Cold precision forging process for bevel gear and mould thereof

A cold precision forging and bevel gear technology, applied in the bevel gear processing technology and its mold field, can solve the problems of low production efficiency, large material waste, poor mechanical properties, etc., and achieve large mold loss, high dimensional accuracy, and no cutting loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

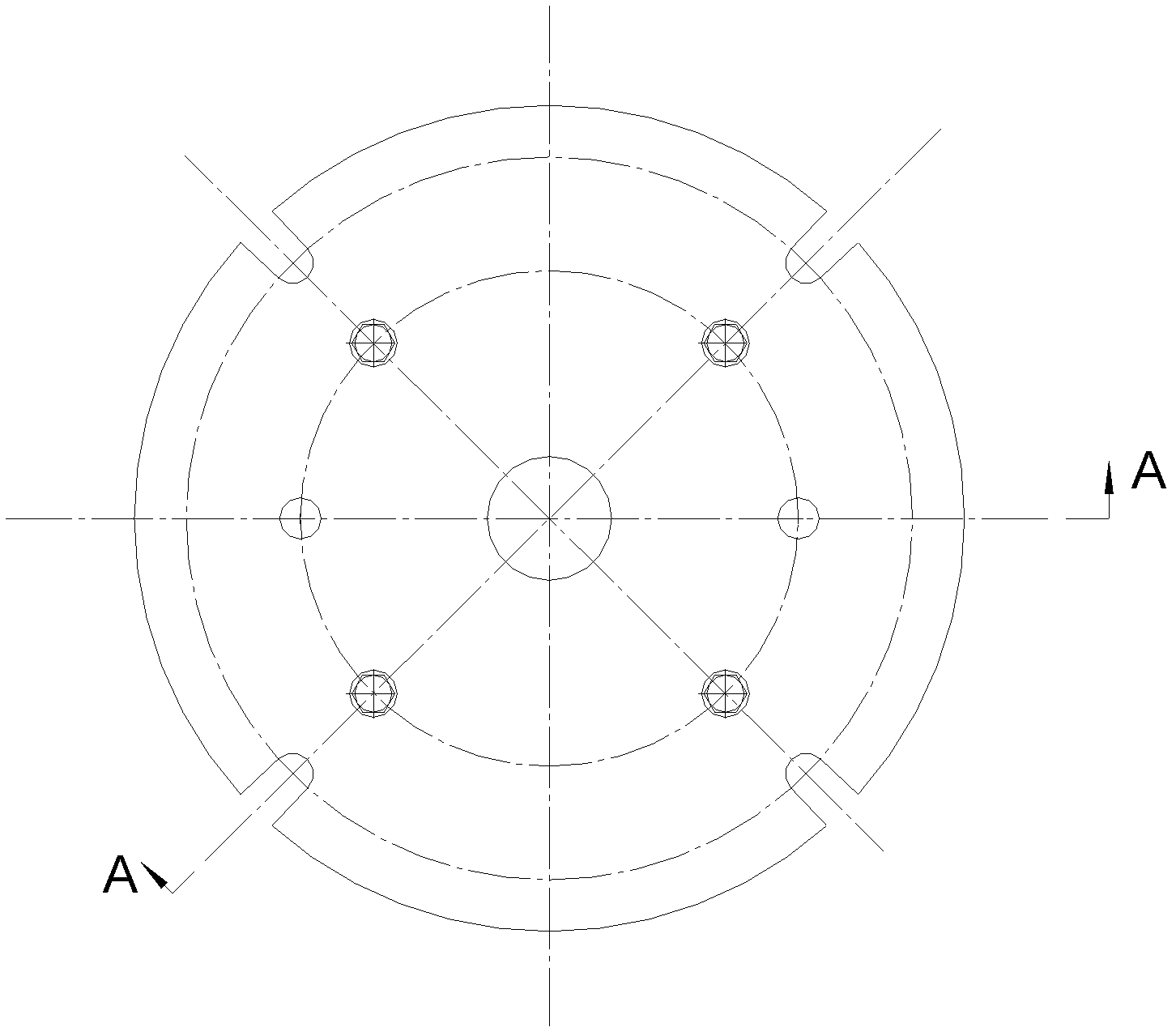

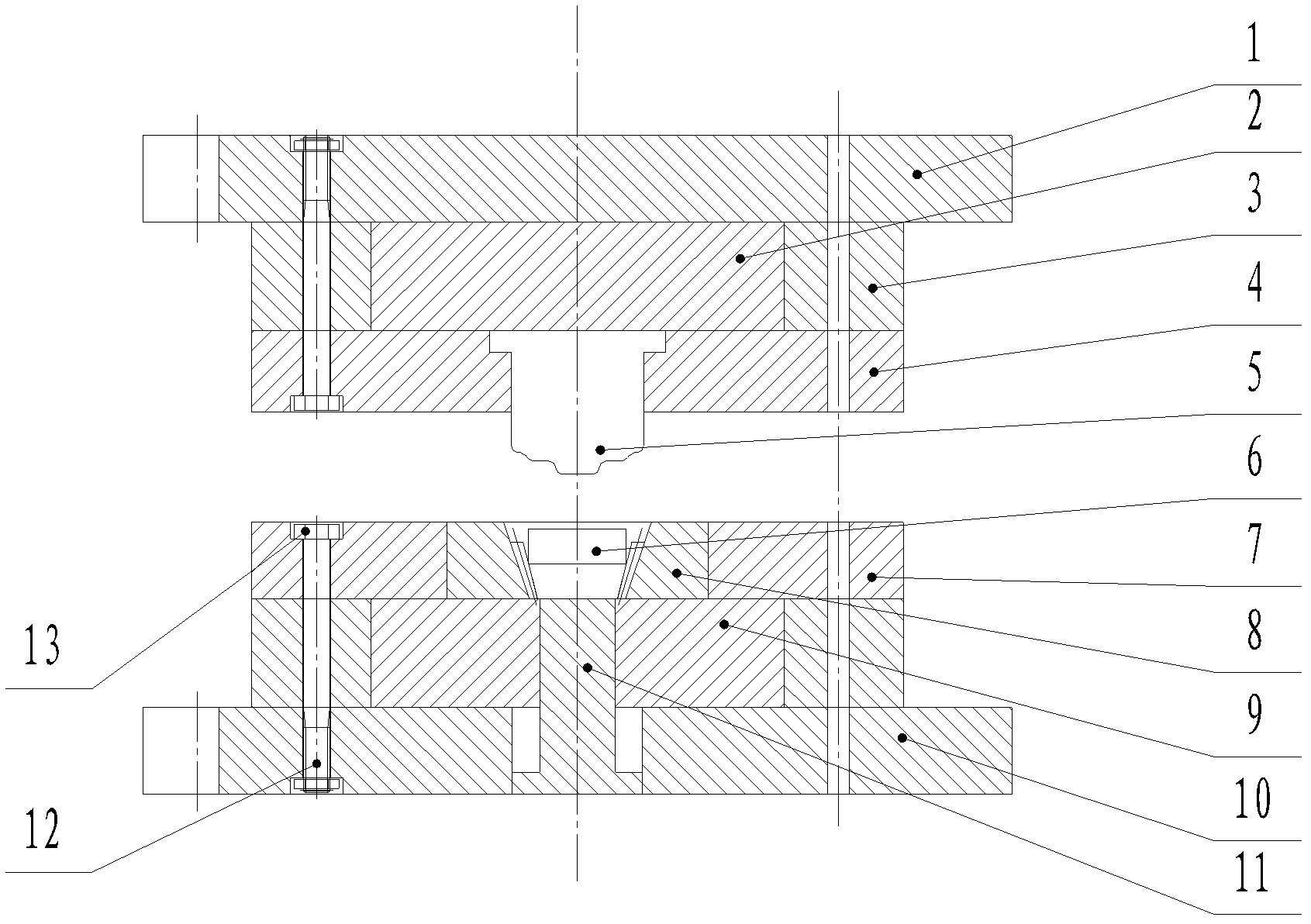

[0027] refer to Figure 1 to Figure 5 , a bevel gear cold precision forging process, the bevel gear cold precision forging process comprises the following steps:

[0028] 1) Use cylindrical bar material to cut and blank;

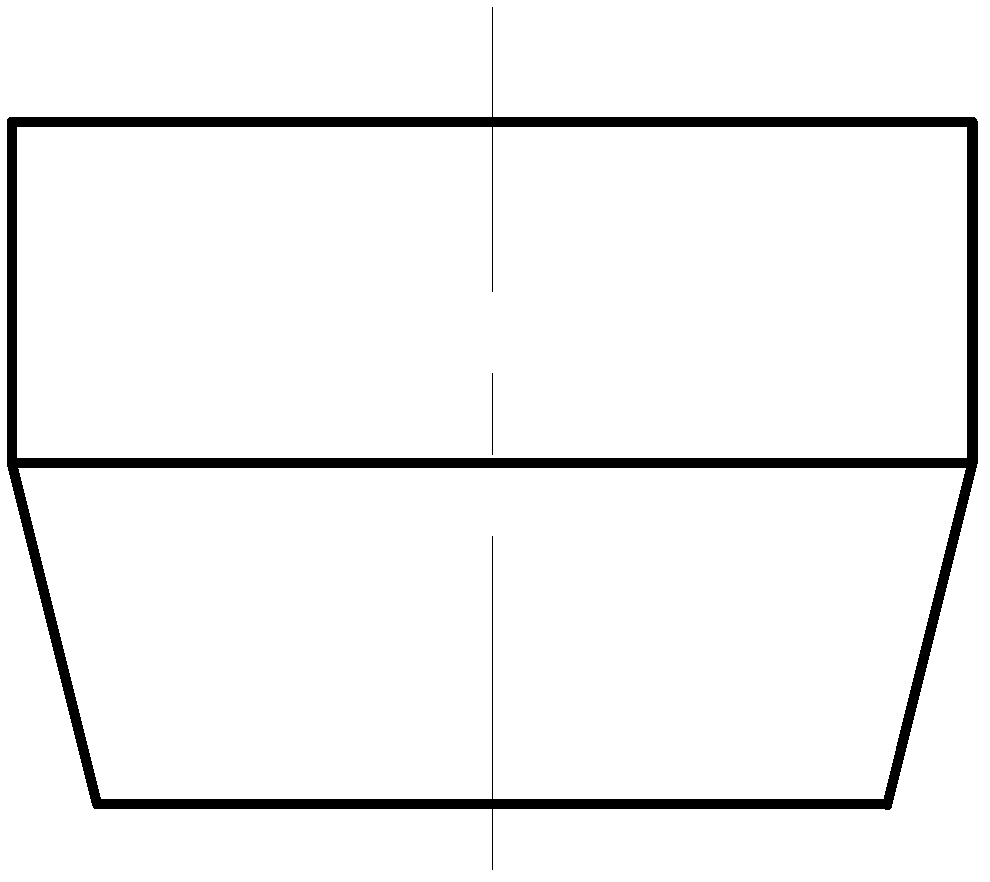

[0029] 2) Turning a taper on the length of the part of the blank as part of the pre-forming, the pre-forming is used for positioning the blank in the die;

[0030] 3) Carry out spheroidizing annealing to the machined blank to reduce its hardness, then pickling to remove scale, phosphating and saponification lubrication treatment;

[0031] 4) The first cold precision forging process: Upsetting and extruding part of the tooth shape in the extrusion die to obtain the first extrusion, which is used as the blank of the second cold precision forging process;

[0032] 5) performing spheroidizing annealing on the first extruded piece again, then pickling to remove scale, phosphating and saponification lubrication treatment;

[0033] 6) The second cold precision f...

Embodiment 2

[0039] refer to figure 1 and figure 2 , a bevel gear cold precision forging die, the die includes a punch mechanism and a die mechanism, the punch mechanism is composed of an upper template 1, a punch pad 2, a punch ring 4 and a punch 5, the punch 5 is fixedly connected with the punch ring 4, the punch ring 4 is fixed on the punch pad 2, the punch ring 2 is fixedly connected with the upper template 1, and the upper template 1 is linked with the press; the die mechanism It is composed of die ring 7, die insert 8, die pad 9, lower template 10 and ejector rod 11. The die ring 7 is assembled with the die insert 6 for placing the blank 6 to be processed. , the die press ring 7 and the die insert 8 are fixed on the die pad 9, the die press ring 7 and the die pad 9 are fixedly connected with the lower template 10; the ejector rods 11 pass through the lower template in turn 11. The through hole in the middle of the matrix pad 9; the upper template 1 or the lower template 10 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com