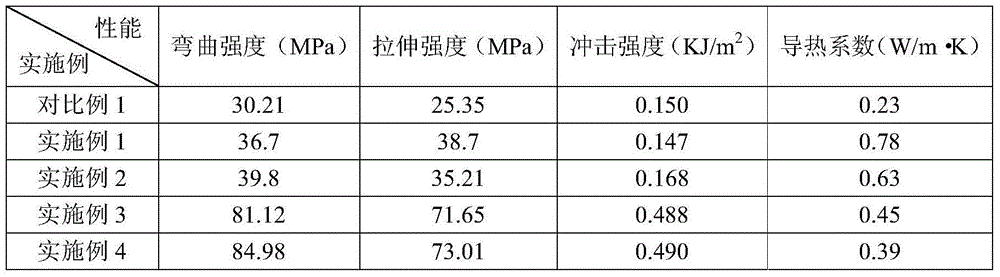

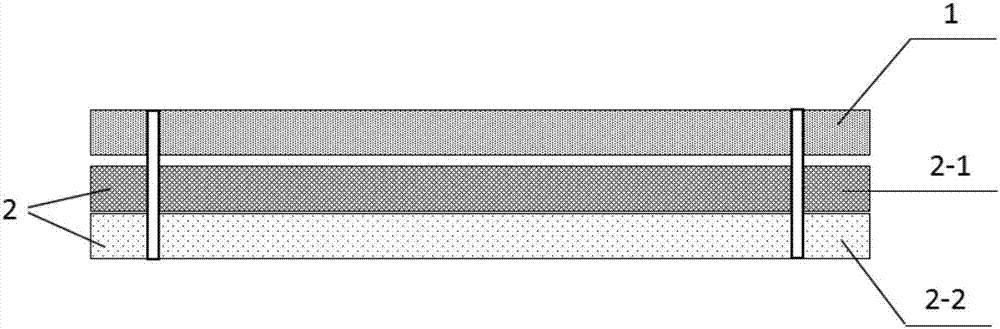

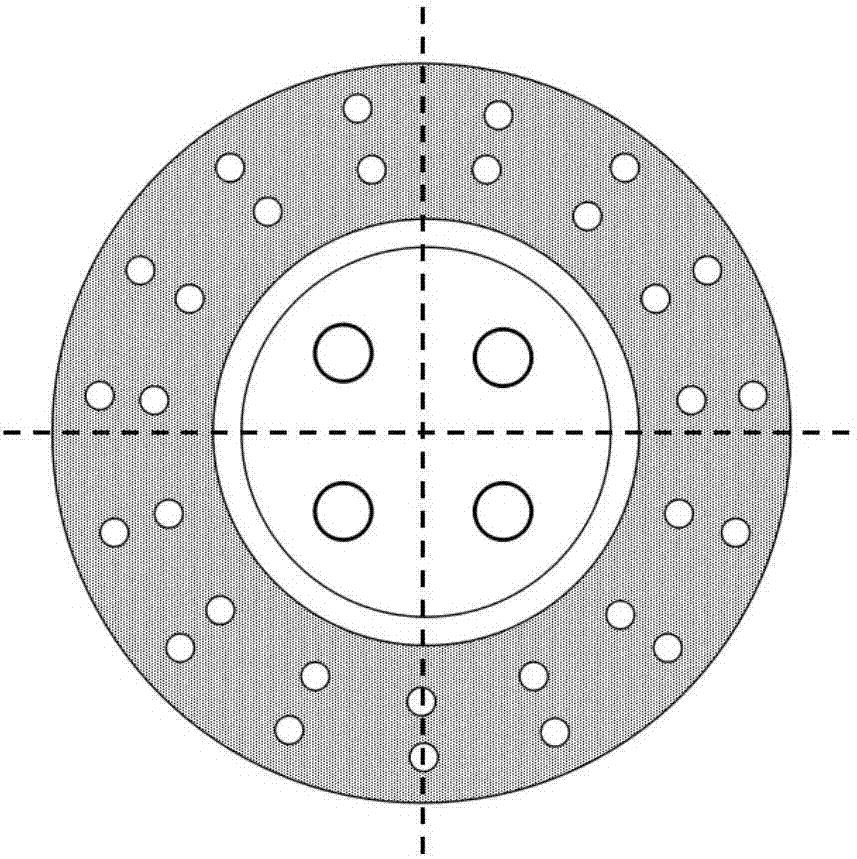

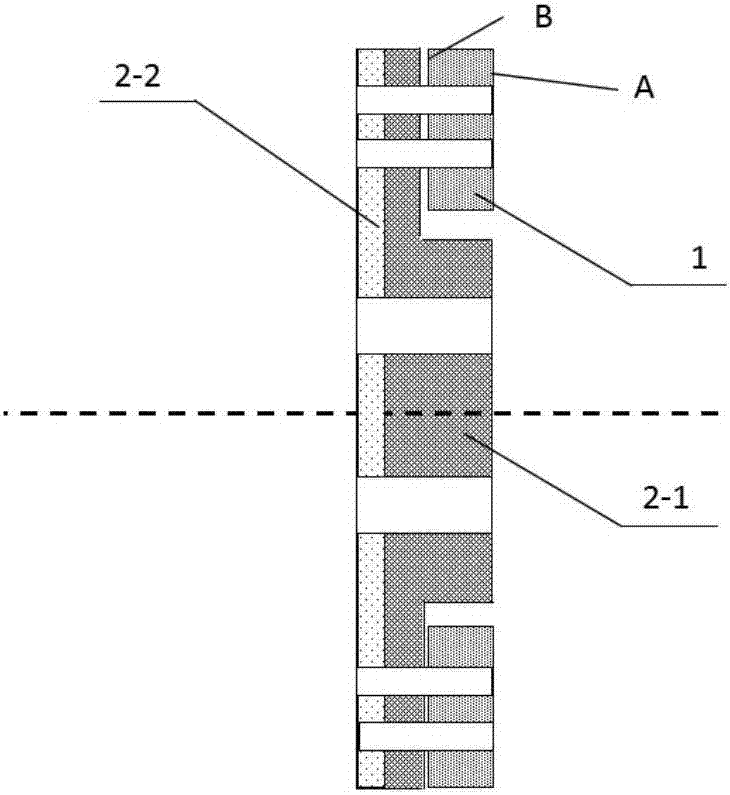

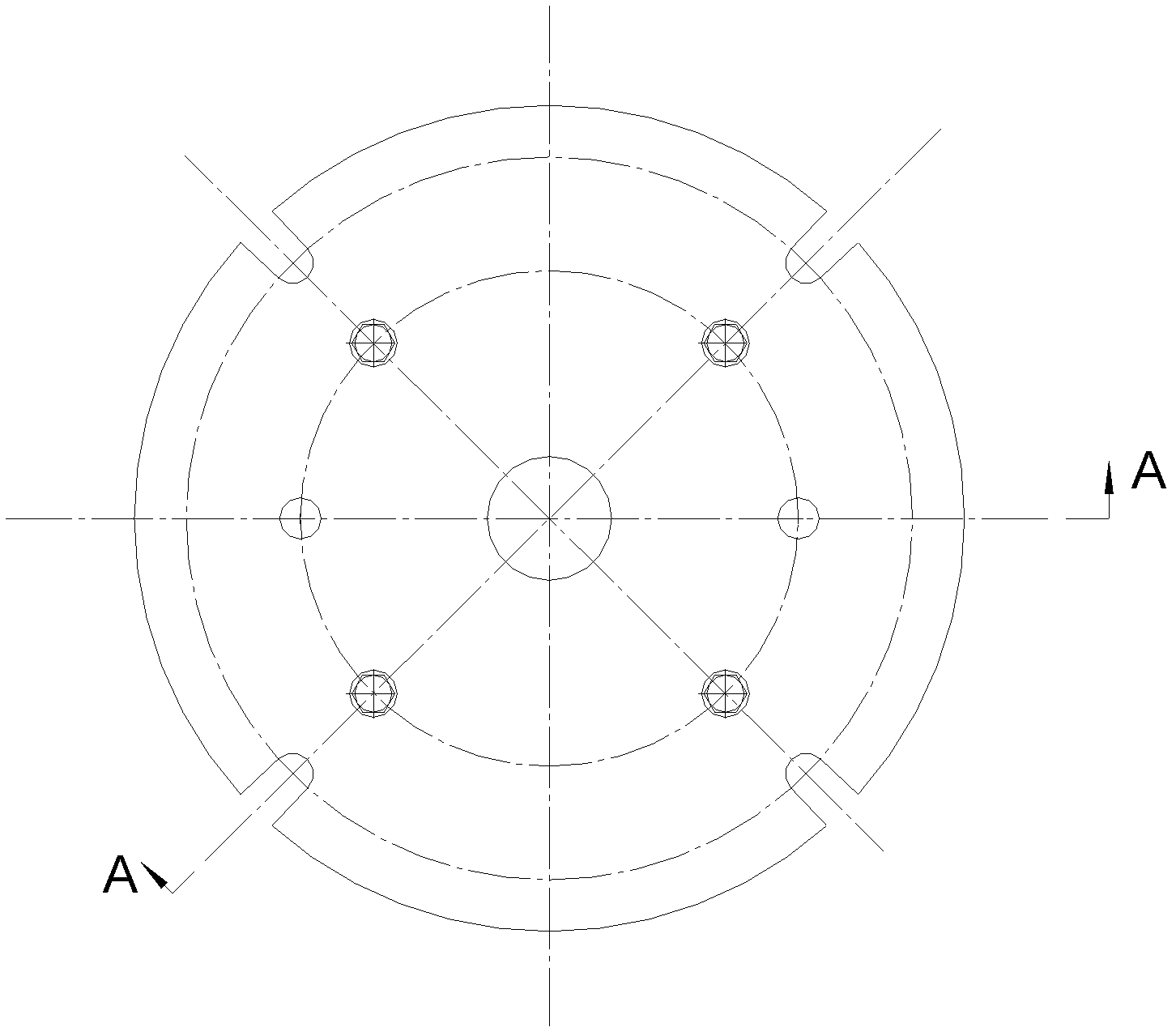

Combined composite brake disc, preparation method and application

ActiveCN107100949AImprove mechanical propertiesImprove wear resistanceBraking discsActuatorsCeramic compositeMaterials science

The invention relates to a combined composite brake disc, a preparation method and application, and belongs to the technical field of development of special brake discs. The combined composite brake disc comprises a friction disc body (1) and a connecting and supporting disc body (2). The friction disc body (1) is of a carbon-ceramic composite, and the connecting and supporting disc body (2) is of a gradient aluminum matrix composite compounded in a hot-pressing mode. The combined composite brake disc comprises the friction disc body (1) of the carbon-ceramic composite and the connecting and supporting disc body (2) of the gradient aluminum matrix composite. The friction disc body (1) of the carbon-ceramic composite and the connecting and supporting disc body (2) of the gradient aluminum matrix composite are connected into a whole through riveting. The brake disc designed in the invention is obviously longer than existing products in service life when being applied to high-speed trains.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

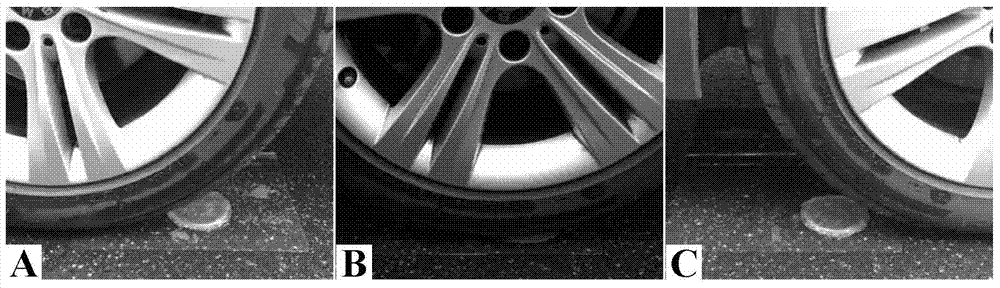

Thermotropic type shape memory composite material

InactiveCN105802188ASmall mechanical propertiesImprove mechanical propertiesWoven fabricsCarbon nanotubeDual function

The invention belongs to the field of shape memory functionalized application technology of high performance polymer matrix composite materials, and provides a thermotropic type shape memory composite material. The material comprises the following components: a shape memory polymer and carbon nanotube, wherein the content of the shape memory polymer is 15-85wt%, and the content of the carbon nanotube is 85-15wt%. The carbon nanotube has excellent mechanical properties, electrical property and thermal conductance performance; the carbon nanotube can be used as an enhancer of the polymer matrix composite material, and can be used as a heating element of the thermotropic type shape memory composite material. The thermotropic type shape memory composite material needs to be heated to a certain temperature in order to realize the function thereof, the carbon nanotube of the carbon nanotube enhanced polymer matrix shape memory composite material can be directly electrified for heating, so that dual functions for enhancing and heating the shape memory composite material are realized.

Owner:AVIC COMPOSITES

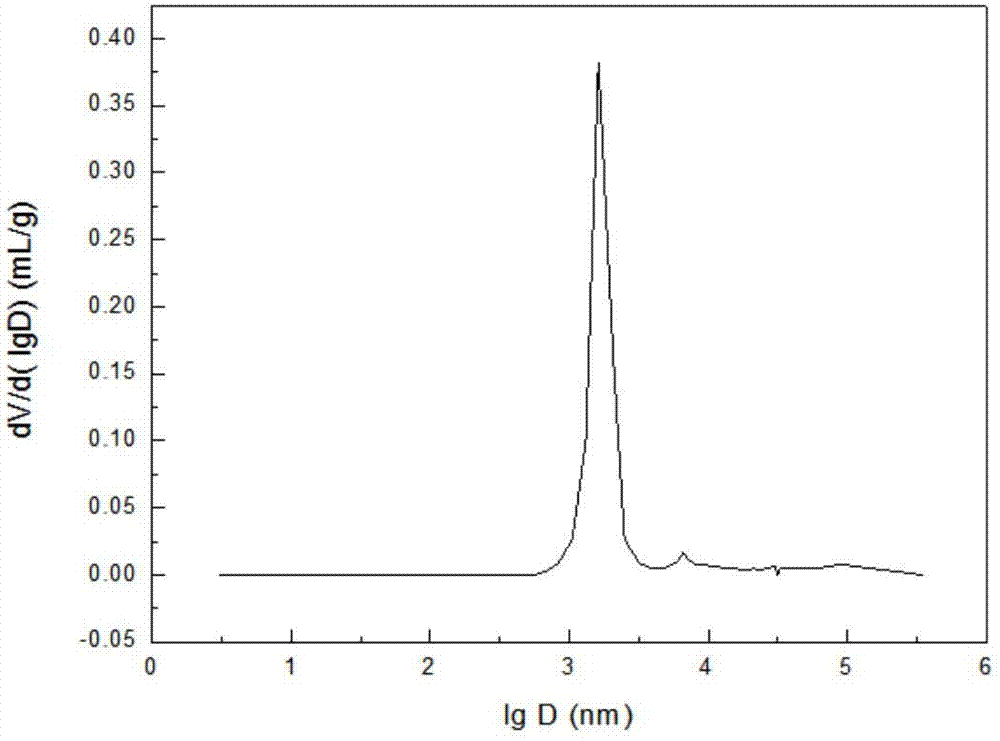

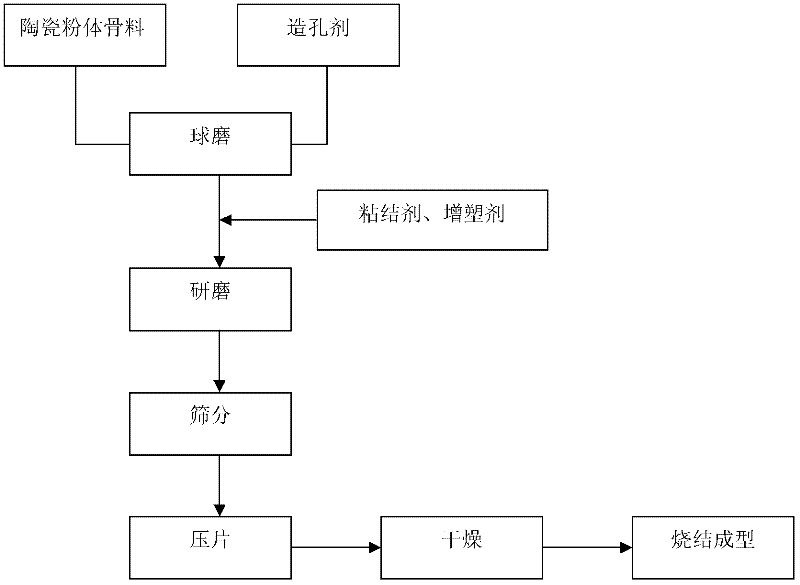

Method for preparing high-porosity porous ceramic membrane support

The invention relates to a method for preparing a high-porosity porous ceramic membrane support, comprising the following specific steps of: performing mixed ball milling and dispersion on a ceramic powder aggregate and a pore-forming agent, adding in a binder and a plasticizer, and then performing grinding, sieving, tabletting, drying and sinter molding. The method provided by the invention overcome the problem of easy formation of large pores in the presence of the pore-forming agent and further improves the porosity of the support without reducing the overall performance of the support by improving the purity of the ceramic powder aggregate and adjusting the content of the pore-forming agent, the size distribution and the sintering schedule; and as a result, the penetrating quality of the support is improved.

Owner:NANJING UNIV OF TECH

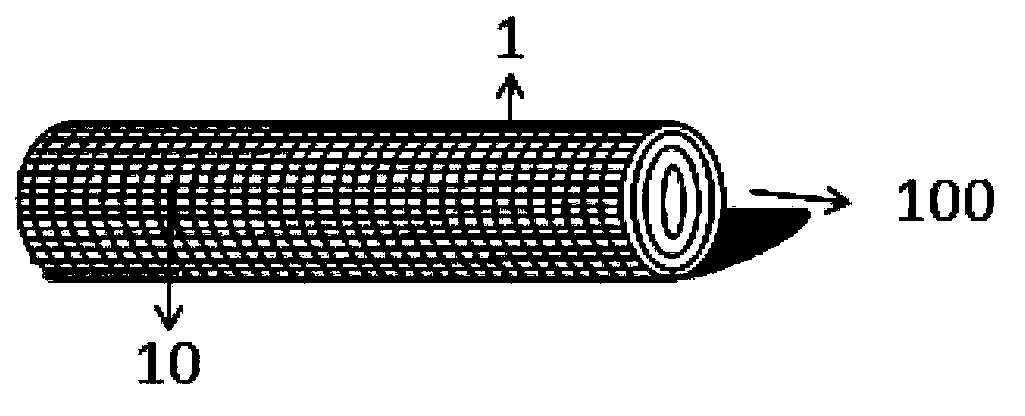

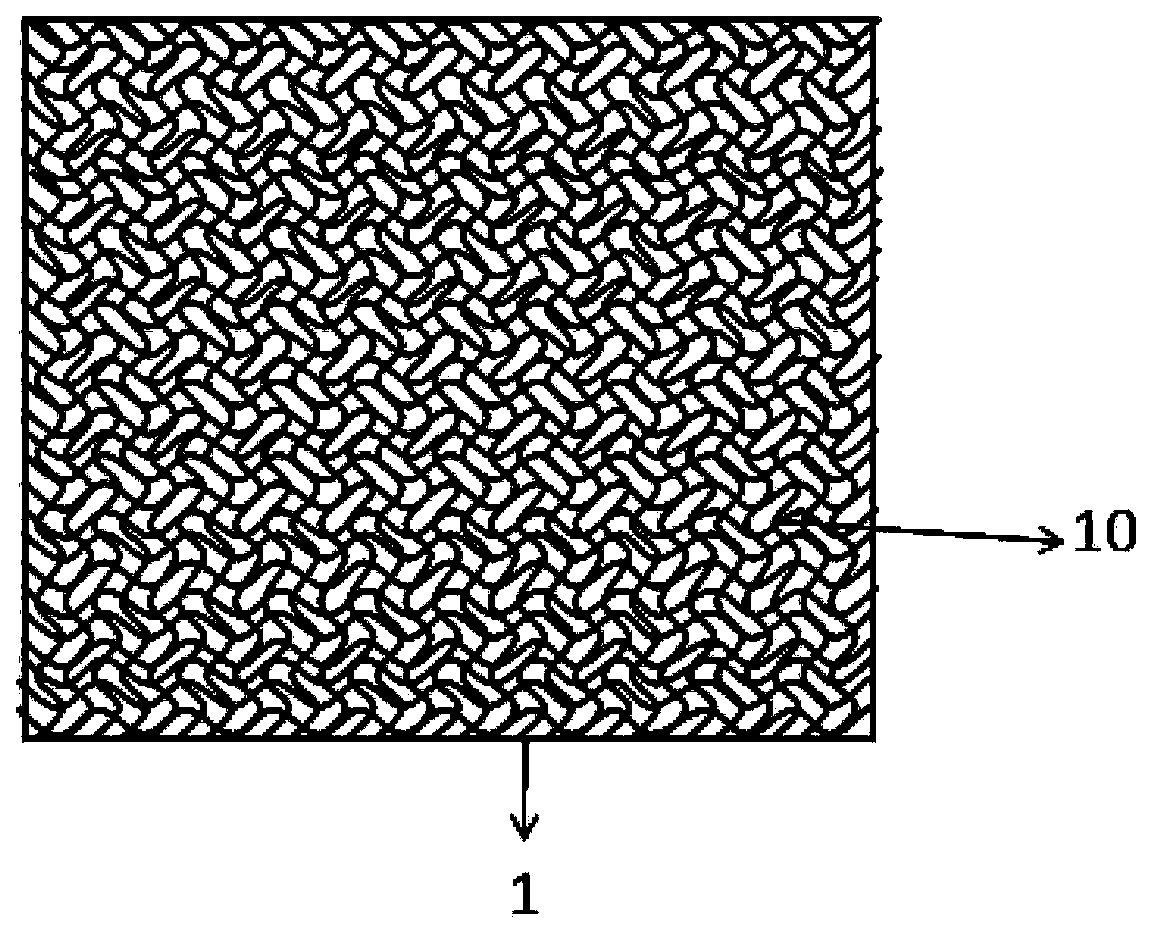

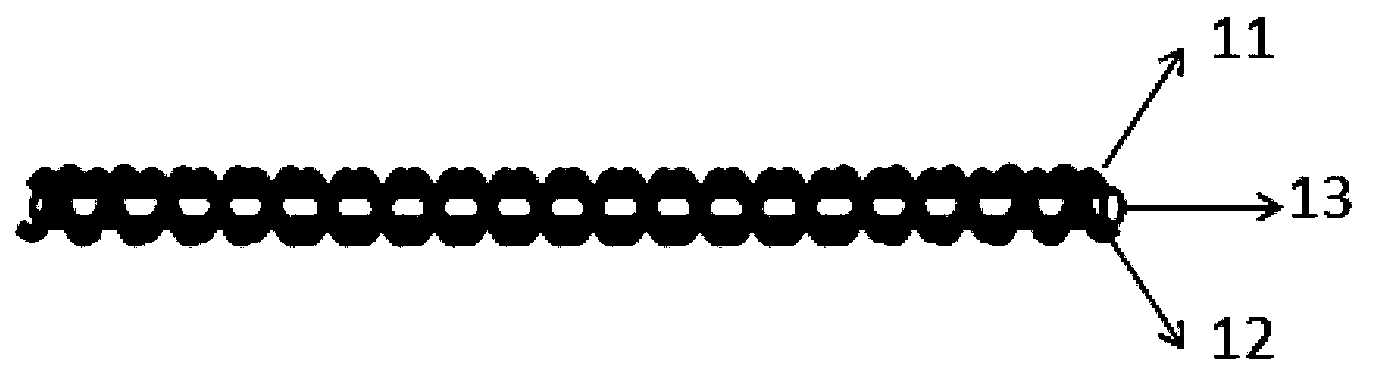

Composite artificial ligament and preparation method thereof

ActiveCN104043151ASolve AbsorbencySolve the degradabilityLigamentsMusclesLigamentBiomedical engineering

The invention relates to a composite artificial ligament and a preparation method thereof. The composite artificial ligament has a rodlike structure formed by reeling of a woven net. The woven net has a net structure formed by weaving of threads. The threads in the rodlike structure tangle with each other to loop together so as to form a mesh interleaving structure. The threads are formed by winding of a variety of filament bundles with different degradation properties, and the variety of filament bundles with different degradation properties are respectively formed by spinning or beam spinning of components with different degradation properties, so that the obtained composite artificial ligament has gradient degradation performance. The composite artificial ligament provided by the invention has good mechanical properties, and can promote the attachment of surrounding tissue and the repair and normal growth of ligament tissue. At the same time, part of components in the body can be gradually biodegradable, and significant decline of the ligament's mechanical properties cannot be caused during degradation.

Owner:SHENZHEN LANDO BIOMATERIALS

Environment-friendly halogen-free flame-proof copolymerized methanal complex and method for producing the same

InactiveCN101508820AImprove flame retardant performanceReduce the degree of toughness lossAntioxidantHeat rejection

The invention relates to an environment-friendly halogen-free flame-retardant copolyoxymethylene compound and a preparation method thereof, belonging to the field of the preparation of flame-retardant polymer material. The compound comprises the components with the mass percentage as follows: 56.0-69.0 percent of copolyoxymethylene resin, 15.0-22.0 percent of flame retardant, 5.0-7.0 percent of flame retardant synergist, 3.0-7.0 percent of char-forming agent, 3.0-5.0 percent of toughener, 0.1-0.5 percent of formaldehyde absorbent, 0.1-1.0 percent of antioxidant and 0.5-3.0 percent of heat rejection and dripping-resistant agent. In the invention, the flame retardant, the flame retardant synergist and the heat rejection and dripping-resistant agent are coated by the toughener to manufacture compound flame retardant; then the compound flame retardant is mixed with the copolyoxymethylene, the formaldehyde absorbent, the char-forming agent and the antioxidant uniformly and the mixture is extruded from a double-screw extruder and granulated; and the copolyoxymethylene compound is obtained. The compound has good flame-retardant performance, the flame-retardant grade reaches UL94V-0 grade, and the compound is friendly to the environment.

Owner:BEIJING UNIV OF CHEM TECH

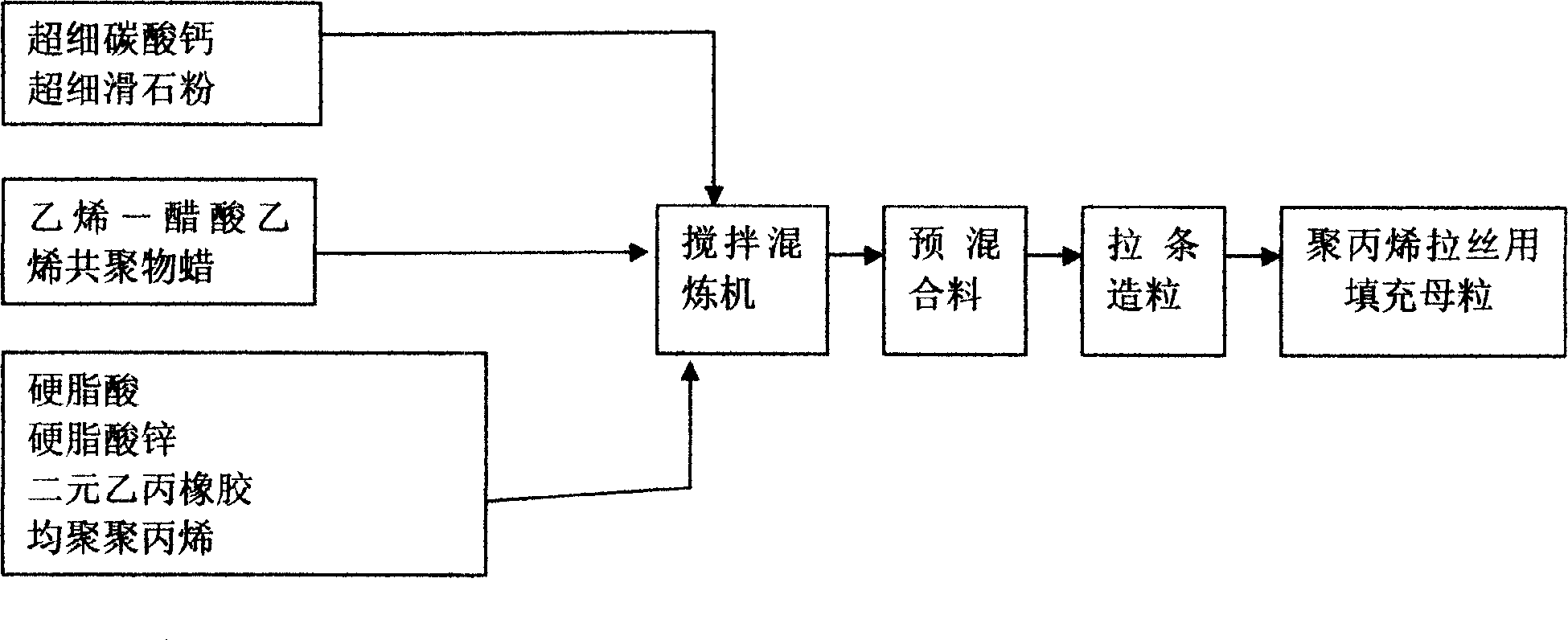

Filling agglomerate for polypropylene wiredrawing and its preparation method

The invention relates to a filling masterbatch used for polypropylene wire-drawing and its preparation method. The said masterbatch includes (weight parts): CaCO3 25~50, and superfine talc (SFT) 5~30, homopolymerized PP 17.5~25, dual EPDM 5~10, ethylene-vinyl acetate copolymer wax 1.5~6, stearic acid 1~4, and zinc stearate 1~2, wherein the average particle size of CaCO3 is 5~10 micron and the average size of SFT is 6-10 micron. The said method comprises: mixing CaCO3 and SFT in a stirring mixer at 100degreeC-130degreeC, adding ethylene-vinyl acetate copolymer wax and mixing 3~5 minutes, respectively adding stearic acid, zinc stearate, dual EPDM, and homopolymerized PP, stirring for 3 min to obtain the pre-mixture, placing the pre-mixture into a cocurrent twin-screw granulation machine, granulating and pelleting, cooling and sifting, separating, and packaging to obtain the final product. The prepared filling masterbatch has good mechanical properties, dispersion, and high economy.

Owner:上海心尔新材料科技股份有限公司

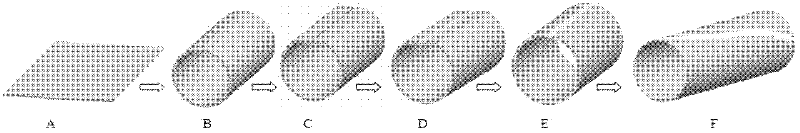

Preparation method of large-diameter aluminum alloy tube

InactiveCN102416413AImprove welding strengthImprove plasticityNon-electric welding apparatusFriction weldingProduction rate

The invention relates to a preparation method of a large-diameter aluminum alloy tube, relating to a preparation method of an aluminum alloy tube and aiming to solve the problems in the prior art that the large-diameter aluminum alloy tube with the tube wall thickness less than 2mm and with an excellent performance cannot be prepared with low cost and high production efficiency. In the method, an aluminum alloy rolled plate is obtained at first through blanking with a plate shearing machine, a cylindrical tube blank is prepared with a plate rolling machine, a tube blank to be welded is obtained through clamping with a clamp, mixing friction welding is carried out for welding, a cylindrical welded tube is obtained through rounding, and the large-diameter aluminum alloy tube is obtained finally sequentially through spinning and thermal treatment. The invention has the advantages that: 1, a high-quality spinning blank can be obtained; 2, a large-diameter tube can be prepared; 3, the mechanical properties are good; 4, the number of spinning procedures is reduced, no annealing treatment is needed in the procedures, the production cycle is shortened, and the cost is decreased; and 5, the dimensional accuracy is high. The method is mainly applied in production of the large-diameter aluminum alloy tube.

Owner:HARBIN INST OF TECH

Method for preparing halogen-free smoke-suppressant and flame-retardant plastic optical fiber sheath

ActiveCN101950044AGuaranteed flame retardant performanceSmall mechanical propertiesCladded optical fibreOptical waveguide light guideTwo stepPlastic optical fiber

The invention discloses a method for preparing a halogen-free smoke-suppressant and flame-retardant plastic optical fiber sheath, which is characterized by comprising the following steps of: (1) modifying magnesium hydroxide; and (2) preparing a flame-retardant plastic optical fiber. The method has the advantages that: by modifying a magnesium hydroxide flame retardant by two steps, the affinity of the magnesium hydroxide flame retardant with a polyethylene matrix is greatly improved, a flame-retardant accelerant and a synergist are added, the reduction of the mechanical properties of the prepared flame-retardant plastic optical fiber sheath is a little under the condition of ensuring the flame retardance, and the mechanical demand of the product can be met.

Owner:江西大圣塑料光纤有限公司

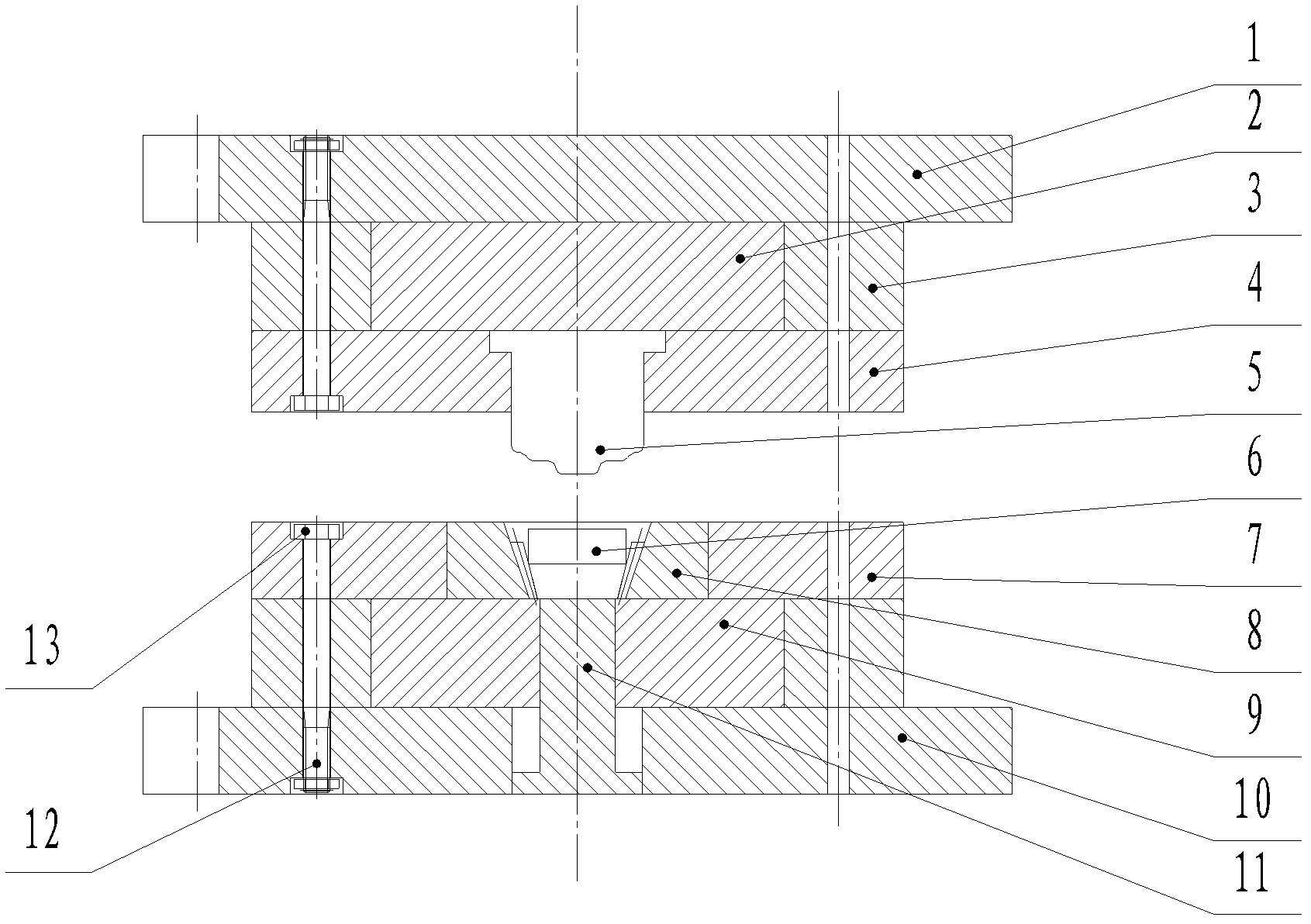

Cold precision forging process for bevel gear and mould thereof

InactiveCN102430692AImprove mechanical propertiesWon't cut offForging/hammering/pressing machinesWheelsHardnessBar stock

A cold precision forging process for a bevel gear is disclosed, and comprises the steps of: cutting the blanking by cylindrical bars; cutting a conical degree on a segmental length of the blank as segmental pre-form for positioning the blank in a die; performing spheroidization for the machined blank to reduce the hardness, then scouring and descaling, phosphorizing, saponifying and lubricating; the first cold precision forging step comprises: upsetting-extruding segmental tooth form in an extrusion mould to obtain a first extrusion which is used as the blank of the second first cold precision forging step; performing spheroidization again for the first extrusion, then scouring and descaling, phosphorizing, saponifying and lubricating; the second cold precision forging step comprises: upsetting-extruding all tooth forms in the extrusion mould to obtain the coarse material of the bevel gear; machining and shaping the coarse material of the bevel gear and cutting unnecessary materials on the end surface to obtain finished products of the bevel gear. The invention further provides an extrusion mould. The invention has higher production efficiency, reduces the material waste, lowers the cost and improves the mechanical property.

Owner:ZHEJIANG UNIV OF TECH

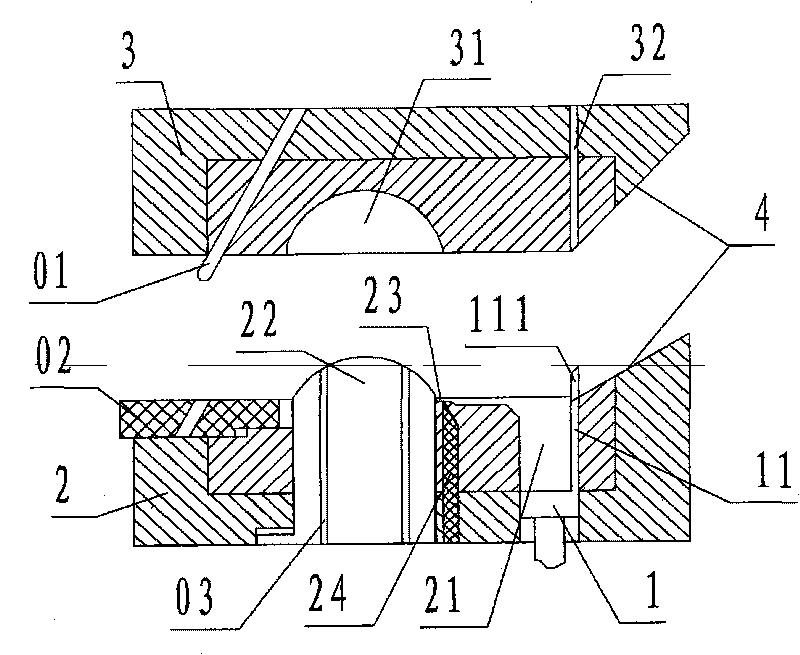

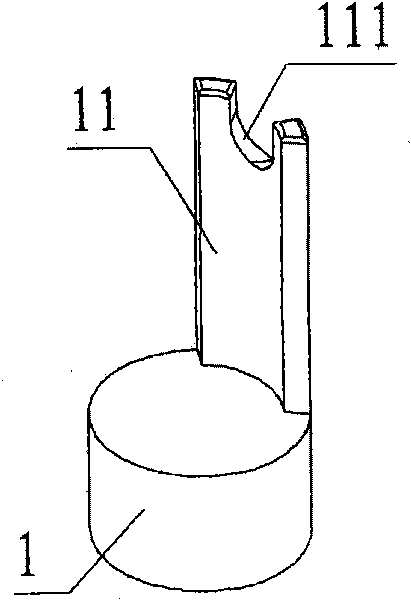

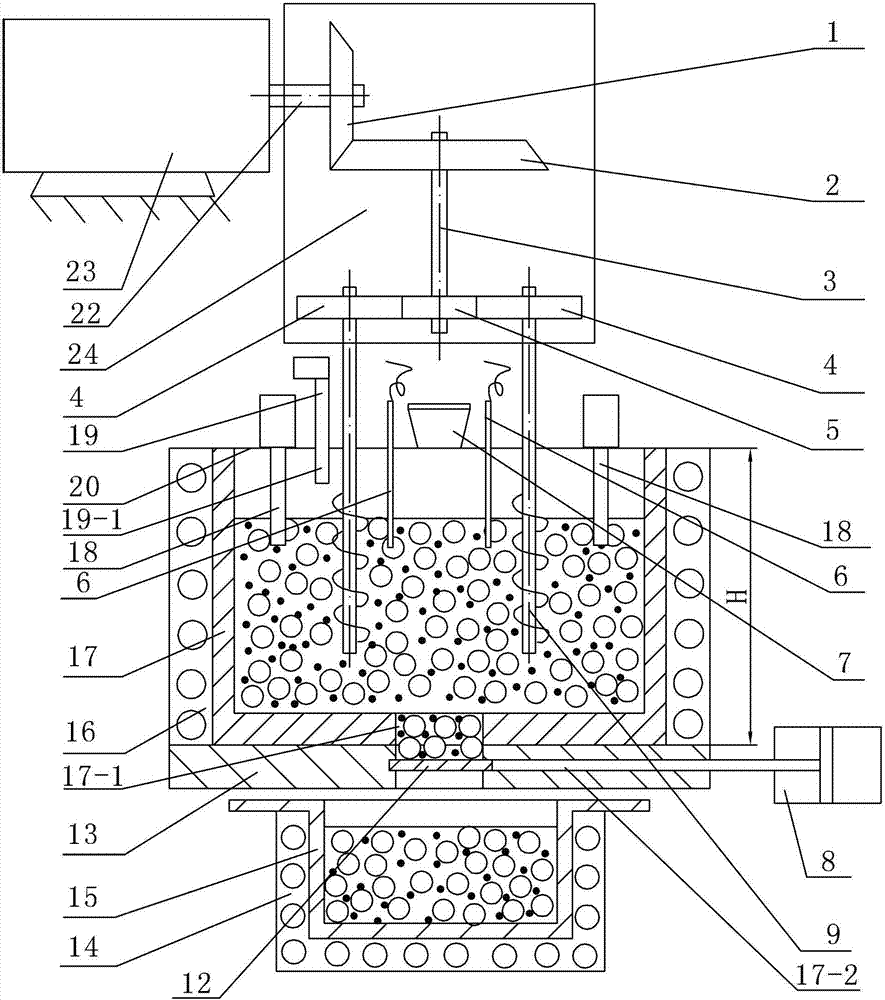

Alloy liquid extrusion casting forming device and process method thereof

The invention discloses an alloy liquid extrusion casting forming device which comprises a hammerhead (1), a static die (2), a movable die (3) and a pouring slot (4). The device adopts the technical scheme that a declined and downward funnel-shaped pouring slot occupied by both the movable die and the static die arranged respectively by half is arranged on the parting plane on one side of a vertical die casting mould; a cylinder chamber type feed liquid chamber and the piston type hammerhead with a sealing knife is arranged on the static die; the hammerhead is controlled to be pushed up, and simultaneously the sealing knife seals the pouring slot. Firstly, feed liquid is filled into the a die cavity at high speed with low pressure, then the semisolid feed filled into the die cavity is extruded at low speed with high pressure, and the semisolid feed is gradually condensed to be formed under high-pressure low-speed extrusion. The alloy liquid extrusion casting forming device and the process method thereof integrate full casting functions of low-pressure filling and high-pressure extrusion into a whole, ensure that forming of alloy casting achieves the purposes of no gas entrapment, no cast seam, no mis-run, no forging crack, no fash, compact texture, fine crystal grain, high mechanical property, capability of performing thermal treatment and sealing, high dimensional accuracy, energy saving and low cost.

Owner:中建投(绍兴)机械科技有限公司

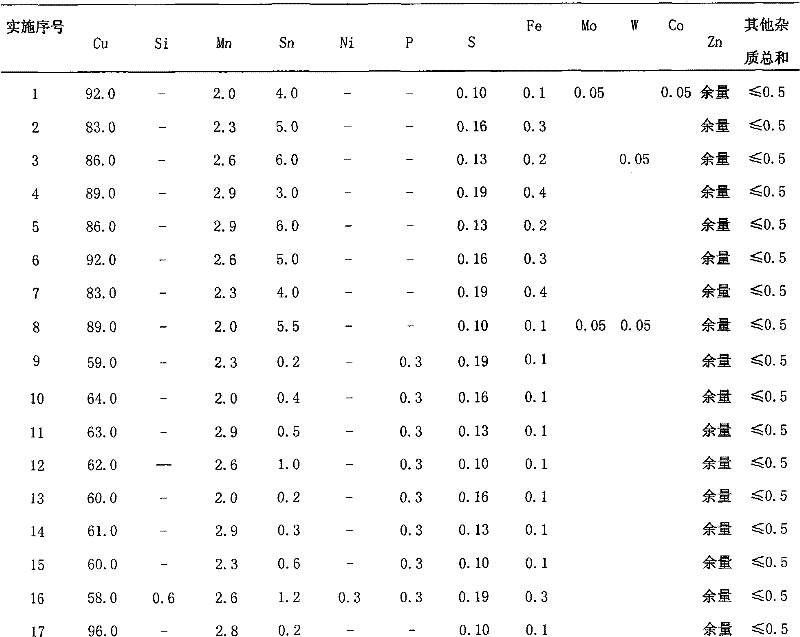

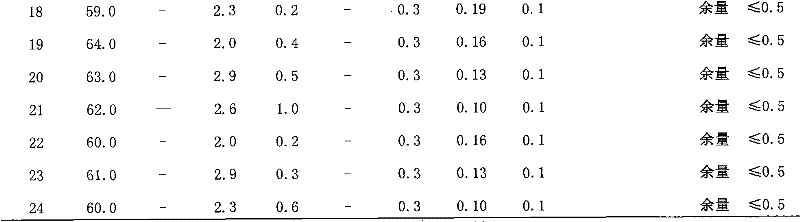

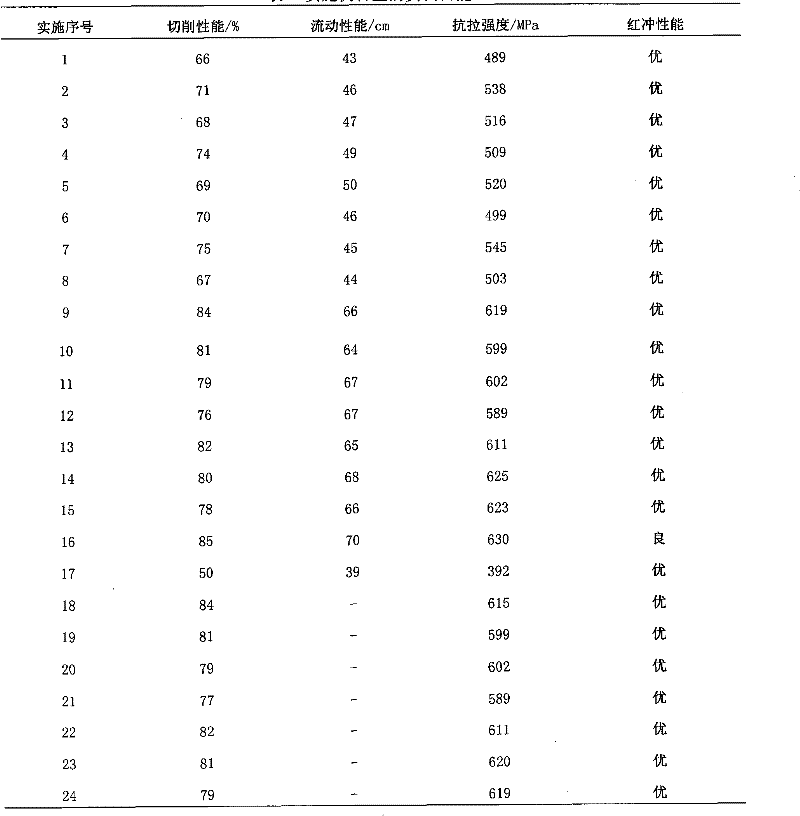

Leadless free-cutting copper alloy and preparation method

A leadless free-cutting copper alloy and a preparation method. The copper alloy comprises the following elements by mass: 58.0%-96.0% of copper, 2.0%-2.9% of manganese, 0.2%-6.0% of tin, not more than 0.3% of phosphor, not more than 0.3% of nickel, 0.10%-0.19% of sulfur, 0.1%-0.9% of the sum of 1-3 elements selected from silicon, iron, molybdenum, tungsten, and cobalt, and the balance of zinc. In the alloy, the mass ratio of manganese and sulfur is more than 10 and less than 30; the other elements are impurities, and the mass fraction of any one of the impurities is not more than 0.03%; the sum of the mass fractions of all the impurities is not more than 0.5%. The preparation method comprises the following steps: melting and alloying the base metal element of copper and the important metal element of manganese, adding other alloy elements and performing homogenization, performing refining, adding sulfide or sulfur, performing homogenization and adding zinc rapidly, immediately casting into a ingot casting or performing atomization to obtain powder. The leadless free-cutting copper alloy and the preparation method of the invention are applicable to cutting processing, hot forging processing, and polishing processing of copper alloy.

Owner:HUNAN TERRY NEW MATERIALS COMPANY

Device and method for preparing nanometer ceramic particle-reinforced aluminum-based composite

A device and a method for preparing a nanometer ceramic particle-reinforced aluminum-based composite relate to a device and a method for preparing a metal matrix composite and aim at solving the problems of long preparing technical path, excessive required equipment and high cost in the existing powder metallurgic method for preparing the nanometer ceramic particle-reinforced aluminum-based composite, as well as the problems of non-uniform distribution, layering and conglobation of nanometer ceramic particles in the existing stirring method. The device comprises a motor, a gearbox, a first gear shaft, a feeding hopper, a baffle, a heating base plate, a first heating device, a slurry collecting groove, a second heating device, a crucible, a cover plate, a hydraulic driving device, an argon protection device, two temperature measuring elements, two screw type stirring impellers and two ultrasonic devices, wherein stirring ends of the screw type stirring impellers extend into the crucible arranged below the gearbox, and probes of the ultrasonic devices penetrate through the cover plate and extend into the crucible. The device and the method, provided by the invention, are used for preparing the nanometer ceramic particle-reinforced aluminum-based composite.

Owner:HARBIN INST OF TECH

Reactive monomer modified nano calcium carbonate/polypropylene master batch and its preparing method

The present invention relates to a reactive monomer modified nano calcium carbonate / polypropylene mother material and its production method. Said mother material is formed from polypropylene base body, nano calcium carbonate filling material, reactive monomer (including maleic anhydride, acrylic acid and its esters and styrene) and universal stabilizing agent D of PP material. Its preparation method includes the steps of uniformly mixing by using high-speed mixing machine and extruding by means of twin screw extruder machine. Said invention can raise the mechanical property of nano calcium carbonate filled polypropylene material.

Owner:SUN YAT SEN UNIV

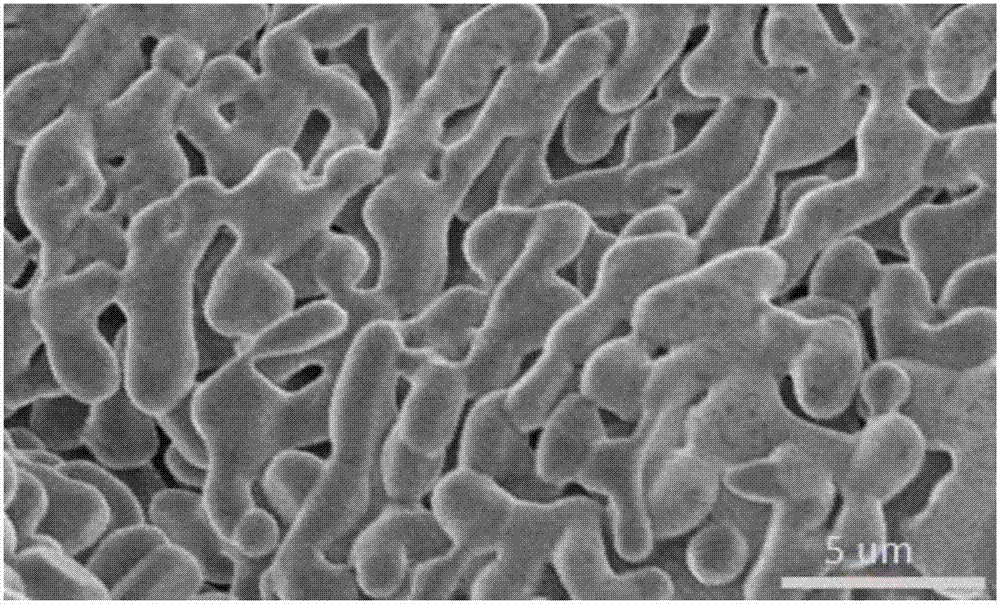

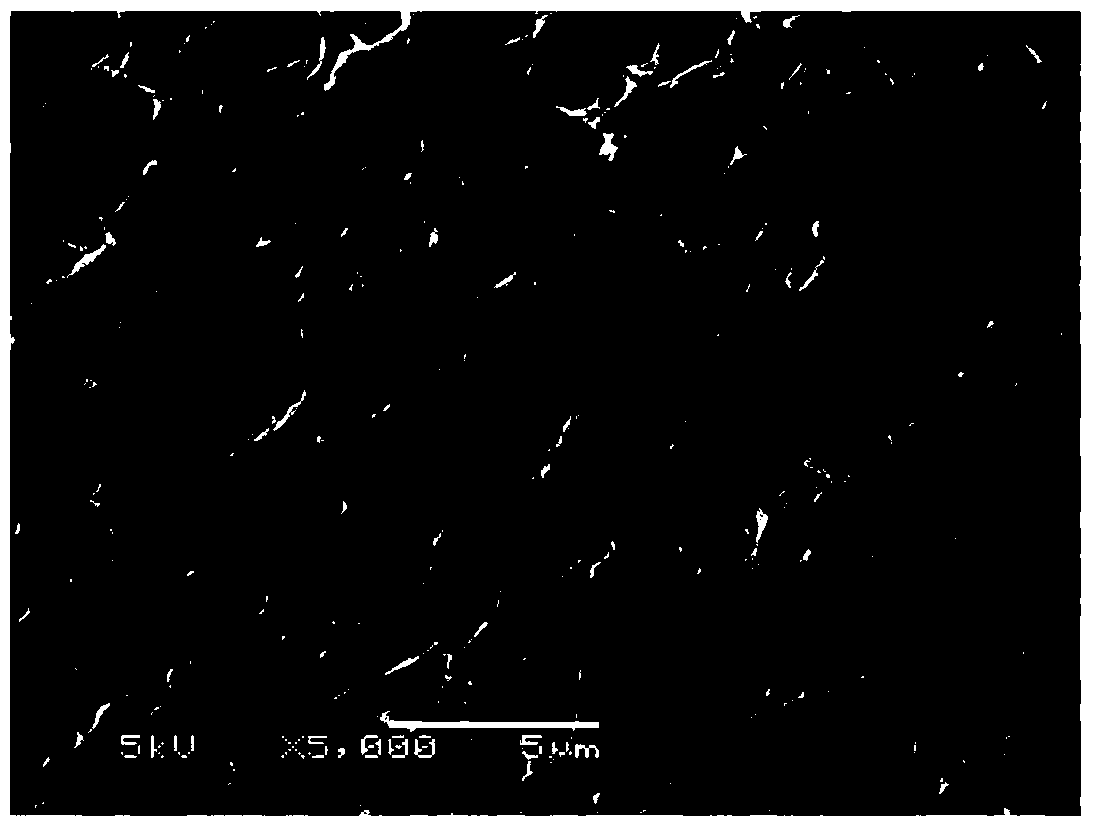

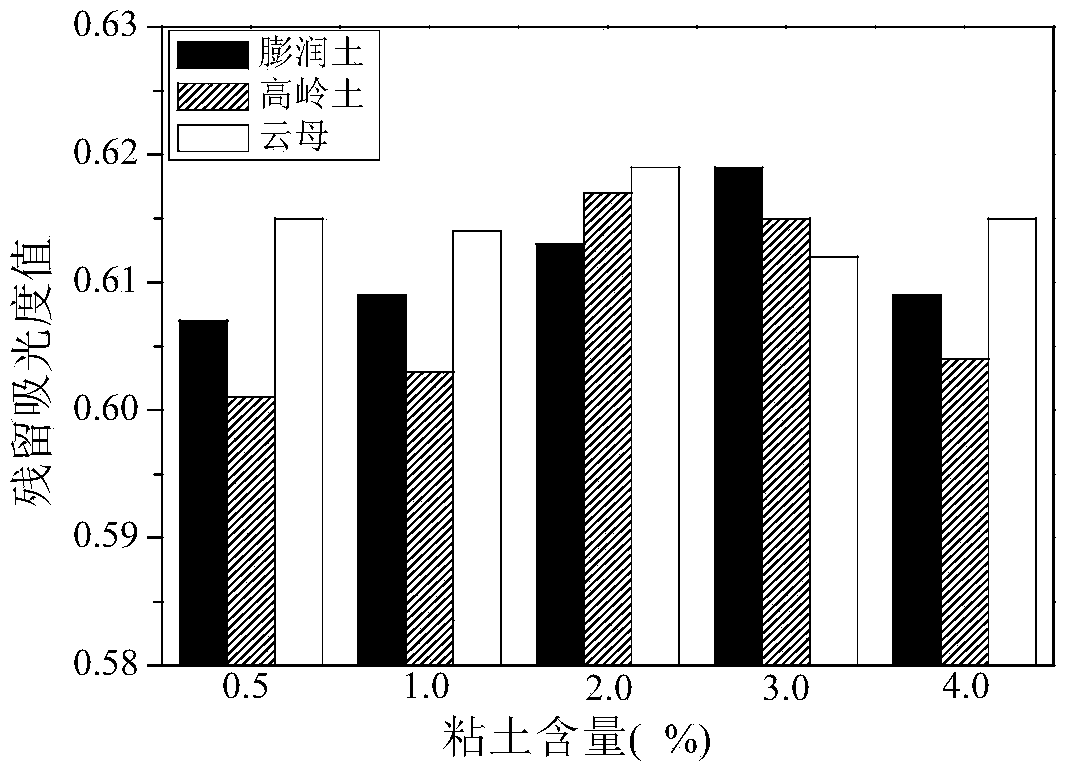

Method for preparing clay modified polyvinyl alcohol antifouling hydrogel

The invention provides a method for preparing clay modified polyvinyl alcohol antifouling hydrogel. The method comprises the following steps: (1) dissolving inorganic clay into deionized water, sufficiently dissolving to obtain suspension, and subsequently performing ultrasonic dispersion on the suspension, so as to obtain uniform clay dispersion liquid; (2) adding polyvinyl alcohol into the clay dispersion liquid, and stirring for 2-3 hours at 80-100 DEG C, so as to obtain a clay modified polyvinyl alcohol hydrogel mixture solution; and (3) repeating a freezing-unfreezing process on the clay modified polyvinyl alcohol hydrogel mixture solution for at least three times, so as to prepare the clay modified polyvinyl alcohol antifouling hydrogel. The method is simple in preparation process, the raw materials are easy to obtain, and the preparation cost is low. The hydrogel system has an excellent antifouling effect, is capable of effectively inhibiting adhesion of protein and marine algae and has a good application prospect in the field of ship antifouling materials.

Owner:HARBIN ENG UNIV

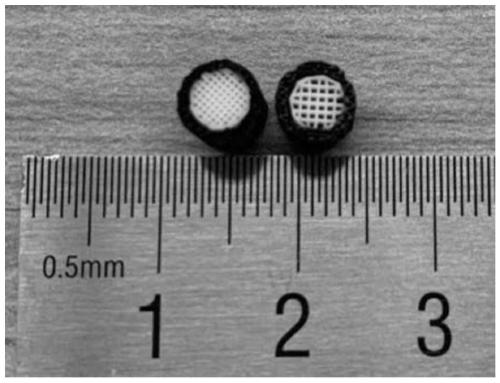

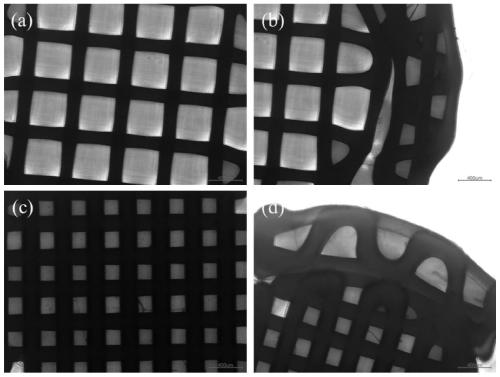

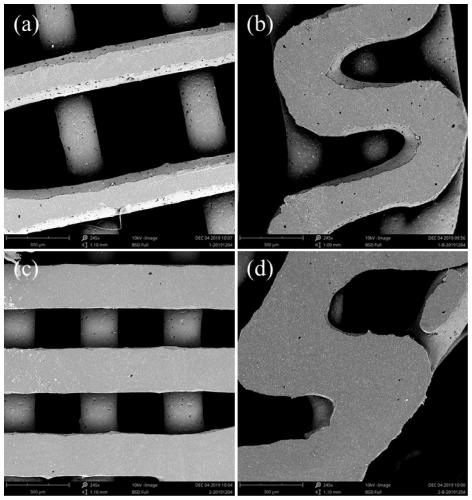

3D-printed multi-structure bone composite scaffold

ActiveCN111110404AHigh simulationImprove mechanical propertiesBone implant3D printingCompact bone structureFiber

The invention relates to a 3D-printed multi-structure bone composite scaffold. The 3D-printed multi-structure bone composite scaffold comprises a multi-layer structure, wherein different layers are made of composite materials in different proportions through 3D printing, and the 3D-printed multi-structure bone composite scaffold has different 3D printing fiber spacings and porosity factors. The specific structure comprises a bionic bone structure, the outer layer is low in porosity and small in aperture to simulate a compact bone structure, the inner layer is high in porosity and large in aperture to simulate a cancellous bone structure, and the scaffold similar to a real bone structure is integrally formed; in an osseointegration structure, the outer layer is high in porosity and large inaperture so as to promote integration with surrounding bones, the inner layer is low in porosity and small in aperture so as to support the overall structure while promoting osseointegration, and thewhole structure is suitable for repairing bone defects. The material of the scaffold is preferably a composite material of tricalcium phosphate (TCP) and polycaprolactone (PCL), and the scaffold hasgood biocompatibility and printability. The bone repair effect is promoted by adding metal ions and performing surface modification treatment.

Owner:NOVAPRINT THERAPEUTICS SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com